Patents

Literature

95results about How to "Reliable quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

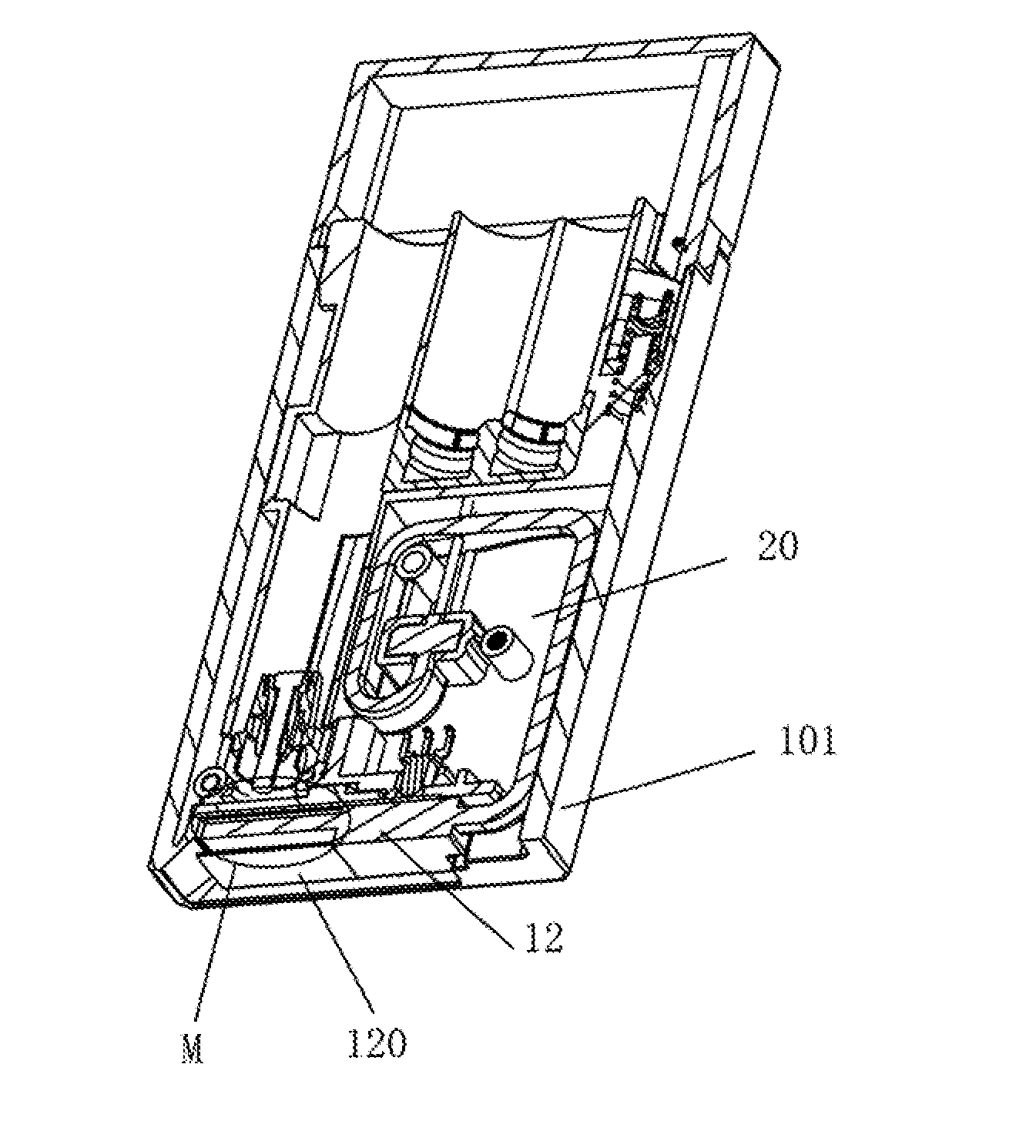

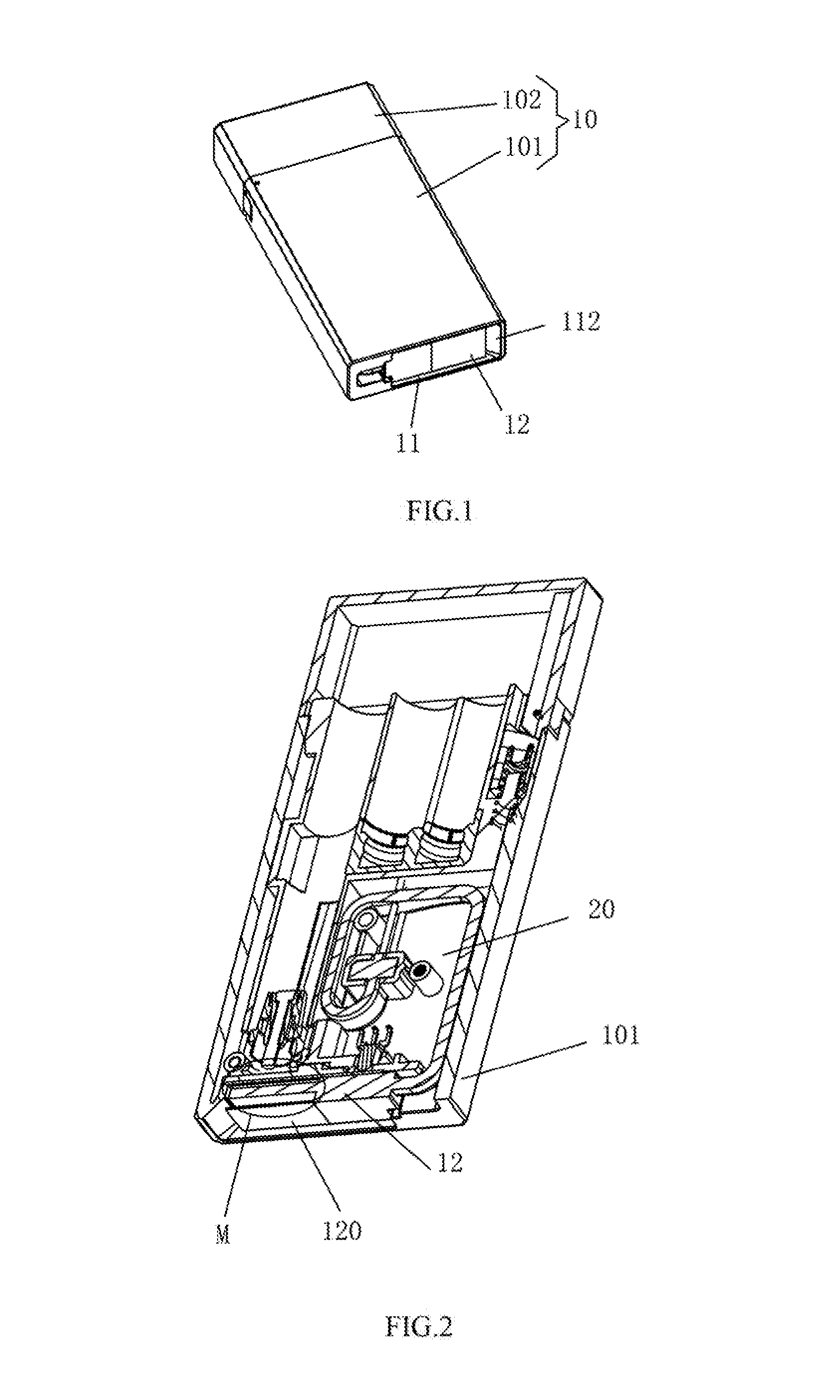

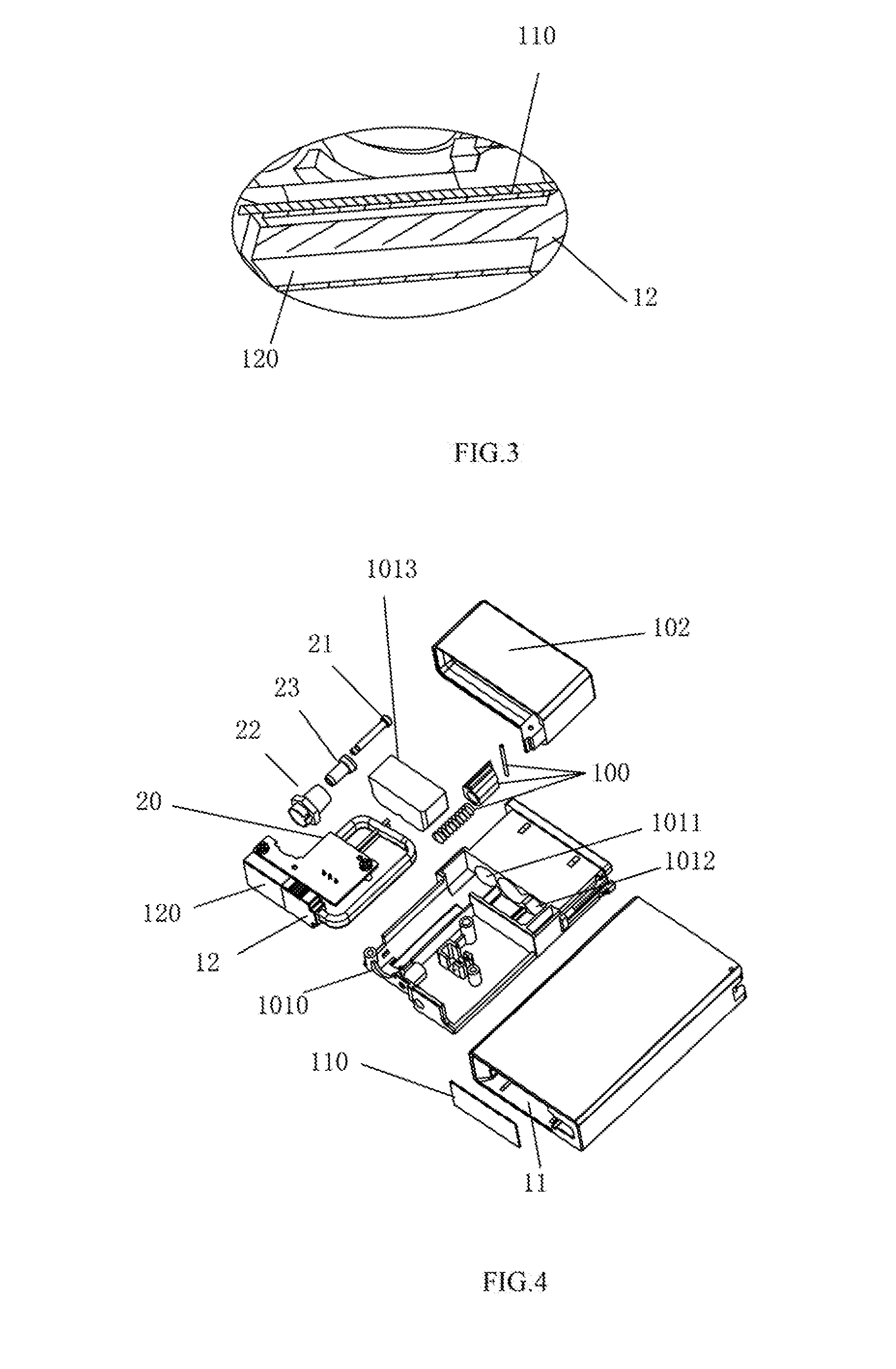

Electronic cigarette case

InactiveUS20160134143A1Reliable qualityQuality improvementBatteries circuit arrangementsTobacco devicesEngineeringElectrical and Electronics engineering

An electronic cigarette case, comprising a case body. The case body is provided on a surface thereof with an accommodation groove. The accommodation groove has movably accommodated therein a charging connector. The charging connector has arranged thereon a first magnetic piece. The accommodation groove has arranged at one side thereof a second magnetic piece that is matched with and magnetically attracted to the first magnetic piece. By employing the technical means of having arranged on the charging connector the first magnetic piece and of having arranged at one side of the accommodation groove the second magnetic piece that is matched with and magnetically attracted to the first magnetic piece, the electronic cigarette case achieves reliable quality and the technical effect that the charging connector does not come loose and allows the charging connector to be fixed without requiring an interference fit.

Owner:KIMREE HI TECH

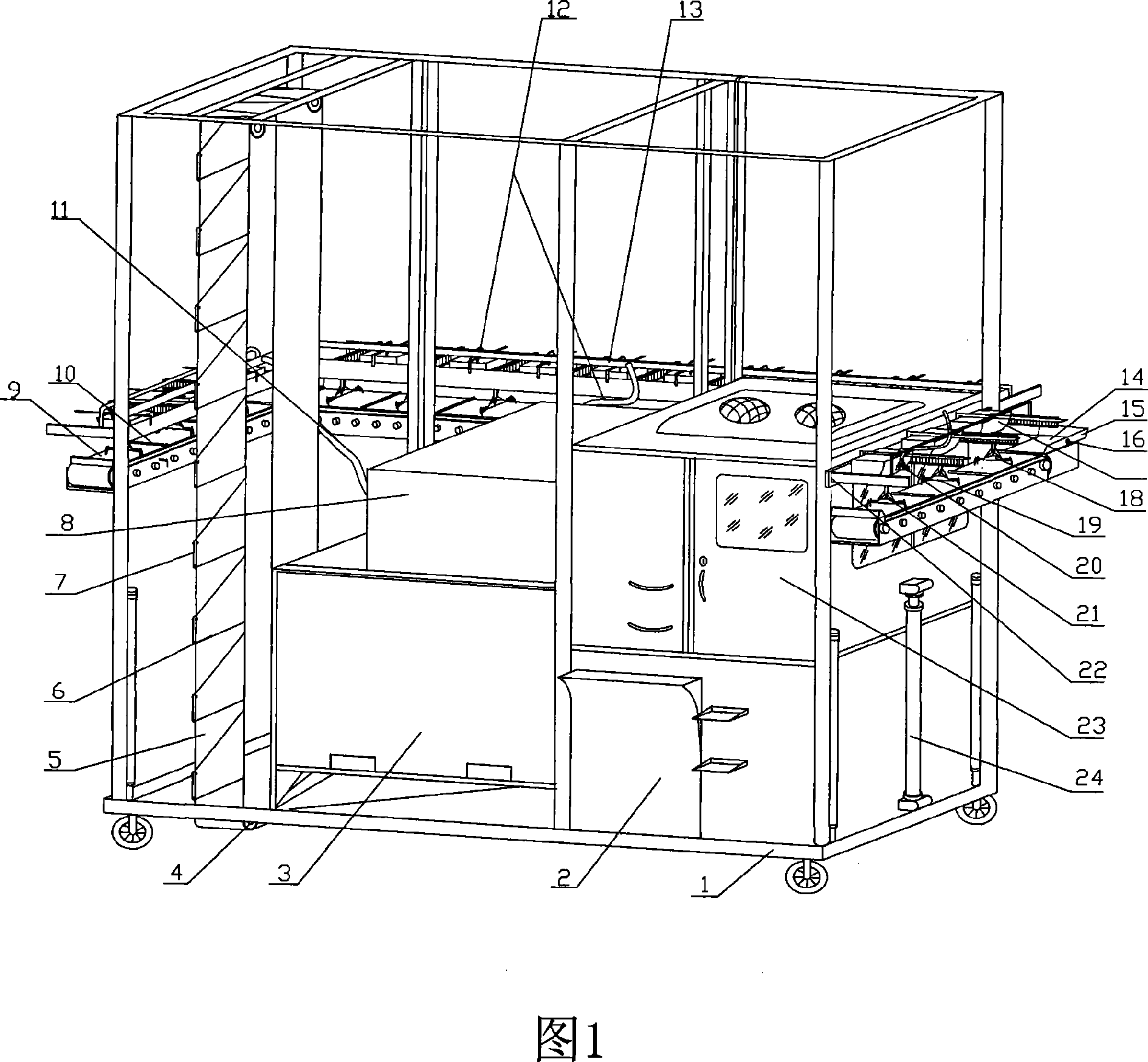

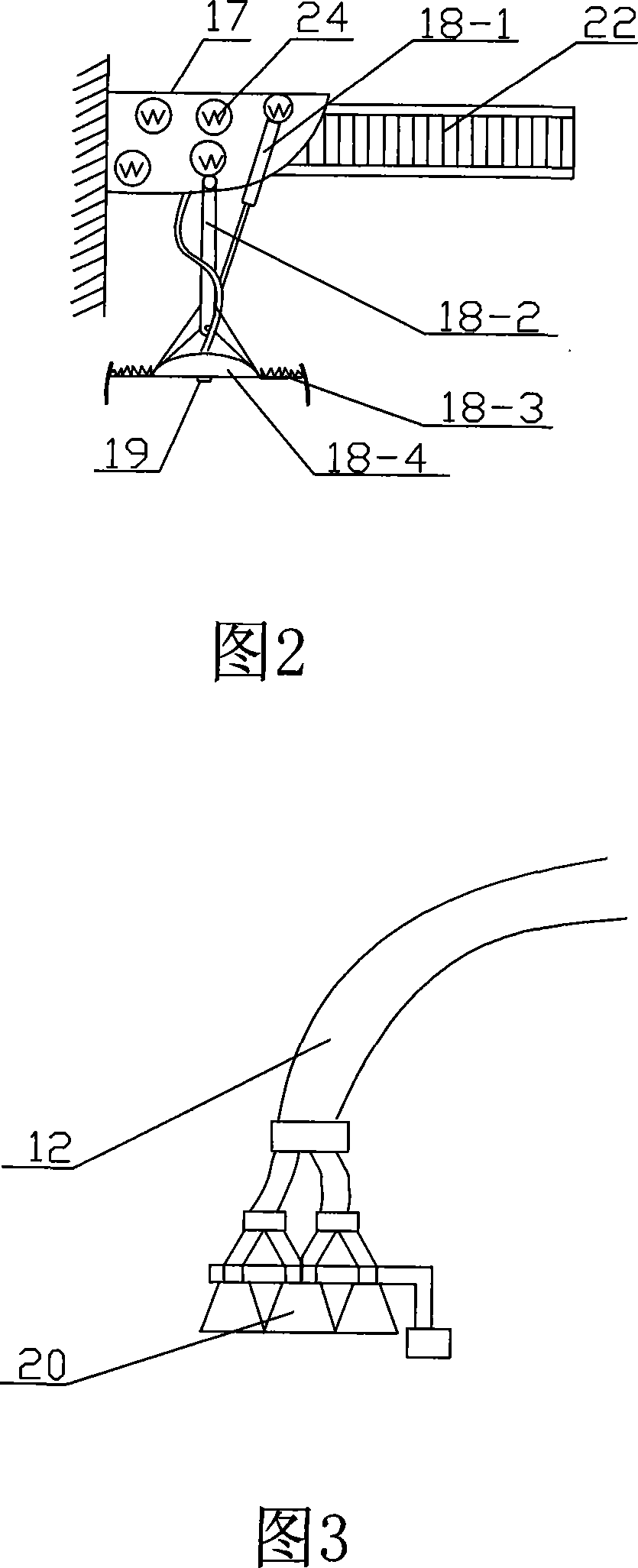

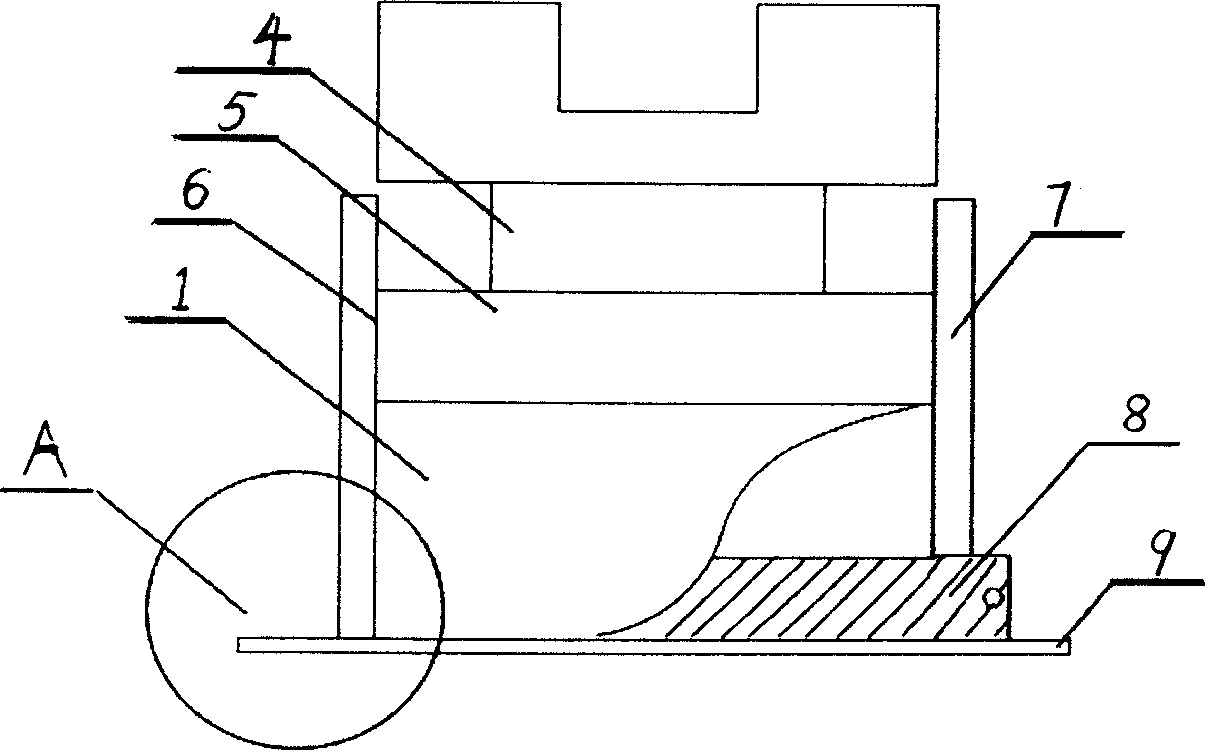

Wall building machine

InactiveCN101100903AImprove work efficiencyReliable qualityBuilding material handlingElectrical and Electronics engineeringNozzle

A bricklaying machine includes machine bracket, brick hopper, brick transmission device, mortar hopper, mortar transmission device and control device. The bricklaying device is installed to the end of the brick and mortar transmission device. The outlet of brick hopper is connected to brick lifting device which is connected to a brick horizontal transmission device. Mortar hopper is connected to bricklaying device through pressure box and transmission pipe. At the end of the transmission pipe, it is installed with mortar paving nozzle and distribution nozzle. Bricklaying device is fixed on the bracket above brick horizontal transmission device with lifting device between the bracket and the main body.

Owner:刘金前

Complete feeds for milking sow

InactiveCN101077136AFull of nutritionReliable qualityFood processingAnimal feeding stuffSOYBEAN SEED OILChemistry

The present invention discloses one kind of complete feed for milking sow. The complete feed consists of corn 50-70 wt%, bran 3-7 wt%, soybean oil 1-2 wt%, soybean dregs 25-28 wt%, DDGS 3-5 wt%, stone powder 0.5-1.5 wt%, light calcium carbonate 1-1.4 wt%, salt 0.2-0.4 wt%, lysine 0.05-0.15 wt%, choline 0.05-0.15 wt%, phytase 0.01-0.02 wt%, additive 0.03-0.05 wt%, sow vitamins 0.05-0.1 wt%, and sow minerals 0.1-0.4 wt% The complete feed can provide milking sow with sufficient energy, protein, vitamins and minerals and make milking sow possess high milk secreting ability and capability of raising immunity of piglets..

Owner:侯彦卫

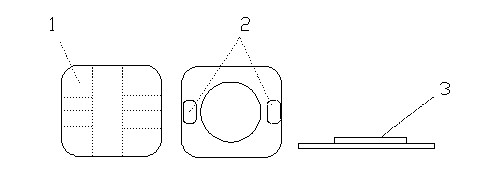

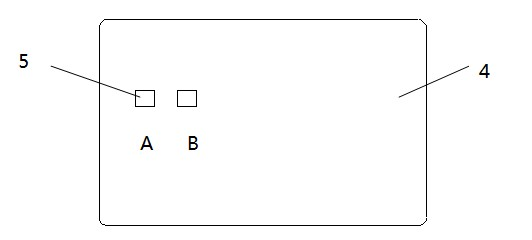

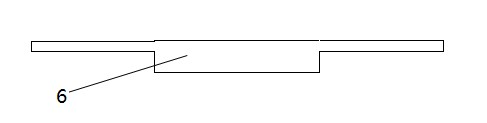

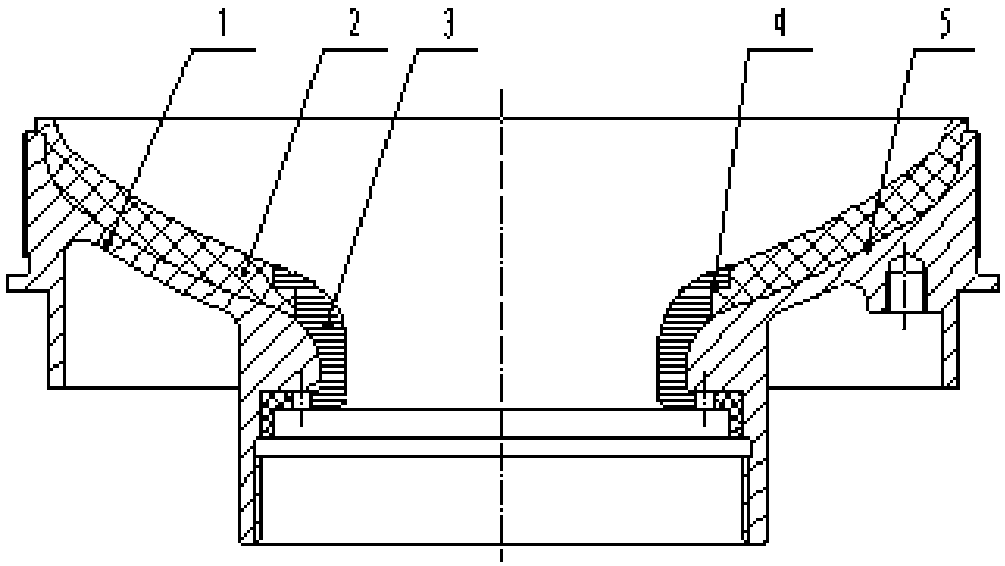

Biface smart card and manufacture method thereof

ActiveCN102024175AReliable qualityLow costRecord carriers used with machinesStructural engineeringElectrical and Electronics engineering

The invention discloses a manufacture method of a biface smart card. The manufacture method comprises following steps: 1, punching a conductive bonding pad accommodating hole on a middle sandwich layer (4); 2, loading a conductive bonding pad; 3, embedding wires and welding; 4, piling up and laminating; 5, utilizing a slotter to mill a first-layer groove (8) and a second-layer groove (9) on a clamp body (11) through one step; 6, milling two conductive holes; 7, filling a conducting material (12) into the two conductive holes (10); and 8, finally packaging to form the biface smart card. The biface smart card provided by the invention has the following advantages: the conductive bonding pad is connected with a chip through the conducting material which has more reliable quality and lower cost than those of the existing conductive adhesive; and in addition, an antenna is connected with the conductive bonding pad though a wire embedding machine, such butt-joint process is widely used in contactless cards at present, and the quality is quite stable.

Owner:WUHAN TIANYU INFORMATION IND

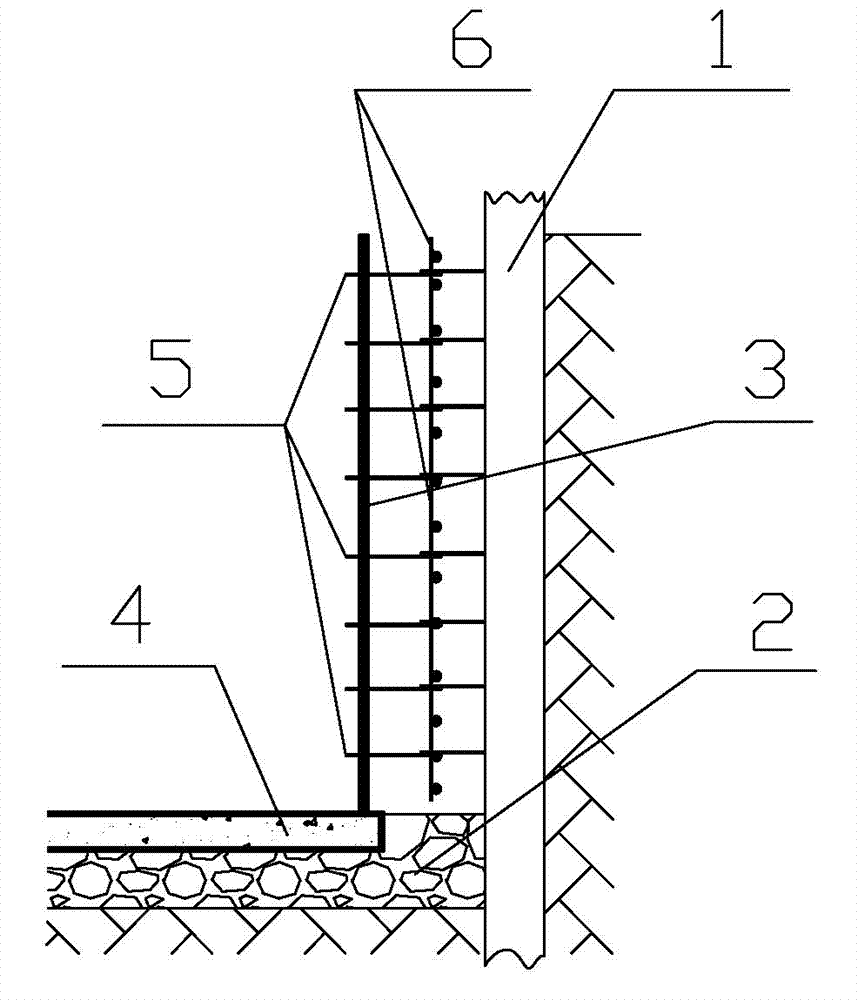

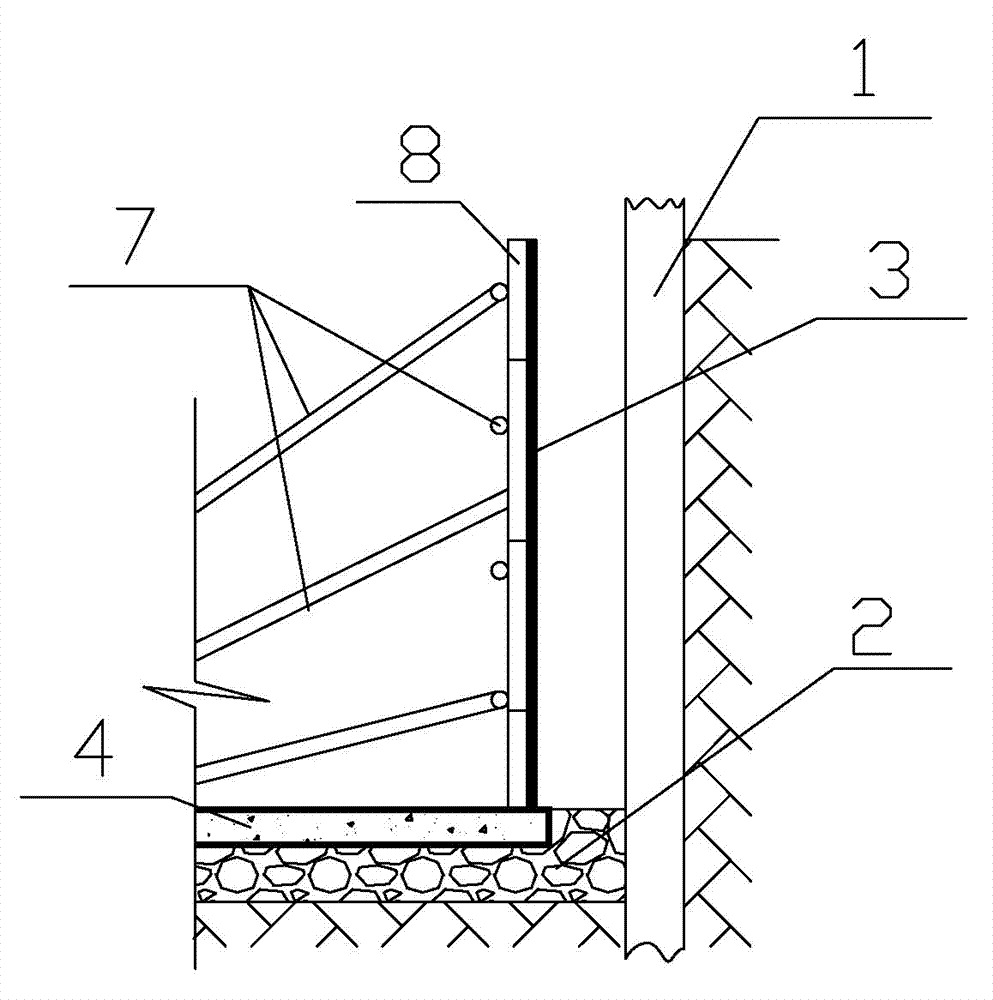

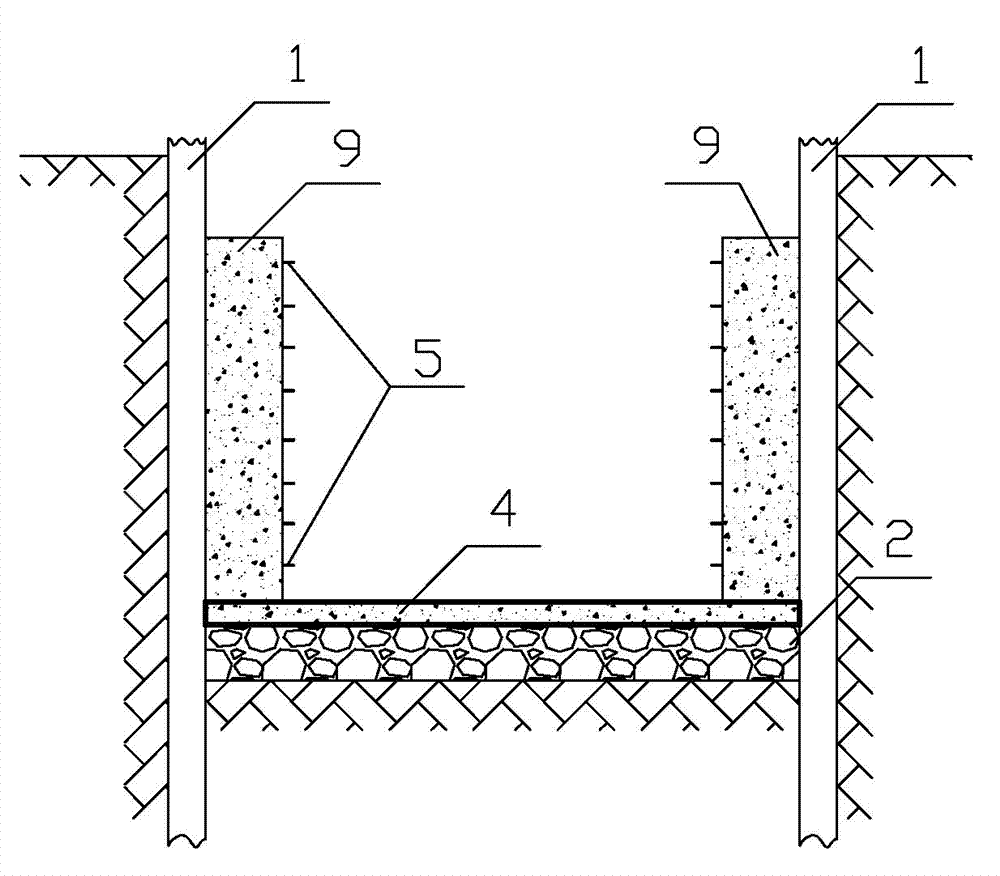

Construction method of underground deep foundation concrete by reverse formworks

A construction method of underground deep foundation concrete by reverse formworks is characterized by including the following steps of firstly, constructing supporting piles; and secondly, excavating foundation pits to set up reverse formworks; thirdly, pouring concrete of the reverse formworks; and fourthly constructing concrete foundation. The step of excavating the foundation pits to set up the foundation formworks includes the following steps of firstly, excavating the foundation pits when the supporting piles reach preservation strength; secondly, excavating to the bottom elevation of the foundation pits to make cushion; thirdly, accurately locating for foundation marking on the cushion; and fourthly, setting up reverse formworks according to the marking. The step four includes: when buried depth of the foundation is larger than -5meters, formworks and walls of the foundation pits are welded by 6- 12mm corner residual steel bars and colligated into steel bar meshes, wool forms for making the reverse formworks are more than seven layers of sandwiched plates, and formwork setting height is equal to height of foundation concrete. The construction method of the underground deep foundation concrete has the advantages that novel deep foundation is additionally built between adjacent buildings, and displacement and destroy of adjacent buildings are avoided during excavation and construction.

Owner:MCC5 GROUP CORP SHANGHAI

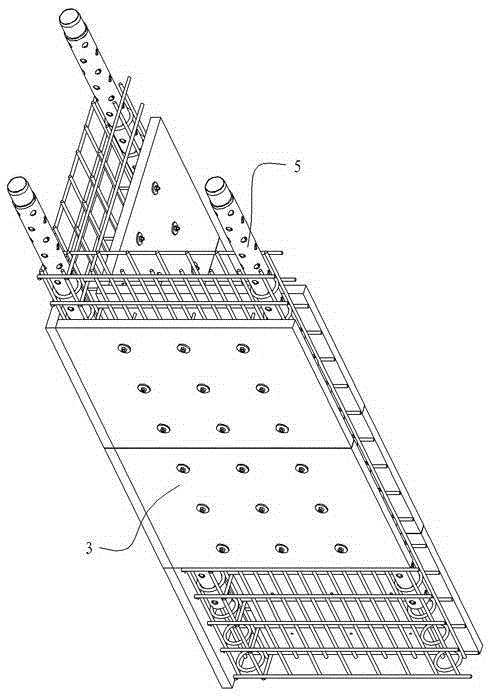

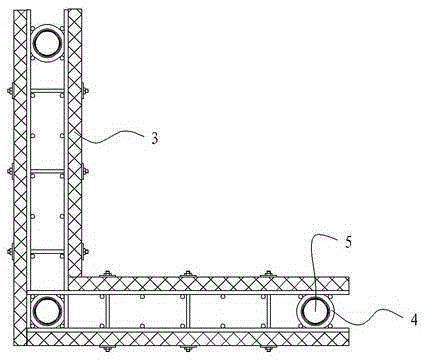

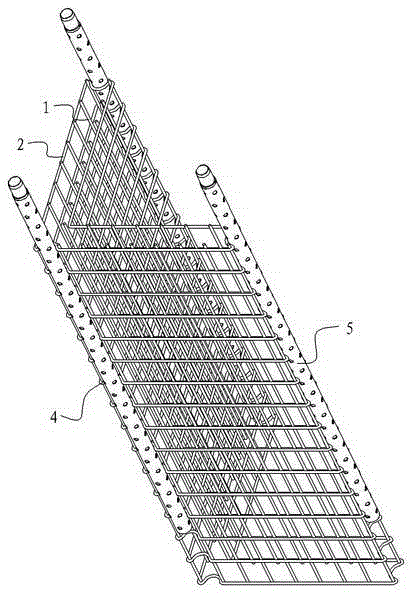

Prefabricated wall, prefabricated wallboard, construction method of prefabricated wall and production method of prefabricated wallboard

ActiveCN105317137AReliable qualityReduce field work timeWallsCeramic shaping apparatusSteel tubeRebar

The invention relates to a prefabricated wall, a prefabricated wallboard, a construction method of the prefabricated wall and a production method of the prefabricated wallboard, belonging to the technical field of building walls. The prefabricated wall comprises steel reinforcement cages arranged at floors, wherein each steel reinforcement cage comprises longitudinal main reinforcements and reinforcement stirrups fixedly arranged on the main reinforcement; the outer surface of each steel reinforcement cage is fixedly provided with two first dismounting-free heat insulation template; each steel reinforcement cage is internally provided with a limiting ring and a locating steel tube extending along the length direction of the main reinforcement; the locating steel tubes are arranged in the limiting rings; the locating steel tubes in the steel reinforcement cages at an upper floor are connected with the adjacent locating steel tubes in the steel reinforcement cages at a lower floor through locating tube sleeves; the mutually-abutted main reinforcements of the steel reinforcement cages at the upper floor and at the lower floor are welded together fixedly; and cast-in-place concrete is solidified in the steel reinforcement cages and holes of the locating steel tubes. The prefabricated wall, the prefabricated wallboard, the construction method of the prefabricated wall and the production method of the prefabricated wallboard have the advantages that the structure is reasonable and rapid construction and installation are conveniently realized.

Owner:史世英

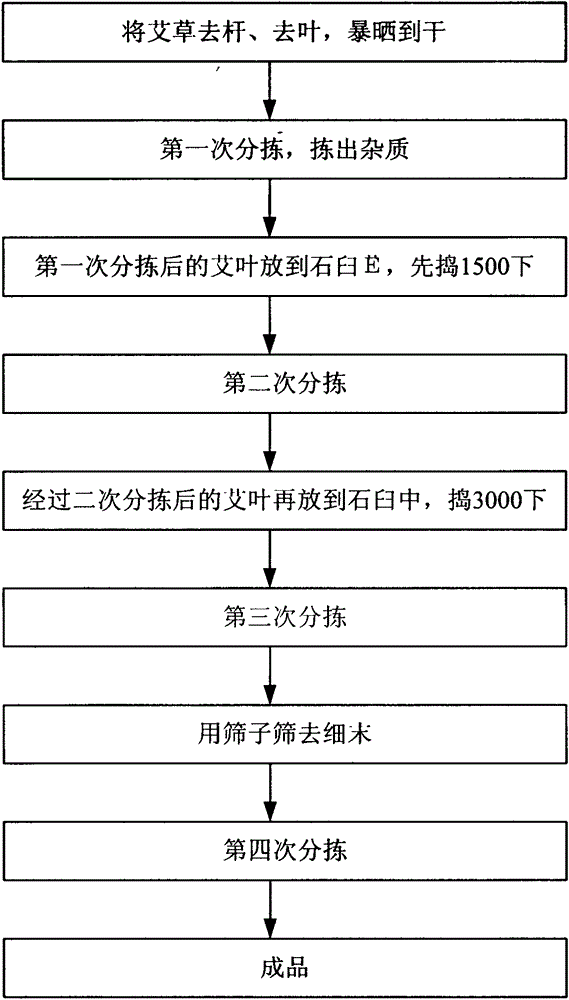

Extraction and preparation process of moxa floss moxibustion sticks and smokeless moxa sticks

ActiveCN105287193AReliable qualityLow impurity contentDevices for heating/cooling reflex pointsPhysical healthFood science

The invention discloses an extraction and preparation process of moxa floss moxibustion sticks and smokeless moxa sticks. The extraction and preparation process includes the following steps: selecting materials, sun-drying, sorting, tamping, sorting, tamping, sorting, screening, sorting and forming finished products. Moxa floss prepared by the process is reliable in quality, low in impurity content, assured in use, smokeless during burning and good for physical health.

Owner:廊坊市艾润堂艾草制品有限公司

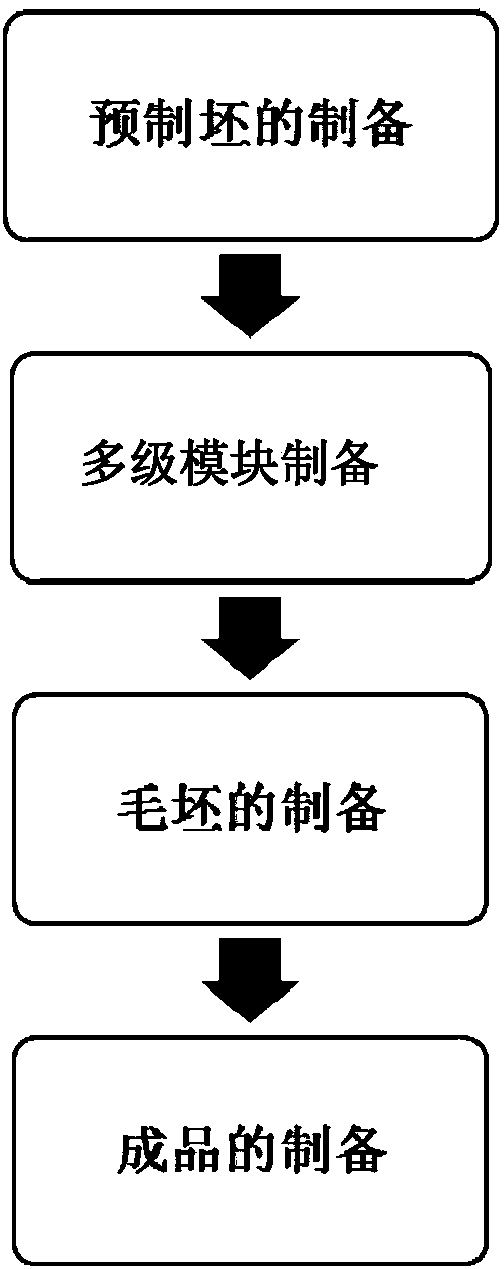

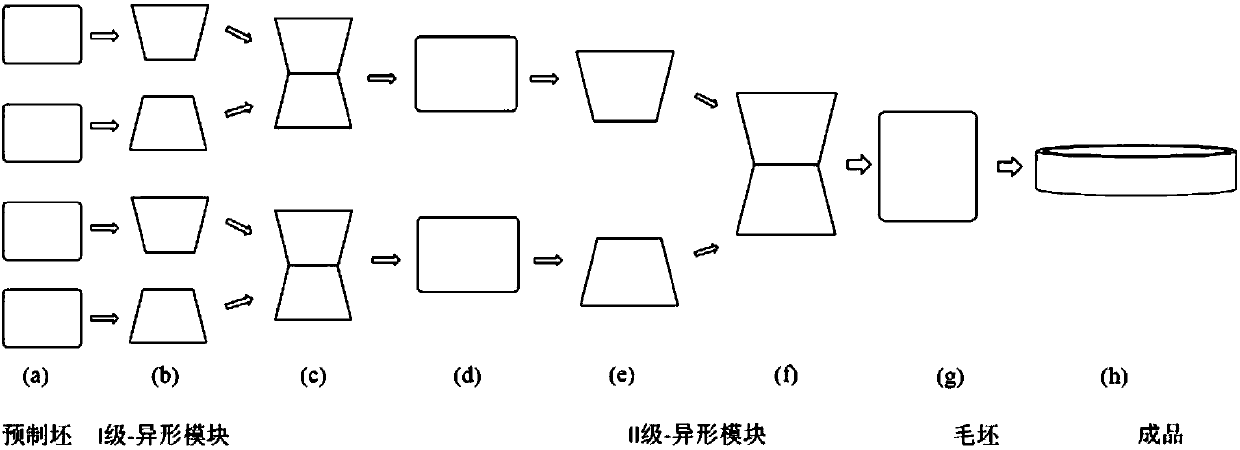

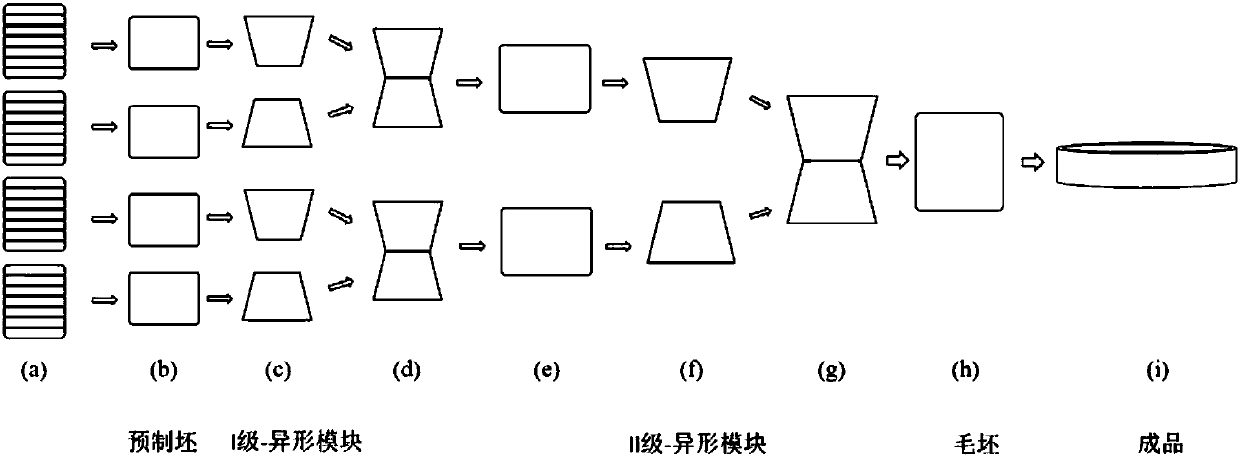

Modular metal constructing forming method

InactiveCN107717341AReliable qualityGuaranteed durationElectron beam welding apparatusEngine componentsForgingMetal

The invention relates to a modular metal constructing forming method. According to the method, a large forging preformed blank is divided into multistage modules to be constructed correspondingly according to concrete conditions, finally, the blank is formed, and parts or components are machined. The constructing quality of the method is more reliable and controllable, each module can be detectedafter being forged, and it is ensured that the modules are recycled after qualification; multiple pieces can be fed during feeding, the project duration can be effectively guaranteed. The method can improve the yield of large metal constructing forming, can greatly improve the production efficiency under the condition of using the same specification press, solves the bottleneck problem in the manufacturing process of large constructed formed forgings, and reduces the production cost.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

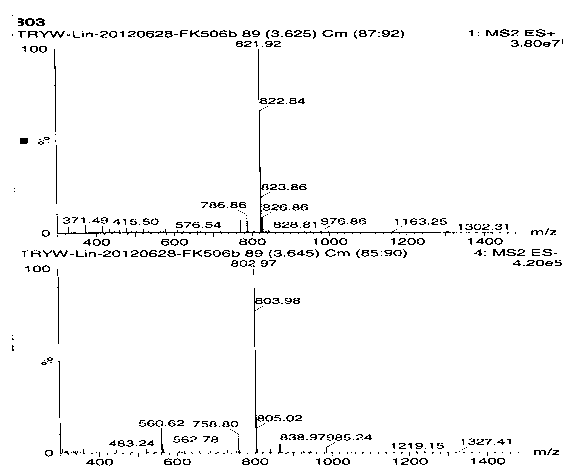

Preparation method of high-purity tacrolimus

The invention discloses a preparation method of high-purity tacrolimus. The preparation method includes subjecting tacrolimus hypha leach liquor to decoloration by using a macroporous decolorizing resin, guiding a tacrolimus decolorizing solution into a macroporous adsorption resin column for adsorption and desorption, concentrating a desorption solution to obtain a tacrolimus contained crude extract, dissolving the crude extract by using a polar solvent, subjecting the crude extract to chromatographic separation by using polymer nanoparticles, and concentrating and drying crystals to obtain the high-purity tacrolimus. The preparation method of the high-purity tacrolimus is simple in process, reliable in quality, high in yield which can reach over 70%, low in solvent consumption and applicable to industrial scale production of officinal tacrolimus raw materials.

Owner:NCPC NEW DRUG RES & DEV

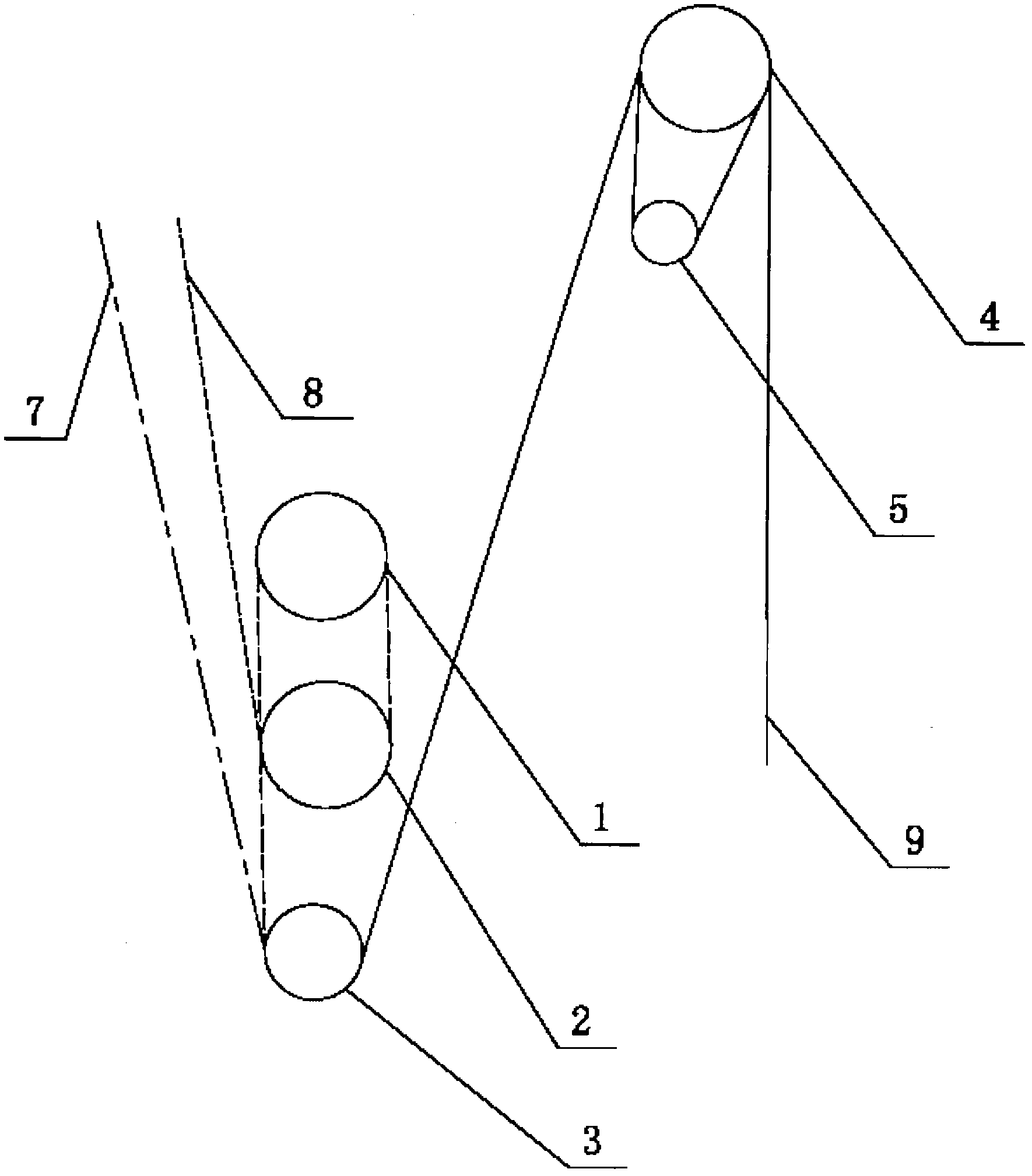

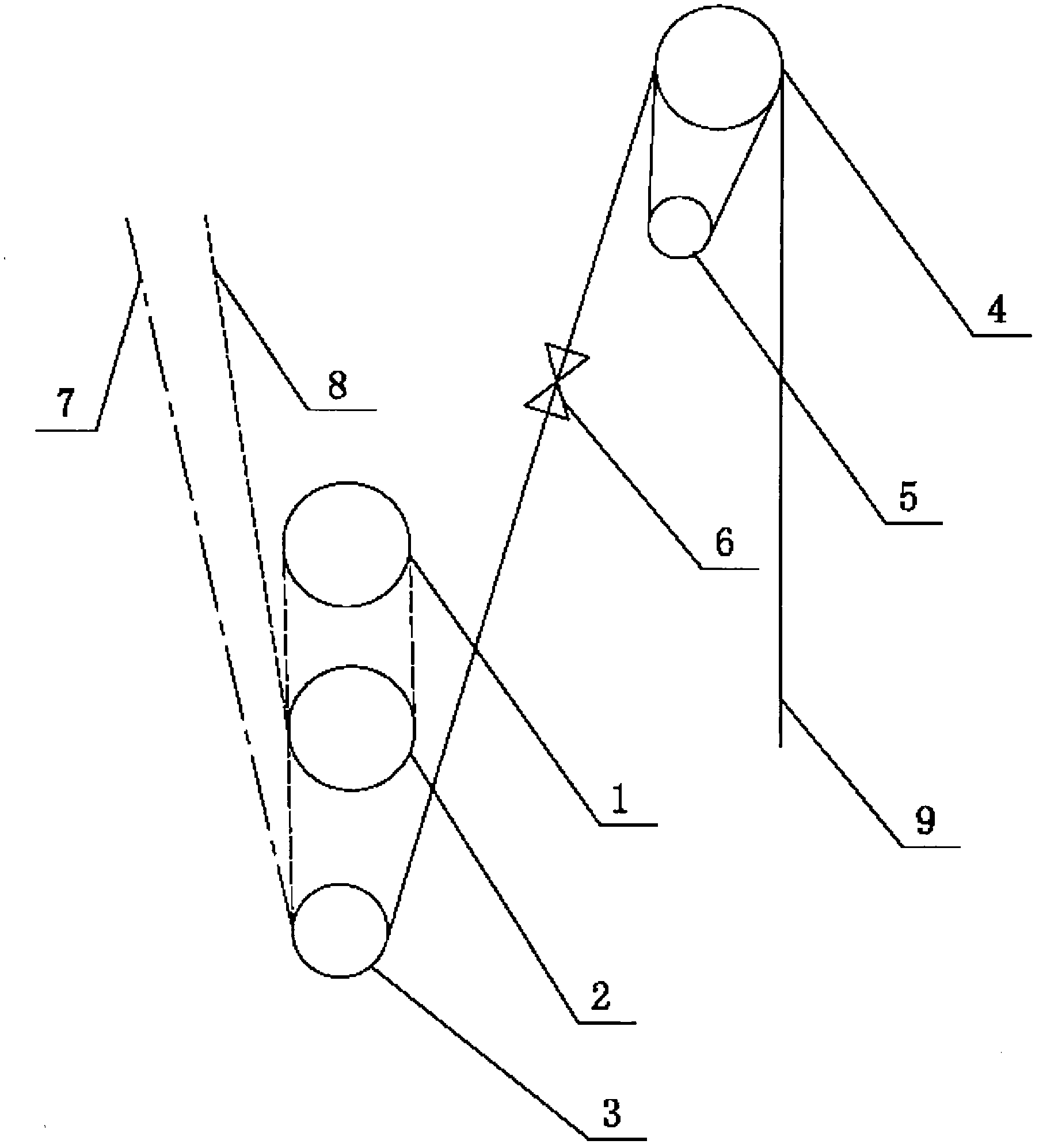

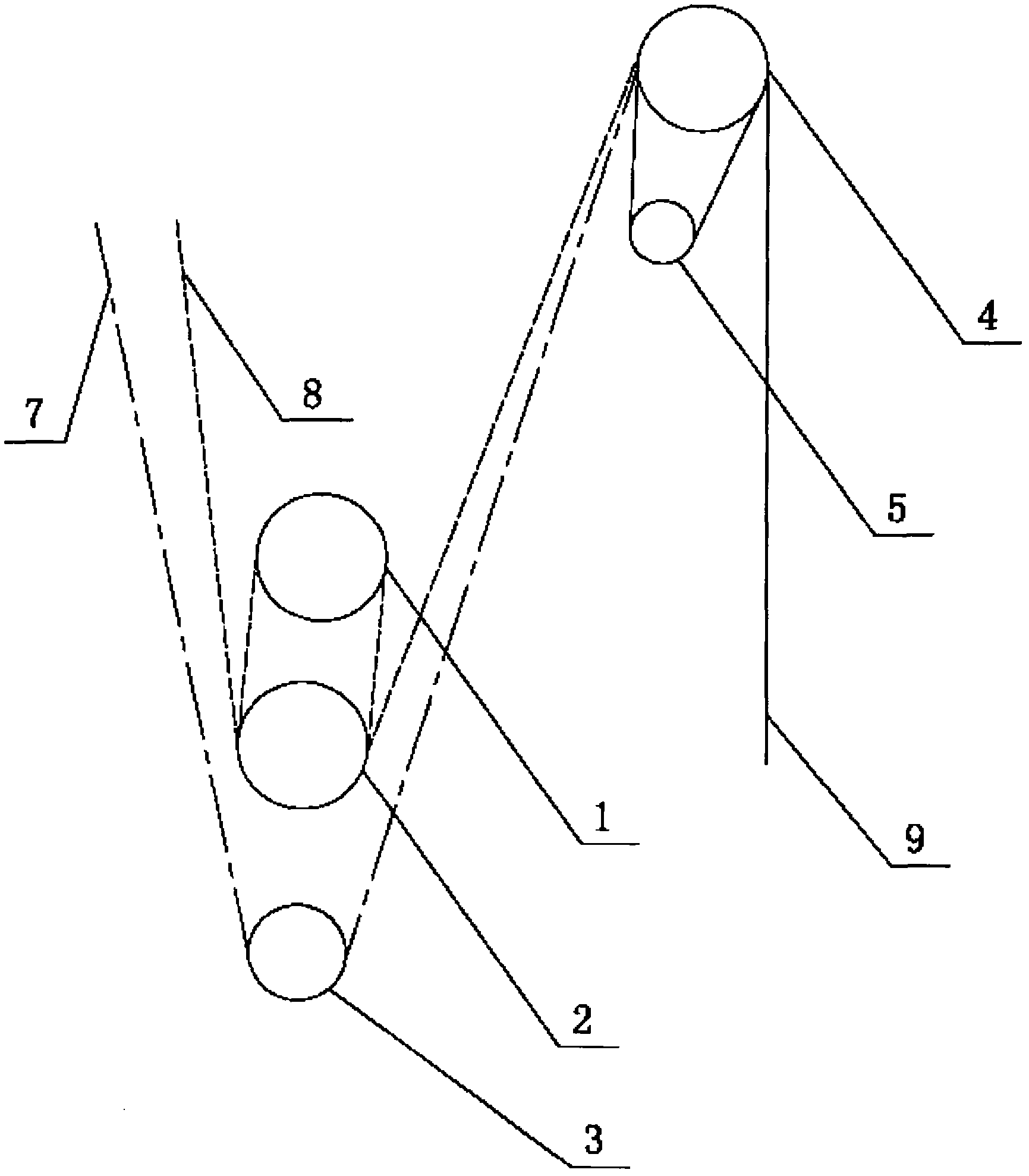

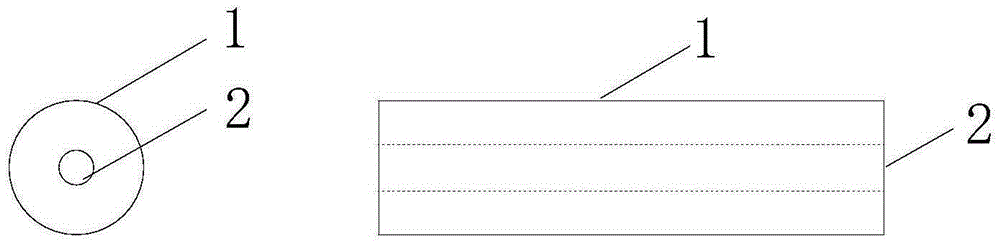

Production method for chemical fiber and polyester composite yarns

InactiveCN102618983AReliable qualityProcess stabilityArtificial filament heat treatmentStretch-spinning methodsYarnMaterials science

The invention relates to a production method for chemical fiber and polyester composite yarns, in particular to a method for producing chemical fiber and polyester composite yarns of partially oriented yarns (POY) and fully drawn yarns (FDY) by one kind of equipment through a one-step method. The POY and the FDY are subjected to composite spinning on the same winding frame, and the spinning process can simultaneously meet process flows required by producing the two kinds of yarns; the FDY and the POY enter a draft area from the same side of a first pair of drawing rollers, wherein the FDY pass through the first pair of drawing rollers consisting of a large-diameter heat roller and a large-diameter heat roller, and, together with the POY, pass through a yarn guide roller below the first pair of drawing rollers, and the FDY and the POY are combined and compounded into a bundle of yarns on the yarn guide roller; and the composite yarn bundle passes through a second pair of drawing rollers consisting of a large-diameter heat roller and a non-heating small-diameter separator roller to form the composite yarns. The effects of saving a production space and saving energy are obvious, the processed fiber composite yarns are reliable in quality, stable in process and high in cohesiveness and the dying property is superior to that of the conventional product.

Owner:北京德厚朴化工技术股份有限公司

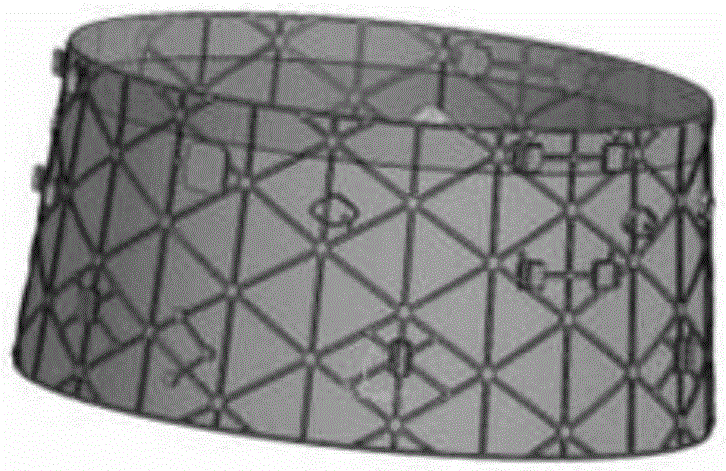

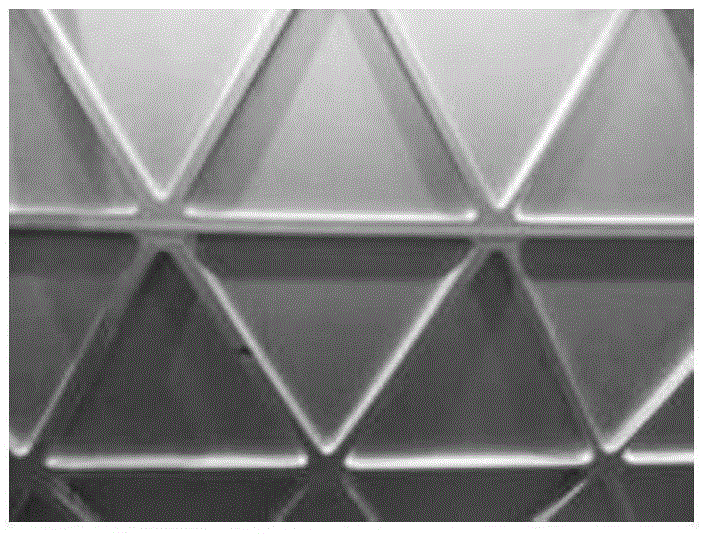

Deep chemical milling method of TA12 and TA15 titanium-alloy large-scale structural components

The invention relates to the field of deep chemical milling of titanium-alloy large-scale cylindrical parts, in particular to a deep chemical milling method of TA12 and TA15 titanium-alloy large-scale structural components. The deep chemical milling method comprises the following technological lines: degreasing, washing, pickling, washing, coating with a protecting adhesive, marking, removing a protecting adhesive film on a to-be-milled surface, chemically milling and conducting vibrating finishing. The method comprises the following steps: a titanium-alloy cylindrical part is processed into a thin-walled grid rib by adopting a deep chemical milling technology, and the thin-walled grid rib is primarily marked and chemically milled to obtain a chemical milling machine case shell with all mounting bases. The manufacturing of integral, thin-walled and grid-shaped titanium-alloy large-scale cylindrical structural components is completed by adopting the titanium-alloy deep chemical milling technology, and the requirement that the large-scale cylindrical parts are chemically milled to form the grid-shaped structure is met; and deformation, caused by machining, is avoided fundamentally, the problem of low strength caused by welding is solved, the overall rigidity of the component is improved, and besides, the production cycle is shortened, and the structural weight is reduced.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Process of forming grooves in the bottom and side of anode carbon block for aluminium electrolysis

InactiveCN1887557AEasy and convenient demouldingReliable qualityMouldsPower consumptionMaterials science

The present invention is process of producing prebaked anode block with grooves in bottom or side through die pressing under vibrating condition. The production process includes mainly a vertical paste distributing step capable of maintaining the flowability of the paste and a secondary cooling step to meet the requirement of demolding on the paste curing state. The production process has easy demolding, low power consumption and high production efficiency.

Owner:淄博联兴炭素科学技术研究所

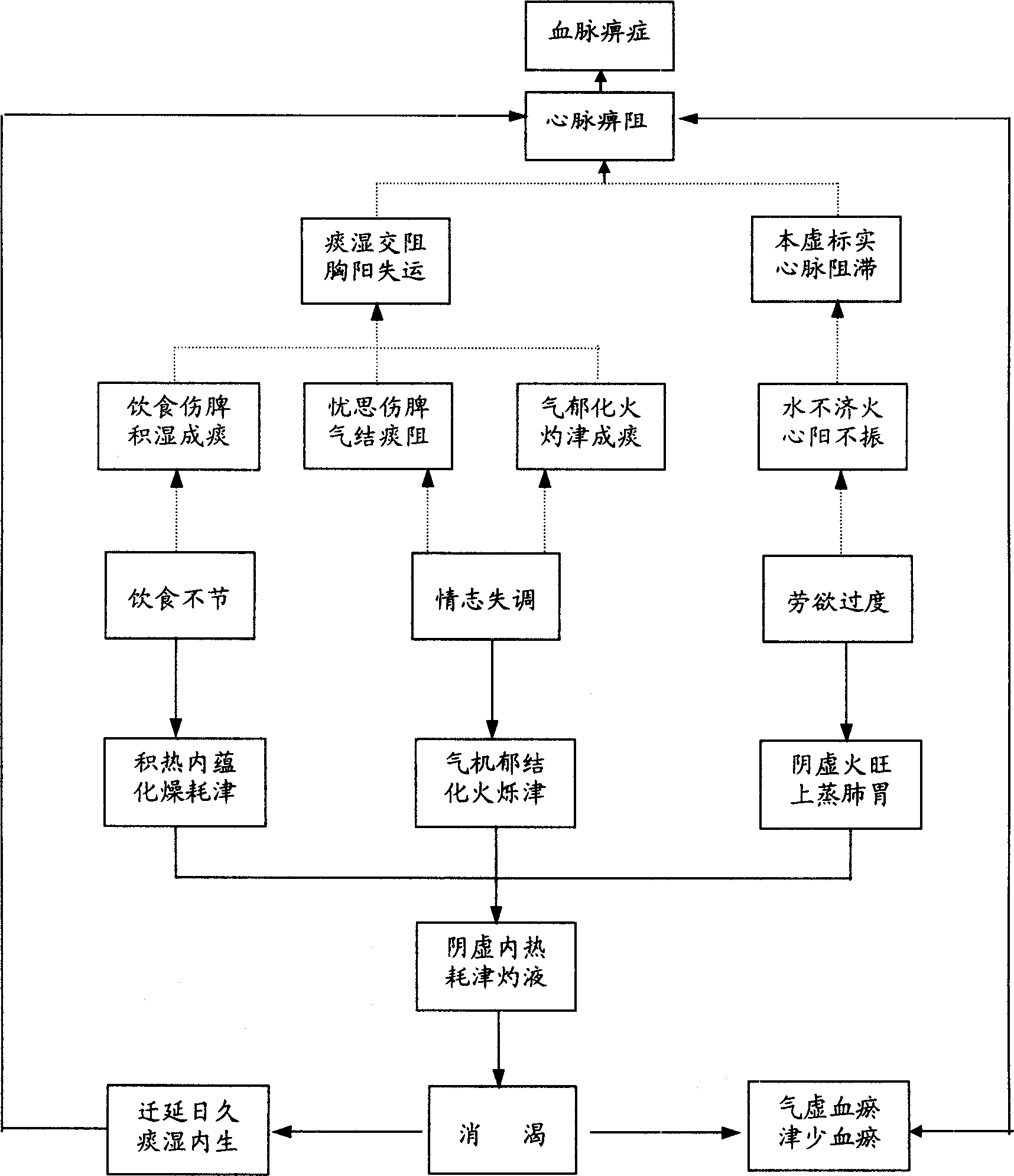

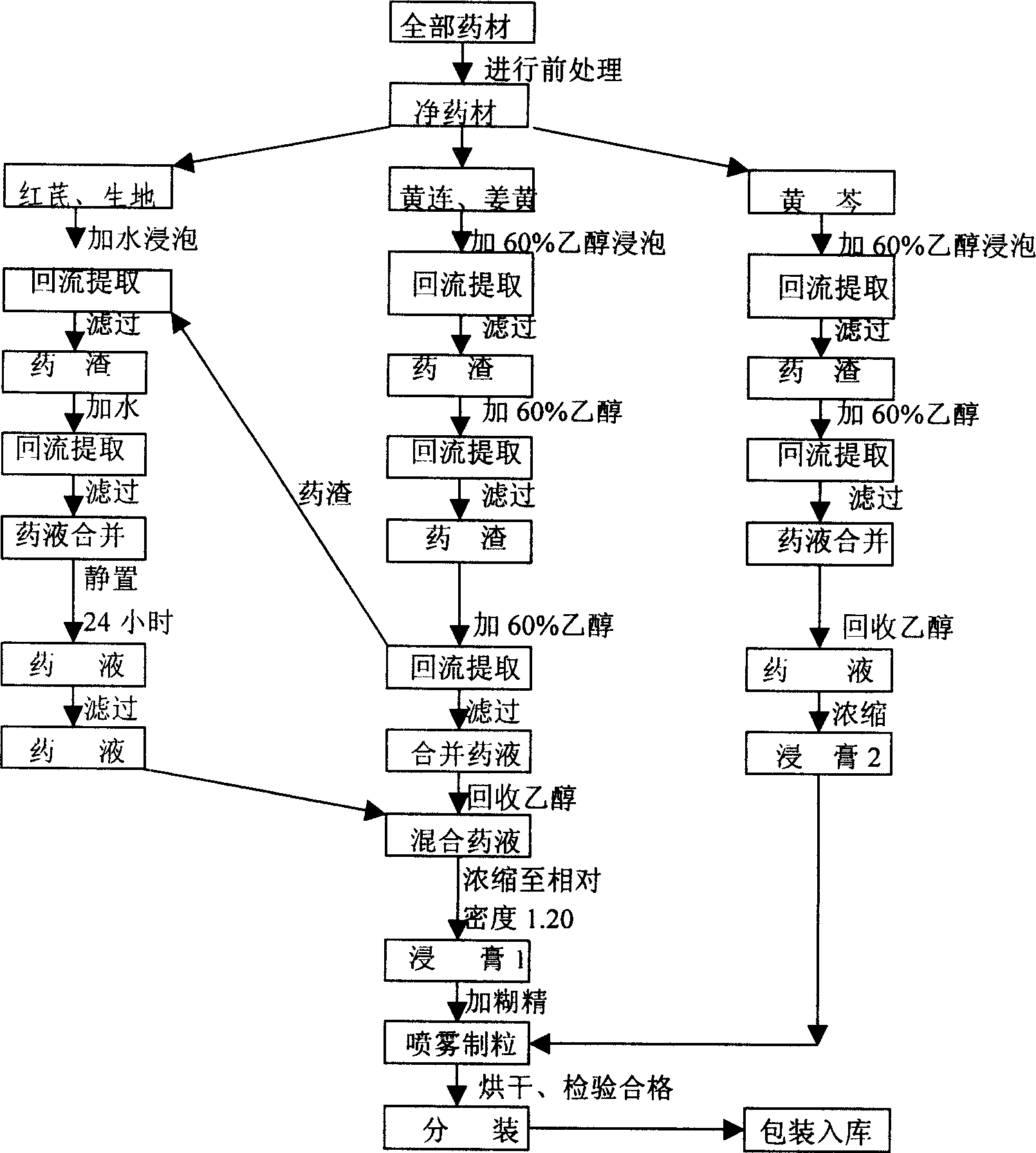

Medicine for treating diabetes, and its prepn. method

ActiveCN1724065AAdvanced technologyReliable qualityMetabolism disorderGranular deliveryDiabetes mellitusCoptis

A Chinese medicine in the form of particles for treating diabetes and its vascular complication and decreasing blood fat is prepared from 5 Chinese-medicinal materials including coptis root, rehmannia root, scutellaria root, turmeric, etc through proportionally immersing them in alcohol, thermal reflux extracting, filter, concentrating, spray granulating and baking.

Owner:CHONGQING DONGTIAN PHARMA

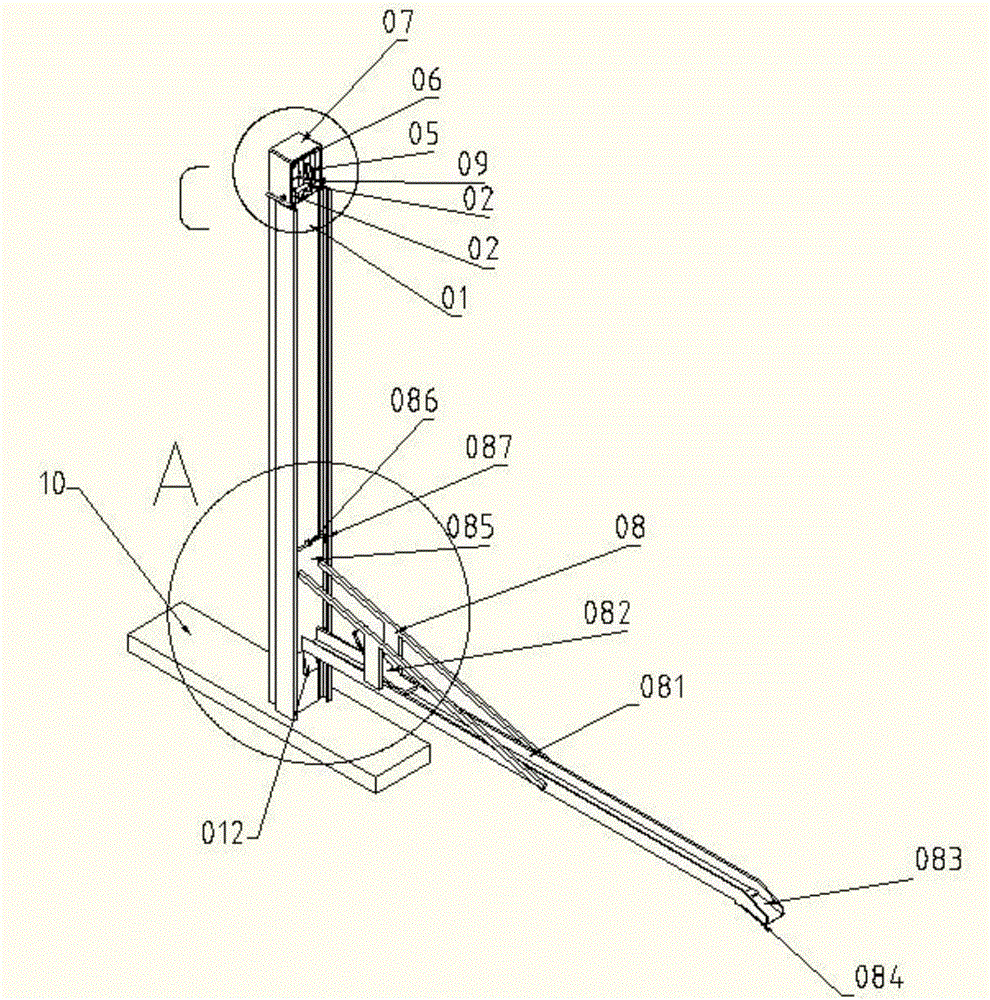

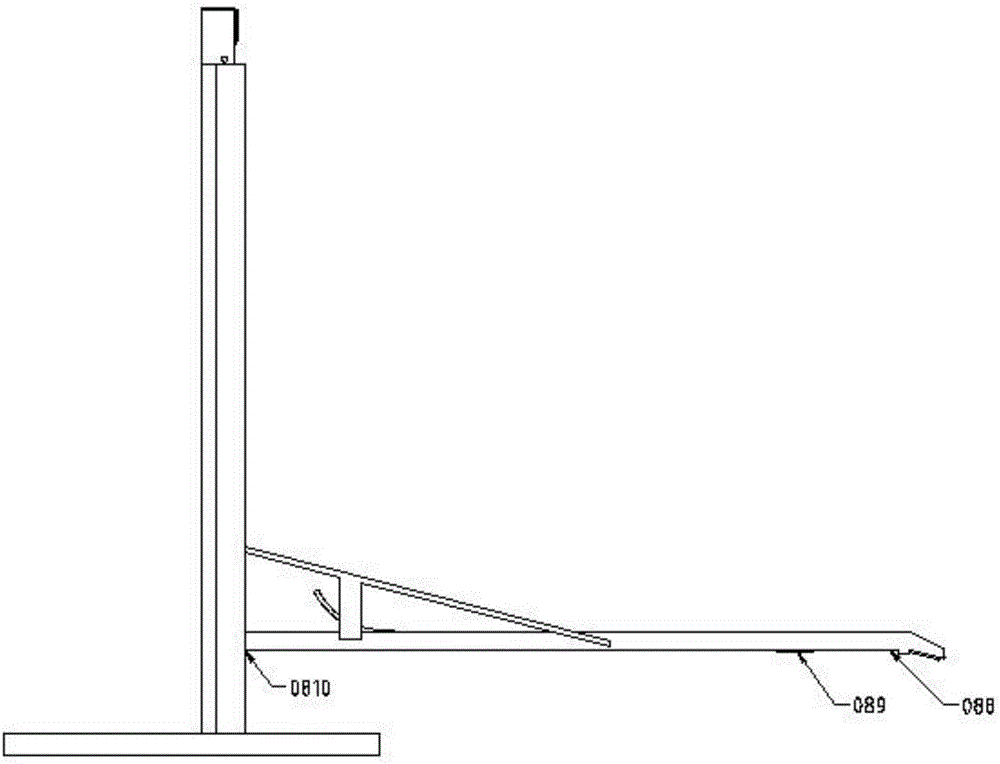

Vertical lifting type bicycle parking rack

The invention relates to a bicycle parking rack and discloses a vertical lifting type bicycle parking rack. The vertical lifting type bicycle parking rack comprises an upright column, a lifting bicycle frame, a nitrogen spring, a first movable pulley component, a second movable pulley component, a steel wire rope, a first fixed pulley component and a second fixed pulley component. The bicycle parking rack has the advantages that the quality is stable and reliable, the stretching and retracting speed is steady due to the nitrogen spring and noise is low. The speed changes little in the process that the lifting bicycle frame is driven to ascend and descend, and the safety hidden hazards that in the prior art, a lifting bicycle frame is suddenly limited when lifted to the highest point, and a built-in bicycle easily jumps due to inertia and falls from the inside of the bicycle frame are eliminated. Meanwhile, the steel wire rope takes the place of a common coil spring, and the technical problems that the exposed coil spring is prone to deformation and too sharp and accordingly safety hidden hazards are caused are solved. Compared with the prior art, the bicycle parking rack has substantive features, and technical progress is remarkable.

Owner:HANGZHOU OS PARKING FACILITIES CO LTD

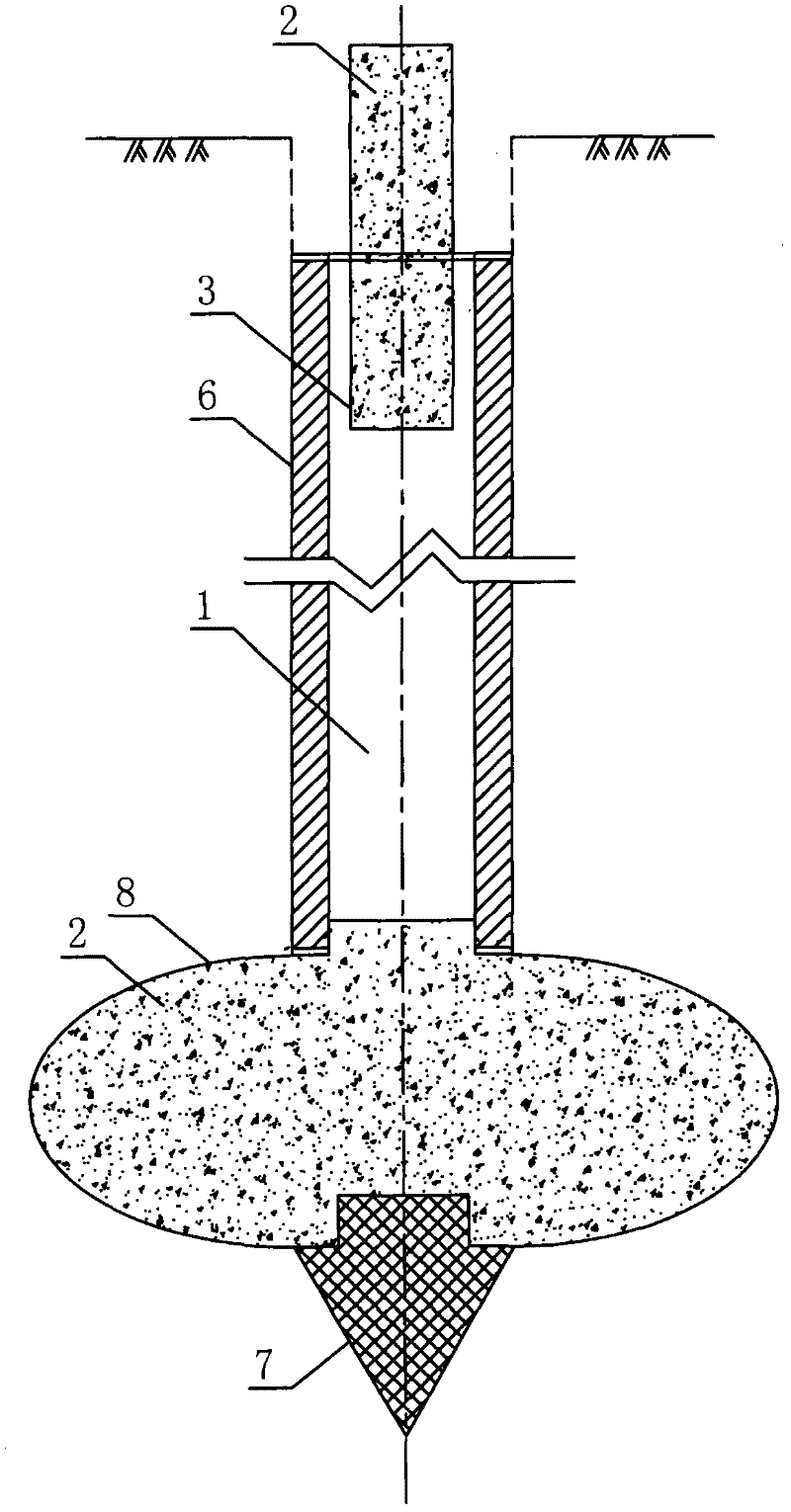

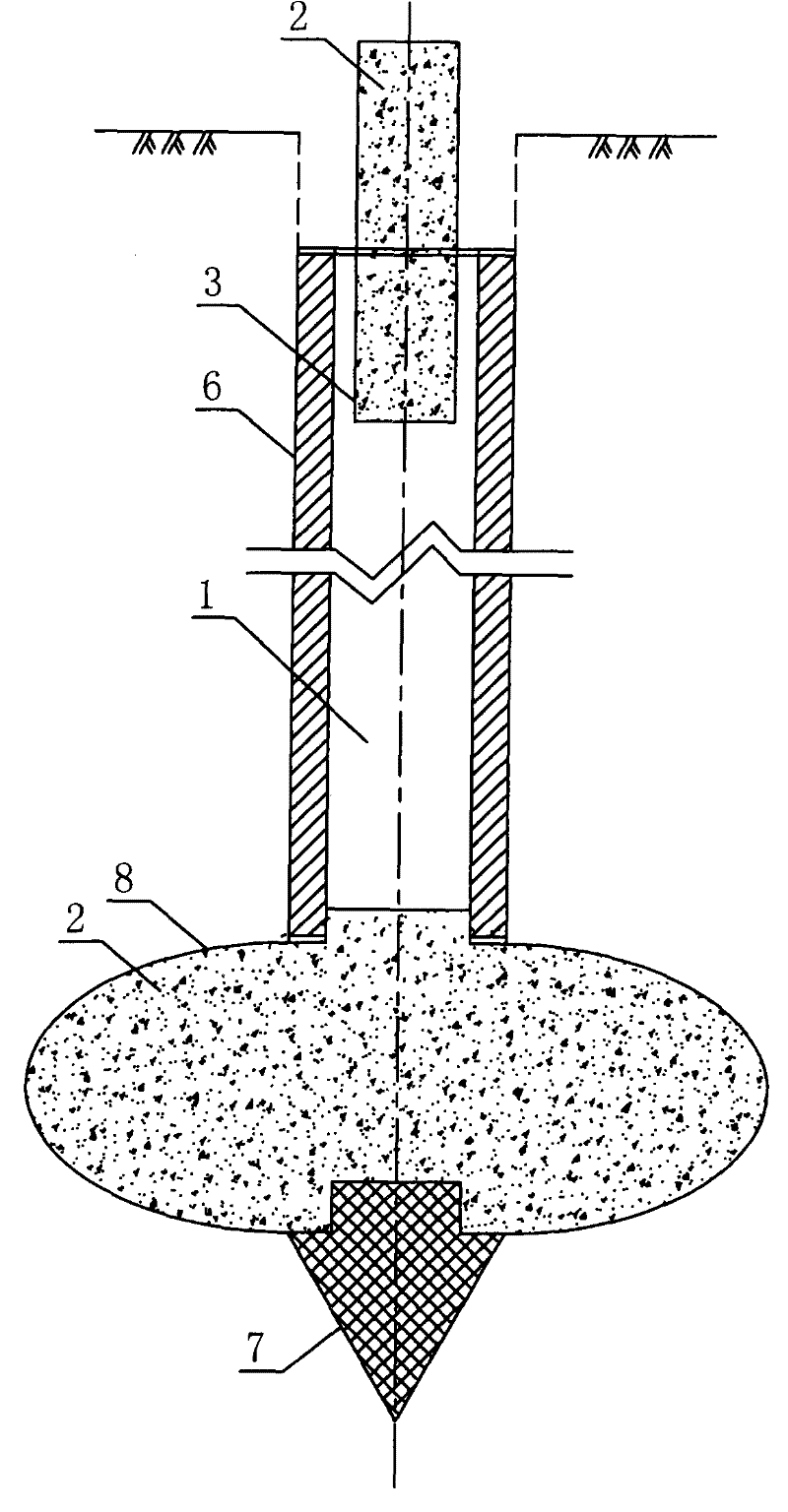

Mixed soil extruded and cured precast pile for soft foundation treatment as well as construction method

The invention discloses a mixed soil extruded and cured precast pile for soft foundation treatment as well as a construction method. Foundation soil is connected with drill holes which are connected with mixed soil extruded and cured precast pile bodies, the mixed soil extruded and cured precast pile bodies are connected with cement mortar through a central hole, and the cement mortar is connected with a seamless steel pipe which is connected with a grouting pipe. The construction method comprises the following steps: A, a vibrating pipe-sunk pile machine is adopted for hole forming; B, the mixed soil extruded and cured precast pile bodies are placed; C, the seamless steel pipe is placed, and a vibrating sunk pipe is pulled out; D, grouting is performed: the a seamless steel pipe is connected with the grouting pipe, pressure cement mortar is grouted into the seamless steel pipe, and the seamless steel pipe and the precast pile bodies form the integral mixed soil extruded and cured precast pile after mortar curing; E, integral construction is performed. The mixed soil pile is precast by waste construction waste and common clay, the manufacture is convenient and fast, the quality is reliable, the transport cost is reduced, modular piling construction is efficient and convenient, and the integral bearing capacity of a foundation is improved effectively.

Owner:WUHAN ZHONGLI GEOTECHN ENG

Rubber-plastic ternary composite material applied to mechanical industry as well as preparation method and application thereof

The invention discloses a rubber-plastic ternary composite material applied to mechanical industry as well as a preparation method and application thereof. The rubber-plastic ternary composite material at least comprises three materials including polyurethane rubber and nitrile rubber as well as polyvinyl chloride plastics, and is formed through mixing by a milling machine or a rubber open mill through an enclosed chamber, wherein the composition and proportion of the three materials including polyurethane rubber and nitrile rubber as well as polyvinyl chloride plastics are as follows: 100 parts of polyurethane rubber, 50-70 parts of nitrile rubber and 15-25 parts of polyvinyl chloride plastics. The rubber-plastic ternary composite material provided by the invention is prepared from the three materials according to a certain proportion, the advantages of the three materials can be integrated effectively, the three materials are supplied mutually, and the comprehensive performances of the material are improved effectively.

Owner:邓舟

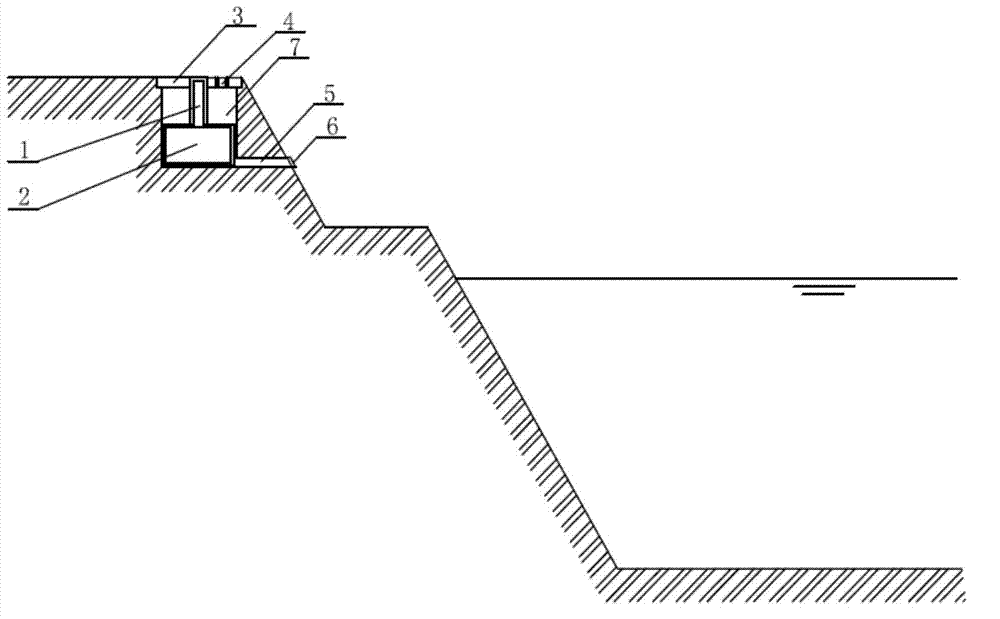

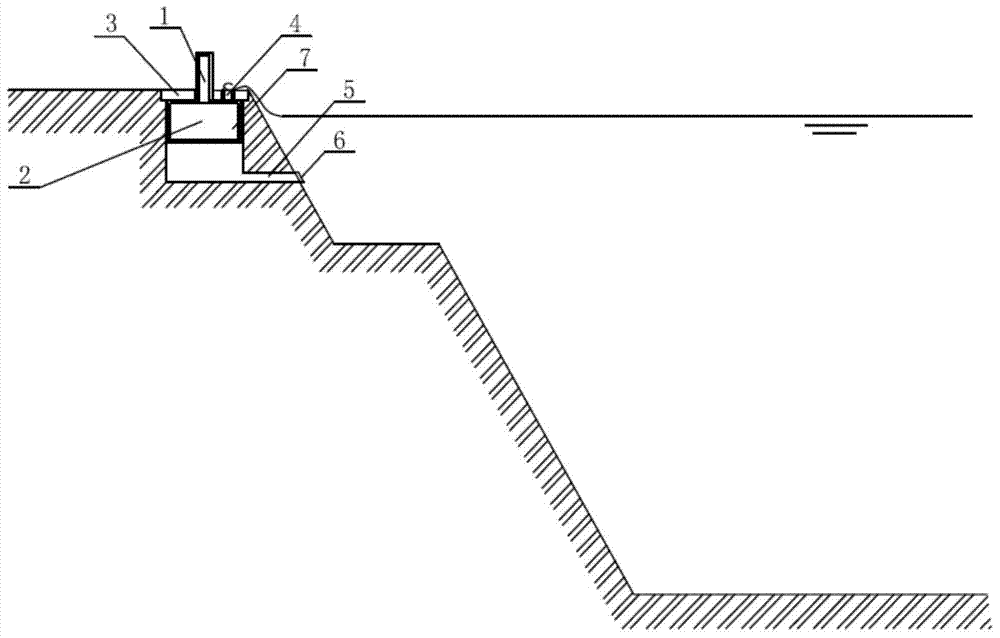

Intelligent self-elevating retention wall

The intelligent self-elevating retention wall which is arranged on a river levee and in single-section or multi-section arrangement comprises a concrete preformed groove, a retention wall body, a buoyant box, a limiting cover plate, a water inlet grate, a drainage channel and a water stopper. The concrete preformed groove is a rectangular longitudinal groove excavated in the river levee; the retention wall body is in an interlayer structure formed by two rectangular steel plates, and the buoyant box is in a premade empty box structure and capable of moving up and down along the side wall of the concrete preformed groove; the water inlet grate is fixed to a water side of the top end of the concrete preformed groove, the drainage channel is positioned on a water side of the bottom of the concrete preformed groove, and the tail end of the drainage channel is provided with the water stopper; the limiting cover plate is fixed to a backwater side of the top end of the concrete preformed groove, and the retention wall body moves up and down between the limiting cover plate and the water inlet grate. The intelligent self-elevating retention wall has the advantages that the retention wall is reliable in quality and simple in construction, the retention wall ascends to give play to wave walls in occurrence of flood and automatically descends to hide in a dam body after flood, and accordingly safety discharging can be guaranteed, and overall intelligence, avoidance of energy consumption and high economy are realized.

Owner:THE FRONTIER TECH RES INST OF TIANJIN UNIV

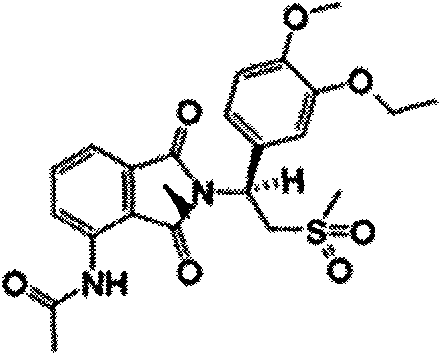

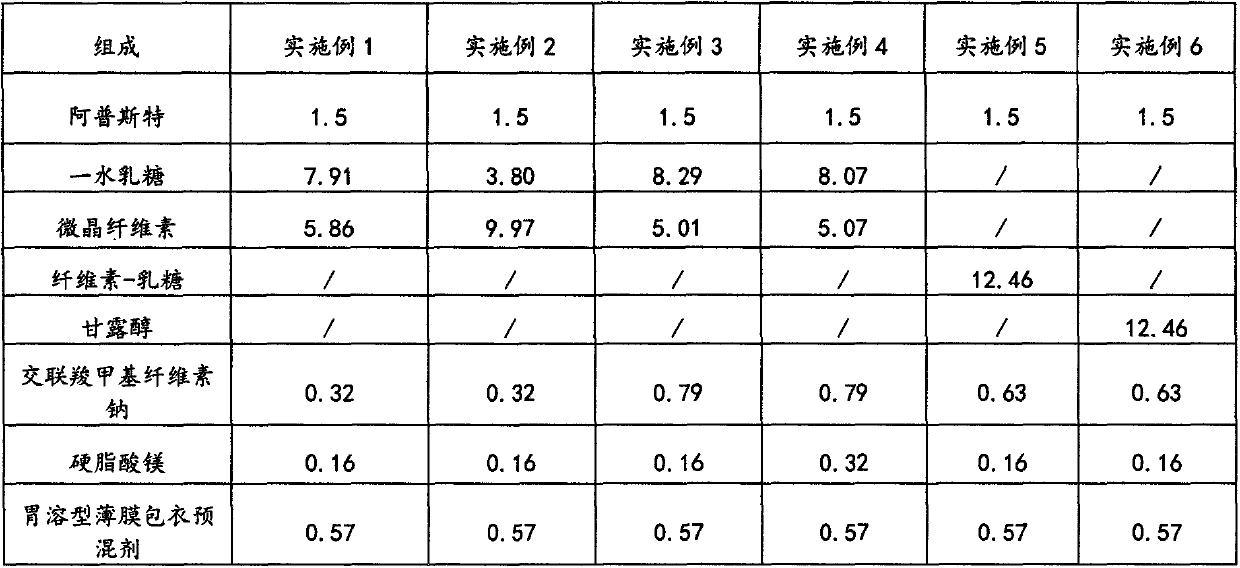

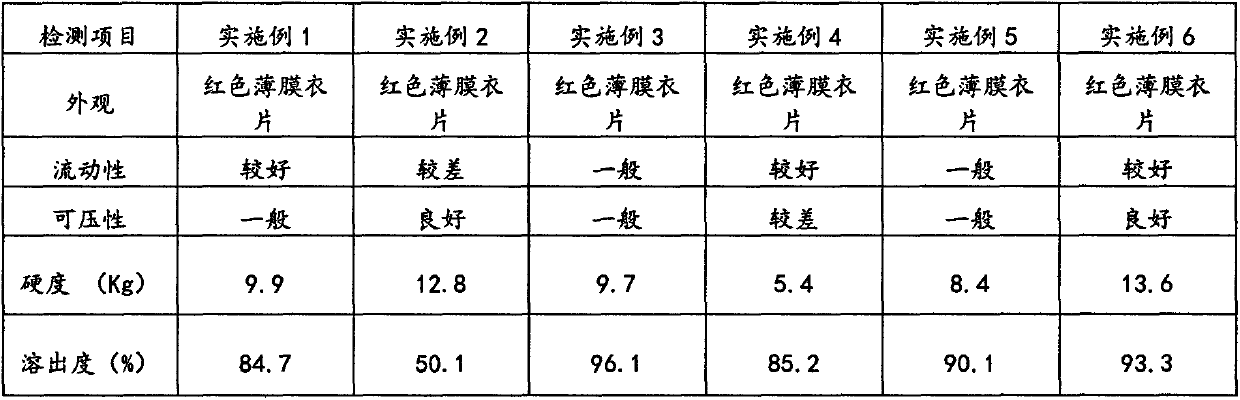

Apremilast oral solid preparation and preparation method thereof

InactiveCN107115310AReliable qualityReduce manufacturing costOrganic active ingredientsAntipyreticDrugApremilast

The invention discloses an apremilast oral solid preparation and a preparation method thereof. The invention belongs to the field of pharmaceutical preparations. The apremilast oral solid preparation is prepared by mixing, pressing and coating active components and excipients. The apremilast oral solid preparation comprises medicine active components, a filling agent, a disintegrating agent, a lubricating agent and a coating material. The compressibility and the flowability of the medicine can be improved by using auxiliary materials, and the oral solid preparation with high dissolvability and stable quality can be prepared by a powder direct tabletting process. The preparation method is simple in operation, low in production, high in efficiency, environment-friendly and suitable for industrialized mass production of the apremilast oral solid preparations.

Owner:广州艾格生物科技有限公司

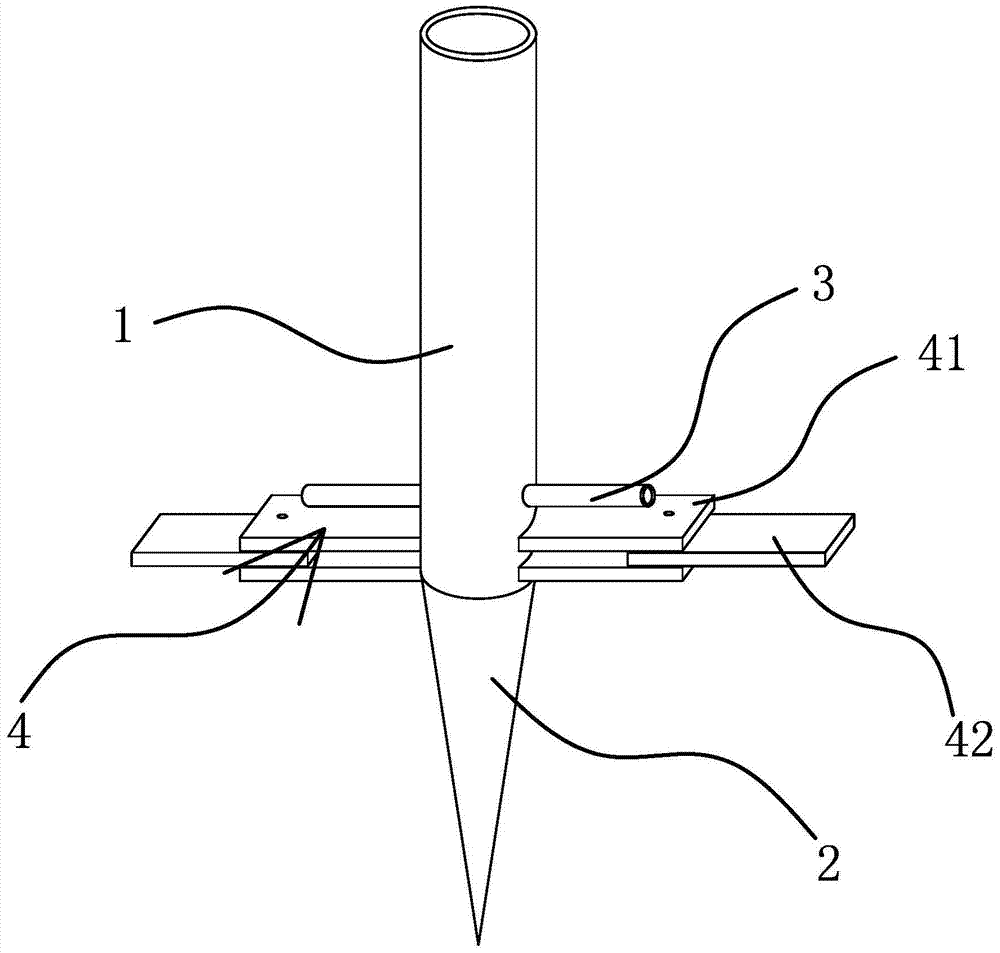

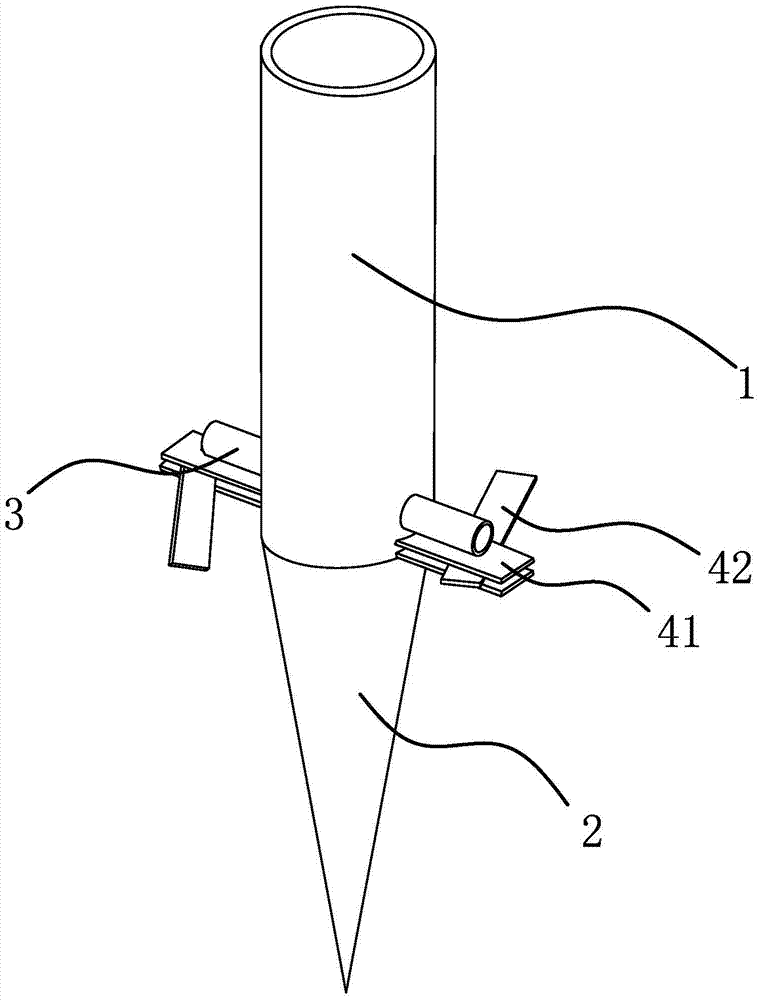

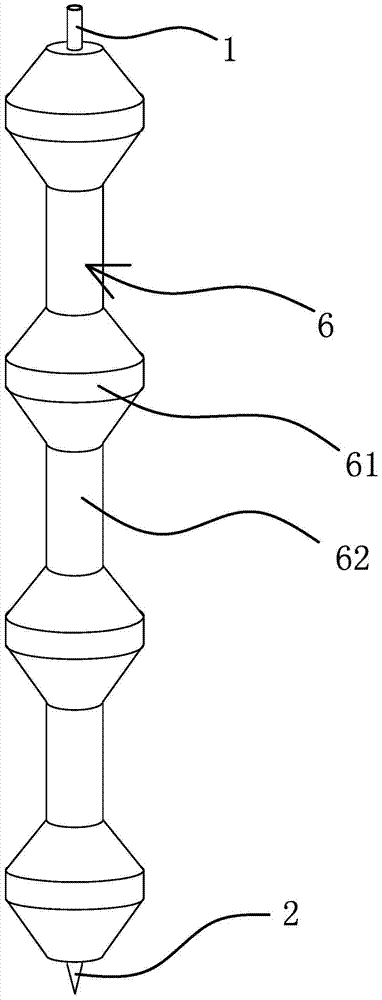

Variable diameter stirring type anchor rod and construction method thereof

The invention provides a variable diameter stirring type anchor rod and a construction method thereof, and belongs to the technical field of the building construction equipment. According to the invention, the technical problem that pulling resistance generated by the traditional anchor rod on a cemented soil enlarging body is not big enough is solved. The anchor rod comprises an anchor rod body, wherein the front end of the anchor rod body is provided with at least one slurry discharging tube and is also fixedly provided with at least one stirring body; the stirring body comprises a first stirring vane which is fixedly connected with the tube wall of the anchor rod body and is vertical to the center line of the anchor rod body; the stirring body also comprises a second stirring vane; the first stirring vane is hinged to one end of the second stirring vane; the second stirring vane can swing in a plane on which the vane surface of the first stirring vane is positioned along a hinged point; a spacing assembly which enables an included angle between the first stirring vane and the second stirring vane to be smaller than 180 degrees is arranged between the second stirring vane and the first stirring vane. The construction method comprises the following steps of: putting the anchor rod, drilling holes and grouting. The invention has the advantages that the constructed cemented soil enlarging body has bigger pulling resistance and the like.

Owner:FANGYUAN CONSTR GRP REAL ESTATE DEVT CO LTD

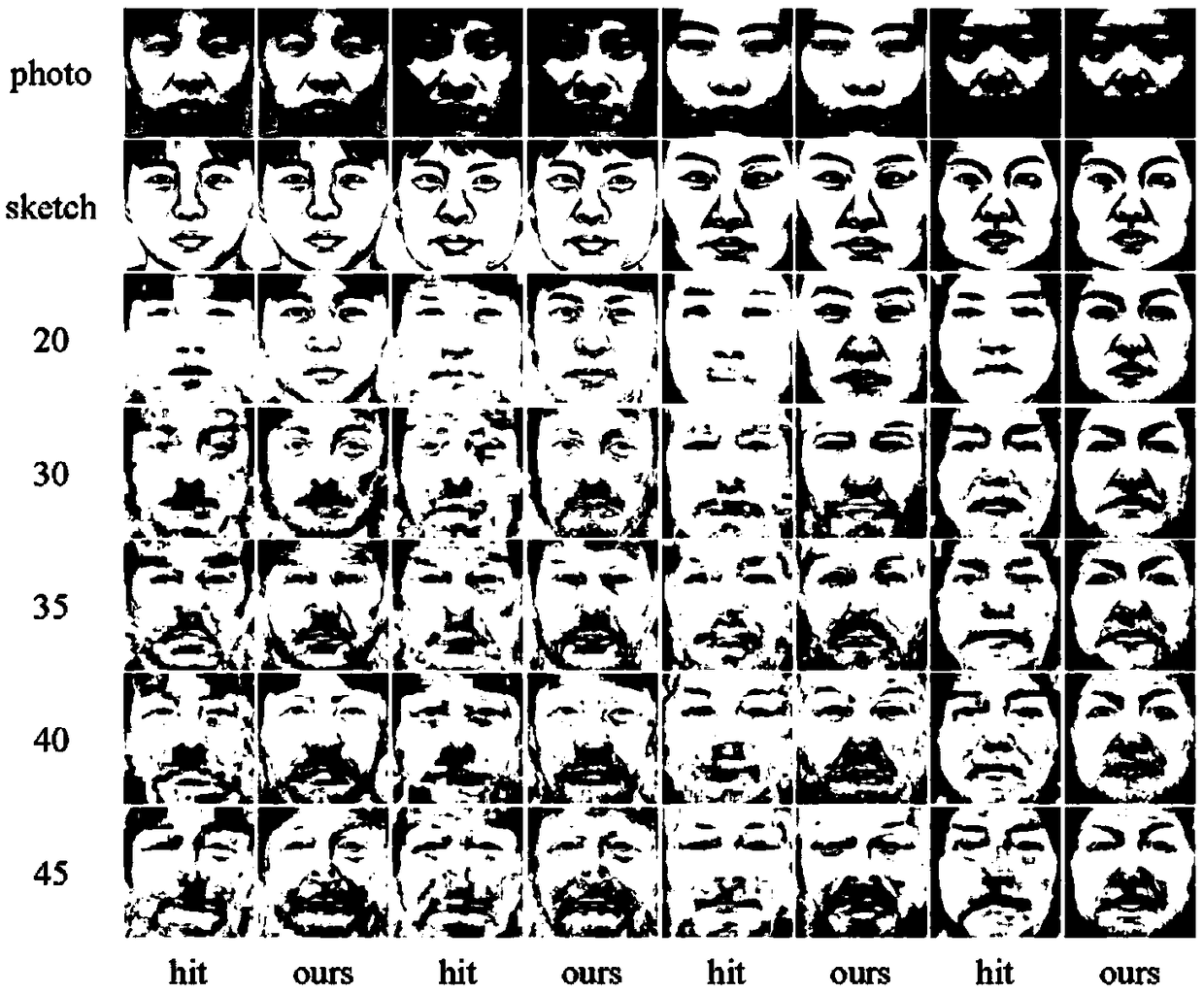

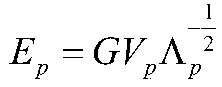

A face aging method based on principal component analysis

InactiveCN109145135ASimple modelReliable qualityCharacter and pattern recognitionStill image data queryingAnalysis of varianceKernel principal component analysis

The invention relates to a face portrait aging method based on principal component analysis. Firstly, photographs in an original aging photograph data set are changed from color images to gray images,then the original aging photograph data set is normalized by samples, and then the eigenvalues corresponding to each photograph are calculated by principal component analysis to obtain a photograph parameter set corresponding to the aging photograph data set. According to the age group sample, the corresponding photo parameter sets of different age groups are obtained, and the average parametersare solved. Through variance analysis of photo parameter set, the age-related eigenvalues are screened out, and then the age-related parameters in the average photo parameters of different age groupsare studied. Given the portrait to be aged, the sample is normalized first, then the normalized portrait is analyzed by principal component analysis, the corresponding eigenvalues are calculated, theage-related features are modified according to the obtained variation law, and finally the corresponding aging portrait is obtained by using principal component reconstruction strategy.

Owner:XIAMEN UNIV

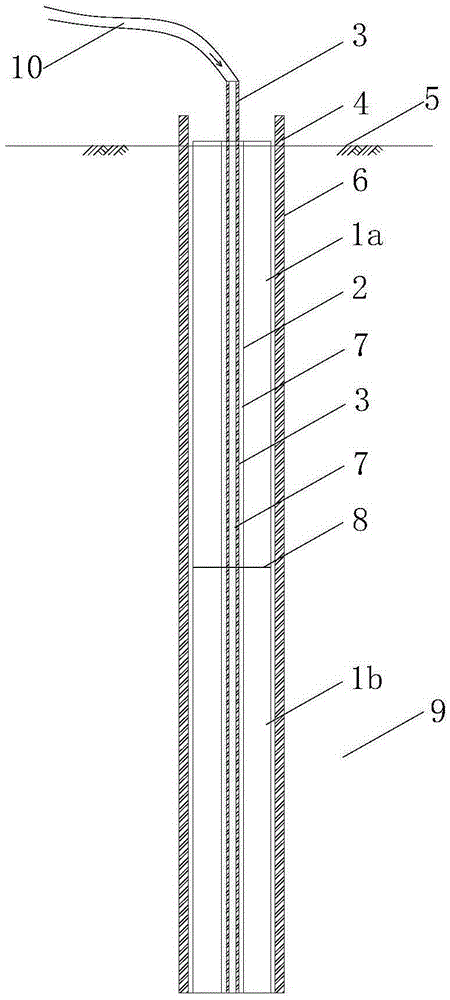

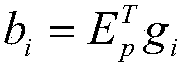

Construction method for concrete bagged pouring in small-diameter pile hole

InactiveCN102477743ASimple construction processReliable qualityBulkheads/pilesFoundation engineeringExtrusion

The invention relates to a construction method for concrete bagged pouring in a small-diameter pile hole in the field of pile foundation engineering. The construction method comprises the following steps of: a) determining a pile position and finishing the construction of the pile hole (1); b) filling immature concrete (2) into a bag (3) of which the section is smaller than that of the pile hole (1); c) placing the immature concrete (2) bagged into the bag (3) in the step b) into the pile hole (1) together with the bag (3); d) determining whether to repeat the step b) and the step c) according to the amount of the concrete required to be poured, if the one-time pouring quantity satisfies the requirements, the step is not required; and e) compactly filling the immature concrete (2) poured into the pile hole (1) into the pile hole (1). The invention also provides a prefabricated extrusion and expansion pile construction method for concrete bagged pouring by utilizing a hollow part of a hollow prefabricated pile (6) taken as the pile hole (1). The invention has the beneficial effects that the pouring construction of the cast-in-place concrete in the small-diameter pile hole (1) can be smoothly finished; the construction method is simple; and the quality is reliable.

Owner:张继红

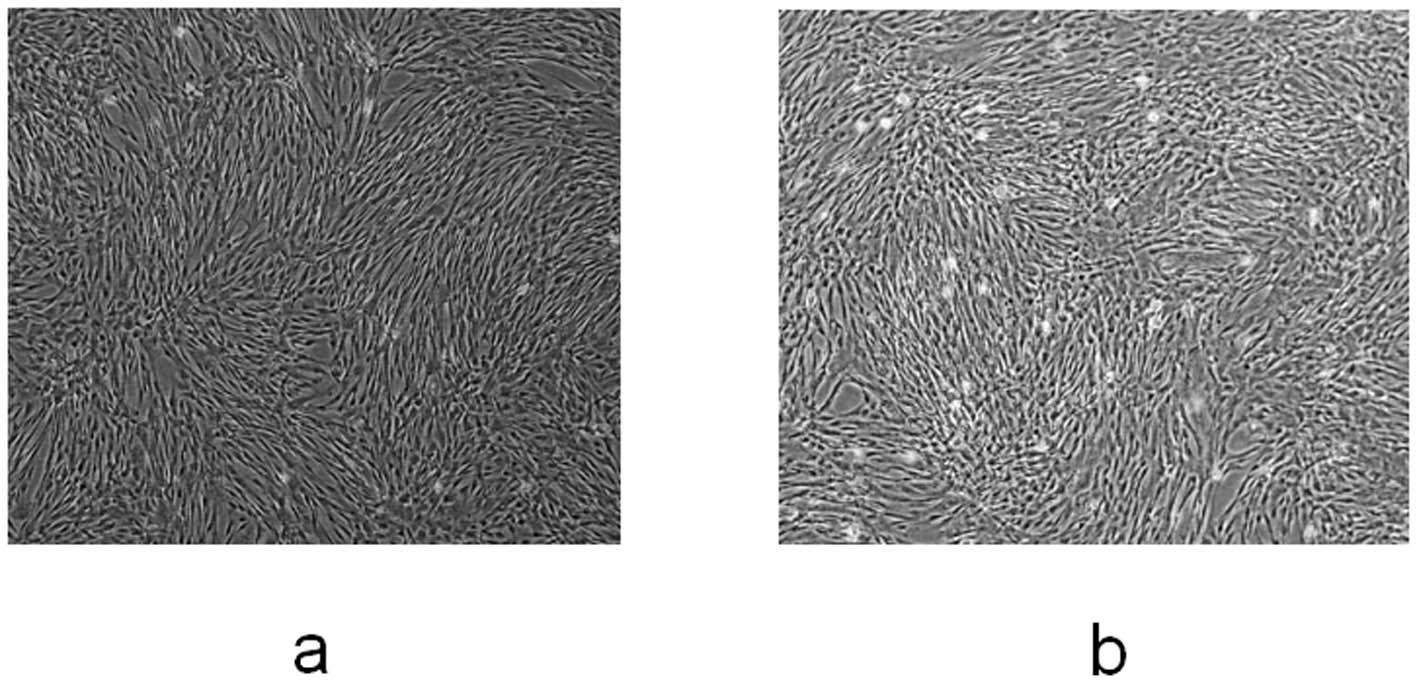

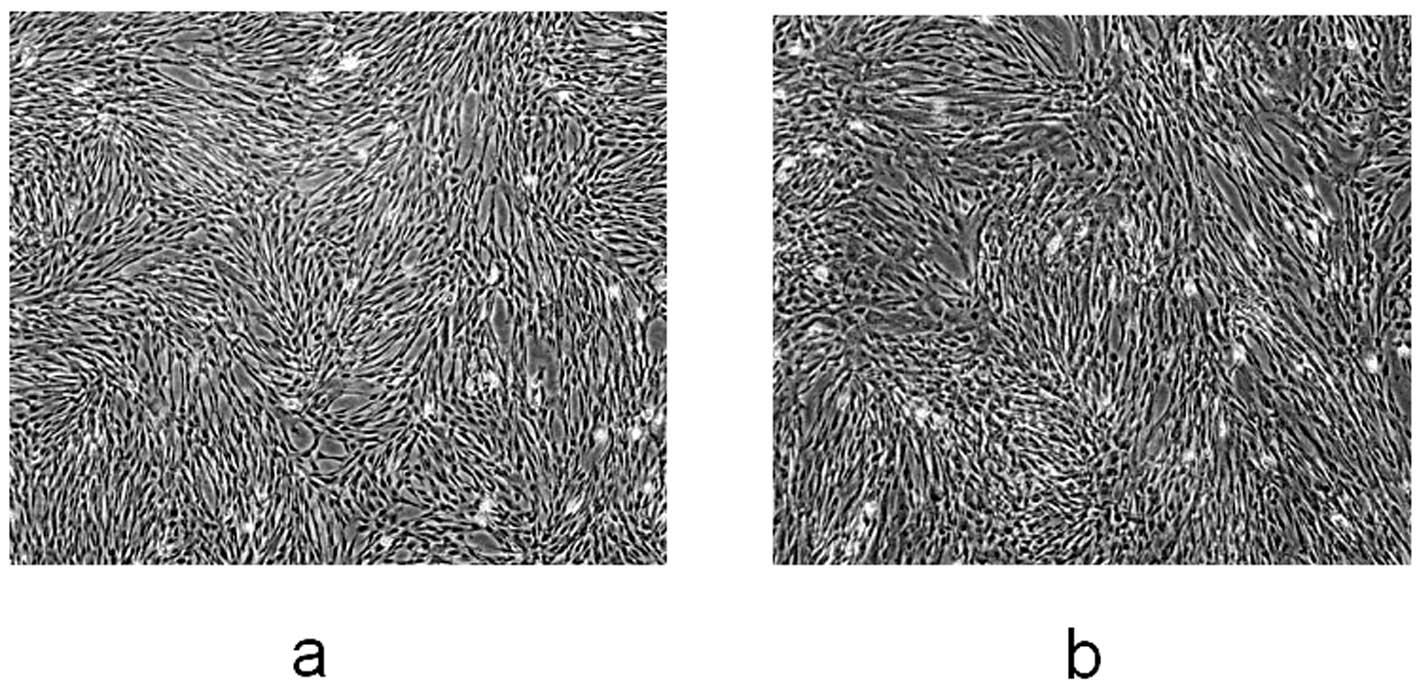

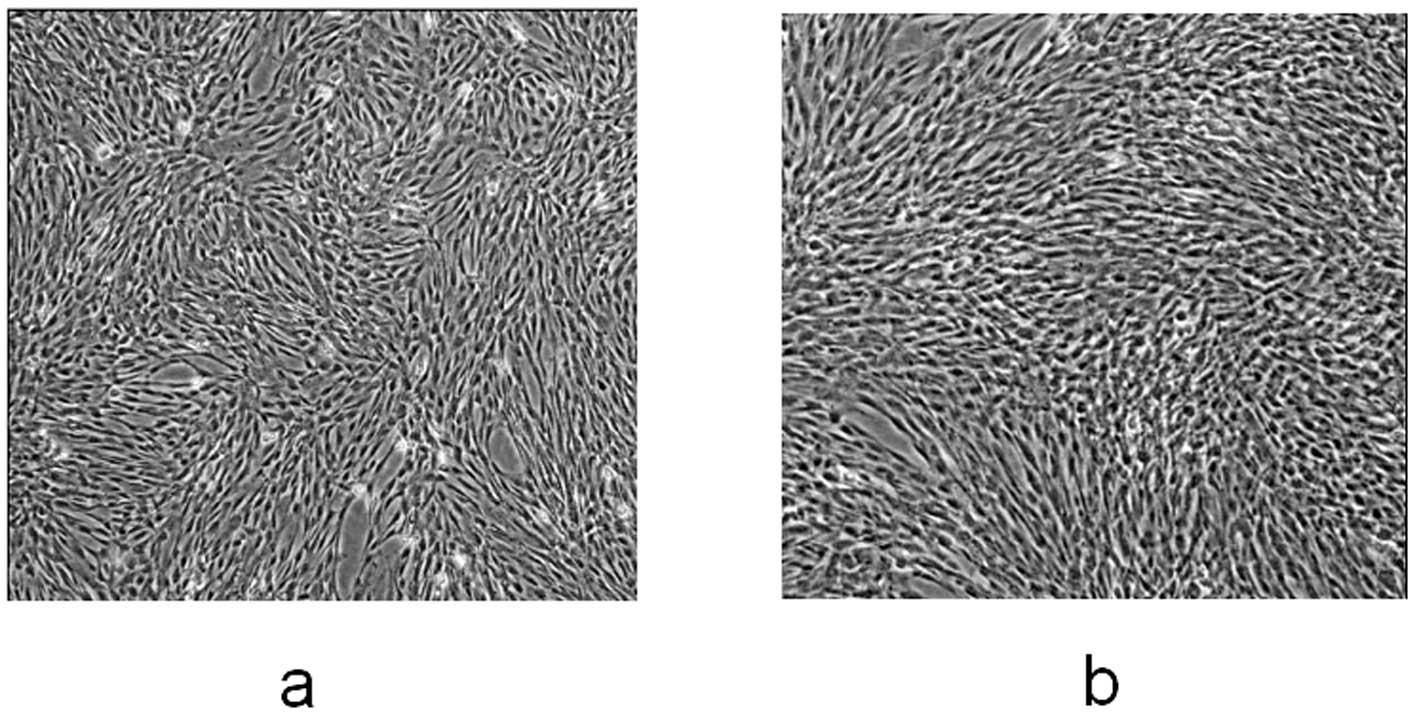

Liquid for preserving umbilical cord tissue

ActiveCN102550543AWide variety of sourcesReliable qualityDead animal preservationBiologyBiomedical engineering

The invention relates to a liquid for preserving an umbilical cord tissue, wherein the liquid is a solution, per ml of physiological saline contains 50-150 U of penicillin and 50-150 mg of streptomycin to form the solution. The preservation liquid has characteristics of wide source, stable quality, and cheap price. The experiment results show that: the liquid of the present invention provides the same effects in bacteriostasis property, effective preservation for the sampled umbilical cord tissue, and other fields as the traditional PBS preservation source, and the validity duration of the preservation liquid of the present invention is at least half a year, and can be prolonged.

Owner:SICHUAN NEO LIFE STEM CELL BIOTECH

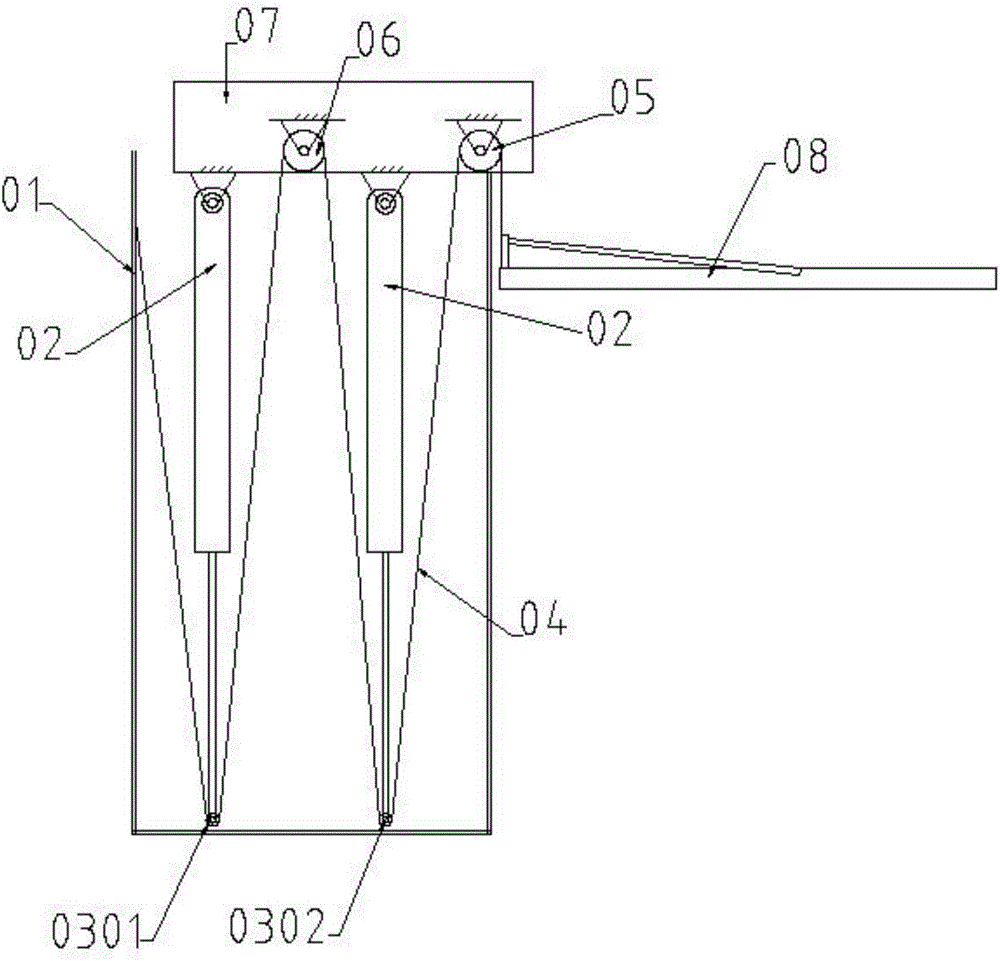

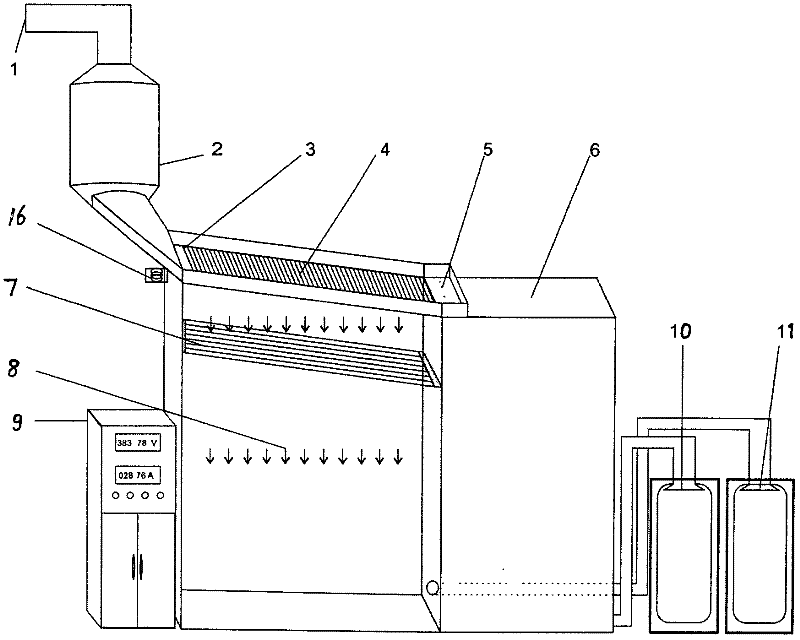

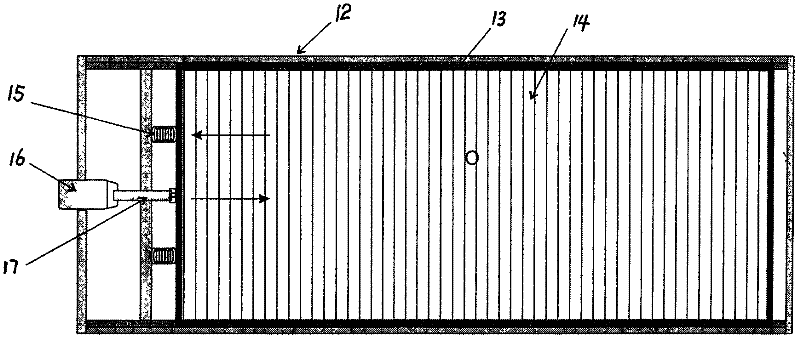

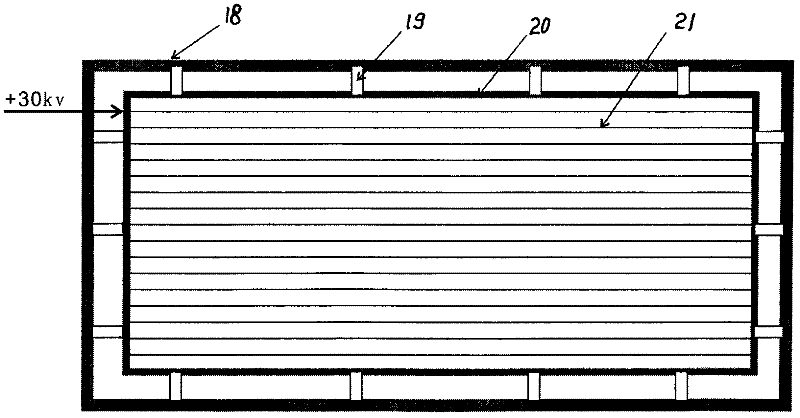

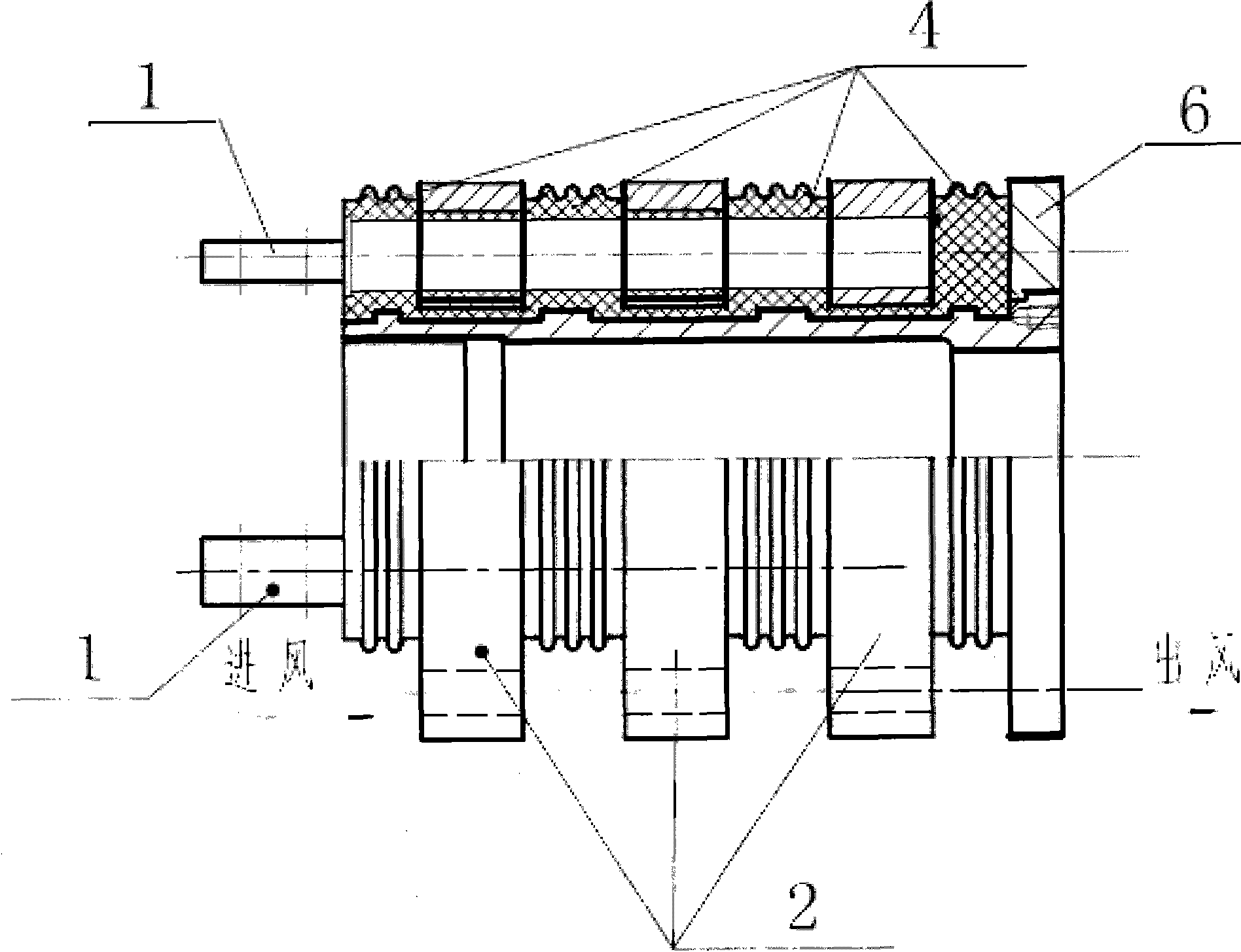

Variable-frequency oscillation high-voltage electrostatic down fiber removing machine

InactiveCN102226302AImprove separation efficiencyReliable qualityFibre separationElectrostatic dischargeFrequency oscillation

The invention discloses a variable-frequency oscillation high-voltage electrostatic down fiber removing machine. The variable-frequency oscillation high-voltage electrostatic down fiber removing machine is a special device for processing down and can be used for separating down from down fiber. The technical scheme is as follows: a material storage barrel 2 is arranged below a down inlet 1, a down discharge port 3 below the material storage barrel 2 corresponds to a strip-shaped oscillating screen 4, a down warehousing port 5 is arranged at the lower end of the strip-shaped oscillating screen4 and is in butt joint with a down warehouse 6, the down warehouse 6 is linked into a down packing machine 10 through a pipeline, an electrostatic screen 7 is arranged at the lower part of the strip-shaped oscillating screen 4, a flying fiber warehouse 8 is arranged at the lower part of the electrostatic screen 7, the flying fiber warehouse is linked into a flying fiber packing machine 11 througha pipeline, and all power cords are connected into a control electrical cabinet 9. The device can be used for down separation processing.

Owner:昆明市鸭绒制品厂

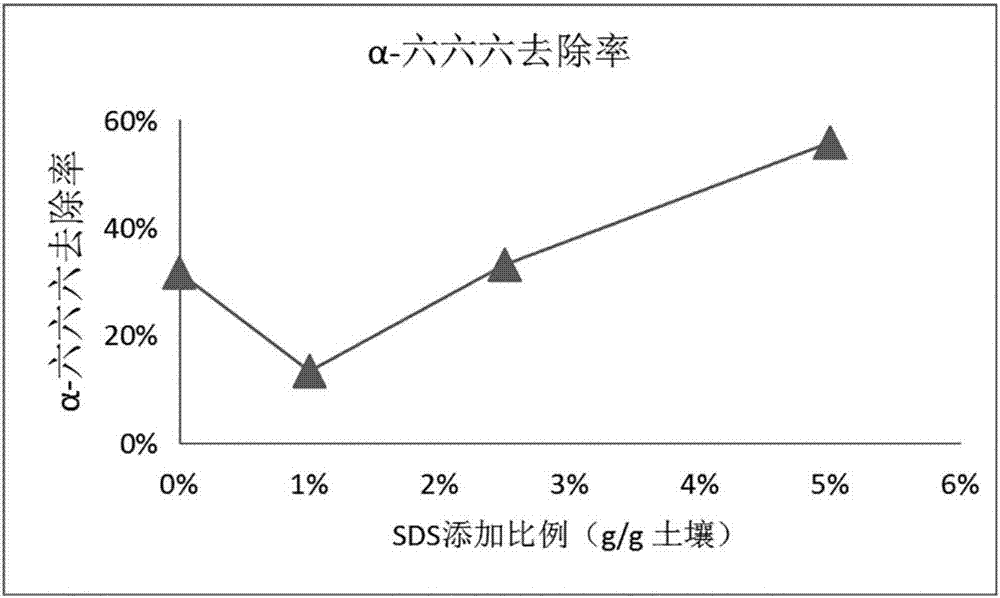

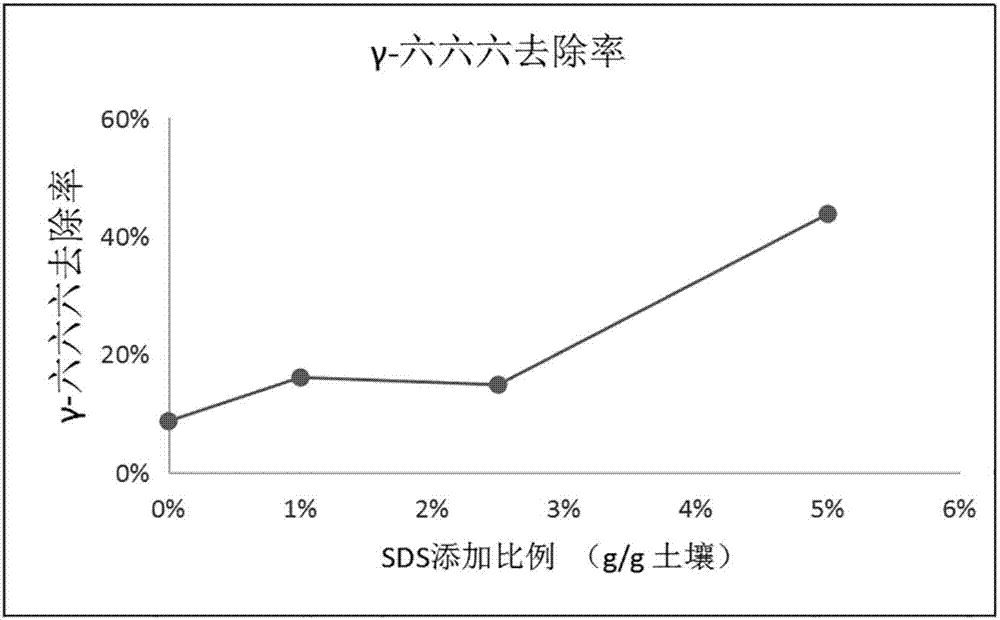

Using method of medicament used for chemically oxidizing and restoring pesticide contaminated soil

InactiveCN107159705AReliable qualityGood oxidation effectContaminated soil reclamationPesticidePre treatment

The invention discloses a using method of a medicament used for chemically oxidizing and restoring pesticide contaminated soil. The medicament comprises a component A and a component B. The component A comprises sodium sulfate, and the component B comprises sodium dodecyl sulfate and calcium hydroxide. The method comprises the steps that 1, the adding ratio of the component A is calculated; 2, the using amount and matching ratio of the component B are calculated, and the component B is prepared; 3, soil is pretreated; 4, the component B is added into the contaminated soil, and the mixture is stirred and mixed to be uniform; 5, the component A is added into the soil into which the component B is added, and the mixture is stirred and mixed to be uniform; 6, the moisture content of the soil into which the component A and the component B are added is adjusted, and maintenance is carried out for 3-7 days; and 7, the soil pH is detected and analyzed in the maintenance period to ensure that the soil pH reaches 10.0 after the mixture is mixed to be uniform. By means of the using method of the medicament used for chemically oxidizing and restoring pesticide contaminated soil, pesticide matter difficult to degrade in soil can be rapidly and efficiently oxidized, decomposed and removed.

Owner:SHANGHAI GREENMENT ENVIRONMENTAL TECH CO L

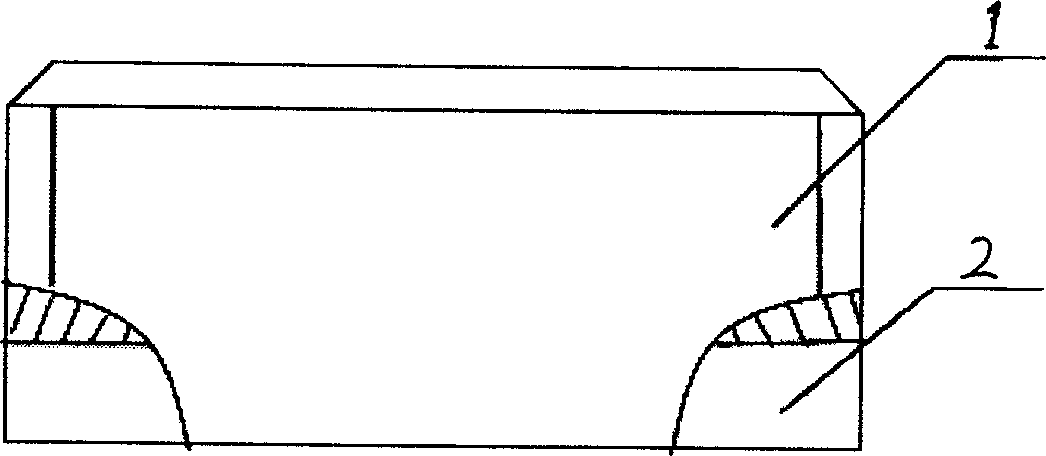

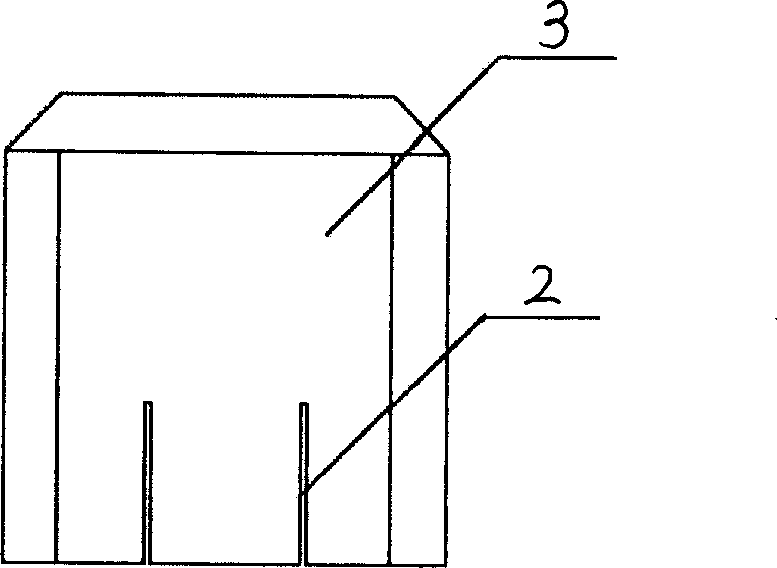

Manufacturing method of plastic concrete inspection well

ActiveCN102392485AOvercome inconvenience and hassleReliable qualitySewerage structuresSewer pipelinesRebarCorrosion resistant

The invention discloses a manufacturing method of a plastic concrete inspection well, which comprises the following steps of: heating a plastic, extruding the plastic into a belt or a strip through a plastic extruding machine, using the obtained belt or the strip and a small amount of steel bars for weaving to form a cage-shaped framework of a formed part, placing into a cavity formed by an inner mold and an outer mold, casting concrete and adding trace plastic fibers into the concrete. By adopting the manufacturing method, the inspection wells in different specifications can be produced, centralized forming can be performed in a factory, the inspection well can be divided into sections for modular manufacturing, and then field assembly is performed, thereby overcoming inconvenience and cumbersome property caused by field construction; and simultaneously, the product is corrosion-resistant and reliable in quality.

Owner:SICHUAN TAIXIN IND DEV

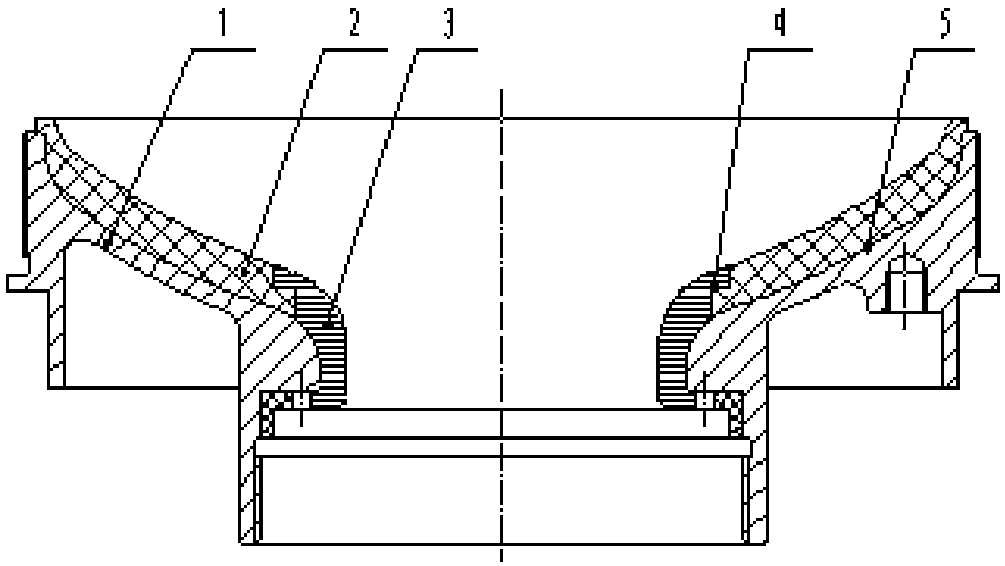

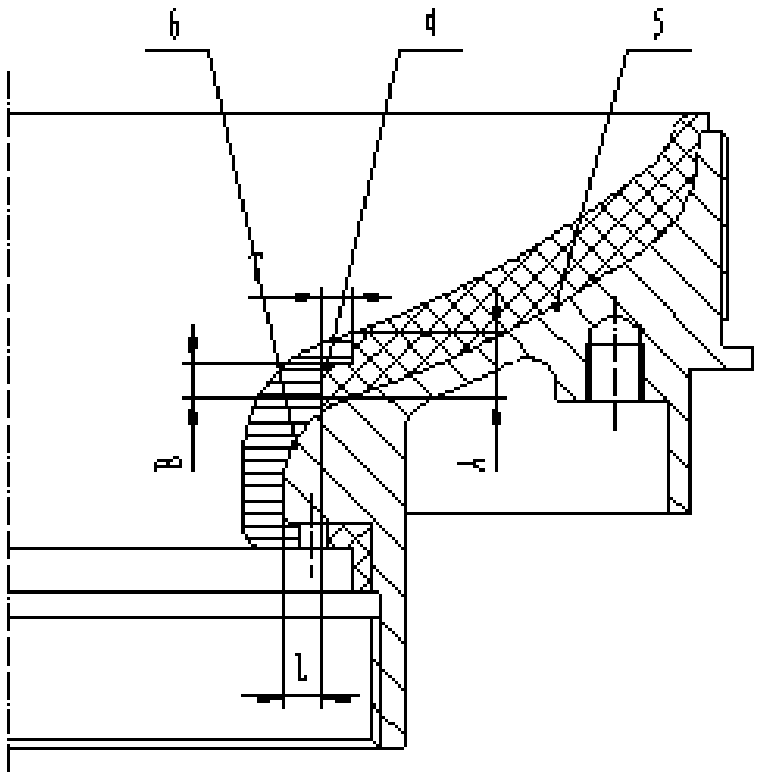

Rear sealing head heat-insulation layer structure for solid rocket engine and forming method of rear sealing head heat-insulation layer structure

The invention discloses a rear sealing head heat-insulation layer structure for a solid rocket engine and a forming method of the rear sealing head heat-insulation layer structure, and belongs to thefield of design and manufacturing of heat insulation layers of heat protection structures for solid rocket engines. At present, a rear sealing head heat-insulation layer structure difficulty meets theuse requirements for light weight, ablation resistance, scouring resistance, high-efficiency manufacturing and low cost simultaneously. According to the rear sealing head heat-insulation layer structure, a heat-insulation body serves as a structural support, pre-formed light rubber heat-insulation materials are arranged and distributed at a large convergence end, pre-formed curing resin heat-insulation materials are arranged and distributed at a narrow convergence channel, the connection positions are in transition butting and lapping through stair-type steps, and overall one-time heat-curingforming is conducted to form an integrated structure through a forming mold tool. Practice proves that all interfaces of the rear sealing head heat-insulation layer structure prepared through the forming method are bonded reliably, the forming efficiency is high, comprehensive performance of a product is good, and the comprehensive use requirements of the rear sealing head heat-insulation structure for the engine can be simultaneously met well.

Owner:HUBEI INST OF AEROSPACE CHEMOTECH

Feed for selenium-rich pigs

InactiveCN104431514AReliable qualityImprove farming efficiencyAnimal feeding stuffNutrientAnimal science

The invention relates to a feed for selenium-containing pigs. The feed comprises corns, wheat bran, vegetable oil, bean meal and a selenium-containing premixed feed, wherein the selenium-containing premixed feed is a high-selenium formula feed prepared from selenium-containing materials, multiple vitamins and Chinese herbal medicines; the Chinese herbal medicines mainly comprise rhizoma coptidis, Shiyao angelica sinensis, Enshi Banqiao radix codonopsis, cortex eucommiae and wild vegetables. The feed is nutrient, healthy and safe; the meat quality can be improved, and the content of selenium of pork is high, so that the content of the selenium of a human body can be increased; besides, the culture benefit can be increased, the daily gain of the pigs can be increased, the material weight ratio is remarkably decreased, and the immunologic functions of the pigs can be enhanced.

Owner:XIYUESHAN AGRI TECH BEIJING

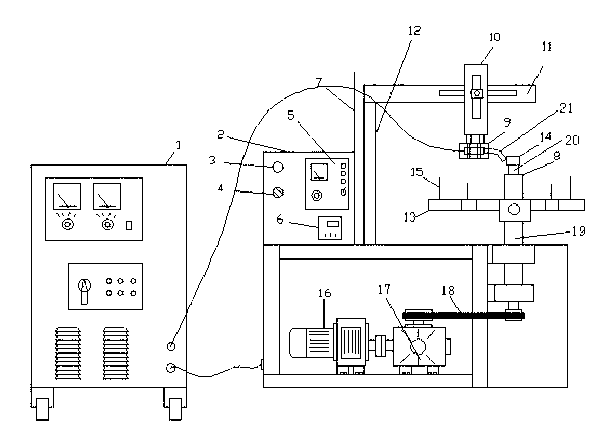

Oil bottom case oil discharge plug seat welding device

InactiveCN103071887AReliable qualityGood securityElectrode supporting devicesElectric machineryEngineering

The invention relates to an oil bottom case oil discharge plug seat welding device, which consists of a speed regulation motor, a bracket, position limiting blocks, a rotating mold, a compression mandrel, a welding gun, an angle regulator, an ascending and descending regulator, a left and right regulator, a support frame, a protection plate, an electric control box, a welding machine and the like, wherein the speed regulating motor drives the bracket to do horizontal rotation, a plurality of position limiting blocks are arranged on the bracket, the rotating mold is arranged on the position limiting blocks, a workpiece is fixedly arranged on the rotating mold through the compression mandrel, in addition, a welding hole of the workpiece is concentric with the rotating mold, the upper end of the workpiece is provided with the welding gun, the welding gun is arranged on the angle regulator, the angle regulator, the ascending and descending regulator and the left and right regulator form a whole and are fixedly arranged on the support frame, one side of the protection plate is provided with the electric control box, and the welding machine is placed at one side of the electric control box. The oil bottom case oil discharge plug seat welding device has the advantages that the automatic welding is realized, the quality is reliable, the safety performance is good, the production efficiency is high, and the like.

Owner:乳山市黄海汽车配件有限公司

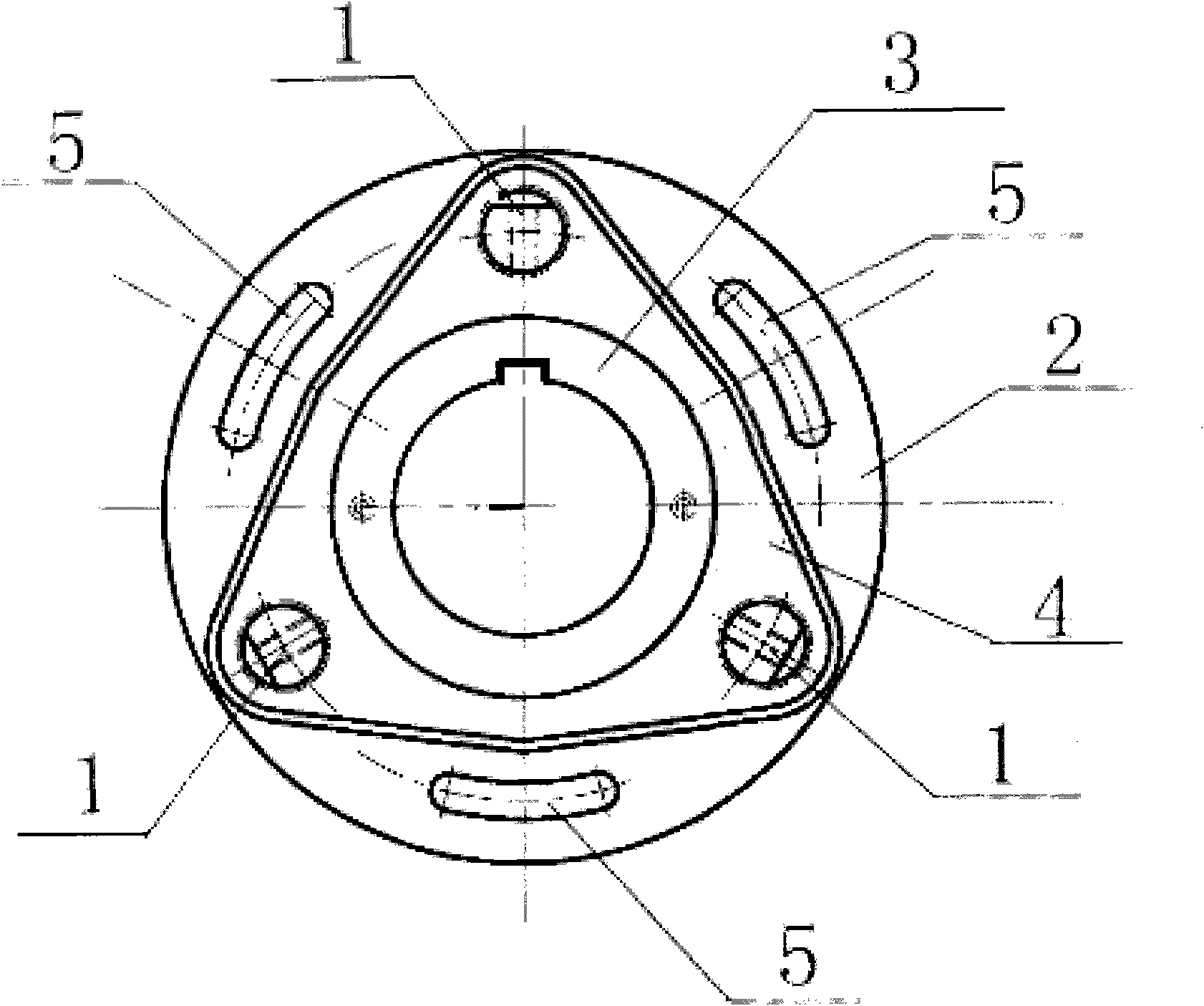

Collector ring

ActiveCN101527418ASimple processReliable qualityRotary current collectorSlip-rings manufactureEngineeringLow noise

The invention relates to a collector ring, which comprises n conducting rods, n conducting rings, one grounded slip ring and one sleeve, and is characterized in that spacing columns made from mixed resin are arranged among the n conducting rings and between the conducting rings and the grounded slip ring, the nth conducting rod runs through n-1 conducting rings and n-1 spacing columns among the n-1 conducting rings and is connected with a corresponding nth conducting ring, the sleeve is positioned in the center of the collector ring and runs through the whole collector ring, and the conducting rings are provided with a plurality of annular equidistantly distributed circular orifices. The collector ring has good integrity, and small wind resistance and low noise under high-speed rotation; each conducting ring including the grounding ring has an axial air hole; in the overall design, an inside fan drives out worn electrical brush dust directly to reduce the inside dust accumulation; and the collector ring also increases the creepage distance.

Owner:上海电气集团上海电机厂有限公司

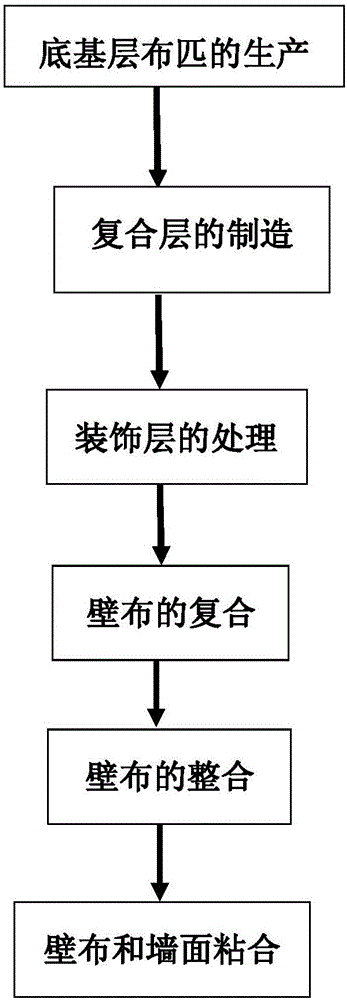

Production technology of wall cloth

InactiveCN105088483AReliable qualityQuality improvementCovering/liningsHeating/cooling textile fabricsDyeingEngineering

The invention discloses a production technology of a piece of wall cloth, which is characterized in that the production technology comprises following steps: producing a piece of under layer cloth: the piece of under layer cloth is acquired by adopting a wide textile machine to produce, nano space cotton to knit and shaping and sorting the nano space cotton; manufacturing a composite layer: the composite layer is acquired by adopting the textile machine to knit cloth material and cotton, shaping, sorting and decorating the knitted cloth material and cotton and then post-processing the knitted cloth material and cotton; processing a decorative layer: the decorative layer is acquired by dyeing, shaping sorting, decorating and post-processing the surface of the decorative layer; compositing the piece of wall cloth: the piece of the wall cloth is acquired by combining together the under layer, the decorative layer and the composite layer with a composite machine; integrating the piece of wall cloth: the wall cloth and plant glue past are composited by the composite machine under the condition of 50 DEG C; sticking the wall cloth and a wall surface: the wall surface is flattened and moisture prevention of the wall surface is processed; and ripping out the plant glue paste and combining the wall cloth and wall surface to make the wall cloth and the wall surface stick.

Owner:JIANGSU FULIYA NEW MATERIAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com