Notched duct type plume rotor aircraft

A rotorcraft and ducted technology, applied in the aviation field, can solve the problems of reduced rotor pulling force, large total lift, and reduced actual angle of attack, and achieve the effects of weight reduction, high aerodynamic efficiency, and high lift.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] specific implementation plan

[0030] The present invention will be further described and illustrated below in conjunction with the accompanying drawings.

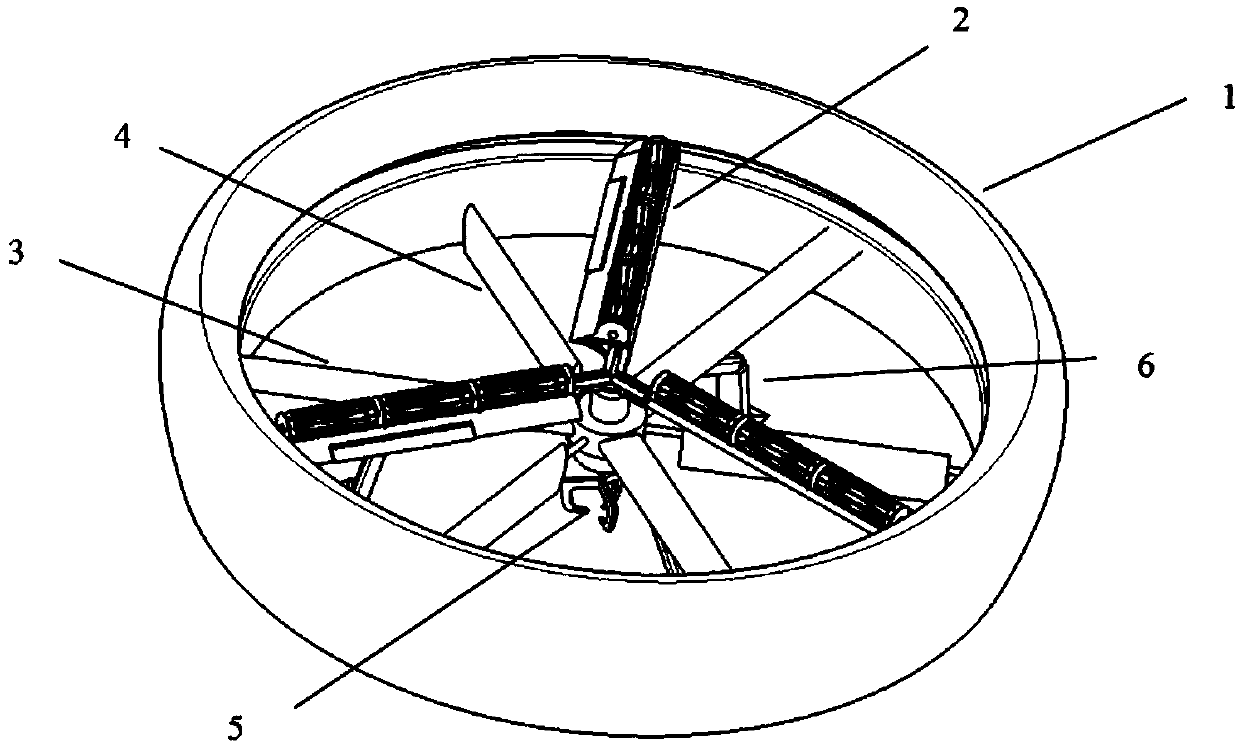

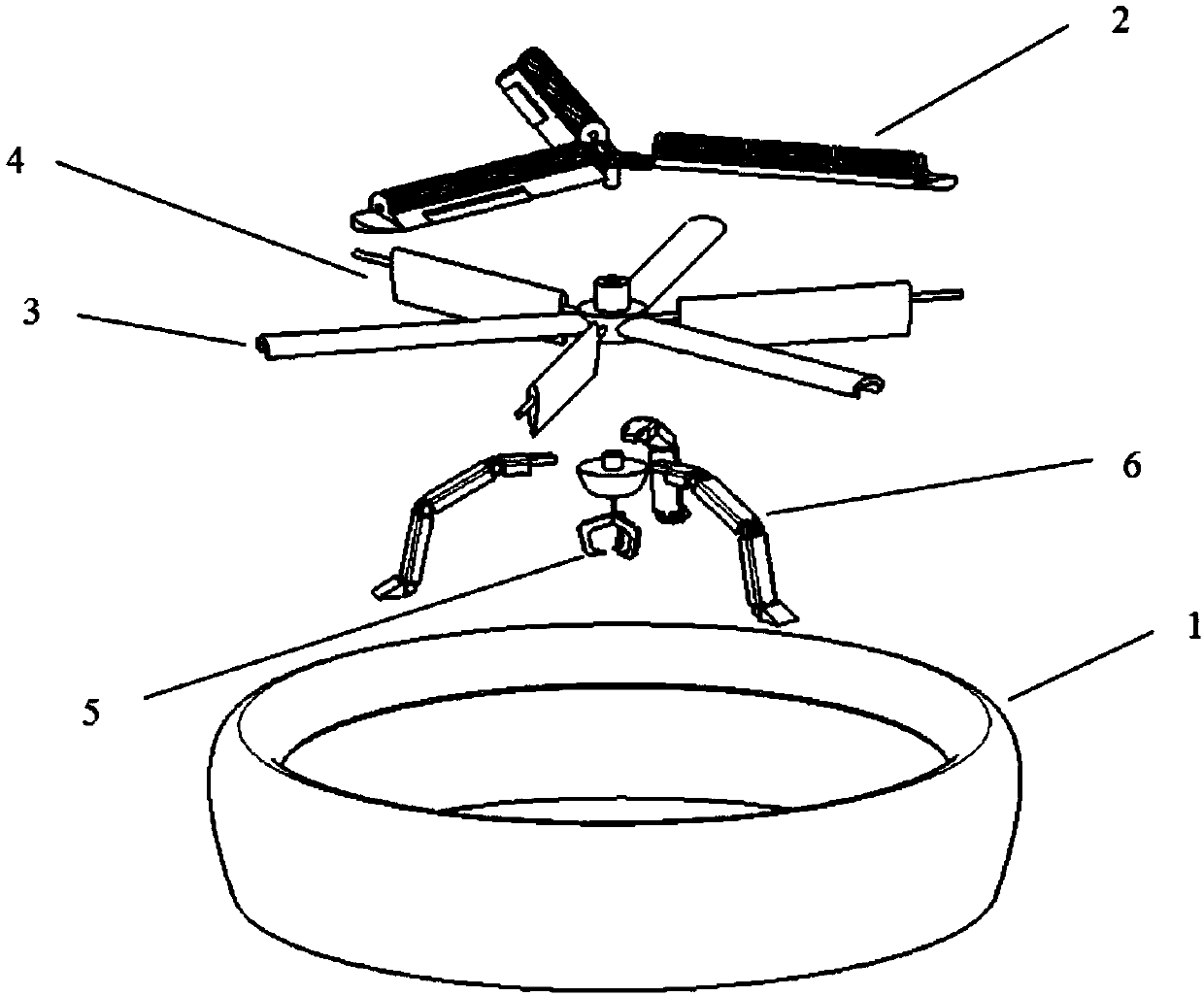

[0031] Such as figure 1 and 2 As shown, the present invention discloses a slotted duct type plume rotor aircraft, comprising a slotted duct, plume rotor, support beam, yaw module, telescopic manipulator and landing gear;

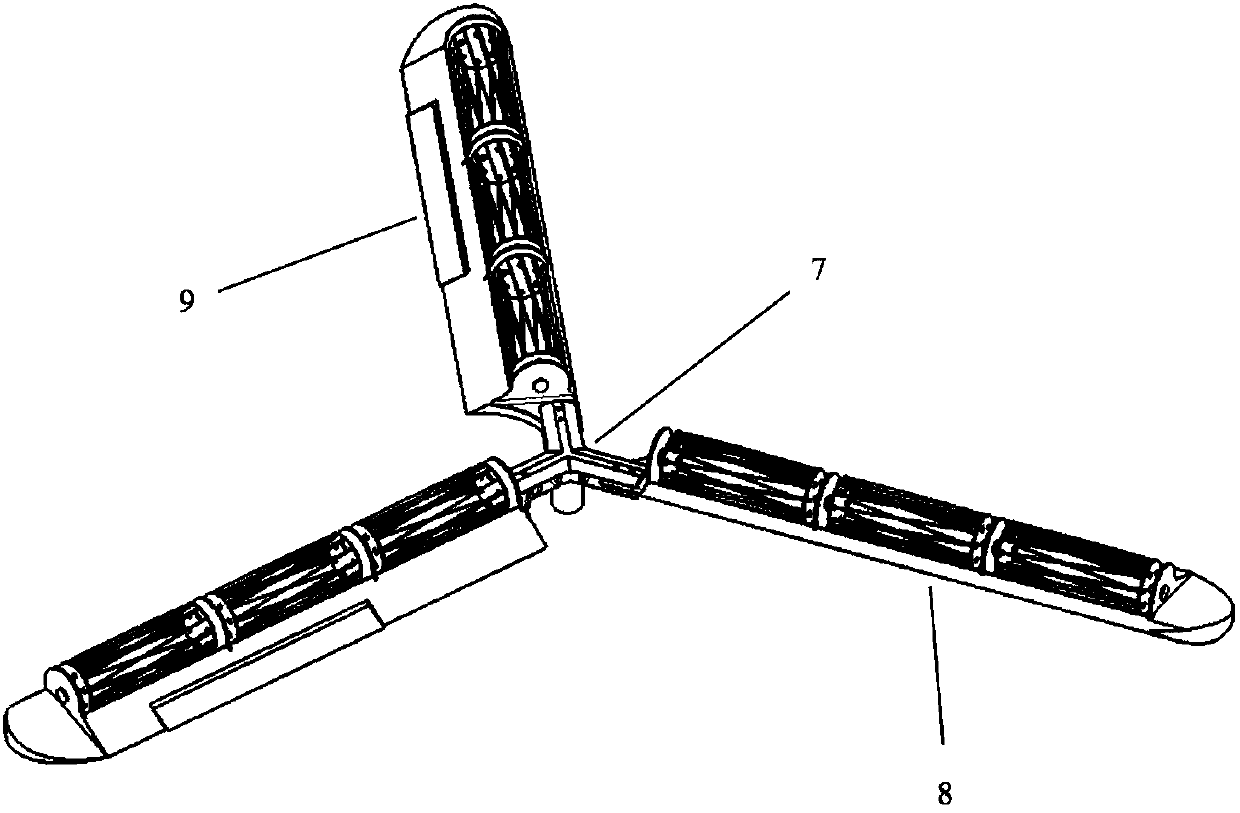

[0032] Such as Figure 6 As shown, the slotted duct is provided with grooves on the inner wall of the duct to suppress the generation of blade tip vortex and reduce the loss of wing tip;

[0033] The supporting beam includes a connecting ring and at least two supporting rods, wherein the connecting ring and the slotted duct are arranged coaxially; the supporting rods are evenly arranged between the connecting ring and the slotted duct, one end and the The connecting ring is fixedly connected, and the other end is fixedly connected to the inner wall of the slotted duct;

[0034] The yaw module...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com