Patents

Literature

212results about How to "Reduce dynamic load" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

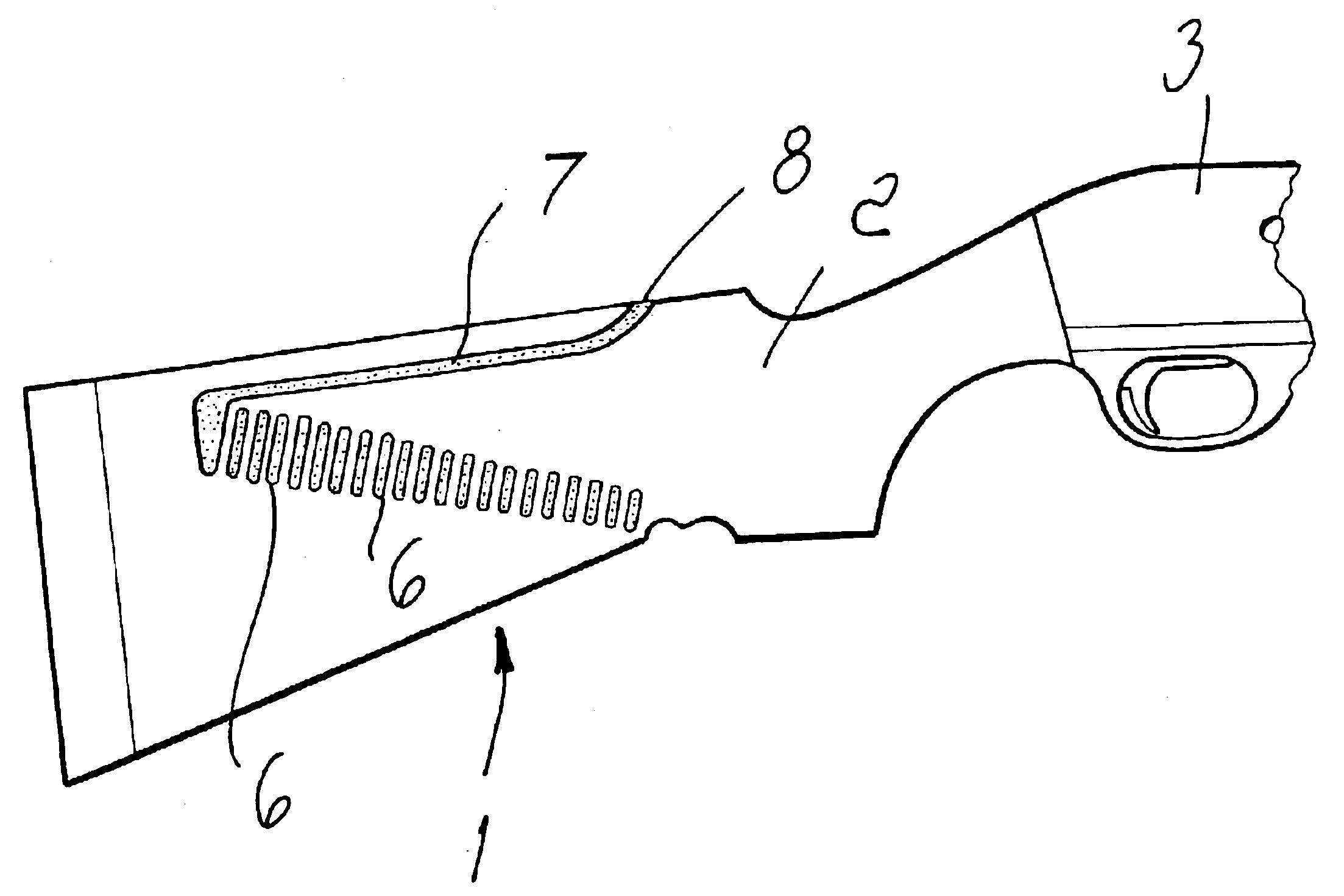

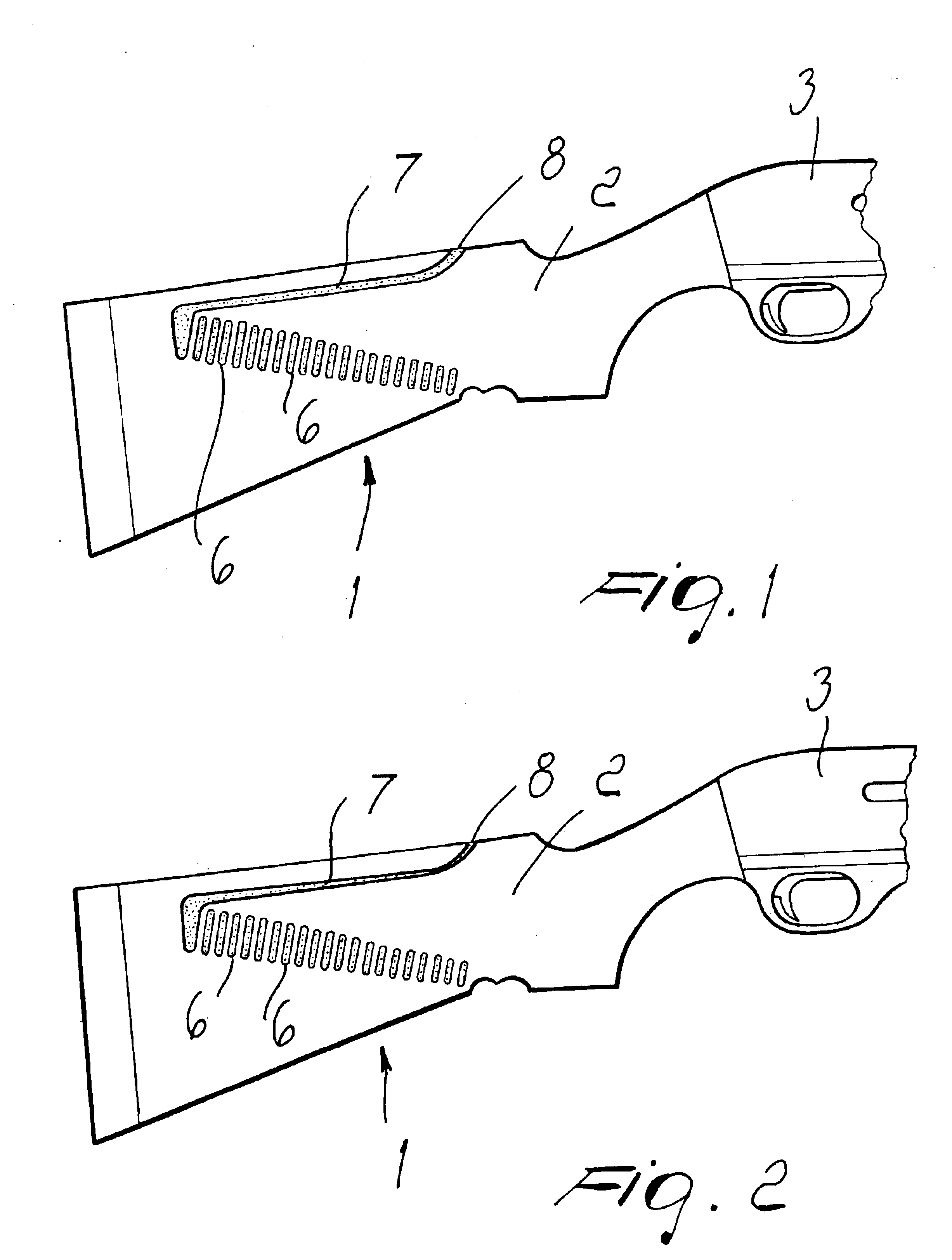

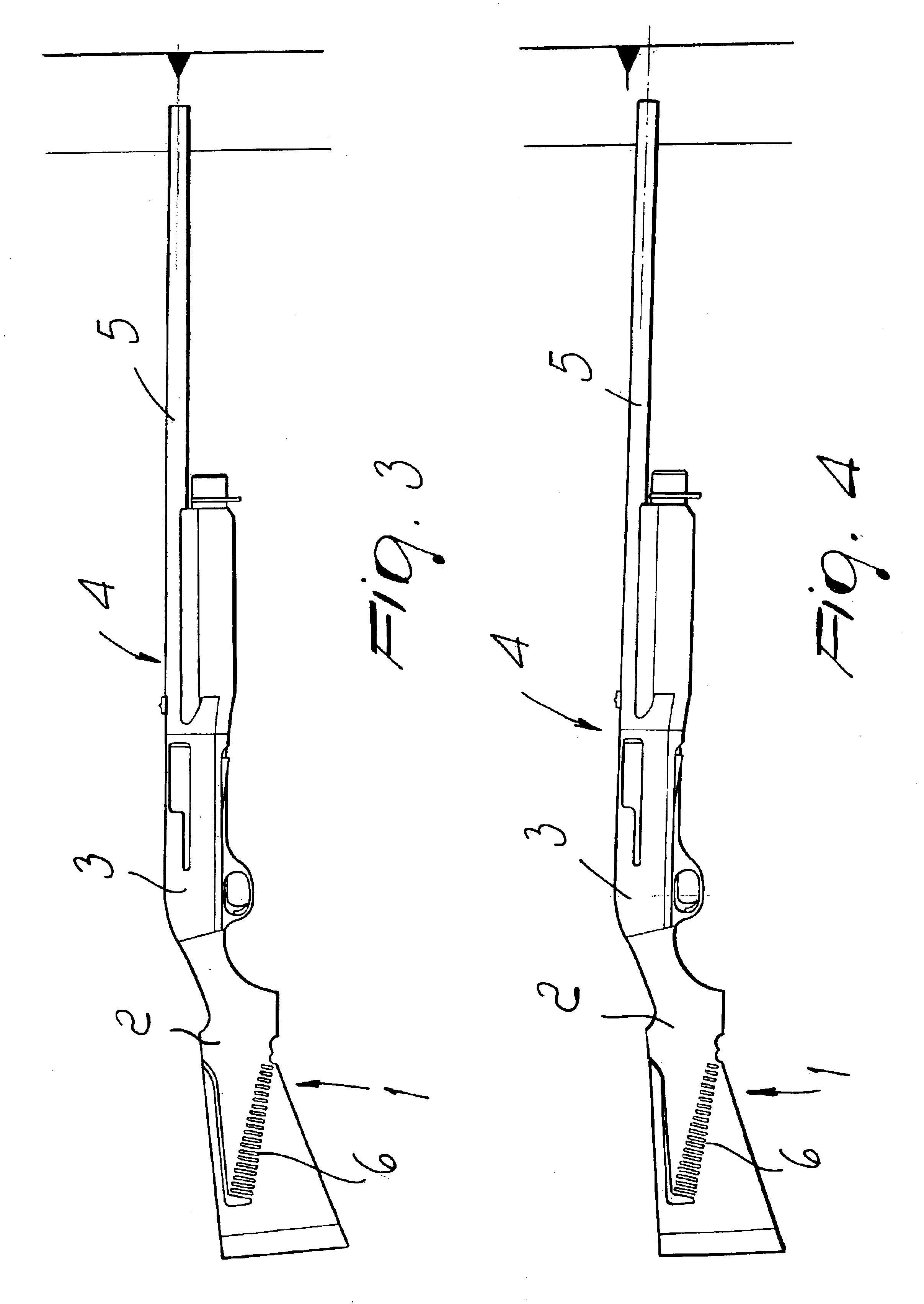

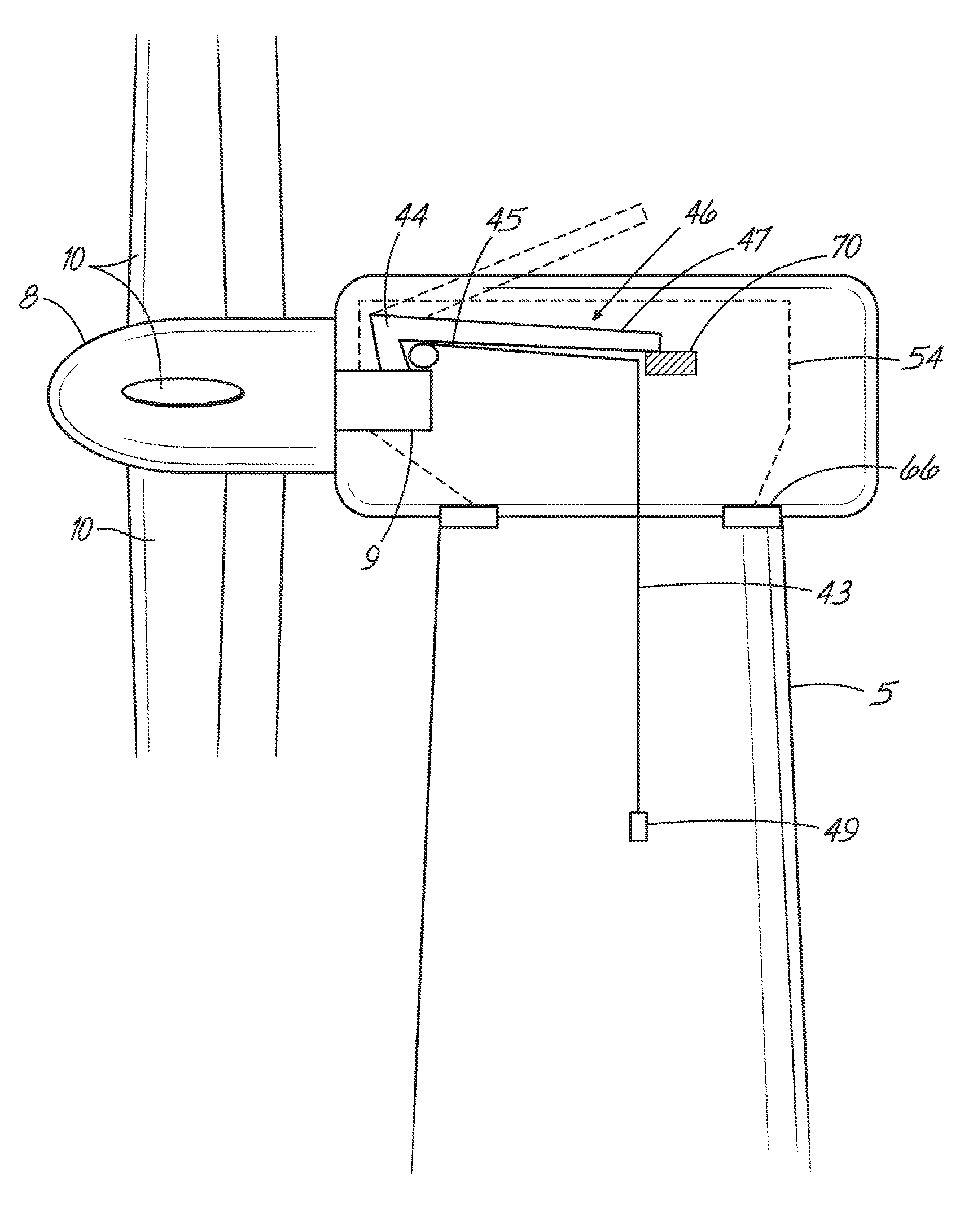

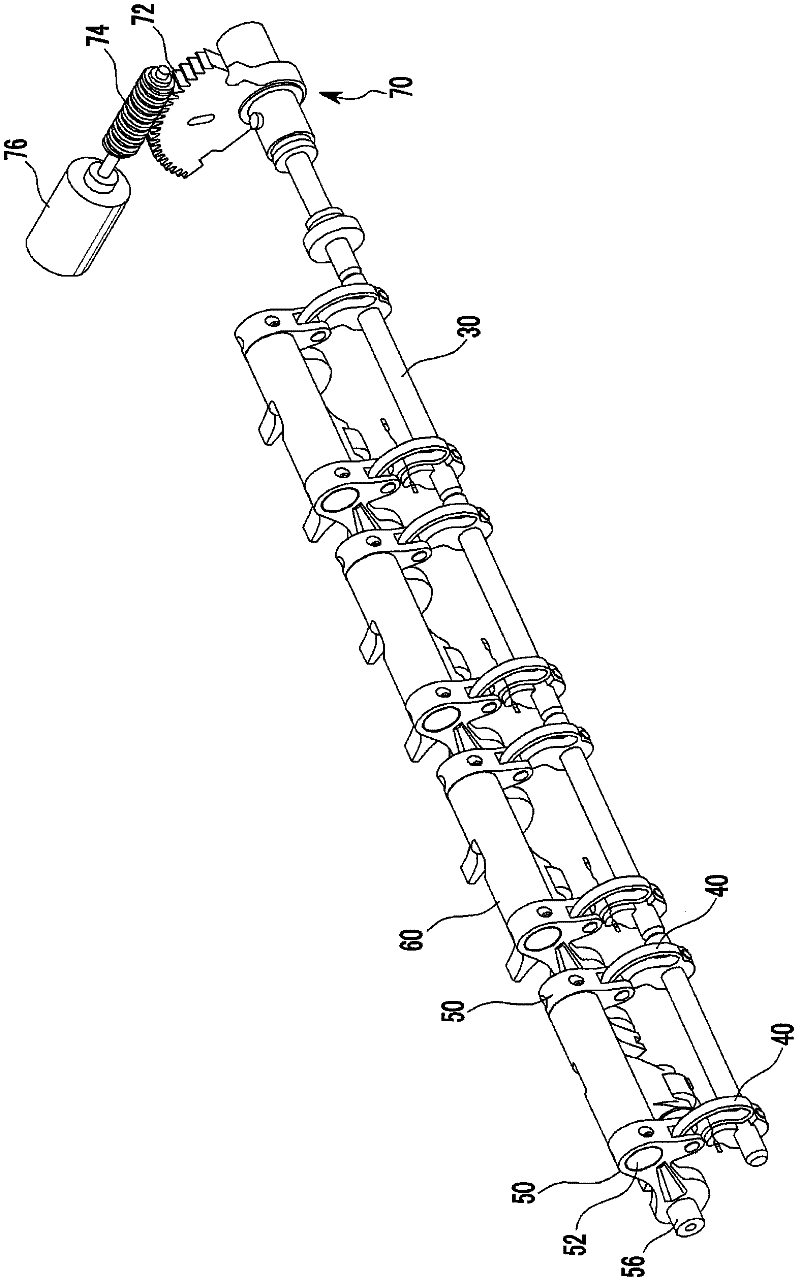

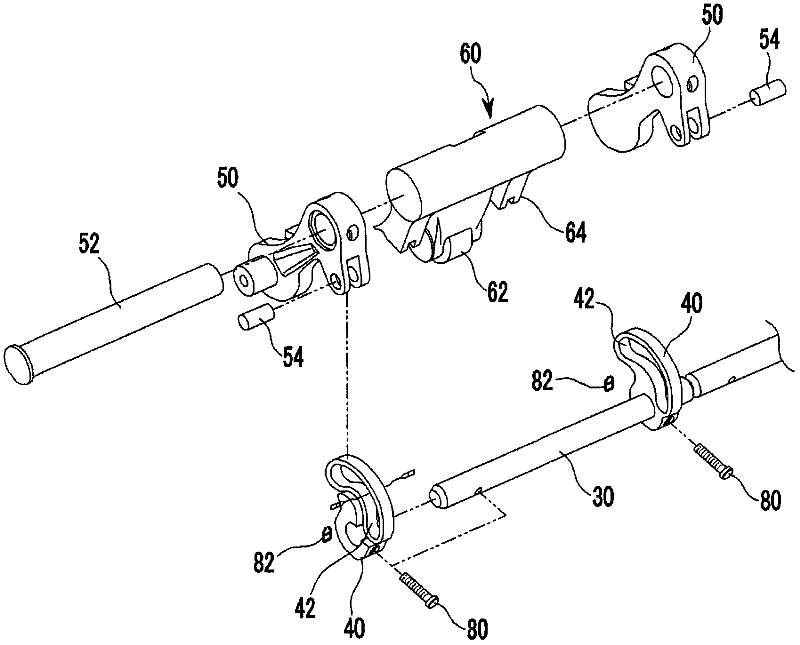

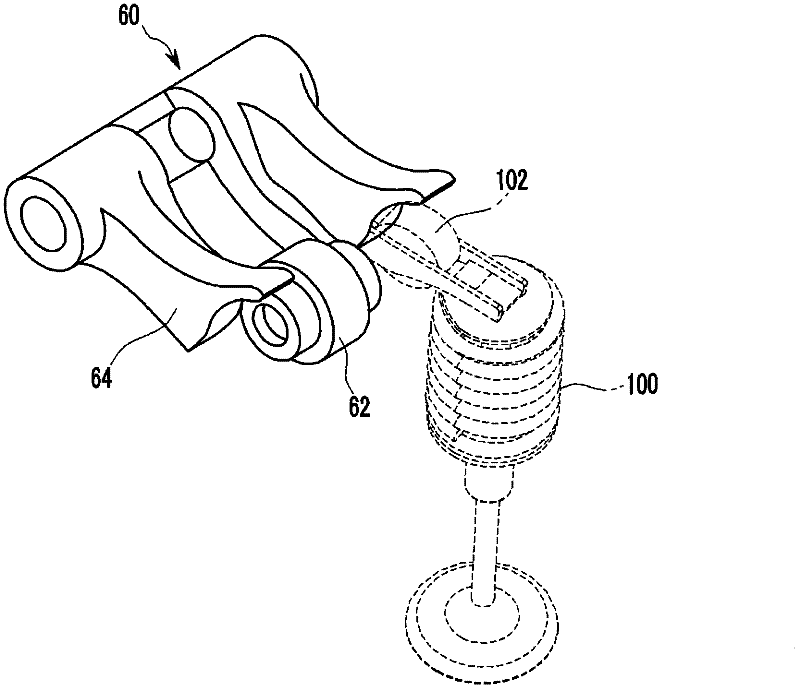

Stock for firearms

InactiveUS6834455B2Reduce dynamic loadIncreasing target acquisition speedButtsAbsorbed energyEngineering

Owner:BENELLI ARMI

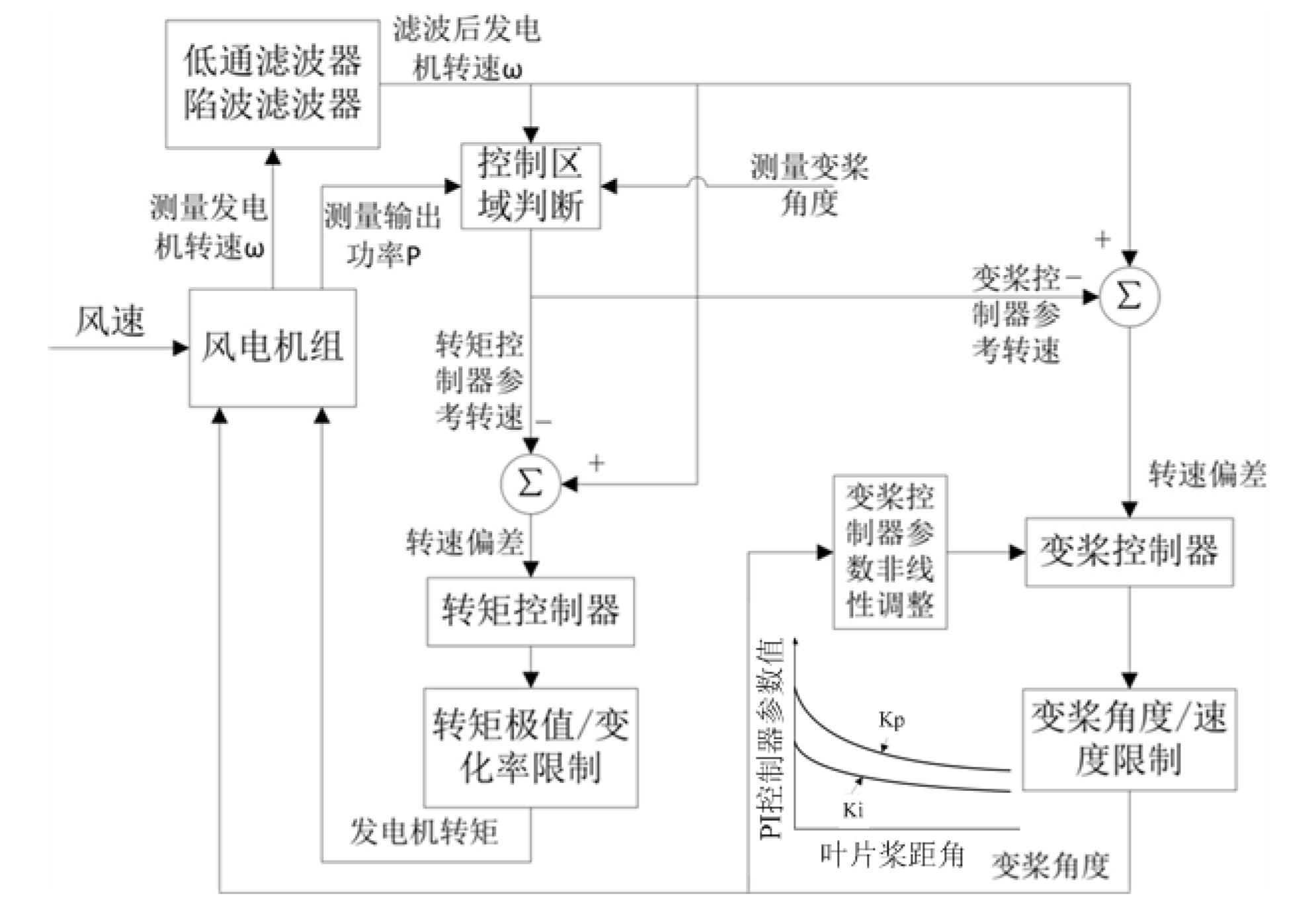

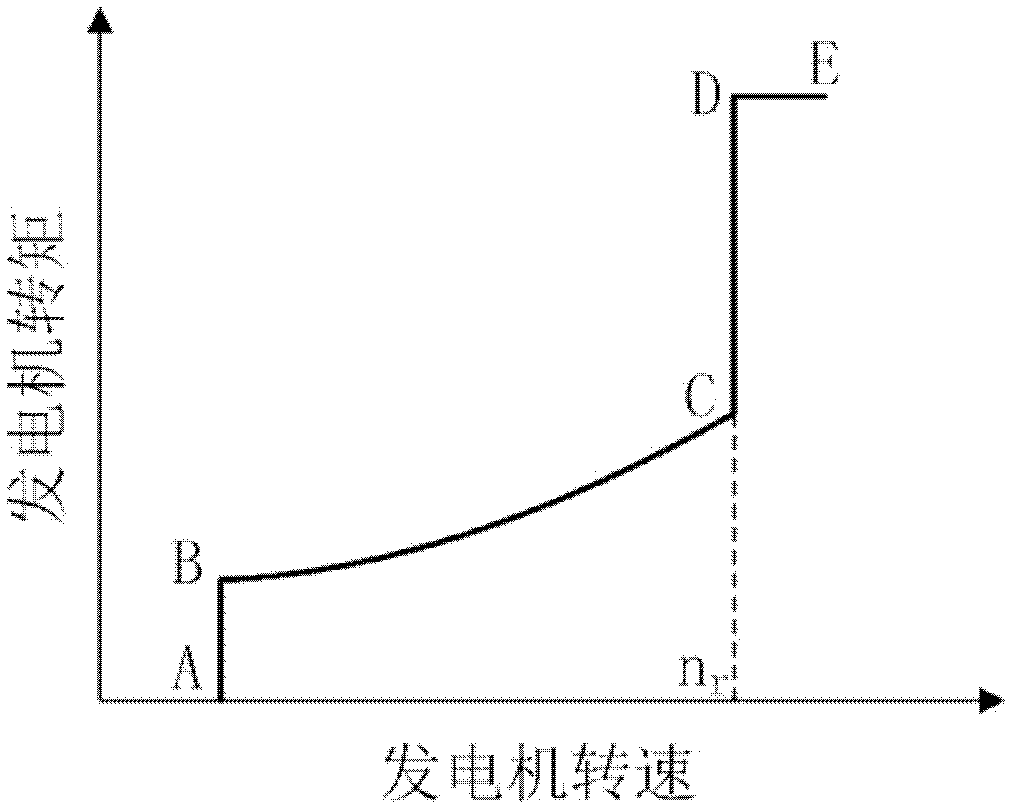

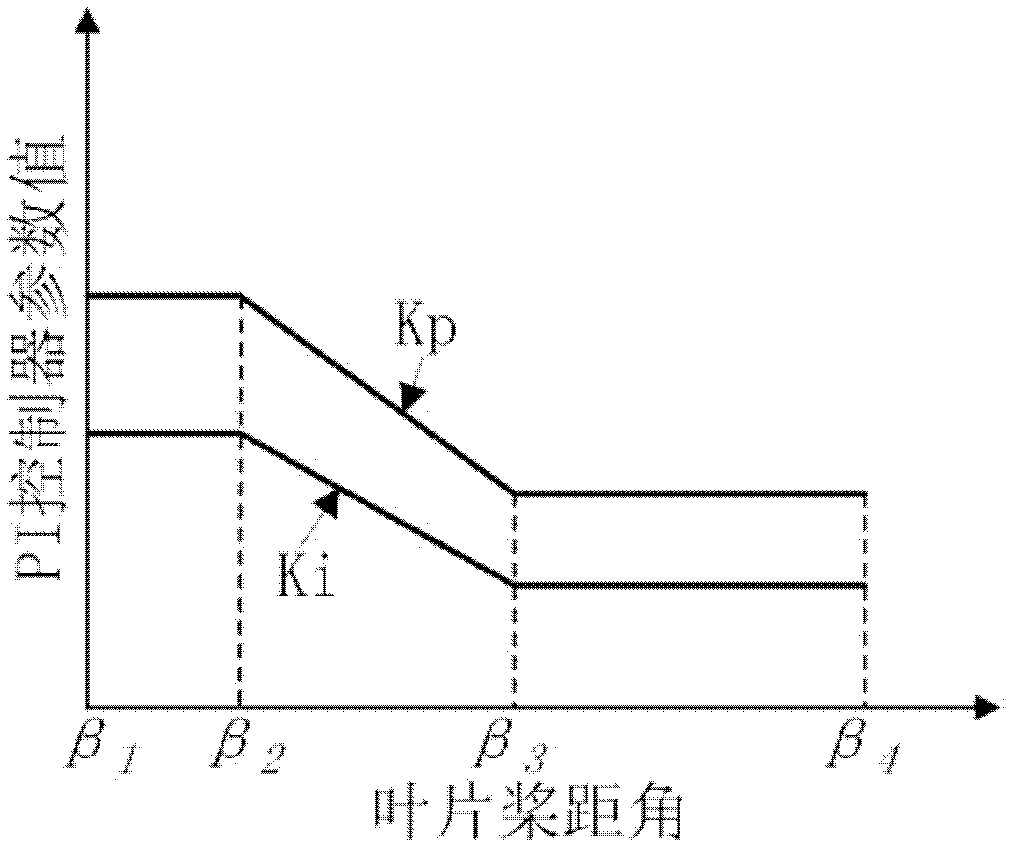

Rotational speed and torque control device and method of wind turbine generator set

ActiveCN102635499AEasy to implement flexible switchingReduce speedWind motor controlMachines/enginesConstant powerAngular degrees

The invention discloses a rotational speed and torque control method of a wind turbine generator set. Under the situation that the measured rotational speed of a power generator is higher than the rated rotational speed and the measured power exceeds the rated power, the torque is switched from a PI (proportional-integral) control way to a constant power control way; under the situation that the pitch angle is smaller than the optimal pitch angle and the measured rotational speed is lowered below the rated rotational speed, the toque is converted from the constant power control way to the PI control way; and the pitch angle is controlled in a PI control parameter non-linear adjustment way, and the pitch control is in an activated state within the whole normal working rotational speed range. According to the rotational speed and torque control method of the wind turbine generator set provided by the invention, the problem of greater fluctuation in the rotational speed caused by desynchrony of the two types of control can be avoided by changing control target points of two controllers in a transition region, the transition region is improved from the original points to a curve, the flexible switching of the control states is easier to realize, and the stability in operation of the unit and the power output of the unit can be ensured.

Owner:CSIC CHONGQING HAIZHUANG WINDPOWER EQUIP

Squeeze film damper with highly variable support stiffness

InactiveUS7798720B1Reduce weight and sizeEasy to controlPump componentsShaftsVariable stiffnessEngineering

A squeeze film damper assembly having a variable stiffness and damping control. The squeeze film damper includes a damper chamber formed by two flexible bellows chambers of the sides. A first pressure source is applied to the damper chamber to regulate the damping. A second pressure source is applied to the flexible bellows chambers to vary the stiffness of the damper. The flexible bellows chambers are secured between an outer member and an inner member of the damper assembly and form the sealed damper chamber. A pressure ratio between the bellows chambers and the damper chamber can vary to control the stiffness of the squeeze film damper.

Owner:FLORIDA TURBINE TECH

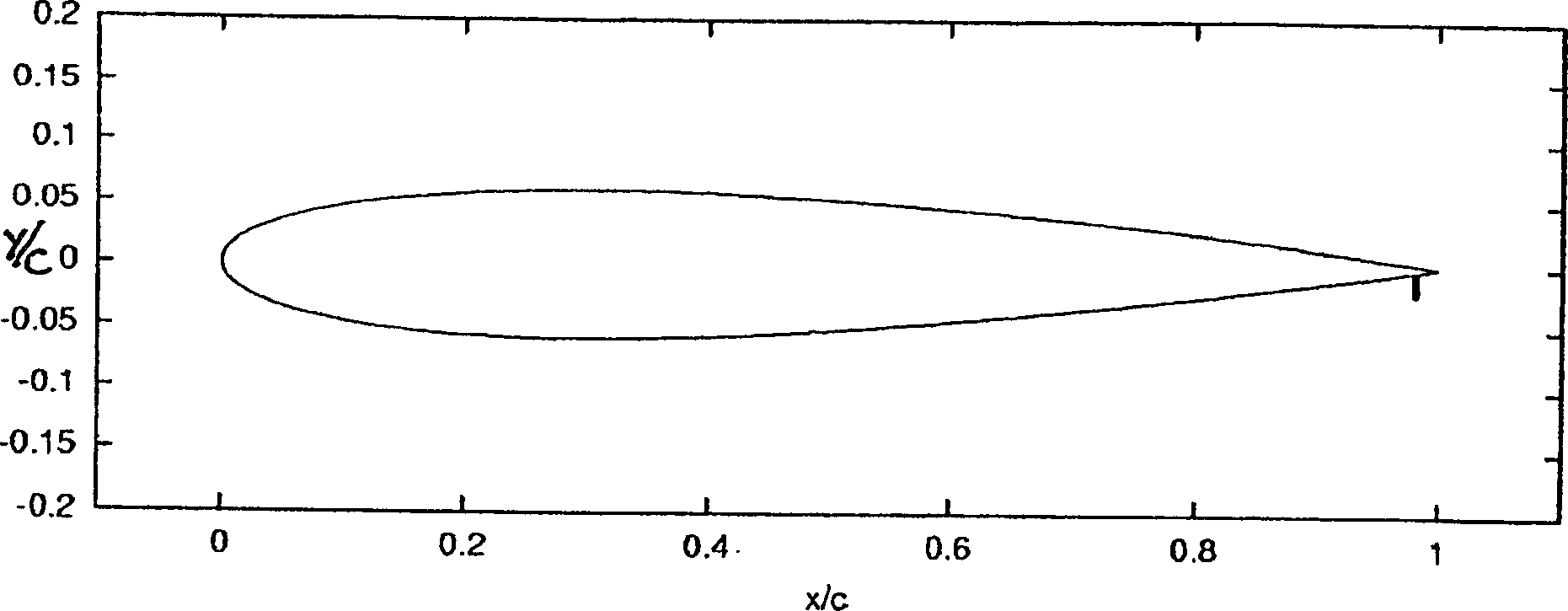

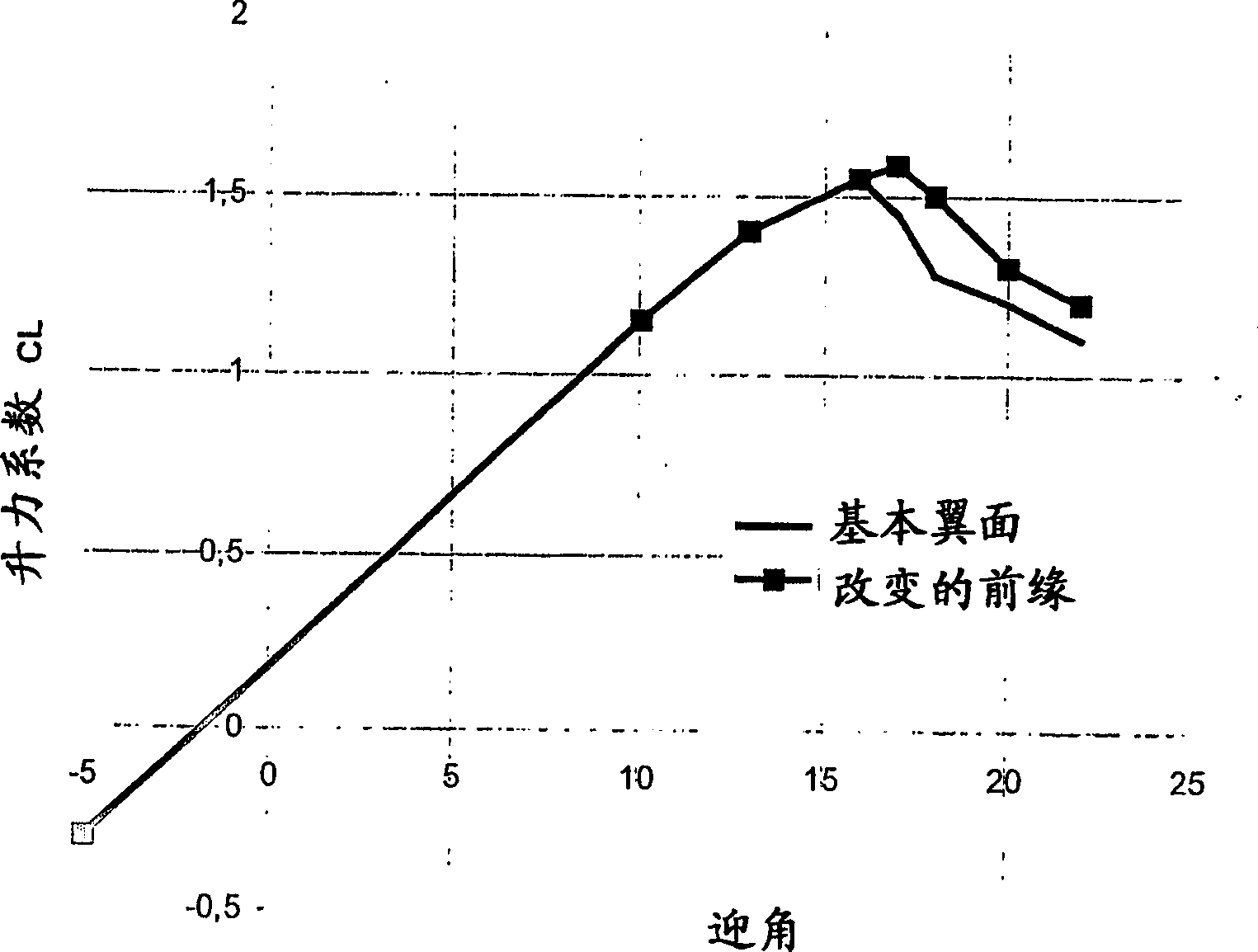

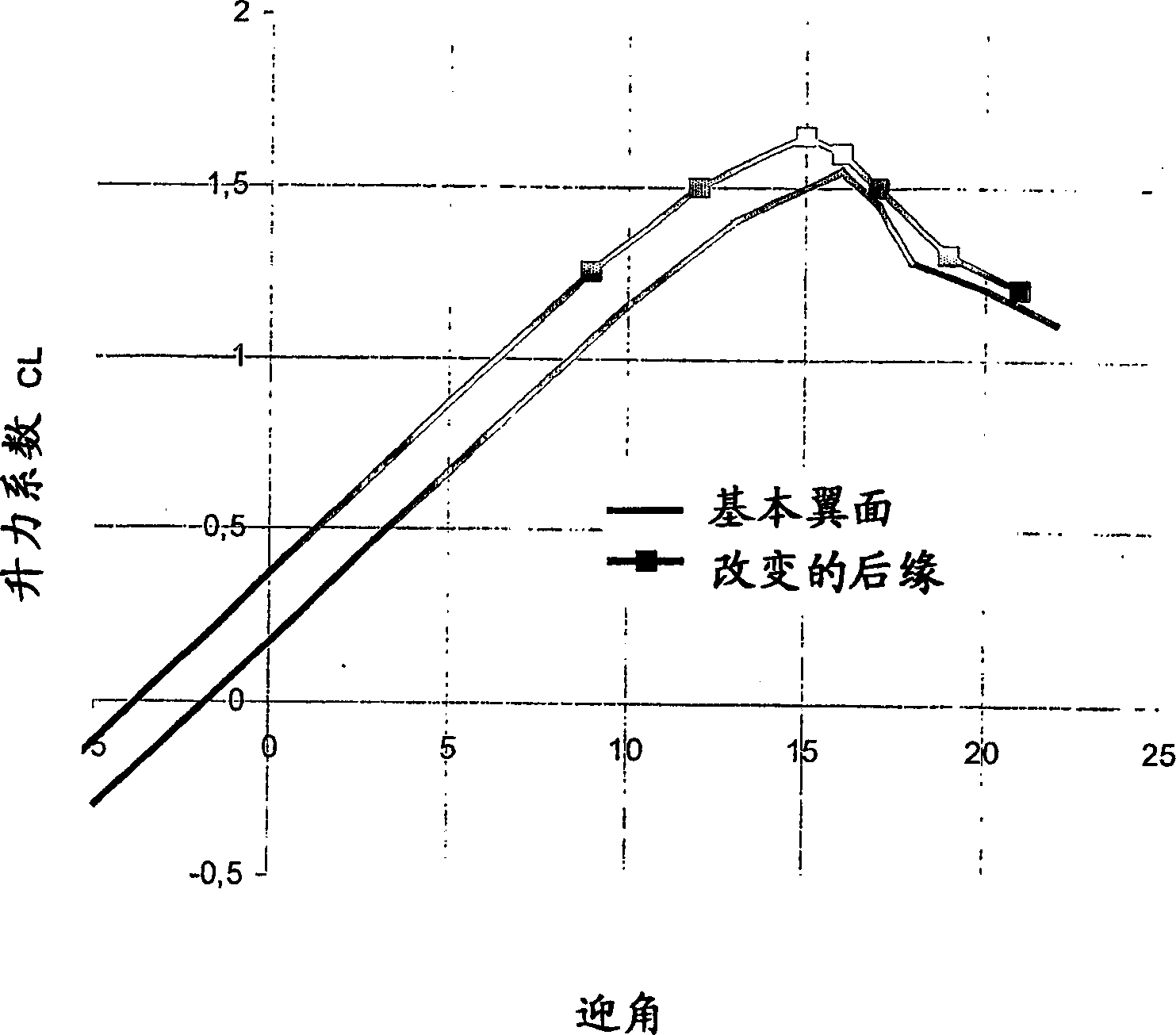

Control of power, loads and/or stability of a horizontal axis wind turbine by use of variable blade geometry control

InactiveCN1780983AReduce loadReduce aerodynamic noiseWind motor controlEngine fuctionsTurbine bladeHorizontal axis

The present invention relates to a design concept according to which, by using active geometry control (for example, smart materials or embedded mechanical actuators), or using passive geometry control (for example caused by the loading and / or deformation of the blade) changes), or a combination of these two methods, allows rapid changes in the blade geometry to control the power, load and / or stability of the wind turbine. In particular the invention relates to a wind turbine blade, a wind turbine and a method of controlling a wind turbine.

Owner:DANMARKS TEKNISKE UNIV

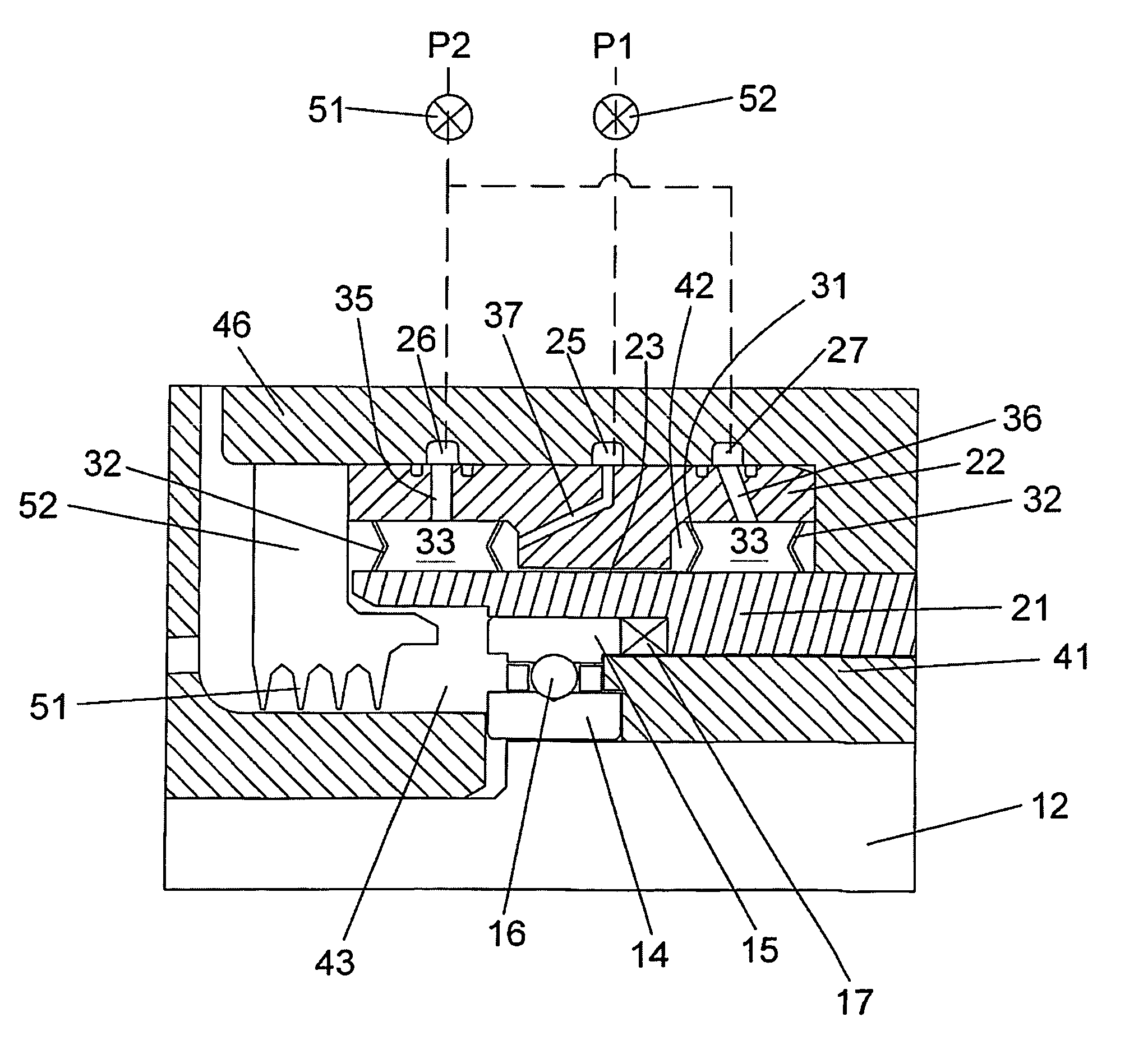

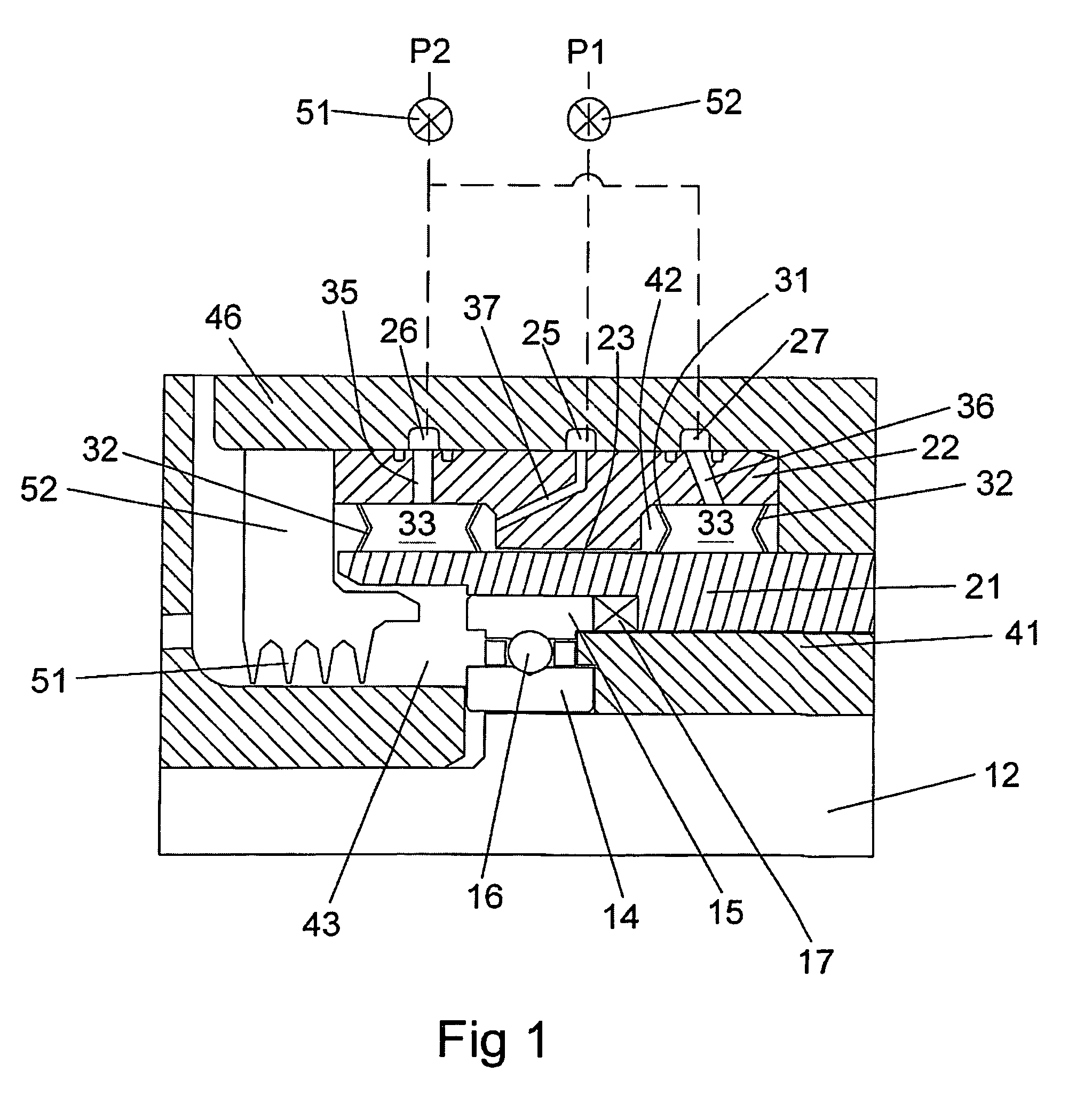

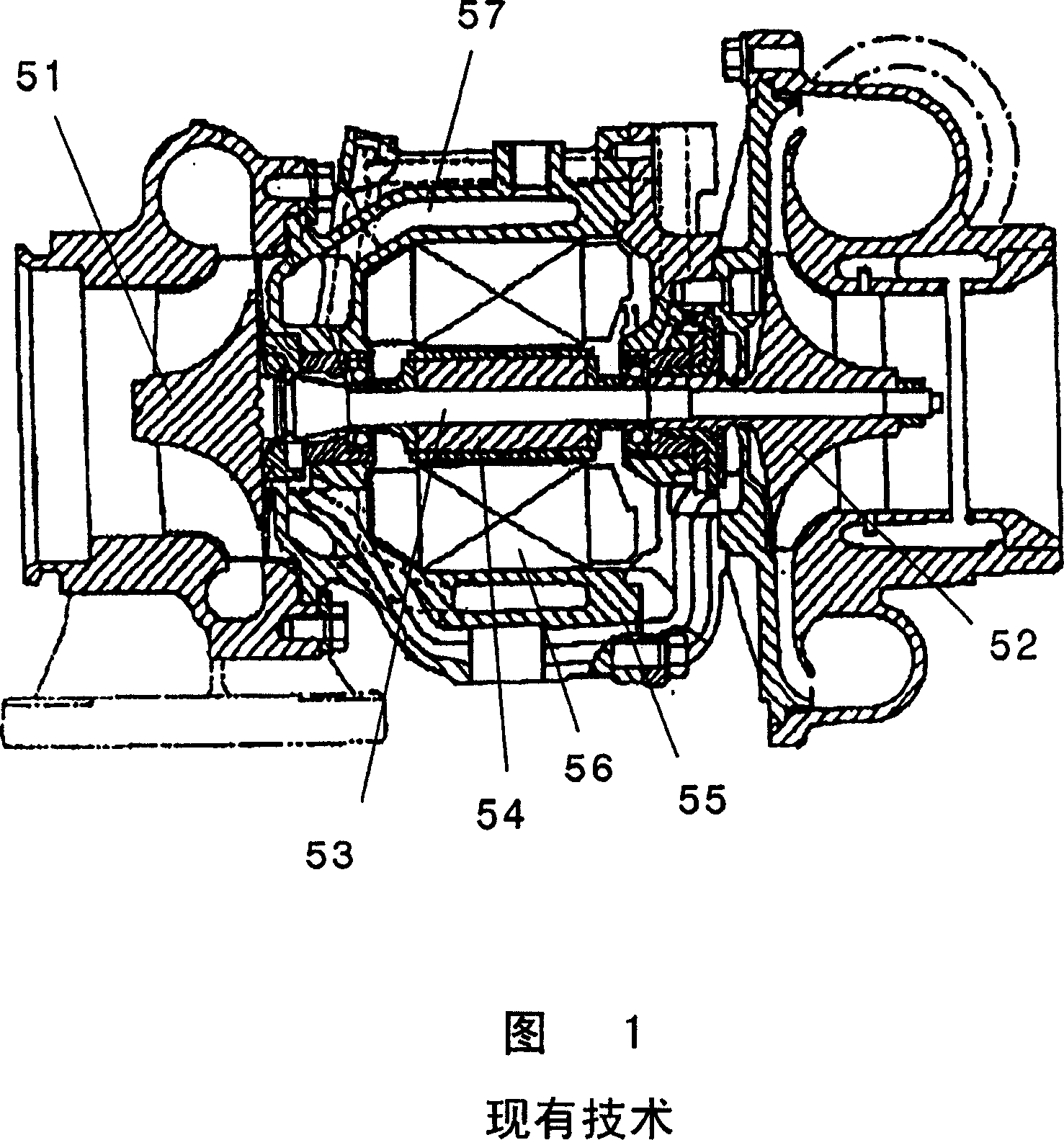

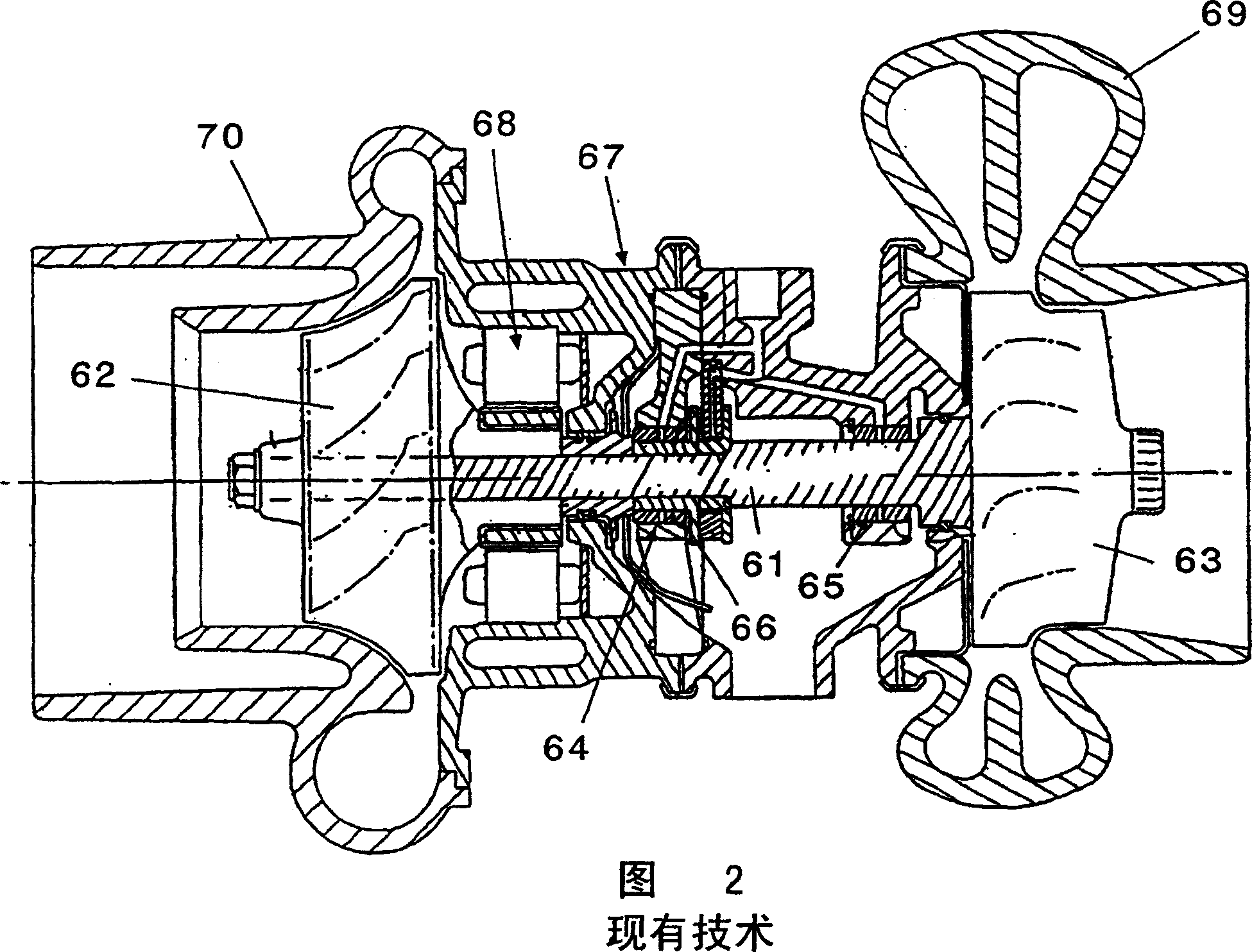

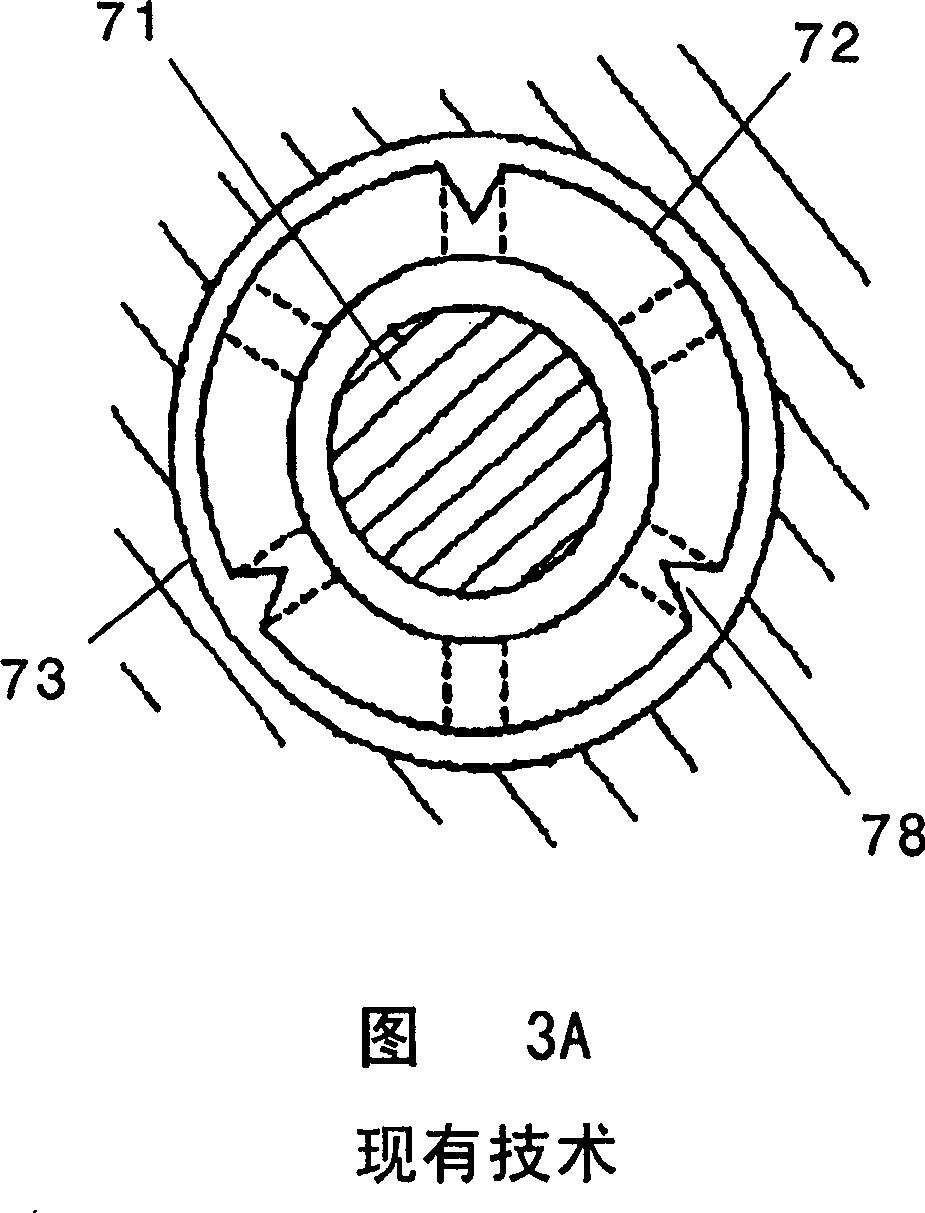

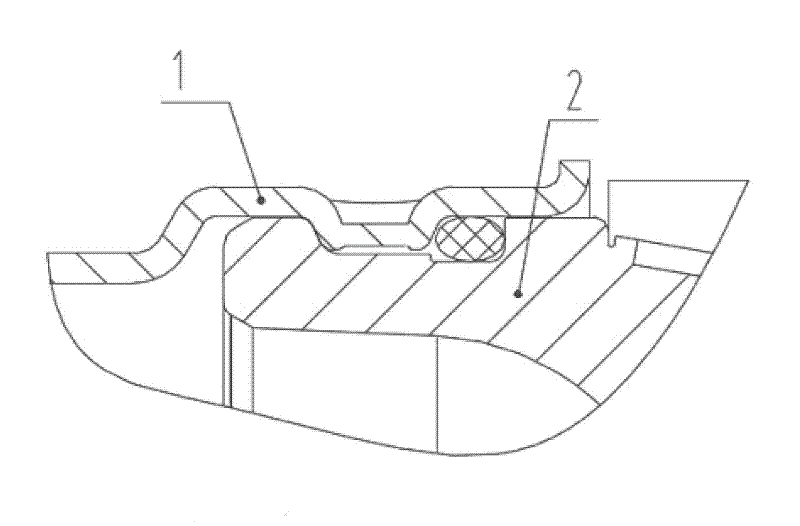

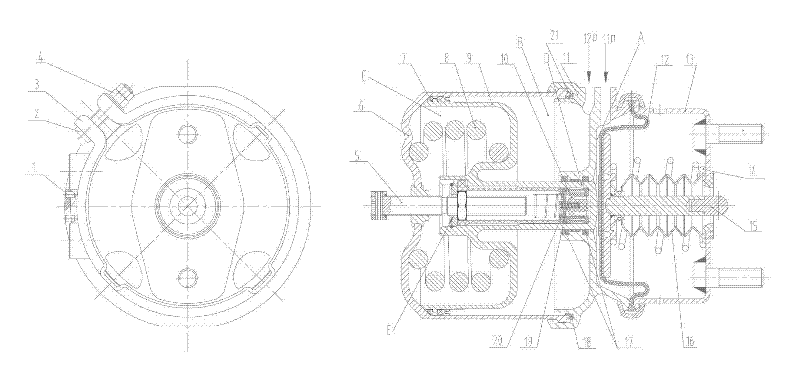

Bearing structure of motor-driven supercharger

InactiveCN1928335AReduce dynamic loadPrevent sinteringEngine manufactureBearing assemblyMotor driveEngineering

A bearing structure is provided with a turbine side bearing metal (30a) and a compressor side bearing metal (30b) in which an outer peripheral surface is fitted to a bearing hole (16a) of a bearing housing (16) with a gap, and an inner peripheral surface rotatably supports a turbine shaft (12), and a bearing locking member (32) holding the turbine side bearing metal and the compressor side bearing metal so as to be movable in a radial direction of the turbine shaft and inhibit a movement in an axial direction and a rotating direction. The inner peripheral surface and / or the outer peripheral surface of the bearing metal (30b) (or 30b) is structured as a non-complete round bearing.

Owner:IHI CORP

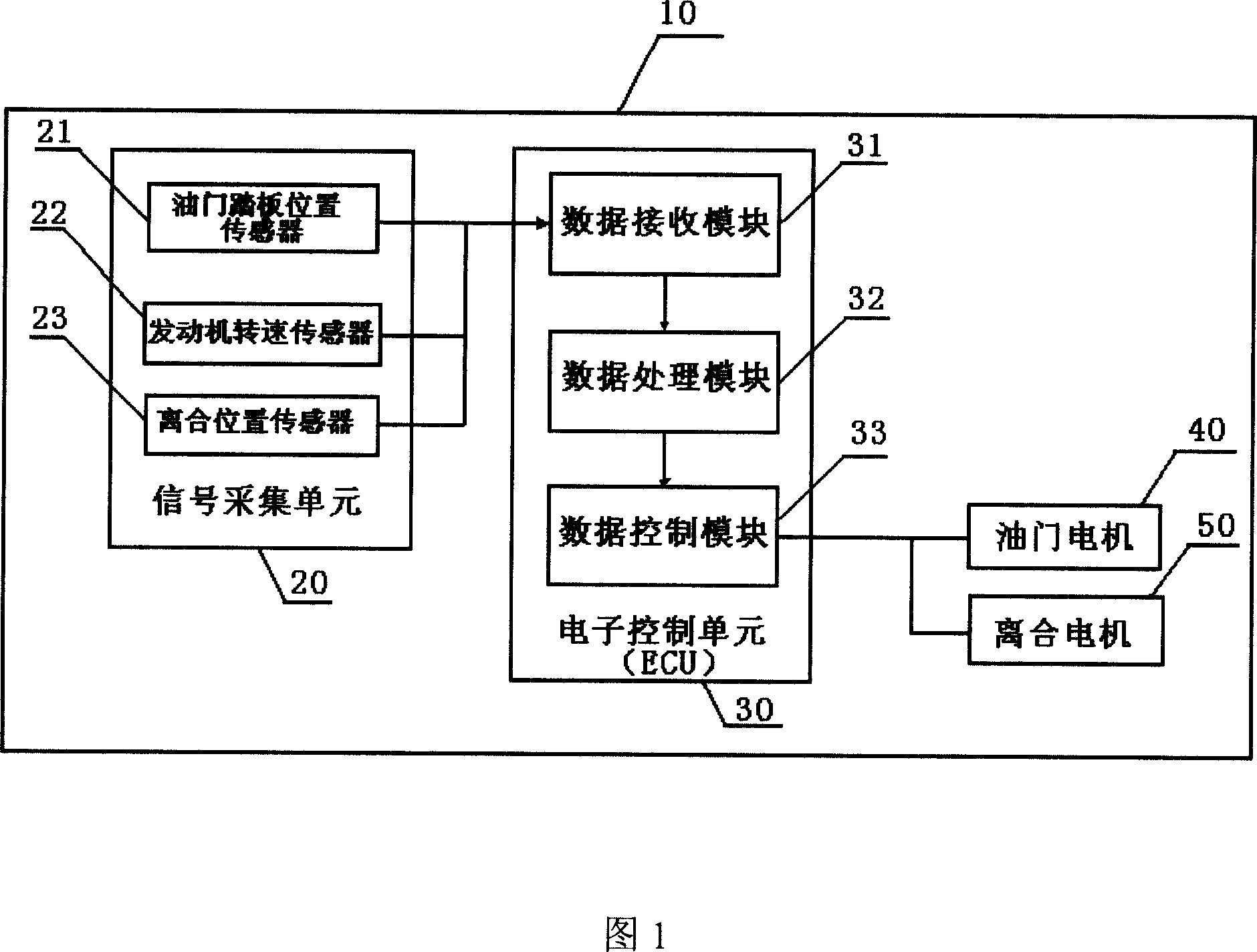

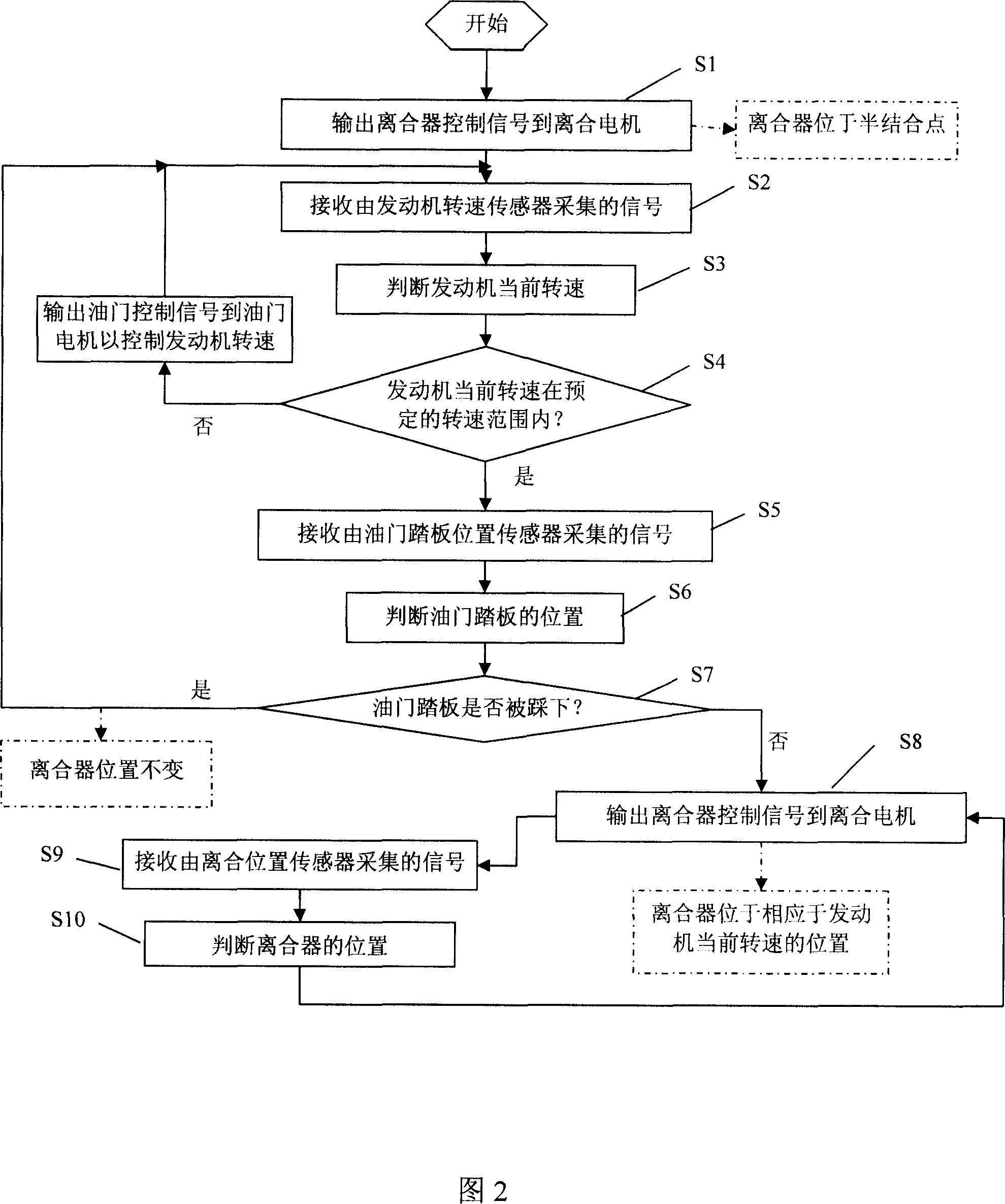

Control device and method for vehicle start

A method for controlling the initial start of vehicle features that the rotation speed of engine and the position of throttle pedal are detected for controlling the position of clutch. Its controller is composed of a signal acquisition unit with throttle pedal position sensor and rotation speed sensor of engine, an electric control unit consisting of data receiving module, data processing module and data control module, throttle motor, and clutch motor.

Owner:BYD CO LTD

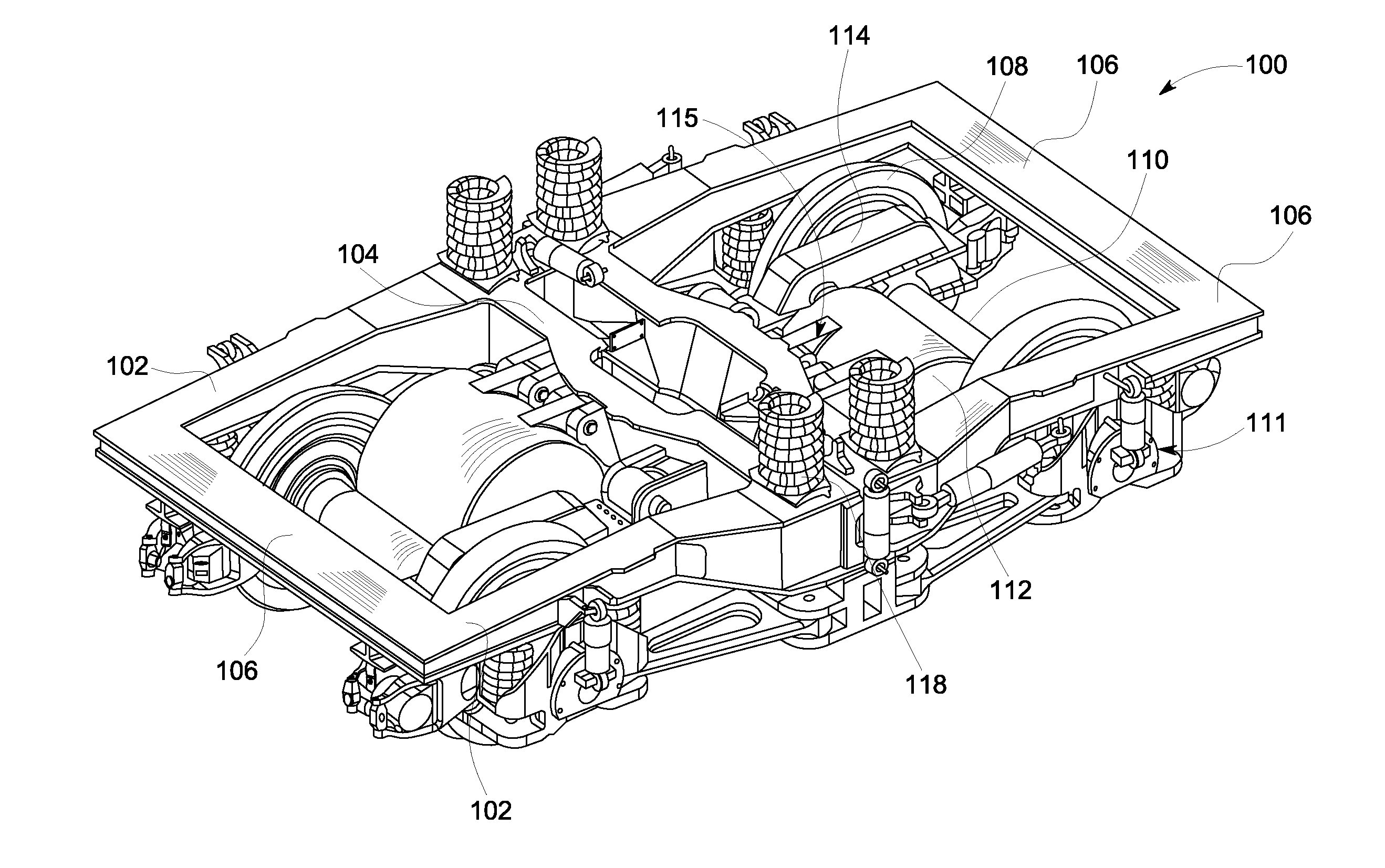

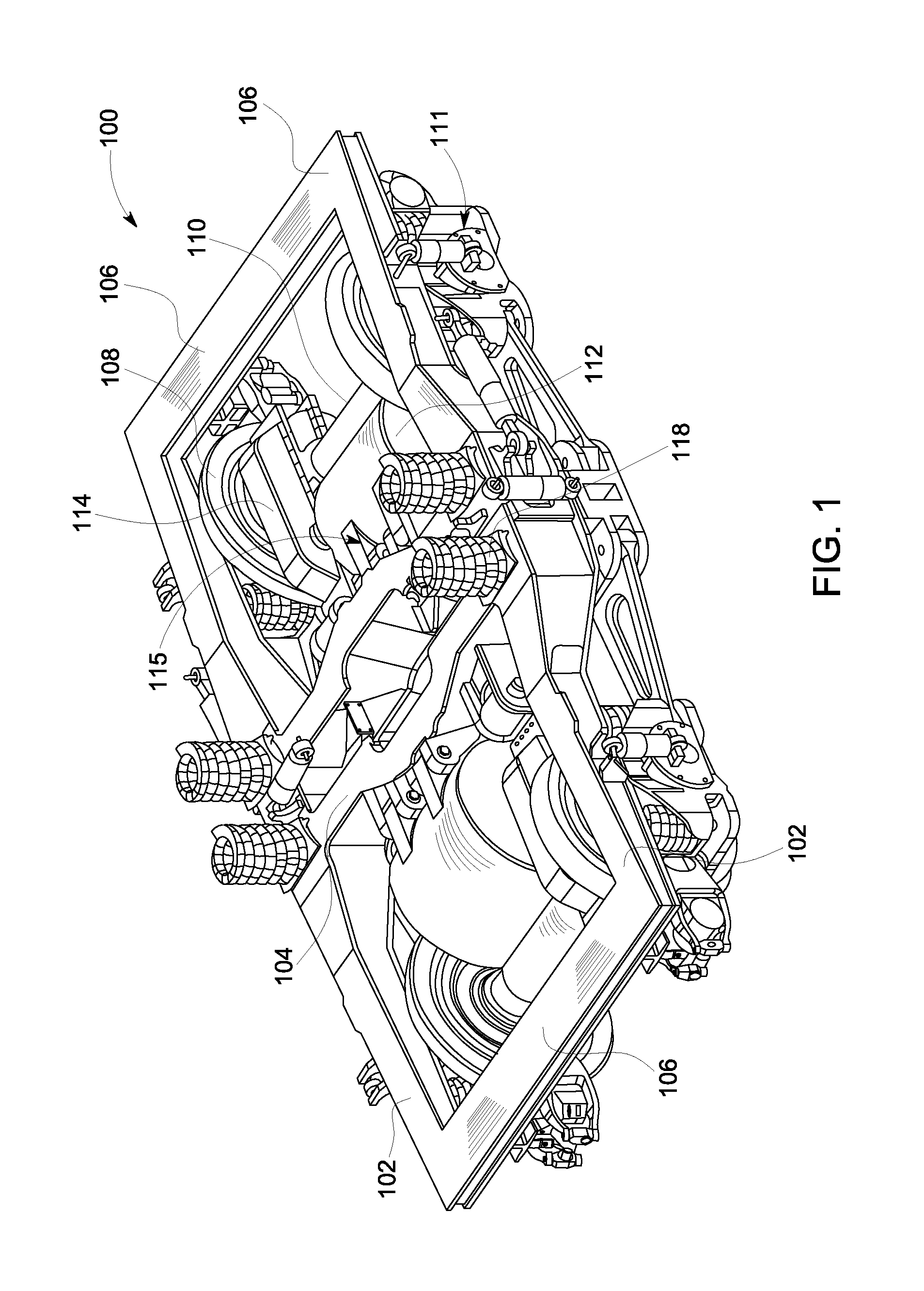

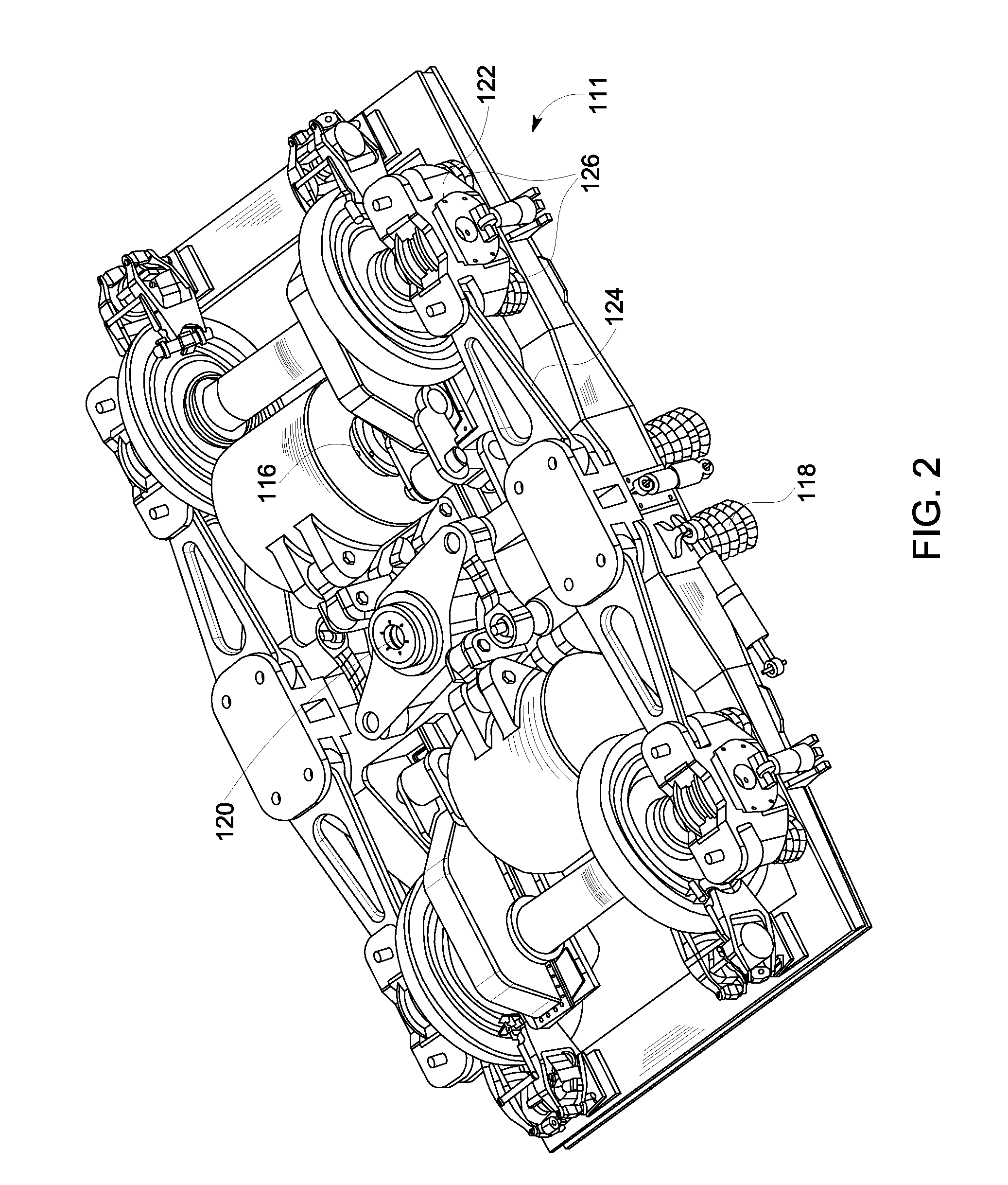

Suspension apparatus and method

ActiveUS20130019774A1Reduce dynamic loadSteam locomotivesElectric motor propulsion transmissionBogieTruck

A suspension apparatus that includes a suspension linkage connected between a traction motor and a rail vehicle truck frame at least at first and second locations. The suspension linkage including at the first location a first pin pivotally connecting the traction motor with a cross member of the truck frame, and, at the second location, at least one elastomeric element deformable to fully suspend the traction motor from the truck frame.

Owner:GE GLOBAL SOURCING LLC

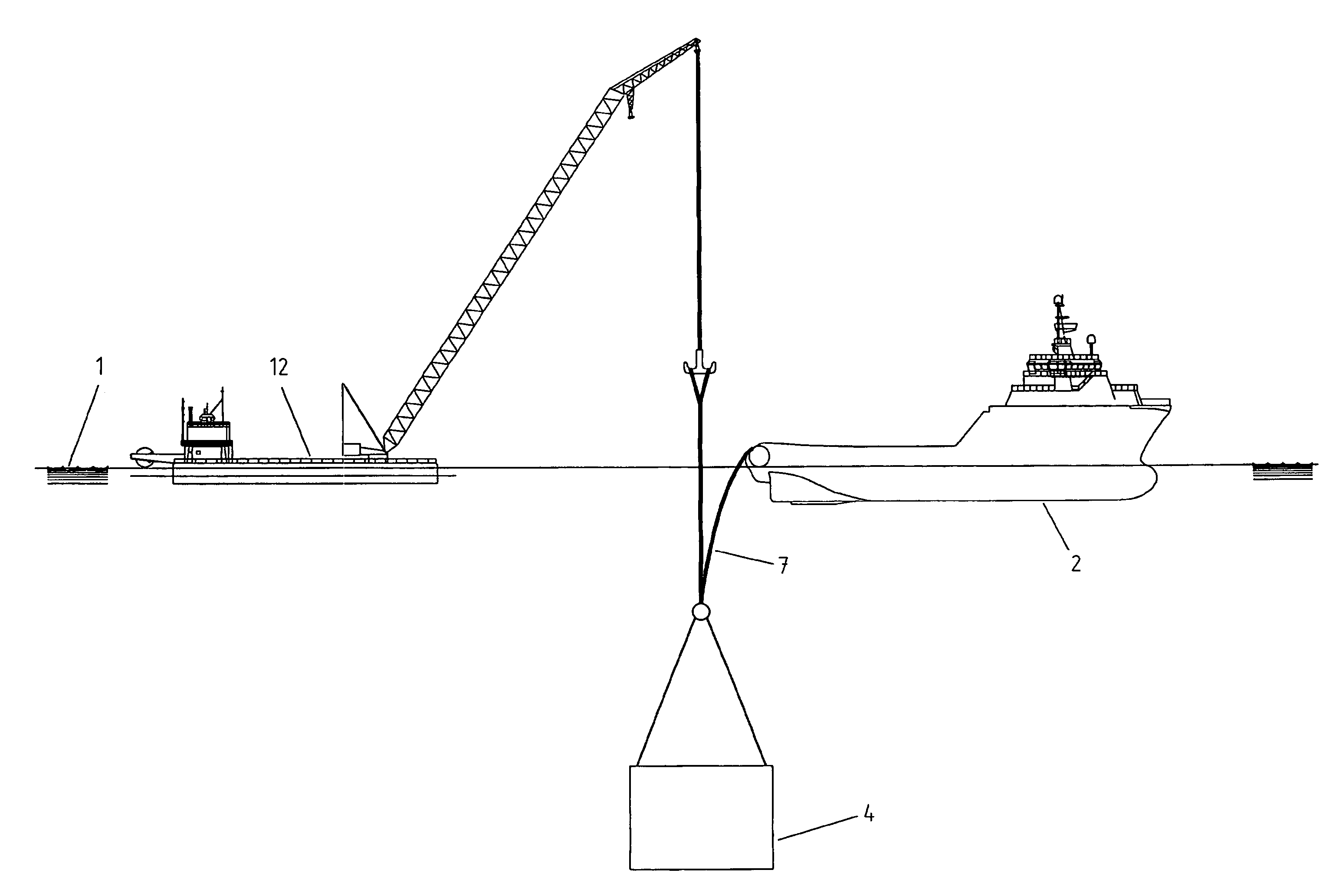

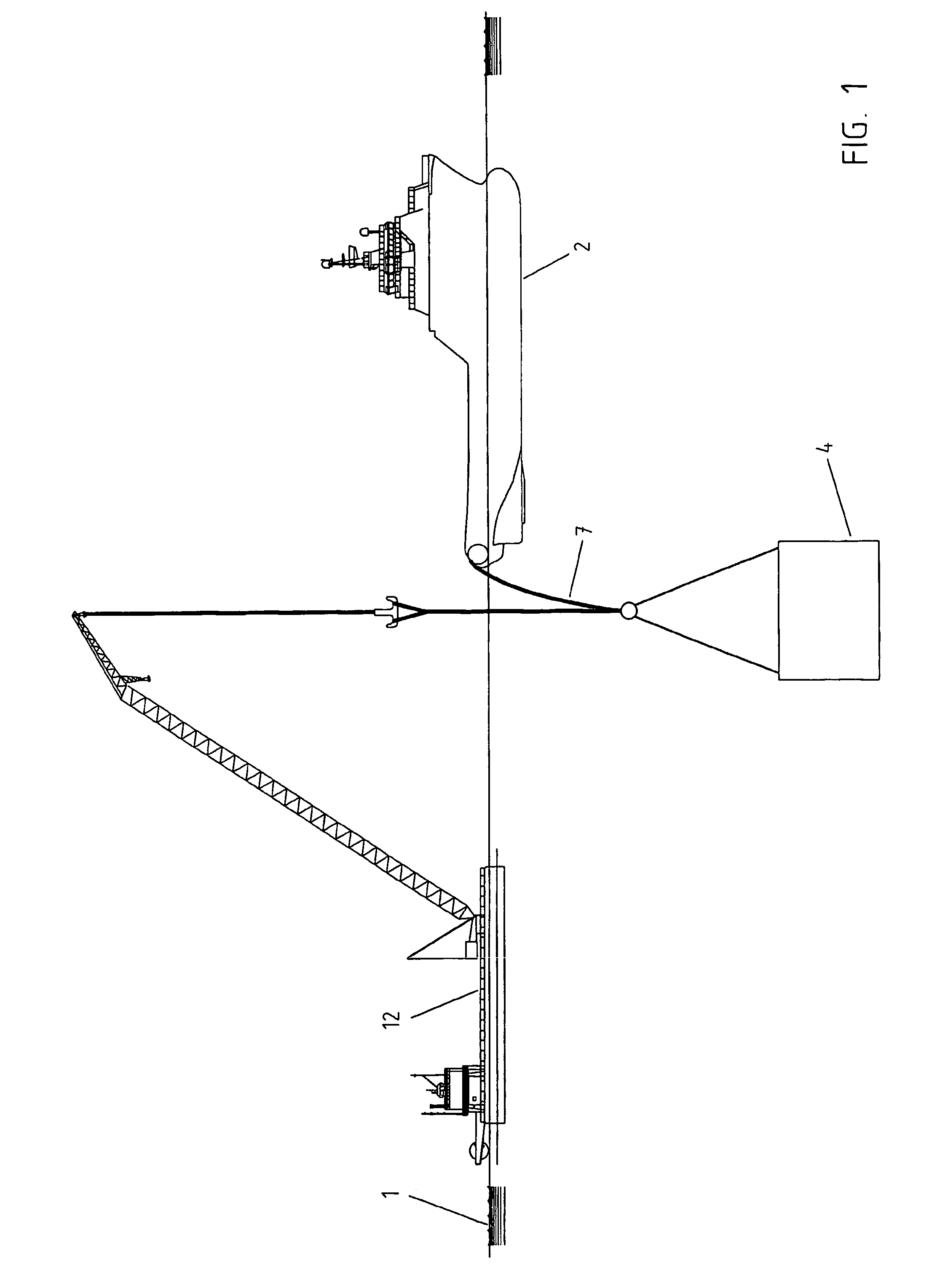

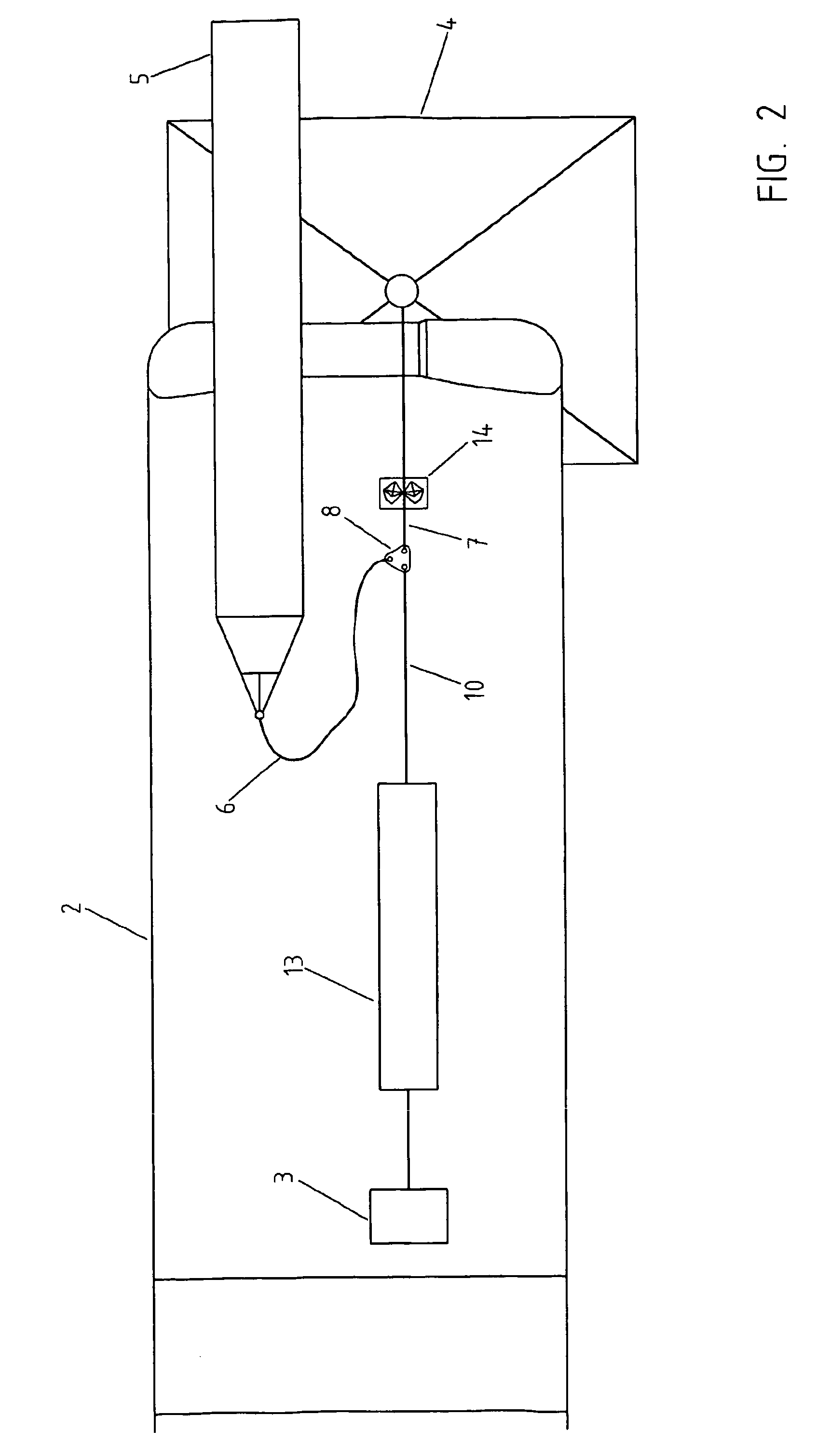

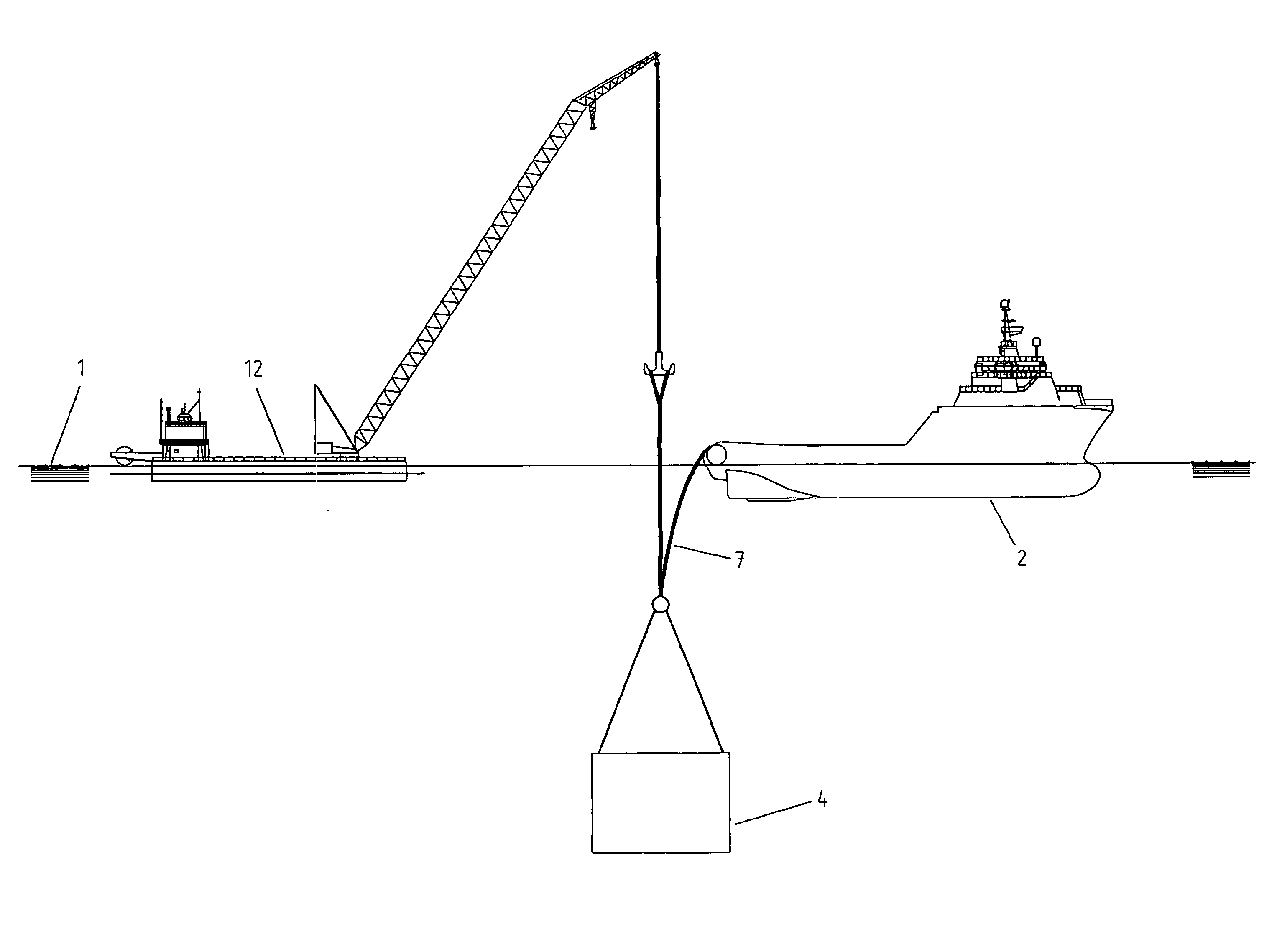

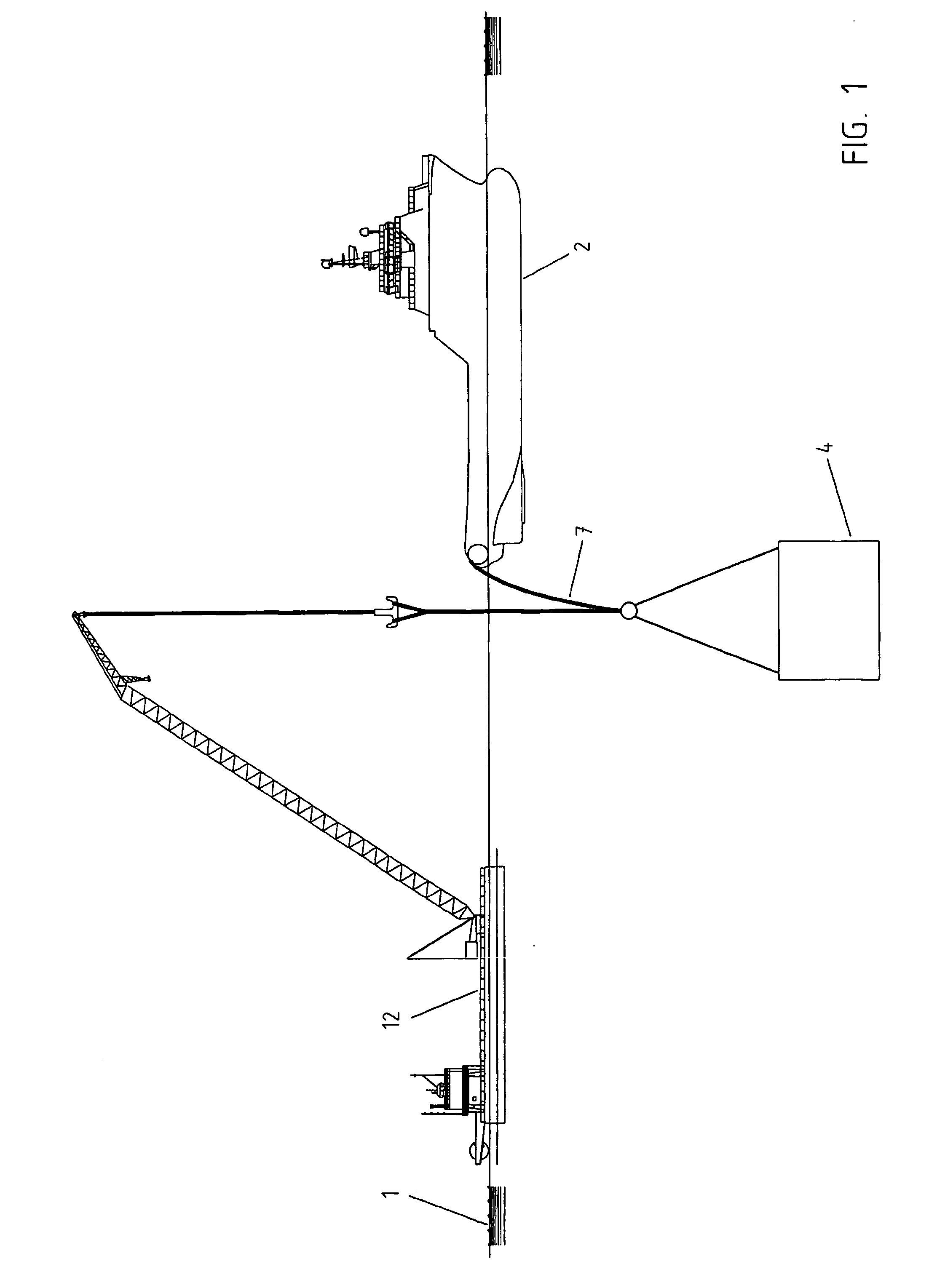

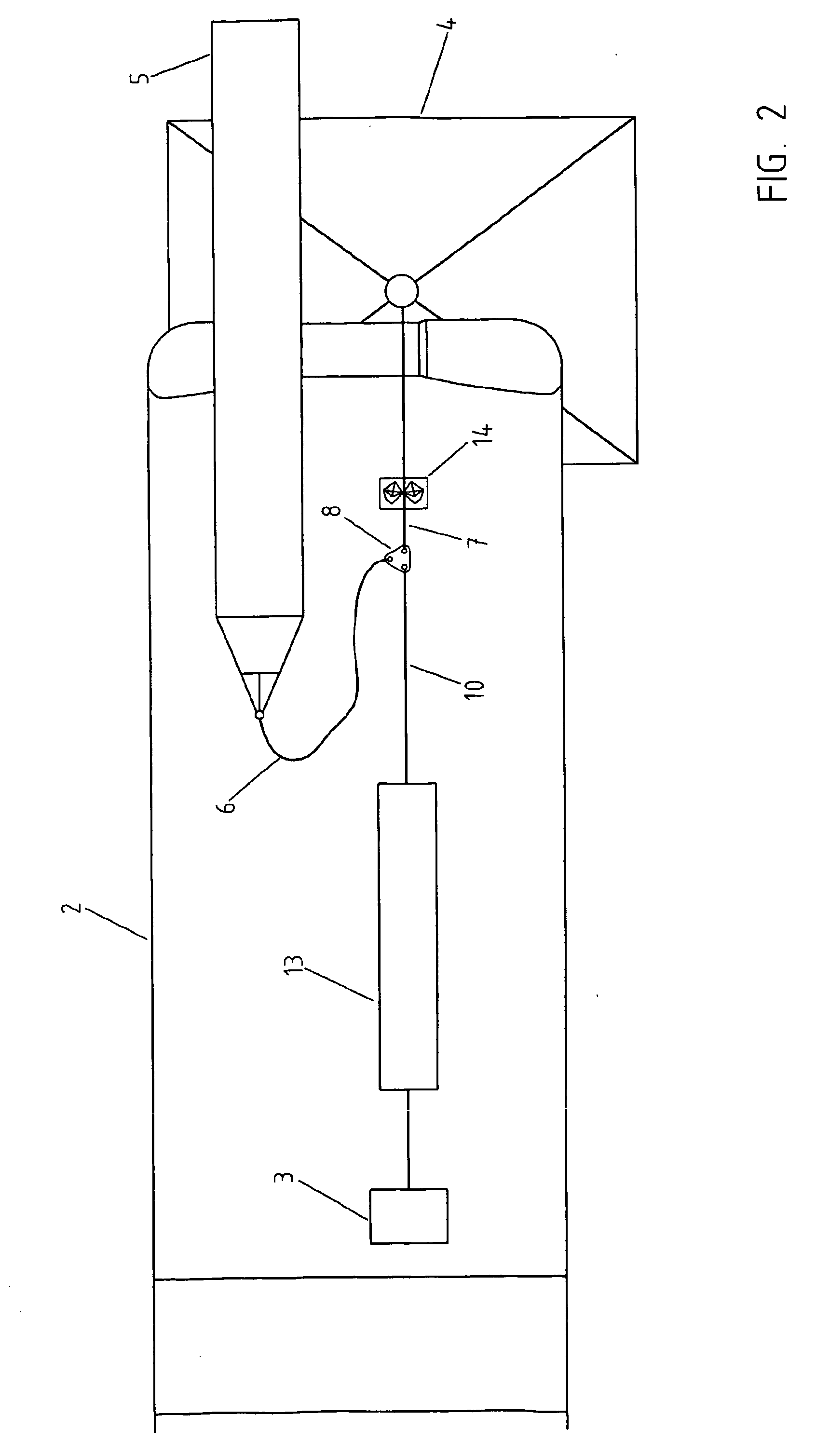

Method for underwater transportation and installation or removal of objects at sea

Method for transport and installation of objects at sea, particularly relating to transport and installation of obs jects that are part of the infrastructure in oil and gas fields offshore, the object (4) is put in the sea at a suitable location near the shore or in sheltered waters, then towed to the installation site while being suspended in a slender buoyancy unit (5) acting much like a heave compensating unit. Upon arrival at the installation site, the suspension of the object (4) is transferred from the buoyancy unit (5) to a heave compensated winch (3) on a surface vessel (2), preferably the same vessel as used for the preceding towing operation. The winch is used to lower is the object (4) to its destination on the sea bottom or a predetermined location above the sea bottom.

Owner:AKER MARINE CONTRACTORS

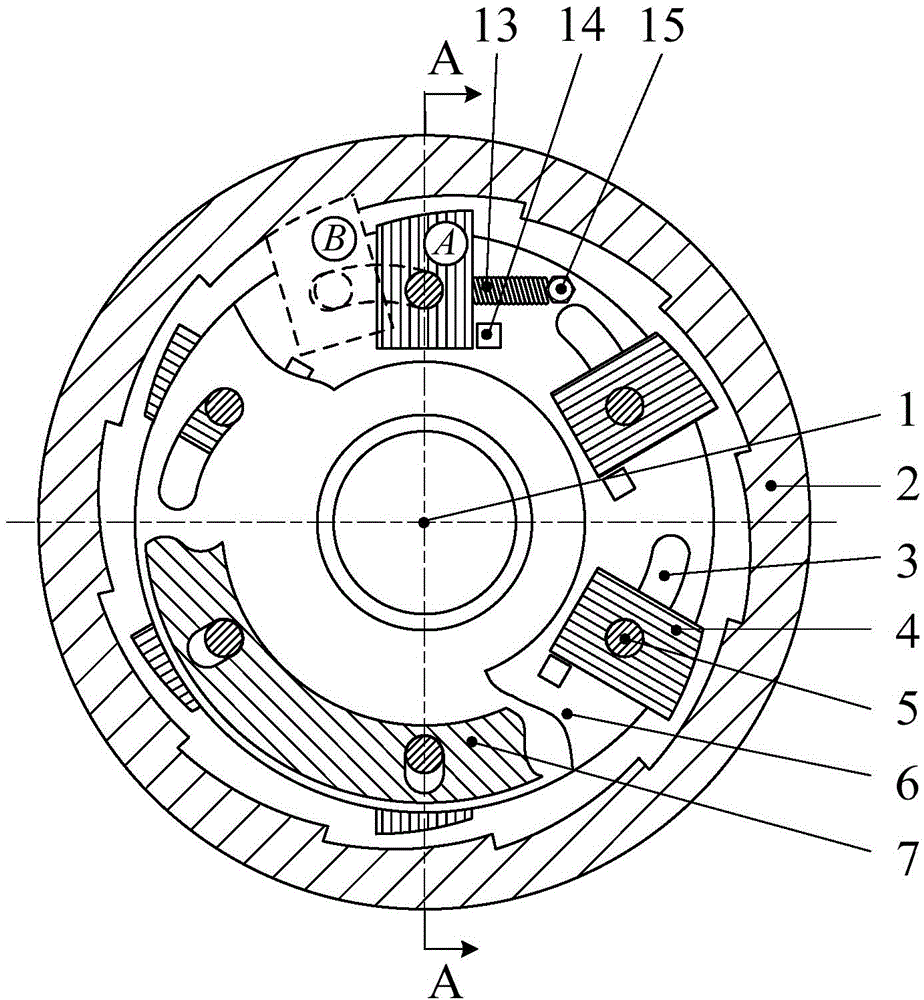

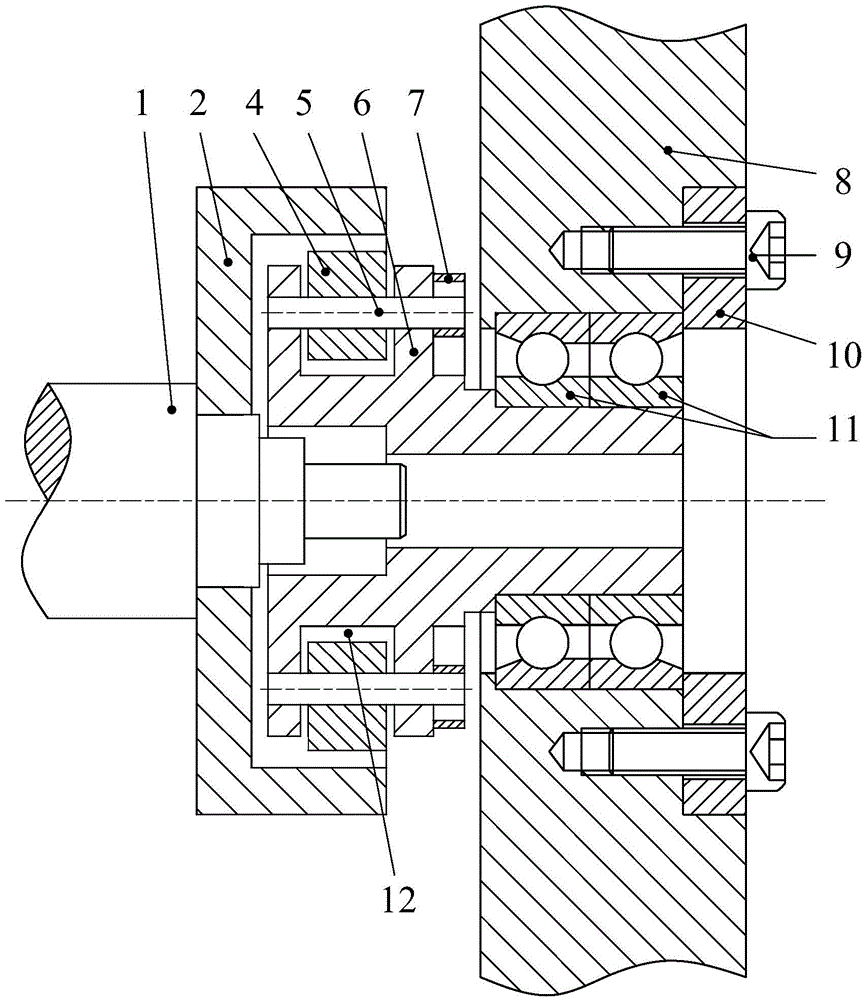

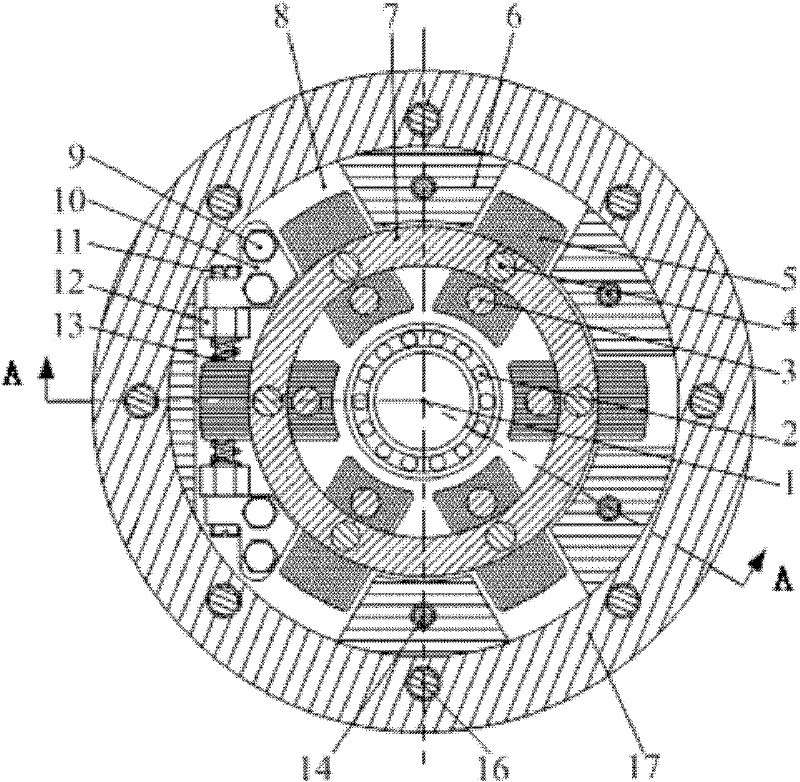

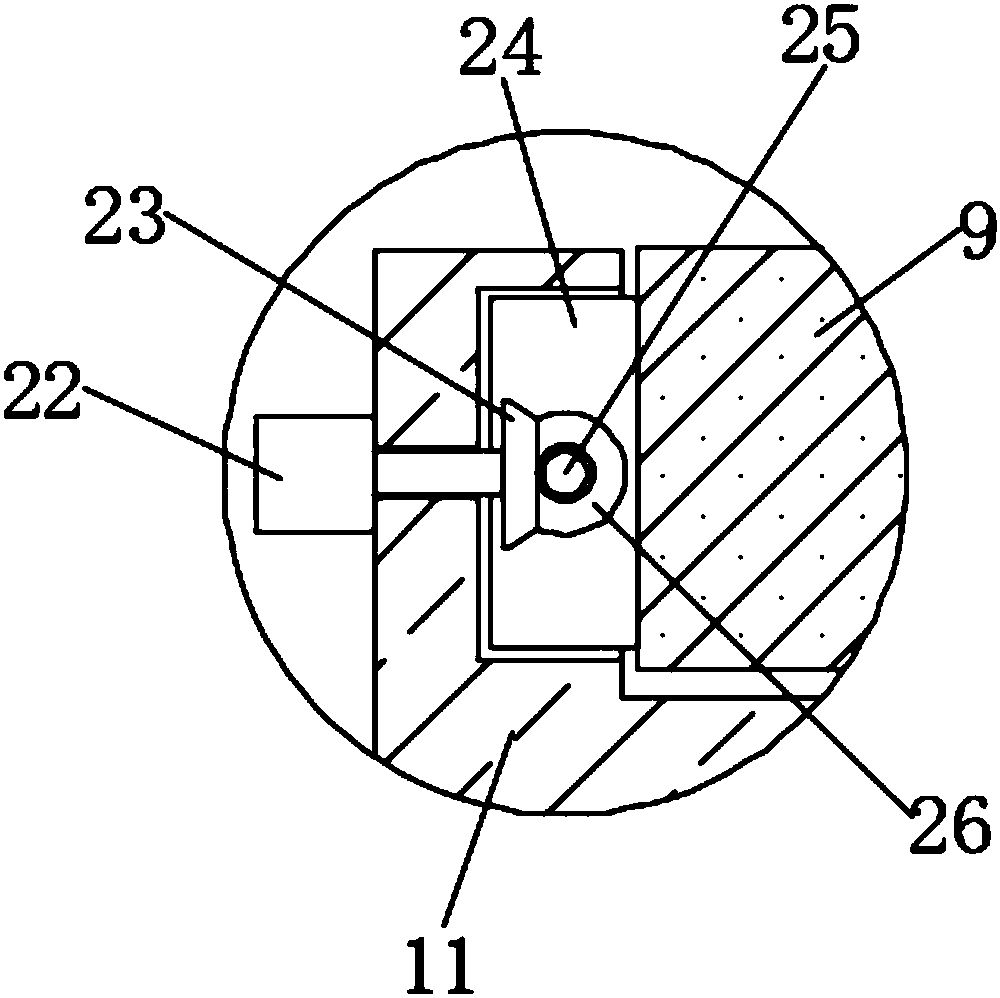

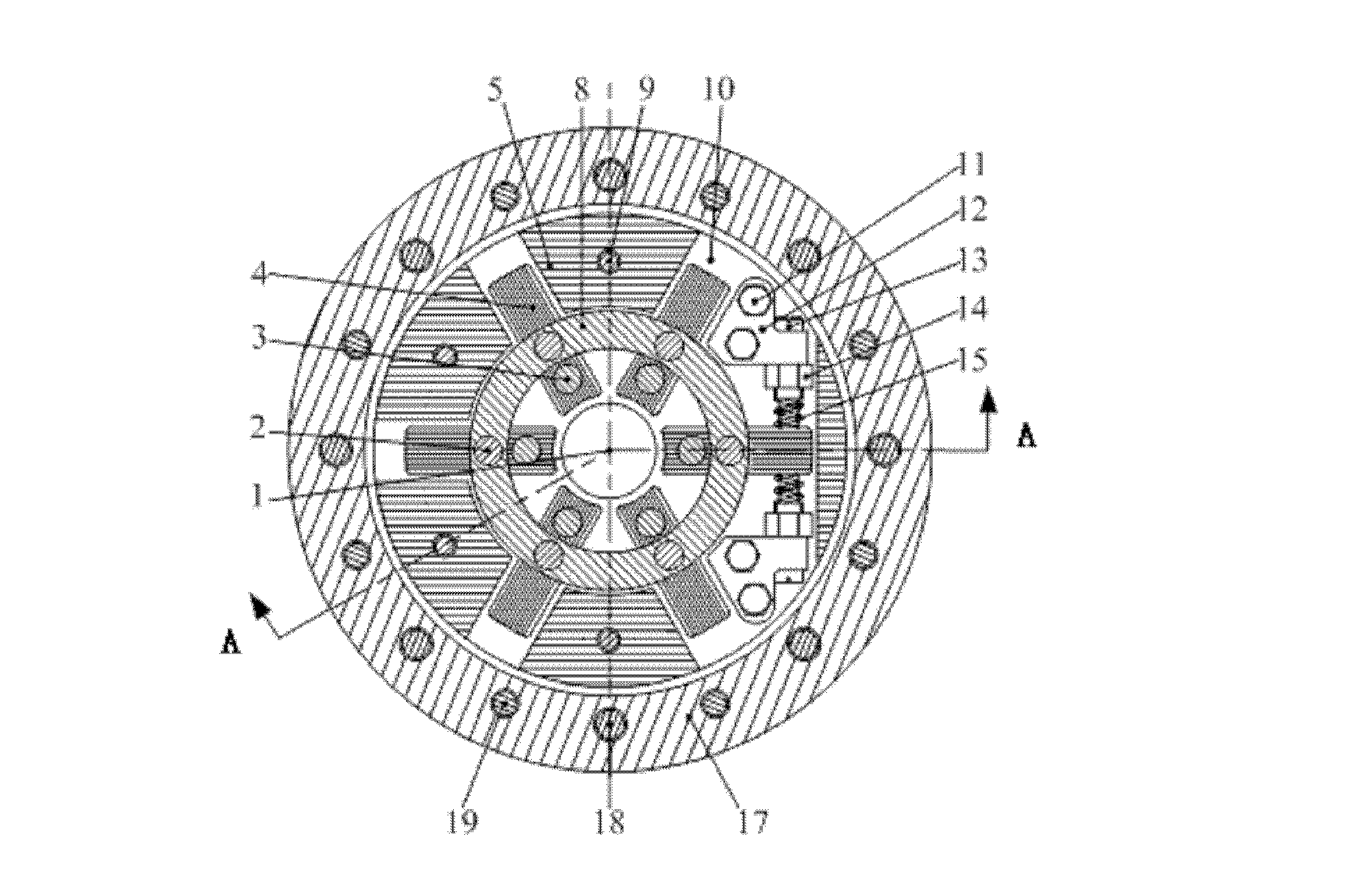

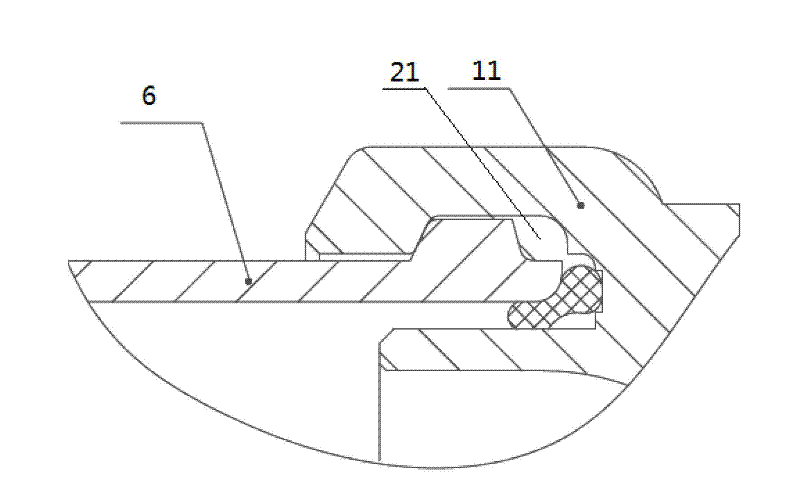

Centripetal thrust protection bearing device for automatically eliminating clearance

InactiveCN103912589AAchieve axial protectionReduce gapRolling contact bearingsBearing unit rigid supportBall bearingRolling-element bearing

The invention discloses a centripetal thrust protection bearing device for automatically eliminating a protection clearance in a magnetic suspension bearing system. The centripetal thrust protection bearing device comprises a rotary shaft, a rotor assembly, a sliding block, an installation seat and a bearing seat, wherein two angular contact ball bearings are arranged between inner cavities of the installation seat and the bearing seat; the sliding block comprises more than two sliding block sub-bodies; each sliding block sub-body is arranged in a sliding block guide groove through a sliding rod; all the sliding rods are connected into a whole through an annular connecting piece; waist-shaped holes are formed in positions, corresponding to the sliding rods, on the annular connecting piece; at least one sliding block sub-body is provided with a sliding block retaining device; a proper axial clearance is formed between the rotary shaft and the installation seat. Therefore, the device can protect a rotor in the radial and axial directions when the magnetic suspension bearing system fails and the rotor drops, and a radial clearance between the rotary assembly and a rolling bearing can be eliminated, so that vibration and impact on the rolling bearing after the high-speed rotor drops are eliminated, and the reliability and the safety of a centripetal thrust protection bearing are improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

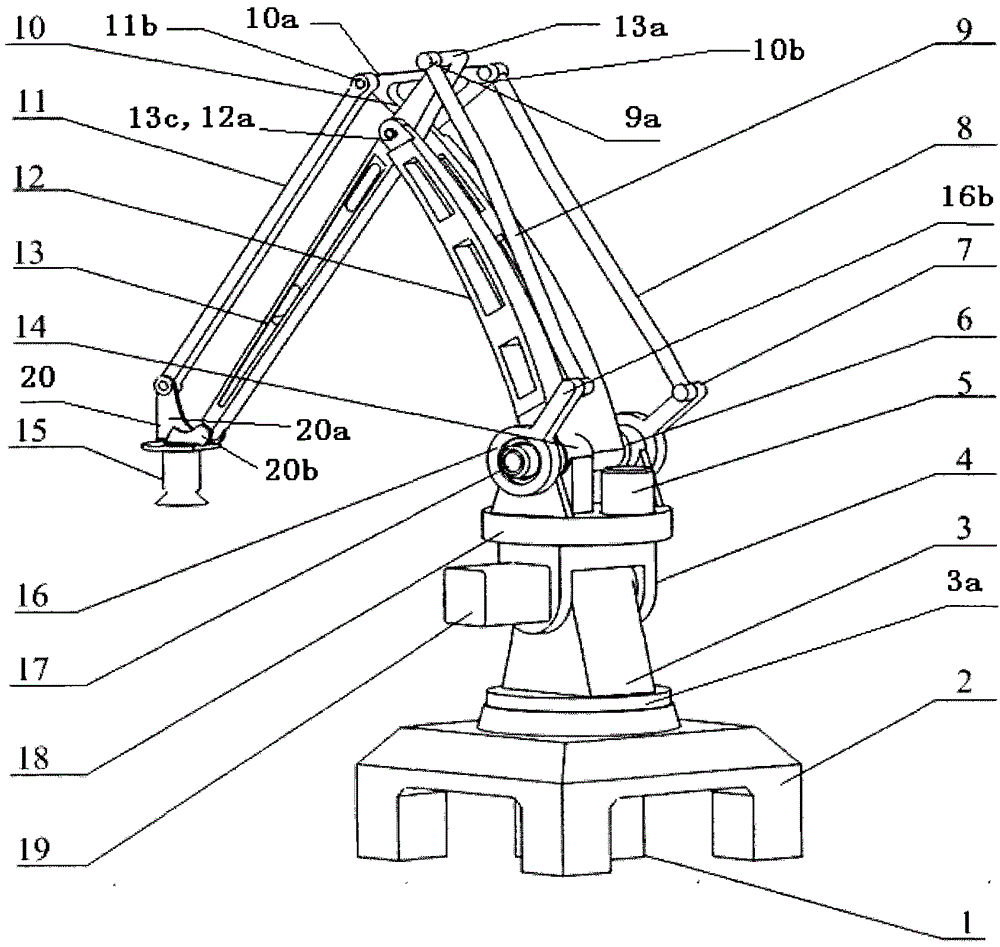

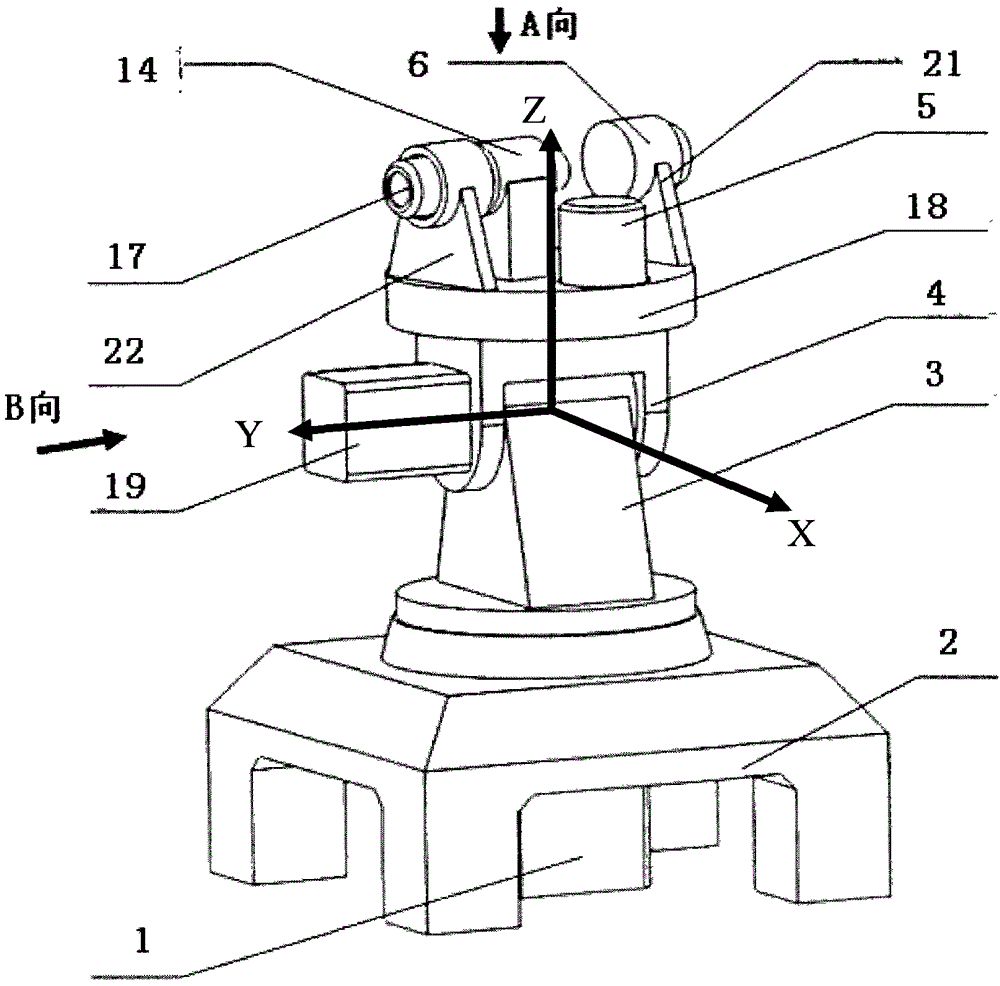

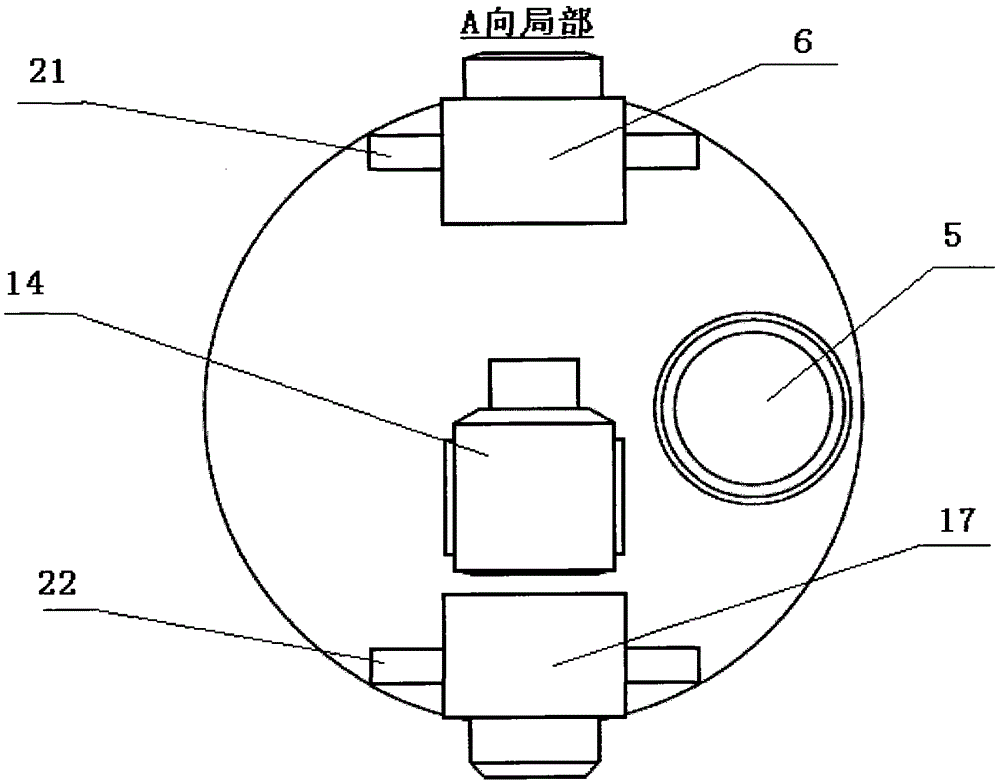

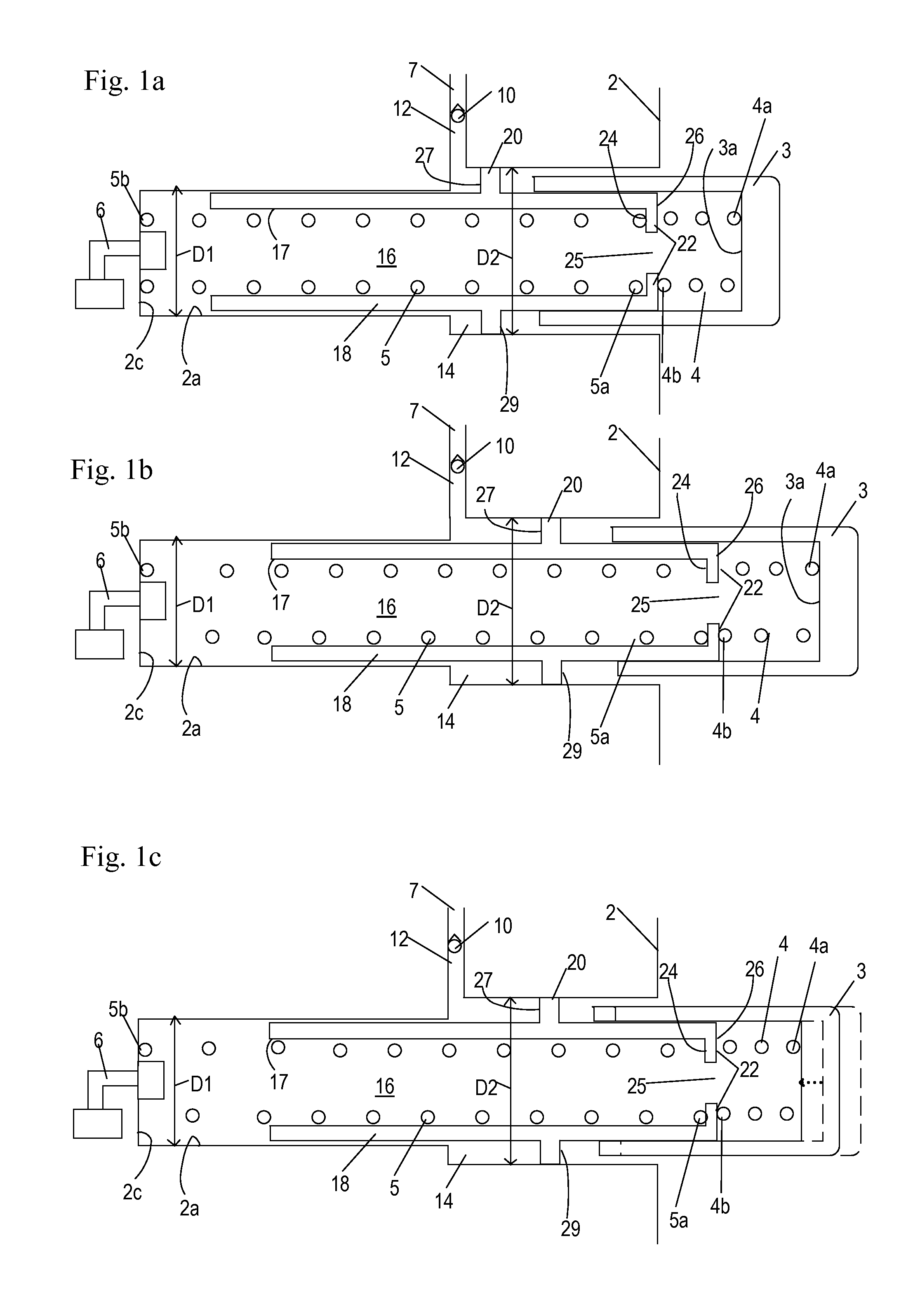

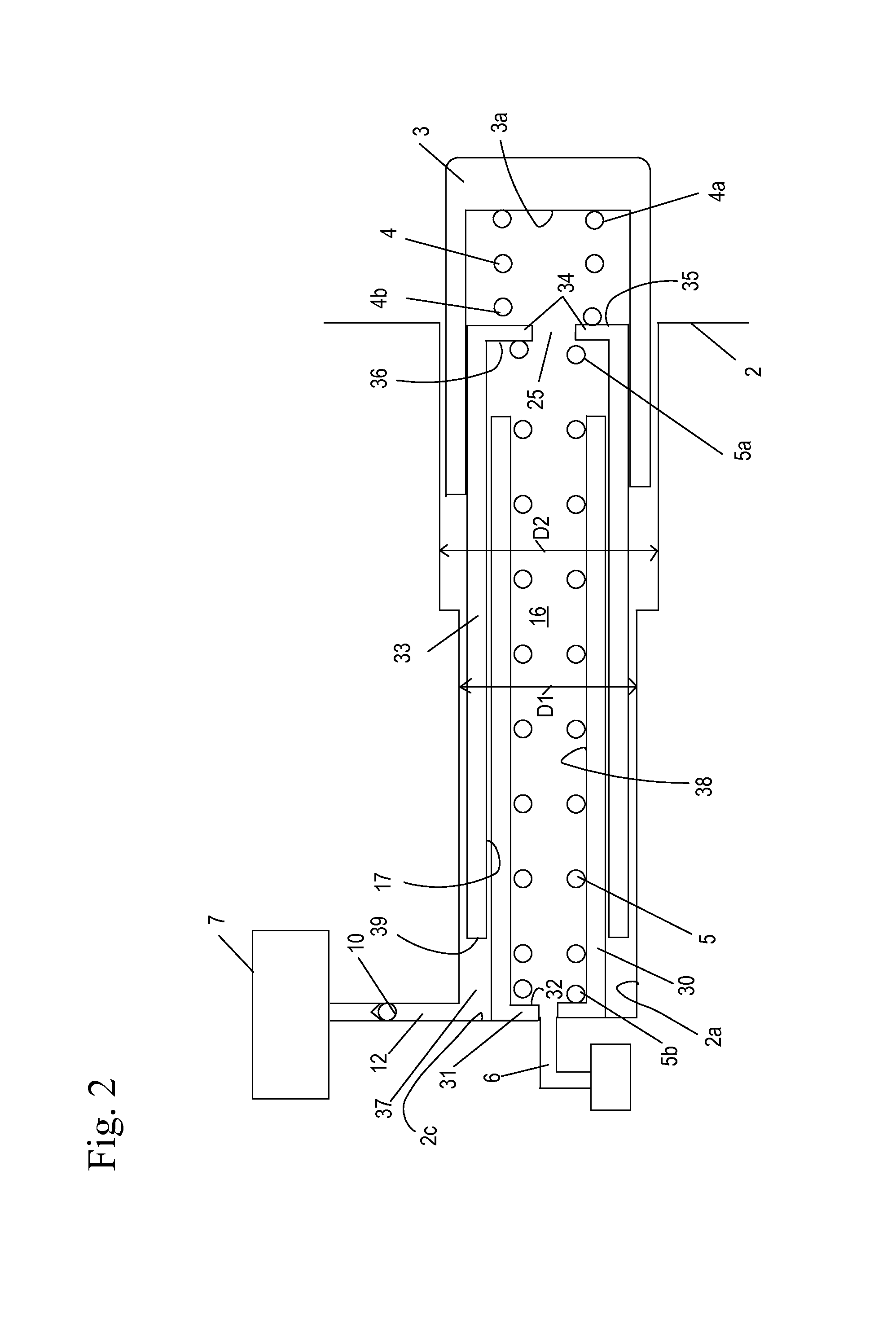

Spraying robot driven by multiple paralleled parallelogram links in series-parallel manner

InactiveCN104923432ALow failure rateAvoid safety hazardsSpraying apparatusManipulatorDrive motorControl theory

The invention provides a spraying robot driven by multiple paralleled parallelogram links in a series-parallel manner. The spraying robot comprises a serial drive pedestal assembly, three sets of paralleled parallelogram link mechanisms and a movable platform (20). The spraying robot is characterized in that the serial drive pedestal assembly comprises a fixed lower pedestal (2), and three rotary pedestals which are connected in series on the lower pedestal (2) and are formed by a middle pedestal (3), an upper pedestal (4) and a top pedestal (18), a platform of the top pedestal (18) is provided with three sets of driving motors (14, 6, 17), and the three rotary pedestals (3, 4, 18) and the three sets of driving motors (14, 6, 17) drive the movable platform (20) through the three sets of paralleled parallelogram link mechanisms in a cooperation manner. Forward and inverse kinematics solutions of the spraying robot are simple and unique, track planning and control can be achieved easily, the work space of the spraying robot is large, and the spraying robot can spray large-outline complex curved surfaces.

Owner:JIANGSU CHANGHONG INTELLIGENT EQUIP CO LTD +1

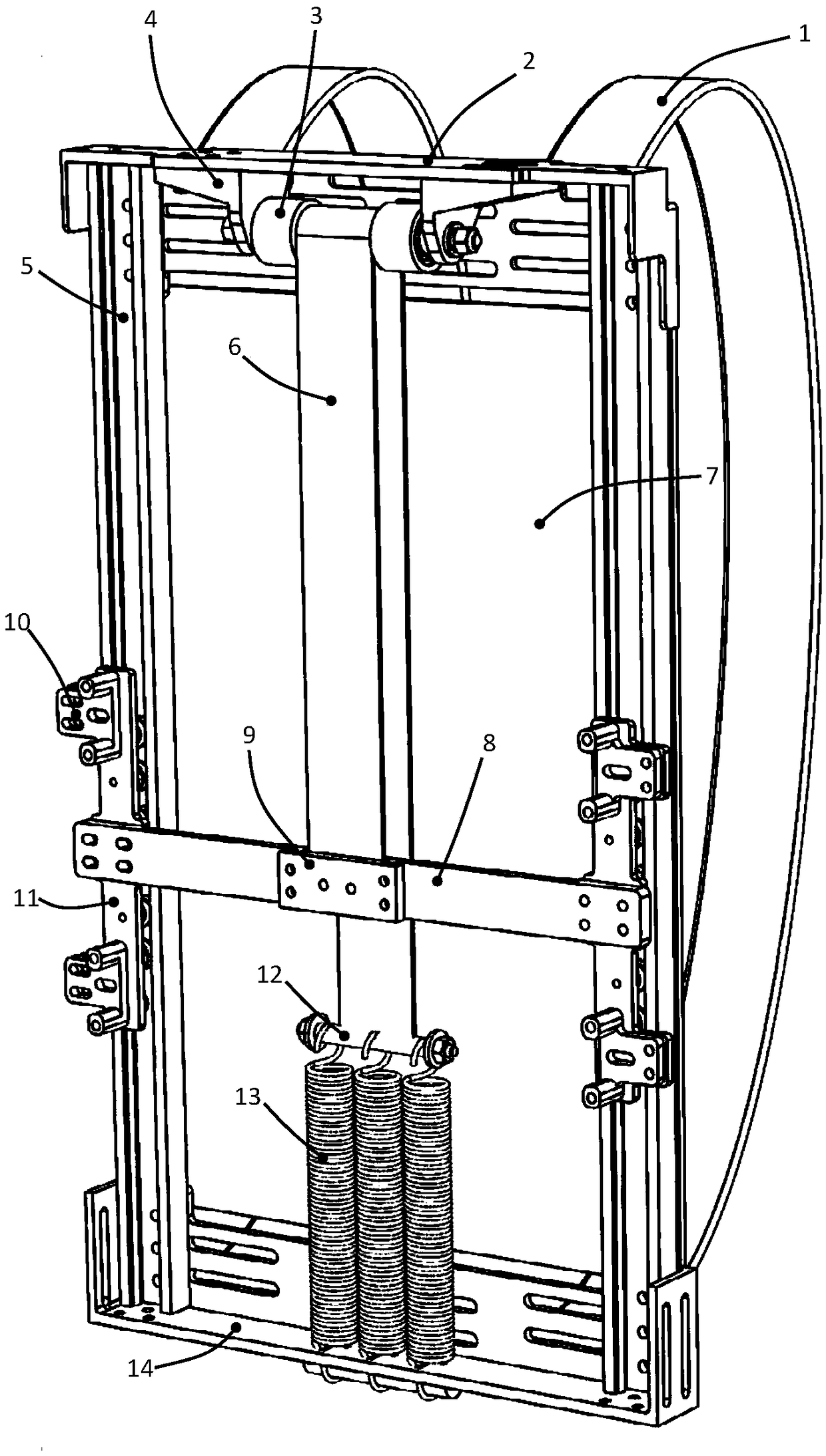

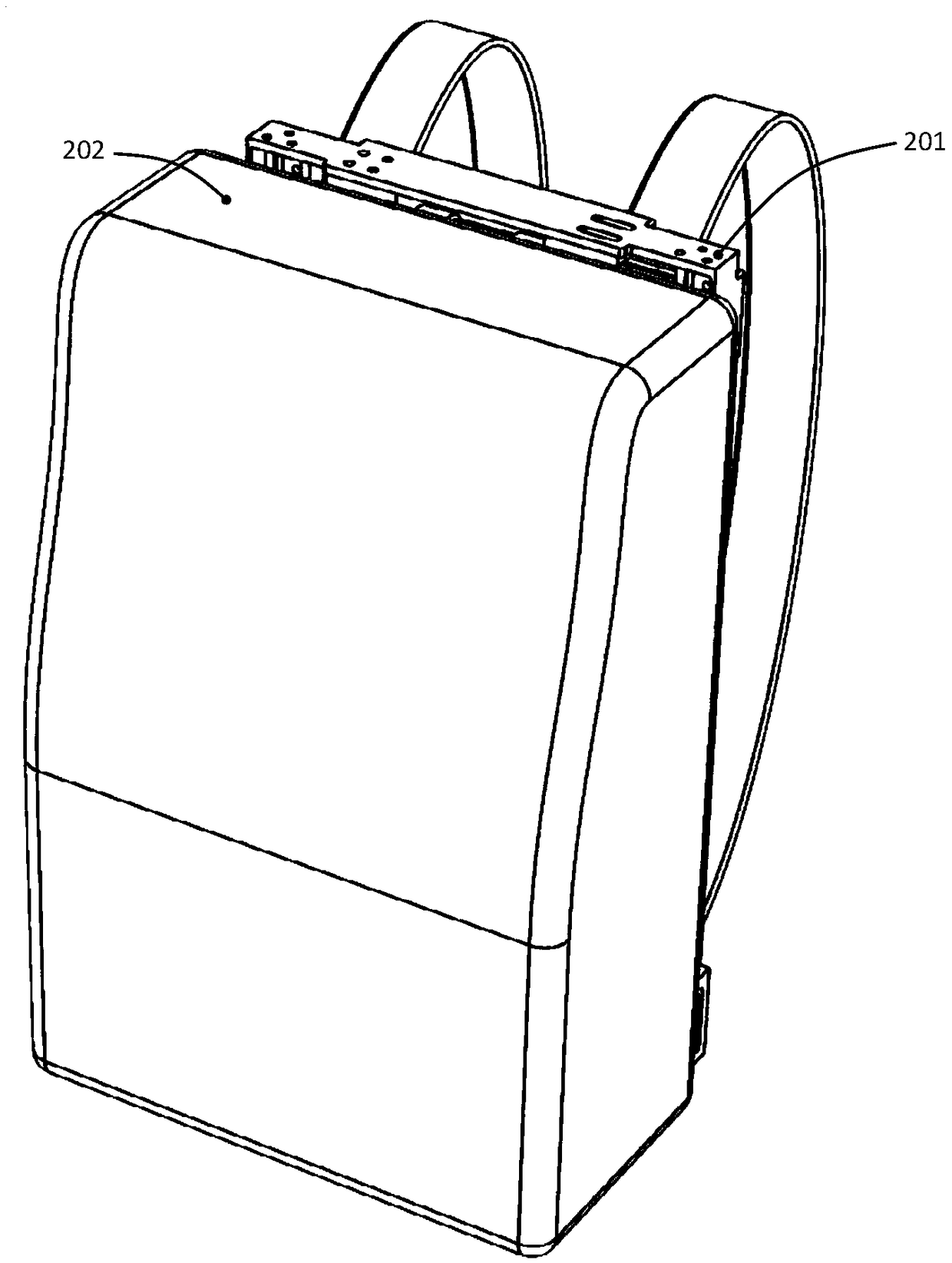

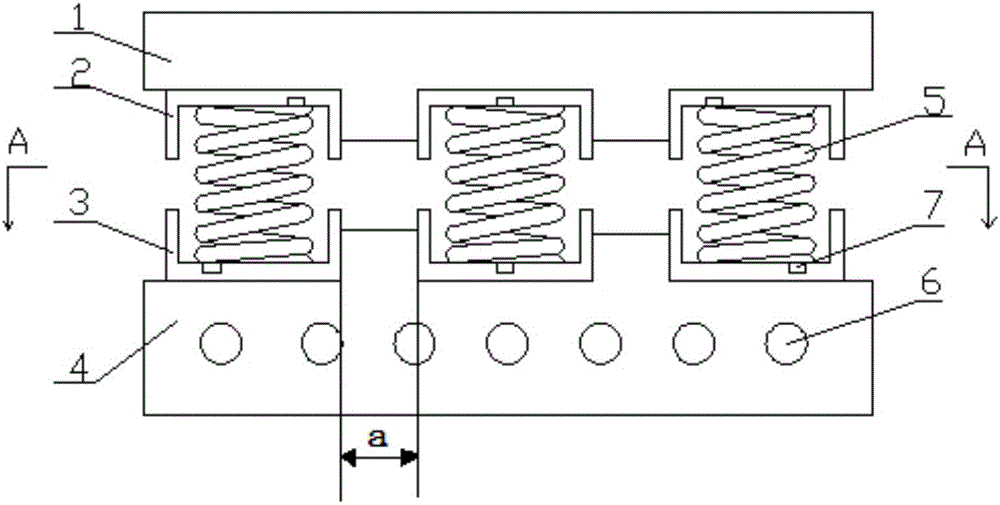

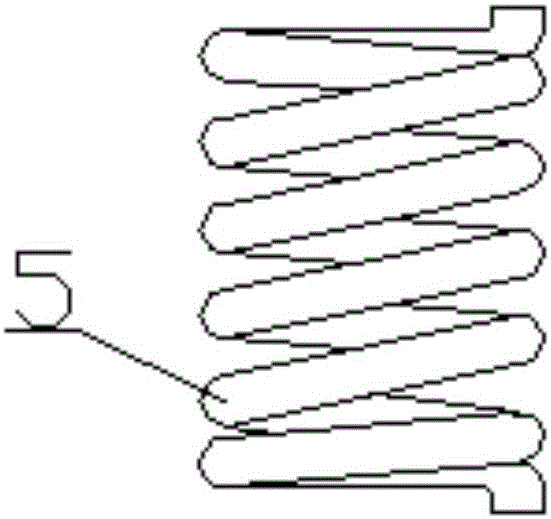

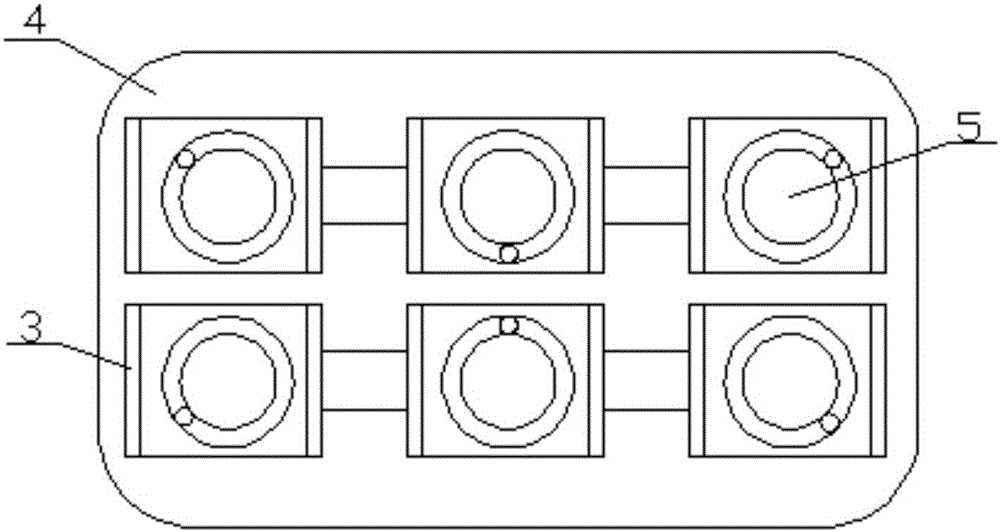

Dynamic load reduction device for backpacks

The invention discloses a dynamic load reduction device for backpacks, comprising an upper cross beam, a lower cross beam, guide rails, guide wheels, guide wheel supports, a sliding connection rack, springs, a spring connection shaft, a pull rope and a back plate. The upper cross beam is connected with the lower cross beam through the guide rails; the guide rails are mounted at the two ends of theupper and lower cross beams and are perpendicular to the upper and lower cross beams; the guide wheel supports are mounted on the upper cross beam and are connected with the guide wheels; the back plate is fixedly connected with the upper and lower cross beams; two ends of the sliding connection rack are fitted to the guide rails on the two sides respectively; one ends of the springs are fixed tothe lower cross beam; the other ends of the springs are fixedly connected with the spring connection shaft; one end of the pull rope is connected with the spring connection shaft, and the other end of the pull rope is passed around the guide wheels and is fixed to the sliding connection rack. The dynamic load reduction device for backpacks reduces load by making use of frequency and phase differences of damping mass and the vibrating human body, operating efficiency is improved, and the burden of field operators is reduced.

Owner:SOUTH CHINA UNIV OF TECH

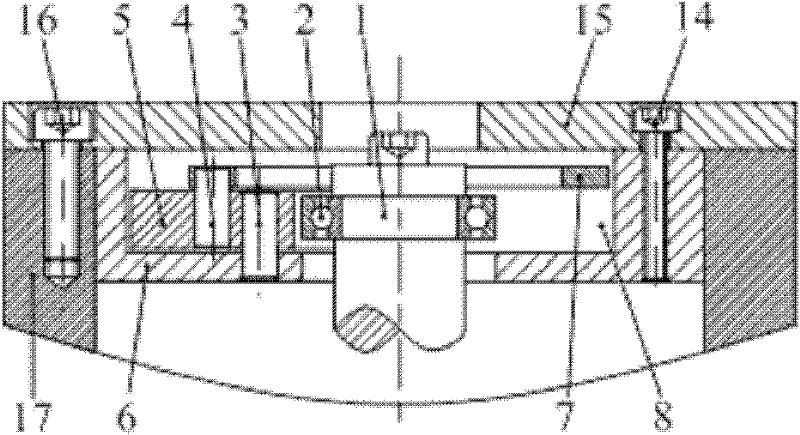

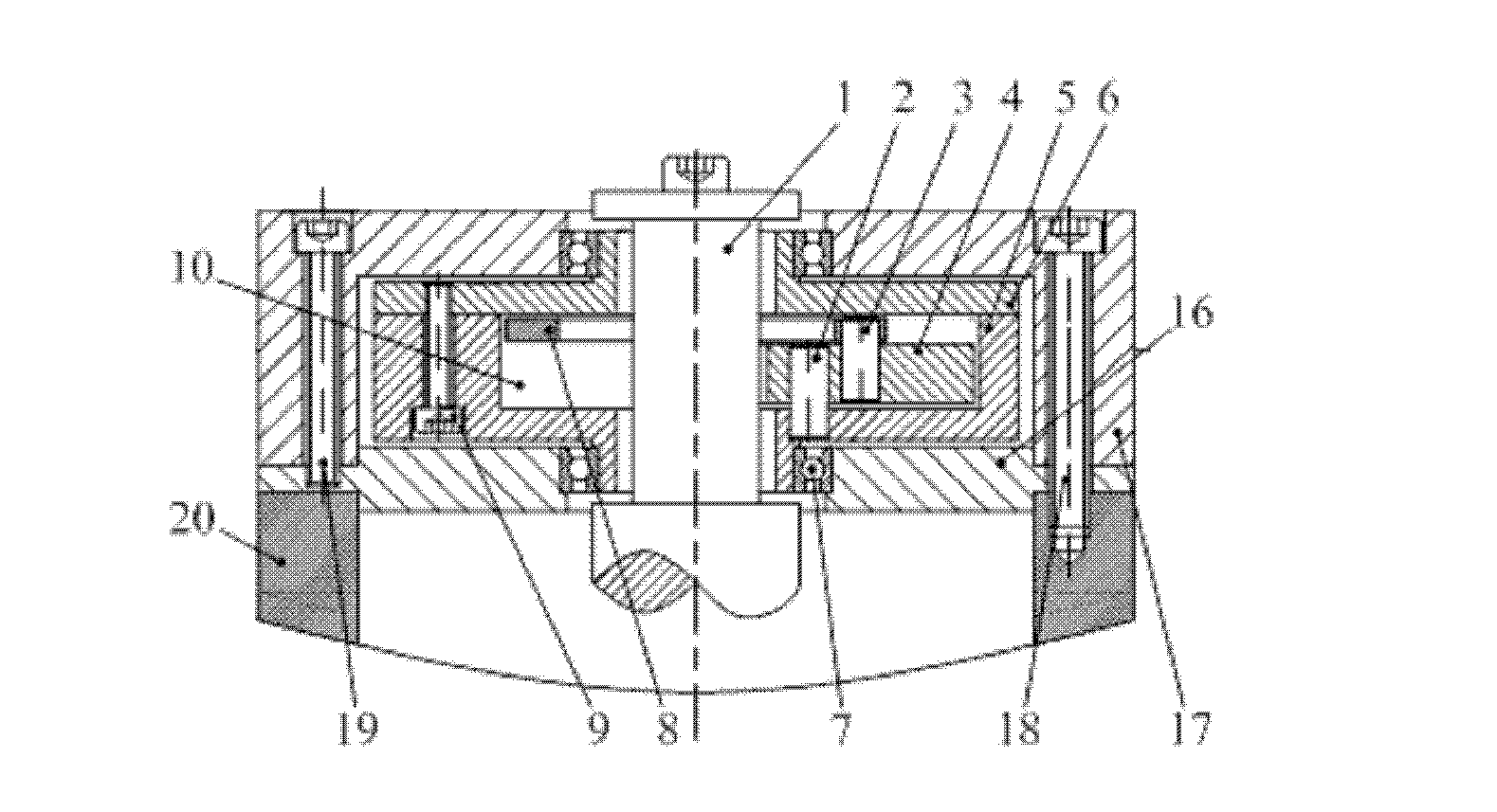

Radial protection bearing device for automatically removing radial clearance of outer ring of rolling bearing

ActiveCN102537045AReduce dynamic loadExtend your lifeBearing assemblyBearingsInterference fitRolling-element bearing

The invention discloses a radial protection bearing device for automatically removing a radial clearance of an outer ring of a rolling bearing. The radial protection bearing device comprises a mounting seat, a support seat, the rolling bearing and a rotor assembly, wherein the rolling bearing is connected with the rotor assembly in an interference fit manner, the support seat and the rotor assembly are concentrically arranged, and a proper radial clearance is formed between an inner circle of the support seat and the outer ring of the rolling bearing; the support seat comprises more than two circumferentially and uniformly arranged support seat branch bodies which are all arranged together with the mounting seat in a locating manner by a first locating pin and are all connected into an integrated body by an annular connecting piece through a second locating pin; at least one support seat branch body is provided with a support seat adjusting device; and the support seat adjusting device comprises two groups of elastic connecting pieces for remaining the concentricity of each support seat branch body and the rotor assembly. Therefore, after the rotor assembly falls down, the radial clearance between the outer ring of the rolling bearing and the support seat can be automatically removed, so that the impact and vibration on the rolling bearing are eliminated, and the reliability and safety of the radial protection bearing are improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

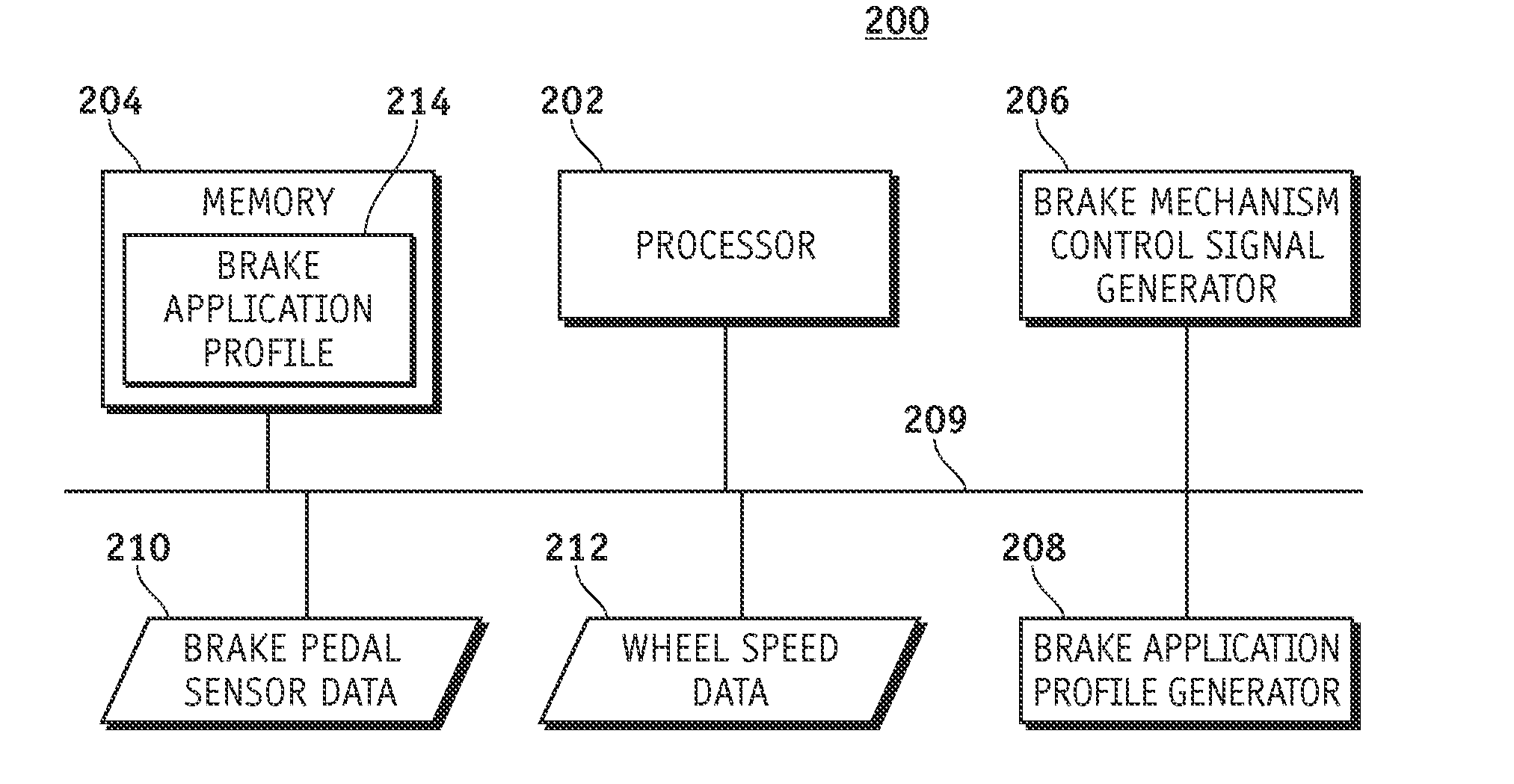

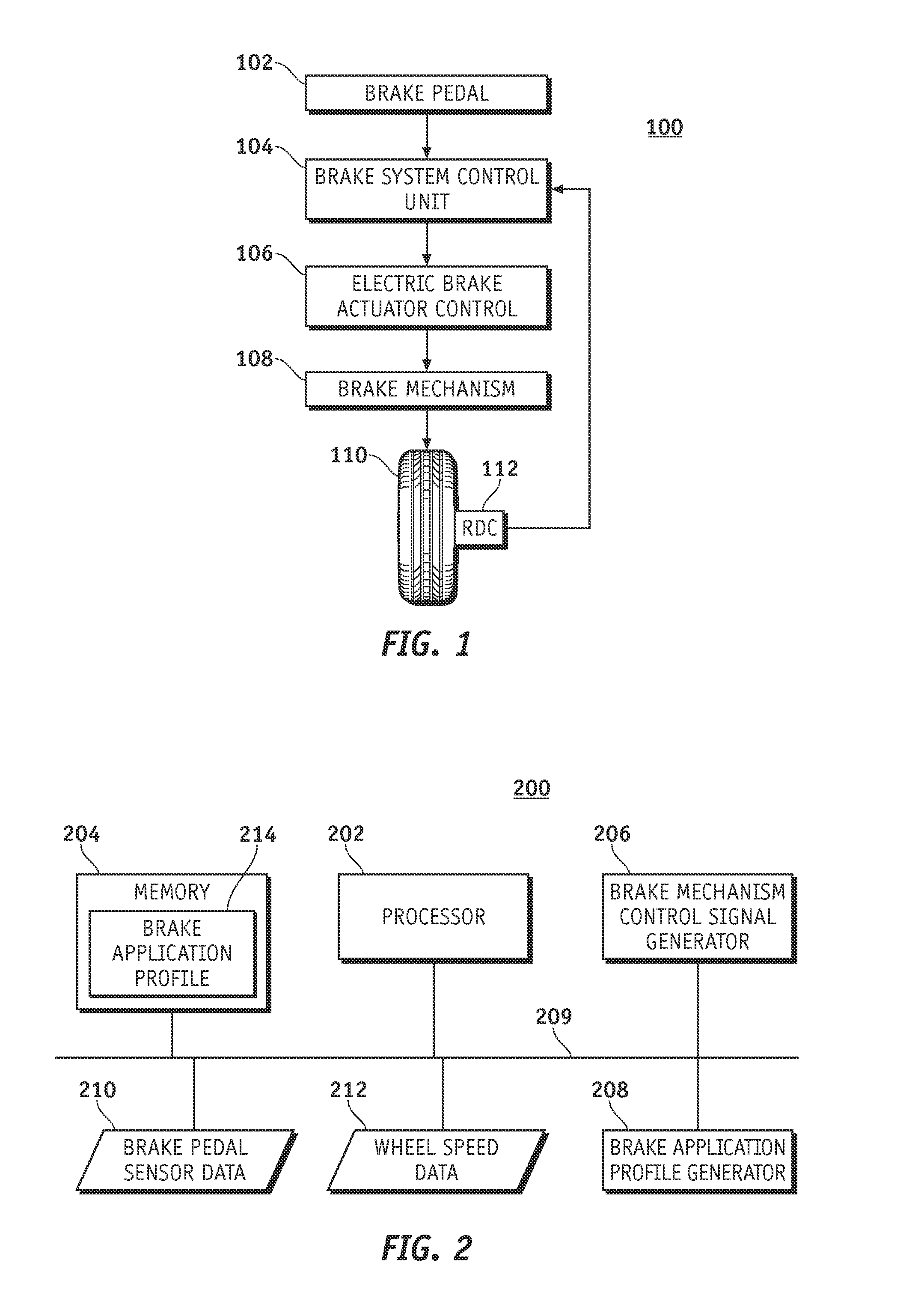

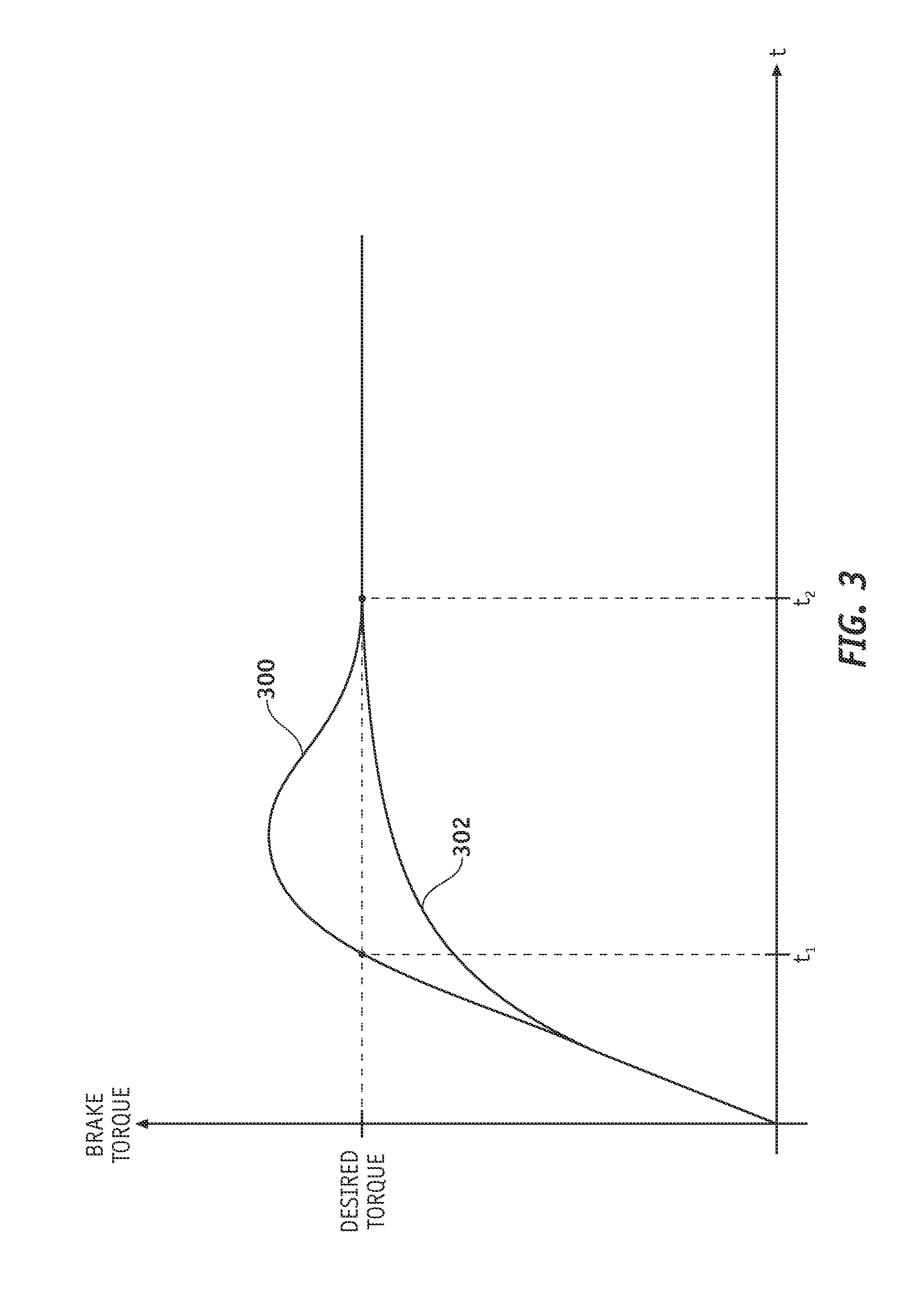

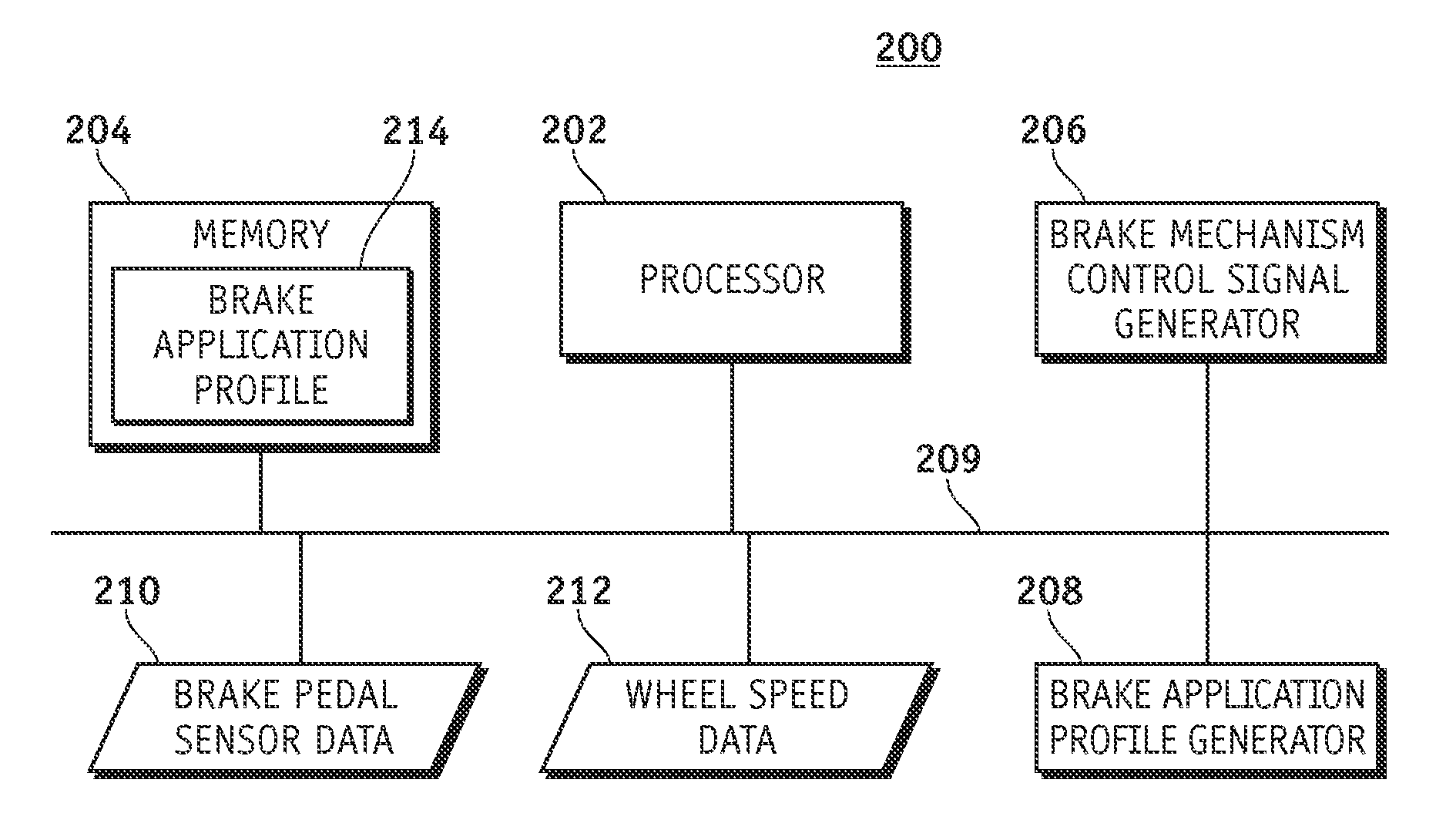

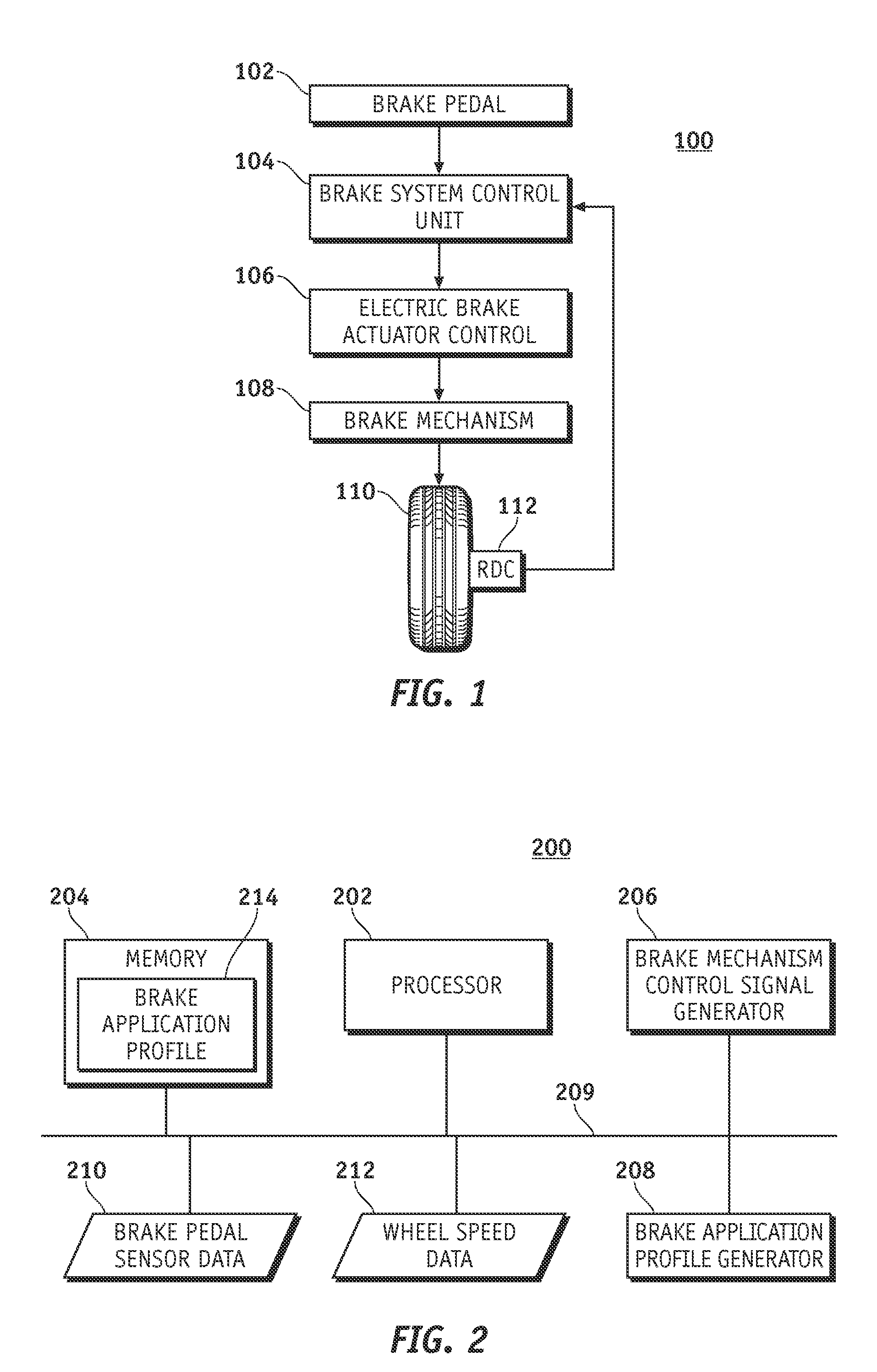

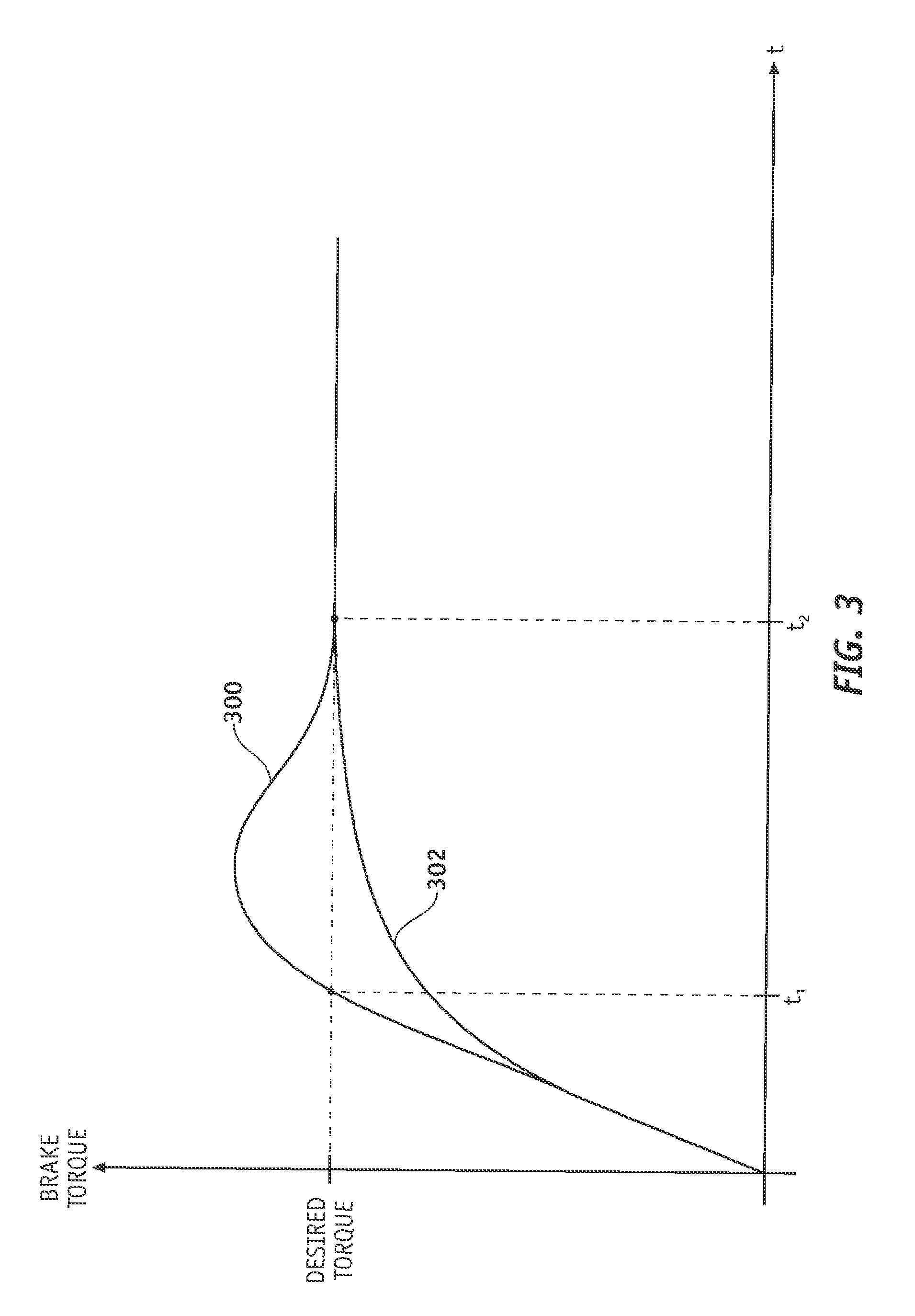

Alleviation of aircraft landing gear loading using a brake control scheme

ActiveUS20100109429A1Reduce dynamic loadHigh dynamic loadBraking action transmissionApplication and release valvesElectricityReal-time data

An electric brake system for an aircraft employs a brake control process to alleviate high dynamic structural loading of the aircraft landing gear caused by braking maneuvers. The system obtains and processes real-time data—which may include the current aircraft speed, the current brake pedal deflection position, and the current brake pedal deflection rate—to determine how best to control the onset of the brakes. The braking control scheme delays the onset of the desired braking condition to reduce high dynamic loading and lurching of the aircraft.

Owner:THE BOEING CO

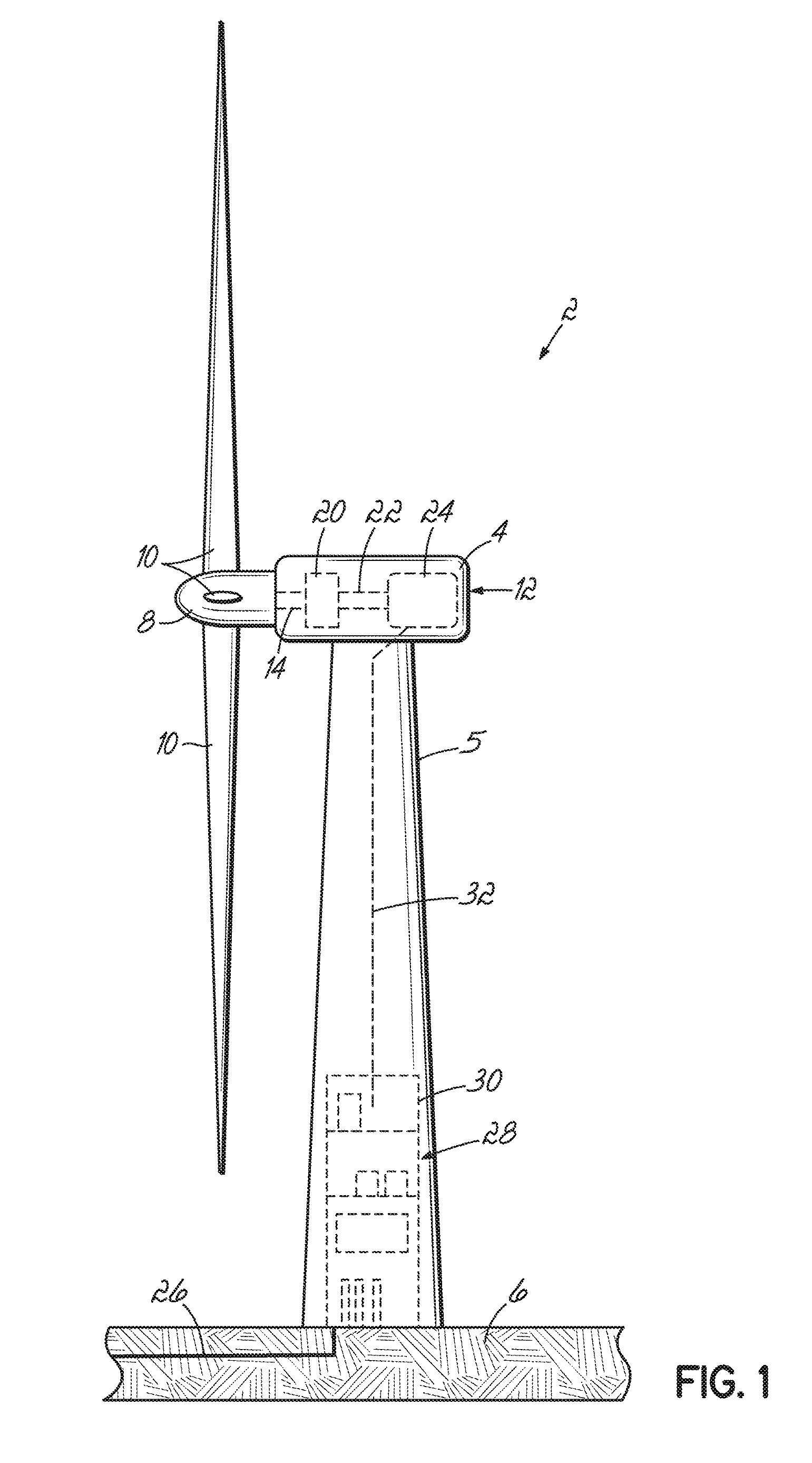

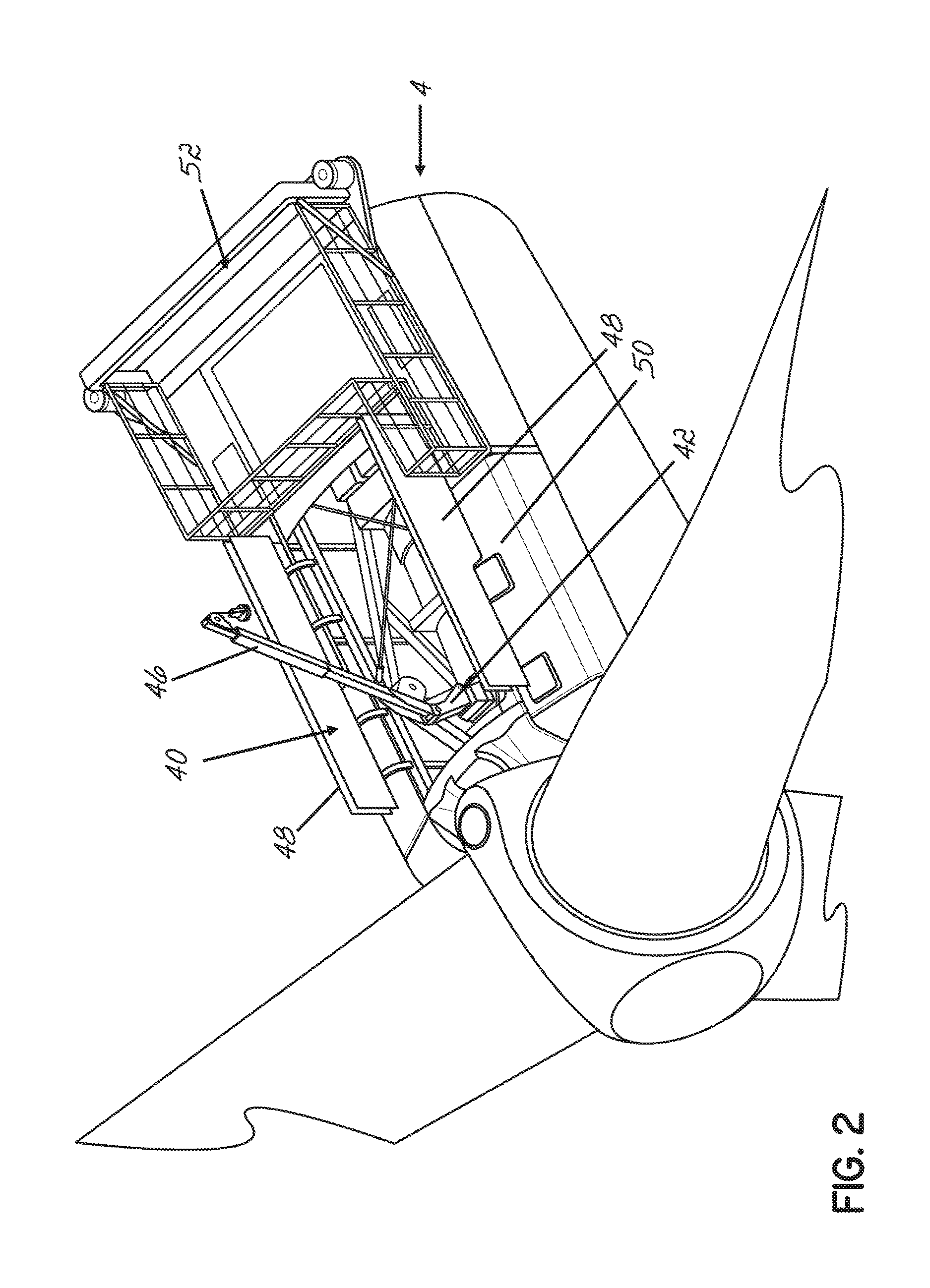

A nacelle for a wind turbine generator including lifting apparatus

ActiveUS20170022966A1Easy to wearImprove reliabilityEngine manufactureFinal product manufactureNacelleLift line

A nacelle for a wind turbine generator comprises a crane articulated on a base fixed to said nacelle. The crane includes a cantilevered telescopic boom, a principal winch with a lifting line and respective azimuth and elevation drive units for moving said boom in azimuth and in elevation relative to said nacelle. The crane has a deployed condition in which said boom is moveable in azimuth and in elevation and a stowed condition. The nacelle comprises a support structure against which said boom is brought to rest in said stowed condition thereof and wherein when in said stowed condition said boom is located into a predetermined position at which it is held to rest at a point along its length against said support structure and wherein said lifting line is in a reference position in relation to said nacelle when said crane is in its stowed condition. A method for operating a crane in a nacelle comprising operating said crane as a static hoist using a principal winch of said crane when in said stowed condition of said crane.

Owner:VESTAS WIND SYST AS

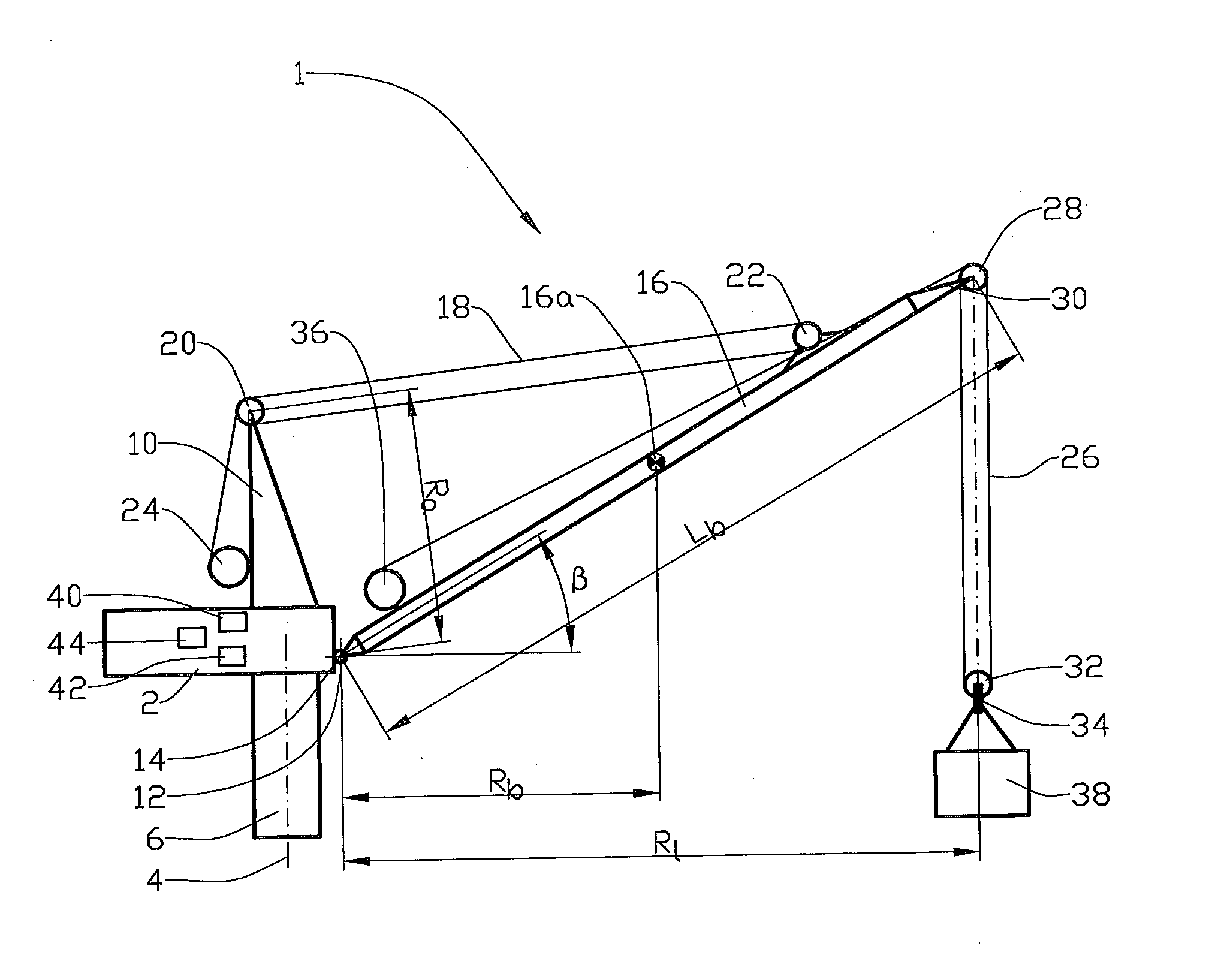

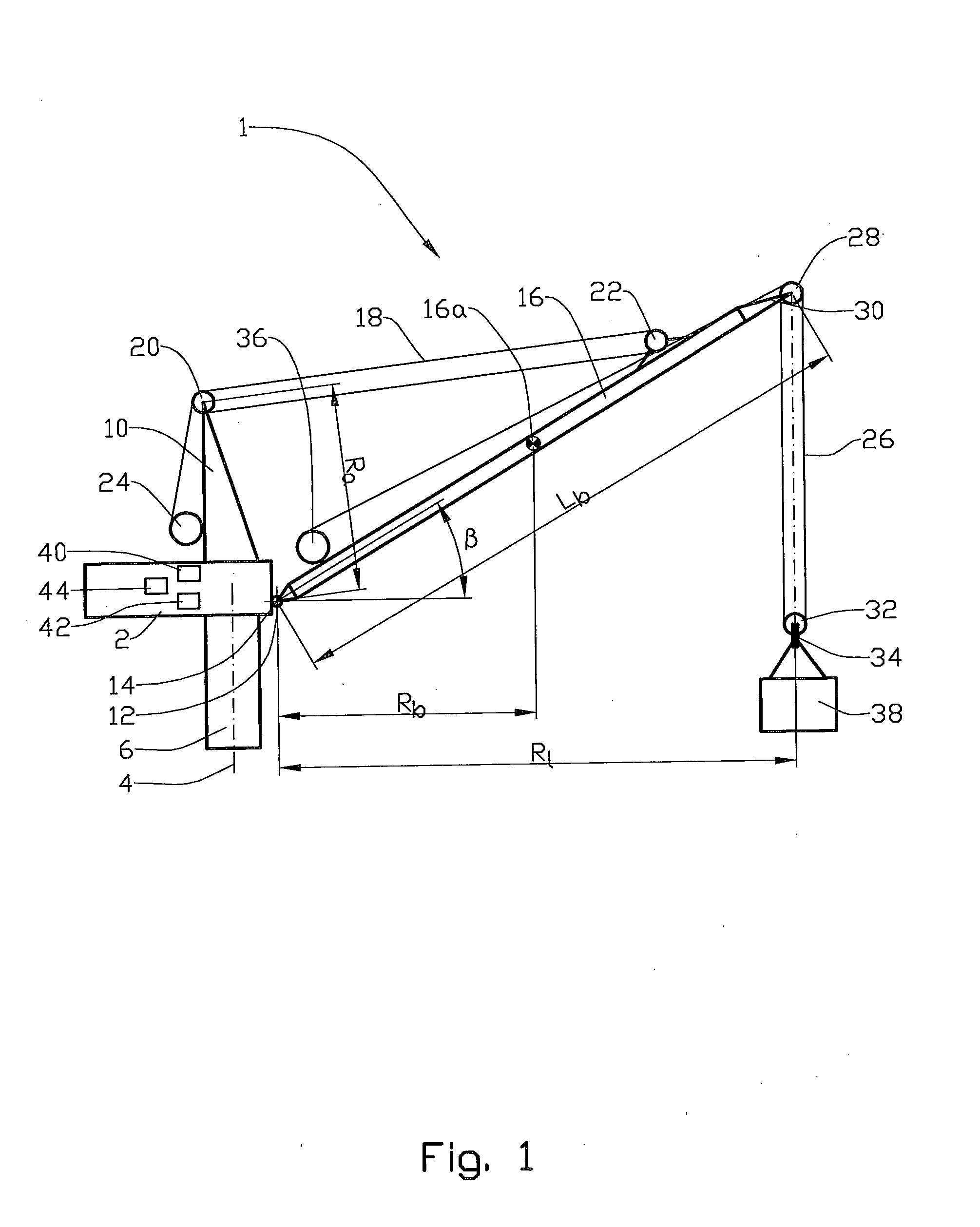

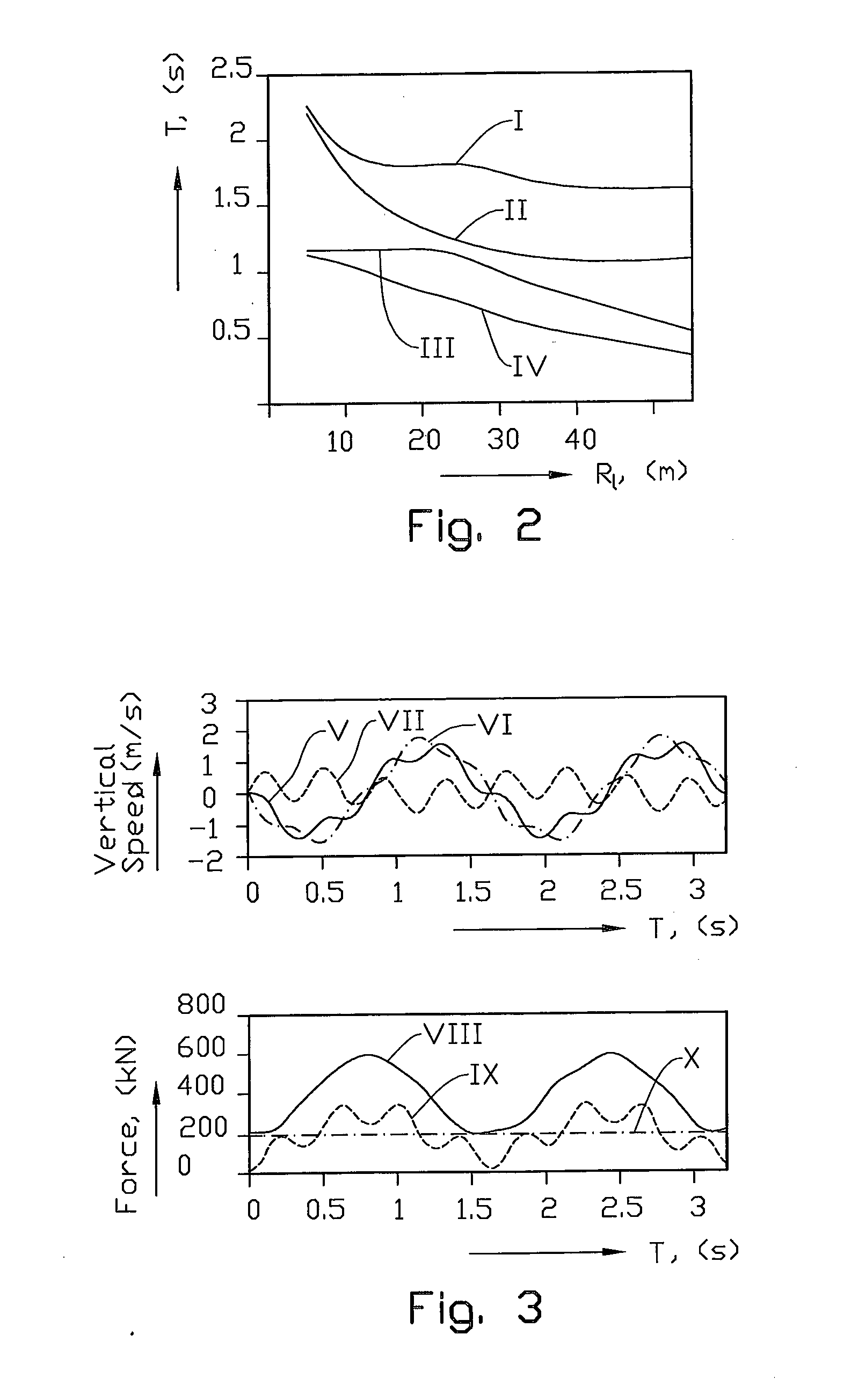

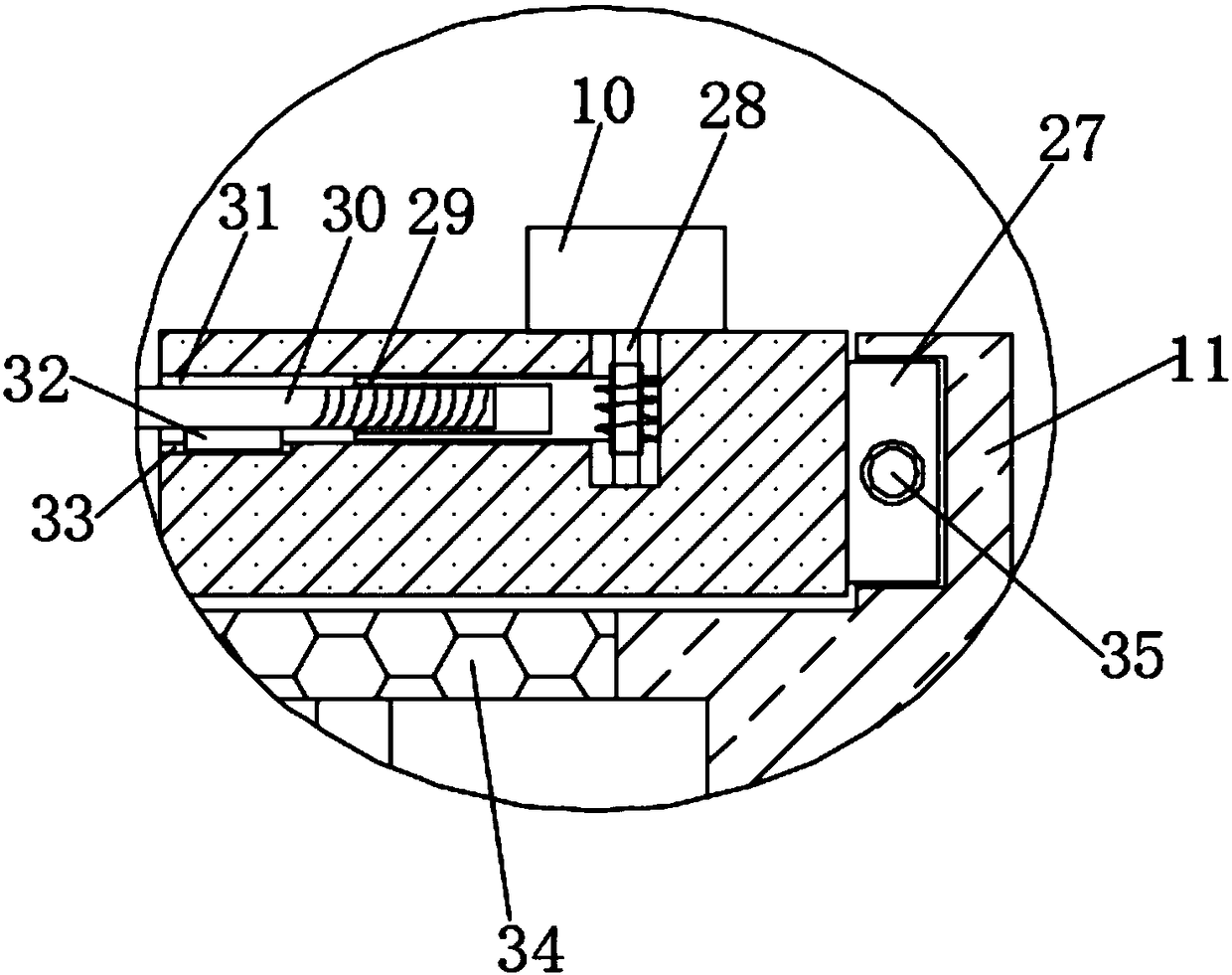

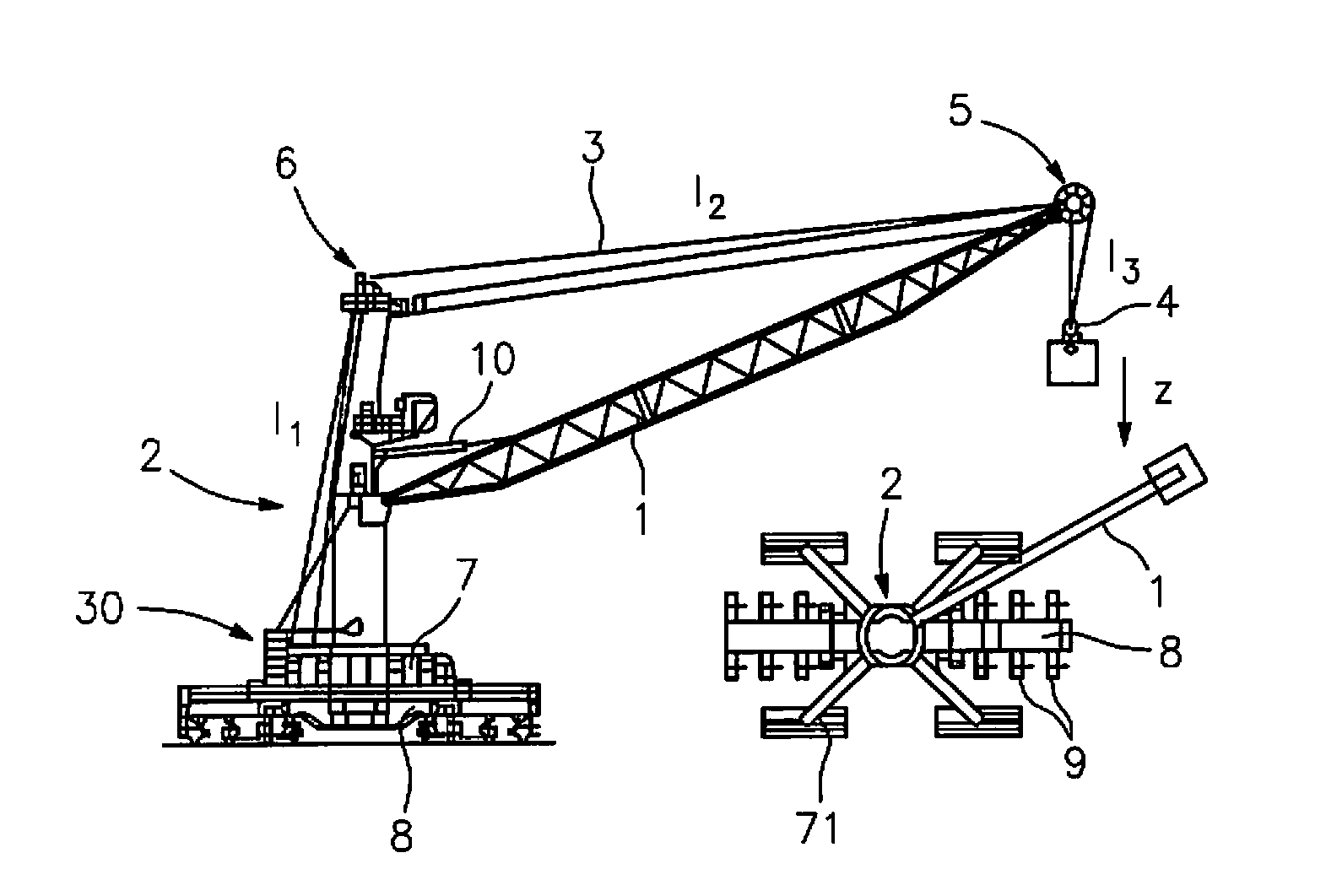

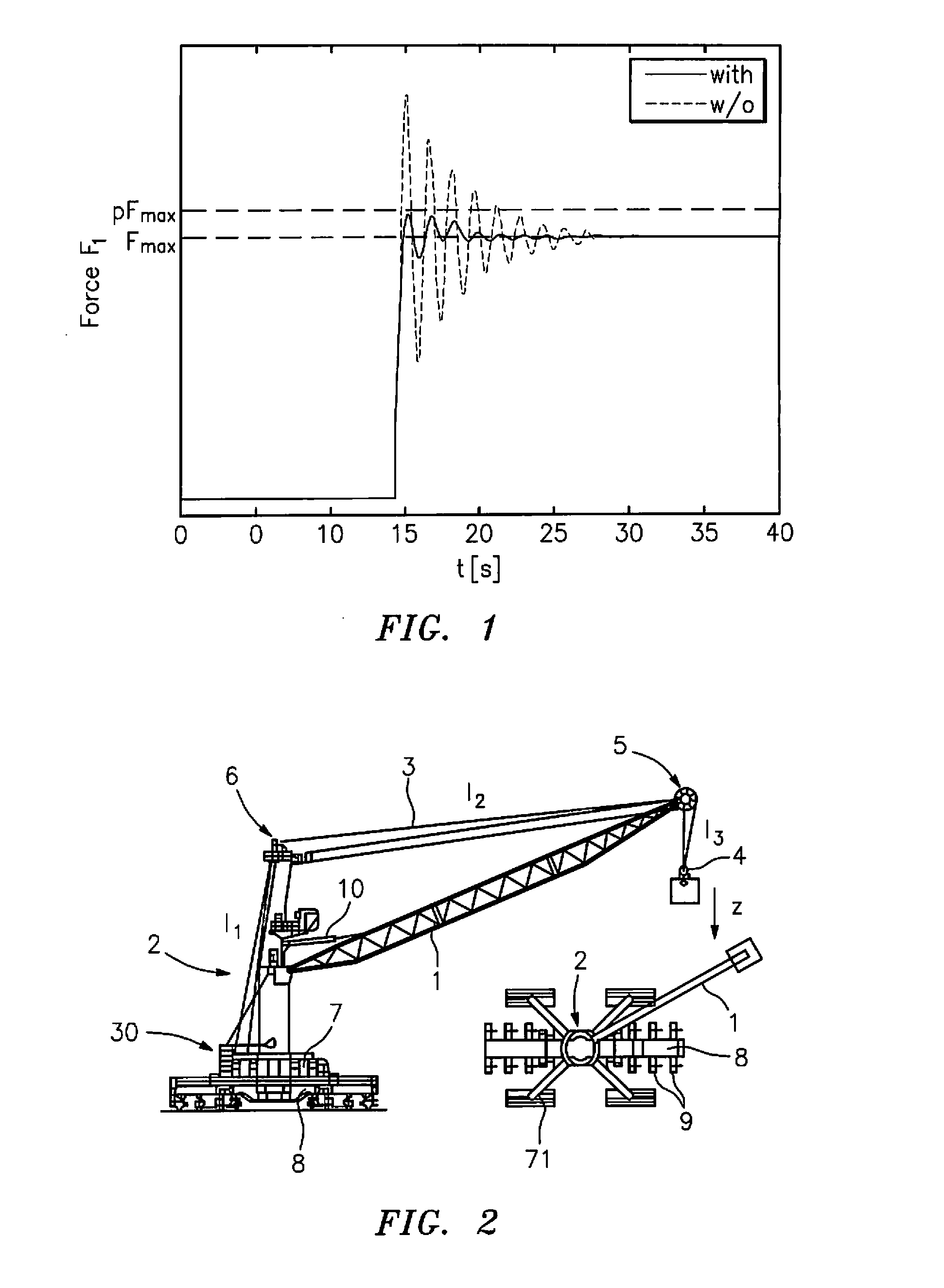

Method for Reducing Dynamic Loads of Cranes

InactiveUS20130213919A1Reduction in dynamic peak loadDampens resonance oscillationWinding mechanismsCranesResonanceEngineering

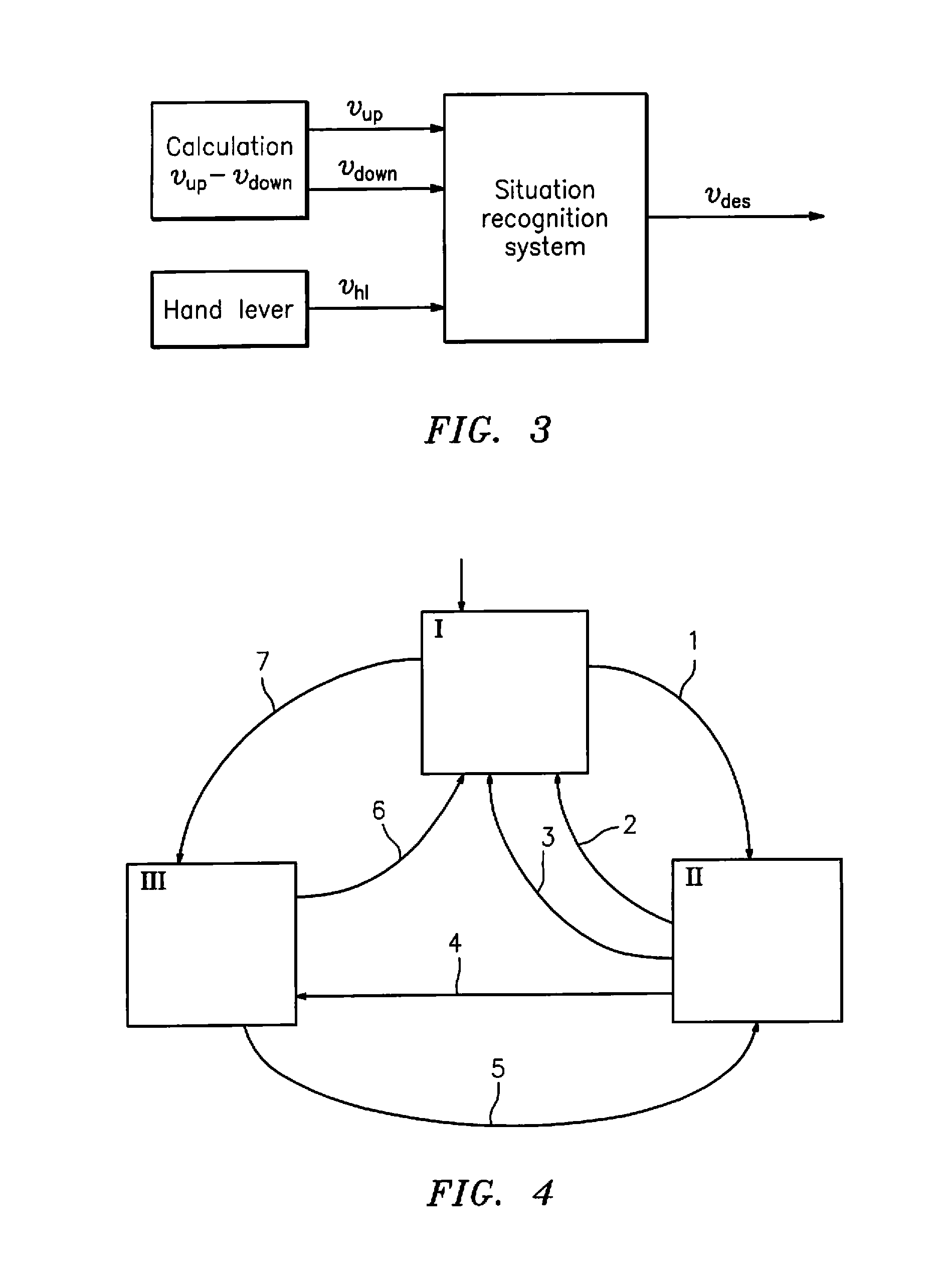

A method for reducing resonant vibrations and dynamic loads of cranes, whose horizontal and vertical motion of the pay load are controlled by a boom winch controlling the luffing motion of a pivoting boom and a hoist winch controlling the vertical distance between a boom tip and the load. Where the method includes determining the resonance frequencies of the coupled crane boom and load system, either experimentally or theoretically at least from data on inertia of the boom and stiffness of at least a boom rope, a hoist rope, a pedestal and an A-frame. The method further includes automatically generating a damping motion in at least one of said winches, that counteracts dynamic oscillations in the crane, and adding this damping motion to the motion determined by a crane operator.

Owner:NAT OILWELL VARCO NORMAY AS

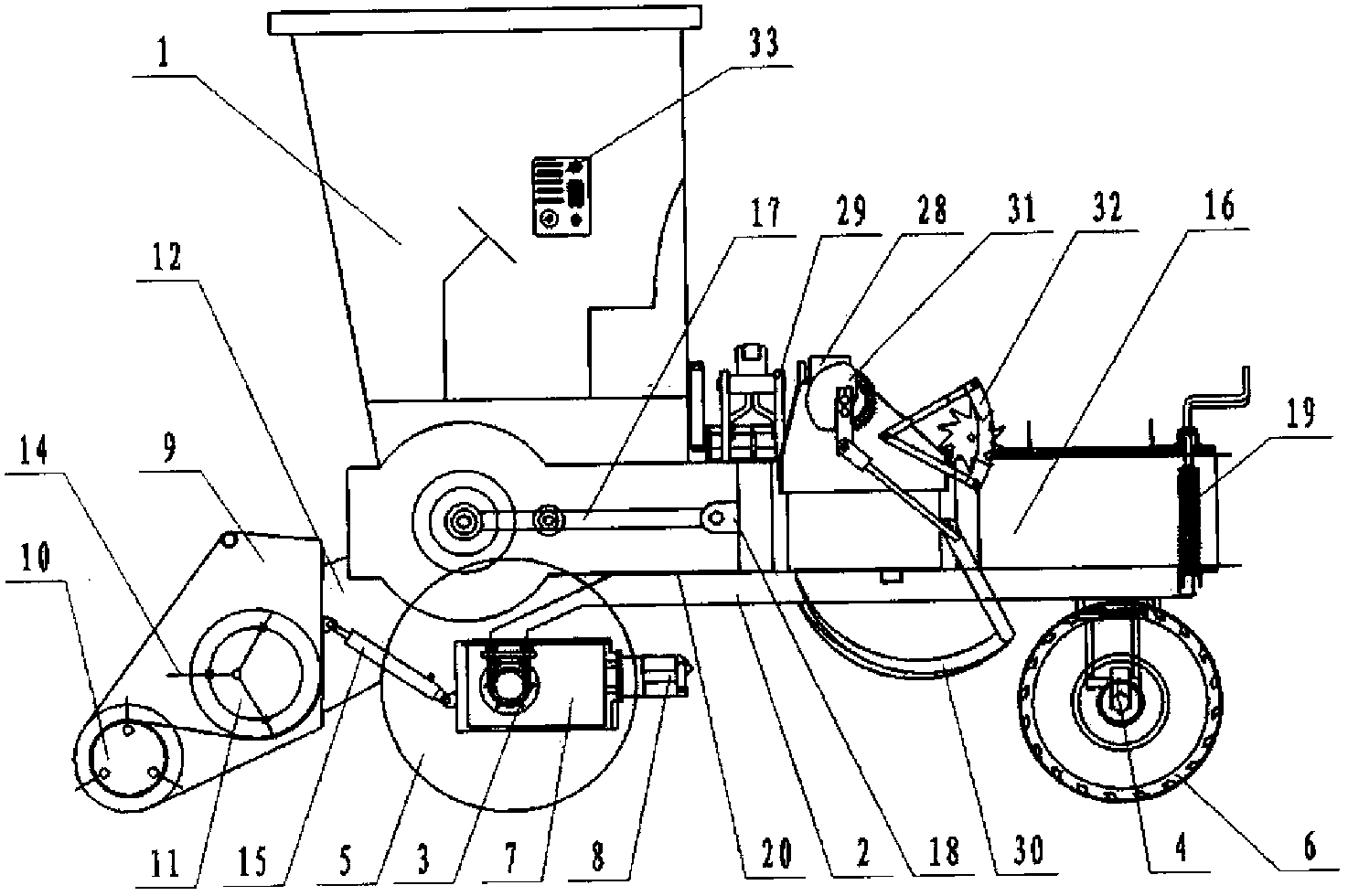

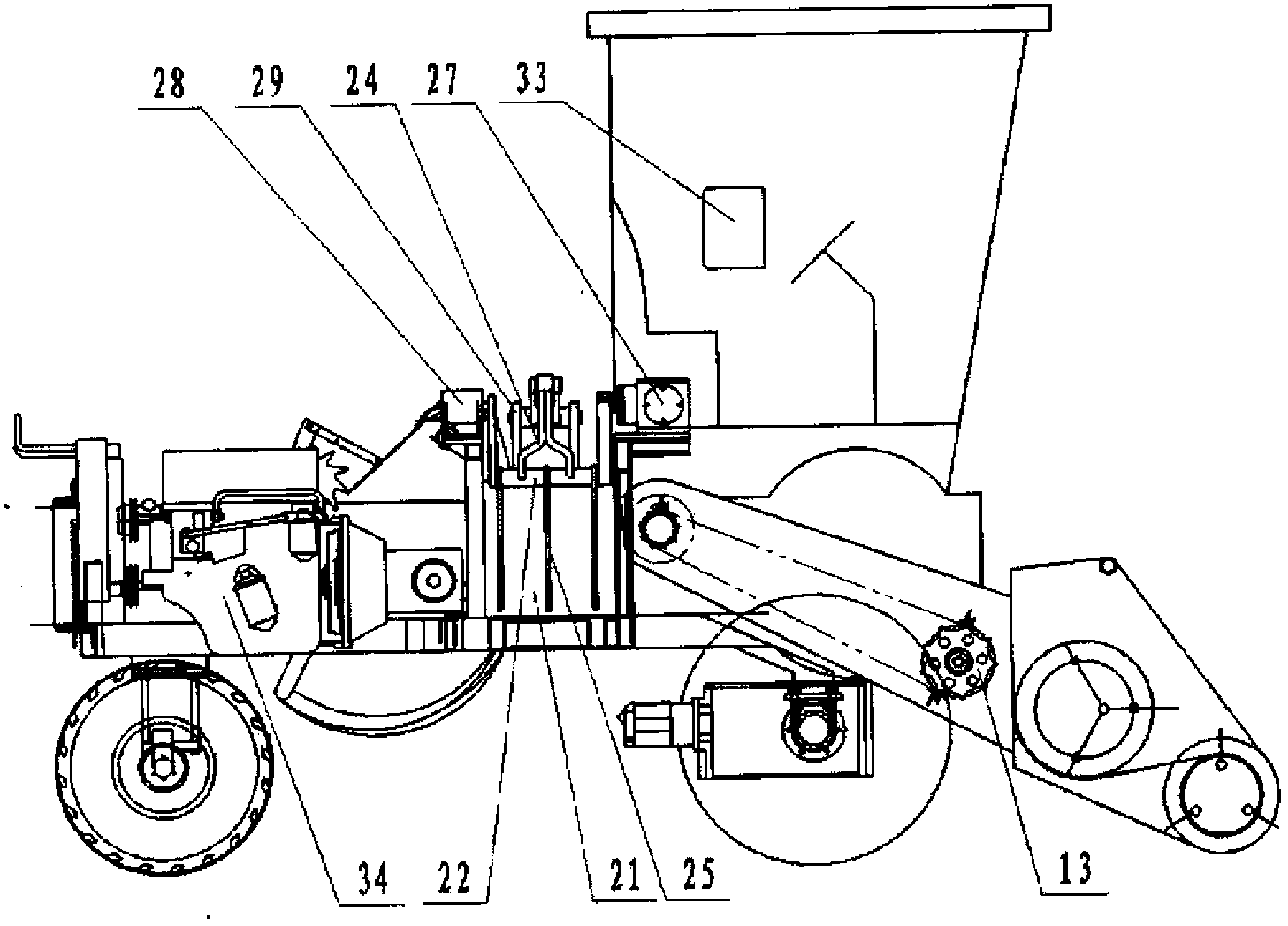

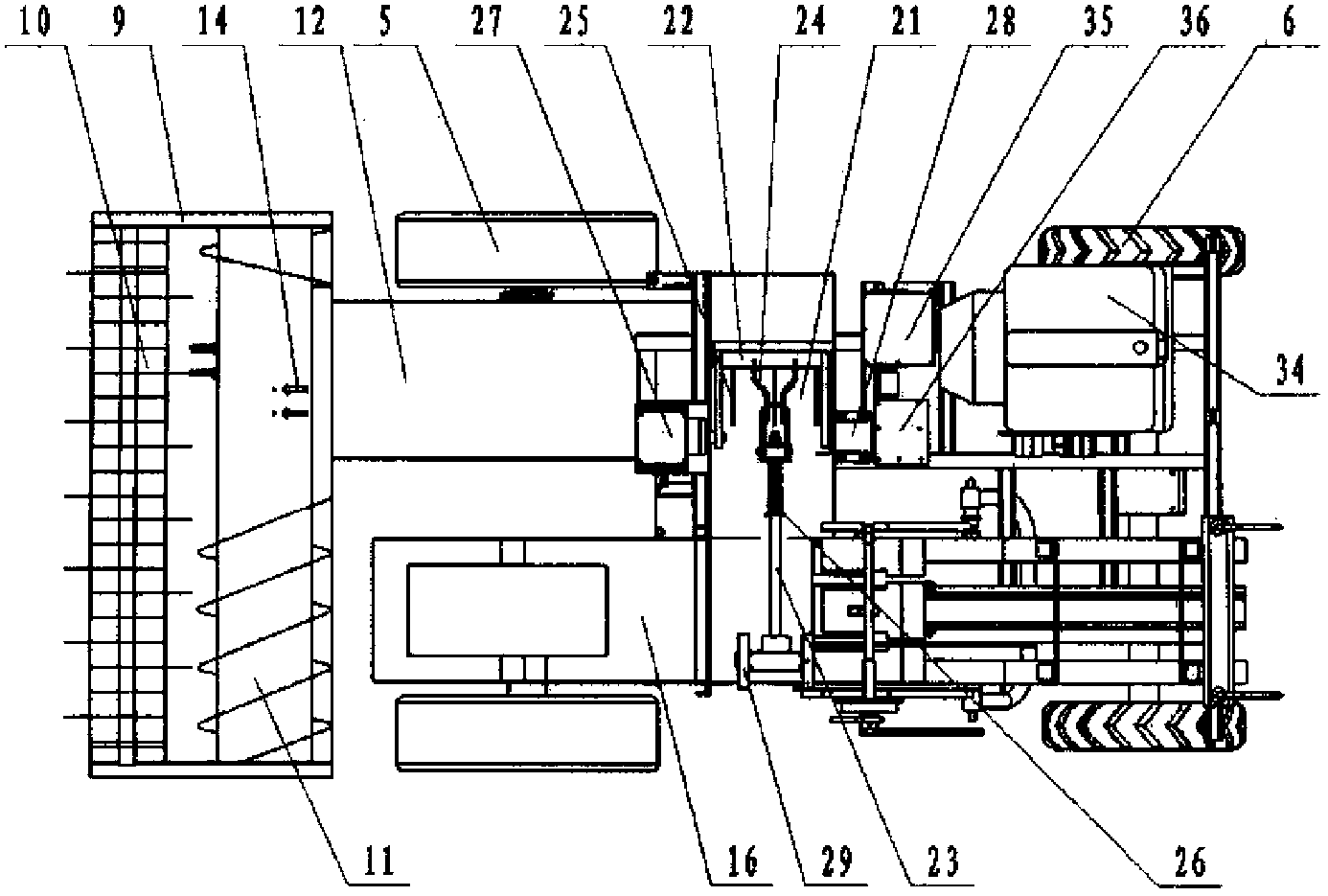

Self-propelled grass block baling machine

InactiveCN102696334ADynamic load reductionBest working pointLoadersBalingVehicle dynamicsVehicle frame

The invention discloses a self-propelled grass block baling machine, which belongs to the field of agricultural machinery. The self-propelled grass block baling machine mainly comprises a base plate part, a cab, a picking-up and conveying part, a feeding part, a compressing and knotting part and a power transmission part, wherein the base plate part is fixedly arranged below a frame; the cab is arranged in front of the frame; and the compressing and knotting part is arranged on the middle part of the frame. The power of the entire machine comes from an engine. According to the self-propelled square grass baling machine, the turning radius is reduced to a great extent by using a self-propelled design and rear wheel steering, and dry grass pick-up and baling combined operation at plots with small planting areas at mountain areas is facilitated; by using hydraulic speed changing and hydraulic steering, a driver can realize larger steering force control by using smaller operation force through the hydraulic speed changing and the hydraulic steering; the traveling speed can be adjusted in real time in operation according to the condition of swath thickness; in addition, the dynamic load of a transmission system is greatly relieved, the vibration is reduced, the situation that the engine works at the optimal working point is guaranteed, and the vehicle dynamic property, the fuel oil economy and the working efficiency are favorably improved; and the self-propelled square grass baling machine has the advantages of safe and reliable performance, and easiness, convenience and flexibility in operation.

Owner:CHINA AGRI UNIV

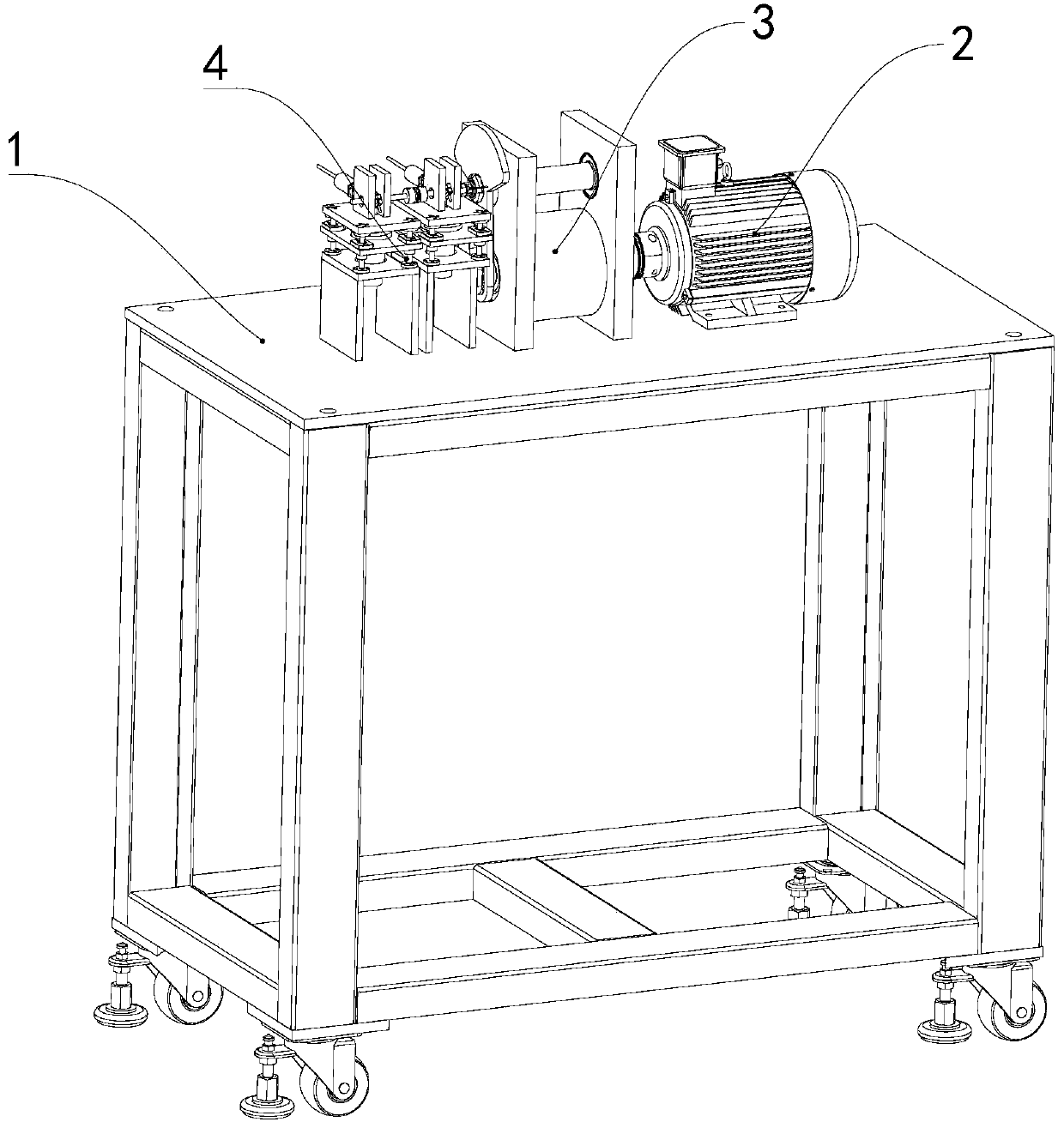

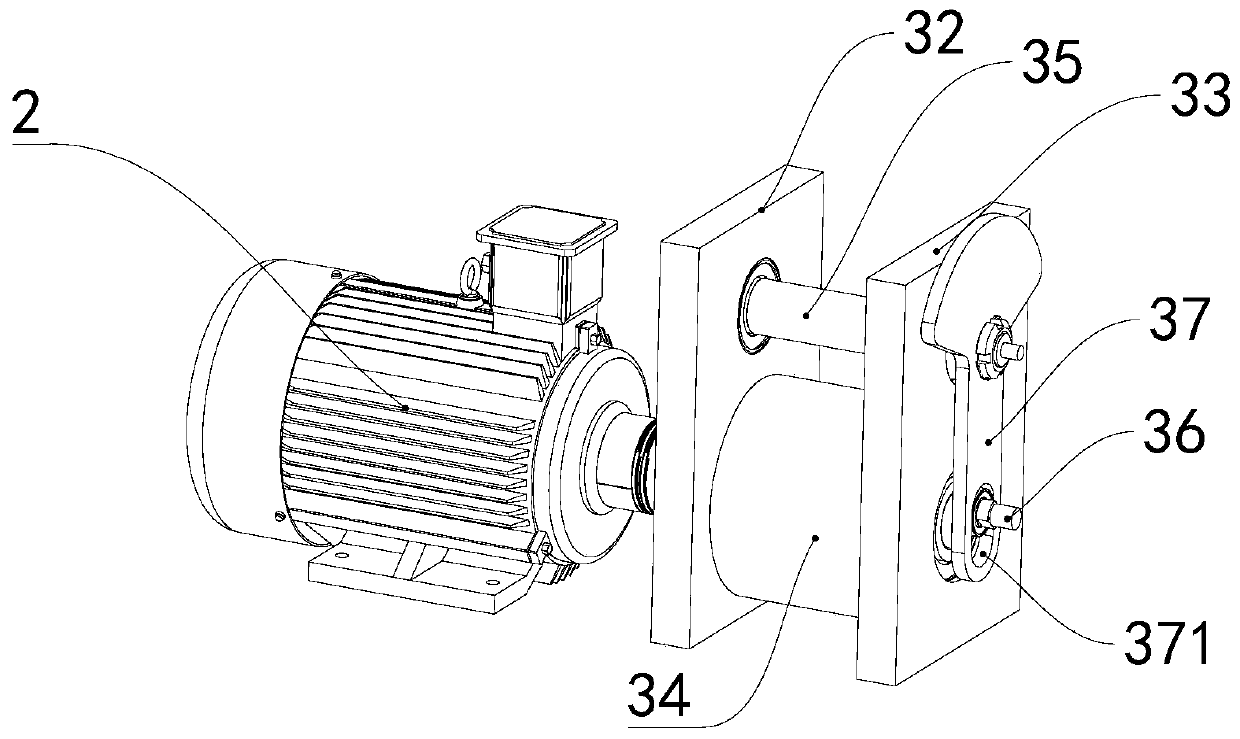

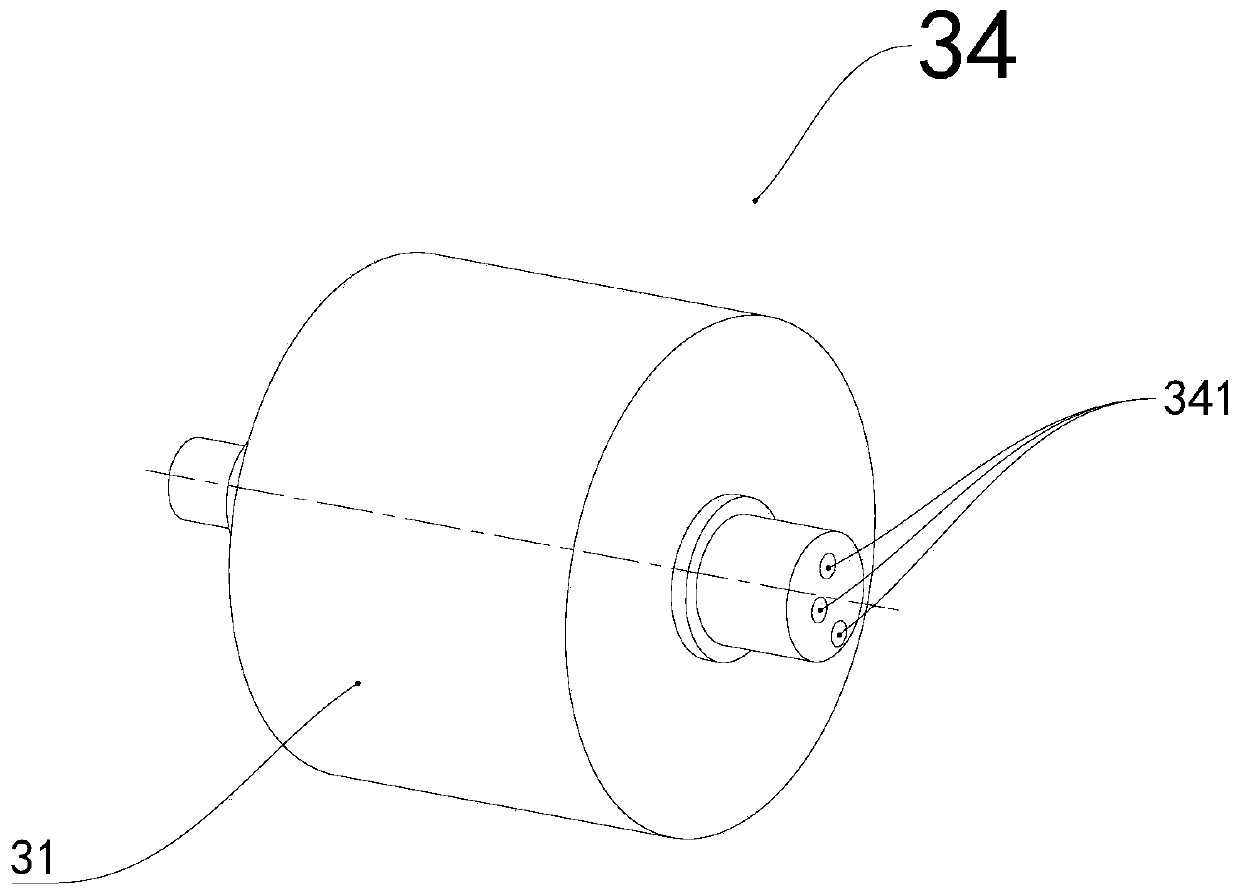

High-speed swing bearing fatigue life test device

PendingCN109752184AGuarantee the rigidity of the connectionReduce dynamic loadMachine bearings testingFriction torqueSpeed wobble

The invention discloses a high-speed swing bearing fatigue life test device. The device comprises a console, and a driving motor, a rotary swing conversion module, a plurality of test modules and testbearings which are arranged on the console, wherein jackets sleeve the test bearings; each test module comprises a radial sine pulse loading module, a friction torque monitoring module, a temperaturedetection module and a bearing supporting module; the radial sine pulse loading modules in the plurality of test modules are connected to each other; the bearing supporting modules in the plurality of test modules are connected to each other; the rotary swing conversion module is provided with a flywheel and is directly connected to a driving motor; the rotary swing conversion module simultaneously drives the test bearings to rotate and swing in a reciprocating manner and the radial sine pulse loading modules to provide pulse radial loads for the test bearings. According to the technical scheme, the friction torque change situation of the plurality of test bearings under different test conditions can be monitored in real time, so that whether the bearing has a failure condition is judged.

Owner:LISHUI UNIV

Method for underwater transportation and installation or removal of objects at sea

InactiveUS20050152748A1Low costReduce dynamic loadTowing/pushing equipmentArtificial islandsOil and natural gasWinch

Method for transport and installation of objects at sea, particularly relating to transport and installation of obs jects that are part of the infrastructure in oil and gas fields offshore, the object (4) is put in the sea at a suitable location near the shore or in sheltered waters, then towed to the installation site while being suspended in a slender buoyancy unit (5) acting much like a heave compensating unit. Upon arrival at the installation site, the suspension of the object (4) is transferred from the buoyancy unit (5) to a heave compensated winch (3) on a surface vessel (2), preferably the same vessel as used for the preceding towing operation. The winch is used to lower is the object (4) to its destination on the sea bottom or a predetermined location above the sea bottom.

Owner:AKER MARINE CONTRACTORS

Continuous variable valve lift apparatus

InactiveCN102477879AReduce frictionReduce manufacturing costValve arrangementsMachines/enginesEngineeringCam

A continuous variable valve lift apparatus may include a camshaft, a first cam disposed on the camshaft, an actuating shaft parallel to the cam shaft, an actuating lever connected to the actuating shaft, a swing arm rotatably coupled to the actuating lever and an engine, a second cam pivotally connected to the swing arm and contacting the first cam to open a valve unit and a control portion which is connected to the actuating shaft and selectively rotates the actuating shaft for pivoting center of the swing arm to move.

Owner:HYUNDAI MOTOR CO LTD +1

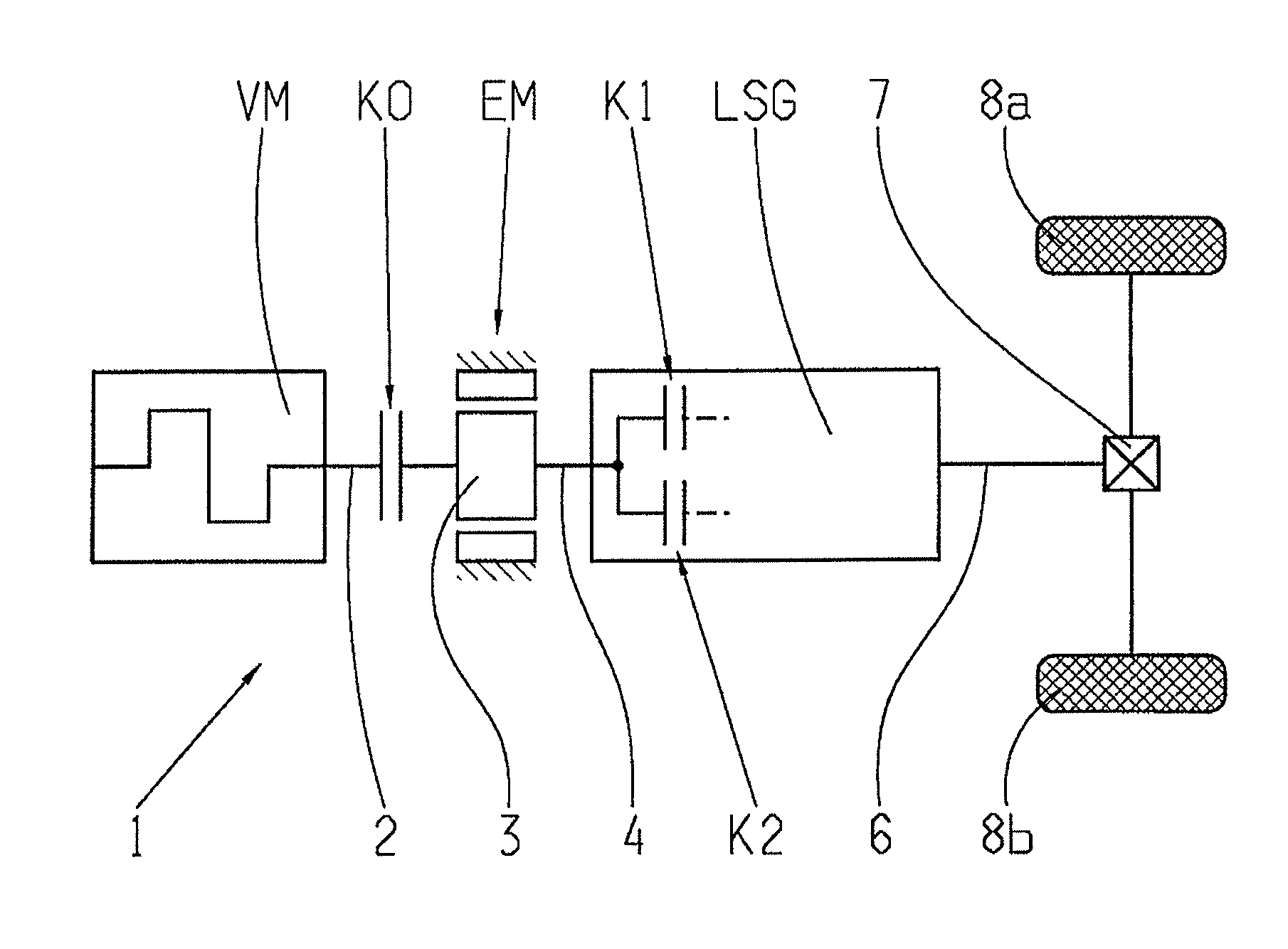

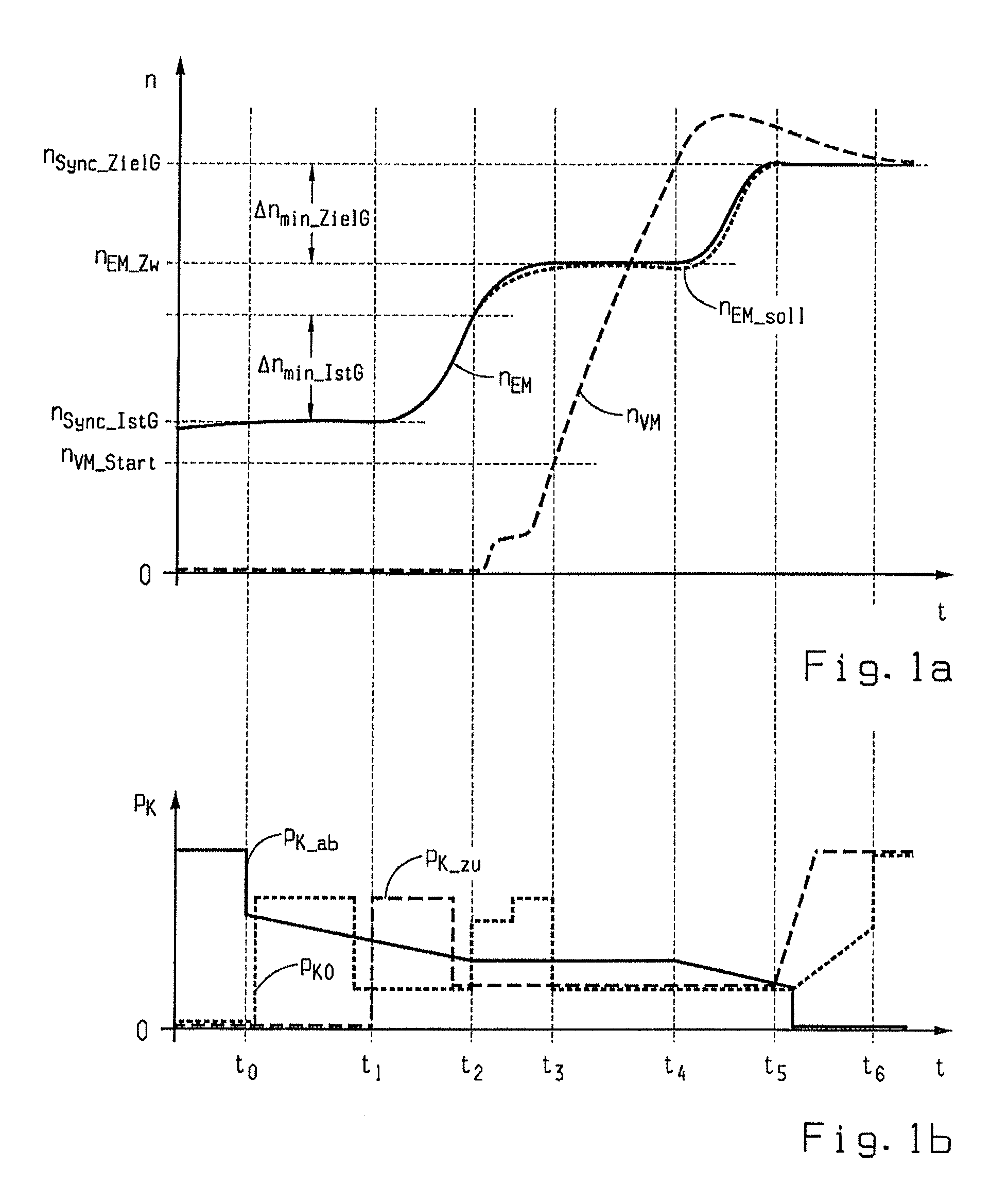

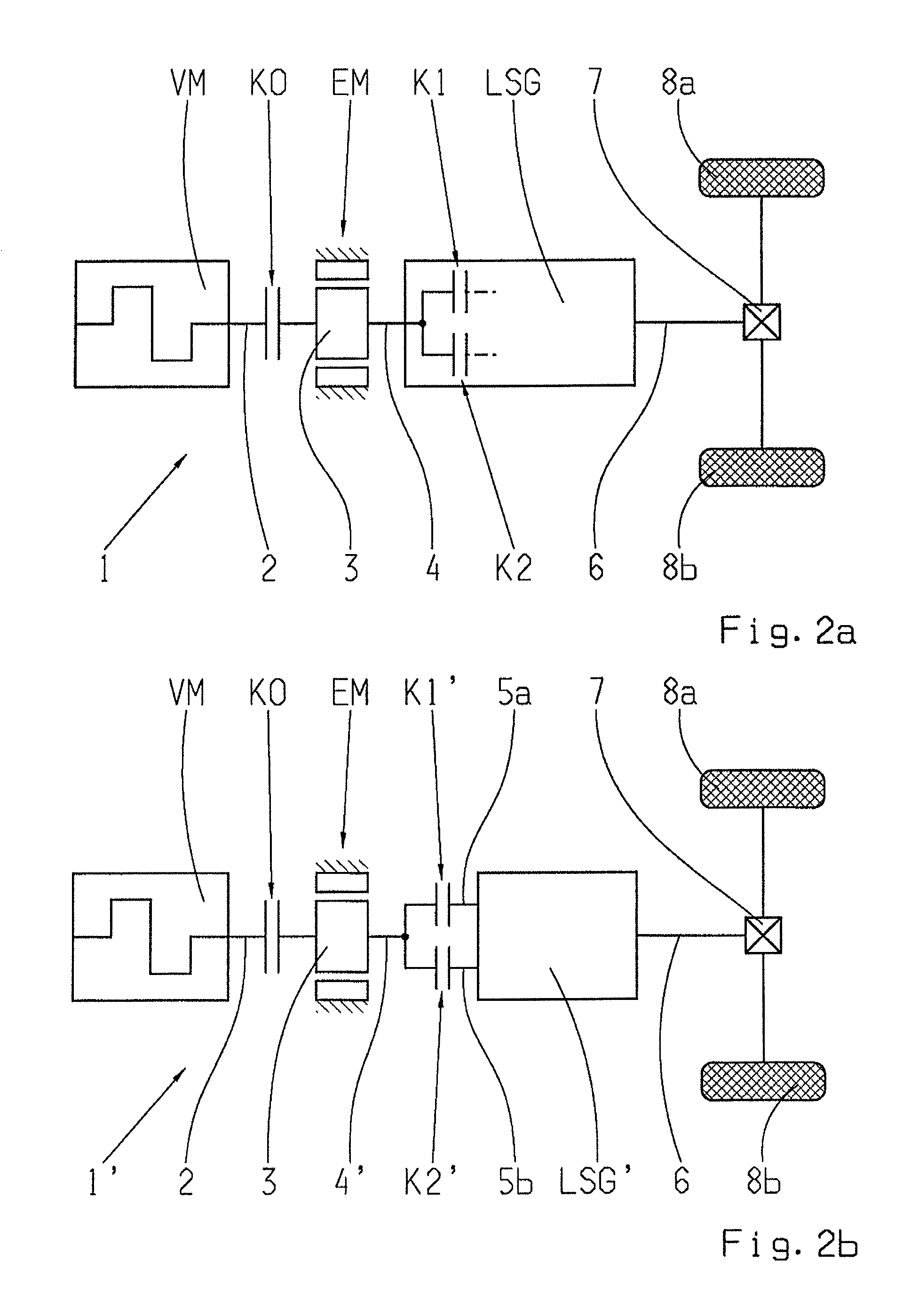

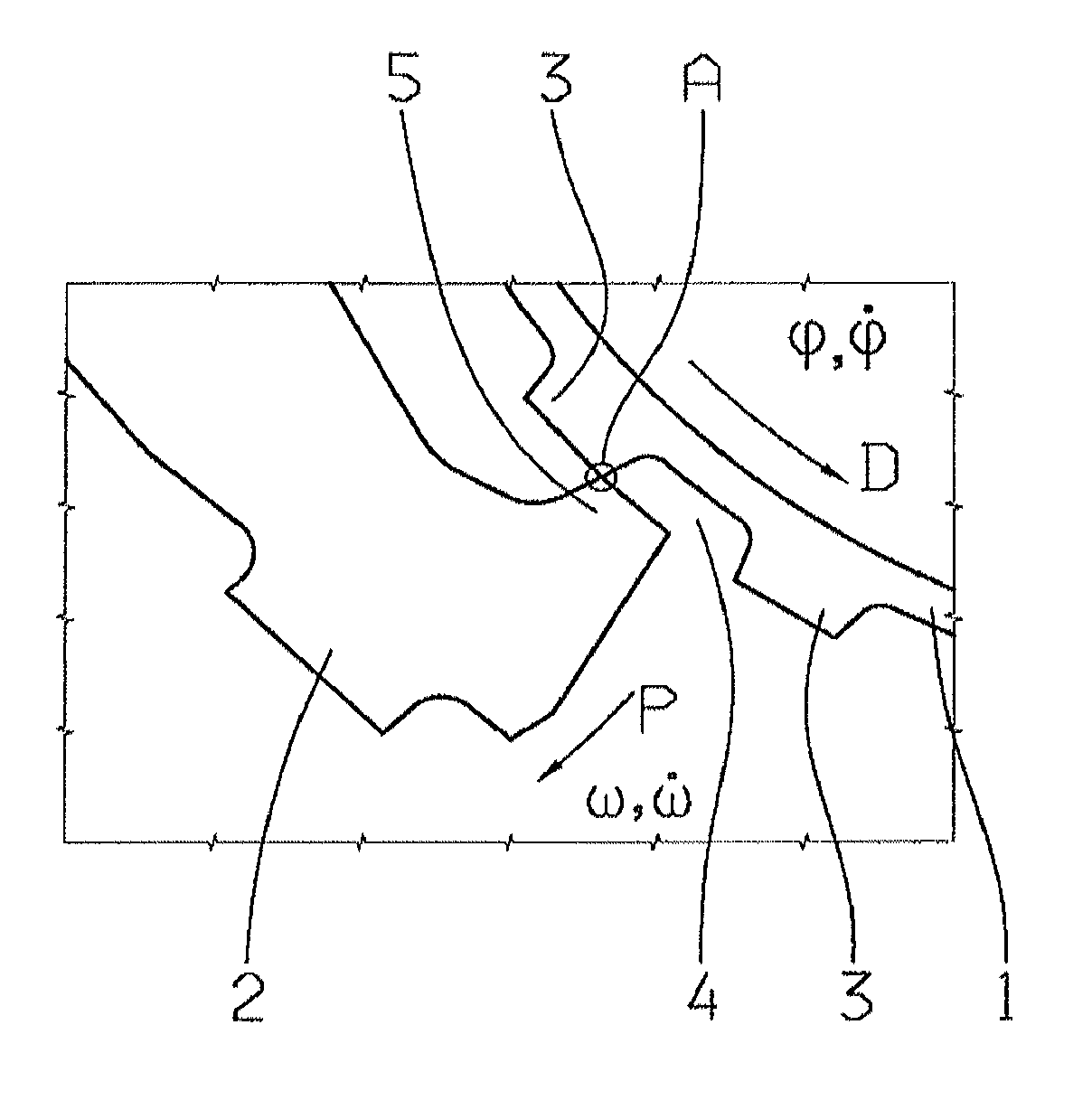

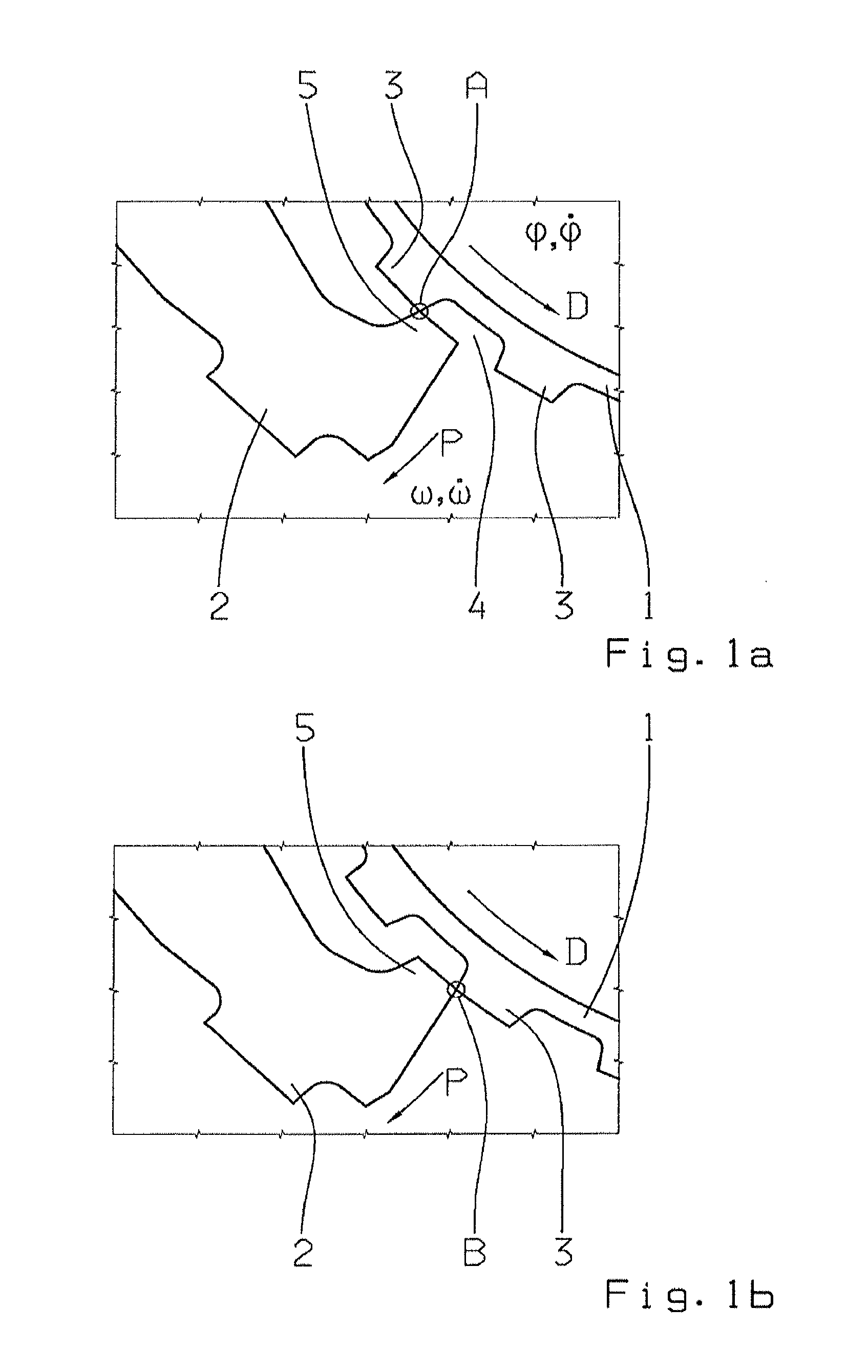

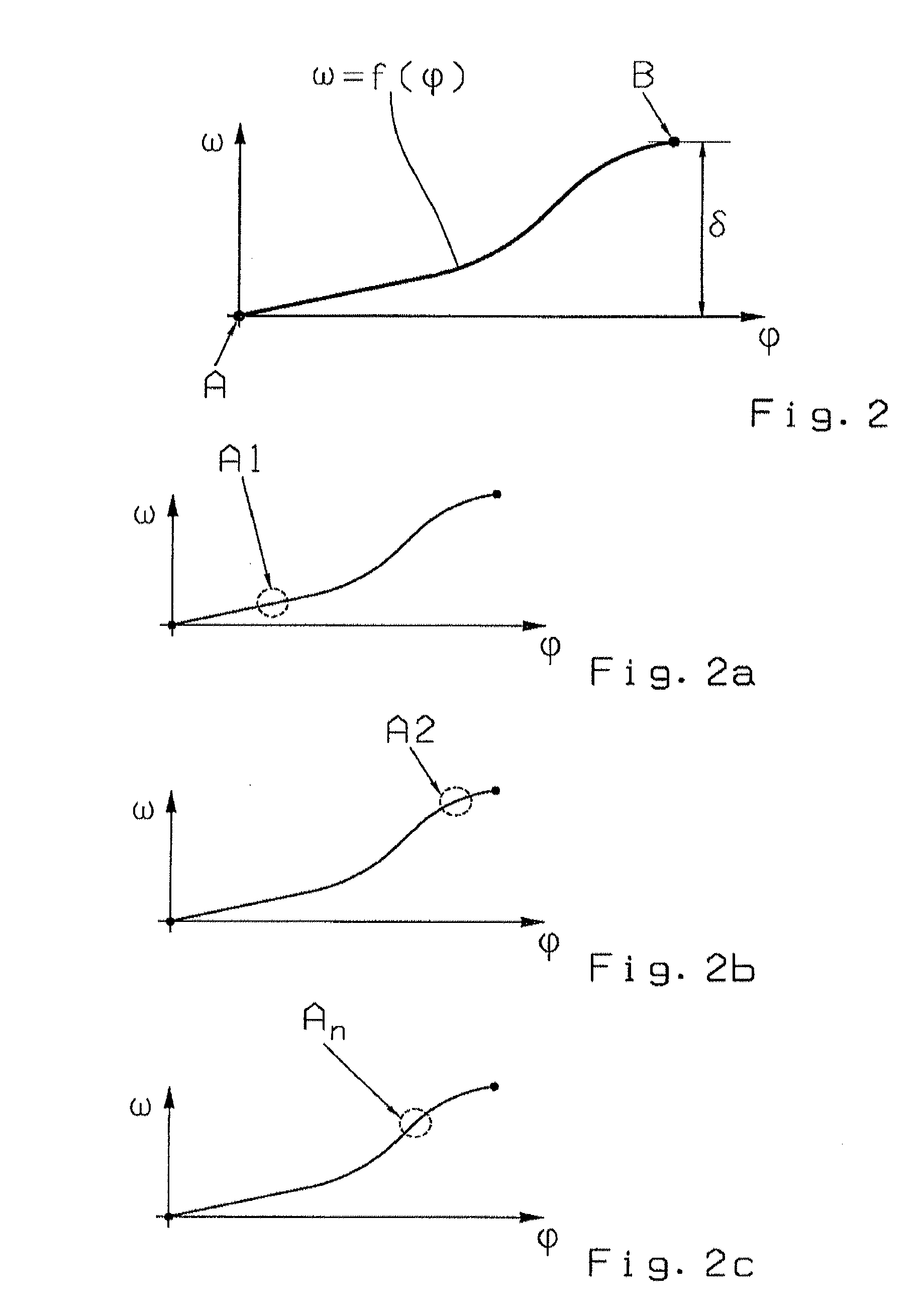

Method for controlling a hybrid drive train of a vehicle

InactiveUS8388494B2Reduce dynamic loadGreater driving comfortGearing controlEngine controllersCombustionAutomatic transmission

A method of controlling a hybrid drive-train of a vehicle in which the hybrid drive-train comprises a combustion engine having a driveshaft, an electric machine that can be connected to the driveshaft of the engine by a clutch, an automated transmission with an input which is connected to the rotor of the electric machine, and shifting elements for shifting between two gears. During electric driving operation with the engine stopped and the clutch disengaged, the engine can be drag-started in combination with a downshift in the transmission. Drag starting of the engine is carried out by disengaging the frictional shifting element to be disengaged to below a slipping limit, engaging the clutch until the engine reaches or exceeds its minimum starting speed, starting the engine self-starts, substantially disengaging the clutch, separately adjusting the engine and electric machine to the synchronous speed of the target gear, and fully engaging and disengaging associated shifting elements.

Owner:ZF FRIEDRICHSHAFEN AG

Alleviation of aircraft landing gear loading using a brake control scheme

ActiveUS7717527B1Reduce dynamic loadImprove carrying capacityBraking action transmissionApplication and release valvesElectricityReal-time data

An electric brake system for an aircraft employs a brake control process to alleviate high dynamic structural loading of the aircraft landing gear caused by braking maneuvers. The system obtains and processes real-time data—which may include the current aircraft speed, the current brake pedal deflection position, and the current brake pedal deflection rate—to determine how best to control the onset of the brakes. The braking control scheme delays the onset of the desired braking condition to reduce high dynamic loading and lurching of the aircraft.

Owner:THE BOEING CO

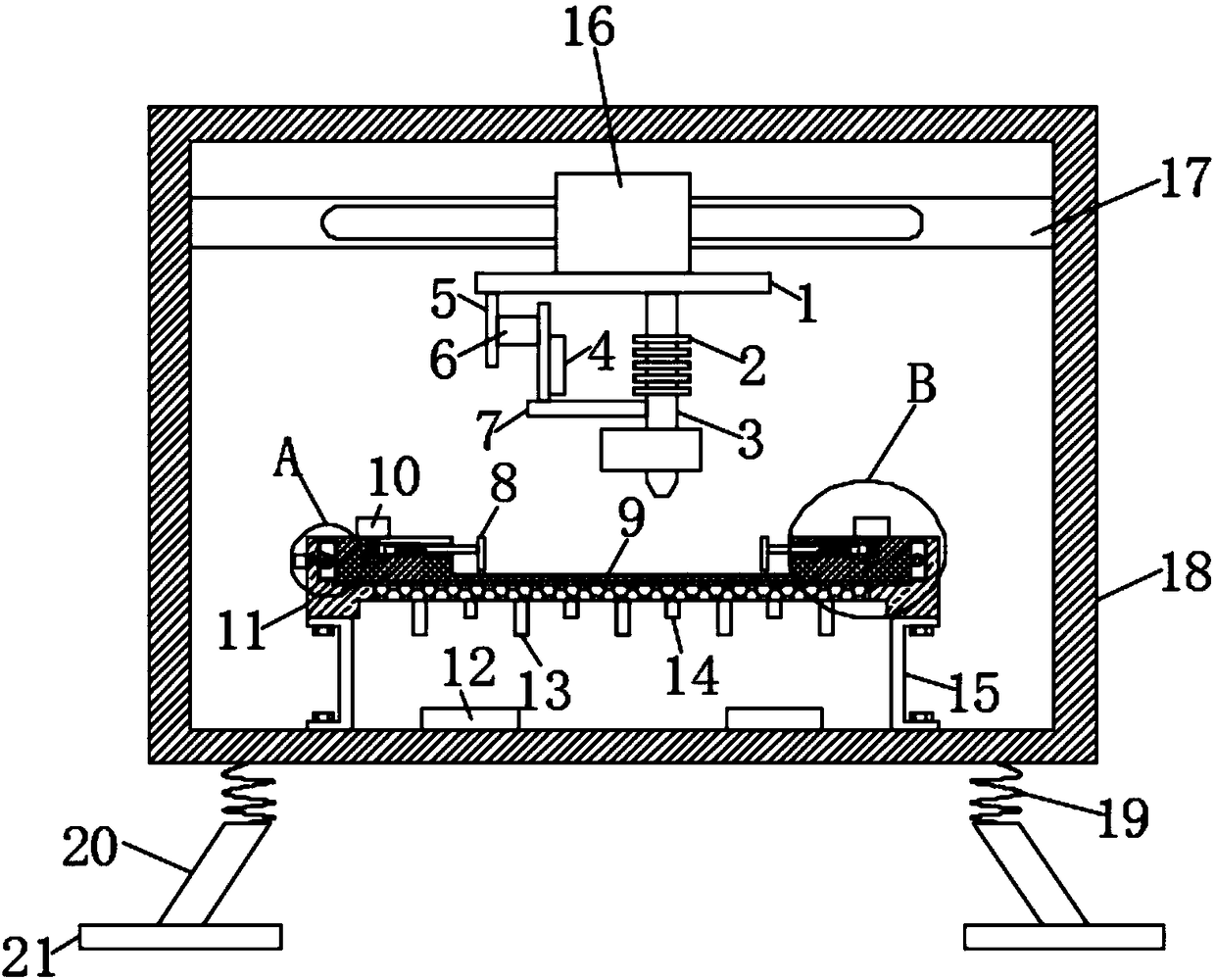

Heat dissipating device for 3D printing nozzle and printing plate

InactiveCN108422656AGuaranteed uptimeReduce noise3D object support structuresApplying layer means3d printerCantilever

The invention discloses a heat dissipating device for a 3D printing nozzle and a printing plate. The heat dissipating device comprises a machine body, wherein an inner wall opposite to the machine body is fixedly connected with a cantilever beam; a slide carriage box is arranged on the cantilever beam; a lower end of the slide carriage box is fixedly connected with a nozzle heat-dissipating device; a fixing plate is arranged in the machine body; the fixing plate is fixedly connected to the inner bottom of the machine body by a support frame; a groove is formed in an upper end of the fixing plate; a printing plate placing device is arranged in the groove; and a lower end of the machine body is fixedly connected with a damping support base. The heat dissipating device provided by the invention is reasonable in structural design and convenient to place and fix a printing plate; the nozzle heat-dissipating device effectively overcomes defects that one heat dissipating fan is directly fixedbeside the nozzle to dissipate heat of the nozzle in the prior art, but vibration generated by operation of the heat dissipating fan can seriously affect the molding quality of a 3D printer in the printing process.

Owner:陈后亥

Crane control for the control of a hoisting gear of a crane

ActiveUS20110006024A1Improved crane controlReduces or damps themLoad-engaging elementsControl theoryRate control

The present invention relates to a crane control for the control of a hoisting gear of a crane which takes account of oscillation dynamics based on the elasticity of the hoist rope on the control of the hoisting gear and reduces them by a suitable control of the hoisting gear.

Owner:LIEBHERR WERK NENZING

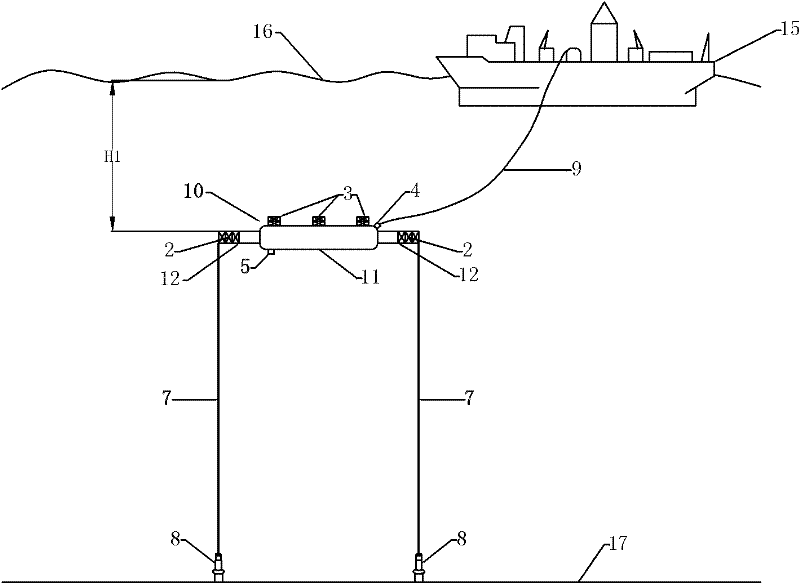

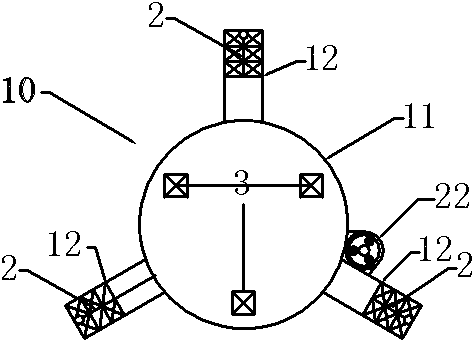

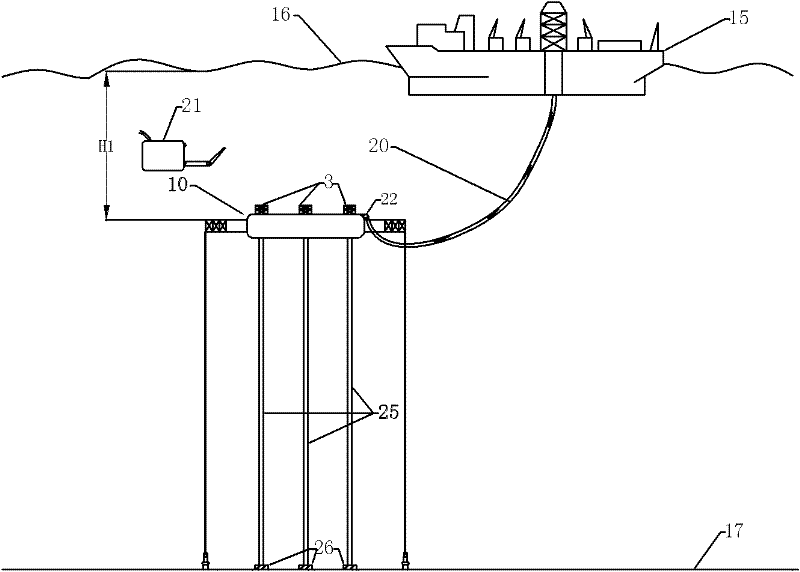

Riser support device under ultra-deep sea water

The invention discloses a riser support device under ultra-deep sea water. The device comprises a riser support buoy, a tension mooring device and an umbilical cable, wherein a wellhead A is formed on the upper part of the riser support buoy; a channel which passes through the riser support buoy is formed on the lower part of the wellhead A; and the riser support buoy has a starfish structure, namely the edge of a central post structure buoy is connected with three rectangular section cantilever buoys which form included angles of 120 degrees on the plane. The tail end of each cantilever buoyhas a truss structure with neutral buoyancy, so that the buoyancy requirement of the riser support buoy can be met by reducing or increasing the length of the truss structure on each cantilever buoy,the construction process difficulty of each cantilever buoy can be greatly reduced, and construction cost is reduced. The riser support buoy provides tension for a top tension riser (TTR), so that a dynamic load supported by a water surface floating production device is reduced, and the requirement on the water surface floating production device is reduced; therefore, the construction cost of thewater surface floating production device is reduced.

Owner:DALIAN UNIV OF TECH

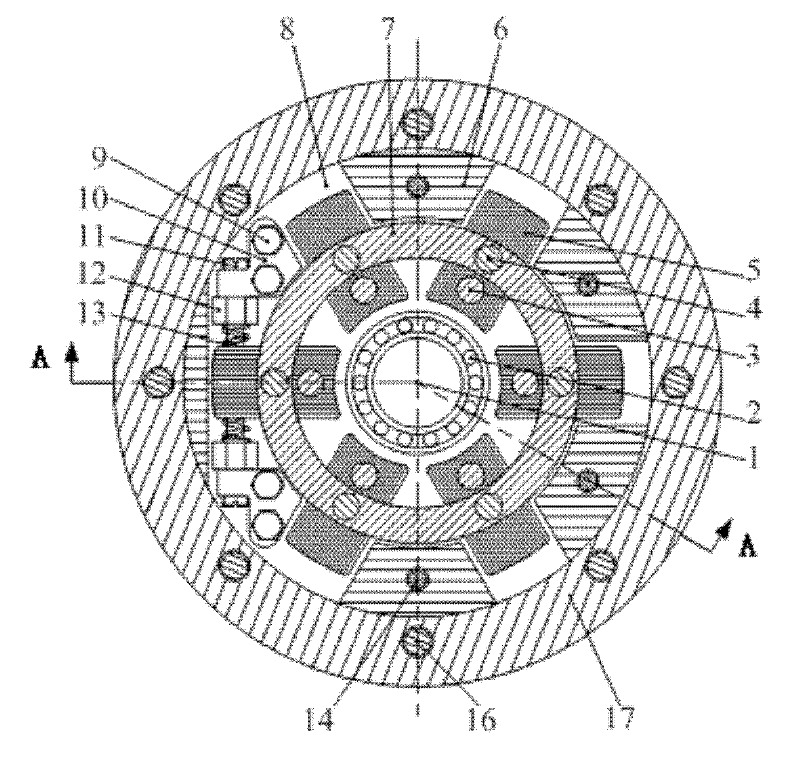

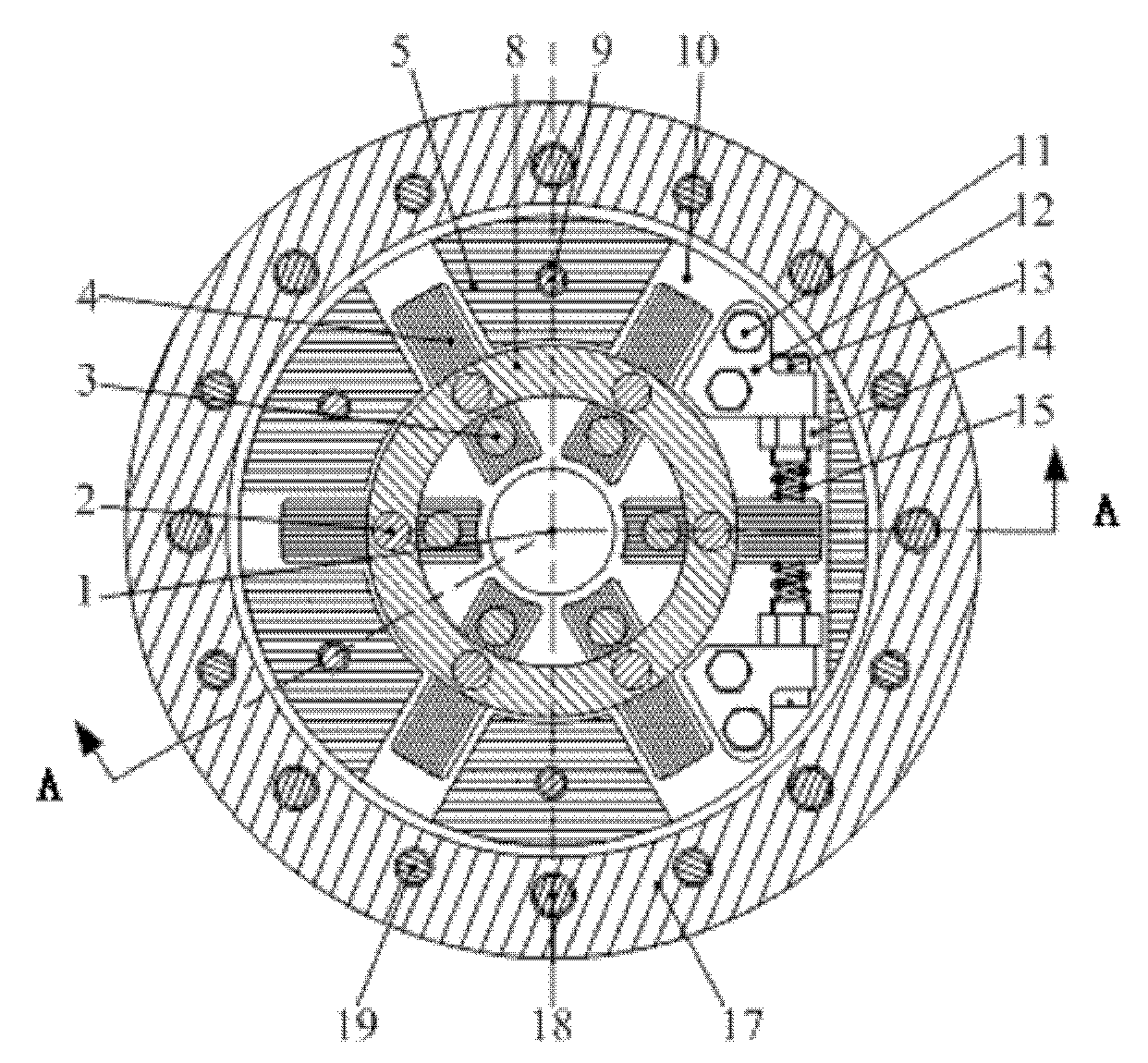

Radial protection bearing device for automatically eliminating radial clearance of rolling bearing inner ring

ActiveCN102562799AExtend your lifeReduce dynamic loadBearing assemblyBearingsRolling-element bearingWhole body

The invention discloses a radial protection bearing device for automatically eliminating the radial clearance of a rolling bearing inner ring. The radial protection bearing device comprises an outer-layer mounting base, an inner-layer mounting base, a support seat and a rotor assembly, wherein a rolling bearing is mounted between a bearing mounting neck of the inner-layer mounting base and an inner cavity of the outer-layer mounting base; the inner circle of the support seat is concentrically arranged with the rotor assembly; the support seat comprises more than two support seat branch bodies which are positioned with the inner-layer mounting base through first positioning pins; the support seat branch bodies are connected to from a whole body by adopting second positioning pins through annular connecting pieces; and at least one support seat branch body is equipped with a support seat adjusting device which can be used for maintaining the concentricity between the support seat and the rotor assembly. Therefore, according to the radial protection bearing device disclosed by the invention, the radial clearance between the rotor assembly and the rolling bearing can be automatically eliminated after a magnetic suspension bearing system is failed and a rotor falls off, furthermore, the impact and the vibration to the rolling bearing caused by the fall of the rotor assembly are eliminated, and the reliability and the safety of the radial protection bearing are enhanced to meet the requirement of a high-speed magnetic suspension bearing system.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Spin-riveting-type spring brake chamber, brake system adopting same and vehicle

ActiveCN102410322AImprove surface qualityHigh dimensional accuracyBrake actuating mechanismsActuatorsEngineeringBraking system

The invention discloses a spin-riveting-type spring brake chamber, a brake system adopting the same and a vehicle. The pin-riveting-type spring brake chamber is characterized in that a cylinder body is made by stretching and precisely cutting an aluminum magnesium alloy plate for a plurality of times, the surface quality of the cylinder body is good, the dimensional precision is high, and the contact surface at the joint between the cylinder body and a middle shell is large; and the cylinder body is assembled and riveted tightly through two cylindrical pins so that the cylinder body and the middle shell do not rotate relative to each other so as to ensure a firm connection.

Owner:RUILI GROUP RUIAN AUTO PARTS CO LTD

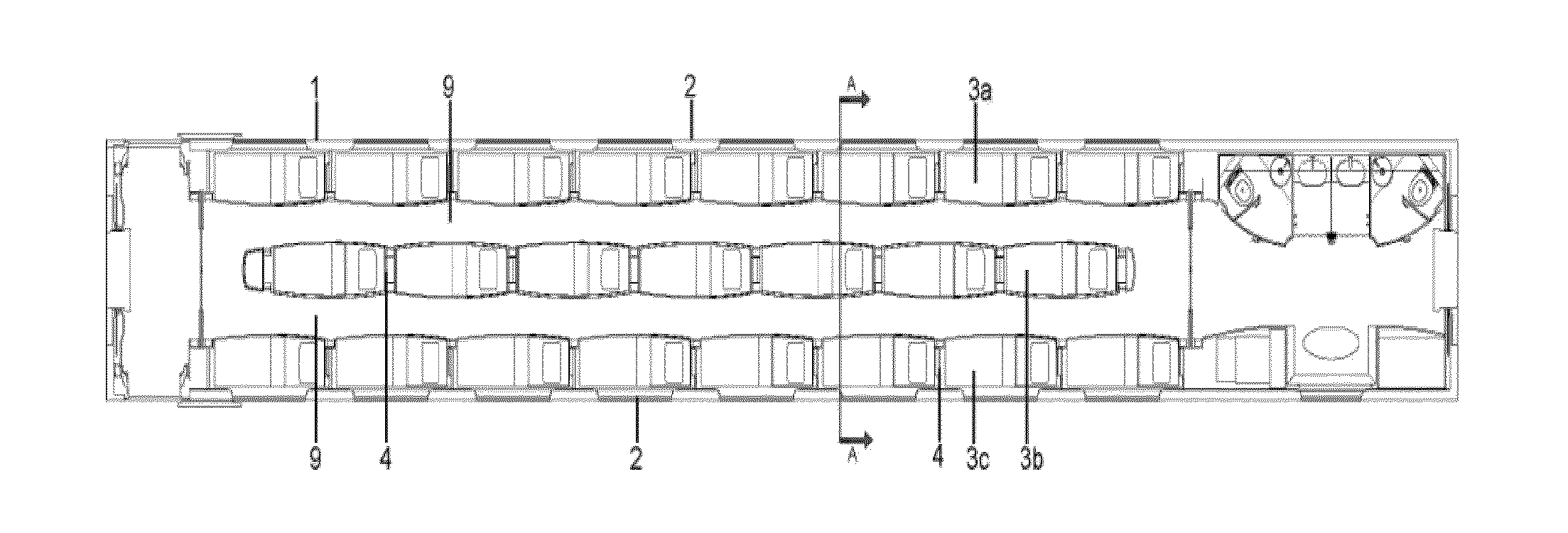

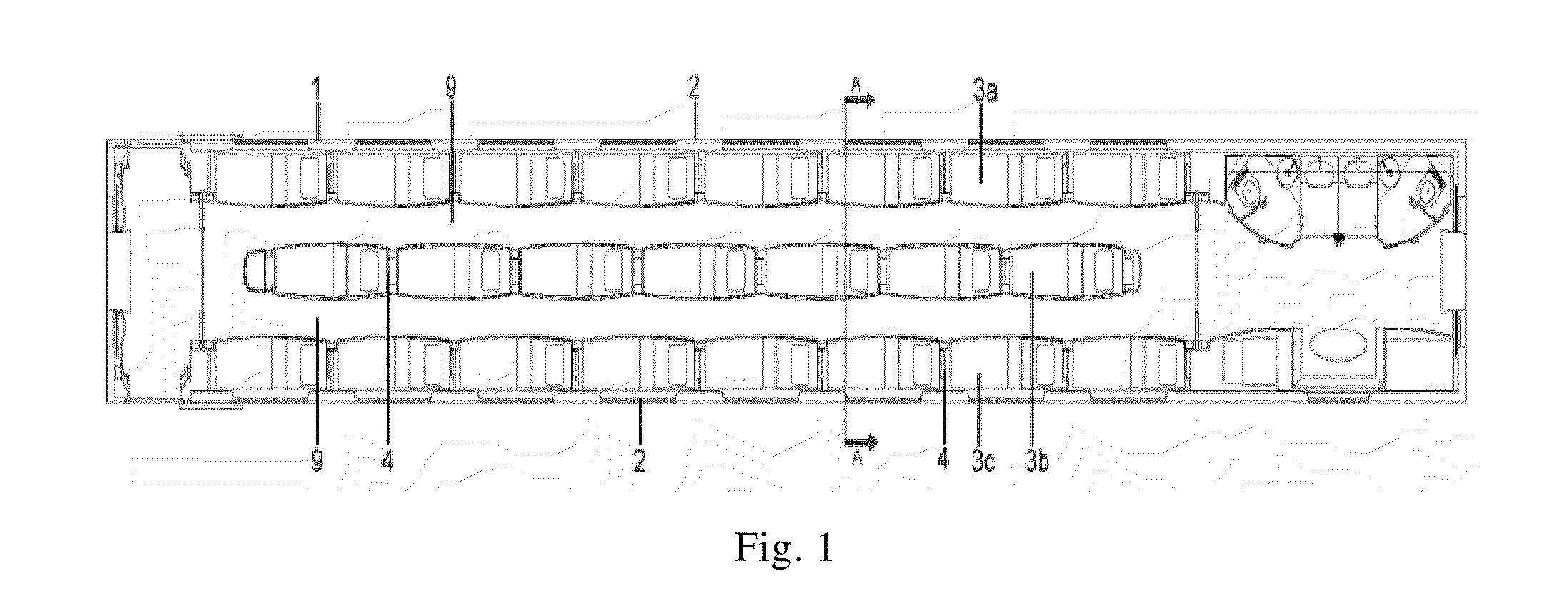

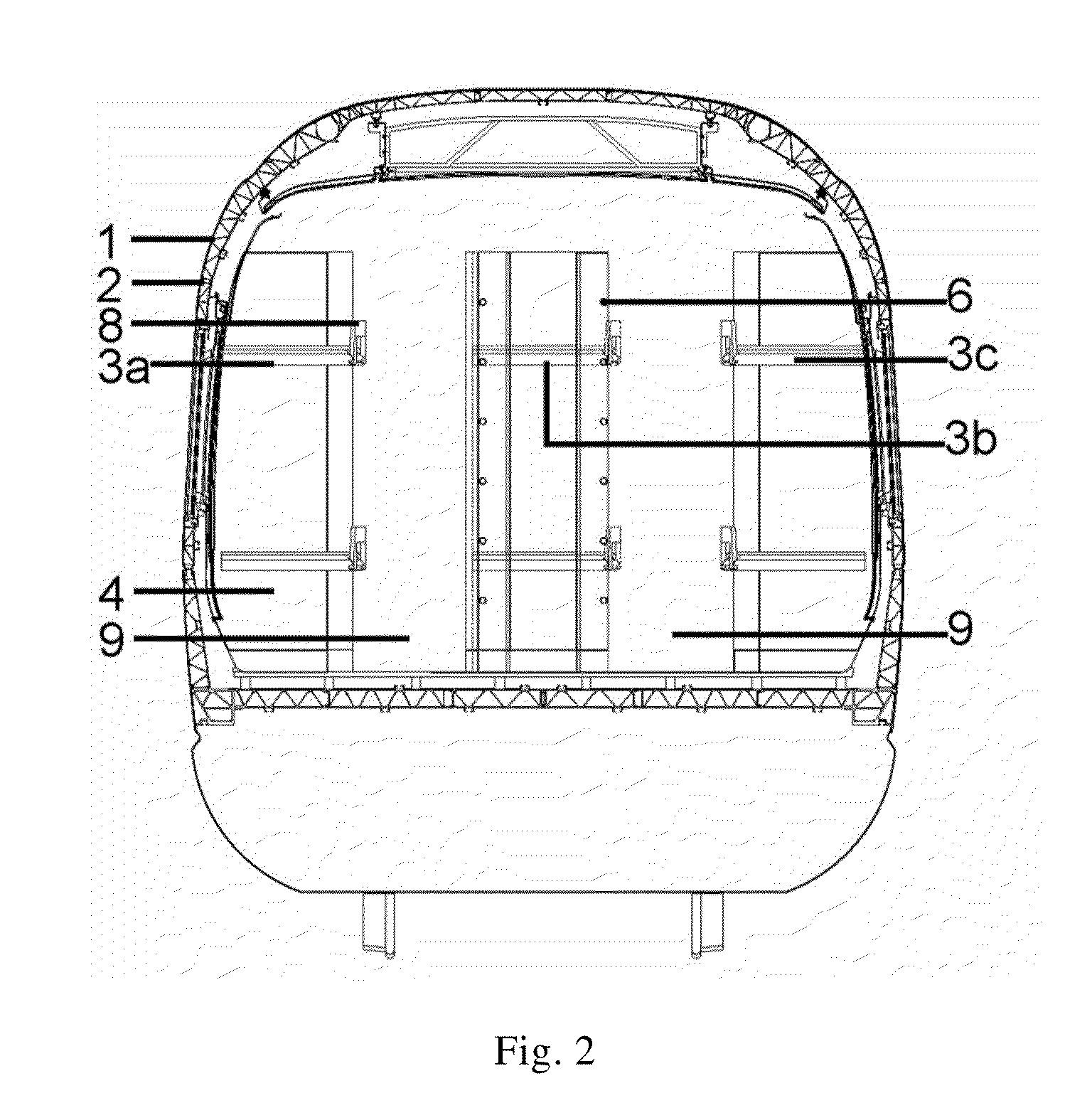

Sleeper compartment of a railroad passenger car

ActiveUS20110253005A1Reduce dynamic loadImprove practicalityVehicle arrangementsSleeping accommodationRailway passenger carEngineering

The present invention relates to the technical field of railroad passenger car, and more particularly relates to a sleeper compartment of a railroad passenger car. The sleeper compartment may be an open type or a private booth type, comprising: sidewalls, partition walls, and two columns of longitudinally arranged sleepers that are parallel with each other; each column of the longitudinally arranged sleepers is formed by no less than two sleepers that are joined together, the sleepers comprise an upper-sleeper layer and a lower-sleeper layer; one partition wall is provided between adjacent sleepers; the length direction of the longitudinally arranged sleepers is consistent with the length direction of the railroad passenger car; the longitudinally arranged sleepers at two sides are fixed to the sidewalls respectively, and a corridor is provided between two adjacent columns of longitudinally arranged sleepers. The weight of the sleeper compartment of a railroad passenger car in this structure is evenly distributed, and passengers have better comfort when traveling.

Owner:CRRC TANGSHAN CO LTD

Parking interlock device for an automotive transmission

ActiveUS20120097497A1Reduce shock loadGentle and material-sparing rejectionBraking element arrangementsGearing controlLinear relationshipEngineering

A transmission parking lock device comprising a gearwheel with teeth and gaps and a pawl having a pawl tooth. The gearwheel rotates and the pawl pivots about axes that are parallel to each other. The gearwheel teeth each have a first contour and tooth flanks with respect to rotation of the gearwheel. The pawl tooth has a second contour and tooth flanks relative to the rotation of the gearwheel, and the gearwheel has an outer radius. The gearwheel and pawl are kinematically linked by a linear relationship between the pivoting and rotational angles. The first and / or second contour are at least partially circular with a radius of the outer radius of the gearwheel, and the teeth and / or the pawl tooth have, in the area of the front tooth flank of the gearwheel or parking lock pawl, a crown tip relief relative to the outer radius of the gearwheel.

Owner:ZF FRIEDRICHSHAFEN AG

High-strength anti-collision buffer fender device

The invention discloses a high-strength anti-collision buffer fender device. The high-strength anti-collision buffer fender device comprises a rubber plate A and a rubber plate B which are parallel to each other. A plurality of sets of elastic units of the same structure are arranged between the rubber plate A and the rubber plate B. Each set of elastic unit comprises a first rigid connecting plate, a second rigid connecting plate and a spiral spring, wherein the first rigid connecting plate is fixedly connected to the side face of one side of the rubber plate A; the second rigid connecting plate is fixedly connected to the side face of the side, adjacent to the rubber plate A, of the rubber plate B; the first rigid connecting plate and the second rigid connecting plate are symmetrically arranged; and the spiral spring is connected between the first rigid connecting plate and the second rigid connecting plate. The side face of the side, used for being connected with the elastic units, of the rubber plate A, and the side face of the side, used for being connected with the elastic units, of the rubber plate B are each provided with a plurality of rubber plate protrusions extending in the height direction of the spiral springs. The high-strength anti-collision buffer fender device is of a two-stage rigidity structure, has the good buffer effect instantly when being stressed and facilitates modularized mounting and manufacturing.

Owner:JIANGSU UNIV OF SCI & TECH

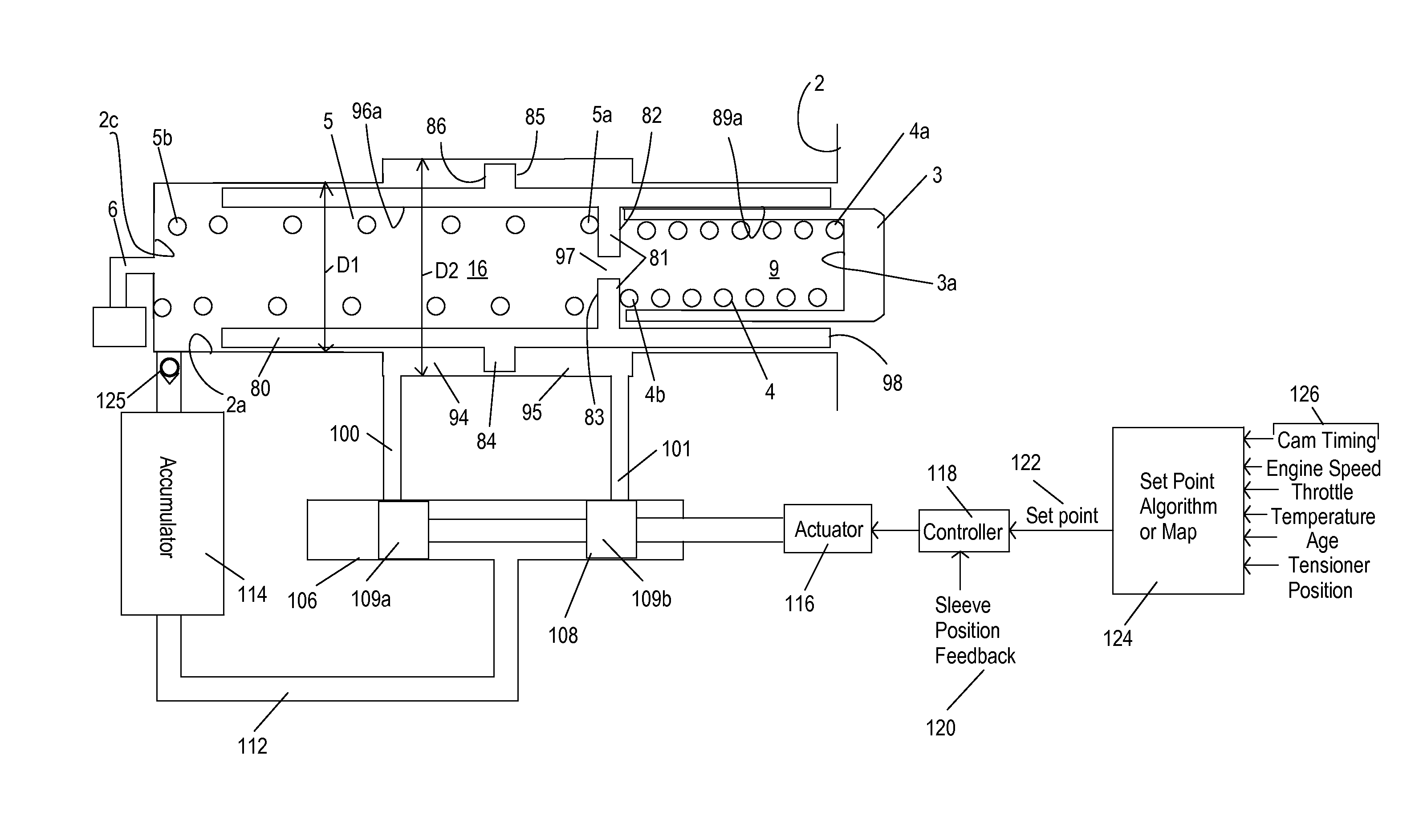

Chain drive tensioner spring force control mechanism

ActiveUS20140187368A1Improve drive efficiencyChain tensionGearingElectrical componentsEngineeringSpring force

Owner:BORG WARNER INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com