Patents

Literature

315results about How to "Increase radius" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

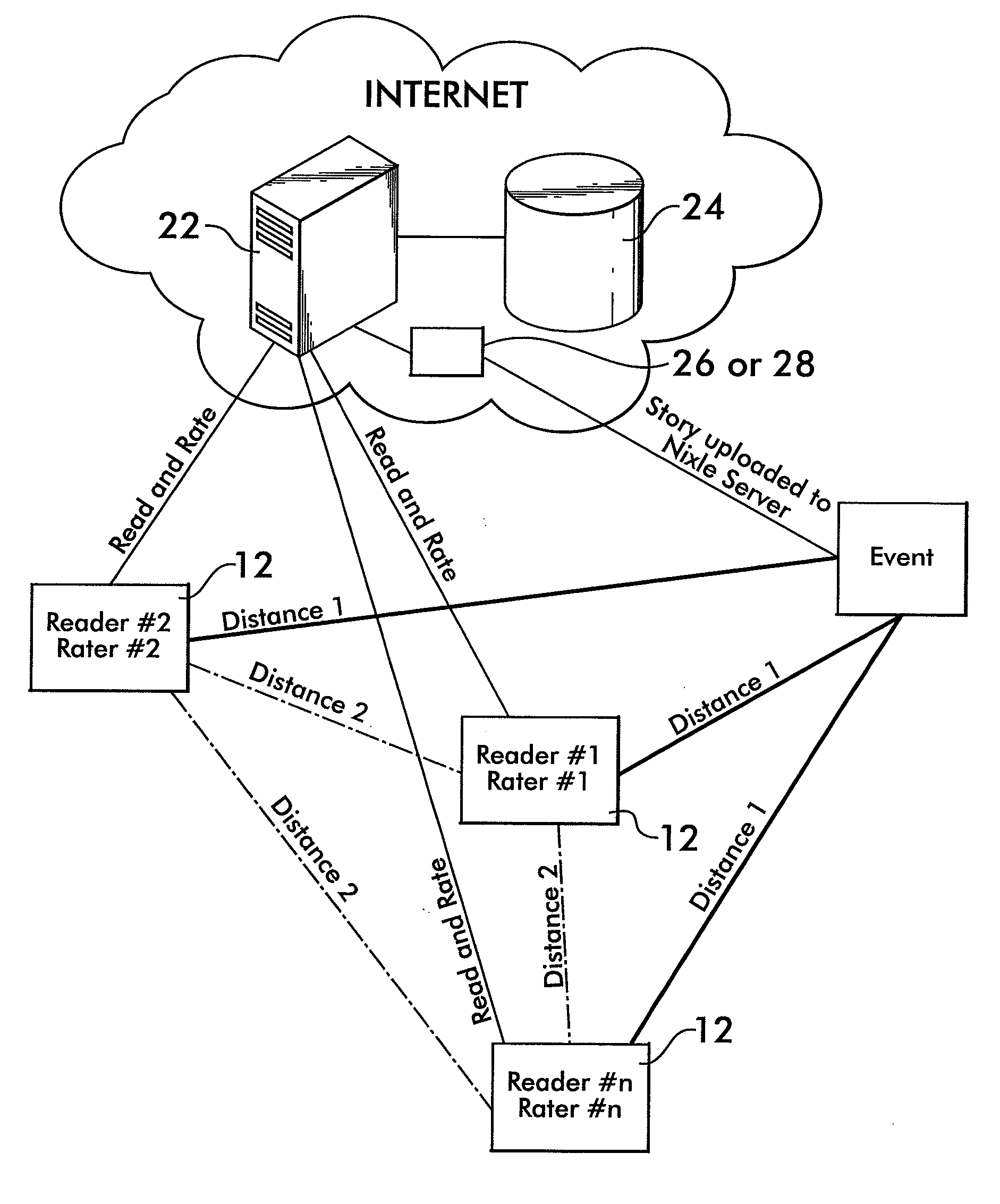

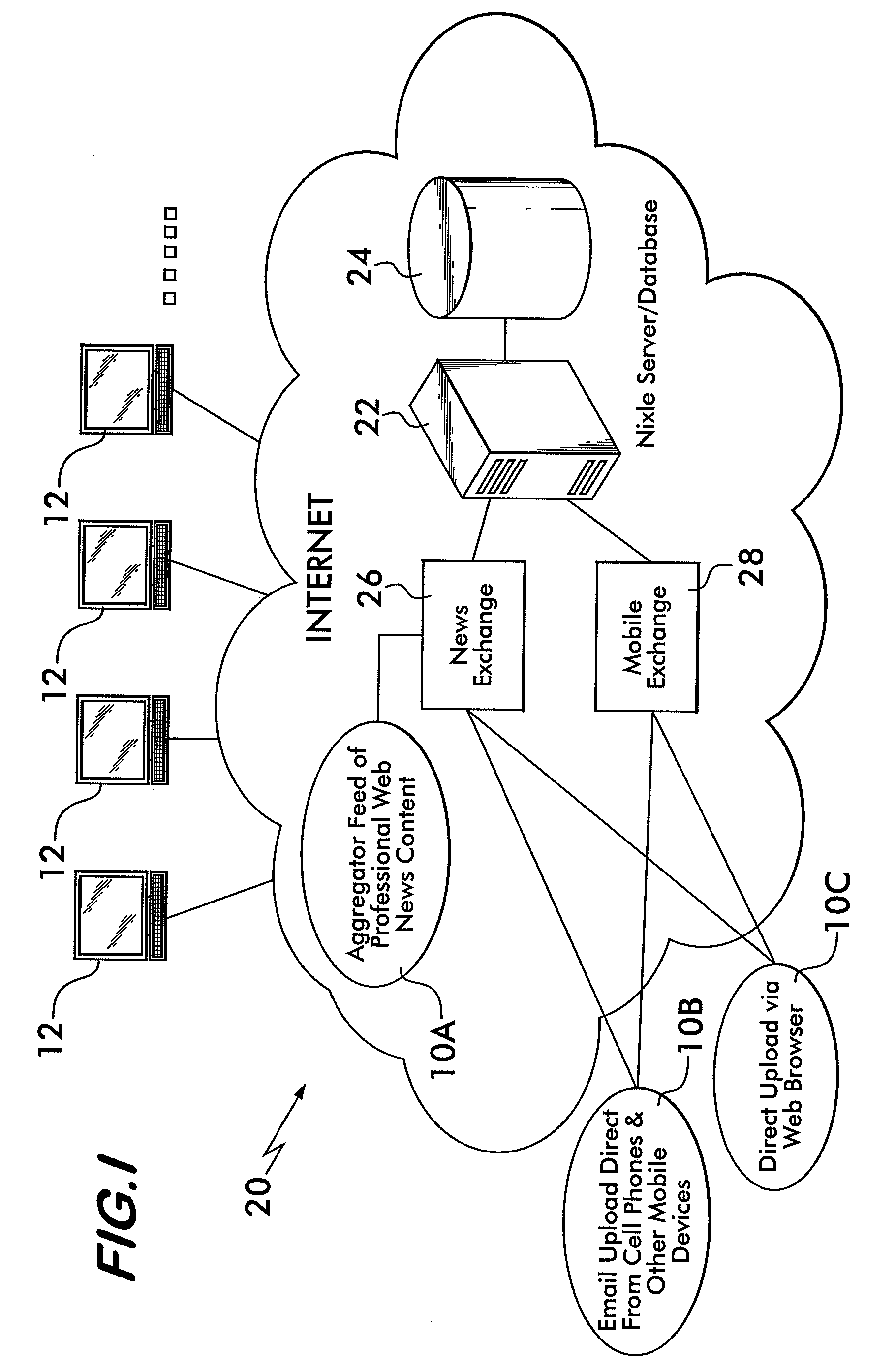

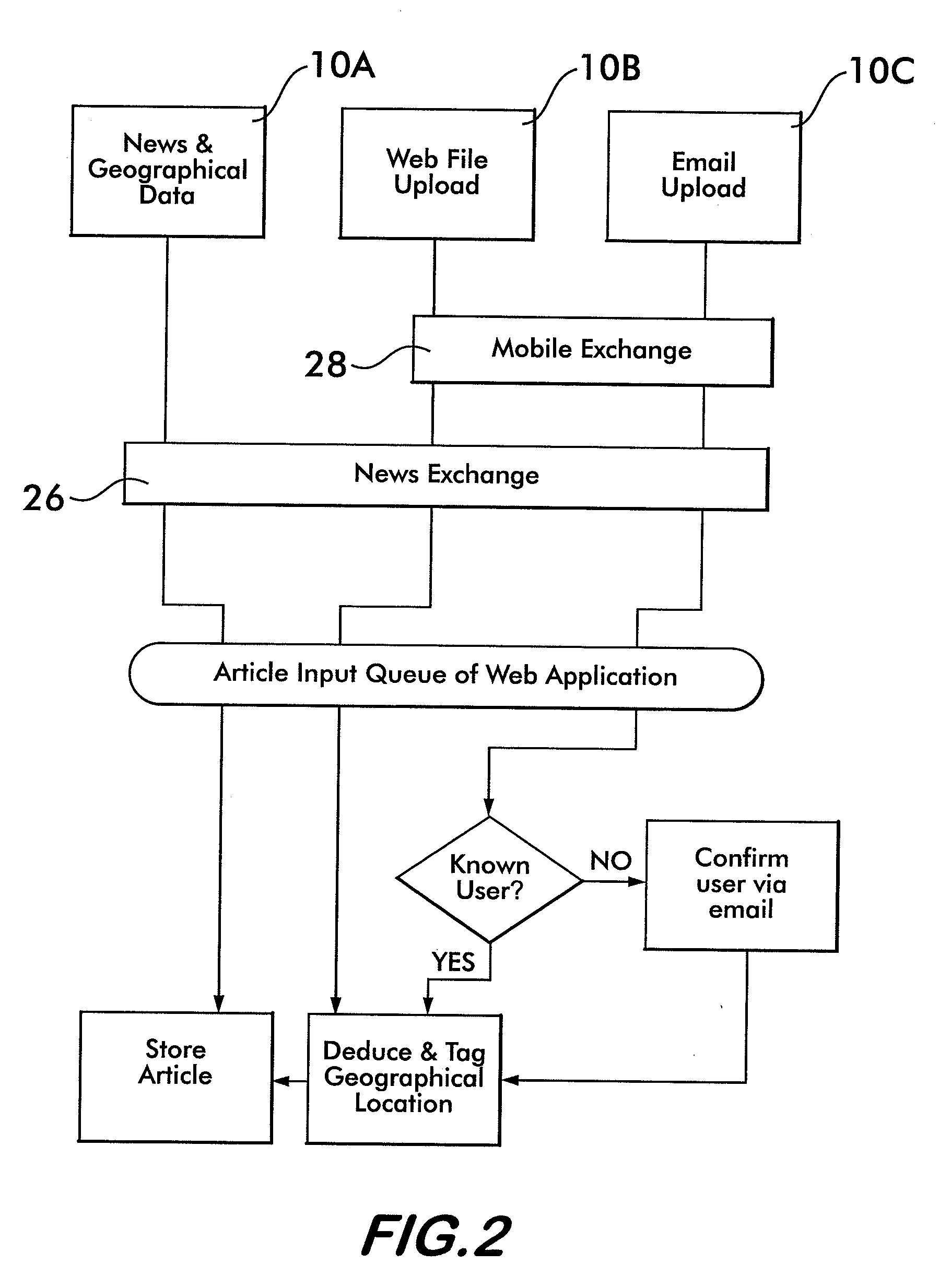

System and Method for Permitting Geographically-Pertinent Information to be Ranked by Users According to Users' Geographic Proximity to Information and to Each Other for Affecting the Ranking of Such Information

ActiveUS20080307053A1Increase radiusMultiple digital computer combinationsGeographical information databasesRankingThe Internet

A system and method for permitting geographically-pertinent information provided on the Internet to be ranked by users, while taking into account the users' geographic proximity to the information, the distance between each user who rates the information, the age of the information, and the age of the users' ratings to determine a ranking for affecting the ranking of information.

Owner:EVERBRIDGE

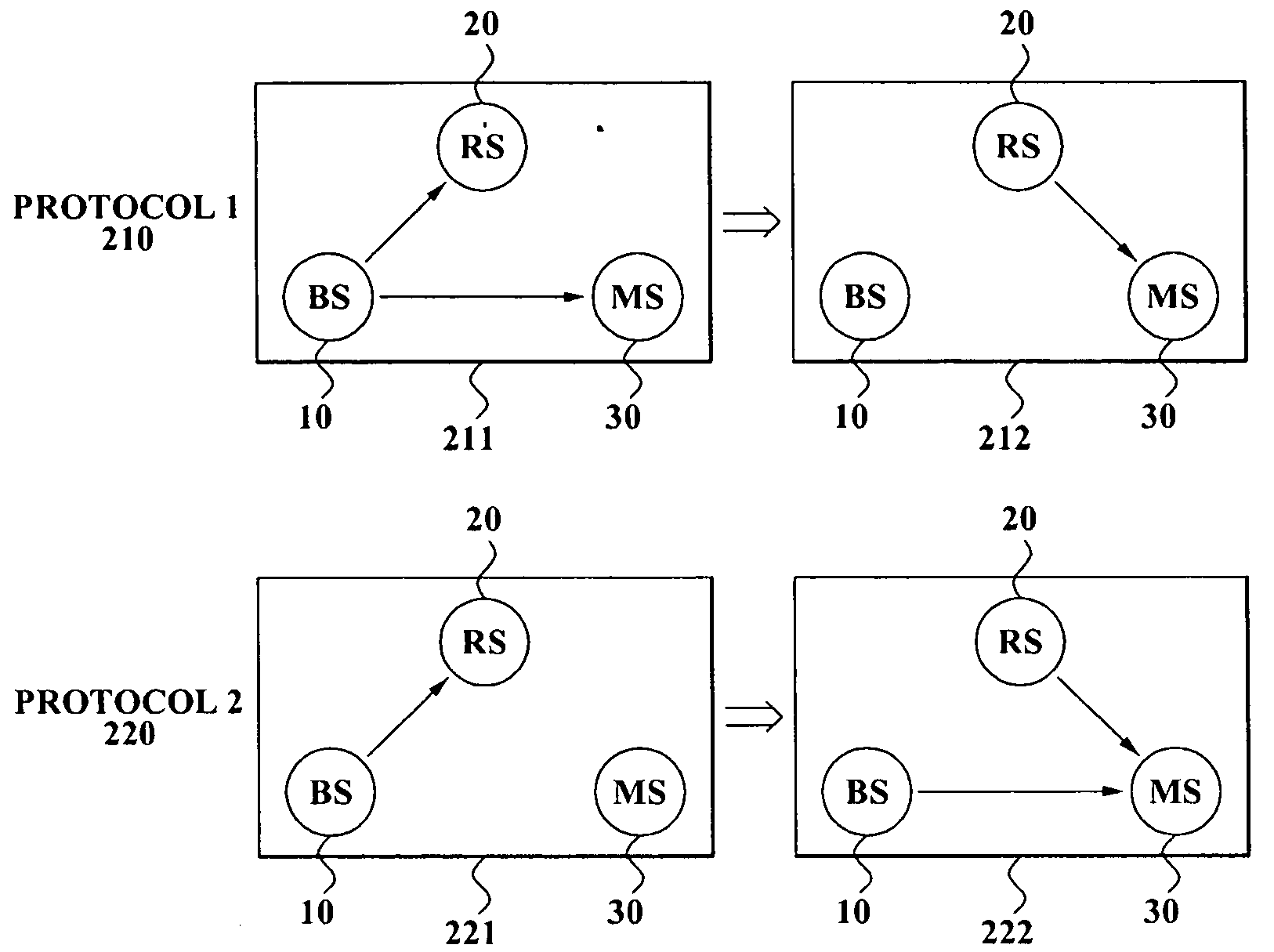

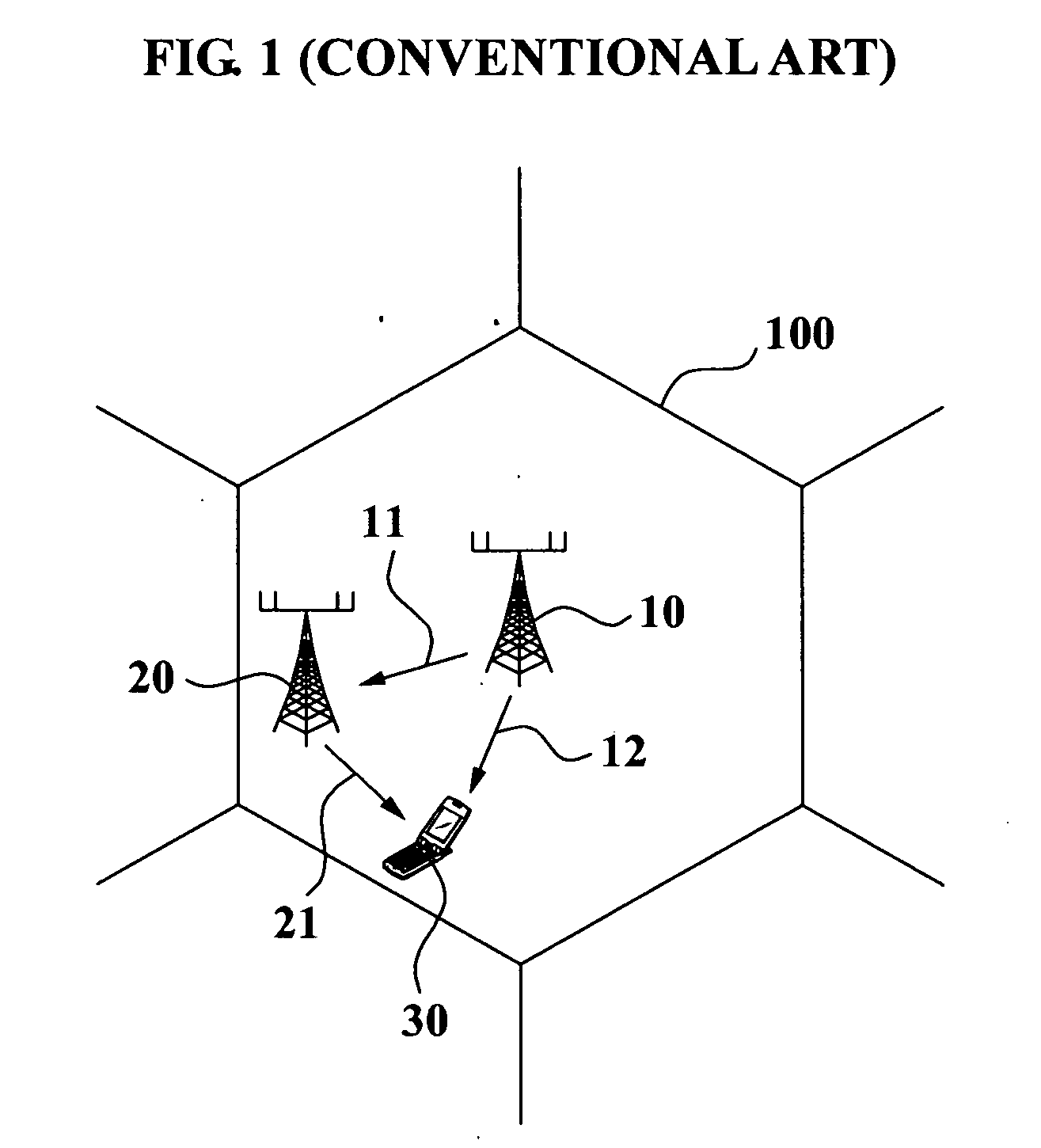

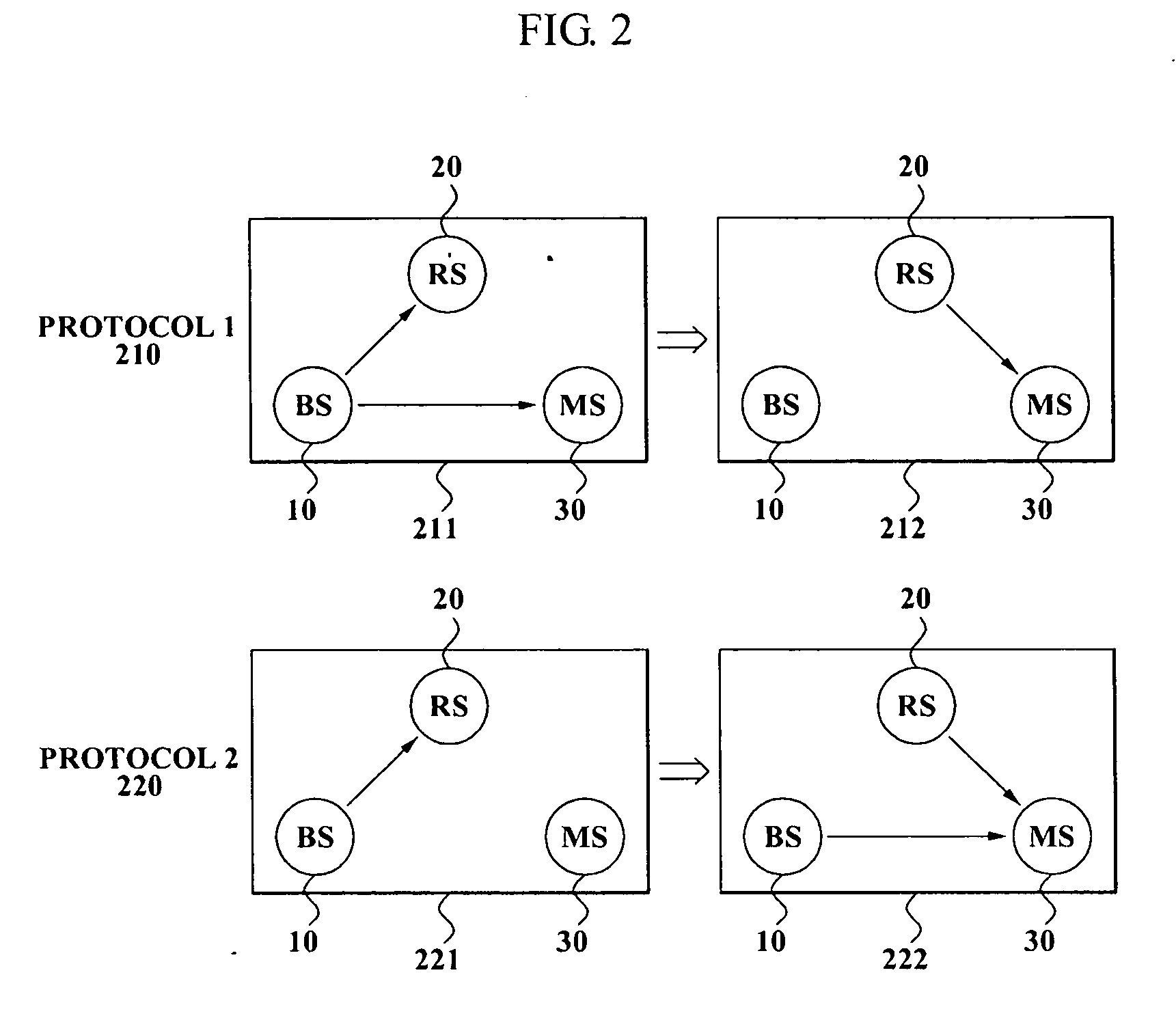

Method of controlling data transmission in a wireless relay system, and the relay system implementing the method

ActiveUS20080045212A1Increase battery capacityImprove throughputFrequency-division multiplex detailsNetwork traffic/resource managementControl dataTransfer mode

A data transmission method in a wireless relay system, and a method of selecting an optimal transmission mode based on a channel capacity of an individual link that is measured by a mobile station. The data transmission method includes: transmitting a first ratio of first partial data of the data from a base station to a mobile station; transmitting a second ratio of second partial data of the data from the base station to a first relay station; and forwarding the second partial data from the first relay station to the mobile station, wherein the first ratio or the second ratio is determined based on any one of a channel capacity of a first link between the base station and the mobile station, and a channel capacity of a second link between the first relay station and the mobile station.

Owner:SAMSUNG ELECTRONICS CO LTD

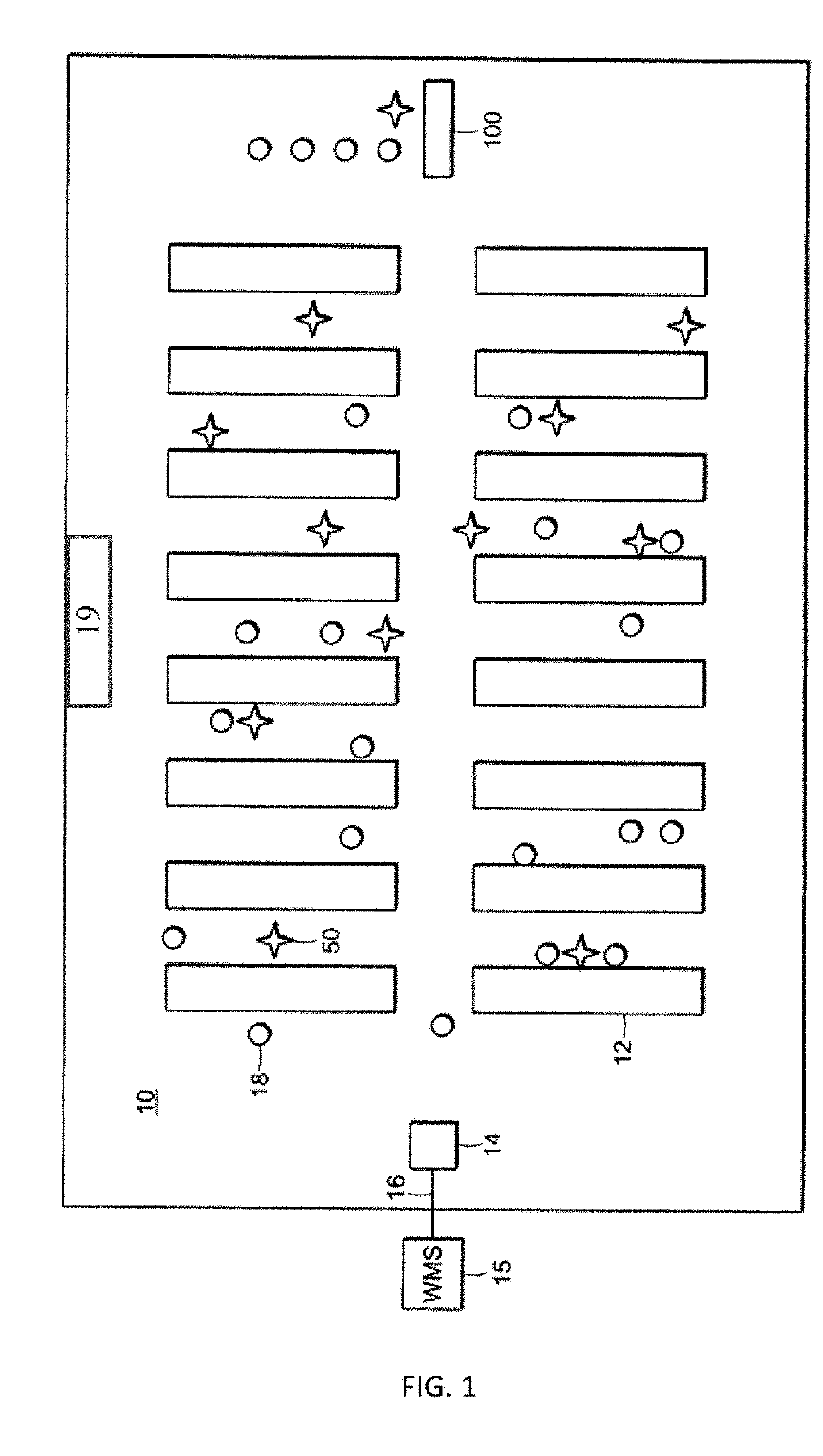

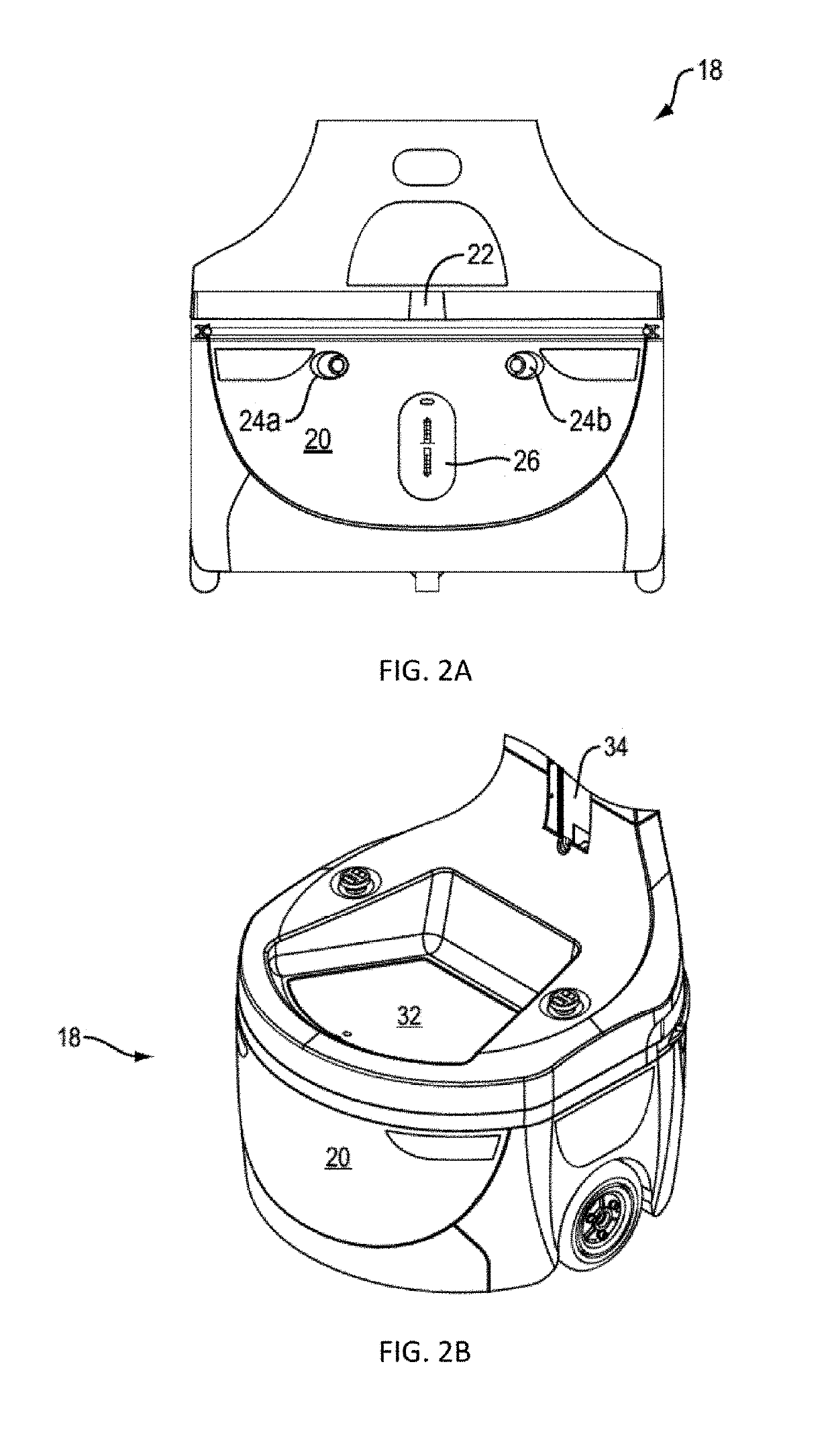

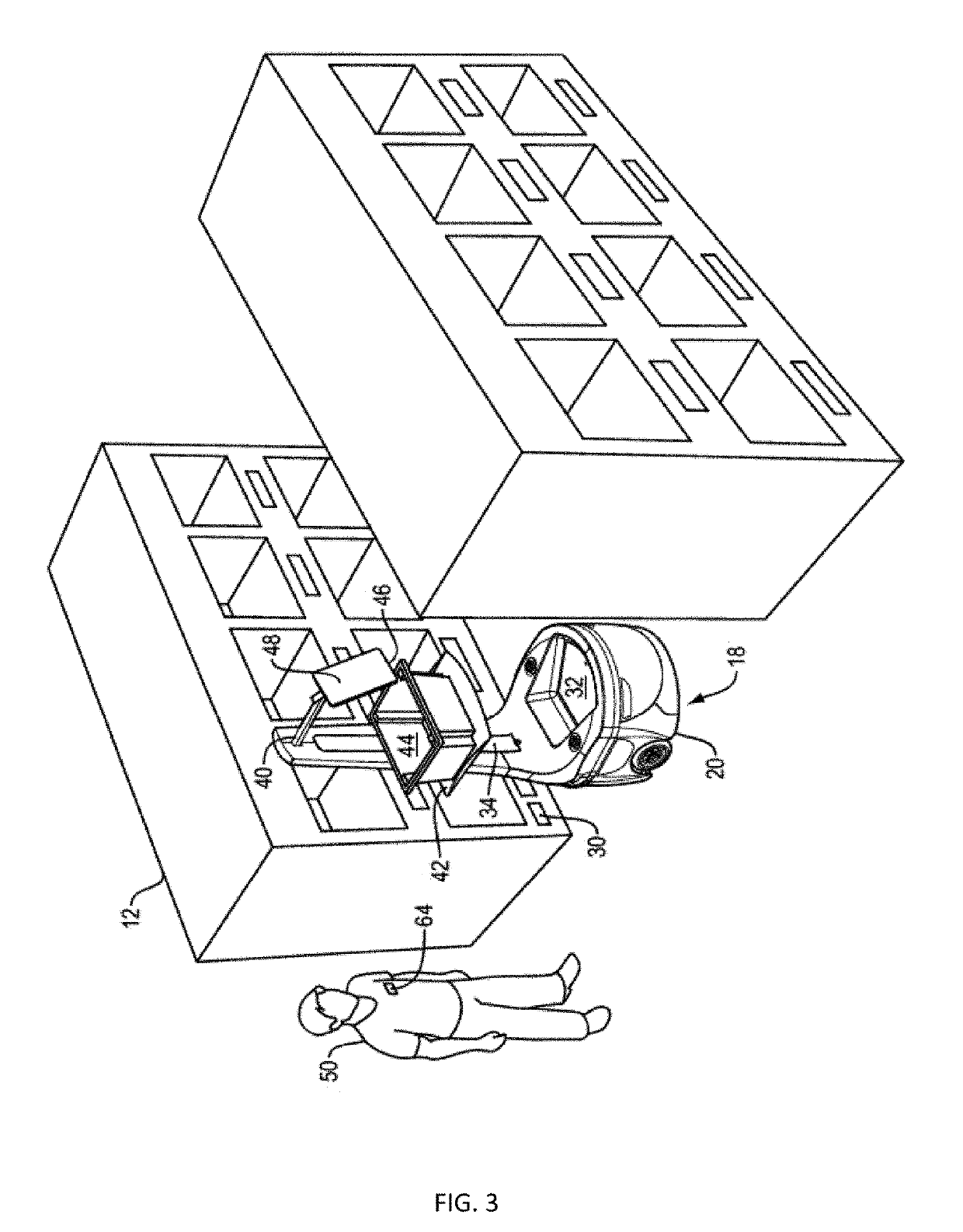

Dynamic window approach using optimal reciprocal collision avoidance cost-critic

ActiveUS20190094866A1Increase radiusRoad vehicles traffic controlForecastingComputer visionMarine navigation

A method and system for navigation of a robot along a goal path and avoiding obstacles. The method includes receiving goal pose for one or more robots and determining a goal path for a first robot while avoiding moving and fixed obstacles of a received obstacle map. A first objective function is evaluated to select a preferred velocity from a generated set of candidate velocities, the selecting based on one or more weighted cost functions. A set of velocity obstacles created based on the poses of the one or more robots and the preferred velocity is used in evaluating a second objective function to determine the motion of the robot in the next time cycle. Creating the set of velocity objects includes converting the preferred velocity from a non-holonomic to a holonomic velocity.

Owner:LOCUS ROBOTICS CORP

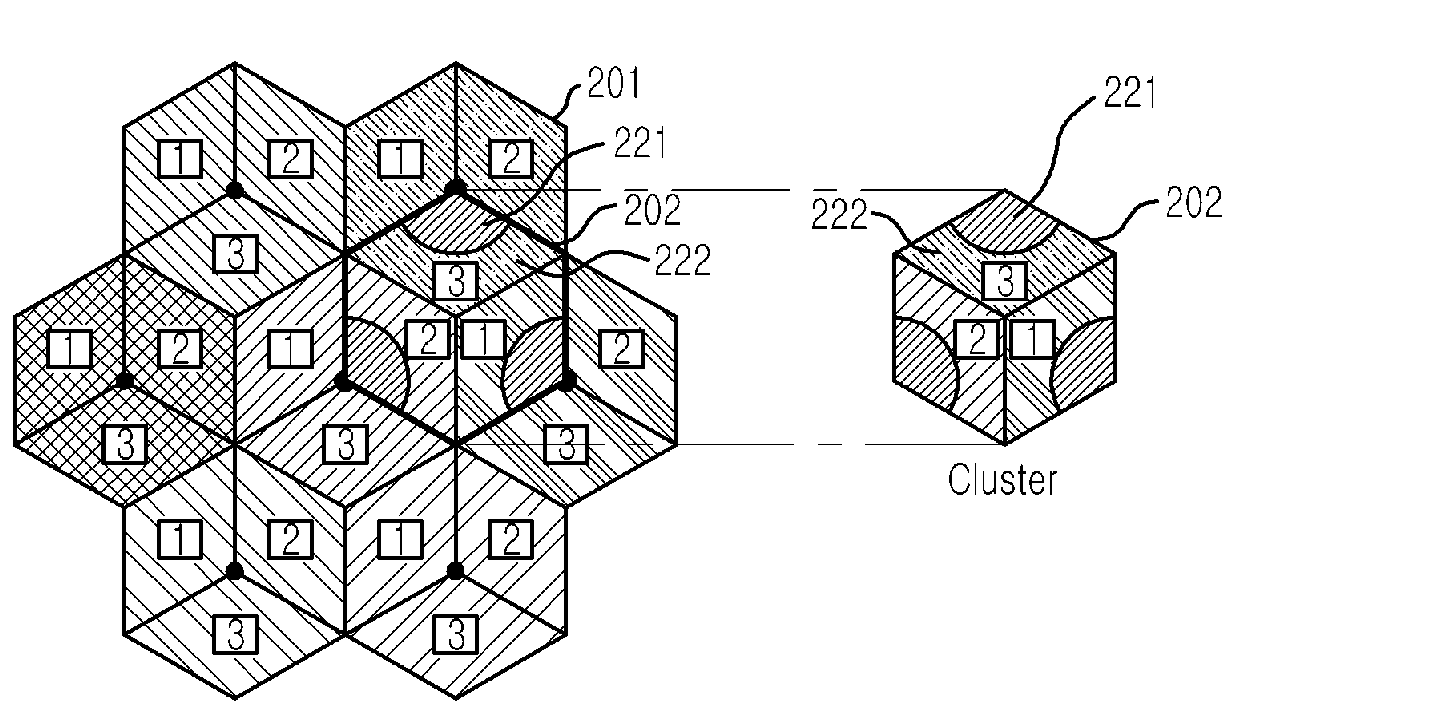

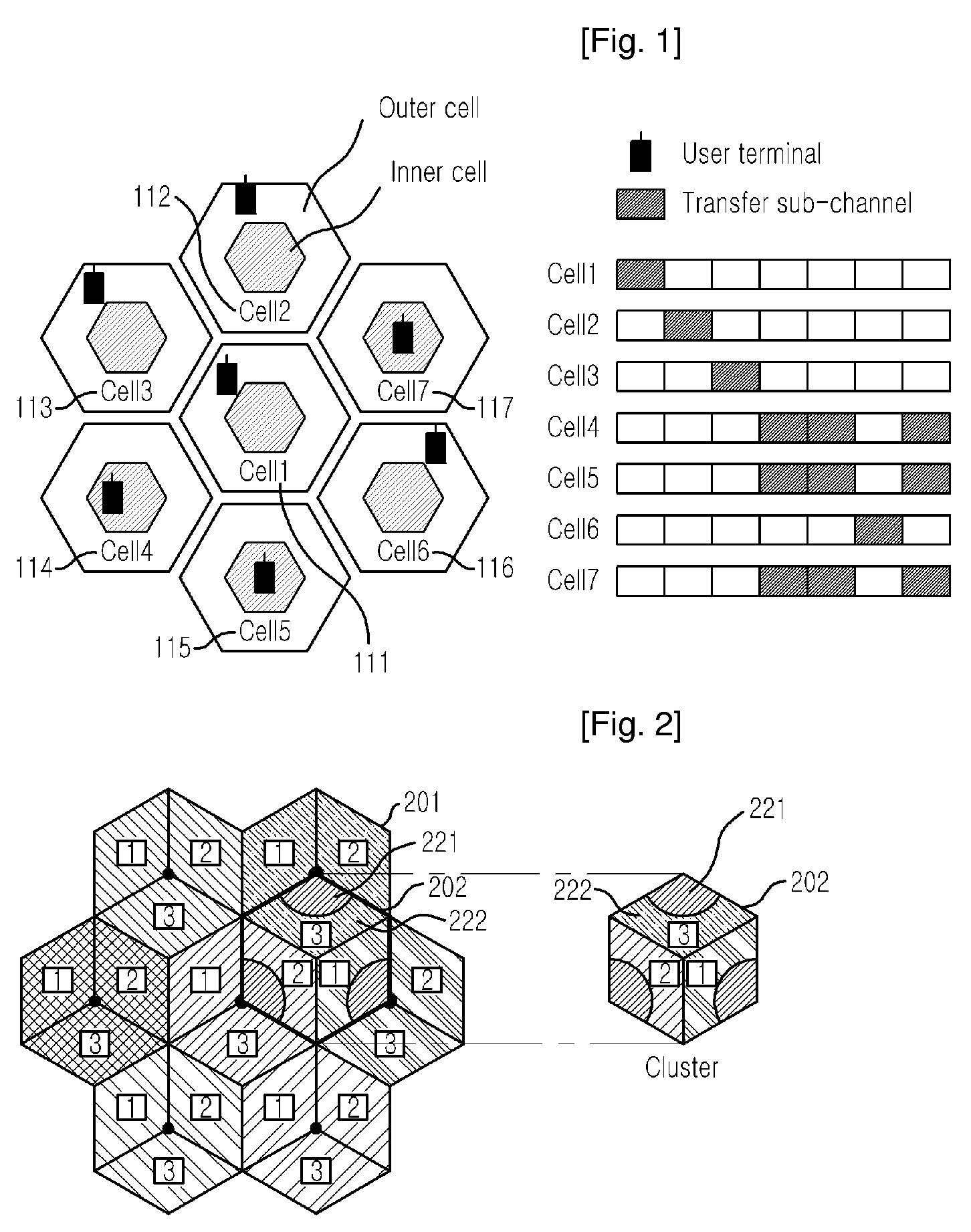

Dynamic Resource Allocation Method Based on Frequency Reuse Partitioning For Ofdma/Fdd System, and Frame Transmission Method Therefor

InactiveUS20080232320A1Reduce outage rateImproving sector throughputError preventionFrequency-division multiplex detailsFrequency reuseDynamic resource

Provided are a dynamic resource allocation method based on frequency reuse partitioning for an Orthogonal Frequency Division Multiple Access (OFDMA) system, and a frame transmission method therefor. The dynamic resource allocation method includes: a) dividing a coverage into cells based on frequency reuse partitioning; b) selecting a candidate user to receive a channel allocated thereto based on the ratio; c) acquiring distance information for the candidate user; and d) checking whether the candidate user is in an inner or outer cell area based on the distance information. If the candidate user is in the inner cell area, a subchannel group among subchannel groups having a Frequency Reuse Factor (FRF) lower than a threshold value is selected and subcarriers of the selected subchannel group is allocated. If the candidate user is in the outer cell area, a subchannel group among subchannel groups having a FRF higher than the threshold value is selected.

Owner:ELECTRONICS & TELECOMM RES INST +1

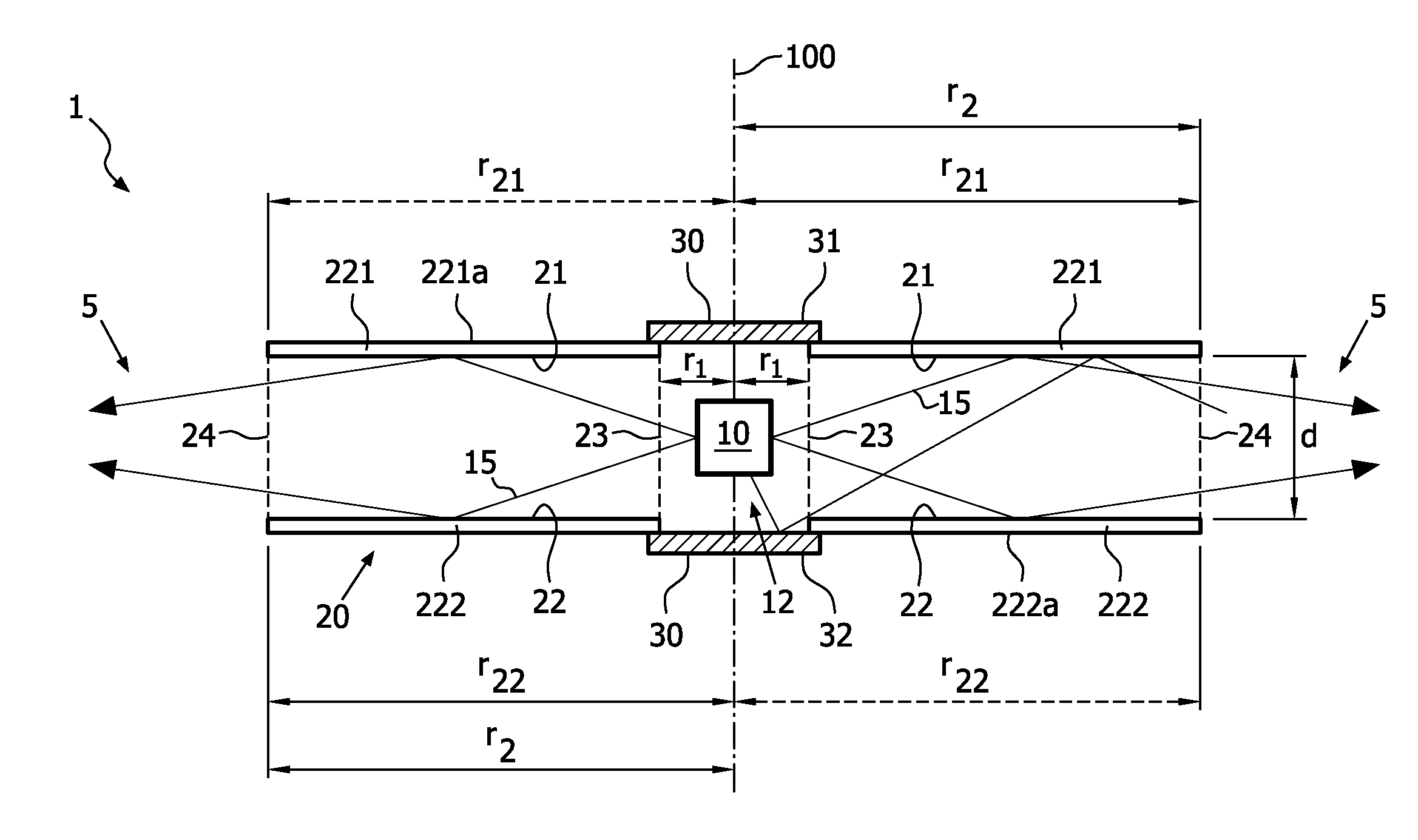

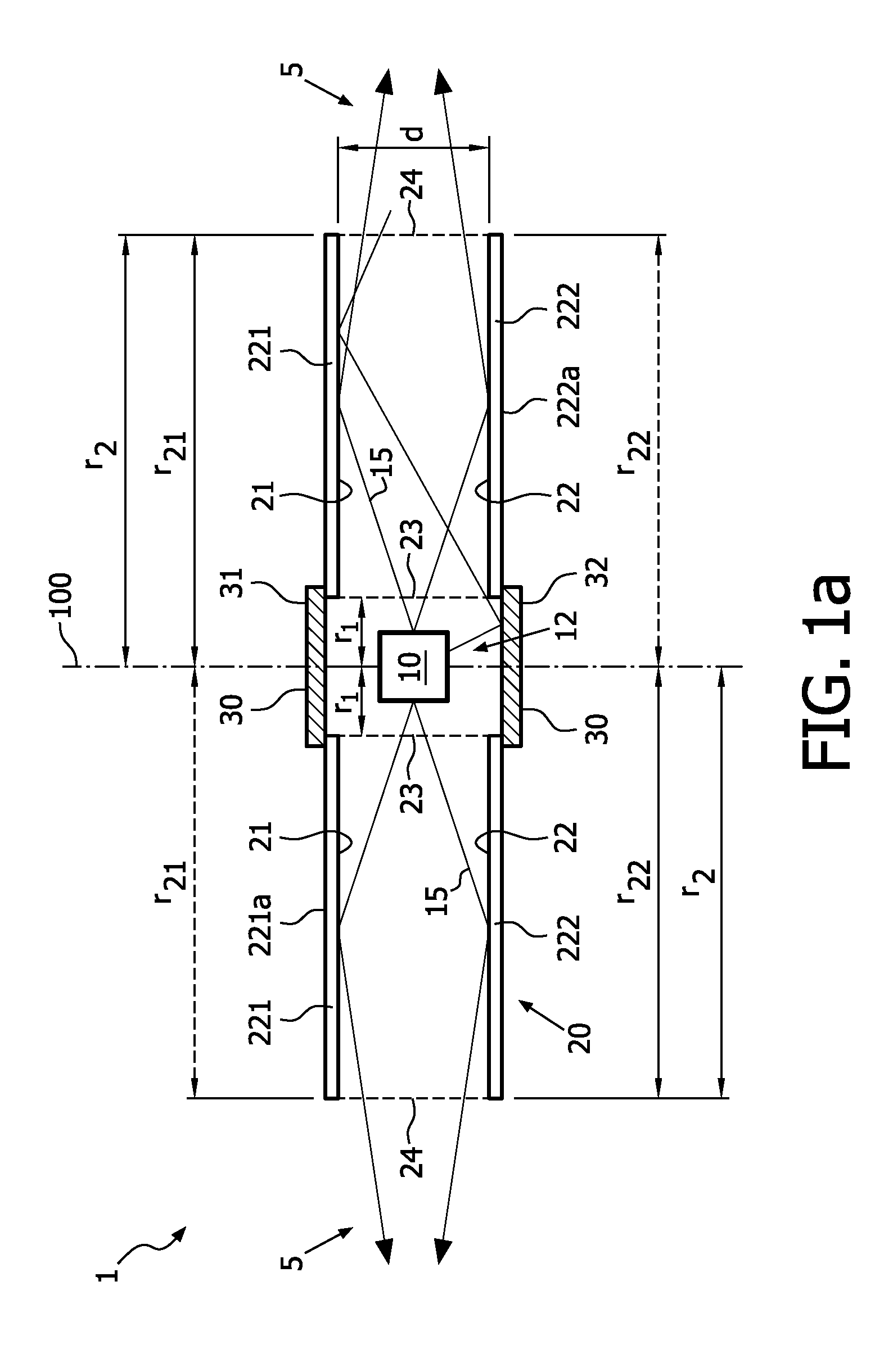

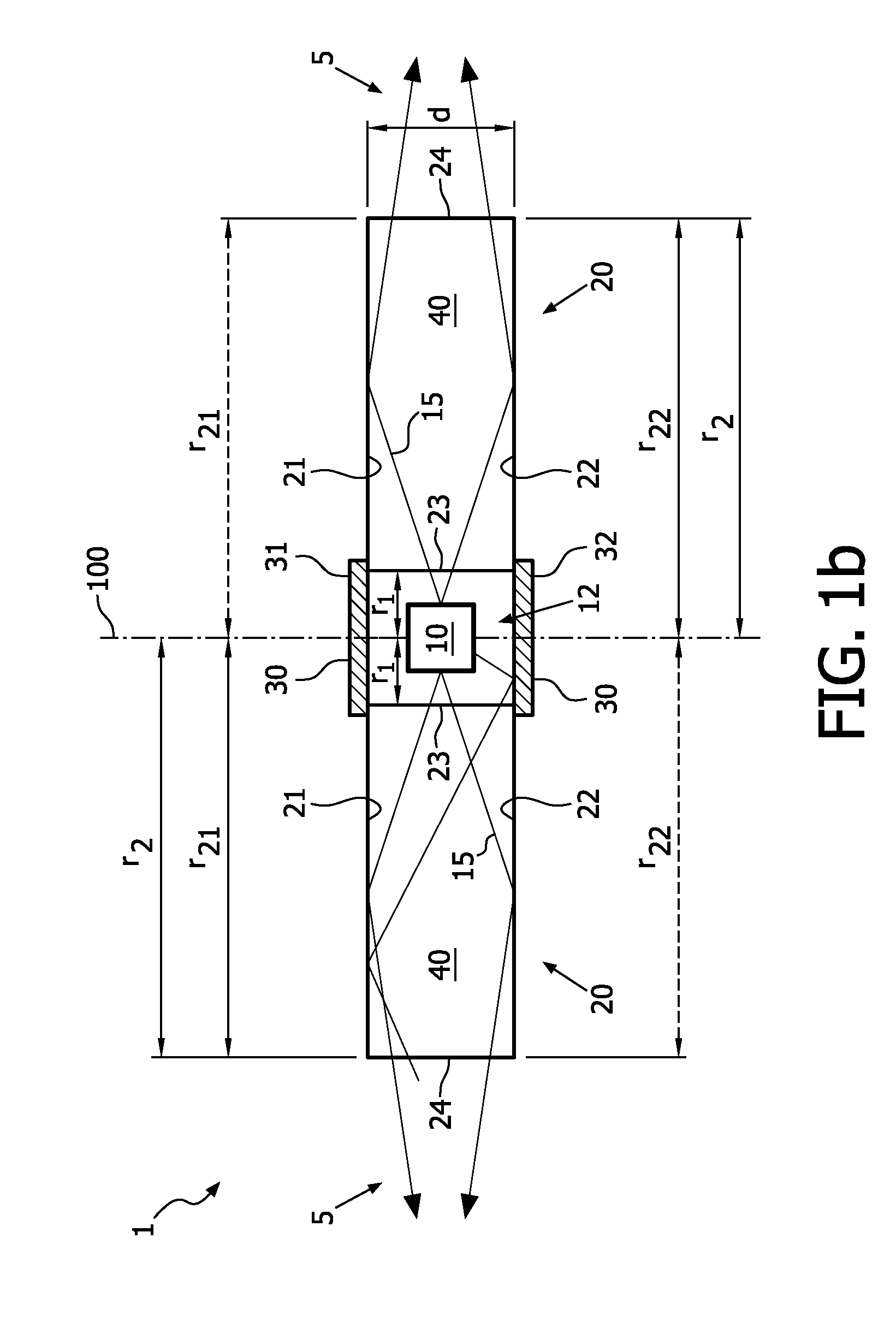

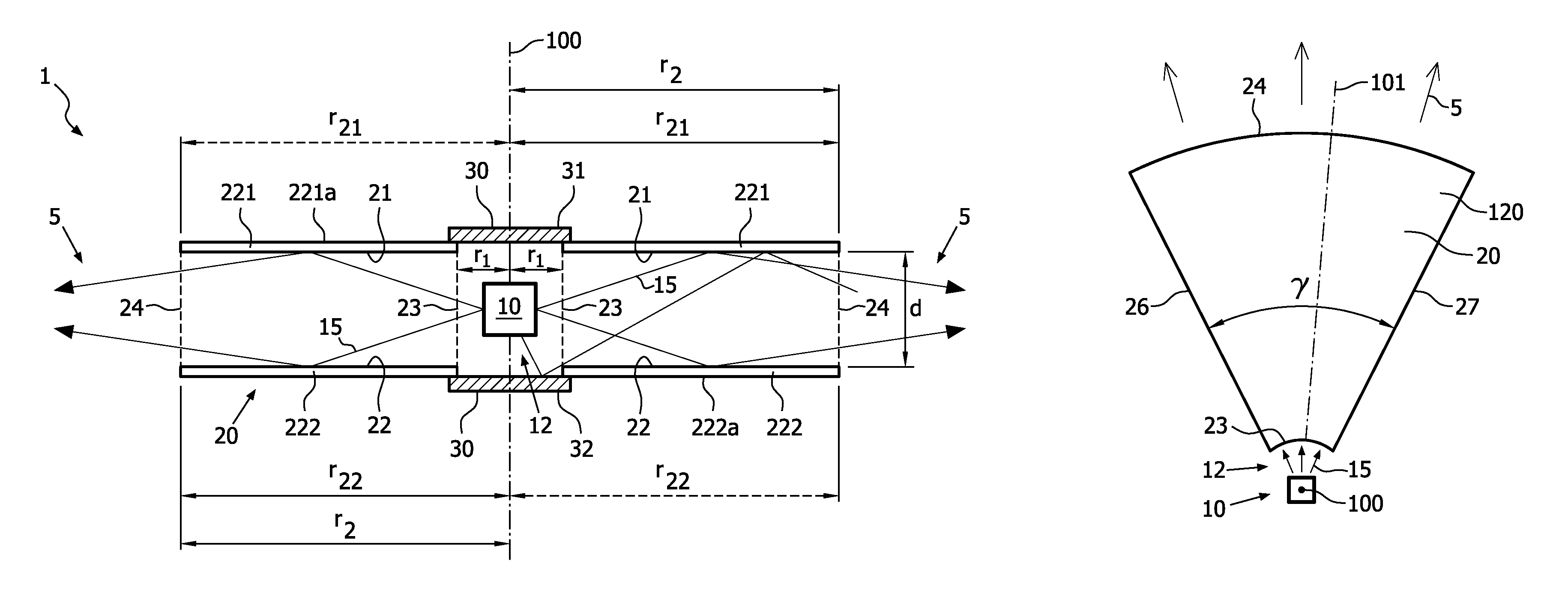

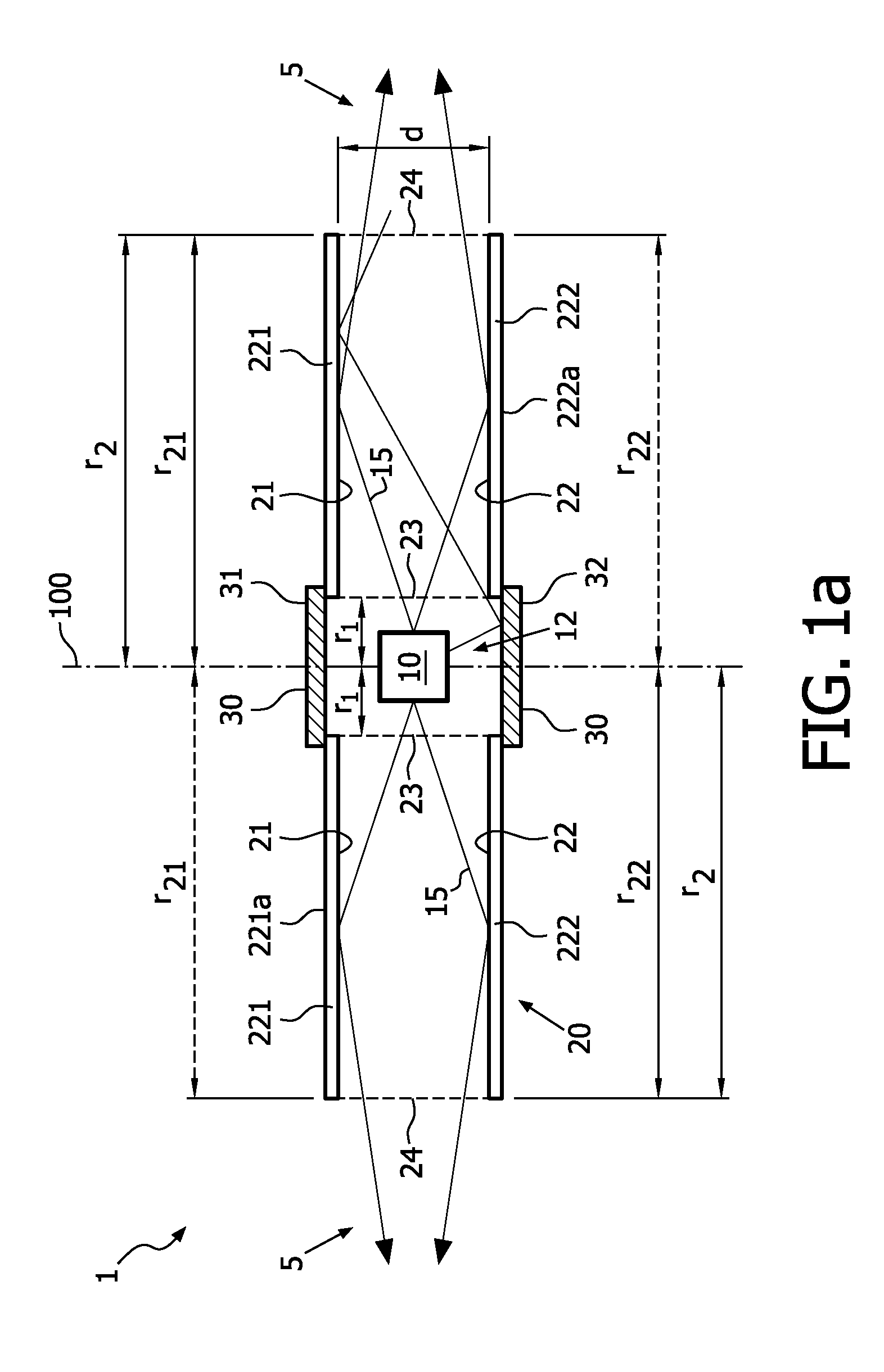

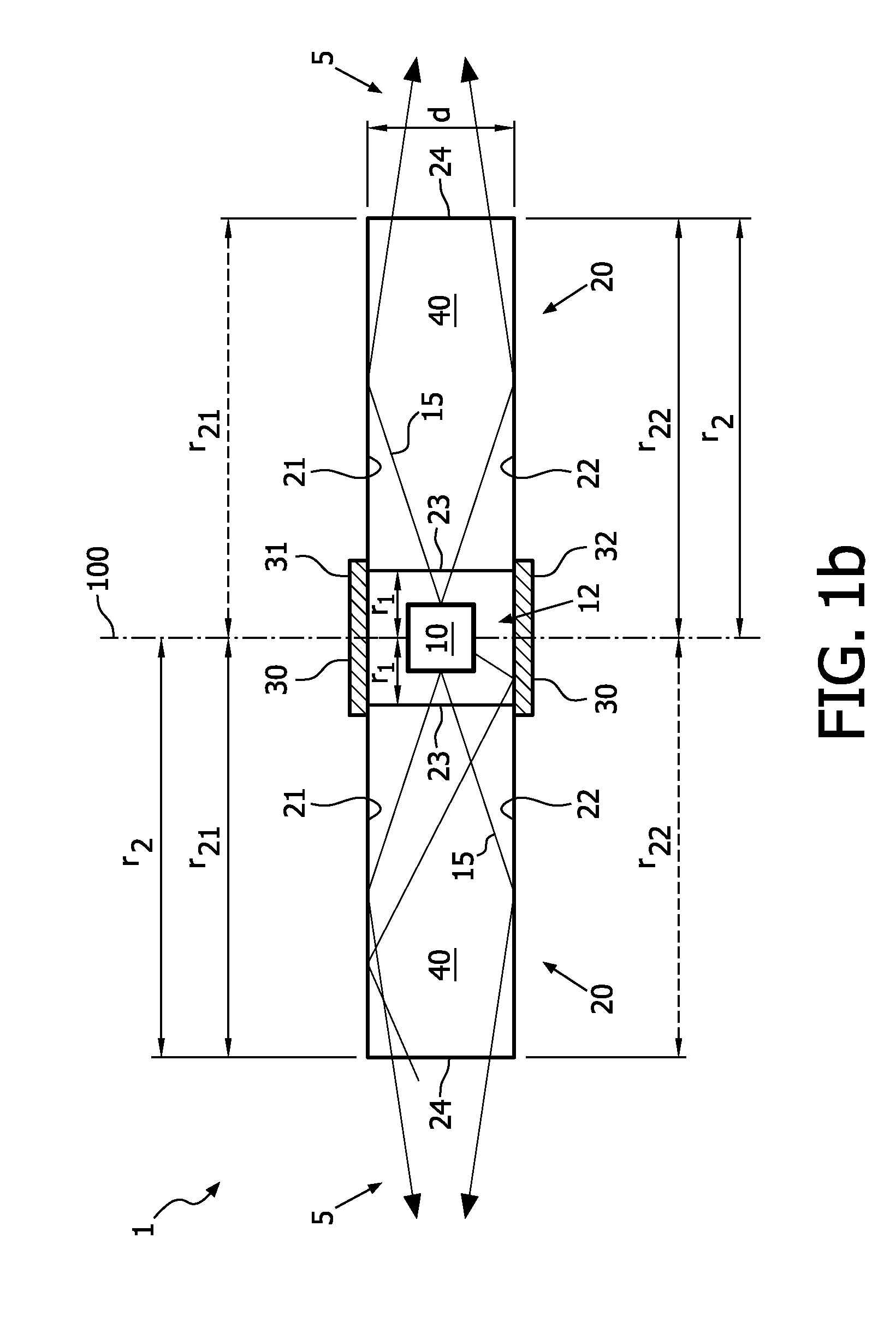

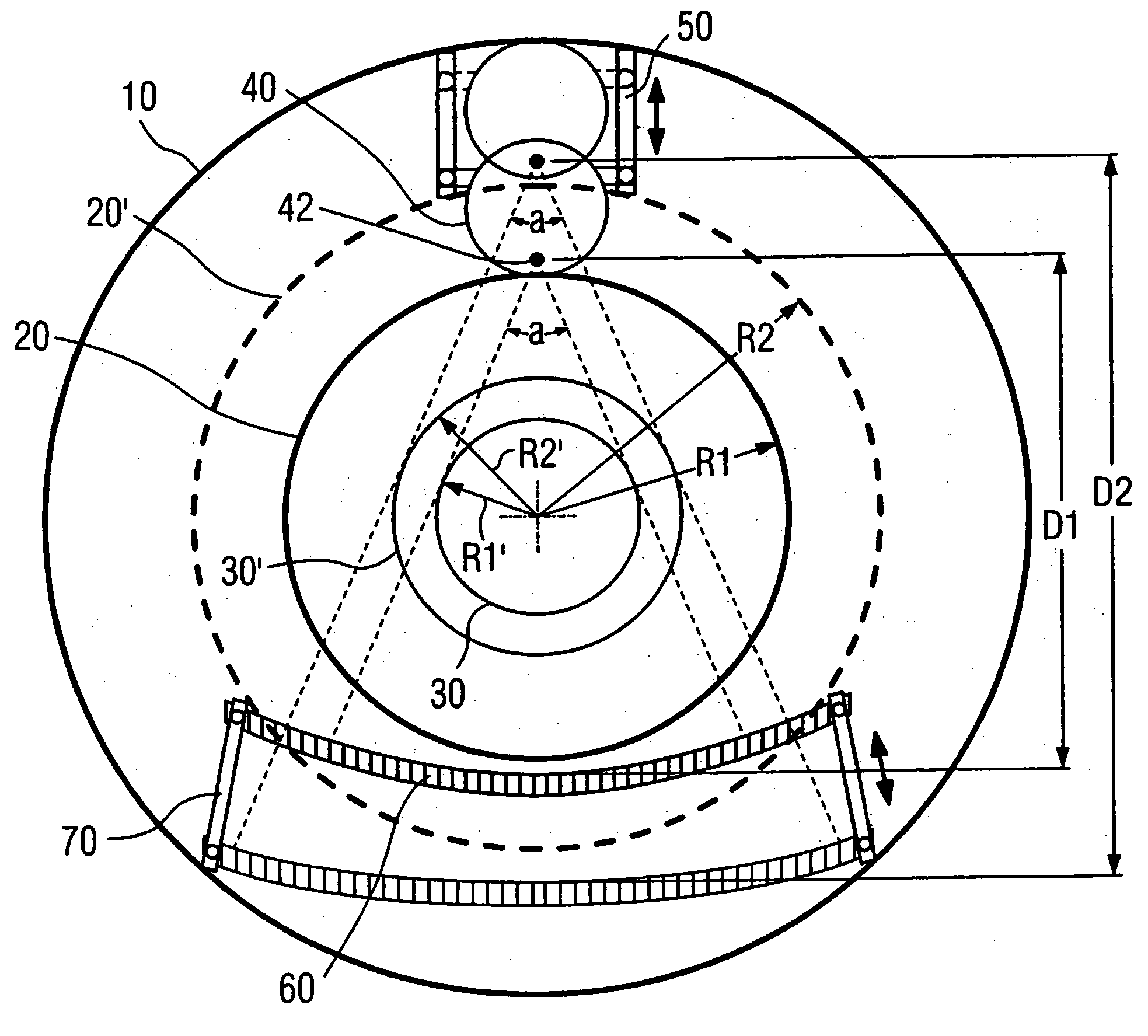

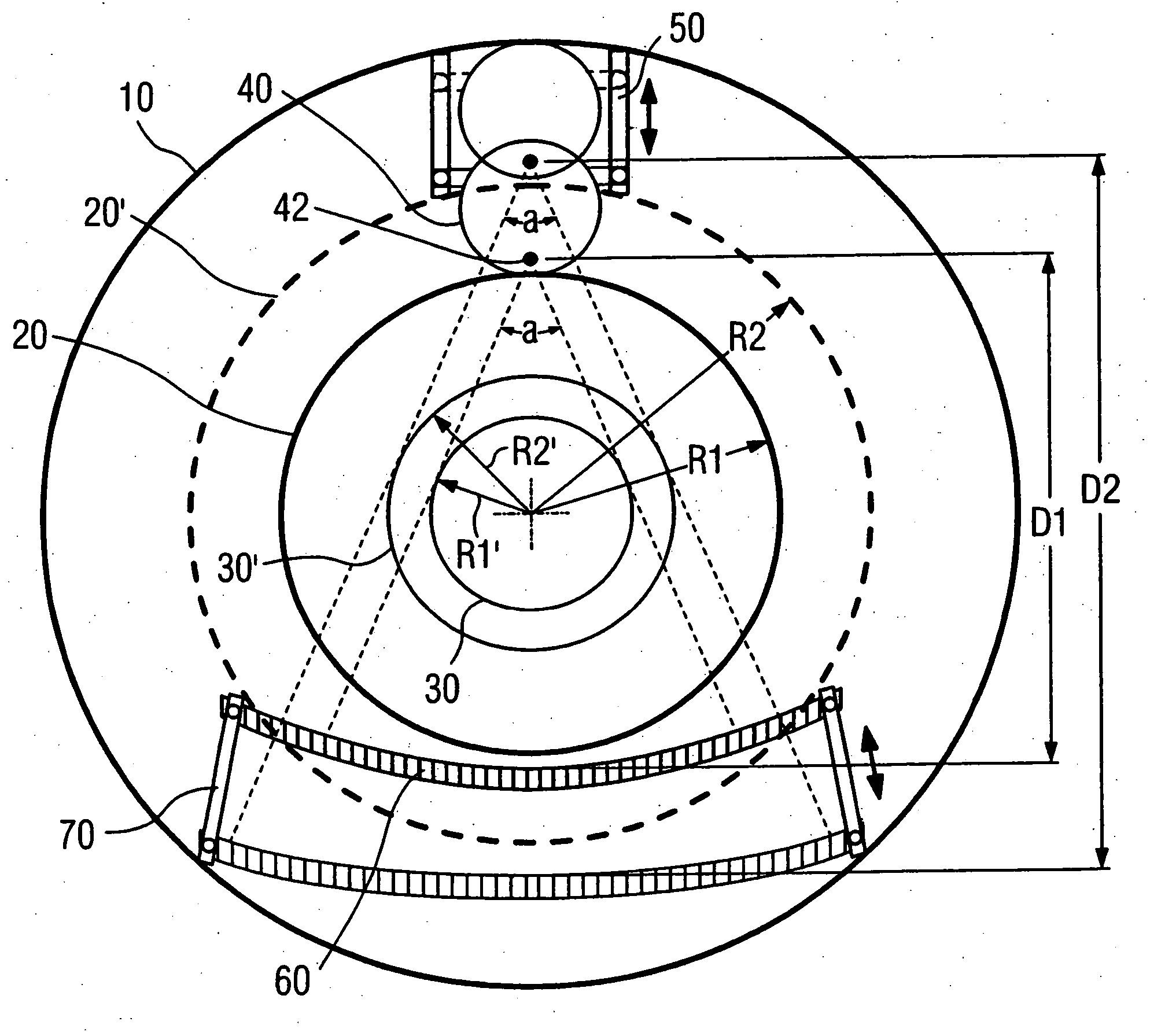

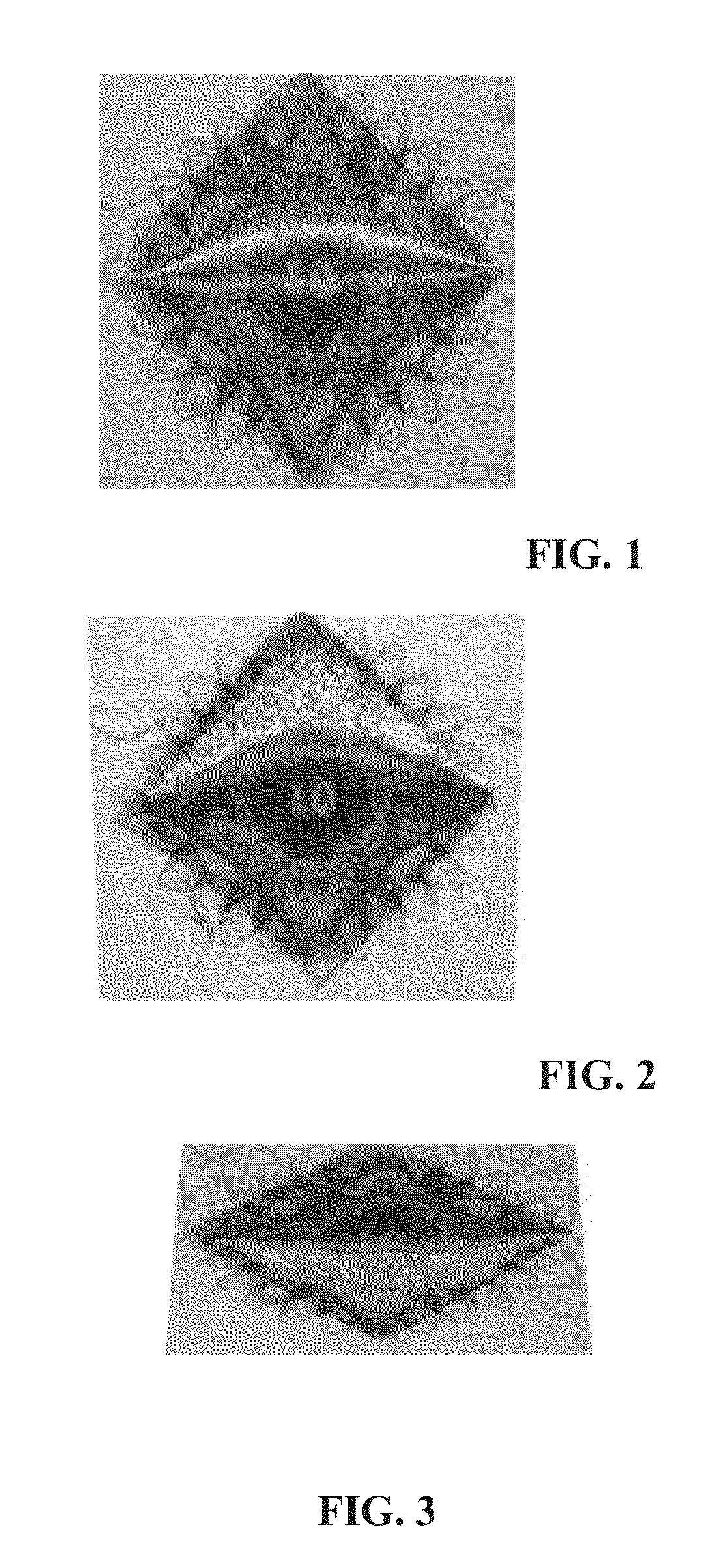

Round illumination device

ActiveUS20110063855A1Improve directionGood collimationGlobesOptical light guidesWaveguideLight source

The invention provides a substantially round illumination device (1) comprising a light source (10) and a substantially round waveguide (20). The waveguide (20) comprises a first waveguide surface (21), a second waveguide surface (22), a substantially round waveguide entrance window (23), a substantially round waveguide edge window (24), and a central axis (100). The first waveguide surface (21) or the second waveguide surface (22) or both the first waveguide surface (21) and the second waveguide surface (22) further comprise a plurality of elongated structures (200) each having an elongation axis (201) substantially parallel to a radius (101) perpendicular to the central axis (100).

Owner:SIGNIFY HLDG BV

Round illumination device

The invention provides a substantially round illumination device (1) comprising a light source (10) and a substantially round waveguide (20). The waveguide (20) comprises a first waveguide surface (21), a second waveguide surface (22), a substantially round waveguide entrance window (23), a substantially round waveguide edge window (24), and a central axis (100). The first waveguide surface (21) or the second waveguide surface (22) or both the first waveguide surface (21) and the second waveguide surface (22) further comprise a plurality of elongated structures (200) each having an elongation axis (201) substantially parallel to a radius (101) perpendicular to the central axis (100).

Owner:SIGNIFY HLDG BV

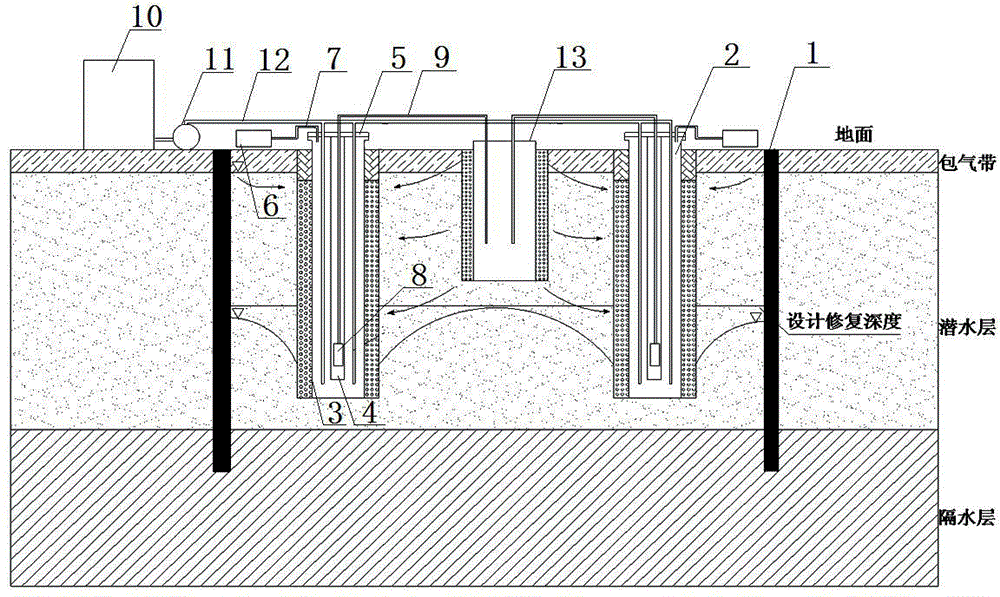

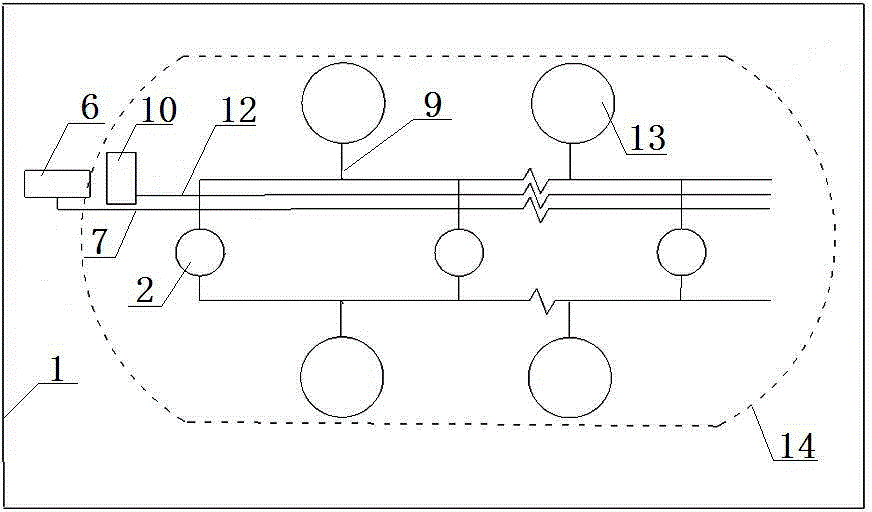

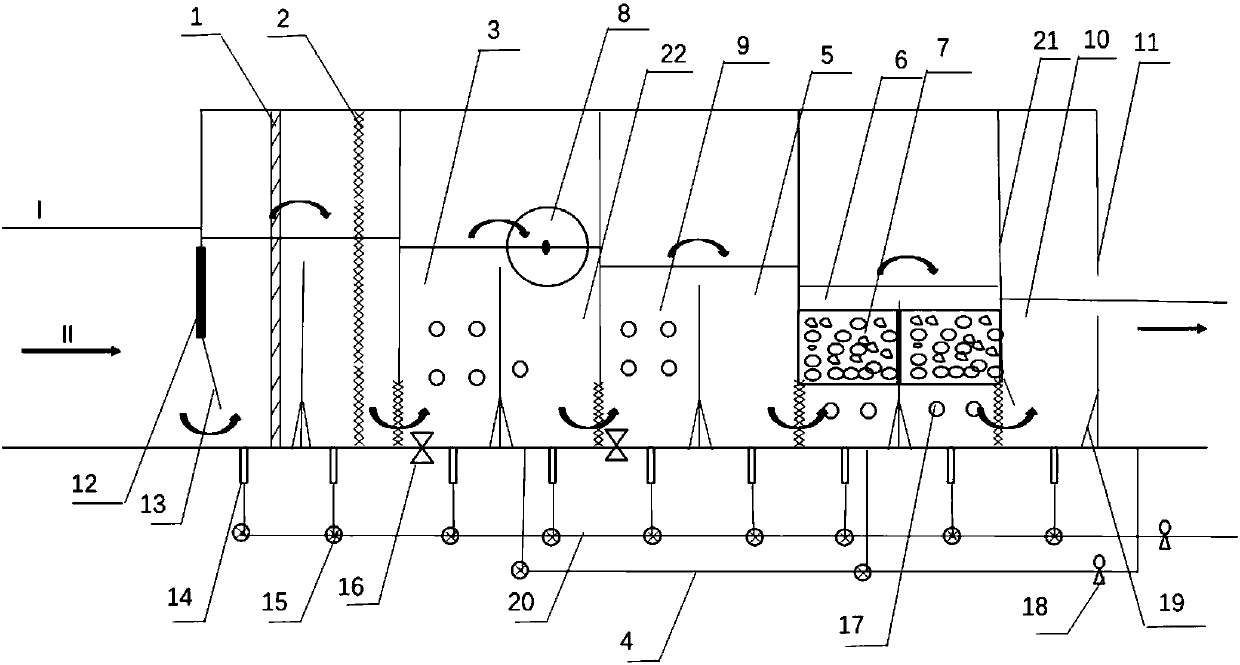

Vacuum tube well precipitation and disposal method for rapidly restoring in-situ water and soil in polluted place

ActiveCN104358267ALarge amount of waterImprove water collection efficiencySoil preservationEnvironmental engineeringVacuum pump

The invention discloses a vacuum tube well precipitation and disposal method for rapidly restoring in-situ water and soil in a polluted place. The method comprises the following steps: arranging a precipitation tube well in a polluted region, and arranging a vacuum pump air extracting system, a submerged pump water pumping system and a chemical filling pipe in the precipitation tube well; arranging a disposal well in the polluted region, and connecting the disposal well with the submerged pump water pumping system; starting the vacuum pump air extracting system so as to guide polluted water in soil to flow into the precipitation tube well; continuously adding a restoring chemical into the chemical filling pipe, and reacting with the polluted water entering the precipitation tube well; after reacting for certain time, starting the submerged pump water pumping system, delivering pumped water into the disposal well, infiltrating the water in the disposal well into the soil again, repeatedly operating in the way, and finishing restoring after detecting that water and oil specimens meet standards. The method has the advantages of low cost, high water collecting efficiency, large affecting radius and capability of promoting underground water hydraulic circulation, and realizes water and soil integrated restoration in the polluted place.

Owner:SHANGHAI GEOTECHN INVESTIGATIONS & DESIGN INST

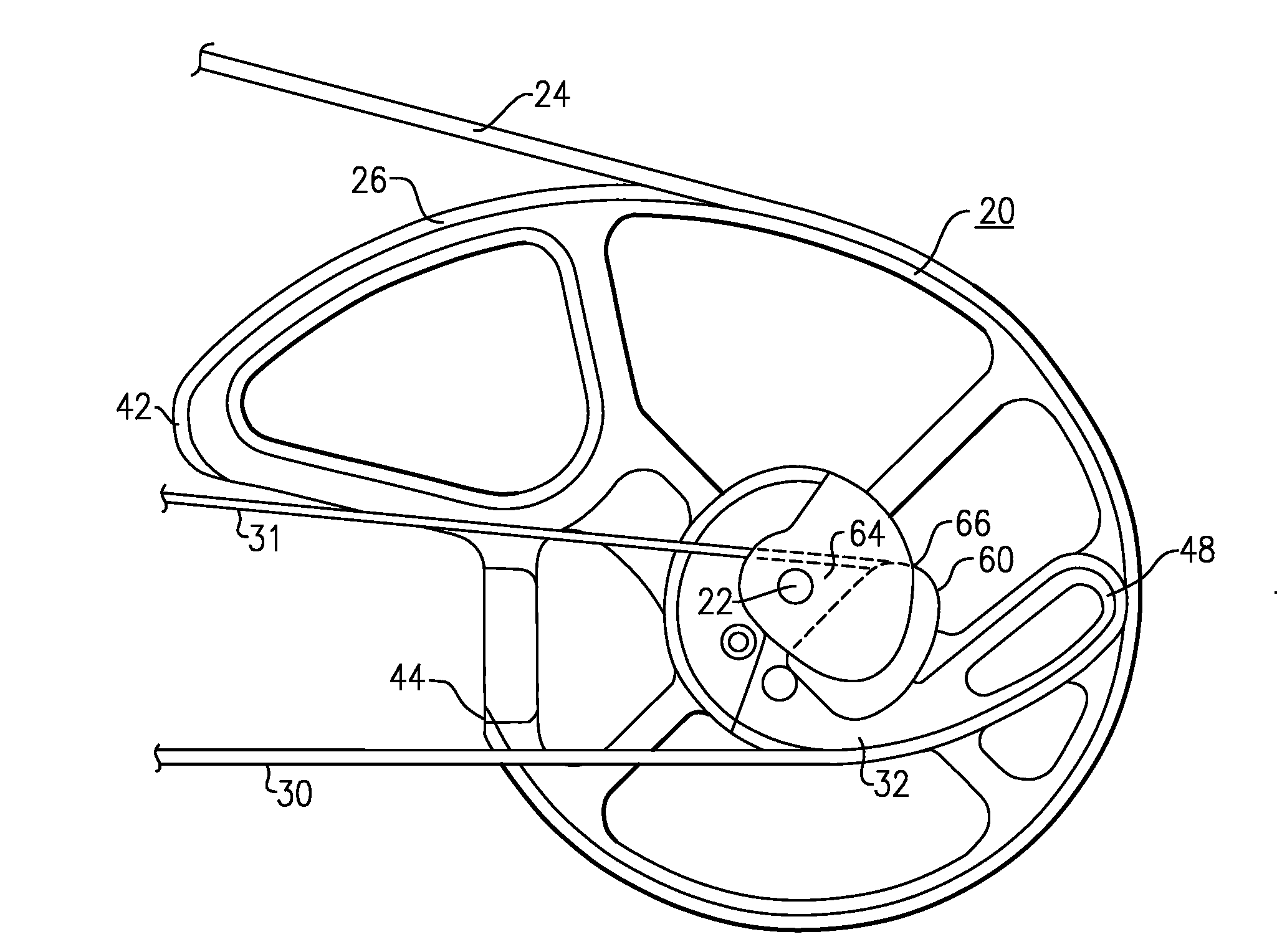

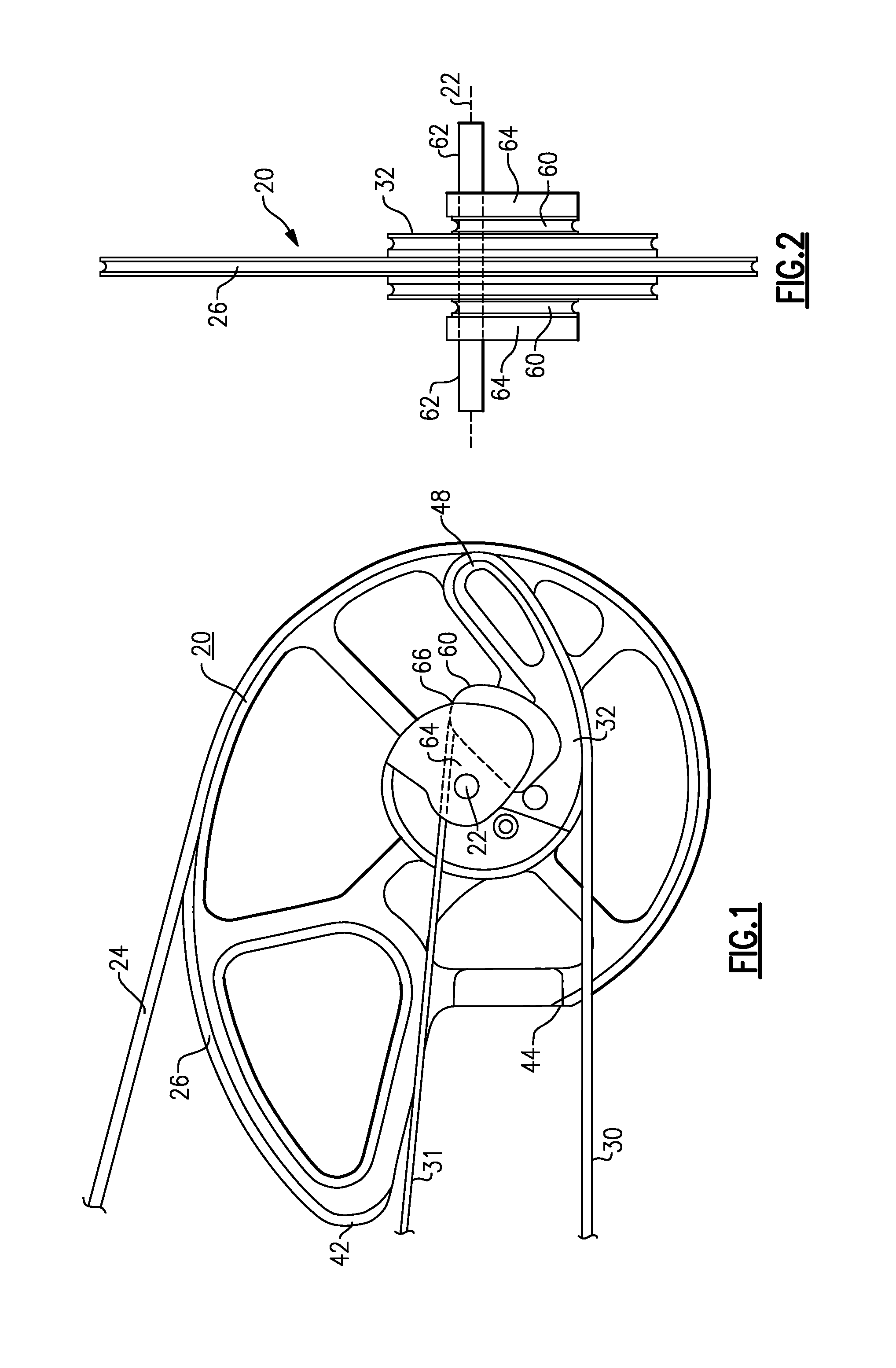

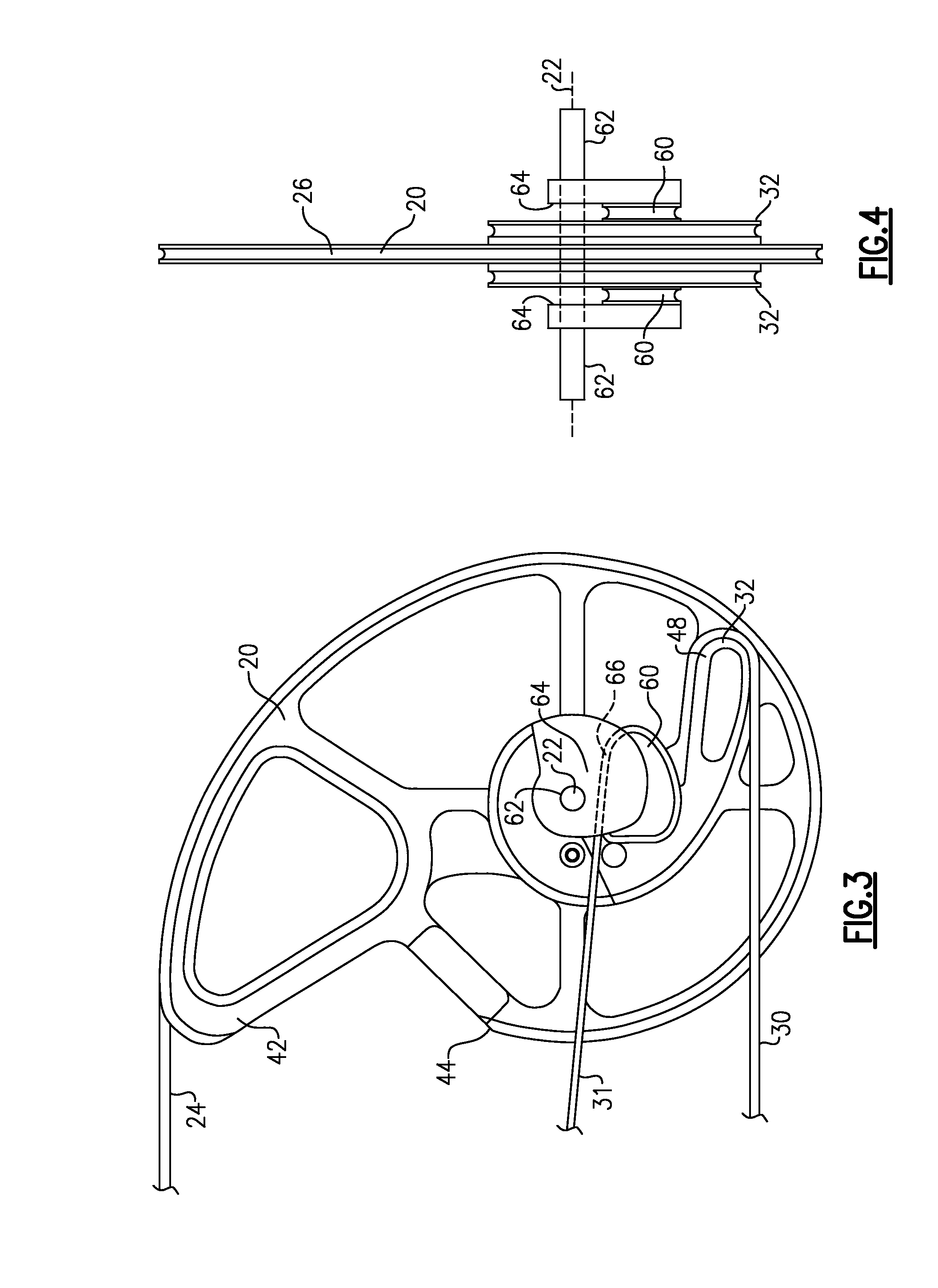

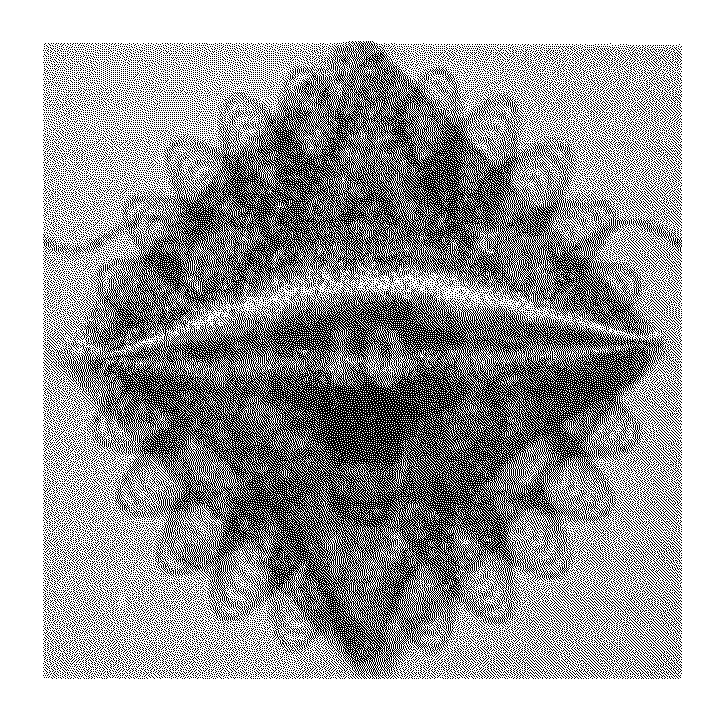

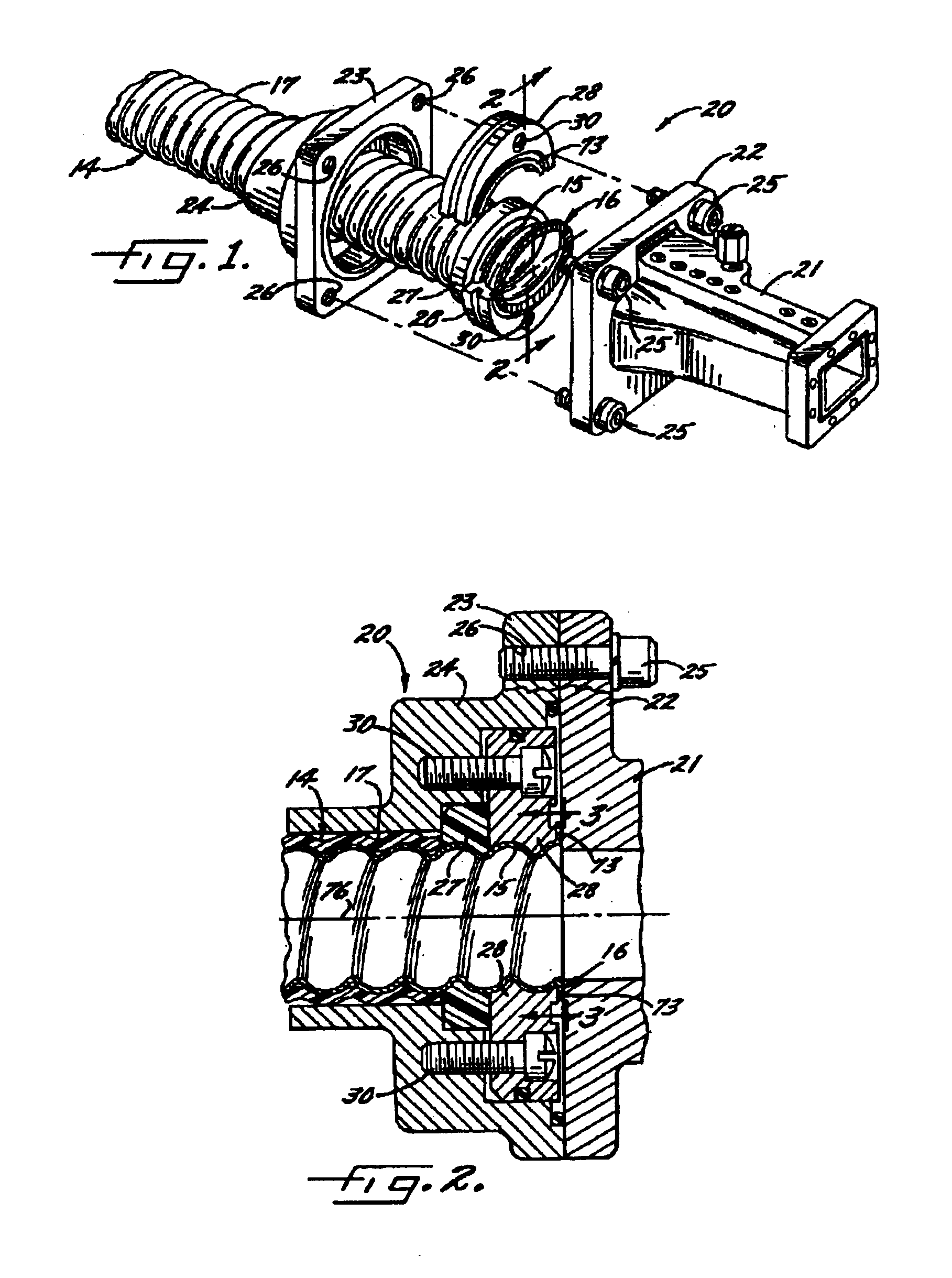

Bowstring Cam for Compound Bow

A bowstring cam assembly for compound archery bow has a bowstring cam member that is journaled at an end of the bow power limb. First and second power cams are affixed onto the bowstring cam member to rotate with it, and first and second flexible inextensible cam cables extend over the periphery of the associated power cams. The cam cables and the power cams cooperate to determine draw characteristics for the bow. The bowstring cam member is provided with an acircular cam profile. The second power cam is situated to one side of the axis of the bowstring cam, such that at an end of travel, i.e., at full release, both the first and second power cables are pulling in a common direction.

Owner:BOICE RICHARD K MR

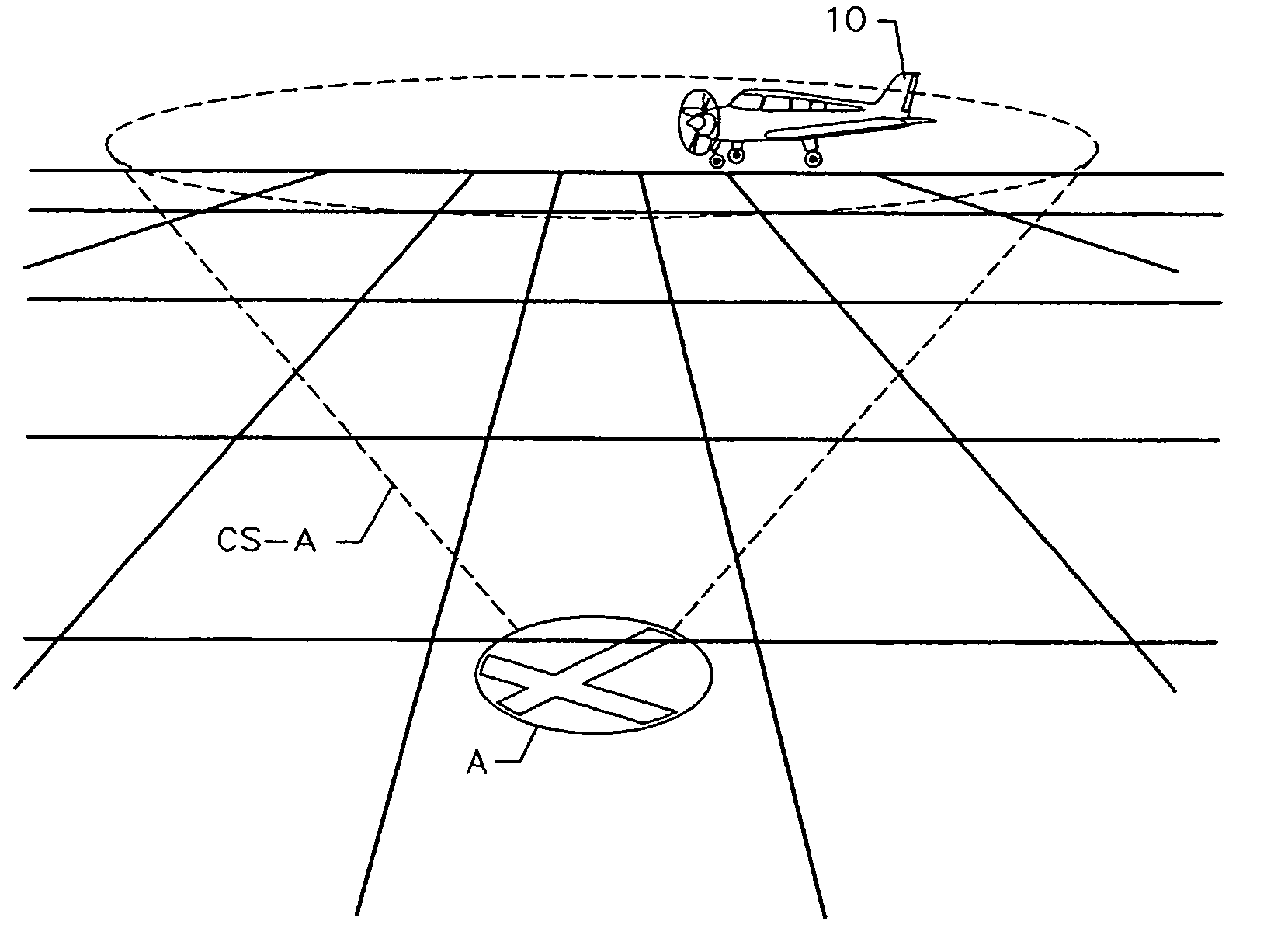

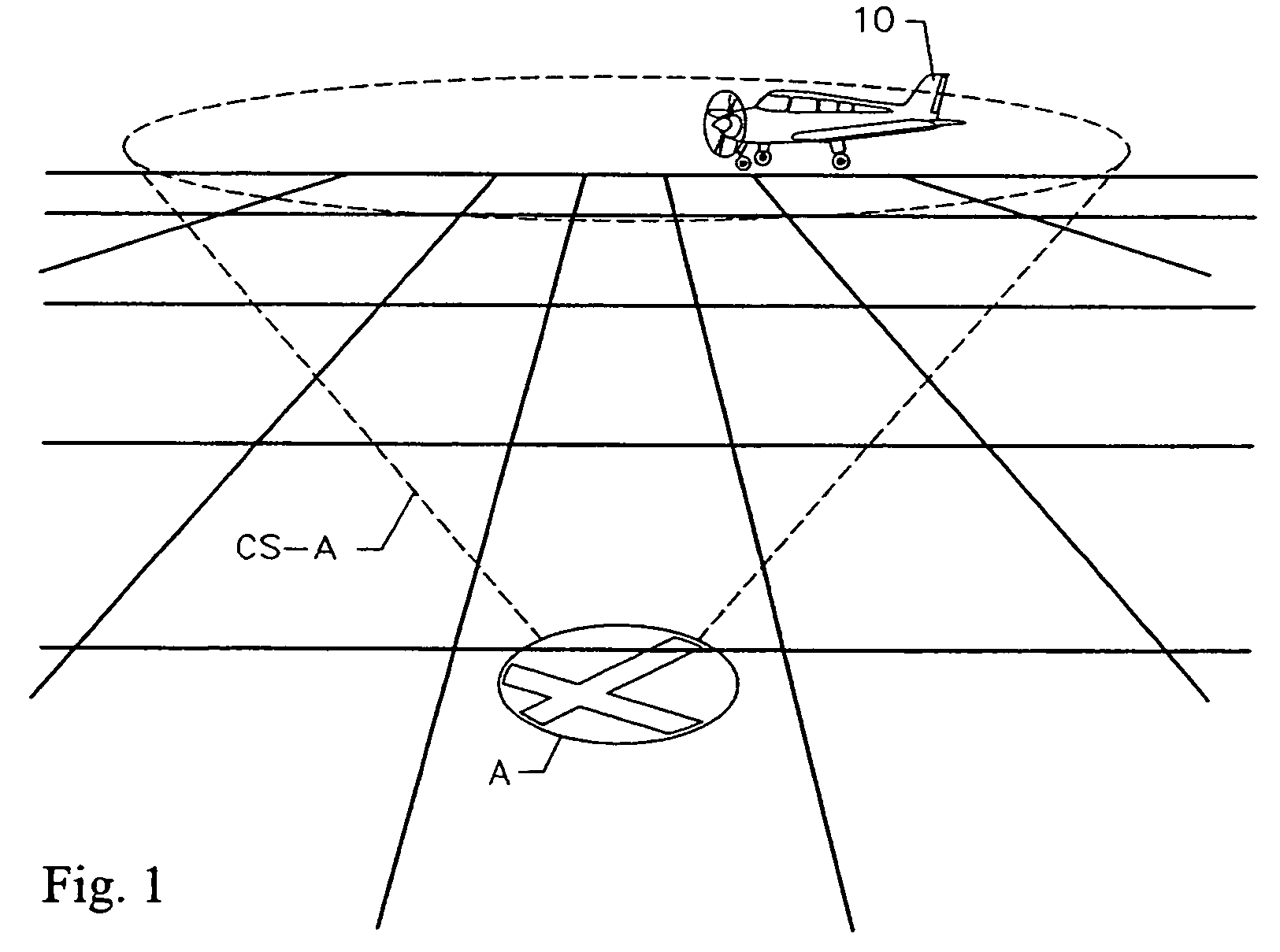

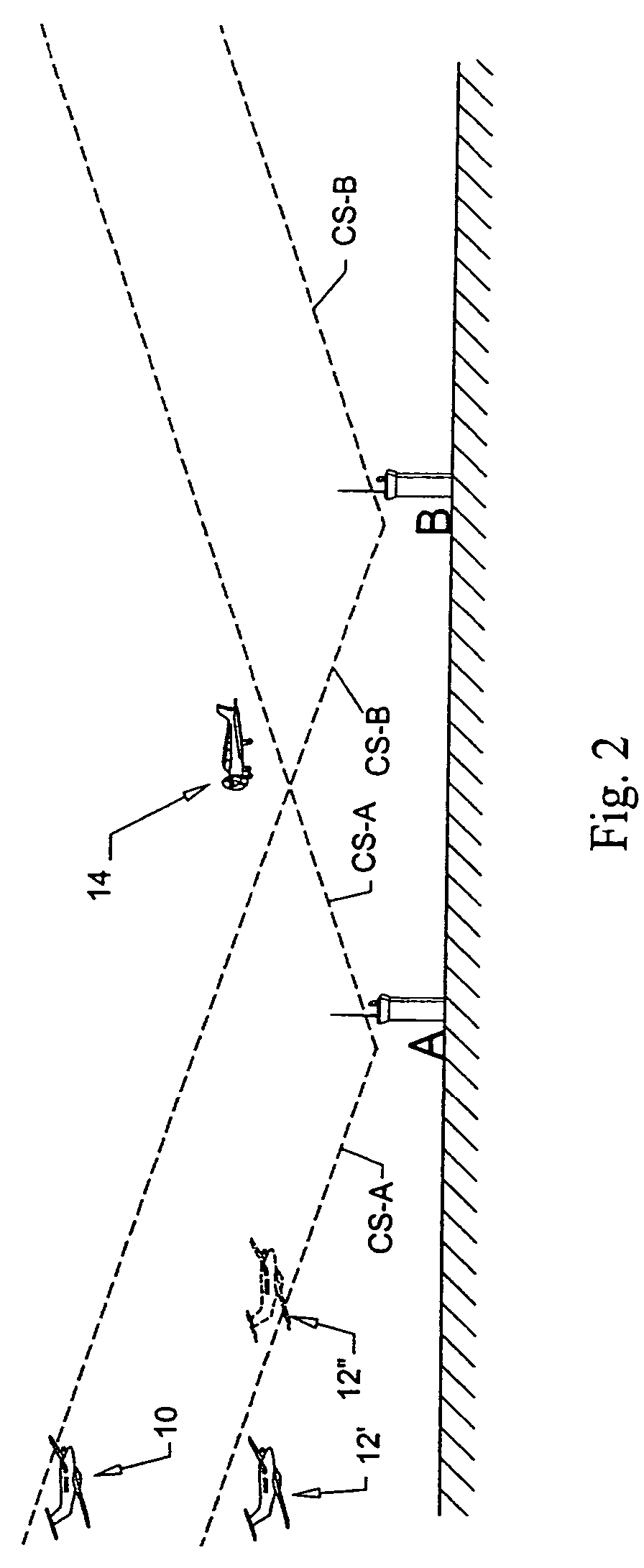

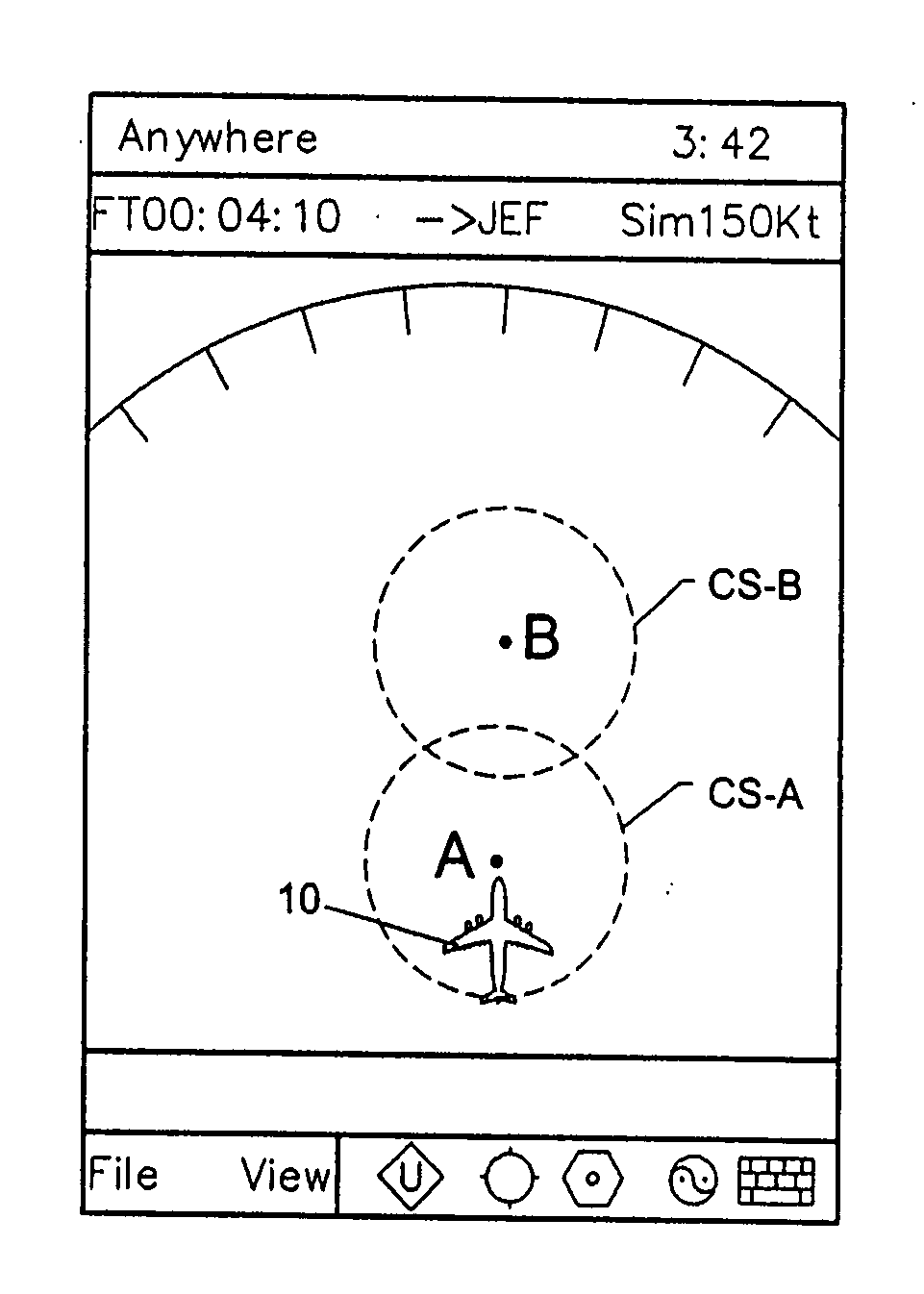

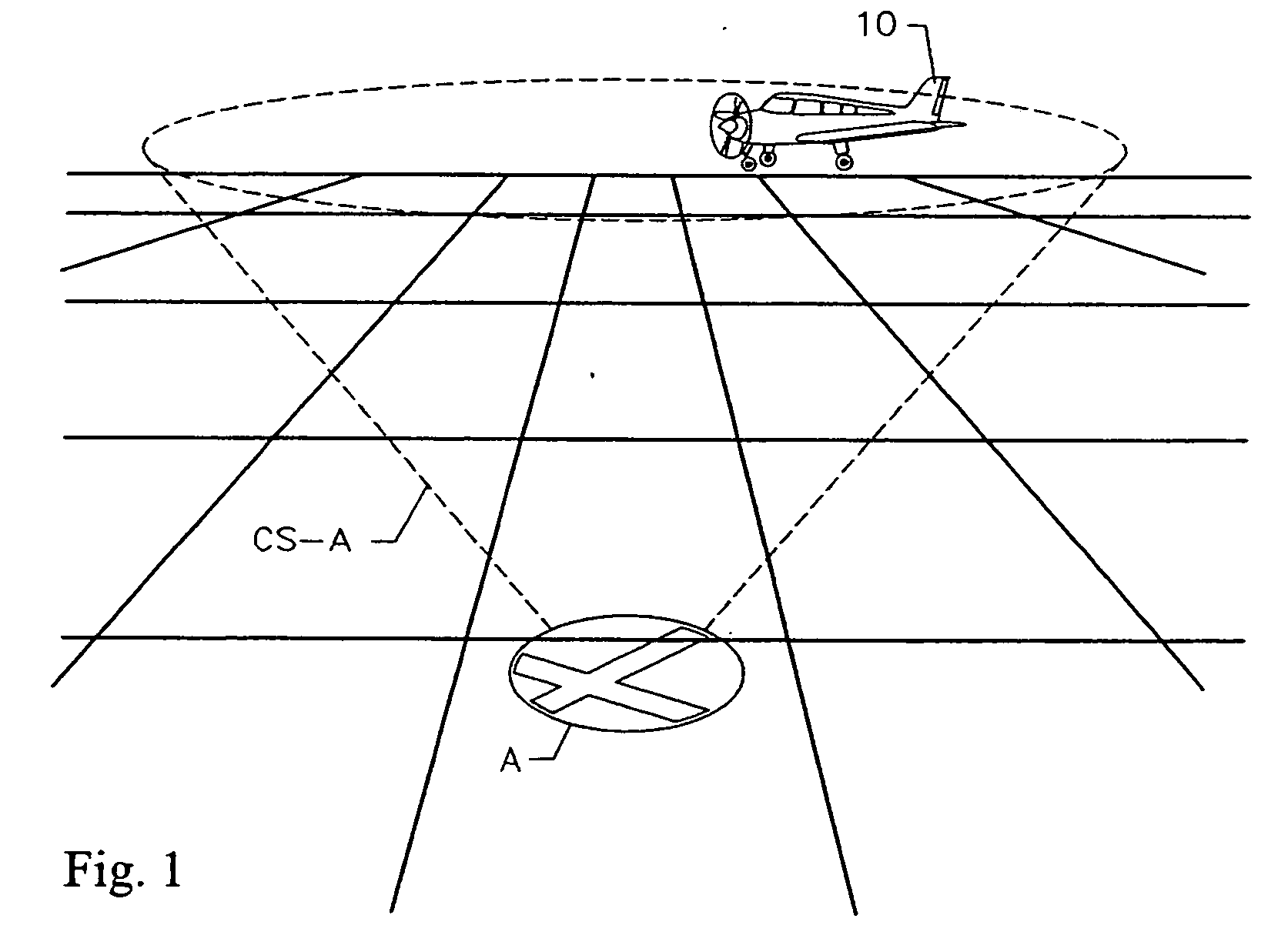

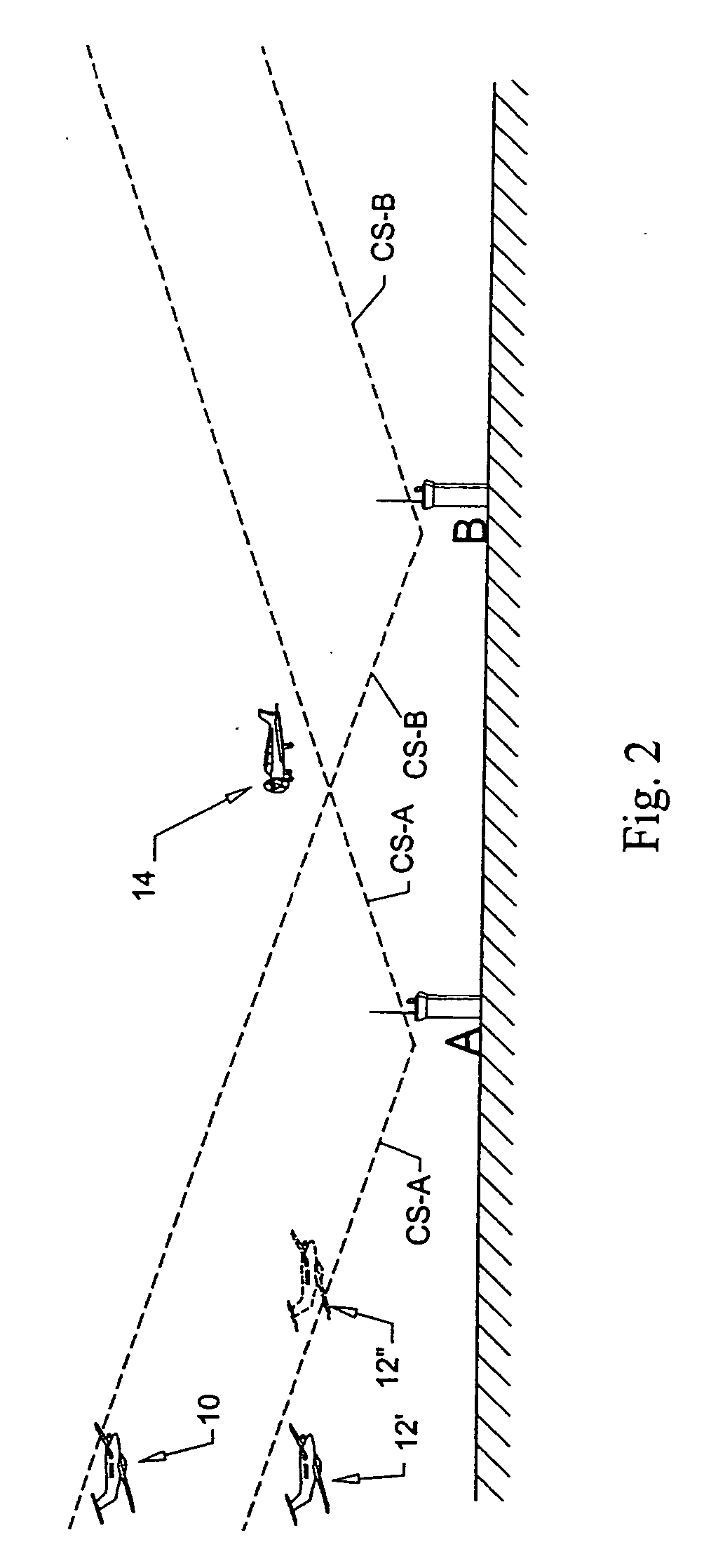

Flight management system and method for providing navigational reference to emergency landing locations

InactiveUS7167782B2Maximize safetyAltitude differential decreasesAnalogue computers for vehiclesAnalogue computers for trafficAviationNavigational system

An aviation navigational system and method for predicting glide range for an aircraft for specific airports and other potential emergency landing locations in proximity to the aircraft. Information is presented to the pilot by complementing a conventional moving map display with symbols centered on each landing location. GPS altitude, airport elevation, and the aircraft's glide ratio are factored into an equation to determine glide range for each airport within proximity to the aircraft. A circular symbol representing the glide range boundary is displayed around each airport. Each circular symbol represents a sectional view of an imaginary inverted cone, having the apex thereof centered on a given landing location. The size and shape of the cone is based on the gliding performance of the aircraft and the altitude differential between the aircraft and the target landing location. As the altitude differential increases the radius of the circle increases. Conversely as the altitude differential decreases, the radius of the circle decreases. As long as the aircraft is anywhere within any one of the three-dimensional inverted cones displayed, as represented by one or more circles on a two dimensional display, it can safely glide to the landing location. This display concept is selectively referred to herein as “cones of safety.”

Owner:CONTROL VISION CORP

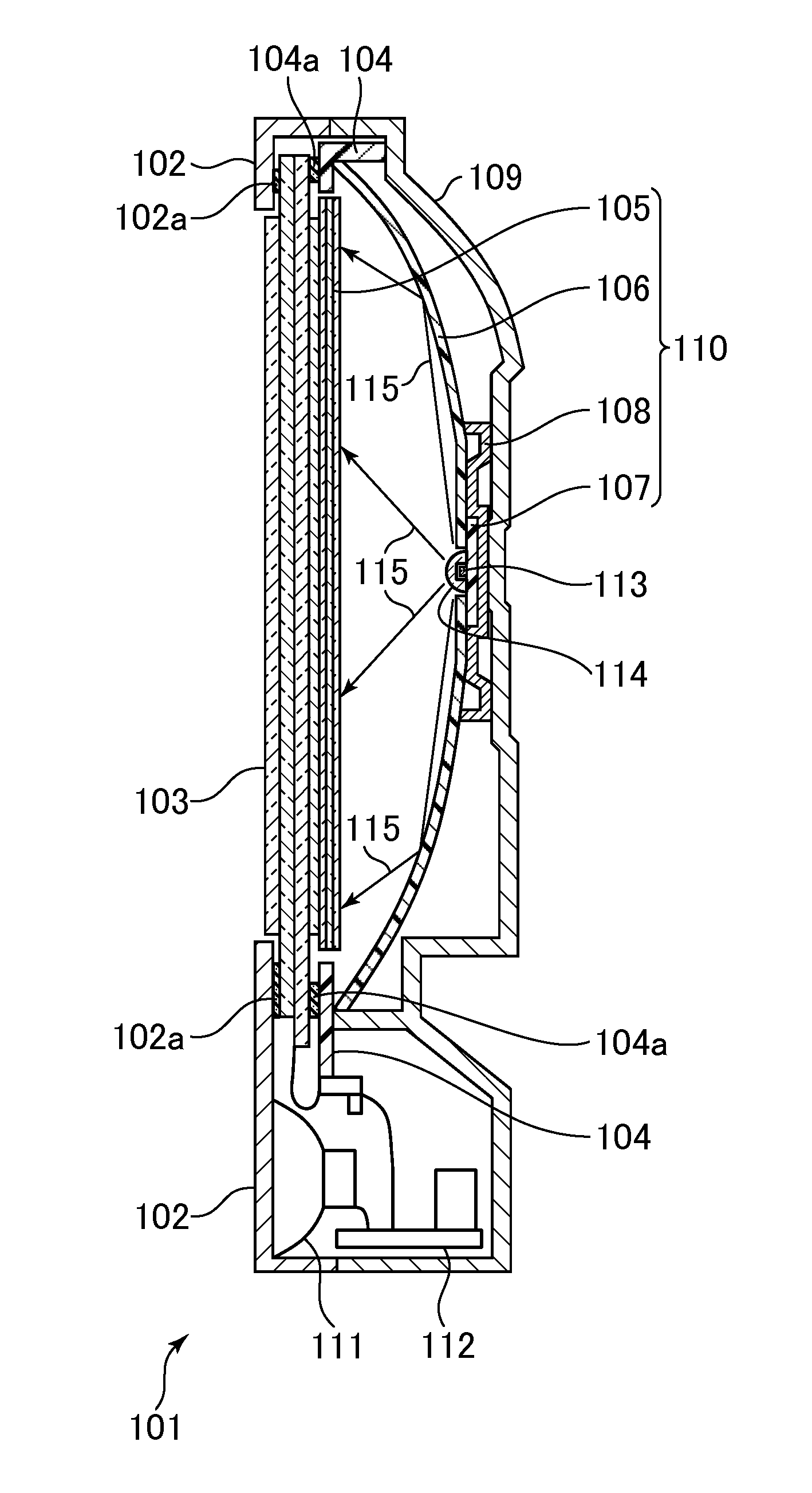

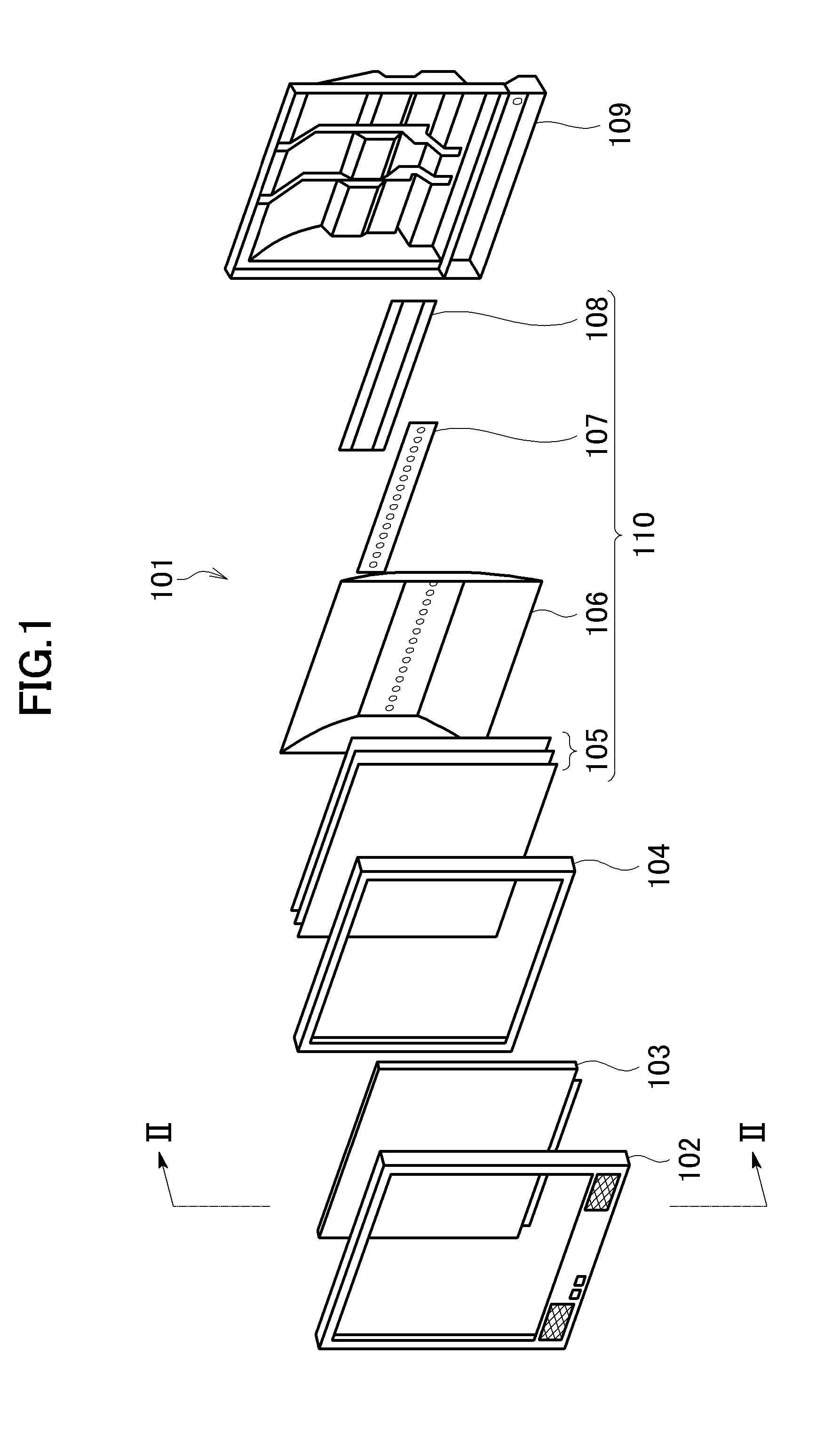

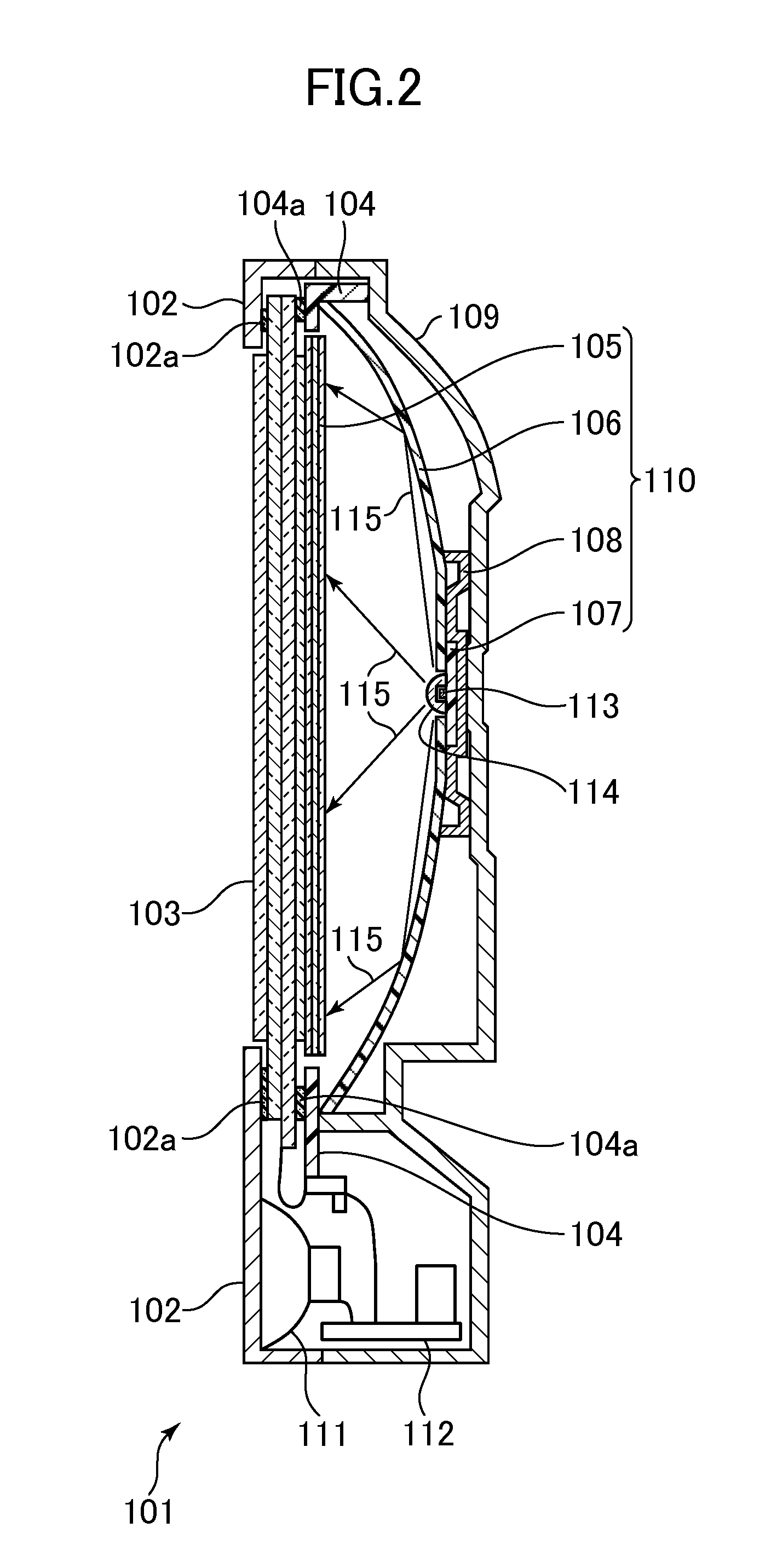

Liquid crystal display device and television receiver

ActiveUS20140313424A1Efficiently dissipatedIncrease radiusTelevision system scanning detailsStatic indicating devicesTelevision receiversLiquid-crystal display

A liquid crystal display device includes: a liquid crystal panel; a reflection sheet arranged on a rear surface side of the liquid crystal panel, the reflection sheet being curved so that a surface facing the liquid crystal panel is recessed; and a light emitting diode substrate including: a light emitting diode array in which a plurality of light emitting diodes are arranged along a longitudinal direction; and electrodes connected to the plurality of light emitting diodes. In a circle which is centered at one light emitting diode and whose diameter is a distance from the one light emitting diode to another light emitting diode adjacent to the one light emitting diode, an area of the electrode connected to a high temperature side electrode of the one light emitting diode is larger than an area of the electrode connected to a low temperature side electrode of the one light emitting diode.

Owner:PANASONIC INTELLECTUAL PROPERTY CORP OF AMERICA

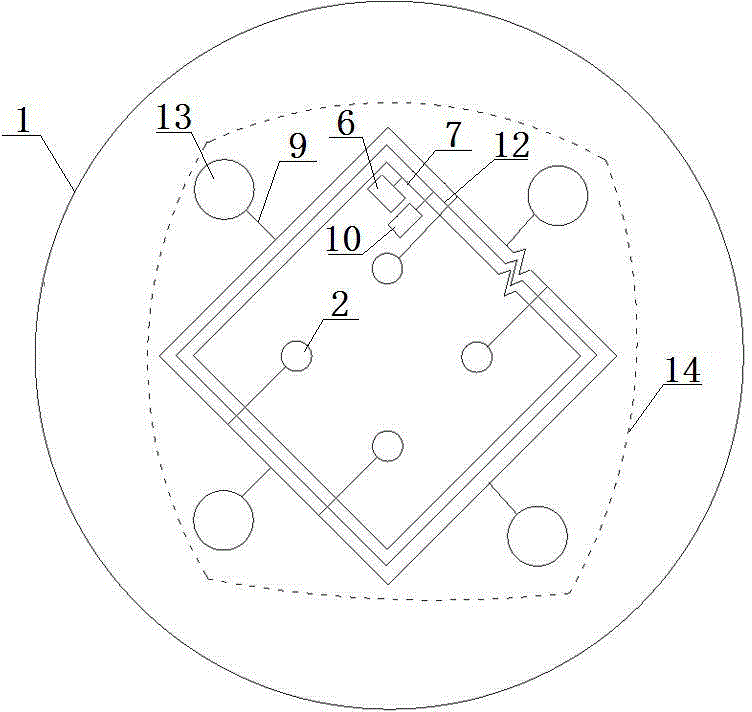

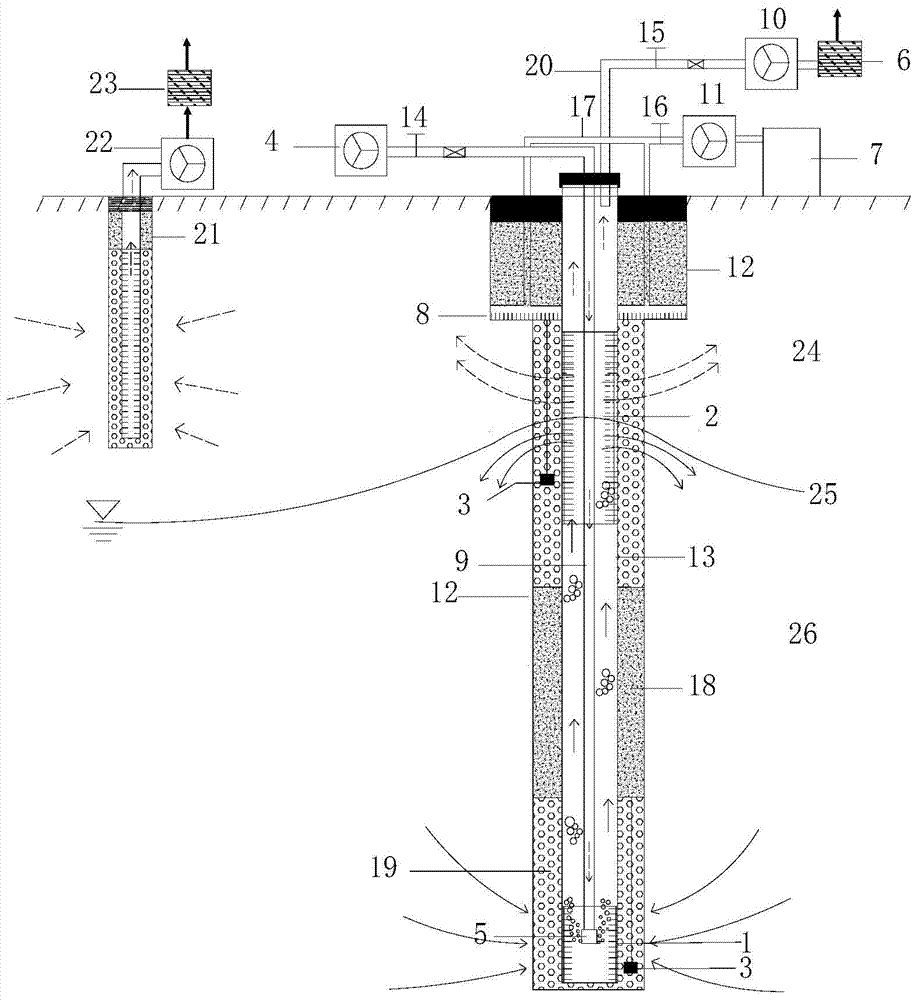

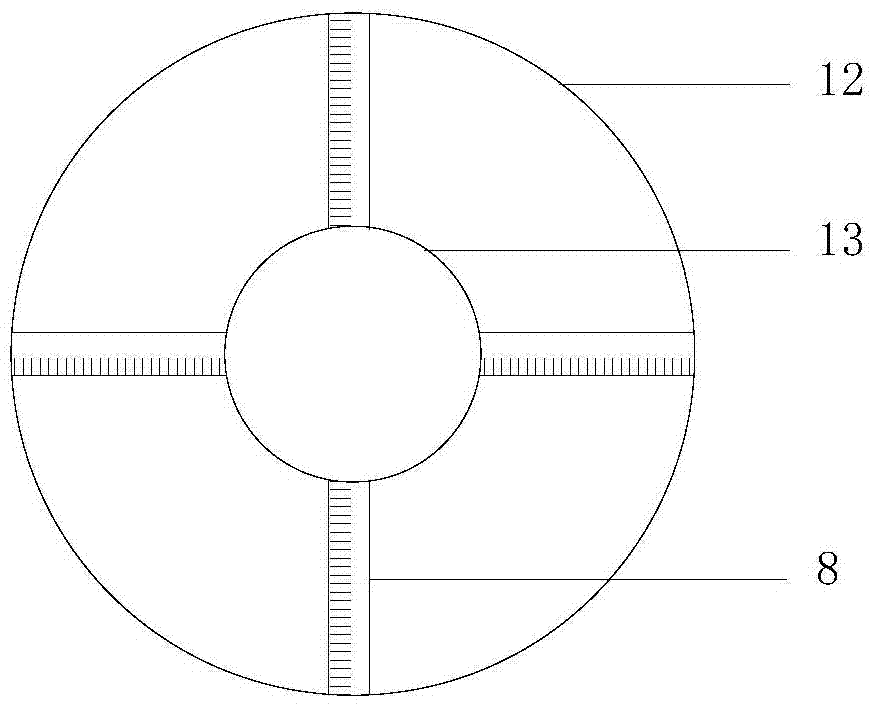

Circulating well system for removing volatile organic compounds in underground water

ActiveCN103864263AGood restorativeEasy to handleContaminated soil reclamationMultistage water/sewage treatmentInjection pressureProduct gas

The invention relates to a circulating well system for removing volatile organic compounds in underground water, and aims at providing a circulating well system suitable for different soil types to solve the problems of hydraulic transmission energy loss and poor soil permeability and avoid airflow short circuit caused by overlarge injection pressure as well as improve the influence radius and achieve remarkable repair effect. The system comprises an outer well, an inner well, a gas injection system, a gas extraction system and a reagent spraying system, wherein the inner well is arranged in the outer well, the gas injection system is used for introducing gas into the water of the inner well for aeration, a part of the gas mingled with organic pollutants is extracted by the gas extraction system and then adsorbed by an active carbon adsorption device to be discharged, the other part of the gas enters the outer well, and the reagent spraying system is used for sprays reagent liquid into the outer well.

Owner:ZHONGKE DINGSHI ENVIRONMENTAL ENG CO LTD

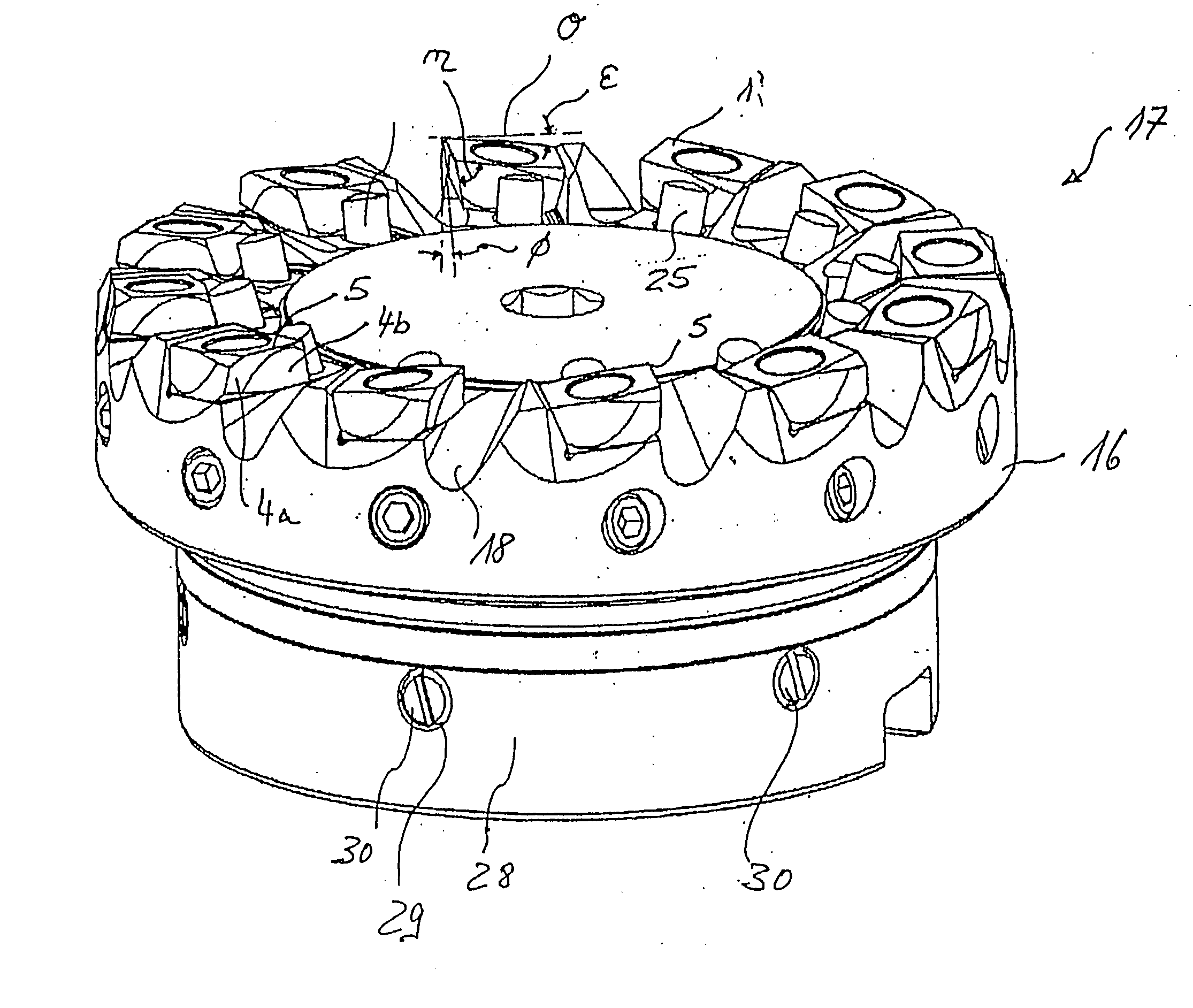

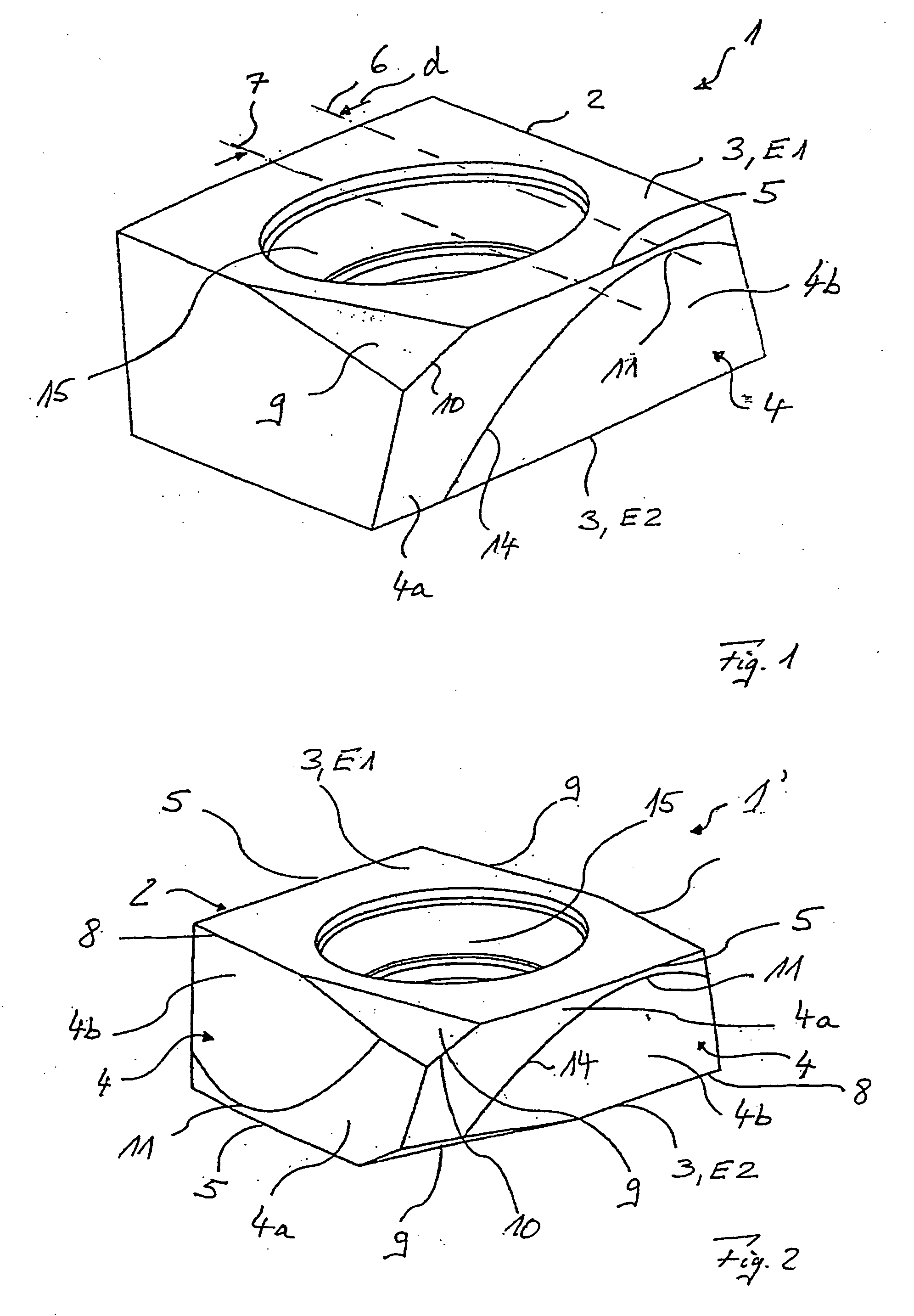

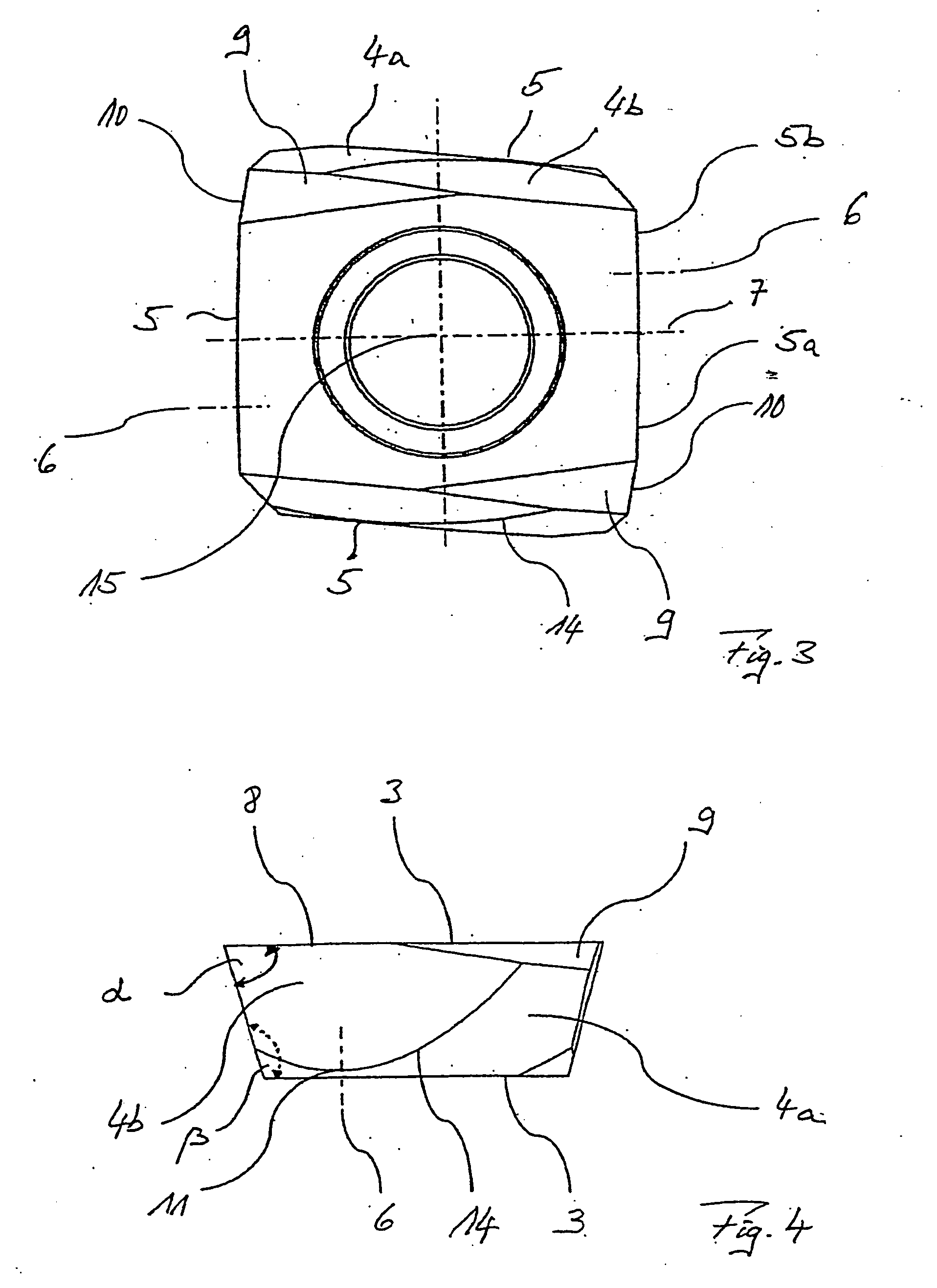

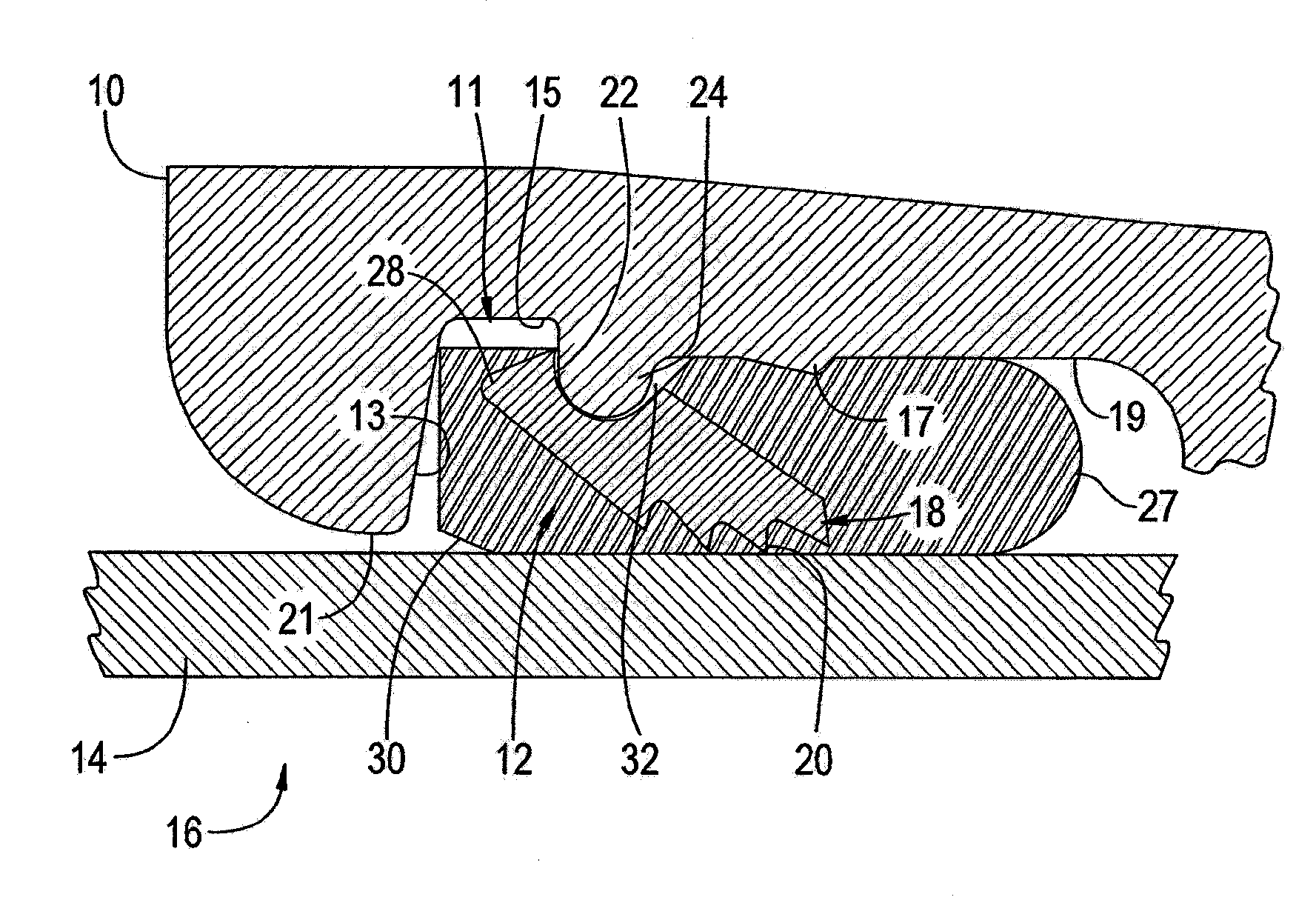

Cutting insert and milling cutter with such a cutting insert

InactiveUS20050023044A1High surface finishIncrease radiusDrill bitsMilling cuttersAcute angleEngineering

A cutting insert 1, 1′, comprising opposite insert planes E1, E2 of a base 2 of one base area 3 wherein a conical surface section 4a of a lateral face 4 and the base area 3 facing the same form an acute angle alpha while forming a cutting edge 5, while a planar surface section 4b of the same lateral face 4 forms an obtuse angle beta with the opposite base area 3. The cone axis 6 of the conical surface area 4a lying in the insert plane E1, E2 runs off-set in parallel to the center insert axis 7 lying in the same insert plane E1, E2 while forming an off-center arcuate profile of the cutting edge 5. A milling cutter 17 comprising a number of such cutting inserts 1, 1′ is characterized in that a cutting insert 1, 1′ preferably disposed on the periphery of the center line M of a tool support 16 is off-set from the center line M by an angle phi equal to 5±3 degrees. The abstract of the disclosure is submitted herewith as required by 37 C.F.R. §1.72(b). As stated in 37 C.F.R. §1.72(b): A brief abstract of the technical disclosure in the specification must commence on a separate sheet, preferably following the claims, under the heading “Abstract of the Disclosure.” The purpose of the abstract is to enable the Patent and Trademark Office and the public generally to determine quickly from a cursory inspection the nature and gist of the technical disclosure. The abstract shall not be used for interpreting the scope of the claims. Therefore, any statements made relating to the abstract are not intended to limit the claims in any manner and should not be interpreted as limiting the claims in any manner.

Owner:KENNAMETAL INC

Flight management system and method for providing navigational reference to emergency landing locations

InactiveUS20050273220A1Maximize safetyAltitude differential decreasesAnalogue computers for vehiclesAnalogue computers for trafficAviationNavigational system

An aviation navigational system and method for predicting glide range for an aircraft for specific airports and other potential emergency landing locations in proximity to the aircraft. Information is presented to the pilot by complementing a conventional moving map display with symbols centered on each landing location. GPS altitude, airport elevation, and the aircraft's glide ratio are factored into an equation to determine glide range for each airport within proximity to the aircraft. A circular symbol representing the glide range boundary is displayed around each airport. Each circular symbol represents a sectional view of an imaginary inverted cone, having the apex thereof centered on a given landing location. The size and shape of the cone is based on the gliding performance of the aircraft and the altitude differential between the aircraft and the target landing location. As the altitude differential increases the radius of the circle increases. Conversely as the altitude differential decreases, the radius of the circle decreases. As long as the aircraft is anywhere within any one of the three-dimensional inverted cones displayed, as represented by one or more circles on a two dimensional display, it can safely glide to the landing location. This display concept is selectively referred to herein as “cones of safety.”

Owner:CONTROL VISION CORP

Computed tomography system with adjustable focal spot-to-detector distance

InactiveUS20060222143A1Improve accessibilityIncrease the diameterMaterial analysis using wave/particle radiationRadiation/particle handlingComputed tomographyX-ray

A computed tomography system with an adjustable focal spot-to-detector distance has a gantry provided with a patient opening, an x-ray tube and a detector, respectively mounted at opposite sides of the gantry. The x-ray tube has a focal spot and the x-ray fan beam radiated from the focal spot exhibits a fixed aperture angle. The x-ray tube is installed on a linear track and can be moved along the rail of the linear track.

Owner:SIEMENS HEALTHCARE GMBH

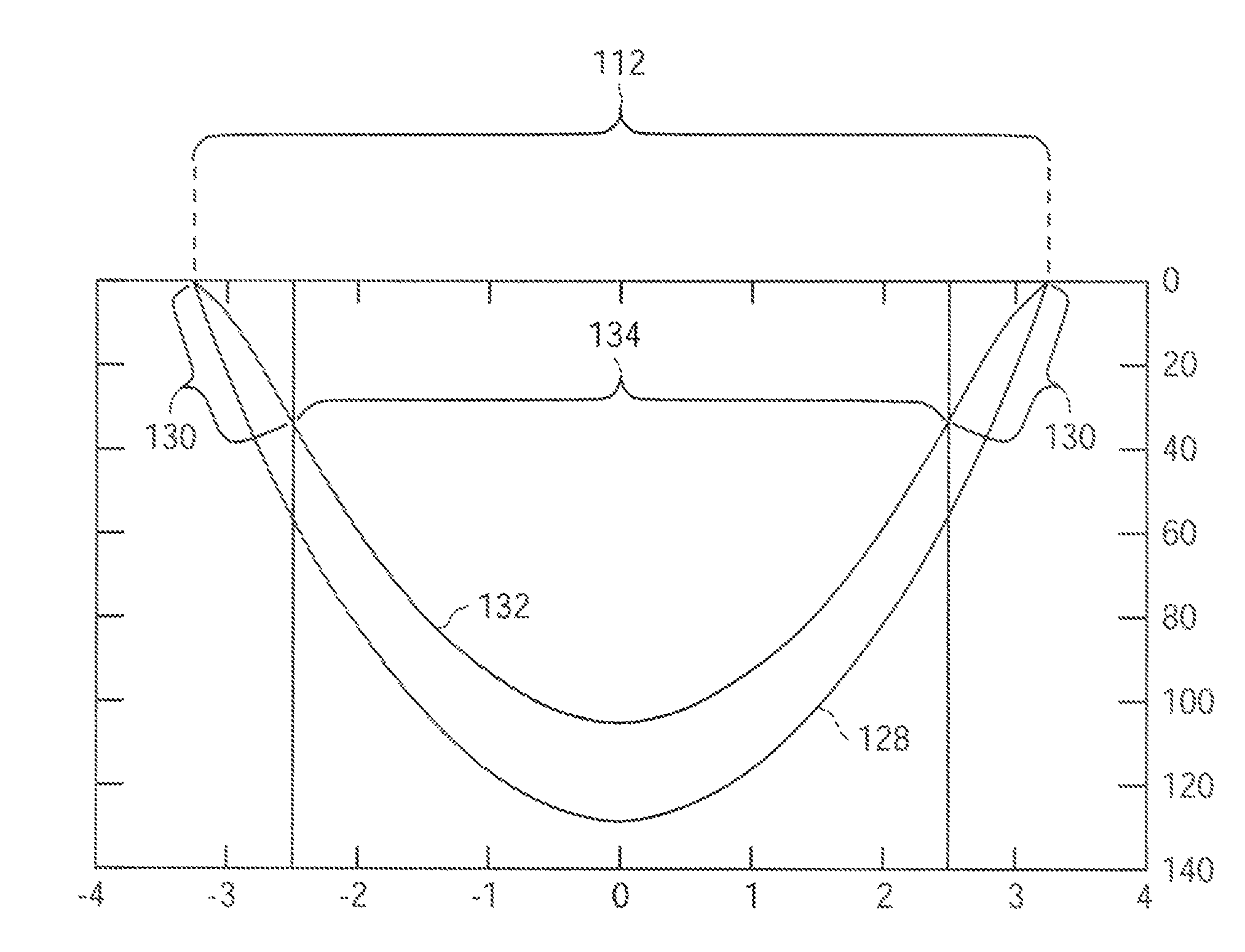

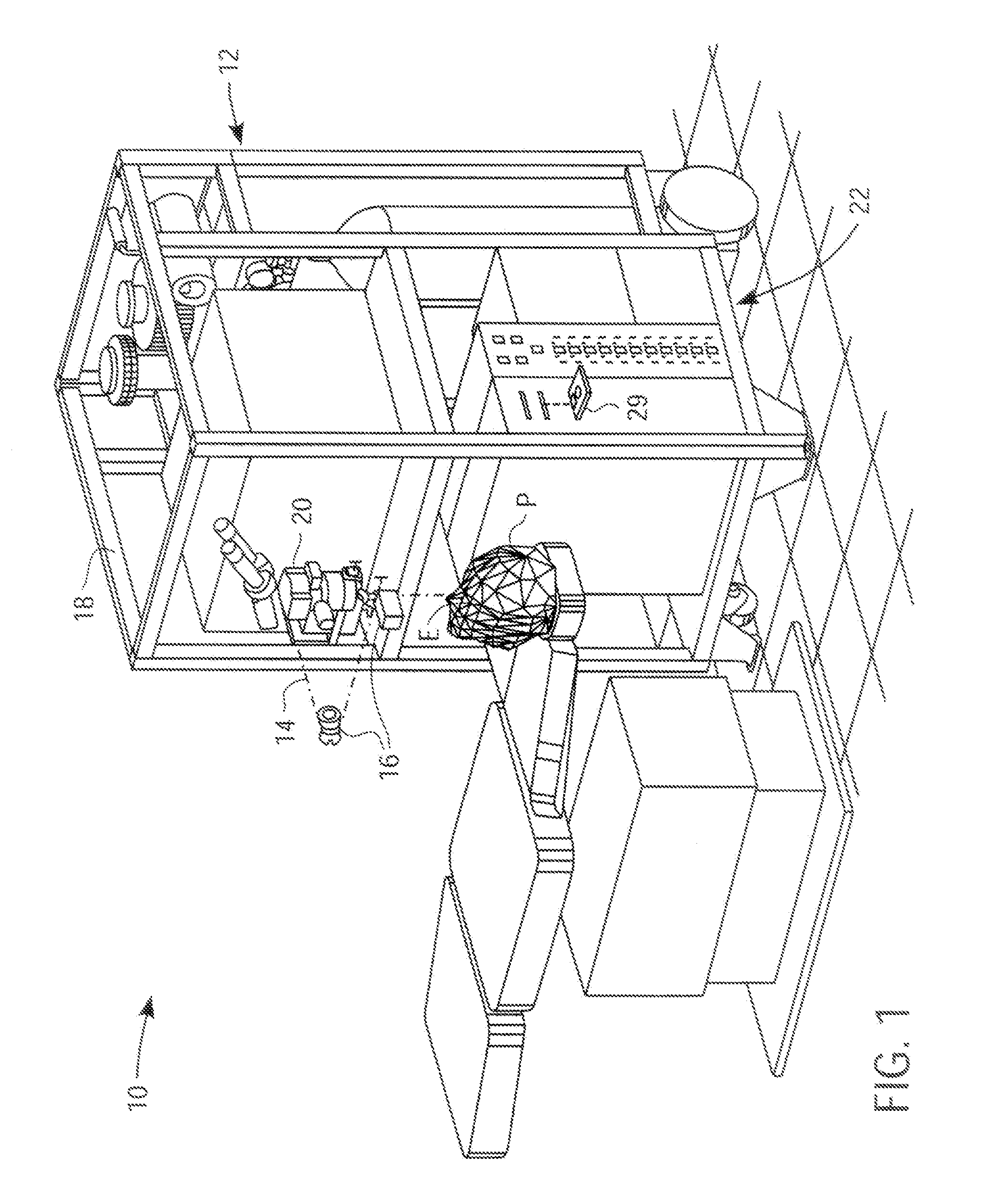

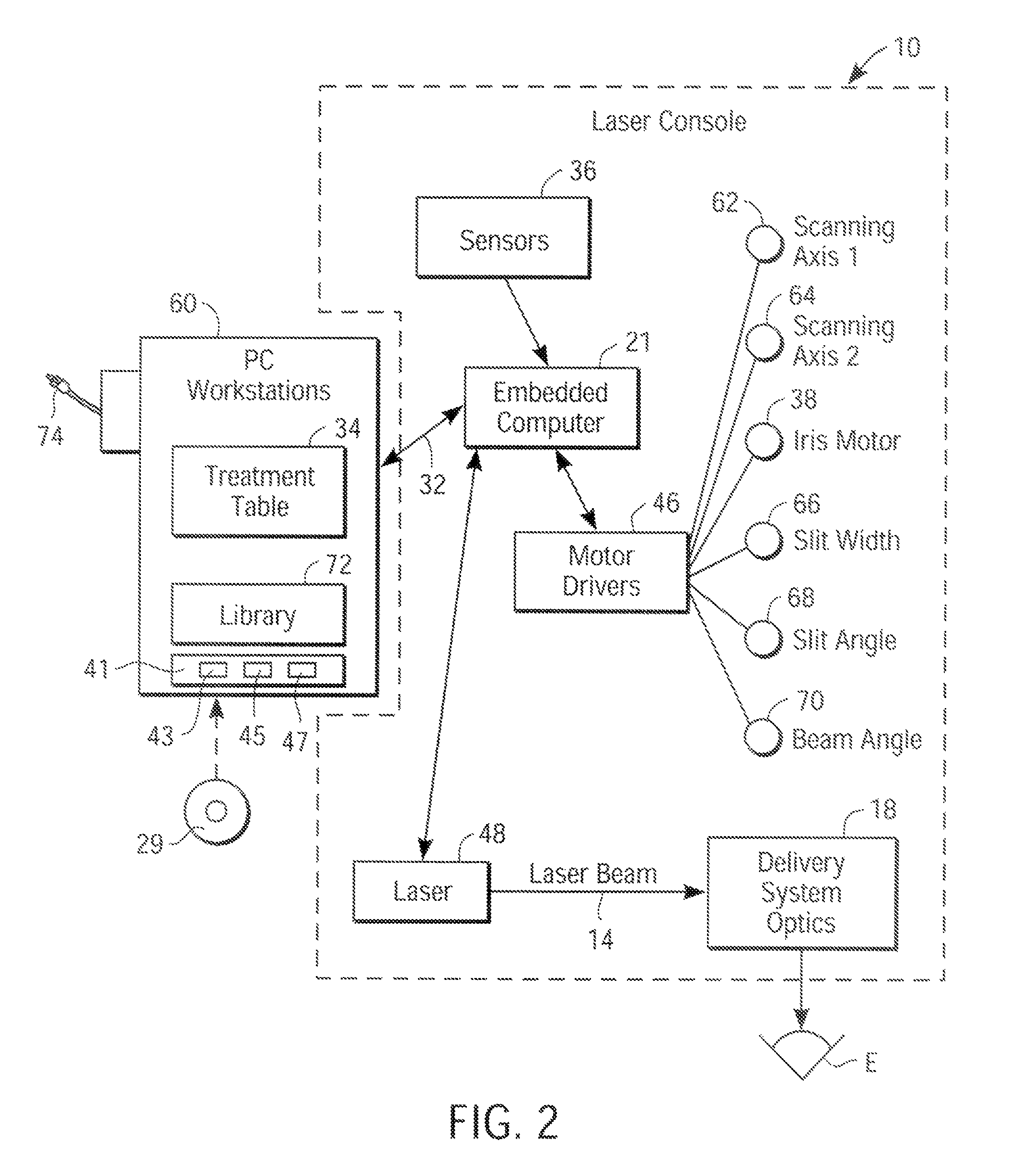

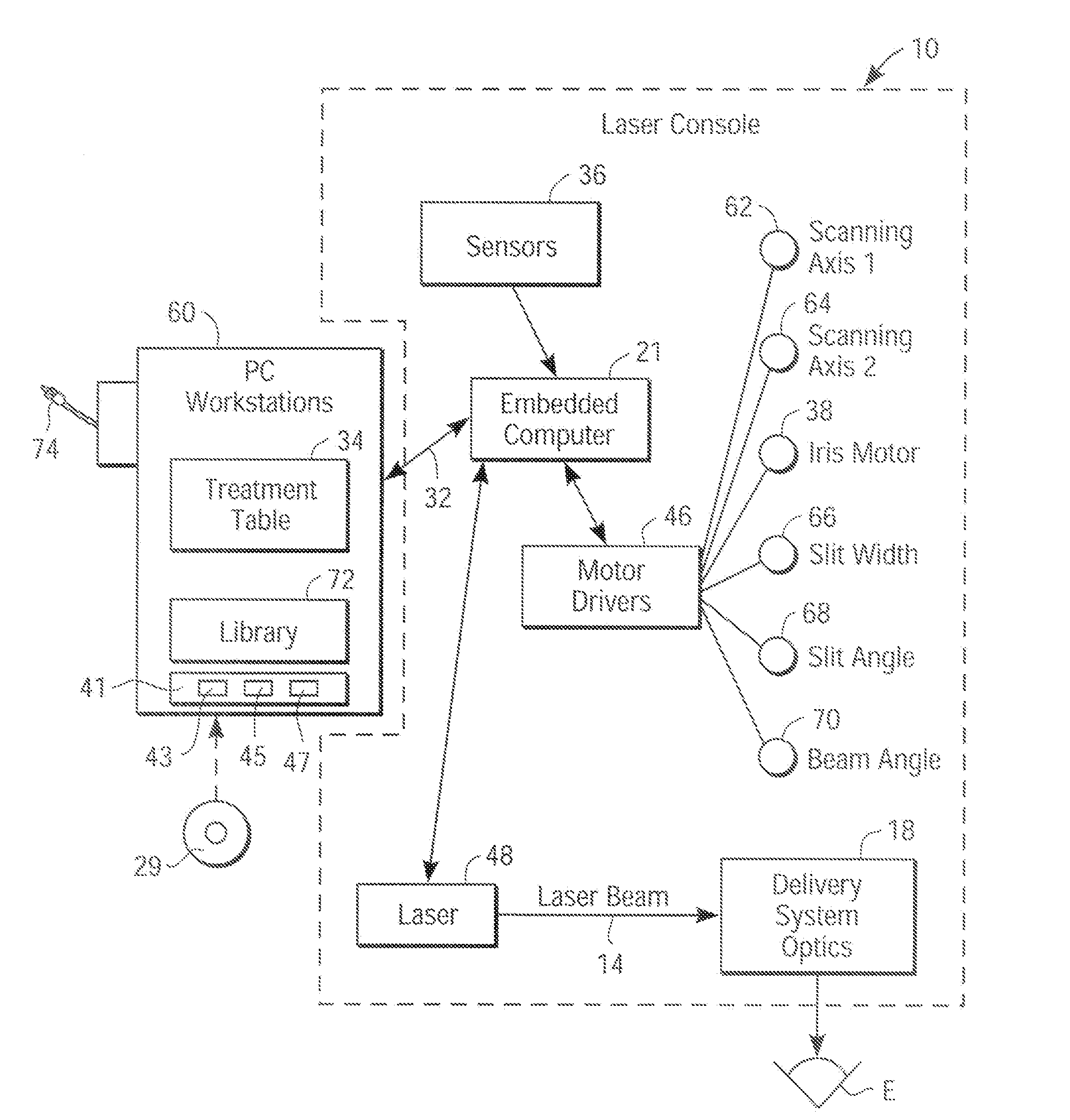

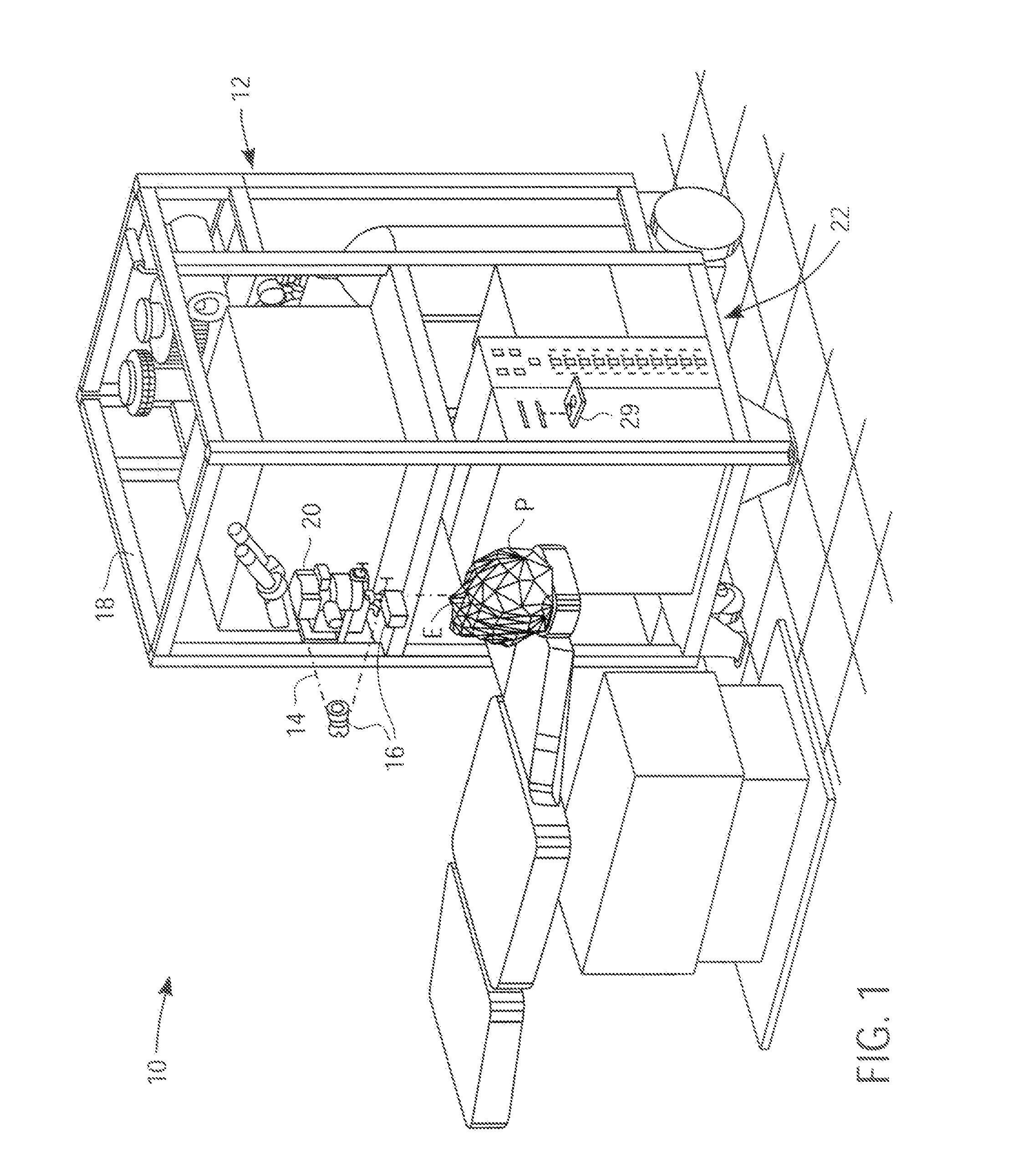

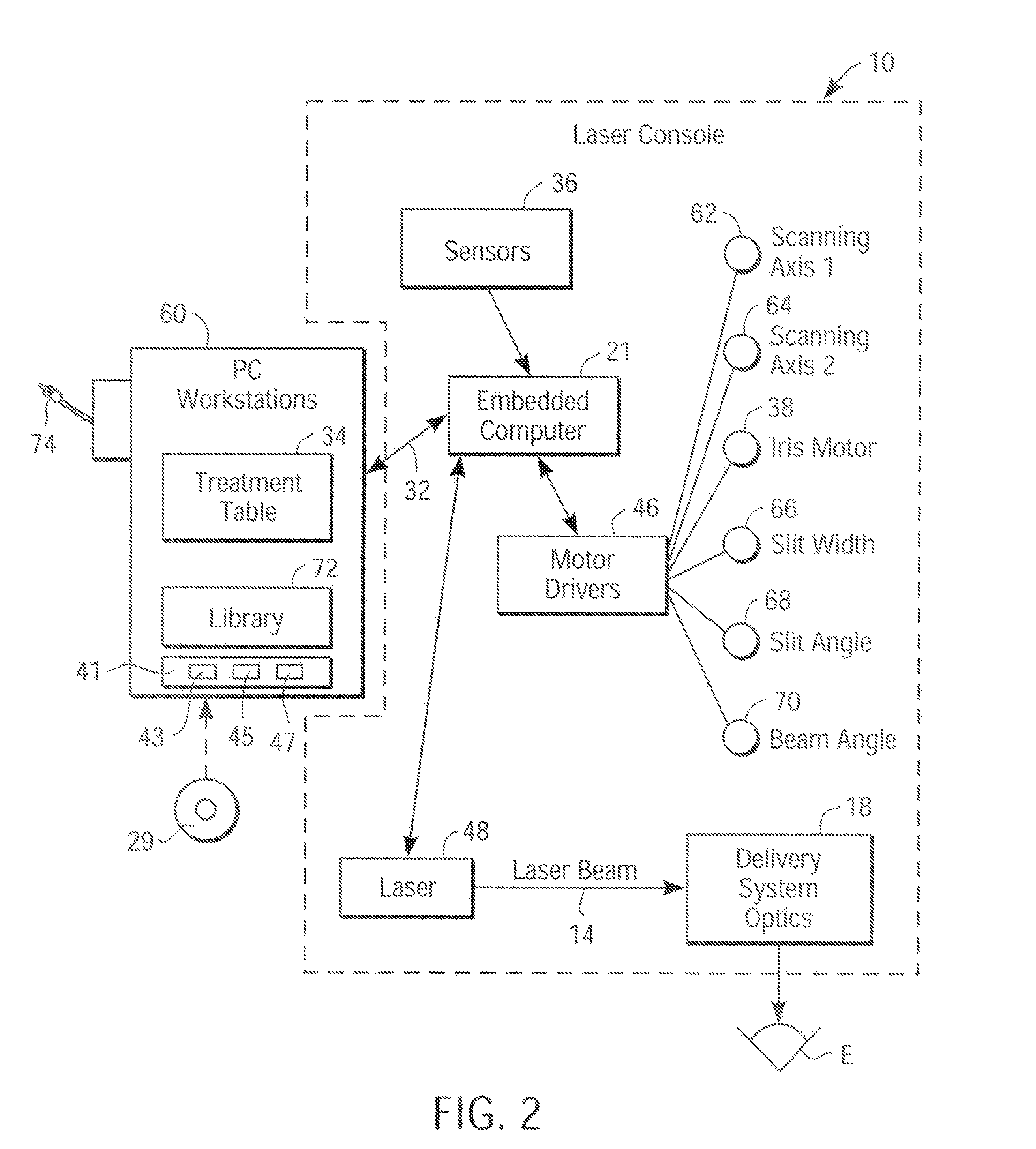

Application of blend zones, depth reduction, and transition zones to ablation shapes

ActiveUS8216213B2Reduce morbidityEnhance flap positioningLaser surgeryDiagnosticsOptical powerCornea

Methods, devices, and systems for reprofiling a surface of a cornea of an eye ablate a portion of the cornea to create an ablation zone with an optically correct central optical zone disposed in a central portion of the cornea, and a blend zone disposed peripherally to the central optical zone and at least partially within an optical zone of the eye. The blend zone can have an optical power that gradually diminishes with increasing radius from the central optical zone.

Owner:AMO MFG USA INC

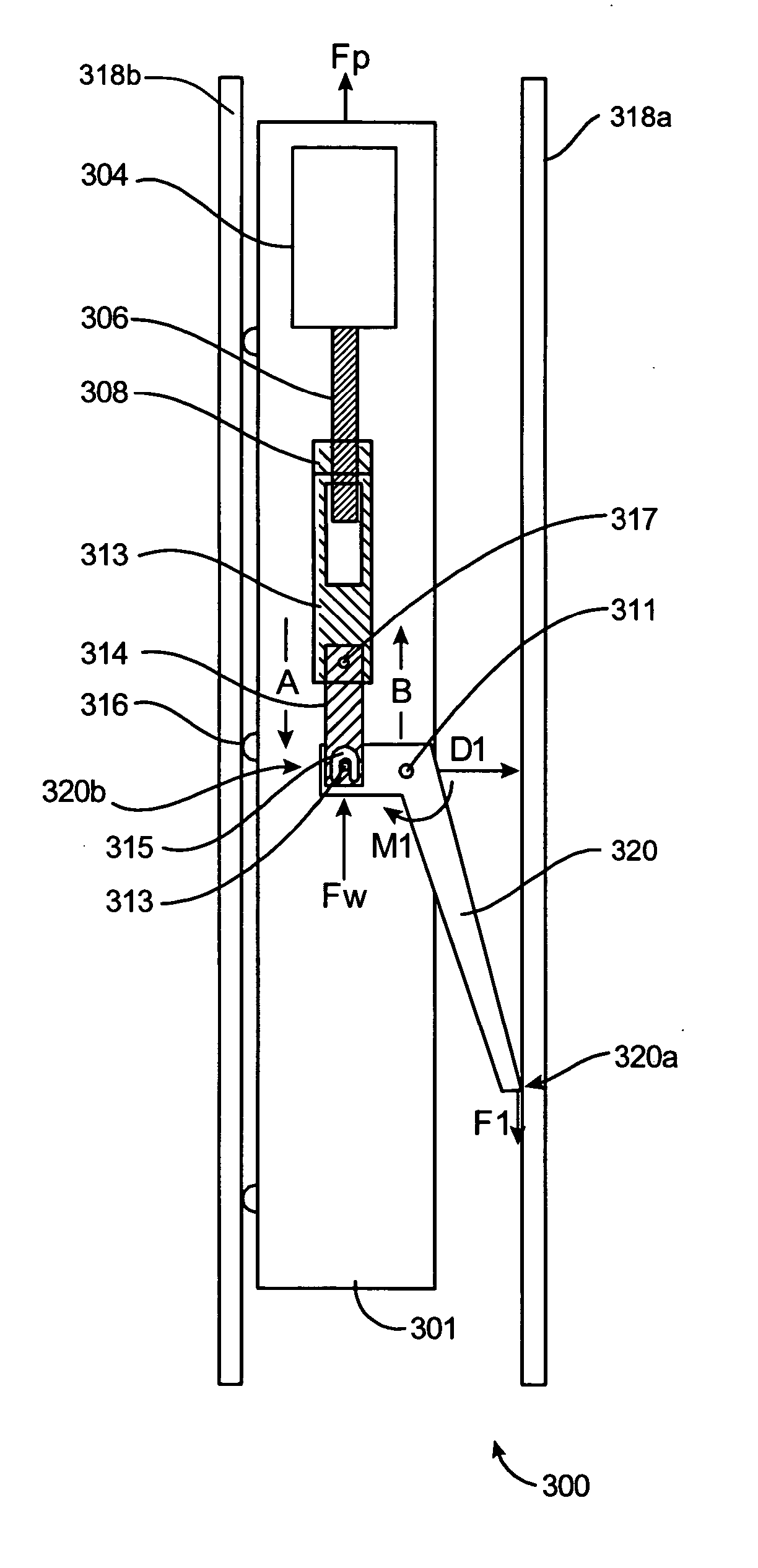

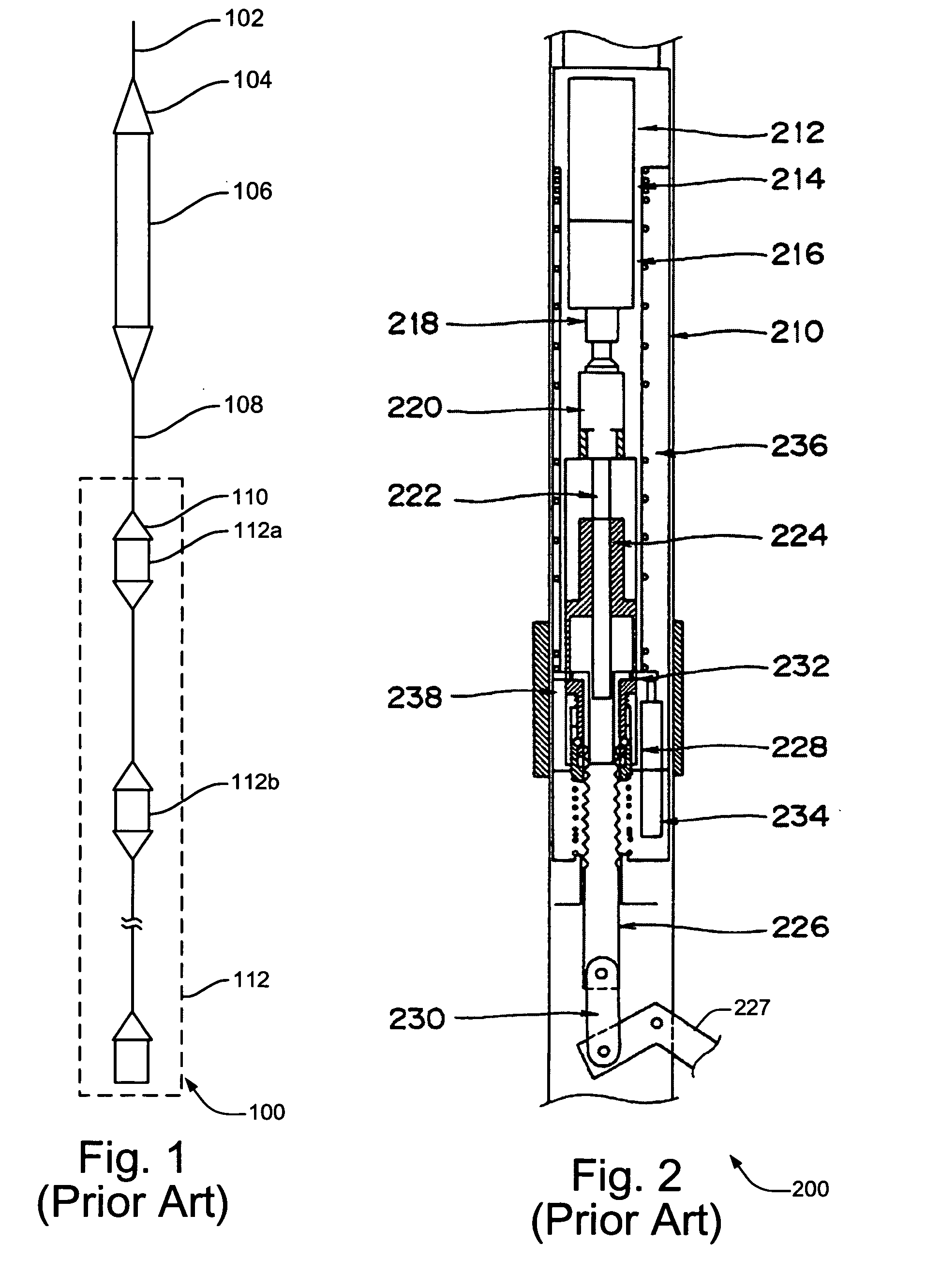

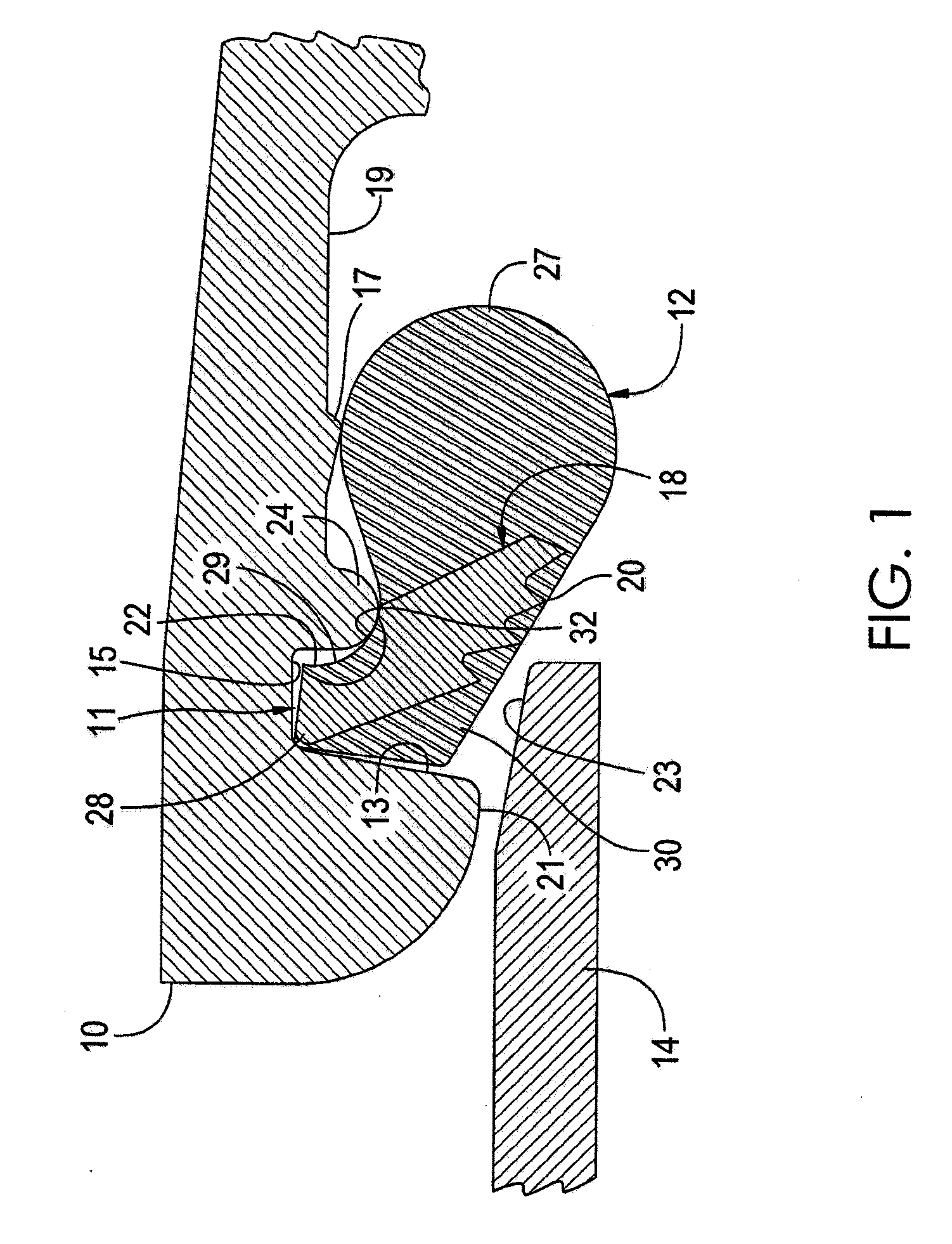

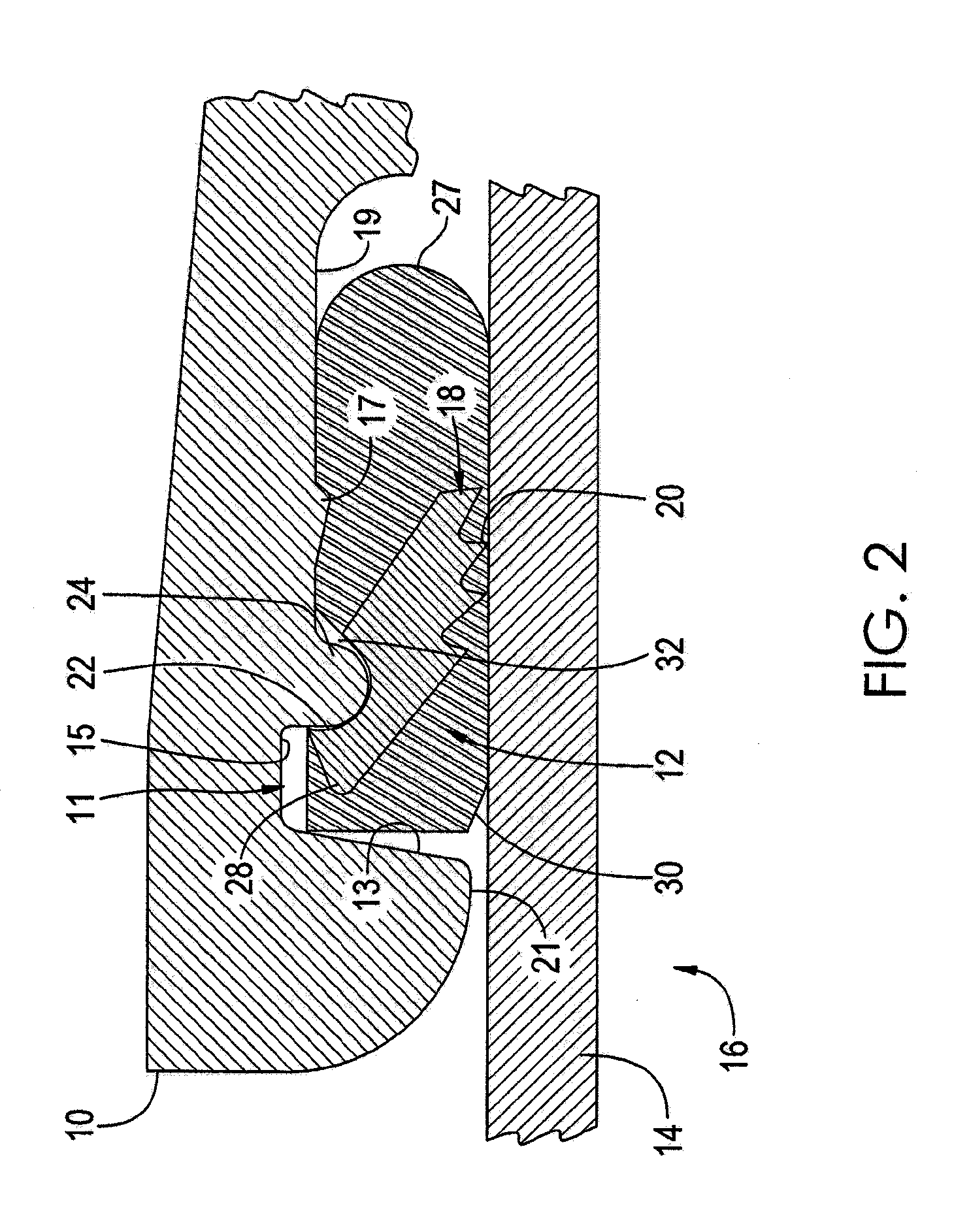

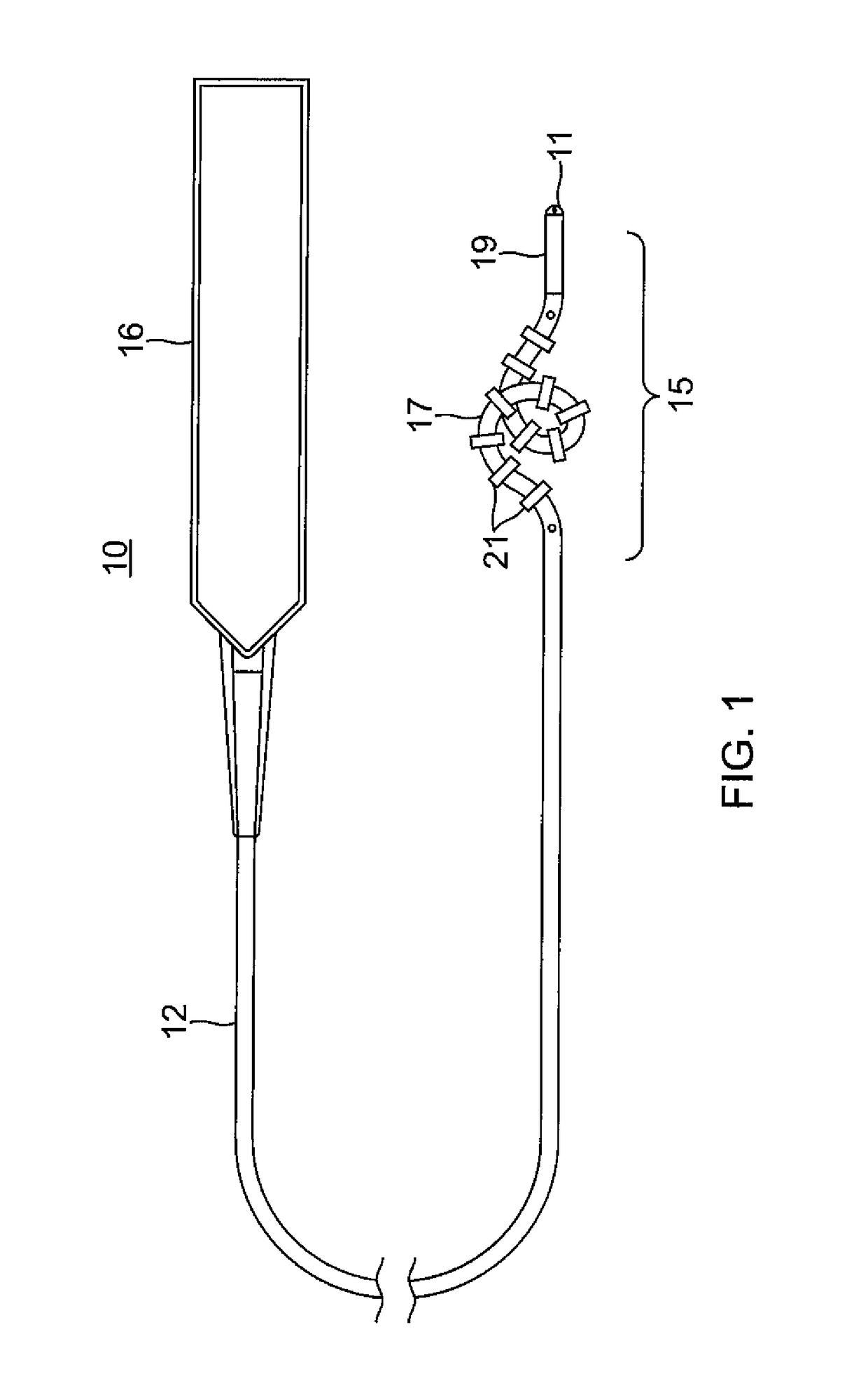

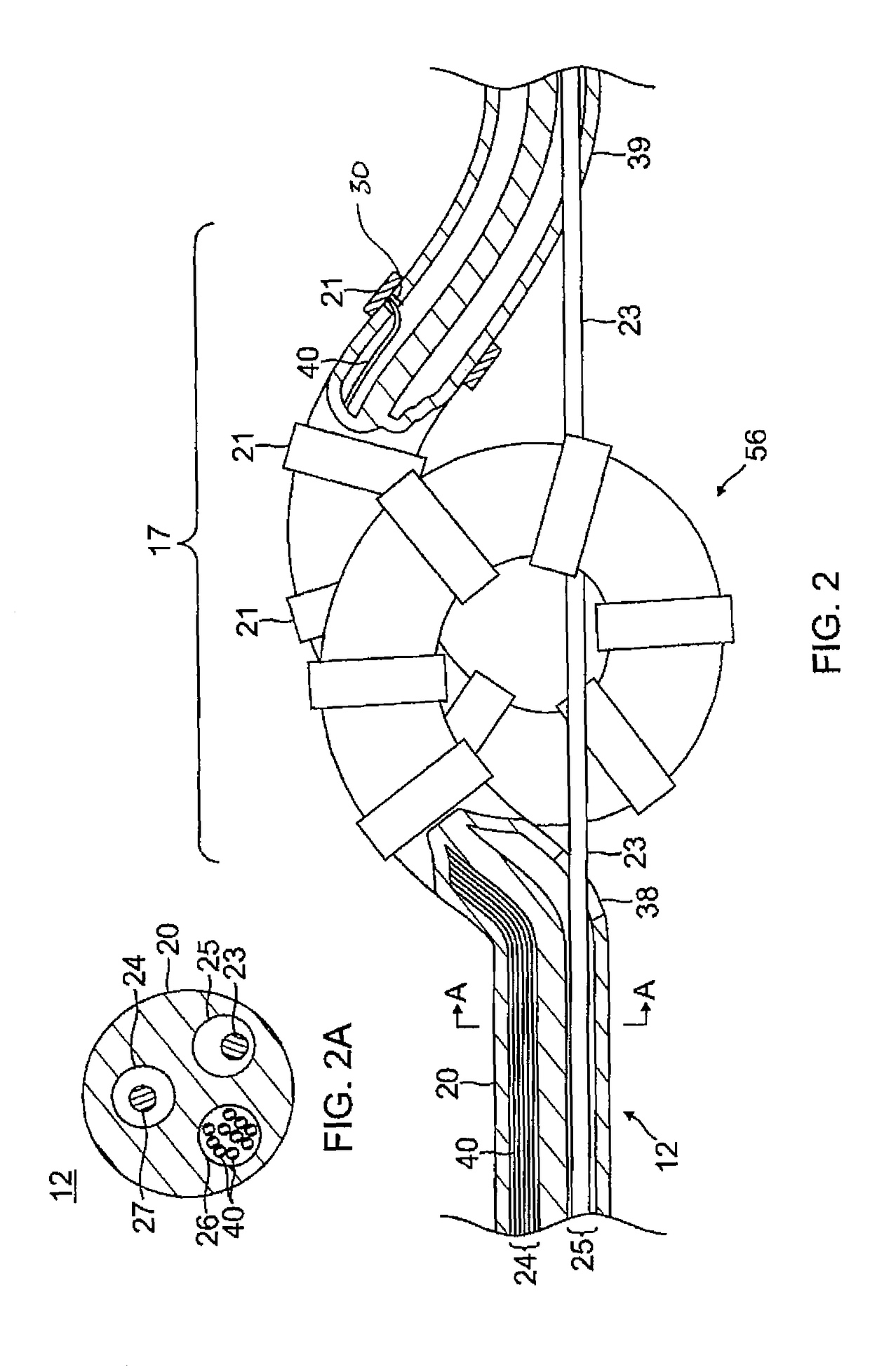

Anchor arm for seismic logging tool

A technique is described for releasing a borehole seismic acquisition tool from a stuck position within a borehole. The borehole seismic acquisition tool includes a tool body having at least one sensor package. The borehole seismic acquisition tool further includes an anchoring arm, and anchoring arm linkage adapted to connect the anchoring arm to the tool body. The anchoring arm linkage includes a weakpoint mechanism adapted to break in response to a minimum threshold amount of breaking force being applied upon the weakpoint mechanism. The anchoring arm includes a first end and a second end. The second end of the anchoring arm is pivotally attached to the anchoring arm linkage. The first end of the anchoring arm includes a tip portion which defines a slot. The anchoring arm also includes a movable cam inserted into the slot and removably secured to the first end via a first connector pin inserted through an aperture in the cam. According to at least one implementation, the cam is at least partially rotatable about the first connector pin. An exposed portion of the cam is engaged with the surface of borehole wall. When a failure of retraction of the anchoring arm is detected, the cam may be caused to rotate against the borehole wall surface in response. The rotation of the cam against the borehole wall surface causes a force to be exerted upon the weakpoint mechanism, which, in turn, causes the weakpoint mechanism to break. The breaking of the weakpoint mechanism results in a release of the borehole seismic acquisition tool from the stuck position. According to a specific embodiment, rotation of the cam against the borehole wall surface may be caused by a pulling force applied to a top portion of the borehole seismic acquisition tool.

Owner:SCHLUMBERGER TECH CORP

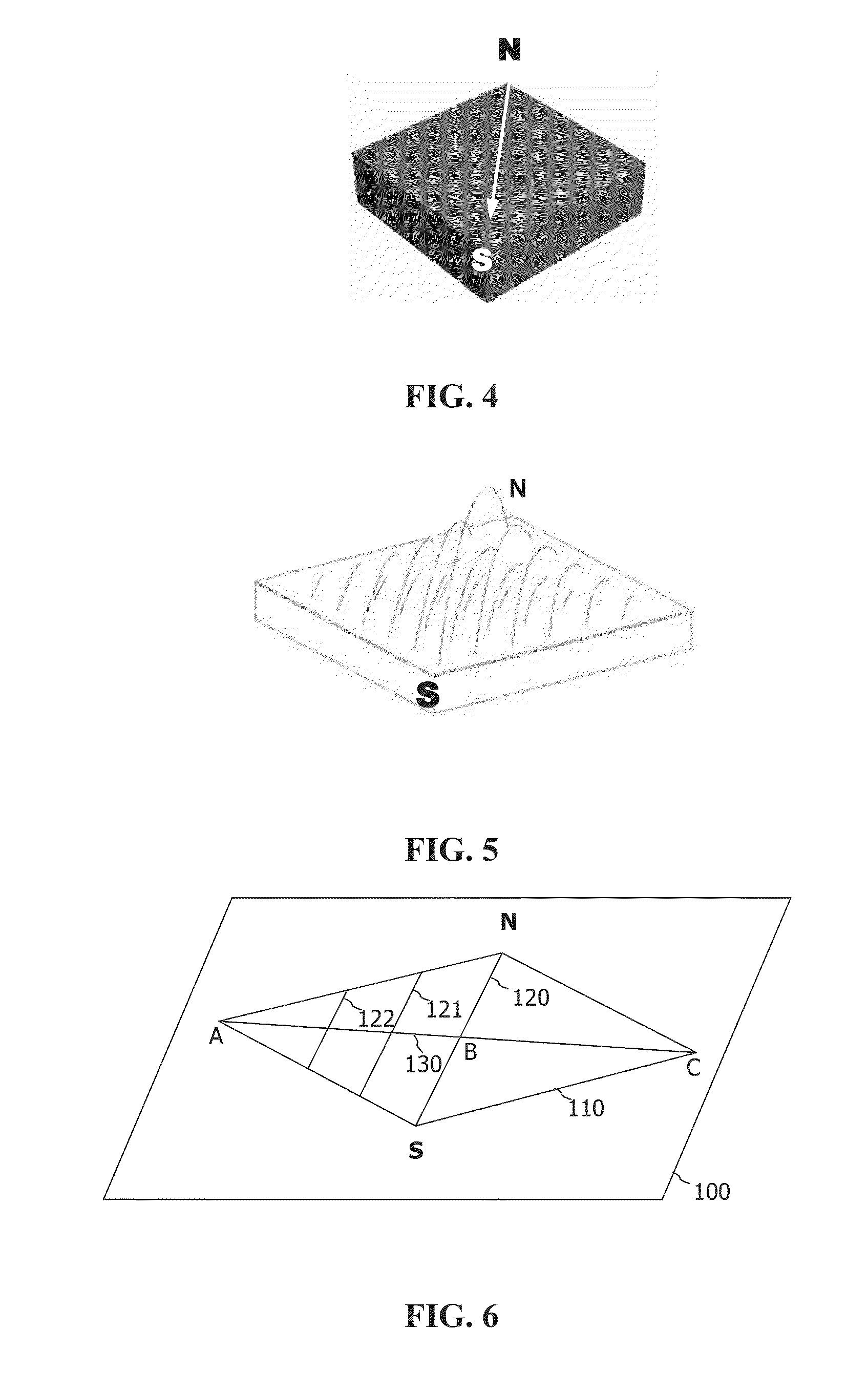

Article with curved patterns formed of aligned pigment flakes

In a printed article, pigment flakes are magnetically aligned so as to form curved patterns in a plurality of cross-sections normal a continuous imaginary line, wherein radii of the curved patterns increase along the imaginary line from the first point to the second point. When light is incident upon the aligned pigment flakes from a light source, light reflected from the aligned pattern forms a bright image which appears to gradually change its shape and move from one side of the continuous imaginary line to another side of the continuous imaginary line when the substrate is tilted with respect to the light source.

Owner:VIAVI SOLUTIONS INC

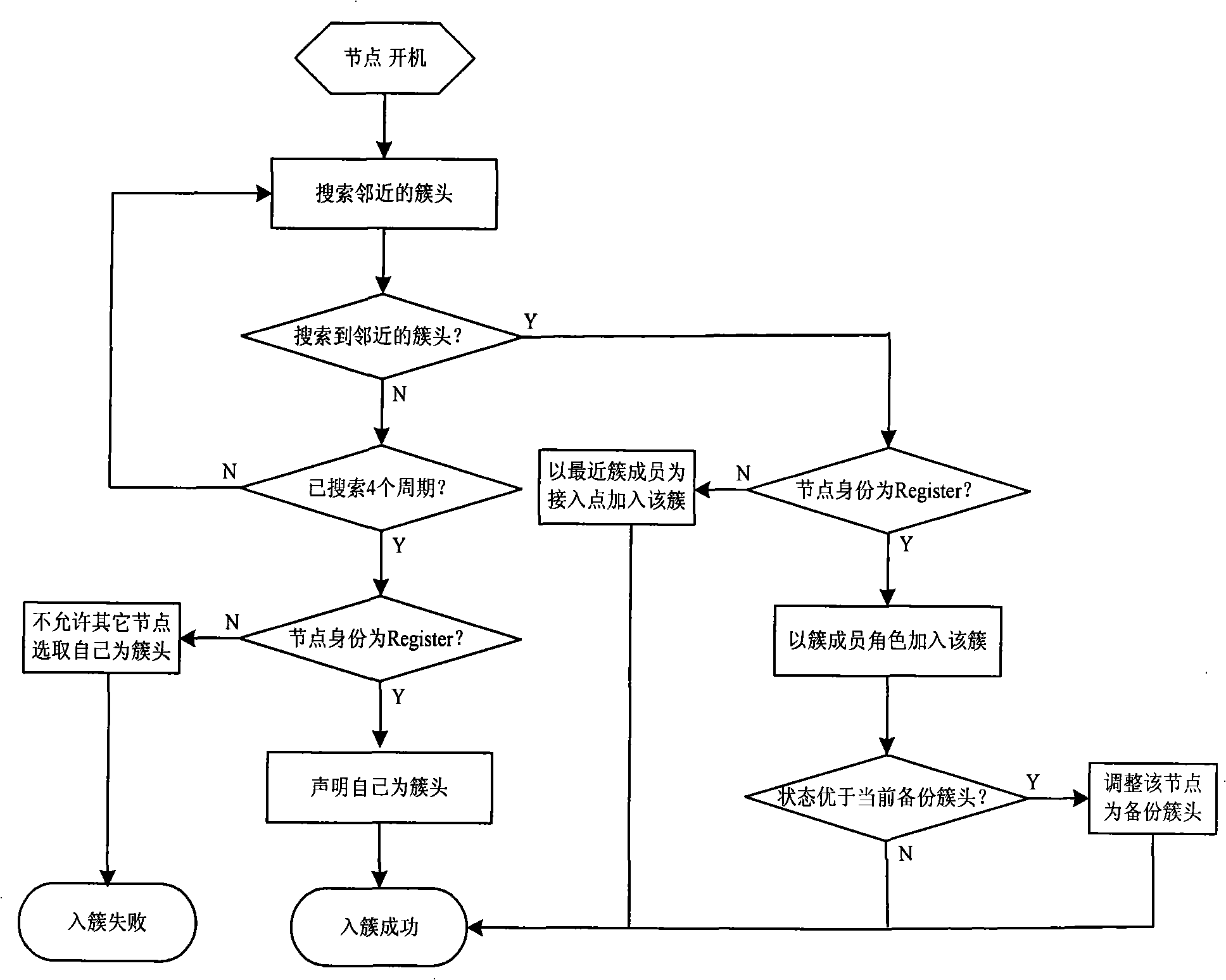

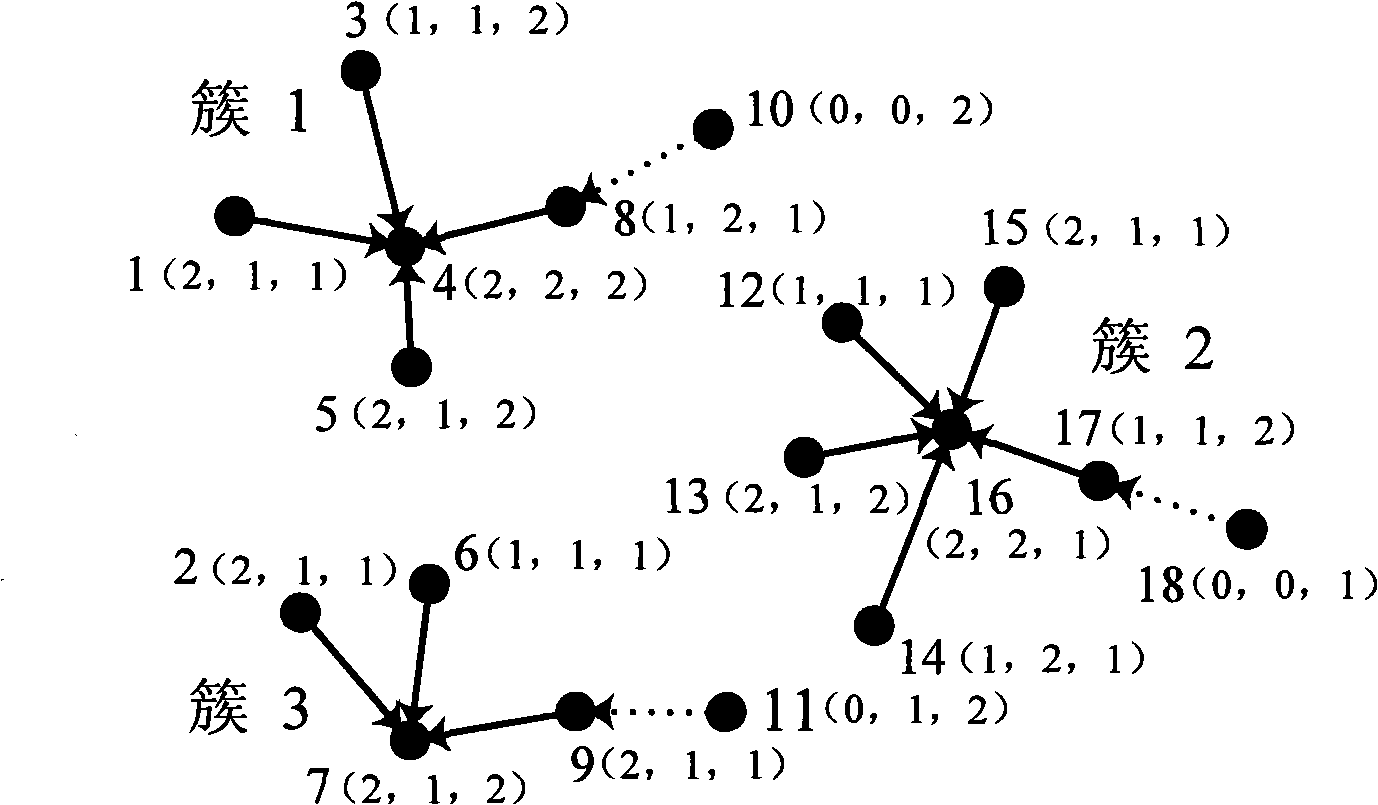

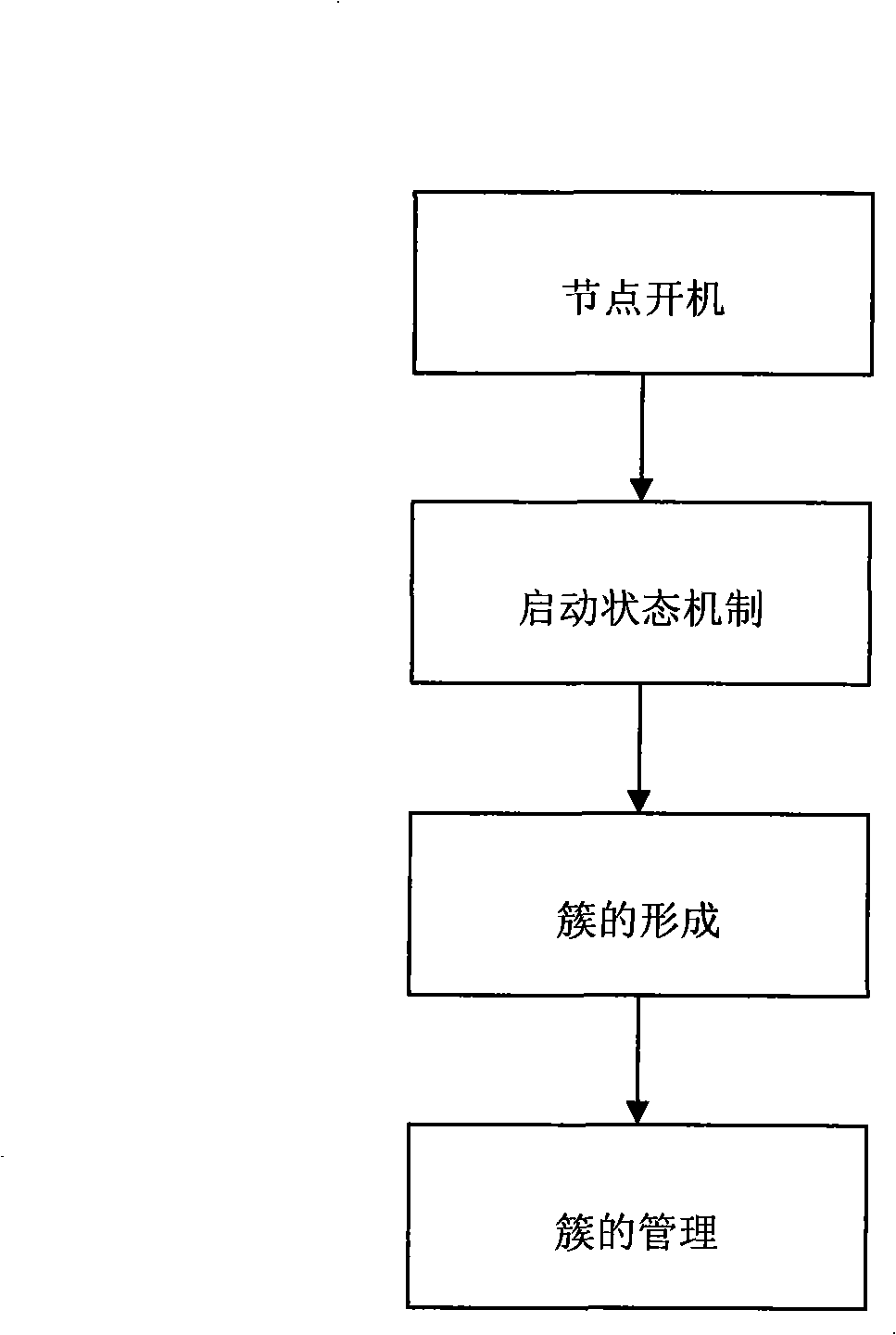

Mobile self-organizing network cluster dividing method based on state mechanism

ActiveCN101360033AImprove stabilityEasy to manageData switching by path configurationMean Survival TimeSelf-organizing network

The invention provides a method of clustering the moving ad hoc network based on the state mechanism, belonging to the wireless communication field in the communication technology. The method respectively grades three factors of the mobility of the node, the size of the cluster and the energy of the node, combines the three factors and puts forward a node state mechanism. According to the node state, two kinds of node identities of Register and Guest are prescribed, and a cluster head, backup cluster heads and cluster members from the nodes of Register identity are selected; while from the nodes of Guest identity, the nearest cluster members are selected as the access points, which join the corresponding cluster through two jumps. The invention is superior to the traditional method in respects of the average survival time of the cluster and the balance degree of the cluster, and improves the performance of the network.

Owner:PANDA ELECTRONICS GROUP +3

In-situ treatment system and method of black and odorous water

ActiveCN107673561AIncrease concentrationTo achieve the effect of phosphorus removalWater treatment parameter controlWater treatment compoundsWater flowWater quality

The invention provides an in-situ treatment system of black and odorous water and a method of using the system to treat black and odorous water. The in-situ treatment system of black and odorous watercomprises a pretreatment zone, an in-situ treatment zone and a separation zone; a certain section of a river channel is modified, more deflections are added to water flows, the water has longer stayin a unit zone, and the land around is scarcely used; in-situ restoration is mainly dependent on a biological method assisted by physicochemical methods, and the quality of the black and odorous wateris finally improved. In the method, the in-situ restoration of the black and odorous water is confined in a smaller area so that the concentration of microbes in the water of this area is increased,reflow can be achieved, contaminants in the water gain full time to degrade, treatment cost is lowered, and treatment is fast, efficient and free of secondary contamination.

Owner:中交生态环保投资有限公司

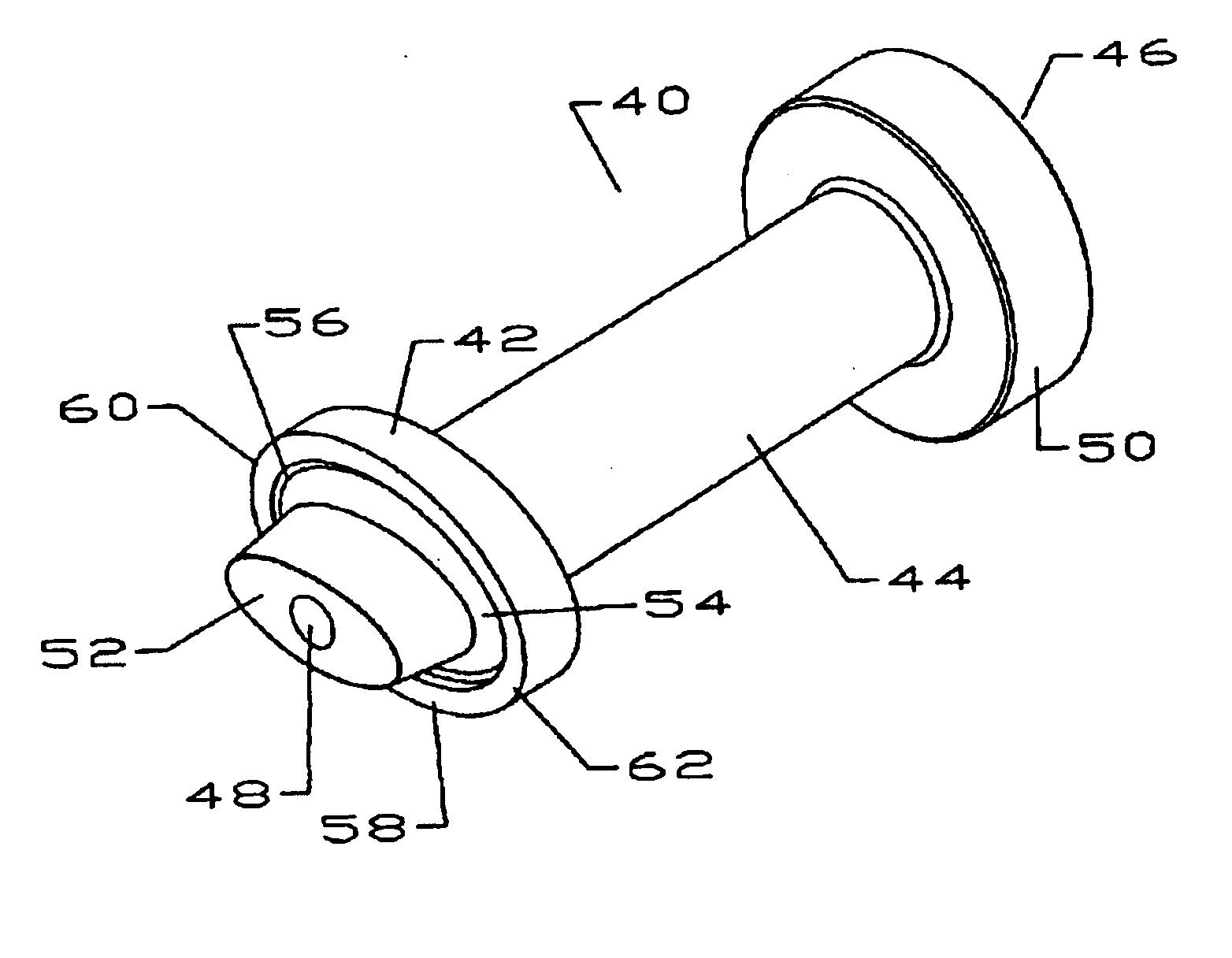

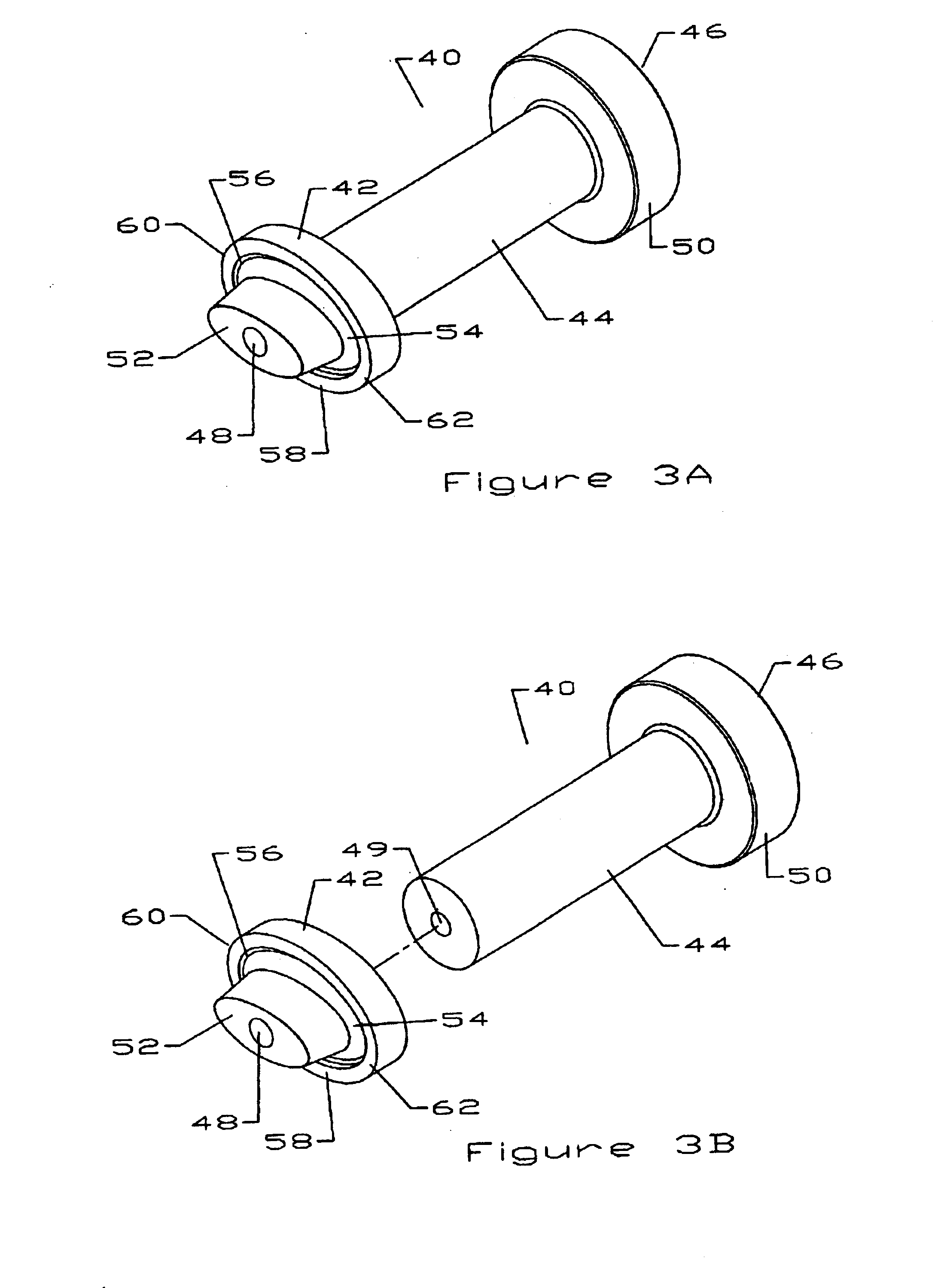

Method and apparatus for flaring a tube

InactiveUS6935153B2Increase radiusHand protectionForging/hammering/pressing machinesPipe-jointsFlareEngineering

A tool for forming flares in, for example, corrugated elliptical tubing. The tool may have a retaining portion having a longitudinal axis located between an impact surface and a die head. The die head is coupled to the retaining portion on a first side, and on a second side the die head has a guide plug extending from an inner area of a flare surface normal to the longitudinal axis; and a bottoming surface extending from a periphery of the flare surface. The bottoming surface is oriented at an angle to the flare surface. A saw guide may be used to obtain an appropriate extension of the tube from a stop which the flare is formed against.

Owner:COMMSCOPE TECH LLC

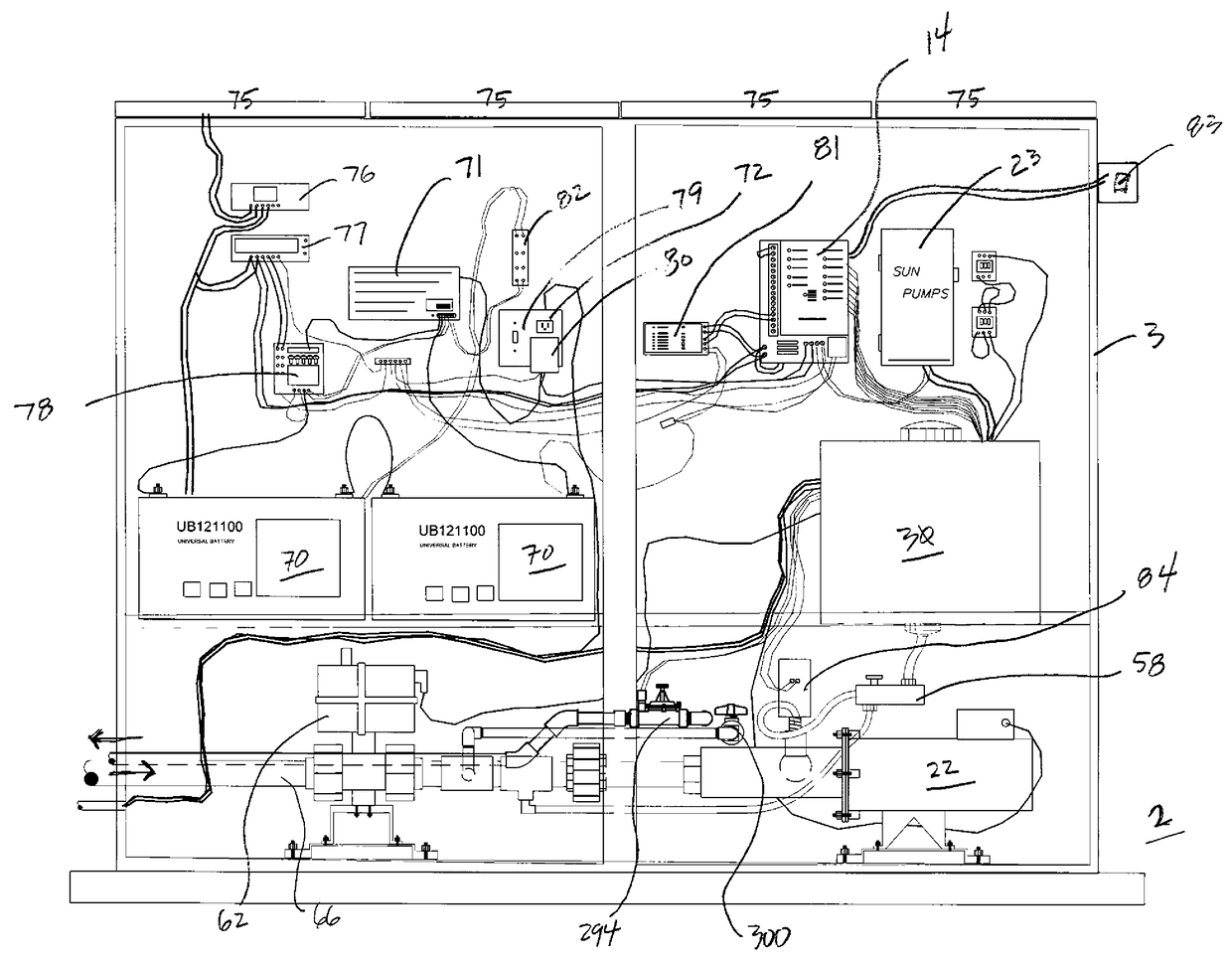

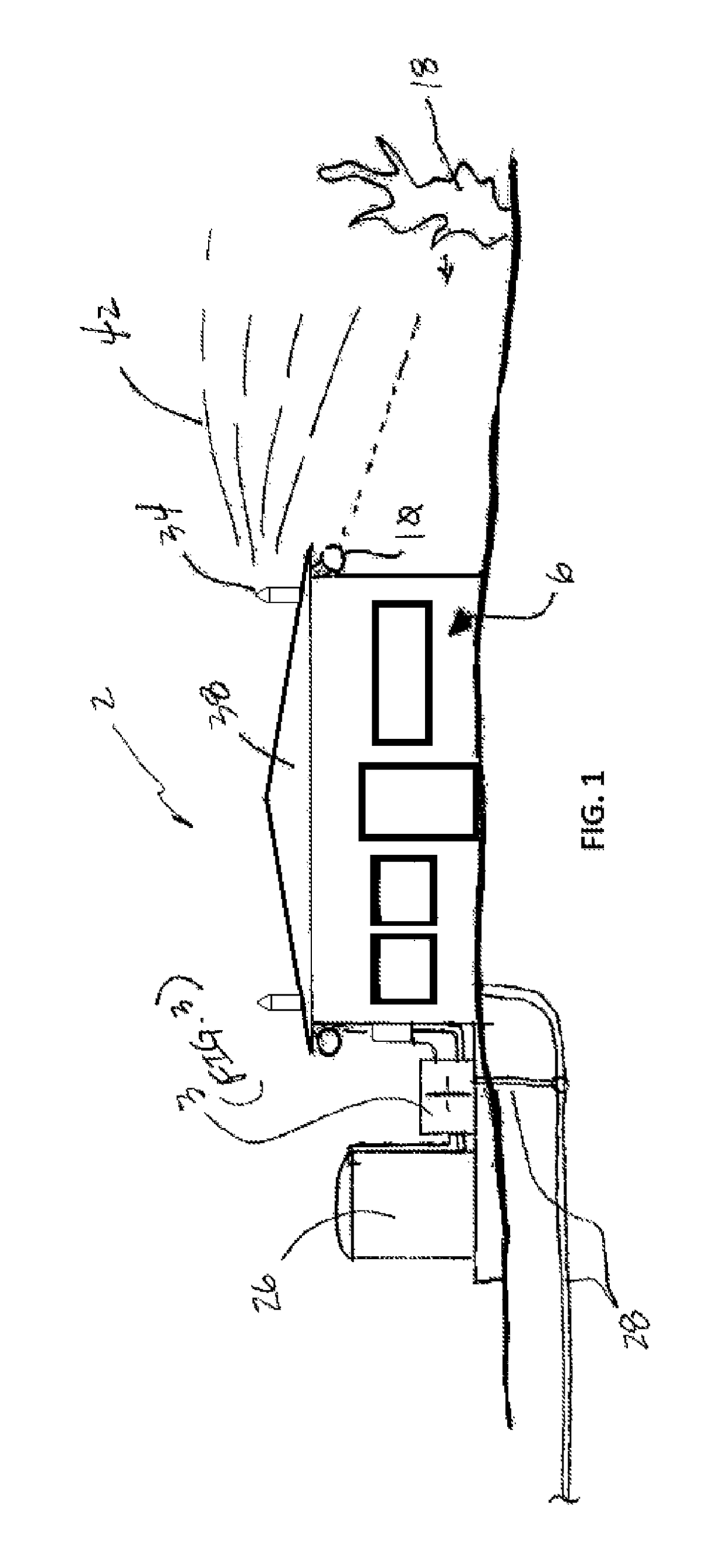

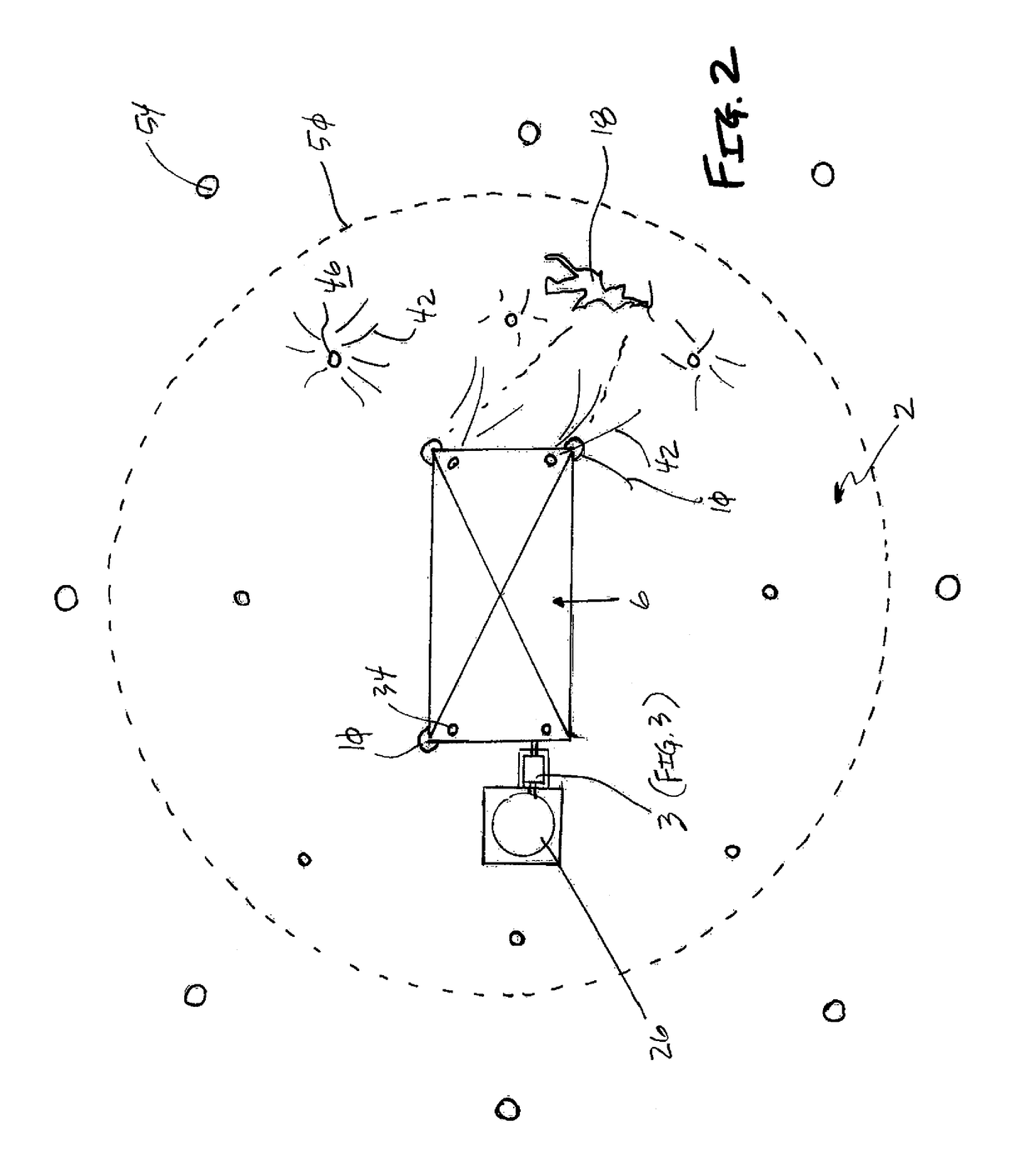

Hydro fire mitigation system

Owner:WAVEGUARD

Pipe Joint Gasket and Method of Using Same

ActiveUS20130043656A1Reduce the possibilityReduce componentsSleeve/socket jointsEngine sealsBiomedical engineering

A gasket for preventing separation of interconnected pipes without damaging the pipes. The gasket includes a compressible body having a plurality of metal segments partially embedded therein. Each of the metal segments includes a row of exposed teeth configured for engaging a spigot end of a pipe and a trough configured for pivotably engaging a bead on a bell. The trough is further configured for shearing or deforming the bead and inhibiting over-pivoting of the segment about the bead when the pipes are partially withdrawn away from one another, for example, during over-pressurization of the pipes.

Owner:MCWANE

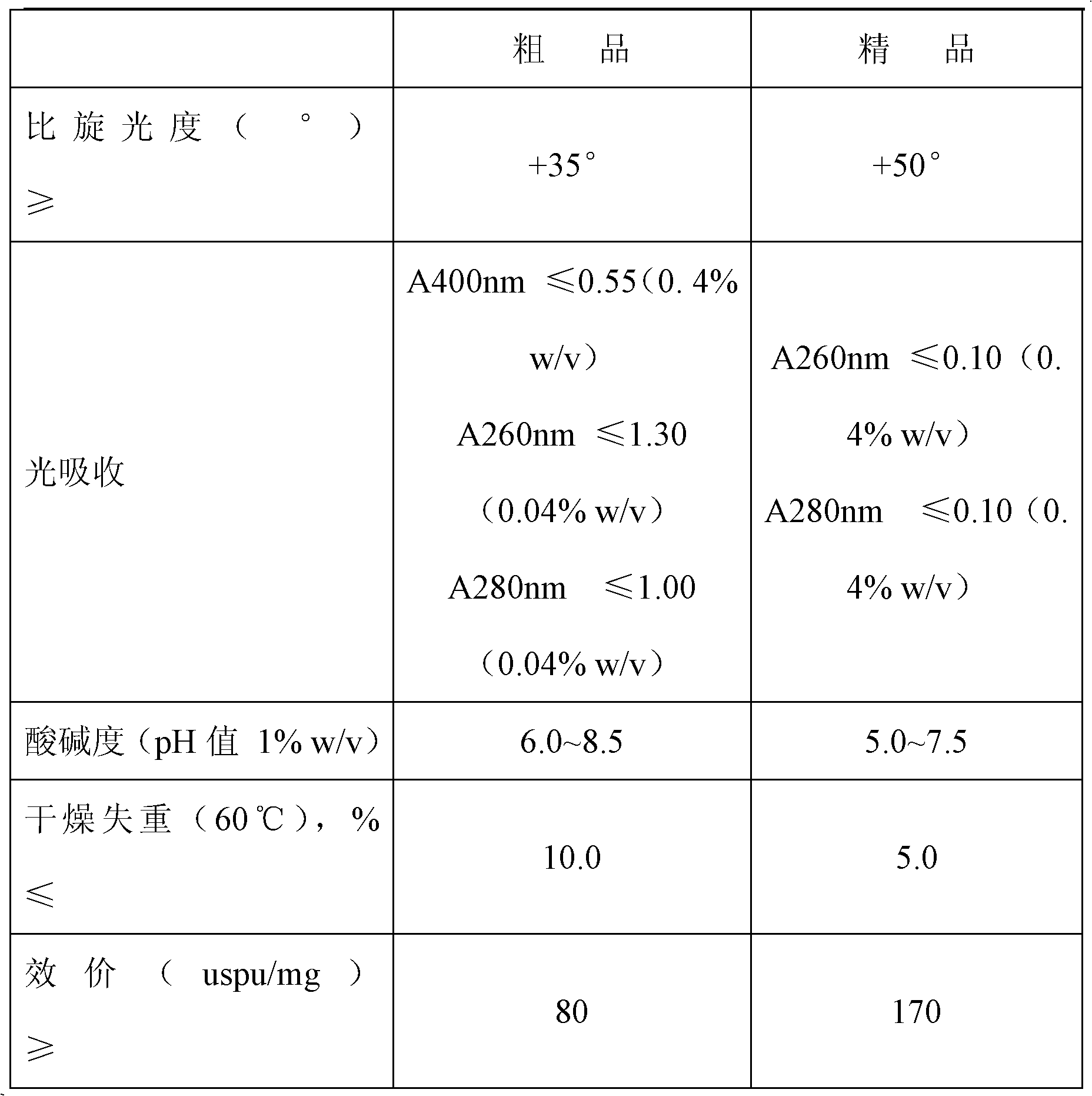

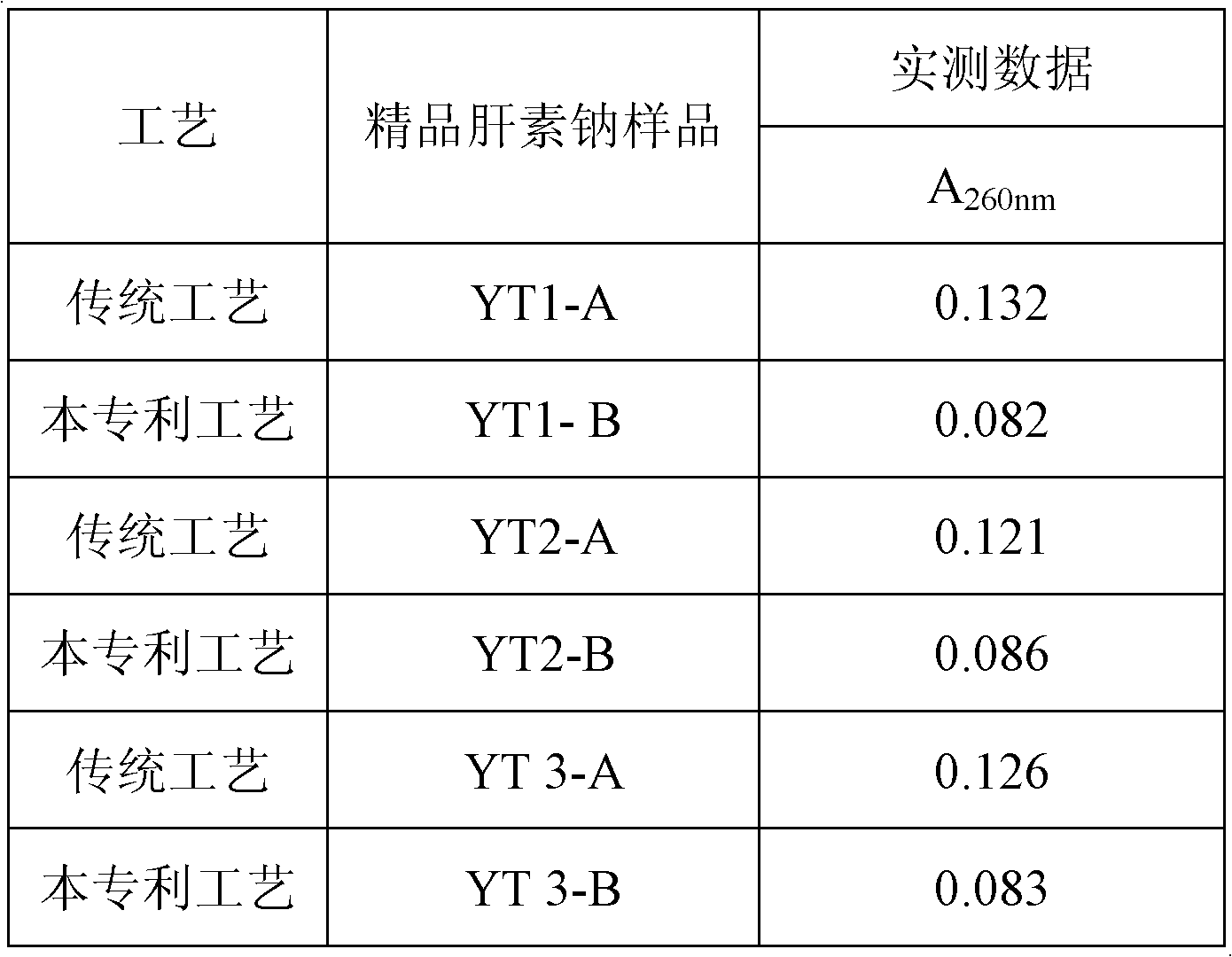

Crude heparin sodium purification technology

The invention relates to a heparin sodium purification technology. The crude heparin sodium purification technology sequentially comprises the following steps: 1, dissolving crude heparin sodium in a sodium chloride solution, and adding an alkaline protease for enzymatic hydrolysis; 2, inactivating, adding diatomite, carrying out high speed centrifugation, and removing insoluble impurities; 3, adding polysilicate, carrying out high speed centrifugation, and removing insoluble impurities; 4, adding alcohol for precipitating, and removing supernatant alcohol; 5, dissolving in the sodium chloride solution, adding hydrogen peroxide for oxidizing, carrying out high speed centrifugation after oxidation, and removing insoluble impurities; 6, adding alcohol for precipitating, and removing supernatant alcohol; and 7, filtering, and carrying out vacuum lyophilizing to obtain refined heparin sodium. The crude heparin sodium purification technology has the advantages of low content of proteins in the refined heparin sodium, and high yield of the refined heparin sodium.

Owner:PUJIANG CAREX BIOTECH

Application of blend zones, depth reduction, and transition zones to ablation shapes

ActiveUS20120271287A1Reduce morbidityEfficiently and effectively helpLaser surgerySurgical instrument detailsOptical powerPhysics

Methods, devices, and systems for reprofiling a surface of a cornea of an eye ablate a portion of the cornea to create an ablation zone with an optically correct central optical zone disposed in a central portion of the cornea, and a blend zone disposed peripherally to the central optical zone and at least partially within an optical zone of the eye. The blend zone can have an optical power that gradually diminishes with increasing radius from the central optical zone.

Owner:AMO MFG USA INC

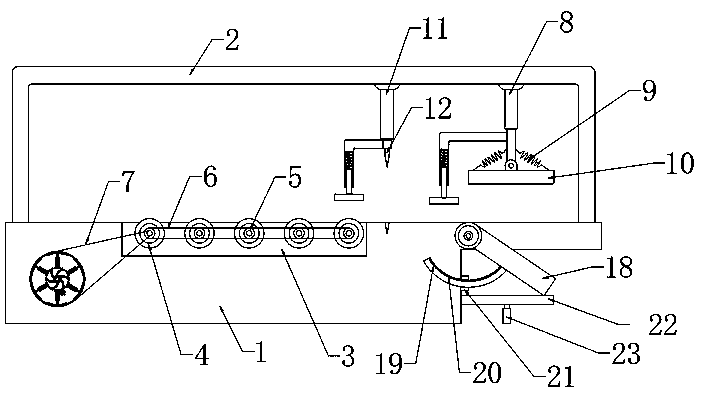

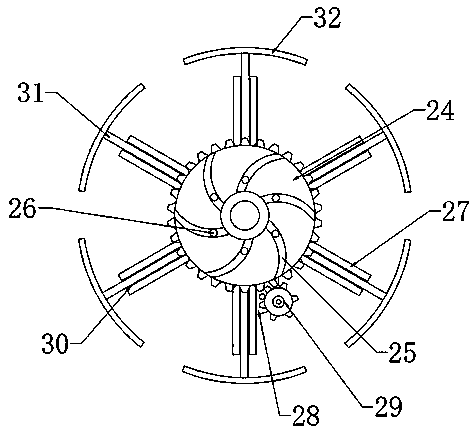

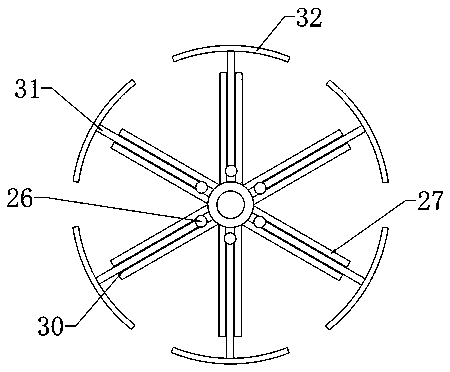

Reshaping device for metal steel processing

ActiveCN111545604ANot easy to moveGuaranteed stabilityMetal-working feeding devicesPositioning devicesElectric machineGear wheel

The invention discloses a reshaping device for metal steel processing. The reshaping device for metal steel processing comprises a workbench. A support is fixedly connected to the workbench. An installation groove is formed in the upper end of the workbench, multiple conveying rollers are connected with the interior of the installation groove in a rotating mode, and a transmission mechanism is arranged among the multiple conveying rollers. A driving motor is installed on the front side of the workbench, a first gear is fixedly connected with the output end of the driving motor, a second gear is installed on the workbench, and the second gear and the first gear mesh with each other. An adjusting mechanism is fixedly connected to the second gear, the adjusting mechanism and the second gear are coaxial, and the adjusting mechanism and the transmission mechanism are connected with each other through a transmission belt. The reshaping device for metal steel processing is reasonable in structure, cutters can be bent into a whole, and therefore the steel plate bending efficiency is greatly improved, the labor workload of a worker is also reduced, steel plates can be subjected to adjustable equal-length cutting operation, the practicability is high, the steel plate bending angle can also be adjusted, and the function is powerful.

Owner:浙江星筑科技有限公司

Float glass

The utility model relates to float glass, batch of the float glass and a production method of the float glass. The compositions of the float glass include silicate glass basic oxide, and 0.01 to 2 percent of lithium oxide by weight and rare earth oxide, wherein, the rare earth is at least three kinds of lanthanum, cerium, yttrium, praseodymium and neodymium, which is sourced from the gangue of the rare earth. The batch of the float glass is mixed by the silicate glass basic raw material and the additives, in weight percent, 87.02-106.0:0.02-4. The additives are the lithium carbonate Li2Co3 and the gangue of the rare earth, and the batch is made into the float glass through a float-glass melting kiln. For the lithium oxide and the rare earth are added, the present invention reduces the melting temperature of the glass, which can be applied to the production of the large-scale float glass while satisfying the electrics, the calorifics, and the stable chemical performance. The float glass concerned in the present invention is more applicable to producing the chemical toughened glass.

Owner:CHINA BUILDING MATERIALS ACAD

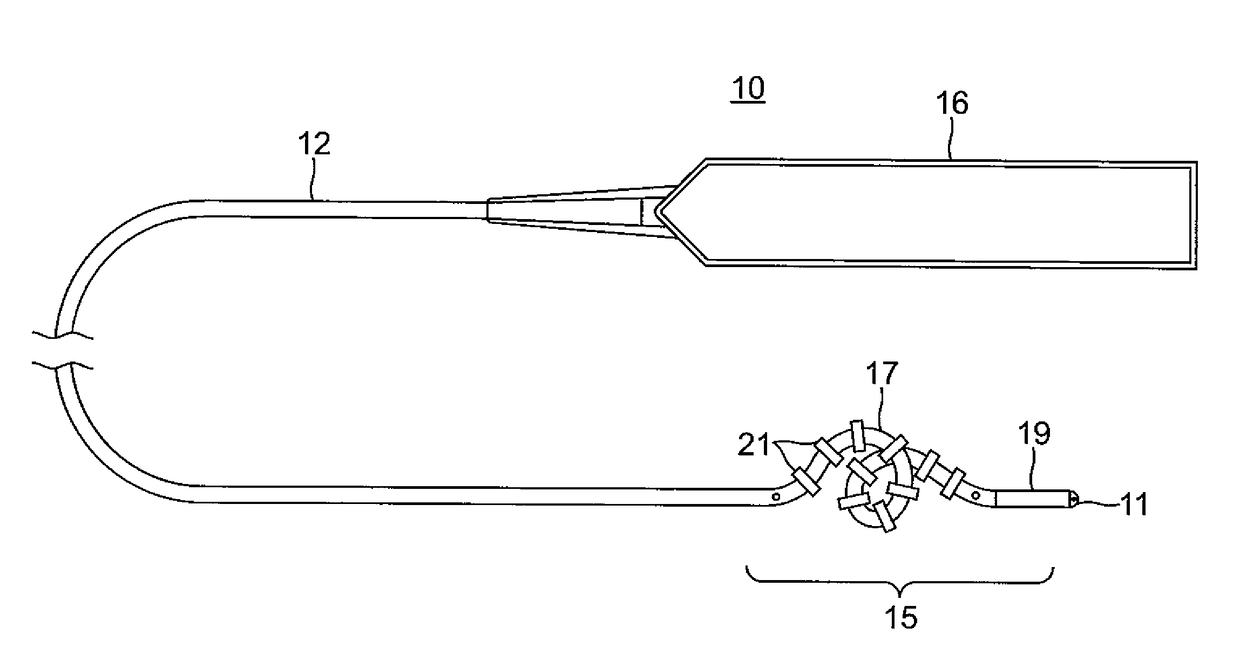

Catheter adapted for use with guide wire for accessing vessels

ActiveUS9848948B2Less traumatic profileIncrease radiusCatheterSurgical instruments for heatingCatheterGuide wires

An ablation catheter adapted for use with a guide wire has a 3-D shaped portion that carries ring electrodes for ablating a vessel or tubular region, including the renal artery. The 3-D shaped portion, for example, a helical portion, enables the ring electrodes to contact an inner surface of the vessel at a plurality of locations at different depths along the vessel to form a conduction block without forming a closed conduction loop which would otherwise increase the risk of stenosis of the vessel. In one embodiment, the catheter has a lumen with entry and exit ports to allow the guide wire to pass through the lumen but bypass the 3-D shaped portion. In another embodiment, the catheter has outer bands providing side tunnels through which the guide wire can pass through.

Owner:BIOSENSE WEBSTER (ISRAEL) LTD

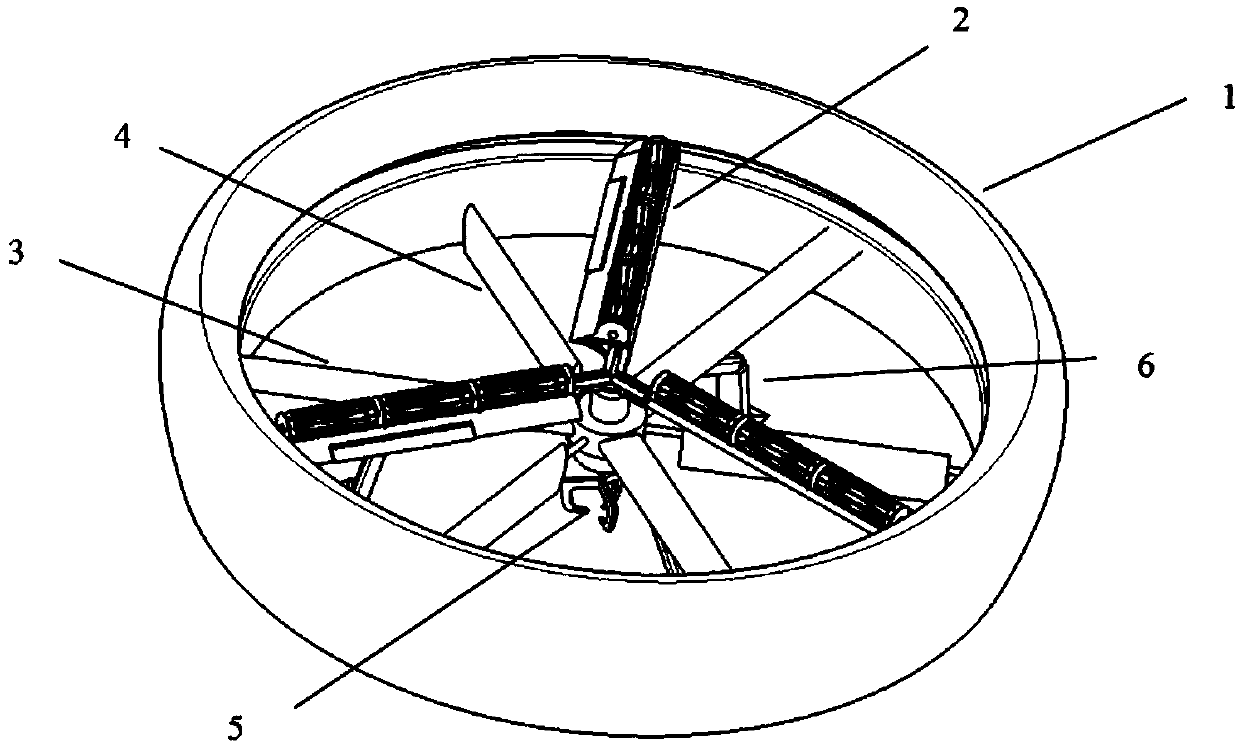

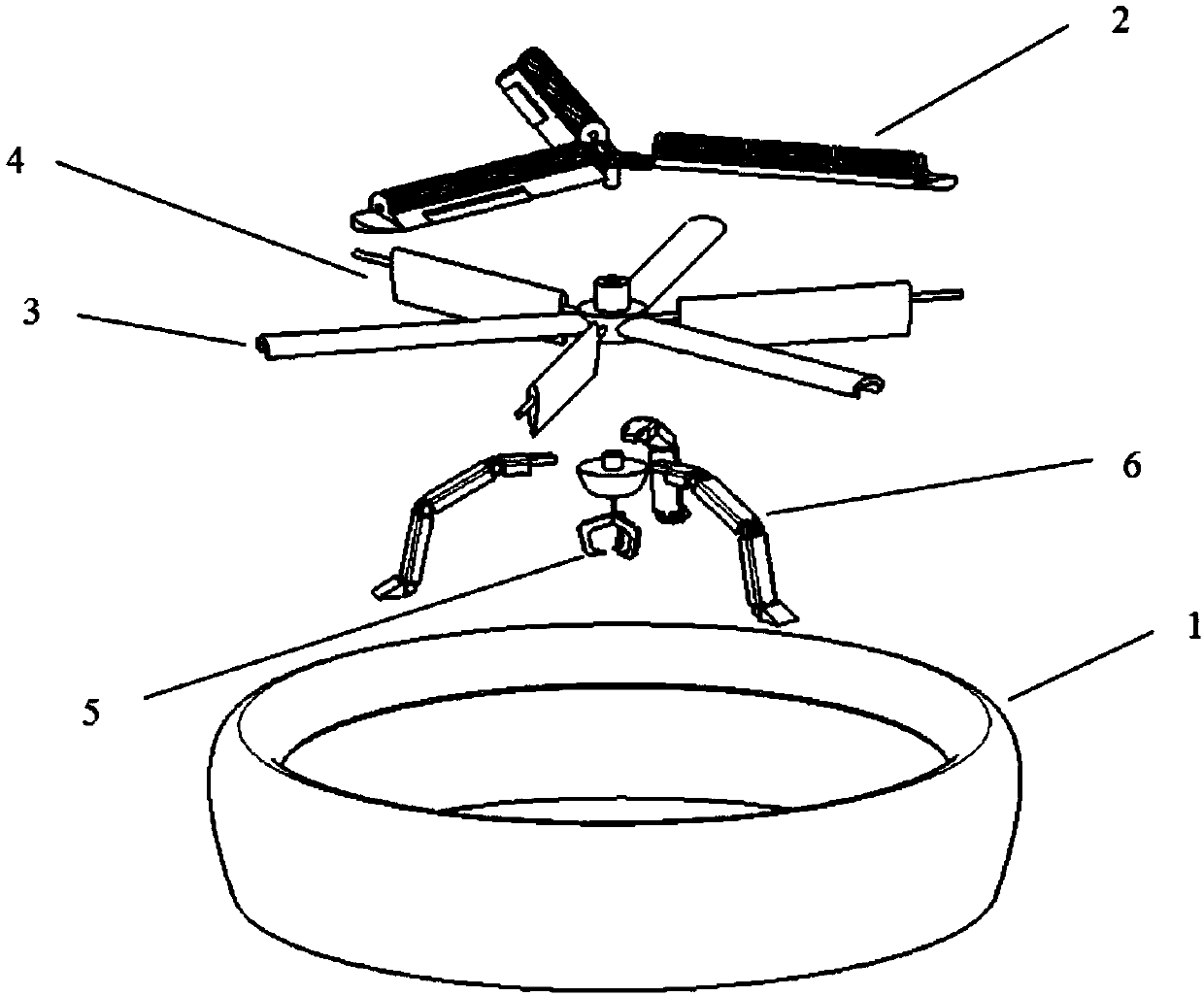

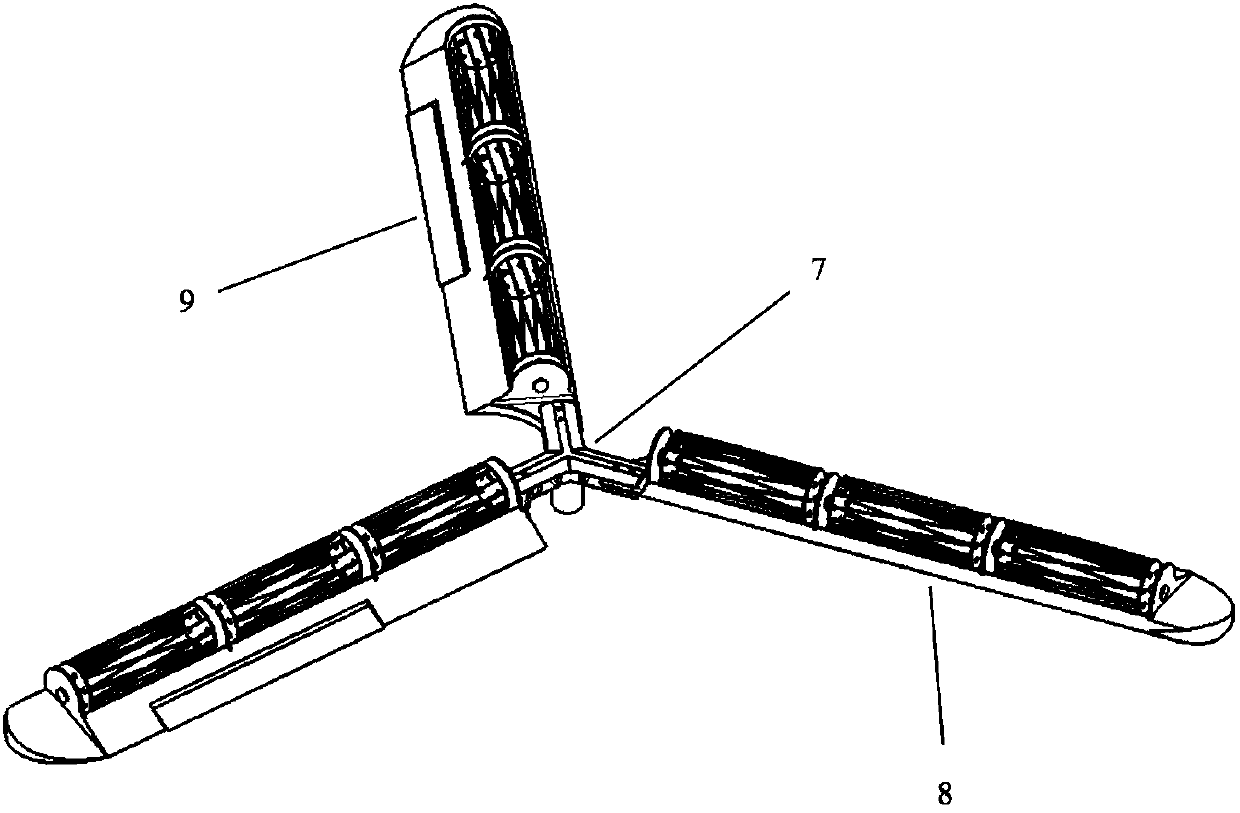

Notched duct type plume rotor aircraft

The invention relates to a notched duct type plume rotor aircraft. The notched duct type plume rotor aircraft comprises a notched duct, a plume rotor, a supporting crossbeam, a yaw rudder surface, a telescopic manipulator and a landing gear, wherein the plume rotor adopts a main lifting force structure; and the notched duct adopts an auxiliary lifting force structure. Through the adoption of the combination form of the notched duct type plume rotor aircraft disclosed by the invention, the lifting force of the aircraft can be improved to a large extent, and an anti-torque cannot be generated; and the notched duct type plume rotor aircraft is very flexible, can be independently used as a module to execute a relevant flight mission such as transporting small-scale objects or executing a monitoring and investigating mission.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

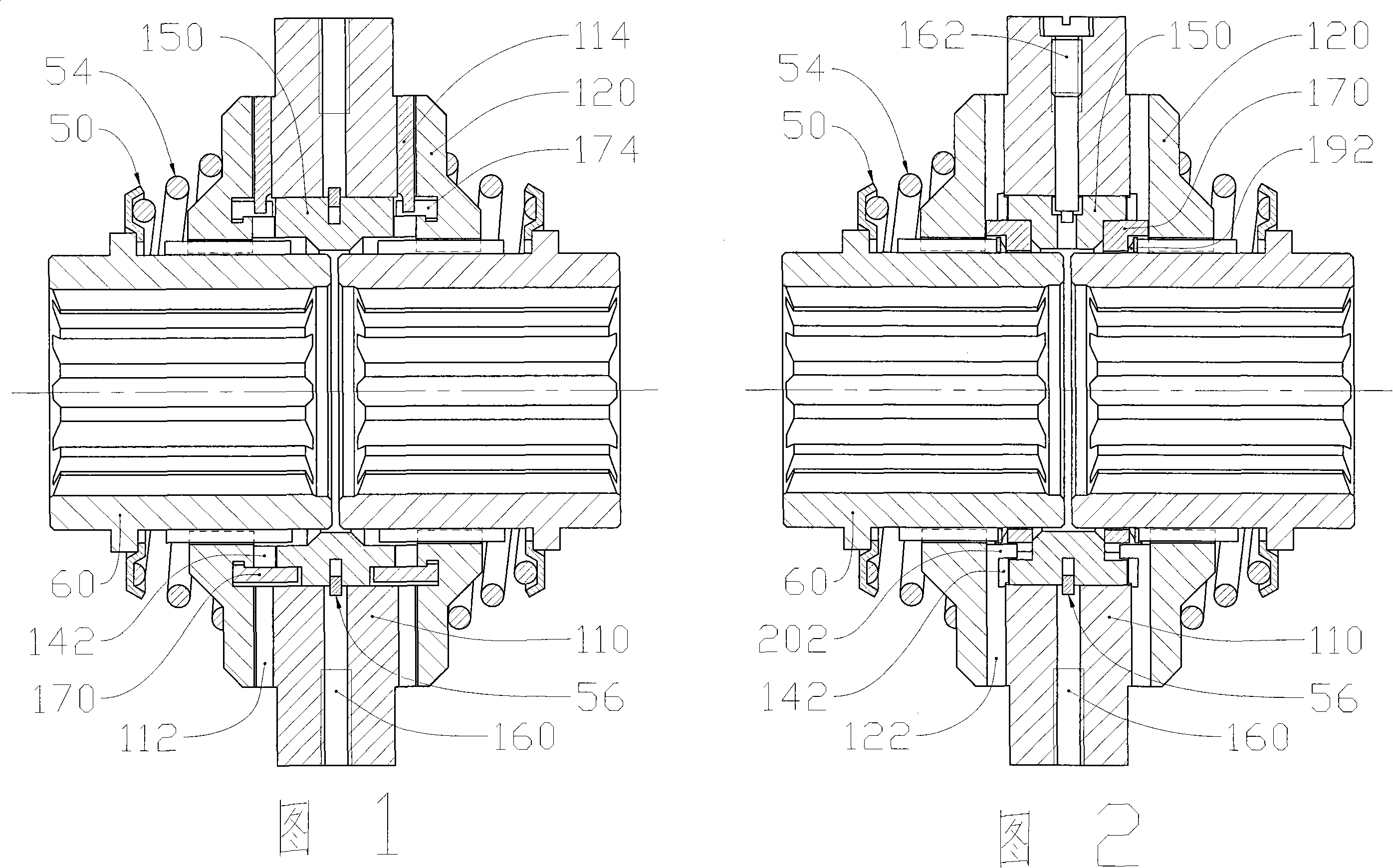

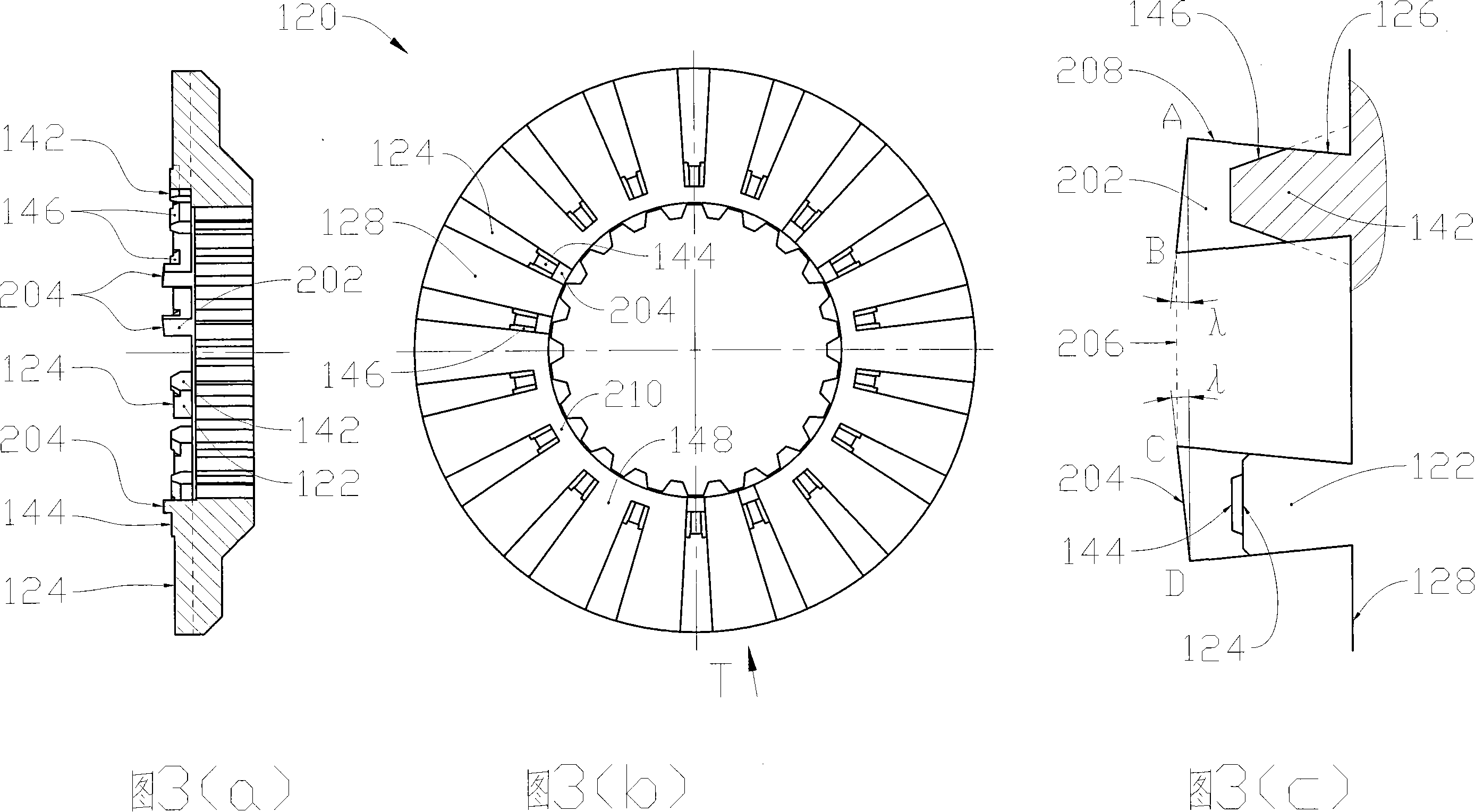

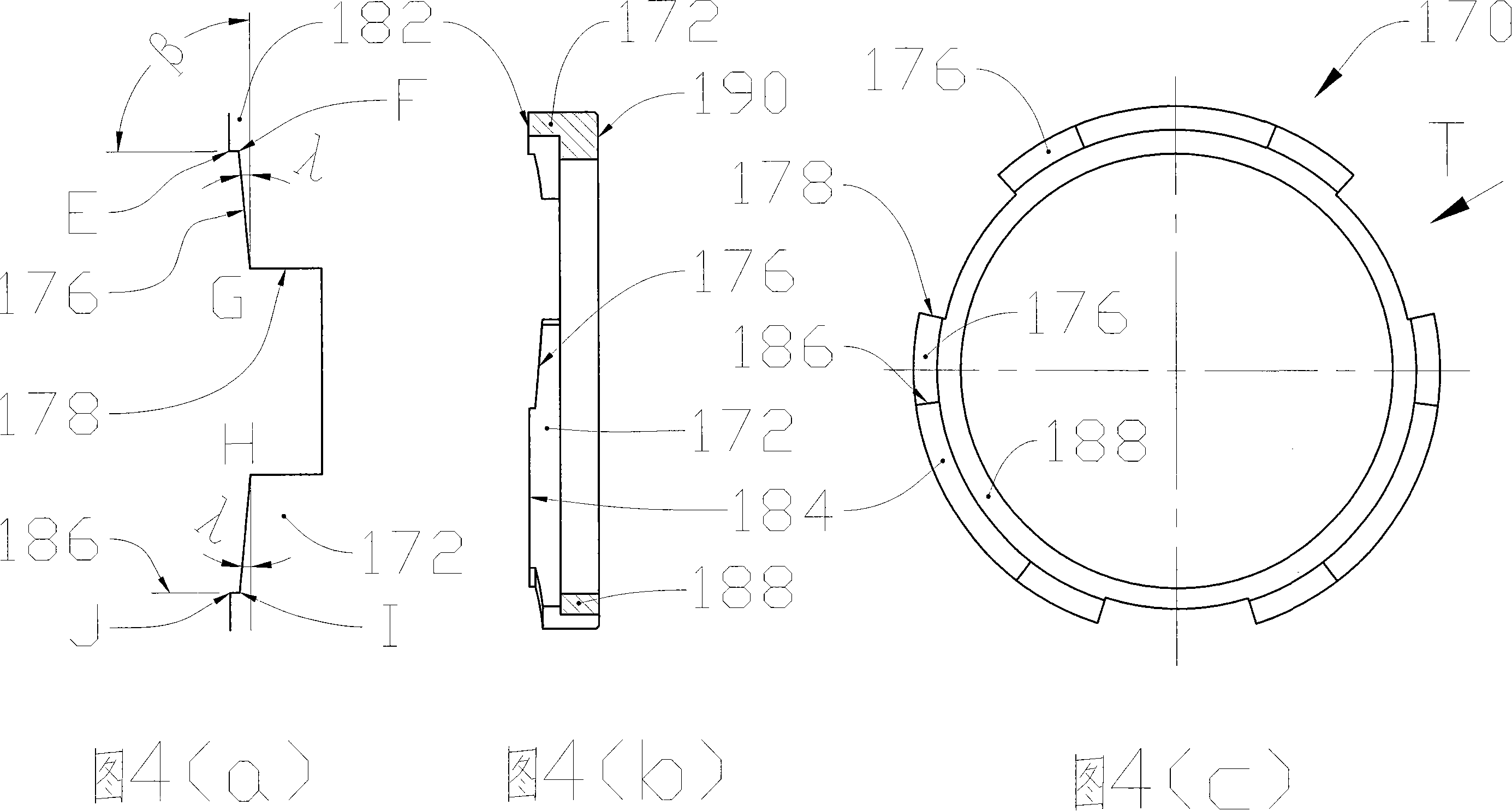

Basic mode jaw self locking speed differential gear

InactiveCN101118005ACircumferential degrees of freedom constantEliminate impact wearDifferential gearingsControl devicesSelf limitingSelf locking

The present invention relates to a basic jaw type self-locking differential, which has the characteristics of no collision, high reliability, and long service life. The present invention is characterized in that a force transmission tooth and separating teeth and an accessory blocking tooth which are positioned on driven rings are connected as a whole; a self-limiting type blocking embedding mechanism is embedded by two embedding mechanisms of a force transmission embedding mechanism and a separation embedding mechanism under the differential condition, and axially positioned in the two mechanisms and radially positioned in the two mechanisms, between the two mechanisms or outside the two mechanisms, a lift angle of both sides blocking the working surface is formed to enough ensure the friction self-locking collided on the both sides and the stability of the blocking operating condition, in order that the lift angle has the capabilities that the adaptive axle base changes and the abrasion is automatically compensated, and the slipping mode of no collision is unvaryingly maintained between the separating teeth in the operating condition, two processes of the self-separating block process and the embedding return process are absolutely reliable, and has no relation to the stability of the spring parameter compacted by the driven rings, hence the problem that the driven rings on the both sides are synchronously separated is not a problem any longer. The processing of the differential is obviously improved, the difficulty of the assembly is largely reduced, and the performance, the service life, and the interchangeability, etc. are remarkably improved.

Owner:洪涛

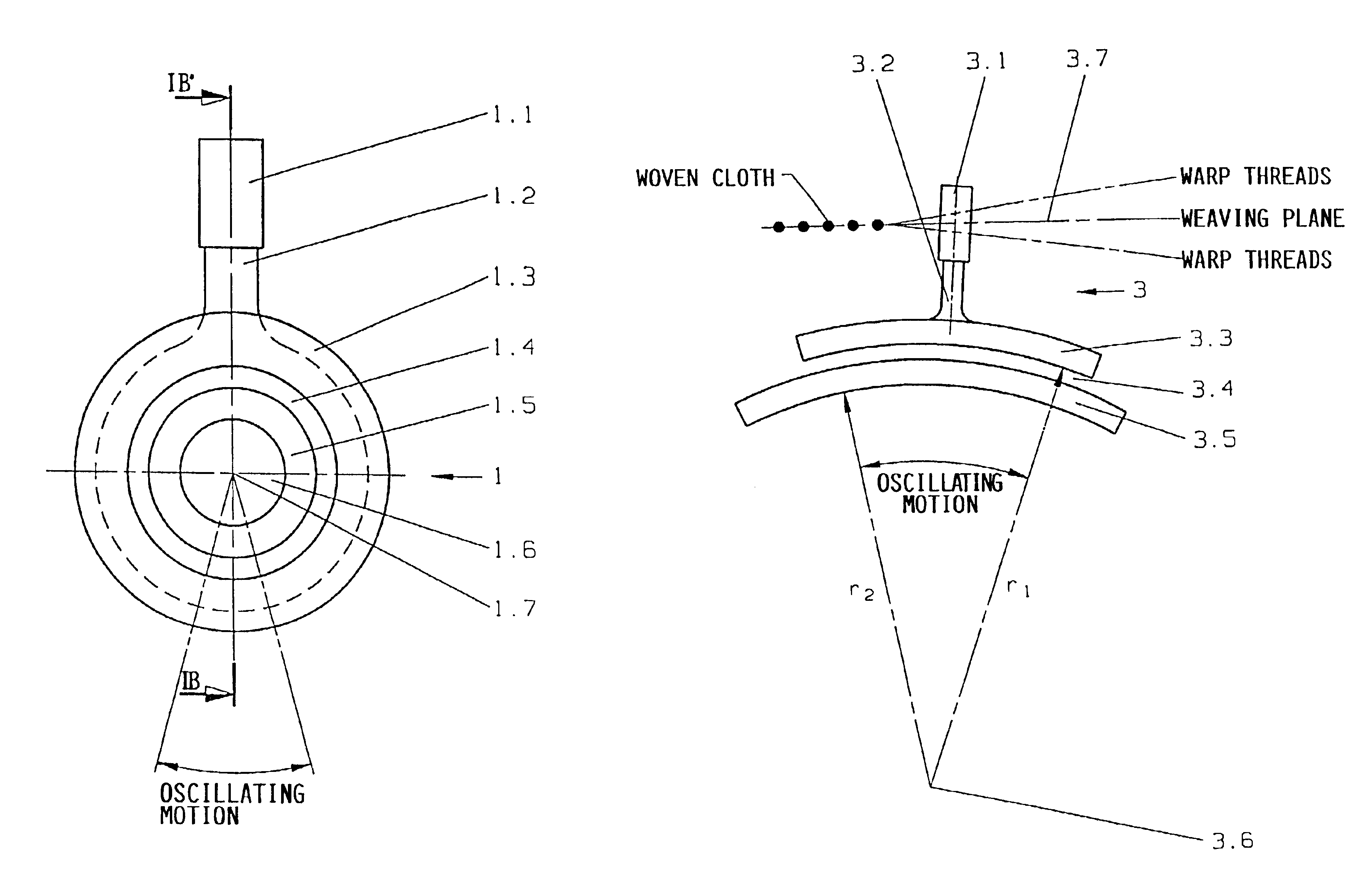

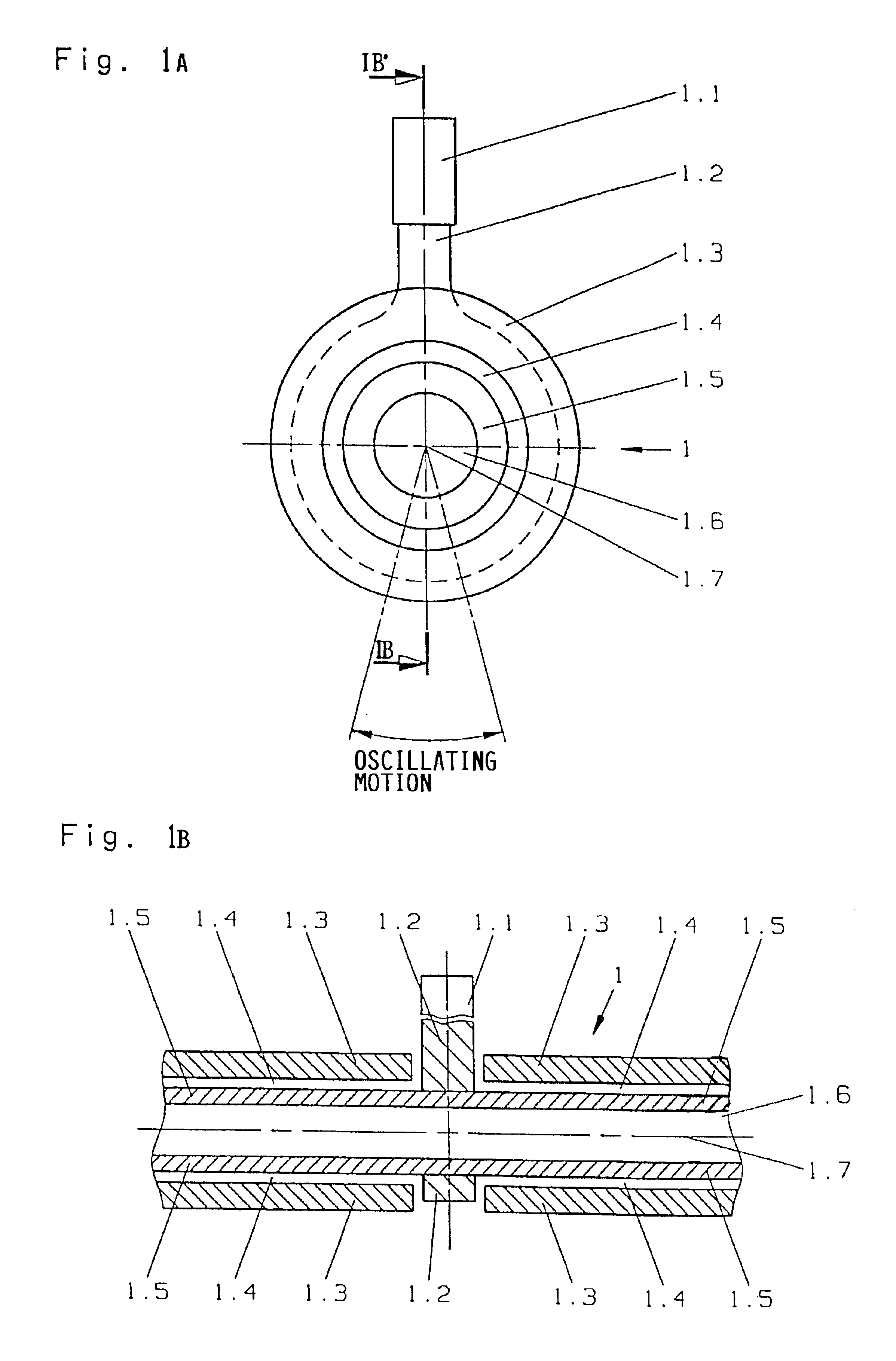

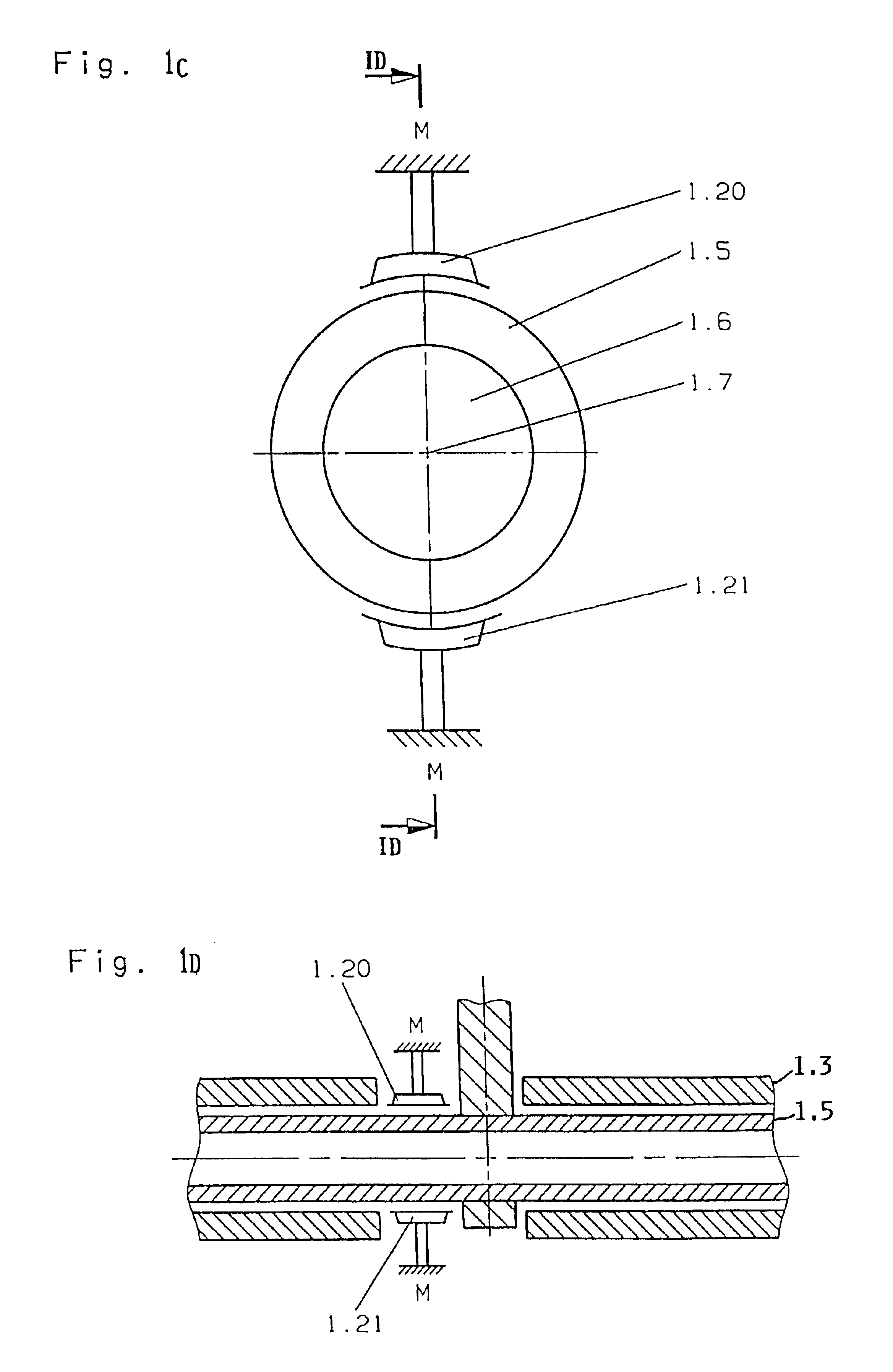

Electric motor direct drive for the reed of a loom

Owner:LINDAUER DORNIER GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com