Patents

Literature

291 results about "Railway passenger car" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

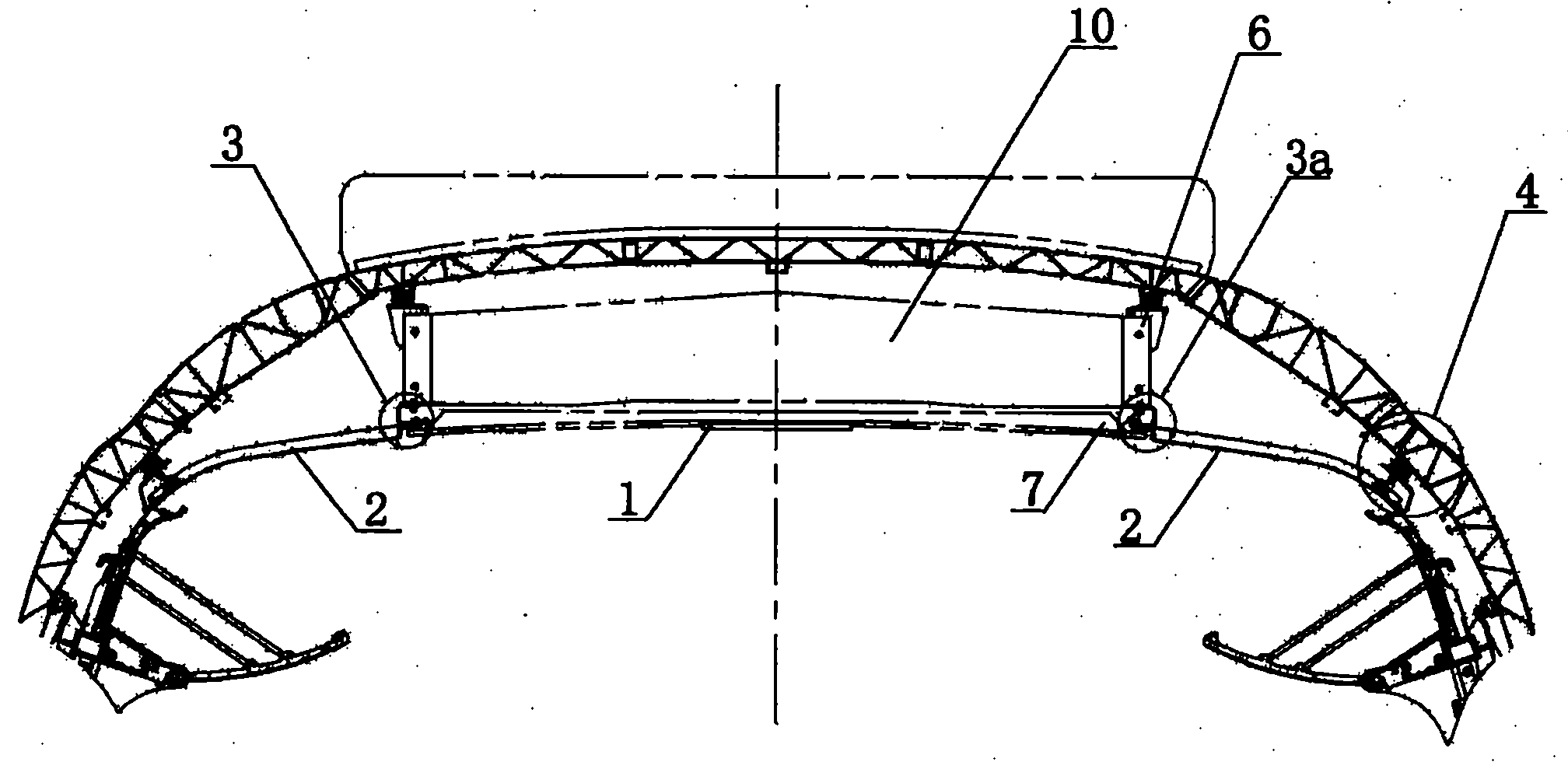

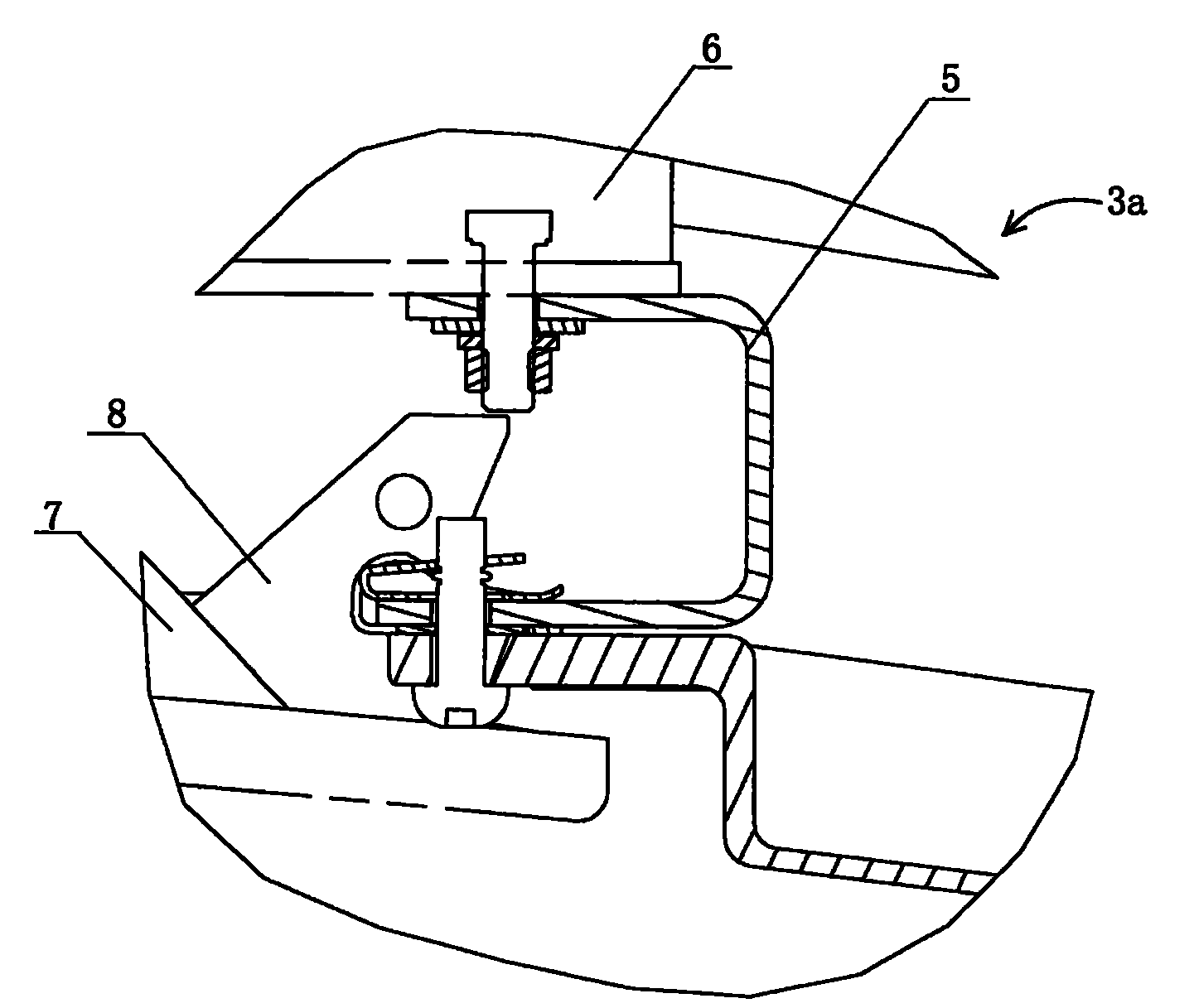

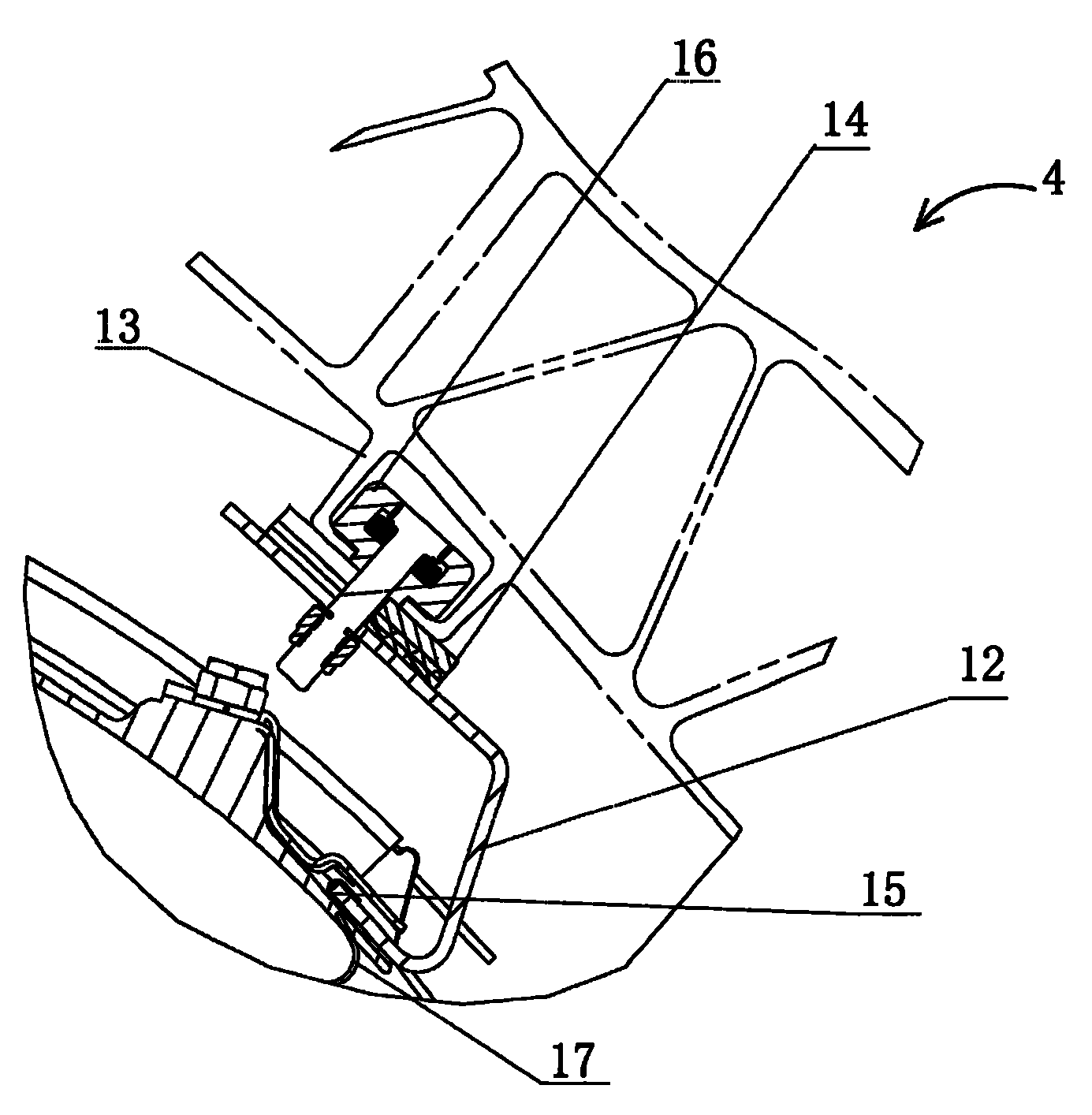

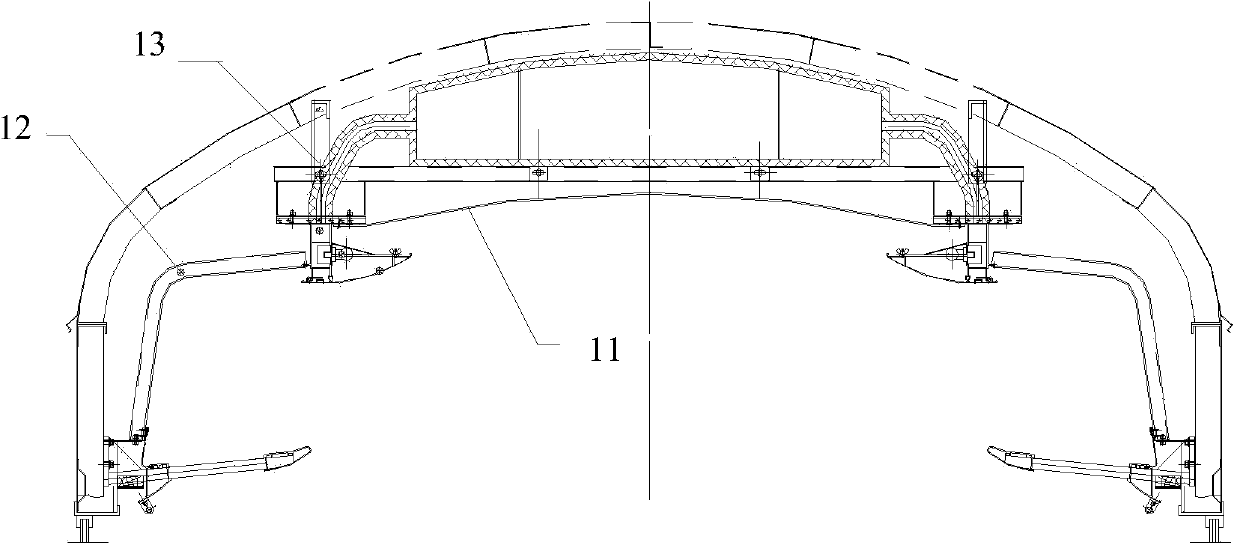

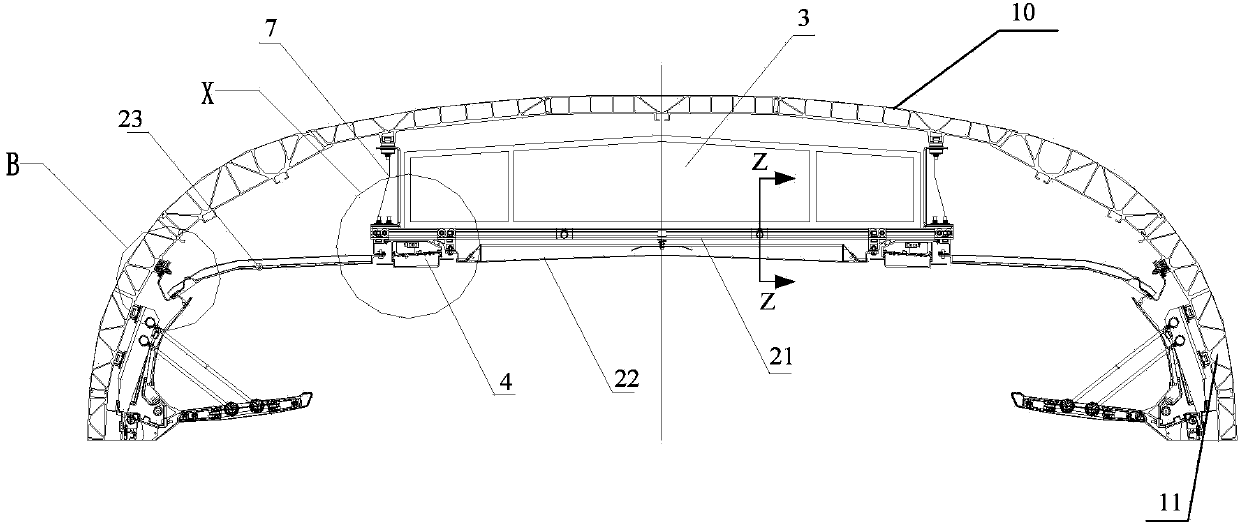

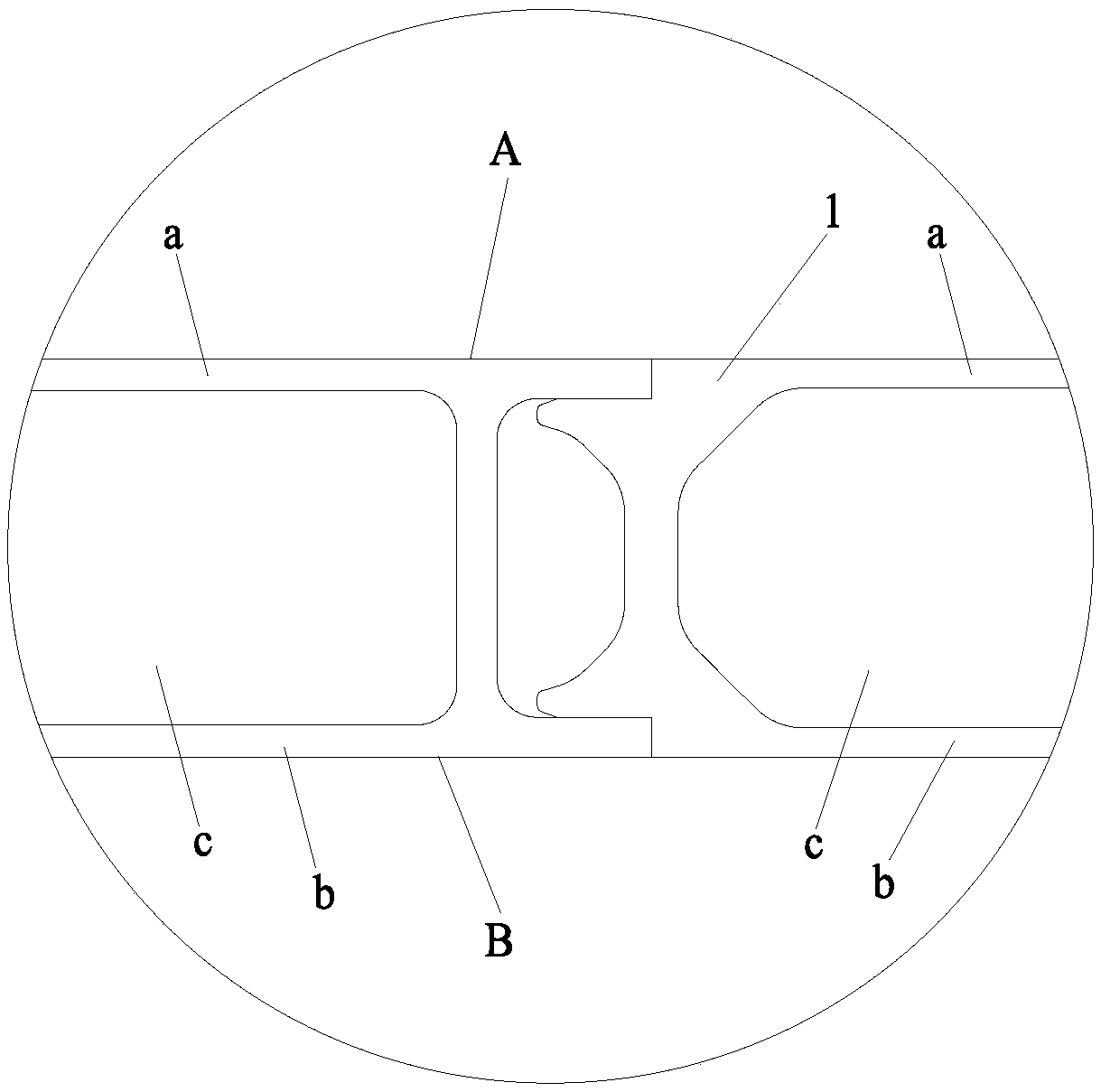

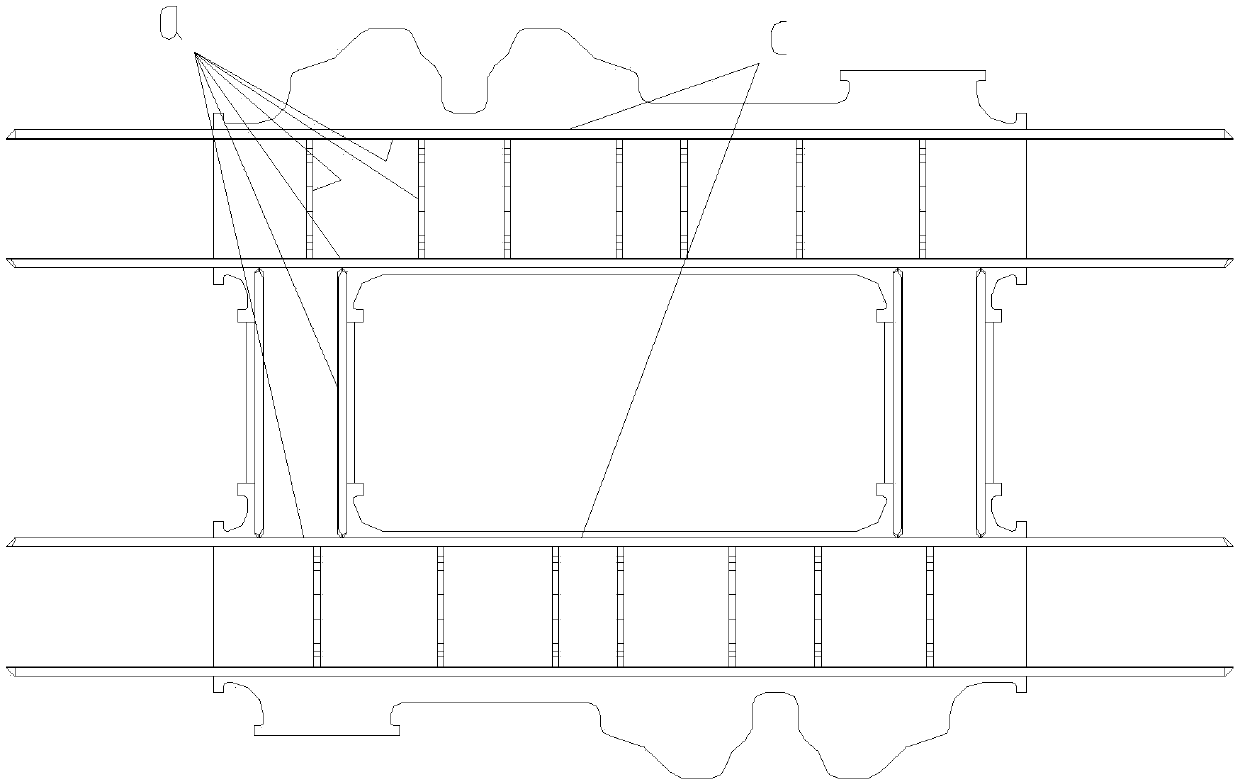

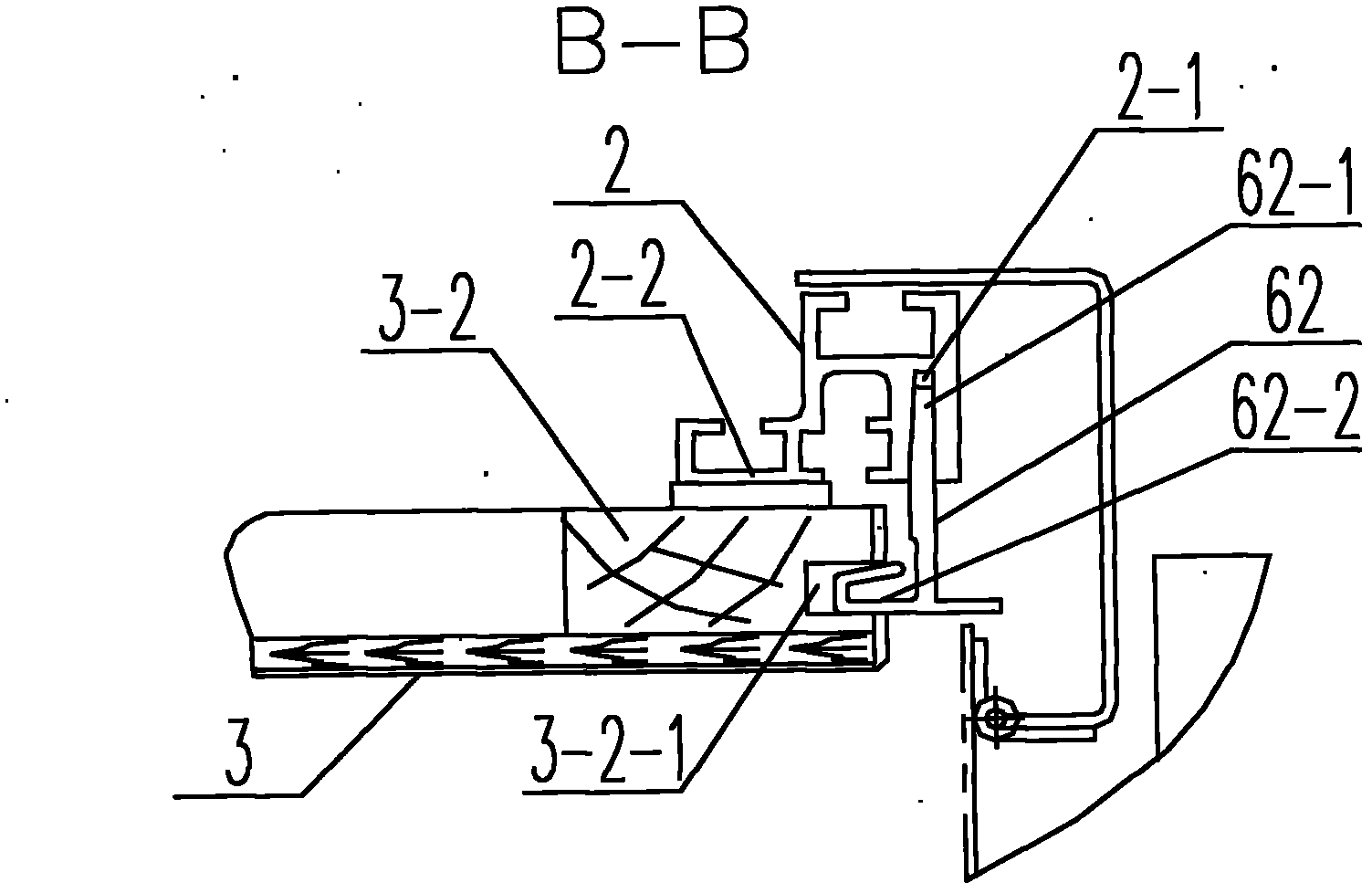

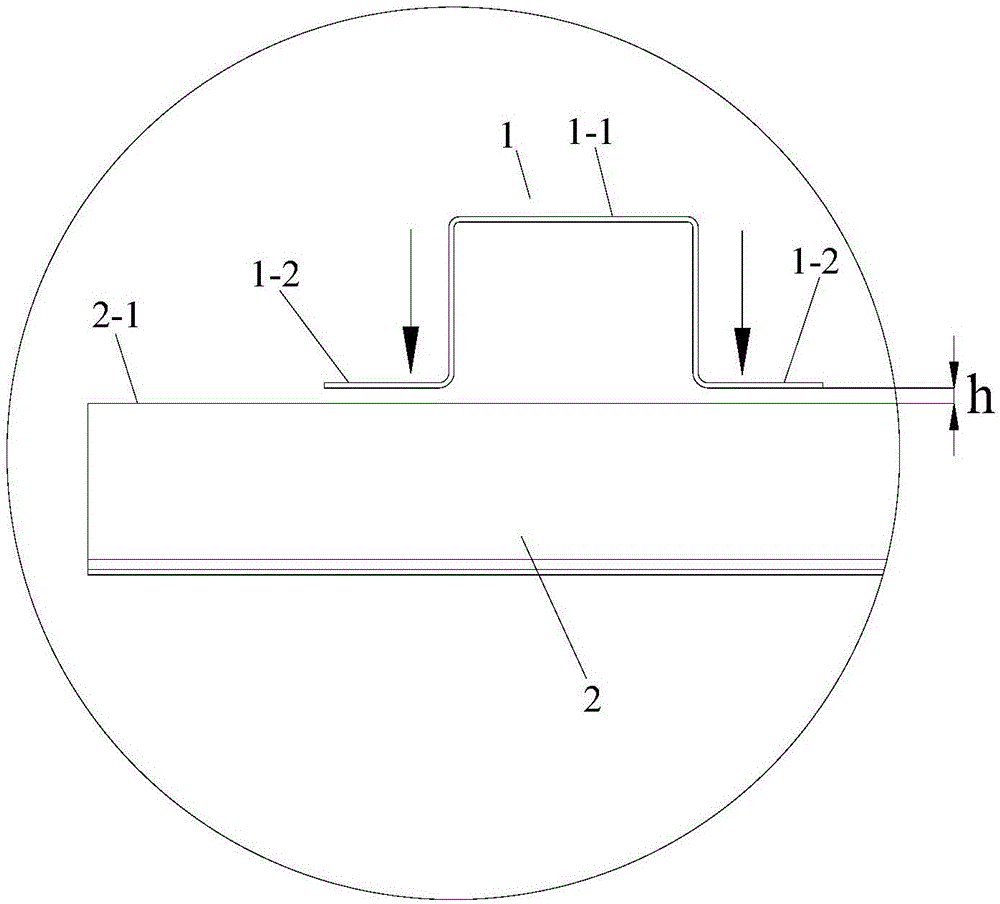

Top slab connecting structure inside railway train roof

ActiveCN101804818AReduce noiseImprove fire performanceRailway roofsMaterial based railway technolgyRailway passenger carFireproofing

The invention relates to the technical field of railway train roofs and discloses a modular designing and manufacturing method of a top slab curved connecting structure in a railway train roof. The top slab connecting structure inside the train proof comprises an intermediate top slab, side top slabs, connecting assemblies of the intermediate top slab and the side top slabs and connecting assemblies of the side top slabs and a train body. Connecting parts of the side top slabs and the intermediate top slab are arranged on air duct affiliated hanging codes through large-stroke screw parts; top slab hanging codes are arranged on an air-conditioning air duct; and the connecting parts of the side top slabs and the train body are fixed on inserts of a C-shaped groove of the train body through fixing clamping pieces of the side top slabs. The curved connecting structure can effectively reduce noise in the train body, improve the fireproofing capability in the train body, can be convenient to overhaul air-conditioning air outlet duct components at the upper part of the top slab in a carriage, ensures uniform air outlet of an air conditioner and greatly improves the comfort and the practicability for passengers to take a seat.

Owner:CRRC TANGSHAN CO LTD

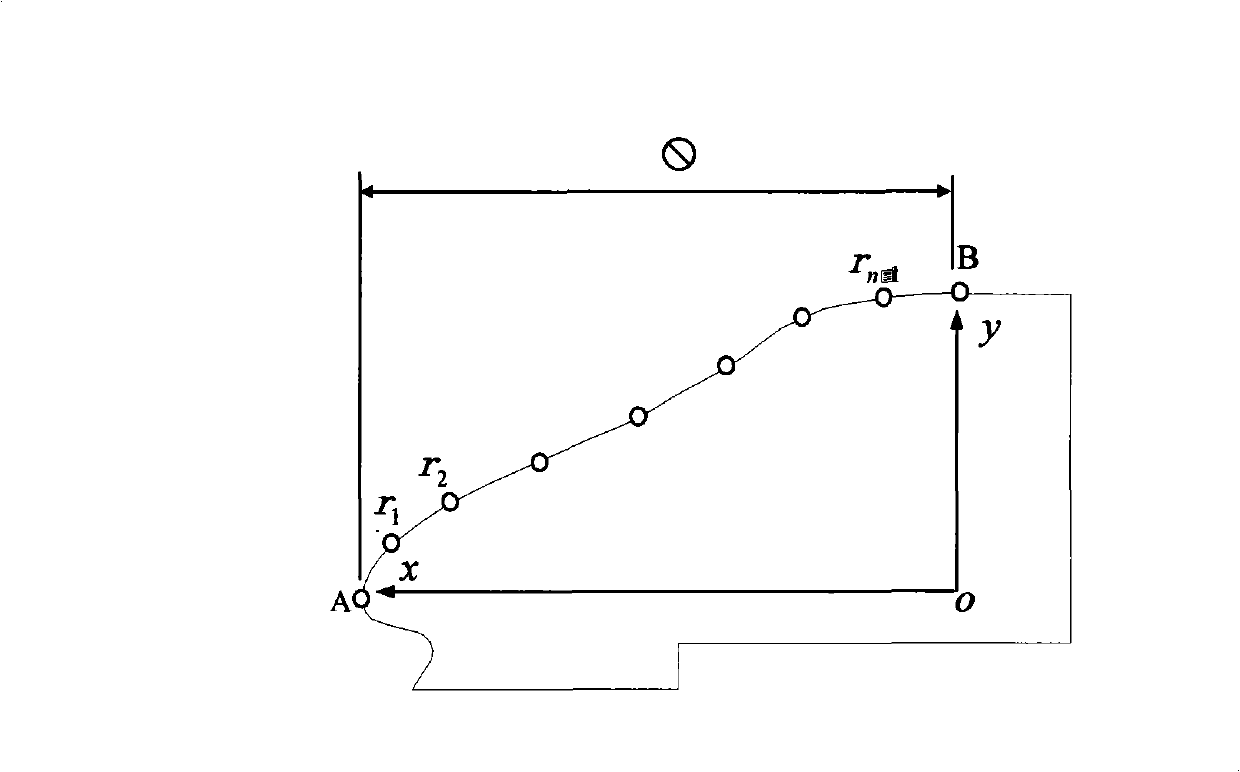

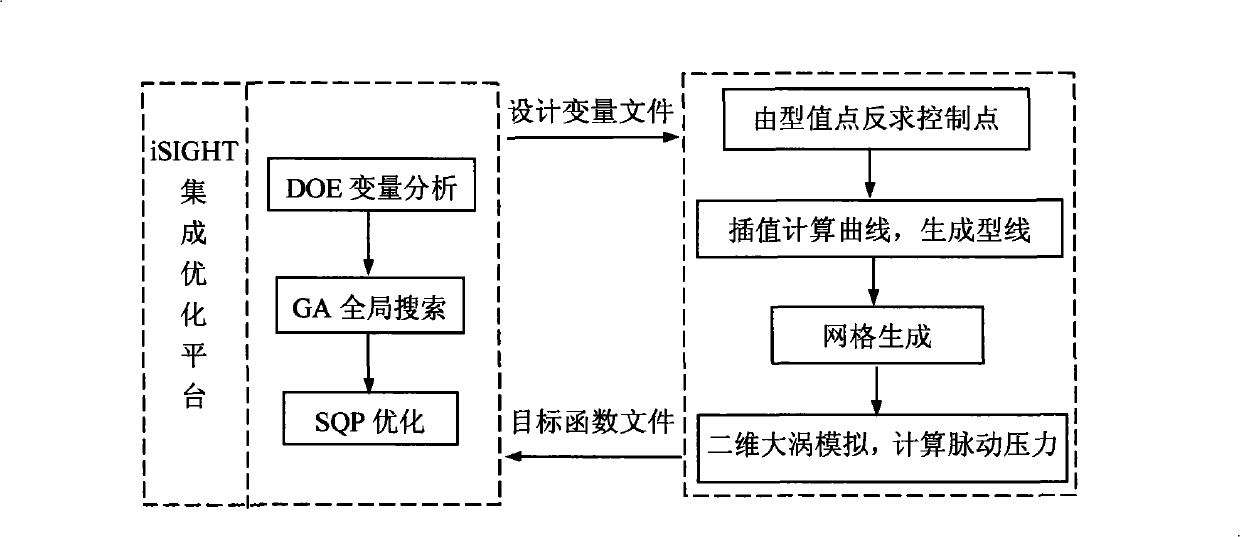

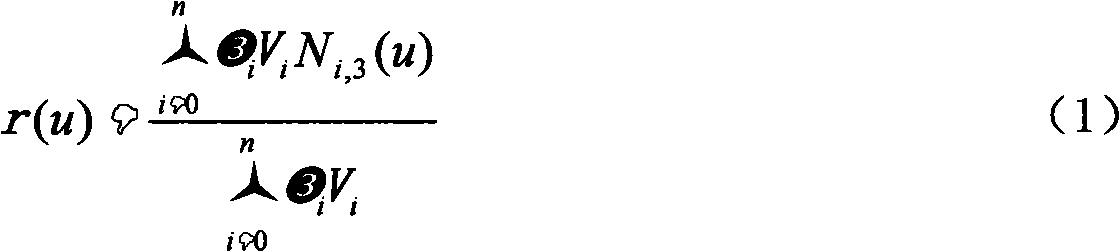

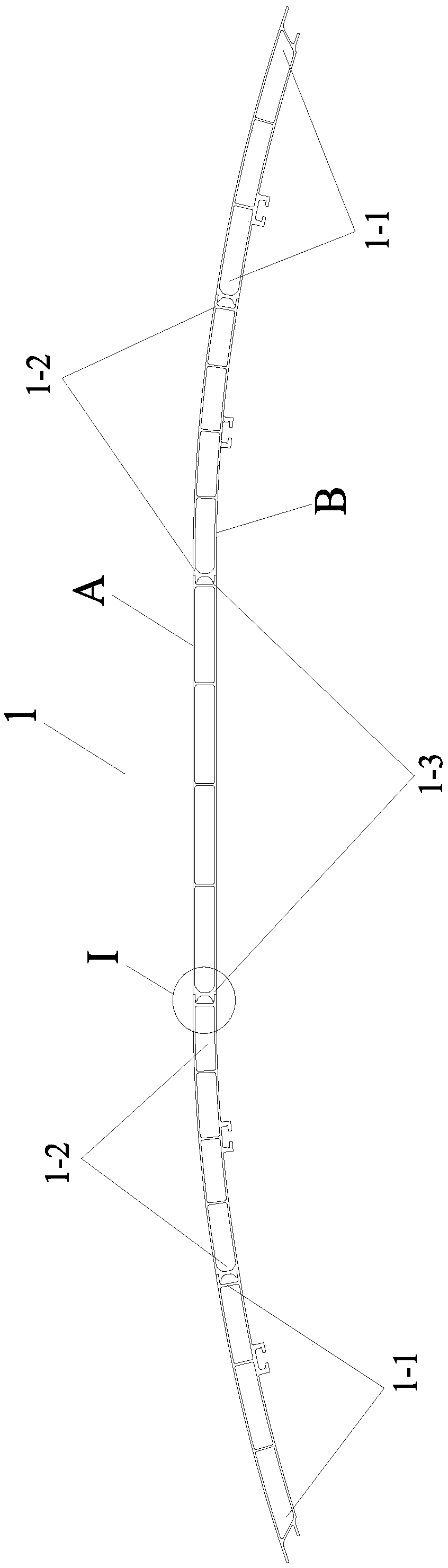

Method for optimizing low pneumatic noise of high-speed train head section longitudinal symmetry plane line

ActiveCN101354729AAccelerated aerodynamic noise controlAerodynamic Noise Control ScienceSpecial data processing applications3D modellingNoise controlRailway passenger car

The invention relates to a method for optimizing low aerodynamic noise of molded lines of longitudinal symmetrical surface for the head part of a high-speed train. The molded lines of the longitudinal symmetrical surface for the head part of the high-speed train are basic molded lines for determining the running trend of the whole appearance, wherein the part of the molded line between nose cone points A and transition points B from the train head to the train body is the key part in the molded line design. The invention is the optimized design of the part. The method performs the parameterized model and CFD value calculation on the molded lines of longitudinal symmetrical surface for the head part of a high-speed train by utilizing the NURBS curves, combines the optimized arithmetic to link the change in the aerodynamic performance of the molded line and the adjustment of the geometrical shape, and adjusts the molded lines repeatedly through a flow field computation program and an optimized program, thereby accurately determining the optimal position of the value point of the molded lines of the longitudinal symmetrical surface so that the aerodynamic noise of the head part of the train is reduced to the minimum, lowering the design and the manufacture costs of the aerodynamic noise control of the high-speed train, accelerating the production process of the high-speed train, and making the noise control of the train more scientific.

Owner:CRRC QINGDAO SIFANG CO LTD

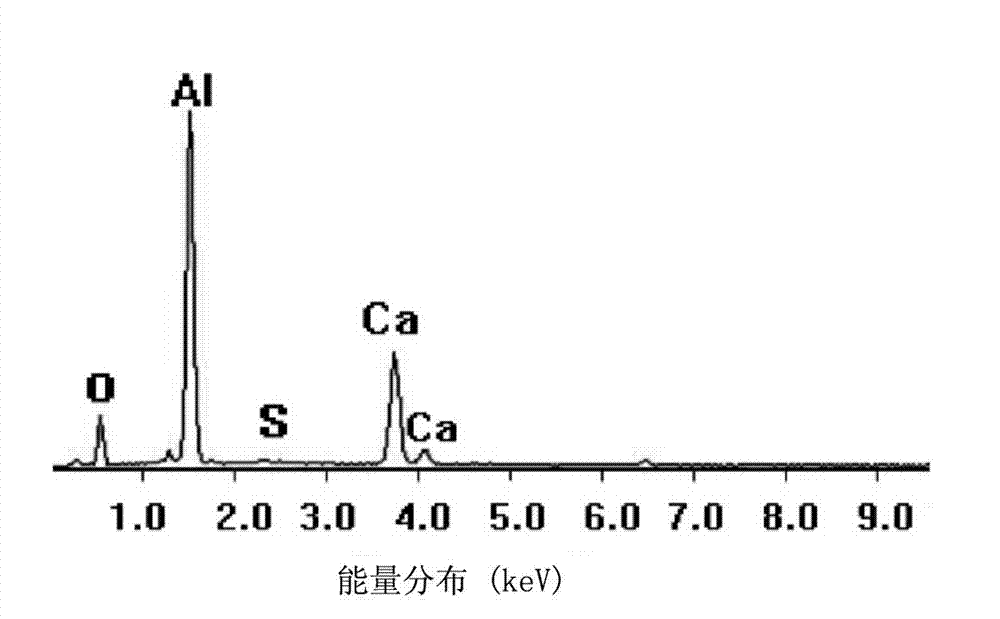

Axle material and application thereof in high-speed railway carriage

The invention relates to an axle material. The influence of different proportions for which elements such as carbon, silicon, manganese, phosphorus, sulphur, chromium, molybdenum, nickel, copper and wolfram account, on material performances is studied, an alloy steel axle material which has good obdurability matching and a good fatigue property is obtained, preferably, the material is applied to production of railway carriage axles, particularly to the production of axles of railway carriages with a speed of more than 200km per hour, and the material also can be applied in high and cold areas.

Owner:TSINGHUA UNIV +2

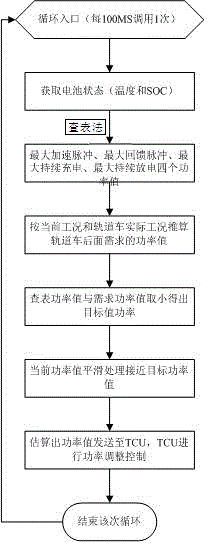

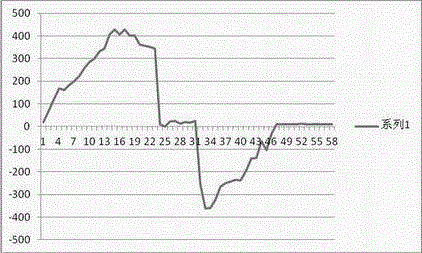

Battery pack power control method suitable for railway passenger car

ActiveCN104442436AImprove performanceExtended service lifeVehicular energy storageElectric propulsionRailway passenger carMotor controller

The invention provides a battery pack power control method suitable for a railway passenger car. The method includes the following steps that a two-dimensional power table of the maximum permitted power, the temperature and the SOC is established; battery state information is acquired; the maximum permitted power value of batteries is acquired through a table lookup method; the needed power value of the railway passenger car in a next working condition is calculated according to a current working condition; the maximum permitted power value acquired through the table lookup method is compared with the needed power value, and the small value is acquired and serves as a target power value; the current power value is smoothened so as to be close to the target power value; the power value is calculated and sent to a motor controller. According to the battery pack power control method in the scheme, through the real-time, regular and online current state of a lithium battery pack and in combination with the current real-time power and the needed power of the railway passenger car, the power value capable of being input and output in real time of the power lithium batteries is calculated and transmitted to a TCU of the railway passenger car so as to be controlled, the requirement for the operating power of the railway passenger car is met, the safety of the power lithium batteries can be effectively guaranteed, the service life of the batteries can be prolonged, and the performance of the railway passenger car can be improved.

Owner:惠州美亿瑞创电气设备有限公司

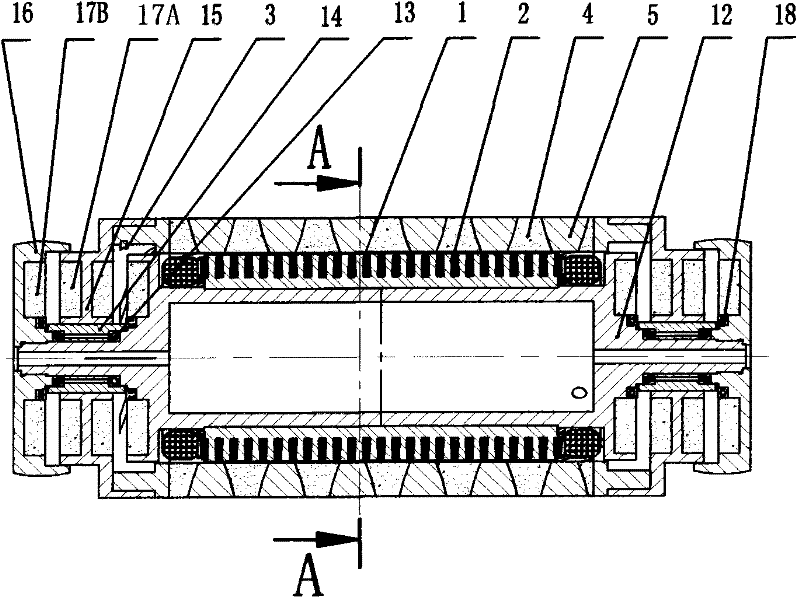

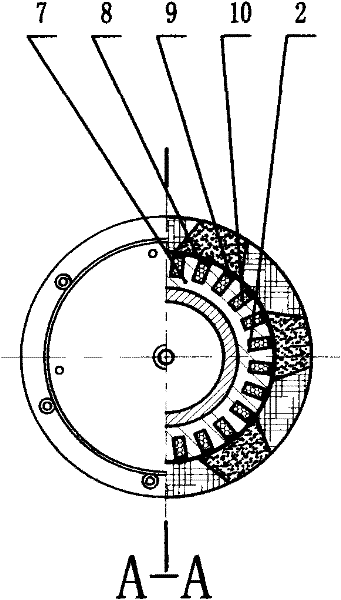

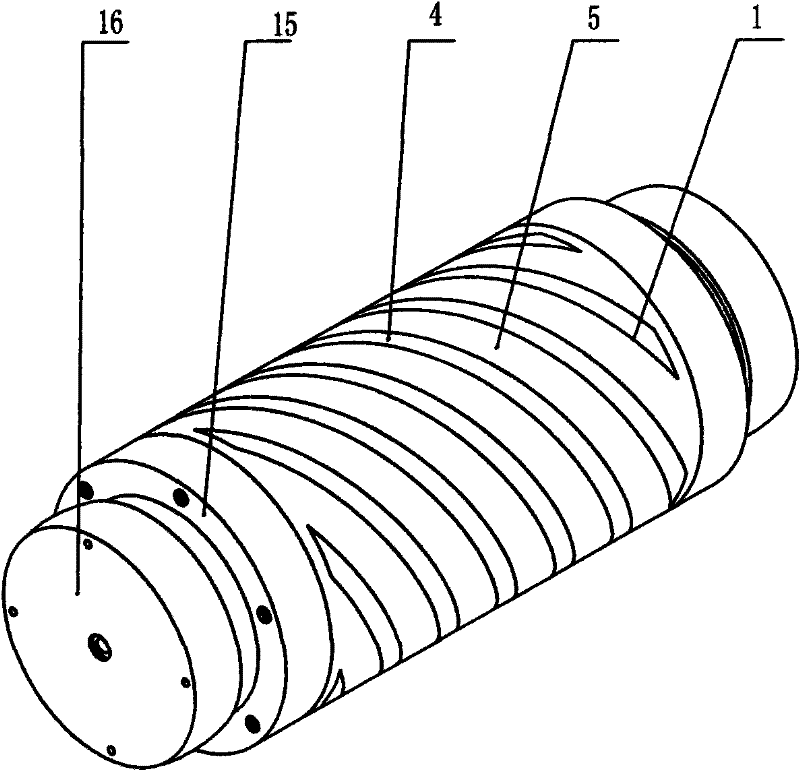

Permanent magnet motor with external spiral rotor and permanent magnet suspension wheeltrack vehicular access system

InactiveCN102447365AEfficient use ofCompact structureDynamo-electric brakes/clutchesMagnetic circuit rotating partsRailway passenger carPermanent magnet motor

The invention provides a permanent magnet motor with an external spiral rotor and a permanent magnet suspension wheeltrack vehicular access system. The external part of the motor is provided with the external spiral rotor, so that larger output power is obtained with the same external diameter. The permanent magnet motor with the external spiral rotor is applied to efficient drive and efficient power generation recovery brake kinetic energy of a magnetic suspension train, can be used for driving a permanent magnet suspension wheeltrack subway, a permanent magnet suspension vehicle and a four-channel elevated railway passenger car, and is used for elevated permanent magnet suspension towing machine to convey cars or trucksin an enegy saving way. Due to the adoption of the elevated bidirectional four-channel permanent magnet suspension wheeltrack high-speed rail, the constructing cost of a permanent magnet suspension high-speed rail can be lower than that of the existing high-speed rail, and a realistic significance is realized on energy conservation of transportation sector and national energy-saving emission reduction.

Owner:刘忠臣

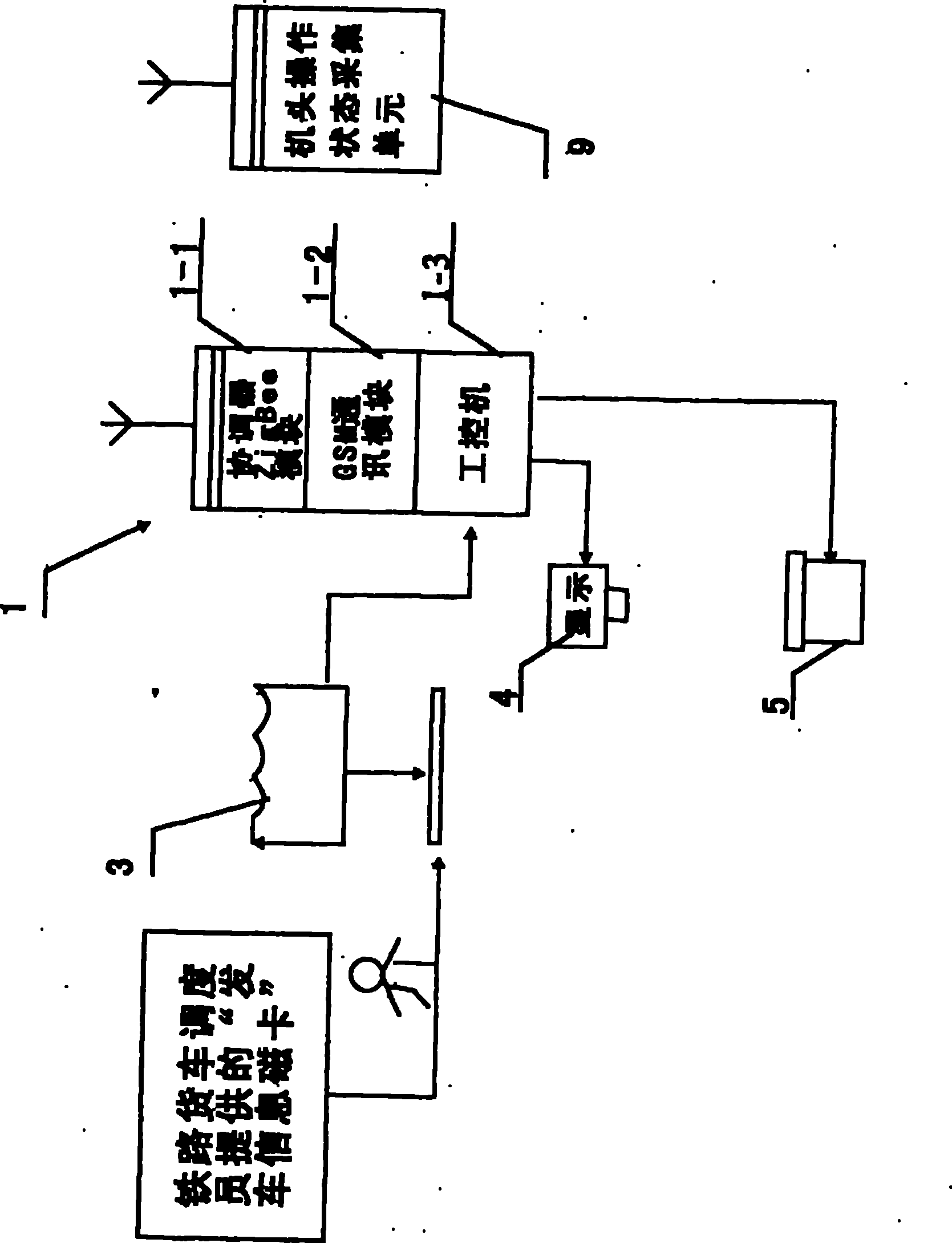

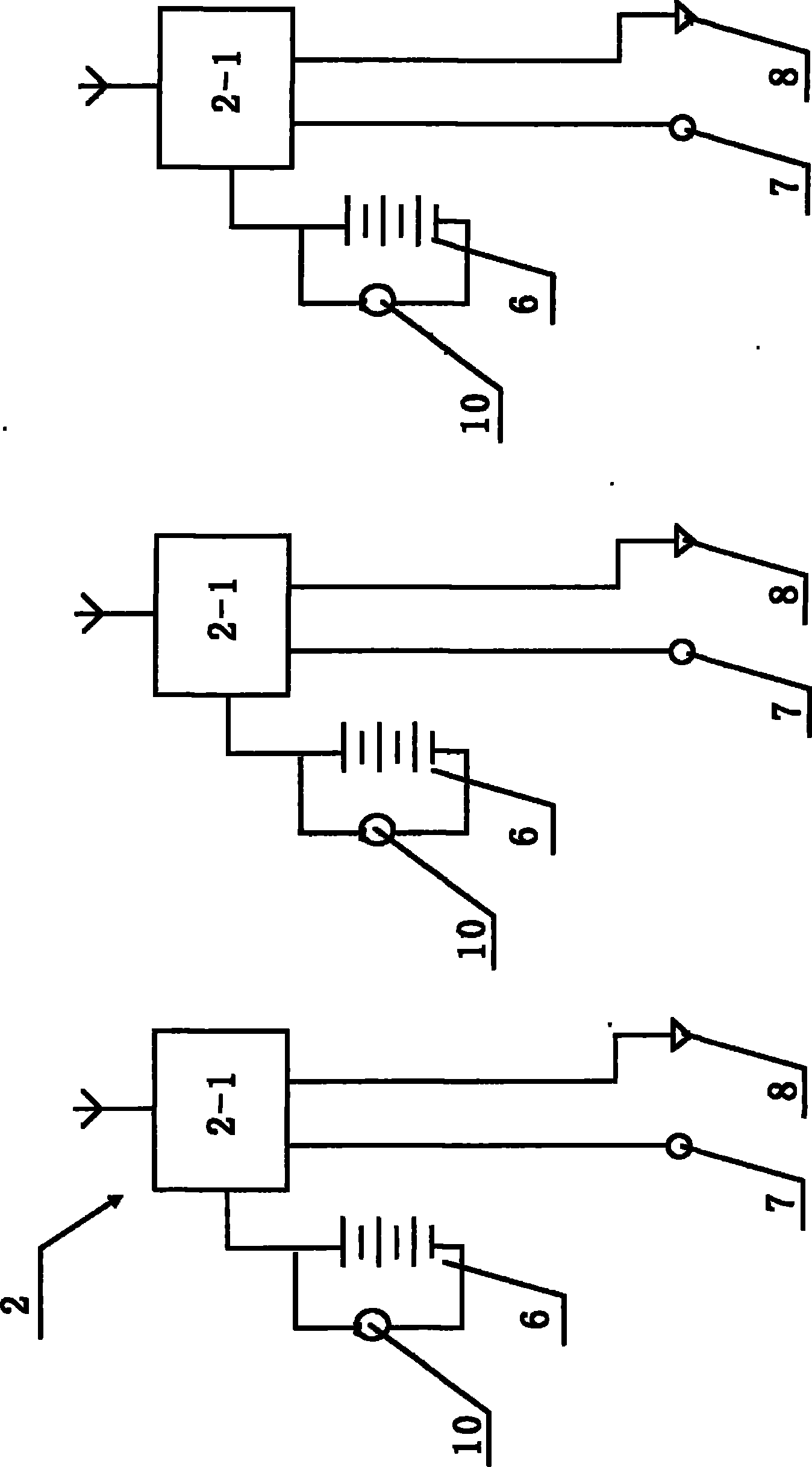

Wheel axle temperature and wind pressure monitoring device based on wireless ad hoc networks and method for railway passenger cars or wagons

InactiveCN102050138AImprove securityExtend working lifeIllumination for points/signallingNetwork topologiesRailway passenger carWifi network

The invention relates to a wheel axle temperature and wind pressure monitoring device based on wireless ad hoc networks and a method for railway passenger cars or wagons, and aims to achieve that random networking can be realized, monitoring work is real-time and accurate, a low power consumption working mode is realized, the operation is simple, the maintenance cost is low, and the maintenance is simple and convenient. The invention adopts the technical scheme that the wheel axle temperature and wind pressure monitoring device based on the wireless ad hoc networks for the railway passenger cars or wagons is characterized in that a locomotive unit and a group of carriage root units are included, a network system with a routing function is built between the locomotive unit and each carriage root unit through a wireless ad hoc network such as a Zigbee network, a WiFi network or a Bluetooth network, wherein, the locomotive unit comprises a coordinator module, a GSM (Global System for Mobile Communications) communication module, an industrial computer and a card reader, and each carriage root unit comprises a root unit module, a parameter collection sensor and a battery. The inventionis suitable for real-time monitoring of physical parameters such as wheel axle temperature, braking wind pressure and the like of a wagon group with a large quantity.

Owner:张兴莲 +1

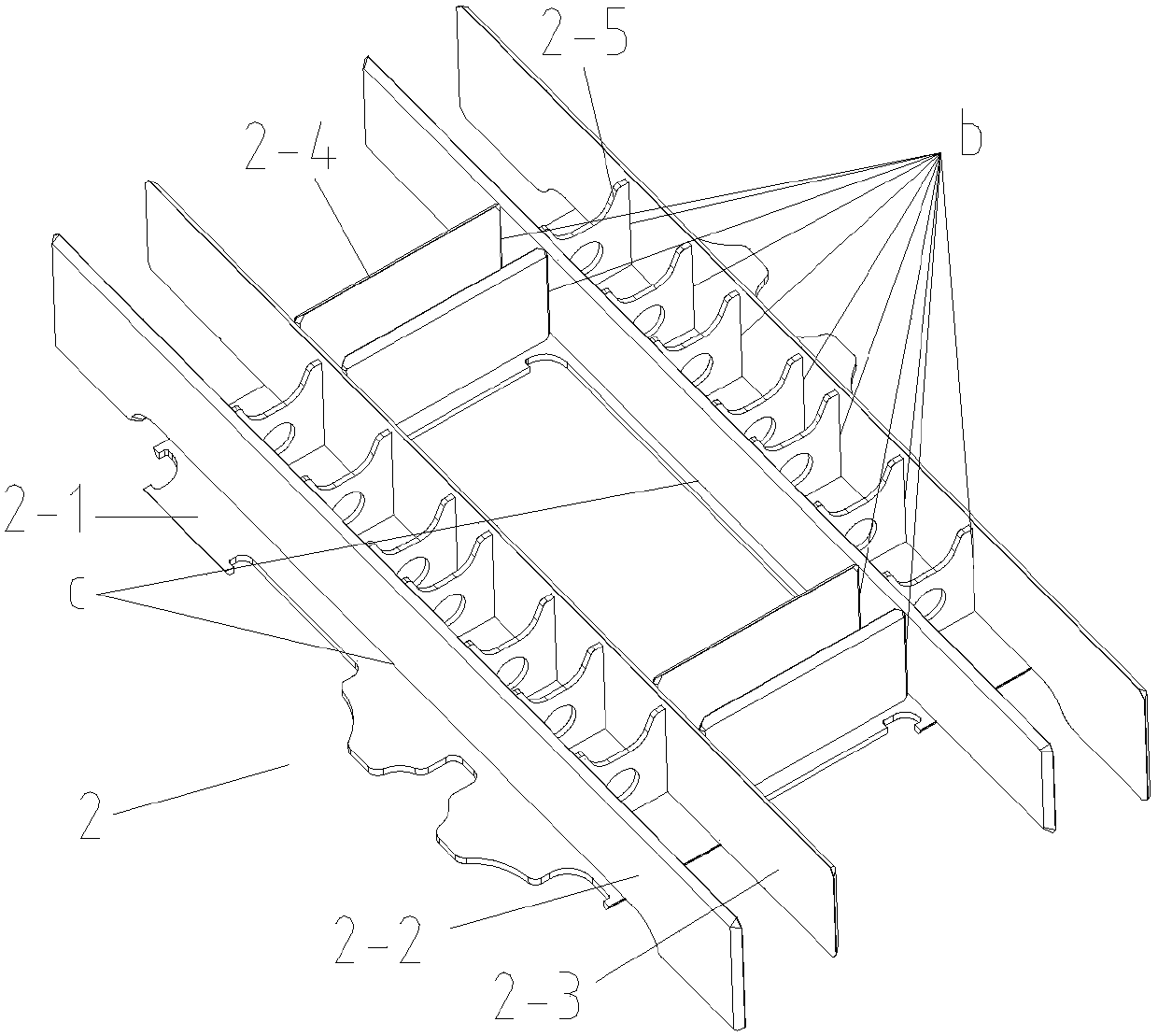

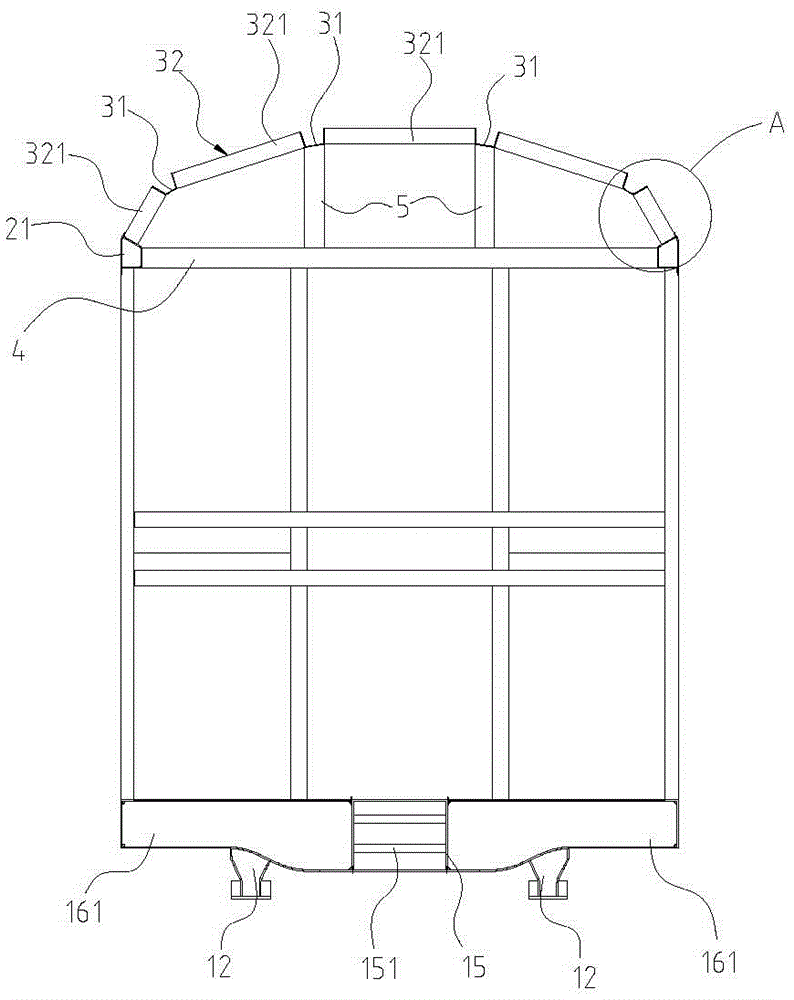

Railway passenger train body and railway vehicle

The invention provides a railway passenger train body and a railway vehicle. The train body comprises a train body steel structure, wherein the train body steel structure comprises train body side walls and a train body top part, the inner side of the train body top part is provided with at least two inner top plate assemblies in the longitudinal direction, each inner top plate assembly comprises a skeleton, a middle top plate and side top plates, the side top plates are respectively positioned at the two sides of each middle top plate, the skeleton comprises at least two longitudinal beams and at least two transverse beams, each middle top plate covers under the skeleton, the two sides of each middle top plate are respectively and fixedly connected with the two longitudinal beams, the butting part of the middle top plates of the two adjacent top plate assemblies is provided with a gap blocking cover plate which is used for blocking a gap between the middle top plates, the two ends of the gap blocking cover plate are respectively and fixedly connected with the two longitudinal beams, one side, facing the skeleton, of each side top plate is respectively and fixedly connected with the corresponding longitudinal beam, and the other side of each side top plate is fixedly connected with the corresponding train body side wall. The railway passenger train body has the advantages that the assembly operation is convenient, the assembly efficiency is improved, and the overhauling and maintenance are conveniently implemented.

Owner:CRRC TANGSHAN CO LTD

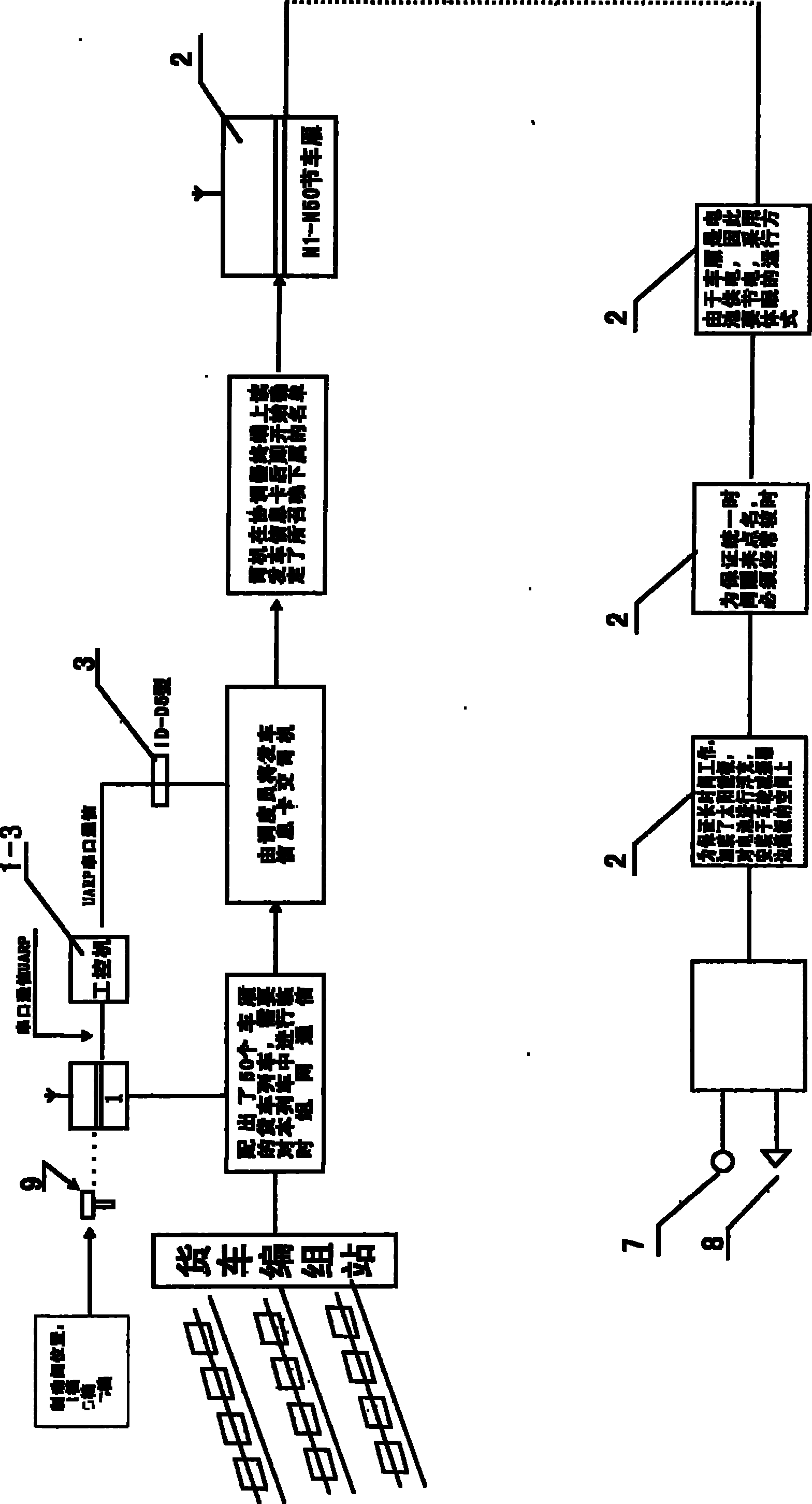

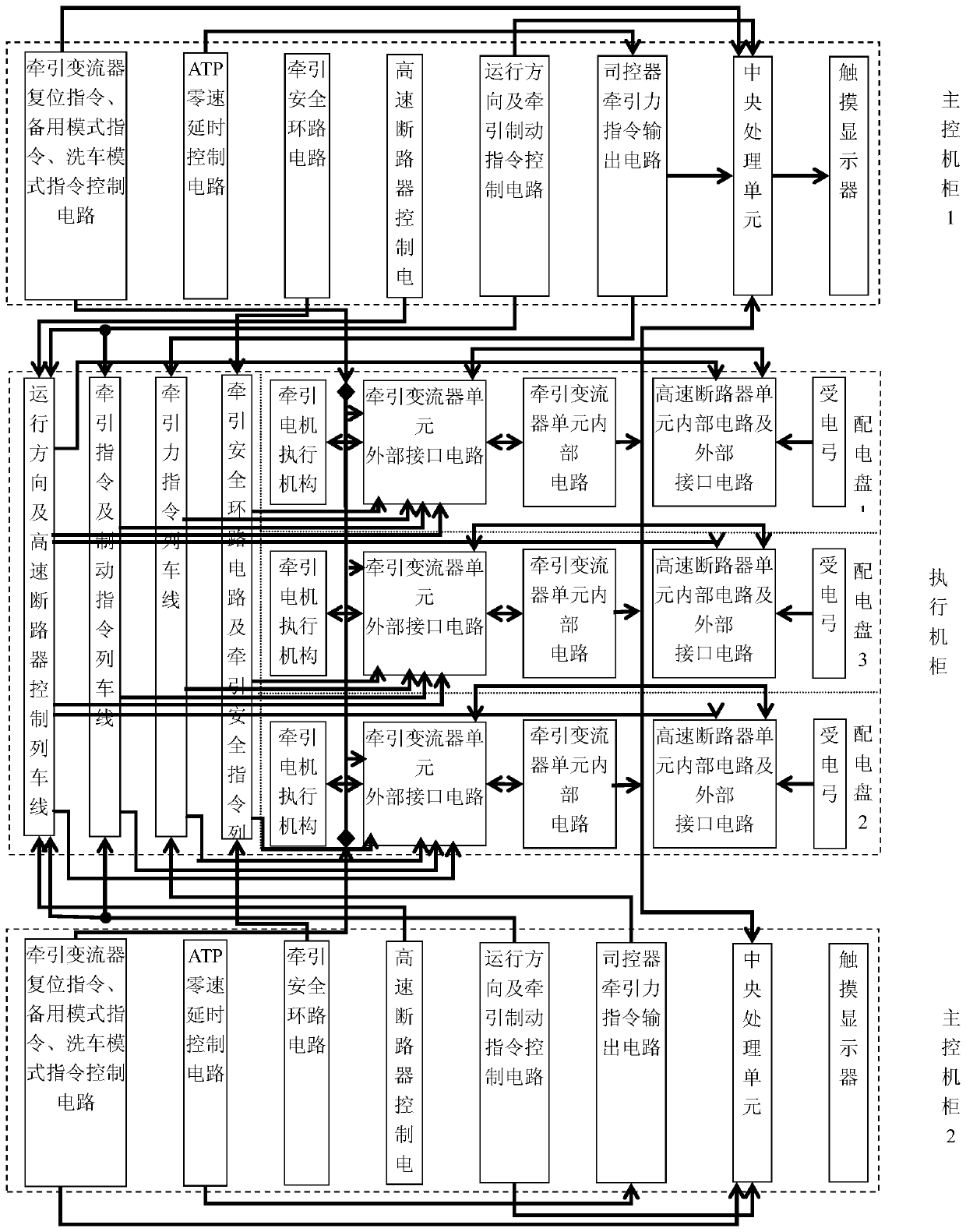

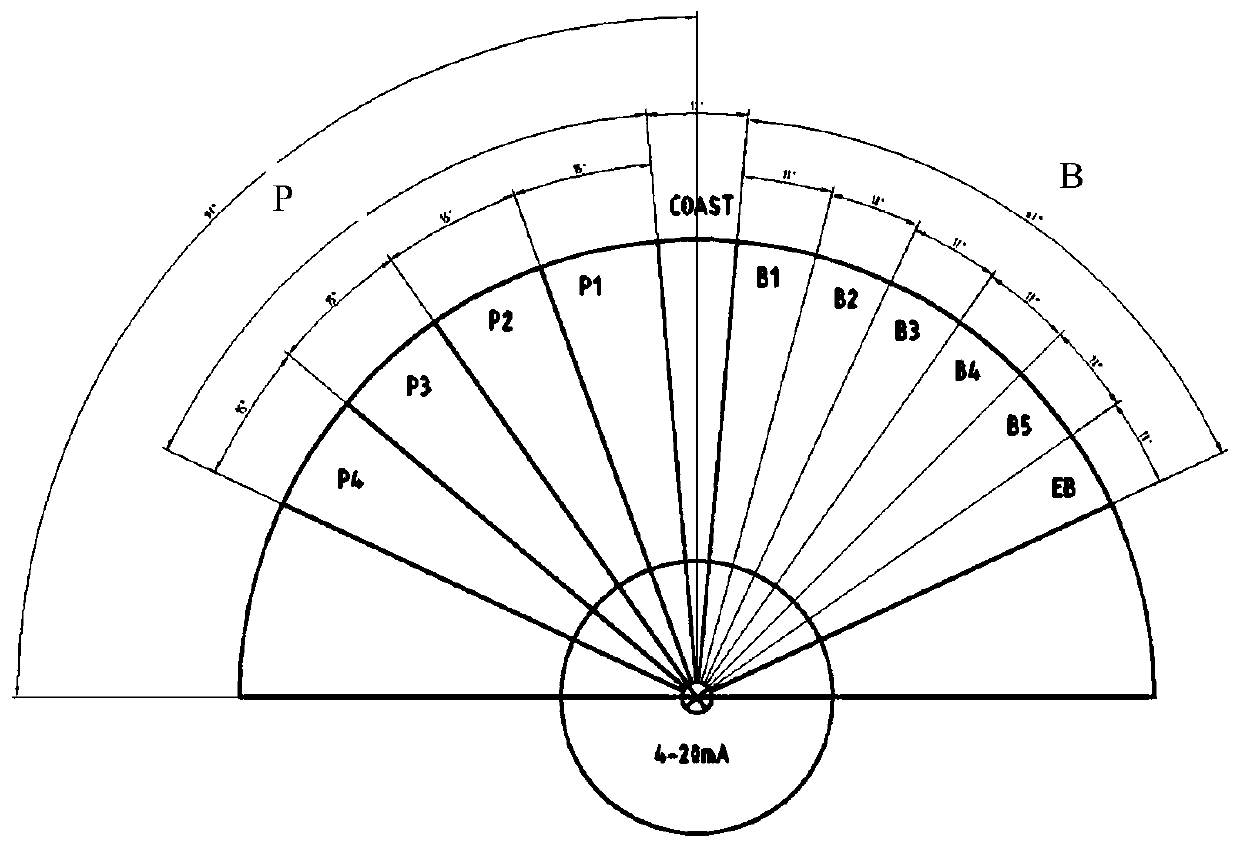

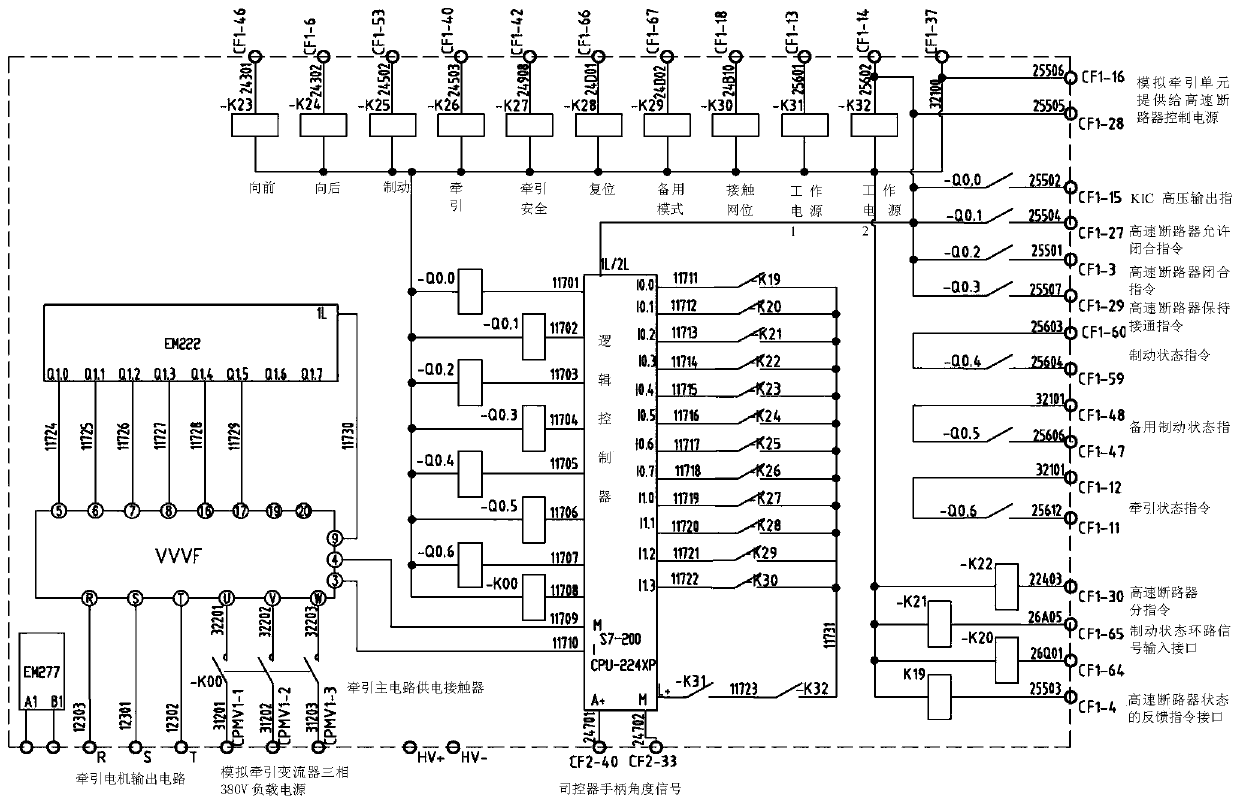

Urban railway passenger car traction control intelligent debugging training system and method

InactiveCN110942690AReflect technical contentLow costCosmonautic condition simulationsSimulatorsRing roadNetwork connection

The invention discloses an urban railway passenger car traction control intelligent debugging and training system . The system comprises two main control units and an execution unit; each main controlunit comprises a touch display, a central processing unit, a driver controller traction force instruction output circuit, a running direction and traction braking instruction control circuit, a high-speed circuit breaker control circuit, a traction safety loop circuit, an ATP zero-speed delay control circuit, a traction converter state instruction control circuit and a braking state monitoring loop circuit; the execution unit comprises three same switchboards and train lines; the logic connection and the network connection of the hardware reflect the main functions of an urban railway vehicletraction system, and the debugging method of the practical training device is compiled according to the debugging content of the urban railway vehicle, so trainees perform standardized operation according to the debugging method; the simulation degree is high, the training efficiency is high, and the cost is low. The simulation degree is high, the trainee can compile the debugging method of the practical training system according to the debugging content of the urban railway vehicle, and compared with real vehicle training, the system is simple, convenient and low in cost, and the problems occurring in real vehicle training are avoided.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

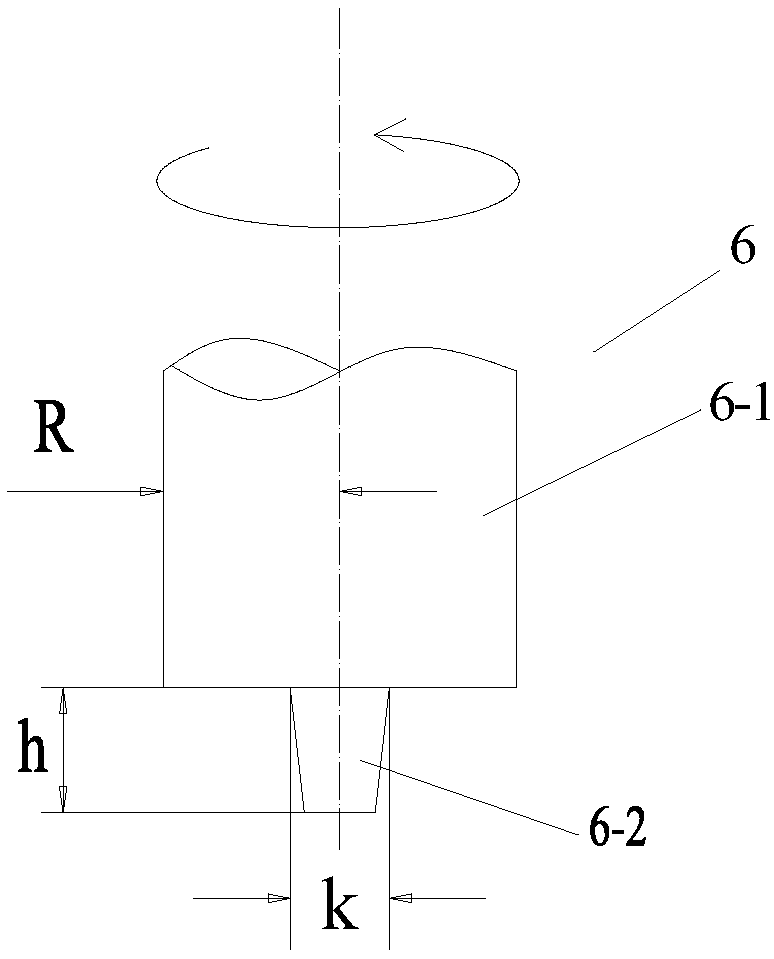

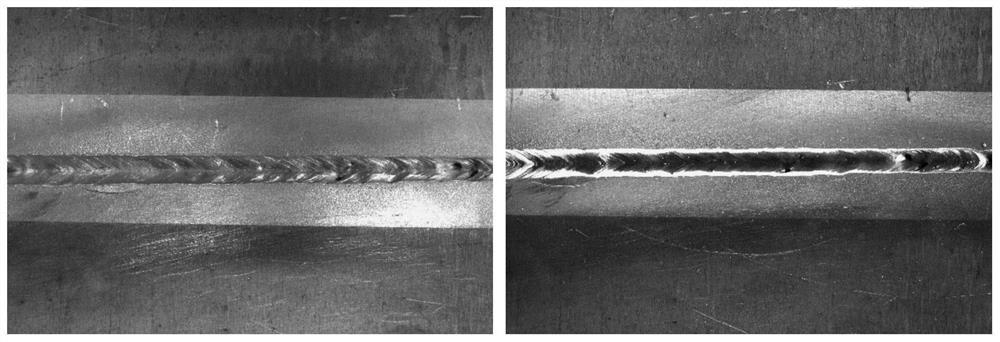

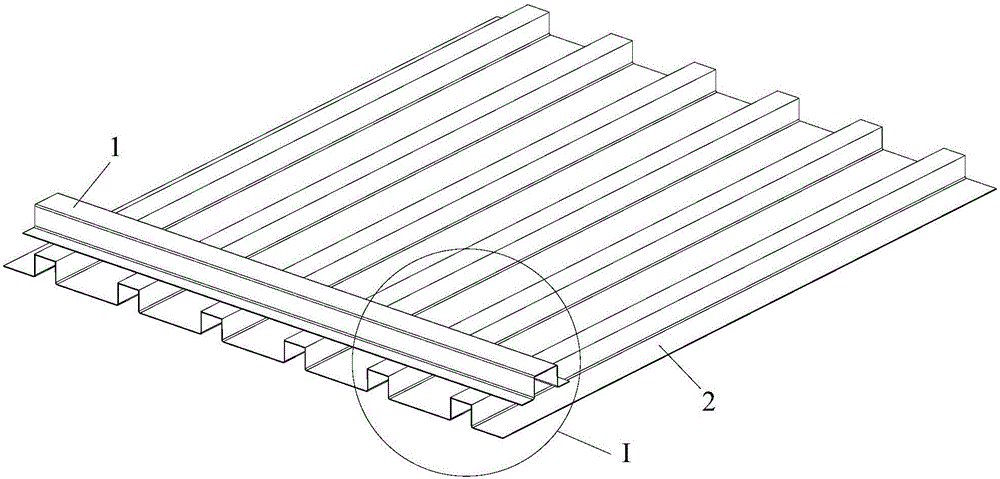

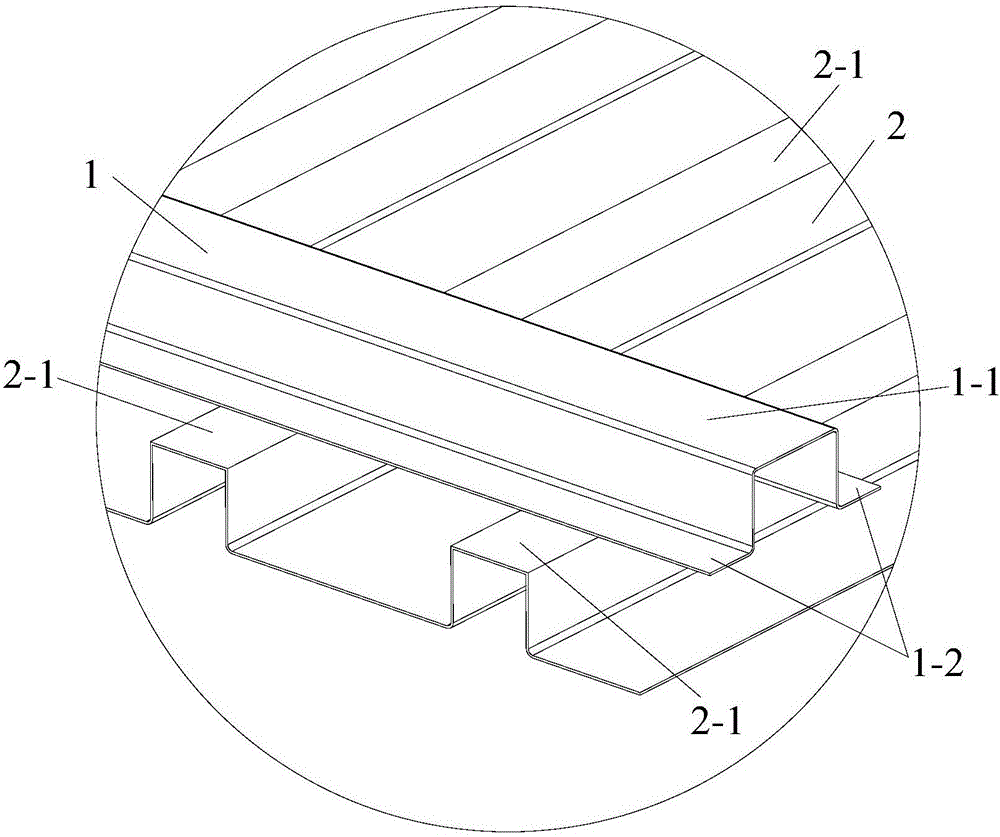

Stir friction welding method for hollow aluminum extruded section splicing arc plate

ActiveCN108723578AReduce incoming materialsLower requirementWorkpiece edge portionsNon-electric welding apparatusFriction weldingRailway passenger car

The invention discloses a stir friction welding method for a hollow aluminum extruded section splicing arc plate, and belongs to the field of welding method of a large arc roof plate component of an aluminum alloy car body of a railway passenger car. For stir friction welding of the aluminum alloy car body roof arc plate component of the railway passenger car, and a welding sequence of one-step reversed assembling and two-step forward assembling and a control method for weldment assembly interval values are proposed; a thickened protrusion is arranged on the position, adjacent to a weld seam,of the outer surface of the aluminum alloy hollow extruded section, the protrusion width and the diameter of the root of a stirring needle are maintained at a ratio of 95% to 105%, in order to ensurethe size of a post-weld workpiece, during the two-step forward assembling, when pre-fabrication reverse deformation friction stir welding is conducted, a thickened raised metal is filled in the gap generated at the weld seam of the outer surface of the pre-fabrication deformed curved section aluminum alloy hollow extruded section by the rotary extrusion of a stirring head, and the friction stir welding does not require additional raised metal grinding removal work; the method ensures the structural size requirement of aluminum alloy product components of the curved section hollow extruded section.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

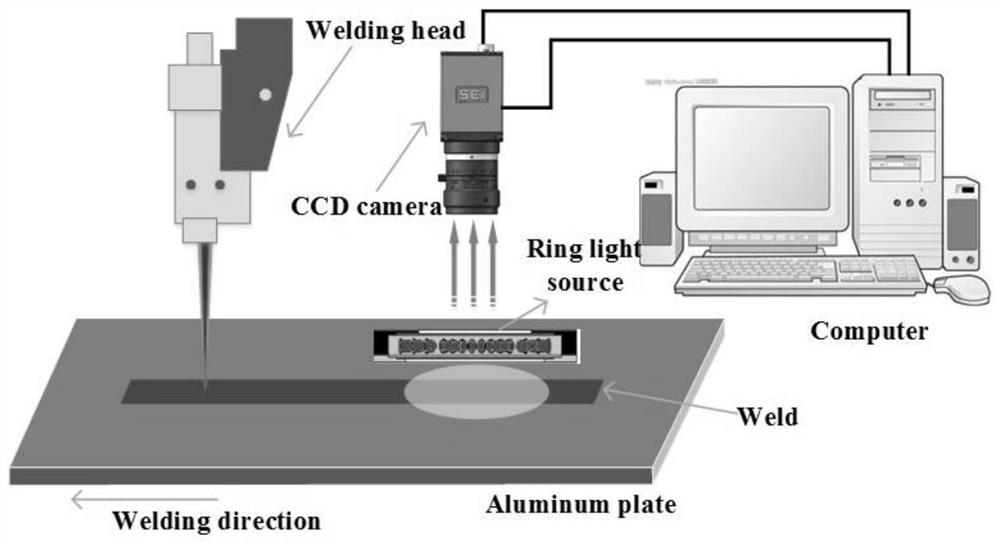

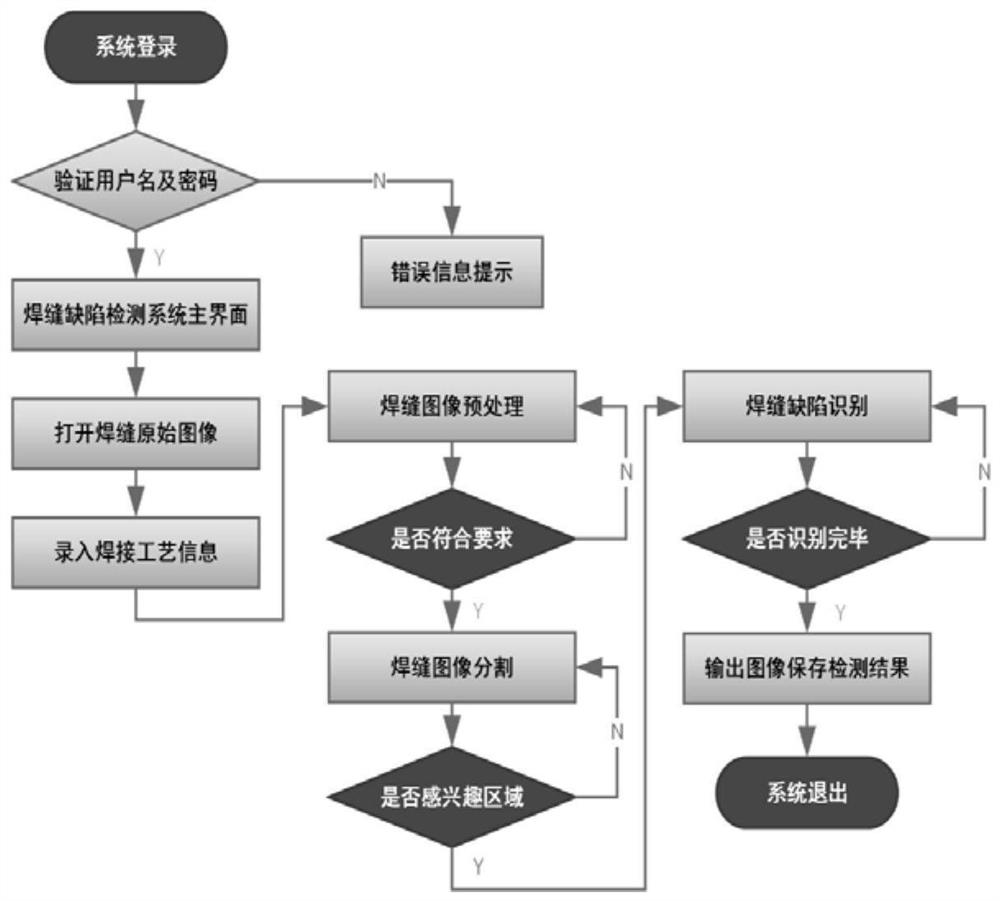

Weld joint surface defect detection method and system based on machine vision

PendingCN111982916AImprove detection efficiencyObvious advantages in reliabilityImage enhancementImage analysisAlgorithmWeld seam

The invention discloses a weld joint surface defect detection method based on machine vision, and manual detection is replaced. A CCD camera and a zero-degree auxiliary light source are arranged to achieve real-time collecting of weld joint images, the surface evenness change of a workpiece can be reflected through lighting, and collapse detection and recognition are facilitated. Meanwhile, a combined algorithm for weld joint surface defect enhancement, segmentation, extraction and recognition is provided, and classified detection of splashing and collapsing is achieved. Automatic qualification diagnosis is realized through the area and characteristics of a weld defect region, and morphological characteristics such as the number, area, perimeter and circularity of weld defects are stored.The detection mode has the characteristics of process visualization, practicability, operation safety and the like, and compared with a traditional visual detection mode, the detection mode can adaptto detection and evaluation of metal welding seams and glue welding seams of carbon steel, stainless steel, aluminum alloy and the like, such as product structures of large railway vehicles, intercityand urban motor train units, high-speed motor train units and the like.

Owner:NANJING ZHONGCHE PUZHEN URBAN RAIL VEHICLE CO LTD

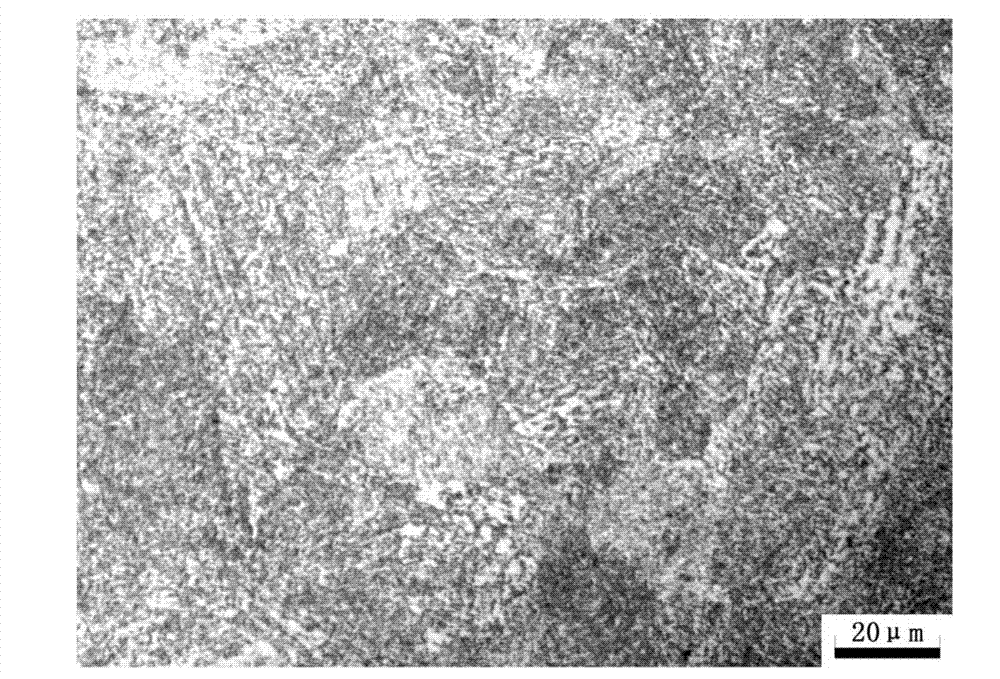

Method for smelting thin-wall ductile iron gearbox

InactiveCN101805868ASolve the problem of low low temperature impact toughnessRaise the ductile-brittle transition temperatureThree stageRailway passenger car

The invention relates to all smelting and casting processes of casting pieces for a ductile iron gearbox of a railway passenger car, in particular to a method for smelting a thin-wall ductile iron gearbox, which is suitable for the smelting and casting process of casting pieces for a bogie gearbox of the railway passenger car. The method for smelting a thin-wall ductile iron gearbox adopts the method of strictly controlling the smelting temperature and casting temperature to guarantee the uniform ingredients of ductile iron and uniform texture, has reasonably-designed alloy ingredients, adopts a three-stage inoculation mode for inoculation treatment, selects accurate spheroidization to guarantee the texture and property of the casting pieces and control the thin-wall ductile iron casting piece to have the spheroidization grade of the fifth grade, the nodularity of more than 90 percent, ferrite content of more than 90 percent, minus 40 DEG C low temperature impact work of more than or equal to 12J, thereby providing a basis for producing the gearbox batch with low temperature strength and good impact toughness. The invention solves the problems of low temperature toughness, poor graphite spheroidization effect and the like of the thin-wall ductile iron casting pieces.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

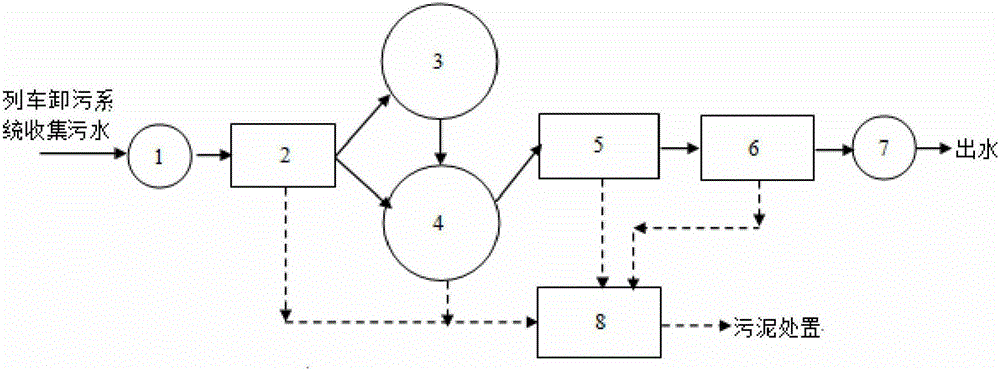

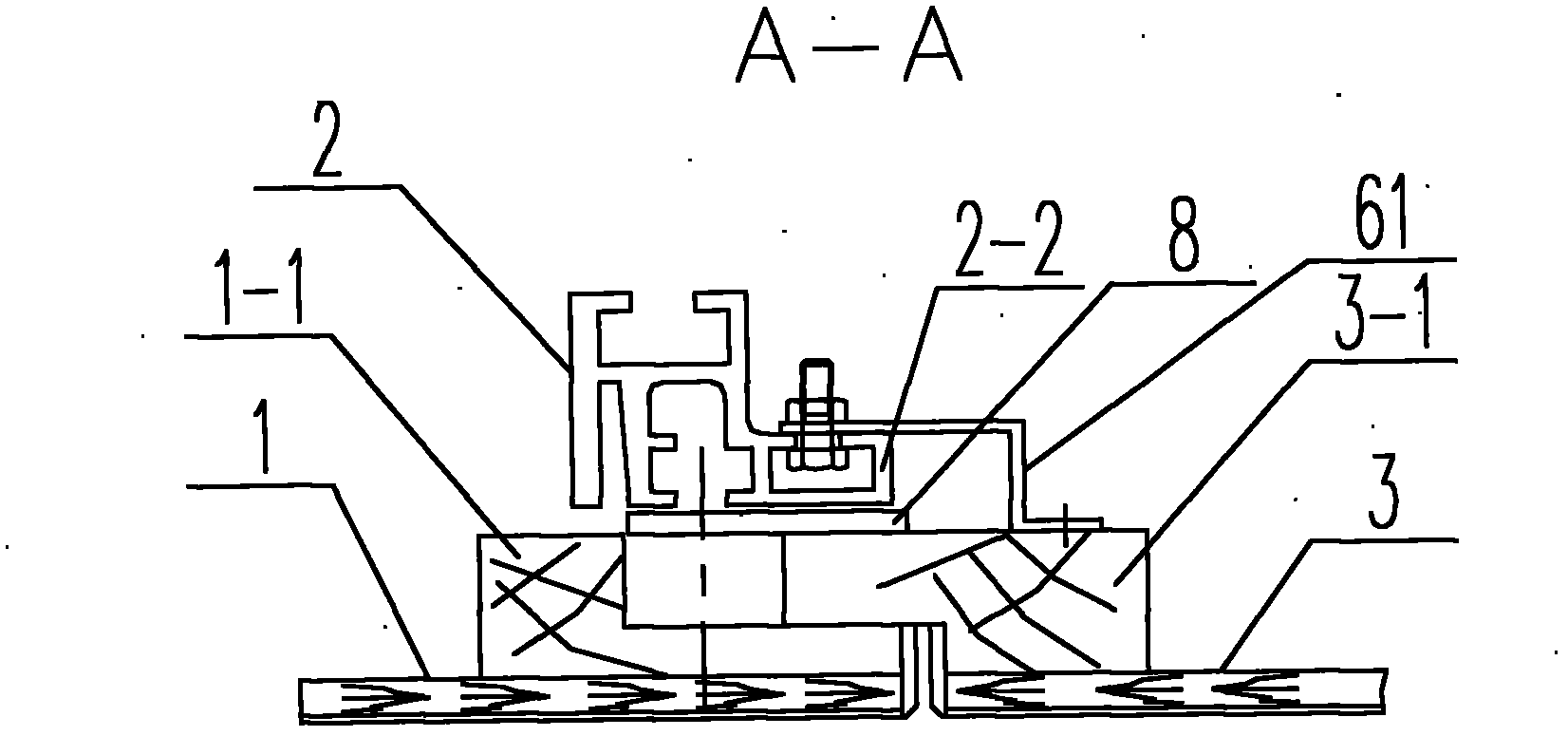

Wastewater centralized treatment system and method for toilet wastewater collectors of high-speed railway passenger cars

ActiveCN106587491AImprove biodegradabilityTreatment by combined electrochemical biological processesTreatment involving filtrationChlorine dioxideElectrolysis

The invention discloses a wastewater centralized treatment system and method for toilet wastewater collectors of high-speed railway passenger cars, and belongs to the technical field of wastewater treatment. A rotating drum grille is used for removing toilet paper and bulk manure in wastewater of the toilet wastewater collectors; a pretreatment regulation pool is arranged and bleaching powder is added for removing a part of ammonia nitrogen and suspended matters in wastewater, and the water quality and water quantity can be regulated; an internal circulation micro oxygen reactor is arranged for receiving 2 / 3 wastewater of the toilet wastewater collectors, 100 to 150-mesh micro electrolysis catalytic carrier particles are added, and shortcut nitrification can be realized through granular sludge; an internal circulation anaerobic reactor is used for removing a part of ammonia nitrogen and nitrate nitrogen; a double-circulation aerobic reactor is arranged for realizing simultaneous nitrification and nitrogen removal by denitrification of aerobic granular sludge; a special nitrogen removal aerated filter is arranged, and advanced treatment of wastewater is realized by using a micro electrolysis catalytic biological carrier; and then treated water is disinfected through ClO2 to achieve standardized discharge.

Owner:BEIJING JIAOTONG UNIV

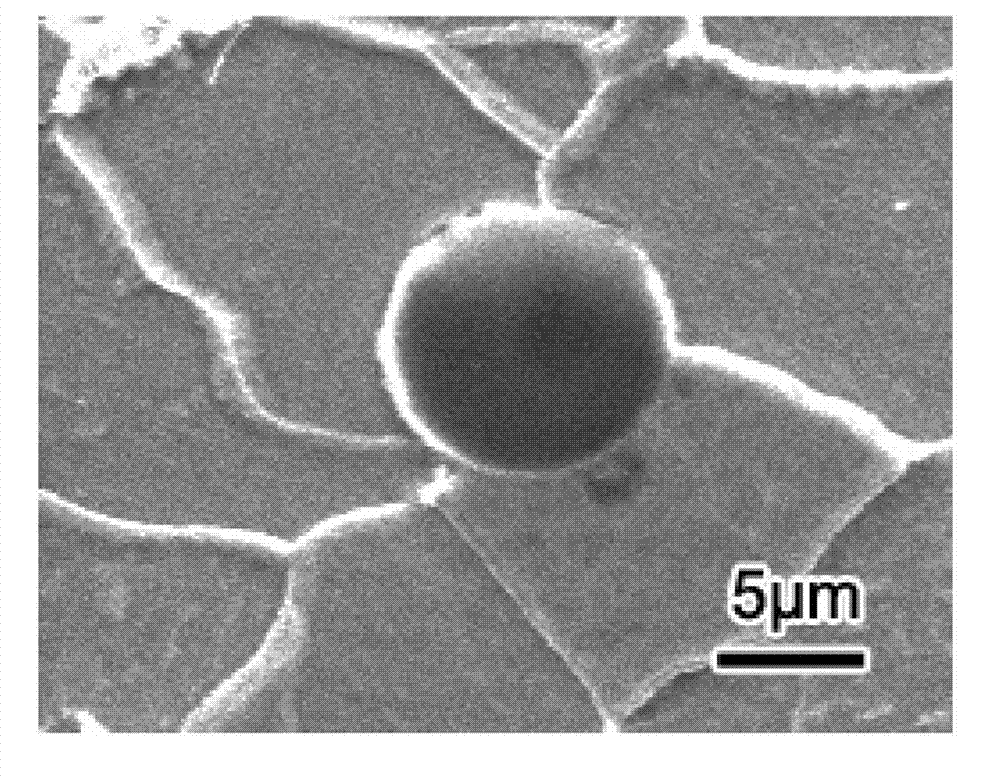

Technology for casting nodular cast iron gearbox for railway passenger car bogie

The invention relates to all casting processes and smelting processes for a nodular cast iron gearbox of a railway passenger car bogie, in particular discloses a method for casting the nodular cast iron gearbox of the railway passenger car bogie, which is suitable for the manufacturing process of the gearbox of the railway passenger car bogie. By adopting a spherical unplugging type pouring cup, the filling time is controlled, so that the liquid metal is filled steadily, and the casting defects of inclusion, air holes, and the like are effectively controlled. By adopting resin sand molding, azircon powder coating is brushed on the surface, so the surface quality of the castings is improved, and the surface machining allowance is reduced. By adopting low-temperature mold dismantling, the thermal stress of the castings is reduced, the casting deformation is reduced, the dimensional precision is improved, and the foundation for the mass production of the gearbox is laid. The method can solve the problems of the casting of the nodular cast iron pieces with a thin-wall complex structure, low temperature resistance of the gearbox, and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

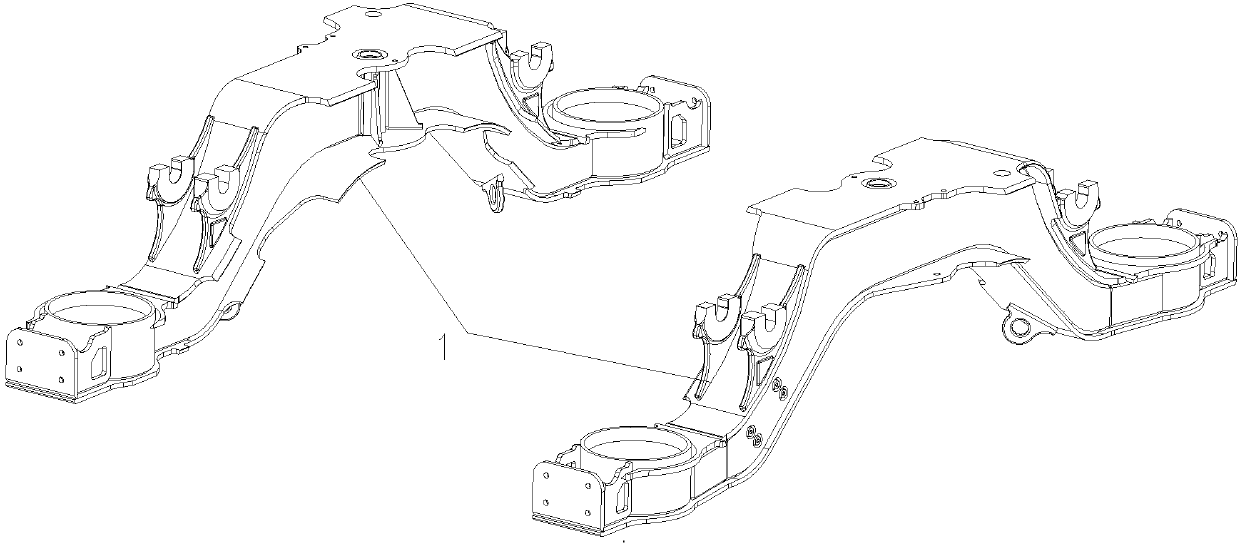

Assembling and welding process for box beam inserted and connected structure framework

ActiveCN107931878AImprove welding qualityReduce the difficulty of assemblyWelding/soldering/cutting articlesMetal working apparatusBogieRailway passenger car

The invention discloses an assembling and welding process for a box beam inserted and connected structure framework and relates to the technical field of railway passenger car bogie framework welding.According to the process, a cross beam is disassembled into two parts; one part is a non-closed box body, composed of an upper cover plate, outer side transverse vertical plates, inner side transverse vertical plates, longitudinal vertical plates and rib plates, namely a half-finished cross beam; and the other part is a cross beam lower cover plate. By means of the reasonable welding sequence andadjusting of the welding amount, it is guaranteed that the deformation amount of the half-finished cross beam after welding is stabilized in an ideal value range; then the half-finished cross beam isassembled with side beams and positioning welding is completed, the cross beam lower cover plate is assembled finally, remaining weld joints of the cross beam and weld joints at the connected positions of the cross beam and the side beams are subjected to overall welding, and finally assembling and welding of the box beam inserted and connected structure framework are completed. According to theassembling and welding process for the box beam inserted and connected structure framework, flexural deformation of the cross beam vertical plates can be controlled, the cross beam after welding is not needed to be subjected to machining, and the production quality and the production efficiency are improved.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

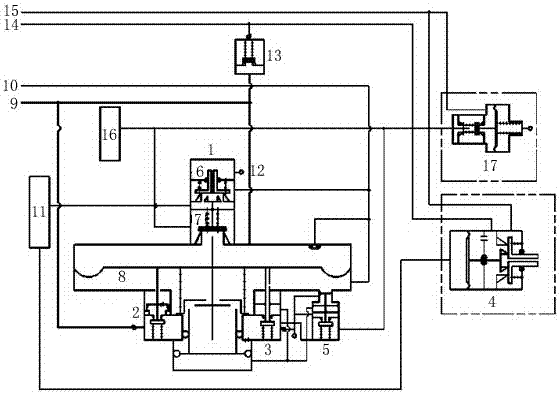

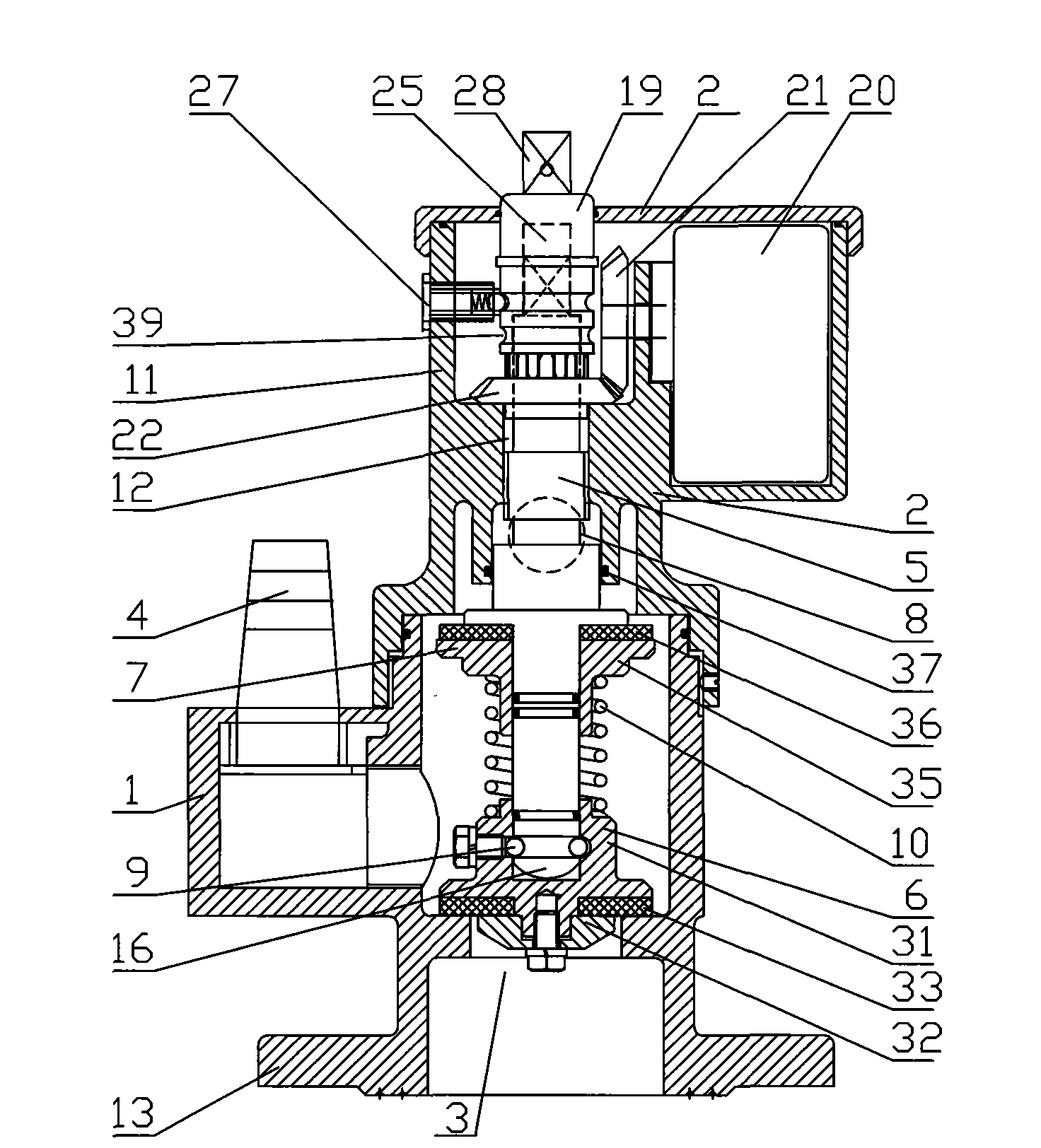

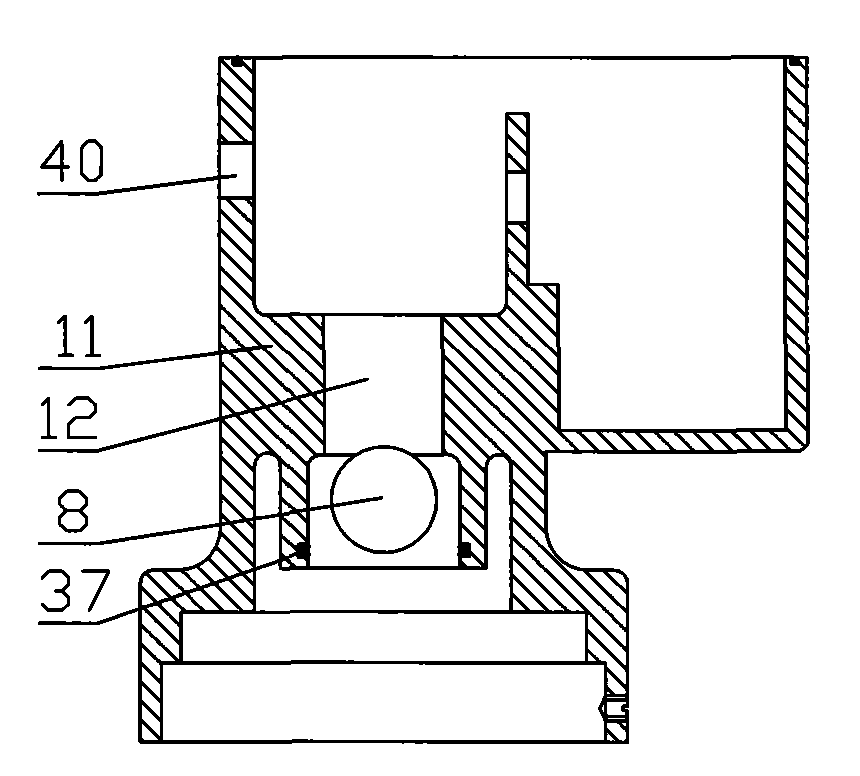

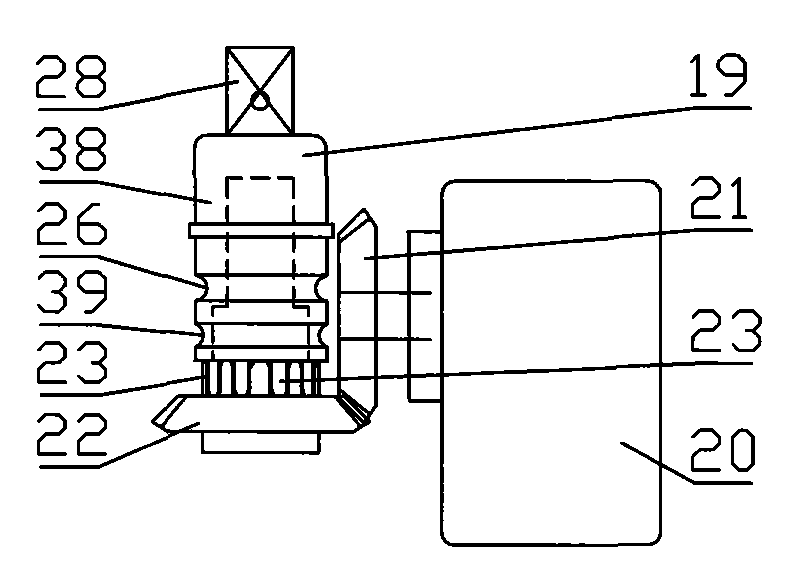

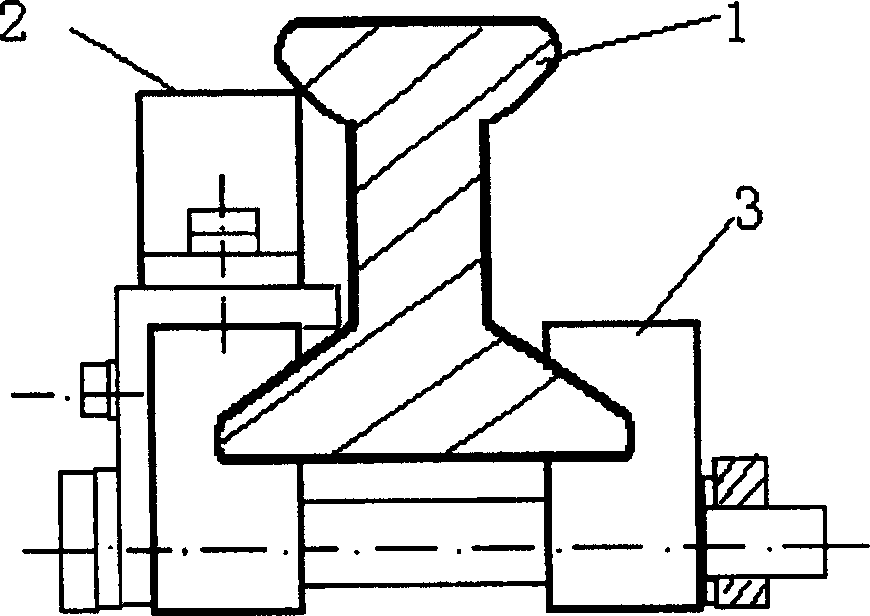

Air brake valve for passenger train

ActiveCN107097770ASimple structureGuaranteed uptimeApplication and release valvesRailway passenger carEngineering

The invention discloses an air brake valve for a passenger train. The brake valve comprises an acting portion, an operating air cylinder charging valve, a counterbalance valve, a balance valve and a local reduction shutoff valve. The acting portion comprises an air supply valve, a stabilizing portion and a main piston assembly. Actions of the brake valve are controlled through pressure differences caused by train pipe pressure variation so as to realize functions of charging, braking, pressure retaining, relieving and the like; the pressure of a braking cylinder is controlled by the pressure of a volume chamber, and two-pressure indirect control of the air brake valve of the passenger train is realized; by replacement of a traditional slide valve structure with a diaphragm plate and check valve plunger structure, structural simplicity and stability and reliability in operation are realized.

Owner:CHINA RAILWAYS CORPORATION +2

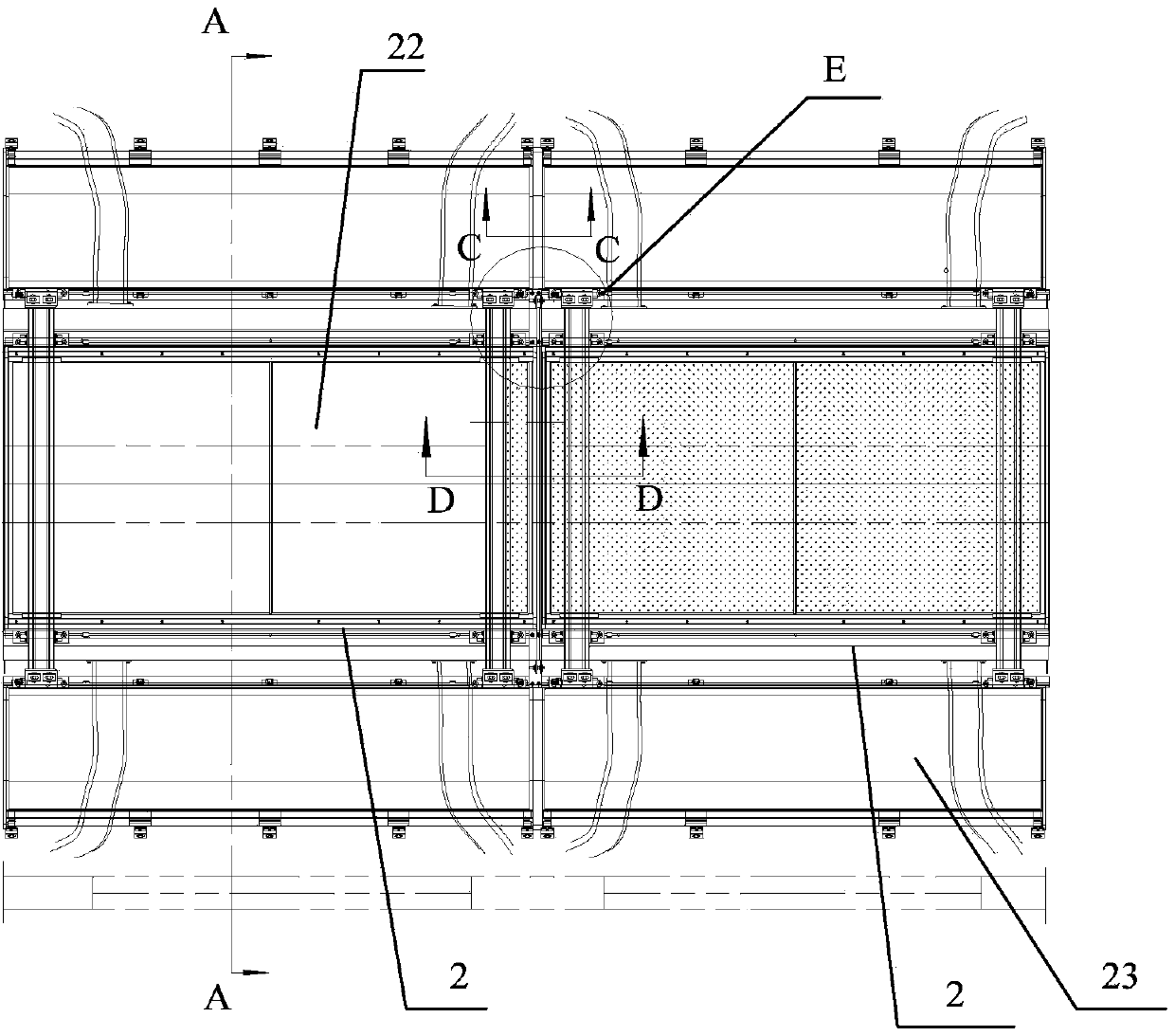

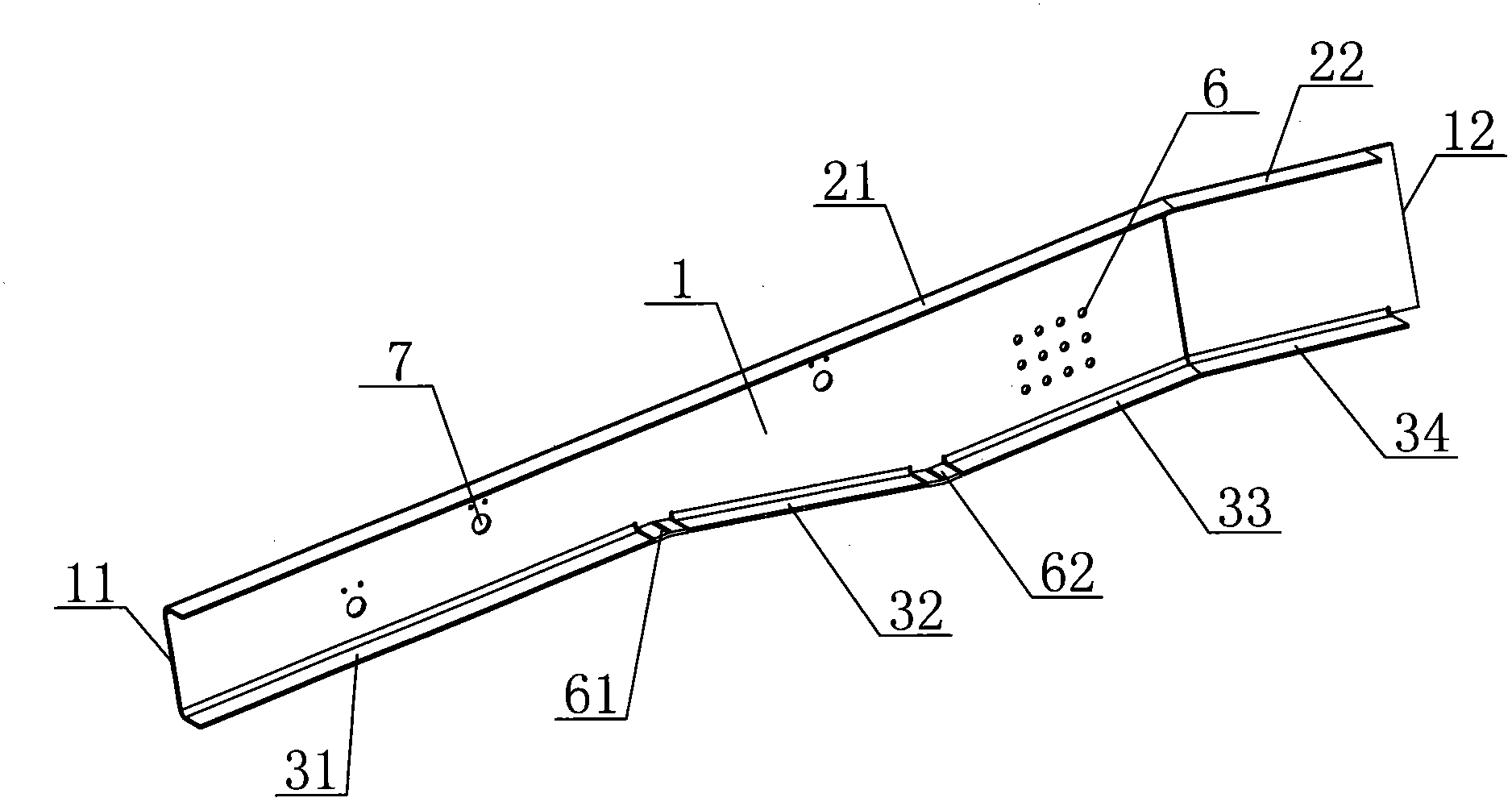

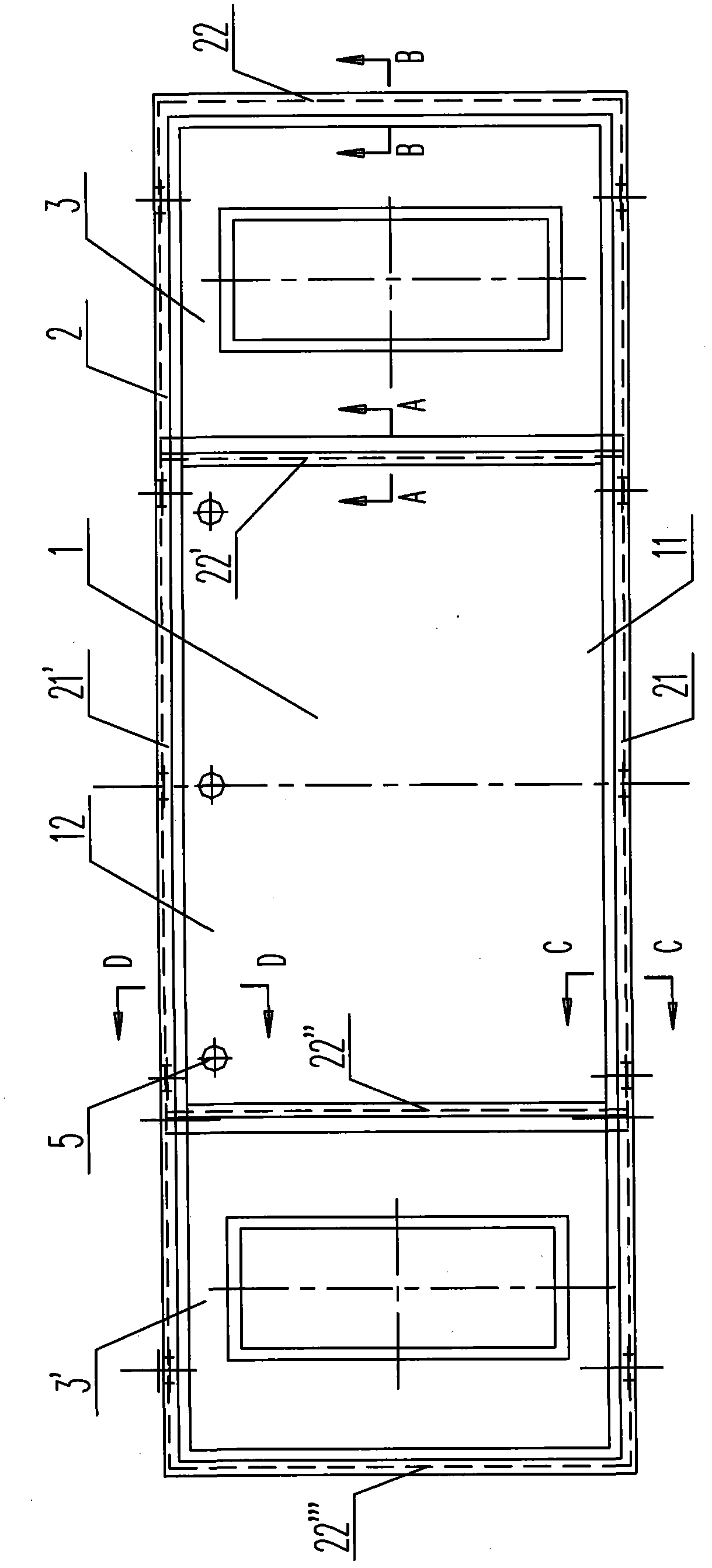

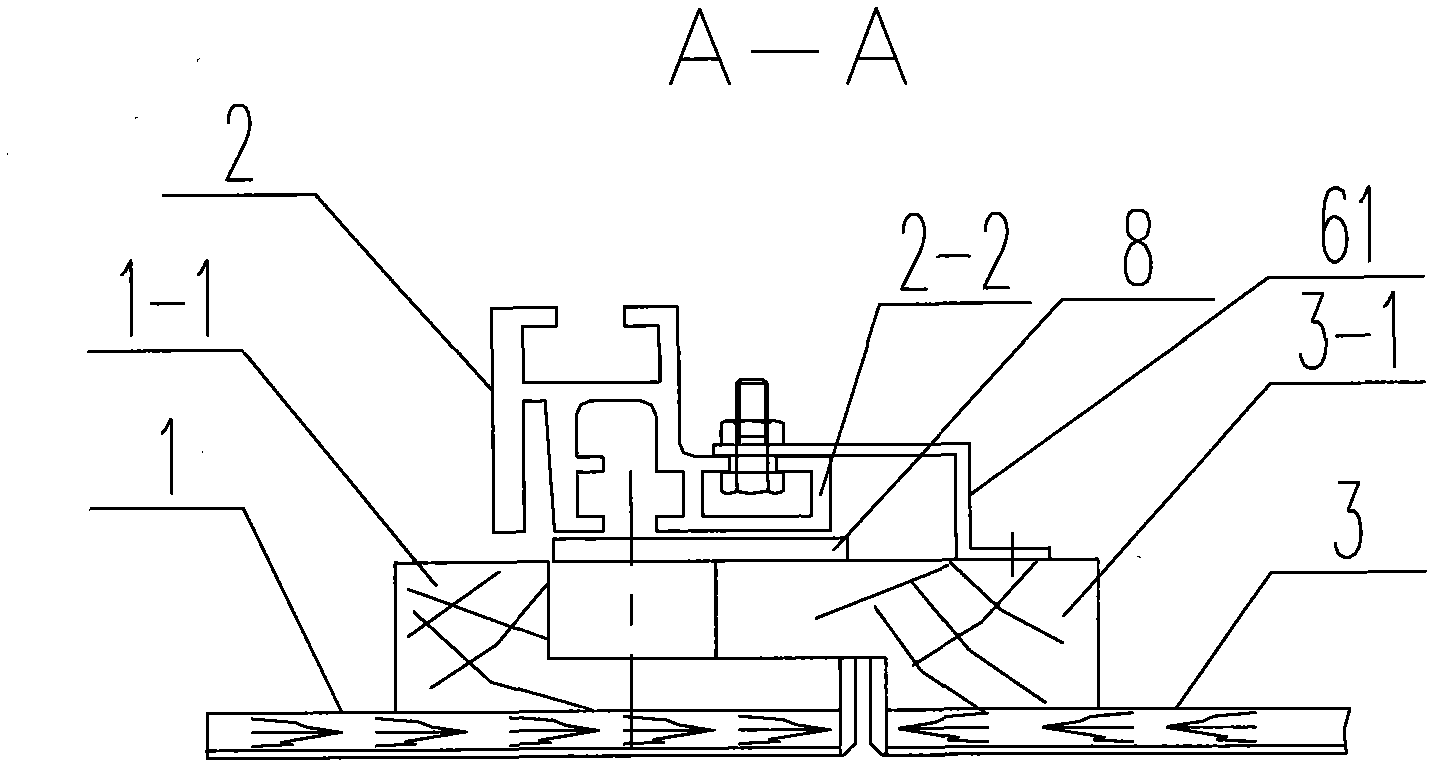

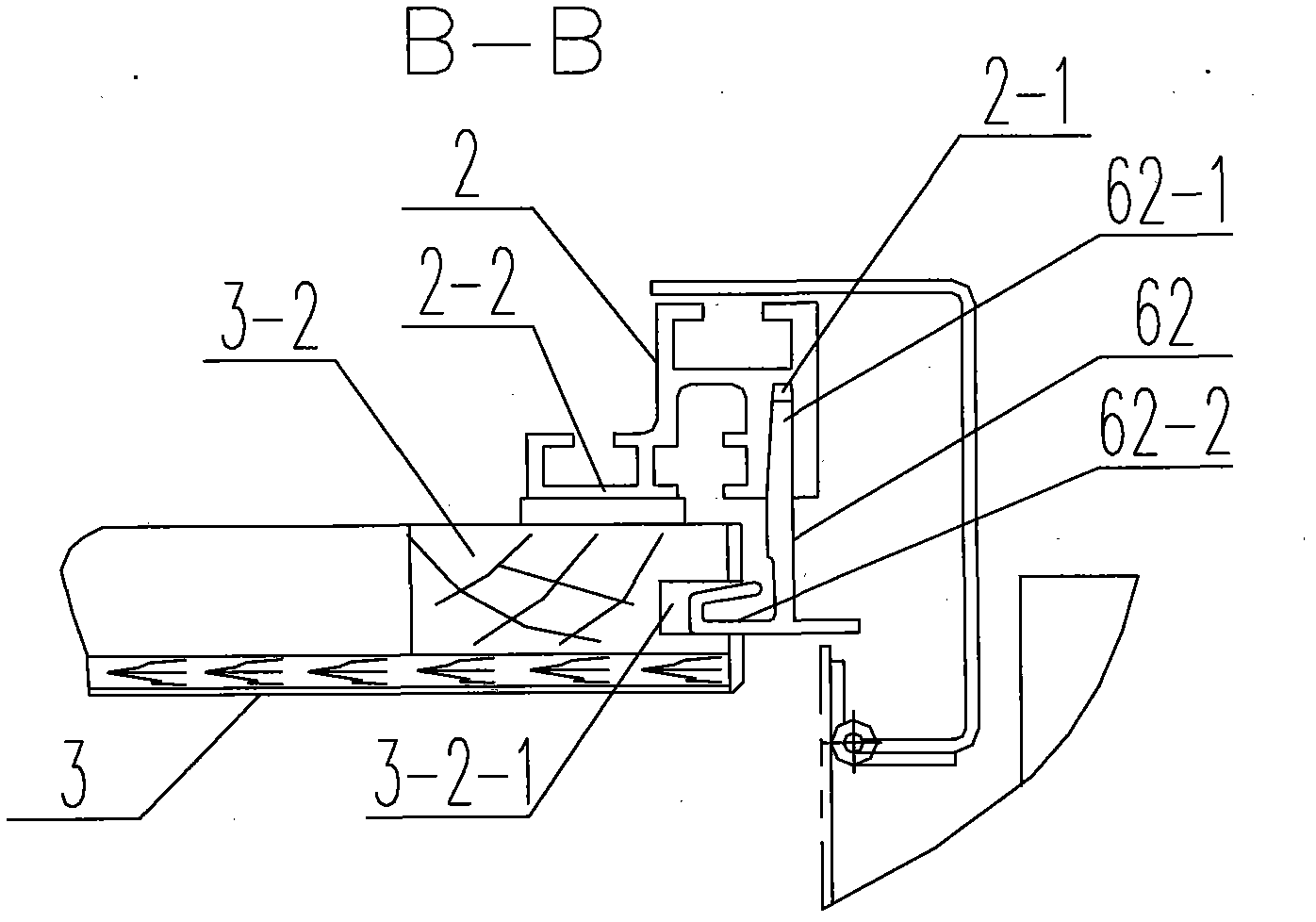

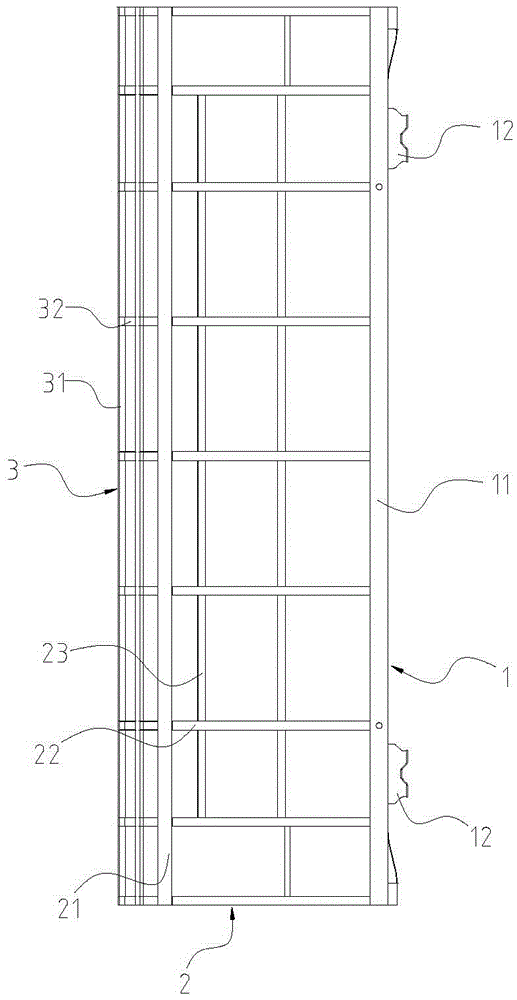

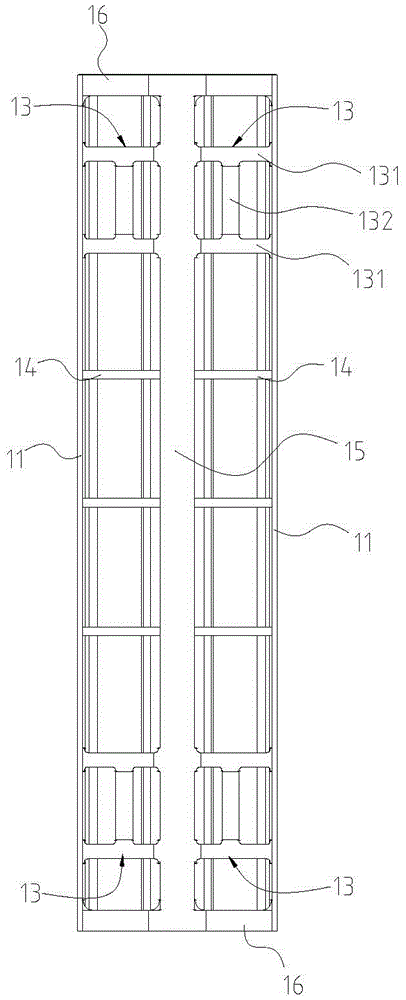

Modular flat top plate of railway passenger car

The invention discloses a modular flat top plate of a railway passenger car, comprising a top plate framework, an intermediate top plate and side top plates, wherein the top plate framework comprises two longitudinal beams and four cross beams and is fixedly connected with a steel structure of a car body; longitudinal inner and outer ends of the side top plates are respectively connected with the cross beams of the top plate framework through a first connecting piece and a second connecting piece; the first transverse end of the intermediate top plate is fixed with a first longitudinal beam of the top plate framework through a third connecting piece; and the second transverse end of the intermediate top plate is fixed with a second longitudinal beam of the top plate framework through a compressing lock. The modular flat top plate can be assembled by the following steps of: firstly, fixing the top plate framework on the steel structure of the car body by attachment lugs; secondly, mounting side top plates at two ends and fixing the side top plates on the top plate framework by the connecting pieces; and finally, mounting the intermediate top plate and fixing the intermediate top plate on the top plate framework through the connecting pieces and the compressing lock. By adopting the modular flat plate structure, each car can be assembled by modules in about half an hour, thus the production efficiency is remarkably improved; meanwhile, the modular flat top plate has higher mounting quality and mounting precision and is convenient for maintenance and overhaul.

Owner:CRRC NANJING PUZHEN CO LTD

Manual and automatic integrated passenger train water-feeding valve

InactiveCN101629633ANo corrosionNo smellOperating means/releasing devices for valvesLift valveRailway passenger carEngineering

The invention relates to a manual and automatic integrated passenger train water-feeding valve, comprising a valve body, a valve cover, a water inlet and a water outlet. The valve cover is installed on the valve body and covers the valve body in a sealing mode, the water inlet is arranged at the bottom of the valve body, and the water outlet is arranged at the sidewall of the valve body. The water-feeding valve further comprises a water intake valve head, a water return opening, a water return valve head, a valve rod, a limit steel ball and a tension opening spring, wherein the water intake valve head is arranged in the valve body and located at the upper part of the water inlet, and the water return opening is arranged at any side of the valve cover; and the valve rod is arranged in the valve body and is a whole rod. The water-feeding valve has the advantages of high strength, good performance, attractive appearance, light weight, high level, simple operation, non-leakage while feeding water, synchronous water-feeding operation for two carriages, largely simplified water-feeding operation, and shorter water-feeding time.

Owner:SCI INST HOHHOT ADMINISTRATION OF RAILWAY

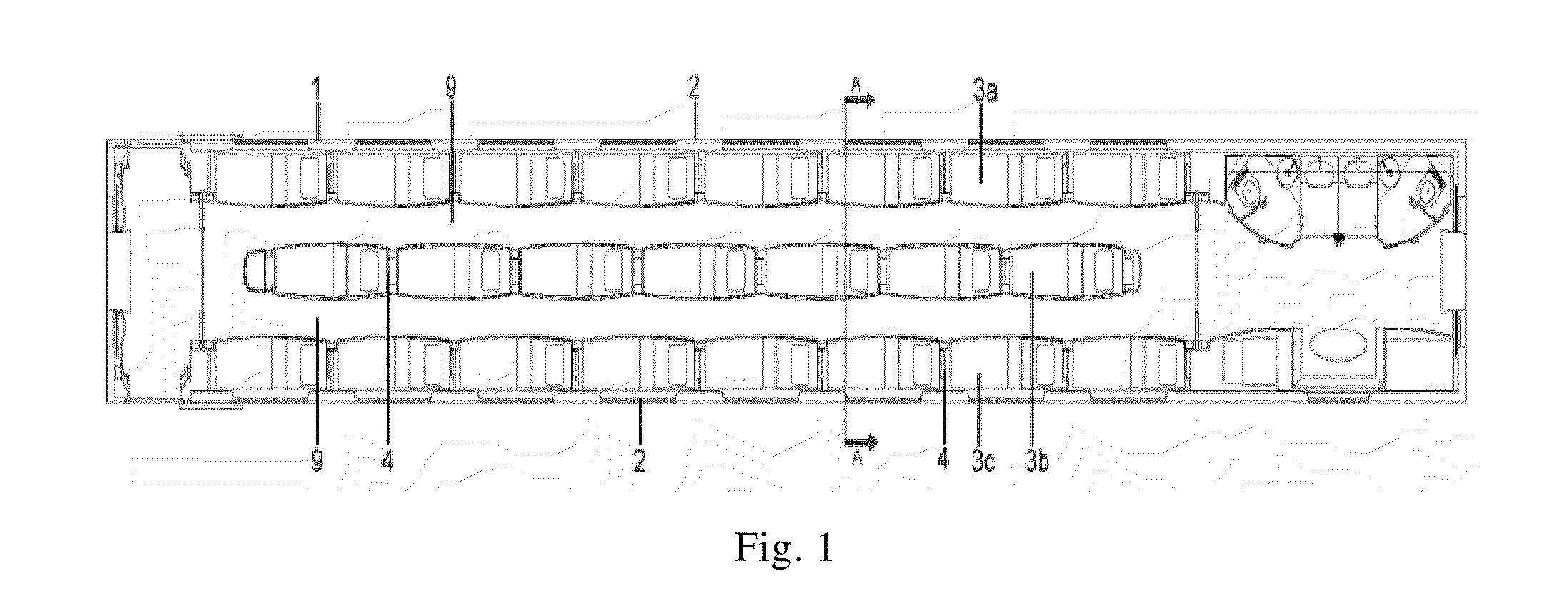

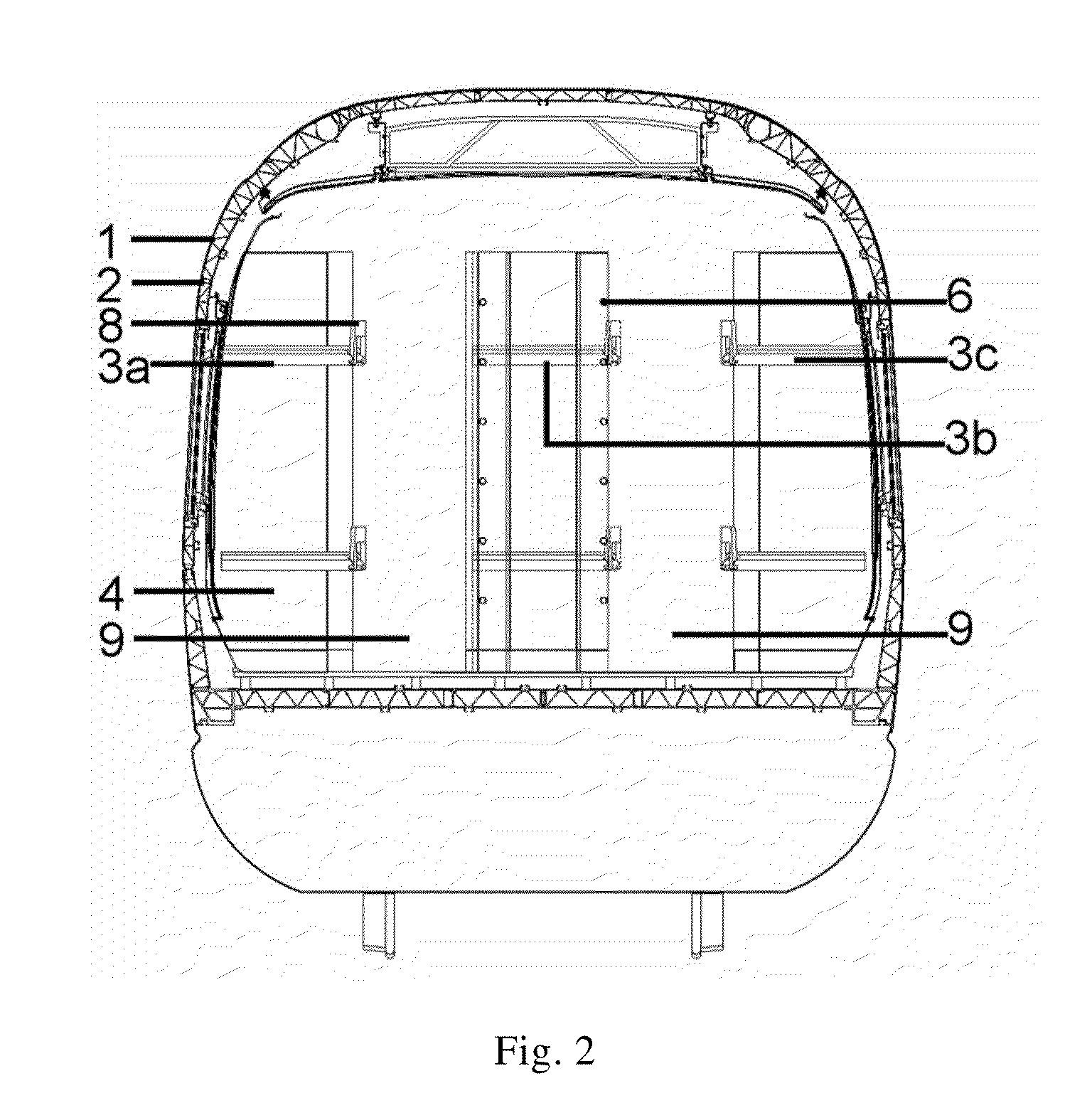

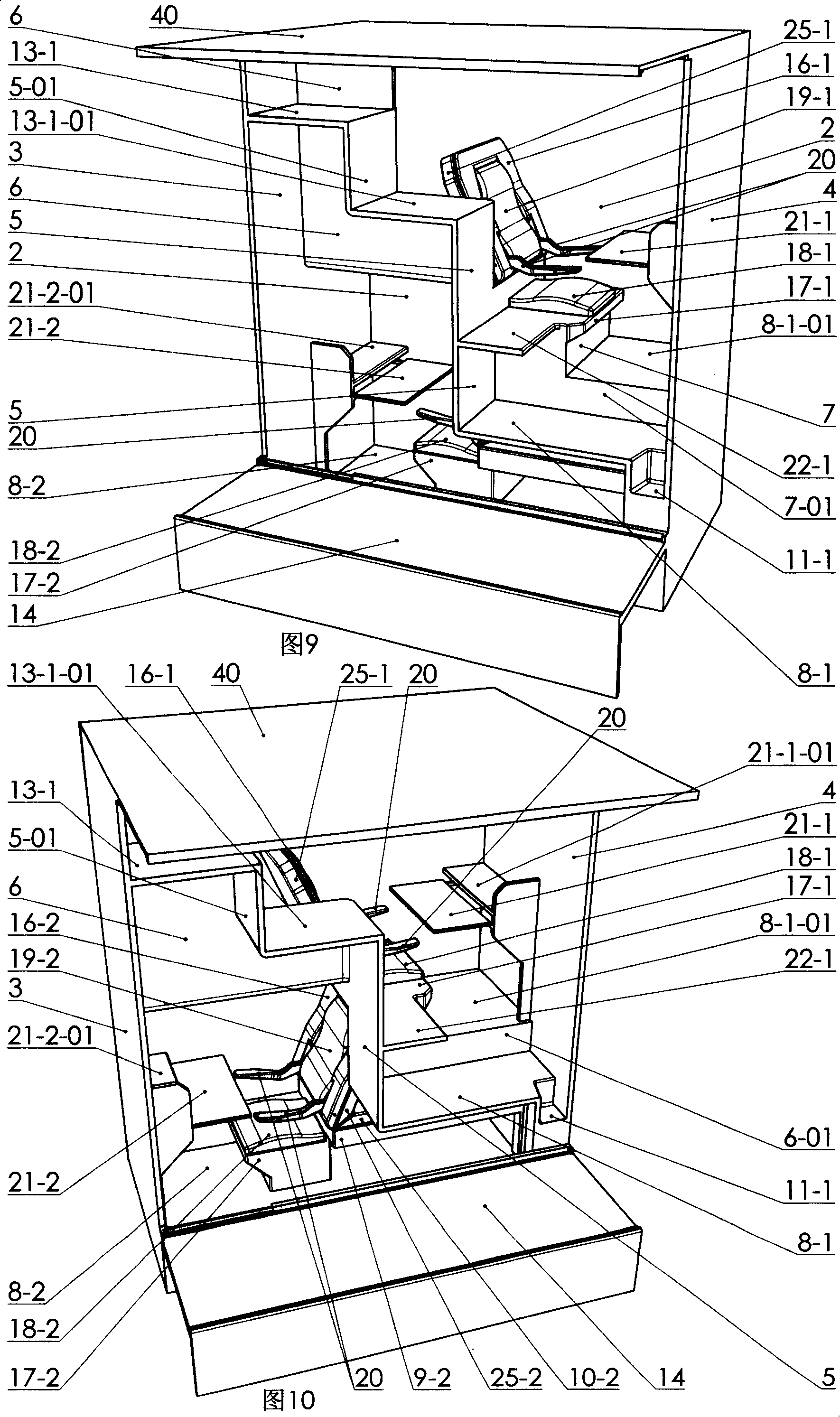

Sleeper compartment of a railroad passenger car

ActiveUS20110253005A1Reduce dynamic loadImprove practicalityVehicle arrangementsSleeping accommodationRailway passenger carEngineering

The present invention relates to the technical field of railroad passenger car, and more particularly relates to a sleeper compartment of a railroad passenger car. The sleeper compartment may be an open type or a private booth type, comprising: sidewalls, partition walls, and two columns of longitudinally arranged sleepers that are parallel with each other; each column of the longitudinally arranged sleepers is formed by no less than two sleepers that are joined together, the sleepers comprise an upper-sleeper layer and a lower-sleeper layer; one partition wall is provided between adjacent sleepers; the length direction of the longitudinally arranged sleepers is consistent with the length direction of the railroad passenger car; the longitudinally arranged sleepers at two sides are fixed to the sidewalls respectively, and a corridor is provided between two adjacent columns of longitudinally arranged sleepers. The weight of the sleeper compartment of a railroad passenger car in this structure is evenly distributed, and passengers have better comfort when traveling.

Owner:CRRC TANGSHAN CO LTD

Process for manufacturing integral chassis towing beam for railway passenger vehicle

ActiveCN102059513AReduce stressImprove quality and efficiencyRailway passenger carWelding deformation

The invention relates to a process for manufacturing an integral chassis towing beam for a railway passenger vehicle, comprising the following steps: preprocessing a steel plate by shot blasting; cutting and blanking, wherein each small blanked part comprises a mainboard, a first upper wing surface, a second upper wing surface, a first lower wing surface, a second lower wing surface, a third lower wing surface and a fourth lower wing surface, wherein the first upper wing surface and the second upper wing surface are distributed along the upper end of the main board, and the first lower wing surface, the second lower wing surface, the third lower wing surface and the fourth lower wing surface are distributed along the lower end of the main board; leveling the blanked parts; bending the blanked parts in sequence by steps, wherein the upper wing surfaces and the lower wing surfaces are bent towards the outside of the mainboard to be perpendicular to the mainboard; welding complementary plates between the first lower wing surface and the second lower wing surface and between the third lower wing surface and the fourth lower wing surface, and welding the joint of the first upper wing surface and the second upper wing surface and the joint of the third lower wing surface and the fourth lower wing surface; and performing ultrasonic flaw detection on welding joints, and welding the hollow welded joints. The welded joint is shortened, thus the welding deformation is reduced and less special welding tools and clamping tools are used; the whole part is integrally blanked by adopting a numerically controlled cuter, thus the pitch of holes is guaranteed; and the working efficiency is improved to a great extent, and the cost is reduced.

Owner:CRRC NANJING PUZHEN CO LTD

Auxiliary pressing tool for eliminating laser stitch welding gaps generate between side wall stand column and corrugated plate

ActiveCN106271128AEfficient and fast hot melt weldingNeat appearanceLaser beam welding apparatusRailway passenger carScrew thread

The invention discloses an auxiliary pressing tool for eliminating laser stitch welding gaps generate between a side wall stand column and a corrugated plate and belongs to the field of gap auxiliary pressing devices used in the laser welding process of a side wall stand column and a corrugated plate of a railway vehicle. The tool comprises a gate type slit clamping plate mechanism, multiple stud pressers and a support platform. The slit clamping plate mechanism comprises double slit clamping plates, a rotating shaft support column, a locking support column and multiple lead screw nuts. Each stud presser comprises a pressing block, a lead screw end protection sleeve and a lead screw threaded rod. By means of the auxiliary pressing tool, all the flat plate flanging weld joint gaps at the two sides of the side wall stand column can be controlled to be smaller than 1mm; the weld joint gaps are uniform, orderly in appearance and attractive in appearance; and the high standard requirements of modern railway passenger cars on the welding process of the side wall stand column are met completely.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

Method for installing modular flat top plate of railway passenger car

ActiveCN102060029AAchieve modularityCompact structureRailway roofsRailway passenger carComputer engineering

The invention provides a method for installing a modular flat top plate of a railway passenger car. The method is characterized by firstly fixing a top plate framework on a steel structure of a car body; then installing side top plates at the two ends and fixing the side top plates on the top plate framework with connecting pieces; and finally installing a middle top plate and fixing the middle top plate on the top plate framework with the connecting pieces and compaction locks. The traditional flat top plate structures are assembled in a scattered manner, the scattered frameworks and linings are firstly installed and then the top plate is installed, thus needing abundant fasteners. Under the condition of the same constructors, the constructors spend 2 to 3 hours on assembling the flat top plate of each car in a scattered manner, but the constructors only spend about half an hour on modularly assembling the flat top plate of each car; therefore, the method has the following beneficial effects: the production efficiency is obviously improved; meanwhile, the installation quality and precision are higher; and the flat top plate is convenient to maintain and overhaul.

Owner:CRRC NANJING PUZHEN CO LTD

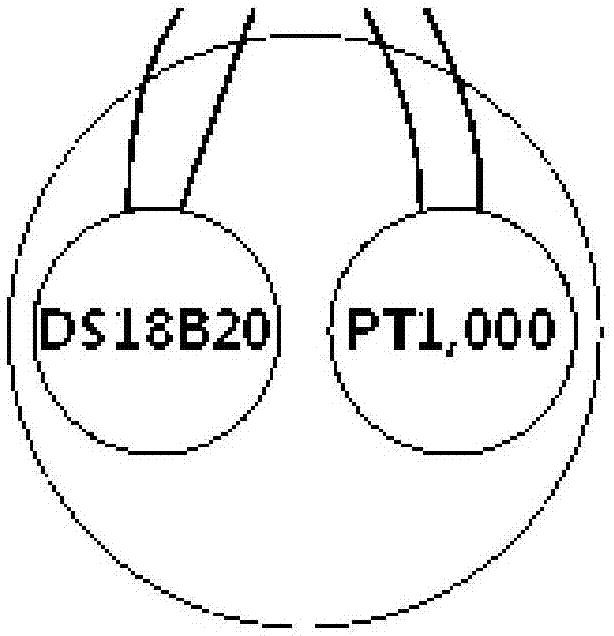

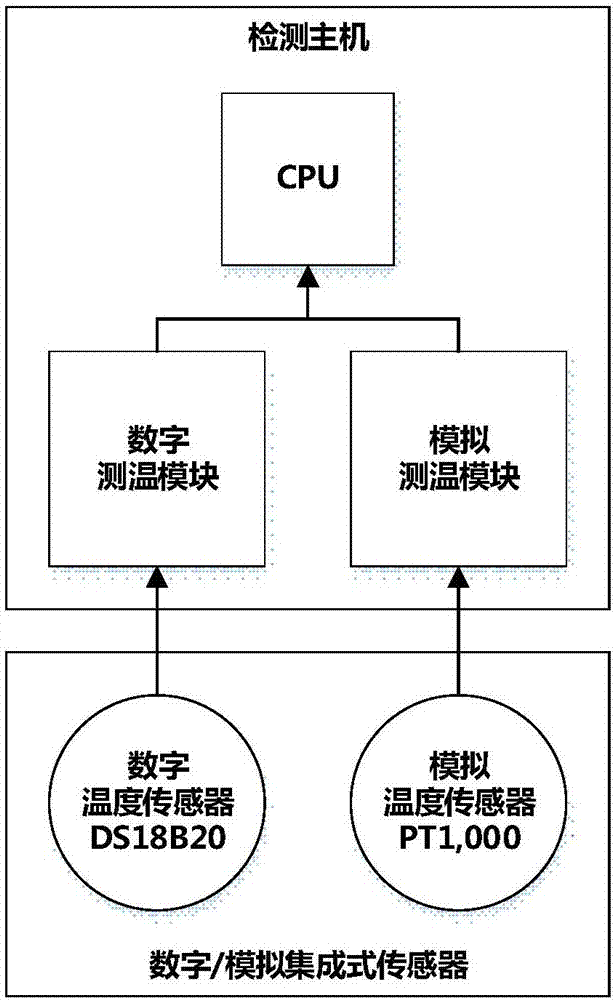

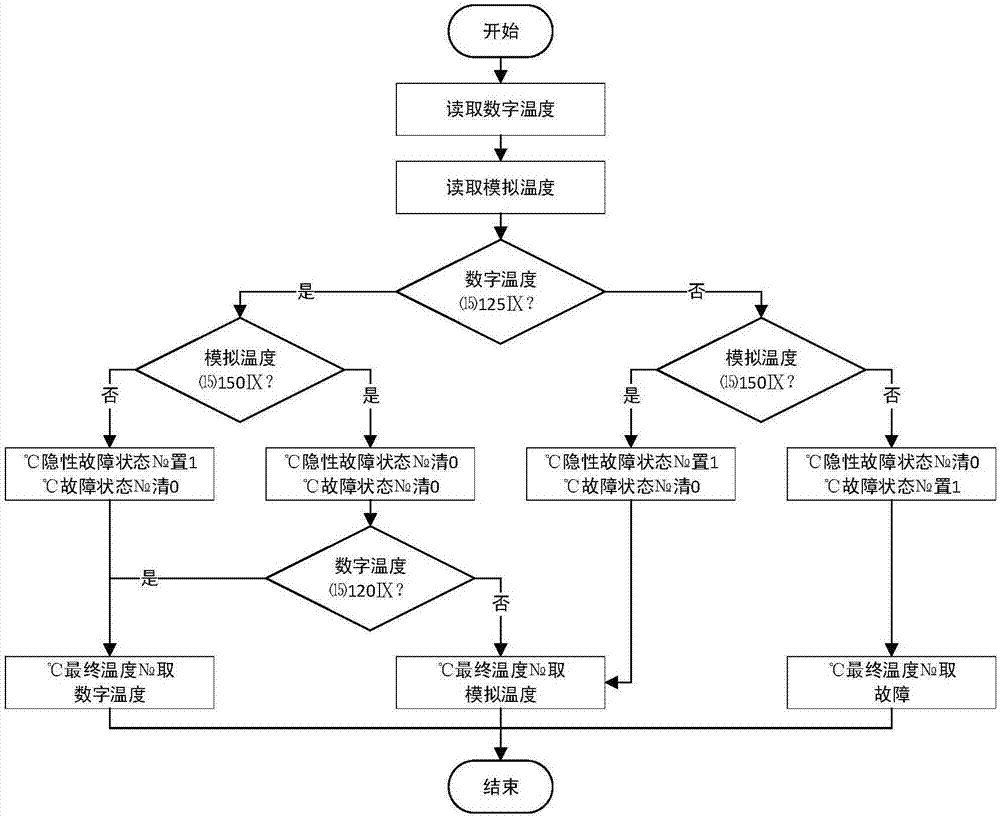

Railway passenger car bearing temperature detection method and digital/analog integrated temperature sensor

ActiveCN107478350AWill not affect normal workNo impact on normal operationThermometer detailsThermometer with A/D convertersRailway passenger carTwo temperature

The invention relates to a railway passenger car bearing temperature detecting method and a digital / analog integrated temperature sensor. The inner part of the sensor probe integrates digital and analog temperature measuring chips, and the two temperature measuring chips detect the temperature of the axle box at the same time and transmit the temperature signals to a detection host through transmission lines; and the detection host receives the two temperature signals sequentially and makes independent judgment on the two signals. Then according to the temperature selection conditions, the two temperatures are selected to finally decide which one to display and analyze. The use of the method for axle temperature detection can achieve more reliable and higher beneficial effects than a single sensor used detection method.

Owner:CRRC NANJING PUZHEN CO LTD

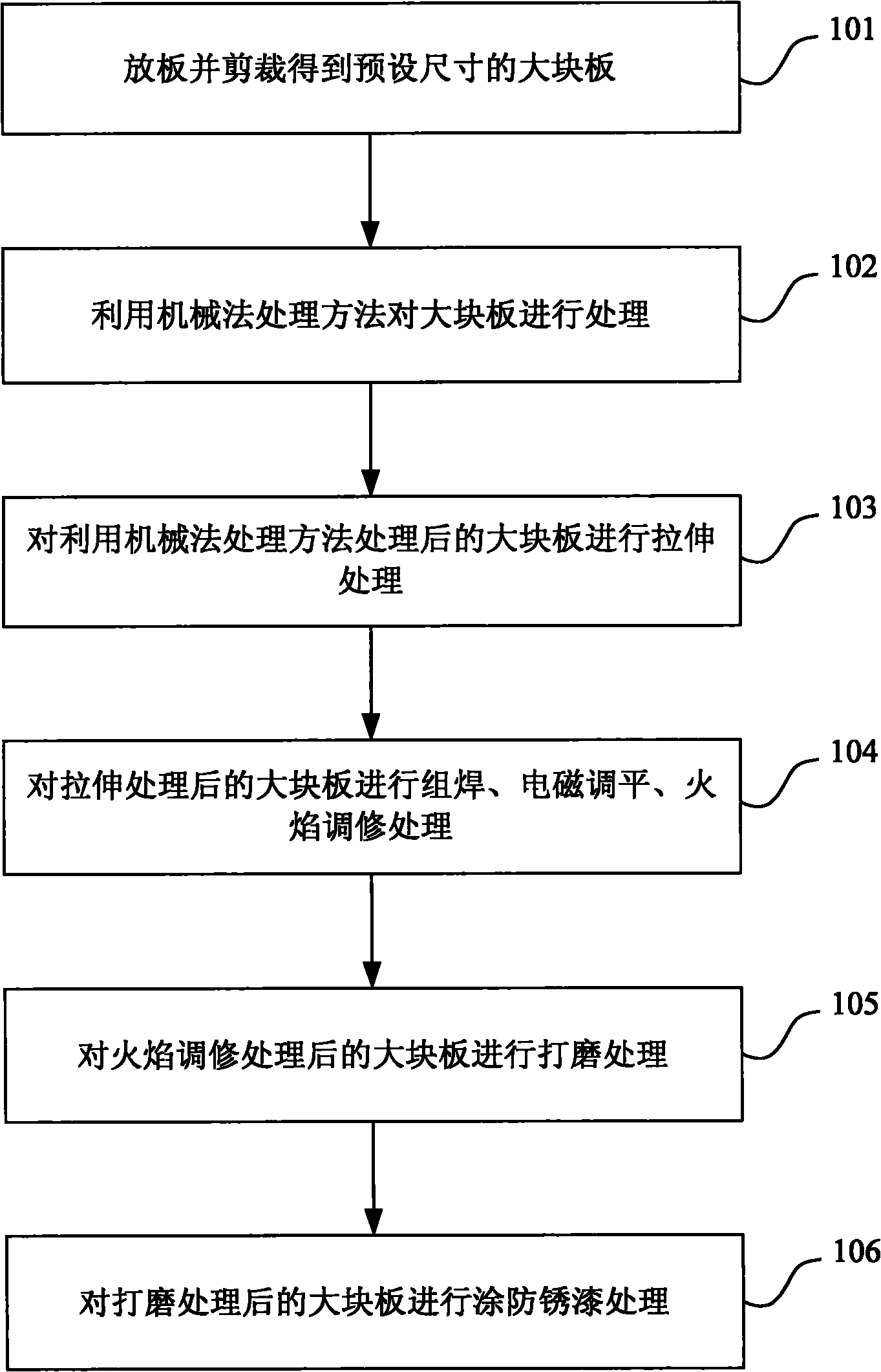

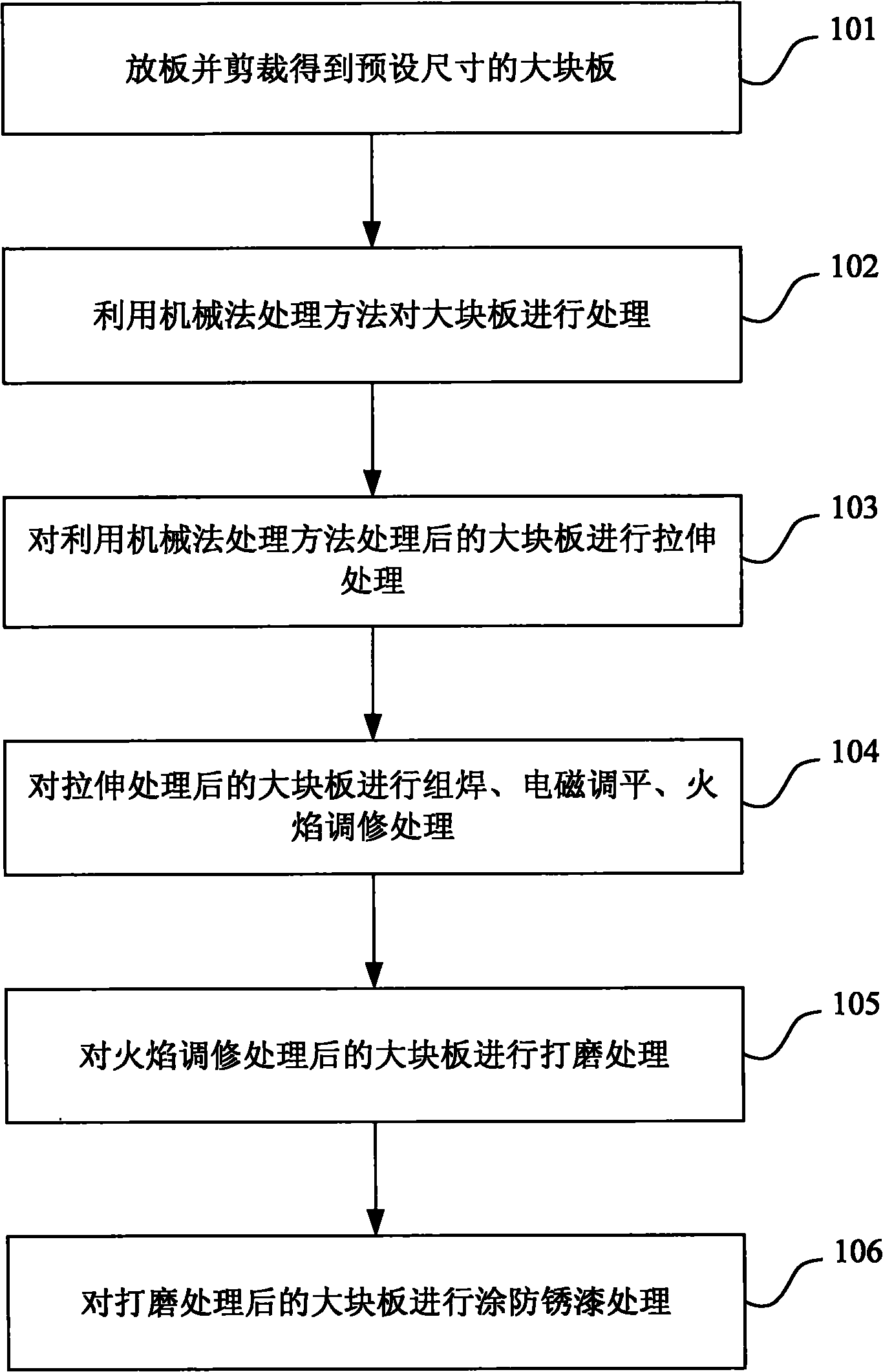

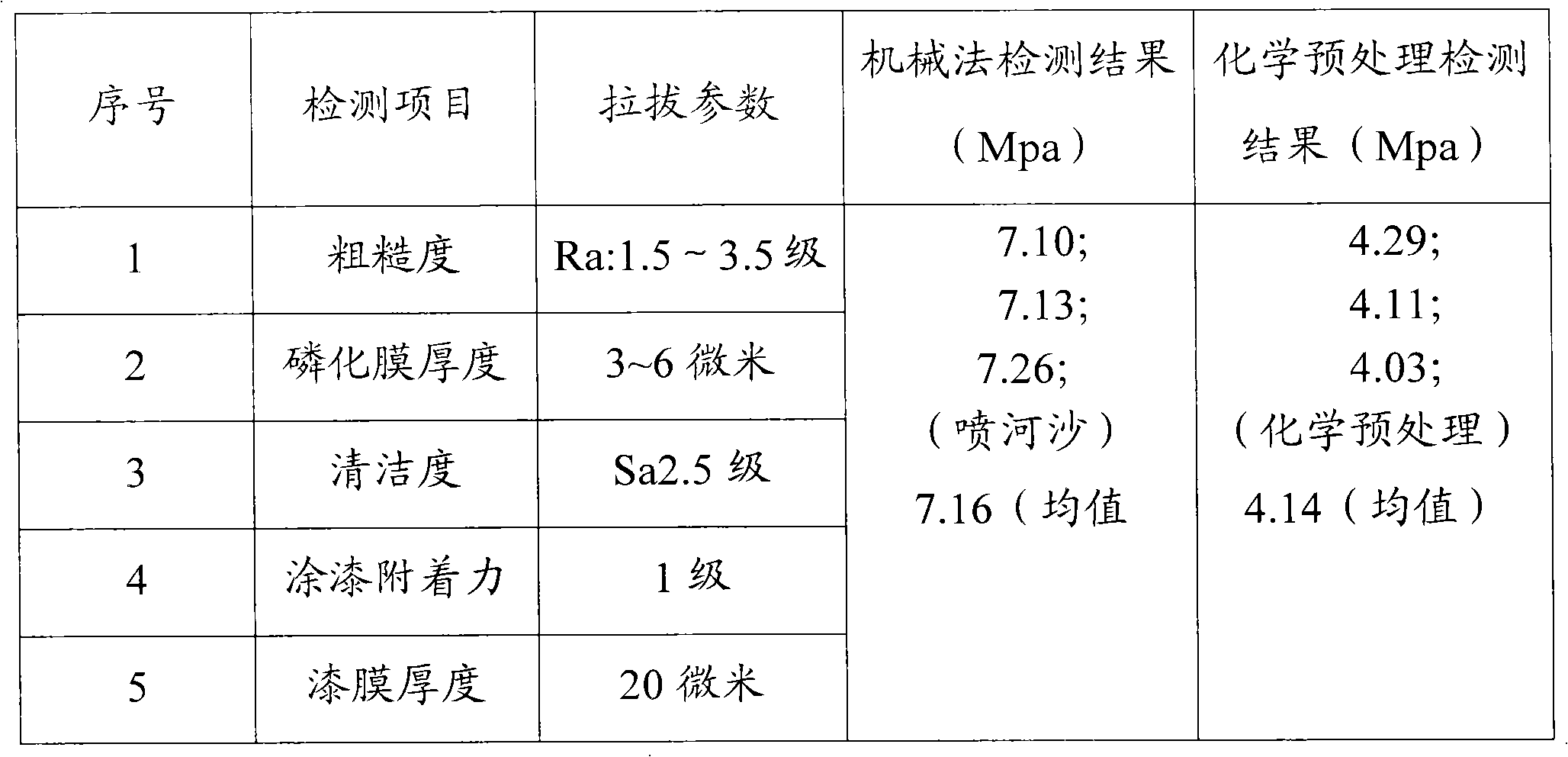

Method for manufacturing sidewall panel of railway passenger vehicle

The invention discloses a method for manufacturing a sidewall panel of a railway passenger vehicle. The method comprises the following steps: placing the panel and cutting the panel into big panels of a predetermined size; and processing the big panels by a mechanical processing method. The method of the invention adopts a simple technical scheme, is low in manufacturing cost and can effectively reduce the deformation during the manufacturing of the sidewall panel and improve the quality of the sidewall panel.

Owner:CRRC TANGSHAN CO LTD

Structural steel framework of railway passenger car body

The invention relates to a structural steel framework of a railway passenger car body. The structural steel framework comprises a base frame welding framework, side wall welding frameworks and a car roof welding framework, wherein a car body framework is formed in a manner that each closed frame body formed by portable assisting beams, vertical beams and a car roof cross beam, and a covering wrapper sheet set are welded together, and has large strength and large rigidity; a bogie of a passenger car is not used, and a scheme of single wheel pairs is used, so that a base frame sleeper beam is replaced with an I-shaped beam, the carrying capacity of the I-shaped beam is better, the I-shaped beam and the base frame welding framework can form a criss-cross beam structure, and the integral stability is good; wheel set seats are large at the upper part and small at the lower part, and are small in size and strong in carrying capacity; a center beam adopts a box type structure, and stiffened plates are arranged in the center beam, so that a closed box type structure is formed for bearing main traction and pulling force; a front end beam and a rear end beam respectively adopt a wing-shaped structure, and the structure is stable; and a longitudinal beam and a cross beam of the car roof welding framework are formed by the welding of deformed steel plates, and the deformed steel plates are high in structural strength, not liable to bend, light in weight, and suitable for the car roof structure.

Owner:GUANGZHOU ELECTRICAL LOCOMOTIVE

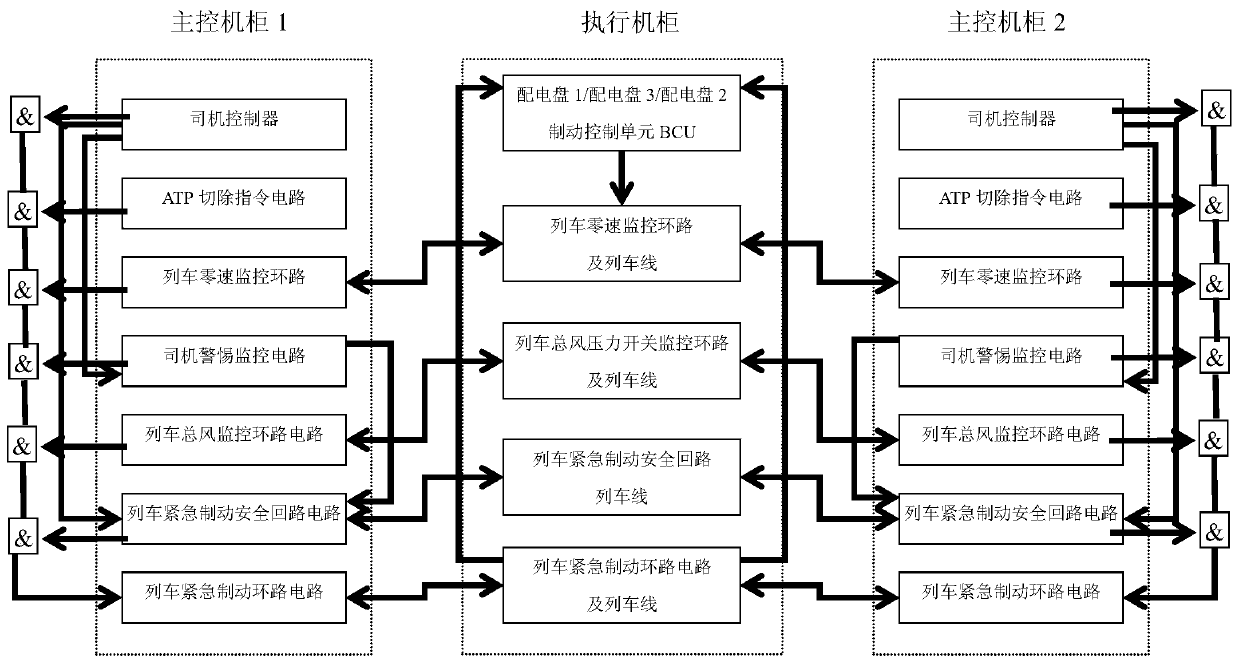

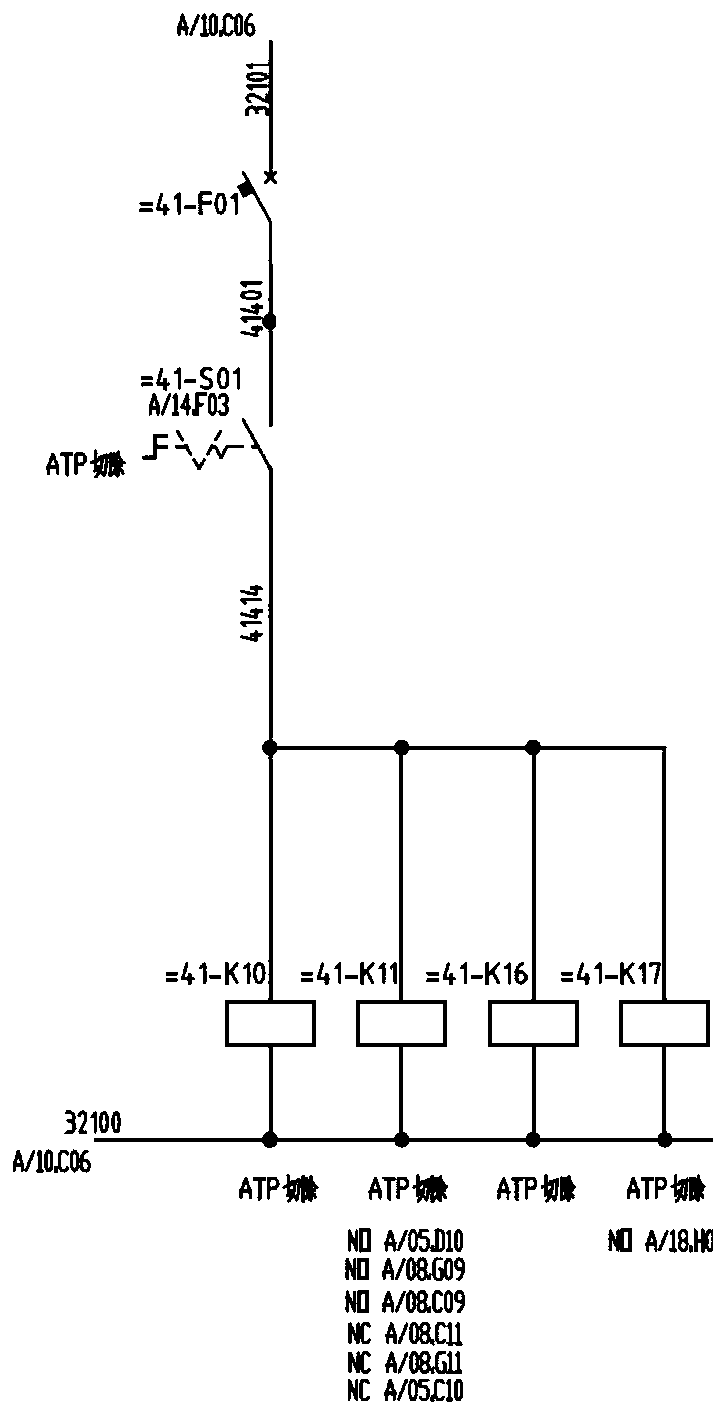

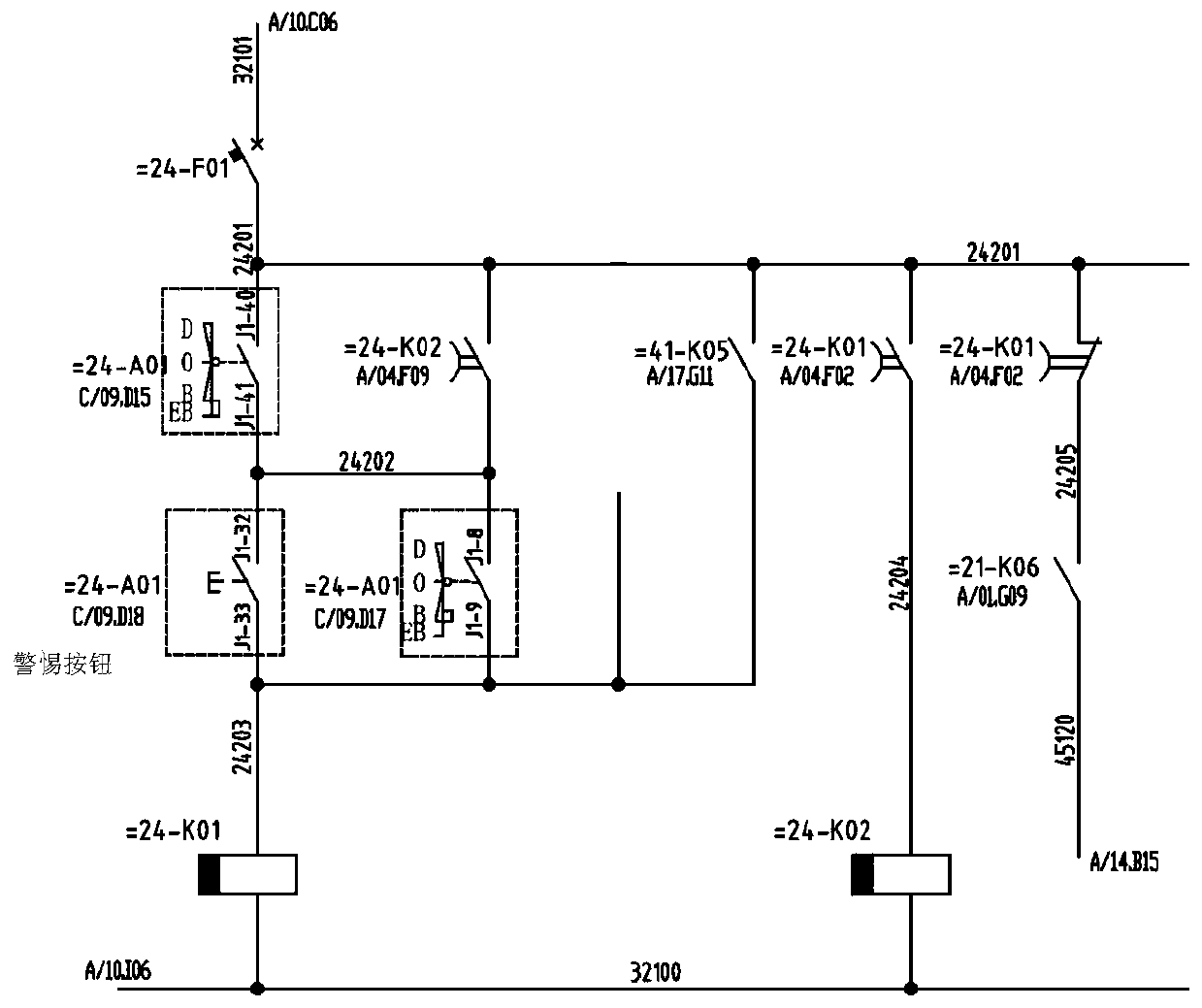

Intelligent debugging and training system and method for urban railway passenger car safety loop

PendingCN111223348AAvoid Unexpected Quality IssuesReduce walking timeCosmonautic condition simulationsSimulatorsRailway passenger carControl engineering

The invention discloses an intelligent debugging and training system for an urban railway passenger car safety loop. The intelligent debugging and training system comprises two main control units andan execution unit, wherein each main control unit comprises a driver controller, an ATP removal instruction circuit, a train zero-speed monitoring loop, a driver alert monitoring circuit, a train total wind monitoring loop circuit, a train emergency braking safety loop circuit and a train emergency braking loop circuit; the execution unit comprises a train zero-speed monitoring loop and train lineand a train total wind pressure switch monitoring loop and train line; the train zero-speed monitoring loop and train line is used for receiving a zero-speed signal transmitted by a BCU; the train emergency braking safety loop circuit is used for transmitting a train emergency braking signal to the brake control unit BCU; and normal monitoring states of the ATP removal instruction circuit, the train zero-speed monitoring loop, the driver alert monitoring circuit, the total wind monitoring loop circuit, the emergency braking safety loop circuit and the driver controller form the train emergency braking loop circuit. Compared with the method of training by using a real vehicle, the intelligent debugging and training system saves time and labor, reduces the influence of training on the functions and performance of the real vehicle, avoids the accidental quality problem of the vehicle, and reduces the loss.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

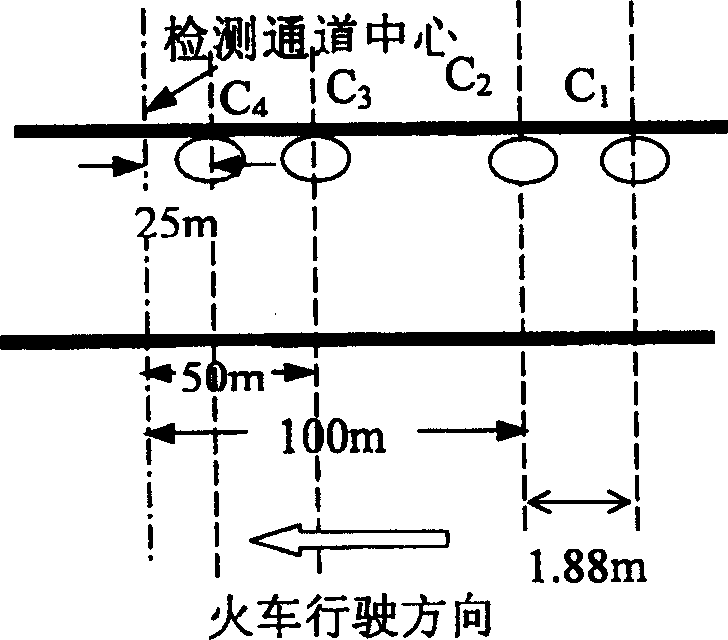

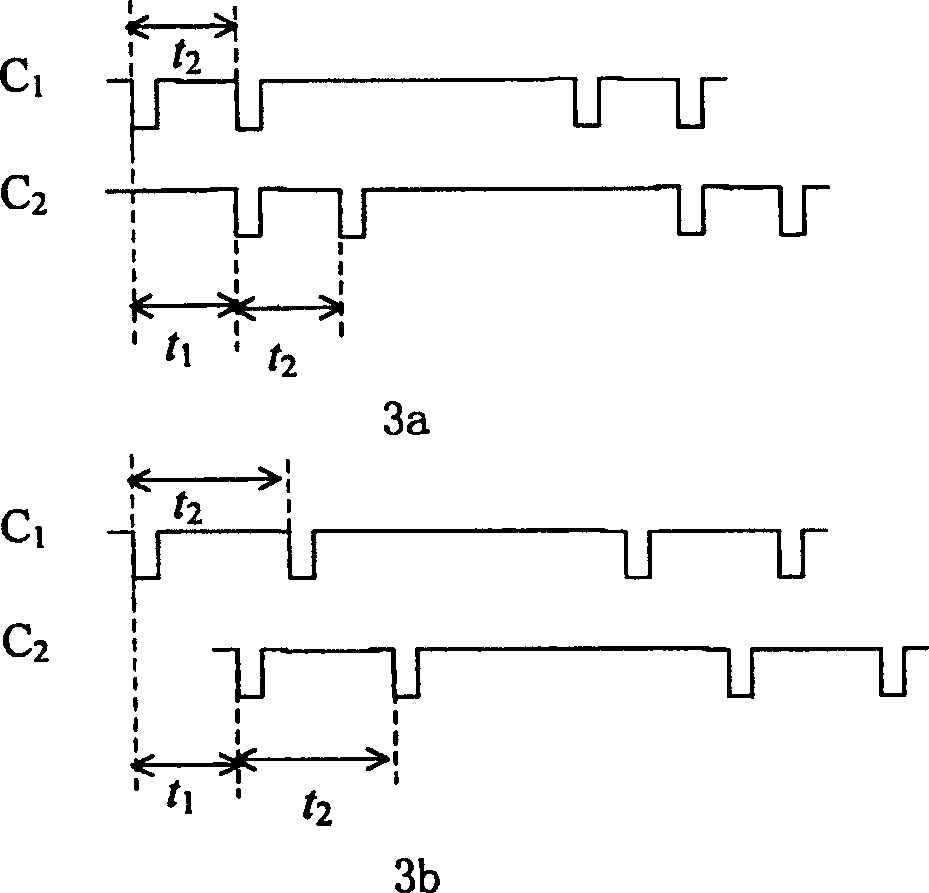

Method and system for distinguishing passenger train from goods train by between-wheel spacing method

InactiveCN1151045CAchieve the expected purposeSignal operation from vehicleVehicle route interaction devicesSignal processing circuitsRailway passenger car

An automatic train type recognition system for distinquishing passenger train from goods train is composed of 4 magnetic sensors, a signal processing circuit and a programmable controller connected in sequence. The 4 magnetic sensors have one pair of magnetic sensor installed to one rail and having a central distance equal to that of two pairs of wheels, one magnetic sensor for shielding locomotive and generating a signal for beginning recognization, and another magnetic sensor for sensing arrival of locomotive, ending the recognition and reading the result. It is based on the reality that the spacing between two groups of wheels of the passenger train is greater than that of goods train.

Owner:TSINGHUA UNIV

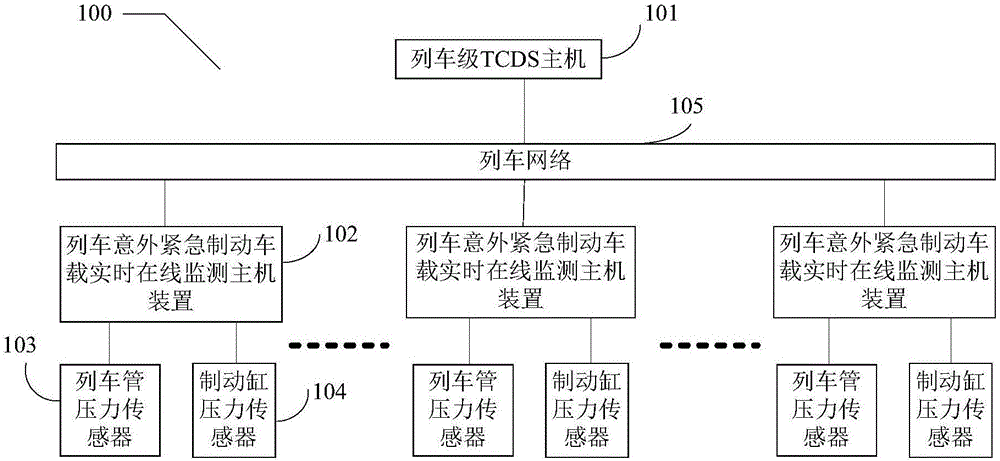

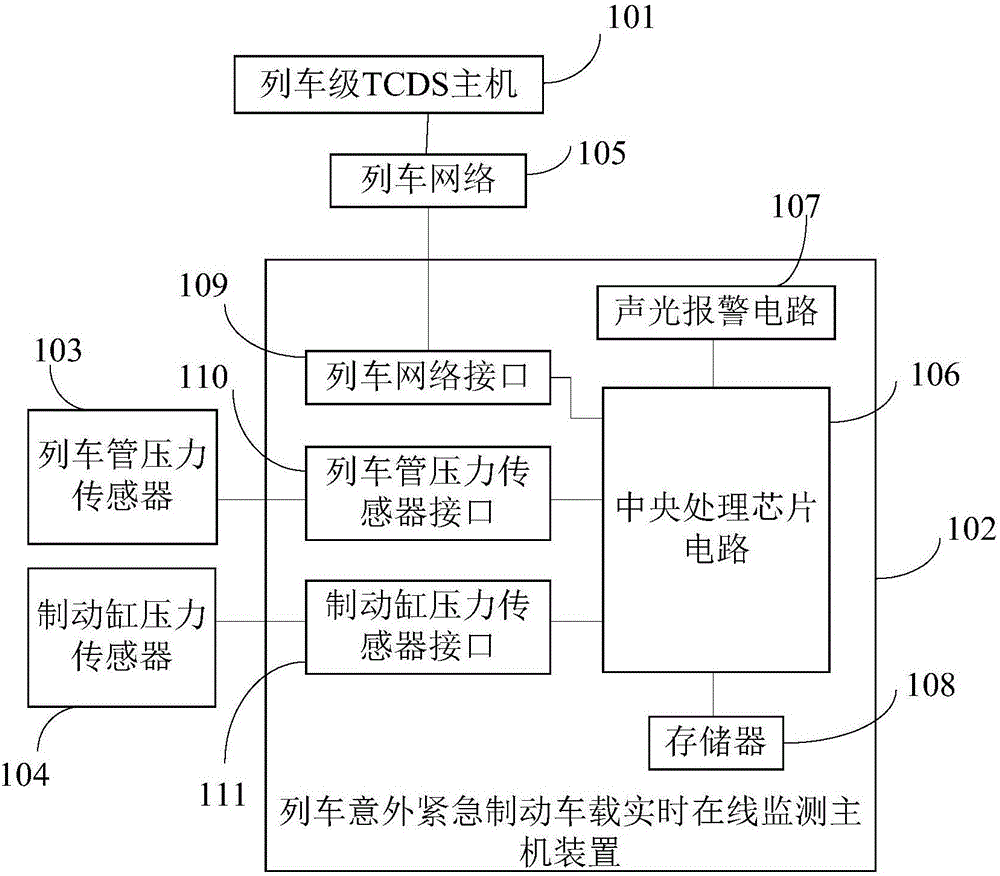

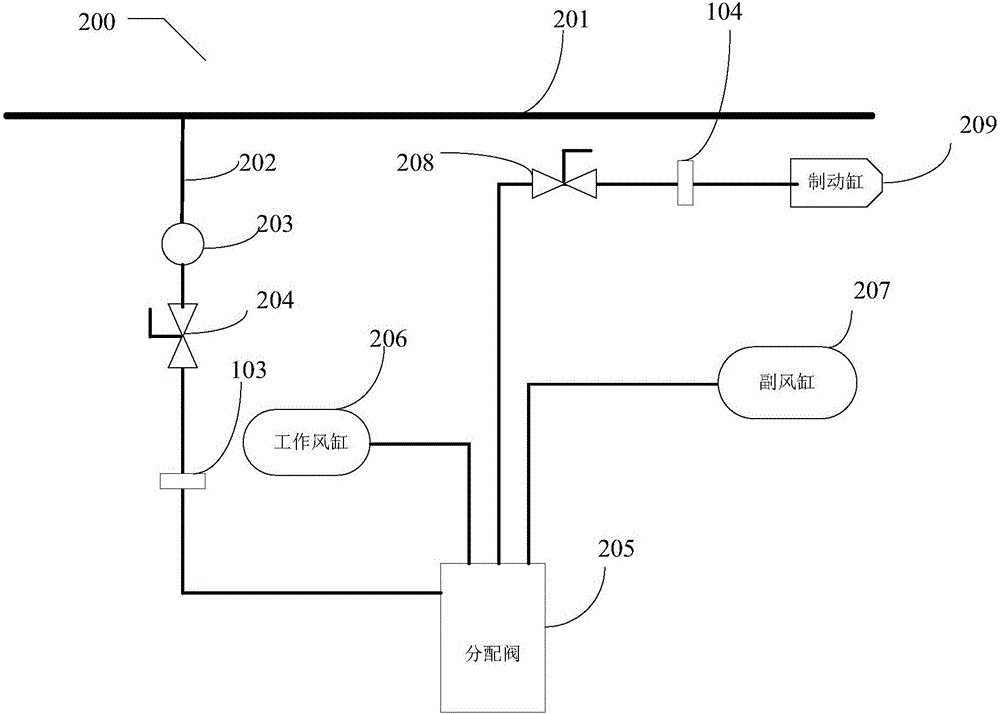

Online real-time online monitoring system, method and device for undesirable emergency braking of train

ActiveCN106274988ASpeed blockAvoid complexitySignalling indicators on vehicleRailway passenger carMonitoring system

The invention provides an online real-time online monitoring system, method and device for undesirable emergency braking of a train, and relates to the technical field of monitoring of railway passenger car braking systems. A train pipe pressure sensor collects train pipe pressure data of a carriage where the train pipe pressure sensor is located in real time; a brake cylinder pressure sensor collects brake cylinder pressure data of a carriage where the brake cylinder pressure sensor is located in real time; online real-time online monitoring hosts of undesirable emergency braking of the train arranged in the carriages determine a train pipe decompression rate in real time according to the train pipe pressure data, determines emergency braking of the carriages of the train when the train pipe decompression rate is greater than a preset decompression rate and when the brake cylinder pressure data is greater than a preset pressure threshold, and sends an emergency braking moment of the present carriage to a train level TCDS host; and the train level TCDS host sorts and judges the emergency braking moments of the carriages, locates the carriage generating the undesirable emergency braking at the earliest time and broadcasts an alarm to the entire train.

Owner:CHINA ACADEMY OF RAILWAY SCI CORP LTD +3

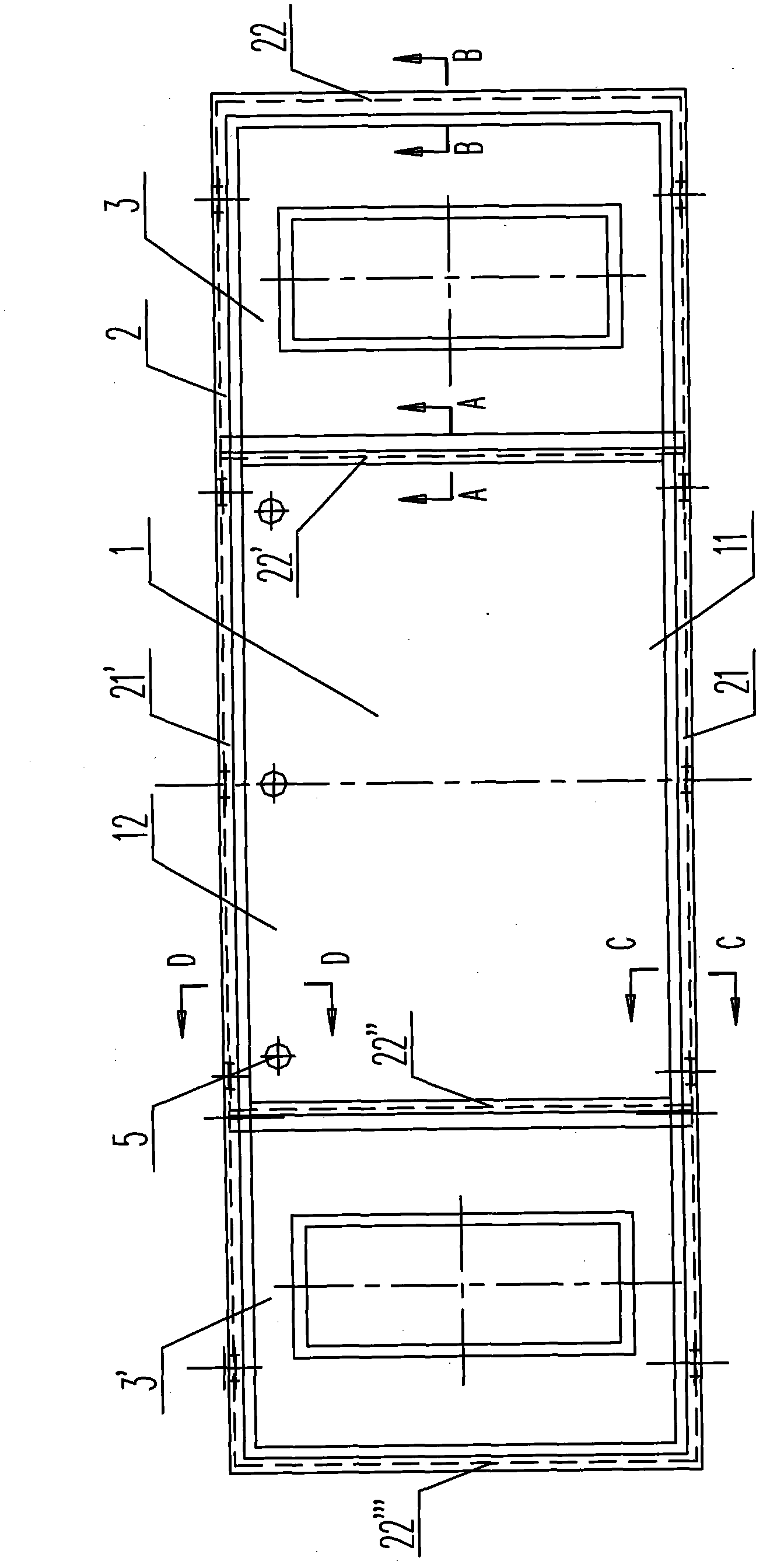

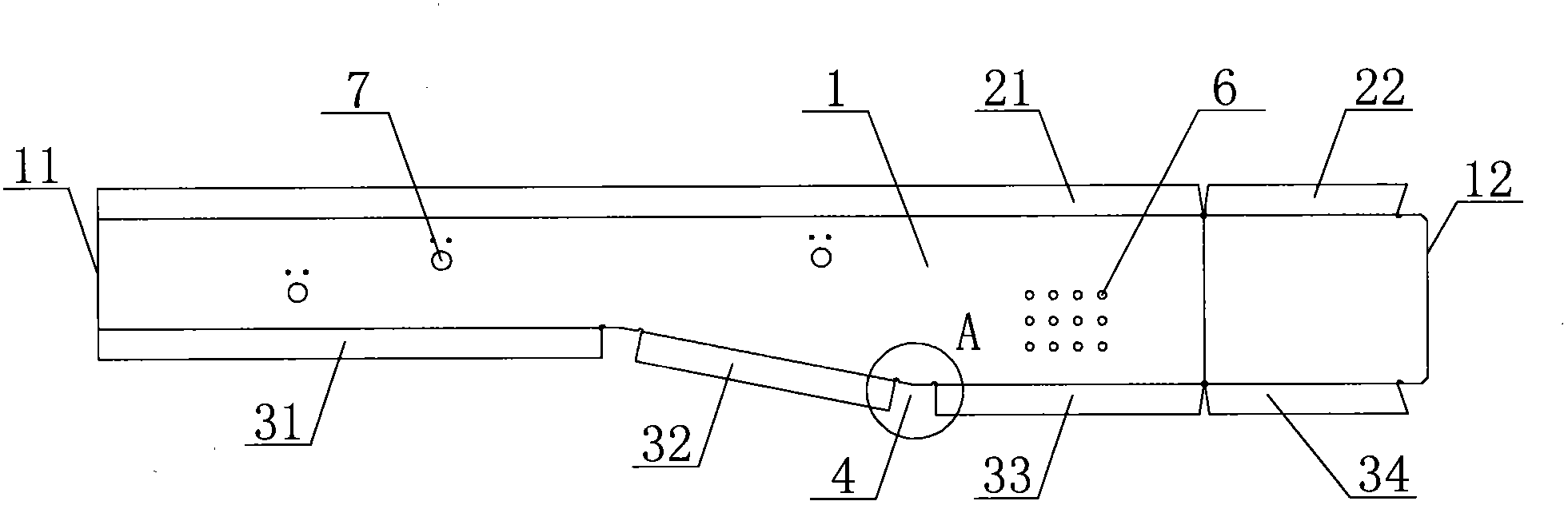

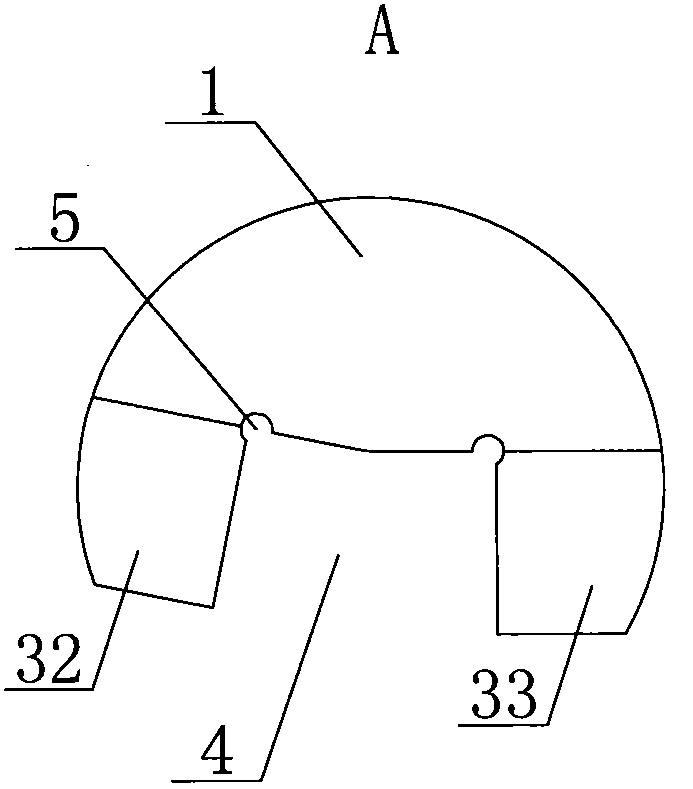

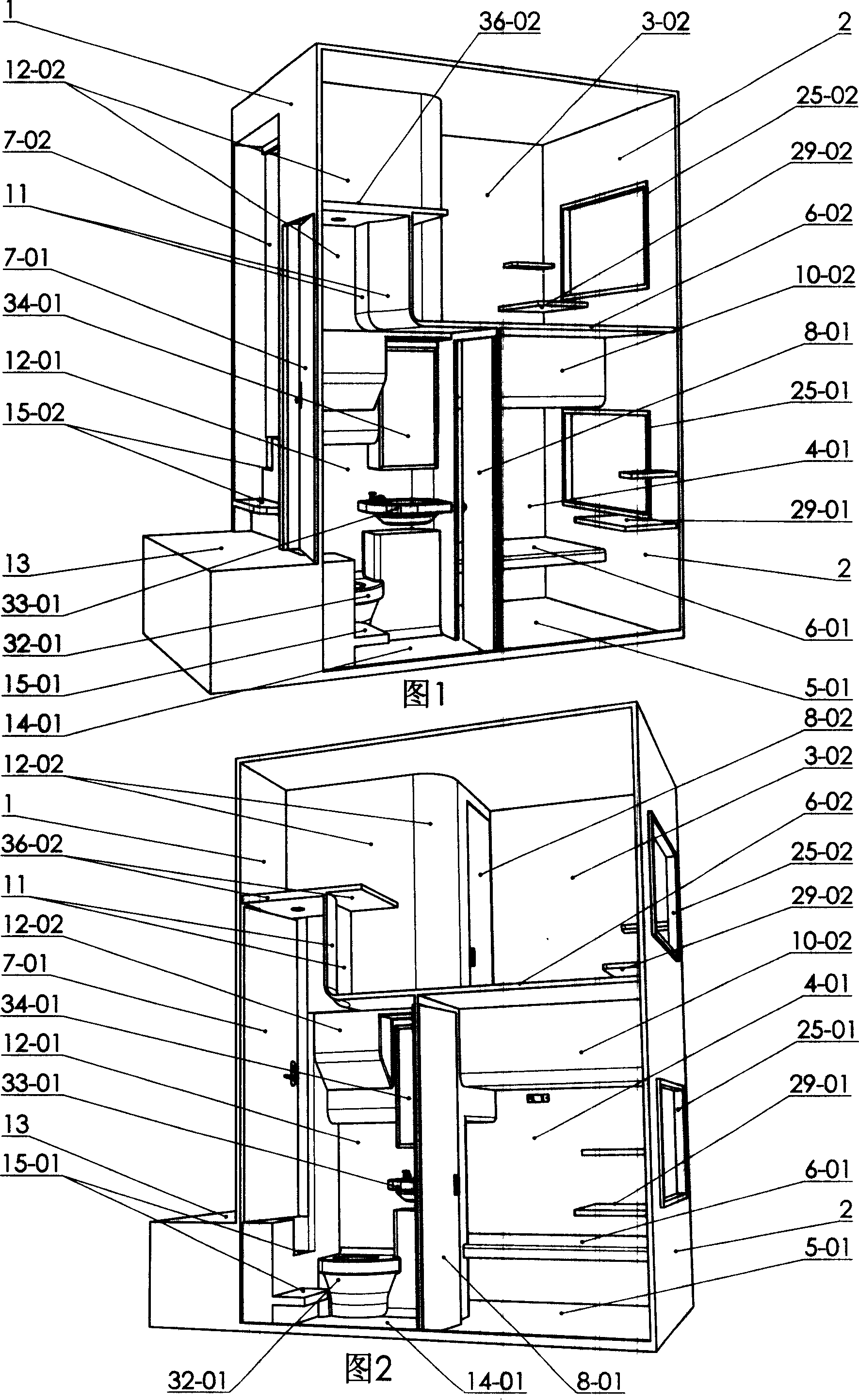

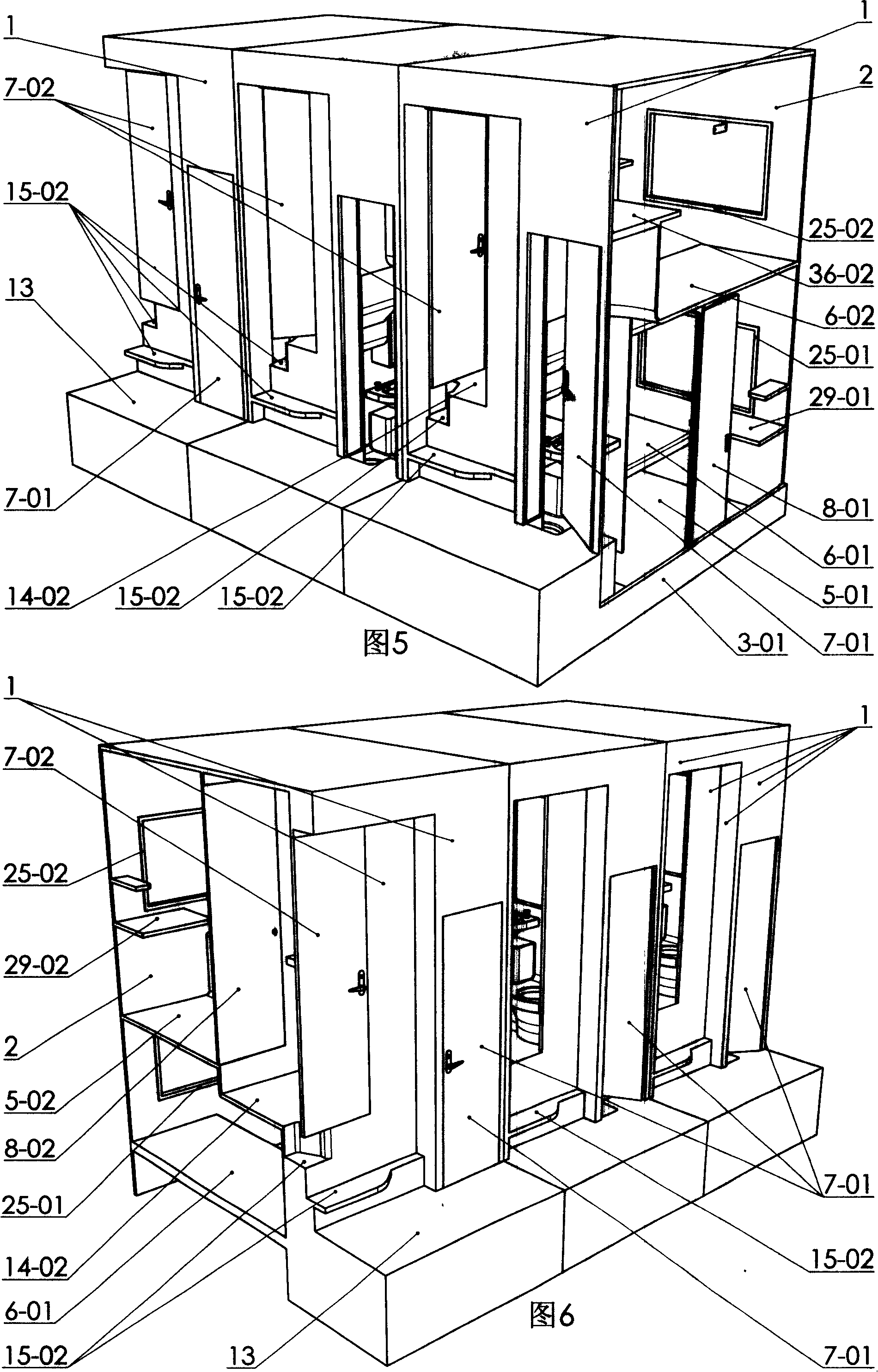

Double layer bed room

InactiveCN101235675AEasy accessImprove comfortSleeping accommodationBedstandsIn vehicleRailway passenger car

A double layer bedroom which is suitable to be applied in vehicles such as carriages of railway passenger cars, passenger ships and hotels comprises an upper sub bedroom and a lower bedroom which are combined mutually, and the floors 5-02, 5-01 in the upper sub bedroom and the lower sub bedroom are respectively higher than a corridor floor 13, and are connected with the corridor floor 13 conveniently by means of an auxiliary foot hold 15. A channel type washroom with a stool 32 and a finger bowl 33 is formed between an inner chamber door 8 of each sub bedroom and a door 7. A chair with armrest which can be modulated angles is formed by bed boards 18 which can be inverted and folded of a bed in bedroom and a seat stand 20. A double room can be formed by the communication between the adjacent left sub bedroom and right sub bedroom by means of a lateral wall door 9. A single passenger compartment which comprises 36 chairs, beds, washroom and video web devices and can communicated with an adjacent passenger compartment can be arranged in a standard 25-tye railway passenger car, thereby providing a comfortable private space with complete functions for passengers in small space.

Owner:于君

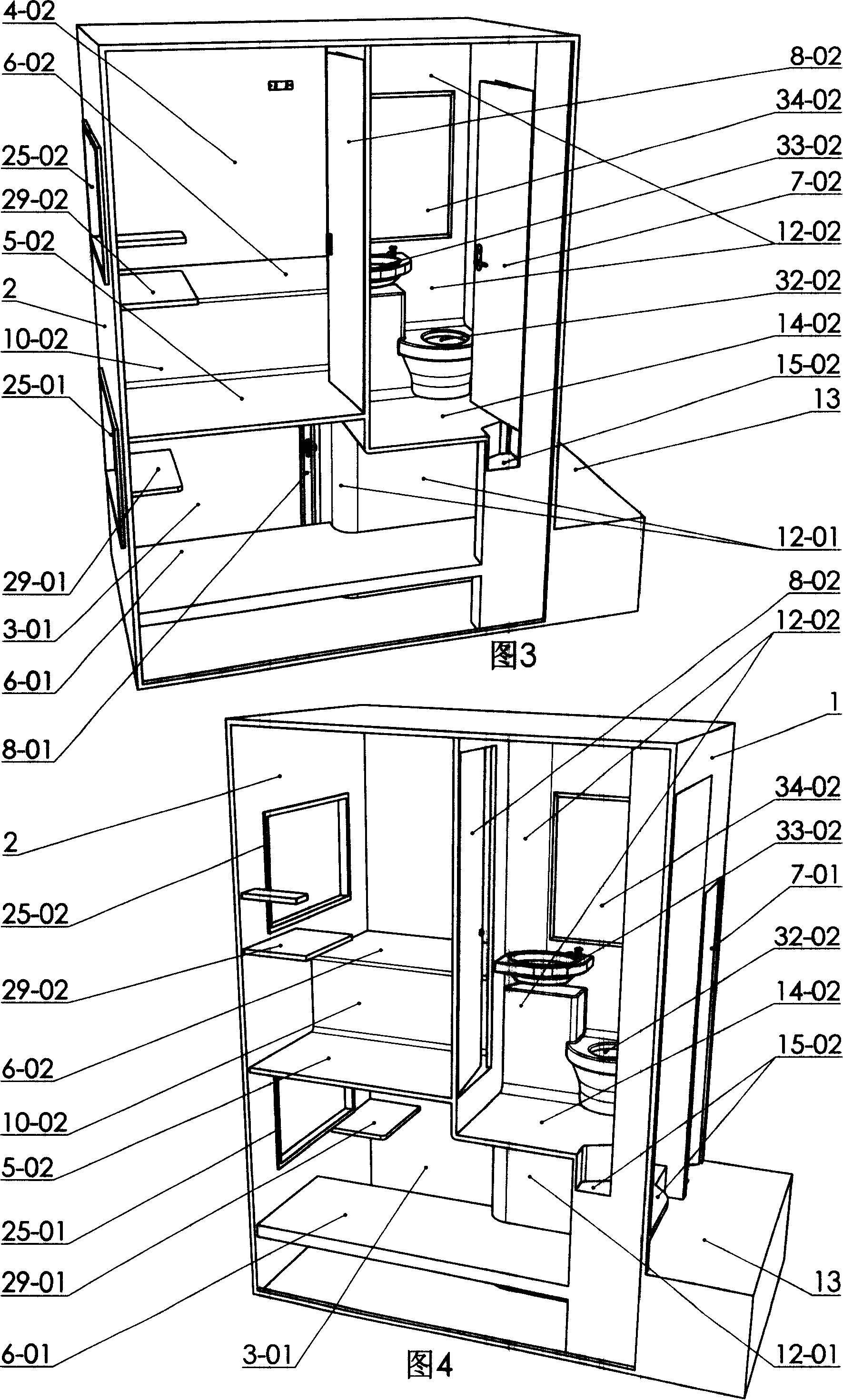

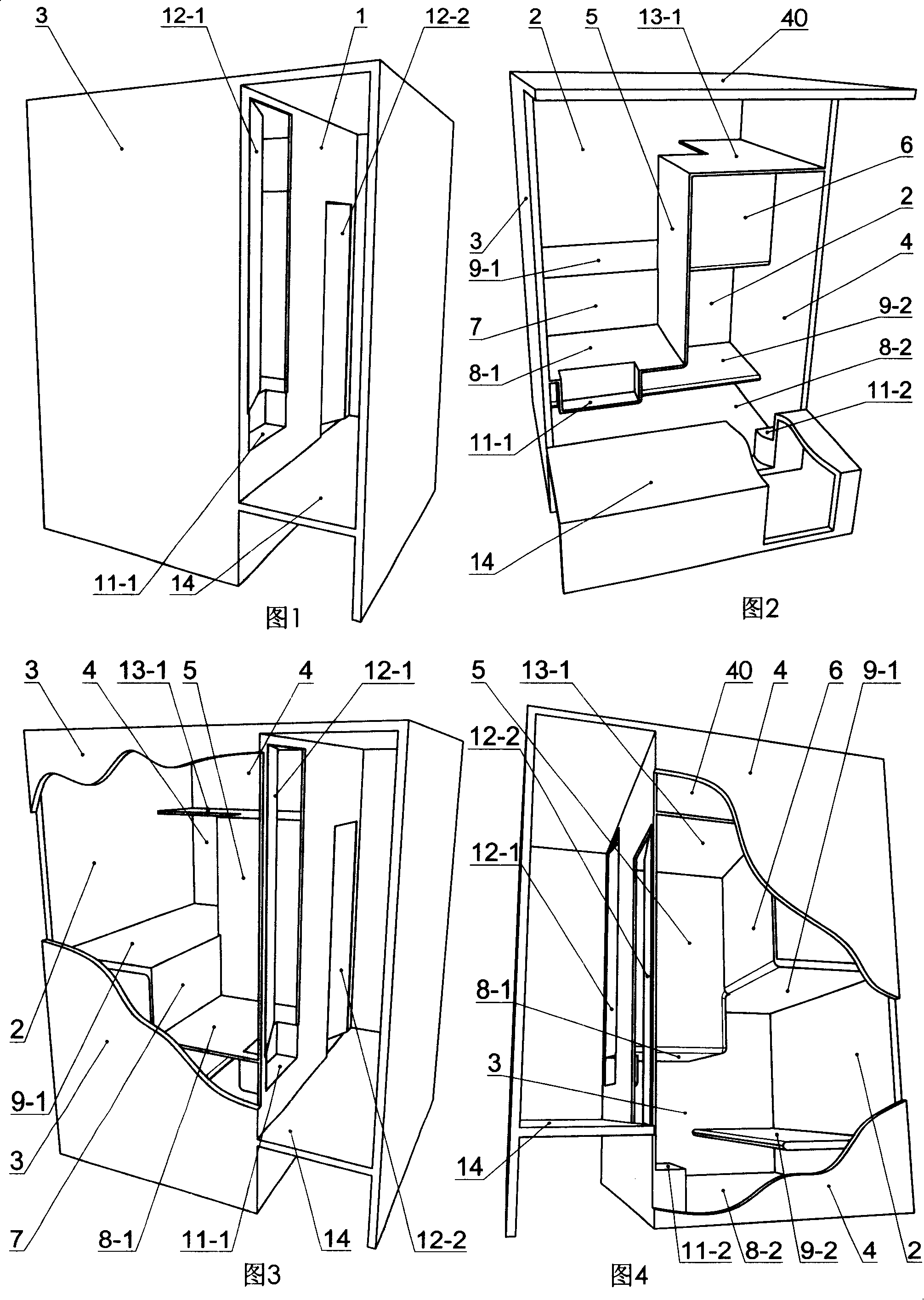

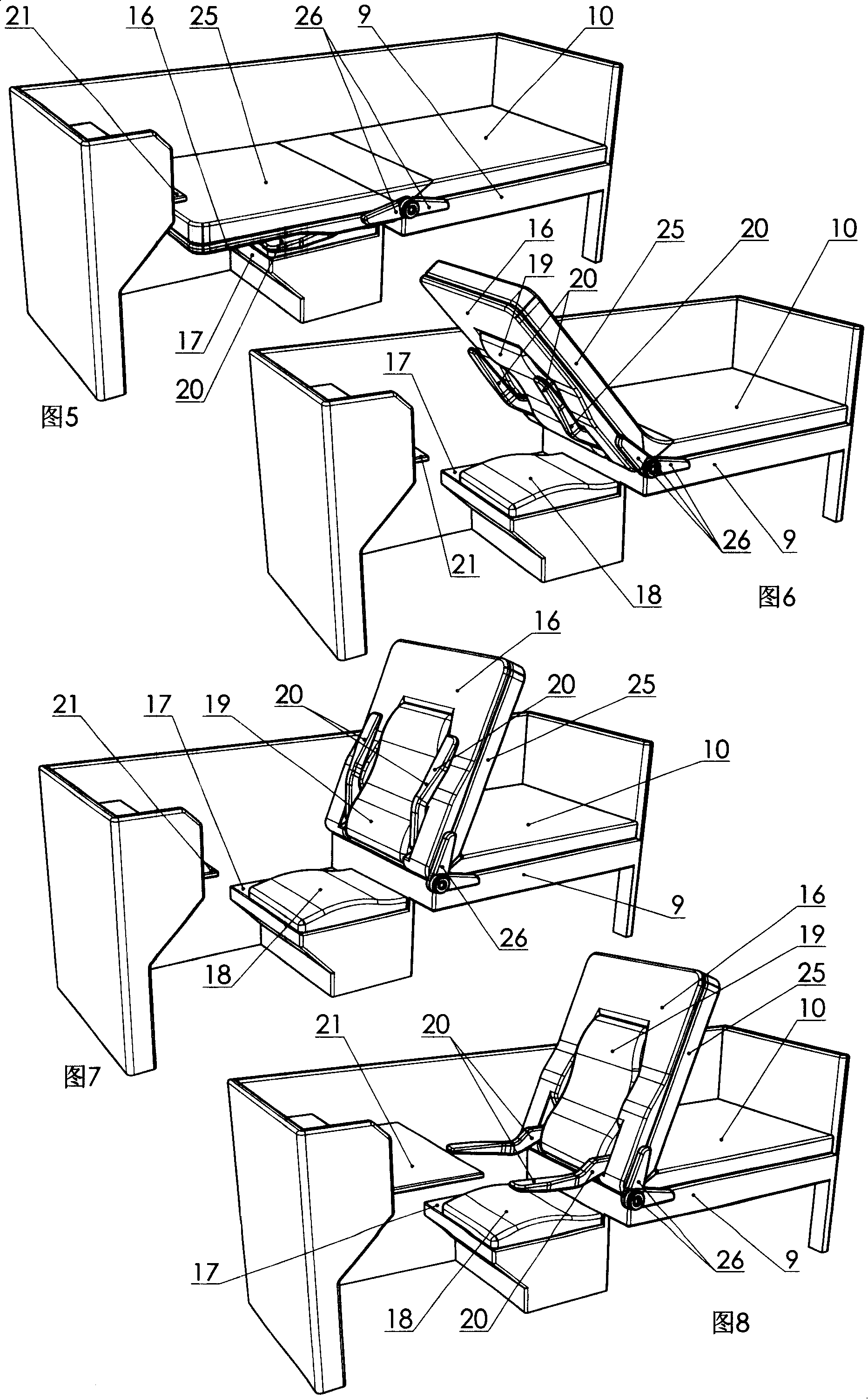

Double layer bedchamber

InactiveCN101235676AEasy accessIndependent private spaceSleeping accommodationBedstandsIn vehicleRailway passenger car

A double layer bedroom which is suitable to be applied in vehicles such as carriages of railway passenger cars, passenger ships and hotels comprises an upper sub bedroom and a lower bedroom which are combined mutually, and the floors 8-1, 8-2 in the upper sub bedroom and the lower sub bedroom are respectively higher than a corridor floor 14, and are connected with the corridor floor 14 conveniently by means of an auxiliary foot hold. A chair with armrest which can be modulated angles is formed by bed boards 16 which can be inverted and folded of a bed in bedroom and a seat stand on the lower portion. A stool which can be used as an additional seat is arranged on the lower surface of a foldable finger bowl 31. A double room can be formed by the communication between the adjacent left sub bedroom and right sub bedroom by means of internal doors. The corridor 14 elevated convenient for people entering the upper sub bedroom and the lower sub bedroom, which can be transformed into a floor for standing by people near to the bed which is close to the chair. A single passenger compartment which comprises 44 chairs, beds, washroom and video web devices and can communicated with an adjacent passenger compartment can be arranged in a standard 25-tye railway passenger car, thereby providing a comfortable private space with complete functions for passengers in small space.

Owner:于君

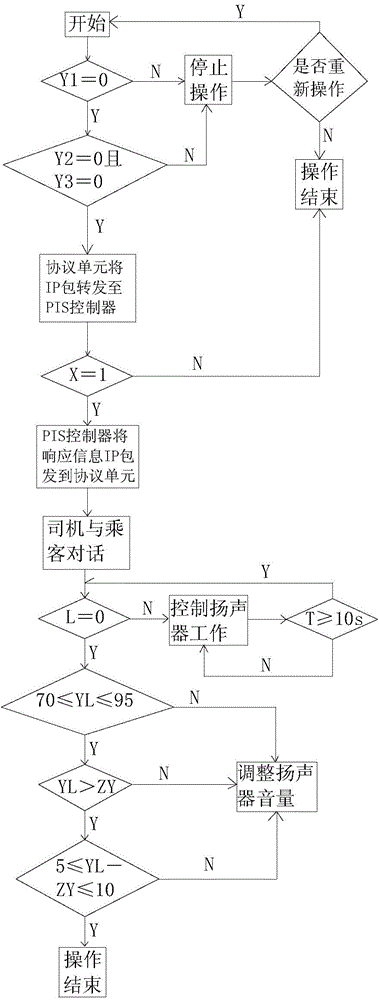

Passenger train broadcast control method

ActiveCN104158614ARadio sound is clearUniform sound intensityBroadcast specific applicationsBroadcast transmission systemsRailway passenger carDependability

The present invention relates to a passenger train broadcast control method, the method comprising following steps: 1, a PIS controller detects the operation status of a broadcast system; 2, a carriage controller detects the operation statuses of a loudspeaker and an emergency interphone for passengers; 3, the PIS controller judges whether the session request from a passenger is accepted; 4, the PIS controller generates response information and realizes the session between the passenger and a cab operator; 5, the PIS controller judges the status of the loudspeaker; 6, a volume control unit judges whether the output volume of the loudspeaker is normal; and 7, the volume control unit judges whether the output volume of the loudspeaker is clear. The present invention is simple in structure and convenient in installation, and not only has high reliability but also improves broadcast tone quality, so the broadcast is clearer and the comfort degree of passengers is increased.

Owner:CRRC NANJING PUZHEN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com