Bi-component externally-mixing marking equipment

A two-component, mixed standard technology, applied in the direction of roads, road repairs, roads, etc., can solve the problems of application restrictions, troublesome construction methods, etc., and achieve the effects of convenient construction process, improved spraying efficiency, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

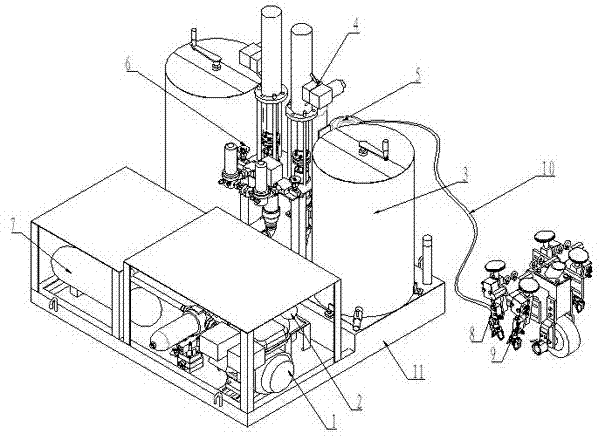

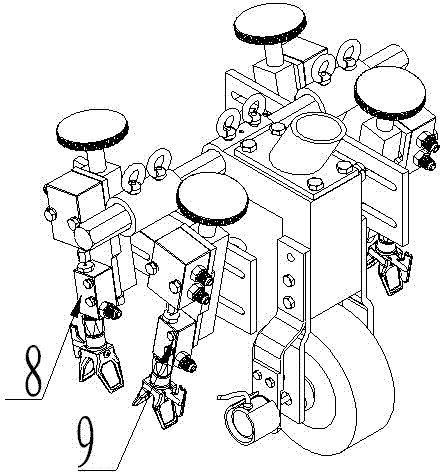

[0022] Such as Figure 1-2 As shown, a two-component external mixing standard line equipment, its structure includes a type A base material barrel 3, the type A base material barrel 3 is connected to a hydraulic cylinder 4, and the hydraulic cylinder 4 is sucked and pressed to the pressure storage tank 5, Pressure storage tank 5 is connected with class A base material spray gun 8 through pipeline 10;

[0023] As preferably, there is a reflux valve in the pipeline 10 to adjust the size of the reflux, and the base material from the pressure storage tank passes through the pipeline 10 to the A-type base material spray gun 8;

[0024] Further, the base material of the pressure storage tank 5 passes through the pipeline 10 to the A-type base material spray gun 8, and the pipeline 10 in the middle contains a solenoid valve and is controlled by a microcompute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com