Patents

Literature

143results about How to "Simple idea" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Remote authentication and transaction signatures

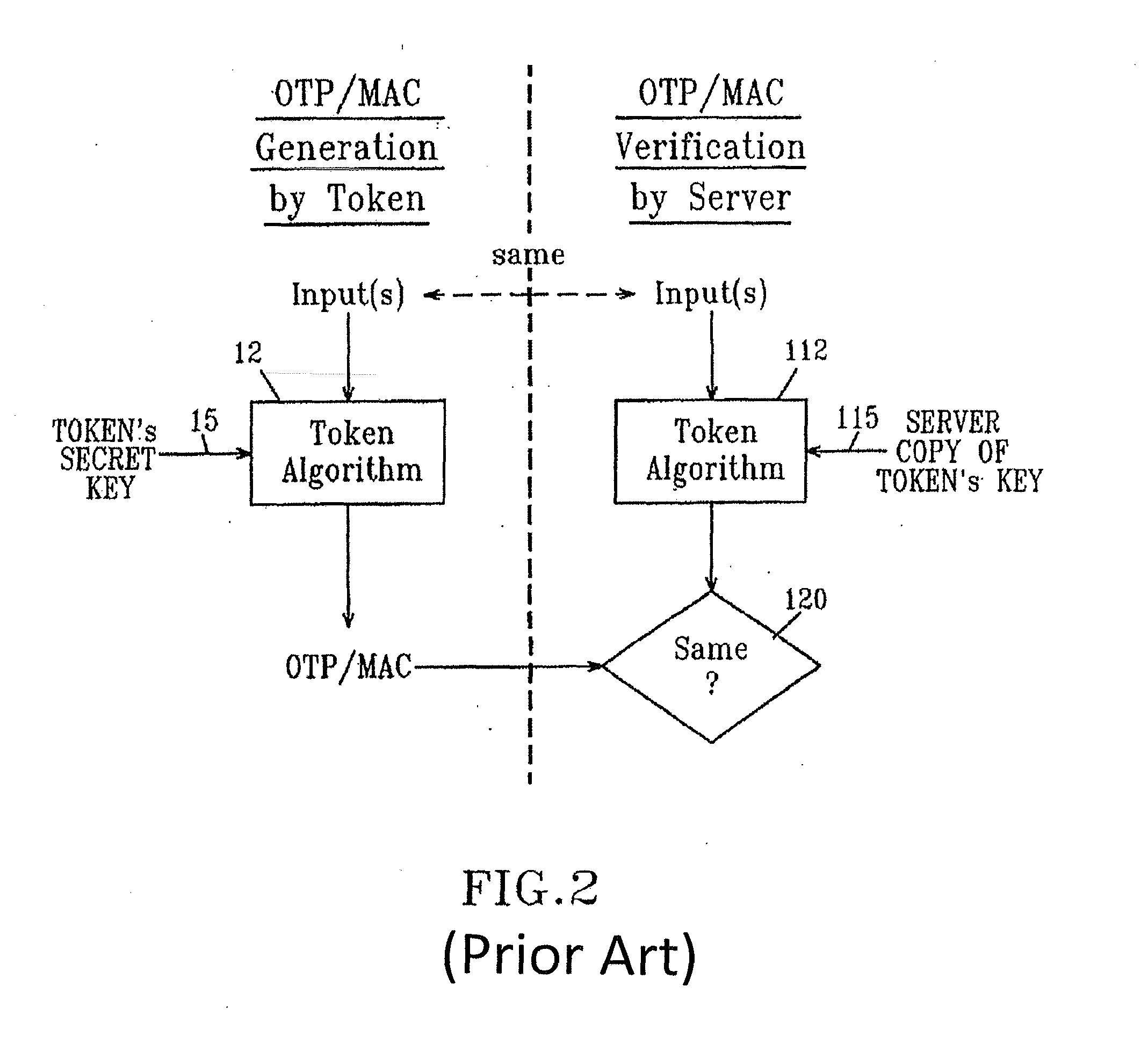

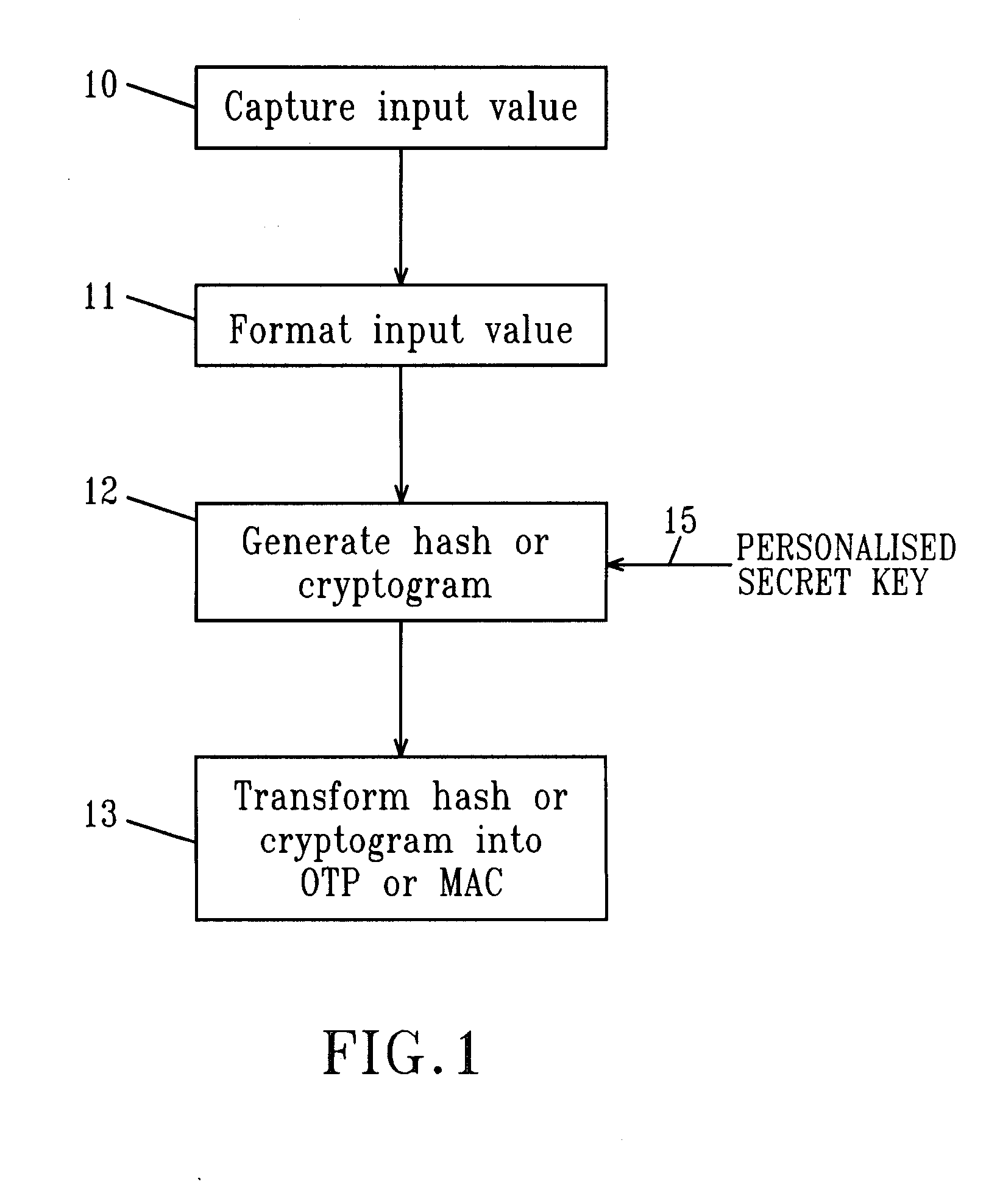

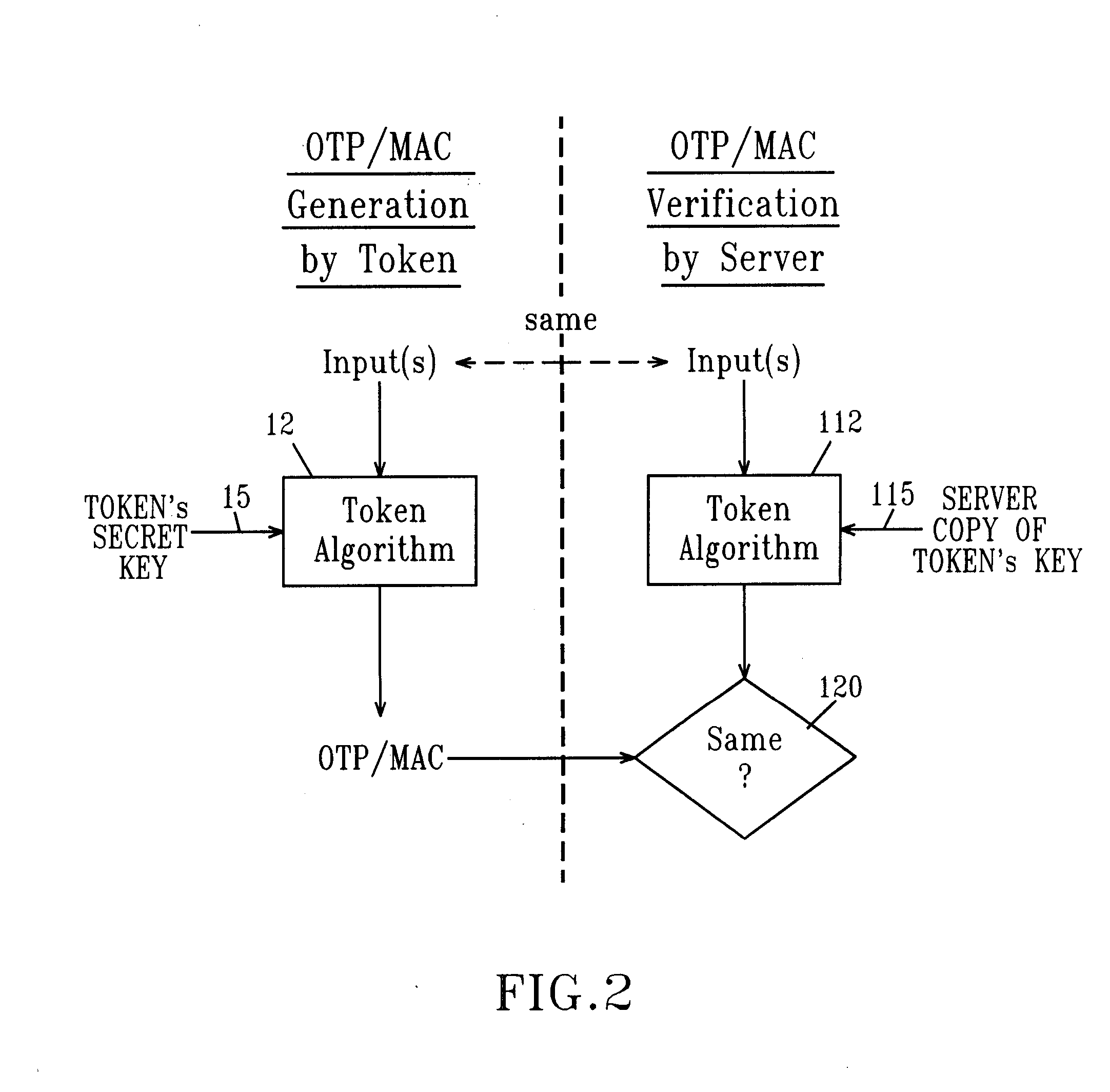

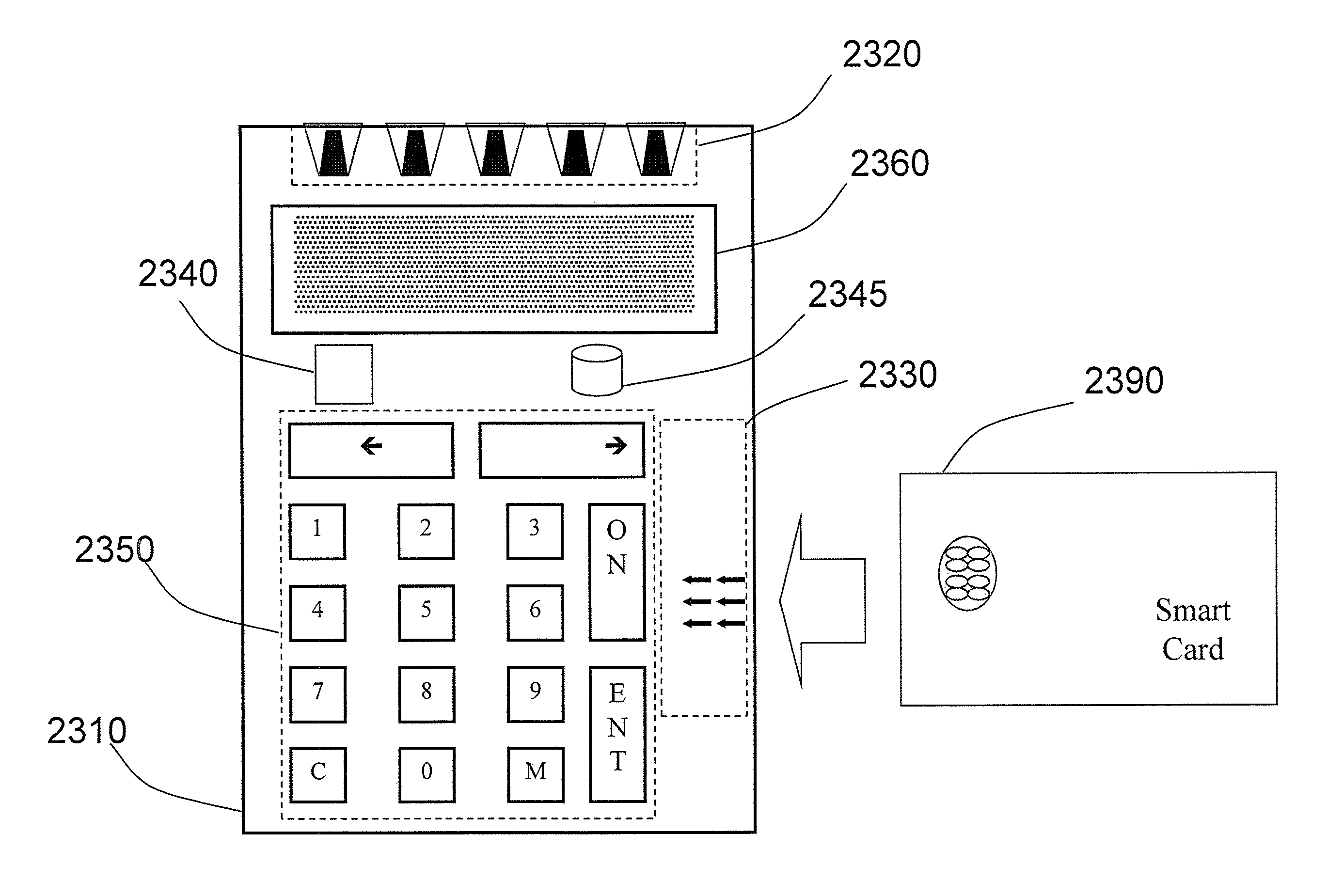

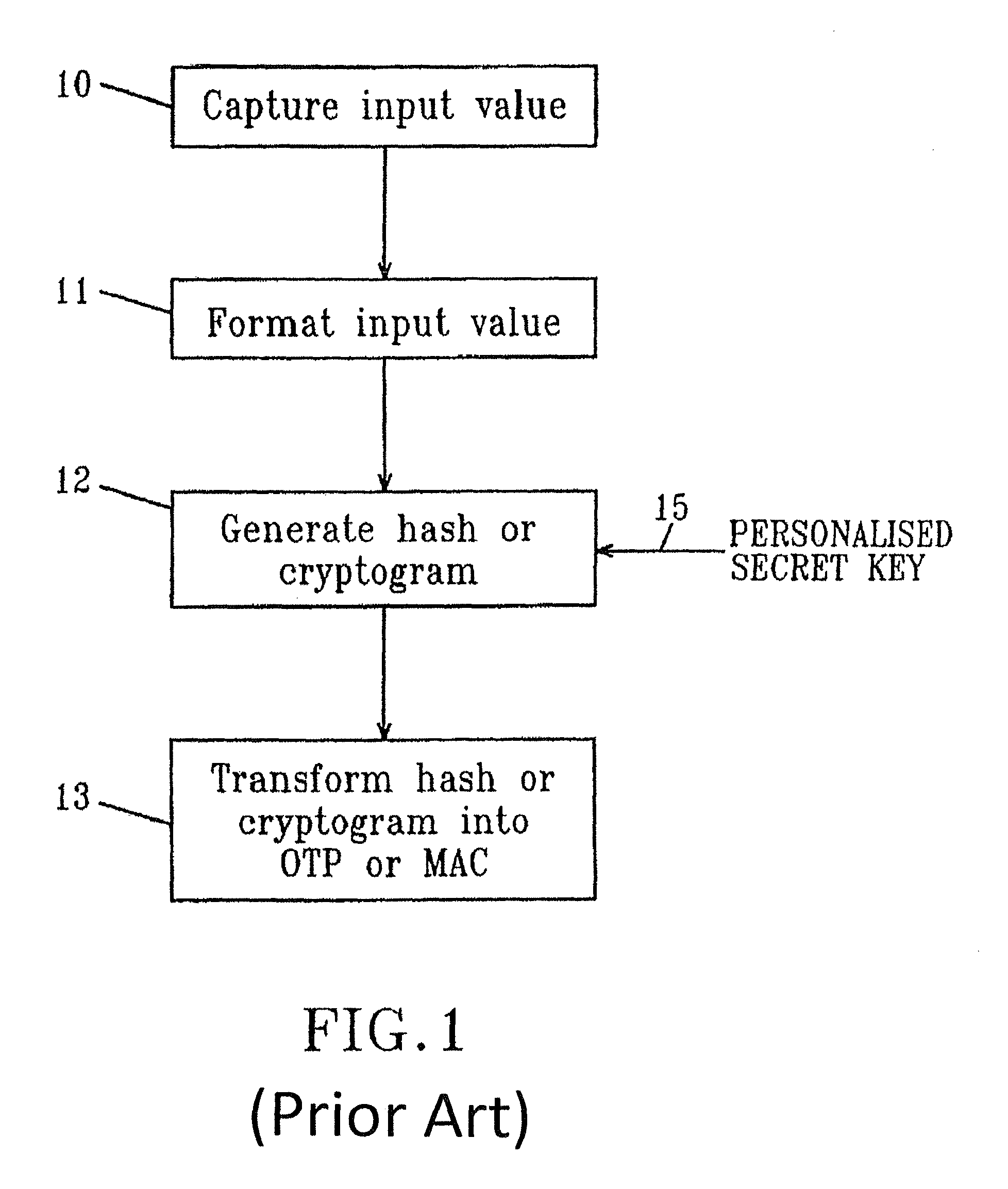

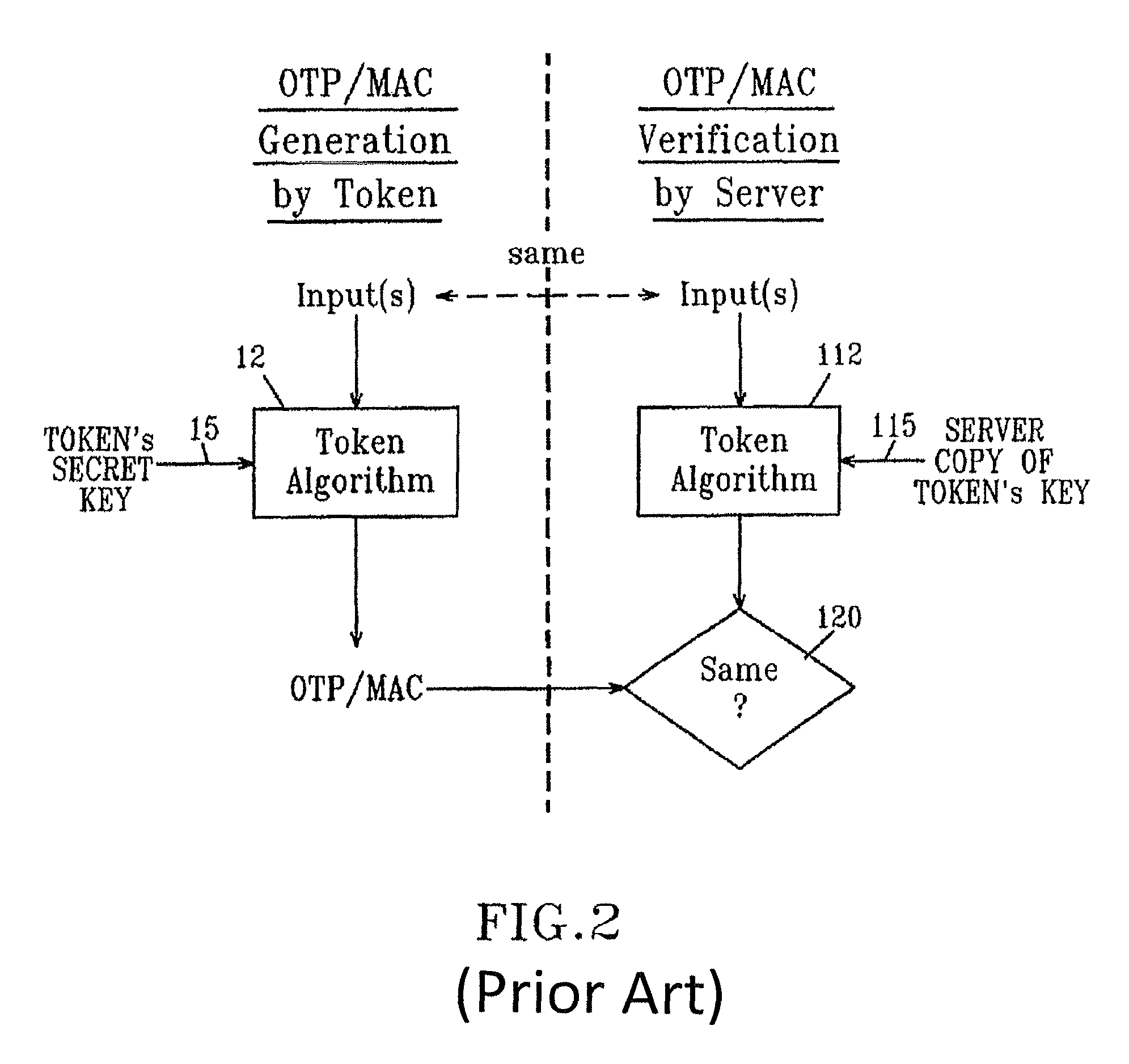

InactiveUS20110258452A1Simple ideaUser identity/authority verificationPayment architecturePersonalizationSmart card

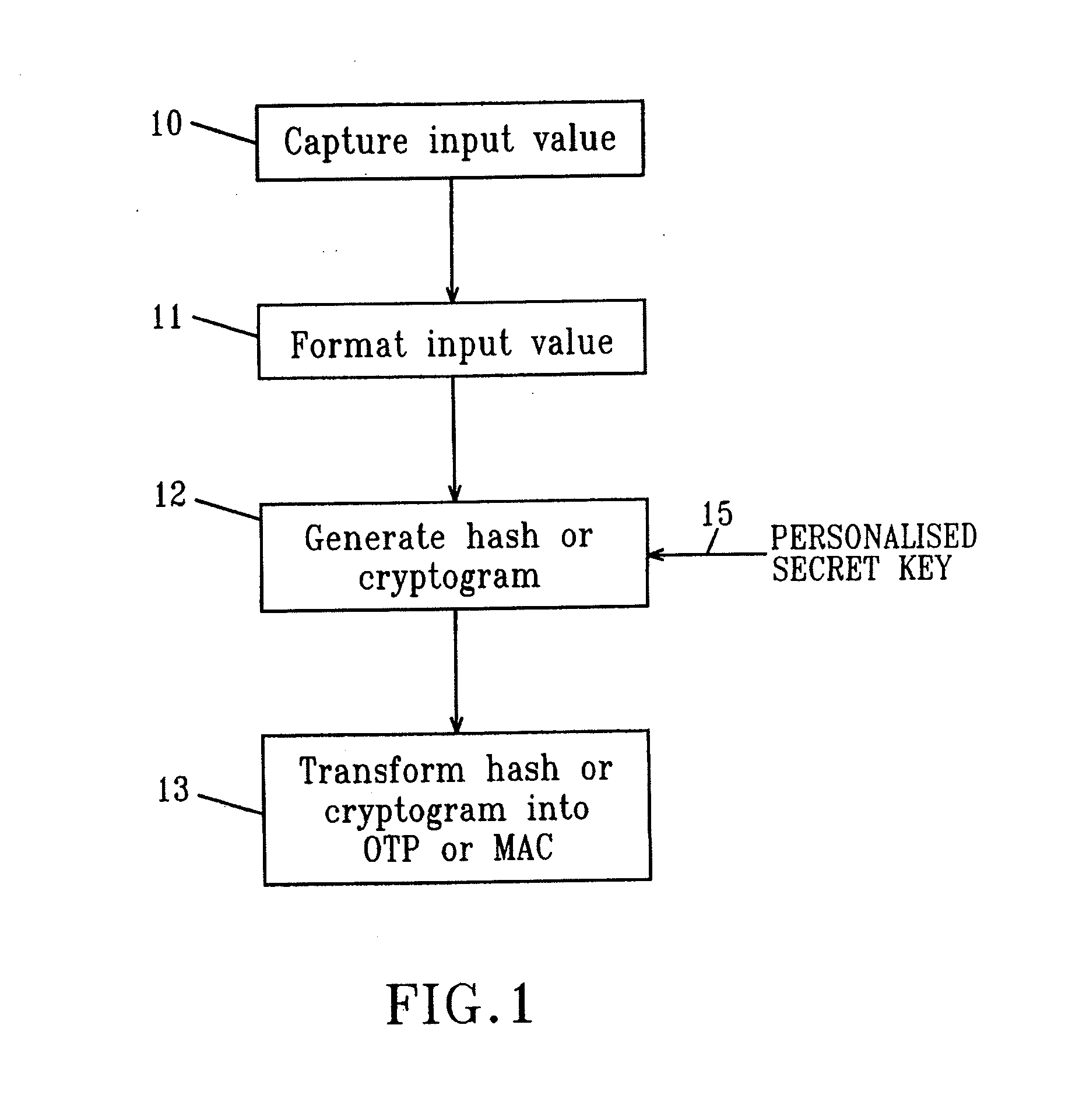

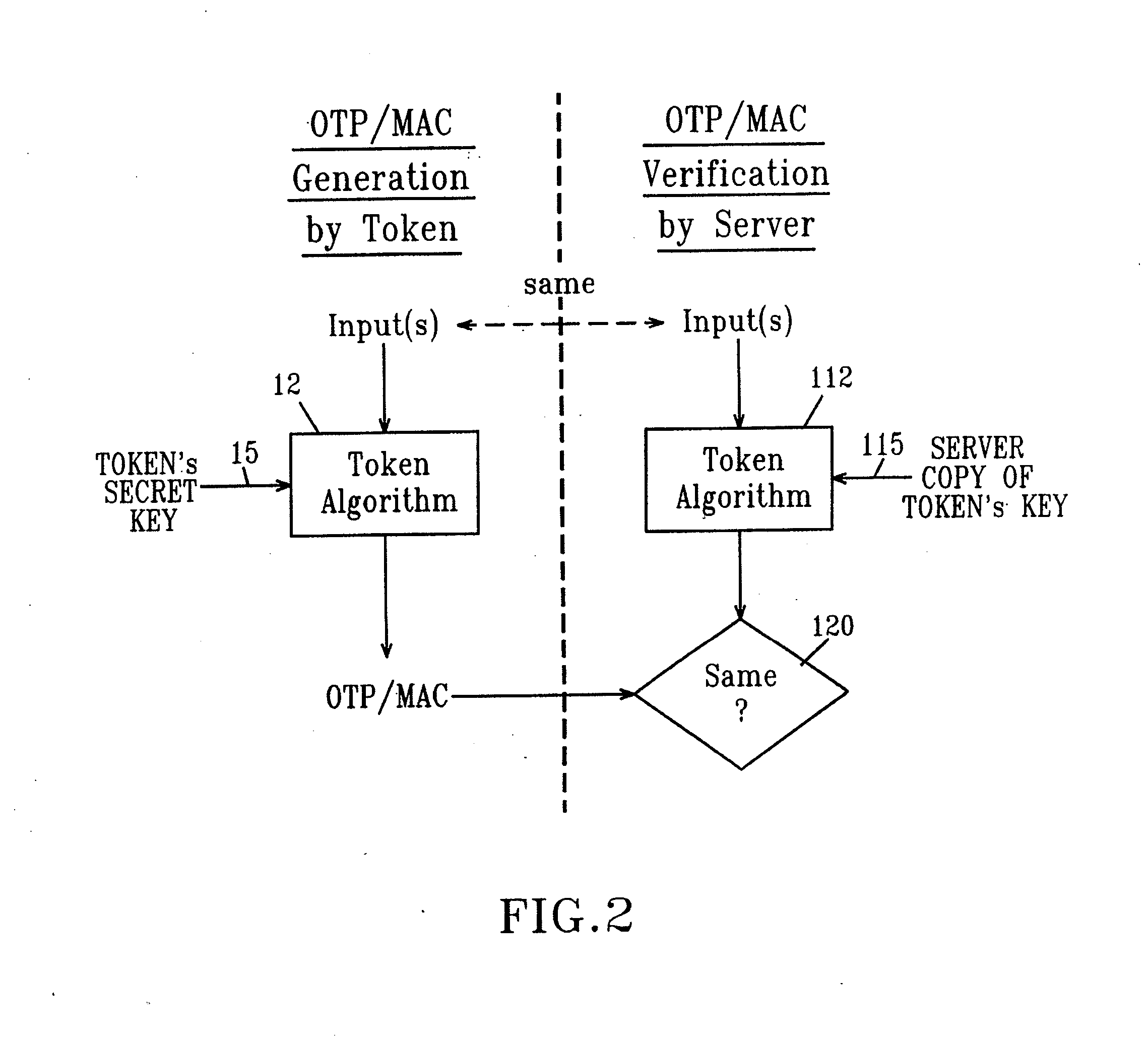

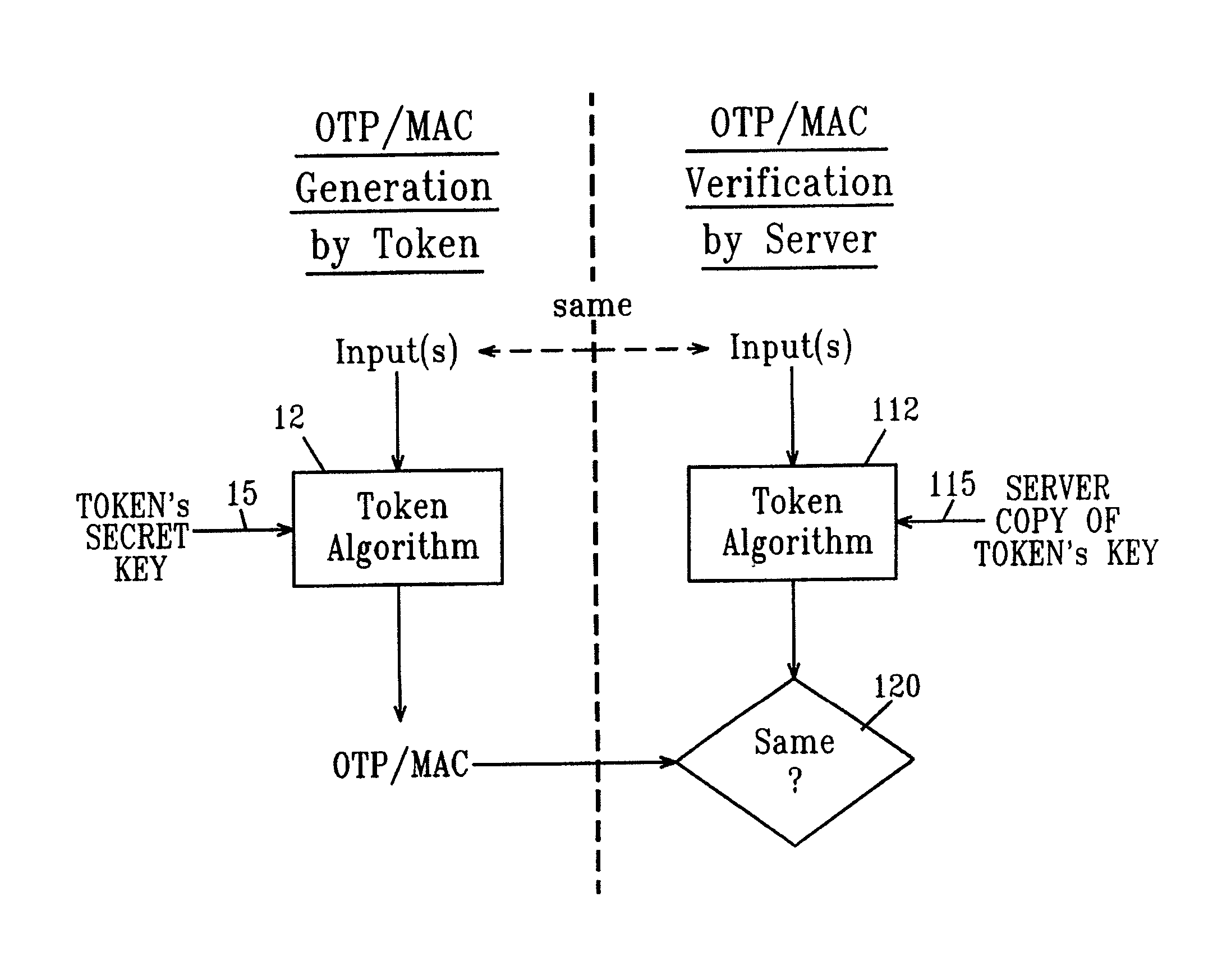

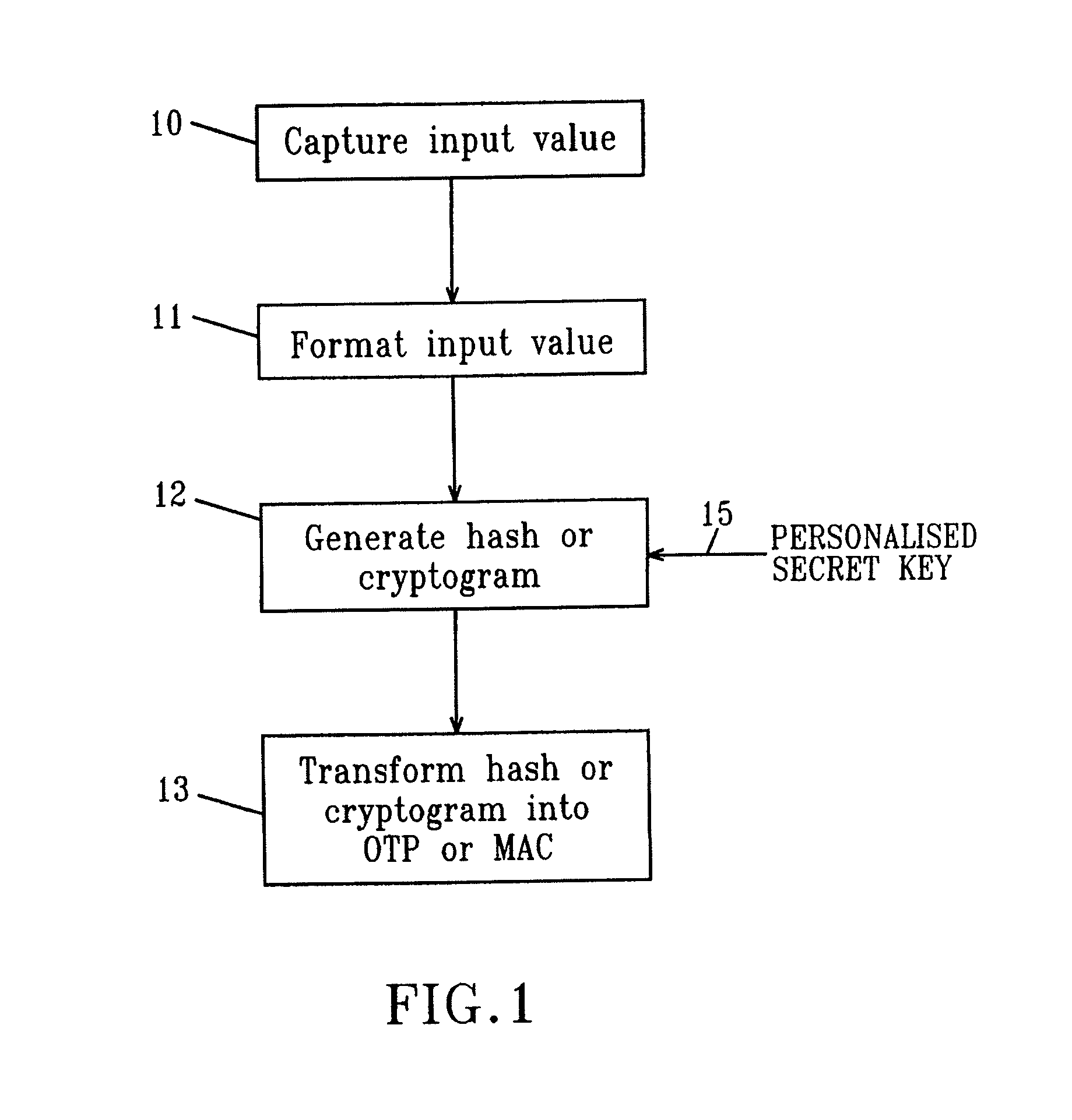

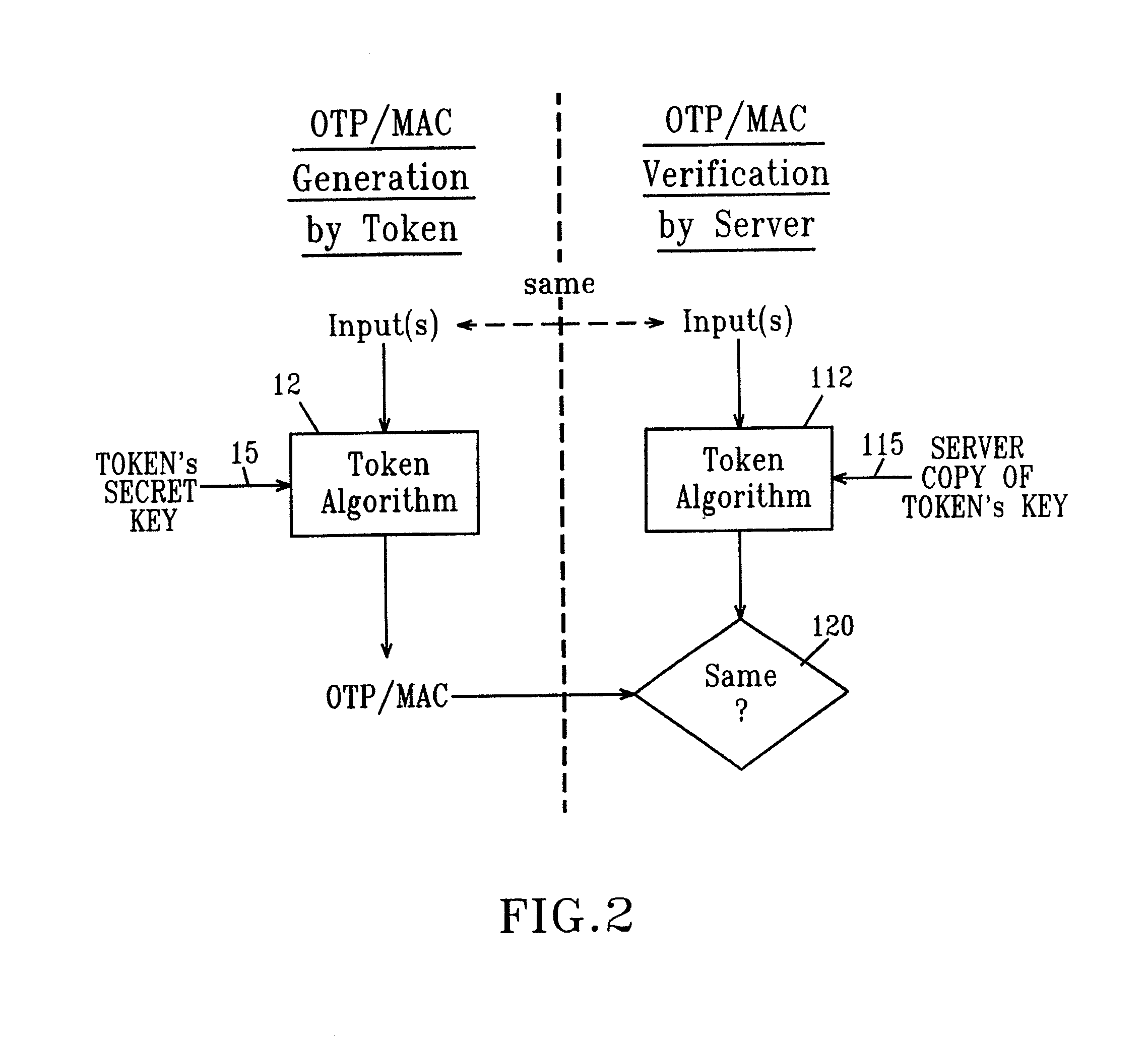

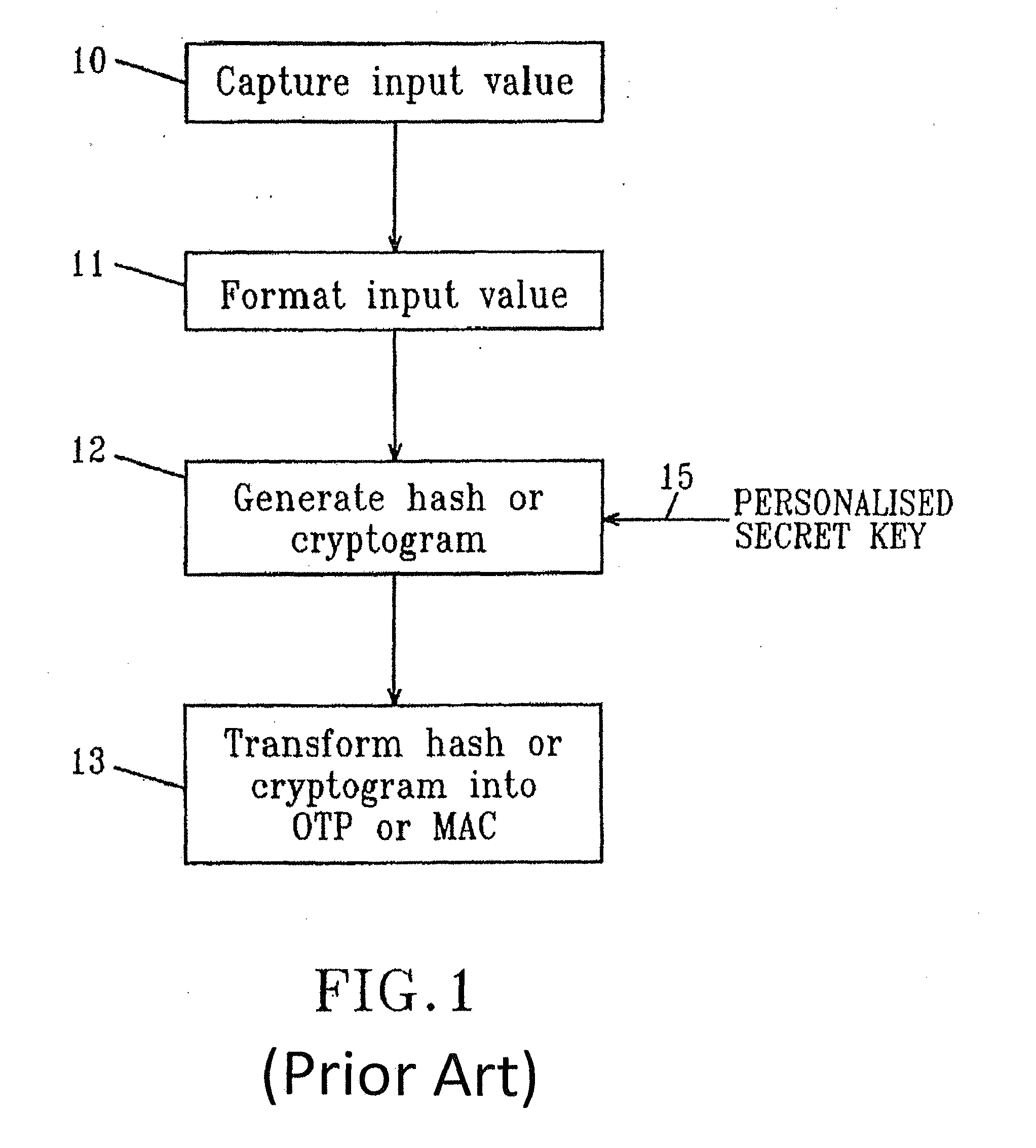

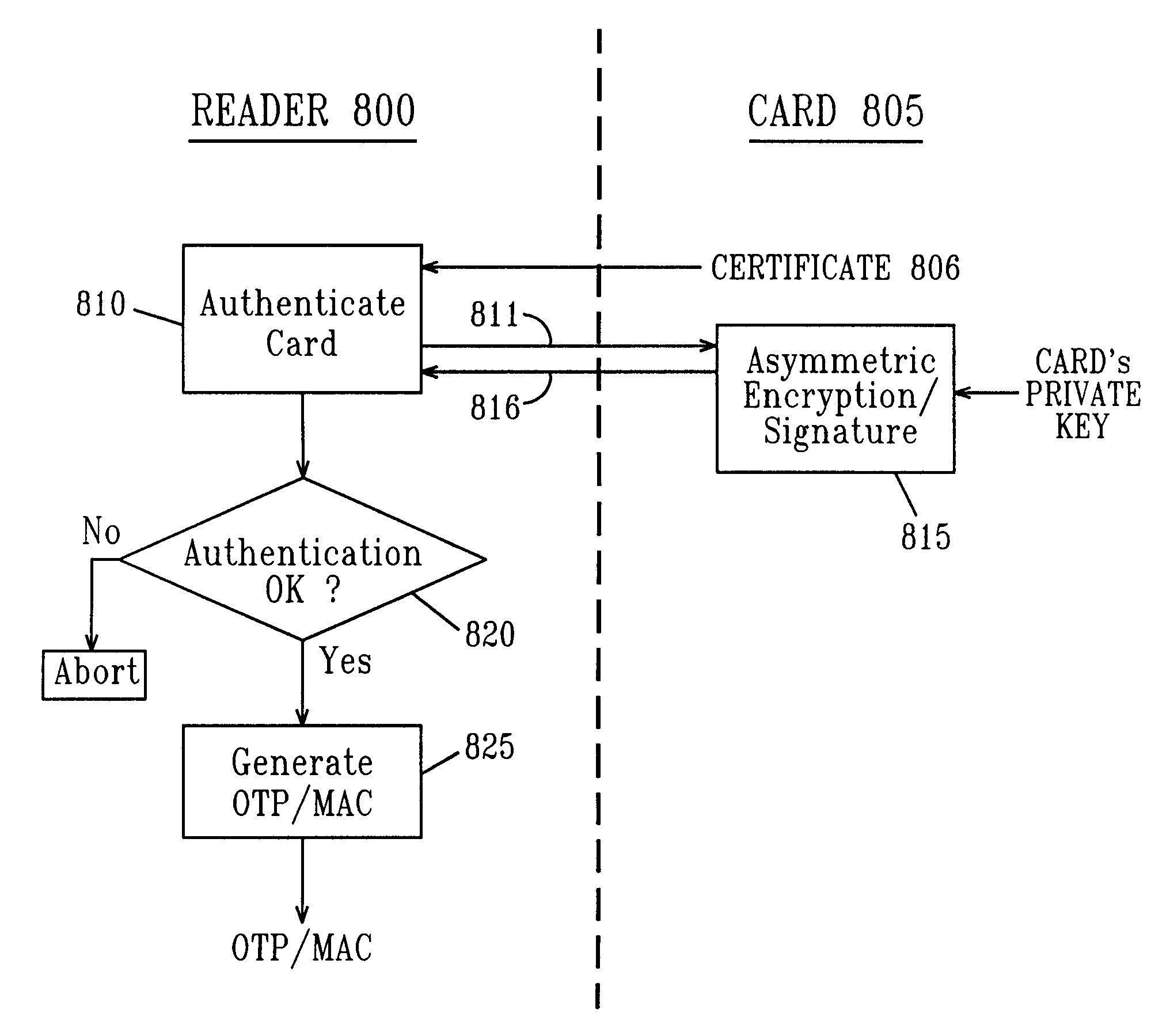

The invention provides a method, apparatus, computer readable medium and signal which allows the usage of devices containing PKI private keys such as PKI-enabled smart cards or USB sticks to authenticate users and to sign transactions. The authenticity of the user and / or the message is verified. Furthermore the operation (authentication and / or signing) occurs without the need for an application to have some kind of a direct or indirect digital connection with the device containing the private key. In addition the operation occurs without the need for the PKI-enabled device containing the private key (e.g. a PKI smart card or USB stick) to either support symmetric cryptographic operations or to have been personalized with some secret or confidential data element that can be read by a suitable reader.

Owner:ONESPAN NORTH AMERICA INC

Remote authentication and transaction signatures

InactiveUS8667285B2Simple ideaDigital data processing detailsUser identity/authority verificationPersonalizationSmart card

The invention provides a method, apparatus, computer readable medium and signal which allows the usage of devices containing PKI private keys such as PKI-enabled smart cards or USB sticks to authenticate users and to sign transactions. The authenticity of the user and / or the message is verified. Furthermore the operation (authentication and / or signing) occurs without the need for an application to have some kind of a direct or indirect digital connection with the device containing the private key. In addition the operation occurs without the need for the PKI-enabled device containing the private key (e.g. a PKI smart card or USB stick) to either support symmetric cryptographic operations or to have been personalized with some secret or confidential data element that can be read by a suitable reader.

Owner:ONESPAN NORTH AMERICA INC

Remote authentication and transaction signatures

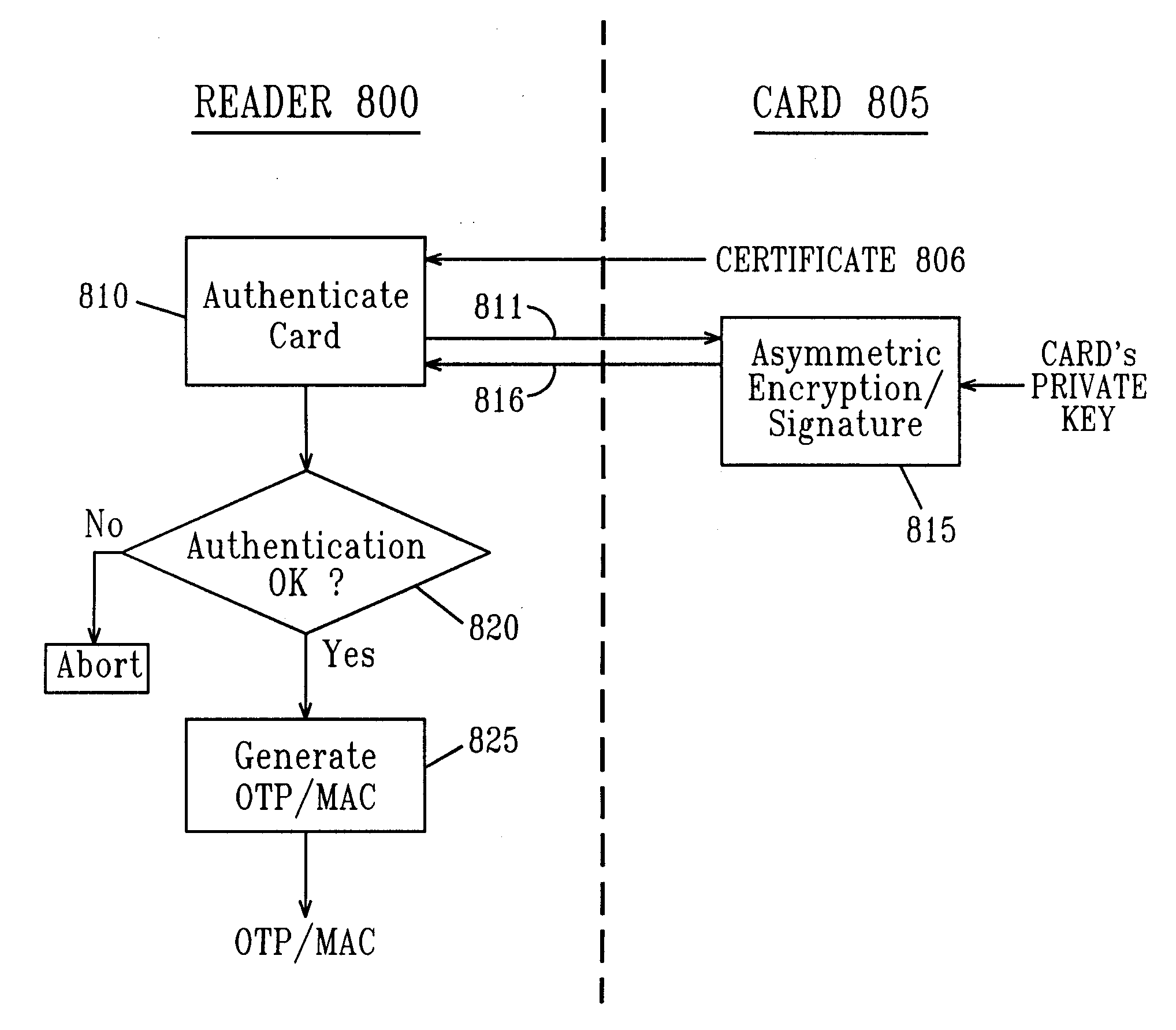

InactiveUS20140189359A1Simple ideaUser identity/authority verificationCommunication interfaceSmart card

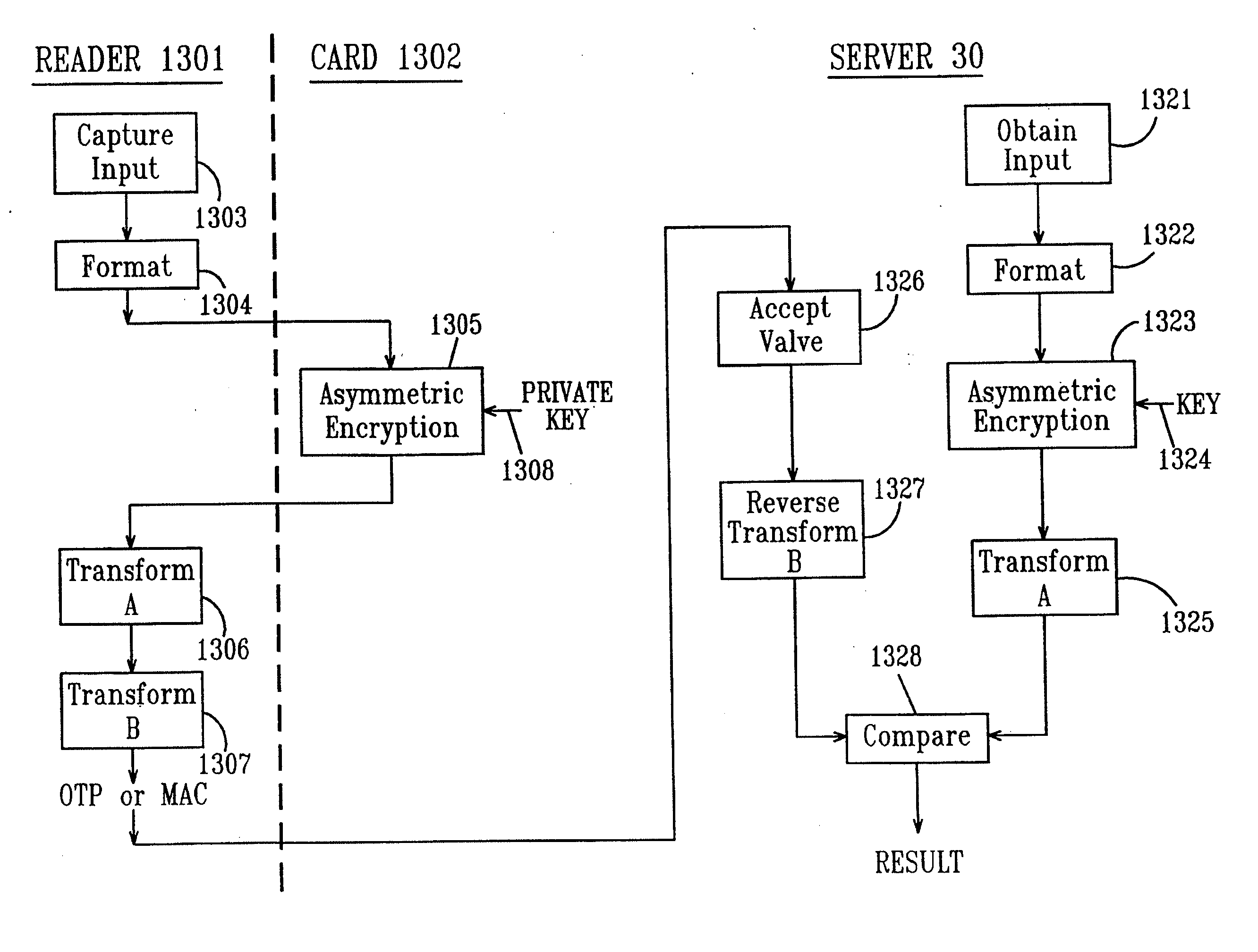

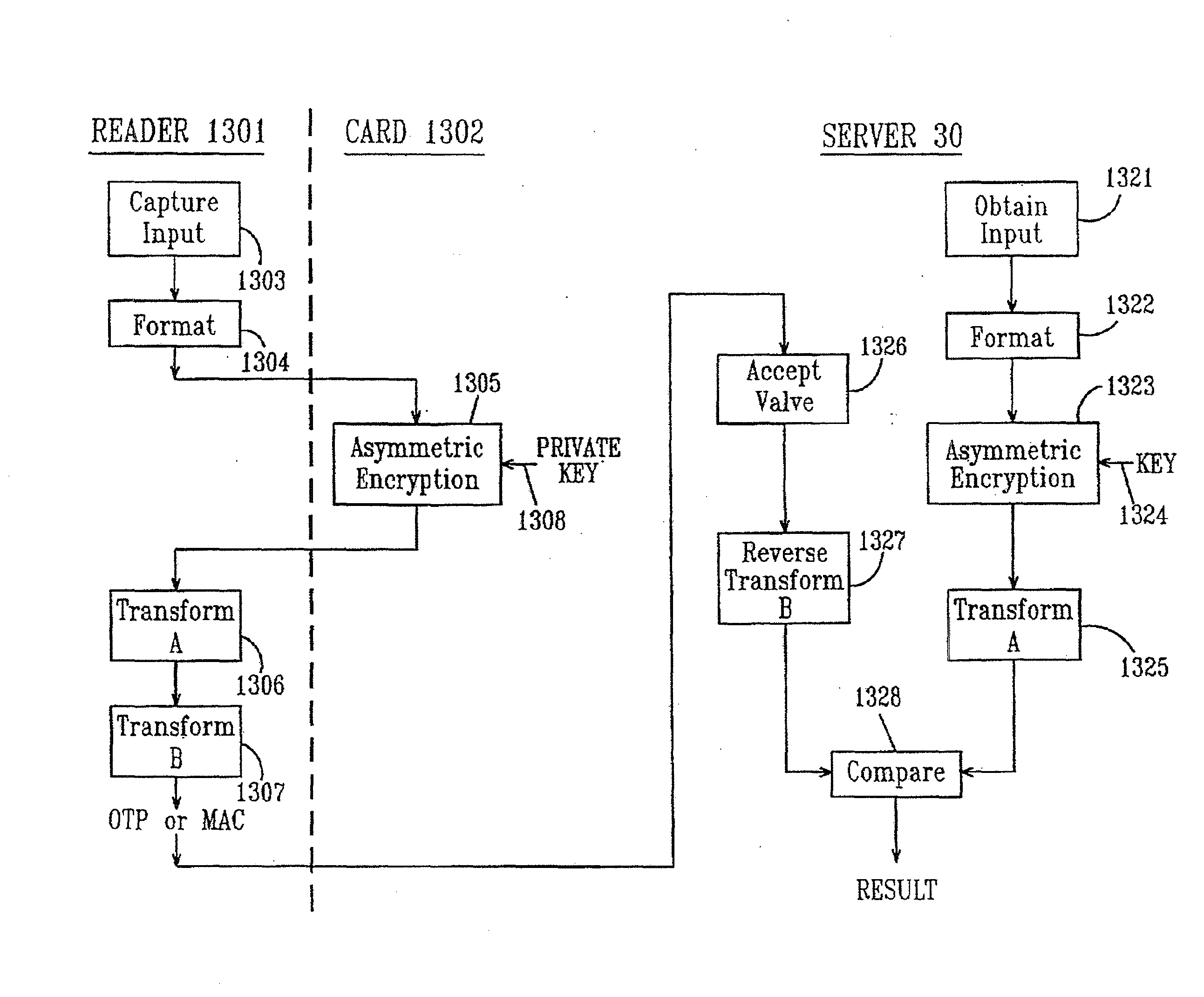

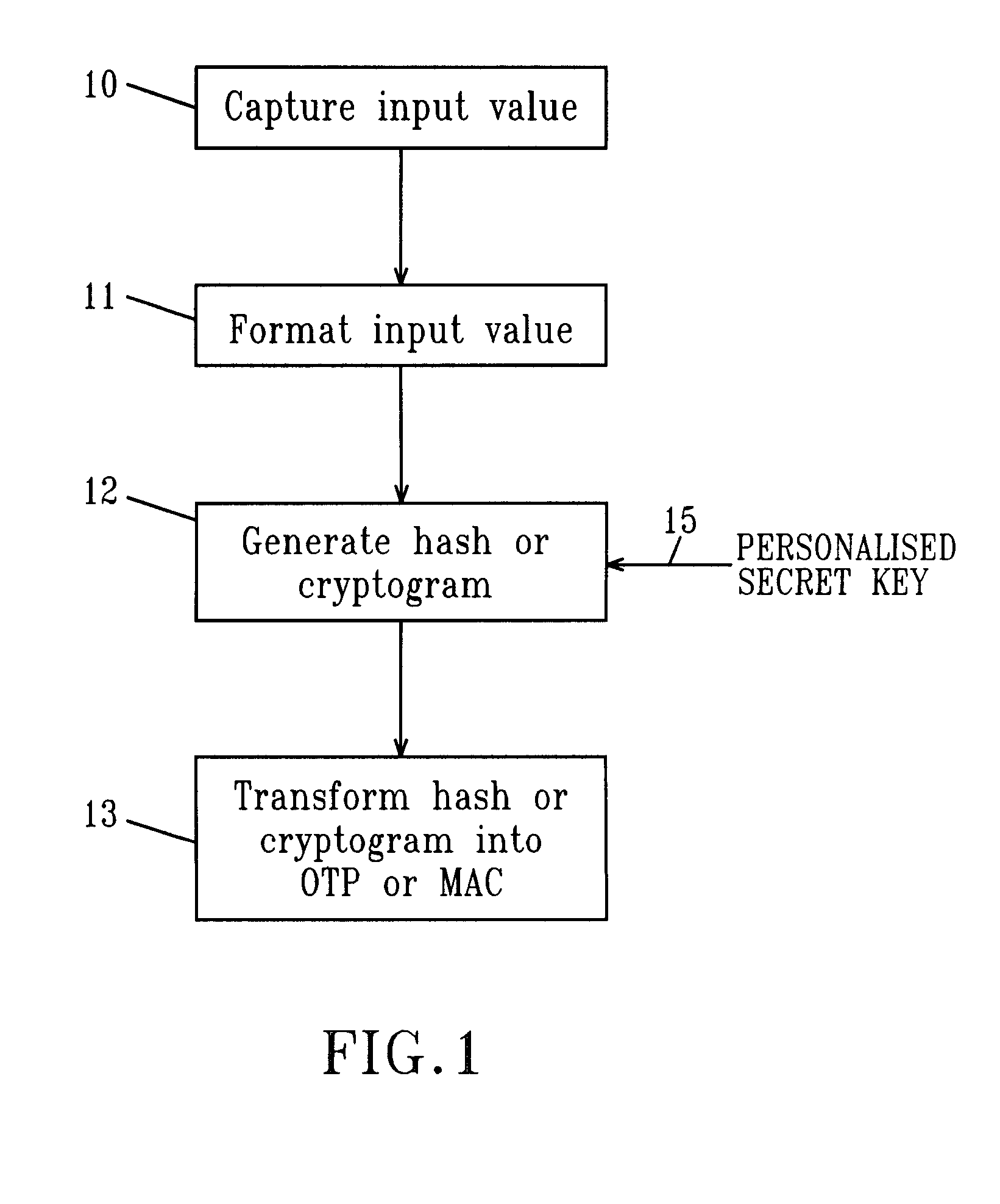

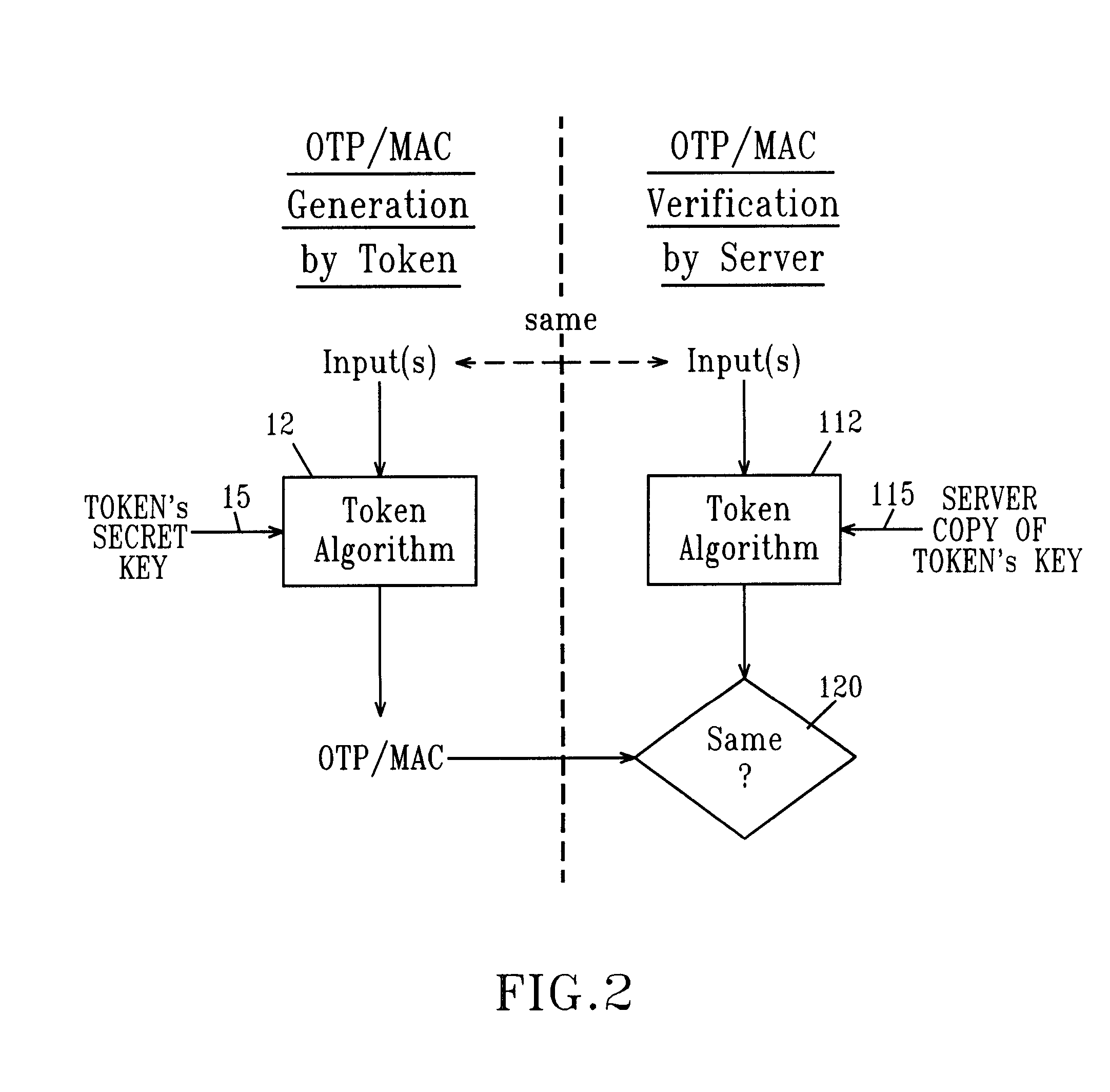

Authentication devices and methods for generating dynamic credentials are disclosed. The authentication devices include a communication interface for communicating with a security device such as a smart card. A dynamic credential such as a one-time password (OTP) or a message authentication code (MAC) may be generated by receiving from a server an encrypted initialization seed encrypted with an asymmetric encryption algorithm using a public key of a public / private key pair, submitting the encrypted initialization seed to a security device, decrypting at the security device the encrypted initialization seed with a private key of the public / private key pair, returning the decrypted initialization seed to the authentication device, deriving at the authentication device a secret credential generation key from the decrypted initialization seed, and generating the dynamic credential by combining a dynamic variable with the secret credential generation key using a symmetric cryptographic dynamic credential generation algorithm.

Owner:ONESPAN NORTH AMERICA INC

Remote authentication and transaction signatures

InactiveUS20080301461A1Simple ideaPayment architectureDigital data authenticationApplication softwarePersonalization

The invention provides a method, apparatus, computer readable medium and signal which allows the usage of devices containing PKI private keys such as PKI-enabled smart cards or USB sticks to authenticate users and to sign transactions. The authenticity of the user and / or the message is verified. Furthermore the operation (authentication and / or signing) occurs without the need for an application to have some kind of a direct or indirect digital connection with the device containing the private key. In other words a digital connection that would allow an application to submit data to the card for signing by the card's private key and that would allow retrieving the entire resulting signature from the card is not required. In addition the operation occurs without the need for the PKI-enabled device containing the private key (e.g. a PKI smart card or USB stick) to either support symmetric cryptographic operations or to have been personalized with some secret or confidential data element that can be read by a suitable reader.

Owner:ONESPAN NORTH AMERICA INC

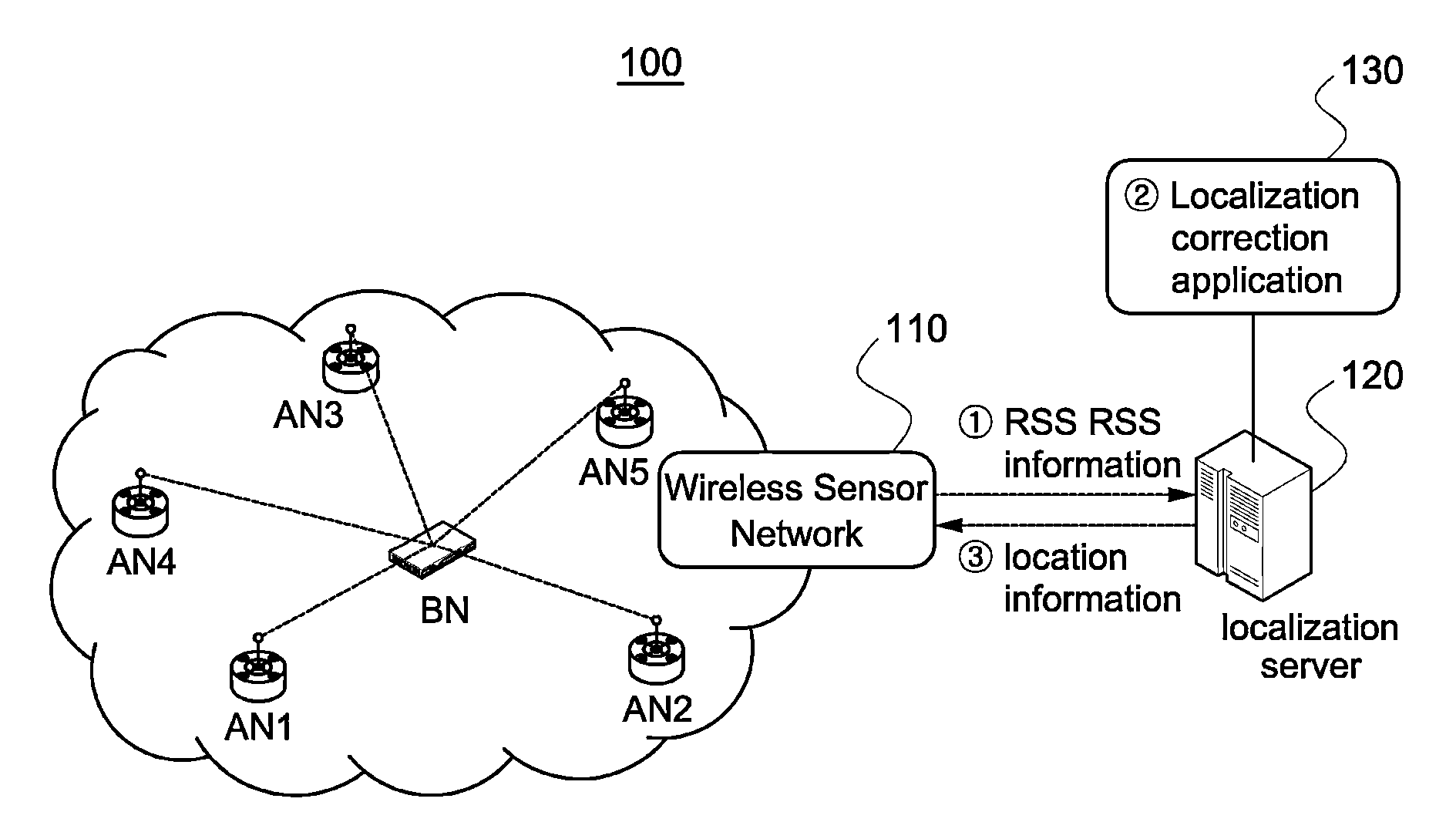

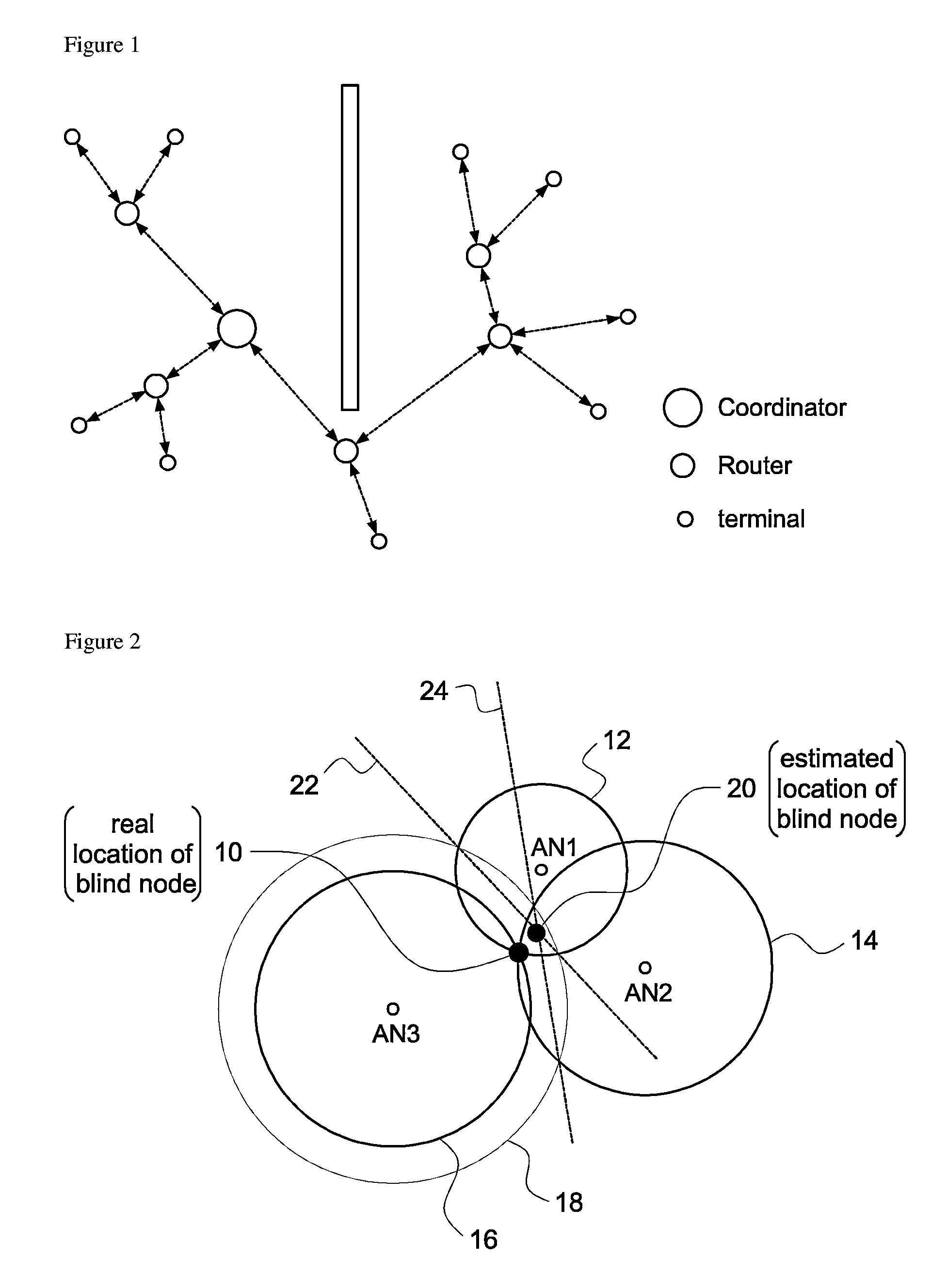

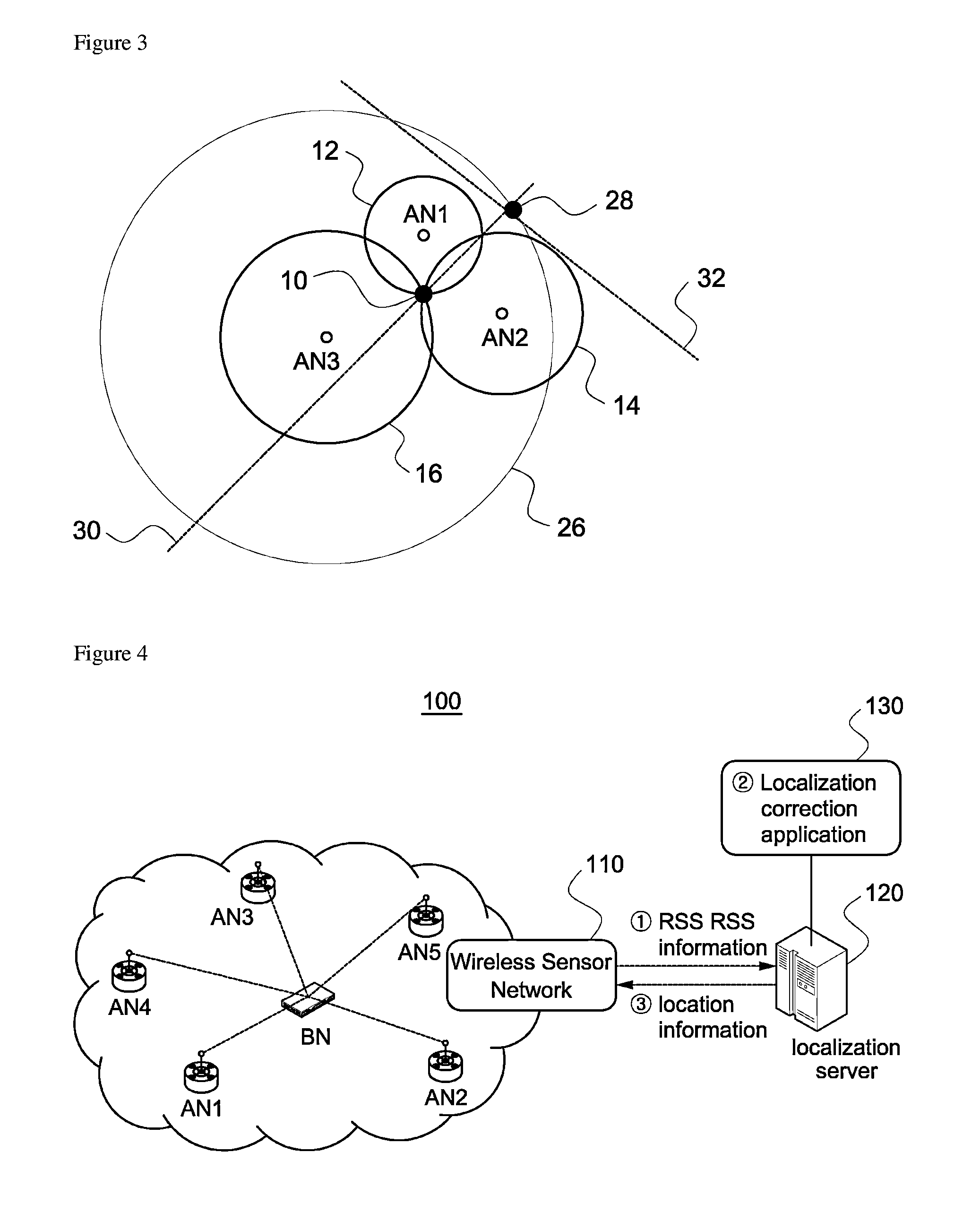

Wireless localization method based on an efficient multilateration algorithm over a wireless sensor network and a recording medium in which a program for the method is recorded

ActiveUS20130045750A1Improve estimation accuracyDistance can be inaccurateDirection finders using radio wavesSpecial service for subscribersWireless mesh networkWireless sensor networking

A wireless localization technology using efficient multilateration in a wireless sensor network is disclosed. After calculating estimated distances from each of at least three reference nodes to a blind node using received signal strength of wireless signals that the at least three reference nodes received from the blind node, the estimated location of the blind node is obtained through multilateration using the calculated estimated distances. To correct error in the estimated location, the estimated distances are used, and the error correction direction and error correction distance for the estimated location are calculated by applying a largest weight to the reference node closest to the estimated location. The error of the estimated location is corrected by move the estimated location of the blind node by the calculated error correction direction and error correction distance. Calculation for the error correction is very simple and fast.

Owner:SEOUL NAT UNIV R&DB FOUND

Remote authentication and transaction signatures

InactiveUS7930554B2Simple ideaPayment architectureDigital data authenticationPersonalizationSmart card

The invention provides a method, apparatus, computer readable medium and signal which allows the usage of devices containing PKI private keys such as PKI-enabled smart cards or USB sticks to authenticate users and to sign transactions. The authenticity of the user and / or the message is verified. Furthermore the operation (authentication and / or signing) occurs without the need for an application to have some kind of a direct or indirect digital connection with the device containing the private key. In other words a digital connection that would allow an application to submit data to the card for signing by the card's private key and that would allow retrieving the entire resulting signature from the card is not required. In addition the operation occurs without the need for the PKI-enabled device containing the private key (e.g. a PKI smart card or USB stick) to either support symmetric cryptographic operations or to have been personalized with some secret or confidential data element that can be read by a suitable reader.

Owner:ONESPAN NORTH AMERICA INC

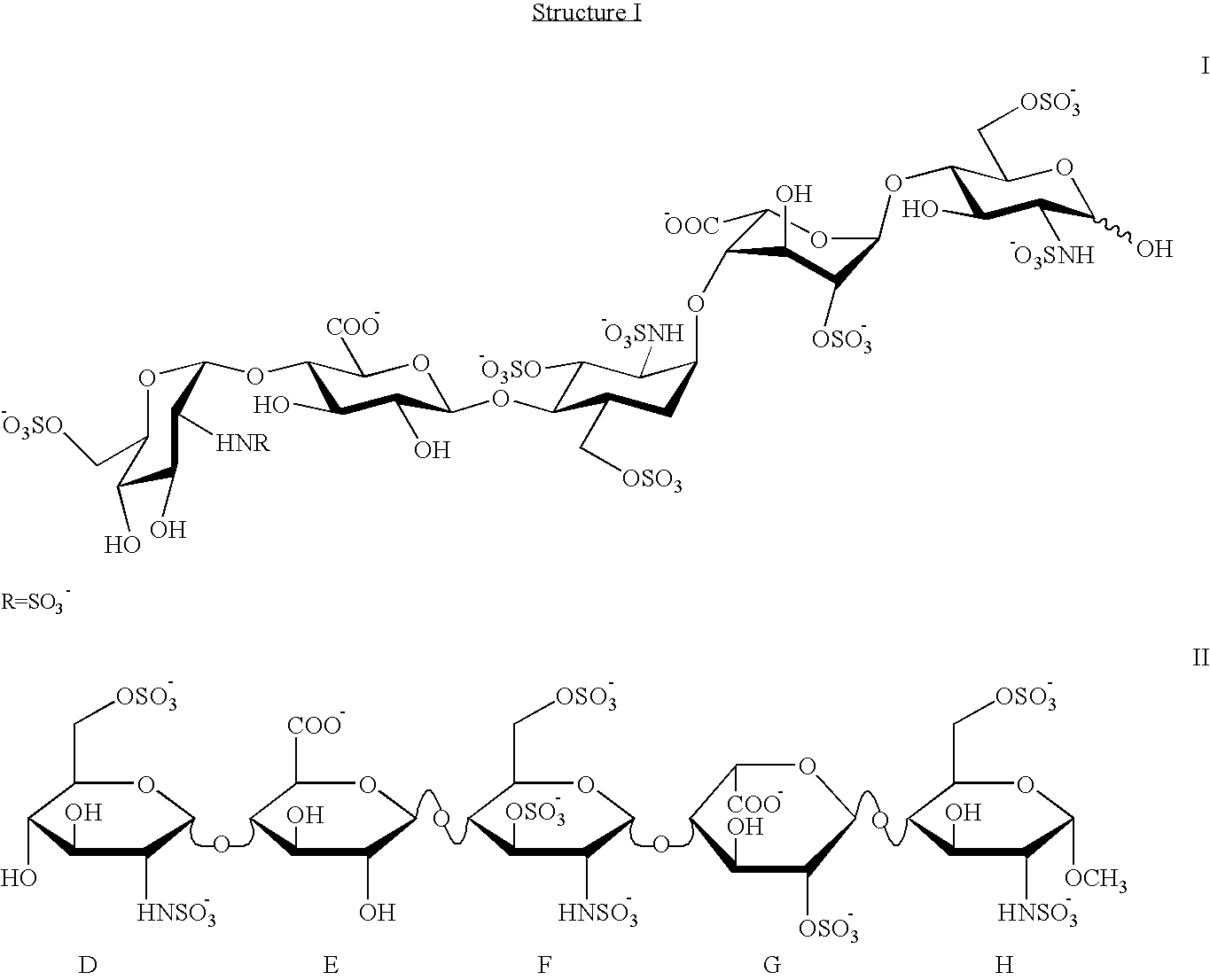

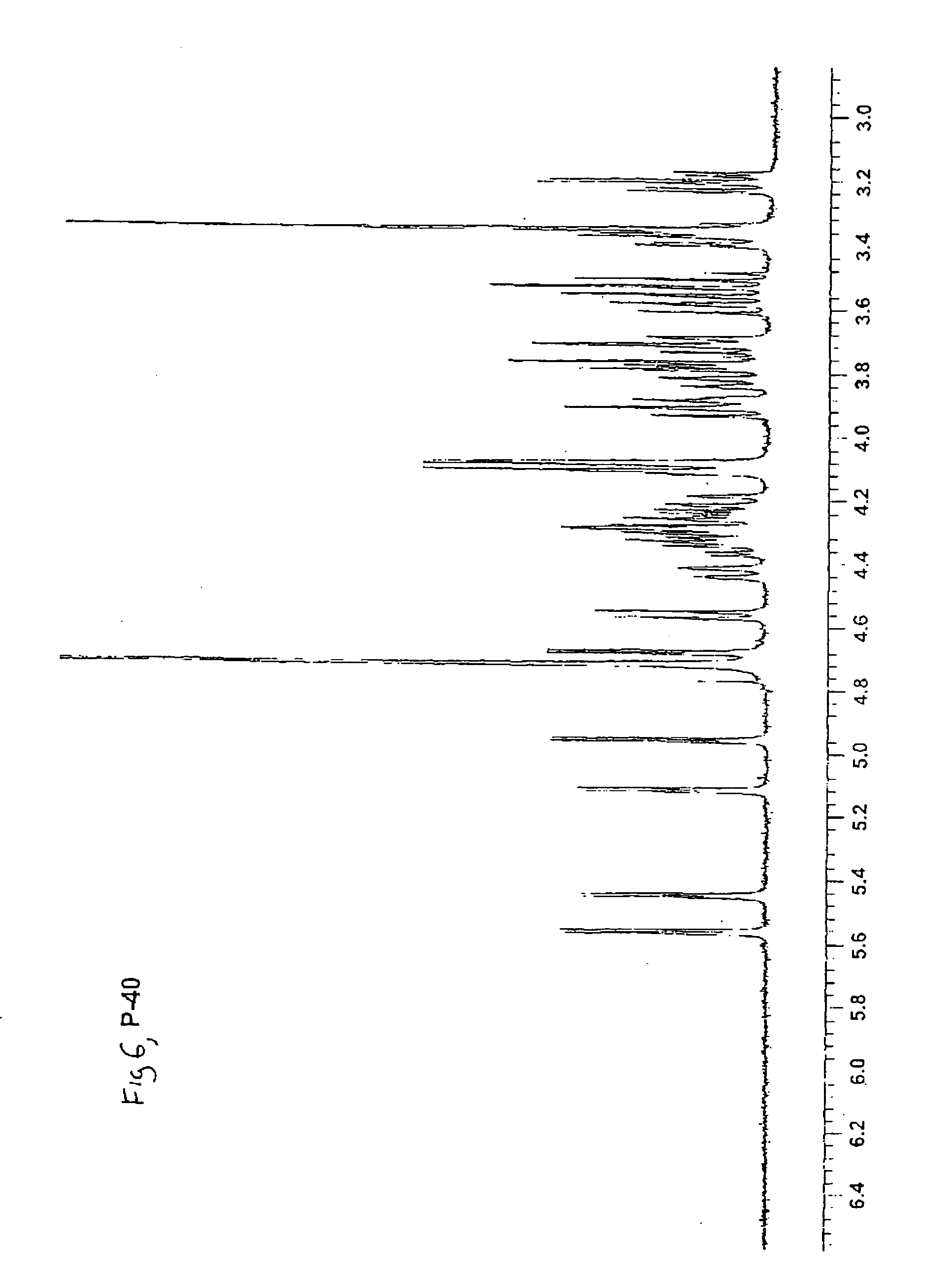

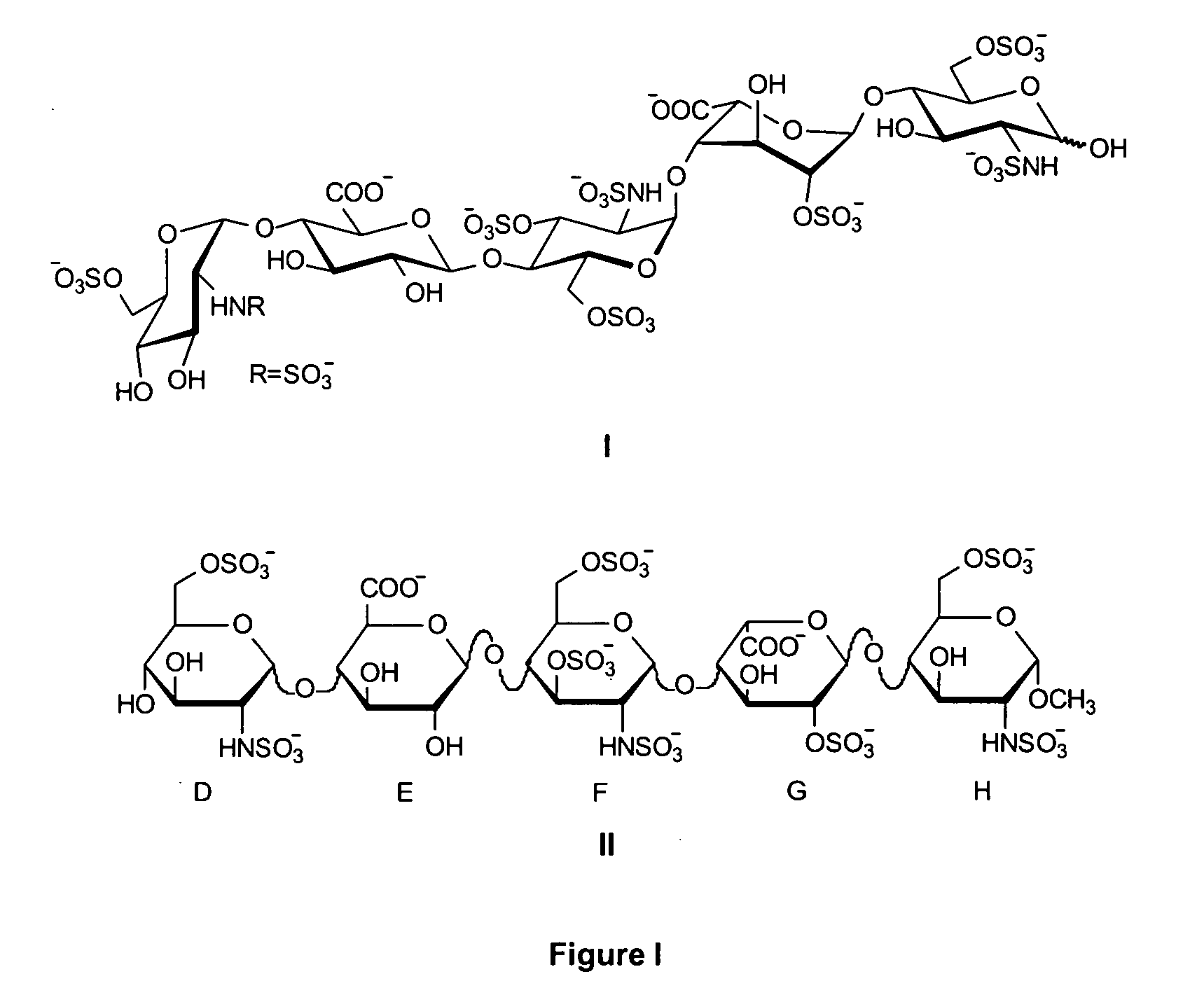

Synthetic heparin pentasaccharides

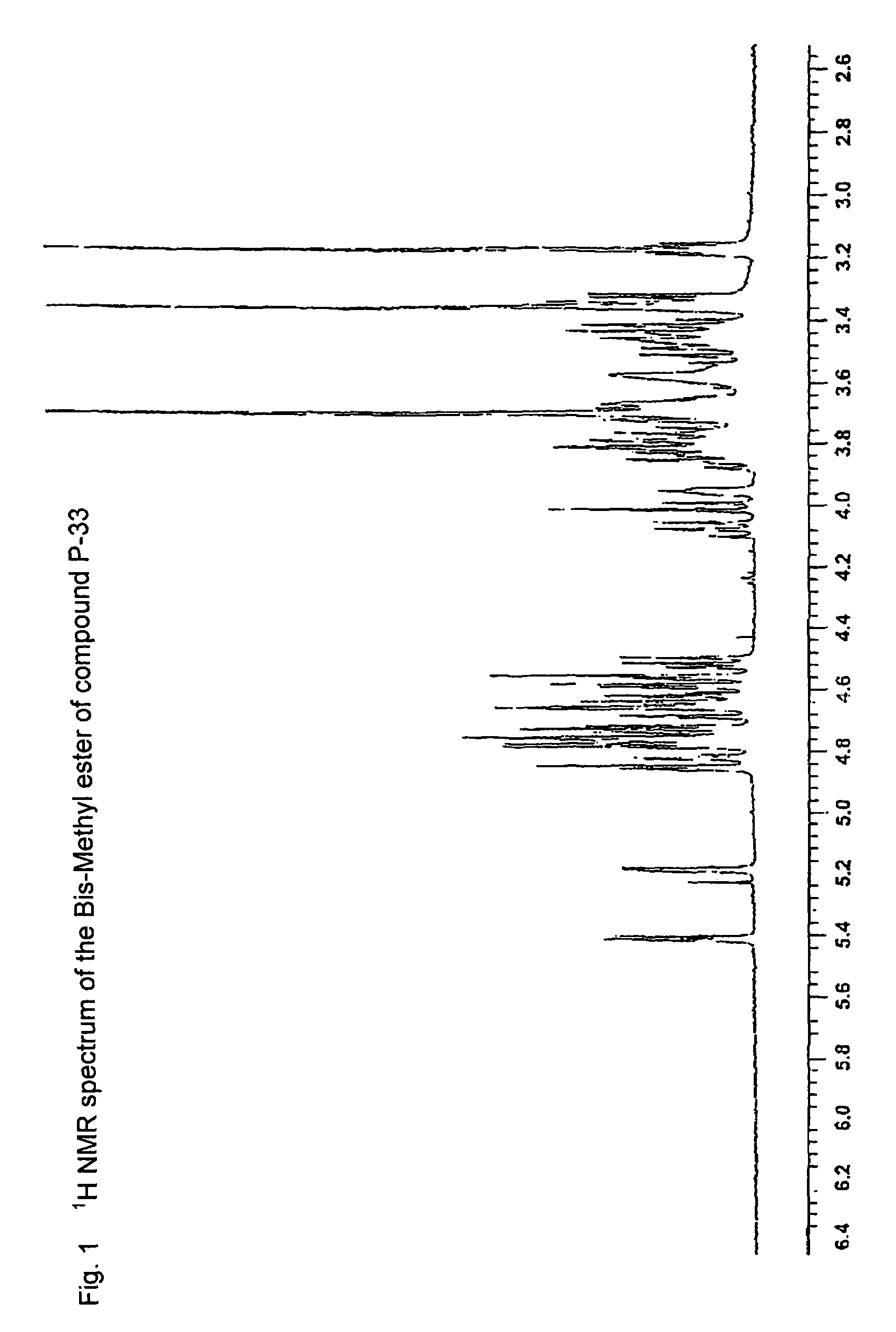

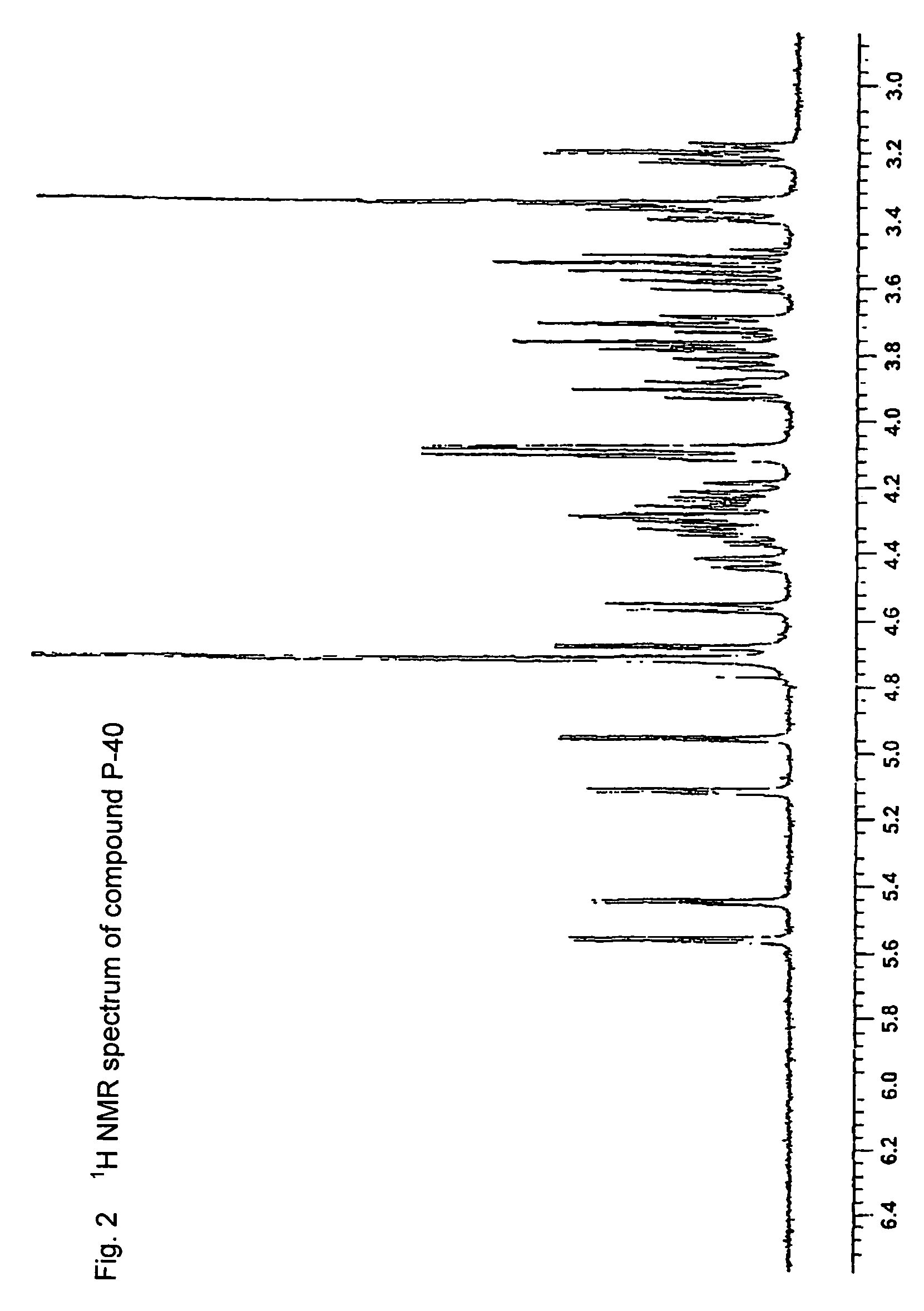

InactiveUS7541445B2Simple ideaImpact successEsterified saccharide compoundsOrganic active ingredientsHeparinoidsTetrasaccharide

Preparation of synthetic monosaccharides, disaccharides, trisaccharides, tetrasaccharides and pentasaccharides for use in the preparation of synthetic heparinoids.

Owner:DR REDDYS LAB SA

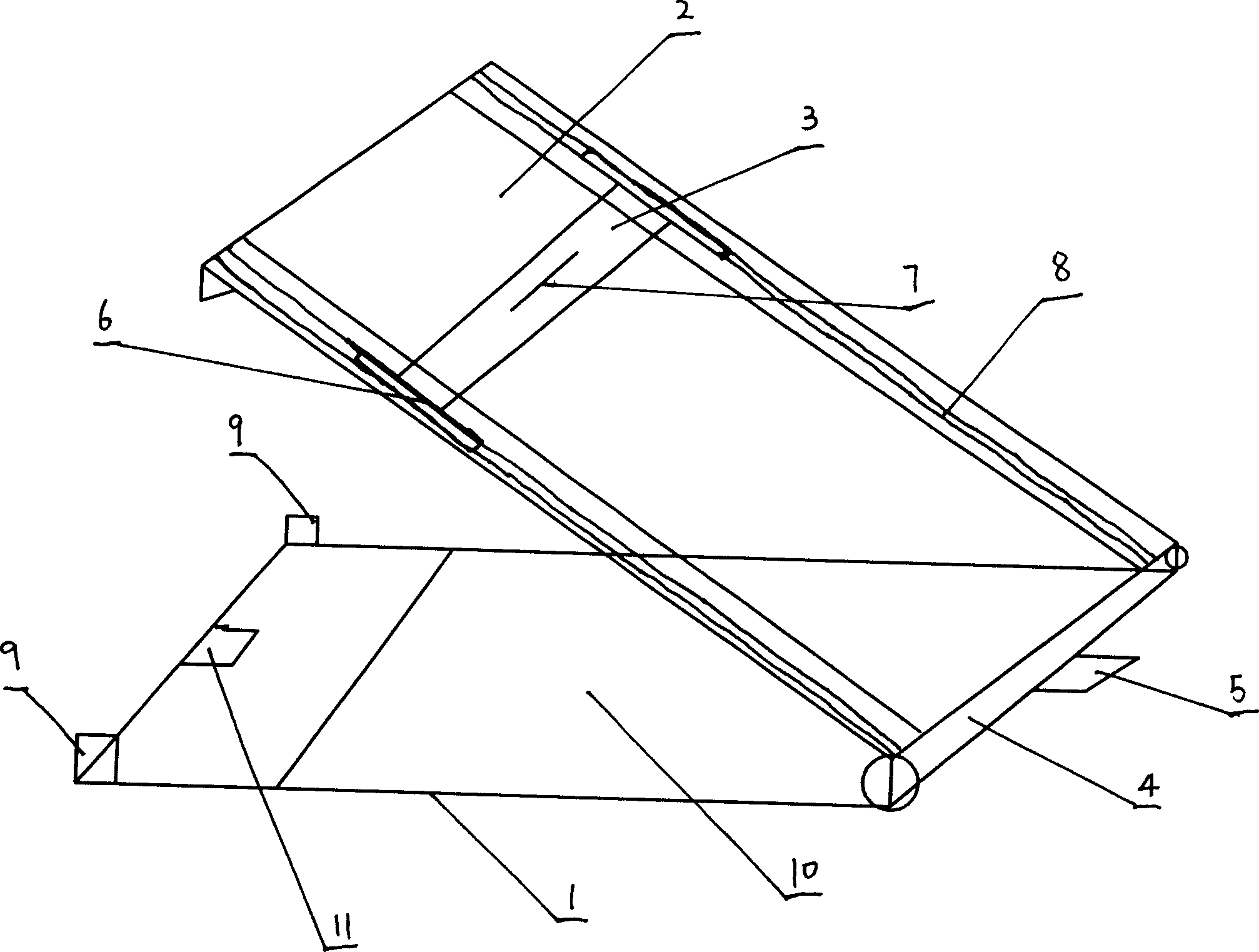

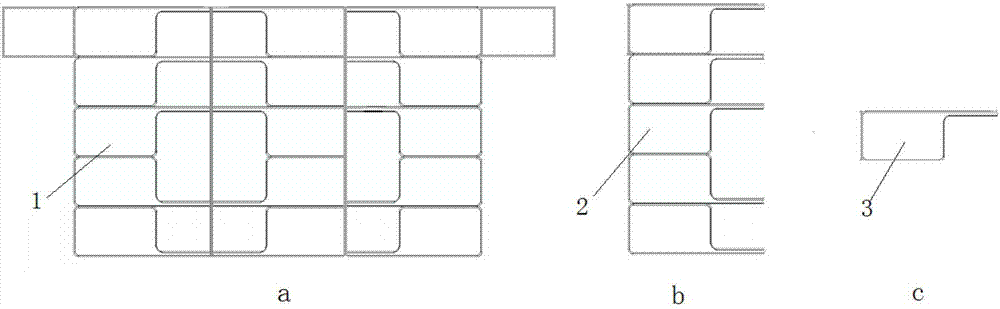

Double-layer wash board with brush

InactiveCN1609323ASimple ideaFunction increaseHand rubbing apparatusHand implementsEngineeringMechanical engineering

The two-layer wash board with brush consists of lower wash board, upper wash board, special brush, pivot, clothing fixing clamp and brush sliding rod. The lower wash board and the upper wash board are pivoted via pivot with spring, the special brush has sliding rods on two side for embedding into the slots on the upper wash board, the lower wash board and the upper wash board have contact legs in the corners of the unconnected side, and the lower wash board has one side with rough part and hook. The present invention is simple, multifunctional, novel and effective in washing.

Owner:李志军

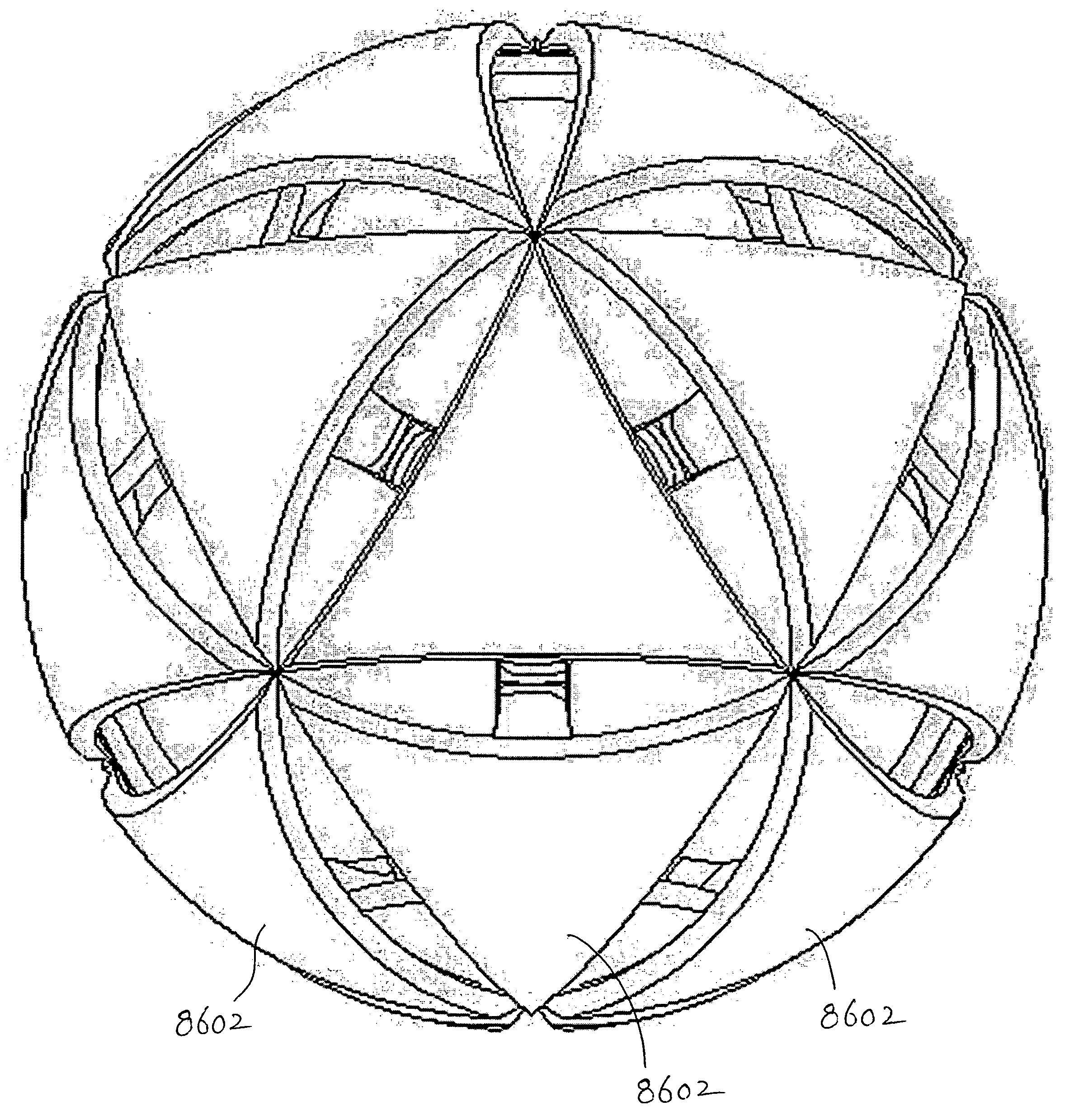

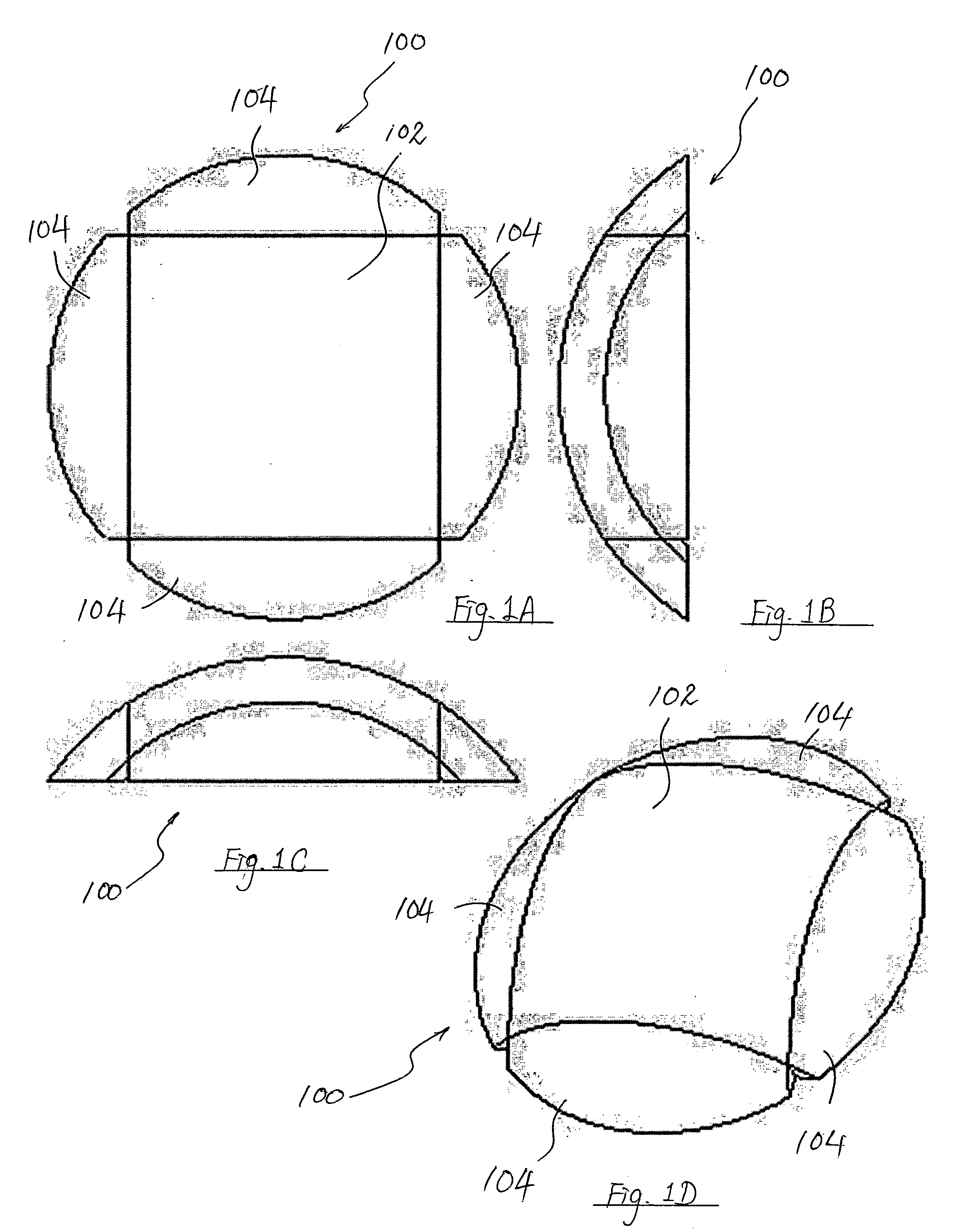

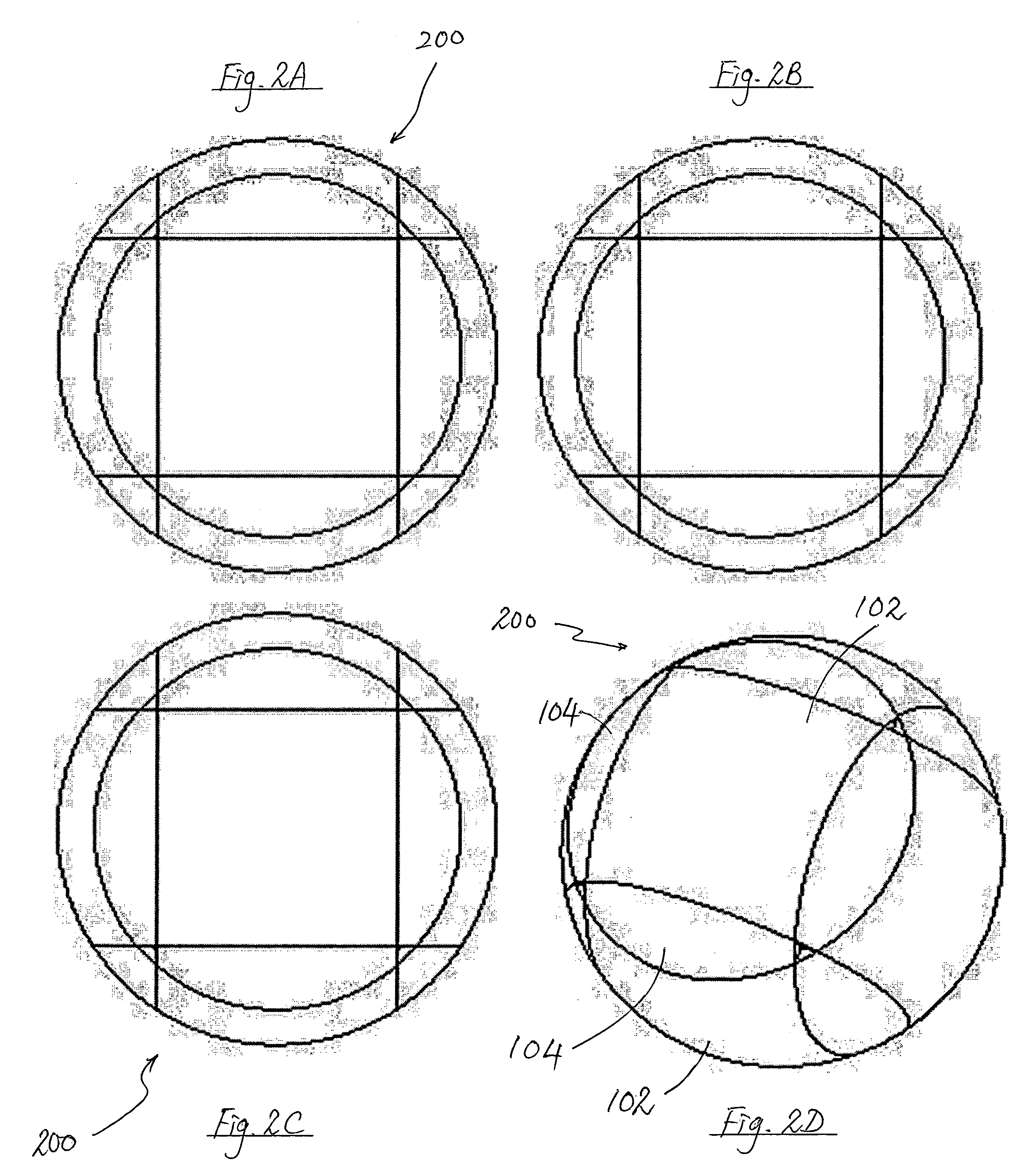

3-Dimensional puzzle and method of forming same

InactiveUS20050269770A1Applied with versatilitySimple ideaIndoor gamesSpherical sectorComputer science

The present invention makes use of the spherical sectors, semi-spheres, cylindrical or circular sections of a solid object or the surface of an object, and breaks them into components. If no such spherical sectors, semi-spheres, cylindrical or circular sections are available on the object, or the existing ones cannot be used for any reason, one can create some adequate ones under allowable circumstances. The puzzle will come into being when any of its broken down components can be shared with (interchanged with components of) other flat or spherical or circular or cylindrical surfaces. The idea of the present invention is rather simple, however it may be applied in a versatile manner.

Owner:MAK CHI YIN

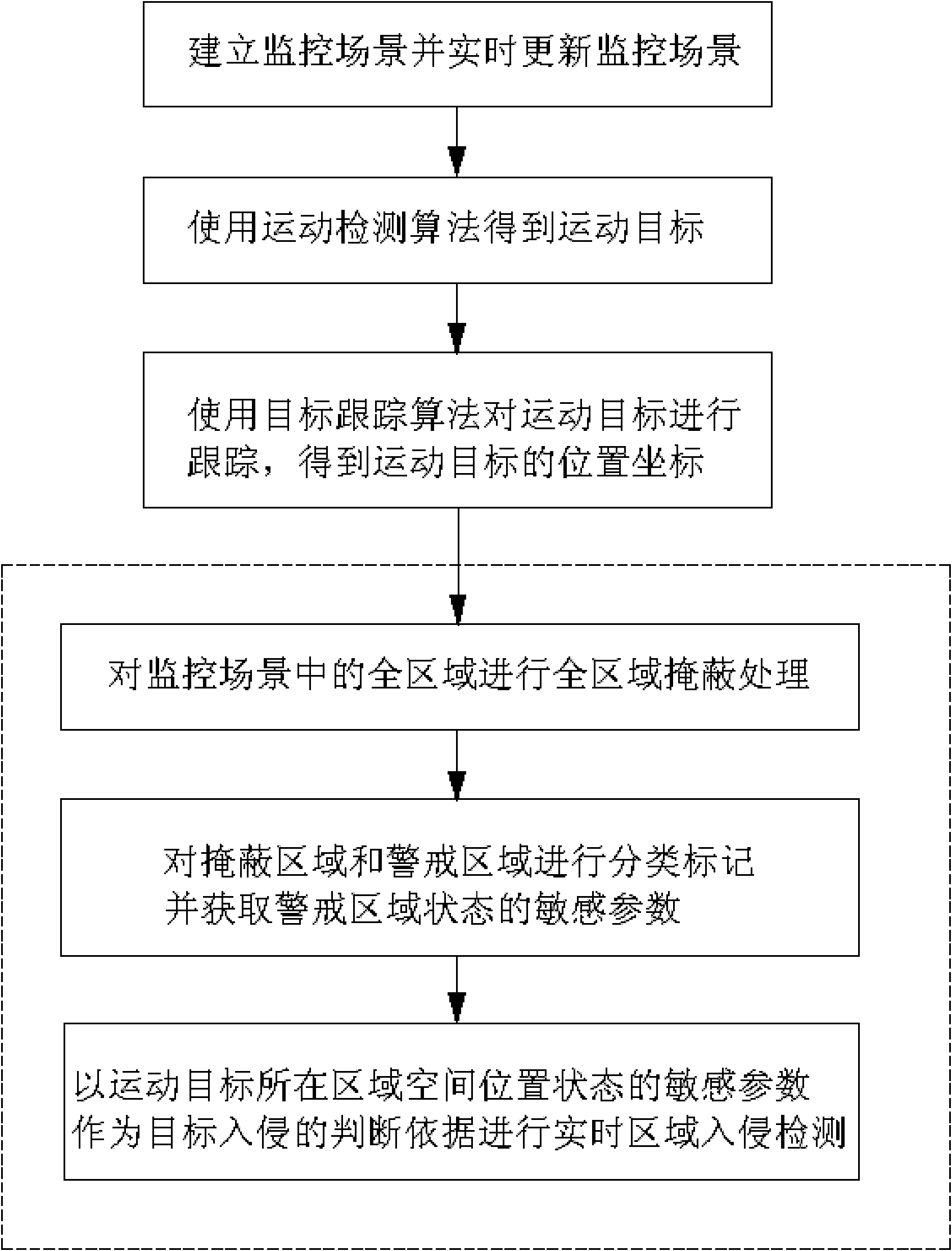

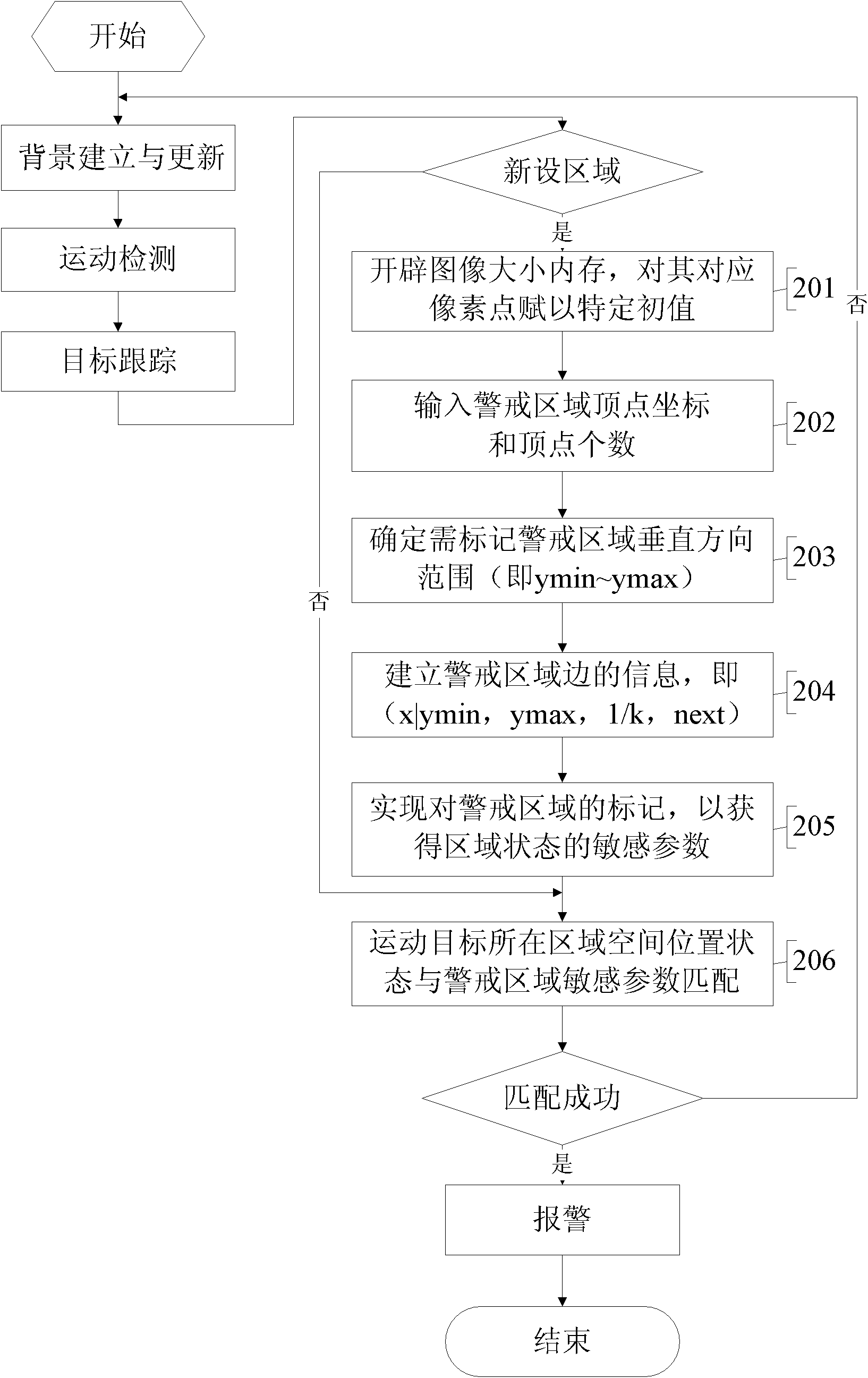

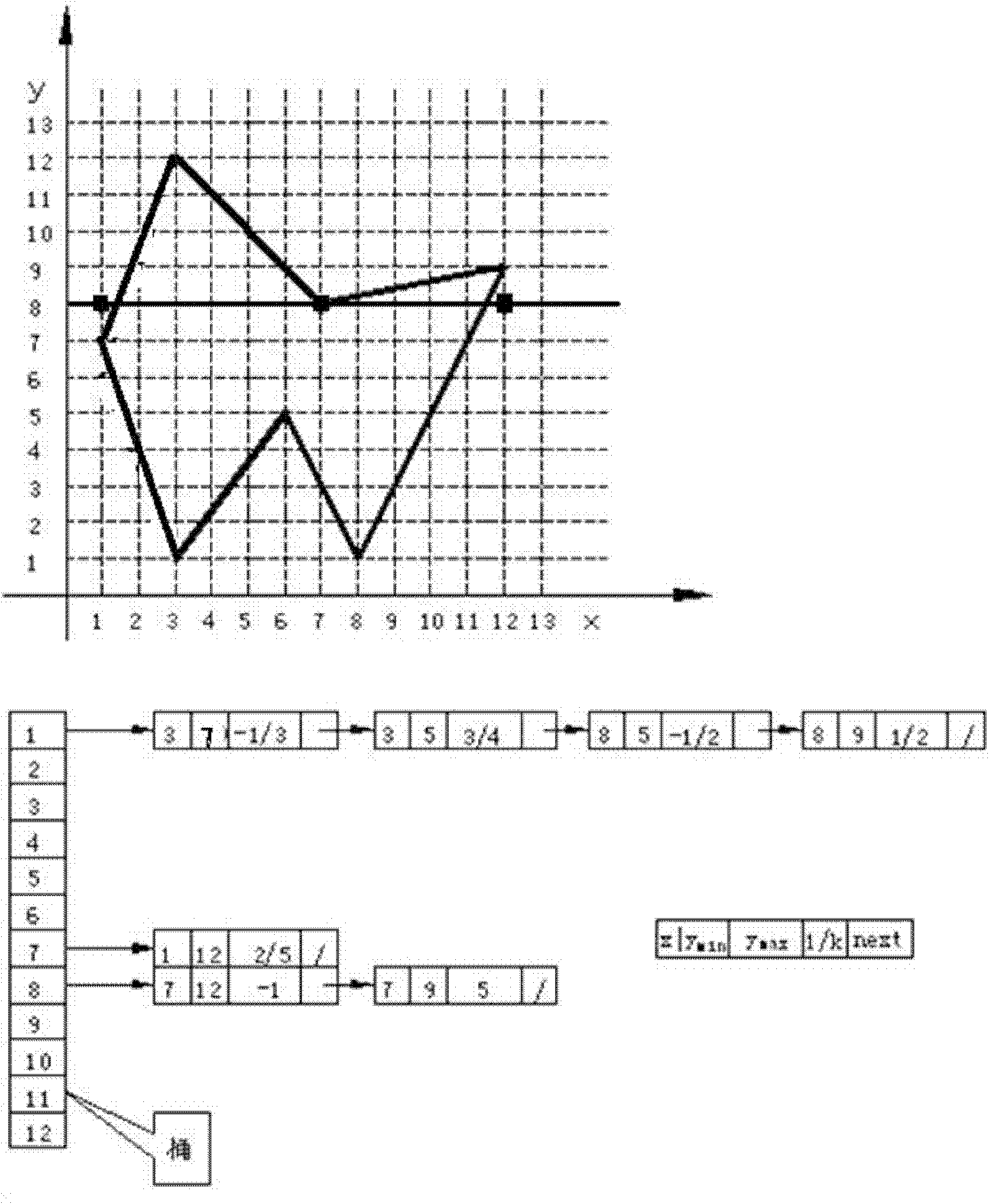

Regional invasion real-time detection method

ActiveCN101835035AReduce the number and complexity of judgmentsSimple ideaImage analysisClosed circuit television systemsRegion detectionObject tracking algorithm

The invention relates to a regional invasion real-time detection method, which comprises the following steps: (1) establishing a monitoring scene according to video frame data and updating the monitoring scene in real time; (2) obtaining a moving target by using a movement detection algorithm; (3) tracking the moving target by using a target tracking algorithm and obtaining position coordinates of the moving target; and (4) performing invasion judgment on the moving target by using a region detection algorithm, namely, performing full-region shielding processing on a full region in the monitoring scene, classifying and marking a shielded region and a warning region, acquiring sensitive parameters of the state of the warning region and taking the sensitive parameters of the state of a regional space position where the moving target is as target invasion judgment bases to realize regional invasion real-time detection. The method has the advantages of rational design, realization of a regional invasion real-time detection function by using a region classifying and marking method, simple concept, easy implementation, improvement on processing speed and execution efficiency and adaptability to the real-time monitoring of regions of any polygonal shape (convex and concave polygons).

Owner:TIANJIN YAAN TECH CO LTD

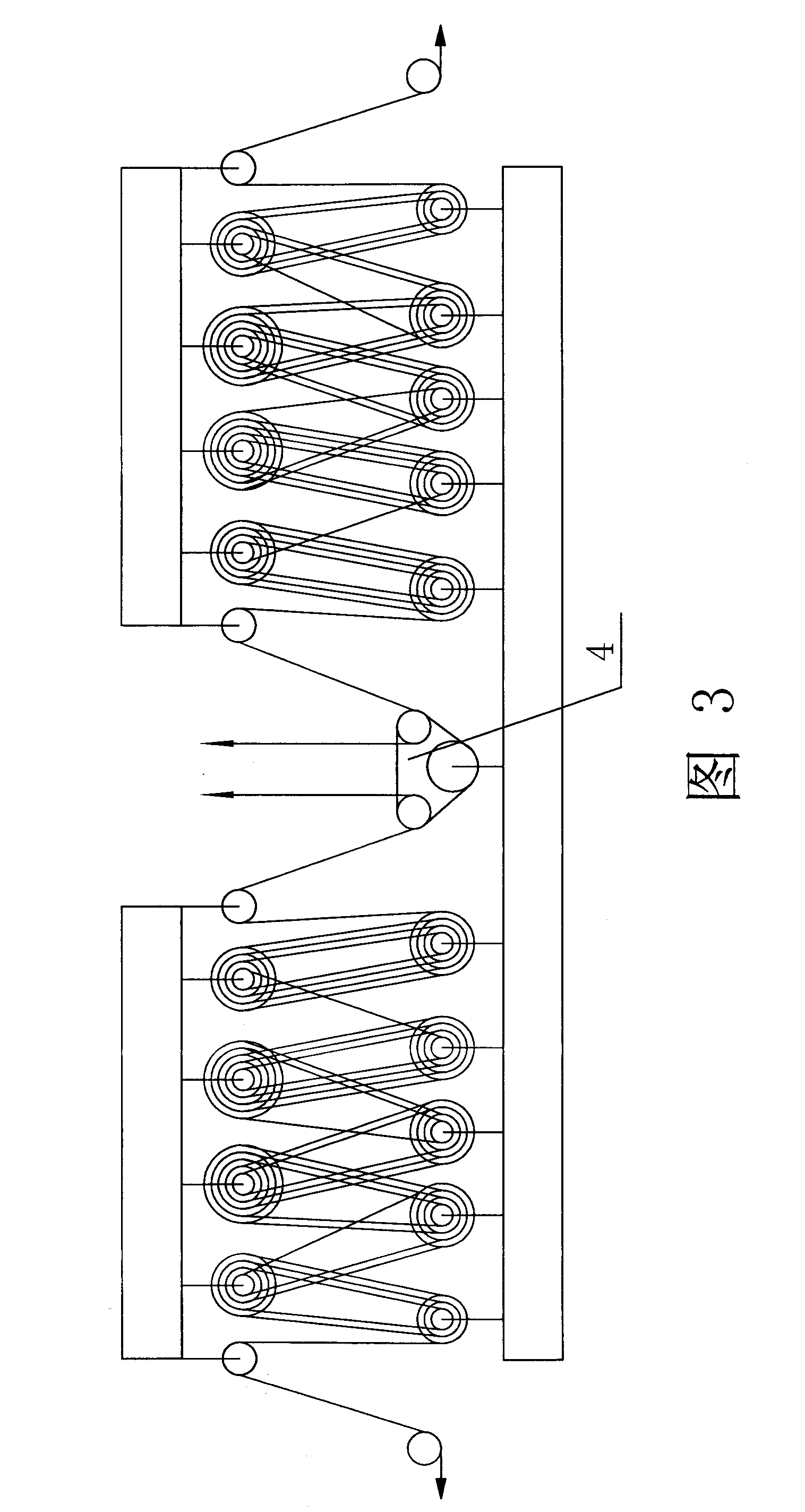

Method for producing terylene pre-tropism continuous yarn by utilizing reclaimed polyester bottle

ActiveCN101144191ALow costReduce energy consumptionMelt spinning methodsSpinning solutions preparationYarnPolyester

The present invention belongs to the fiber producing method field, in particular relates to a method which uses a reclaimed PET bottle to produce the terylene preoriented filament in particular. The present invention mainly solves the problems of the prior art that the cost of raw materials for production is high, the drying efficiency is low, and the uniformity is poor, etc., and provides a method which uses the reclaimed PET bottle to produce the terylene preoriented filament with low cost of the raw materials for production, high drying efficiency, and good uniformity. The present invention has the major steps that the bottle piece of the PET bottle is produced; the bottle piece is continuously crystallized and dried by passing through a pre-crystallizer and a drying tower; the dried bottle piece directly enters a threaded rod extrusion machine, and is melted and extruded by a spinning threaded rod; the molten polyester material is continuously filtrated by a molten mass filter with a big filtering area of one level or two levels, to enter a spinning manifold; a thread line is cooled by passing through a cross air blasting, to wind to form the preoriented filament.

Owner:浙江聚元新材料股份有限公司

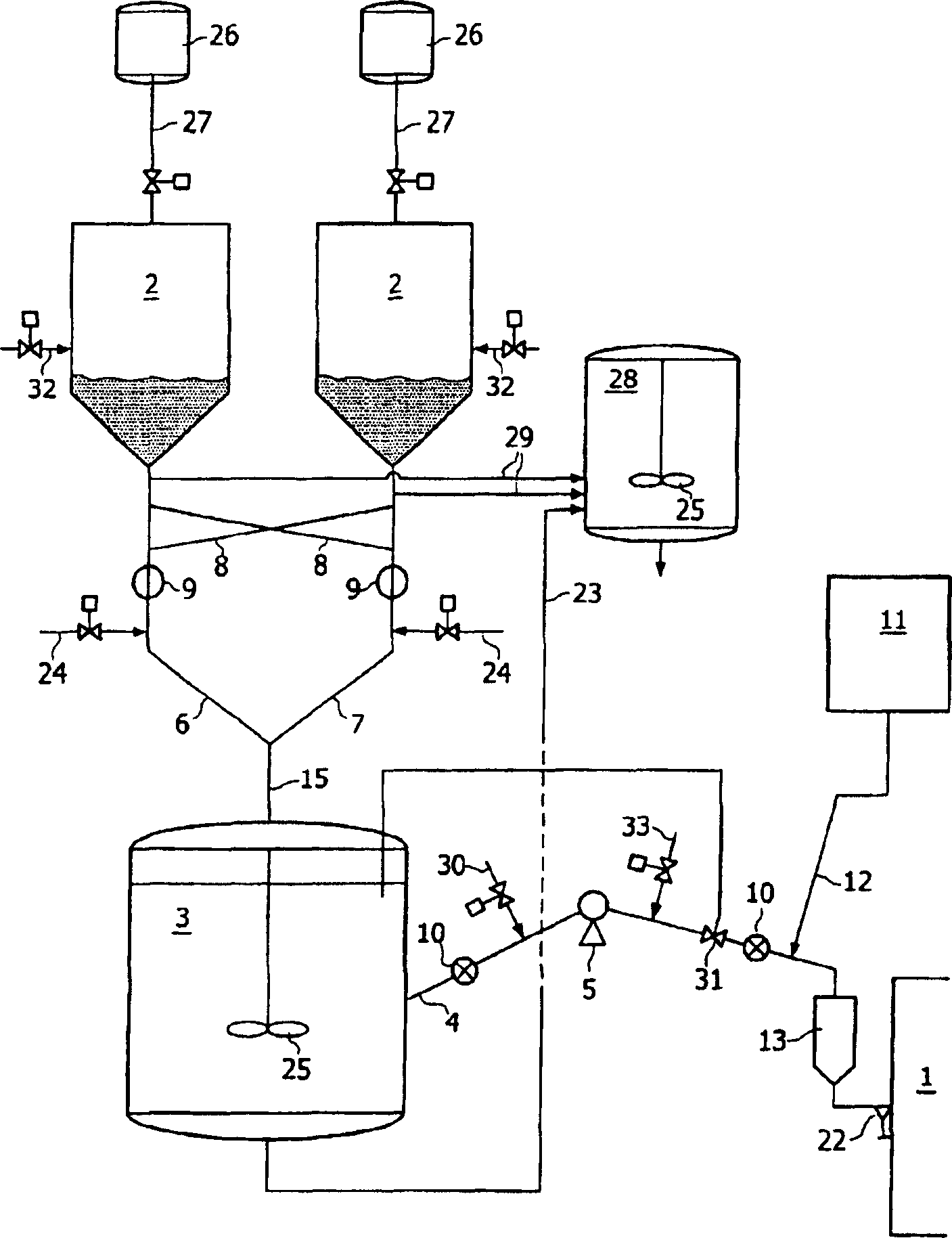

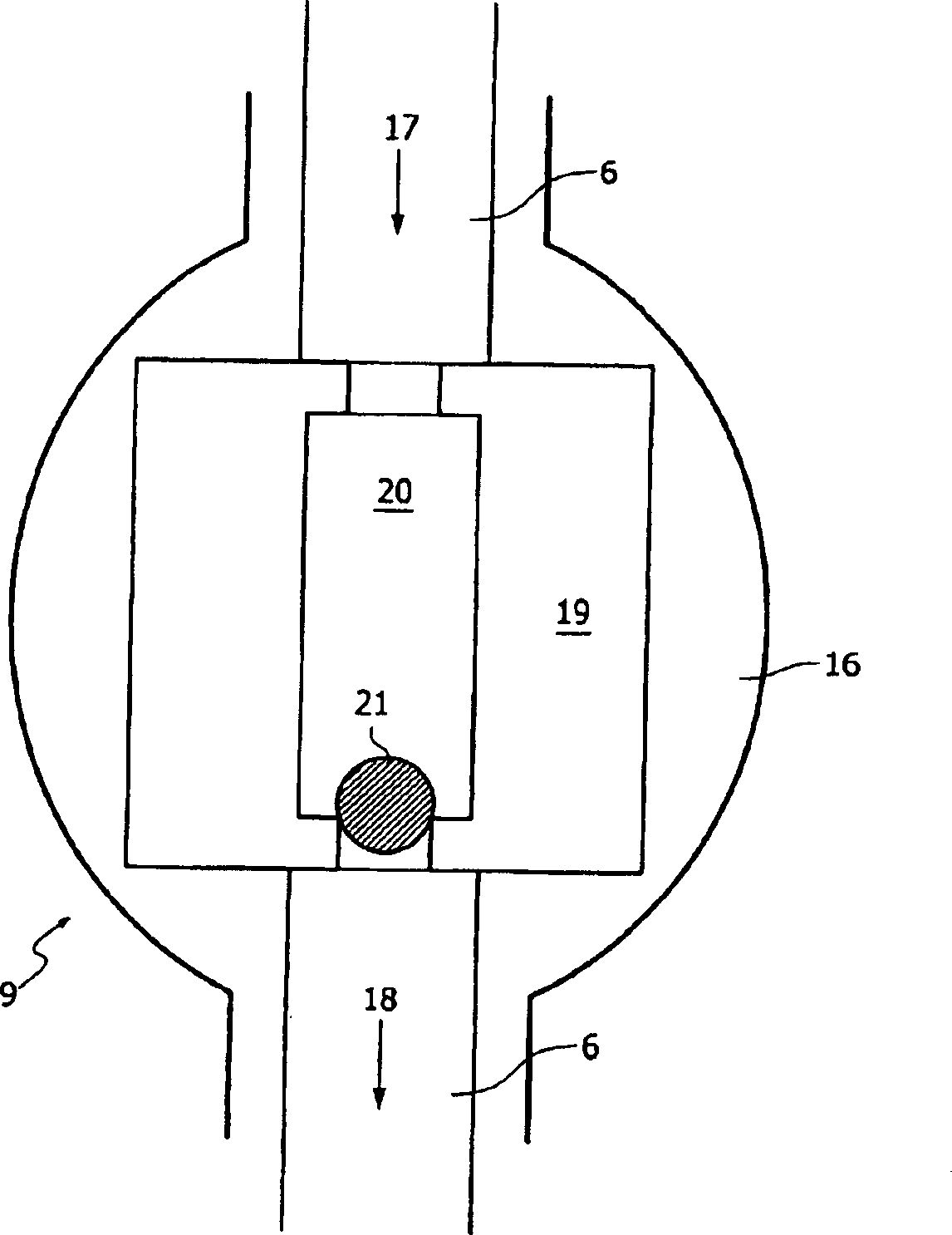

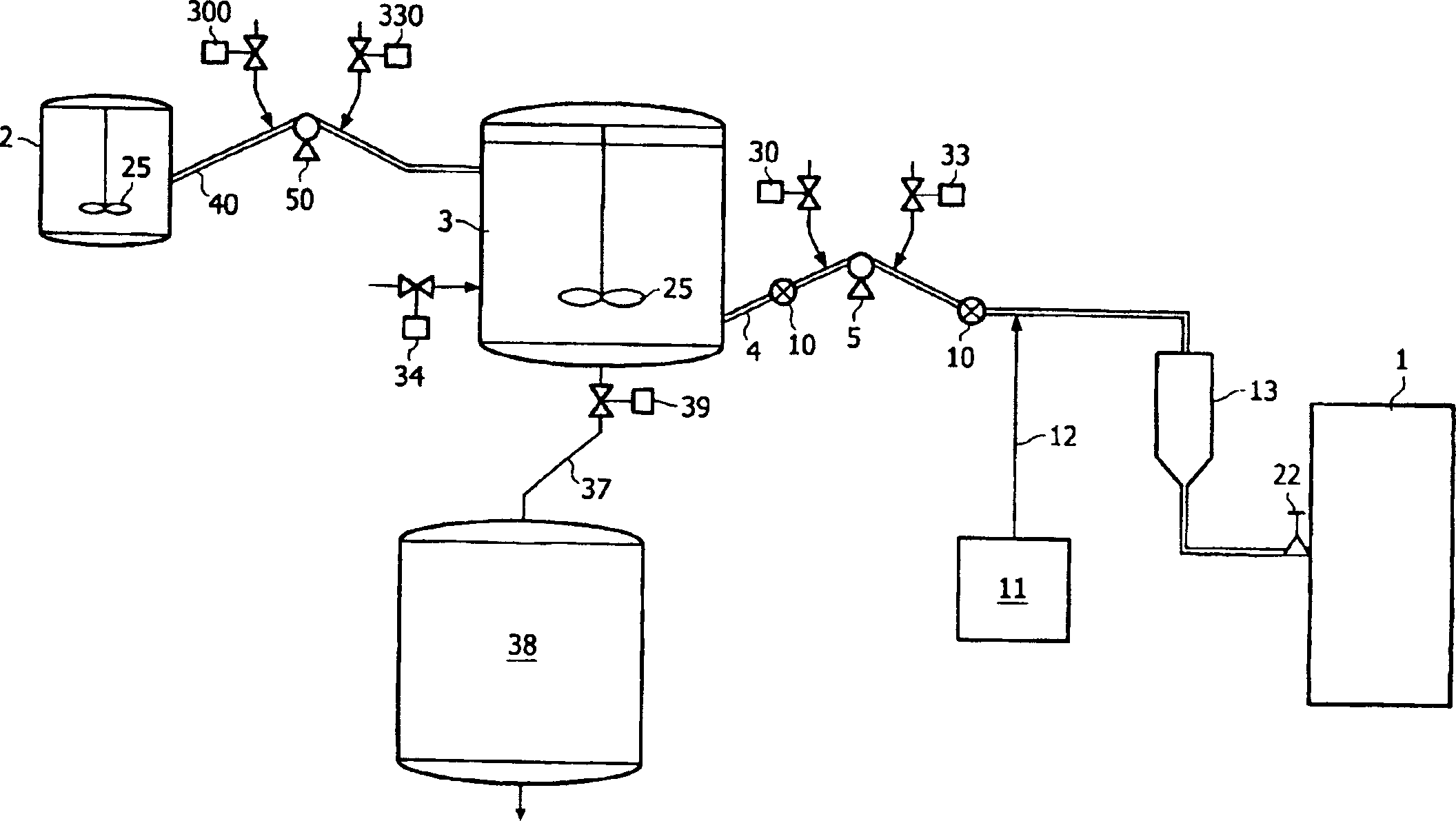

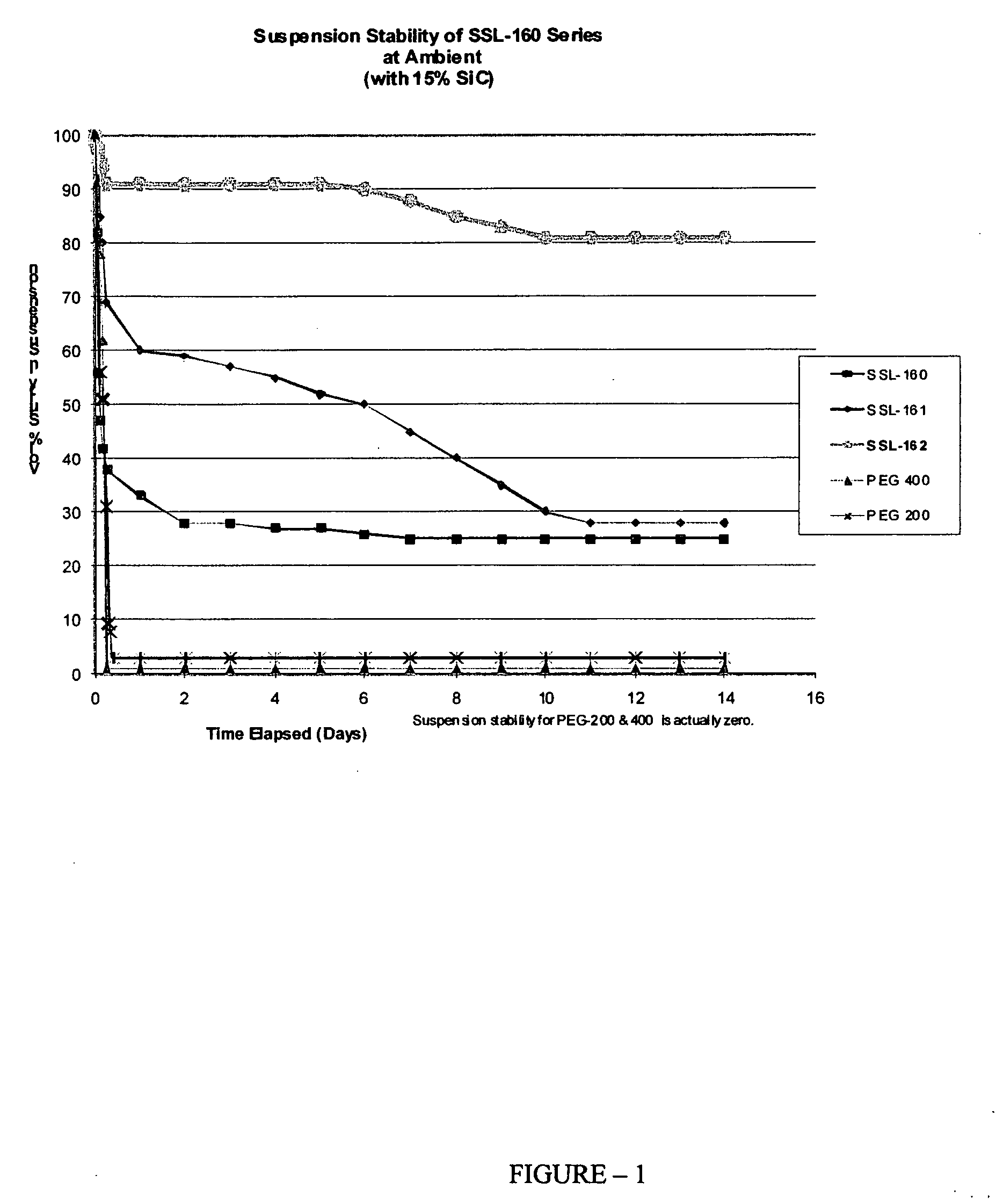

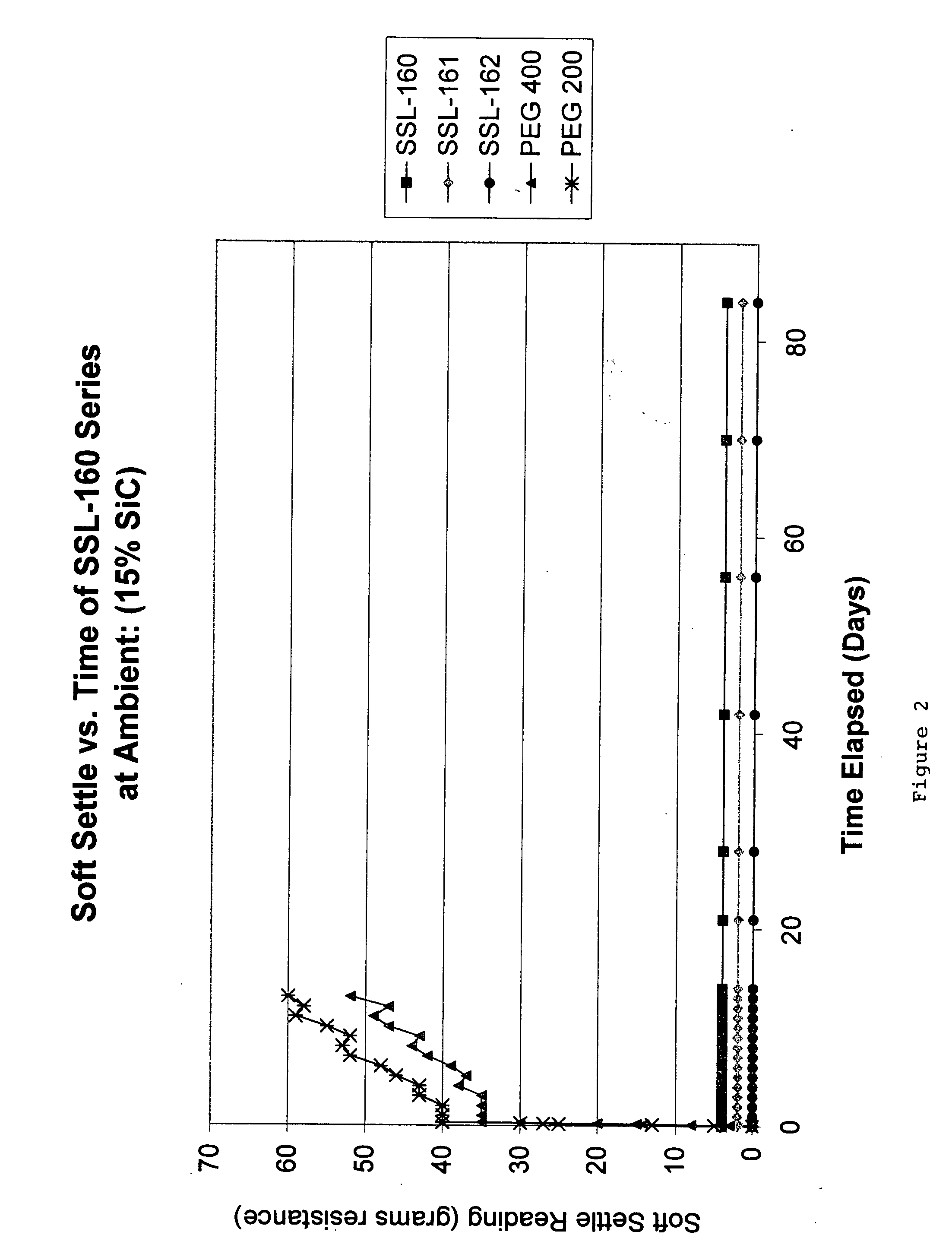

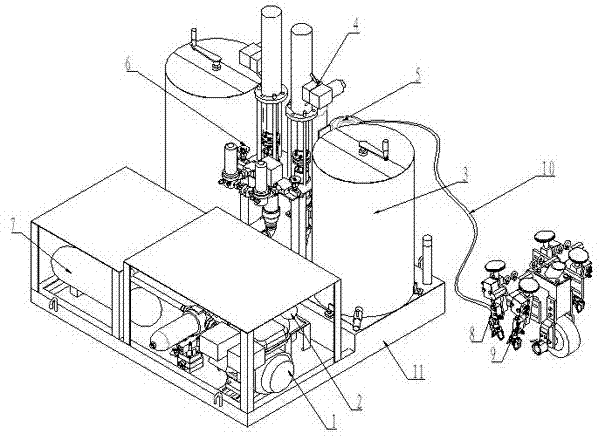

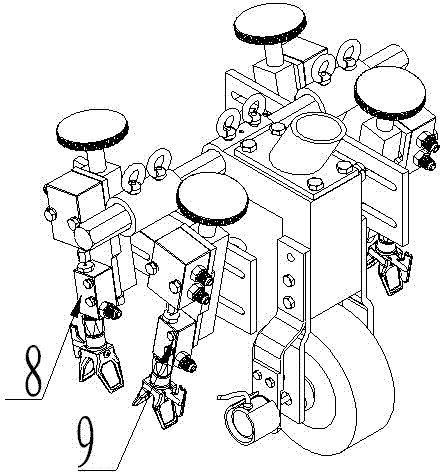

Method and apparatus for preparing and supplying catalyst slurry to a polymerisation reactor

InactiveCN1917949AImprove the yield of polymerization reactionsQuality improvementChemical/physical/physico-chemical stationary reactorsSlurryReagent

The present invention relates to an apparatus for preparing and supplying catalyst to an ethylene slurry loop polymerisation reactor and to an apparatus for controlling the injection of catalyst slurry in a polymerization reactor wherein polyethylene is prepared. The present invention a Iso relates to a method for optimising catalyst supply to a polymerisation reactor. The diluted catalyst is transferred to the reactor (1) using a membrane pump (5) controllable in function of the concentration of a reactant in said reactor (1).

Owner:TOTAL RES & TECH FELUY

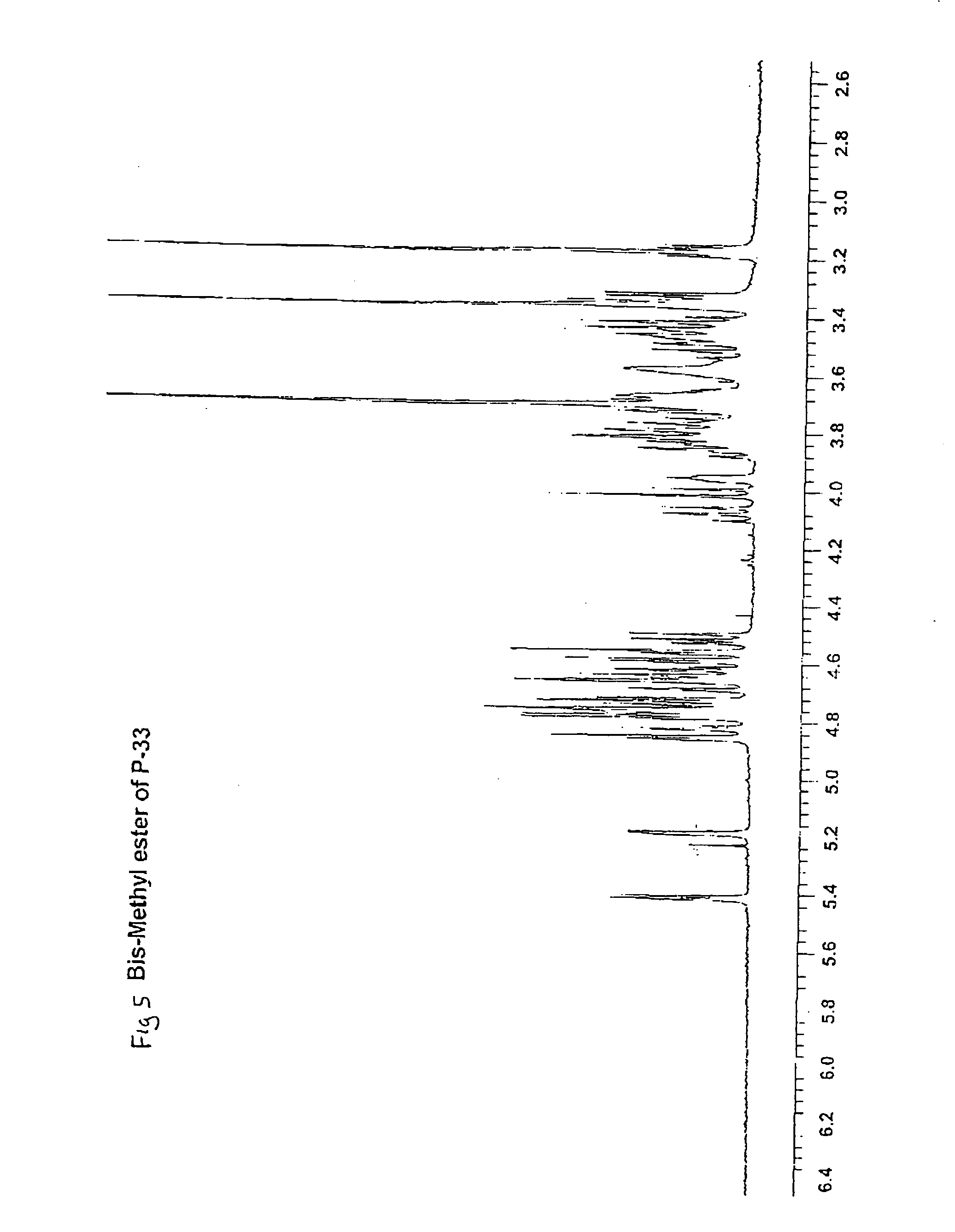

Synthetic heparin pentasaccharides

InactiveUS20050080042A1Simple ideaImpact successEsterified saccharide compoundsOrganic active ingredientsHeparinoidsDisaccharide

Preparation of synthetic monosaccharides, disaccharides, trisaccharides, tetrasaccharides and pentasaccharides for use in the preparation of synthetic heparinoids.

Owner:DR REDDYS LAB SA

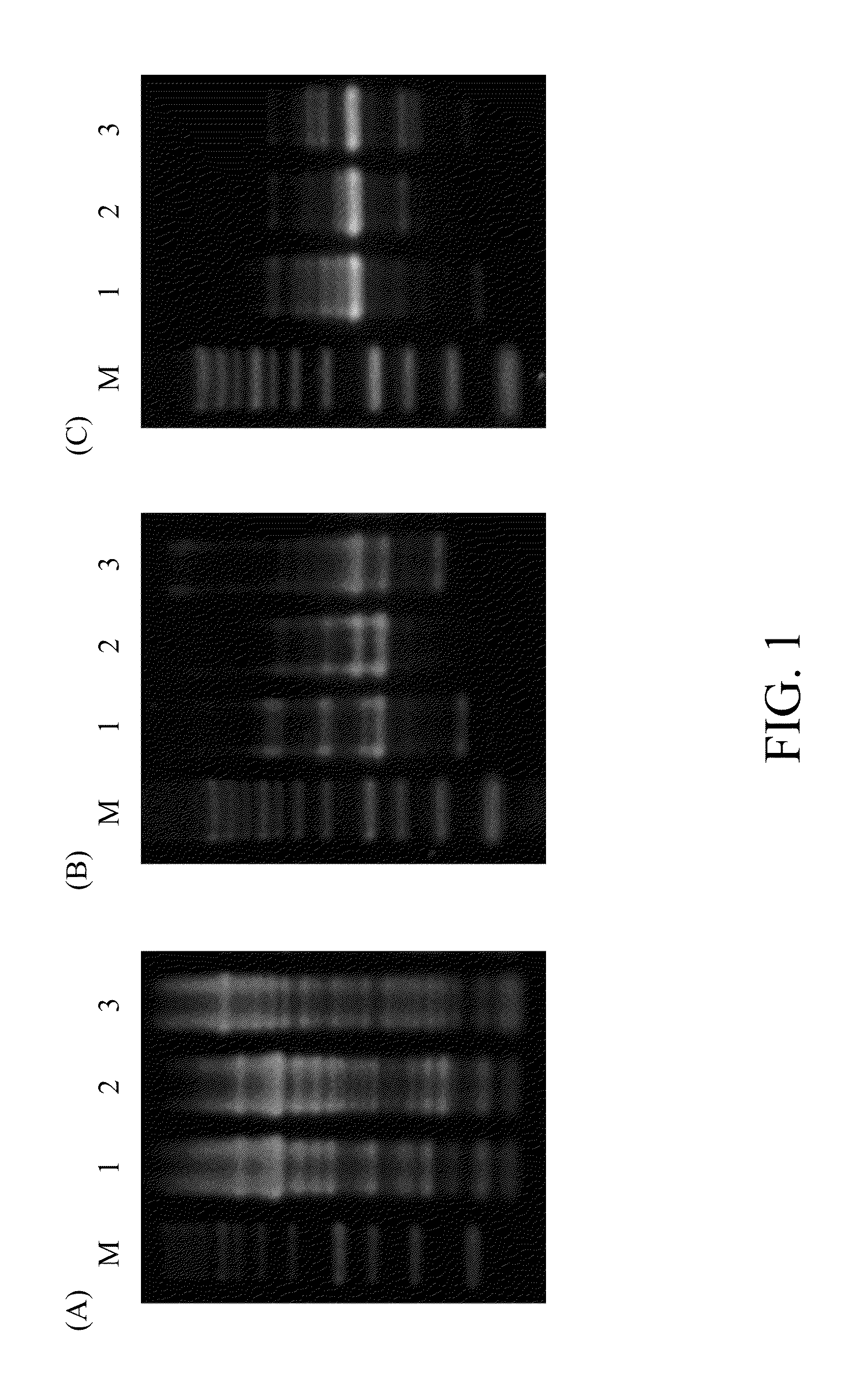

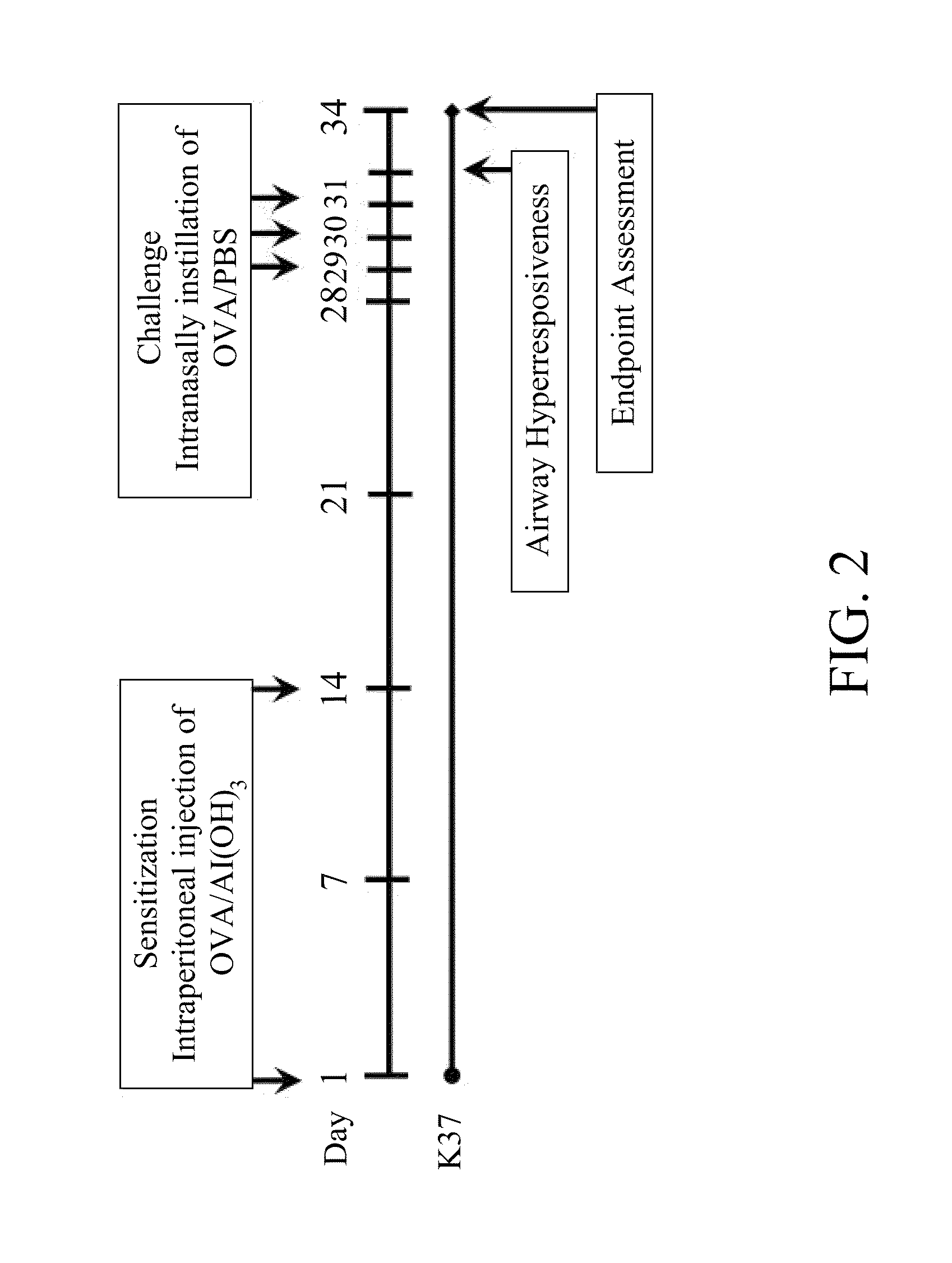

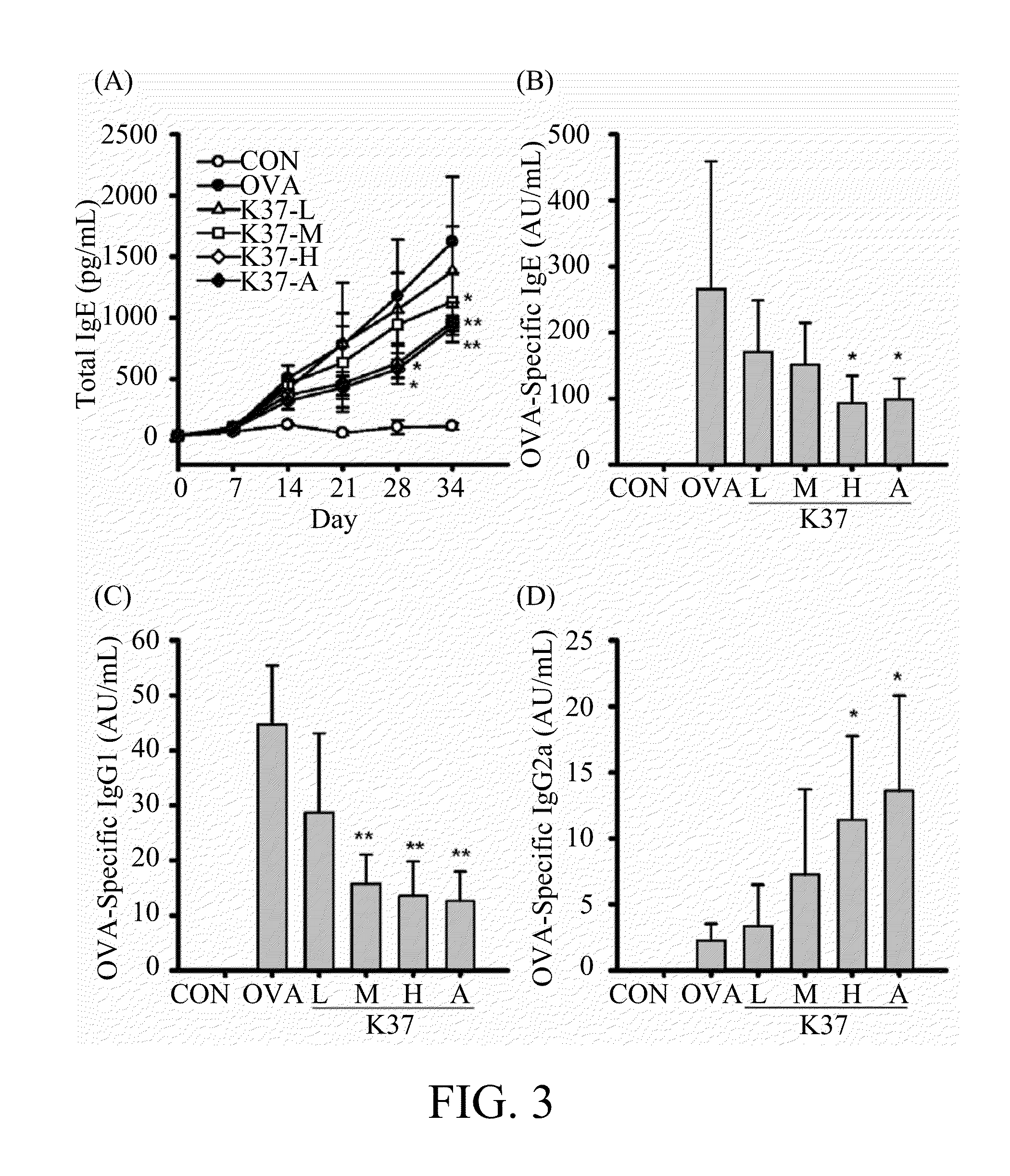

Lactic acid bacterium having immunomodulatory and Anti-allergic effects and pharmaceutical composition containing the same

ActiveUS20150240200A1ExpressionHigh expressionBacterial antigen ingredientsBacteriaLactobacillusMicrobiology

The present invention provides an isolated lactic acid bacterium, Lactobacillus plantarum subsp. plantarum K37 strain, deposited in DSME-DEUTSCHE SAMMLUNG VON MIKROORGANISMEN UND ZELLKULTUREN GmbH under Accession No. DSM 27445. The present invention further provides a pharmaceutical composition comprising the isolated lactic acid bacterium (Lactobacillus plantarum subsp. plantarum K37). Moreover, the present invention provides a method for preventing or treating a disorder in a subject, comprising a step of administering an effective amount of the isolated lactic acid bacterium (Lactobacillus plantarum subsp. plantarum K37) to the subject.

Owner:BENED BIOMEDICAL CO LTD

Remote authentication and transaction signatures

Authentication devices and methods for generating dynamic credentials are disclosed. The authentication devices include a communication interface for communicating with a security device such as a smart card. A dynamic credential such as a one-time password (OTP) or a message authentication code (MAC) may be generated by receiving from a server an encrypted initialization seed encrypted with an asymmetric encryption algorithm using a public key of a public / private key pair, submitting the encrypted initialization seed to a security device, decrypting at the security device the encrypted initialization seed with a private key of the public / private key pair, returning the decrypted initialization seed to the authentication device, deriving at the authentication device a secret credential generation key from the decrypted initialization seed, and generating the dynamic credential by combining a dynamic variable with the secret credential generation key using a symmetric cryptographic dynamic credential generation algorithm.

Owner:ONESPAN NORTH AMERICA INC

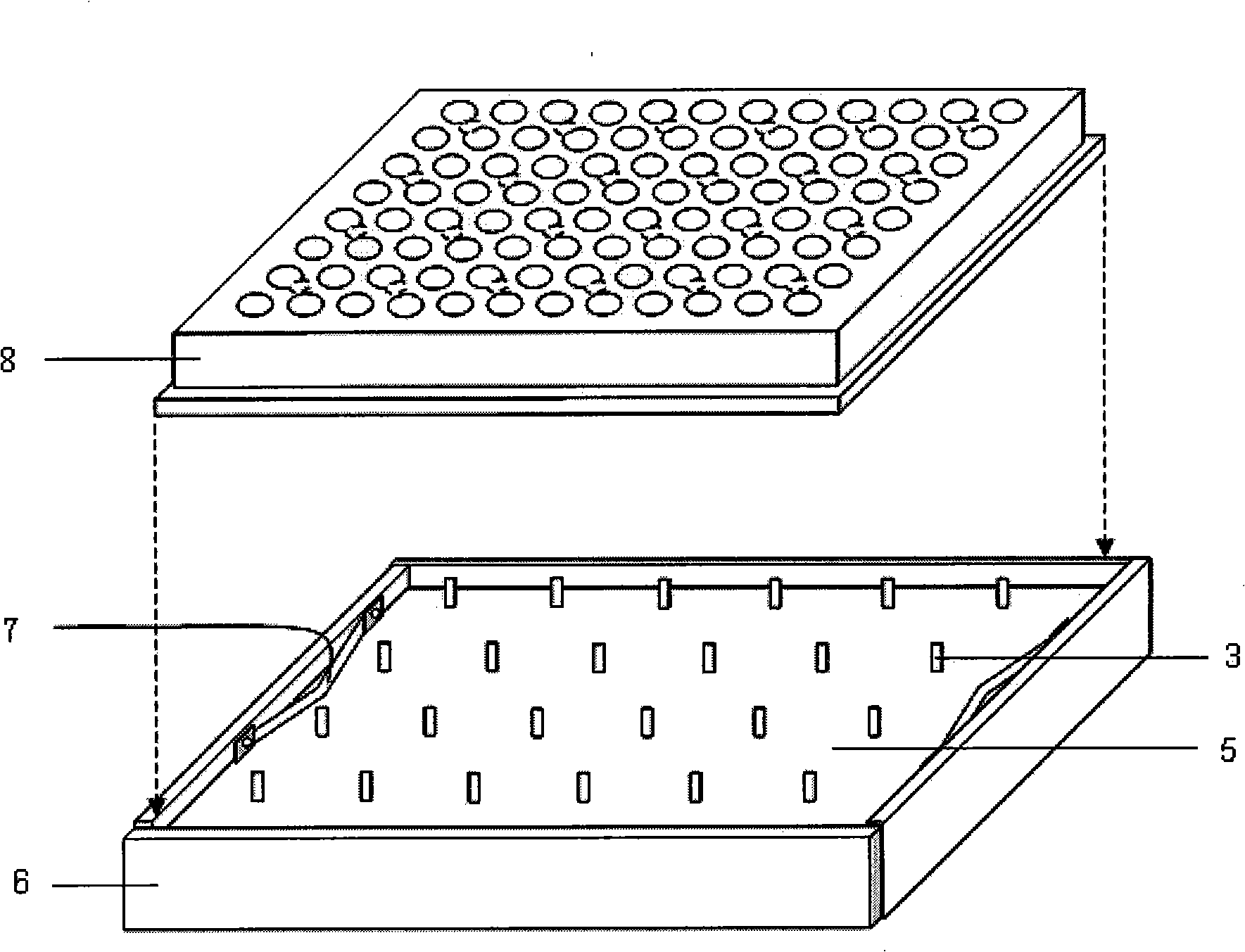

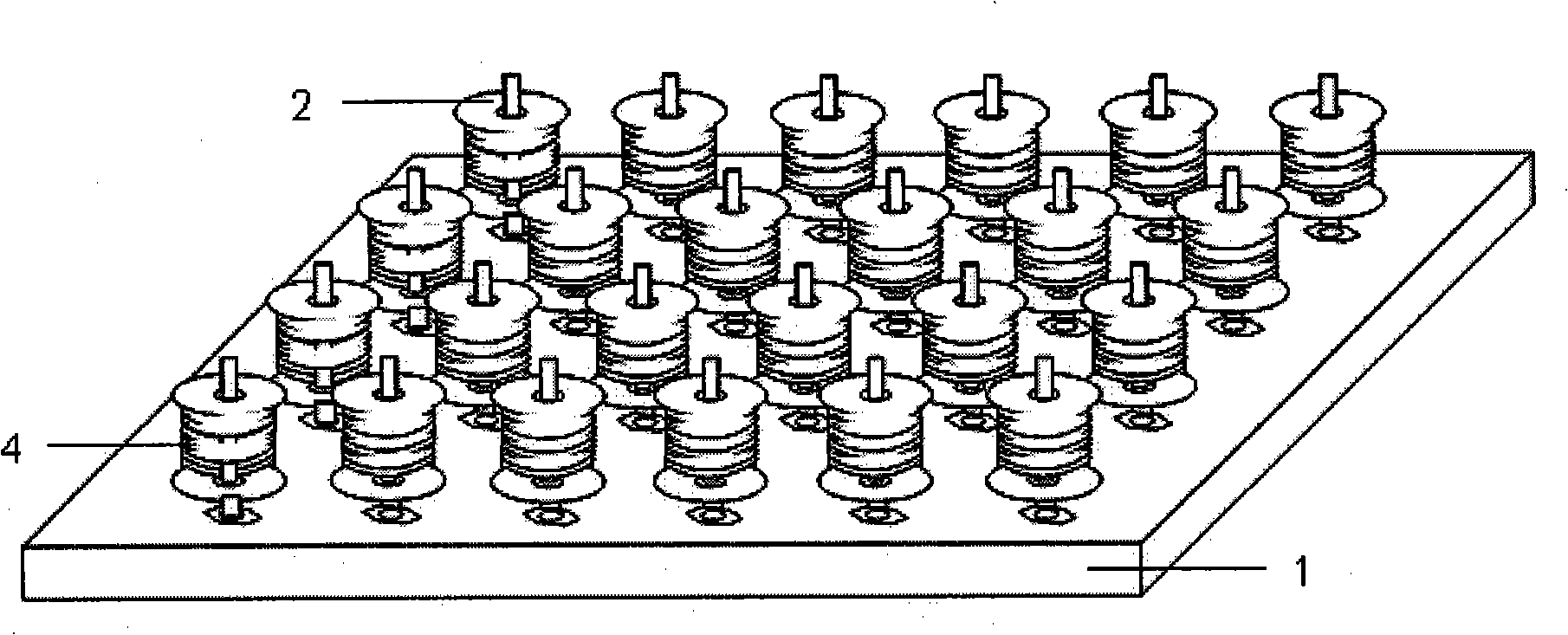

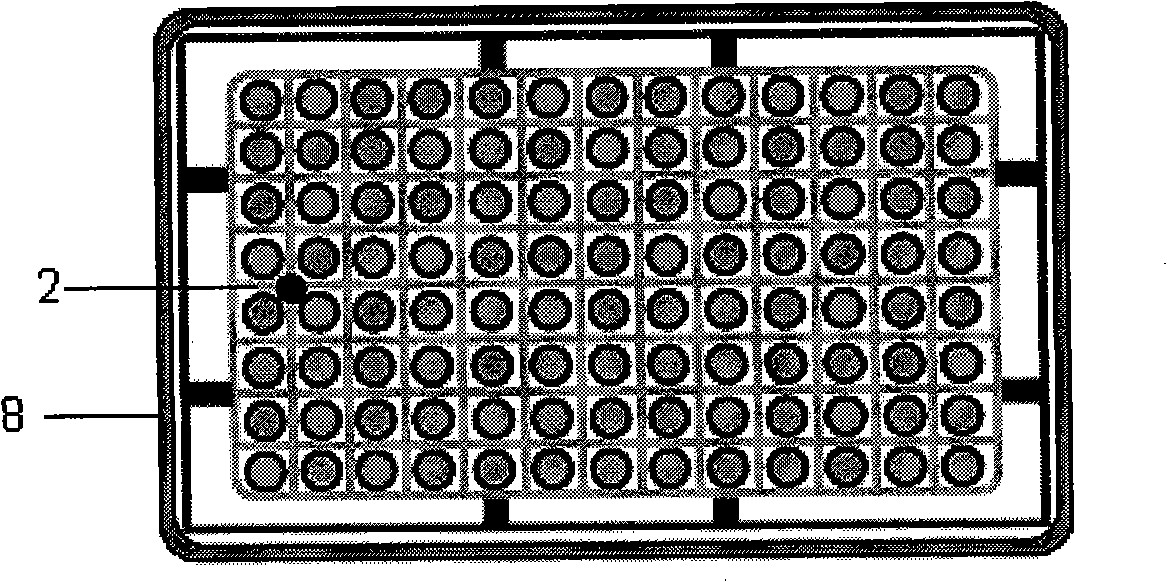

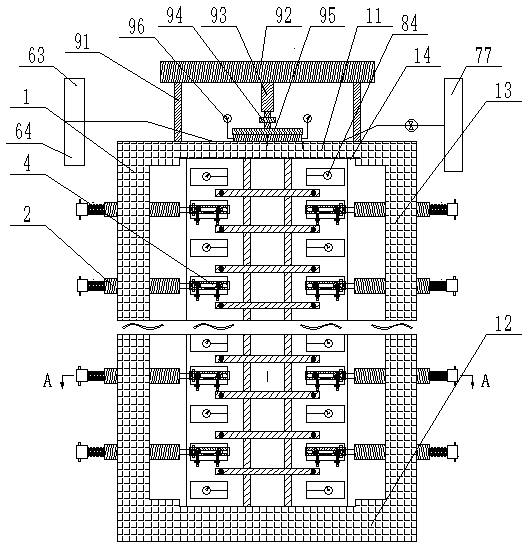

Micro-pore plate type electromagnetic separator

ActiveCN101319976AReduce volumeFully automatedChemiluminescene/bioluminescencePreparing sample for investigationEngineeringLaboratory facility

A millipore plate electromagnetic separator includes a salver; an electric magnet array consisting of a plurality of small electric magnets is arranged on the salver; each small electric magnet includes a magnetic core and a loop sheathed outside the magnetic core; the two ends of the loop are connected with powers; the upper surface of the electric magnet array is provided with a cover plate; a hole corresponding to the magnetic core is arranged on the cover plate; a pair of clamping springs are arranged in the two corresponding frames of the salver; a millipore plate is arranged at the top part of the cover plate and is clamped on the lower surface of the two clamping springs; the centers of 4 to 6 neighboring millipores on the millipore plate are corresponding to one small electric magnet. The millipore plate electromagnetic separator has the advantages of simple structure, low cost, fast separating speed and high efficiency; can realize single or uniformed control on each small electric magnet, is flexibly operated, is conveniently combined with an automatic plate washing device to realize the automatization of separation and can play the important roles on the aspects like clinical laboratory, environment detection, bioanalysis, drug screening, etc.

Owner:TSINGHUA UNIV

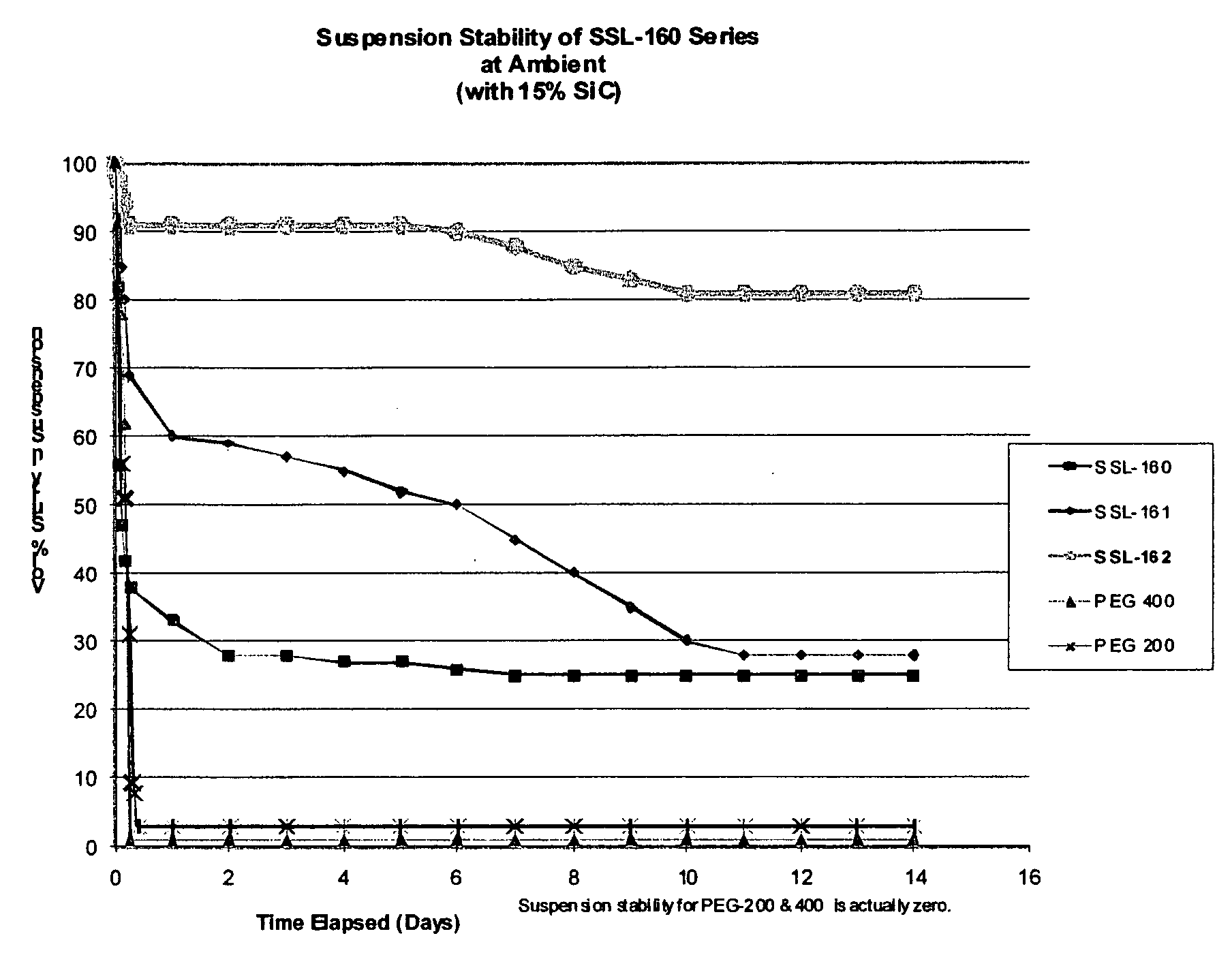

Cutting and lubricating composition for use with a wire cutting apparatus

InactiveUS20090270293A1Evenly distributedEffective and useful for precision cutting and grindingOrganic chemistryBase-materialsPolyelectrolyteWire cutting

The invention relates to a cutting and lubricating suspension composition containing gelatinous particles for cutting hard and brittle material with a wire saw. The composition contains an in situ partially neutralized polyelectrolyte and a glycol which suspends abrasive particles used in the cutting operation.

Owner:PPT RES

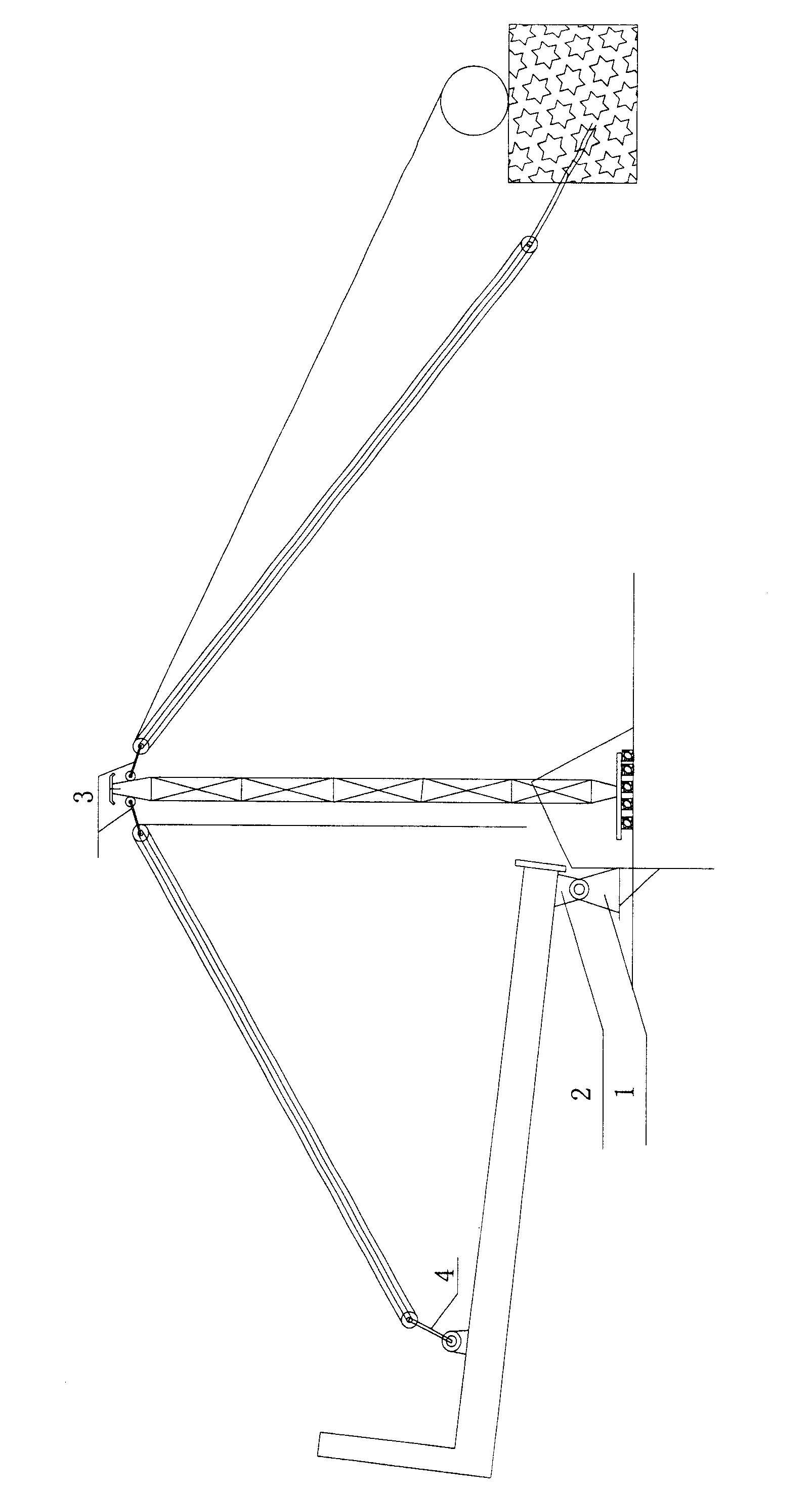

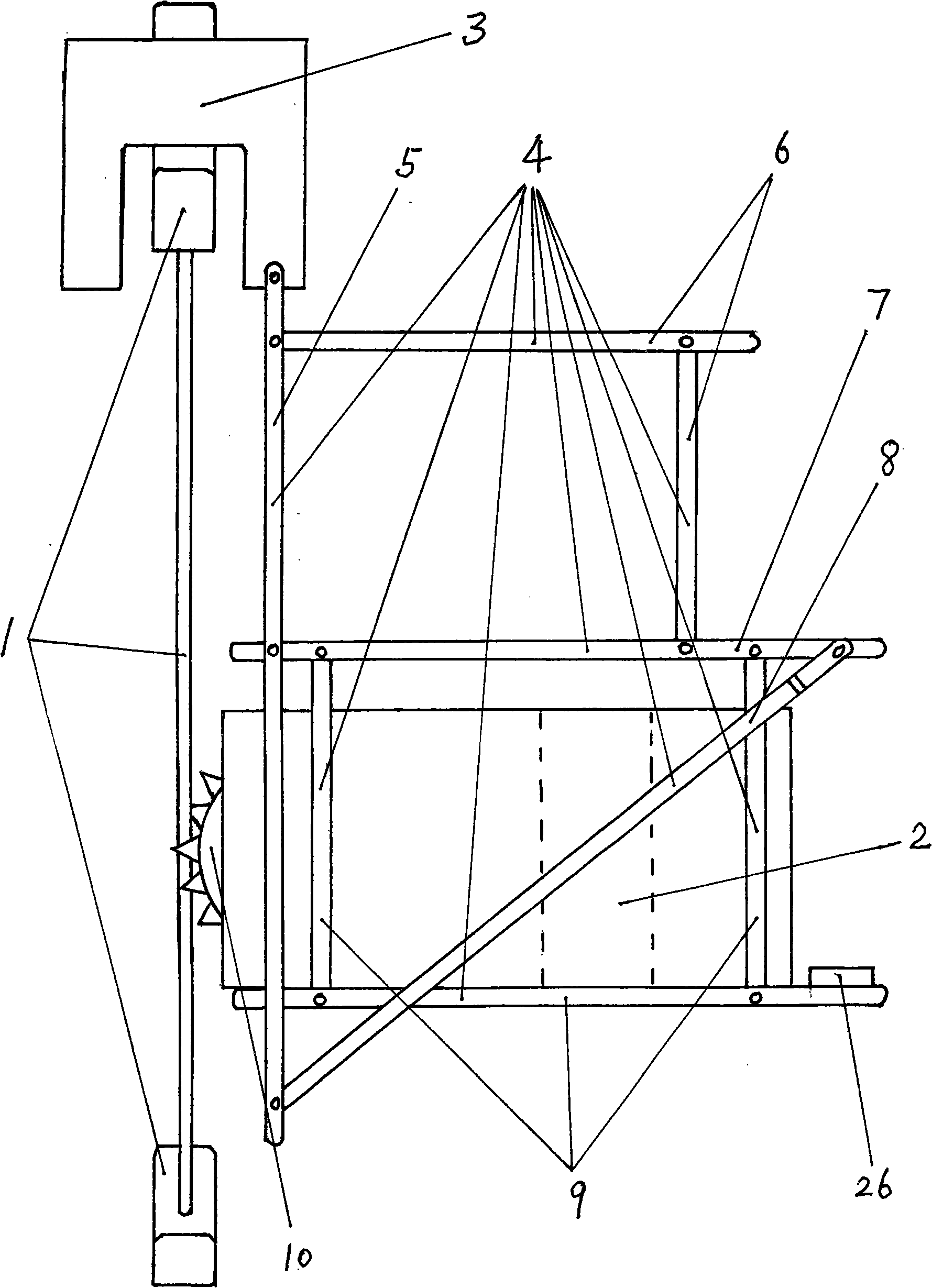

Mine using great steel derrick lifting special tool

When erecting a steel structure headframe, by traditional operation method, when using a tackle, the tackle is fixed on a holding rod by a steel wire rope and easily rotates and wrings, and causes uneven stress of the rope; therefore, a headframe can not be accurately hoisted to a correct position, which thus brings about bigger security hidden trouble. A main inclined frame part is fixed by a leg-stumble ground anchor to overcome horizontal thrust of the main inclined frame; but larger emplacement deviation is caused on the main inclined frame; when hoisting by using a plurality of steady vehicles, discrepant stress of each vehicle can create lopsidedness of a single vehicle and cause safety accident. In order to remove the three technological obstacles, in operation process of 60 headframes in recent 20 years, three technologies of a special fixture for holding a rod head, a steel foldout and a balance rope threading method and equipments (1. the special fixture for holding a rob head; 2. the foldout; 3. the balance rope threading method) are progressively researched and developed. Hidden troubles in the process of erecting the headframe are thoroughly overcome.

Owner:CHINA COAL NO 3 CONSTR GRP +1

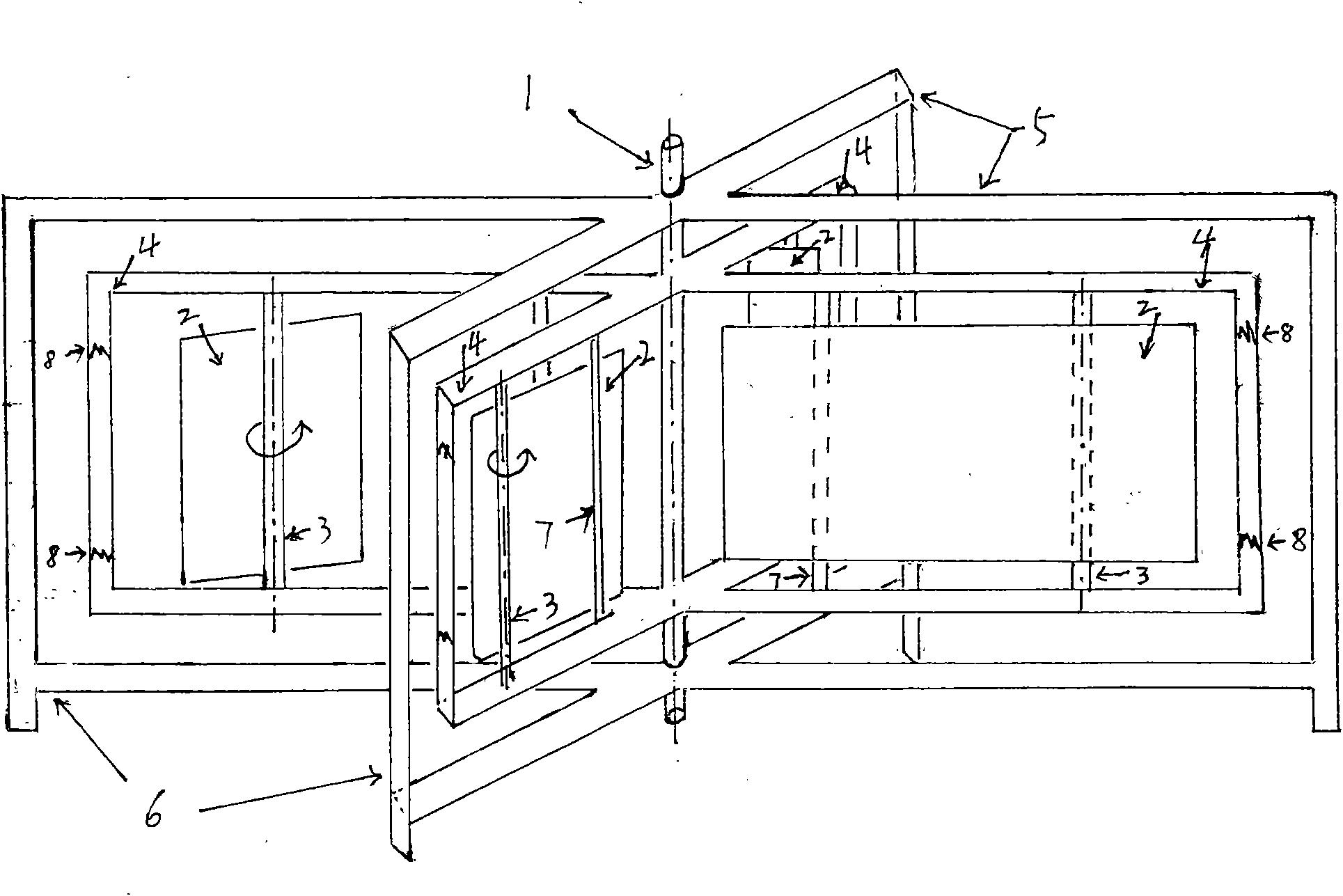

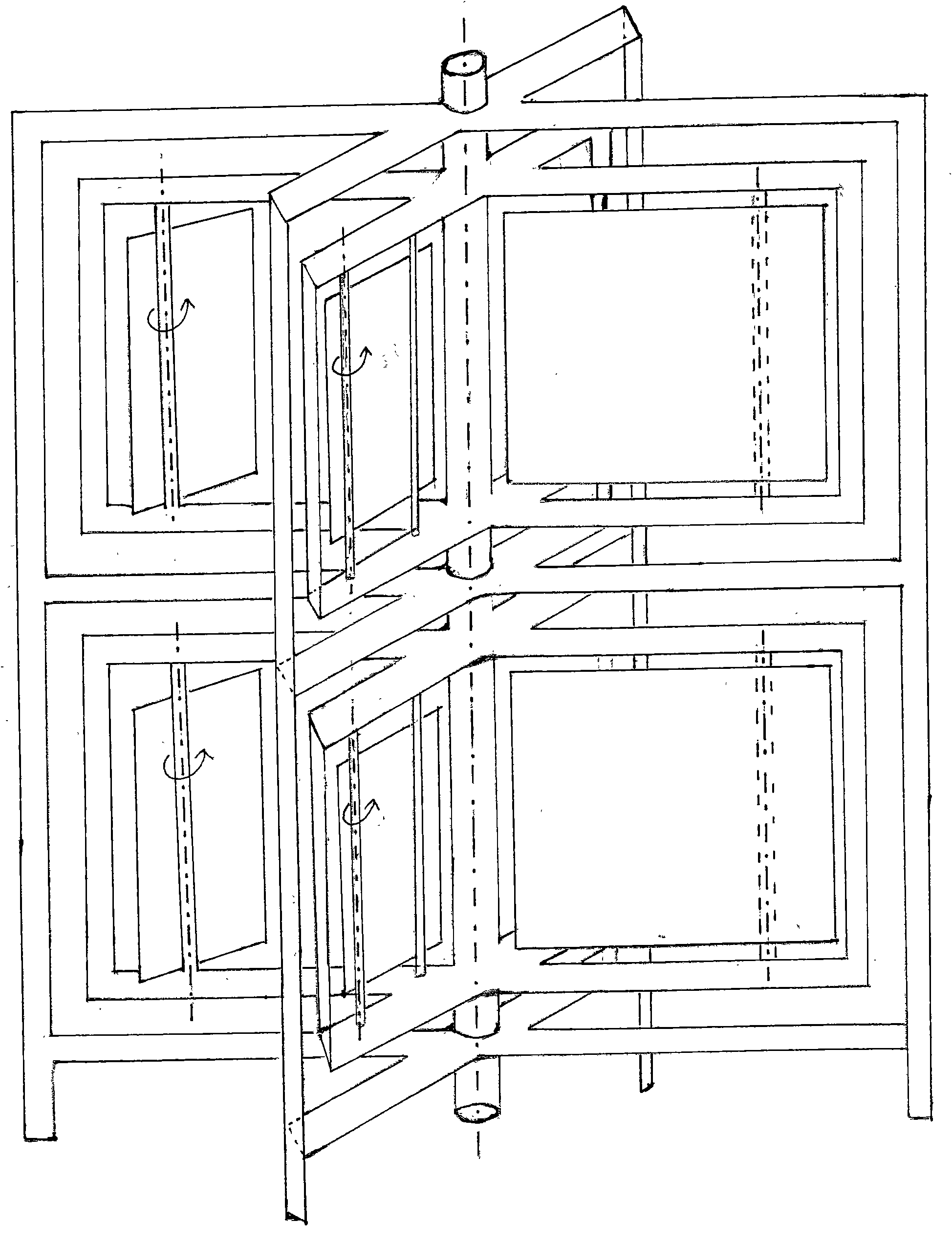

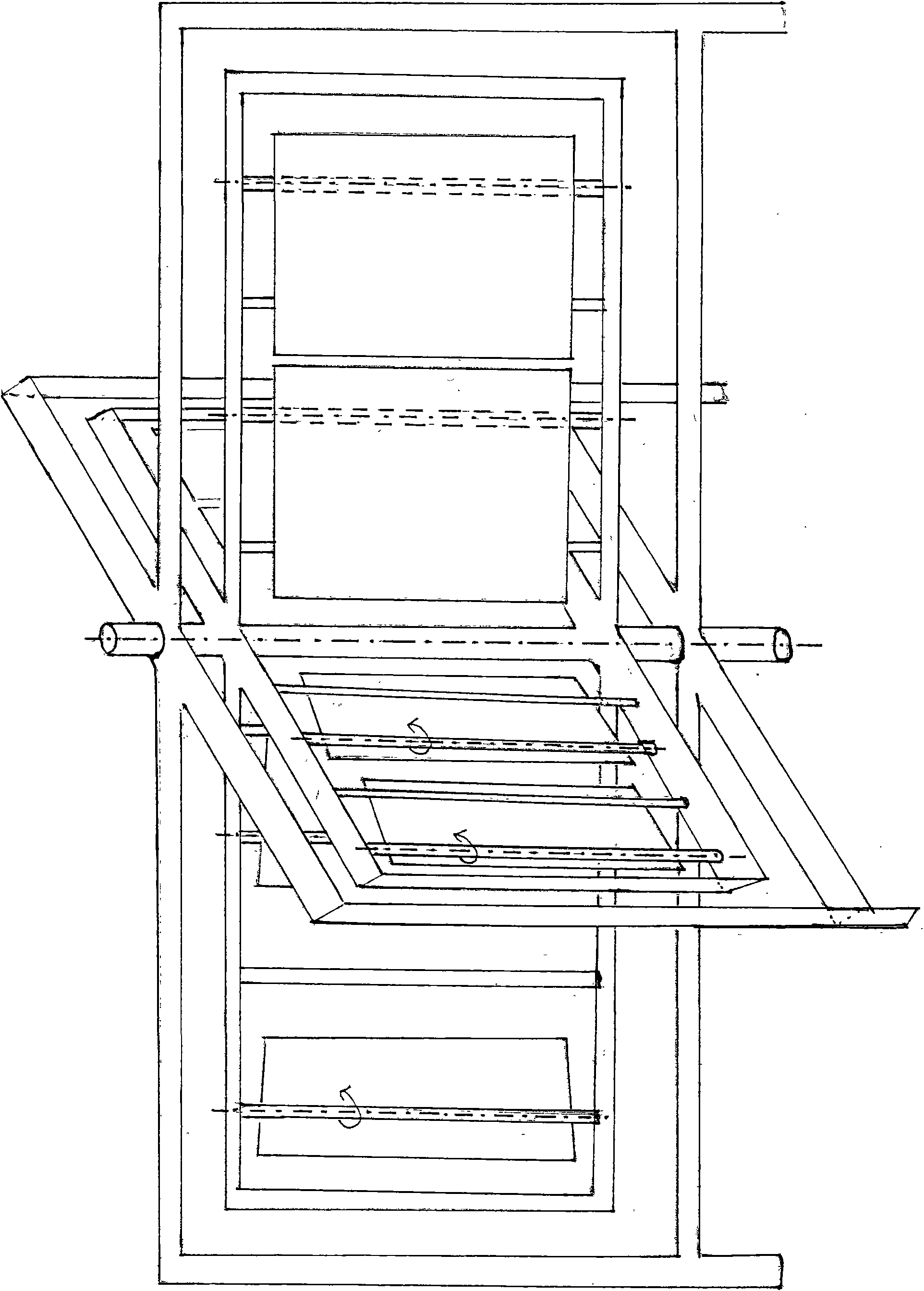

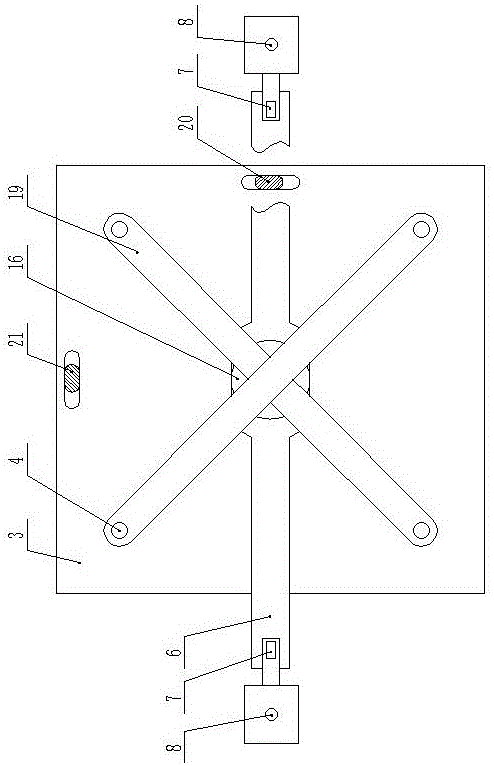

Door type self-return vertical shaft geomantic vehicle

InactiveCN101566125AIngenious ideaIngenious manufacturingMachines/enginesEngine componentsNew energyEngineering

The invention relates to a door type self-return vertical shaft geomantic vehicle which belongs to air collecting equipment with superiority in the new energy field. Each layer of the door type self-return vertical shaft geomantic vehicle is provided with a crisscross symmetrical door frame. One or a plurality of doors can be installed in one door frame according to needs. The door type self-return vertical shaft geomantic vehicle with the up-down structure can be made into one layer by design and installation and can also be made into a plurality of layers by design and installation on the same central rotating vertical shaft and can adopt the design and installation mode of one layer with one door, one layer with a plurality of doors, a plurality of layers with one door, or a plurality of layers with a plurality of doors. A plurality of door type self-return vertical shaft geomantic vehicles can be combined to be beneficial to saving raw materials and fields, increasing power and enlarging scale. The special computing formula for the door type self-return vertical shaft geomantic vehicle solves many problems which are difficult to explain in theory and provides a theoretical foundation for guiding practical application.

Owner:王文清

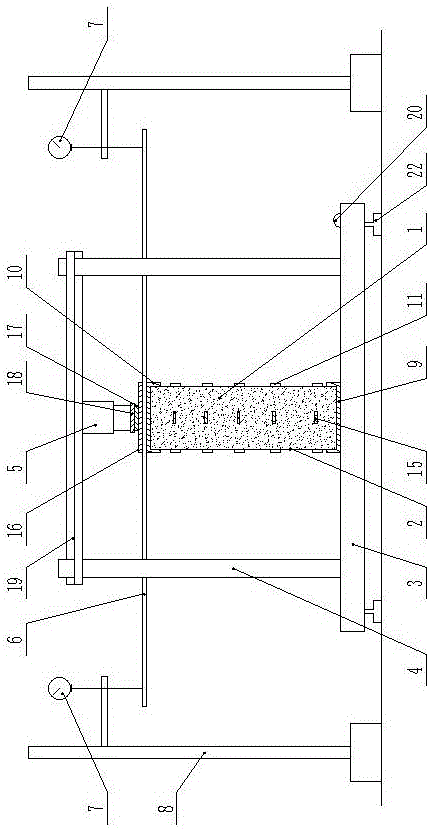

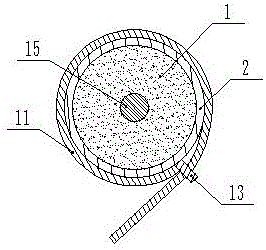

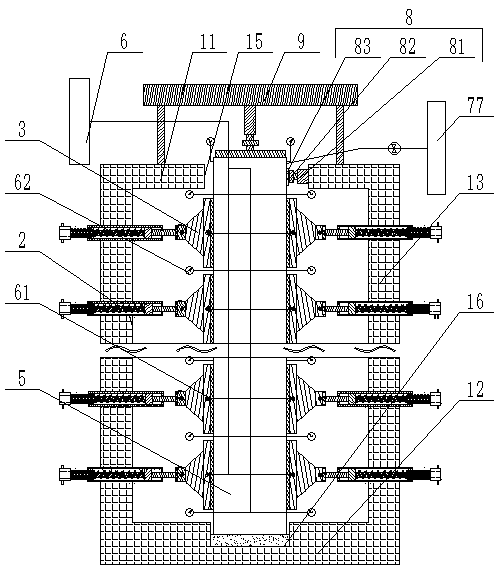

Discrete material reinforcement composite foundation model pile, test device and test method

The invention discloses a discrete material reinforcement composite foundation model pile, a test device and a test method, and belongs to the technical field of discrete material composite foundation simulation and test. The technical problem to be solved is to provide the discrete material reinforcement composite foundation model pile, the test device capable of testing stress and deformation along pile body height of the model pile, and a test method for parameter acquisition. According to the technical scheme adopted by the invention, the structure of the discrete material reinforcement composite foundation model pile is as follows: a packaging coiled material is formed by coiling a stepped thin plate, and the packaging coiled material is filled with a filling material; the test device comprises the model pile, a loading device, a leveling device, a force test device and a deformation test device; and the test method comprises the following steps: manufacturing the stepped thin plate into a cylindrical shape, filling a hollow part with the filling material to form the model pile; mounting a soil pressure box and a perimeter deformation measuring scale inside and outside the model pile; mounting a pressure sensor and a settlement surveying dial gauge on the top of the model pile; and carrying out vertical step loading.

Owner:ZHONGBEI UNIV

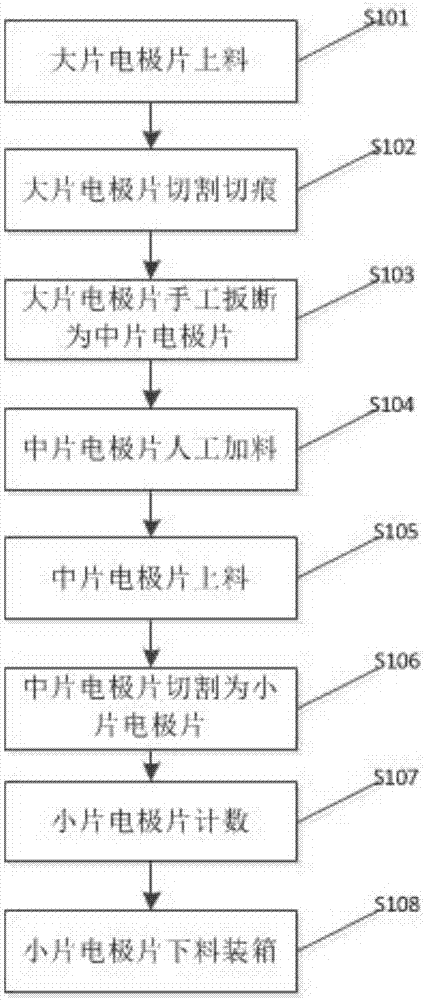

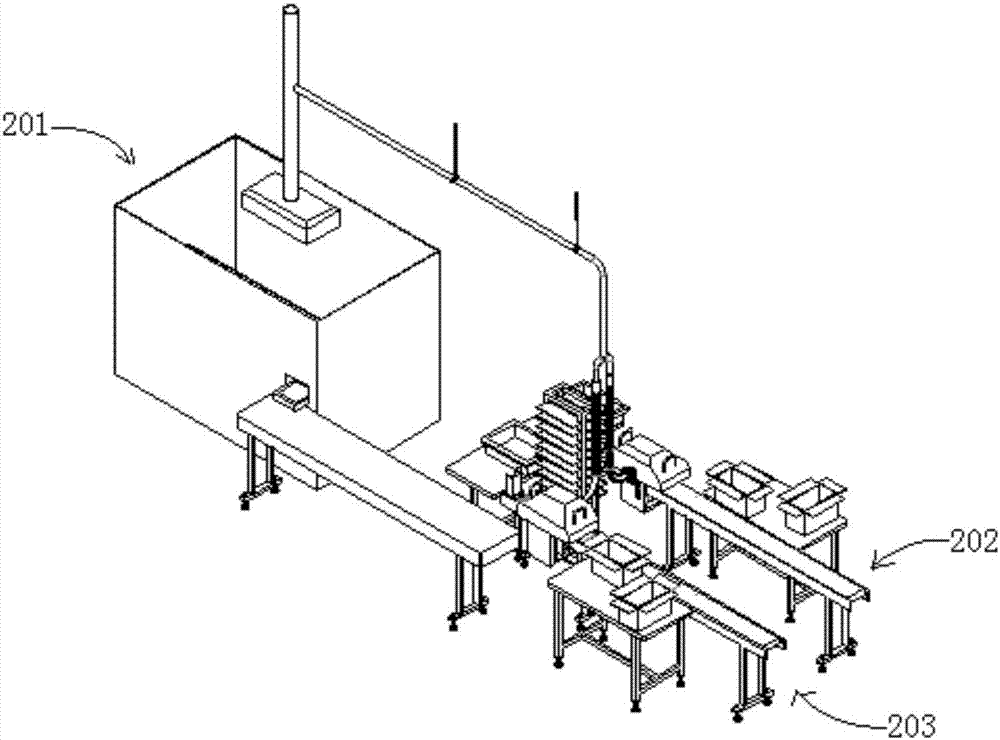

Semi-automatic slicing method and system for battery electrode slices

ActiveCN107403901ASimple ideaEasy to implementElectrode manufacturing processesLarge distanceEngineering

The invention discloses a semi-automatic slicing method and system for battery electrode slices. In the process of cutting medium electrode slices into small electrode slices, the medium electrode slices are stacked in a separating cylinder and automatically hooked out of the separating cylinder by chains with pulling sheets slice by slice; the medium electrode slices are conveyed to a slicer and are sliced into a group of small electrode slices arranged orderly; the small electrode slices are driven to be away from the slicer by pressure belts dependent on friction; a sensor is arranged at the front section of a conveying belt for discharging, and moves one small step forward automatically for each group of small slices and counts the number automatically for each group of small slices entering; when the counted number reaches the set value of the electrode slices in one box, an arranging conveying belt moves a large distance rapidly, so that a box of the electrode slices which can be distinguished remarkably is formed on the conveying belt; the semi-automatic slicing system comprises a production line for cutting large slices into medium slices and a production line for cutting medium slices into small slices. According to the semi-automatic slicing method and system for the battery electrode slices, an existing production line is transformed, the slicer and corresponding conveying lines are added, the purpose of cutting large electrode slices into small electrode slices is achieved, and body burdens of workers are reduced while production efficiency is improved.

Owner:GUANGDONG INST OF INTELLIGENT MFG +1

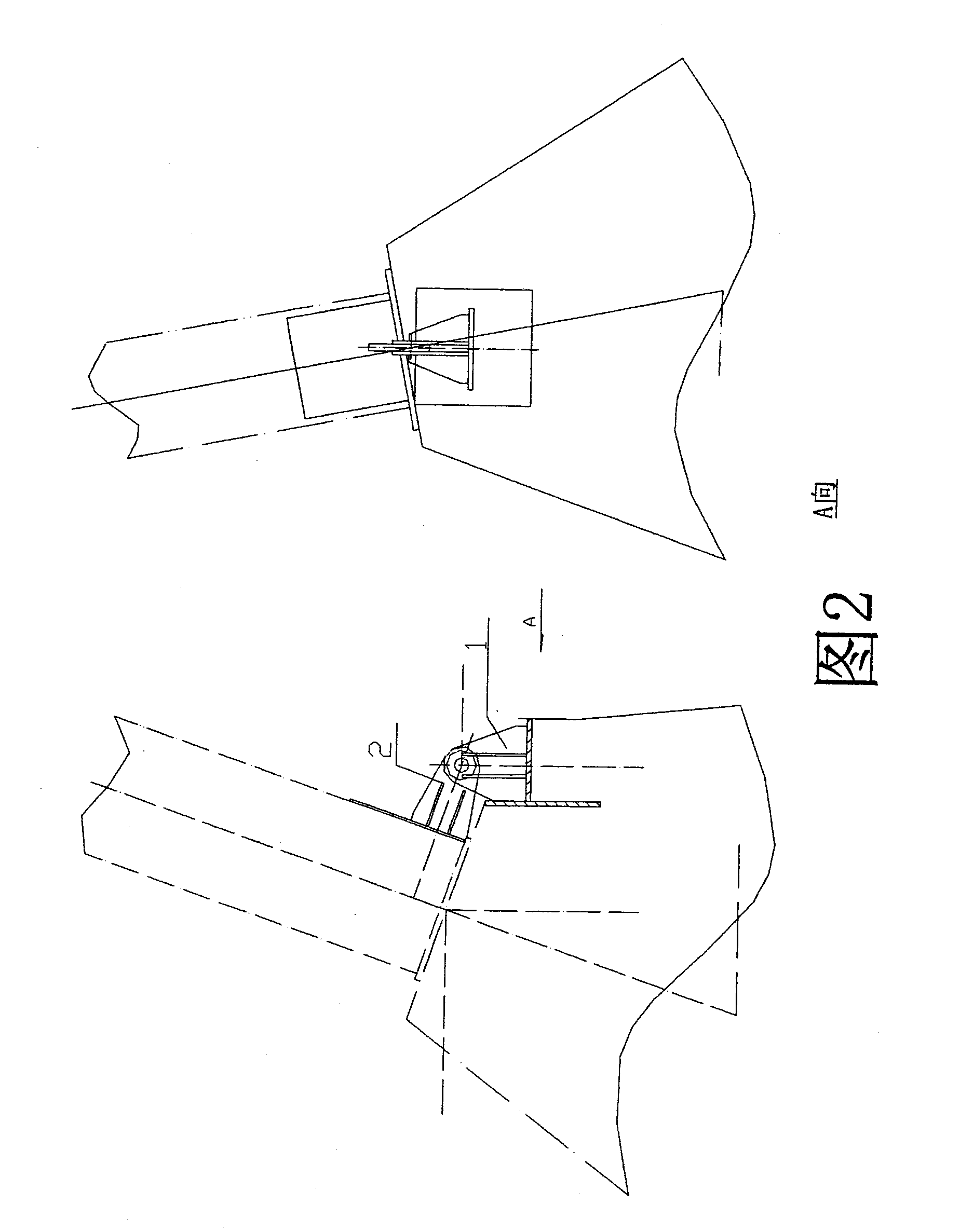

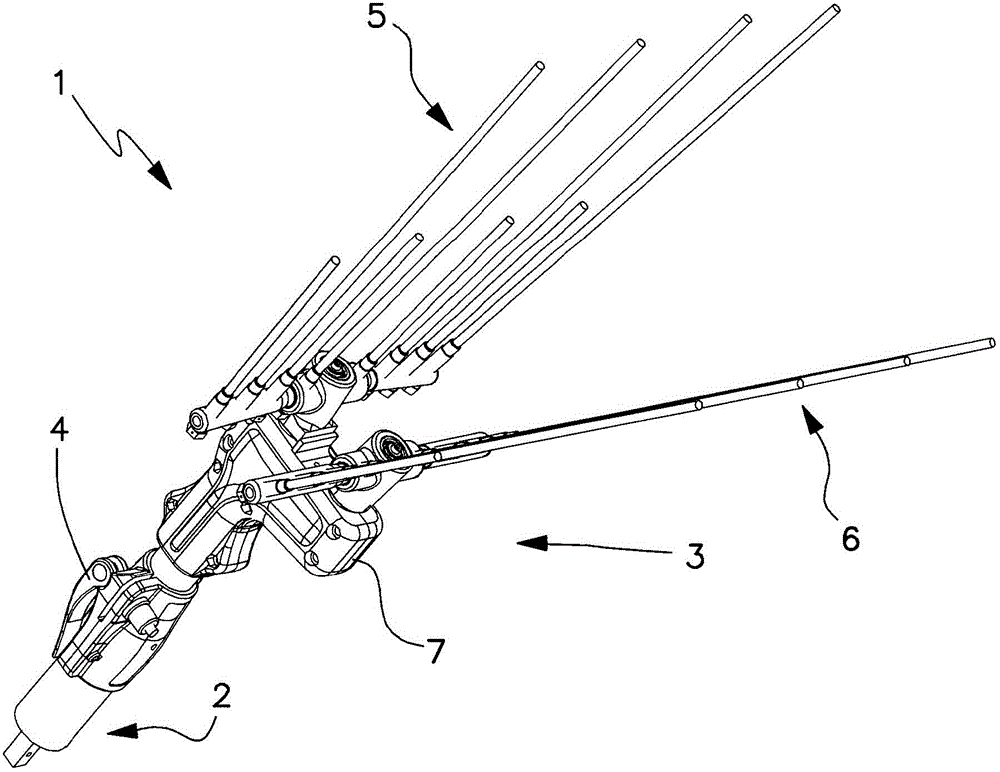

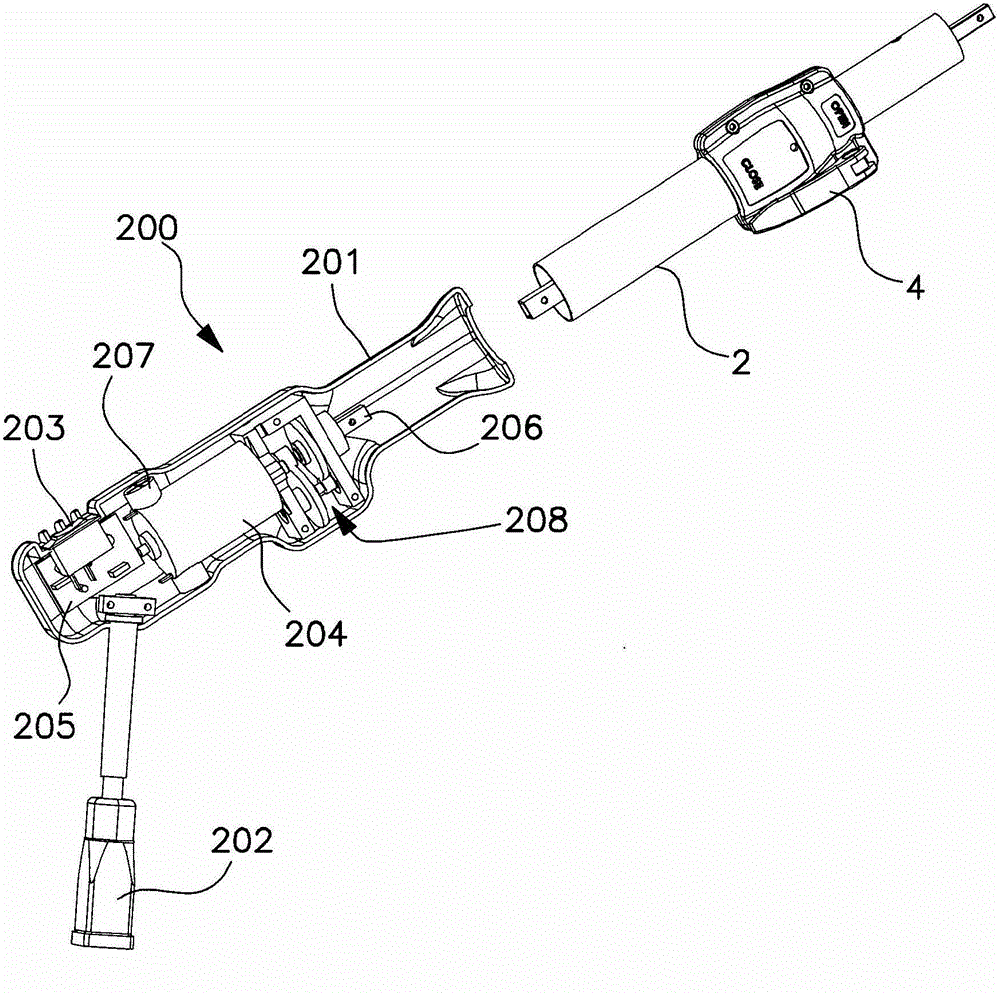

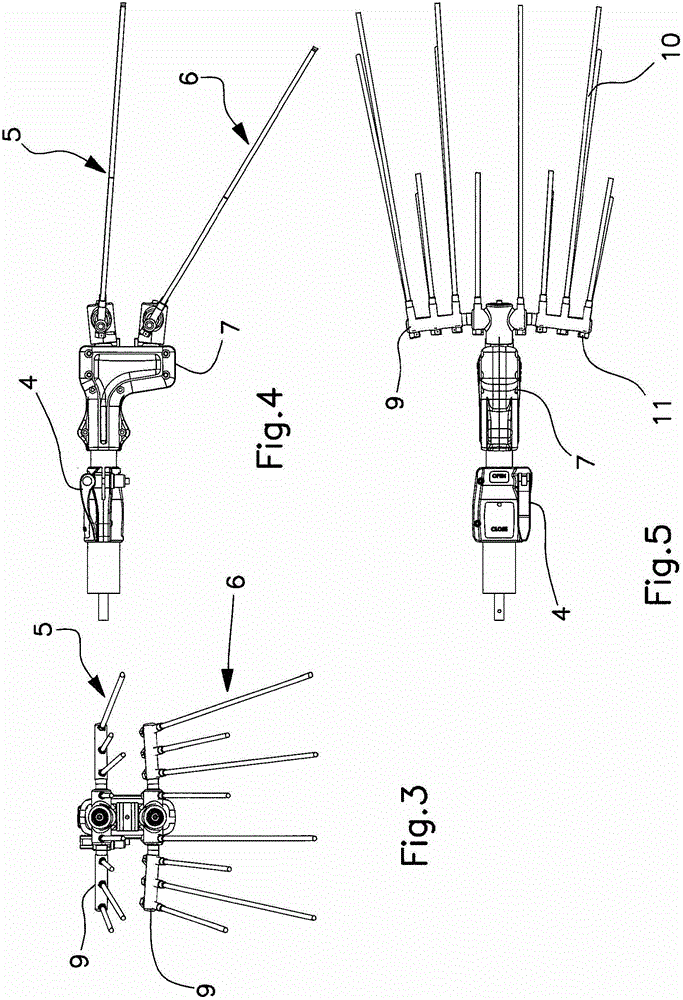

Apparatus for picking olives and the like

The apparatus for picking olives and similar products comprises a support rod (2) suitable to be grasped, a shaker unit (3) comprising a containment box (7) suitable to be mounted at the top of the support rod (2); at least one comb sector (5, 6) shaping a crossbar (9) provided with a plurality of teeth (10), carried mobile by the containment box (7), a motor member (204) to actuate the comb sector (5, 6) in a substantially tilting motion, a drive shaft (14) arranged substantially aligned to the longitudinal axis of the support rod (2) and suitable to be actuated in a rotary motion by the motor member (204). The drive shaft (14) is associated with at least one respective driven shaft (18, 19) shaping an inclined end portion (23). Support means (25) for the crossbar (9) of the comb sector (5, 6) are suitable to be engaged rotatably on the inclined portion (23) of the driven shaft (18, 19) by means of the interposition of rolling means (28). Control means (13) for the motion of the comb sector (5, 6) are associated with the support means (25), the support means (25) being suitable to cooperate reciprocally abutting with the control means (13) at respective coupling portions (30, 31) externally to the containment box (7), to transform the rotary motion actuated by the motor member (204) into the tilting motion of the comb sector (5, 6).

Owner:MINELLI ELETTROMECCANICA

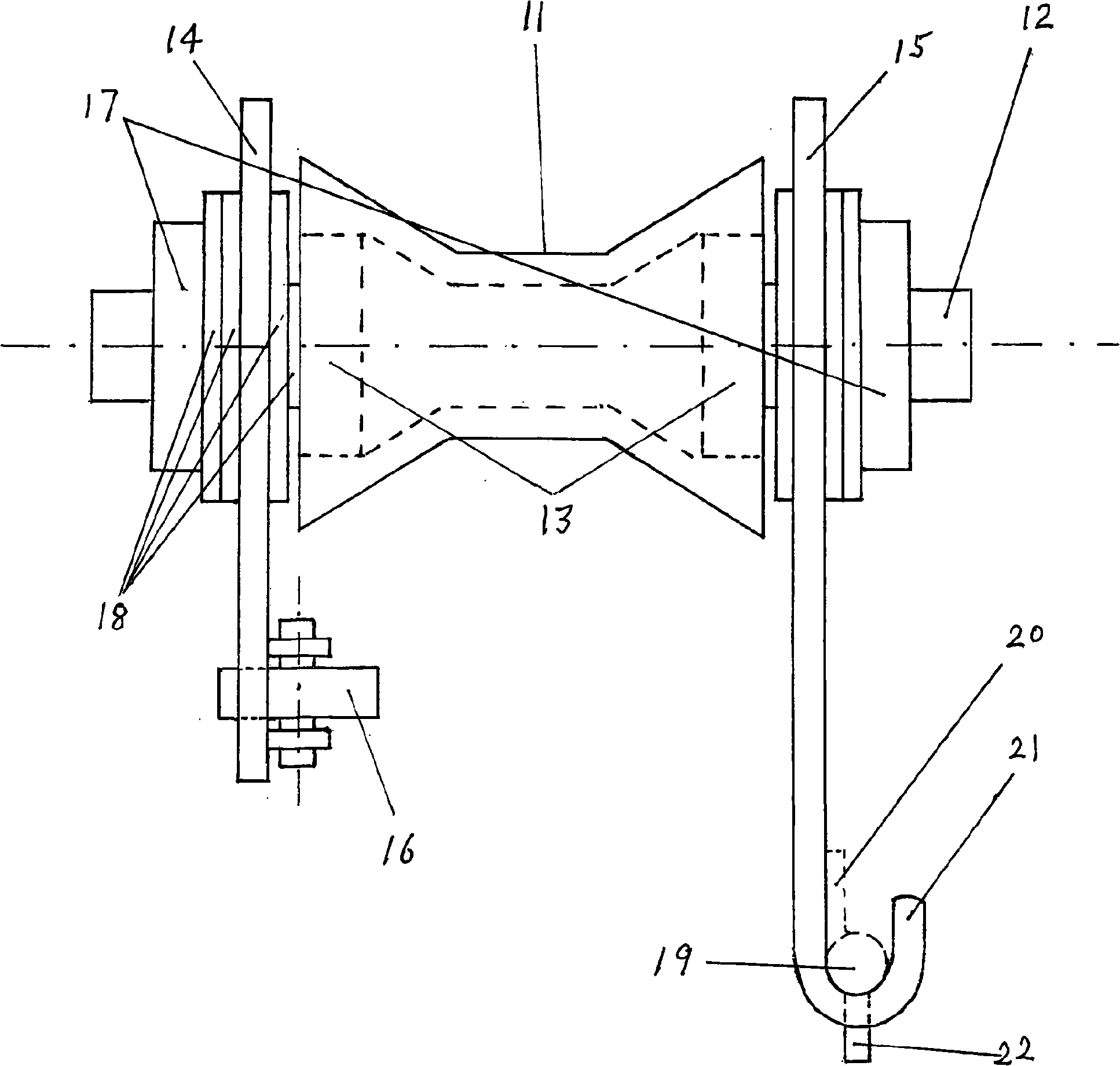

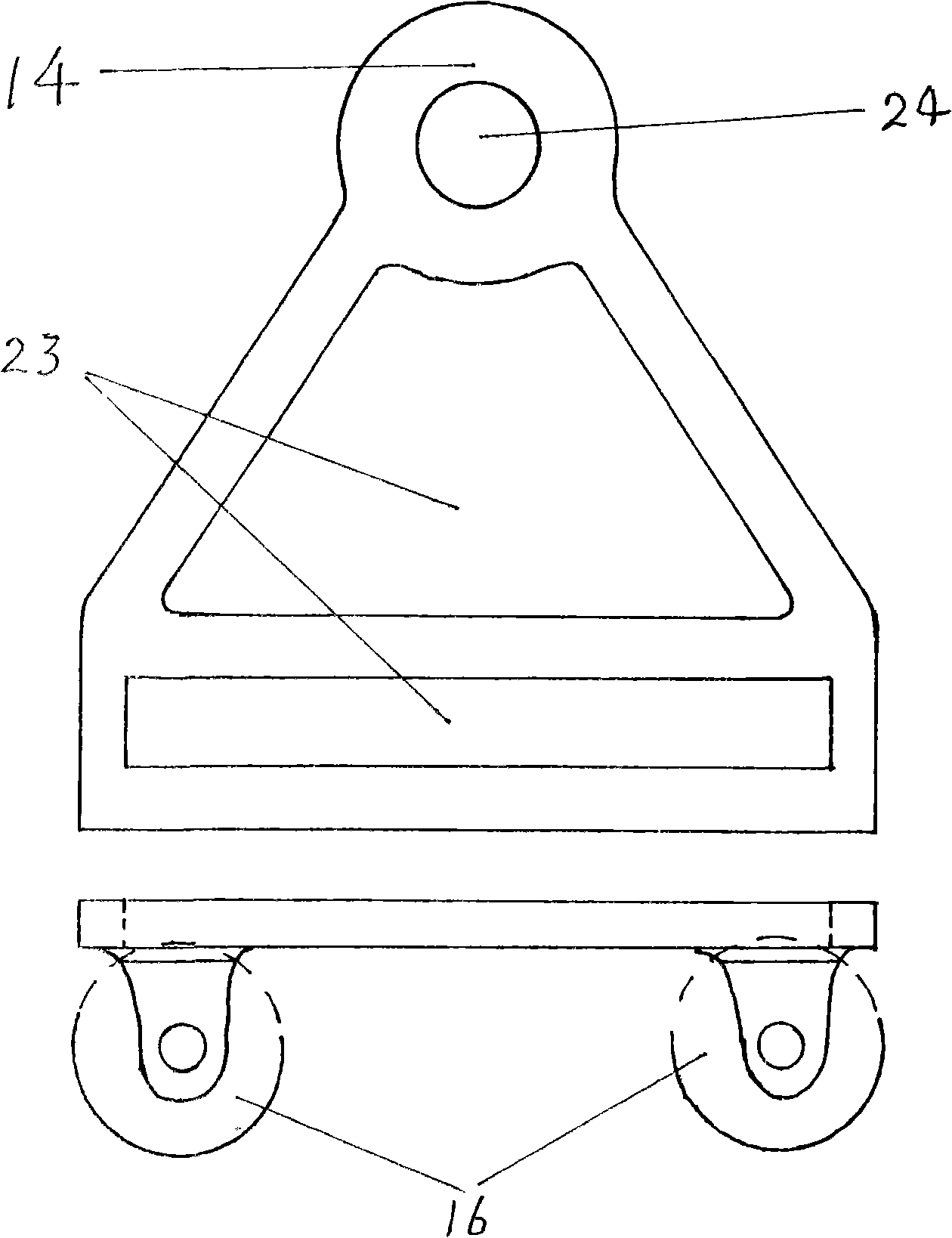

Domestic stair porter robot

The invention relates to a mechanically-electrically integrated home stairs porter robotics system which is driven by electric power, can go up and down the stairs and can carry heavy objects. The home stairs porter robotics system is composed of a driven running and steering system work chamber 3 at the upper part, a braced strut supporting frame system work chamber 4 at the middle part and an electric drive running controlling system work chamber 2 at the lower part. In China, stairs hand banisters composed of concrete iron, cement and wooden banisters are commonly installed in low buildings without elevators and below eight floors, and the home stairs porter robotics system uses and goes along the stairs hand banisters to trippingly go up and down the stairs. Senior citizens with inconvenience in walk or patients can sit on the robotics system conveniently to go up and down the stairs, and the robotics system can also carry hundreds of kilograms of heavy objects to go up and down the stairs, thus the mechanically-electrically integrated home stairs porter robotics system of the invention can be a piece of new equipment quite appropriate for removers, property management companies and construction companies.

Owner:任海

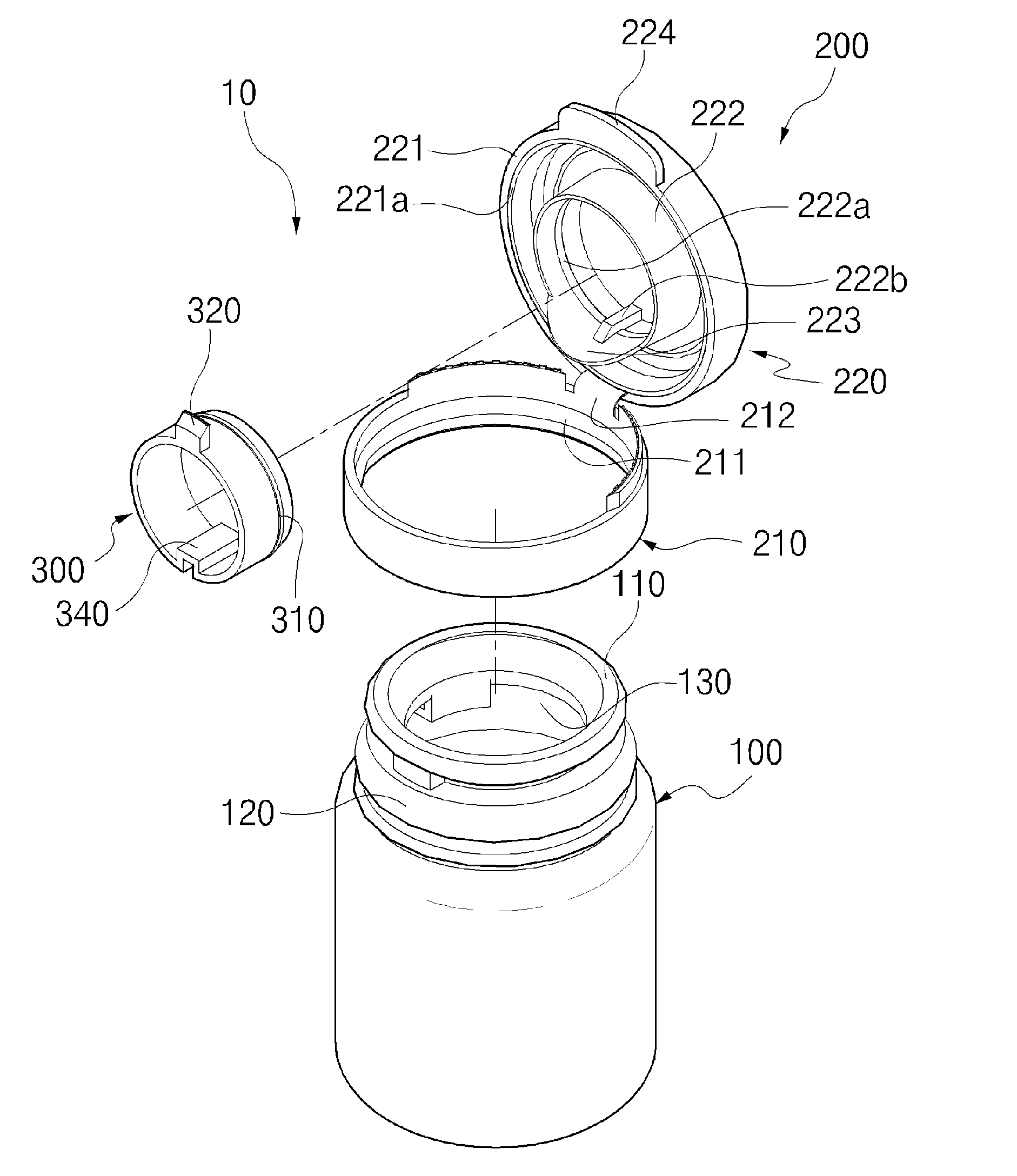

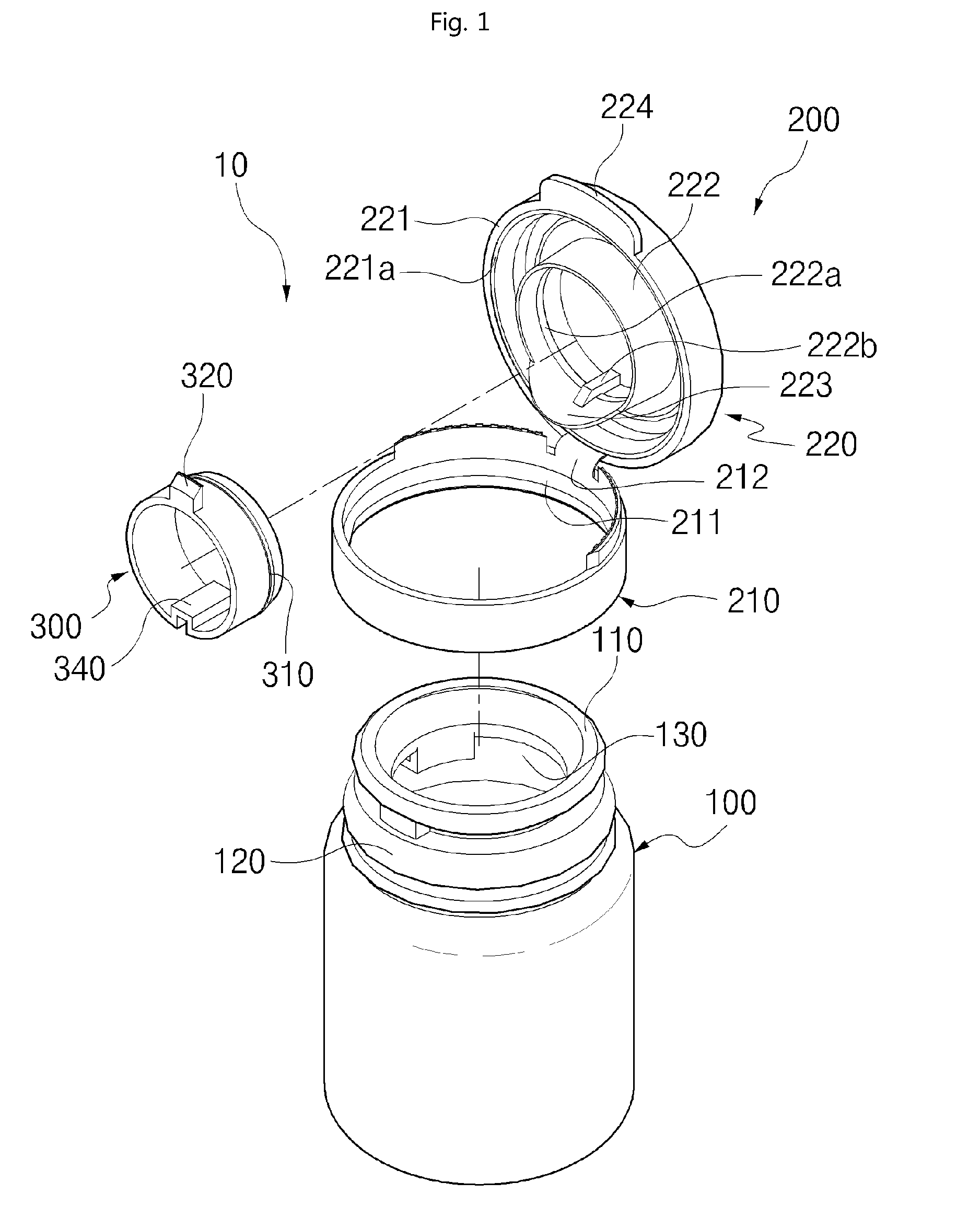

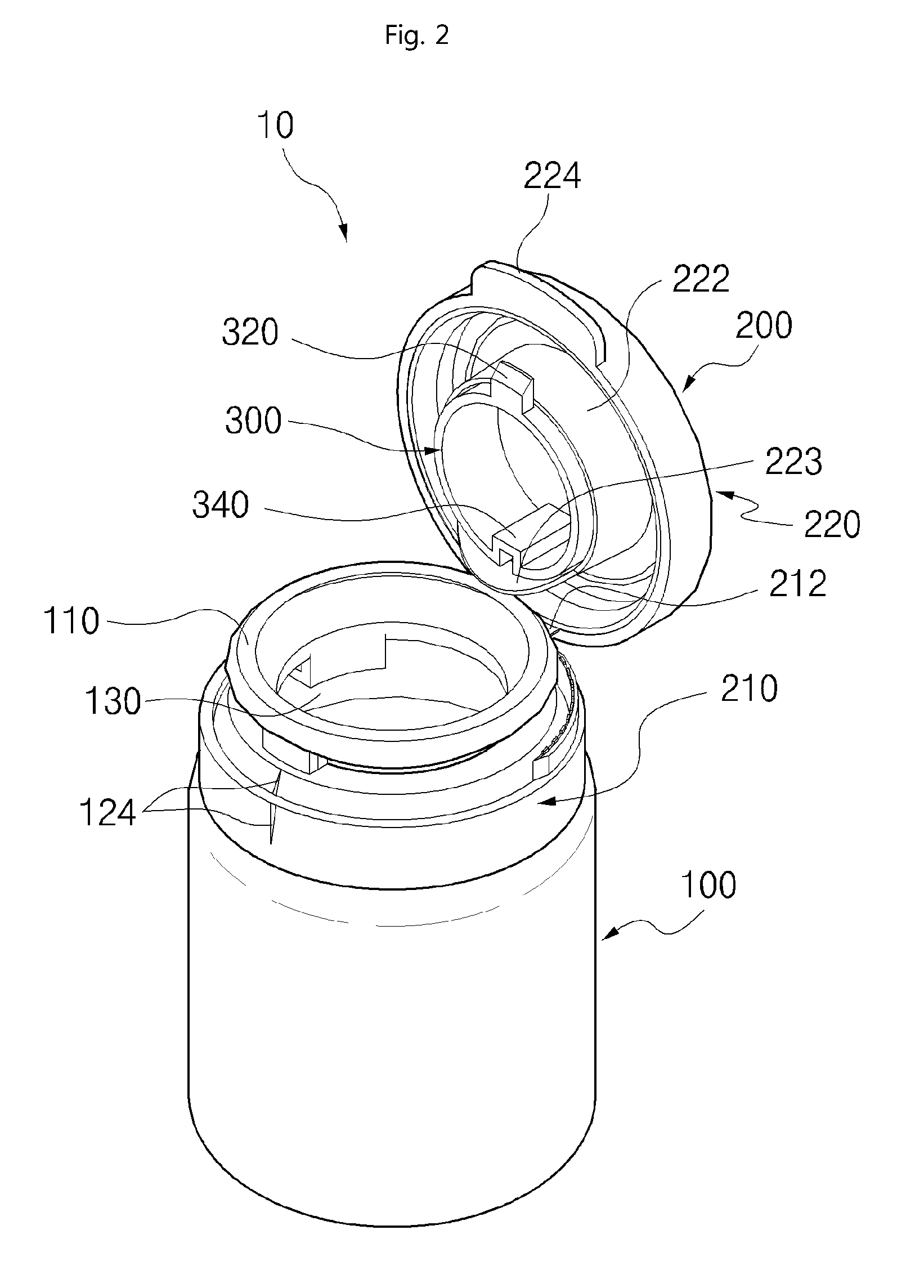

Safety container with safety locking part

InactiveUS8636160B2Improve securitySimple ideaCapsClosure using stoppersEngineeringMechanical engineering

Owner:PARK SUK WOO

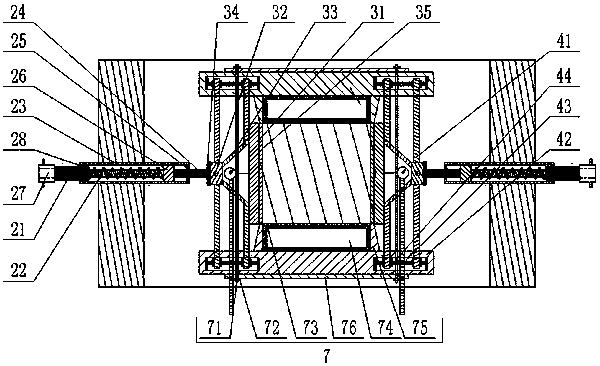

Method for simulating stressed process and load-transferring mechanism of equivalently and horizontally loaded pile

InactiveCN108319805ASimple ideaRealize the constraint effectGeometric CADFoundation testingTransfer mechanismEngineering

The invention discloses a method for simulating a stressed process and a load-transferring mechanism of an equivalently and horizontally loaded pile. By the method, physical simulation and visual teaching of the stressed process of the horizontally loaded pile (an axial force on the pile top can be selectively added) are achieved; the method is of a certain guiding significance on research on thehorizontally loaded pile; a pressure applying assembly and a pressure transmitting assembly are correspondingly connected together to apply an initial soil pressure initial earth pressure to a model pile arranged in a counterforce frame in a direction parallel to the application direction of a pile-top horizontal force, a lateral friction system applies pile-side frictional forces to both sides ofthe model pile in a direction parallel to the horizontal force loading direction, a pile body testing system is used for testing changes of pressure and displacement of each section of the pile bodyof the model pile; a horizontal cyclic force is applied to the pile top of the model pile or a vertical force is applied to the pile top in advance in a grading manner through a pile-top horizontal loading system and a pile-top vertical loading system, and horizontal deformation and vertical deformation of the pile top during grading application of the horizontal cyclic force are tested, so that simulation of the stressed process of the horizontally loaded pile is achieved.

Owner:ZHONGBEI UNIV

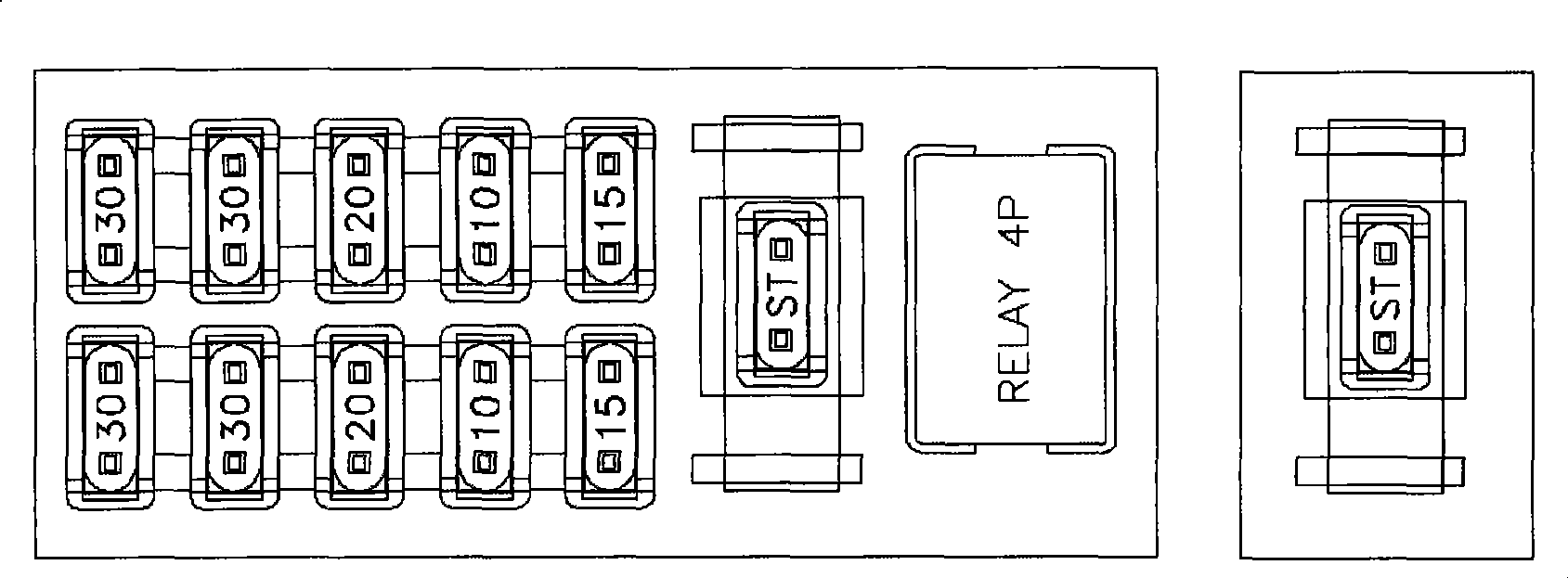

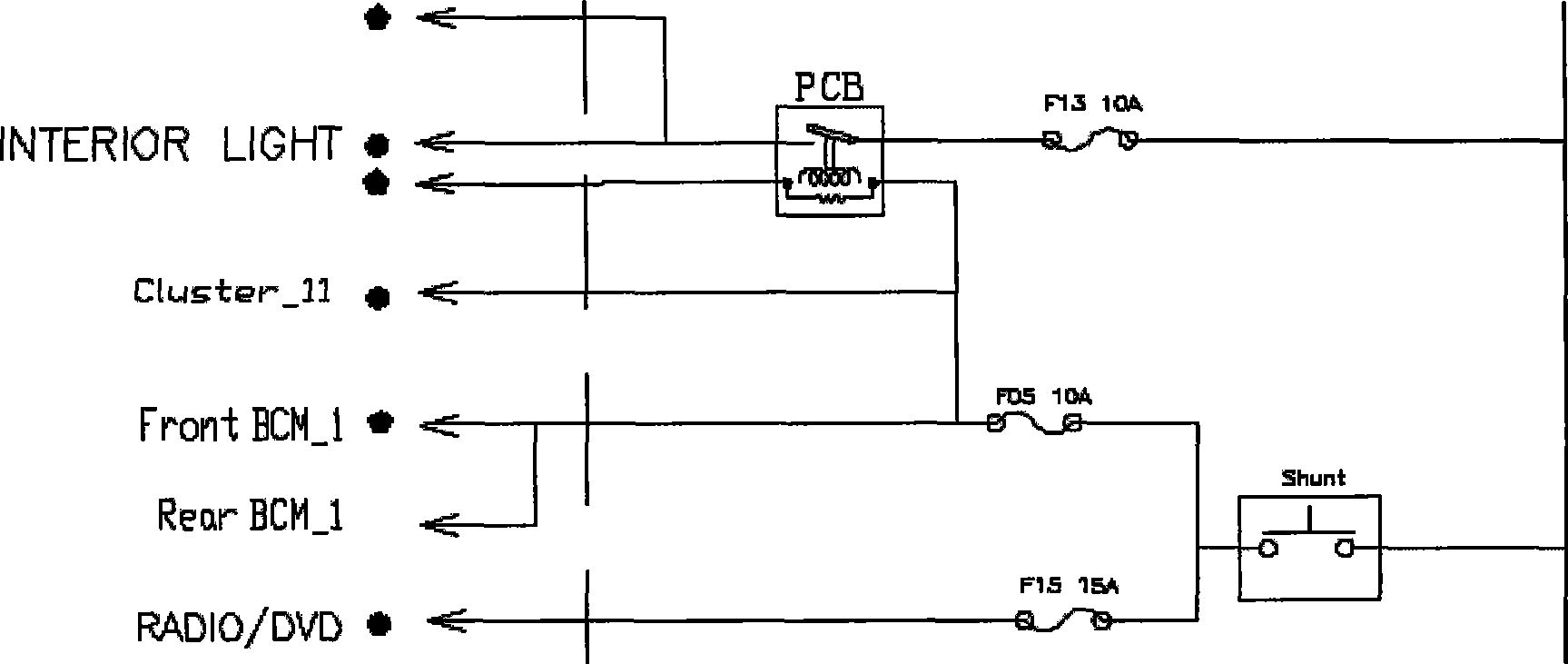

Entire vehicle quiescent current control circuit and current control method thereof

InactiveCN101367364AEasy to operateSimple ideaElectric switchesElectric powerControl circuitEconomic shortage

The invention relates to an entire vehicle quiescent current control circuit and a current controlling method thereof. During the design process of the entire vehicle circuit, long electrical power supplies, which affect the quiescent current, of various electrical appliances are integrated in a main circuit in which a main switch for easily operating the on and off is added. The entire vehicle quiescent current control circuit prevents the frequently-appeared phenomenon of power shortage in entire vehicle, and avoids that the entire vehicles cannot be started during the transportation process or when arriving at the destination.

Owner:CHERY AUTOMOBILE CO LTD

Bi-component externally-mixing marking equipment

InactiveCN103526682ASimple structureReasonable designRoads maintainenceHydraulic cylinderMicrocomputer

The invention discloses bi-component externally-mixing marking equipment which structurally comprises an A base material barrel and a B base material barrel. The A base material barrel is connected with a hydraulic cylinder, the hydraulic cylinder can suck to pressurize a pressure storage tank, the pressure storage tank is connected with an A base material spray gun through a pipeline, and B base materials are arranged in the B base material barrel and directly pressurized by an air compressor to be sent to a B base material spray gun through a pipeline. The A base material spray gun and the B base material spray gun are installed in a front-back mode side by side at the same height, the A base material spray gun and the B base material spray gun can simultaneously spray, and the A base materials and the B base materials can be externally and fully mixed. An A base material power mechanism and a B base material power mechanism share the same power source, namely a diesel engine or a gasoline engine. The externally-mixing marking equipment can control line type and length through a microcomputer controller in marking. The spray guns are controlled by the microcomputer controller to be opened and closed. In spraying solid lines, outlet pipelines are cleaned at intervals. The bi-component externally-mixing marking equipment has the advantages of being reasonable in design, flexible to adjust, ingenious in idea and the like.

Owner:山东路美交通设施有限公司

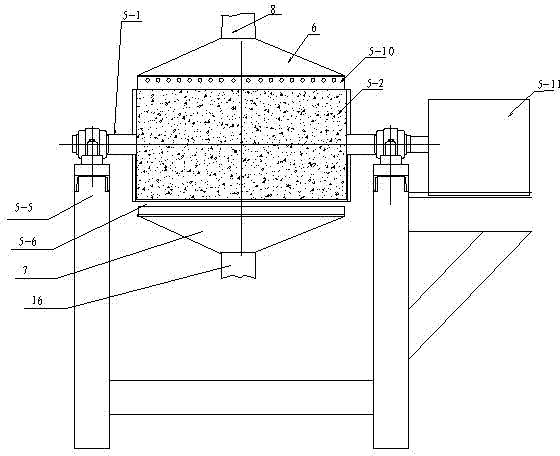

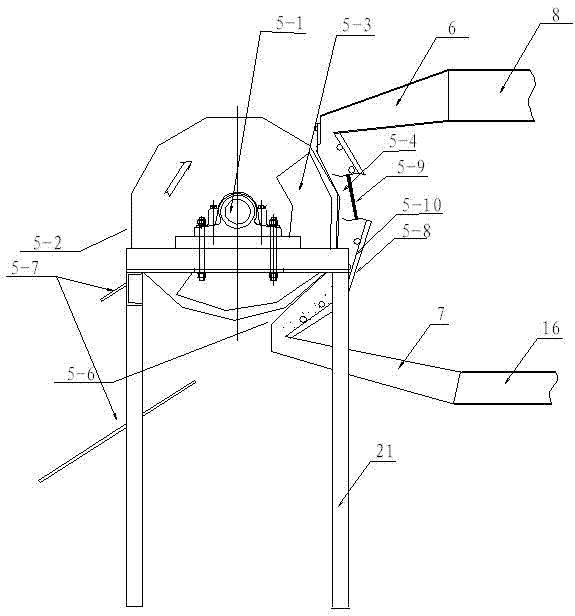

Mineral powder gas delivery dry-type magnetic separation device and method

InactiveCN102847619ANovel ideaSimple structureReversed direction vortexMagnetic separationMagnetic separatorGravity separation

The invention discloses a mineral powder gas delivery dry-type magnetic separation device and a method, belonging to a magnetic separation device for separating solid materials from a fluid, particularly relating a dry-type ore grinding and selecting device. The device comprises a ball mill, a roller screen, a belt conveyor and a magnetic selection mechanism, characterized in that the magnetic selection mechanism is provided with an arc-shaped magnetic separation air duct, a feeding flat mouth tube and a negative pressure air pipe which are connected with a feeding hopper are arranged above the arc-shaped magnetic separation air duct, the negative pressure air pipe is provided with an air regulation valve which is connected with a pressure air pipe, the pressure air pipe is provided with a shunt pipe which is connected with a deduster, a tailing flat mouth pipe, a return duct, a gravity separator, and an induced pipe which are connected with the air inlet of a fan are arranged below the arc-shaped magnetic separation air duct. According to the invention, the idea is novel; by replacing water with air to select ores, the structure is simple and reasonable; mineral powder is delivered by using a negative pressure air flow, and fine iron powder is selected in gases, thus the resistance is low, the yield of iron ore concentrates is raised, and mineral resources are effectively utilized; the energy is saved, the consumption is reduced, and the device operating rate is raised; ore selection without water generates no ore selecting floated water or dust, there is no need for constructing tailings ponds, the environmental pollution is prevented, the water consumption is saved, and ore selecting conditions are created for water-deficient areas.

Owner:黄恩权

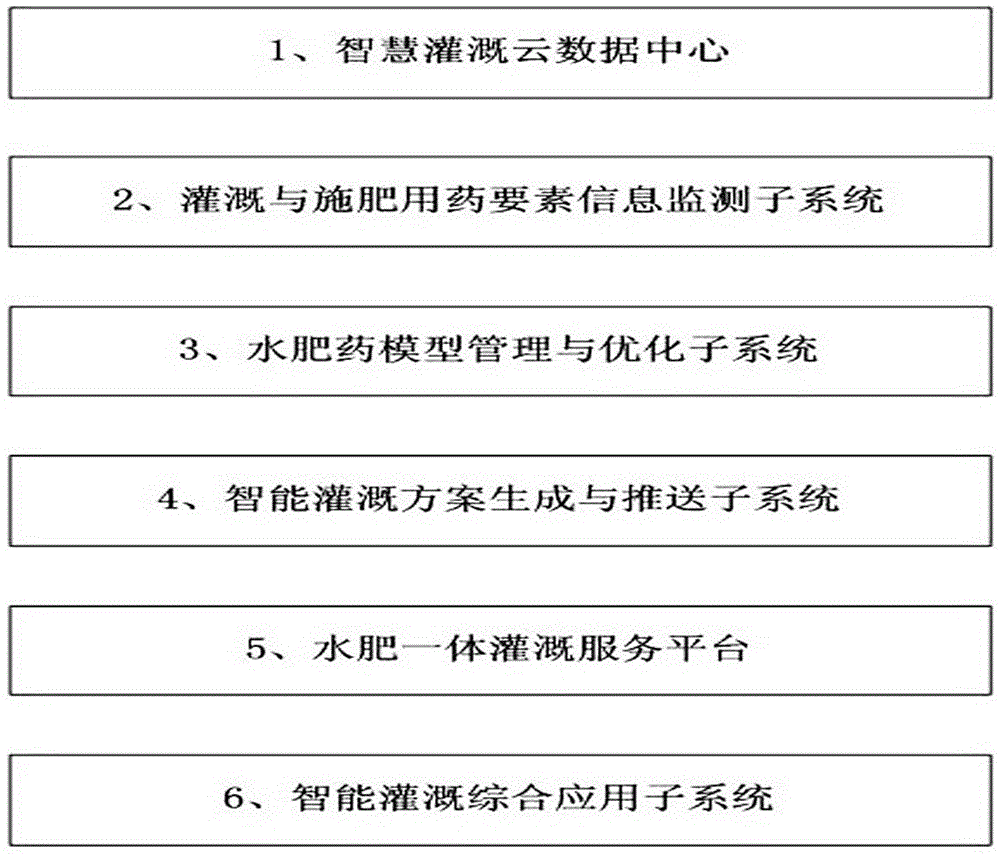

Intelligent irrigation cloud platform based on internet

InactiveCN106171866AImprove abilitiesImprove management levelWatering devicesCultivating equipmentsModel managementThe Internet

The invention provides an intelligent irrigation cloud platform based on the internet. The intelligent irrigation cloud platform comprises an intelligent irrigation cloud data central unit module achieving the effects of data collection, transmission, storage, processing and utilization and an irrigation and fertilization dosage element information monitoring subsystem unit module which is responsible for receiving and storing of crop growth environment and growth trend monitoring information. The intelligent irrigation cloud platform based on the internet is novel in conception, an expert system, model management, big data and an artificial intelligence technology are integrated into a whole, the water conservancy facility project construction process is monitored and managed in an all-dimensional mode, intellectualization of management dispatching and decision-making scientization are achieved, and conversion to dynamic management, precision management and quantitative management is achieved; meanwhile, an inter-sector cooperative office way is achieved, and the treating capacity of water conservancy interconnection is improved.

Owner:山东锋士信息技术有限公司

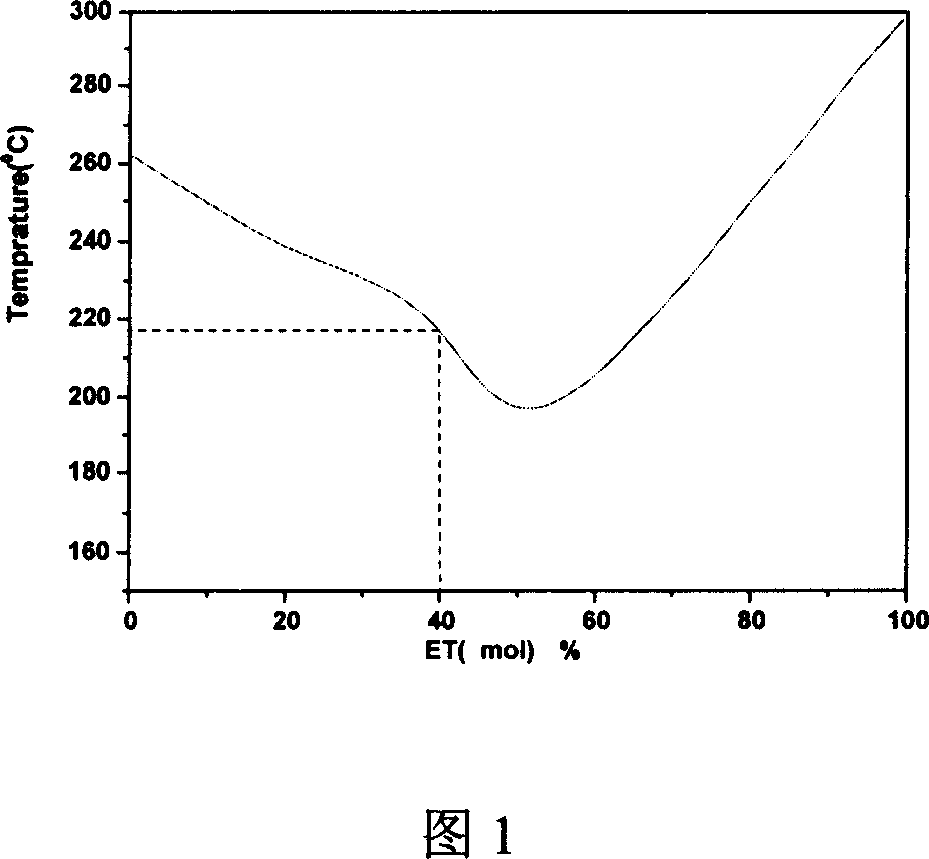

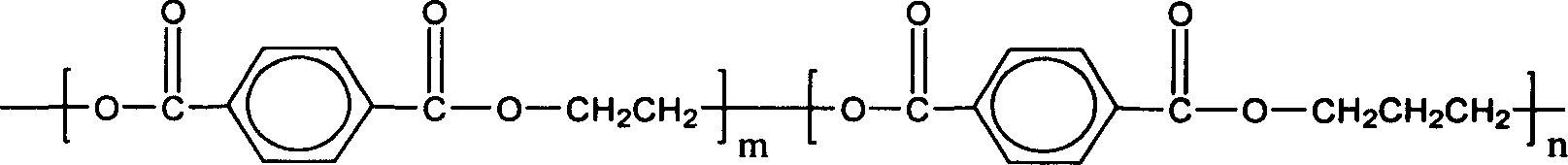

PET/PTT copolyester fiber and its production process

InactiveCN1932093AReduce manufacturing costEasy to processMonocomponent copolyesters artificial filamentMelt spinning methodsFiberChain structure

The present invention discloses one kind of PET / PTT copolyester fiber and its production process. The PET / PTT copolyester fiber has chain structure with ET units accounting for 0.05-0.95 of the total chain units and limiting viscosity value of 0.6-0.9 dL / g. The PET / PTT copolyester fiber is superior to Dacron in softness, dyeability, elasticity, etc. and has high strength similar to that of Dacron. The production process optimizes the performance of the fiber and lowers the production cost.

Owner:DONGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com