Multi-pipeline pump driving type fiber impregnation system

A fiber dipping, fiber technology, applied in the direction of coating, etc., to achieve the effect of improving production efficiency, expanding the selection range, improving fiber exhaust and wetting speed and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

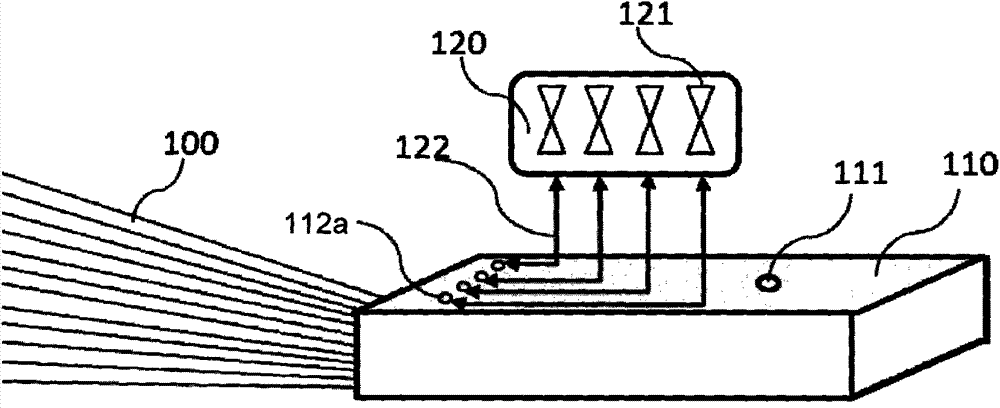

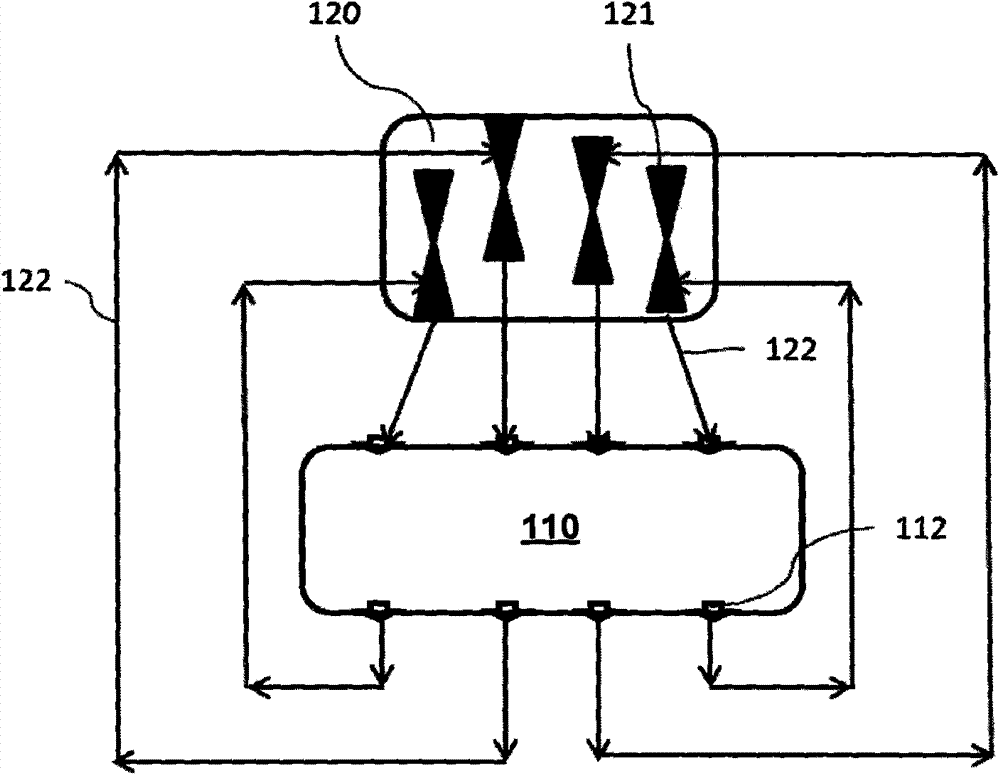

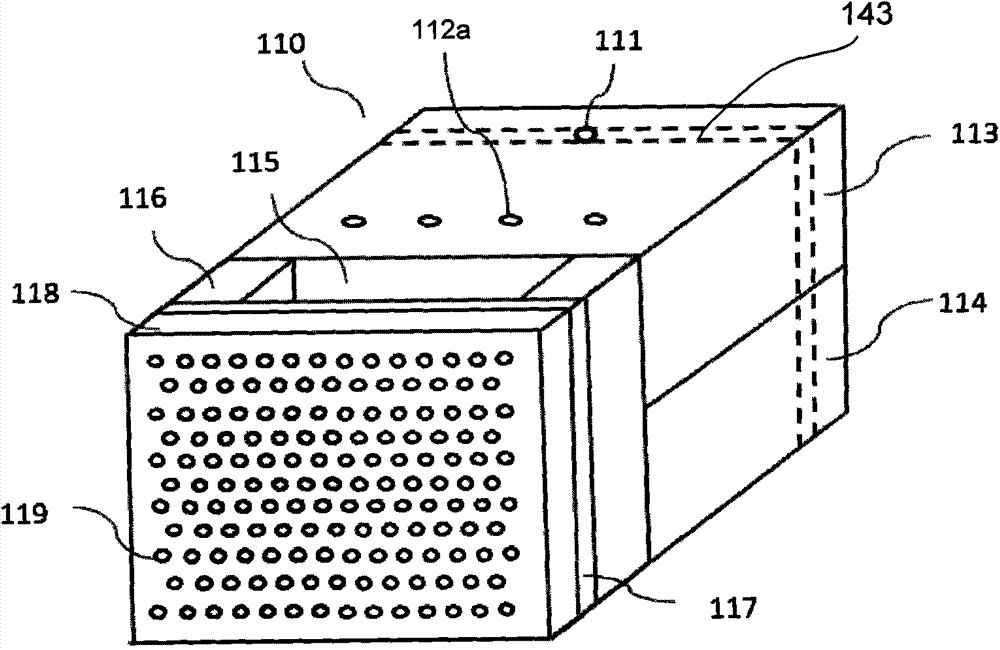

[0079] See Figure 7 , the composite material forming equipment in Example 1 of the present invention is arranged sequentially along the direction in which the fiber 100 enters the equipment and the pultruded profile 200 is pulled out of the equipment, with an inlet plate 150, a multi-pipeline pump-driven fiber impregnation system (including Glue box 110 and preformed plate 160), outlet plate 170 and forming curing device 180, wherein fiber 100 is initially wetted in the fiber dipping box 110 of the fiber impregnation system, and is further positioned by preformed plate 160 and outlet plate 170 to form a close The shape of the section of the profile 200 is further wetted, and the curing is completed in the cavity of the forming and curing device 180 , and finally the composite material profile 200 is formed and pulled out of the forming and curing device 180 .

[0080] Although Figure 7 Only one stage of preformed panels 160 is designed in the shown apparatus, but it is clea...

Embodiment 2

[0093] See Figure 8 , except for the number of preformed plates 160, the overall structure of the composite material forming equipment of the second embodiment of the present invention is basically the same as that of the composite material forming equipment of the first embodiment of the present invention. Such as Figure 8 As shown, it can be seen that two preformed plates 160 are arranged before the outlet plate 180 , so that two communication passages 130 are formed between the two preformed plates and between the preformed plate 160 and the outlet plate 170 .

[0094] Although Figure 8 Only two stages of preformed panels 160 are designed in the shown plant, but it is clear to a person skilled in the art that more than two stages of preformed panels 160 can also be designed. The preform plate 160 is provided with a series of small holes and / or slits which function to bend the fabric into a shape close to the cross-section of the final product and position the yarns in ...

Embodiment 3

[0102] See Figure 9 , in the composite material molding equipment of Embodiment 3 of the present invention, a closed cavity 142 is formed between the outlet plate 170 and the molding and curing device 180, and a vacuum suction port 141 can be equipped for the closed cavity 142, so that the cavity A specified vacuum degree is generated inside, so as to further improve the impregnation quality of the resin to the fiber. In the working state, the vacuum suction port 141 is opened to generate a certain negative pressure in the closed cavity 142 to help the air bubbles inside the fiber to escape, thereby impelling the resin to soak into the fiber.

[0103] In addition, the airtight cavity 142 can be opened or closed independently, so as to facilitate on-line processing of process failures of fibers at the mouth of the forming and curing device or other process equipment, such as yarn blocking and breaking. For this reason, the return end of the third return hose 122-3 may be dire...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com