Patents

Literature

383results about How to "Unlimited length" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

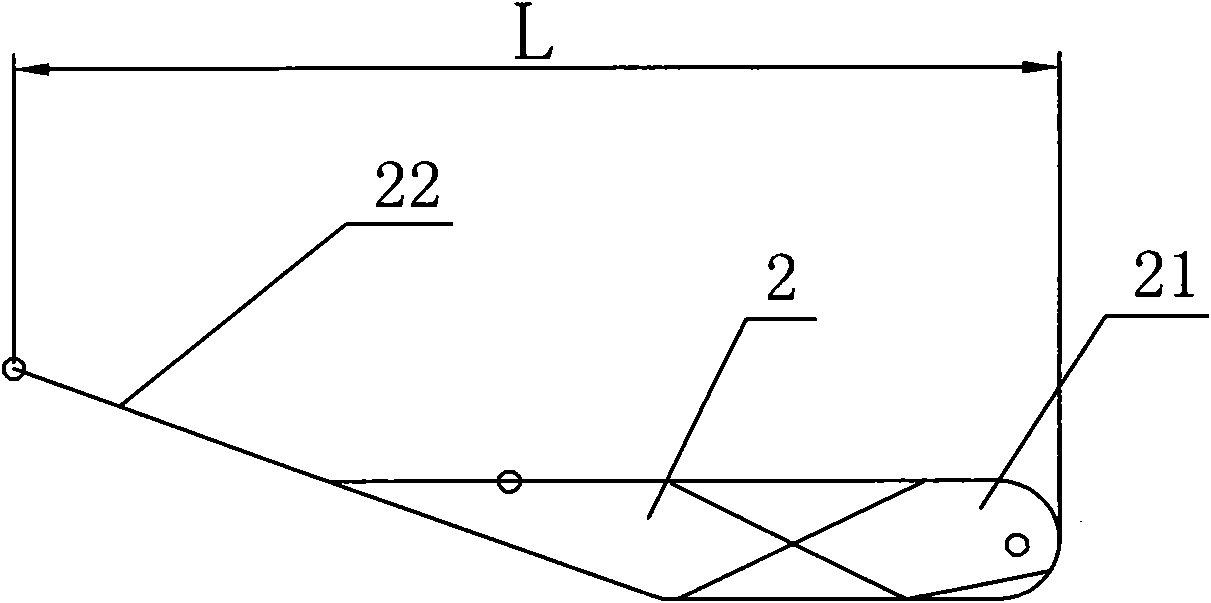

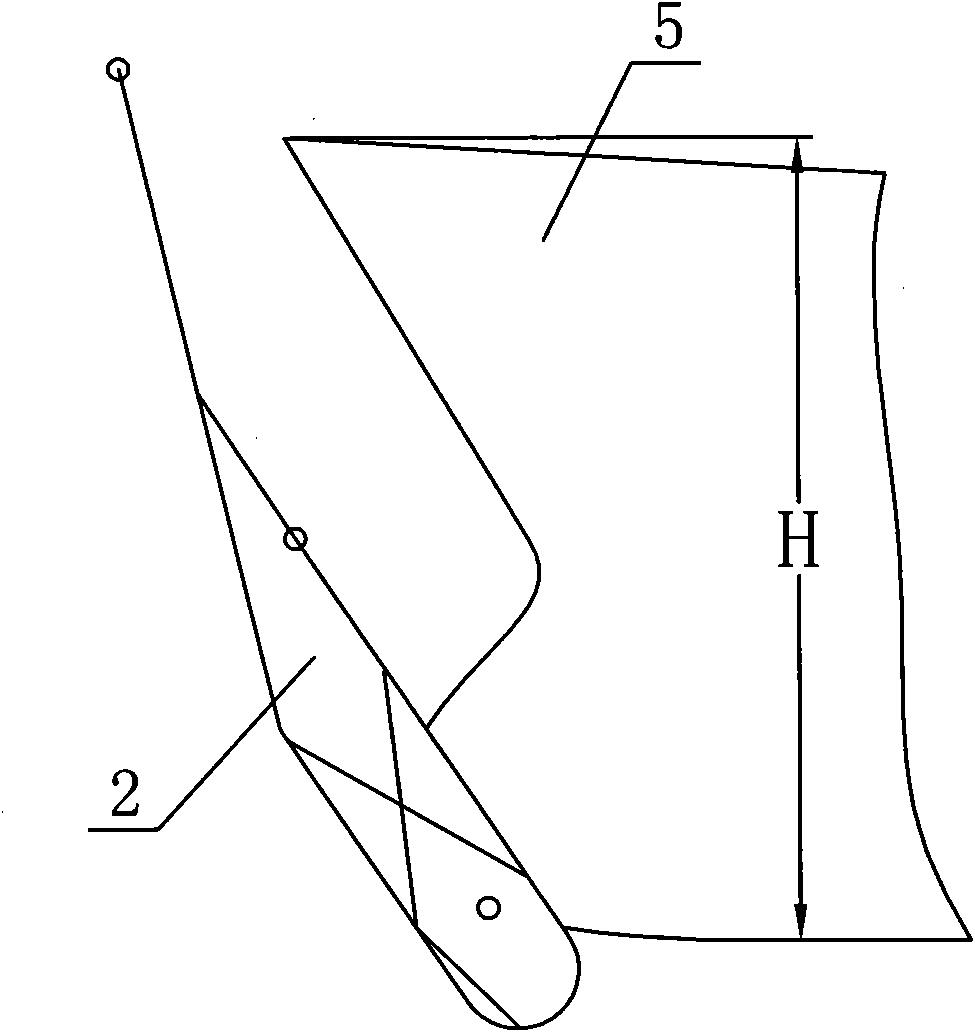

Production method of transverse wedge-shaped rolled thickness-variable steel plate

InactiveCN103302094AUnlimited lengthImprove efficiencyRoll mill control devicesMetal rolling arrangementsSteel platesSheet steel

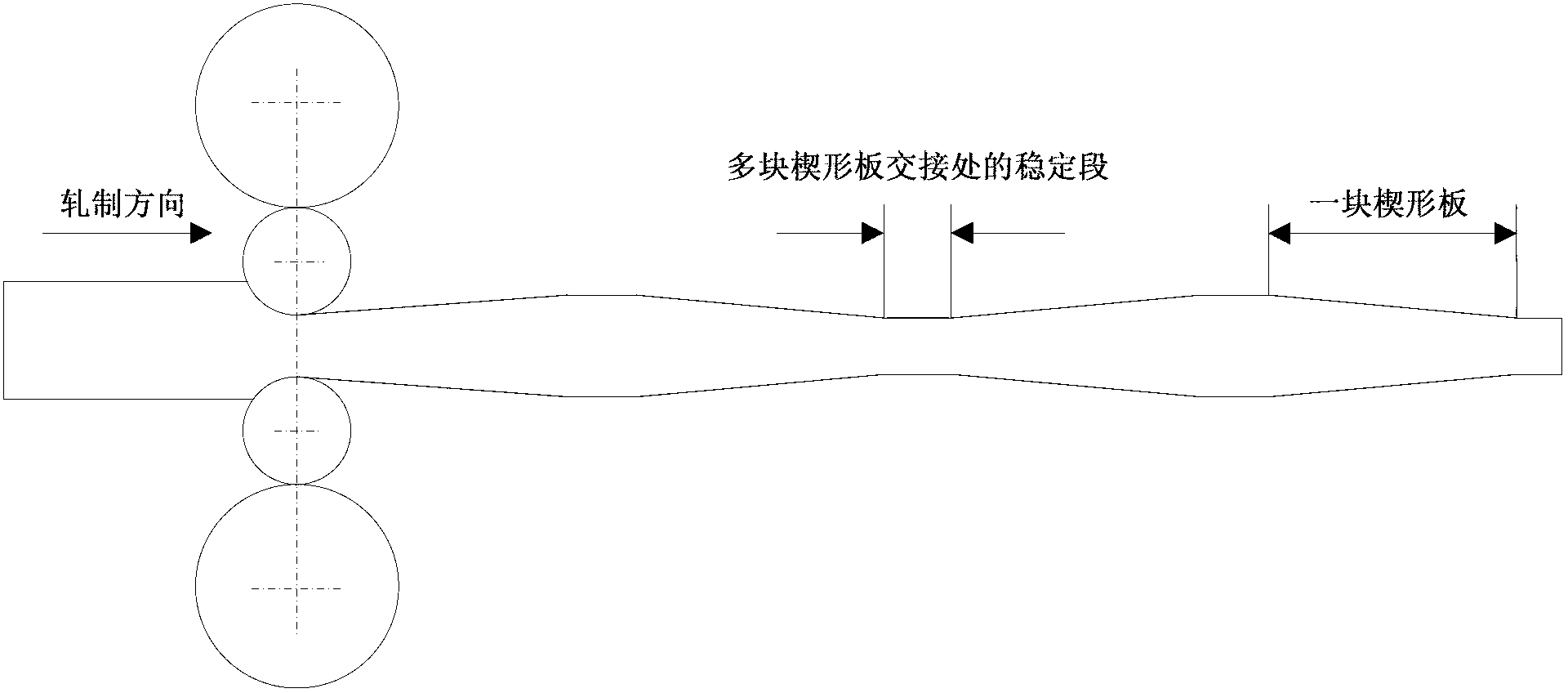

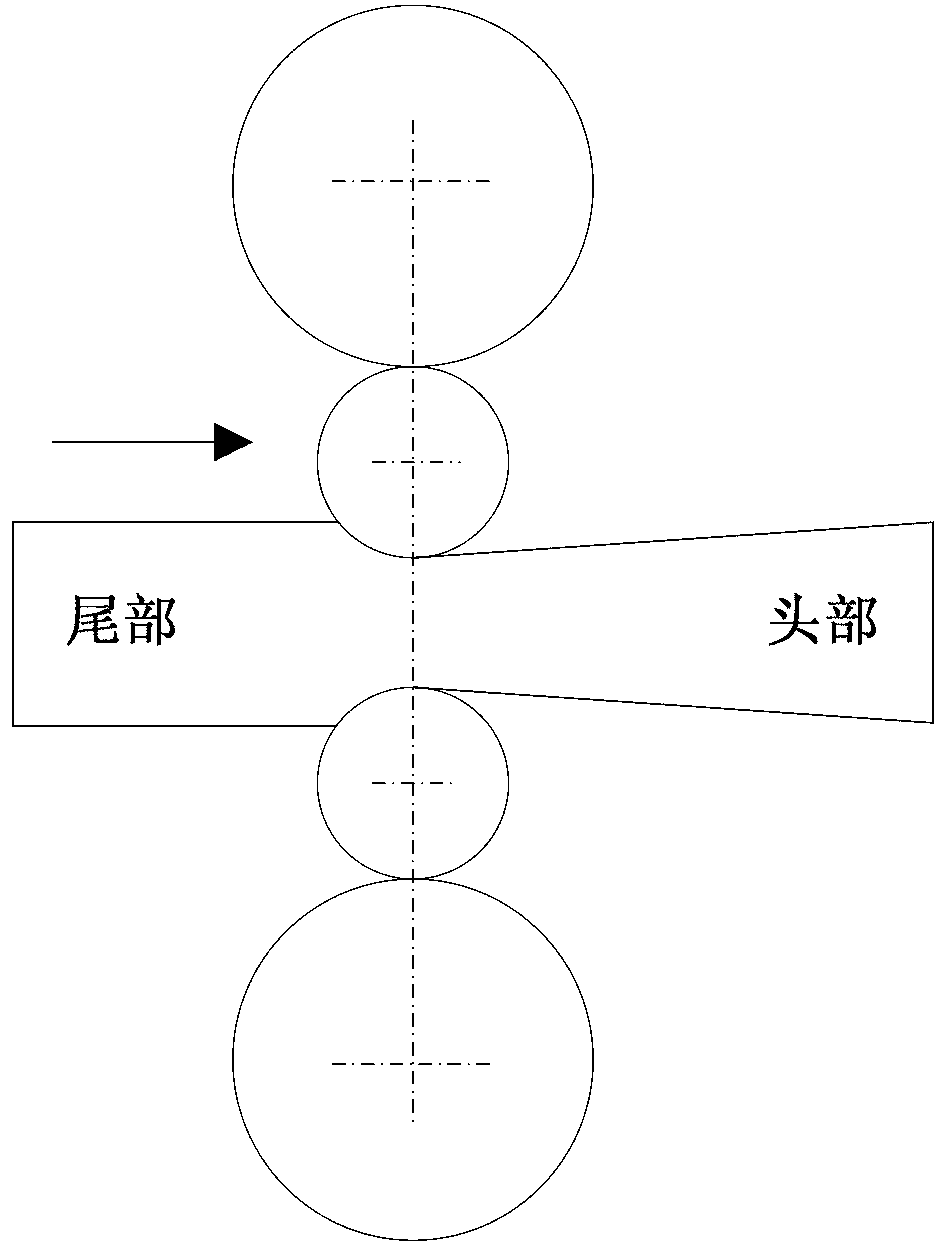

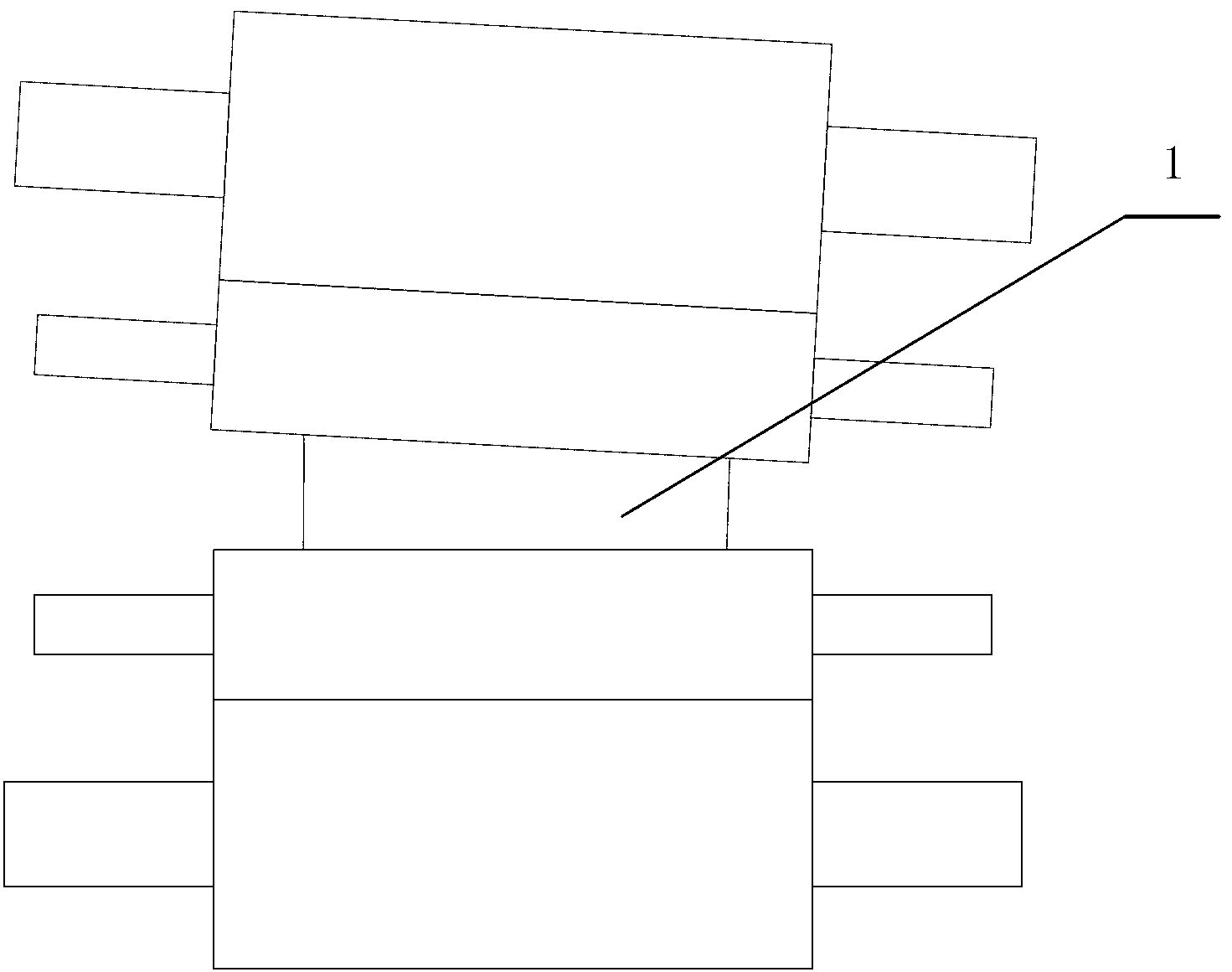

The invention discloses a production method of a transverse wedge-shaped rolled thickness-variable steel plate, belongs to the technical field of rolling, and provides the production method of the transverse wedge-shaped rolled thickness-variable steel plate by employing a thickness-variable steel plate in a transverse wedge-shaped rolling mode. The production method is high in yield and high in production efficiency. The production method comprises the following steps: step 1, transversely rolling, namely, carrying out longitudinal cross section-variable rolling on the steel plate according to average thickness set values of the head part and the tail part of the steel plate in the last rolling in the transverse rolling period; and step 2, longitudinally rolling, namely, firstly, in the longitudinal rolling period, carrying out transverse equal-proportion wedge-shaped rolling according to head-tail longitudinal thickness-variable values generated in the transverse rolling period, and secondly setting roller seam adjustment amount and roll bending force set values by employing an influence function method according to rolling schedule distribution, and ensuring that the transverse thickness distribution in the longitudinal rolling meets the equal-proportion wedge-shaped requirements.

Owner:NORTHEASTERN UNIV

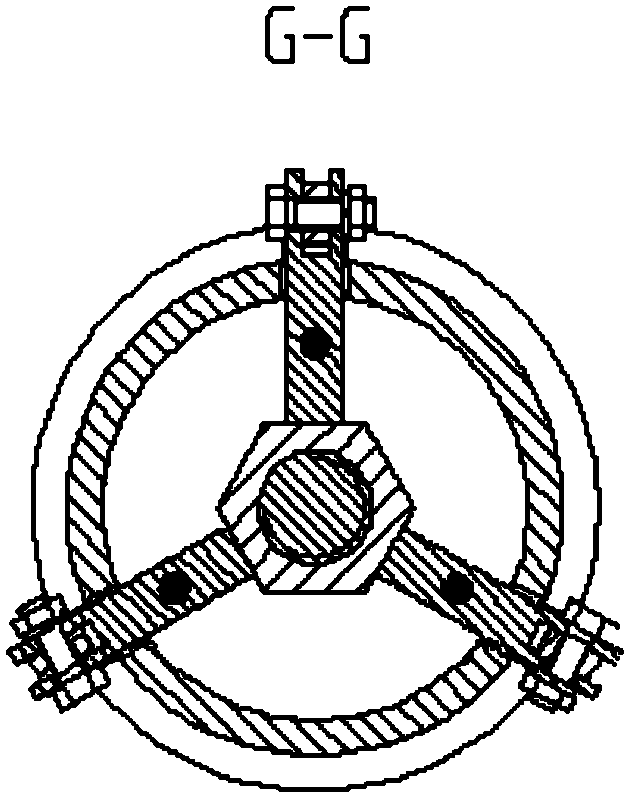

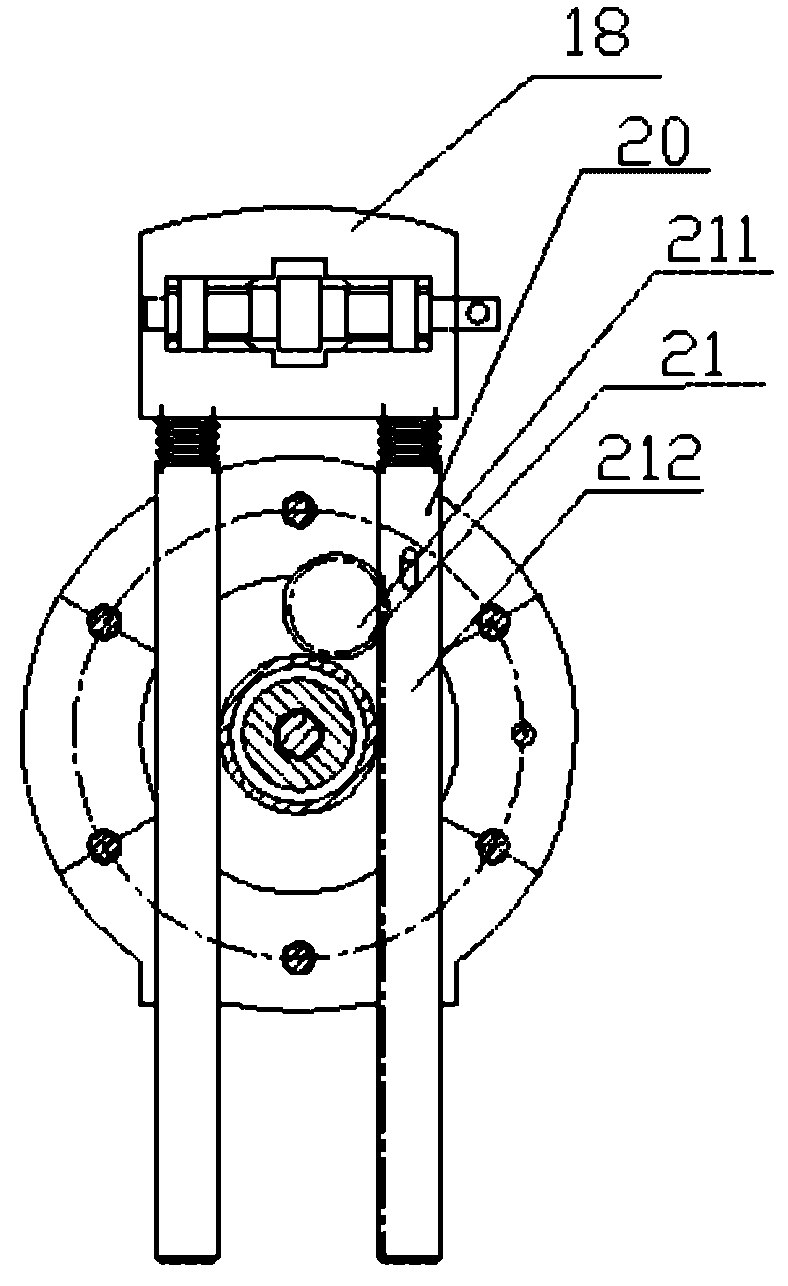

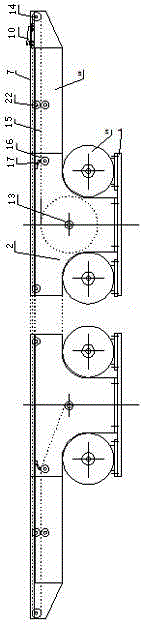

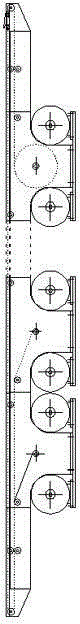

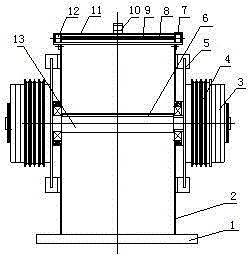

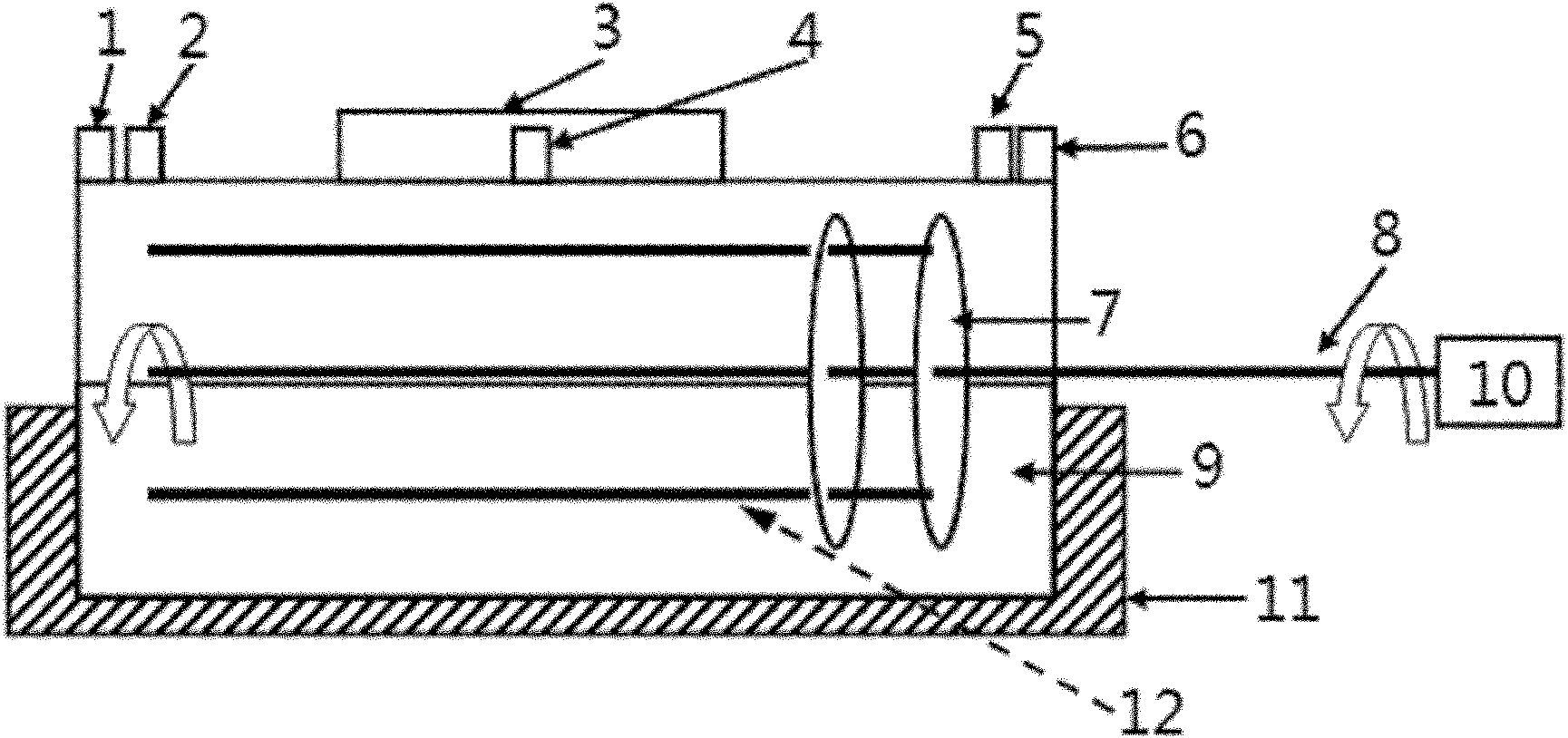

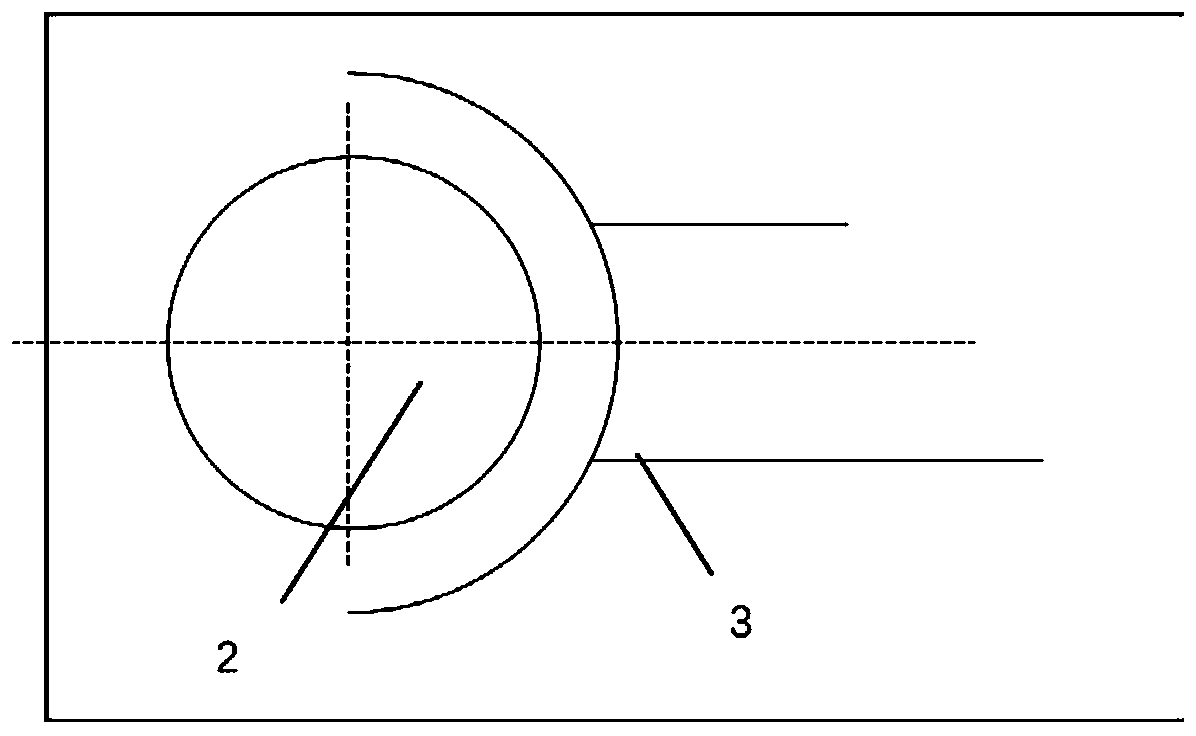

Automatic polishing machine for inner circle of long pipe

ActiveCN102320027AReduce energy consumptionGood degree of automationPolishing machinesMechanical engineering

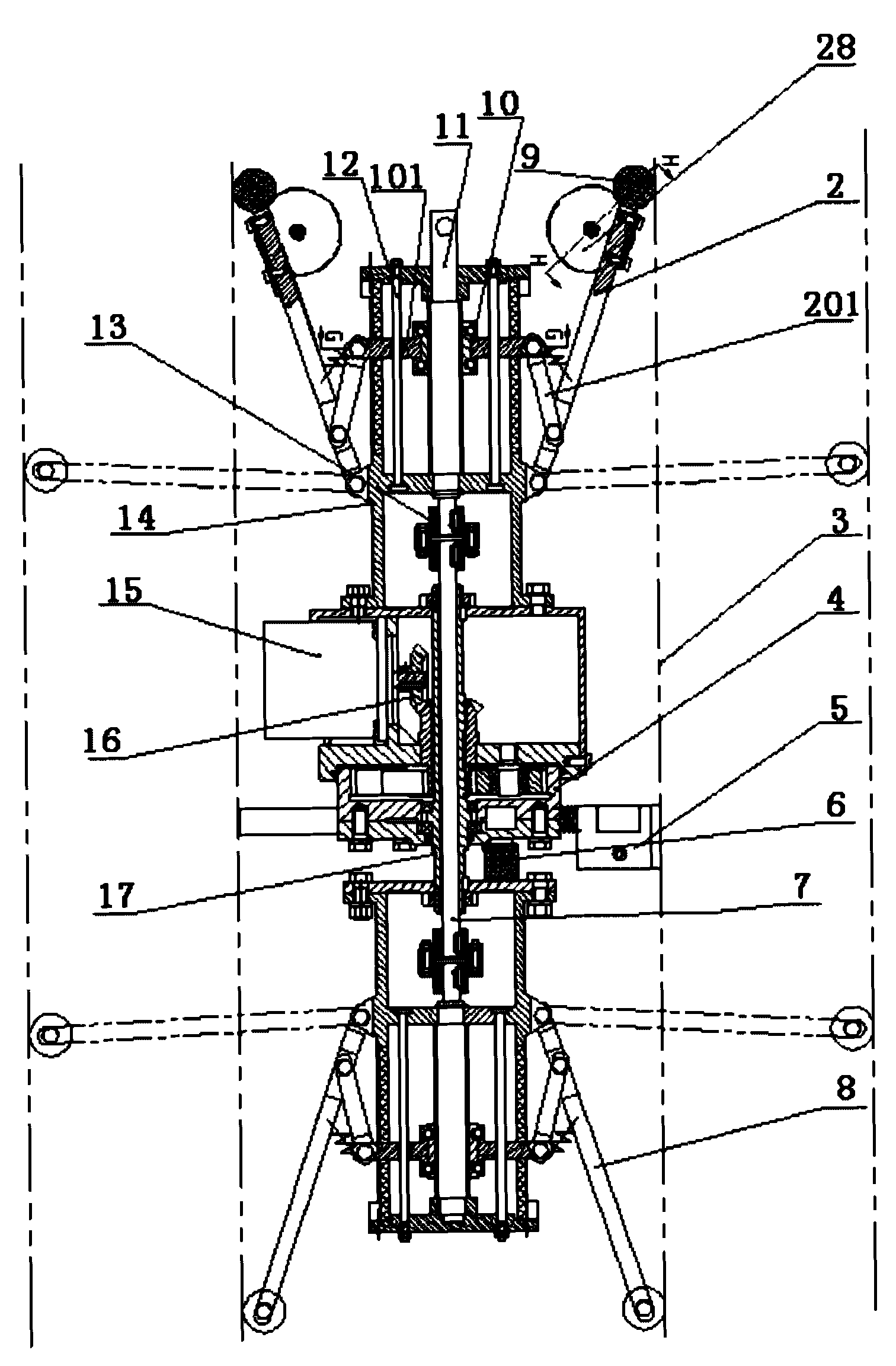

The invention discloses an automatic polishing machine for an inner circle of a long pipe. The automatic polishing machine consists of a polishing mechanism and a travelling mechanism. The polishing mechanism consists of a circumferential feeding mechanism and a polishing chuck; the circumferential feeding mechanism is realized by driving a planet gear mechanism through a motor; the polishing chuck consists of an adjusting mechanism and a polishing head clamping mechanism; the adjusting mechanism of the polishing chuck is a gear rack mechanism; and the polishing head clamping mechanism consists of left and right spiral mechanisms and a V-shaped chuck, and can be used for clamping polishing heads of different types. The travelling mechanism mainly consists of an adaptive pipe diameter mechanism and a long pipe axial feeding mechanism; the adaptive pipe diameter mechanism consists of a lead screw and a connecting rod; and in the long pipe axial feeding mechanism, small wheels are drivento rotate by a motor fixed on the connecting rod so as to push the polishing machine to advance in the inner circle of the pipe along the axial pipe axis. The automatic polishing machine is mainly applied to polishing of the inner circle of the relatively long pipe with certain diameter.

Owner:ZHEJIANG UNIV OF TECH

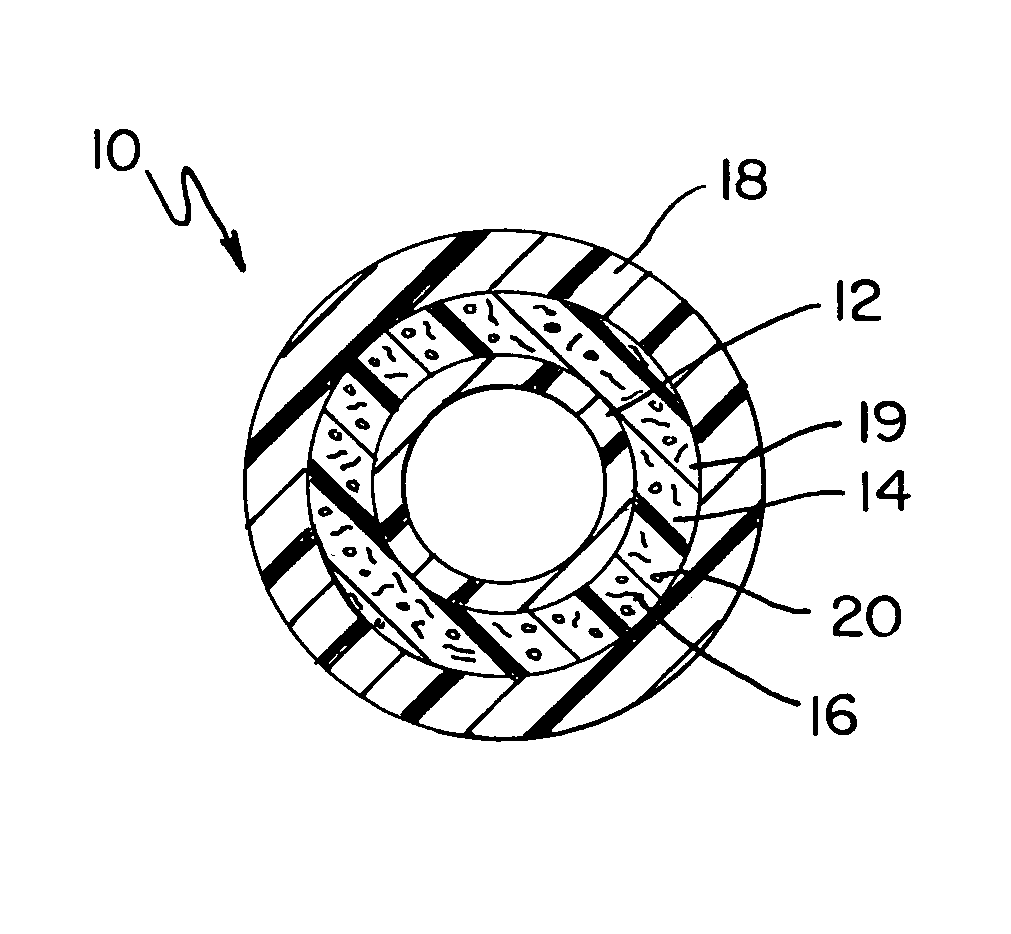

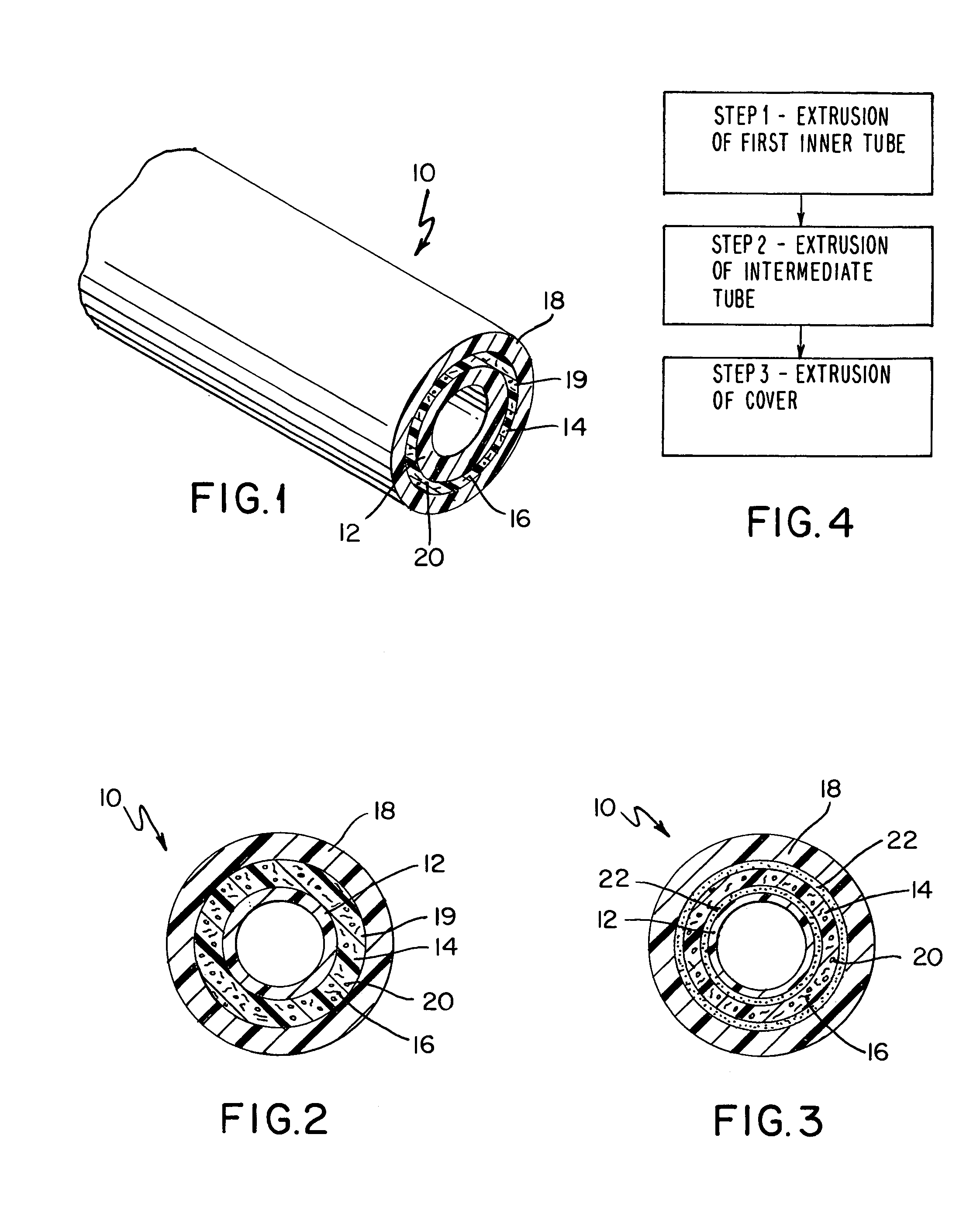

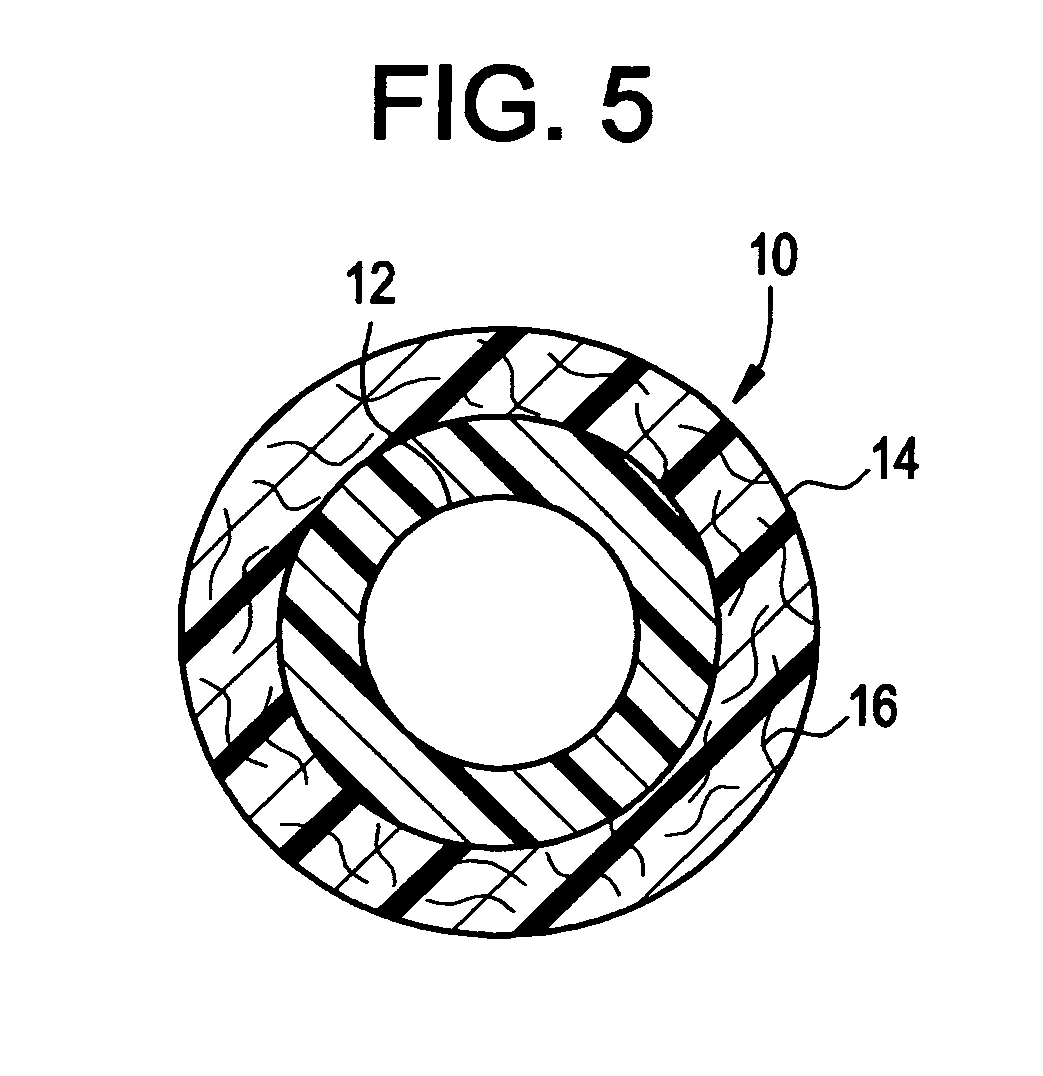

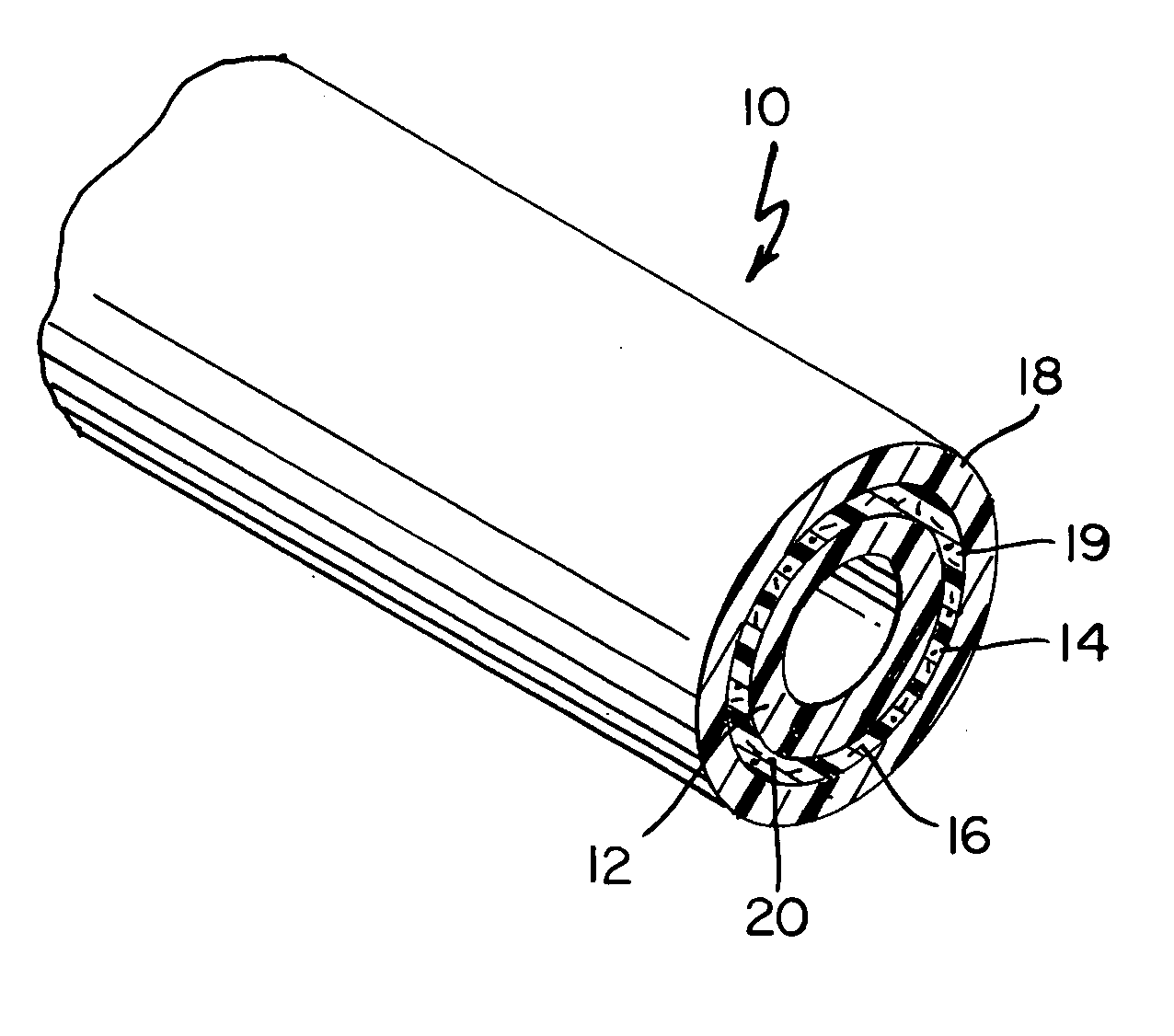

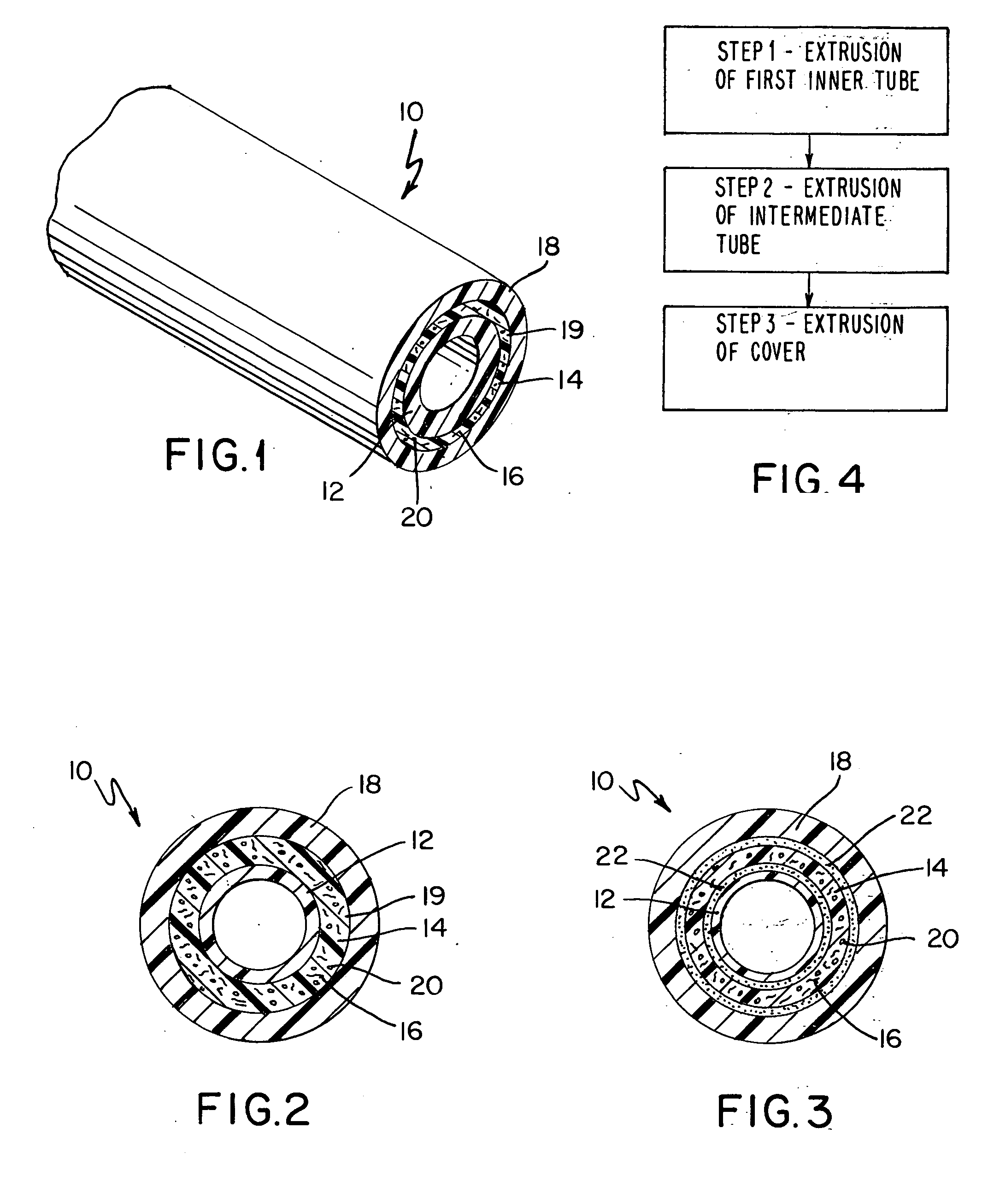

Multi-layered flexible tube

InactiveUS7281547B2Enhanced hoop strengthImprove adhesionSynthetic resin layered productsLaminationBiomedical engineeringPolymer architecture

Owner:FLUID ROUTING SOLUTIONS

Multi-layered flexible tube

InactiveUS20050170118A1Increase in production rateDecrease production cost and complexitySynthetic resin layered productsLaminationBiomedical engineeringPolymer architecture

Owner:FLUID ROUTING SOLUTIONS

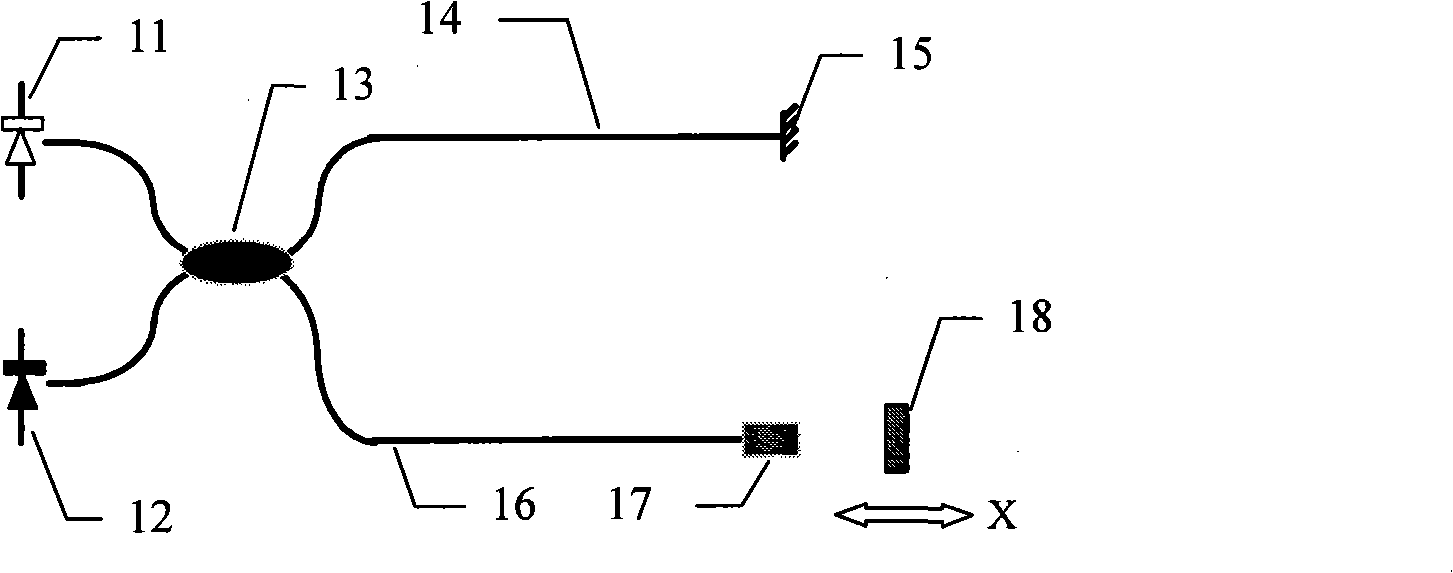

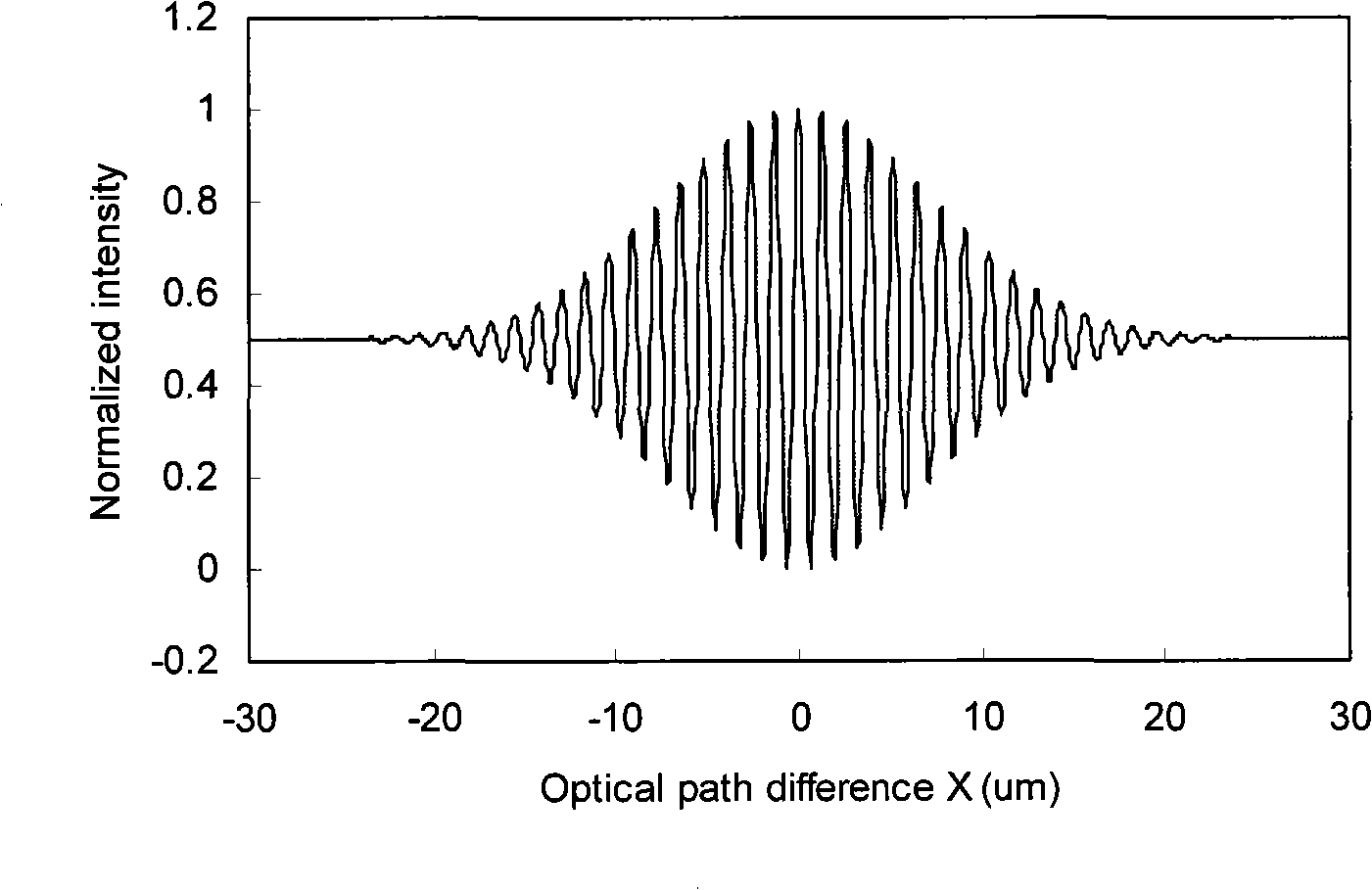

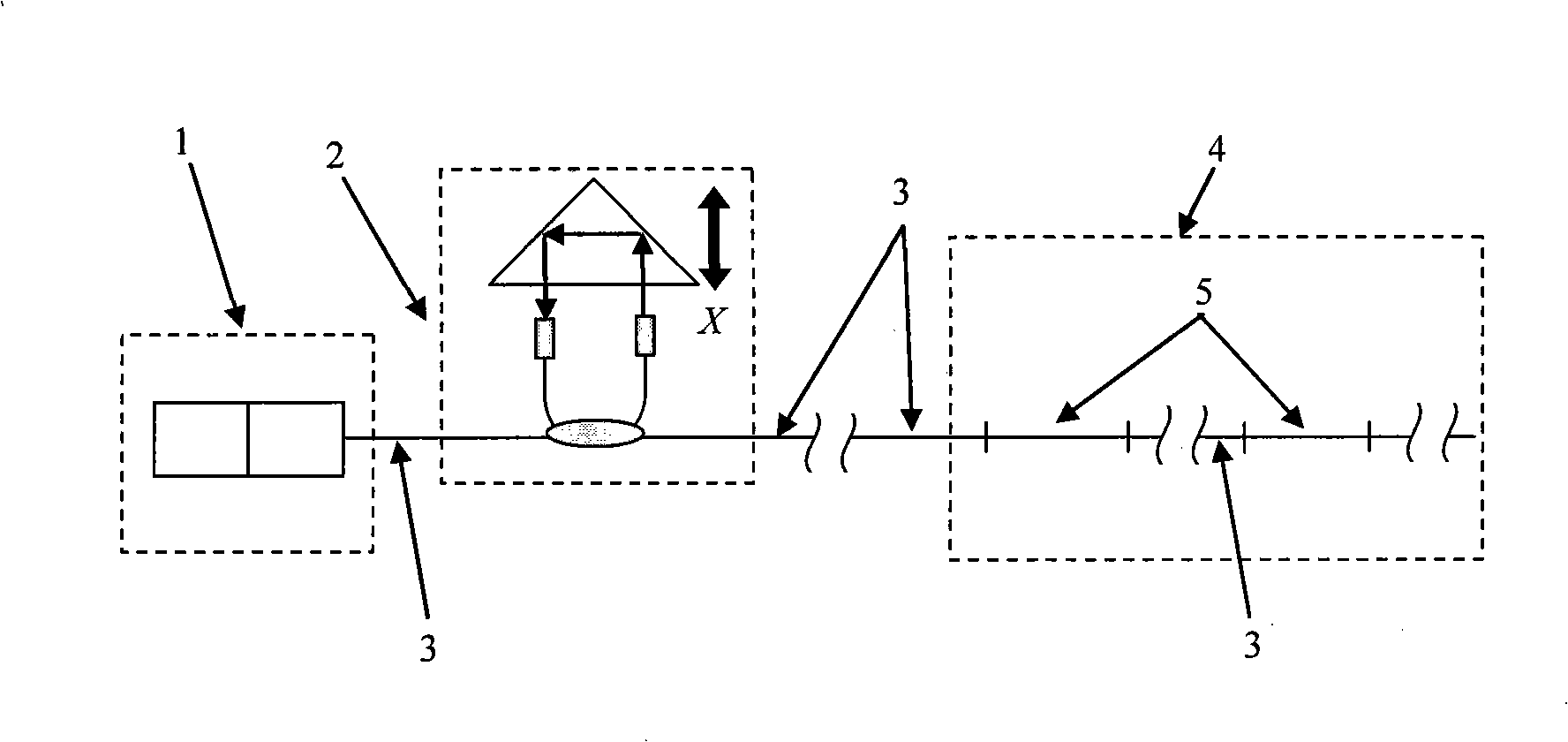

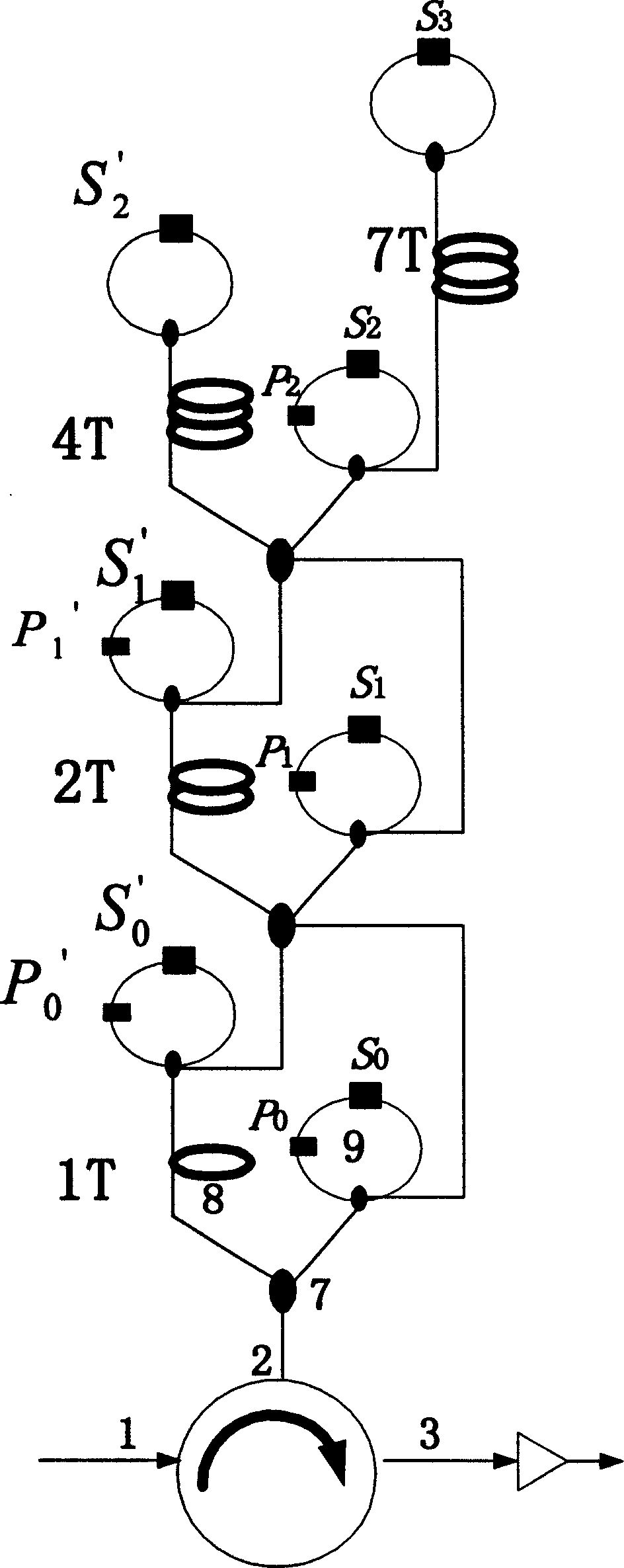

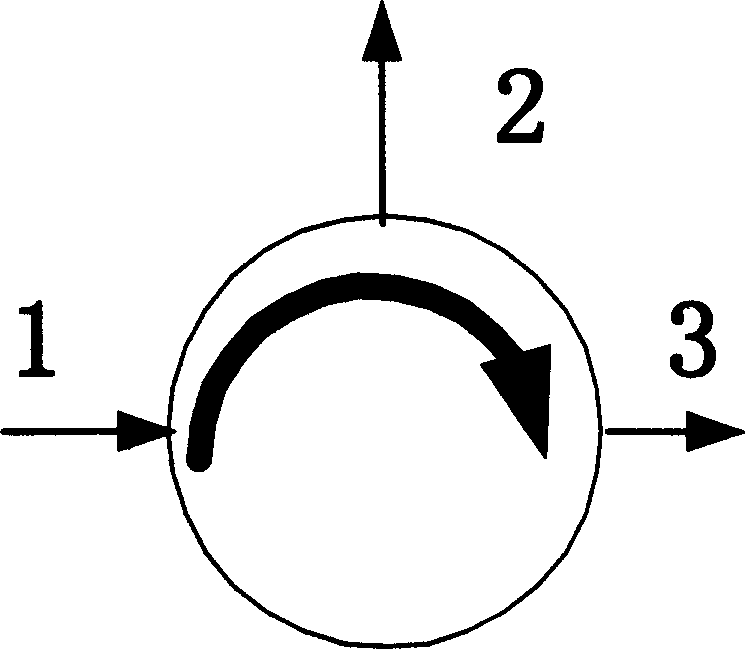

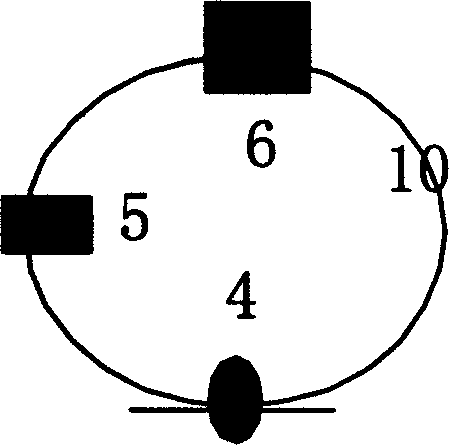

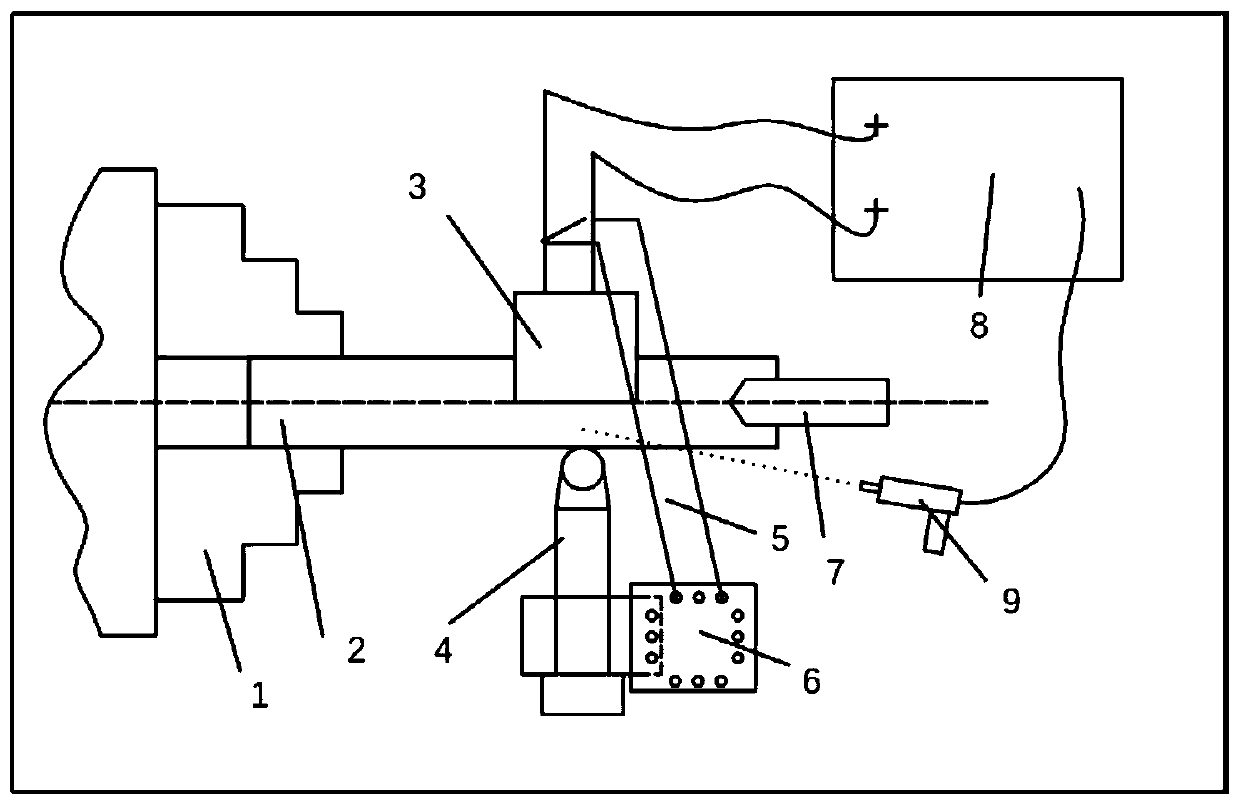

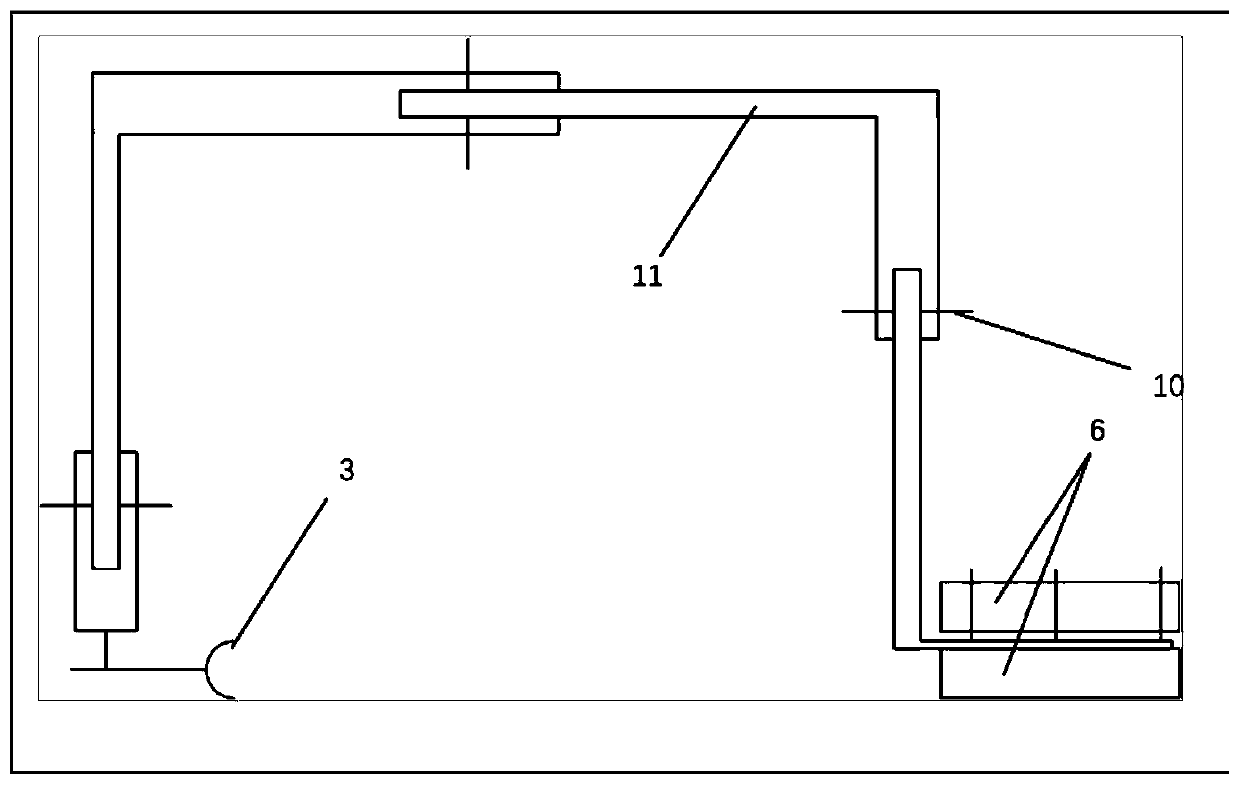

Simplifying type multiplexing white light interference optical fiber sensing demodulating equipment

InactiveCN101324444ASimple structureEasy to implementCoupling light guidesConverting sensor output opticallyPhotodetectorOpto electronic

The invention provides a simplified multiplexing white light interference fiber sensing demodulating device, which comprises a single-fiber two-way optical transmitting / receiving module, an optical fiber resonant cavity, a single-mode transmission fiber, and an optical fiber sensing array, wherein the single-fiber two-way optical transmitting / receiving module is composed of a semiconductor light source as the transmitting terminal, a semiconductor photodetector as the receiving terminal and related devices packaged together; and an optical fiber annular cavity is composed of an optical fiber coupler, an optical fiber self-focusing lens and a movable corner reflector. The device can achieve enquiry and measurement of a plurality of optical fiber sensors by embedding the single-fiber two-way optical transmitting / receiving module and the optical fiber resonant cavity in the single-mode optical fiber, and has the advantages of simple structure, easy implementation, no length restriction of the transmission cable, no influence caused by the external environment, and good stability and reliability. The device can be used for the measurement of physical quantities such as distributed deformation, strain and temperature, and can be used for multi-task sensing, multi-element sensing, local strain sensing, large-scale deformation sensing, etc.

Owner:HARBIN ENG UNIV

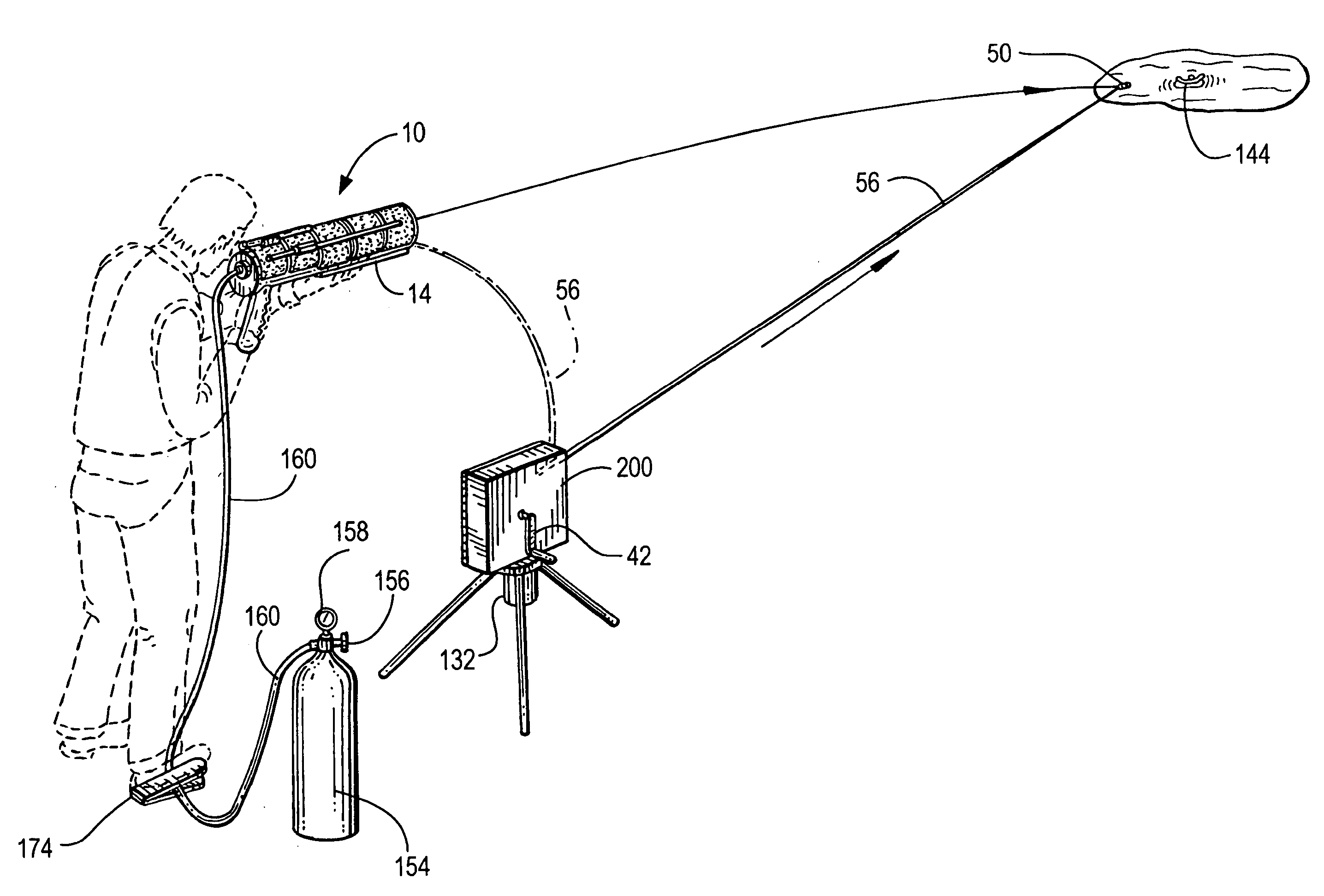

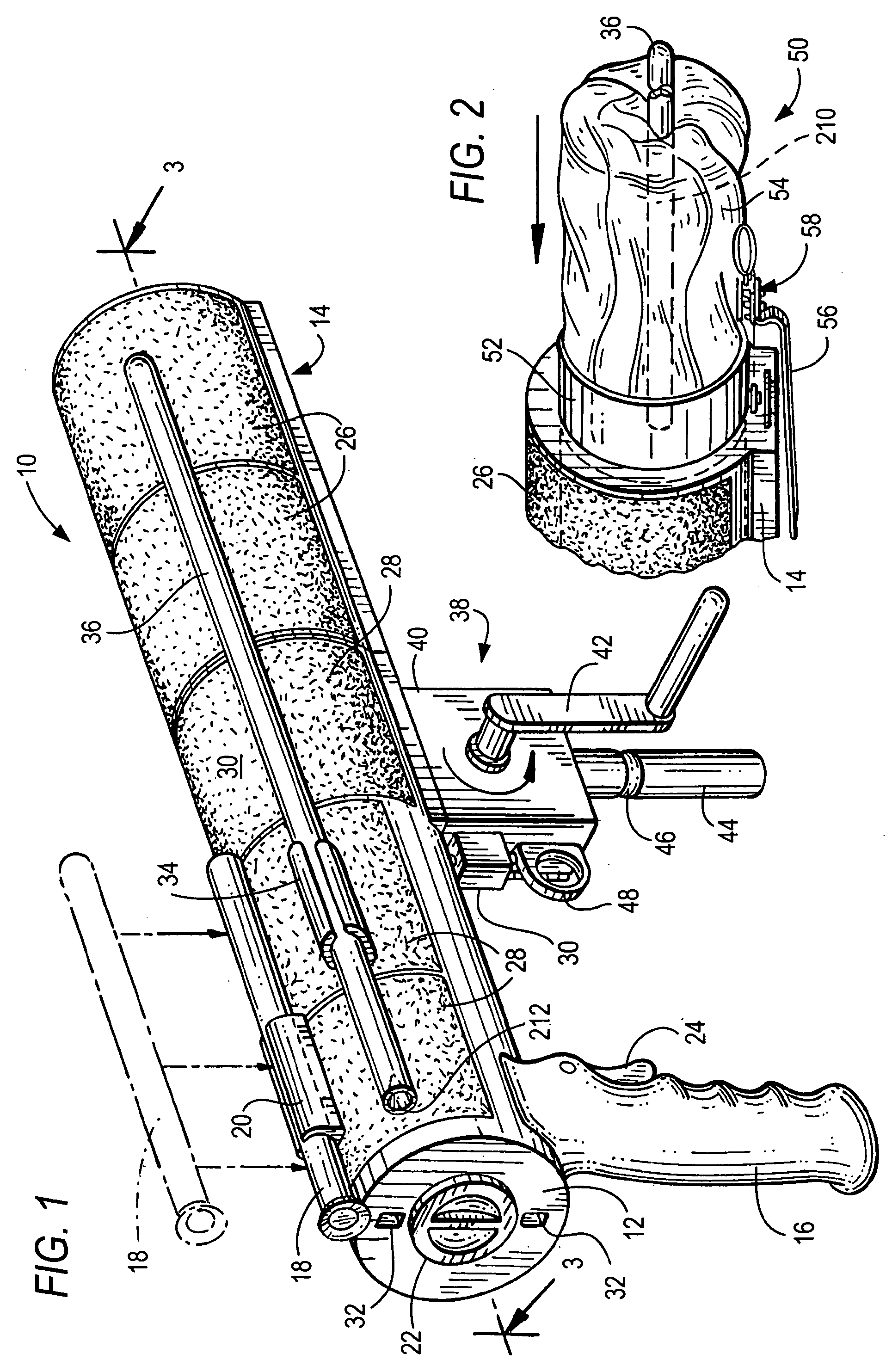

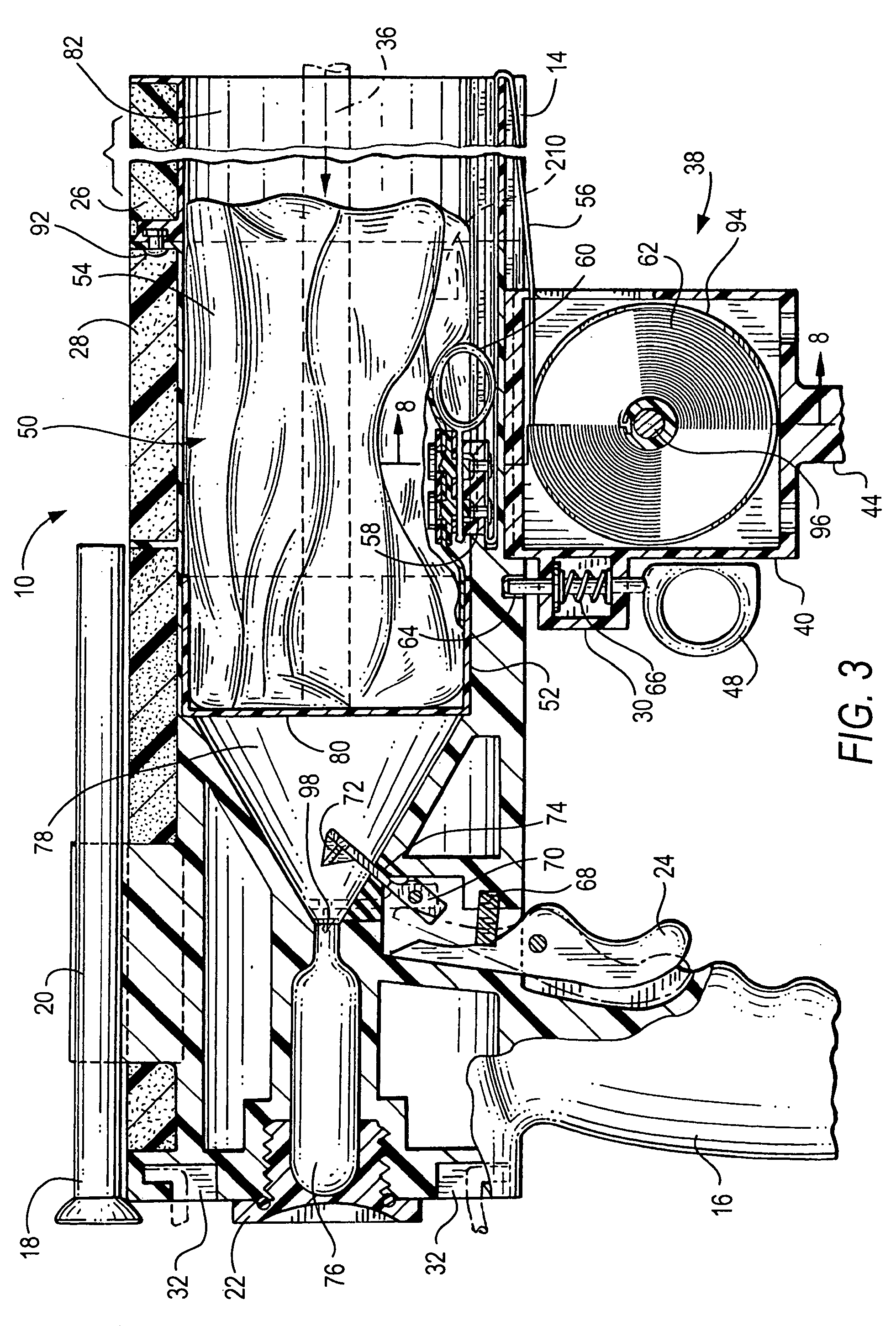

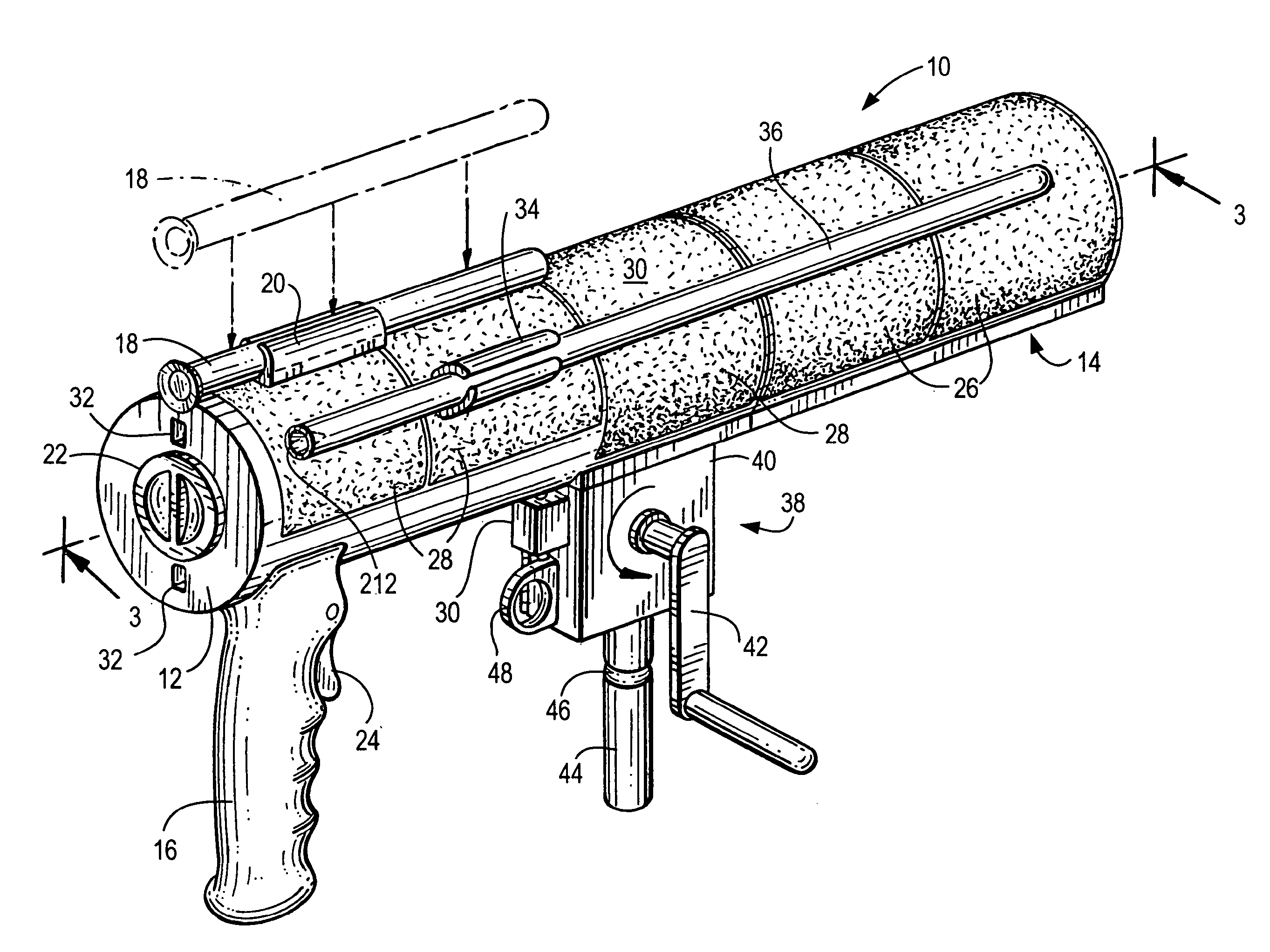

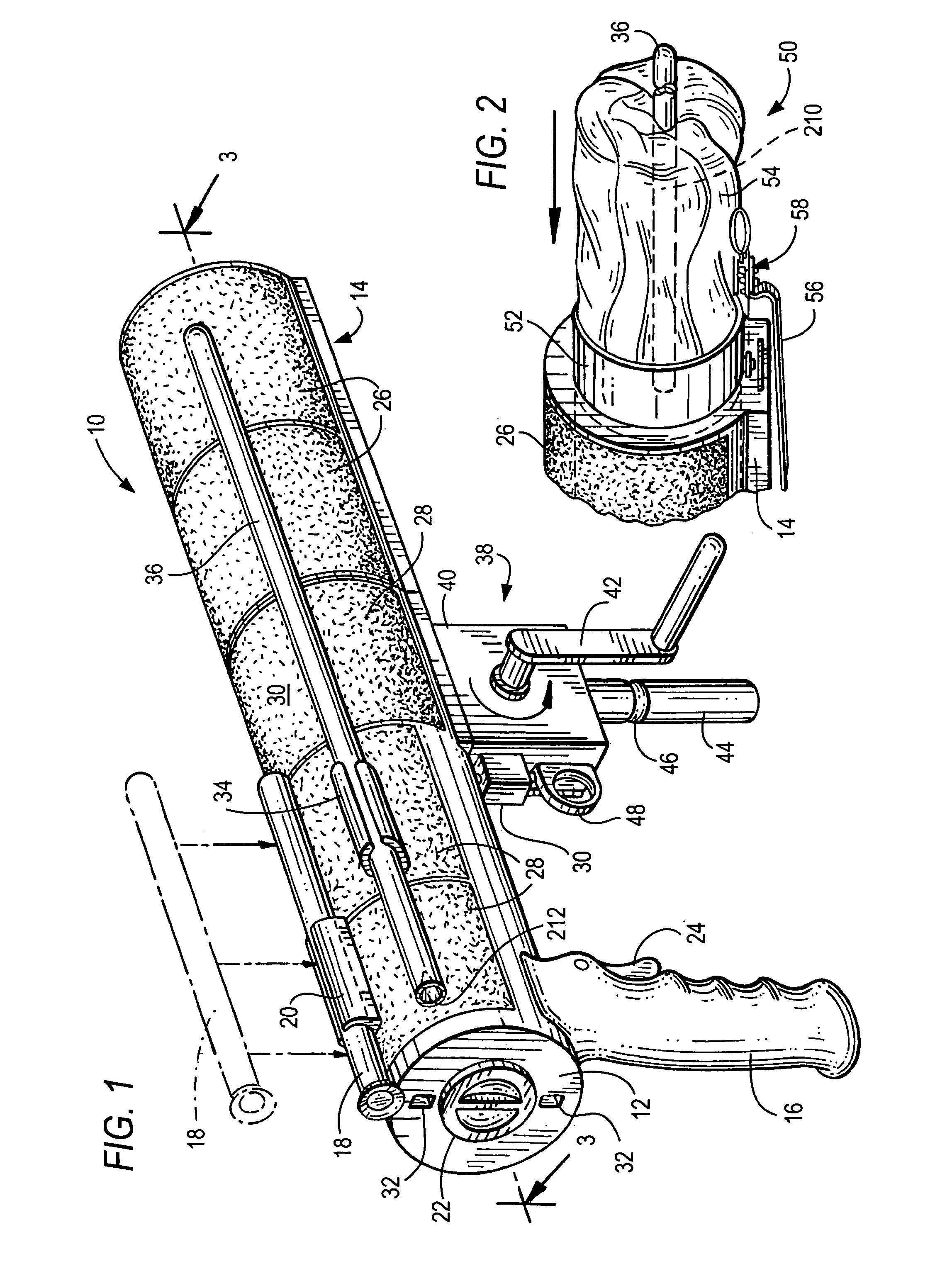

Rescue and retrieval apparatus and system and method of using same

InactiveUS20130239937A1Unlimited lengthGuaranteed rapid successionCast linesCompressed gas gunsHigh intensitySTI Outpatient

An system is disclosed which incorporates a projectile delivery launcher which may assume numerous forms and perform numerous functions, including launching a water rescue preservation device such as a life jacket, military supplies, survival supplies, fire extinguishing supplies, or the like. The device includes a unique barrel having a low friction chrome plated inner surface which provides maximum range deployment of a safety projectile. A unique clutch-type crank mounted below the barrel and houses a thin stainless high strength steel ribbon to provide deployment of a projectile, and retrieval of a victim, supplies or the like. A C02 cartridge system, which incorporates a novel explosive chamber is also used. A method and apparatus of rescuing a victim or delivering supplies in emergency situations, or even establishing a line contact, is also disclosed.

Owner:MACRI JOHN G +1

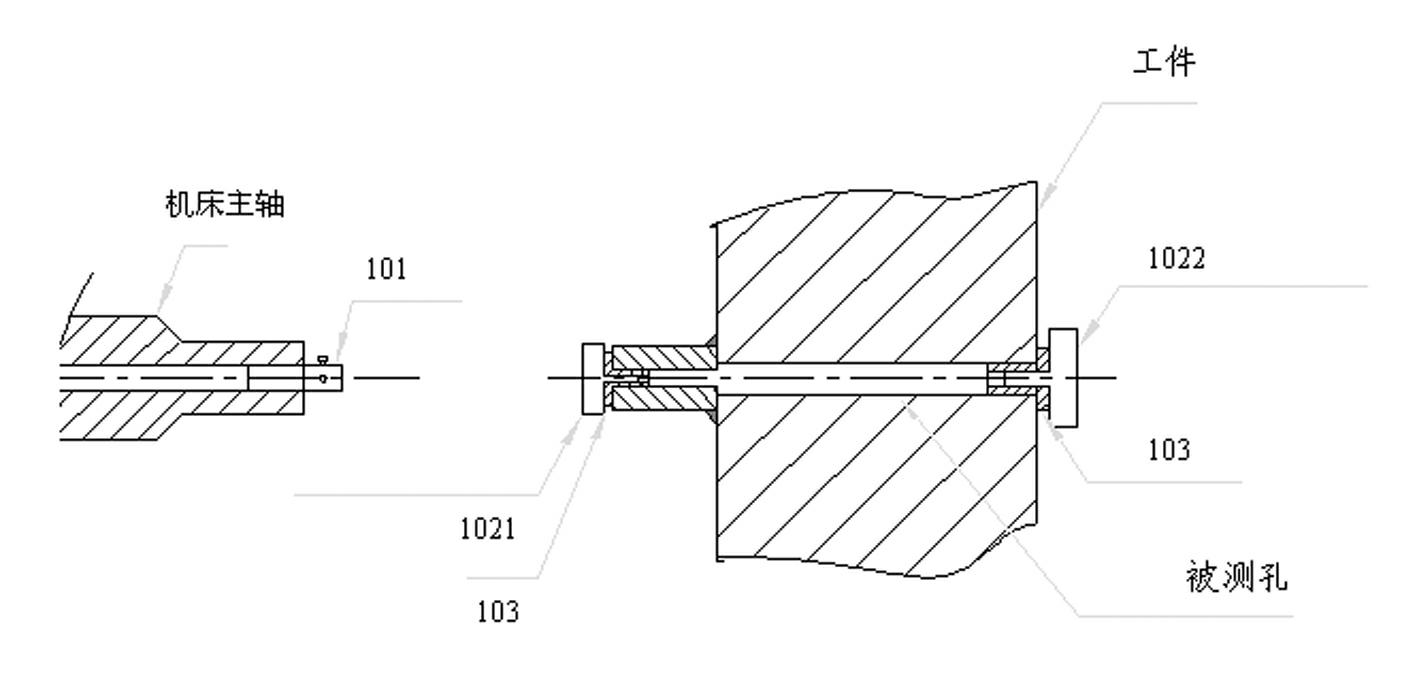

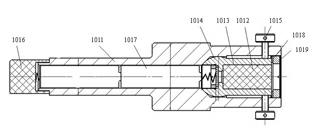

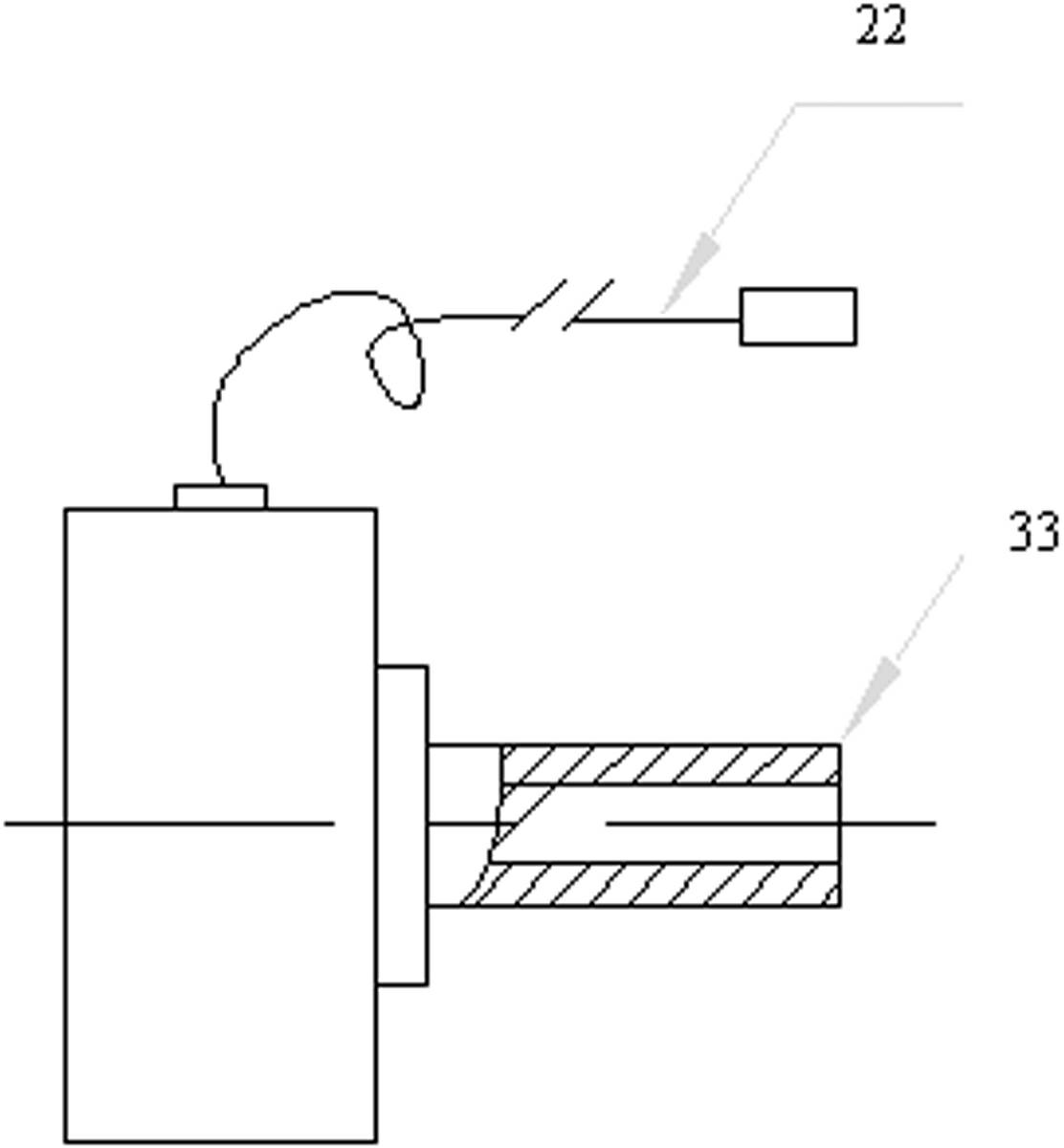

Laser adjustable multipurpose measuring device and measuring method thereof

ActiveCN102305604AEasy to measure onlineEfficient online measurementUsing optical meansLaser transmitterMeasurement device

The invention discloses a laser adjustable multipurpose measuring device and a measuring method thereof. The measuring device comprises an adjustable laser transmitter mounted on a machine tool, transition sleeves arranged in two ends of a measured hole, a forward laser receiver and a reverse laser receiver which are respectively arranged in the transition sleeves. The method comprises the following steps: firstly, levelling the base plane of the measured hole and the machine tool; fixing the adjustable laser transmitter on a main shaft of the machine tool; regulating the laser beam of the laser and the stretching direction of the main shaft of the machine tool on the same straight line; moving the main shaft of the machine tool to the approximate central position of the measured hole; inserting the forward laser receiver and the reverse laser receiver into the transition sleeves; and then inserting the transition sleeves to two sides of the measured hole, and respectively reading thenumerical value of the forward laser receiver and the reverse laser receiver, thus the verticality or concentricity of the measured hole relatively to the base plane is obtained. According to the invention, the verticality of a deep hole and the base plane and the concentricity of the stretching direction of the main shaft of the machine tool and the hole axis line can be convenient and efficientto measure on line and the product quality can be ensured.

Owner:SHANGHAI ELECTRIC NUCLEAR POWER EQUIP CO LTD

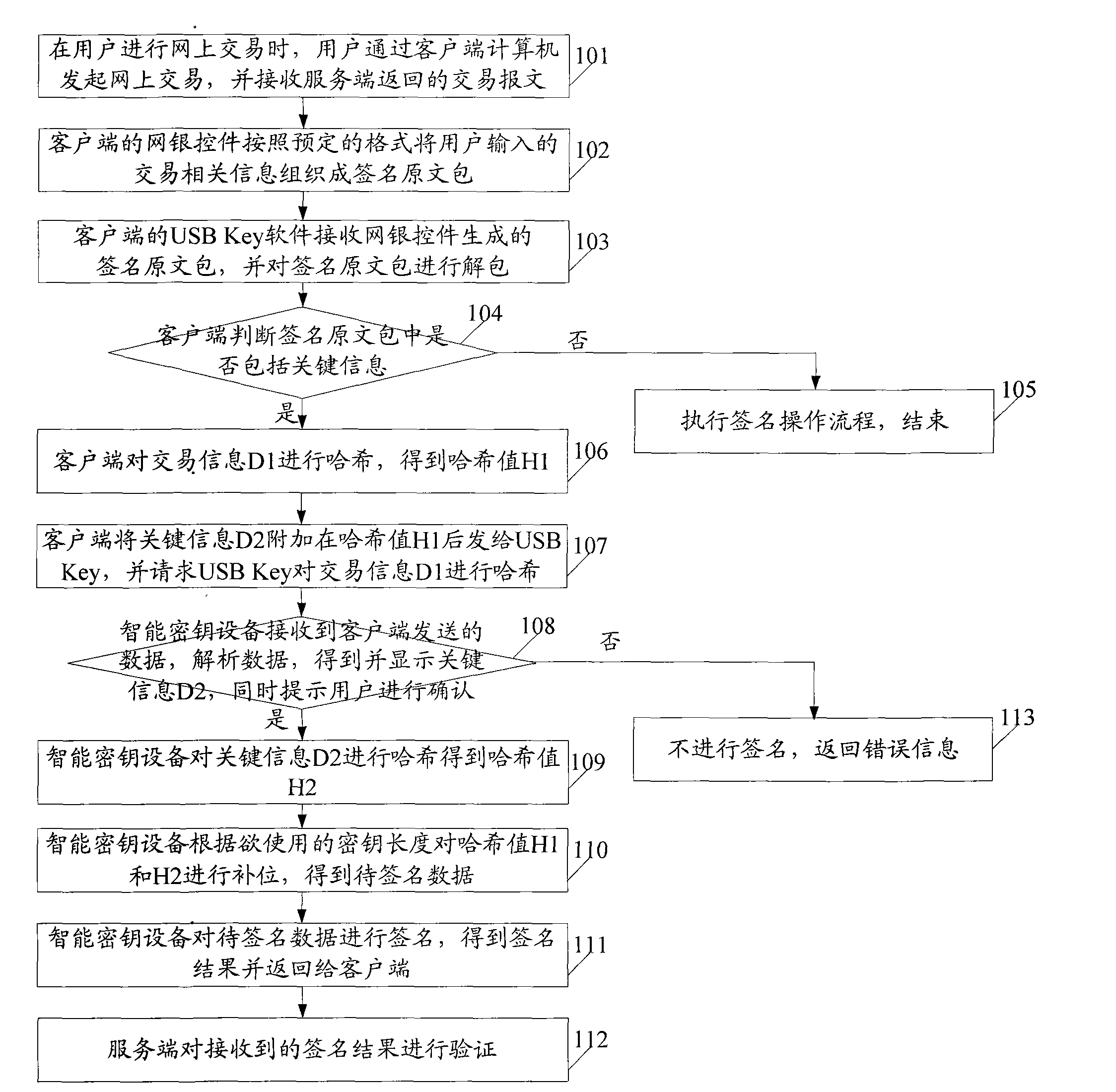

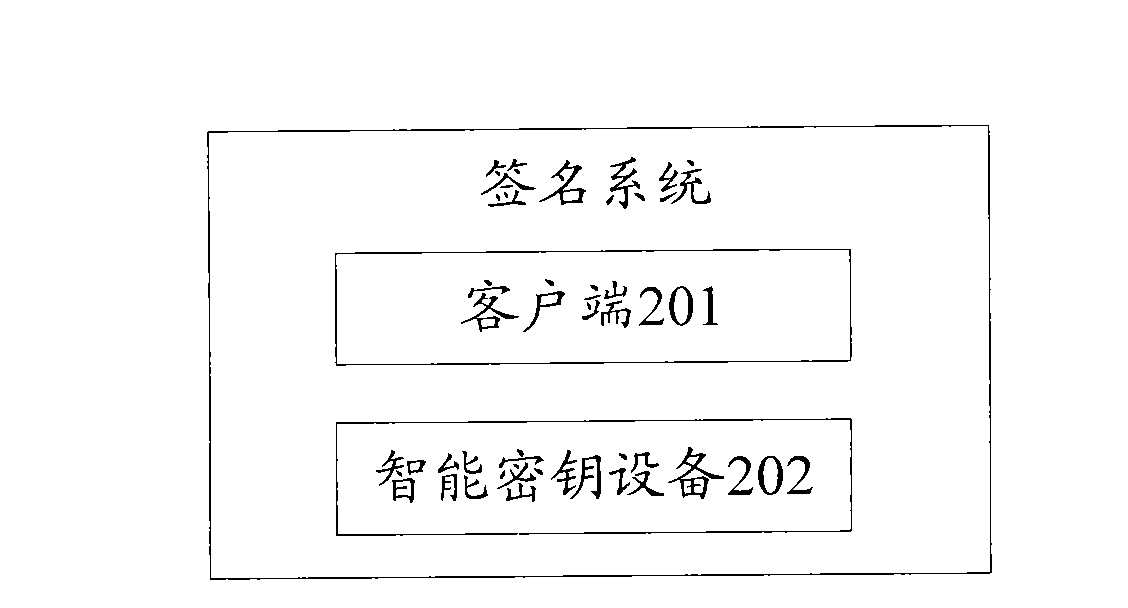

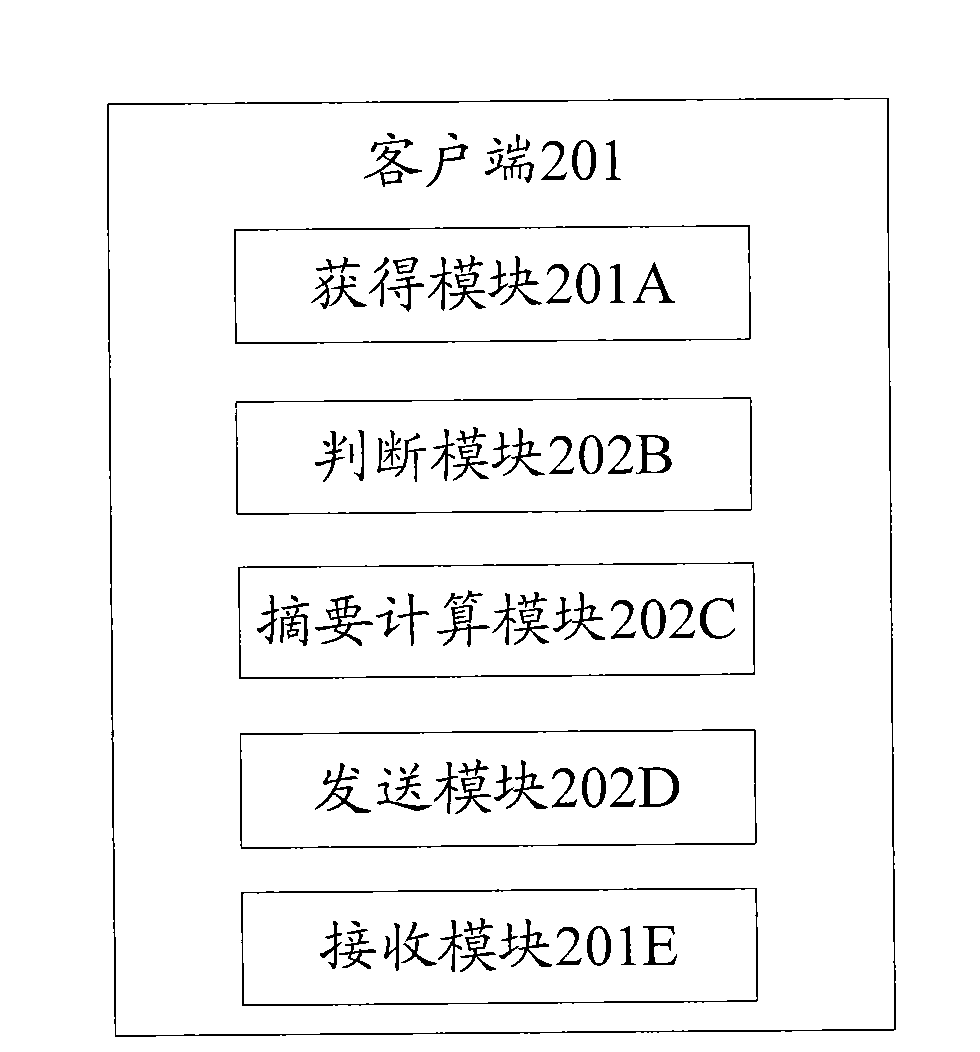

Signing method and system thereof

ActiveCN101631022AUnlimited lengthSolve the problem of limited data lengthUser identity/authority verificationClient-sideInformation security

The invention discloses a signing method and a system thereof, belonging to the field of information security. The method comprises the following steps: a user terminal obtains a signing original packet, and judges whether the signing original packet has second information; when the signing original packet has second information, the user terminal computes and abstracts first information to obtain a first abstract value; the user terminal sends the second information and the first abstract value to intelligent key equipment connected therewith; the intelligent key equipment outputs the second formation to the user and judges whether receives confirm information of the user; and if the confirm information of the user is received in a preset time, the intelligent key equipment computes and abstracts the second information to obtain a second abstract value, combines and compensates the first abstract value with the second abstract value to obtain a date to be singed, returns a singing result which is obtained by signing the date to be singed back to the user terminal, and otherwise, ends the operation.

Owner:FEITIAN TECHNOLOGIES

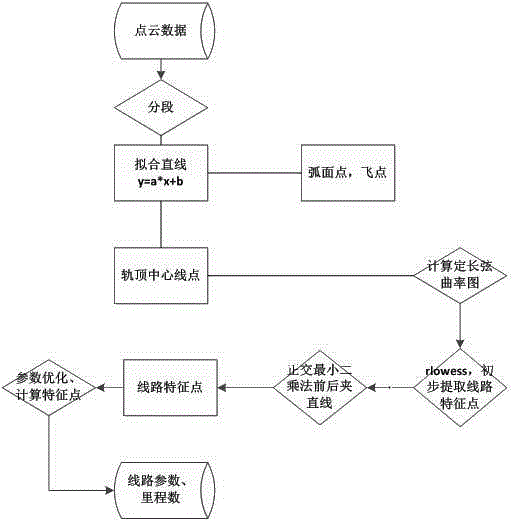

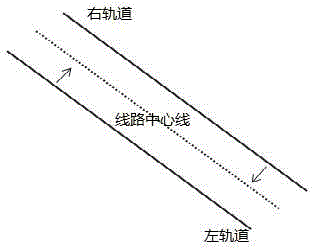

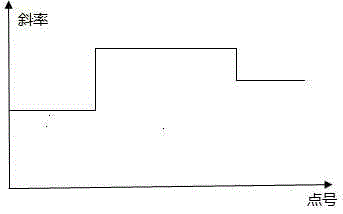

Existing railway measuring method based on LIDAR (Light Detection and Ranging) track point cloud data

ActiveCN104634298AUnlimited lengthSimple and convenient timelinessDistance measurementPoint cloudIntersection of a polyhedron with a line

The invention relates to an existing railway measuring method based on LIDAR (Light Detection and Ranging) track point cloud data. The existing railway line measurement has the defects of poor flexibility and limited measuring length. The method comprises the following steps: recording continuous three-dimensional coordinate data in a track running process by using a vehicle-mounted LIDAR measurement instrument for serving as track point cloud data; extracting a center line between two tracks, translating o obtain a route center line, and calculating the fixed-length chord slope of the route center line: evaluating the slope by taking new data serving as a point set as a difference, generating a fixed-length chord slope sequence, and filtering; picking segmentation points on the basis of the smooth fixed-length chord slope, and decomposing a continuous route into curve units; evaluating the intersection points among the curves according to front and back intermediate straight lines of each unit, fitting the radius and circle center of a circular curve part of the route, and resolving a corresponding route parameter and mileage. A basic unit set of route curve elements is constructed according to the LIDAR track point cloud data, so that the aims of route reconstruction and retesting are fulfilled, high flexibility, high measuring efficiency and a simple process are realized, and measured data is accurate and reliable.

Owner:CHINA RAILWAY FIRST SURVEY & DESIGN INST GRP

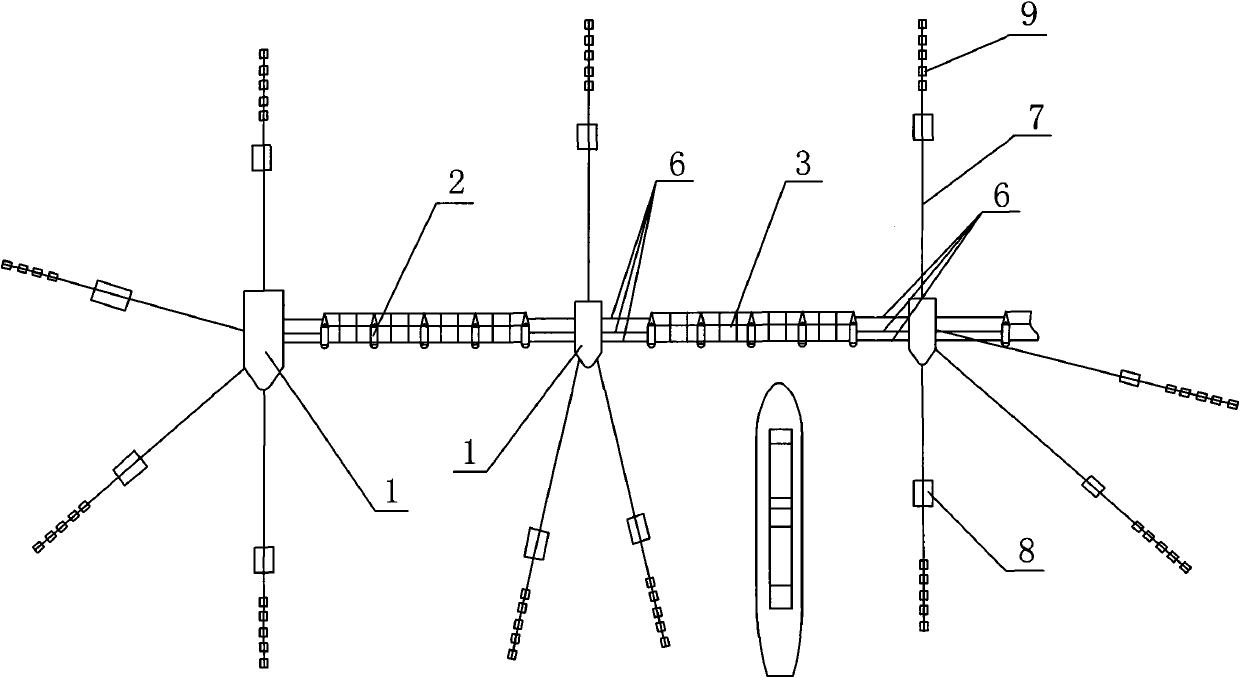

Belt type carrier-based aircraft booster system and decentralized energy storage and concentrated random boosting working method

ActiveCN103332297AScientific and reasonable designFulfil requirementsLaunching/towing gearDrive shaftTransmission belt

The invention provides a belt type carrier-based aircraft booster system and a decentralized energy storage and concentrated random boosting working method. The system comprises a boosting module assembly, a return module assembly, a runway module, a slide shuttle module and a controller module, wherein the boosting module assembly consists of more than one boosting module which is arranged below the runway module; the boosting module comprises a T-shaped box body, motors, a transmission shaft, a clutch, a brake and a pedestal; the bottom of the T-shaped box body is fixed to the middle part of the pedestal; the motors are fixedly arranged on the pedestal and are positioned on the two sides of the T-shaped box body; the transmission shaft penetrates through the middle part of the T-shaped box body through a bearing pedestal; the two ends of the transmission shaft are provided with the clutch and the brake respectively; a driven part of the clutch and the brake are fixed to the transmission shaft; a driving part of the clutch is connected with the belt pulley; the belt pulley is connected with the transmission shaft through a bearing; the outer circle of the belt pulley is connected with the belt pulley at the motor shaft end through the belt; and the two ends of the folded transmission belt are fixed on the transmission shaft in the middle of the T-shaped box body through belt pressing plates. The system has the characteristics of simple structure, easiness in machining, transportation, mounting, debugging and maintenance, high modularization and the like, and is a piece of optimal equipment for an aircraft carrier.

Owner:如东县岔河污水处理有限公司

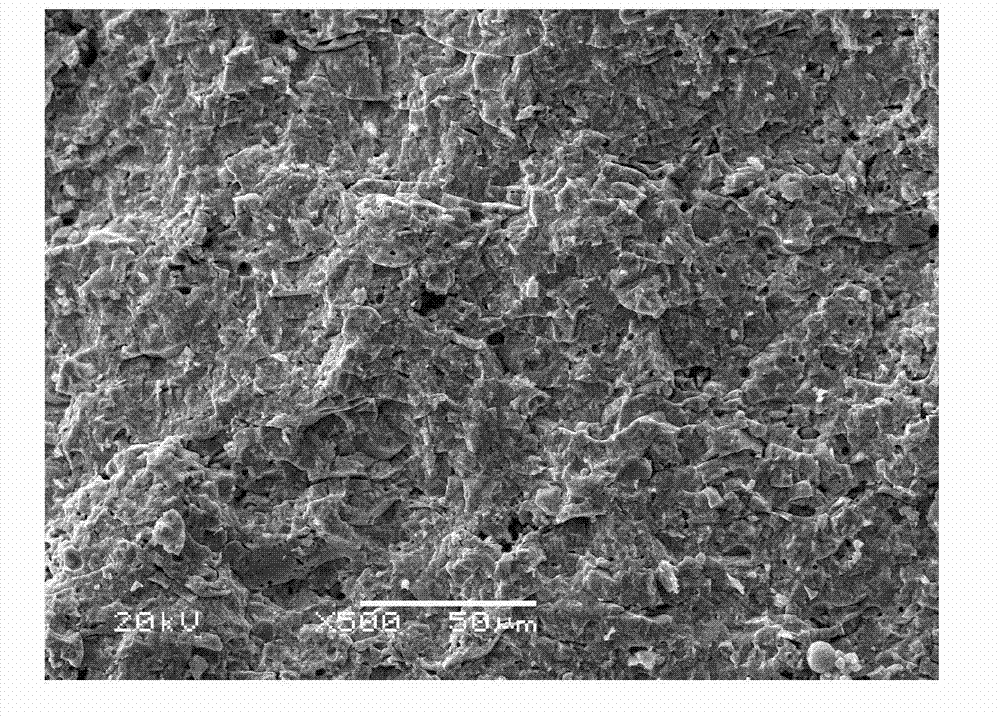

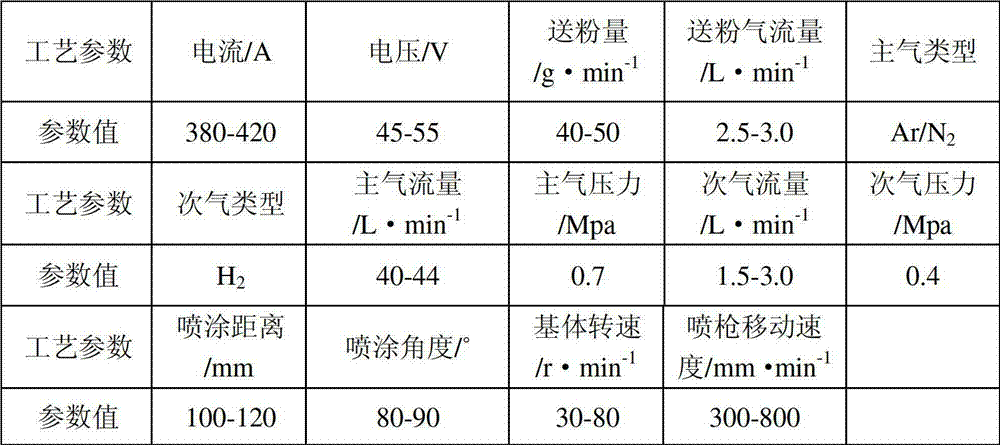

Rotary niobium oxide target material and preparation method thereof

ActiveCN103045995ACompact structureUniform compositionMolten spray coatingVacuum evaporation coatingVolumetric Mass DensityNiobium oxide

The invention relates to a rotary niobium oxide target material and a preparation method thereof. The preparation method comprises the following steps: preparing a niobium oxide spraying powder, treating a spraying matrix, spraying a priming coat and spraying the niobium oxide spraying powder on a matrix tube by using a plasma spraying process. The rotary niobium oxide target material prepared by the preparation method provided by the invention has the advantages of compact structure, uniform components, no crack and no limitation on spraying length and diameter; the thickness of the rotary niobium oxide target material can reach 12 mm, the density of the rotary niobium oxide target material is 4.6-5.2 g / cm<3>, and the component of the target is Nb2O4.3-4.9. The preparation method provided by the invention has the advantages of simple and convenient production process and lower cost.

Owner:宁夏中色新材料有限公司

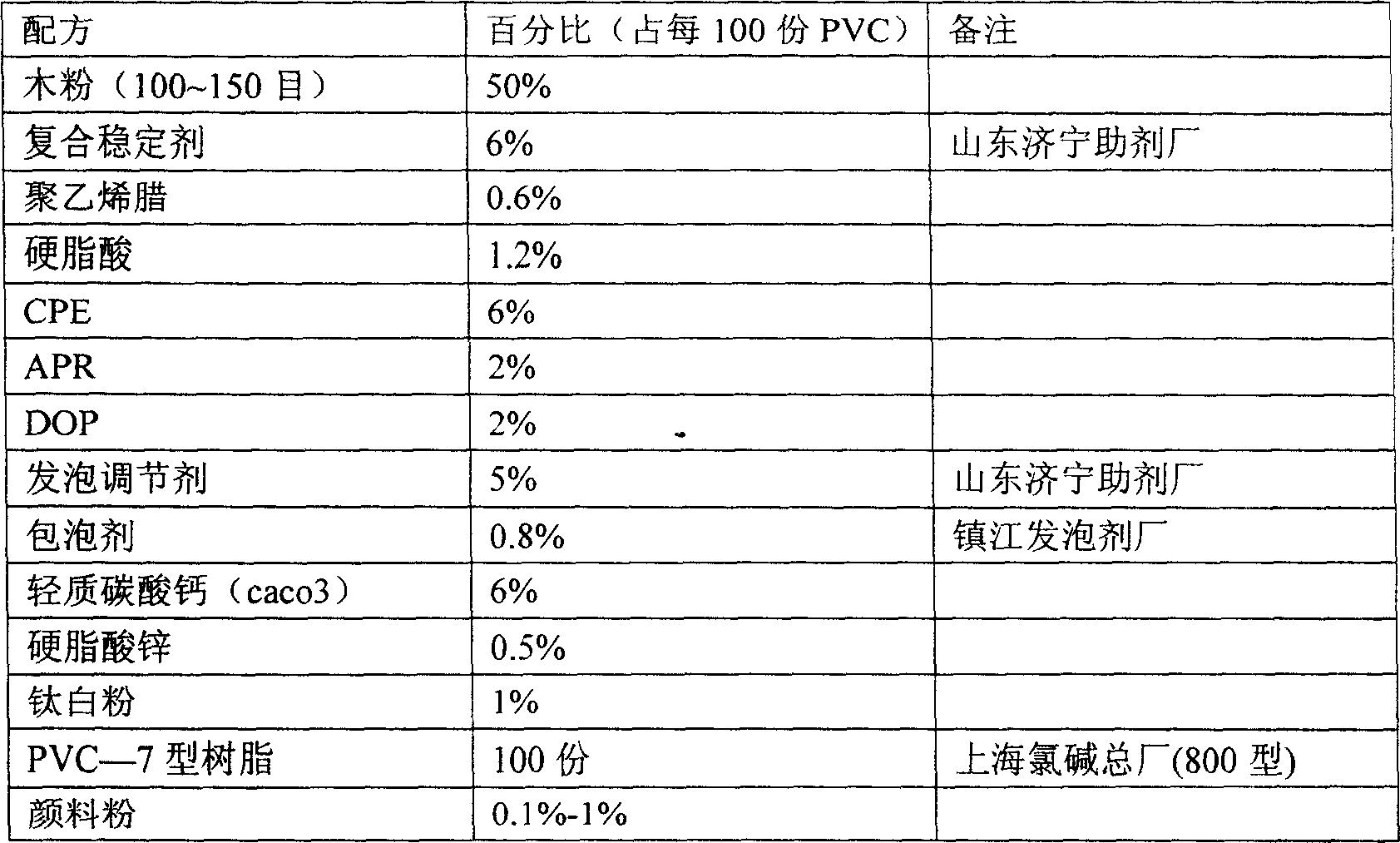

Formulation of extrusion forming wood-plastic foaming decoration section bar and preparation method

InactiveCN1923903AUnlimited lengthThere is no color difference problemProcedure AgentsMaterials science

The invention discloses a squeezing-typed wood-plastic foaming decorative formula, which comprises the following parts: plastic, wood powder and additive, wherein the additive contains composite stabilizer, external lubricant, internal lubricant, impaction-proof modifier, manufacturing adjuvant, thickener, foaming adjusting agent, foamer, light-weight CaCO3, accessory foamer, aging-proof agent and dye powder. The preparing method comprises the following steps: selecting wood powder; modifying; blending wood powder and plastic.

Owner:上海净鑫置业有限公司 +1

Jig for forming a box joint

InactiveUS20050056344A1Convenient ArrangementLength can be usedTongue/grooves making apparatusMulti-purpose machinesMechanical engineeringBackplane

A box joint jig, including a bottom plate; a back plate joined to the bottom plate; and an alignment member the alignment member structured to orient four boards positioned adjacent the bottom plate for a router and a method of forming a box joint, including the steps of mounting four boards in a jig; routing the boards through a groove; routing the boards through additional grooves; dismounting the boards; and joining the corners of the boards interlacing the routes cut in the boards.

Owner:FREIDLUND PAUL

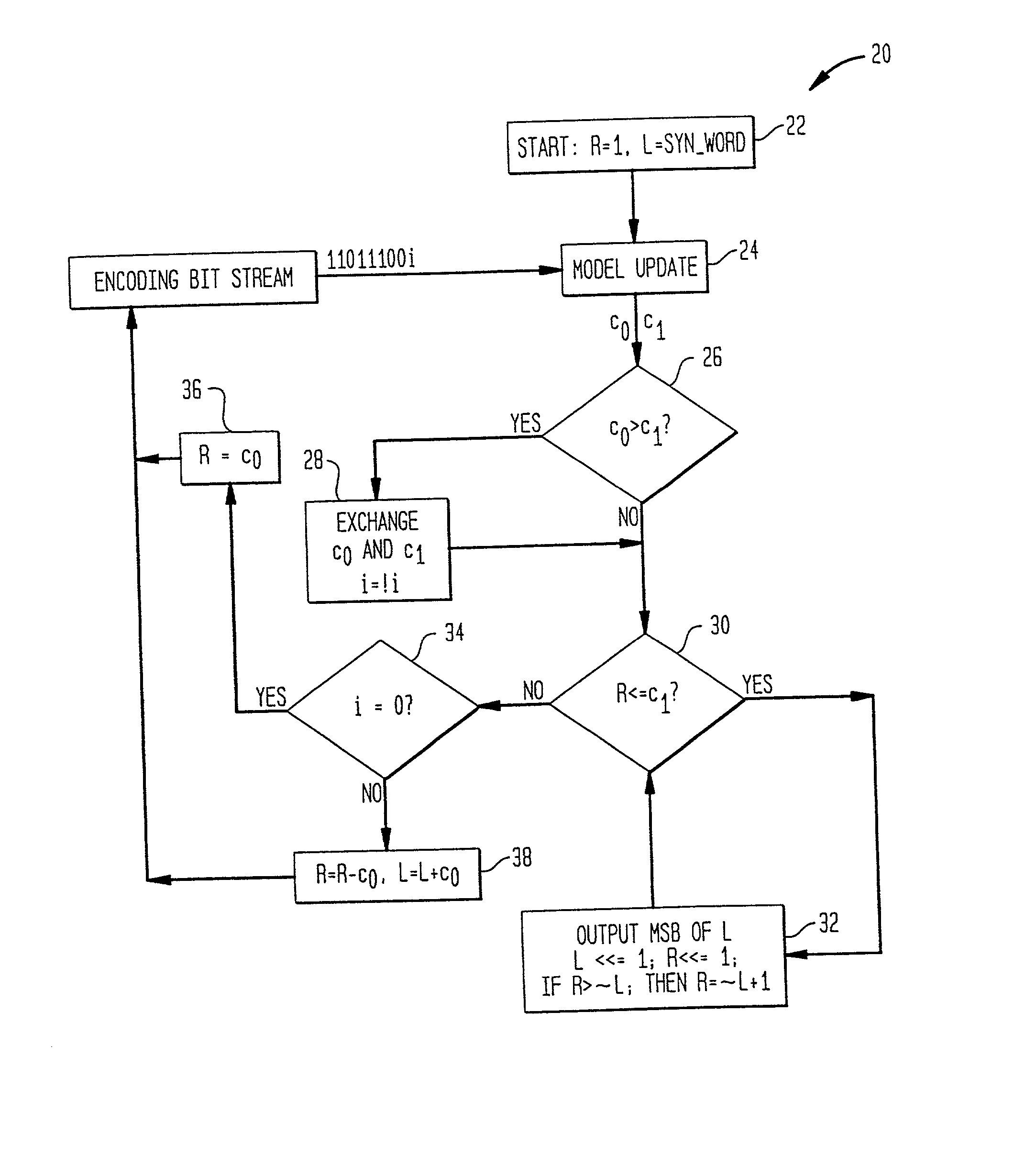

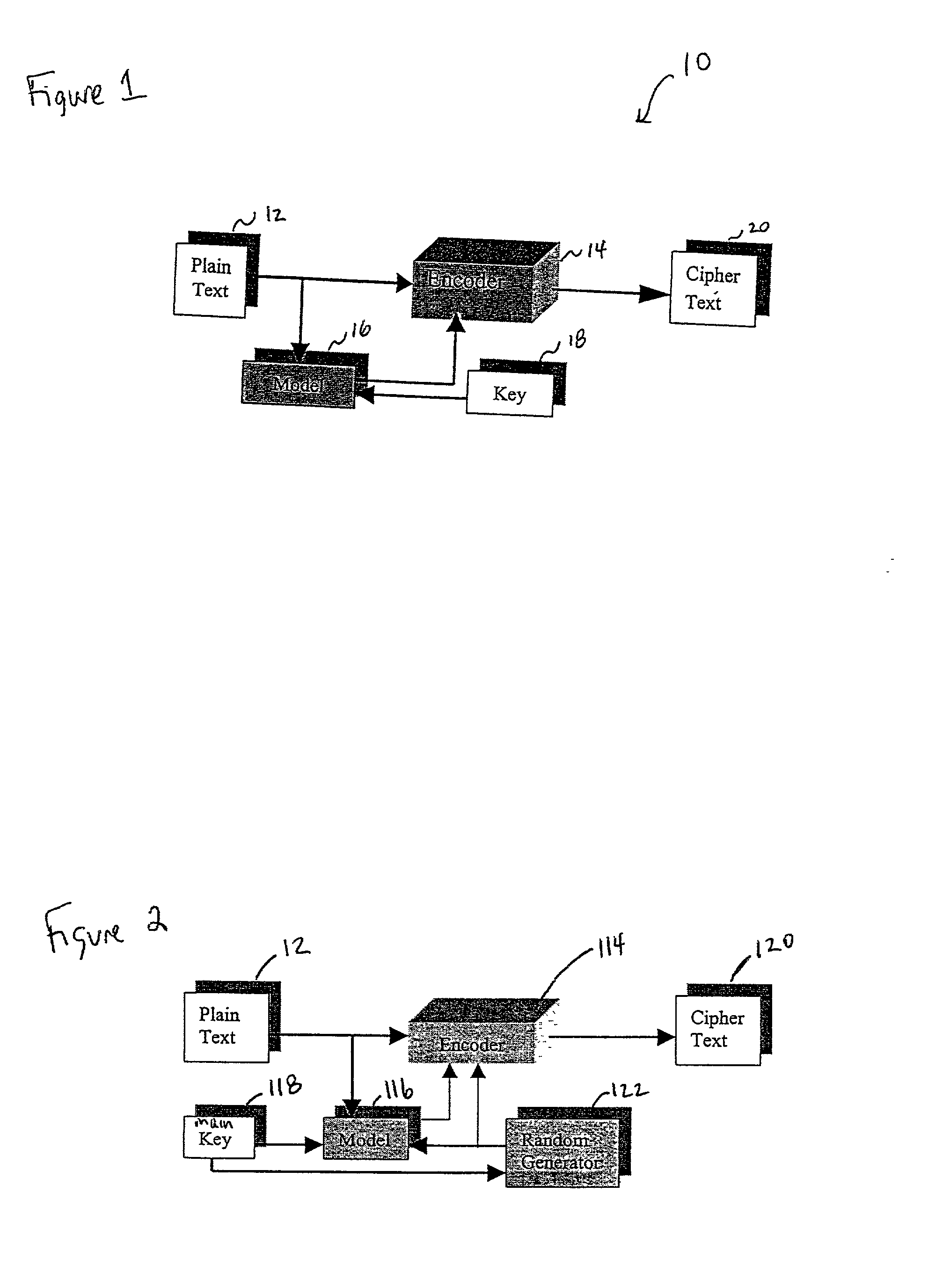

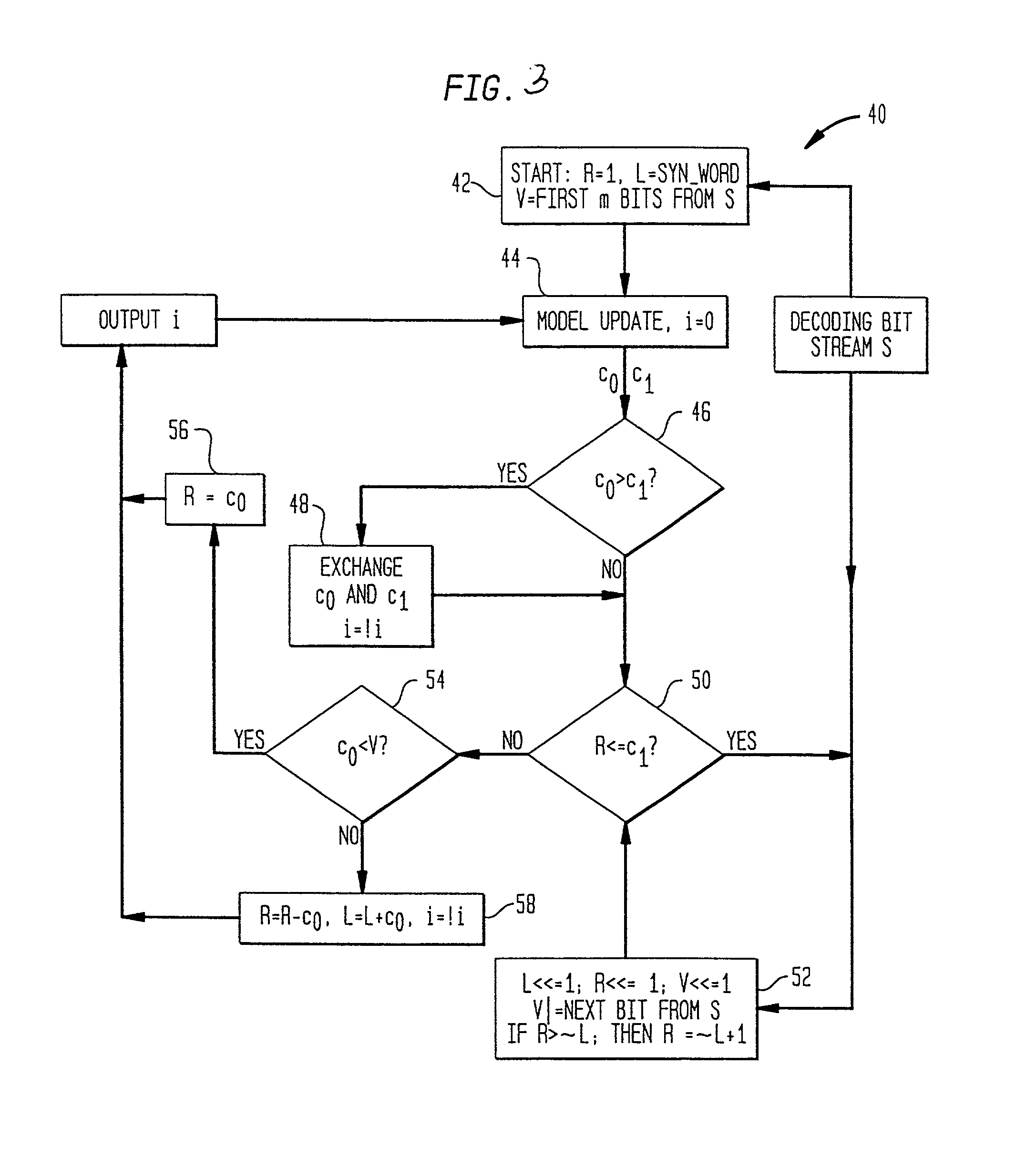

Variable size key cipher and method and device using the same

InactiveUS20020094080A1Unlimited lengthSimplify hardware designEncryption apparatus with shift registers/memoriesSecret communicationPlaintextComputer hardware

An encryption device and method and decryption device and method which implement a bit-based encryption scheme and hardware design. The encryption device includes a random number generator, receiving a main key, determining a working key using at least one random number and outputting a working key, a model, receiving the main key, the working key and plain text to be encoded and generating at least two frequency counts. The encryption device further includes an encoder, which outputs encoded text based on the working key, the plain text and the at least two frequency counts. The encryption device and method and decryption device and method progress encrypted text that is based upon a stream structure with an unlimited key length and may be compressed by 50%. The encoded text is changeable with different environments even for the same plain text and the same key. Operations of the hardware design are based on arithmetic additions and shifts, and not multiplications and divisions. As a result, the hardware design is simple and applicable to cryptography and e-commerce.

Owner:AGERE SYST INC

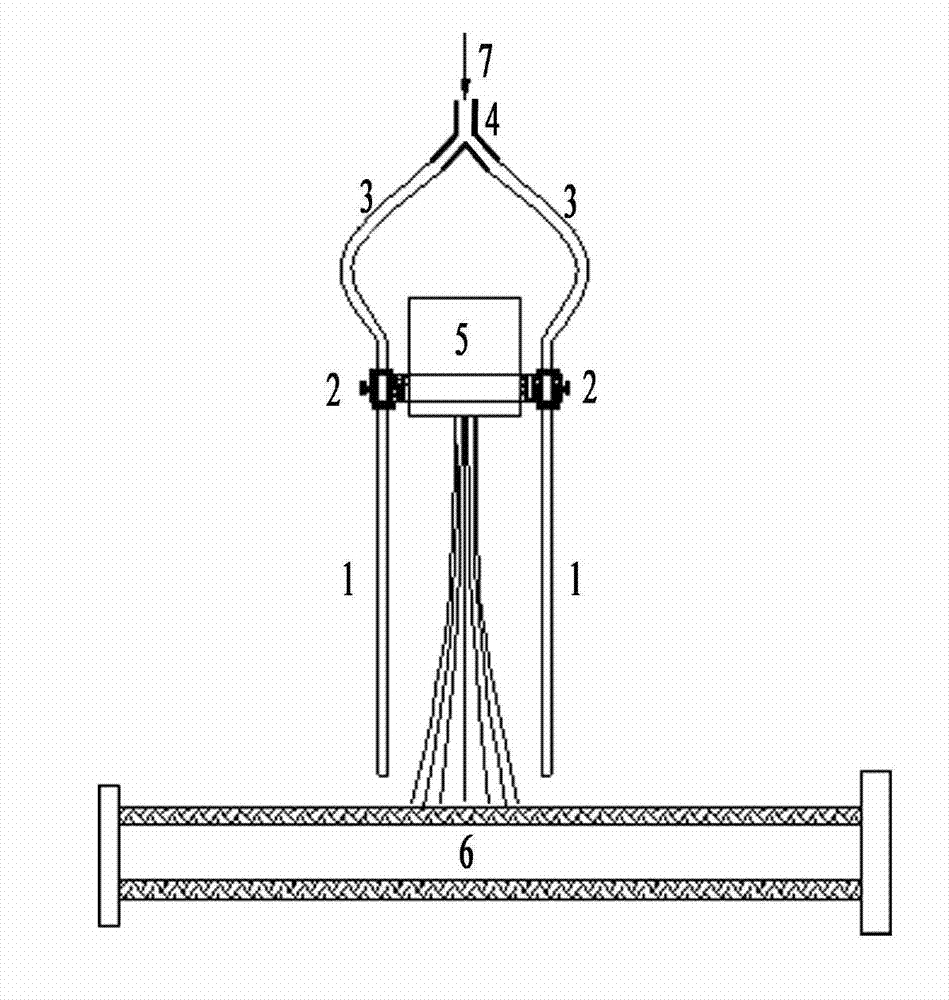

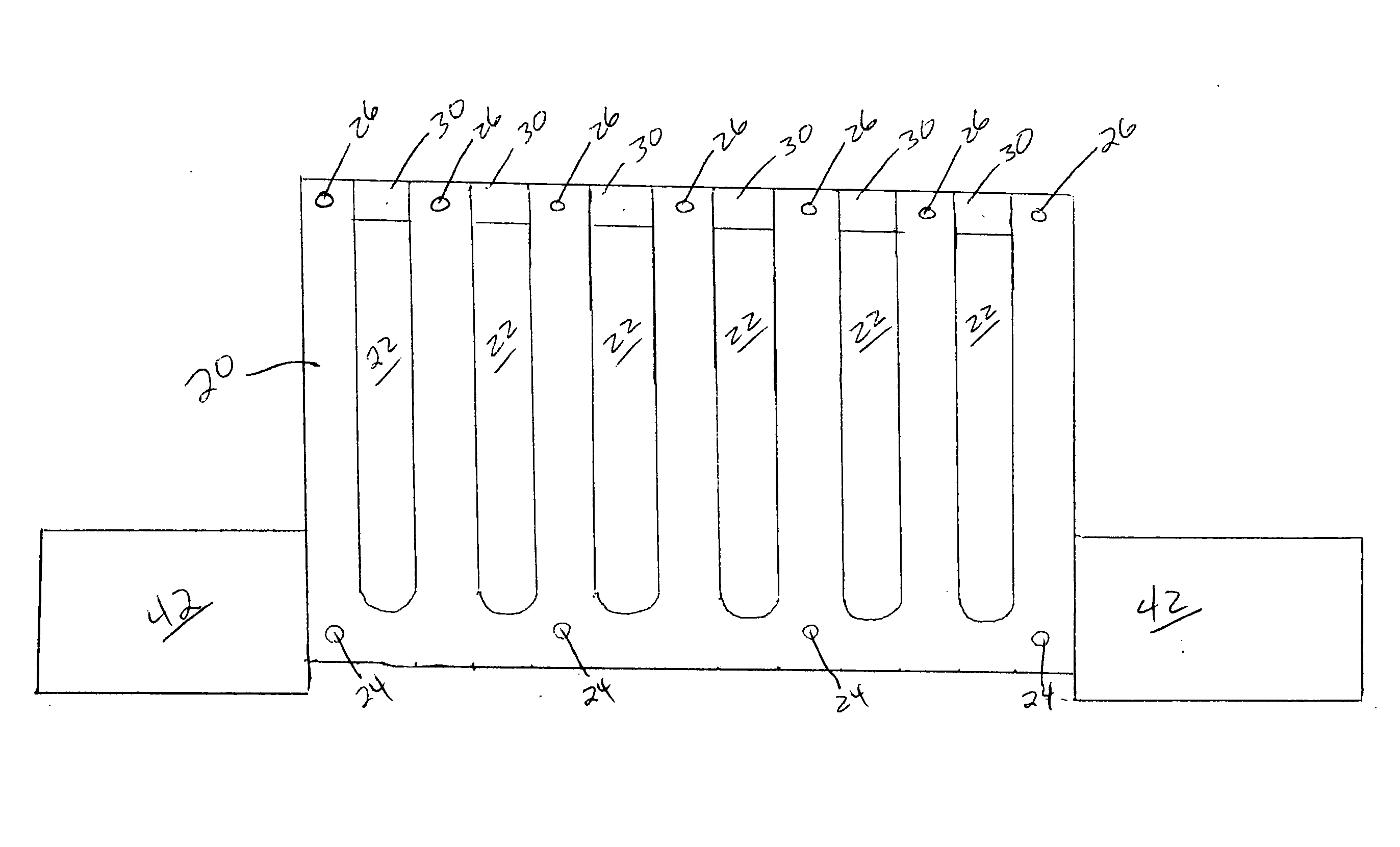

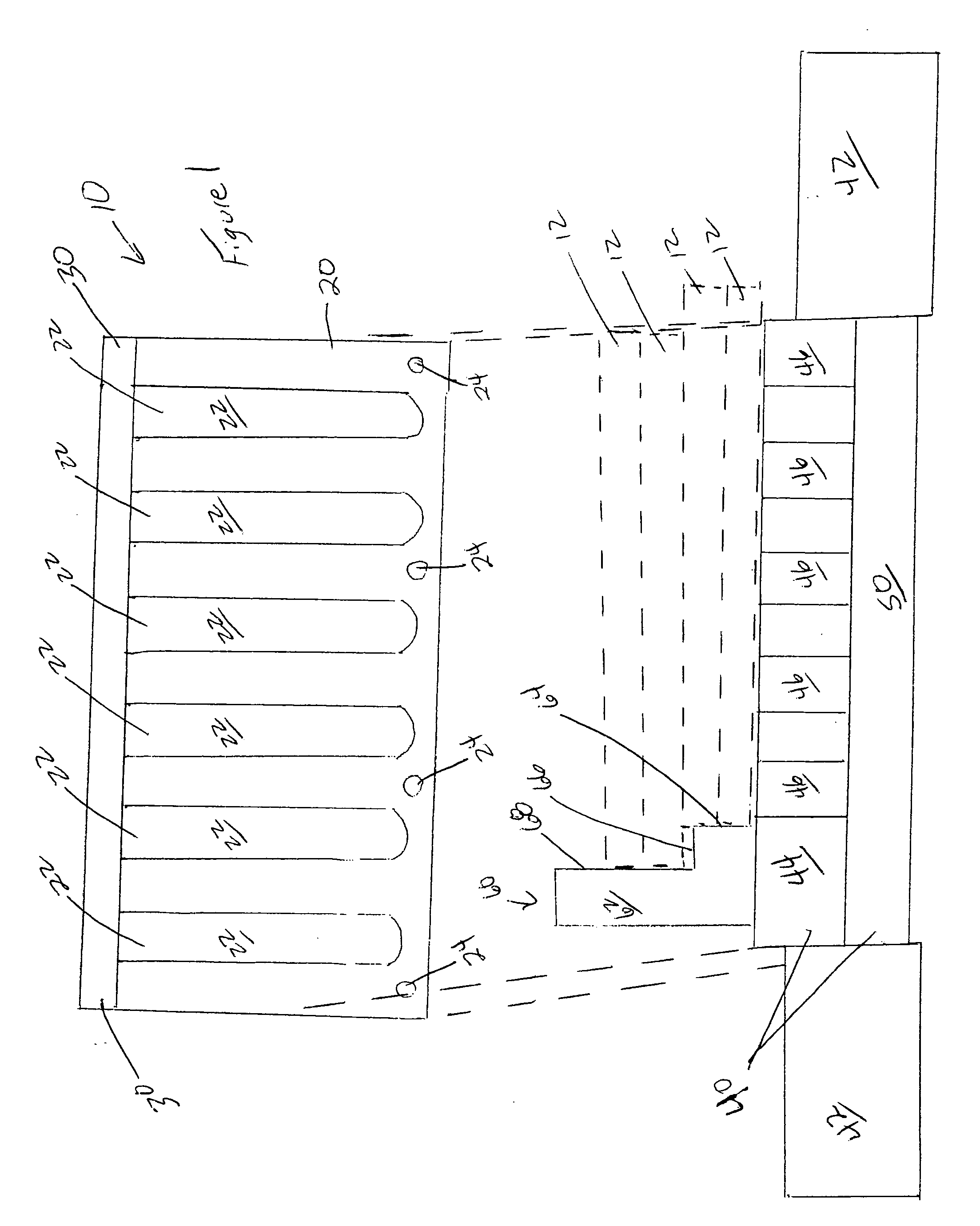

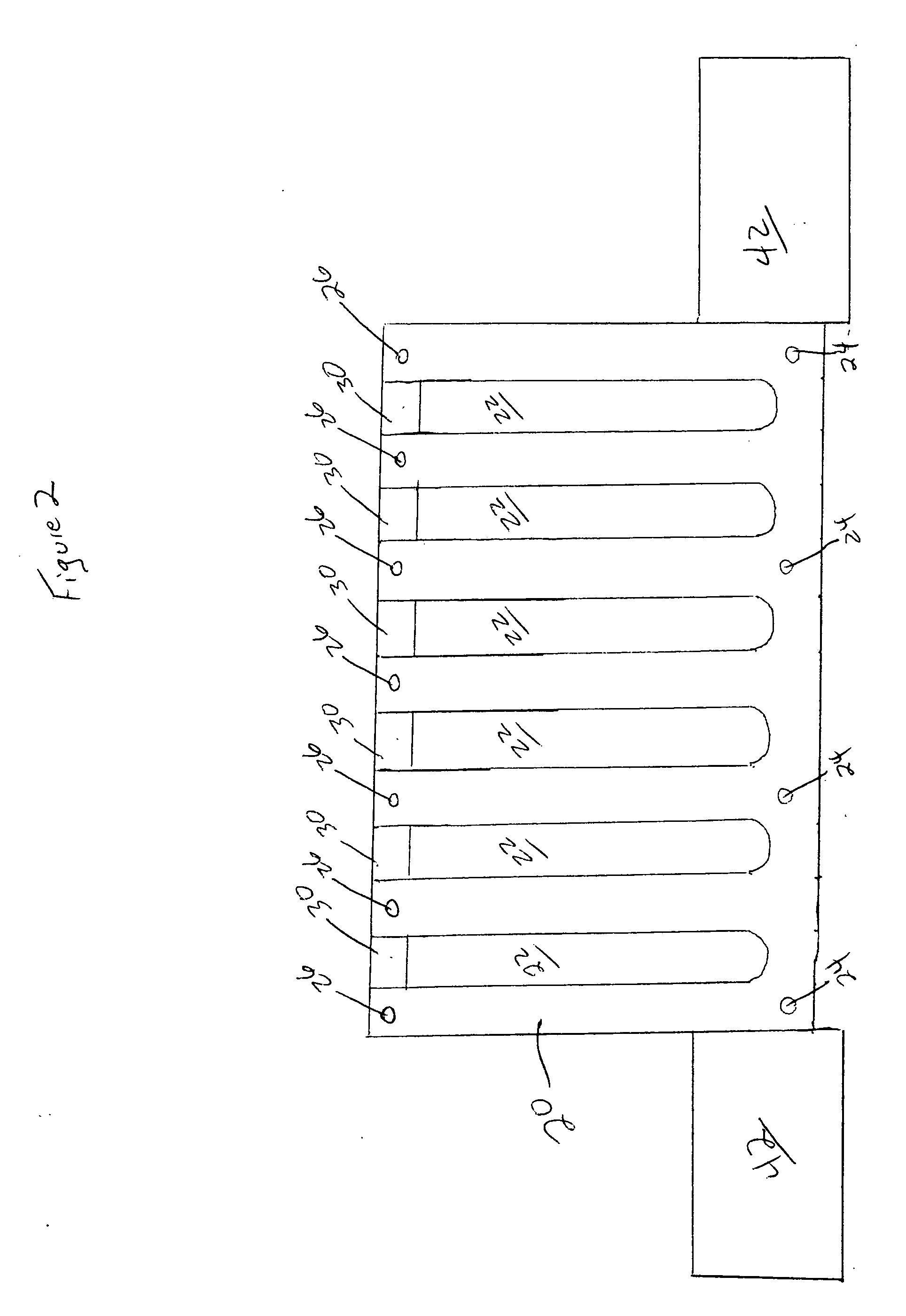

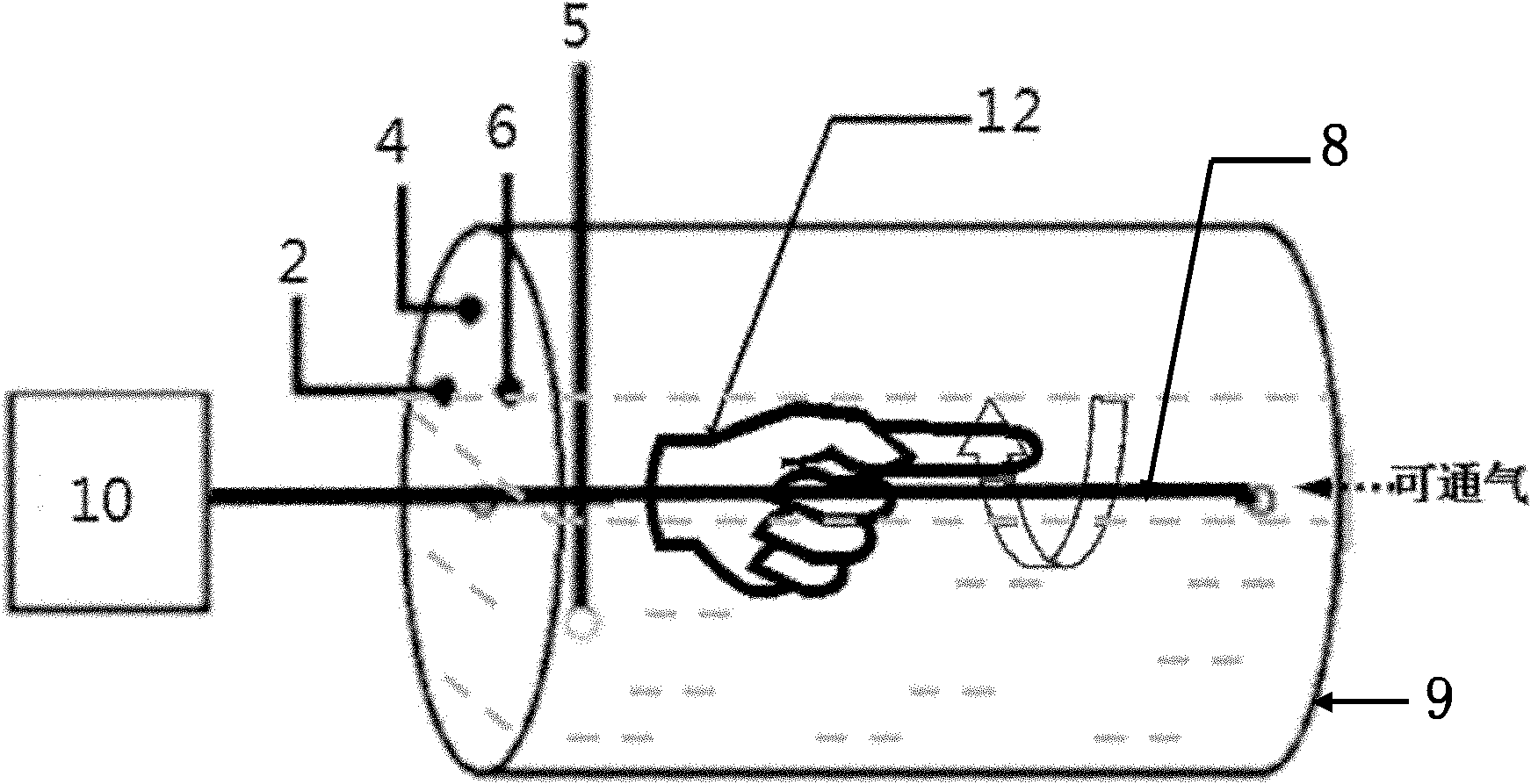

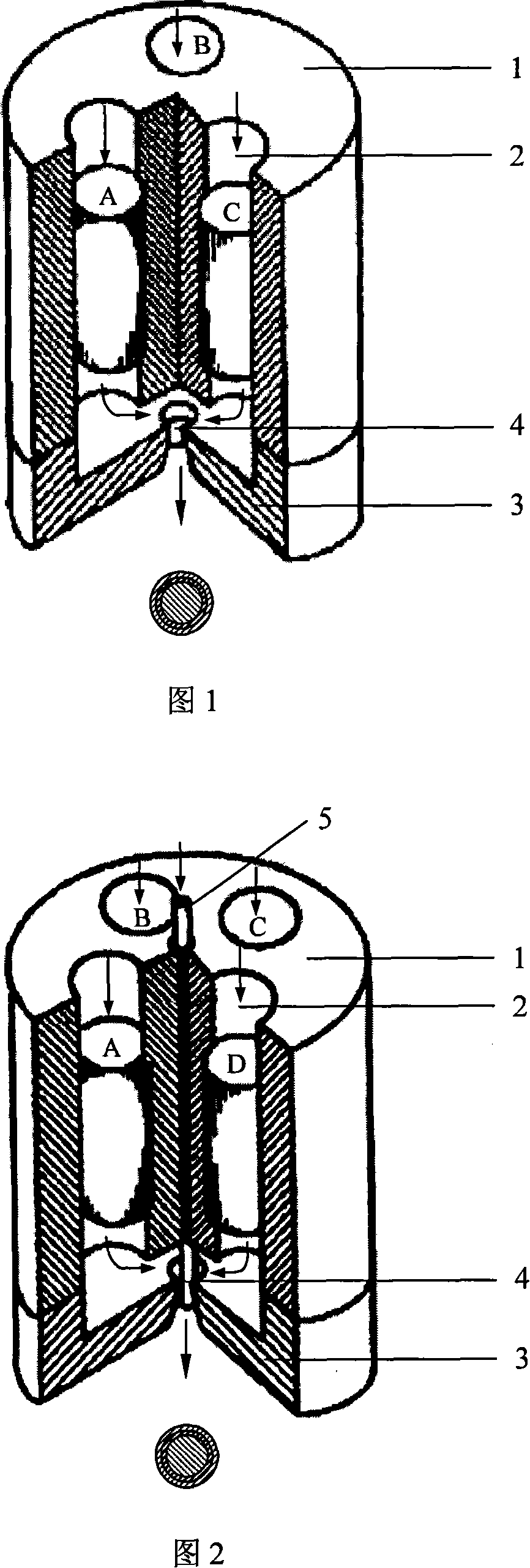

Device and method for dynamically preparing heterocavity bacterium cellulose materials

ActiveCN101914434AUnique three-dimensional network nanostructureHigh chemical purityBioreactor/fermenter combinationsBiological substance pretreatmentsFiberNerve fiber bundle

The invention relates to a device and a method for dynamically preparing heterocavity bacterium cellulose materials. The device comprises a thermometer hole, an acid liquor and alkali liquor adding hole, a handle, a venting hole, a pH meter hole, a nutrition supplement hole, a rotating shaft, a fermentation tank, a motor, a water bath device and a mould. The preparation method comprises the following steps of: inoculating bacterium cellulose strains into a fluid nutrient medium to be propagated and then transferring to a fermentation device provided with specific shape moulds for later dynamic disturbance cultivation, and then obtaining the heterocavity cellulose materials after the cultivation step. The size and the shape of the heterocavity BC (Bacterium Cellulose) materials prepared by utilizing the invention are controllable, and the moulds of the fermentation device can be detached to be reused. The preparation method has the advantages of simple and convenient implementation, low cost and high production efficiency, and is suitable for industrialization production. The heterocavity BC materials can be widely applied to cavity organ succedaneums of artificial vessels, nerve fiber conduits and the like, and can be used as food packing materials, such as meat sausage wrappers, jelly wrappers and the like.

Owner:DONGHUA UNIV

Dynamic reconfigurable multi-granularity optical buffer for all-optical switching network

InactiveCN1633108AUnlimited lengthSatisfy the requirements of optical cacheMultiplex system selection arrangementsElectromagnetic transmissionFiberTime delays

A full optical exchange net dynamic reconstructive multigrain optical buffer memory based on fiber delay lines and SOA gain optical switch has a read-write speed of nanosecond level to support data packet. The optical buffer memory cascaded by different grains of optical delay line trees, each tree is composed of four optical delay lines with different grains and provides the buffer storage time delay of 10 basic units by combination of two different grains of delay lines to the most, therefore, the optical buffer memory cascaded by two level optical delay line trees can provide the time delay of 100 basic units.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

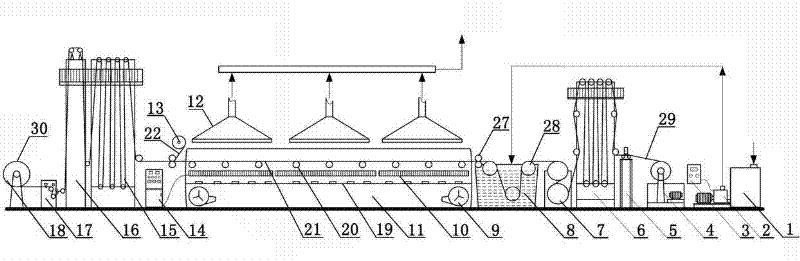

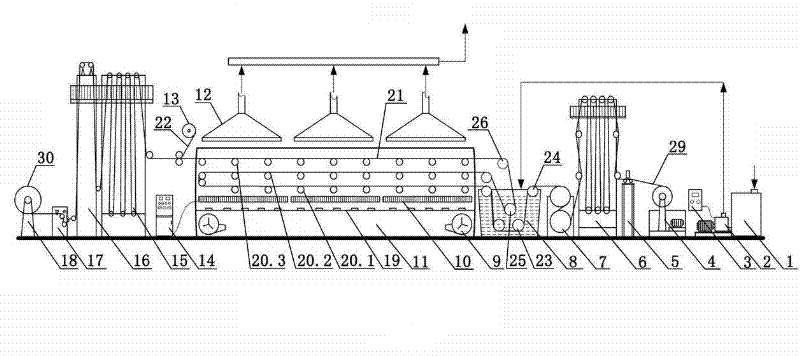

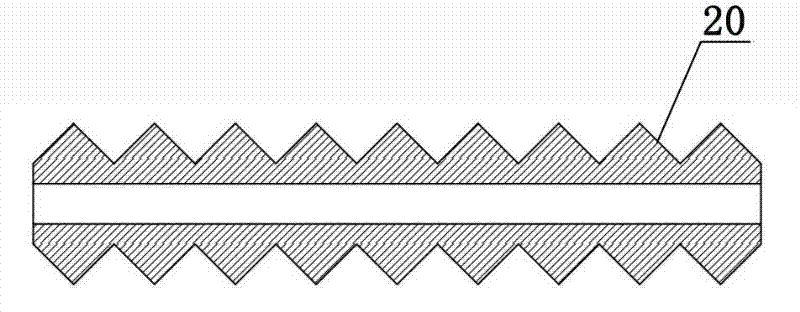

Production equipment and method of self-adhesive layer band

InactiveCN102350852AGuaranteed bondingControl UniformityLamination ancillary operationsFilm/foil adhesivesEngineeringError correcting

Production equipment and a method of a self-adhesive layer band. A base material is treated by a base material unfolding machine, a head-tail-overlapping machine, a base material buffering adjusting bracket and a base material dryer successively, enters into a gluing pool for gluing, then enters a dryer for drying; the dried base material is rolled with an isolated film on a surface thereof by a mulch applicator, cooled by a self-adhesive layer buffering adjusting bracket and adjusted by an automatic error correcting controller; then the base material can be packaged by a product winder and finally cut into dimensions required by production specifications by a cutting machine. After gluing, the base material is dried and returns to the gluing pool for a second gluing; and base material enters into the dryer again for drying after the second gluing, so as to increase peeling intensity of a self-adhesive waterproof coiled material and bonding strength of the material with a base, accelerate drying speed and increase product quality. According to the invention, base material treatment, gluing, drying, coating, cooling, rolling and packaging can be finished in a line, so as to realizeflexible operation, high degree of automation and good product quality.

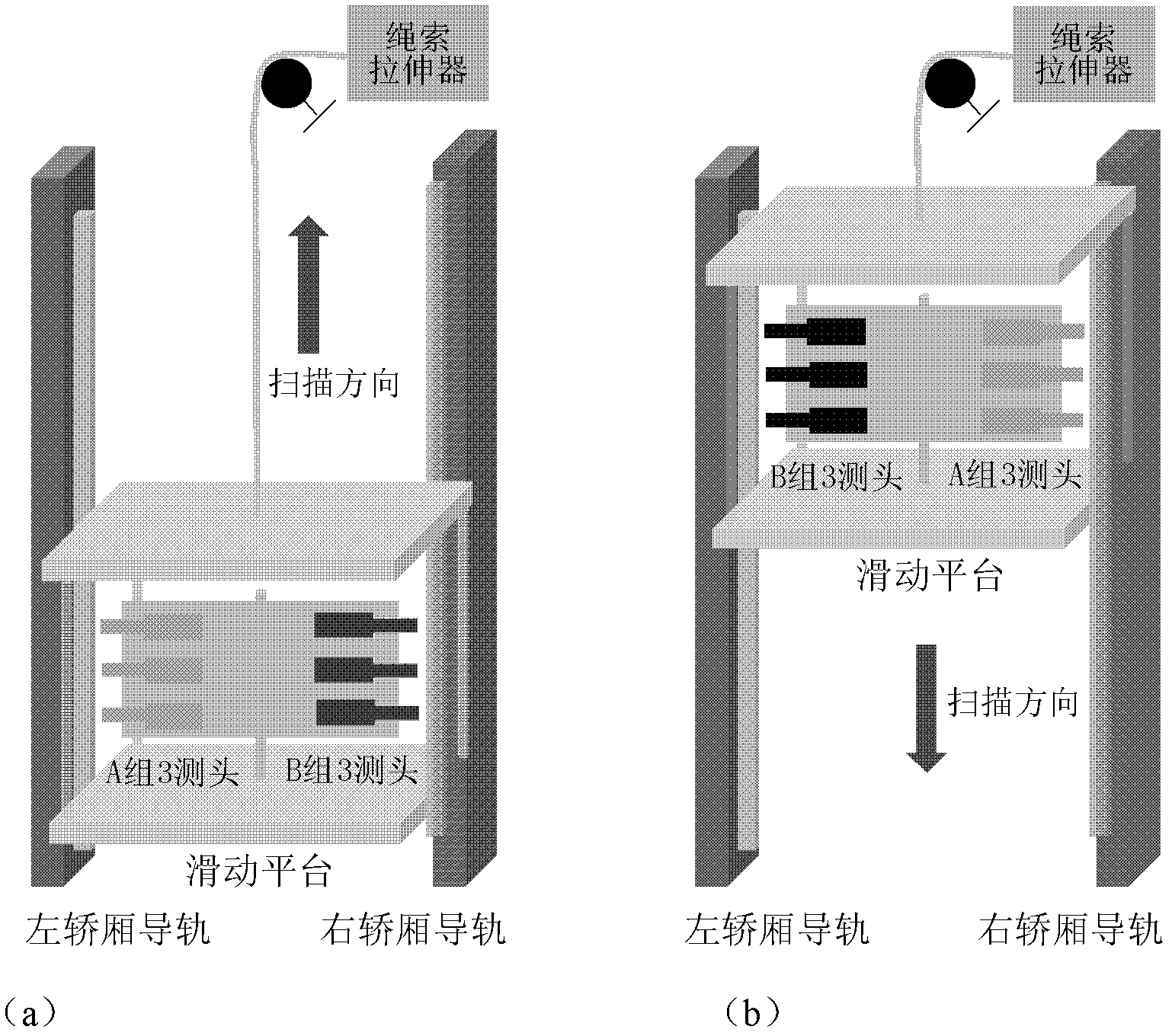

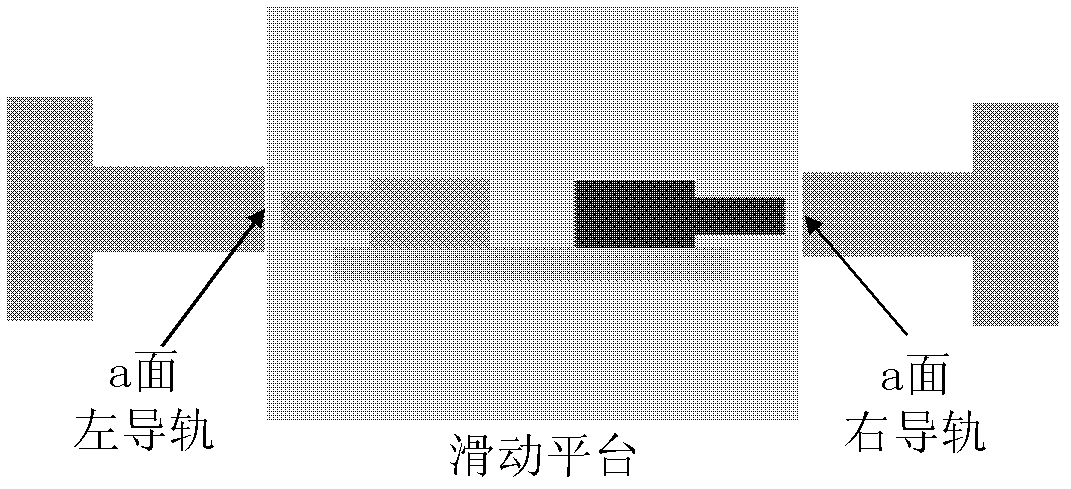

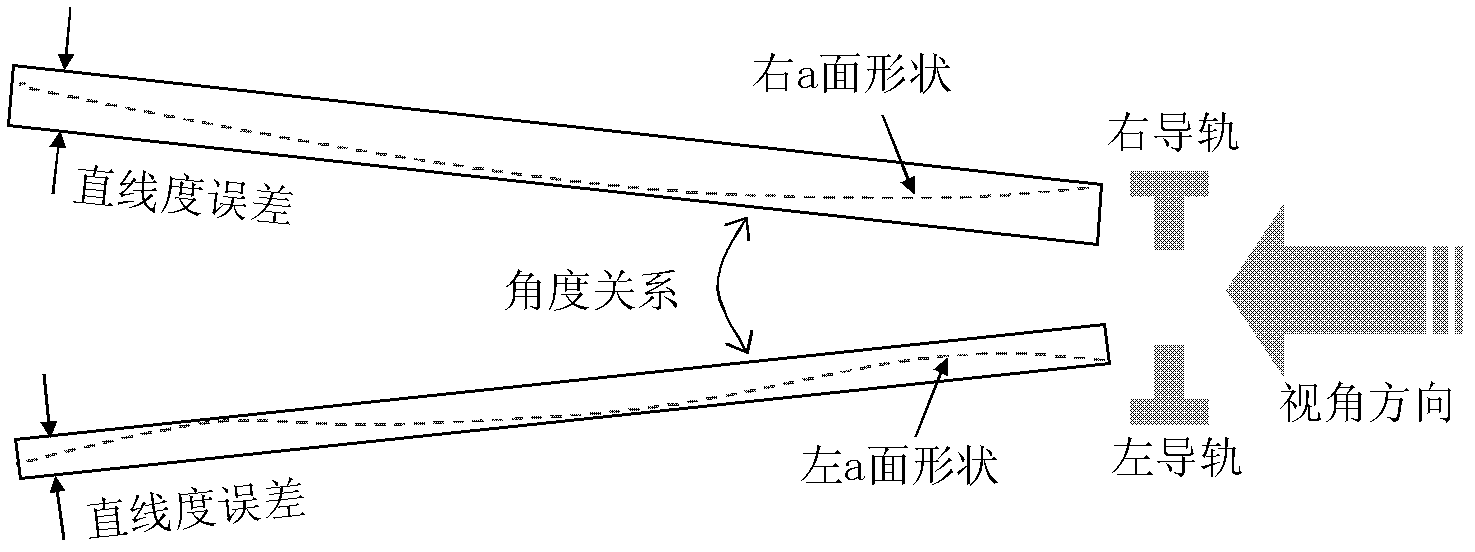

Device and method of guide rail straightness measuring

InactiveCN103033161AUnlimited lengthMeasurement applicableMeasurement devicesTraction systemMeasurement device

The invention discloses a device and a method of a guide rail straightness measuring. The device of the guide rail straightness measuring comprises displacement sensor installation arms, a data acquisition system, a slide platform and an upper computer control system, wherein each array of the displacement sensor installation arms are provided with a plurality of displacement sensor assemblies which are arranged at the roughly same intervals, and sensor measuring faces are basically in the same plane. Compared with the background technology of a guide rail straightness measuring device, scan guide rails do not need to be additionally and specially arranged, and the existing lift car and the traction system are only needed to be borrowed. The length of each measured guide rail is not limited, three faces of a single guide rail can be respectively measured, and spatial position relationship between two guide rails can be measured. By adopting the guide rail straightness measuring device, guide rail straightness and the spatial position relationship of the guide rails can be on-position high-accurately measured, the device and the method of the guide rail straightness measuring particularly has no limit on the length of each installed measured lift guide rail and is suitable for measuring the installed lift guide rails.

Owner:SHANGHAI MITSUBISHI ELEVATOR CO LTD

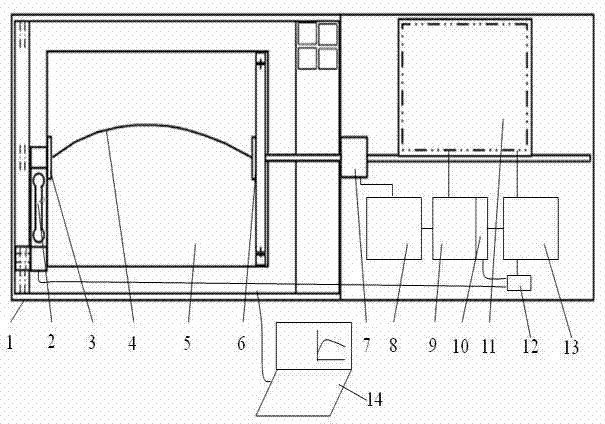

Induction heating auxiliary surface ultrasonic rolling device and method

InactiveCN111531322AImprove versatilitySimple structureMetal working apparatusEngineeringInfrared temperature measurement

The invention discloses an induction heating auxiliary surface ultrasonic rolling device and method. The device comprises a lathe chuck, a running center and a lathe cutter holder, the surface ultrasonic rolling device further comprises an induction coil, a movable arm, an induction power source and an infrared temperature measuring gun, one end of the movable arm is used for mounting of the induction coil, the other end of the movable arm is fixed to the lathe cutter holder, the surface ultrasonic rolling device is fixed to the lathe cutter holder, the induction heating power source is turnedon, meanwhile, a lathe is started, a part rotates, a part in the induction coil work area is heated to the high temperature, in the whole process, the temperature is measured through the infrared temperature measuring gun, when a sample is heated to the needed temperature, the part is subjected to surface ultrasonic rolling machining, through induction heating, the part deforming resistance is reduced, the surface ultrasonic rolling machining effect is better, the device is simple in structure, convenient to use, economic and environment-friendly, and the device can be used for machining shaft parts with high machining hardness and poor surface quality.

Owner:SOUTH CHINA UNIV OF TECH +1

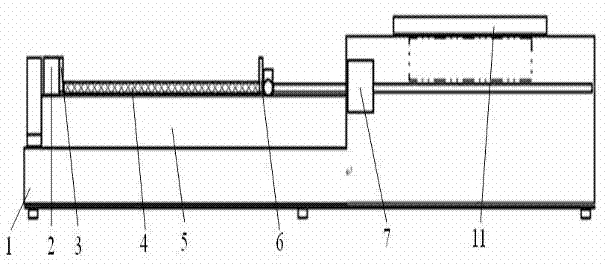

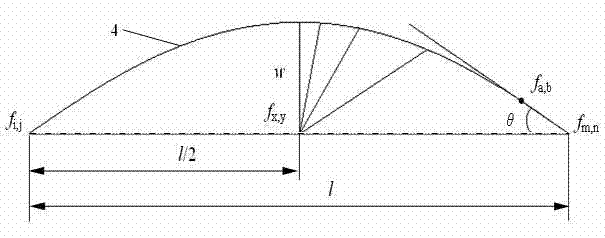

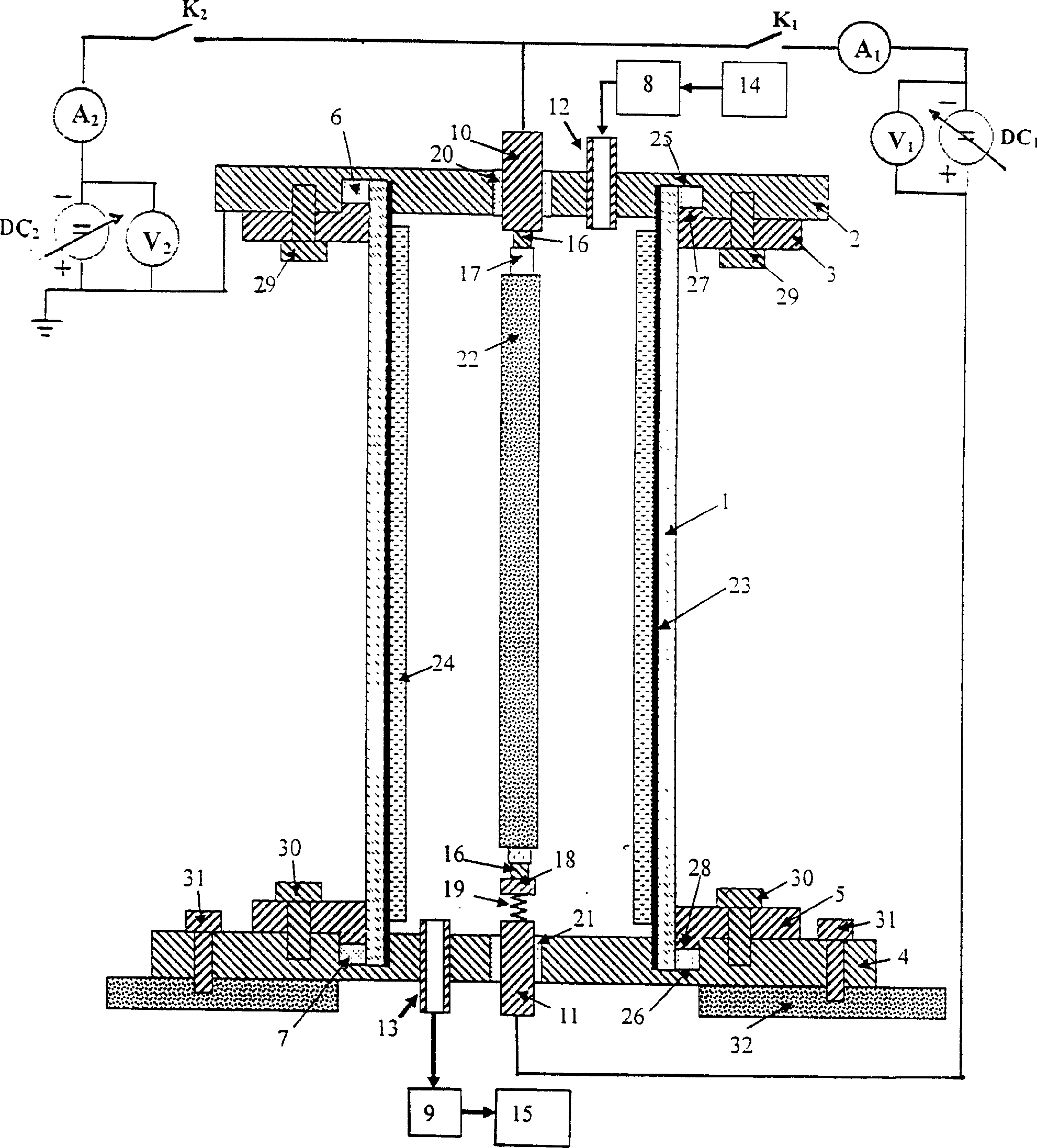

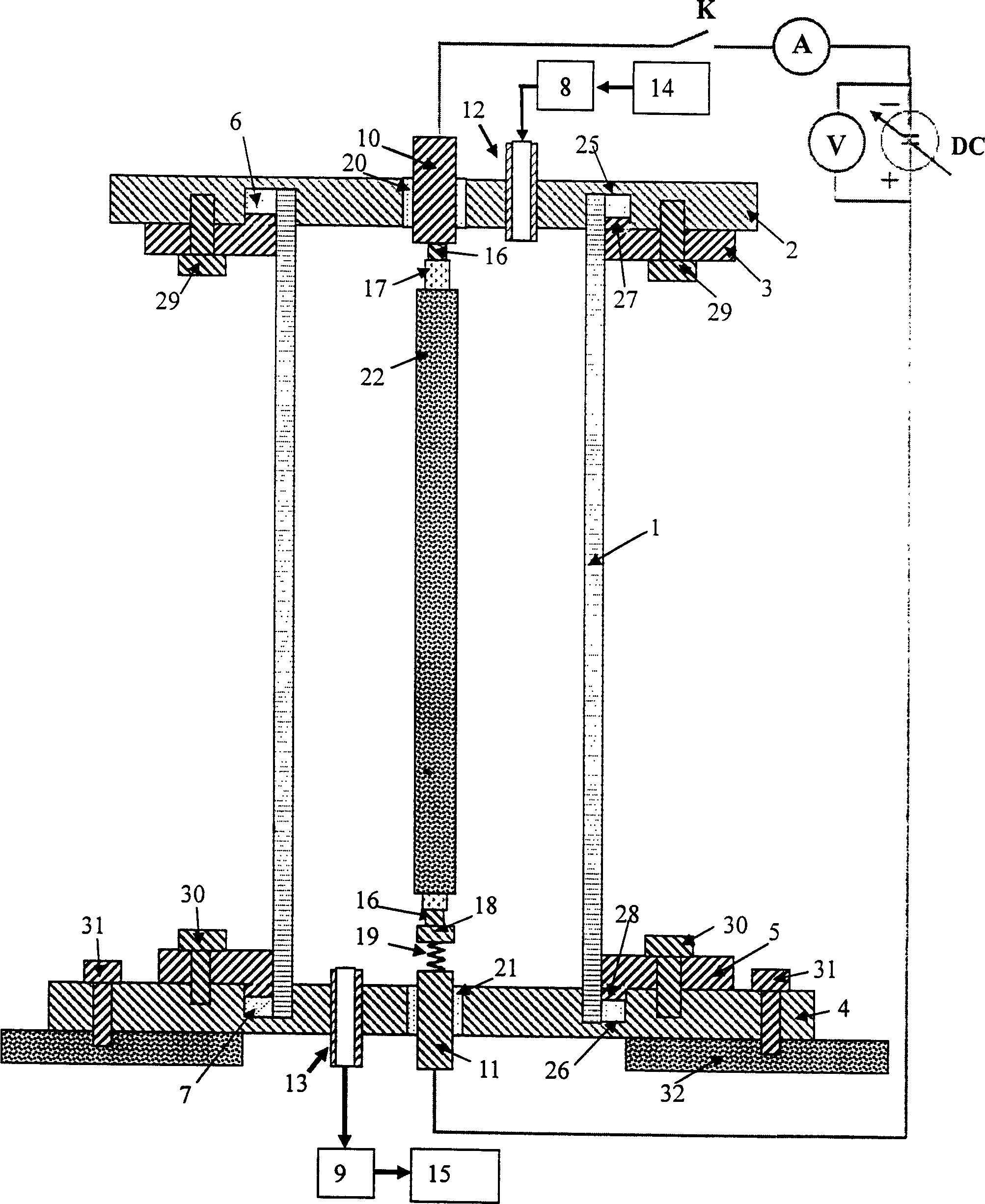

Method and apparatus for simultaneous determination of post-buckling deformation parameters and elastic moduli of elastomeric material

InactiveCN102818732ARealize simultaneous measurementMiniaturizationMaterial strength using steady bending forcesImaging processingMiniaturization

The invention discloses a method and an apparatus for simultaneous determination of post-buckling deformation parameters and elastic moduli of an elastomeric material. The method is as follows: a PLC controller controls a linear stepping motor through a driver, a movable supporting baffle plate is pushed by the linear stepping motor so as to allow a sample to undergo post-buckling deformation, a scanner acquires a post-buckling deformation image of the sample and transfers the image to a notebook computer, and image processing analysis software is used to process the sample so as to obtain the skeleton of the post-buckling deformation image; a coordinate of a point at a leftmost end of the sample and a coordinate of a point at a rightmost end of the sample are determined according to the skeleton of the post-buckling deformation image, a coordinate of the midpoint of chord length between the leftmost end point coordinate and the rightmost end point coordinate is calculated, and then flexibility of the midpoint, corners at the ends and elastic moduli are calculated. According to the invention, synchronous determination of the elastic moduli in a pressure bar post-buckling method and the post-buckling deformation parameters of the pressure bar are realized, which enables the processes of determination and calculation of the elastic moduli to be simplified; test operation is simple, determination precision is improved, and miniaturization, intelligentization and automation of the apparatus are realized.

Owner:JIANGSU UNIV

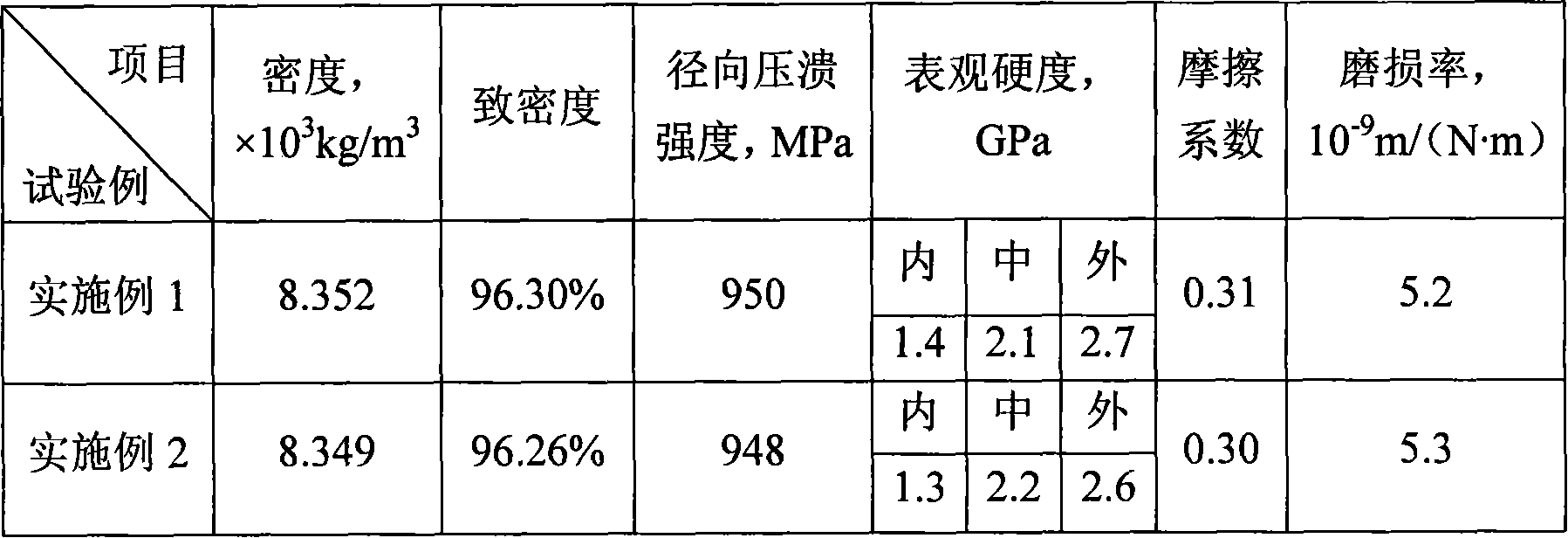

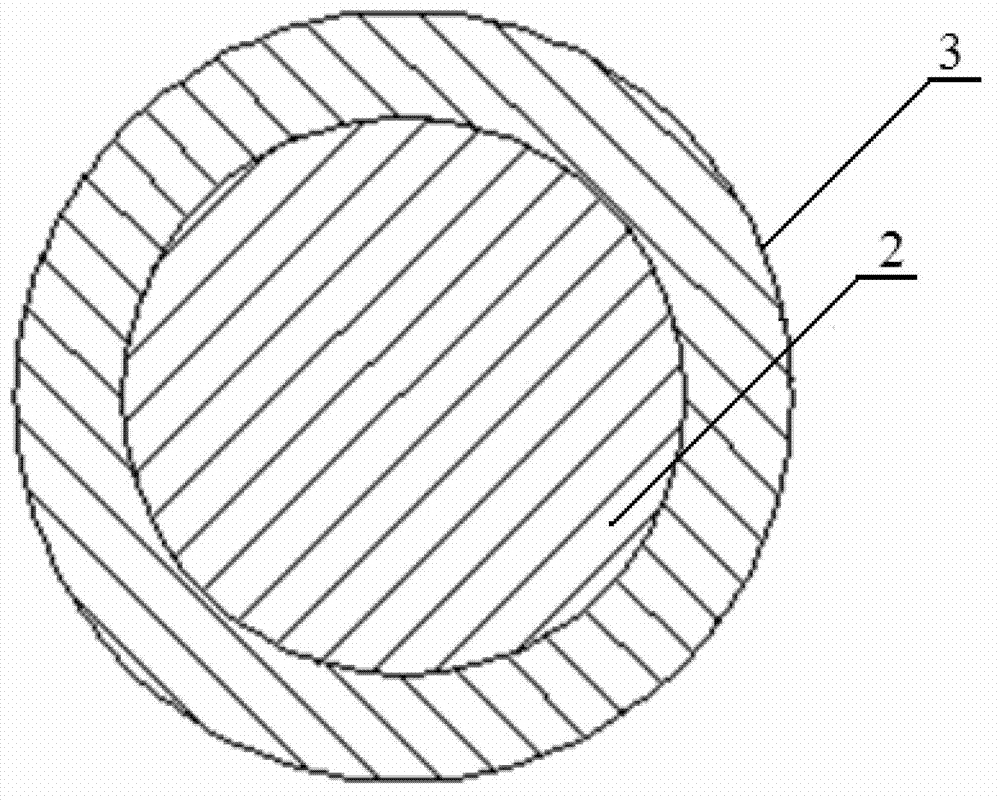

Integral gradient self-lubricating bearing, and fabricating method

This invention relates to an integral grad self-lubricating bearing and its manufacturing method, in which the bearing is composed of a bearing layer, a lubricating layer and a transition layer in the middle, and the bearing layer is made up of carbon steel, stainless steel or bearing steel, the lubricating layer is mixed by a solid lubricating matrix material and a solid lubricant, and the matrix is made of bronze or brass, the solid lubricant is made of MoS2, Sn or graphite, the matrix material is mixed with the solid lubricant to form a solid lubricating layer, the middle transition layer is formed by mixing the bearing material and the solid lubricating material in proportion, which has higher intensity, better rub-reduction and better integration.

Owner:UNIV OF SCI & TECH BEIJING

Self-adaptive ship-intercepting method

ActiveCN101793017AGuaranteed interception effectLow costClimate change adaptationShipping equipmentSelf adaptiveEngineering

The invention discloses a self-adaptive ship-intercepting method. The method has the following advantages that: the method overcomes the problem that because buoys and intercepting cables can be pressed into water by ships in the past, the anti-collision intercepting facilities can fail; moreover, because buoys and intercepting nets normally horizontally float on the water surface and the lengths of the buoys and the intercepting nets do not have affection on the stability of the whole system, the lengths of both the buoys and the intercepting nets are not limited, thereby the intercepting effect is ensured, and moreover, when the intercepting system used in the method normally horizontally floats on the water surface, sight on the sea surface cannot be affected; in addition, the intercepting system used in the method has the advantages of low construction cost, high economical efficiency, long service life and convenient replacement and maintenance; and moreover, the method can be flexibly transported to different places for use, and can change the arrangement position of the intercepting system.

Owner:NINGBO UNIV

Preparation method of artificial blood vessel and its application

InactiveCN101284148AControl microstructureUnlimited lengthHollow filament manufactureNon-woven fabricsHollow fibre membraneOrganic solvent

The invention relates to a method for preparing an artificial vessel and the application thereof. The preparation method comprises the following steps: (1) in the preparation of membrane liquid, polymer that is 7 to 30 percent by weight proportion is added into organic solvent the weight proportion of which is 70 to 93 percent, so that casting solution is obtained through swelling and solution under the temperature between 40 DEG C and 80 DEG C; (2) in the preparation of the artificial vessel, a hollow fibre membrane is formed through the filtration and deaeration of the membrane liquid, serosity is squeezed out from a spinneret composed of two concentric tubes, the serosity which enters into precipitating bath through dry spinning then is processed through a post treatment process to obtain the artificial vessel. The method includes the application that the artificial vessel is transplanted to a physical organ or any organs which need quantities of vascular tissues to transport aliment, gas and waste. The artificial vessel obtained by using the preparation method has good adaptability, penetrability and biocompatibility, matches the self vessels, and has controllable outside diameter and wall thickness of the materials.

Owner:DONGHUA UNIV

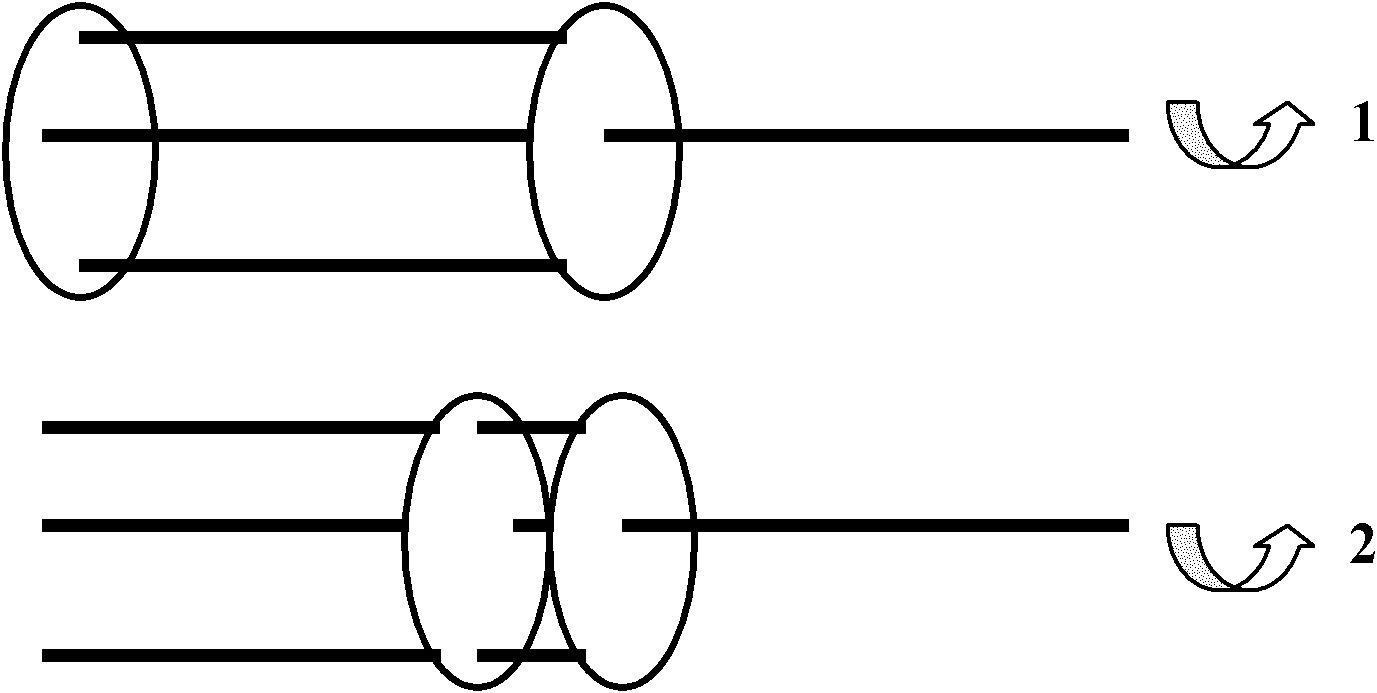

Linear nano carbon tube composite-field emission source and method for preparing same and dedicated device therefor

InactiveCN1877774AExcellent field emission characteristicsReduce energy consumptionIndividual molecule manipulationDischarge tube/lamp detailsFiberComposite field

The invention discloses a linear nanometer carbon pipe composite field launching source and making method and specific device, which contains a conductive fiber weaving line substrate with single wall or multiple-wall nanometer carbon pipe film deposited on the substrate. The making method comprises the following steps: predisposing the surface of fiber weaving line; utilizing self-power pyrolytic CVD method grow single-wall or multiple-wall nanometer carbon pipe on the fiber weaving fiber. The length of composite field launching source is not limited, which produces linear pattern product. The device is fit for pipe-typed nanometer carbon pipe field launching luminous bulb, which can observe the field emitting condition.

Owner:北京北大新世纪科技发展有限公司

A license plate recognition method based on deep learning

ActiveCN109165643AInhibit adhesionInhibition of fractureCharacter and pattern recognitionNeural architecturesMinimum bounding rectangleLicense

The invention discloses a license plate recognition method based on deep learning, which comprises the following steps: step 1, training a deep convolutional neural network model M for license plate character detection; constructing a license plate character label set B; step 2, inputting the positioned license plate image I to a license plate character detection network M, and outputting a candidate license plate character set H; step 3, reordering the candidate license plate character set H obtained in the step 2 according to the abscissa hi.x of the upper left corner of the smallest circumscribed rectangle of the candidate license plate character from small to large to obtain a set C; step 4, further executing screening operation on the set C obtained in the step 3; step 6, sequentiallytraversing the set E obtained in the step 5; step 7, returning that license plate recognition result L obtained in the step 6. The method has the beneficial effects of effectively inhibiting the influence of license plate character adhesion, fracture, deformation, license plate dirt, license plate inclination, residual shadow on the license plate and the like.

Owner:ZHEJIANG UNIV OF TECH

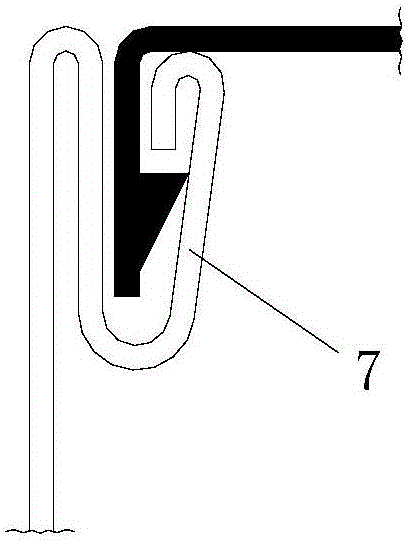

Pressure resisting type air pipe air leakage preventing structure of ventilation air conditioner system and air pipe joint machining method

The invention discloses a pressure resisting type air pipe air leakage preventing structure of a ventilation air conditioner system. The pressure resisting type air pipe air leakage preventing structure comprises a pressure resisting type sealing structure and a clamping structure. The pressure resisting type sealing structure comprises a pressure resisting type sealing strip located between two flange edges of an air pipe flange. The clamping structure comprises a clamping piece clamped on the two flange edges. The pressure resisting type sealing strip is a T-shaped sealing strip. The T-shaped sealing strip comprises a clamping strip and a limiting strip located at the bottom of the clamping strip. The pressure resisting type air pipe air leakage preventing structure is simple, reasonable in design, convenient to install, good in using effect and capable of effectively reducing the air leakage amount of an air pipe of the ventilation air conditioner system. Meanwhile, the invention discloses an air pipe joint machining method. The method comprises the first step of metal panel cutting, the second step of seaming machining, the third step of flange machining edge machining, the fourth step of pipe joint body panel bending and the fifth step of seaming joint closing and compacting. The machining method is simple in step, manufacturing is easy and convenient, the using effect is good, and the air pipe joint machining process can be easily, conveniently and rapidly finished.

Owner:SCEGC EQUIP INSTALLATION GRP COMPANY

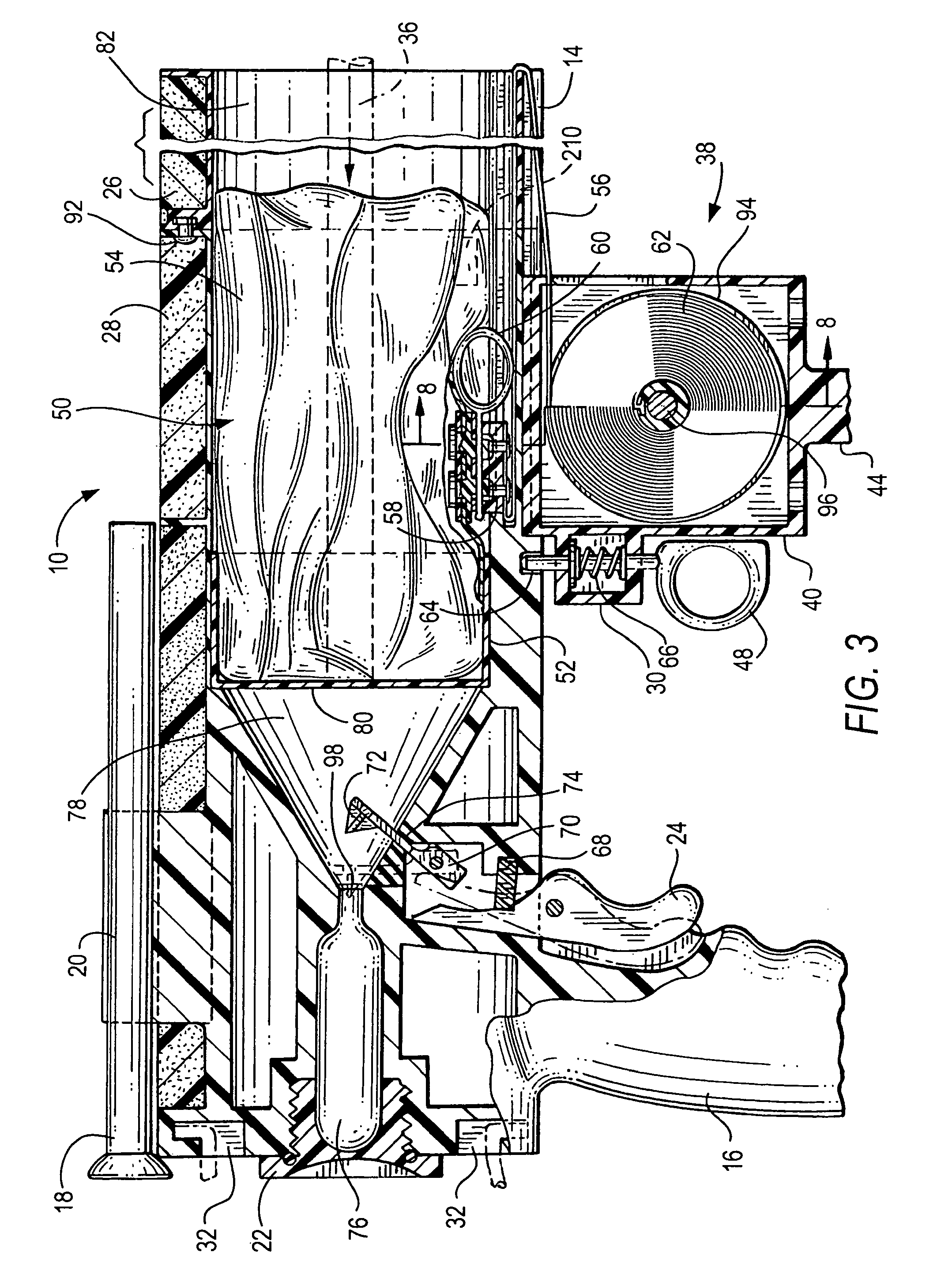

Rescue and retrieval apparatus and system and method of using same

InactiveUS9056661B2Save livesUnlimited lengthAmmunition projectilesCast linesSTI OutpatientLow friction

A system is disclosed which incorporates a projectile delivery launcher which may assume numerous forms and perform numerous functions, including launching a water rescue preservation device such as a life jacket, military supplies, survival supplies, fire extinguishing supplies, or the like. The device includes a unique barrel having a low friction chrome plated inner surface which provides maximum range deployment of a safety projectile. In one embodiment a unique clutch-type crank is mounted below the barrel and houses a thin stainless high strength steel ribbon to provide deployment of a projectile, and retrieval of a victim, supplies or the like. A CO2 cartridge system, which incorporates a novel explosive chamber is also used. In another embodiment a compressed gas tank is connected to the launcher for selective release of the gas to deploy the projectile. A method and apparatus for rescuing a victim or for delivering supplies in emergency situations, or even establishing a line contact, is also disclosed.

Owner:MACRI JOHN G +1

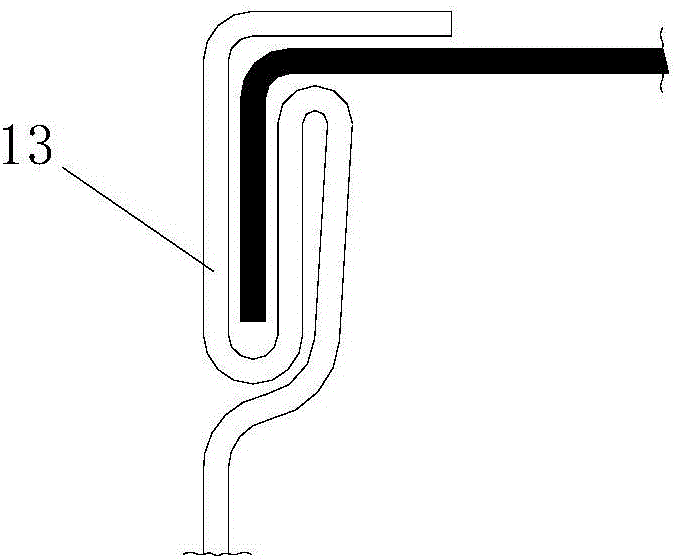

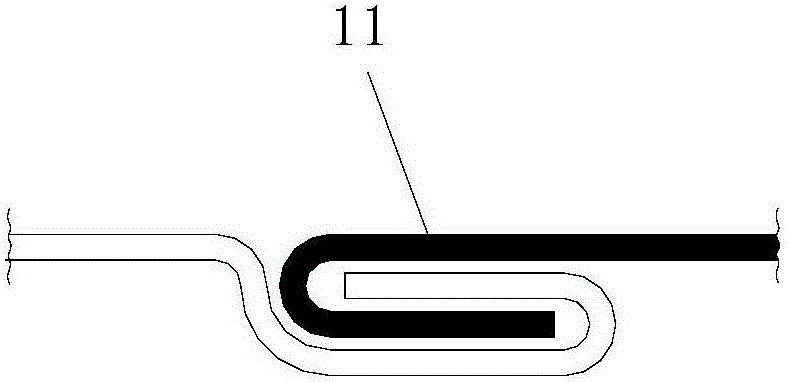

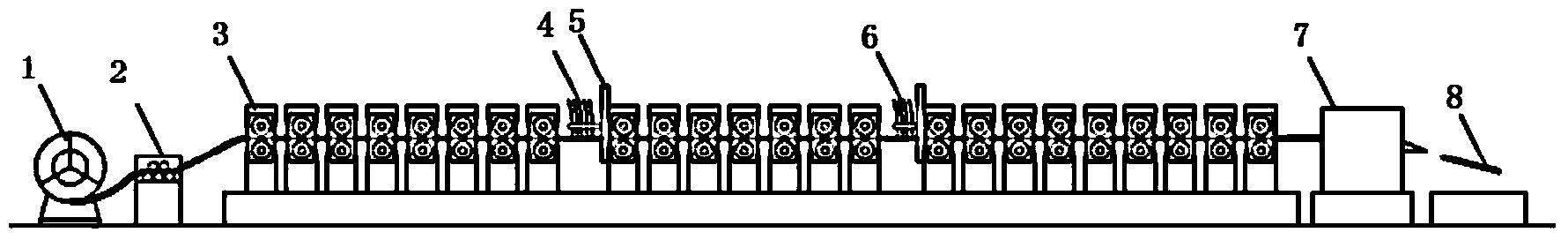

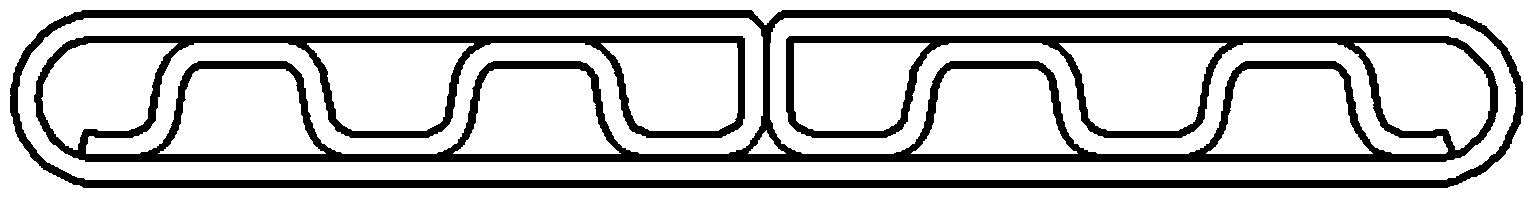

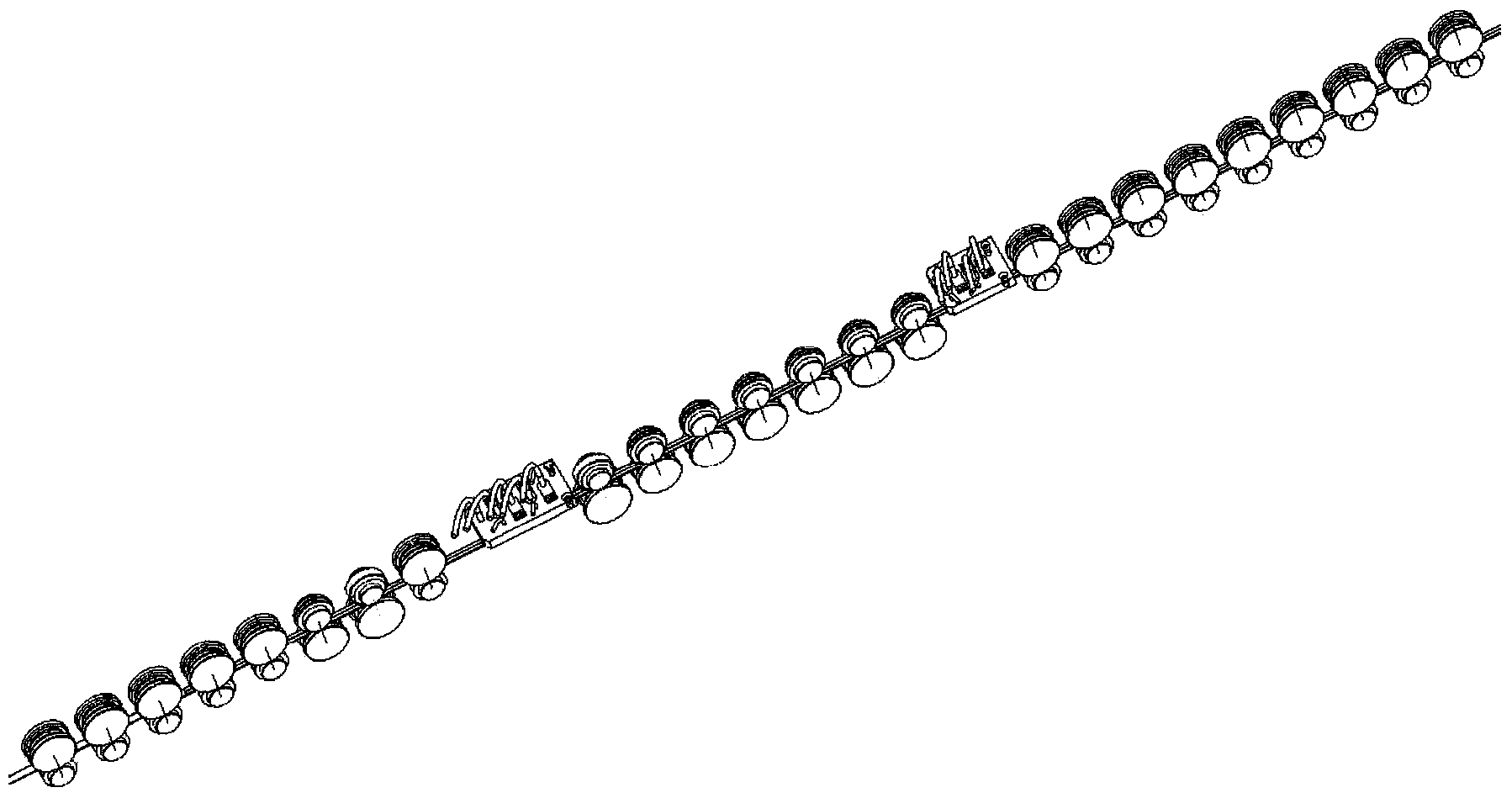

Roll bending forming device and forming method for ten-hole micro-channel flat tubes

ActiveCN103753162AImprove stress statusSolution to short lifeOther manufacturing equipments/toolsEngineeringWelding process

The invention discloses a roll bending forming device for ten-hole micro-channel flat tubes. The roll bending forming device comprises an uncoiling machine, a straightening machine and a roll bending forming unit which are sequentially arranged. The roll bending forming unit comprises an upper row of mill rolls, a lower row of mill rolls, a brazing flux coating device and a product straightening device, multi-pass roll bending forming roll pairs are sequentially configured to form the upper row of mill rolls and the lower row of mill rolls, the brazing flux coating device and the product straightening device are arranged among the roll bending forming roll pairs, gaps are reserved between the upper row of mill rolls and the lower row of mill rolls, and the shapes and the sizes of the gaps are matched with the shapes and the sizes of the ten-hole micro-channel flat tubes. The invention further discloses a forming method implemented by the forming device. The roll bending forming device and the forming method have the advantages that precision dies can be omitted, a series of problems caused during continuous extrusion can be solved, and the manufactured flat tubes are stable in quality; the extrusion speed normally ranges from 2 meters per minute to 3 meters per minute when ten-hole micro-channel flat tubes are manufactured in an extrusion mode, but the roll bending technological manufacturing speed is higher than 80 meters per minute, and the manufacturing efficiency can be improved by 20 times as compared with the traditional extrusion mode; additional welding techniques are omitted in roll bending forming procedures, and integral heat exchangers can be manufactured only by the aid of a brazing technique.

Owner:上海瀚兰通科技有限公司

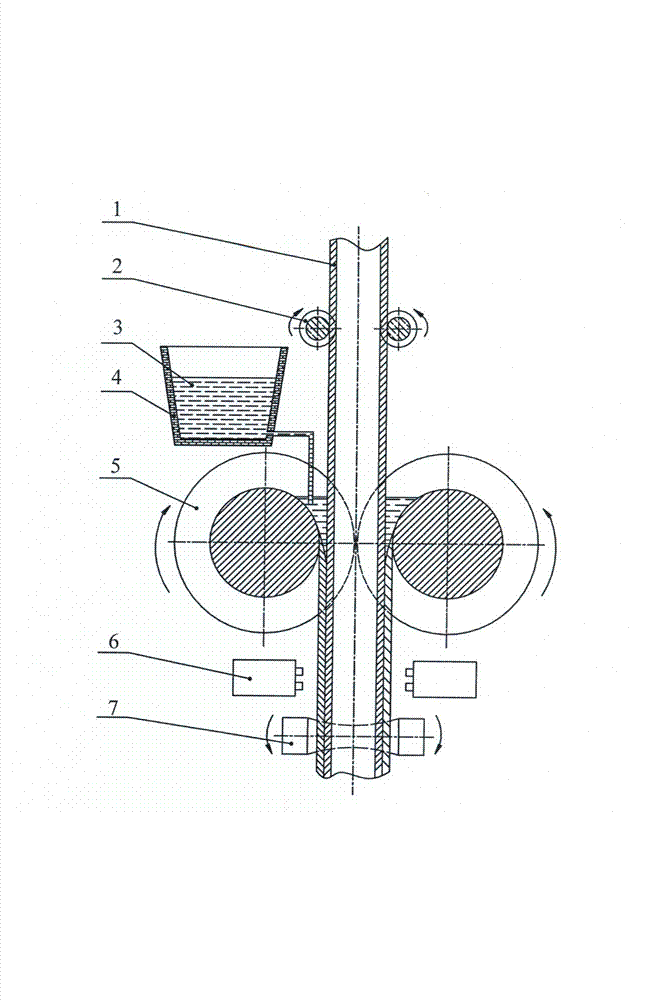

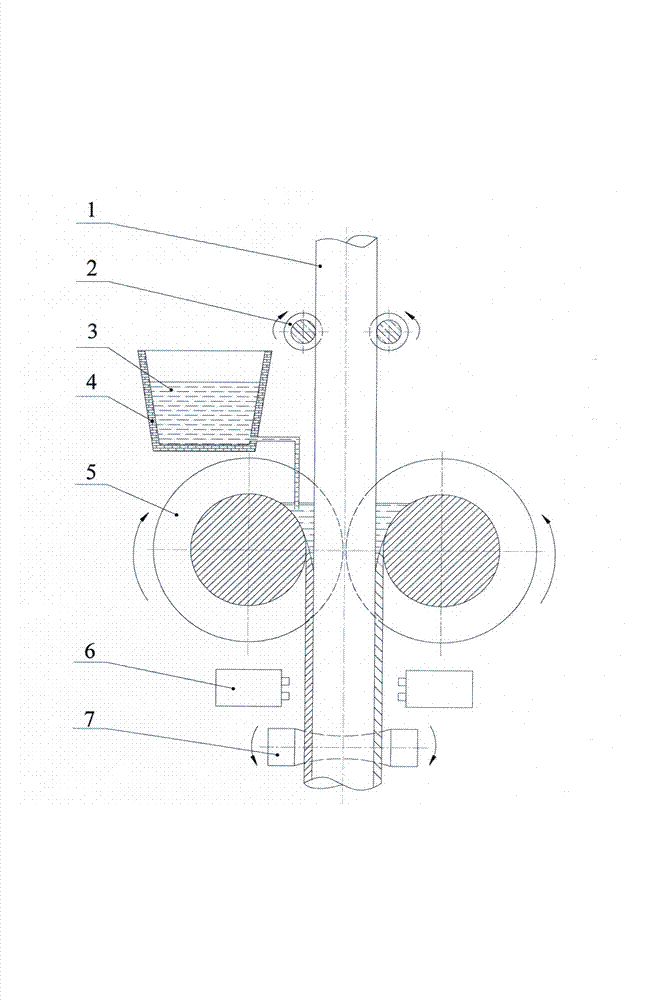

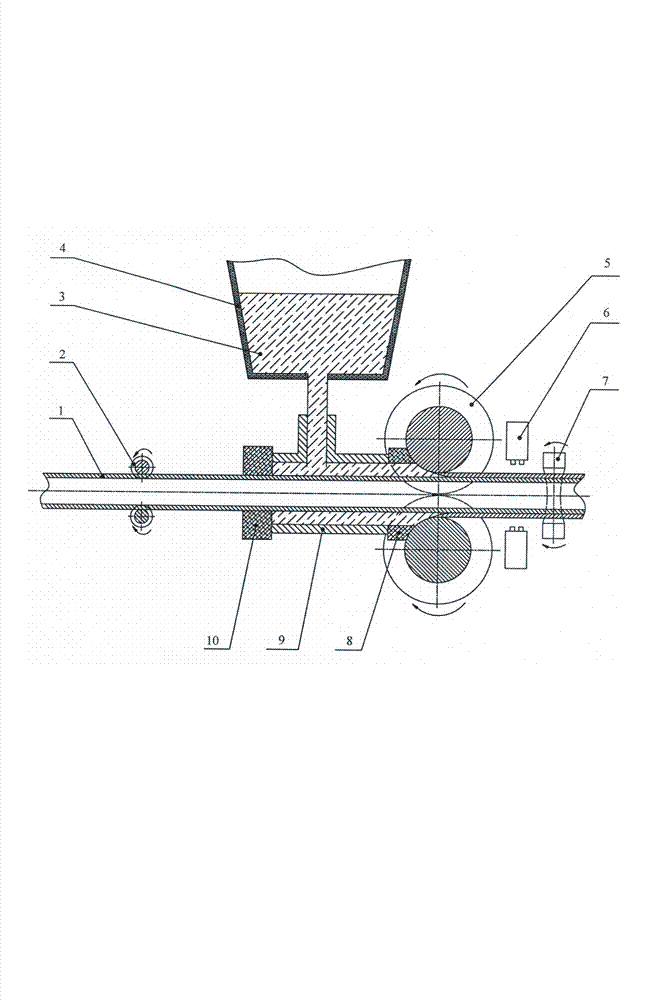

Method for producing bimetal composite material by adopting cold core continuous casting and rolling process

ActiveCN102825067ALow requirements for billet size and shape accuracyHigh yield and metal utilizationMetal rolling arrangementsManufacturing engineeringPipe

The invention relates to a method for producing a bimetal composite material by adopting a cold core continuous casting and rolling process. The method is characterized by comprising the following steps of: using an inlet pinch and guide device to feed a cold core base material into a groove of a casting and rolling roller, continuously pouring a molten-state covering material in a ladle into an annular crystallizer constituted by the base material and the groove of the casting and rolling roller, driving the casting and rolling roller, continuously and uniformly coating the molten-state covering material on the surface of the cold core base material, and arranging a secondary cooling device and an outlet pinch and guide device on the outlet side so as to realize cold core continuous casting and rolling composite molding of a bimetal composite pipe or rod. The method has the advantages that the bimetal composite pipe or rod produced by the technological method has the advantages of low requirements on size and shape precision of a stock, no need of pre-assembly, high finished product rate, high metal utilization rate, no limitations on length and thickness of a covering layer of a product, a wide range of specifications of the product and the like, and the method is of a high-efficient production technological method. The product can be directly used as a finished product or be used as the stock for pipe rolling, cold drawing and other process steps.

Owner:YANSHAN UNIV

Medical degradable magnesium alloy meniscus suture line

InactiveCN102805878AImprove physiological functionsHigh hardnessSuture equipmentsMeniscal sutureHardness

The invention provides a medical degradable magnesium alloy meniscus suture line, and relates to a meniscus suture line, aiming at solving the technical problems such as high brittleness and limited length when a catgut line is taken as a suture line. The medical degradable magnesium alloy meniscus suture line consists of a degradable magnesium alloy suture line and a degradable medicine-carried coating layer. The meniscus suture line provided by the invention is high in hardness, and unlimited in length, and the suture line is degradable per se after a meniscus is healed, so that the healed meniscus can play the physiological function more perfectly.

Owner:HARBIN ENG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com