Mixed soil extruded and cured precast pile for soft foundation treatment as well as construction method

A technology of soft foundation treatment and mixed soil, which is applied in the direction of foundation structure engineering, sheet pile walls, buildings, etc., can solve problems such as poor work efficiency, uncontrollable pile type, and difficult quality assurance, so as to improve the overall bearing capacity and realize modularization Construction and the effect of reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

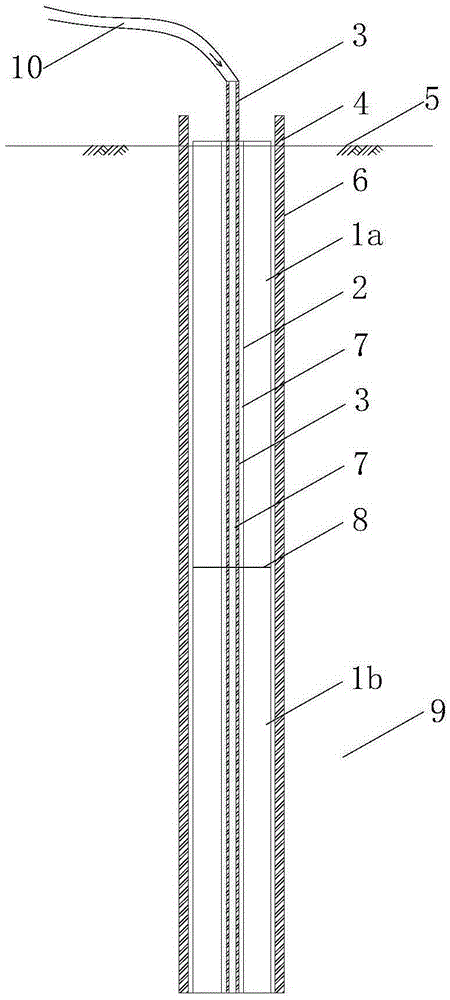

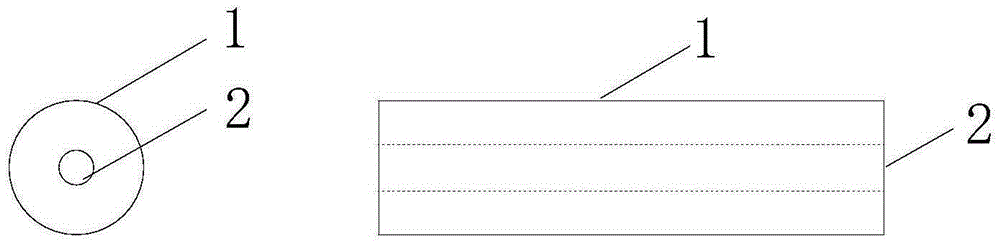

[0037] Combine below figure 1 , figure 2 The present invention is described in further detail:

[0038] A mixed soil extruded and solidified prefabricated pile for soft foundation treatment, which consists of a first mixed soil extruded and solidified prefabricated pile 1b, a second mixed soil extruded and solidified prefabricated pile 1a, a central hole 2, a seamless steel pipe 3, vibration Immersed tube 4, ground surface 5, borehole 6, cement mortar 7, pile joint 8, foundation soil 9, grouting pipe 10, center hole 2, such as figure 1 It can be seen that from bottom to top, it is characterized in that: the foundation soil 9 is connected with the vibrating immersed tube 4, the vibrating immersed tube 4 is connected with the borehole 6, and the borehole 6 is respectively squeezed and solidified with the first mixed soil prefabricated pile 1b, and the second mixed soil The soil extruded and solidified prefabricated pile 1a is connected, the second mixed soil extruded and soli...

Embodiment 2

[0041] A construction method of mixed soil extruding solidified prefabricated piles for soft ground treatment, the steps are:

[0042] ① Hole forming:

[0043] Using a vibratory pipe sinking pile machine, starting from the ground surface 5, using the vibrating sinking tube 4 in the foundation soil 9, drilling 6 from top to bottom to the design depth (generally 20m), the vibrating sinking tube 4 is temporarily left in the foundation soil 9, as the support of the borehole 6, provides a precondition for the sequential installation of the mixed soil extruded and solidified prefabricated piles 1.

[0044] ② Hanging mixed soil extrusion solidification prefabricated piles:

[0045] Using a vibrating tube-immersing pile machine, the first mixed soil extruded and solidified prefabricated pile 1b and the second mixed soil extruded and solidified prefabricated pile 1a are sequentially hoisted into the vibrating immersed tube 4 temporarily left in the borehole 6, the first mixed soil Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com