Patents

Literature

108results about How to "Evenly compacted" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

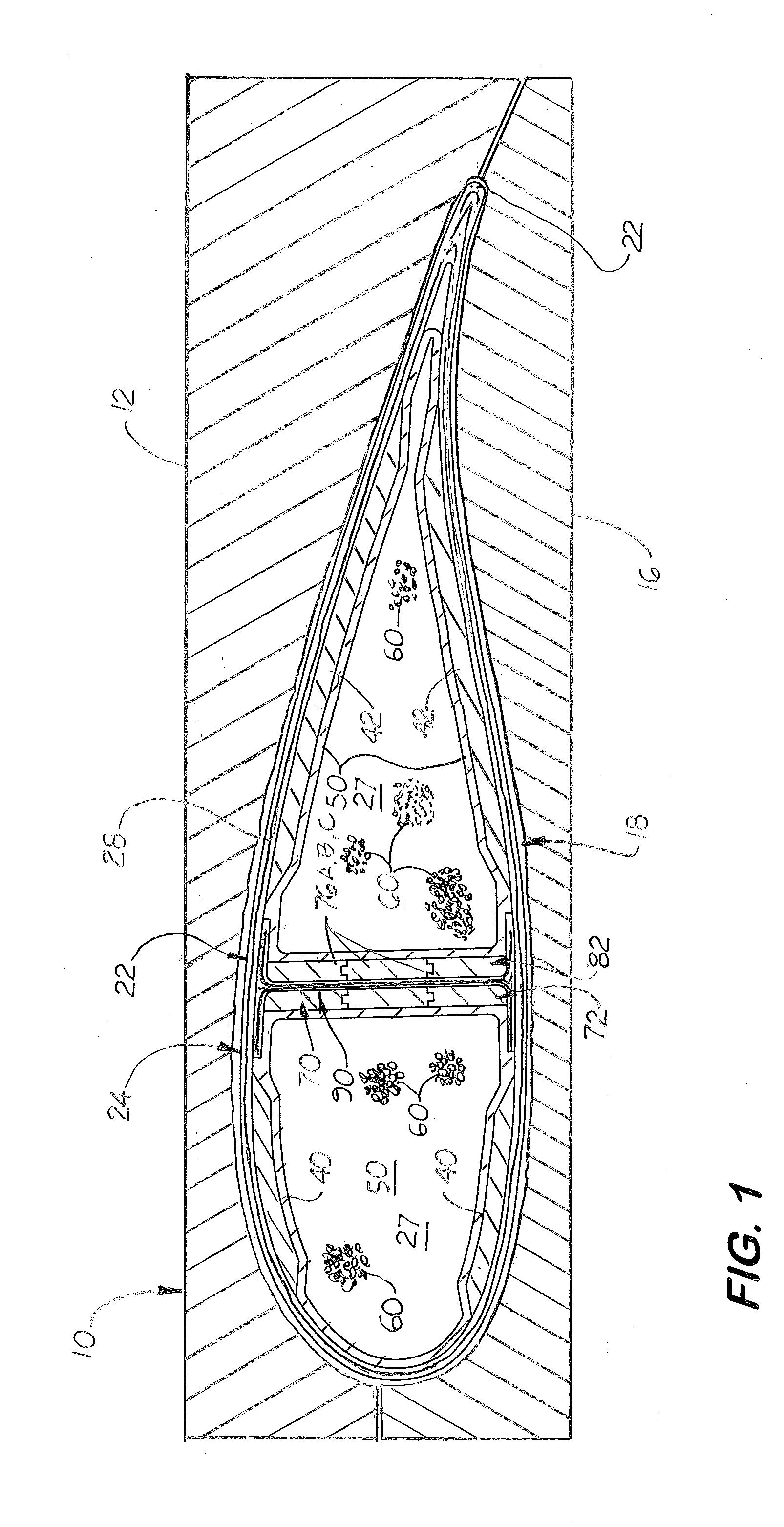

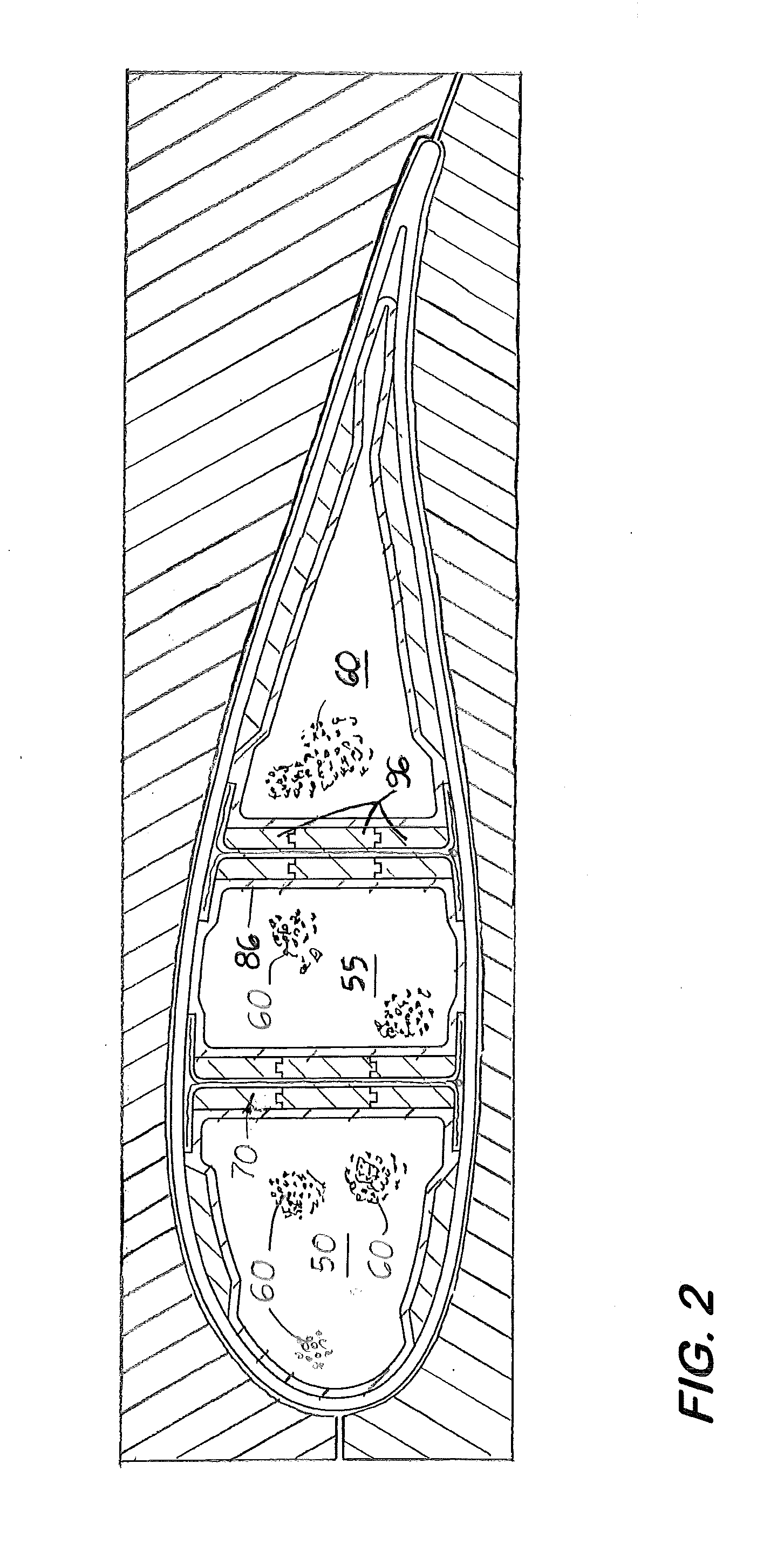

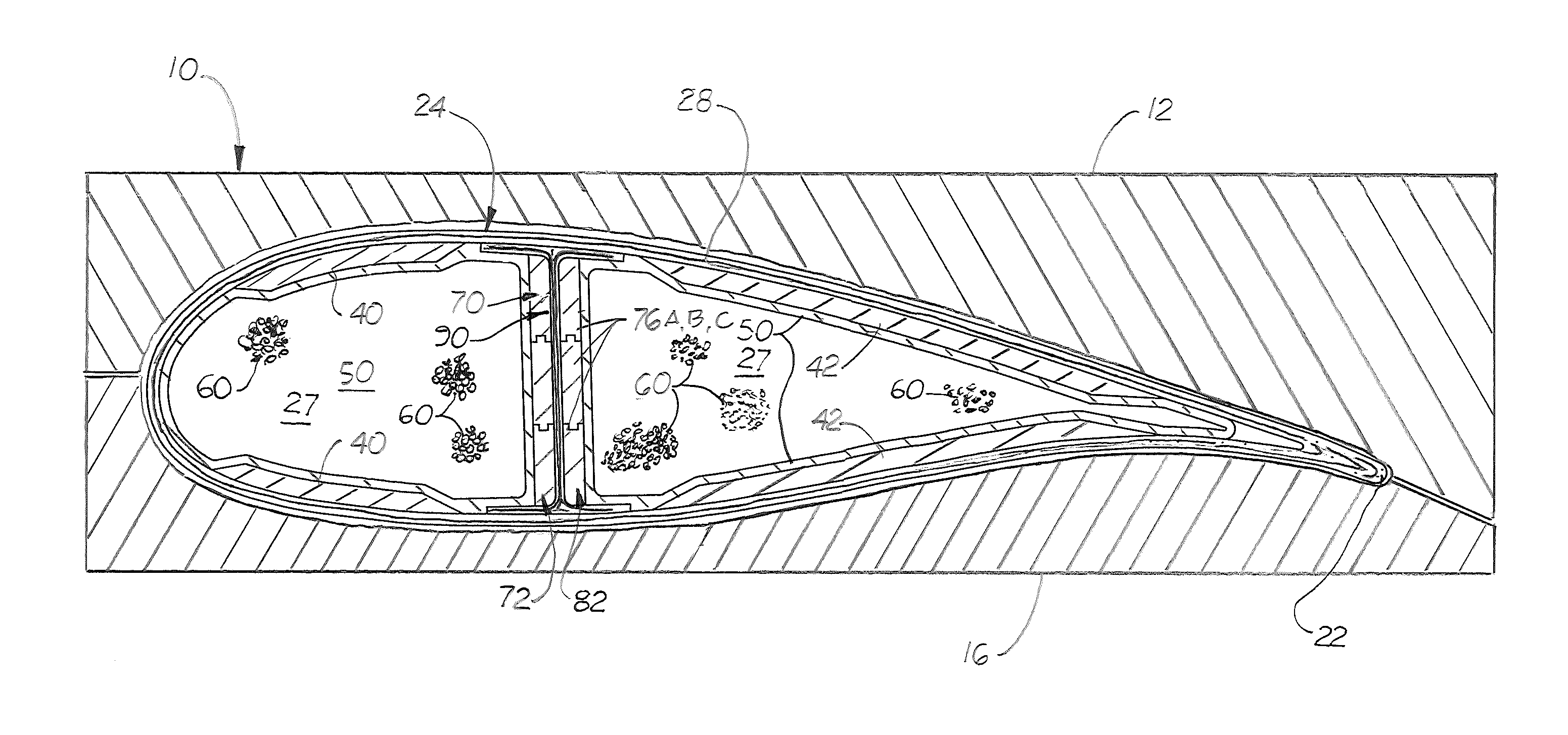

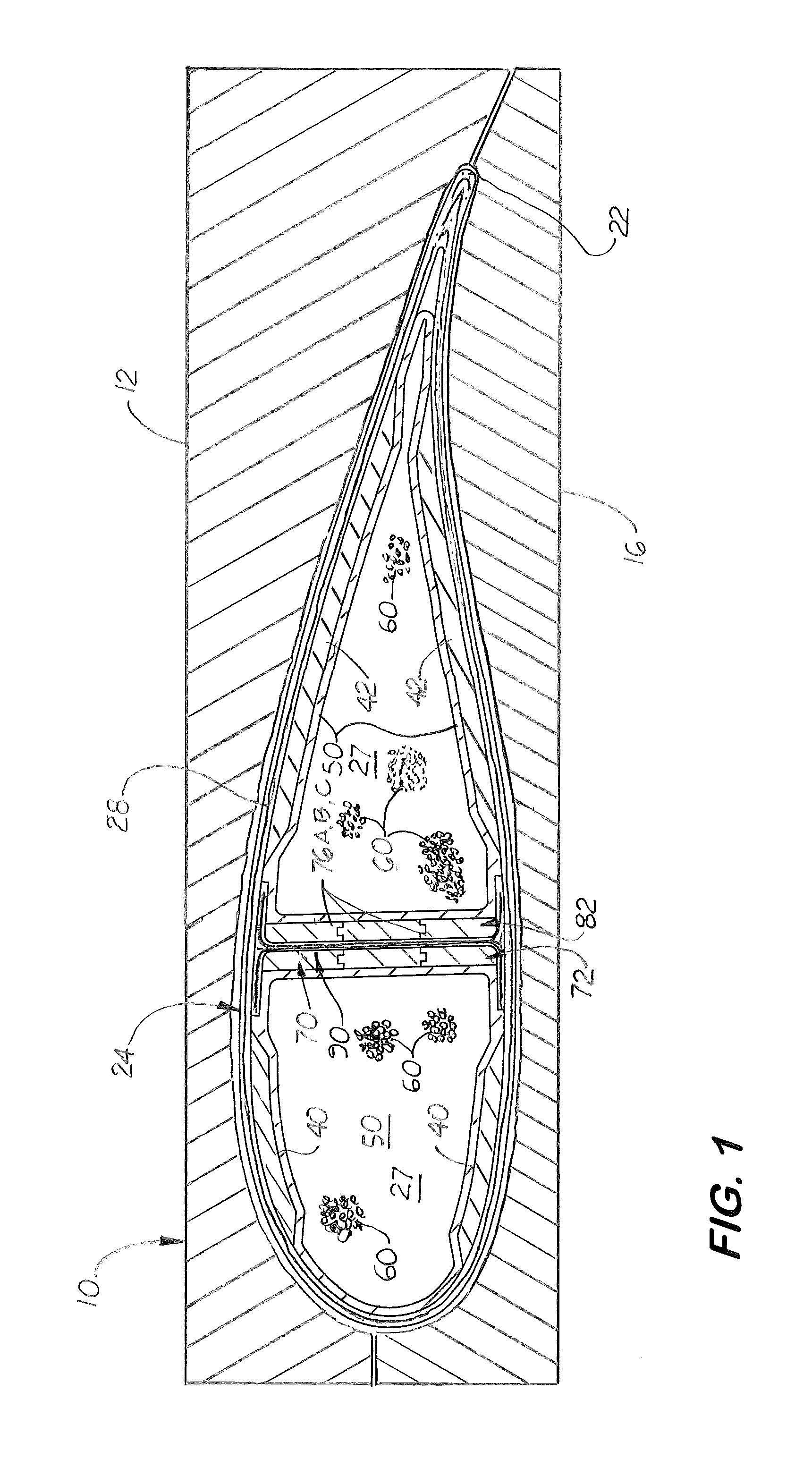

Method of making an expandable medical device formed of a compacted porous polymeric material

InactiveUS6863757B1Easy to manufactureBroaden applicationLaminationLamination apparatusCatheterMedical device

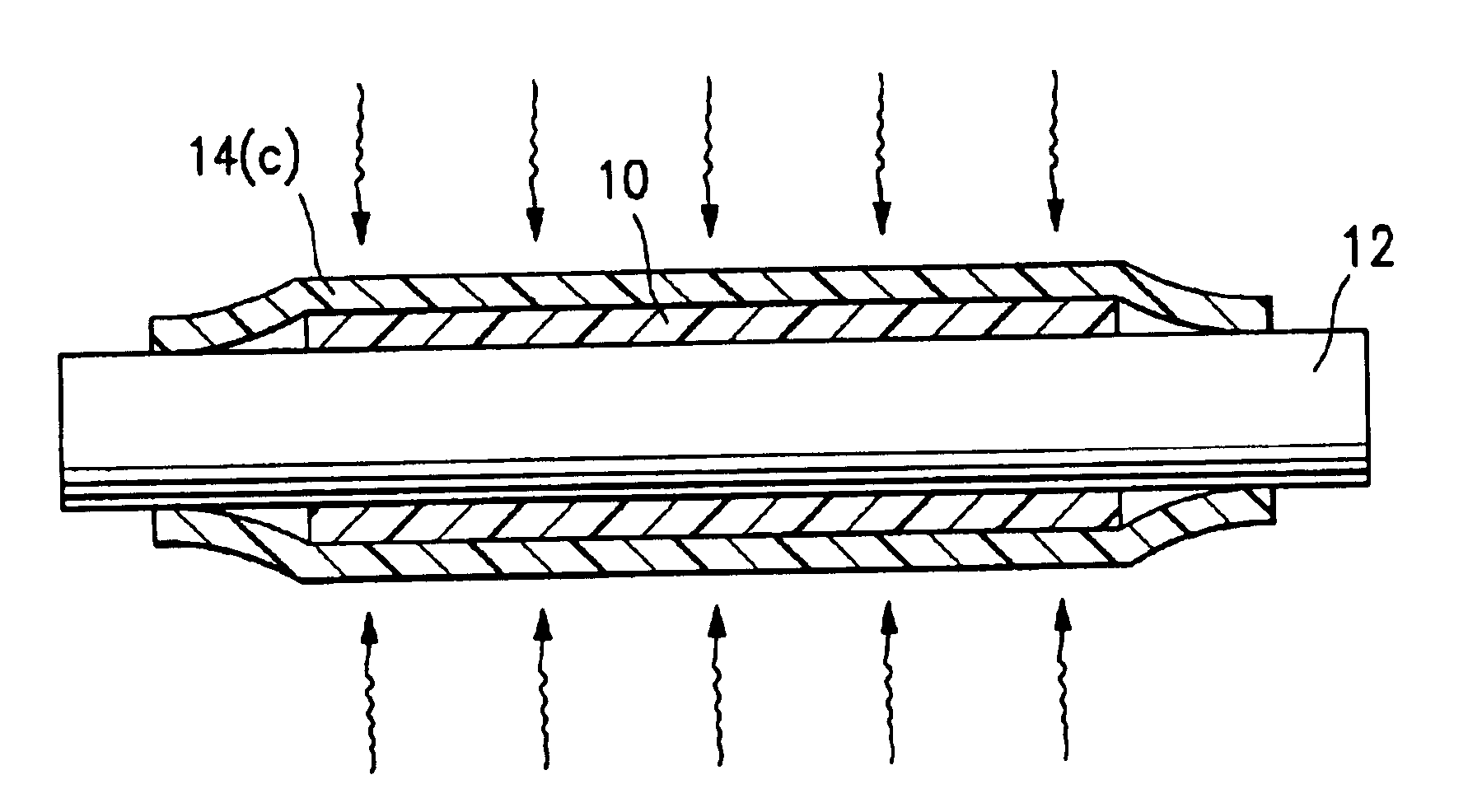

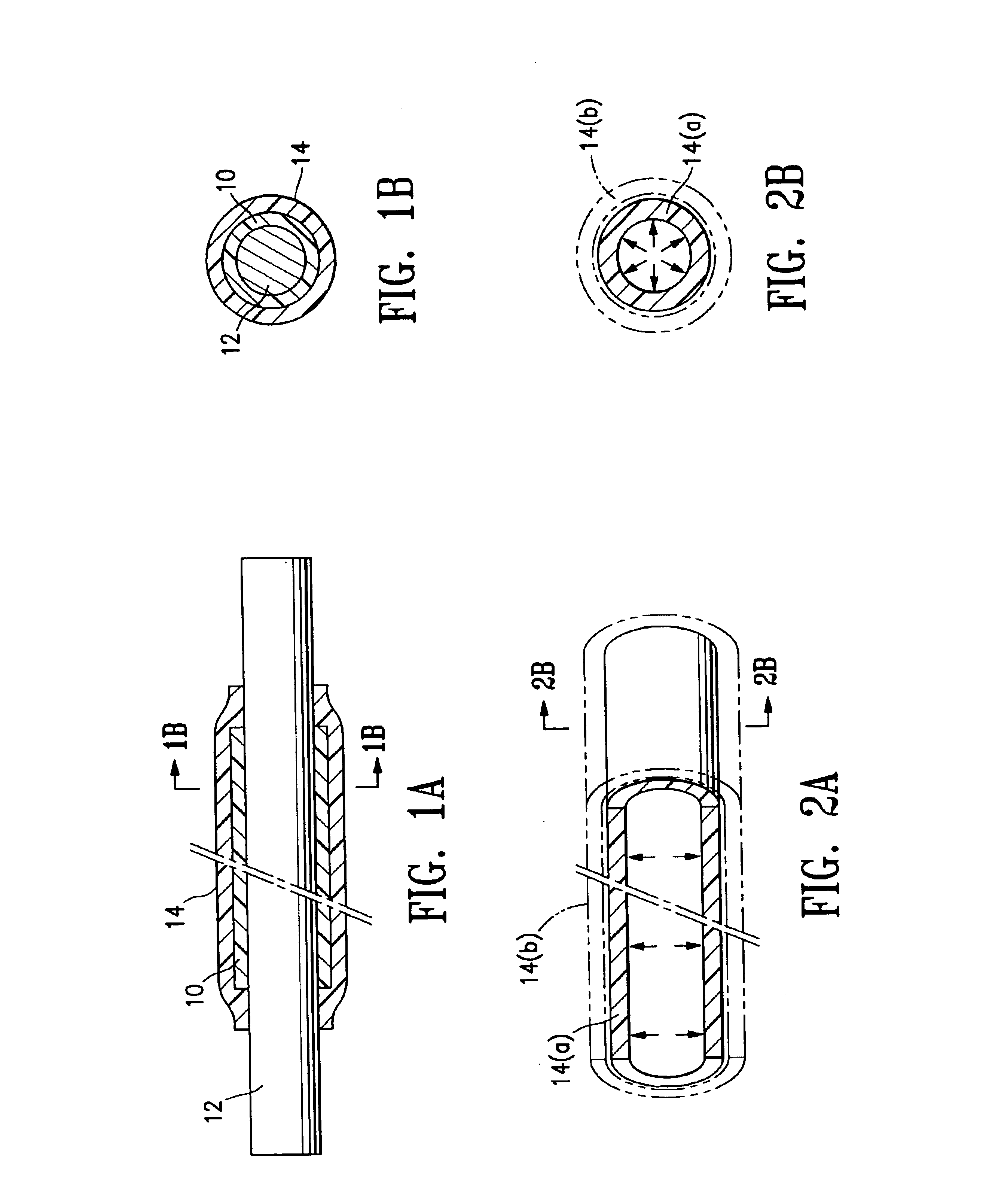

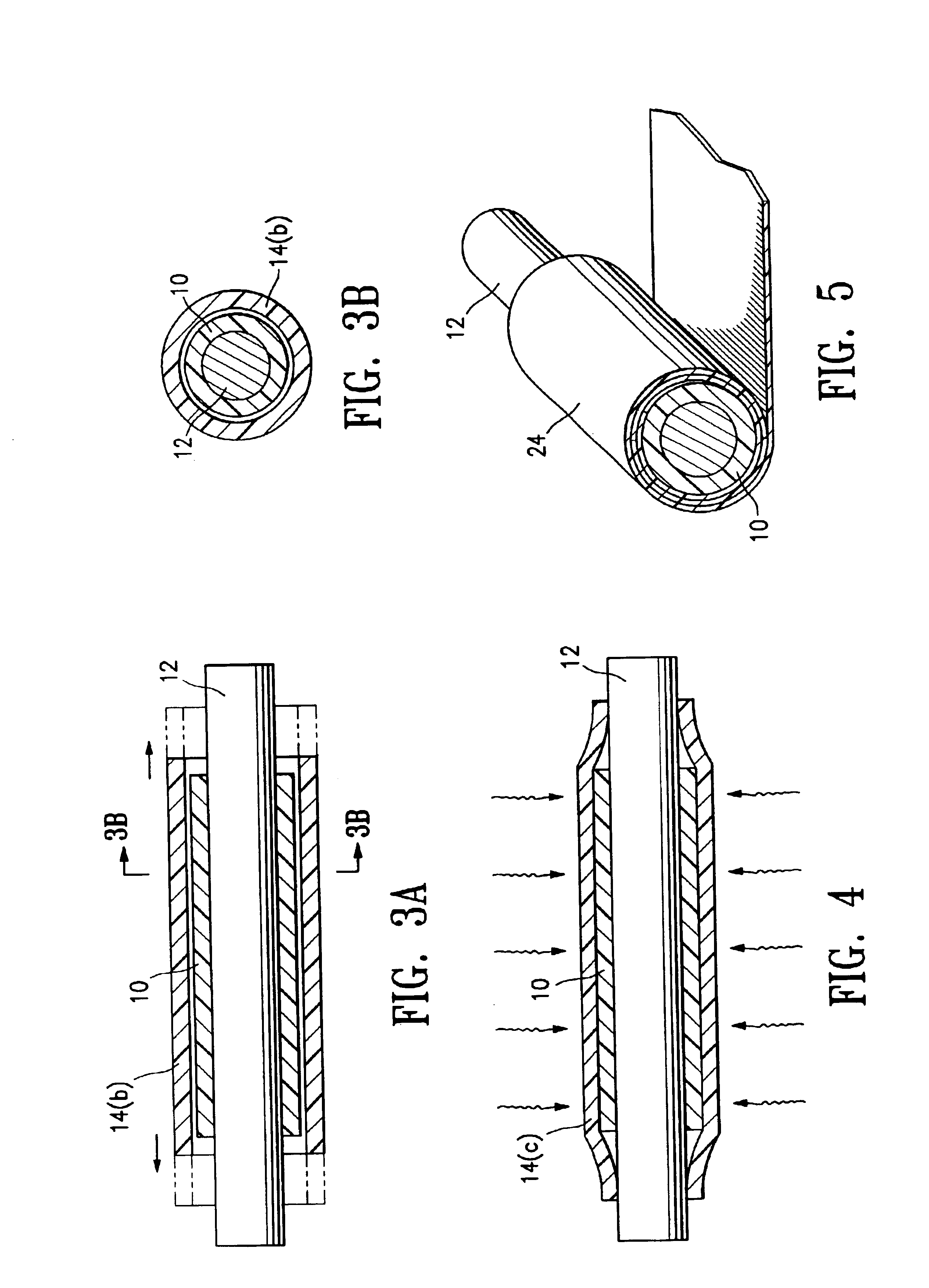

A method of making a catheter balloon or other expandable tubular medical device or component thereof formed of a compacted porous polymeric material, in which a tube of porous polymeric material is axially compacted, preferably without increasing the outer diameter of the tube, by positioning heat shrink material on the porous polymeric tube and heating the heat shrink material to decrease the length and diameter of the heat shrink material.

Owner:ABBOTT CARDIOVASCULAR

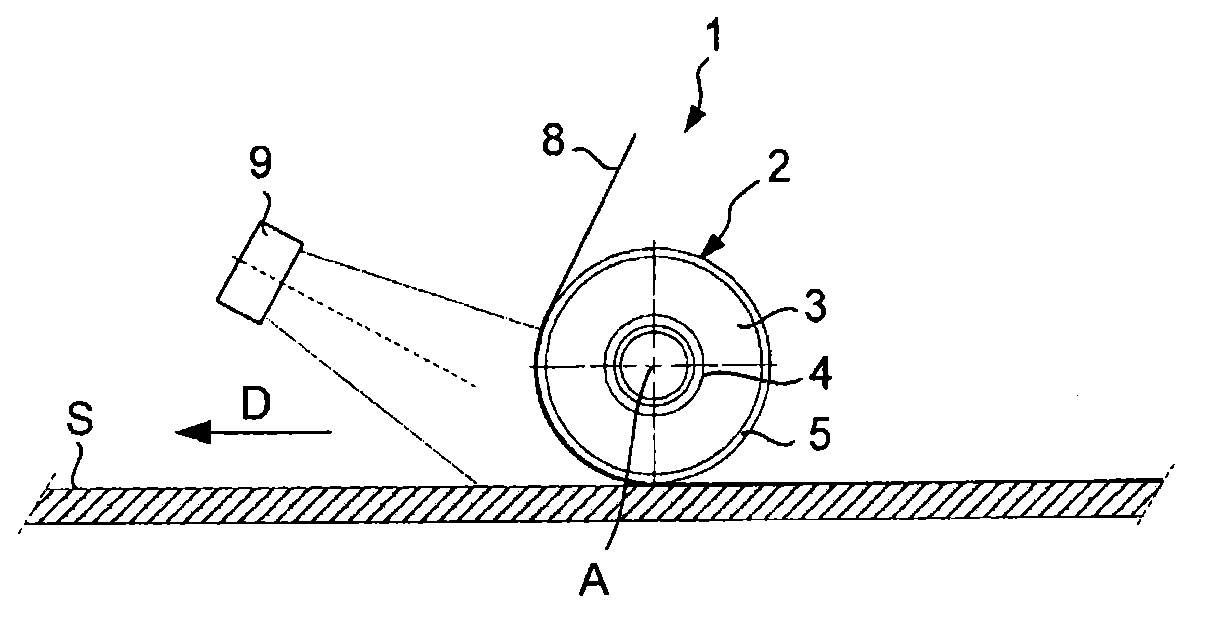

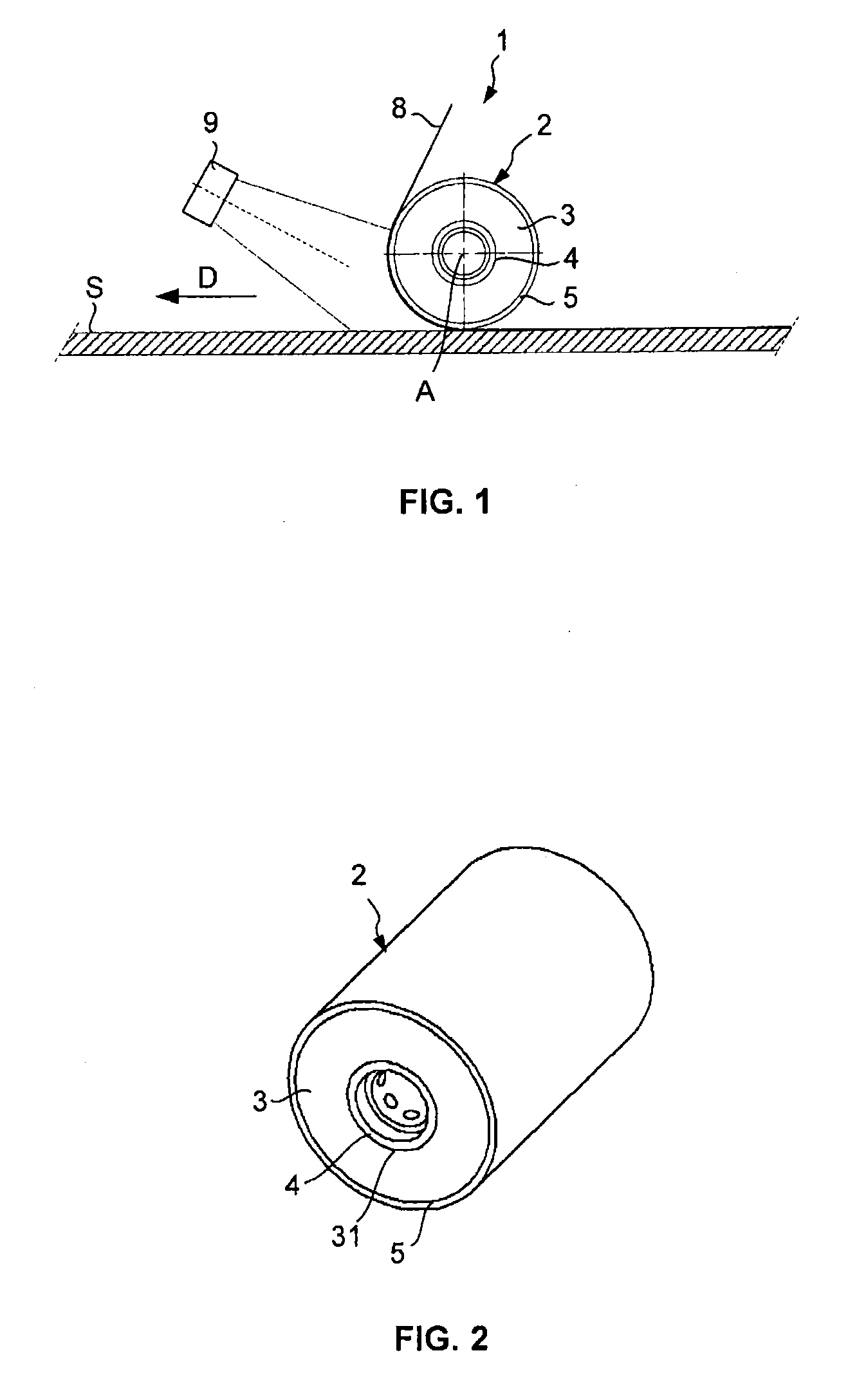

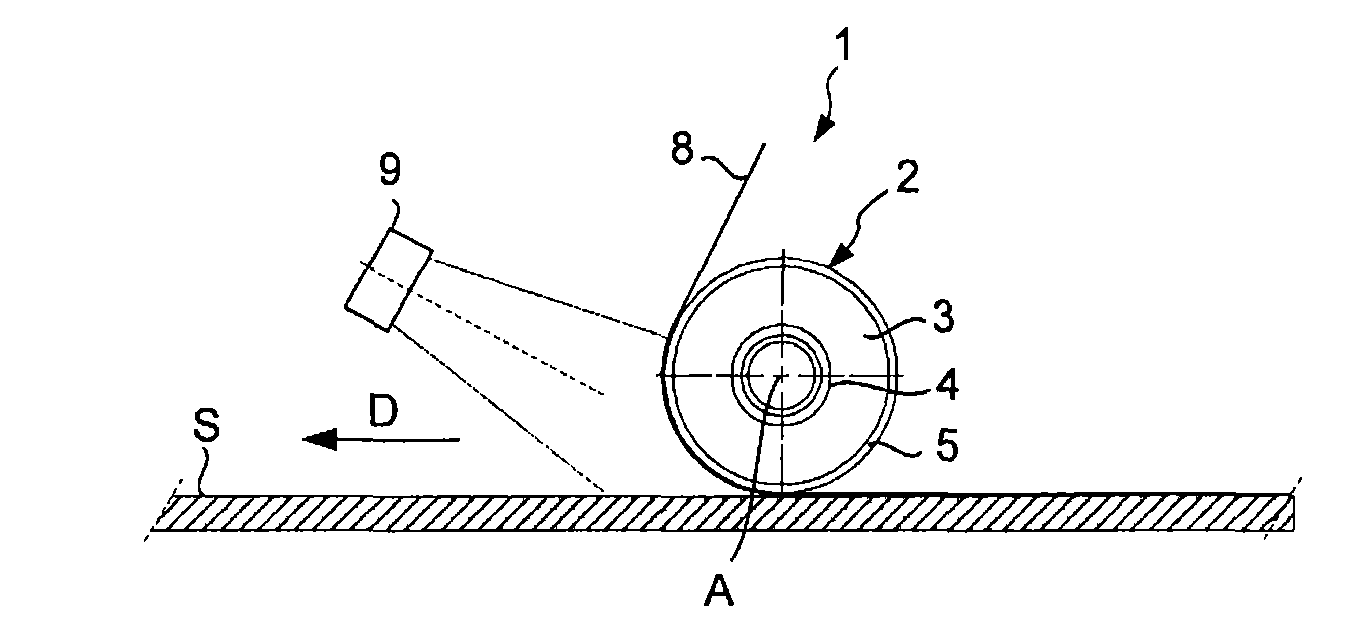

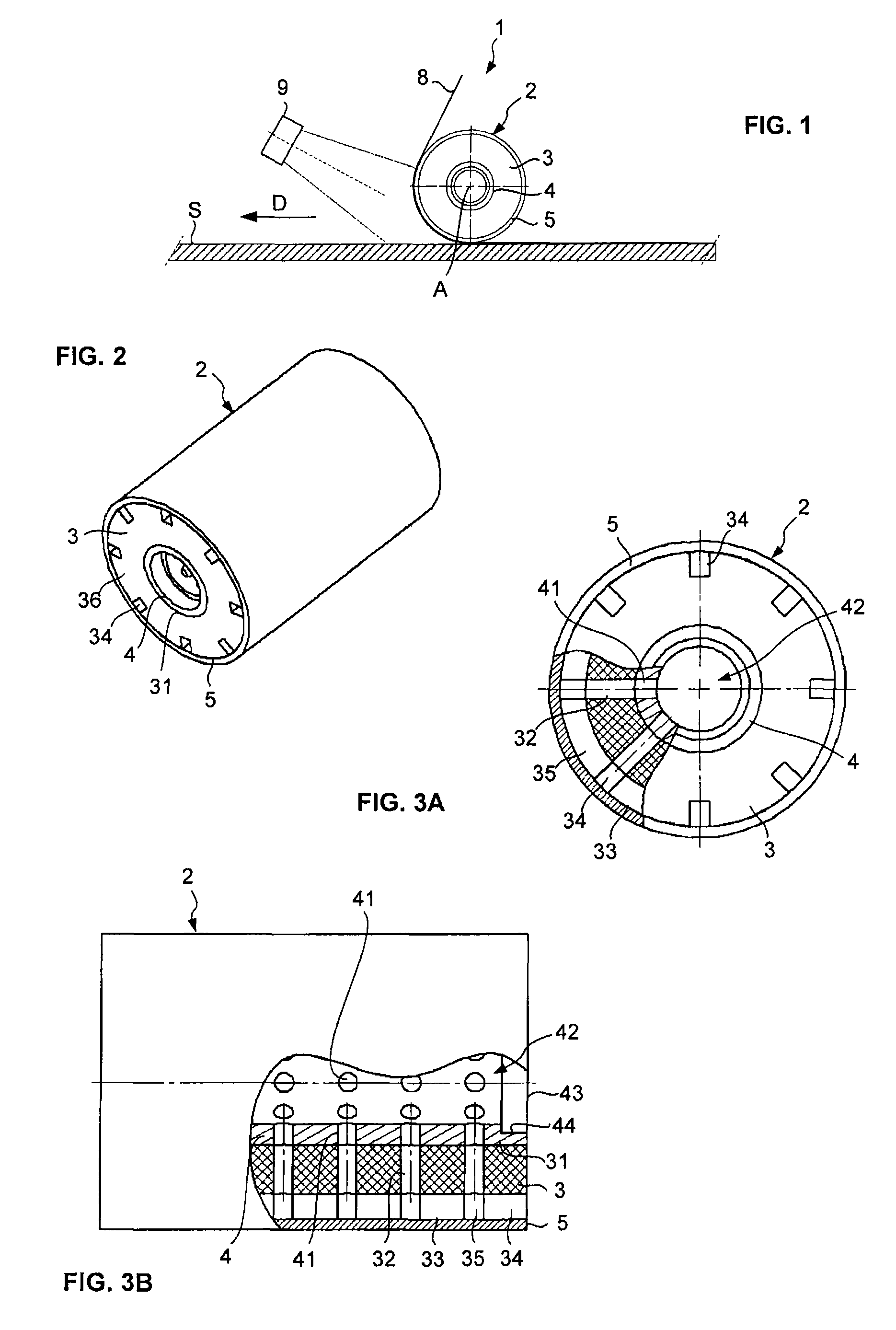

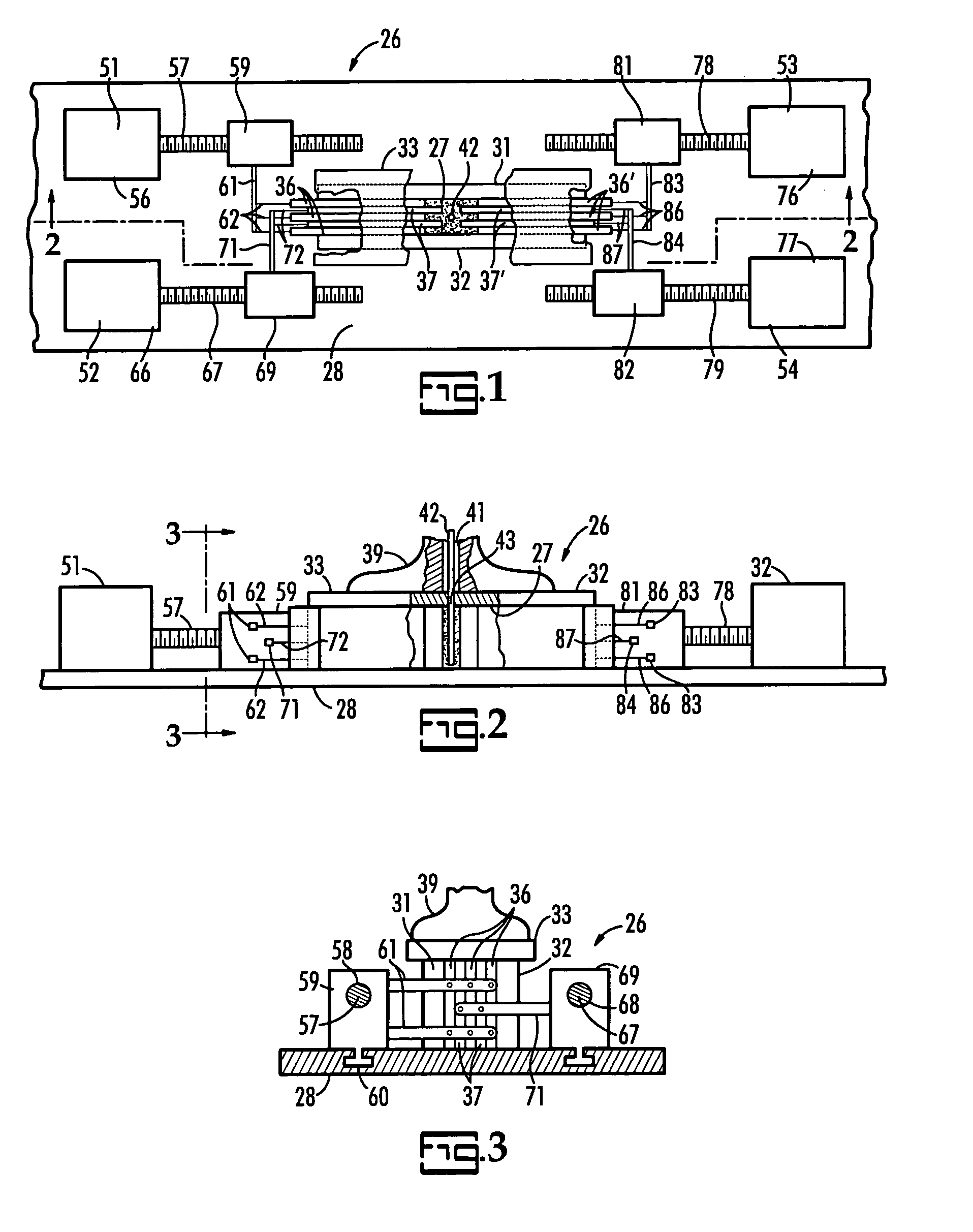

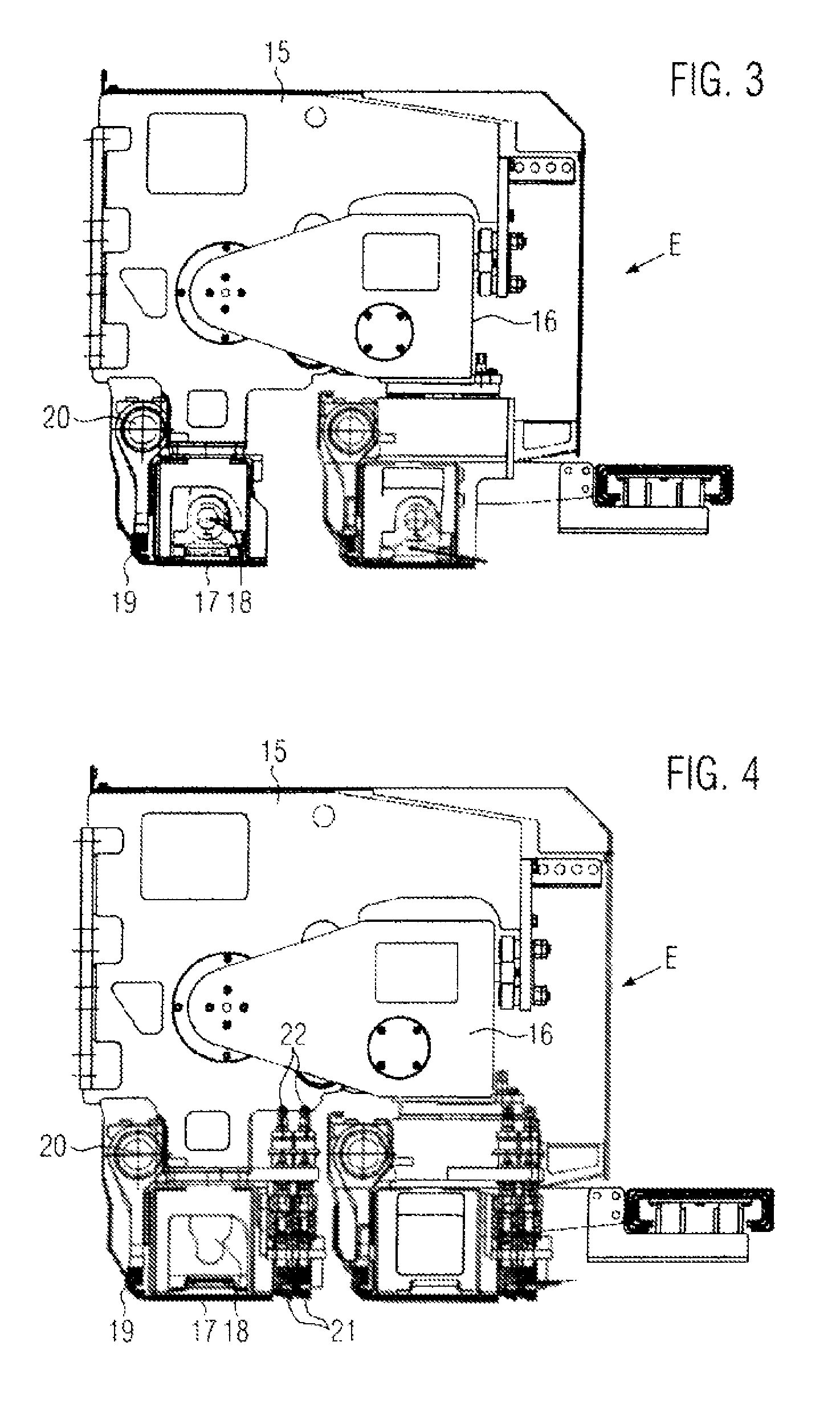

Fiber application machine with compacting roller transparent to the radiation of the heating system

A fiber application machine for the production of parts made of composite materials comprising a compacting roller for applying on an application surface a band of at least a resin pre-impregnated flat fiber, and a heating system able to emit a heat radiation towards the band. The compacting roller comprises a cylinder made of an elastically deformable flexible material and substantially transparent to said heat radiation.

Owner:CORIOLIS COMPOSITES

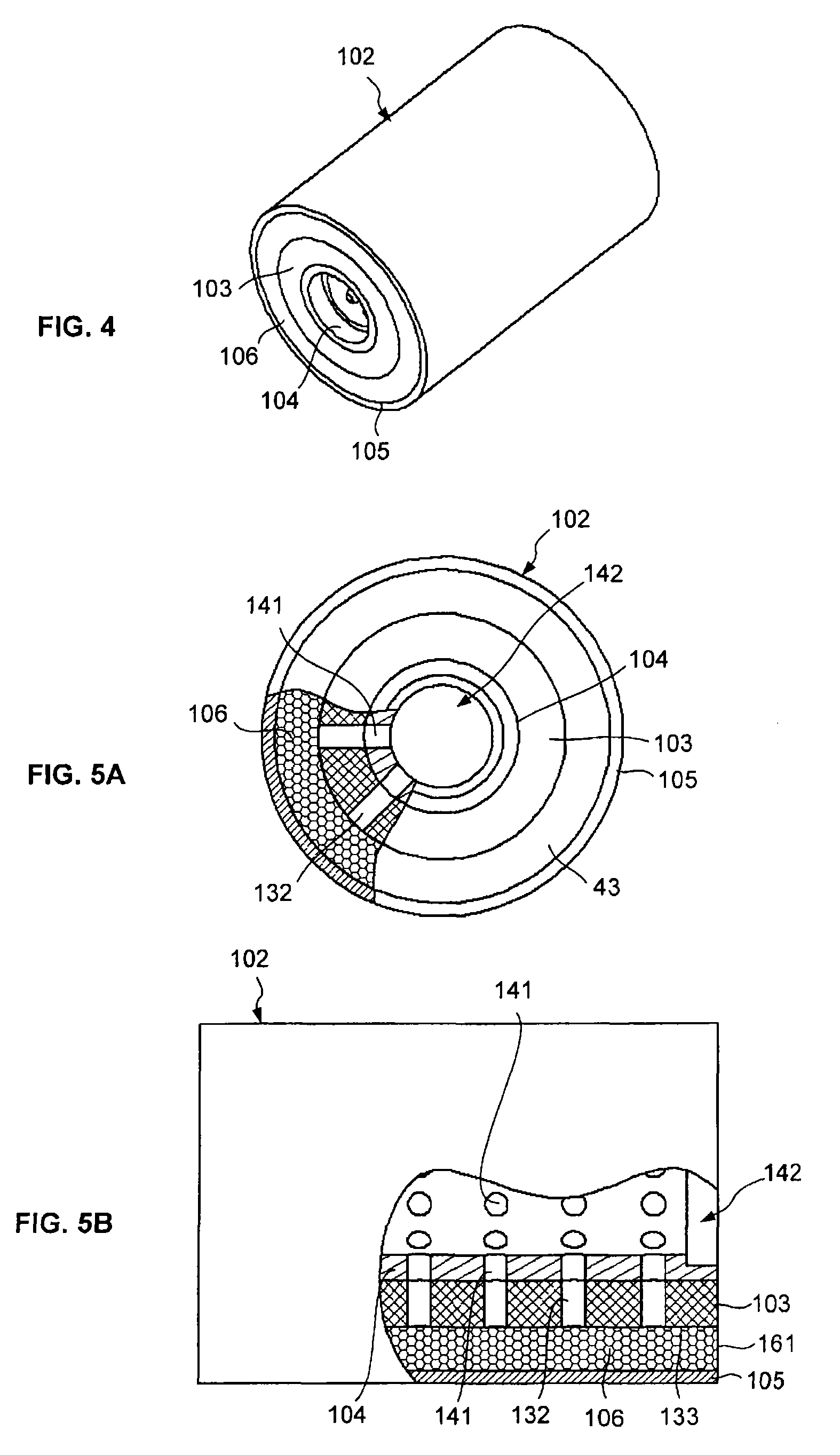

Fiber application machine comprising a flexible compacting roller with a thermal regulation system

A fiber application machine for the production of parts made of composite materials comprising a compacting roller for applying on an application surface a band formed of at least a resin pre-impregnated flat fiber, and a heating system able to emit a heat radiation towards the band. The compacting roller comprises a rigid central tube provided with radial holes, and a cylinder made of an elastically deformable, flexible material, assembled on the central tube, and having a fluid communication assembly that brings the radial holes into fluid communication with the external surface of the cylinder. The machine includes a thermal regulation system that injects a thermal regulation fluid in the central tube internal passage.

Owner:CORIOLIS GRP

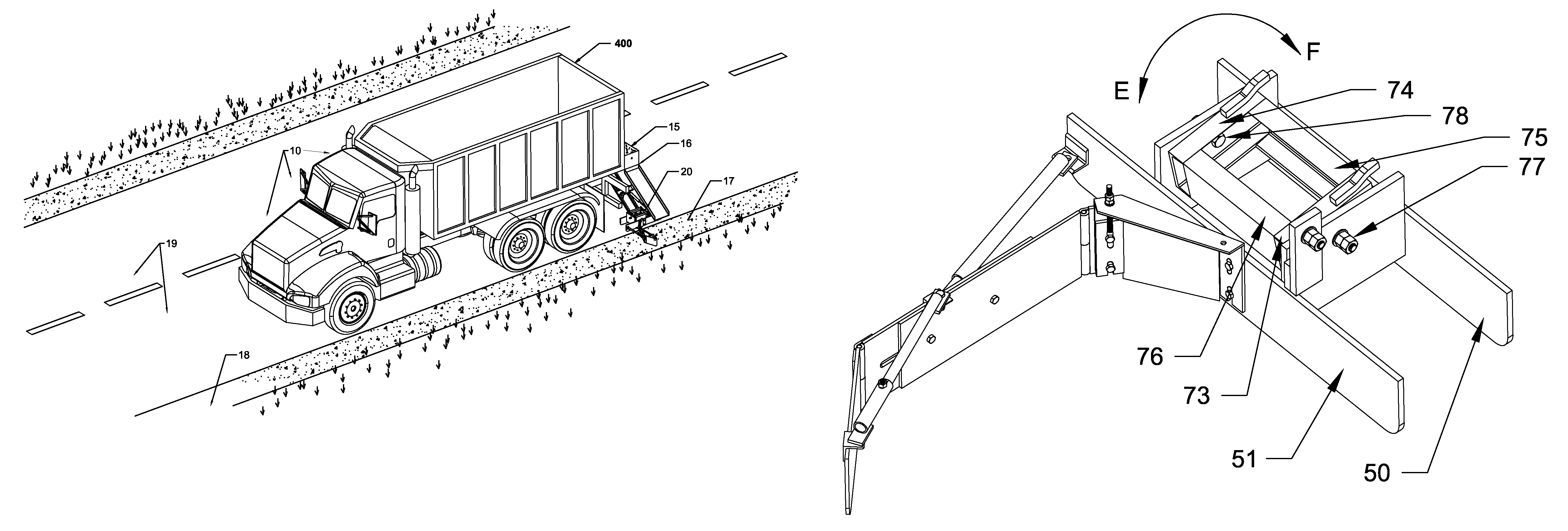

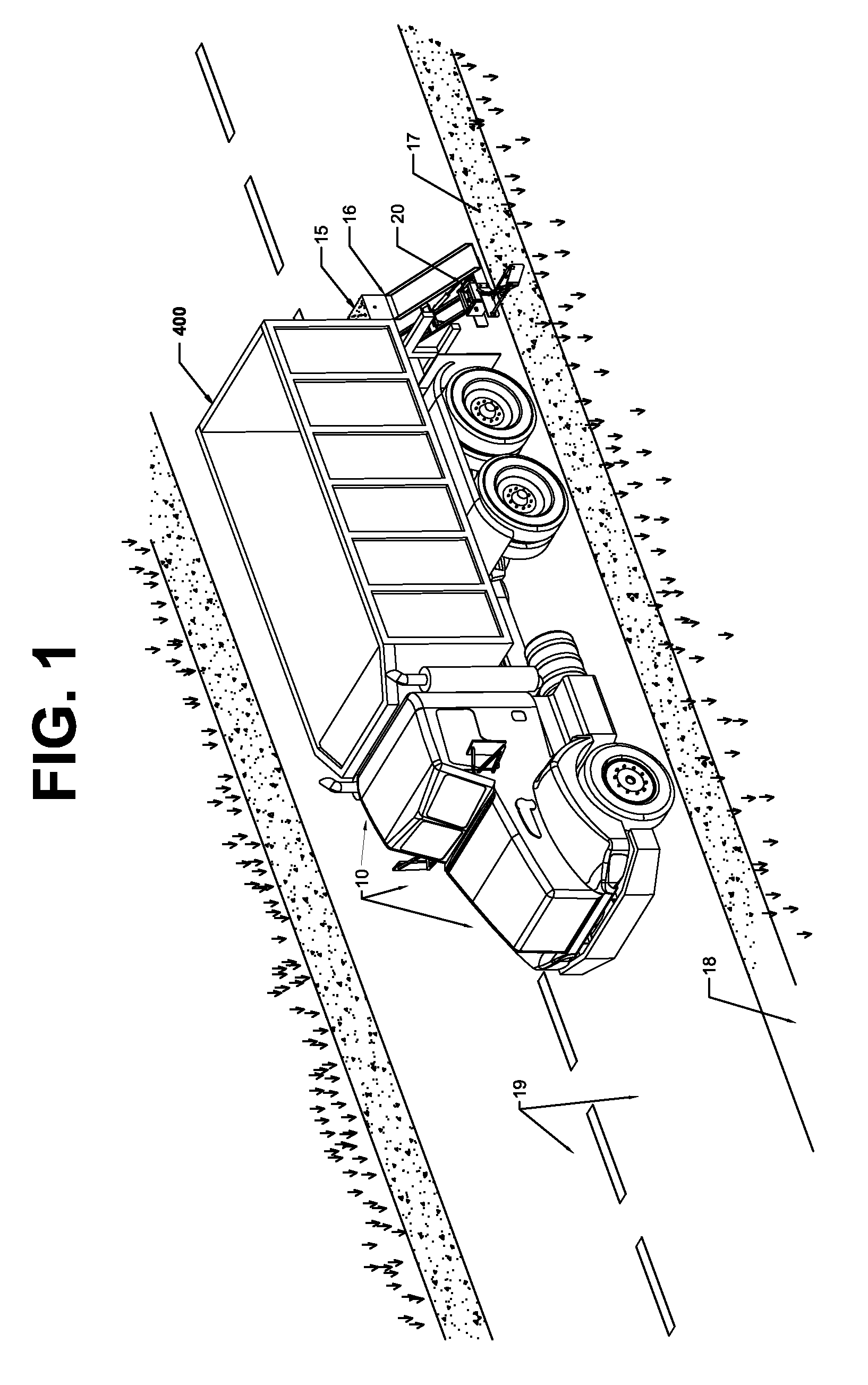

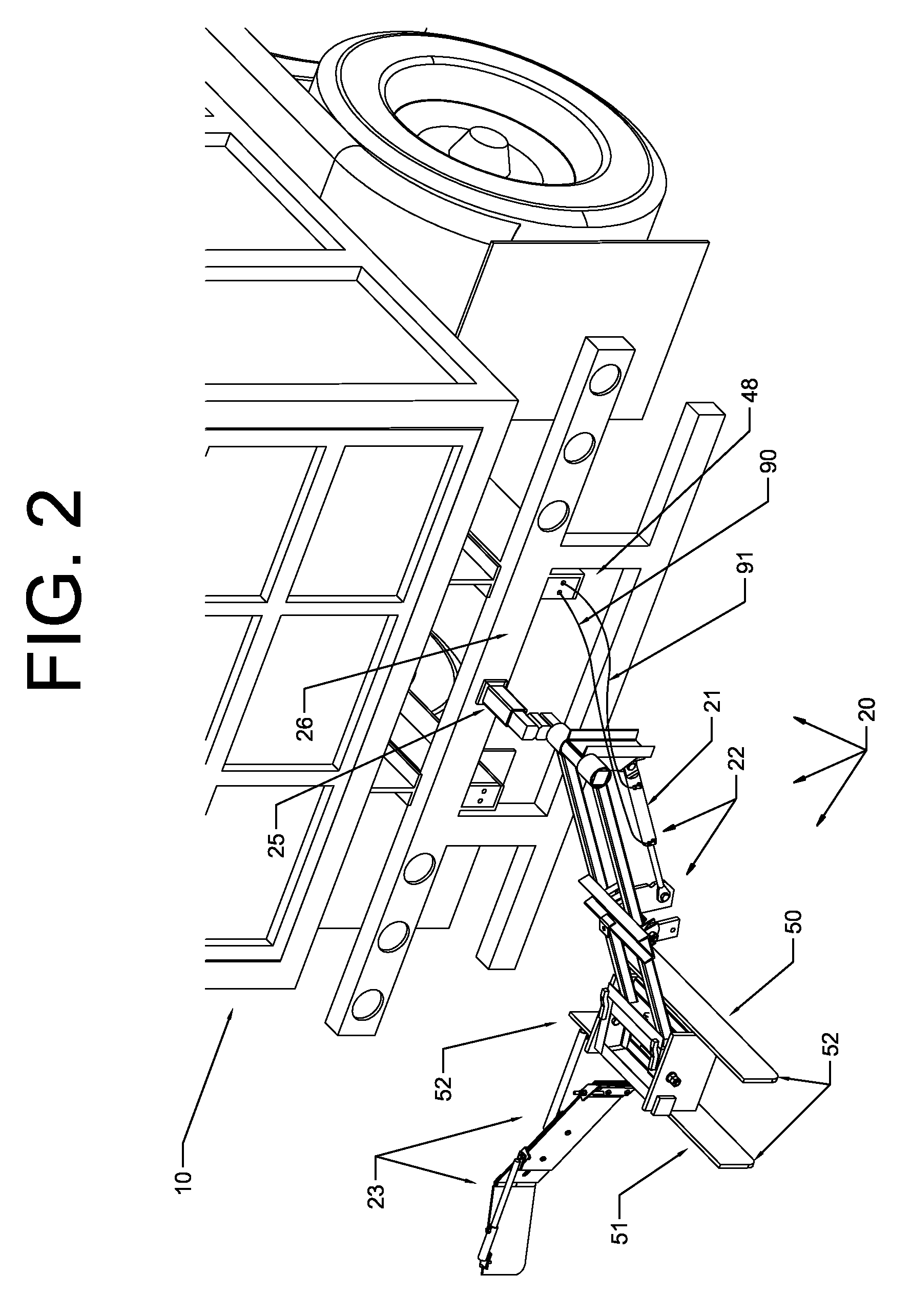

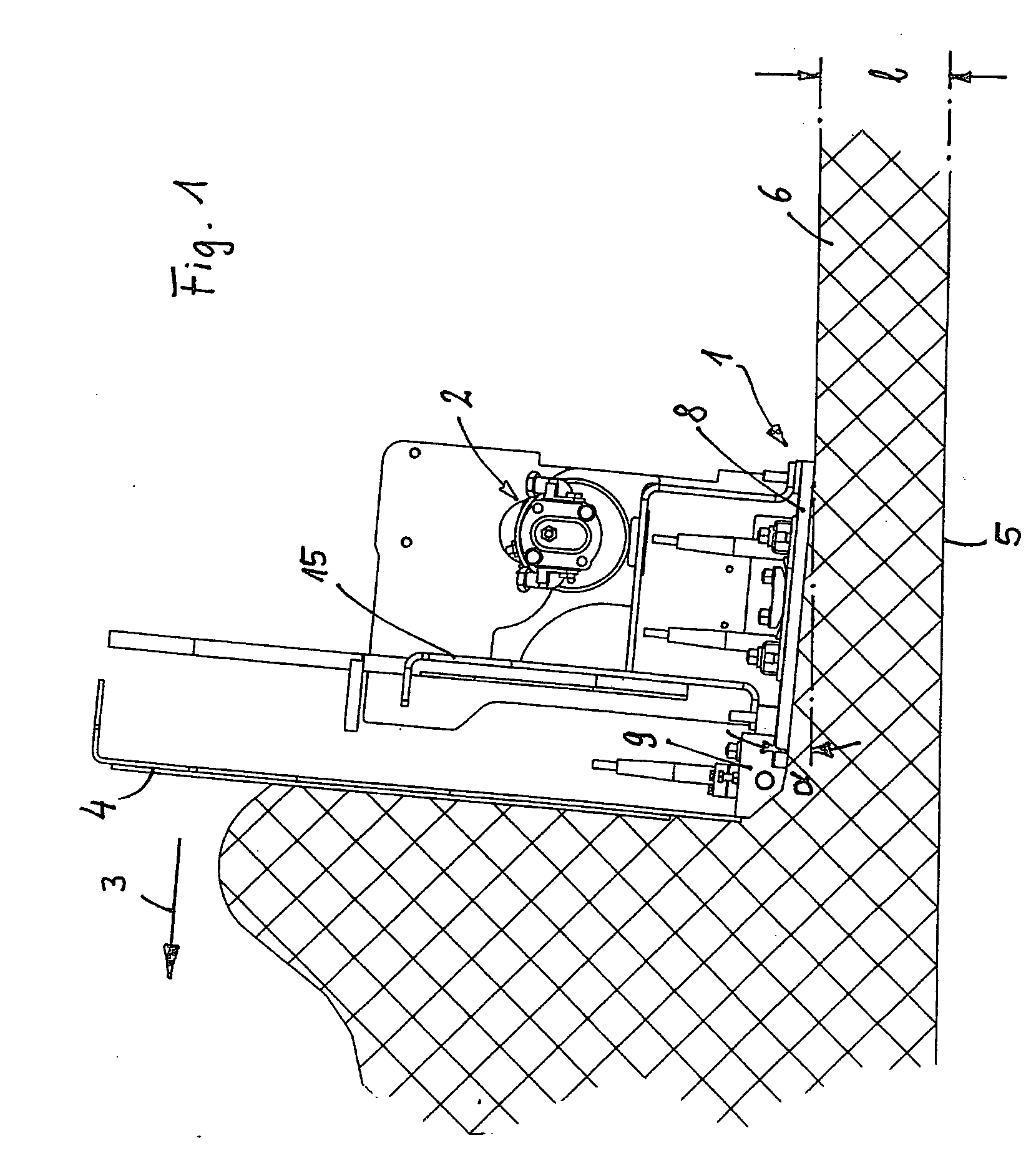

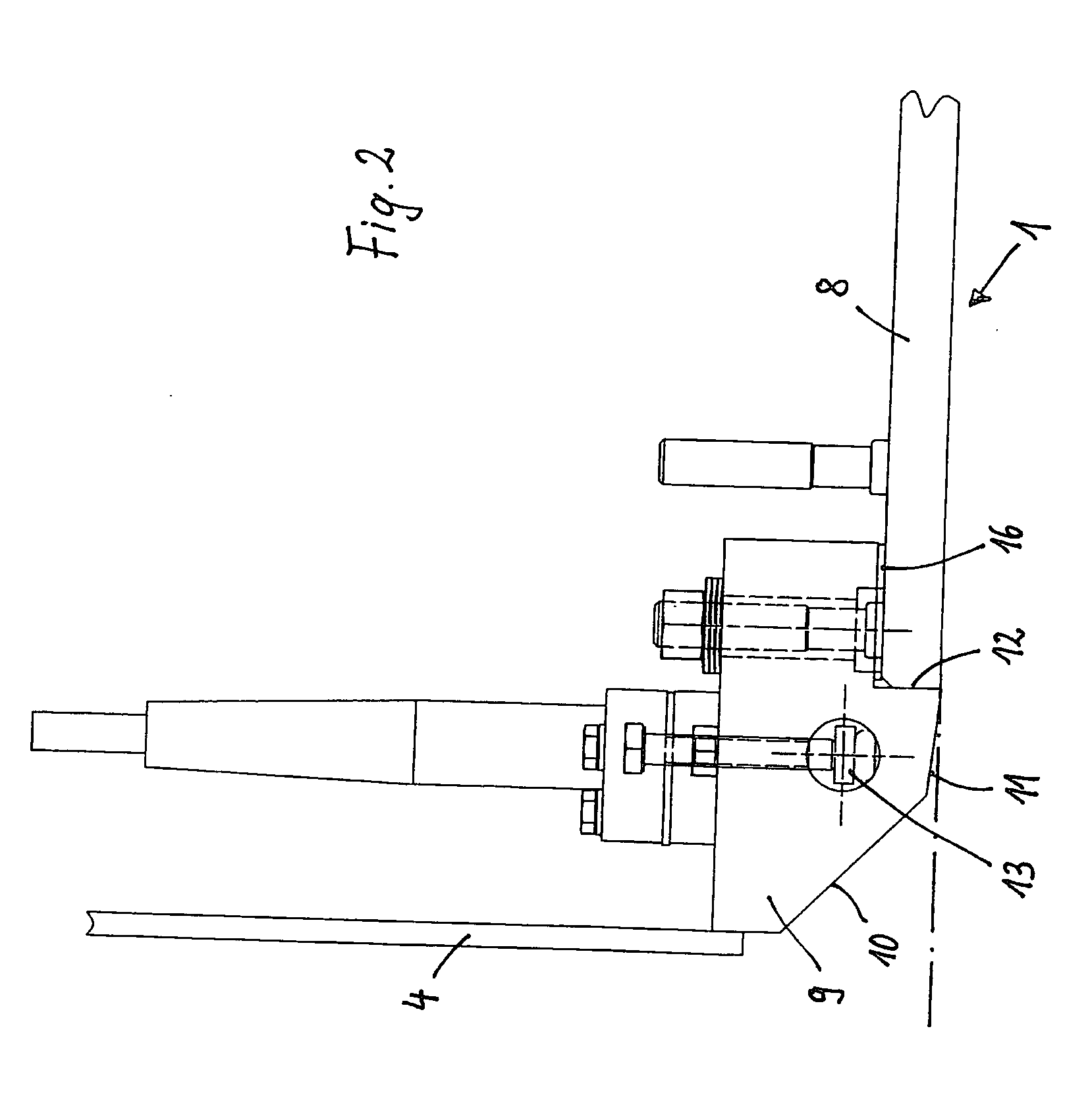

Adjustable method and apparatus for laying, leveling and compacting road shoulders

ActiveUS8297879B1Facilitate depositionEasily and quickly convertedMechanical machines/dredgersPaving gutters/kerbsRepair materialTruck

An apparatus for attachment to dump trucks having a dump bed and a chute for discharging material onto a road shoulder and / or roadway. The apparatus allows the truck with a single operator to perform shoulder and / or roadway surfacing and / or repair by receiving and grading repair material into place. The attachment being adjustable as to pitch, width and depth of the repair material. The attachment being adjustable to allow a greater or lesser amount of material to be applied to a shoulder closer to the roadway surface if a deeper fill is required. The apparatus allows for rotational movement between the apparatus and the dump truck in a direction parallel to the roadways length and perpendicular to the roadways surface. The tires of the dump truck being utilized to compact the repair material. The apparatus being stored in a vertical position when not in use.

Owner:BONNELL INDS

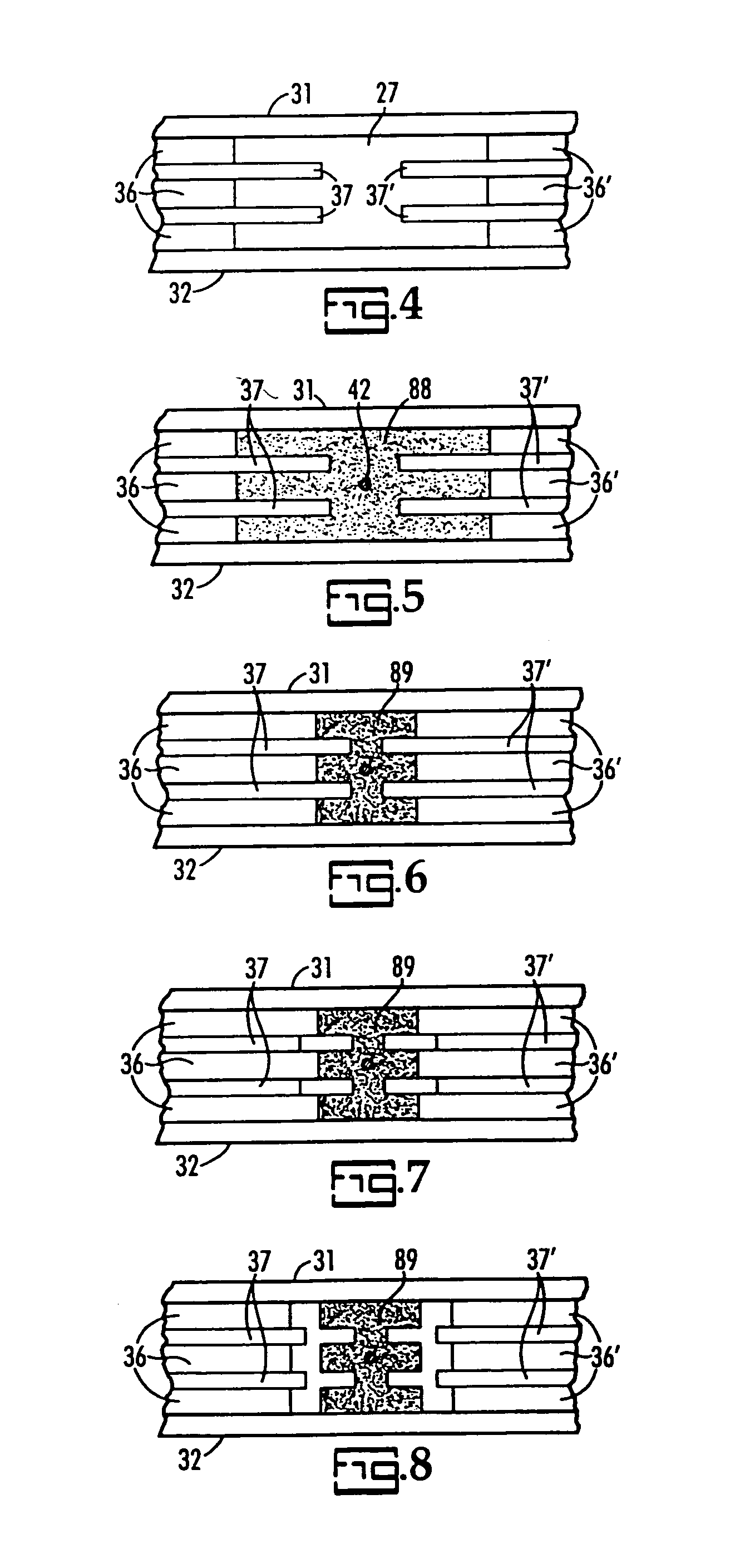

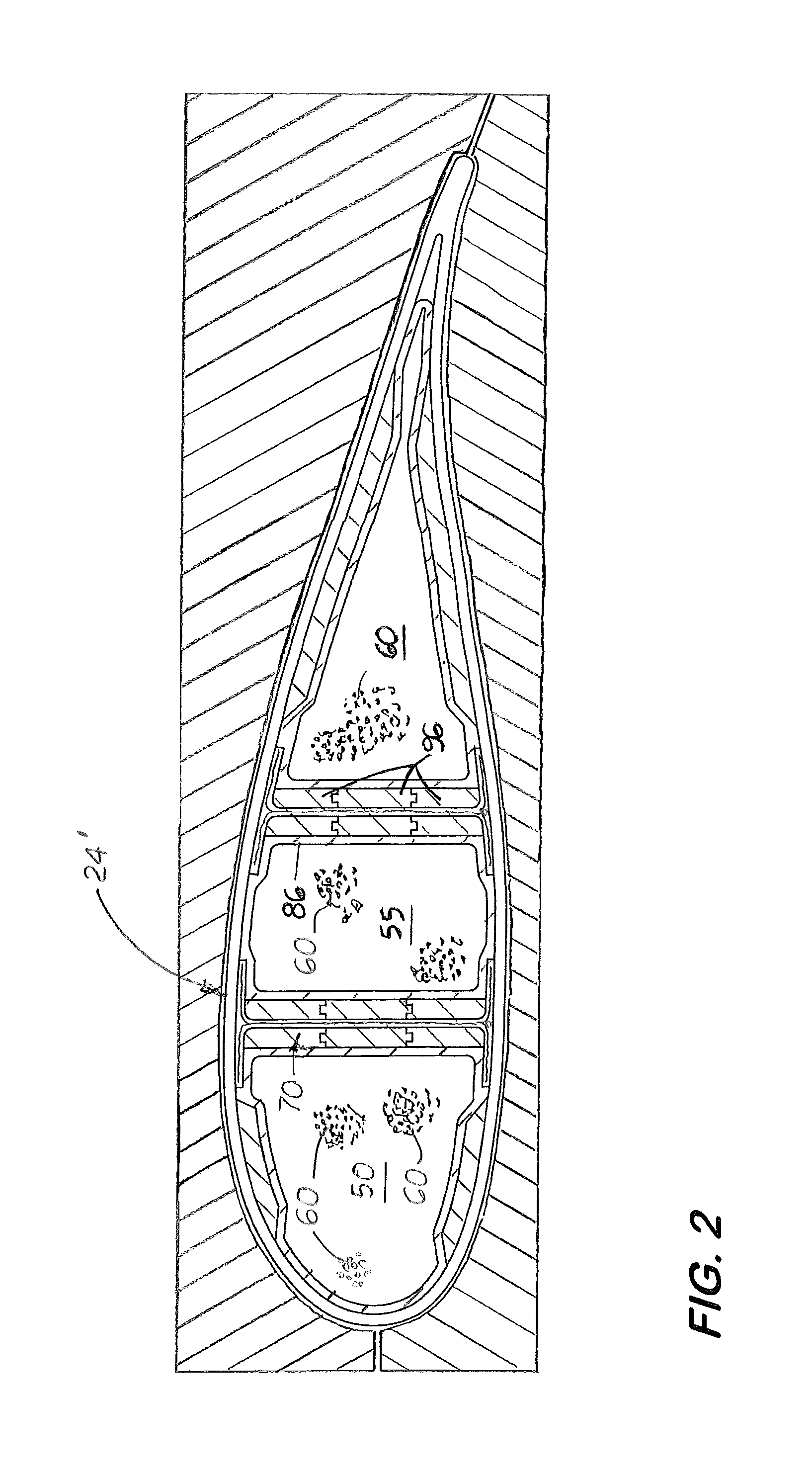

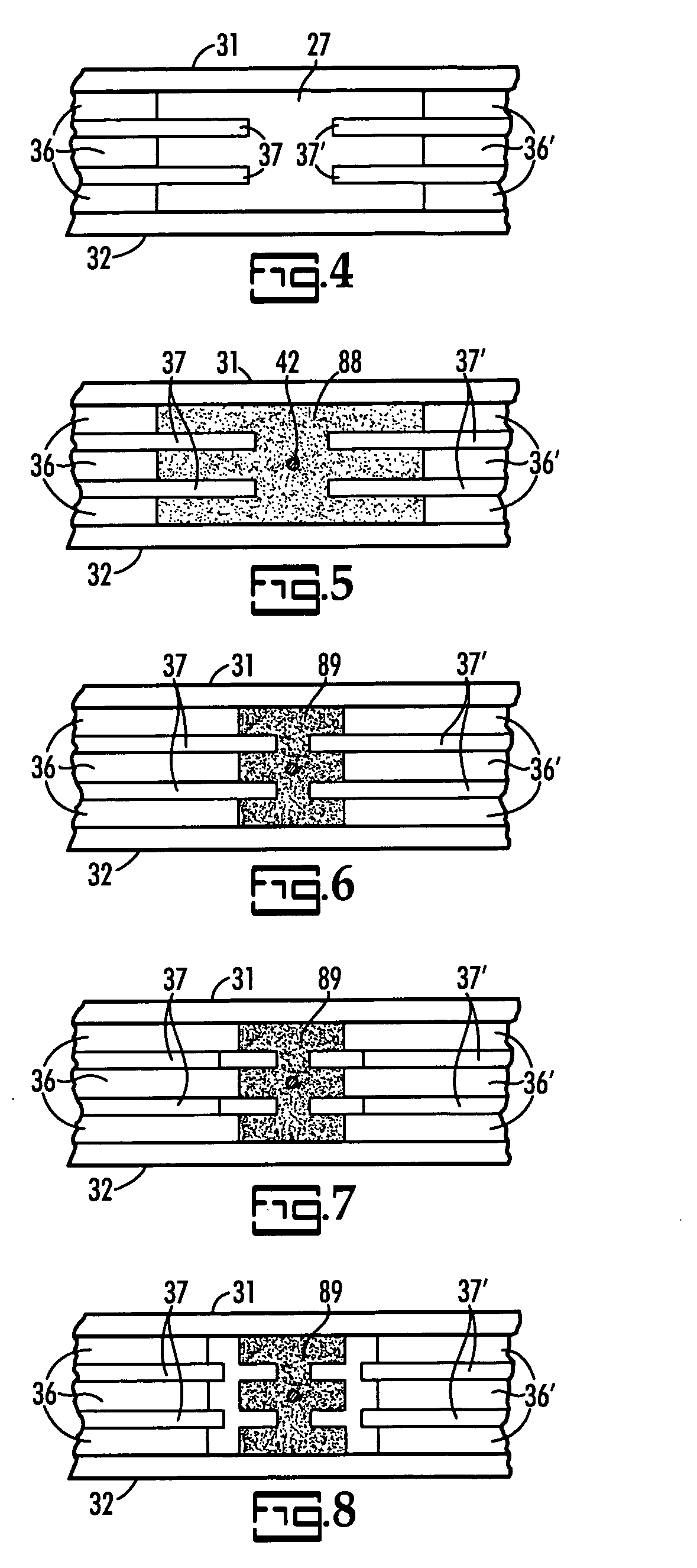

Method of Manufacturing Hollow Composite Parts with In Situ Formed Internal Structures

InactiveUS20130075025A1Easy to disassembleEvenly compactedFinal product manufactureConfectioneryEngineeringPosterior composites

A method for manufacturing complex hollow composite parts with at least one internal structure formed in situ by laying laminated layers around a removable mandrel assembled inside the part's inner cavity. The inner mandrel is made up of two jig plate assemblies aligned in a parallel manner and space apart where the internal structure is to manufactured. Each jig plate assembly is made up of at least three jig plates stacked in an edge-to-edge manner Located on opposite sides of each jig plate assembly is an elastic envelope filled with spherical objects. When evacuated, the envelope collapses and relaxes and composite material may then laid up inside the inner cavity and around the envelopes. When exposed to a heat, the envelopes expand and in situ and form internal structures inside surface of the cavity. Each envelope and each jig plate assemblies can be easily dissembled and reused.

Owner:GUITTON MAURICE

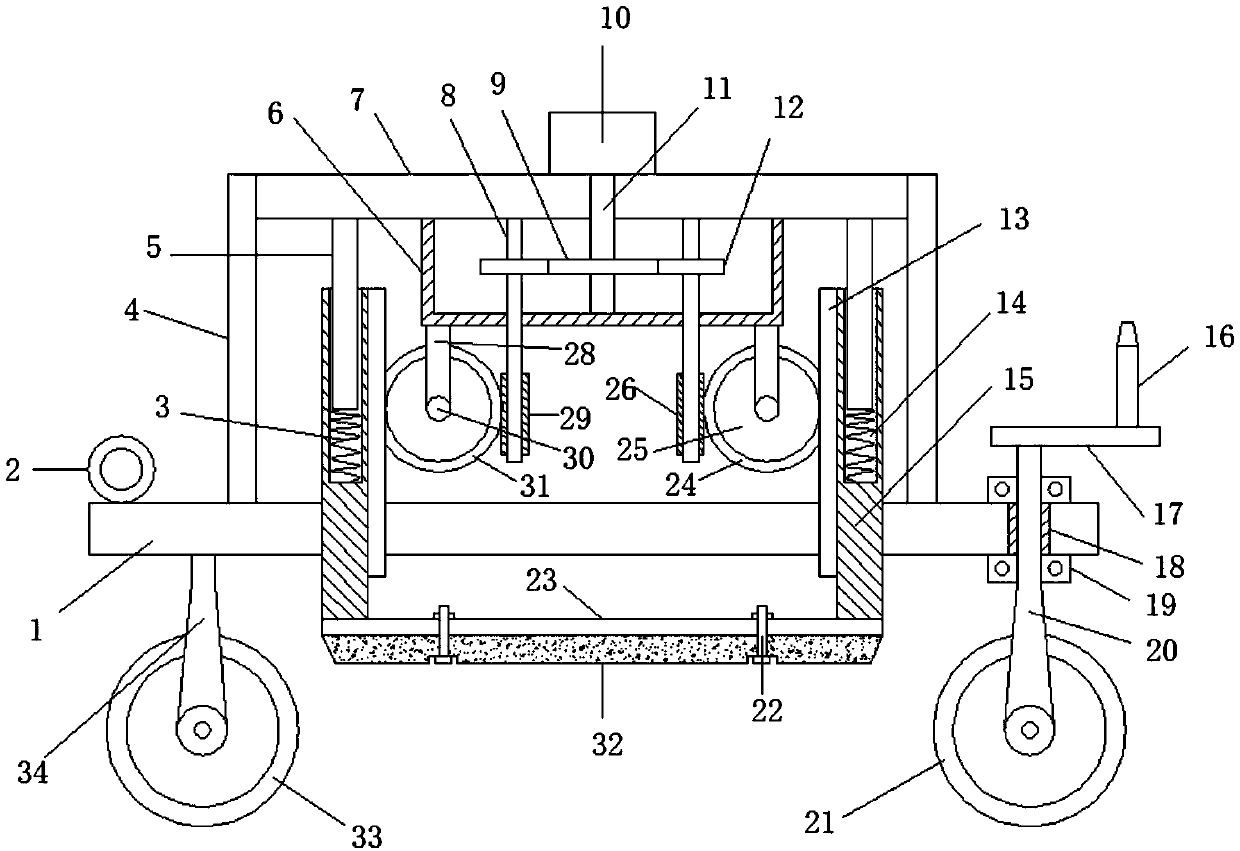

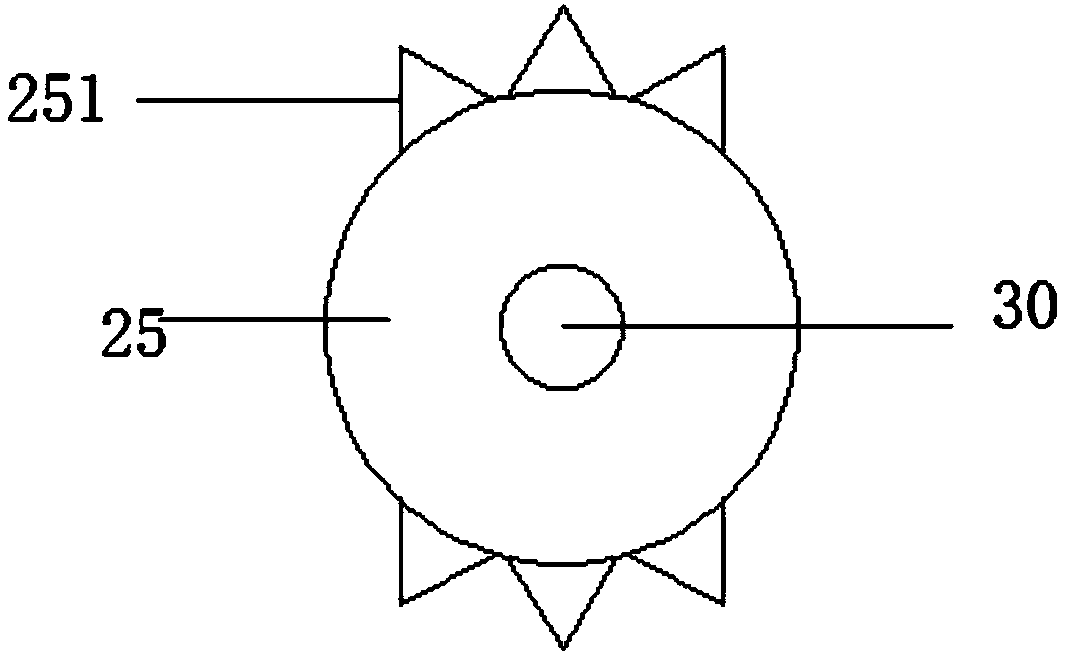

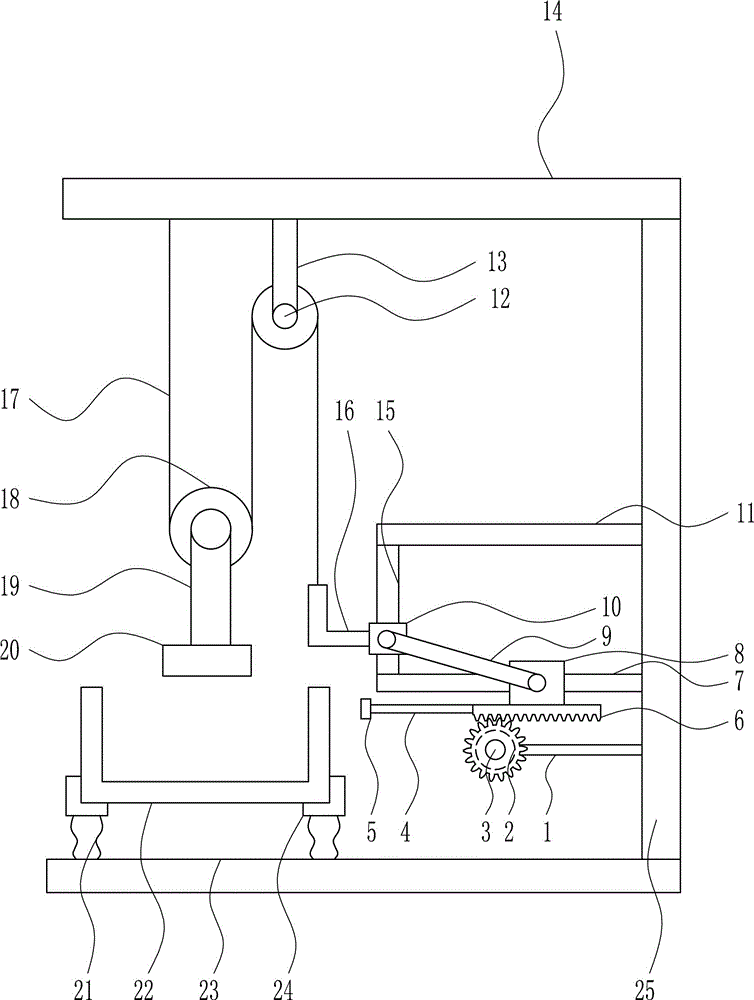

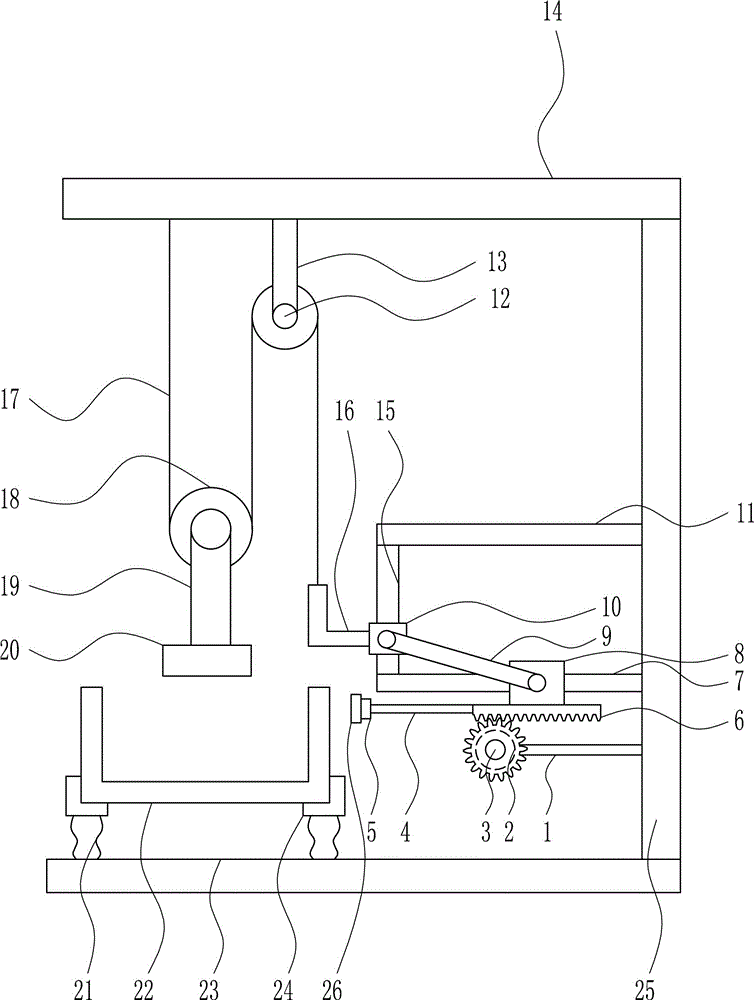

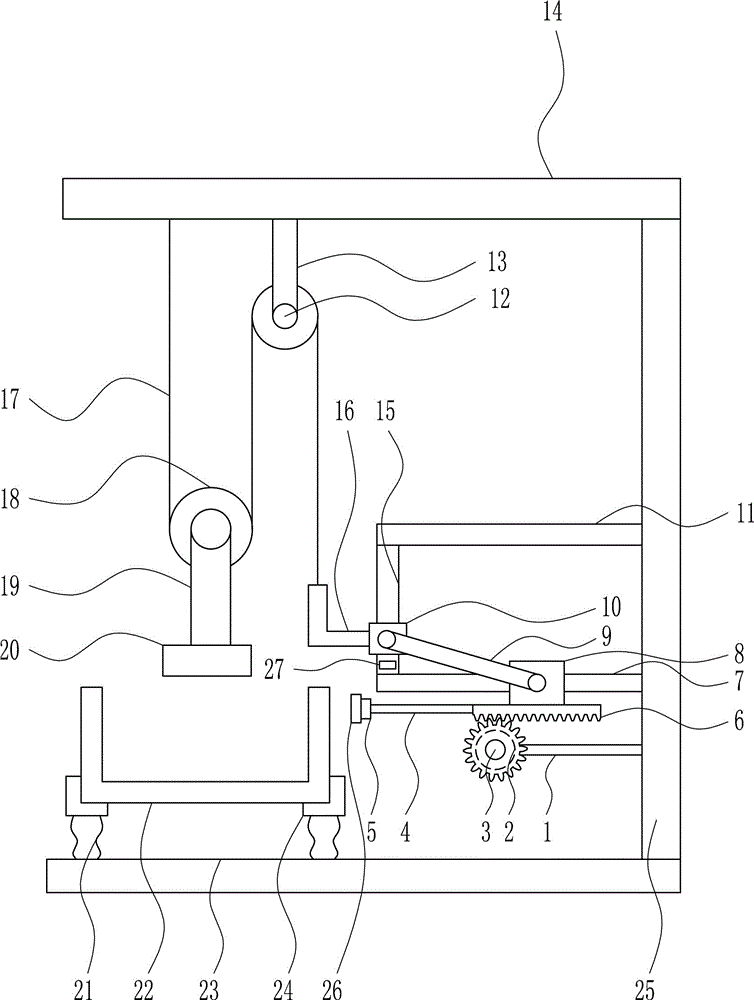

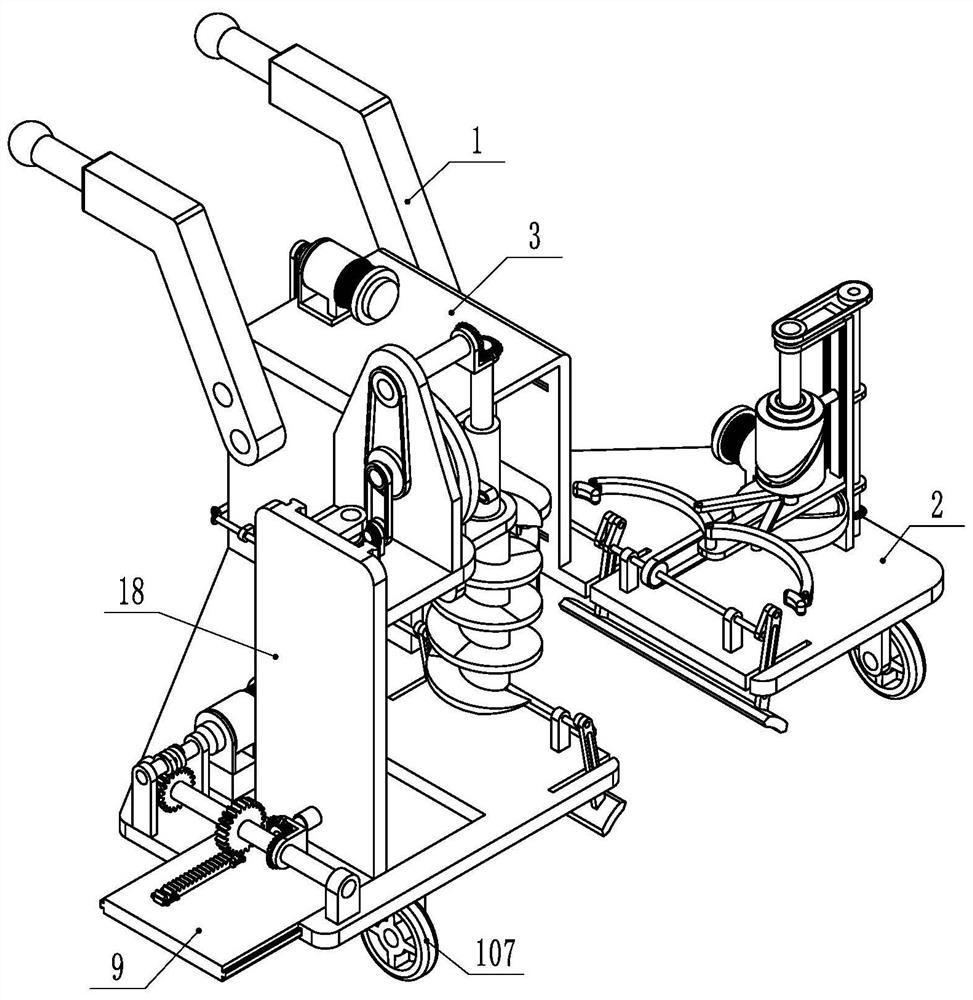

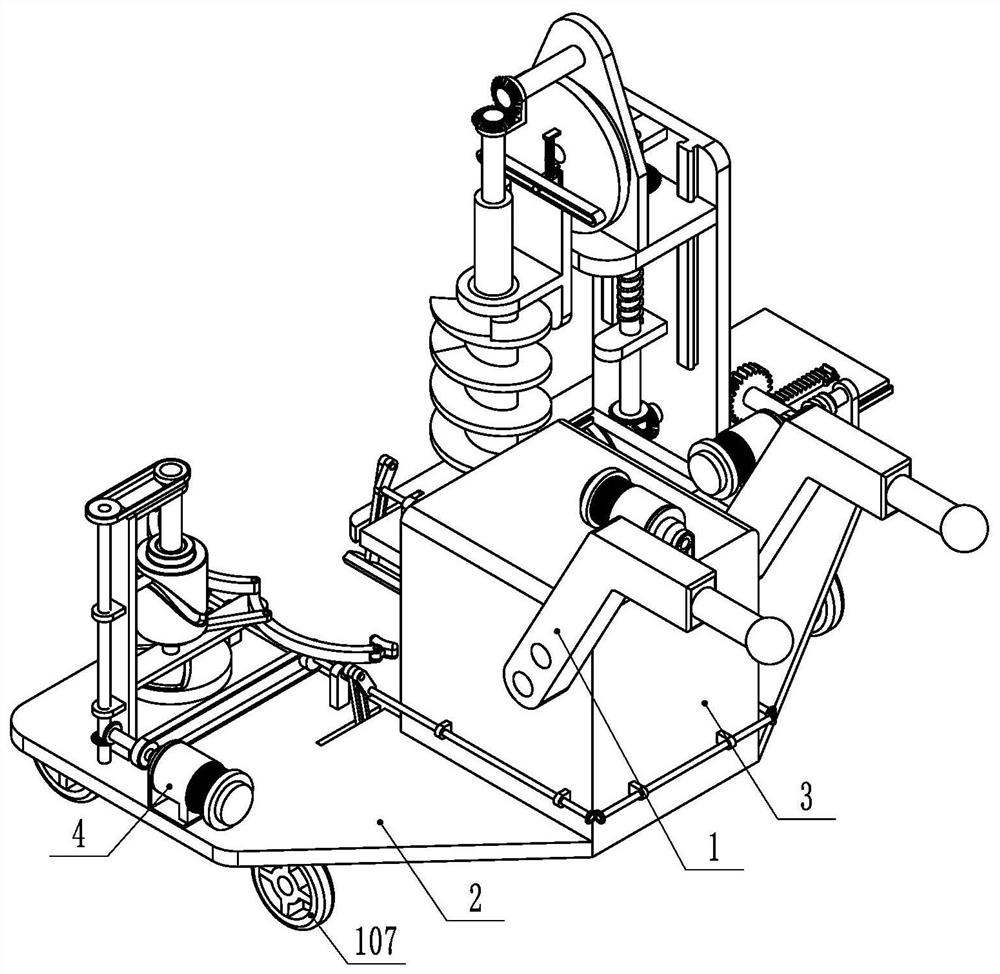

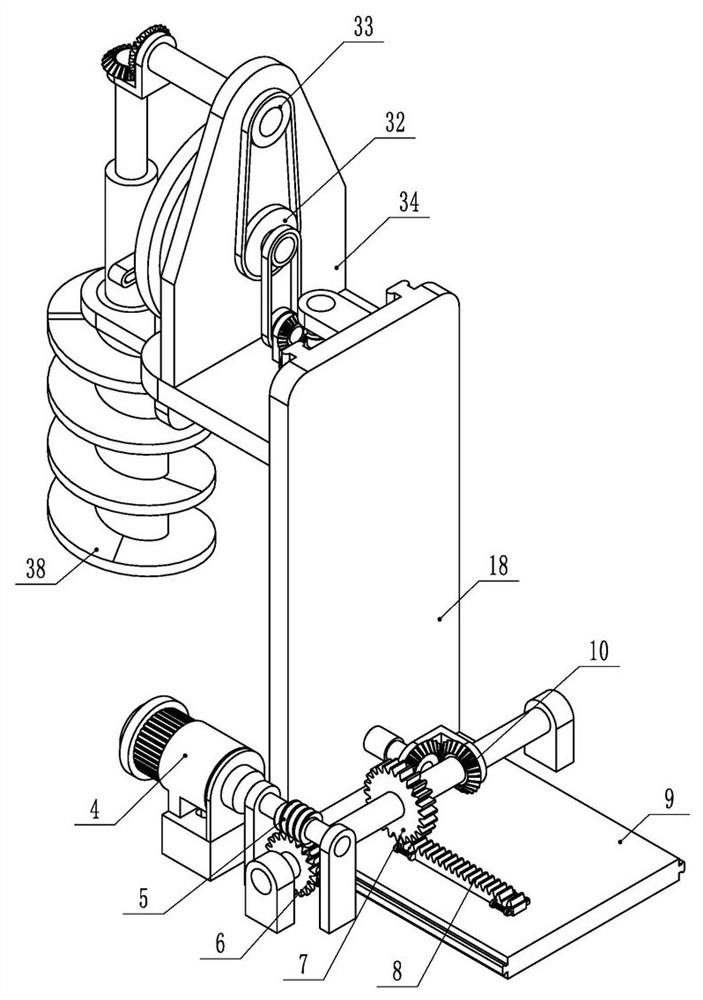

Dead weight type compaction device for road repairing of municipal construction

The invention discloses a dead weight type compaction device for road repairing of municipal construction. The dead weight type compaction device comprises a supporting plate, wherein supporting frames are respectively mounted on two sides of the upper end of the supporting plate; a crossbeam is mounted at the upper end of the supporting frame; a driving motor is mounted at the middle part of theupper end of the crossbeam; a driving shaft is mounted at the lower end of the driving motor; a driving gear is mounted in the middle part of the driving shaft; a rotating gear is meshed with each oftwo ends of the driving gear; a rotating shaft is mounted in the middle part of each rotating gear; a first worm is mounted at the lower end of a left side rotating shaft, and a first worm wheel is meshed with the left end of the first worm; a second worm is mounted at the lower end of a right side rotating shaft, and a second worm wheel is meshed with the right end of the second worm; fixing shafts are respectively mounted in the middle part of the first worm wheel and the middle part of the second worm wheel; a meshing gear is mounted at the middle part of the front end of each fixing shaft;and a lifting rack is meshed with the outer side of each meshing gear. According to the dead weight type compaction device disclosed by the invention, the up-and-down reciprocating movement of a compaction plate is realized, so that the compaction effect to road surfaces is realized by the gravity of the compaction plate, and the compaction requirements for different road surfaces are also met.

Owner:SHENZHEN SHENGXIANG INTPROP CO LTD

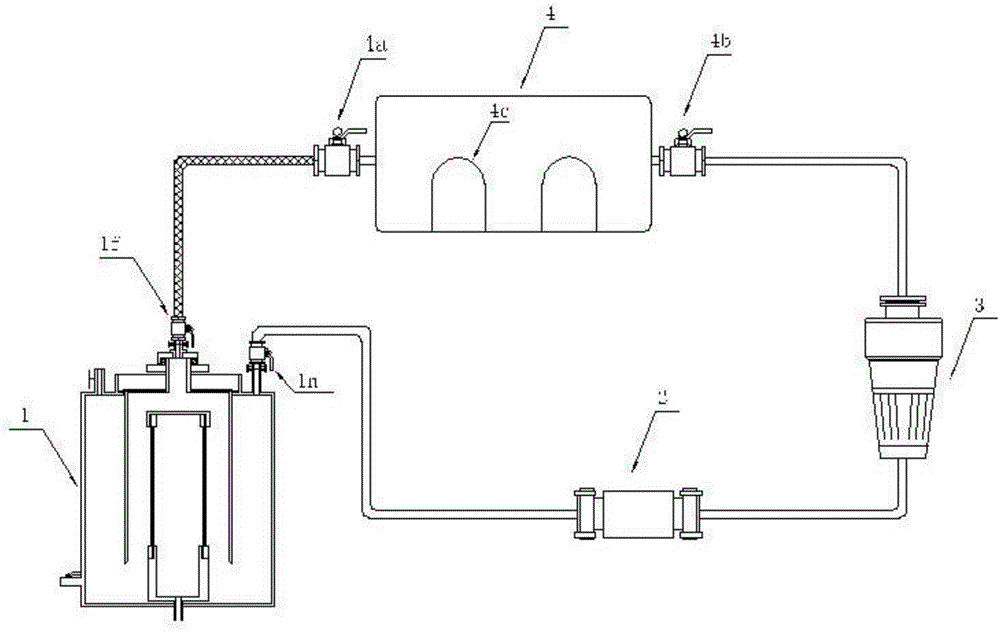

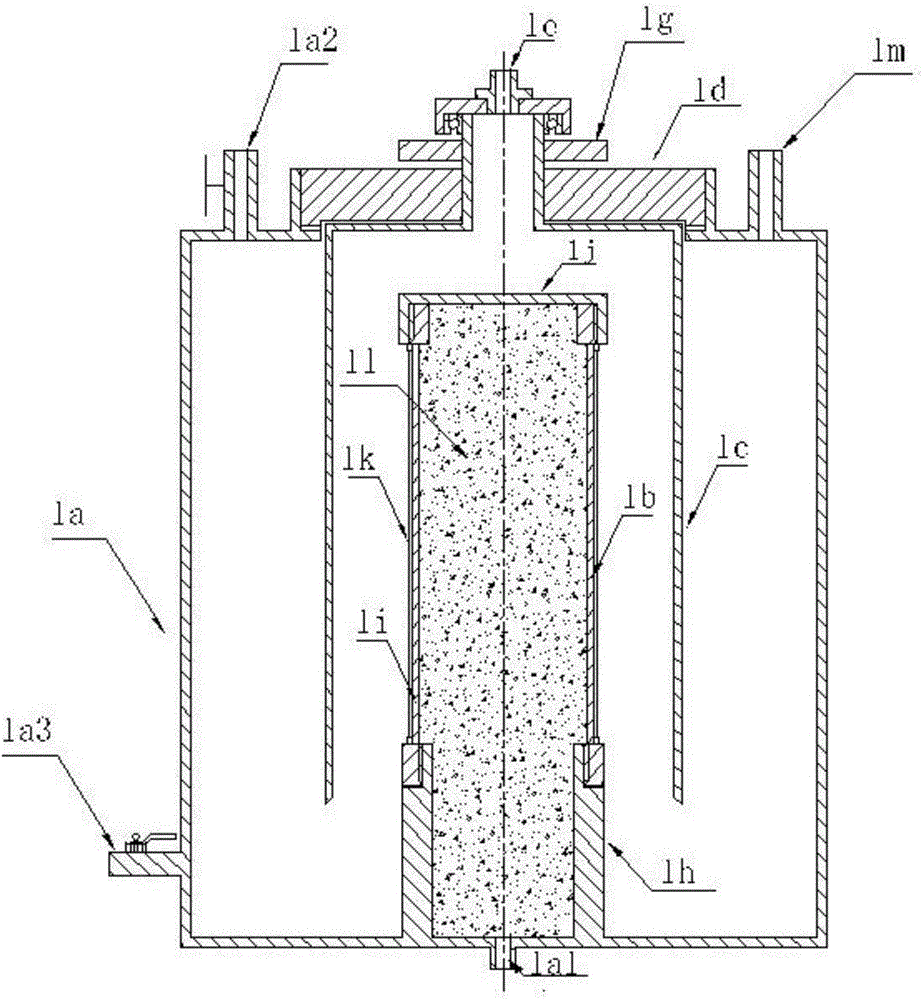

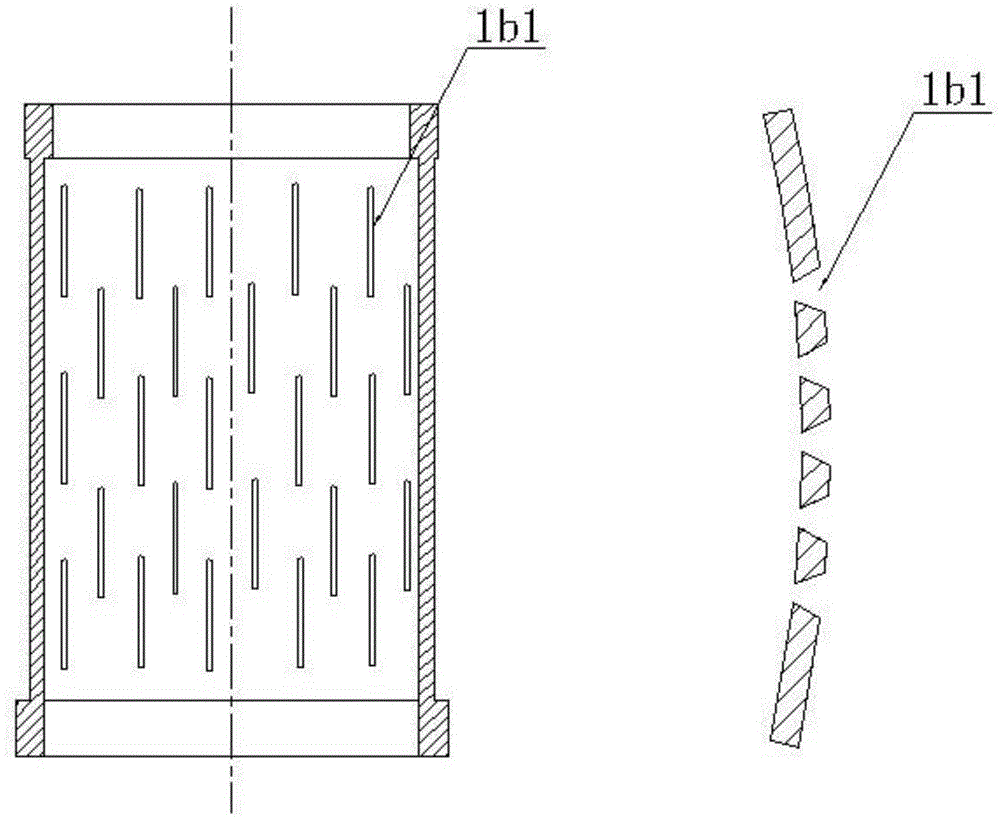

Evaluation device and method of well cementation flushing efficiency

The invention provides an evaluation device and method of well cementation flushing efficiency. Designed according to the Reynolds number equality theory, the device comprises a simulated well casing, a heating water tank, a power pump and an electromagnetic flowmeter, wherein the simulated well casing mainly comprises an inner barrel and an outer barrel; the inner barrel comprises an inner barrel body, steel screen meshes with different mesh numbers and an inner barrel end cover; the inner barrel can simulate a stratum under the circumstance that the steel screen meshes are covered with filter paper or the inner barrel is filled with quartz sand; the outer barrel can rotate; guide vanes with different forms are designed to simulate a casing pipe. The method is easy to operate, high in comparability and low in workload, can effectively form a filter cake, simulate and evaluate the characteristics of the flushing efficiency under the circumstance that the casing pipe rotates or a spiral centralizer is used, can evaluate the flushing efficiency of flushing fluid for a first interface and a second interface, can evaluate and optimally select the flushing fluid system and design the dosage of the flushing fluid, and is wide in application.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

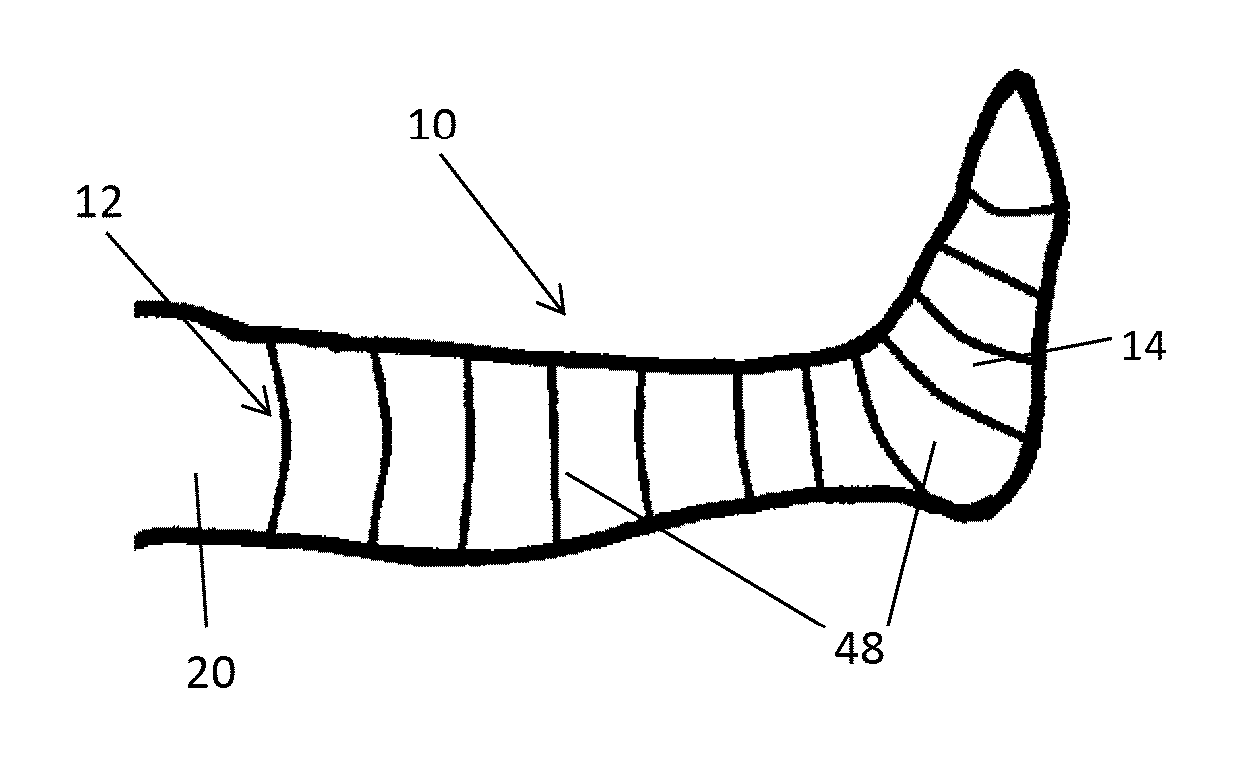

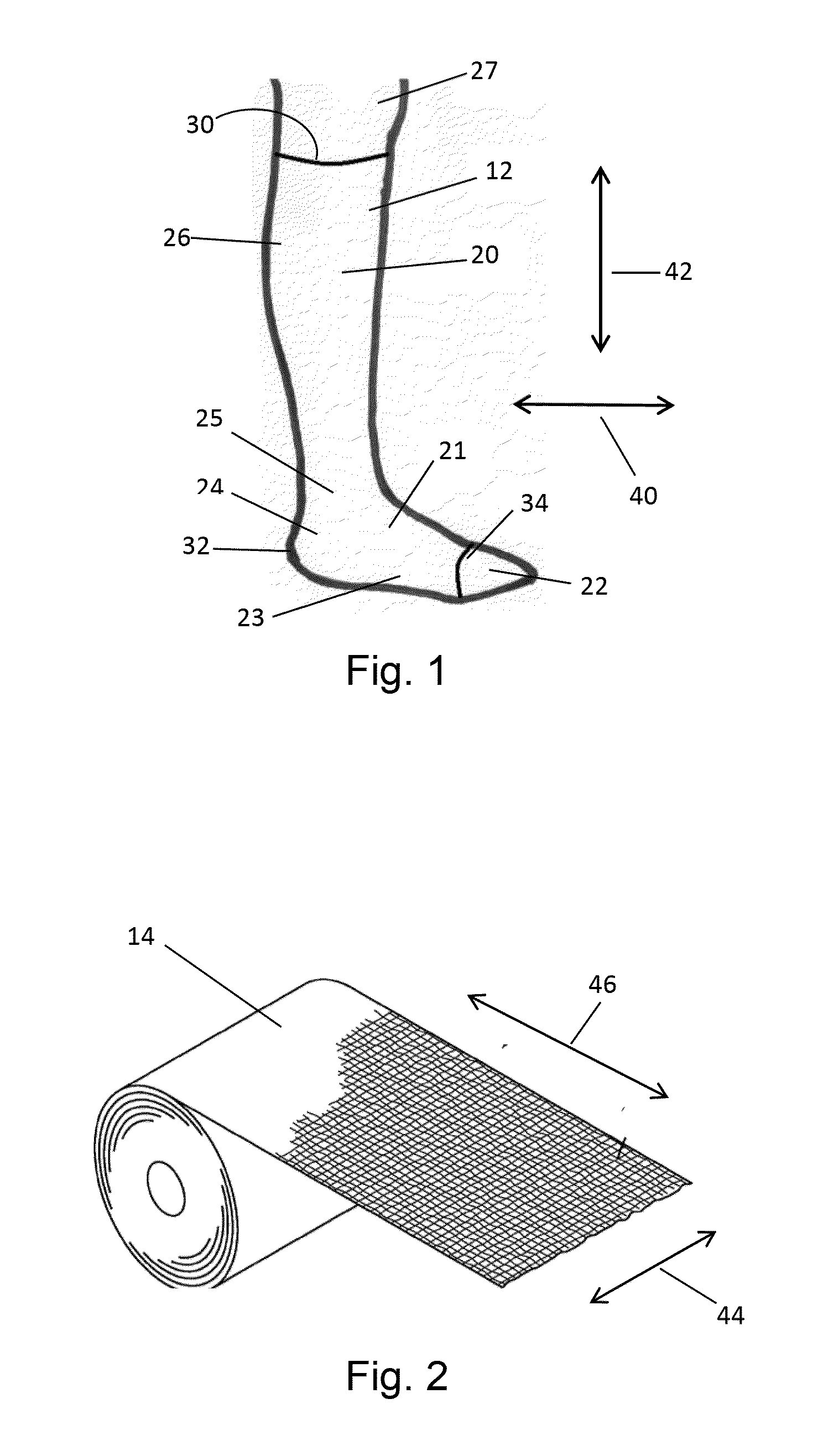

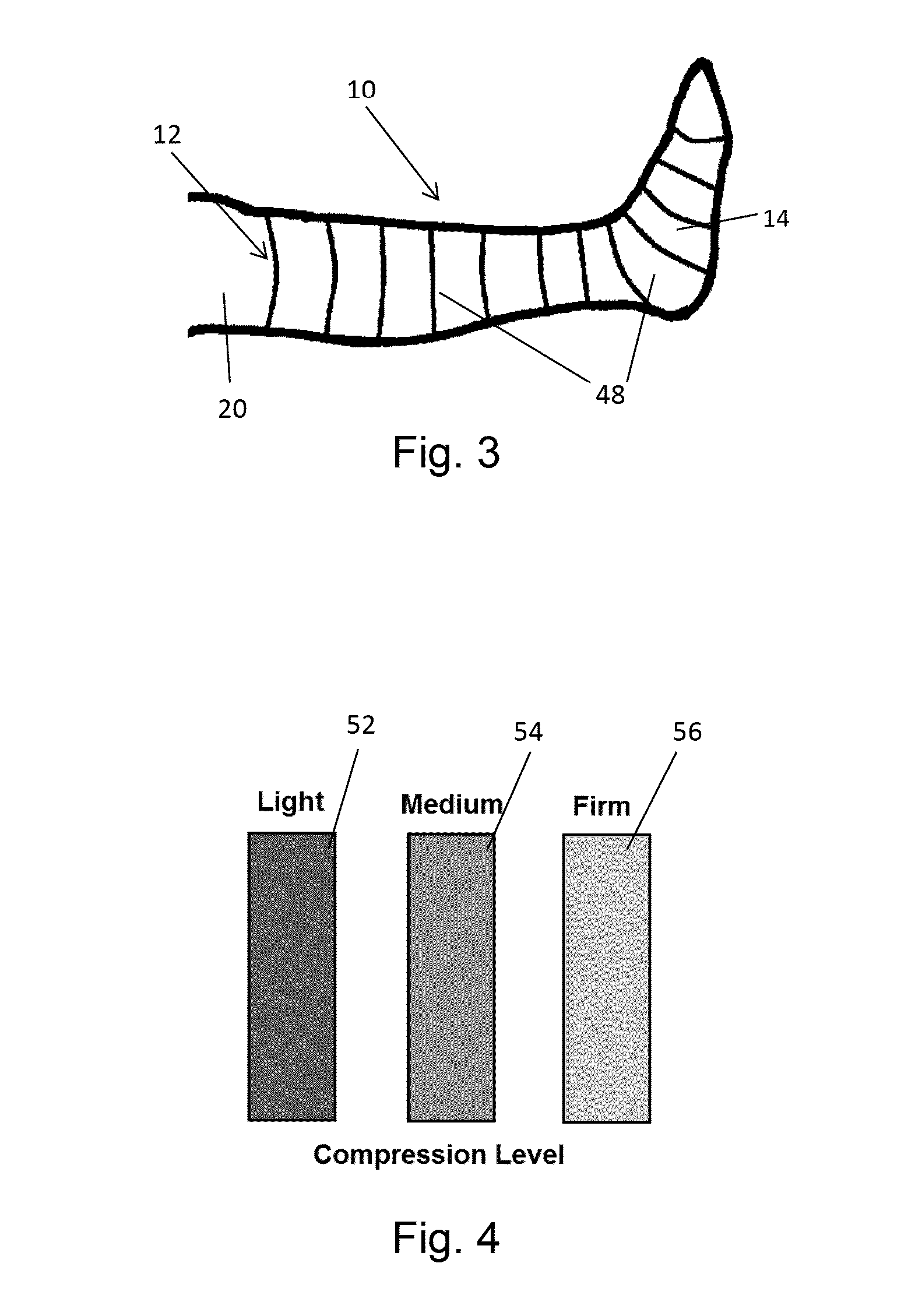

Sleeve-Wrap Compression System and Method

InactiveUS20150157524A1Minimal vertical stretchEvenly compactedChiropractic devicesFeet bandagesElastomerEngineering

A sleeve-wrap compression system can include a seamless, inner sleeve comprising a long-stretch elastomeric material and an interior terry surface; and an elongated outer wrap comprising a long-stretch elastomeric material. When applied to a patient's limb, the inner sleeve can exert a first compressive pressure that secures the inner sleeve in a therapeutic position on the limb. When applied by stretching over the inner sleeve, the outer wrap can exert a second compressive pressure and frictionally engage the inner sleeve, thereby securing the compression system as a single compressive entity in the therapeutic position on the limb.

Owner:CAROLON

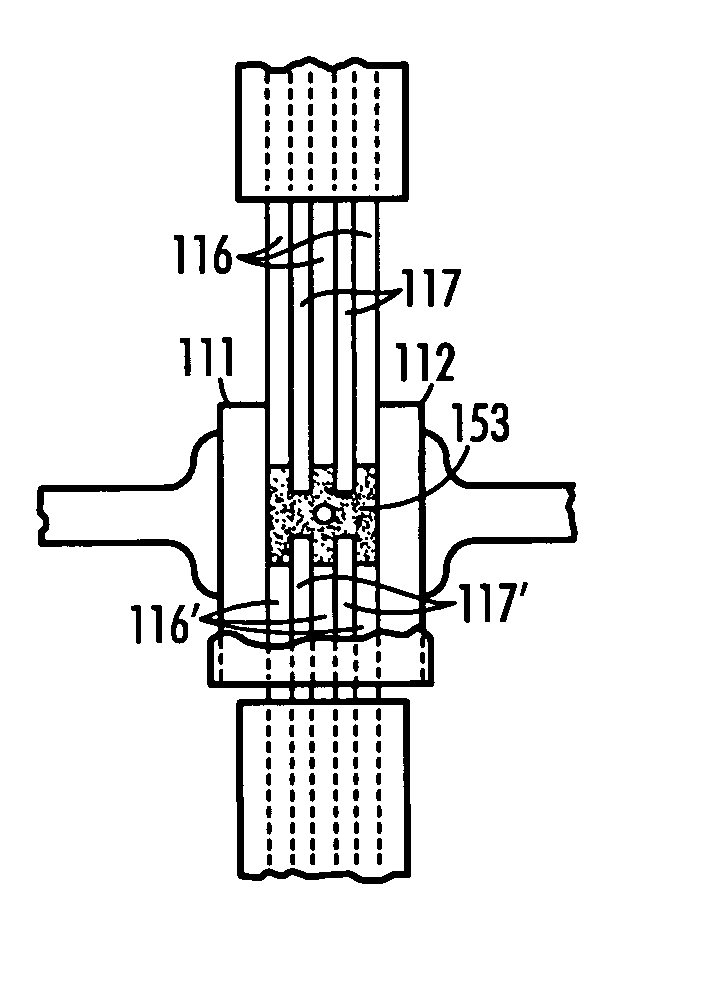

Powder compaction press for capacitor anodes

ActiveUS7207103B2Uniform degreeEvenly compactedSolid electrolytic capacitorsLiquid electrolytic capacitorsEngineeringVolumetric Mass Density

Owner:KEMET ELECTRONICS CORP

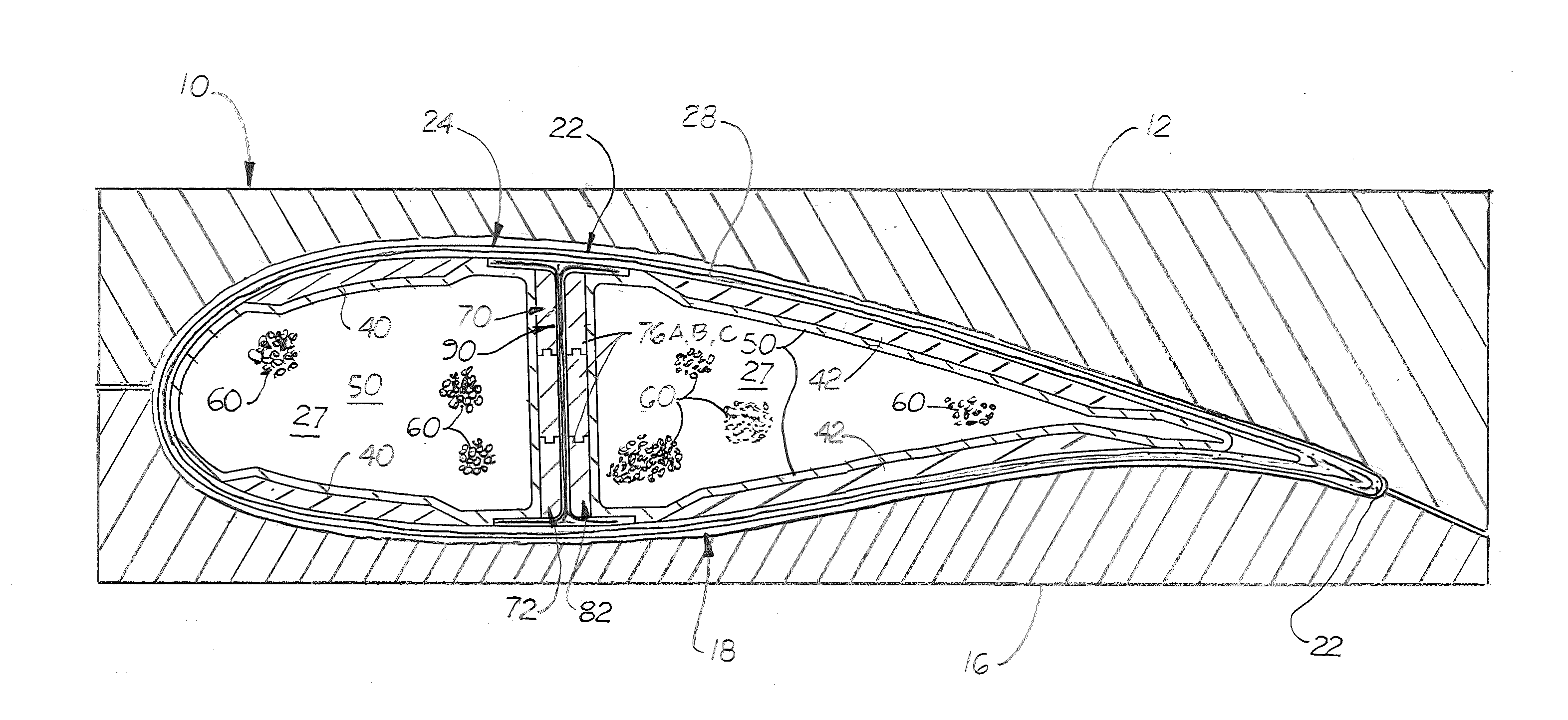

Method of manufacturing hollow composite parts with in situ formed internal structures

InactiveUS8668800B2Evenly compactedEasy to disassembleMouldsFinal product manufactureEngineeringPosterior composites

A method for manufacturing complex hollow composite parts with at least one internal structure formed in situ by laying laminated layers around a removable mandrel assembled inside the part's inner cavity. The inner mandrel is made up of two jig plate assemblies aligned in a parallel manner and space apart where the internal structure is to manufactured. Each jig plate assembly is made up of at least three jig plates stacked in an edge-to-edge manner Located on opposite sides of each jig plate assembly is an elastic envelope filled with spherical objects. When evacuated, the envelope collapses and relaxes and composite material may then laid up inside the inner cavity and around the envelopes. When exposed to a heat, the envelopes expand and in situ and form internal structures inside surface of the cavity. Each envelope and each jig plate assemblies can be easily dissembled and reused.

Owner:GUITTON MAURICE

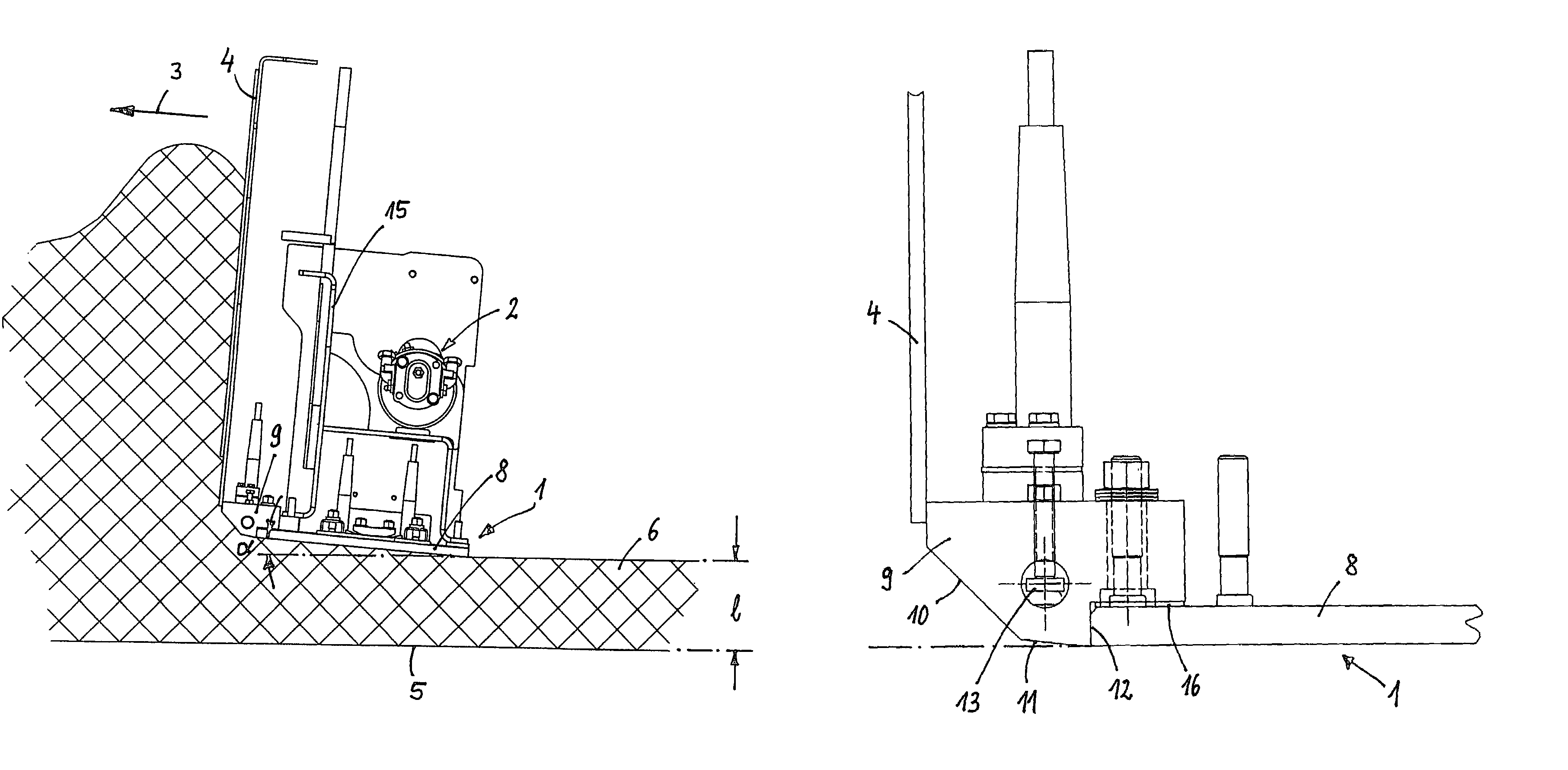

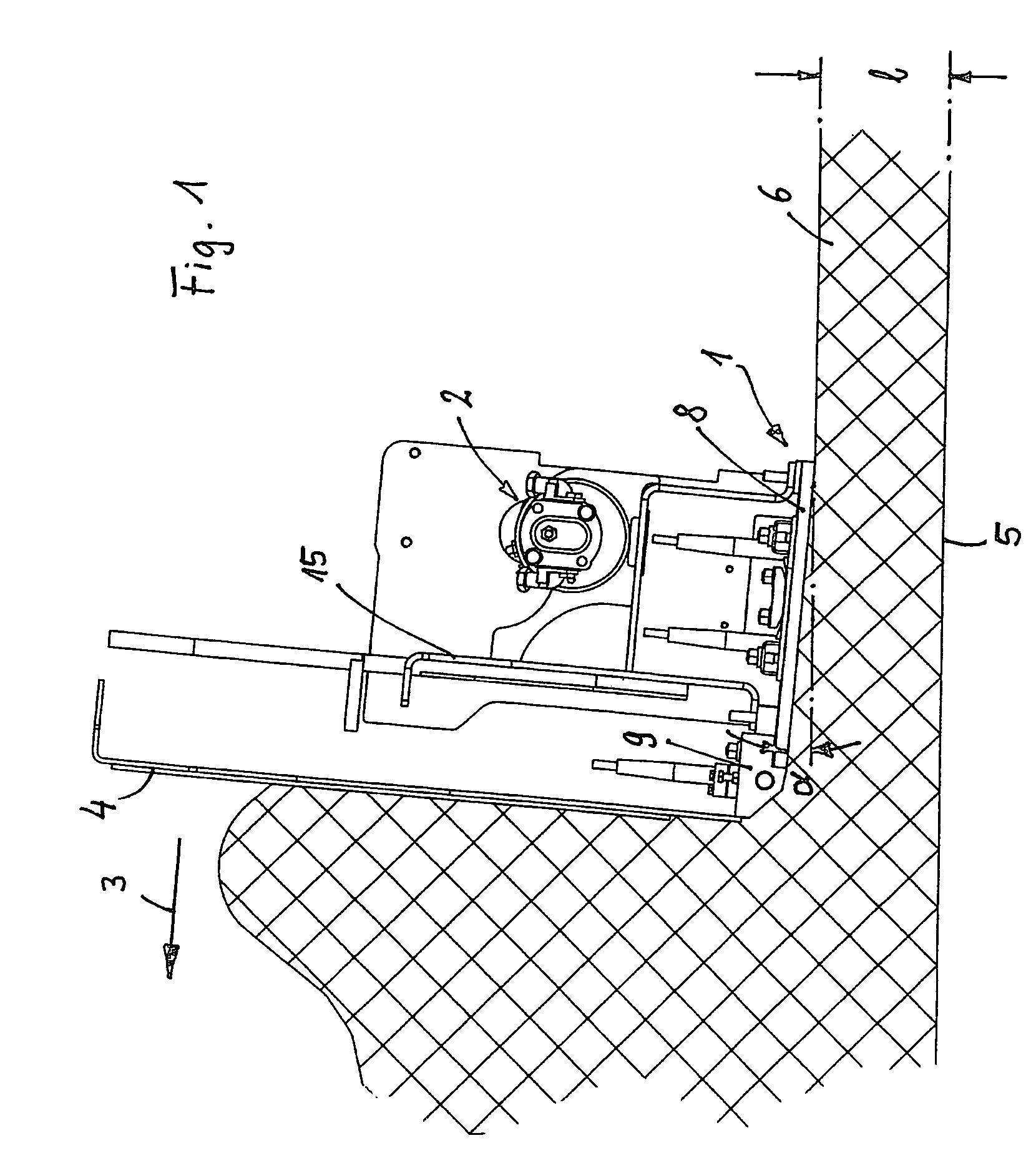

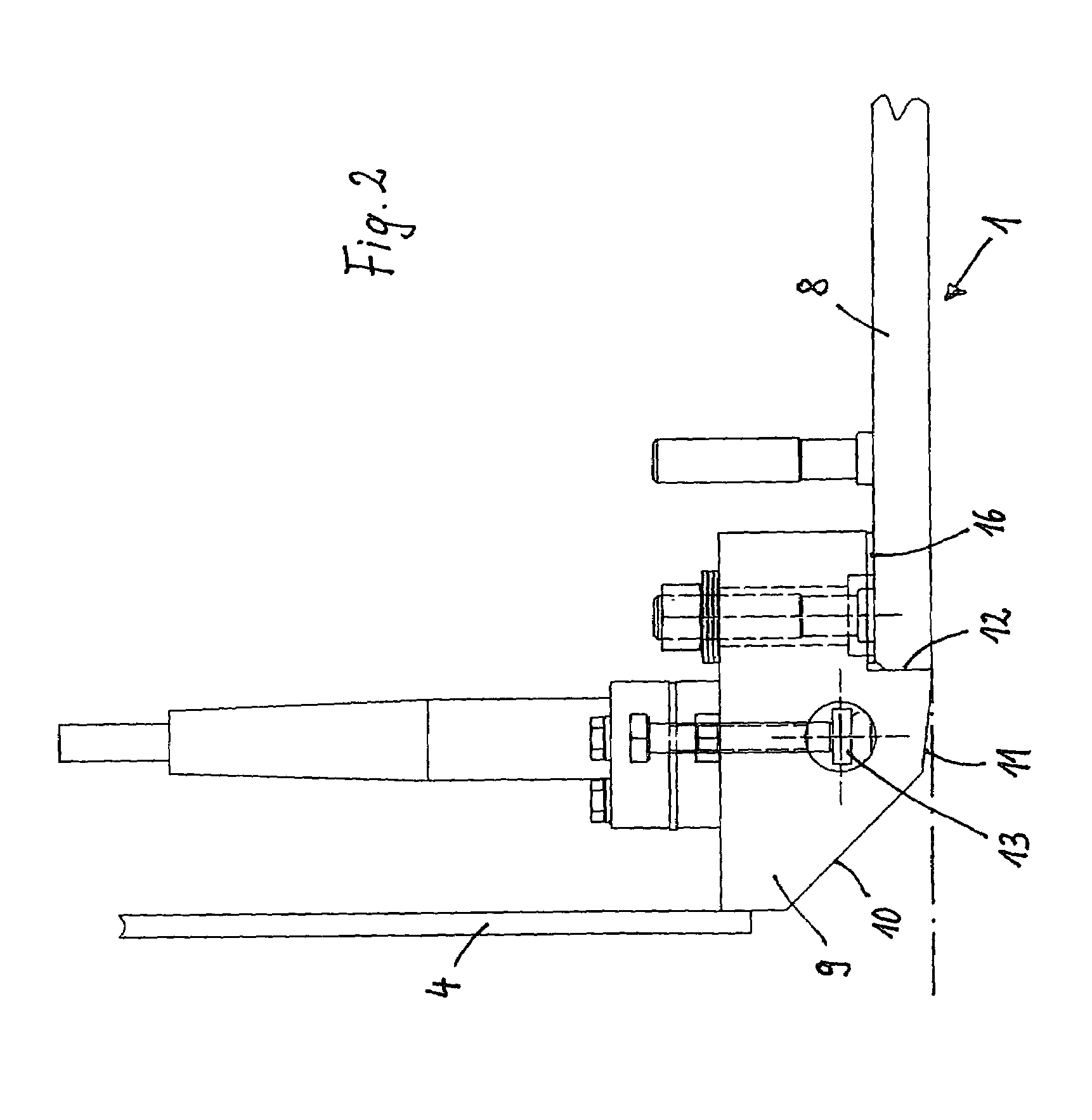

Vibratory paving screed for a paver

The invention relates to a vibratory paving screed for a paver, comprising a baseplate and a vibration drive therefor and also comprising a front wall which is mounted upstream of the baseplate in the paving direction, is fixed with respect to the baseplate and engages with the baseplate, in which arrangement the baseplate comprises a section of uniform thickness and, in the region of its front edge, a separate, solid strip which is connected to the section and has a metering slope and a flat run-in bevel situated behind.

Owner:ABG ALLG BAUMASCHINEN GMBH

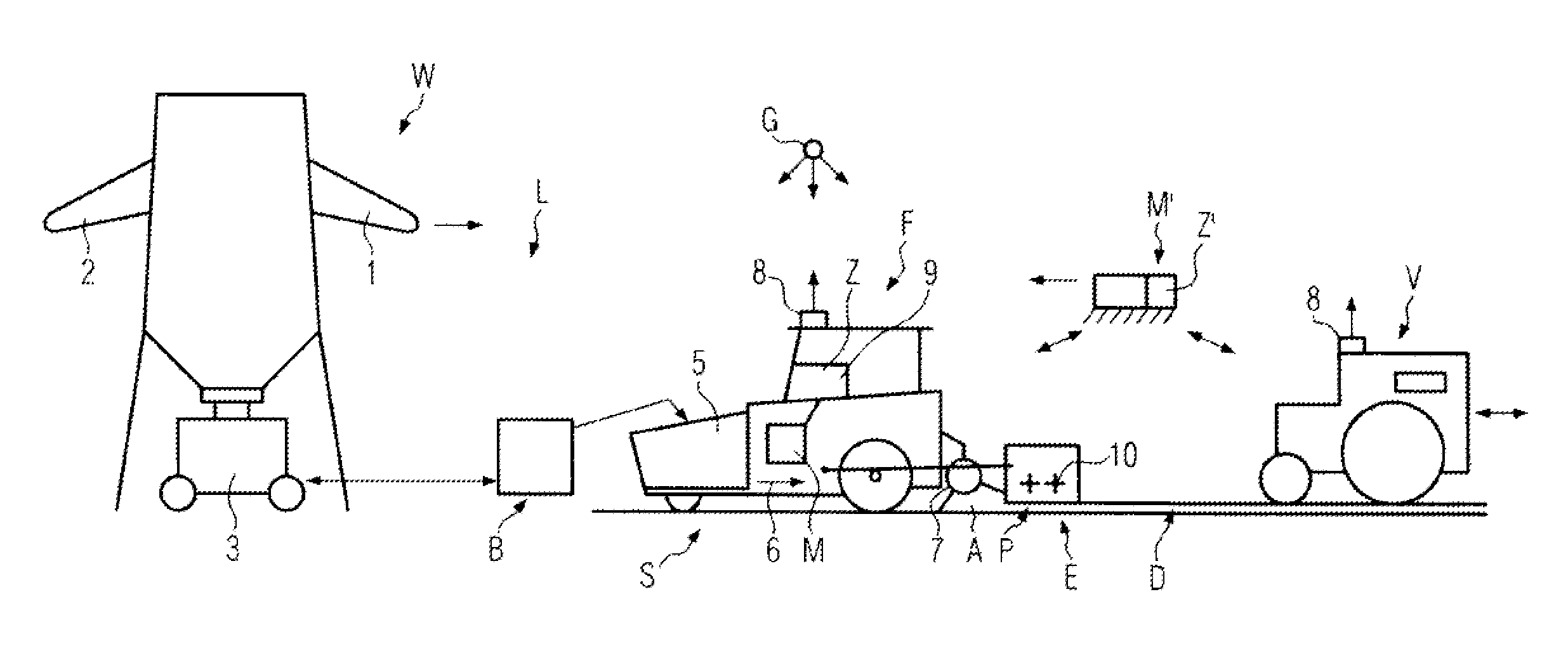

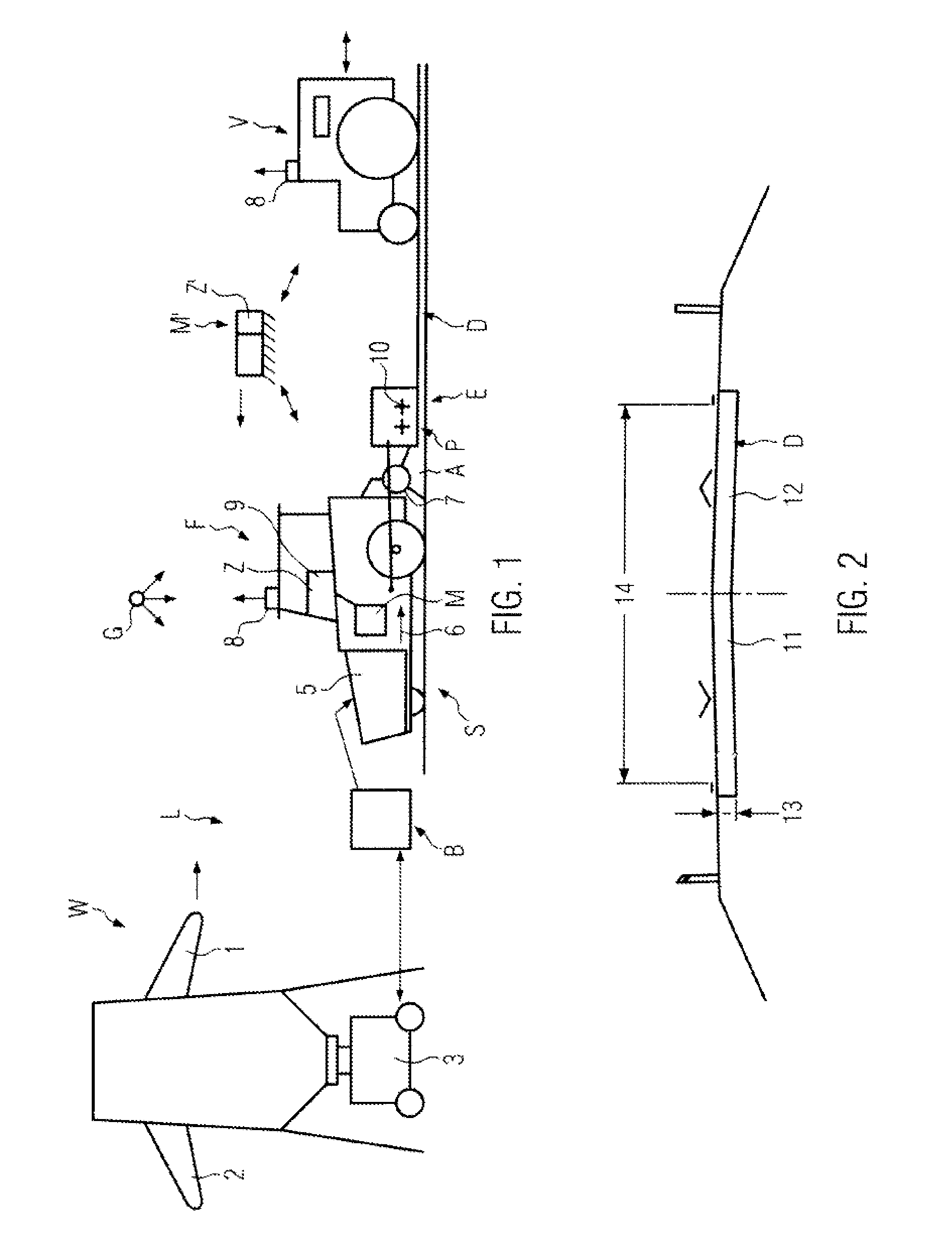

System and method for laying down and compacting an asphalt layer

ActiveUS9068295B2High final degree of compactionEvenly compactedPaving detailsRoads maintainenceScreedRoad surface

Owner:JOSEPH VOEGELE AG

A tamping apparatus for road engineering

The invention belongs to the technical field of tamping apparatuses, in particular to a tamping apparatus for road engineering. Aiming to solve problems that local cavities in the road surface, uneventamping, a lot of dust during work and inconvenient movement are likely to occur, the invention proposes the following scheme: the tamping apparatus comprises a bottom plate and a mounting rack; theouter walls on both sides of the top end of the bottom plate are fixed by bolts with vertically arranged positioning posts; the outer wall of one side of the top end of the bottom plate is fixed witha vibration motor by bolts; the side walls of the two positioning posts are sleeved with connecting sleeves; and the two connecting sleeves are respectively fixed by bolts at intermediate positions onthe outer walls of the two sides of the mounting rack; and shock absorbing rods are hinged at positions, close to four corner portions, of the outer wall of the two sides of the mounting rack. The tamping apparatus of the invention can realize graded tamping, improve the tamping effect, make the tamping more uniform, avoid the local cavity phenomenon, collect dust, reduce the amount of dust in the working process and improve the working environment.

Owner:明磊建设集团有限公司

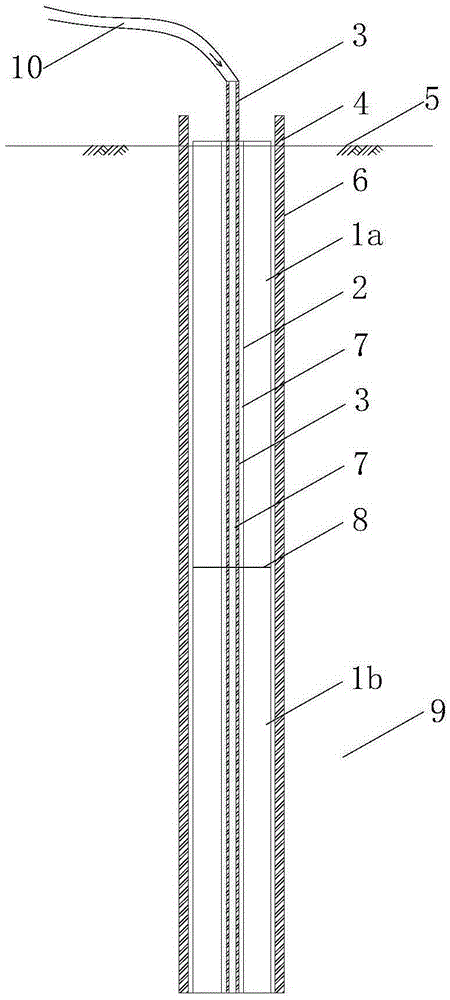

Mixed soil extruded and cured precast pile for soft foundation treatment as well as construction method

The invention discloses a mixed soil extruded and cured precast pile for soft foundation treatment as well as a construction method. Foundation soil is connected with drill holes which are connected with mixed soil extruded and cured precast pile bodies, the mixed soil extruded and cured precast pile bodies are connected with cement mortar through a central hole, and the cement mortar is connected with a seamless steel pipe which is connected with a grouting pipe. The construction method comprises the following steps: A, a vibrating pipe-sunk pile machine is adopted for hole forming; B, the mixed soil extruded and cured precast pile bodies are placed; C, the seamless steel pipe is placed, and a vibrating sunk pipe is pulled out; D, grouting is performed: the a seamless steel pipe is connected with the grouting pipe, pressure cement mortar is grouted into the seamless steel pipe, and the seamless steel pipe and the precast pile bodies form the integral mixed soil extruded and cured precast pile after mortar curing; E, integral construction is performed. The mixed soil pile is precast by waste construction waste and common clay, the manufacture is convenient and fast, the quality is reliable, the transport cost is reduced, modular piling construction is efficient and convenient, and the integral bearing capacity of a foundation is improved effectively.

Owner:WUHAN ZHONGLI GEOTECHN ENG

Powder compaction press and method for manufacturing of capacitor anodes

ActiveUS20050122663A1Uniform degreeEvenly compactedSolid electrolytic capacitorsLiquid electrolytic capacitorsEngineeringVolumetric Mass Density

Owner:KEMET ELECTRONICS CORP

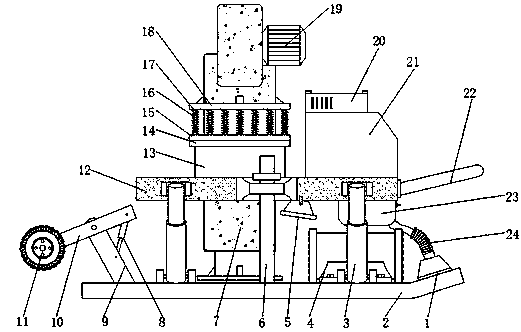

Environment-friendly cement block crushing, compacting and recycling device used in construction

The invention relates to a cement block crushing, compacting and recycling device, in particular to an environment-friendly cement block crushing, compacting and recycling device used in construction. The technical purpose of the invention is to provide the environment-friendly cement block crushing, compacting and recycling device used in construction, wherein the environment-friendly cement block crushing, compacting and recycling device used in construction is simple and compact in structure, high in crushing speed and uniform in compaction. For realizing the technical purpose, the environment-friendly cement block crushing, compacting and recycling device used in construction comprises a first connecting rod, a motor, a gear, a shipper rod, a collision block, a rack, a first slideway, a first sliding block, a first connecting rod, a second sliding block, a second connecting rod, a fixed pulley, a third connecting rod, and the like. Springs are symmetrically arranged on the left side of the top of a baseboard. The environment-friendly cement block crushing, compacting and recycling device used in construction achieves the effects of being simple and compact in structure, high in crushing speed and uniform in compaction, and is low in manufacturing cost, easy to maintain and repair, and convenient to utilize. Furthermore, parts of actions are achieved by relying on gravity so that energy consumption can be lower.

Owner:麻城小龟龟机械科技有限公司

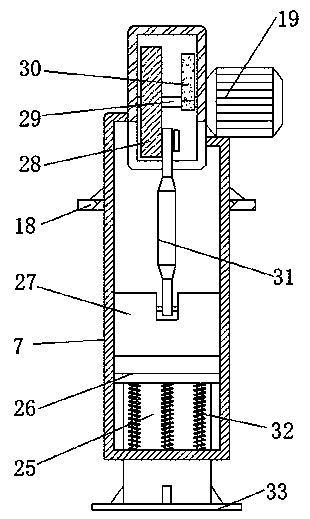

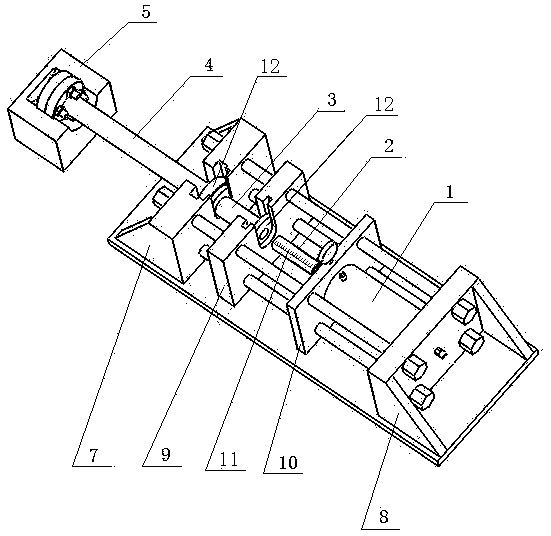

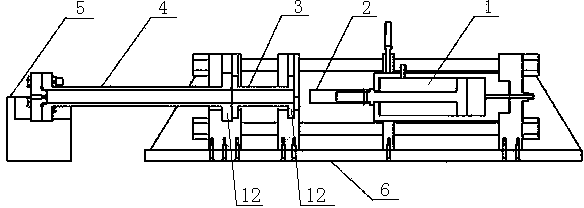

Corestone compaction device

The invention relates to a corestone compaction device. The corestone compaction device comprises a frame base, a plunger type hydraulic cylinder, a filling tube, a sand-filled tube and a sand-filled tube rear bracket. The plunger type hydraulic cylinder is horizontally located at the rear end of the frame base, a compaction head is arranged at the front end of a plunger of the plunger type hydraulic cylinder, and the compaction head is provided with scale marks. The sand-filled tube is connected and communicated with the filling tube, the filling tube is arranged corresponding to the compaction head, and the sand-filled tube, the filling tube and the compaction head are placed in the same horizontal axis. The rear end of the plunger type hydraulic cylinder is just positioned in a frame base rear support, and the front end of the plunger type hydraulic cylinder is placed in a rear supporting plate. A U-shaped groove is formed in a frame base front support, and a U-shaped groove is also formed in a front supporting plate. The two ends of the filling tube and the two ends of the sand-filled tube are respectively provided with a flange, the flange at one end of the filling tube is placed in the U-shaped groove of the frame base front support, and the flange at the other end of the filling tube is placed in the U-shaped groove of the front supporting plate. The flange at the front end of the sand-filled tube is mounted on the sand-filled tube rear bracket, and the flange at the rear end of the sand-filled tube is placed in the U-shaped groove of the frame base front support. By means of the corestone compaction device, one-time even corestone compaction can be achieved, and the diameter of the filling tube and the diameter of the sand-filled tube cannot be limited.

Owner:HENGYE ELECTRONICS JIAXING CITY

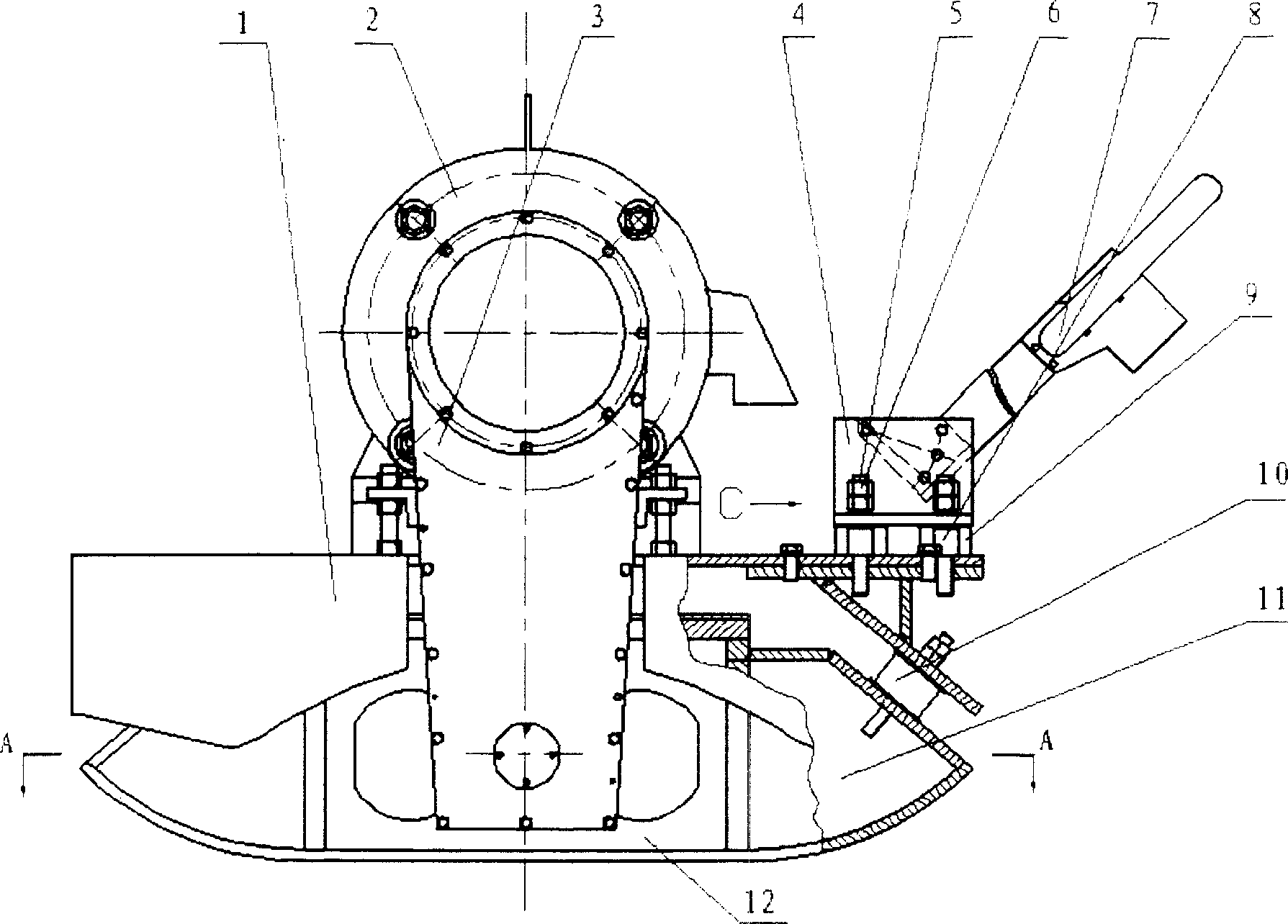

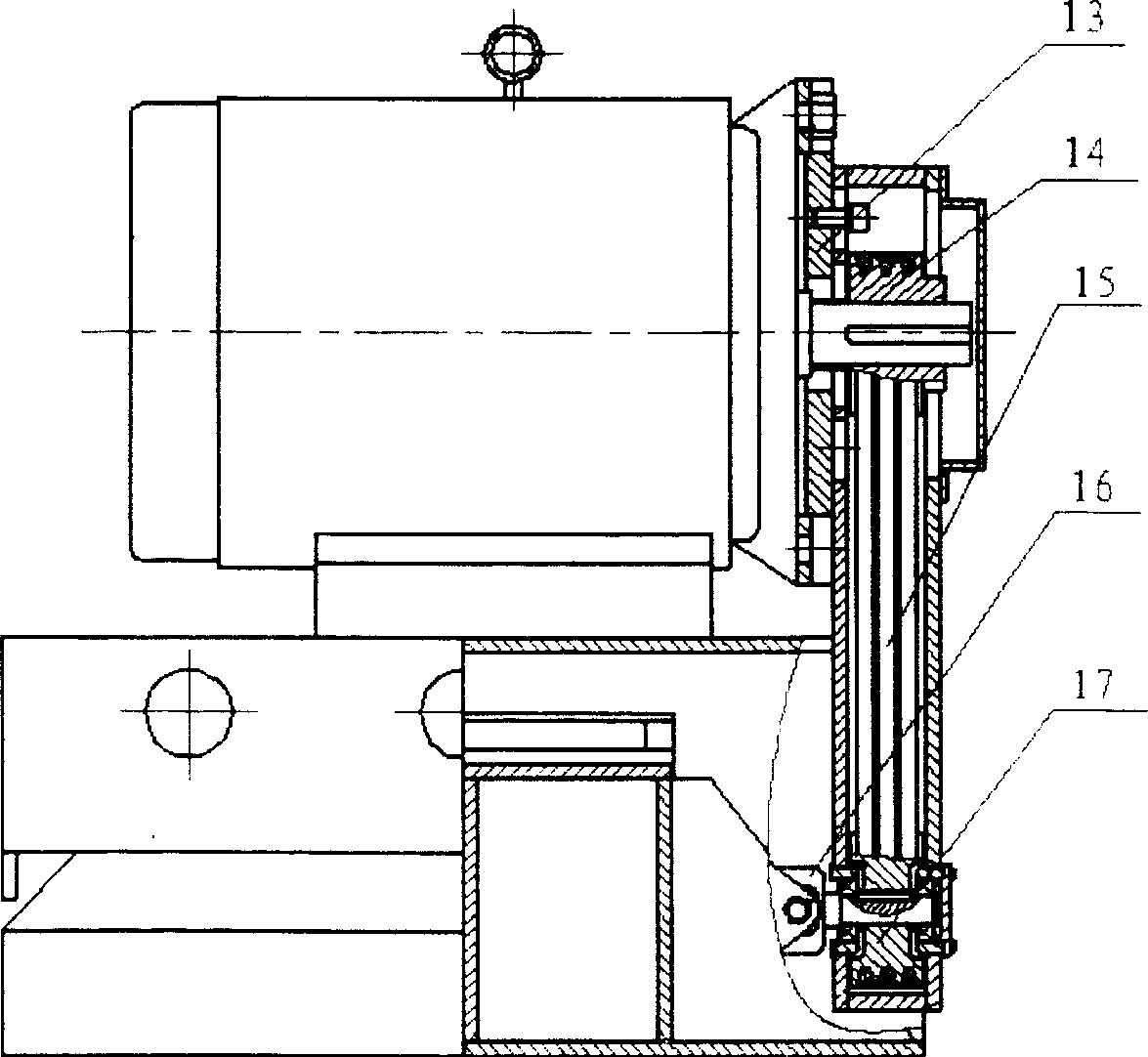

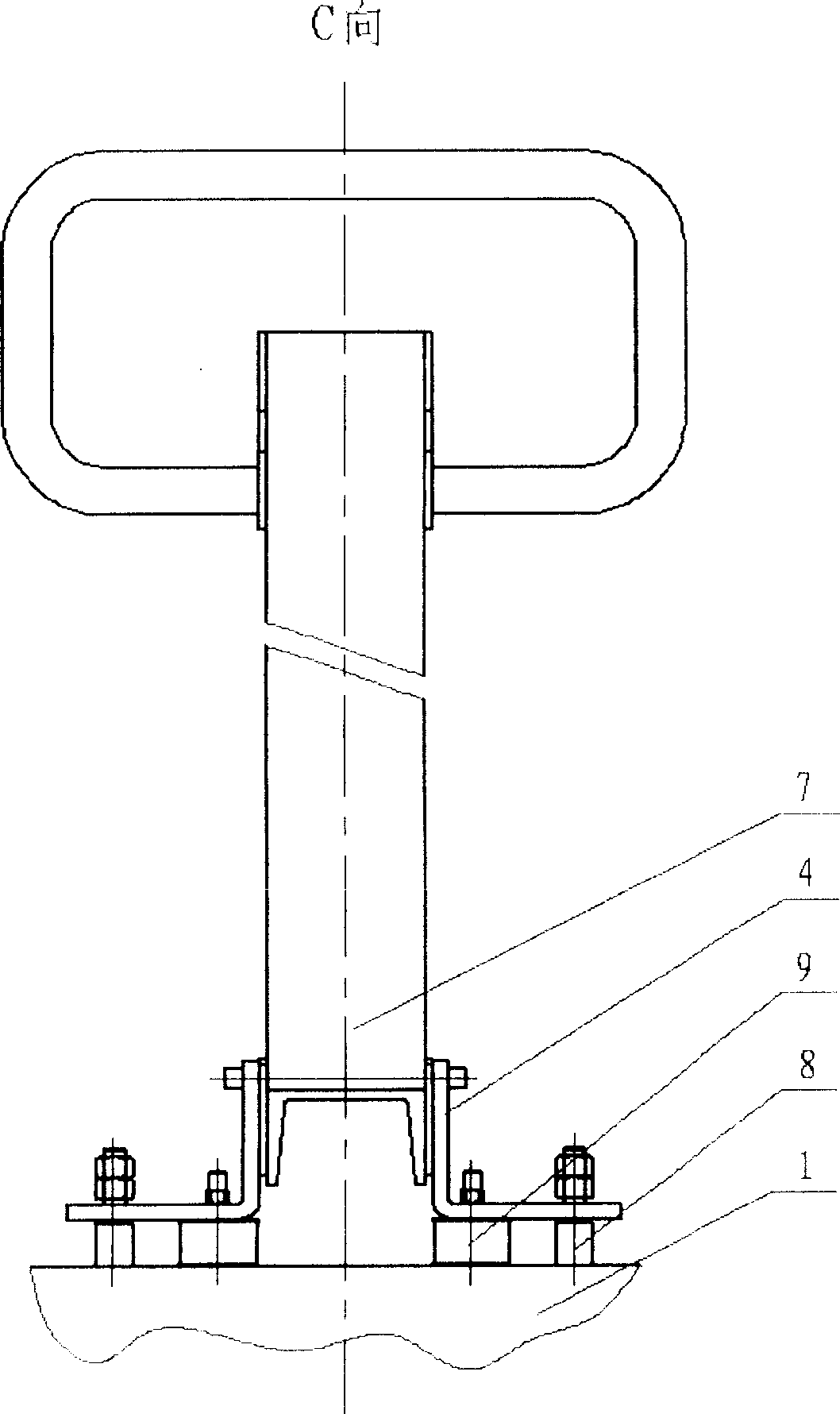

Vibrating slab tamper

The invention discloses a vibration flat rammer, which is characterized by the following: setting motor on the frame and armrest on the armrest seat; fixing flange on the motor; setting arm seat absorber and absorber protector between armrest seat and upper installment plate; fixing the loading system on the rack lower installment plate; setting pulley box with driving structure in connection with the motor and loading system on the installment flange; adapting front eccentric block, middle eccentric block and back eccentric block in the loading case to generate exciting force to compact ground foundation through motor driving system; setting lubrication system in the loading case to lubricate the operation part and reduce noise. The invention adapts universal joint as driving part, which avoids the rigidity driving shaft breakdown phenomenon.

Owner:CHANGAN UNIV

Feeding compaction assembly of mushroom seed packing machine

The invention provides a feeding compaction assembly of a mushroom seed packing machine, and belongs to the technical field of machines. The problem that base materials are loose and unbeneficial to transportation in the existing mushroom seed manual packing process is solved. The feeding compaction assembly of the mushroom seed packing machine comprises a rack and a shell, a feeding opening and a discharging opening are formed in the shell, a conveying plate capable of moving in a circulating mode is arranged in the shell, material separation plates are evenly and vertically arranged on the conveying plate, and are evenly arranged in the feeding direction of the conveying plate, two side plates are fixedly connected to the middle of the shell and arranged on the two sides of the conveying plate respectively, a material pressing cavity is formed among the two side plates and two corresponding material separation plates, and a material pressing plate and a lifting mechanism capable of driving the material pressing plate to do reciprocating lifting motion are arranged on the upper side of the material pressing cavity. The feeding compaction assembly of the mushroom seed packing machine has the advantage of being capable of compacting the base materials.

Owner:ZHEJIANG HONGYE EQUIP TECH

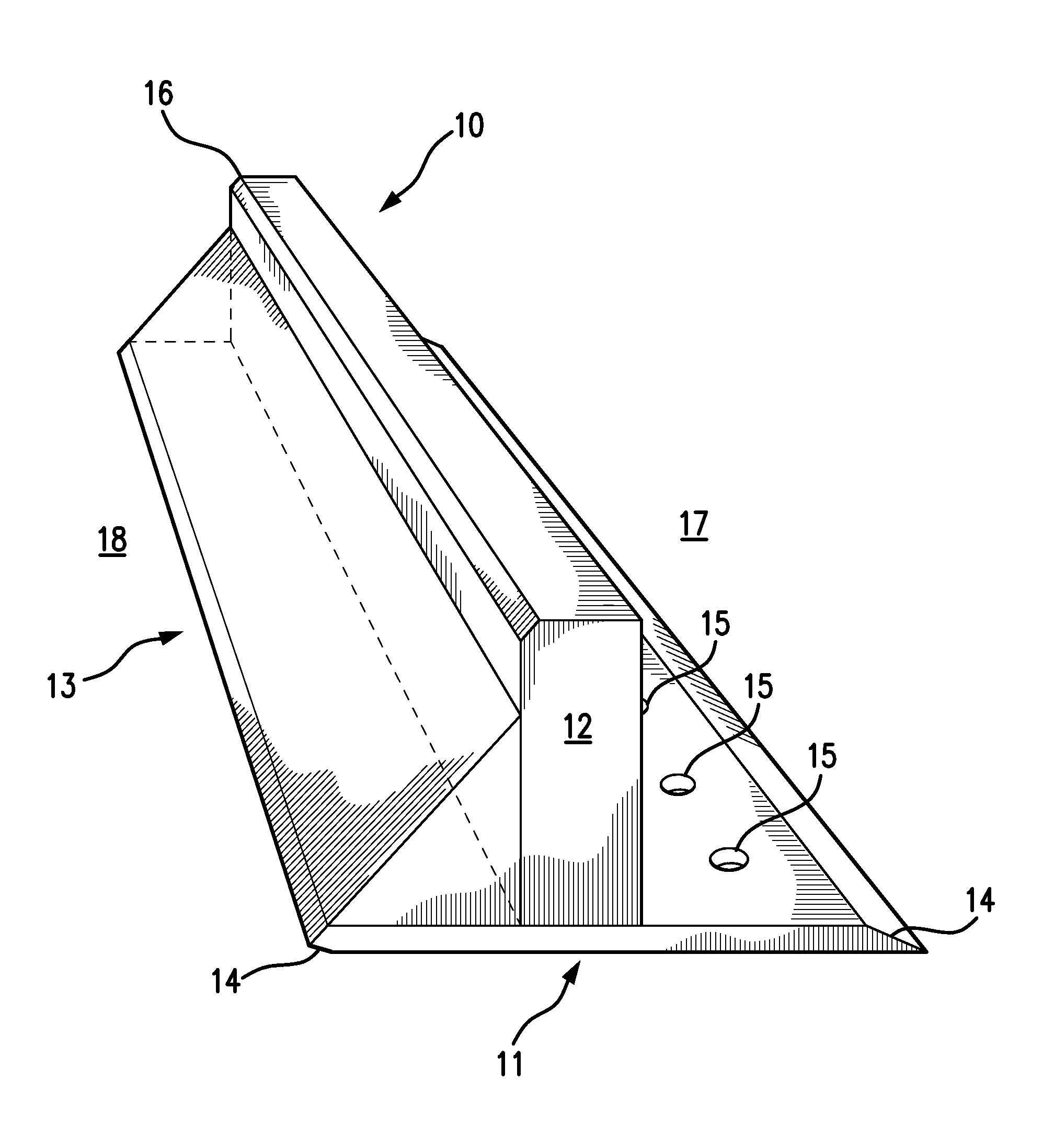

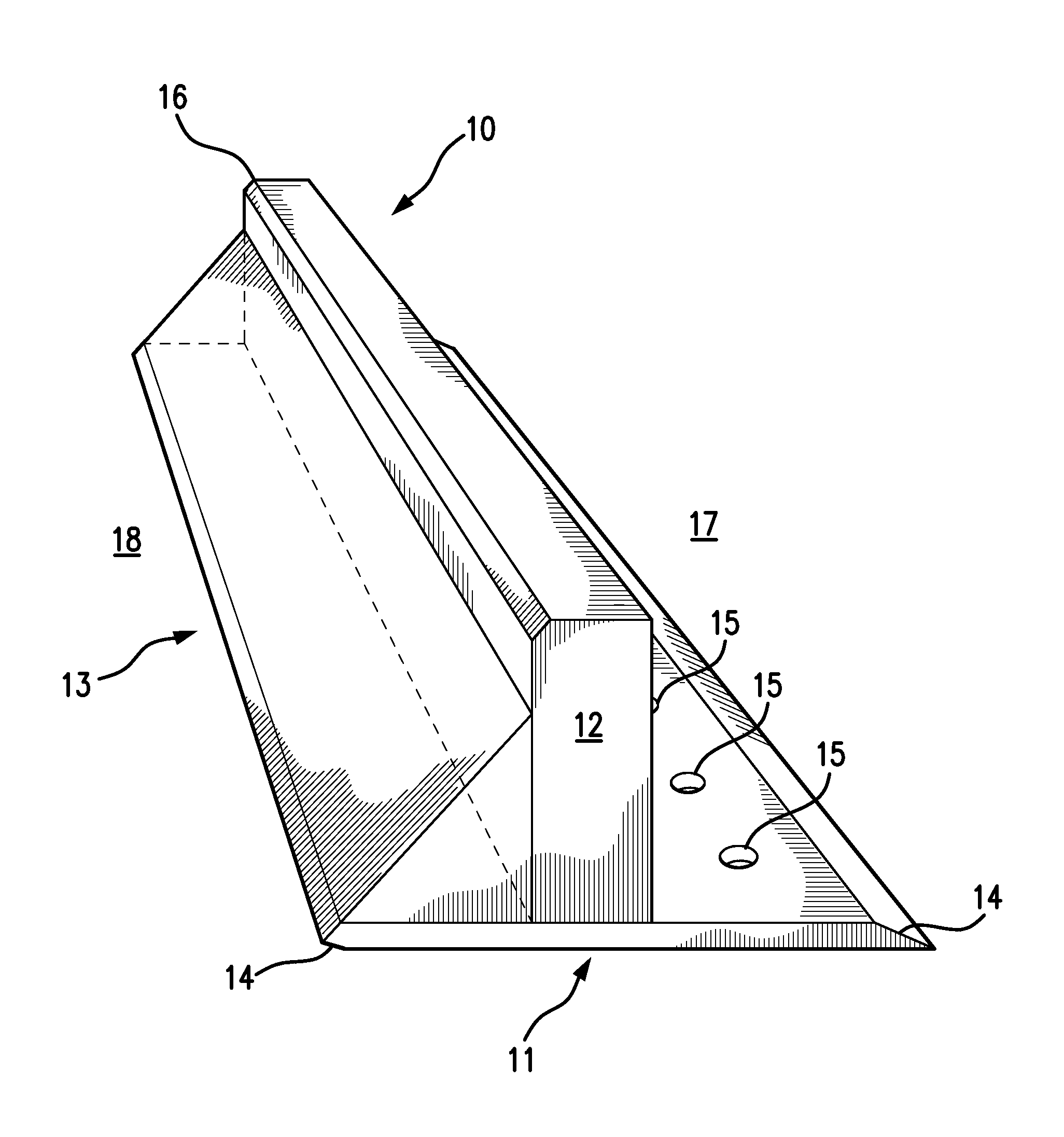

Asphalt paving seam gasket

An asphalt paving seam gasket comprises a footing sheet, a seam wall and a ramp extension. Once the footing sheet is anchored to the substrate, the seam wall provides a supporting buttress for the compaction of an initial lane of paving, while the ramp extension provides a sloped access for vehicles to mount the initial lane during the interval before the adjoining lane of paving is applied. Optionally, an adhesive resin is applied to the contact surfaces of the gasket to strengthen their bonding to the asphalt material and prevent moisture penetration between the gasket and the asphalt material.

Owner:DIAMOND RICHARD

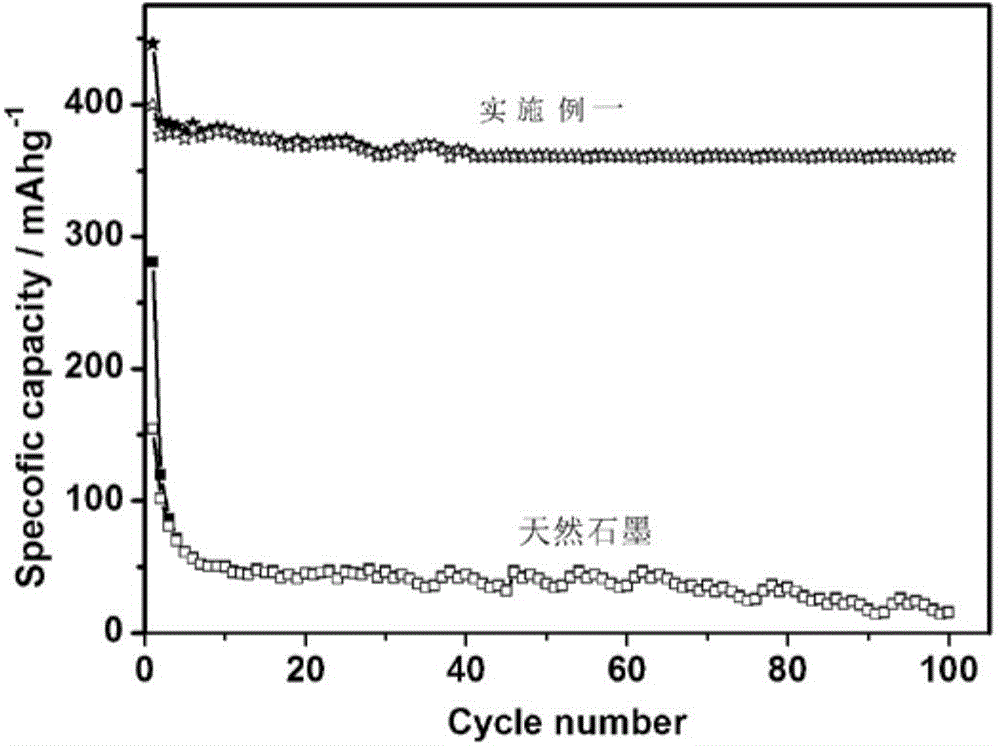

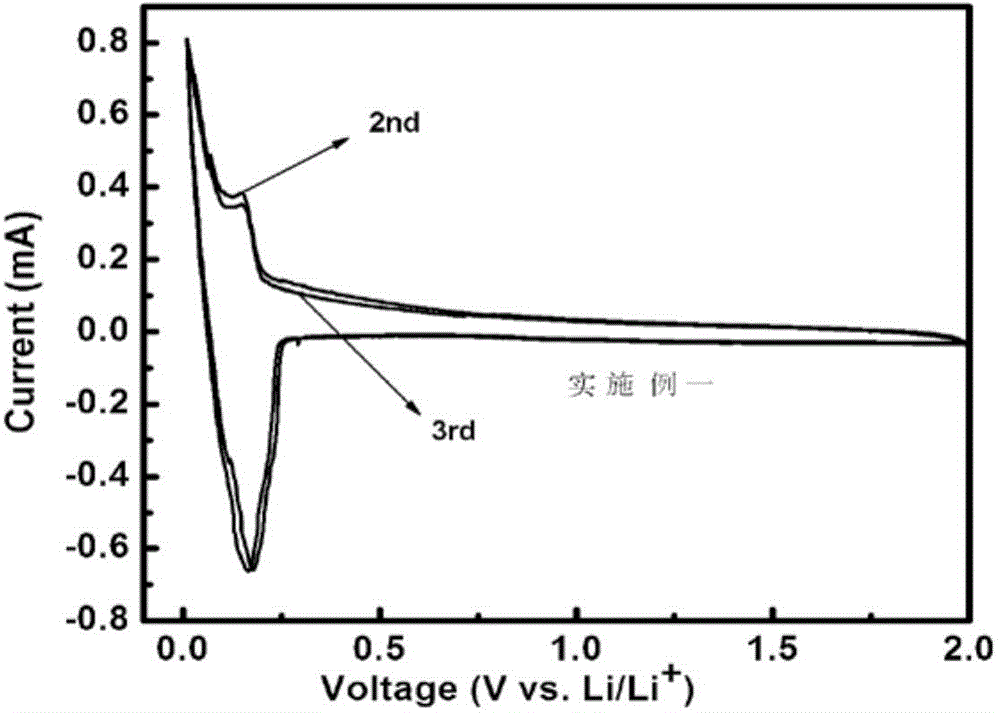

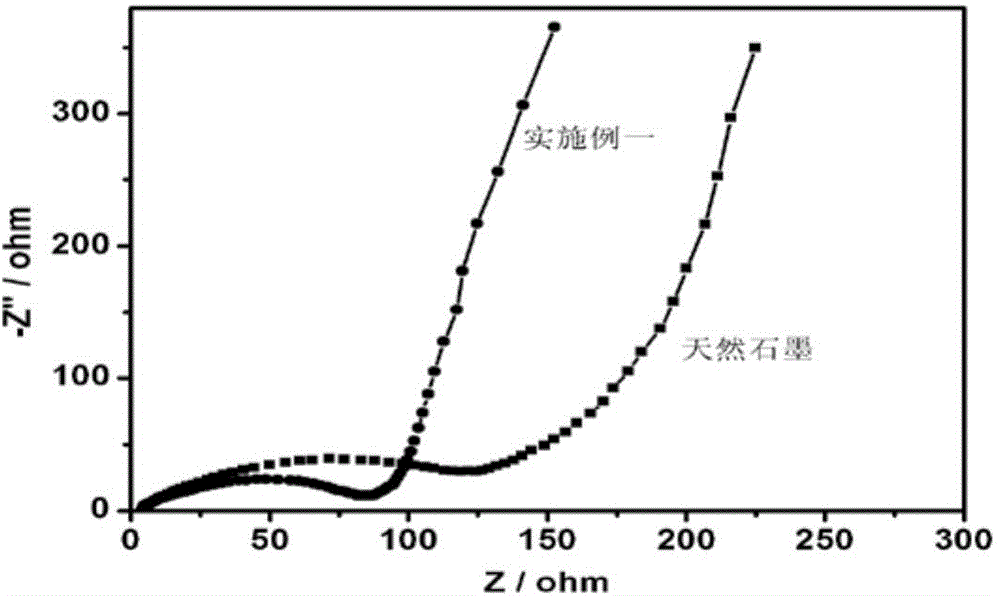

Preparation method of natural graphite composite N-doped carbon nanofibers webs cathode material

ActiveCN103606680AImprove cycle stabilityFacilitate de-intercalationCell electrodesSecondary cellsArgon atmosphereCarbon nanofiber

Belonging to the technical field of lithium ion battery electrode material preparation, the invention particularly discloses a preparation method of a natural graphite composite N-doped carbon nanofibers webs cathode material. The method includes: firstly subjecting natural flake graphite to spheroidizing treatment, and activating natural graphite under a small argon flow, then mixing the activated natural graphite with a mixed solution of emulsified asphalt / water-soluble polymer uniformly in certain proportion, conducting spray drying, then performing high temperature heat treatment in an argon atmosphere, mixing the obtained product with N-doped carbon nanofibers webs, an inorganic lithium salt and a composite conductive agent according to certain mass ratio, and then carrying out spheroidizing fusion treatment, sieving, and vacuum heat treatment, thus obtaining the natural graphite composite N-doped carbon nanofibers webs cathode material. The method provided by the invention can effectively improve the conductivity and structural stability of the material, greatly increases the compaction density of natural graphite, enhances the specific capacity, the reversible capacity and the coulombic efficiency, and effectively improves the cycle stability of the lithium ion battery cathode material.

Owner:百吉瑞(天津)新能源有限公司 +1

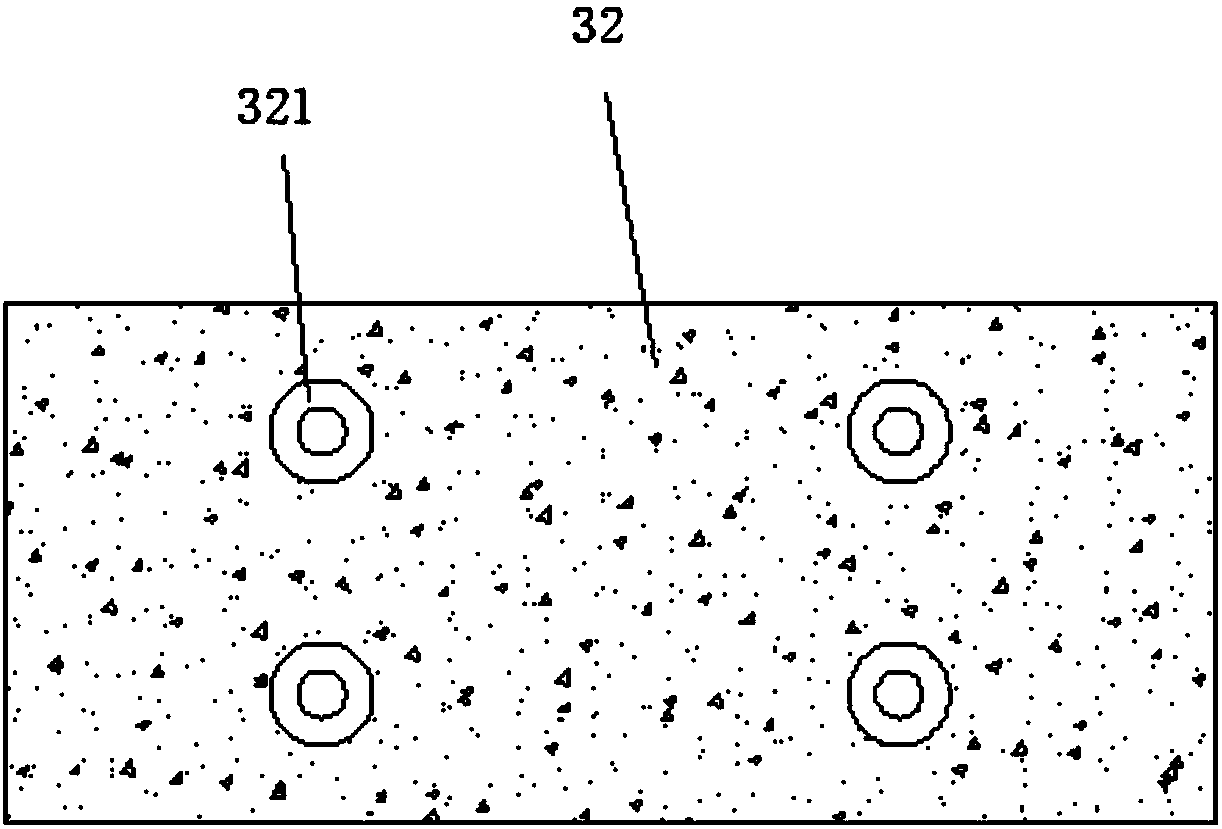

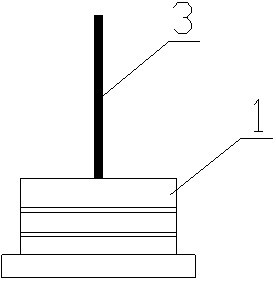

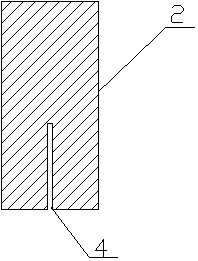

Preparation device and application method of triaxial test sample provided with structure in contact with soil

ActiveCN102607910AGuarantee product qualityEvenly compactedPreparing sample for investigationEngineeringTest sample

The invention discloses a preparation device of a triaxial test sample provided with a structure in contact with soil. The preparation device comprises a test sample base, a rubber diaphragm, a split die and a cylinder, wherein the diameter of the cylinder is the same as that of the triaxial test sample, a narrow groove is formed at one end of the cylinder, and width and height of the narrow groove are completely consistent with those of the structure to be simulated. According to the invention, soil body nearby the contact surface is uniformly compacted, and the rubber diaphragm can be effectively prevented from being damaged during the preparation of the test sample, so that preparation quality of the test sample is ensured, and working efficiency is obviously increased.

Owner:HOHAI UNIV

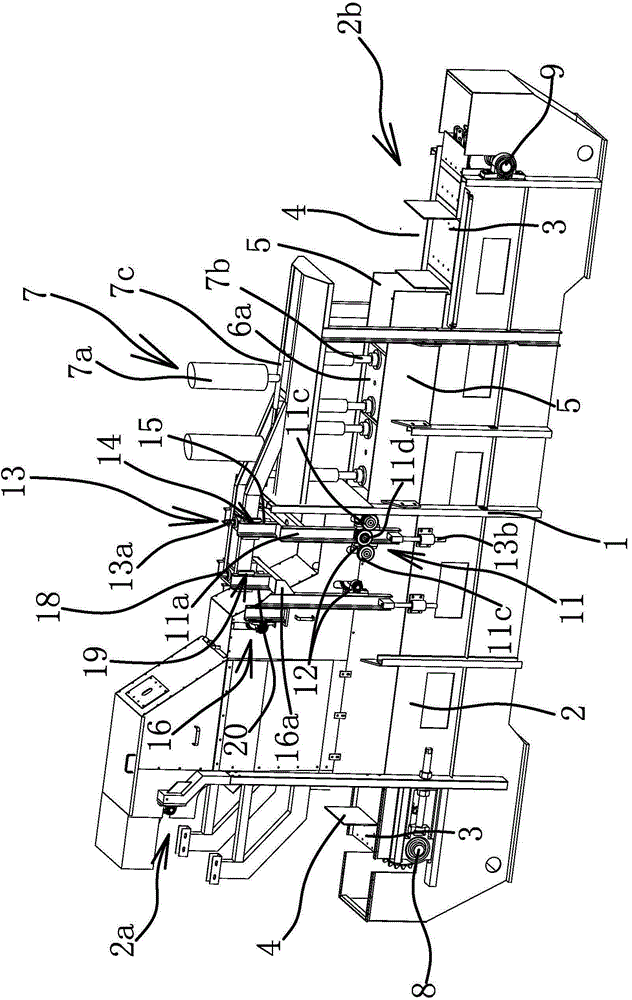

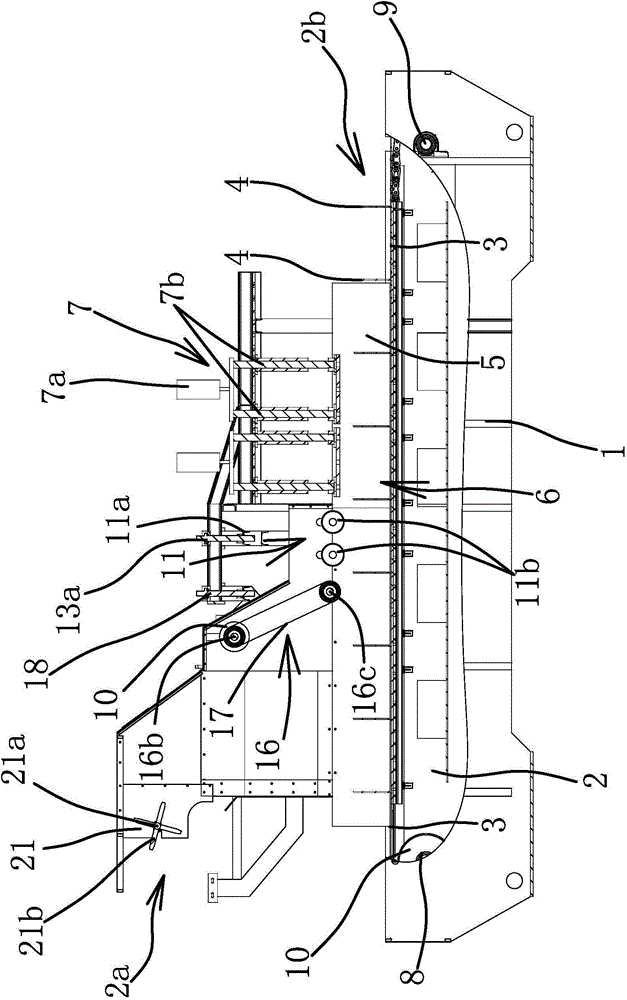

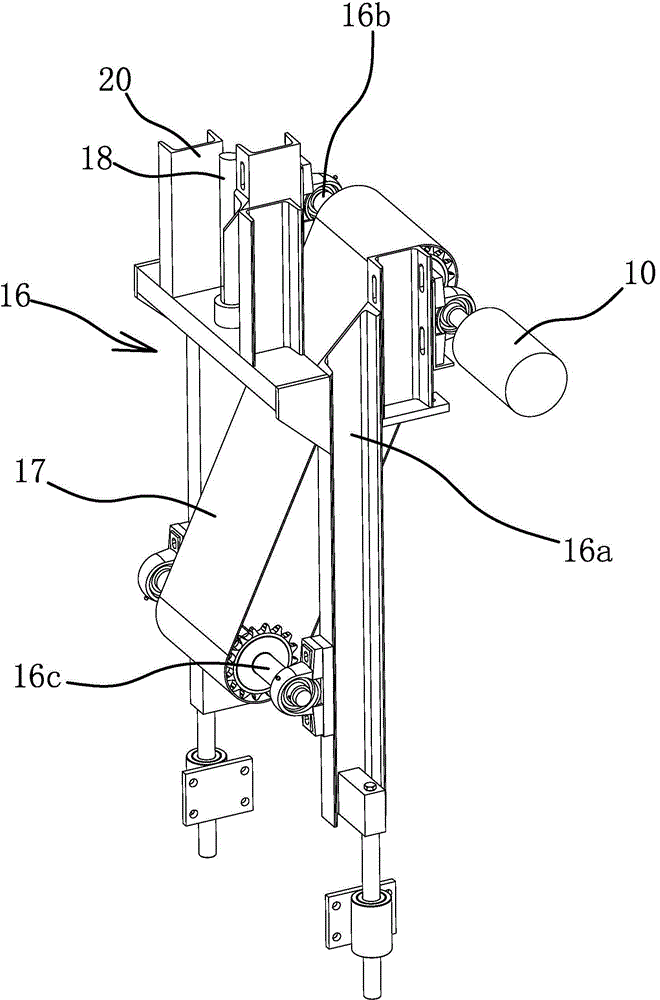

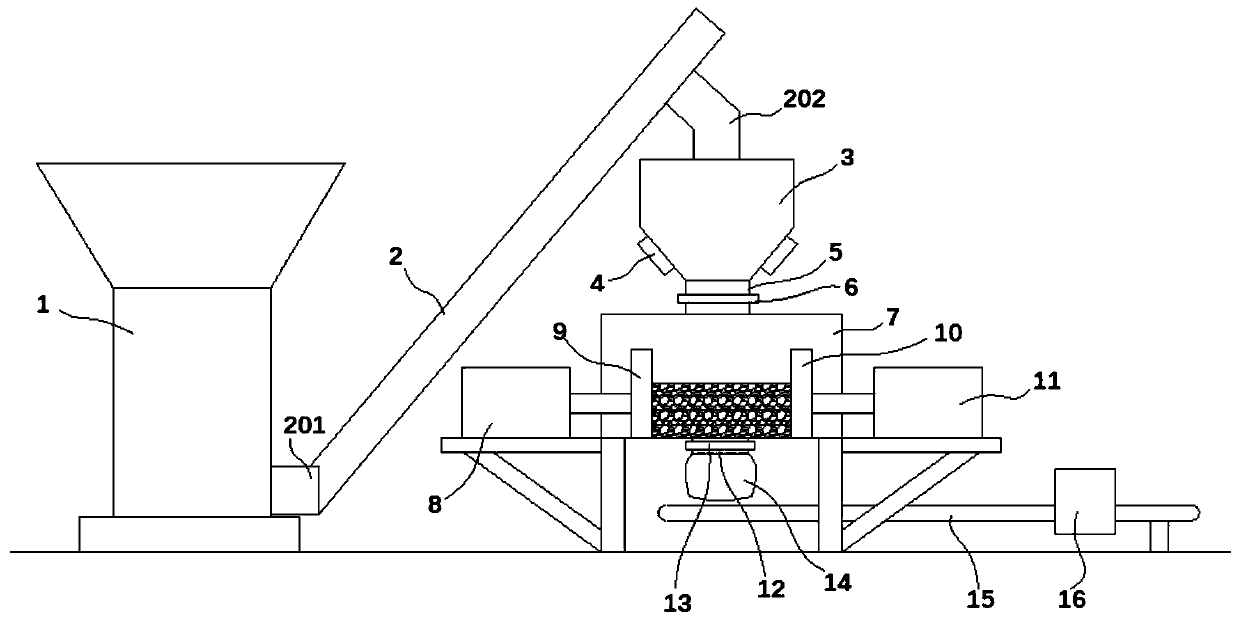

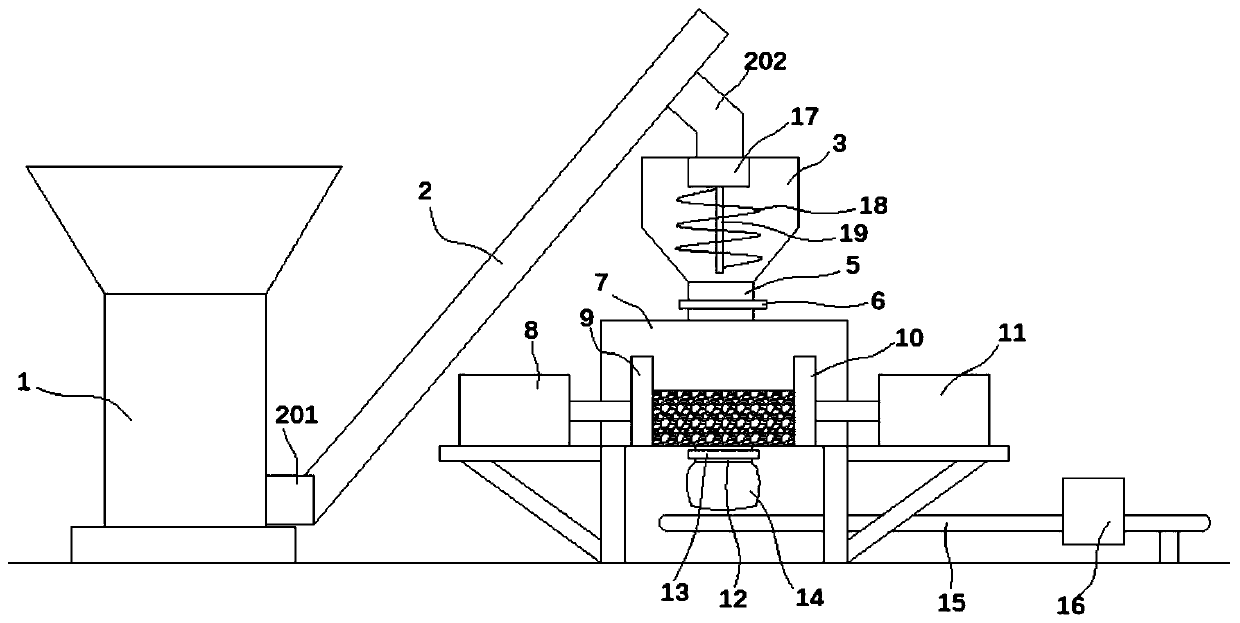

Continuous straw feed production line

PendingCN110584173ASmall footprintEasy to storeFeeding-stuffFood processingContinuous productionEngineering

The invention discloses a continuous straw feed production line which comprises a crushing device, a material feeding device, a material collecting cabin, a straw compaction device, a finished productconveying device and a controller, wherein the inlet end of the material feeding device is connected with a material discharging opening of the crushing device; the outlet end of the material feedingdevice is connected with the material collecting cabin; a first material discharging passage is arranged at the bottom of the material collecting cabin; a first electric control material dischargingvalve is arranged on the first material discharging passage; the straw compaction device comprises a compaction cabin and a compaction mechanism used for compacting materials entering the compaction cabin; the material collecting cabin is arranged on the top of the compaction cabin; the first material discharging passage communicates with the compaction cabin; a second material discharging passageis arranged at the bottom of the compaction cabin; a second electric control material discharging valve is arranged on the second material discharging passage; the lower end of the second material discharging passage is provided with a compaction feed bag in a sleeved way; and the finished product conveying device is positioned under the second material discharging passage. The continuous straw feed production line has the advantages that the crushing, compaction and bag charging continuous production can be realized; the production efficiency is high; the occupied space of straw feed is reduced; and the transportation and the storage of the straw feed are facilitated.

Owner:陈建钧

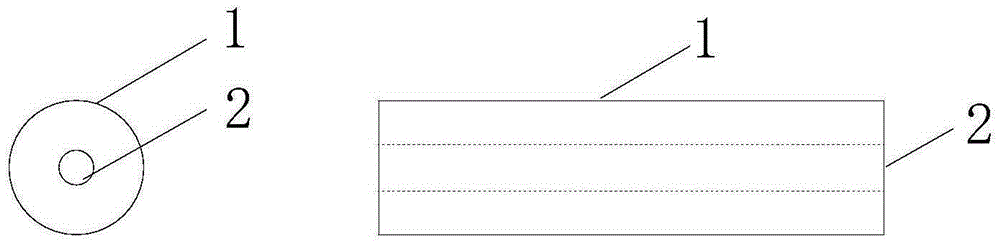

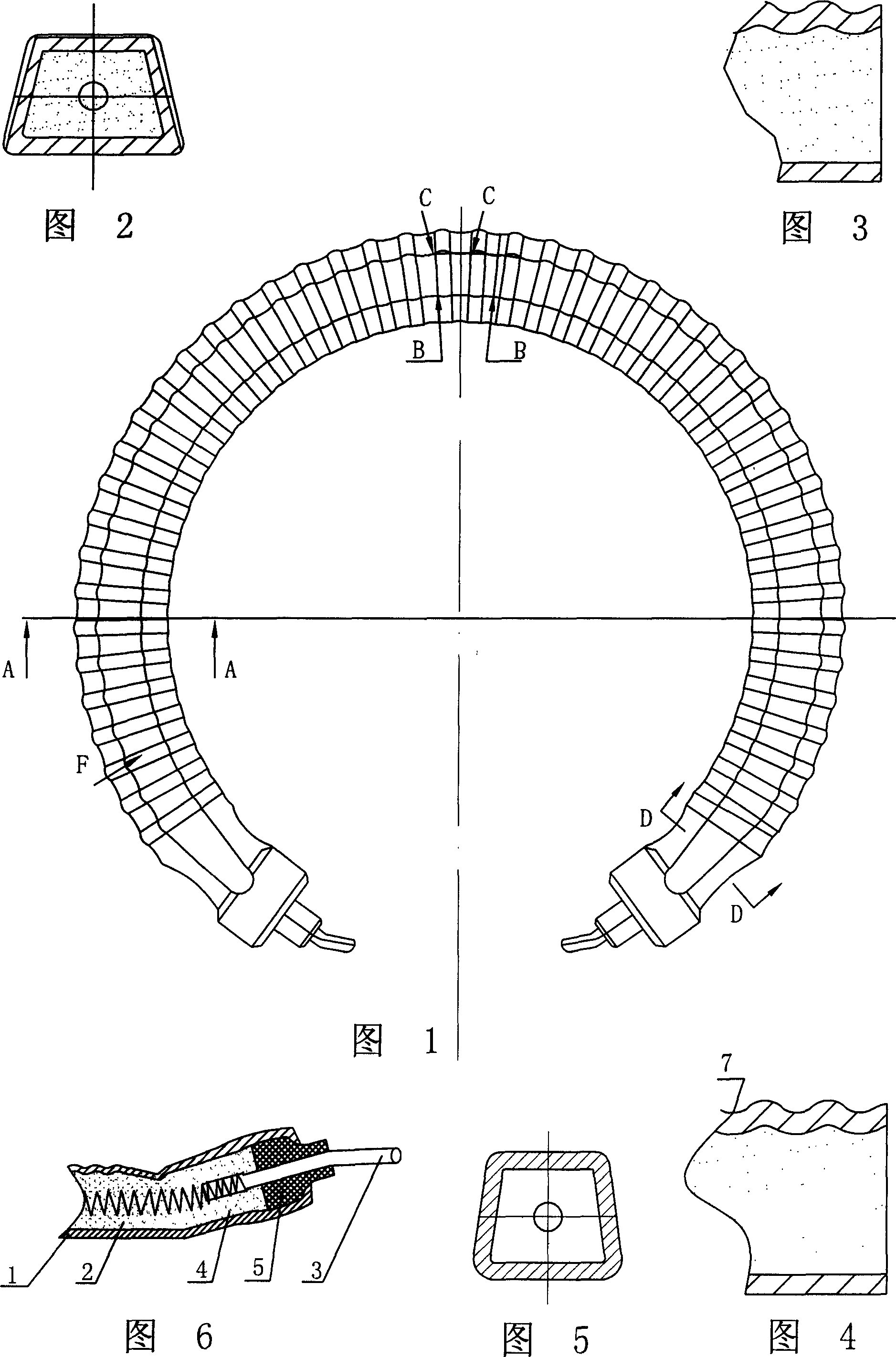

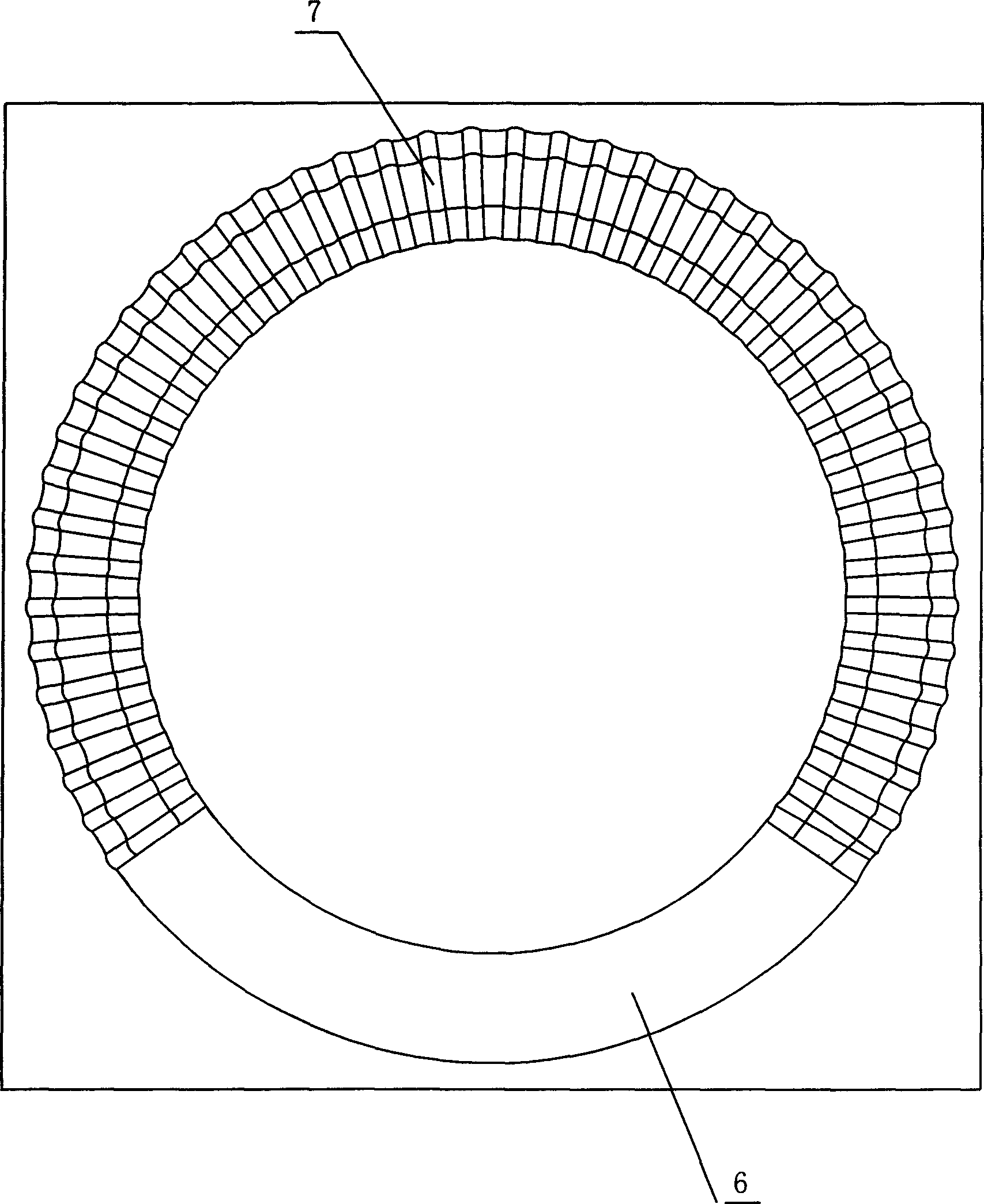

Electrothernal tube and its forming method

This invention is an electro-thermal tube and its molded method. It solves the question of electro-thermal tube which would be extended in length when they heating in the mould, then its length and shape cannot be controlled very accurately, and the insulation power inside the tube would not be compressed tightly. In the figure we can see the electro-thermal tube and in its inner insulation powder and electric resistance, block up at inlet of the metal tube, they keep distance with the rube and keep distance with the metal rod too. This tube has been shaped by a metal tube which has ellipse section in its face having concave and convex structure and at least has one plane structure. The step of forming the tube is to put the tube on the proper place into the model A, at the concave place on this model, and press model B upon model A. shape concave and convex structure on the metal tube's face and extend this action along the tube, when the shaping action finished, take out of the models.

Owner:何伟

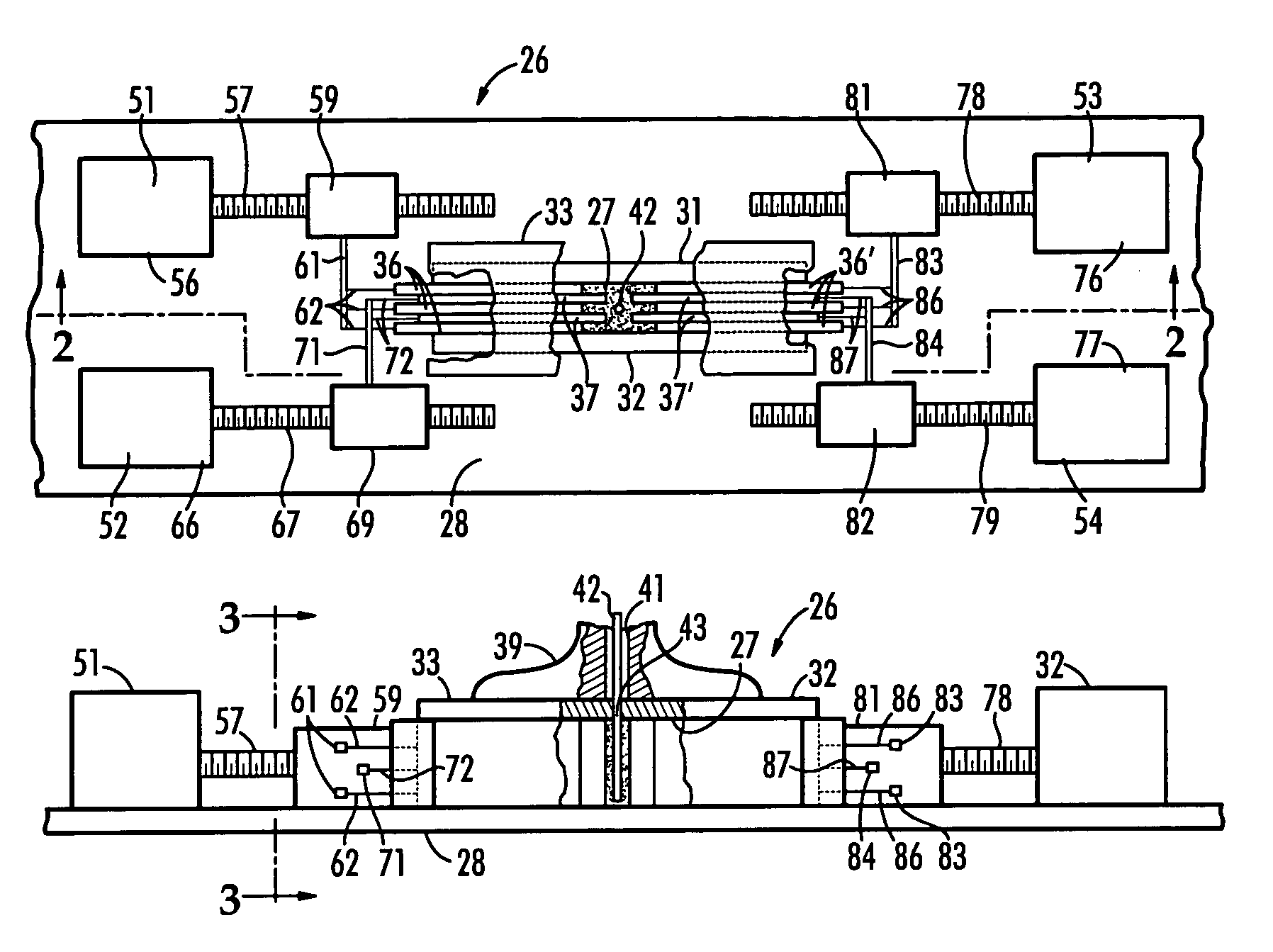

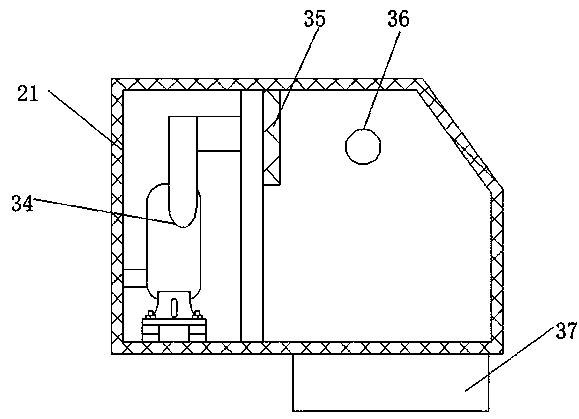

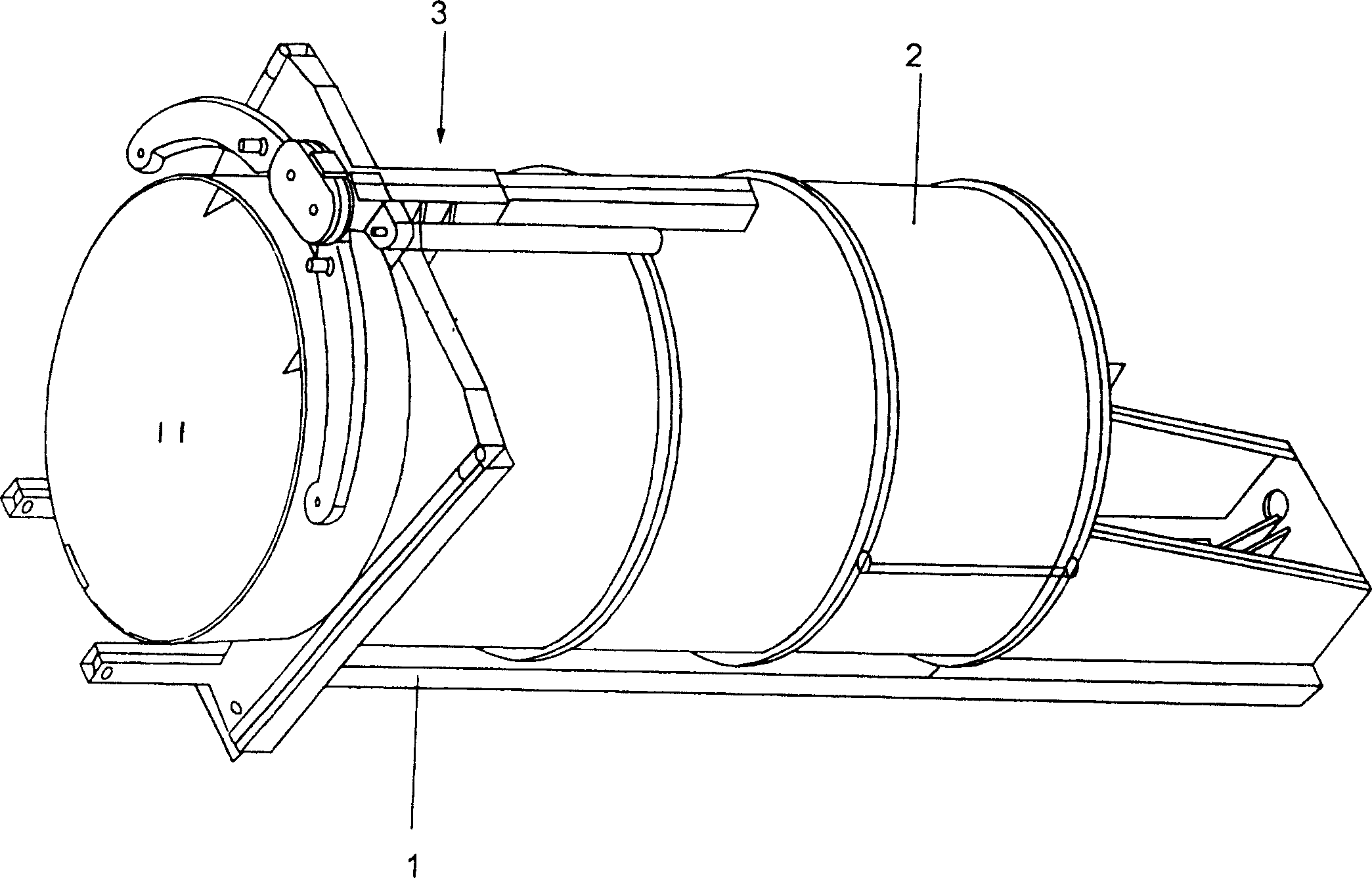

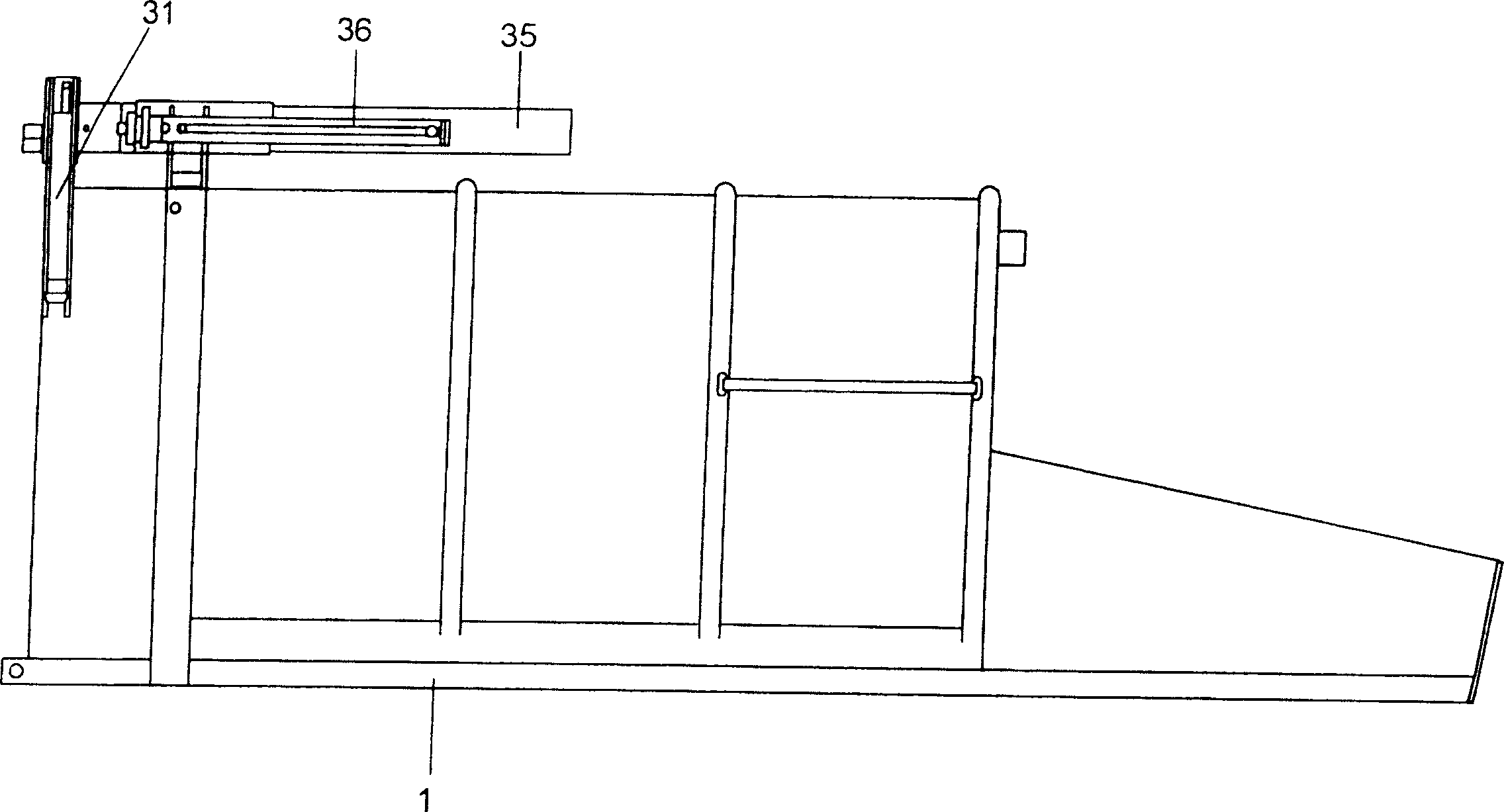

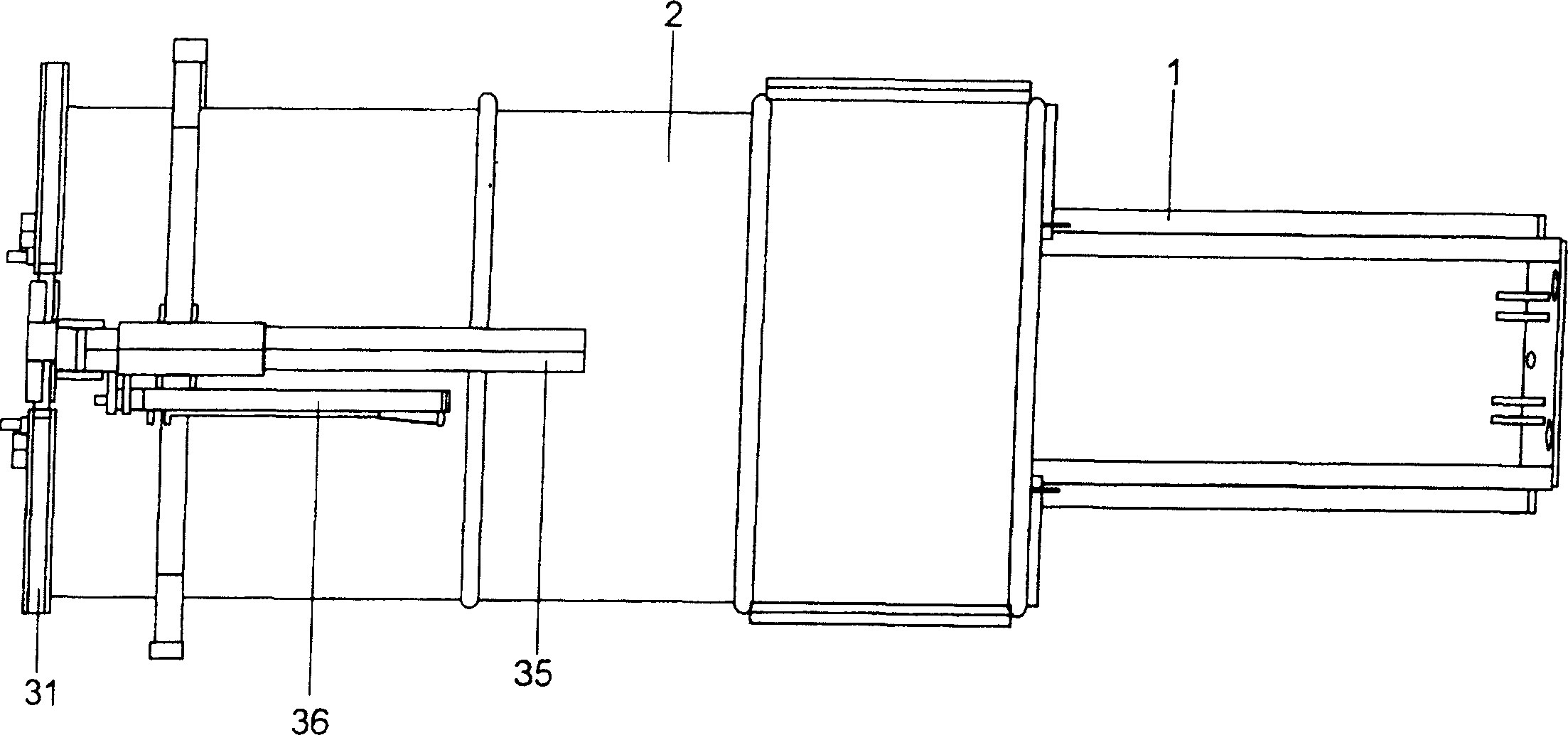

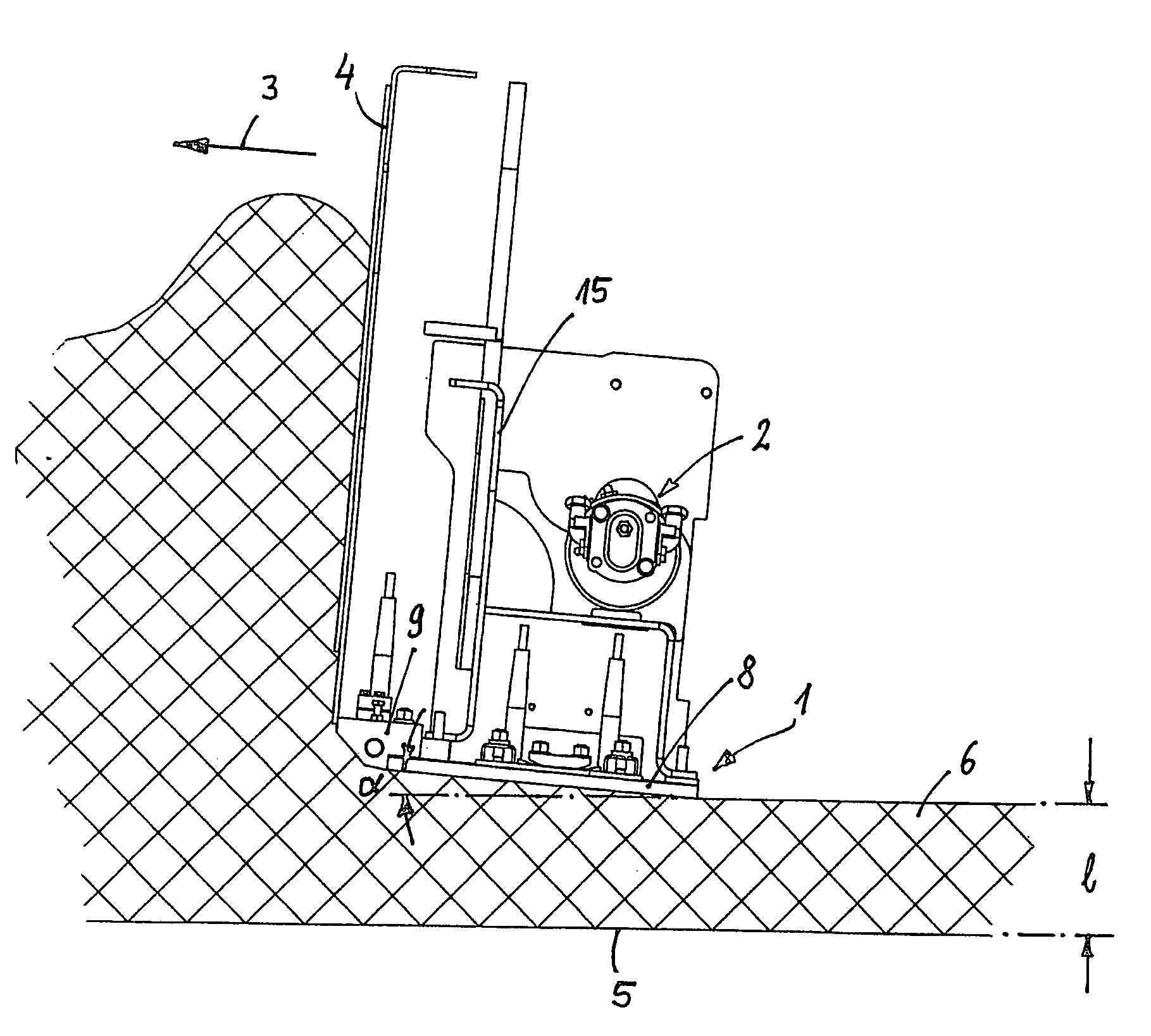

Device for generally waste collection, compaction and bagging

InactiveCN1756649AReduce volumeIncrease the compression ratioSolid materialRefuse vehiclesHydraulic cylinderWaste collection

This invention refers to a self-transported or towed equipment whose purpose is to collect, compact, and bag domestic, industrial and farming waste. The equipment is made up of a chassis ( 1 ) supporting a closed body ( 2 ) that is opened at both ends and has a back cover ( 4 ) to close the body and a moveable front compression plate ( 5 ). A clasping device of the accordion-like tube encircles the back part of the body ( 1 ). A bag sealing mechanism ( 3 ), operated by hydraulic cylinders ( 35, 36 ) and pliers ( 31 ) presses the loaded bag and squeezes it so as to place a sealing band manually. The lower part of the back cover ( 4 ) pivots on the chassis through a hydraulic cylinder ( 41 ) which is placed at the bottom of the chassis ( 1 ) and pulls cables ( 42 ) through grooved pulleys ( 43 ). The compression plate ( 5 ) is operated through a hydraulic system ( 6 ) made up of telescopic arms ( 61 ) propelled by independent hydraulics cylinders ( 62 ).

Owner:AICHSOL ECOLOGICAL RESOLUTION

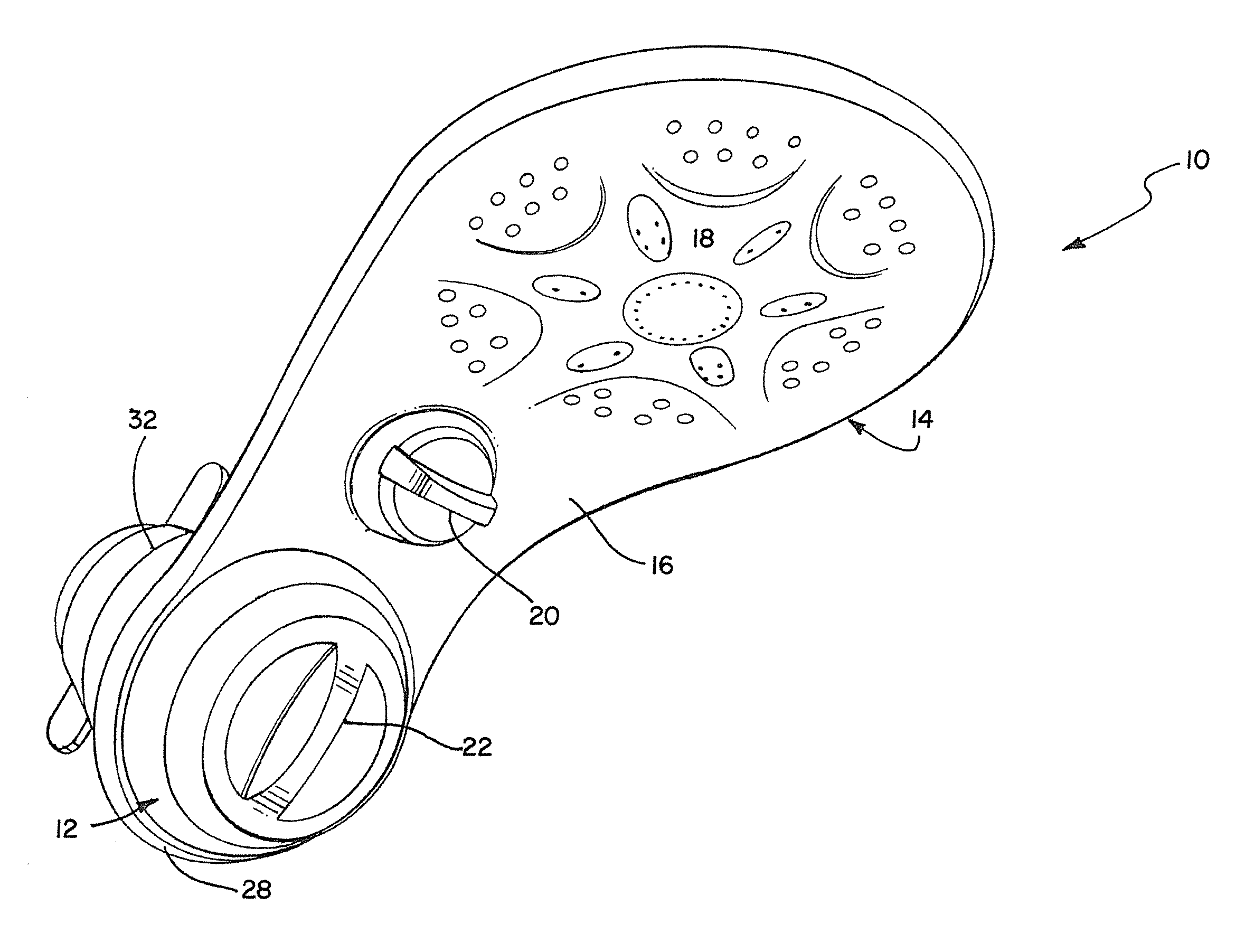

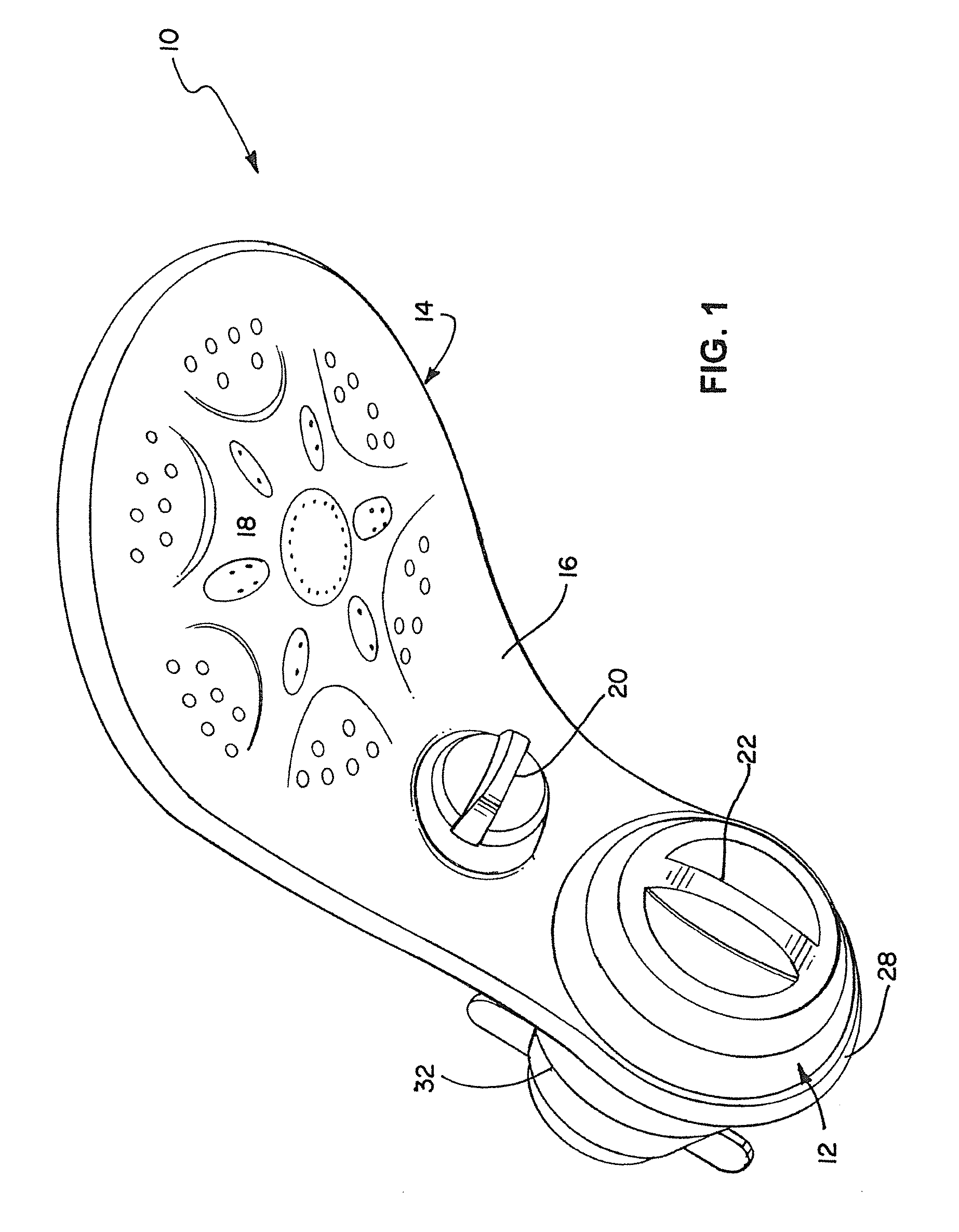

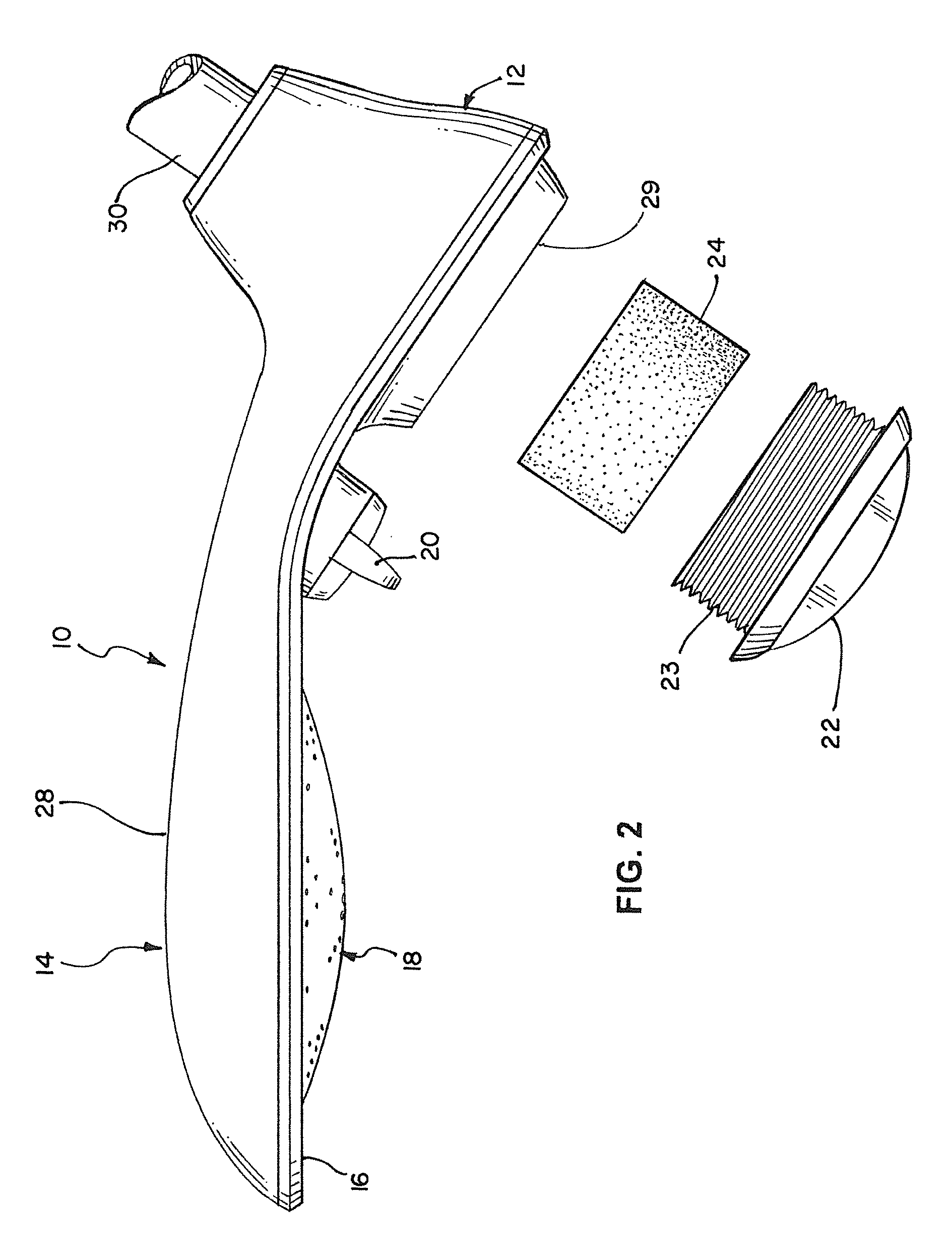

Offset filtered showerhead

ActiveUS9504940B2Improve filtering effectPoor filtration performanceTreatment involving filtrationDomestic plumbingWater filterMode switch

A multi-mode showerhead has a housing with a front and a back and an offset integrated water filter system incorporated into the showerhead so that the showerhead with the integrated water filter system may be easily mounted to a normal shower arm without the need of special tools. A water filter cartridge is easily added to or removed from a hollow filter chamber formed in the showerhead by the removal of a front facing filter chamber cap. A multi-mode switch thatselectively changes the spray pattern is mounted on the front between the water filter system and a plurality of nozzles. The entire showerhead and integrated offset water filter system is mounted on a shower arm by means of a swivel joint forming an inlet on the back of the housing and fluidly connected to the hollow filter chamber.

Owner:FARLEY MICHELLE

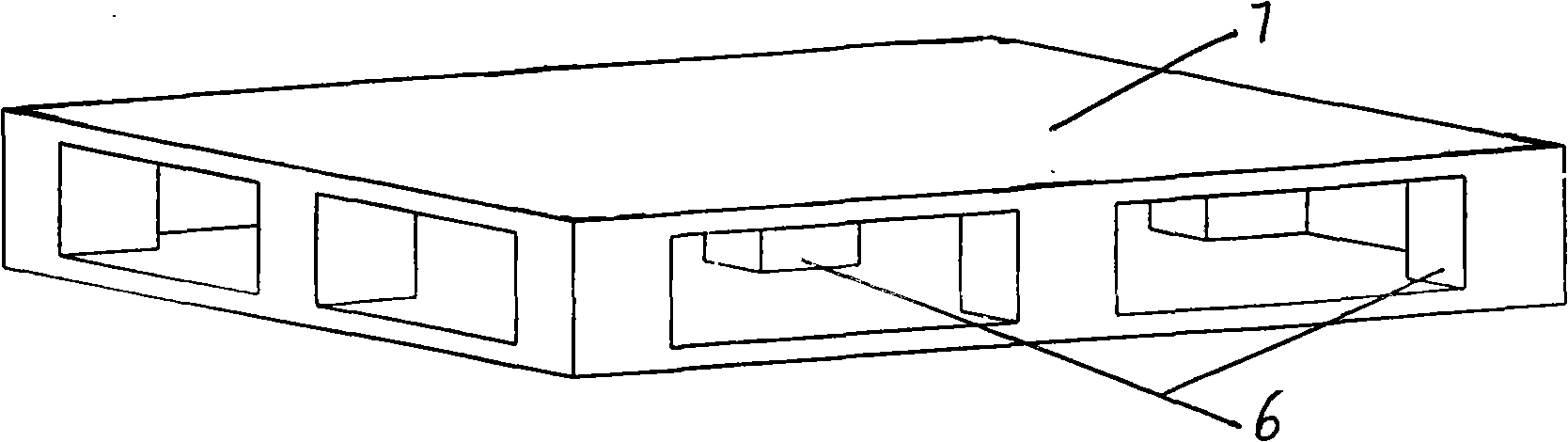

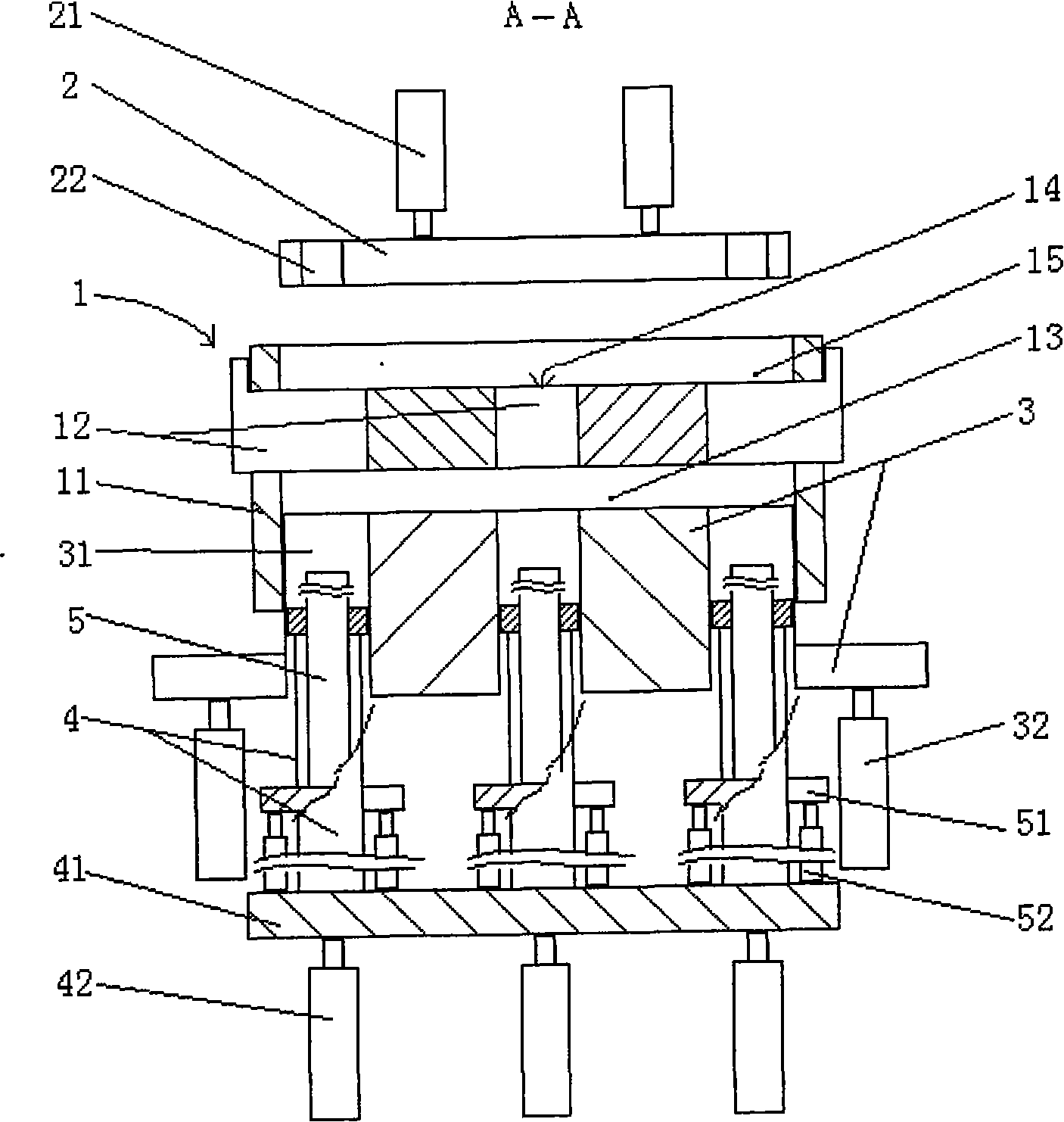

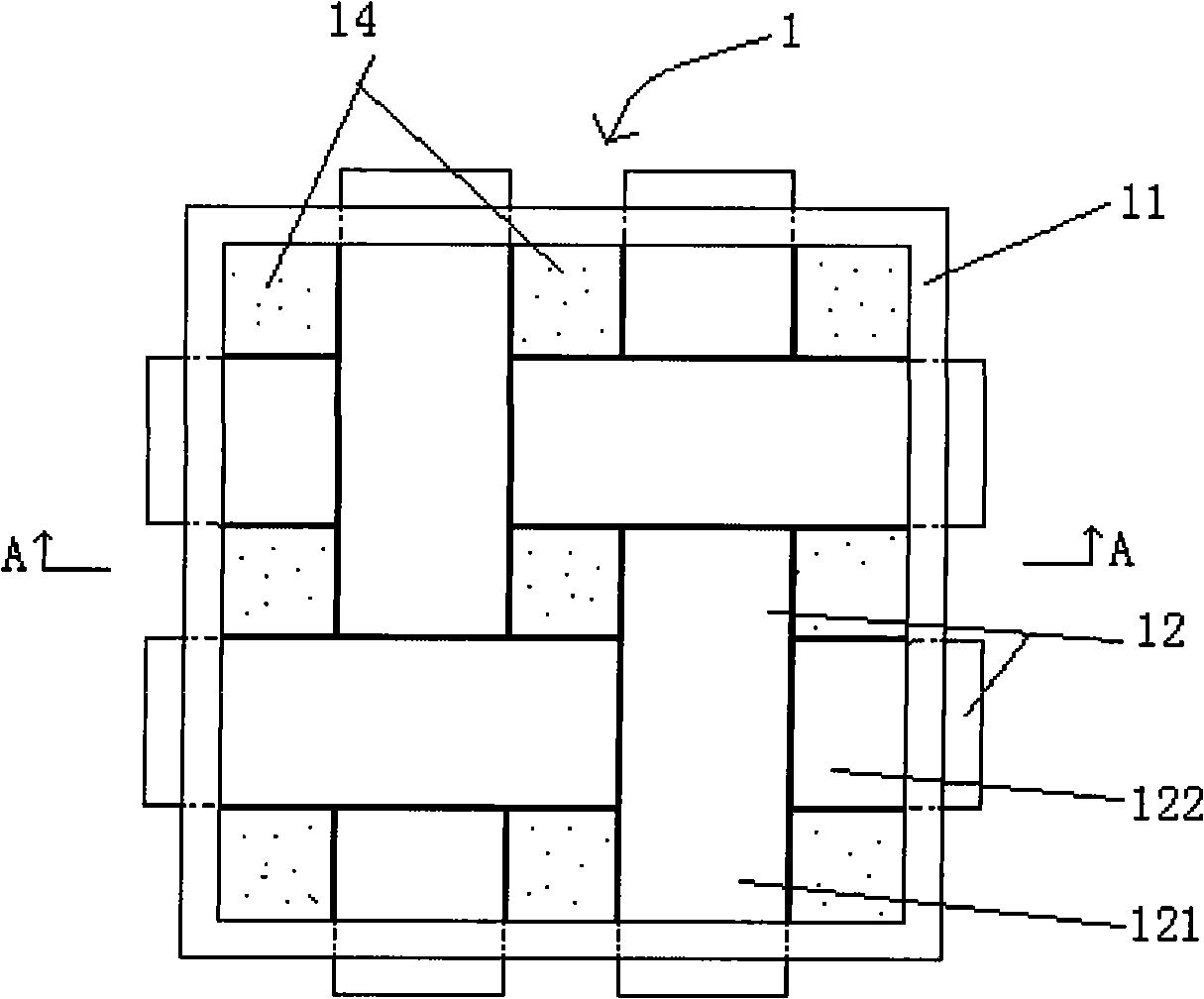

Double plank vegetable fibre tray as well as integral pressing method and special mould thereof

InactiveCN101525065AUniform axial densityEvenly compactedWood working apparatusDomestic articlesFiberEngineering

The invention discloses a double plank vegetable fibre tray as well as an integral pressing method and a special mould thereof. The special mould comprises a female mould, an upper punch, a lower punch, a core rod movably connected with the lower punch, and a power device, wherein the female mould comprises a frame and a spacing mould; the spacing mould extends into the middle of a frame cavity to divide the frame cavity into an upper plank die cavity, a lower plank die cavity and at least two supporting leg die cavities arranged between an upper plank and a lower plank; the lower punch comprises a lower punch A and a lower punch B; the punch head of the lower punch A axially moves in the lower plank die cavity of the female mould; and the punch head of the lower punch B axially moves in a die cavity hole of the lower punch A. The pressing method comprises the steps that: first, the upper plank is pressed by the upper punch; then the lower plank is pressed by the lower punch A; and supporting legs are pressed through the coordination of the lower punch B and the core rod. The invention has the advantages of even pressing, small damage ratio, large bearing force of finished products and low cost.

Owner:李苏扬

Vibratory paving screed for a paver

The invention relates to a vibratory paving screed for a paver, comprising a baseplate and a vibration drive therefor and also comprising a front wall which is mounted upstream of the baseplate in the paving direction, is fixed with respect to the baseplate and engages with the baseplate, in which arrangement the baseplate comprises a section of uniform thickness and, in the region of its front edge, a separate, solid strip which is connected to the section and has a metering slope and a flat run-in bevel situated behind.

Owner:ABG ALLG BAUMASCHINEN GMBH

Forestry sapling planting bending righting device

InactiveCN113303192AAvoid CatonPrevent damage to the spiral knife phenomenonPlantingFurrow making/coveringAgricultural engineeringSlide plate

The invention discloses a forestry sapling planting bending righting device. The device comprises a bottom plate, a first supporting plate capable of moving left and right is mounted on the inner wall of the right end of the bottom plate, a long vertical plate is fixedly connected to the surface of the upper end of the first supporting plate, a first sliding plate is slidably connected to the surface of the left end of the long vertical plate, and a spiral cutter is mounted at the left end of the first sliding plate. When the first supporting plate moves leftwards, a structure that the first sliding plate moves downwards can be formed, and when the first sliding plate moves downwards to the bottom end, a structure that the spiral cutter moves up and down while rotating can be formed. A rotatable first rotating shaft is installed at the left side of the upper end of the bottom plate, two arc-shaped connecting rods which are symmetrical in the front-back direction and mutually hinged in inner sides are arranged at the right end of the first rotating shaft, and when the first rotating shaft rotates, a structure that the arc-shaped connecting rods are folded towards the inner sides and then move upwards can be formed. Through the arc-shaped connecting rods which can be folded towards the inner sides and then move upwards, bent or inclined saplings can be righted.

Owner:邢红丽

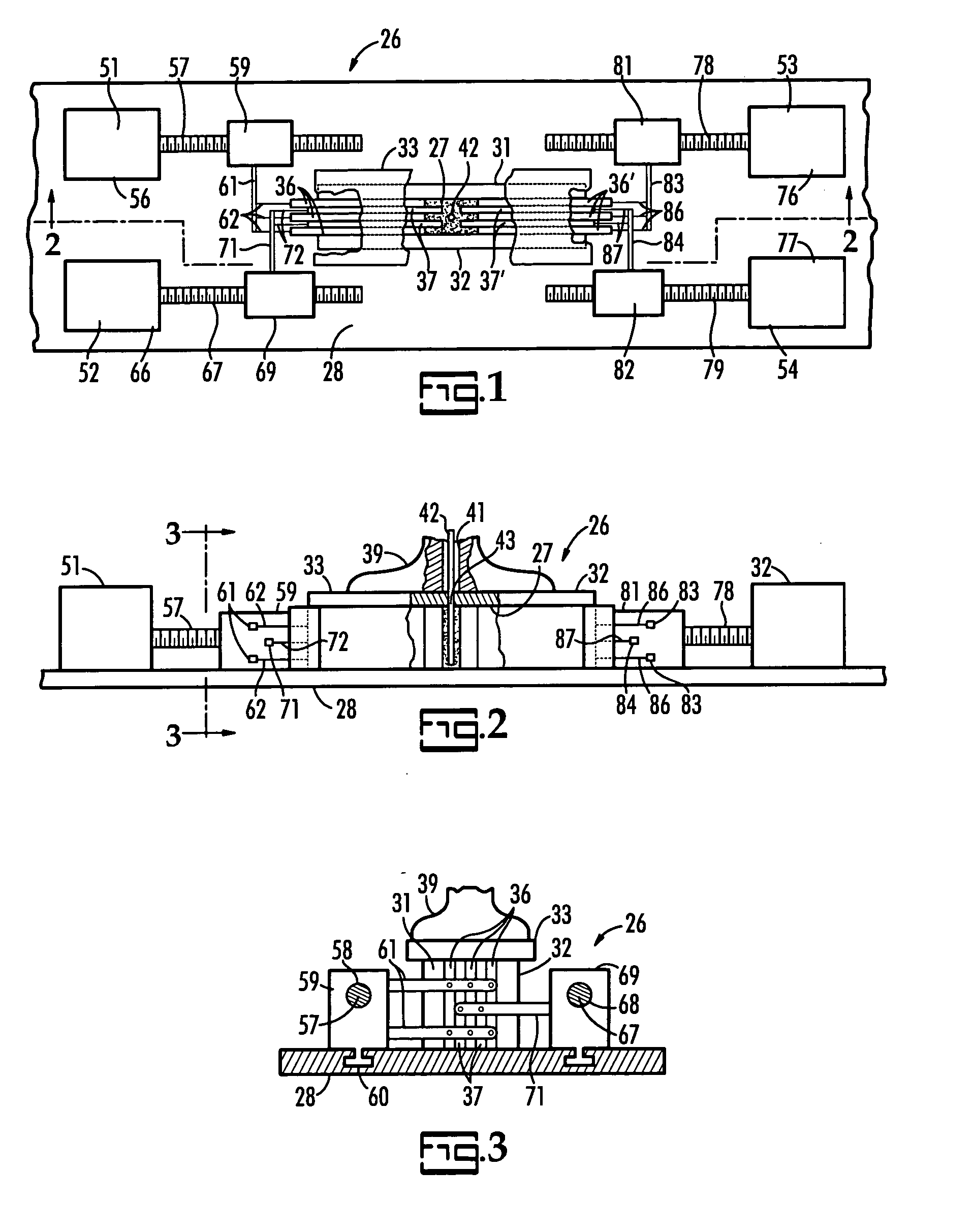

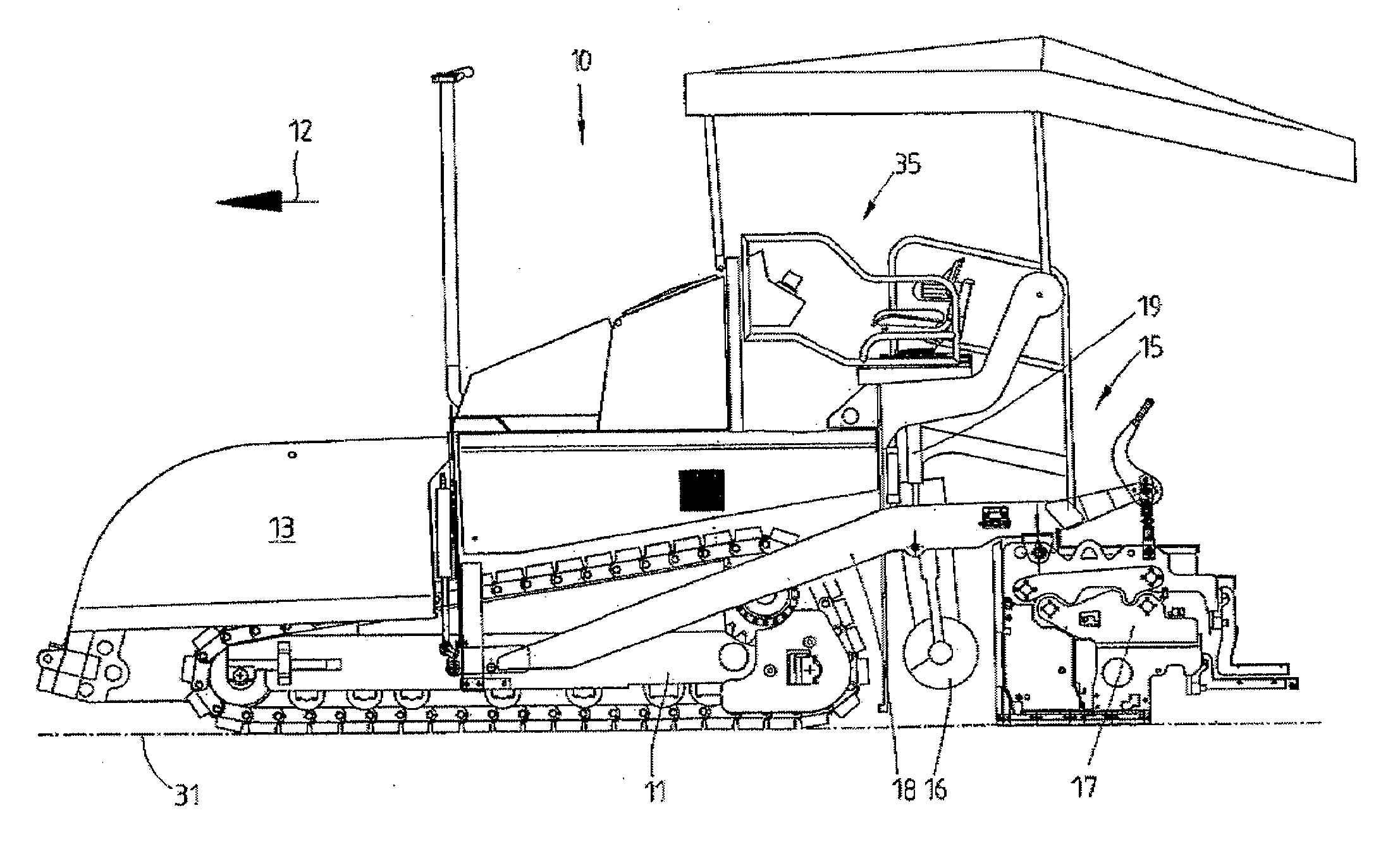

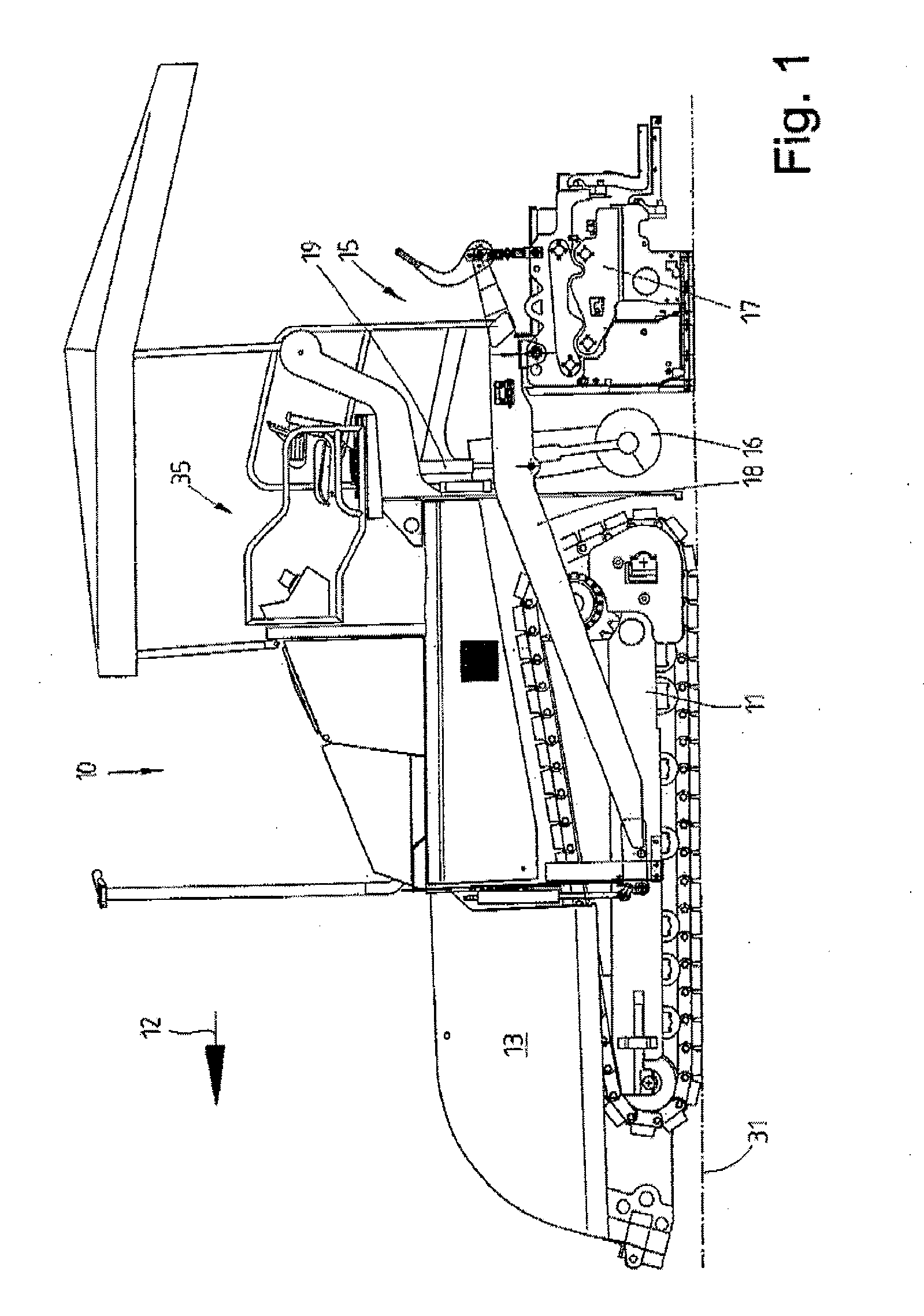

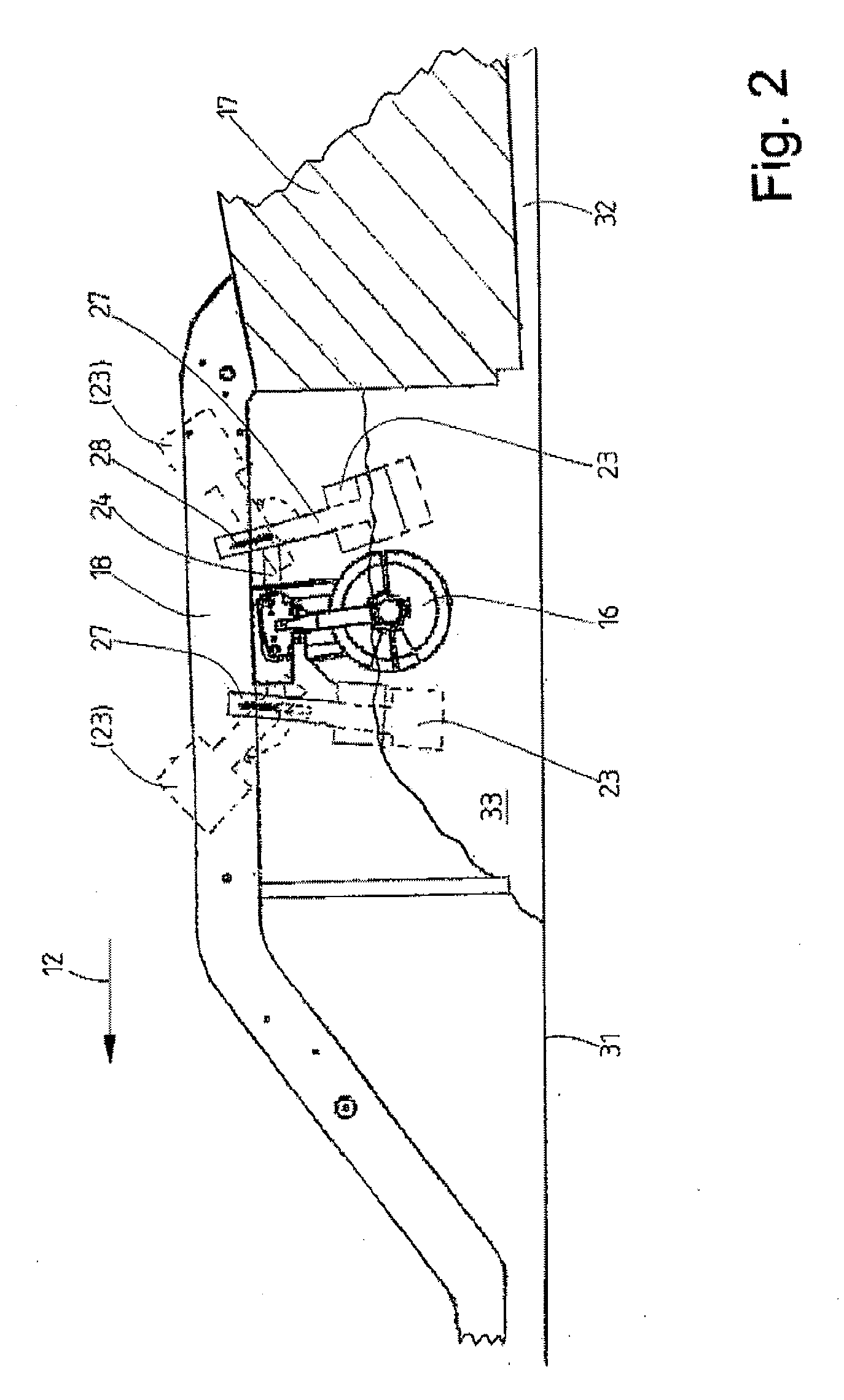

Method for Producing a Road Surface, Preferably a concrete road surface, and road paver

In the production of road surfaces of asphalt and concrete (33), it has been necessary hitherto to use different road pavers, which requires additional complexity, in particular when a wearing course (32) of concrete (33) is to be applied to a base (31) of asphalt. The invention provides to produce road surfaces of concrete (33) with a road paver intended for the processing of asphalt in that suspended vibrating bodies (23) are used which are inserted at least partially into the concrete (33) to be compacted. As a result, a road surface of concrete (33) can be produced with a road paver intended for the laying of road surfaces of asphalt. A laying screed (17) of the road paver is preferably guided rigidly, that is to say non-height-adjustably.

Owner:DYNAPAC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com