Mold for injection molding, and manufacturing method for rubber product molded by using same

A technology of injection molding and mold, which is applied in the field of rubber product manufacturing, can solve problems such as inability to take out, lower productivity, rubber G1 residue, etc., and achieve the effect of suppressing residue and suppressing fracture

Inactive Publication Date: 2013-09-11

SUMITOMO RUBBER IND LTD

View PDF5 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] However, in the case of the rubber product W, there is a problem that when the rubber product W is removed from the mold A, the exposed rubber g breaks at the root j of the sprue portion b1, and the rubber in the sprue portion b1 g1 remains on the mold side and cannot be taken out

In addition, the rubber g1 remaining in the sprue part b1 becomes a cause of a decrease in productivity, such as the inability to perform continuous automatic molding, so it must be removed.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0065] In order to confirm the effect of the present invention, according to the specifications of Table 1, a prototype was formed as figure 1 A mold for injection molding with the structure shown is shown, and 240 rubber rollers for copying machines were formed using this trial mold.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Login to View More

Abstract

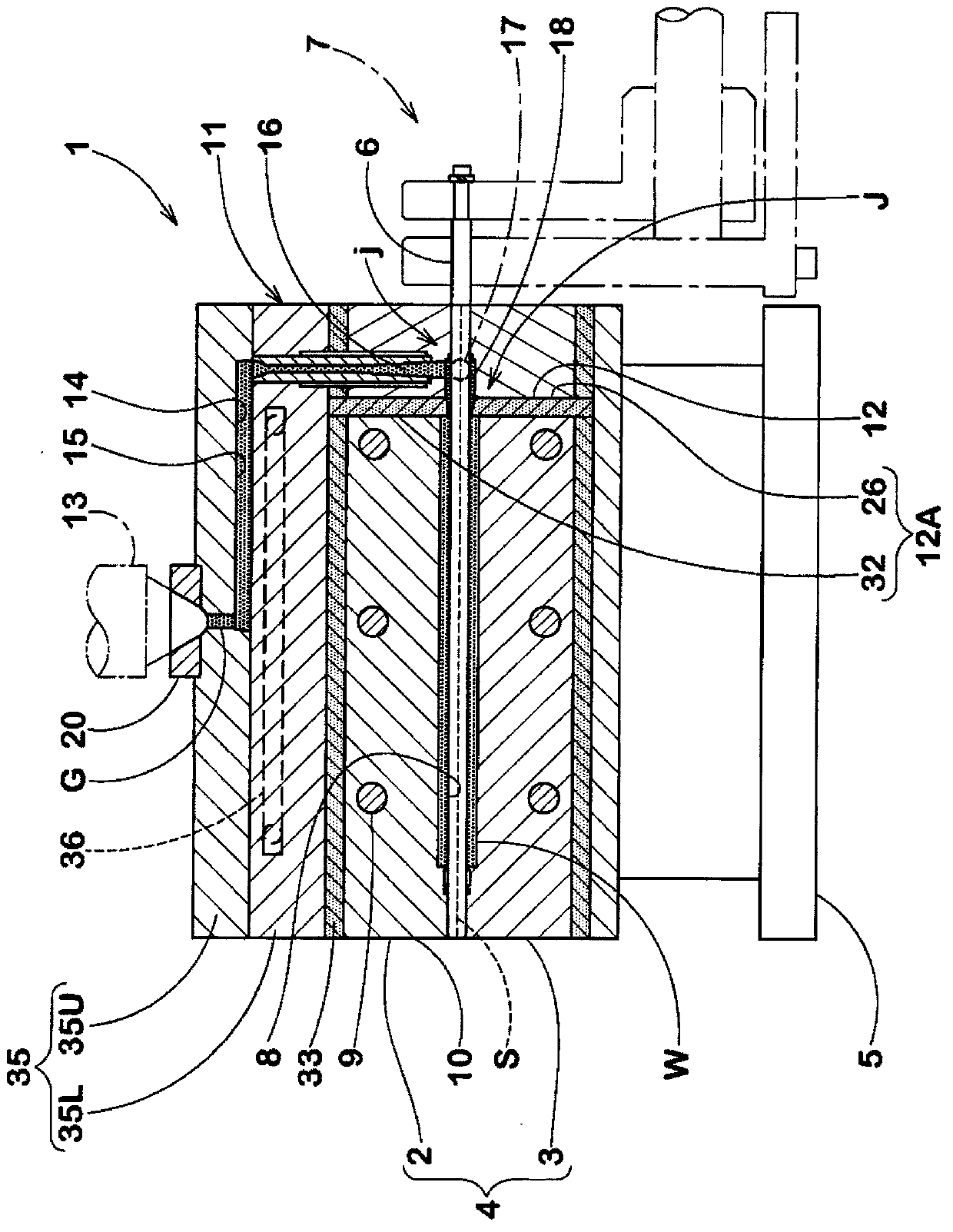

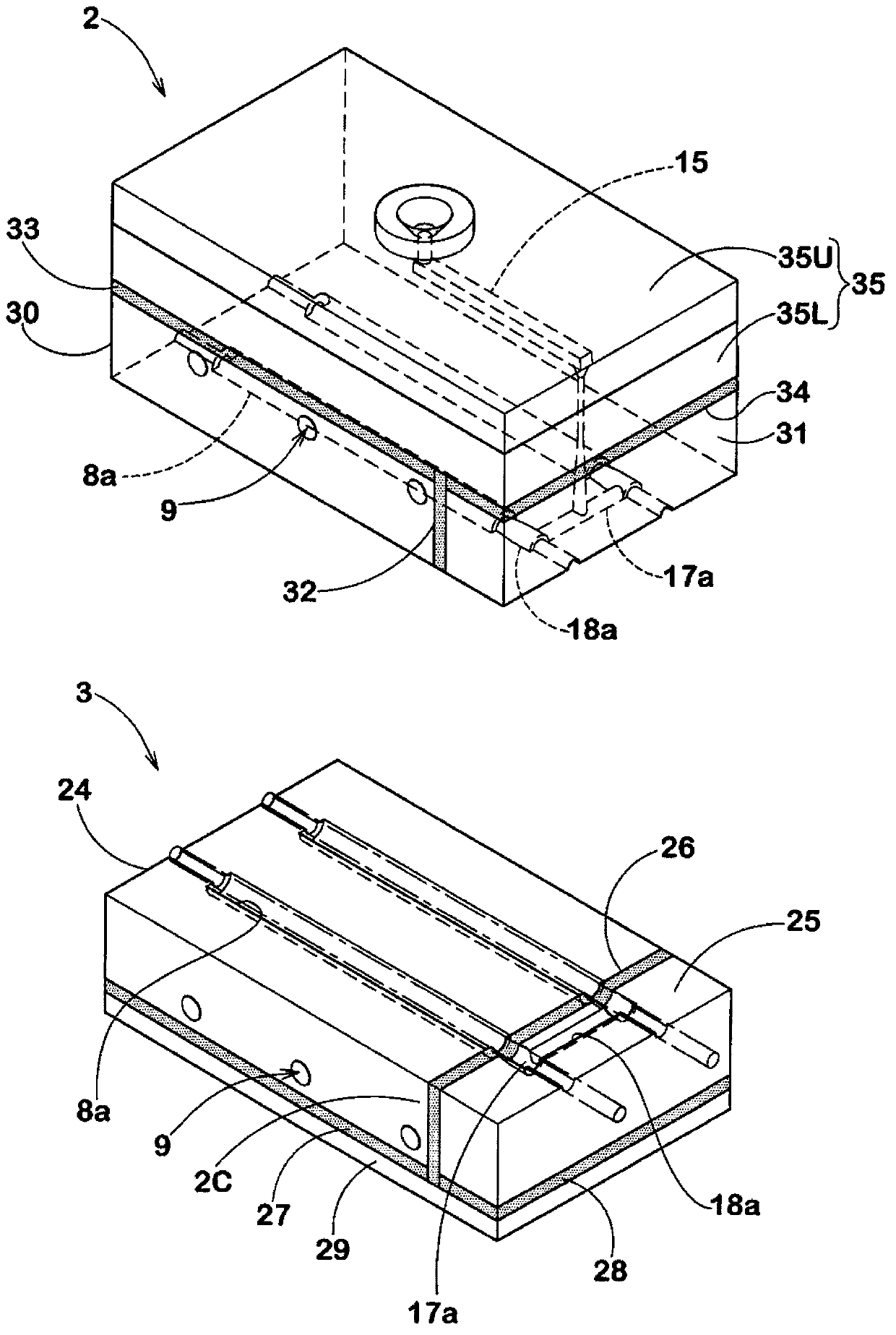

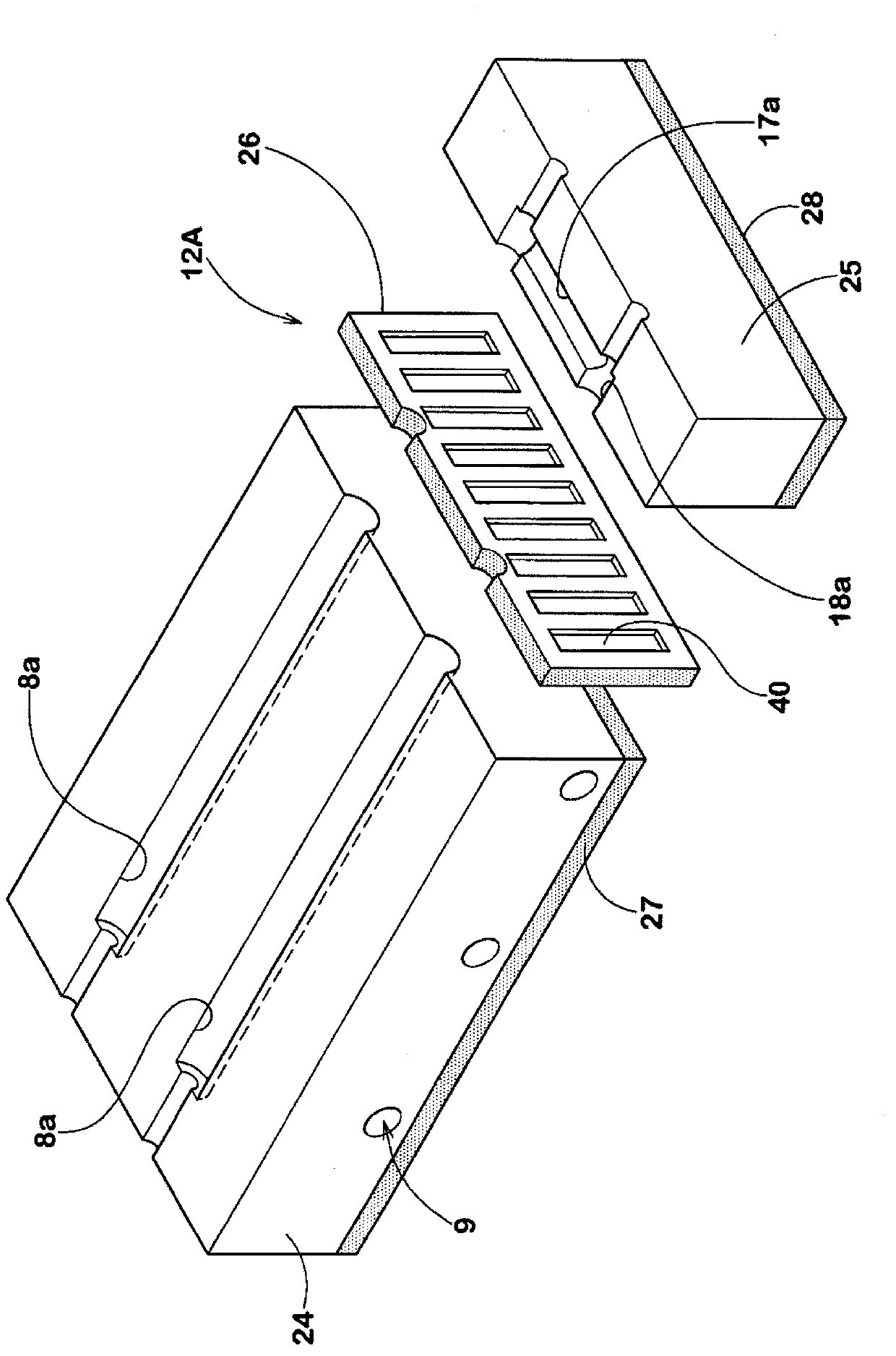

The present invention provides a mold for injection molding, and a manufacturing method for a rubber product molded by using the same. The mold can prevent rubber in a sprue portion from fracturing at the root of the rubber and residing in the sprue portion. A mold main body is divided into a product forming region and a rubber material feeding region, wherein the product forming region is provided with a mold cavity for forming the rubber product and a heater for heating and vulcanizing the rubber materials in the mold cavity; and the rubber material feeding region is provided with a rubber feeding flow path comprising a cooling runner portion, a sprue portion and a pouring gate portion. A thermal baffle plate is disposed between the product forming region and the rubber material feeding region. The thermal baffle plate inhibits the temperature of the rubber materials in the sprue portion, the runner portion and the pouring gate portion from increasing.

Description

technical field [0001] The present invention relates to a mold for injection molding that prevents the rubber in the sprue portion exposed from the rubber product from being broken at its root and remaining in the sprue portion (inside the mold) when the rubber product is removed from the mold, and a method using the mold Methods of manufacture of rubber products. Background technique [0002] E.g Figure 7 As shown in (A) and (B), in the injection mold A for injection molding the rubber product W, the rubber material is filled in the cavity c for forming the rubber product through the rubber supply flow path b, and the rubber material The supply channel b includes a cold runner (not shown), a sprue b1 , a runner b2 , and a gate b3 . Furthermore, the filled rubber material is heated and vulcanized in the cavity c, whereby the rubber product W is formed. [0003] Here, when the rubber product W is removed from the mold A, in order to make the rubber g in the sprue portion b...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B29C45/26B29C45/27B29C45/73B29C35/02B29C45/38B29K21/00

Inventor 吉里成弘

Owner SUMITOMO RUBBER IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com