Spraying robot driven by multiple paralleled parallelogram links in series-parallel manner

A parallelogram and spraying robot technology, applied in the direction of manipulators, spraying devices, manufacturing tools, etc., can solve the problems of reducing failure rate and maintenance cost, complex motor control, high failure rate, etc., to reduce failure rate and maintenance cost, improve safety performance and reliability, and the effect of improving spray quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] The following will describe the inventive concept of the present invention in detail in conjunction with the accompanying drawings, aiming to explain the technical problems to be solved by the present invention, the technical means adopted, and the role and function of each technical feature adopted in solving the above technical problems, And explain the technical effects that can be achieved by the technical problems solved by the above-mentioned technical means.

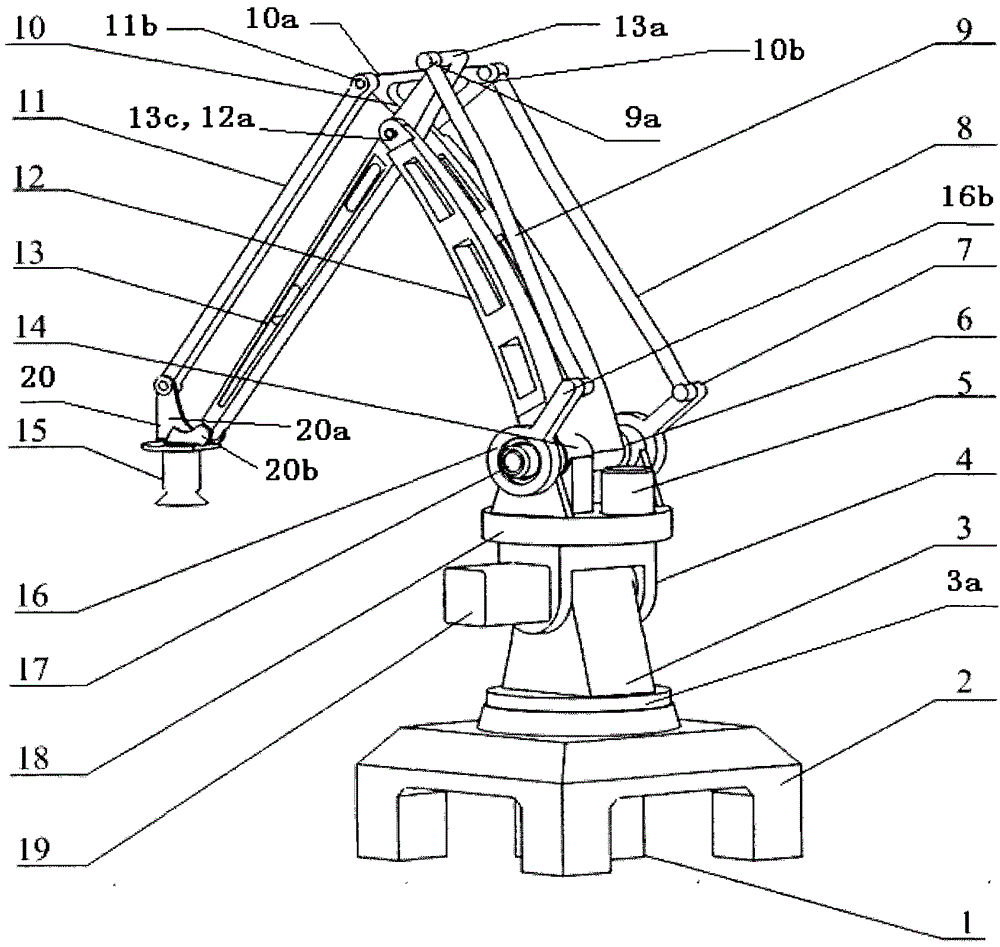

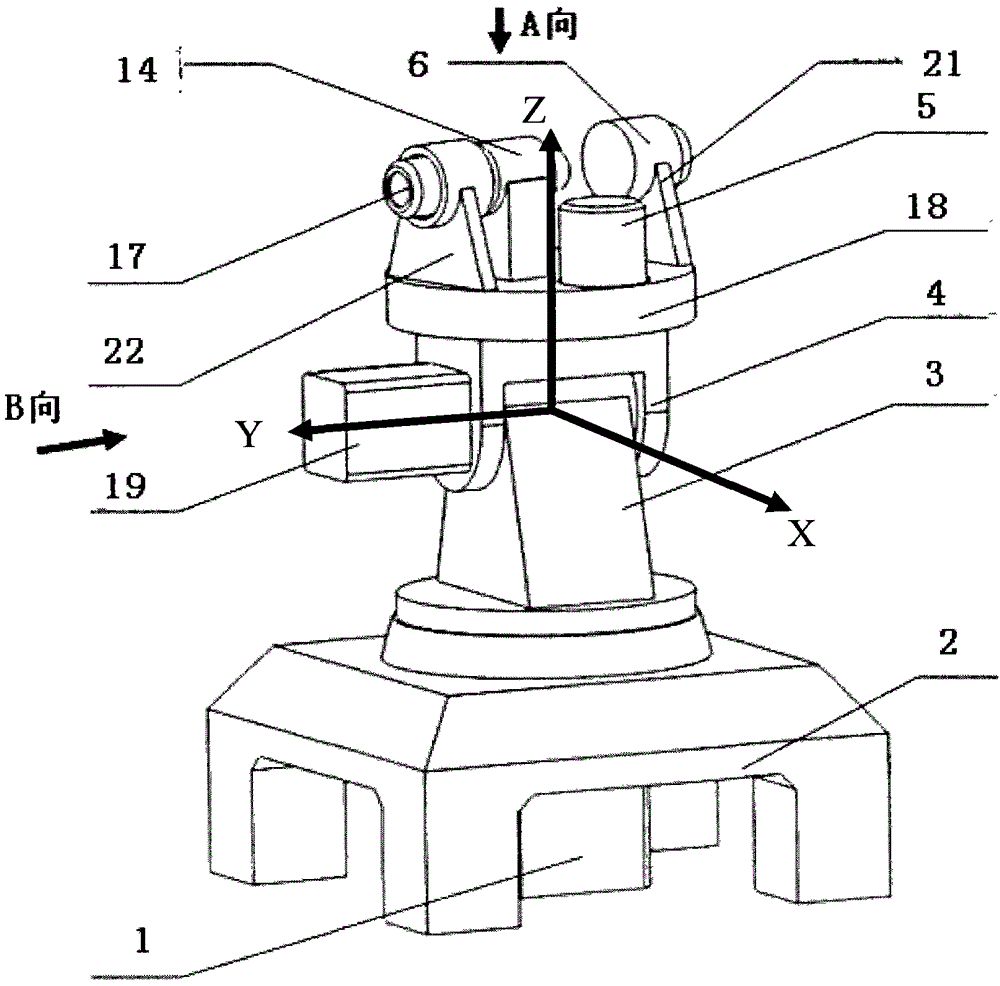

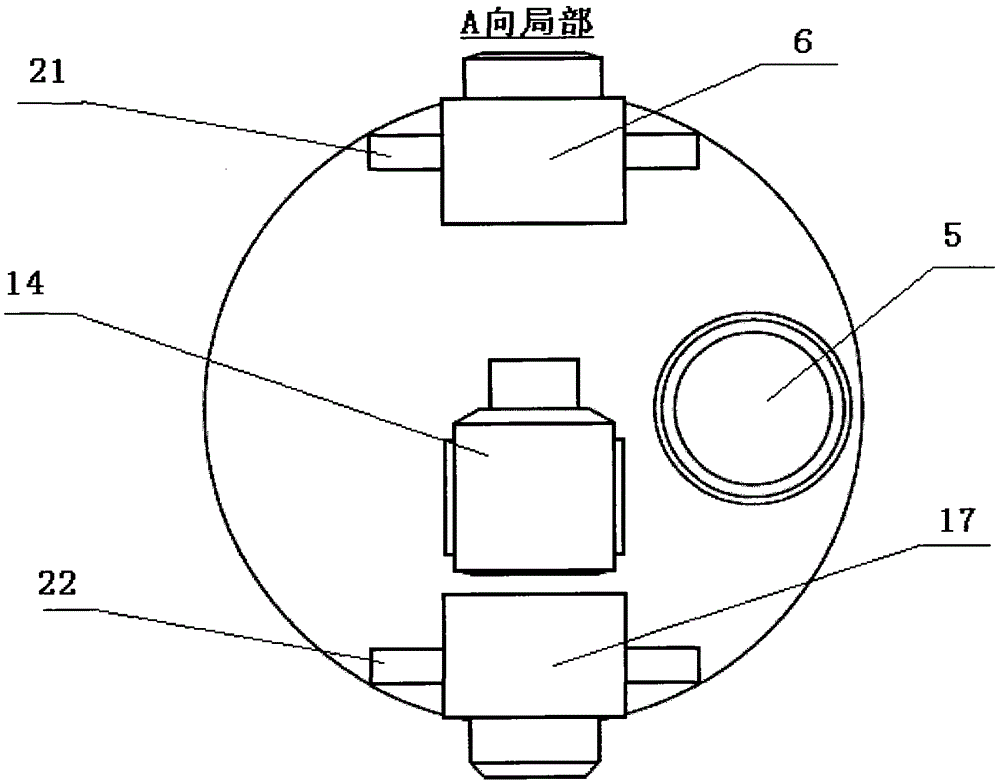

[0077] Such as Figure 1-2 as shown, figure 1 It is a schematic diagram of the overall structure of a series-parallel drive spraying robot with multiple parallelogram connecting rods in parallel in the present invention; figure 2 It is a structural schematic diagram of the sub-assembly of the base subassembly of the multi-parallelogram connecting rod parallel series-parallel drive spraying robot of the present invention. The base subassembly includes a rotating top base 18, a rotating upper base 4, a ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com