Double plank vegetable fibre tray as well as integral pressing method and special mould thereof

A plant fiber and overall pressing technology, which can be applied to other household appliances, household appliances, applications, etc., can solve the problems such as difficult to produce qualified products, and achieve the effect of simple demoulding, small damage rate, and uniform compaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

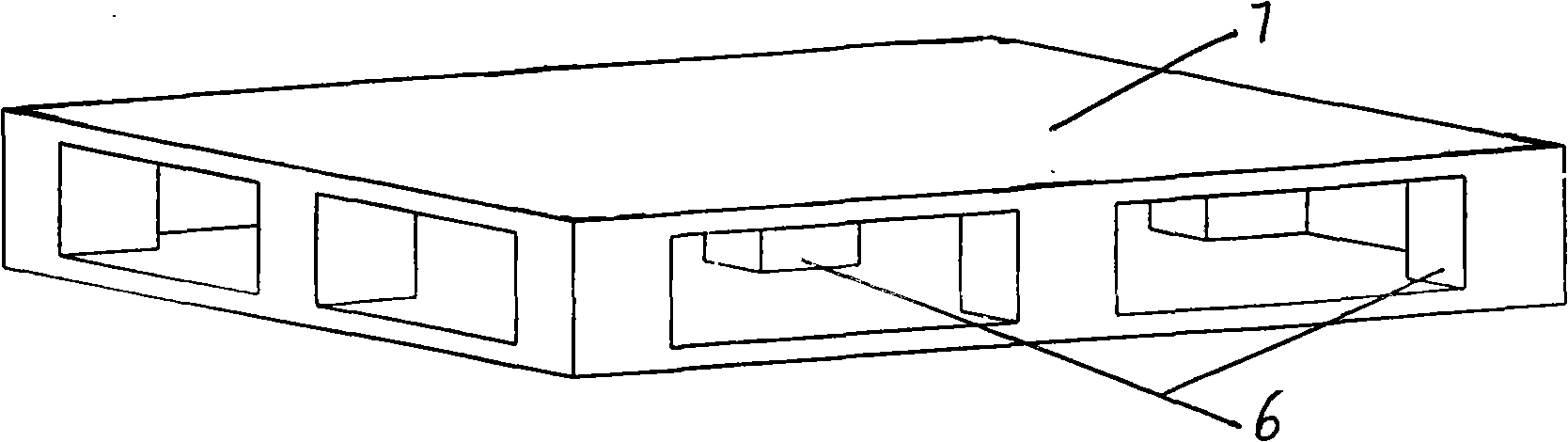

[0031] like figure 1 As shown, the double-plank plant fiber pallet includes a plate and support feet connected to the plate. In this embodiment, nine supporting legs 6 are arranged between the upper and lower plates 7, the supporting legs 6 are hollow structures, and the lower plate 7 is provided with a hole pattern (not shown) communicating with it.

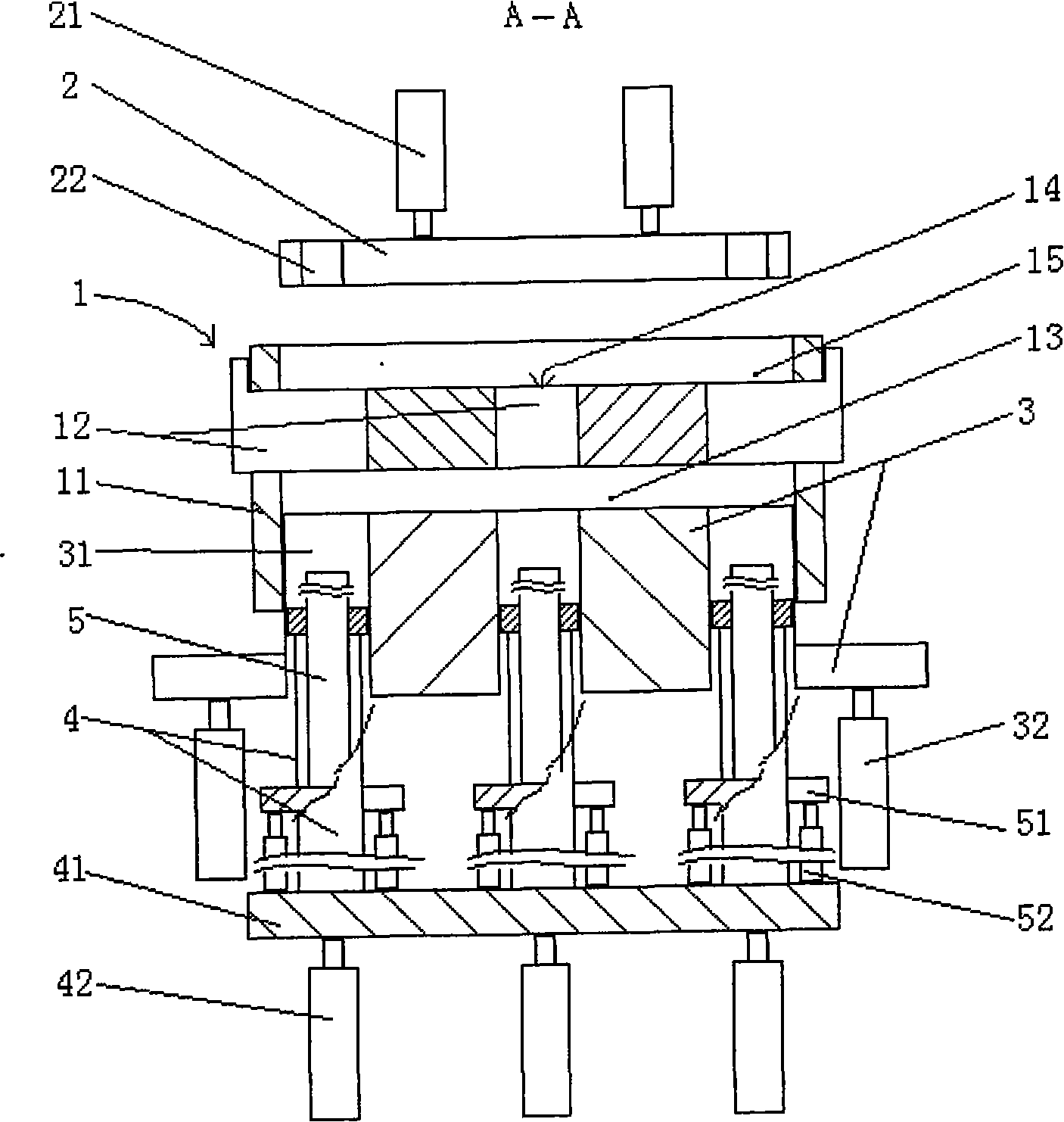

[0032] like figure 2 As shown, the special mold of the present invention includes a female mold provided with an electric heating device, an upper die punch, a lower die punch, a core rod movably connected with the lower die punch, and a power device.

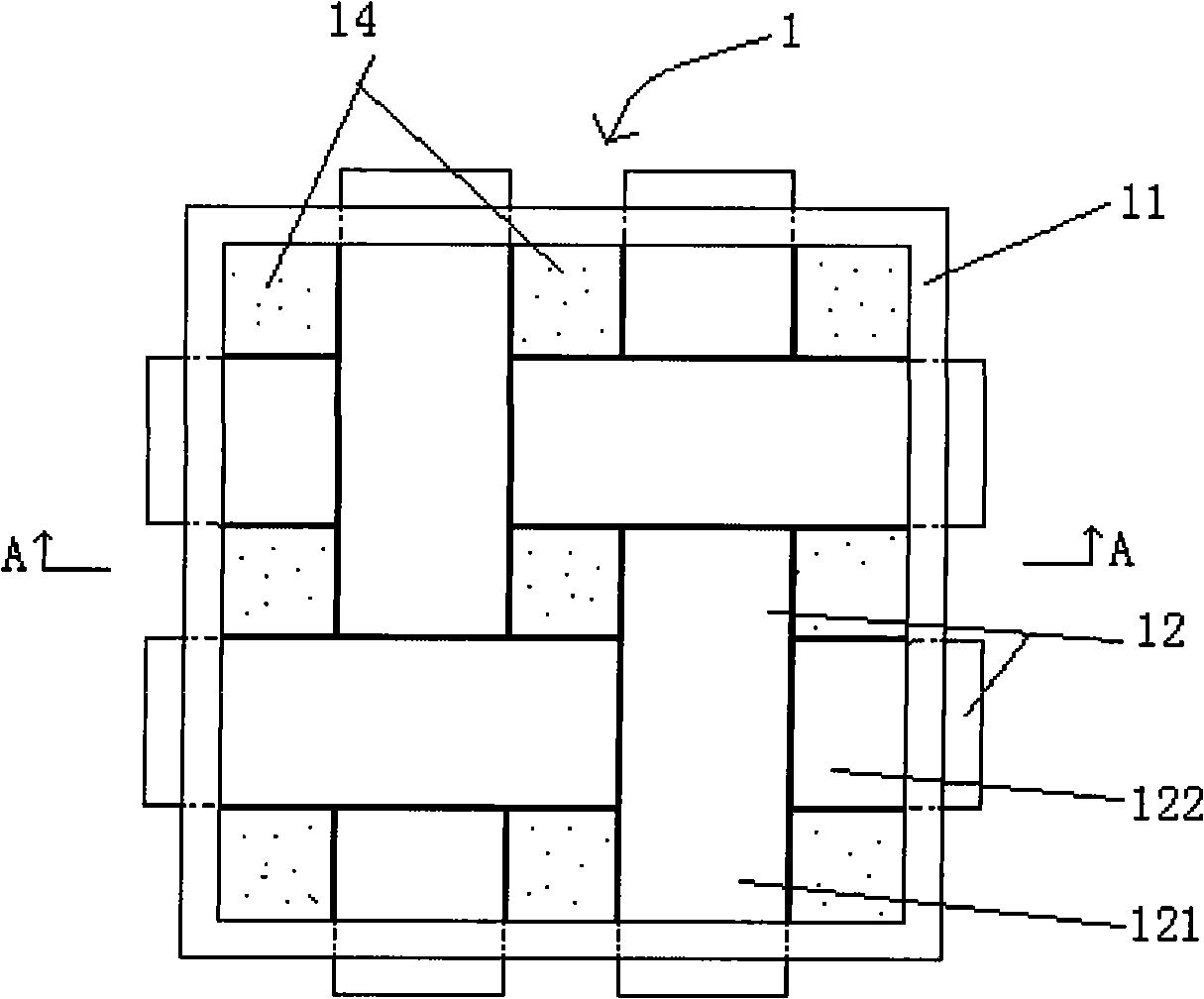

[0033] still as figure 2 As shown, the female mold 1 is composed of a frame 11 and a spacer module 12, two jacks are arranged on each side wall around the frame 11, and the projections of the four side walls and the two jacks arranged on it overlap, so The spacer module 12 is matched with the jack, and the jack extends horizontally into the cavity of the frame 11 to separate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com