High-performance polyimide fiber reinforced epoxy resin composite material and preparation method thereof

A technology of polyimide fiber and epoxy resin, which is applied in the field of new epoxy resin composite materials and its preparation, can solve the problem of surface inertness and poor adhesion of thermosetting resin, poor resistance to ultraviolet radiation of aramid fiber, and limitation of aramid fiber. The use of weather resistance of fiber fibers and other issues, to achieve excellent mechanical properties, excellent comprehensive mechanical properties, the effect of large interaction force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 2

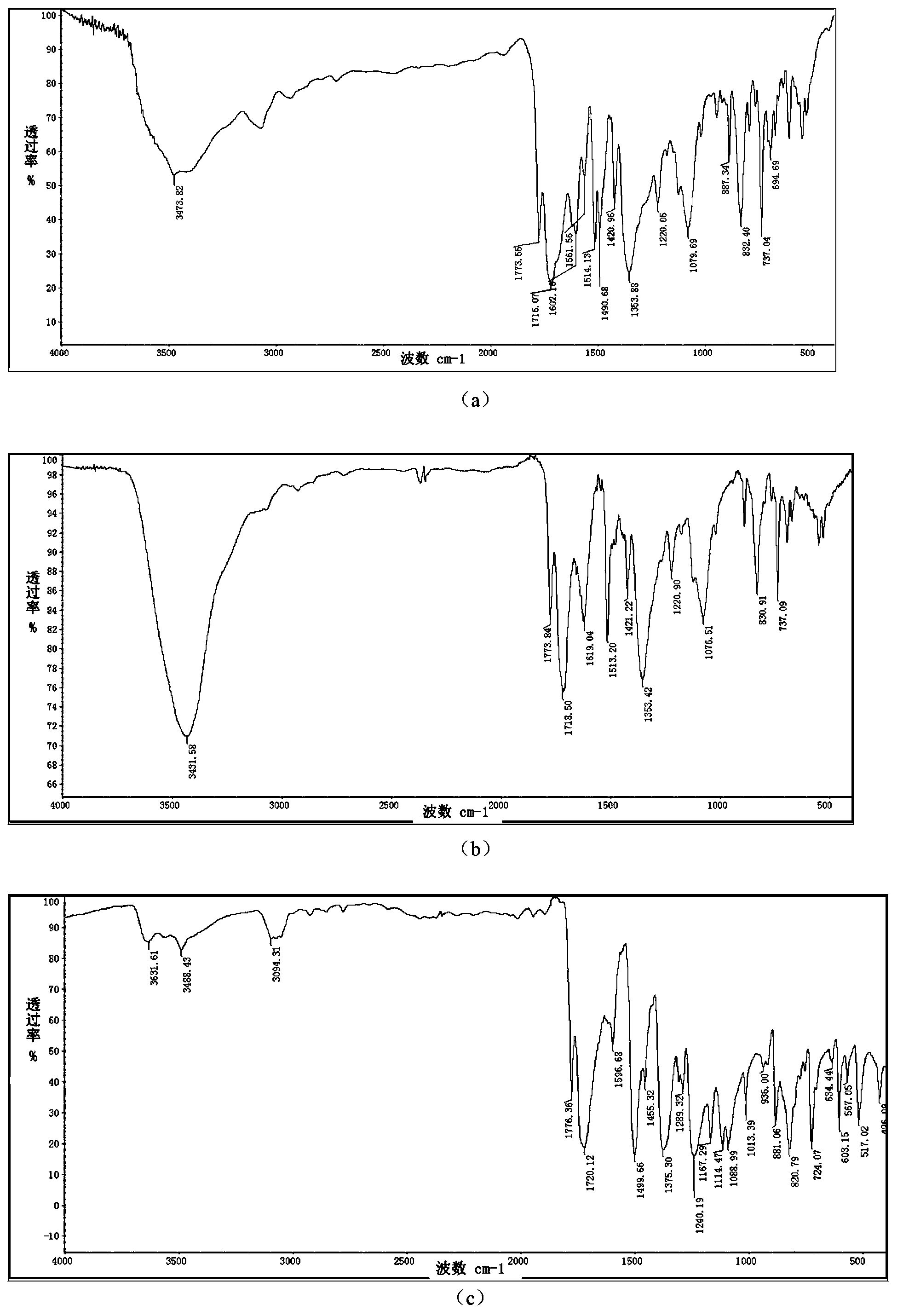

[0028] In order to more clearly illustrate the technical solutions and characteristics of the implementation cases of the present invention or the prior art, the present invention will be further elaborated below in conjunction with specific examples. Obviously, the described examples are only some of the examples of the present invention, not all of them. the embodiment. Based on the embodiments of the present invention, all implementation cases obtained by ordinary persons in the art without creative efforts belong to the protection scope of the present invention. The epoxy resin of the following examples is selected from bisphenol A type epoxy resin (DGEBA, such as grade E-44, E-51, etc.), polyfunctional glycidylamine resin (TGDDM, grade AG80, etc.), aliphatic glycidol Ester epoxy resin (DGEAC, brand TDE-85, etc.), the fiber volume fraction in the product obtained in the following examples is 50% ± 5%, and the fiber volume fraction in the final product can be controlled by ...

Embodiment 1

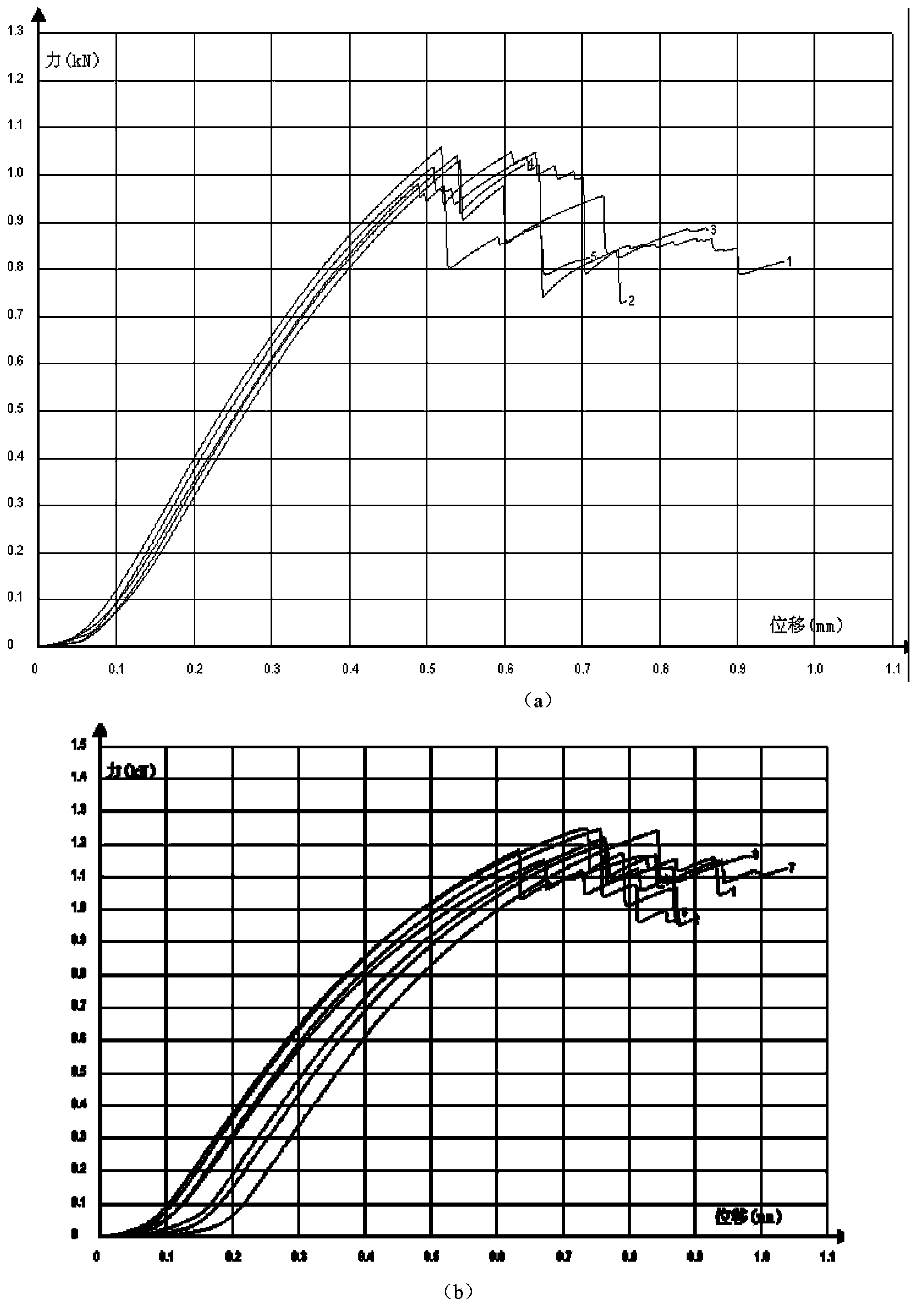

[0029] Example 1: Dissolve 35g of diaminodiphenylsulfone (DDS) in 80g of bisphenol A epoxy resin (E-51) at 100°C, then add 20g of polyethylene glycol diglycidyl ether and 1g of imidazole well mixed. Then the polyimide fiber (PI-Q) is continuously dipped and wound. The temperature of the resin glue solution is controlled at 40°C during dipping, and the wrapped fiber that has been dipped is vacuumed at 50°C for 20 minutes. Then put it into a concave-convex mold, pre-cure at 110°C for 2 hours, cure at 150°C for 2 hours, and post-cure at 200°C for 3 hours. The glass transition temperature of the composite material is 180°C, the interlaminar shear strength is 60MPa, and the bending strength is 650MPa.

Embodiment 2

[0030] Example 2: 40g diaminodiphenylmethane (DDM), 60g polyfunctional glycidylamine resin (AG80), 30g aliphatic glycidyl ester epoxy resin (TDE-85), 10g n-butyl base glycidyl ether (BGE), and then carry out continuous dipping and winding of polyimide fiber (PI-BIA). Vacuum down for 20min. Then put it into a concave-convex mold, pre-cure at 80°C for 2 hours, cure at 150°C for 4 hours, and post-cure at 180°C for 2 hours. The glass transition temperature of the composite material is 170°C, the interlaminar shear strength is 63MPa, and the bending strength is 690MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Modulus | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com