Complete equipment for treating chromium wastewater

A complete set of equipment, the technology of chromium wastewater, applied in the direction of metallurgical wastewater treatment, multi-stage water treatment, water/sewage treatment, etc. Influence and other problems, to achieve the effect of simple structure, reasonable design and good stirring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

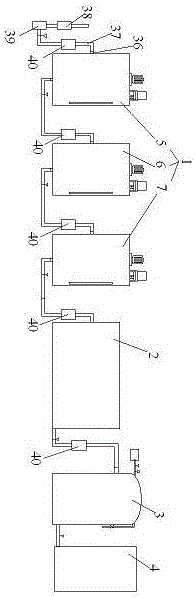

[0020] A complete set of chromium wastewater treatment as shown in the figure is characterized in that it includes a reaction tank 1, a filter press 2, a mechanical filter 3 and an activated carbon adsorber 4, the number of the reaction tank 1 is 3, and the reaction tank 1 Divided into acidification tank 5, chromium breaking tank 6 and reduction tank 7, the acidification tank 5, chromium breaking tank 6, reduction tank 7, filter press 2, mechanical filter 3 and activated carbon adsorber 4 are connected in sequence through pipelines ;

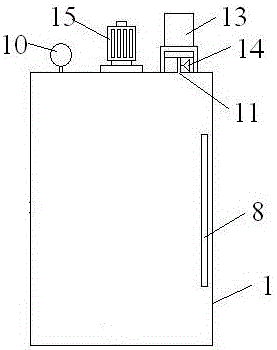

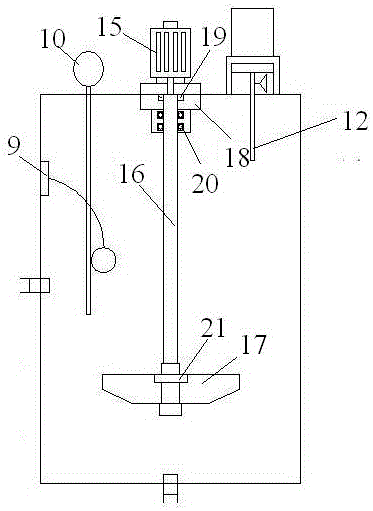

[0021] The reaction tank 1 is provided with a water level gauge 8, a float switch 9, a pH sensor 10, a liquid medicine inlet 11 and a stirring device, the float switch 9 is arranged in the reaction tank 1, and the liquid medicine inlet 11 is provided with There is an injection pipe 12, the lower end of the injection pipe 12 is located in the reaction tank 1, and its upper end stretches out of the reaction tank 1, and communicates with the liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com