Method for simulating stressed process and load-transferring mechanism of equivalently and horizontally loaded pile

A technology of load transfer and simulation method, which is applied in the field of indoor physical simulation of civil engineering, can solve problems such as complex calculation and influence of foundation pile safety degree, and achieve the effect of wide application range, simple and reasonable conception, and horizontal isotropy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

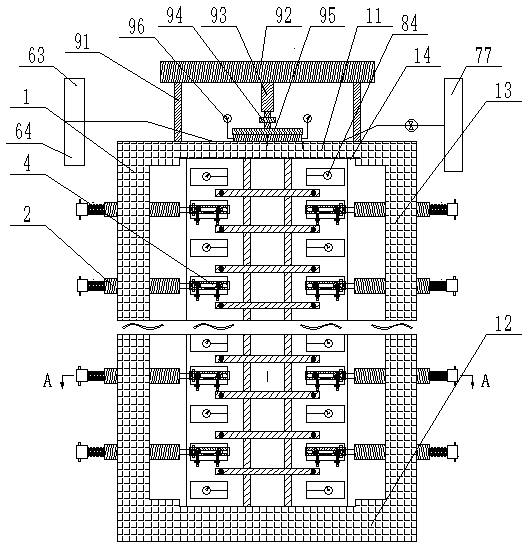

[0062] Example 1: Pile top horizontal and vertical loaded pile simulation device

[0063] 1. Install the reaction force frame and the horizontal loading system at the top of the pile. Fix the bottom beam of the reaction force frame to the ground, and make the top surface of the beam horizontal, assemble the side beams on both sides and the top beam in turn, keep the axes of the side beams on both sides on the plumb line, and ensure that the axes of the top beam and the bottom beam are in line with the The axes of the side beams on both sides are vertical to complete the installation of the reaction frame. Install a horizontal oil cylinder on the right side wall of the pile delivery hole of the reaction force frame, install a horizontal force sensor and a horizontal force bearing plate on the piston rod of the horizontal oil cylinder in sequence, and connect the horizontal oil cylinder and the oil cylinder control system at the same time.

[0064]2. Determine the calculated pi...

Embodiment 2

[0079] Embodiment 2: Simulation method of pile top horizontally loaded pile.

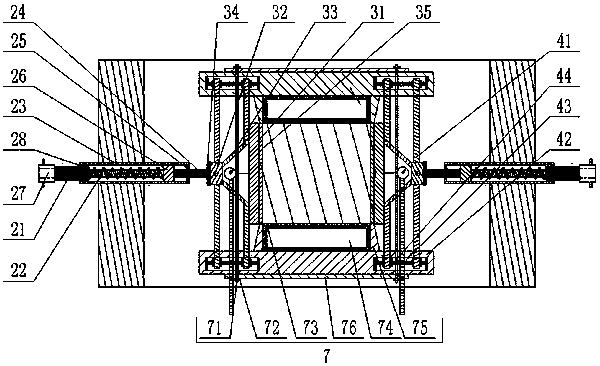

[0080] 1. The production of the model pile, the installation of the model pile device, and the loading of the initial earth pressure on the side of the horizontally loaded model pile are the same as steps 1 to 11 in the first embodiment, and it is assumed that the soil layer of the pile side soil pressure on the side of the model pile 2 has a segment length of m. thickness.

[0081] 2. Loading simulation of pile top horizontally loaded pile and test of pile structure deformation and internal force. Adopt the "Technical Specification for Testing of Building Pile Foundation" (JGJ106) to load the model pile with the slow maintenance load method to load the test pile. The unidirectional multi-cycle grading load should not be greater than the estimated horizontal ultimate bearing capacity or 1 / 10 of the maximum test load. ; After each level of load is applied, the horizontal displacement can be measured...

Embodiment 3

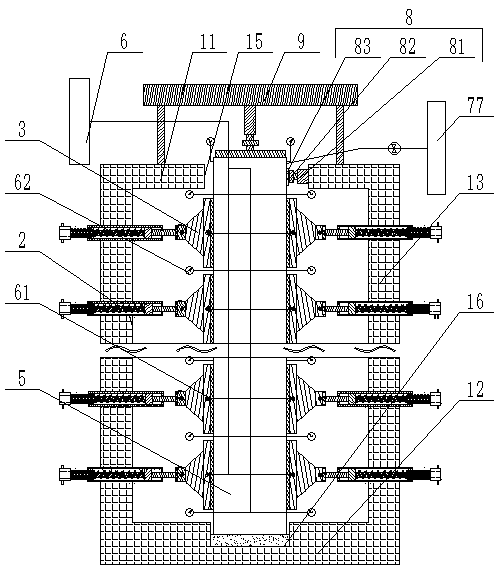

[0083] Example 3: Simulation of a horizontally loaded pile when the top of the pile is subjected to a vertical constant load.

[0084] 1. The production of the model pile, the installation of the model pile device, and the loading of the initial soil pressure on the side of the horizontally loaded model pile are the same as steps 1 to 13 in the first embodiment, and the segmental length h of the soil pressure on the side of the model pile is assumed to be the thickness of the soil layer.

[0085] 2. A constant vertical force is applied to the top of the pile. Before loading, the axis of the adjustment oil cylinder and the longitudinal axis of the model pile are in the same line, and pass through the geometric center of the bearing plate. The oil cylinder is connected with the oil cylinder control system through the oil pipe, and the sensor is connected with the sensor control system. The displacement meter is installed on the top surface of the model pile. On the side fulcrum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com