Corestone compaction device

A compaction device and core technology, applied in the direction of forming indenters, etc., can solve the problems of decreased experimental quality and uneven stress on the core, and achieve the effects of easy transportation, increased success rate, and good structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

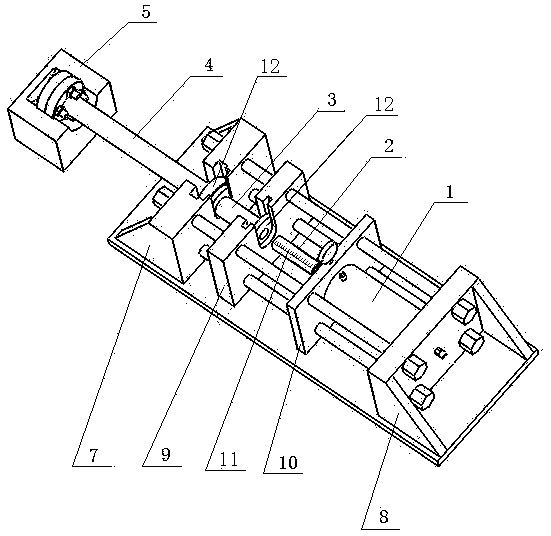

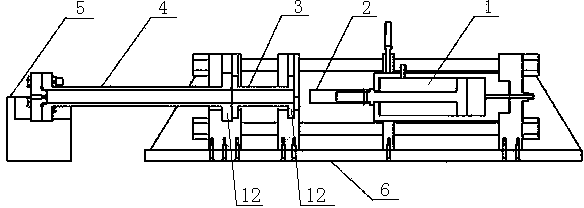

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

[0017] combine figure 1 , figure 2 As shown, this core compacting device includes a frame seat 6, a plunger type hydraulic cylinder 1, a filler pipe 3, a sand filling pipe 4, and a rear bracket 5 for the sand filling pipe. The two ends of the frame seat 6 have supports, two There are two support plates in the middle of the support, and the support at both ends and the two support plates are tightened by four steel columns to bear the pressure, and the support at both ends and the two support plates are used with the bottom plate of the frame seat. Tighten the large screw in place.

[0018] The front end of the plunger hydraulic cylinder 1 is located in the rear support plate 10, the plunger head is provided with a compaction head 2, and the scale line 11 is set on the compaction head 2, and the rear end of the plunger hydraulic cylinder 1 just sits on the rear suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com