Patents

Literature

362 results about "Mechanical filter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A mechanical filter is a signal processing filter usually used in place of an electronic filter at radio frequencies. Its purpose is the same as that of a normal electronic filter: to pass a range of signal frequencies, but to block others. The filter acts on mechanical vibrations which are the analogue of the electrical signal. At the input and output of the filter, transducers convert the electrical signal into, and then back from, these mechanical vibrations.

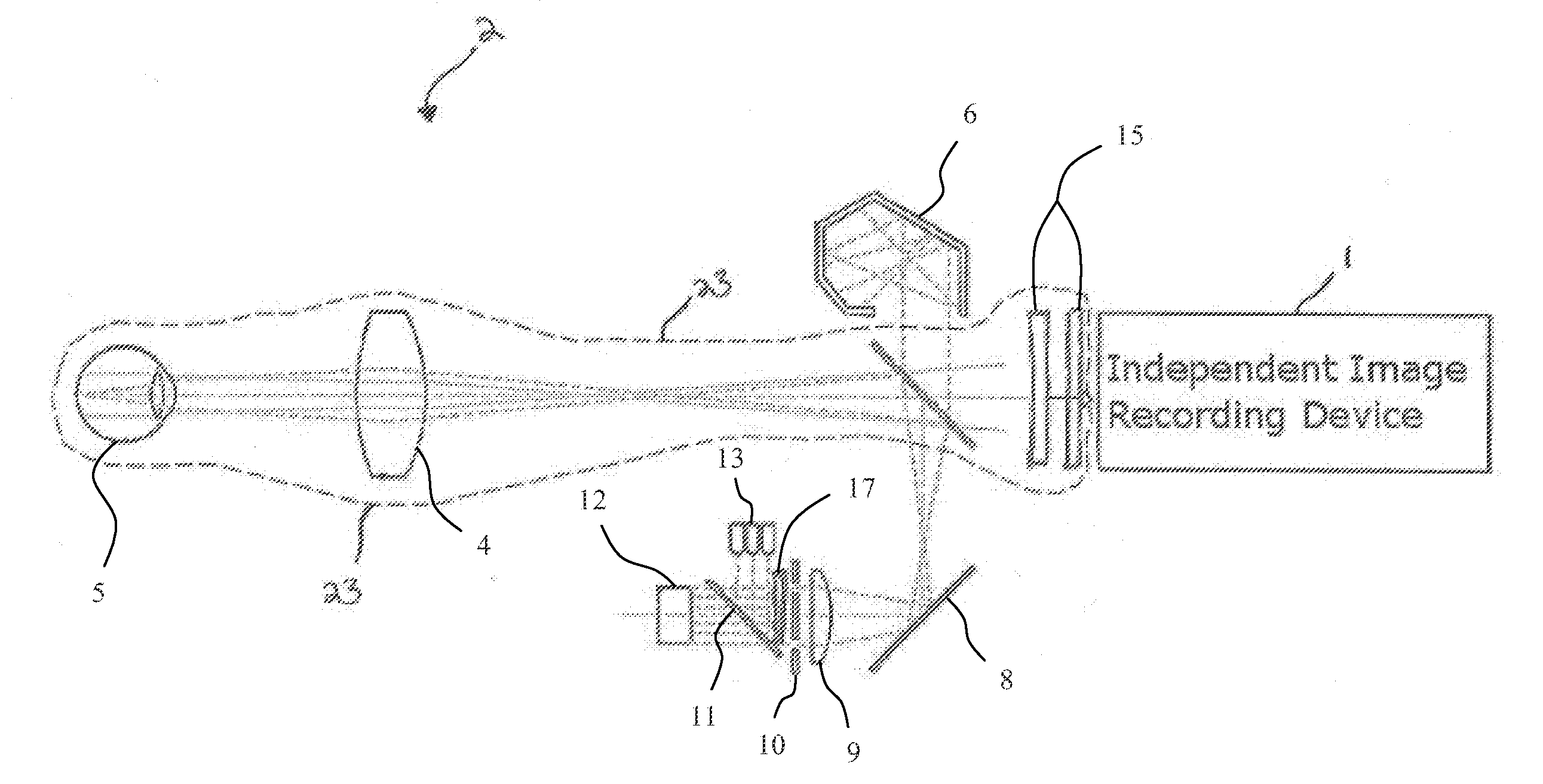

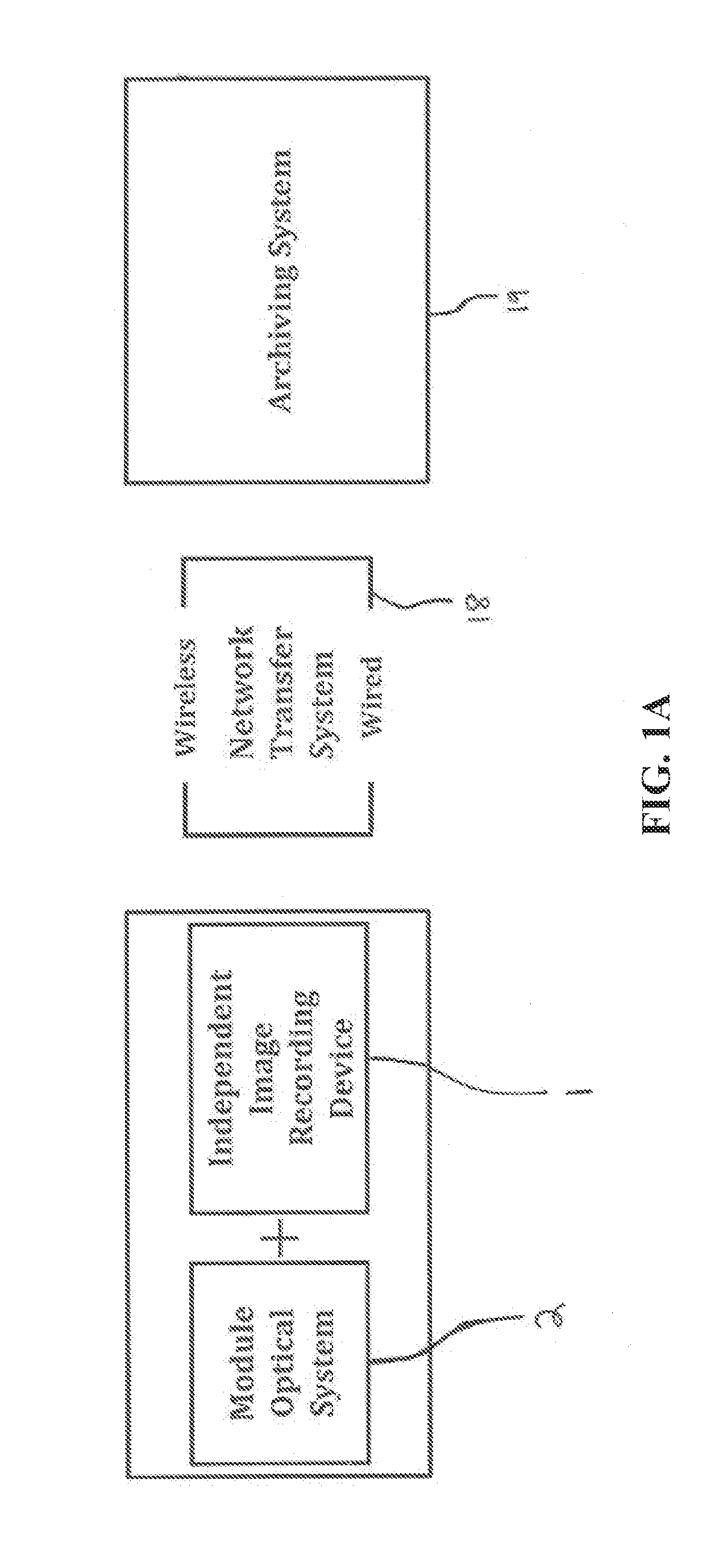

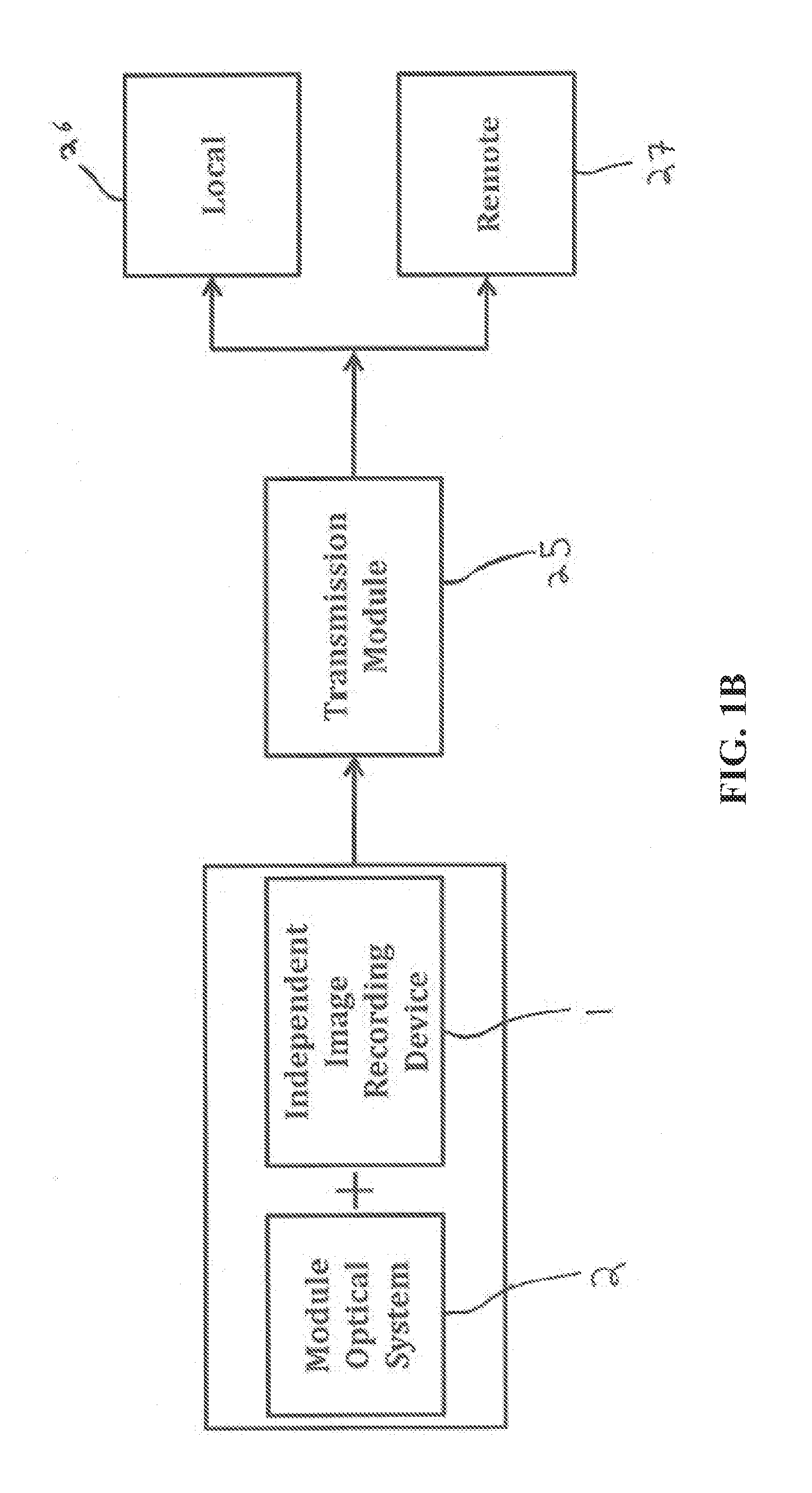

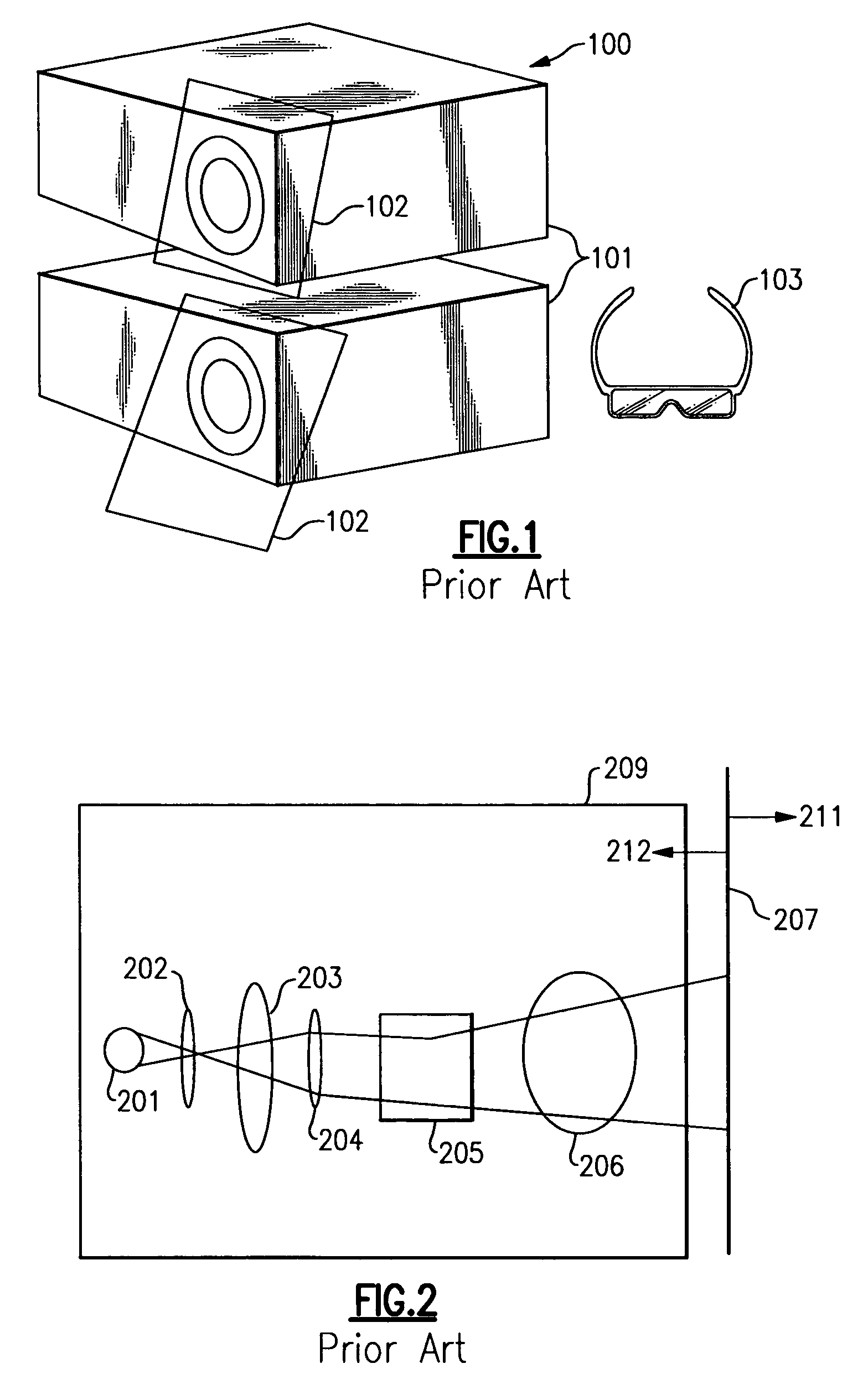

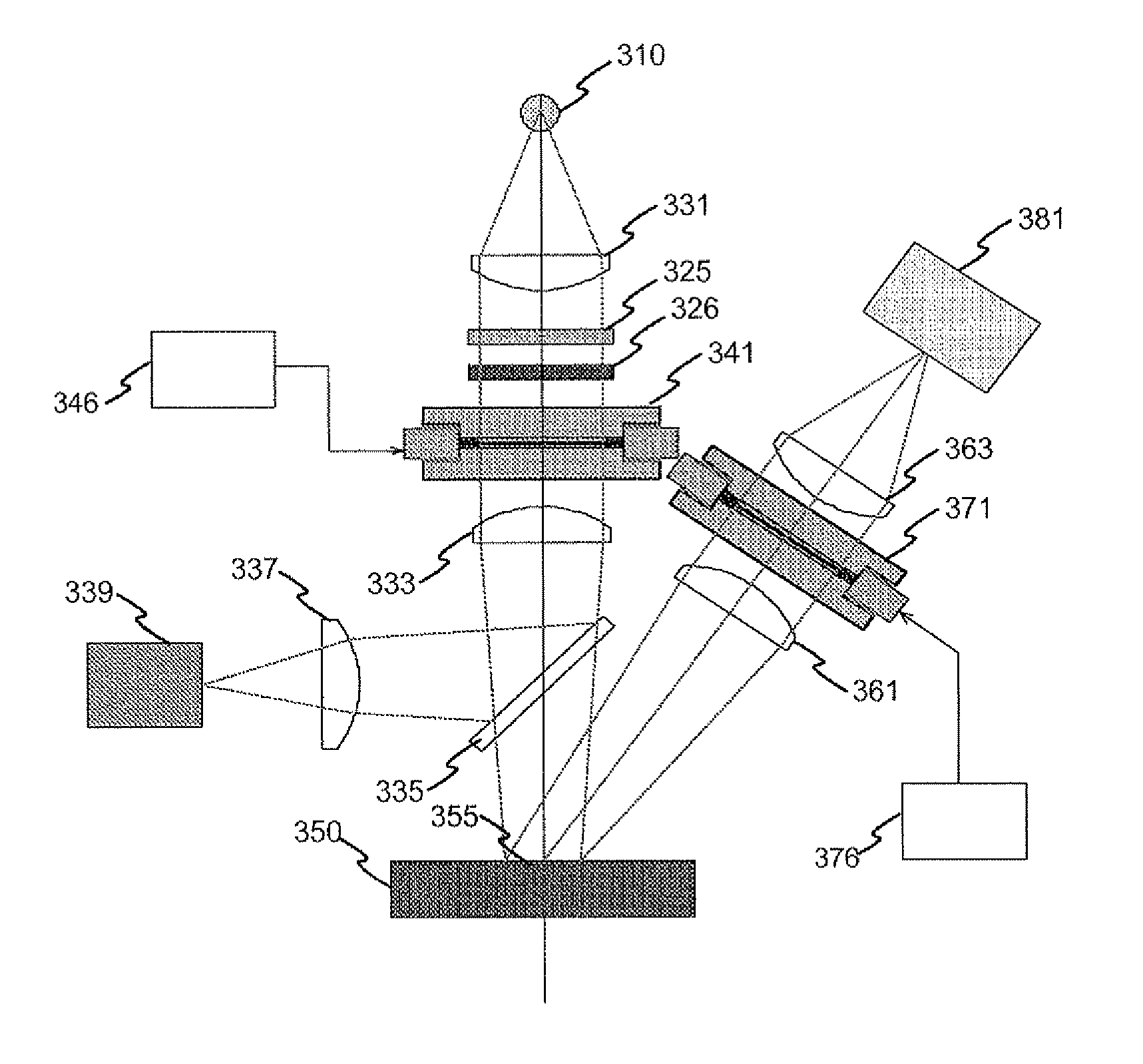

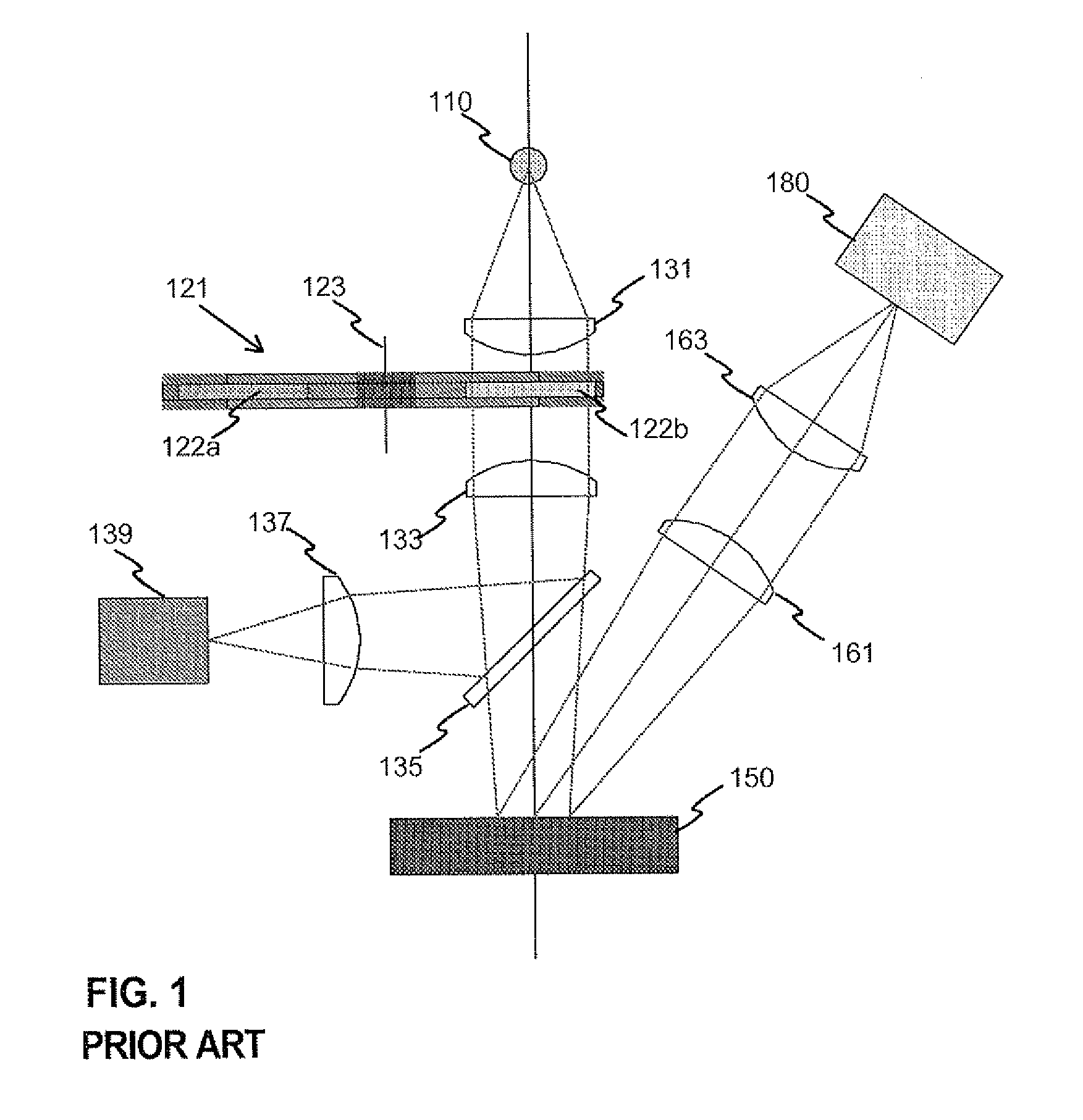

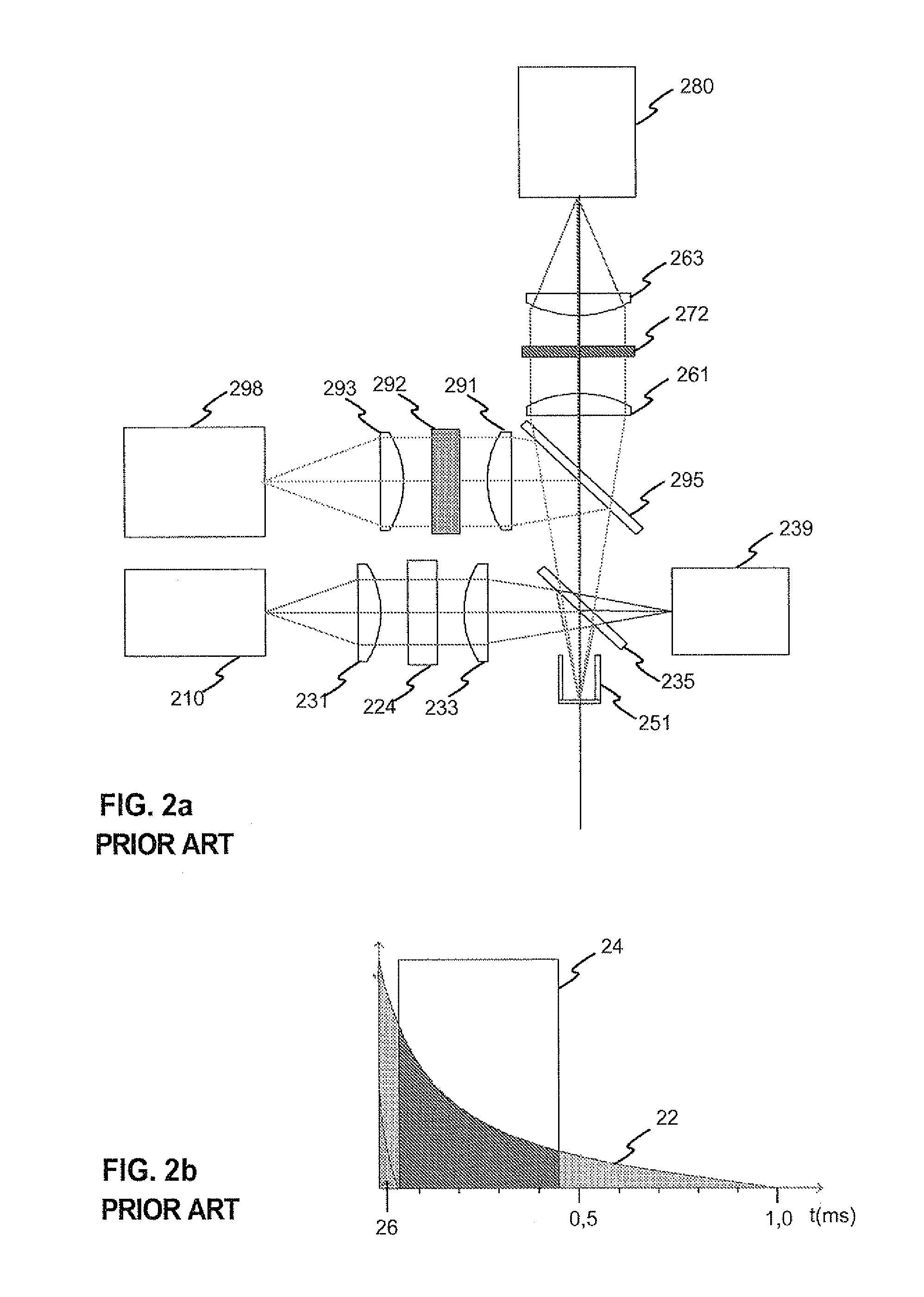

Hand-held portable fundus camera for screening photography

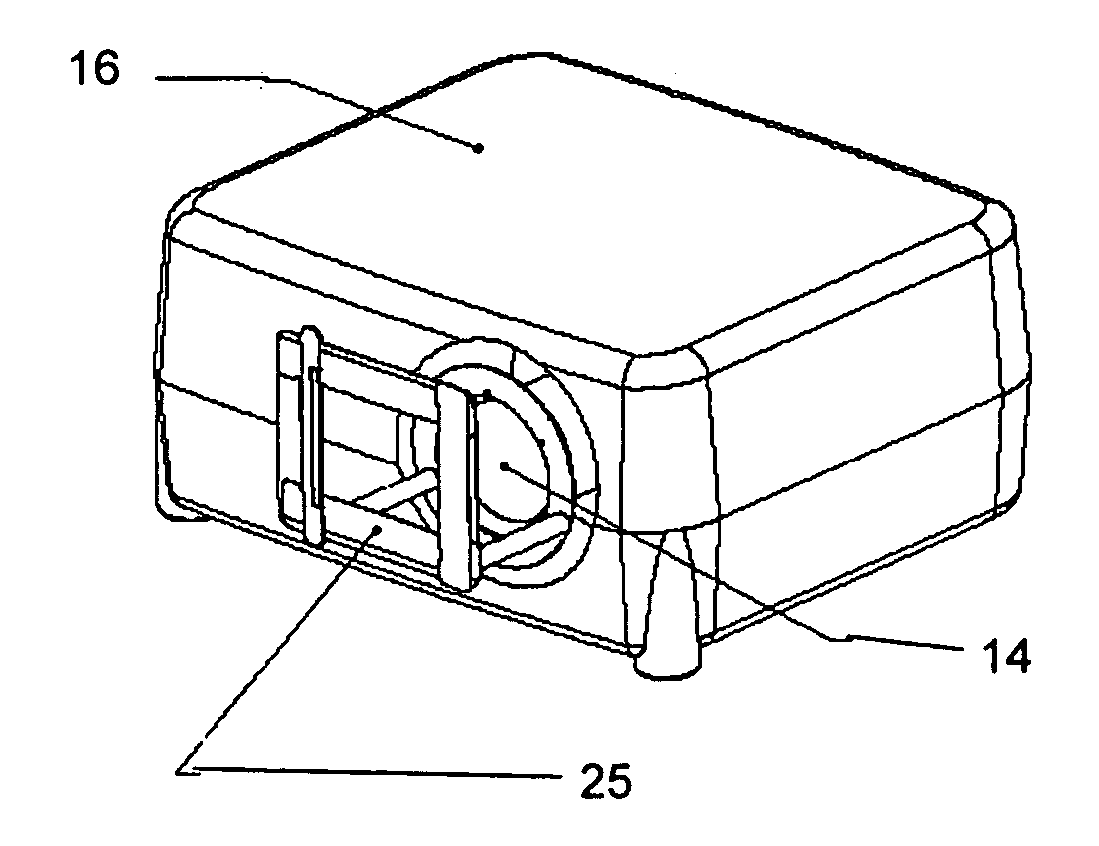

ActiveUS20120229617A1Low costEasy to useTelevision system detailsAcquiring/recognising eyesFundus cameraHand held

System and Method pertaining to the modification and integration of an existing consumer digital camera, for example, with an optical imaging module to enable point and shoot fundus photography of the eye. The auto-focus macro capability of existing consumer cameras is adapted to photograph the retina over an extended diopter range, eliminating the need for manual diopter focus adjustment. The thru-the-lens (TTL) auto-exposure flash capability of existing consumer cameras is adapted to photograph the retina with automatic flash exposure eliminating the need for manual flash adjustment. The consumer camera imaging sensor and flash are modified to allow the camera sensor to perform both non-mydriatic focusing of the retina using infrared illumination and standard color flash photography of the retina without the need for additional imaging sensors or mechanical filters. These modifications and integration of existing consumer cameras for fundus photography of the eye significantly improve ease of manufacture and usability over existing fundus cameras.

Owner:UNIV OF VIRGINIA ALUMNI PATENTS FOUND

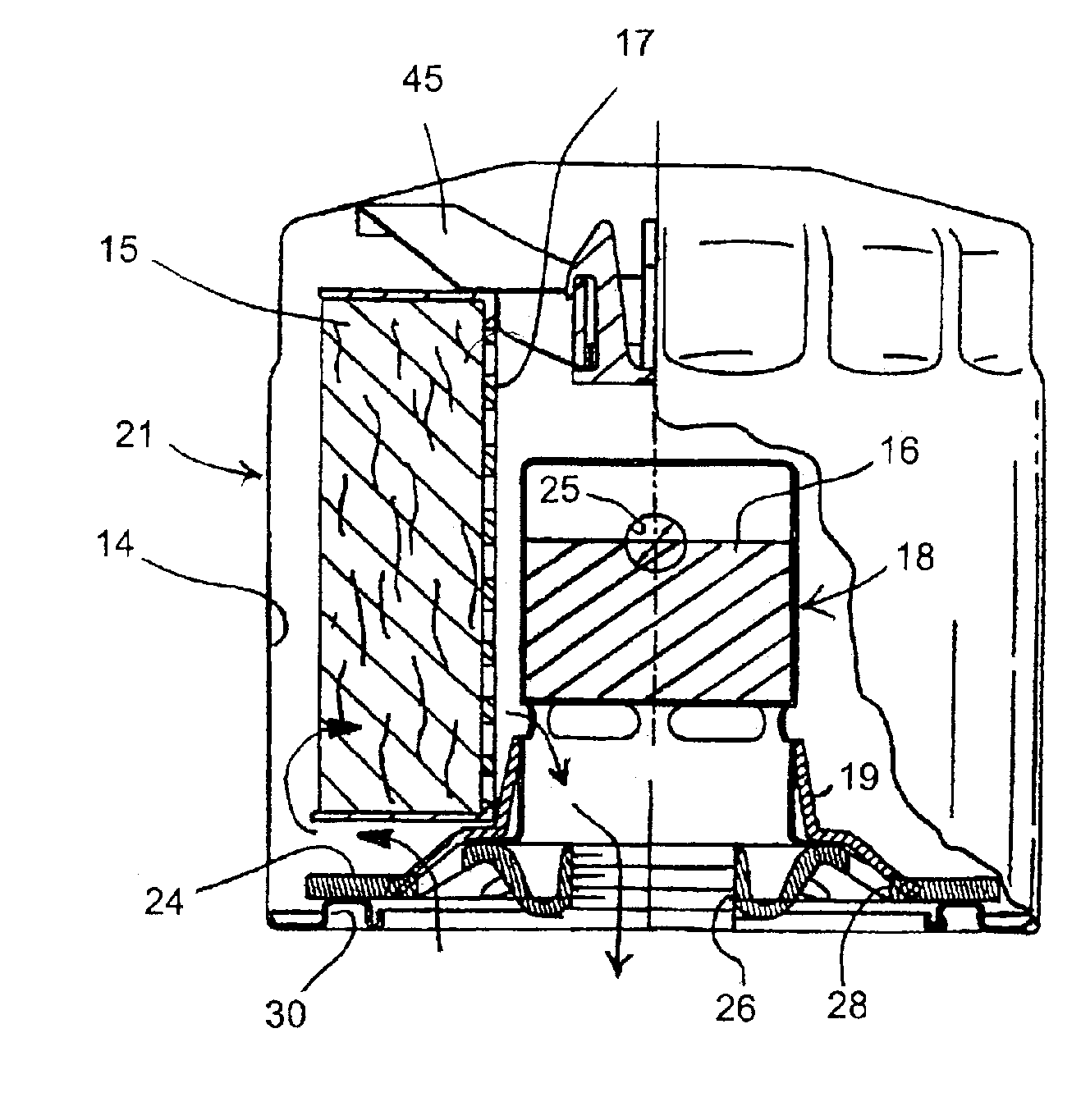

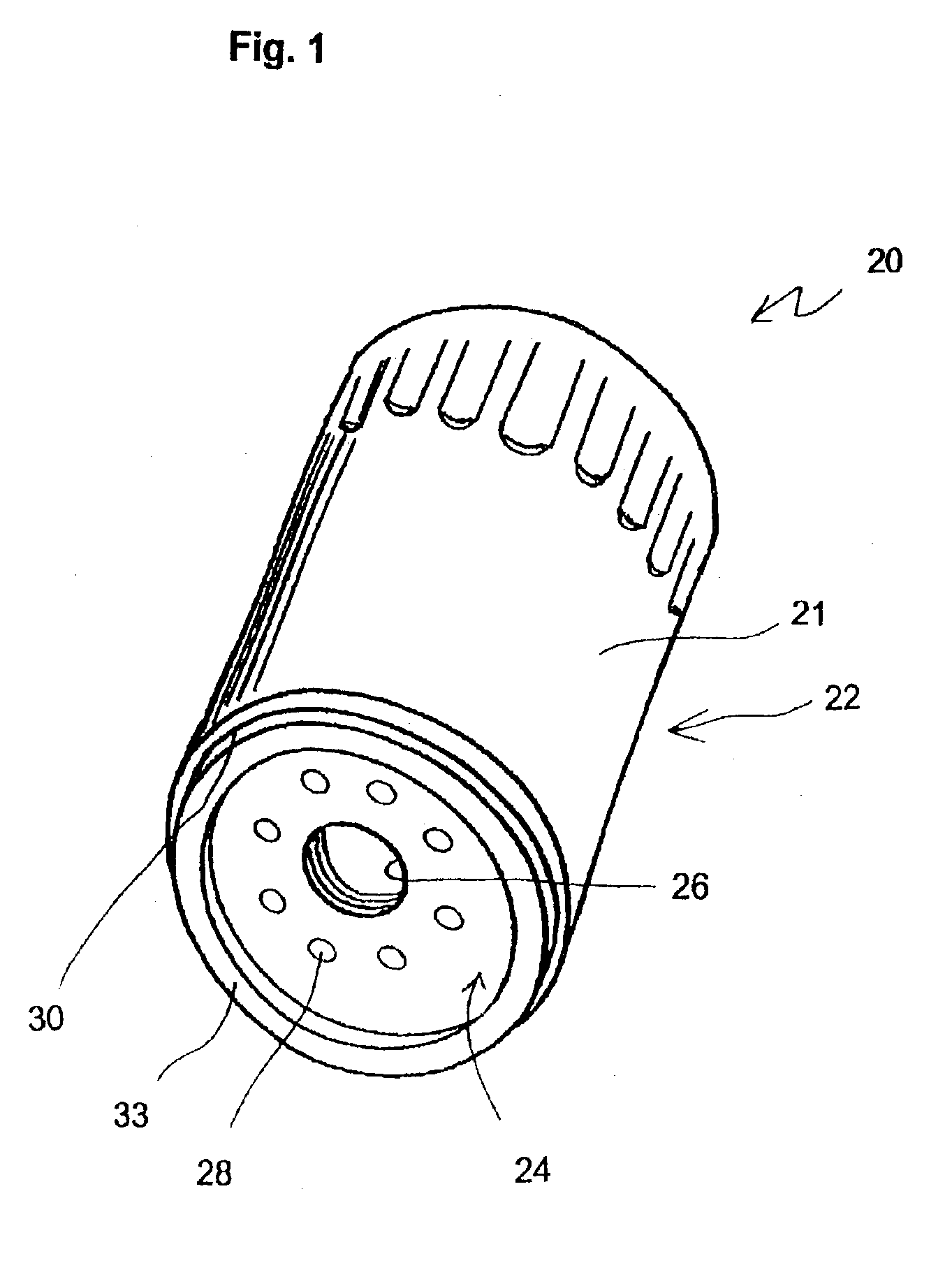

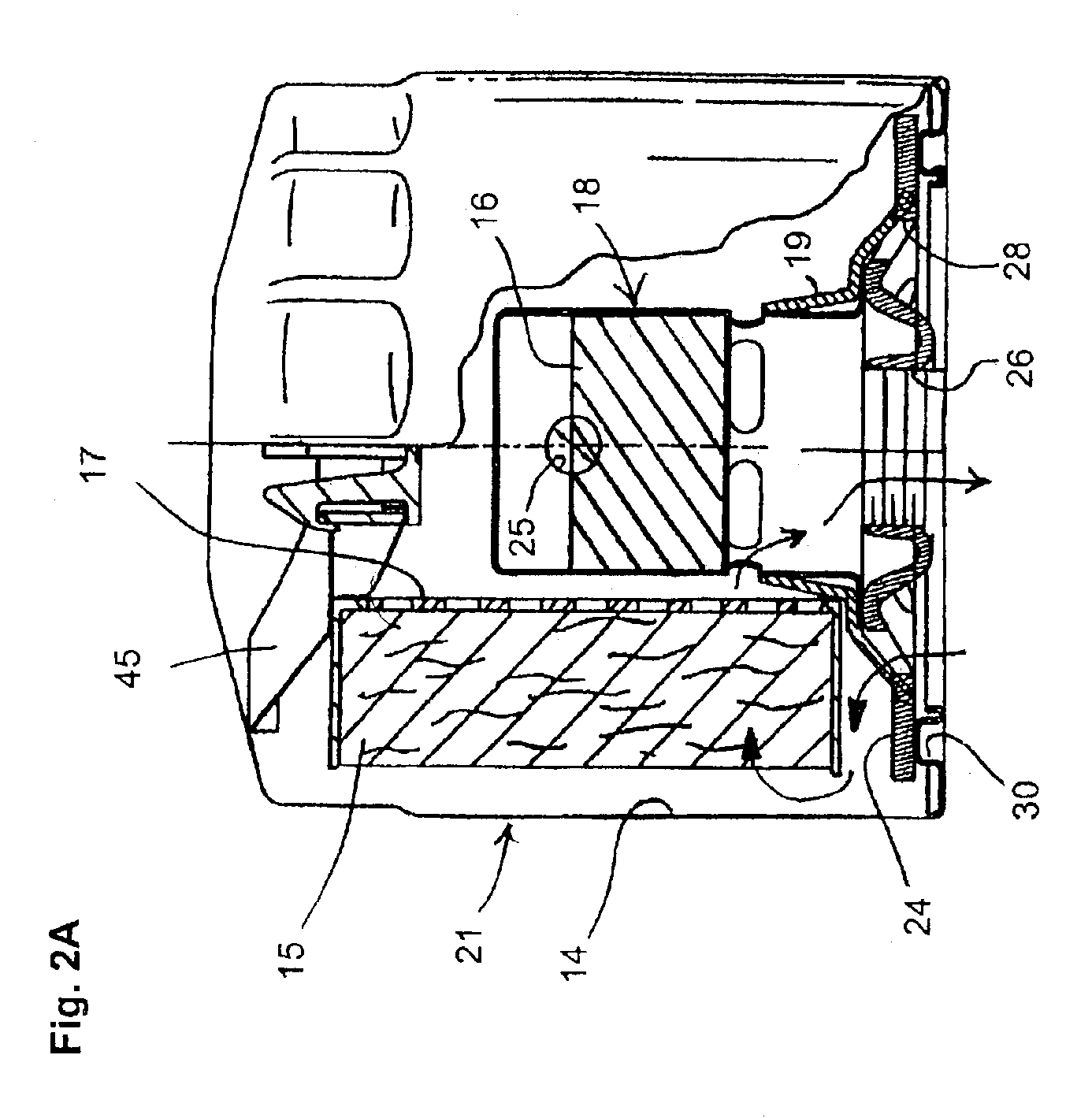

Additive dispensing cartridge for an oil filter, and oil filter incorporating same

InactiveUS7018531B2Control rateMachines/enginesSolid materialInternal combustion engineMechanical filter

An oil-conditioning filter, for use with an internal combustion engine, includes a mechanical filter element and a central additive cartridge, for gradually dispensing an oil additive over time. The additive cartridge has a beneficial oil-conditioning agent contained therein. The additive may be provided as a solid block within a storage chamber of the cartridge, or may be a plurality of pellets. Central placement of the cartridge allows for fluid filtration through the mechanical filter element before the additive is added thereto, reducing the likelihood that the additive will be filtered out prematurely upon its initial release. An additive cartridge for installation in an oil filter is also described, including a baffle portion and a storage chamber. Alternative exemplary embodiments of the additive cartridge may include a cylindrical shell, a basket which is operatively attached to an oil filter center tube, or a porous center tube.

Owner:FRAM GROUP IP +1

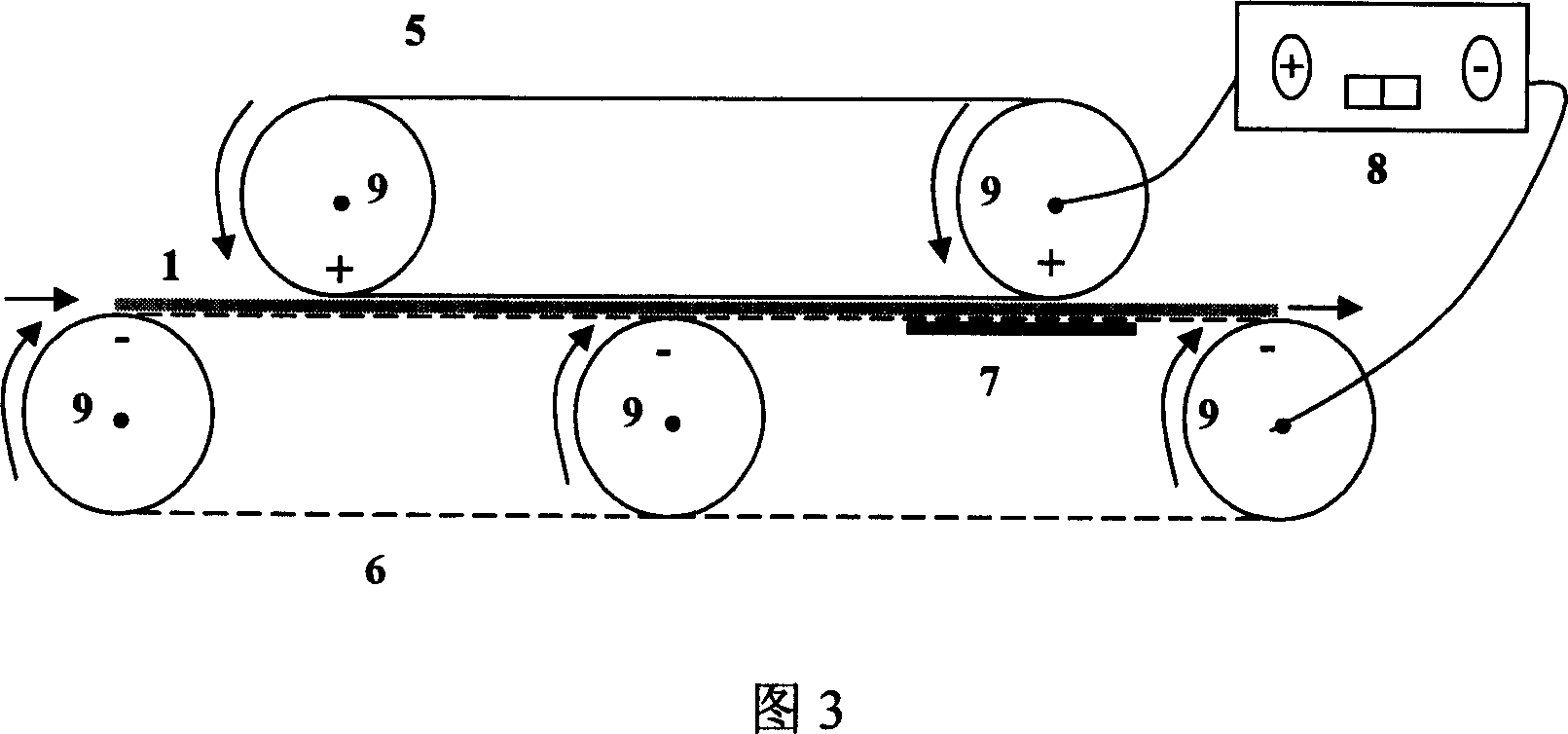

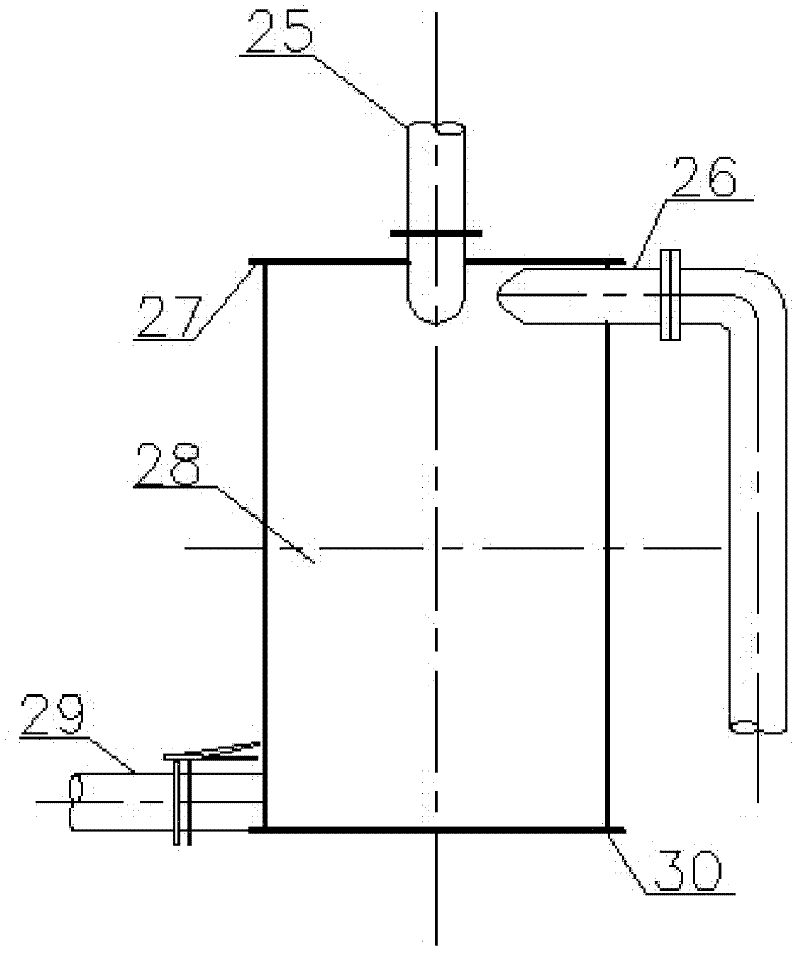

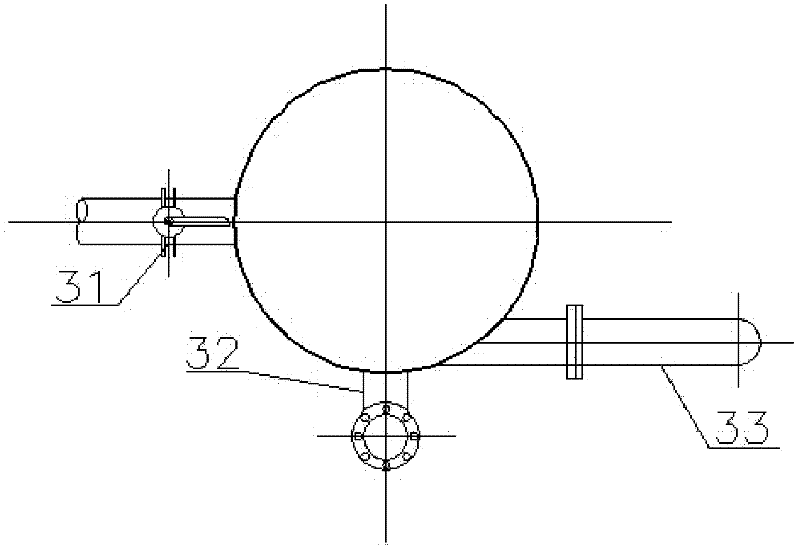

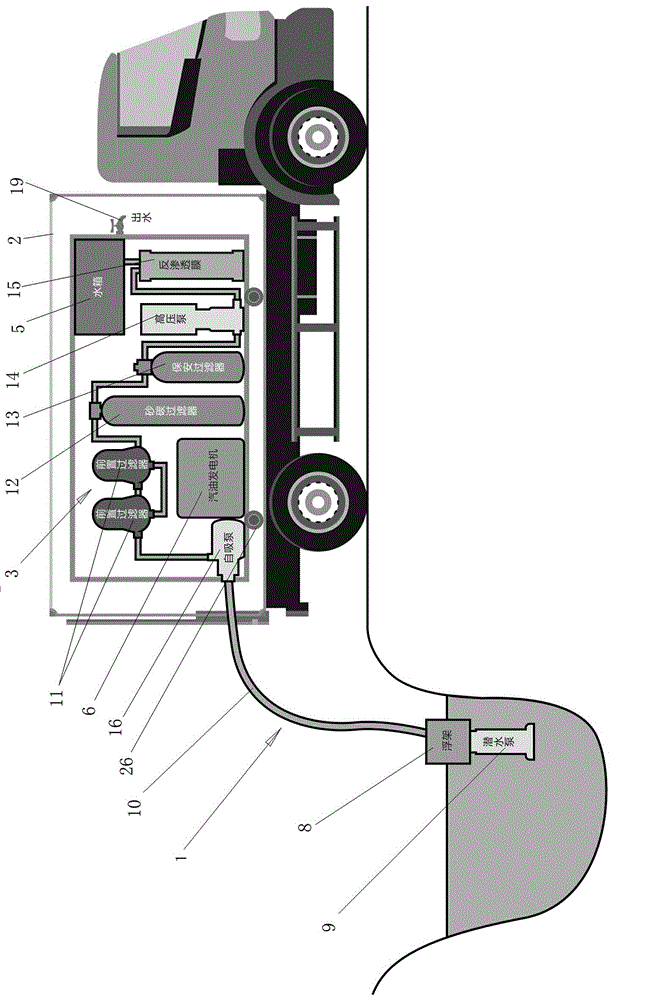

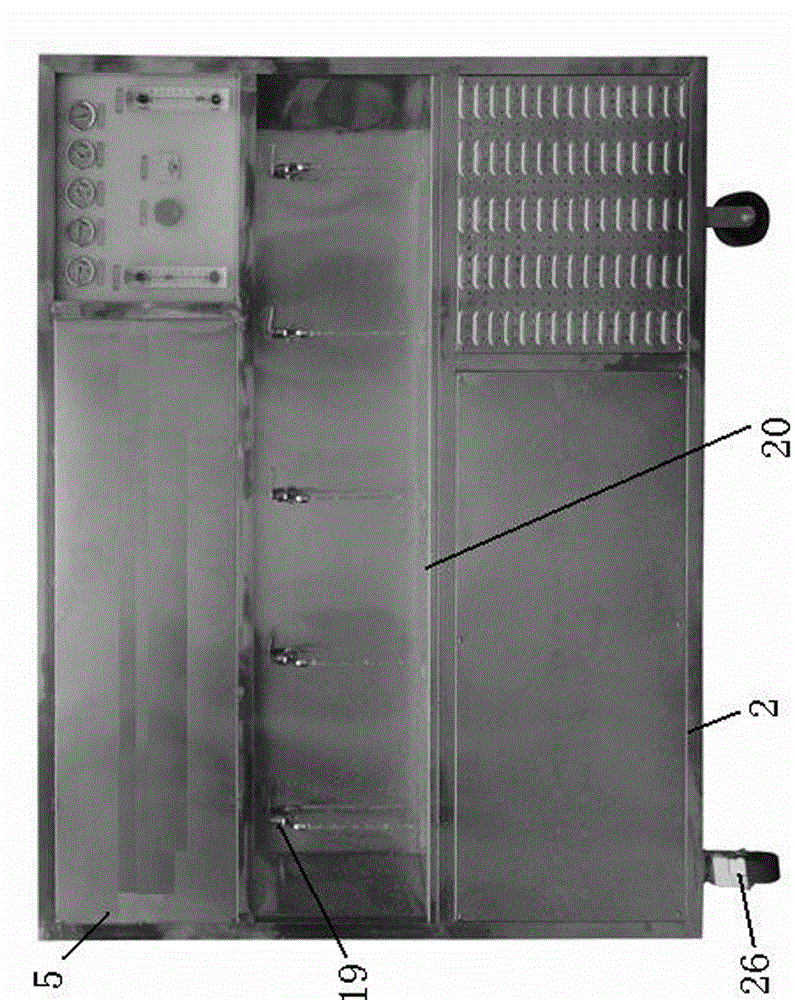

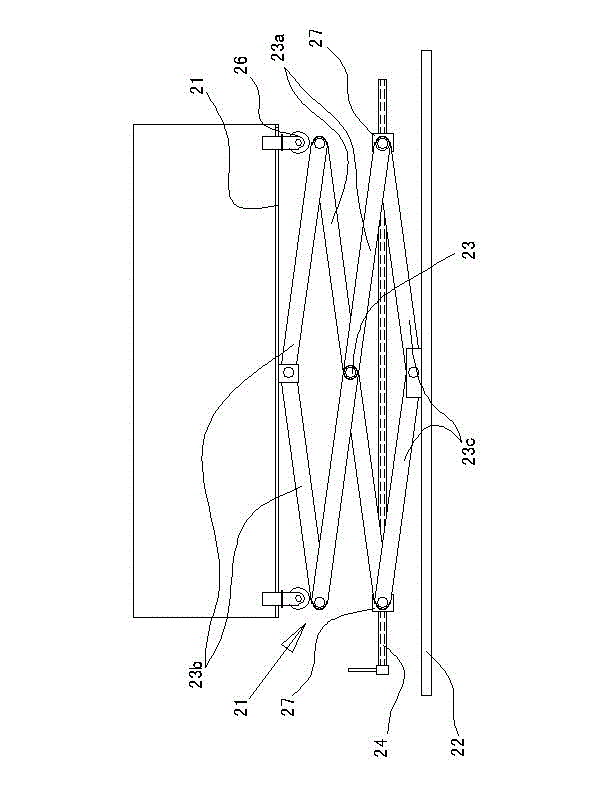

Dewatering technology of mud and its device

InactiveCN1948192ADehydration fastReduce moisture contentSludge treatment by de-watering/drying/thickeningIt equipmentBiomedical engineering

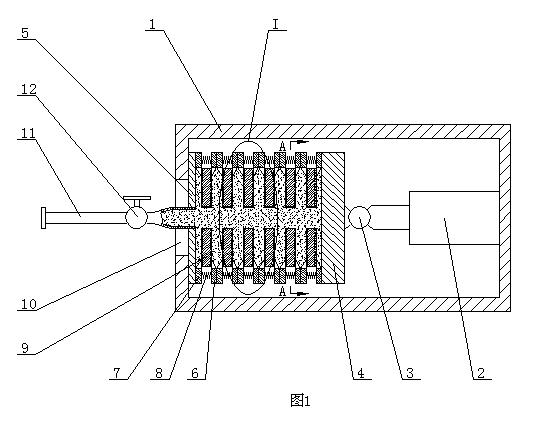

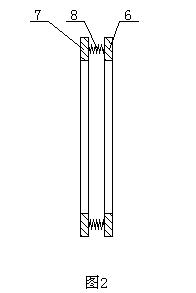

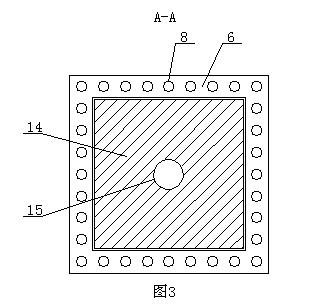

The present invention relates to a sludge dehydration process and its equipment. Said equipment includes a mechanical filter pressing device, an ultrasonic quality-improving device, a pressure synergistic electroosmosis dehydration device and an adsorption dehydration material device. The cathode of the pressure synergistic electroosmosis dehydration device is placed at one side of sludge dehydration device, and its anode is placed at another side of sludge. Said ultrasonic quality-improving device is mainly composed of three portions of ultrasonic generator, ultrasonic convertor and ultrasonic contact. Besides, said invention also provides its working principle and concrete operation method and steps.

Owner:TIANJIN UNIV

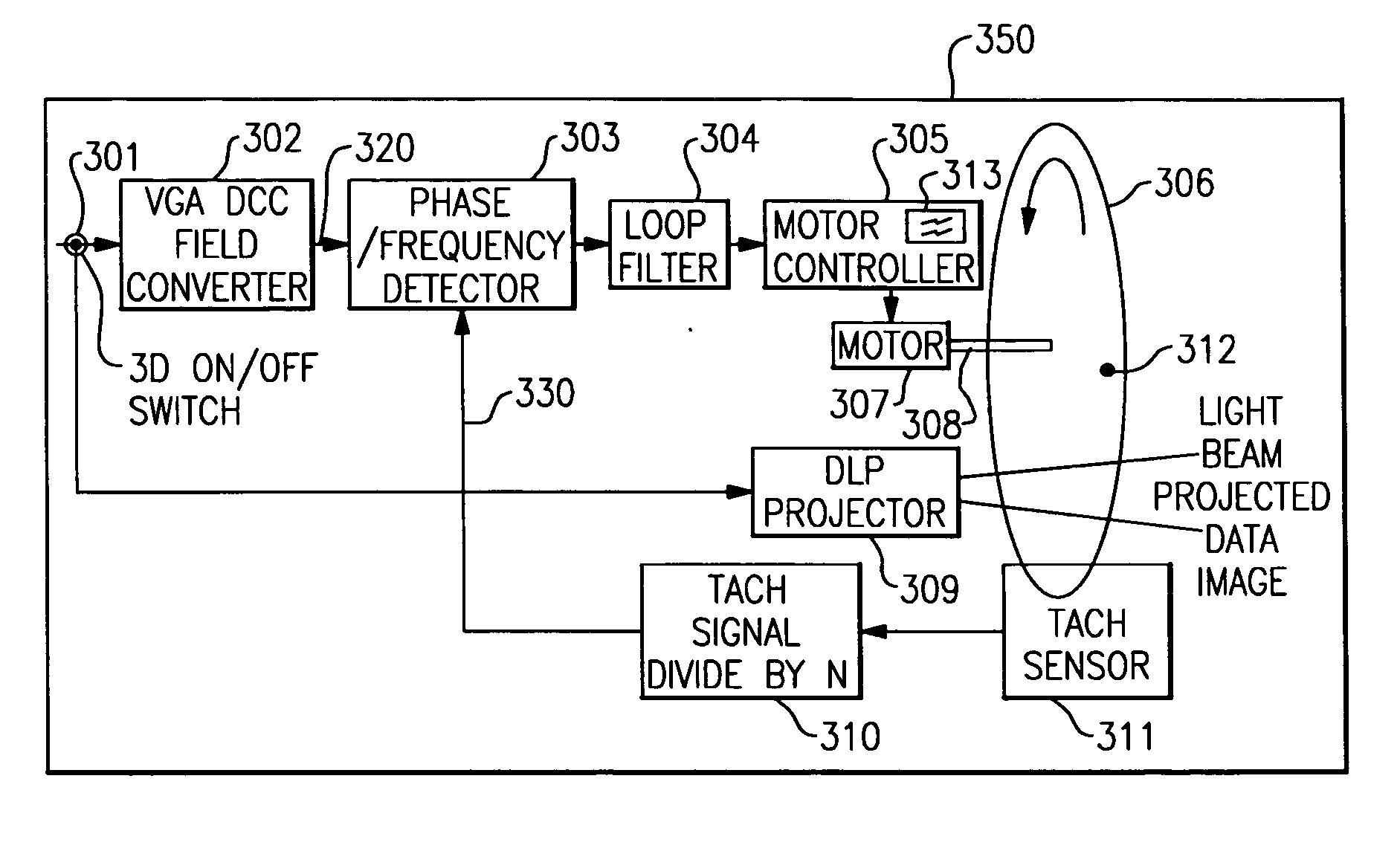

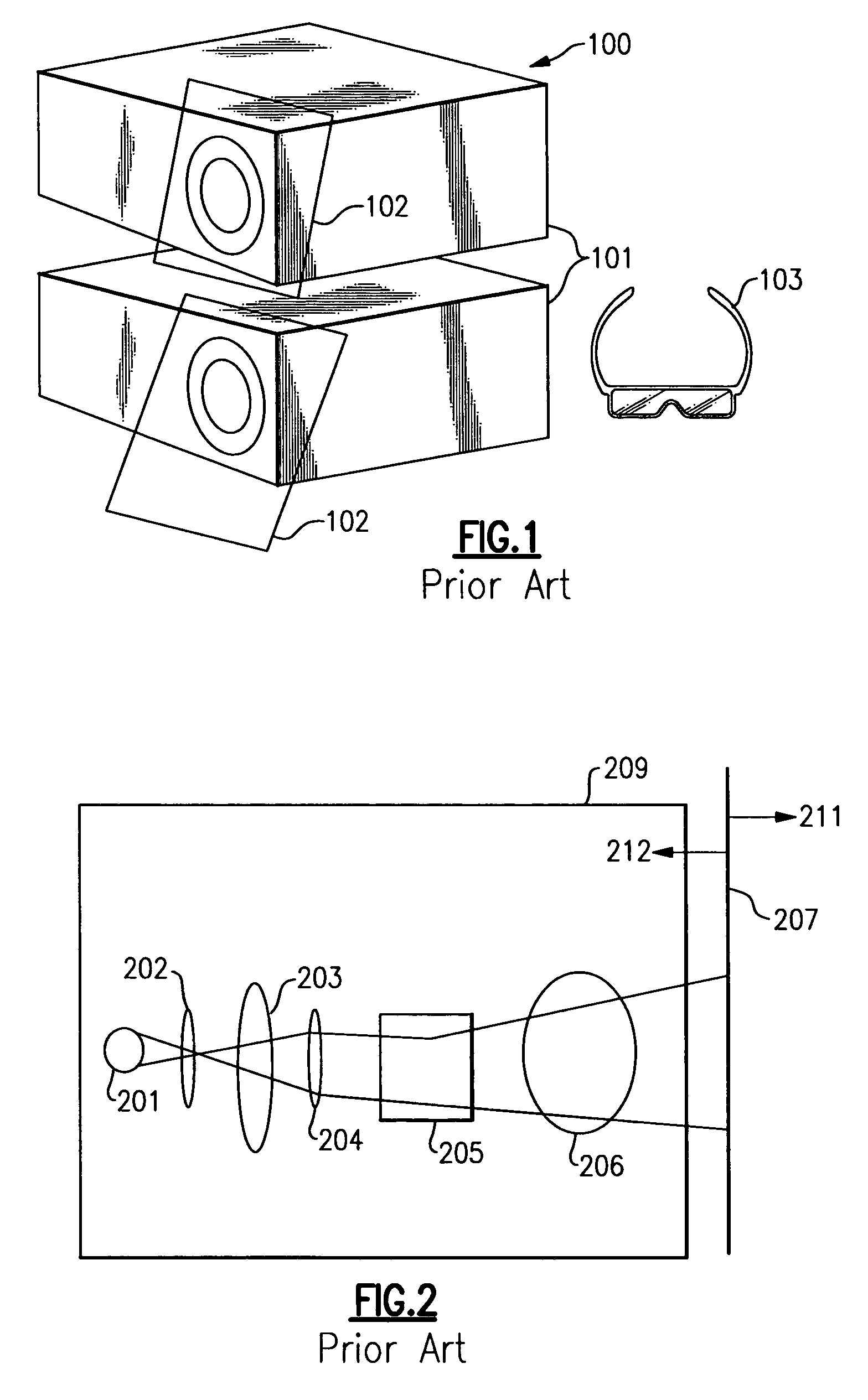

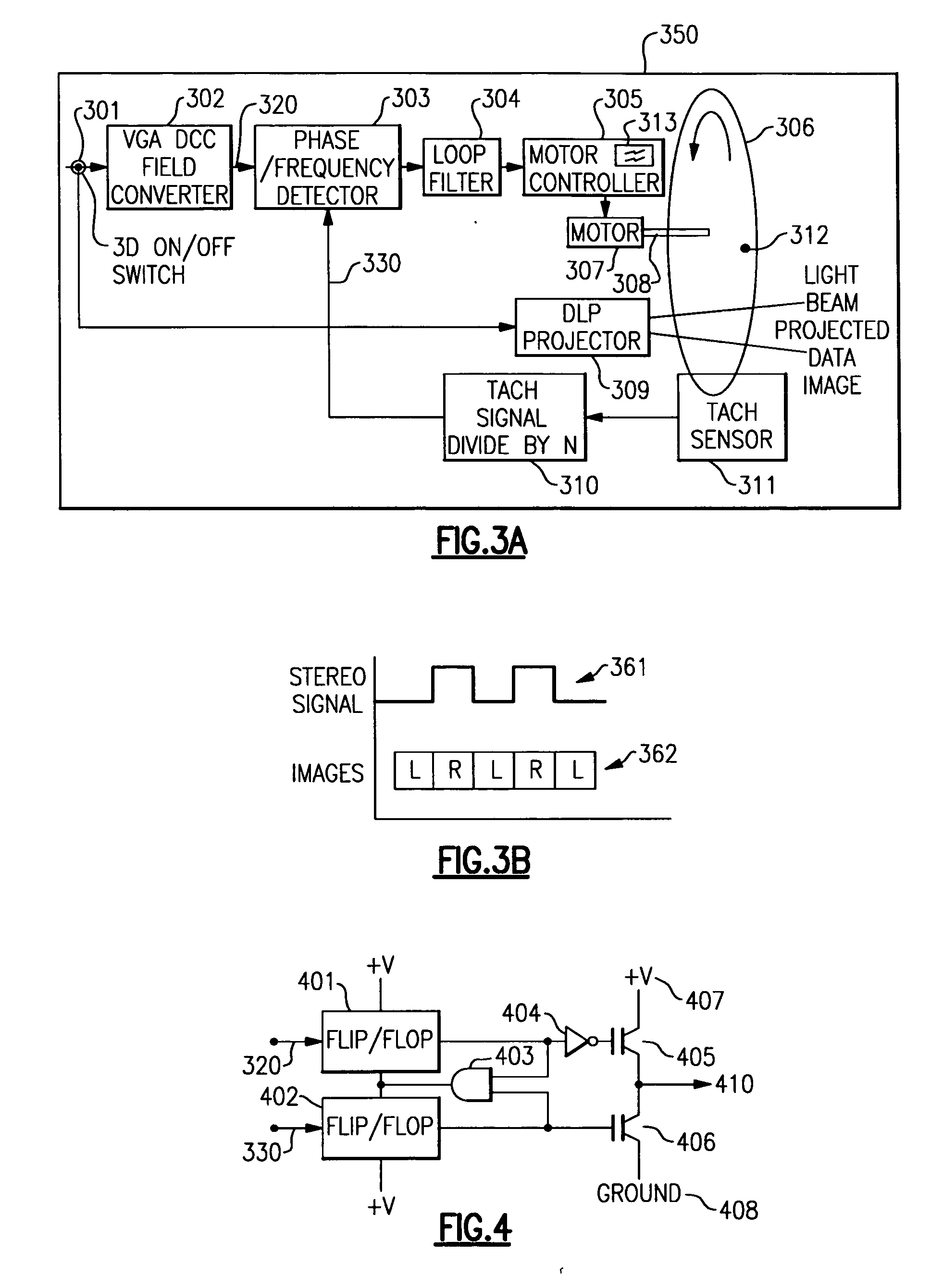

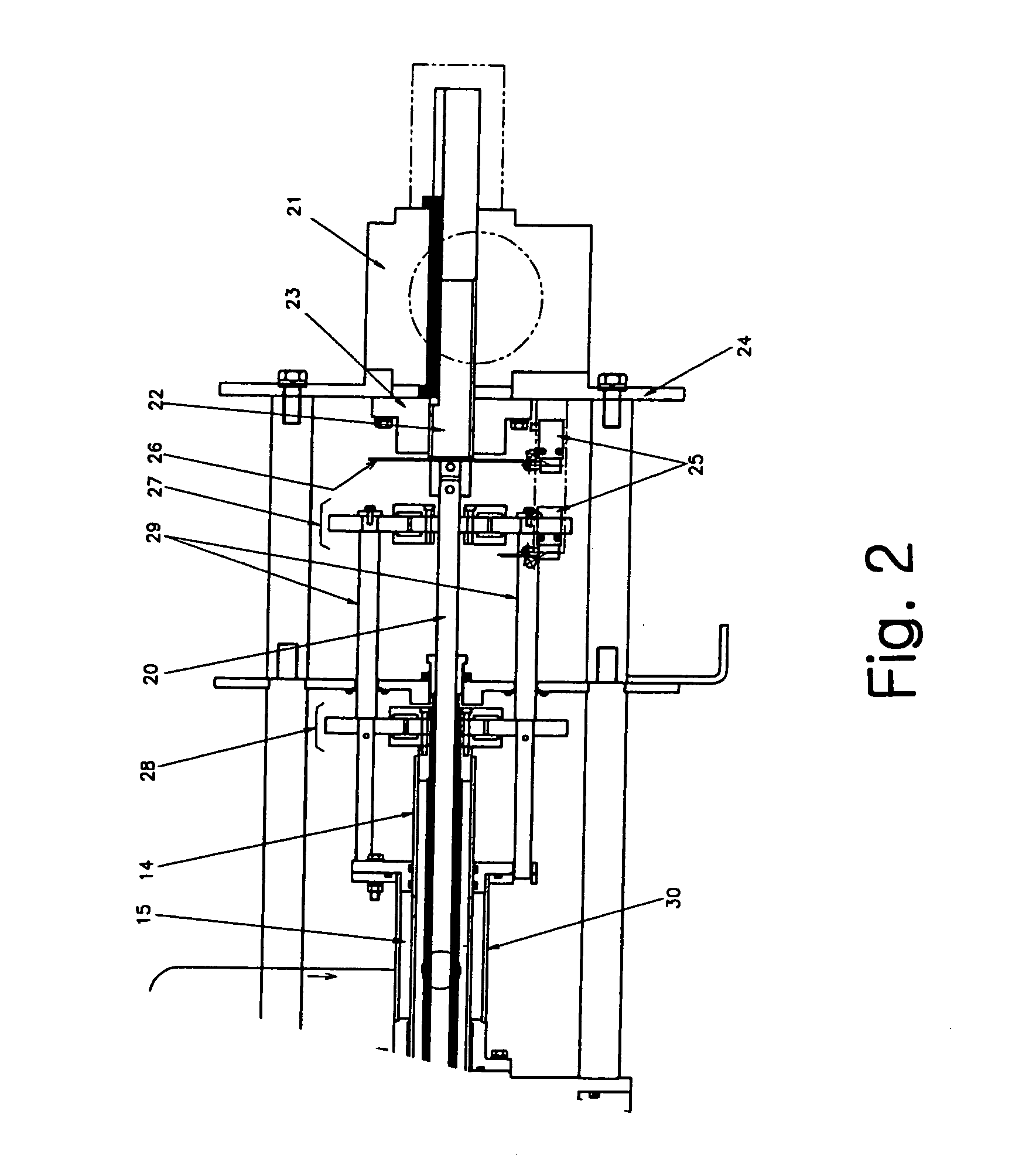

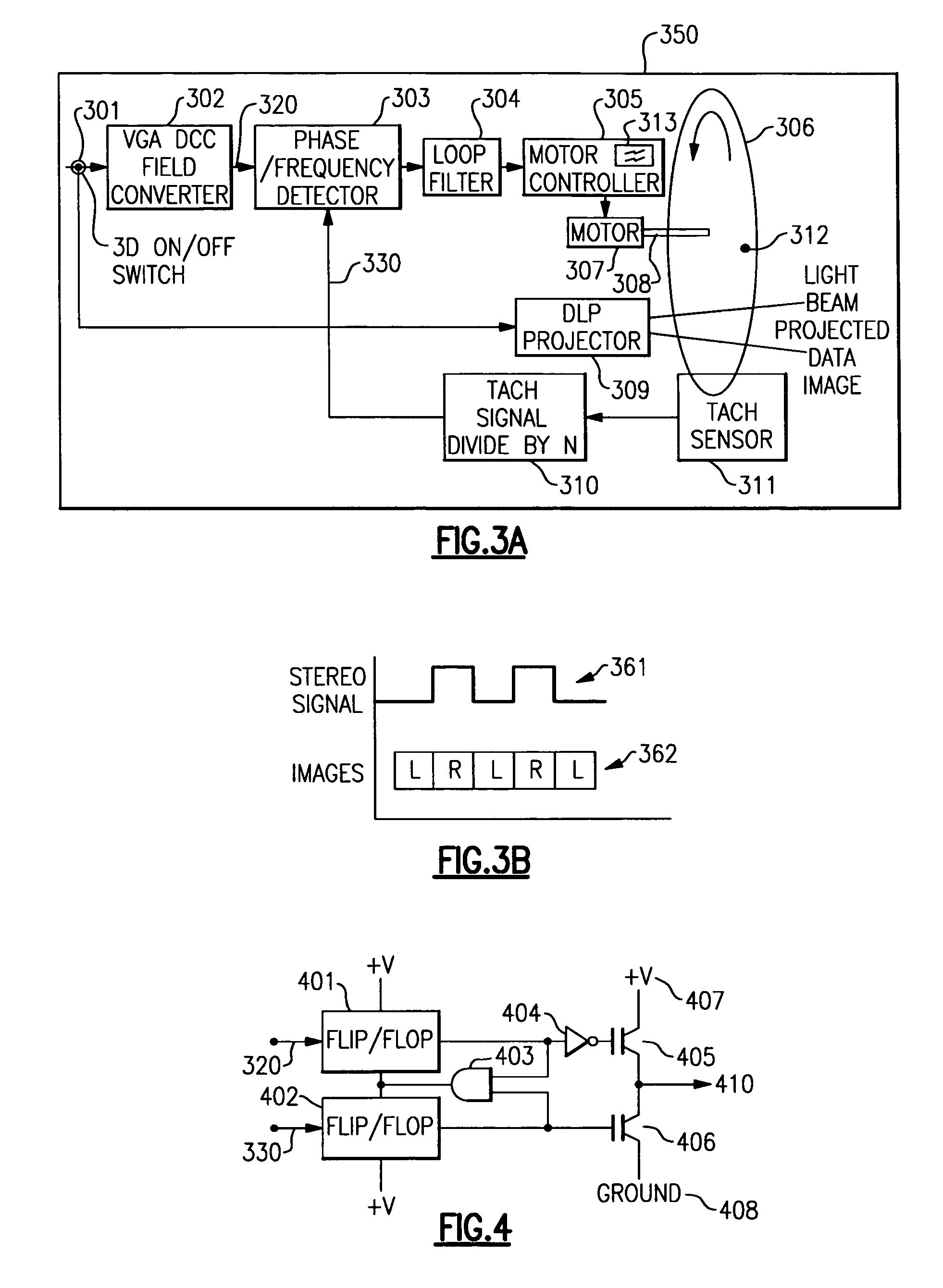

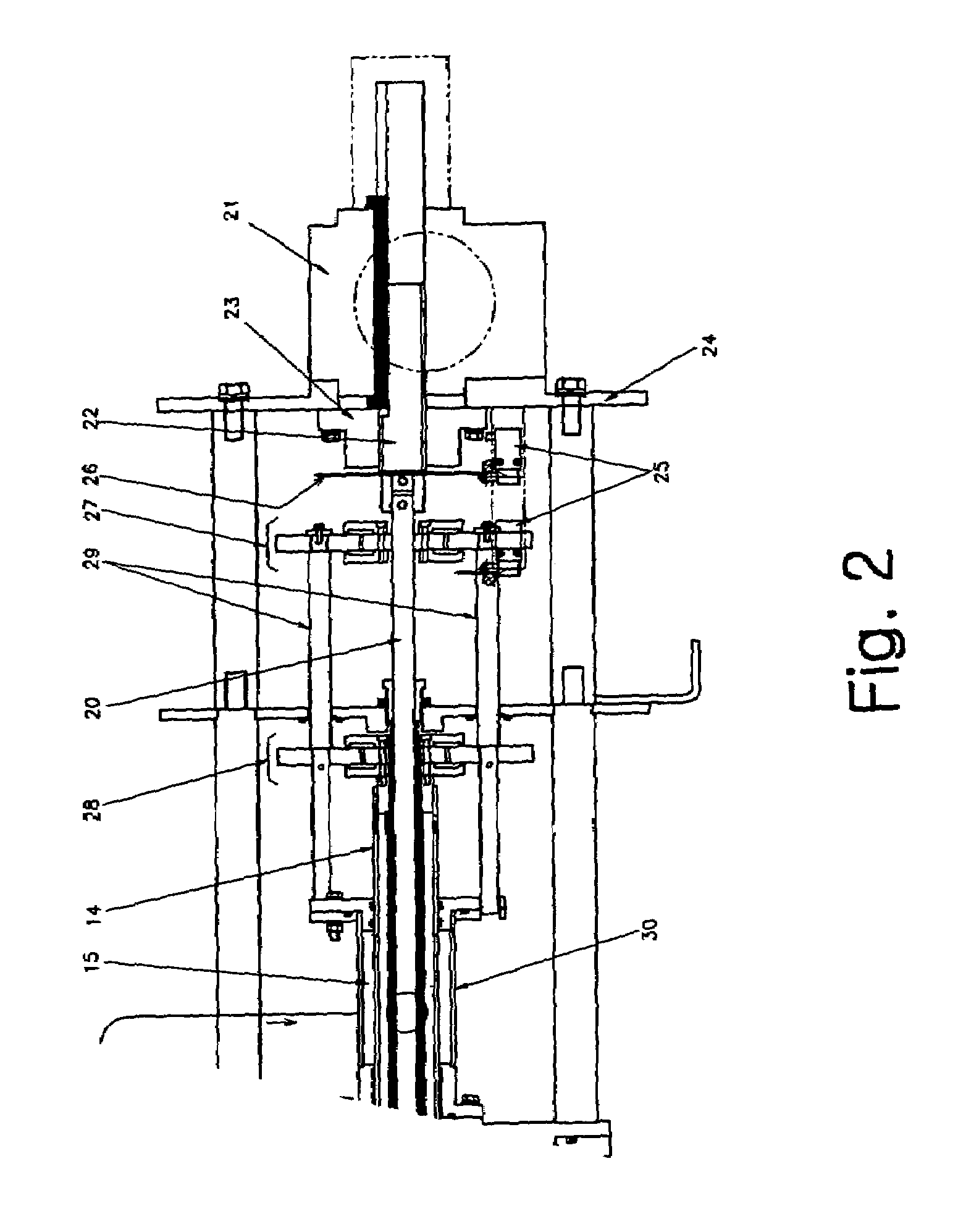

Method and system for synchronizing opto-mechanical filters to a series of video synchronization pulses and derivatives thereof

InactiveUS20070139624A1Improve visual qualityImprovement in perceived depthProjectorsShuttersComputer scienceElectromechanical actuator

A method and system for synchronizing rotating machinery or other electromechanical actuator devices to a series of sync pulses derived from a video stream comprising point optimized control laws.

Owner:IBM CORP

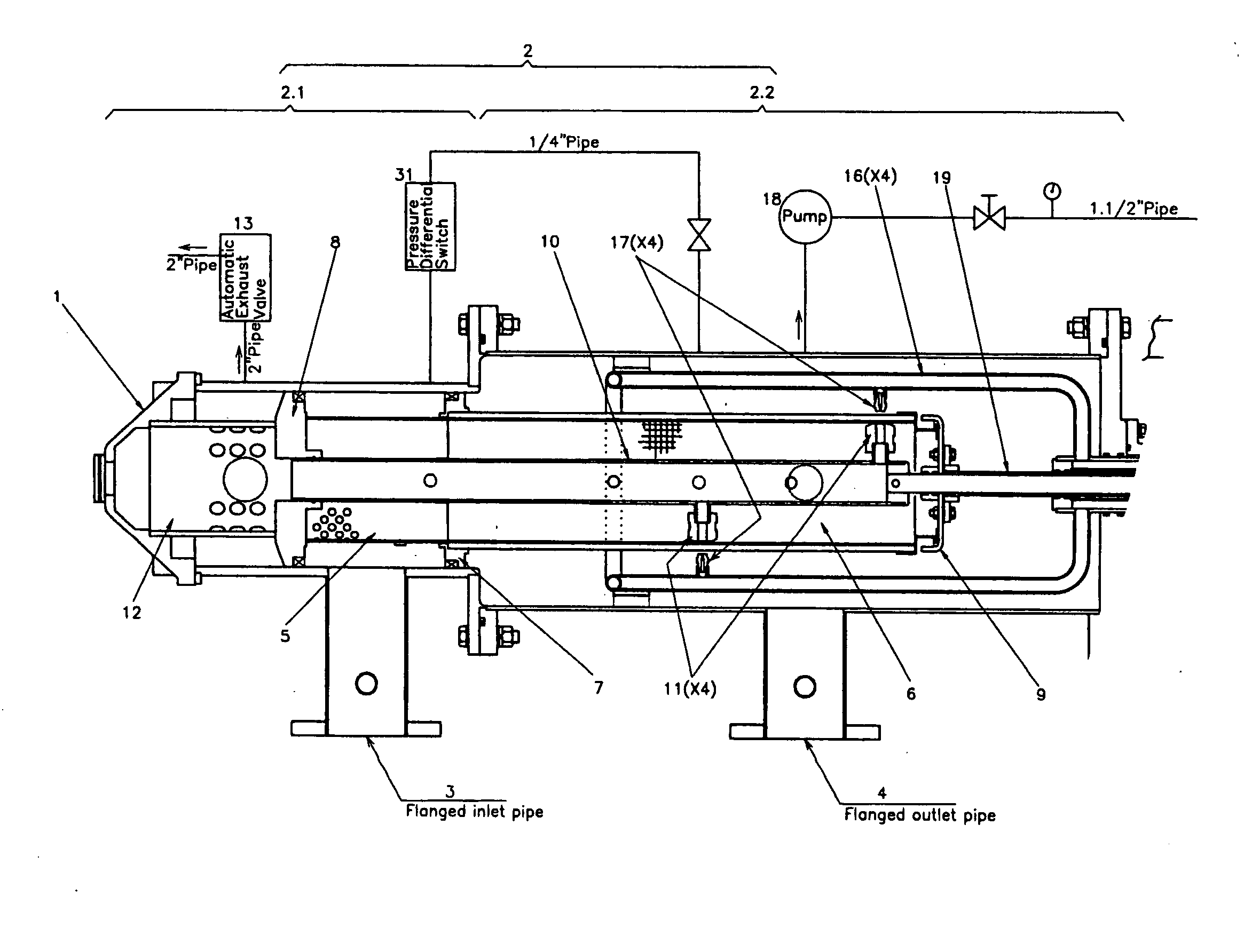

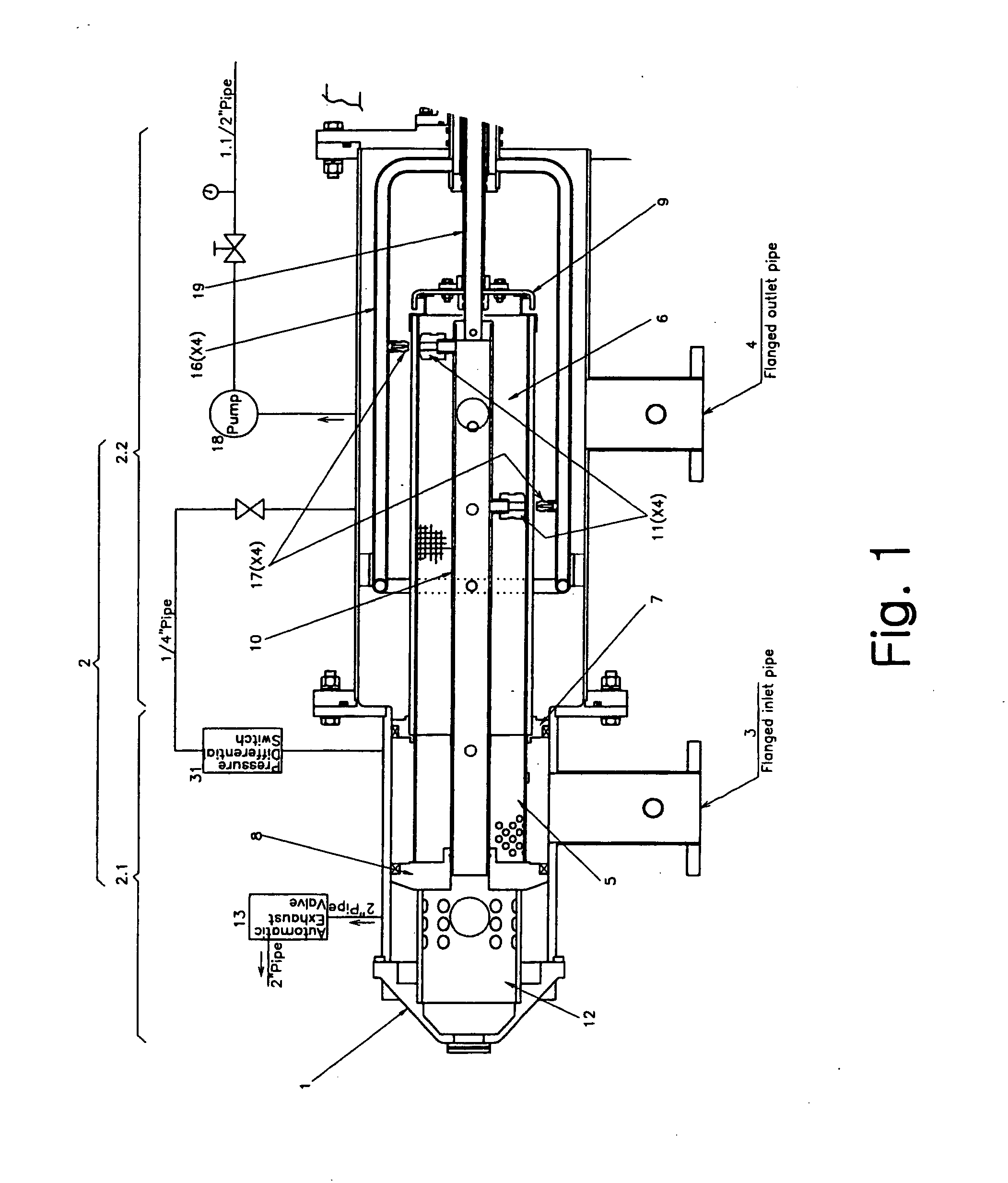

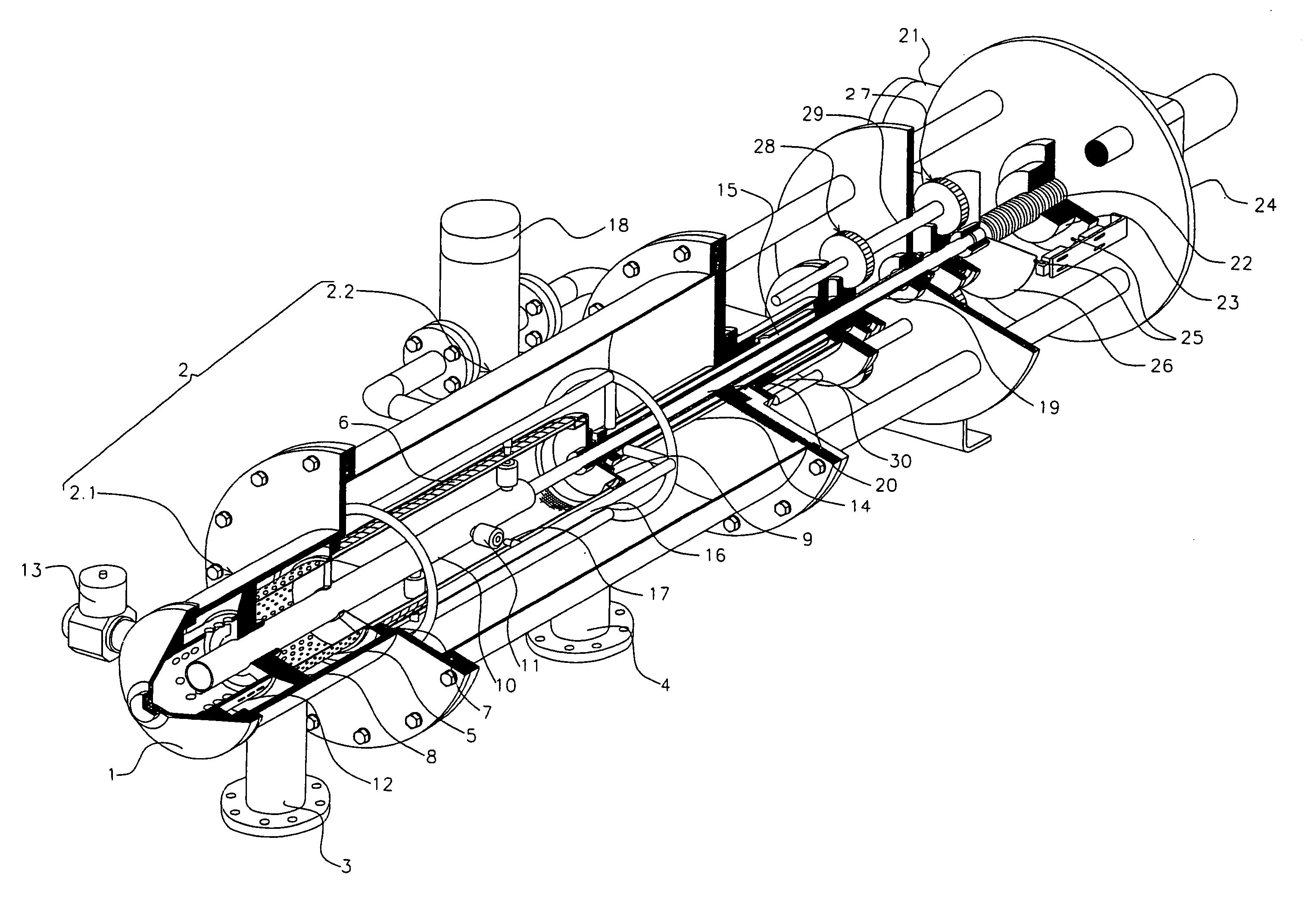

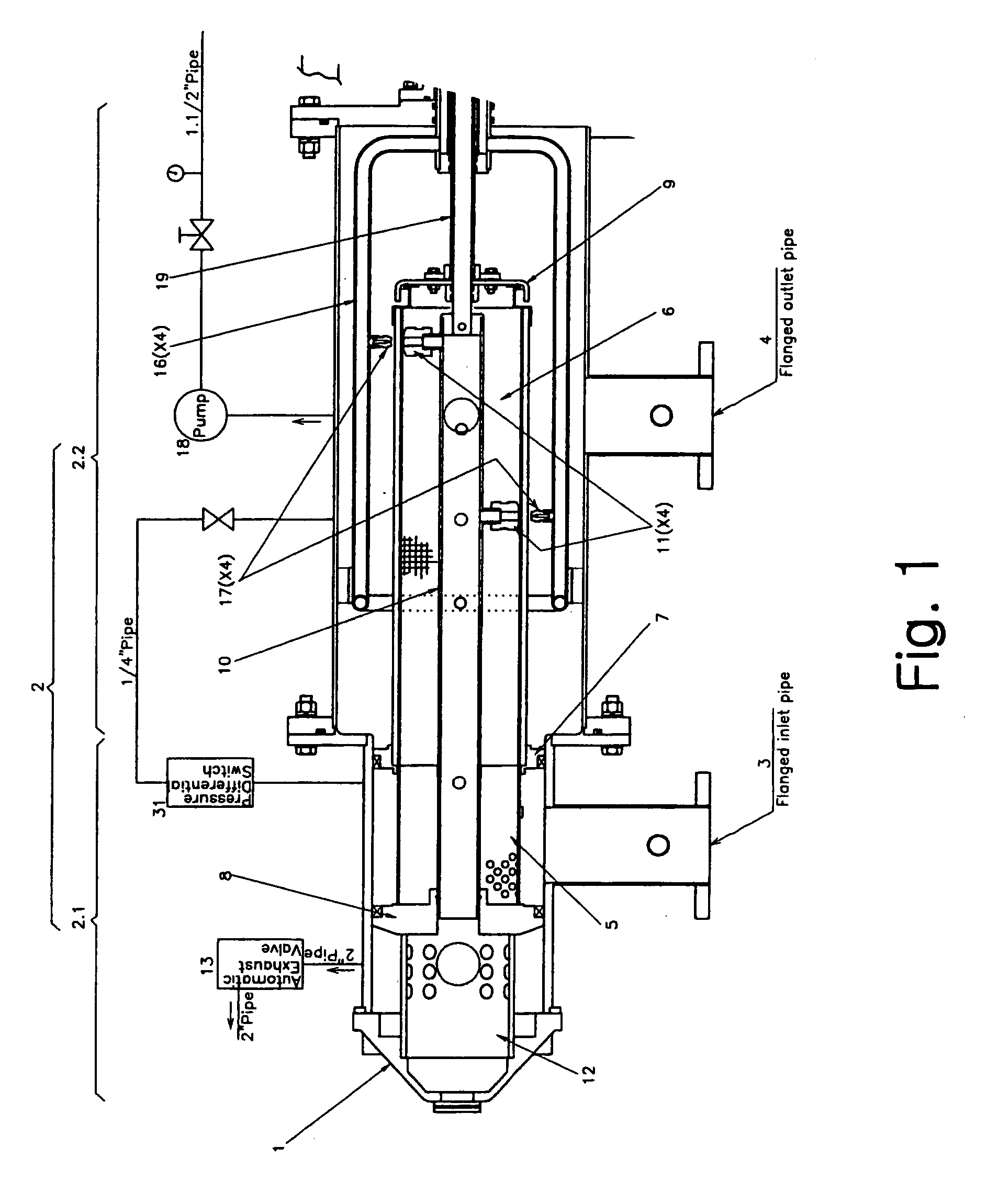

Self-cleaning mechanical filter

ActiveUS20060043014A1Long operationClean enoughMembrane filtersLoose filtering material filtersEngineeringMechanical filter

A self-cleaning mechanical filter comprises a mechanism for simultaneously cleaning the internal surface and the external surface of a filter element. The filter is provided with structure for performing suction scanning of solid materials accumulated on the internal surface of the filter element, and structure which can be operated in synchronization with the suction scanning structure for backwashing the external surface of the filter element during a self-cleaning process.

Owner:AJ BASSTECH

Method and system for synchronizing opto-mechanical filters to a series of video synchronization pulses and derivatives thereof

InactiveUS7635189B2Reduce the ratioEasy to separateProjectorsShuttersComputer scienceElectromechanical actuator

A method and system for synchronizing rotating machinery or other electromechanical actuator devices to a series of sync pulses derived from a video stream comprising point optimized control laws.

Owner:IBM CORP

Self-cleaning mechanical filter

ActiveUS7055699B2Long operationClean enoughMembrane filtersLoose filtering material filtersEngineeringMechanical filter

A self-cleaning mechanical filter comprises a mechanism for simultaneously cleaning the internal surface and the external surface of a filter element. The filter is provided with structure for performing suction scanning of solid materials accumulated on the internal surface of the filter element, and structure which can be operated in synchronization with the suction scanning structure for backwashing the external surface of the filter element during a self-cleaning process.

Owner:AJ BASSTECH

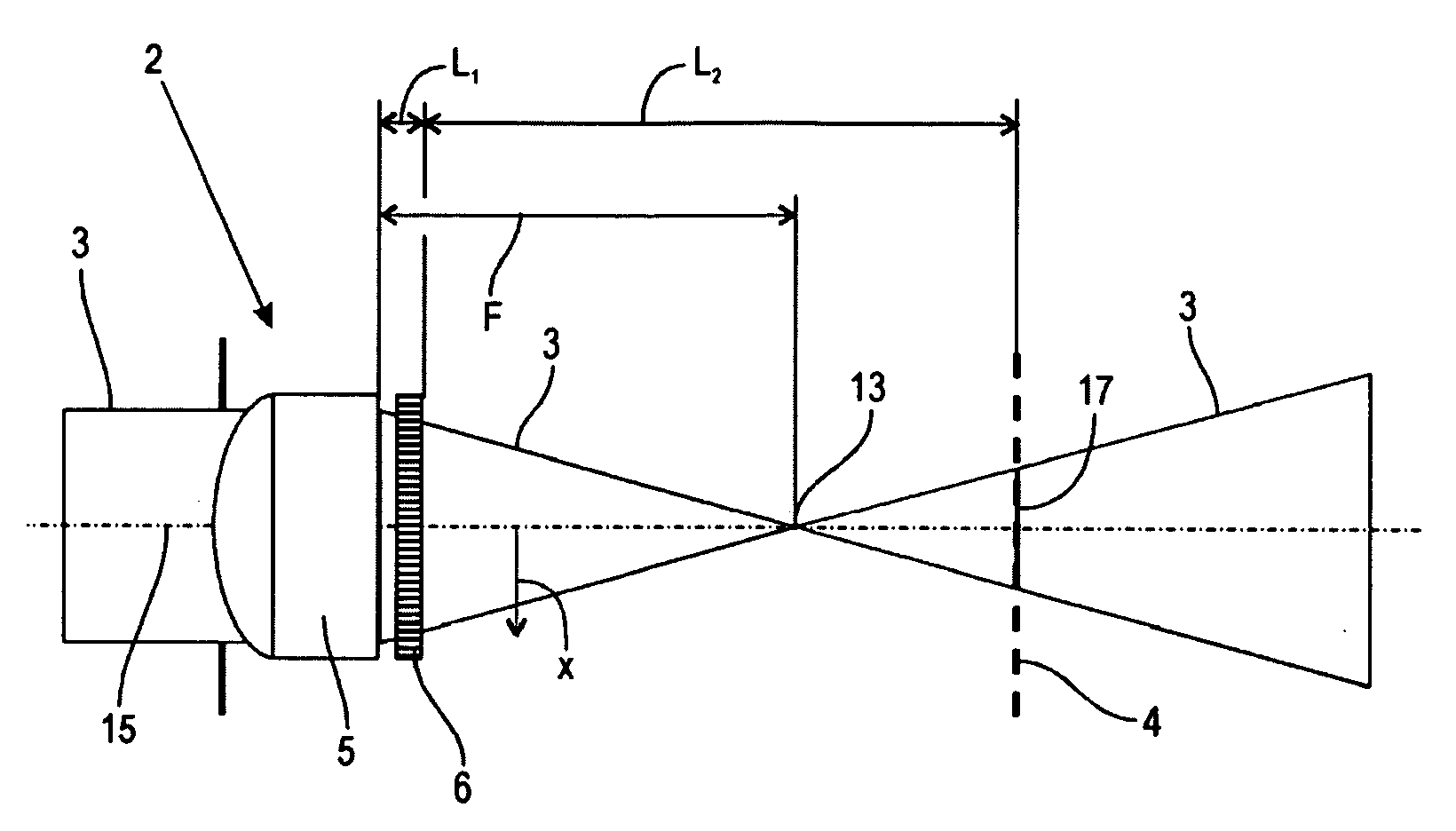

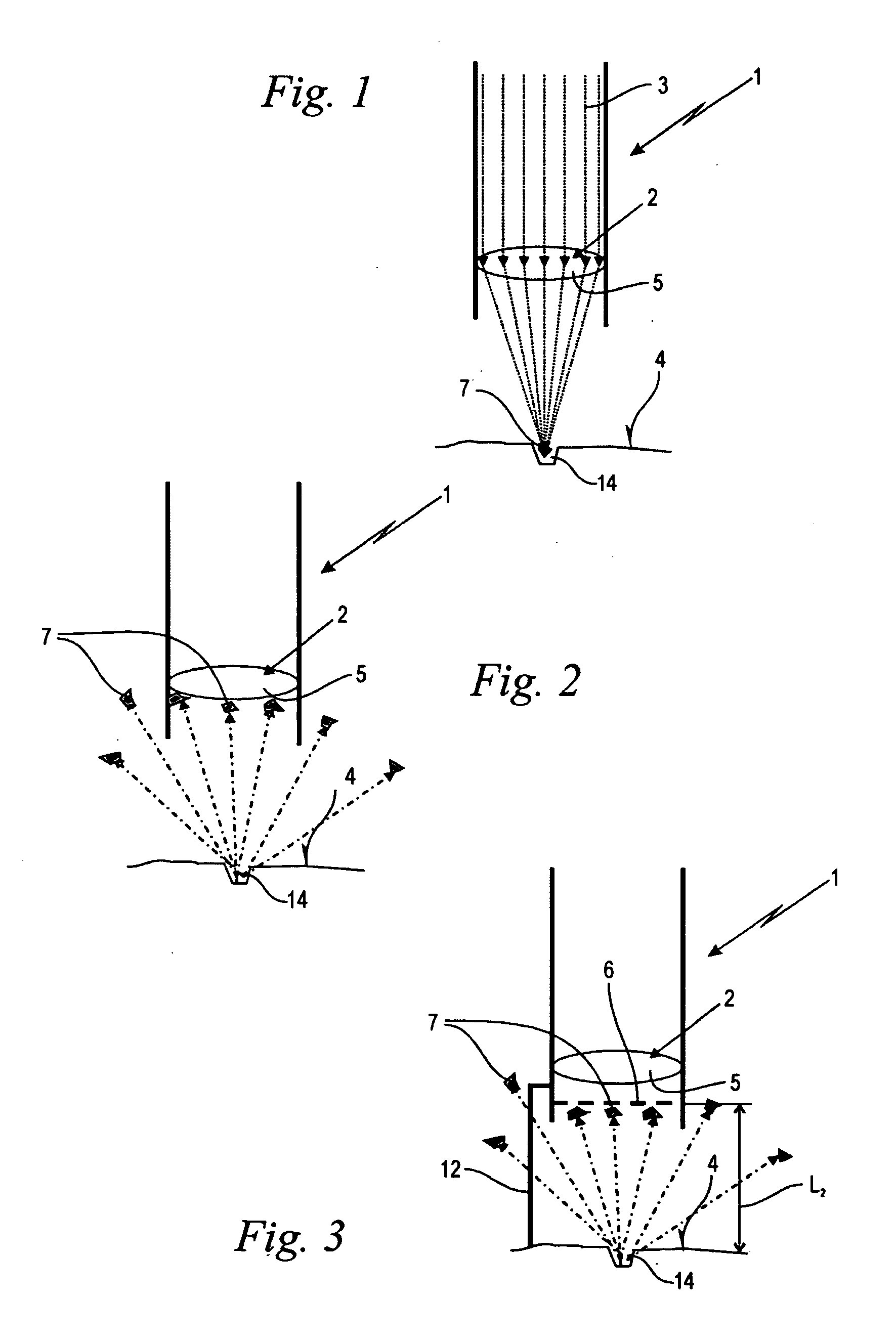

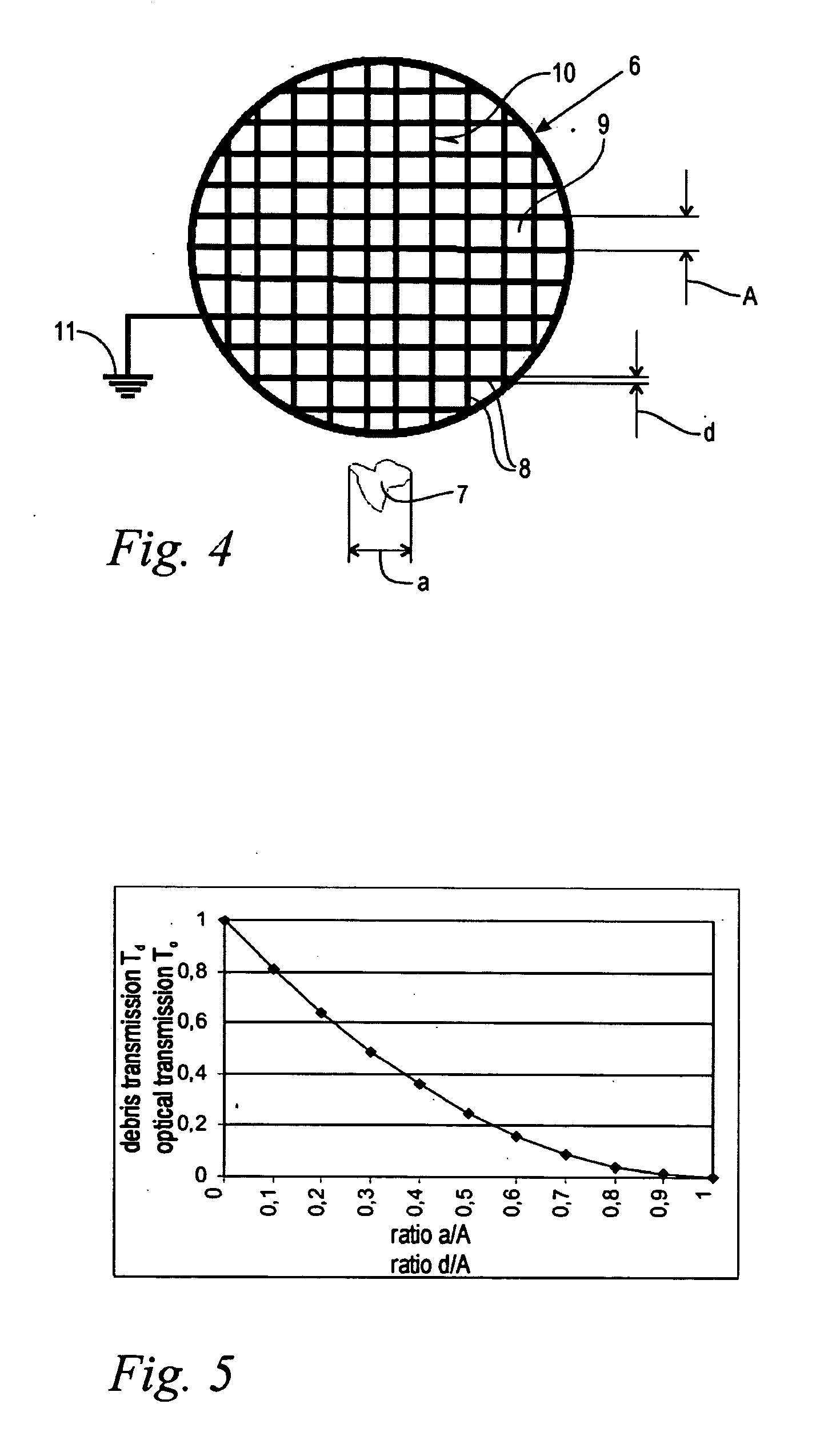

Laser System for Medical and Cosmetic Applications

InactiveUS20090059994A1Keep the distanceLarge intensityOptical resonator shape and constructionSurgical instrument detailsTarget surfaceOptoelectronics

A laser system for medical and cosmetic applications has an optical delivery system for guiding a laser beam to a target surface, wherein the optical delivery system has an external optical element facing toward the target surface. A mechanical filter in the form of a protective screen for shielding the external optical element from particles ejected away from the target surface by the laser beam is arranged at an exit side of the external optical element. The protective screen has structural elements that delimit screen openings. The laser system has spacers that maintain a spacing of the protective screen relative to the target surface.

Owner:FOTONA D D

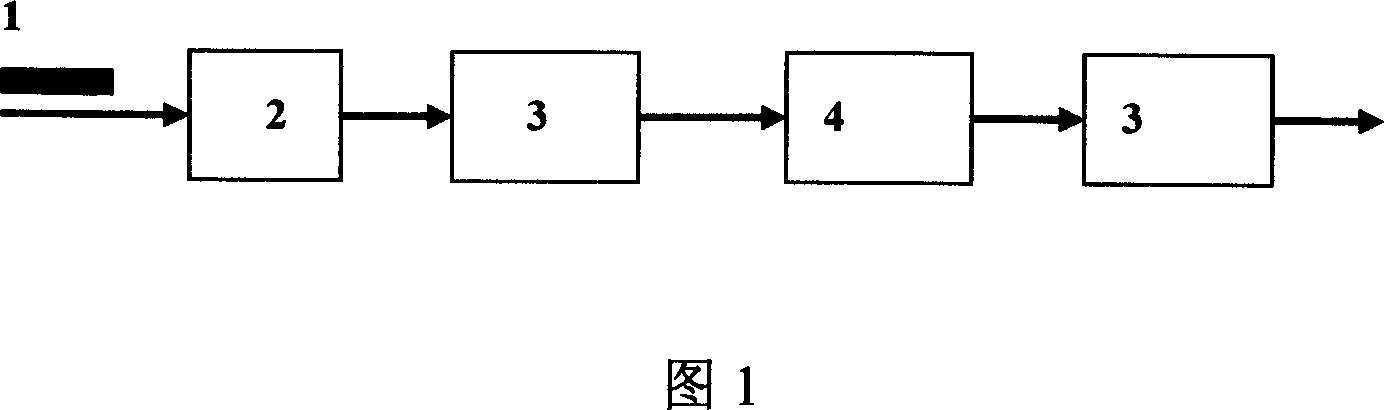

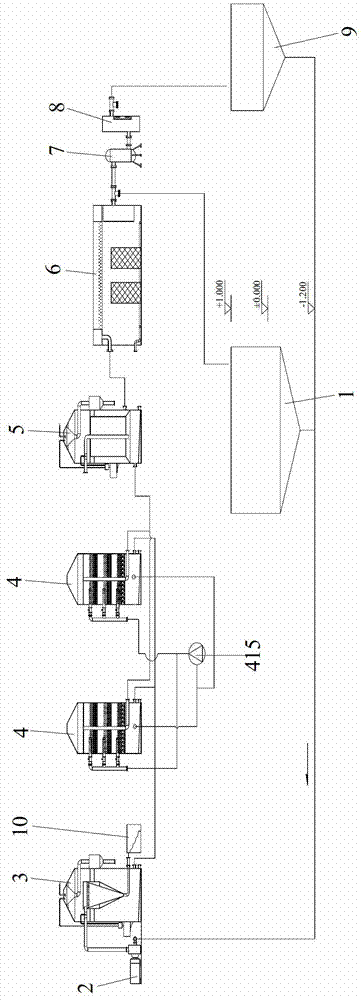

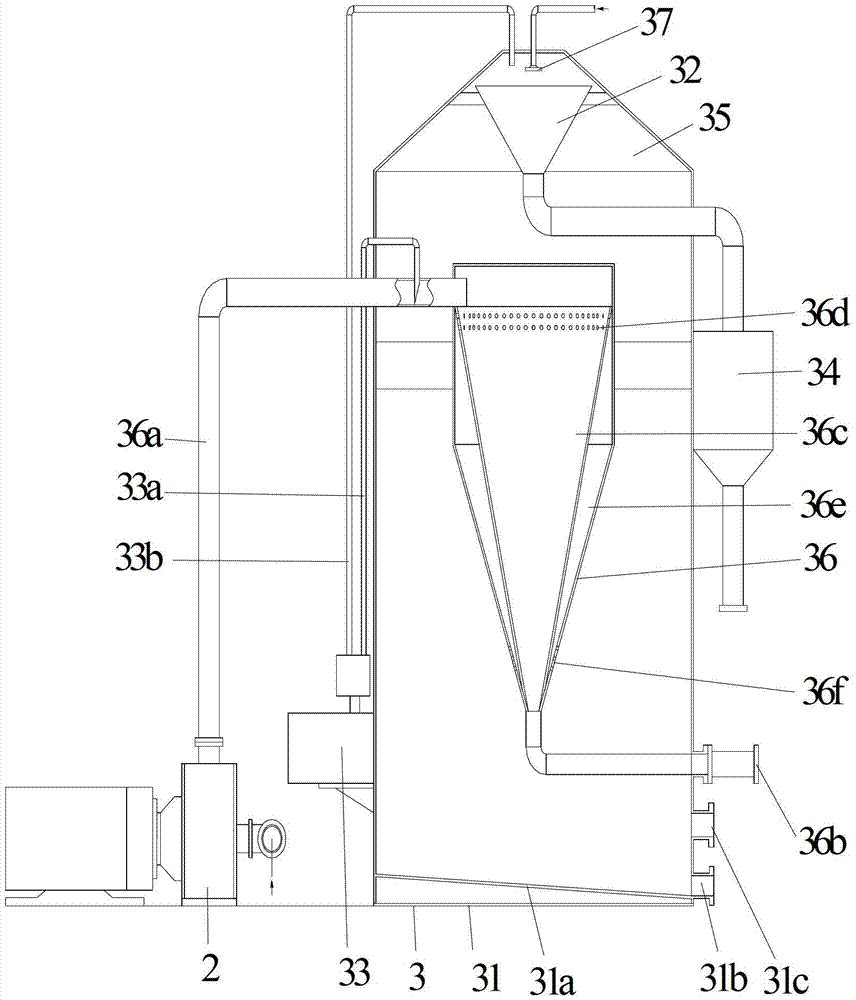

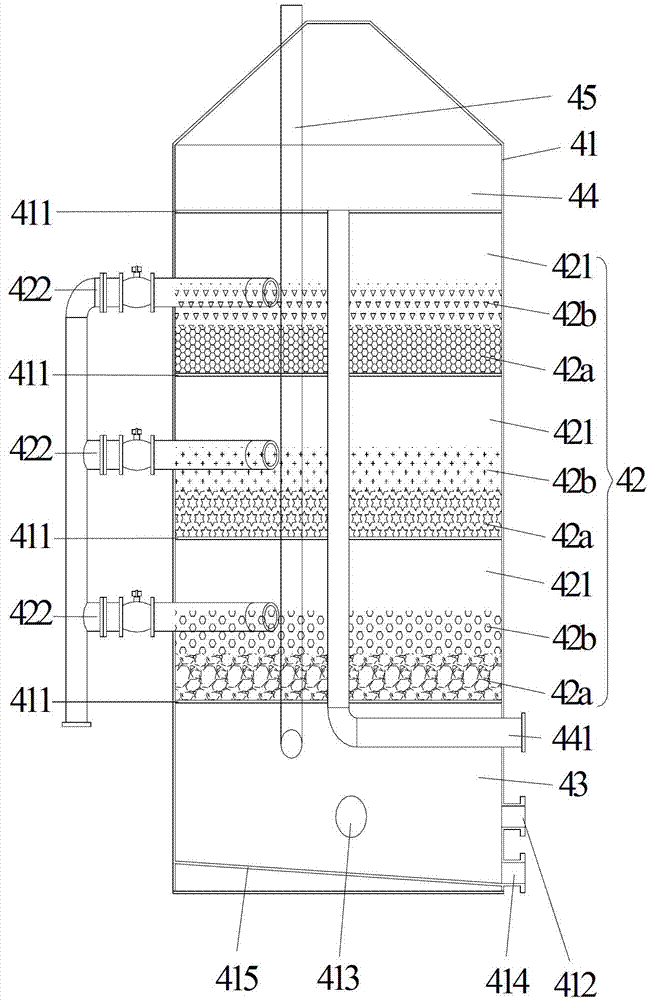

Aquaculture water circulation purification method and device

ActiveCN103112996AReduce occupancySmall diameterPisciculture and aquariaMultistage water/sewage treatmentPurification methodsFiltration

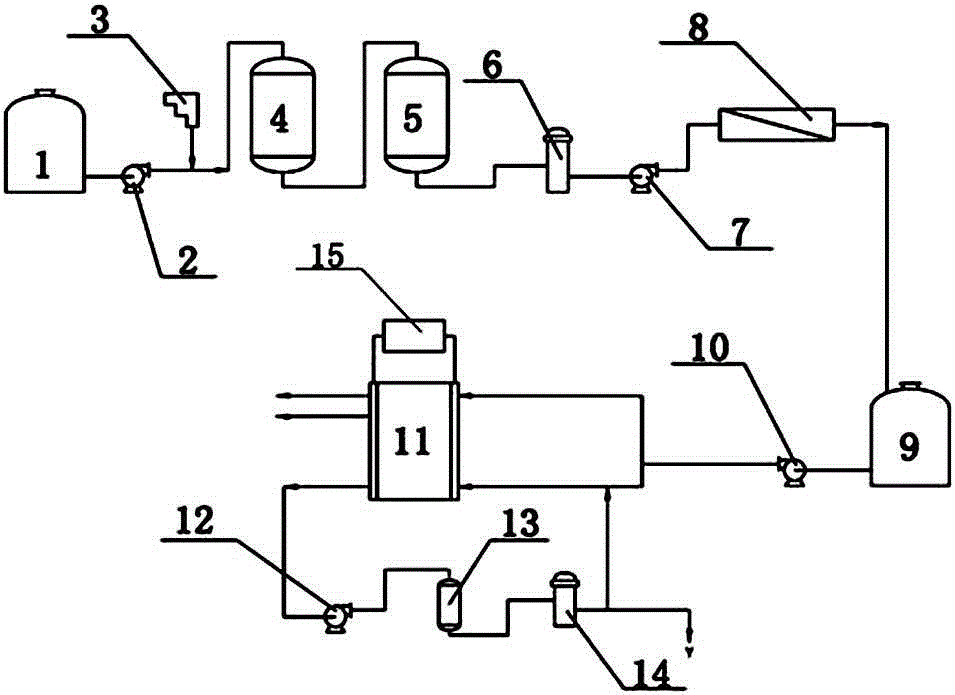

The invention discloses an aquaculture water circulation purification method. The method comprises the following steps: by utilizing a circulating water pump, pumping aquaculture water in an aquaculture pond into a protein separator to carry out protein separation, wherein the ozone accounting for 20% to 30% of the total required ozone quantity is added when the water is pumped into the protein separator; enabling the aquaculture water treated by the protein separator to overflow into a biological mechanical filter to carry out mechanical filtration and biological decomposition; enabling the aquaculture water filtered by the biological mechanical filter to overflow into a disinfection treater to carry out secondary ozone treatment, wherein the ozone accounting for 70% to 80% of the total required ozone quantity is added when the water overflows into the disinfection treater; enabling the aquaculture water treated by the disinfection treater to overflow into an aeration tank to remove the ozone and other harmful gas; and enabling the aquaculture water treated by the aeration tank to overflow into the aquaculture pond. The method disclosed by the invention has the advantages of being less in land occupation, small in civil engineering quantity, low in cost and energy-saving as well as environment-friendly. Therefore, the method is suitable for the aquaculture.

Owner:GUANGZHOU CHUANGLING AQUATIC TECH CO LTD

Complete technology for resource utilization of rainwater

InactiveCN102505728ATake advantage ofEnsure reasonable deploymentSewerage structuresGeneral water supply conservationResource utilizationReclaimed water

The invention relates to a complete technology for resource utilization of rainwater. The complete technology comprises the steps of: purifying rainwater from different underlaying surfaces by adopting split-flow and filtering methods, disinfecting, and combining the clean rainwater with a tap water or reclaimed water supplying system so as to realize resource utilization of the rainwater. According to the invention, pipelines / channels are used for sequentially connecting a rainwater overflow well, a rainwater grid well, a rainwater sedimentation tank, a rainwater split-flow tank, an inspection well, a regulation and storage tank and a clean water tank; a lift pump lifts rainwater in the rainwater clean water tank to an elevated water tank, the bottom of the elevated water tank is connected with the bottom of a mechanical filter through a pipeline, the top of a mechanical filter is sequentially connected with a filter pump and the regulation and storage tank through pipelines, and a disinfecting tank passes through a tee pipe and is respectively connected with the clean water tank and the mechanical filter by related pipeline systems so as to jointly form a rainwater colleting system, a high-efficiency purifier, a rainwater recycling system, a rainwater treatment system and a chemical feeding disinfection system.

Owner:云南高科环境保护科技有限公司 +1

Method for recovering cutting solution from by-product of silicon chip cutting processing

InactiveCN101239246ATake advantage ofReduce pollutionVacuum distillation separationSedimentation settling tanksCelsius DegreeRoom temperature

The present invention provides a method for recovering cutting fluids from the silicon chip cutting processing byproduct. The silicon chip cutting processing byproduct is added to a separating agent after being mixed according to the technical method of the invention, the mixing temperature is normal temperature or 50-80 celsius degree; 50-95% paste riching in carborundum and 5-50% suspending liquid poor in carborundum are obtaind by mechanical separator; the paste riching in carborundum is used for carborundum recycling; suspending liquid poor in carborundum is solid-liquid separated by solid-liquid separation device, the temperature of the solid-liquid separation is normal temperature or 50-80 celsius degree; solid-liquid separating fluid is added with stabilizing agent, reacting 1-12 hours under the temperature 70-130 celsius degree, after the reaction finished, suspending liquid poor in carborundum is cooled to temperature suitable for mechanical filter, filtering solid particles of the suspending liquid poor in carborundum obtains a recovery cutting fluid. Recovering cutting fluid is used fpr cutting silicon chip.

Owner:JIANGNAN UNIV +1

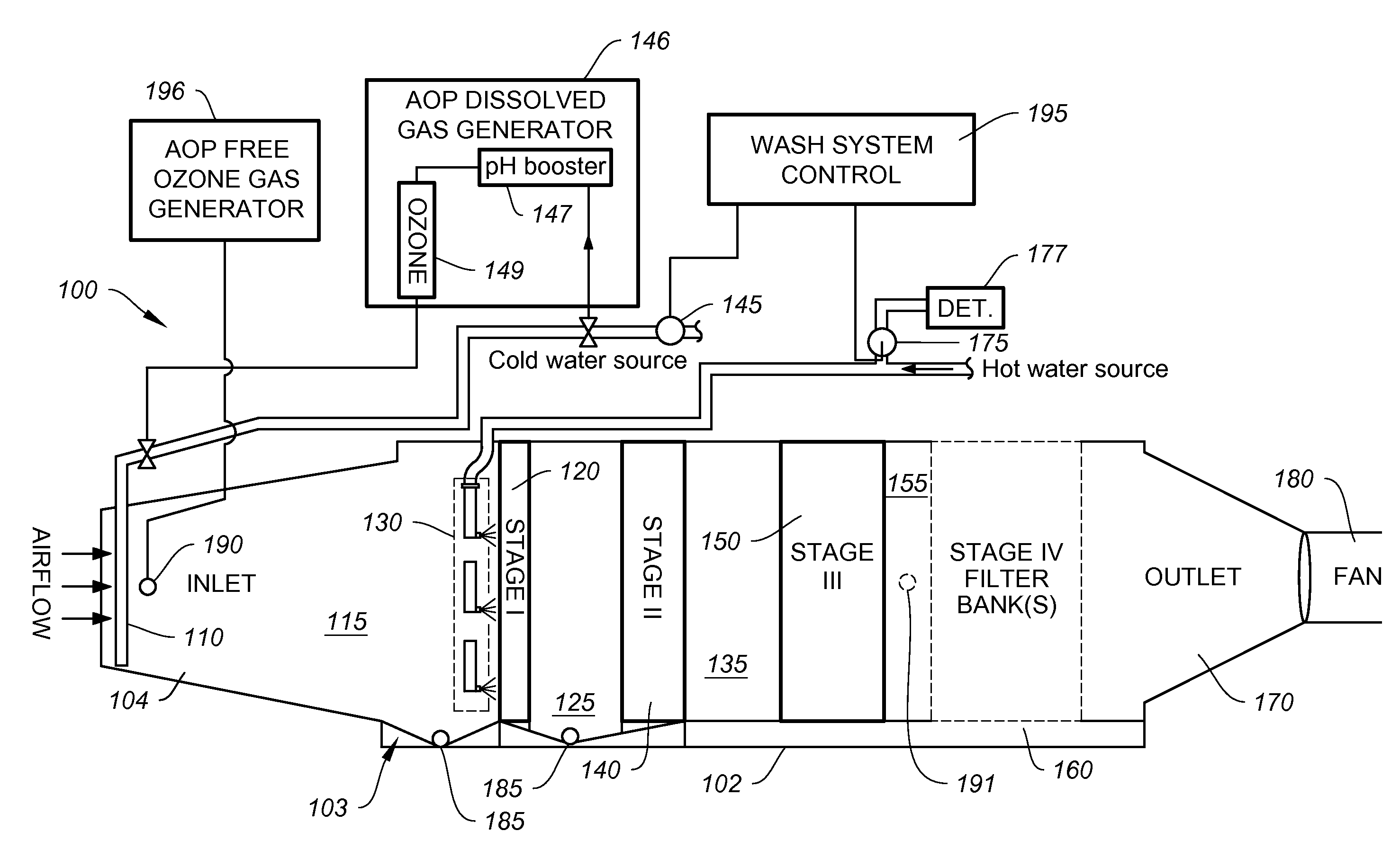

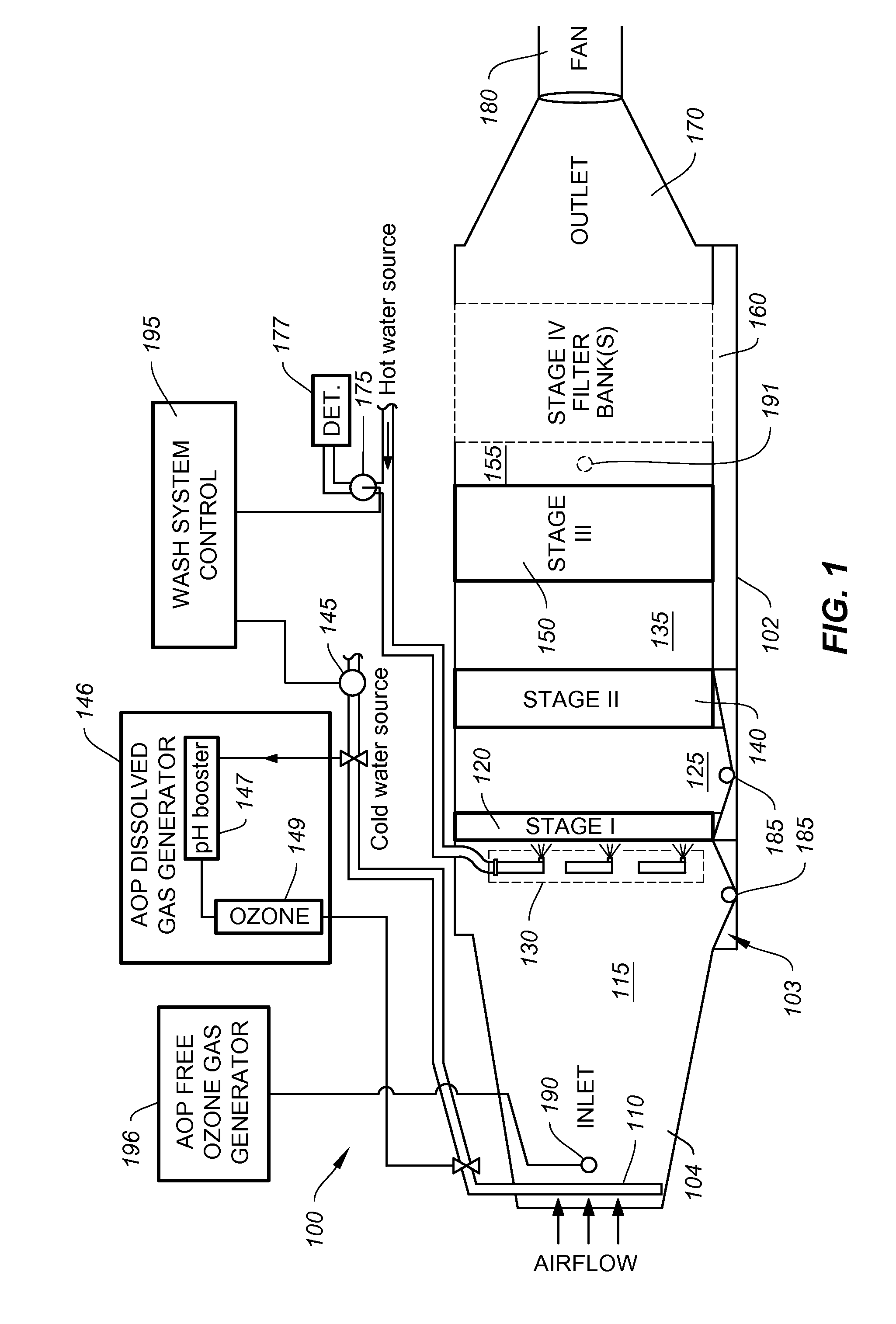

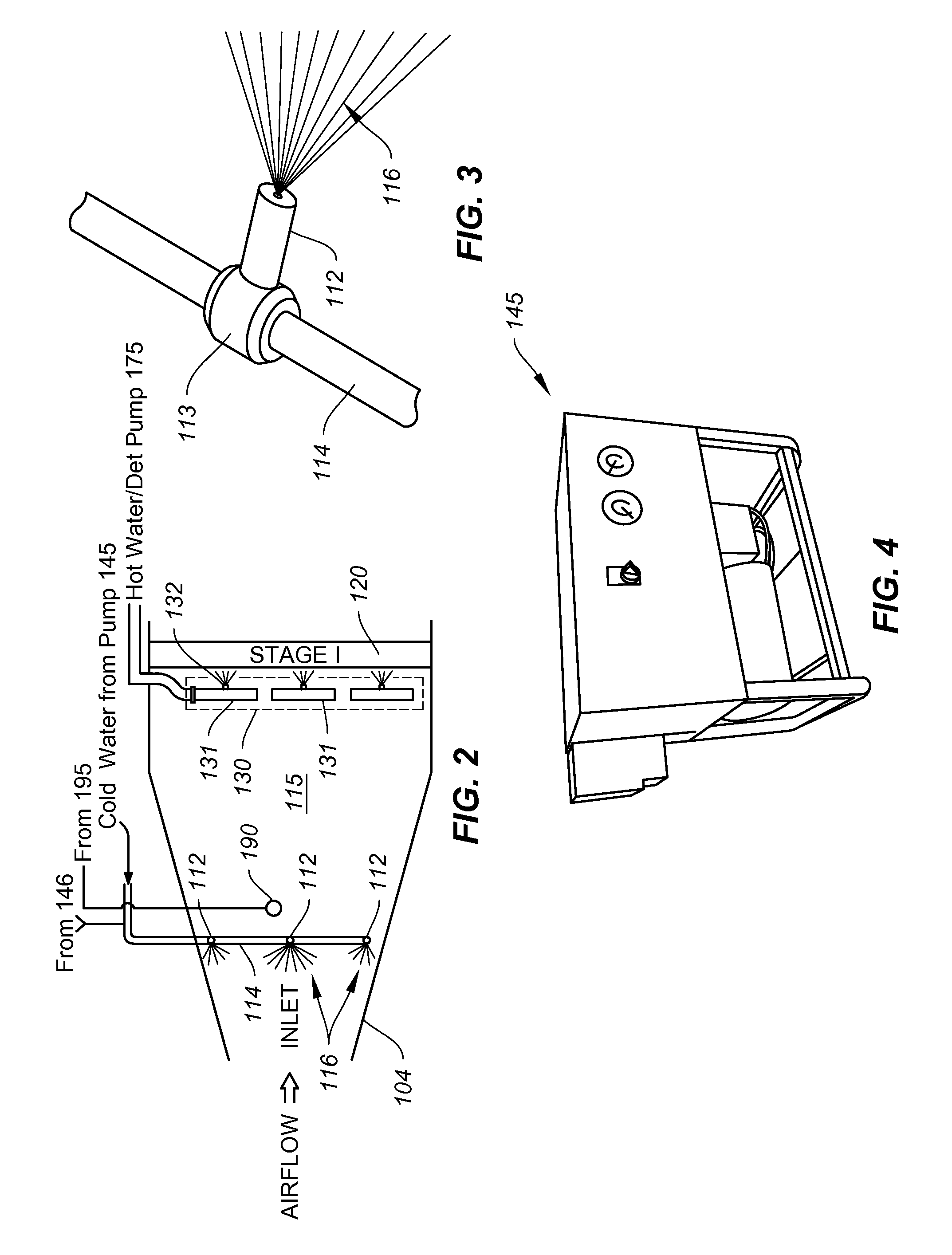

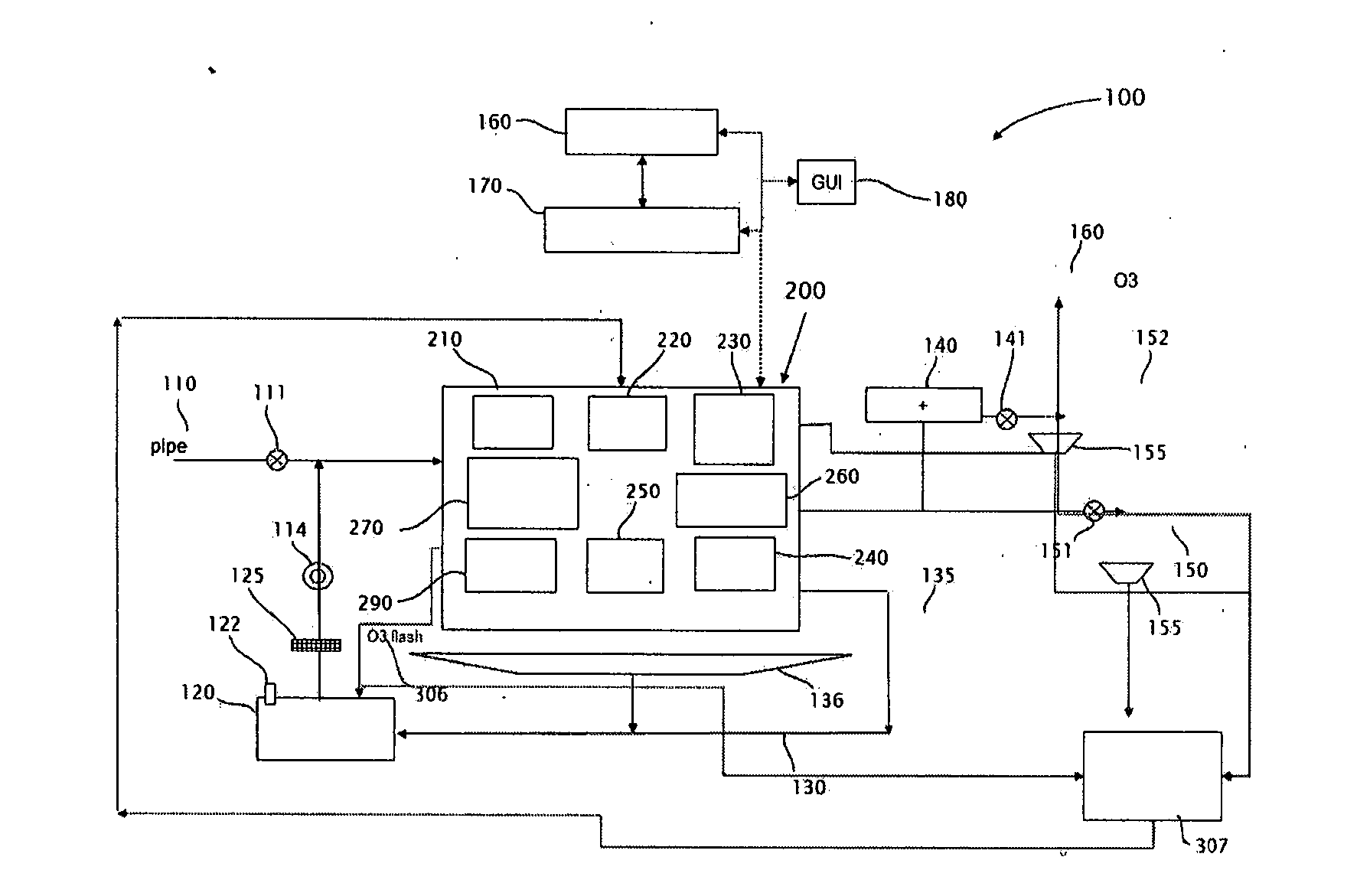

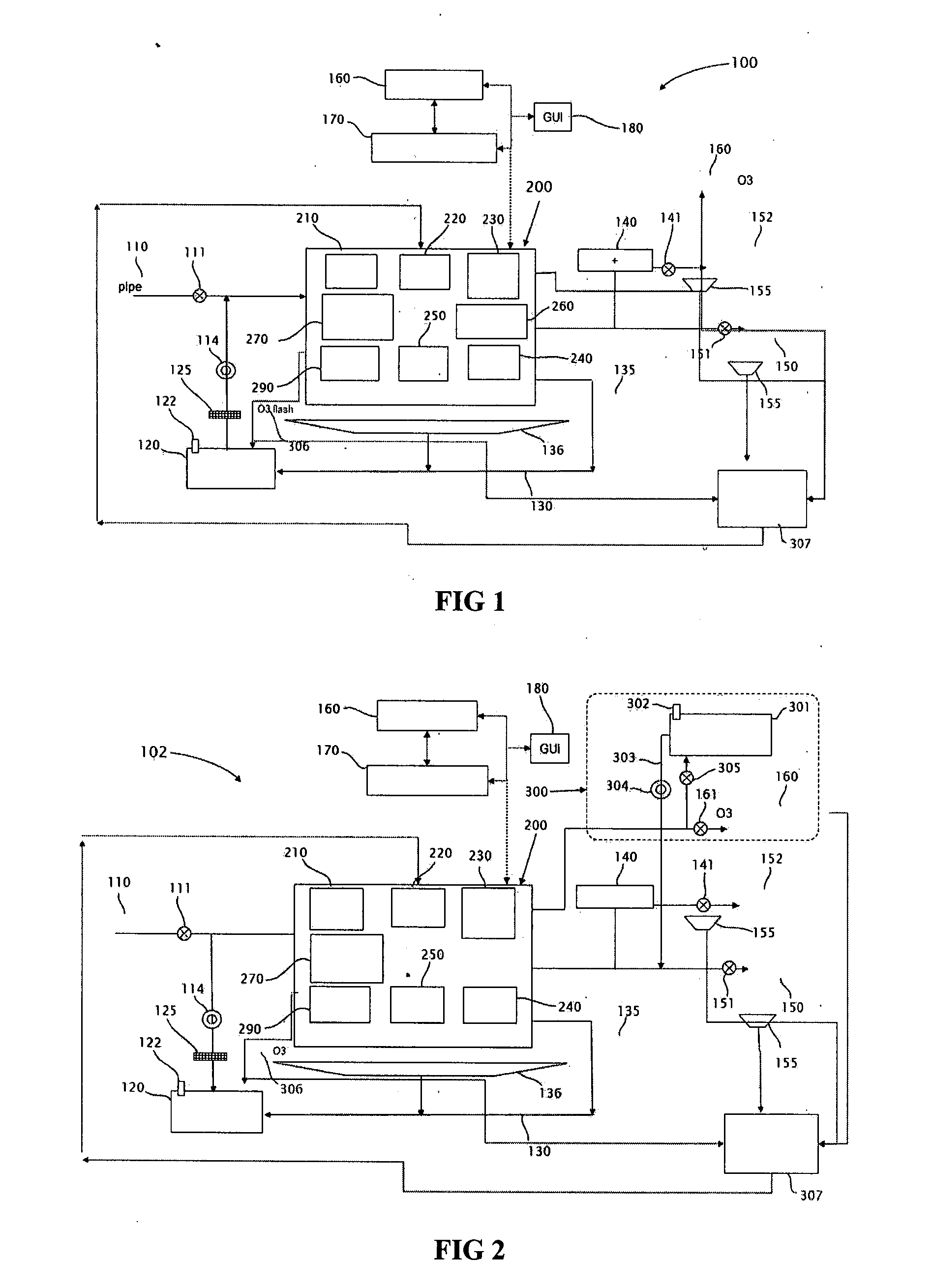

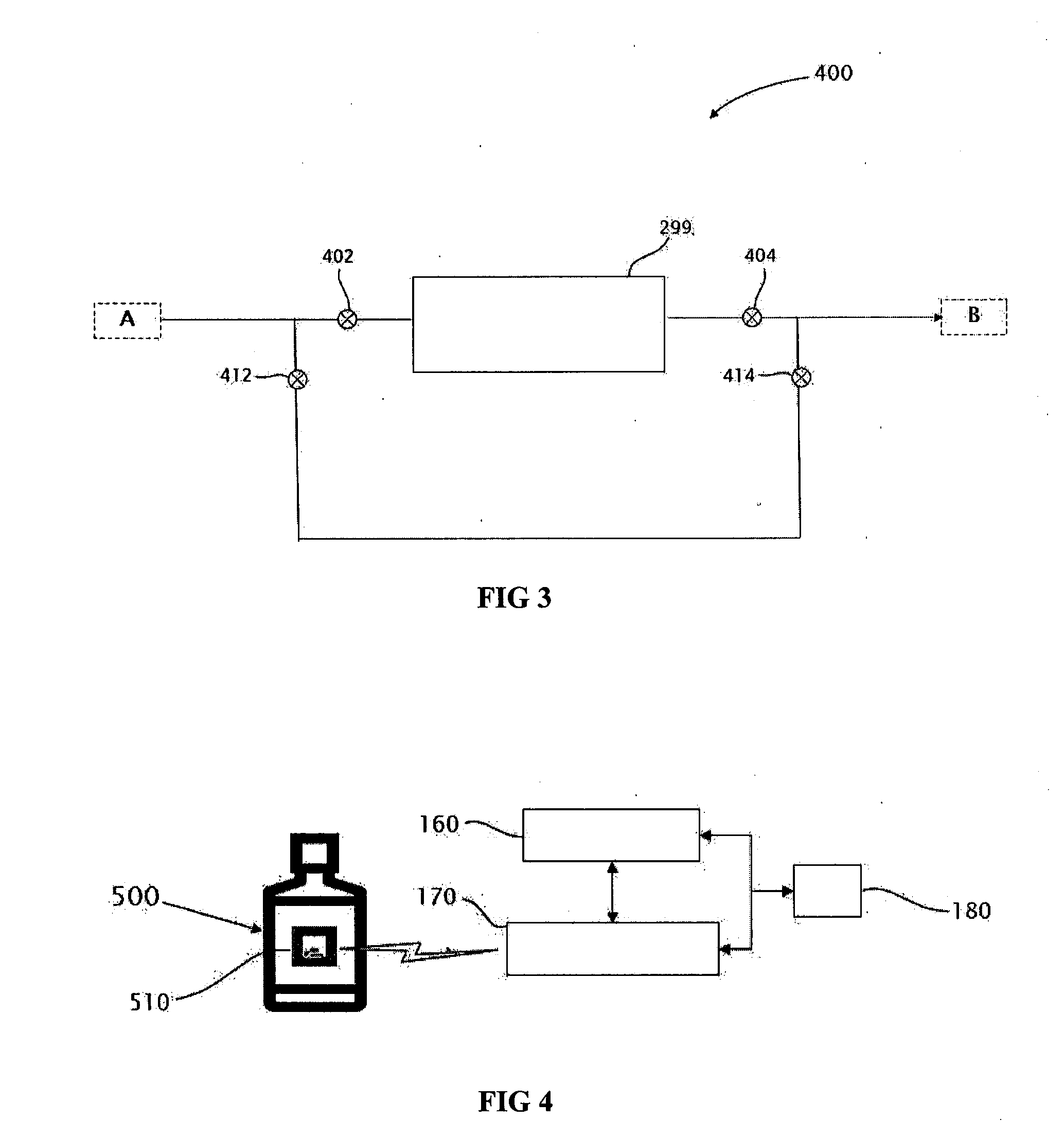

Mechanical filter-based pollution control system to remediate cooking emissions

A mechanical filter-based air pollution control system for removing particle and gas phase pollutants in a waste airstream exhausted from commercial cooking operations is described, which includes a housing enclosing at least three filter stages to remove particle and gas pollutants in the airstream. The example system may include a fogger assembly that sprays fog droplets into the waste airstream to condense a portion of gas phase pollutants into condensed particles, a wash mechanism including spray nozzles to wash surfaces of the first stage filter to remove grease therefrom, and injection means for injecting activated ozone, which comprises ozone with a surplus of hydroxyl radicals, into the housing to initiate advanced oxidation processes (AOPs) to decompose particle and gas phase pollutants within the waste airstream in the filters. Where activated ozone is employed, the system includes a fourth stage filter that adsorbs and retains gas phase pollutants for subsequent oxidation.

Owner:AJEMIAN ROBERT C

Sludge dewatering agent and use method thereof

InactiveCN107032580ALower specific resistanceReduce the amount addedSludge treatment by de-watering/drying/thickeningBio-organic fraction processingPorosityResource utilization

The invention relates to a sludge dewatering agent which is formed by a filter aid, a flocculant and a superoxide, the specific resistance of sludge can be effectively reduced, the sludge dewatering agent can be taken as an accessory for further aerobic composting treatment of the dewatered sludge, the accessory consumption of the composting stage is reduced, the turning times can be reduced due to high porosity, the composting power consumption is reduced, and the sludge dewatering agent has multiple purposes; substances of lime and the like which influence follow-up resource utilization are not contained; ferric chloride is not contained, corrosion to the steel structure is not produced, the colloid structure of the sludge is changed by the superoxide, and the addition of the filter aid is reduced greatly. The invention further relates to a use method of the sludge dewatering agent, the method comprises the following steps that firstly thickened sludge is heated to 40 DEG C to 50 DEG C, then the superoxide is added, the flocculant and the filter aid are added, the treated sludge is subjected to mechanical filter pressing, and the moisture content is reduced to 70% or below.

Owner:北京首创污泥处置技术有限公司

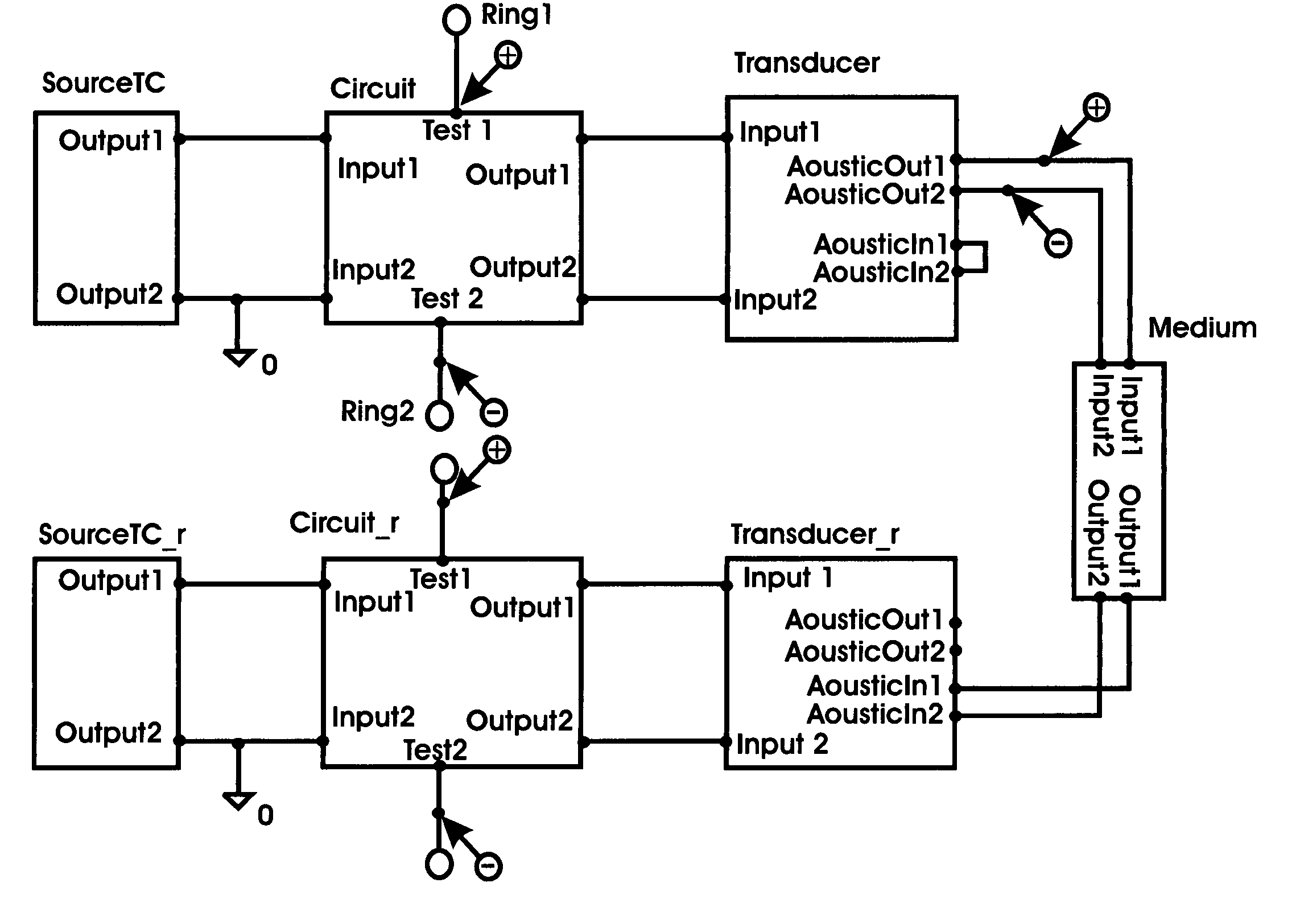

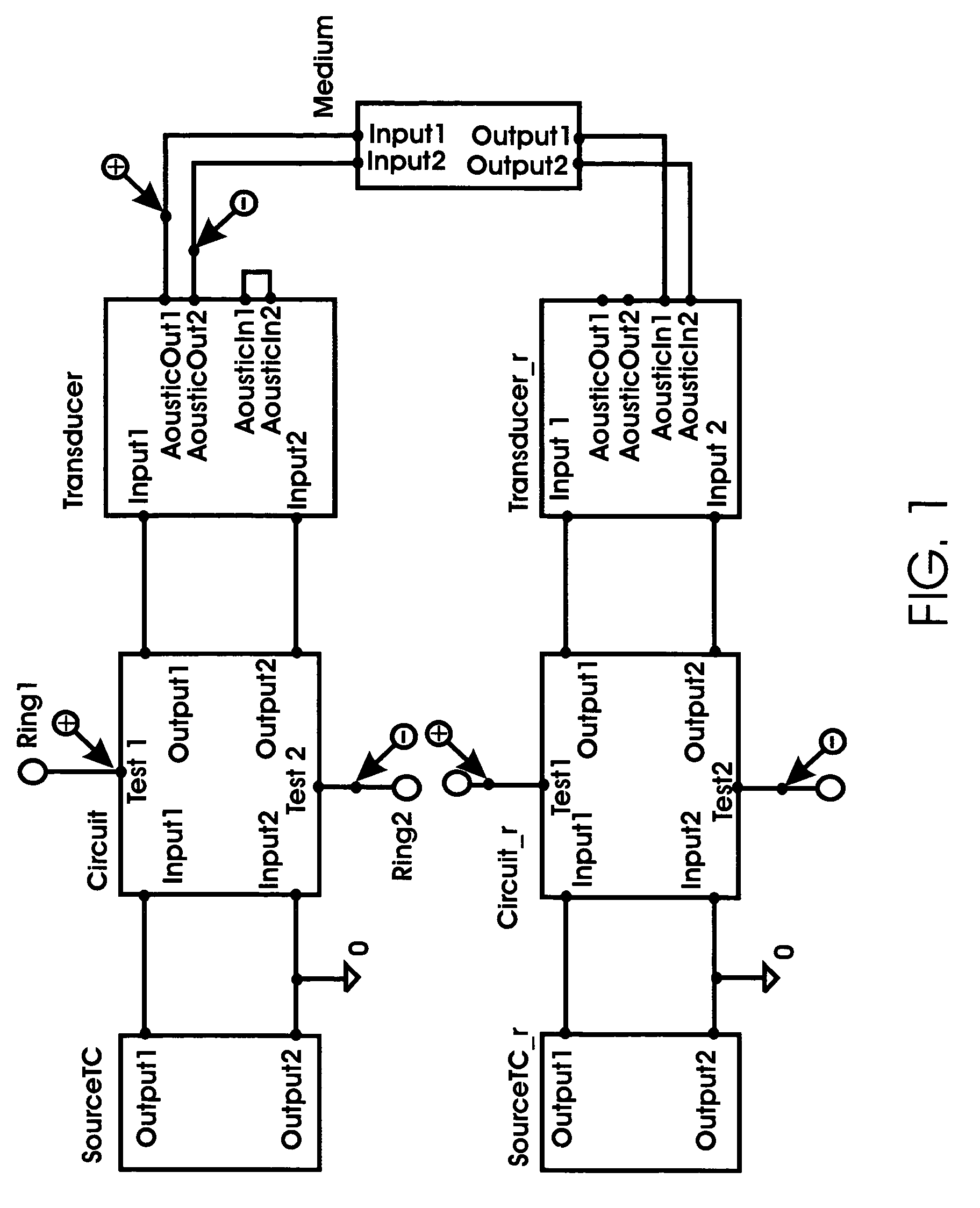

System and method for eliminating audible noise for ultrasonic transducers

InactiveUS7079450B2Reducing and suppressing audible clickingSuppress clicking of ultrasonic air-coupled resonant transducersMechanical vibrations separationTransmissionSonificationAir coupled

Methods for reducing clicking of ultrasonic air-coupled transducers in which a mechanical filter that attenuates audible frequencies relative to ultrasonic frequencies is placed in the path of the ultrasonic waves as the travel from the transducer to a target such as an object in the vehicle compartment.

Owner:AMERICAN VEHICULAR SCI

System and method for optical measurement of a target

ActiveUS20120038928A1High repetition rateAccurate wavelengthRadiation pyrometryInterferometric spectrometryFluorescenceLight beam

Owner:TEKNOLOGIAN TUTKIMUSKESKUS VTT

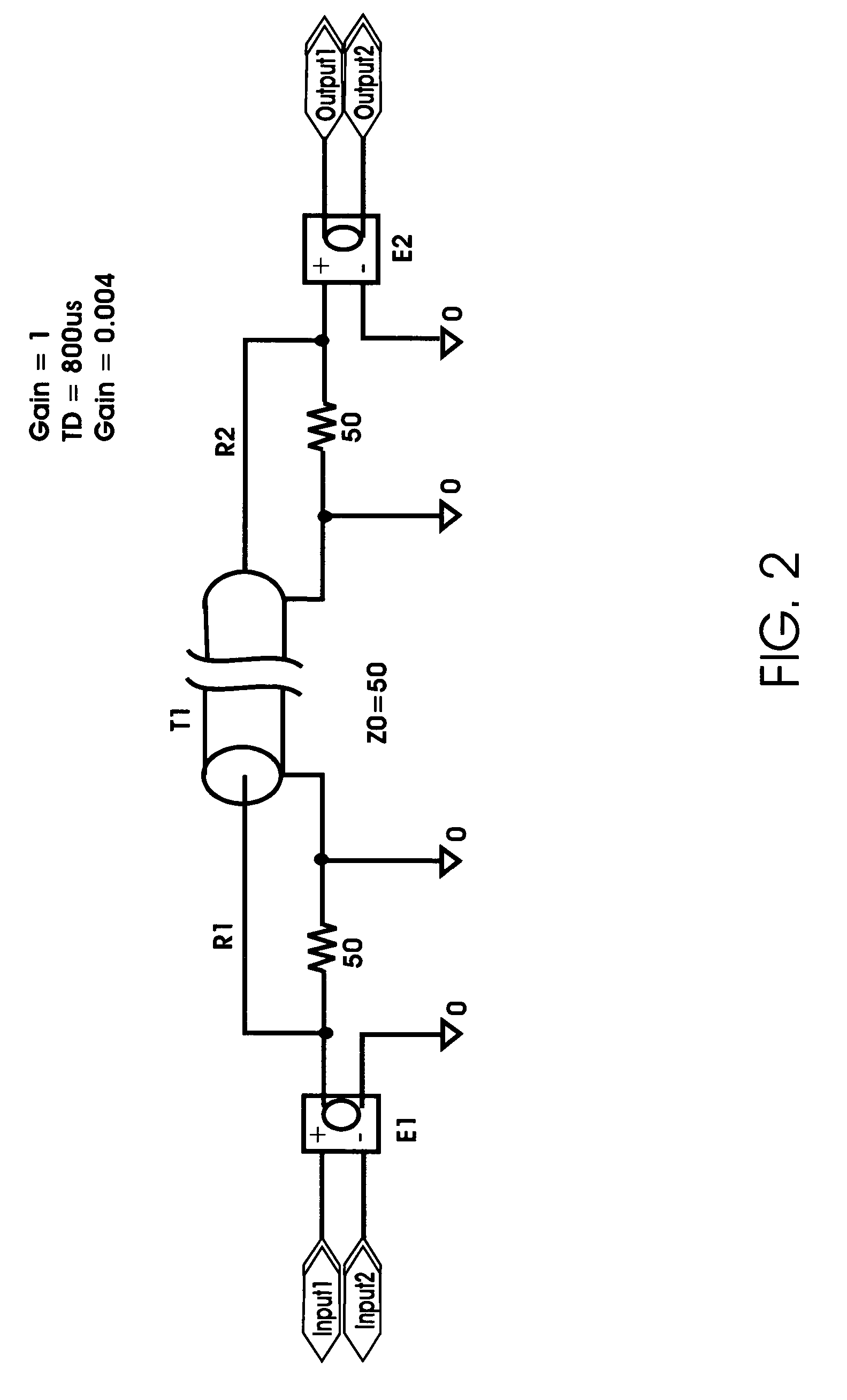

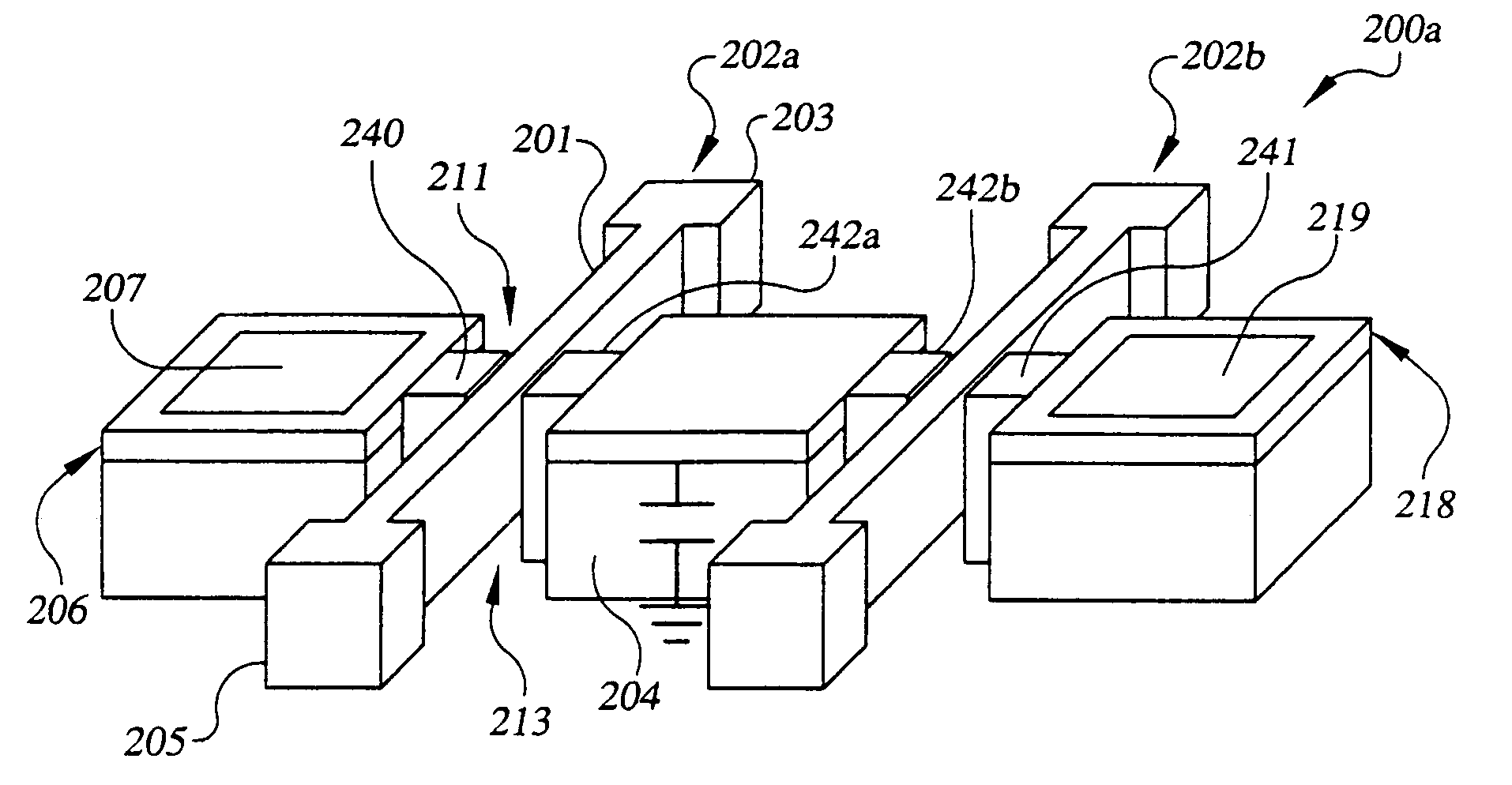

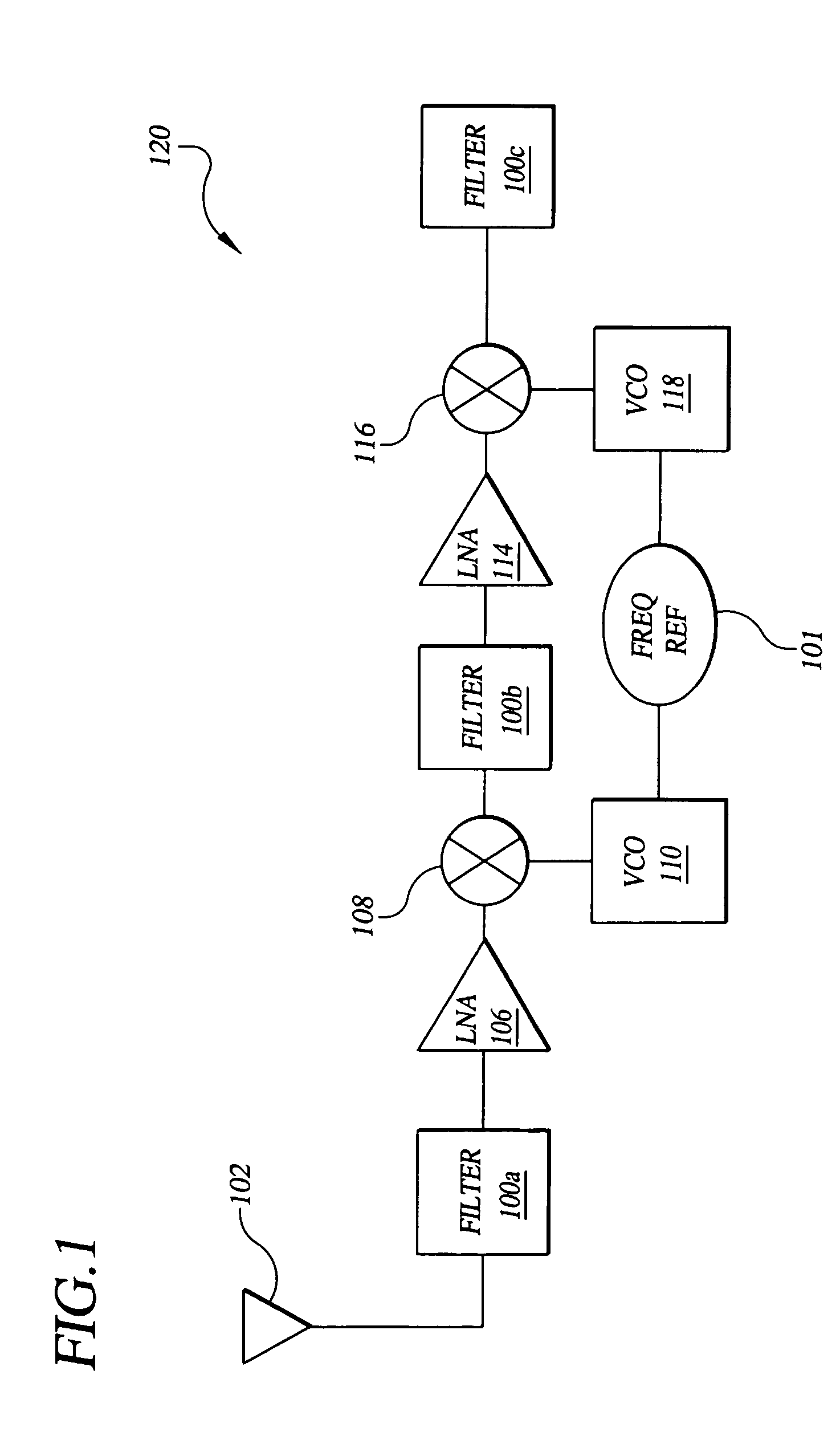

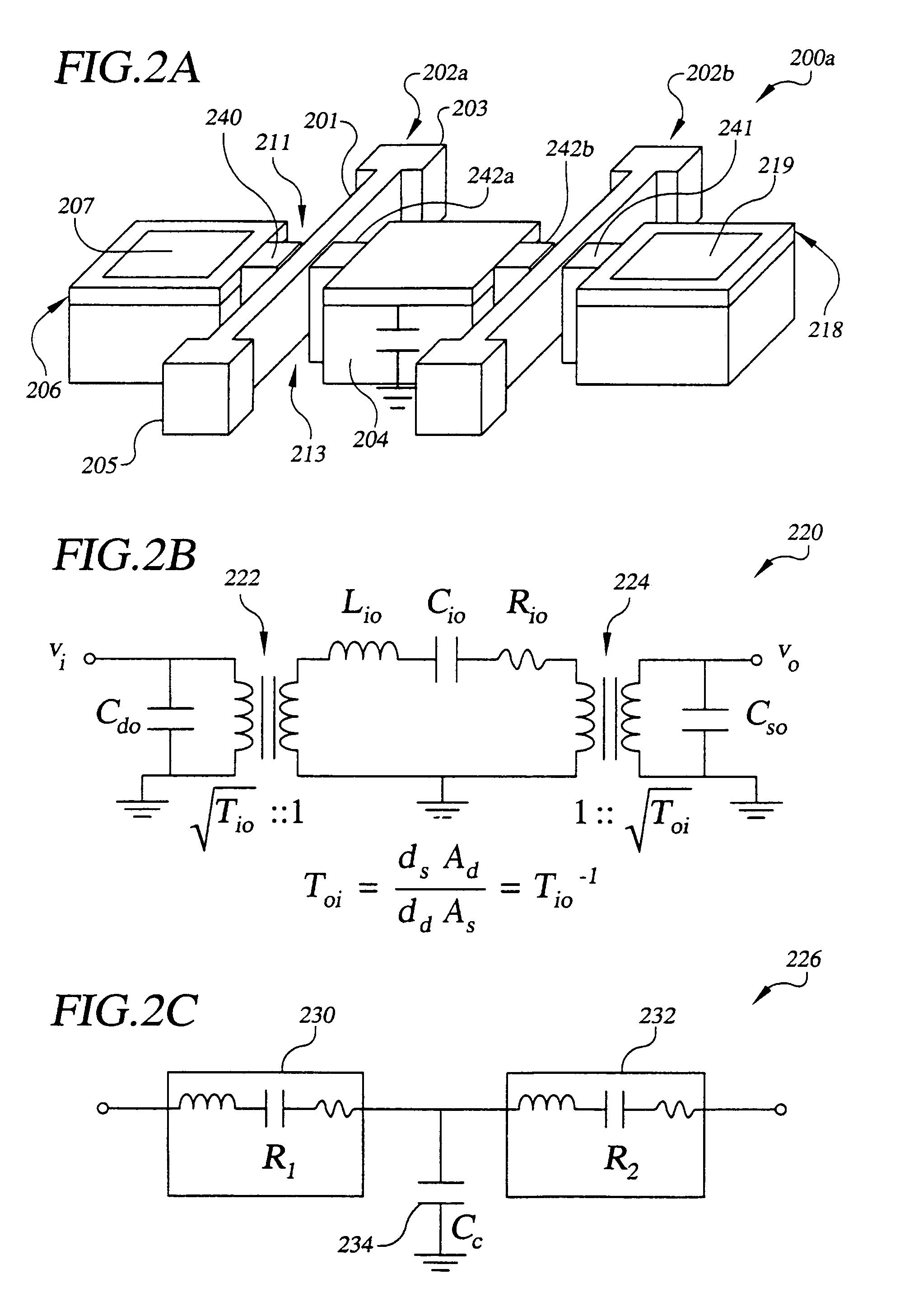

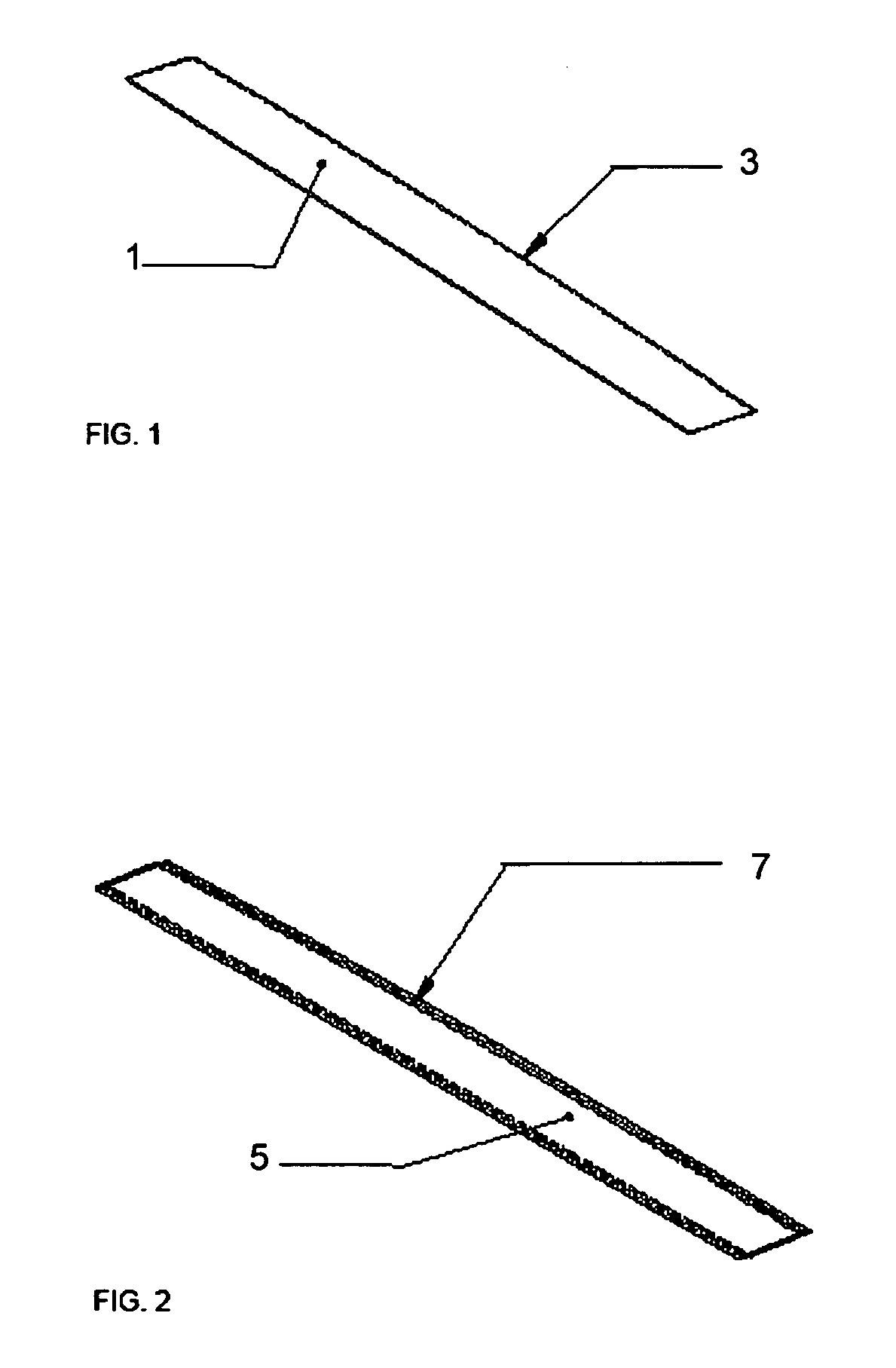

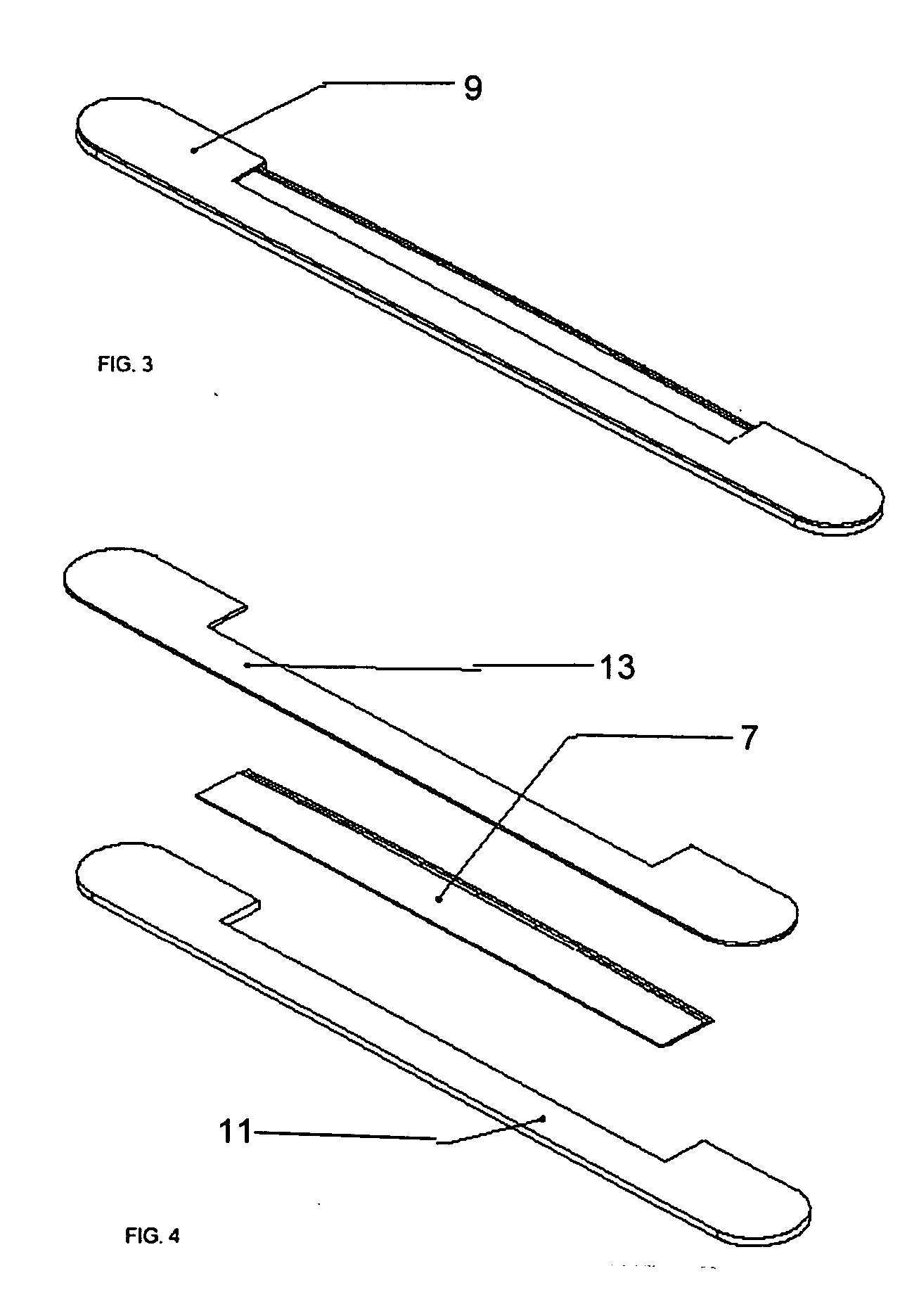

Electrically-coupled micro-electro-mechanical filter systems and methods

InactiveUS7098757B2Electrically conductive connectionsImpedence networksFilter systemMicroelectromechanical systems

An electrically-coupled micro-electro-mechanical system (MEMS) filter system and method are disclosed. In one embodiment, the MEMS filter system comprises a first microelectromechanical system (MEMS) resonator comprising a first resonating element, a second MEMS resonator comprising a second resonating element, the sescond resonating element closely spaced and mechanically separate from the first resonating element, wherein the first MEMS resonator is coupled to the second MEMS resonator through the electrostatic force acting between resonating portions of the MEMS resonators, and additional MEMS resonators electrically coupled to the first MEMS resonator, the second MEMS resonator, or the first and second MEMS resonators.

Owner:GEORGIA TECH RES CORP

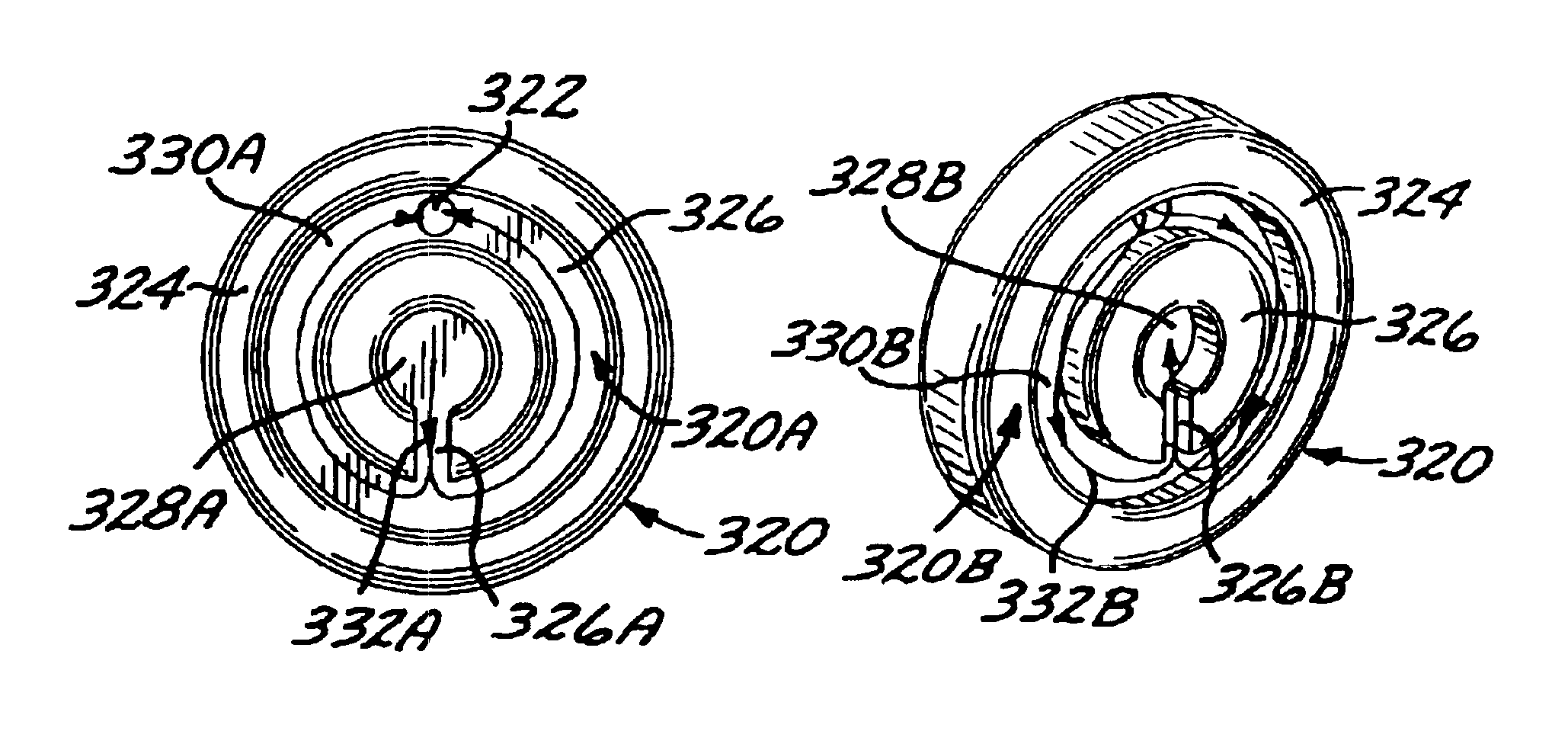

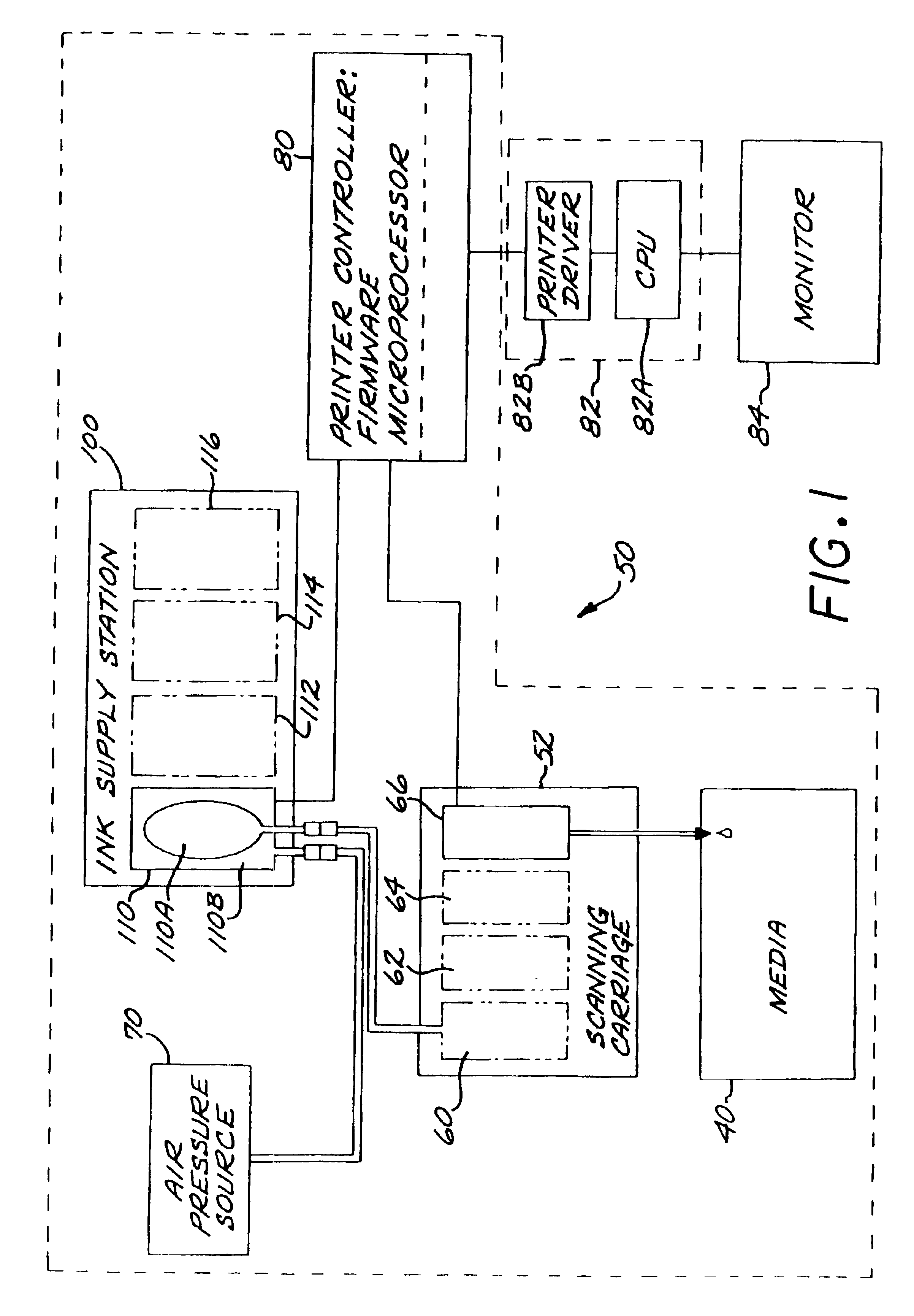

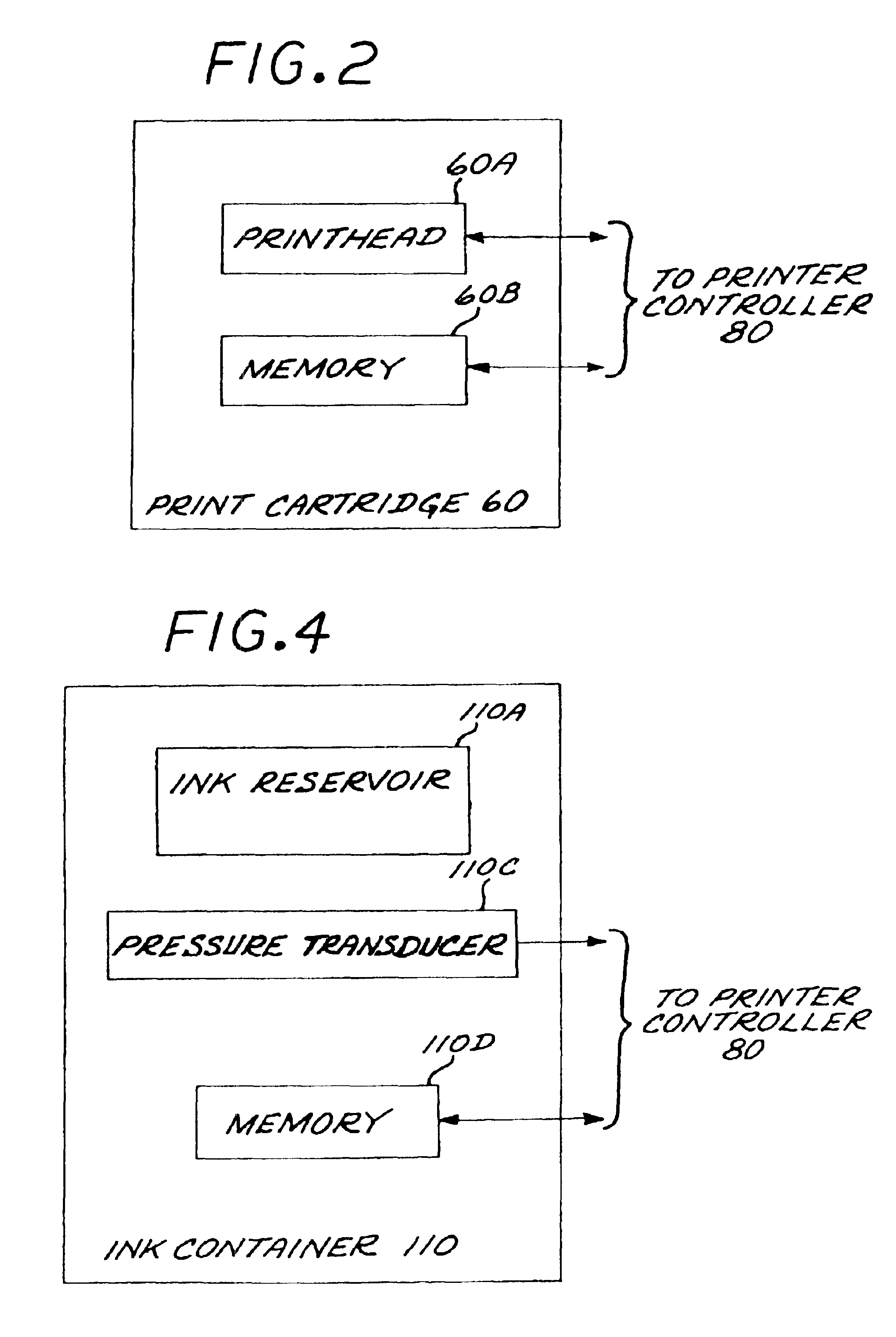

Techniques for improving pressure sensor shock robustness in fluid containment devices

InactiveUS6886929B2Fluid pressure measurement using ohmic-resistance variationFluid pressure measurement by mechanical elementsElastomerEngineering

Techniques are disclosed for improving pressure sensor shock robustness in fluid containment devices by providing a mechanical filter configured to prevent high-frequency pressure shocks from damaging the pressure sensor. One approach includes a body of elastomeric material disposed on an external surface of the sensor. Another approach is a porous plug in a fluid pathway leading to the sensor. Yet another approach is to provide a seal structure with a labyrinth fluid path.

Owner:HEWLETT PACKARD DEV CO LP

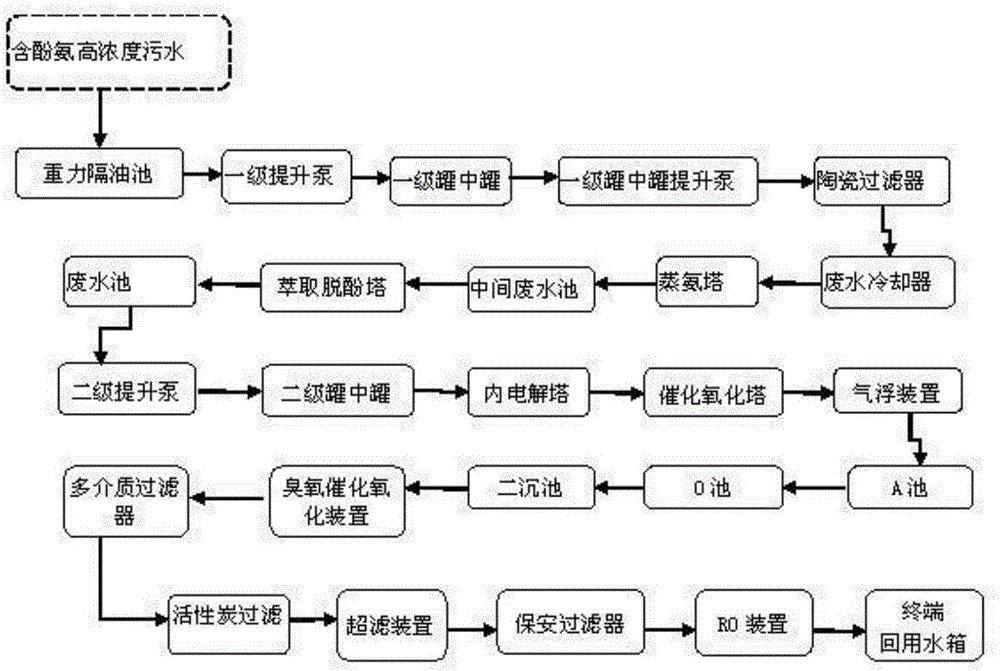

Phenol-ammonium waste water treatment device

InactiveCN104926021ASolve processing problemsRecyclableMultistage water/sewage treatmentChemical industryFiltration membrane

The invention provides a phenol-ammonium waste water treatment device. The phenol-ammonium waste water treatment device comprises section-I pretreatment, section-II biochemical treatment and section-III further treatment; the section-I pretreatment includes gravity oil separation, oil-water separation, ceramic filter, ammonium steaming and extraction dephenolization process; the section-II biological treatment include catalytic oxidation, air floatation, hydrolysis acidification, A / O biochemical treatment, coagulating sedimentation and mechanical filter process; the section-III advanced treatment includes ozone catalytic oxidation, active carbon filter, ultra-filtration membrane filter and RO reverse-osmosis process, the section-I pretreatment, the section-II biochemical treatment and the section-III further treatment are controlled by a PLC control system, so that the automatic operation of the whole set of system is realized. The phenol-ammonium waste water treatment device innovatively solves the difficulty for treating the phenol-ammonium-containing waste water in the field of coal gas chemical industry and also has the characteristics of recyclability, compact structure, high investment return rate, stability and reliability in operation, high automation degree and the like.

Owner:上海延庆环保科技股份有限公司

Formula for deep dehydration of sludge and operation method of formula

InactiveCN105330123AEfficient dehydrationImprove dehydration effectSludge treatment by de-watering/drying/thickeningCeramic materials productionSludgeSewage

The invention relates to deep dehydration of sludge, in particular to a formula for deep degradation of sludge and an operation method of the formula. The formula comprises steps as follows: preparation of auxiliary materials, primary treatment of the sludge, thermal refining of the sewage, mechanical filter pressing and backflow of filtrate. According to the formula for deep dehydration of the sludge and the operation method of the formula, continuous treatment can be performed, the treatment efficiency is improved, energy is saved, consumption is reduced, the controllability is high, and recycling is realized.

Owner:ZHEJIANG JIEFENG ENVIRONMENTAL PROTECTION TECH ENG COMPANY

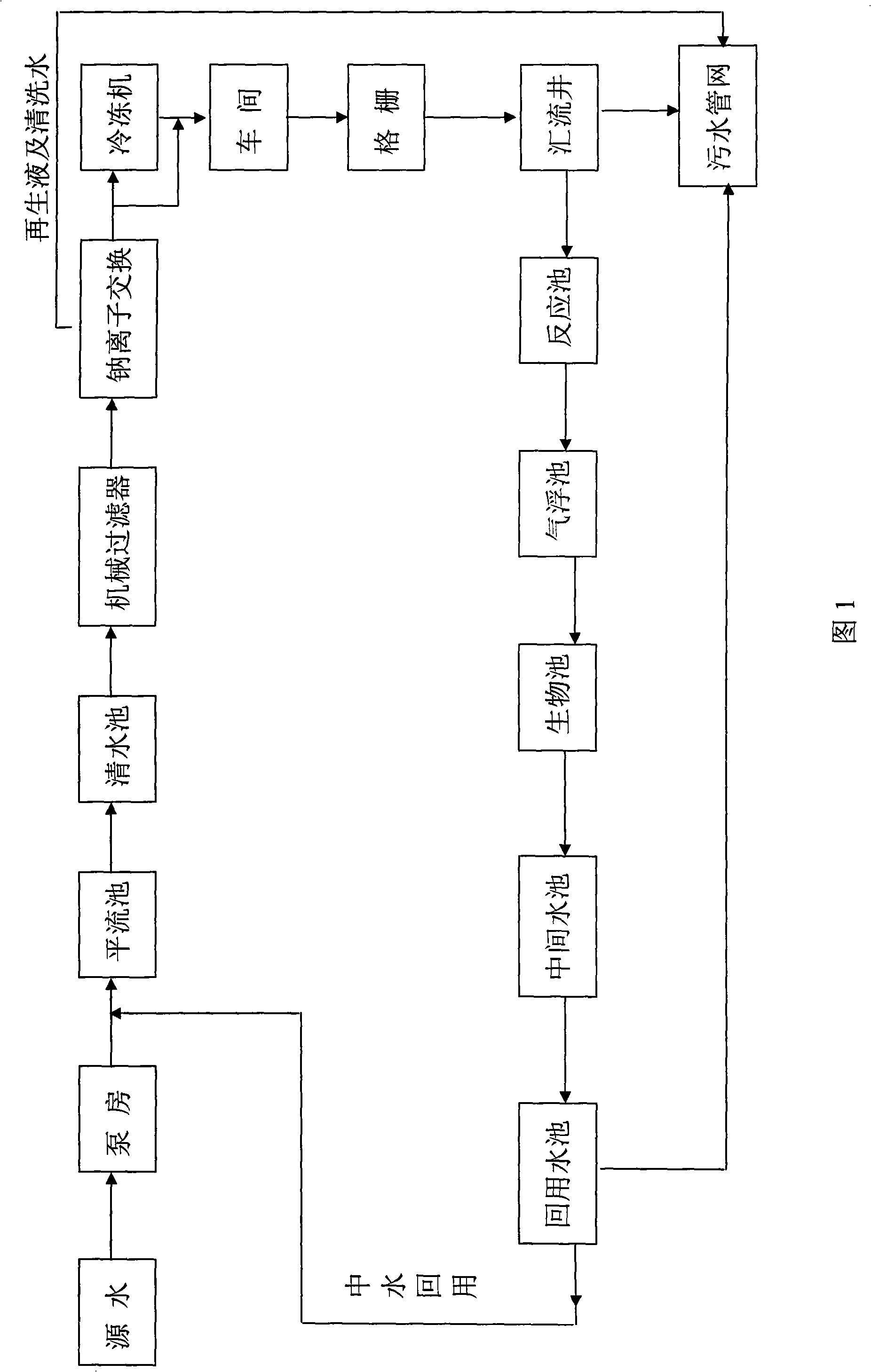

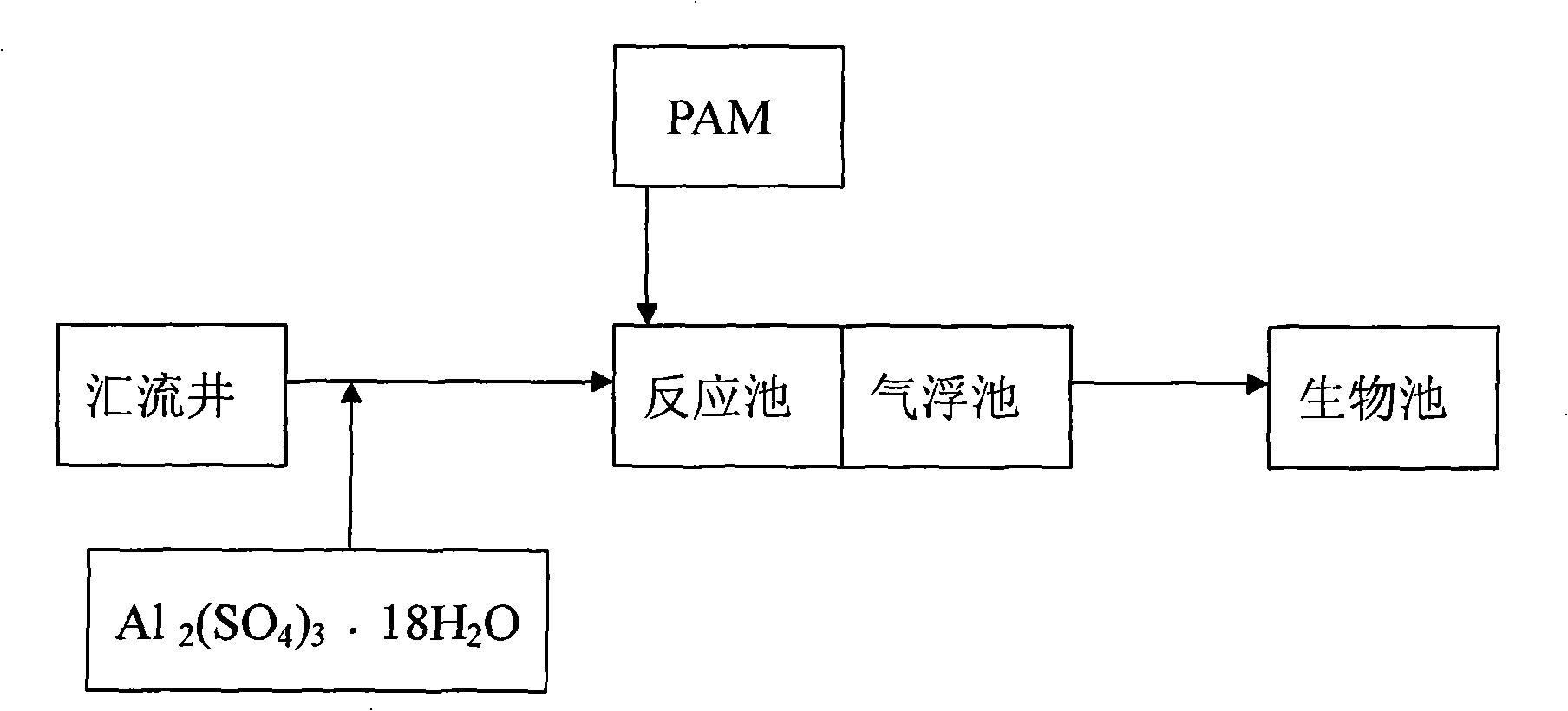

Reclaiming treatment method for hydraulic loom waste water

ActiveCN101265001AEasy to sinkIncrease opportunities for mutual contactWater/sewage treatment by ion-exchangeMultistage water/sewage treatmentHazardous substanceSludge

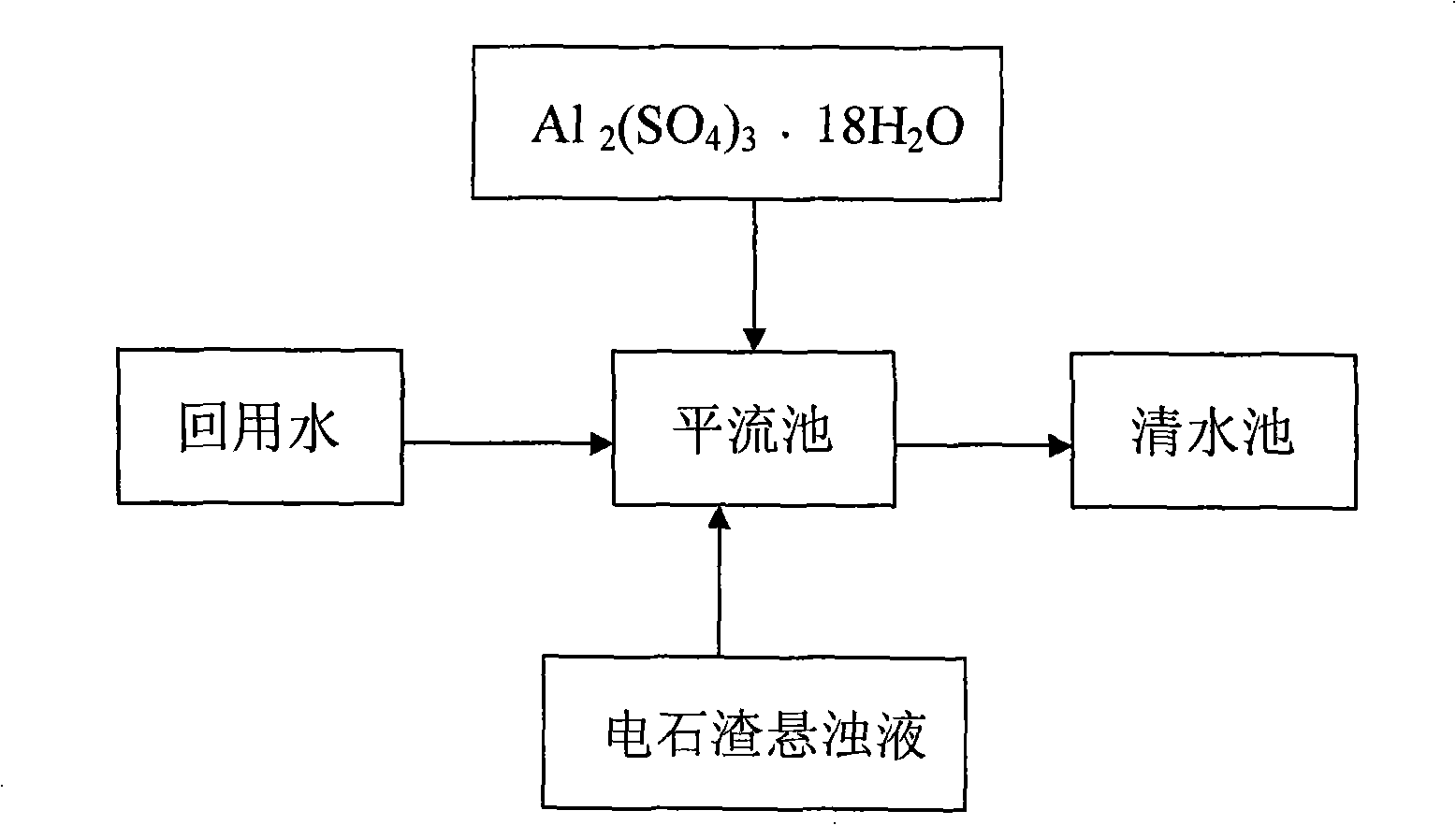

The invention provides a method for treating and reutilizing hydraulic loom wastewater, comprising the following steps of: (1) lifting the adjusted wastewater to a reaction tank, performing coagulation and floatation, feeding the separated sludge into a sludge concentration tank, and feeding the rest parts into a biological tank; (2) performing biological treatment and sedimentation of wastewater, feeding into a horizontal sedimentation tank together with supplementing water, adding chemicals, adjusting pH value, coagulating, settling, and disinfecting the effluent into a clean water tank; (3) filtering the disinfected effluent with a mechanical filter, and performing sodium ion exchange; and (4) delivering the treated process water into hydraulic looms in a workshop. The inventive method avoids harmful substances entering recycled water in chemicals addition and ion exchange steps by using wastewater treatment and recycled water reusing combined techniques, so as to improve recycled water treatment effect and process water quality, thereby improving recycled water reuse ratio.

Owner:ZHEJIANG TAIHUA NEW MATERIAL

Opto-mechanical filter for blending of images from a digital projector

A filter mounting apparatus for use with an optical filter placed between a projector lens and screen. The filter mounting apparatus comprises a metallic disk connected to the projector lens, and an assembly magnetically connected to the metallic disk for mounting the optical filter a predetermined distance from the projector lens.

Owner:CHRISTIE SA

Sludge treatment process

InactiveCN102167489AHydrophobicLow running costSludge treatment by de-watering/drying/thickeningClimate change adaptationDolomiteMoisture

The invention discloses a sludge treatment process which comprises the following steps of: (1) diluting sludge with water; (2) pouring the diluted sludge to a stirring tank, and then adding a sludge modifier according to the weight before the sludge is diluted and then stirring, wherein the sludge modifier is prepared from the following raw materials: 40-70 percent of modified dolomite and 30-60 percent of magnesium chloride; (3) pumping the sludge in the step (2) to a plate-and-frame filter press and carrying out filter pressing and dewatering, wherein a spring is arranged between every two filter frames of the plate-and-frame filter press, the springs are uniformly distributed around the filter frames, and a feeding valve is arranged on a feeding pipe; (4) naturally drying the sludge dewatered in the step (3) at normal temperature; and (5) taking sludge as a combustion raw material, a cement raw material or a fertilizer raw material and bagging. By adopting additives and the mechanical filter pressing method, moisture in the sludge is removed, the moisture content in the sludge is lower than 45 percent, and heavy metals are solidified in the sludge and cannot be absorbed by root systems of plants, therefore damages to soil and human bodies cannot be caused.

Owner:郑建国

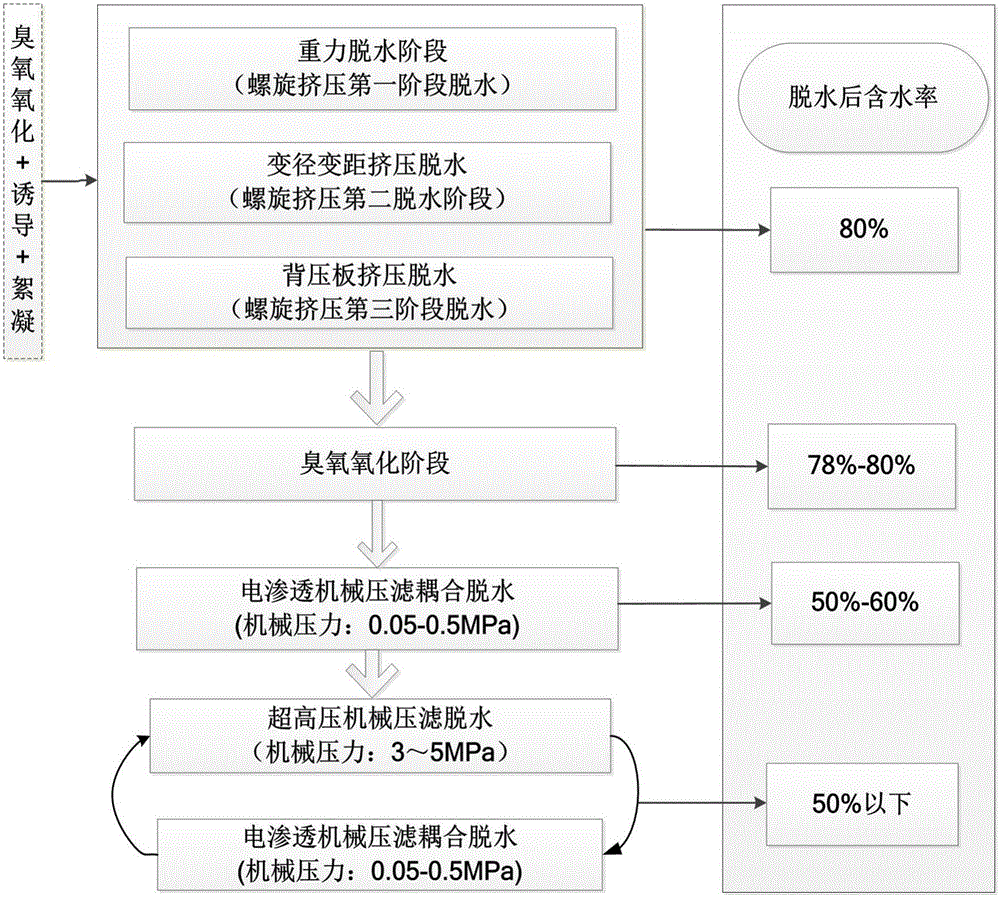

Sewage sludge dewatering device based on cooperation of oxidization, electroosmosis and mechanical filter pressing

InactiveCN105923968AReduce moisture contentImprove contact tightnessSludge treatment by de-watering/drying/thickeningSludge treatment by oxidationSludgeSewage

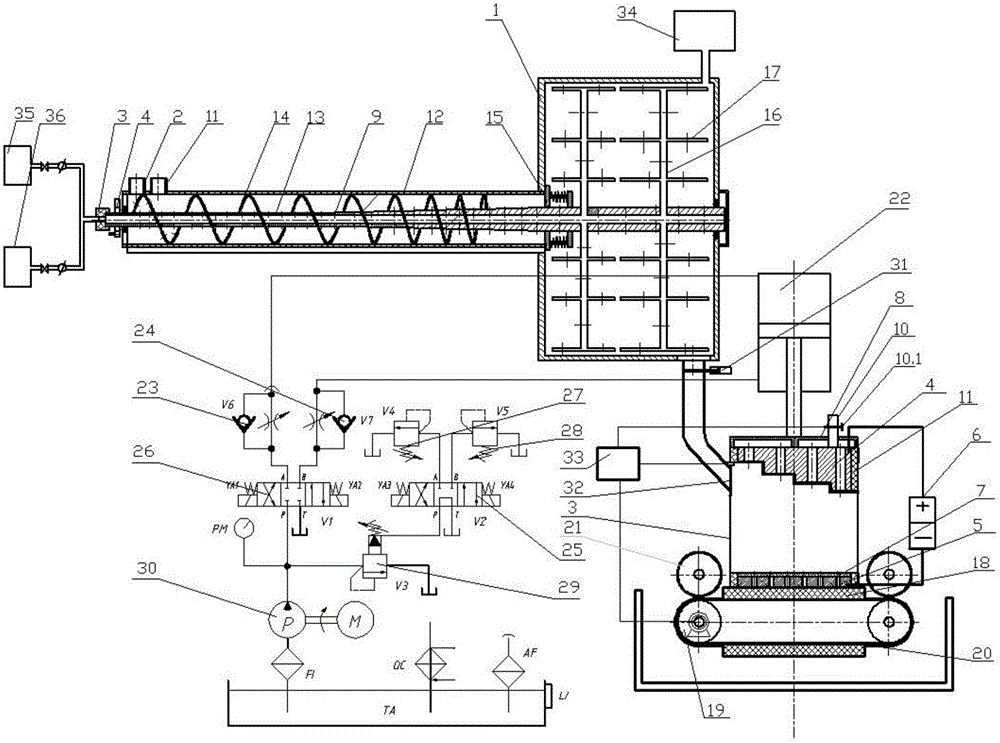

The invention discloses a sewage sludge dewatering device based on cooperation of oxidization, electroosmosis and mechanical filter pressing. The sewage sludge dewatering device comprises a spiral filter pressing device, an oxidation cylinder and an electroosmosis extrusion dewatering device, wherein a sewage sludge inlet is formed in the front end of the spiral filter pressing device; the rear end of the spiral filter pressing device is connected with the oxidation cylinder; the oxidation cylinder is communicated with the electroosmosis extrusion dewatering device; the electroosmosis extrusion dewatering device comprises an electroosmosis extrusion container, an anode plate, a cathode plate and a hydraulic system; the anode plate and the cathode plate are arranged in the electroosmosis extrusion container; after electroosmosis dewatering is completed by the electroosmosis extrusion dewatering device, the sludge water content of the anode plate is low, electroosmosis dewatering can be stopped, and pressure between the anode plate and the cathode plate is enlarged, so that ultrahigh pressure filter pressing dewatering is realized; the hydraulic system is connected with the anode plate, and the hydraulic system comprises a hydraulic oil cylinder and a high-low pressure regulating device. According to the sewage sludge dewatering device disclosed by the invention, high-water content sludge can be directly treated, and the dewatering energy consumption and the sludge water content are reduced through a multi-cooperation dewatering mode.

Owner:CHINA JILIANG UNIV

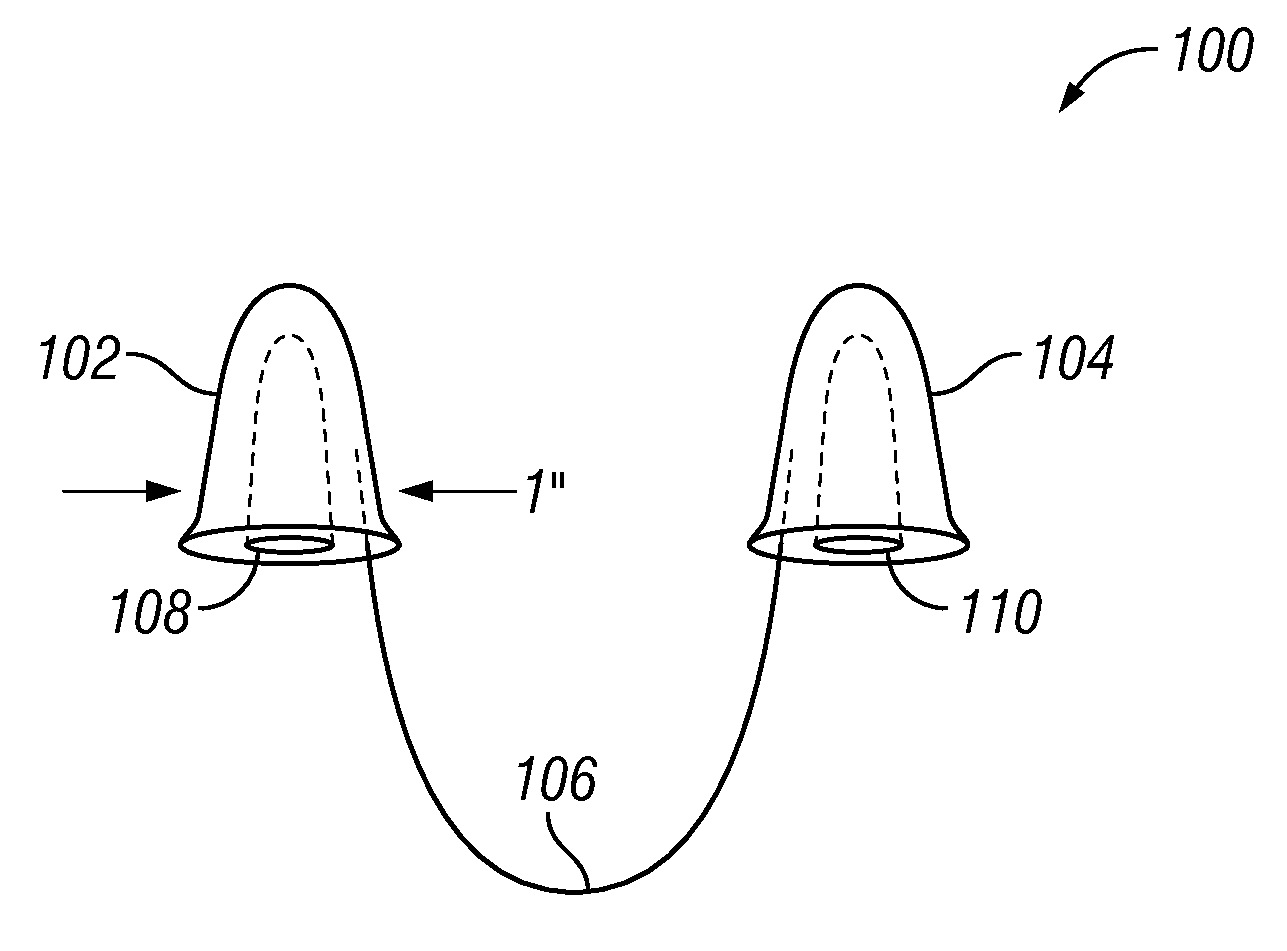

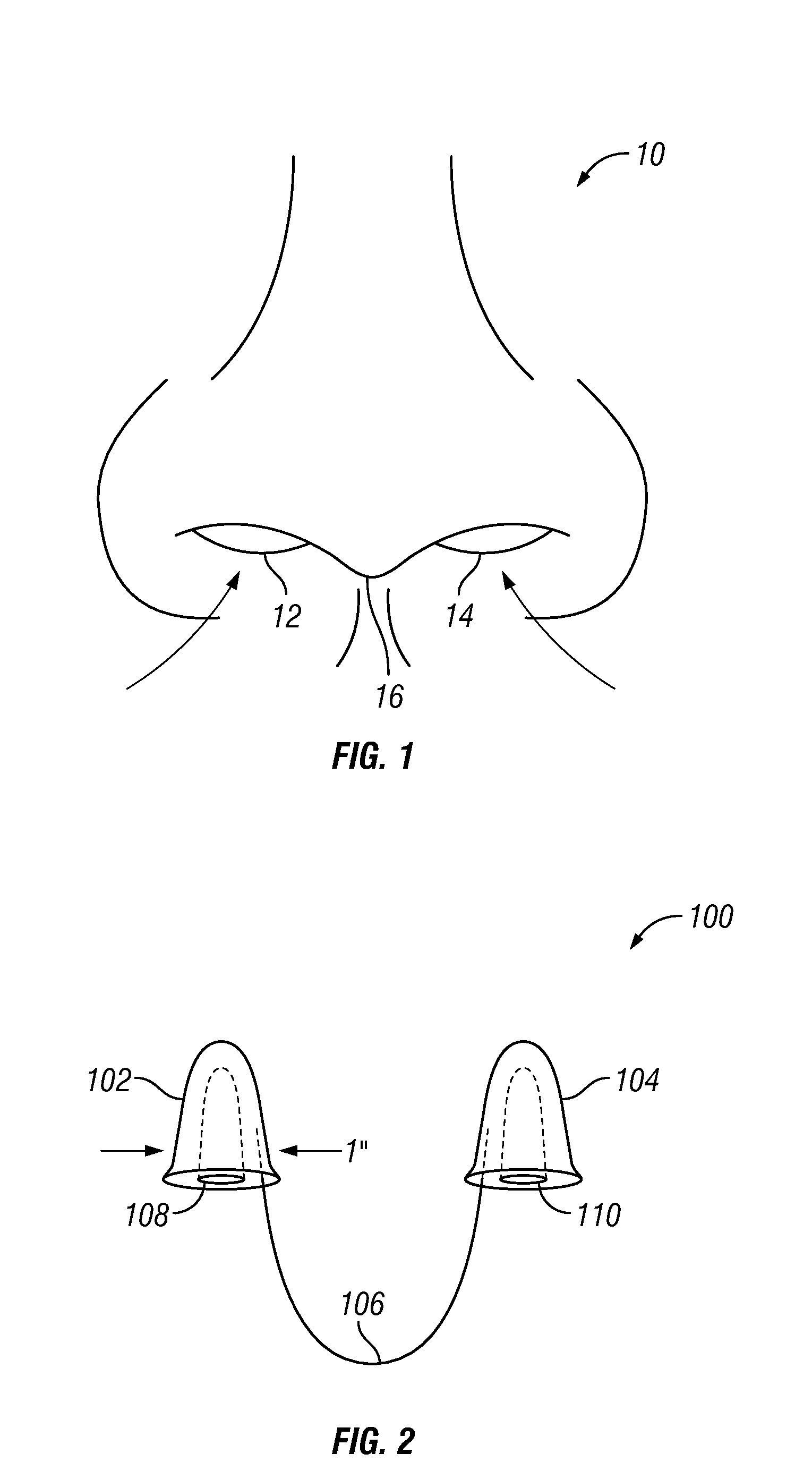

Nasal filtration system

A system for filtering breathing air and apparatus for accomplishing the same. The invention describes a nasal filtration system which can be inserted into the nasal cavities. The filters comprise cavities through which air is inhaled or exhaled. The filter performs as a mechanical filter to catch and prevent the inhalation of undesirable particulate. Further, the filter comprises a disinfectant agent, such as colloidal silver, which kills germs, bacteria, and viruses to prevent the spreading of disease.

Owner:ARCH HLDG LP

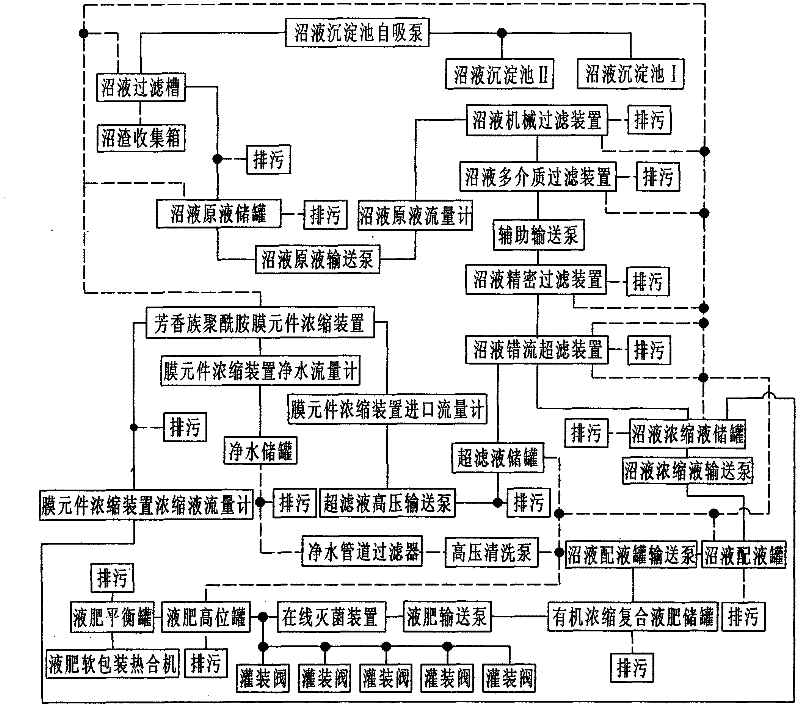

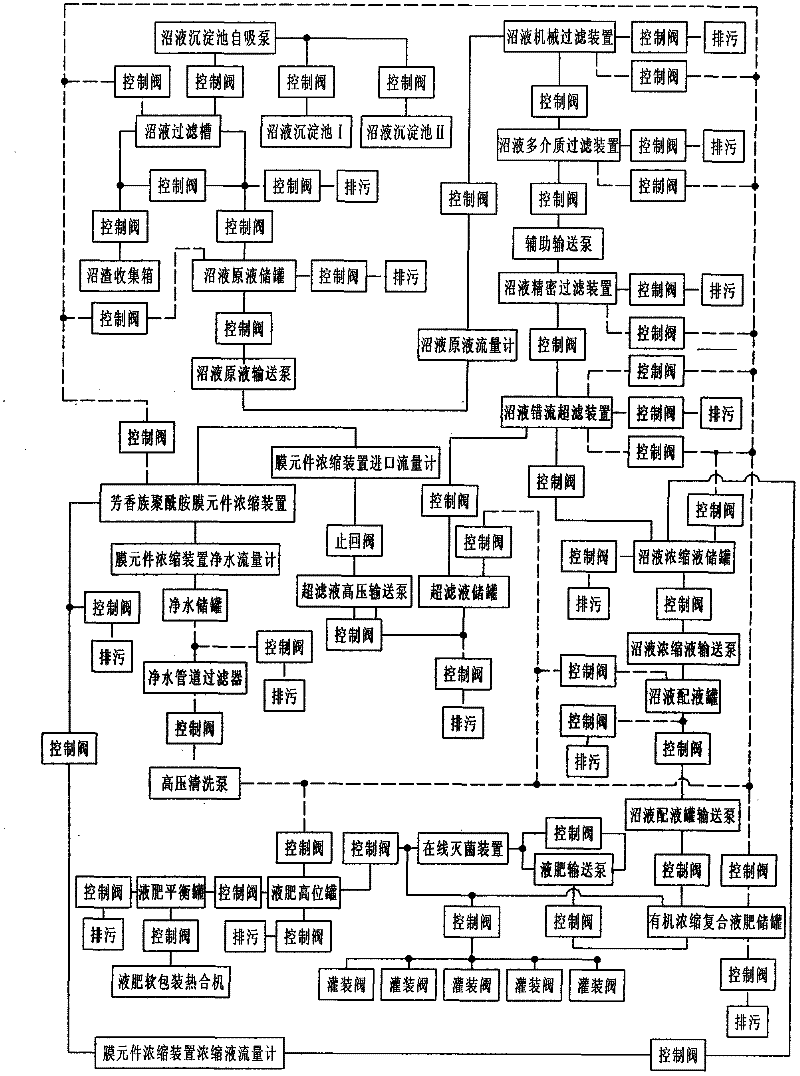

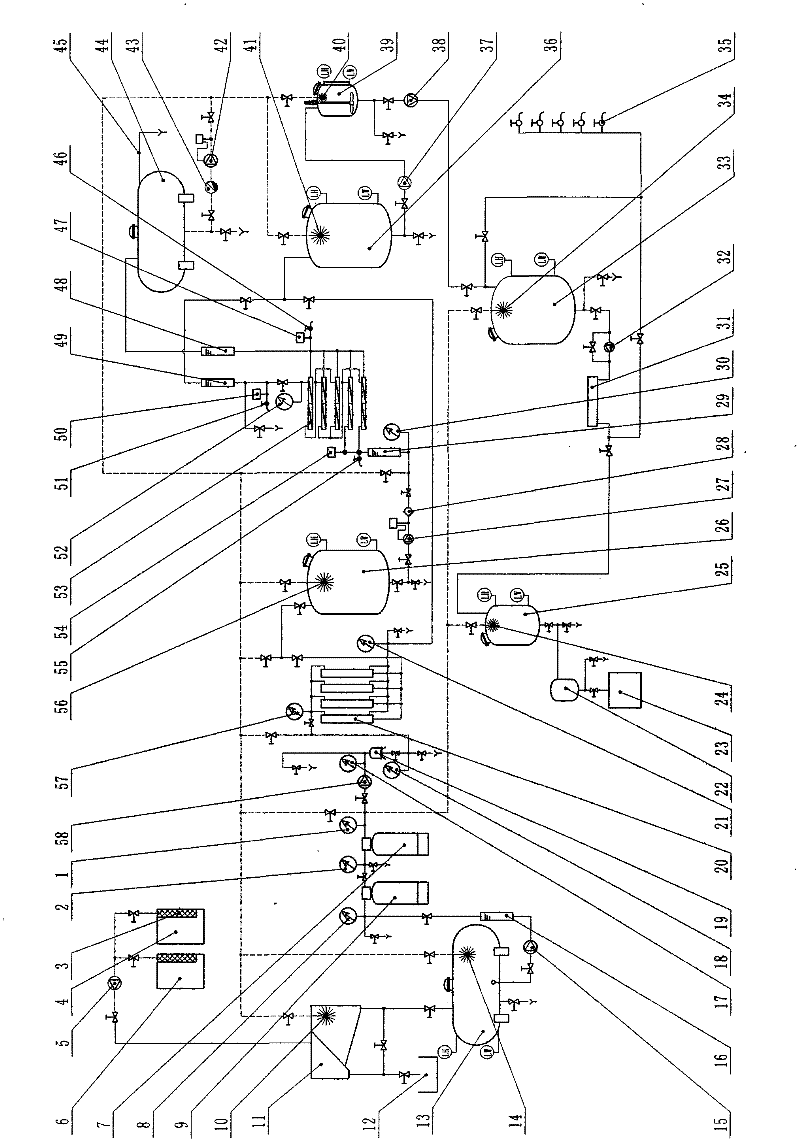

Method and device for producing organic concentrated compound liquid fertilizer from marsh liquid at normal temperature

InactiveCN102249743AReduce corrosionReduce odorBio-organic fraction processingClimate change adaptationFiberWater storage tank

The invention provides a method and device for producing an organic concentrated compound liquid fertilizer from marsh liquid at normal temperature, and aims to provide a method for producing an organic concentrated compound liquid fertilizer from marsh liquid, which has the advantages of low cost and high degree of automation. The method comprises steps as follows: marsh liquid is filtered by a marsh liquid filter pond to remove large-granule substances containing plant fibers and sand grains, enters a marsh liquid stock solution storage tank, is pumped to a marsh liquid mechanical filter, a marsh liquid multimedia filter and a marsh liquid precision filter to remove high-molecular substances containing algae, pesticide residues, and bacteria, and is filtered by a marsh liquid cross-flow ultrafilter; the unfiltered liquid enters a concentrated liquid storage tank, and the filtrate enters an aromatic polyamide membrane element concentration device to be concentrated and separated; the separated concentrated liquid enters the concentrated liquid storage tank, and is delivered to a marsh liquid preparation tank to prepare the liquid fertilizer; the filtrate enters a pure water storage tank for cleaning equipment; and the liquid fertilizer is sterilized by an on-line sterilizer, and then packaged to serve as a plant liquid fertilizer for crops, flowers and the like.

Owner:CHANGCHUN AGRI MACHINERY

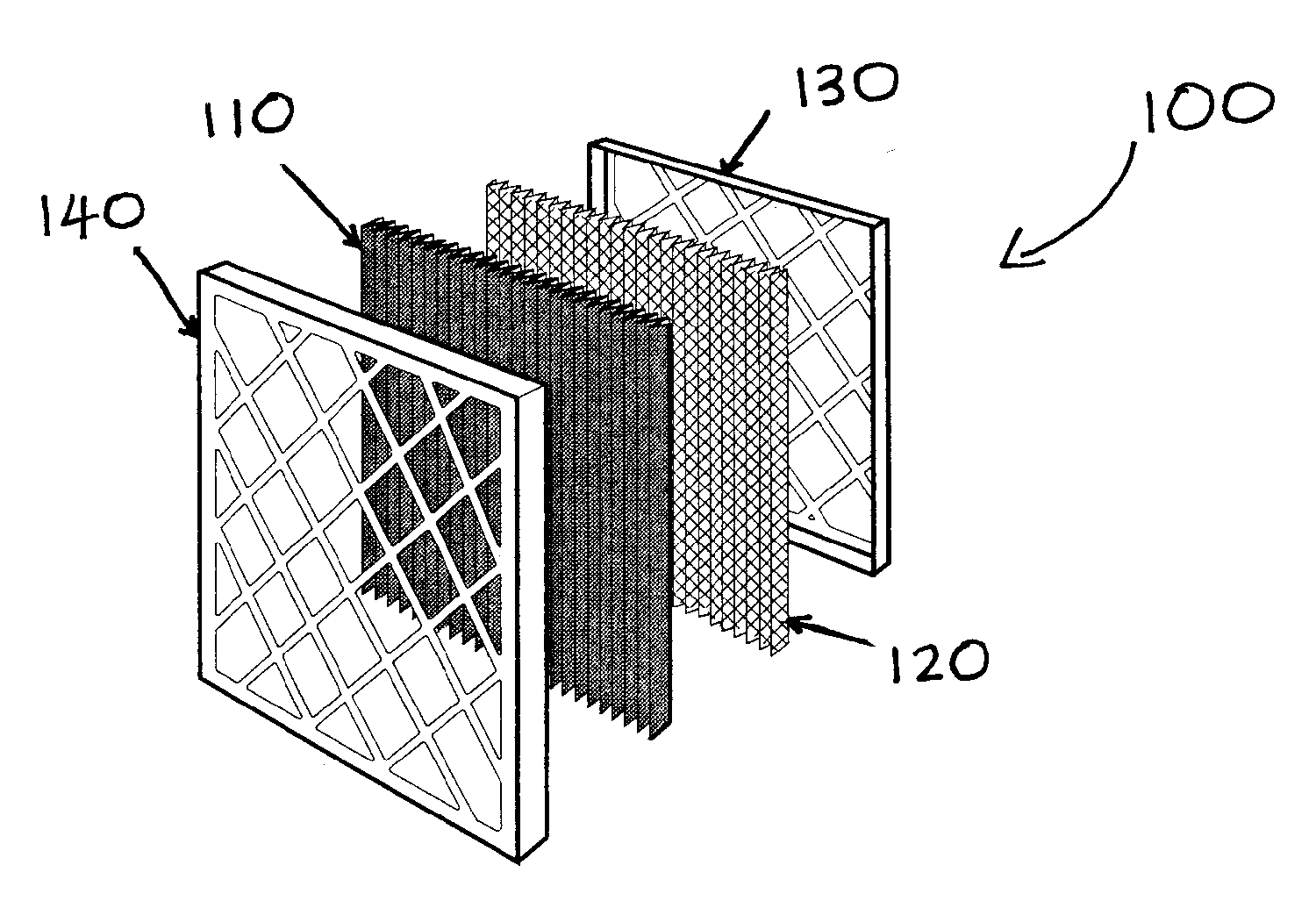

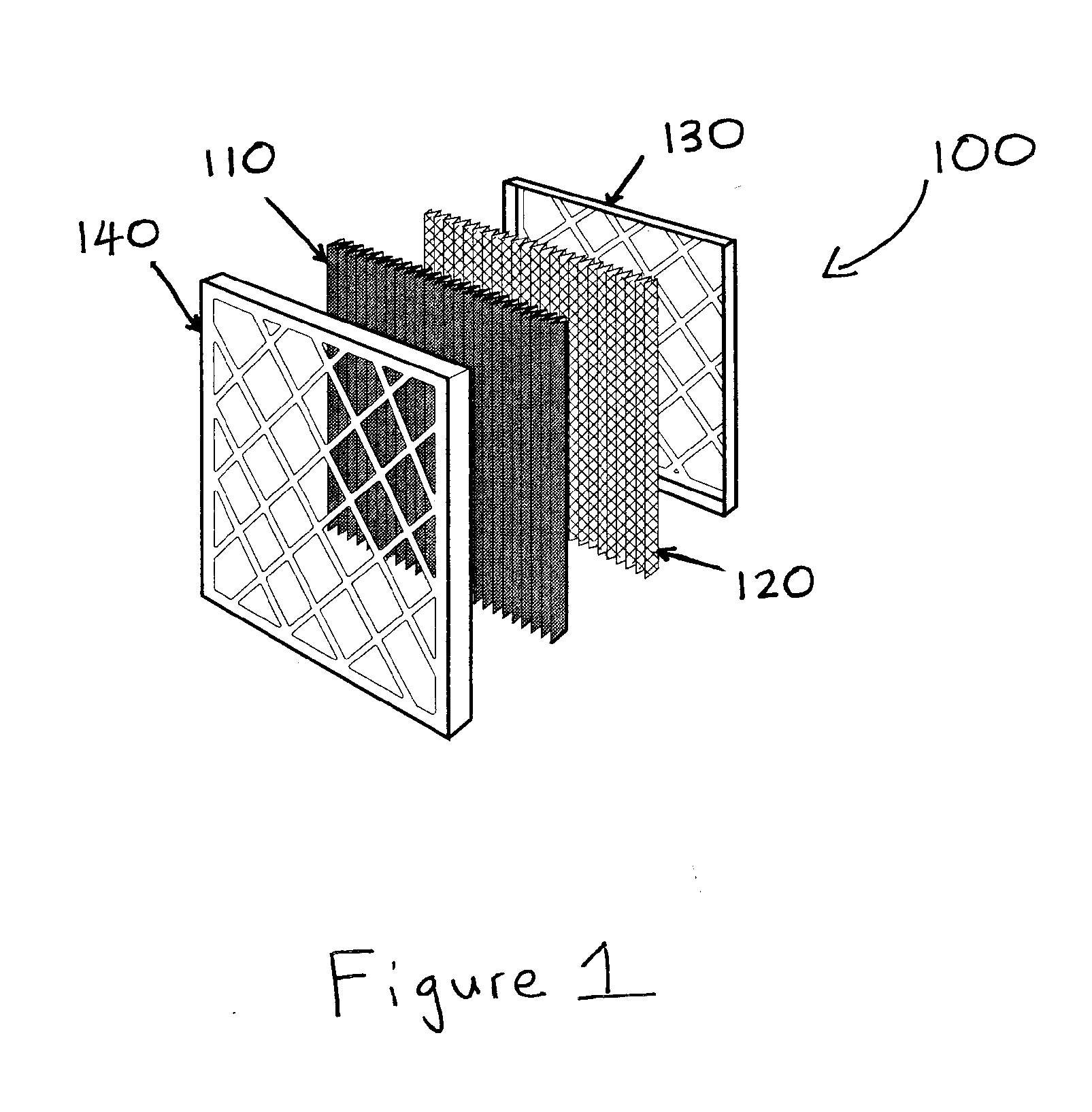

Antimicrobial and carbon treated indoor air filter

An indoor air filter is disclosed. The filter includes non-woven fibers, carbon, and an antimicrobial. The carbon and the antimicrobial are bonded to the fibers to form a filter media. The filter media is pleated. The carbon is activated. The antimicrobial can be silver. The non-woven fibers can be synthetic, and the filter media can be a mechanical filter media.

Owner:GATES JAMES LEE +1

Drinking water vending dispenser facilitated to collect and purify drainage water

ActiveUS20150136666A1Avoid small quantitiesTreatment involving filtrationSolid sorbent liquid separationActivated carbon filtrationEnvironmental engineering

A drinking water vending dispenser for dispensing purified water comprising a coarse mechanical filter, an RO purification unit, an ozone purification unit, a UV purification unit, an active carbon filter, a chemical base purification unit and a fine mechanical filter.

Owner:WOOSH WATER SYST

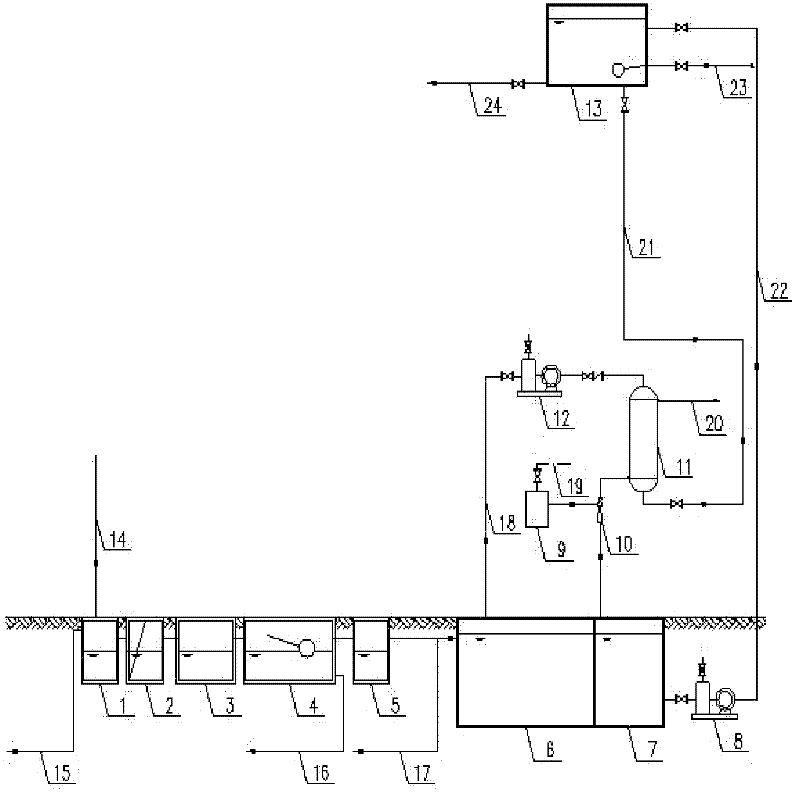

Ultra-pure water preparation system and method capable of preventing electrodeionization device from scaling

InactiveCN105198133AReduce salt contentAvoid formingMultistage water/sewage treatmentNon-contaminated water treatmentActivated carbon filtrationIon exchange

The invention provides an ultra-pure water preparation system and method capable of preventing a electrodeionization device from scaling. The preparation system is mainly composed of a raw water pretreatment system, a reverse osmosis system and an electrodeionization system. The raw water pretreatment system comprises a raw water booster pump, a mechanical filter, an active carbon filter and a precision filter, raw water enters the booster pump through a pipeline, and the mechanical filter, the active carbon filter and the precision filter are sequentially connected to the back of the booster pump; the reverse osmosis system comprises a high-pressure pump and a first-grade reverse osmosis device which is composed of a membrane component, a membrane shell, a pipe valve and a control system; the electrodeionization system comprises a fresh water pump, an EDI membrane stack and a rectifier; a water producing tank arranged at the back of the first-grade reverse osmosis device is connected to the membrane stack through the fresh water pump, the rectifier provides an electric field to form a membrane stack electric current, ion exchange resin in the EDI membrane stack continuously removes anions and cations in water through ion exchange, and the ultra-pure water is produced.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

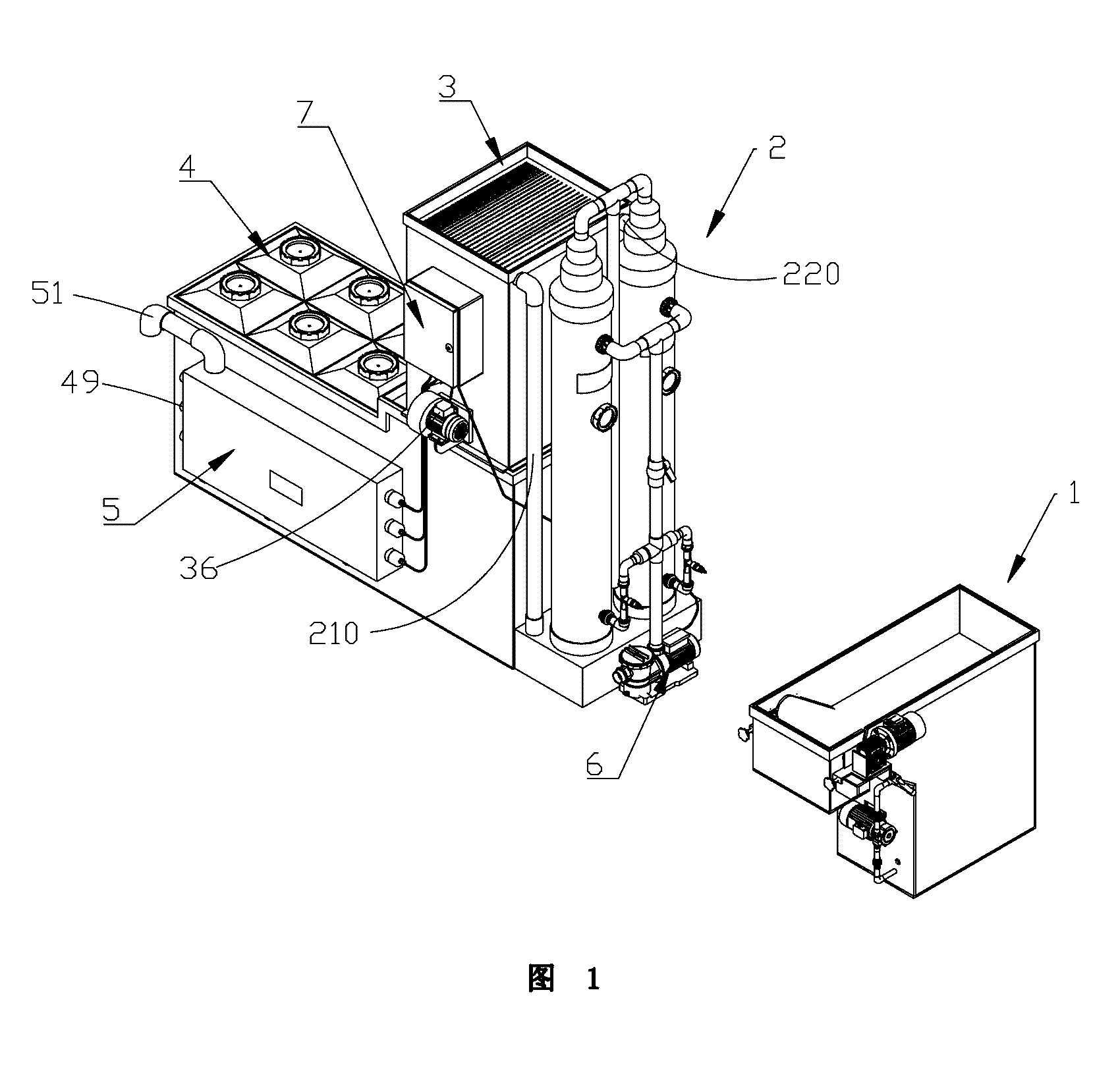

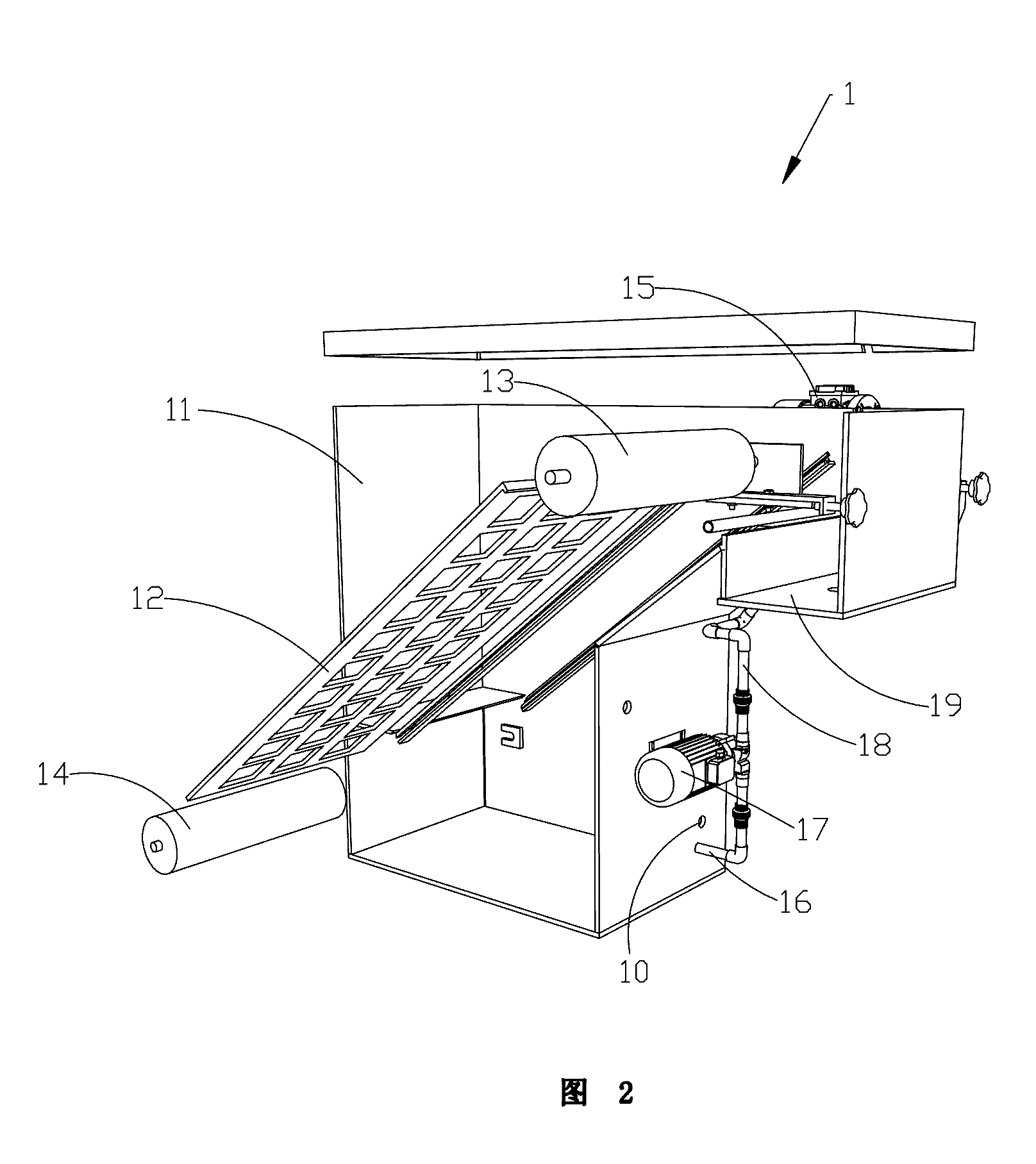

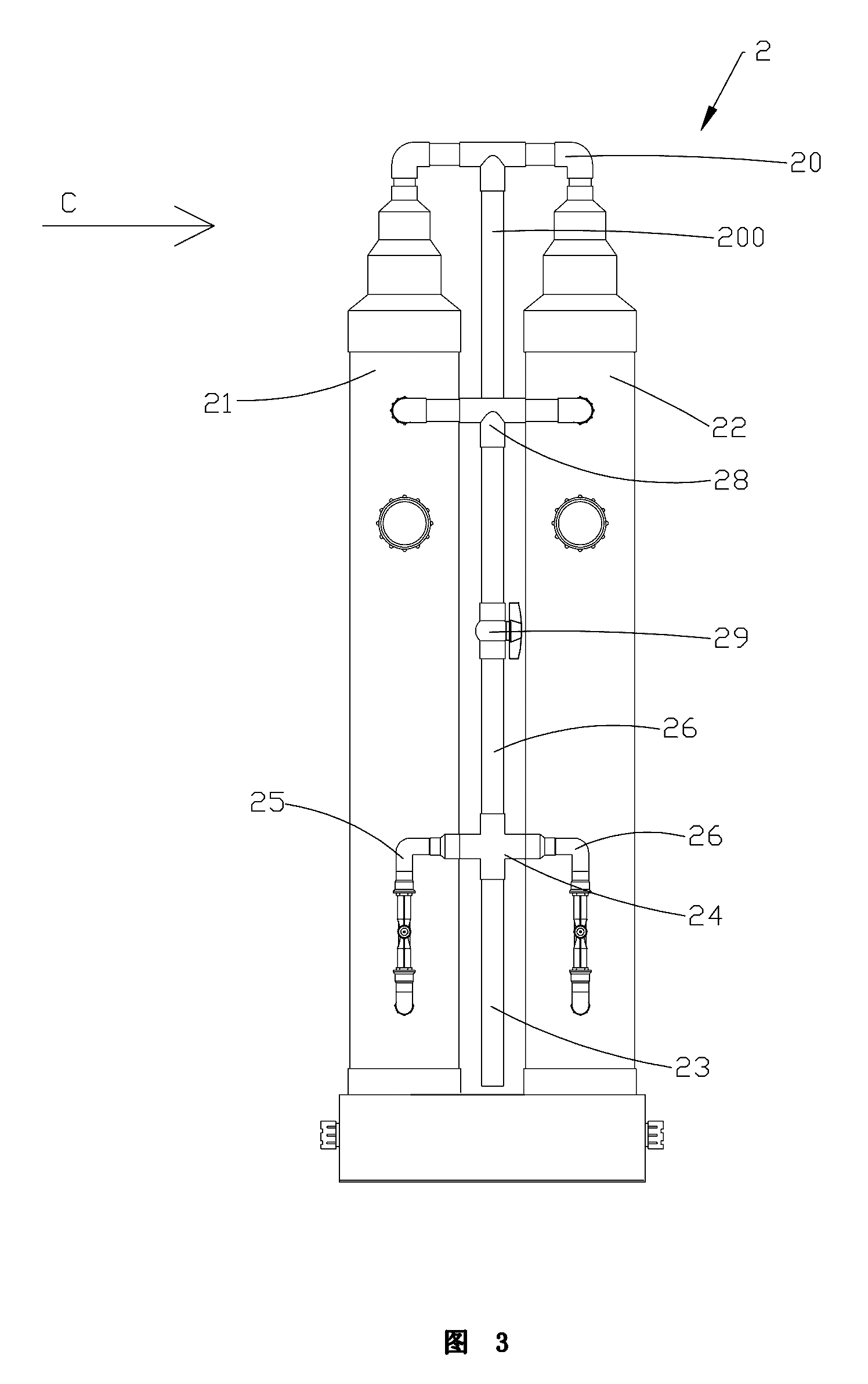

Combined modular circulating water cultivating system

ActiveCN103070127ASolve the cost problemSolve space problemsPisciculture and aquariaSystems designElectronic controller

The invention discloses a combined modular circulating water cultivating system, which comprises a belt type mechanical filter, a protein separator, a dripping box, a bio-filter, an ultraviolet disinfector and a central electronic controller, wherein the protein separator is connected with the belt type mechanical filter; the dripping box is connected with the protein separator; the bio-filter is connected with the dripping box; the ultraviolet disinfector is connected with the bio-filter; the belt type mechanical filter is used for pumping water into the protein separator through a water pump; the dripping box is arranged above the bio-filter; the highest water level of the protein separator is higher than the highest water level of the dripping box; the highest water level of the bio-filter is higher than the highest water level of the ultraviolet disinfector; and both the ultraviolet disinfector and the water pump are connected with the central electronic controller. According to the combined modular circulating water cultivating system, the defects of high manufacturing cost, large occupied space, complex pipeline connection, difficulty in maintaining, high running cost, poor treatment effect and the like caused by the complex and single equipment system design of the conventional circulating water cultivating system are overcome completely; and the combined modular circulating water cultivating system is more convenient and practicable.

Owner:GOLDBILL FUJIAN AQUACULTURE TECH

Vehicle-mounted emergency drinking water production device

The invention relates to a vehicle-mounted emergency drinking water production device which is characterized by consisting of a water pumping device, a frame, a drinking water production device, a drinking water tank, a power generation device and a control device; the water pumping device comprises a submersible pump and a water pipe; the drinking water production device comprises a disk-type mechanical filter, a sand-carbon mixing filter, a precise filter, a constant pressure pump and a reverse osmosis membrane filter; the electric signal output end of a liquid level detection device is connected with the electric signal input end of the control device; and the control electric signal output end of the control device is respectively connected with the control electric signal input end of the submersible pump, the control electric signal input end of the self-cleaning device of the disk-type mechanical filter and the control electric signal input end of the constant pressure pump. Compared with the prior art, the vehicle-mounted emergency drinking water production device has the advantage that drinking water can be provided for a lot of people in emergency.

Owner:佛山市雅洁源科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com