Method for producing potato flake with high dietary fiber content

A technology of high dietary fiber and potato whole powder, applied in food preparation, food science, application, etc., can solve problems such as perishable deterioration, inhibition of enthusiasm and motivation, and difficulty in removing water, so as to alleviate the damage of color and flavor, Good economic and social benefits, reduce the effect of diffusion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

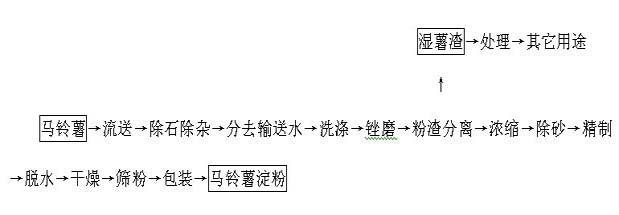

Image

Examples

Embodiment 1

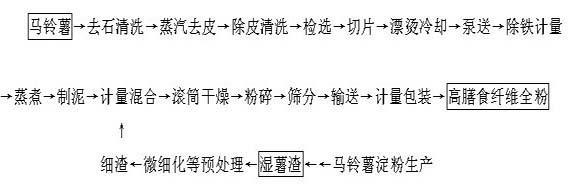

[0050] Such as figure 2 Shown, the production process of the potato powder of high potato dietary fiber content of the present invention, comprises the following steps:

[0051] (1) Destone and clean the potatoes, and steam peel them: send them into a steam peeler, and the potato skins will burst open through the instantaneous action of 1.2MPa steam in the peeler, and then removed by a dry peeler and a washing machine. Skin dregs are sent to the conveyor belt for manual inspection immediately, and potato slices that are not suitable for processing due to mildew, green, low peeling rate, mechanical damage or other diseases are removed; in a standardized slicer, the potatoes are cut into The 10mm thick slices are continuously sprayed with water through the sprinklers installed on the conveying line to keep the surface of the potatoes moist. Put the potato chips into the blanching machine, after blanching at 65°C for 15 minutes, wash the precooked potato chips with cold water t...

Embodiment 2

[0057] The production method of the whole potato powder of high potato dietary fiber content comprises the following steps:

[0058] (1) Destone and clean the potatoes, and steam peel them: send them into a steam peeler, and the potato skins will burst open through the instantaneous action of 1.6MPa steam in the peeler, and then removed by a dry peeler and a washing machine. Skin dregs are sent to the conveyor belt for manual inspection immediately, and potato slices that are not suitable for processing due to mildew, green, low peeling rate, mechanical damage or other diseases are removed; in a standardized slicer, the potatoes are cut into The 15mm thick slices are continuously sprayed with water through the sprinklers installed on the conveying line to keep the surface of the potatoes moist. Send the potato chips into the blanching machine, after blanching at 75°C for 25 minutes, then wash the precooked potato chips with cold water, so that the center temperature of the pot...

Embodiment 3

[0064] The production method of the whole potato powder of high potato dietary fiber content comprises the following steps:

[0065] (1) Destone and clean the potatoes, and steam peel them: send them into a steam peeler, and the potato skins will burst open through the instantaneous action of 1.2MPa steam in the peeler, and then removed by a dry peeler and a washing machine. Skin dregs are sent to the conveyor belt for manual inspection immediately, and potato slices that are not suitable for processing due to mildew, green, low peeling rate, mechanical damage or other diseases are removed; in a standardized slicer, the potatoes are cut into The 10mm thick slices are continuously sprayed with water through the sprinklers installed on the conveying line to keep the surface of the potatoes moist. Put the potato chips into the blanching machine, after blanching at 65°C for 15 minutes, wash the precooked potato chips with cold water to lower the center temperature of the potato chip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com