Small-size welding machine special for steel structure

A steel structure and welding machine technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of large welding machine structure and unfavorable welding of building steel structures, so as to improve safety and avoid welding effects Unsatisfactory, the effect of improving slip resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

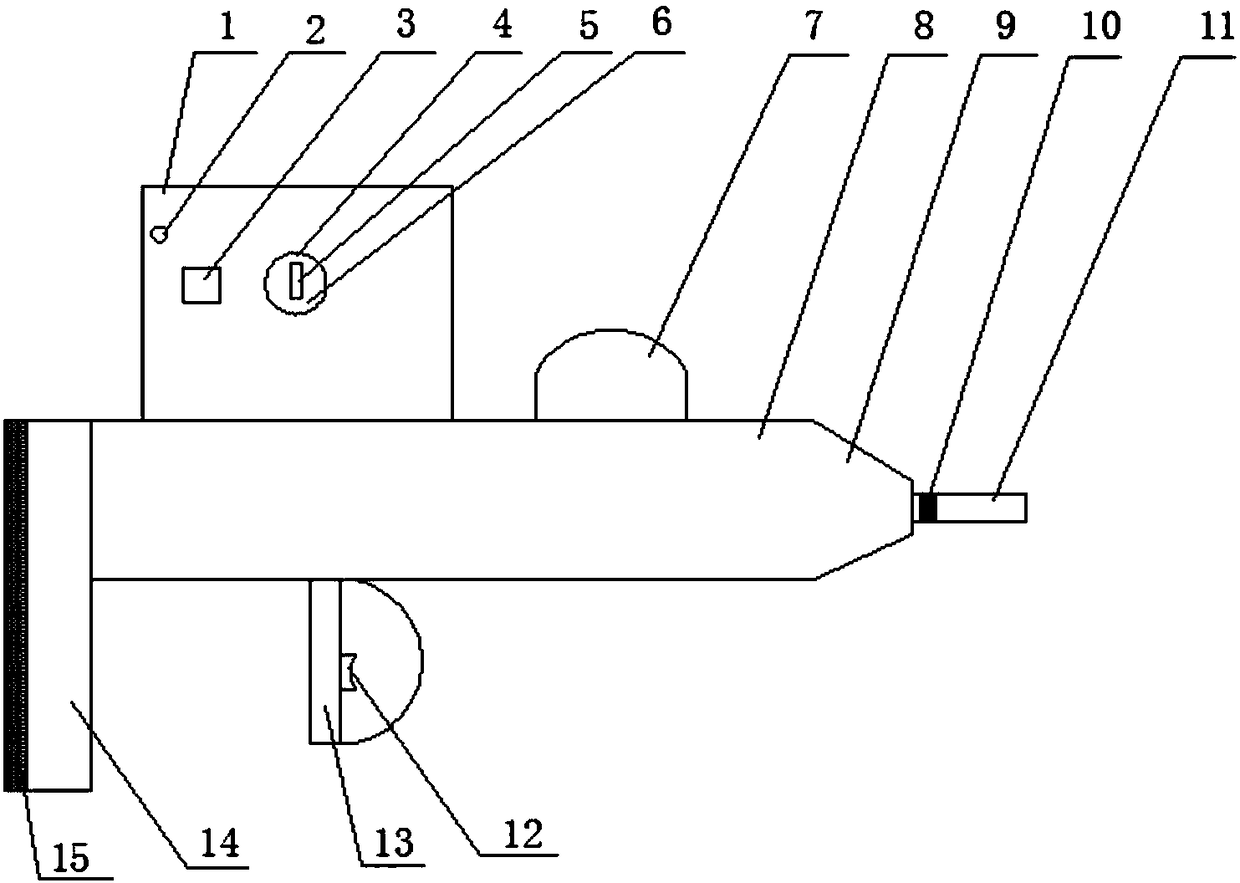

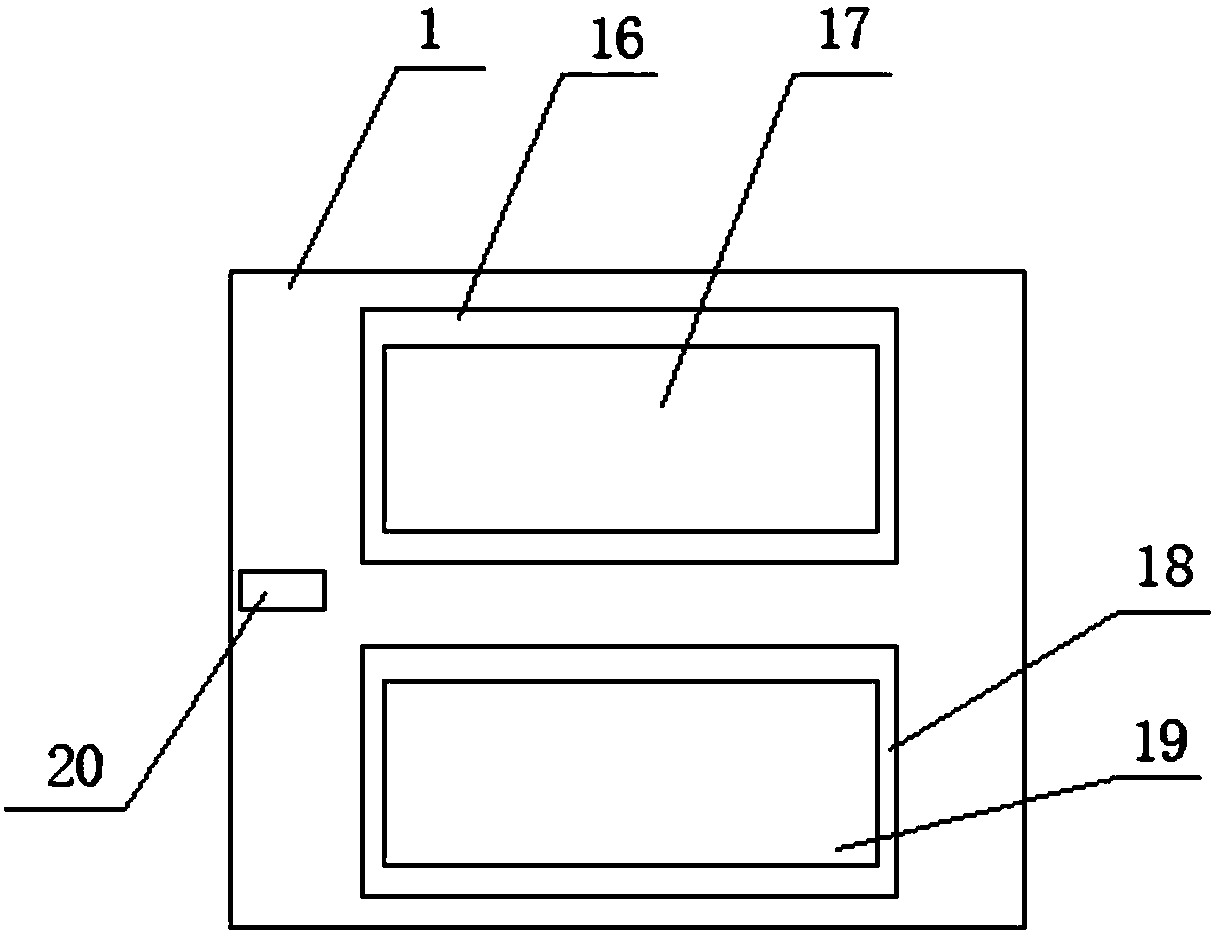

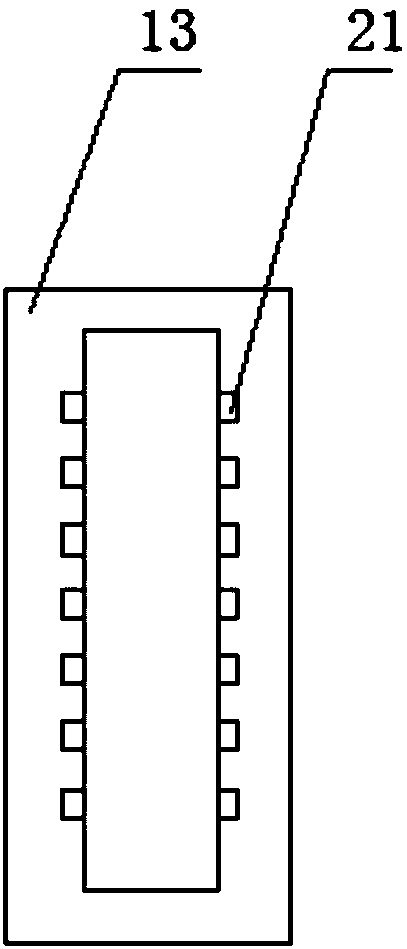

[0018] Example: see Figure 1-3 , the special small welding machine for steel structure of the present invention comprises a control room 1 and a welding torch 8, a welding torch 8 is provided on one side of the control room 1, and the control room 1 is fixedly connected with the welding torch 8, and the control room 1 is provided with The first power supply chamber 16 and the first storage battery 17 arranged in the first power supply chamber 16, the second power supply chamber 18 and the second storage battery 19 arranged in the second power supply chamber 18 are arranged on one side of the first power supply chamber 16 One side of the control room 1 is provided with a charging port 20, the control room 1 is provided with a power switch 3 and a power indicator light 4 arranged on one side of the power switch 3, and one side of the welding torch 8 is provided with a handle 14, One side of the handle 14 is provided with a handle 13, the handle 13 is provided with a start key 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com