Patents

Literature

233results about How to "Inhibition of fracture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for modifying surface of ultrafiltration membrane

InactiveCN102029117AThe reaction conditions are mild and easy to controlSimple and safe operationUltrafiltrationUltrafiltrationChemistry

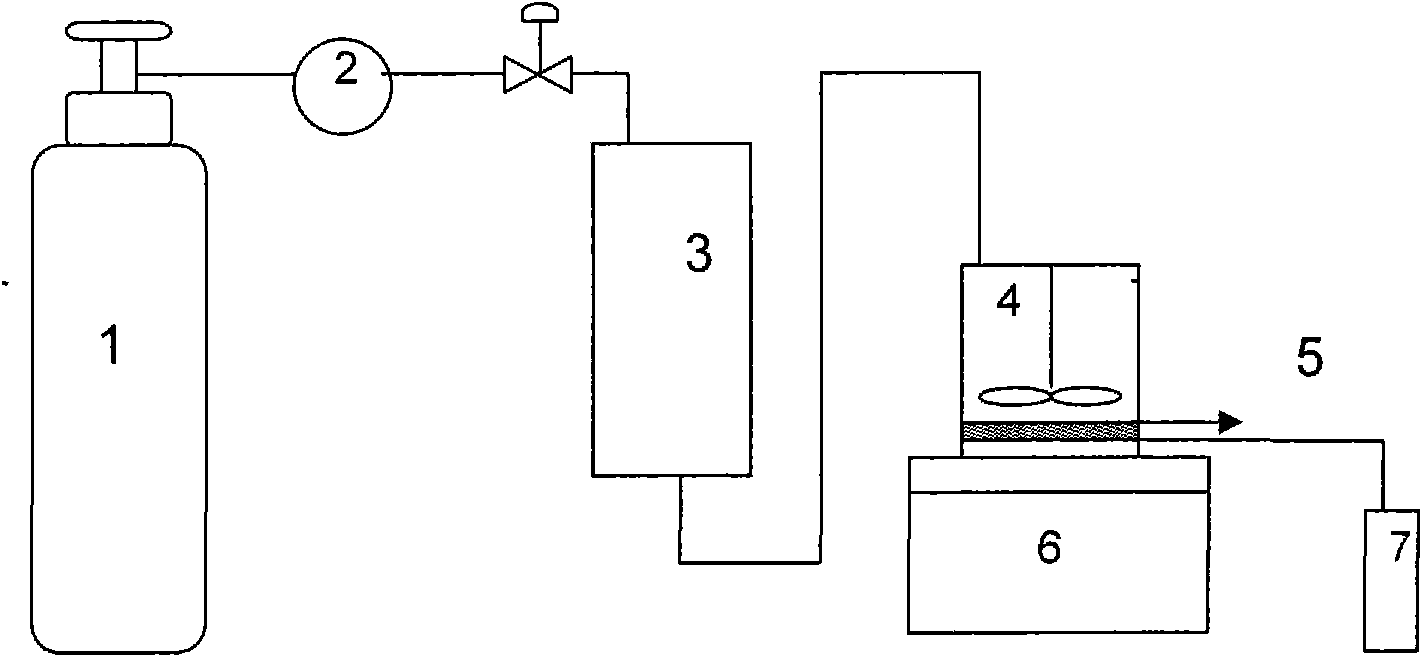

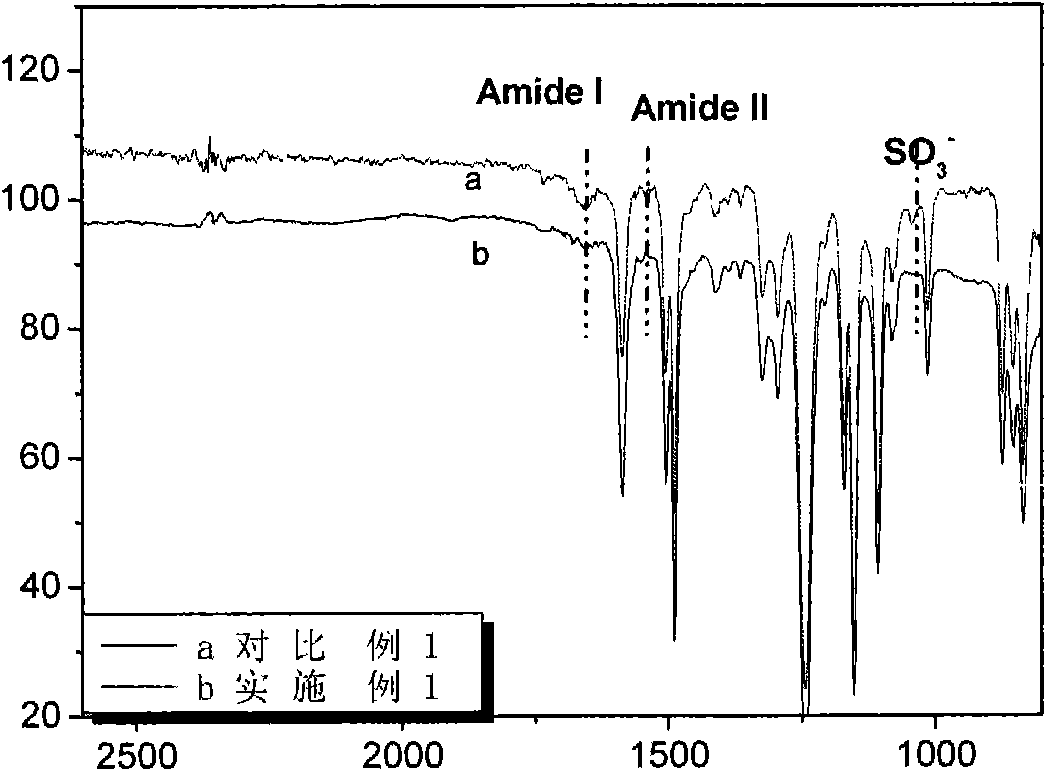

The invention relates to a novel method for modifying the surface of a polysulfone ultrafiltration membrane, used for improving the pollution resistance of a separation membrane. In the invention, by using polysulfone as a surface modification basement membrane, a living radical is generated on the membrane surface with an ultraviolet initiator or a thermal initiator to further graft a hydrophilic monomer on the surface of the membrane, thereby finishing grafting modification to a polysulfone ultrafiltration membrane. The method is convenient to operate, efficiently inhibits generation of polysulfone main chain fracture and also keeps the interception performance of the ultrafiltration membrane. In the prepared ultrafiltration membrane, the hydrophilicity is obviously improved, and the pollution resistance is remarkably enhanced.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

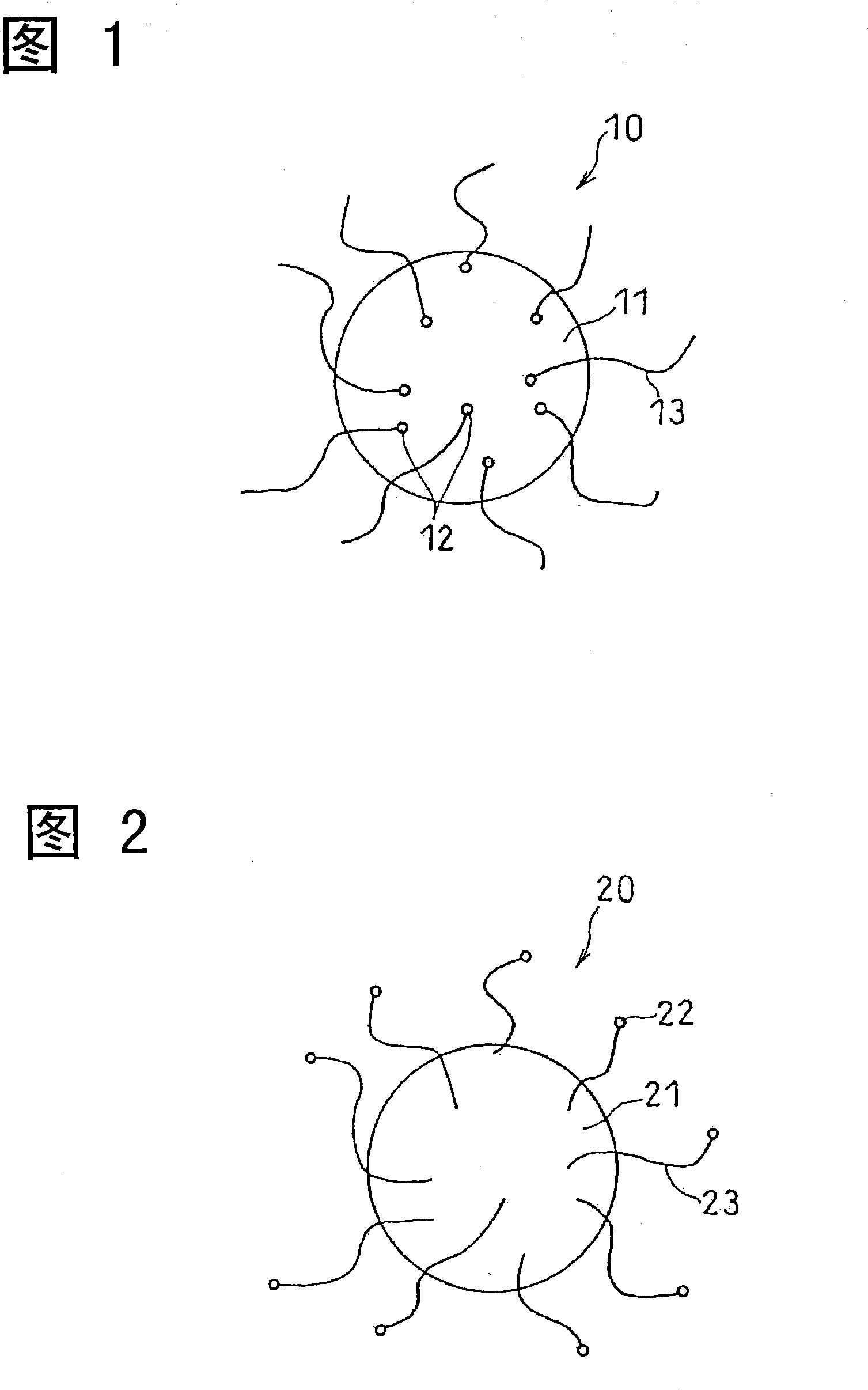

Negative electrode material used for lithium battery and preparation method and application thereof

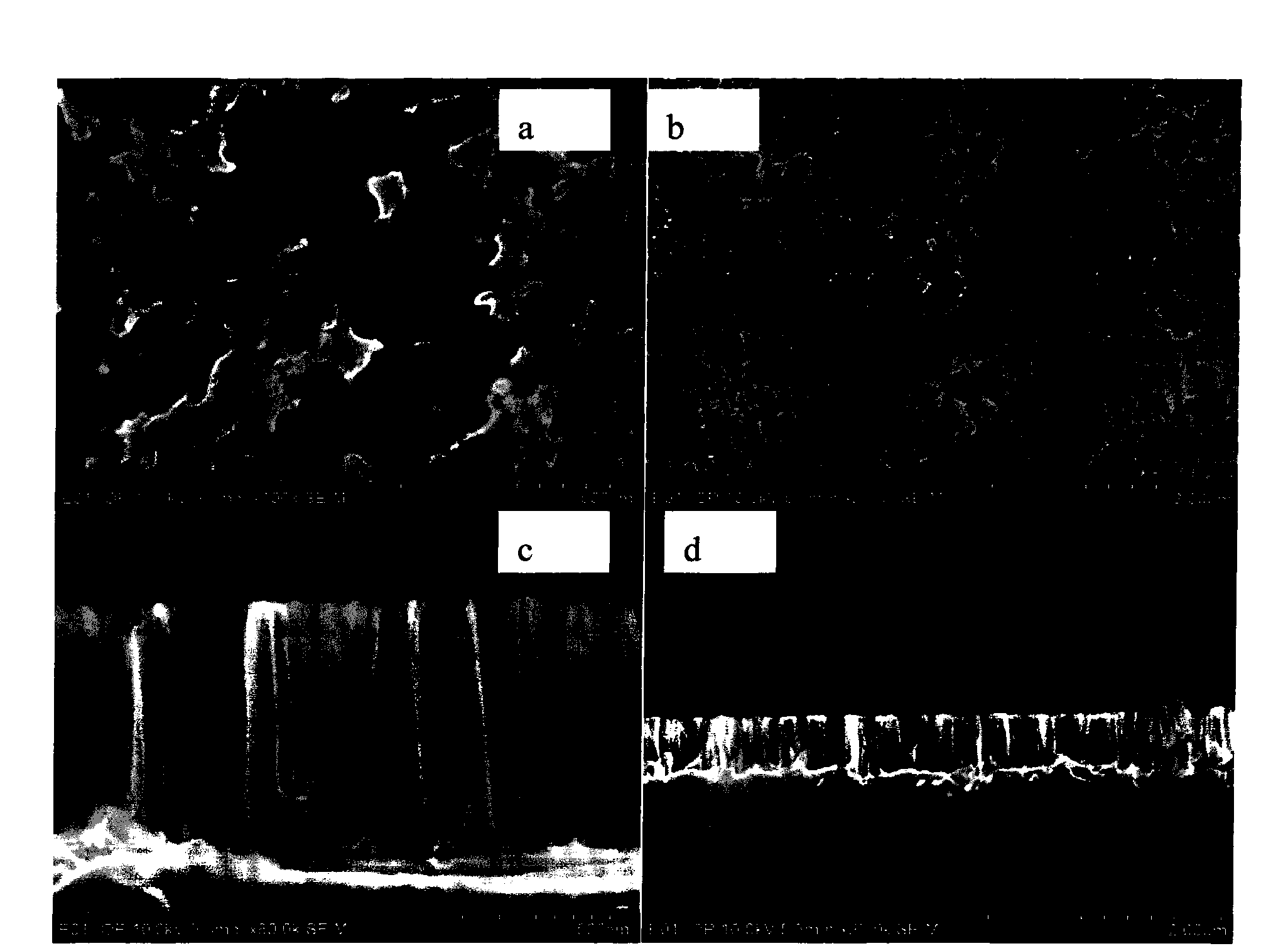

ActiveCN103474632AStable structureImprove performanceMaterial nanotechnologyCell electrodesPorosityMicro nano

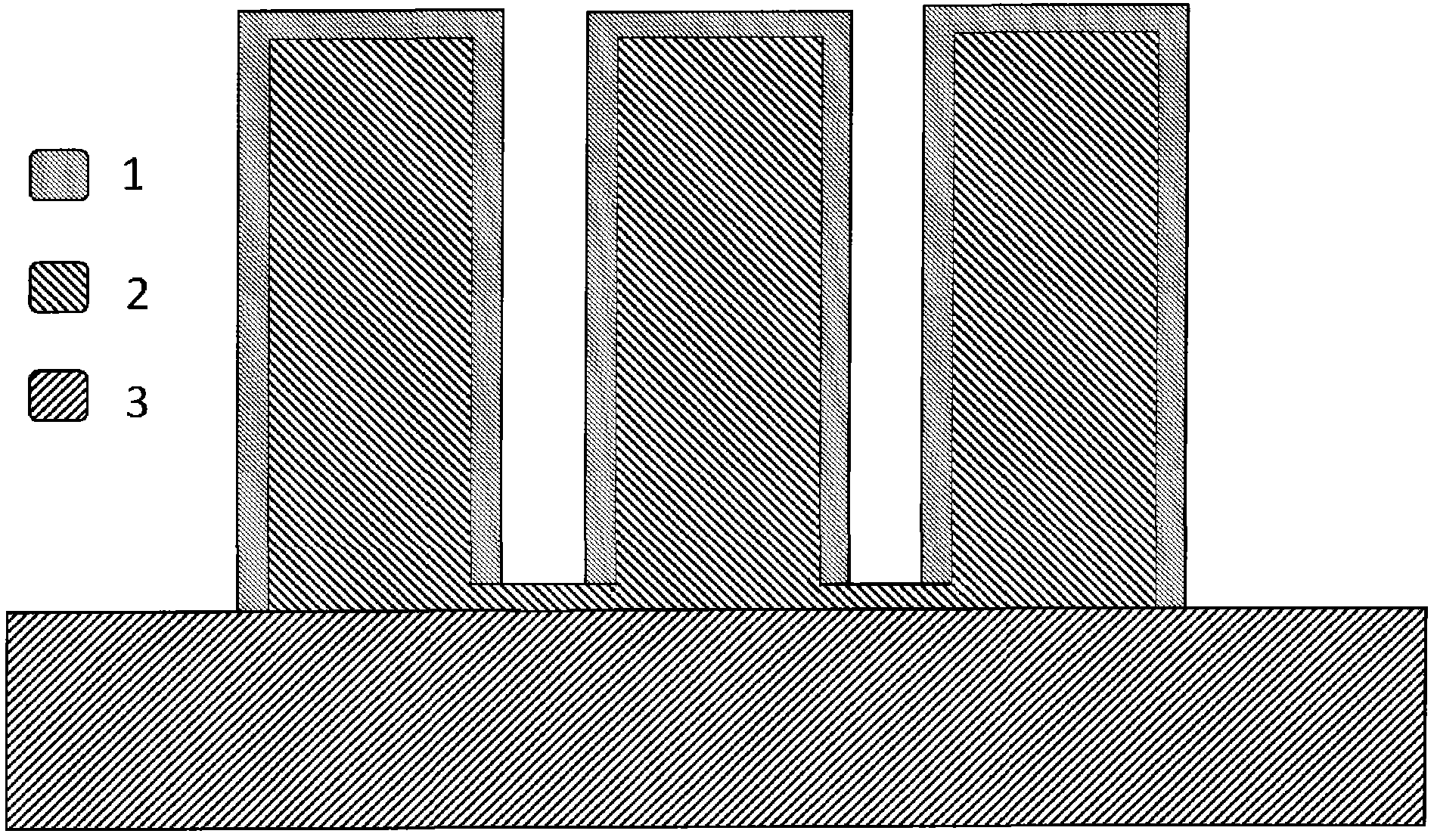

The invention relates to a negative electrode material used for a lithium battery and a preparation method and application thereof, the negative electrode material includes a conductive substrate material layer and a silicon based thin film material layer, the silicon based thin film material layer contains one or more components selected from the group consisting of silicon element, SiOX and silicon alloy, wherein, 0 < X =< 2; in the silicon based thin film material layer, silicon accounts for 10-100% of the weight of the silicon based thin film material layer; the silicon based thin film material layer is a thin film formed by regular and / or irregular columnar and / or fibrous micro nano naps, wherein the micro nano naps are connected with each other by root parts, and the root parts of the micro nano naps are connected with the conductive substrate material layer; gaps are existed among the micro nano naps, and the porosity among the micro nano naps is 2%-98%; the diameter size of the micro nano naps is 1 nm to 10 mum, and the thickness of the silicon based thin film material layer is 50 nm-10 mum.

Owner:LIYANG TIANMU PILOT BATTERY MATERIAL TECH CO LTD

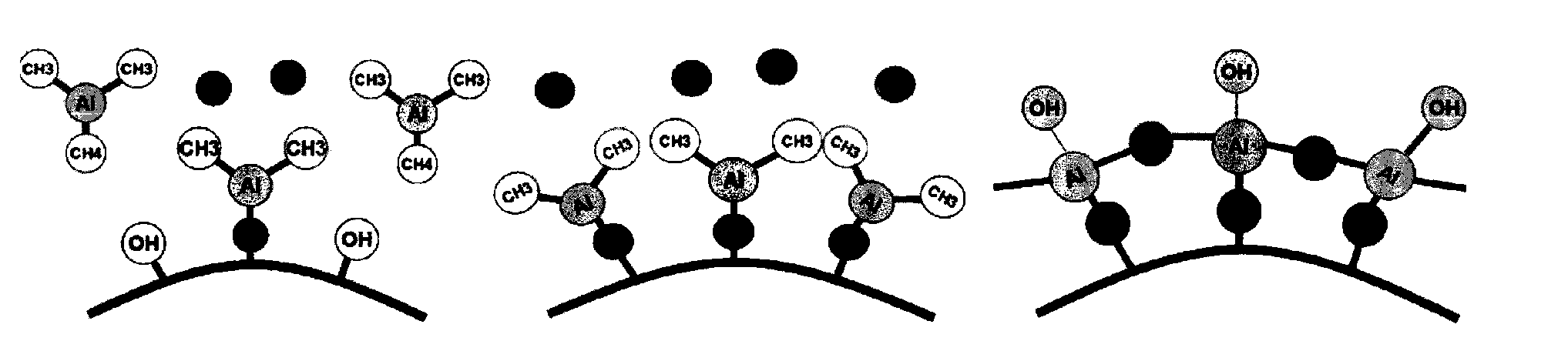

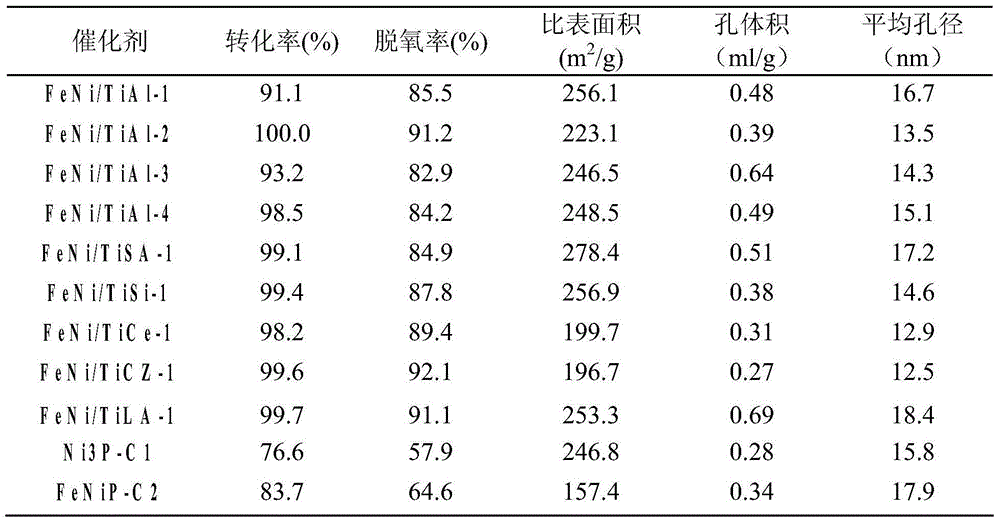

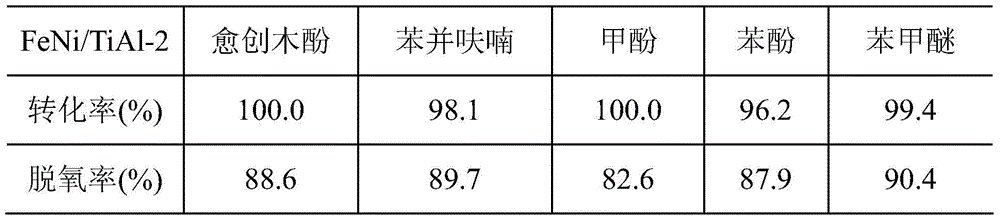

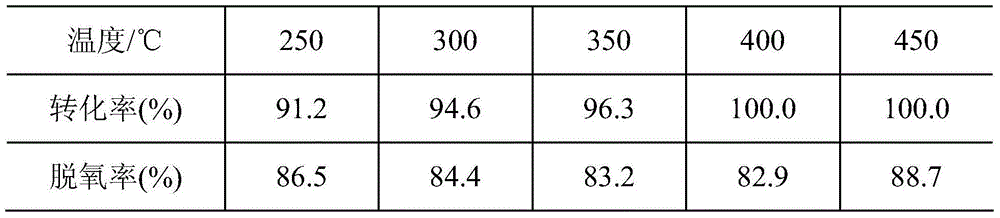

Loaded type iron-nickel phosphide catalyst material and application thereof

InactiveCN105727957ALarge specific surface areaConducive to loadLiquid hydrocarbon mixture productionBio-feedstockAlloyComposite oxide

The object of the invention is to provide a loaded type iron-nickel phosphide catalyst material, a preparation method therefor and an application of the loaded type iron-nickel phosphide catalyst material. The loaded type iron-nickel phosphide catalyst material is characterized in that a catalyst active component is a multicomponent alloy compound which is formed through mutually doping elements, i.e., Fe, Ni and P, a catalyst carrier is a composite oxide carrier which is prepared from TiO2 and a second kind component, the second kind component is one or more of SiO2, Al2O3, ZrO2, CeO2 and La2O3, the weight percent of TiO2 accounts for 5.0wt% to 95wt% the weight of the composite carrier, the loaded amount of the catalyst active component Fe is 0.5wt% to 80wt%, the loaded amount of the metal active component Ni is 0.05wt% to 30wt%, and the loaded amount of the nonmetal adjuvant P is 0.5wt% to 15wt%. The catalyst has very good reaction activity, stability and selectivity, can be applied to a reaction for preparing aromatic compounds through catalyzing the degradation of biomass oil and can also be applied to a hydrodeoxygenation reaction for compounds containing aromatic hydrocarbon C-O bonds or alkyl C-O bonds.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

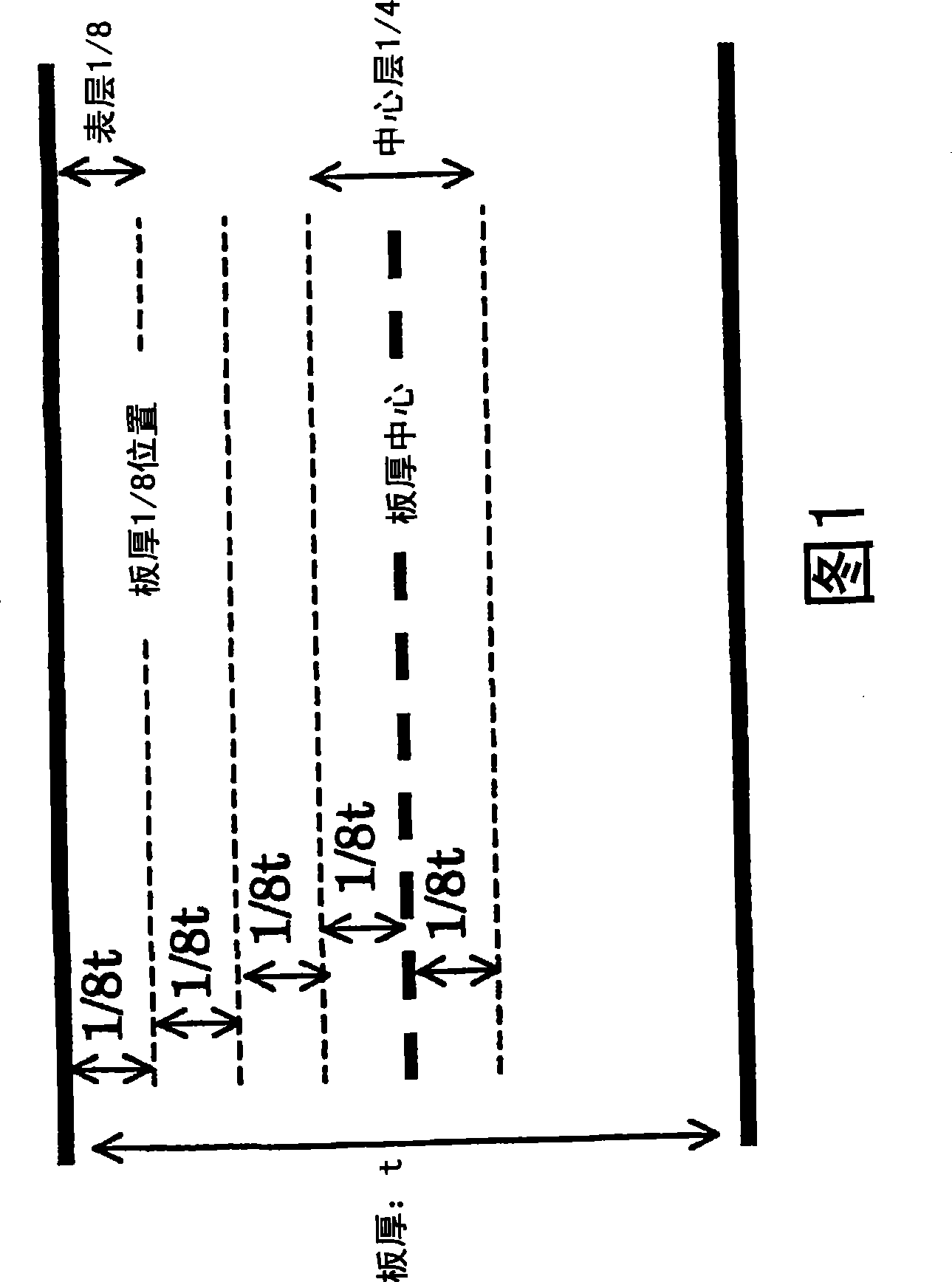

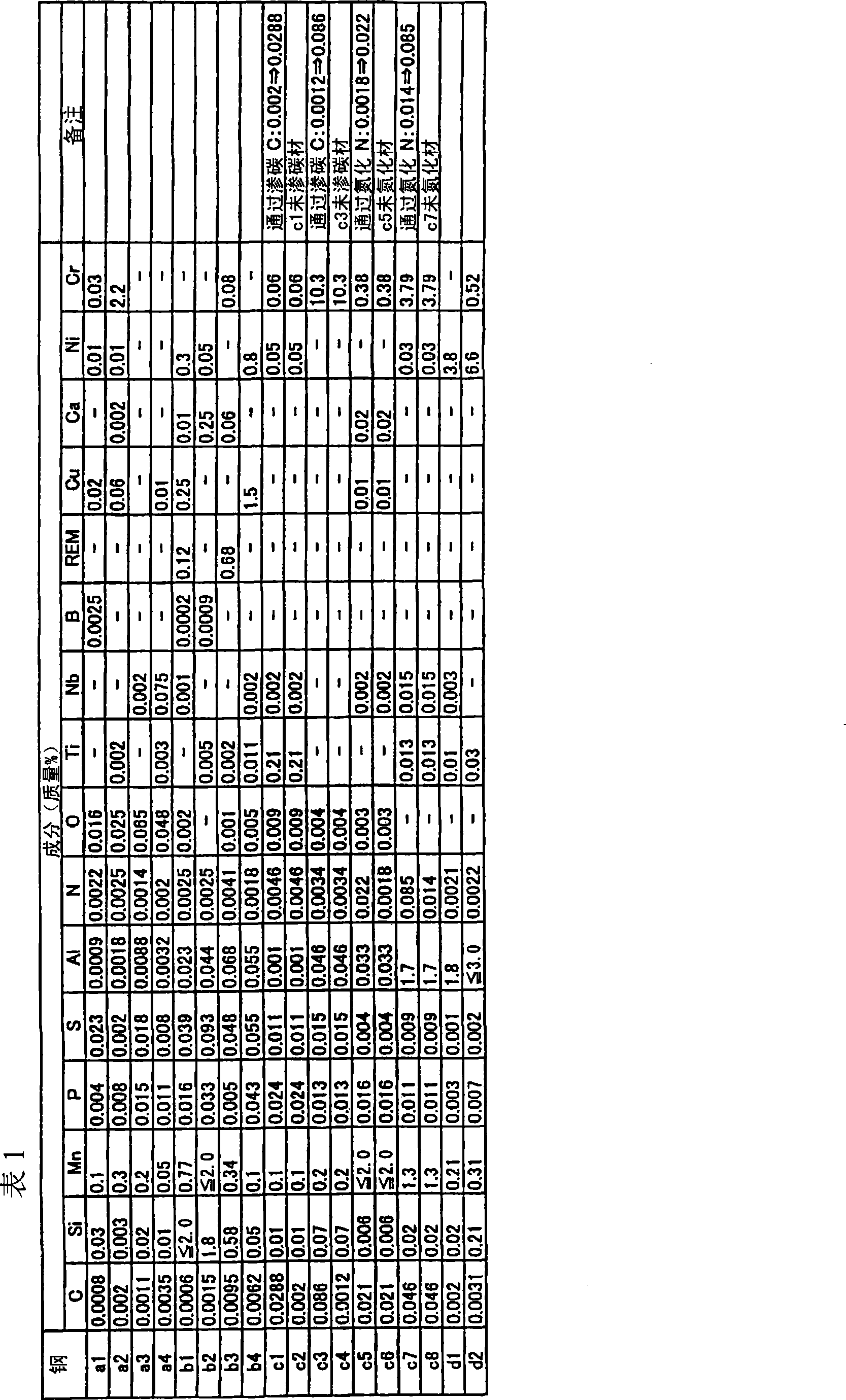

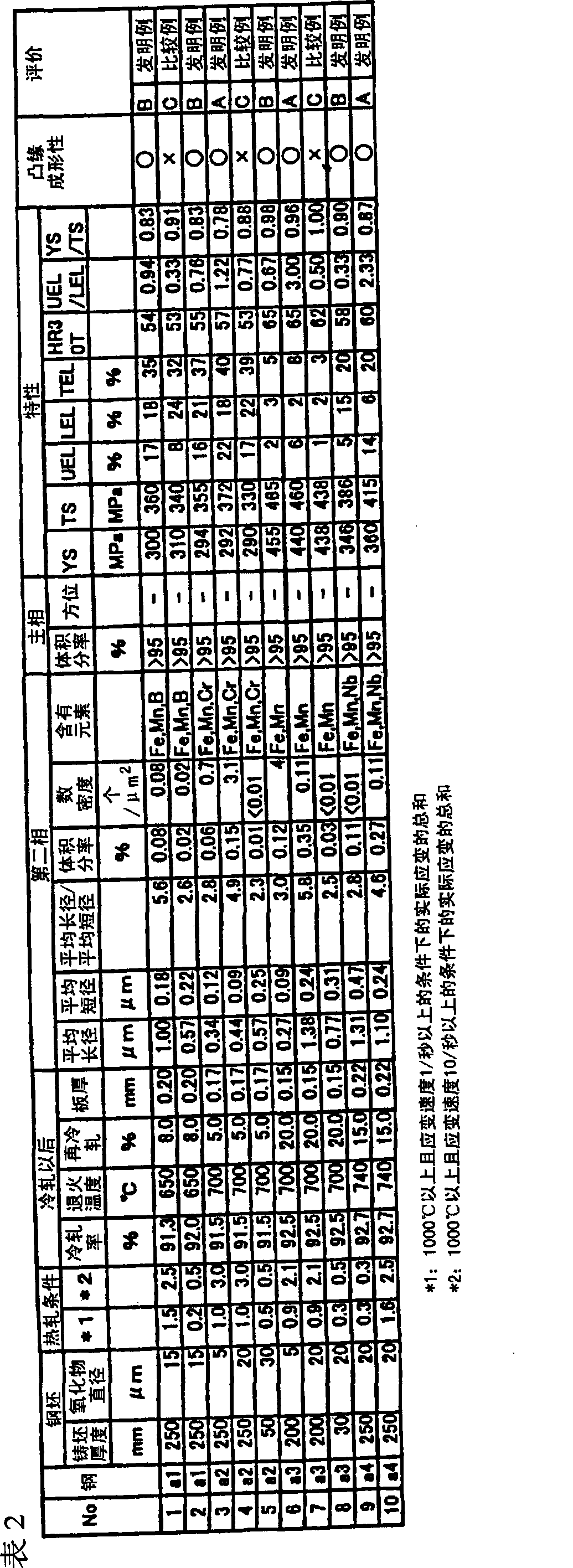

Very thin hard steel sheet and method for producing the same

ActiveCN101415851ASuppress local deformationUniform elongation heightFurnace typesMetal rolling arrangementsSheet steelVolume fraction

Disclosed is a very thin hard steel sheet having a thickness of not more than 0.400 mm and containing, in mass %, 0-0.800% (inclusive) of C, 0-0.600% (inclusive) of N, 0-2.0% (inclusive) of Si, 0-2.0% (inclusive) of Mn, 0-0.10% (inclusive) of P, 0-0.100% (inclusive) of S, 0-3.0% (inclusive) of Al and 0-0.200% (inclusive) of O. Secondary phases having an average length of not less than 0.10 [mu]m and an average breadth of not less than 0.05 mu m, while satisfying the following relation: average length / average breadth >= 2.0 are contained in the steel sheet at a volume fraction of not less than 0.05%.

Owner:NIPPON STEEL CORP

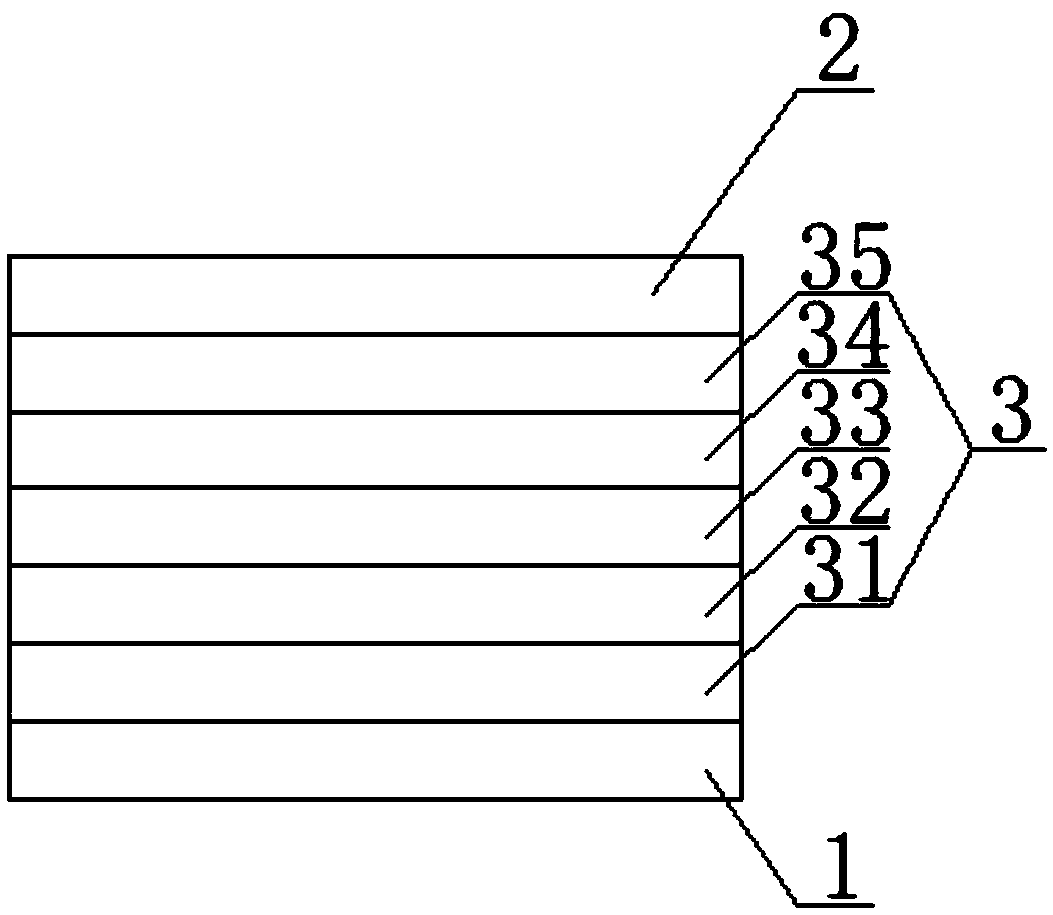

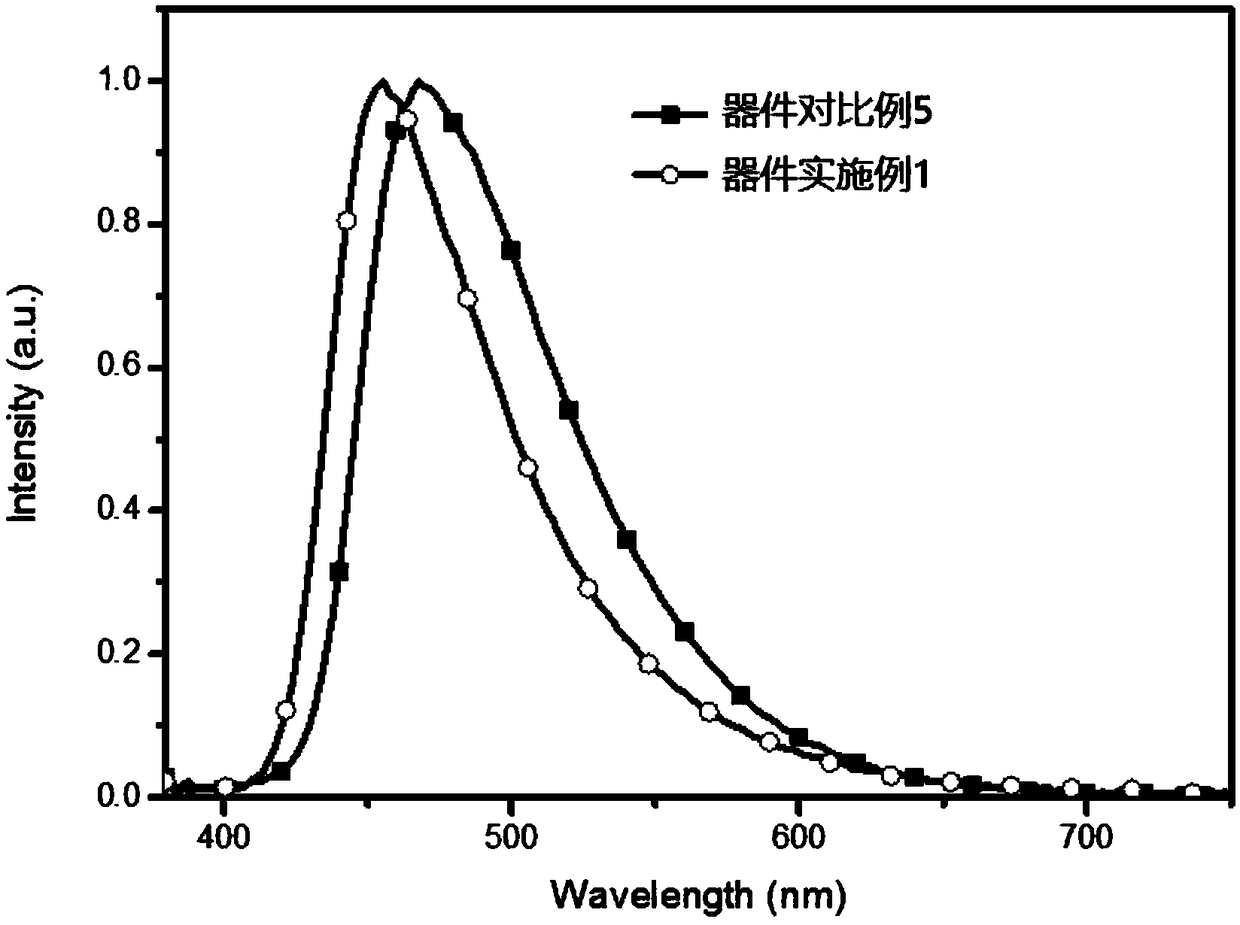

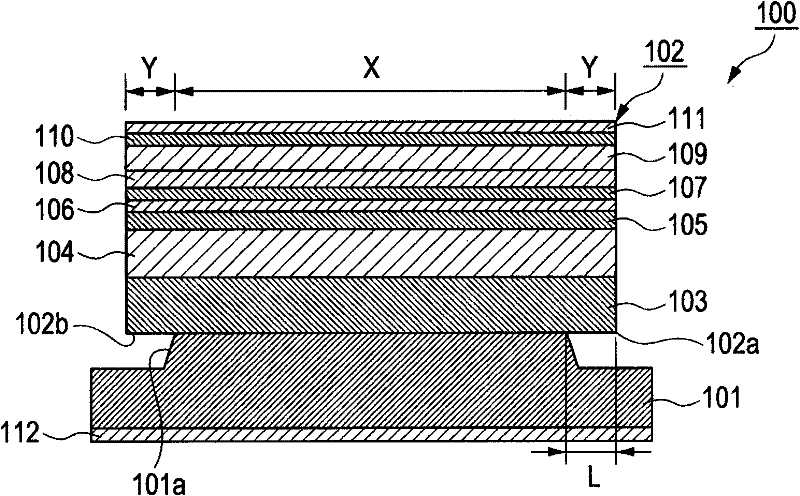

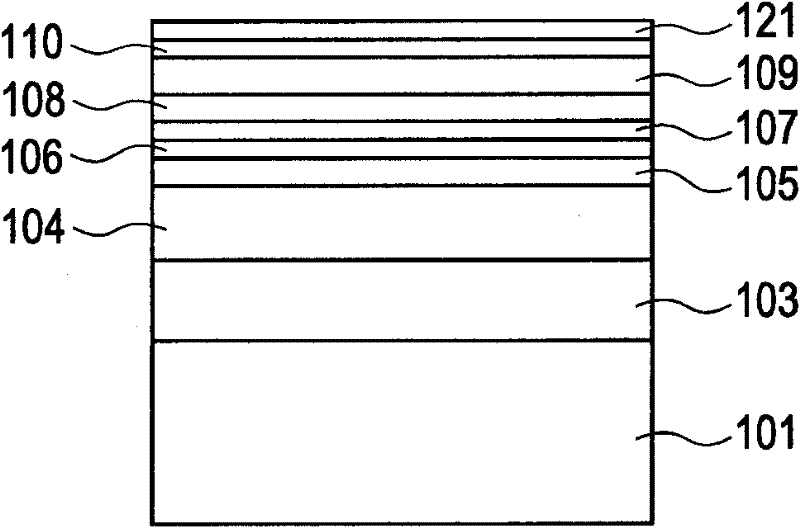

Organic electroluminescent device

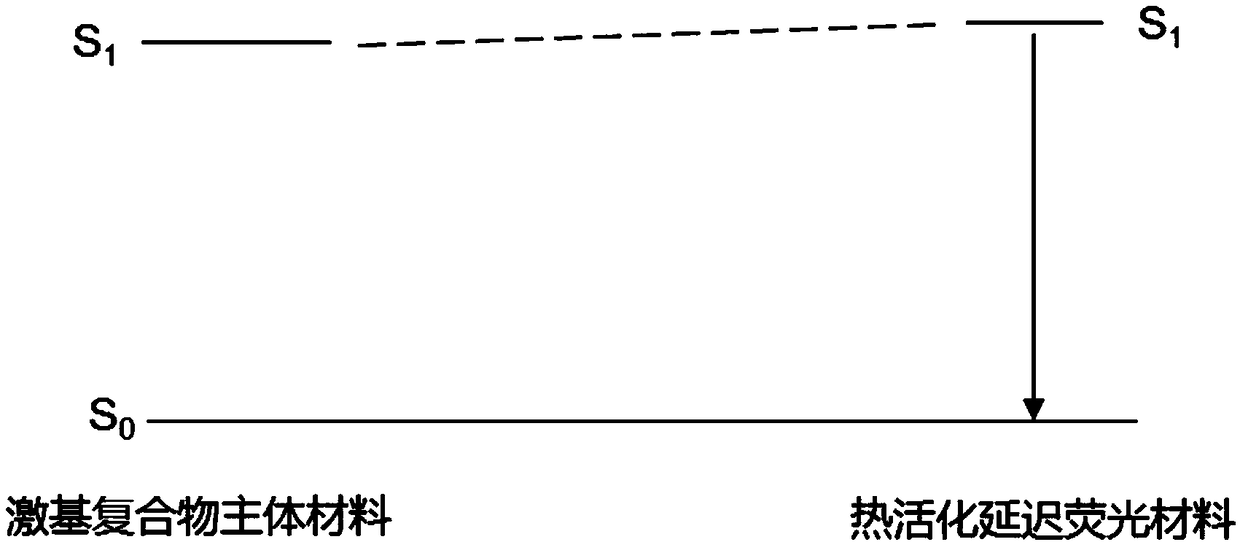

ActiveCN108695440AAchieve conversionIncrease the rate of energy transferSolid-state devicesSemiconductor/solid-state device manufacturingOrganic electroluminescenceSinglet state

The invention discloses an organic electroluminescent device. A light-emitting layer comprises a host material and a guest material. The host material is an exciplex formed by an electron donor material and an electron acceptor material, and the guest material is a thermally activated delayed fluorescent material. The singlet-state energy level of the host material is lower than the singlet-stateenergy level of the guest material. Since the singlet-state energy level of the exciplex as the host material in the light-emitting layer is lower than the singlet-state energy level of the thermallyactivated delayed fluorescent material, the generation of high-energy excitons is prevented, and molecular bond breakage due to high excitation energy is effectively suppressed. The singlet-state energy level of the exciplex is low, which is beneficial to reduce the excitation energy of the excitons in the device, and suppress the triplet state-triplet state annihilation, the triplet state-polaronquenching and the singlet state-triplet annihilation phenomena in the device, thereby reducing the efficiency roll-off of the device and prolonging the service life of the device.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD +1

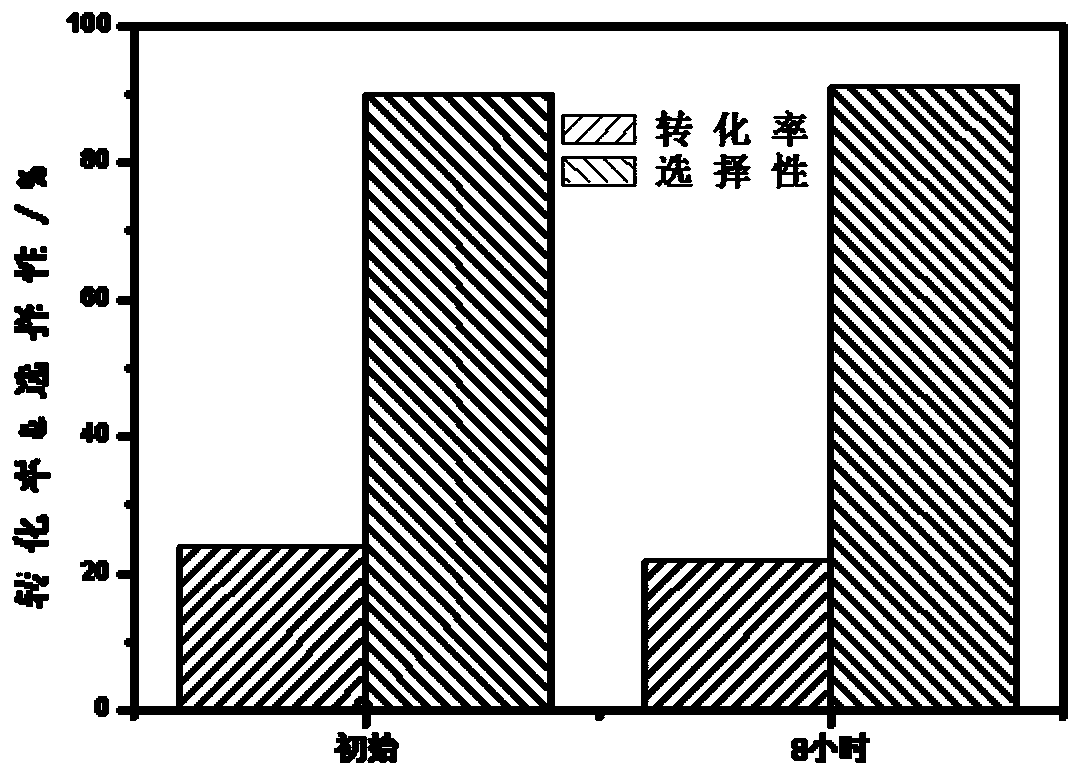

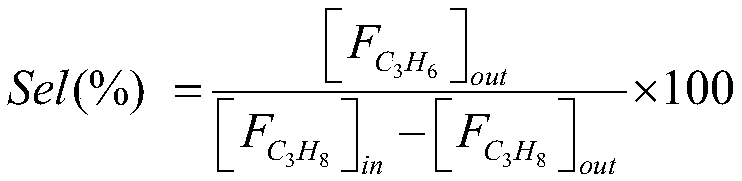

Aluminum oxide loaded PtCu monatomic alloy catalyst and preparation method and application thereof

ActiveCN108620092AHigh activityPt content decreasedHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsAlkaneDehydrogenation

The invention discloses an aluminum oxide loaded PtCu monatomic alloy catalyst and a preparation method and application thereof. The catalyst takes Al2O3 as a carrier, takes Cu as an auxiliary, and loads a small amount of active components Pt; the mass percent of Pt is 0.025%-0.15%, and the mass percent of Cu is 5%-20%; and during preparation, a co-impregnation method is used, the Al2O3 carrier isimpregnated in an aqueous solution of chloroplatinic acid and copper nitrate, the PtCu / Al2O3 catalyst is obtained after drying and roasting and high-temperature reduction, and the catalyst has high activity and high stability, and is low in price and low in toxicity. The catalyst is suitable for reaction for producing olefin by dehydrogenation through low alkane, and is particularly suitable forreaction for producing propylene by dehydrogenation through propane in a hydrogenation atmosphere, the dehydrogenation activity is quite high under the condition of high temperature, the selectivity of the propylene can reach 90% or above, the stability is good, the use amount of Pt is small, the utilization rate is high, and compared with an industrial Pt series catalyst, the aluminum oxide loaded PtCu monatomic alloy catalyst is cheaper.

Owner:TIANJIN UNIV

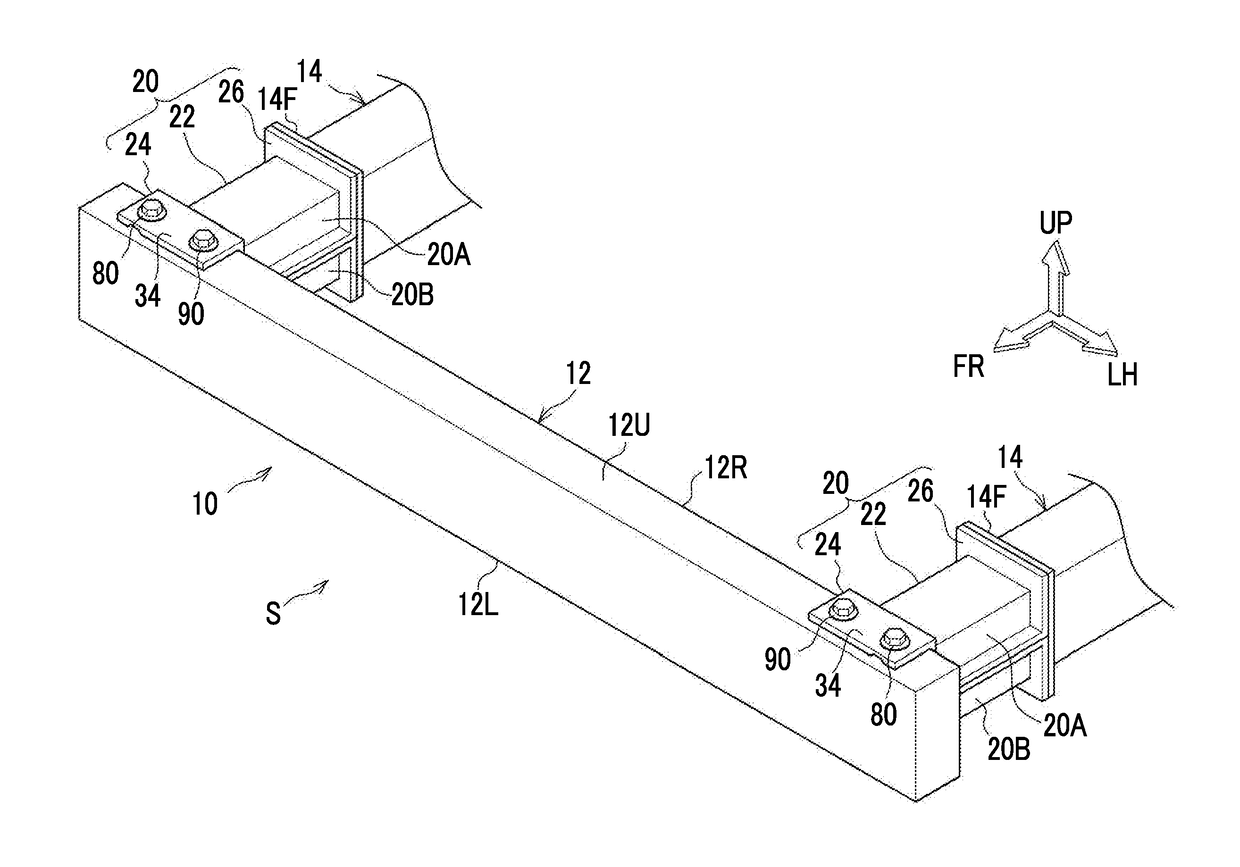

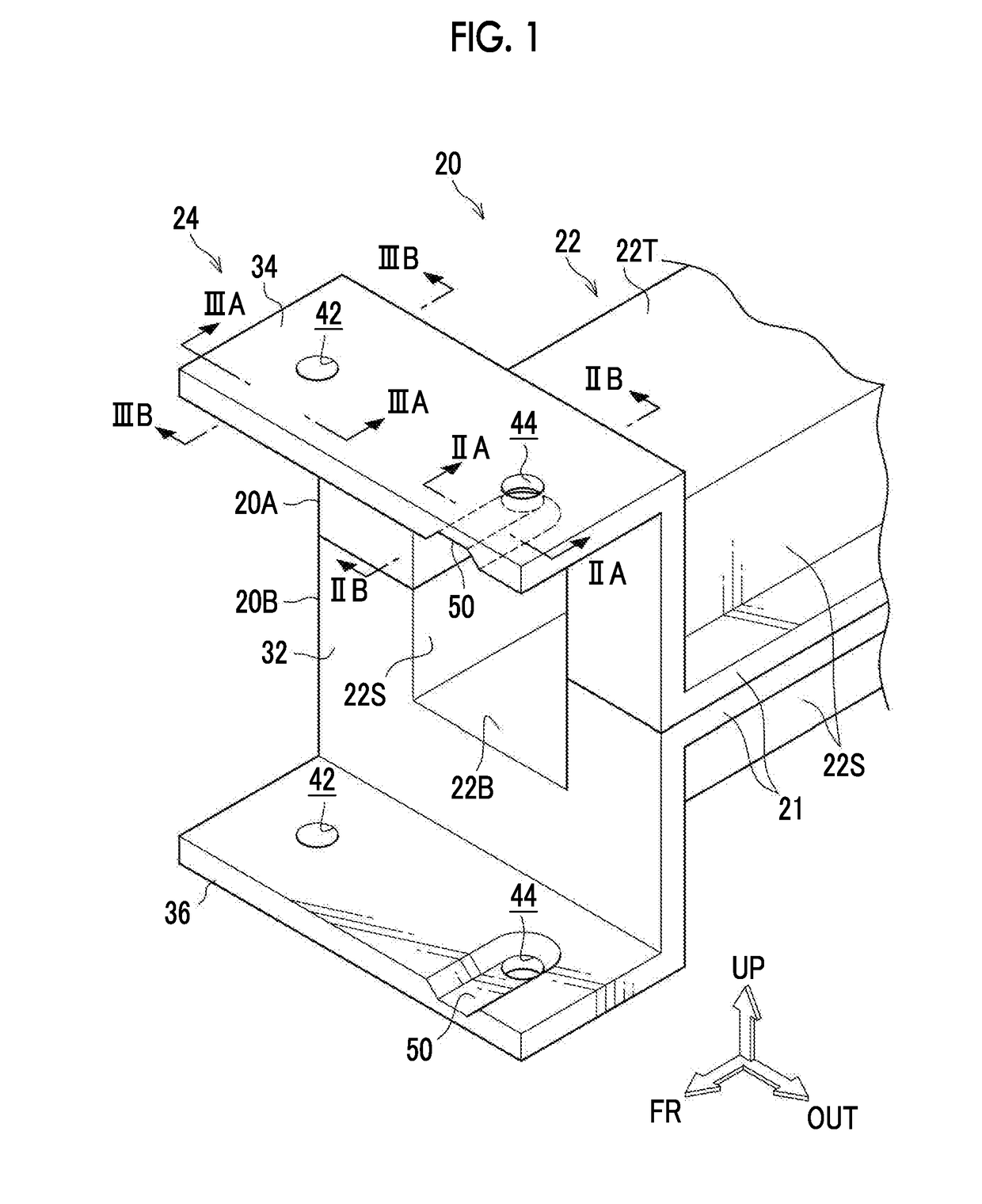

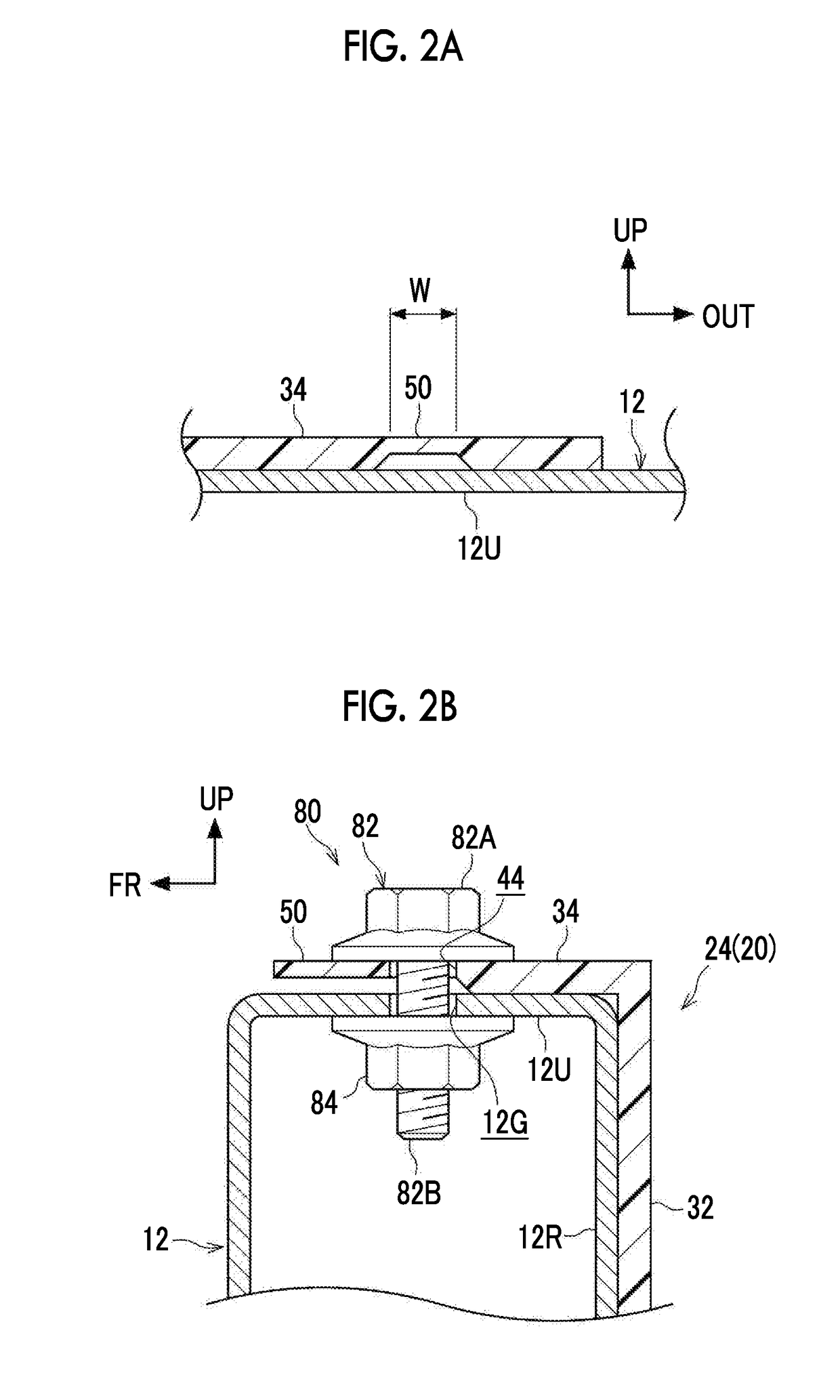

Energy absorption structure

An energy absorption structure includes a bumper RF and a crush box. The crush box includes a main body part and a coupling part. The coupling part includes an inner fastening part that is fastened to a bumper RF by an inner fastener, and an outer fastening part that is fastened to the bumper RF by an outer fastener at a position behind a position where the inner fastening part is fastened to the bumper RF outward from the center in a vehicle width direction of a vehicle. The outer fastening part includes a weakened part having a structure different from the inner fastening part such that the outer fastening part is easily crushed as compared to the inner fastening part when a load toward a side far from the center in the forward-rearward direction of the vehicle acts on the outer fastener.

Owner:TOYOTA JIDOSHA KK

A license plate recognition method based on deep learning

ActiveCN109165643AInhibit adhesionInhibition of fractureCharacter and pattern recognitionNeural architecturesMinimum bounding rectangleLicense

The invention discloses a license plate recognition method based on deep learning, which comprises the following steps: step 1, training a deep convolutional neural network model M for license plate character detection; constructing a license plate character label set B; step 2, inputting the positioned license plate image I to a license plate character detection network M, and outputting a candidate license plate character set H; step 3, reordering the candidate license plate character set H obtained in the step 2 according to the abscissa hi.x of the upper left corner of the smallest circumscribed rectangle of the candidate license plate character from small to large to obtain a set C; step 4, further executing screening operation on the set C obtained in the step 3; step 6, sequentiallytraversing the set E obtained in the step 5; step 7, returning that license plate recognition result L obtained in the step 6. The method has the beneficial effects of effectively inhibiting the influence of license plate character adhesion, fracture, deformation, license plate dirt, license plate inclination, residual shadow on the license plate and the like.

Owner:ZHEJIANG UNIV OF TECH

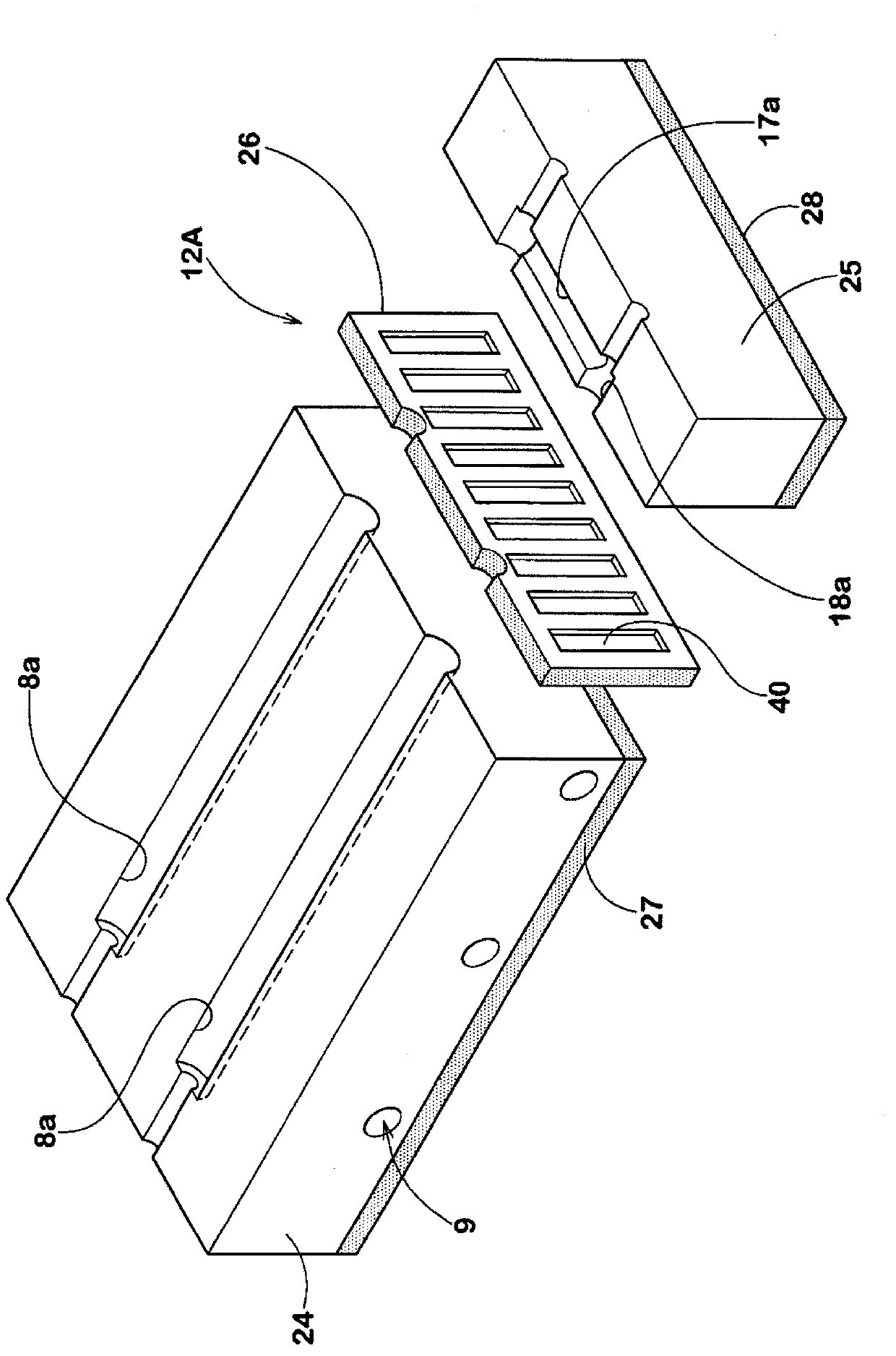

Semiconductor element and electrical apparatus

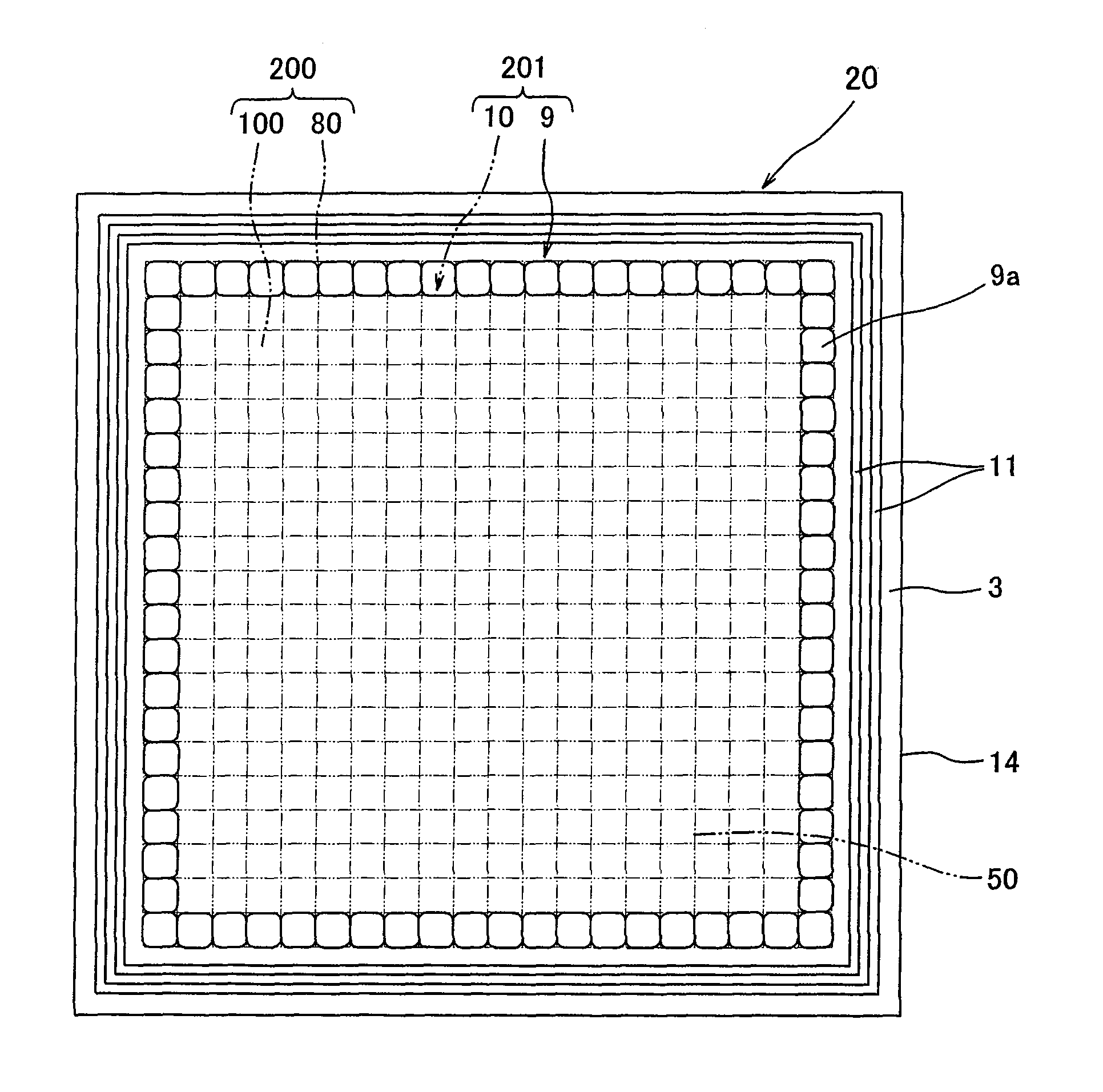

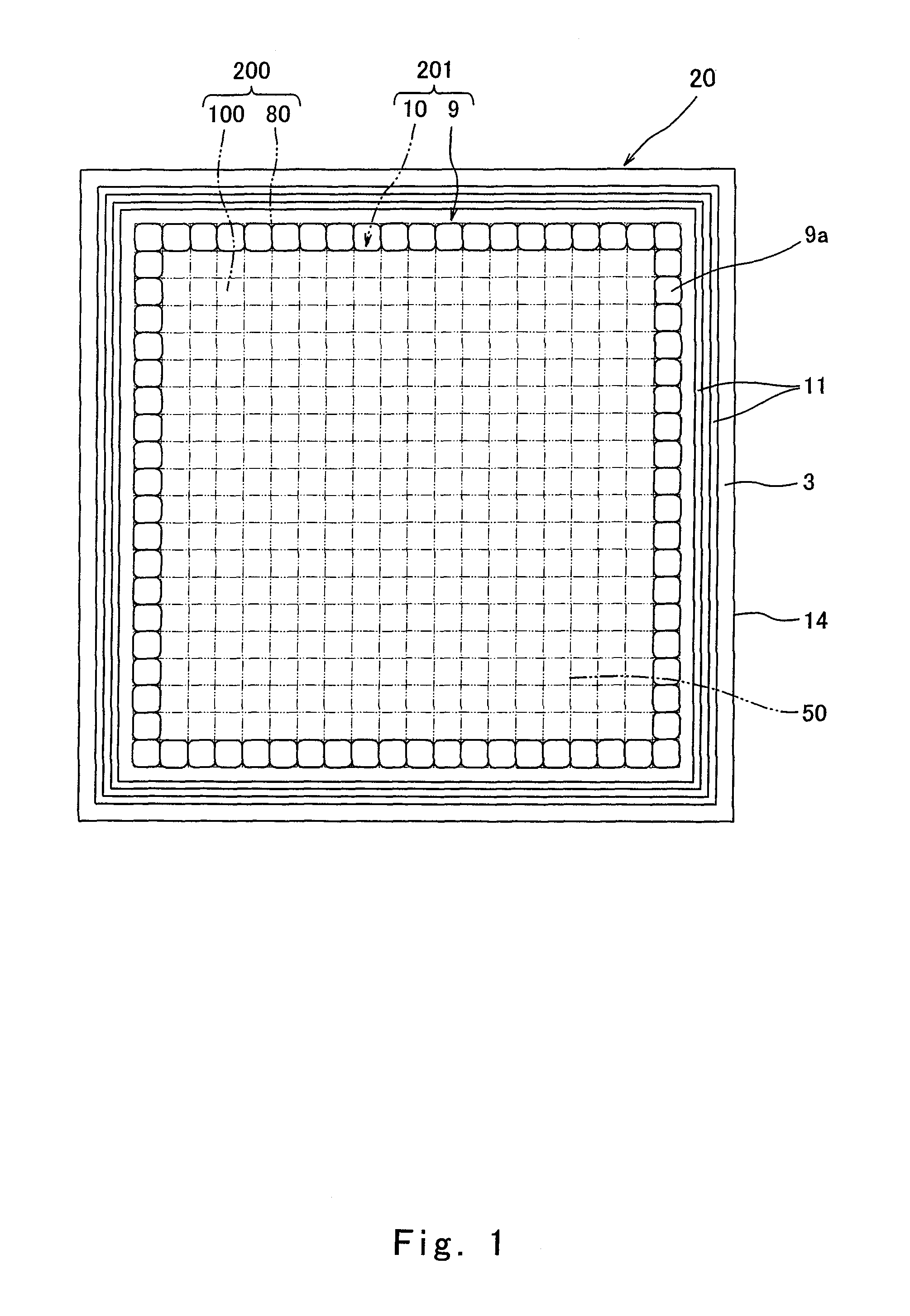

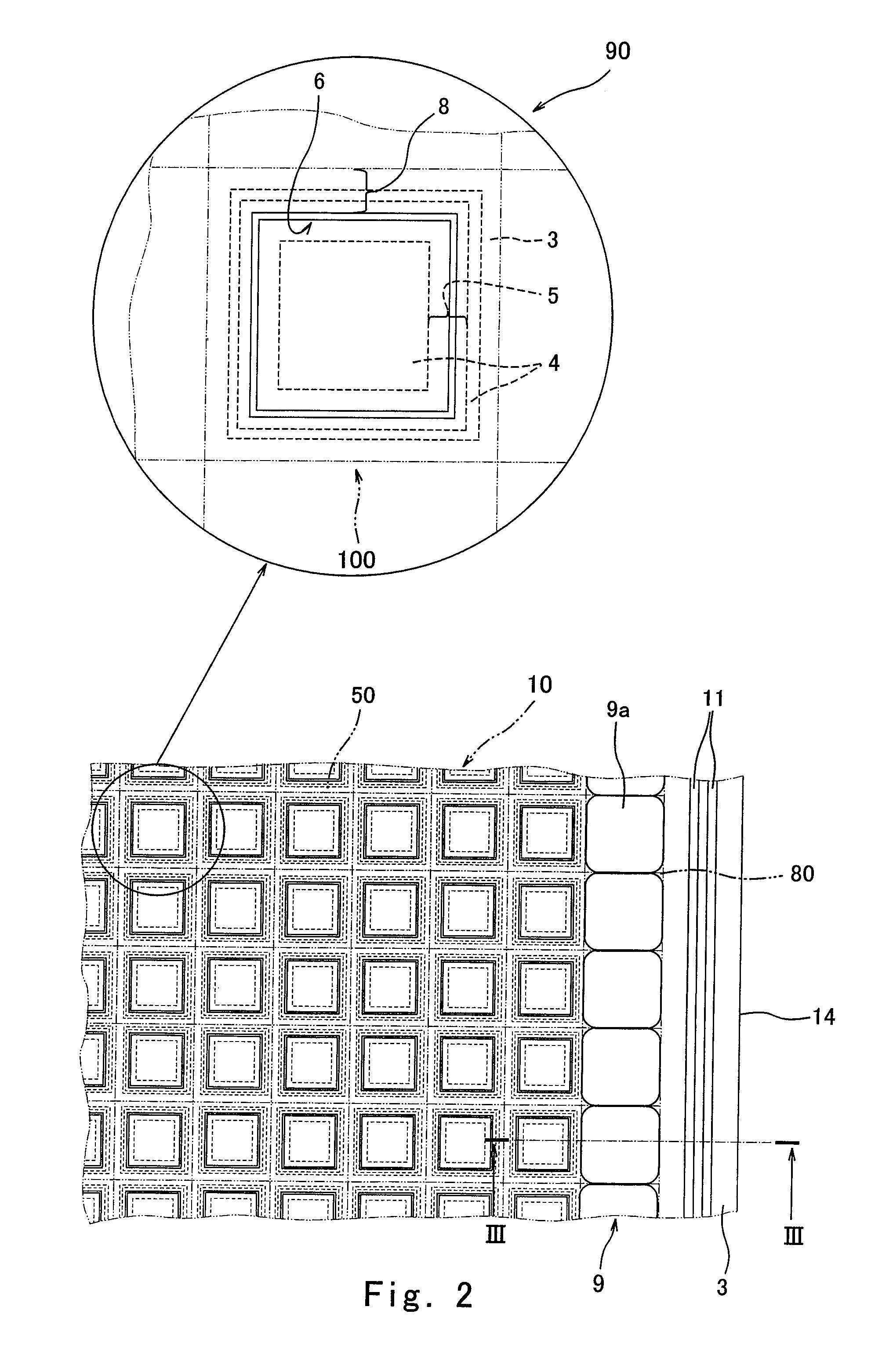

ActiveUS7791308B2Inhibition of fractureRun at high speedAC motor controlVector control systemsEngineeringField-effect transistor

A semiconductor element (20) of the present invention includes a plurality of field effect transistors (90) and a schottky electrode (9a), and the schottky electrode (9a) is formed along an outer periphery of a region where the plurality of field effect transistors (90) are formed.

Owner:PANASONIC CORP

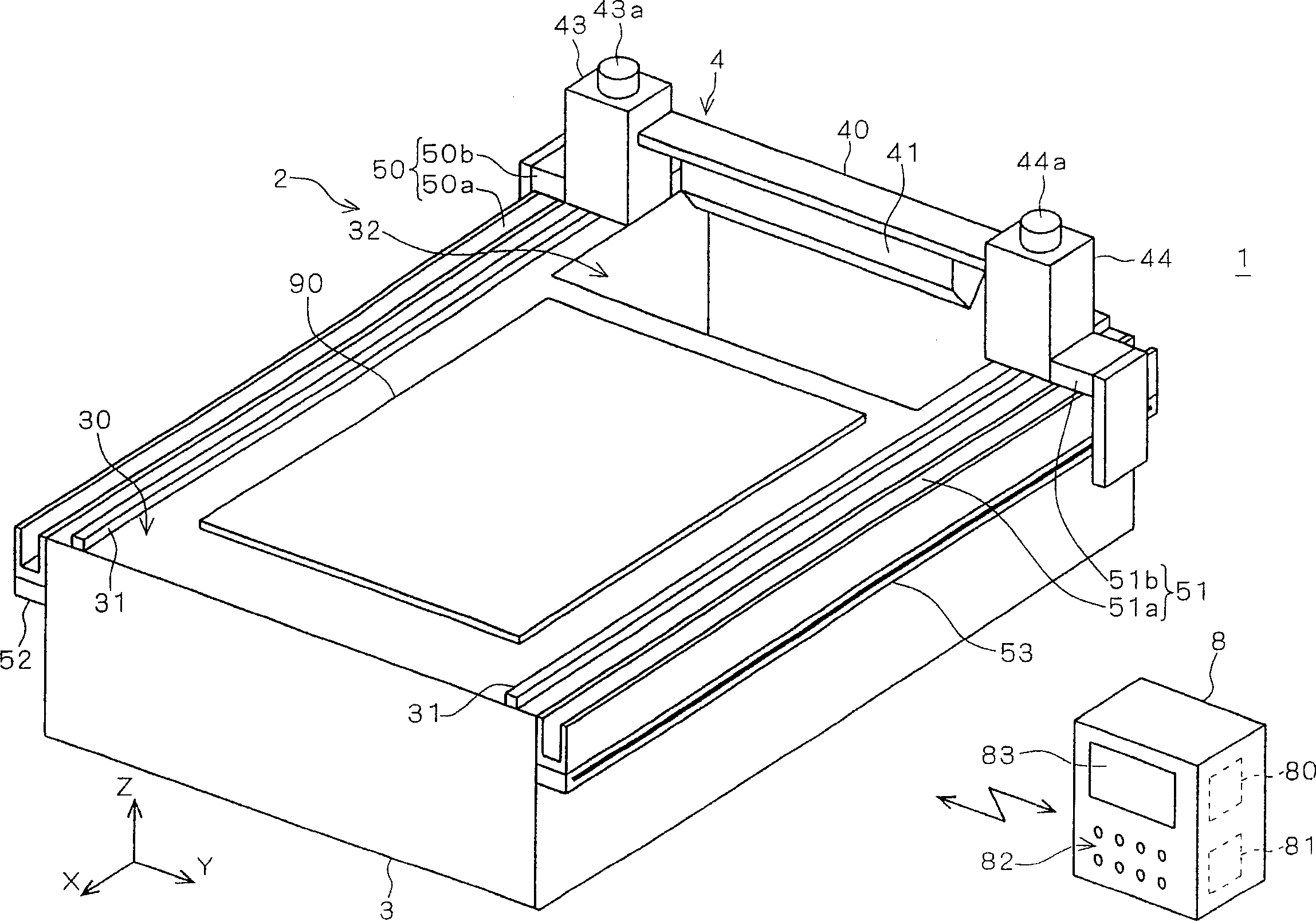

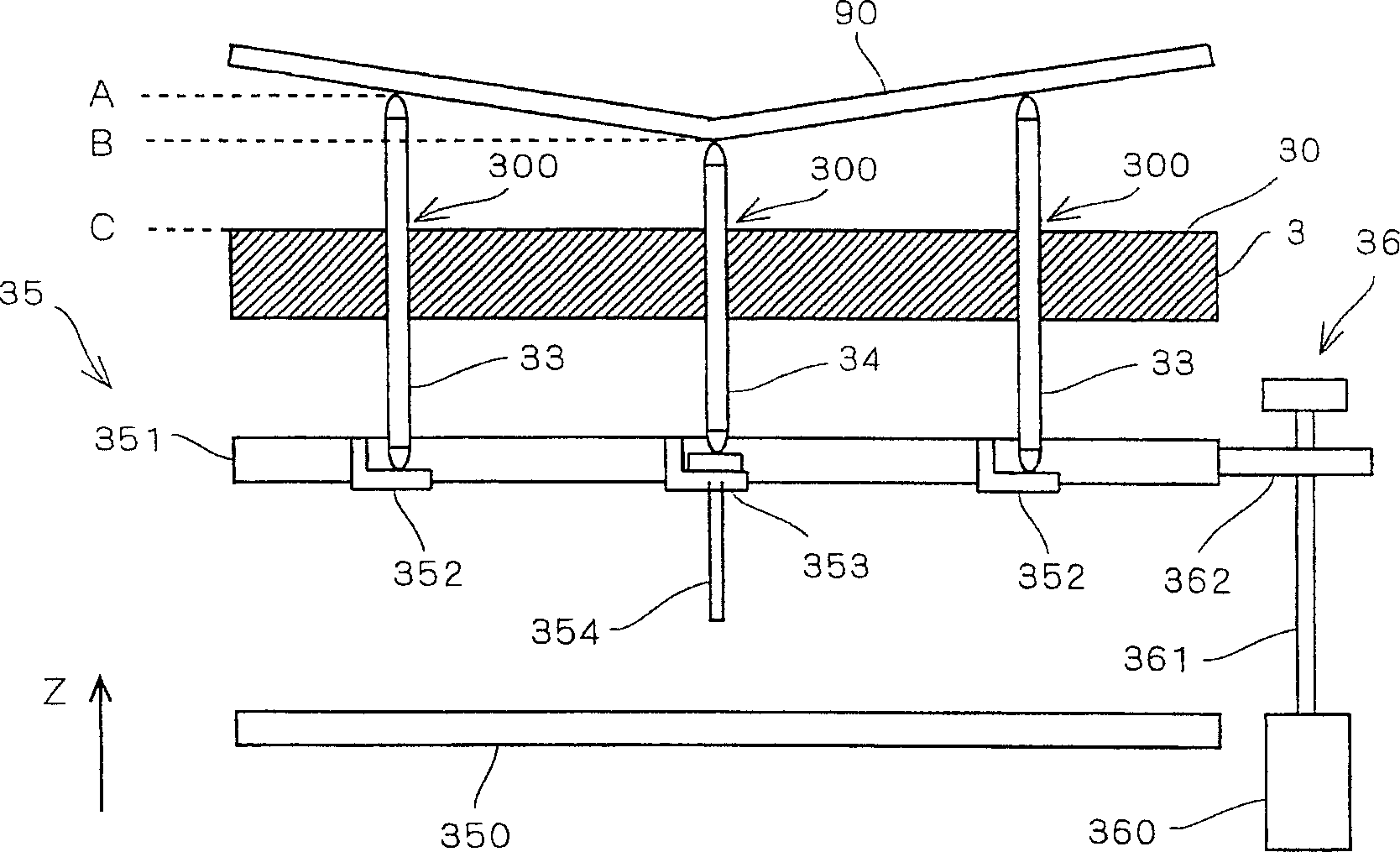

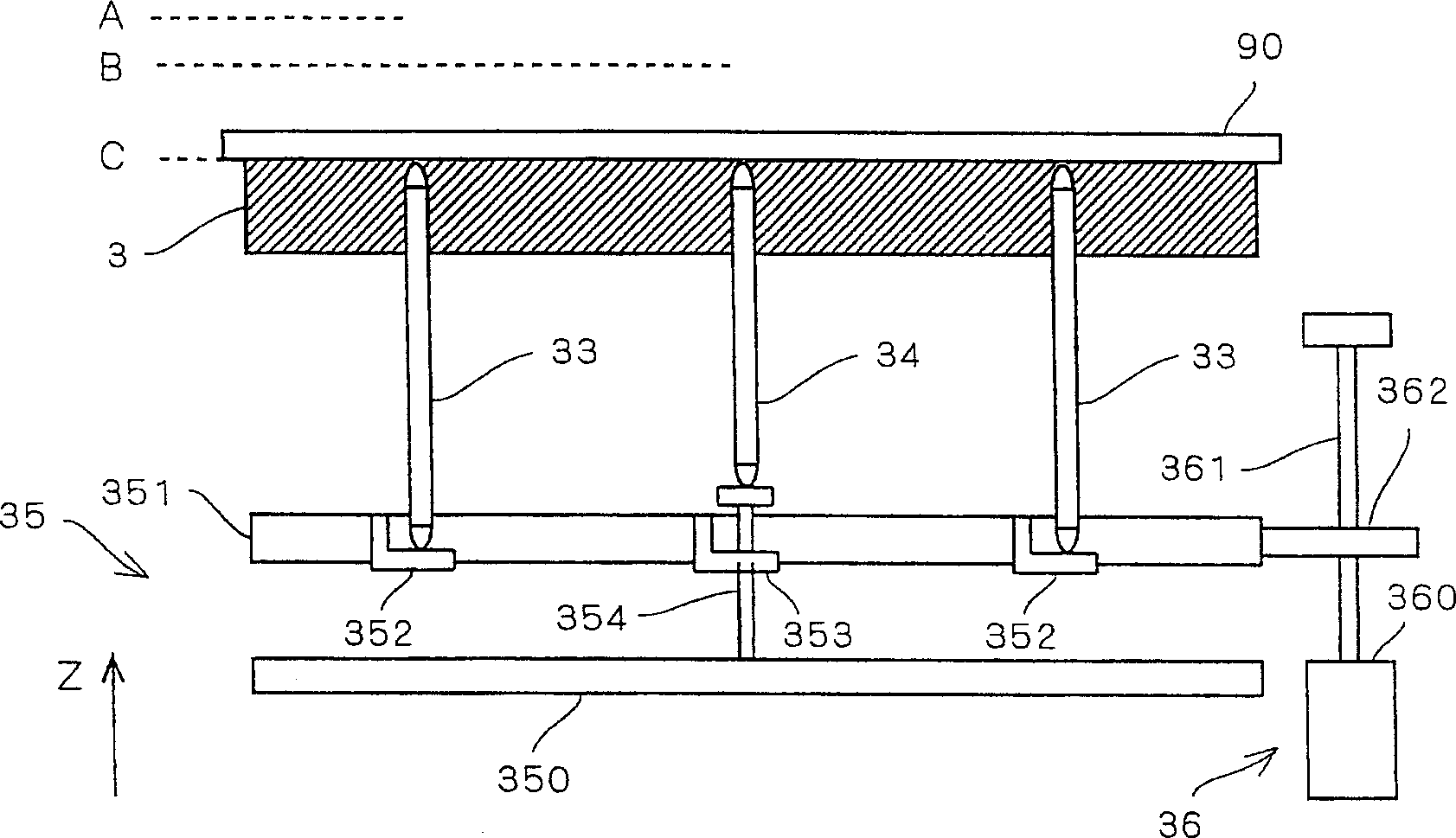

Substrate processing device

ActiveCN1855416ASuppression of bending stressAvoid breakingSemiconductor/solid-state device manufacturingConveyor partsEngineeringSliding contact

An object of the present invention is to provide a mechanism that properly supports the substrate on a support table during processing of the substrate, while also properly handling the substrate when the substrate is loaded onto or lifted from the support table. A first support pin (33) in contact with the peripheral portion of the base plate (90) and a second support pin (34) in contact with the central portion of the base plate are provided. The lower end of the first support pin is supported by a sliding contact plate (352) fixedly arranged on the lift plate (351), and the lower end of the second support pin is supported by a raising and reinforcing member (354). The lower part of the elevating reinforcement member is arranged so as to penetrate through a sliding contact plate (353) fixed on the lift plate, and is supported freely up and down within a predetermined range with respect to the lift plate. It is designed in such a manner that the size of the second support pin and the up-down direction of the raising reinforcement member is equal to the size from the holding surface (30) to the upper surface of the fixing plate (350).

Owner:DAINIPPON SCREEN MTG CO LTD

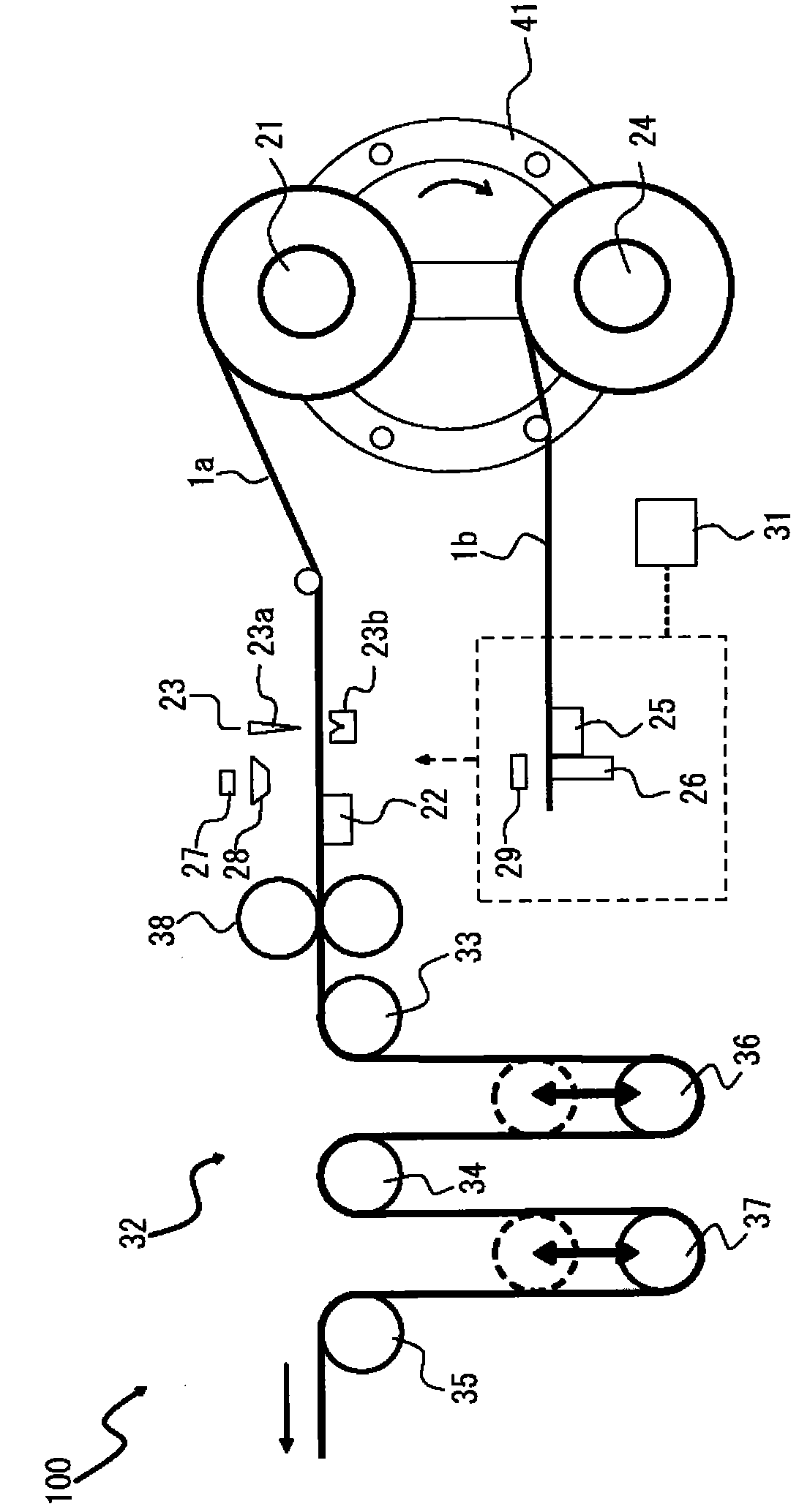

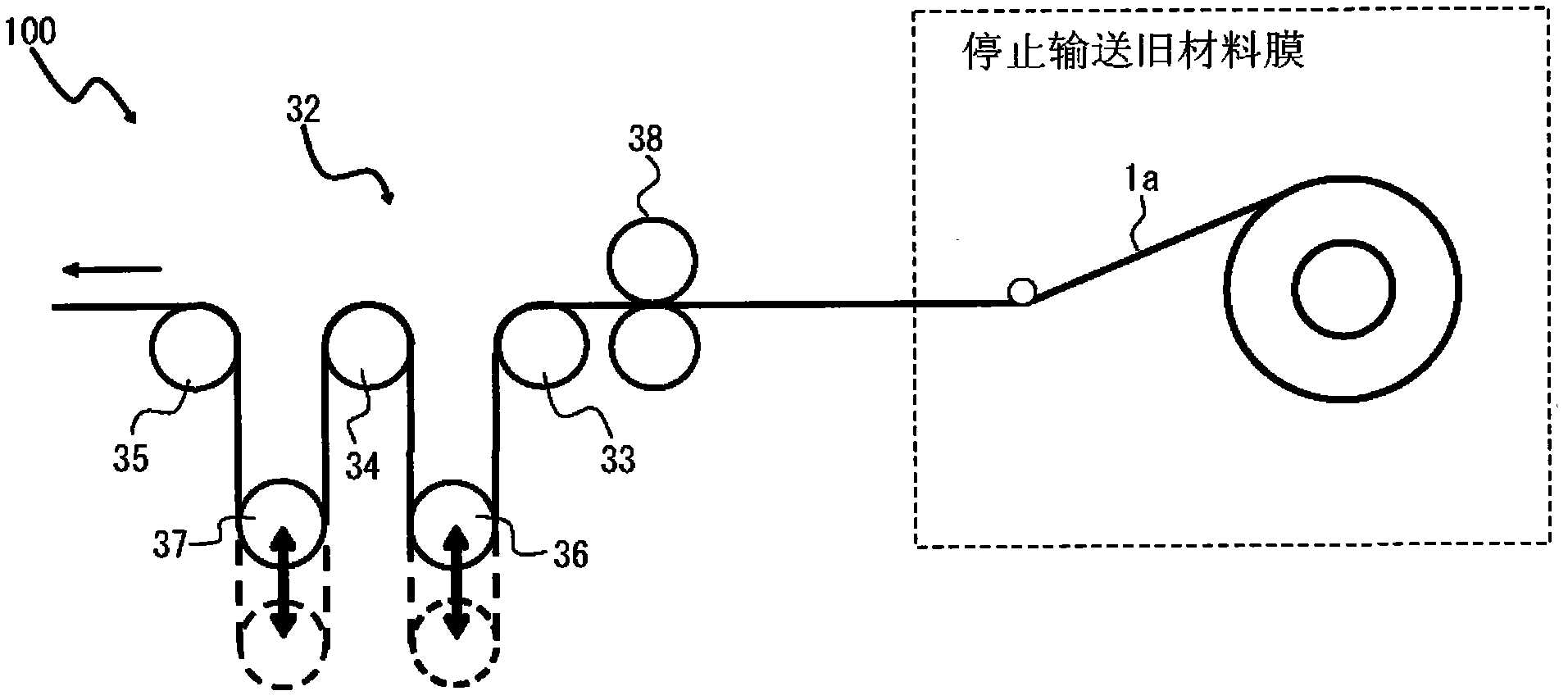

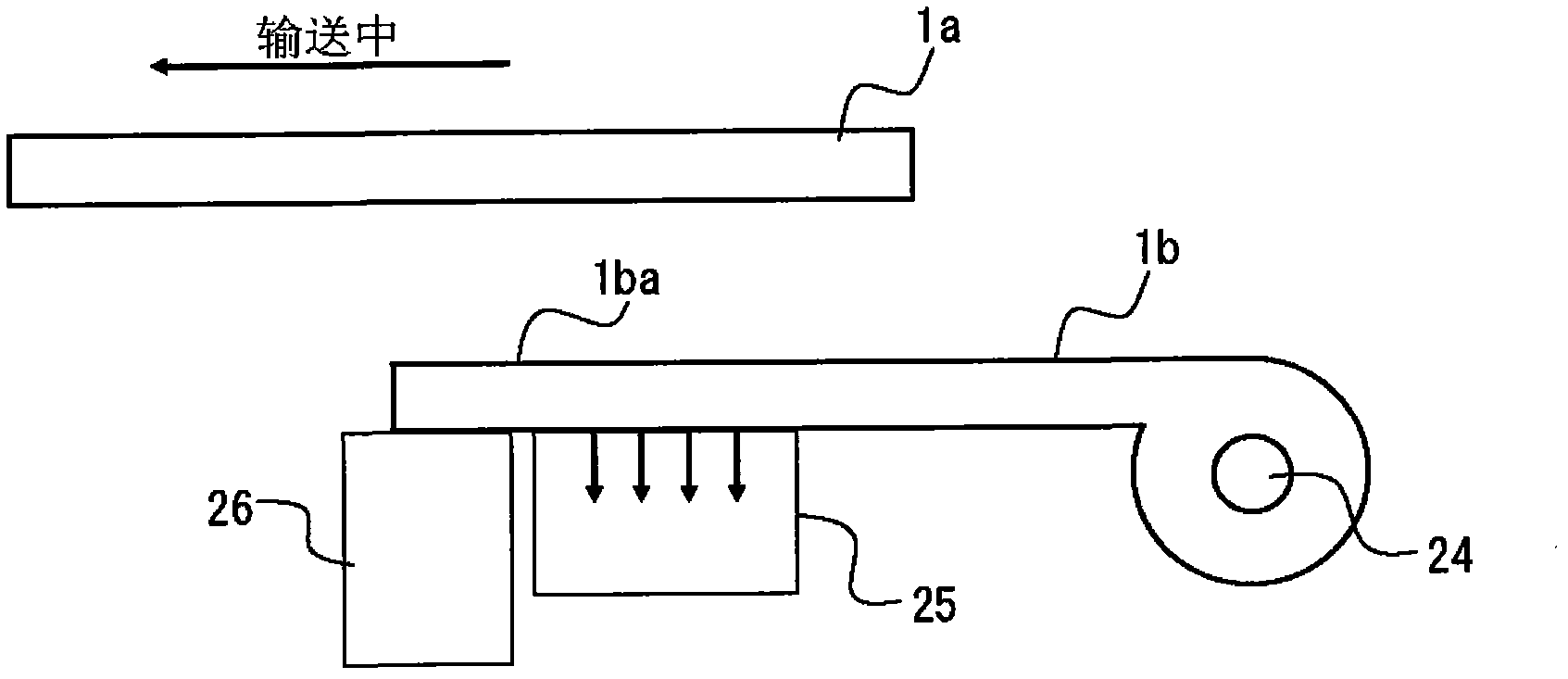

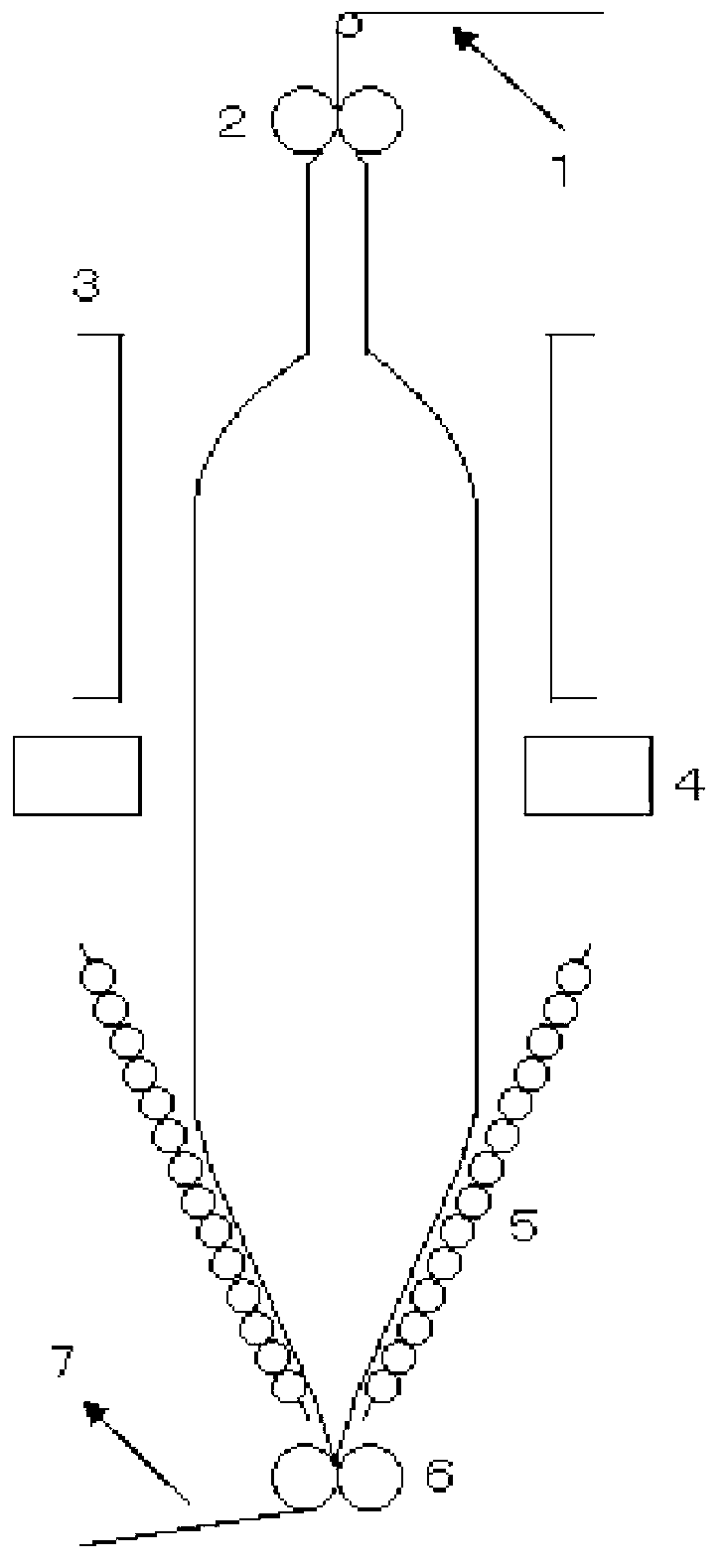

Method of producing sheet joined body and apparatus for producing sheet joined body

InactiveCN102431168AInhibition of fractureSynthetic resin layered productsLaminationProcess regionEngineering

Producing method and apparatus for a sheet assembly are provided to prevent the breaking of a joint from a rear processing region, and to combine a resin sheet member without stopping a returning process of a sheet member. A producing method for a sheet assembly comprises the following: supporting the tip end of a second resin sheet member(1b); spreading a light absorbing agent to the tip end of the second resin sheet member; laminating a first resin sheet member(1a) flowing from the upper side, and discharging the laminated first resin sheet member to the lower direction; returning the first resin sheet member to a processing region through a sheet lamination unit having the same carrying-in speed and carrying-out speed of the first resin sheet member; returning the first resin sheet member on the lower side of the sheet lamination unit, and stopping the returning process of the first resin sheet member on the upper side of the sheet lamination unit; cutting the first resin sheet member, and folding the tip end and the cut end of the first resin sheet member using a light absorbing agent; and fusing the ends using a laser.

Owner:NITTO DENKO CORP

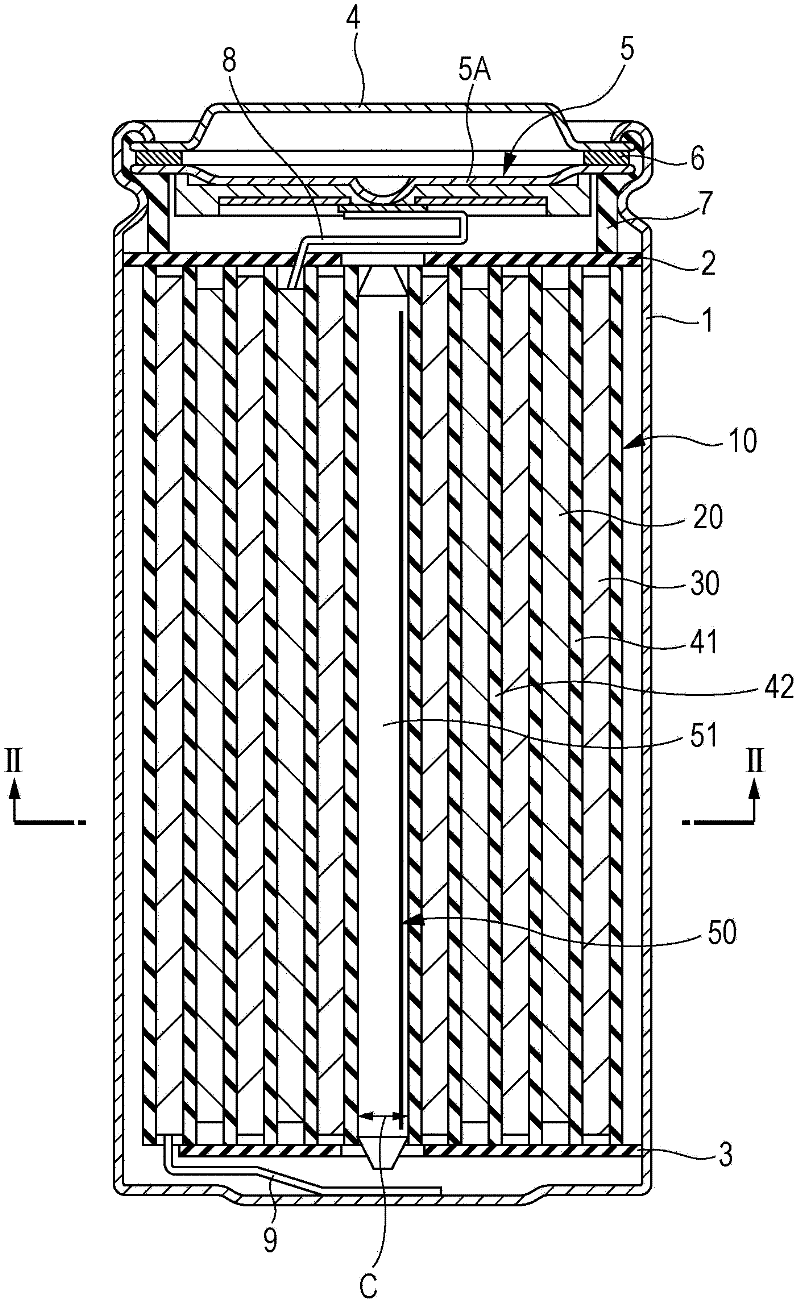

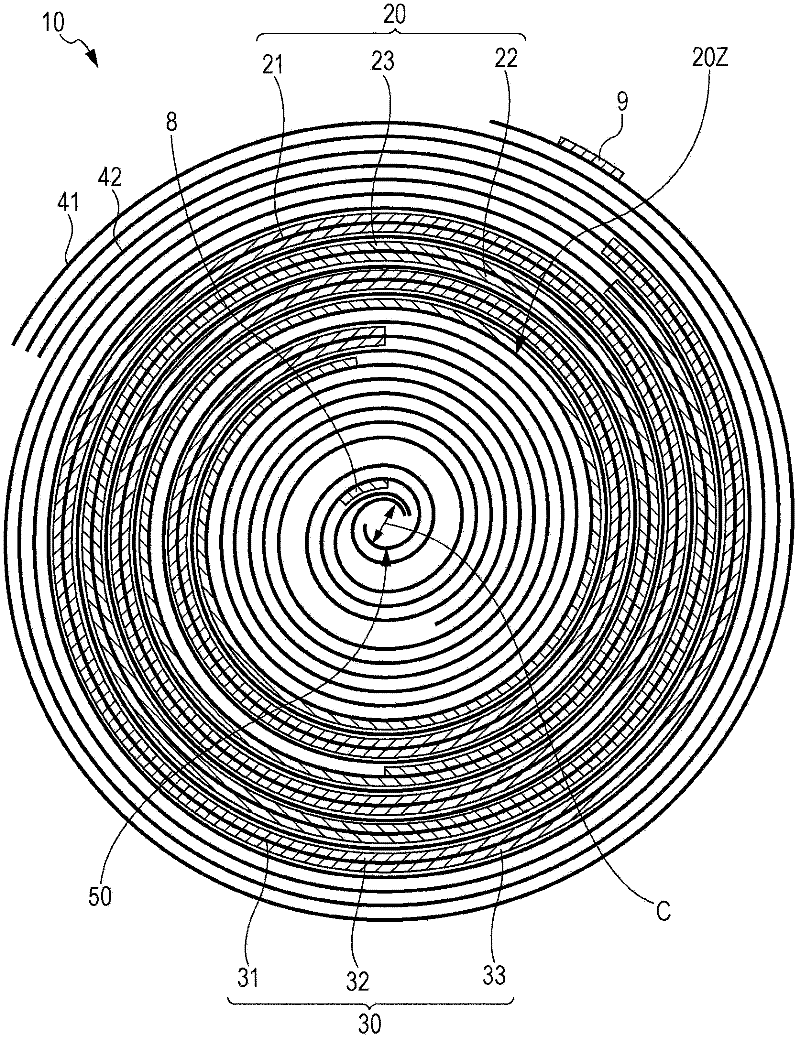

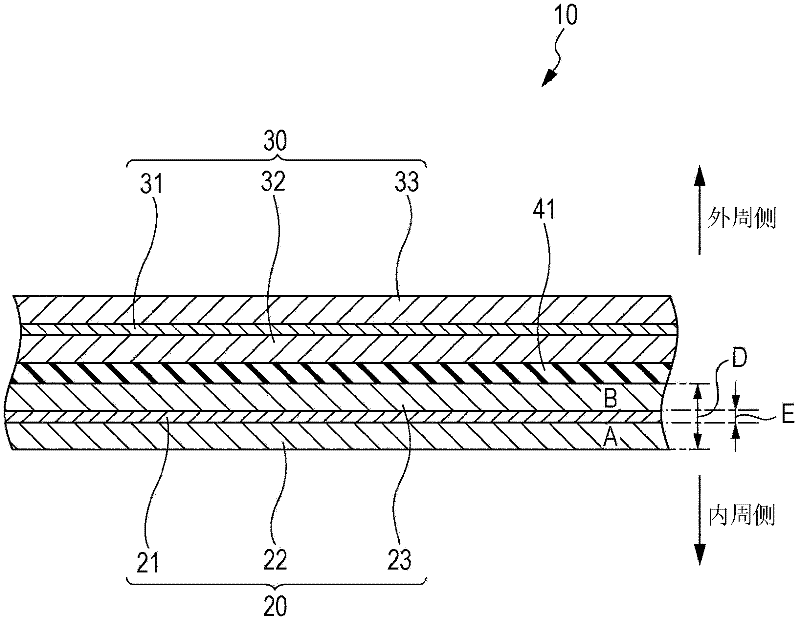

Secondary battery, battery pack, electronic apparatus, electric tool, electric vehicle, and power storage system

ActiveCN102544589AConvenient lengthOptimize volumeFinal product manufactureElectrode carriers/collectorsElectrical batteryEngineering

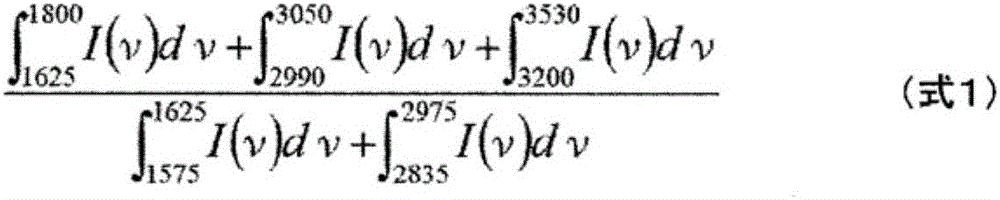

The invention provides a ssecondary battery, a battery pack, an electronic apparatus, an electric tool, an electric vehicle and a power storage system. The secondary battery including: spirally wound electrode body in which positive electrode and negative electrode are laminated via separator and spirally wound, wherein the positive electrode includes an inner circumference side positive electrode active material layer and an outer circumference side positive electrode active material layer while including a single side active material layer formation region, the ratio A / (A+B) of an area density A of the inner circumference side positive electrode active material layer and an area density B of the outer circumference side positive electrode active material layer, an inner diameter C of the coil opening portion, and the ratio D / E of a thickness D of the positive electrode and a thickness E of the positive electrode collector satisfy the relationship expressed in Formula 1, and a length F of the single side active material layer formation region satisfies the relationship expressed in Formula 2.

Owner:MURATA MFG CO LTD

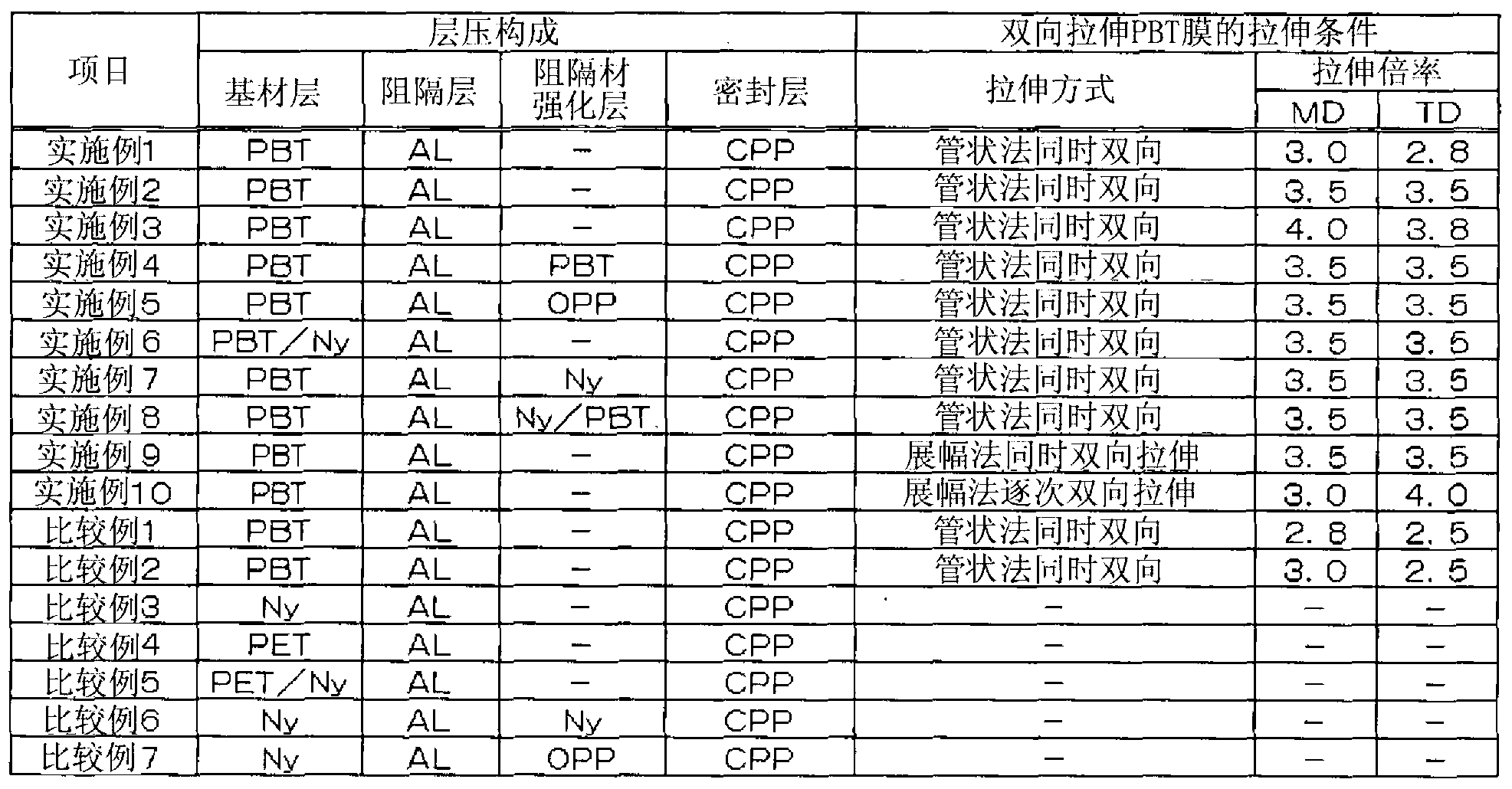

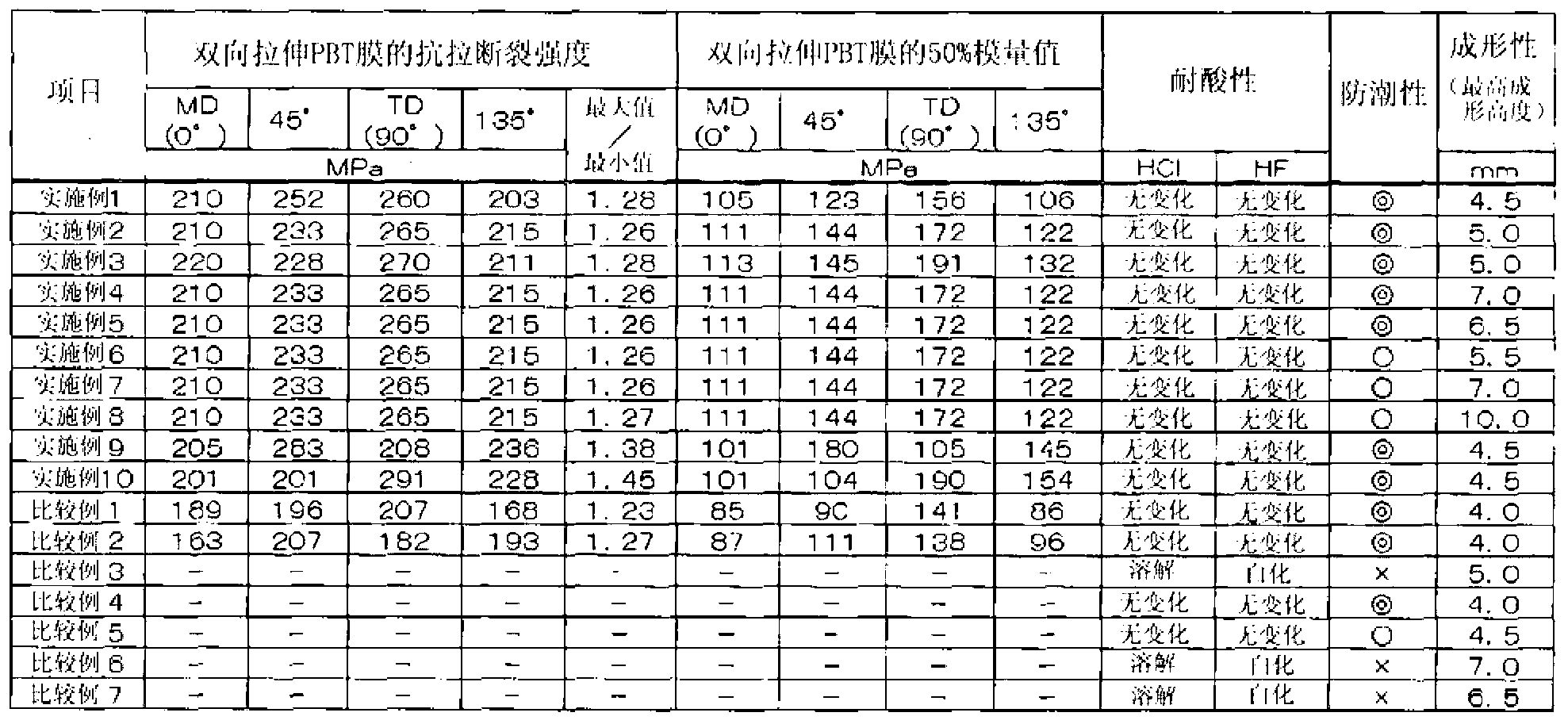

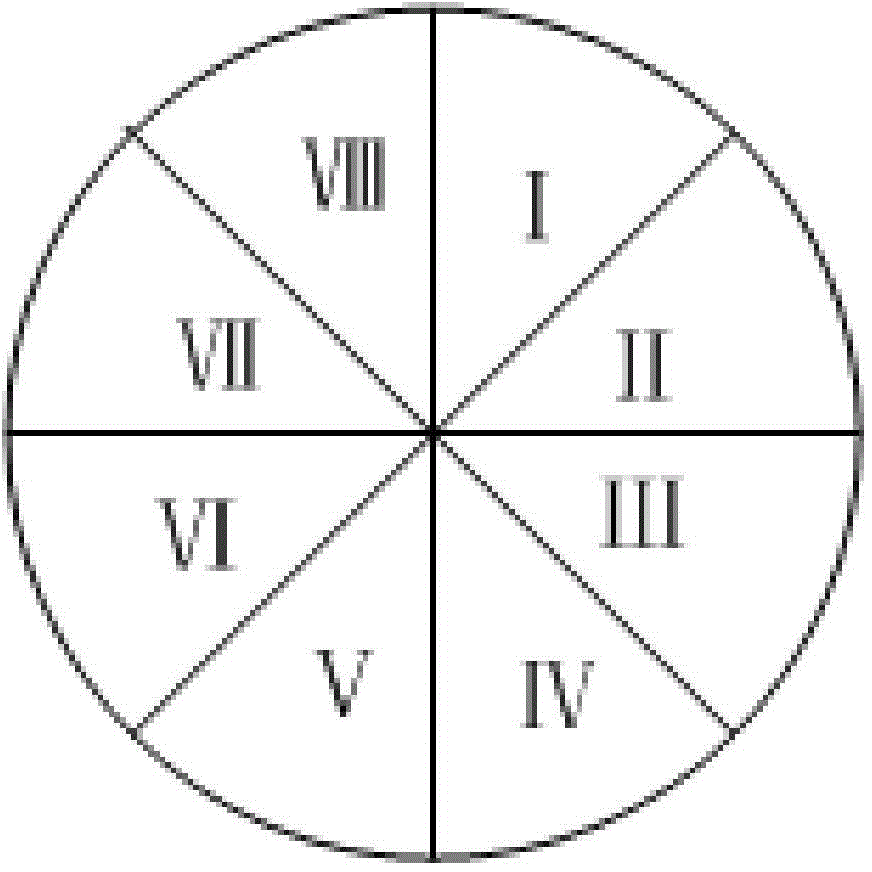

Battery case packaging material for cold molding comprising biaxially-stretched polybutylene terephthalate film

ActiveCN103222083AInhibition of fractureStable formabilitySynthetic resin layered productsSecondary cellsLithiumPolyethylene terephthalate

To provide a battery case packaging material for cold molding, in which a biaxially-stretched polybutylene terephthalate film is used as a base layer and / or a barrier material reinforcing layer, whereby it becomes possible to produce a packaging material for cold molding, particularly a packaging material for a battery such as a lithium ion secondary battery, which contains a biaxially-stretched polybutylene terephthalate film that does not lose acid resistance or moisture-proof properties and maintains excellent cold-moldability, and therefore has excellent moisture-proof properties, acid resistance and cold moldability. A battery case packaging material for cold molding, comprising a base layer, a barrier layer and a sealant layer laminated in this order, or comprising a base layer, a barrier layer, a barrier material reinforcing layer and a sealant layer laminated in this order, wherein a biaxially-stretched polybutylene terephthalate film is used as the base layer and / or the barrier material reinforcing layer.

Owner:KOHJIN FILM & CHEM

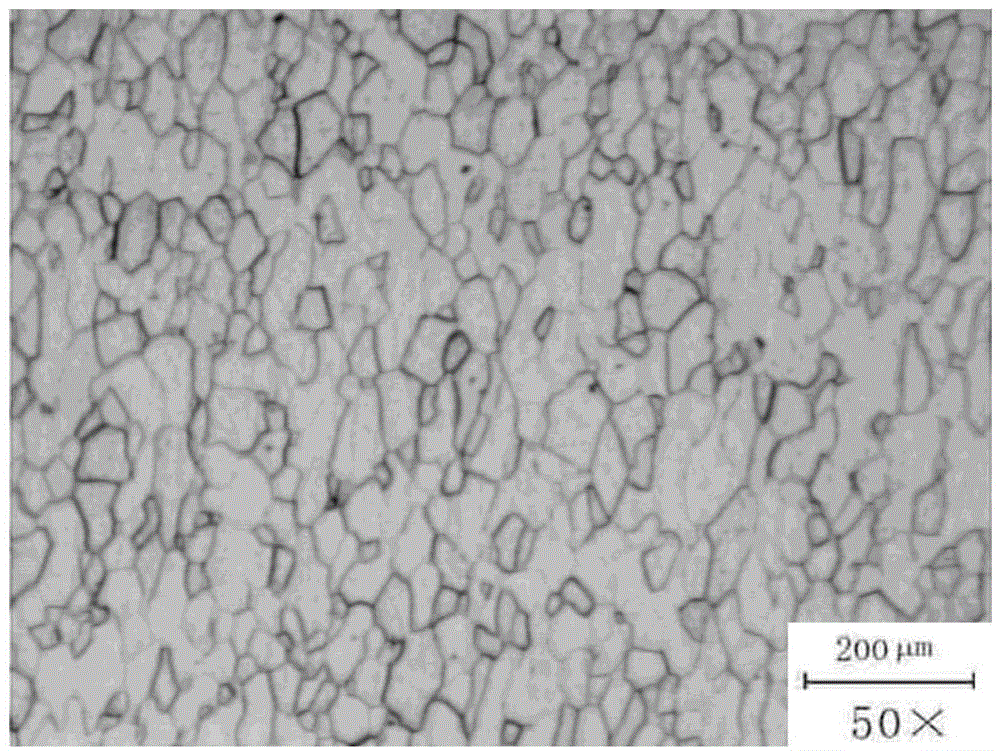

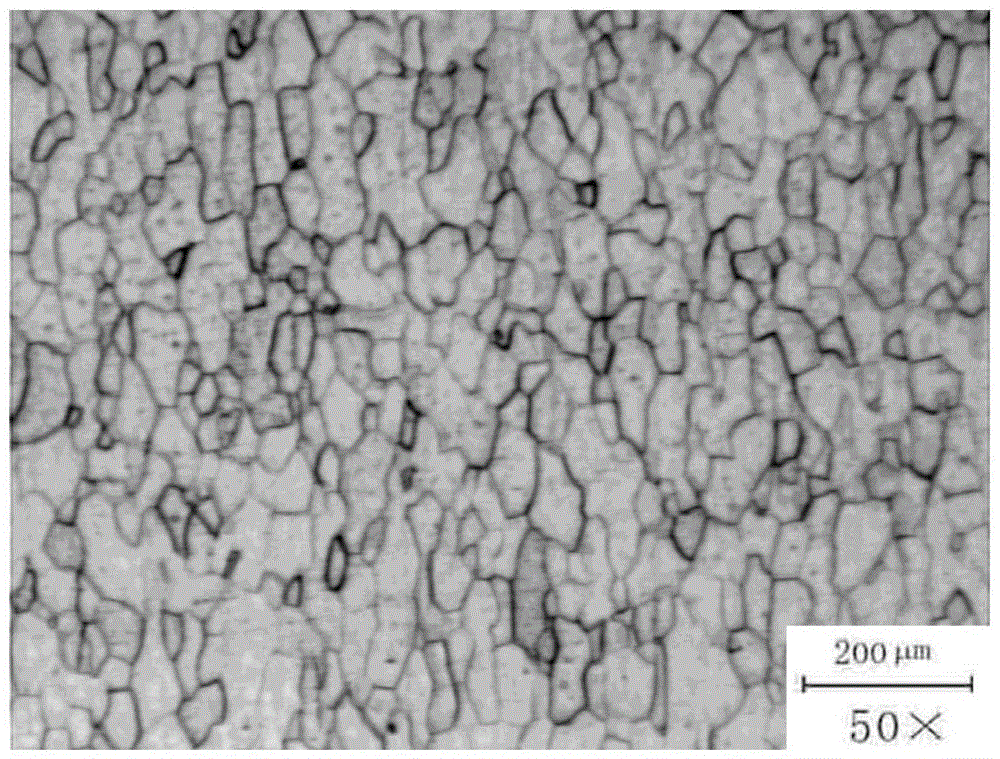

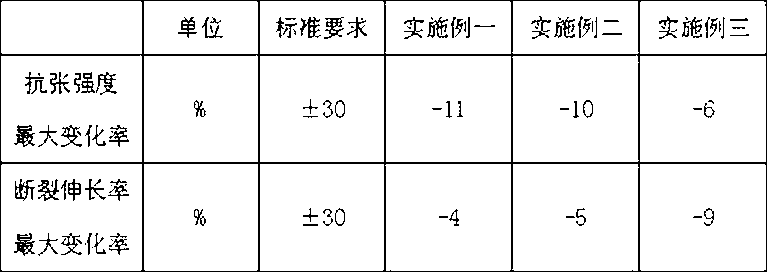

Preparation method of shaped charge liner tantalum 5 tungsten material

The invention provides a preparation method of a shaped charge liner tantalum 5 tungsten material. The preparation method comprises the following steps: A) performing hot forging on a tantalum 5 tungsten cast ingot for three times, wherein a hot forging way is axial upsetting and radial stretching, the upsetting ratio of the axial upsetting is 1.5-2.0, and the stretching ratio of the radial stretching is 0.8-1.0; performing annealing treatment on a tantalum 5 tungsten blank subjected to the hot forging for three times; B) rolling the tantalum 5 tungsten blank subjected to the annealing treatment, wherein the processing rate of rolling is 70-85 percent; C) performing annealing treatment on the tantalum 5 tungsten blank obtained in the step B) to obtain the shaped charge liner tantalum 5 tungsten material. In the process of preparing the tantalum 5 tungsten material, the grain structure inside the prepared tantalum 5 tungsten material is small by adopting the processing methods of the hot forging for three times and the rolling and through controlling parameters in forging and rolling processes, and all mechanical properties are uniform.

Owner:NINGXIA ORIENT TANTALUM IND

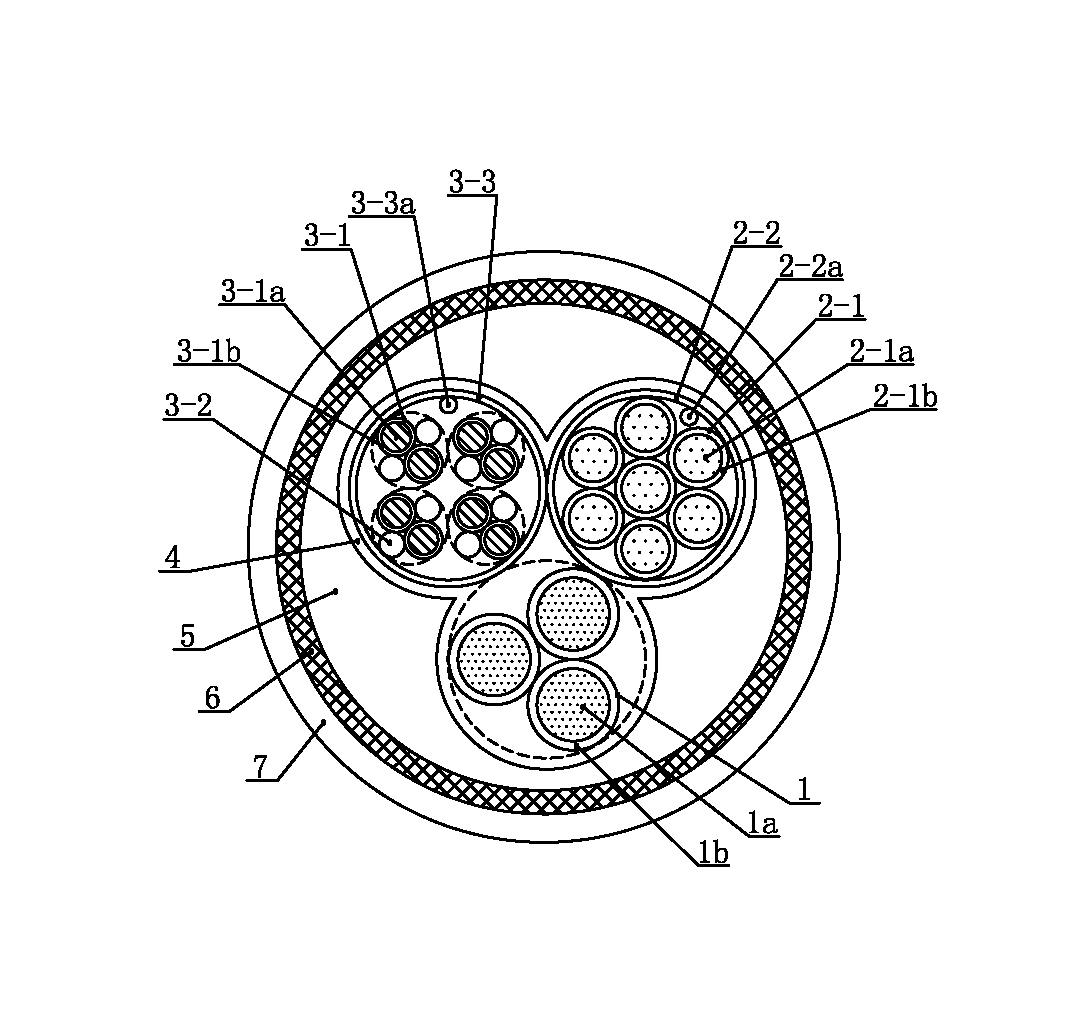

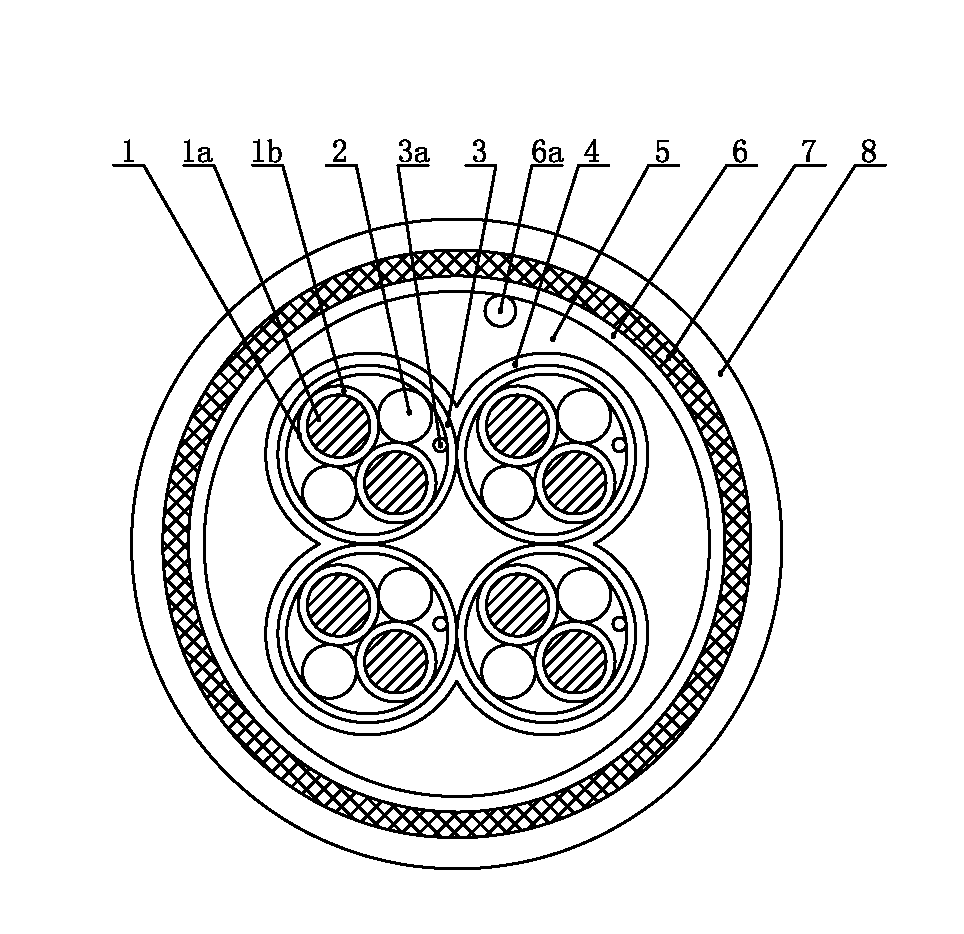

Composite cable for flame-retardant fireproof boat and manufacturing method thereof

ActiveCN103226992AIncrease working temperatureEliminate voidsInsulated cablesInsulated conductorsPower cableEngineering

The invention relates to a composite cable for a flame-retardant fireproof boat and a manufacturing method thereof. A power cable core, a control cable core and an instrument cable core are stranded into a composite cable core; the periphery of the composite cable core is coated with a low-intensity non-woven fabric longitudinally-covered layer; an inner jacket is extruded on the periphery of the low-intensity non-woven fabric longitudinally-covered layer in a wrapping way; the periphery of the inner jacket is coated with an armor braid; and an outer jacket is extruded on the periphery of the armor braid in a wrapping way. The low-intensity non-woven fabric longitudinally-covered layer is completely in fit with each insulated conductor in shape, so that gaps between the low-intensity non-woven fabric longitudinally-covered layer and the insulated cores are eliminated, and flame can be conveniently prevented from being spread inwards; and meanwhile, the inner jacket and the insulated cores are guaranteed not to be adhered, so that the insulated cores are not damaged when the jacket is stripped in the constructing process.

Owner:浙江华威设备制造有限公司

Cold work tool steel

InactiveCN1696326AEasy to processInhibition of fractureFurnace typesHeat treatment furnacesQuenchingTool steel

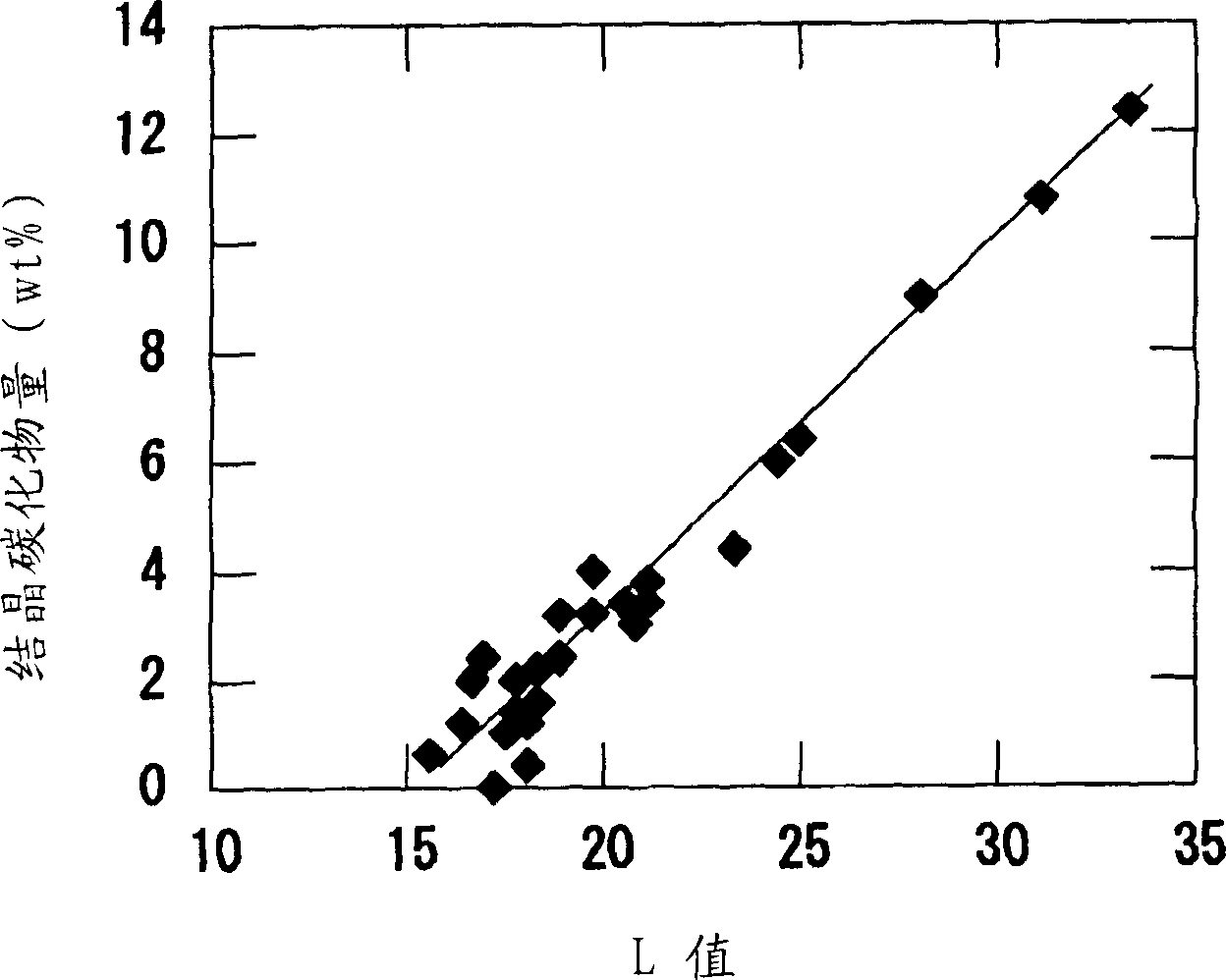

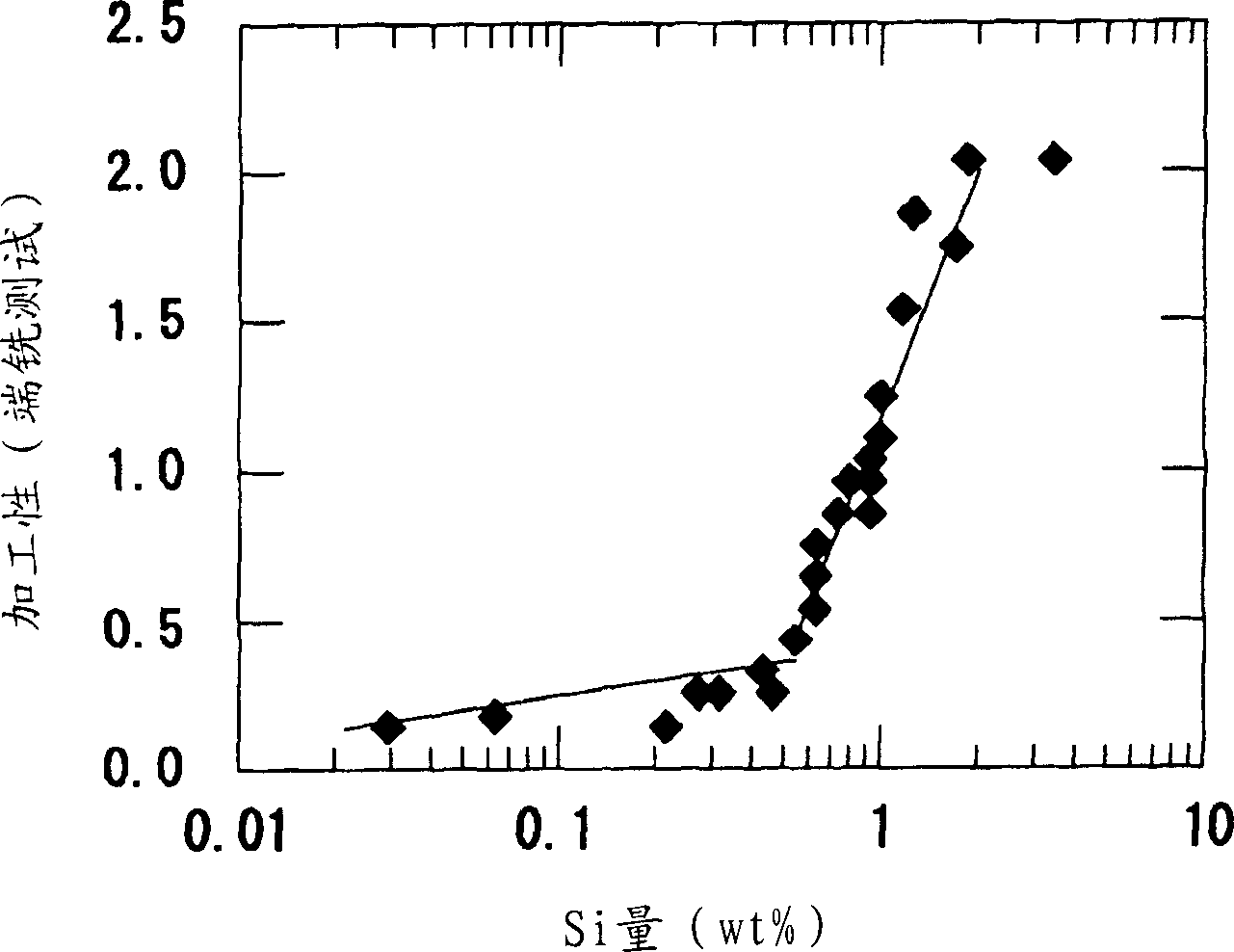

Cold work tool steel of the present invention comprises 0.4<=K value<=2.6 (K value Cr(wt %)-6.8C (wt %)), 15.5<=L value<=21.0 (L value=Cr(wt %)+15.5C (wt %), 0.60 wt %<=Si<=2.0 wt %, 0.10 wt %<=Mn<=1.0 wt %, 0.03 wt %<S<=0.2 wt %, 1.25 wt %<Mo+0.5 W<3.0 wt %, 0.05 wt %<=V<=1.0 wt %, and the balance Fe and inevitable impurities, in which the highest hardness obtained by tempering at 450 DEG C. or higher after quenching is HRC 61 or more.

Owner:DAIDO STEEL CO LTD

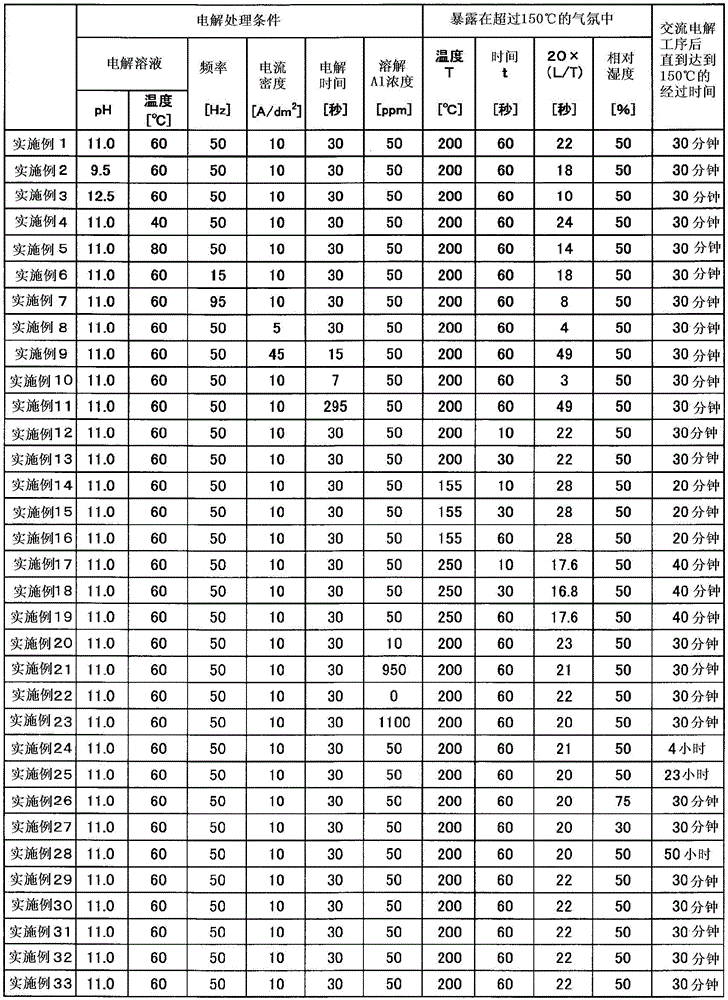

Treated surface aluminum material and manufacturing method therefor as well as said treated surface aluminum material/resin layer bonded material

ActiveCN106460221AExcellent adhesionGood adhesionAnodisationMetal layered productsMoistureAluminium oxide

[Problem] To provide a treated surface aluminum material with excellent long term resin adhesiveness over the entire surface of the aluminum material and a stable manufacturing method for such a treated surface aluminum material. [Solution] Provided are a treated surface aluminum material and a manufacturing method therefor, wherein the treated surface aluminum material comprises an aluminum material and an oxide film formed on at least one surface thereof and is characterized in that the oxide film is obtained from a 20-500 nm thick porous aluminum oxide film layer formed on the front surface side and a 3-30 nm thick barrier aluminum oxide film layer formed on the base surface side, 5-30 nm diameter pores are formed in the porous aluminum oxide film layer, and the moisture content contained in the oxide film is not more than 10 [mu]g / cm2.

Owner:FURUKAWA SKY ALUMINUM CORP

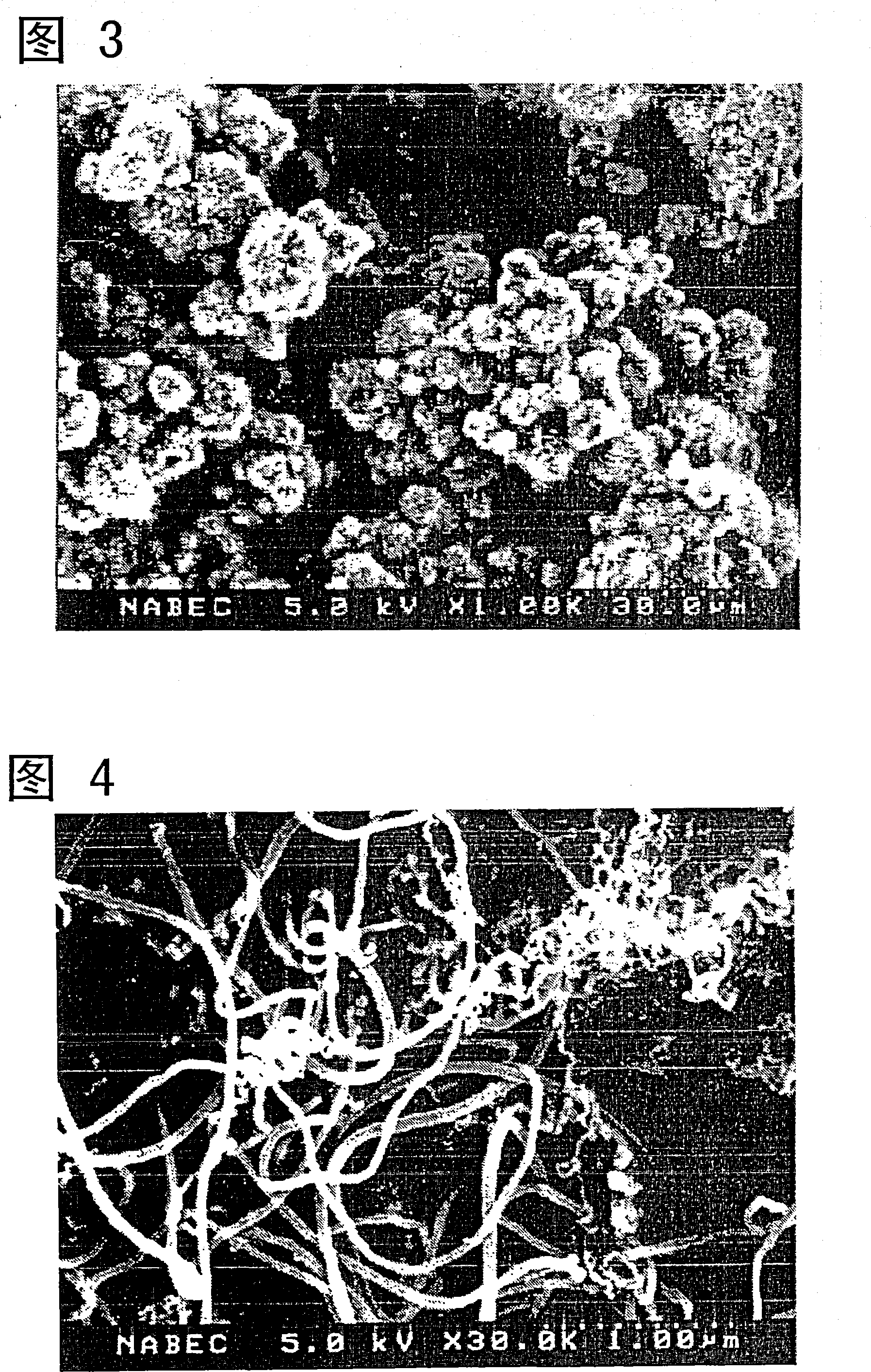

Composite negative-electrode active material, process for producing the same and nonaqueous-electrolyte secondary battery

InactiveCN101010820AImprove electronic conductivityExcellent initial charge/discharge characteristicsMaterial nanotechnologyActive material electrodesLithiumCarbon nanofiber

A composite negative-electrode active material, comprising grains of silicon oxide of the formula SiOx (0.05 H01M 4 / 48 B01J 23 / 74 H01M 4 / 58 H01M 10 / 40 C01B 31 / 02 H01M 4 / 02 2 30 3 2005 / 8 / 23 101010820 2007 / 8 / 1 000000000 Matsushita Electric Ind Co., Ltd. Japan Ishida Sumihito Matsuda Hiroaki Yoshizawa Hiroshi yuhui 72002 NTD Patent & Trademark Agency Ltd. Units 1805-6, 18th Floor, Greenfield Tower, Concordia Plaza, No.1 Science Museum Road, Tsimshatsui, east, Kowloon, Hong Kong 100045 Japan 2004 / 12 / 22 371255 / 2004 2007 / 2 / 26 PCT / JP2005 / 015266 2005 / 8 / 23 WO2006 / 067891 2006 / 6 / 29 Japanese

Owner:PANASONIC CORP

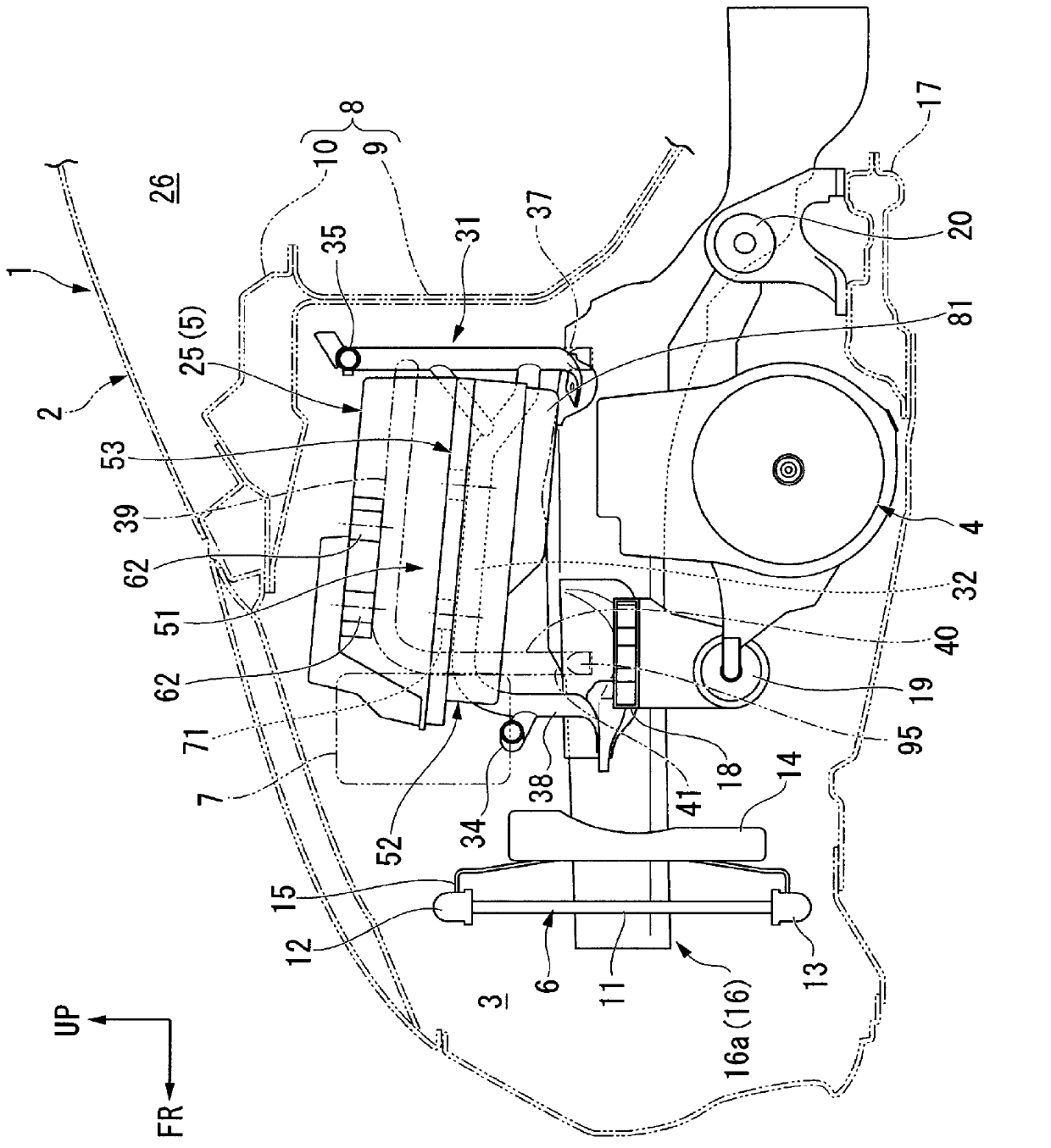

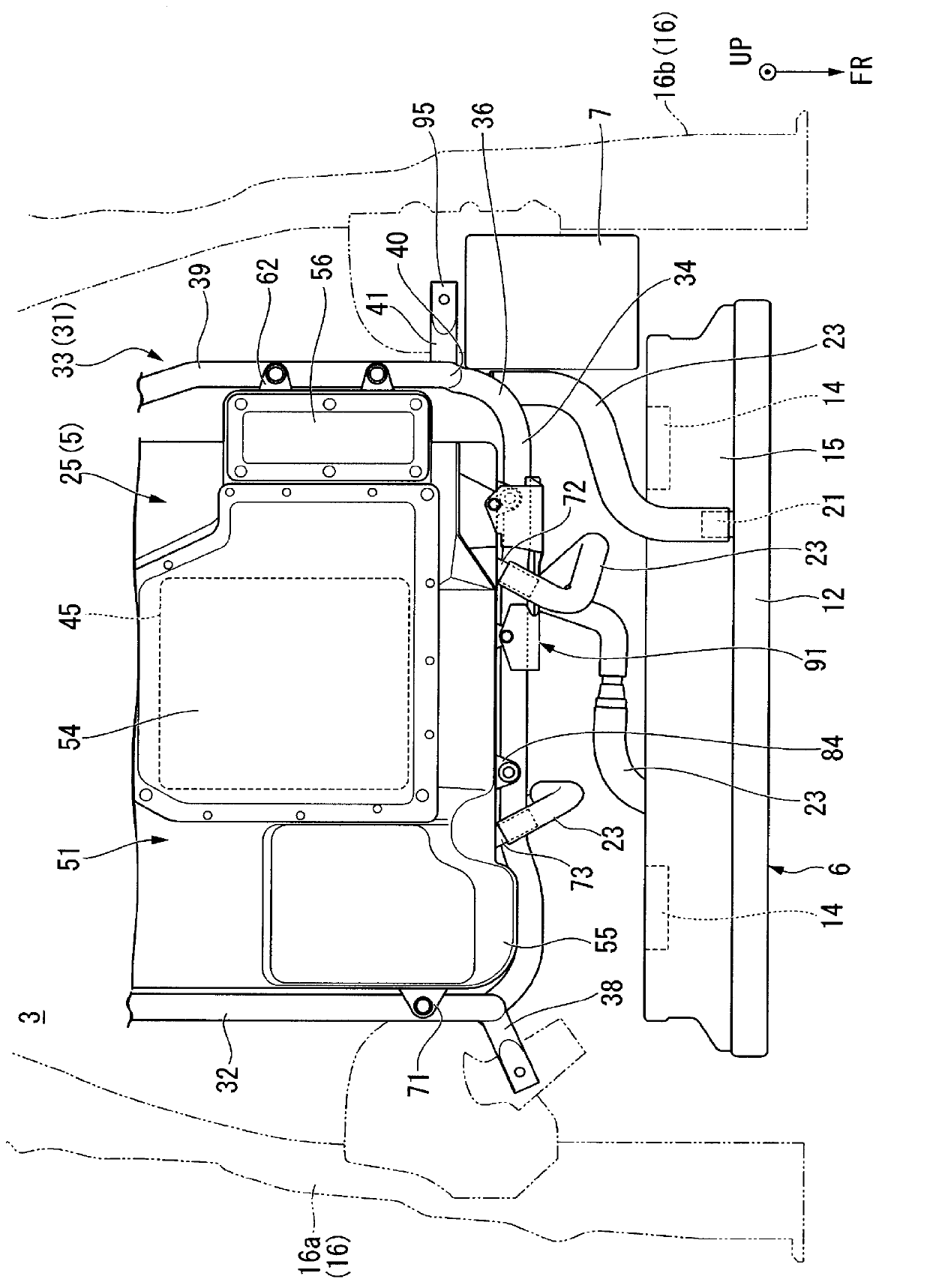

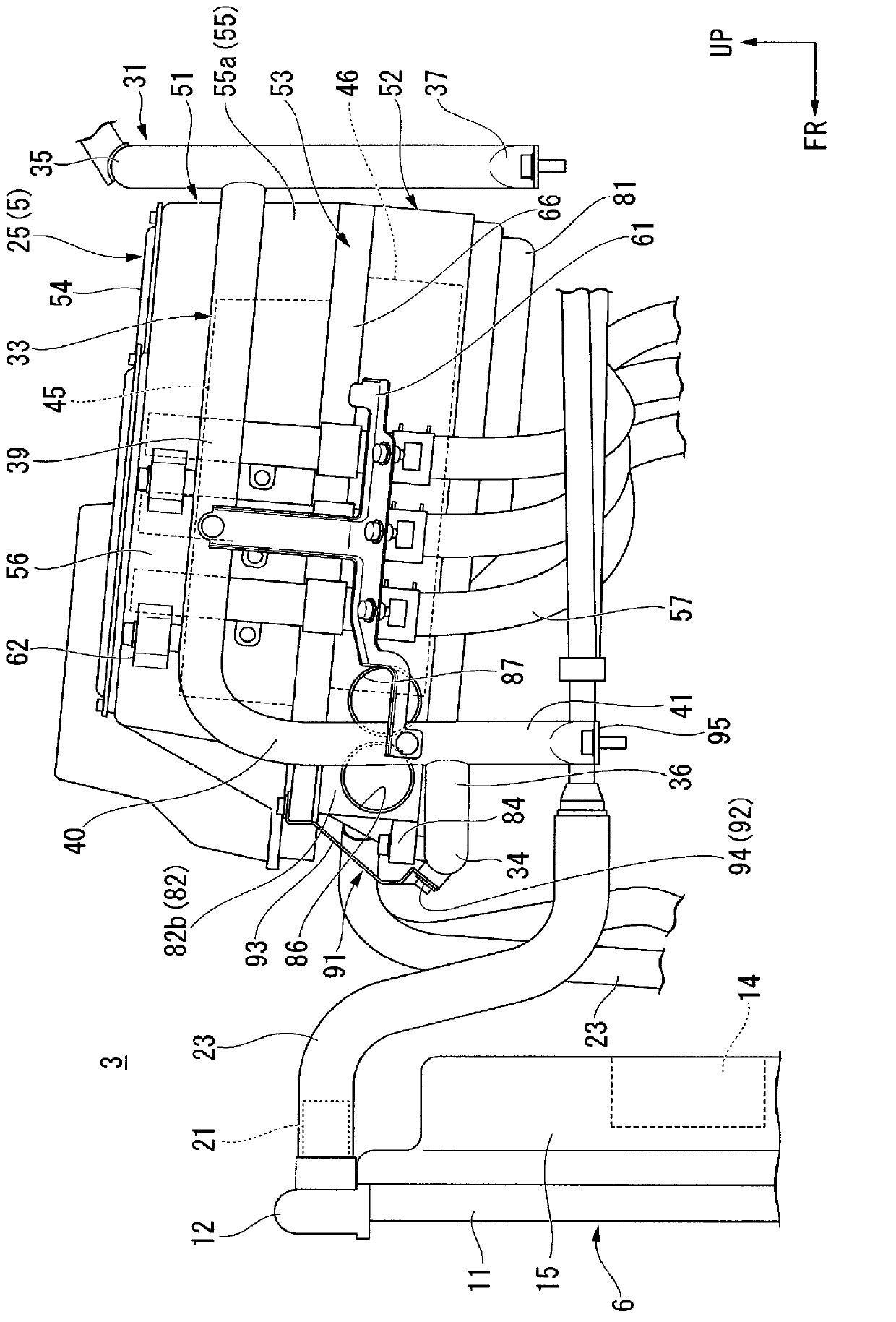

Protection structure of power control unit

InactiveCN103101431APrevent intrusionLow costElectric/fluid circuitPropulsion coolingVehicle frameEngineering

A protection structure of a power control unit capable of realizing low cost and light weight, and protecting the power control unit is provided. Therefore, a protective holding rack (91) and an installing part (94) of a front supporting frame (34) are in a left-side-offset arrangement relative to a central part in a vehicle width direction of a PCU (5), and further, the installing part (94) is disposed between a fixed point of a left side vehicle rack (16b) and a foot part (41), namely a vehicle body side fixed part (95), and a fixed point of the front supporting frame (34) and the PCU (5), namely an installing sheet (84).

Owner:HONDA MOTOR CO LTD

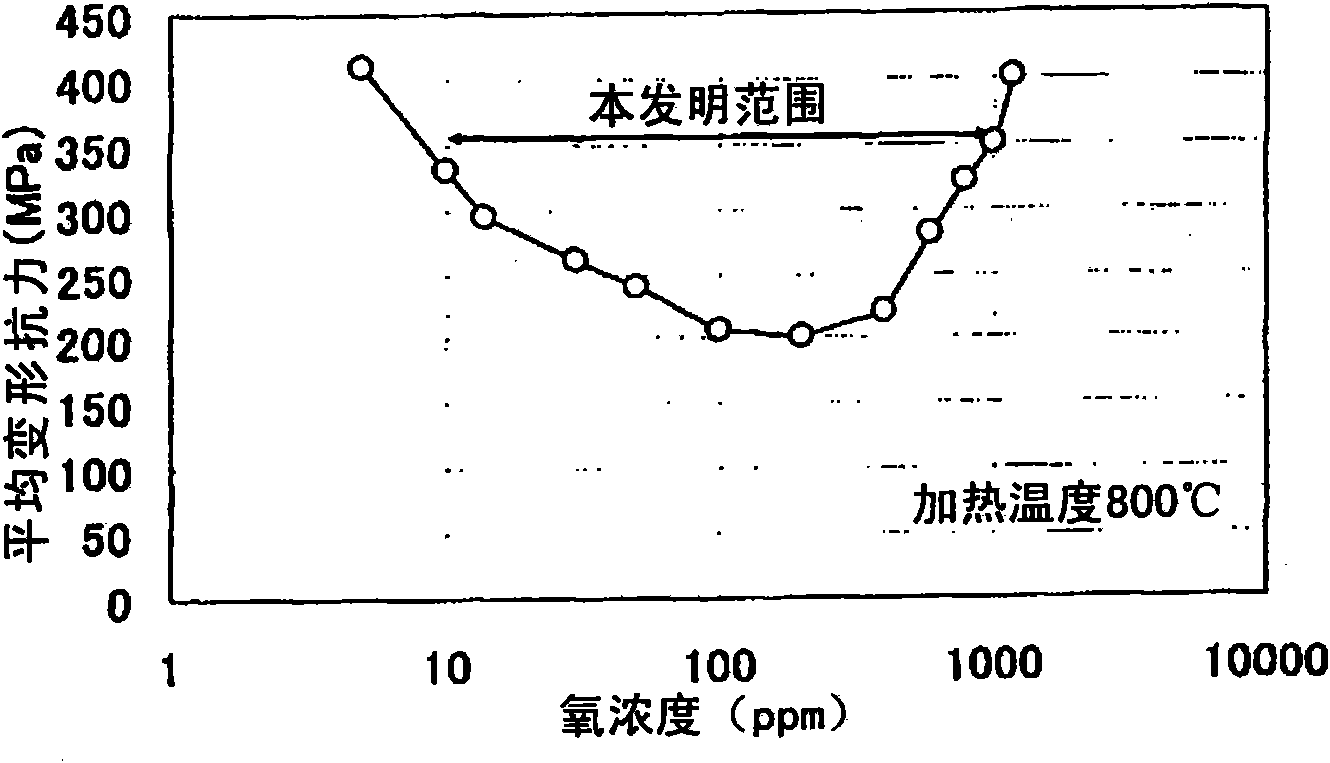

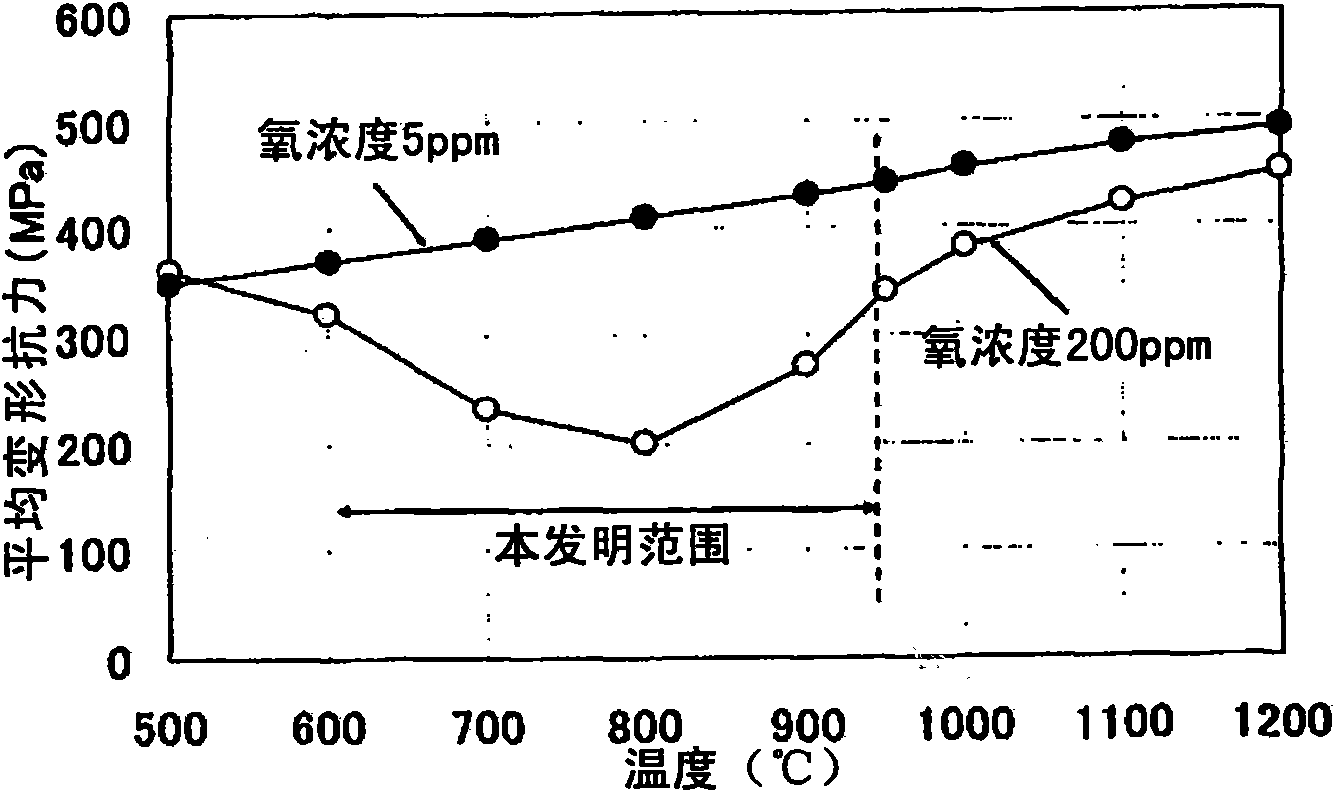

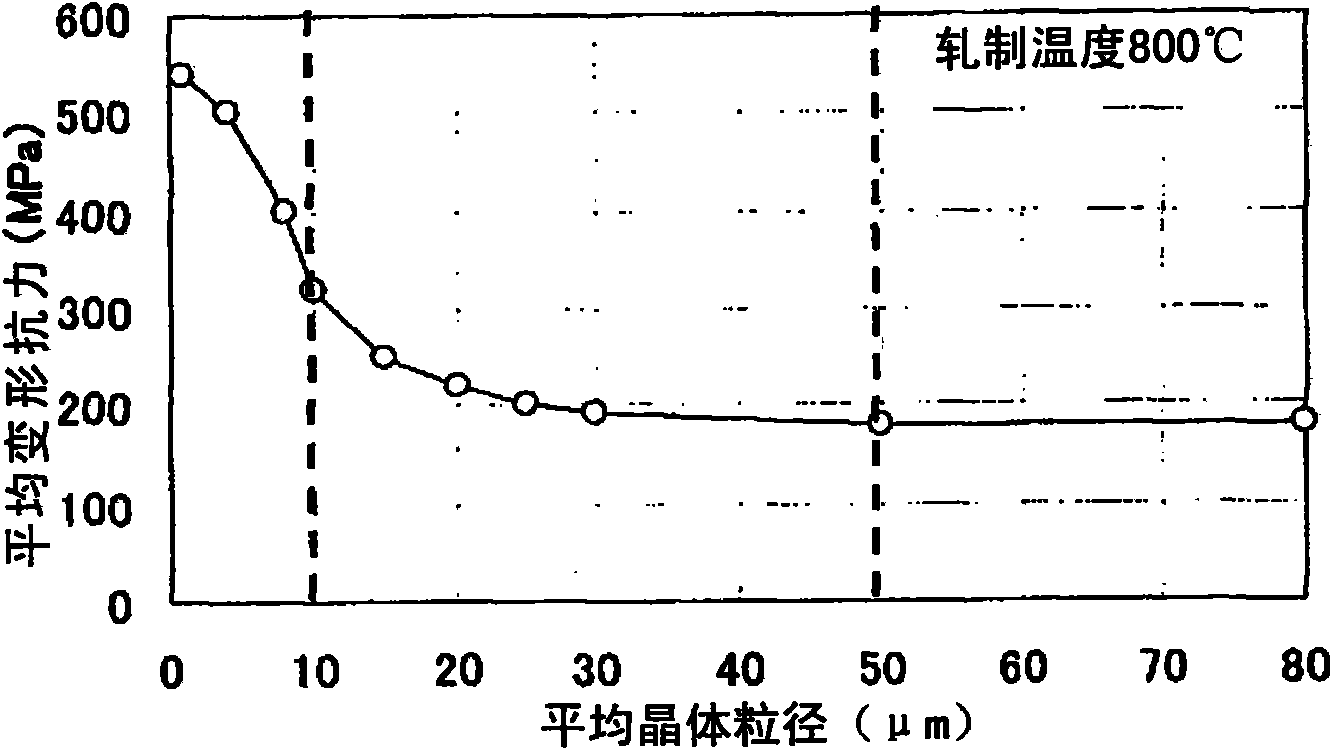

Process for producing molybdenum-based sputtering target plate

InactiveCN101611165AEfficient preparationInhibition of fractureVacuum evaporation coatingSputtering coatingTrace elementIngot

The present invention provide a process for efficiently producing a molybdenum-based target plate having a large area in a high yield by combining a requirement concerning the content of a trace element with conditions for rolling to thereby reduce deformation resistance and inhibit the occurrence of cracks such as edge cracks. The process, which is for producing a molybdenum-based sputtering target plate by rolling a molybdenum-based ingot, is characterized by comprising a step in which a molybdenum-based ingot is produced while regulating the oxygen concentration therein to 10 to 1,000 mass ppm and a step in which the molybdenum-based ingot is heated and rolled at a rolling temperature of 600-950 DEG C.

Owner:NIPPON STEEL MATERIALS CO LTD

Preparation method for colored paper pulp moulded product

ActiveCN109082947APromote growthImprove regenerative abilityWater-repelling agents additionPaper/cardboardEnvironmental resistanceAdhesive

The invention discloses a preparation method for a colored paper pulp moulded product. The method comprises the steps that bamboo fiber sizing agent is prepared, and an adhesive, a water-proofing agent and an anionic emulgator of corresponding weight parts are added and stirred into paper pulp suspension liquid; direct sun-proof black or direct sun-proof orange is diluted and added into the abovepaper pulp suspension liquid; finally the paper pulp suspension liquid is put into a mould machine for dehydration and subjected to hot press molding. The invention further discloses the colored paperpulp moulded product prepared by the above method. The moulded product is uniform in coloring, can be easily degraded in a natural environment and is an environmentally friendly colored paper pulp moulded product.

Owner:WING FAT (HENAN) MOLDED FIBER TECH DEV CO LTD

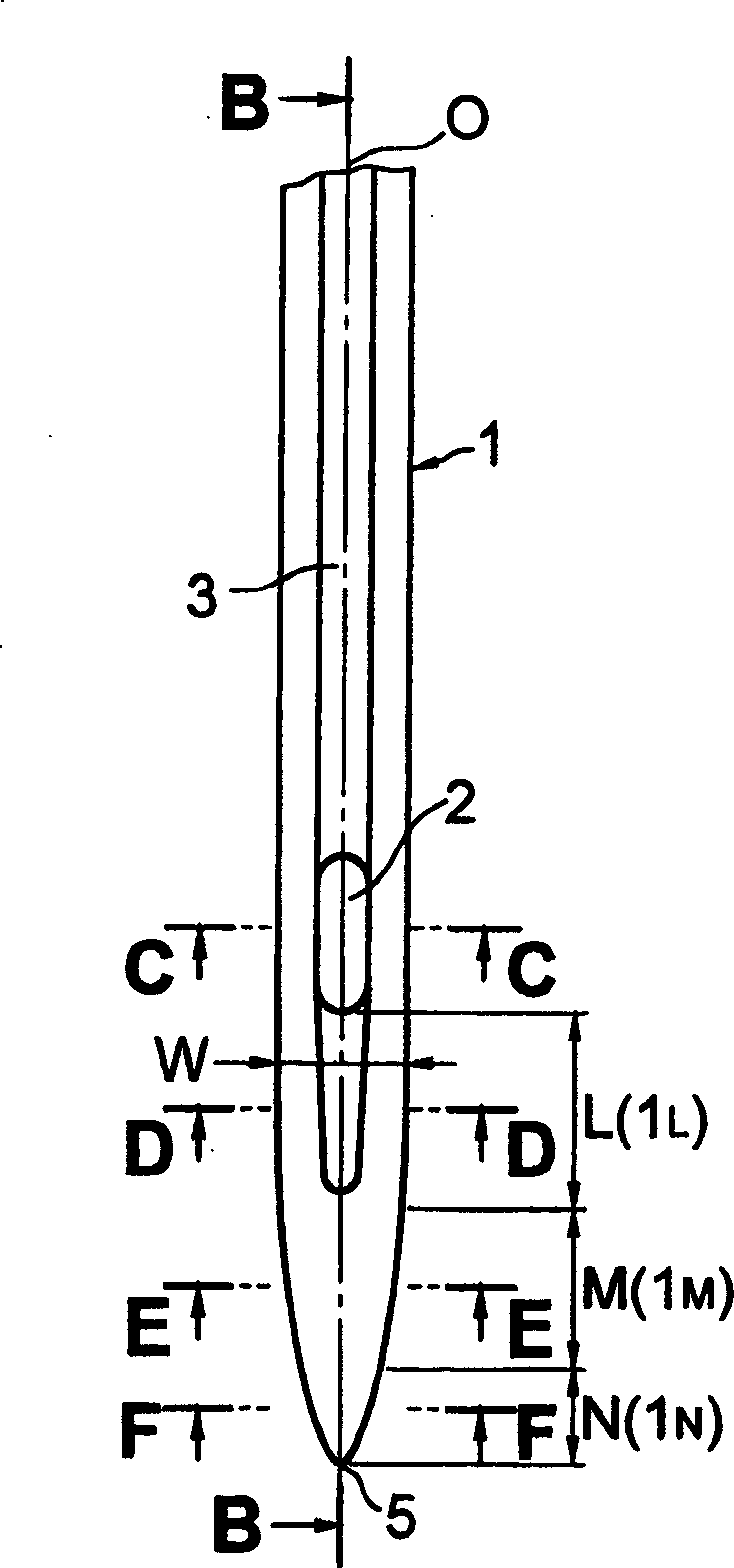

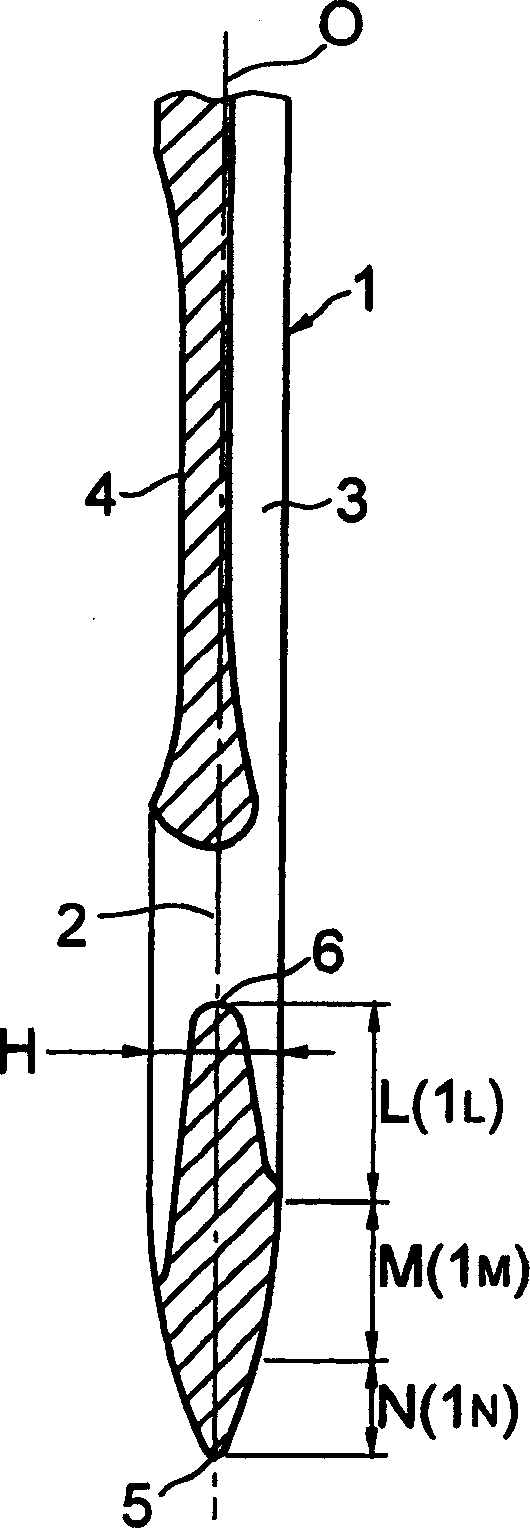

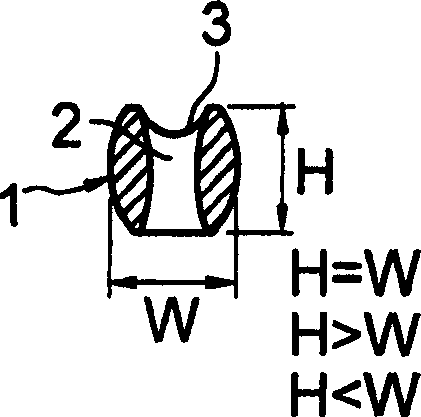

Sewing machine needle

A sewing machine needle capable of preventing stitch skipping and fabric yarn breakage, irrespective of high-speed and multifunction sewing machines and diversified materials being used. Over a predetermined length from an edge, closer to a needle point, of a needle eye toward the needle point, a blade has a straight profile extending parallel to a longitudinal axis of the needle as viewed from a side of the needle in a direction orthogonal to a direction in which the needle eye extends. Over a predetermined length from the straight profile portion toward the needle point, the profile of the blade is a flat cross-section in which the thickness thereof in the direction in which the needle eye extends is larger than the width thereof in the direction orthogonal to the direction in which the needle eye extends. In a needle point portion following the flat cross-section portion and extending to the needle point, the blade has a sectional shape of a perfect circle.

Owner:ORGAN NEEDLE CO LTD

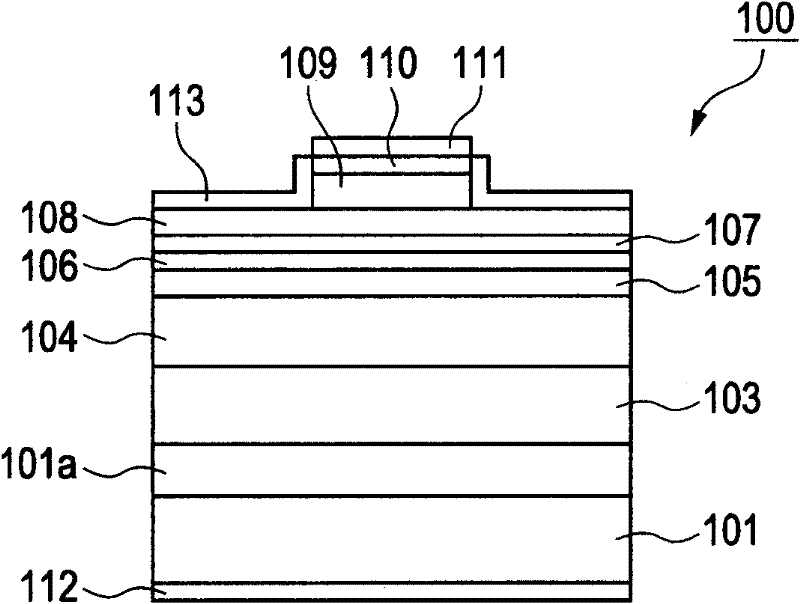

Semiconductor laser and manufacturing method thereof

InactiveCN102237634AReduce strainLarge band gap when strainedOptical wave guidanceLaser detailsSemiconductor packageNitride semiconductors

The invention provides a semiconductor laser and a manufacturing method thereof. The semiconductor laser includes a semiconductor substrate and a resonator formed over the semiconductor substrate and containing a nitride semiconductor layer. A strain exerting on a region near the facet of the resonator is smaller than a strain exerting on the region between the regions near the facet.

Owner:RENESAS ELECTRONICS CORP

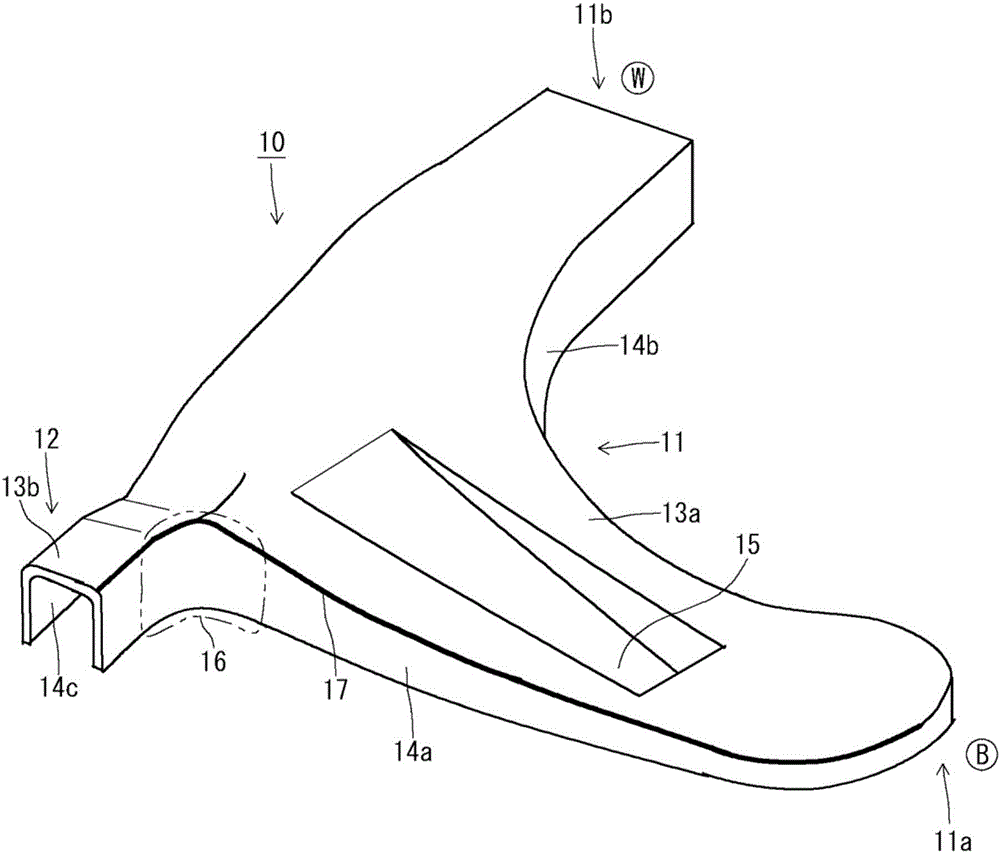

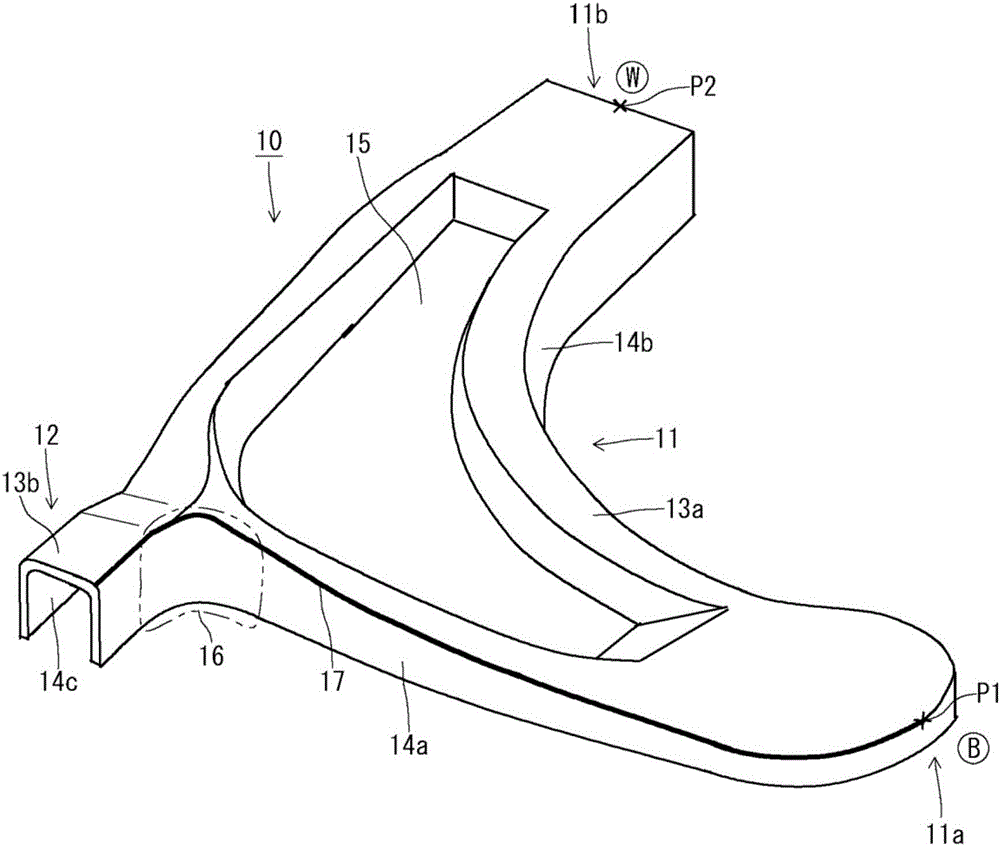

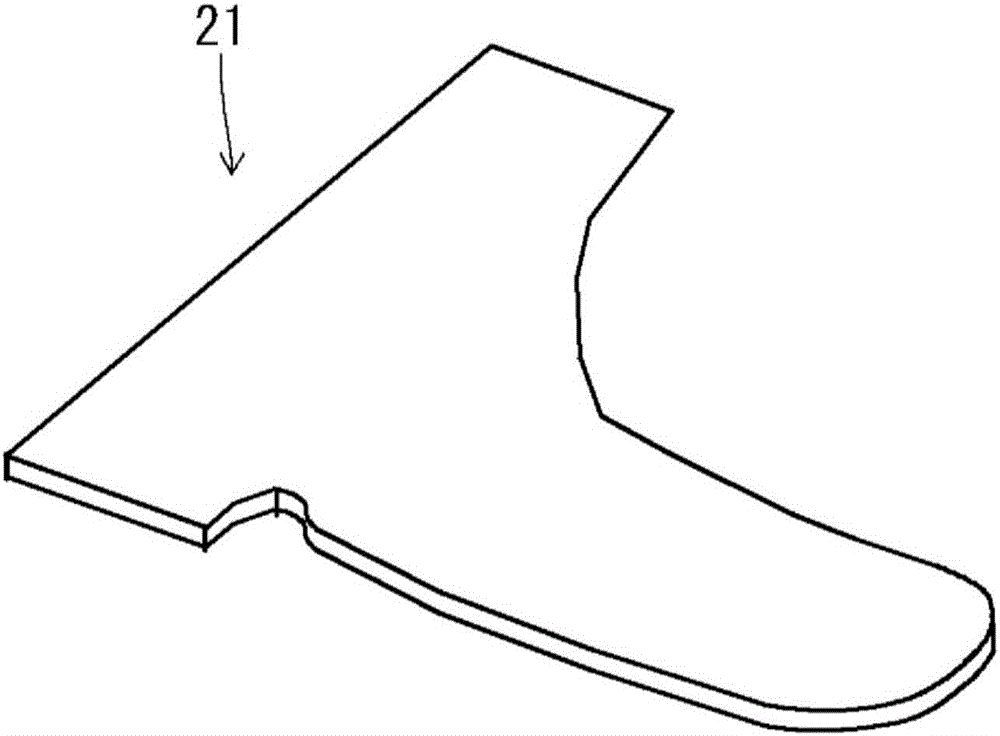

Press-moulded article manufacturing method and vehicle lower arm

ActiveCN106163689AInhibition of fractureHigh strengthPivoted suspension armsAcute angleBiomedical engineering

A press-moulded article (10) which includes: a body section (11) that has a first end section (11a) and a second end section (11b) respectively at both ends thereof; and a protruding section (12) which projects from a curved section of the body section (11) and at the curve outer side. A groove section (15) in a region at the first end section (11a) side from the root of the protruding section (12) is provided on the surface of a top plate section (13a) of the body section (11). A first longitudinal wall section (14a) which extends from the first end section (11a) of the body section (11) to the protruding section (12) has a corner section (16) which links the body section (11) and the protruding section (12). The angle formed by a portion from the corner section (16) towards the body section (11) and a portion from the corner section (16) towards the protruding part (12) is an acute angle. A method for manufacturing the press-moulded article (10) includes: a first step in which the first longitudinal wall section (14a) is further moulded without moulding the shape of the groove section (15) within the surface shape of the top plate section (13a); and a second step in which the shape of the groove section (15) is moulded within the surface shape of the top plate section (13a).

Owner:NIPPON STEEL CORP

Method for preparing polychlorinated phenyl trichlorosilane through catalysis of ionic liquid

InactiveCN102633827AImprove conversion rateHigh yieldGroup 4/14 element organic compoundsChemical recyclingPtru catalystPhysical chemistry

The method relates to a method for preparing polychlorinated phenyl trichlorosilane through catalysis of ionic liquid, and belongs to the technical field of application of the ionic liquid. According to the method, methyl trichlorosilane is catalyzed and chloridized to prepare polychlorinated phenyl trichlorosilane with Cl2 serving as a chlorinating agent, and (BMIM)Cl-nFeCl3 (n=0.5, 1, 1.5 and 2) acidic ionic liquid serving as a catalyst. According to the method, the technology is simple, the reaction condition is mild, the conversion rate of the raw material is high, and the product yield is high. The (BMIM)Cl-nFeCl3 ionic liquid catalyst can be reutilized through simple liquid-liquid separation, and the catalytic activity of the (BMIM)Cl-nFeCl3 ionic liquid catalyst remains unchanged fundamentally. Compared with the conventional catalyst such as FeCl3 and AlCl3, the (BMIM)Cl-nFeCl3 ionic liquid catalyst can effectively inhibit side reaction, namely the breakage of Si-C bond, and thus the product yield can be improved.

Owner:JIANGSU UNIV

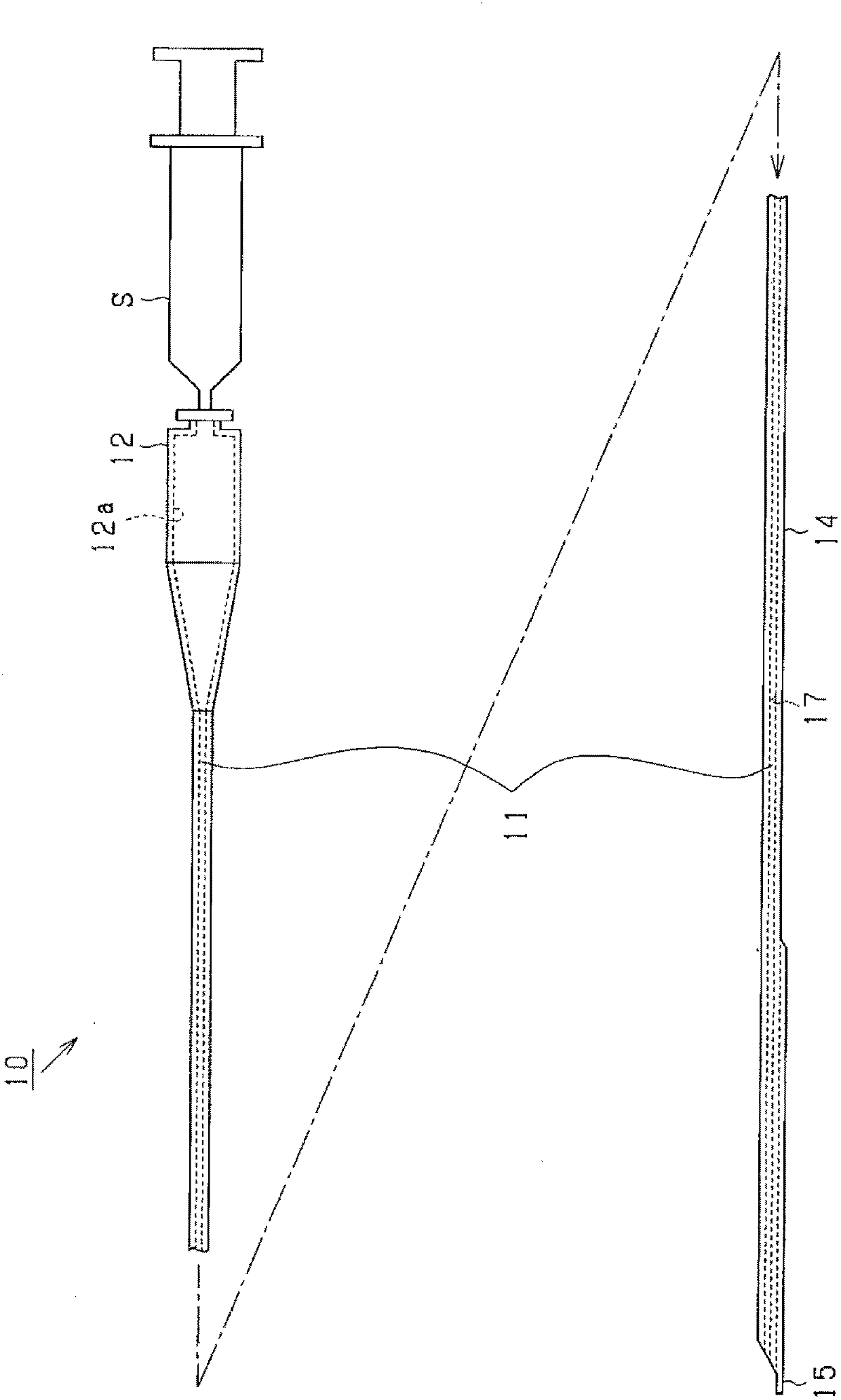

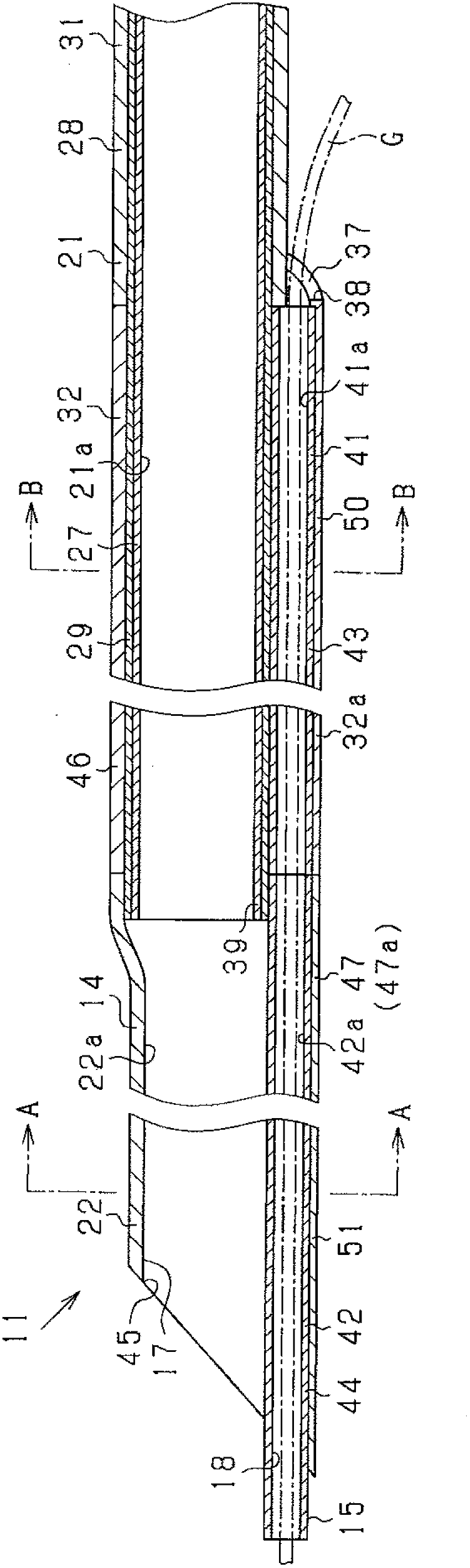

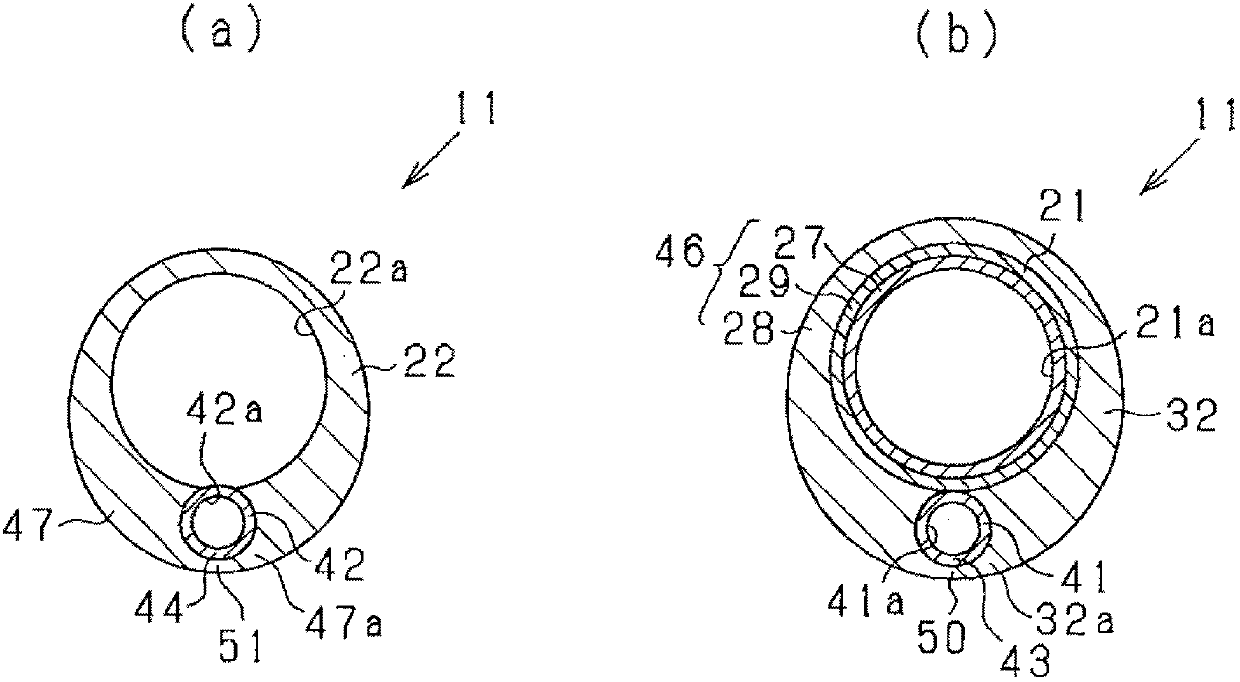

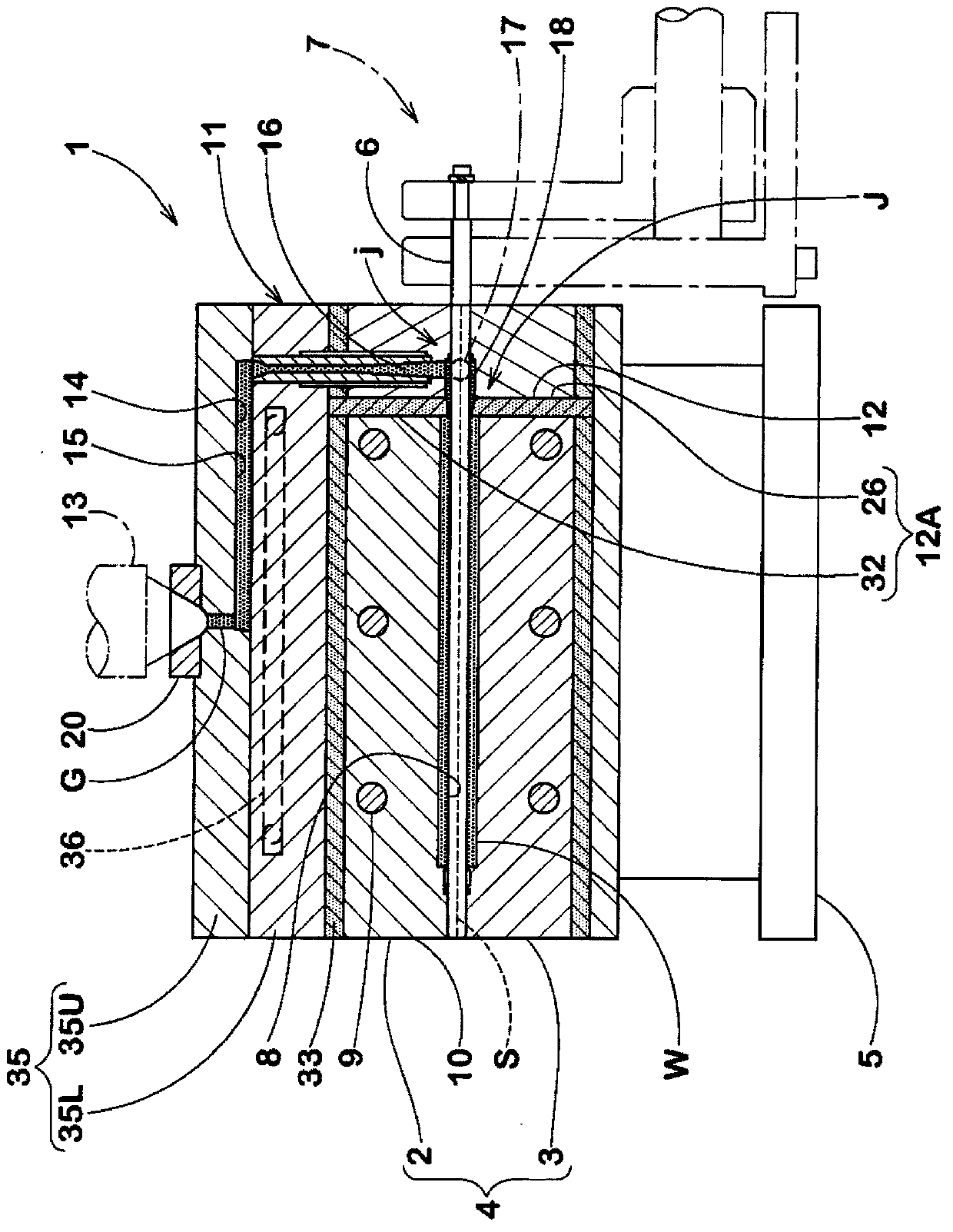

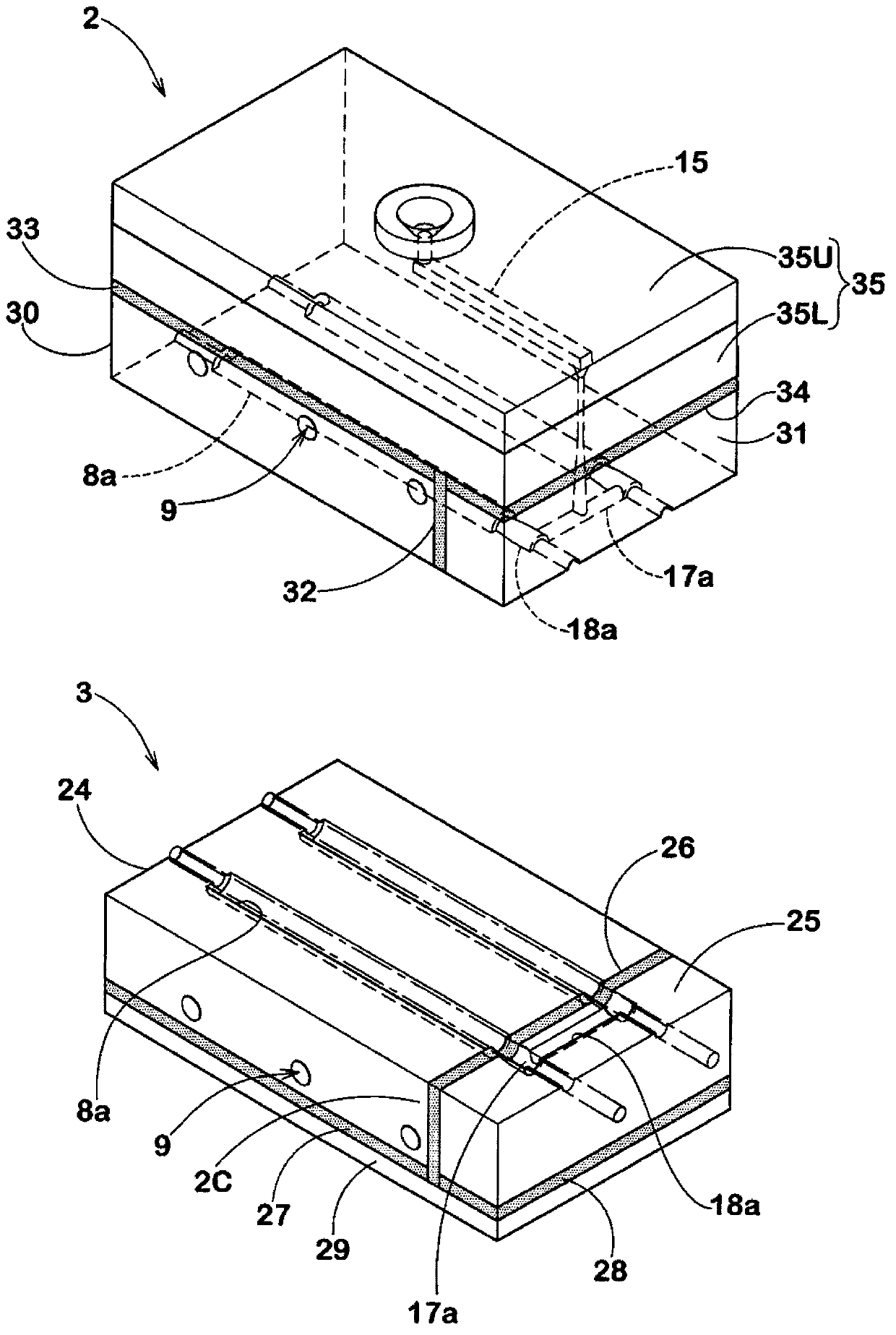

Conduit

The invention provides a structure in which a texturing tube buried on the periclinal wall of a main tube. The conduit can inhibit decline of passing through by preventing the texturing tube from detaching from the main tube. The main tube body of a suction tube comprises a suction tube (1) and a texturing tube (15). A easy-break (50,51) parts are positioned at the thick wall part of the periclinal wall of the suction tube (14) of the main body of the conduit, in the center of the periclinal wall (15), on the side contrary to the texturing tube lumen (17) and suction tube lumen (18) along X direction that the tube lumen is arrayed. The easy-break (50,51) parts which respectively depart from the suction tube (14) at the outlet of a guide wire (G) and bend toward one side are easier to break than the part between the suction tube lumen (17) in the center of the periclinal wall of the suction tube (14) , and the texturing tube lumen.

Owner:GOODMAN & COMPANY

Double-shielded instrument cable for flame-resistant and fire-resistant ship and manufacture method thereof

ActiveCN103187126AIncrease working temperatureEliminate voidsInsulated cablesInsulated conductorsFiberCopper conductor

The invention relates to a double-shielded instrument cable for a flame-resistant and fire-resistant ship and a manufacture method of the double-shielded instrument cable. The periphery of a twisted copper conductor is extruded and packed with a flame-resistant and fire-resistant ethylene propylene rubber insulating layer to form insulated cable cores, the insulated cable cores are twisted with one another two by two to form a twisted conductor pair, a gap of each twisted conductor pair is filled with a flame-resistant non-absorbent fiber filling core, and the periphery of each set of the twisted conductor pairs is warped with twisted conductor pair copper foil shield layers to form pair twist sets; and the plurality of sets of pair twist sets are twisted with one another to form a cable core, and the periphery of the cable core is sequentially packed with a low-intensity non-woven fabric lengthways-packed layer, an inner jacket, a cable core copper foil shield layer, an armor weaving layer and an outer jacket. The low-intensity non-woven fabric lengthways-packed layer is completely matched with the shape of the insulated cable core, so that gaps between the low-intensity non-woven fabric lengthways-packed layer and the insulated cable core can be eliminated, and the flame can not inwards extend conveniently; and the non-stickiness between the inner jacket and the insulated cable core can be guaranteed, and the insulated cable core can be hardly damaged when the jackets are stripped during construction.

Owner:嘉兴君宏汽车配件有限公司

Process and equipment for preparing paper-plastic molded high-quality yellow serofluid product

ActiveCN111041886APromote growthImprove regenerative abilityWater-repelling agents additionPaper/cardboardFiberMolding machine

Owner:WING FAT (HENAN) MOLDED FIBER TECH DEV CO LTD

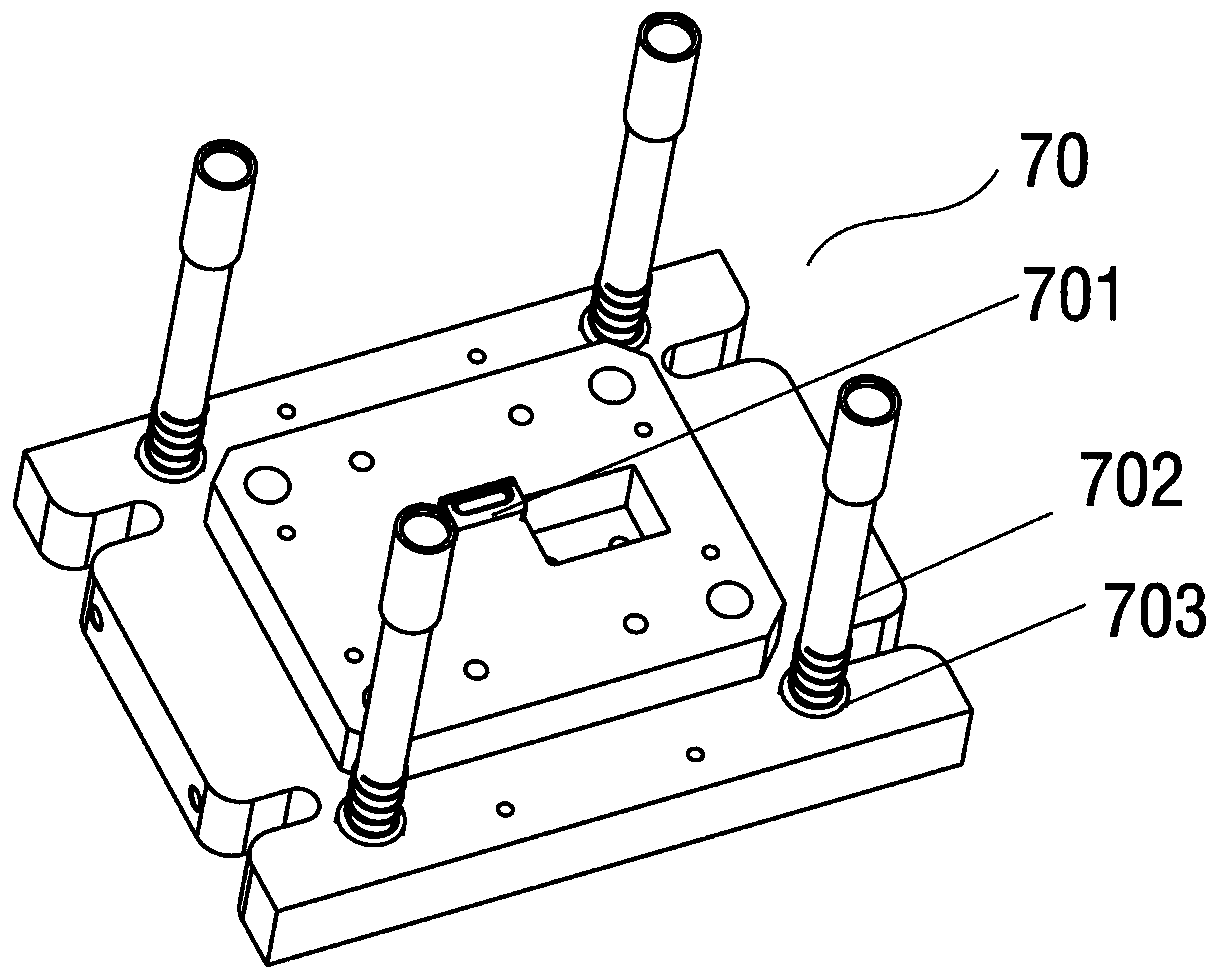

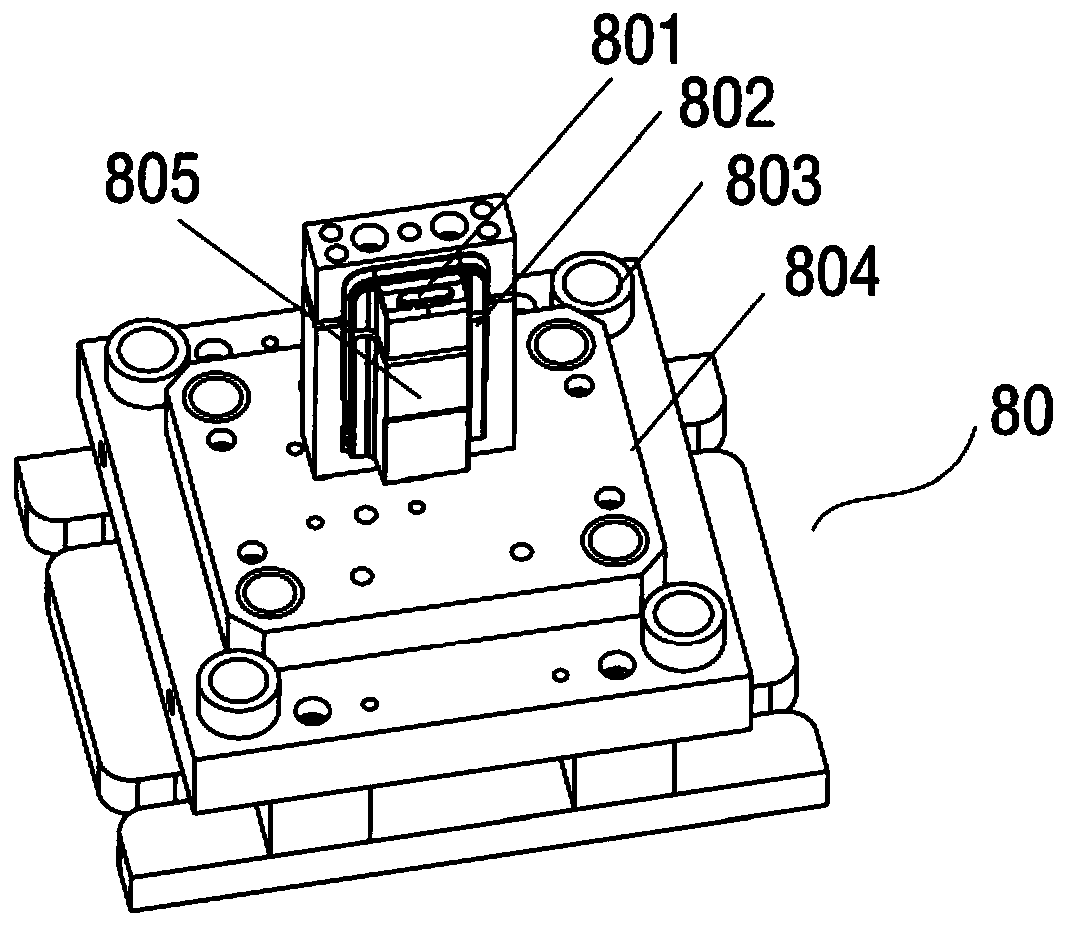

Mold for injection molding, and manufacturing method for rubber product molded by using same

InactiveCN103286916AIncrease temperatureDelayed vulcanization start timeRubber materialPolymer science

The present invention provides a mold for injection molding, and a manufacturing method for a rubber product molded by using the same. The mold can prevent rubber in a sprue portion from fracturing at the root of the rubber and residing in the sprue portion. A mold main body is divided into a product forming region and a rubber material feeding region, wherein the product forming region is provided with a mold cavity for forming the rubber product and a heater for heating and vulcanizing the rubber materials in the mold cavity; and the rubber material feeding region is provided with a rubber feeding flow path comprising a cooling runner portion, a sprue portion and a pouring gate portion. A thermal baffle plate is disposed between the product forming region and the rubber material feeding region. The thermal baffle plate inhibits the temperature of the rubber materials in the sprue portion, the runner portion and the pouring gate portion from increasing.

Owner:SUMITOMO RUBBER IND LTD

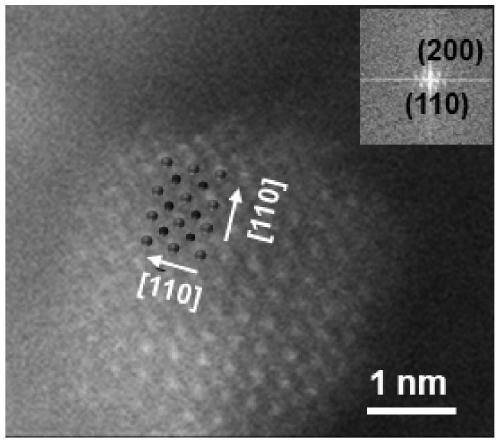

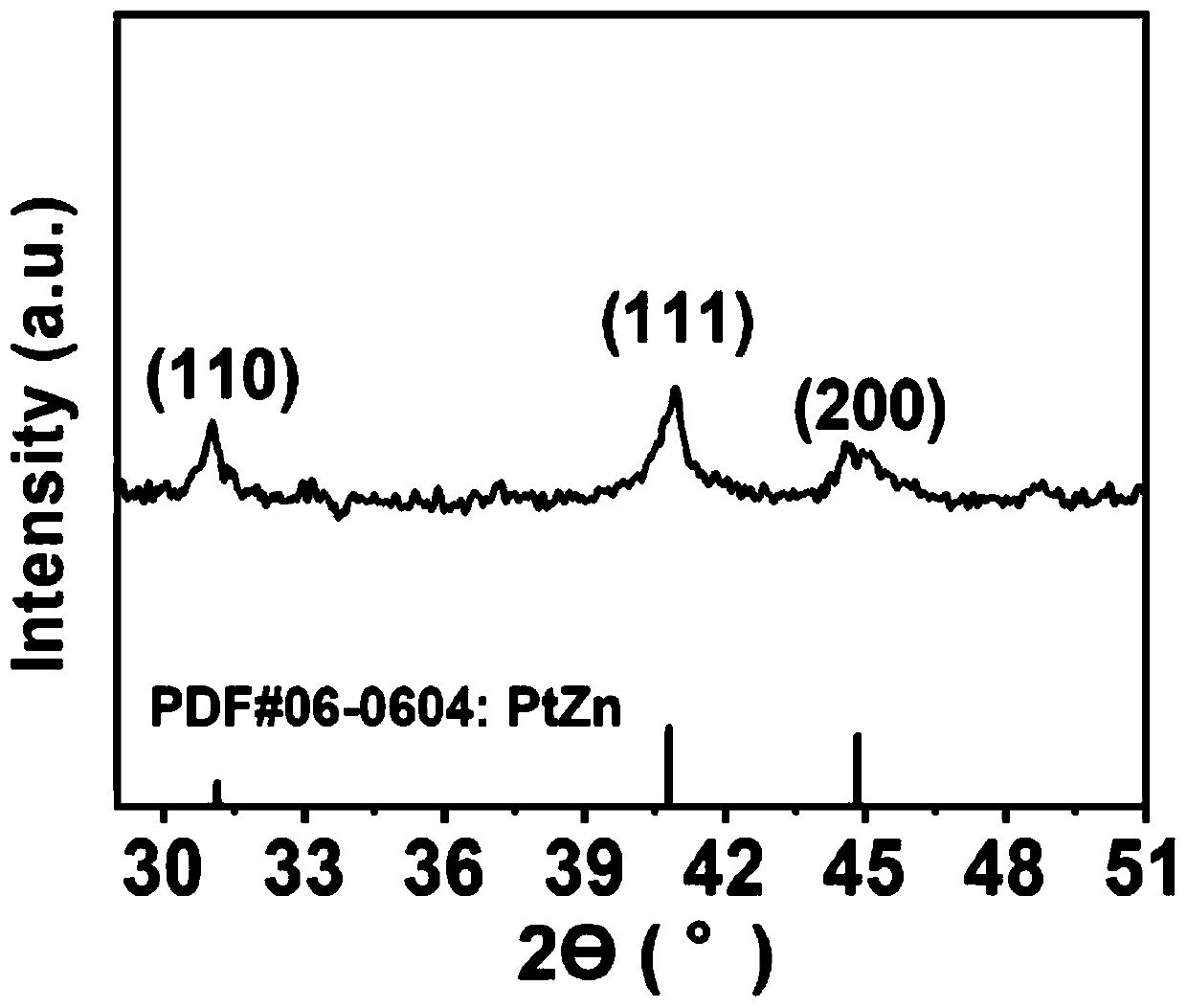

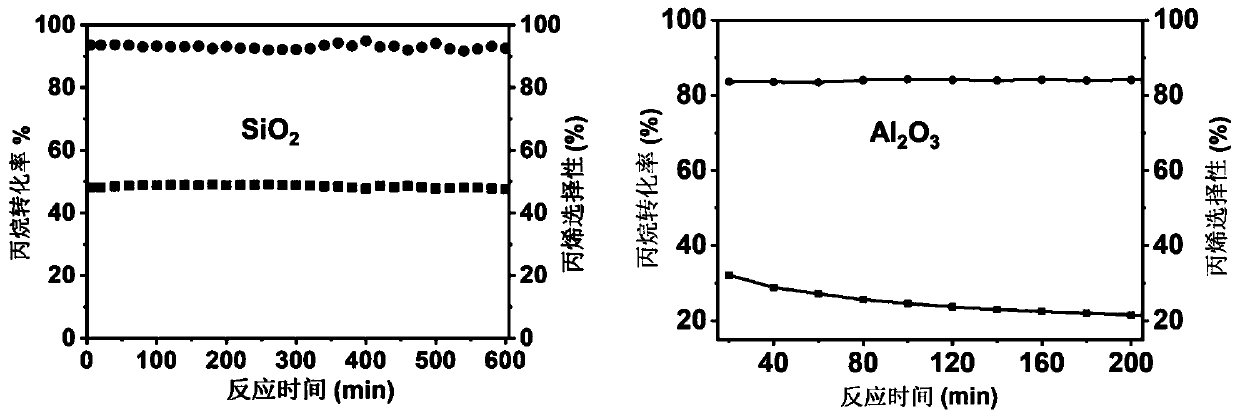

Supported PtZn intermetallic alloy catalyst as well as preparation method and application thereof

ActiveCN111408370APt content decreasedLow costCatalystsHydrocarbon preparation catalystsAlkanePtru catalyst

The invention discloses a supported PtZn intermetallic alloy catalyst as well as a preparation method and an application thereof. The SiO2 is used as a carrier of the catalyst, Zn is used as an assistant of the catalyst, and a small amount of active component Pt is loaded; wherein the mass percentage content of Pt is 0.025%-1%, and the mass percentage content of Zn is 0.025%-1.7%; during preparation, a co-impregnation method is adopted, the SiO2 carrier is impregnated in an aqueous solution of chloroplatinic acid and zinc nitrate, the PtZn / SiO2 catalyst is obtained after drying and high-temperature reduction, and the catalyst has high activity, high stability, low price and low toxicity. The catalyst disclosed by the invention is suitable for a reaction for preparing olefin by dehydrogenating low-chain alkane, particularly for preparing propylene by dehydrogenating propane in a hydrogen atmosphere, has very high dehydrogenation activity under a high-temperature condition, has good stability, low Pt consumption and high utilization rate, and is cheaper than an industrial Pt catalyst, and the propylene selectivity can reach 90% or above.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com