Control of power, loads and/or stability of a horizontal axis wind turbine by use of variable blade geometry control

A technology of wind turbines and wind turbine blades, applied in the field of design concepts, can solve problems such as increased aerodynamic noise, achieve the effects of reducing aerodynamic noise, improving aerodynamic efficiency, and suppressing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

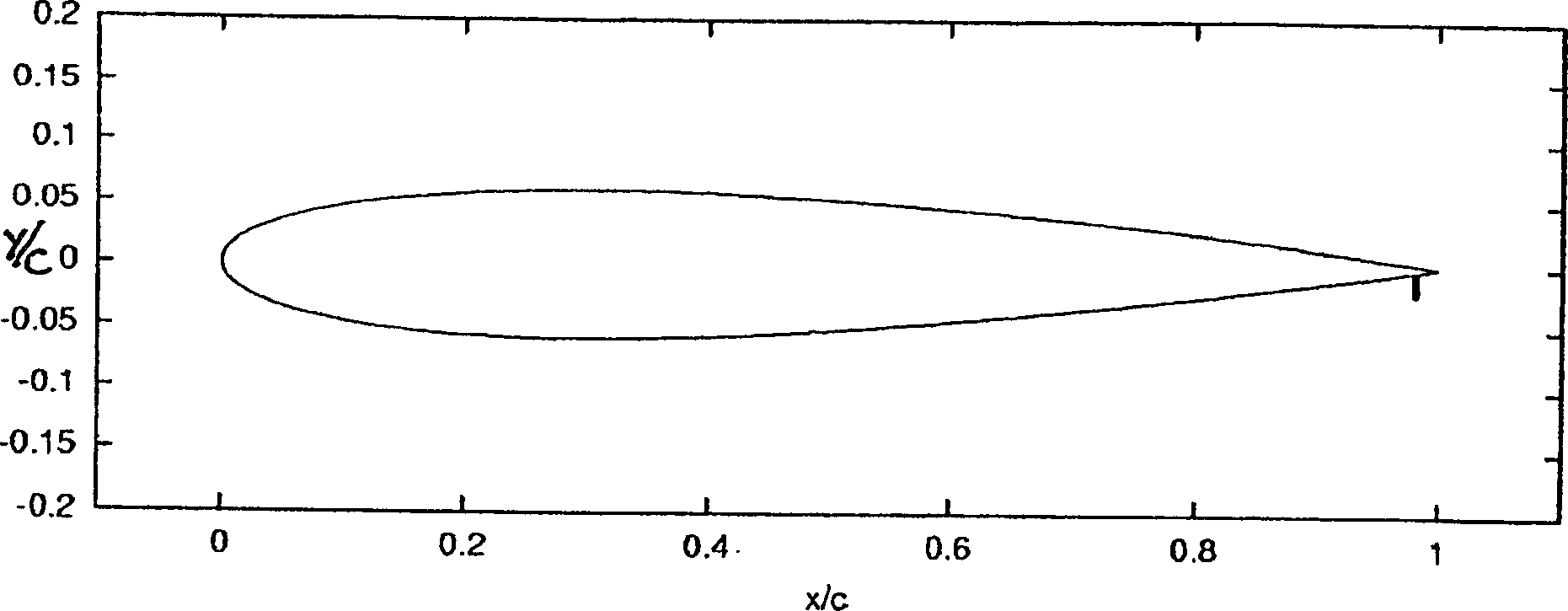

[0053] exist Figure 4 Inside, an airfoil part 1 is schematically shown with two deformable parts, ie a deformable leading edge and a trailing edge region. The initial shape of the airfoil portion 1 is indicated by the solid line, wherein the leading edge region 10 and the trailing edge region 12 are not deformed, and the deformed shape of the airfoil portion is indicated by the dashed line, wherein the leading edge region and the trailing edge region are deformed by Figure 4 The leading edge region and the trailing edge region are indicated by reference numerals 10a and 12a inside. Furthermore, the airfoil portion 1 comprises a non-deformable portion 14 designed to support the loads generated by the airfoil portion. Such as Figure 4 As shown, the deformation of the airfoil part 1 does not introduce any discontinuity to the outer surface of the airfoil part 1 , which remains smooth during and after deformation.

[0054] The wing may have a deformable portion extending acr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com