Patents

Literature

458 results about "Retting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Retting is a process employing the action of micro-organisms and moisture on plants to dissolve or rot away much of the cellular tissues and pectins surrounding bast-fibre bundles, and so facilitating separation of the fibre from the stem. It is used in the production of fibre from plant materials such as flax and hemp stalks and coir from coconut husks.

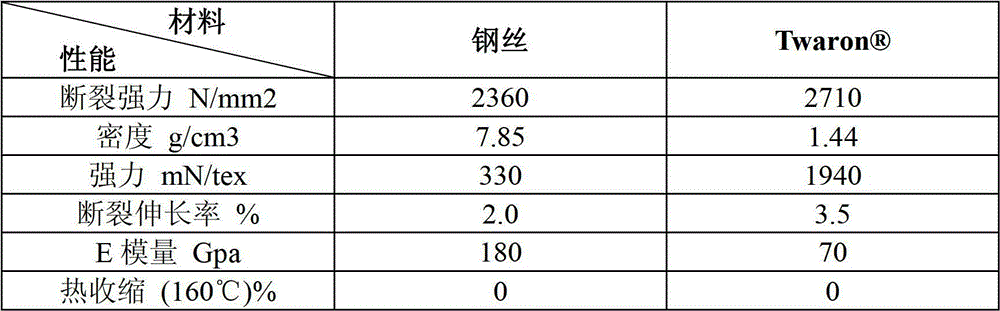

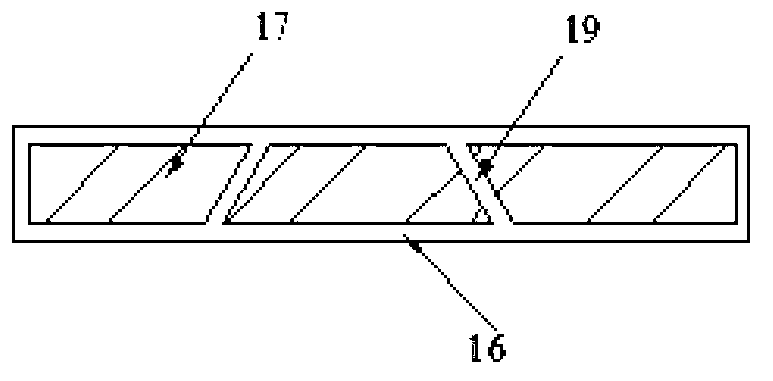

Energy-saving high strength aramid fiber conveyer belt and preparation method thereof

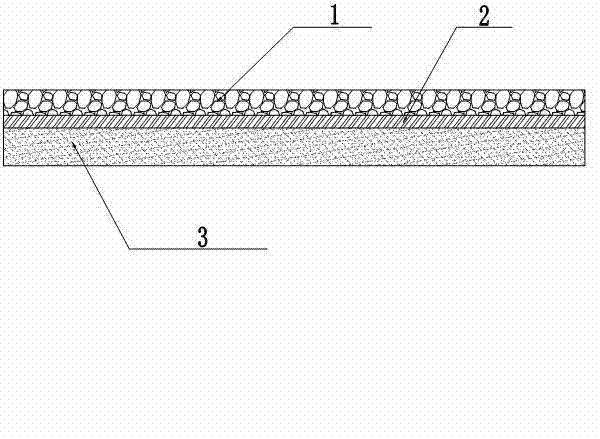

The invention relates to an energy-saving high strength aramid fiber conveyer belt and a preparation method thereof. The conveyer belt is composed of a skeleton layer, adhesive glue and an upper-lower cover adhesive laminated structure. Firstly, the skeleton layer employs aramid fiber canvas after dipping treatment to replace a conventional steel wire rope, so that the problems of large weight of the steel wire rope which brings much inconvenience for processes of shaping, installing, maintaining and the like is solved. Secondly, the aramid fiber canvas has structure in broadwise direction, has excellent anti-tear and anti-impact performances, so that phenomena of longitudinal tear and the like of the steel wire rope conveyer belt cab be prevented. Compared with a conventional steel wire rope high strength conveyer belt, the energy-saving high strength aramid fiber conveyer belt has high strength, good corrosion resistance, wear resistance and impact and fatigue resistance, and greatly reduce the weight and thickness of the conveyor belt, so that conveying power energy consumption is saved. The energy-saving high strength aramid fiber conveyer belt is expected to have longer service life and better energy-saving and environment-friendly properties, and is particularly suitable for long-distance material conveyance in industries such as coal mine, metallurgy, mine, etc.

Owner:WUXI BOTON TECH CO LTD +1

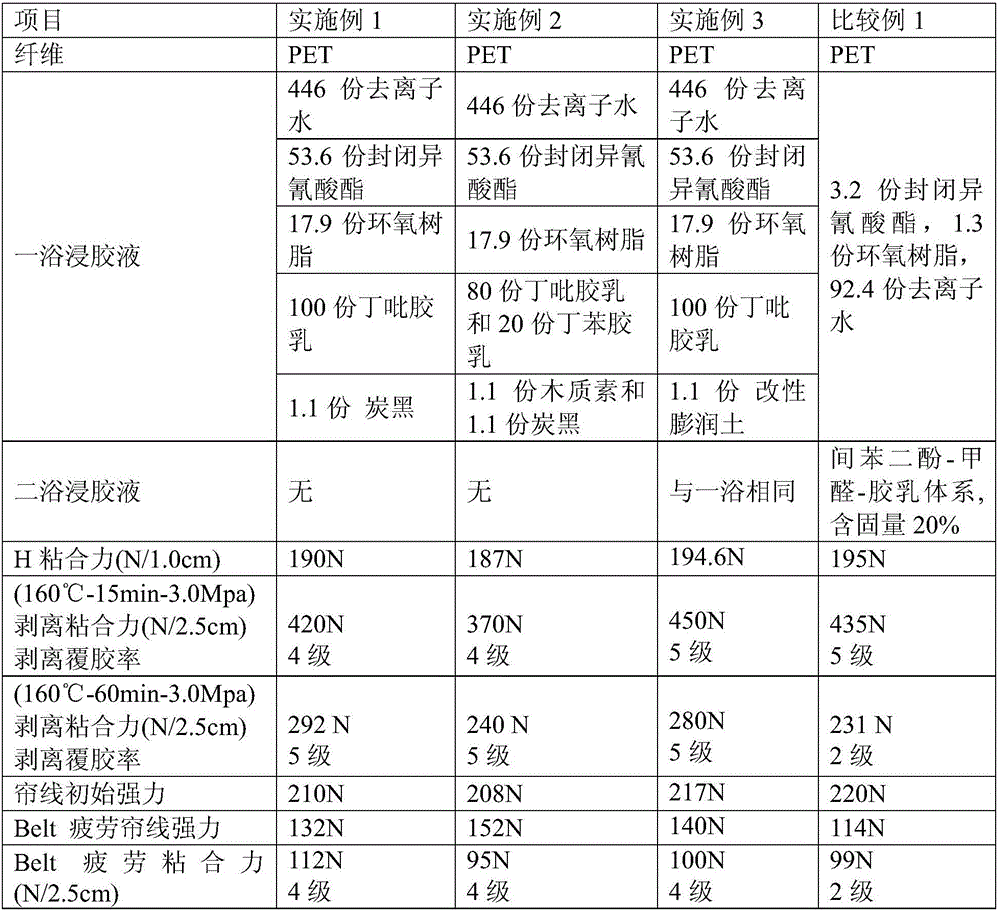

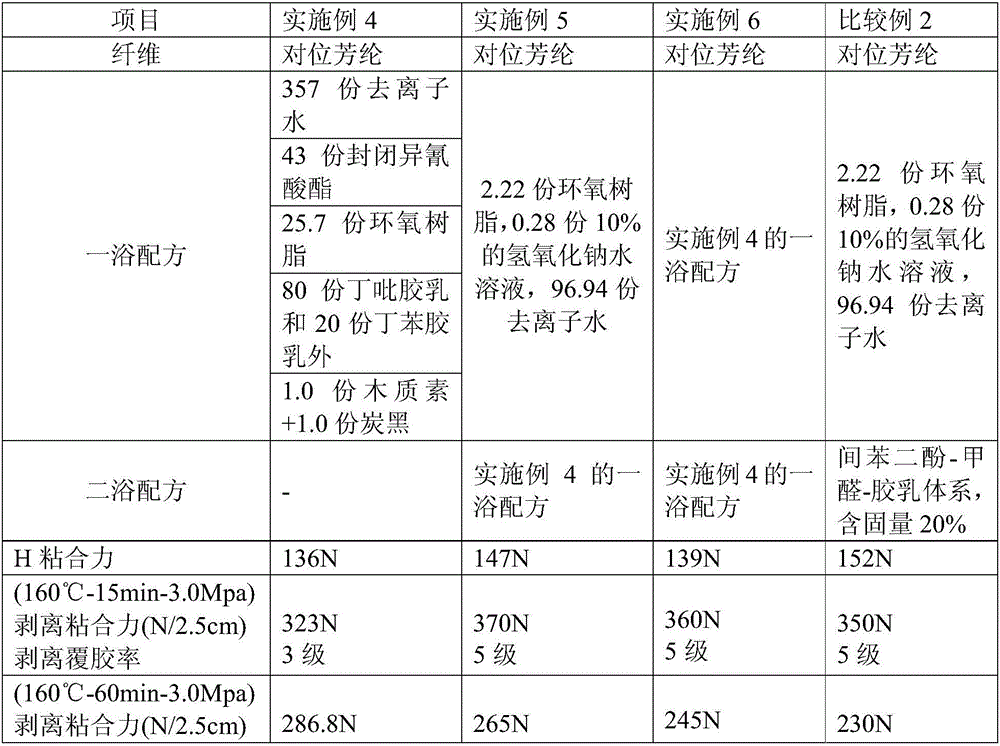

Environment-friendly fiber framework material dip solution and dipping process

The invention relates to an environment-friendly fiber framework material dip solution and a dipping process. The dip solution comprises, by weight parts, 3.3-190 parts of blocked isocyanate compound by dry weight, 6.6-140 parts of epoxy compound by dry weight, 80-100 parts of rubber latex by dry weight, 0.5-20 parts of rubber modifier by dry weight, and the balance water. The content of the dip solution is 5-25%, and a one-bath or double-bath dipping process is adopted to perform coating on a fiber framework material. The dip solution does not contain harmful substances such as resorcinol and formaldehyde and does not cause pollution to the environment, the dipping process is simple in steps and easy to operate, an organic fiber after dipping treatment is low in rigidity and facilitates postprocessing, and the dip solution has a good effect of being bonded to rubber and has a better dipping effect than conventional RFL.

Owner:JIANGSU TAIJI IND NEW MATERIALS CO LTD

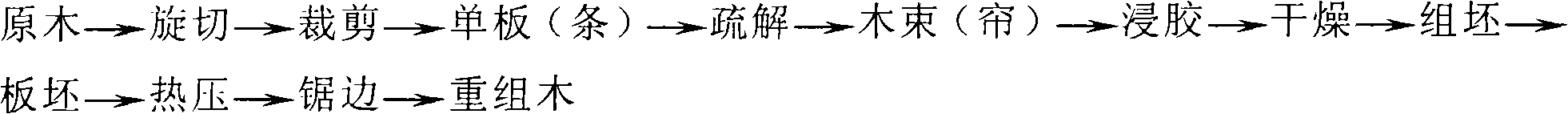

Recombination wood and manufacturing method thereof

ActiveCN101357470AEfficient use ofIncrease productivityAldehyde/ketone condensation polymer adhesivesFlat articlesPulp and paper industryMechanical property

The invention provides a method for manufacturing reconstituted wood. Rotary cut is carried out on the raw wood for preparing a veneer or a veneer strip, defibering is carried out on the veneer, the forming points and / or wood bunch shades or wood bunches of striation crack are formed along the natural texture of wood on the veneer, then dipping, drying and hot pressing for molding the reconstituted wood are carried out. Compared with the prior art, the method of the invention solves the problem that wood bunch is irregular; the rate of utilizing wood and production efficiency of wood bunch are improved; defibering process is simplified and energy consumption for defibering is lowered. The process facilitates the cracks on the wood bunch shades and wood bunches to be very even and facilitates the dipping of wood bunch shades or wood bunches to be very even in the following dipping process; the product problems such as warp, deformation, jump fibre, and the like, are overcome, which are aroused by uneven defibering in making wood bunches from raw wood directly in the prior art, and the boards that the surface is very smooth, the mechanical performances such as stiffness and intensity, and the like, are higher than the raw material itself are made, therefore the fast-growing forest wood with worse performances and wider source can be made into the products of reconstituted wood which can compare beauty with noble hardwood.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

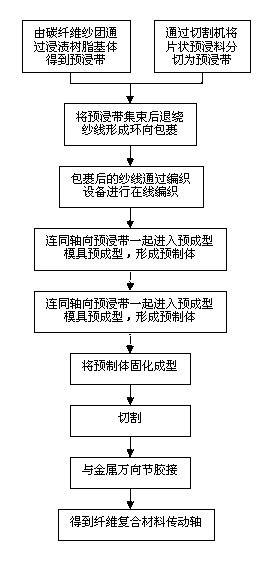

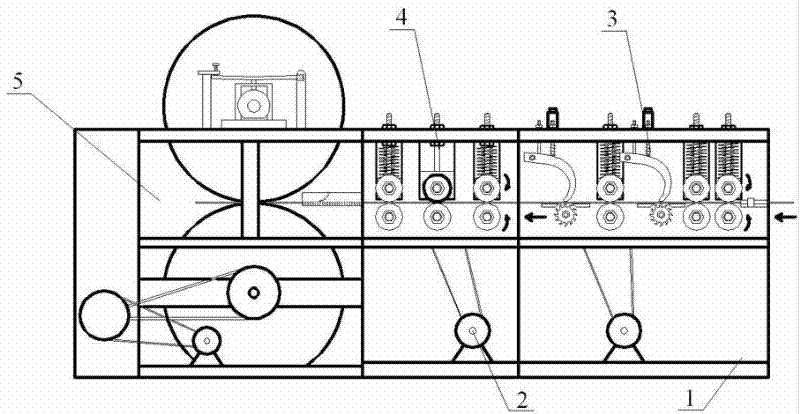

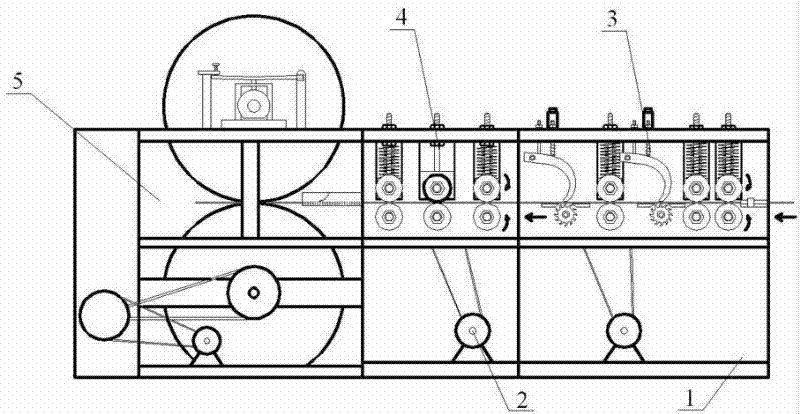

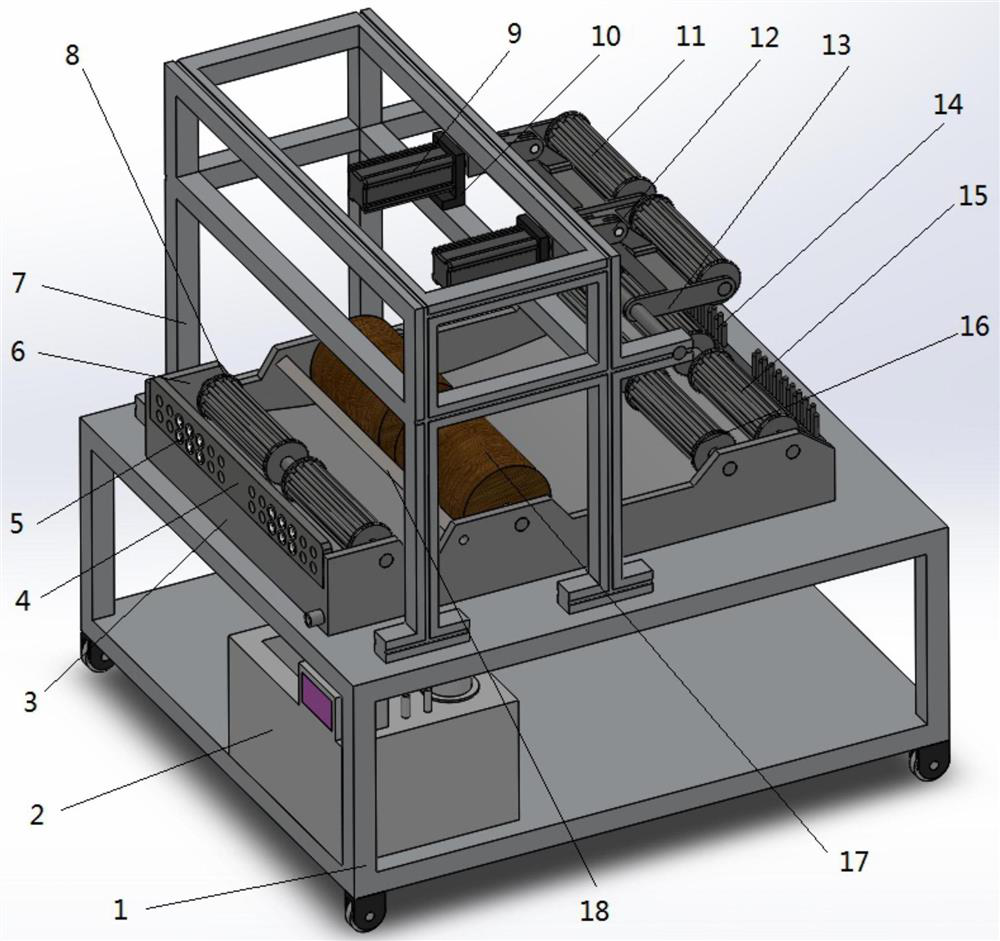

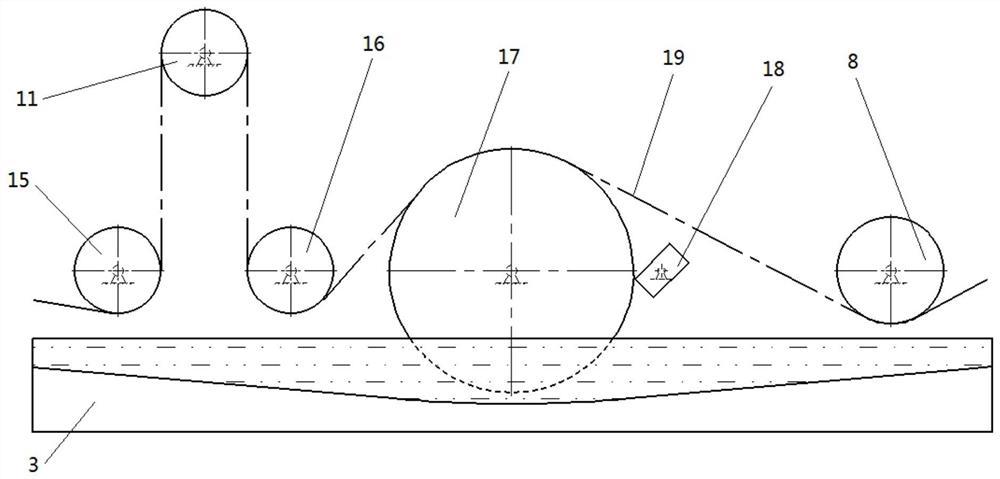

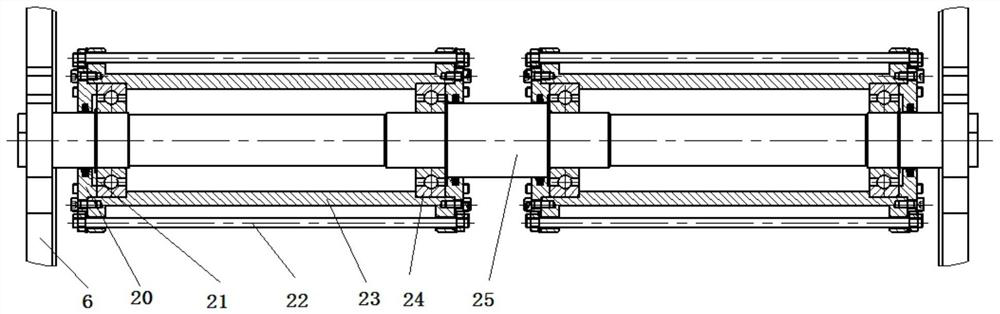

Continuous pultrusion manufacturing method and production device for fibrous composite drive shaft

The invention provides a continuous pultrusion manufacturing method for a fibrous composite drive shaft. The continuous pultrusion manufacturing method comprises the following steps: preparing a pre-dipping belt, pre-forming a mould, curing and forming, and mechanically processing. A production device for the fibrous composite drive shaft comprises a yarn creel, a pre-forming mould, a curing and forming mould, a traction mechanism and a cutting mechanism, wherein the yarn creel and the pre-forming mould are provided with a winding and braiding mechanism respectively; the winding and braiding mechanism comprises a yarn collecting plate, an annular winding disc and at least one braiding roller which are arranged in sequence; and an infrared heater is also arranged between the braiding roller and the pre-forming mould. According to the invention, a rod piece of a drive shaft can be directly subjected to pultrusion through a mould without the traditional gum dipping process and is cut and gummed so as to finish the production of the fibrous composite drive shaft, so that the production cost of the fibrous composite drive shaft is reduced, and meanwhile, the defects of difficultly controlled gum content and high gum waste in the traditional gum dipping process, easily damaged fibers and the like are avoided, and the production quality is improved.

Owner:HENGSHEN

Manufacturing method of bamboo-wood composite laminated timber

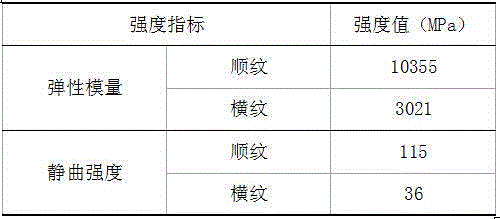

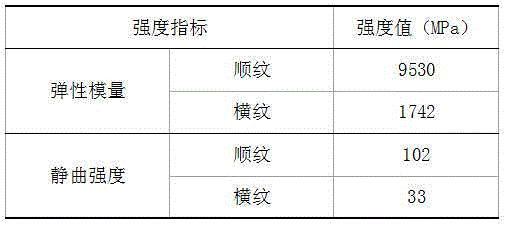

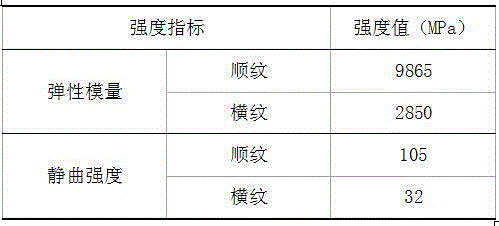

InactiveCN105196368AImprove longitudinal strengthReduce horizontalCane mechanical workingWood veneer joiningComposite laminatesFiber array

The invention provides a manufacturing method of a bamboo-wood composite laminated timber and belongs to the technical field of bamboo-wood processing. The manufacturing method comprises the following process steps: (1) preparing raw materials; (2) drying; (3) braiding bamboo bundles; (4) immersing in glue; (5) drying; (6) assembling; (7) prepressing; (8) hot pressing; and (9) ageing. Compared with a traditional process for manufacturing recombined bamboo by adopting a mold pressing manner, mechanization is realized in a manufacturing process of a bamboo bundle single board; the spreading of a plate blank is similar with the spreading of a plywood; and compared with the spreading of a recombined bamboo plate blank, the spreading is relatively simple, and the production efficiency is relatively high. Meanwhile, a traditional recombined bamboo product has the same fiber array direction so that the longitudinal strength of the product is remarkably higher than transverse strength. According to the bamboo-wood composite material manufactured by the manufacturing method, the method is carried out by symmetrically assembling the bamboo bundle single board and a wood single board, so that the difference of the transverse strength and the longitudinal strength of the material is reduced and the transverse strength is remarkably improved.

Owner:国家林业局竹子研究开发中心 +1

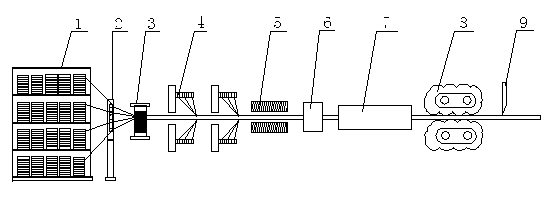

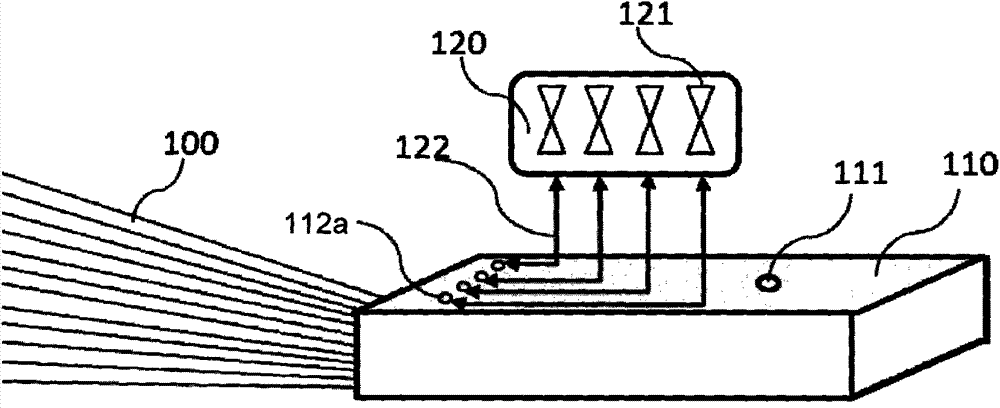

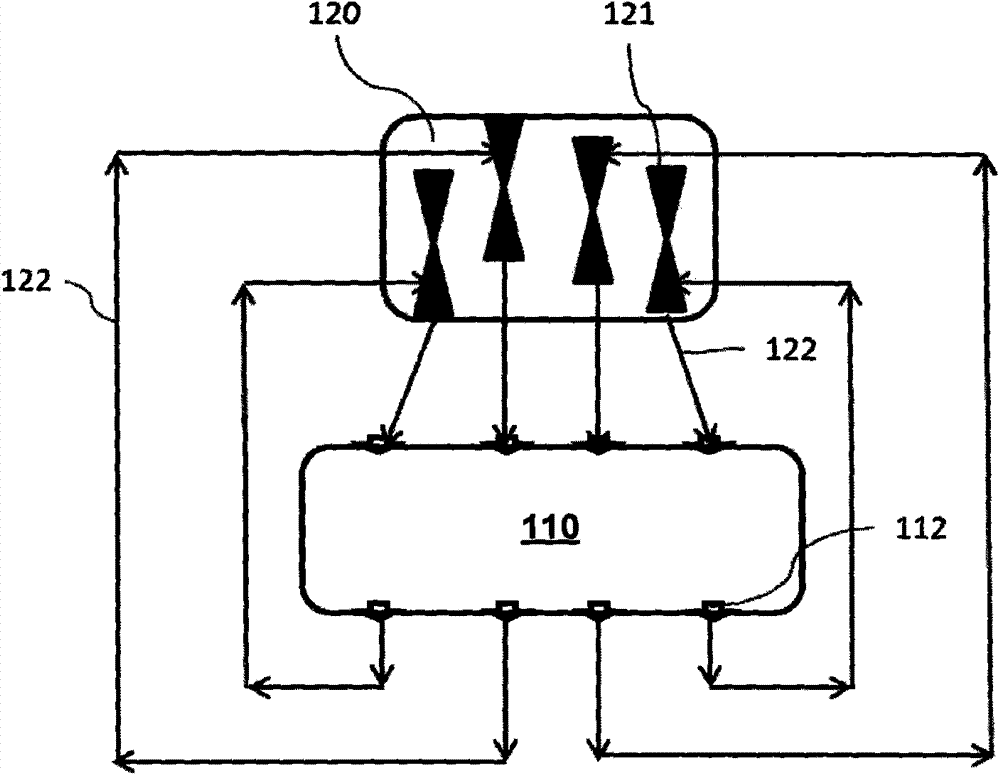

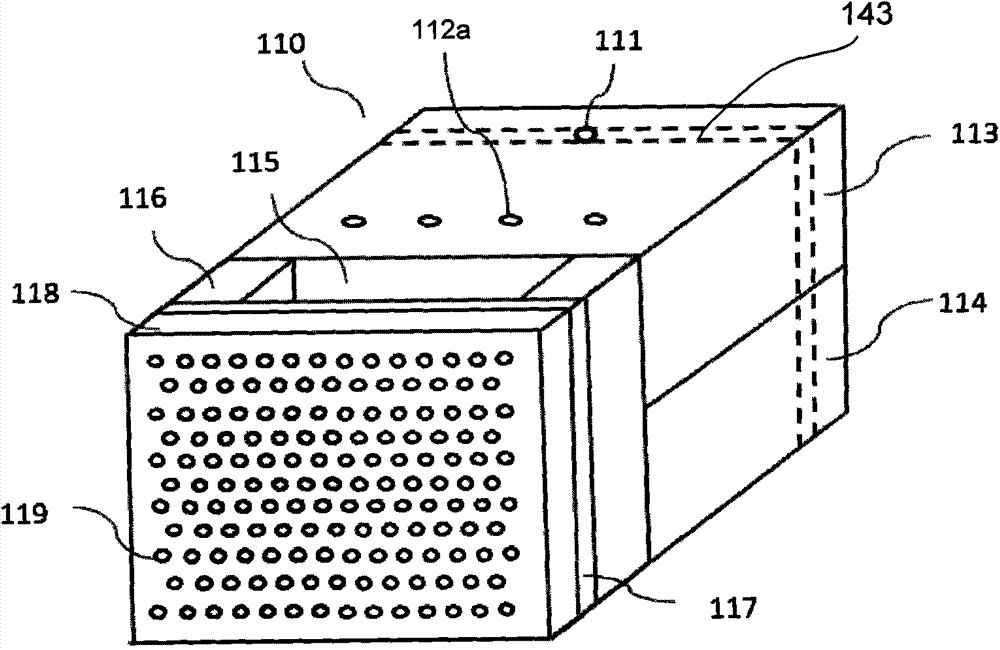

Multi-pipeline pump driving type fiber impregnation system

ActiveCN104742274AChange the unfavorable situationRaise the exhaustCoatingsPeristaltic pumpDiaphragm pump

The invention relates to a fiber impregnation system. The fiber impregnation system comprises a fiber impregnation box (110) and a driving pump (120) connected with the fiber impregnation box (110) by one or more refluxing hoses (122), wherein the refluxing hoses (122-1, 122-2 and 122-3) are used for recycling resin from the fiber impregnation box and refilling the fiber impregnation box with the resin under the driving action of the driving pump; and preferentially, the driving pump (120) is a peristaltic pump or a diaphragm pump. Besides, the invention also relates to equipment for performing pultrusion on fibers (100) to obtain a section material (200) by use of the fiber impregnation box. According to the fiber impregnation system, the fiber impregnation box and the peristaltic pump provided with at least one pump head are combined, and the quantity of pumps, pump heads and pipelines is increased as required by production and processing, thus, the fiber impregnation box is not required to be closely connected with a corresponding molding and solidifying device, and a yarn guiding plate can be arranged in the fiber impregnation box; and the fiber impregnation box and the corresponding molding and solidifying device can be separable and vacuumizing operation is carried out, and thus, the fiber exhaust efficiency is improved.

Owner:COVESTRO DEUTSCHLAND AG

Continuous production equipment and continuous production technology of foam core composite material sandwich plate

The invention discloses continuous production equipment of a foam core composite material sandwich plate. The continuous production equipment is convenient to popularize, simple and easy to operate and high in production efficiency, and can realize the industrialized continuous production. The continuous production equipment comprises a foam forming device, a sandwich plate forming plate, a traction device and a cutting device which are connected in sequence, wherein the foam forming device comprises a feeding mixing system, an extrusion forming system and a heating cooling system; the sandwich plate forming device comprises a foam surface processing system, a core material primary positioning device, a fiber gum dipping device, a guiding mold and a heating mold; the foam surface processing system is connected with the heating cooling system of the foam forming device; the core material primary positioning device, the guiding mold and the heating mold are arranged in a running path of a core material in sequence; and the fiber gum dipping device and the heating device are arranged in a running path of composite material fibers in sequence. The invention further discloses a continuous production technology of the foam core composite material sandwich plate.

Owner:NANJING UNIV OF TECH

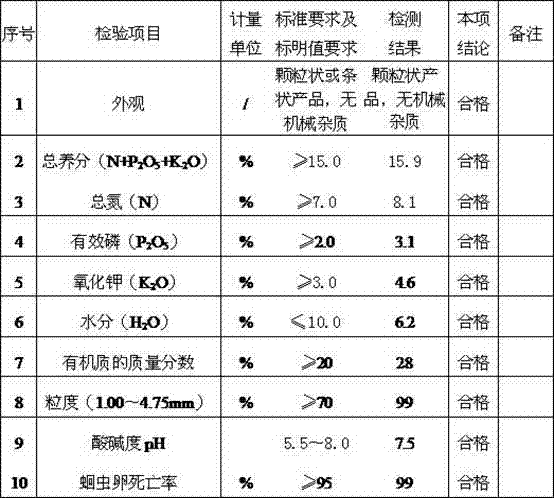

Organic-inorganic compound fertilizer produced by fermented material of traditional Chinese medicine decoction dregs and method thereof

InactiveCN102731195AMeet the design requirementsModernize operationsBio-organic fraction processingOrganic fertiliser preparationAdditive ingredientPhosphate

The invention relates to an organic-inorganic compound fertilizer which is produced by fermented material of traditional Chinese medicine decoction dregs and a method of the organic-inorganic compound fertilizer. The traditional Chinese medicine decoction dregs are taken as the main material; crude fiber degradation bacteria, turf or other plant fibers are added properly after drying and wetting processing for mixed retting fermentation to obtain semi-finished products of organic fertilizer of fermented material of traditional Chinese decoction dregs; monoammonium phosphate, ammonium sulfate, potassium chloride or potassium sulfate are added according to the needed content of nitrogen, phosphorus and potassium; and the materials are mixed evenly, pelleted and dried to obtain the finished product fertilizer. The fertilizer contains organic materials and inorganic materials of nitrogen, phosphorus and potassium and the content of the organic materials is more than 20%; nitrogen, phosphorus and potassium are rich in nutrient and the total nutrient content is more than 15%, so that the products are characterized by comprehensive nutritional ingredient, good effect, no pollution and the like. Fermented material of traditional Chinese medicine decoction dregs is adopted to produce the organic-inorganic compound fertilizer provided by the invention, so that the pollution to the environment by the decoction dregs is eliminated and the waste is recycled to realize the benefit of comprehensive development of environment friendliness, energy and fertilizer.

Owner:GUANGDONG FUERKANG CHEM TECH

Process for producing oxide dispersion strengthening ferrite type alloy by using chemical dipping method

InactiveCN1664145AAnnealing recrystallization temperature is lowUniform sizeSolution treatmentSolid solution

The present invention provides a dispersion strengthening method of ferrite alloy using oxide by chemical retting, which belongs to dispersion strengthening area of ferrite alloy using oxide and is adapt for fuel can in fast neutron breeder in nuclear energy domain. Placing master alloy powder in solution of Y(NO3)3.6H2O to soak, drying and heating the powder to get intensified phase of oxide, encasing disintegrating powder into jacket, sealing in vacuum, shaping with heat, forging and processing with solid solution treatment to get alloy of ODS that contains Y2O3 intensified phase. Invention realizes reasonable dispersion distribution of intensified phase Y2O3 of oxide. Ferrite alloy with rational adaption assistance, used as fuel can in nuclear energy fast reactor, has the properties of low plumping, low radioactivity, fine elevated temperature strength, few aeolotropism in cold working and low annealing recrystallization temperature. The invention can reduce the cost greatly and improve product quality.

Owner:UNIV OF SCI & TECH BEIJING

Biological organic fertilizer produced from fermented traditional Chinese medicine residue and method for producing fertilizer

InactiveCN102910976AModernize operationsLabor savingBio-organic fraction processingOrganic fertiliser preparationBiotechnologyWater Hyacinths

The invention relates to a biological organic fertilizer produced from fermented traditional Chinese medicine residue and a method for producing the fertilizer. The method comprises the following steps of: carrying out dry-wet treatment on the traditional Chinese medicine residue serving as a main raw material; then adding crude fiber degrading bacteria, water hyacinth, platycodon grandiflorum and other plant fiber or turf for mixed stack retting and fermentation, so as to prepare semi-finished fermented traditional Chinese medicine residue organic fertilizer; based on a dry material, preparing a finished product from 85-90wt% of semi-finished organic fertilizer and 10-15wt% of microbial active bacteria. The product not only contains organic materials and active effective bacteria, but also contains trace element inorganic components, wherein the content of the organic materials accounts for more than 25%; and the product has the characteristics of no pollution, no public hazard, scientific formula, rich nutrient, high efficiency and the like. According to the invention, the problem that medicine residue pollutes environment is solved, waste is turned into wealth, good benefits of environmental protection and comprehensive development and utilization of energy sources and fertilizers are realized, and the process technology has innovation, scientificity and advancement.

Owner:GUANGDONG FUERKANG CHEM TECH

Soil improvement method

InactiveCN103120050AImprove compactionImprove fertilityBio-organic fraction processingOrganic fertiliser preparationActive enzymeFeces

The invention provides a soil improvement method which is characterized by the following steps: strip ridges which are formed by stacking and retting of animal waste, straws, crop bran and the like are fermented, wherein the cross sections of the strip ridges are trapezoid, and fermented substrate is obtained; earthworms are bred so that earthworm waste is obtained, and the earthworm waste is separated, collected, dried and smashed; and the earthworm waste is spread, wherein the dosage of the spread earthworm waste is not less than 600 kg / mu. Due to the fact that the earthworm waste contains a lot of major elements, such as nitrogen, phosphorus and potassium, needed by plants, and is rich in 18 types of amino acid which is not contained in normal animal waste, 5 types of biological active enzyme and a lot of microelements such as copper, zinc, manganese, iron, selenium, calcium and magnesium, by means of the ion exchange theory and salt transformation theory, and by the mutual combination of a quick effect and a slow effect, soil hardening and physicochemical shape of salt and alkali can be improved, potential of hydrogen (pH) value and salt content can be reduced, fertility of soil can be improved, and alkali changing and fertility fostering are integrated. Due to the fact that the raw materials are wide in source, production cost is easy to control, the soil improvement effect is good, crops can grow very well and income of farmers can be improved.

Owner:TIANJIN JIAWO TECH

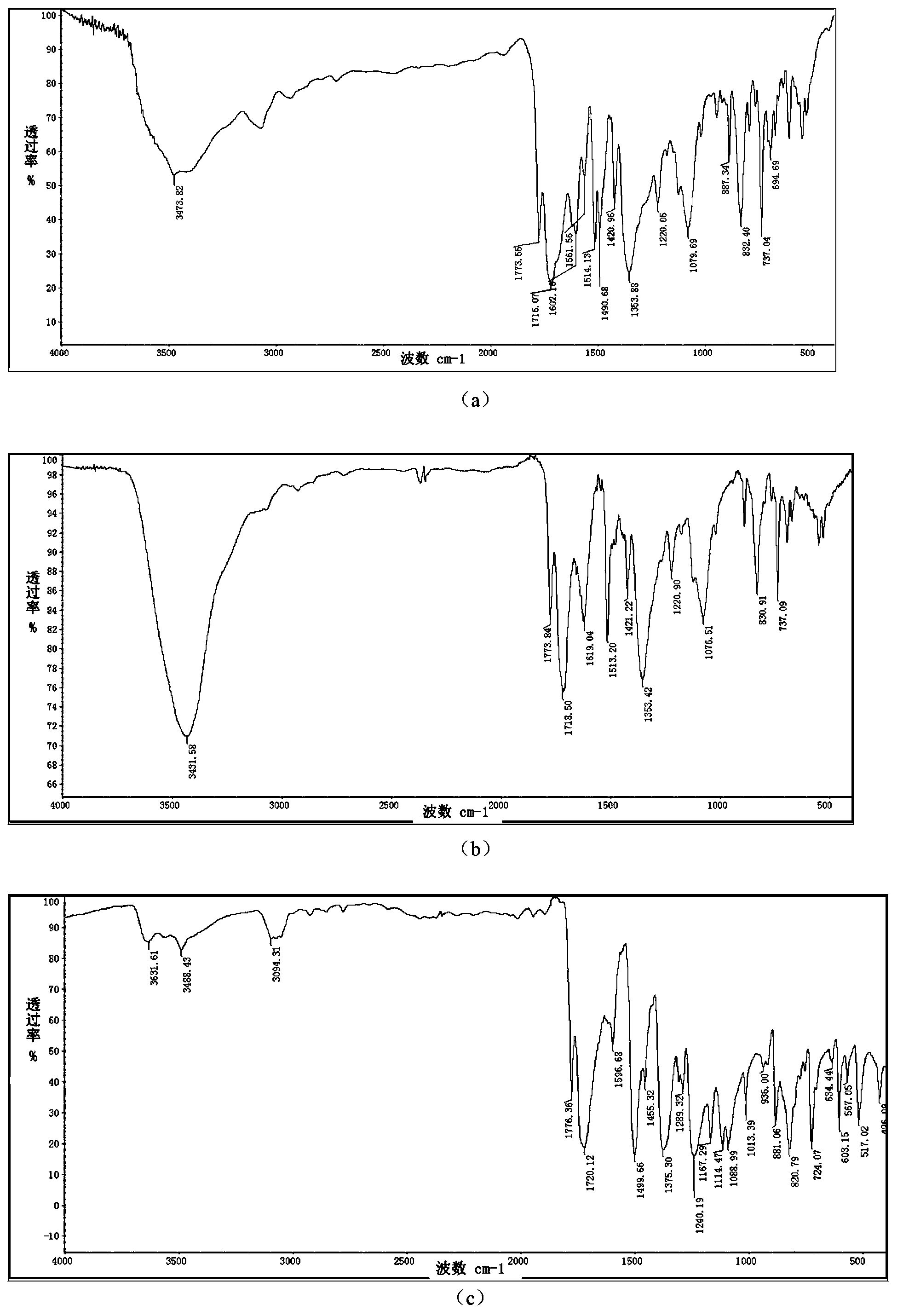

Improved impregnation formula for adhesion of terylene tyre cord and rubber and preparation method thereof

The present invention relates to recipe and preparation process of improved glue for adhering dacron fabric cord to rubber. The improved glue consists of water soluble polyurethane with carboxyl group or sulfonyl group containing chain expander, acrylate emulsion and butyronitrile latex. It can raise the adhesion strength of the dacron / rubber interface and improve the heat performance of the interface greatly. Its preparation process includes the steps of: preparing water soluble polyurethane, preparing acrylate emulsion, and adding water soluble polyurethane and preparing acrylate emulsion into butyronitrile latex. The present invention has environment friendship, low cost and convenient use.

Owner:DONGHUA UNIV

Microorganism retting flax method for crudefiber crops

InactiveCN101285211AShort fermentation timeHigh rate of numbnessBacteriaMicroorganism based processesFiber cropMicroorganism

The invention provides a method for retting flax with microbe mild water for bast-fiber crops, belonging to a retting technology for the bast-fiber crops. The method comprises the following steps of: adding degumming bacteria into a retting vessel according to 0.5 to 1.0 per thousand of the total weight of aqueous solution; heating up to 30 to 40 DEG C after injecting water to 100 percent of the total weight of the aqueous solution; and finishing retting after 40 to 50 hours. The industrial production of the degumming bacteria is completed via primary strain culture, secondary strain culture and industrial production. The method has the characteristics of short retting fermentation period, high percentage of fiber extraction, high fiber stress, small water consumption, low energy consumption, retting water economization, zero drainage of retting water and no environmental pollution.

Owner:黑龙江省科学院亚麻综合利用研究所

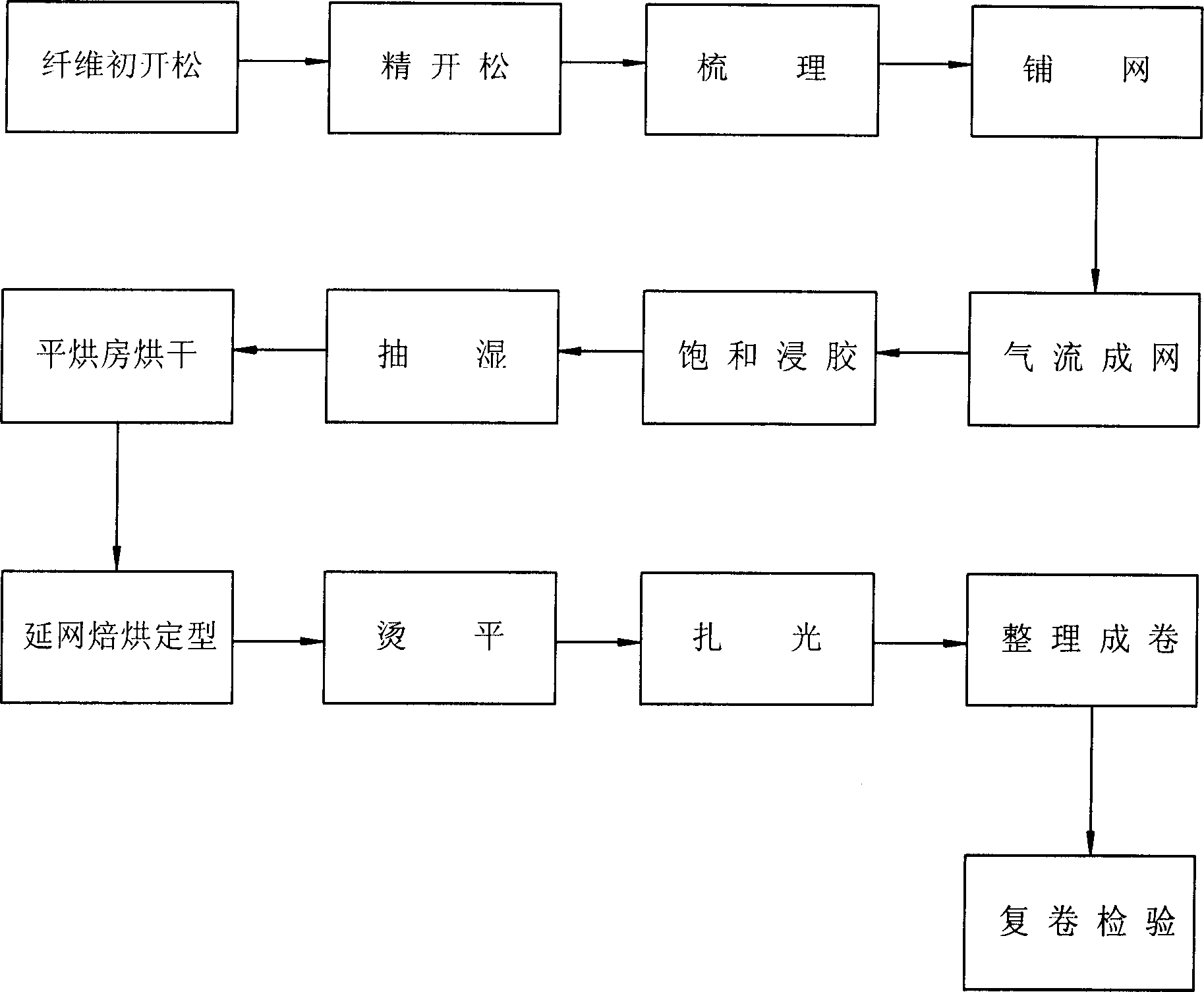

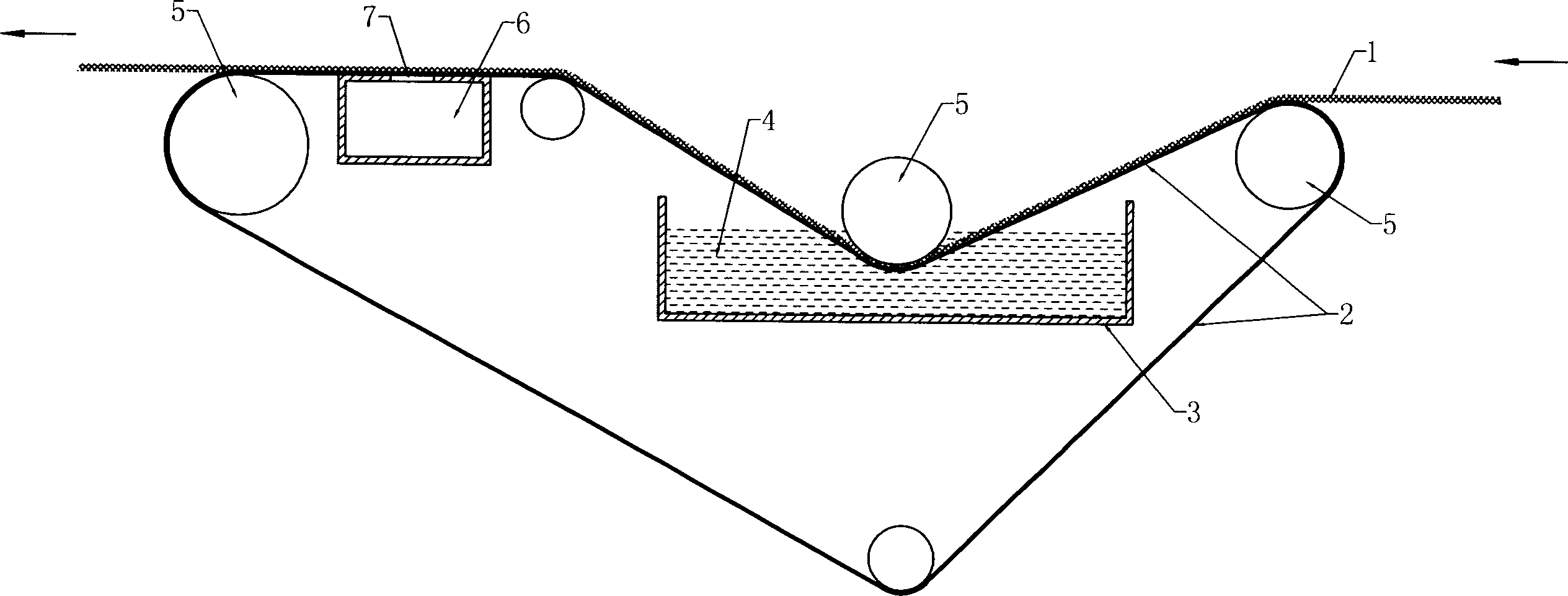

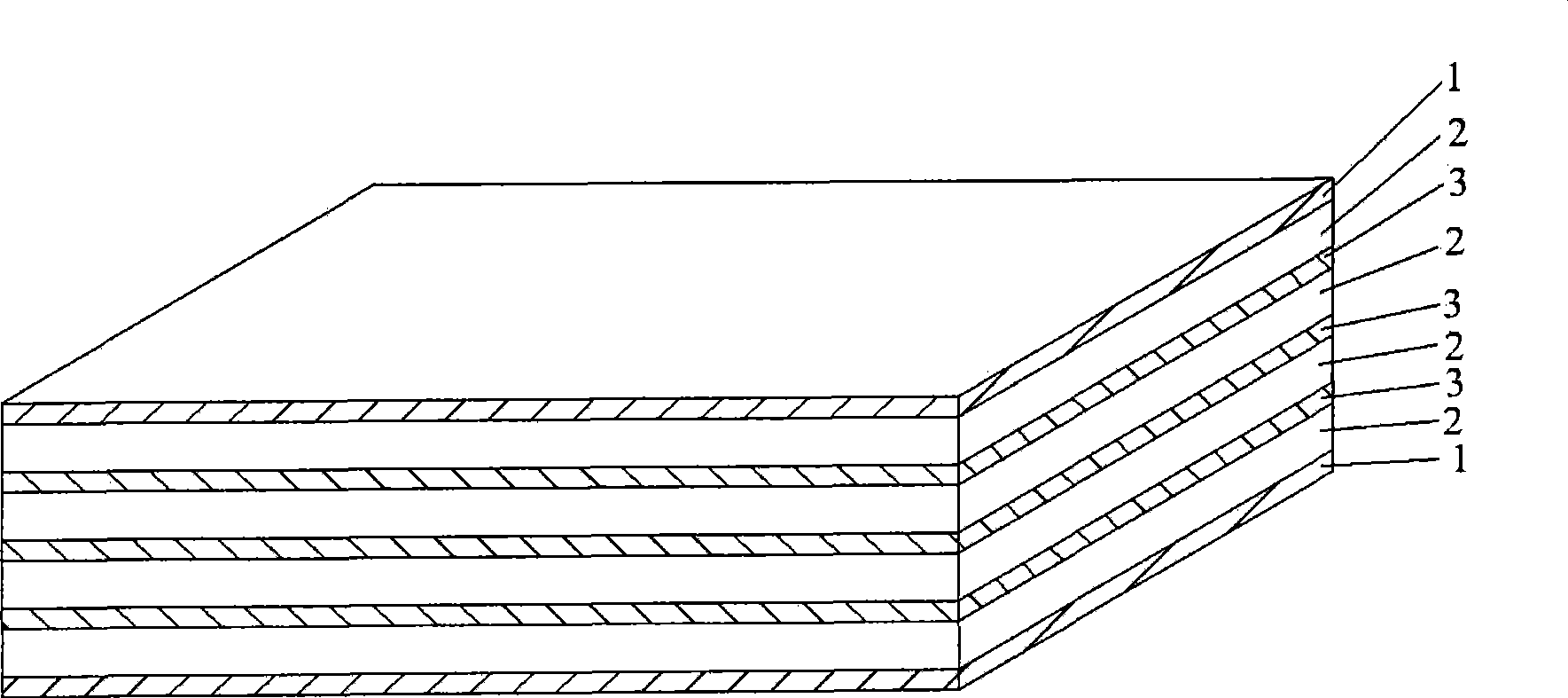

Water-soluble nonwoven cloth and its proparing method

InactiveCN1814884AEnhanced horizontal and vertical tensionGuaranteed stabilityNon-woven fabricsWoven fabricWater soluble

This invention relates to a soluble non-woven fabric and its preparation method, especially the one made of PVA short fibers as the raw materials and the PVA adhesive agent as the binder, in which, the preparation includes: initially carding fibers, accurately carding fibers, carding, spreading the net, forming a net by gas flow, dipping in saturation, drawing the wetness, drying, extending the net, drying and shaping, ironing out, smoothing, arranging to rolls and checking. This invented ''dipping in saturation and drawing humid'' technology replaces the original method of applying glue with foams to strengthen the horizontal and longitudinal pull of the product and the technology of drawing humid can absorb unwanted glue to either ensure the stability of the drying step or recover and use the unwanted glue again.

Owner:郑志勇

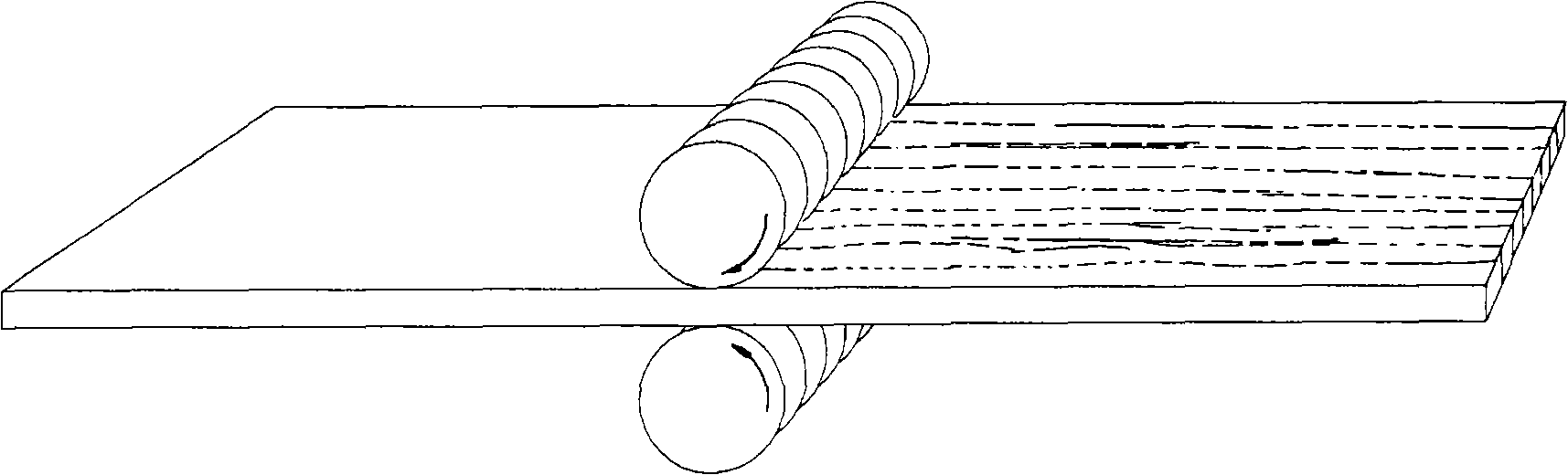

Bamboo wood composite plywood for concrete form panel and manufacturing method thereof

InactiveCN101486208AIncrease profitReduce manufacturing costWood veneer joiningWood layered productsEnvironmental resistanceSurface layer

The invention relates to a bamboo wood composite plywood for a concrete template and a method for manufacturing the same. The bamboo wood composite plywood is provided with a body which is manufactured from a first log rotary cut veneer and a bamboo curtain in alternate arrangement through hot pressing; the body has odd layers; and the first log rotary cut veneer is positioned on the surface layer of the body. The outer side of the body can also be a composite bamboo mat or a veneer. The method for manufacturing the bamboo wood composite plywood comprises the steps of carrying out assembly, prepressing, aging, and hot pressing on the log rotary cut veneer, the bamboo curtain and / or the bamboo mat, and the like. The bamboo wood composite plywood realizes combination of bamboo and the log rotary cut veneer, improves the utilization rate of wood and the bamboo, simultaneously improves the performance greatly, has a more stable structure, and greatly improves bonding strength and transverse static bending strength; and in the manufacturing process, the method does not need to carry out complex gum dipping and other treatment on the bamboo curtain, the bamboo mat, and the like, greatly reduces the use amount of an adhesive, reduces the machining cost, and is favorable for environmental protection.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

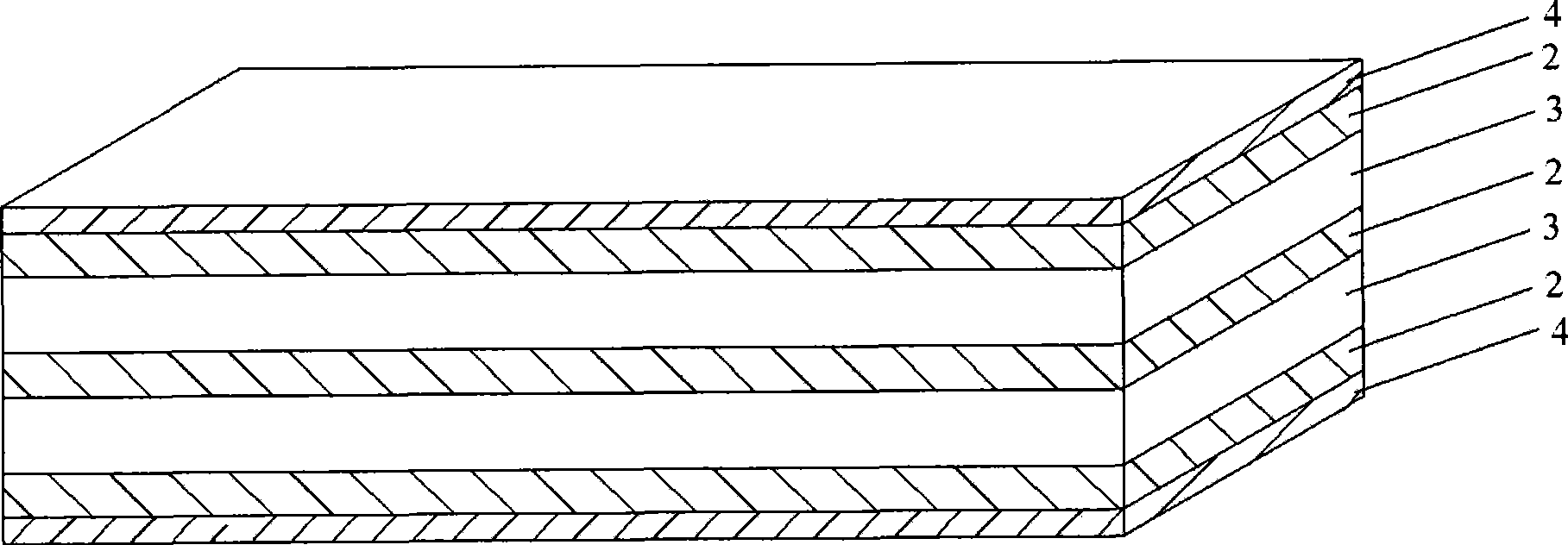

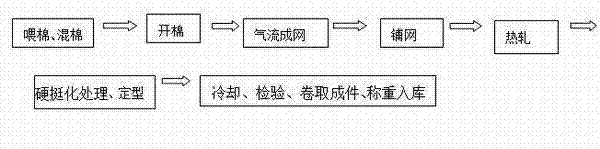

Production method of hot-rolled non-woven base material and product of production method

InactiveCN102899805AIncrease flexibilityImprove breathabilitySynthetic resin layered productsFiltration separationGramAirflow

The invention discloses a production method of a hot-rolled non-woven base material and a product of the production method of the hot-rolled non-woven base material. The production method of the hot-rolled non-woven base material comprises the following steps of: A, feeding and mixing cotton; B, breaking and opening; C, air laying; D, lapping; E, hot rolling; F, stiffening process and shaping; and G, cooling, inspecting and coiling to obtain the base material, and weighing and entering warehouse. The stiffening process is one or combination of gumming and surface gluing. The gram weight range of the product obtained by the production method of the hot-rolled non-woven base material is 50 to 250g / m<2>, the thickness range is 0.1 to 0.8mm, the air permeability is 500 to 6,000L / m<2>.s, and the longitudinal and transverse stiffness can reach 500mg or more. The hot-rolled non-woven base material has very strong flexibility and excellent air permeability; furthermore, the hot-rolled non-woven base material is low in thickness, therefore, the area of a filter material can be increased, the resistance of a filter unit is reduced, and the clogging capacity of the filter unit is improved; meanwhile, the hot-rolled non-woven base material is excellent in stiffness, therefore, the different folding and forming requirements are met; and the cost of the hot-rolled non-woven base material has a more obvious advantage than that of materials with the same application aim.

Owner:ZHEJIANG ZHAOHUI FILTRATION TECH

Processing technique for bamboo batten of bamboo floor

InactiveCN102310441AFull and even absorptionEvenly distributedWood treatment detailsAdhesive glueEngineering

The invention relates to a processing technique for bamboo products, in particular to a processing technique for a bamboo batten of a bamboo floor. The processing technique for the bamboo batten of the bamboo floor comprises the following steps of: (1) cutting off bamboo according to the requirement and then breaking the cut bamboo into pieces, and removing bamboo joints to obtain bamboo chips; (2) further finely cutting the bamboo chips and separating bamboo chips with bamboo green from bamboo chips with tabasheer; (3) pressing the bamboo chips with the tabasheer into bundled bamboo silks with fiber bamboo filaments by using a bamboo batten press wheel crusher; (4) carrying out carbonizing or bleaching treatment on the bamboo silks; and (5) placing the bamboo silks obtained in the step (4) into a drying room and drying until the water content is not higher than 7 percent. According to the processing technique disclosed by the invention, after strip bamboo battens are pressed by using the pressure of a wheel press, the interiors of fine strip bamboo battens are gradually pressed and scattered to form complete fiber bamboo filament bundles by using a filament pressing wheel with a sharp edge blade. When the bamboo battens are immersed with glue, the glue can completely penetrate into the interiors of the fiber bamboo filament bundles, the phenomena of filament jumping, cracking, burrs and the like can be avoided, and the quality of the floor is greatly improved.

Owner:JIANGXI NANFENG ZHENYU IND GRP

Dip solution of flame retardant dipped canvas and preparation method thereof

The invention aims to provide a dip solution of a flame retardant dipped canvas and a preparation method thereof. The dip solution and the preparation method have the beneficial effects that a two-bath dipping system is adopted; water-based latex is adopted in the first bath, namely the water dispersion solution of epoxy resin and blocked isocyanate; the water-based latex has the advantages of environment friendliness and safety; a dichloromethane organic solvent is adopted as styrene-butadiene latex of a dispersing agent in the second bath and can effectively improve the canvas and conveyor belt covering rubber bonding property; a blended aromatic brominated flame retardant and an antimonous oxide synergistic flame retardant system are adopted, so that the bonding strength of the canvas is improved and the flame retardance of the canvas is ensured while not affecting other indexes of the dipped canvas.

Owner:WUHU SHZ IND FABRIC

Bamboo glue sleeper and preparation method thereof

InactiveCN107009457AReduce carbon emissionsShorten the growth cycleBallastwayWood treatment detailsFiberCarbonization

The invention discloses a bamboo glue sleeper and a preparation method thereof. The preparation method comprises the following steps: (1) selecting a raw material; (2) cutting off the raw material according to a specified length, sectioning the cut-off raw material into strips, removing tabasheer and the bamboo outer skin, and processing the strips into thin bamboo skin pieces; (3) carrying out carbonization treatment on the thin bamboo skin pieces obtained in the step (2); (4) grinding the carbonized thin bamboo skin pieces into a siamesed fiber state; (5) putting the material obtained in the step (4) in phenol glue to carry out pressurization gumming; (6) carrying out automatic dehumidification on the material obtained in the step (5); (7) pressing and curing the material obtained in the step (6) into a slab; and (8) sawing the periphery width of the slab by 5 cm to eliminate the fringe effect during compression. The bamboo glue sleeper is low in carbon emission, environment-friendly and safe, does not deform when being affected with damp due to water, and is antiseptic, prevented from damage by worms, antiflaming and suitable for being used under a complex condition.

Owner:BEIJING JIAOTONG UNIV

Application of grain amaranth in repairing cadmium contaminative soil

InactiveCN101104175AReduce cadmium contentPollution level achievedContaminated soil reclamationGrazingHabit

The invention relates to the application of grain amaranth (Amaranthus hypochondriacus L.CU.) in restoration of cadmium pollution in soil. The invention is to sow three kinds of optimized grain amaranth of R104, K112 and K427 in cadmium polluted soil, and then reap the above-ground biomass to conduct centralized retting and landfill for effectively clearing cadmium in soil. The invention has high efficiency, easy operation, non-secondary pollution and low cost, and the grain amaranth is the common grazing, which is easy to plant, people are familiar with the growth and agronomic habit, so the promotion and application are easy, the concentration coefficient is high, cadmium gathered from the 5mg / kg of polluted farmland shows that the concentration of cadmium in leaf is about 120mg / kg, the stem part is about 65mg / kg, root part is about 69mg / kg, total biomass of the first-cut can reach 4-6t per mu, the yearly amount can reach 10-15t per mu, the first-cut can lower the cadmium pollution level of the plow layer (0-20cm) by 0.4-0.6mg / kg each year, and farmland of the middle and low degree cadmium pollution can meet the safety production requirements in a few years, so the invention is suitable for deposition type pollution cultivated land in delta areas.

Owner:SOUTH CHINA BOTANICAL GARDEN CHINESE ACADEMY OF SCI +1

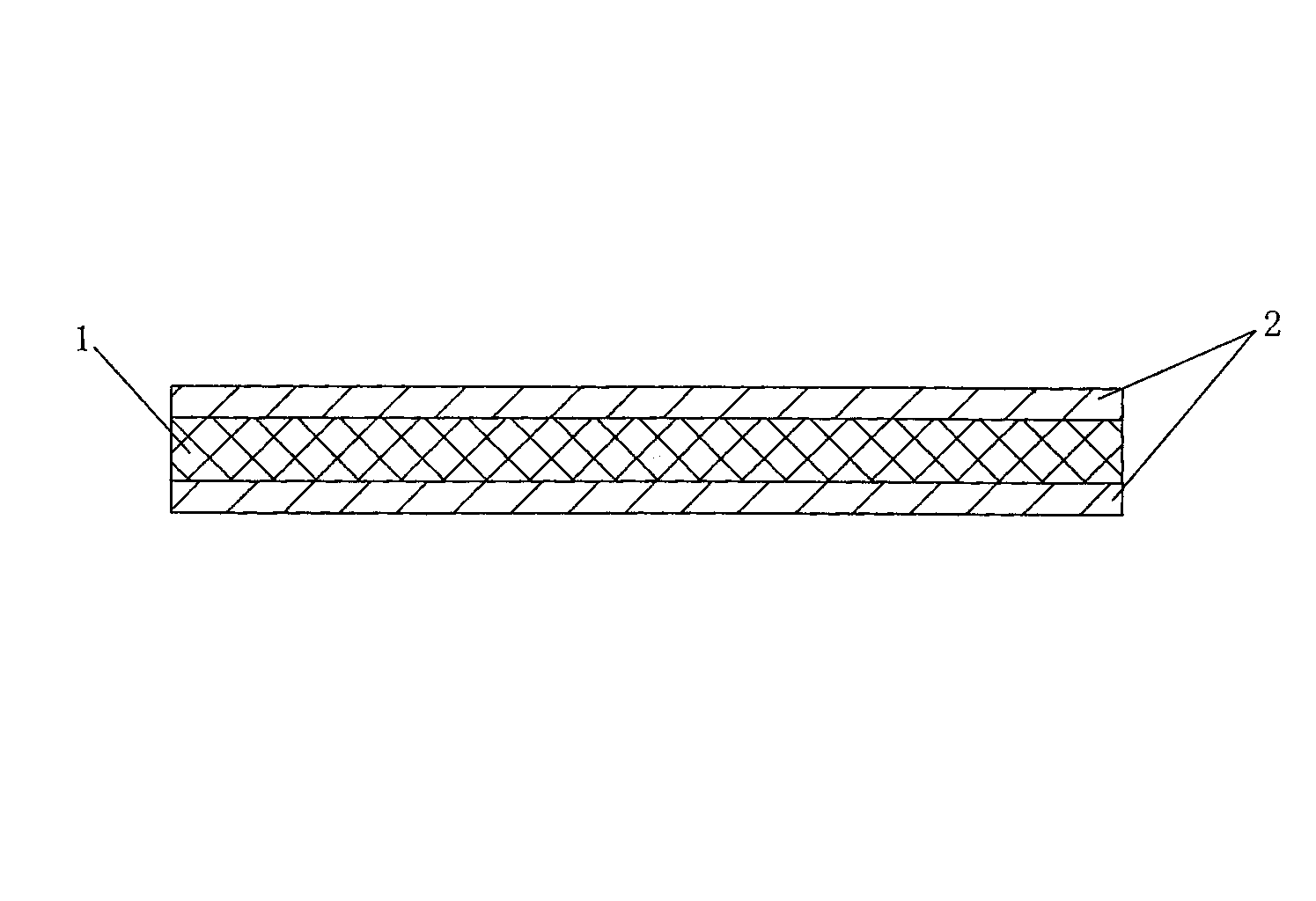

Low-smoke halogen-free flame-retardant gum-dipped elastic cloth and preparation method thereof

InactiveCN102700202AReasonable selection of raw materialsImprove flame retardant performanceFibre treatmentSynthetic resin layered productsPolyesterGlass fiber

The invention discloses low-smoke halogen-free flame-retardant gum-dipped elastic cloth and a preparation method of the cloth, and belongs to the technical field of special fabrics. The low-smoke halogen-free flame-retardant gum-dipped elastic cloth comprises flame-retardant fiber base cloth and a flame-retardant layer bonded onto the two side surfaces of the flame-retardant fiber base cloth, wherein the flame-retardant fiber base cloth is prepared by knitting or non-weaving high-strength flame-retardant polyester fibers, high-strength flame-retardant nylon fibers or glass fibers, and the flame-retardant layer comprises the following raw materials by weight: 80-300 g of flame retardant, 20-100 g of polymer, 100-500 g of solvent and 2-20 mg of defoamer. The low-smoke halogen-free flame-retardant gum-dipped elastic cloth has excellent flame retardance and outstanding strong force capable of being against the influence of an external force, is not easily broken and has ideal elasticity and softness as well as sealing and oxygen isolating effects; and the process steps in the provided method are short and have no strict requirements on equipment, so that the technical effect of the low-smoke halogen-free flame-retardant gum-dipped elastic cloth can be guaranteed, and the industrial large-scale production requirements can be met.

Owner:CHANGZHOU YUHONG SPECIAL PRINTING MATERIALS

Watches and method for their production

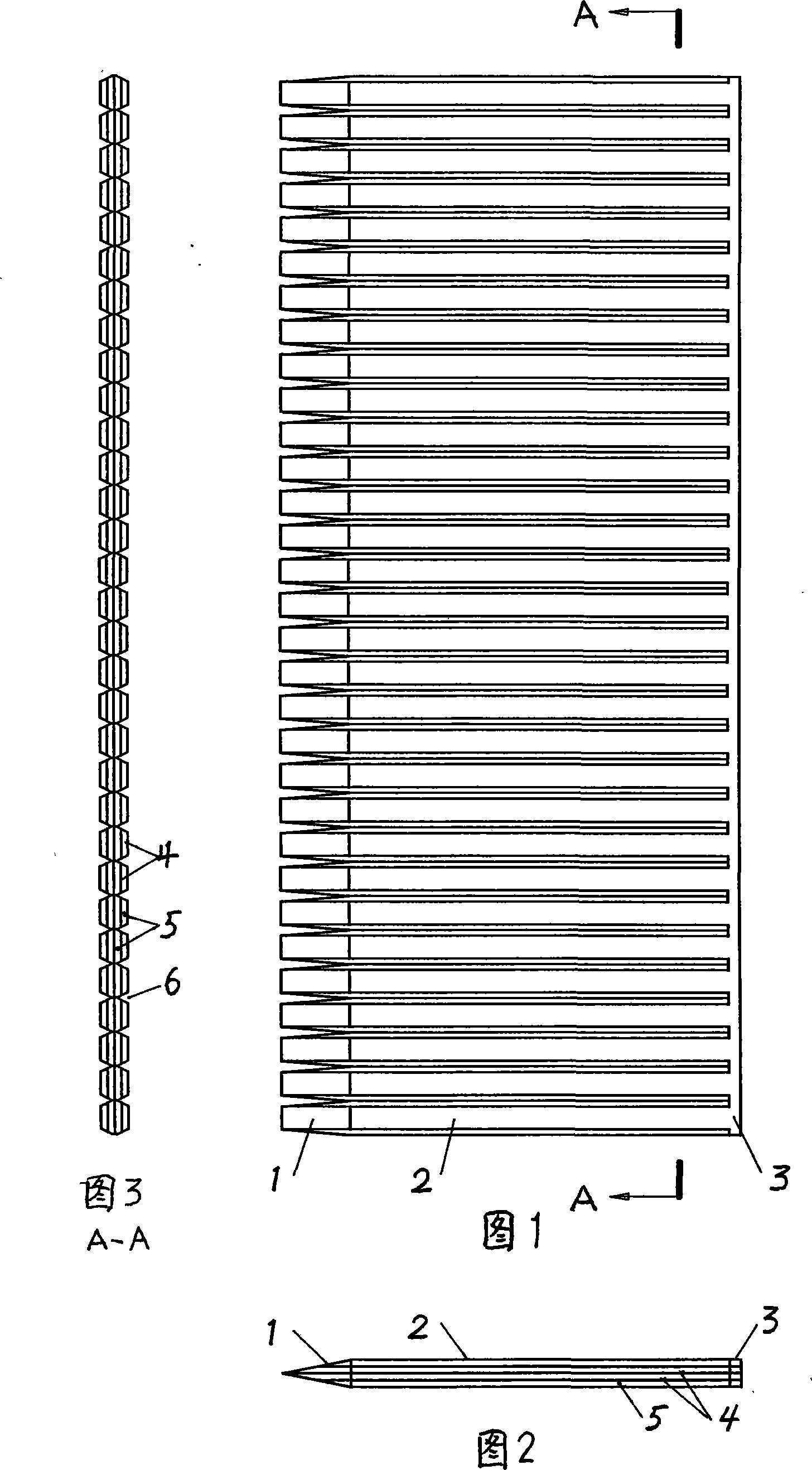

The invention relates to a bamboo straight nail row. All bamboo nails are longitudinally arranged in parallelism along the fiber direction of the bamboo and are in a row; the head (1) of the nail is in wedge-shape and the section area of the tail (3) of the nail is larger than the section area of the nail body (2); the whole nail is the laminated structure with interval of a glue layer (4) and a thin bamboo piece layer (5), with the density more than 1000kg / m(SUP)3( / SUP). The manufacture of the bamboo straight nail row comprises the steps of production of thin bamboo piece, drying in kiln, glue dipping or glue coating on two surfaces, re-drying, blanking in orientation, hot pressing by press, cutting according to the length requirement of the nail, milling process into the nail row. The invention can replace general metal nail row; in the application of decoration engineering, vine furniture and wood products, the invention has the advantages of low cost, no rust, large density, high strength, self-control to the depth in the wood, nailing the wood with high density, etc. compared with the existing bamboo wood nails.

Owner:钱一辰

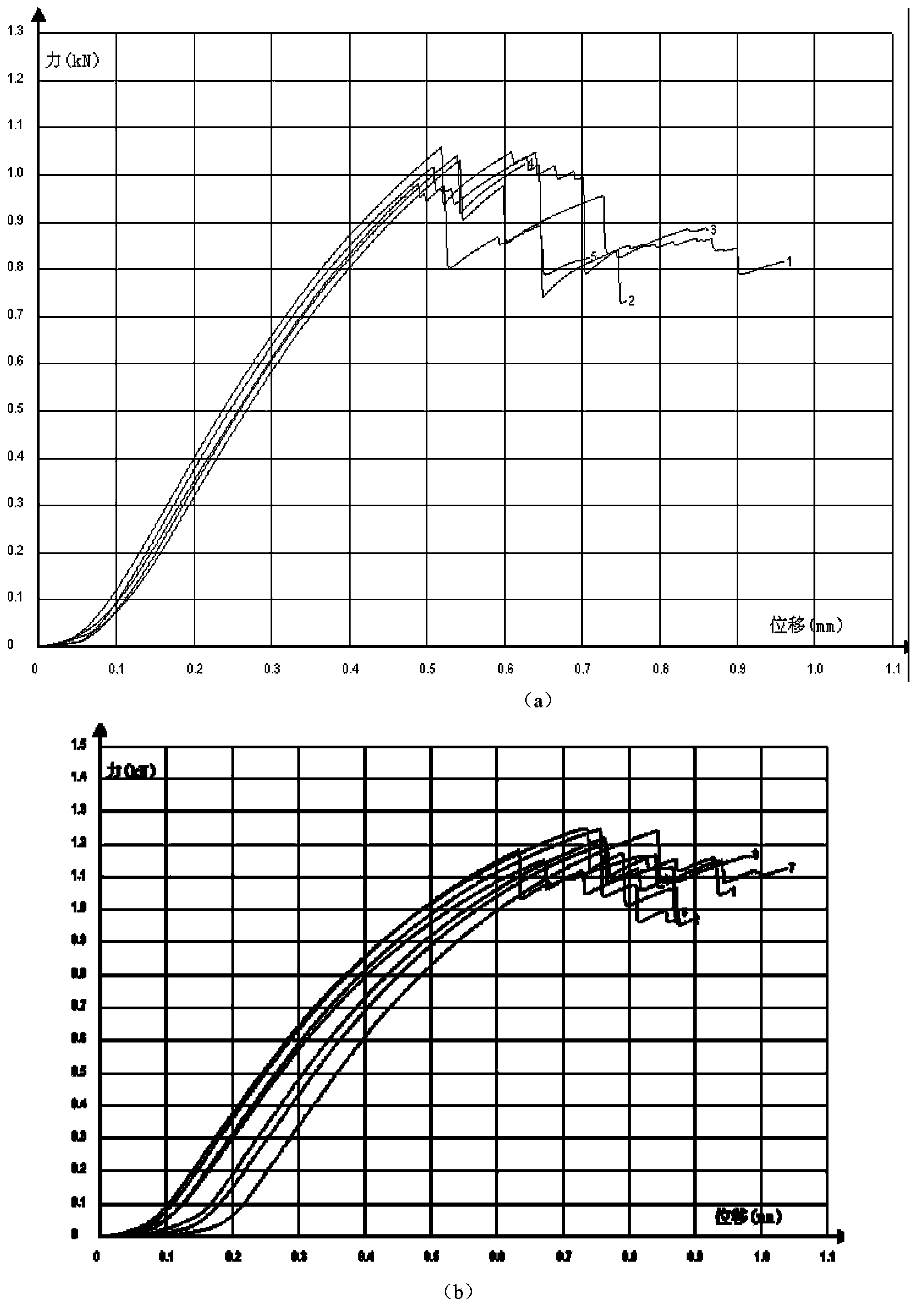

High-performance polyimide fiber reinforced epoxy resin composite material and preparation method thereof

The invention relates to a high-performance polyimide fiber reinforced epoxy resin composite material and a preparation method thereof, and belongs to the technical field of high-performance composite materials. The preparation method which selects a copolymerized high-performance polyimide fiber containing aromatic heterocyclic diamine as a reinforcement, an epoxy resin as a matrix material and an aromatic amine compound and imidazole compound mixture as an epoxy resin curing agent comprises the following steps: mechanically stirring the epoxy resin, the curing agent and a diluent at 40-120DEG C for uniform mixing; impregnating copolymerized high-performance polyimide in a resin glue solution at 40-80DEG C, evacuating at a temperature in a range of room temperature to 50DEG C for 10-60min, and carrying out curing heating in a die according to a curing program comprising the heat insulation at 80-110DEG C for 1-2h, the heat insulation at 120-160DEG C for 1-4h and the heat insulation at 170-200DEG C for 1-4h. The composite material has excellent comprehensive mechanical performances and an excellent interface adhesion strength.

Owner:BEIJING UNIV OF CHEM TECH

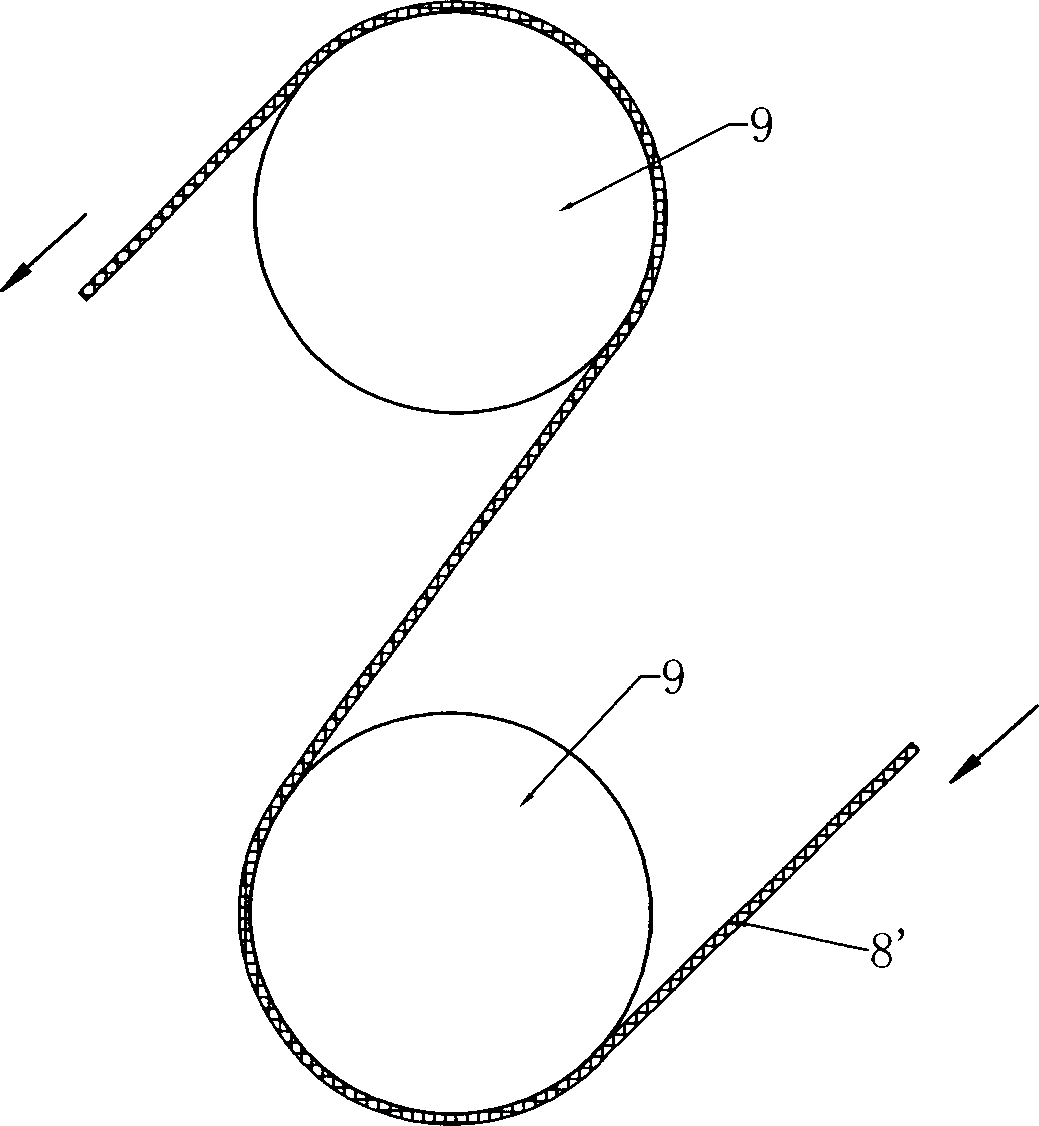

Constant-temperature impregnation device for composite fiber winding

The invention provides a constant-temperature impregnation device for composite fiber winding. The constant-temperature impregnation device for composite fiber winding is used for impregnating glass fiber and carbon fiber in the winding process and balancing fluctuation of the tension value during winding reversing and can be placed on a fiber winding tension control system to cooperate with a fiber winding mainframe to together complete processing of winding products. The constant-temperature impregnation device can be transversely and longitudinally moved according to the actual size of winding parts. The constant-temperature impregnation device is composed of a U-shaped impregnation tank, a constant-temperature device, a low-friction guide roll set, a fiber guiding device, a tension balancing device, an impregnation roll, an adjustable scraping knife and other components. Through the constant-temperature impregnation device for composite fiber winding, the technical problems that fiber is impregnated insufficiently and unevenly and fluffs due to dry friction, the constant-temperature effect of an adhesive solution is poor, the fiber is impregnated unevenly due to fluctuation ofthe fiber tension value and the quality of the winding products is affected through the existing fiber wet winding impregnation technology can be solved.

Owner:CHANGCHUN EQUIP TECH RES INST

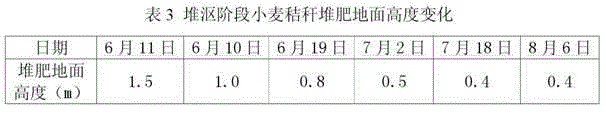

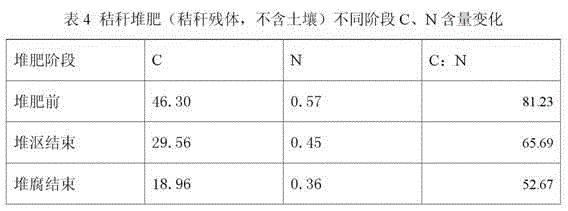

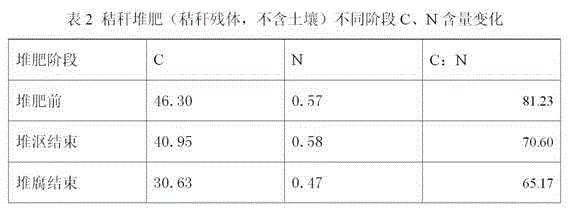

Straw composting method

InactiveCN104355714ASufficient water absorptionEnsuring the effect of compostingBio-organic fraction processingBiological combination treatmentWaxDecomposition

The invention discloses a straw composting method. The straw composting method comprises two stages of stack retting and compositing, wherein the stack retting stage comprises the following steps: establishing a stack retting pit, then, putting the straws into the stack retting pit, adding thin-layer soil every 50cm-thick straws, stacking the straws to a position 1.5-2 meters above the ground to form a straw pile which is high at the periphery of the stack top and sunken in middle, then, watering from the straw pile until the pit blow the straw pile body is filled up with water, adding soil to cover the top, and carrying out stack retting for 45-70 days; the composting stage comprises the following steps: turning over the stack-retting straws in the pit to the ground, stacking the straws into a pile, and performing semi-aerobic decomposing until the straws are thoroughly decomposed, and the compositing time is 30-50 days; the straws become brown to black brown, the wet straw residues are soft and easy to break, and the straws are broken upon touch after being dried in air to obtain a compost product. The straw composting method disclosed by the invention comprises two stages of early-stage stack retting and later-stage composting. By virtue of the straw stack retting, the straws absorb water sufficiently to reduce the compost size, and ester bonds of straw wax layers of the straws which do not absorb water are opened by virtue of the retting, so that the decomposition of the straws is promoted; by virtue of the later-stage semi-aerobic decomposing, humus substances are produced to ensure the quality of the compost.

Owner:INST OF SOIL & FERTILIZER ANHUI ACAD OF AGRI SCI

Microorganism rapid degumming and warm water retting method for flax

InactiveCN1594675AShorten the fermentation cycleHigh rate of numbnessBacteriological rettingWarm waterFlax fiber

Provided is a microorganism rapid degumming and warm water retting method for flax. The inventive retting method for flax comprises: activating the bacterial for 24 hours at 30 DEG C by pectin solid medium, inoculating the activated bacterial with the 1 wt.% of the flax protocorm in the retting container to the retting container, in which the flax protocorm is soaked for 2-4 hours in warm water, then topping up the retting container with clean water, heating to 30-37 DEG C, meanwhile adding 46.3-92.6 g / m3 sodium chloride and 92.6-129.6 g / m3 urea, finishing the retting after 78-100 hours. The method can shorten the zymolysis cycle, improve the yield rate of the flax fiber, increase the intensity of the flax fiber, improve the flax fiber quality, reduce the sewage in the retting.

Owner:HEILONGJIANG UNIV

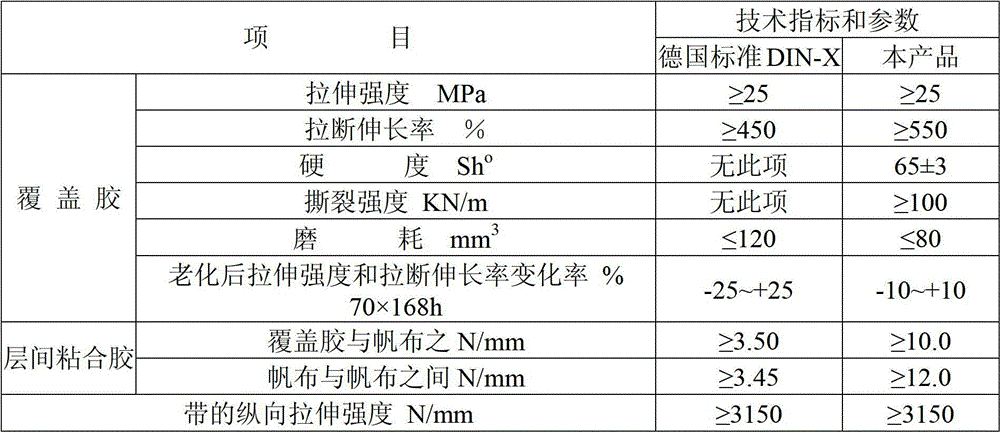

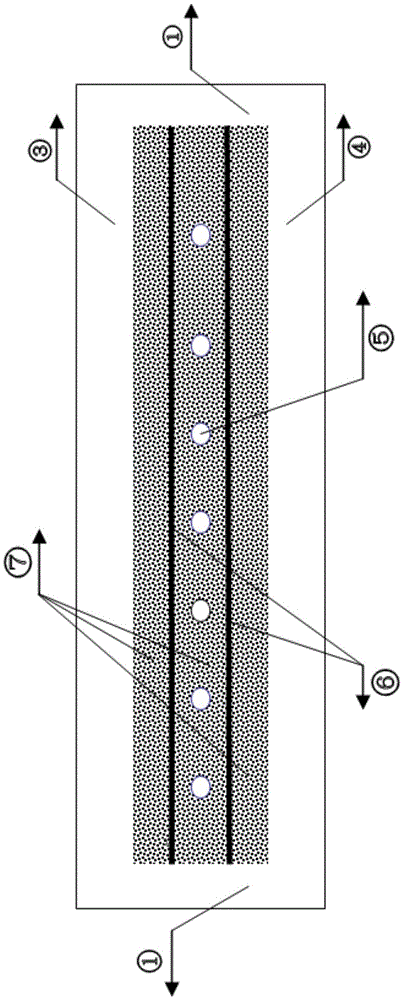

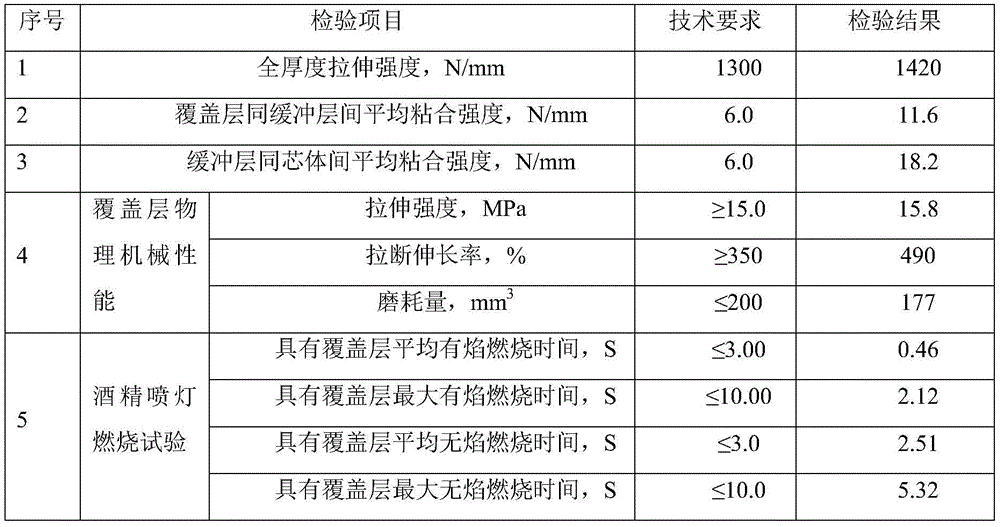

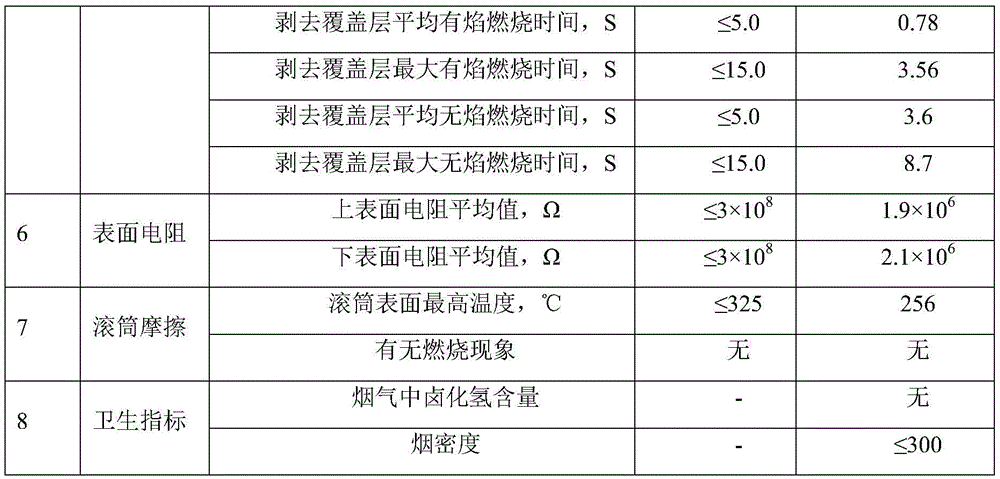

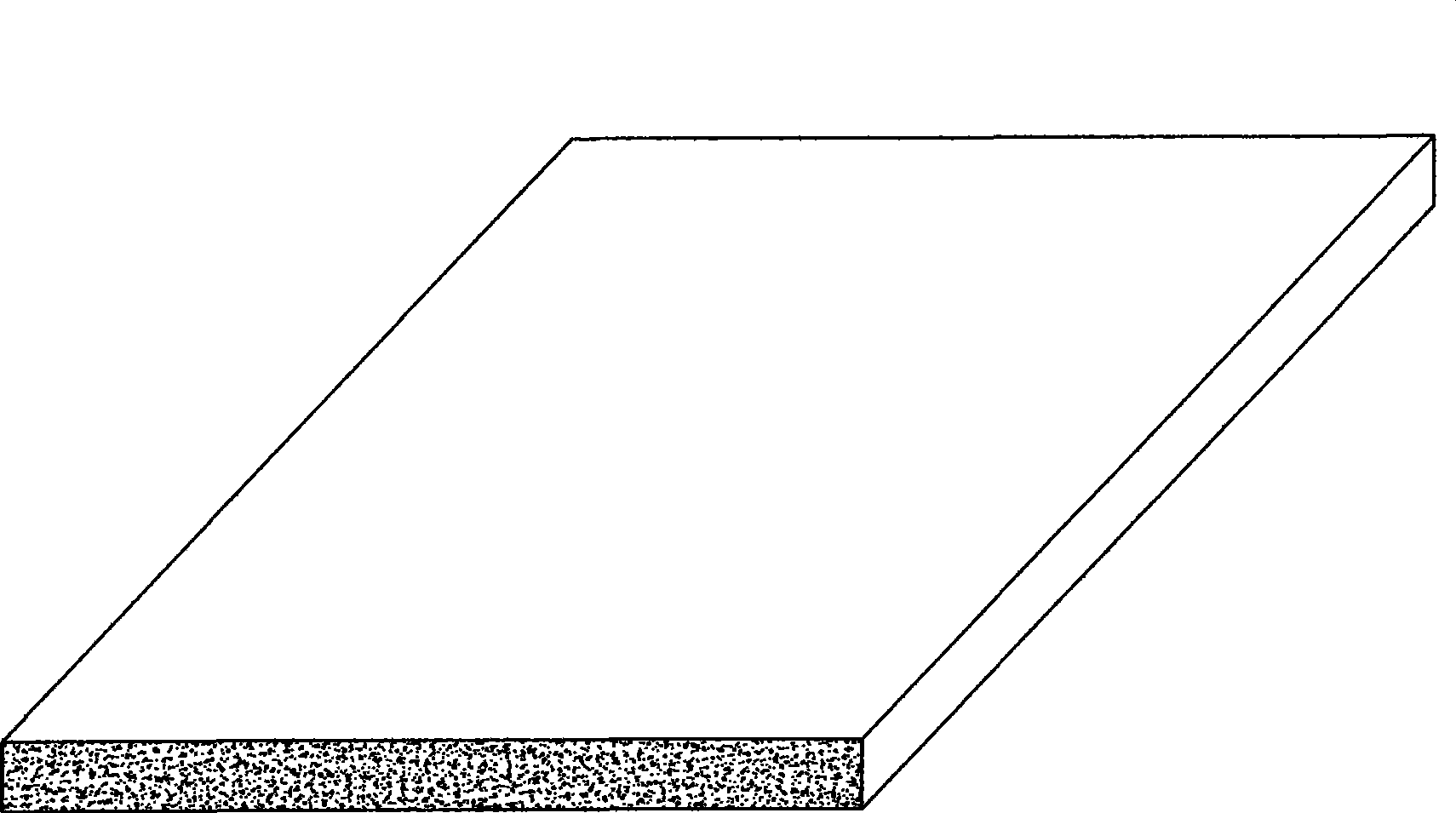

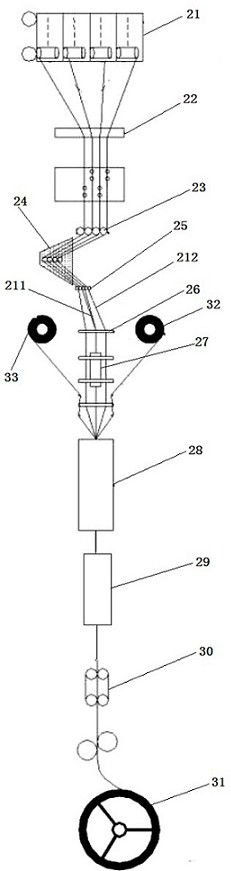

Environment-friendly and flame-retardant conveying belt with aramid fiber thread rope core and production technology thereof

The invention relates to a flame-retardant conveying belt for mines, in particular to an environment-friendly and flame-retardant conveying belt with an aramid fiber thread rope core and a production technology thereof. The conveying belt is composed of an aramid fiber impregnation thread rope framework layer, anti-tearing buffering layers, an upper covering glue layer, a lower covering glue layer and side glue layers, wherein the anti-tearing buffering layers are arranged on the upper side and the lower side of the aramid fiber impregnation thread rope framework layer respectively, the aramid fiber impregnation thread rope framework layer and the anti-tearing buffering layers are bonded through flame-retardant bonding glue and are integrated after being vulcanized, and the anti-tearing buffering layers and the upper covering glue layer, the lower covering glue layer and the side glue layers are bonded through flame-retardant bonding glue and are integrated after being vulcanized; the aramid fiber impregnation thread rope framework layer is formed by re-twisting folded yarns formed by twisting para-aramid filaments for forming thread ropes, impregnating the thread ropes with glue and arranging the thread ropes according to certain distance and tensioning degree. The environment-friendly and flame-retardant conveying belt with the aramid fiber thread rope core is retardant to flames, resistant to static electricity and small in smoke density, meets the safety requirements of a flame-retardant environment, is small in smoke and toxicity in the flame combustion process and is friendly to the environment. The consumption of operating kinetic energy is small, the equipment investment is low, and the comprehensive performance is excellent.

Owner:ANHUI OUNAI RUBBER & PLASTIC IND

Method of obtaining hemp plant juice and use of same for the production of beverages

The present invention relates to a method for producing beverages on the basis of juice from the hemp plant. The invention relates to a method for obtaining juice suitable for human consumption from the hemp plant, wherein the complete hemp stem is pressed after harvest without prior drying or retting. The invention further provides a method for obtaining juice from the hemp plant, wherein the upper leafy part of the hemp plant is cut, the leaves are stripped of the remaining stem, fibers and shives being separated from each other at the stem, the leafy part of the stem, the fibers and the shives being pressed individually under pressure and the so obtained pressed juices are being mixed in a controlled manner. In a yet further aspect, the invention relates to a method for the manufacturing of beverages on the basis of juice from the hemp plant, wherein the hemp juice is mixed with yeast and than fermented.

Owner:CLAREMONT COLLECTION HANDELSGMBH +1

Bamboo fiber bundles recombination single-plate and production method thereof

InactiveCN101391433AQuality improvementImprove the decorative effectWood treatment detailsWood veneer joiningFiber bundleSingle plate

Disclosed is a bamboo fiber bundle reconstructed veneer and a producing method thereof, which relates to a bamboo plate. The veneer is glued by the bamboo fiber bundle which is processed by making bamboo into fiber bundle loosing surface with interlaced connection and maintaining the an original fiber arraying direction. The thickness of the veneer is 0.1mm to 2mm, the producing method of the veneer includes the steps that the bamboo prepared to be glued is dried and dipped, the material is paved, the bamboo is arranged in a press, and the pressing and curing process is performed; the method is characterized in that the bamboo prepared to be glued is first made into fiber bundle before the drying process, the plate after being pressed and cured is softened, then is sliced or peeled into a 0.1mm to 2mm veneer through veneer slicer. The veneer has the advantages that the seeped adhesive quantity is high and uniform, and the density is high; the drying shrinkage variable and the humidity expansion variable of the veneer are low after the veneer is sliced or peeled, the veneer is uniform, the cracking is not easy, the quality of the plate is improved a grade, and the appearance decorativeness of the veneer is optimized. The large and small bamboo all can be utilized, the process is simple, the efficiency is high, and the scale production is favorable.

Owner:杨明杰 +1

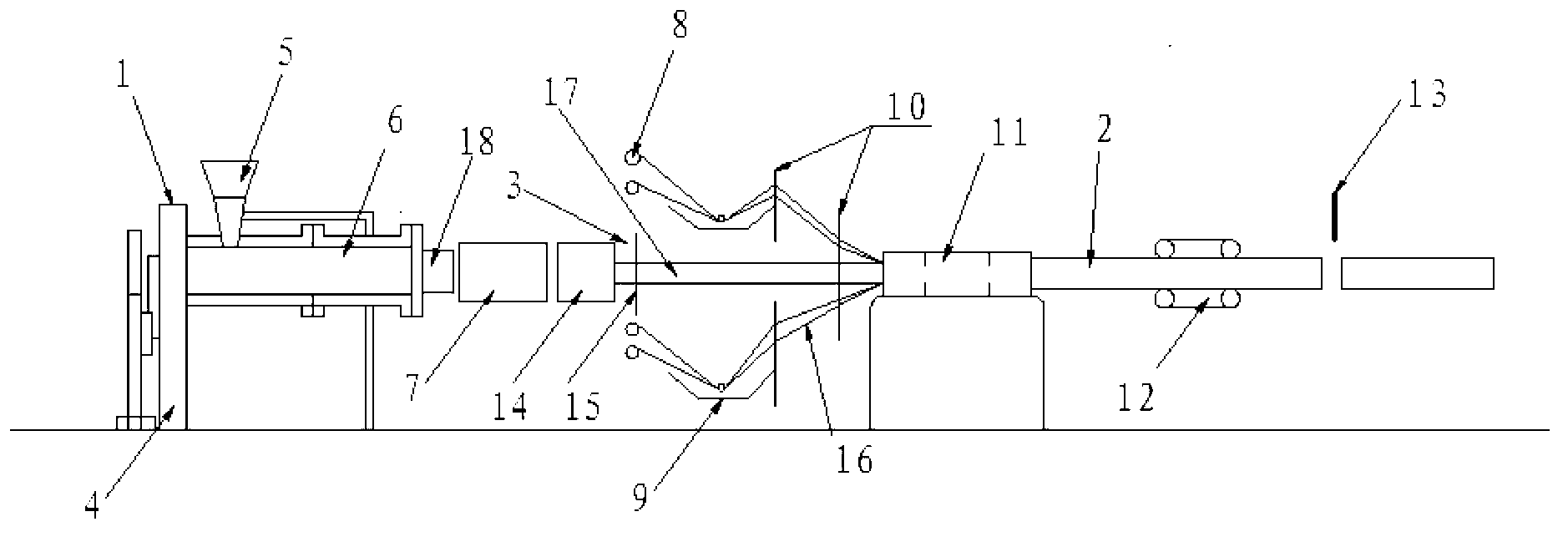

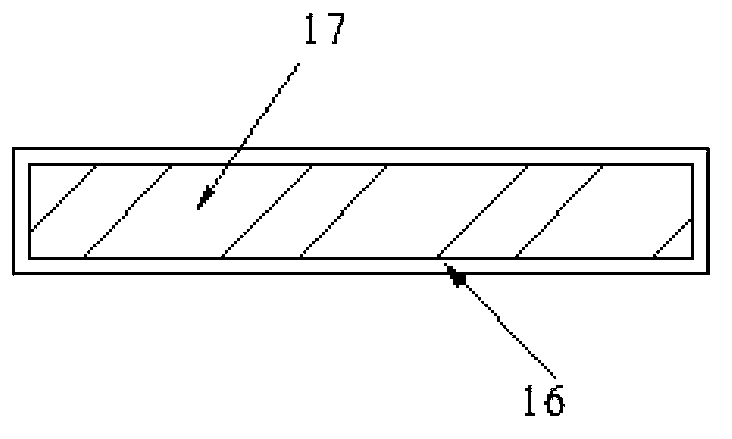

Carbon glass fiber composite pultrusion plate and production process and production equipment thereof

PendingCN111959058AImprove mechanical propertiesImprove toughnessSynthetic resin layered productsGlass/slag layered productsGlass fiberYarn

The invention discloses a carbon glass fiber composite pultrusion plate, which is formed by using carbon fibers and glass fibers to impregnate a resin material and then performing pultrusion, and a glass fiber layer wraps a carbon fiber layer. The invention also discloses a production process of the carbon glass fiber composite pultrusion plate. The production process comprises the following steps: (1) calculating the required use amounts of carbon fibers and glass fibers, (2) sequentially making the carbon fibers and the glass fibers penetrate through a yarn collecting plate and a layered yarn plate and then carrying out gum dipping treatment, (3) feeding the impregnated carbon fibers into a pre-forming mold, (4) feeding the glass fibers and the carbon fibers passing through the pre-forming mold into a forming mold together, and performing pultrusion to form a plate, and (5) curing, cooling, drawing and rolling the formed plate. The weight of the composite pultrusion plate is far lower than that of a pure glass fiber pultrusion plate, the composite pultrusion plate has excellent mechanical properties and strong performance designability, the strength and modulus of the composite pultrusion plate meet the material requirements of a large fan blade girder, the cost is low, and the composite pultrusion plate is beneficial to wide popularization and application.

Owner:JIANGSU AOSHENG COMPOSITE MATERIALS HI TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com