Patents

Literature

6667results about How to "Beautiful appearance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electronic Cigarette

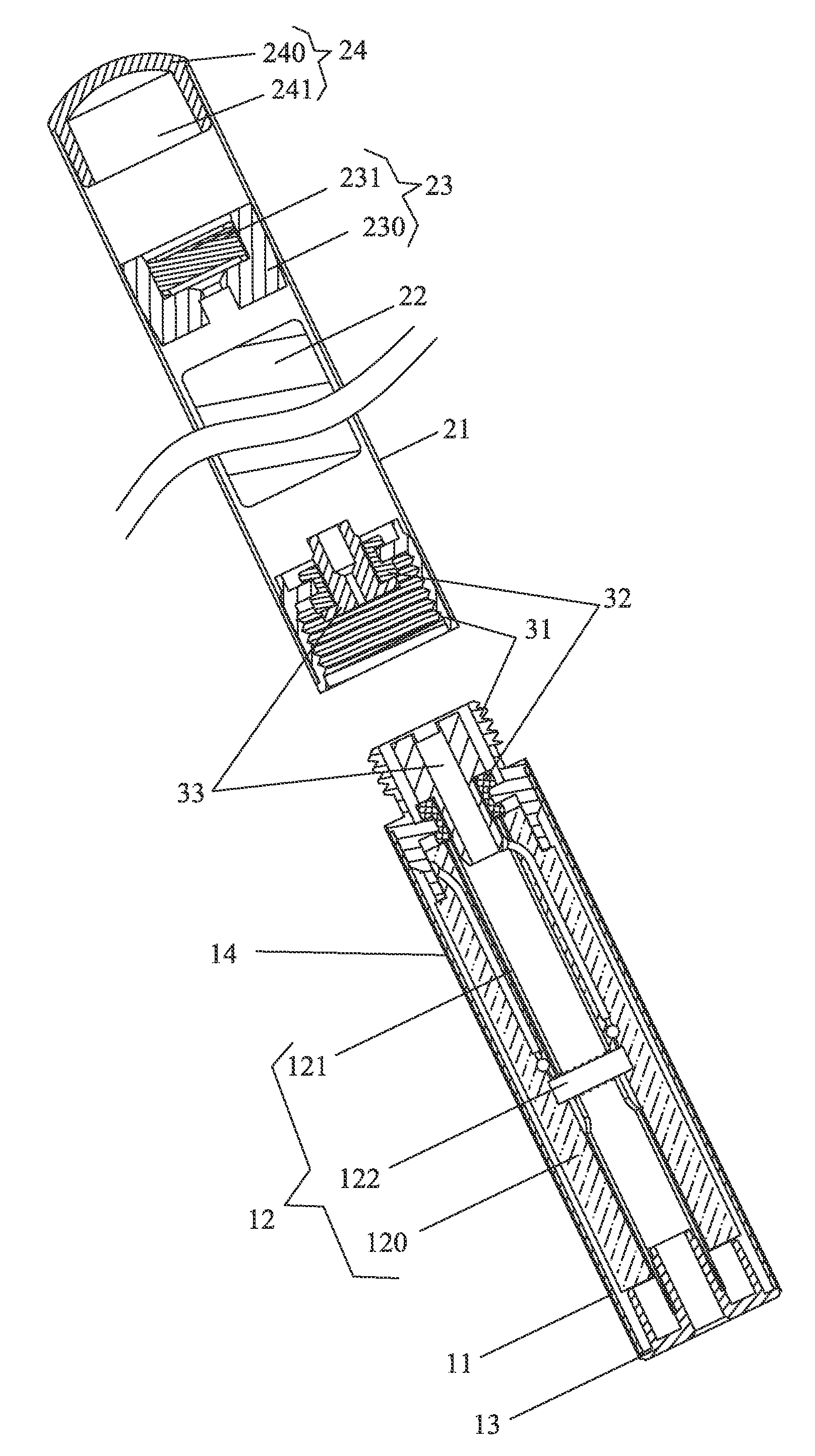

InactiveUS20140007891A1Easy to useEasy and fast assemblyRespiratorsTobacco treatmentElectricityElectrical conductor

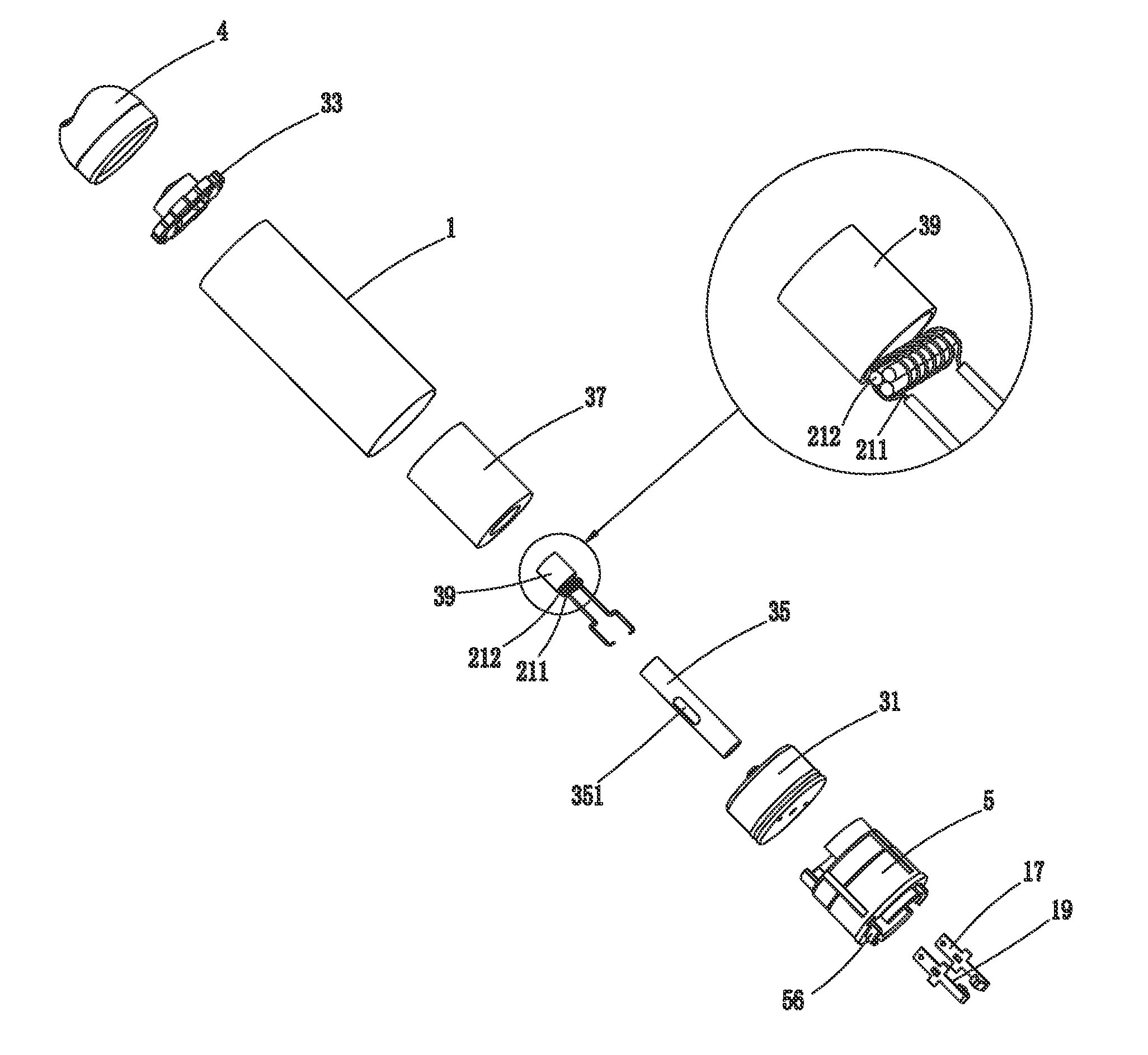

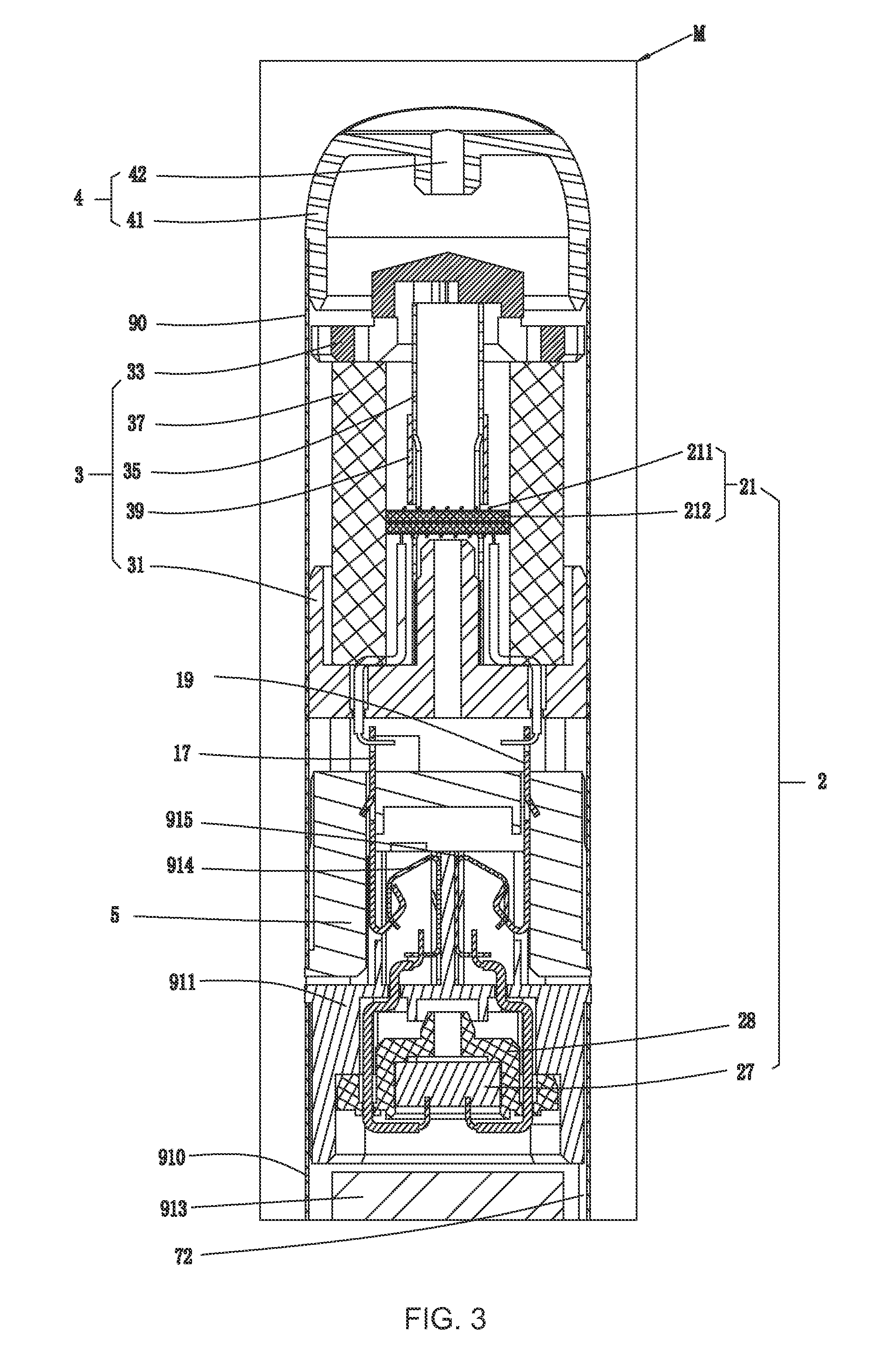

The invention is related to an electronic cigarette which is equipped with a universal serial bus (USB) connector. The electronic cigarette includes a cigarette body and a connecting device. The connecting device is retractably disposed in the cigarette body so as to be hidden therein, and the connecting device includes a connector and a conductor of which a length is extendable. When not in use, the conductor is foldably retracted to be hidden within the cigarette body together with the connector, while the connecting device is in use, the connecting device is pulled away and the conductor extends to a predetermined length to electrically connect the electronic cigarette to an external electronic device or power. Because the USB connector and the conductor are disposed in the electronic cigarette, the electronic cigarette is capable of being used conveniently and assembled quickly.

Owner:HUIZHOU KIMREE TECH

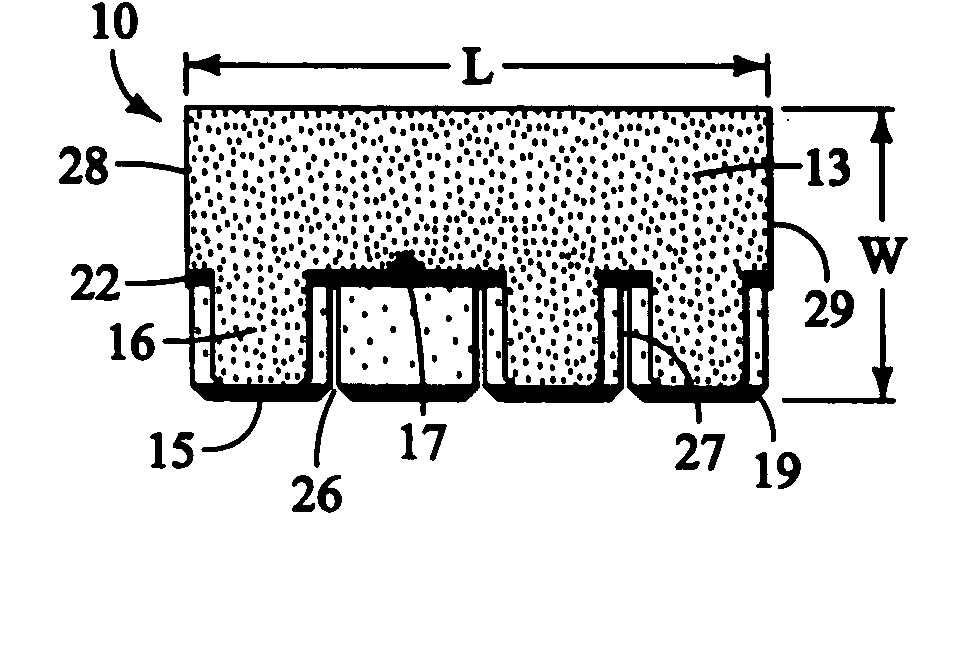

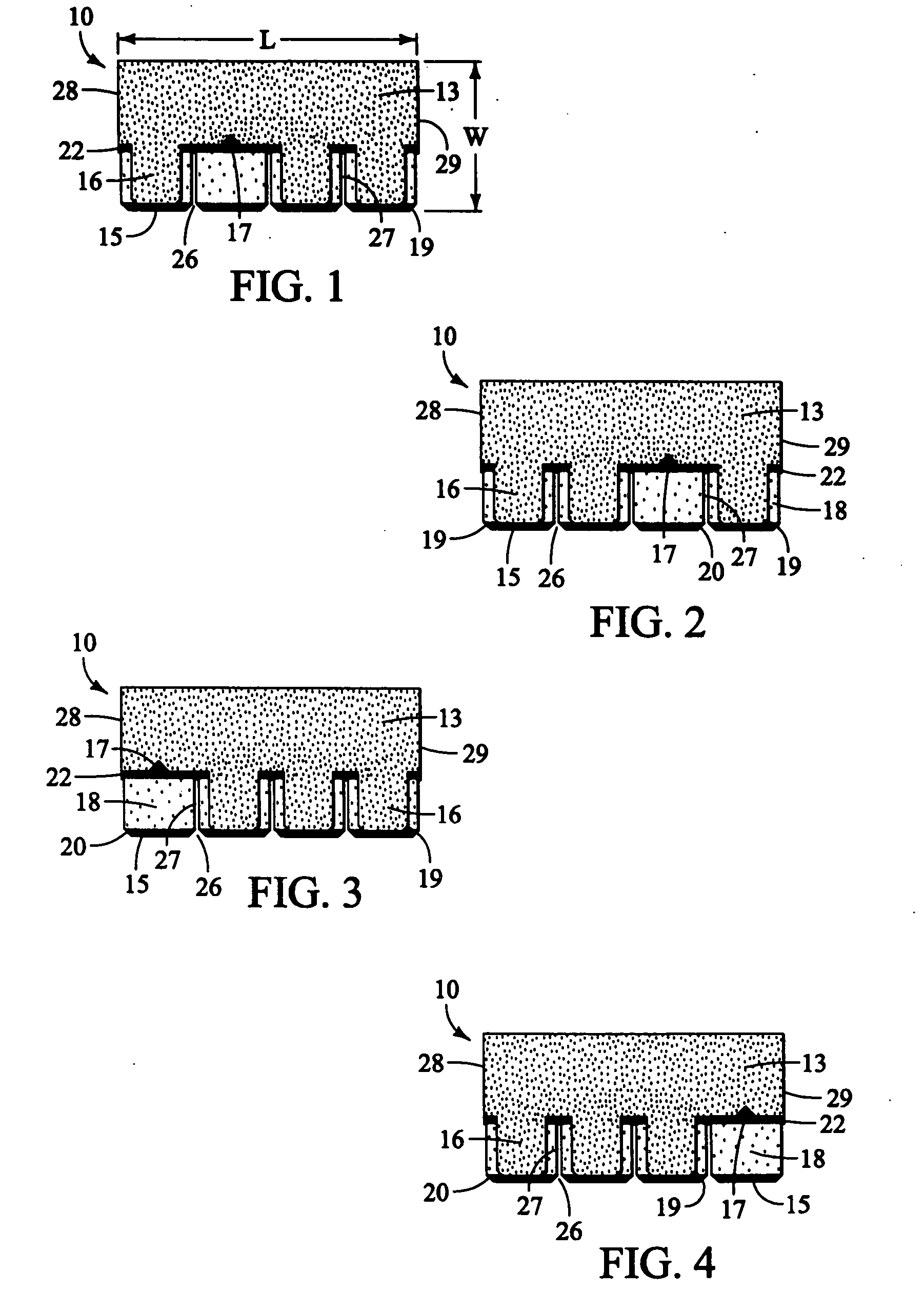

Ceramsite water permeable brick and preparation method thereof

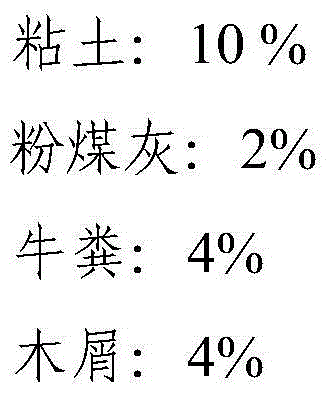

The invention provides a ceramsite water permeable brick, which comprises the following components by weight: 80-100 parts of ceramsite, 10-15 parts of silicon sand, 20-40 parts of cement, a setting accelerator accounting for 2-4% of the weight of the ceramsite, and a water reducing agent accounting for 2-4% of the weight of the ceramsite. According to the invention, silicon sand dust made ceramsite is combined with a small quantity of cement, the setting accelerator, the water reducing agent and a silicon sand fabric to manufacture the ceramsite water permeable brick. One the one hand, the water permeable brick has a beautiful appearance, and on the other hand it combines the lightweight and high strength characteristics of ceramsite. At the same time, ceramsite is round stone rather than polygonal, and usually the gap between round objects is larger than that between polygonal objects, so that the prepared water permeable brick has good permeability effect. The water permeable brick prepared by the method has compressive strength of greater than or equal to 30Mpa and a permeability coefficient of greater than or equal to 0.05cm / s, and the other properties of the brick meet the JCT945-2005 industrial standard.

Owner:RENCHSAND ECO ENVIRONMENT PROTECTION SCI & TECH CO LTD

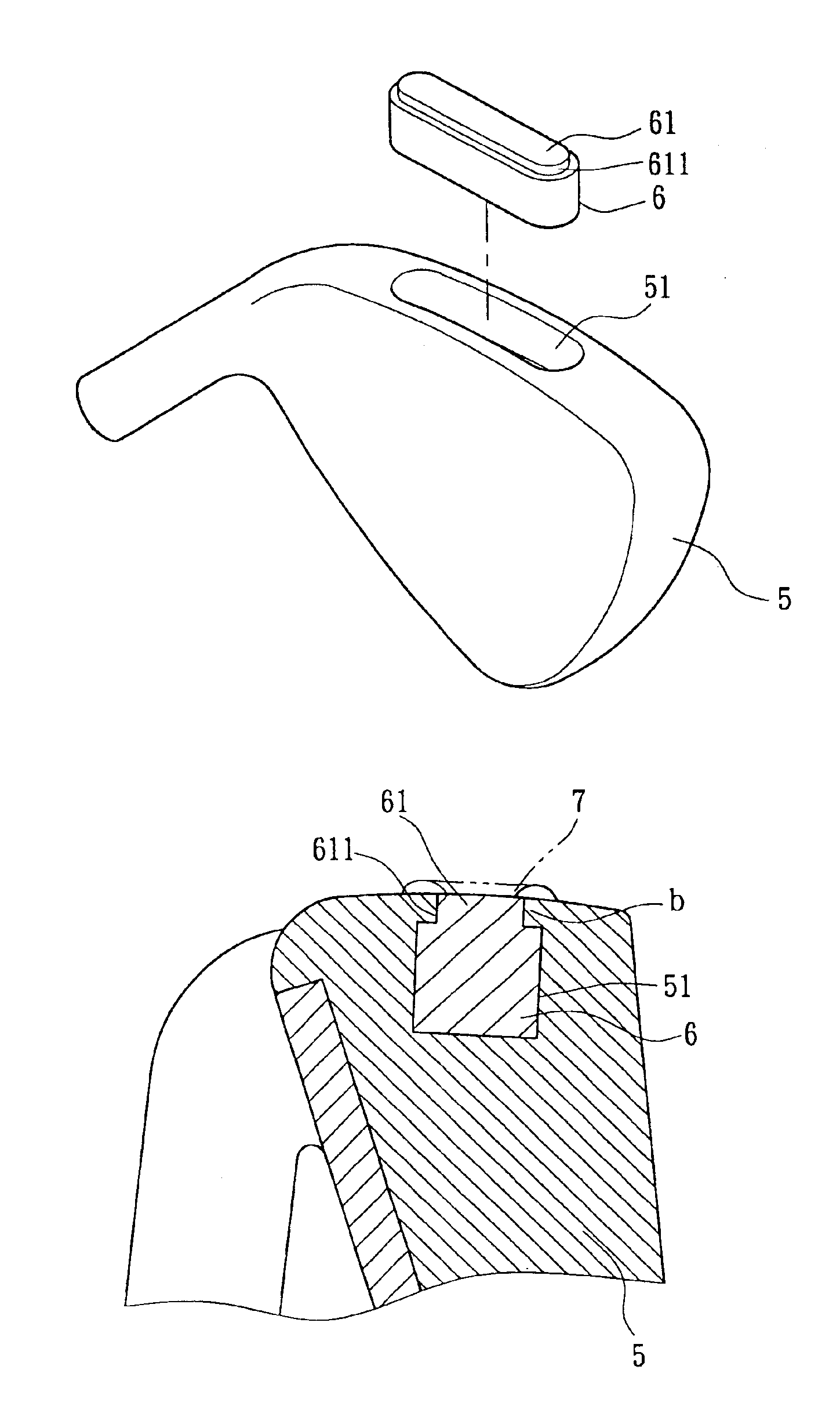

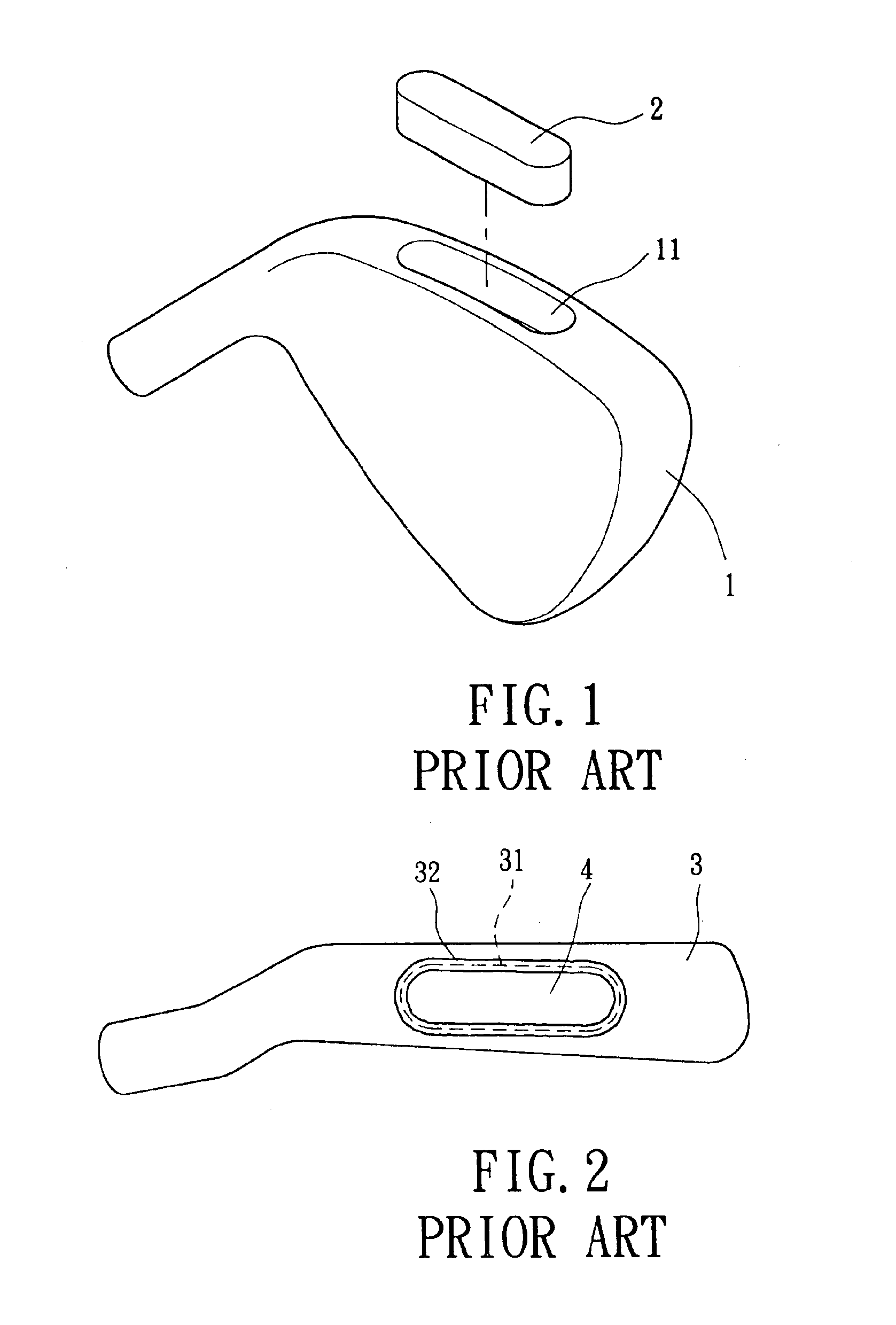

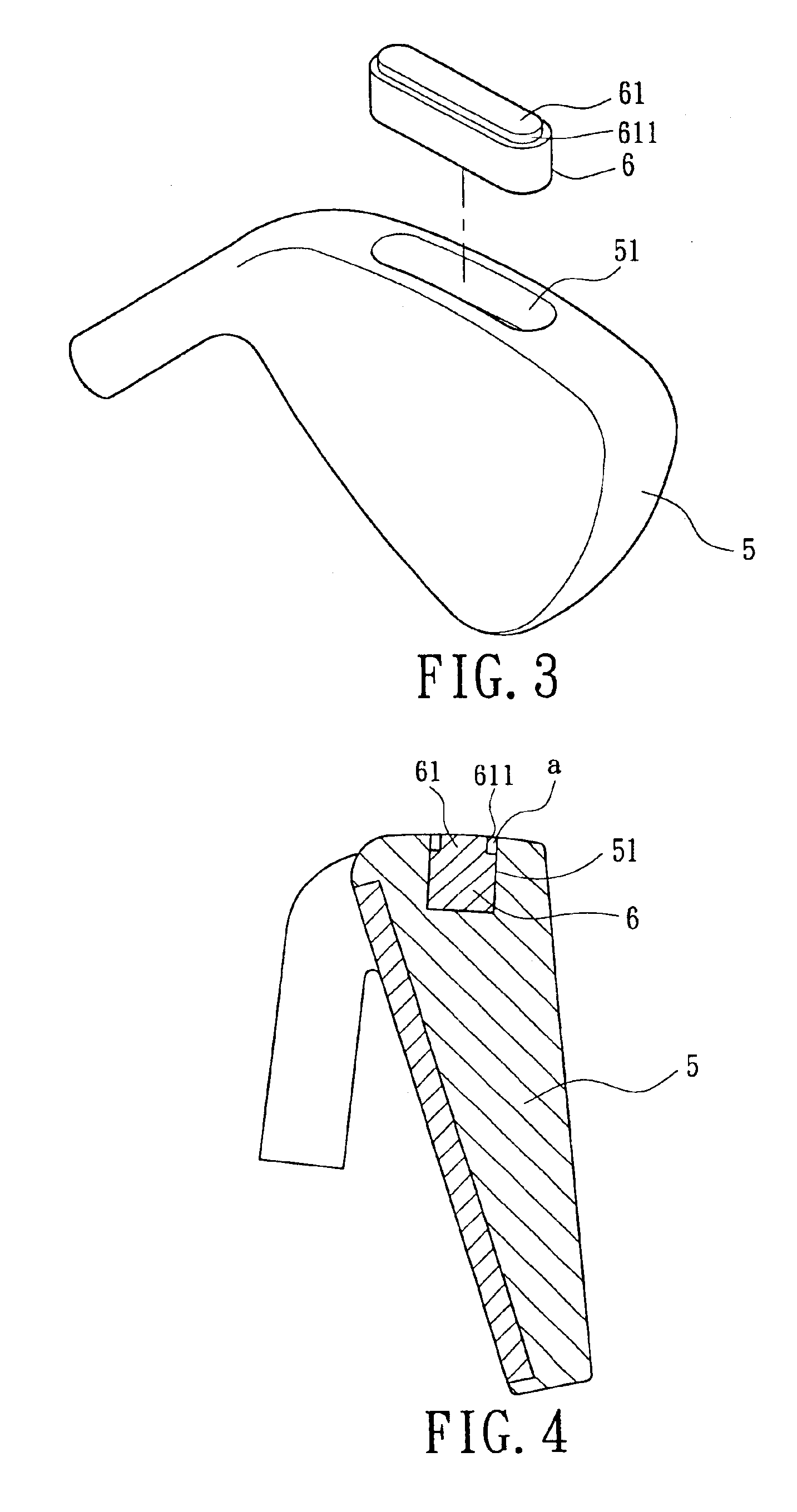

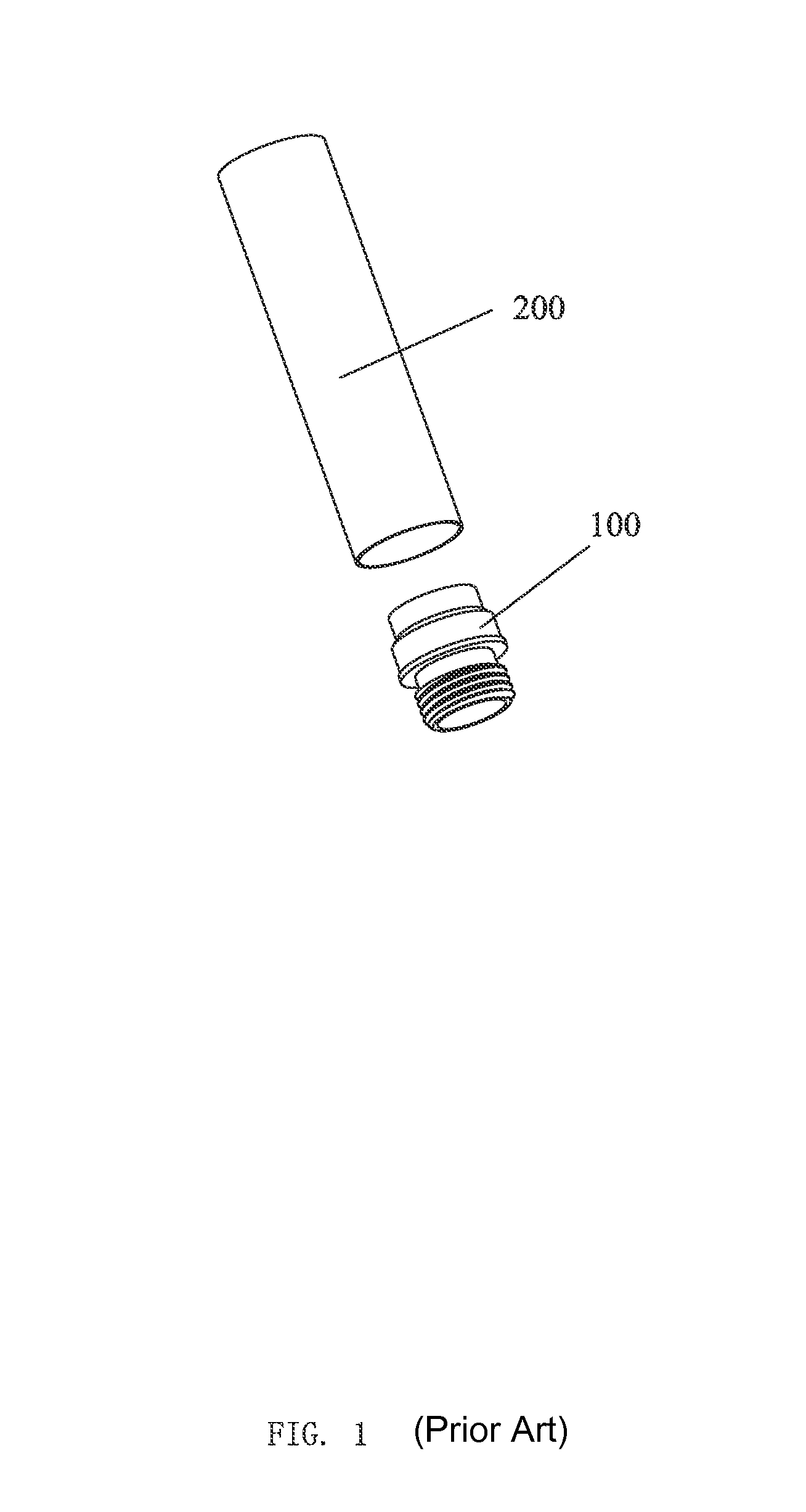

Weight number for a golf club head

A golf club head includes a golf club head body and a weight member. The golf club head member has a recession in which the weight member is mounted. The weight member is securely mounted in the recession of the golf club head body by a welding procedure that uses a welding material. The weight member is made of a material having a melting point higher than that of the golf club head body, avoiding melting of the weight member during the welding procedure. Only a portion of the golf club head body fuses with the welding material while using the welding material for proceeding with the welding procedure for the weight member.

Owner:FUSHENG PRECISION

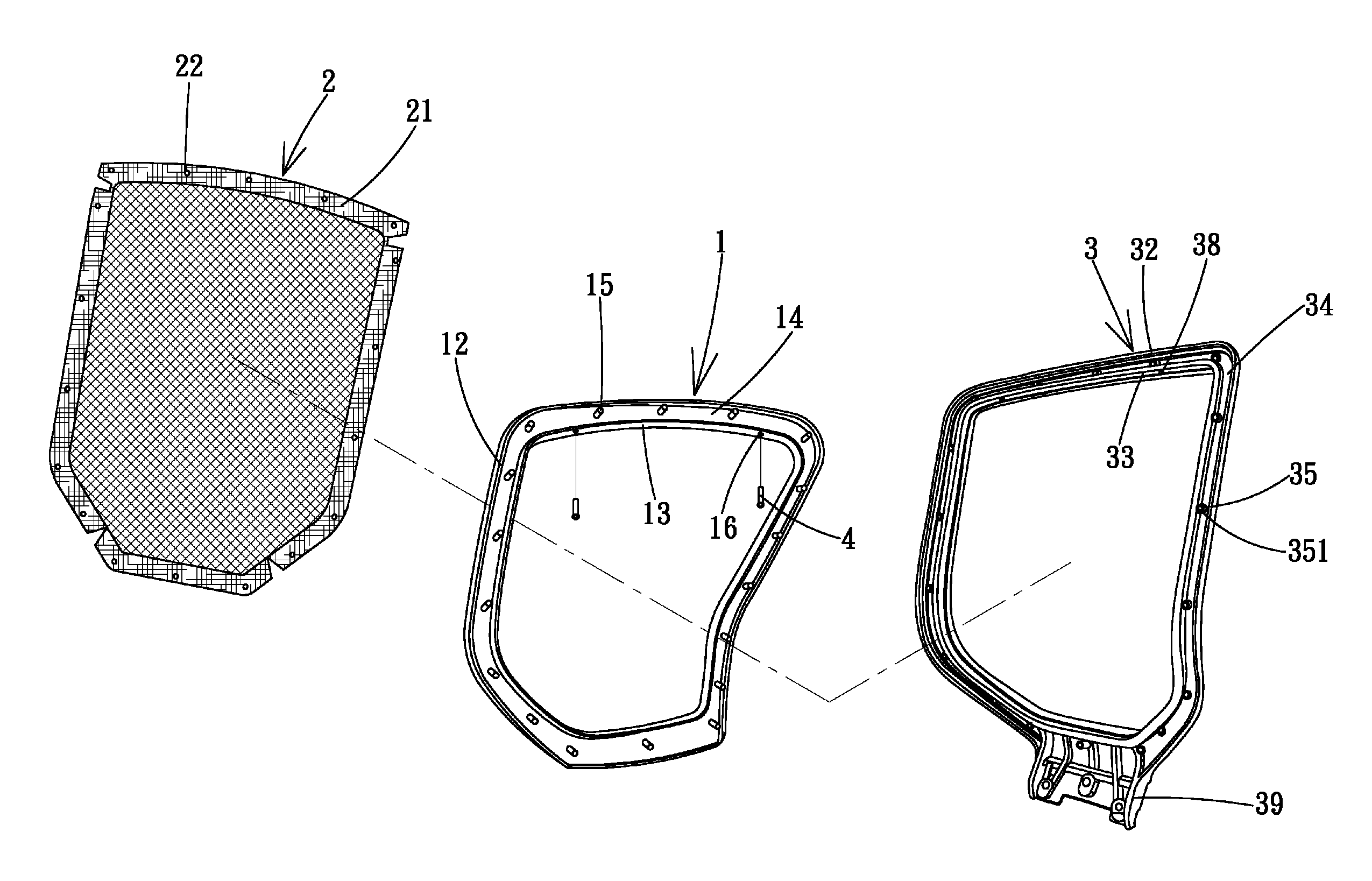

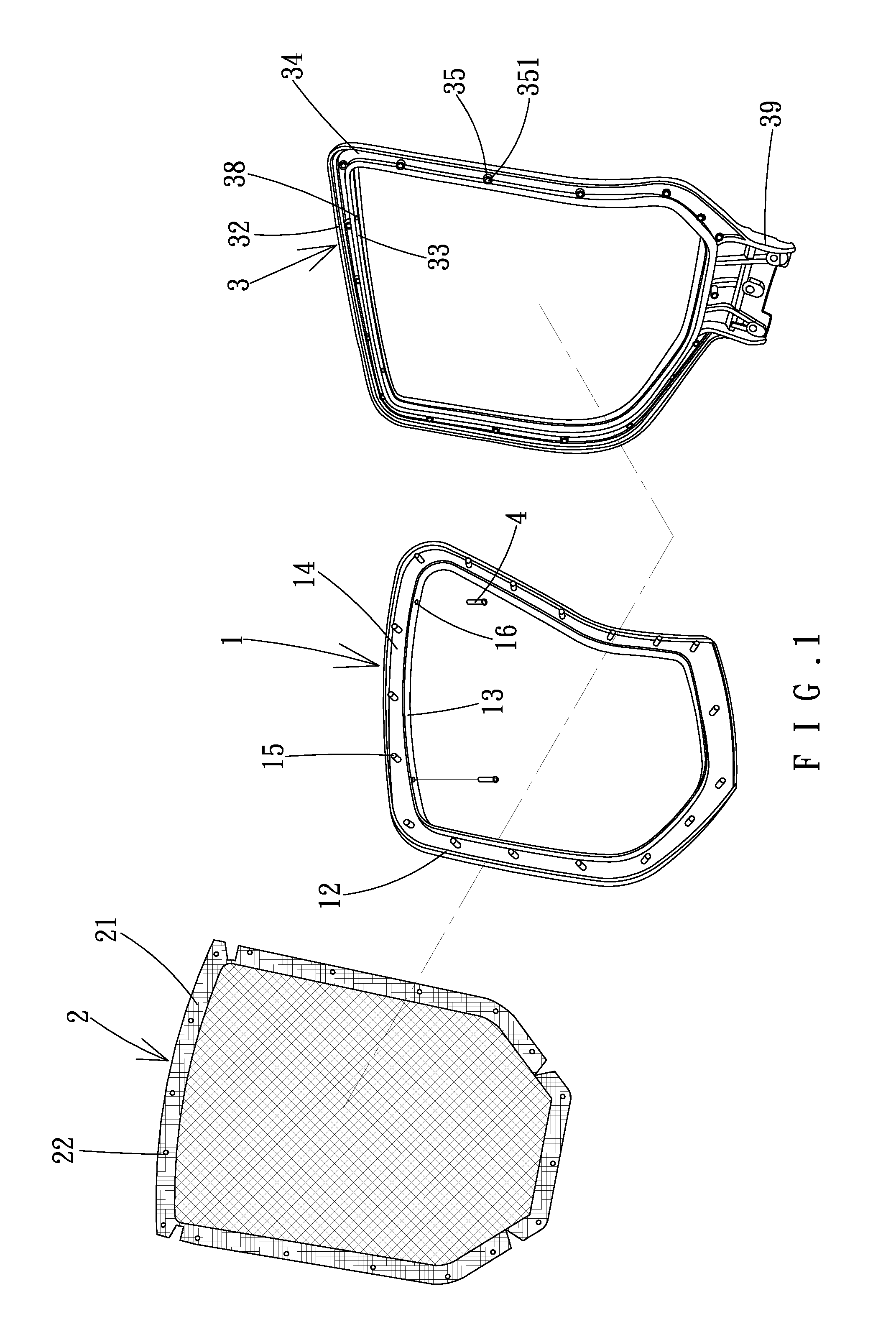

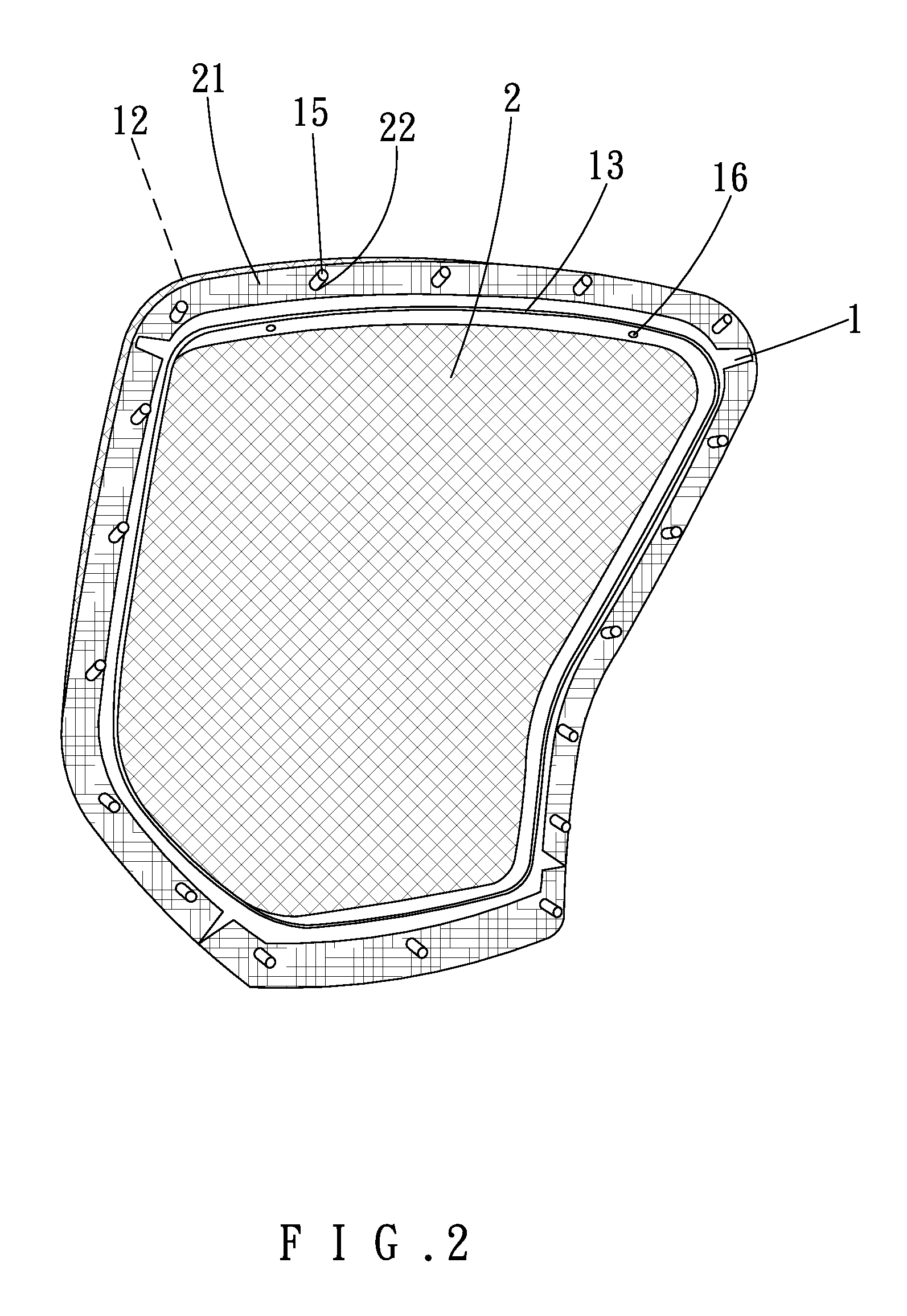

Backrest assembly

A backrest assembly includes an annular front frame having a front surface on which inner and outer annular flanges are formed, defining a first annular groove therebetween. A plurality of pegs is formed in the annular groove. A net is mounted in front of the front frame in a tightened state and includes a plurality of peg holes. A periphery of the net covers the outer annular flange of the front frame and is received in the first annular groove. Each peg of the front frame extends through one of the peg holes. Inner and annular wall are formed on a front face of an annular rear frame and define a second annular groove therebetween. A plurality of stubs is formed in the second annular groove. Each stub includes a receptacle receiving one of the pegs. Fasteners are extended through engaging holes in the front and rear frames.

Owner:SU TUNG HUA

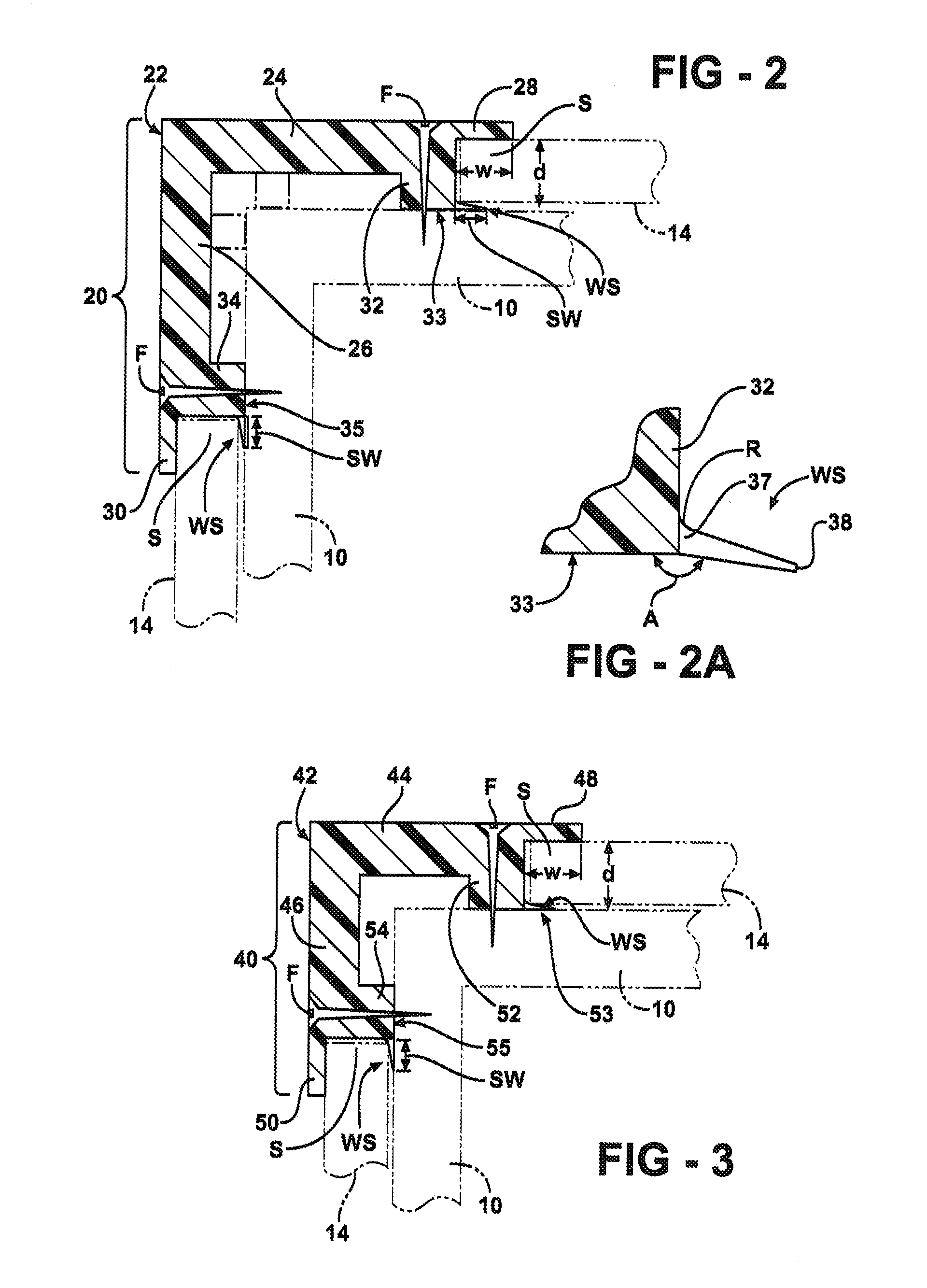

Exterior trim pieces with weather stripping and colored protective layer

Exterior trim pieces for use on exteriors of buildings. The exterior trim pieces include outside corner trim pieces, inside corner trim pieces, and framing trim pieces for providing an aesthetically pleasing appearance to an exterior of a building. Each of the trim pieces include a body and at least one flange extending from the body to define a concealing space for hiding siding ends and the like. Each of the trim pieces also includes at least one weather strip to assist in sealing the trim pieces to the exterior to prevent the intrusion of water and other elements behind the trim pieces. Each body of the trim pieces is preferably formed from co-extruded rigid cellular PVC and an acrylic-based protective layer. The rigid cellular PVC and the protective layer are formed in matching colors to yield colored-through trim pieces.

Owner:TAPCO INTERNATIONAL CORPORATON

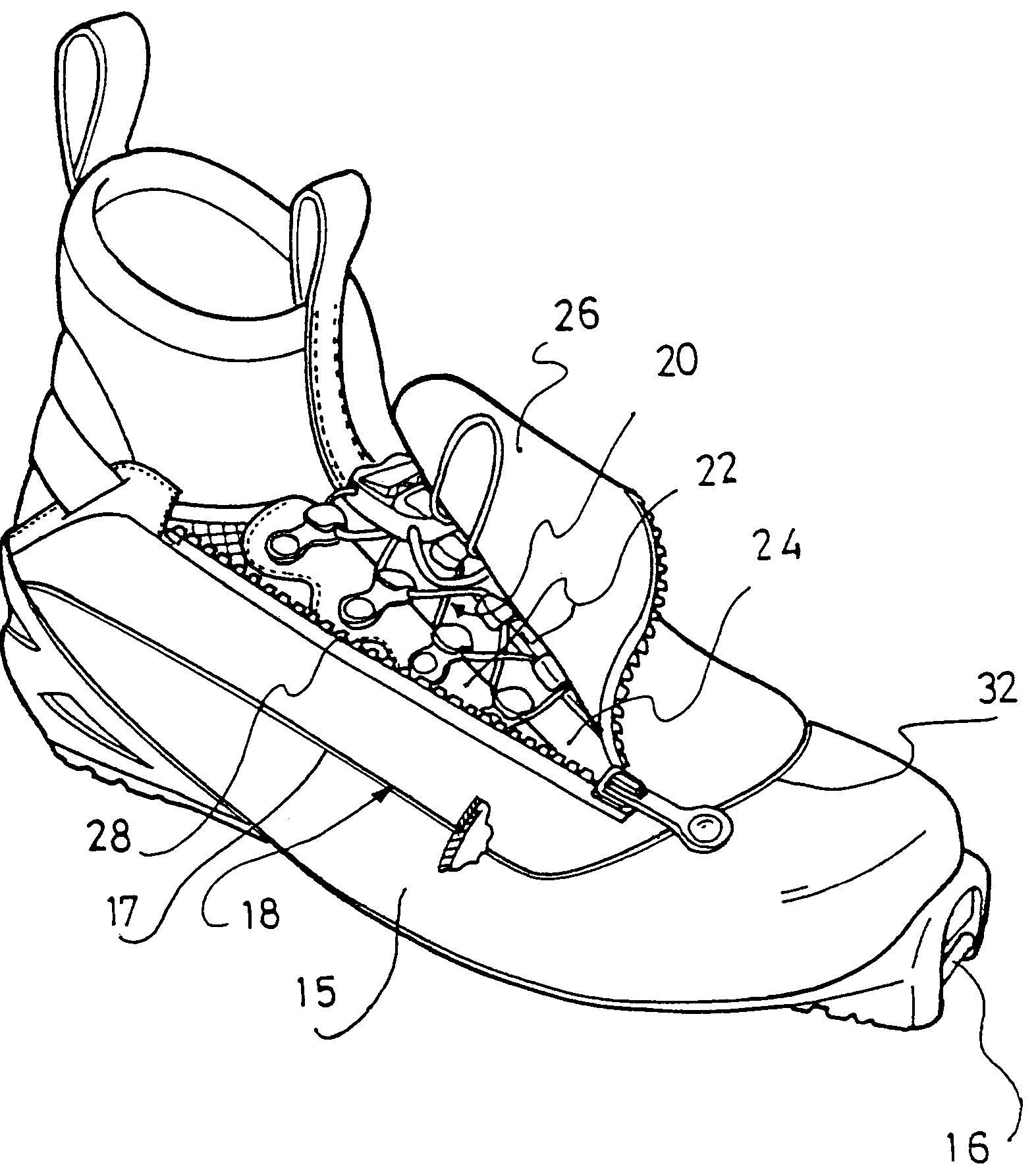

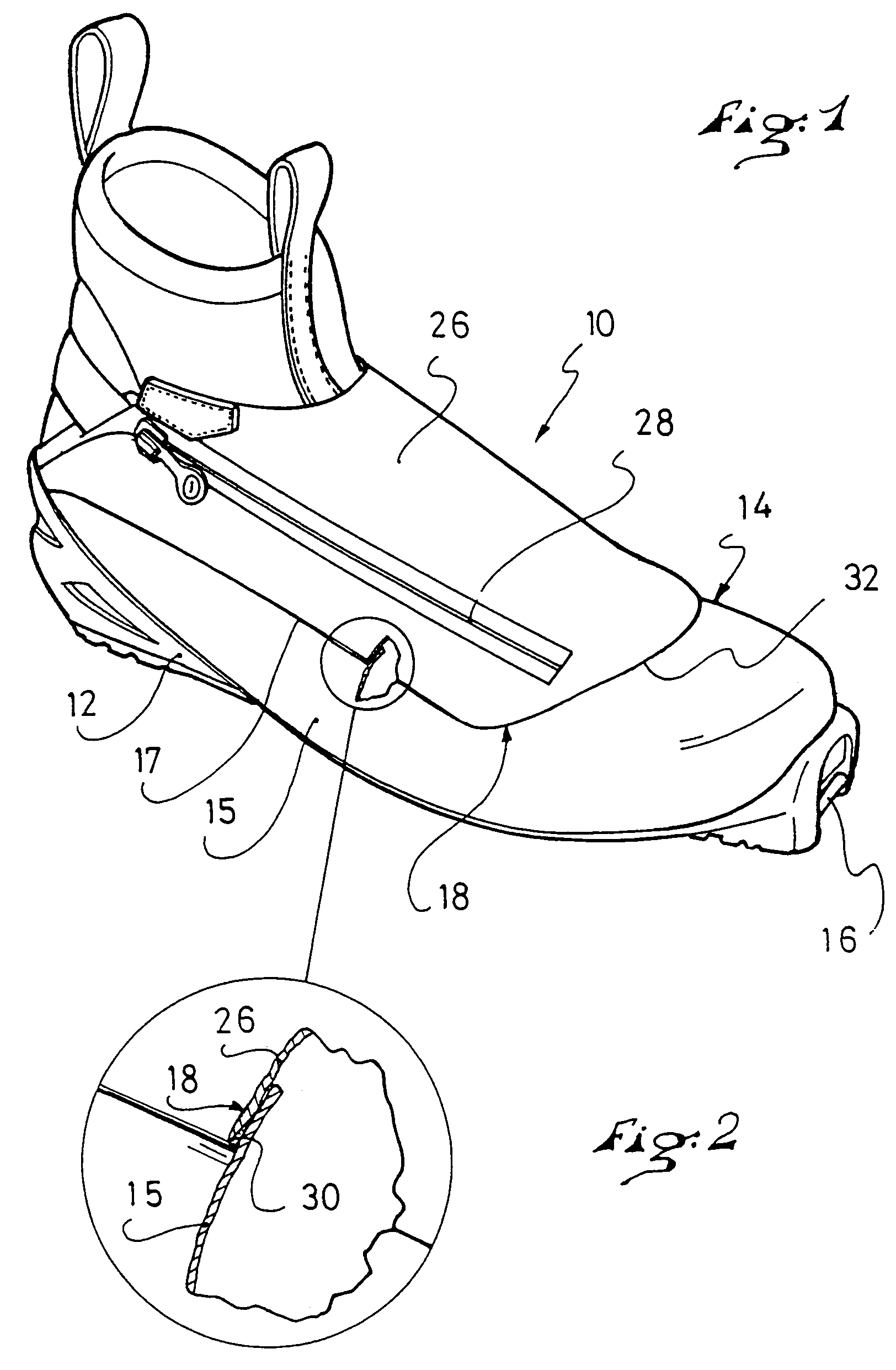

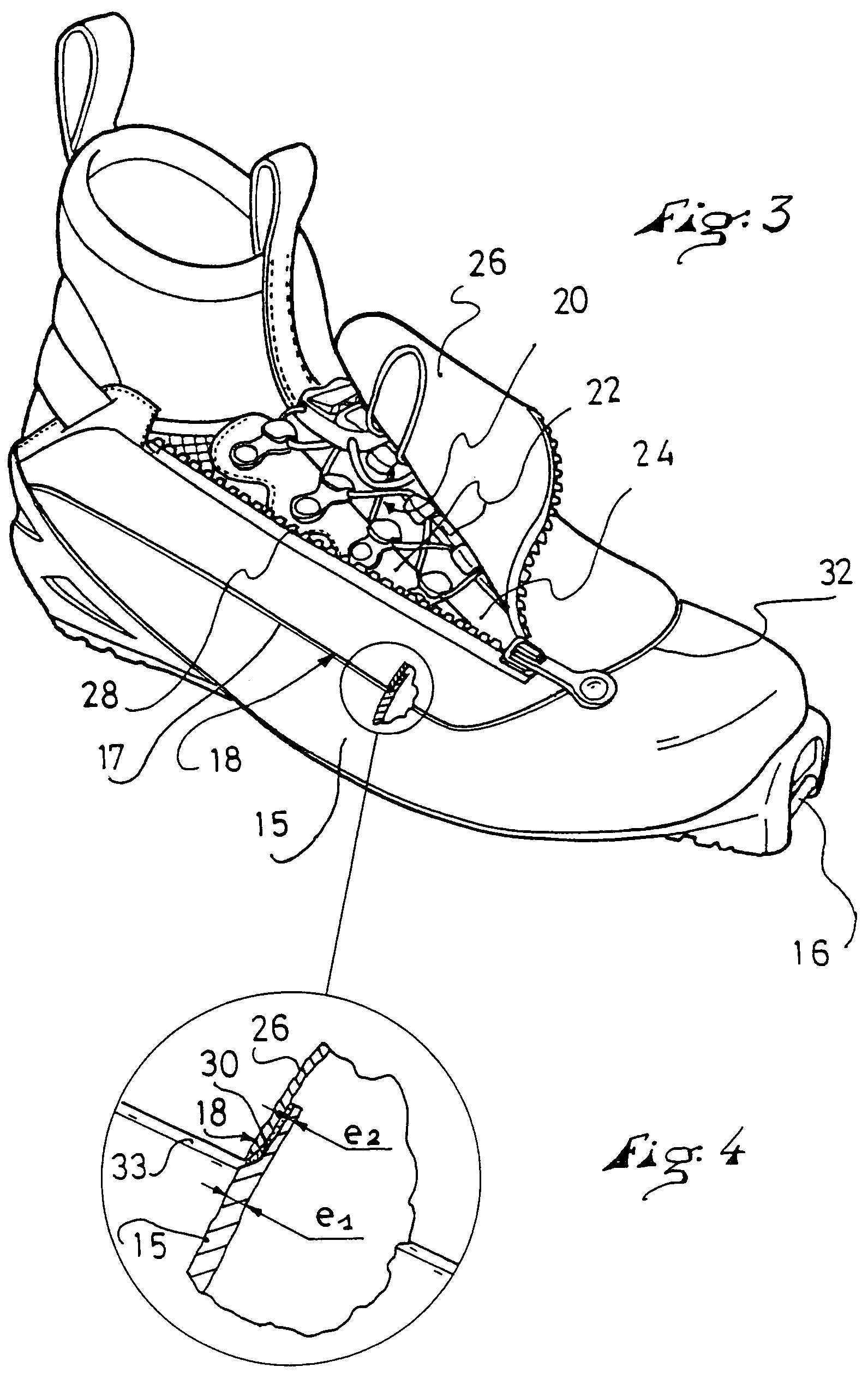

Footwear with an upper having at least one glued element

InactiveUS7650705B2Improve permeabilityEasy to wearLacing hooksUpperMechanical engineeringEngineering

Owner:SALOMON SA

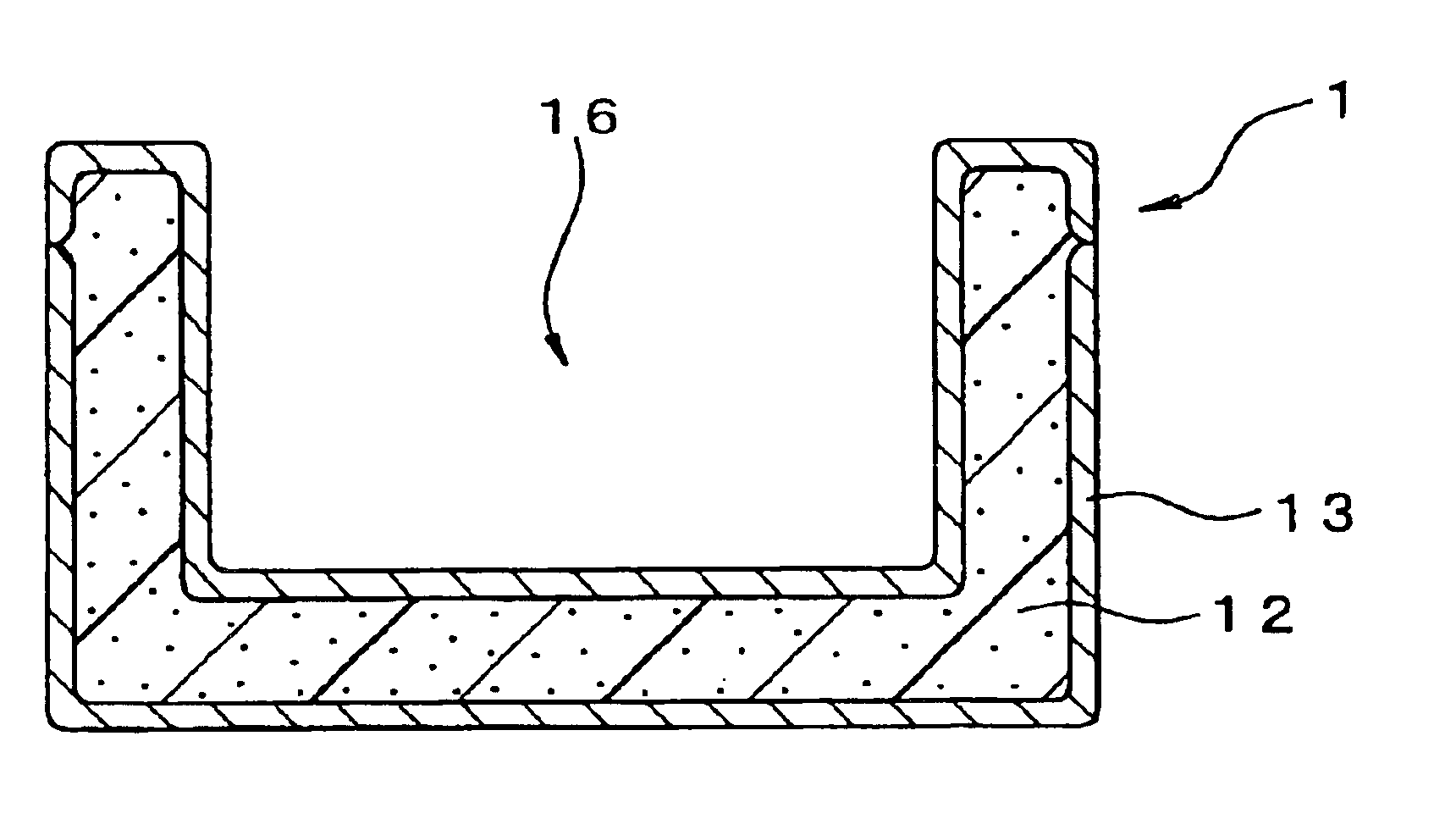

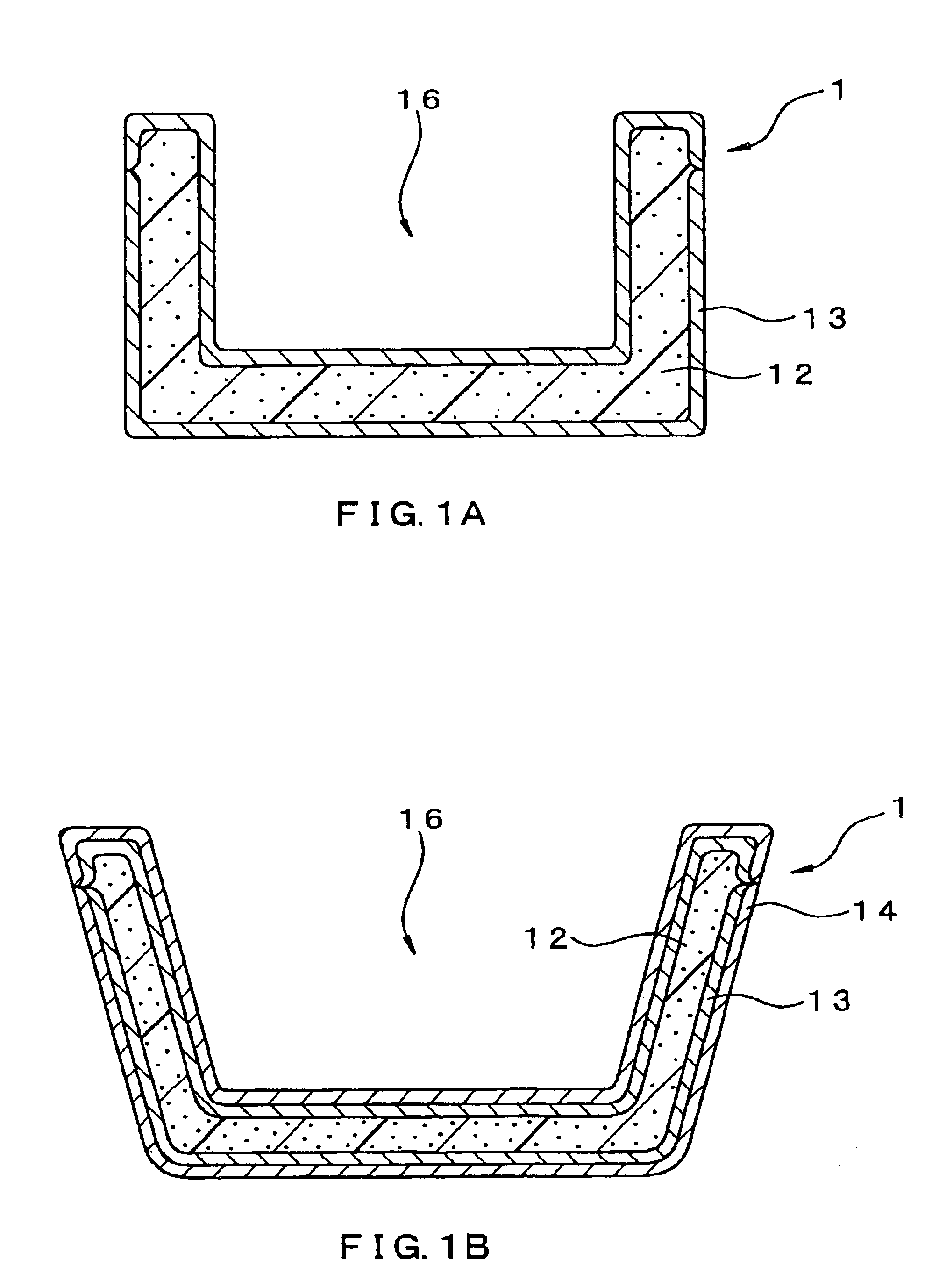

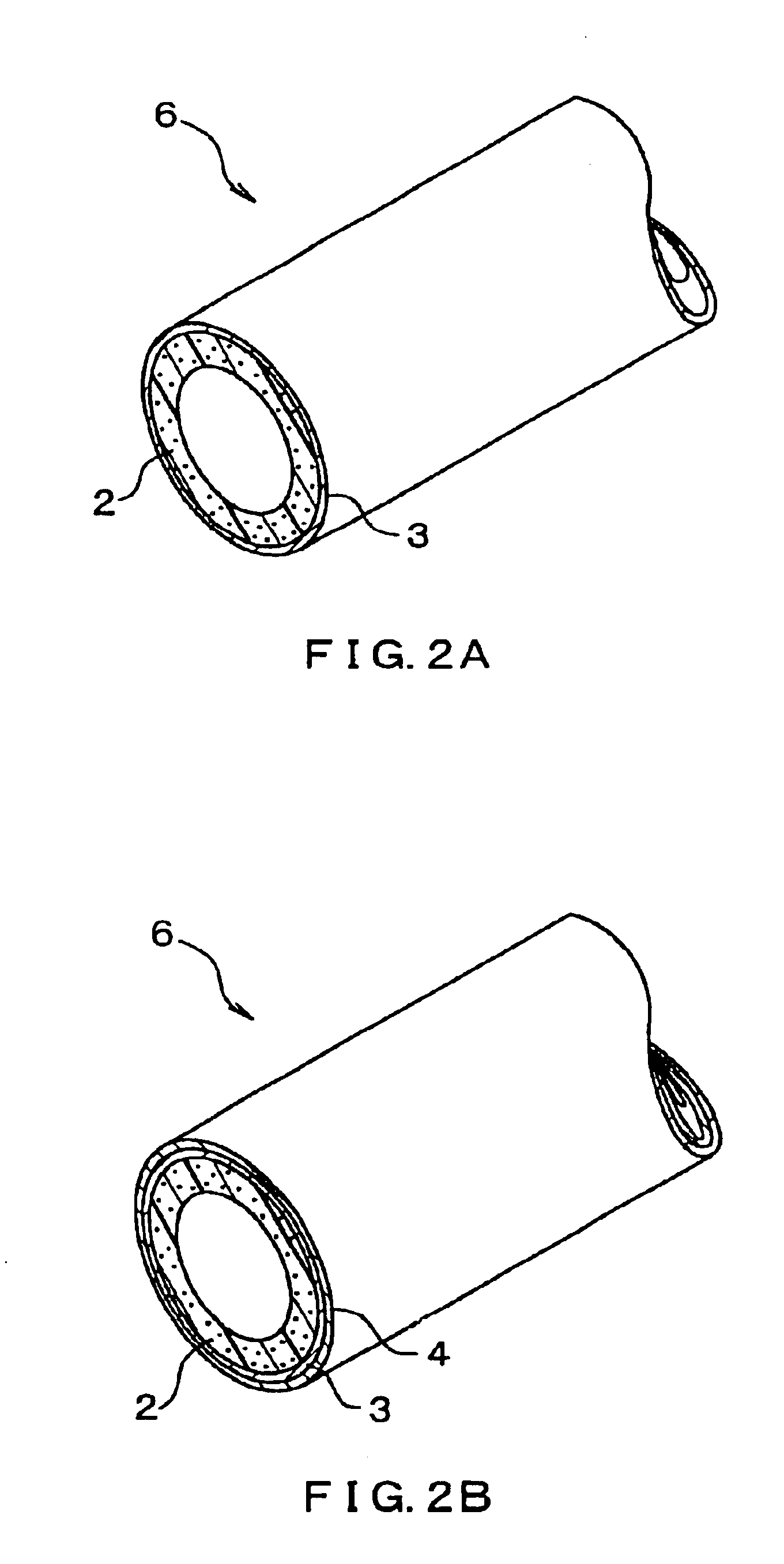

Multi-layer expansion-molded article of polypropylene resin, production process thereof, and container, shock-absorbing material for automobile and automotive member formed of the multi-layer expansion-molded article of polypropylene resin

InactiveUS6875484B1Beautiful appearanceExcellent in lightweight propertyEnvelopes/bags making machineryDomestic containersShell moldingPolypropylene

A multi-layer expansion-molded article of a polypropylene resin, which is obtained by molding a multi-layer parison comprising a foamed resin layer and a resin layer provided on the outer side of the foamed resin layer in a mold in such manner that at least part of the opposed inner surfaces of foamed resin layer in the parison are fusion-bonded to each other, and has a polypropylene resin layer on the surface of a foamed polypropylene resin layer, wherein a melt tension, MTfr (gf) and a melt flow rate, MFRfr (g / 10 min) obtained by measurement to a polypropylene resin forming the foamed resin layer in the expansion-molded article satisfy the relationship [log MTfr>−0.74 log MFRfr+0.66], and a melt tension, MTur (gf) and a melt flow rate, MFRur (g / 10 min) obtained by measurement to a polypropylene resin forming the resin layer on the surface of the foamed resin layer satisfy the relationship [log MTur>−1.02 log MFRur+0.47].

Owner:JSP CORP

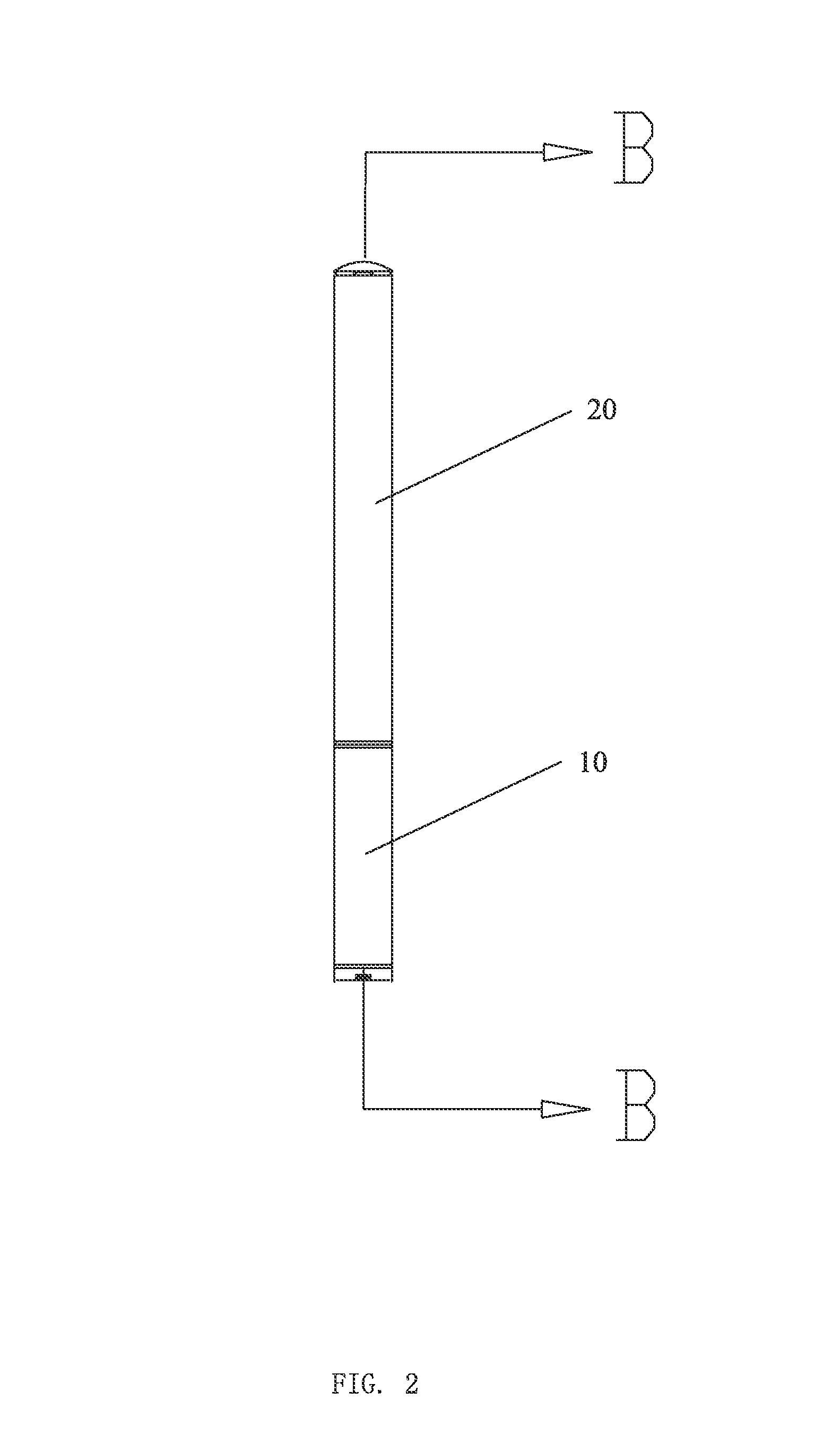

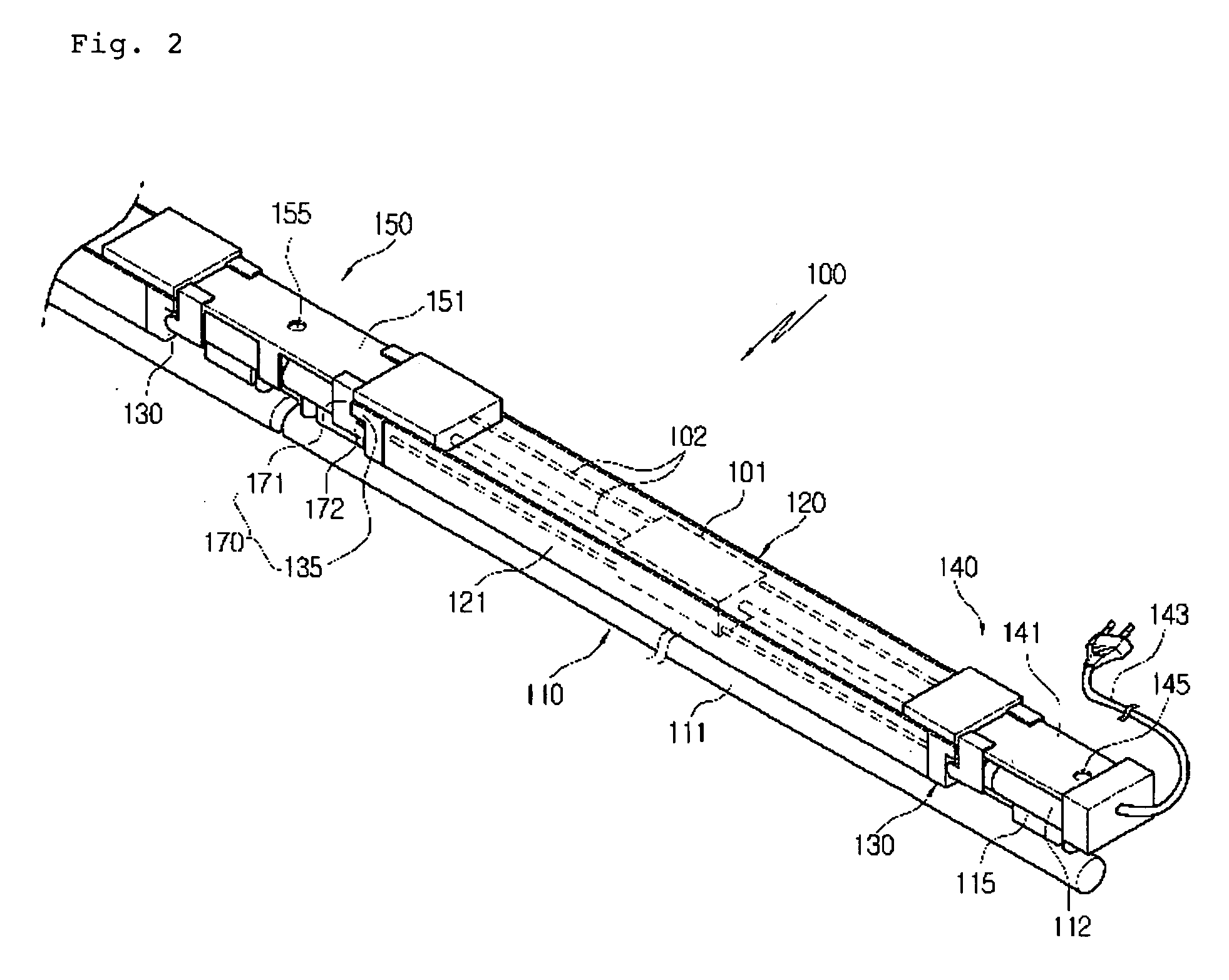

Electronic cigarette inhalation rod and electronic cigarette using the same

InactiveUS20140373833A1Stable structure productEasy to assembleMedical devicesTobacco devicesEnvironmental healthInhalation

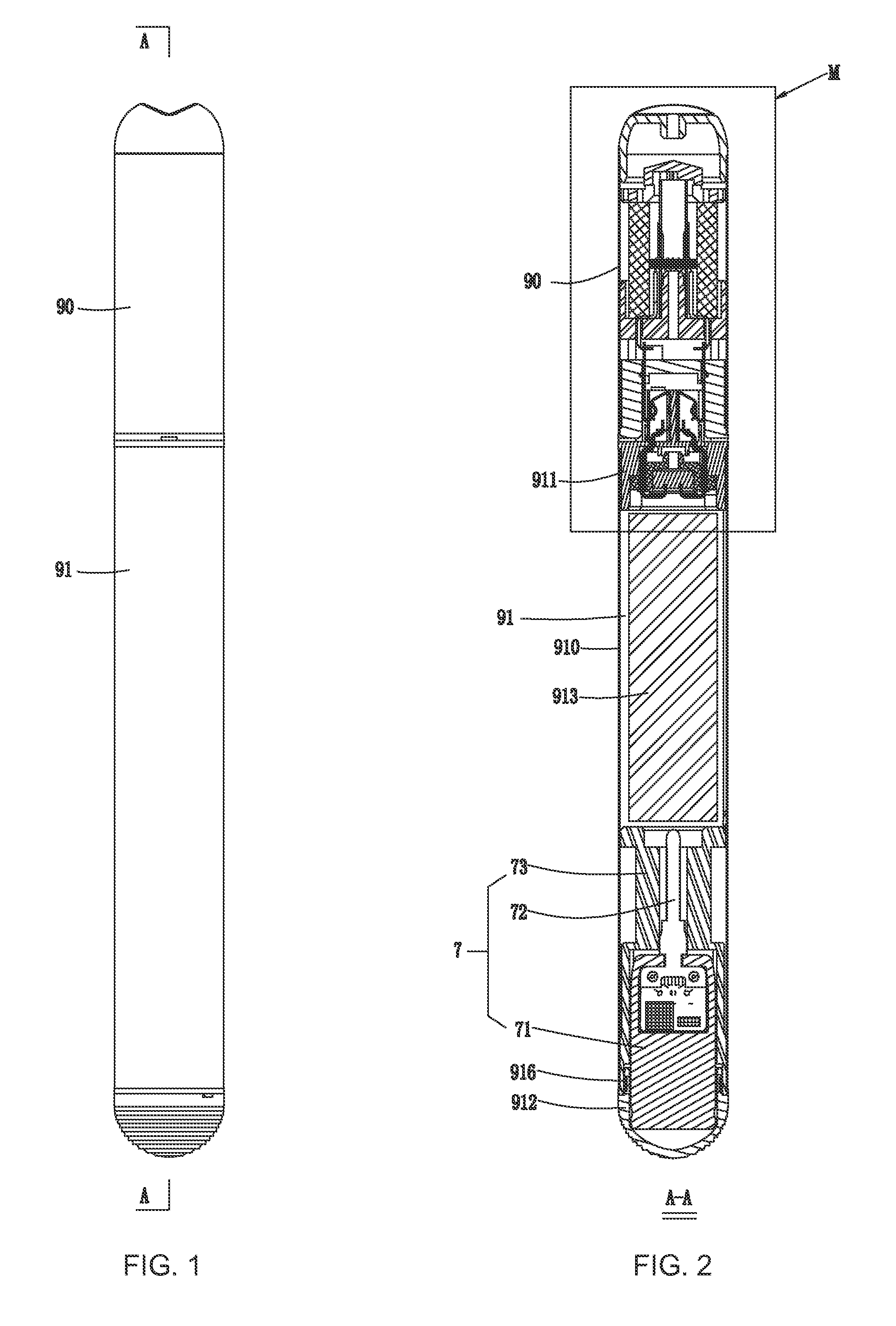

The present invention relates to an electronic cigarette inhalation rod and an electronic cigarette. The electronic cigarette inhalation rod includes an inhalation tube and a first connector disposed at one end of the inhalation tube. The inhalation tube and the first connector are an integrally formed structure. Therefore, by the integral formed structure of the inhalation tube and the first connector, on one hand the first connector will not fall down from the inhalation rod, the product is of stable structure, good quality, and easy to use; on the other hand, the assembly is convenient and the appearance is beautiful. The electronic cigarette includes the inhalation rod and a battery rod. The electronic cigarette inhalation rod and the battery rod are matchingly connected.

Owner:KIMREE HI TECH

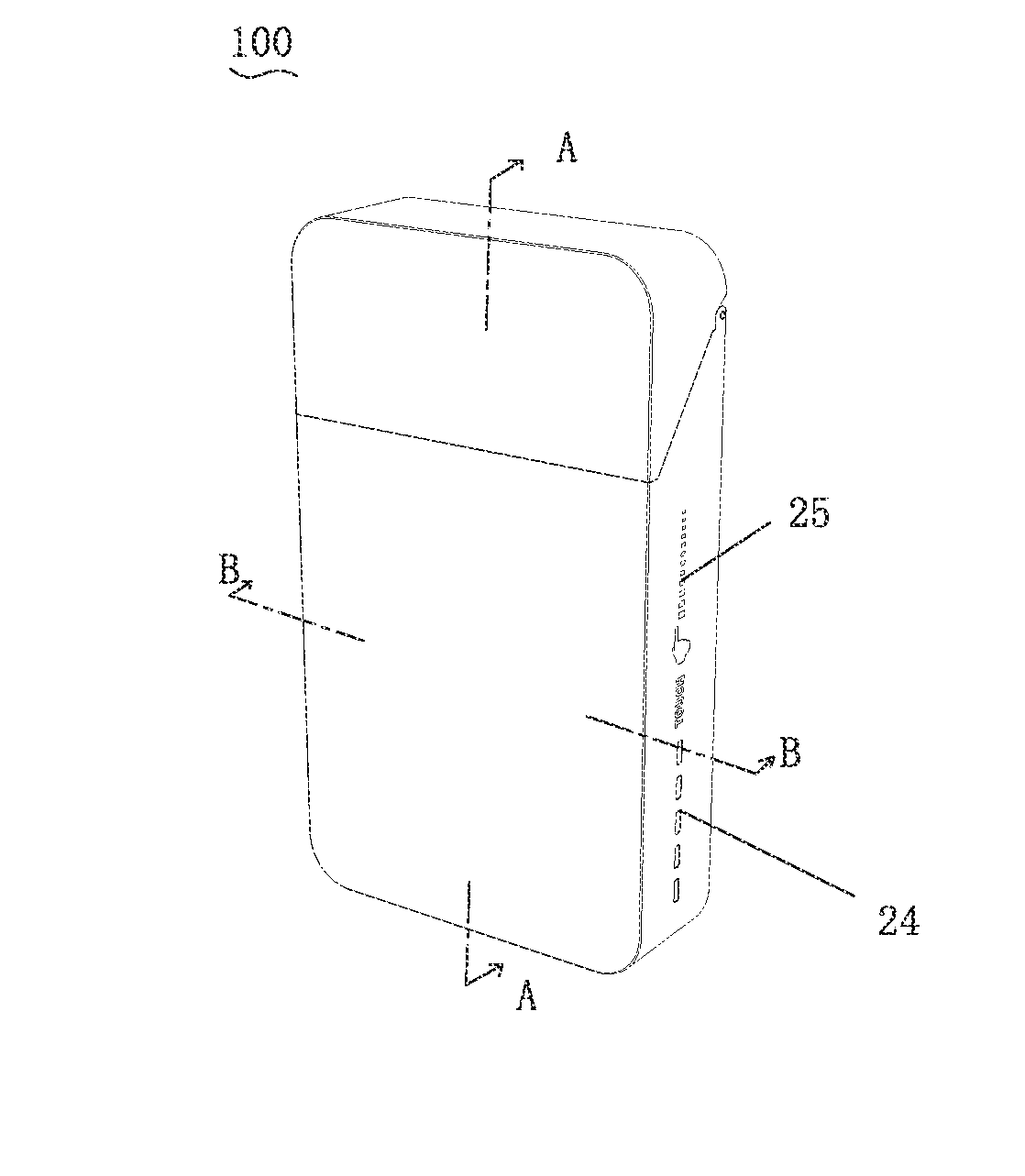

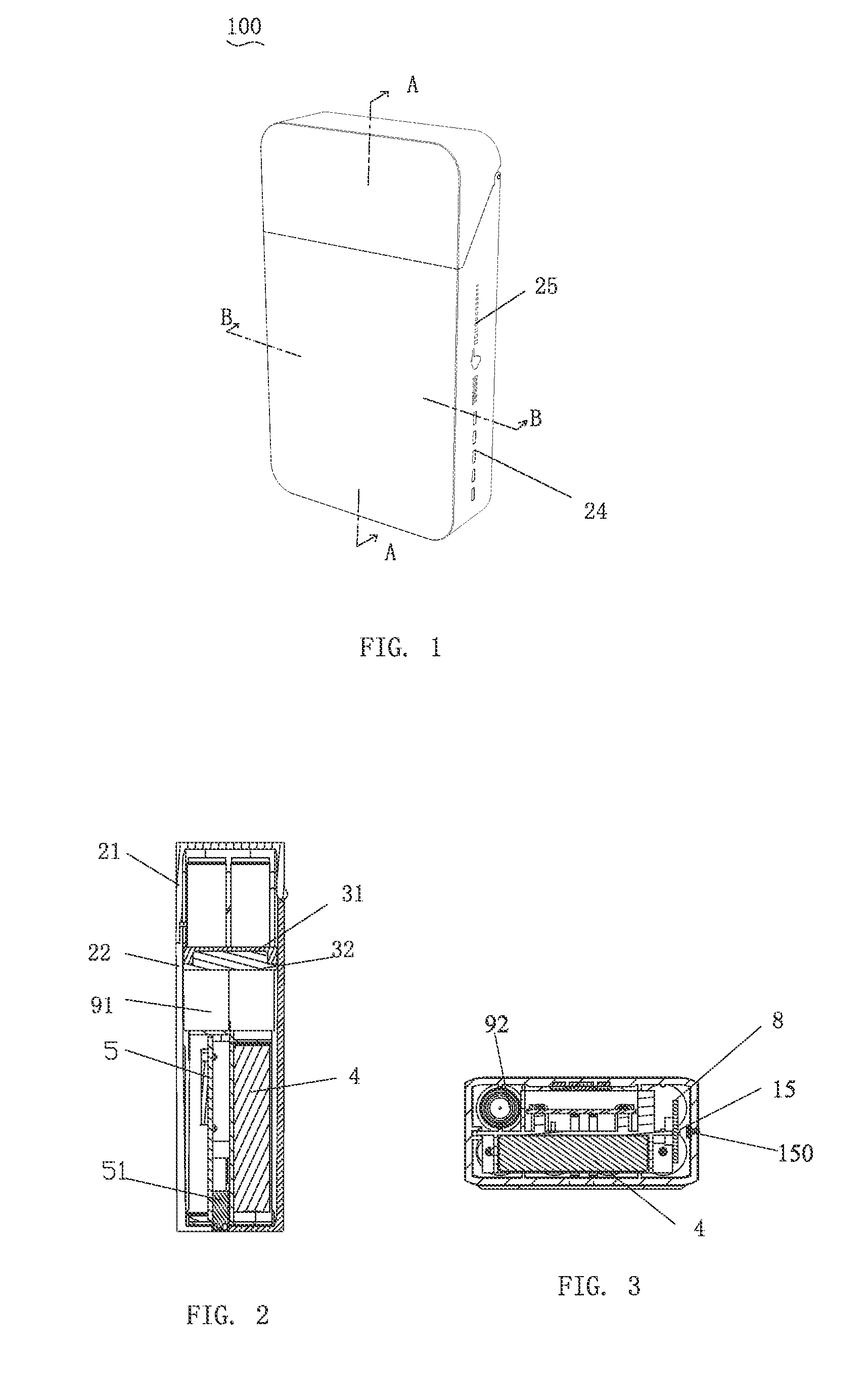

Electronic cigarette case

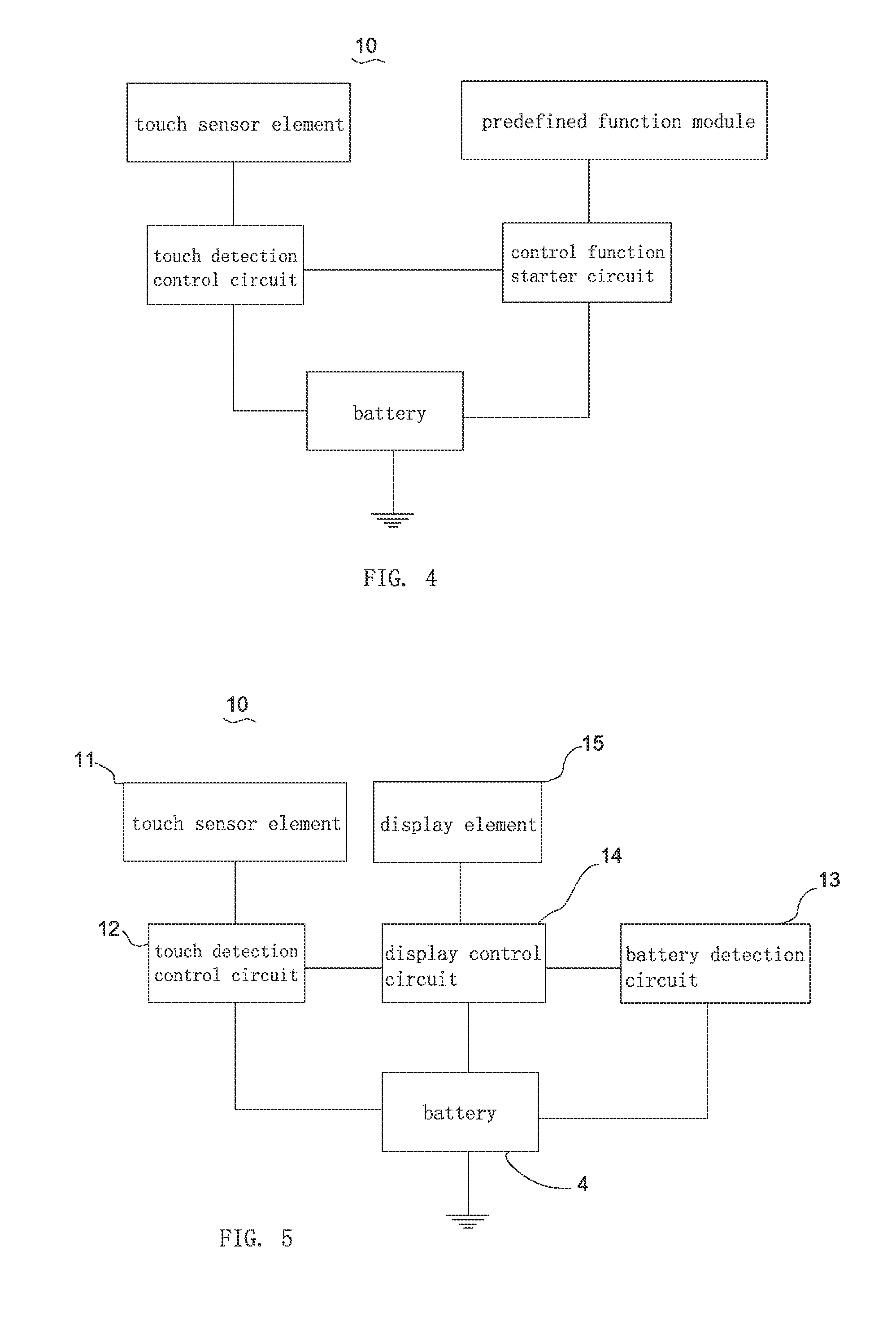

InactiveUS9271525B2Rapid responseSave spaceTobacco pipesElectronic switchingComputer moduleElectronic cigarette

The present invention relates to an electronic cigarette case, including a case body, a frame module disposed in the case body, a battery module, and a printed circuit board (PCB) module. The electronic cigarette case further has a touch control method for performing at least a predefined function. The touch control method includes: defining a touch zone on the case body, and providing a touch control module in the case body. The at least a predefined function is performed to indicate an electric quantity of a battery when a finger touch gesture is detected on the touch zone by the touch control module. The electronic cigarette case is durable, waterproof and dustproof, rapidly response, space saving, and easy to use.

Owner:HUIZHOU KIMREE TECH

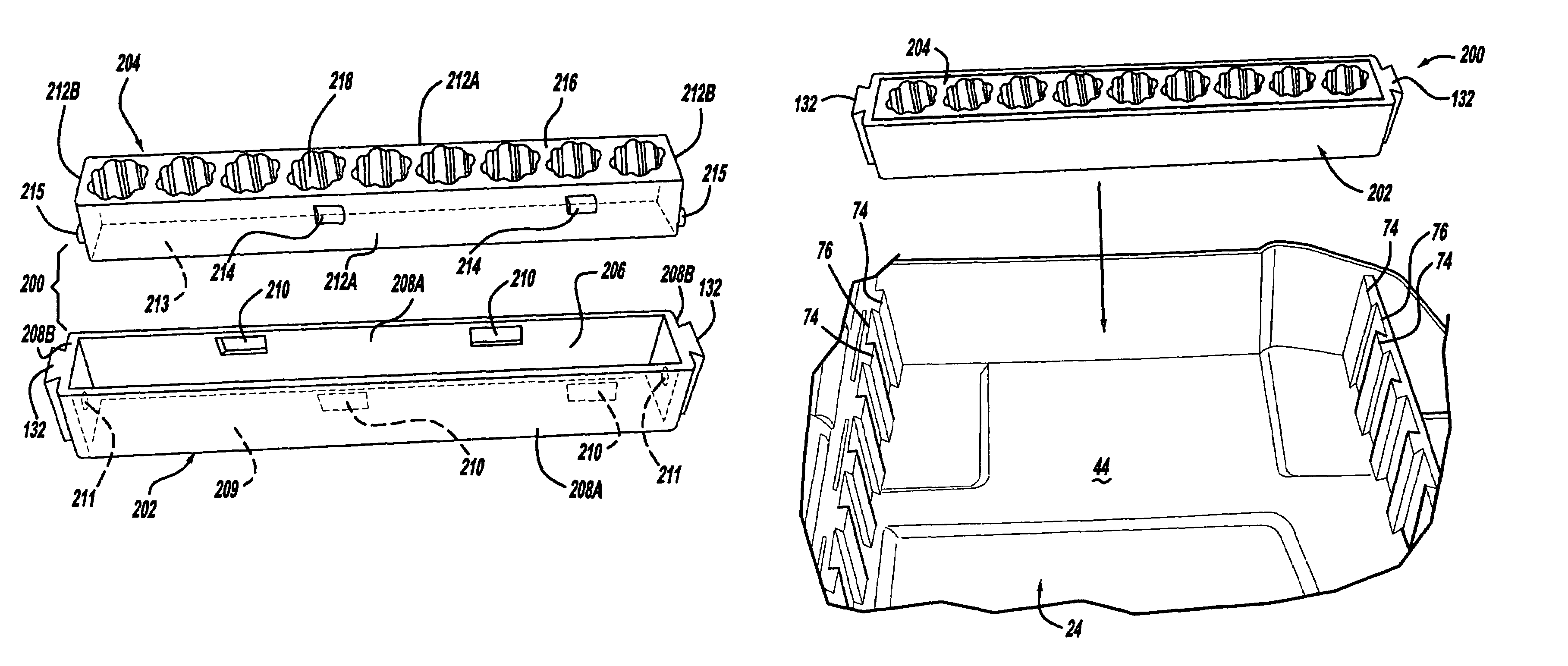

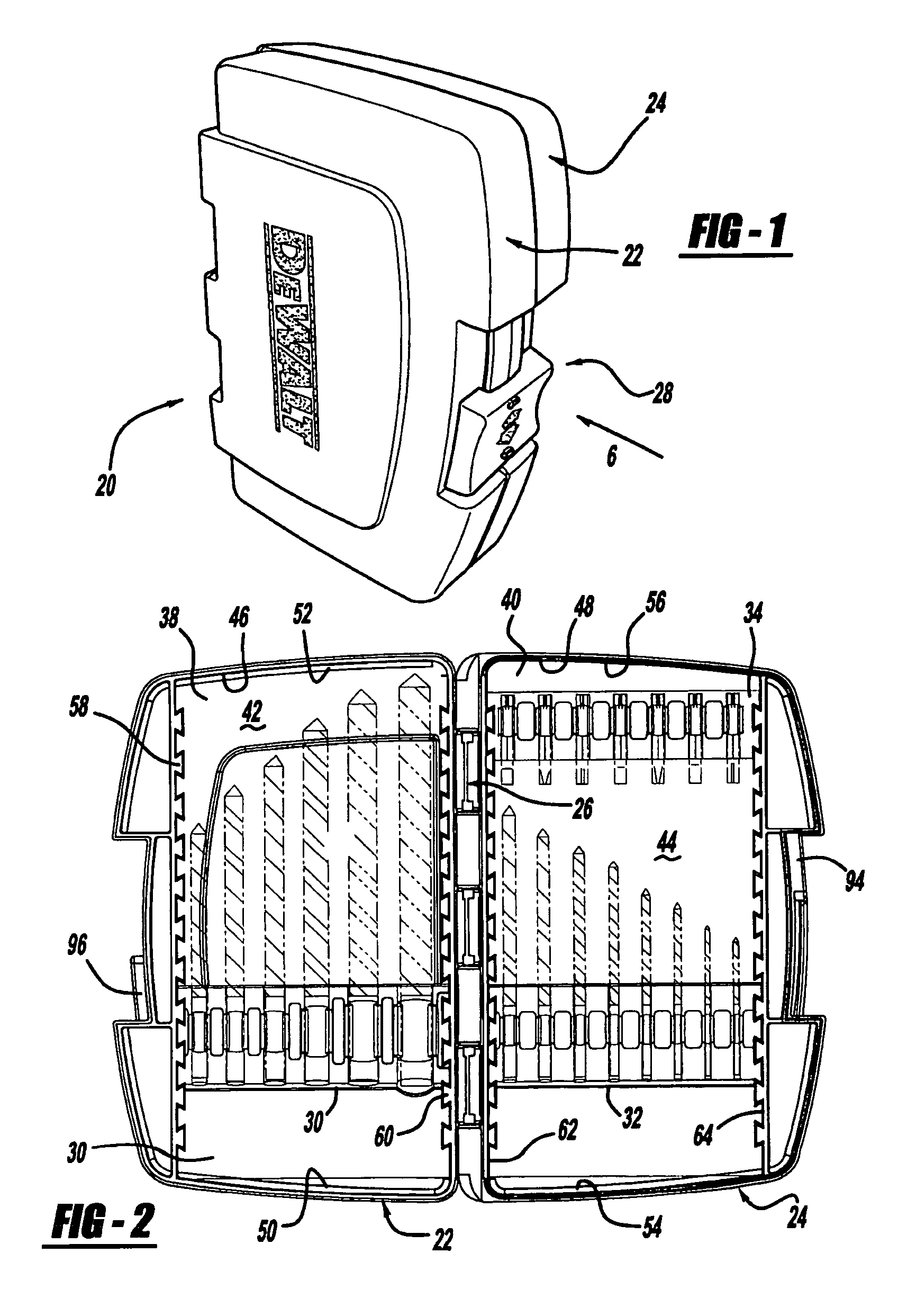

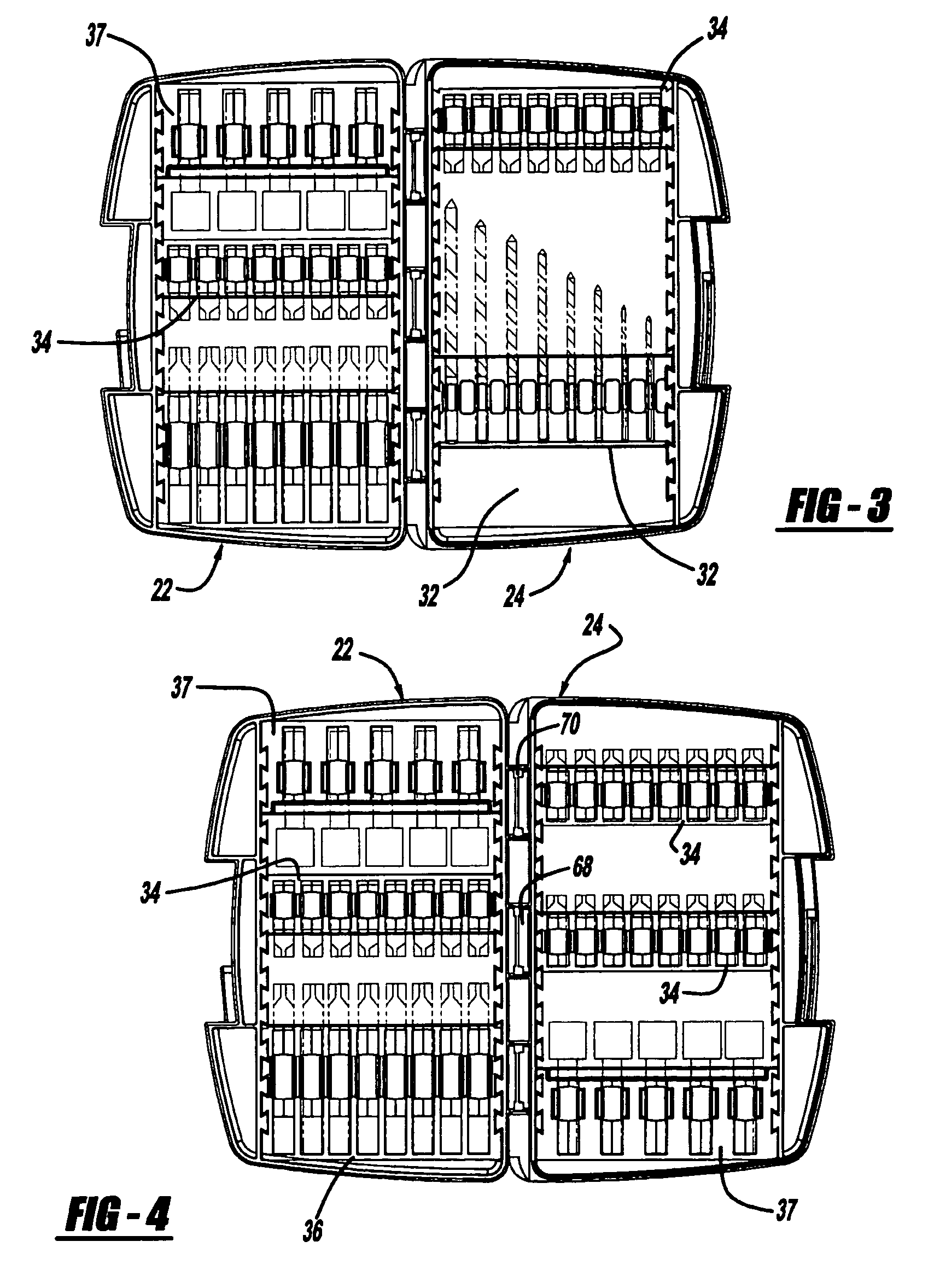

Tool container

ActiveUS7322470B2Easy to operateDurableOther accessoriesContainer/bottle contructionMechanical engineeringEngineering

Owner:BLACK & DECKER INC

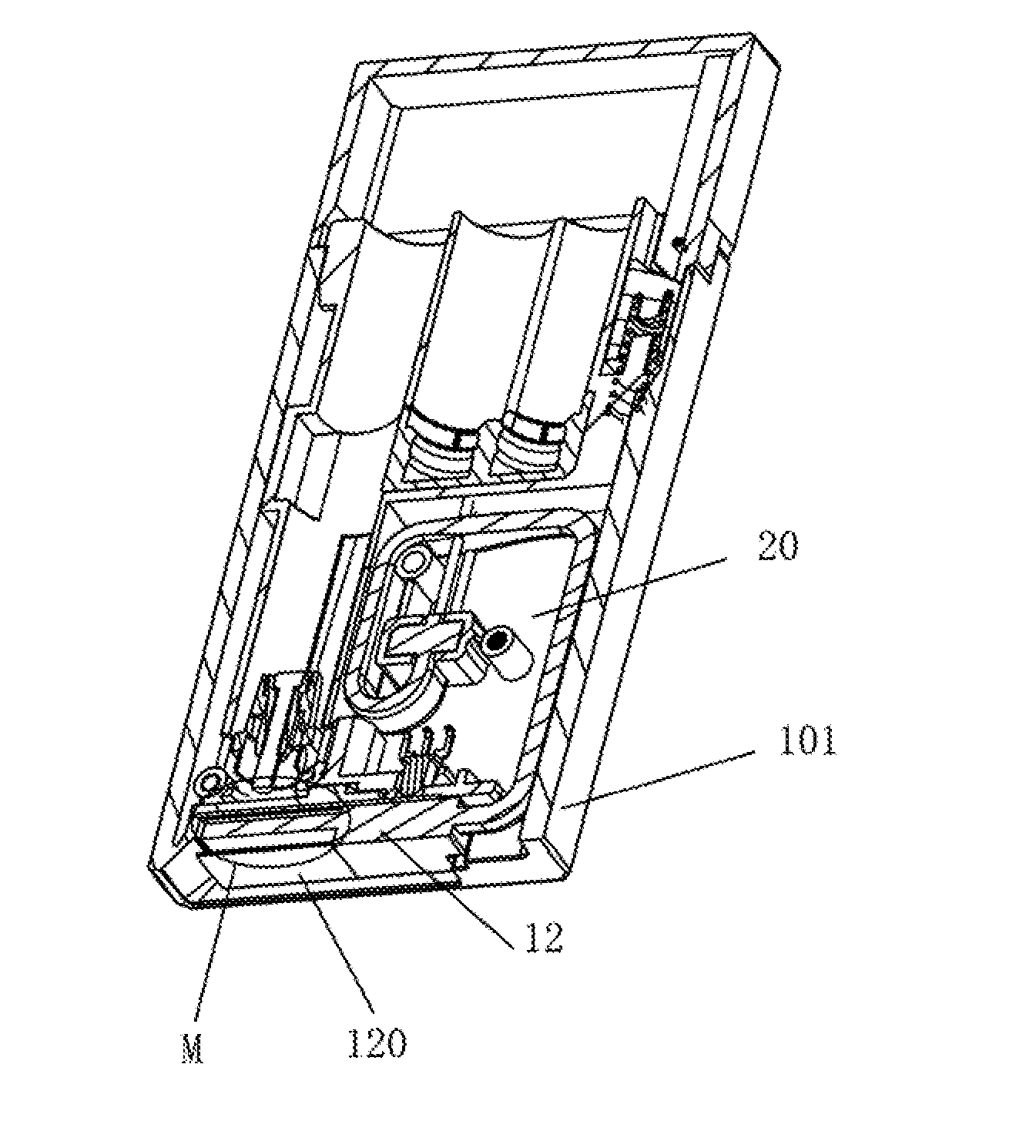

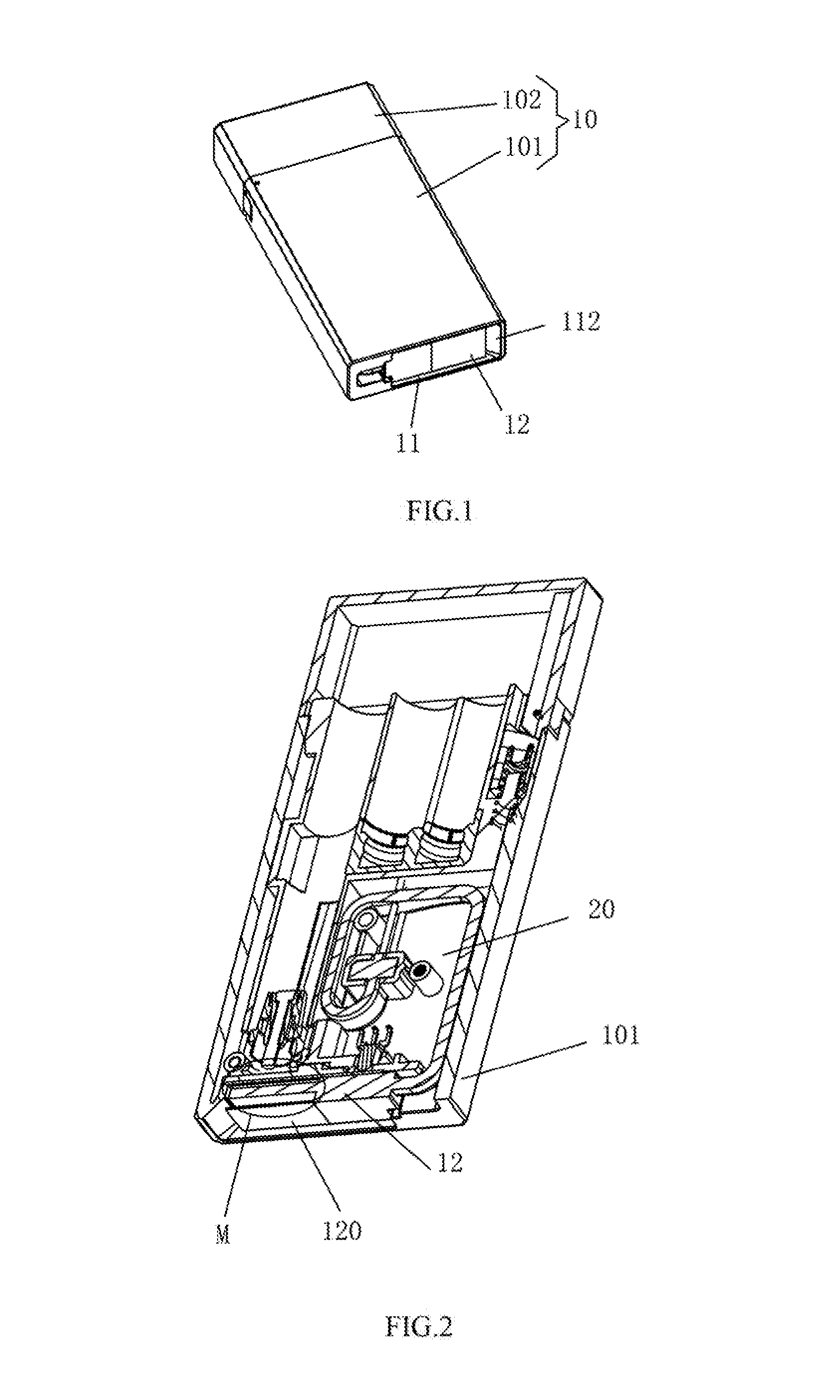

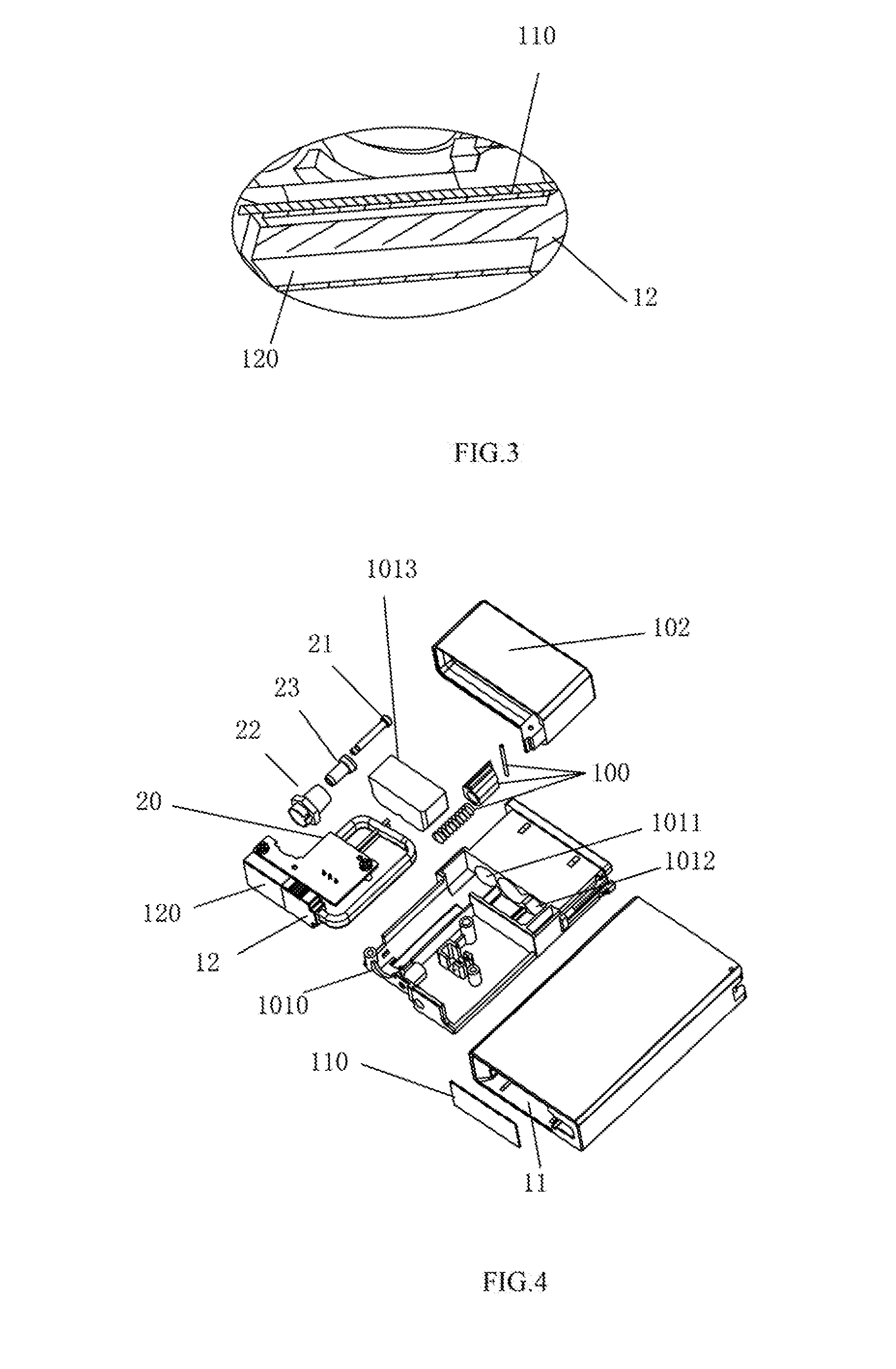

Electronic cigarette case

InactiveUS20160134143A1Reliable qualityQuality improvementBatteries circuit arrangementsTobacco devicesEngineeringElectrical and Electronics engineering

An electronic cigarette case, comprising a case body. The case body is provided on a surface thereof with an accommodation groove. The accommodation groove has movably accommodated therein a charging connector. The charging connector has arranged thereon a first magnetic piece. The accommodation groove has arranged at one side thereof a second magnetic piece that is matched with and magnetically attracted to the first magnetic piece. By employing the technical means of having arranged on the charging connector the first magnetic piece and of having arranged at one side of the accommodation groove the second magnetic piece that is matched with and magnetically attracted to the first magnetic piece, the electronic cigarette case achieves reliable quality and the technical effect that the charging connector does not come loose and allows the charging connector to be fixed without requiring an interference fit.

Owner:KIMREE HI TECH

Cement concrete permeable brick, permeable road and production methods thereof

InactiveCN101671987AComply with quality deviationMitigate the heat island effectSingle unit pavingsClimate change adaptationPondingBrick

The invention relates to a cement concrete permeable brick, a cement concrete permeable road and production methods thereof. At present, most of urban construction adopting the rigid hardened ground has the problems of dust blowing at a fine day, water accumulation and impermeable ground at a rainy day, no groundwater level supplement, no relief of urban heat island effect, and the like. The invention aims to develop a cement concrete permeable brick, a cement concrete permeable road and production methods thereof. The cement concrete permeable brick is formed by pressing and molding a base material layer and a surface material layer, and both the base material layer and the surface material layer contain cement, sand, stone, water adsorbing resin, asphalt powder, diffusant and a water reducing agent. The production method of the permeable brick is realized by molding the permeable brick by a computer full-automatic building block forming machine; and the production method of the cement concrete permeable road is realized by directly pressing the cement concrete permeable road through a road roller. The invention can achieve the aims of water adsorption, water retention, permeability and practicability, can be widely used for a highway, an airport runway, a roadway, a footway, a square, garden construction, and the like and solve the problem of road icing.

Owner:SHAANXI SUNSHINE RAIN ECOLOGICAL TECH

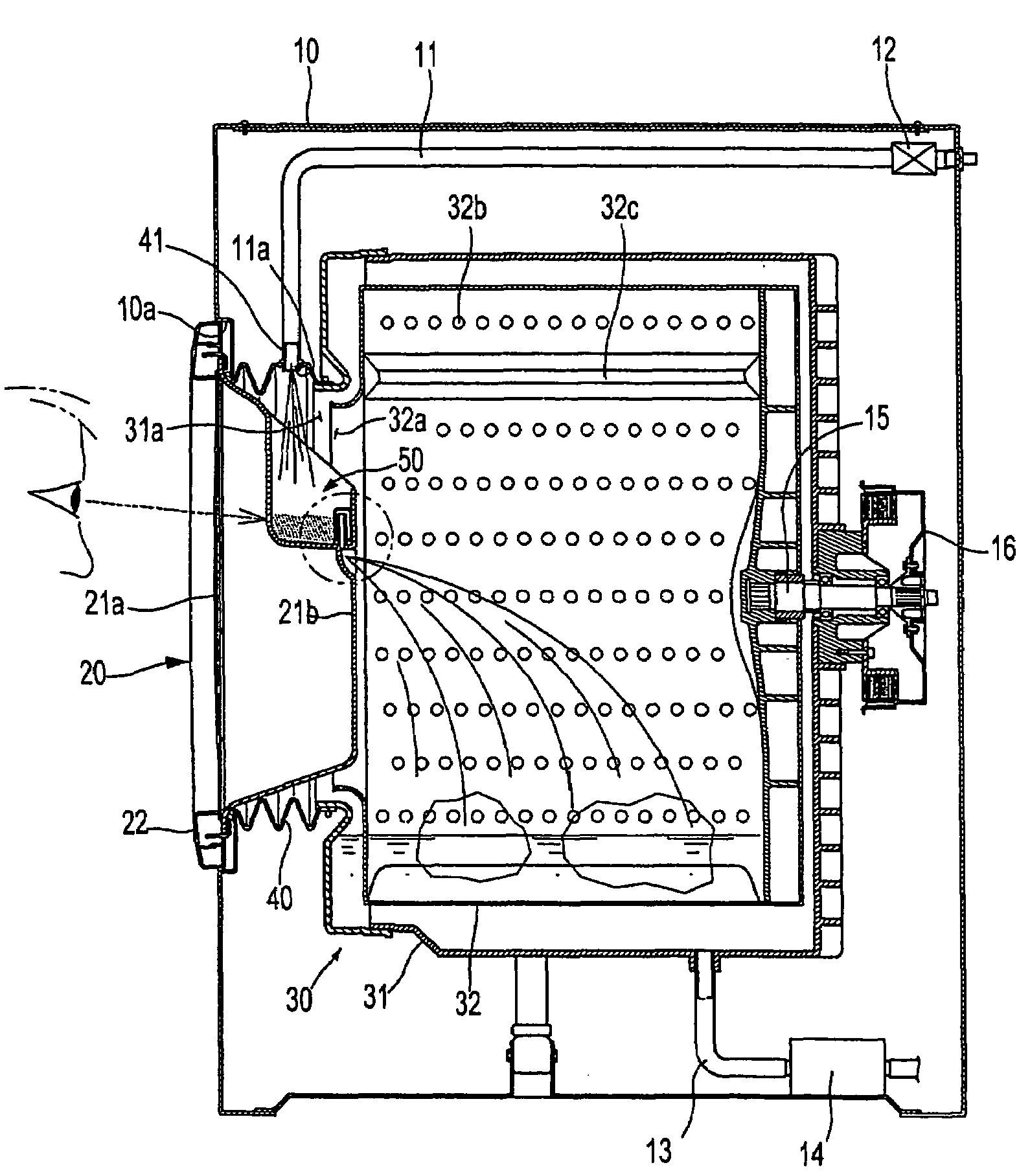

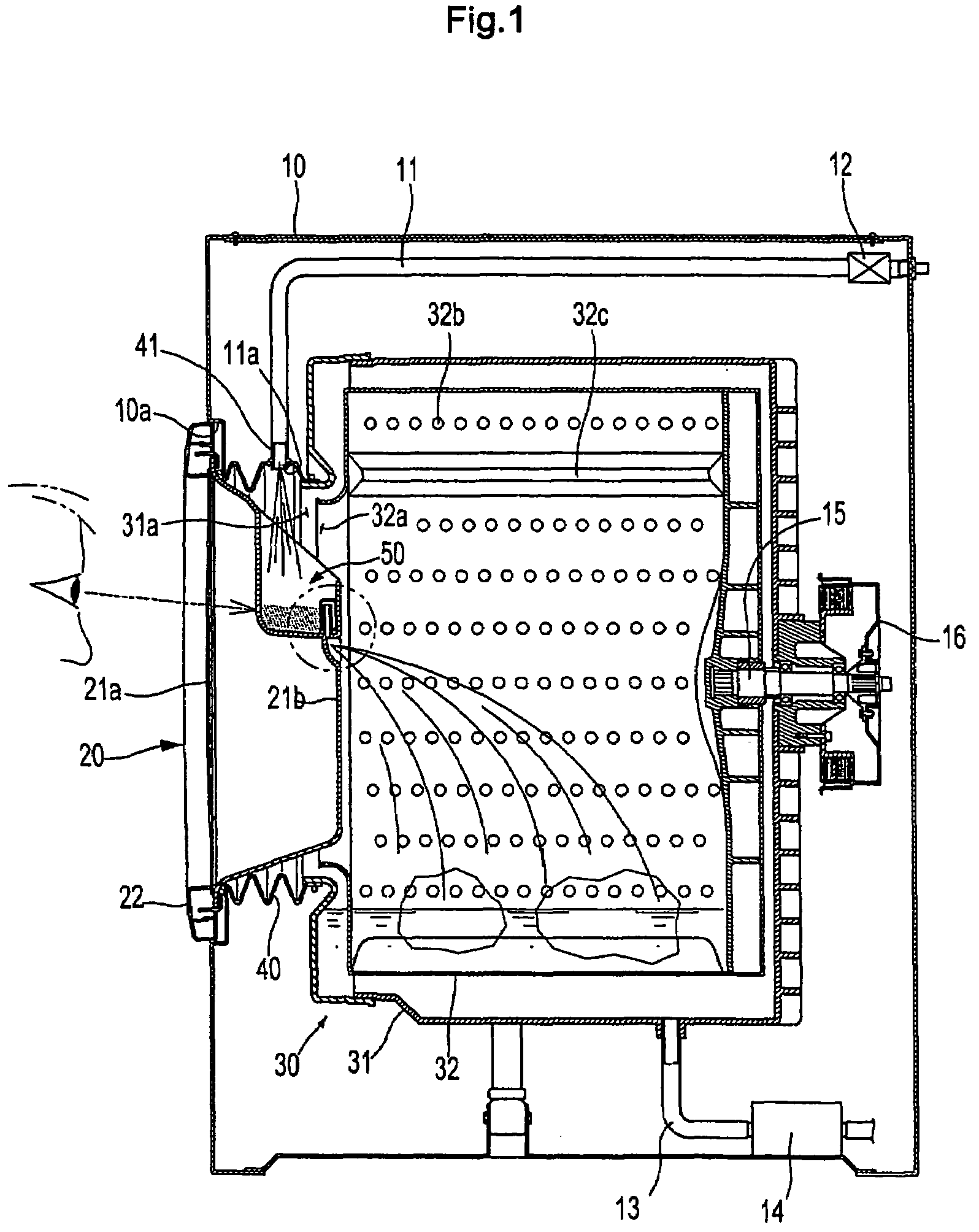

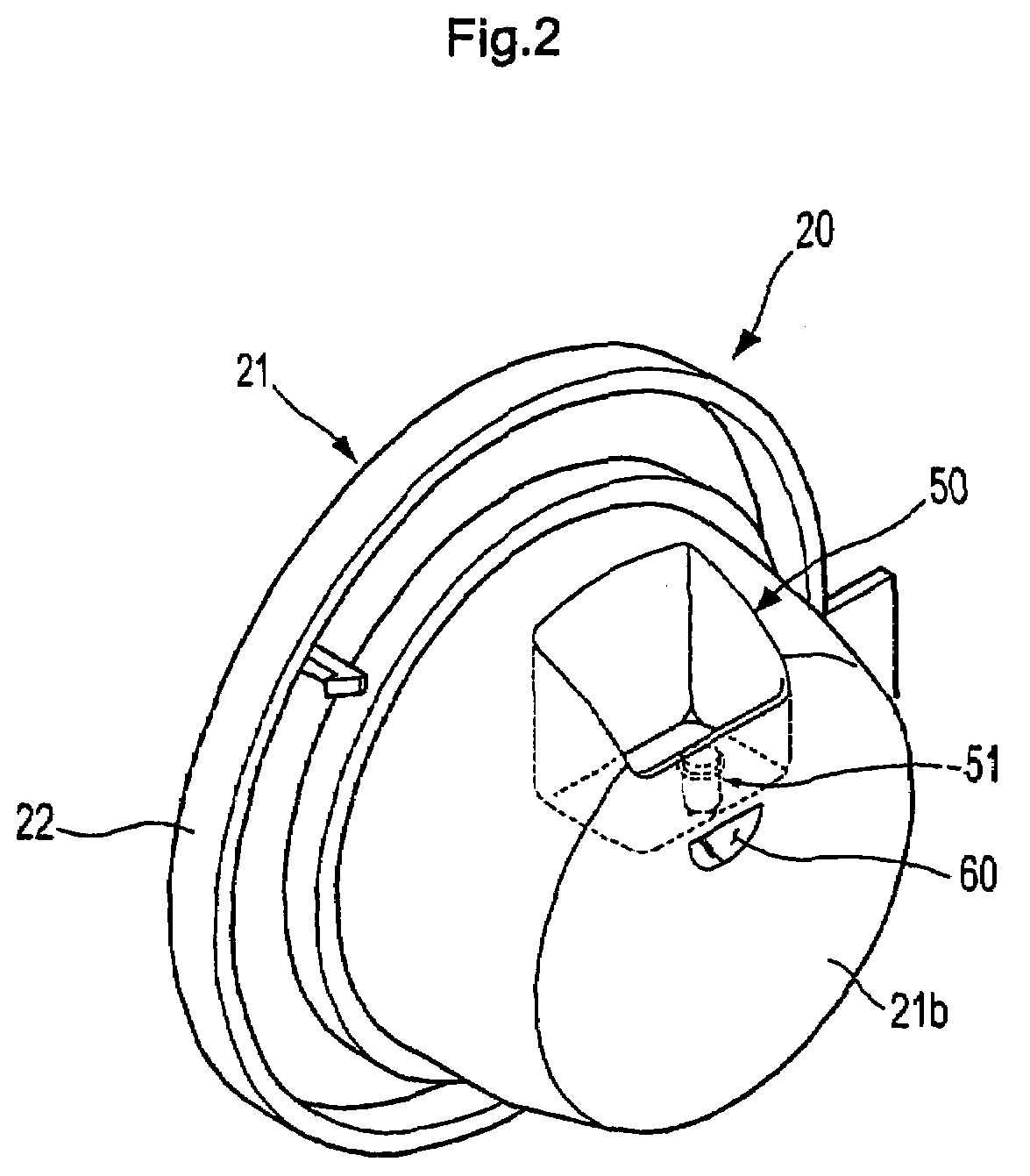

Drum washing machine with detergent supply device

InactiveUS20070240456A1Easy to manufactureLow production costOther washing machinesTextiles and paperSiphonWater level

A drum washing machine having a detergent supply device supplying water containing detergent to a washing tub. The detergent supply device is integrally formed with a door of the washing machine. The detergent supply device is provided with a discharge unit discharging detergent dissolved in the water to the washing tub when the level of the water supplied to the detergent supply device reaches a designated value. The discharge unit delays the discharge of the washing water supplied to the detergent supply device by a siphon, thus improving the solubility of the detergent.

Owner:SAMSUNG ELECTRONICS CO LTD

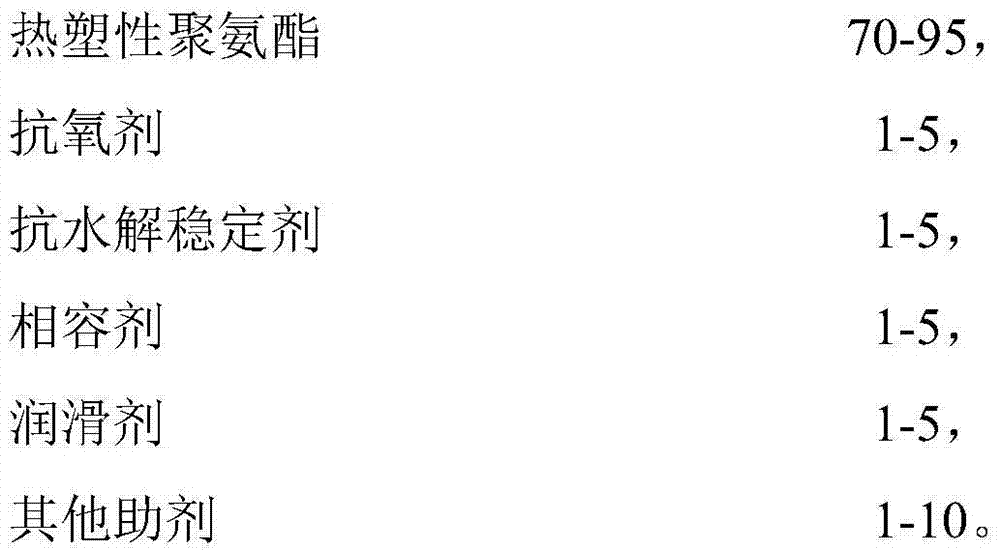

Thermoplastic polyurethane modified composite material for FDM (frequency division multiplexing) 3D printing and preparation method thereof

The invention relates to a thermoplastic polyurethane modified composite material for FDM (frequency division multiplexing) 3D printing and a preparation method thereof. The composite material is prepared from the following components in parts by weight: 70-95 parts of thermoplastic polyurethane, 1-5 parts of antioxidant, 1-5 parts of hydrolysis-resistant stabilizer, 1-5 parts of compatilizer, 1-5 parts of lubricant and 1-10 parts of other assistant. Compared with the prior art, the antioxidant, hydrolysis-resistant stabilizer, lubricant and other assistants are added, so that the modified composite material has the advantages of favorable mechanical properties, high elasticity, favorable wear resistance, higher heat stability, hydrolysis resistance, higher oxidation resistance and higher processability. When being used for FDM 3D printing, the thermoplastic polyurethane modified composite material has the characteristics of smooth printing process, no odor, smooth printing product surface, beautiful appearance, stable size, low tendency to shrinkage, favorable mechanical properties, high flexibility, high heat stability, high hydrolysis resistance, high oxidation resistance and high processability.

Owner:SHANGHAI RES INST OF MATERIALS CO LTD

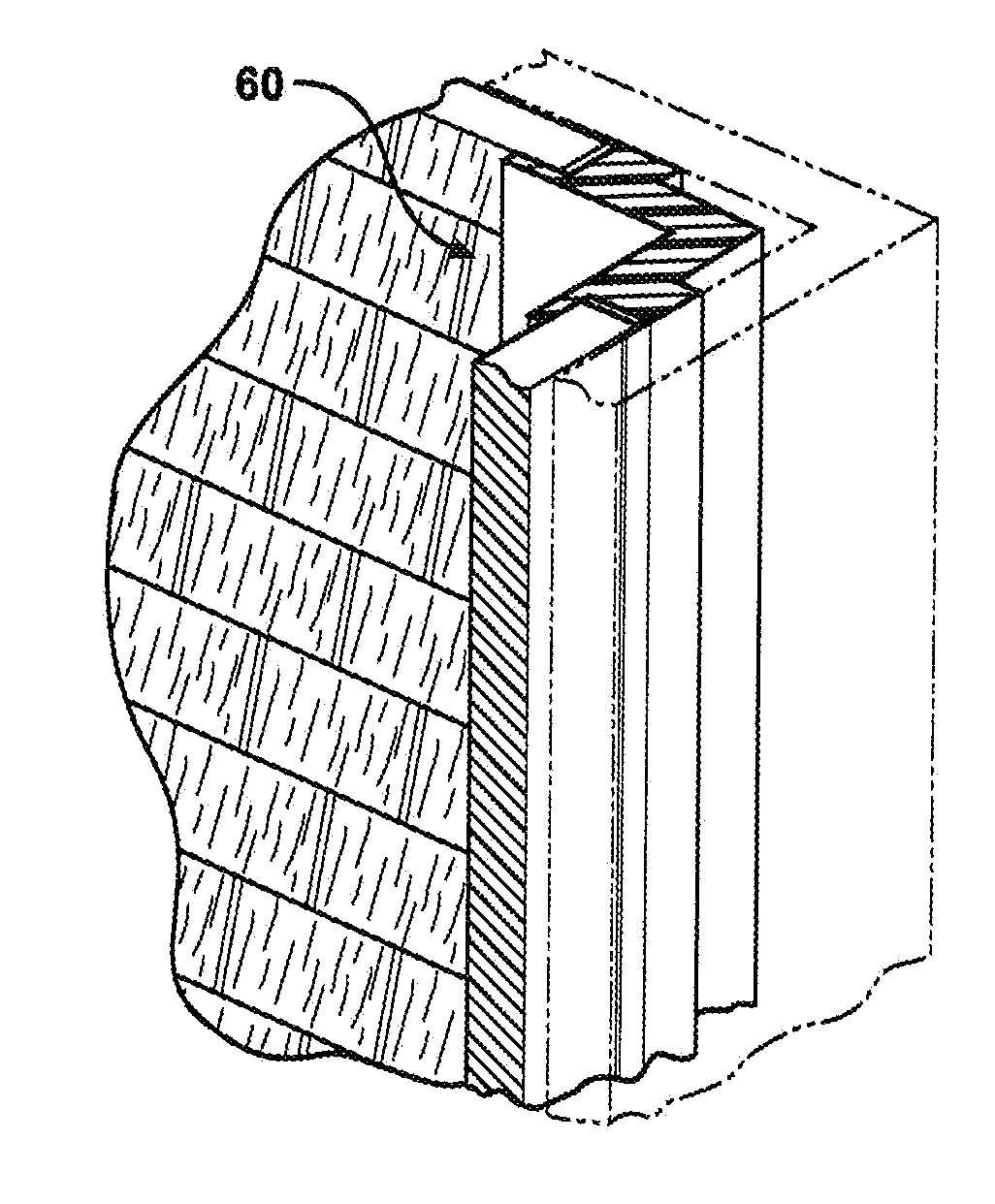

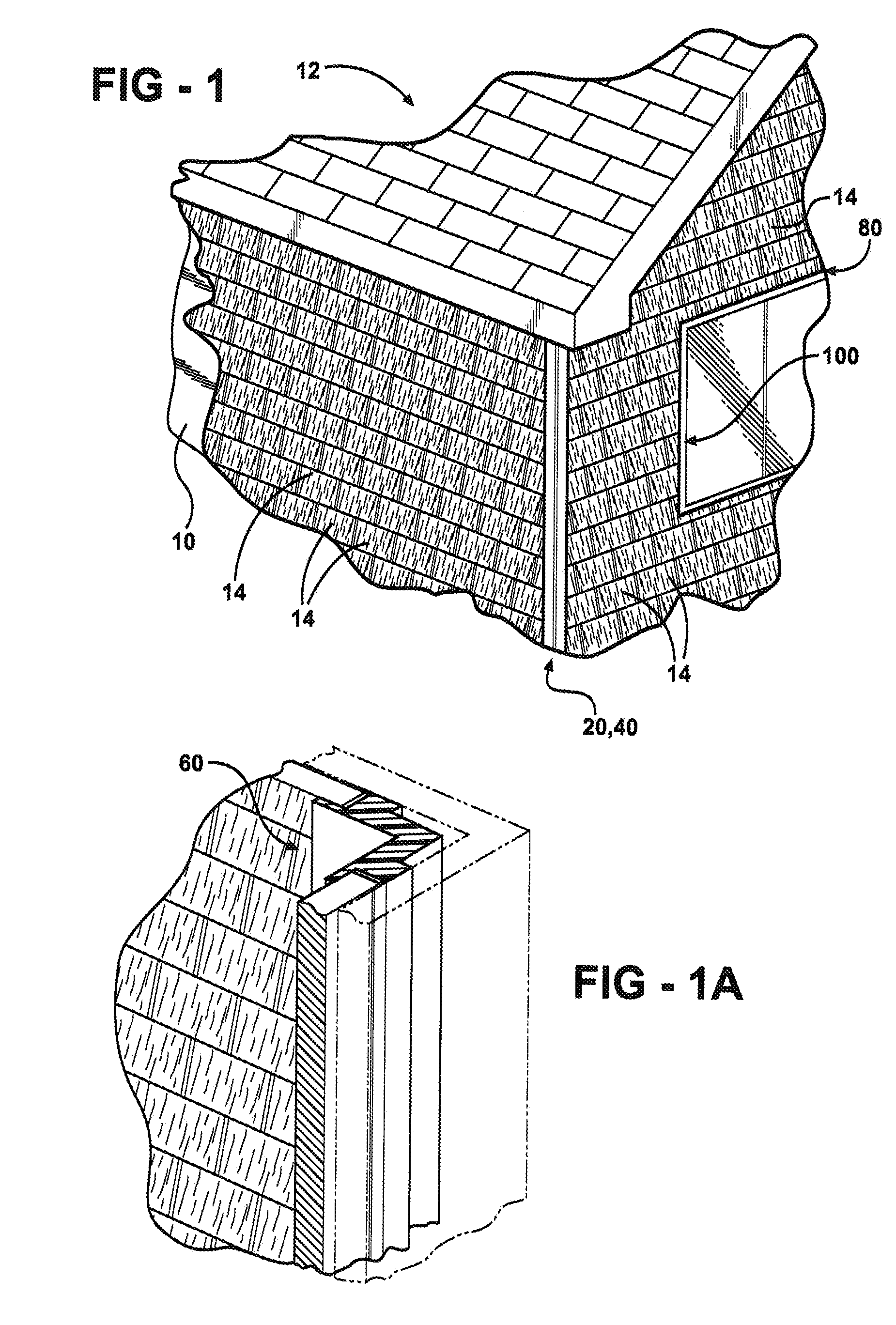

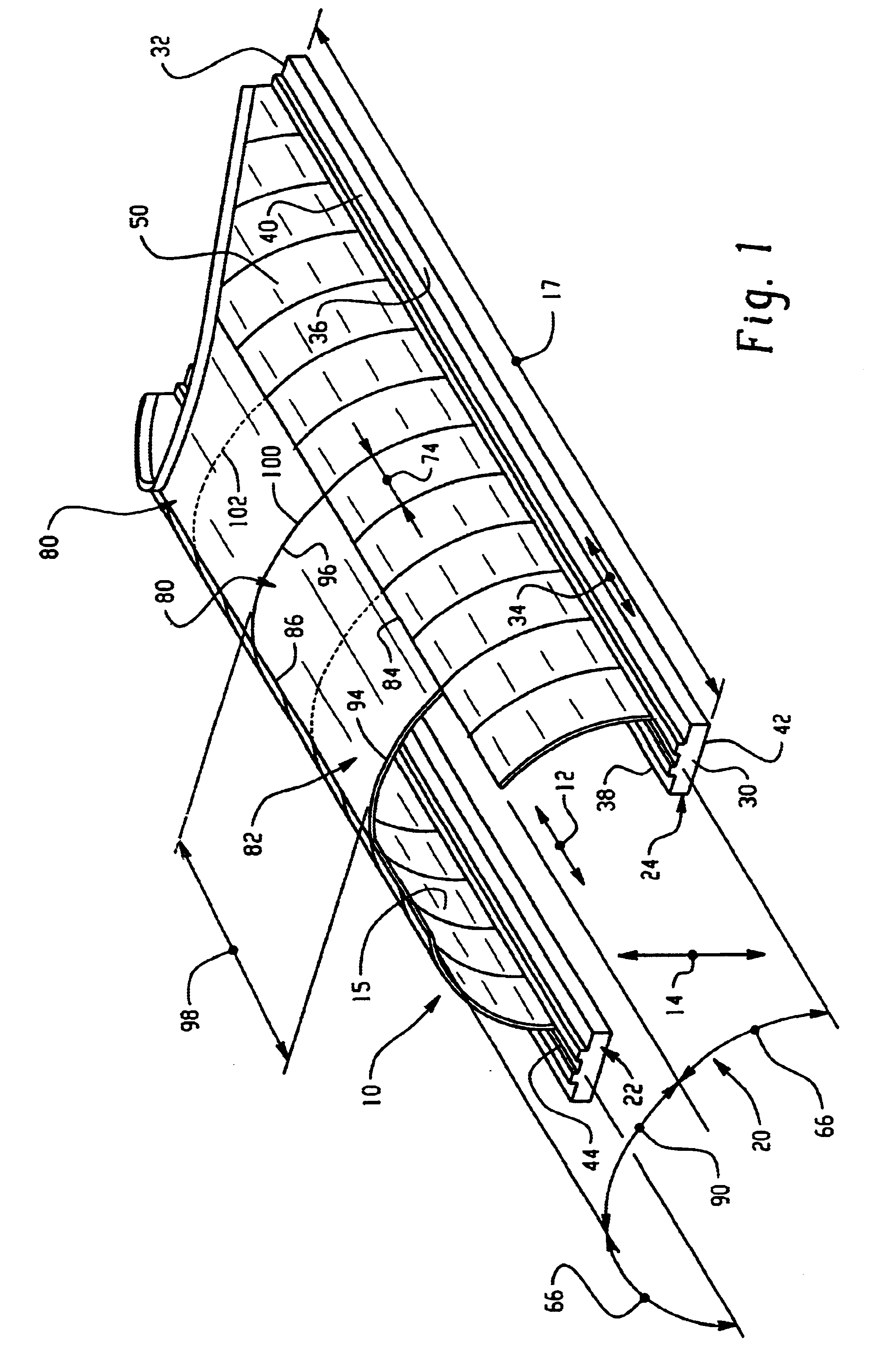

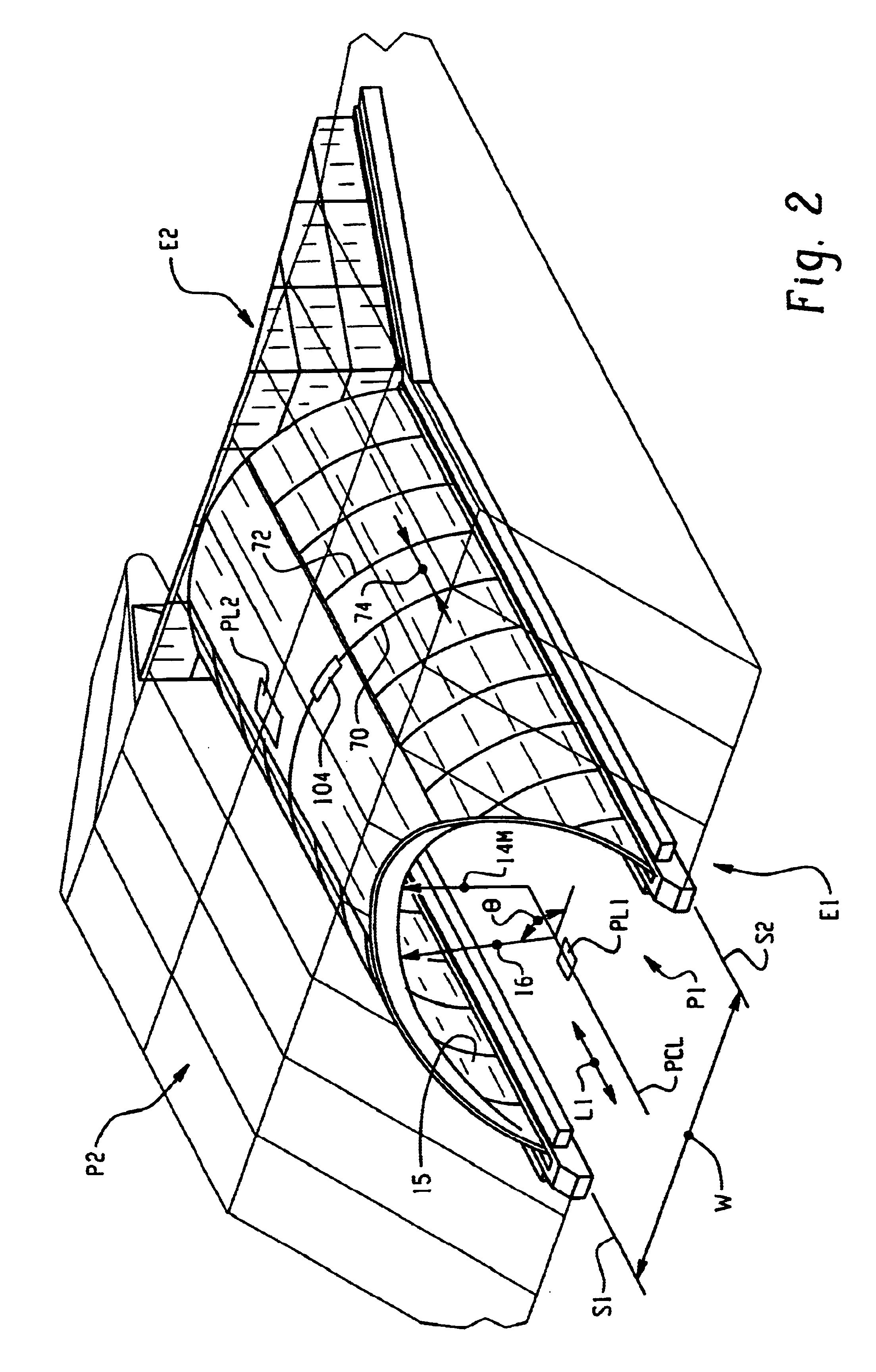

Roofing shingle

ActiveUS20050193673A1Good weather resistanceBeautiful appearanceRoof covering using tiles/slatesLamination ancillary operationsEngineeringShingles

The present invention provides a roof shingle comprising a shingle with at least one layer having a head lap and a butt, the head lap including at least one alignment notch and the butt including at least one corner that corresponds to the alignment notch. Also, the present invention provides a roofing shingle comprising at least one layer formed from a cutting cylinder having a circumference that is a fraction of said roofing shingle length. The present invention also provides a method for manufacturing the inventive shingles and a method for installing the inventive shingles upon a roofing area.

Owner:BMIC LLC

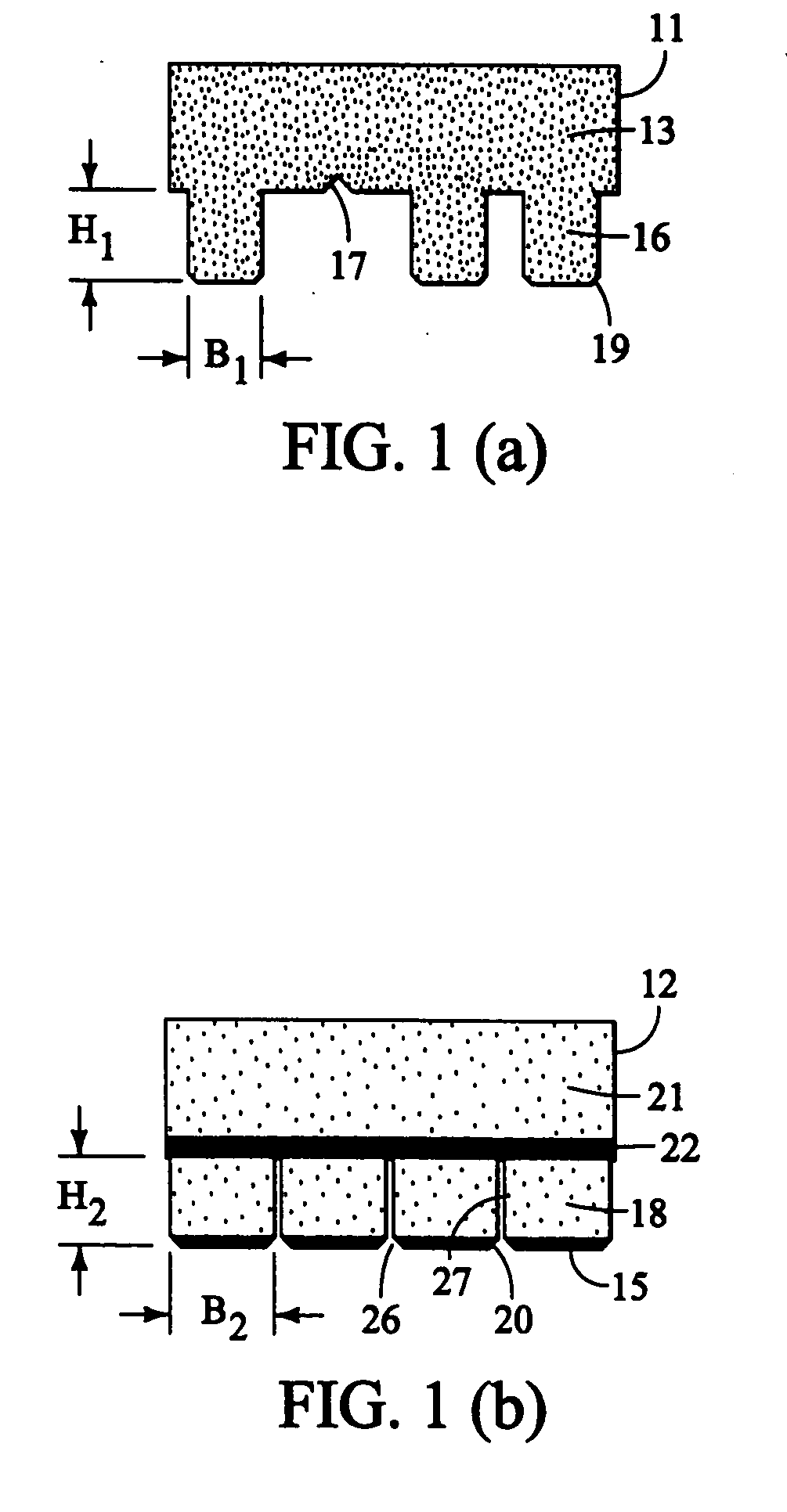

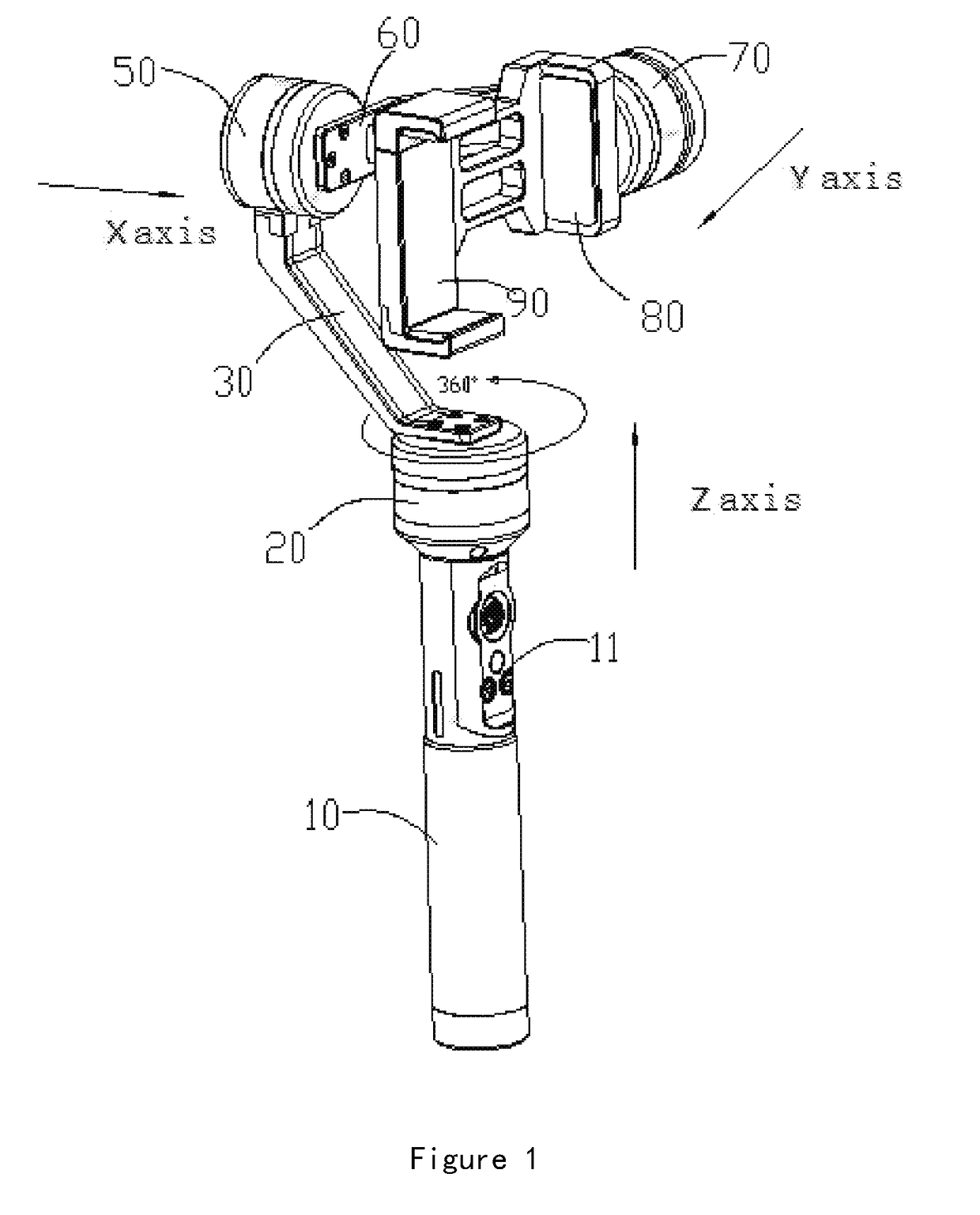

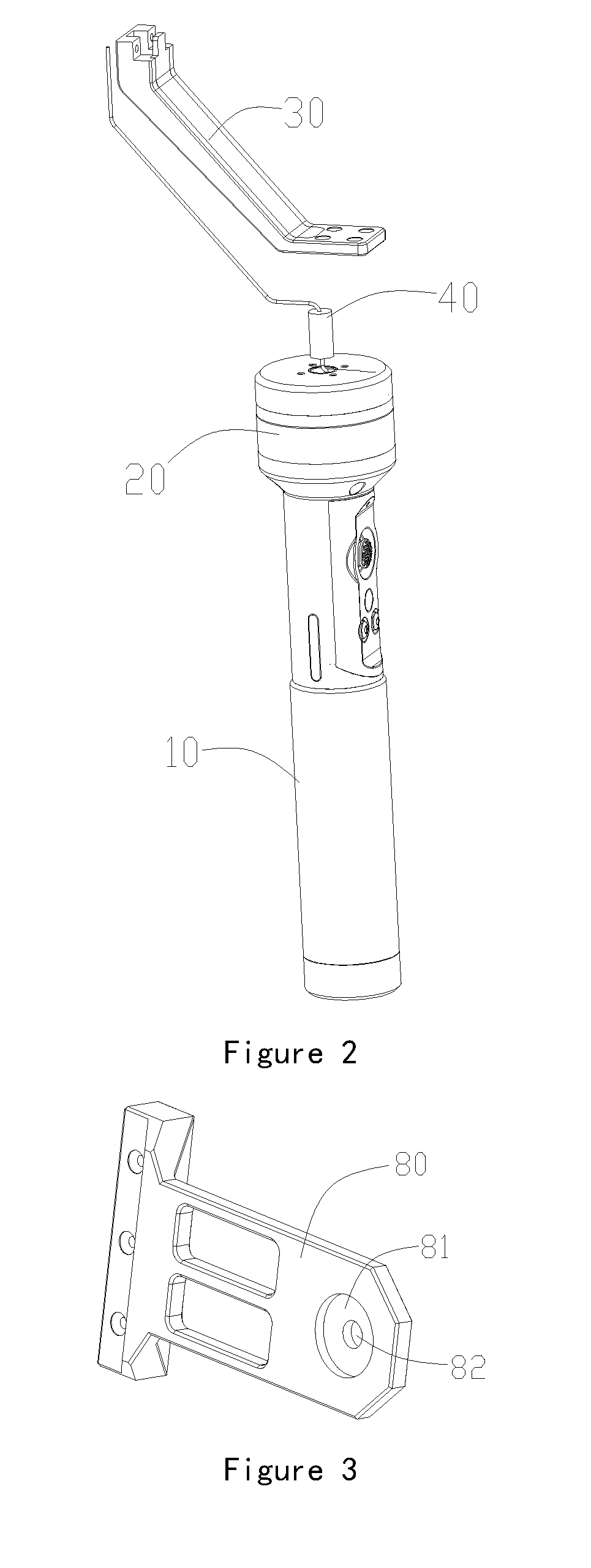

A hand-held three-dimensional panoramic pan-tilt kit

ActiveUS20170241589A1Simple structurePrecise positioningTelevision system detailsStands/trestlesHand heldEngineering

The present disclosure provides a hand-held three-dimensional panoramic pan-tilt kit, comprising a hand-held portion, a first motor, a second motor and a third motor that are perpendicular to each other in spatial positions, the first motor is located at a top end of the hand held portion, a first connecting arm is connected to the first motor, the other end of the first connecting arm is connected to the second motor, a second connecting arm is connected to the second motor, the other end of the second connecting arm is connected to the third motor, the third motor is fixedly connected with a connecting member, a front end of the connecting member is connected with a holding member, a first slip ring is arranged between a rotating shaft of the first motor and the first connecting arm, a second slip ring is arranged between a rotating shaft of the second motor and the second connecting arm , a third slip ring is arranged between a rotating shaft of the third motor and the connecting member. By using the slip rings, the present invention ensures 360-degree rotation of the first connecting arm, the second connecting arm and the connecting member during use of the pan-tilt kit, enables the pan-tilt kit to be suitable for a variety of shooting conditions and scenes, thus utilization ratio of the pan-tilt kit is significantly increased and consumers' demand for use is satisfied.

Owner:WUHAN AI BIRD UAV

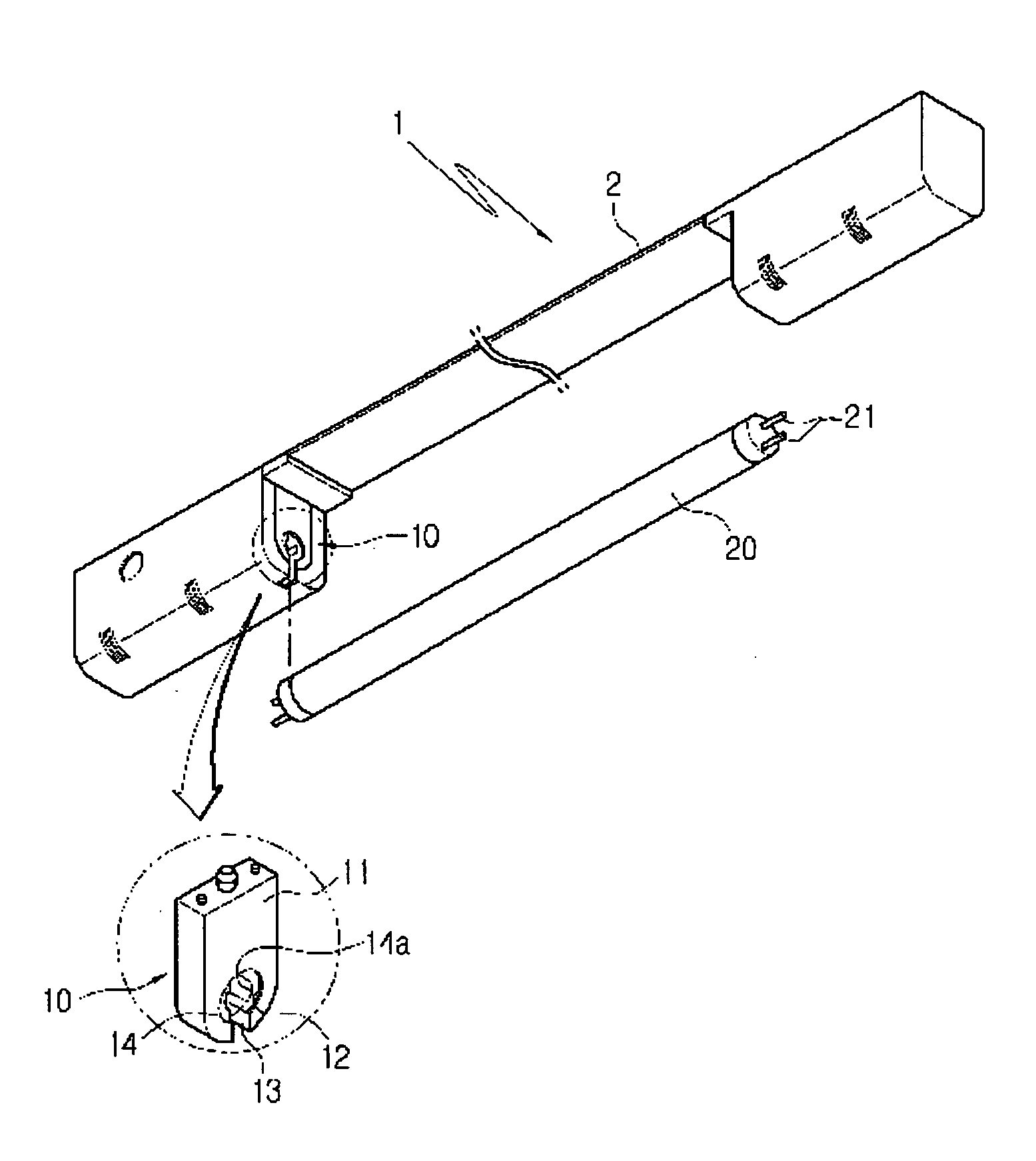

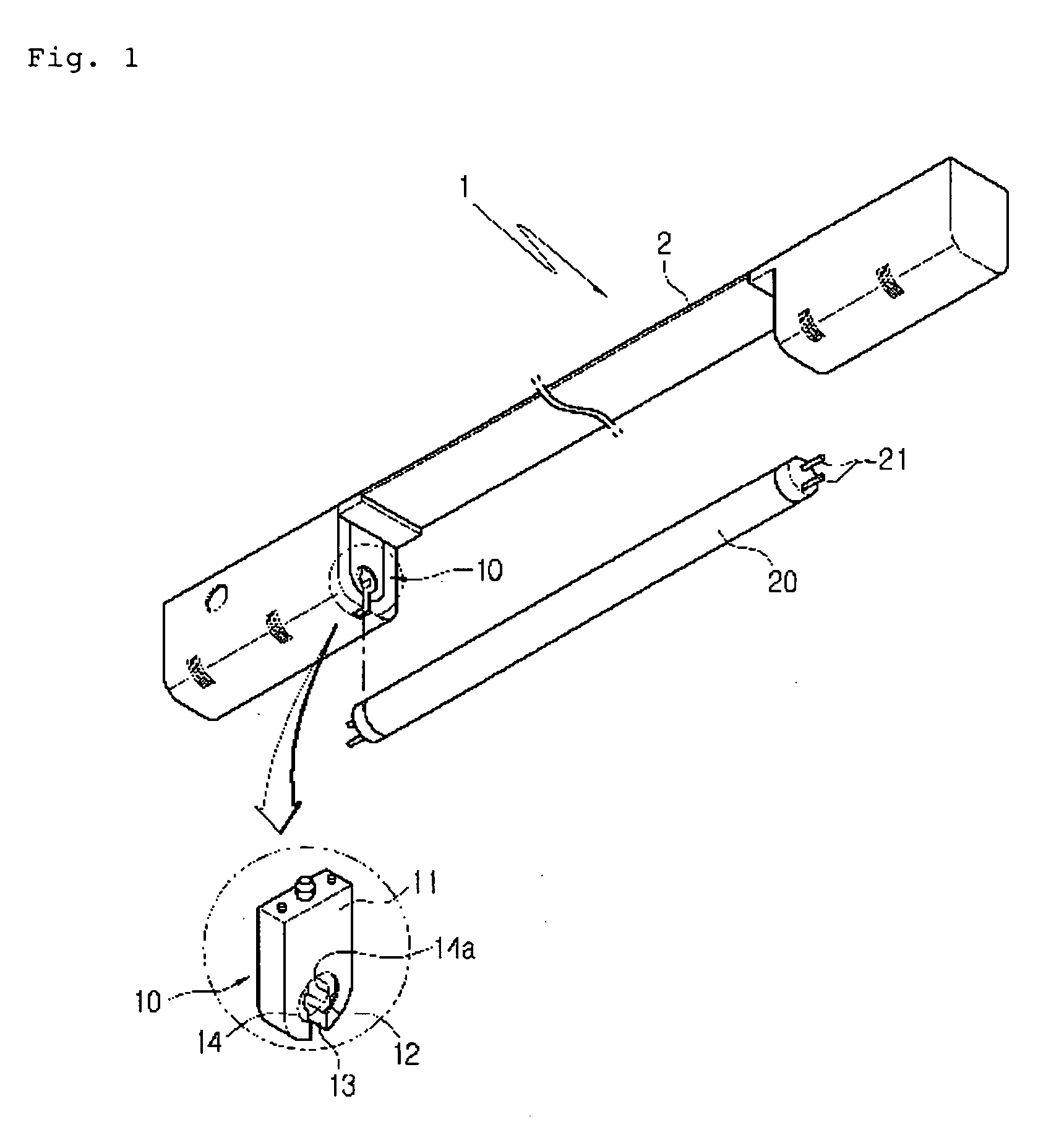

Fluorescent lighting fixtures

InactiveUS20060012981A1Beautiful appearanceImprove lighting effectsCoupling device connectionsNon-electric lightingElectricityFluorescence

The present invention relates to fluorescent lighting fixtures, which are aligned in series at regular intervals, which are easily connected one another, and which prevent discontinuation of illumination occurring between fluorescent lamps. The fluorescent lighting fixture includes: a fluorescent lamp having a tube type lamp body, auxiliary tubes mounted at the tops of both ends of the lamp body, and terminal pins inwardly formed at an end of each auxiliary tube; a body having a stabilizer mounted therein for lighting the fluorescent lamp, connection terminals located at both ends thereof at a predetermined interval and electrically connected with the stabilizer; and sockets mounted at both ends of the body, each of the sockets having a support slit formed in the outer surface thereof for fixing and supporting the terminal pins of the fluorescent lamp, and a receiving slit for allowing the terminal pins to be inserted into the support slit.

Owner:FEELUX CO LTD

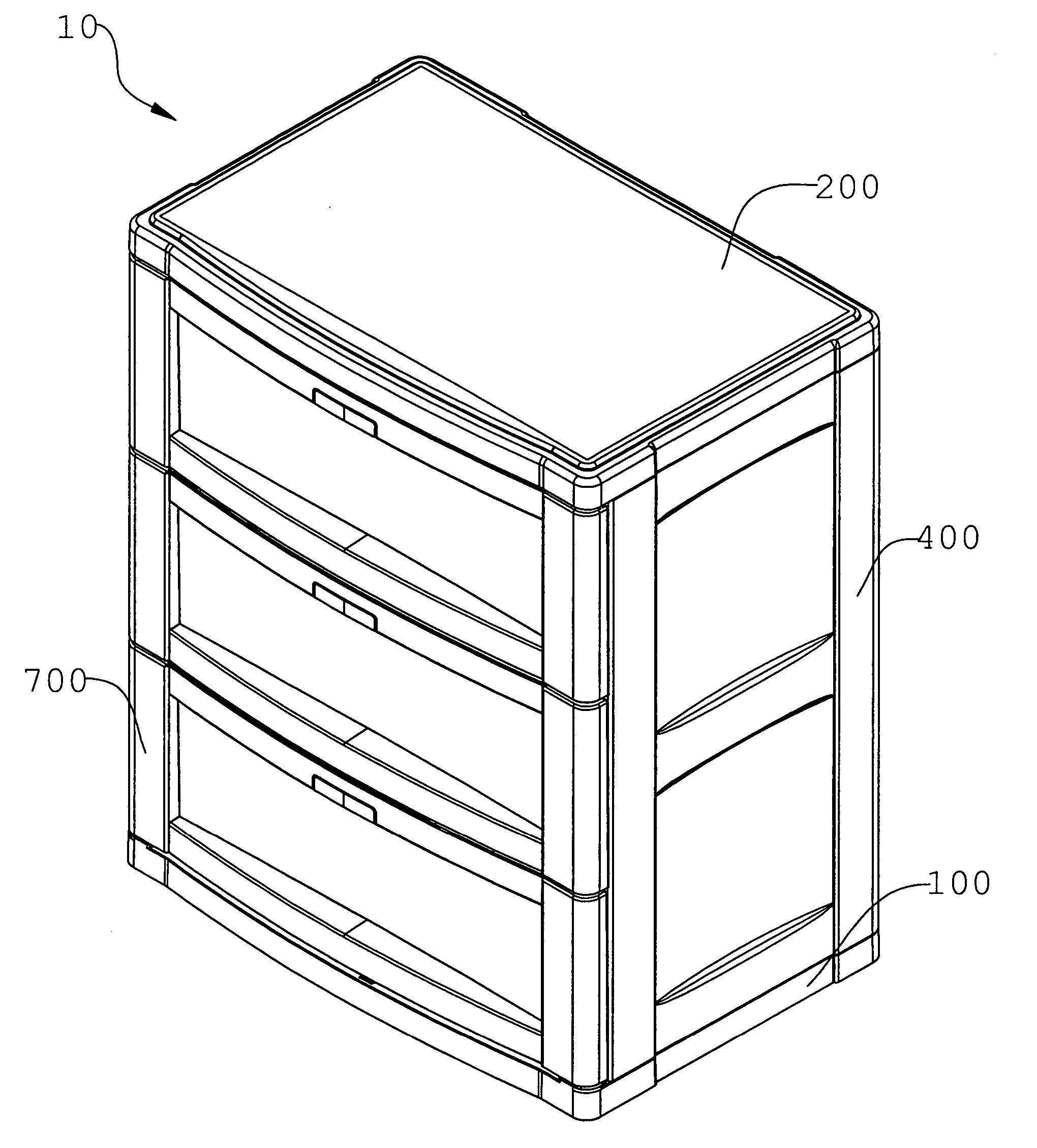

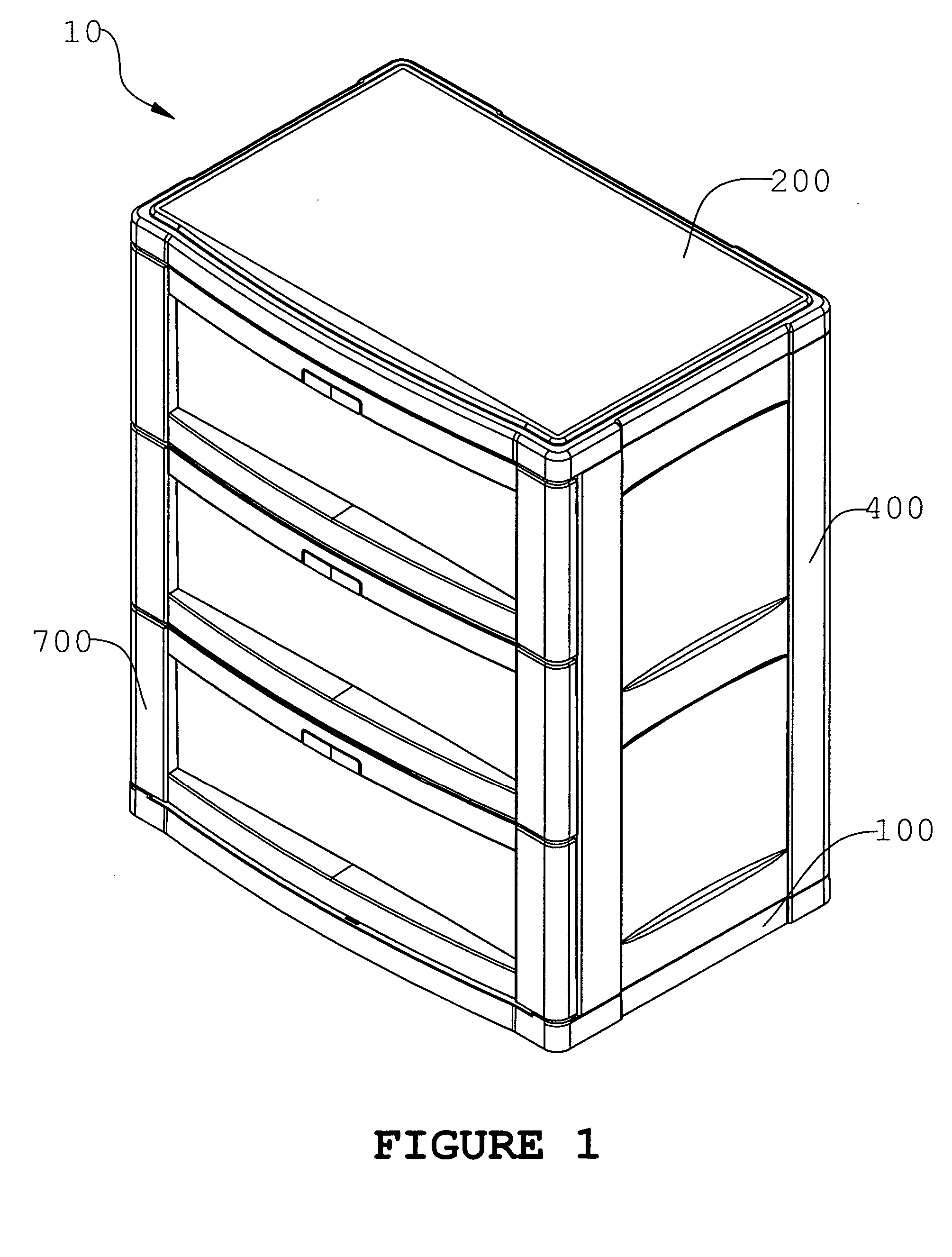

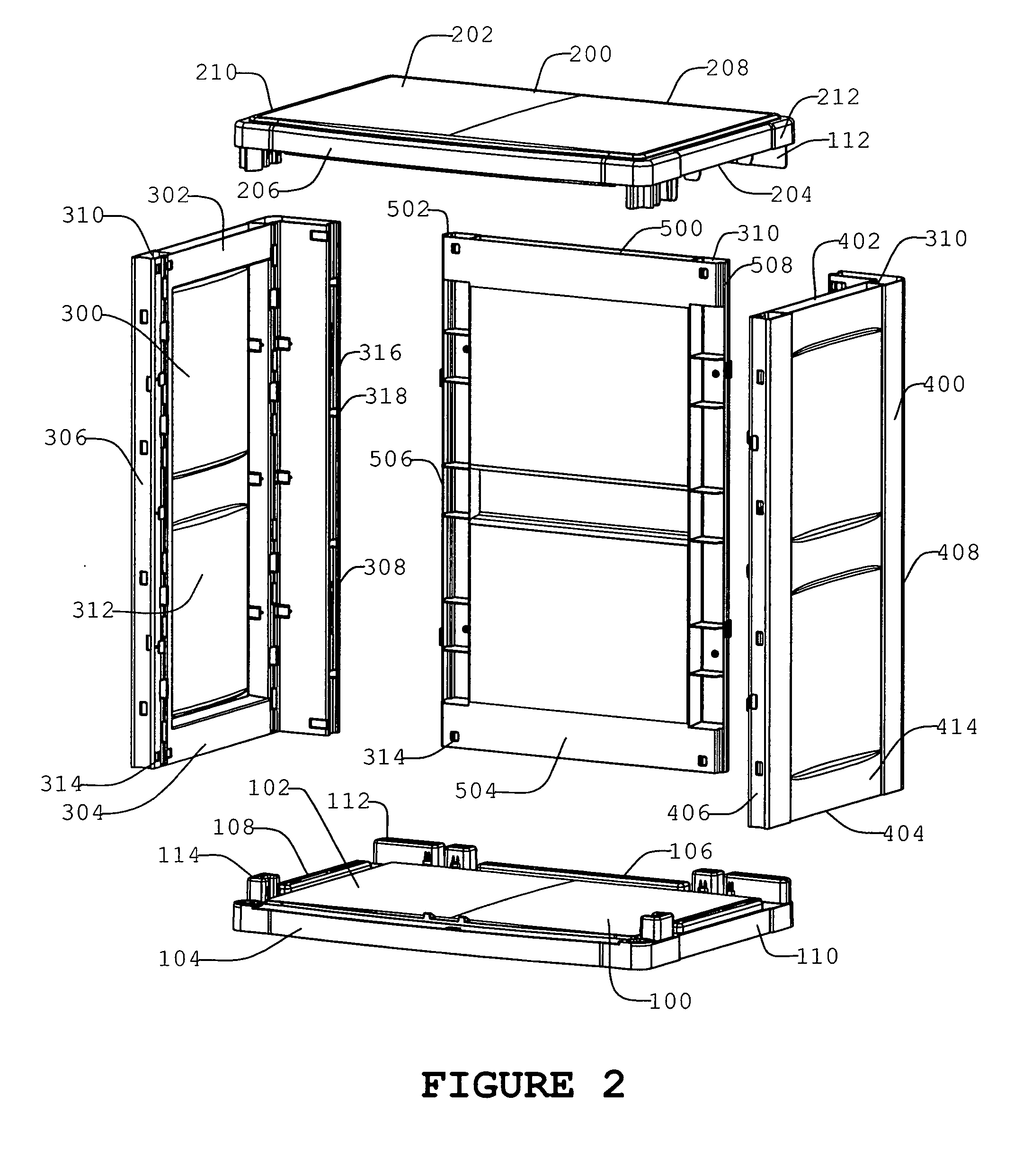

Drawer cabinet storage kit

InactiveUS20050168115A1Simplifies drawer cabinet constructionMinimize the numberChestsDressing tablesInjection mouldingFastener

The present invention provides an assembly, or kit, of injection molded panels having integrated connectors which combine to form a drawer cabinet. The panels are formed of injection molded plastic to interlock with one another without the need for separate fasteners or connectors. The interior of the cabinet is constructed and arranged to accept a plurality of cooperating drawer guides and drawers which snap into place to fill the cabinets interior.

Owner:SUNCAST

Pearlescent film coating systems and substrates coated therewith

ActiveUS6902609B2High degreeExcellent oxygen barrier propertiesConfectioneryPretreated surfacesPowder mixtureMedicine

The present invention is directed to film coating systems for use on oral dosage forms such as compressed tablets and orally-ingestible substrates which have improved pearlescent qualities. The film coating systems can be applied either directly to a substrate or after the substrate has been coated with a subcoat. In preferred aspects, the pearlescent film coating is prepared as a dry powder mixture containing a cellulosic polymer, a detackifier, a gloss enhancer, and a pearlescent pigment. Film coating compositions containing an aqueous suspension of the powder mixtures, methods of applying the coatings to substrates and the coated substrates are also disclosed.

Owner:BPSI HLDG LLC

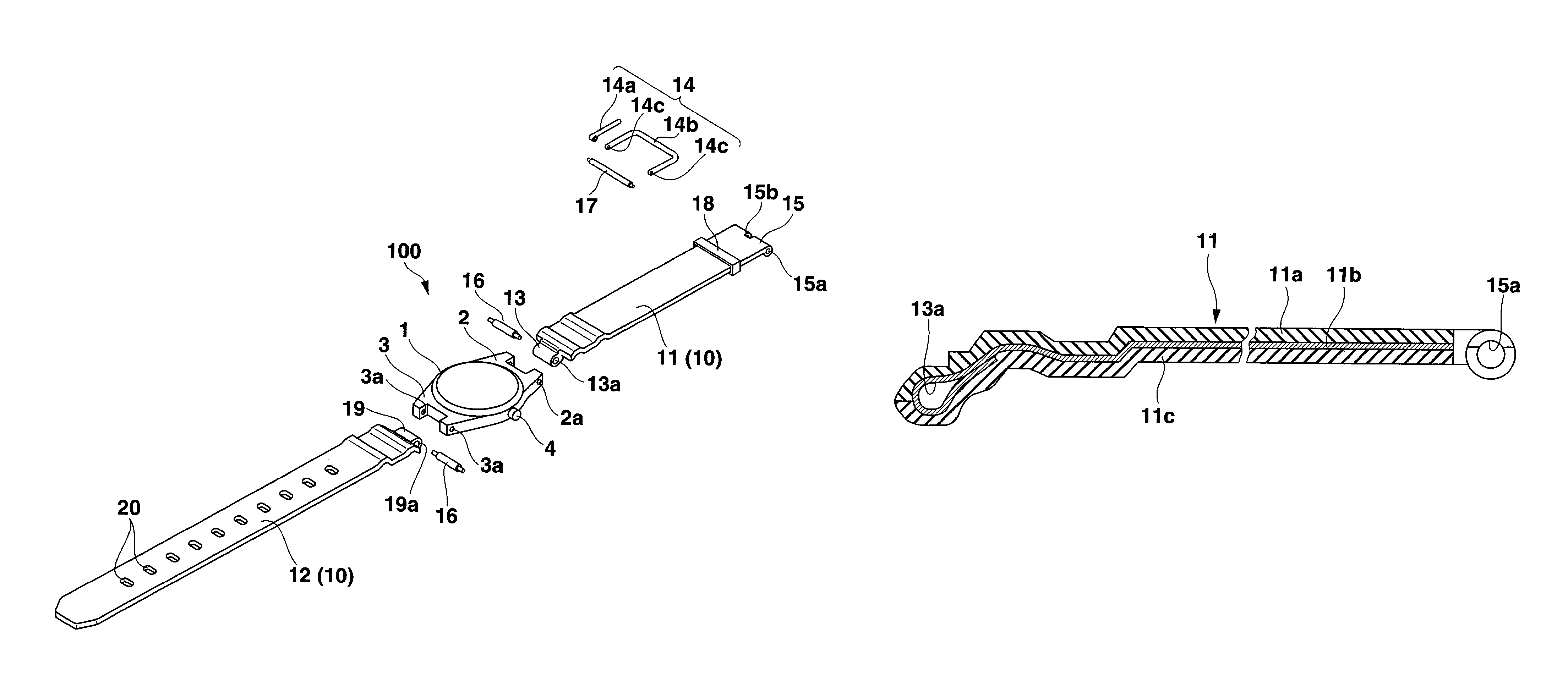

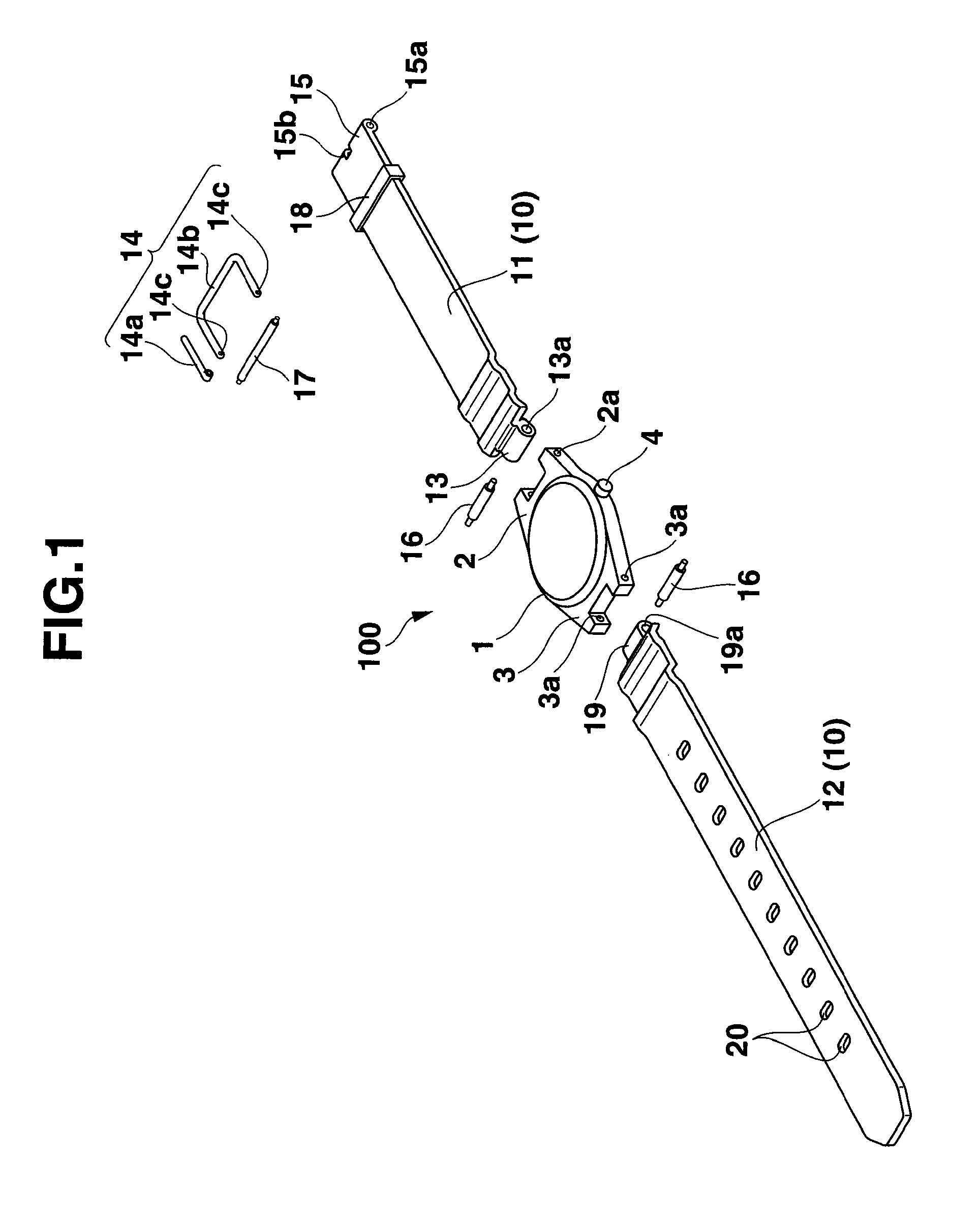

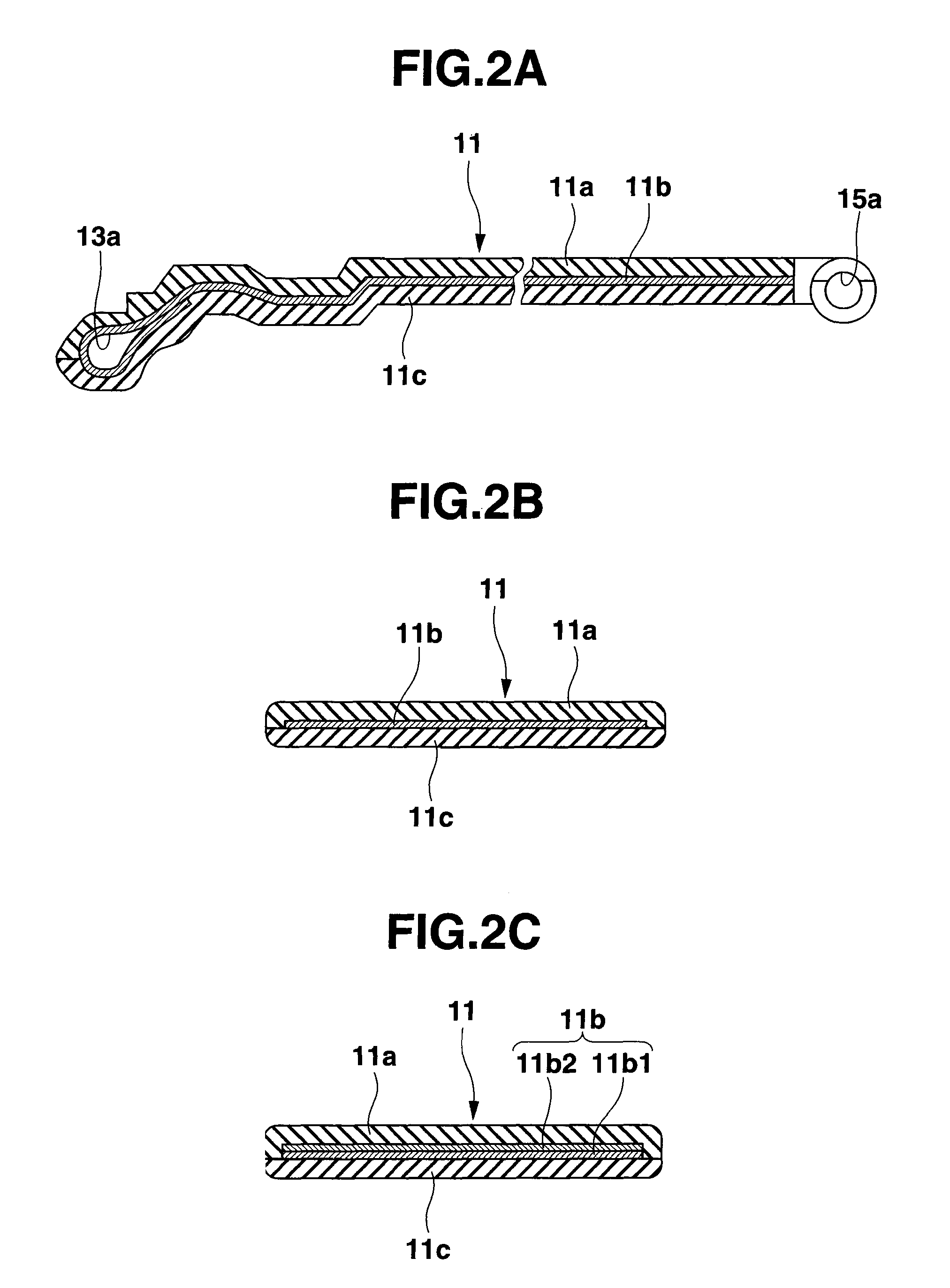

Band, wristwatch with the band and method of making the band

ActiveUS8613544B2High strengthEasy to liftSynthetic resin layered productsBraceletsPolymer scienceFiber bundle

A band, a wristwatch with the band and a method of making the band are described. The band includes a strip-like body with a series of holes provided therein along a length thereof for adjusting an effective length thereof. The body includes a band-shaped support layer of woven or knit fabric of bundles of one or more kinds of fibers, the fibers being selected from a group including carbon fibers, glass fibers, aramid fibers and boron fibers. The body also includes a first resin layer adhering closely to one surface of the support layer, and a second resin layer adhering closely to the other surface of the support layer. The fibers of the support layer extend at a predetermined angle to longitudinal and transverse directions of the body.

Owner:CASIO COMPUTER CO LTD

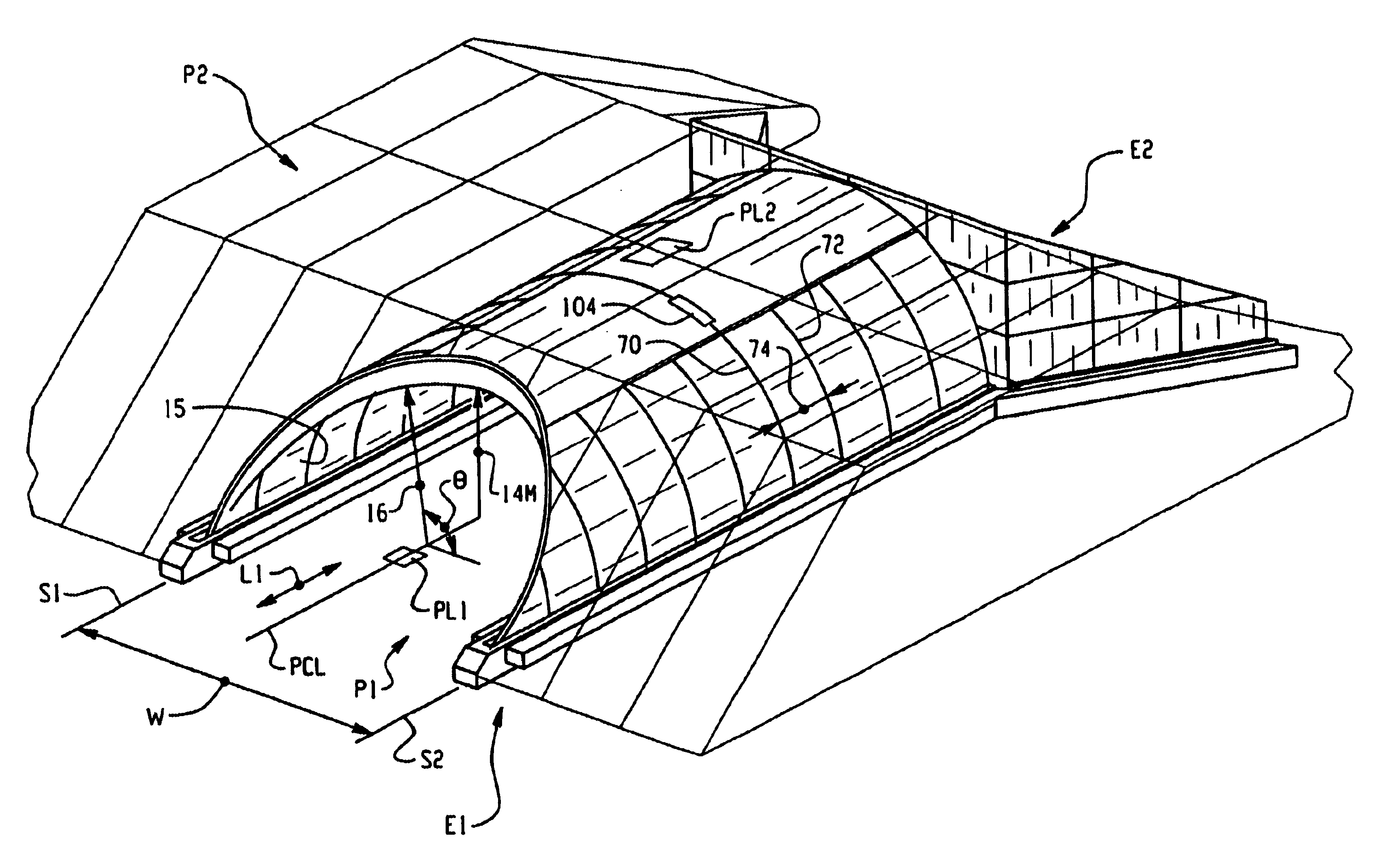

Hybrid arched overfilled structure

InactiveUS6640505B1Reduces initial capital investment requiredLow costBuilding roofsArtificial islandsEngineeringHorizontal orientation

A hybrid arched overfilled structure includes a combination of pre-cast side elements and at least one cast-in-place crown sector element. The side elements are pre-cast generally in a horizontal orientation and subsequently lifted into place. The crown sector element is cast in place between the side elements. In one form of the invention, each of the three sections makes up about one-third of the overall arch span.

Owner:CONTECH ENGINEERED SOLUTIONS

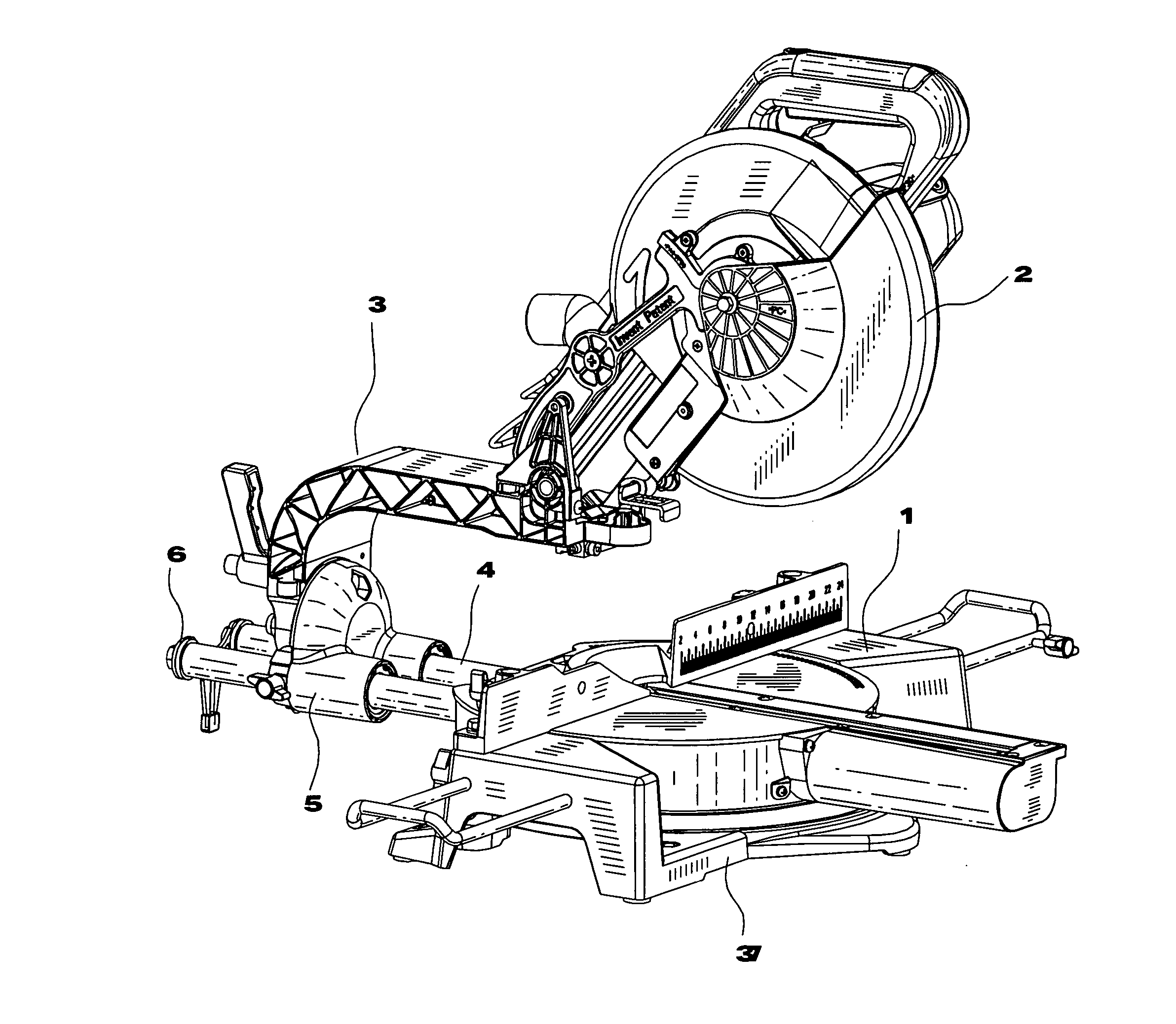

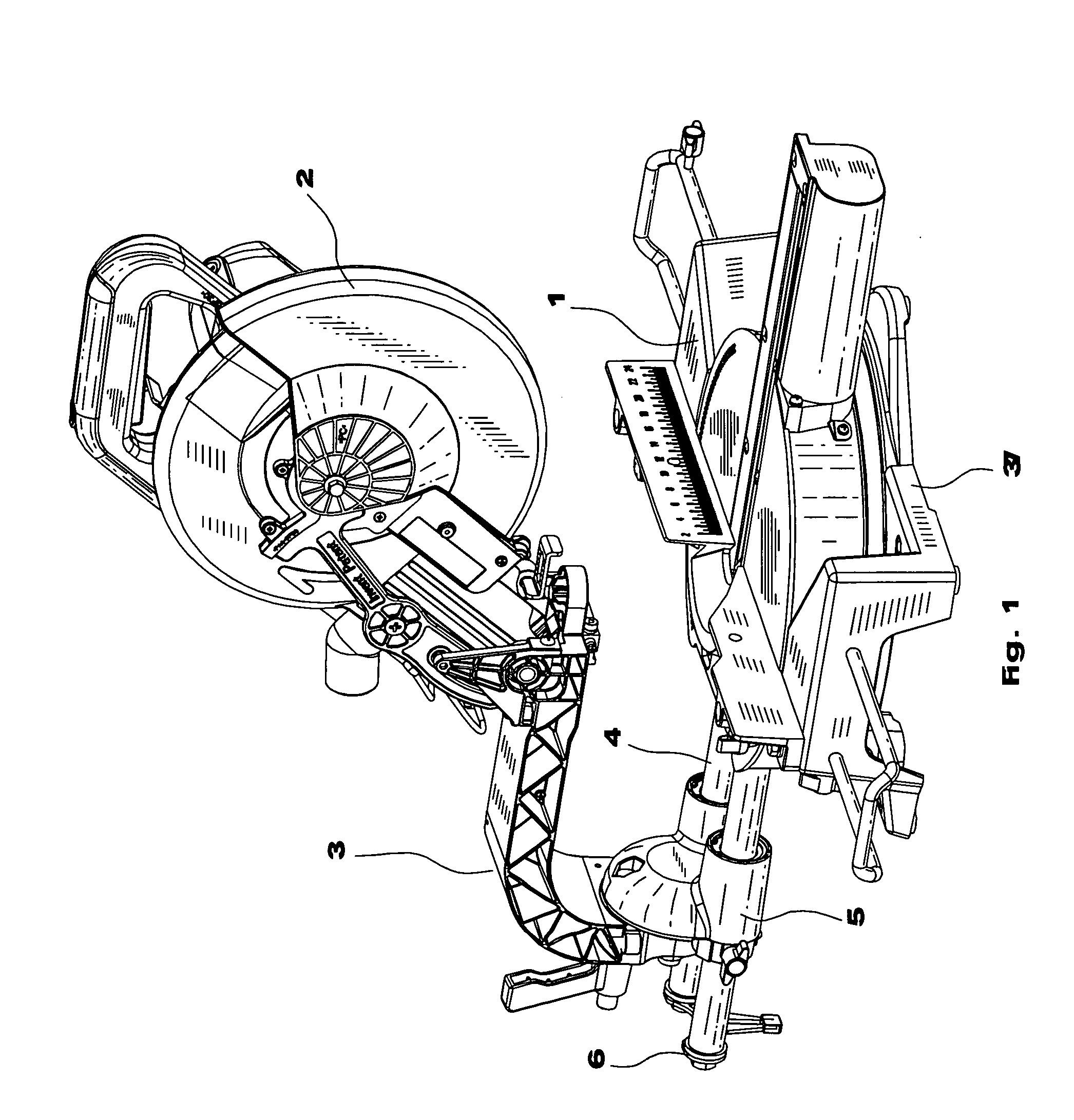

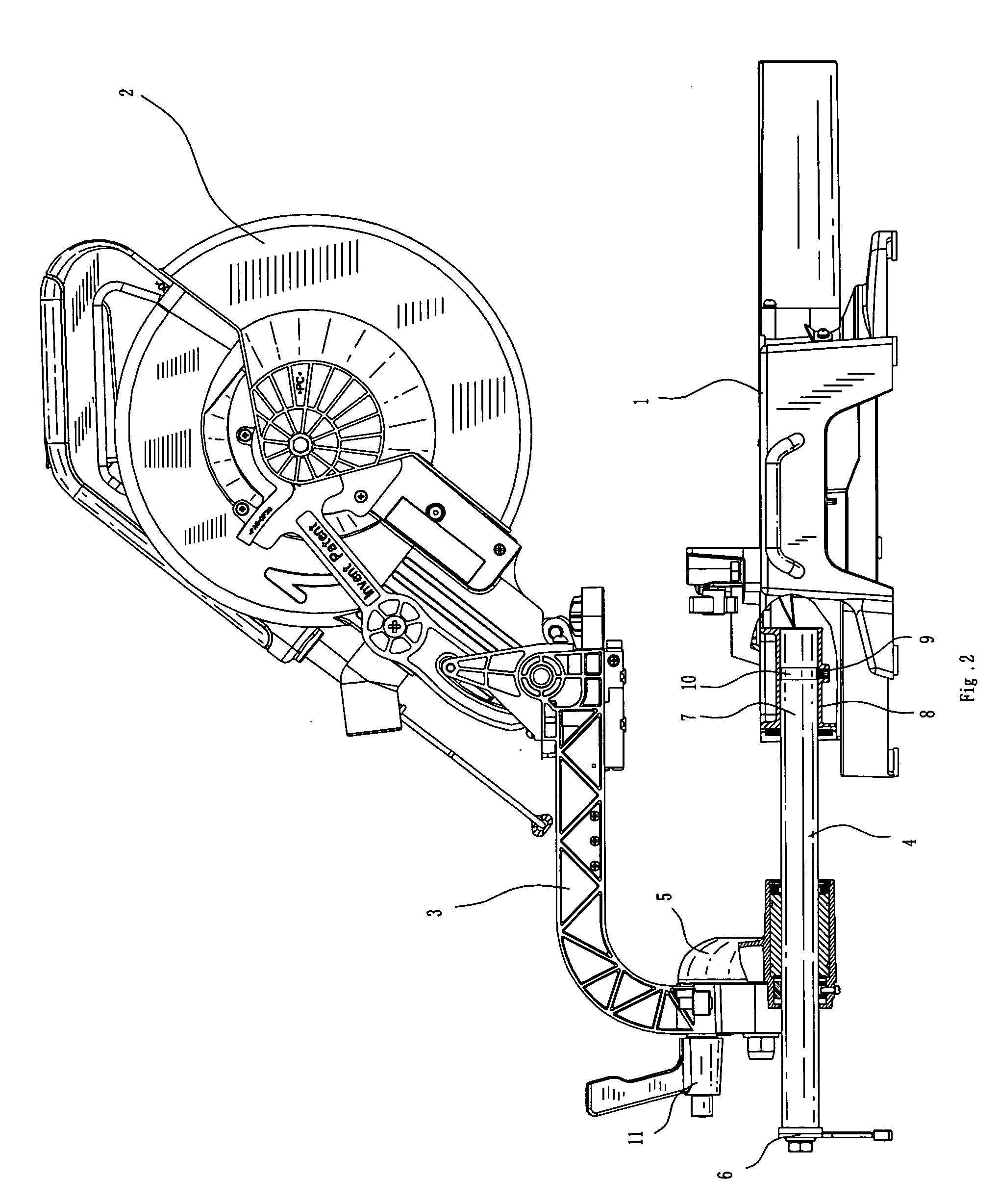

Electric miter saw

InactiveUS20050098010A1Safe and steady slideLong cutting strokeMetal sawing devicesGuide fencesBall bearingScrew thread

An electric miter saw includes a base, a cutting table, a cutting member and a link arm. The cutting table is mounted on the base. The upper portion of the link arm is connected to a cutting member with the cutting saw blade driven by a motor. The lower portion of the link arm is connected to the upper portion of a supporting member and secured by a threaded central bolt. The linear ball bearing is mounted in the inner aperture of the supporting member, which is slidably connected to the slide rod by a linear ball bearing. At the outer end of the slide rod is mounted a position limit socket. The inner end of the slide rod is connected and secured beneath the cutting table via a releasable securing configuration mentioned above. A flexible blade guard is also provided.

Owner:NING BO YANG MING ELECTRIC TOOLS COMPANY

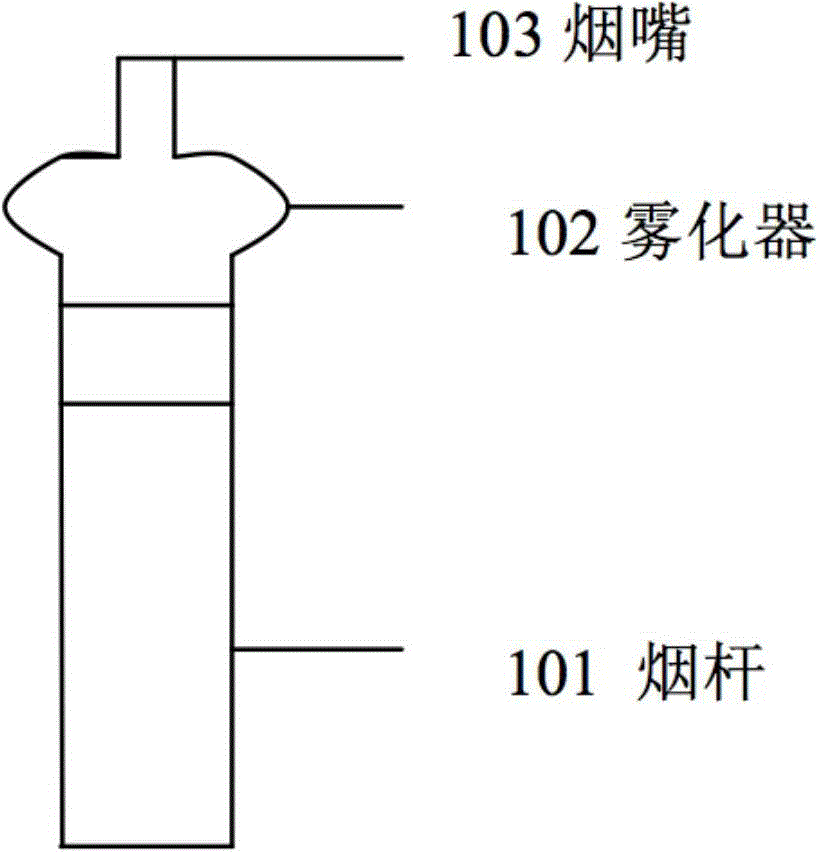

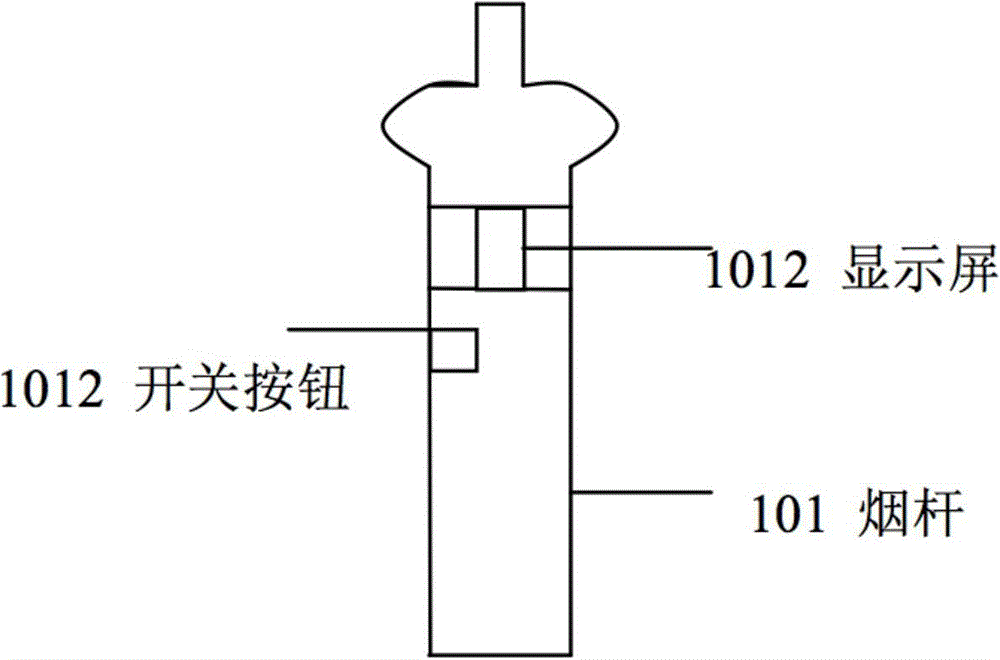

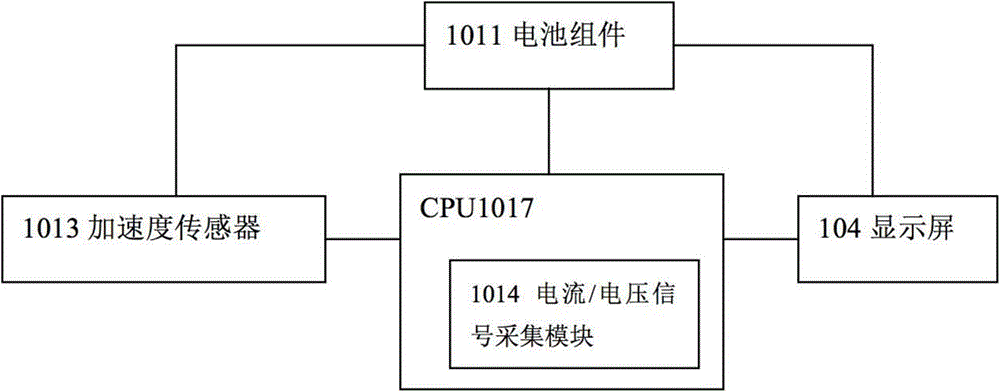

Electronic cigarette

InactiveCN104432537ASave volume and spaceSmooth appearance curveTobacco devicesEngineeringCommunicating Junction

The invention relates to an electronic cigarette which comprises a cigarette rod, an atomizer and a cigarette holder. The cigarette rod, the atomizer and the cigarette holder are connected in sequence. A switch button and a display screen are arranged outside the cigarette rod. A battery assembly, a signal acquisition module, a circuit board, an acceleration sensor and a central processing unit are arranged inside the cigarette rod. The switch button and the display screen are electrically connected with the circuit board. The signal acquisition module is in communication connection with the display screen. The central processing unit is in communication connection with the acceleration sensor. The information acquisition module outputs the electric quantity and voltage information of the battery assembly through the display screen, information is visual and concise, and electronic charging time can be accurately controlled; the acceleration sensor is adopted, the acceleration sensor sends out different electric signals through different shaking frequencies, and the central processing unit controls the display screen to display different kinds of information according to different electric signals so as to achieve the information interface switching effect; no display screen switching push button needs to be added, the display screen is switched on or switched off in a shaking mode, and operation is convenient.

Owner:冯林

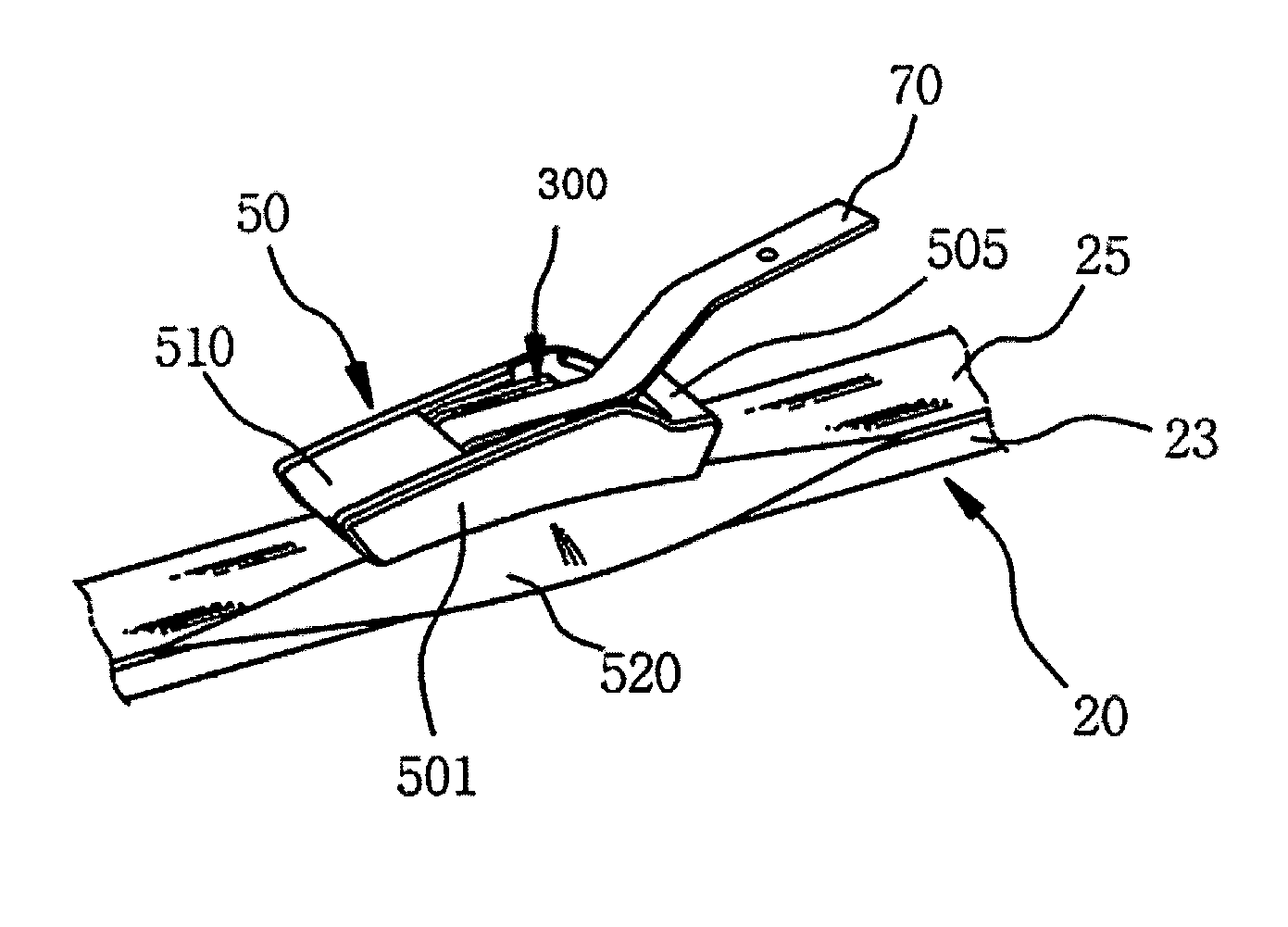

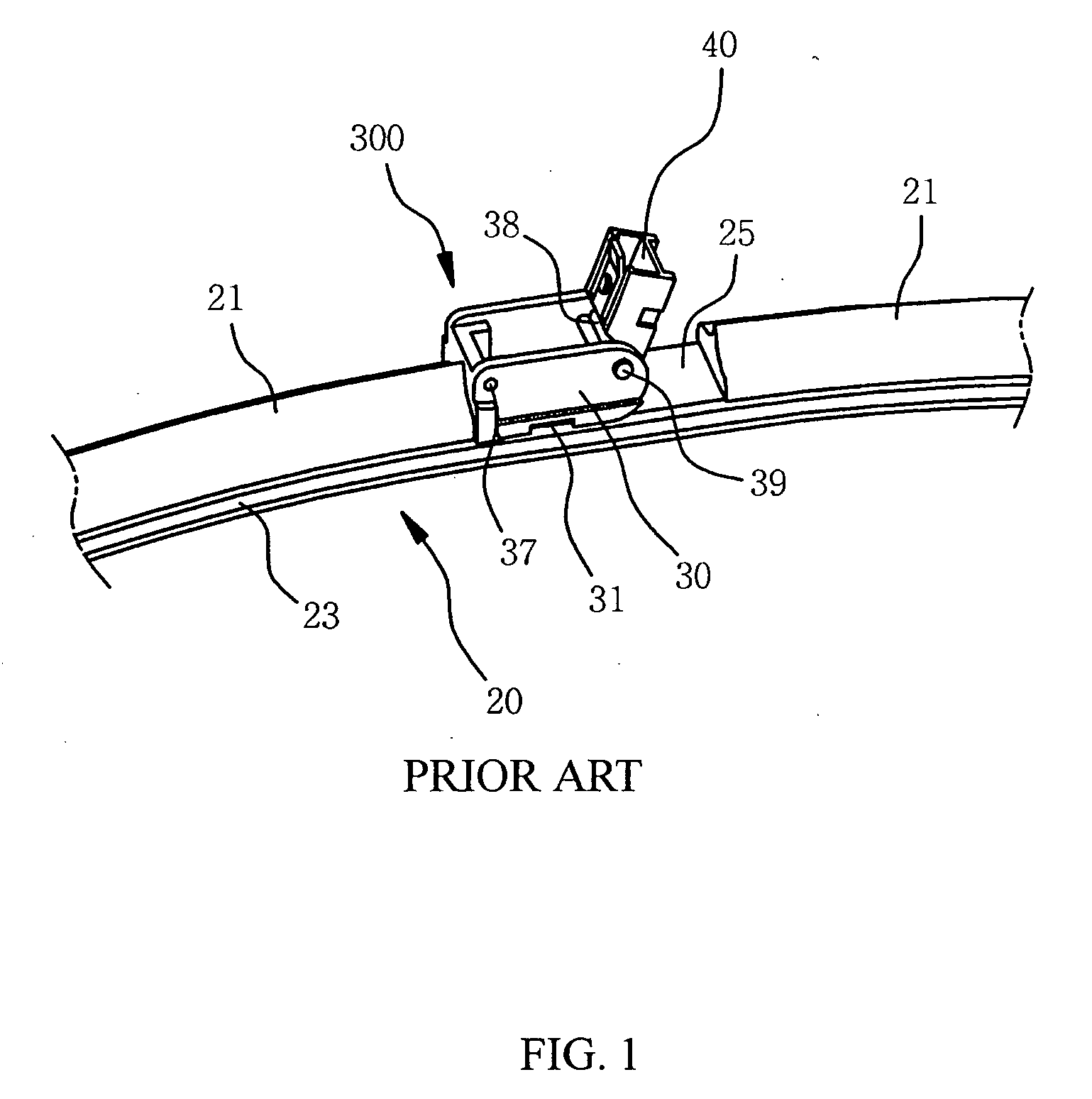

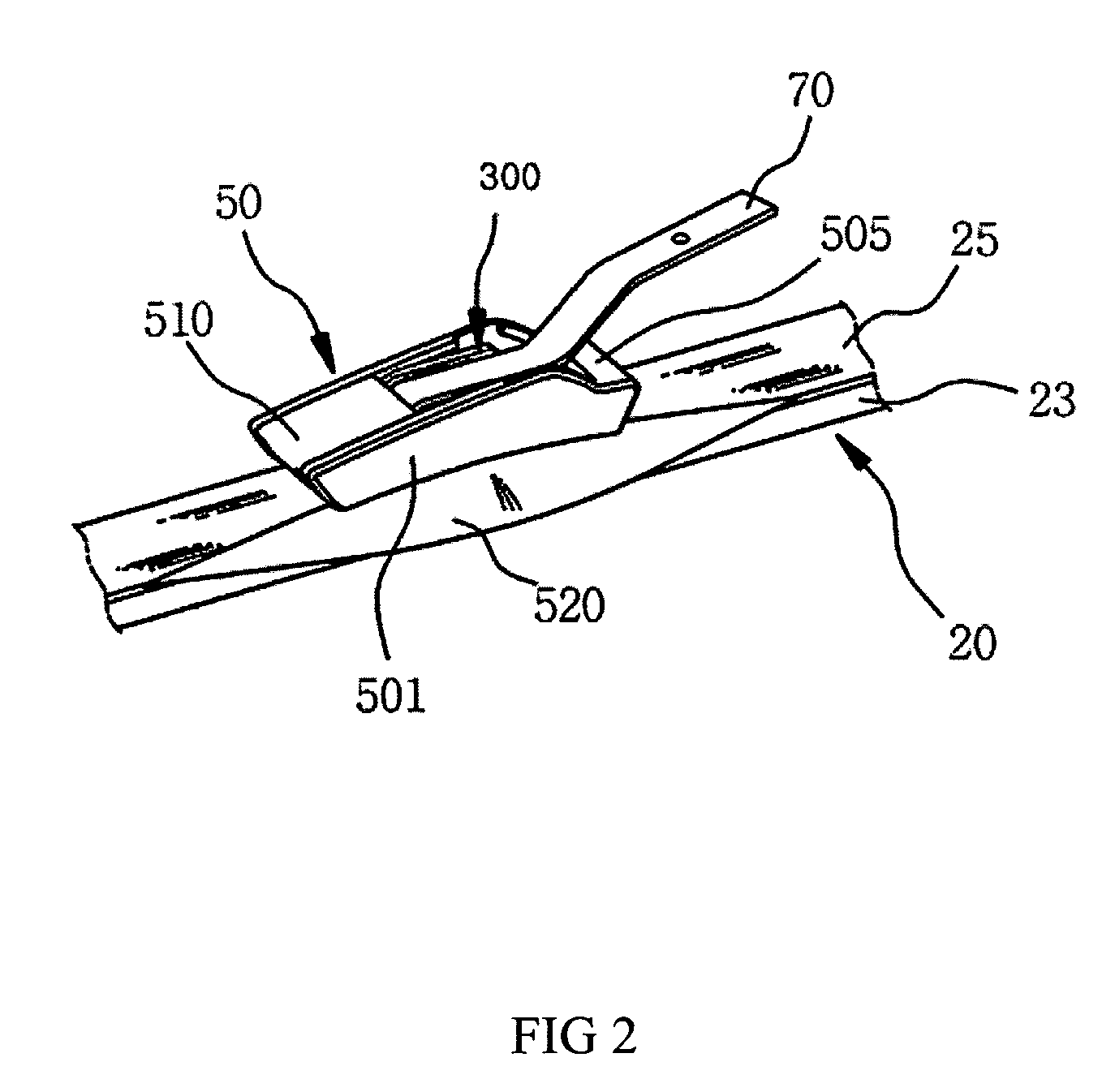

Cap for wiper connector

InactiveUS20060230571A1Aesthetic appearanceBeautiful appearanceLighting and heating apparatusWindow cleanersMechanical engineeringMotorized vehicle

Owner:KB WIPER SYST CO LTD +1

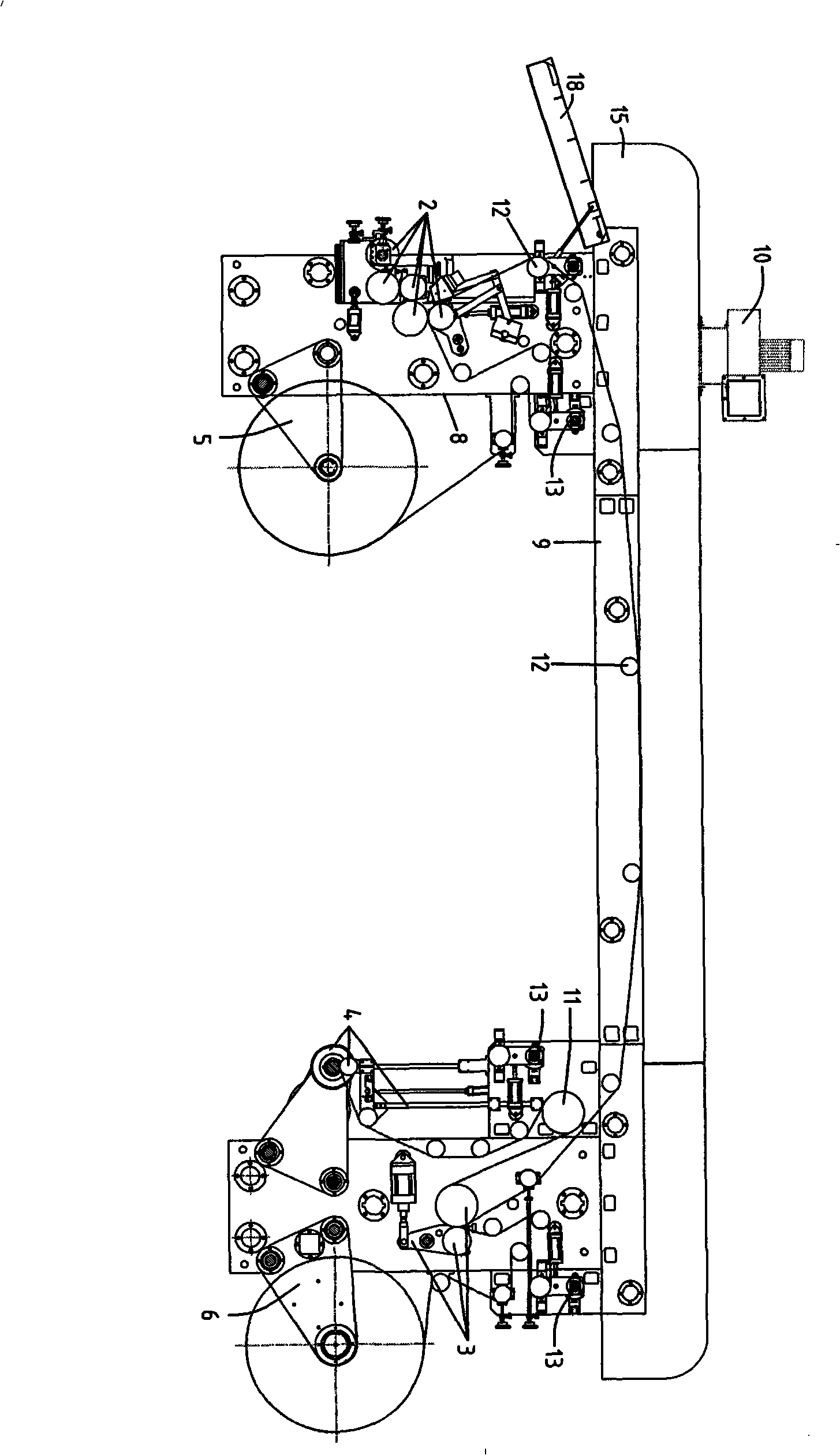

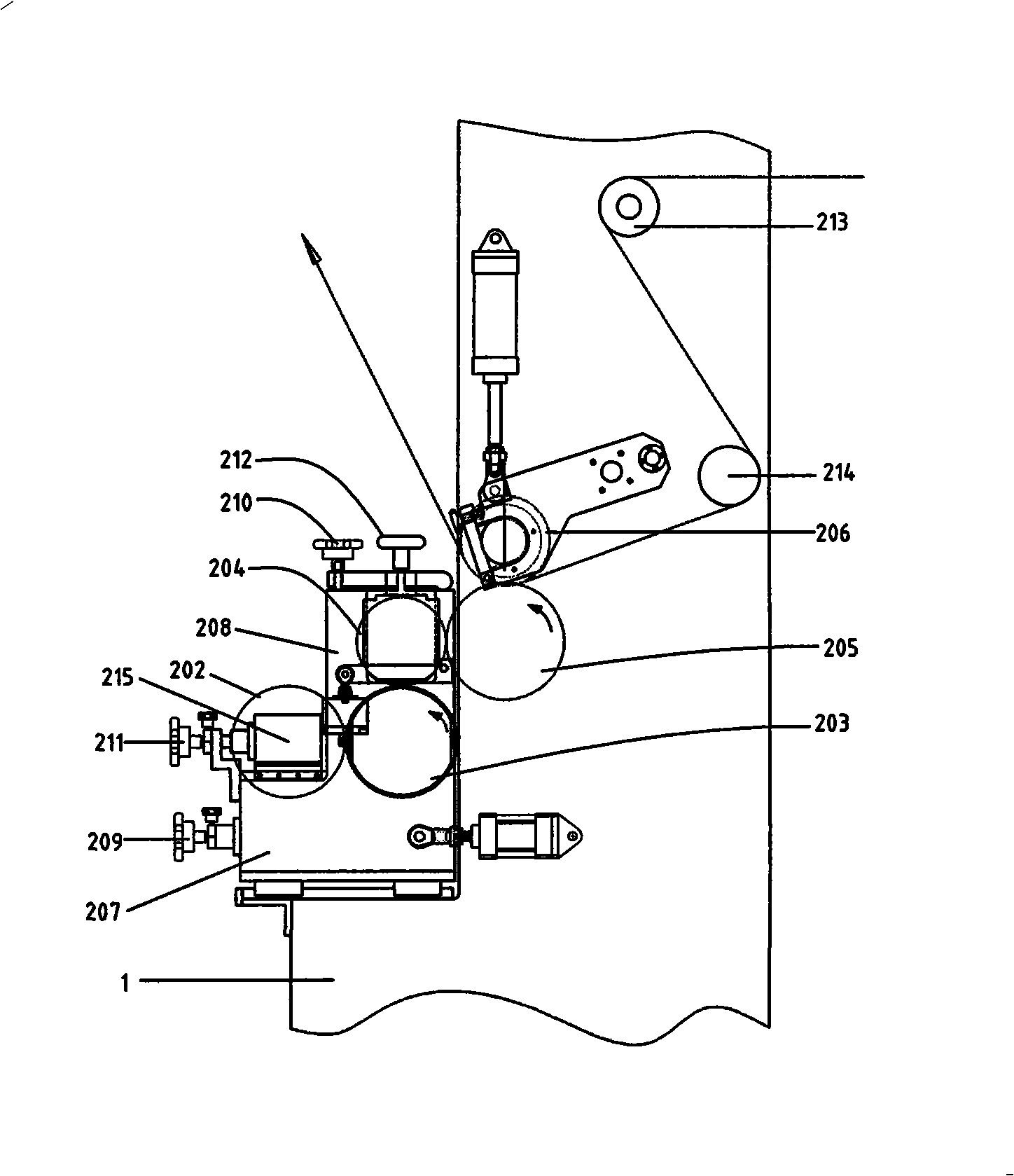

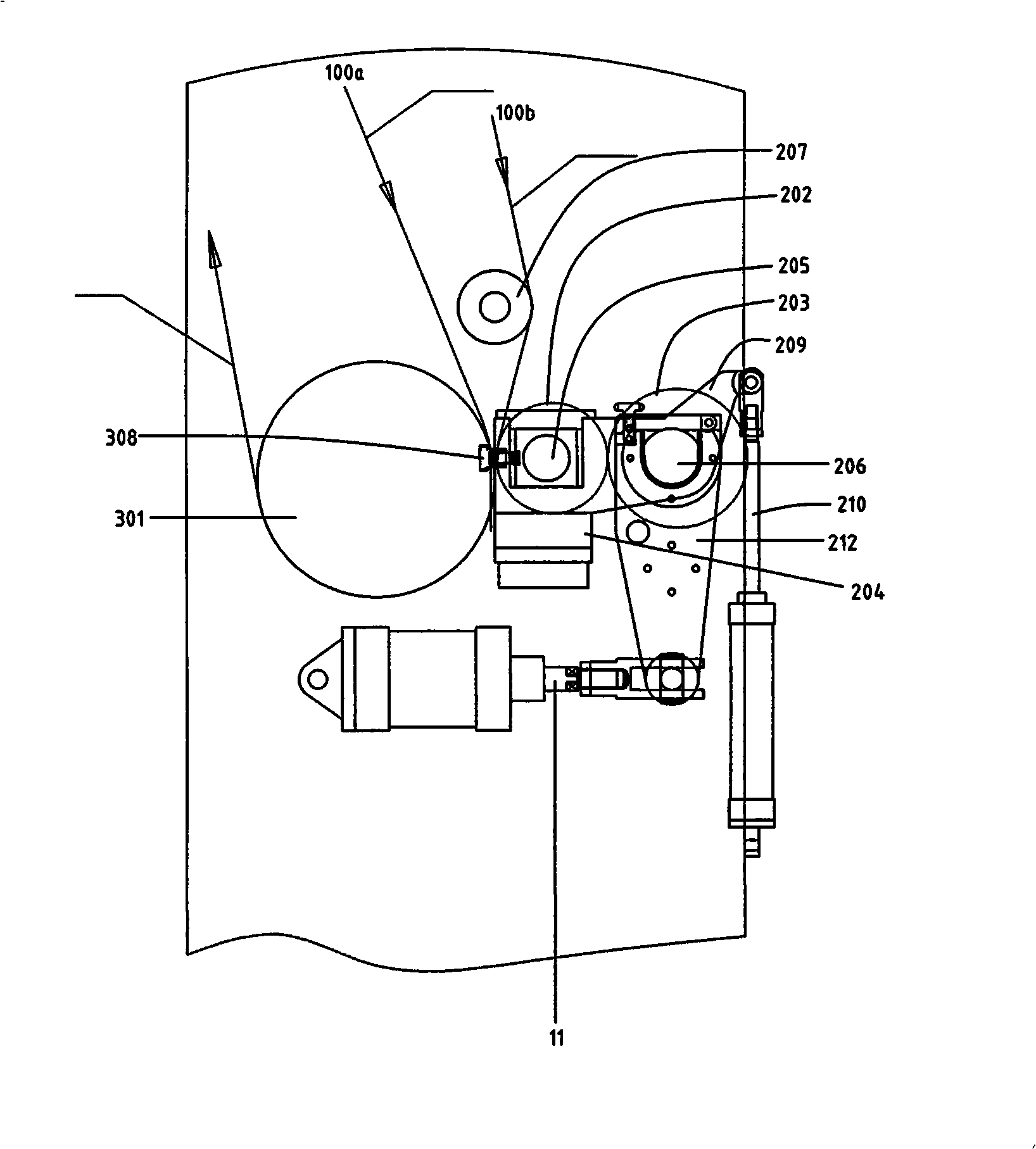

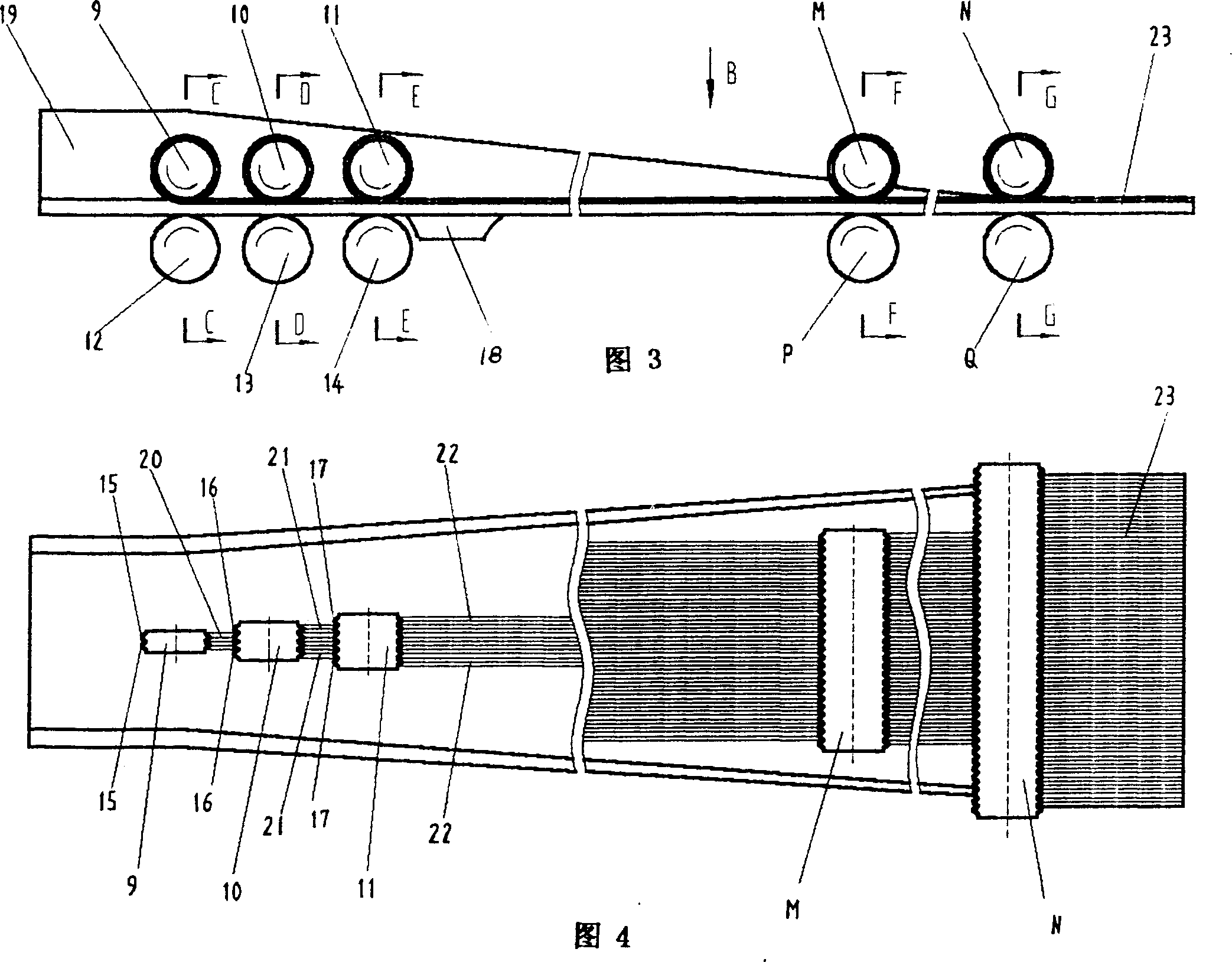

Solvent-free composite machine

ActiveCN101259772AGuaranteed cleanlinessEnsure safetyLamination ancillary operationsControlling laminationSolvent freeEngineering

The invention aims to provide a novel high-safety and high-production-efficiency solvent-free compound machine with good finished product quality, which comprises a frame, a coating mechanism, a recombination mechanism, a winding mechanism, a first unwinding mechanism, a second unwinding mechanism, a power mechanism, a wallboard, a machine head, a waste gas recycling part, a cooling steel sword, a transition steel sword group, a swing tension steel sword group and a control box; the clearance and pressure between various steel swords of the coating mechanism can be independently adjusted and a novel structure in which centers of separate steel swords are in the same horizontal line is applied to the compound mechanism; in the winding mechanism, the winding pressure is kept constant during the winding in any diameter and a novel mechanism which pneumatically controls an observation window is applied to the observation window; a novel humanized control panel mechanism with reasonable operation panel structure which can adjust the lighting direction is applied to the control box, thus ensuring the efficiency, quality and safety of the production. Furthermore, the compound machine can be more conveniently operated, has more reasonable structure and more pleasant shape compared with the original equipment.

Owner:SINOMECH CORP

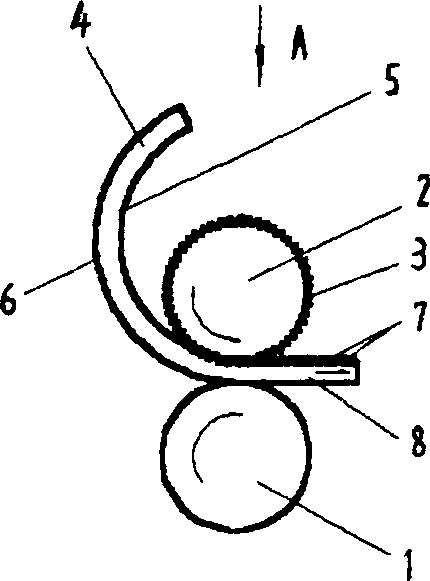

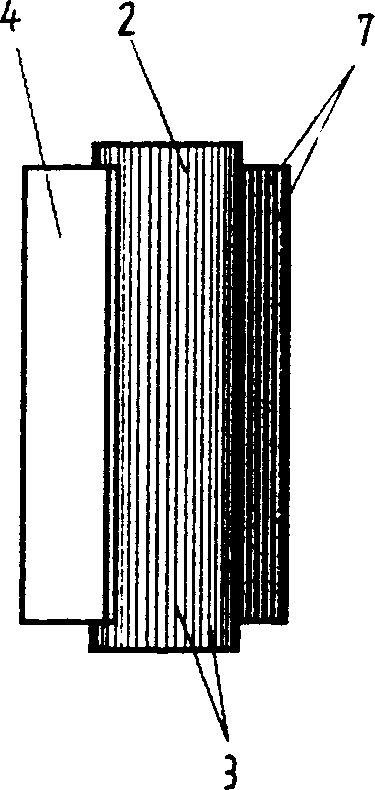

Method and apparatus for flattening bamboo wood without flaws

InactiveCN1485182AAvoid stretchingAvoid crackingOther plywood/veneer working apparatusWood treatment detailsEngineering

A method of spreading bamboo material without cracks and its device. First, remove bamboo green portion and outside nodes, cut open the bamboo sections, remove bamboo yellow portion and inner nodes, preheat to make bamboo sections soft, apply rollers with teeth to press and roll longitude grooves in the inner wall of bamboo material, to extend the arc length of bamboo material, thus flat bamboo material. The bamboo material could be fed along circumference of bamboo or in longitude direction, so there have two kinds of flatting devices: one has a smooth roller, a longitude toothed roller parallel to the smooth roller; another has two rows of rollers, each roller on one of rows has at least two teeth along the circumference, each end of the next roller have at least one more tooth than that of the former roller. when spreading bamboo material with more than 180íÒ,there wouldn't have cracks, then a flat bamboo plate is obtained.

Owner:刘觉春

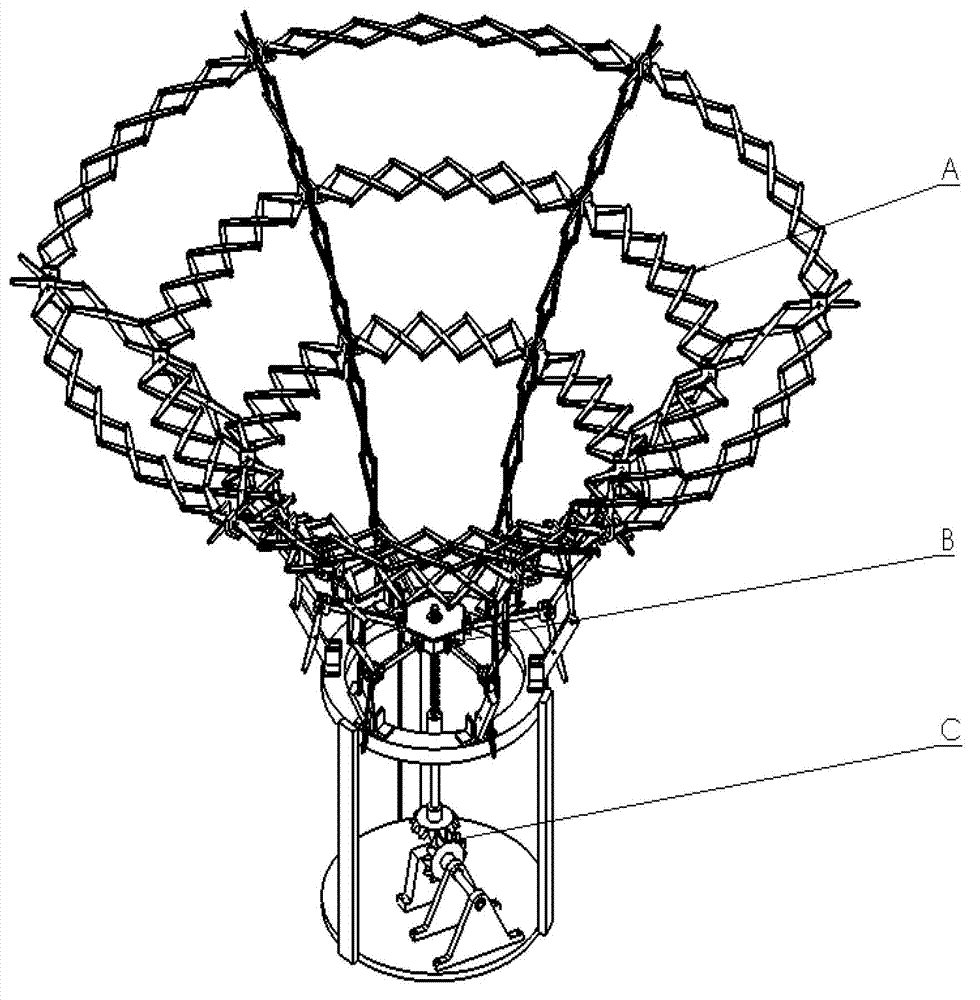

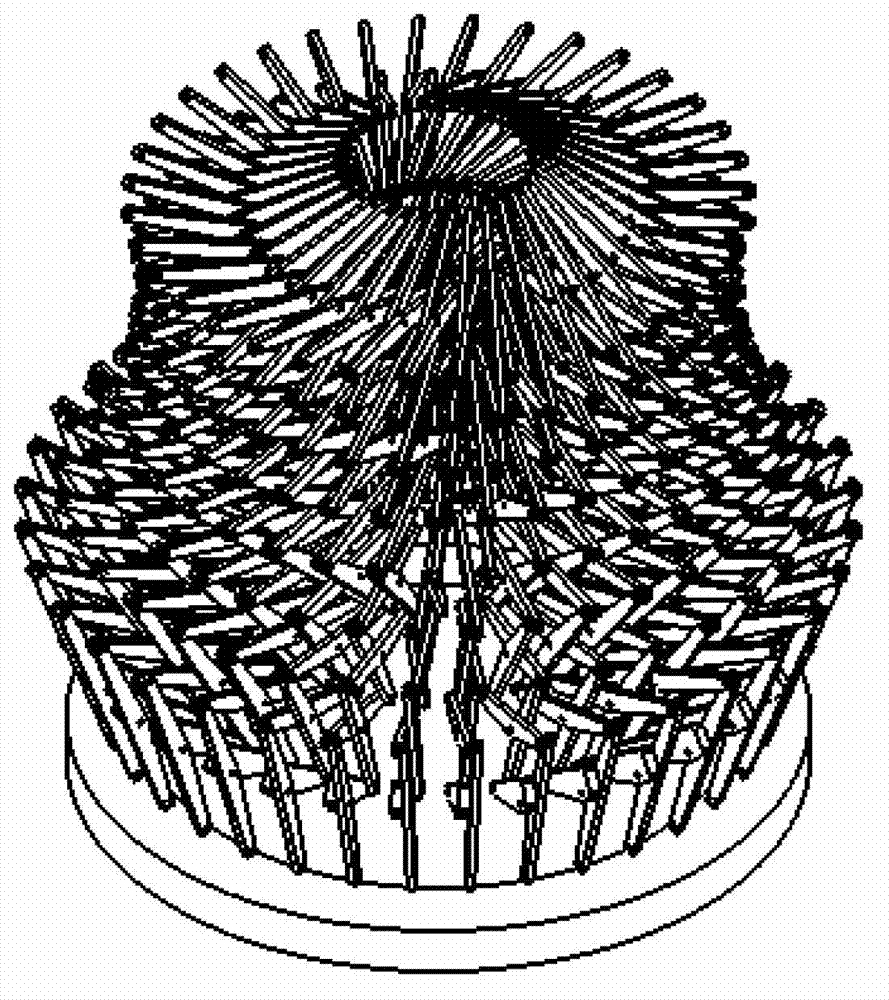

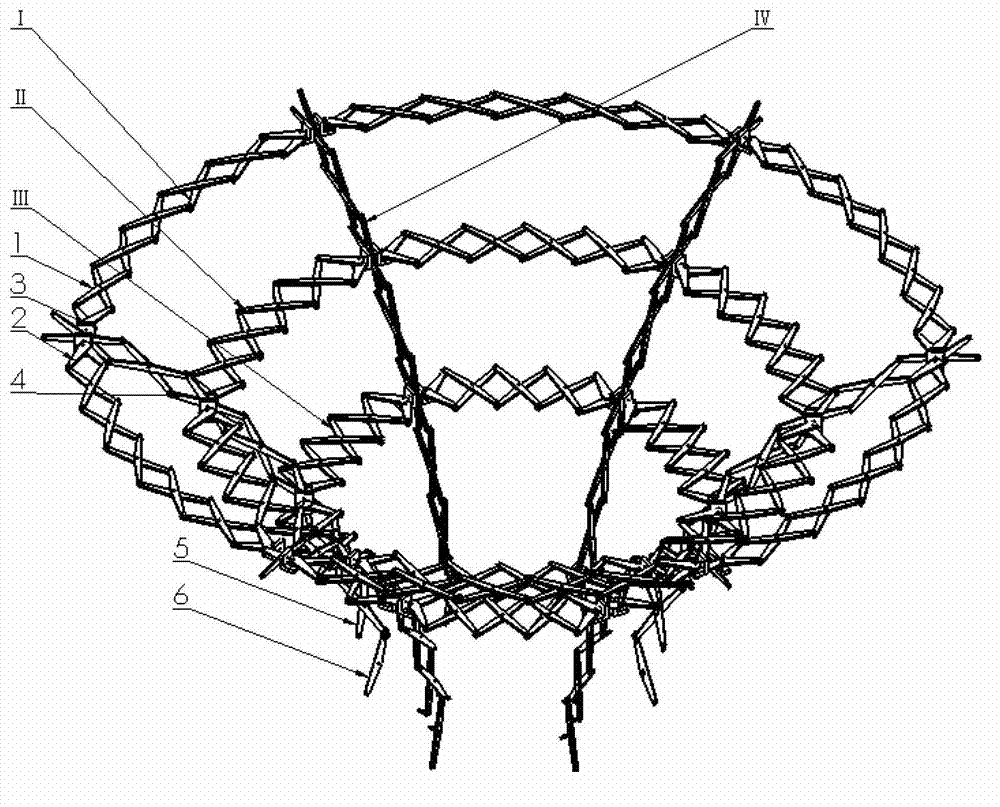

Scalable novel deformed lamp

ActiveCN103090232AForward rotationAchieve reversalSpecial ornamental structuresElectric lightingCouplingDrive motor

The invention provides a scalable novel deformed lamp which comprises a rod group part A, a drive part B and a motive power input part C, wherein the rod group part A is connected with the drive part B through a revolute pair formed by a rod (6) and a support rod (8). A rod (5) and the rod (6) on a rod group (IV) of the rod group part A are respectively connected with a rod (7) and the connections form a parallelogram. The shape of the parallelogram is the same with shapes of the other parallelograms formed on the rod group (IV), the rod (7) and the vertical direction form an included angle, and the shape of the whole lamp can be adjusted through the included angle. The drive part B and the motive power input part C are connected with a coupler (14) through a lead screw. The rod group part A of the lamp is a dimensional circular arc camber, a main body of the lamp is formed by the camber, and a bulb of the lamp can be positioned on each rod piece. Scale deformation of the lamp is divided into two conditions of contraction and unfolding, degrees of the contraction and the unfolding are controlled by time of positive and negative rotating of a drive motor, and the overall shape of the lamp is flowerlike.

Owner:BEIJING JIAOTONG UNIV

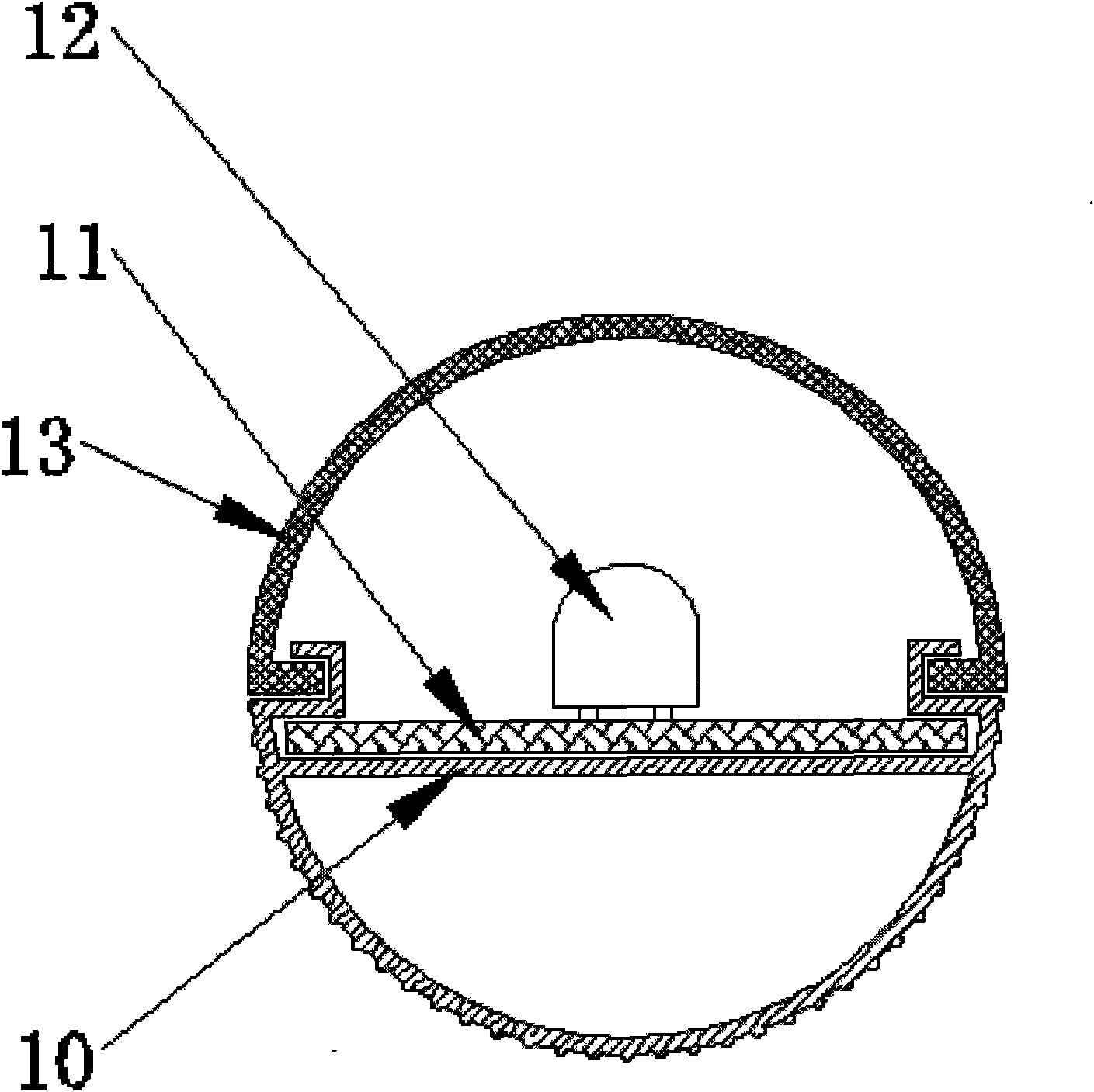

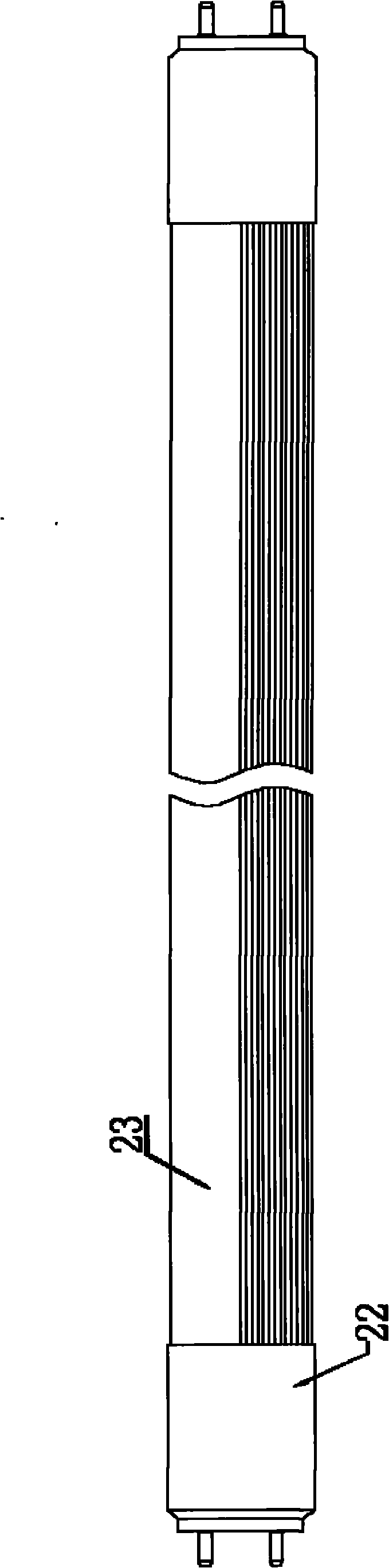

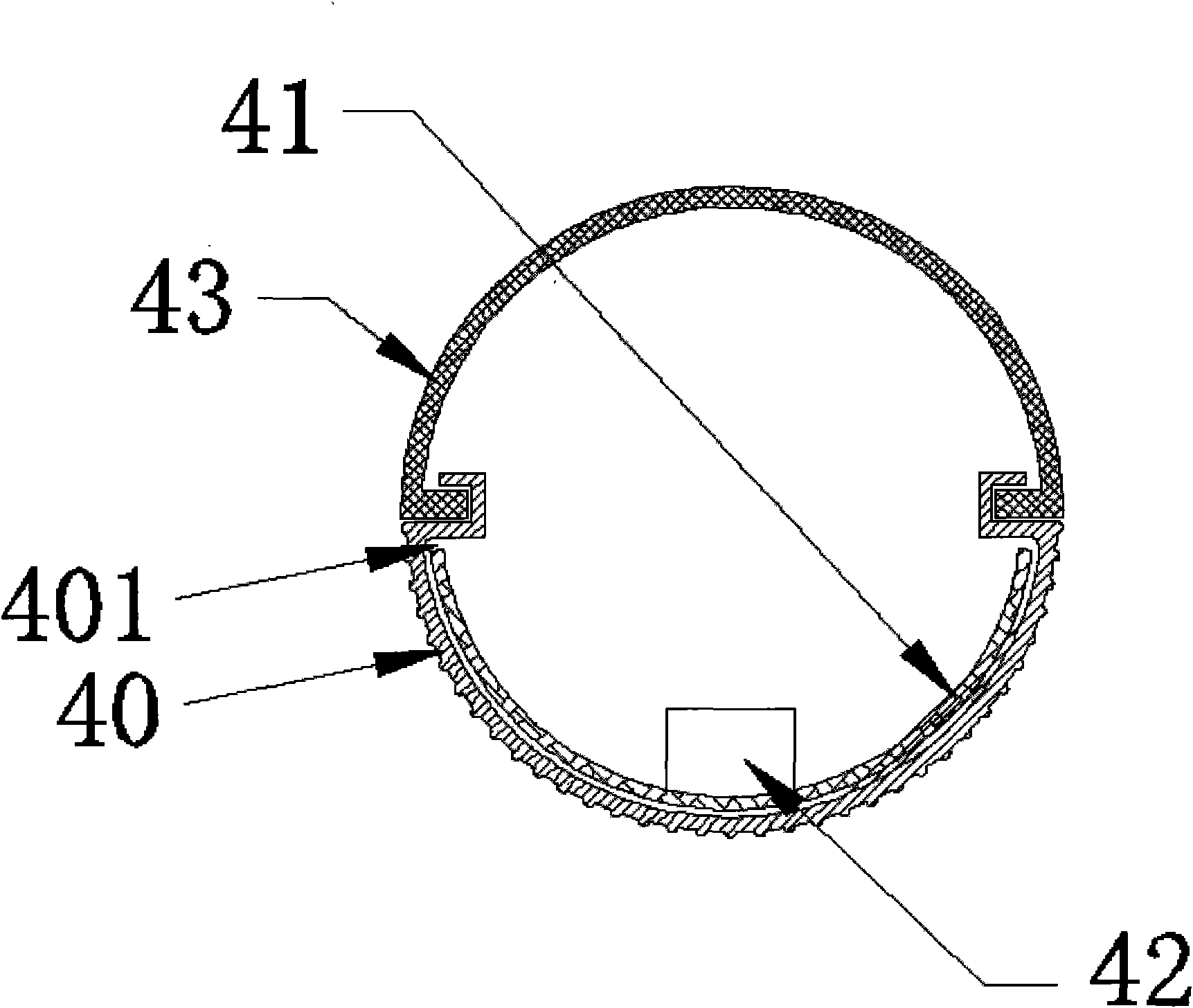

LED (light emitting diode) fluorescent lamp

InactiveCN102121578AImprove cooling effectGood secondary light distribution effectPoint-like light sourceElongate light sourcesElectricityEngineering

The embodiment of the invention discloses an LED (light emitting diode) fluorescent lamp which comprises a fluorescent lamp tube, fluorescent lamp end covers and a constant current source circuit, wherein the fluorescent lamp end covers are installed at two ends of the fluorescent lamp tube; the constant current source circuit is connected between an LED lamp bank in the fluorescent lamp tube and the metal needles of the end covers, and is used for supplying electricity for the LED lamp bank. The LED fluorescent lamp is characterized in that the fluorescent lamp tube comprises a tube body; the tube body is composed of an arc-shaped metal sectional material and a transmitting lamp cover which is arranged above the metal sectional material; the part, which is positioned at the inner side of the tube body, of the metal sectional material is provided with a clamping groove; a flexible PCB (printed circuit board) which has bending radian same as that of the metal sectional material is buckled on the clamping groove; and the LED lamp bank is welded on the flexible PCB. The LED fluorescent lamp has good radiation performance, and the secondary grading effect of the LED is good.

Owner:刘昌贵

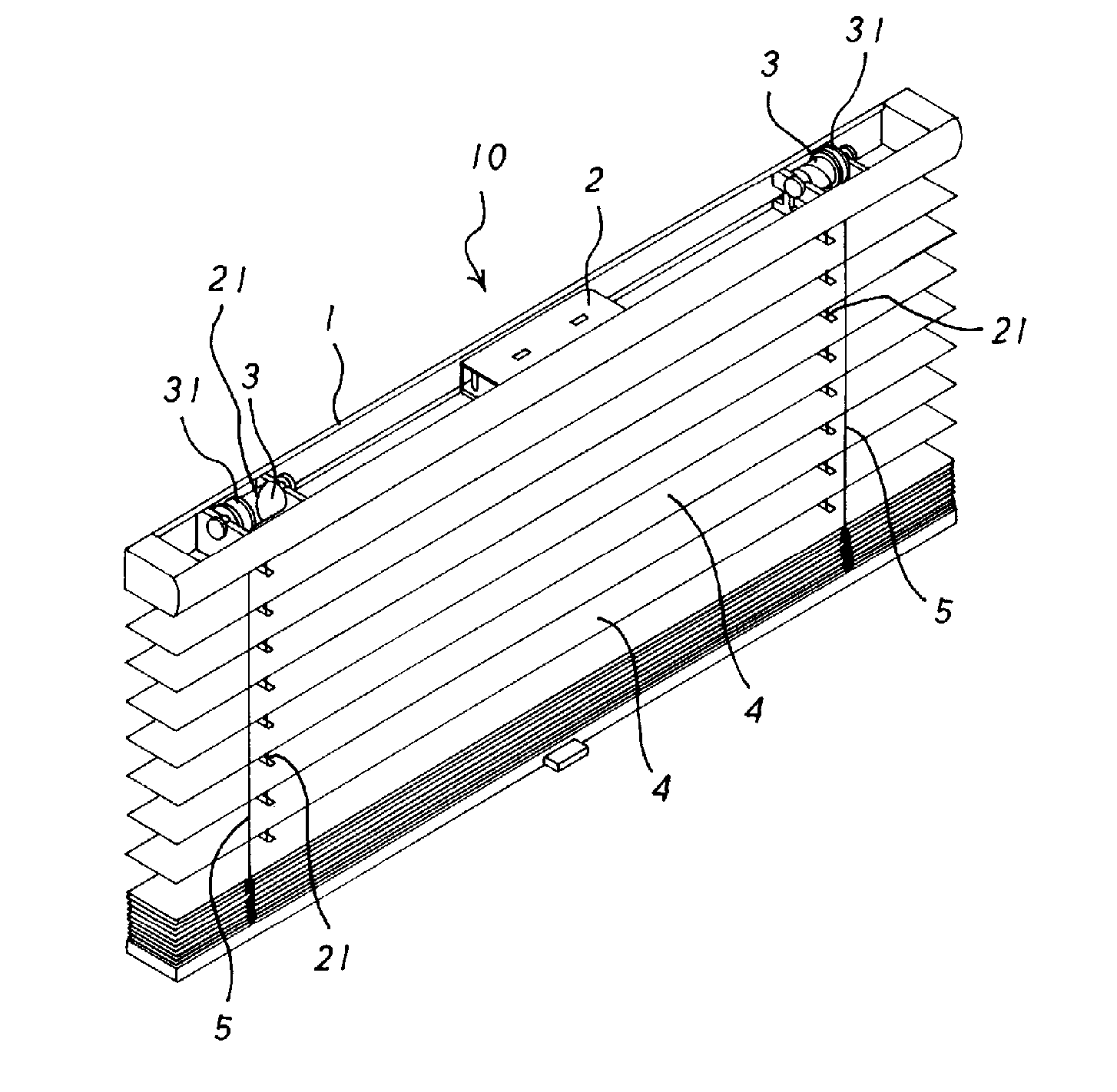

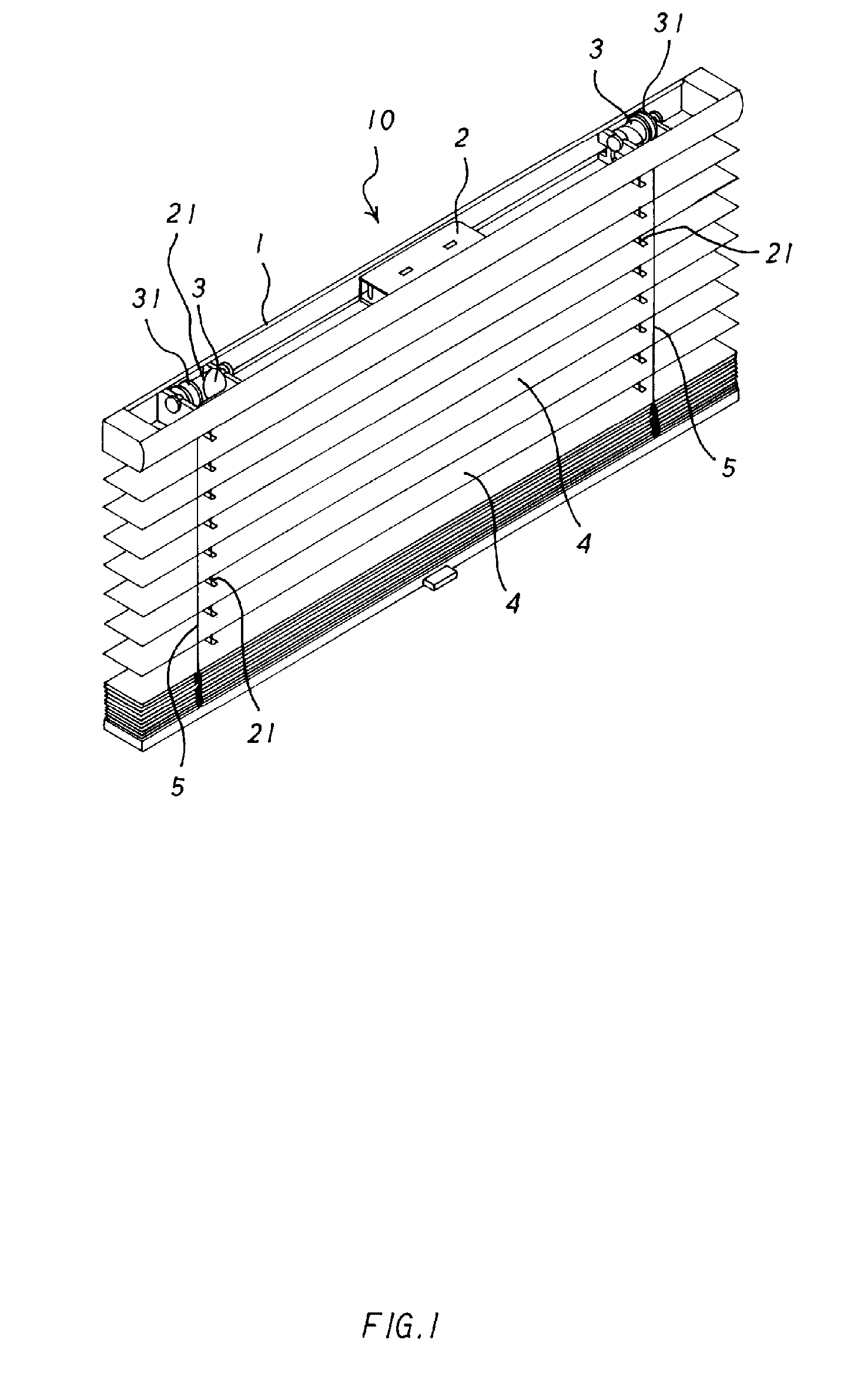

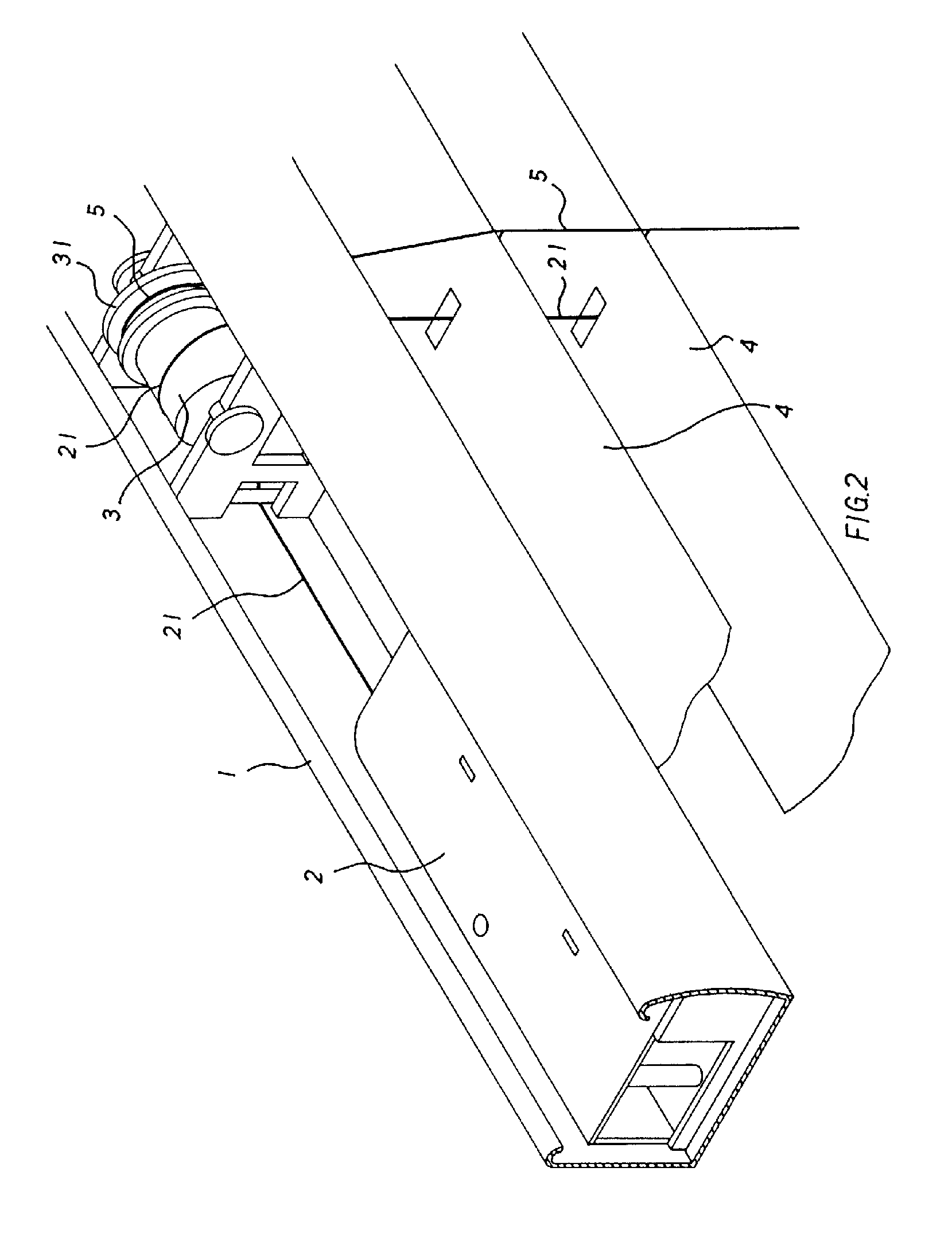

Adjusting structure of a curtain for adjusting the angle of curtain blade

An adjustable structure of a curtain for adjusting the angle of curtain blades includes a winding tube disposed in an upper rail. A pulling string is wound around the winding tube for controlling the rise and fall of the curtain and then passes through the curtain blades. One end of the winding tube is disposed with a rubbing wheel for hanging the top end of a suspending string provided for insertion of the curtain blades. Thereby, during the rise and fall of the curtain blades, the suspending string is pulled towards the rotating direction of the winding tube, so that the angle of the curtain blades is adjusted.

Owner:LEADER DEV IND

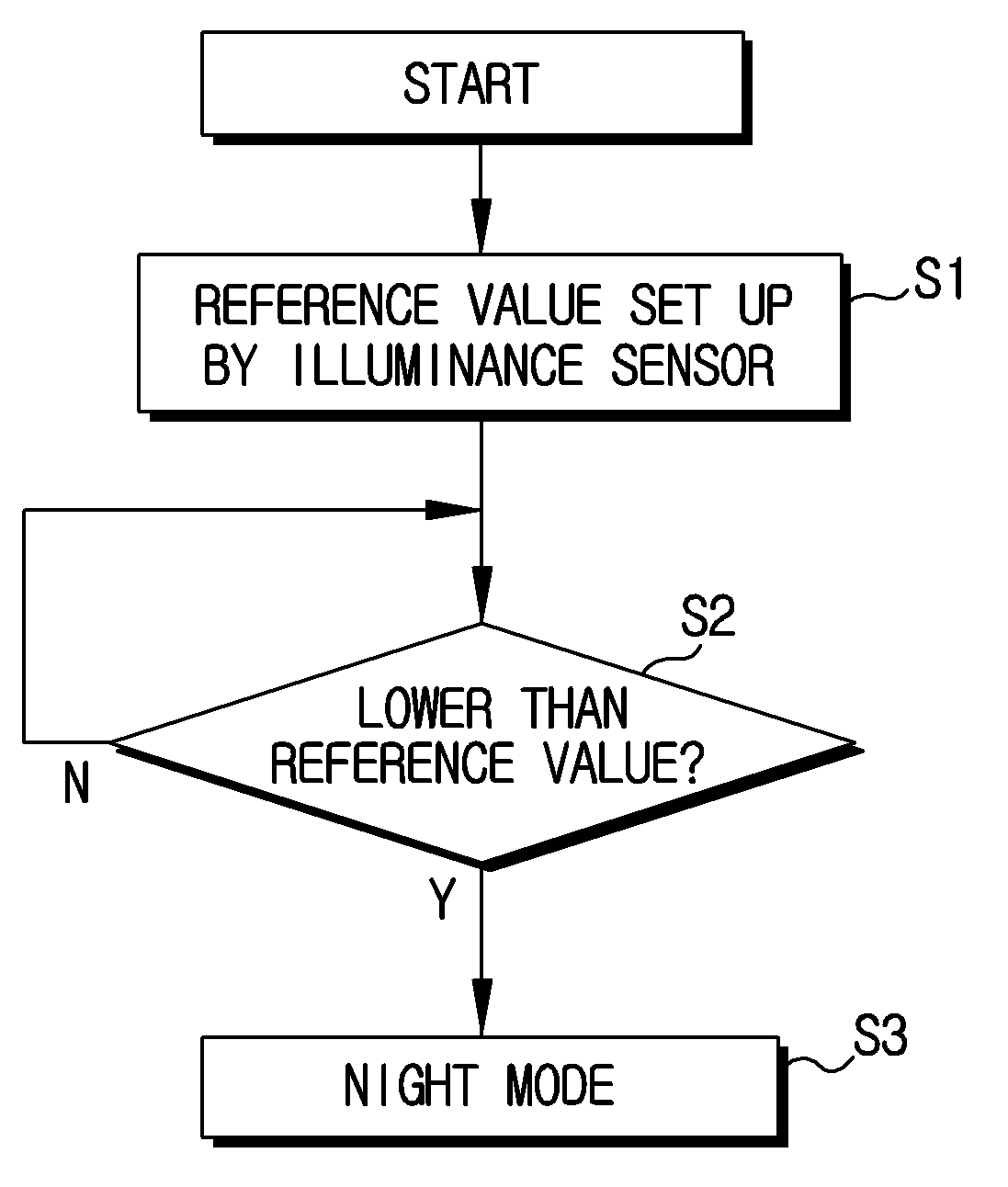

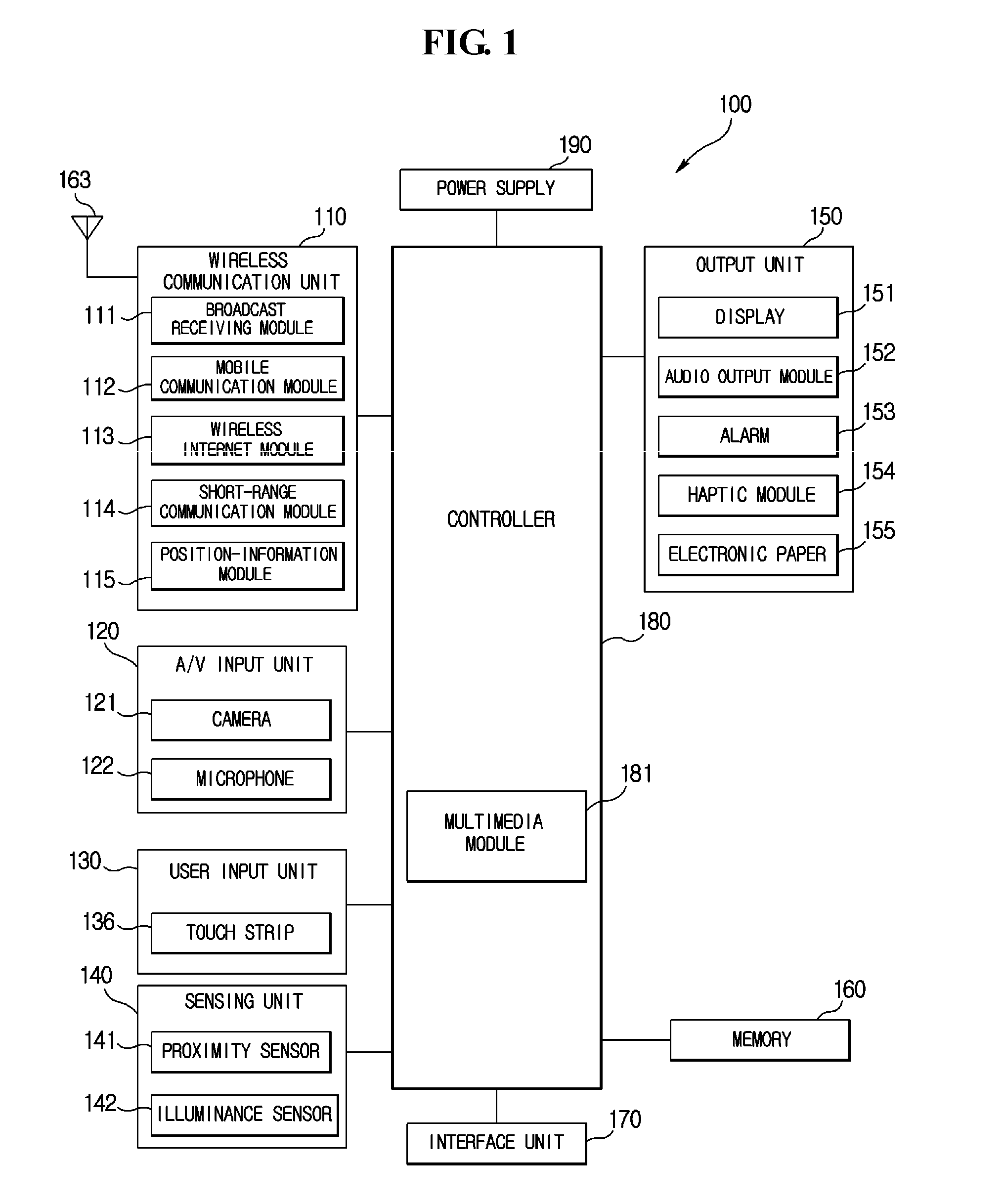

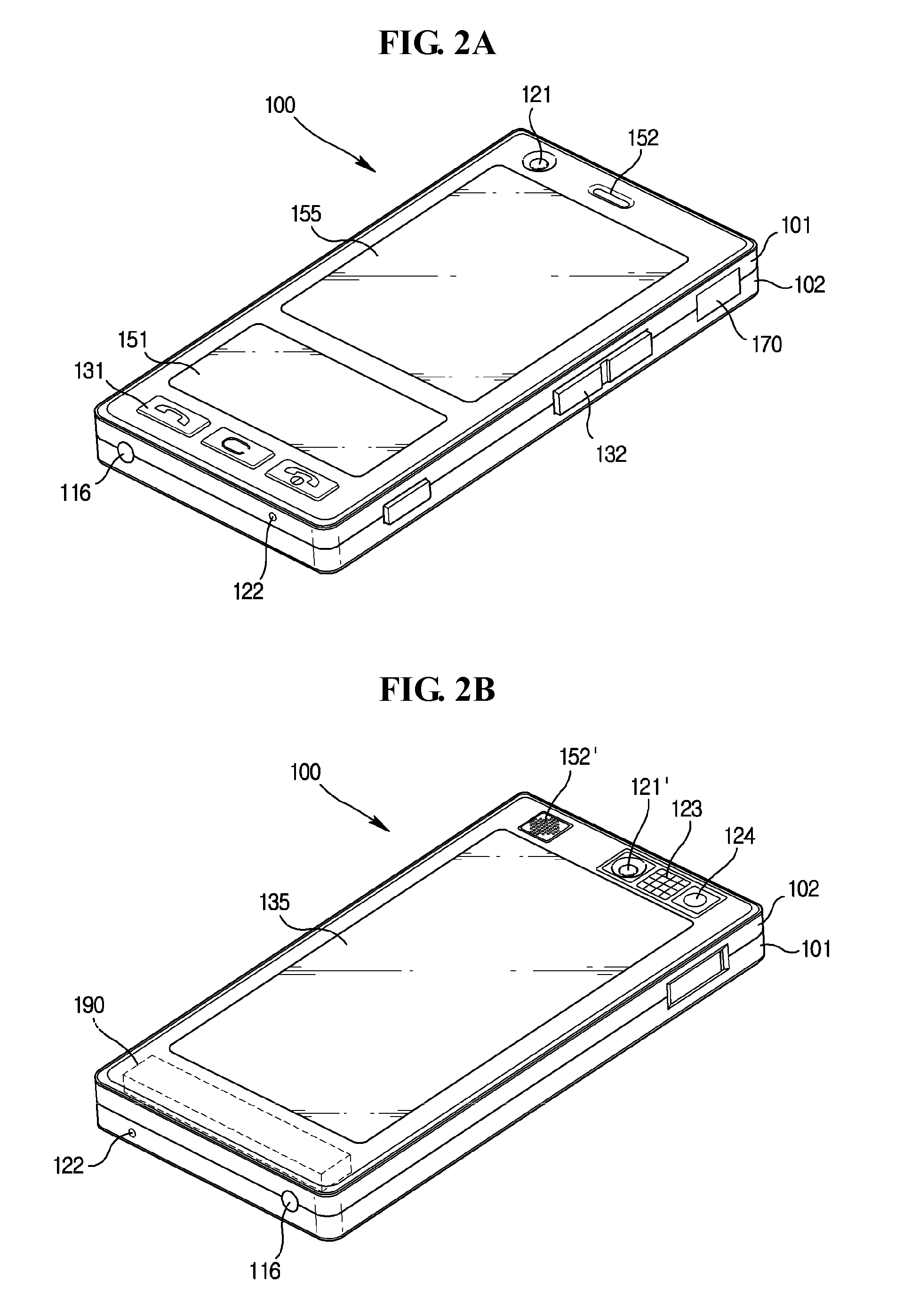

Mobile terminal having electronic paper and method for controlling the same

InactiveUS20100184485A1Reduce consumptionBeautiful appearanceDevices with multiple display unitsDevices with sensorEmbedded systemProgram control

A mobile terminal having electronic paper and a method for controlling the same are provided, wherein the mobile terminal comprises: a first display unit configured to implement a role of electronic paper; a second display unit configured to be mounted at one side of the first display unit for implementing a role of a light emitting display unit; a memory configured to store a program for implementing a predetermined menu; and a controller configured to display the menu on the first display unit or the second display unit.

Owner:LG ELECTRONICS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com