Auxiliary pressing tool for eliminating laser stitch welding gaps generate between side wall stand column and corrugated plate

A corrugated plate and laser technology, which is applied in laser welding equipment, welding equipment, manufacturing tools, etc., can solve the problems that cannot meet the high standard requirements of laser welding technology, and achieve the effect of neat appearance and uniform weld gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

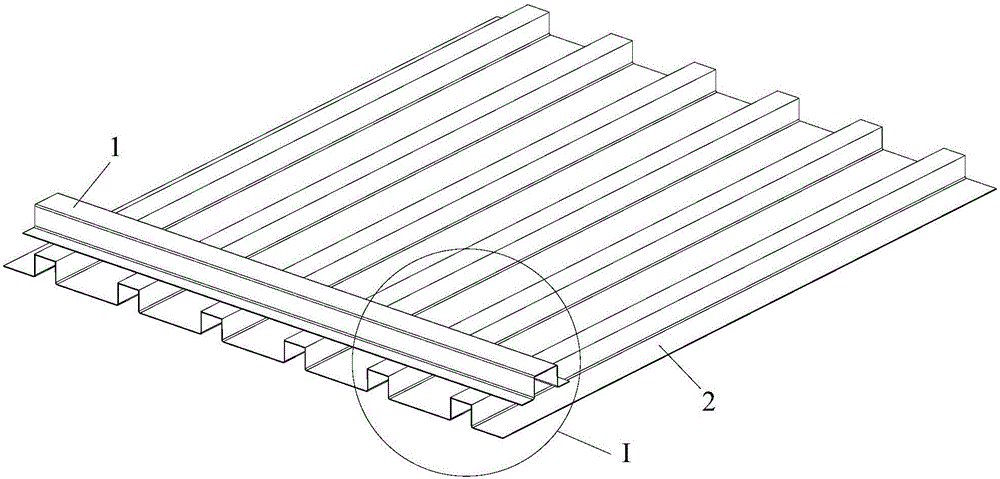

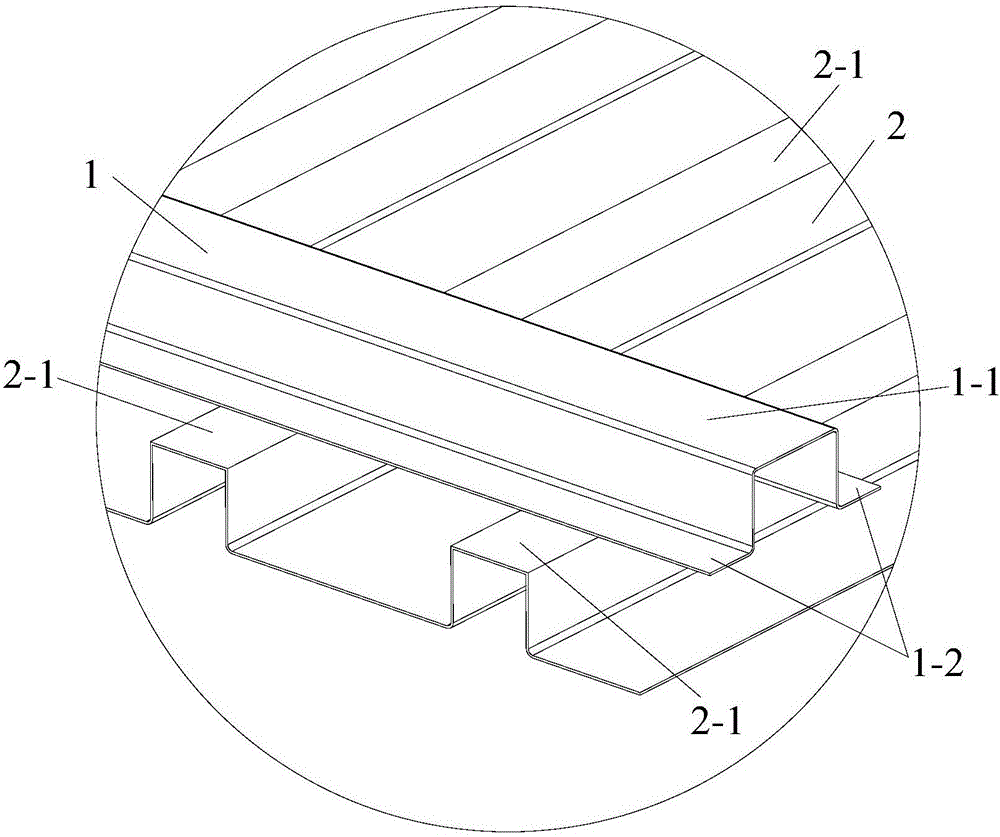

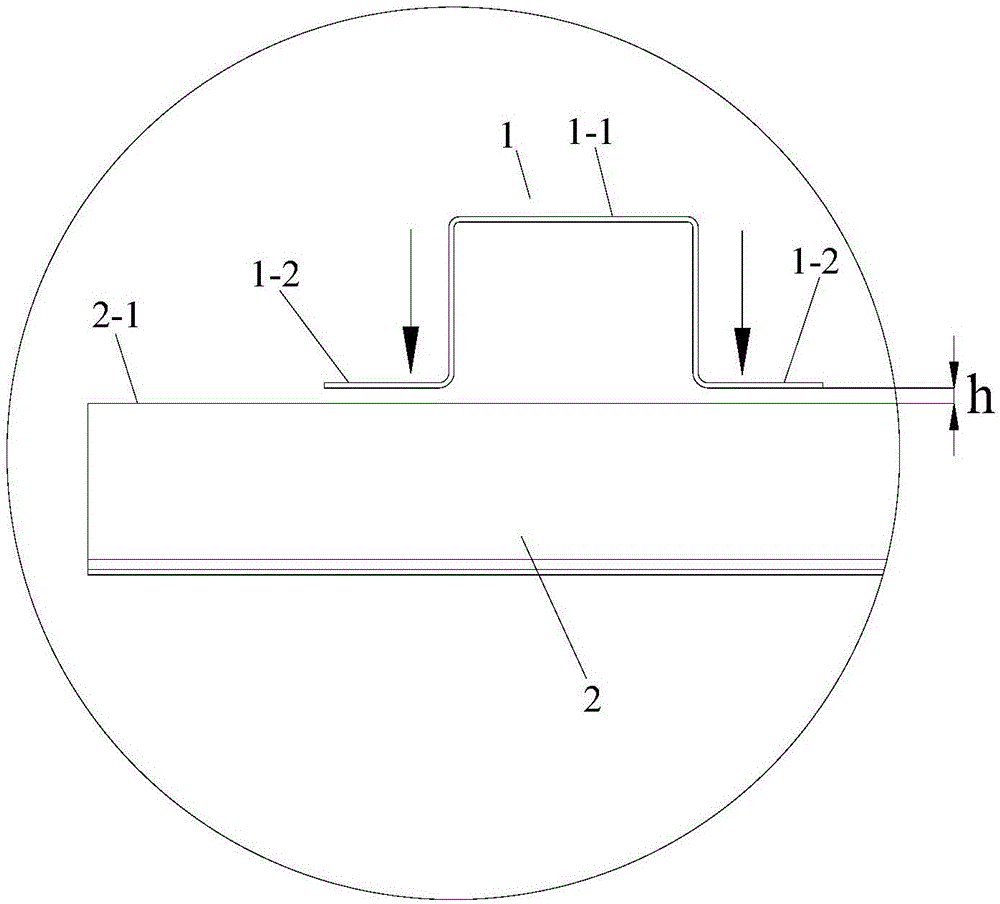

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0028] Such as Figure 4 to Figure 13 As shown, the auxiliary pressing tool for eliminating the gap between the side wall column and the corrugated plate laser stitch welding in the present invention includes a door-shaped slit splint mechanism 3, six stud compactors 4 and a support platform 5, and a slit splint Mechanism 3 comprises slit double splint 3-1, rotating shaft support 3-2, locking support 3-3 and six lead screw nuts 3-4, and the lower ends of rotating shaft support 3-2 and locking support 3-3 are respectively connected with The upper end surface of the support platform 5 is fixedly connected, the slit double splint 3-1 is parallel to the upper end surface of the support platform 5, one end of the slit double splint 3-1 is axially connected with the top end of the shaft support 3-2, and the other end is It is fixedly connected with the top of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com