High-temperature resistant optical fiber and method for manufacturing same

A manufacturing method and high-temperature-resistant technology, applied in clad optical fiber, manufacturing tools, glass manufacturing equipment, etc., can solve the problems of mechanical property weakening, failure, coating material aging, etc., to achieve durability, stable use characteristics, good persistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below through the embodiments and the accompanying drawings.

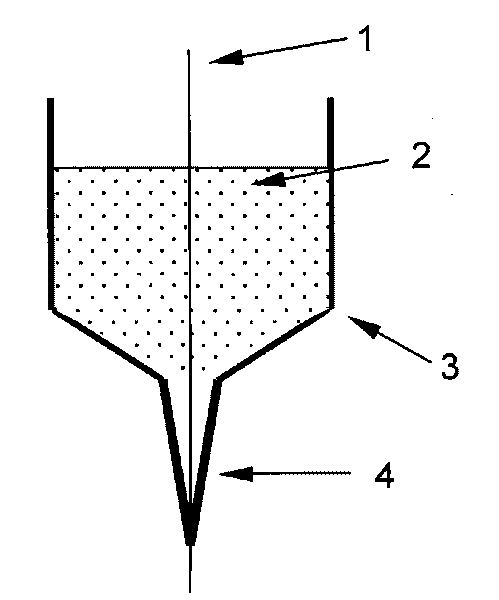

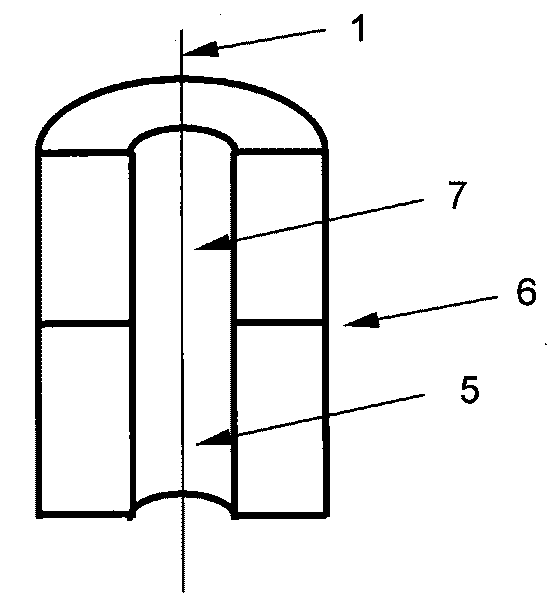

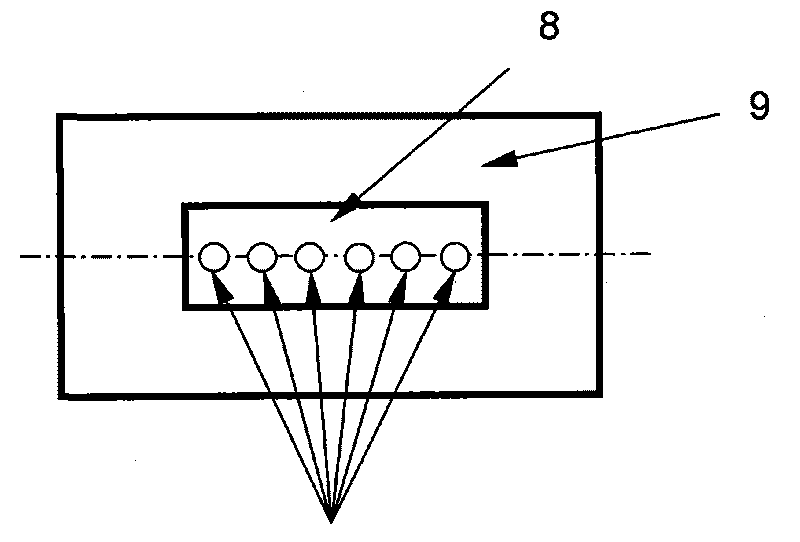

[0036] Various high temperature resistant optical fibers in the present invention are prepared by pre-coating plus secondary coating process. The key to the process lies in the temperature setting of the pre-curing furnace and box-type electric furnace and the temperature setting of the preform electric melting furnace. Embodiments of the present invention are further described below.

[0037] The first embodiment: the fiber type is HT50 / 55 / 65, which is a kind of ultraviolet transmission fiber. The preform rod with a diameter of 21mm is melted and shrunk in a high-temperature heat field of 2180°C and stretched to form an optical fiber. At a pulling speed of 12m / min, it is coated with a polyimide coating to form a finished optical fiber. The cladding diameter of the optical fiber silica glass is 55 μm, the diameter of the polyimide coating is 65 μm, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com