Production method of granulated calcium ammonium nitrate

A kind of technology of calcium ammonium nitrate and production method, which is applied in the direction of nitrate fertilizer, nitrogen fertilizer, fertilizer mixture, etc., can solve the problems of high investment, insoluble ammonium nitrate and calcium, large dosage, etc., and achieve low production cost, unique method, easy The effect of the operation

Inactive Publication Date: 2013-03-06

JIAOCHENG SANXI CHEM CO LTD

View PDF3 Cites 12 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] At present, there are disadvantages of insoluble ammonium nitrate and calcium in the fertilizer industrial production

However, the simultaneous application of two kinds of fertilizers has the problems of large amount and high investment.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

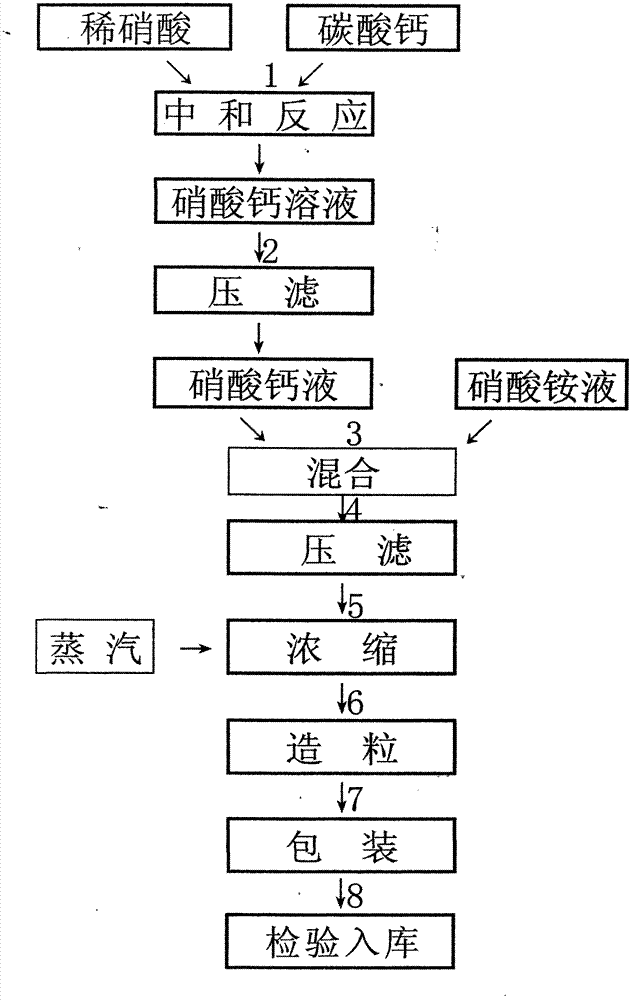

[0008] Specific examples are given by the legends. The illustration shows the process flow chart of the production method of granulated calcium ammonium nitrate, which includes neutralization reaction 1, pressure filtration 2, mixing 3, pressure filtration 4, concentration 5, granulation 6, packaging 7, inspection and storage 8 .

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention belongs to the field of fertilizer industry, and relates to a production method of granulated calcium ammonium nitrate. The method comprises the steps that: dilute nitric acid and calcium carbonate are subjected to a neutralization reaction; a calcium nitrate solution is subjected to pres-filtration; the calcium nitrate liquid is mixed with an ammonium nitrate liquid; press-filtration, concentration, granulation, packaging, and inspecting are carried out; and the obtained granulated calcium ammonium nitrate is stored. The method provided by the invention has the advantages of novel design, unique method, low production cost, easy operation, and high practicality. The method can be popularized.

Description

technical field [0001] The invention relates to a production method of granulated calcium ammonium nitrate, belonging to the fertilizer industry. Background technique [0002] At present, there is a disadvantage of insoluble ammonium nitrate and calcium in the fertilizer industrial production. However, the simultaneous application of two kinds of fertilizers has the problems of large consumption and high input. Contents of the invention [0003] The invention provides a method for producing granulated calcium ammonium nitrate, which can overcome the above drawbacks. [0004] The present invention is realized by adopting the following technical scheme: a production method of granulated calcium ammonium nitrate, which comprises dilute nitric acid, calcium carbonate neutralization reaction, calcium nitrate solution pressure filtration, calcium nitrate liquid, ammonium nitrate liquid mixing, pressure filtration , concentration, granulation, packaging, inspection and storage,...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C05C5/04C05G5/00

Inventor 蔺拴全

Owner JIAOCHENG SANXI CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com