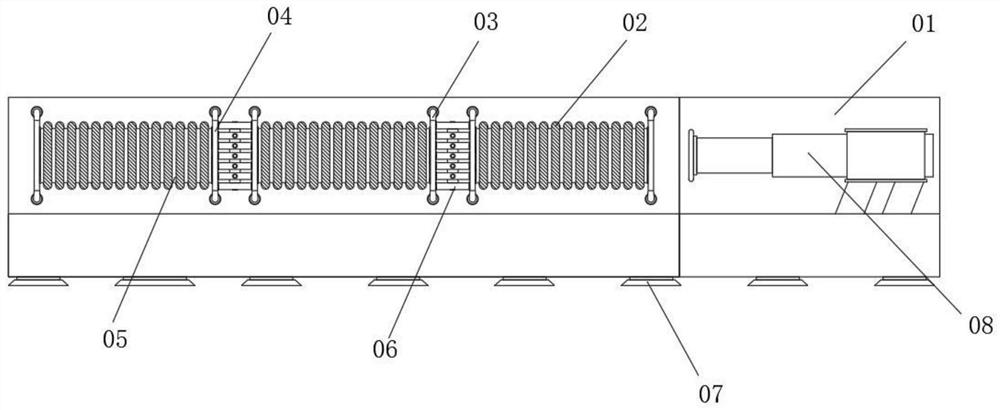

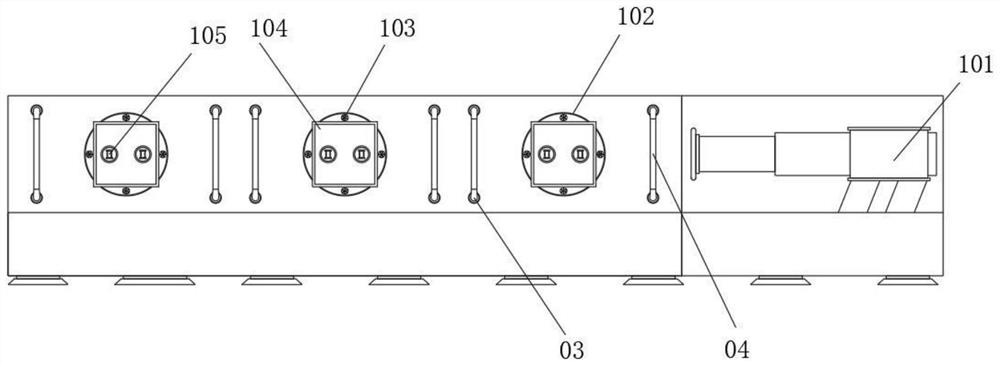

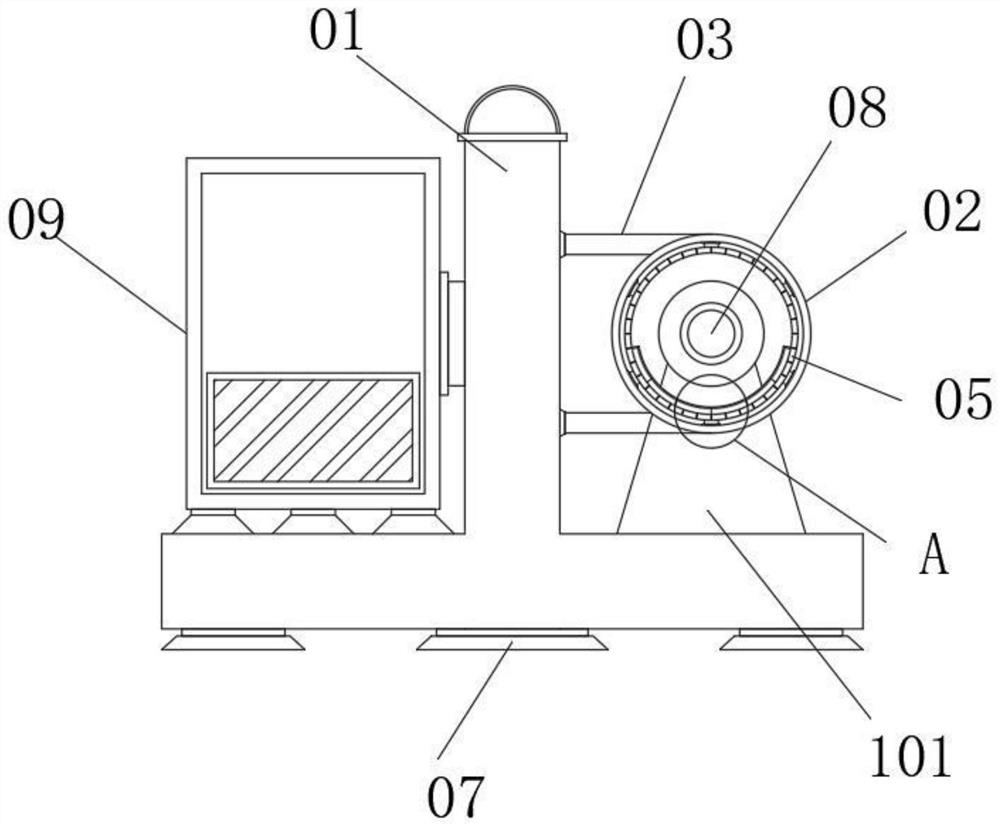

Copper bar heating furnace

A technology of heating furnace and copper rod, which is applied in the field of metal processing, can solve the problems of inconvenient movement of copper rods and unbalanced heating temperature of copper rods, etc., and achieve the effects of good heating treatment, good load carrying and good current intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] A number of embodiments of the present invention will be disclosed with illustrations below, and many physical details will be described together in the following description for the sake of clarity. However, it should be understood that these physical details should not be used to limit the invention. That is, in some embodiments of the invention, these physical details are not necessary. In addition, for the sake of simplifying the illustration, some conventional structures and components will be shown in a simple schematic way in the illustration.

[0030] In addition, the technical solutions of the various embodiments can be combined with each other, but it must be based on the realization of those skilled in the art. When the combination of technical solutions is contradictory or cannot be realized, it should be considered that the combination of technical solutions does not exist , nor within the scope of protection required by the present invention.

[0031] se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com