Full-automatic picking car for warehouse and control method of full-automatic picking car

A fully automatic, truck technology, which is applied in the direction of program control manipulators, manufacturing tools, electromagnetic radiation induction, etc., can solve the problems of high error rate of manual picking, increased workload of pickers, and high labor intensity of pickers, etc., to achieve Strong practicability, improved picking efficiency, novel design effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

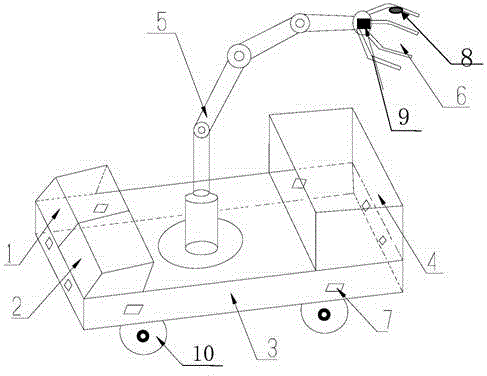

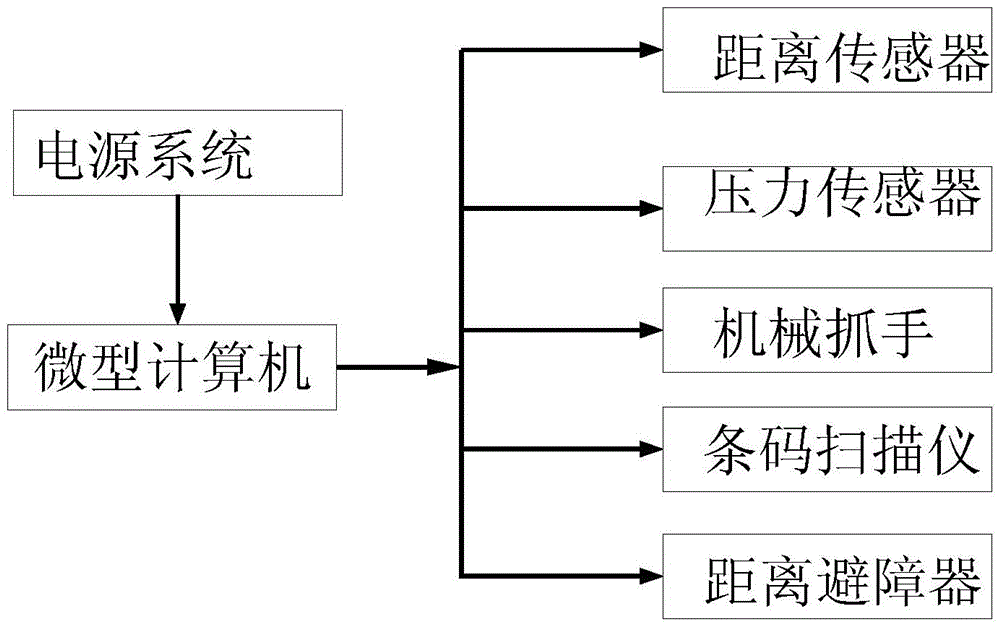

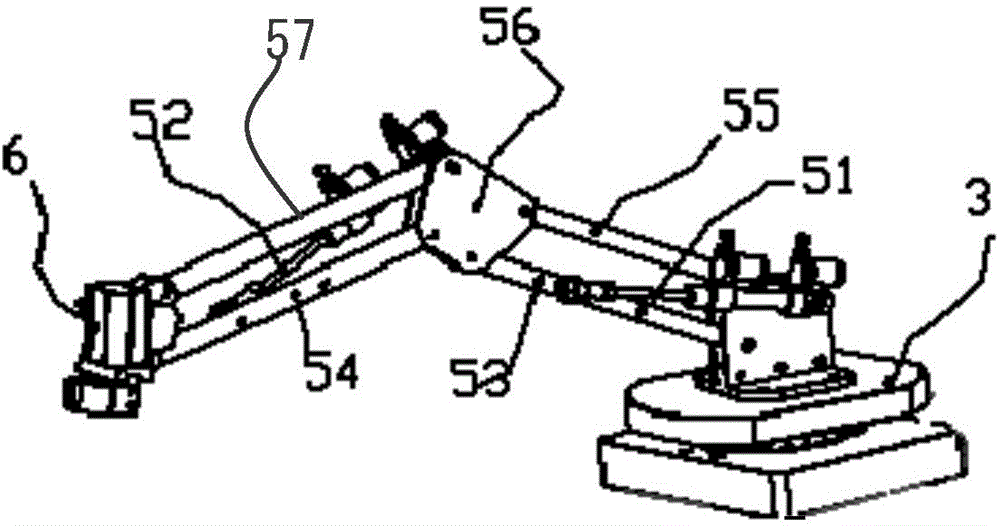

[0025] Such as figure 1 As shown, a fully automatic picking vehicle in a warehouse includes a picking vehicle body 3, a mechanical arm 5, and a mechanical gripper 6. The picking vehicle also includes a microcomputer 1 and a power supply system 2, and the microcomputer 1 and the power supply system 2 are fixedly installed. At the front end of the picking car body 3; the rear end of the picking car body 3 is also fixedly provided with a storage box 4, and four wheels 10 are installed at the bottom of the picking car body 3; one end of the mechanical arm 5 is rotatably connected to the picking car body 3, the other end is equipped with a mechanical gripper 6; the mechanical arm 5 is precisely positioned for three degrees of freedom, and it is an extended mechanical arm with a 360...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com