Method of producing biosurfactants

a biosurfactant and biotechnology technology, applied in the direction of drug compositions, well accessories, sealing/packing, etc., can solve the problems of limiting the usefulness of particular soil types, affecting the yield of biosurfactants, and affecting the quality of biosurfactants, etc., to achieve good yield and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

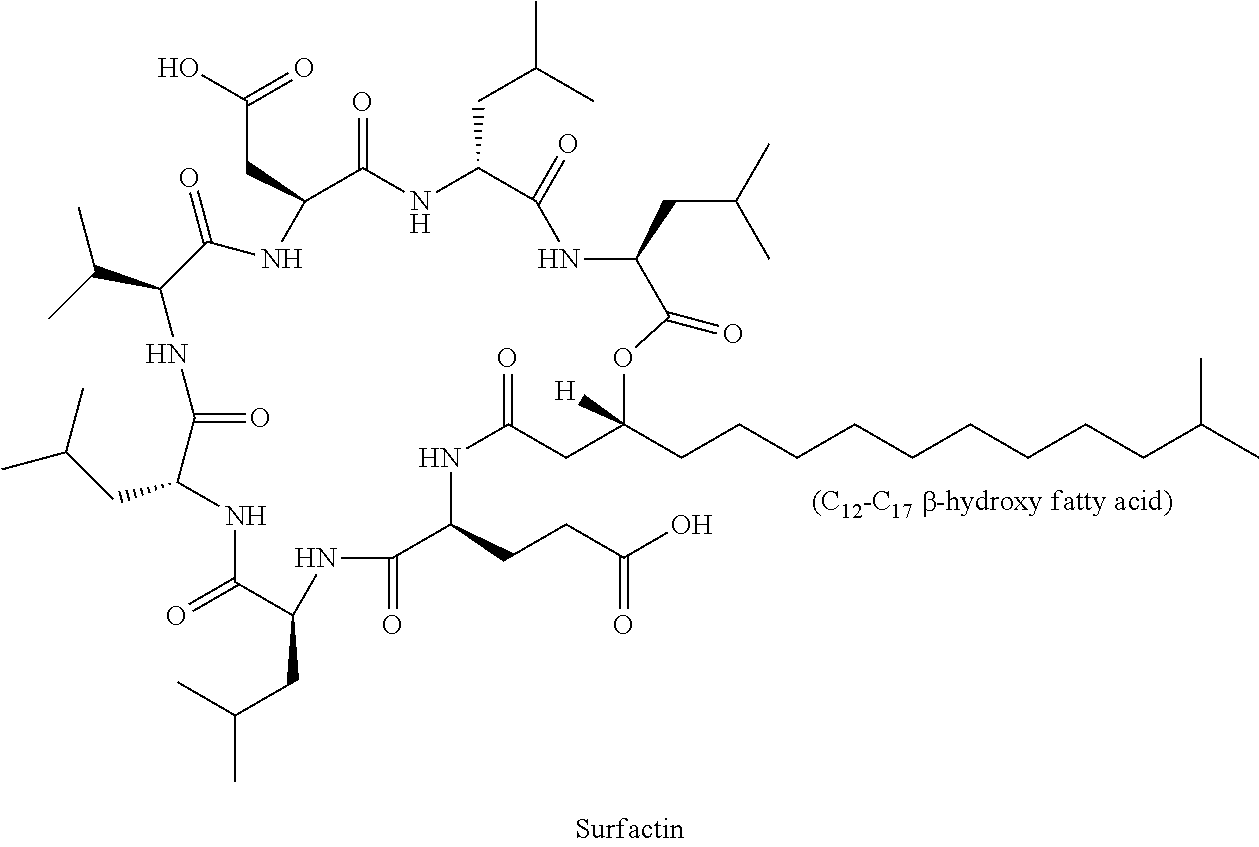

Production of Surfactin

[0082]Bacillus subtilis NRRL B-3383 strain (originally obtained from the United States Department of Agriculture) from bacterial culture on nutrient agar plates was transferred at a 2% volume by volume inoculum into 4 L shake flasks containing 2.5 L of 10% vinasse based MMS broth. The vinasse based MMS broth containing:

componentquantityVinasse100mLAmmonium nitrate4.1gsodium phosphate dibasic5.68gtetrasodium tetrahydrate EDTA1.8mgManganese sulfate6.8mgautoclaved deionized waterto 1L

[0083]The flasks were placed on orbital shakers (SKC 6100, Jeio Tech) at 150 rpm while incubating at 30° C. (MCO-801C Incubator, Sanyo). After 72 hours, flasks were removed from the incubator and the biomass removed from the crude culture broth by centrifugation at 8,500 rpm for 20 min at 4° C. (Sorvall Evolution RC).

[0084]The pH of the resulting supernatant was brought to a pH of 2.0 using HCl which resulted in precipitation of surfactin and the supernatant stored overnight at 4° C....

example 2

Production of Blends of Surfactin and Lichenysin

[0087]Bacillus subtilis and Bacillus licheniformis were used to inoculate 4 L shake flasks containing 10% molasses based MMS broth. The molasses based MMS broth containing:

componentquantitymolasses100mLAmmonium nitrate4.1gsodium phosphate dibasic5.68gtetrasodium tetrahydrate EDTA1.8mgManganese sulfate6.8mgautoclaved deionized waterto 1L

[0088]The flasks were placed on orbital shakers (SKC 6100, Jeio Tech) at 150 rpm while incubating at 30° C. (MCO-801C Incubator, Sanyo). After 72 hours, flasks were removed from the incubator and the biomass removed from the culture broth by centrifugation at 8,500 rpm for 20 min at 4° C. (Sorvall Evolution RC).

[0089]The crude products were labelled MEGR102, MEGR103 and MEGR104, each being blends of varying concentrations of surfactin and lichenysin.

example 3

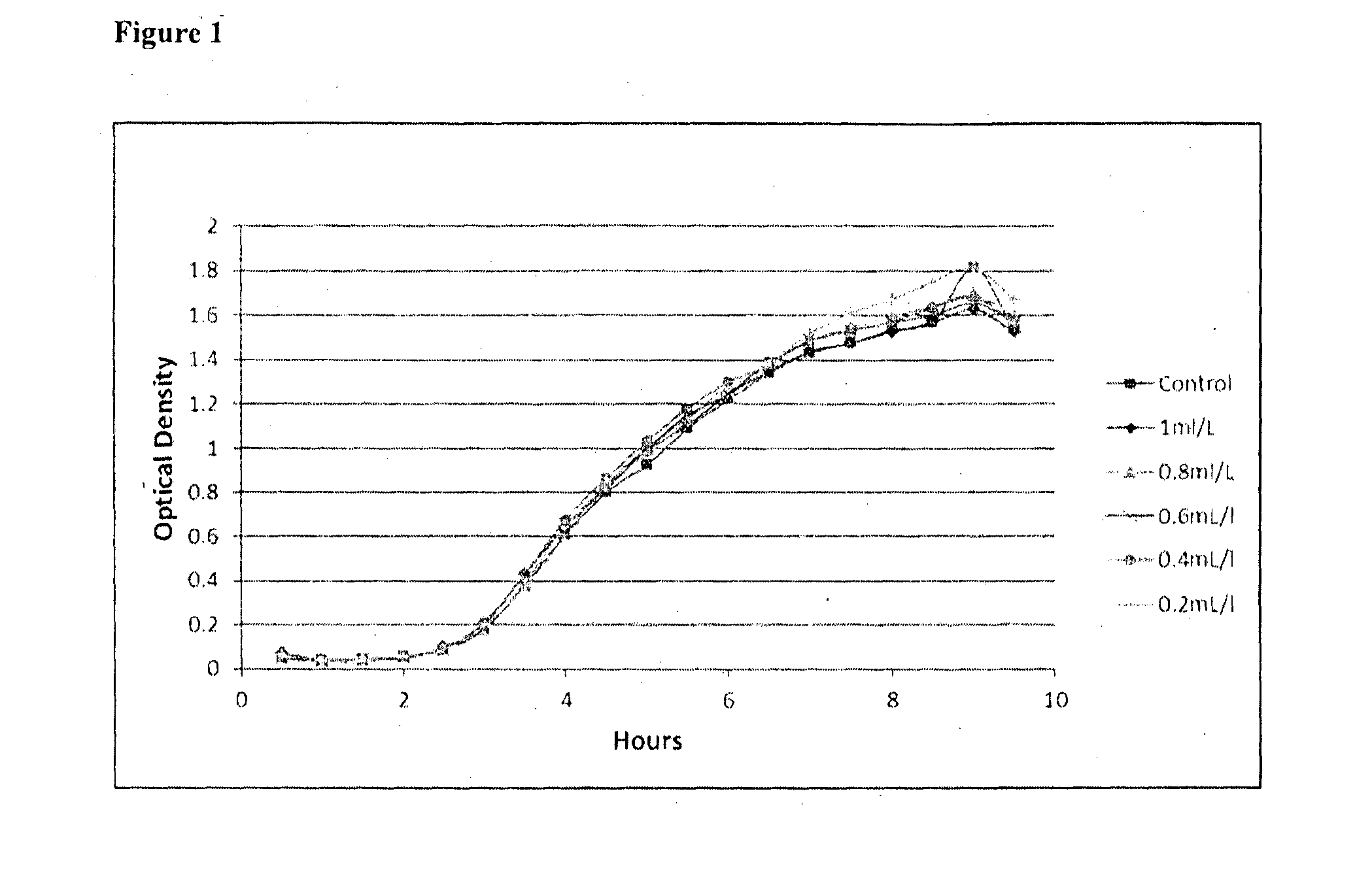

Antibiotic Properties of MEGR102, MEGR103 and MEGR104

[0090]Each composition MEGR102, MEGR103 and MEGR104 was tested for antibiotic properties against E. coli, Desulfotomaculum halophilum and Acidithiobacillus ferrooxidans.

[0091]Each composition was tested by adding the composition to 7% salt water containing 54,356 mg / L NaCl, 16,151 mg / L CaCl2, 2,383 mg / L MgCl2 and 535 mg / L KCl (to simulate hydrofracking water) in amounts of 1 mg / L, 3 mg / L and 5 mg / L. The salt water compositions of each concentration were then inoculated with E. Coli (108 cfu), Desulfotomaculum halophilum (108 cfu) and Acidithiobacillus ferrooxidans (108 cfu).

[0092]The controls were inoculation of the 7% salt water with each bacteria in equal amounts to the test samples without the addition of MEGR composition.

[0093]The compositions were cultured at room temperature. At time intervals, samples were taken and were analysed for culture growth on agar plate to determine visual count of cfu.

[0094]The results are shown ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com