Elbow connecting pipe

A technology for connecting pipes and elbows, applied in the field of quartz mortar conveying pipes, can solve the problems of difficult disassembly, pipe elbow impact, easy damage, etc., and achieve the effects of easy maintenance and disassembly, slowing down direct erosion, and slowing down the flow rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

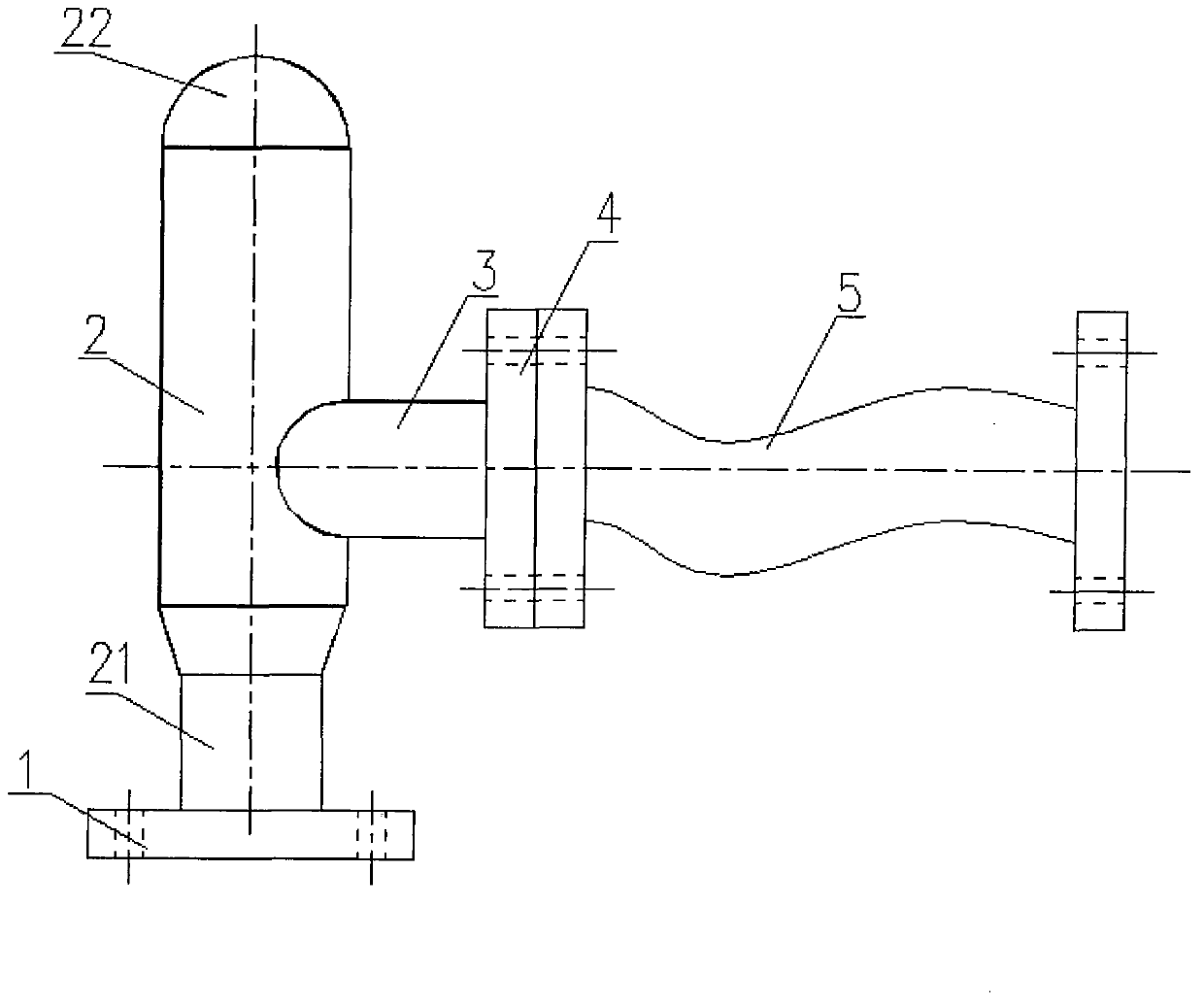

[0011] Such as figure 1 As shown, an elbow connecting pipe of the present invention includes a straight pipe 2, one end of the straight pipe 2 is provided with a flange 1, and the other end is a circular arc-shaped closed end 22, which is on the pipe wall in the middle of the straight pipe 1. There is an elbow 3 placed vertically with the straight pipe and communicated with the straight pipe, the end of the elbow 3 is provided with a flange 2 4, and the flange 2 at the end of the elbow 3 is connected to a rubber connecting pipe 5 One part of the flange of the straight pipe 2 has a narrowing 21, so that the diameter of one part of the flange of the straight pipe 2 is smaller than the diameter from the flange of the straight pipe to the arc-shaped closed end. The straight pipe 2 is used to slow down the flow rate of the water slurry material. The length of the straight pipe 2 can be changed according to the flow rate of the water slurry material. When the flow rate is large, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com