Method for modifying surface of ultrafiltration membrane

A surface modification, ultrafiltration membrane technology, applied in ultrafiltration, chemical instruments and methods, membrane technology, etc., can solve problems such as increasing operation difficulty and production cost, membrane fouling, affecting membrane separation performance and service life, etc. Improved hydrophilicity and chargeability, easy and safe operation, and improved contamination resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

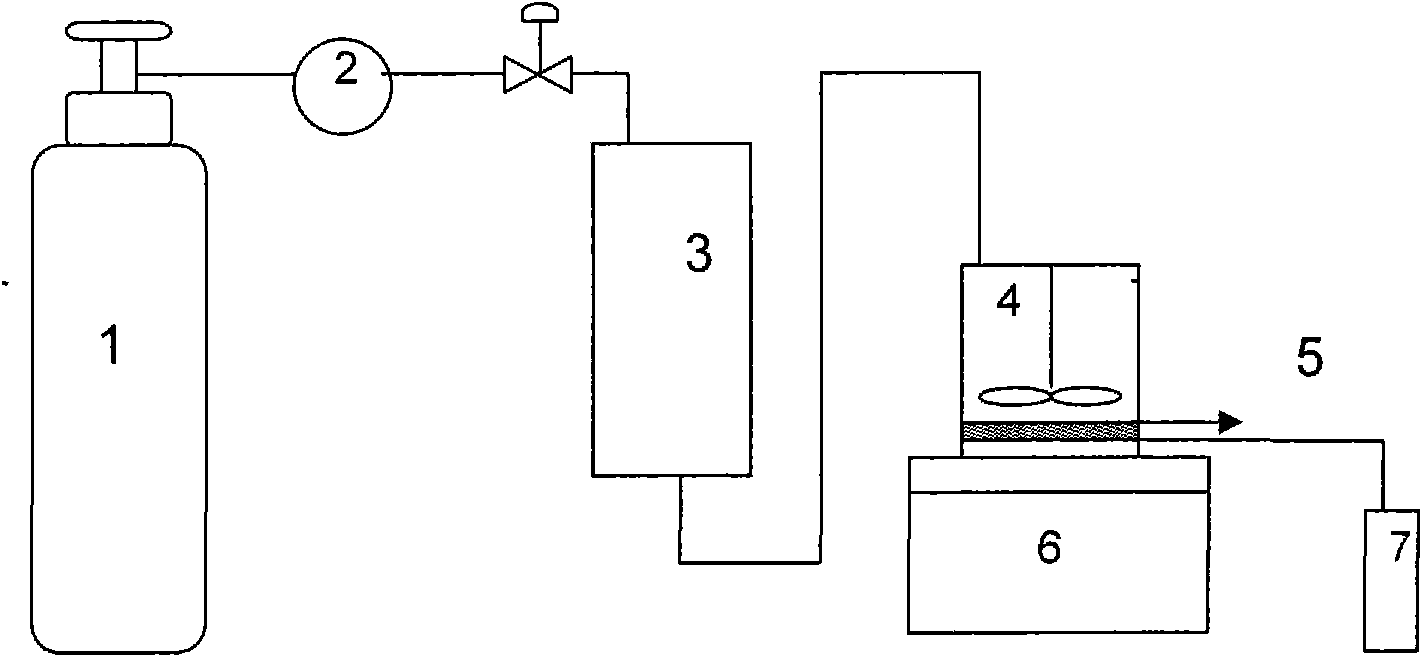

Method used

Image

Examples

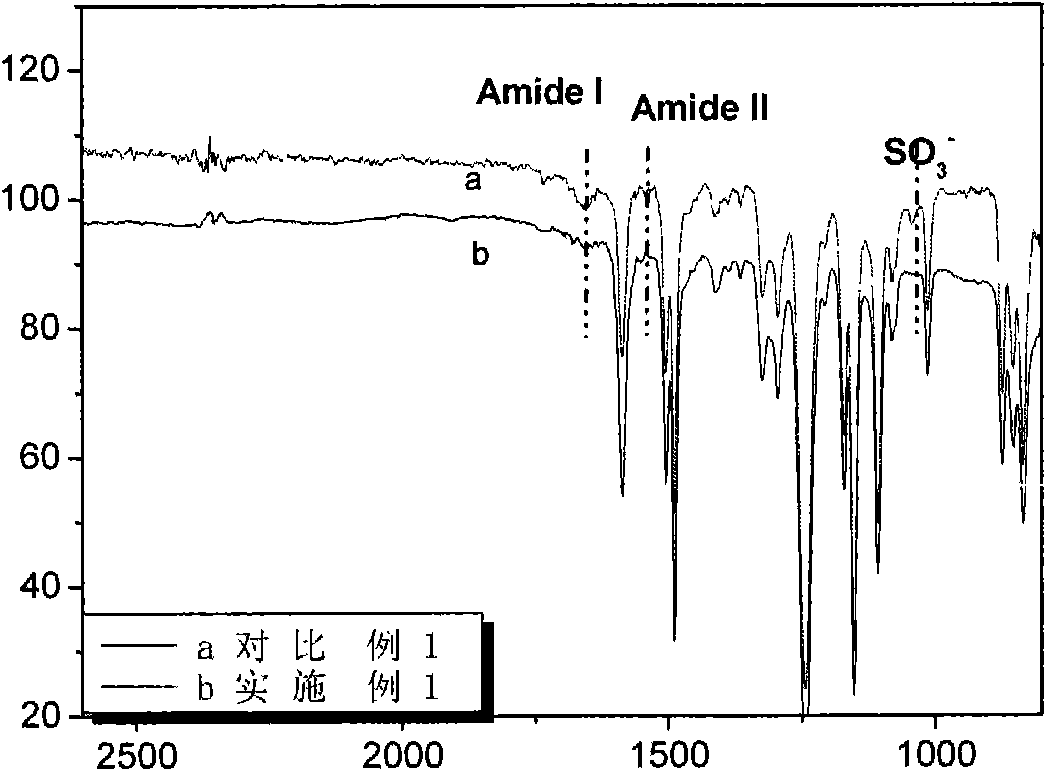

Embodiment 1

[0033] Add 15g of polysulfone and 6g of polyethylene glycol 600 to 79g of DMAc, at 80°C, mechanically stir for 12 hours to make a casting solution, filter, scrape the film on a clean glass plate after defoaming, and gel in deionized water Produce ultrafiltration membranes.

[0034] Soak the polysulfone flat ultrafiltration membrane in 0.04mol / L benzophenone ethanol solution for 30min, take out the ultrafiltration membrane and soak it in 40g / L SPP aqueous solution, irradiate with 312nm ultraviolet light for 30min in a nitrogen atmosphere, take out the ultrafiltration membrane The contamination resistance test was carried out after the filter membrane was cleaned.

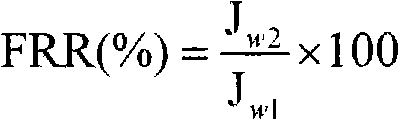

[0035] The flow recovery rate of the modified membrane is 90.5%, and the rejection rate of BSA is above 97%.

Embodiment 2

[0037]Add 15g of polysulfone and 6g of polyethylene glycol 600 into 79g of DMAc, at 80°C, mechanically stir for 12 hours to make a casting solution, filter, and perform dry-wet spinning after defoaming, and gel in deionized water. ultrafiltration membrane.

[0038] Soak the polysulfone hollow fiber ultrafiltration membrane in 0.04mol / L benzophenone ethanol solution for 30min, take out the ultrafiltration membrane and soak it in 40g / L DMMSA aqueous solution, and irradiate it with 312nm ultraviolet light for 30min under nitrogen atmosphere, then The hydrophilic monomer solution was replaced and the hollow fiber membrane was turned over, and then irradiated with ultraviolet light for 30 minutes under nitrogen atmosphere again. After the ultrafiltration membrane was taken out and cleaned, the pollution resistance test was carried out.

[0039] The flow recovery rate of the modified membrane is 89.5%, and the rejection rate of BSA is above 96%.

Embodiment 3

[0041] Add 15g of polysulfone and 6g of polyethylene glycol 1000 to 79g of DMAc, at 80°C, mechanically stir for 12 hours to make a casting solution, filter, scrape the film on a clean glass plate after defoaming, and gel in deionized water Produce ultrafiltration membranes.

[0042] Soak the polysulfone flat ultrafiltration membrane in 0.2mol / L benzophenone ethanol solution for 30min, take out the ultrafiltration membrane and soak it in 10g / L PEGA aqueous solution, irradiate with 312nm ultraviolet light for 40min under nitrogen atmosphere, take out the ultrafiltration membrane The contamination resistance test was carried out after the filter membrane was cleaned.

[0043] The flow recovery rate of the modified membrane is 85.5%, and the rejection rate of BSA is above 97%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com