Preparation method of 1D Sb2S3 nanorod/3D ZnIn2S4 composite structure

A composite structure and nanorod technology, applied in catalyst activation/preparation, nanotechnology, nanotechnology, etc., can solve undiscovered problems, achieve mild and easy-to-control reaction conditions, abundant raw material sources, and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

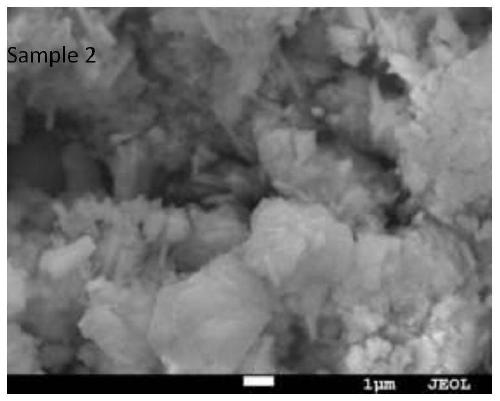

[0026] (1) Weigh SbCl at a molar ratio of 0.3:0.6:0.6 3 , Na 2 S·9H 2 O and L-cysteine were dissolved in 15 mL of deionized water, stirred ultrasonically for 3 hours to obtain a uniform dispersion, and then transferred to a reaction kettle for hydrothermal reaction at a temperature of 100°C for 18 hours. to room temperature, washed and dried to collect samples to obtain one-dimensional Sb 2 S 3 Nano stave;

[0027] (2) Weigh 0.0026g Sb 2 S 3 The nanorods were added to 20 mL of deionized water, ultrasonically dispersed for 5 min to obtain a light black dispersion, and then 0.075 g of CTAB (cetyltrimethylammonium bromide) was added, stirred for 10 min to obtain a mixed solution, and then 0.3 g of CTAB was added thereto. :0.5:1.5 molar ratio of Zn(CH 3 COO) 2 2H 2 O, InCl 3 4H 2 O and TAA (thioacetamide), stirred until dissolved, and finally carried out hydrothermal reaction at 100°C for 2 hours to obtain 1D Sb 2 S 3 Nanorod / 3DZnIn 2 S 4 Composite structure. whe...

example 2

[0030] (1) Weigh SbCl at a molar ratio of 0.5:1:1 3 , Na 2 S·9H 2 O and L-cysteine were dissolved in 25mL of deionized water, and stirred ultrasonically for 4 hours to obtain a uniform dispersion, which was then transferred to a reaction kettle for hydrothermal reaction at 120°C for 24 hours. to room temperature, washed and dried to collect samples to obtain one-dimensional Sb 2 S 3 Nano stave;

[0031] (2) Weigh 0.0106g Sb 2 S 3 Add the nanorods into 35mL of deionized water, ultrasonically disperse for 15min to obtain a light black dispersion, then add, for example, 0.15g CTAB (cetyltrimethylammonium bromide), stir for 15min to obtain a mixed solution, and then add 0.6 :1:3 molar ratio of Zn(CH 3 COO) 2 2H 2 O, InCl 3 4H 2 O and TAA (thioacetamide), stirred until dissolved, and finally carried out hydrothermal reaction at 120 ° C for 3 hours to obtain 1D Sb 2 S 3 Nanorod / 3D ZnIn 2 S 4 Composite structure. where Sb 2 S 3 The mass percentage in the composite...

example 3

[0035] (1) Weigh SbCl at a molar ratio of 0.6:1.2:1.2 3 , Na 2 S·9H 2 O and L-cysteine were dissolved in 40mL of deionized water, stirred ultrasonically for 4 hours to obtain a uniform dispersion, and then transferred to a reaction kettle for hydrothermal reaction at a temperature of 140°C for 28 hours. to room temperature, washed and dried to collect samples to obtain one-dimensional Sb 2 S 3 Nano stave;

[0036] (2) Weigh 0.0324g Sb 2 S 3 Nanorods were added to 40mL of deionized water, ultrasonically dispersed for 20min to obtain a light black dispersion, then 0.3g CTAB (cetyltrimethylammonium bromide) was added, stirred for 20min to obtain a mixed solution, and then 1.2 :2:6 molar ratio of Zn(CH 3 COO) 2 2H 2 O, InCl 3 4H 2 O and TAA (thioacetamide), stirred until dissolved, and finally carried out hydrothermal reaction at 140 °C for 4 hours to obtain 1D Sb 2 S 3 Nanorod / 3D ZnIn 2 S 4 Composite structure. where Sb 2 S 3 The mass percentage in the composi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com