Method and device for producing organic concentrated compound liquid fertilizer from marsh liquid at normal temperature

A technology of compound liquid and concentrated liquid, which is applied in the fields of organic fertilizer, biological organic part treatment, fertilizer made of biological waste, etc., can solve the problems of waste, secondary pollution of farmland, and insufficient utilization of biogas slurry, and reduce corrosion. , the effect of reducing odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

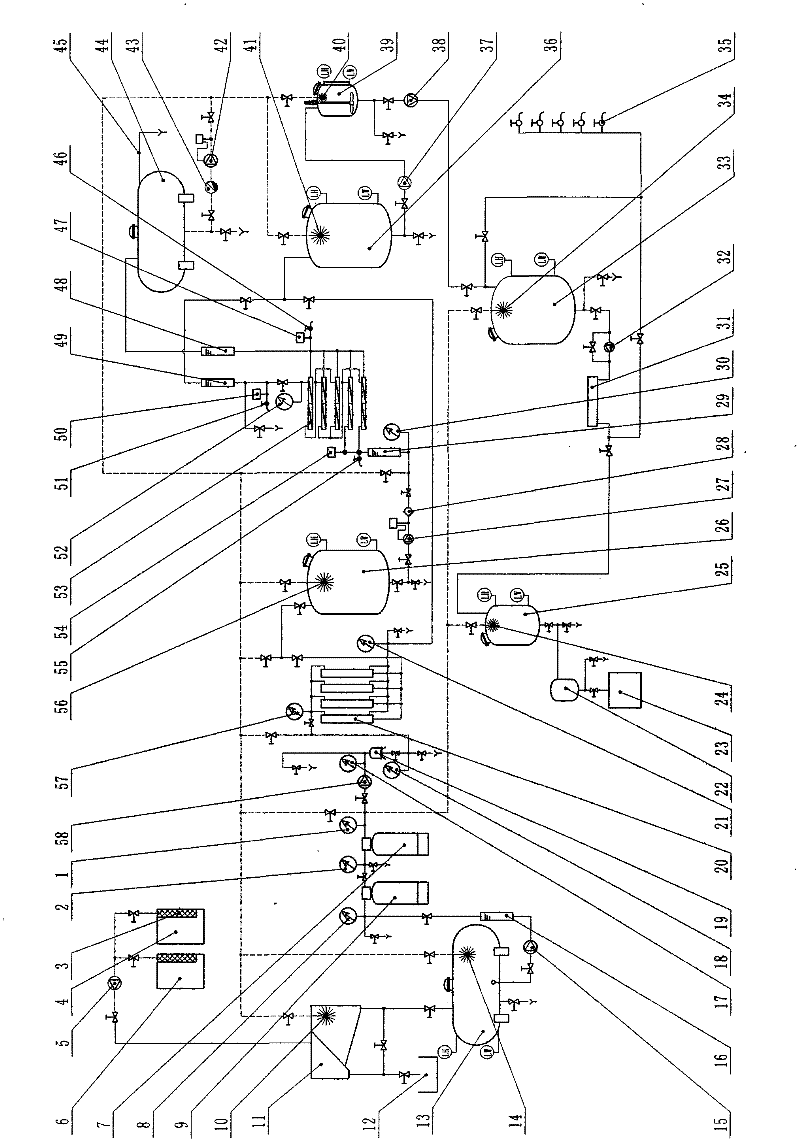

[0045] The present invention will be described in detail below in conjunction with accompanying drawing

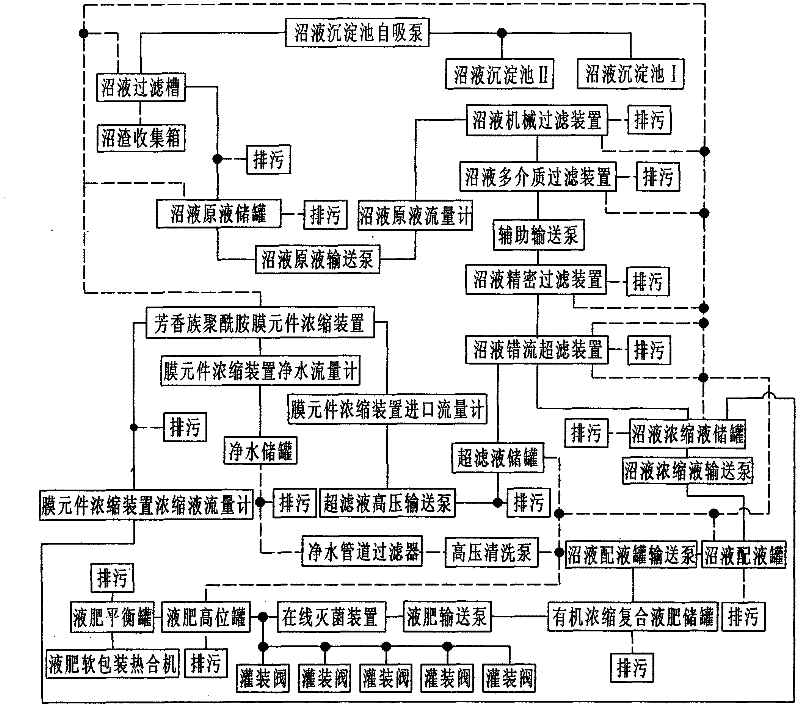

[0046] see figure 1, is a schematic diagram of the production process for producing organic concentrated compound liquid fertilizer from biogas slurry at room temperature. The dotted line in the figure shows the flow direction of the clean water on-line cleaning pipeline, and the solid line shows the flow direction of the biogas slurry through filtration, concentration, liquid preparation, on-line disinfection and sterilization, storage, and liquid fertilizer packaging.

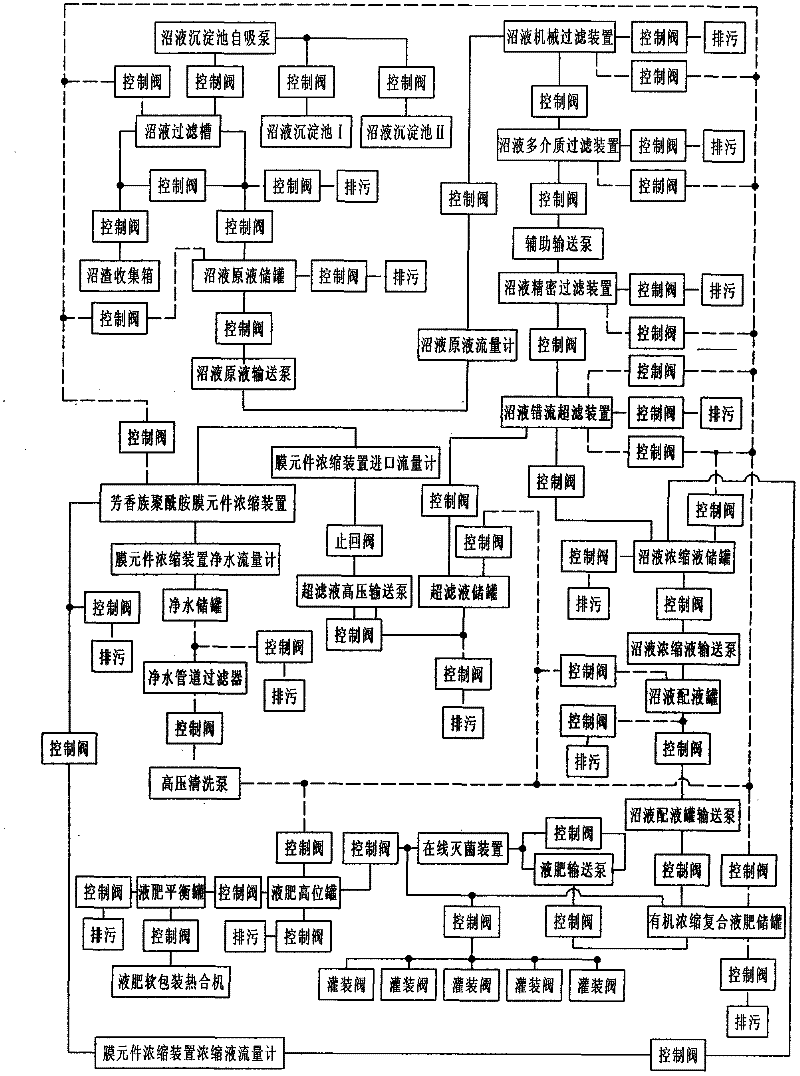

[0047] see figure 2 , is a production process flow diagram of biogas slurry to produce organic concentrated compound liquid fertilizer at normal temperature. The production process of the whole production of organic concentrated compound liquid fertilizer is shown in detail. figure 1 On the basis of the above, the details of the control valve control pipeline are added, and the production process cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com