Patents

Literature

379 results about "Segment length" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and apparatus for controlling a videotape recorder in real-time to automatically identify and selectively skip segments of a television broadcast signal during recording of the television signal

InactiveUS6404977B1Television system detailsPicture reproducers using cathode ray tubesData miningCable television

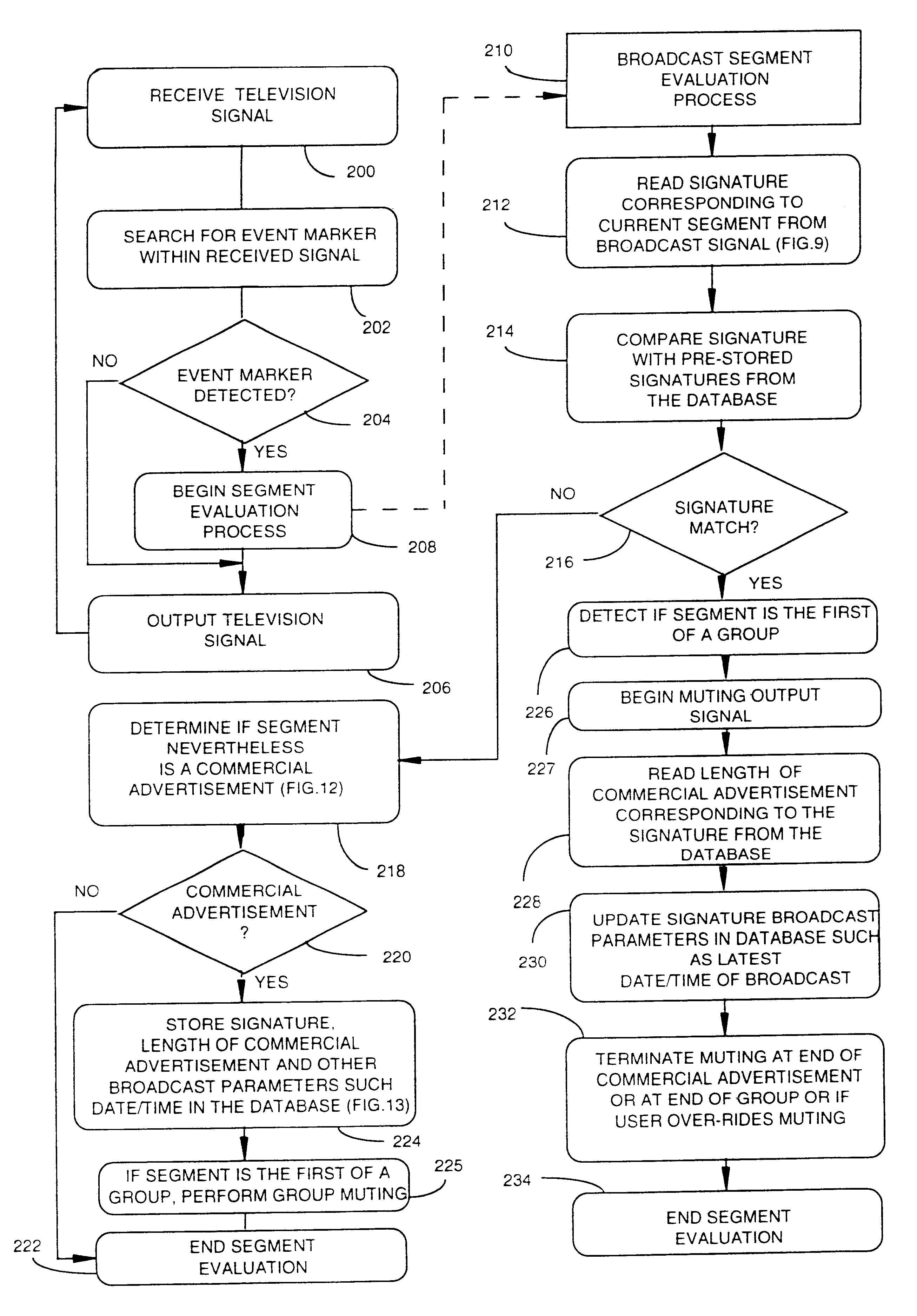

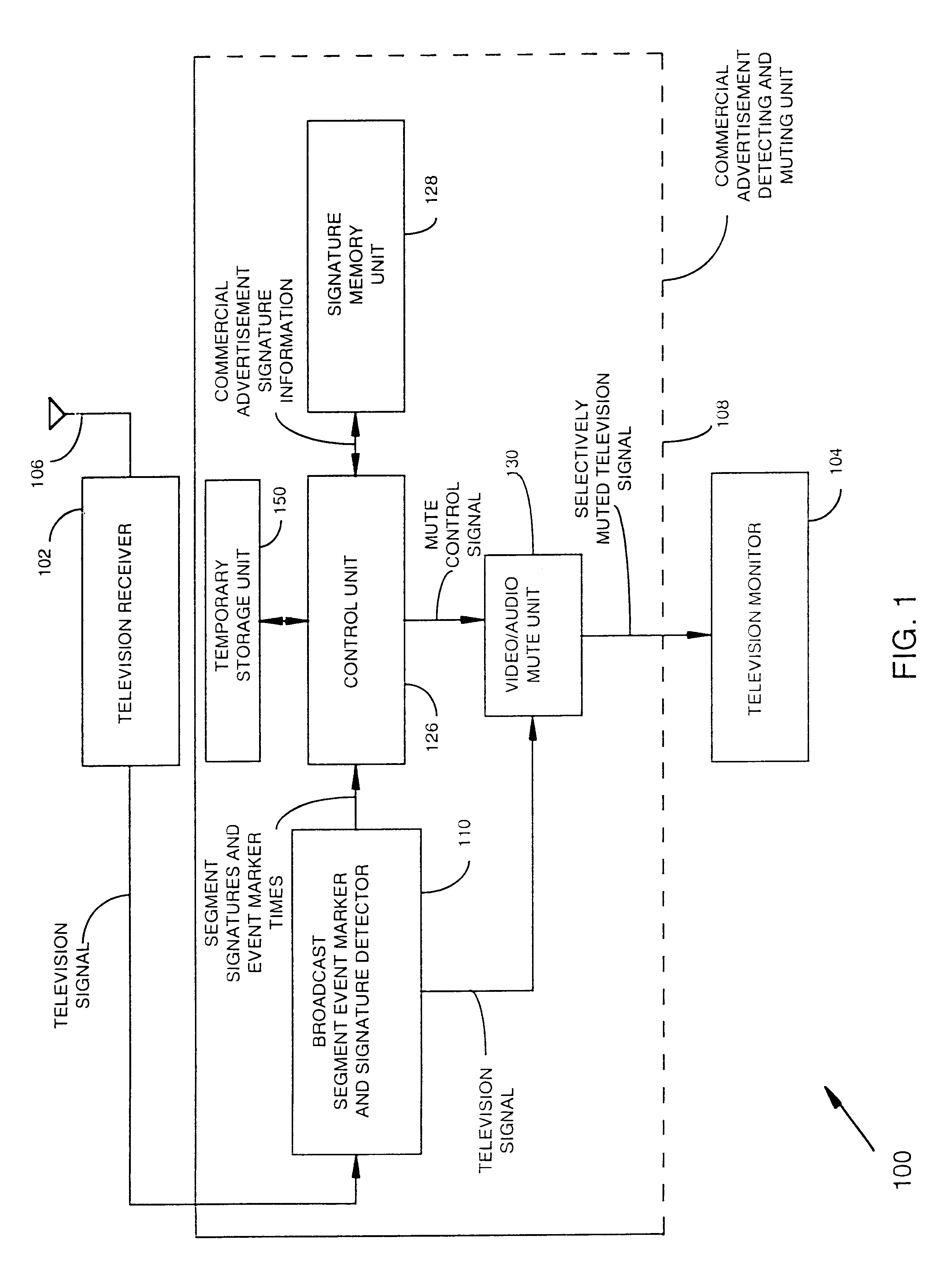

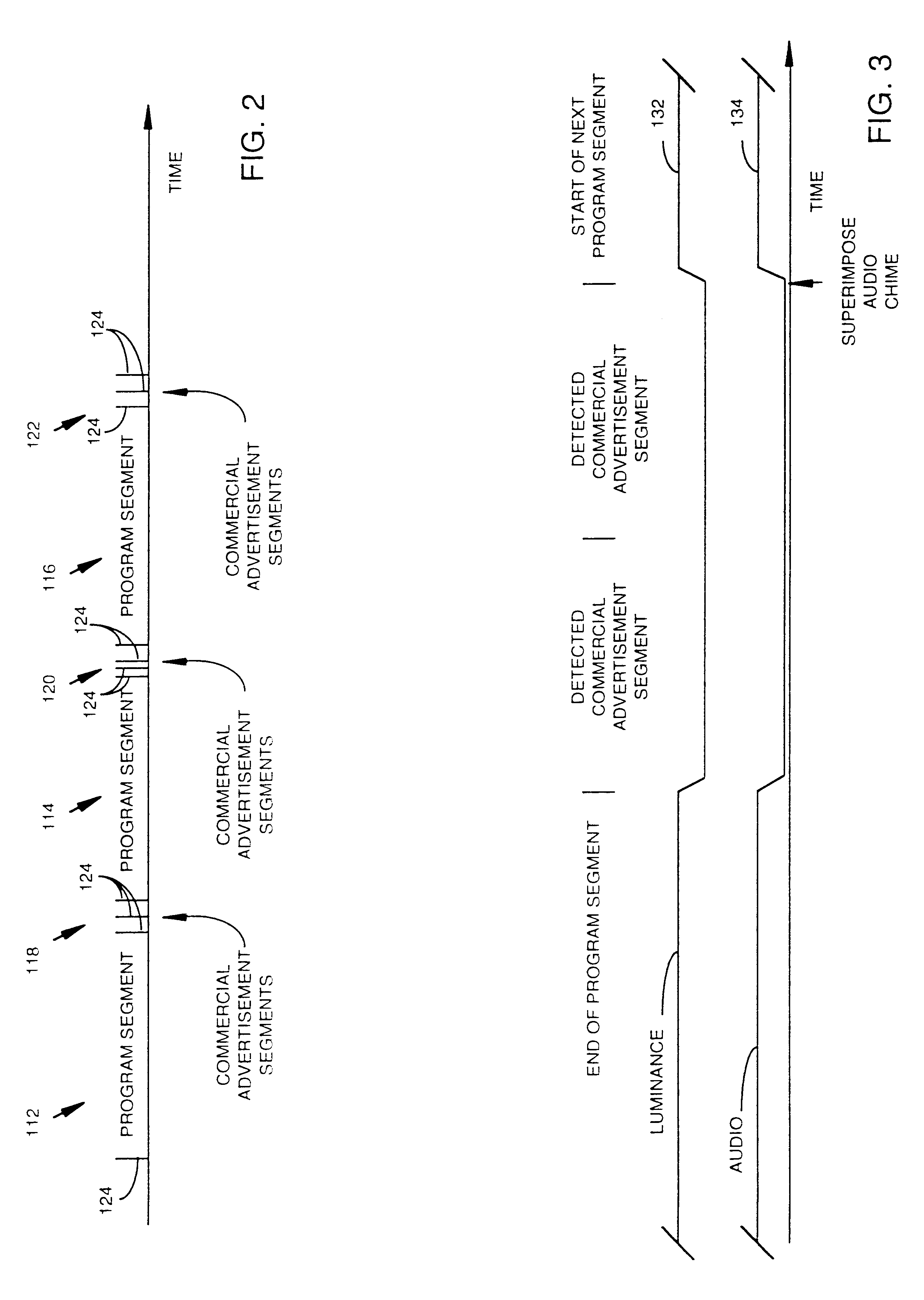

The method and apparatus operates in a VCR to identify selected broadcast segments, such as commercial advertisements, of a television signal in real-time for the purpose of suspending recording of the television signal during each unwanted segment. A signature pattern associated with each segment of the television signal is detected and compared to stored signature patterns representative of selected segments such as commercial advertisement segments. If the signature pattern matches one of the stored signature patterns, the segment is thereby immediately identified as being one of the selected segments and is processed in real-time to suspend recording during the segment. If the signature pattern of the segment does not match any of the stored signature patterns, the segment is analyzed to determine whether the segment is nevertheless a selected segment and, if so, its signature pattern is stored along with the stored signature patterns. The analysis to determine whether the segment is nevertheless a selected segment is performed by detecting the length of the segment upon its completion and then determining whether the length of the segment matches one of a pre-determined set of permissible selected segment lengths such as standard commercial advertisement segment lengths of 15 seconds, 30 seconds, or 60 seconds. If so, the segment is identified as being a selected segment and its signature pattern is stored along with the other stored signature patterns such that, the next time the same segment is encountered, its signature will then match the stored signature and therefore the segment can be immediately identified and recording of the segment can be immediately suspended.

Owner:TELEVENTIONS

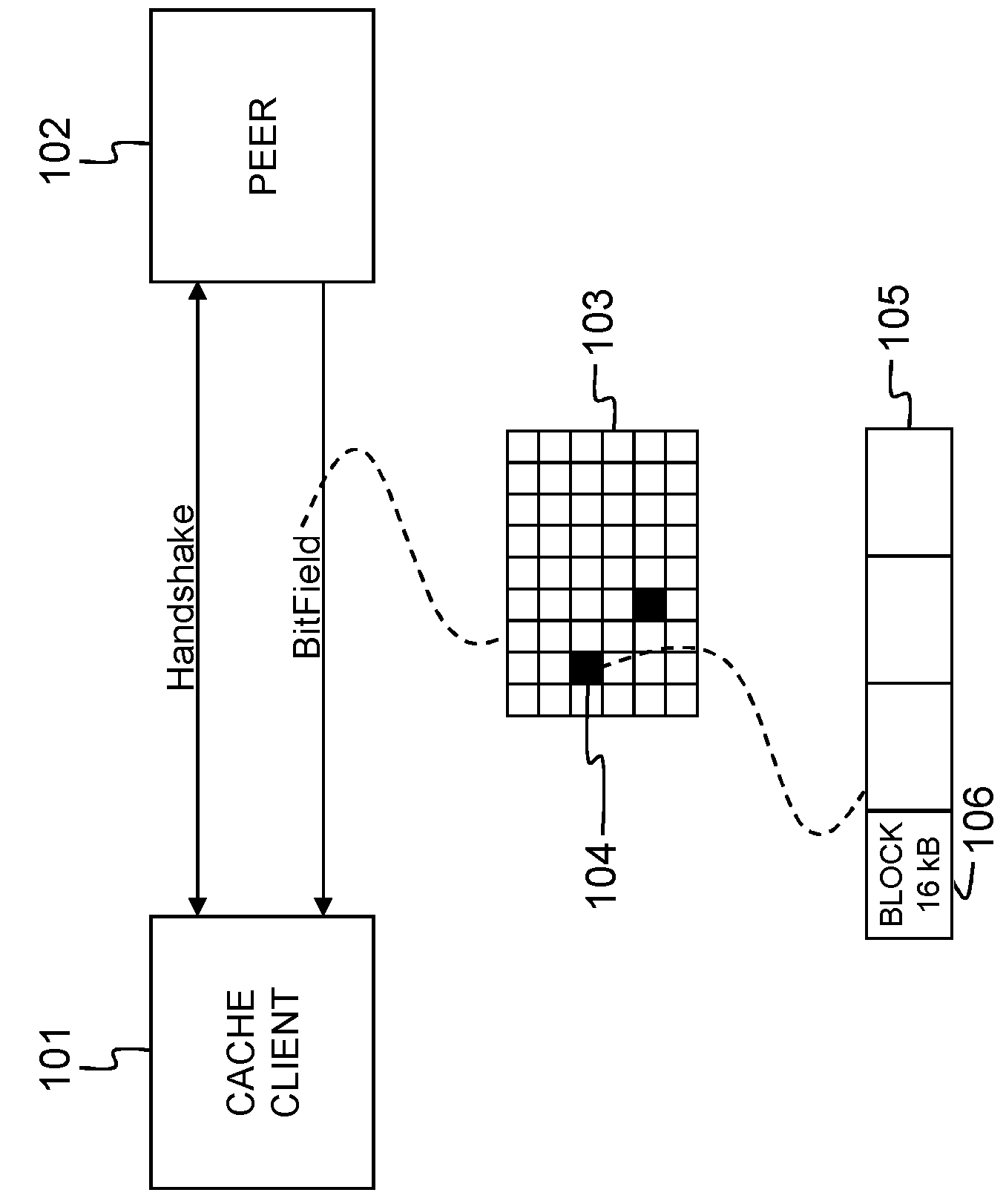

Method and device for reconstructing torrent content metadata

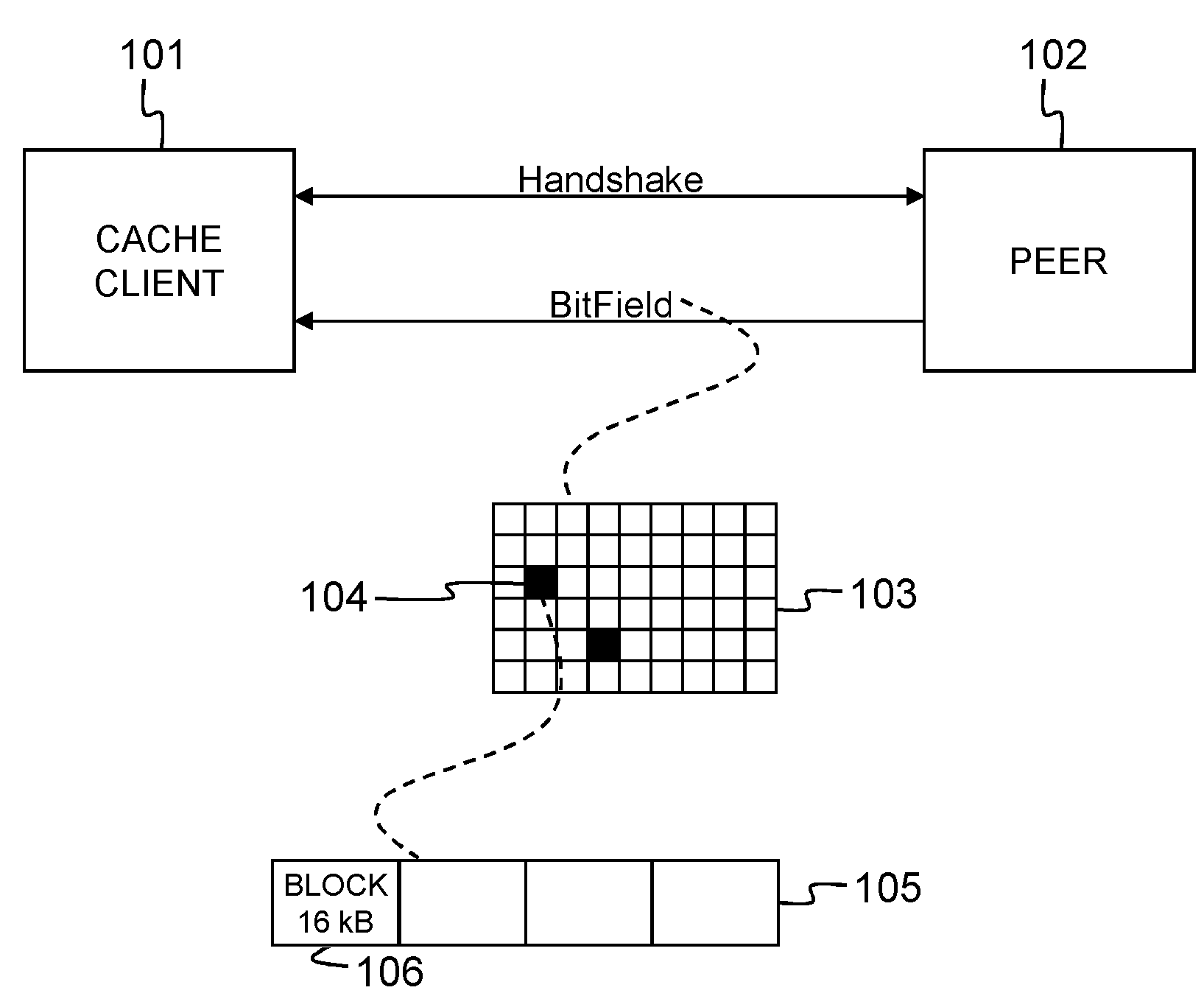

A method for reconstructing torrent content metadata, i.e. a torrent identifier, a segment length and an amount of segments of a torrent content file, without access to the torrent content metafile, comprises the steps of: A. obtaining the torrent content identifier from torrent signaling from a client; B. obtaining a torrent content file size from said torrent signaling from said client; C. obtaining a tracker address from said torrent signaling from said client: D. obtaining a peer address from a tracker; E. contacting a peer via the peer address; F. downloading sequential minimum size blocks of a full size segment from the peer in order to determine the segment length; G. calculating the amount of segments from the torrent content file size and the segment length.

Owner:PIECE FUTURE PTE LTD

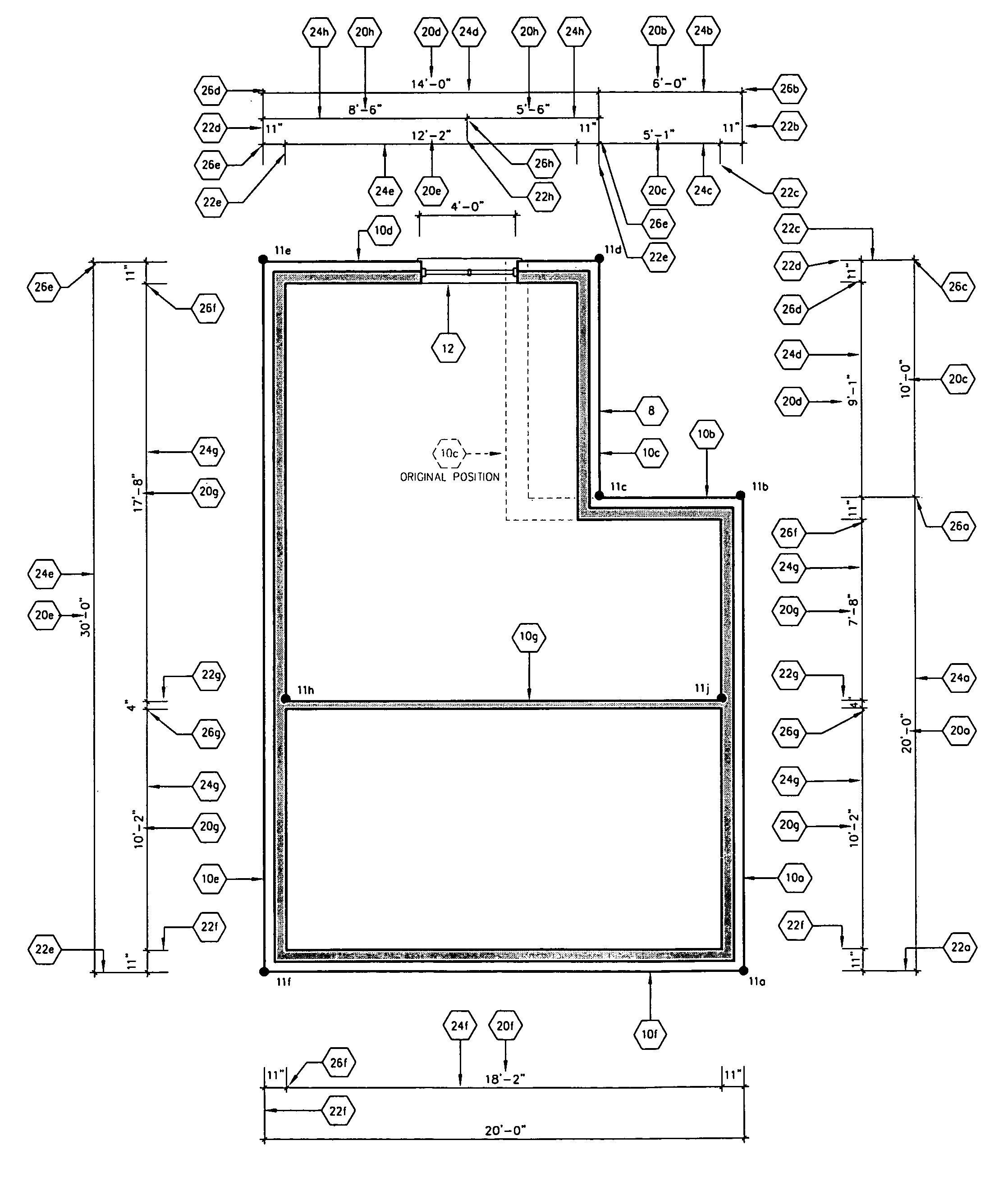

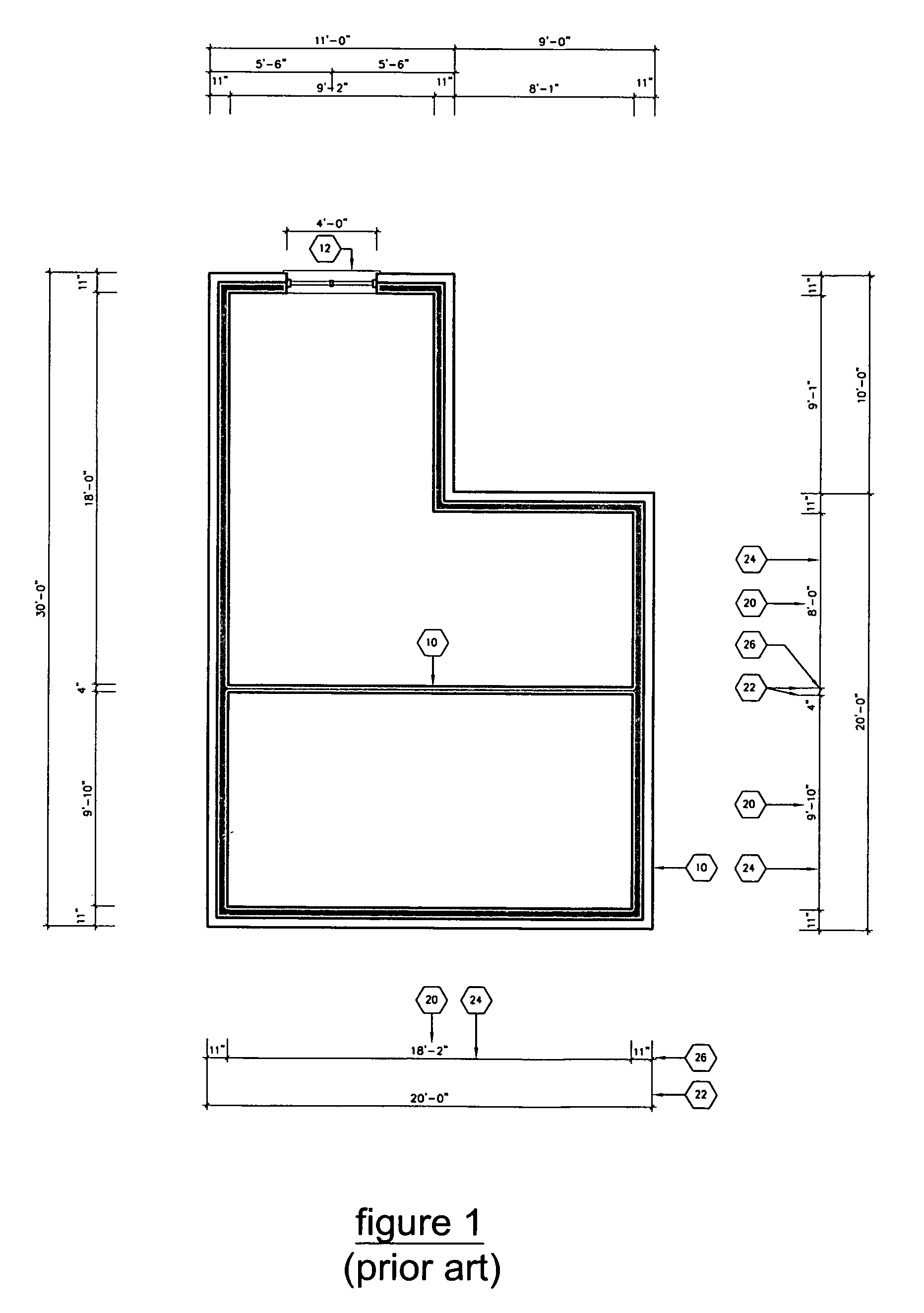

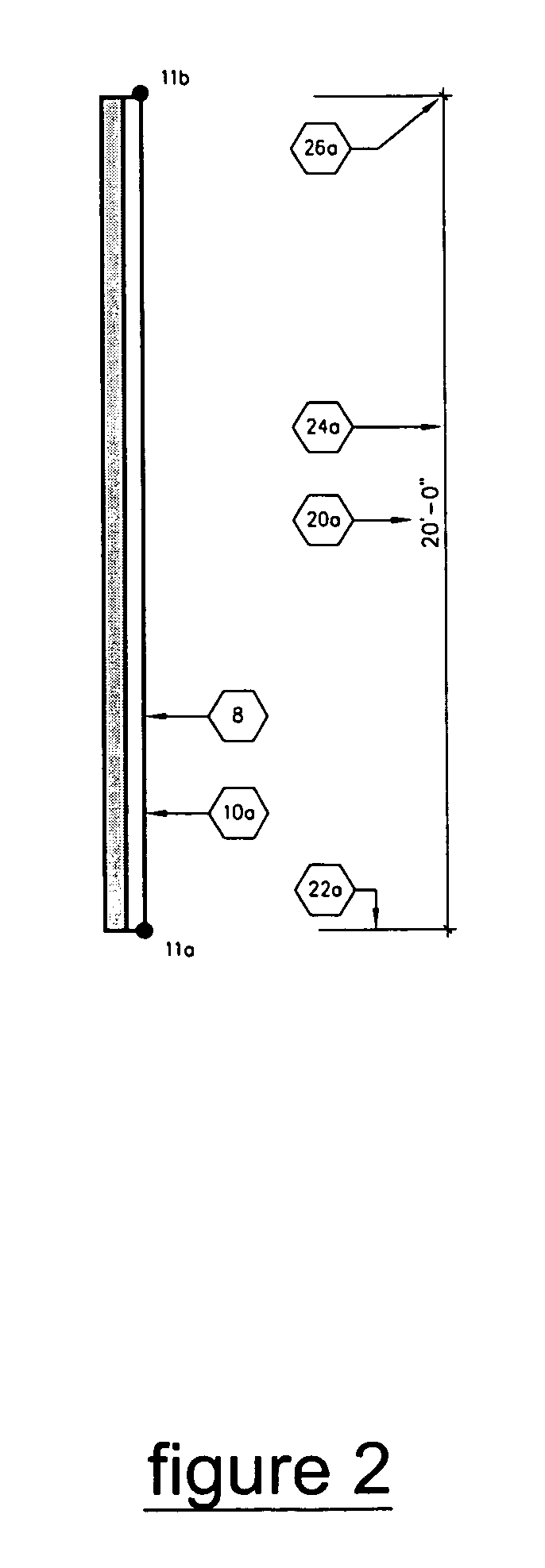

Automatic adaptive dimensioning for CAD software

InactiveUS7039569B1Shorten production timeGeometric CADData processing applicationsProgramming languageAlgorithm

An automatic adaptive dimensioning program for CAD software in which dimension annotations are created by the CAD program automatically as an object is drawn and automatically associated with the object. Thereafter, changing the length of the object automatically changes the associated dimension annotation, or alternatively, changing the associated dimension annotation automatically changes the length of the object. When another object is interposed into or superposed onto an intermediate position of the existing object, the automatic adaptive dimensioning annotation feature of the invention automatically creates dimension annotations corresponding to the position of the new object relative to the existing object. The new object can be automatically positioned in relation to the existing object by specifying interposition dimensions or segment lengths in the dimension annotations.

Owner:HAWS RICHARD R +1

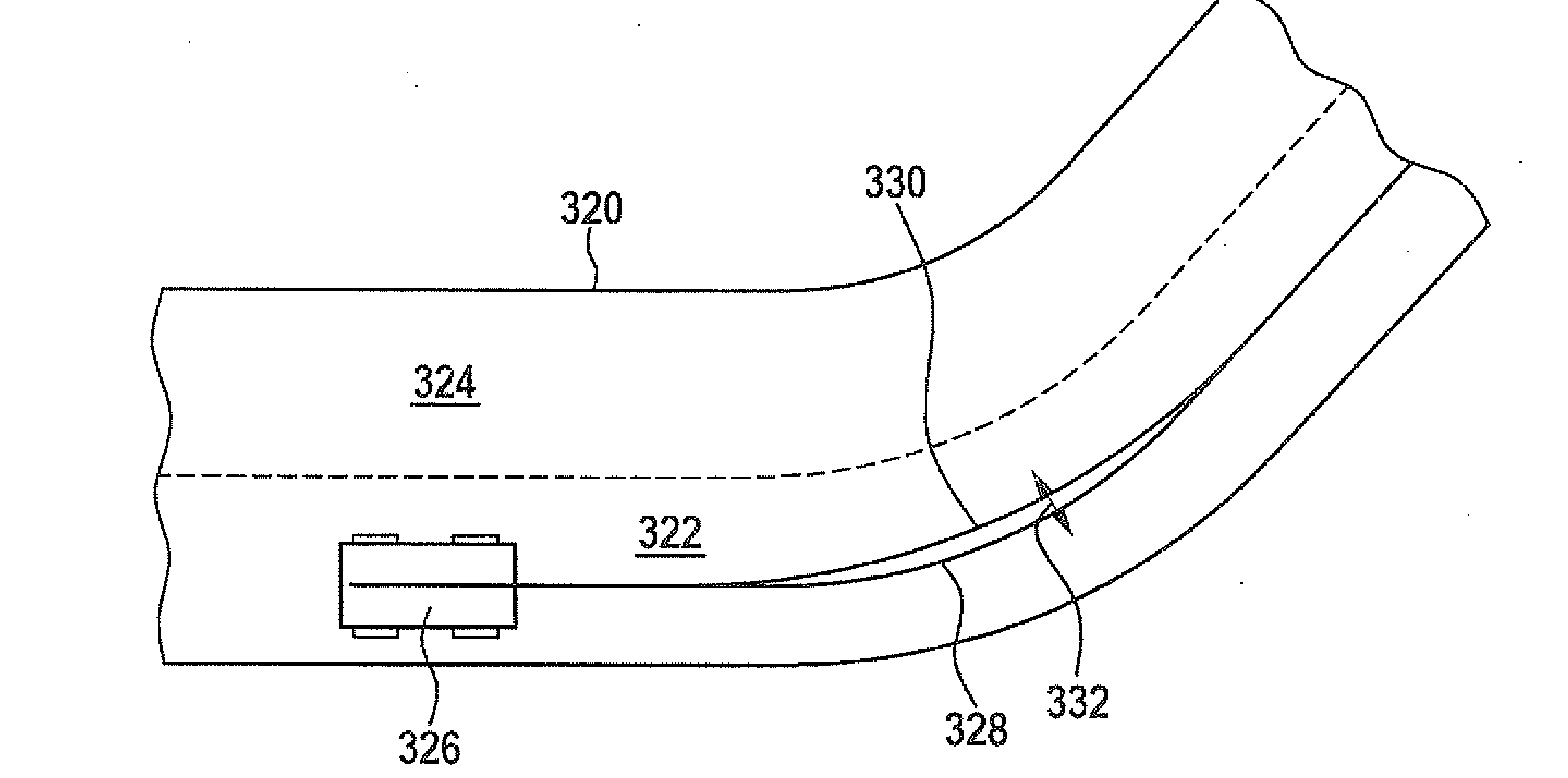

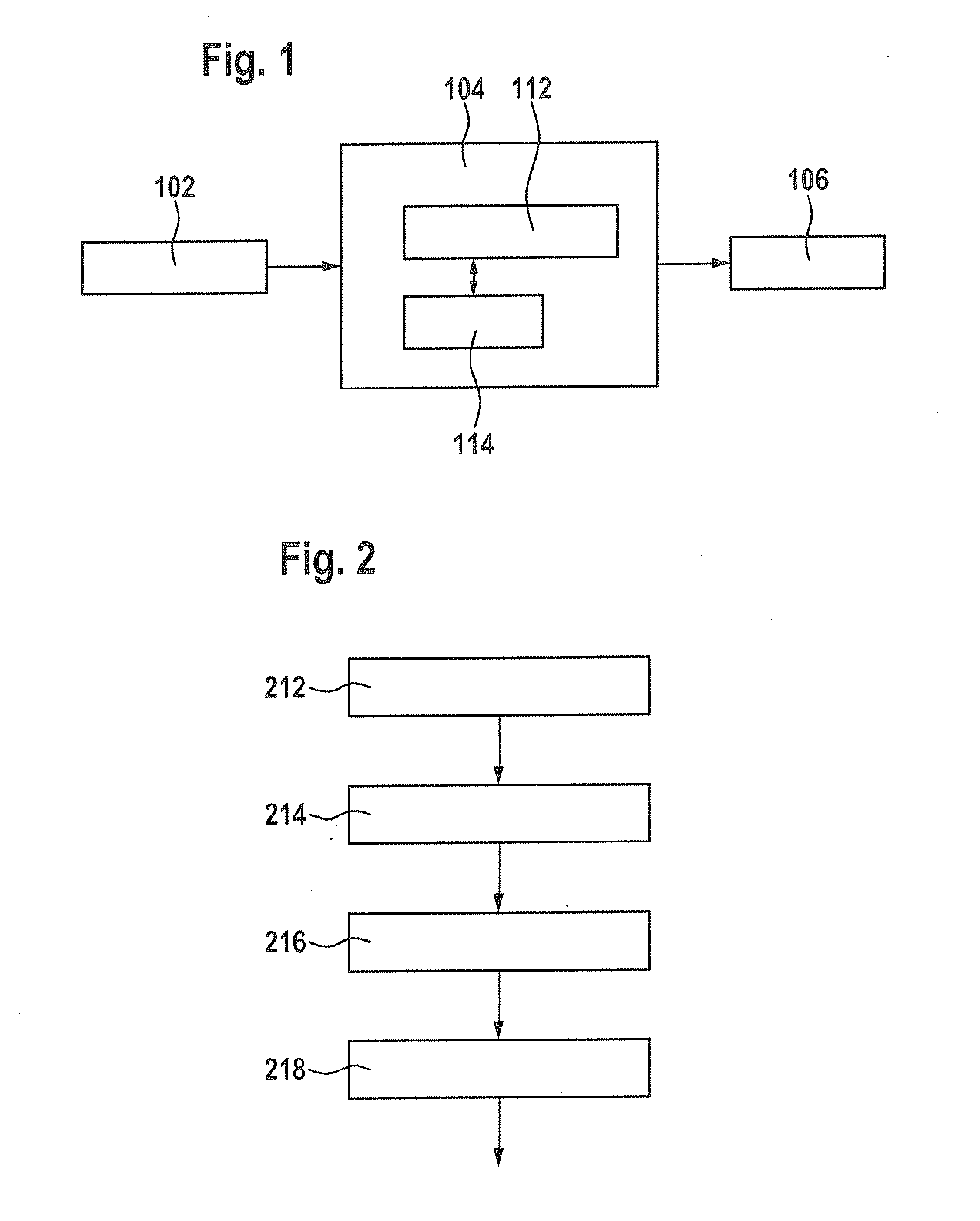

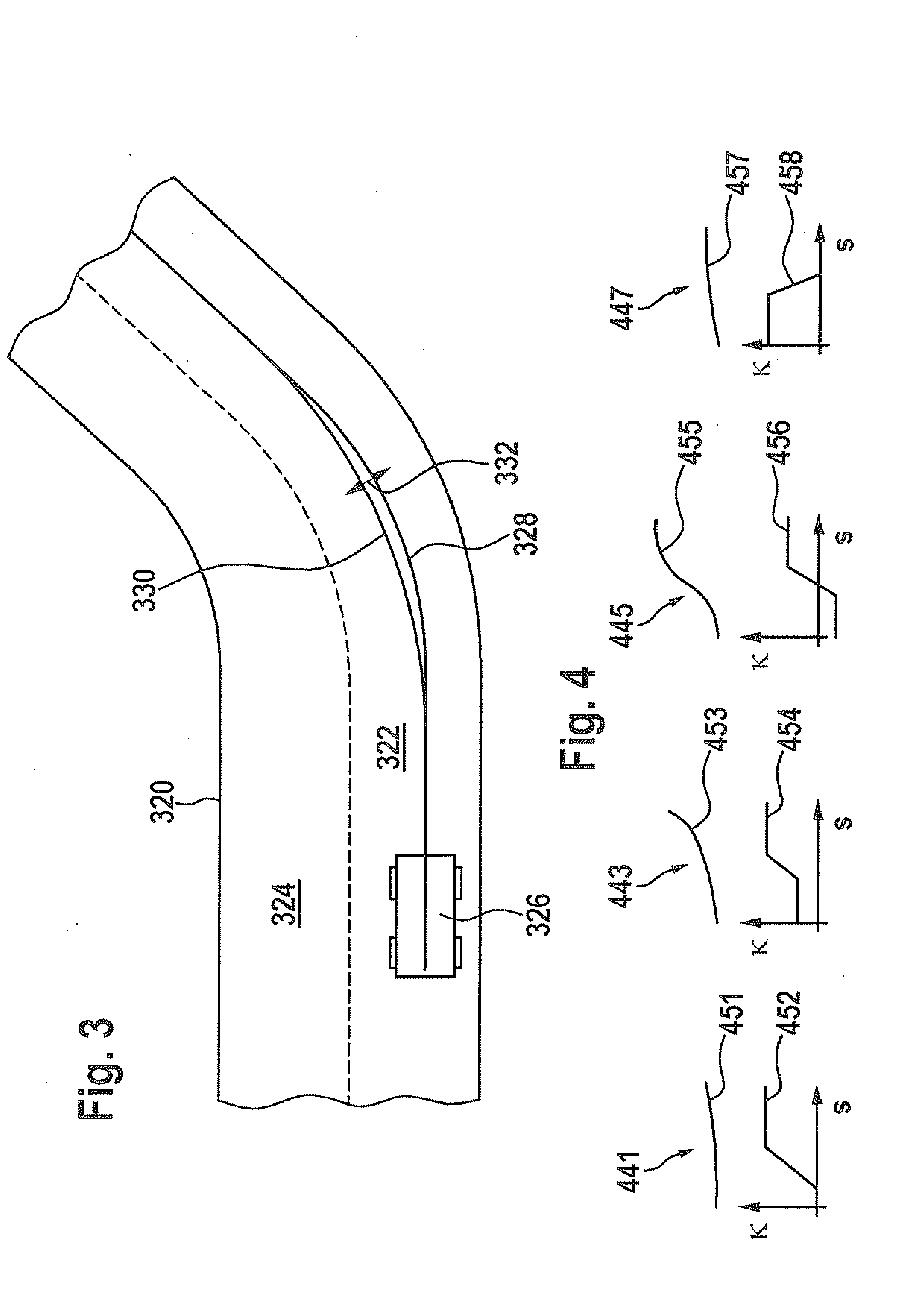

Method and control unit for determining a cutting trajectory of a curve section of a roadway

ActiveUS20130006473A1Increase radiusImprove securitySteering initiationsDigital data processing detailsMechanical engineeringLine segment

A method for determining a cutting trajectory that enables a curve section of a lane to be cut by a vehicle. In the method, information about the curve section is received, and the curve section is divided into at least one curve segment having a segment length and a start curvature, the curve segment being a straight-line segment or a circular arc segment or a curve segment whose curvature is a function of an arc length of the curve segment. This is followed by determination of a cutting trajectory from the at least one curve segment, so that, at a specific point of the curve section, the cutting trajectory has a predetermined offset relative to a center of the lane.

Owner:ROBERT BOSCH GMBH

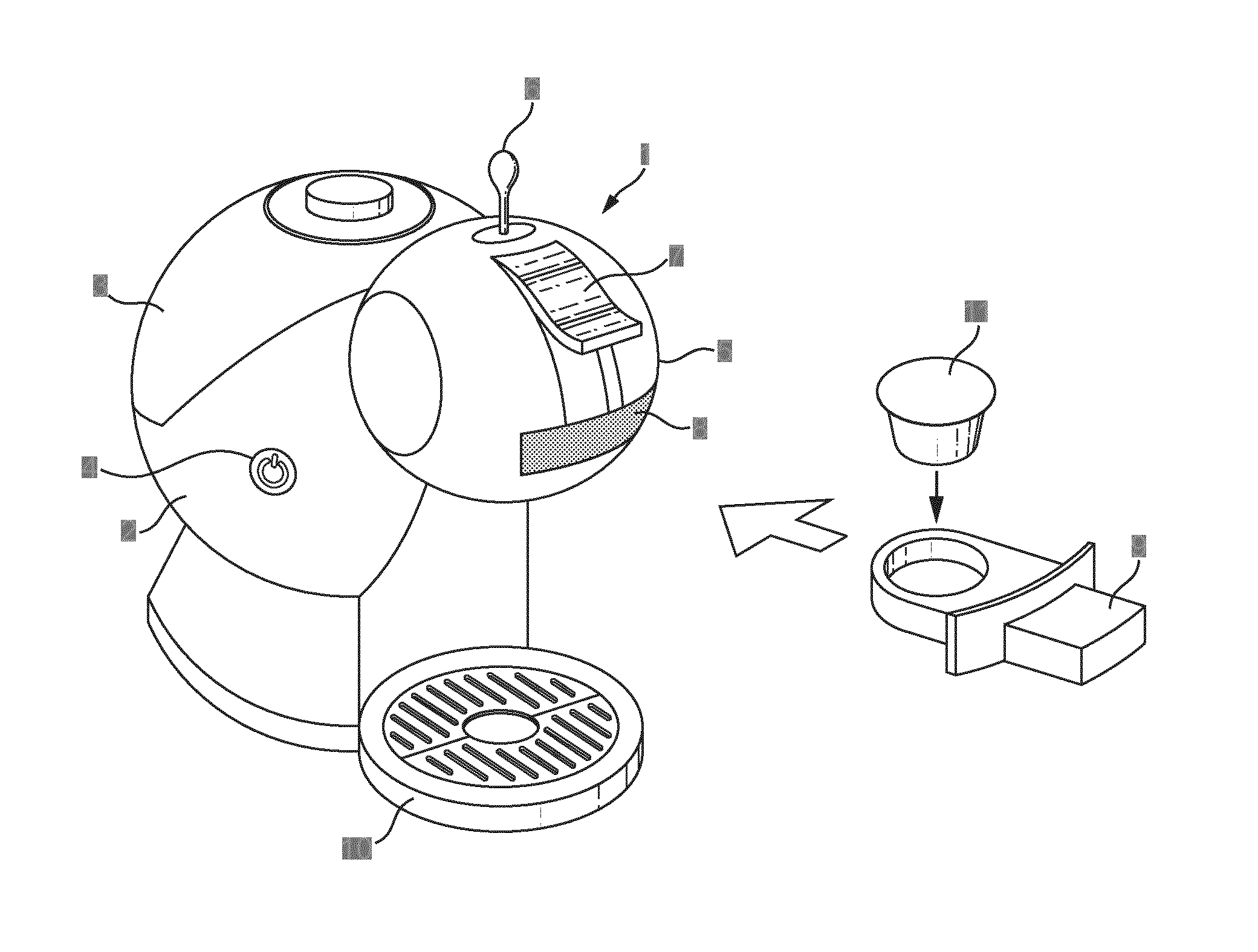

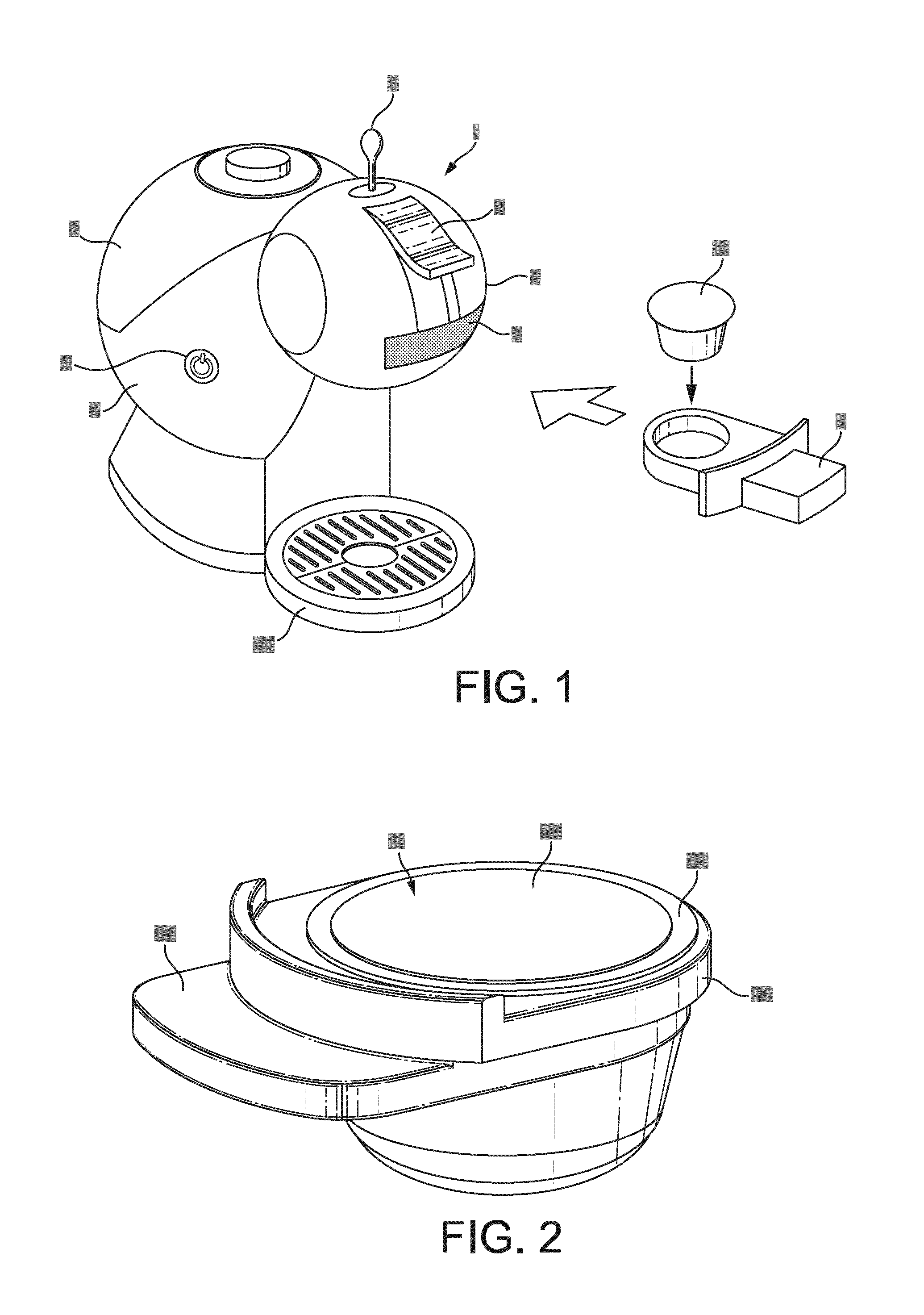

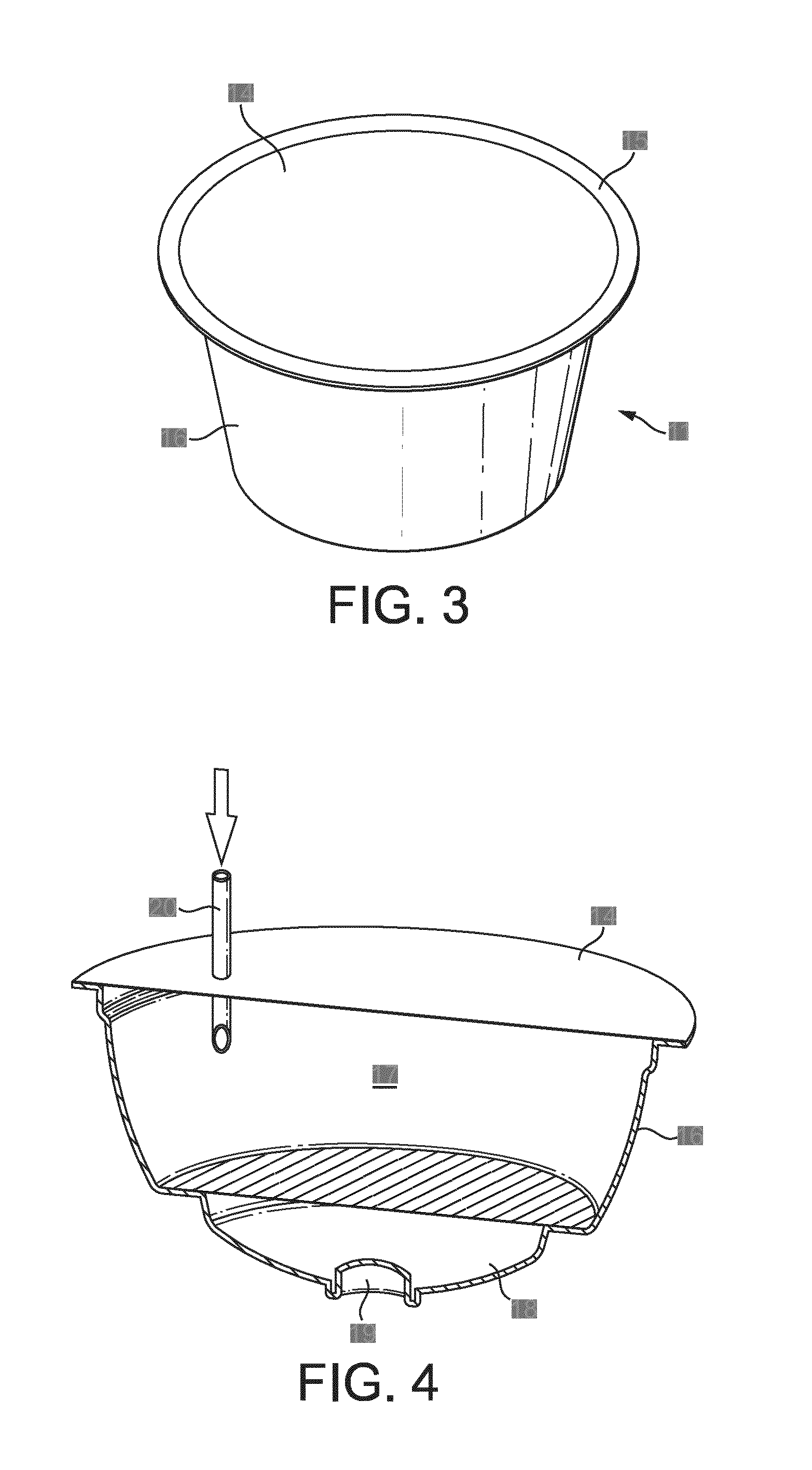

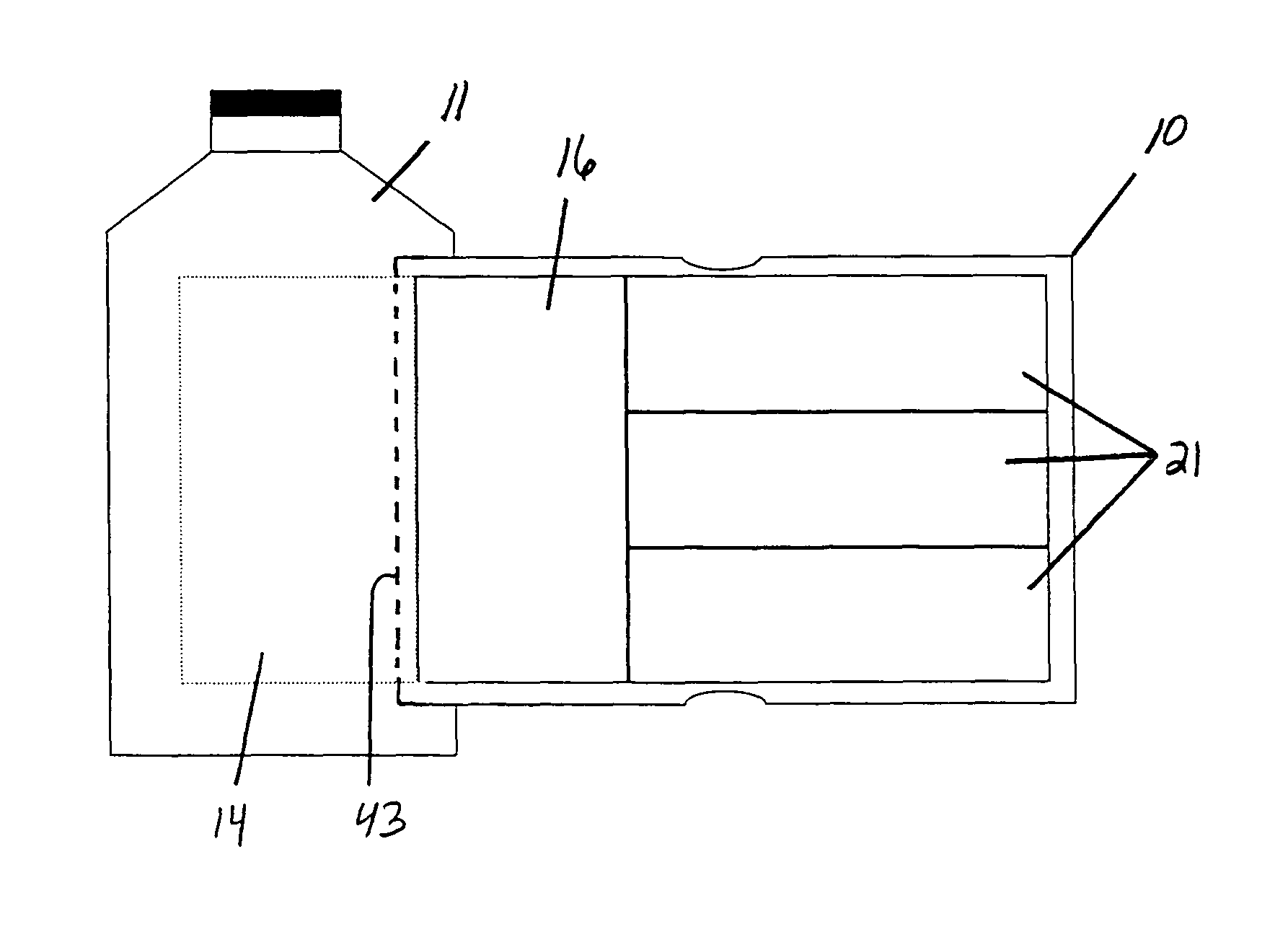

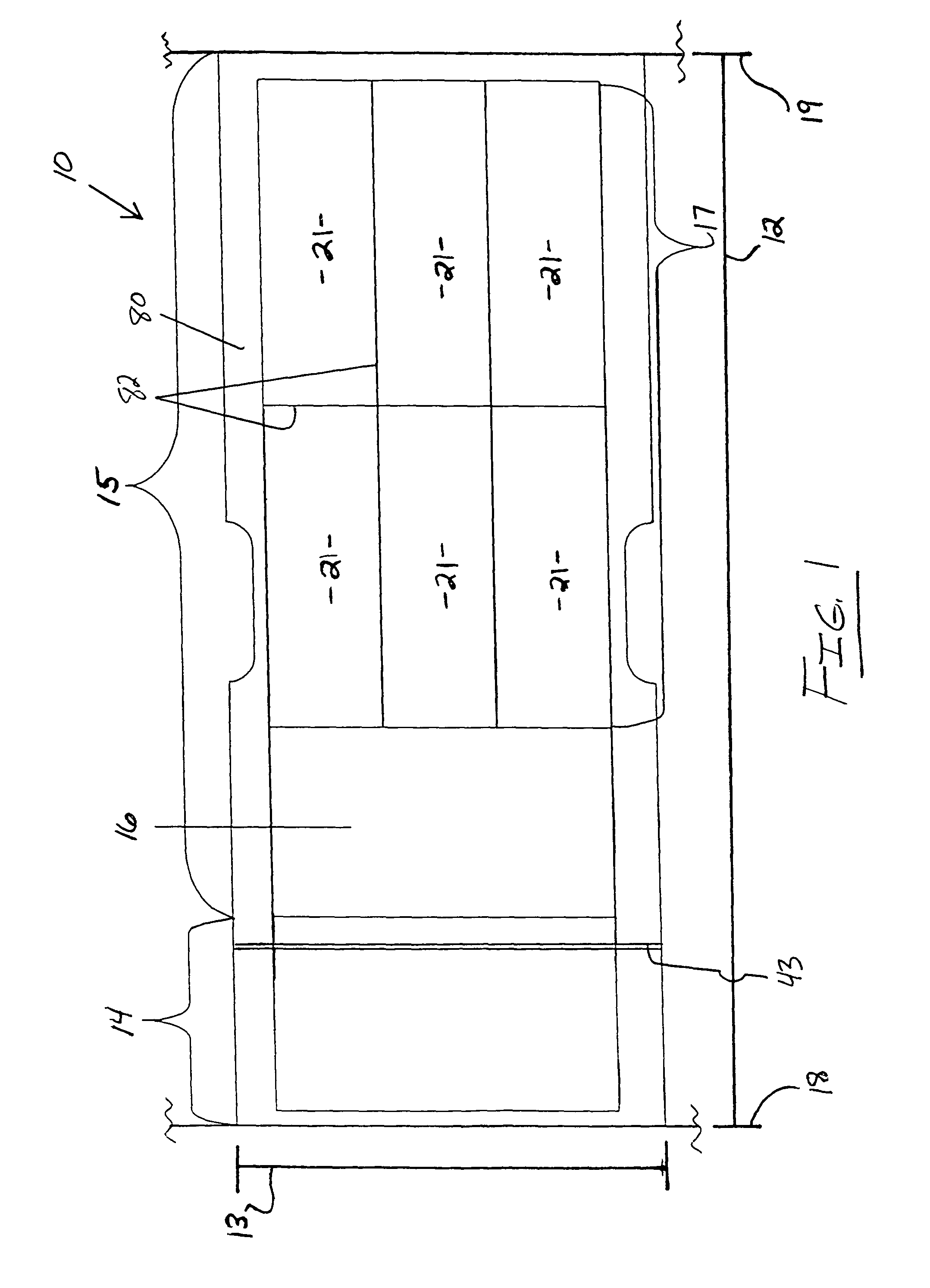

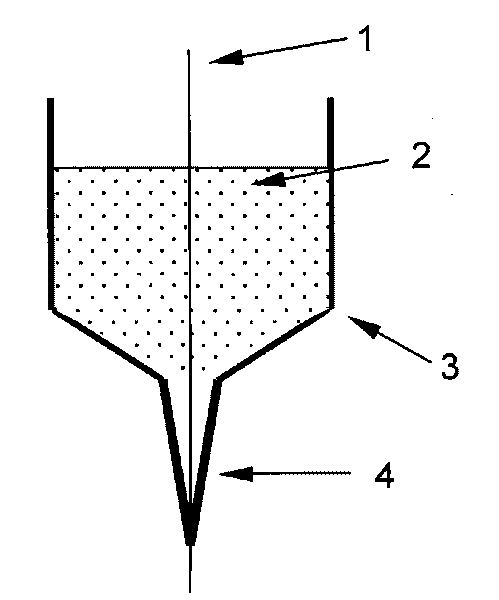

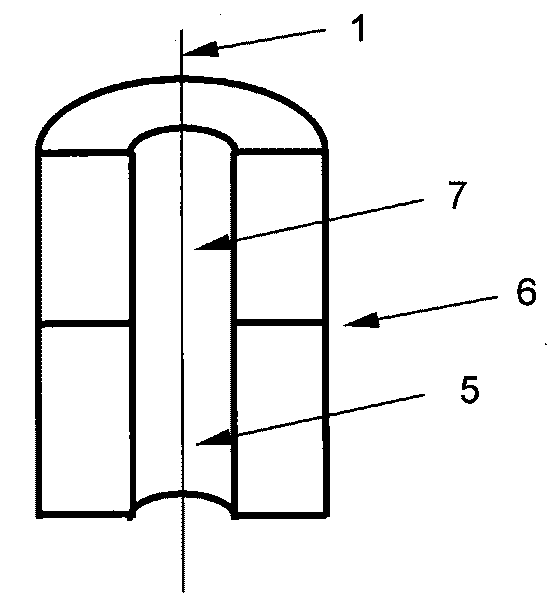

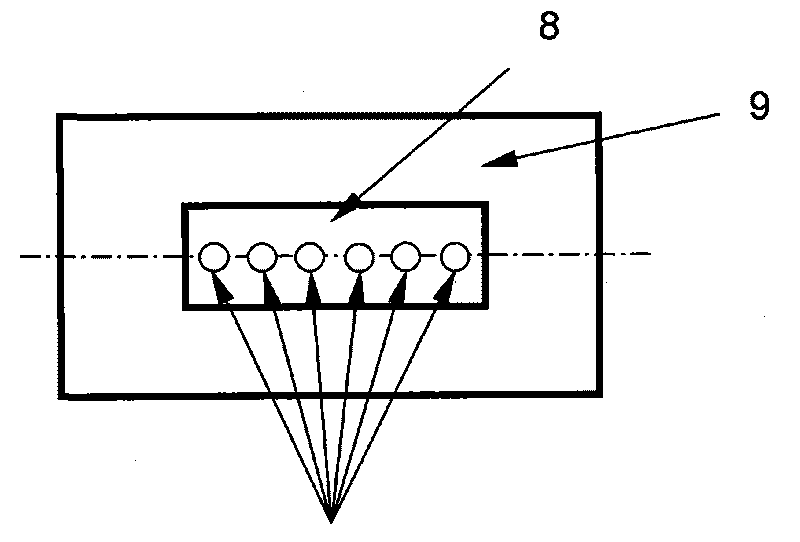

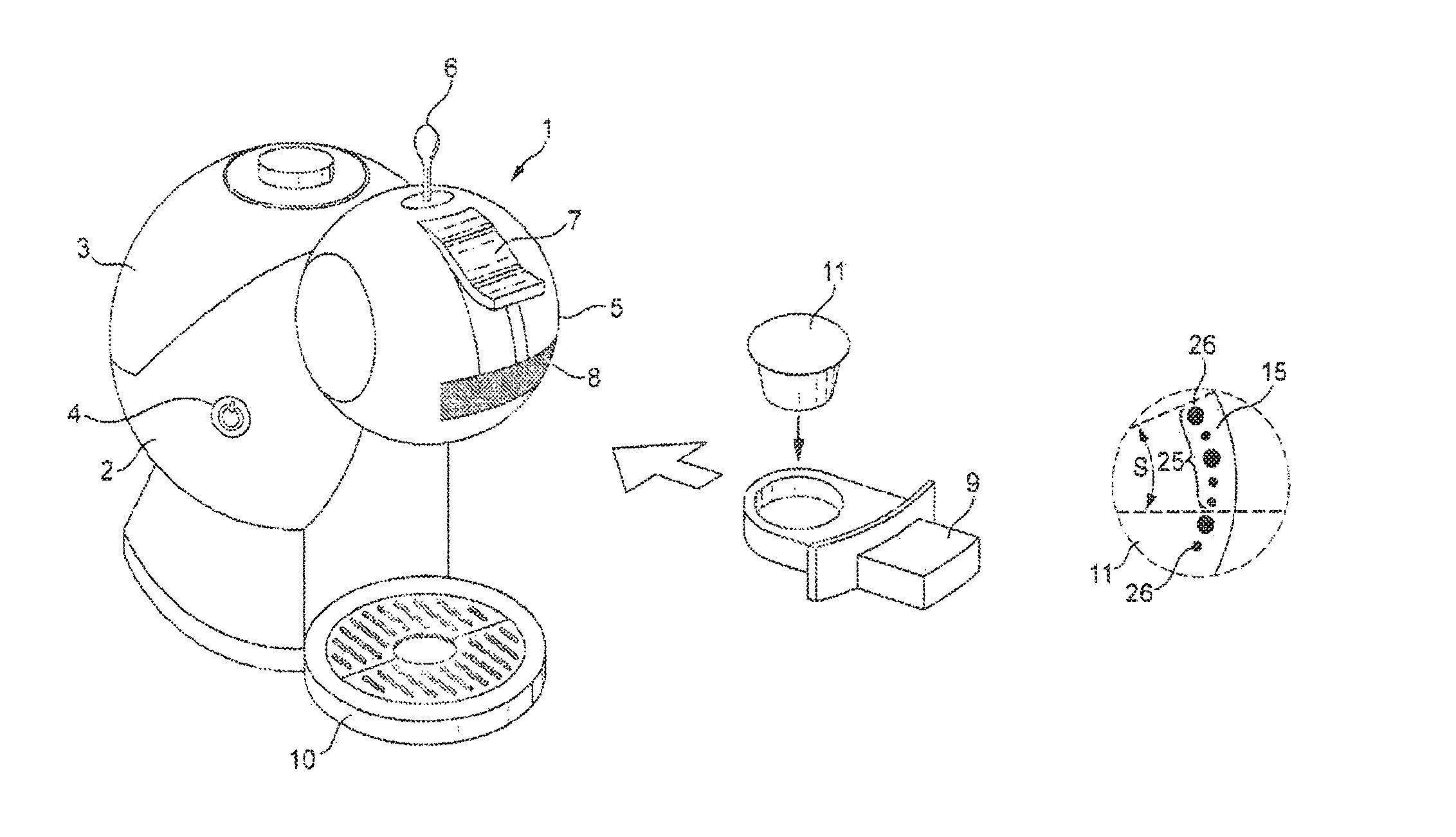

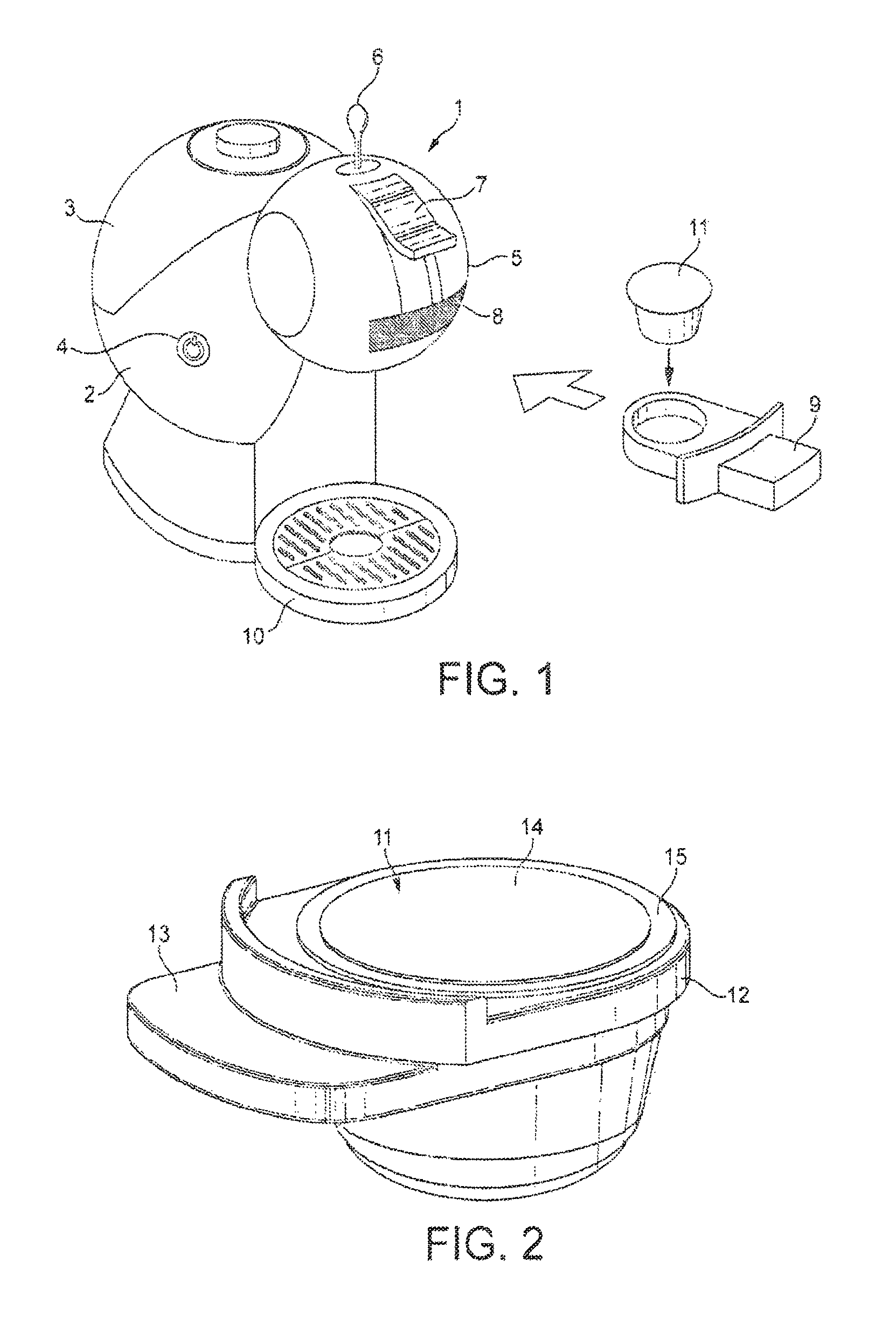

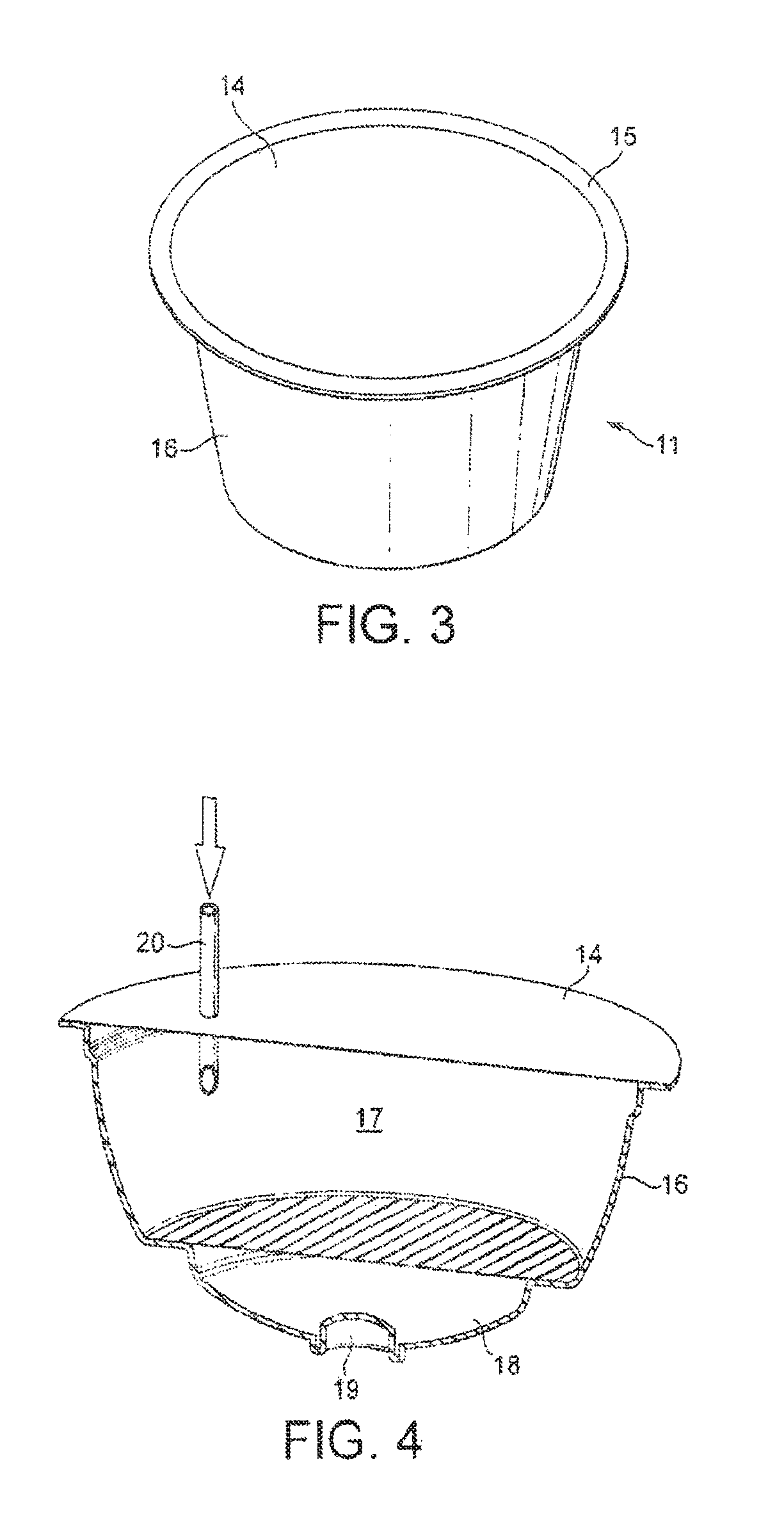

Barcode for a beverage preparation capsule

A beverage preparation system comprising: (i) a capsule (1 1) with side (16), bottom (18) and top (14) walls, said capsule having a shape that is substantially symmetrical around a vertical axis, and said capsule is suitable for containing a beverage preparation ingredient to be dissolved, and / or infused, and / or extracted under pressure, by action of a fluid circulating into said capsule through said ingredient, (ii) a beverage preparation machine (1) suitable for receiving said capsule (11), and circulating said fluid into said capsule, (iii) optionally a capsule holder (9) for holding said capsule (1 1), at least at the time said capsule is disposed into said machine, characterized in that: the machine (1) comprises a linear barcode reader (21) suitable for reading a linear barcode sequence (25) contained in a segment S having a segment length LR, said linear barcode reader (21) being disposed in the machine such that it can read a barcode printed on the capsule while said capsule is being inserted inside said machine, and the capsule (1 1) comprises a barcode sequence (25) that is repeatedly printed along a peripheral path of the capsule, each sequence being disposed in an arc having a linear projected length LS that is inferior to LR and said sequence (25) is composed of dots (26) spaced apart from one another along said arc, such that their projected point images along a linear segment are also spaced apart.

Owner:SOC DES PROD NESTLE SA

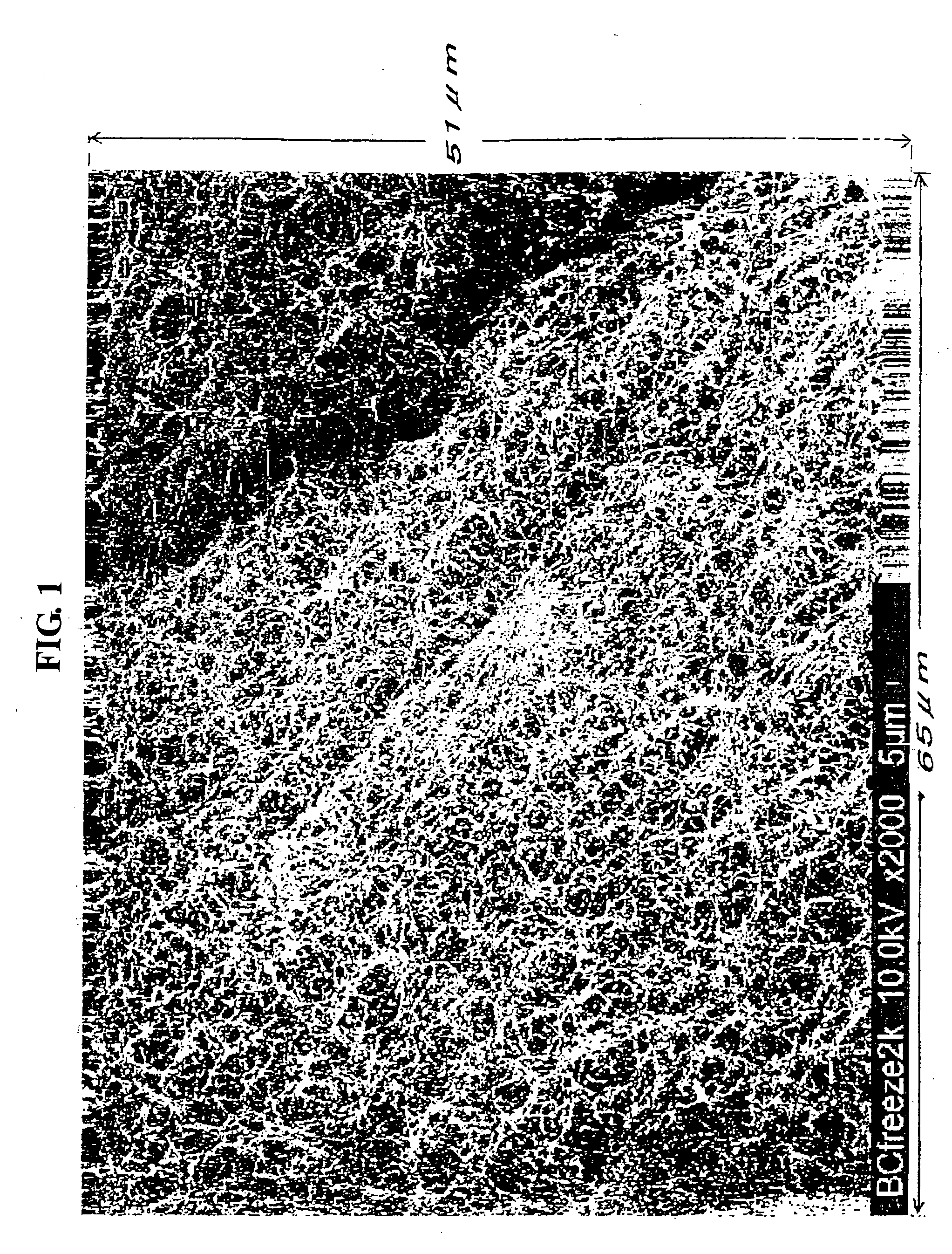

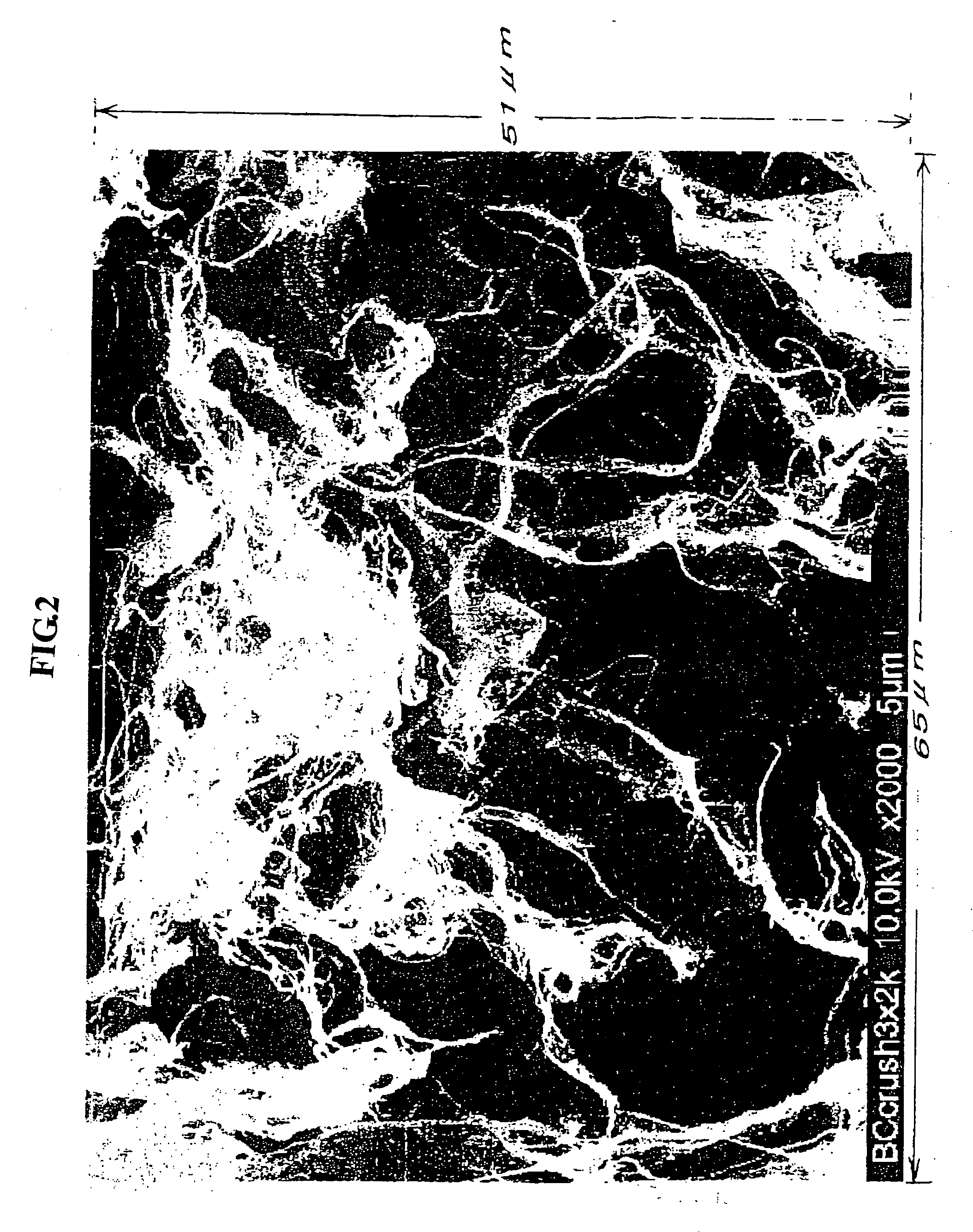

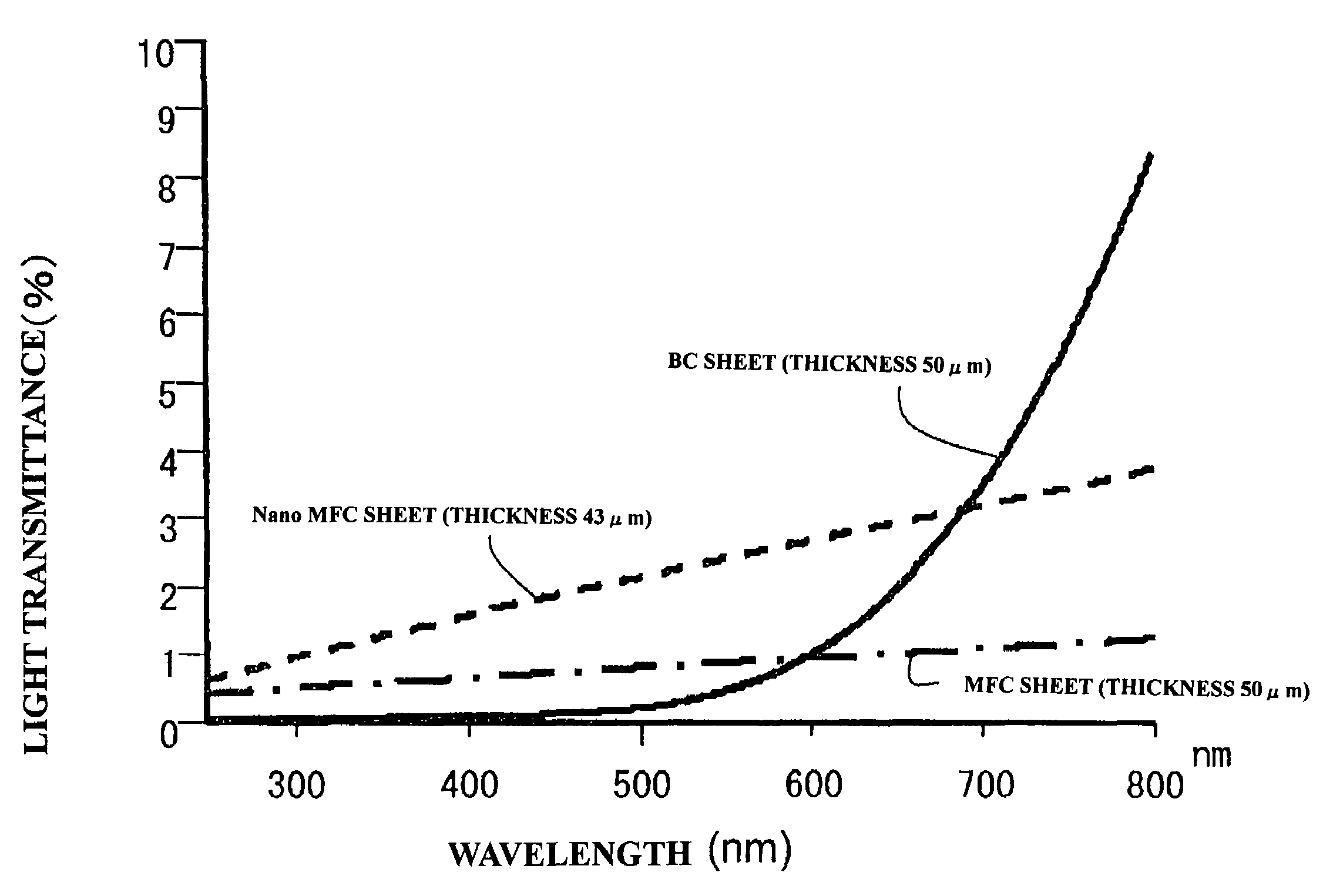

Fiber-reinforced composite material, method for manufacturing the same and applications thereof

ActiveUS20060182941A1High transparencyLight weightMaterial nanotechnologyTransparent dielectricsTransmittanceFiber-reinforced composite

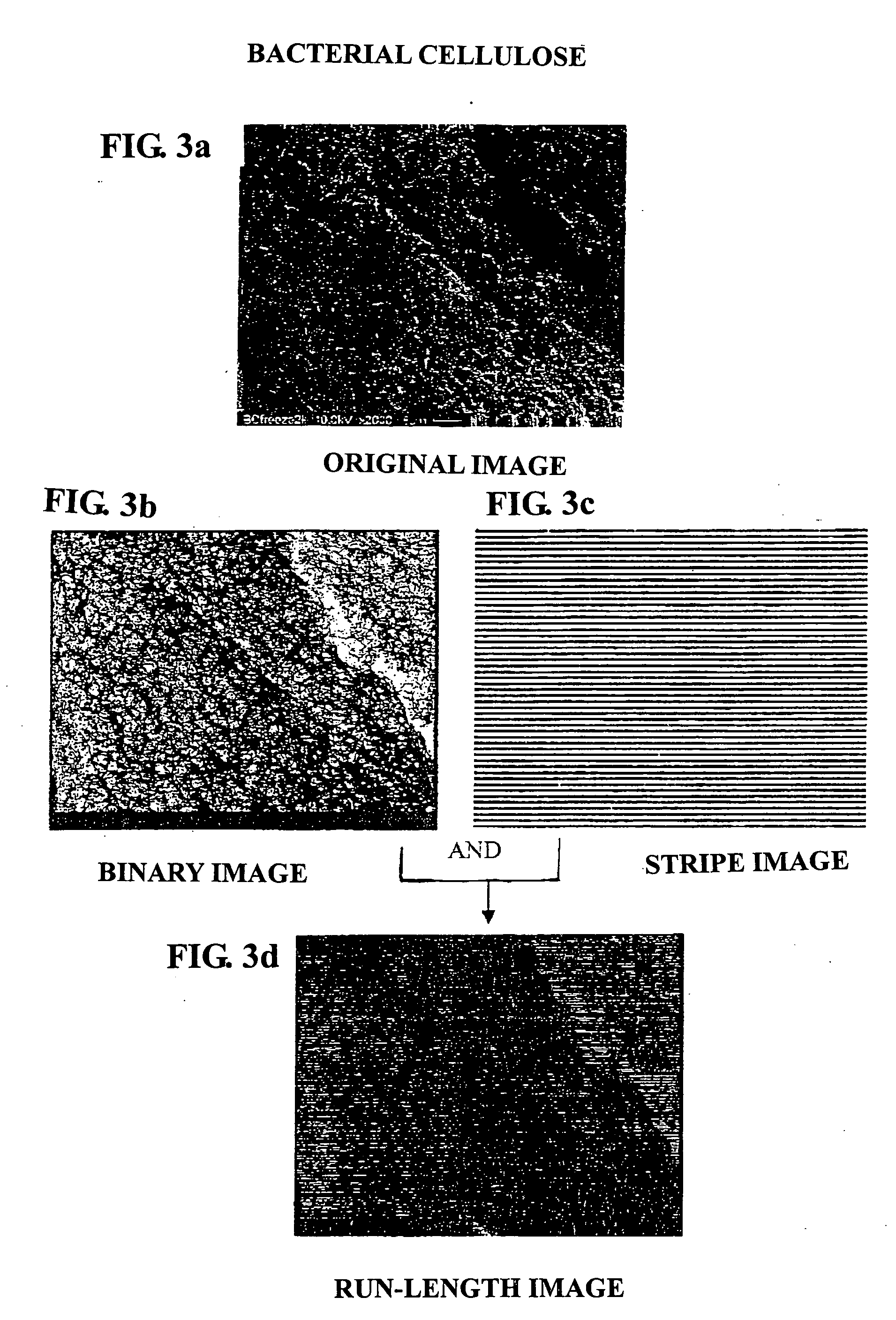

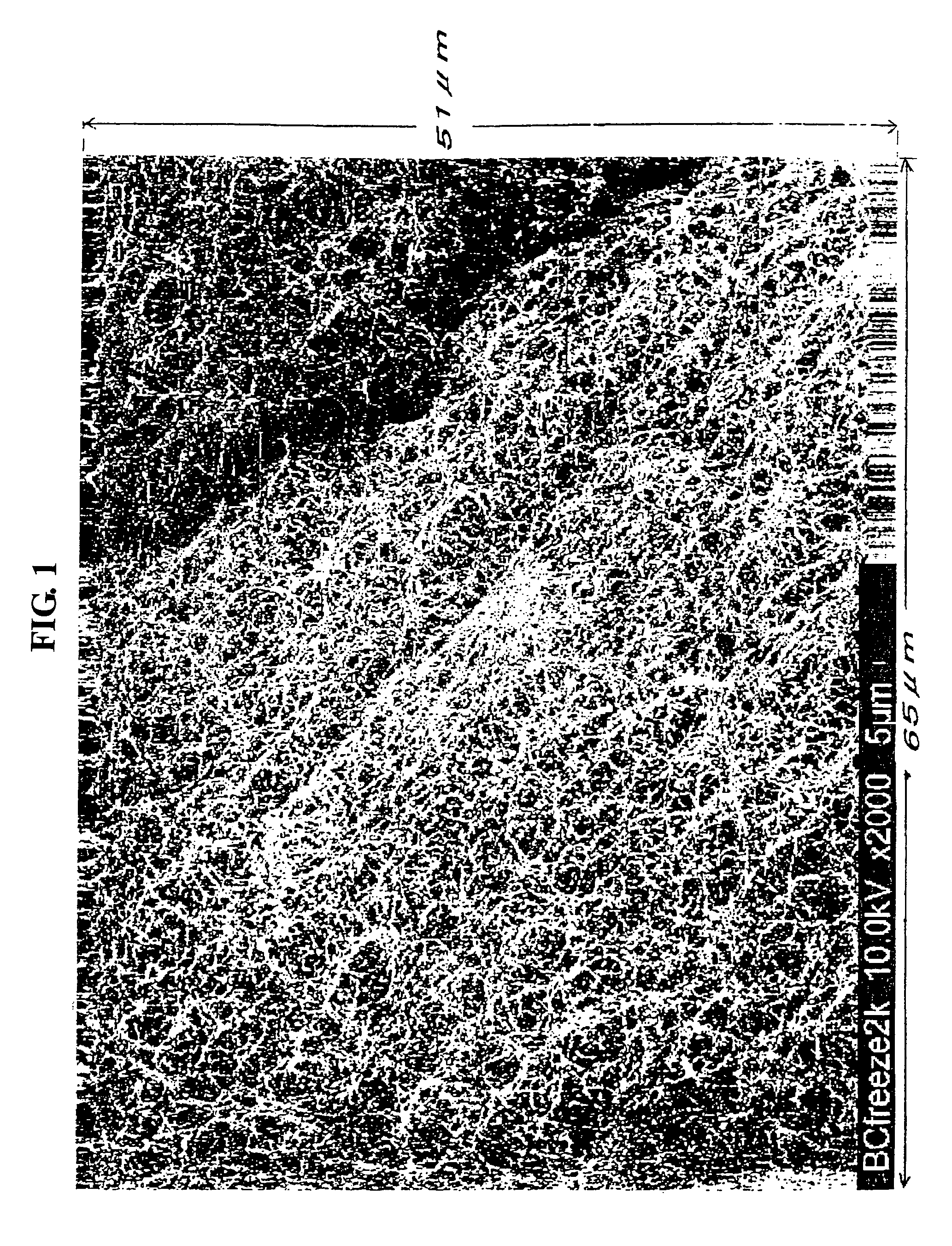

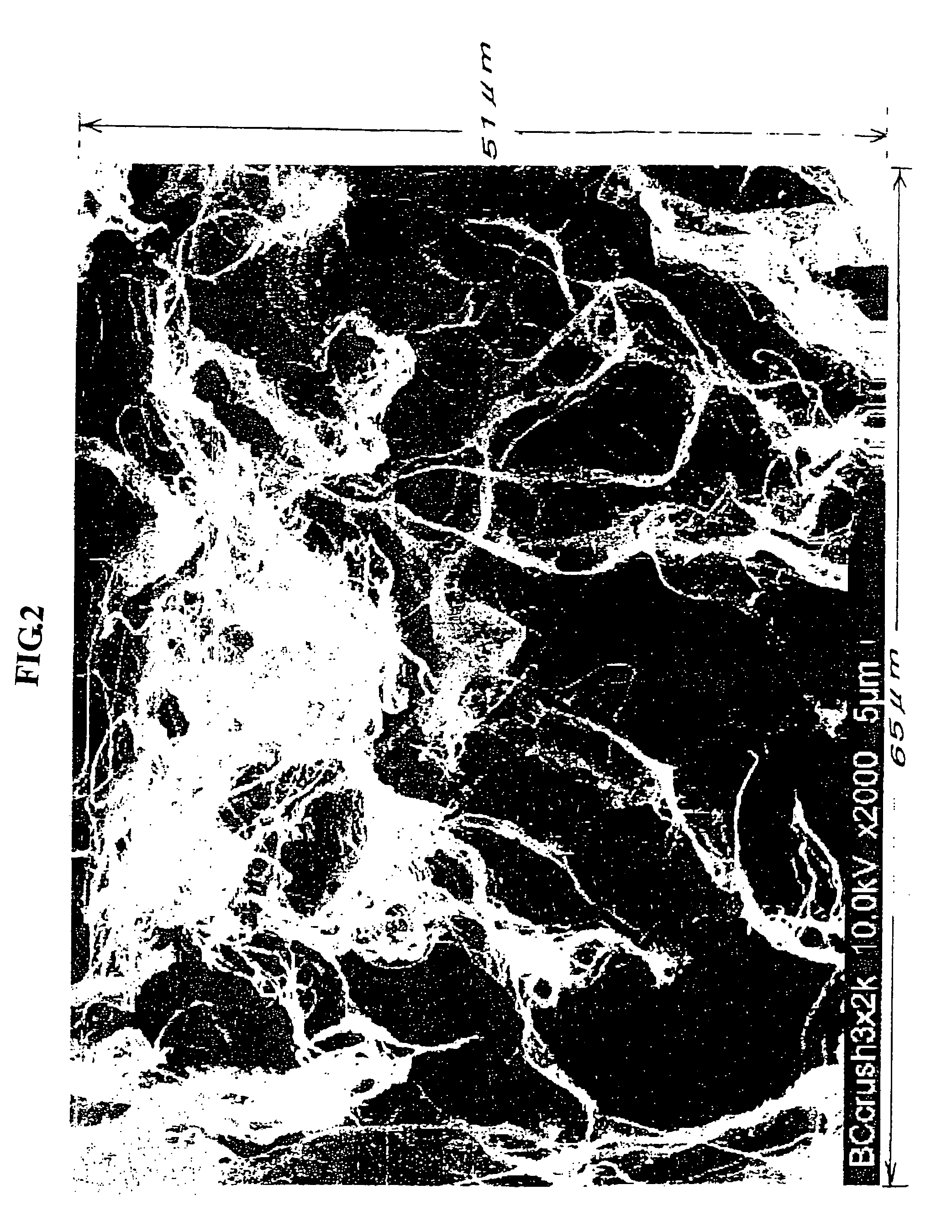

There is provided a fiber-reinforced composite material containing fibers having an average fiber diameter of 4 to 200 nm and a matrix material, the composite material having a visible light transmittance of 60% or more at a wavelength of 400 to 700 nm, which is a conversion value based on a thickness of 50 μm. A fiber-reinforced composite material composed of a matrix material and a fiber aggregate impregnated therewith is provided, in which when a segment length of a bright region corresponding to a pore region of the fiber aggregate is represented by L, which is obtained by statistical analysis of a unidirectional run-length image formed from a binary image obtained by binarization of a scanning electron microscopic image of the fiber aggregate, the total length of segments that satisfy L≧4.5 μm is 30% or less of the total analyzed length. A transparent multilayered sheet, a circuit board, and an optical waveguide are provided which use a transparent substrate formed from this fiber-reinforced composite material.

Owner:MITSUBISHI CHEM CORP +2

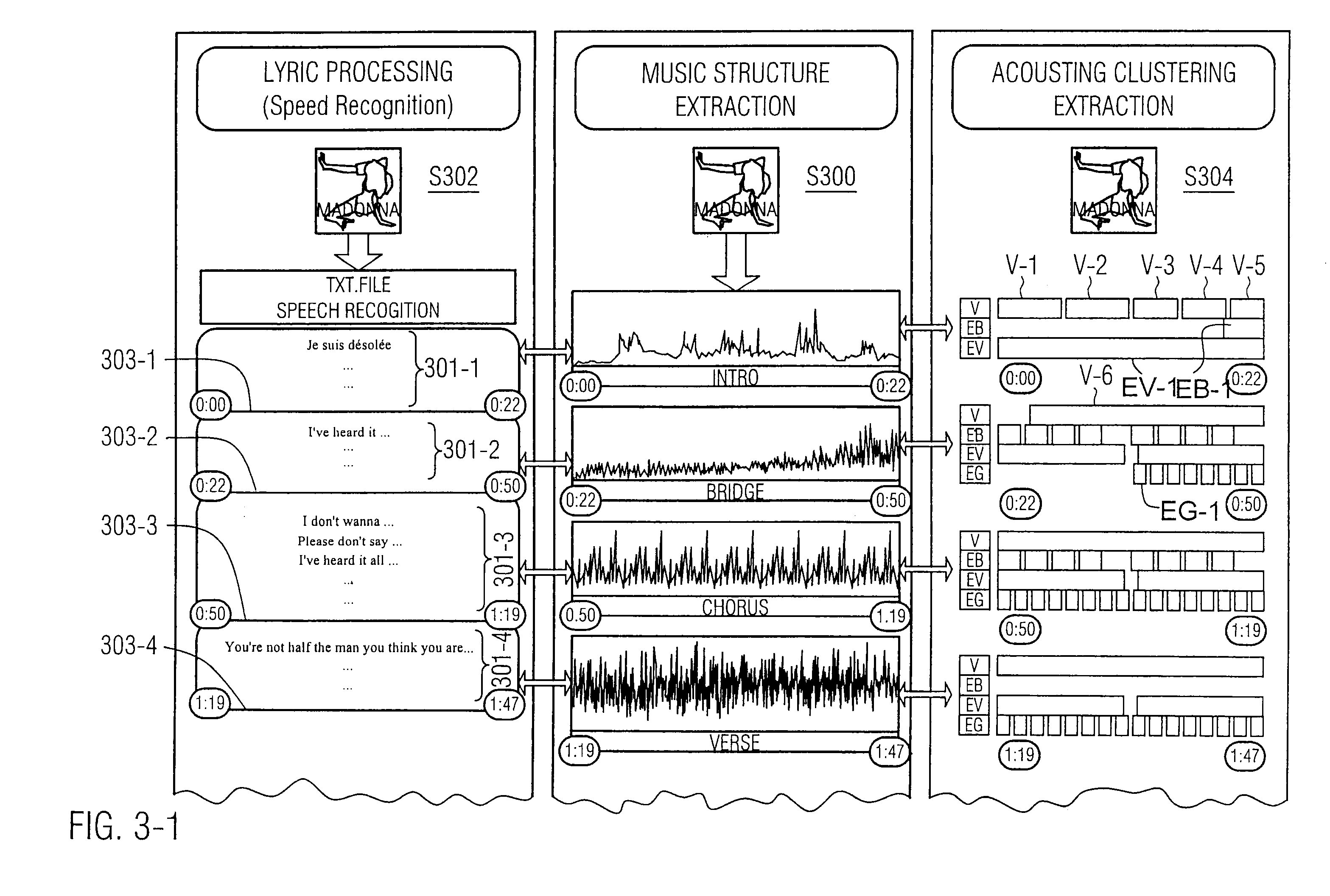

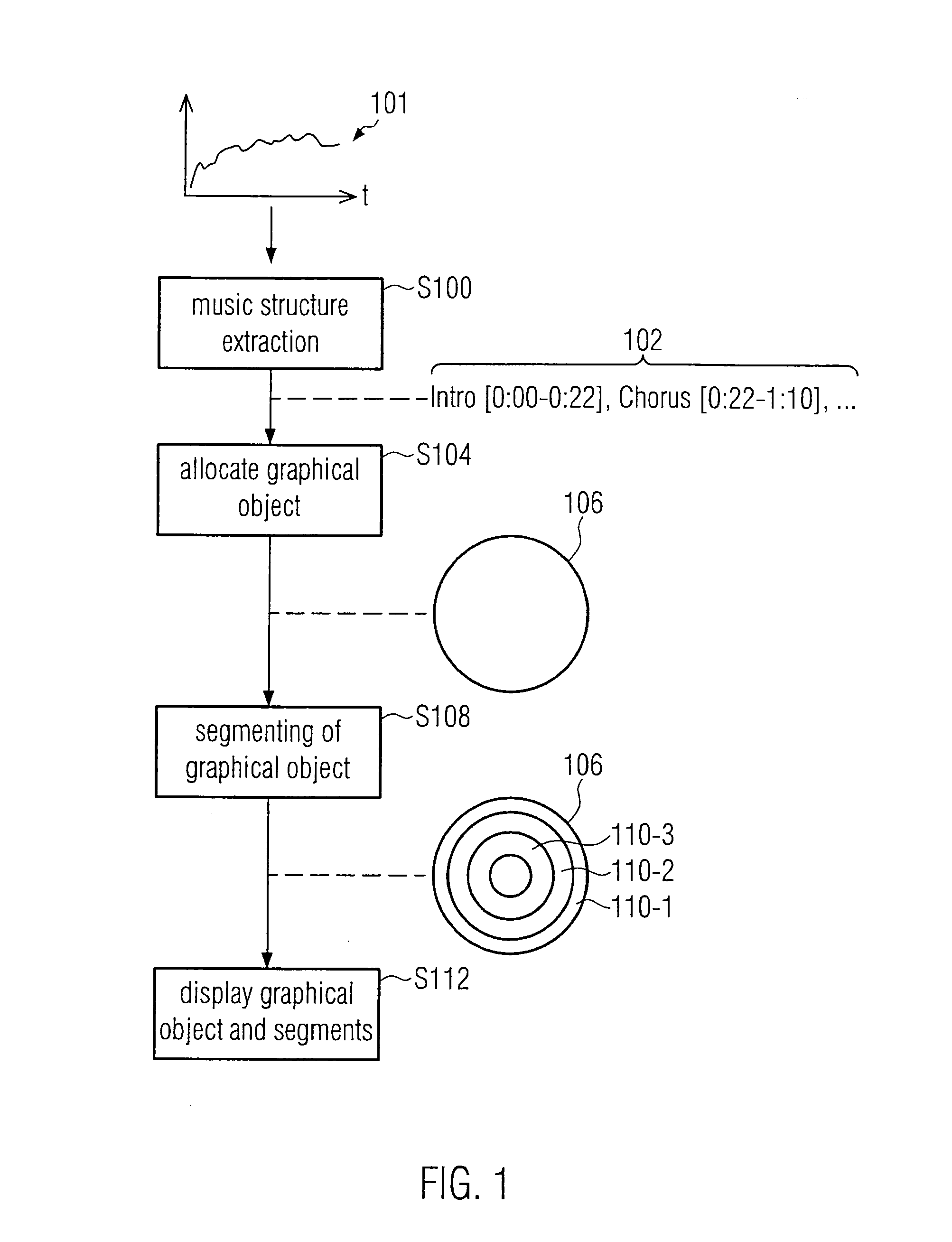

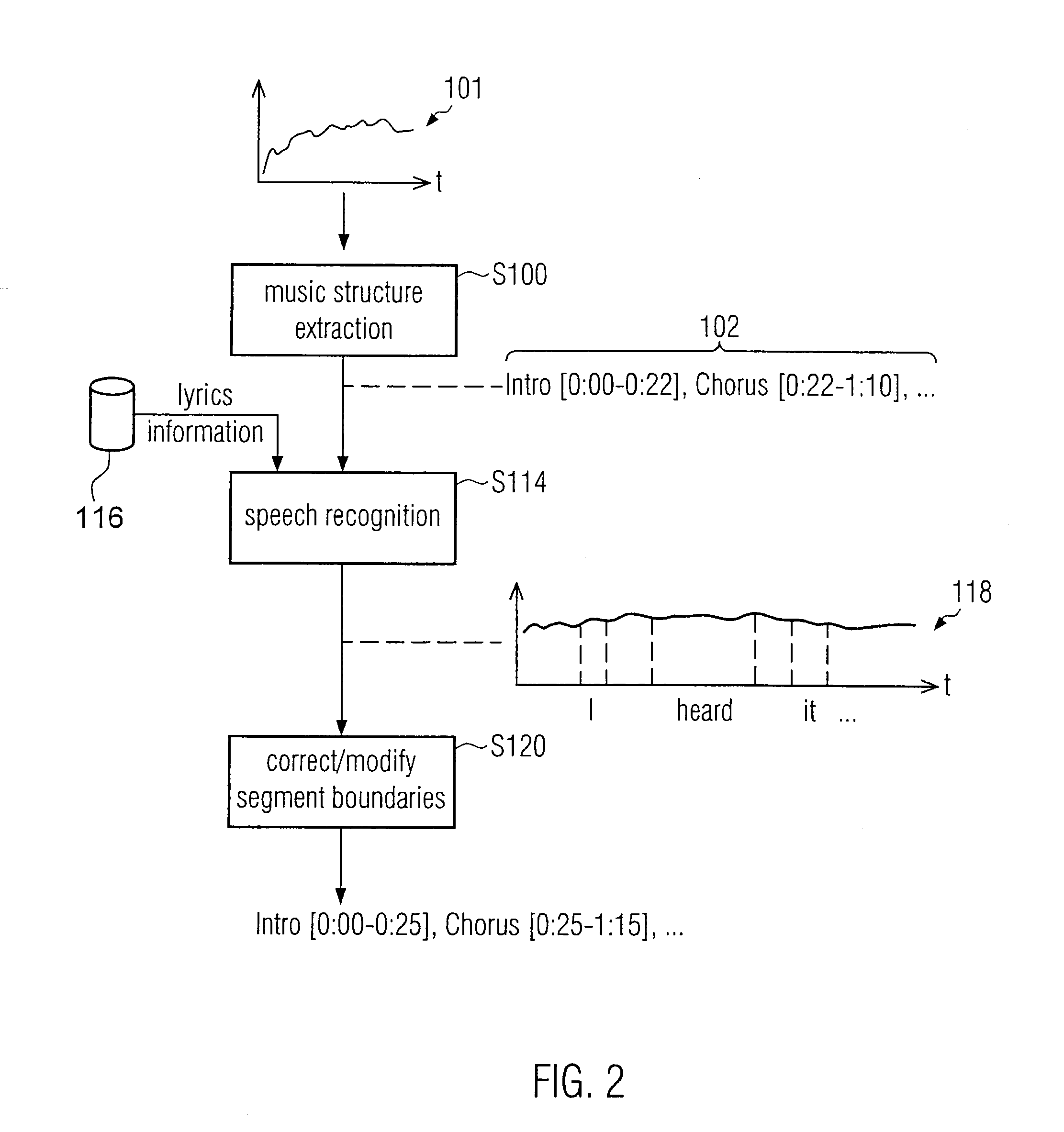

Method for visualizing audio data

InactiveUS20090228799A1Efficient executionMetadata audio data retrievalElectrophonic musical instrumentsGraphicsDisplay device

A Method for visualizing audio data corresponding to a piece of music, comprising the steps of: determining a structure of said piece of music based on said audio data, said structure comprising music structure segments each having a music structure segment length; allocating a predetermined graphical object to said piece of music, said graphical object having a predetermined size; segmenting said graphical object into graphical segments, wherein each graphical segment has a size representing said music structure segment length; and displaying said graphical object and said graphical segments on a display.

Owner:SONY CORP

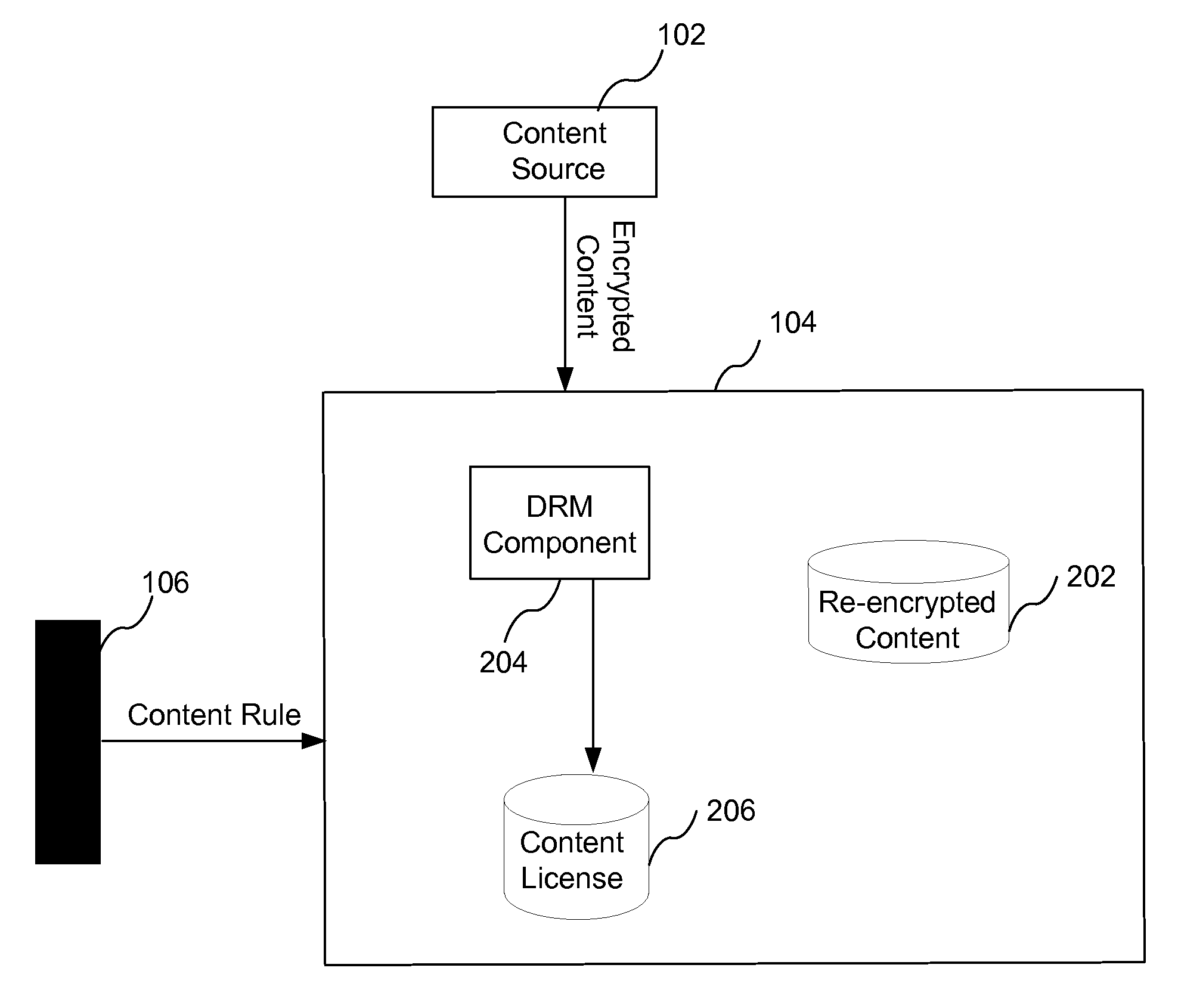

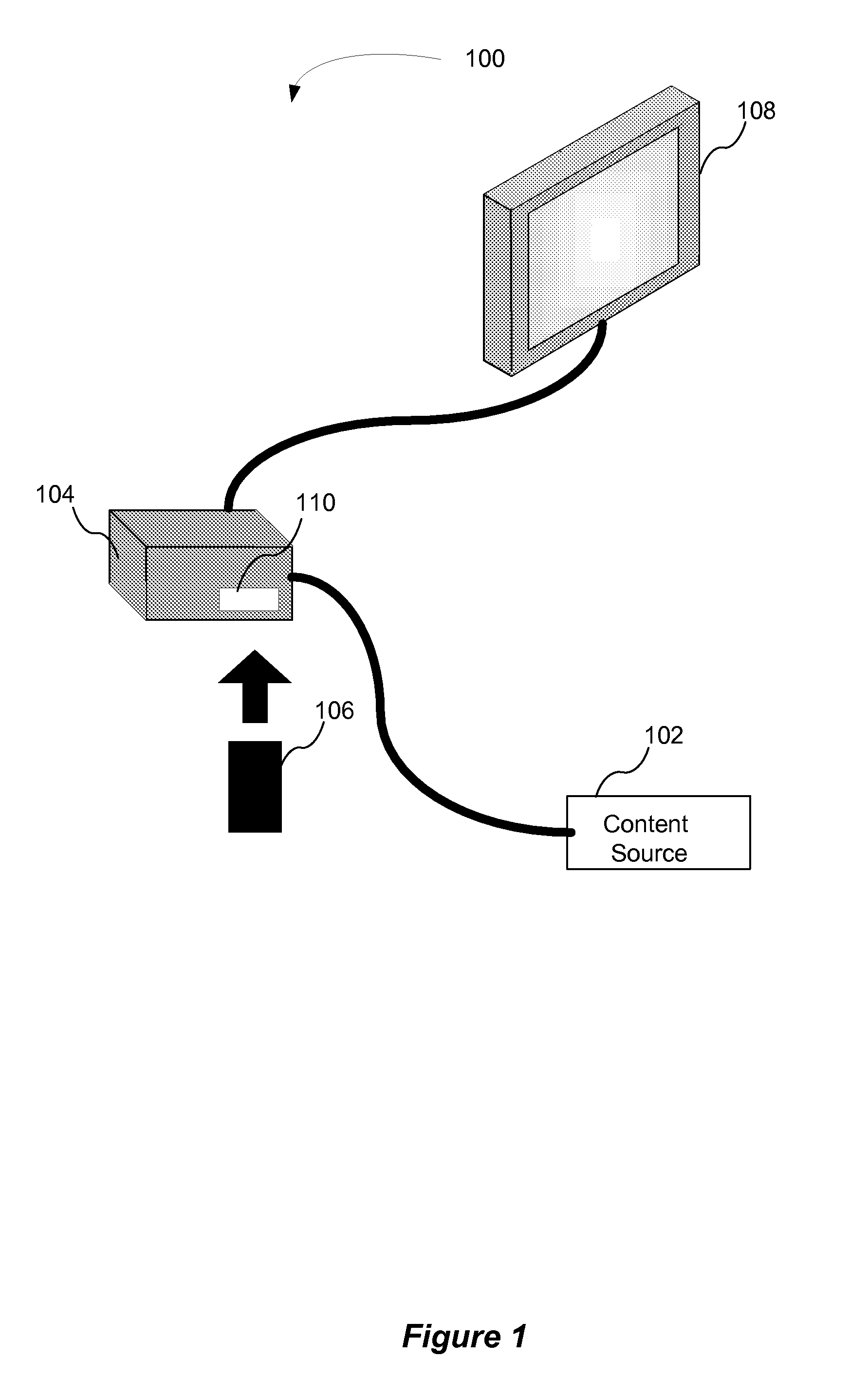

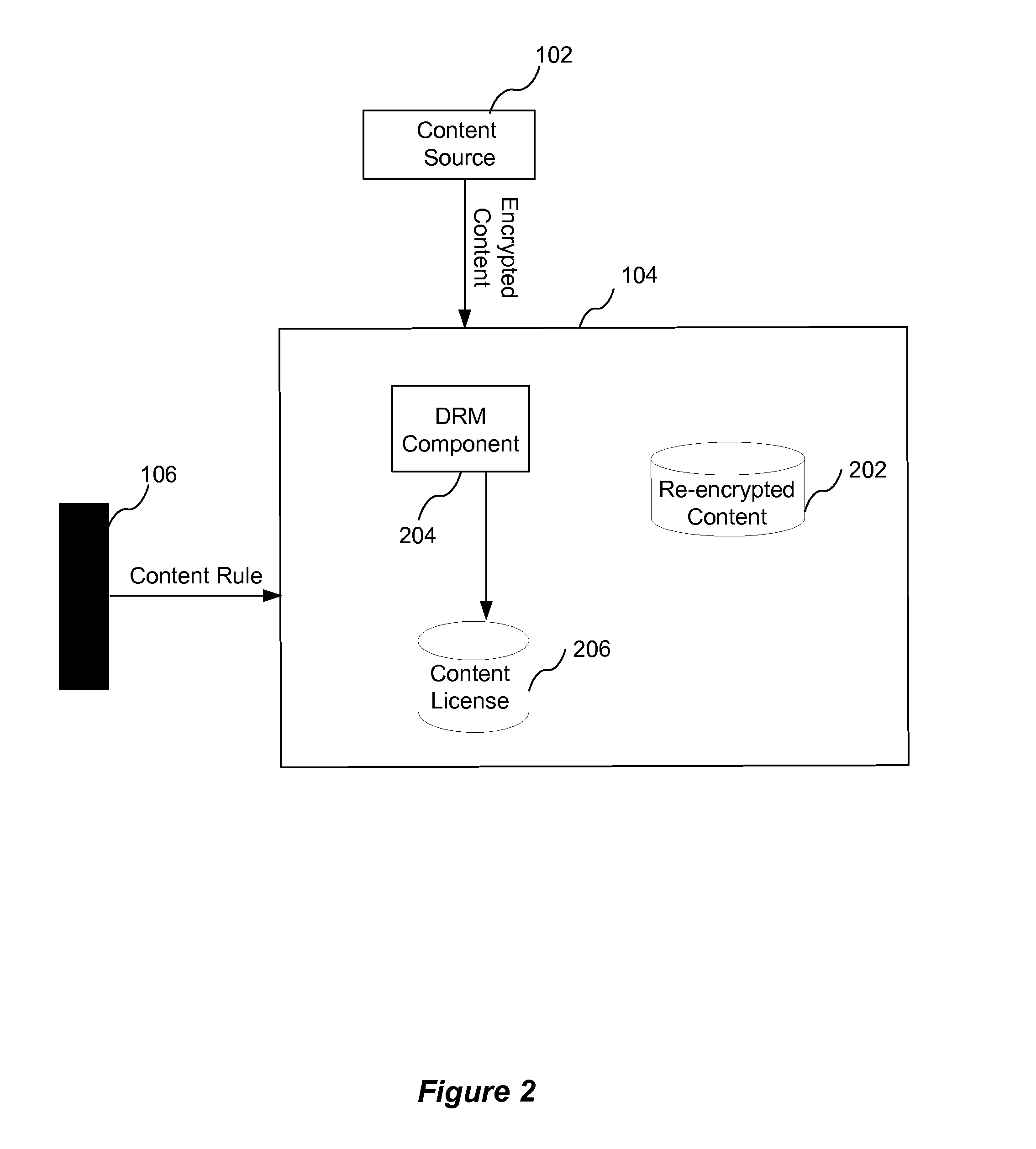

Method and Apparatus for Providing a Secure Trick Play

InactiveUS20080270308A1Program/content distribution protectionSelective content distributionComputer hardwareTime limit

A process may be utilized by a DVR. The process characterizes a set of content as a plurality of segments as the set of content is received. Each of the segments has a segment length according to a predetermined time interval. Further, the process encrypts each of the segments with a corresponding content encryption key to generate a plurality of encrypted segments. The corresponding content encryption key for each of the segments is generated by the DRM component. In addition, the process stores each of the encrypted segments for playback with trick play features in accordance with an expiration content rule having a time limit on the temporary playability of the set of content.

Owner:GENERAL INSTR CORP

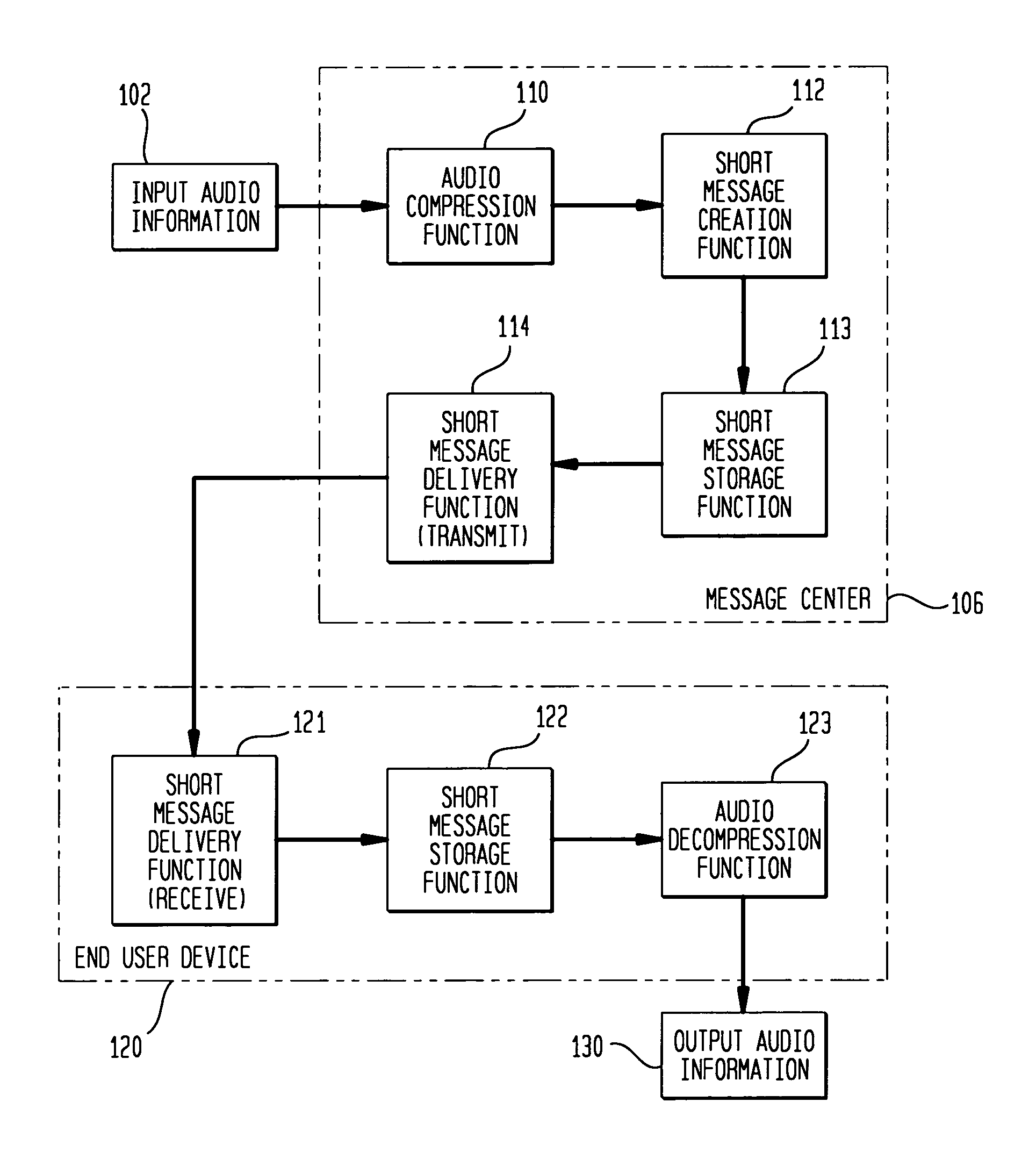

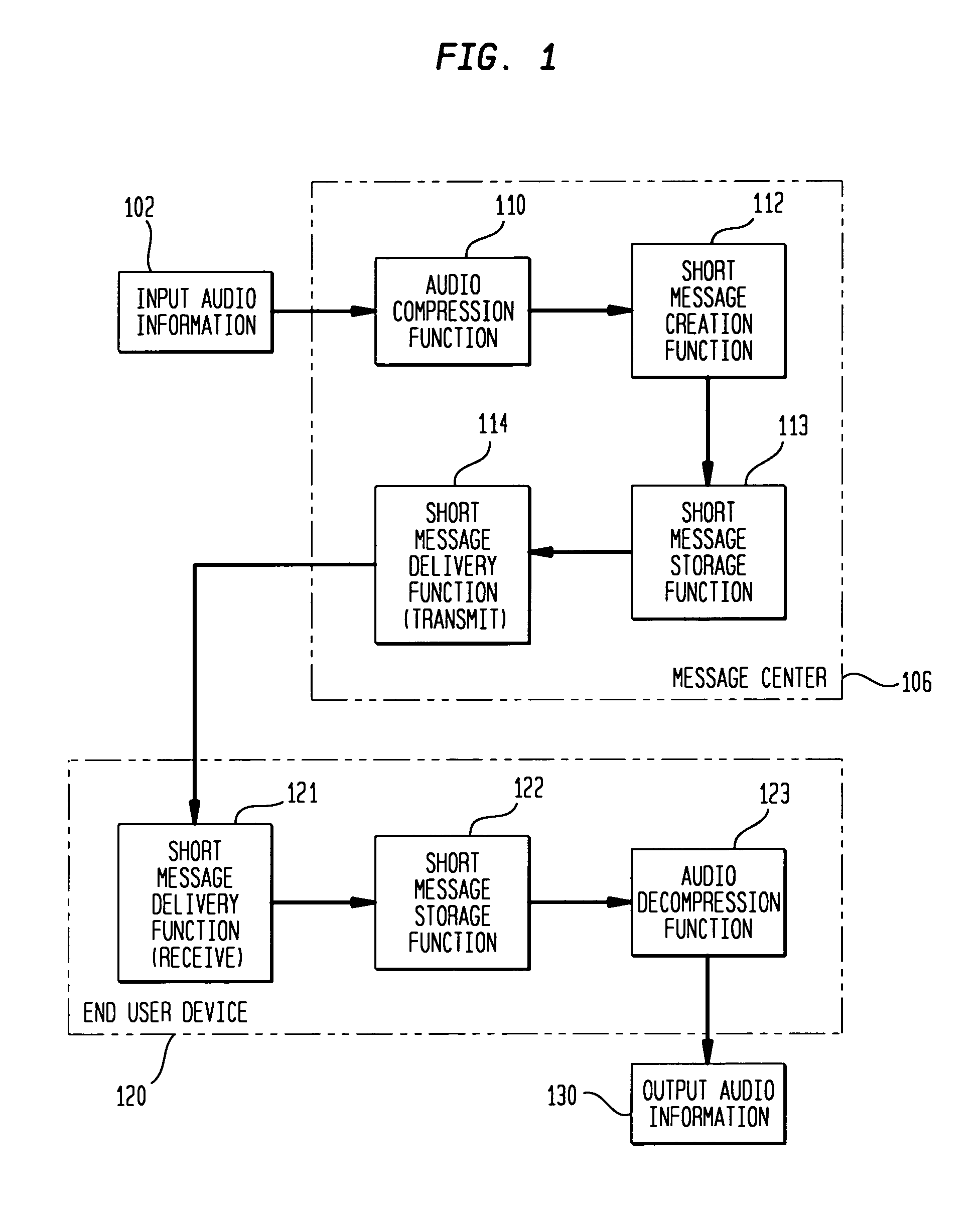

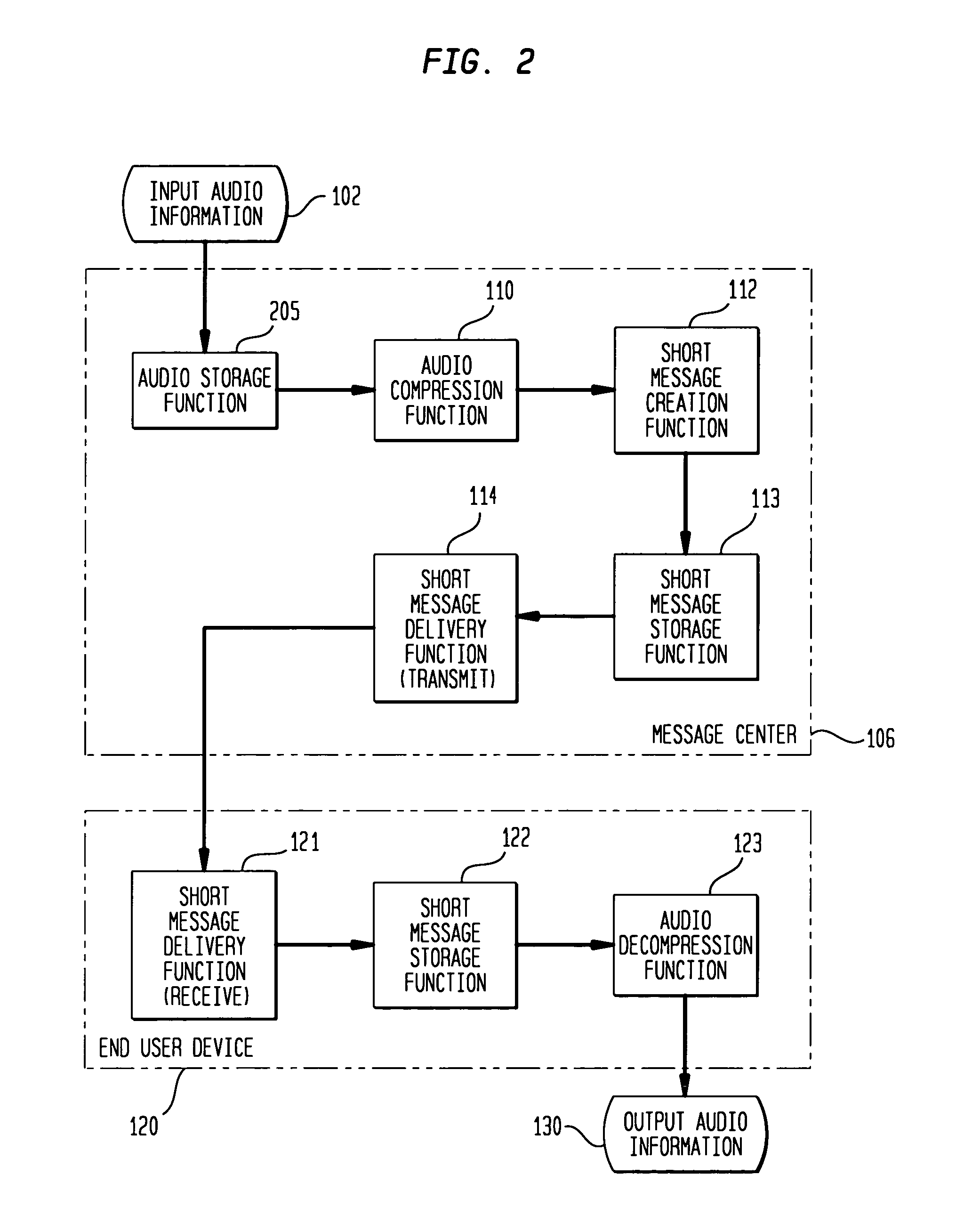

Using discrete message-oriented services to deliver short audio communications

InactiveUS6977921B1Information formatAutomatic call-answering/message-recording/conversation-recordingComputer hardwareShort Message Service

Delivery of short audio communications to remote end user devices uses discrete message-oriented service messages for delivery of the audio messages. Audio information is captured, encoded by means of audio compression technology, and stored at a message center. Alternatively, the audio information may be stored in an uncompressed format and compressed immediately before delivery. The compressed audio information is transmitted by means of Short Message Service or another discrete message-oriented service to the end user device, where it is decompressed and played to the recipient. Message delivery can be accomplished in parallel with some other ongoing activity at the end user device. The major fields in a Short Message Service message used to carry encoded audio information are a Type of Data field, including information on the type of translator needed to decompress the message field, a Short Message Identifier, a Length field, and the coded audio information. If the audio information is too large to be contained in a single Short Message, segmentation and reassembly techniques commonly known in the art are applied to break the information into segments, each of which is placed into a separate Short Message having the fields: Type of Data; Short Message Identifier; Total Segments; Number of Enclosed Segment; Segment Length; and Coded Audio Information Segment. At the end user device, the Short Message can be stored until the end user listens to the audio information. The intervening network can be a radio link, the Internet, or some other network. The invention may also be utilized by a mobile user to send short audio messages to a message center and / or a second end user device.

Owner:LUCENT TECH INC +1

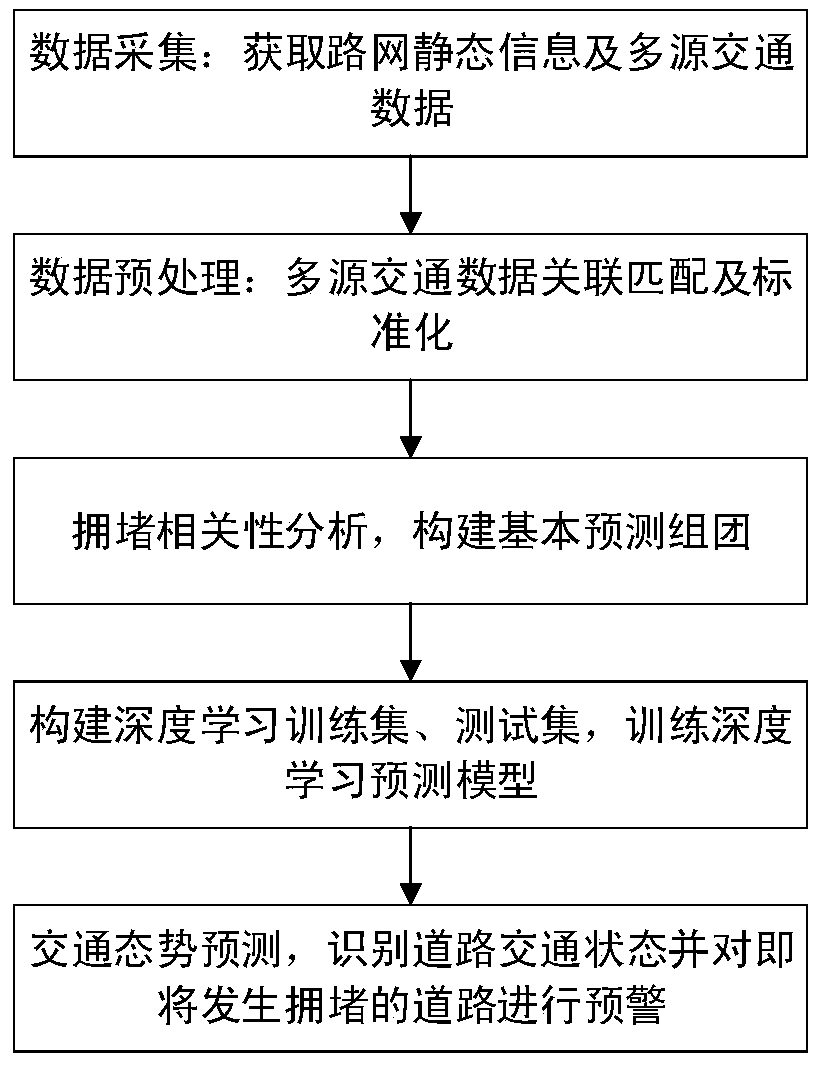

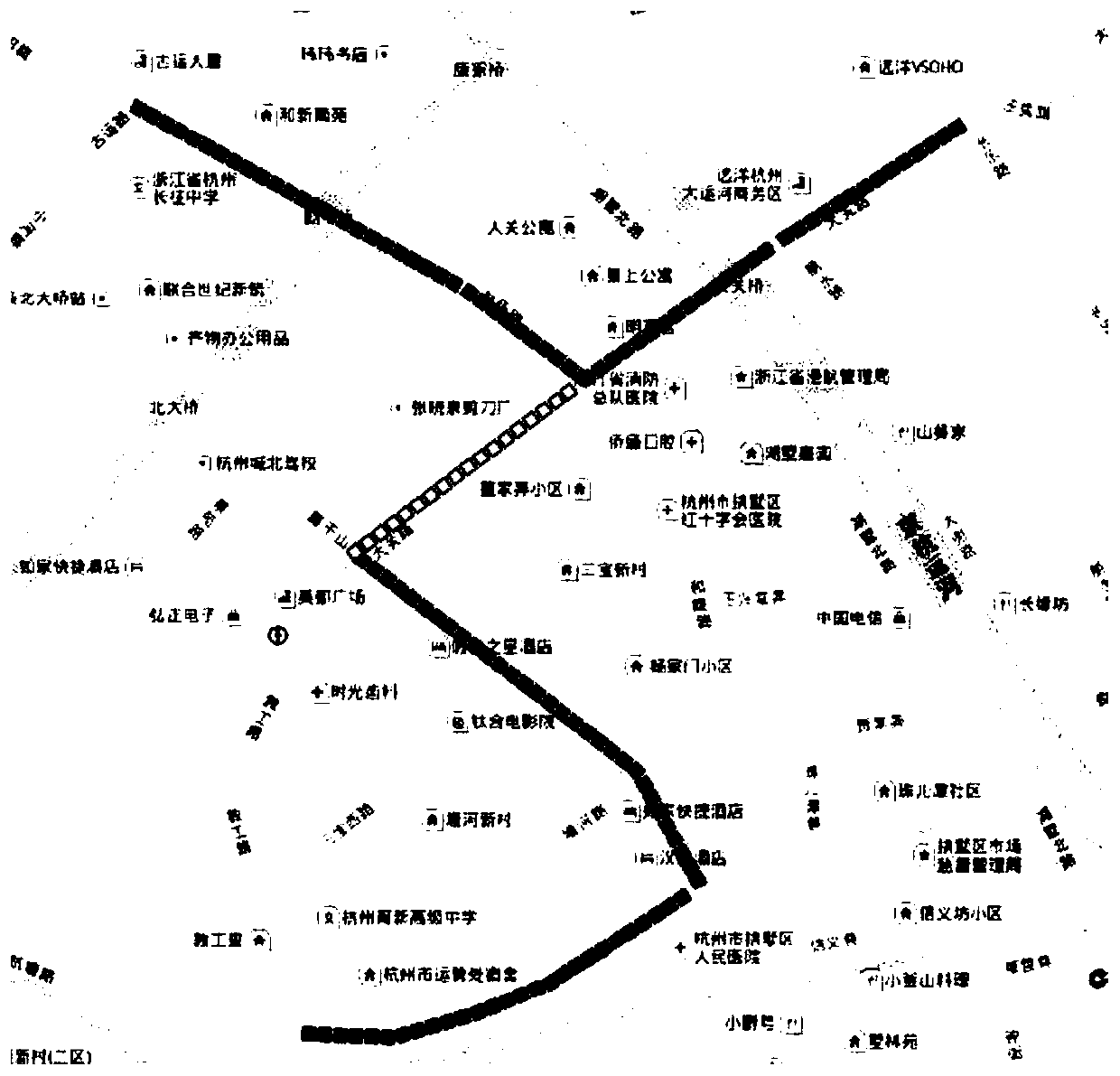

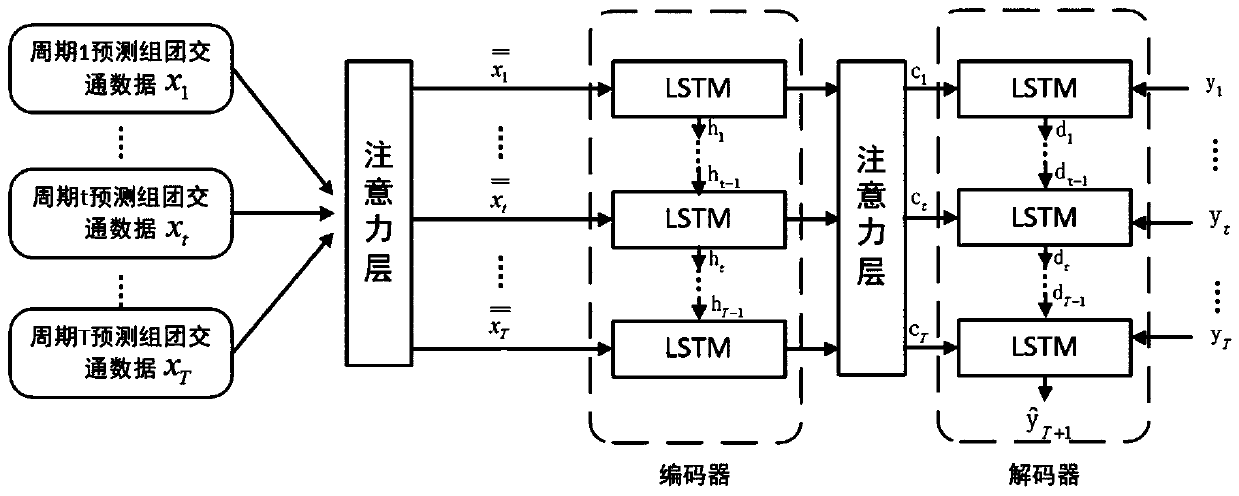

Depth learning-based road network traffic situation forecast method and system

ActiveCN110570651AOvercoming the problem of poor portabilityImprove forecast accuracyDetection of traffic movementLearning basedTraffic capacity

A depth learning-based road network traffic situation forecast method comprises the following steps of S1, acquiring multi-source traffic data and road network static configuration information, and building a traffic flow parameter model, wherein the multi-source traffic data comprises internet road segment speed data, detector flow data and signal machine control scheme data, and the road networkstatic configuration information comprises road network space geographical position information, intersection number, road segment class, road segment length, road segment number, lane number and lane function; S2, analyzing road network congestion relevancy, and building a basic forecast group; S3, building a dual-stage attention mechanism-based depth learning traffic situation forecast model; and S4, building a traffic situation forecast system. The forecast accuracy and the transportability are relatively good.

Owner:ZHEJIANG UNIV OF TECH +1

Data rarefying and smooth processing method based on vector map

ActiveCN103839228AThe display effect is conciseSave data spaceImage enhancementImage codingPolygonal lineAlgorithm

The invention a data rarefying and smooth processing method based on a vector map. The method mainly comprises the following steps: the data volume is reduced by rarefying curve characteristic points, and the protruded edge problem is solved by smoothly processing closed curve characteristic points. The curve characteristic points are compressed by setting different segment length threshold values, angle threshold values and vertical distance threshold values, and unsmoothed broken lines are smoothly processed through the smooth processing algorithm, so the display effect of closed curves having disadvantages of large curvature change and protruded edges can be effectively improved.

Owner:XIAMEN YAXON NETWORKS CO LTD

Multi-flag label

ActiveUS7941949B2Quickly and reliably inputtingEasy to disassembleStampsOther printing matterCross-linkBack cutting

A multi-flag label label-links a primary container to at least one secondary container. The multi-flag label comprises multiple layers and multiple regions intermediate its length. A back cut separates a first layer into unequal segment lengths. A transparent second layer is removably and adhesively attached to the first layer and is dimensioned such that the first layer frames the second layer with a peripheral boundary. A third layer is permanently bonded to the second layer and terminates adjacent the back cut, thereby exposing the back cut via the second layer. The third and second layers adjacent the back cut provide a parent label region; the remainder of the second and third layers provide a child label region, which region may be die cut into patterns for effecting child label(s). The parent and child labels may comprise information for cross-linking a source container to at least one secondary dose container.

Owner:ACCU CHART PLUS HEALTHCARE SYST INC

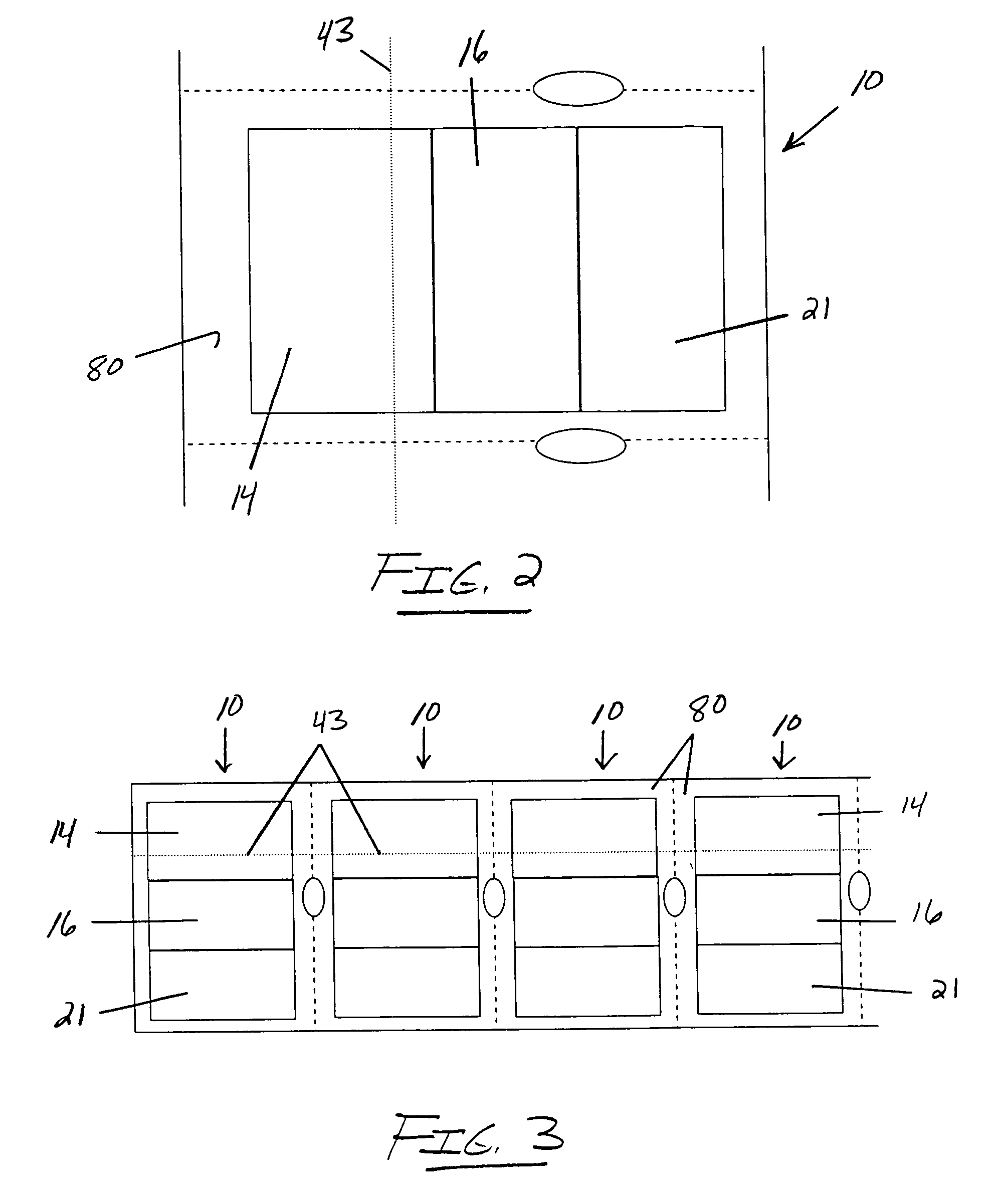

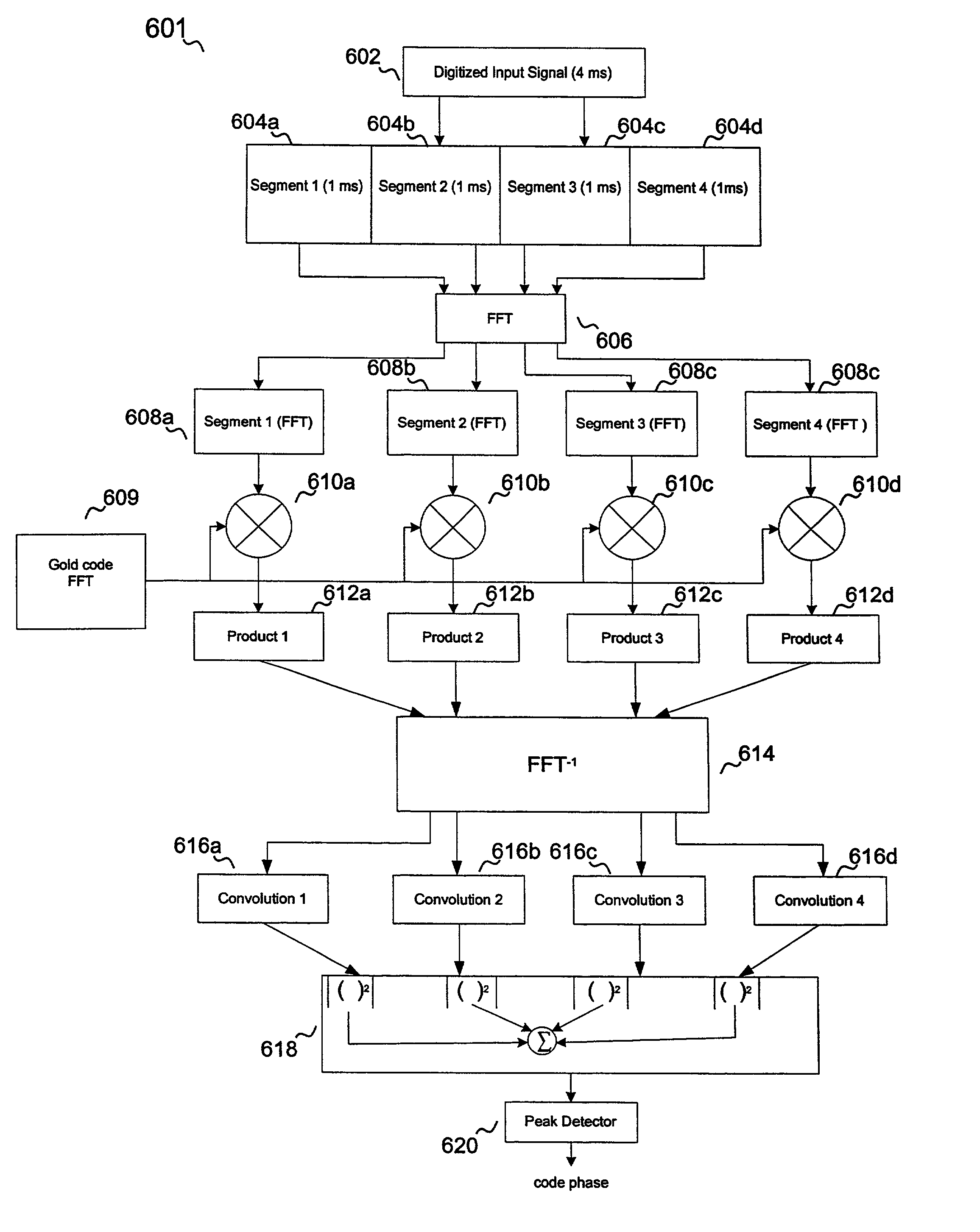

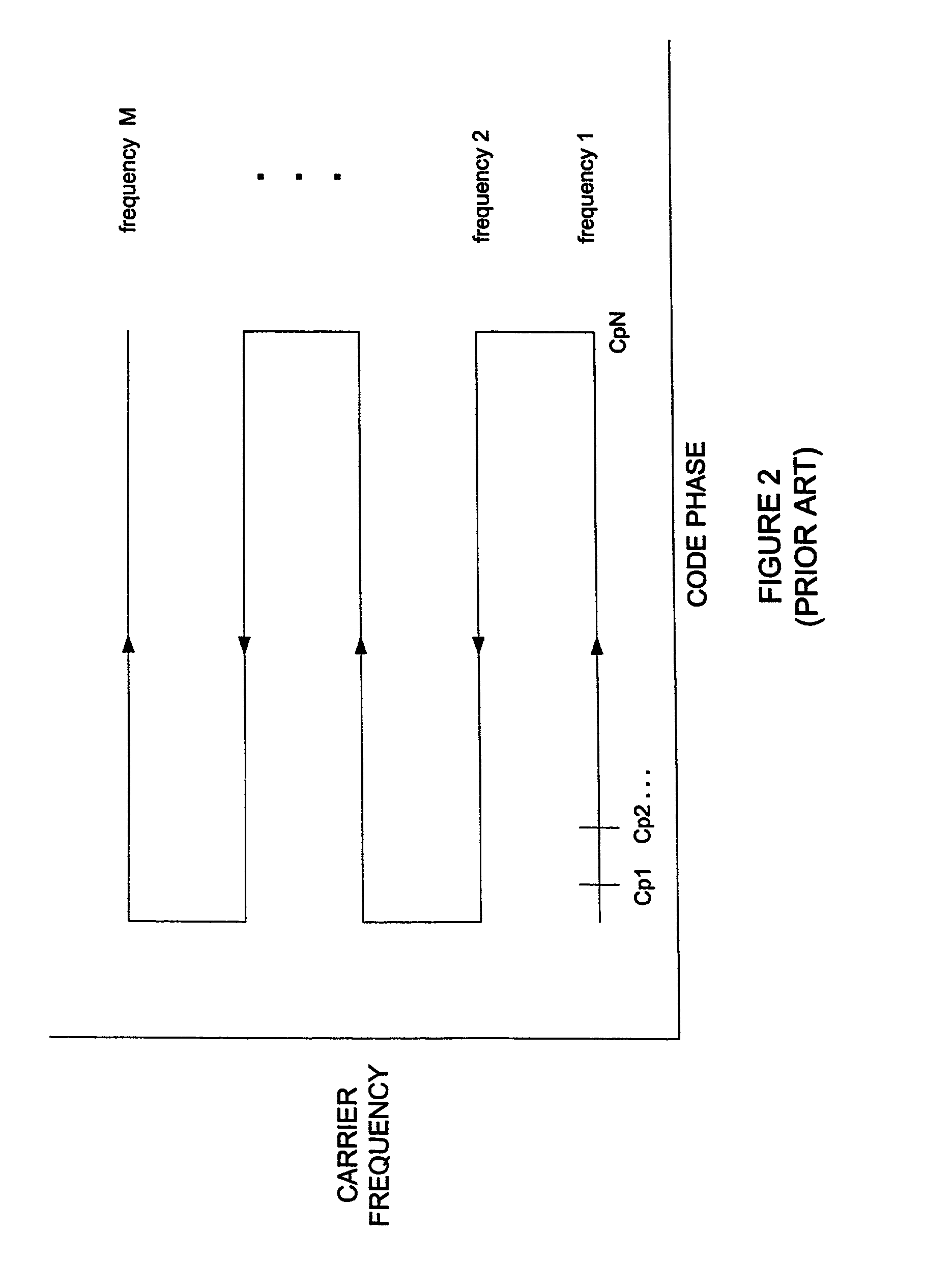

System and method for fast code phase and carrier frequency acquisition in GPS receiver

InactiveUS7027486B2Improve acquisitionShorten the timeBeacon systemsSatellite radio beaconingCarrier signalLong segment

A GPS receiver acquires carrier frequency and Gold code phase using short segments of a received GPS signal. In one embodiment, a 1-ms segment of the GPS signal is transformed to the frequency domain. This is multiplied by a frequency representation of the Gold code. The resulting product is converted to the time domain, and a peak is detected. The location of the peak corresponds to the code phase. If no peak is located, the carrier frequency is changed. Full- and half-bin steps in carrier frequency are considered. Processing gain is achieved by using longer segments of the input signal, for example 4 or 16 ms and integrating 1-ms segments. Considerations are provided for compensating for the effects of a transition, should it occur in the short segment of the GPS signal being processed. Integrations can be performed using non-coherent and coherent techniques. Adjustments are made for non-integral millisecond segment lengths.

Owner:SKYBITZ INC

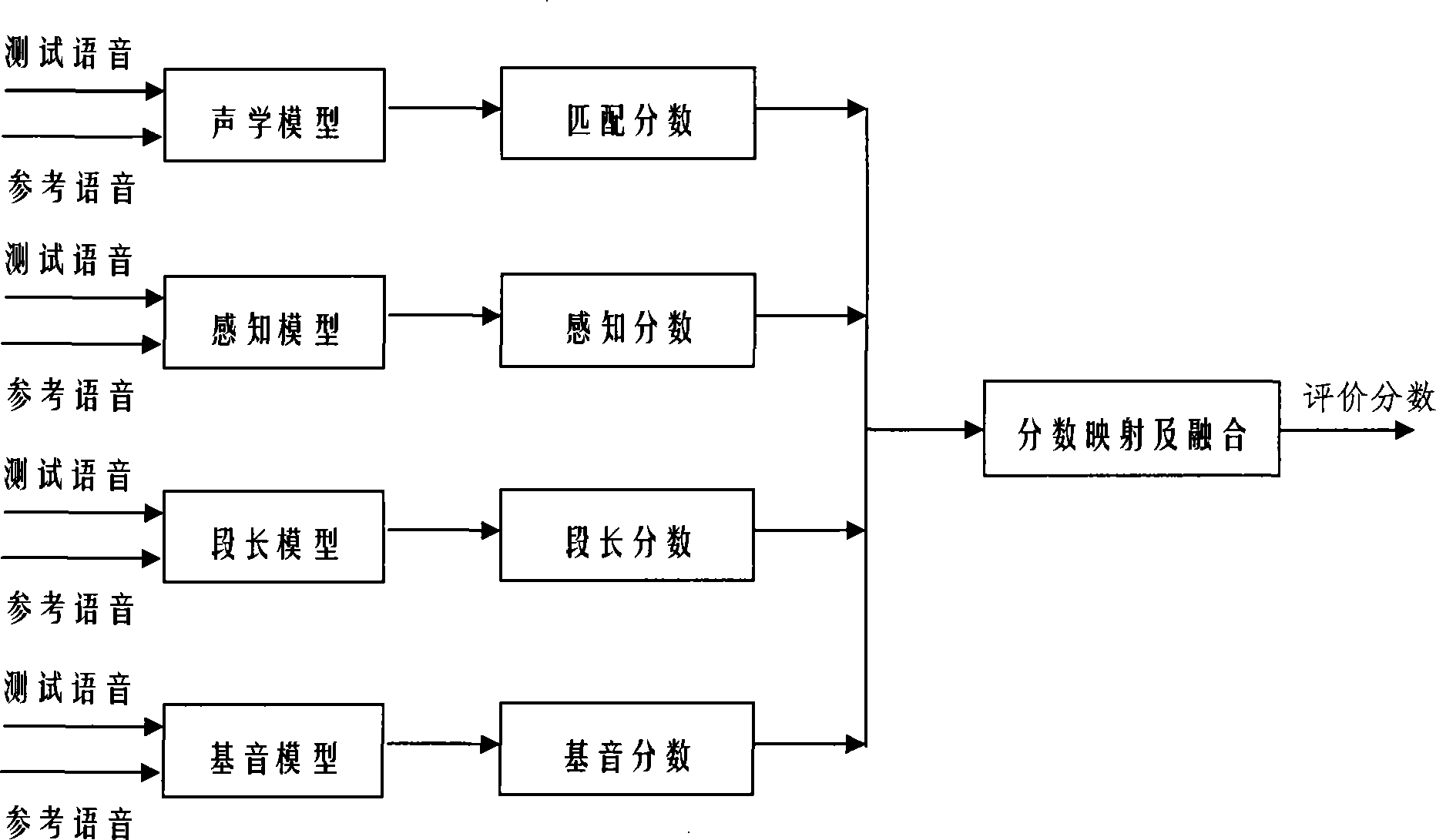

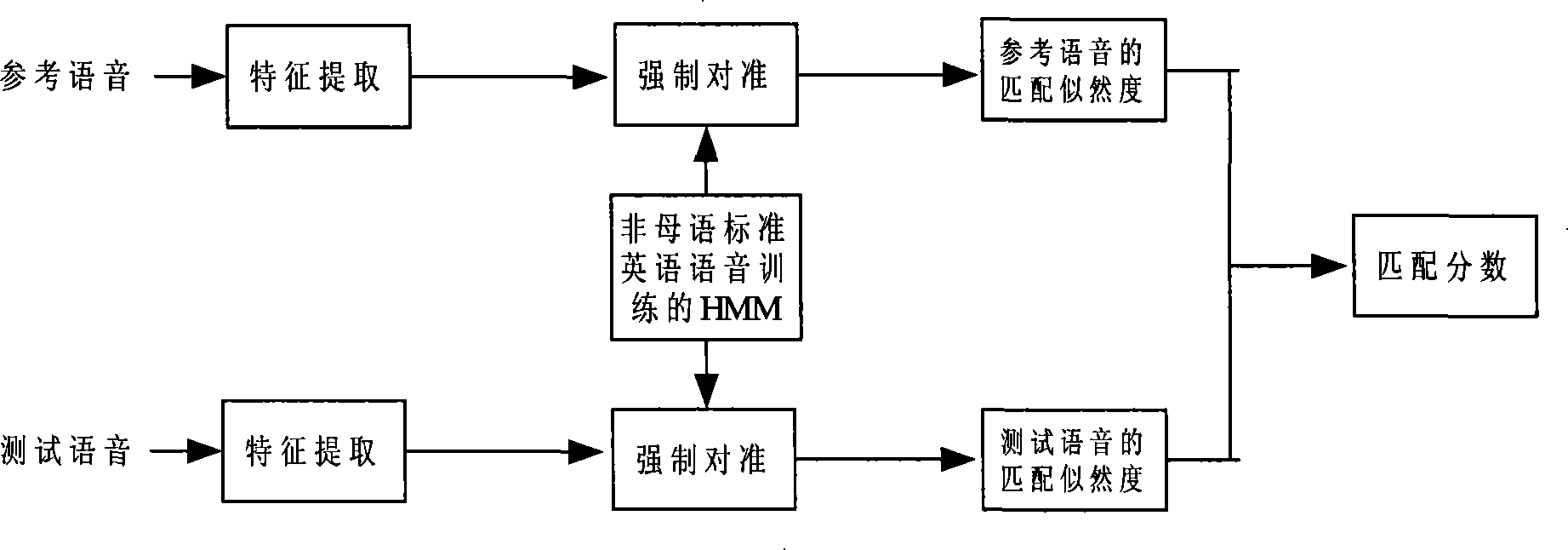

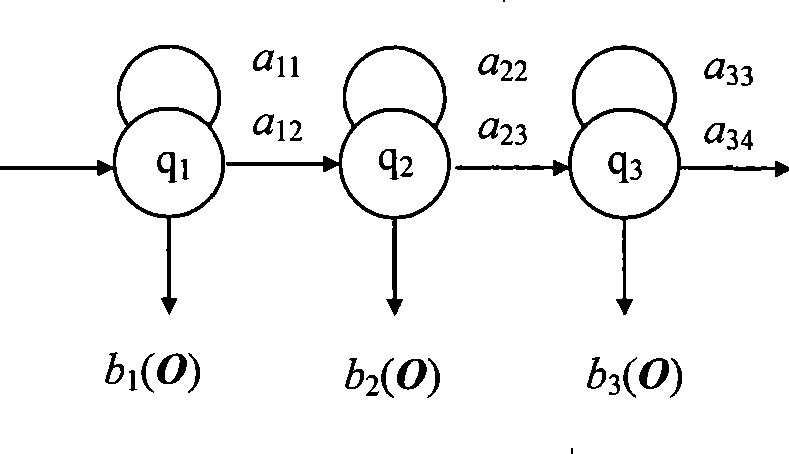

Pronunciation quality evaluation method of computer auxiliary language learning system

ActiveCN101246685AImprove robustnessImprove performanceSpeech analysisTeaching apparatusSpoken languageComputer-aided

The present invention belongs to voice field of technology, pronunciation quality evaluation method of computer Computer Aided Language Learning system includes: calculation of the matching fraction, calculation of the sensing fraction based on Mel frequency scale, calculation of the segment length fraction and calculation of the keynote fraction, and processing fusion after mapping the above fractions; the pronunciation quality evaluation method of the invention has better robustness, high pertinency with the expert evaluation, used for interactive language learn and automatic spoken language test.

Owner:北京华控智加科技有限公司

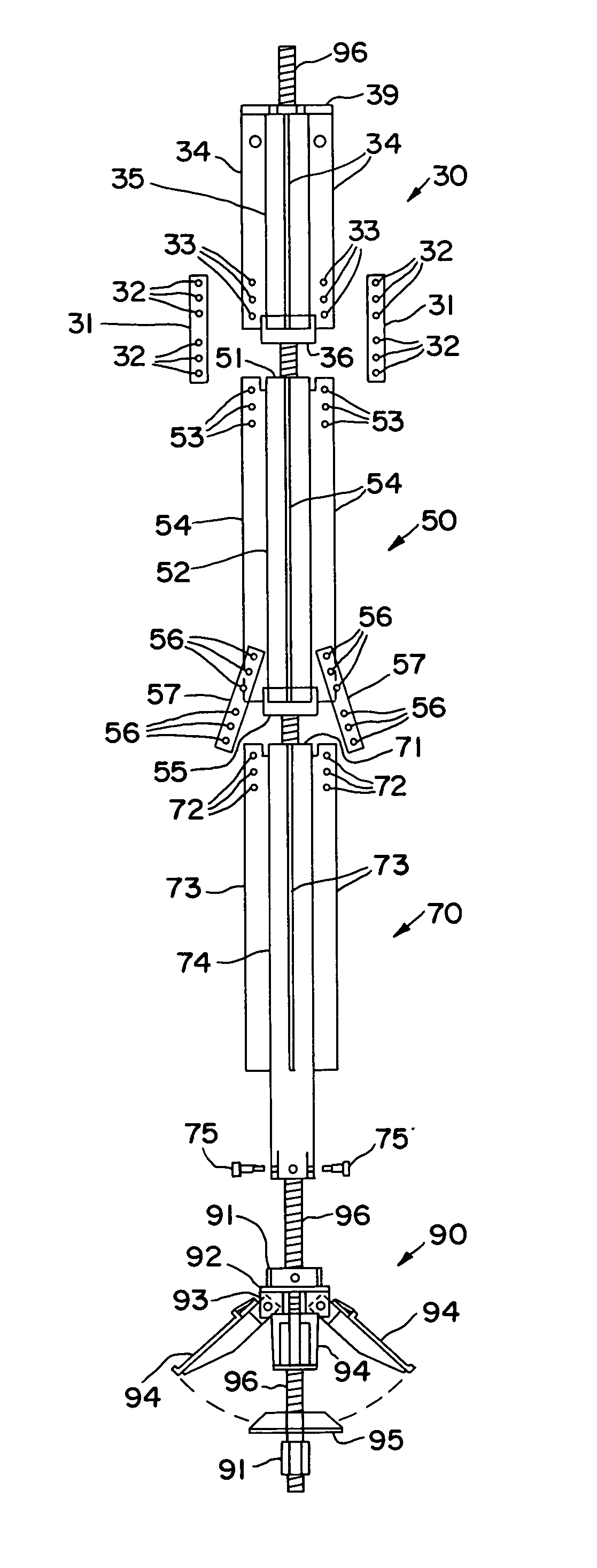

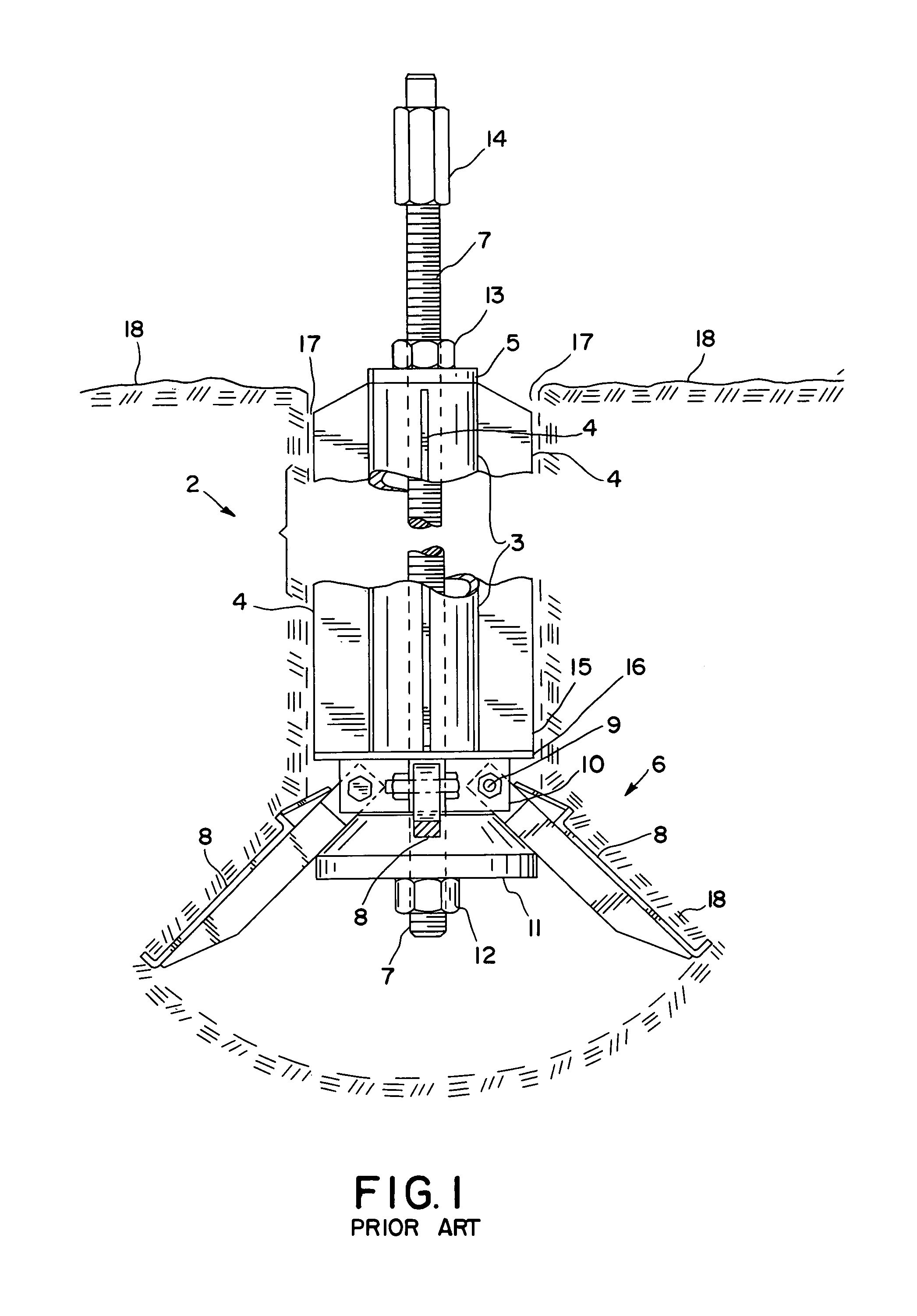

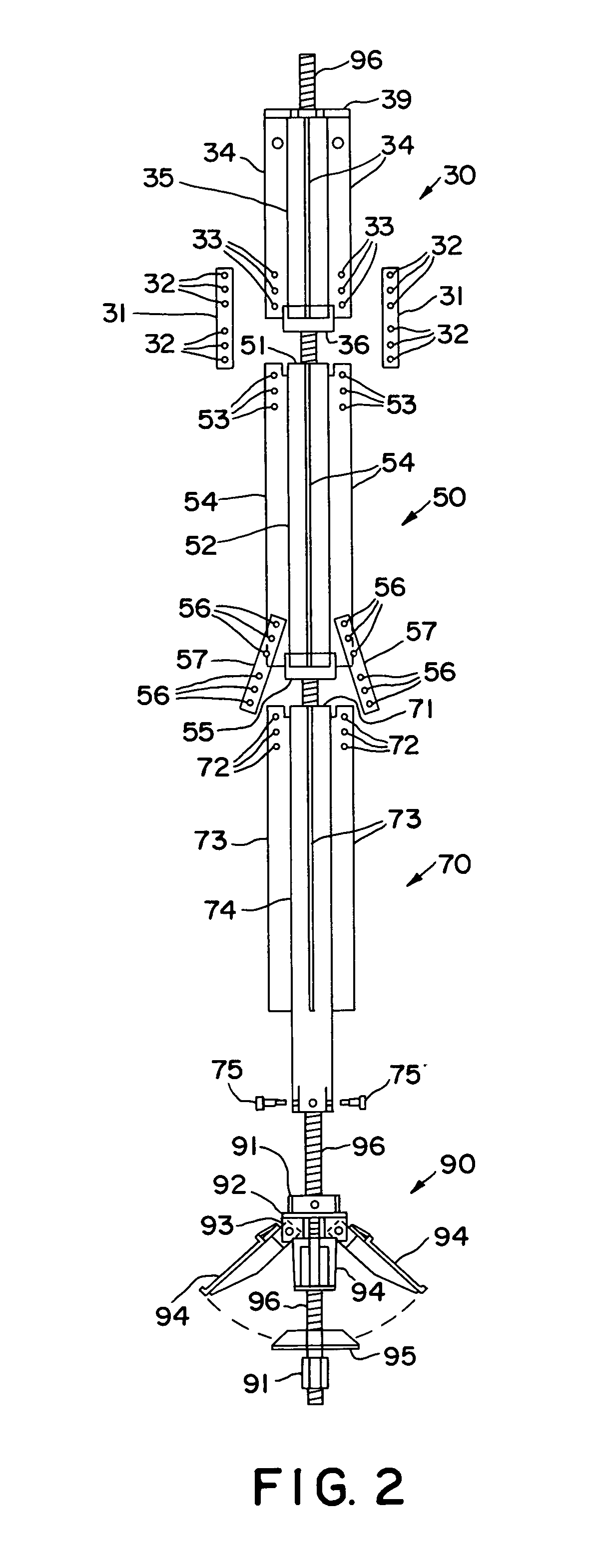

Segmented foundation installation apparatus and method

InactiveUS7621098B2Readily availableEasy to assembleProtective foundationBuilding repairsEngineeringMechanical engineering

Owner:METAL FOUND ACQUISITION

High-temperature resistant optical fiber and method for manufacturing same

ActiveCN101726792AOvercome the inadequacies of being unable to withstand harsh working environmentsStable use characteristicsGlass making apparatusCladded optical fibreFiberHigh power lasers

The invention relates to high-temperature resistant optical fiber and a method for manufacturing the same and belongs to the technical field of special optical fiber communication and high-power laser communication and sensing. The high-temperature resistant optical fiber comprises optical fiber and a coating coated on the outer surface of the optical fiber, wherein the coating is the polyimide coating of which the single-sided thickness is 5 to 25mum, the Young modulus of the cured polyimide coating is equal to or more than 2GPa, the glassy state transition temperature is equal to or more than 300 DEG C, and the range of refractive index is 1.38 to 1.78; and the polyimide coating if formed by dipping the solution of polyimide on the outer surface of the optical fiber, and then heating the fiber to cure the solution of the polyimide, and the whole process comprises pre-coating, pre-curing and secondary coating. The high-temperature resistant optical fiber can be used at a high temperature and under severe working conditions; and when the high-temperature resistant optical fiber is used for a long time, the temperature reaches 300 DEG C, the operational performance is stable, and good persistence is kept. The high-temperature resistant optical fiber product, manufactured by the method, possesses a screening strength of 100kpsi and a segment length of 4km, even 6km.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

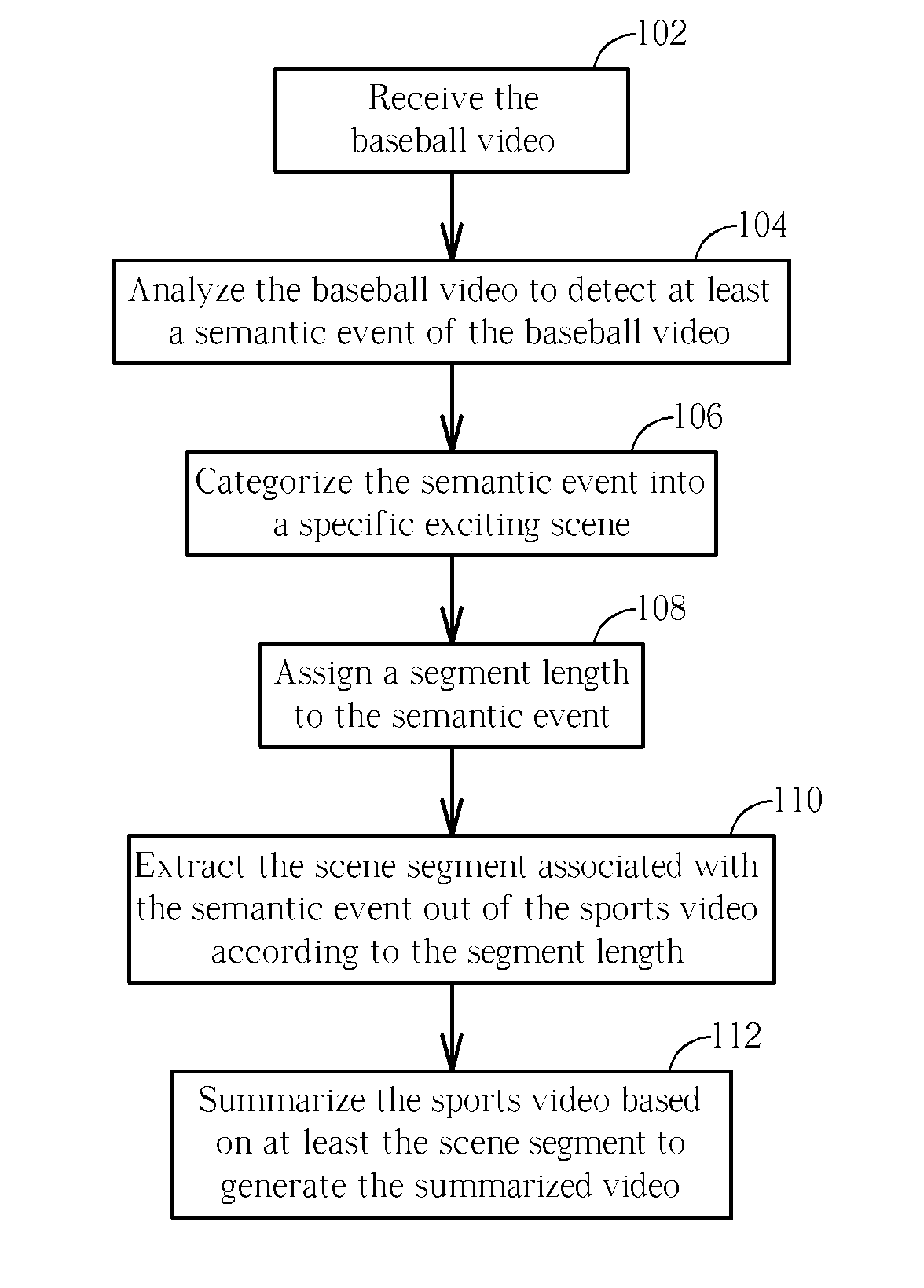

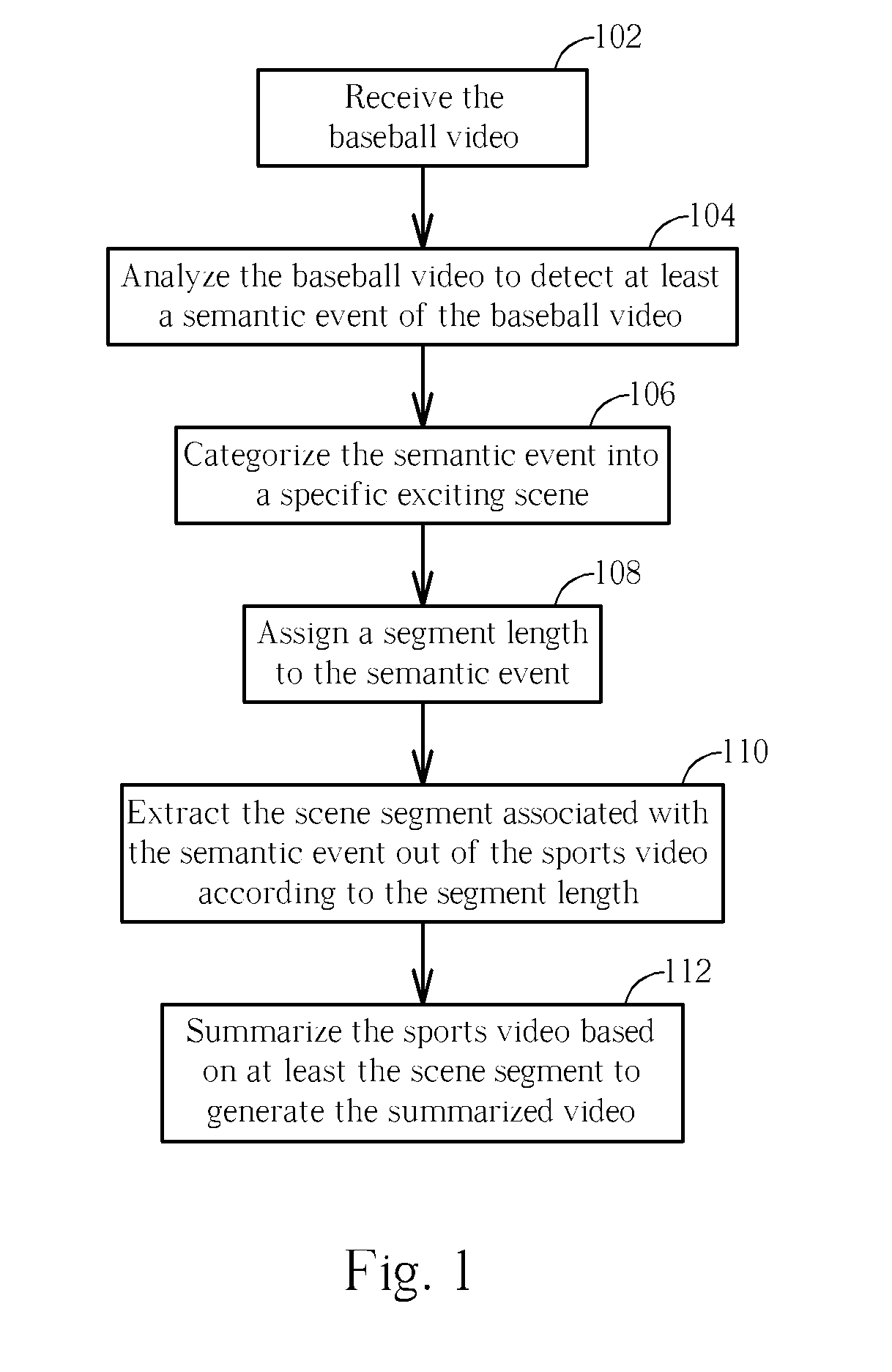

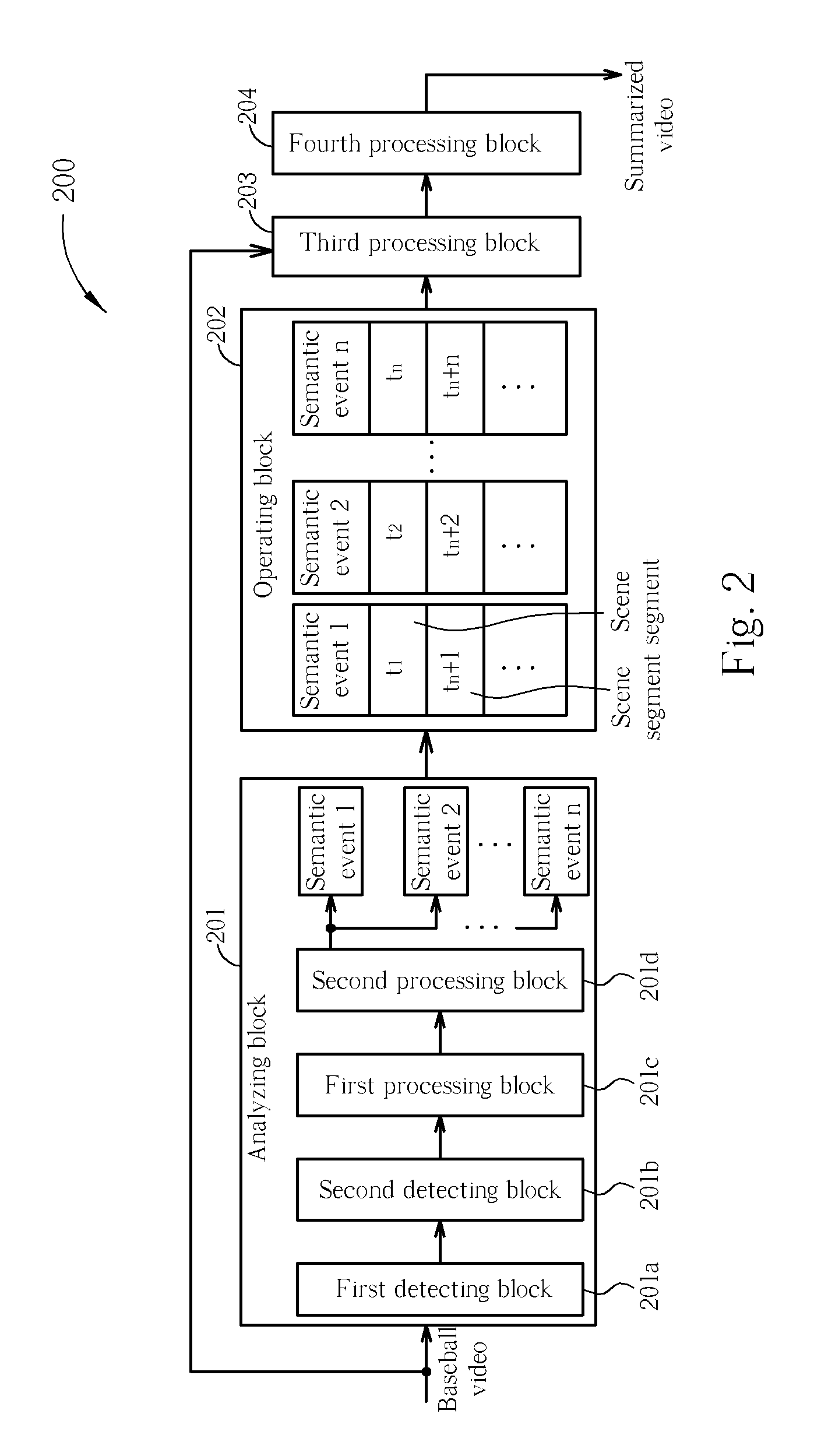

Method for processing a sports video and apparatus thereof

ActiveUS20080282287A1Television system detailsDigital data information retrievalComputer graphics (images)Segment length

The present invention discloses a method of processing a sports video. The method includes the steps of: analyzing the sports video to detect at least one semantic event and each of the at least one semantic event associated with a segment length; and generating a summarized video according to the detected at least one semantic event.

Owner:CYBERLINK

Barcode for a beverage preparation capsule

A beverage preparation system comprising: (i) a capsule (1 1) with side (16), bottom (18) and top (14) walls, said capsule having a shape that is substantially symmetrical around a vertical axis, and said capsule is suitable for containing a beverage preparation ingredient to be dissolved, and / or infused, and / or extracted under pressure, by action of a fluid circulating into said capsule through said ingredient, (ii) a beverage preparation machine (1) suitable for receiving said capsule (11), and circulating said fluid into said capsule, (iii) optionally a capsule holder (9) for holding said capsule (1 1), at least at the time said capsule is disposed into said machine, characterized in that: the machine (1) comprises a linear barcode reader (21) suitable for reading a linear barcode sequence (25) contained in a segment S having a segment length LR, said linear barcode reader (21) being disposed in the machine such that it can read a barcode printed on the capsule while said capsule is being inserted inside said machine, and the capsule (1 1) comprises a barcode sequence (25) that is repeatedly printed along a peripheral path of the capsule, each sequence being disposed in an arc having a linear projected length LS that is inferior to LR and said sequence (25) is composed of dots (26) spaced apart from one another along said arc, such that their projected point images along a linear segment are also spaced apart.

Owner:SOC DES PROD NESTLE SA

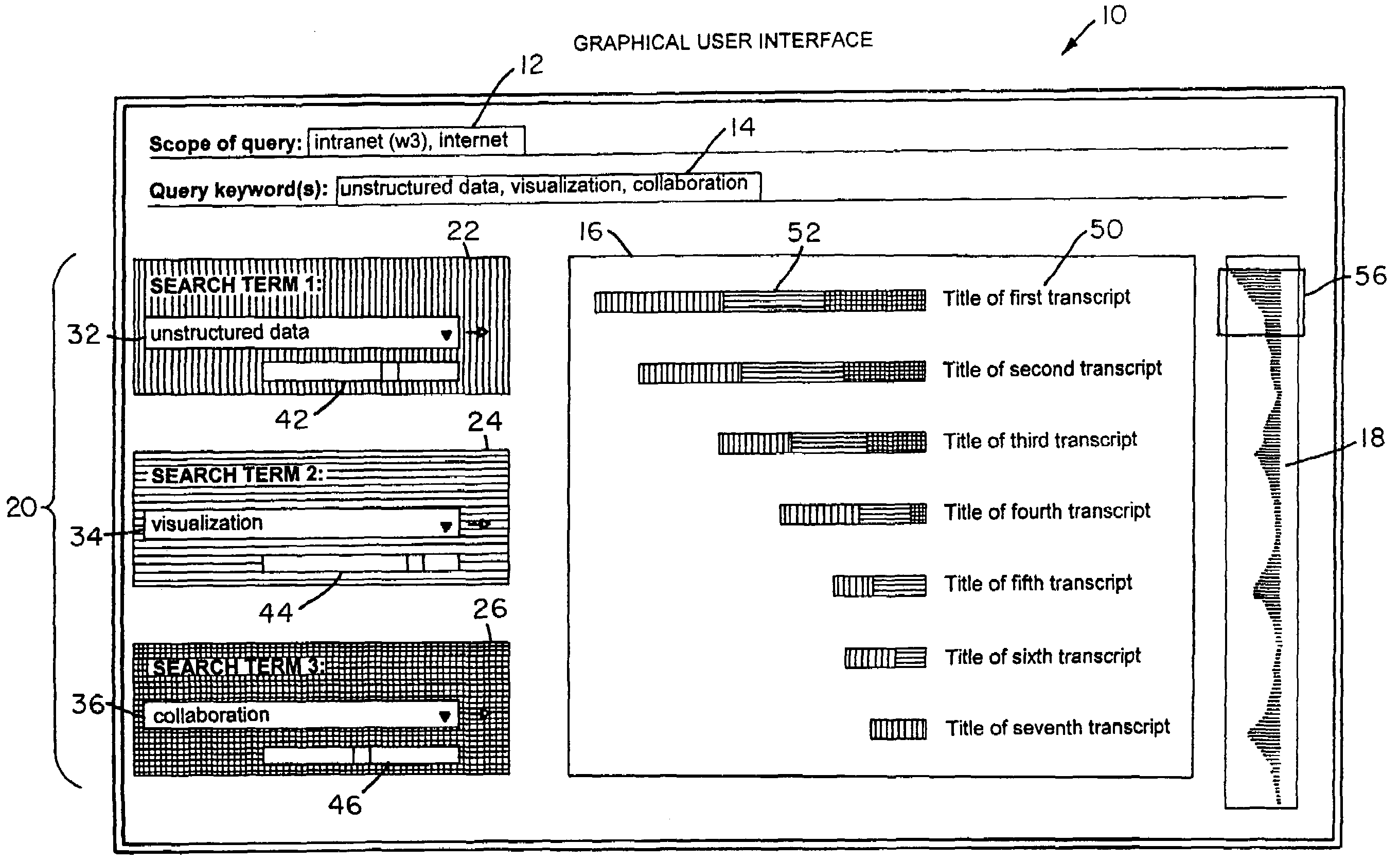

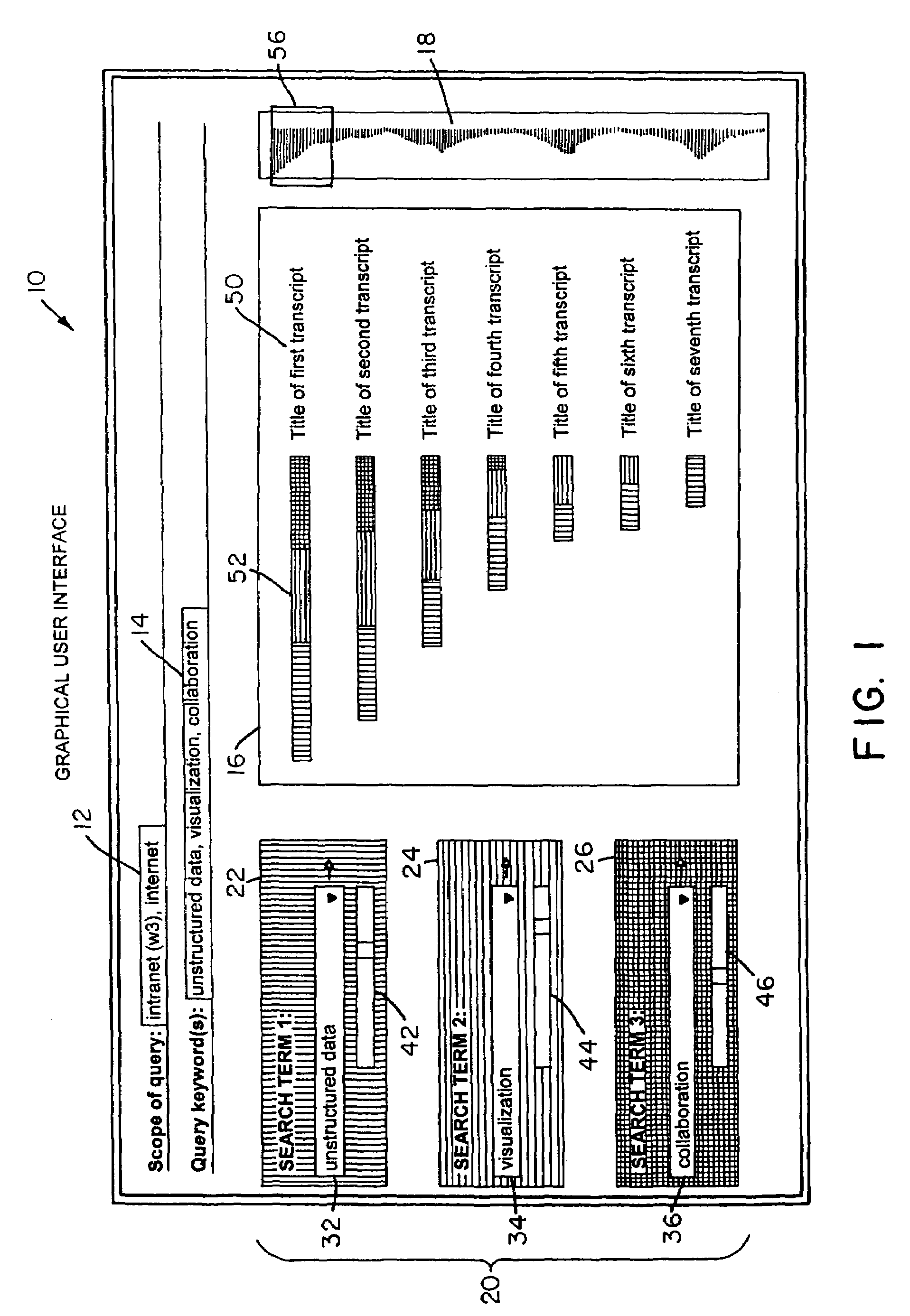

Method, system, and article to specify compound query, displaying visual indication includes a series of graphical bars specify weight relevance, ordered segments of unique colors where each segment length indicative of the extent of match of each object with one of search parameters

InactiveUS7296021B2Data processing applicationsSpecial data processing applicationsClient-sideData mining

A method of searching a collection of data that includes specifying a compound query having two or more search parameters; identifying data objects in the collection that match the search parameters; and providing results that include both an identification of matching data objects and an extent to which the objects match respective ones of the search parameters. The extent of match is shown by graphical bars having elongated segments of a unique color associated with each search parameter so that the user may visually appreciate the relevance of respective parameters in the compound query. A client device communicating with a server, receives an applet to effect the user interface. Each search parameter has an associated unique color and the user may specify a range of relevance desired in the results by altering the strength of any one of the search parameters. A computer-readable medium embodying program code and a corresponding apparatus are also disclosed.

Owner:INT BUSINESS MASCH CORP

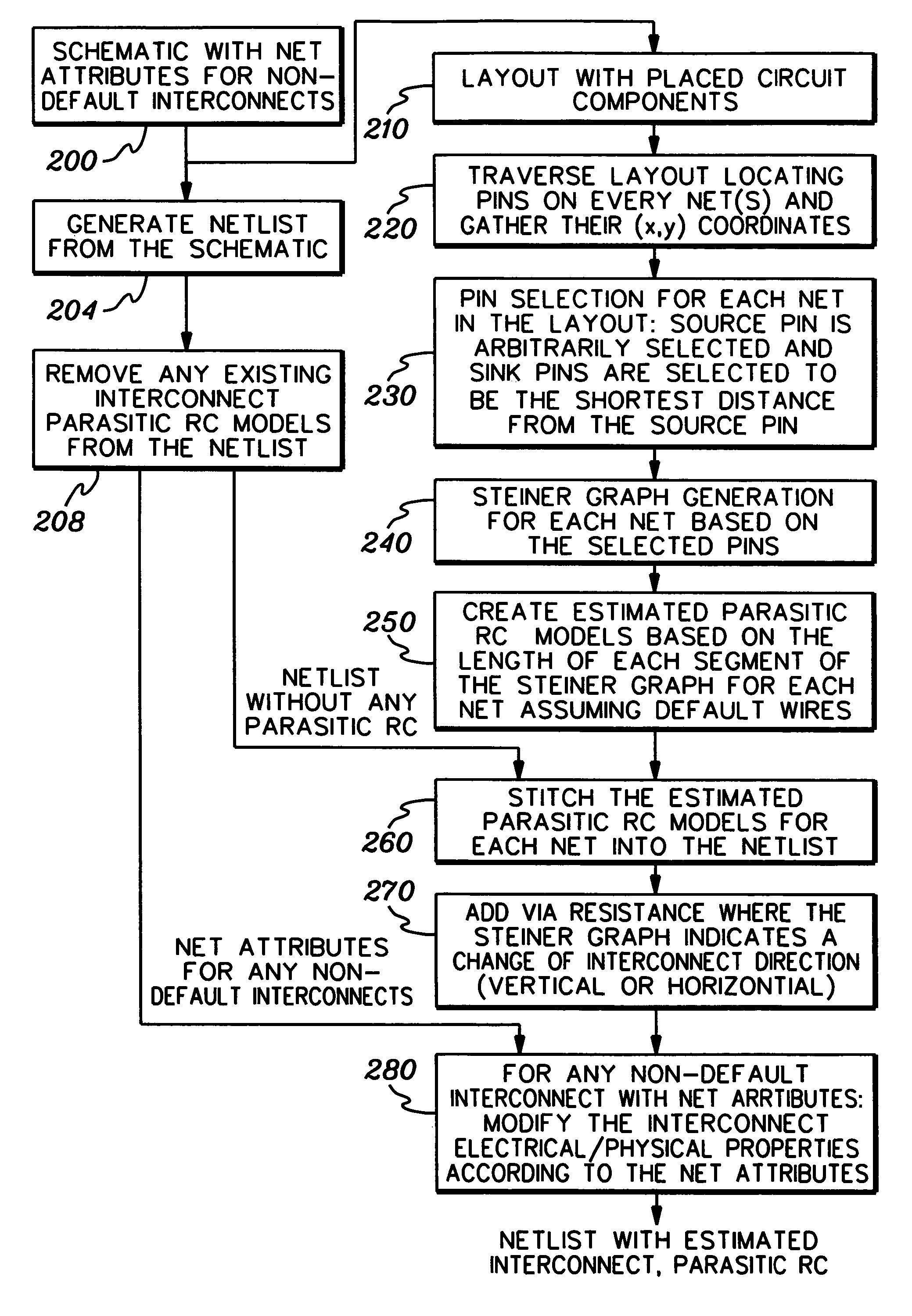

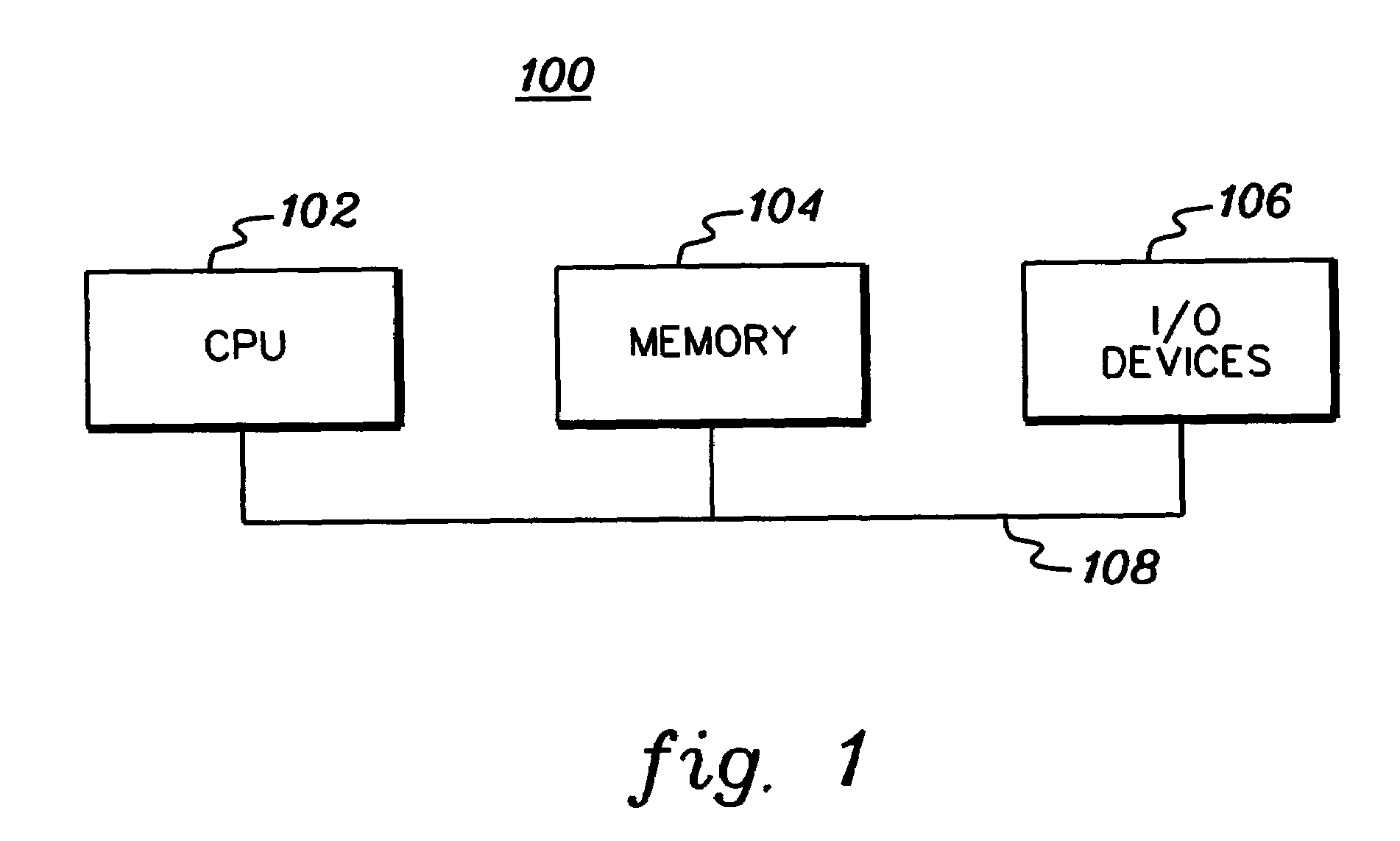

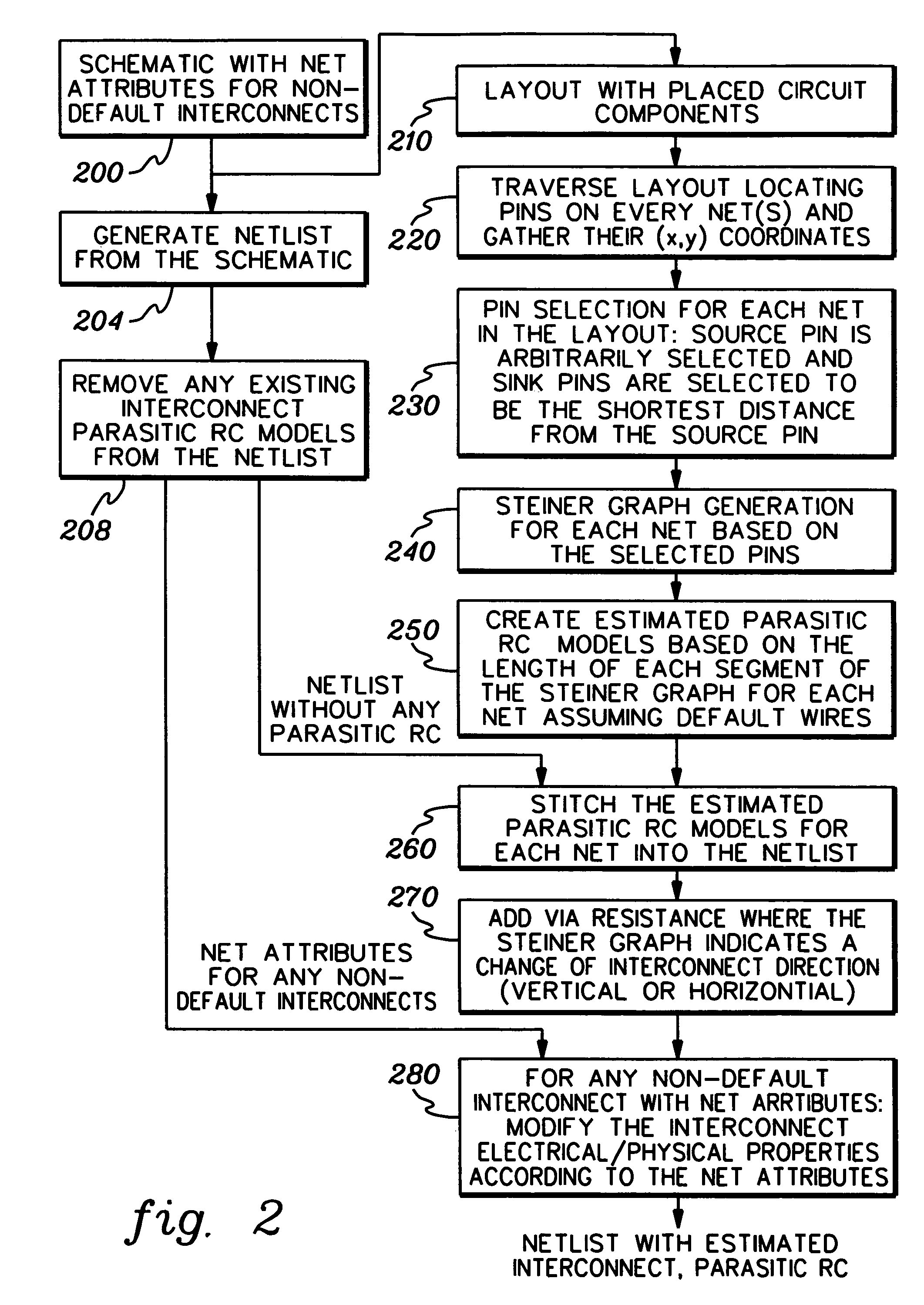

Method, system and computer program product for automatically estimating pin locations and interconnect parasitics of a circuit layout

InactiveUS7228514B2Computer aided designSoftware simulation/interpretation/emulationElectrical resistance and conductanceResistance capacitance

A circuit design technique is provided for automatically estimating lengths of interconnect segments to be employed in interconnecting at least some circuit components of a plurality of placed circuit components of a circuit layout. The automatically estimating includes automatically generating pin locations for a plurality of pins in at least one level of the hierarchy to be employed with the at least some circuit components of the circuit layout, wherein the interconnect segments interconnect the plurality of pins. A route estimator is employed to estimate lengths of the interconnect segments based on the pin locations of the plurality of pins. The estimated interconnect segment lengths are then employed in automatically estimating resistance capacitance interconnect parasitics for the interconnect segments to be employed in the circuit layout.

Owner:GLOBALFOUNDRIES INC

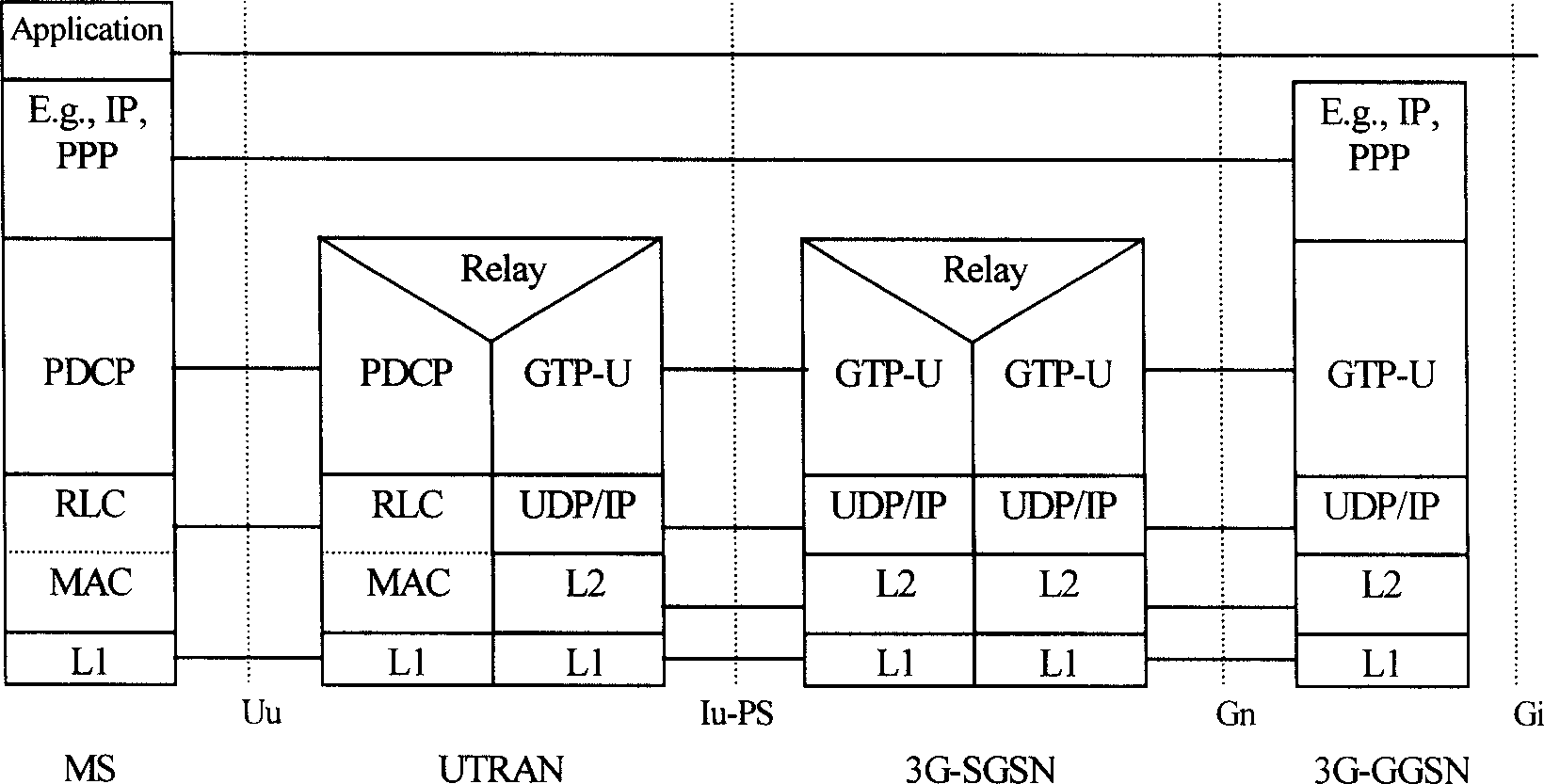

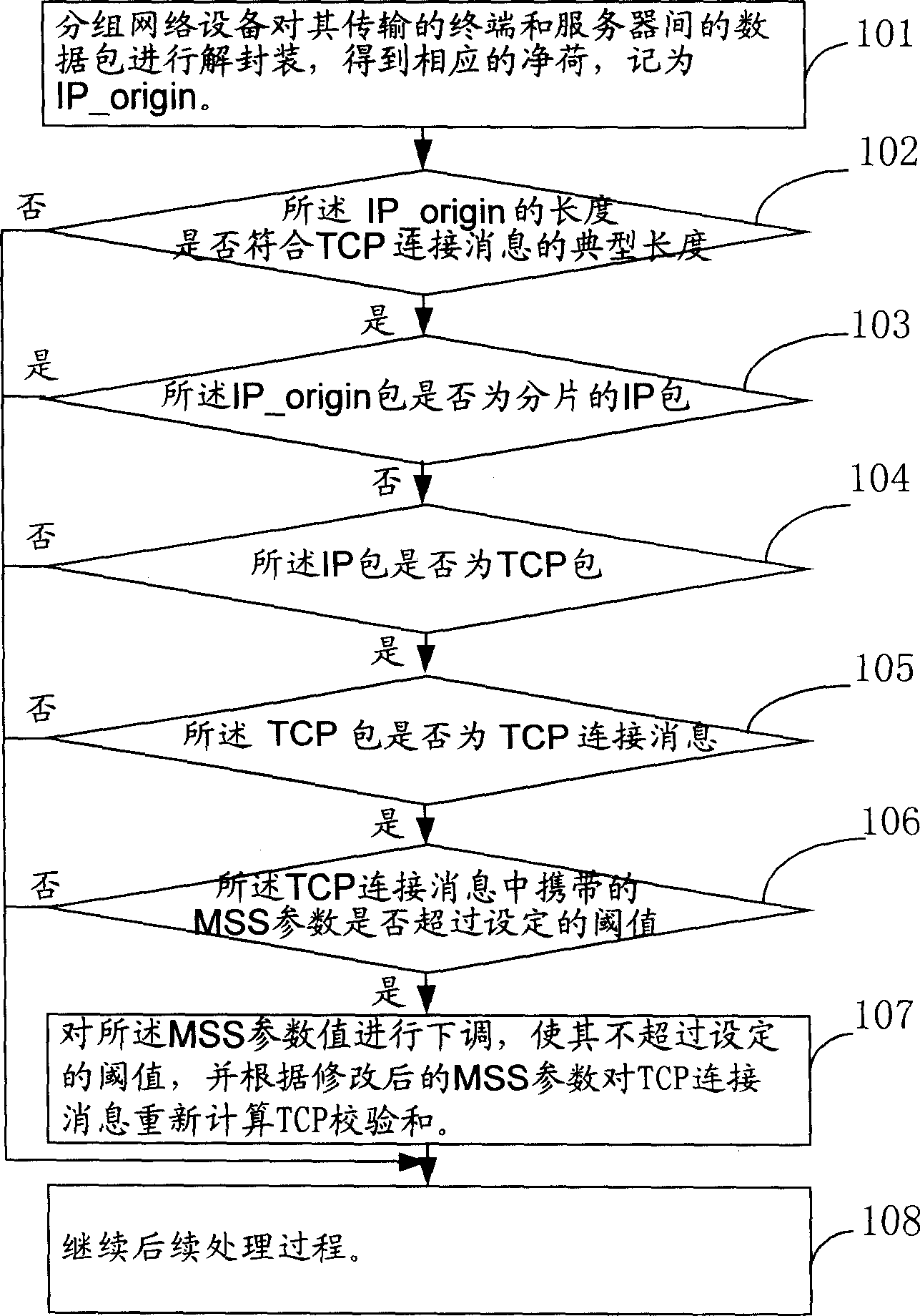

Method for reducing data IP fragmentation quantity in PS network

The invention relates to a method for reducing the number of data IP fragments in packet domain network, and its kernel: packet network device regulates MSS parameter value of maximum transfer unit carried in TCP connection information between terminal and service according to the set MSS parameter threshold and sends out the regulated TCP connection information; the terminal or server learns a longest message segment length supported by the opposite terminal through MSS parameter carried in the TCP connection information, and compares this longest message segment length with its own longest message segment length, and selects the smaller value to make segment handling on TCP transfer data. And the invention can reduce IP packet fragments between packet network devices by regulating MSS parameter value, reduce data packet handling delay and improve packet device handling ability.

Owner:HUAWEI TECH CO LTD

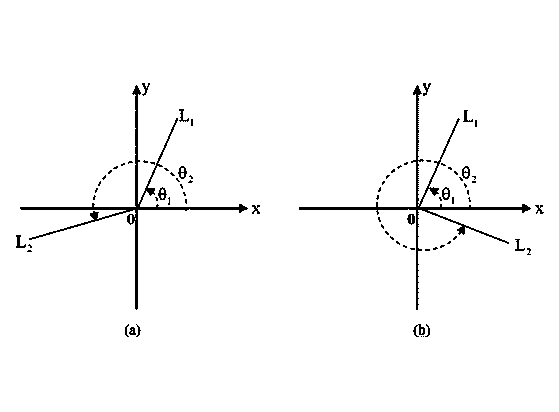

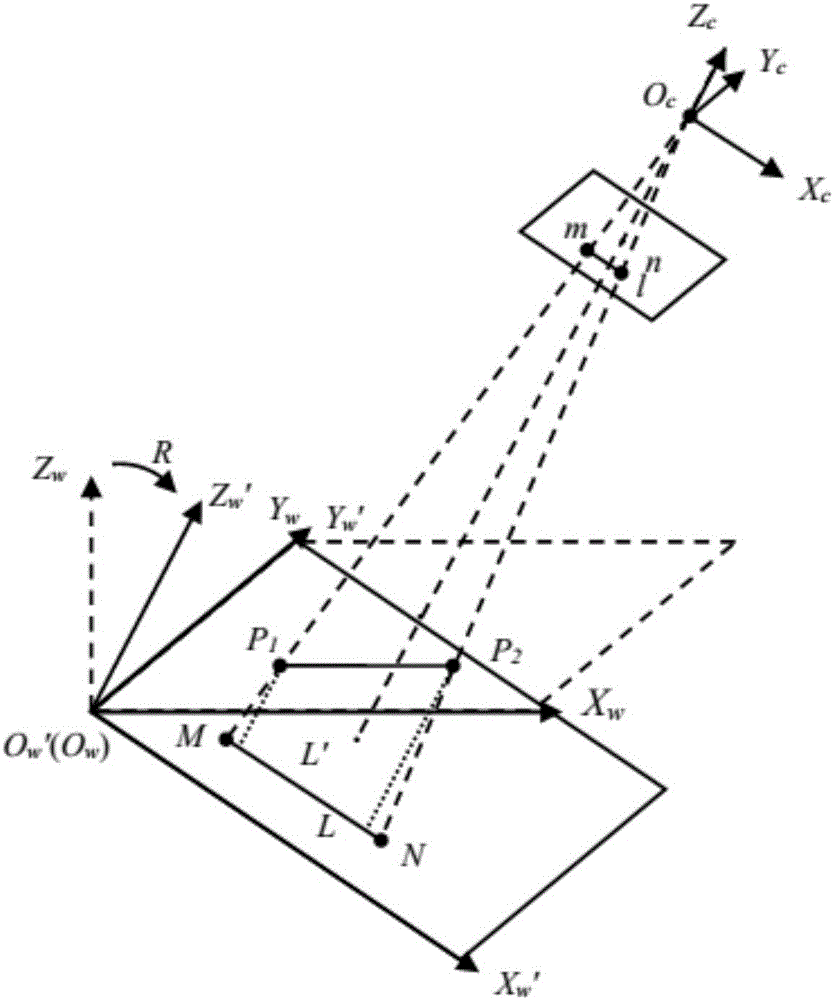

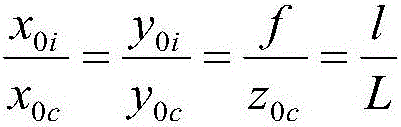

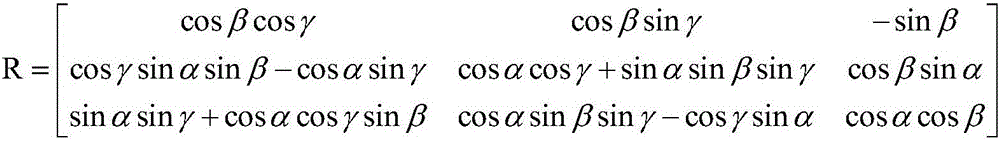

Improved position and orientation estimation method based on Tsai algorism

InactiveCN105809702AHigh precisionImprove real-time performanceImage enhancementImage analysisEstimation methodsLine segment

The invention discloses an improved position and orientation estimation method based on a Tsai algorism.The method includes the steps that a utilized camera is subjected to calibration, and the camera focal length is obtained; under the currently utilized position and orientation of the camera, five or more coplanar feature points in the space are subjected to imaging, any feature point P0 in the feature points serves as an original point to establish a world coordinate system, and world coordinates and image coordinates of the feature points are obtained; the rotation matrix R of a camera coordinate system relative to the world coordinate system is solved through the Tsai algorism; the translation vector T of the camera system where the camera is located relative to the world coordinate system is solved according to the rotation matrix R, the camera focal length and obtained segment length between every two feature points; position and orientation parameters of the camera are solved according to the rotation matrix R and the translation vector T.The improved position and orientation estimation method has the advantages that on the basis of solving the rotation matrix R through the Tsai algorism, the solving process of the translation vector T is improved, precision and real-time performance of position and orientation estimation are improved, and thus the application range is greatly improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Fiber-reinforced composite material, method for manufacturing the same and applications thereof

ActiveUS7455901B2High transparencyLight weightMaterial nanotechnologyCellulosic plastic layered productsTransmittanceFiber-reinforced composite

There is provided a fiber-reinforced composite material containing fibers having an average fiber diameter of 4 to 200 nm and a matrix material, the composite material having a visible light transmittance of 60% or more at a wavelength of 400 to 700 nm, which is a conversion value based on a thickness of 50 μm. A fiber-reinforced composite material composed of a matrix material and a fiber aggregate impregnated therewith is provided, in which when a segment length of a bright region corresponding to a pore region of the fiber aggregate is represented by L, which is obtained by statistical analysis of a unidirectional run-length image formed from a binary image obtained by binarization of a scanning electron microscopic image of the fiber aggregate, the total length of segments that satisfy L≧4.5 μm is 30% or less of the total analyzed length. A transparent multilayered sheet, a circuit board, and an optical waveguide are provided which use a transparent substrate formed from this fiber-reinforced composite material.

Owner:MITSUBISHI CHEM CORP +2

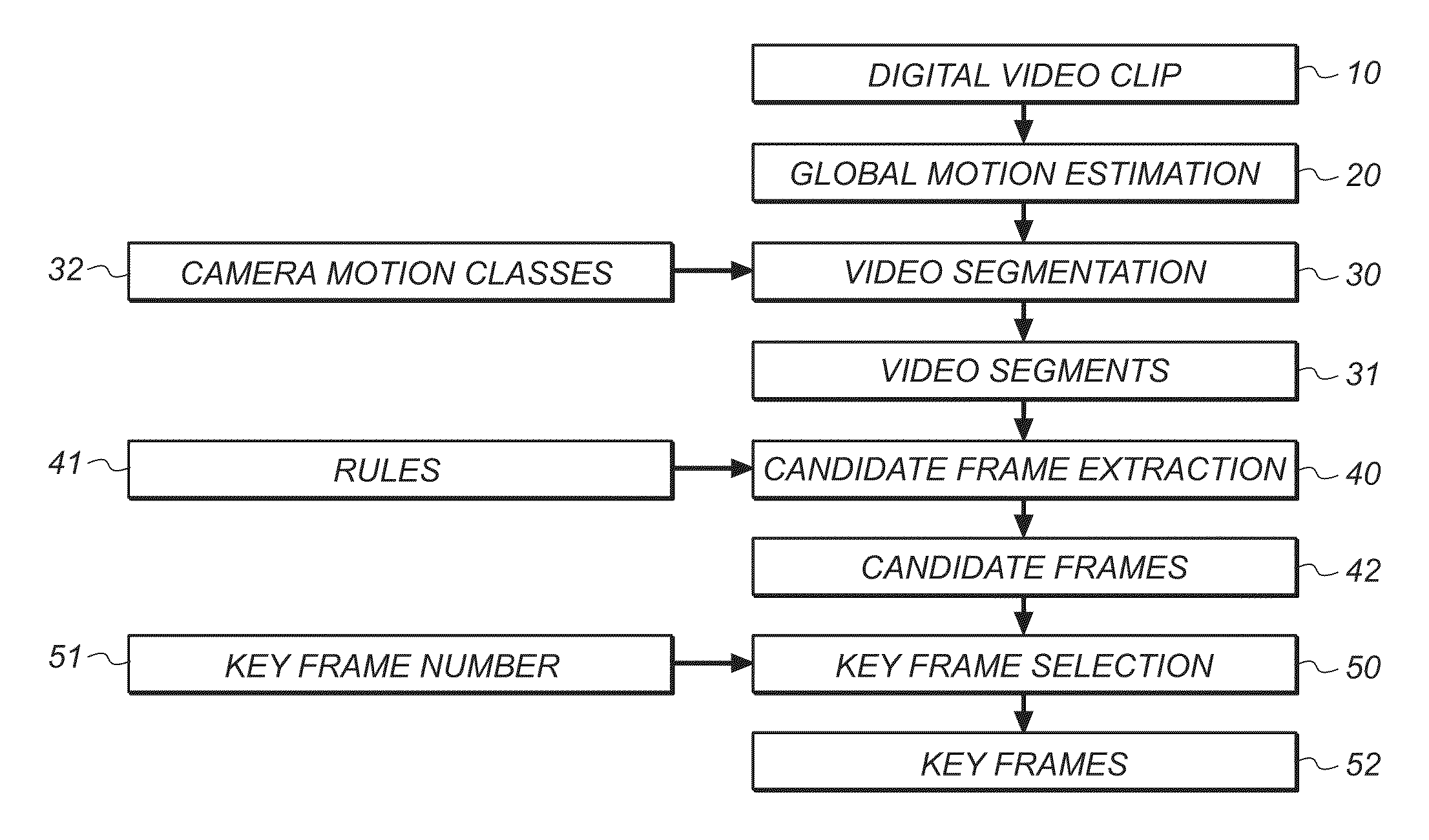

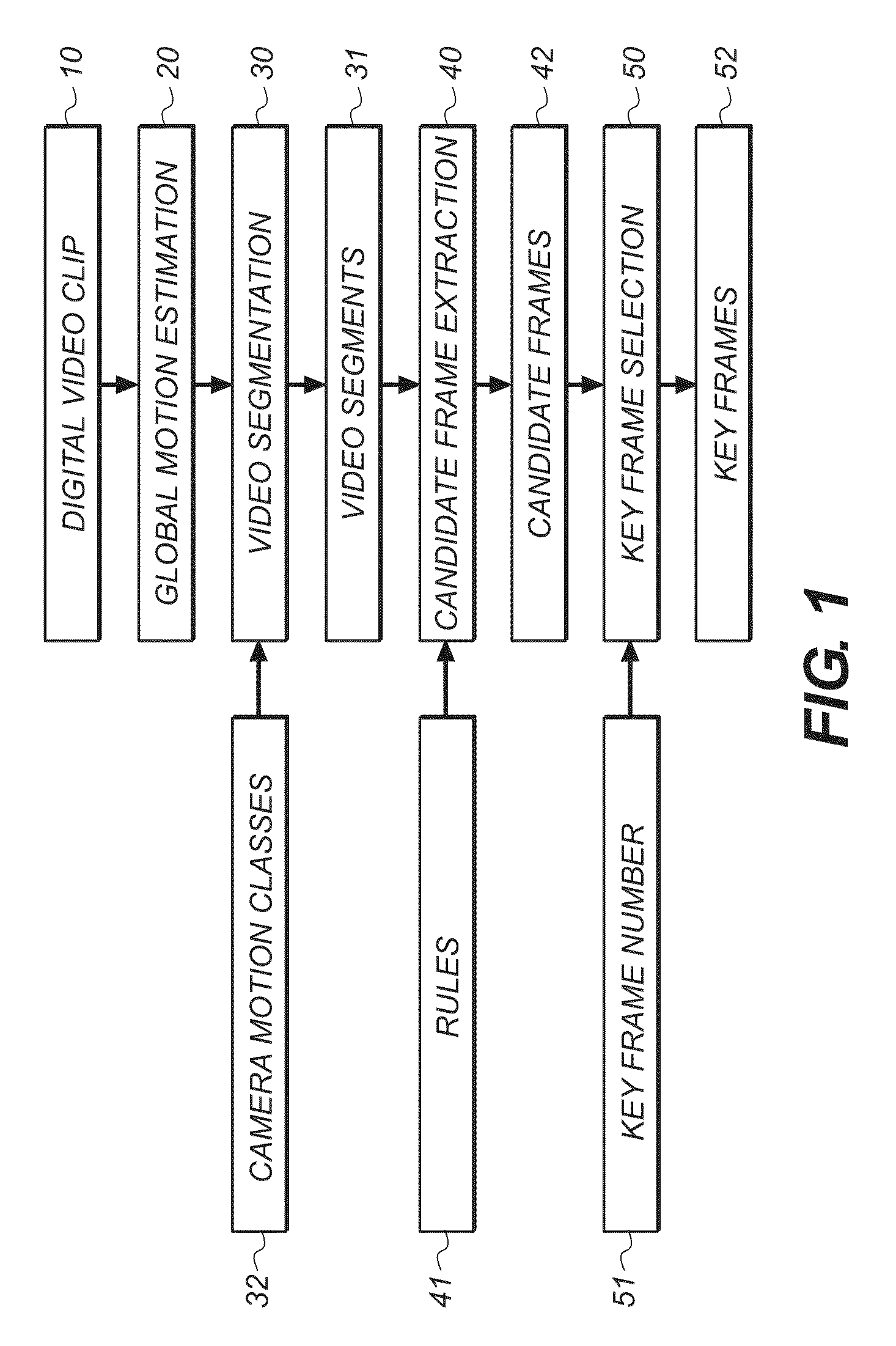

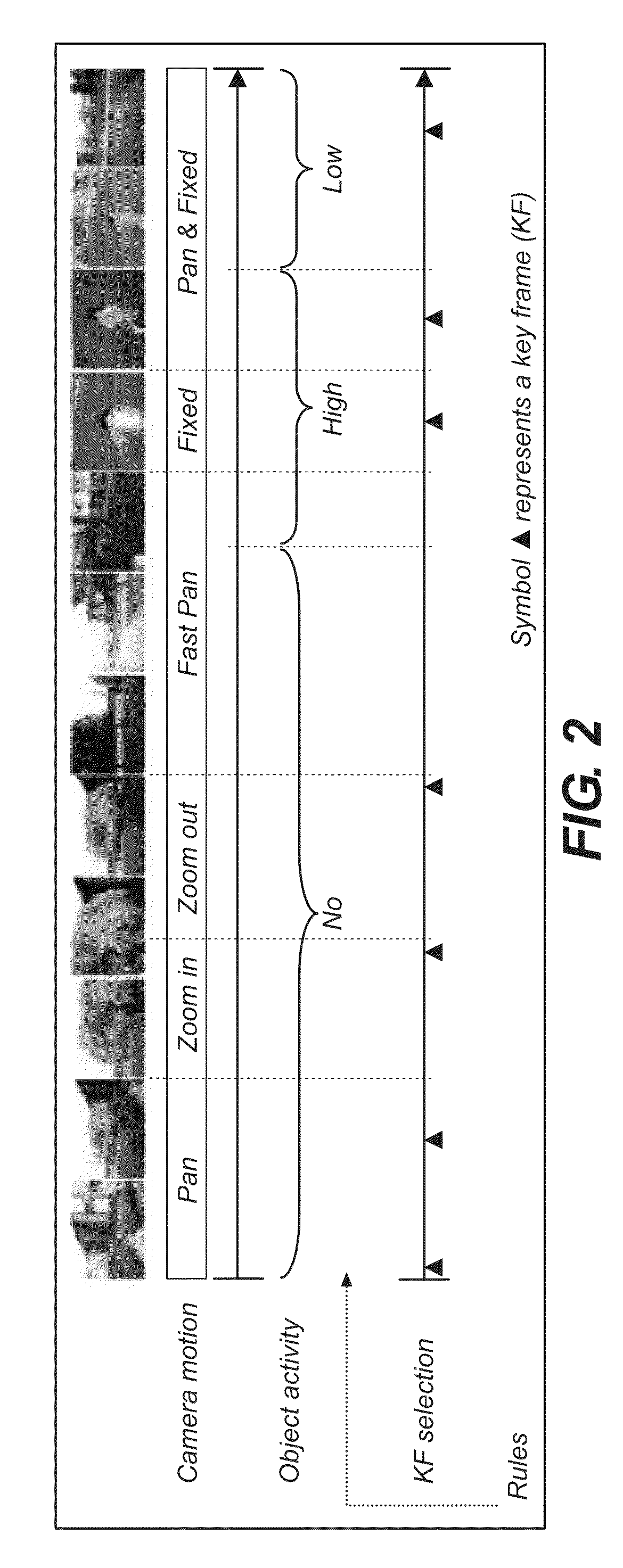

Extracting key frame candidates from video clip

InactiveUS7889794B2Satisfied with the resultTelevision system detailsTelevision system scanning detailsDigital videoObject motion

A method of analyzing a digital video clip to determine candidate frames for subsequent key frame selection, includes: performing a global motion estimate on the video clip that indicates translation of a scene or camera, or scaling of the scene; and forming a plurality of video segments based on the global motion estimate and labeling each segment in accordance with a predetermined series of camera motion classes. The method further includes extracting key frame candidates from the labeled segments and computing a confidence score for each candidate by using rules corresponding to each camera motion class and a rule corresponding to object motion. An important feature of the invention is that the rules corresponding to camera motion include extracting a candidate frame for a pan segment with a confidence score related to a translation amount during the pan, and not extracting candidate frames for object motion based frames for fast pan and zoom segments, and the rule corresponding to object motion includes extracting a candidate frame for a fixed segment with a confidence score related to the segment length.

Owner:APPLE INC

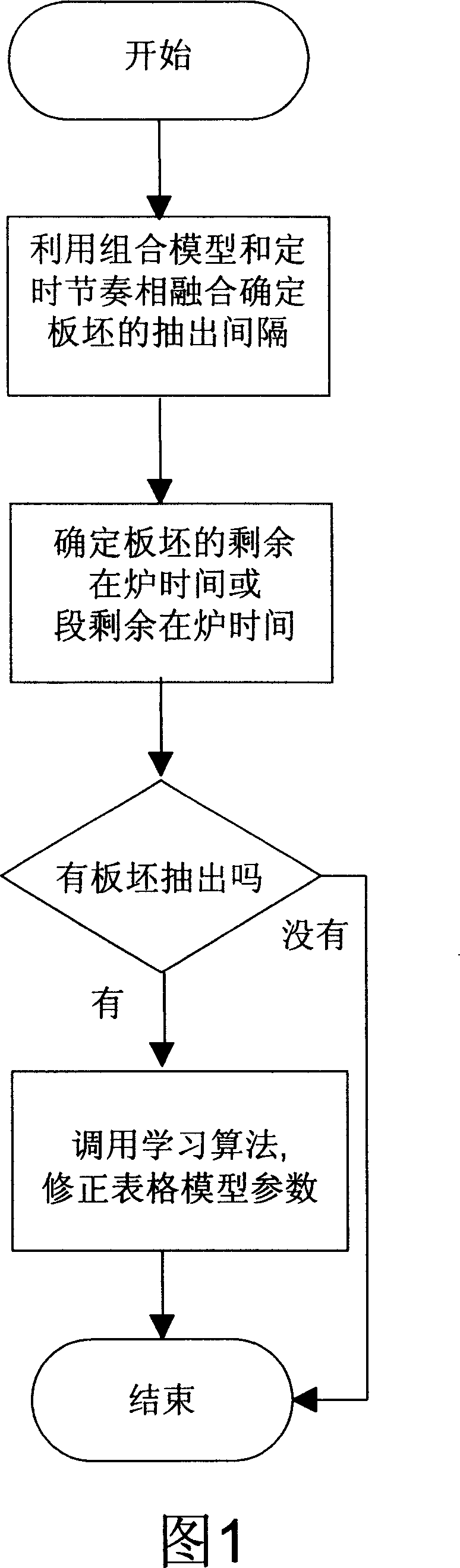

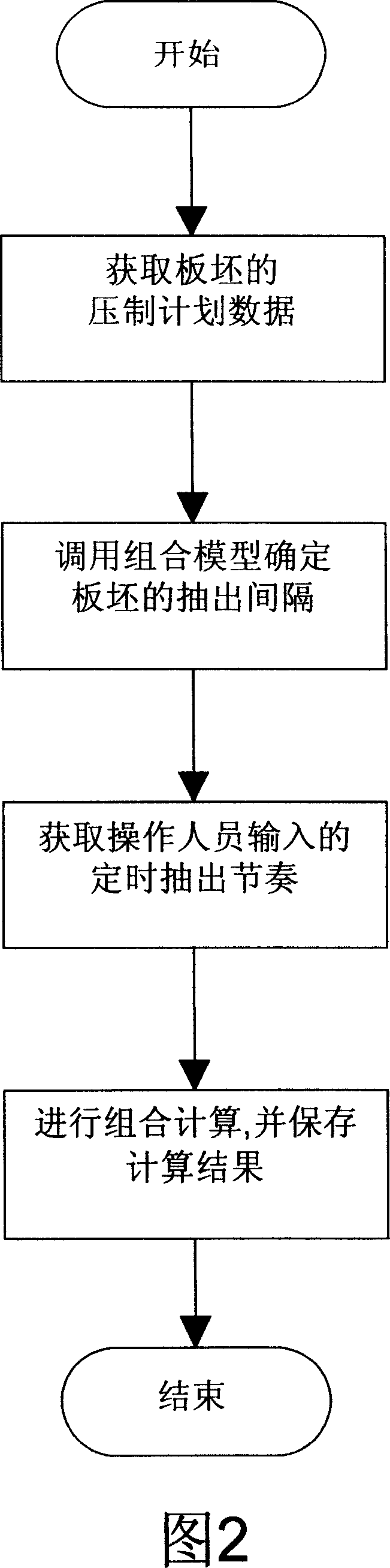

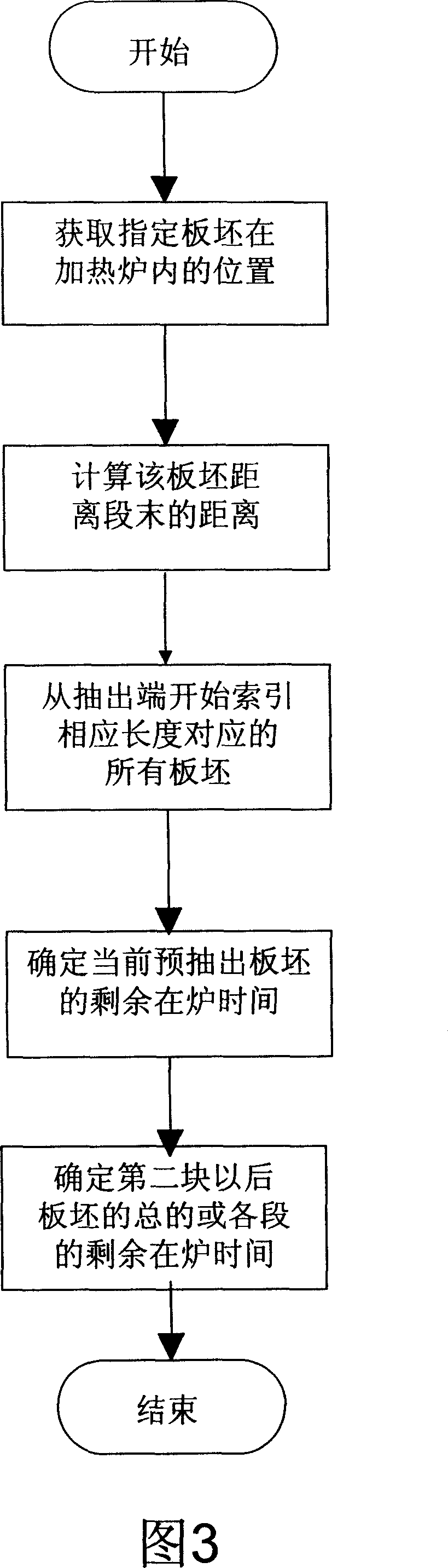

Method for determining the time of hot rolling heating stove bar plate leavings in furnace

ActiveCN101082814AForecast temperatureImprove the level of temperature controlCharge manipulationFurnace typesTemperature controlHardness

The invention discloses an affirming method of residual time of hot-rolled heater slab in the furnace, which comprises the following steps: calculating extracting interval of slab in the furnace through combined prediction model of slab extracting interval according to the length, product breadth and product thickness of slab in the furnace and the length, product breadth, thickness and hardness grade of slab; fusing the extracting time with present timely extracting time; indexing from extracting end according to the present position of each segment length of heater and slab and the length from slab to end; accumulating the extracting interval of slab within index scale to calculate; affirming the residual time of slab in the furnace or segment; fitting automatically; repairing the residual time to predict the temperature of slab precisely. The invention can control the temperature of heater precisely to make the slab reach the regulated goal temperature, which is benefit to improve the temperature control level of slab in the heater and heating quality of slab with low energy consumption.

Owner:BAOSHAN IRON & STEEL CO LTD

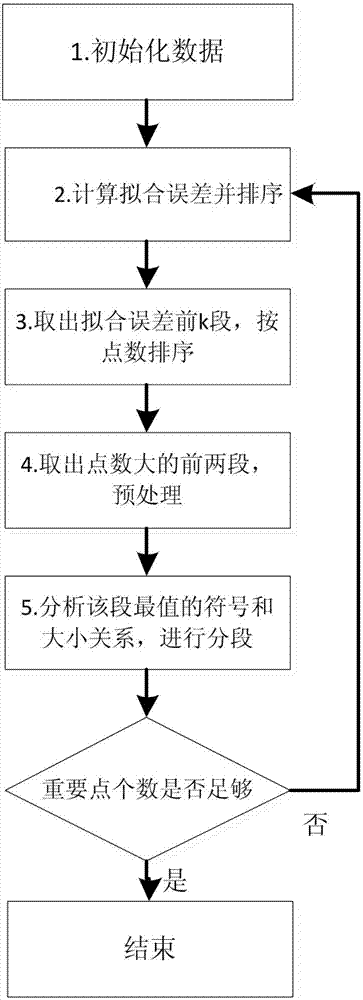

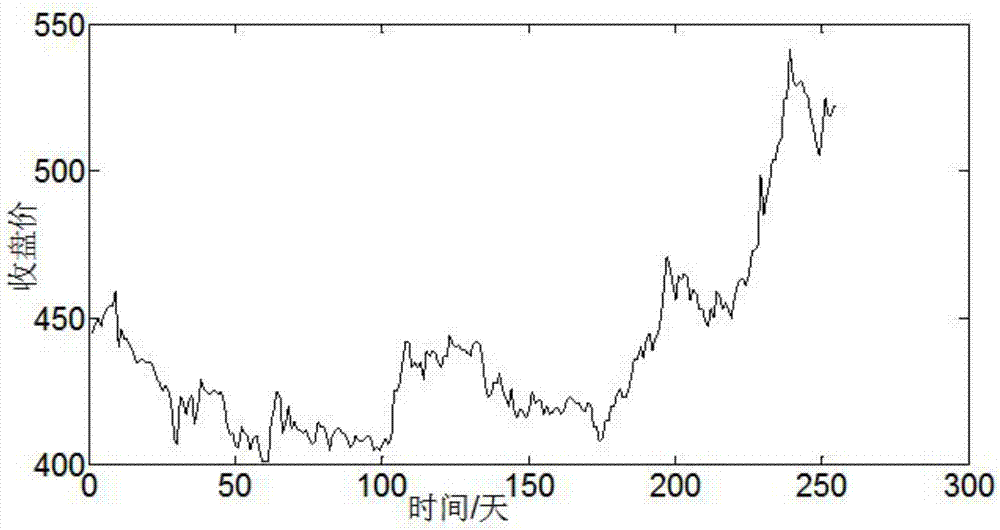

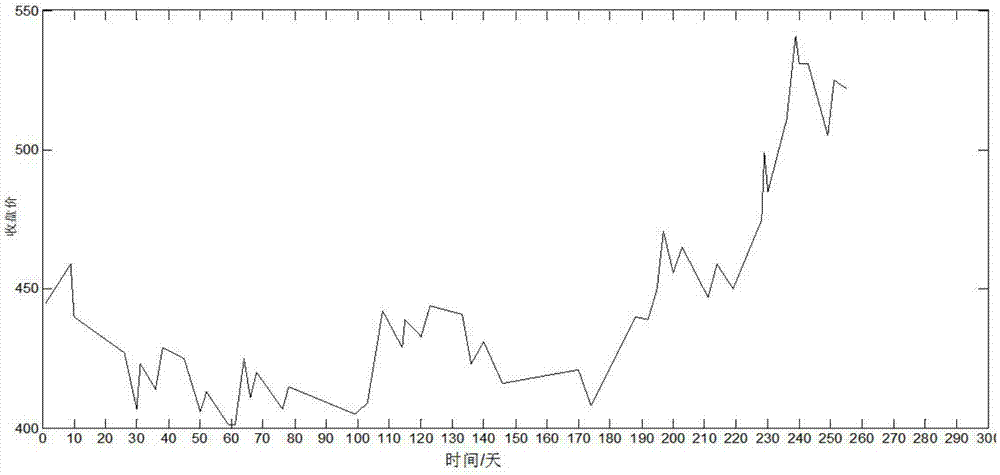

Important point-based time sequence fixed segmentation algorithm

InactiveCN107463604AAvoid typingPreserve featuresSpecial data processing applicationsAnomaly detectionAlgorithm

The invention relates to an important point-based time sequence fixed segmentation algorithm. According to the main technical characteristics, the algorithm comprises the steps of performing normalization processing on time sequence data; calculating segmentation fitting errors and performing sorting according to priorities of the segmentation fitting errors from high to low; extracting first k segments with maximum fitting errors and performing sorting from long to short according to segment lengths of a time sequence; extracting first two segments sorted according to the segment lengths, and performing fitting preprocessing; and comparing symbol and value relationships of maximum values and minimum values of the fitting errors in segmentation, determining important points to perform segmentation, progressively increasing the number of the important points, and performing loop iteration until a fixed segment number is reached. The algorithm is reasonable in design, greatly reduces the fitting errors, improves the segmentation efficiency, has very good fitting effect and adaptability, and can be widely used in the fields of time sequence prediction, clustering, anomaly detection and the like.

Owner:TIANJIN UNIV OF SCI & TECH

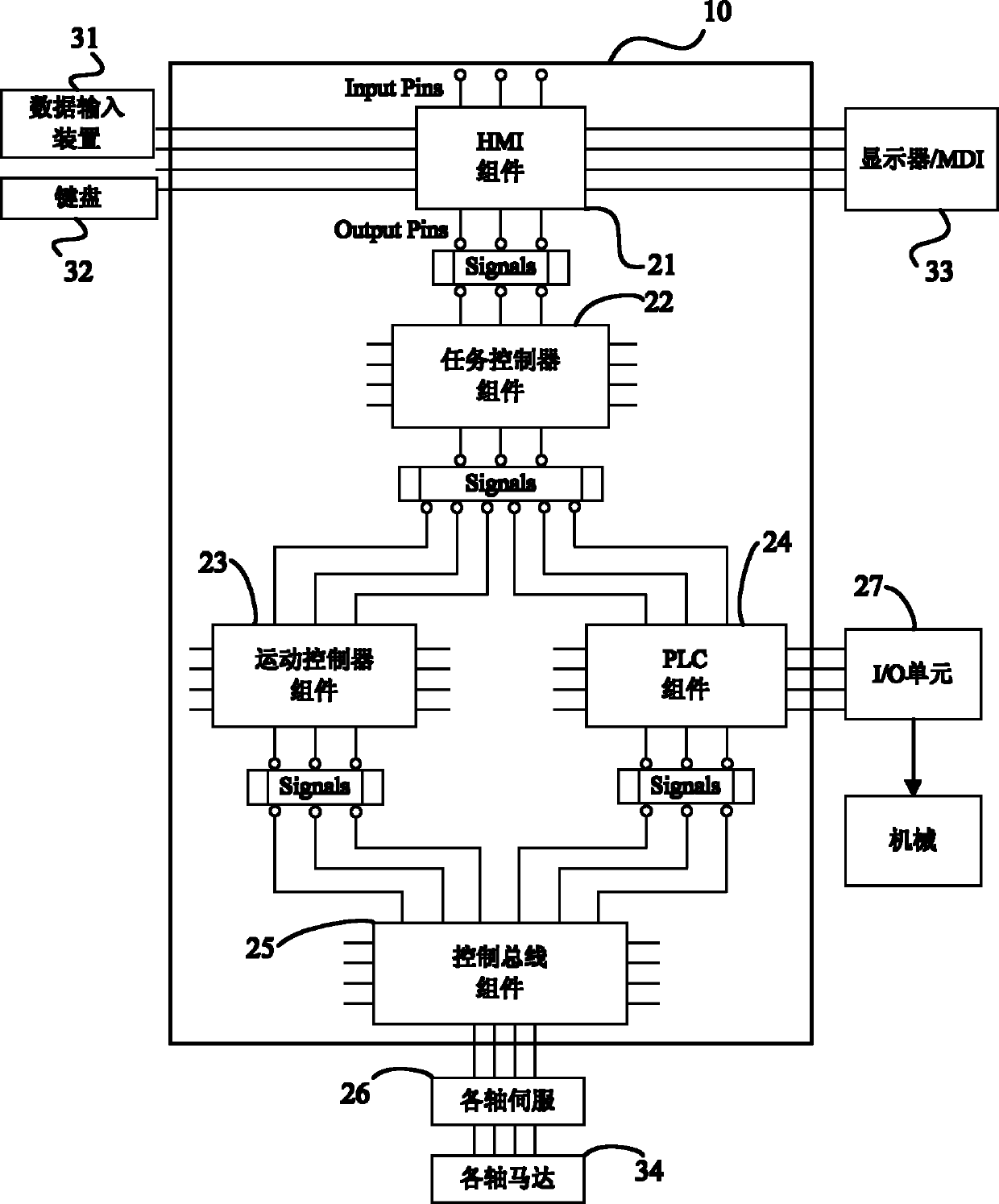

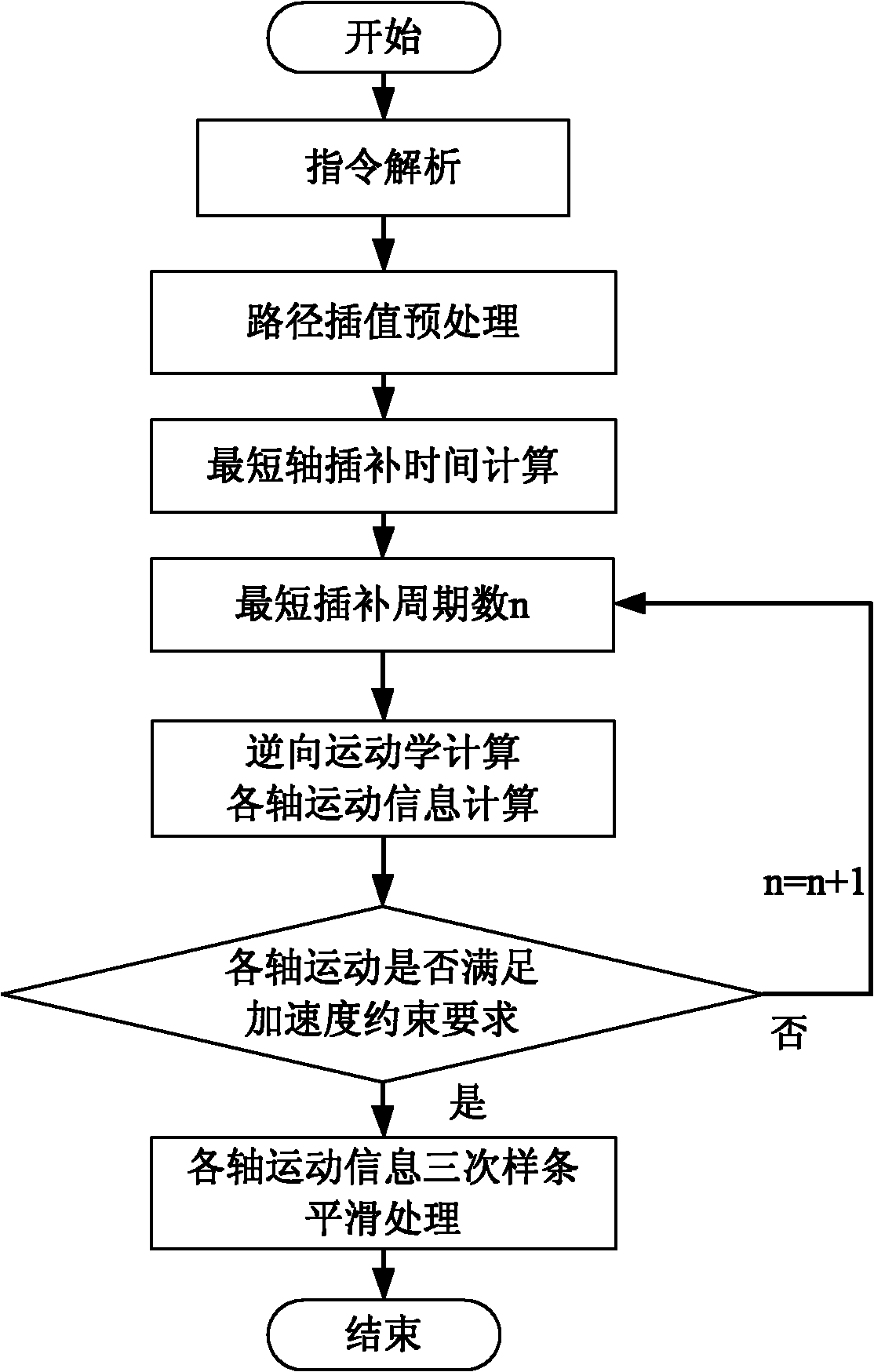

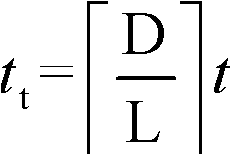

Five-shaft numerical control system cutter center point interpolation path interpolation method

ActiveCN102566511AInterpolation smoothProgramme controlComputer controlProgram instructionDirection information

The invention relates to a five- shaft numerical control system cutter center point interpolation path interpolation method. The method comprises the following steps: determining cutter center point position information, cutter direction information, cutter center point feeding speed and an interpolation period; determining a conversion relation of programming instruction information in a workpiece coordinate system to machine tool coordinate system lower shaft position information; determining a cutter center point interpolation step length and segment length, and a motion stroke of each shaft, and combined with maximum restriction speed of each shaft, calculating shortest shaft interpolation time and shaft interpolation period number which are needed by completing a cutter center point interpolation path; determining a shortest interpolation period number under a speed constraint condition; determining a motion position of each interpolation period of each shaft, and completing motion information calculation of each shaft; when motion of each shaft is in accordance with an acceleration constraint requirement, carrying out three times of batten smooth processing of motion information of each shaft, sending the motion information to a servo, and ending present operation. According to the method, a programming path is subjected to interpolation processing, thus smooth five- shaft processing cutter center point interpolation can be carried out through a five-shaft machine tool with two rotating shafts.

Owner:中国科学院沈阳计算技术研究所有限公司

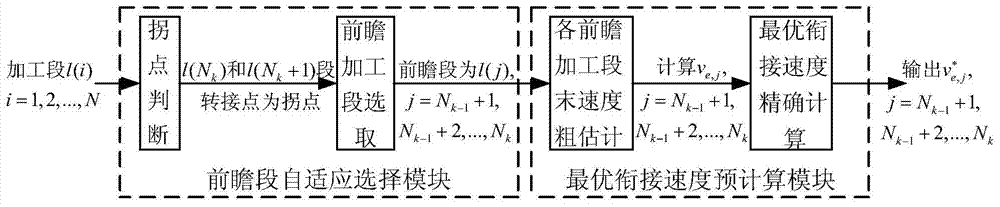

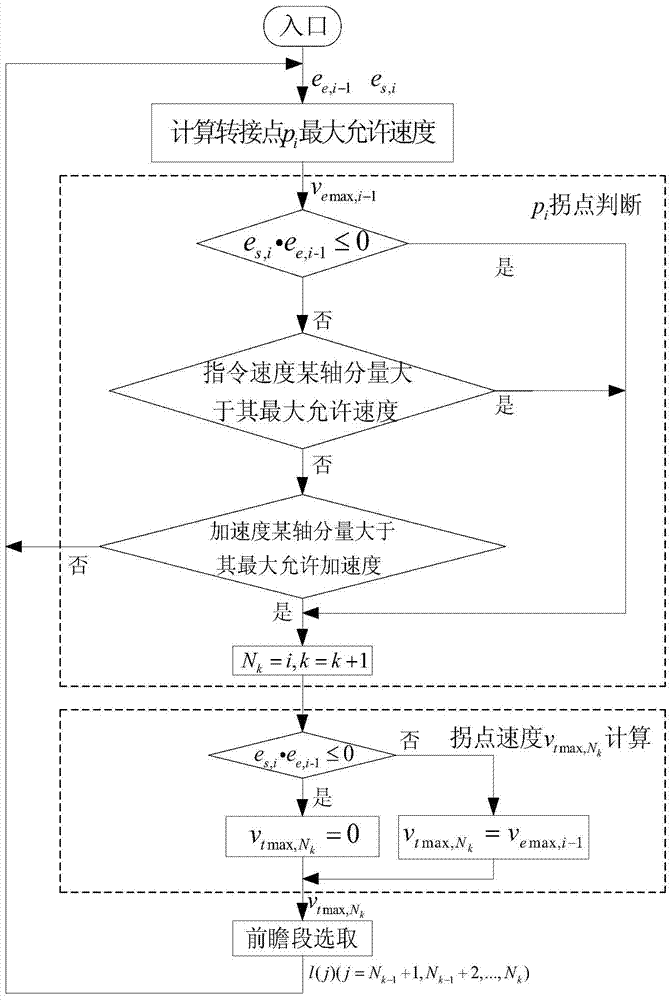

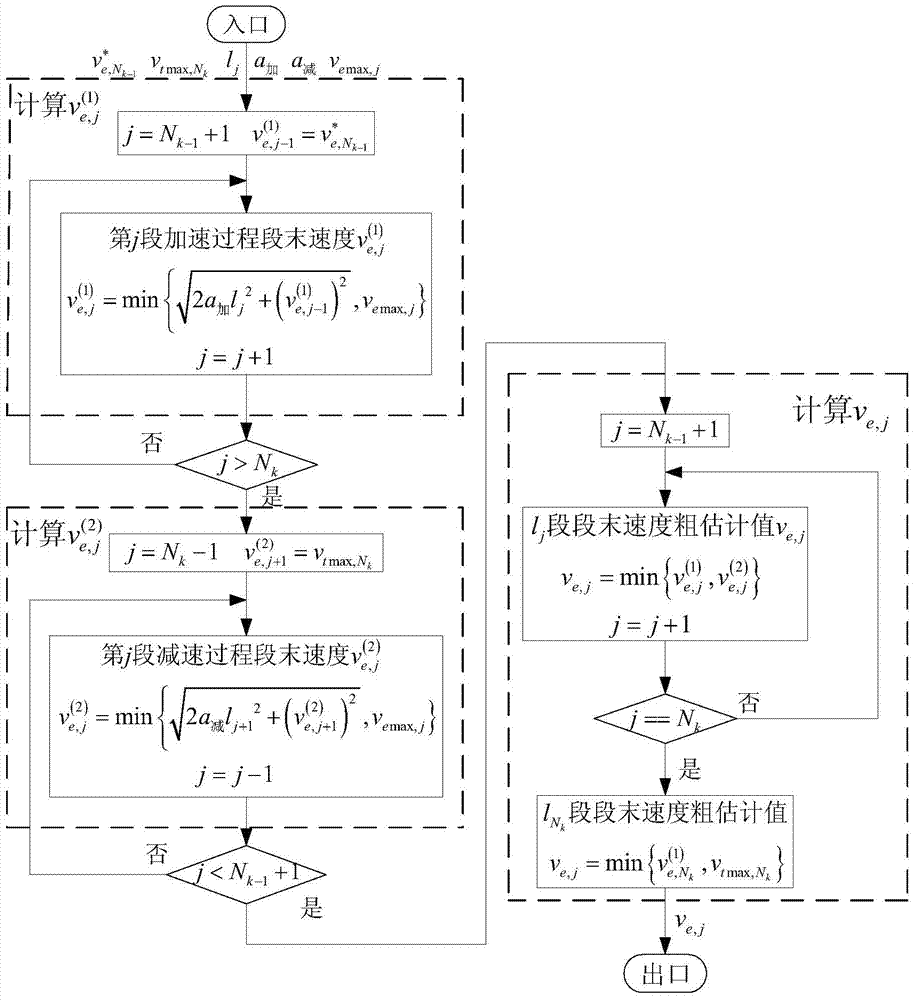

Velocity look-ahead preprocessing method oriented to efficient processing of tiny line segments

ActiveCN104331025AHigh real-time requirementsHigh feed speedNumerical controlPretreatment methodAdaptive selection

The invention discloses a velocity look-ahead preprocessing method oriented to efficient processing of tiny line segments. The velocity look-ahead preprocessing method comprises the steps of dynamically and adaptively selecting the number of look-ahead preprocessing segments, and performing optimization preprocessing on the cutting velocity of each look-ahead segment to guarantee a high feed velocity and smooth join; the velocity look-ahead preprocessing method comprises the two steps of adaptive selection of the look-ahead segments and pre-calculation of the optimal join velocity; a numerical control system adaptively selects the look-ahead preprocessing segments by determining the positions of inflection points according to the processing path change trend; according to the path change trend of the look-ahead segments, firstly, the final velocity of each look-ahead segment is roughly estimated, and then the optimal join velocity of each look-ahead segment is accurately planned according to the instruction velocity, the rough estimated value of the final velocity, the accelerated velocity and the segment length constraint of each look-ahead segment. The velocity look-ahead preprocessing method oriented to the efficient processing of the tiny line segments is high in velocity, and capable of realizing efficient and smooth join of the feed velocity to meet the velocity control requirements of high-velocity digital numerical devices.

Owner:XI AN JIAOTONG UNIV +1

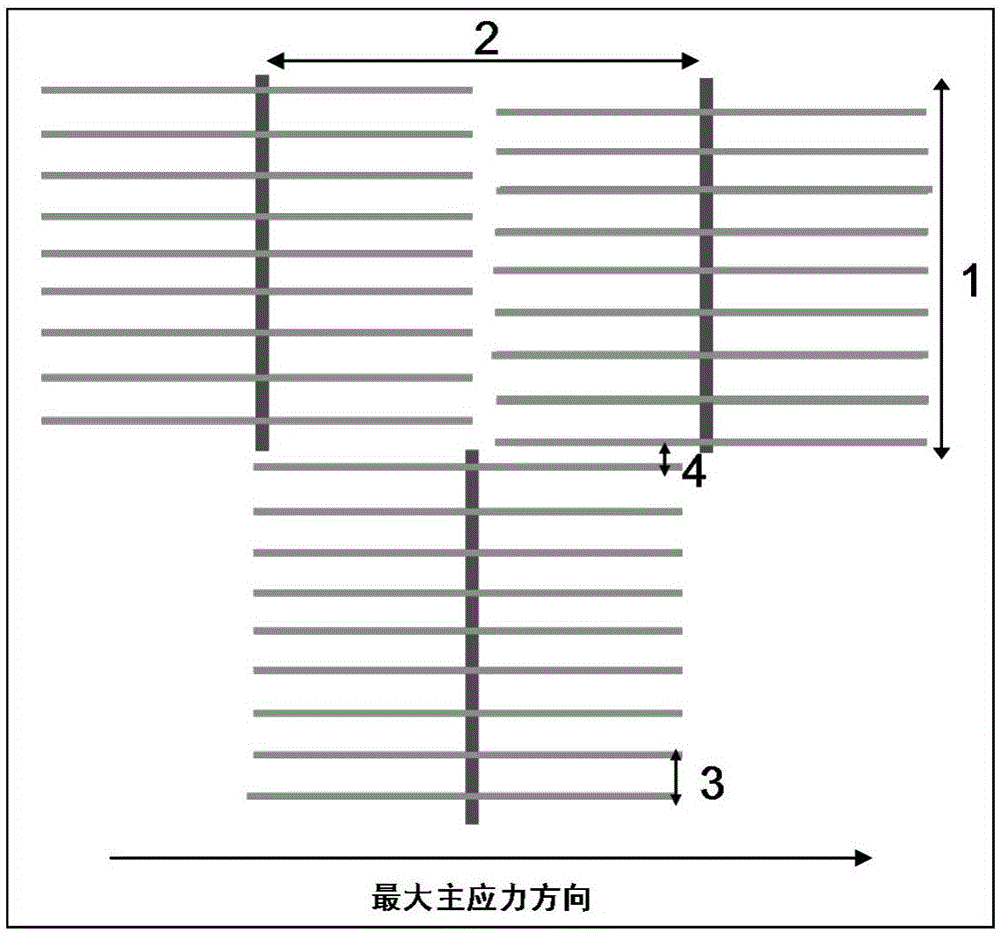

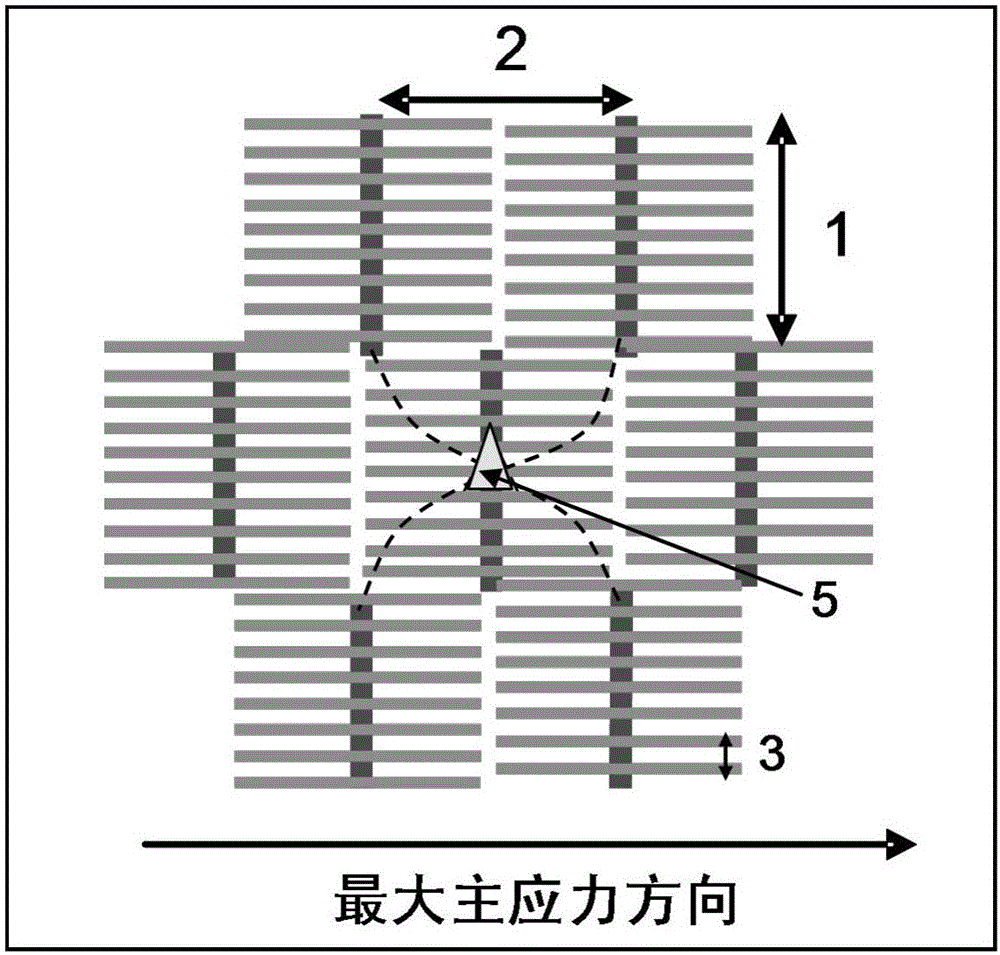

A staggered well arranging method for ultra-low permeability tight oil reservoir volume fracturing horizontal well quasi-natural energy exploitation

ActiveCN105952432AAvoid the risk of water penetrationPlay an initial role in replenishing energyFluid removalNetwork deploymentWater flooding

The invention provides a staggered well arranging method for ultra-low permeability tight oil reservoir volume fracturing horizontal well quasi-natural energy exploitation. The method comprises the steps of 1) firstly carrying out comprehensive geological research, selecting a horizontal well network deployment area preferably, carrying out reservoir classification evaluation, and determining a main contribution interval; 2) optimizing the horizontal segment length; 3) optimizing the well spacing; 4) optimizing the segment distance between fracturing fractures; 5) determining the array distance. The method can utilize the natural energy oil drainage function of horizontal well volume fracturing fracture networks to the greatest degree and avoids the risk of water breakthrough in water flooding exploitation; volume fracturing retention fluid achieves the effects of replenishing energy at an early stage.

Owner:PETROCHINA CO LTD

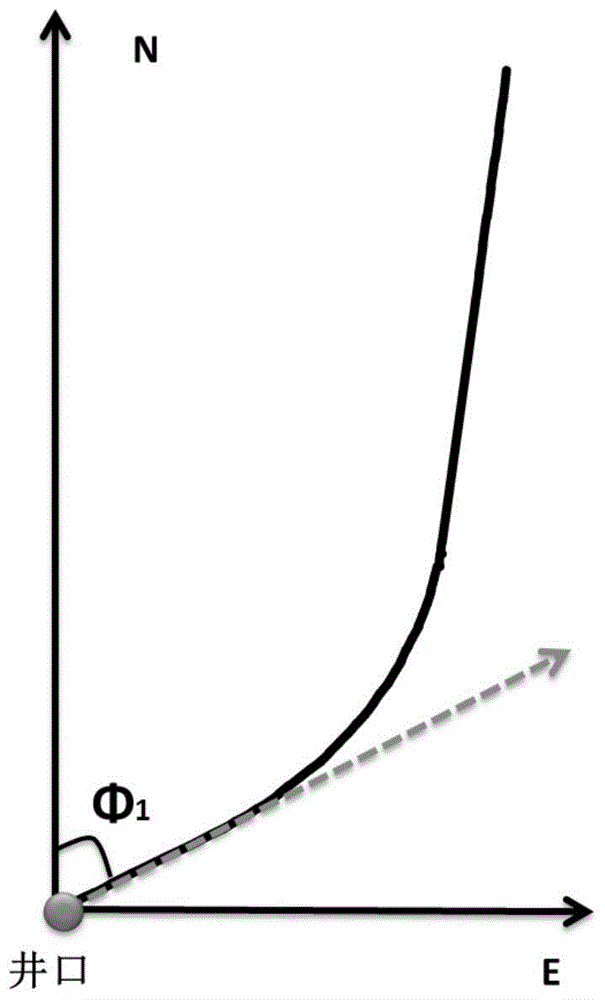

Determination method for initial well deviation azimuth angle of three-dimensional horizontal well borehole trajectory

ActiveCN104653172ALow costReduce Orientation WorkloadSurveyDirectional drillingPetroleumPetroleum engineering

The invention relates to a determination method for an initial well deviation azimuth angle of a three-dimensional horizontal well borehole trajectory and belongs to the technical field of petroleum natural gas drilling. The determination method comprises the following steps: determining a final target-entering deviation angle and a well deviation azimuth angle according to parameters of a target point A and a target point B; determining a minimum stable deviation section length and a well deviation angle behind a twisting direction by using a vertical depth error of the target point A; determining a deviation change rate of a deviation change tool according to a deviation change capability of a drilling tool needing to be used; determining a borehole curve rate needed by a needed entering sleeve according to a sleeve type needing to be adopted; predicating a natural deviation change rate of a stratum according to adjoining well data; determining a first two-dimensional deviation increasing section maximum well deviation rate and a three-dimensional deviation increasing and twisting direction finishing point maximum deviation increasing rate; and combining the parameters to determine the initial well deviation azimuth angle of the three-dimensional horizontal well borehole trajectory. The quantified design is realized, and field drilling and oriented construction are convenient to realize; the oriented working amount is reduced and the drilling engineering cost is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com