Patents

Literature

18413results about "Bioloigcal waste fertilisers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Biochar

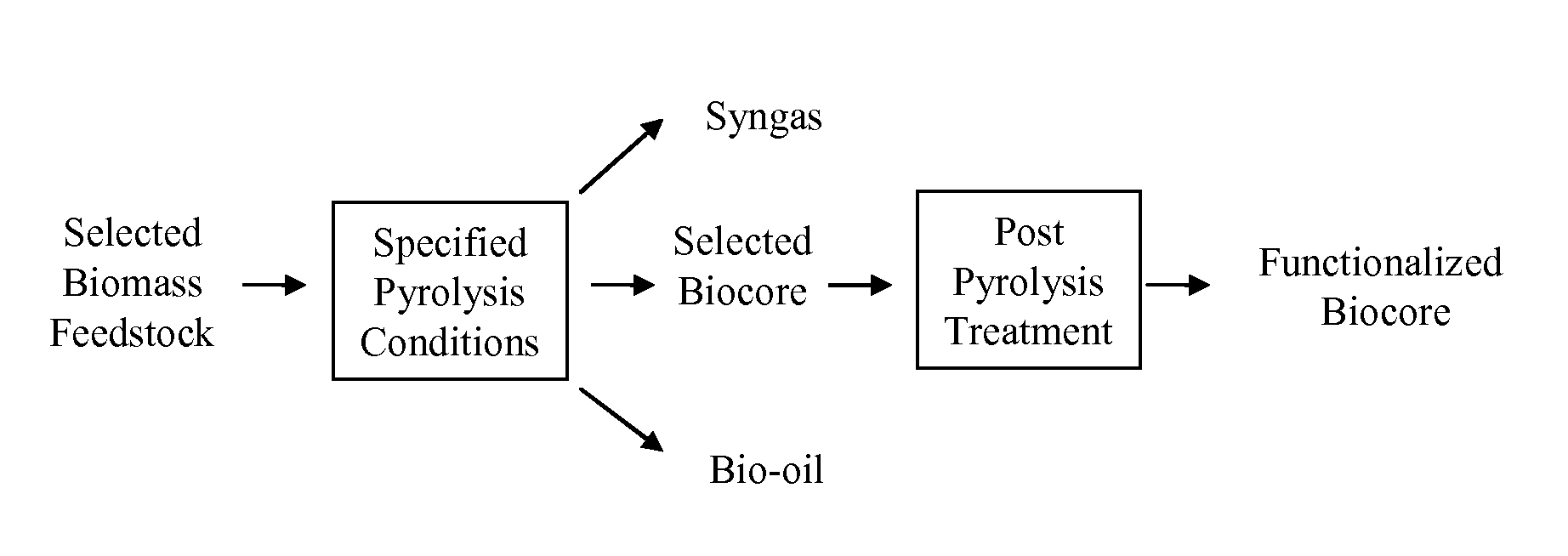

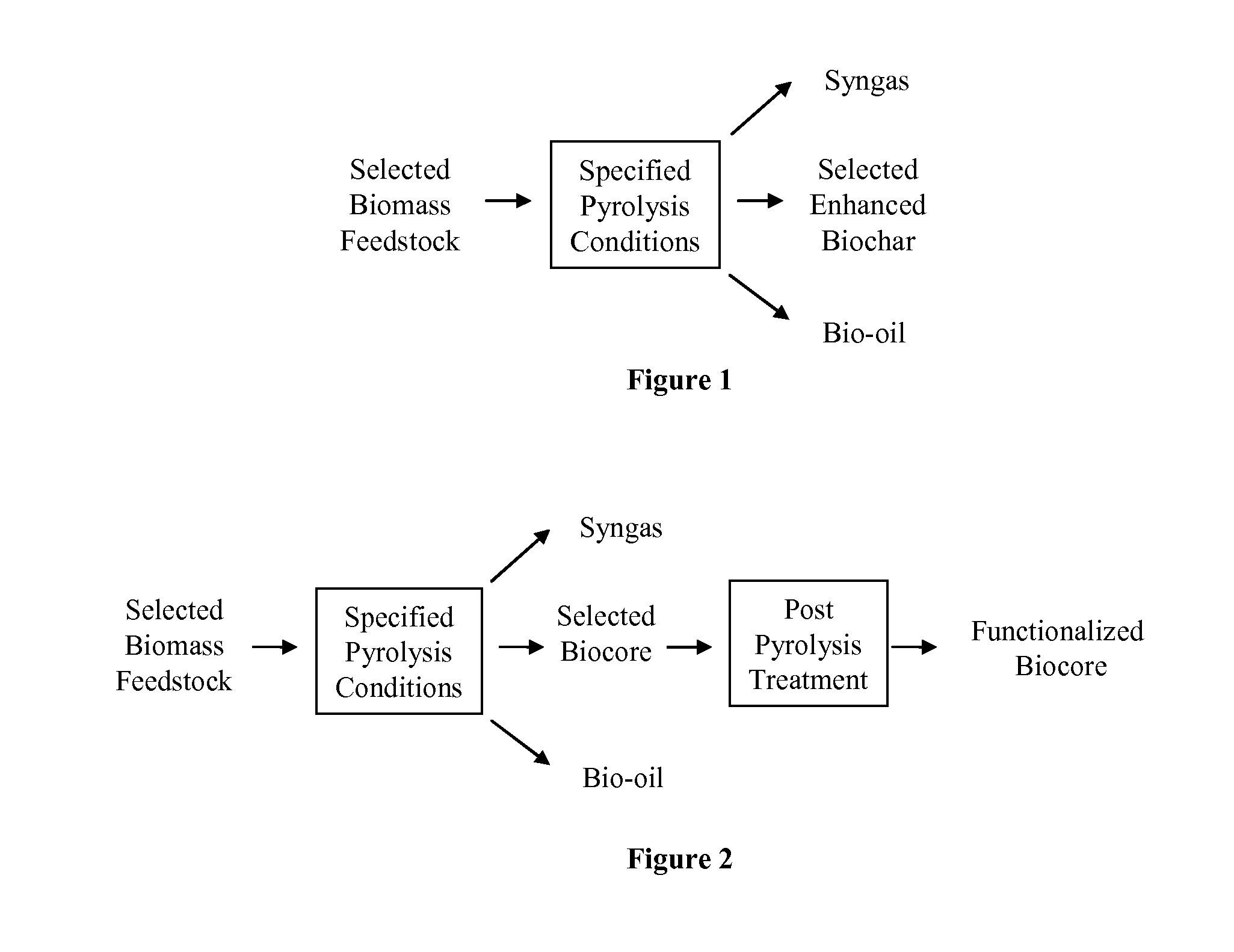

ActiveUS8361186B1Enhanced and functionalizedCalcareous fertilisersMagnesium fertilisersForming gasBiological activation

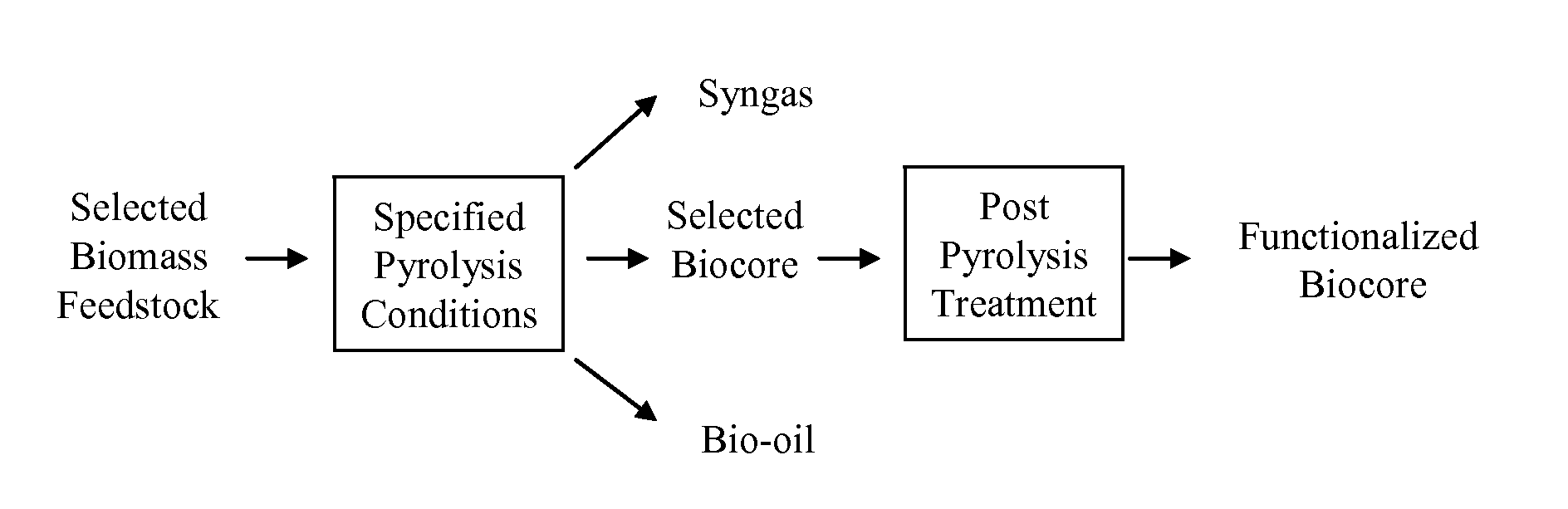

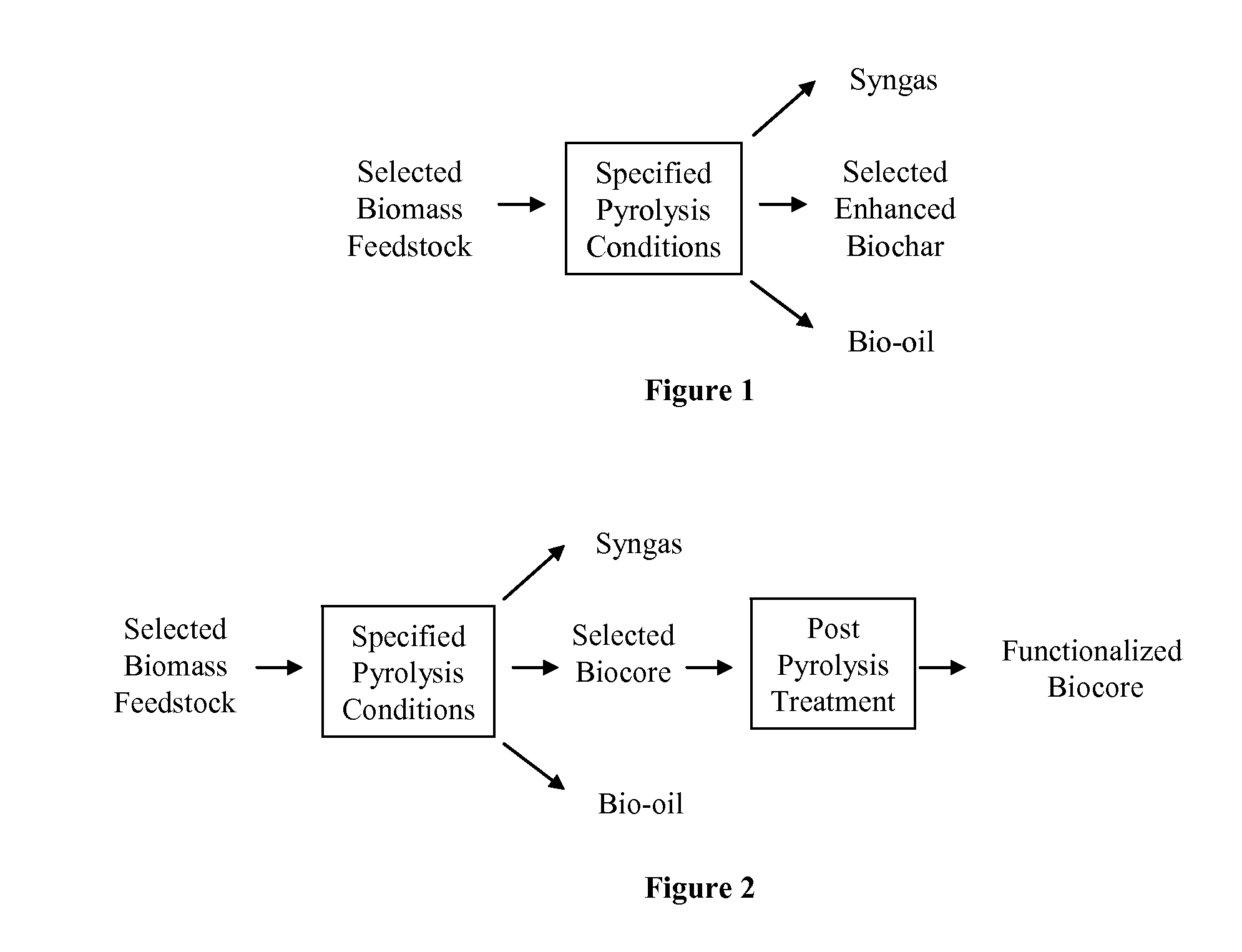

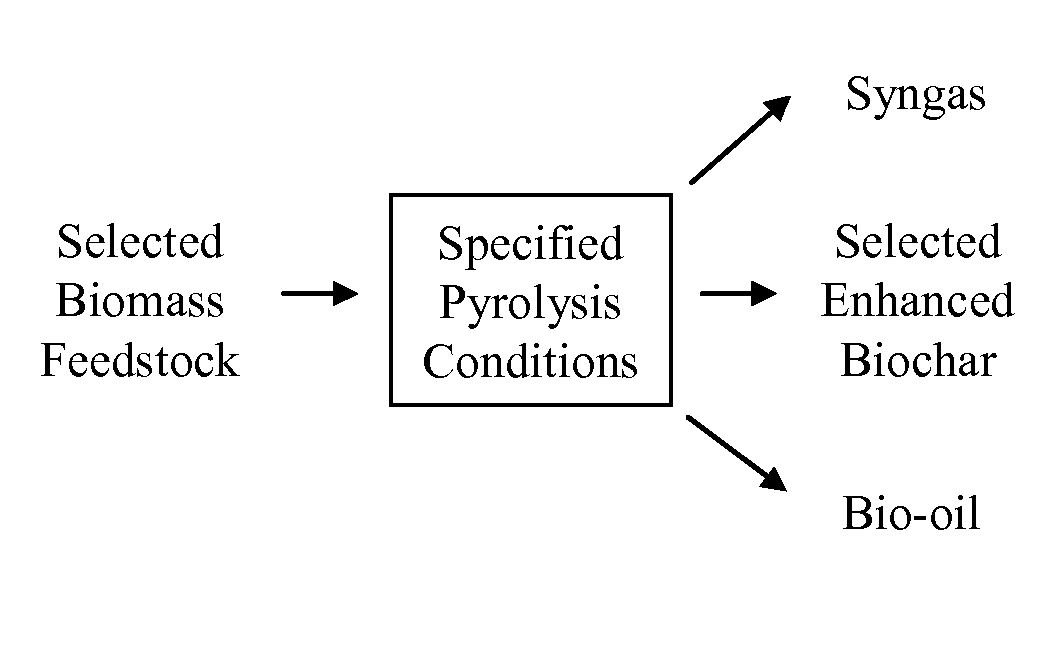

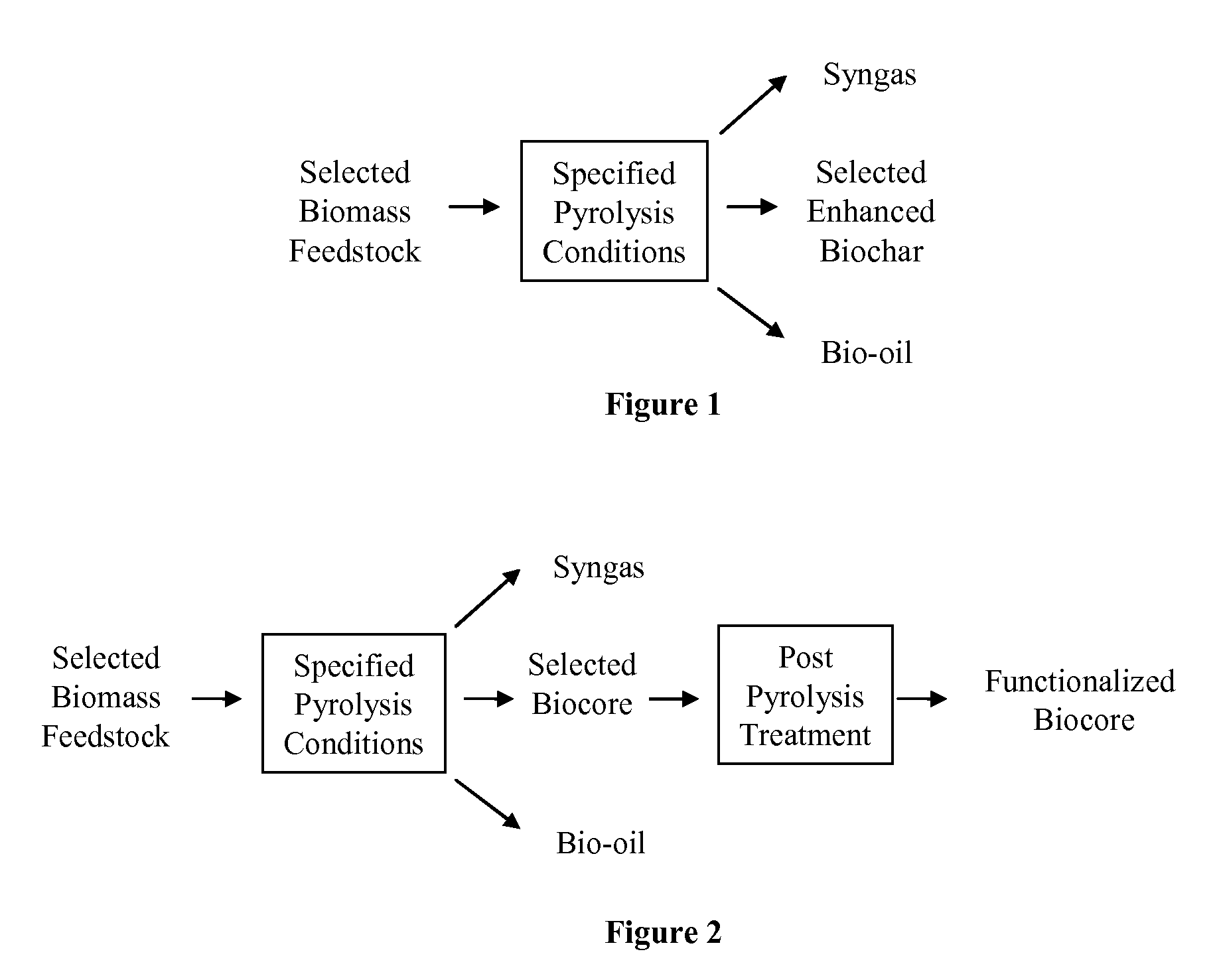

The invention provides for methods, devices, and systems for pyrolyzing biomass. A pyrolysis unit can be used for the pyrolysis of biomass to form gas, liquid, and solid products. The biomass materials can be selected such that an enhanced biochar is formed after pyrolysis. The biomass can be pyrolyzed under specified conditions such that a selected biochar core is formed. The pyrolysis process can form a stable biochar core that is inert and / or resistant to degradation. The biochar or biochar core can be functionalized to form a functionalized biochar or functionalized biochar core. Functionalization can include post-pyrolysis treatments such as supplementation with microbes or physical transformations including annealing and / or activation.

Owner:FULL CIRCLE BIOCHAR

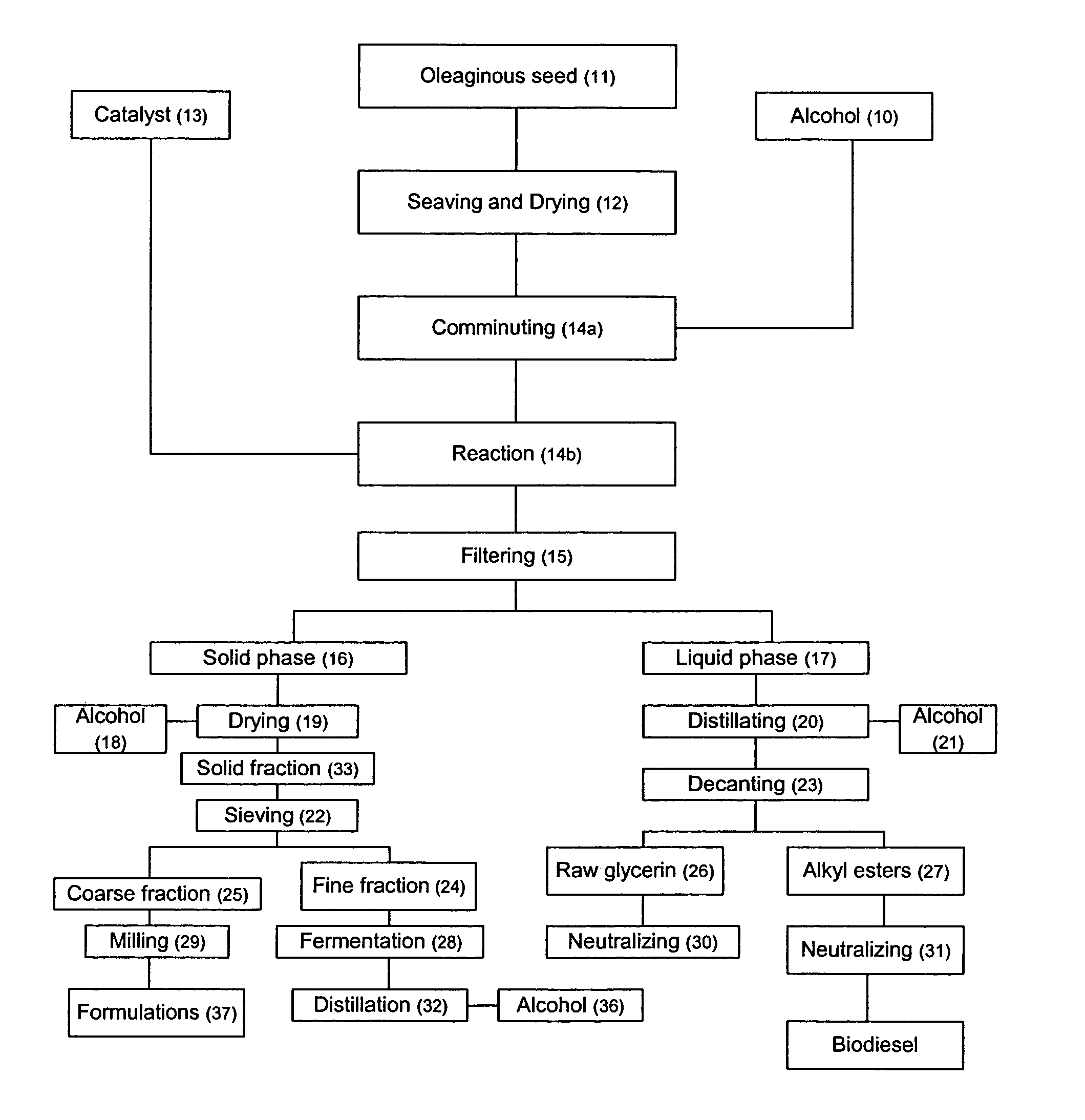

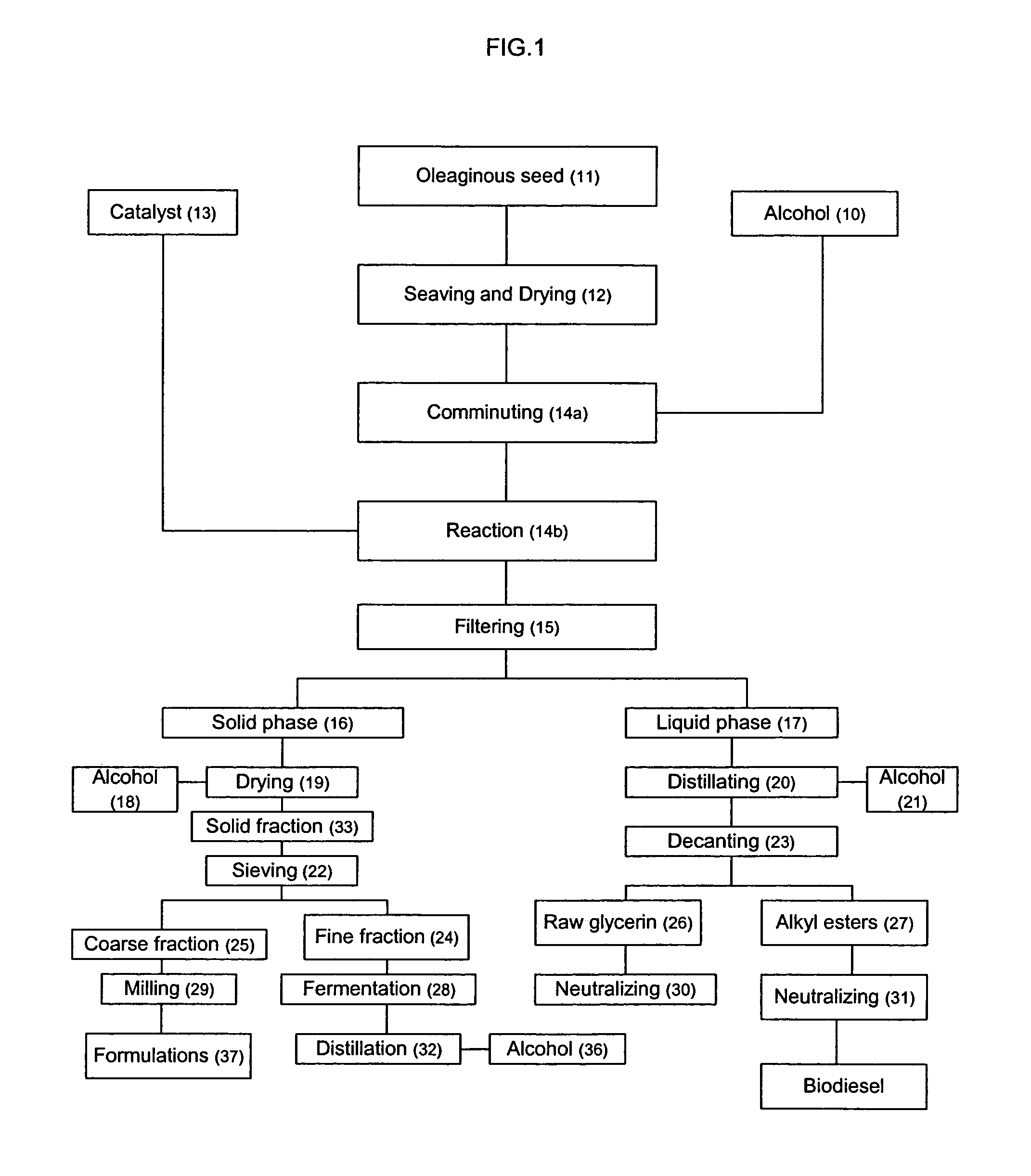

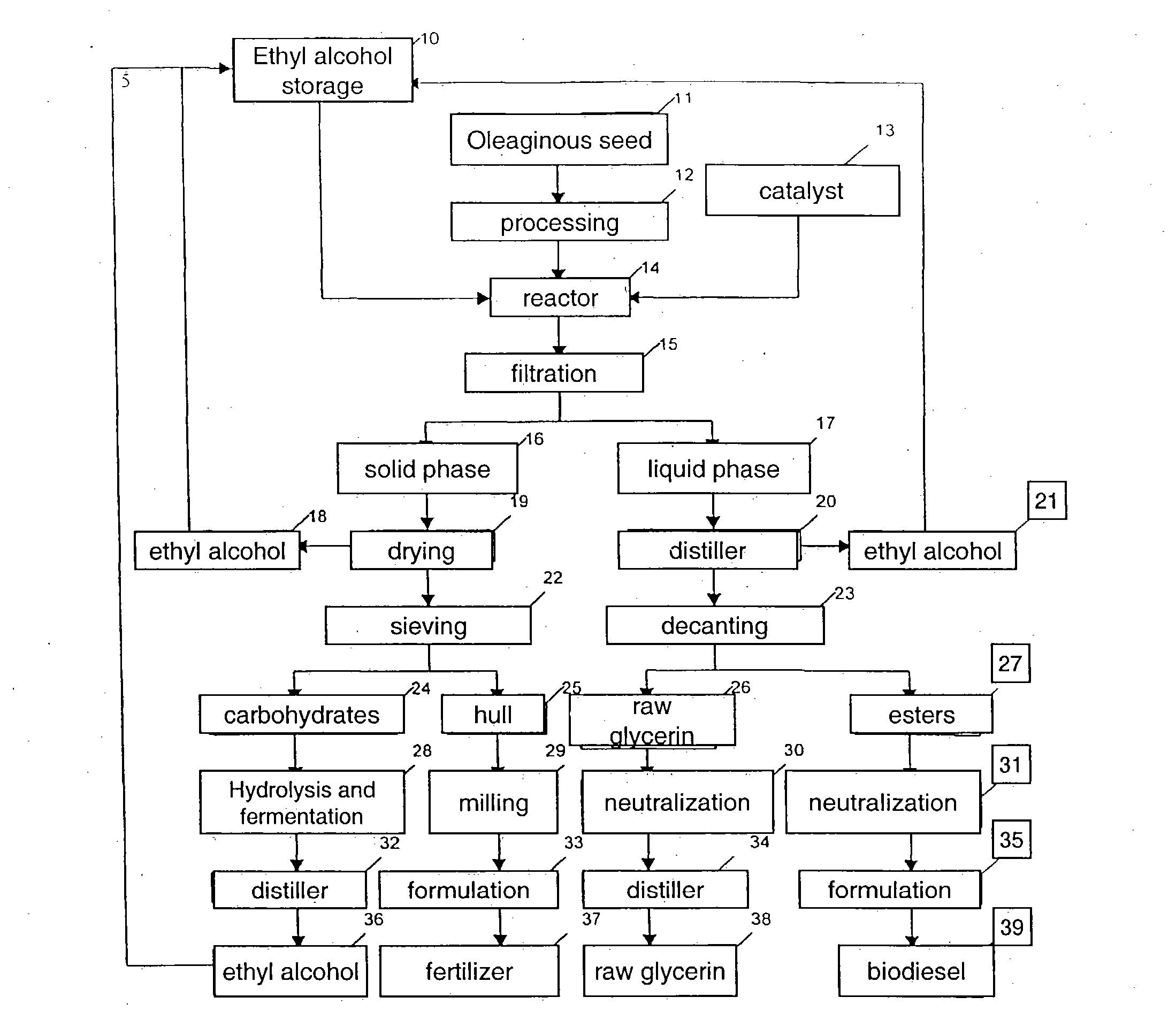

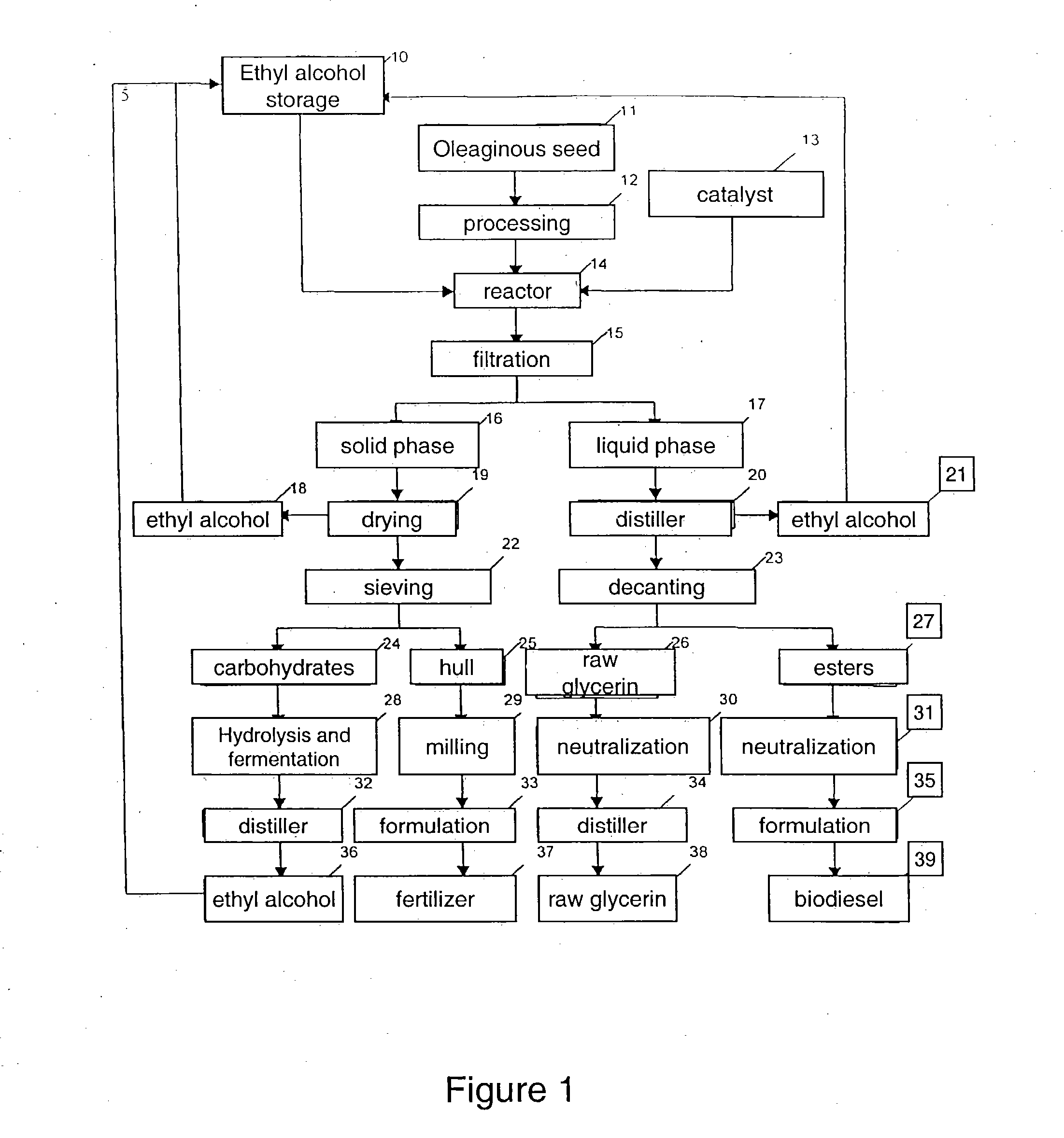

Process for producing biodiesel fuel using triglyceride-rich oleagineous seed directly in a transesterification reaction in the presence of an alkaline alkoxide catalyst

InactiveUS7112229B2Fatty oils/acids recovery from wasteFatty acid esterificationOil and greaseBiodiesel

An integrated process is described for producing biodiesel from oleaginous seeds, preferably castor bean seeds. The inventive process includes a transesterification reaction where the seeds themselves react with anhydrous ethyl alcohol in the presence of an alkaline catalyst. The resulting ethyl esters are then separated by decantation and neutralized and used as fuel for diesel engines, co-solvents for diesel and gasoline mixtures with anhydrous or hydrated ethyl alcohol. The solid fractions may be used as fertilizers, for feeding cattle and as a raw material for producing ethyl alcohol.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

Organic soil treatment compound and method of making and using

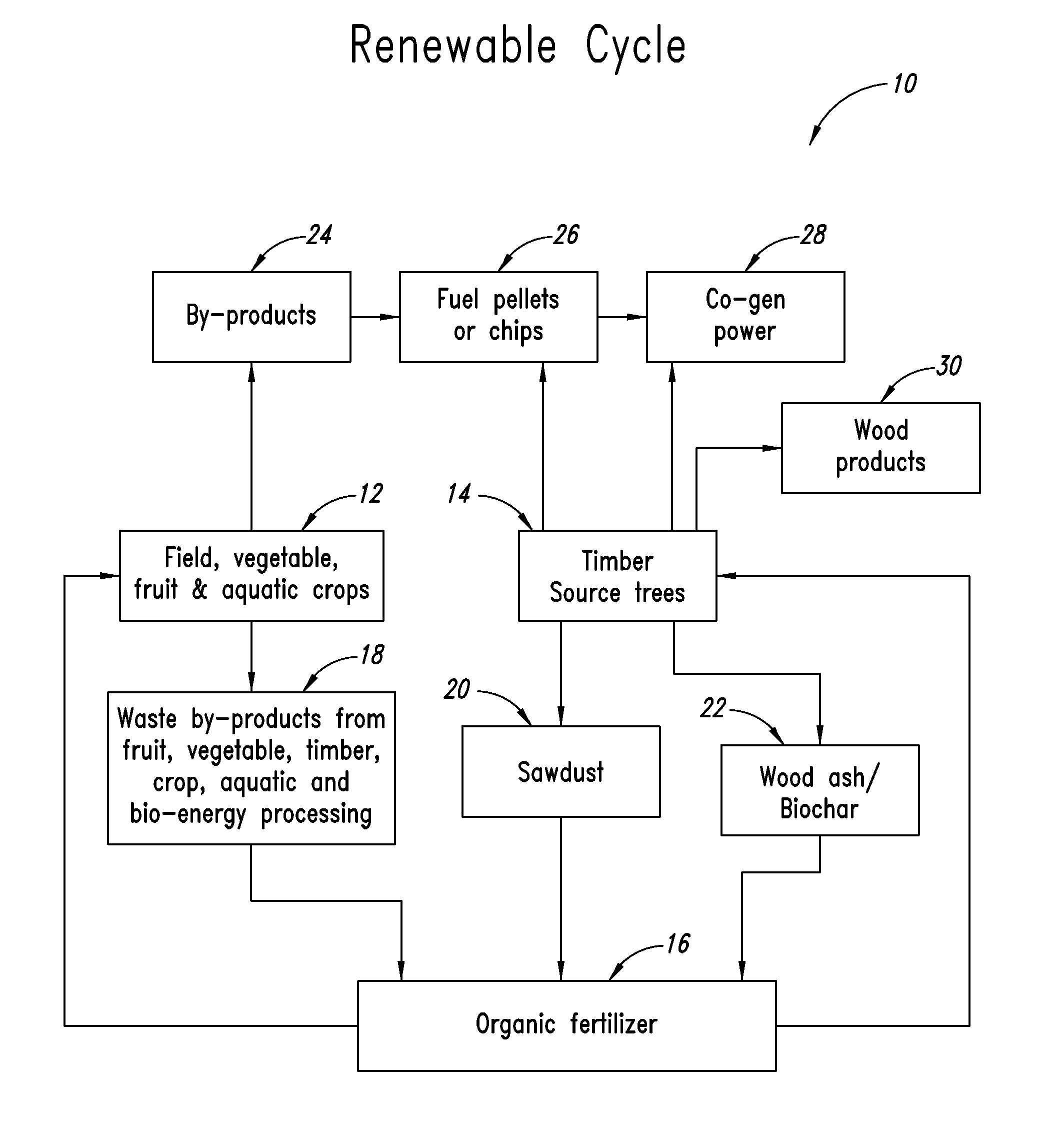

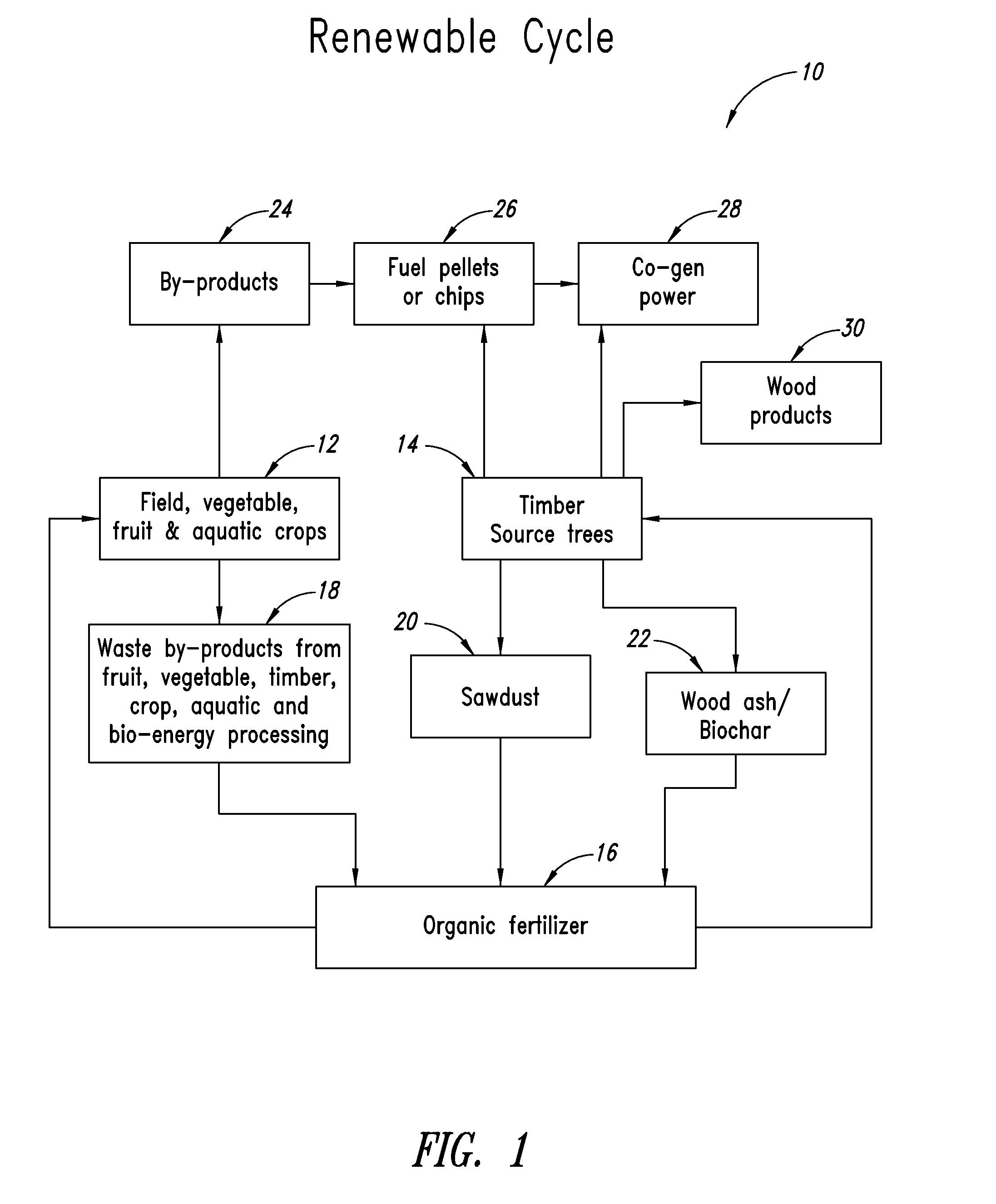

InactiveUS20110023566A1Promote plant growthImprove scalabilityClimate change adaptationBioloigcal waste fertilisersParticulatesSoil treatment

A composition is provided that includes particulates from wood, chaff, hulls, crop compost, biochar, or waste residue, wood or crop ash and biochar, and a nitrogen source from waste residue from gasification processes, food processing waste water or other residual by-products of forest, aquatic, food or feed processing. Ideally, all of the components are environmentally friendly, from natural products, and free of manufactured chemicals.

Owner:ECOTRAC ORGANICS

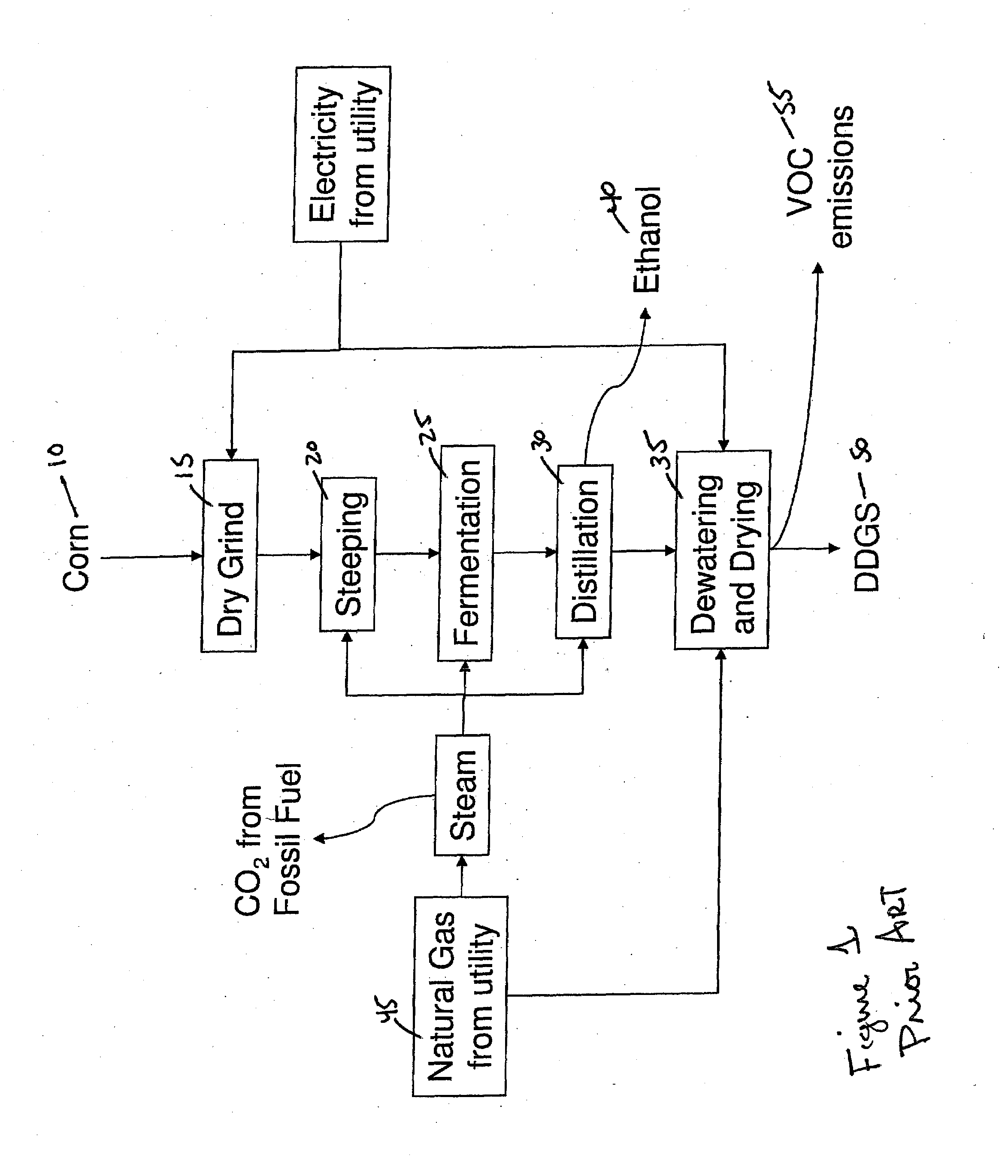

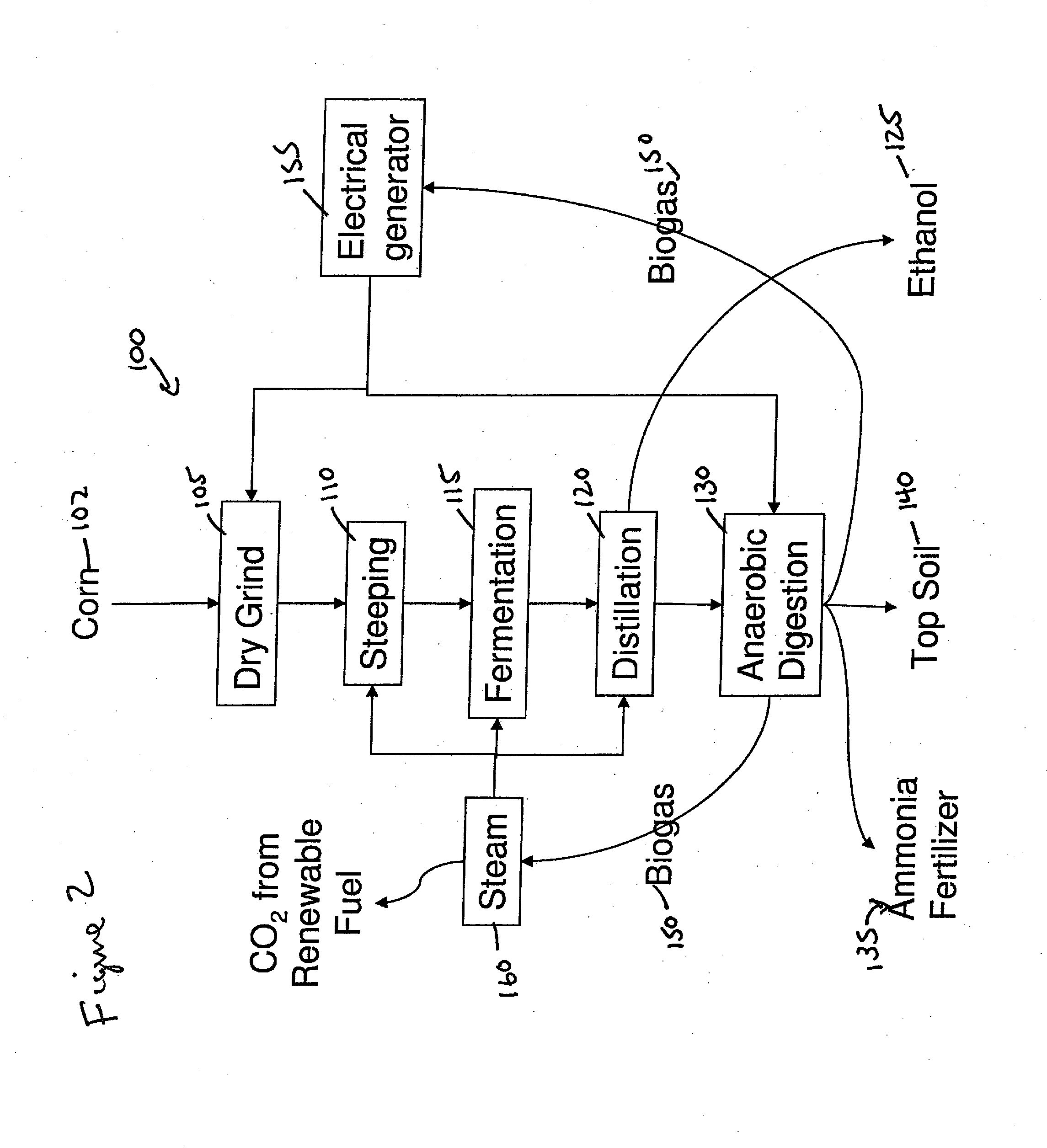

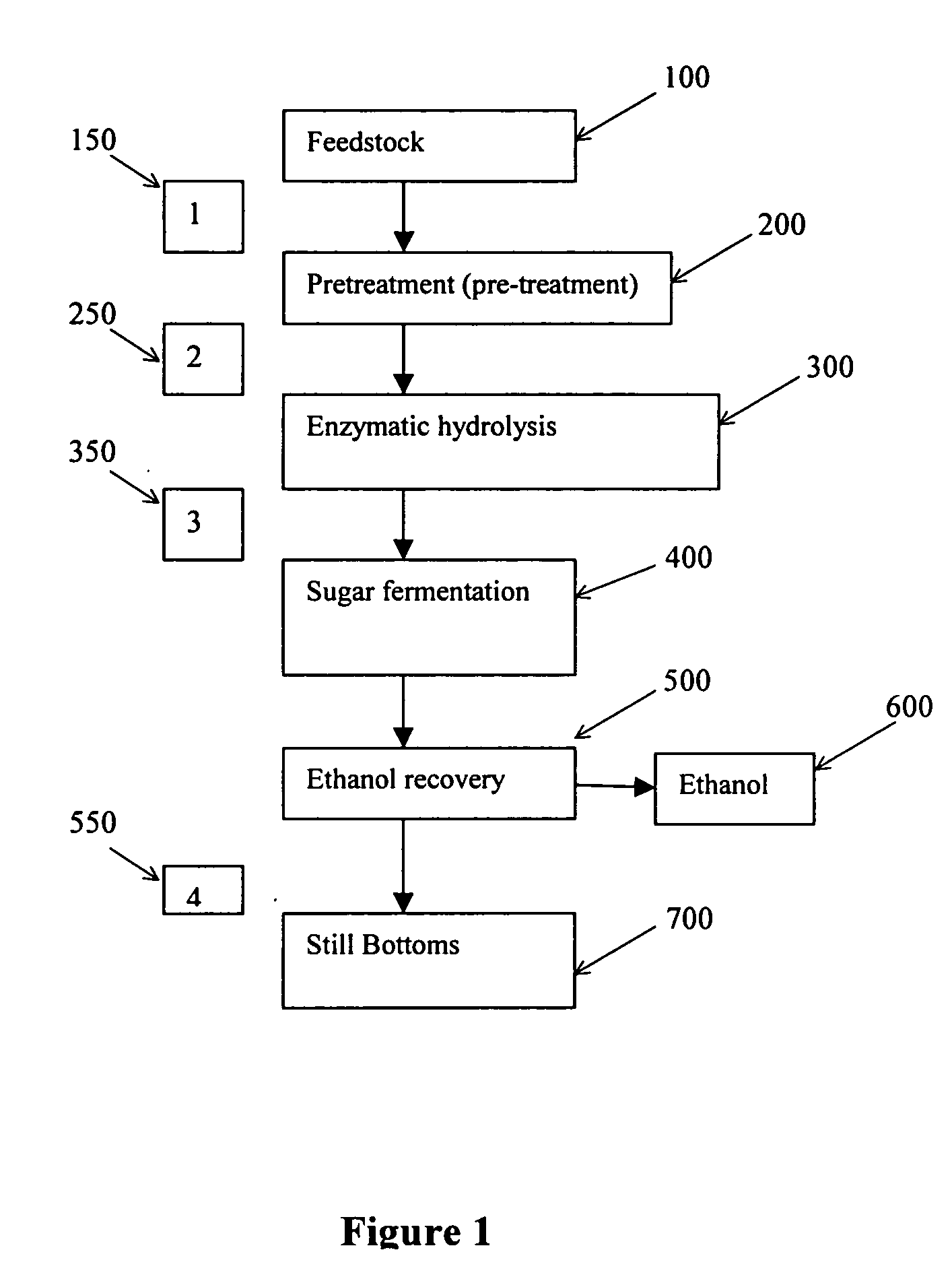

Process for producing ethanol and for energy recovery

InactiveUS20070141691A1Increasing net energy valueReducing the reliance of the ethanol industryBioreactor/fermenter combinationsBio-organic fraction processingElectricityDistillation

The present invention is directed to a process for the production of ethanol and energy. The process includes the steps of fermenting a corn mash in an aqueous medium to produce a beer. Next, the beer is distilled to produce ethanol and a whole stillage. The whole stillage is anaerobically digested to produce a biogas and a residue. The biogas is combusted to produce electricity and steam. The electricity and steam are used during the fermentation and distillation process. The residue may further be separated into a liquid fertilizer and top soil residue.

Owner:STANLEY CONSULTANTS

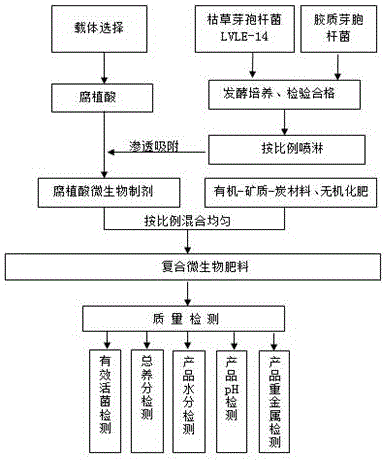

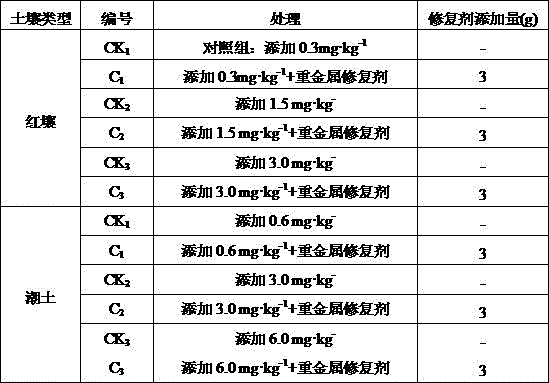

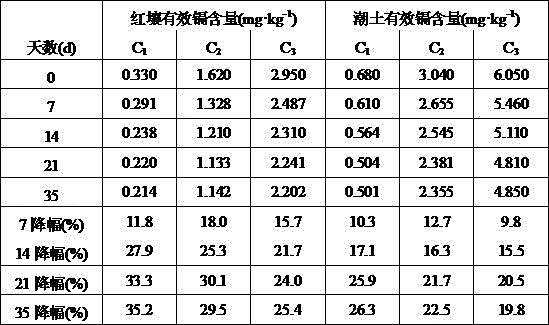

Soil heavy mental repairing agent and preparation method and application thereof

InactiveCN106495939AReduce the effective contentReduce heavy metal contentCalcareous fertilisersAgriculture tools and machinesEcological safetyMicrobial agent

The invention discloses a soil heavy mental repairing agent and a preparation method and an application thereof. The soil heavy mental repairing agent is composed of an organic material, a mineral raw material, a carbon material, an inorganic fertilizer and a microbial agent, wherein the viable count of the microbial agent is 1*10<7>-1*10<10>, the content of N, P2O5 and K2O is 8%-15% of the content of total nutrient, the content of the organic material is 20%-40% and pH is 5.5-8.5. The invention also provides an application method of the soil heavy mental repairing agent. The dosage is 80-150kg / mu; the effective heavy metal content of the soil can be effectively reduced; the heavy metal absorption of the crop can be obviously restrained; the crop yield and quality can be improved; the yield and income can be increased; the soil heavy mental repairing agent has significance in promoting social stability, economic growth and environmental diplomacy and guaranteeing ecological safety, food safety and human health.

Owner:SHANGHAI NUOTONG INFORMATION TECH CO LTD

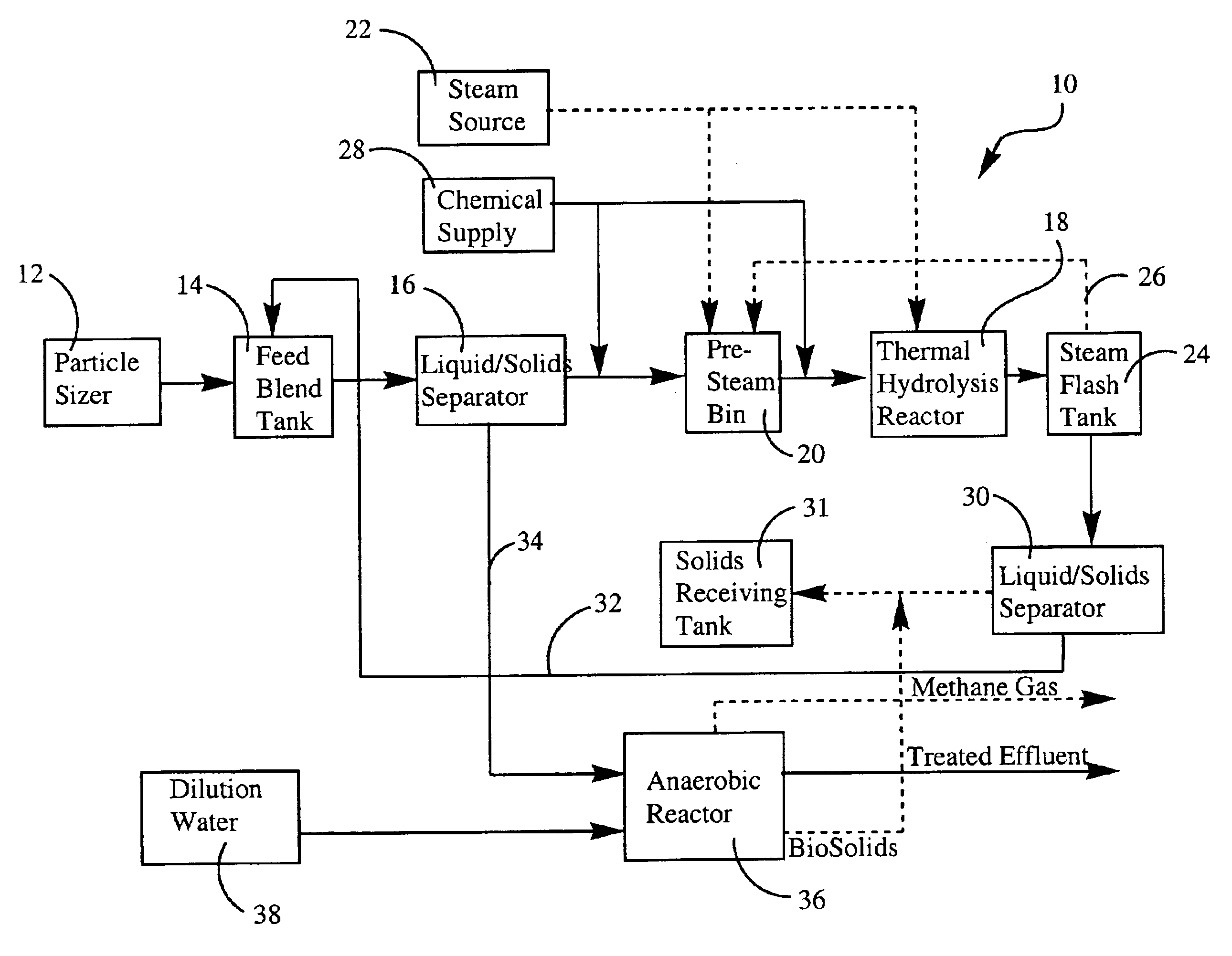

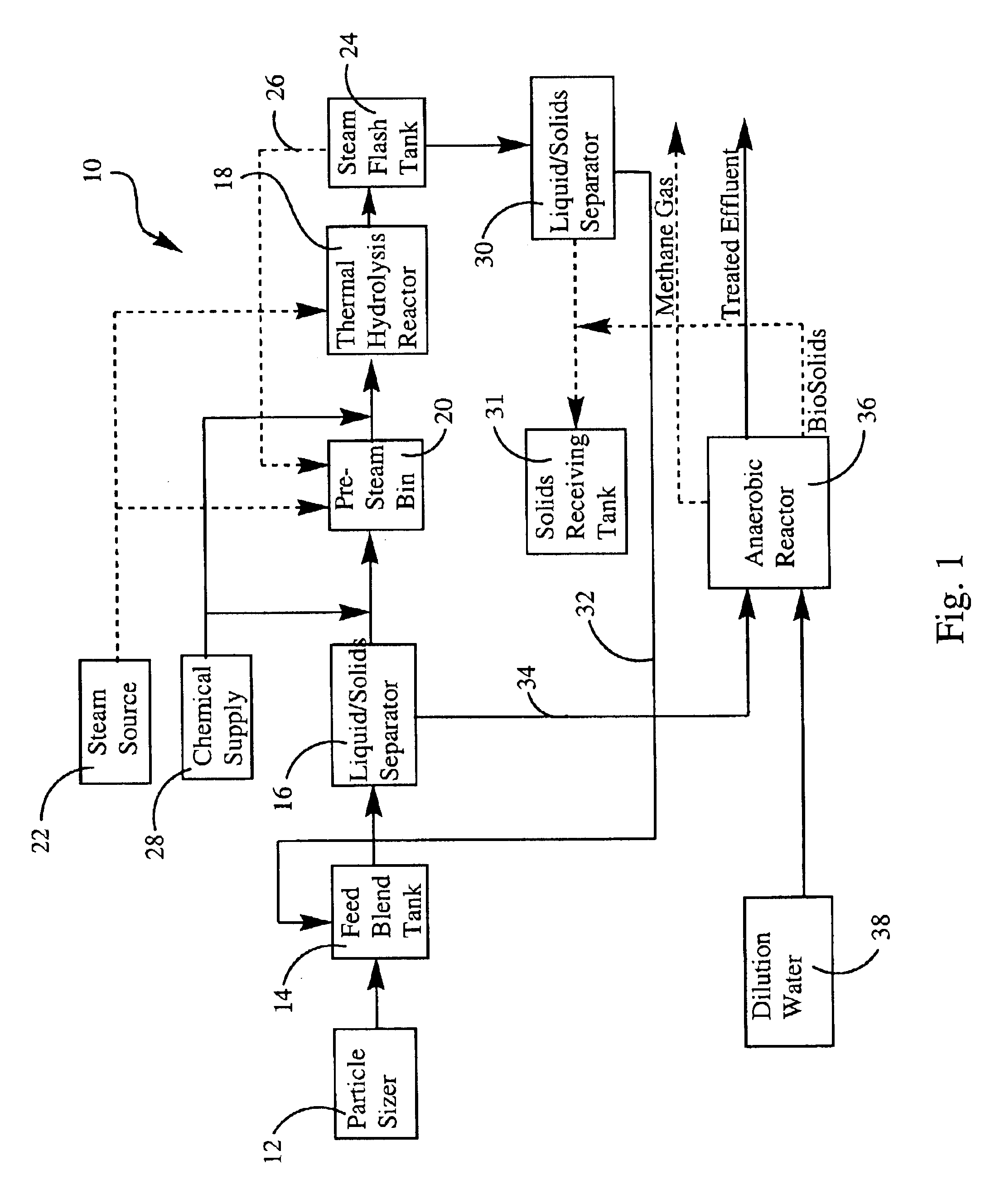

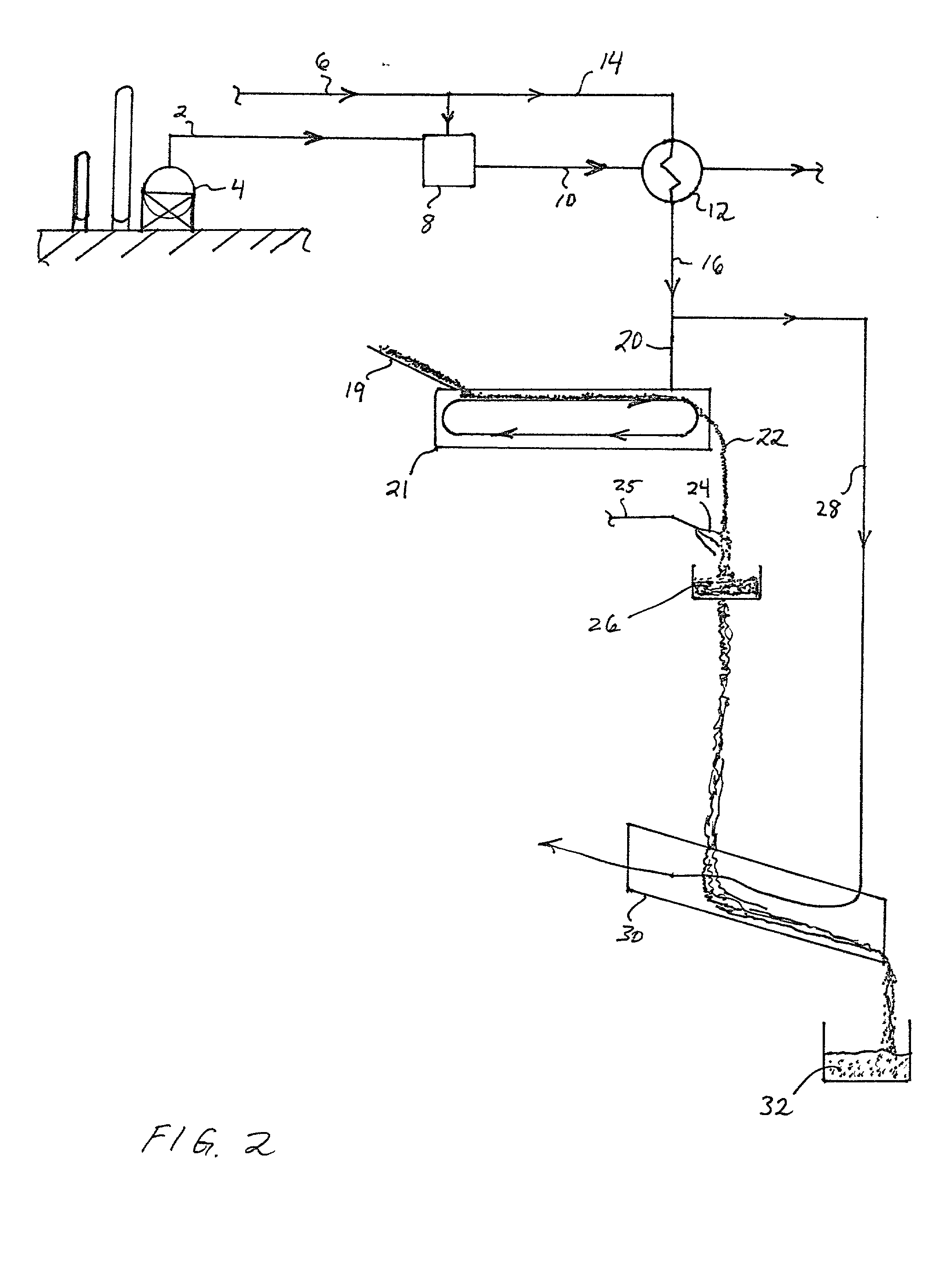

Method and apparatus for the treatment of particulate biodegradable organic waste

InactiveUS6905600B2Lower the volumeSaving in volume requirementBio-organic fraction processingBiological substance pretreatmentsPotassium hydroxideSaturated water vapor

A method for treating particulate biodegradable organic waste includes sizing the waste and adding a base prior to introducing the waste to a thermal hydrolysis reactor and hydrolyzing the waste at a temperature of about 130° C. or greater and a pressure greater than the saturated water vapor pressure to produce a slurry including solubilized organic material and residual solids. The solubilized organic material is separated from the residual solids using a liquid / solid separator and the solubilized organics are subjected to anaerobic digestion to produce a methane gas. The base is preferably potassium hydroxide (KOH) at a concentration of about 1%. The method may further include preheating the particulate biodegradable organic waste with latent heat of the separated solubilized organic material prior to thermal hydrolysis.

Owner:CH2M HILL

Whole-nutrition biological flushing and spreading fertilizer and preparation method thereof

InactiveCN101037369ASolve the single nutrientSolve solubilityClimate change adaptationAlkali orthophosphate fertiliserMicroorganismNicotiana tabacum

A full nutrition fertilizer of biology type and its producing method belongs to organic complex fertilizer field in biology type. The components of the full nutrition fertilizer is 20-50% of organic waste liquid, 10-30% of urea, 8-15% of diammomium phosphate, 10-25% of potassium sulfate, 5-20% of medium trace element, 1-5% of microbial inoculum, 0-0.2% of root-promoting agent; 0-2% of solutizer, effective viable count content of the microbial inoculum of more than 1010 / g. The fertilizer is produced by adding the urea, diammomium phosphate, potassium sulfate, medium trace element, root-promoting agent, solutizer into organic waste liquid and blending uniformly, then adding microbial inoculum. The invention uses the wastes to produce fertilizer with a low cost a high availability and a good prospect in the fertilizer industry. The fertilizer can be widely applied to the vegetables, melon and fruits, food, tobacco, forests and different commercial crops.

Owner:INST OF SOIL & FERTILIZER SHANDONG ACAD OF AGRI SCI

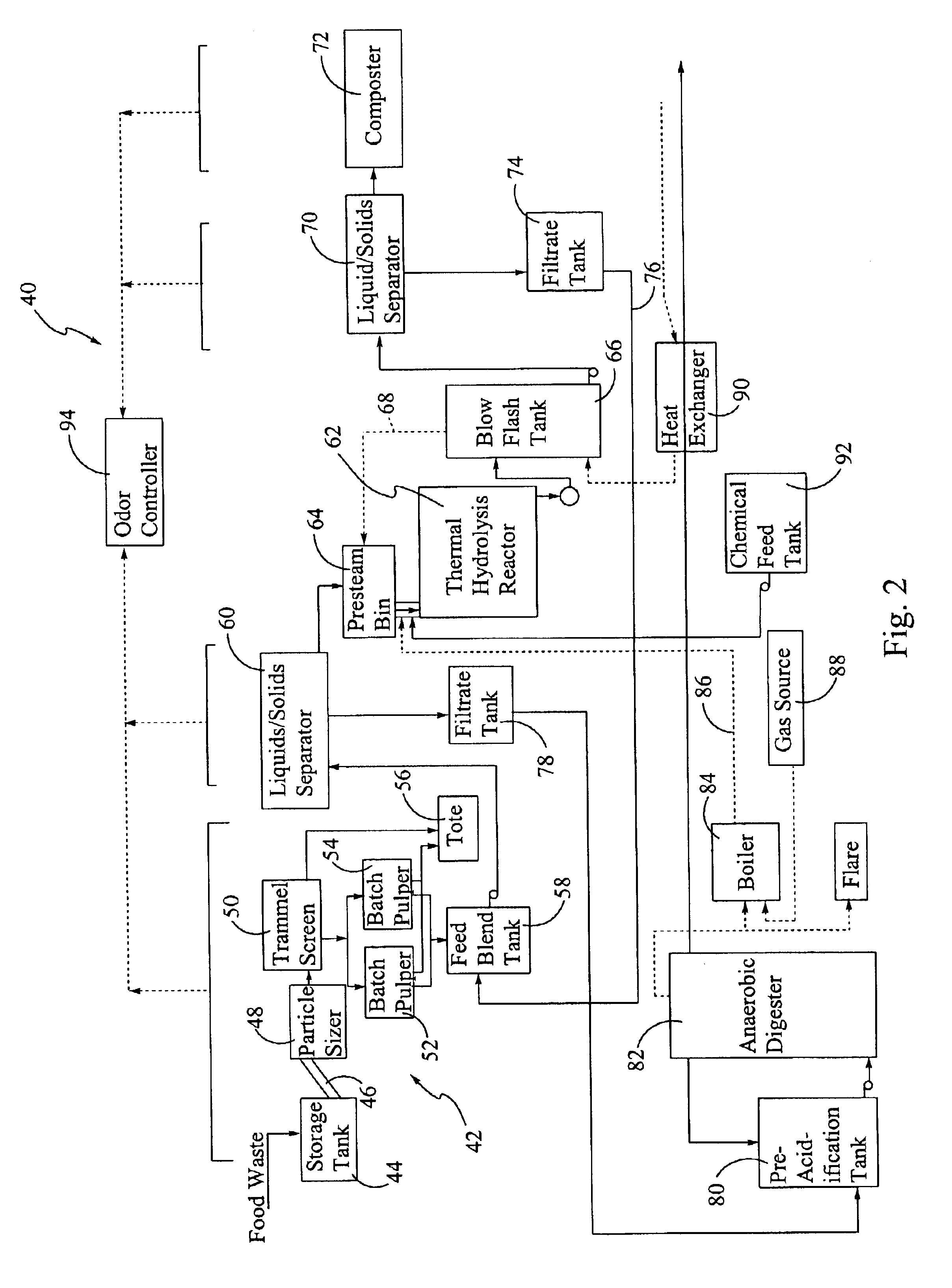

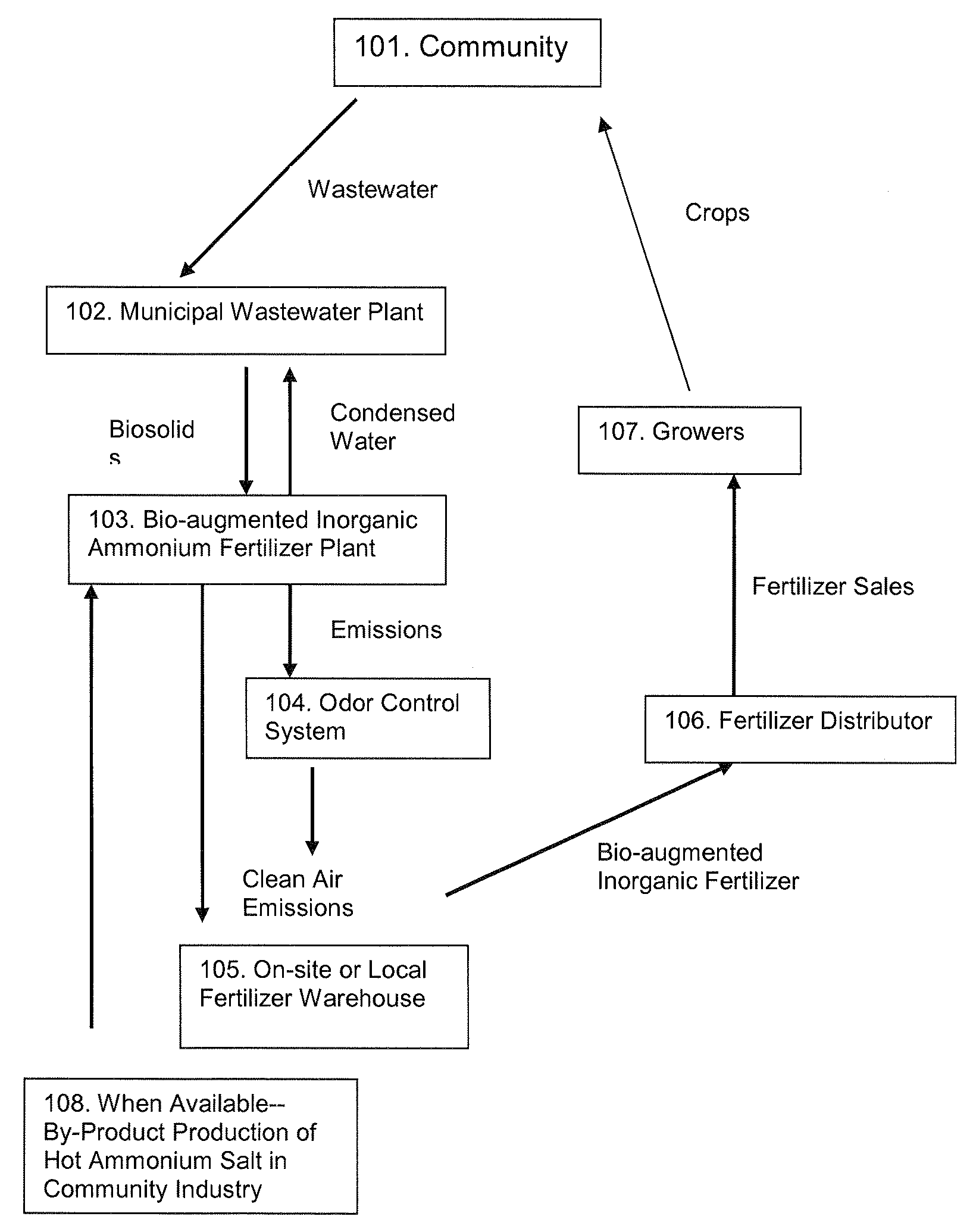

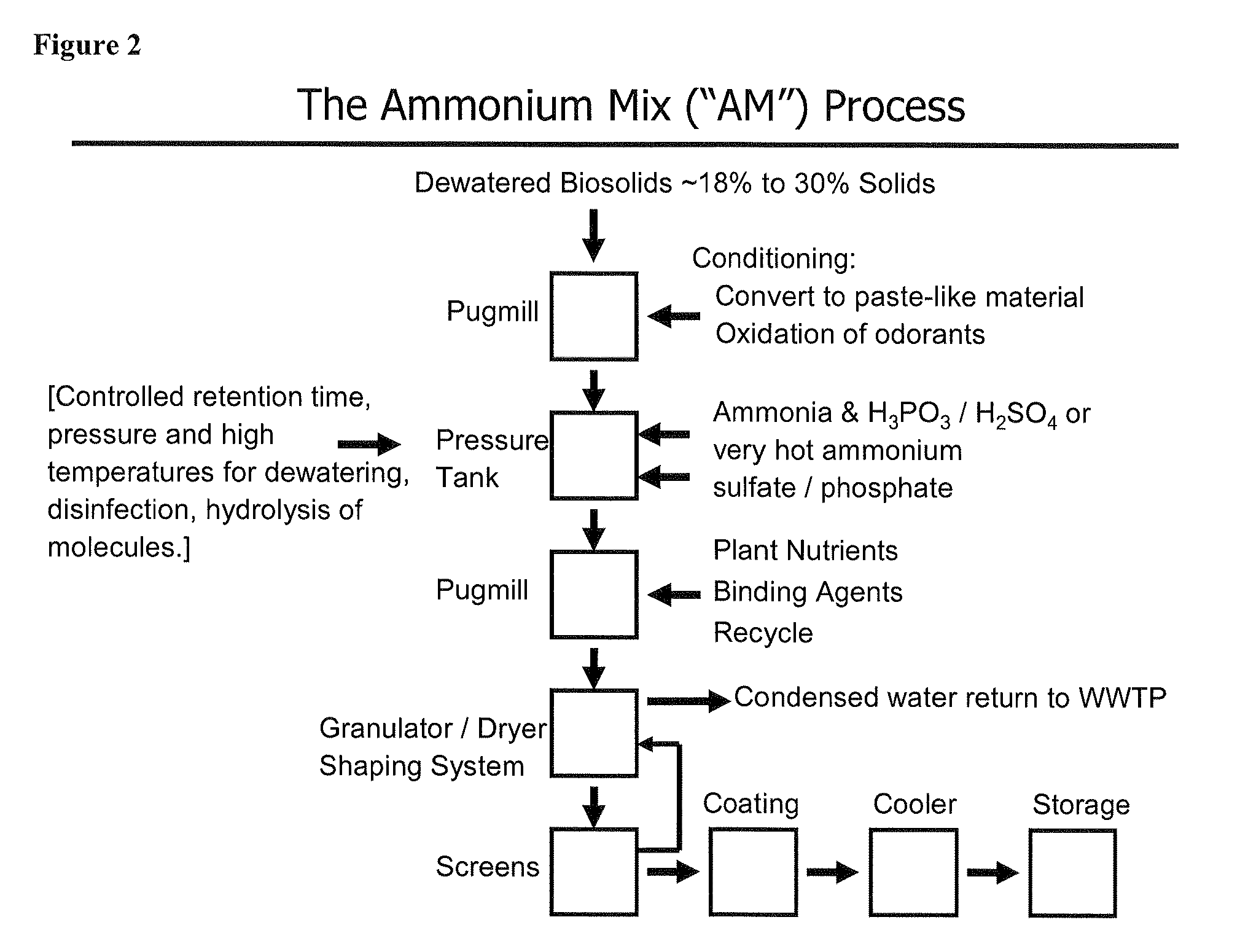

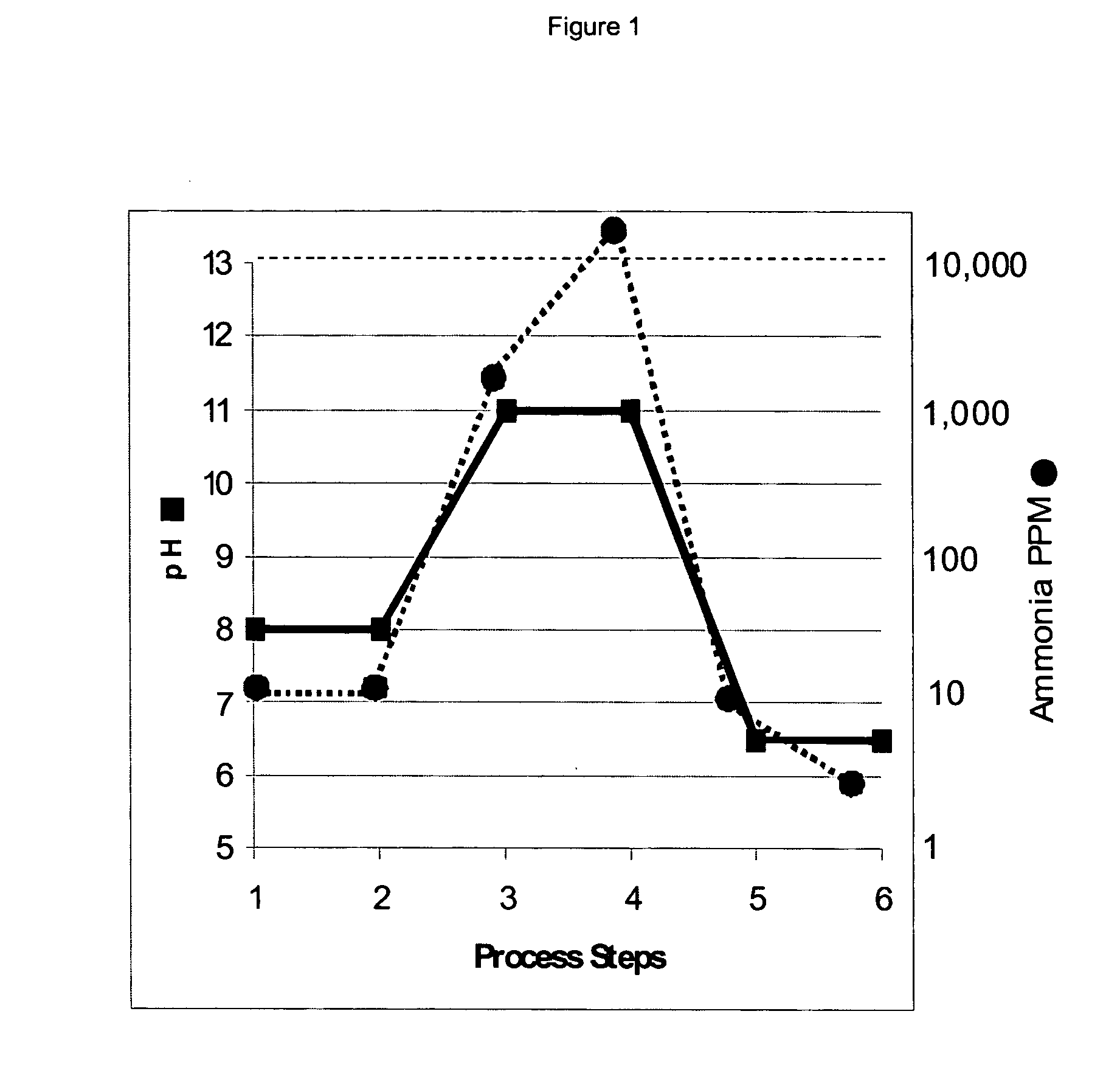

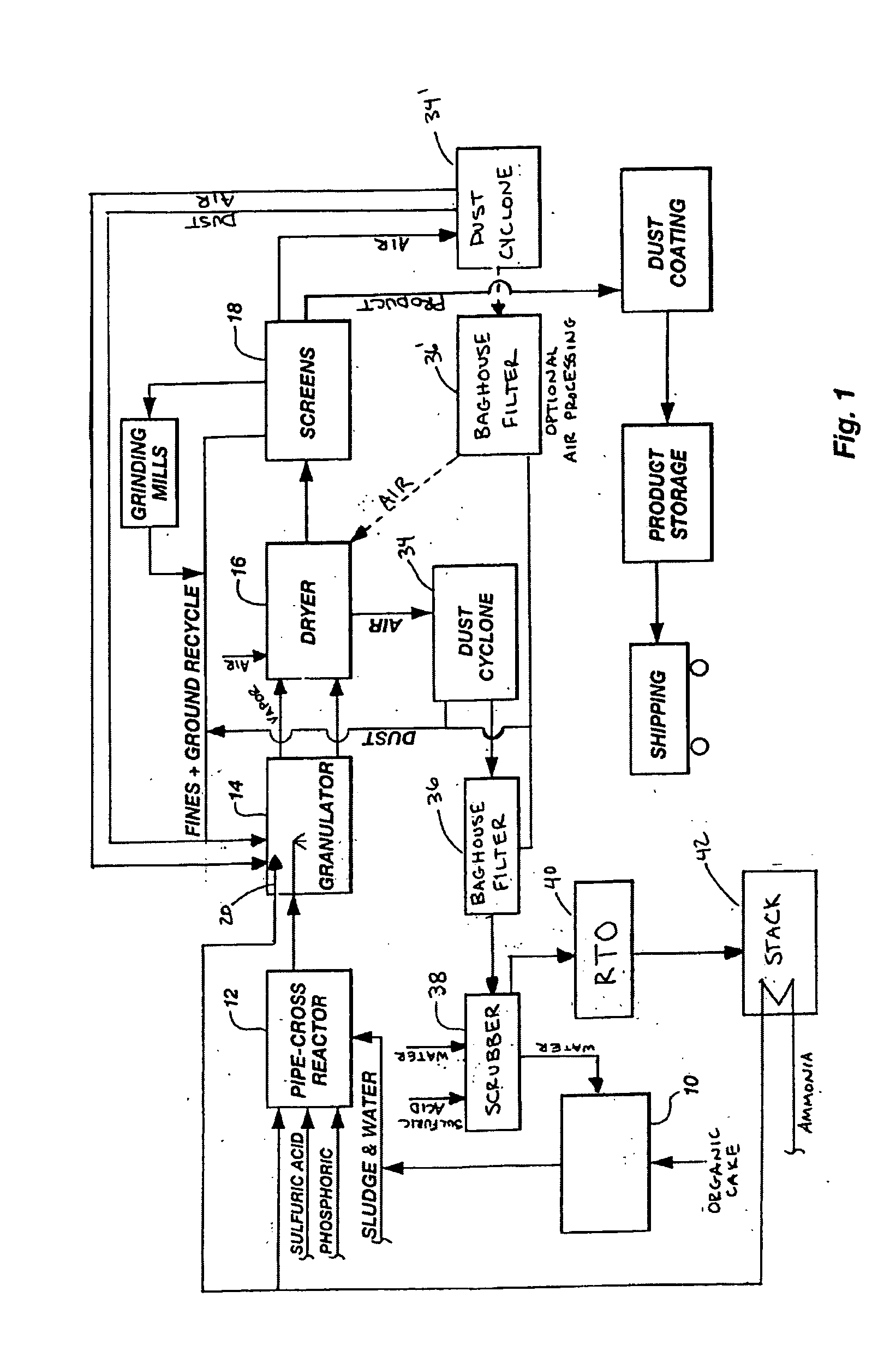

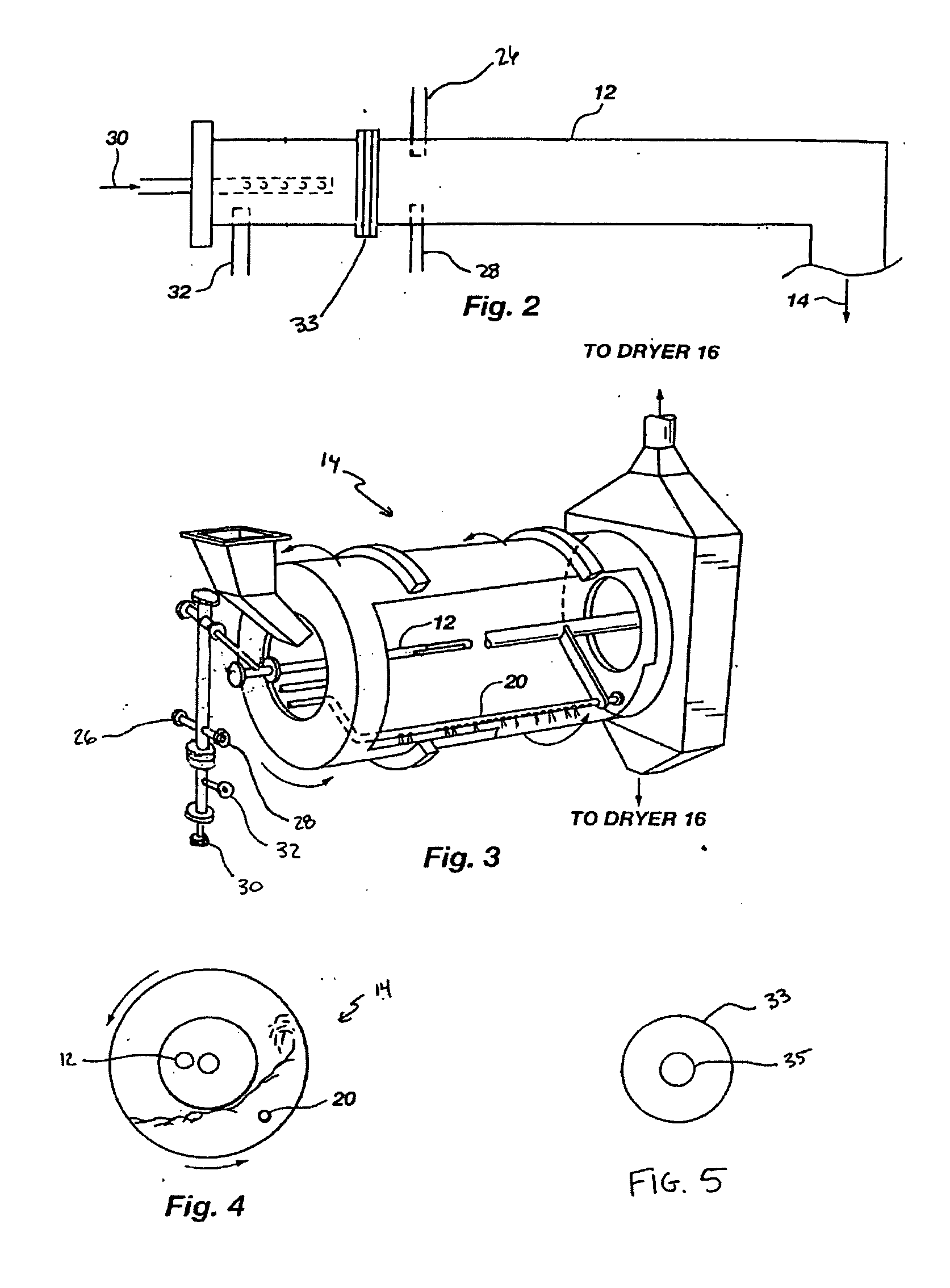

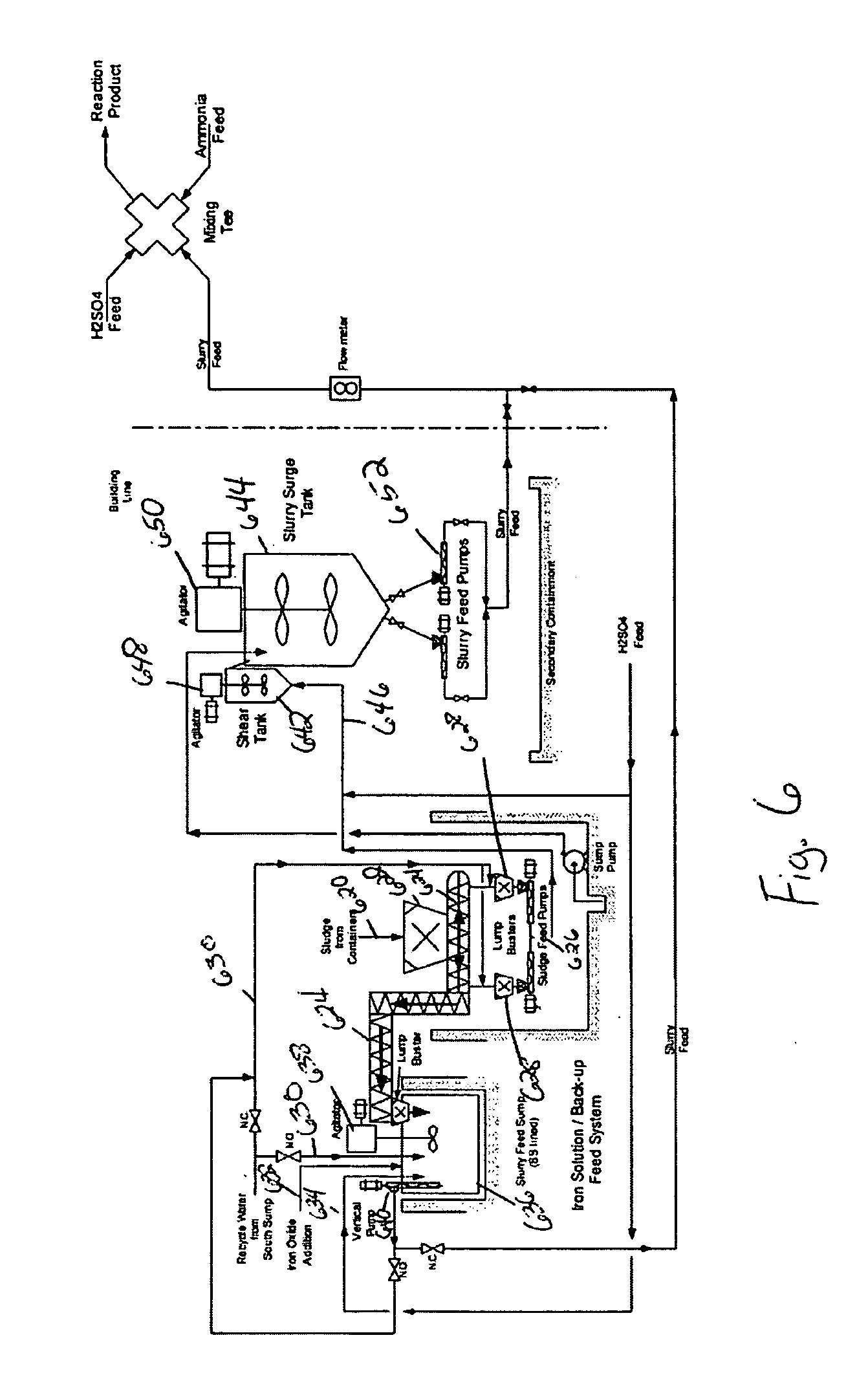

Process for treating sludge and manufacturing bioorganically-augmented high nitrogen-containing inorganic fertilizer

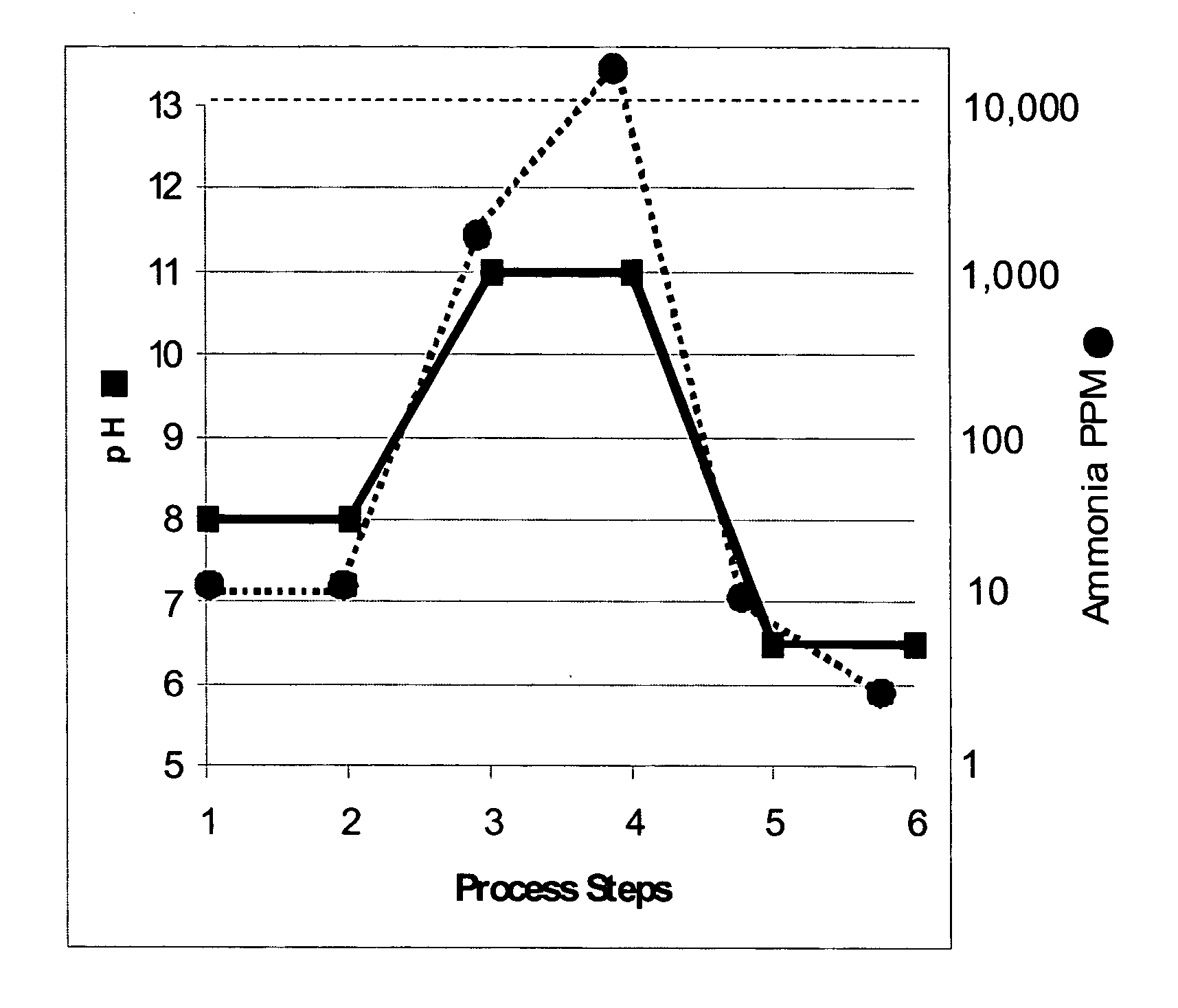

ActiveUS20080230484A1Reduce logisticsReduces liabilityByproduct vaporizationExcrement fertilisersPhosphateRetention time

The invention describes a new method for treating sludge, which can result in the production of high nitrogen organically-augmented inorganic fertilizer that incorporates municipal sludges or biosolids or organic sludges that can compete with traditional fertilizers such as ammonium phosphate, ammonium sulfate and urea on the commodity fertilizer marketplace. The method takes advantage of the thixotropic property of dewatered biosolids or organic sludge to create a pumpable paste-like material from the biosolids or organic sludge that is then treated with an oxidizer to reduce odorant effects and an acid. This mix is then interacted with concentrated sulfuric and or phosphoric acids and an ammonia source or alternatively a hot or molten melt or salt of ammonium sulfate / phosphate to form a fertilizer mix. The present invention controls the heat, atmospheric pressure and retention time of the fertilizer mix in the reaction vessel. When a fertilizer melt is formed ammoniation is subsequently completed by the specific use of vaporized ammonia. The invention can also be an add-on to commercial production of ammonium salts. The fertilizer produced by the present invention contains more than 8 wt. % nitrogen and preferably 15 wt. % nitrogen. The invention is oriented to be tailored to the biosolids production for individual municipal waste treatment plants in order to keep the fertilizer manufacturing plants of the present invention small with a minimization of logistics and liability.

Owner:GENERATE LENDING LLC +1

Biochar

The invention provides for methods, devices, and systems for pyrolyzing biomass. A pyrolysis unit can be used for the pyrolysis of biomass to form gas, liquid, and solid products. The biomass materials can be selected such that an enhanced biochar is formed after pyrolysis. The biomass can be pyrolyzed under specified conditions such that a selected biochar core is formed. The pyrolysis process can form a stable biochar core that is inert and / or resistant to degradation. The biochar or biochar core can be functionalized to form a functionalized biochar or functionalized biochar core. Functionalization can include post-pyrolysis treatments such as supplementation with microbes or physical transformations including annealing and / or activation.

Owner:FULL CIRCLE BIOCHAR

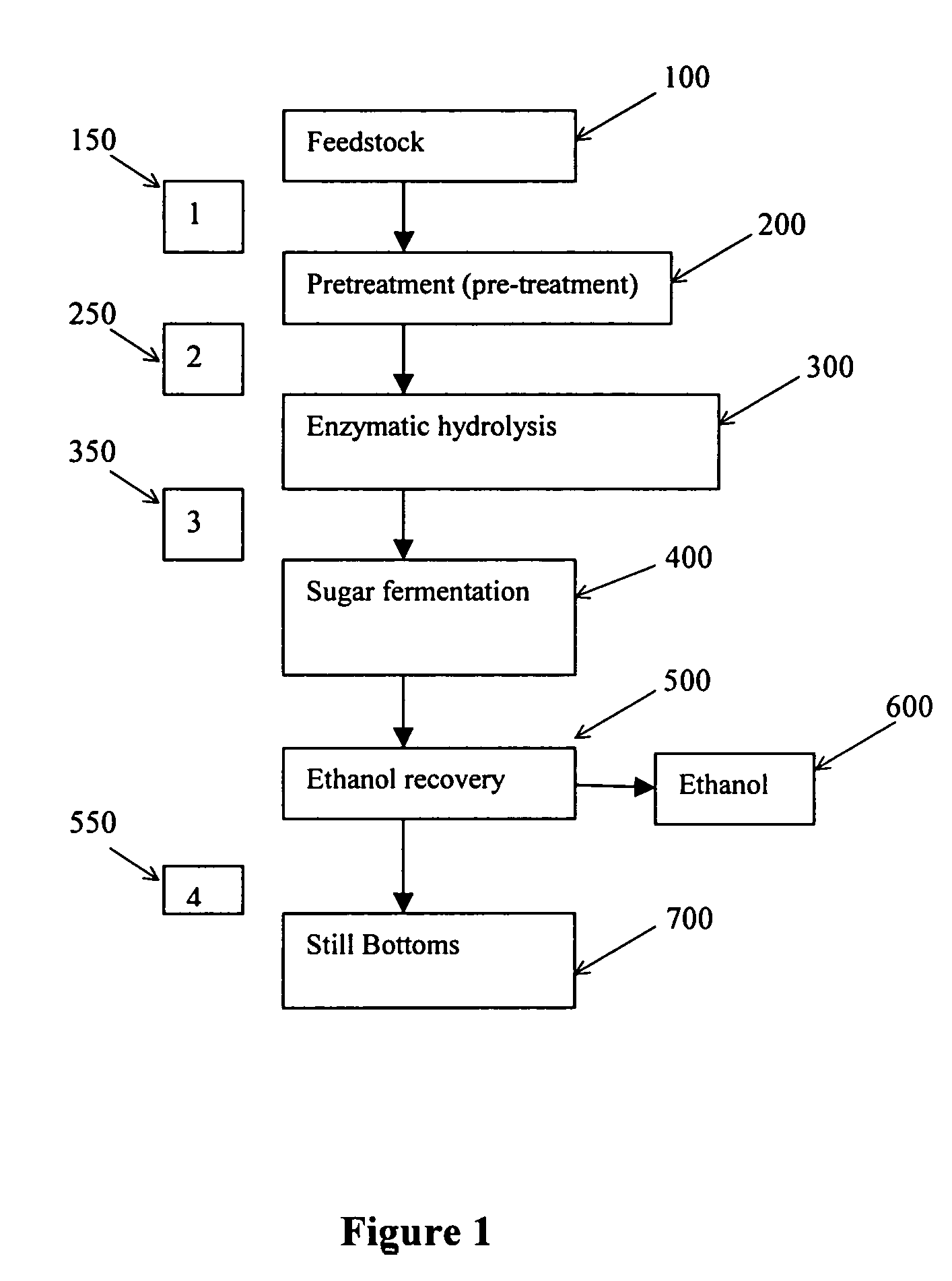

Recovery of inorganic salt during processing of lignocellulosic feedstocks

ActiveUS7585652B2Reduce inhibitionMeet cutting requirementsMagnesium fertilisersIon-exchanger regenerationCelluloseInorganic salts

A method for recovering inorganic salt during processing of a lignocellulosic feedstock is provided. The method comprises pretreating the lignocellulosic feedstock by adding an acid to the feedstock to produce a pretreated lignocellulosic feedstock. A soluble base is then added to the pretreated lignocellulosic feedstock to adjust the pH and produce a neutralized feedstock. The neutralized feedstock is then enzymatically hydrolyzed to produce an enzyme hydrolyzed feedstock and a sugar stream. Inorganic salt is recovered from either a stream obtained from the lignocellulosic feedstock prior to the step of pretreating, a stream obtained from the pretreated lignocellulosic feedstock, a stream obtained from the neutralized feedstock, a stream obtained from the sugar stream, or a combination of these streams. The inorganic salt may be concentrated, clarified, recovered and purified by crystallization, electrodialysis drying, or agglomeration and granulation, and then used as desired, for example as a fertilizer.

Owner:IOGEN ENERGY CORP

Organic containing sludge to fertilizer alkaline conversion process

InactiveUS20070062233A1Increases plant nutrient contentReduce odorCalcareous fertilisersBio-organic fraction processingSludgeOrganic manure

This invention is directed to systems, devices and methods for treating organic-containing sludges and converting such sludges to high value fertilizers containing both inorganic and organic fertilizer components, which creates an inorganically-augmented bioorganic fertilizer. The invention describes methods to create a thixotrophic or paste-like material via the application of mixing energy to the organic sludge followed by an alkaline treatment and a subsequent ammoniation. The invention further describes a method to increase the plant nutrient content in the organic containing product to a level which permits the finished granular fertilizer product to compete in the commercial agricultural fertilizer marketplace. Further, the invention reduces odors associated with said organic-containing sludges.

Owner:GENERATE LENDING LLC

Organic matter decomposing inoculant, and preparation method and application thereof

ActiveCN102212494APromote growthEfficient decompositionBio-organic fraction processingFungiDiseaseAdditive ingredient

The invention discloses an organic matter decomposing inoculant, and a preparation method and application thereof. The organic matter decomposing inoculant comprises the following ingredients in part by weight: 10 to 20 parts of aspergillus niger microbial inoculum, 10 to 20 parts of lactobacillus plantarum microbial inoculum, 20 to 30 parts of saccharomyces cerevisiae microbial inoculum and 40 to 60 parts of bacillus subtilis microbial inoculum. The organic matter decomposing inoculant mainly comprises various microbial floras with mutual promotion and mutual synergy effects. The organic matter decomposing inoculant can decompose various organic matters quickly, can effectively kill germs, ova and weed seeds in the decomposed raw materials, can reduce diseases, weed and insect pests, andcan remove water and odor. The organic matter decomposing inoculant can stimulate growth and development of crops, can improve disease resistance, drought resistance and cold resistance, can increasesoil nutrients, can improve the soil structure, and can increase the utilization ratio of chemical fertilizer. The organic matter decomposing inoculant can be used directly and can also be used for producing commercial organic fertilizer, biological organic fertilizer, organic and inorganic complex fertilizer, biological organic and inorganic complex fertilizer and the like.

Owner:BEIJING SHIJI WANYEYUAN BIOENG TECHCO

Soil improvement type straw compound organic fertilizer and preparation method of soil improvement type straw compound organic fertilizer

InactiveCN105777429AImprove physical and chemical propertiesImprove qualityCalcareous fertilisersBio-organic fraction processingCompound organicPhosphate

The invention provides a soil improvement type straw compound organic fertilizer and a preparation method of the soil improvement type straw compound organic fertilizer. The soil improvement type straw compound organic fertilizer is prepared from the following raw materials in parts by weight: 30 to 35 parts of rice straw, 25 to 30 parts of animal excrement, 20 to 25 parts of biological charcoal, 10 to 15 parts of soybean meal, 5 to 10 parts of cassava residue, 5 to 10 parts of diatom ooze, 2 to 2.5 parts of plant ash, 2 to 2.5 parts of turfy soil, 2 to 3 parts of zeolite powder, 3 to 4 parts of a microorganism bacterium agent, 2 to 3 parts of sodium benzoate, 2 to 3 parts of ammonium monohydrogen phosphate, 1 to 2 parts of calcium chloride, 1 to 2 parts of amino acid, 1 to 2 parts of starch, 1 to 2 parts of molasses powder and 1 to 2 parts of humic acid. The soil improvement type straw compound organic fertilizer takes plant wastes as raw materials; the quality of soil can be easily improved and the production cost can also be reduced, so that the physicochemical properties of the soil are improved, and the structure of the soil is comprehensively improved, and furthermore, the soil quality has the effects of softness, air permeability, water retention and fertilizer conservation; the aim of producing an environment-friendly high-quality organic fertilizer through preferably selecting heavy metal capable of being passivated, the biological charcoal capable of improving the fertilizer efficiency of the organic fertilizer, and conversion products of organic wastes including the biological humic acid and the like as composting base materials, and optimizing a composting process.

Owner:JIXI YUANDAO AGRI IND TECH

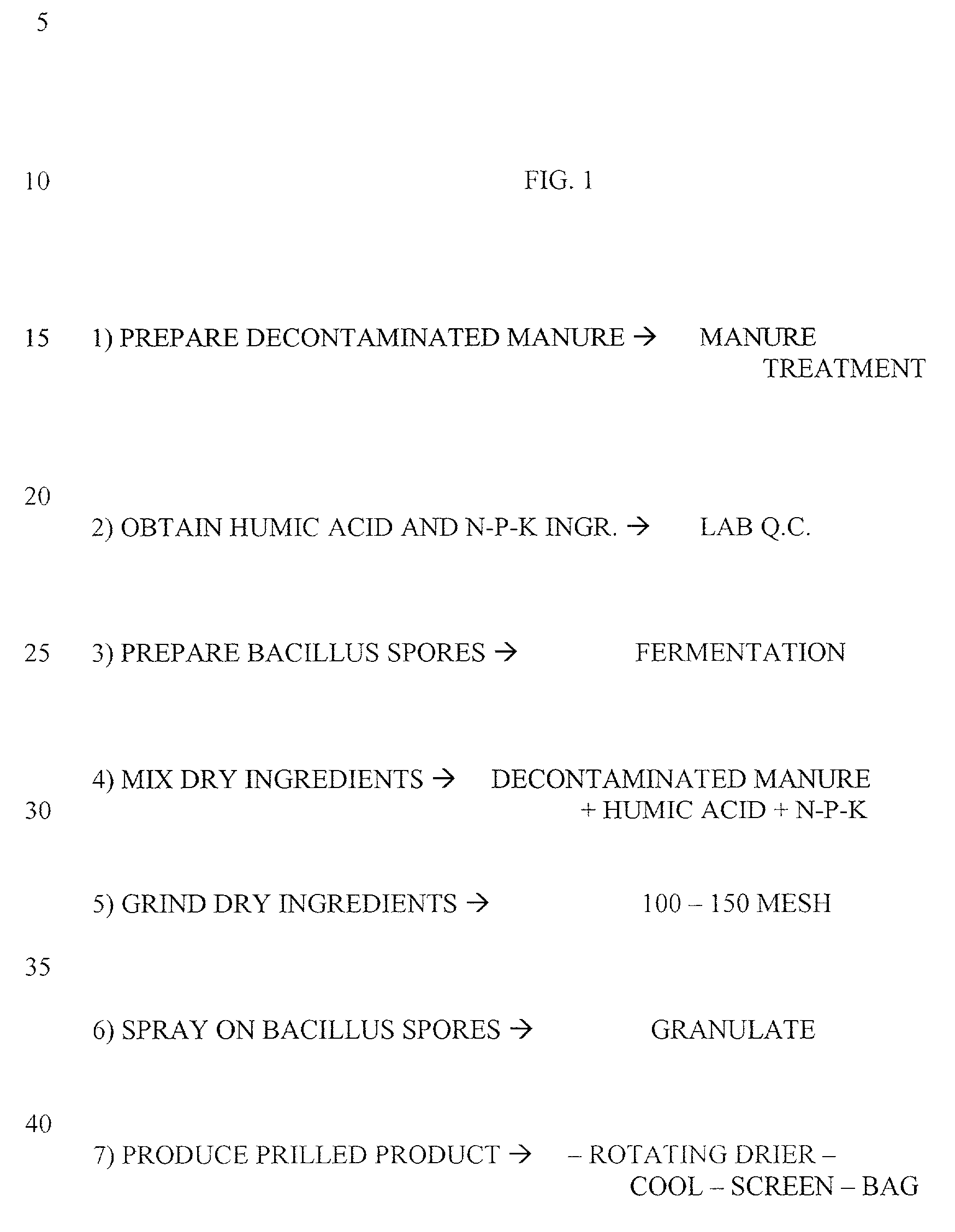

Fertilizer compositions and methods of making and using same

Fertilizer compositions for plant production are described, comprised of decontaminated manure and Bacillus spores, preferably a humic acid derived from lignite and, optionally, one or more of N compounds, P compounds, K compounds, and combinations of two or more of these compounds. Preferred compositions are those wherein the ingredients are blended into an admixture resulting in a granular product. Other preferred compositions are those blended into an admixture resulting in a powdered product. Preferably, the ingredients are formed into hardened prills or pellets. Processes for production and use are also presented.

Owner:MICROBES

Process for producing biodiesel

InactiveUS20050011112A1Fatty oils/acids recovery from wasteFatty acid esterificationBiodieselSolid fraction

An integrated process is described for producing biodiesel from oleaginous seeds, preferably castor bean seeds, comprising a transesterification reaction where the seeds themselves react with anhydrous ethyl alcohol in the presence of an alkaline catalyst. The resulting ethyl esters are then separated by decantation and neutralized and used as fuel for diesel engines, co-solvents for diesel and gasoline mixtures with anhydrous or hydrated ethyl alcohol. The solid fractions may be used as fertilizers, for feeding cattle and as a raw material for producing ethyl alcohol.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

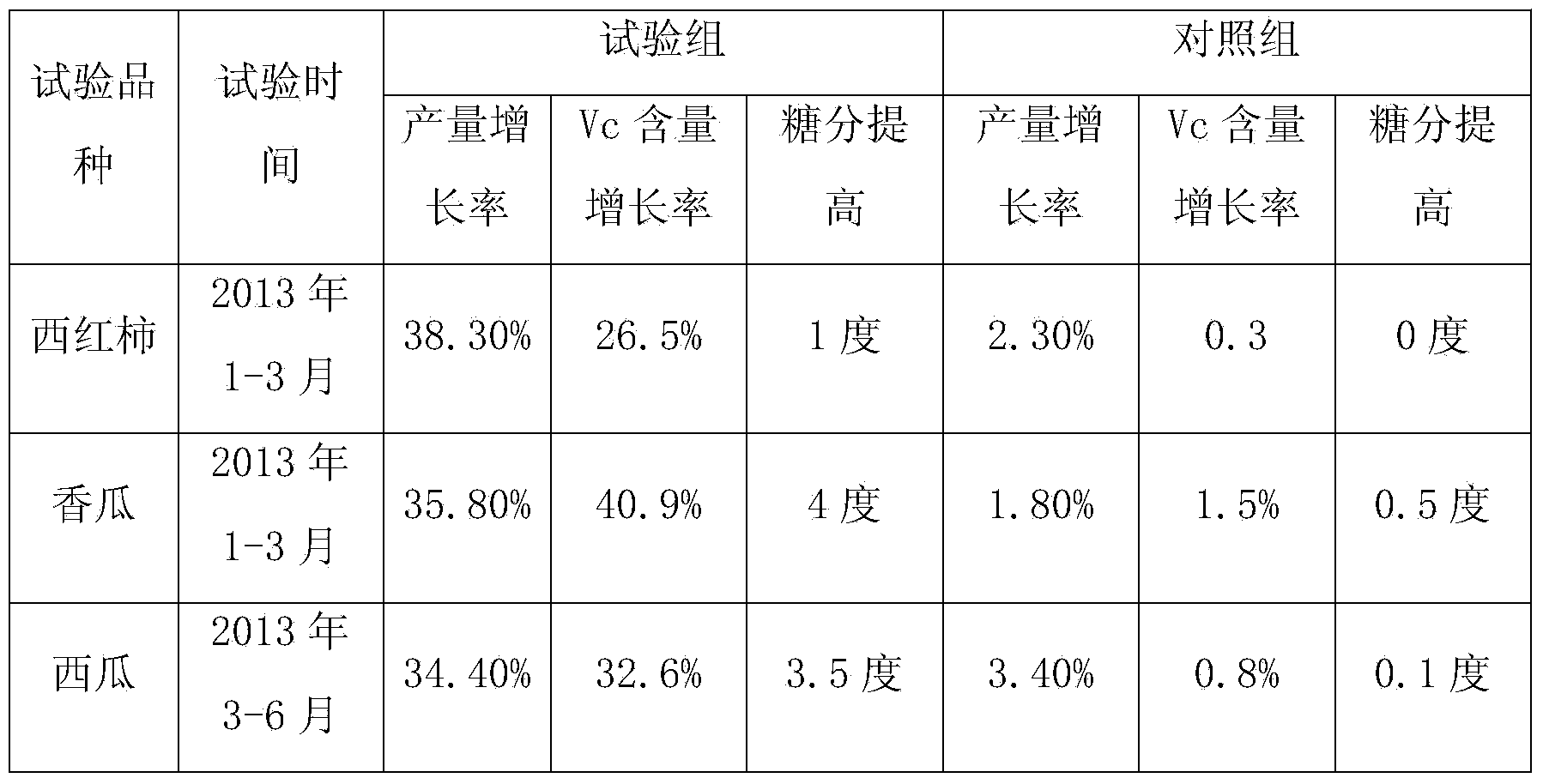

Chinese medicine residue organic fertilizer and production method thereof

InactiveCN104262055ANo pollution in the processAvoid pollutionBio-organic fraction processingExcrement fertilisersLivestock manureAdditive ingredient

The invention provides a Chinese medicine residue organic fertilizer. Wastes after extraction of Chinese traditional medicines can be fully utilized, utilization of waste materials is realized, and a bactericidal and insect disease preventing organic fertilizer full of nutritional ingredients is also provided for agricultural production. The Chinese medicine residue organic fertilizer is prepared by fermenting Chinese medicine residue, excrement of animals, solid waste, bacillus subtilis and EM. The Chinese medicine residue organic fertilizer has the advantages that the Chinese medicine residue, excrement of animals and solid waste are mixed, biological fermentation bacteria are added for carrying out rapid fermentation, organic fertilizer is processed, waste materials are changed into things of value, harm is turned into good, the problem of treatment of abandoned herb residue produced by a Chinese medicine factory is solved, and waste treatment cost is also greatly reduced, so that a win-win situation of environmental protection and economic development is realized. By adopting the organic fertilizer made from the Chinese medicine residue, soil can be effectively improved, crop pest also can be effectively prevented, and quality, yield and safety of crops are improved.

Owner:INST OF S&T INFORMATION SHANDONG ACADEMY OFAGRI SCI

Comprehensive treatment agent for soda alkaline land and use method thereof

InactiveCN101481281ALower pHSimple structureClimate change adaptationExcrement fertilisersDesorptionIon exchange

Owner:中农网联(北京)科技发展有限公司

A biologic organic fertilizer, and preparation method

InactiveCN1872803APromote growthImprove the ecological environmentBio-organic fraction processingClimate change adaptationOil processingPotassium

This invention relates to a method for manufacturing bioorganic fertilizer. The bioorganic fertilizer is manufactured by: mixing sugar industry waste, breeding industry waste, oil-processing waste, phosphoric fertilizer, trace element fertilizer and silicon fertilizer, and performing aerobic fermentation and post fermentation. The effective components of the bioorganic fertilizer are: organic matters (greater than or equal to 30%), N, P and K (greater than or equal to 8%), beneficial microorganisms (greater than or equal to 200,000,000 / g), active silicone (greater than or equal to 5%), magnetic components (0.25%), and Fe, Zn and Mo (0.5-1%). The bioorganic fertilizer has abundant raw material sources, and is environmentally friendly.

Owner:成官文

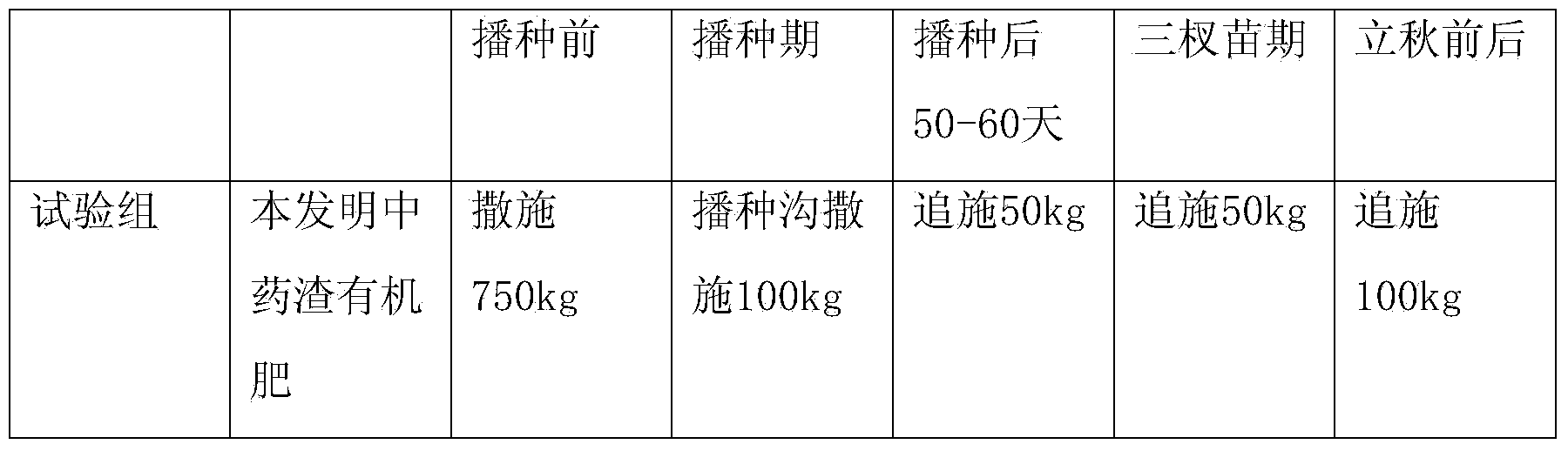

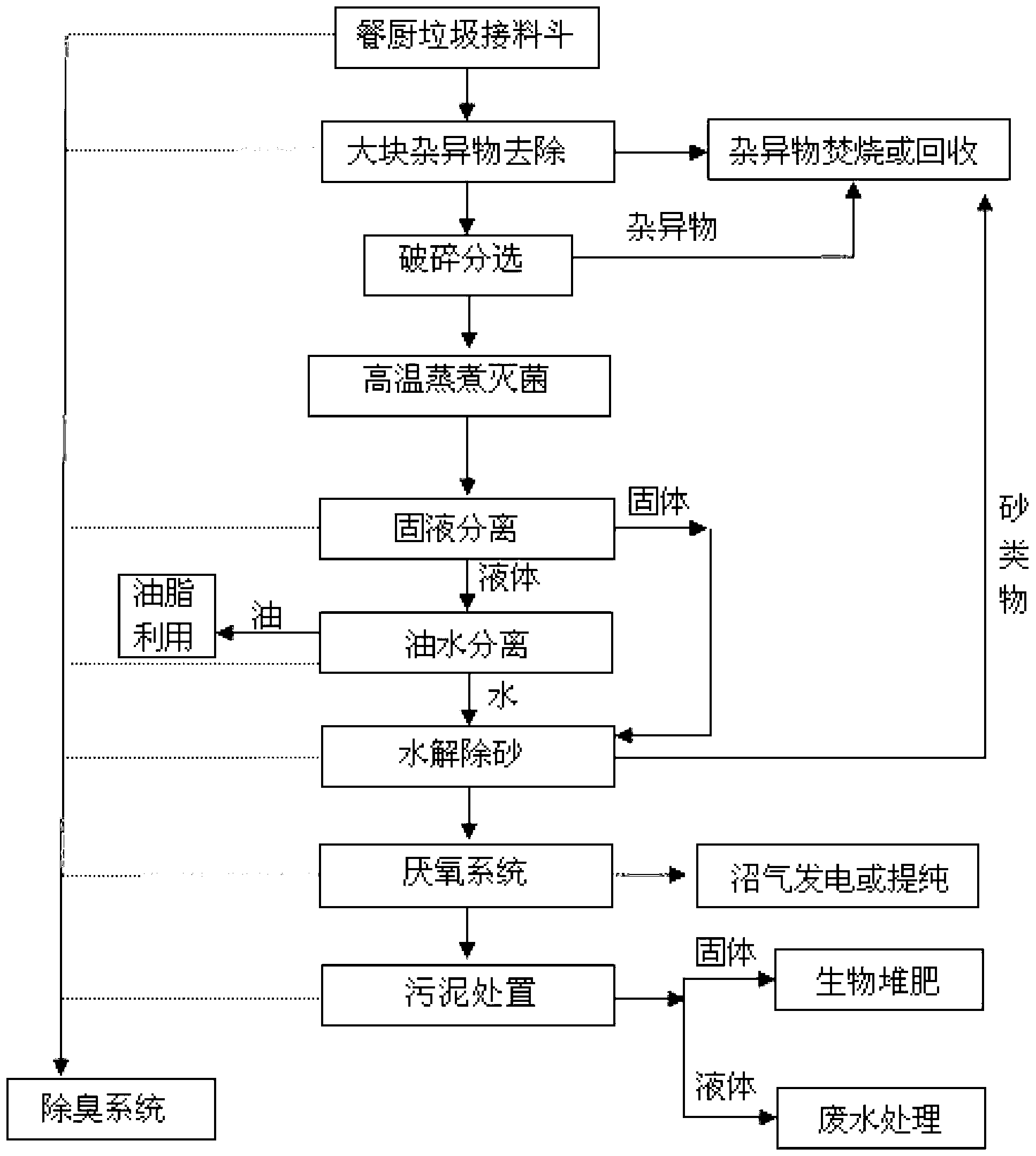

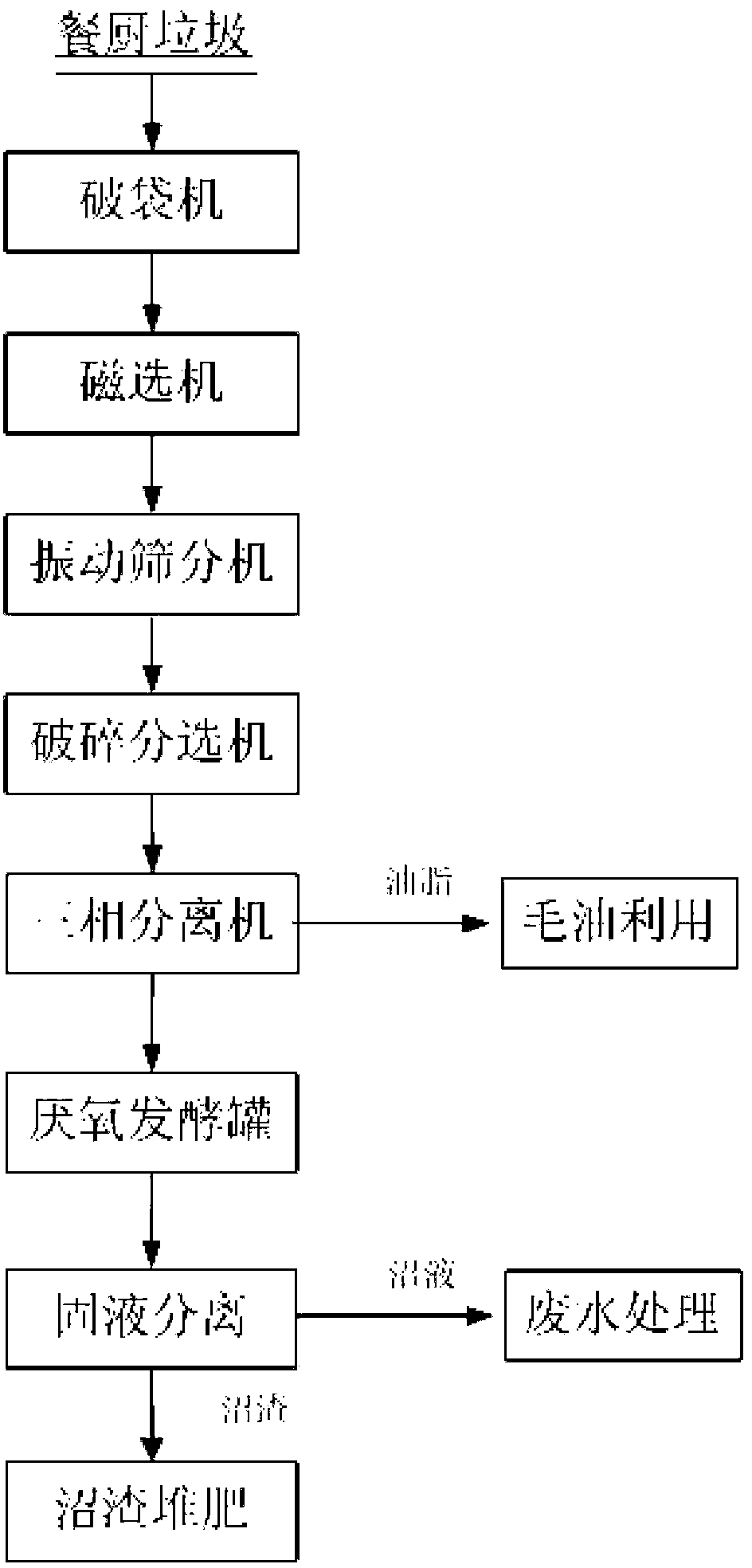

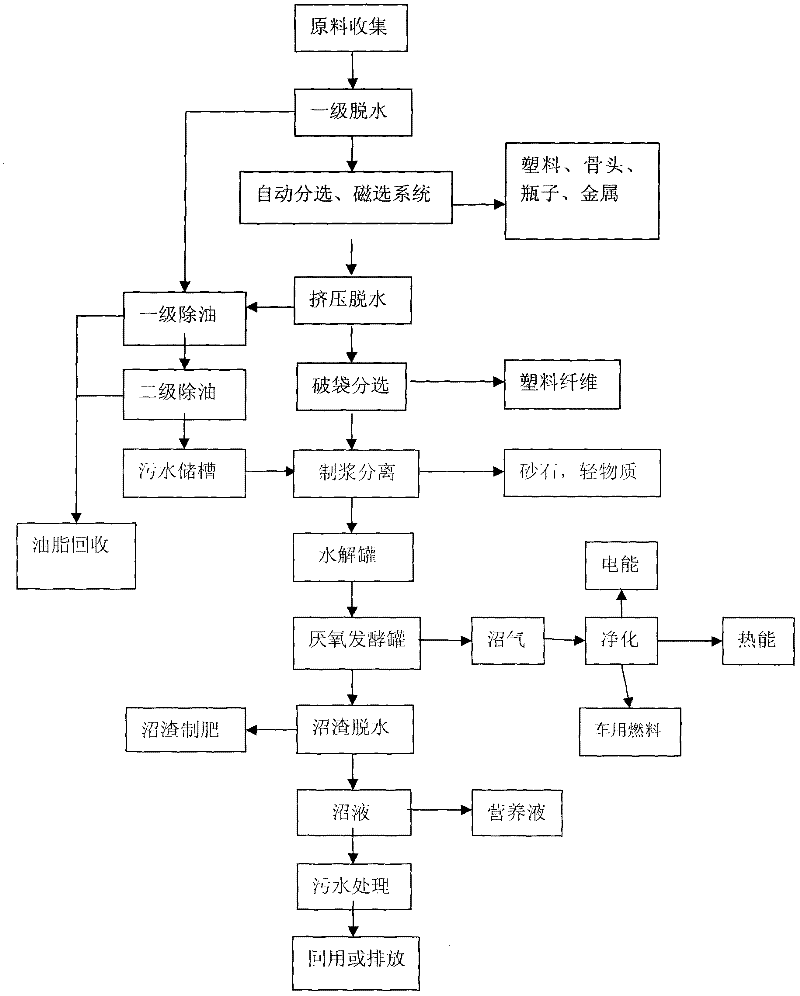

Efficient resourceful treatment method through separation and anaerobic fermentation for kitchen waste

InactiveCN103074381AHarmlessStable in natureFatty oils/acids recovery from wasteBio-organic fraction processingEconomic benefitsOil water

The invention discloses an efficient resourceful treatment method through separation and anaerobic fermentation for kitchen waste. The method includes the steps of firstly performing preliminary bag breaking and leachate collection on original kitchen waste, and removing chunks of miscellaneous and foreign materials; then performing breaking separation, high temperature sterilization, solid-liquid separation and the like; and then performing oil-water separation, hydrolytic sand removal, hydrolytic acidification, anaerobic fermentation and the like. The method has the advantages that not only harmless kitchen waste is achieved, but also extracted crude oil and produced biogas have high economic benefit simultaneously, and the impurity removal rate of the kitchen waste can reach above 90%.

Owner:SOUND ENVIRONMENTAL RESOURCES

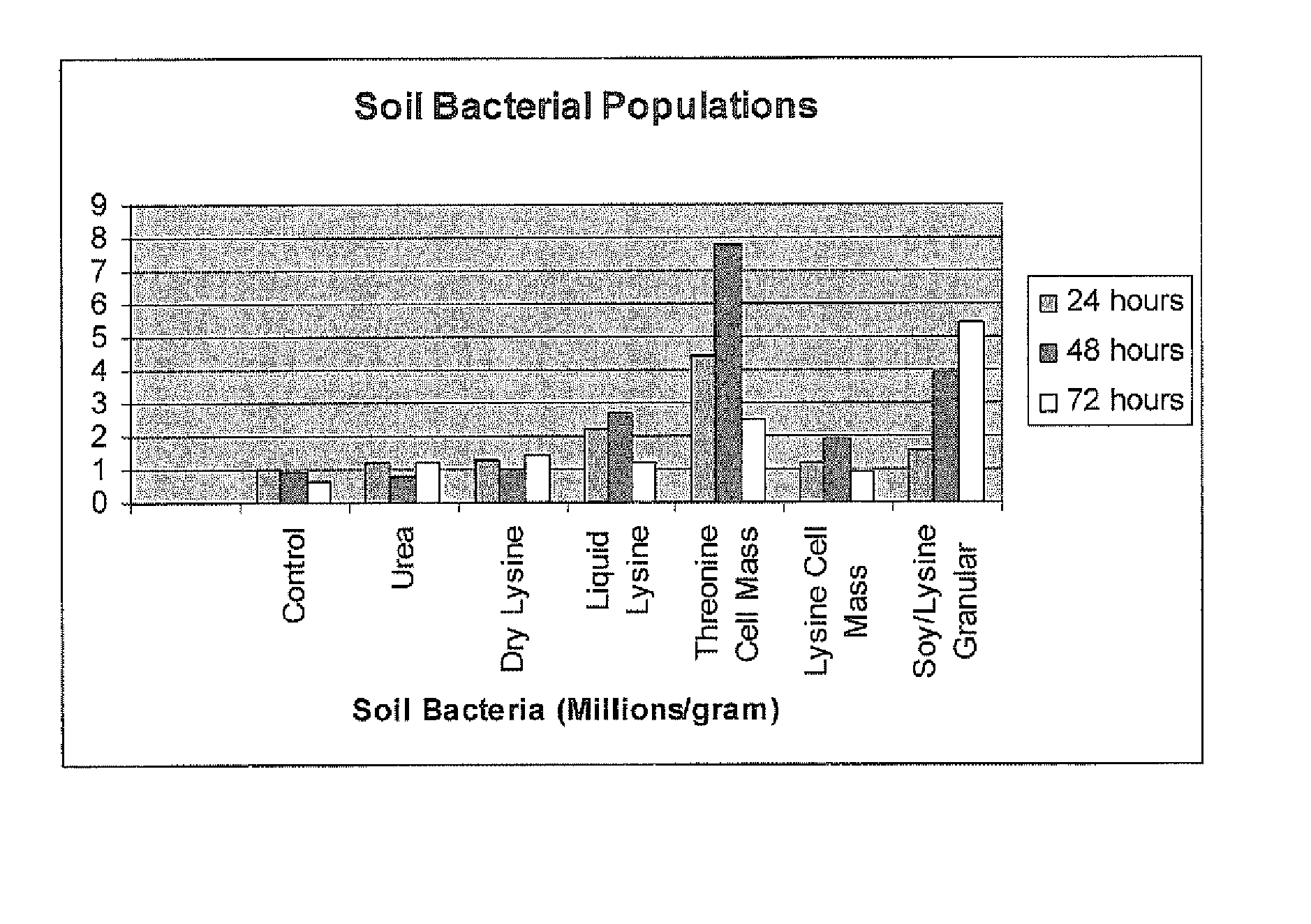

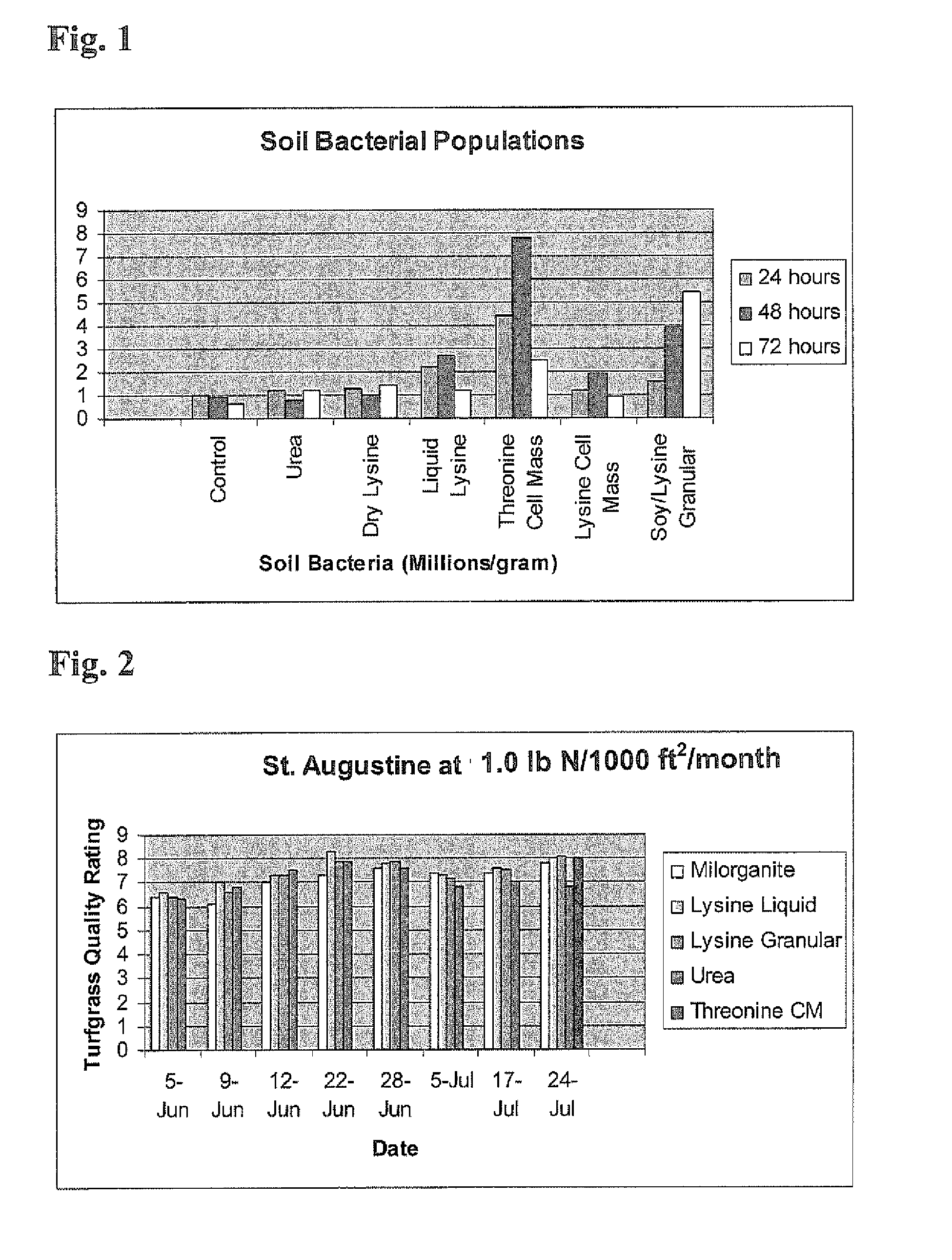

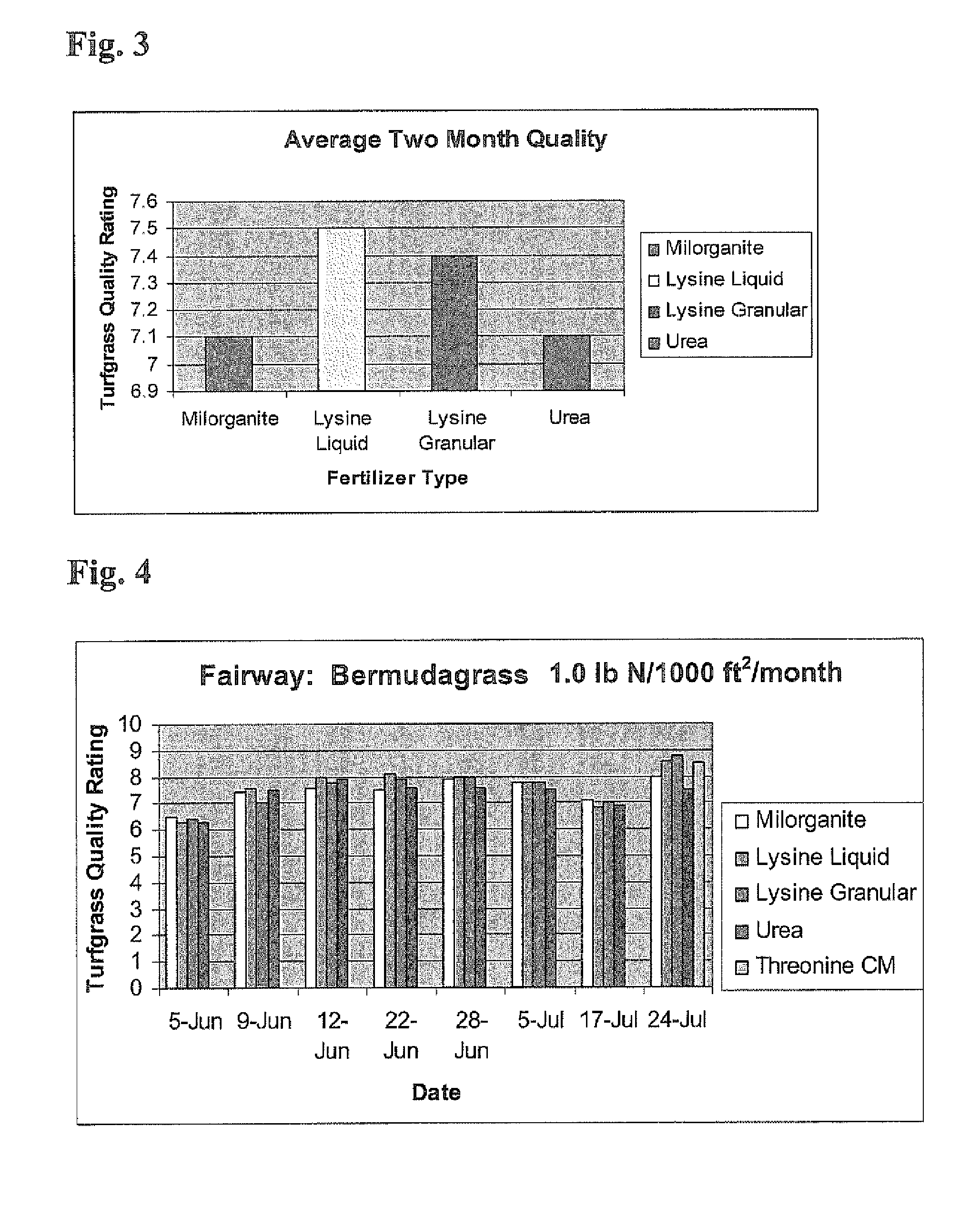

Fertilizer compositions and methods of using

ActiveUS20070131010A1High nitrogen contentEasy to grow plantsClimate change adaptationBioloigcal waste fertilisersNitrogen atomCrop production

Provided are various embodiments of a fertilizer composition. The fertilizer compositions include one or more compounds having a high nitrogen content, which may be measured by a carbon to nitrogen atom ratio. Also provided are methods for increasing nitrogen content in soil, promoting crop production and fertilizing.

Owner:ARCHER DANIELS MIDLAND CO

Recovery of inorganic salt during processing of lignocellulosic feedstocks

ActiveUS20050244934A1Decreases acid requirementReduce inhibitionMagnesium fertilisersIon-exchanger regenerationCelluloseInorganic salts

A method for recovering inorganic salt during processing of a lignocellulosic feedstock is provided. The method comprises pretreating the lignocellulosic feedstock by adding an acid to the feedstock to produce a pretreated lignocellulosic feedstock. A soluble base is then added to the pretreated lignocellulosic feedstock to adjust the pH and produce a neutralized feedstock. The neutralized feedstock is then enzymatically hydrolyzed to produce an enzyme hydrolyzed feedstock and a sugar stream. Inorganic salt is recovered from either a stream obtained from the lignocellulosic feedstock prior to the step of pretreating, a stream obtained from the pretreated lignocellulosic feedstock, a stream obtained from the neutralized feedstock, a stream obtained from the sugar stream, or a combination of these streams. The inorganic salt may be concentrated, clarified, recovered and purified by crystallization, electrodialysis drying, or agglomeration and granulation, and then used as desired, for example as a fertilizer.

Owner:IOGEN ENERGY CORP

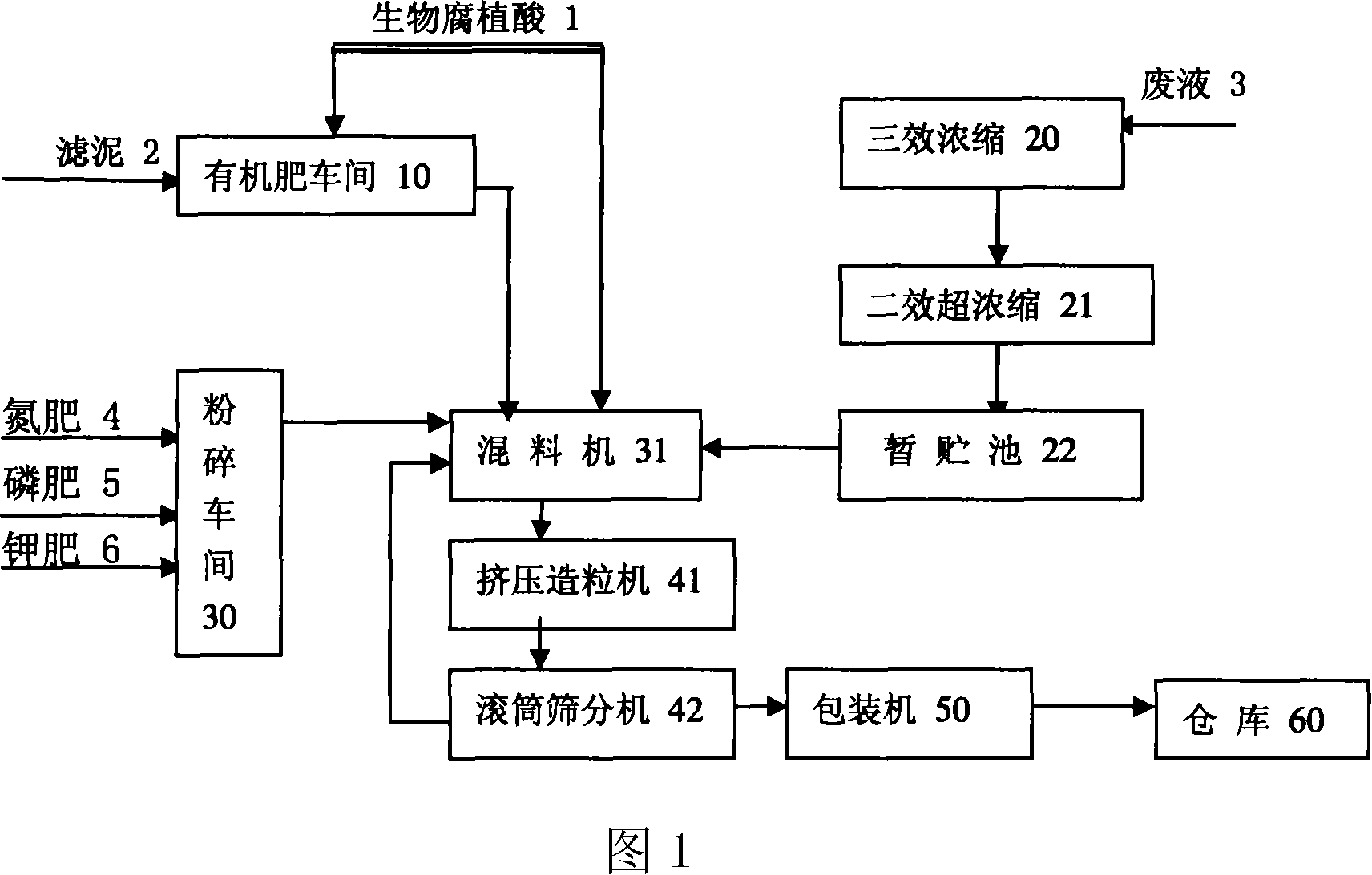

Method of manufacturing organic, inorganic compound fertilizer with molasses zymolysis waste liquor and lime sludge

InactiveCN101108779AImprove efficiencyLow efficiencyBio-organic fraction processingClimate change adaptationLiquid wasteContinuous fermentation

The invention provides a method producing the organic-inorganic compound fertilizer by the molasses fermentation waste liquor and the lime sludge, which relates to a method producing the fertilizer through fermentation and solves the problem of reclaiming and processing the molasses fermentation waste liquor continuously on a large scale. The method of the invention is that the biological humic acid with weight per cent of 0.4 per cent to 0.6 per cent and made by the bagasse is mixed with the lime sludge of 65 per cent to 68 per cent, bagasse powder of 10 per cent to 12 per cent, wheat bran of 1.5 per cent to 2.5 per cent and regulator of 16 per cent to 25 per cent to ferment fully and continuously in a shorter time. The fermented materials with water of 10 per cent to 12 per cent are gained after opening and drying and are crushed into the lime sludge organic fertilizer. The molasses fermentation waste liquor with water of 90 per cent is condensed to the hyperconcentration liquor with water of 26 per cent to 28 per cent by the three-effect forced circulating concentration system and then through the two-effect scraping and steaming hyperconcentration system. The hyperconcentration liquor of 30 per cent to 33 per cent and the biological humic acid of 9 per cent to 10 per cent are stirred and mixed uniformly based on the weight per cent and are added with the fertilizer of 32 per cent to 34 per cent and the lime sludge organic fertilizer of 25 per cent to 27 per cent to stir to produce the organic-inorganic compound fertilizer through dry extrusion and prilling.

Owner:越百年创新肥业(海南)有限公司

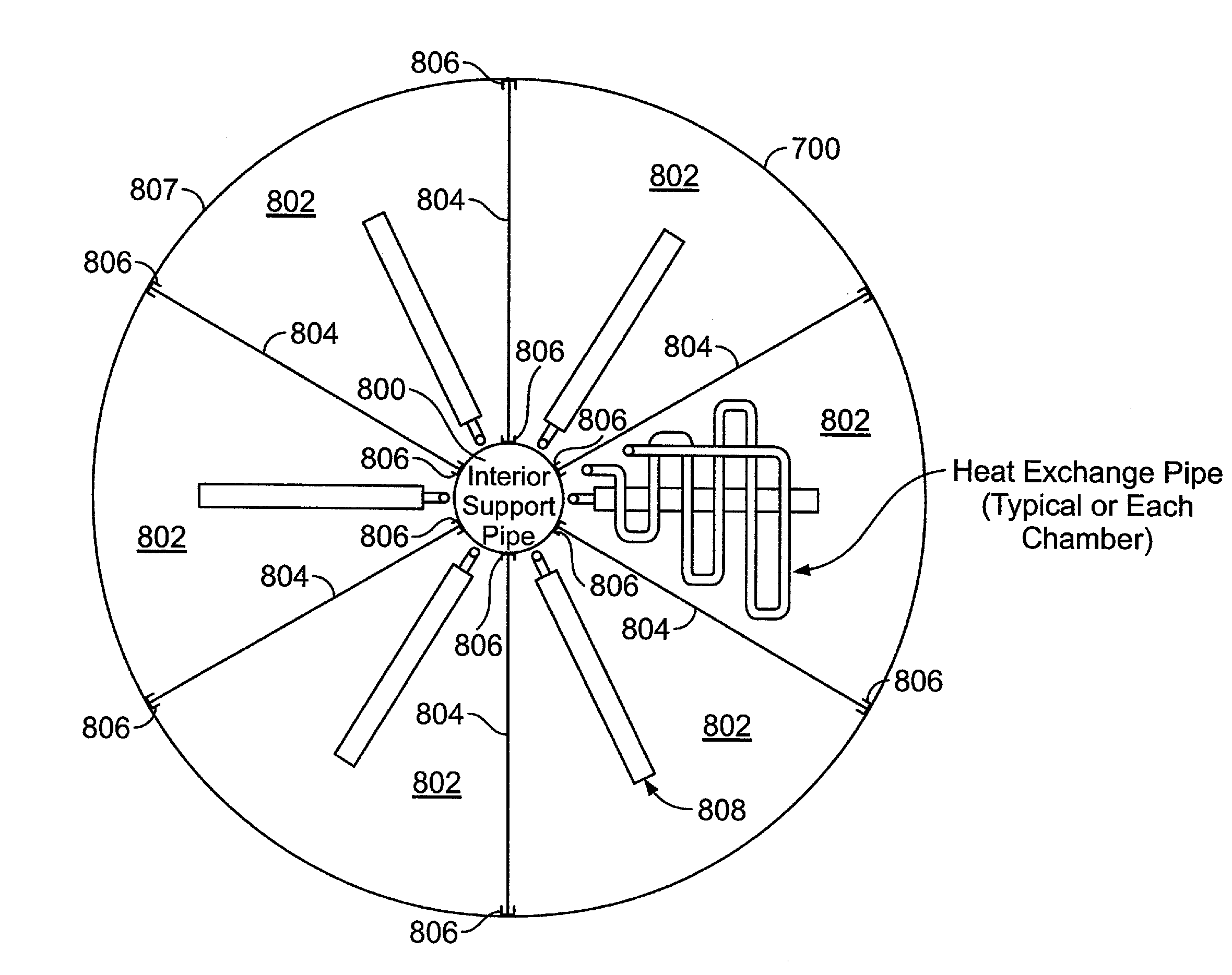

Biochar

The invention provides for methods, devices, and systems for pyrolyzing biomass. A pyrolysis unit can be used for the pyrolysis of biomass to form gas, liquid, and solid products. The biomass materials can be selected such that an enhanced biochar is formed after pyrolysis. The biomass can be pyrolyzed under specified conditions such that a selected biochar core is formed. The pyrolysis process can form a stable biochar core that is inert and / or resistant to degradation. The biochar or biochar core can be functionalized to form a functionalized biochar or functionalized biochar core. Functionalization can include post-pyrolysis treatments such as supplementation with microbes or physical transformations including annealing and / or activation.

Owner:FULL CIRCLE BIOCHAR

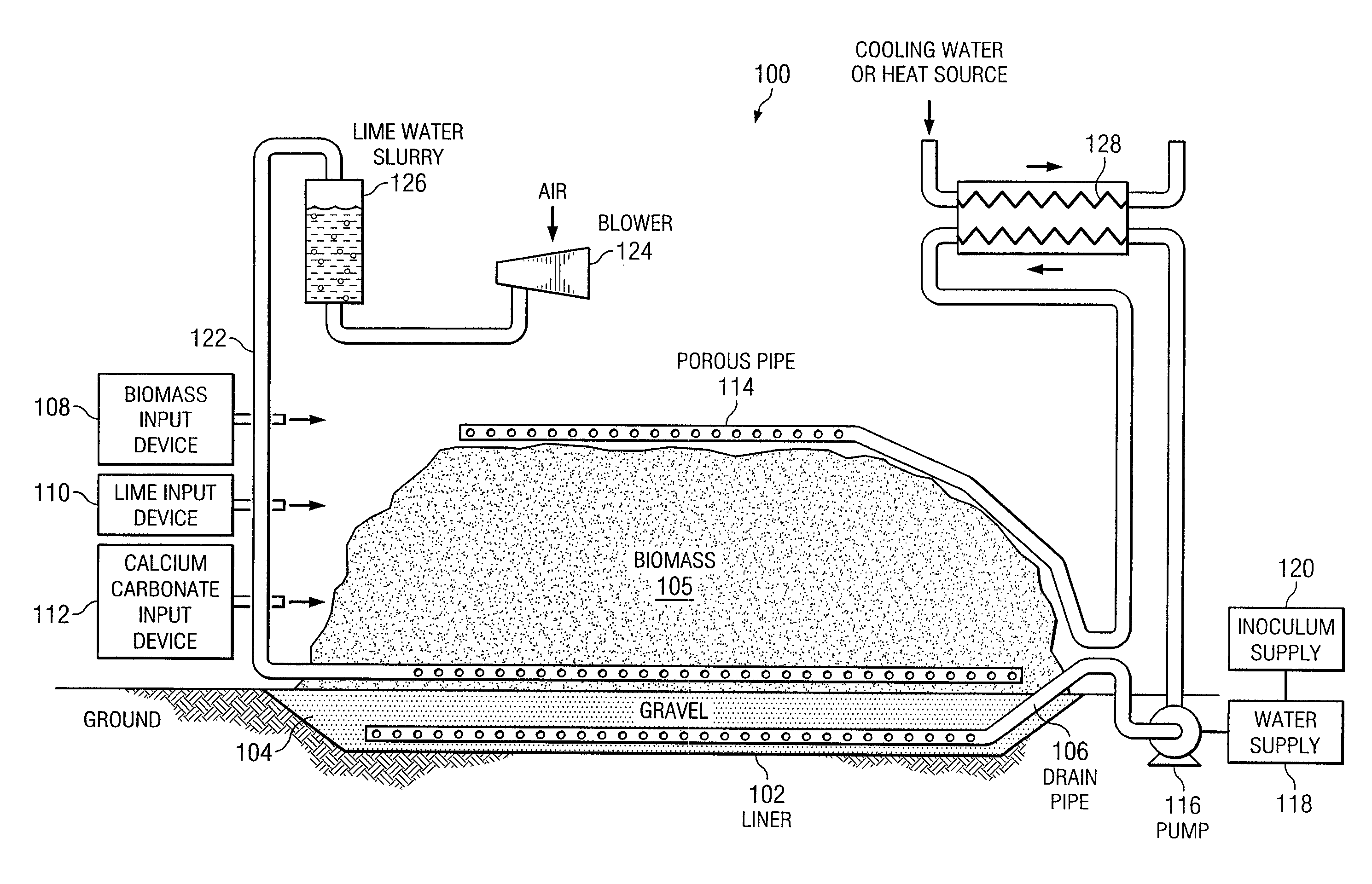

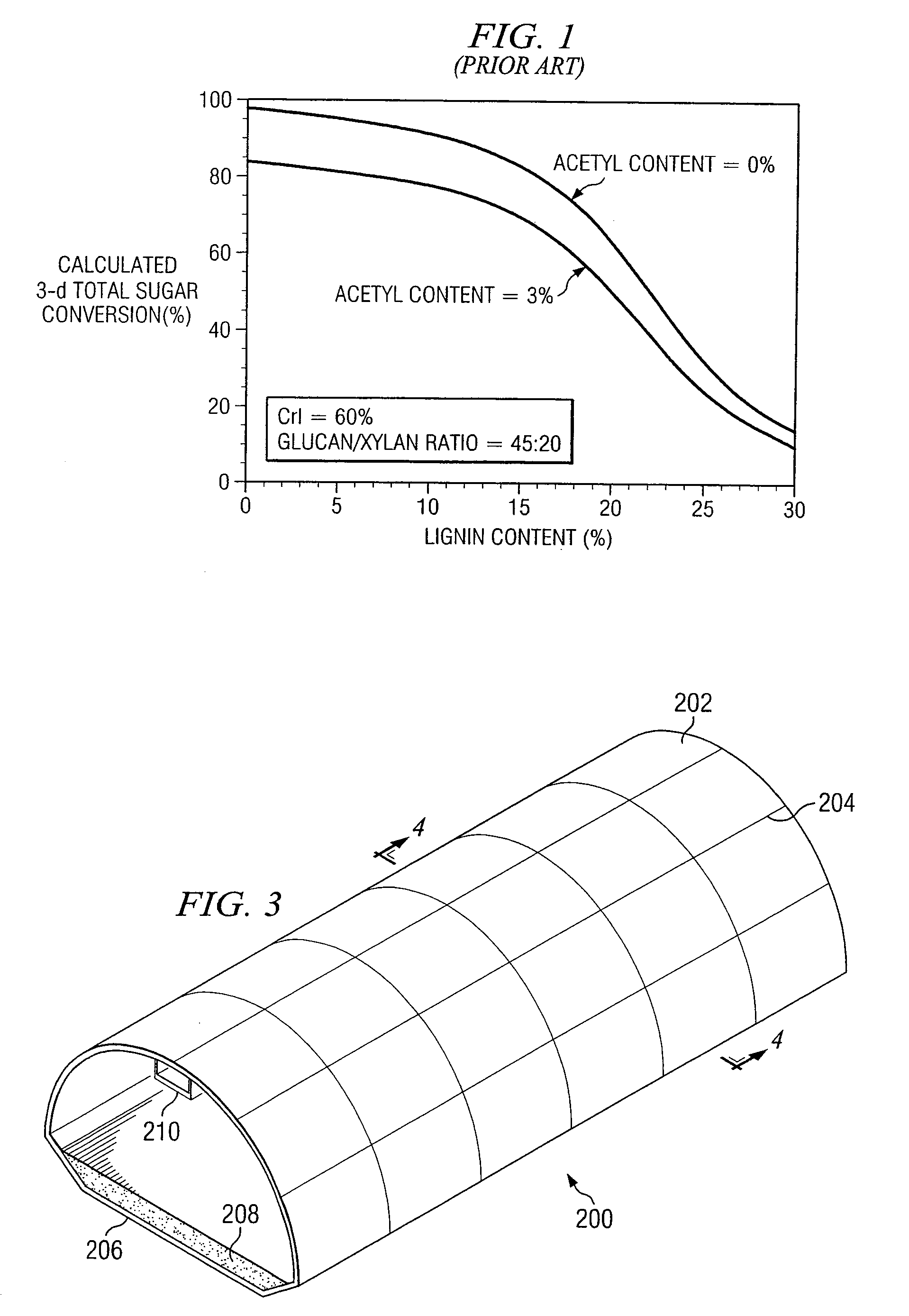

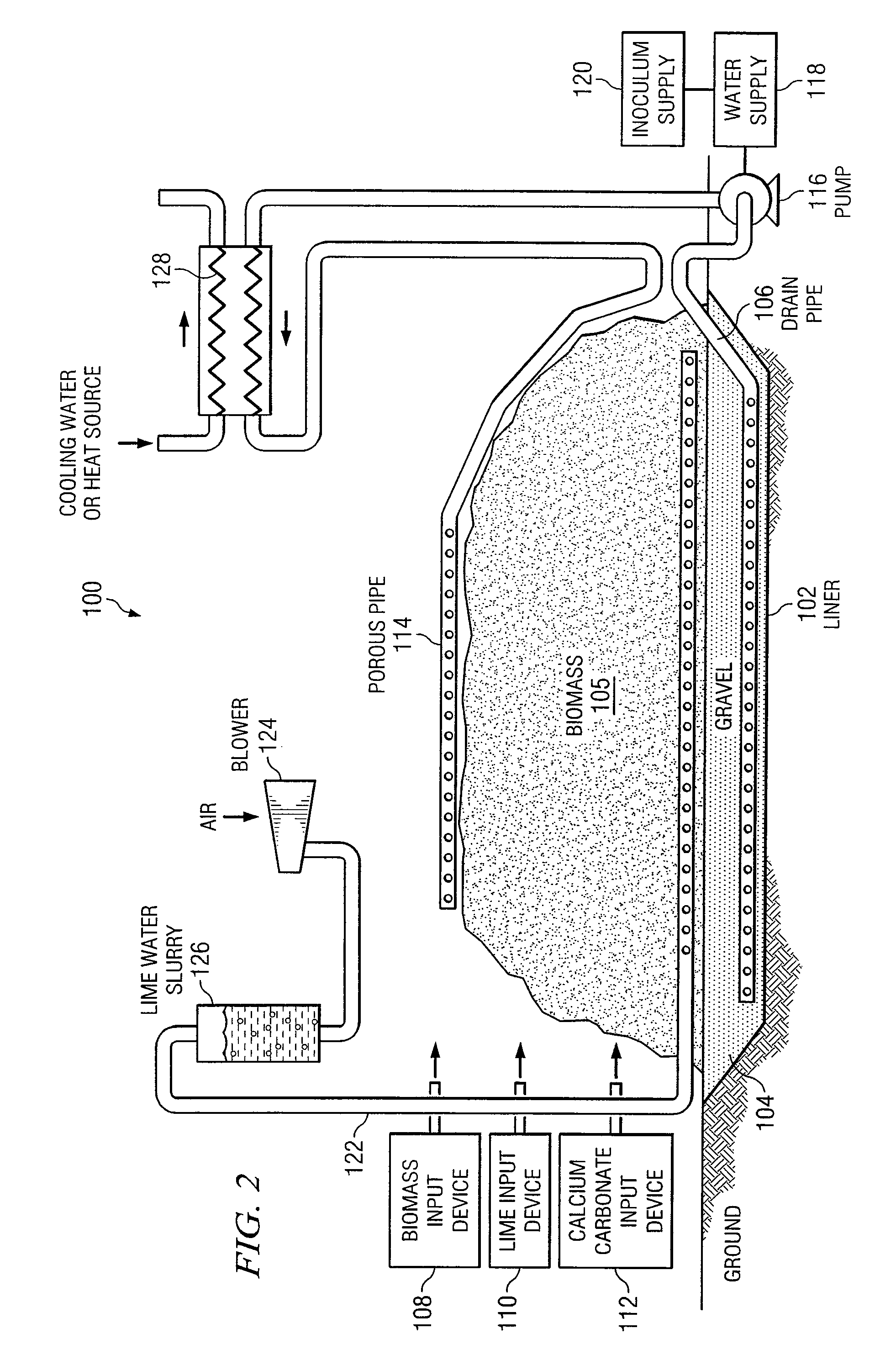

Methods and Systems for Pretreatment and Processing of Biomass

InactiveUS20080121359A1Increasing enzyme digestibilityLow lignin contentBio-organic fraction processingProductsEnzymatic digestionCellulose

According to one embodiment of the invention, a system for processing biomass includes a water-impermeable bottom liner, a gravel layer supported by the bottom liner, a drain pipe disposed within the gravel layer, a biomass input device operable to deliver biomass over the gravel layer to form a biomass pile, a lime input device operable to deliver lime to the biomass for pretreating the biomass, a distribution pipe elevated above the gravel layer, and a pump operable to circulate water through the biomass pile by delivering water to the distribution pipe and receiving water from the drain pipe after it has traveled through the biomass pile.According to another embodiment, a method for biomass pretreatment with alkali, conducted at ambient pressure for approximately 4-16 weeks at temperatures ranging from approximately 25° C. to 95° C. Biomass may be lignocellulosic biomass and may be rendered suitable for enzymatic digestion or pulp production.

Owner:TEXAS A&M UNIVERSITY

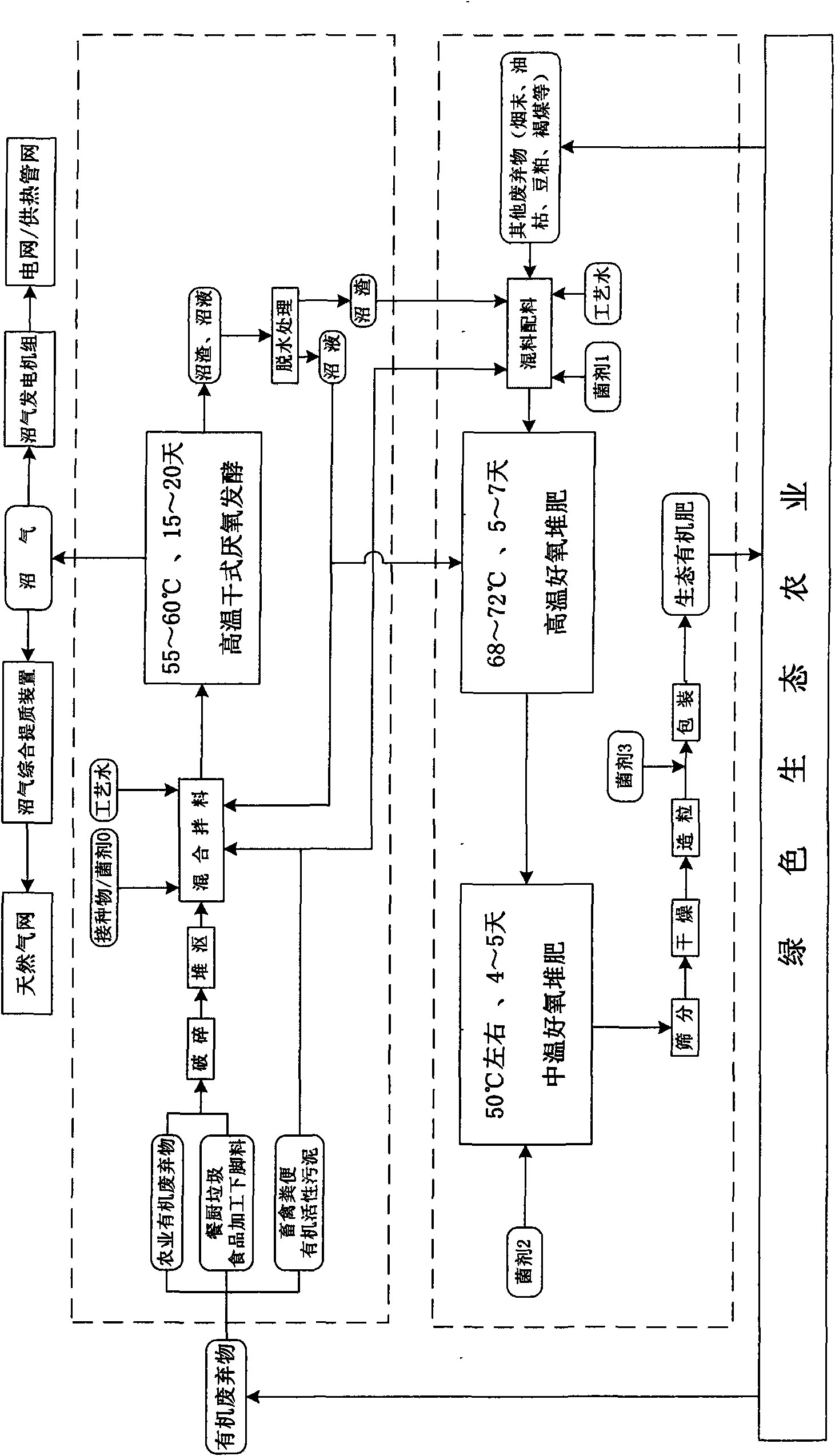

Comprehensive processing technology of organic wastes

ActiveCN101637778AImprove efficiencyStable nutrientsBio-organic fraction processingSolid waste disposalThermal energyProcess systems

The invention provides a comprehensive processing technology of organic wastes, belonging to the technical field of environmental protection, and in particular relates to resourcing comprehensive processing technology of organic wastes. The invention comprises the following steps: a. preparing materials: placing liquid or solid organic wastes into different storing tanks; b. pretreating: crashingthe organic wastes to particles with the granuality of being equal to or less than 30 mm, conveying the well-crashed materials into a stackretting tank for stackretting; c. mixing and matching variousorganic wastes and process water, wherein, the carbon nitrogen ratio (C / N) of the materials is 20-30:1, and the concentration of TS is 30%-35%; d. adding the inoculum, adopting high temperature dry anaerobic fermentation to carry out anaerobic fermentation on pretreated materials; and e. manufacturing from the biogas residues generated in step d into efficient multifungus composite ecological organic fertilizer, backflowing the generated biogas liquid to adjust the state of the anaerobic fermentation system or ensure the biogas liquid to enter the aerobic composting process flow, and introducing the generated biogas to a thermoelectricity cogeneration unit to provide electrical energy and thermal energy required by the process system. In the invention, composite microorganism agent and biogas residues and other base stocks are adopted for composite preparation, thus greatly improving fertilizer efficiency, lowering cost, having effects of diversification of nutrients, stable fertilizer efficiency and non pollution, and being suitable for being applied for various crops.

Owner:YUNNAN KUNMING SHIPBUILDING DESIGN & RESEARCH INSTITUTE

Organic recycling with metal addition

InactiveUS20050039508A1Reduce slurry viscosityAvoid flowAnimal corpse fertilisersAlkali orthophosphate fertiliserSolubilityIron sulfate

The invention is directed to methods for producing a granular nitrogen fertilizer from an organic material comprising adding a metallic salt to said organic material to form a slurry. Preferably the organic material comprises dewatered biosolids and contains water from a scrubber. Metallic salts that can be used comprise a salt of iron, zinc, or a mixture thereof. Preferred iron salts comprises ferric sulfate or ferric oxide, and preferred zinc salts comprises zinc sulfate or zinc oxide. Preferably, the metallic salt is mixed with an acid such as sulfuric acid to form an acidified metal salt. Slurry pH ranges from approximately 2-2.5. The acidified metal salt is added to the organic material in sufficient quantity to lower viscosity of the slurry such that the resulting fluid does not hinder fluid flow during operation. When the metallic salt comprises acidified ferric sulfate or ferrous sulfate, sufficient iron can be present to produce a fertilizer product with 0.1 weight percent to 10 weight percent iron sulfate calculated on a dry weight basis. The invention is also directed to fertilizer products made by the methods of the invention. Preferred products are granules and the metallic salt increases product hardness. Fertilizer granules preferably contain metal that is bioavailable to a plant when used as a fertilizer. Solubility of the metal of the product in water is enhanced, and the product is low staining.

Owner:UNIFIED ENVIRONMENTAL SERVICES GROUP +1

Reutilization treatment method of kitchen waste

InactiveCN102503595AHigh degree of resource utilizationHigh yieldFatty oils/acids recovery from wasteBio-organic fraction processingSlurryNutrient solution

The invention discloses a reutilization treatment method of kitchen waste, belonging to the technical field of rubbish treatment; the kitchen waste is treated by such procedures as pre-sorting, hydraulic pulping, anaerobic fermentation, organic fertilizer preparation by residues and oil-water separation, and the like, so that the grease in the kitchen waste is recycled, the organic matters are prepared to marsh gas by hydrolytic acidification and anaerobic fermentation, and the marsh gas is purified to be used as fuel, power generation or automobile fuel gas; in the whole treatment process, the liquid part in the kitchen waste except the removed grease is used for pulping in a pulp homogenizing system, all pulp participate in the anaerobic fermentation process, and the fermented biogas slurry is after-treated to prepare nutrient solution so as to realize the recycle of resources and zero release of pollutants; the treatment process is completely sealed, and the collected off-flavor is collected and treated by a deodorization system to be exhausted after reaching to the discharge standard. The method of the invention has the advantages of maximally recycling the resources, recycling the kitchen waste, guaranteeing non-pollutant discharge during the whole treatment process, and realizing the efficiency, reclamation and harmlessness of kitchen waste treatment.

Owner:北京世纪银河环境科技有限公司

Method for treating solid organic wastes by biological method

InactiveCN101709006AAchieve recyclingAchieve reductionBio-organic fraction processingAnimal corpse fertilisersEcological environmentFermentation

The invention relates to a process for treating solid organic waste resources (food residues, domestic garbage, vegetable market garbage, wastes and leftovers of slaughter houses and food products factories, beer lees, distilled spirit lees, stevia rebaudiana residues, Chinese medicinal herbal dregs and the like), which comprises the following steps of: removing impurities (plastic bags, bottle caps, napkins, metals and the like) from solid organic wastes; adding mixed bacteria, an enzyme preparation and auxiliary materials into the organic wastes; stirring the mixture and controlling the temperature by hot blast; performing fermentation treatment on the mixture by adopting a staged temperature raising method; and drying and crushing the mixture to obtain an organic fertilizer. The invention finds a process capable of effectively treating the solid organic wastes, which can convert the solid organic wastes into the organic fertilizer by using microorganisms to change the organic wastes into valuable and realize the recycling use and the quantity reduction of waste resources; besides, the used microorganisms are harmless to human and the ecological environment.

Owner:TIANJIN UNIV OF SCI & TECH

Process of preparing pig manure bio-organic fertilizer by microbial fermentation method

ActiveCN104261913AEffectively adjust the balanceEliminate compactionBio-organic fraction processingDi-calcium phosphate fertilisersPig breedingFermentation starter

The invention discloses a process of preparing a pig manure bio-organic fertilizer by a microbial fermentation method. The process comprises the following step: by taking the pig manure as a raw material and supplementing straws, earthworm cast, seaweeds, and the like, performing a two-step fermentation process of a biological fermenting agent to prepare the pig manure bio-organic fertilizer. The process is high in resource utilization degree, easy for large-scale industrial production, beneficial to realizing resource utilization of live pig breeding wastes and capable of a pig breeding environmental pollution problem at present. The pig manure bio-organic fertilizer has the effects of the bio-organic fertilizer and the seaweed fertilizer, is rich in functional active ingredients of seaweeds and a large number of probiotics, capable of effectively regulating equilibrium of microorganisms in soil, decomposing organic or inorganic components such as organic substances and mineral substances in the soil, eliminating soil hardening, desertification, salinization and the like caused by abuse of a chemical fertilizer throughout the year, increasing the yield of crops, and has the special effects of improving the quality of the crops and improving the stress resistance of the crops. Besides, the pig manure bio-organic fertilizer is long in acting period, and is an ideal fertilizer for developing green ecological agriculture.

Owner:东辽县日月星有机肥有限公司

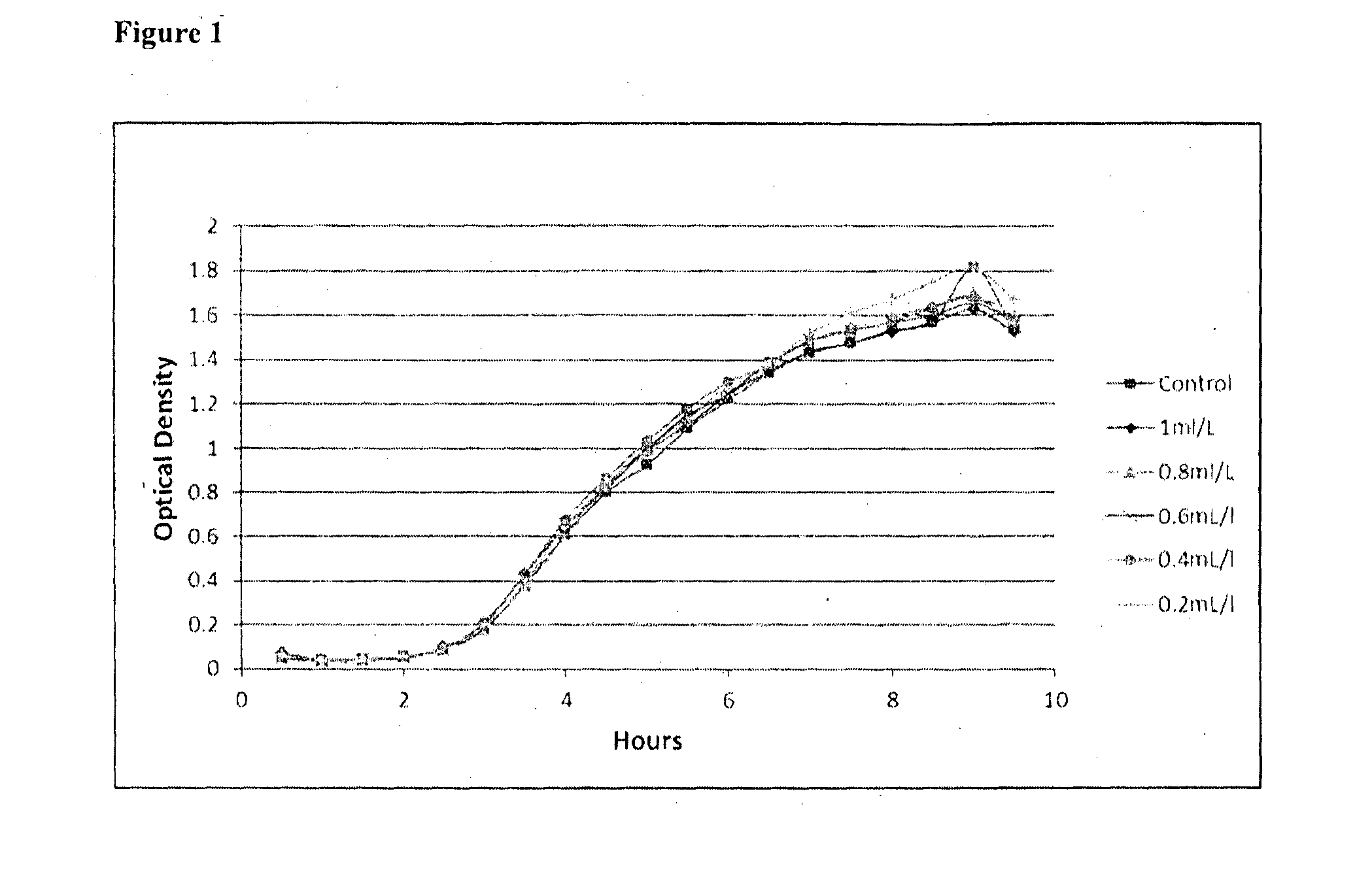

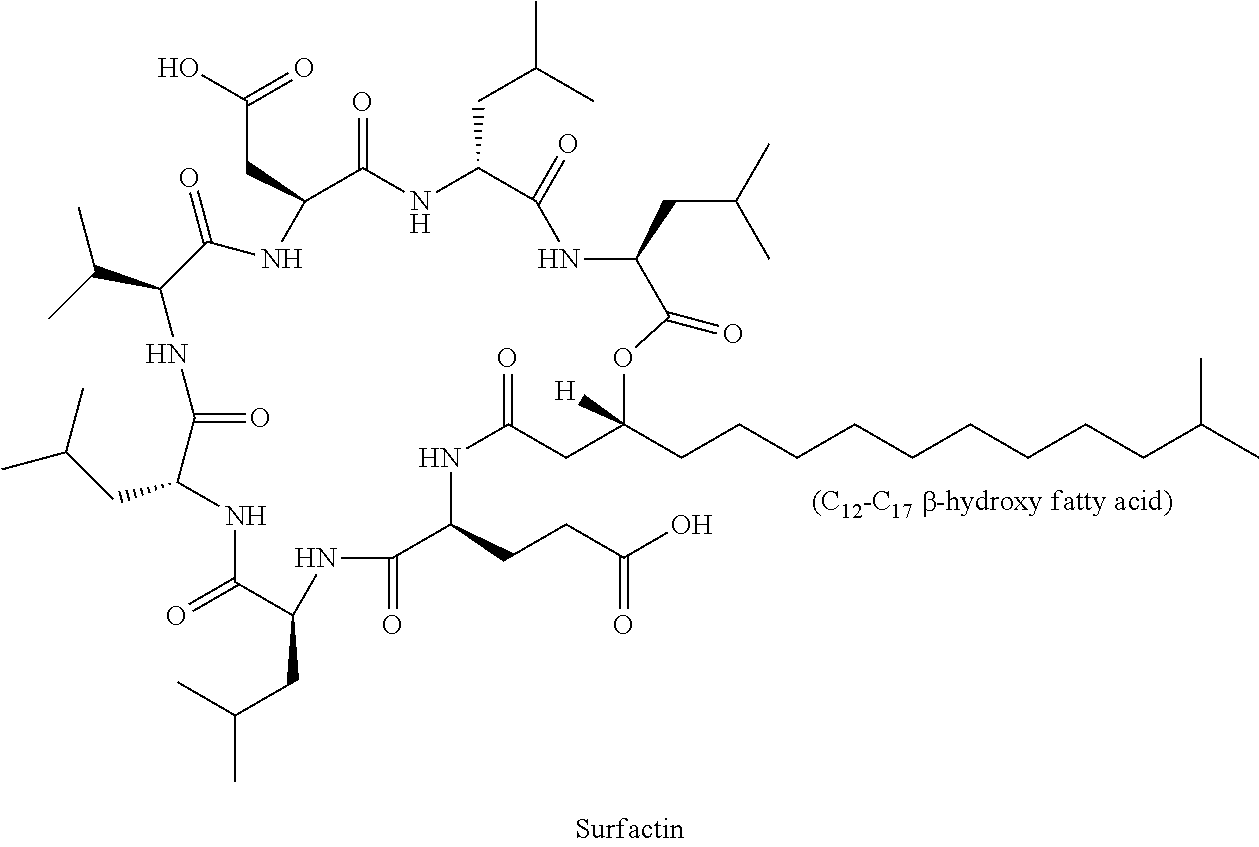

Method of producing biosurfactants

Owner:GLOBAL BIOPROTECT IP PTY LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com