Patents

Literature

100 results about "Fertilizer industry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

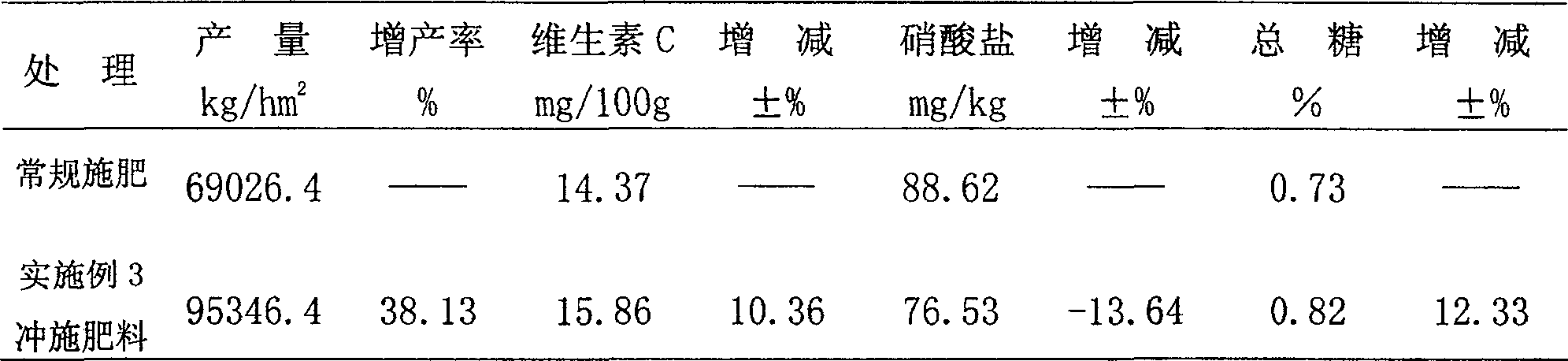

Whole-nutrition biological flushing and spreading fertilizer and preparation method thereof

InactiveCN101037369ASolve the single nutrientSolve solubilityClimate change adaptationAlkali orthophosphate fertiliserMicroorganismNicotiana tabacum

A full nutrition fertilizer of biology type and its producing method belongs to organic complex fertilizer field in biology type. The components of the full nutrition fertilizer is 20-50% of organic waste liquid, 10-30% of urea, 8-15% of diammomium phosphate, 10-25% of potassium sulfate, 5-20% of medium trace element, 1-5% of microbial inoculum, 0-0.2% of root-promoting agent; 0-2% of solutizer, effective viable count content of the microbial inoculum of more than 1010 / g. The fertilizer is produced by adding the urea, diammomium phosphate, potassium sulfate, medium trace element, root-promoting agent, solutizer into organic waste liquid and blending uniformly, then adding microbial inoculum. The invention uses the wastes to produce fertilizer with a low cost a high availability and a good prospect in the fertilizer industry. The fertilizer can be widely applied to the vegetables, melon and fruits, food, tobacco, forests and different commercial crops.

Owner:INST OF SOIL & FERTILIZER SHANDONG ACAD OF AGRI SCI

Coated fertilizer for inducing root growth and preparation method and application thereof

ActiveCN103102216AReduce releaseImprove physical and chemical propertiesFertiliser formsFertilizer mixturesAtherion elymusRoot growth

The invention discloses a coated fertilizer for inducing root growth and a preparation method and an application thereof, belonging to the field of fertilizer industry. The coated fertilizer comprises a fertilizer core and a coated layer, wherein the fertilizer core comprises organic matters, compound amino acid, humic acid materials, macroelements, secondary elements, microelements and an inorganic conditioner, the coated layer comprises a binder, a coated agent, a root system inducer, an alginate solution and a calcium ion solution. The preparation method comprises the following steps of smashing raw materials of the fertilizer core, after mixing, tabletting so as to form granulated fertilizer, spraying the binder, the coated agent mixed with the root system inducer, the alginate solution and the calcium ion solution on the granulated fertilizer sequentially so as to form a coated layer, and obtaining the coated fertilizer for inducing root growth after drying. On the one hand, the coated fertilizer can induce the root system to grow rapidly around the fertilizer due to the addition of the root system inducer, so that the fertilizer use ratio is improved; on the other hand, the fertilizer core is extruded and bonded by adopting a physical manner, so that the slow-release effect of the fertilizer core guarantees the fertilizer to be used efficiently.

Owner:湖南杜高生物科技有限公司

Compound liquid fertilizer with high suspension degree, and preparation method and application thereof

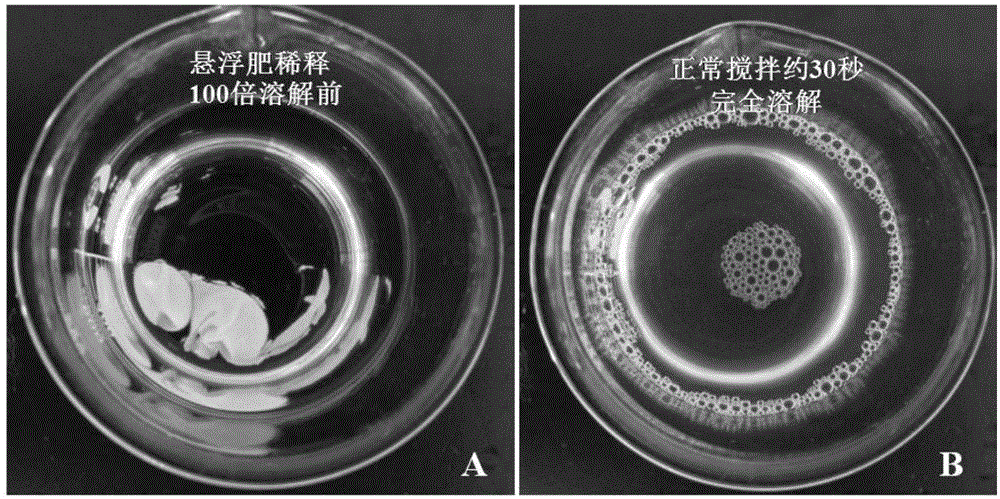

The invention discloses a compound liquid fertilizer with high suspension degree, and a preparation method and an application thereof, and belongs to the liquid fertilizer industry field. The preparation method comprises the steps: adding macromolecule organic sugar into a clay material to be used as a basal suspending agent I, and carrying out first suspension chelation of a major element and a trace element at the temperature of 40-60 DEG C; followed by controlling the temperature at 20-30 DEG C, slowly adding a plant growth regulator and a surface active material, fully mixing uniformly, finally adding macromolecule cellulose and an analog thereof as a suspending agent II, carrying out second suspension chelation, and fully stirring to obtain the compound liquid fertilizer with high suspension degree. The prepared compound liquid fertilizer with high suspension degree has comprehensive nutrients, high content, low cost, good liquidity, good stability and good dissolvability, and is beneficial for crops to efficiently absorb and utilize. The preparation method is simple in process and easy to implement. The compound liquid fertilizer is an ideal fertilizer source for water and fertilizer integration for drip irrigation, sprinkler irrigation, water flushing and the like.

Owner:SOUTH CHINA AGRI UNIV +1

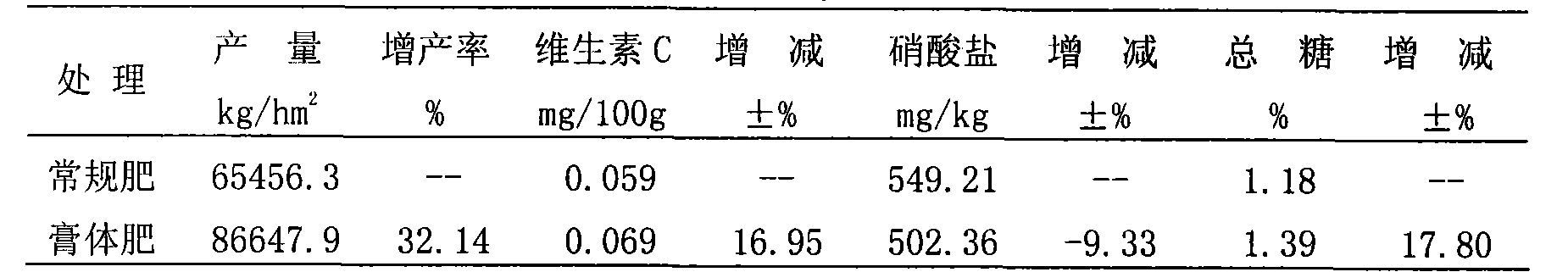

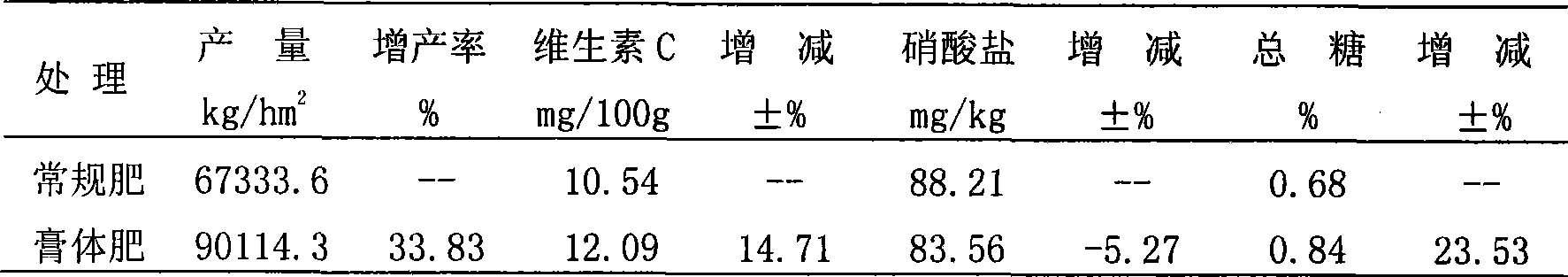

Fermented liquid pasty fertilizer and preparation method thereof

InactiveCN101544522AFull of nutritionReasonable ratioBio-organic fraction processingClimate change adaptationSolubilityLivestock manure

The invention discloses fermented liquid pasty fertilizer which relates to the technology of utilizing fermented liquid for producing pasty and organic compound fertilizer, in particular to a method mixing fermented liquid of livestock manure with humic acid raw materials to prepare the pasty fertilizer and the application of the method, belonging to the technical field of novel organic fertilizer and the cyclic utilization of the resource of agricultural wastes. The pasty fertilizer includes the main component of fermented liquid, and is additionally provided with carbamide, diammonium phosphate, lemery, aminated wood coal, thickening agent and other additives; and the carbamide, the diammonium phosphate, the emery, the aminated wood coal, the thickening agent and the other additives are added to and uniformly mixed and stirred with the fermented liquid, and the mixture is pulverized to form a pasty shape. The invention which utilizes the fermented liquid to prepare the pasty fertilizer turns the wastes into resources, the preparation method is easy, and required equipment is simple, thereby the invention is easy to be easily popularized and applied to the fertilizer industry. The pasty fertilizer has the advantages of favorable dissolvability, full nutrition and obvious effect of yield and quality improvement and can be widely applied to vegetables, fruits, foodstuffs, forests and various cash crops.

Owner:INST OF SOIL & FERTILIZER SHANDONG ACAD OF AGRI SCI

Special peanut film-coating slow-release fertilizer and preparation process thereof

InactiveCN101885633APlay a role in reducing costsPerfection and improvement of fertilization technologyOrganic fertilisersFertilizer mixturesCross-linkContinuous cropping

The invention discloses a special peanut film-coating slow-release fertilizer and a preparation process thereof. The special peanut film-coating slow-release fertilizer utilizes the effects of exchange, adsorption, combination and chelation of humic acid, and a reactant, a cross-linking agent and a film-forming agent are added to the humic acid to prepare a special peanut slow-release film-coating agent; then special peanut slow-release film-coating agent is mixed with a proportioned special peanut fertilizer; and an obtained mixture is subjected to granulating, film coating, dehumidifying, cooling and screening to prepare the special peanut film-coating slow-release fertilizer. The humic acid contained in the special peanut film-coating slow-release fertilizer is a high-quality organic fertilizer, and not only can be decomposed to provide nutrients, but also can stimulate the activity of root nodules, enhance the nitrogen fixing capacity and improve the disease resistance and the continuous cropping resistance. The special peanut film-coating slow-release fertilizer and the preparation process not only are a break of a slow-release technology of the fertilizer industry, but also are the perfection and the improvement of a peanut fertilizing technology, and achieve the purposes of increasing the yield, reducing the cost and realizing high efficiency on peanut production.

Owner:李振永

Method for performing pig manure resource treatment by utilizing hermetia illucens

InactiveCN106614398AResource processing time is shortRealize resource processingBio-organic fraction processingExcrement fertilisersHermetia illucensAntibiotic Y

The invention discloses a method for performing pig manure resource treatment by utilizing hermetia illucens, belonging to the field of solid waste treatment. The method comprises the following technological steps: (1) mixing pig manure with oilseed meals so as to adjust the water content of pig manure; (2) performing primary fermentation to the mixture by adopting bacillus subtilis, and further fermenting with brewer yeast; (3) feeding black soldier fly Hermetia illucens for raising according to a certain proportion; and (4) after the raising period is finished, collecting the black soldier fly Hermetia illucens and ooze. The method is simple to operate, and fast for pig manure resource treatment process. After conducting the above technological treatment, pig manure and oil seed meals are converted into black soldier fly Hermetia illucens and excreta ooze thereof, the residual tetracycline antibiotics (oxytetracycline, chlorotetracycline and tetracycline) in the pig manure cannot be detected in the black soldier fly Hermetia illucens and ooze. The method not only can solve the problems of pig manure environment pollution, the antibiotics residues, human health damage and the like, but also can provide black soldier fly Hermetia illucens and ooze with rich nutrients for feed and fertilizer industries.

Owner:JIANGSU UNIV

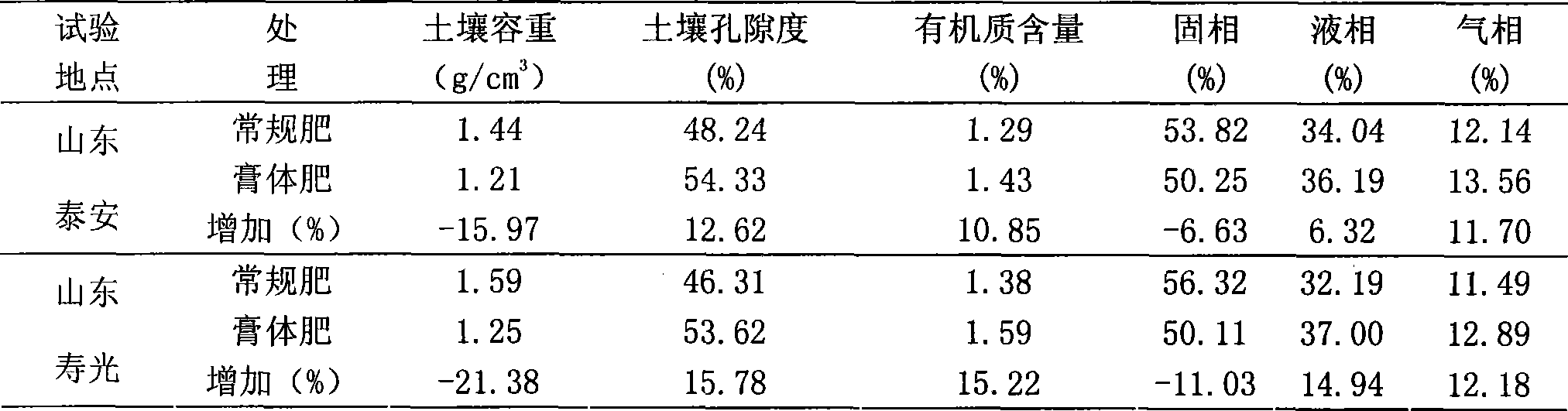

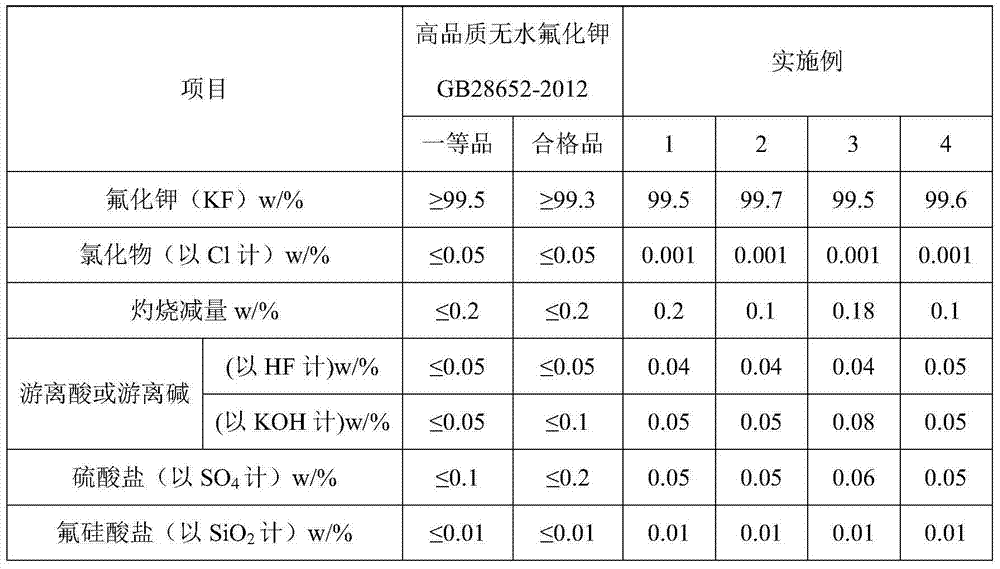

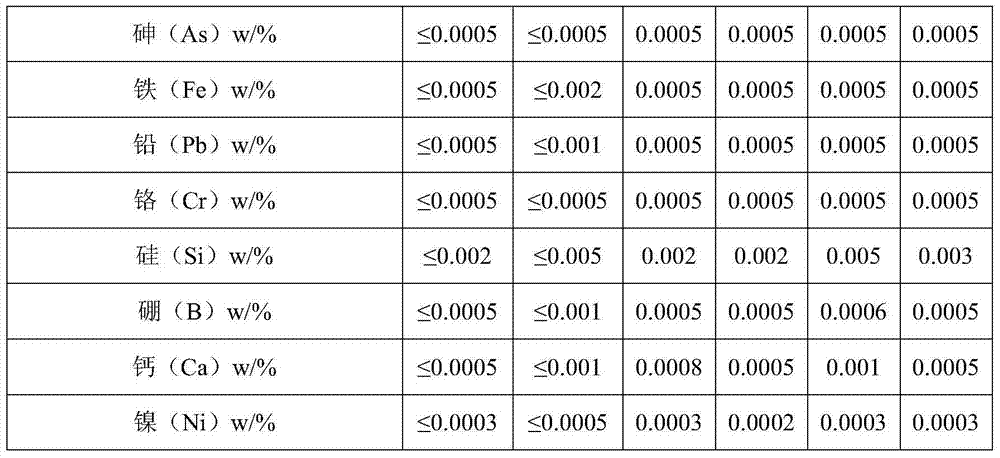

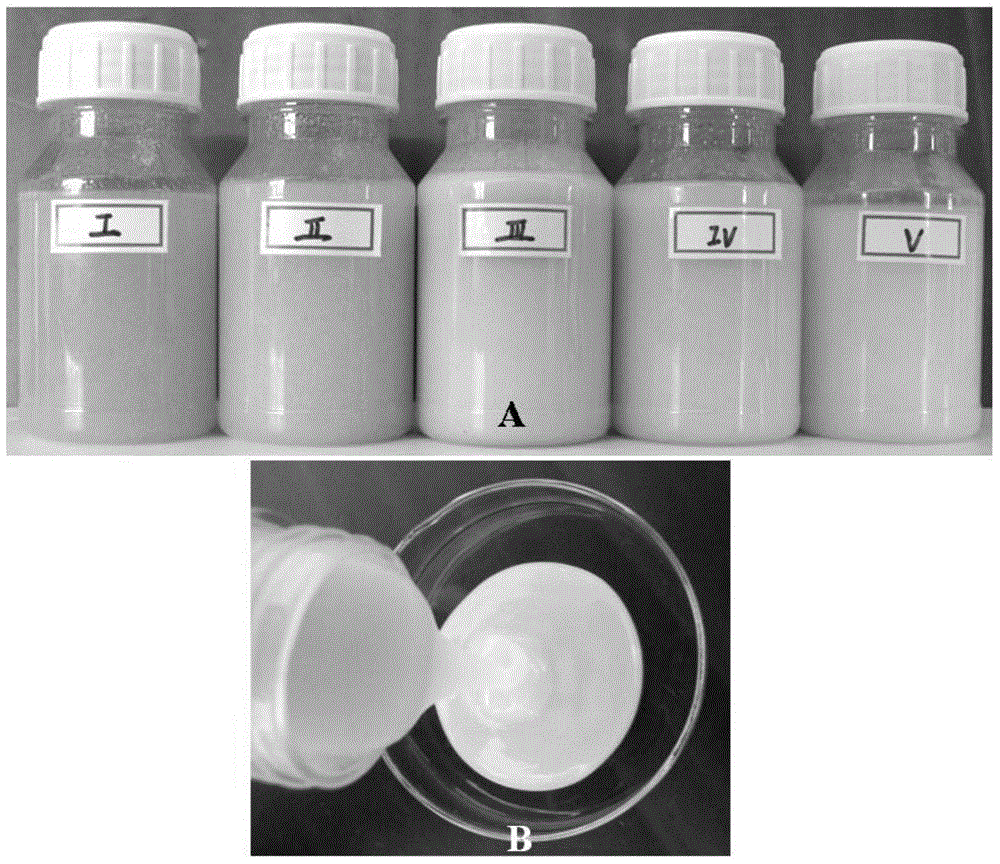

Method for preparing potassium fluoride by employing fluosilicic acid with co-production of white carbon black

ActiveCN104326475ARealize industrial productionHigh activitySilicaAlkali metal fluoridesPotassium fluorideFiltration

The invention discloses a method for preparing potassium fluoride by employing fluosilicic acid with co-production of white carbon black. The method includes following steps: (1) adding potassium carbonate in a fluosilicic acid solution and performing filtration after the reaction to obtain a potassium fluosilicate paste and a mother liquid A; (2) adding calcium oxide or calcium hydroxide to the mother liquid A, performing filtration after the reaction for removing precipitation, and adding potassium carbonate with filtration to obtain a mother liquid B; (3) mixing the potassium fluosilicate paste and the mother liquid B, adding hydrofluoric acid and SiO2 for reaction to obtain a potassium fluosilicate slurry material B; and (4) adding a white carbon black seed crystal to the potassium fluosilicate slurry material B with addition of potassium carbonate for performing an alkaline hydrolysis reaction, performing filtration to obtain a potassium fluoride solution and white carbon black paste and drying the potassium fluoride solution and the white carbon black paste. In the method, by means of the technologies of step-by-step alkaline hydrolysis and impurity removing in the mother liquids, a problem of accumulation of PO4<3-> and SO4<2-> in the raw material fluosilicic acid solution in a product. The potassium fluoride and the white carbon black are high in qualities and are low in production cost. High-quality and cleaning production of fluorine and silicon resources in phosphatic fertilizer industry and hydrofluoric acid industry is achieved.

Owner:DUOFUDUO KUNMING TECH DEV CO LTD

Preparation method of medium temperature ferric oxide desulfurizer

ActiveCN101590358ASimple processFew stepsDispersed particle separationCalcium hydroxideHigh volume manufacturing

The invention provides a preparation method of a medium temperature ferric oxide desulfurizer, and the active component of the medium temperature ferric oxide desulfurizer is amorphous ferric oxide of high activity. The preparation method of the medium temperature ferric oxide desulfurizer comprises the steps of directly kneading soluble ferrite, calcium hydroxide and a binder, extruding, drying and roasting. The desulfurizer obtained by using the preparation method of the invention has high content of ferric oxide, high sulphur capacity and good desulfurizing property; in addition, the preparation method of the invention has the advantages of simple process, low cost and suitability for industrialized mass production. The desulfurizer of the invention is mainly used for medium temperature desulfurization of hydrogen sulfide in chemical fertilizer industry synthesis gas.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

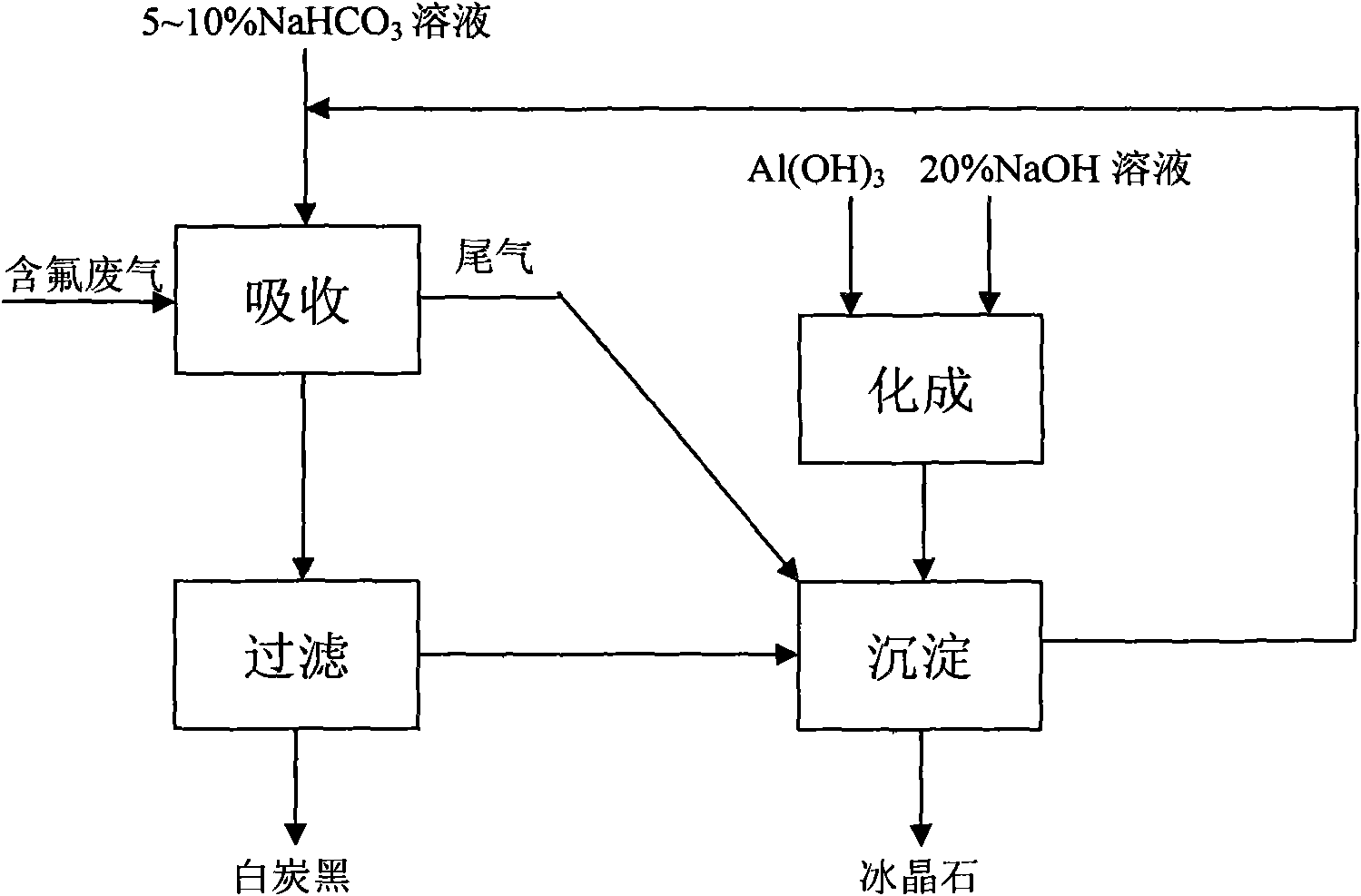

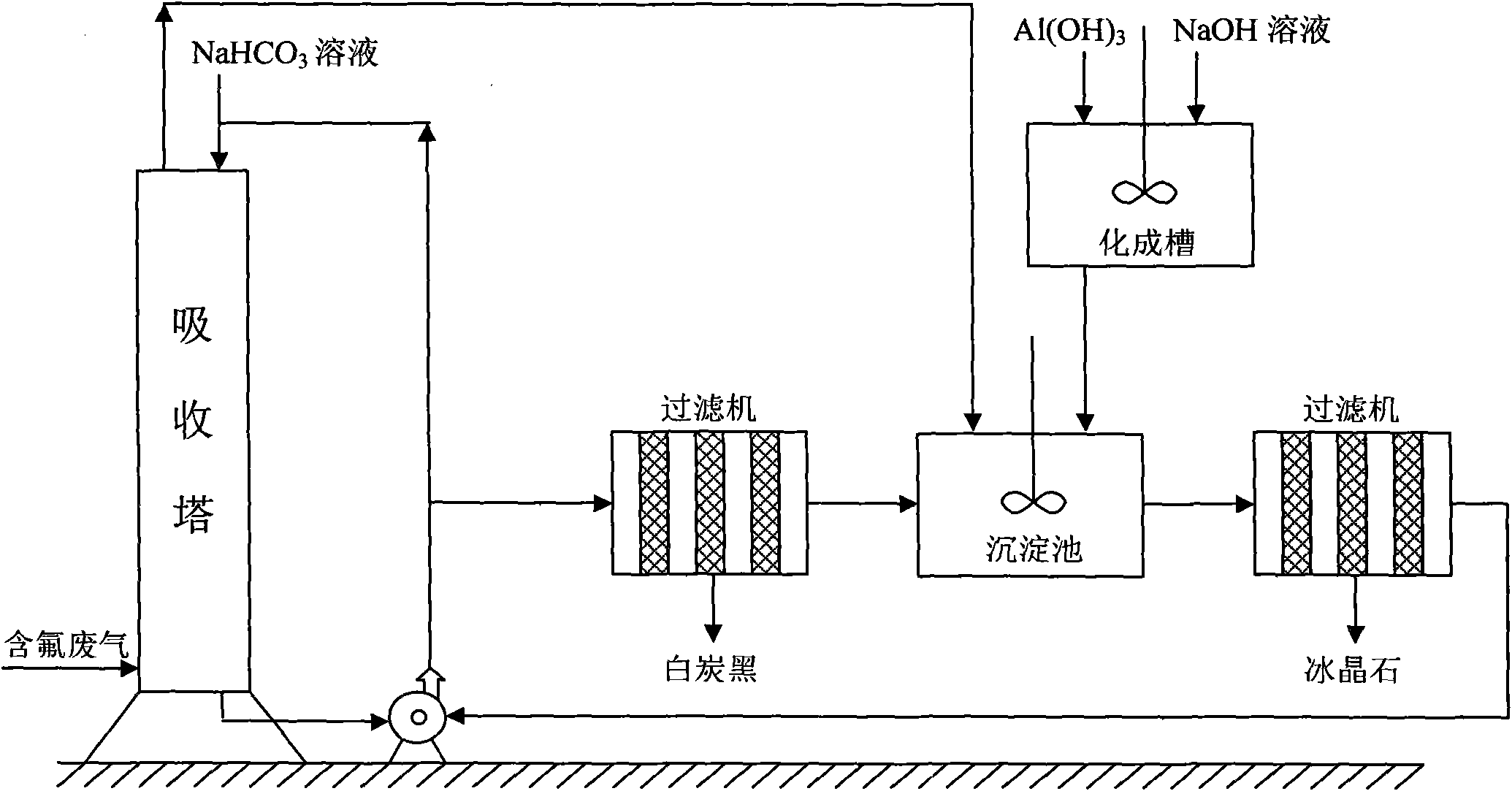

Method for preparing high-molecule-ratio cryolite by using phosphoric acid industrial fluorine-containing waste gas

InactiveCN102464347AAvoid pollutionTake advantage ofAluminium fluoridesSodium bicarbonatePhosphoric acid

The invention relates to a method for preparing high-molecule-ratio cryolite by using phosphoric acid industrial fluorine-containing waste gas, belonging to the field of inorganic chemical engineering. Fluorine-containing waste gas is absorbed by adopting circulation of a sodium bicarbonate solution, so that the problems of secondary pollution and high processing cost in a process of treating the fluorine-containing waste gas are solved, and chemical products such as cryolite, white carbon black, and the like with high additional value are prepared at low cost by using the fluorine-containing waste gas. The principle is as follows: HF and SiF4 in the fluorine-containing waste gas are absorbed by using sodium bicarbonate so as to generate NaF and SiO2.H2O; by using the characteristic that the NaF is slightly dissolved in water and SiO2.H2O is not dissolved in a NaHCO3 solution, the SiO2.H2O is removed through filtering and further processed into white carbon black; and the white carbon black with high specific surface area can be prepared through changing the pH of an absorption solution. The filtered NaF solution reacts with NaAlO2, and CO2 is blown, so that the cryolite can be prepared; and the cryolite with molecule ratio of more than 2.90 can be prepared through controlling excessive percentage of the NaF. The invention can be used in treatment of the fluorine-containing waste gas in phosphoric acid and phosphatic fertilizer industries.

Owner:WUHAN UNIV OF SCI & TECH

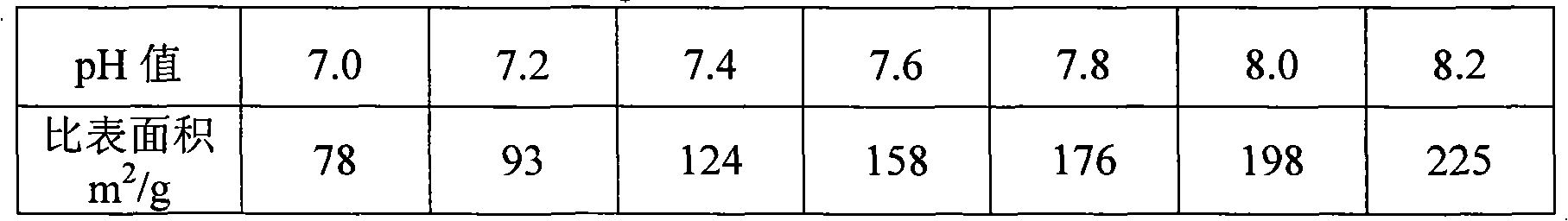

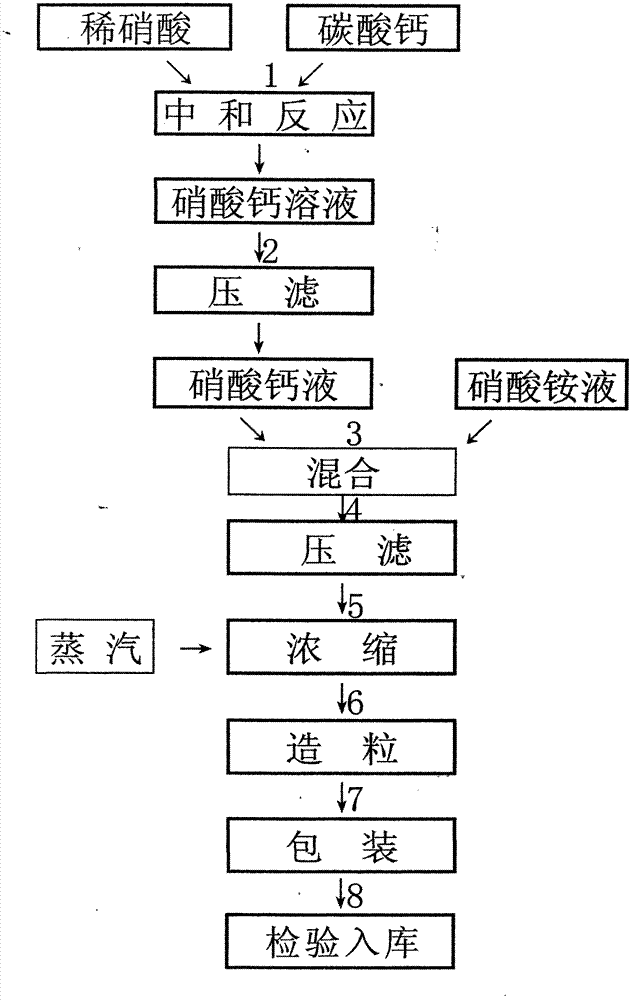

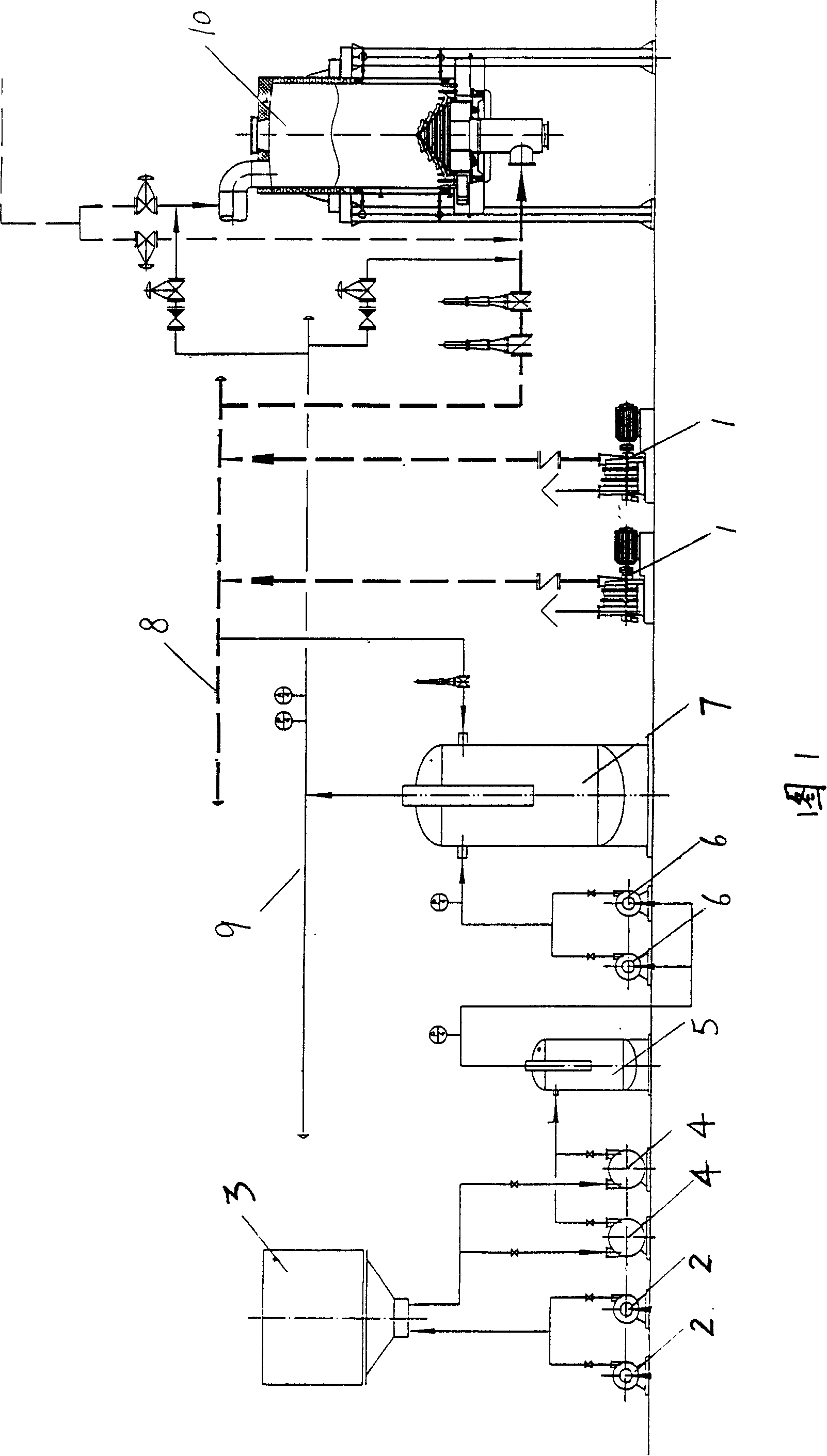

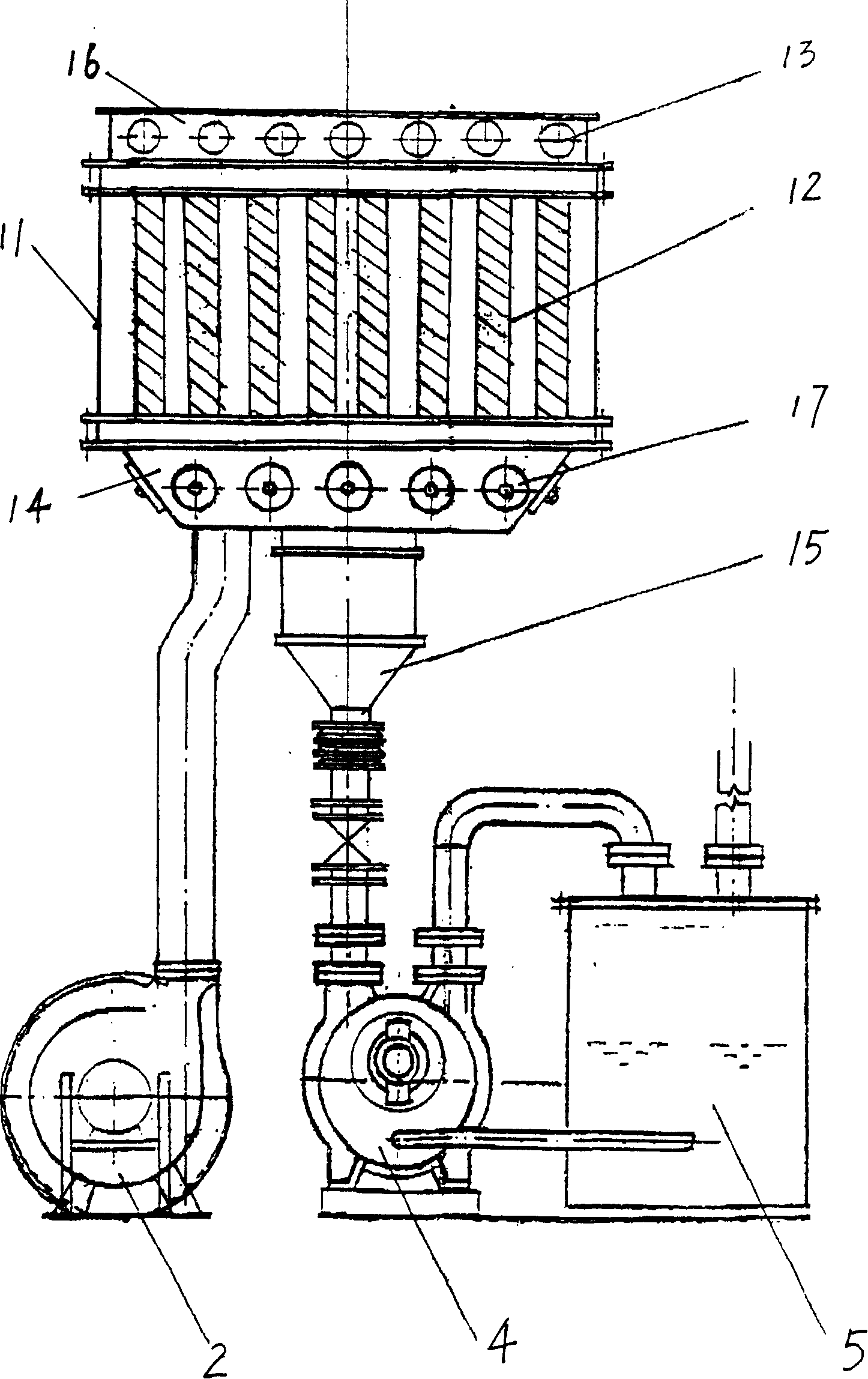

Production method of granulated calcium ammonium nitrate

InactiveCN102951933AInnovative designUnique methodFertiliser formsNitrate fertilisersFiltrationAmmonium nitrate

The invention belongs to the field of fertilizer industry, and relates to a production method of granulated calcium ammonium nitrate. The method comprises the steps that: dilute nitric acid and calcium carbonate are subjected to a neutralization reaction; a calcium nitrate solution is subjected to pres-filtration; the calcium nitrate liquid is mixed with an ammonium nitrate liquid; press-filtration, concentration, granulation, packaging, and inspecting are carried out; and the obtained granulated calcium ammonium nitrate is stored. The method provided by the invention has the advantages of novel design, unique method, low production cost, easy operation, and high practicality. The method can be popularized.

Owner:JIAOCHENG SANXI CHEM CO LTD

Acid soil conditioner preparation and application method

ActiveCN104926565ARaise the pHPH adjustableFertilising methodsFertilizer mixturesSoil sciencePhosphate

The invention discloses an acid soil conditioner preparation method. The acid soil conditioner preparation method comprises the steps that 1, waste materials including calcium mud and magnesium mud generated in the chemical fertilizer industry are dried separately to enable the water content of the waste materials to be decreased to 13 percent-15 percent, and then the waste materials are smashed to be below 10 mesh; 2, by mass, 15-25 parts of the calcium mud and 20-30 parts of the magnesium mud prepared in the step 1, 10-15 parts of commercial urea, five-eight parts of commercial monoammonium phosphate and two-three parts of commercial potassium sulfate are weighed out, all the raw materials are mixed to be uniform, then granulation is performed, the particles are dried to enable the water content to be 10 percent-12 percent, the particles are packaged, and finished products are prepared. According to an acid soil conditioner application method, farming after fertilizer broadcasting before seeding is adopted, the products are uniformly mixed with soil as far as possible, and the application rate is determined according to the pH value of the acid soil, and when the pH value of the acid soil is 5-6.5, the application rate per hectare per year is suggested to be 300 kg-600 kg; when the pH value of the acid soil is 4.5-5, the application rate per hectare per year is suggested to be 600 kg-900 kg; when the pH value of the acid soil is smaller than 4.5, the application rate per hectare per year is suggested to be 900 kg-1,200 kg.

Owner:SHANXI AGRI UNIV +1

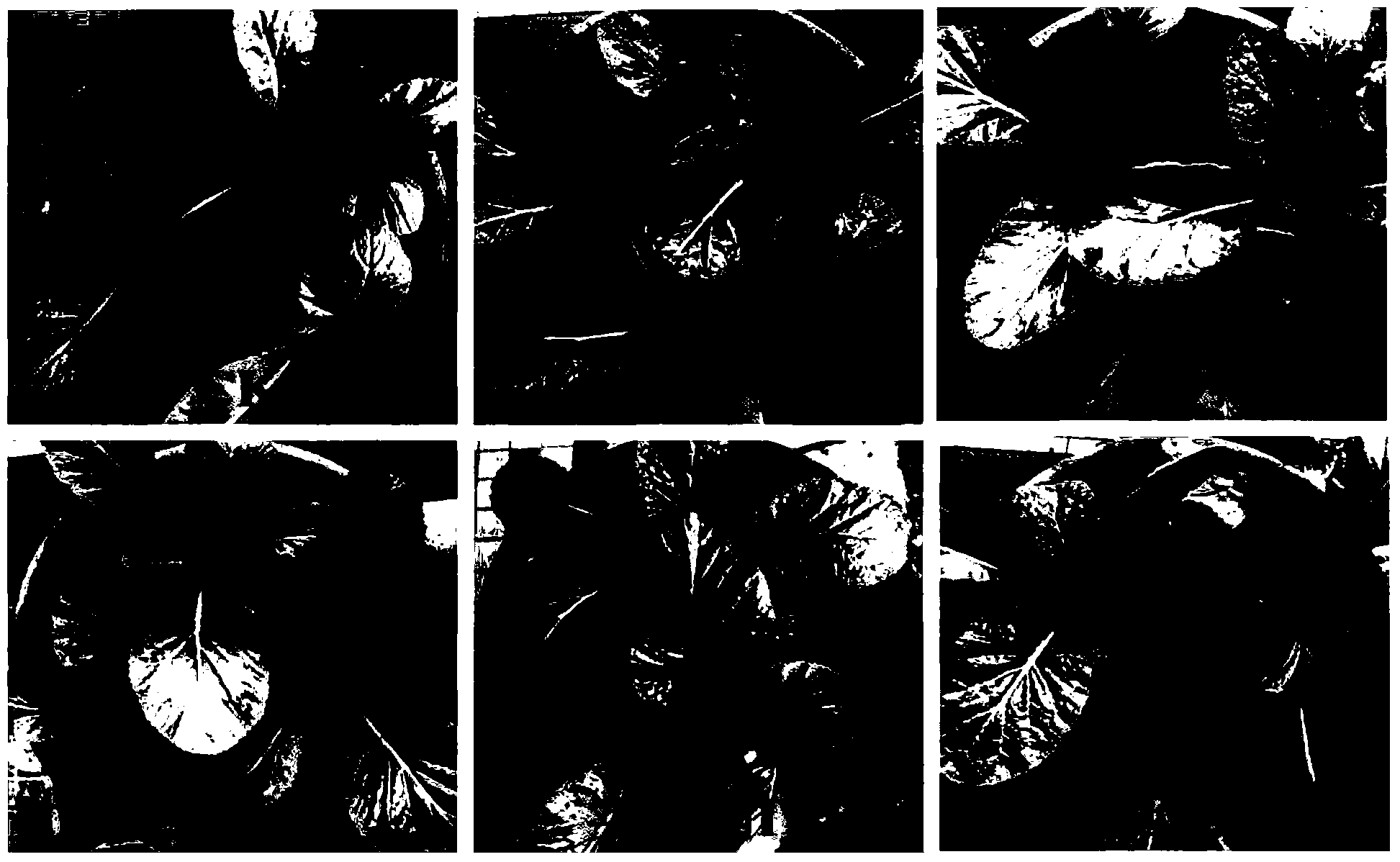

Special compound fertilizer for bamboo and preparing method thereof

InactiveCN101560122AMeet the requirements of fast and stable productionLess investmentAlkali orthophosphate fertiliserClimate change adaptationSodium BentoniteSludge

A special compound fertilizer for bamboo takes urea, ammonium phosphate, potassium chloride, organic materials and bentonite as the main raw materials, and the raw materials are processed into granular fertilizer, the weight percentages of the components are as follows: 15 percent of organic matter, 10 percent to 12 percent of N, 4 percent to 5 percent of P2O5, 10 percent to 12 percent of K2O, the proportion of N to P2O5 to K2O is 2 to 3:1:2 to 3, and the total nutrient accounts for 25 percent to 28 percent; the organic materials are one or mixture of more than two materials of vinasse, peat, bamboo waste and treated papermaking sludge, or that the organic materials are fermented and matured, thus forming the organic fertilizer. By using the special compound fertilizer for bamboo, the bamboo product can increase 15 percent to 20 percent, namely, the product per mu can increase over 210kg. The fertilizer can provide necessary nutrient elements timely in different stages according to the growth characteristics of bamboo, and the fertilizer has the advantages of high safety, high efficiency, less investment, according with the developing direction of fertilizer industry, meeting the demand of rapid growth and steady product of bamboo and being especially suitable for application to paper pulp sympodial bamboo stands.

Owner:GUIZHOU CHITIANHUA

Device and method for producing half-water gas by employing oxygen-enriched air

InactiveCN101225328AIncrease oxygen concentrationRaise the gasification decomposition temperatureCombustible gas productionDecompositionProcess engineering

The invention discloses a device for producing semi water gas by utilizing oxygen-enriched air, which is characterized in that: the input of the gas making furnace is connected with the output of the air mixing tank, input of the air mixing tank is connected with ordinary windpipes, the other end of the air mixing tank is connected with the output of the oxygen-enriched generator and the input of the generator is connected with the blower. The device for producing semi water gas by utilizing oxygen-enriched air has the advantages that: by increasing the oxygen concentration of the input gas, the gasification decomposing temperature in the gasification furnace, the steaming decomposition efficiency and the water gas yield can be increased, while the coal consumption and the steam consumption are reduced; meanwhile, the device does not change the original gas making system and the one-time investment is saved. The device and the method are in particular suitable for the retrofit of the gas making furnaces for existing chemical fertilizer industry.

Owner:SHANGHAI MEMBRANE OXYGEN ENRICHMENT ENERGY SAVINGPROJECT

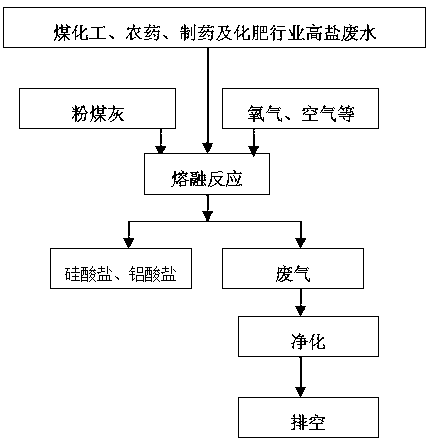

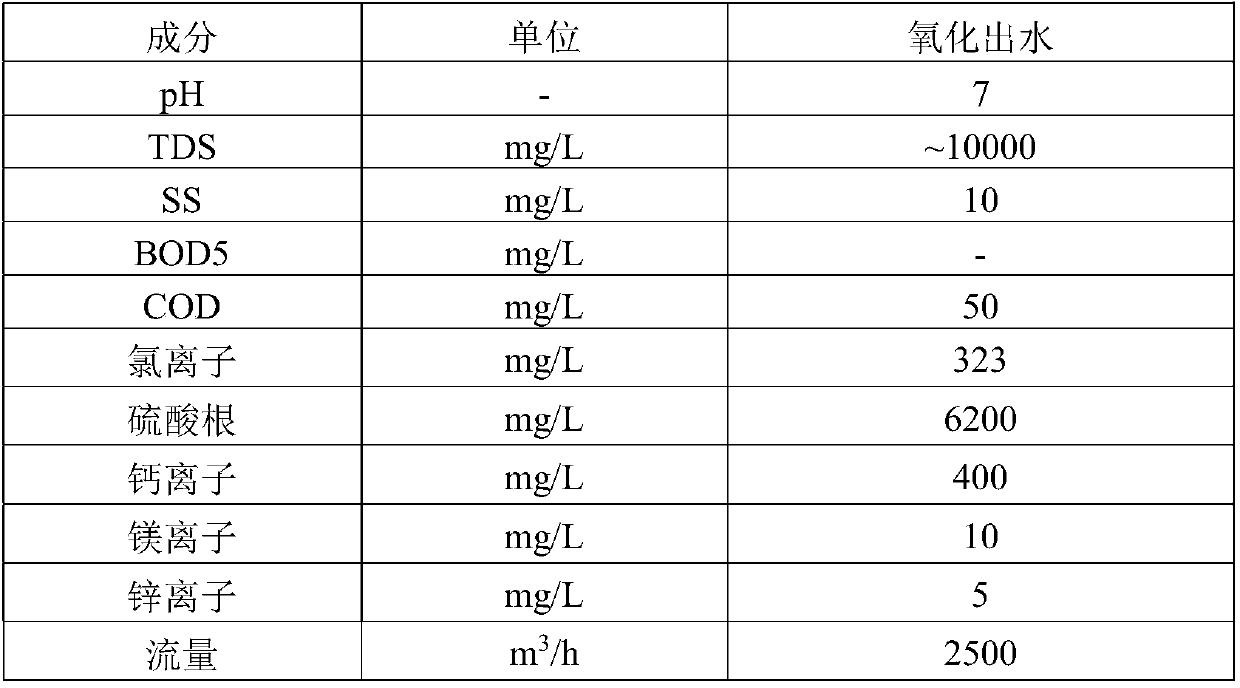

Method for harmlessly treating high-salt wastewater by using fly ash as additive

InactiveCN108571736AEasy complex conversionEasy to burn and gasifyIndirect carbon-dioxide mitigationIncinerator apparatusMelting tankChemical industry

The invention relates to a method for harmlessly treating high-salt wastewater by using fly ash as an additive, and belongs to the field of harmless treatment of dangerous waste and environment protection and the industries of coal chemical industries, fertilizer industries, agricultural chemicals industries and pharmaceutical industries. The invention provides a novel approach of harmlessly treating the high-salt wastewater by using the fly ash as the additive. The high-salt wastewater is placed in an electric stove to heat materials, a certain amount of the fly ash is added to the materialsafter the materials are in a melted state, oxidation gas is added to a melting pool through a jetting gun to perform oxygen enriched combustion of organic pollutants and the like to achieve oriented conversion of sodium salt and potassium salt in harmlessly treated organic pollutants and the like in the high-salt waste water, and purifying processing is conducted on generated fumes enriched with harmful substances such as HCL, NOX, SOX and the like to finally achieve the harmless treatment of the high-salt wastewater of the coal chemical industries, the fertilizer industries, the agriculturalchemicals industries and the pharmaceutical industries. The process of the method is simple to operate and has better industrial application prospect.

Owner:泫龙(北京)环保科技有限公司

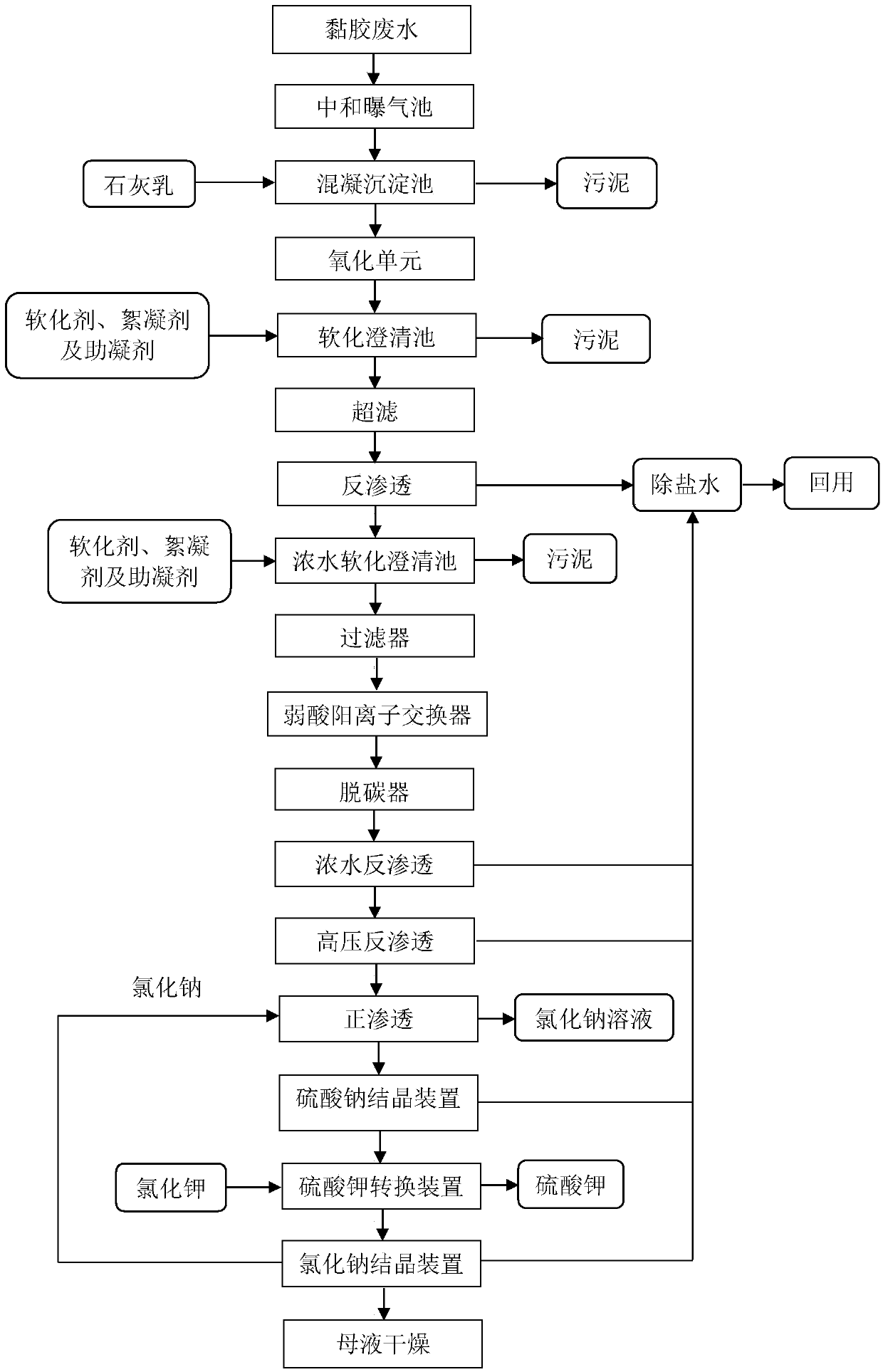

Viscose wastewater resourceful treatment method

ActiveCN111362283AAchieving zero emissionsAvoid pollutionGeneral water supply conservationAlkali metal chloridesFiltrationIon exchange

The invention provides a viscose wastewater resourceful treatment method, which comprises the following steps: sequentially carrying out neutralization aeration, coagulating sedimentation, advanced oxidation, primary softening clarification, ultrafiltration, reverse osmosis, concentrated water softening clarification, filtration, ion exchange, concentrated water reverse osmosis, high-pressure reverse osmosis, forward osmosis, evaporative crystallization, potassium sulfate conversion, sodium chloride crystallization and mother liquor drying treatment on viscose wastewater so as to achieve reuseof all the wastewater and produce potassium sulfate and sodium chloride crystalline salts. According to the method, zero discharge of viscose wastewater is realized, and water is completely recycledthrough membrane concentration and evaporative crystallization so as to avoid pollution to the external environment; multi-stage reverse osmosis and forward osmosis processes are comprehensively utilized, so that the load of a thermal evaporation stage is greatly reduced, the method has the advantages of low energy consumption and high efficiency, and the operation and investment cost of the system can be reduced; and the produced sodium sulfate is converted into potassium sulfate with high value, and the potassium sulfate can be used in the chemical fertilizer industry, so that the problem ofwater pollution of fiber production enterprises is solved, and high economic value can be brought.

Owner:GREENTECH ENVIRONMENTAL CO LTD

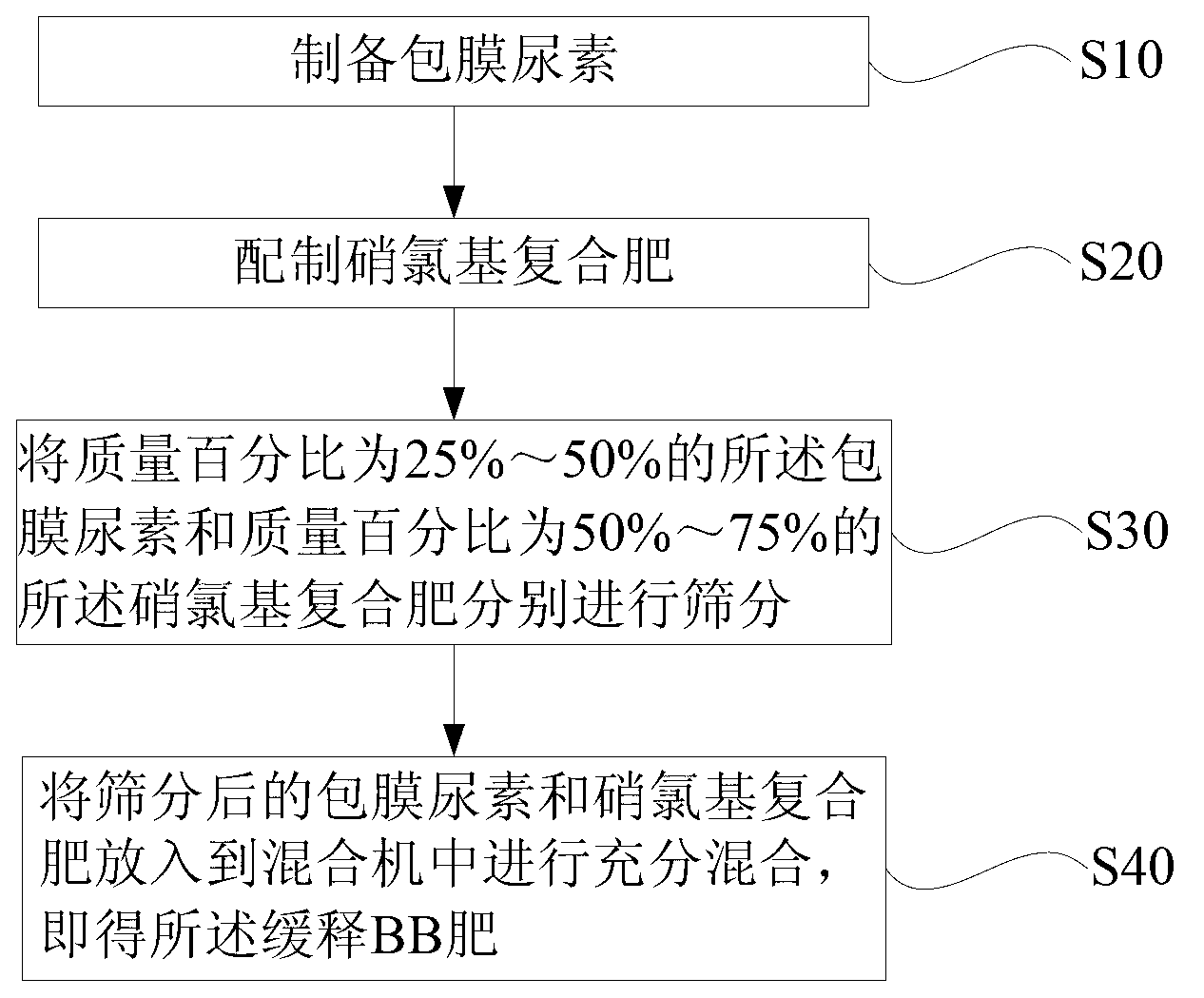

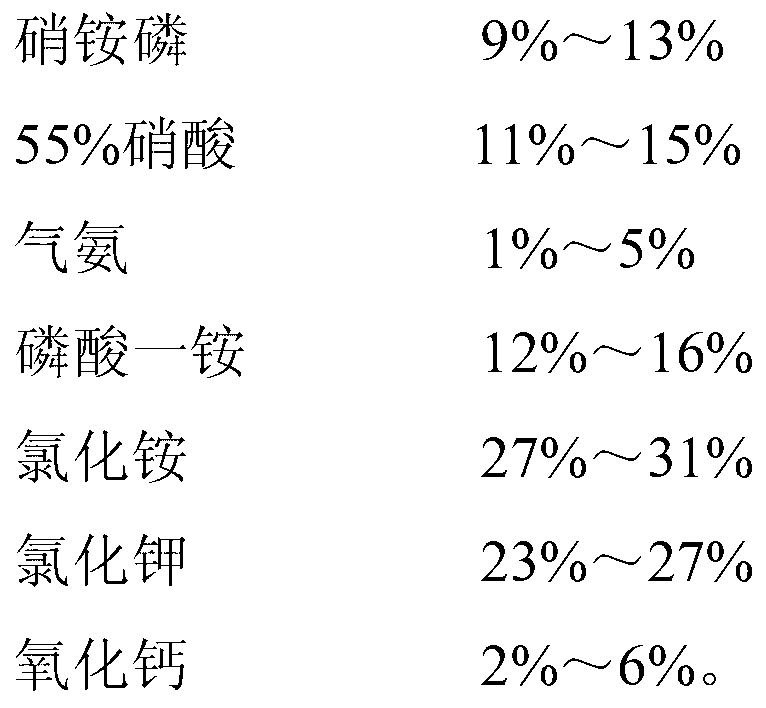

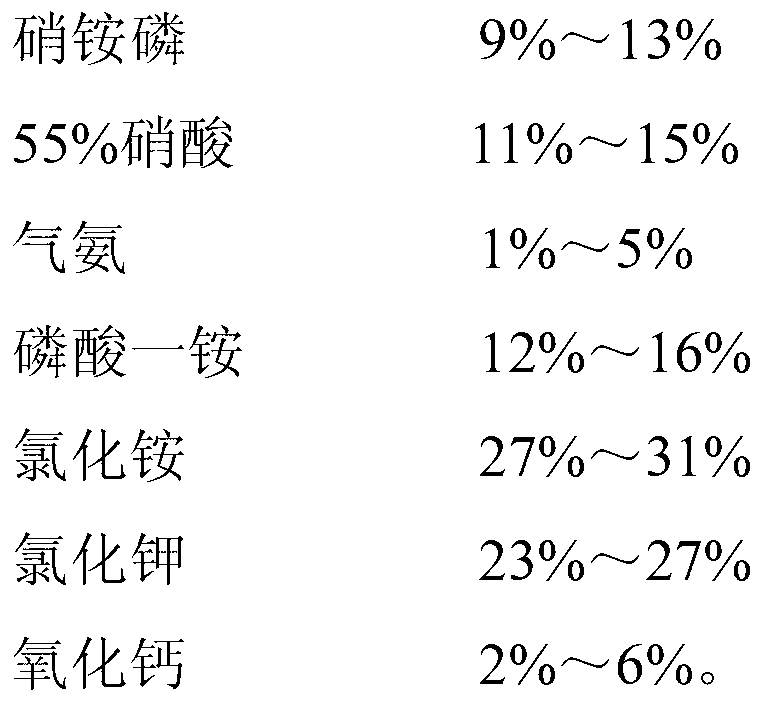

Slow release BB (bulk blending) fertilizer and preparation method thereof

The invention relates to a slow release BB (bulk blending) fertilizer and a preparation method thereof. The slow release BB fertilizer comprises 25-50 mass percent of coated urea and 50-75 mass percent of a chlorine nitrate based compound fertilizer. The slow release BB fertilizer and the preparation method thereof have the following beneficial effects: (1) the application effect is good: the slow release BB fertilizer can be prepared by blending in an appropriate ratio according to growth needs of crops, is suitable for various crops and can be applied once as a base fertilizer, and an additional fertilizer is not needed afterwards, so that labor and time are saved; (2) the utilization ratio of urea is high: the loss of urea can be reduced to ensure that ammonia generated by the decomposition of urea is maintained in soil for a long time, the fertilizer requirement in the whole growth and development process of the crops is met, the earlier stage does not have excessive fertilizer, the middle stage is not lack of fertilizer, and the later stage does not lose fertilizer, so that the loss of a nitrogen fertilizer is significantly controlled, and the environmental pollution is reduced; and (3) the production process is extremely simple to favor the popularization and application of the slow release BB fertilizer and the preparation method in the chemical fertilizer industry.

Owner:嘉施利(应城)化肥有限公司

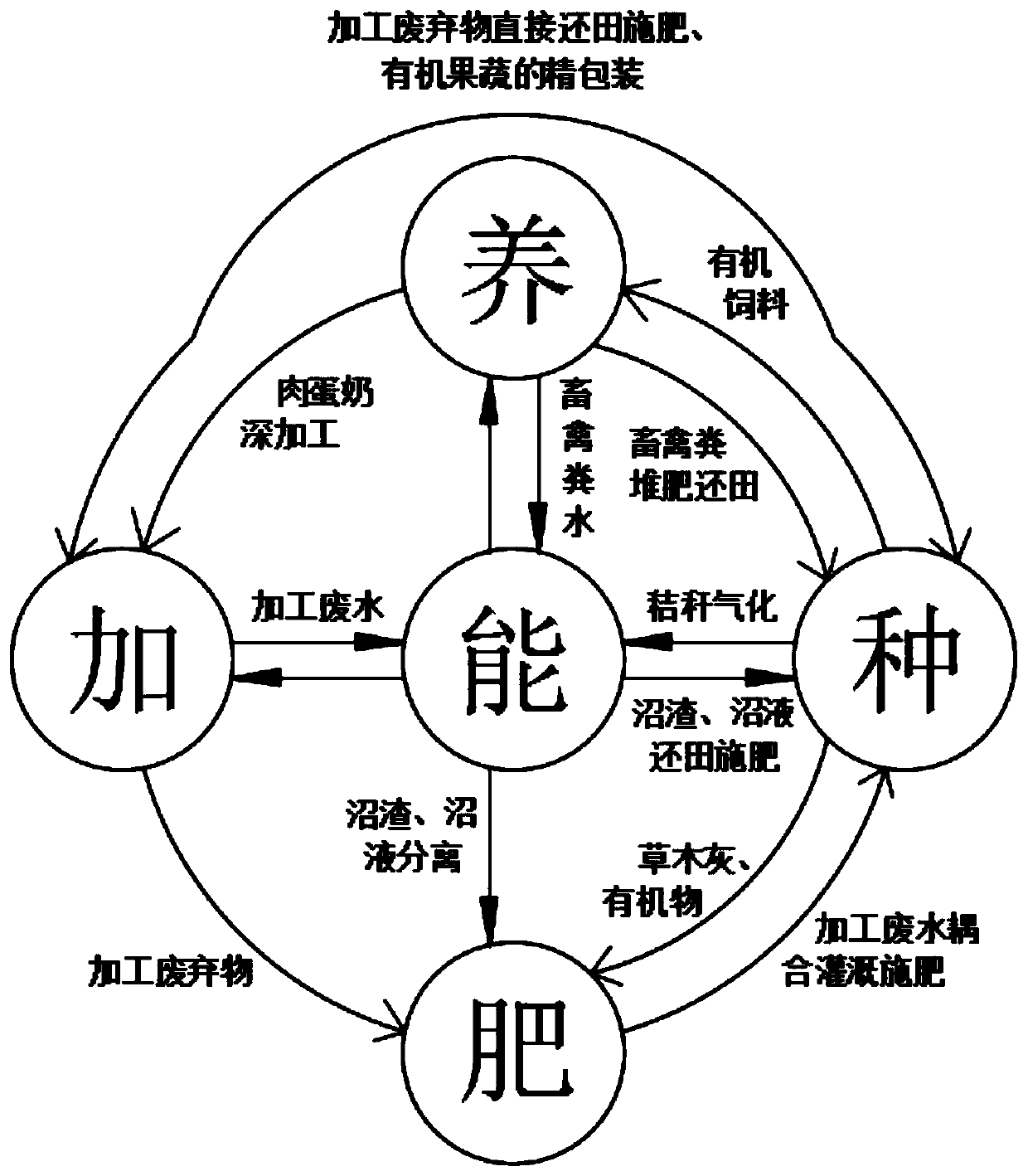

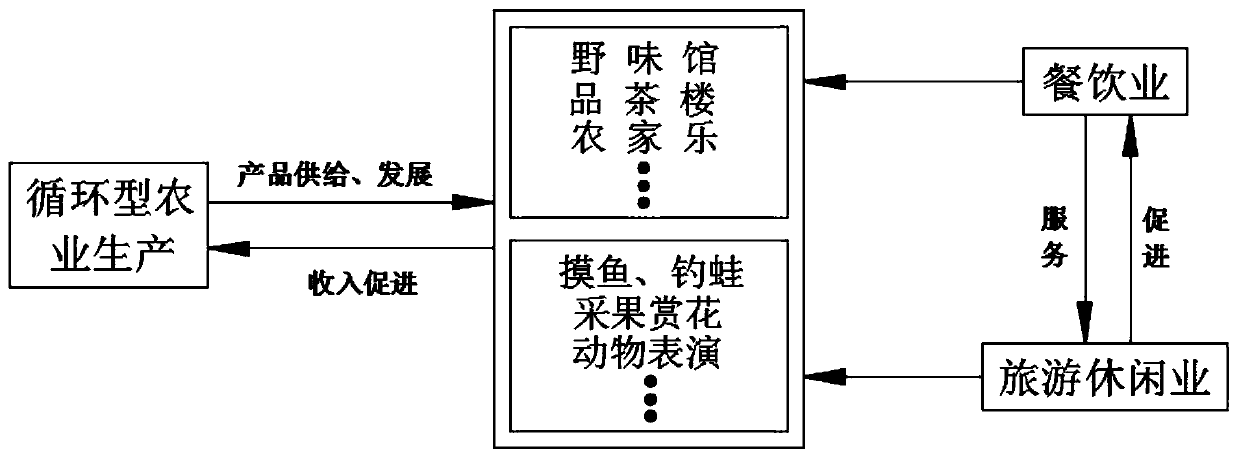

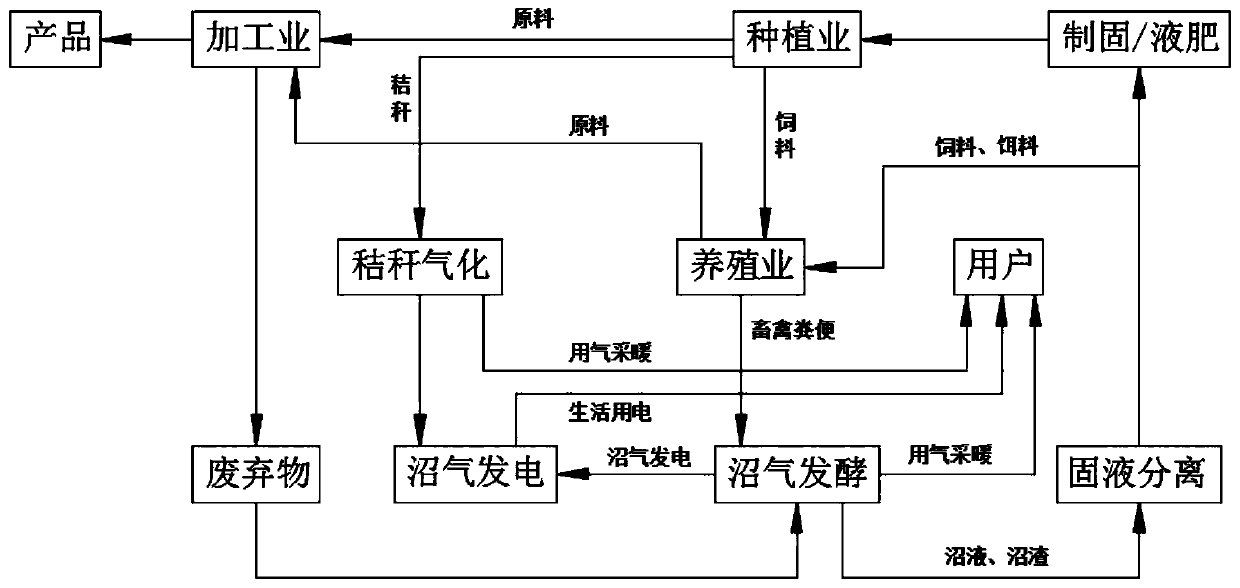

Production method for circulating type modern efficient agriculture

InactiveCN110269041AQuality improvementImprove efficiencyClimate change adaptationExcrement fertilisersResource utilizationAlternative technology

The invention discloses a production method for circulating type modern efficient agriculture, and particularly relates to the technical field of agricultural production. A circulating agricultural production framework adopting planting industry, breeding industry, processing industry, renewable energy and fertilizer industry as cores is formed, the circulating agricultural production framework specifically comprises the substitute technology for replacing conventional resources, materials and products by developing and using novel agricultural resources and improving the agricultural resource utilization efficiency. By constructing the circulating agricultural production framework adopting planting industry, breeding industry, processing industry, renewable energy and fertilizer industry as cores, the good circulation is formed that circulating type agricultural production product supply and catering industry development, the catering industry helps tour industry, and the tour industry promotes development of the catering industry, and meanwhile rapid development of the catering industry and the tour industry can further promote development of the circulating type agriculture.

Owner:漳州市芗林信息咨询服务有限公司

Compound liquid fertilizer with high suspension degree, and preparation method and application thereof

The invention discloses a compound liquid fertilizer with high suspension degree, and a preparation method and an application thereof, and belongs to the liquid fertilizer industry field. The preparation method comprises the steps: adding macromolecule organic sugar into a clay material to be used as a basal suspending agent I, and carrying out first suspension chelation of a major element and a trace element at the temperature of 40-60 DEG C; followed by controlling the temperature at 20-30 DEG C, slowly adding a plant growth regulator and a surface active material, fully mixing uniformly, finally adding macromolecule cellulose and an analog thereof as a suspending agent II, carrying out second suspension chelation, and fully stirring to obtain the compound liquid fertilizer with high suspension degree. The prepared compound liquid fertilizer with high suspension degree has comprehensive nutrients, high content, low cost, good liquidity, good stability and good dissolvability, and is beneficial for crops to efficiently absorb and utilize. The preparation method is simple in process and easy to implement. The compound liquid fertilizer is an ideal fertilizer source for water and fertilizer integration for drip irrigation, sprinkler irrigation, water flushing and the like.

Owner:SOUTH CHINA AGRI UNIV +1

Coating pulp for controlled release fertilizer and production method and application thereof

The invention relates to a coating pulp for a controlled release fertilizer and a production method and application thereof, belonging to the technical field of fertilizer industry. The production method of the coating pulp includes the following steps: preparing rice straw or wheat straw into straw thickened pulp; mixing diluted hydrochloric acid with high-density chitosan, and stirring the mixture into high-density chitosan pulp under the condition of 30-50 DEG C; and then mixing the straw thickened pulp with the high-density chitosan pulp, thus obtaining the coating pulp. In ammonia atmosphere, a granular fertilizer is immersed in the coating pulp to form a wrapping film on the surface of the granular fertilizer by the coating pulp; and then the granular fertilizer is dried and cured in dry ammonia atmosphere, thus obtaining the coated biological controlled release fertilizer. The coating pulp also can be sprayed on the surface of the granular fertilizer in the ammonia atmosphere to form the wrapping film on the surface of the granular fertilizer by the coating pulp; and then the granular fertilizer is dried and cured in the dry ammonia atmosphere, thus obtaining the coated biological controlled release fertilizer. The invention can be used for producing the controlled release fertilizer with the coating pulp, and is applicable to the production for preparing an inorganic fertilizer or a compound fertilizer into the biological type controlled release fertilizer.

Owner:YANGZHOU UNIV

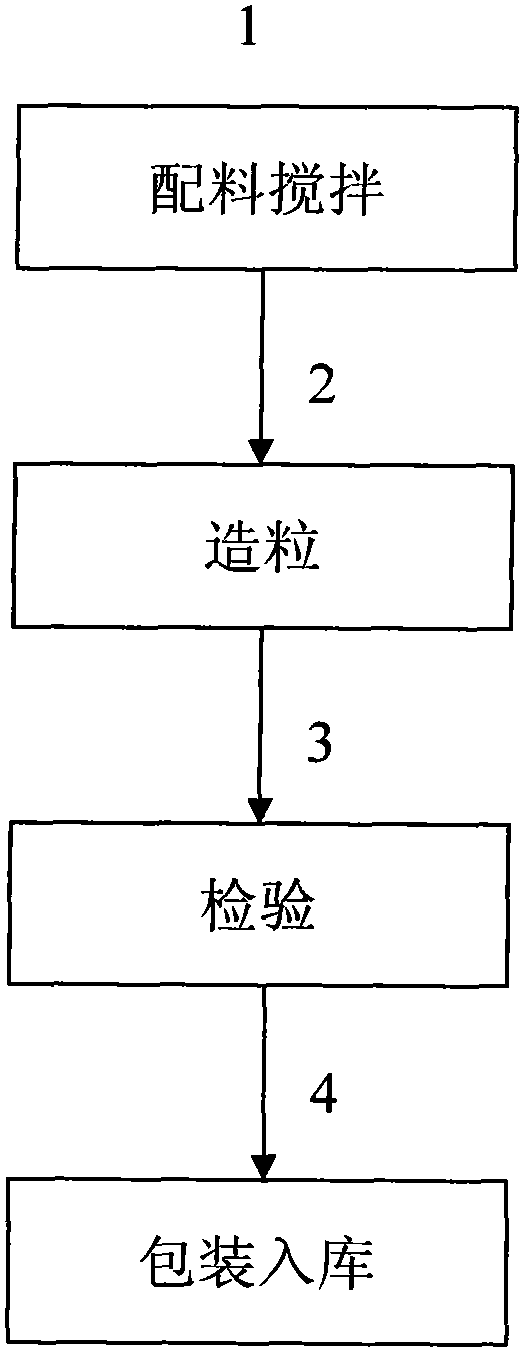

Preparation technology for fully water-soluble calcium and boron fertilizers with superactivity

A preparation technology for fully water-soluble calcium and boron fertilizers with superactivity belongs to the fertilizer industry. The preparation technology comprises ingredient stirring, granulation, inspection, packing and warehouse storage. The preparation technology achieves novel design, advanced process, unique method and extensive use. The activity of the calcium and boron fertilizers is improved, and the calcium and boron fertilizers can be directly sprayed, absorbed and utilized on leaves. The preparation technology for the fully water-soluble calcium and boron fertilizers with superactivity achieves low manufacturing cost, is easy to operate, and exceptionally achieves practicability and popularization performance.

Owner:SHANXI JIAOCHENG HONGXING CHEM

Method for preparing biological organic fertilizer by utilizing wastewater separate substances of livestock and poultry

InactiveCN102701807AGood effectHigh organic contentBio-organic fraction processingOrganic fertiliser preparationMicroorganismWastewater

The invention relates to a method for preparing a biological organic fertilizer by utilizing wastewater separate substances of livestock and poultry, in particular to a method for preparing a biological organic fertilizer by utilizing wastewater of livestock and poultry and functional microbes and application of the biological organic fertilizer, and belongs to the technical fields of novel organic fertilizers and the recycling of agricultural wastes. According to the method, microbial inocula which are prepared from pseudomonas fluorescens, bacillus cereus and erwinia mitsuencis which serve as functional strains are added into organic wastes such as rotten bran, straw powder and mushroom dregs to be rotten and fermented to prepare the organic fertilizer. According to the method, the organic fertilizer is prepared by utilizing the wastewater of the livestock and poultry, so that the wastes are recycled; and the preparation method is simple and convenient, and is easy to popularize and apply in fertilizer industry.

Owner:HAINAN FANGLVYUAN TECH DEV

Method for preparing organic fertilizers from livestock wastewater separation substances

InactiveCN102701849AGood effectComprehensive nutritionFertilizer mixturesSolubilityAdditive ingredient

The invention relates to a method for preparing organic fertilizers through livestock wastewater separation, in particular to a method for preparing organic fertilizers through mixing livestock wastewater and humic acid type raw materials and an application, and belongs to the technical field of novel organic fertilizers and the technical field of waste resource circulation utilization. Major ingredients of the organic fertilizers are livestock wastewater separation substances, and in addition, humic acid, diammonium phosphate, zinc sulfate, potassium sulfate and other additives are added. The method has the advantages that biogas residues are used for preparing the organic fertilizers, wastes are changed into resources, in addition, the preparation method is simple and convenient, the required equipment is simple, and the method is easily popularized and applied in fertilizer industry. The solubility of the fertilizers is good, the nutrients are complete, and the yield increase and the quality improvement effect are obvious. The organic fertilizers can be widely applied to vegetables, melons and fruits, grains, forests and various cash crops.

Owner:HAINAN FANGLVYUAN TECH DEV

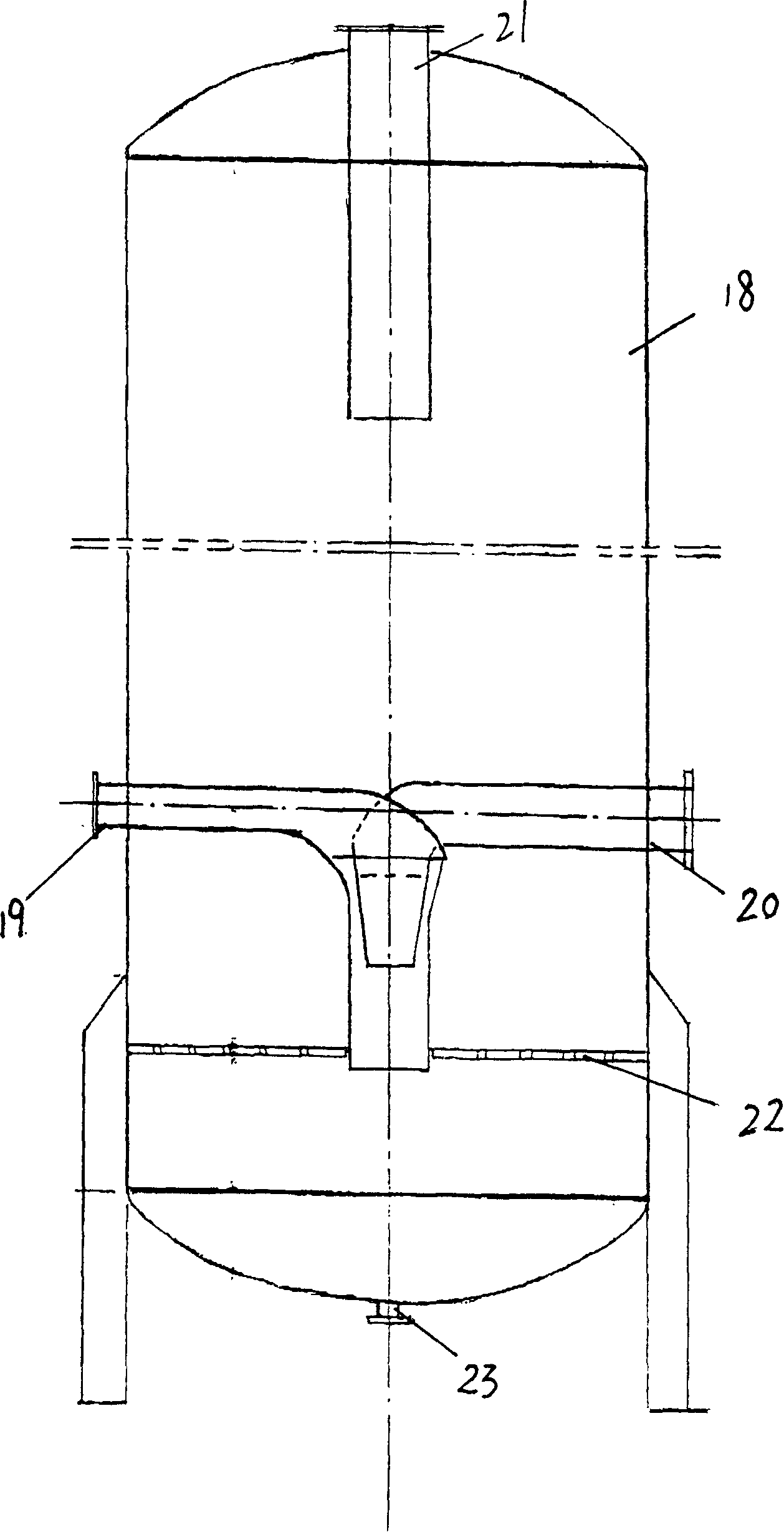

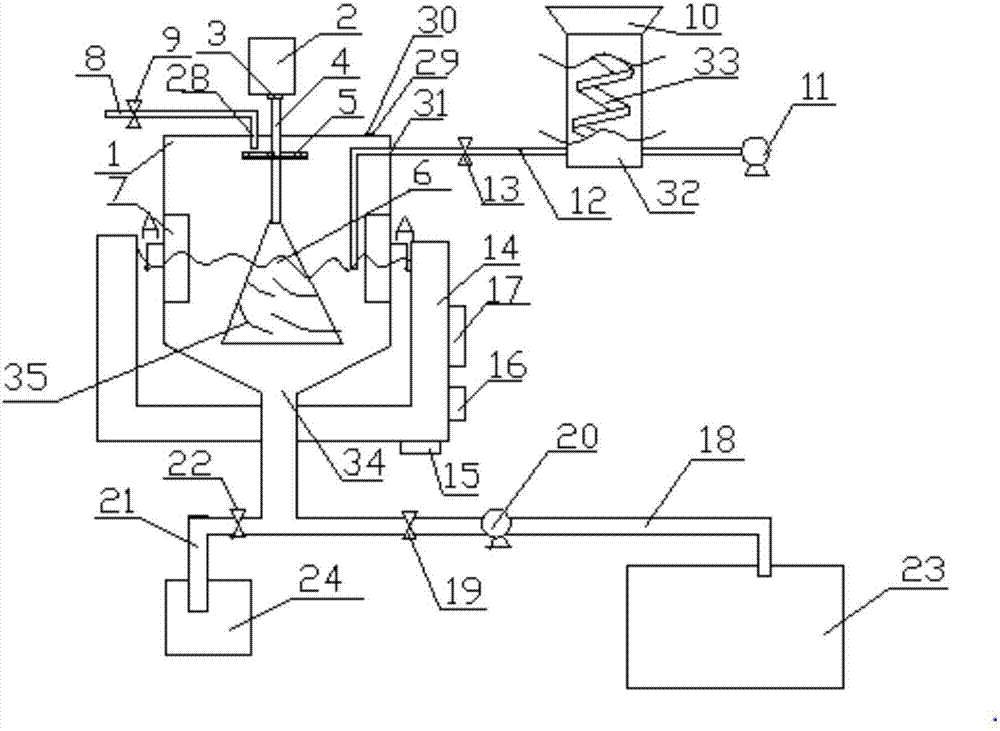

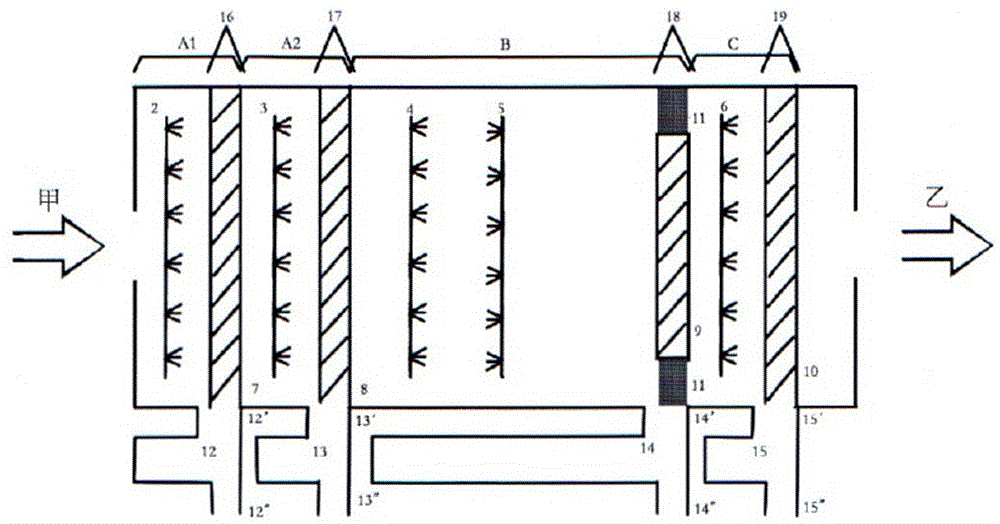

Liquid chelated fertilizer production device

ActiveCN107138116AExtend your lifeEasy to observeChemical industryChemical/physical/physico-chemical stationary reactorsChemical industryTrace element

The invention belongs to the technical field of chemical equipment, relates to a fertilizer production device, in particular to a liquid chelated fertilizer production device, and is applied to a production occasion of foliage-spraying fertilizer chelated with medium and trace elements in the chemical industry. By the adoption of the liquid chelated fertilizer production device, the problems are solved that when feeding is conducted, dust is easily generated, pipelines are easily clogged and the stirring effect is relatively poor. By the adoption of a tower-type stirrer, the operation inconvenience caused by adjusting the length of a stirring shaft according to the height of liquid level can be avoided, and in coordination with a spoiler in a reactor, turbulent motion of fluid can be promoted; a circular-ring-shaped rotation disc is arranged on the upper portion of the stirring shaft in a penetrating mode, and after water inflow, water can be uniformly splashed in a sprinkler mode along with the rotation disc; a spiral guide plate is adopted to be combined with a blower, the safety is improved, and the problem is effectively solved that a feeding opening is clogged; the whole structure is simple, the principles are reliable, the manufacturing and running costs are low, the operation is convenient, the application environment is friendly, and the liquid chelated fertilizer production device has a positive promoting effect on the liquid fertilizer industry and the agricultural production and has good economic benefits and wide market prospects.

Owner:QINGDAO UNIV +1

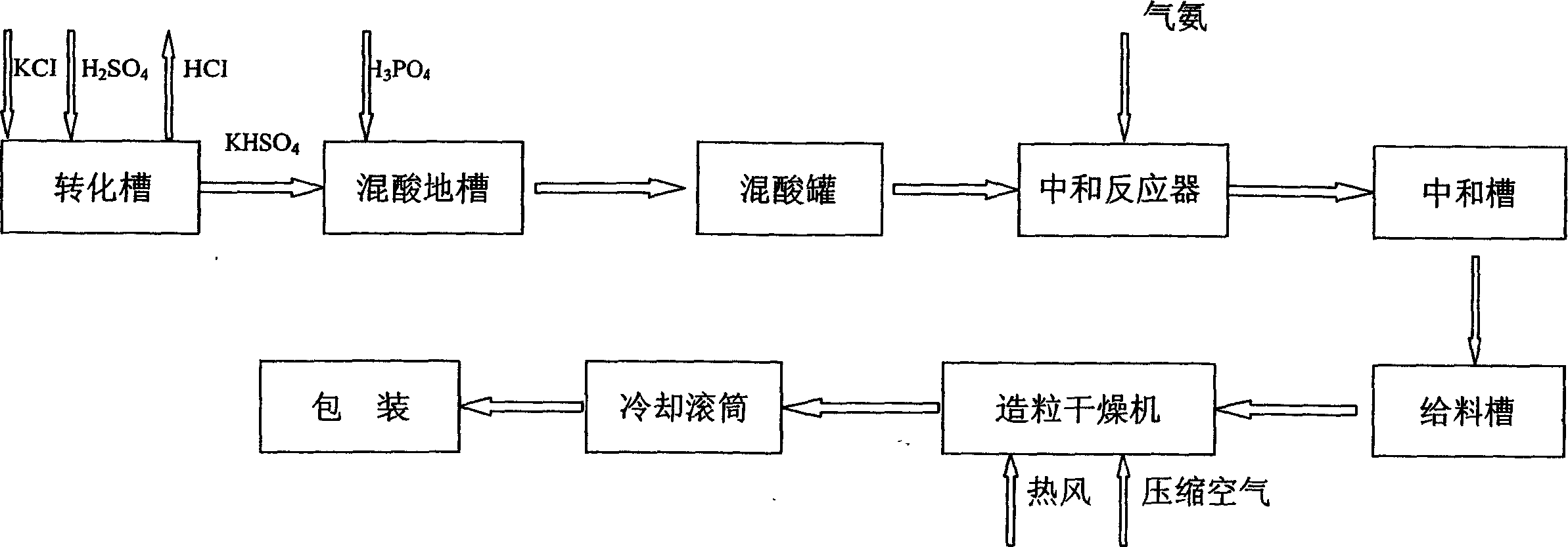

Prodn method of high azote, high potassium and sulfenyl 3-element compound fertilizer

InactiveCN1834071ASolve production problemsIncrease nitrogen and potassium contentFertiliser formsUrea compound fertilisersMasterbatchSpray Granulation

This invention relates to a method to produce high-nitrogen and high-potassium sulphur-based three-element composite fertilizers, which is attributed to composite fertilizer production in the field of chemical engineering. It mainly solves the problems existing in high-nitrogen and high-potassium sulphur-based three-element composite fertilizer production with current facilities and has the characteristics that, according to the low-chlorine ion and high-potassium specificity of potassium sulphate and the nutrient structure, a potassium sulphate melting groove is added based on current apparatus or small potassium sulphate particles as masterbatch are directly added at the granulator head at a certain ratio, and then spray granulation is carried out. In this method, only a small modification towards the apparatus and the technique is taken and no big investment is necessary. Products produced in this method have stable quality, easily adjustable structure, comparatively great nutrient with promoted nitrogen and potassium content. It provides mighty guarantee for development of domestic economics and nutrient demand of economic crops and expands new development path for domestic phosgene composite fertilizer industries.

Owner:山东聊城鲁西化工第四化肥有限公司

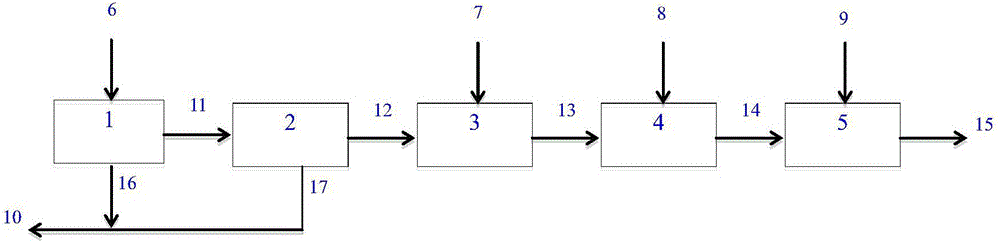

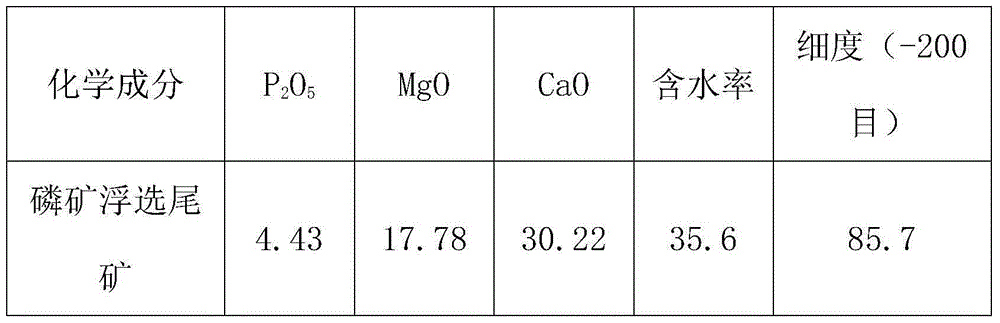

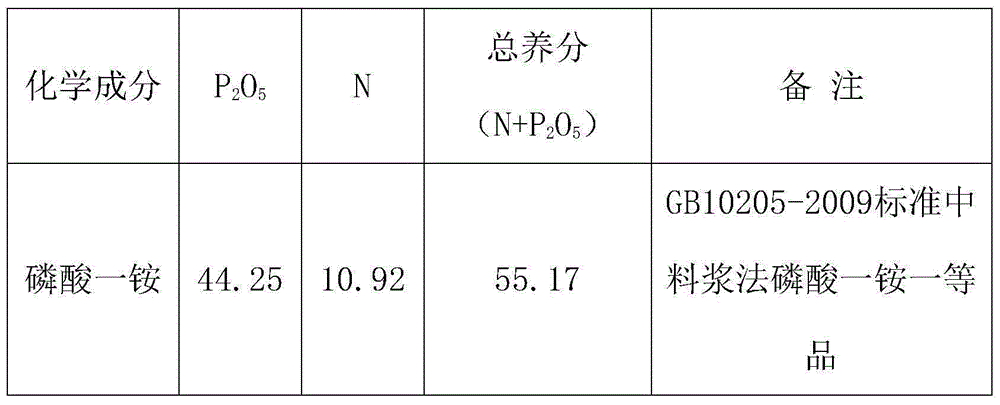

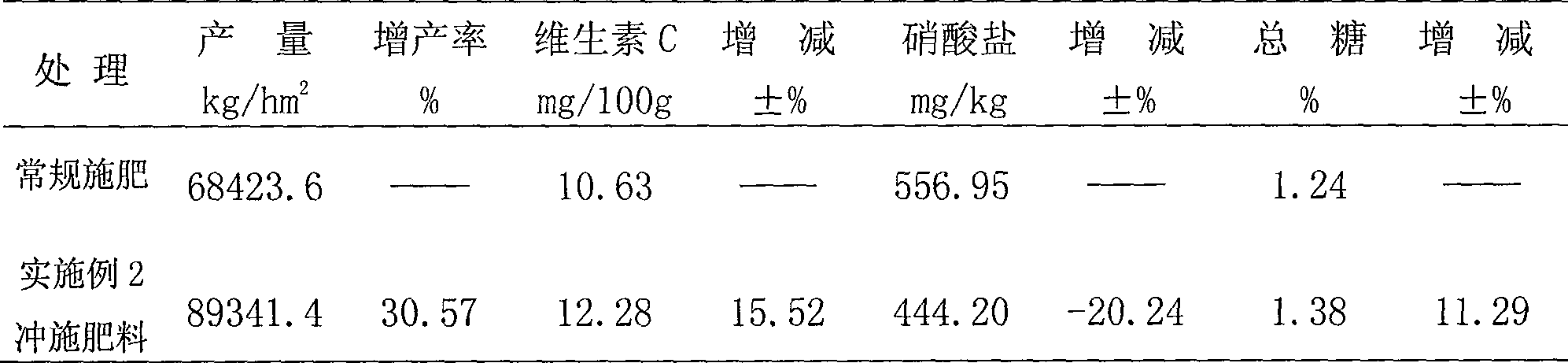

Method for adjusting enriched nutrients in monoammonium phosphate through utilizing phosphate flotation tailings

ActiveCN105036816AGood coordination effectIncrease profitAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersPhosphate productSlurry

The invention provides a method for adjusting enriched nutrients in monoammonium phosphate through utilizing phosphate flotation tailings. The method includes the following steps: taking phosphate flotation tailings as raw materials, and adding phosphate flotation tailings subjected to concentration and treated by a filter to diluted phosphoric acid for mixed reaction; introducing ammonia gas for neutralizing and then adding nitrogenous fertilizer, uniformly mixing for nitrogen increment, so as to obtain qualified monoammonium phosphate slurry; performing concentration, spraying granulation, drying, sieving, cooling, wrapping and package to the slurry to obtain the monoammonium phosphate product. According to the invention, an effective technological approach is provided for the comprehensive utilization of phosphate flotation tailings, the method has important practical significances in saving phosphate rock resources, improving the pelleting performance of monoammonium phosphate slurry, increasing the nutritional value of the monoammonium phosphate product, adjusting the enriched nutrients of the monoammonium phosphate product, reducing discharge and stockpiling of phosphate flotation tailings and promoting the sustainable development of the phosphate and compound fertilizer industry; besides, raw materials are wide in source and low in cost, and new waste residues and waste water cannot be generated.

Owner:SINOCHEM YUNLONG

Preparation method of incomplete dehydrated magnesium chloride snow-melting agent

InactiveCN107381606AReduce pollutionPromote sustainable developmentMagnesium fertilisersOther chemical processesEcological environmentSnow melting

The invention belongs to the technical field of comprehensive utilization of salt lake resources and particularly relates to a preparation method of an incomplete dehydrated magnesium chloride snow-melting agent. The preparation method comprises the following step: performing one-section dehydration on a byproduct bischofite of a salt lake in fluidization equipment at the temperature of 50-70 DEG C, so as to obtain a first incomplete dehydrated magnesium chloride snow-melting agent, wherein incomplete dehydrated magnesium chloride in the first incomplete dehydrated magnesium chloride snow-melting agent contains 4-6 crystal water molecules. According to the preparation method of the incomplete dehydrated magnesium chloride snow-melting agent, one-section dehydration is performed by utilizing the byproduct bischofite under strict temperature control to obtain the first incomplete dehydrated magnesium chloride snow-melting agent, so that a solving way of comprehensively utilizing the resources and turning waste into wealth is provided, the pollution to the ecological environment of the salt lake is reduced, and the sustainable development of the salt lake potash fertilizer industry is promoted; and besides, the preparation method provided by the invention also has the advantages of being low in preparation cost, simple in processes, good in snow-melting effect and the like.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Whole-nutrition biological flushing and spreading fertilizer and preparation method thereof

InactiveCN100486941CIncrease productionImprove qualityClimate change adaptationAlkali orthophosphate fertiliserMicroorganismNicotiana tabacum

A full nutrition fertilizer of biology type and its producing method belongs to organic complex fertilizer field in biology type. The components of the full nutrition fertilizer is 20-50% of organic waste liquid, 10-30% of urea, 8-15% of diammomium phosphate, 10-25% of potassium sulfate, 5-20% of medium trace element, 1-5% of microbial inoculum, 0-0.2% of root-promoting agent; 0-2% of solutizer, effective viable count content of the microbial inoculum of more than 1010 / g. The fertilizer is produced by adding the urea, diammomium phosphate, potassium sulfate, medium trace element, root-promoting agent, solutizer into organic waste liquid and blending uniformly, then adding microbial inoculum. The invention uses the wastes to produce fertilizer with a low cost a high availability and a good prospect in the fertilizer industry. The fertilizer can be widely applied to the vegetables, melon and fruits, food, tobacco, forests and different commercial crops.

Owner:INST OF SOIL & FERTILIZER SHANDONG ACAD OF AGRI SCI

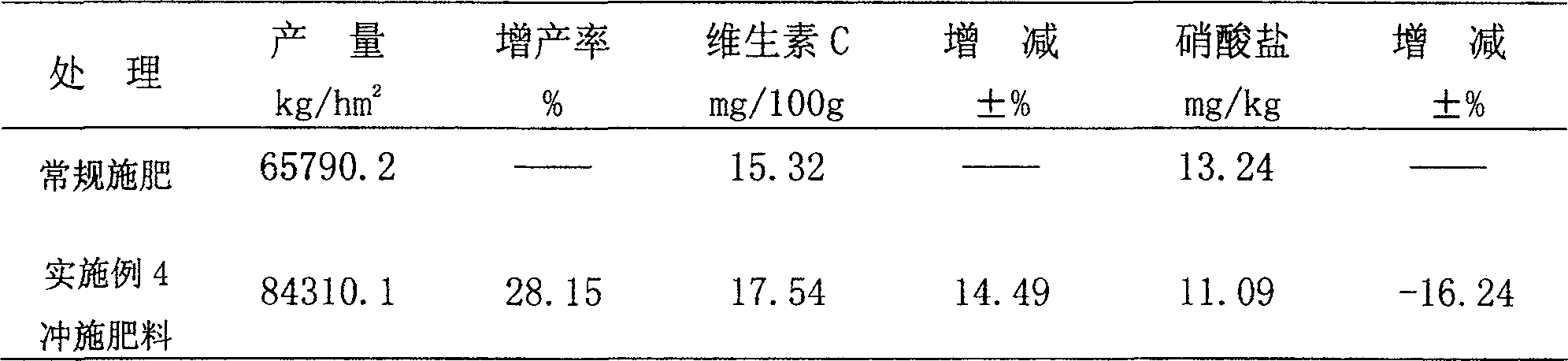

Horizontal multi-stage aerosol scrubber

ActiveCN106237775AImprove purification effectLow costCombination devicesChemical industryMain processing unit

The invention discloses a horizontal multi-stage aerosol scrubber. A gas inlet is formed in the front end of a treatment chamber; a gas outlet is formed in the rear end of the treatment chamber; a pretreatment unit, a main treatment unit and a retreatment unit are sequentially arranged from the front end to the rear end of the treatment chamber; the pretreatment unit comprises at least one pretreatment spraying device and at least one pretreatment filtering layer; the main treatment unit comprises at least one main treatment spraying device and at least one main treatment filtering layer; the retreatment unit comprises at least one retreatment spraying device and at least one retreatment filtering layer. The horizontal multi-stage aerosol scrubber provided by the invention has the good purifying effect for submicron particles, aerosol, liquid droplets and acid mist in the gas, is low in cost, is applicable to the removal of submicron pollutants in waste gases and the recovery of raw materials in the chemical industry, petrochemical industry, metallurgical industry, chemical fertilizer industry, electronic semiconductor component production industry, power plant and waste incineration industry, and has the purification efficiency of more than 99.5%.

Owner:北京柯美瑞环保科技有限公司

Purification method of impurity iodine in silicon tetrafluoride gas

The invention discloses a purification method of impurity iodine in a silicon tetrafluoride gas. The purification method comprises the following steps of: (1) collecting a fluorine-containing gas generated in the process of treating rock phosphate by using wet processing, introducing the fluorine-containing gas into a reactor to which sulfuric acid and silicon dioxide are added so that HF (Hydrogen Fluoride) in the fluorine-containing gas is converted into a SiF4 gas; or mixing and heating fluosilicic acid and concentrated sulfuric acid, introducing a generated gaseous compound into a container filled with the concentrated sulfuric acid, removing impurities and obtaining the SiF4 gas; (2) introducing the obtained SiF4 gas into a purification tank, removing moisture and oxygen containing siliconfluoride in the SiF4 gas by using the concentric sulfuric acid or the mixture of the concentrated sulfuric acid and hydrofluoric acid; (3) enabling the SiF4 gas to sequentially enter filters which are filled with pre-dried activated carbon and diatomaceous earth so that the impurities in the SiF4 gas are filtered out; and (4) introducing the purified the SiF4 gas into a freezing plant, and removing HI and I2 by freezing. The purification method is used for producing high-purity silicon tetrafluoride by resolving the industrial byproduct fluosilicic acid in a phosphatic fertilizer industry, and therefore, high-purity raw materials for producing silicon series products are supplied for electronics, photovoltaic, and optical fiber industries.

Owner:贵州瓮福蓝天氟化工股份有限公司 +1

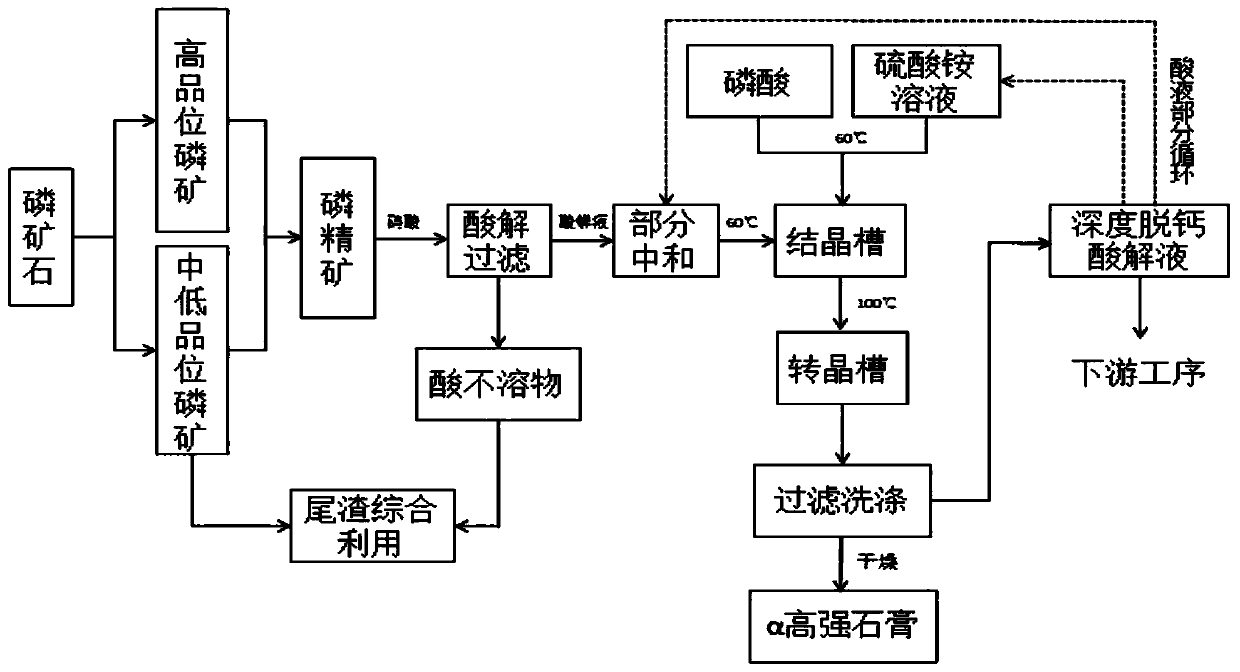

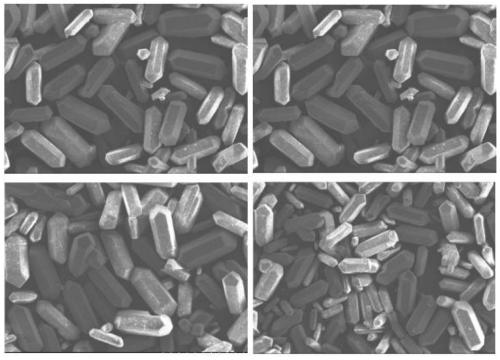

Method for decomposing phosphate rock acidolysis liquid by nitric acid to remove calcium byproduct alpha high-strength gypsum

ActiveCN111533154AReduce manufacturing costTake advantage ofCalcium/strontium/barium sulfatesPhosphoric acidChemical industryO-Phosphoric Acid

The invention discloses a method for decomposing a phosphate rock acidolysis liquid by nitric acid to remove calcium byproduct alpha high-strength gypsum. The method comprises: decomposing phosphoriteby nitric acid, filtering out acid insoluble substances, partially neutralizing the acidolysis liquid, regulating and controlling the concentration of calcium ions in the acidolysis liquid, adding the acidolysis liquid into a crystallization tank containing a mixed solution of additional phosphoric acid and ammonium sulfate, controlling the reaction temperature to be 50-70 DEG C and the reactiontime to be 0.5-2 hours to firstly generate dihydrate gypsum, then, making the reaction slurry flow into a crystal transformation tank, and raising the temperature to 95 to 110 DEG C for reacting for aperiod of time so that an alpha-type high-strength gypsum product can be produced as a byproduct. According to the invention, the acidolysis liquid can be used for producing products such as fine phosphate, high-water-solubility phosphate fertilizer and the like, meanwhile, calcium resources in the acidolysis liquid are converted into an alpha high-strength gypsum product, solid waste phosphogypsum is changed into product phosphogypsum, environmental risks caused by the fact that a large amount of solid waste phosphogypsum is produced as a byproduct in the ammonium phosphate industry are eliminated, the phosphorus compound fertilizer industry is promoted to adjust the product structure, solid waste emission is reduced, and sustainable development of the phosphorus chemical industry is promoted.

Owner:GUIZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com