Horizontal multi-stage aerosol scrubber

A scrubber and aerosol technology, which is applied in the field of horizontal multi-stage aerosol scrubbers, can solve the problems of poor purification effect of acid mist and achieve good purification effect, high purification efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to better understand the technical solutions provided by the embodiments of the present invention and better compare with the technical solutions of the embodiments of the present invention, the following briefly introduces the implementation solutions in the prior art by way of examples.

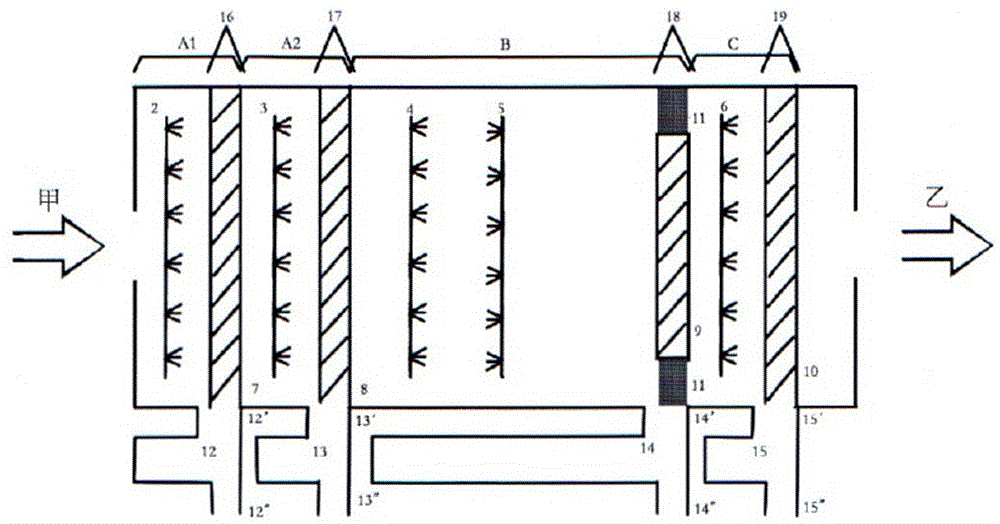

[0017] figure 1 In the horizontal multi-stage aerosol scrubber of the present invention, the front end of the treatment chamber is A, and the rear end of the treatment chamber is B. Exhaust gas enters from A and exits from B. An air inlet is arranged at the front end of the processing chamber, an air outlet is arranged at the rear end of the processing chamber, and preprocessing units A1, A2, a main processing unit B and a reprocessing unit C are sequentially arranged from the front end to the rear end of the processing chamber; The pretreatment units A1, A2 include two pretreatment spray devices 2, 3 and two pretreatment filter layers 7, 8; the main treatment unit B includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com