A preparation method of high stability conductive plastic with good mechanical properties

A technology with high stability and mechanical properties, applied in the field of preparation of high-stability conductive plastics, can solve the problems of affecting graphene performance, graphene structure damage, poor mechanical quality of plastics, etc., to improve comprehensive use quality and improve adsorption capacity. , the effect of easy processing and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

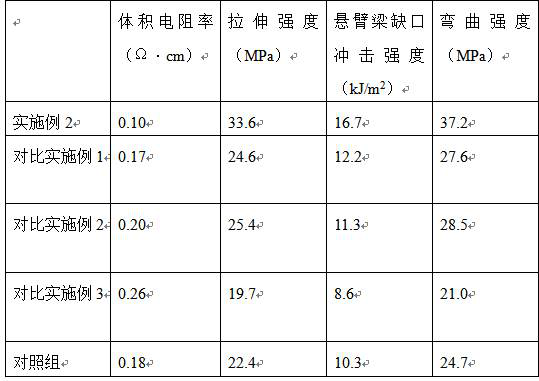

Examples

Embodiment 1

[0031] A method for preparing a high-stability conductive plastic with good mechanical properties, comprising the steps of:

[0032] (1) Preparation of characteristic fillers:

[0033] a. Put the bentonite into the calcination furnace for calcination treatment, control the calcination temperature to 750°C, and take it out after 1 hour for later use;

[0034] b. Mix the bentonite, foaming agent, dimethyl sulfoxide, sodium pyrophosphate, and water after the calcining treatment in operation a into the mixing tank according to the weight ratio of 5:3:25:2:90, and keep stirring After processing for 40min, filter, and drain the surface moisture of the filtered bentonite for later use;

[0035]c. Immerse the bentonite treated in operation b into the modified treatment solution, heat to keep the temperature of the modified treatment solution at 33°C, and filter out the bentonite after ultrasonic treatment for 1 hour for later use; the modified treatment solution consists of the follo...

Embodiment 2

[0053] A method for preparing a high-stability conductive plastic with good mechanical properties, comprising the steps of:

[0054] (1) Preparation of characteristic fillers:

[0055] a. Put the bentonite into the calcination furnace for calcination treatment, control the calcination temperature to 780°C, and take it out after 1.5h for later use;

[0056] b. Mix the bentonite, foaming agent, dimethyl sulfoxide, sodium pyrophosphate, and water after the calcining treatment in operation a into the mixing tank according to the weight ratio of 6:4:28:4:95, and keep stirring Filter after processing for 43 minutes, drain the surface moisture of the filtered bentonite and set aside;

[0057] c. Immerse the bentonite treated in operation b into the modified treatment solution, heat to keep the temperature of the modified treatment solution at 35°C, and filter out the bentonite after ultrasonic treatment for 1.1h for later use; the modified treatment solution is prepared as follows ...

Embodiment 3

[0075] A method for preparing a high-stability conductive plastic with good mechanical properties, comprising the steps of:

[0076] (1) Preparation of characteristic fillers:

[0077] a. First put the bentonite into the calcination furnace for calcination, control the calcination temperature to 800°C, and take it out after ~2h for later use;

[0078] b. Mix the bentonite, foaming agent, dimethyl sulfoxide, sodium pyrophosphate and water corresponding to the weight ratio of 7:5:30:5:100 after operation a and put them into the mixing tank, and keep stirring After processing for 45 minutes, filter, and drain the surface moisture of the filtered bentonite for later use;

[0079] c. Immerse the bentonite treated in operation b into the modified treatment solution, heat to keep the temperature of the modified treatment solution at 36°C, and filter out the bentonite after ultrasonic treatment for 1.2 hours for later use; the modified treatment solution is prepared as follows The m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| electron mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com