Patents

Literature

1308results about How to "Guaranteed pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

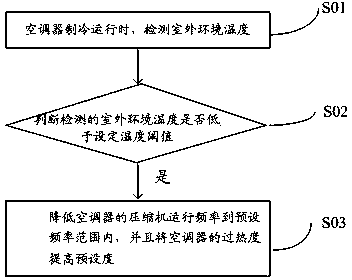

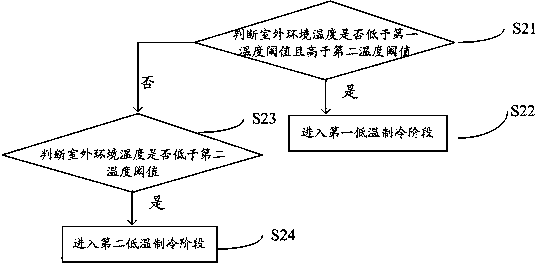

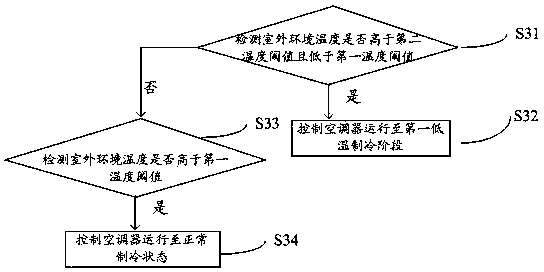

Low-temperature refrigerating control method of air conditioner and air conditioner

InactiveCN105627496AImprove cooling capacityImprove cooling performanceSpace heating and ventilation safety systemsLighting and heating apparatusContinuous operationThermal threshold

The invention provides a low-temperature refrigerating control method of an air conditioner and the air conditioner. By the adoption of the low-temperature refrigerating control method of the air conditioner and the air conditioner, the technical problem that an air conditioner cannot conduct refrigeration continuously under a low-temperature condition is solved. The control method comprises the following steps that when the air conditioner conducts refrigeration, the outdoor environment temperature is detected; whether the detected outdoor environment temperature is lower than a set temperature threshold value or not is judged; and if so, the operation frequency of a compressor of the air conditioner is lowered to be within a preset frequency range, and the superheat degree of the air conditioner is increased by preset degrees. According to the air conditioner adopting the control method, the effect that an indoor heat exchanger cannot enter a freeze protection mode at the low temperature is guaranteed, the indoor heat exchange capacity is improved, and then the refrigerating capacity is improved; in addition, continuous operation of the compressor is achieved, and the technical effect of continuous refrigeration is achieved at the low temperature.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

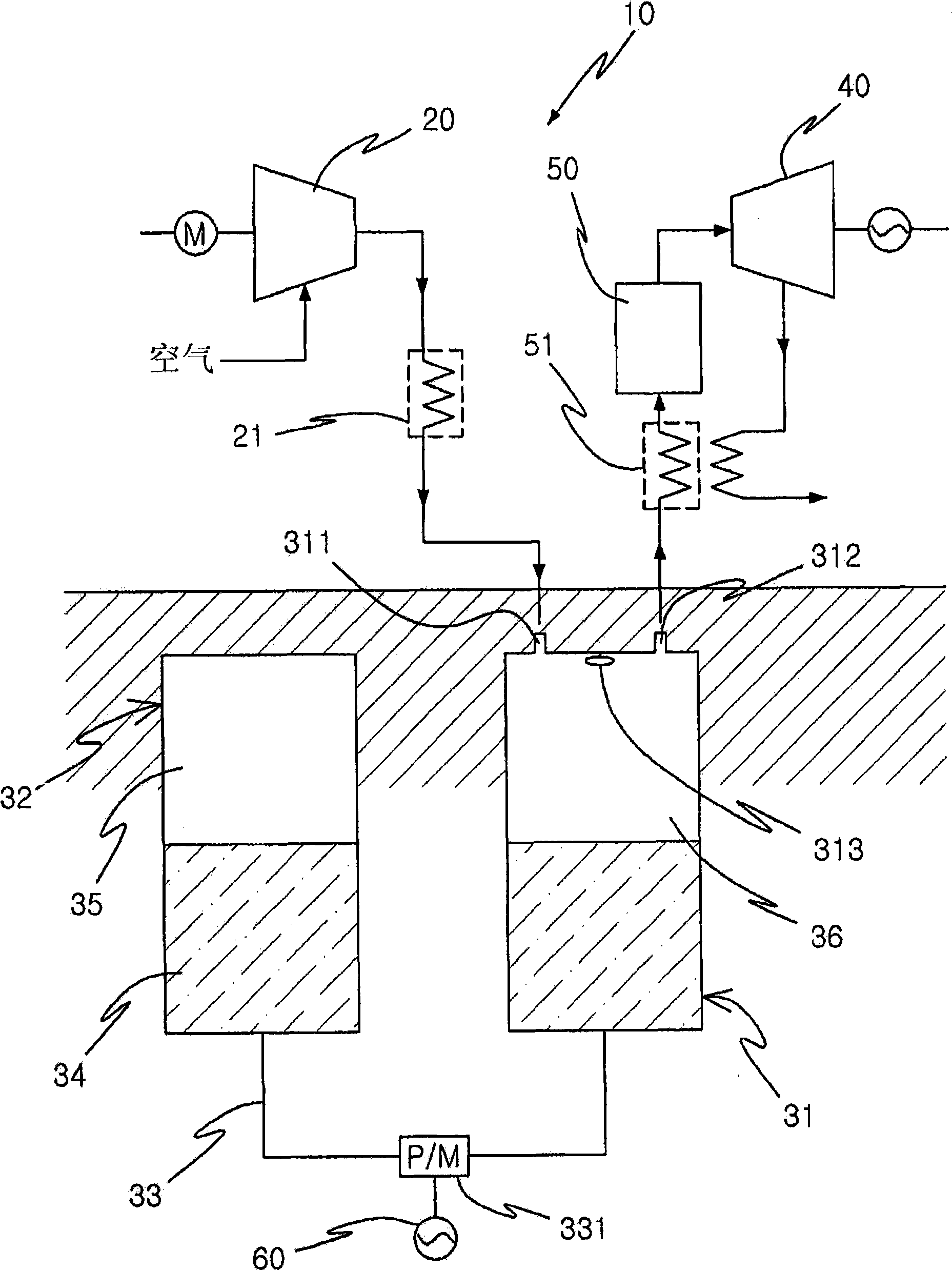

Compressed-air-storing electricity generating system and electricity generating method using the same

Disclosed are a compressed air energy-storing electricity generating system and an electricity generating method using the same, in which air of a high pressure is injected into a tank laid under the ground using midnight electricity and surplus produced electricity, and the air of the high pressure in the tank is uniformly discharged so as to drive a generator during a time period when the consumption of electric power is high, thus efficiently managing energy.

Owner:KOREA INST OF MASCH & MATERIALS

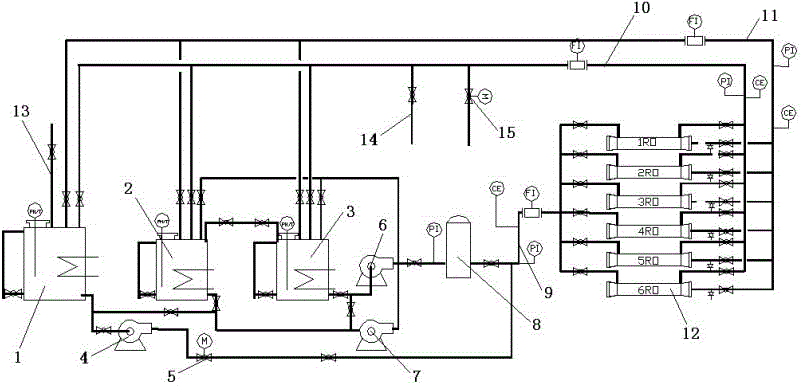

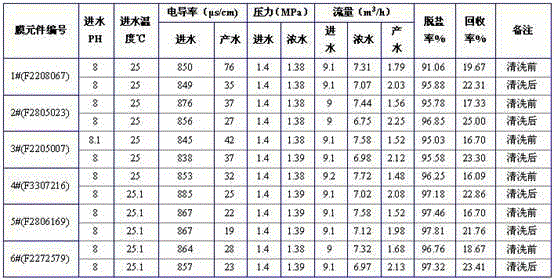

Offline cleaning and evaluating device of reverse osmosis membrane element and application method of device

ActiveCN103331102ARestore performanceEnsure cleaning flowSemi-permeable membranesReverse osmosisEngineering

The invention discloses an offline cleaning and evaluating device of a reverse osmosis membrane element and an application method of the device, belonging to the technical field of water treatment. The method can be used for evaluating the performance of the reverse osmosis membrane element, typically selecting cleaning agents according to the pollutant ingredients and contents and cleaning a single reverse osmosis membrane element in off-line multi-angle and multilevel manner by means of such operations as washing by a large amount of water, reverse washing, positive washing and soaking, and in the cleaning process, the method can be used for monitoring the performance of the reverse osmosis membrane element and controlling such factors as cleaning flow rate, pressure, cleaning time and temperature, so as to improve a cleaning effect. The offline cleaning and evaluating device disclosed by the invention can be also used for evaluating and testing the performance of the agents and the reverse osmosis membrane by simulating the onsite operation conditions.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

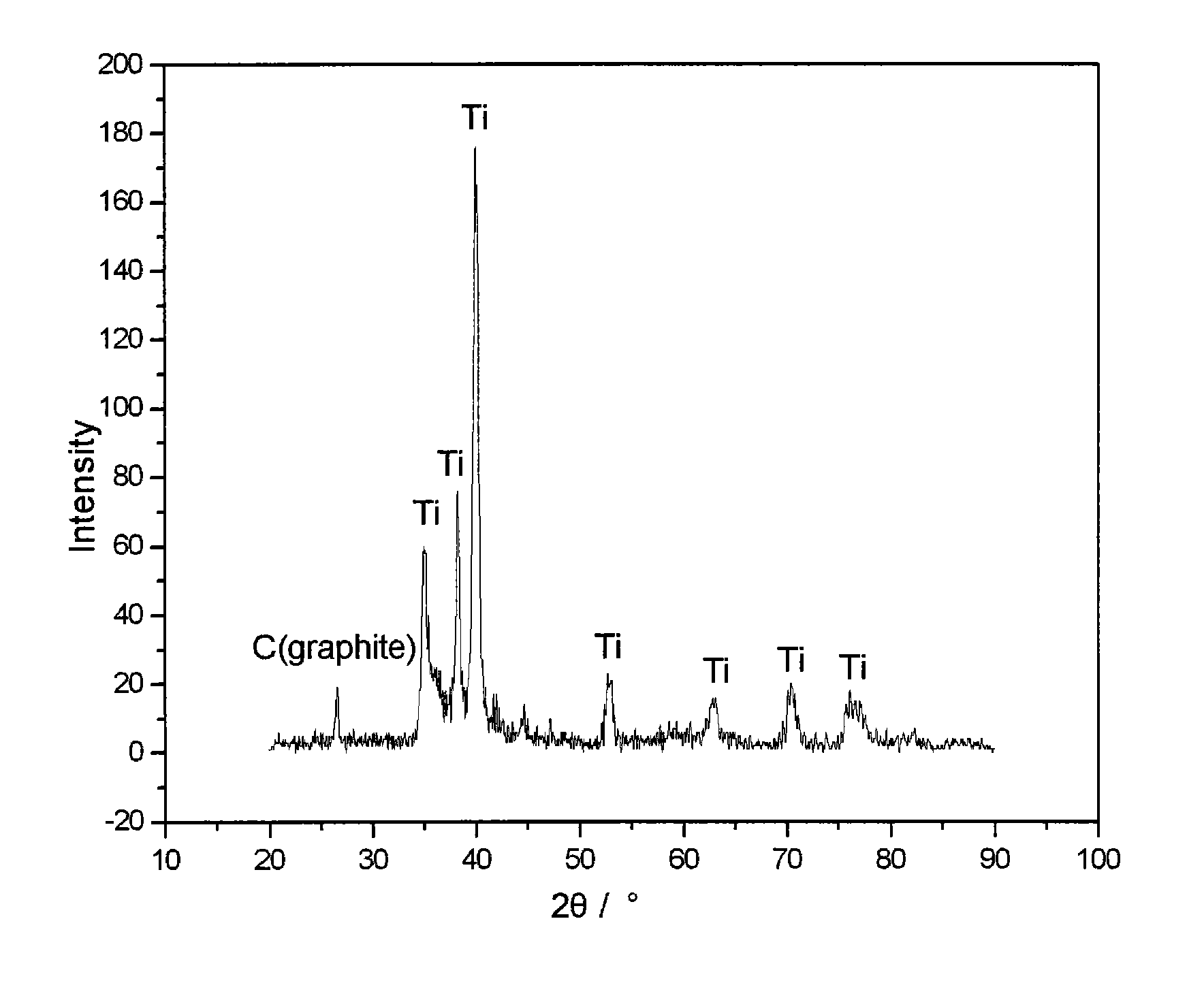

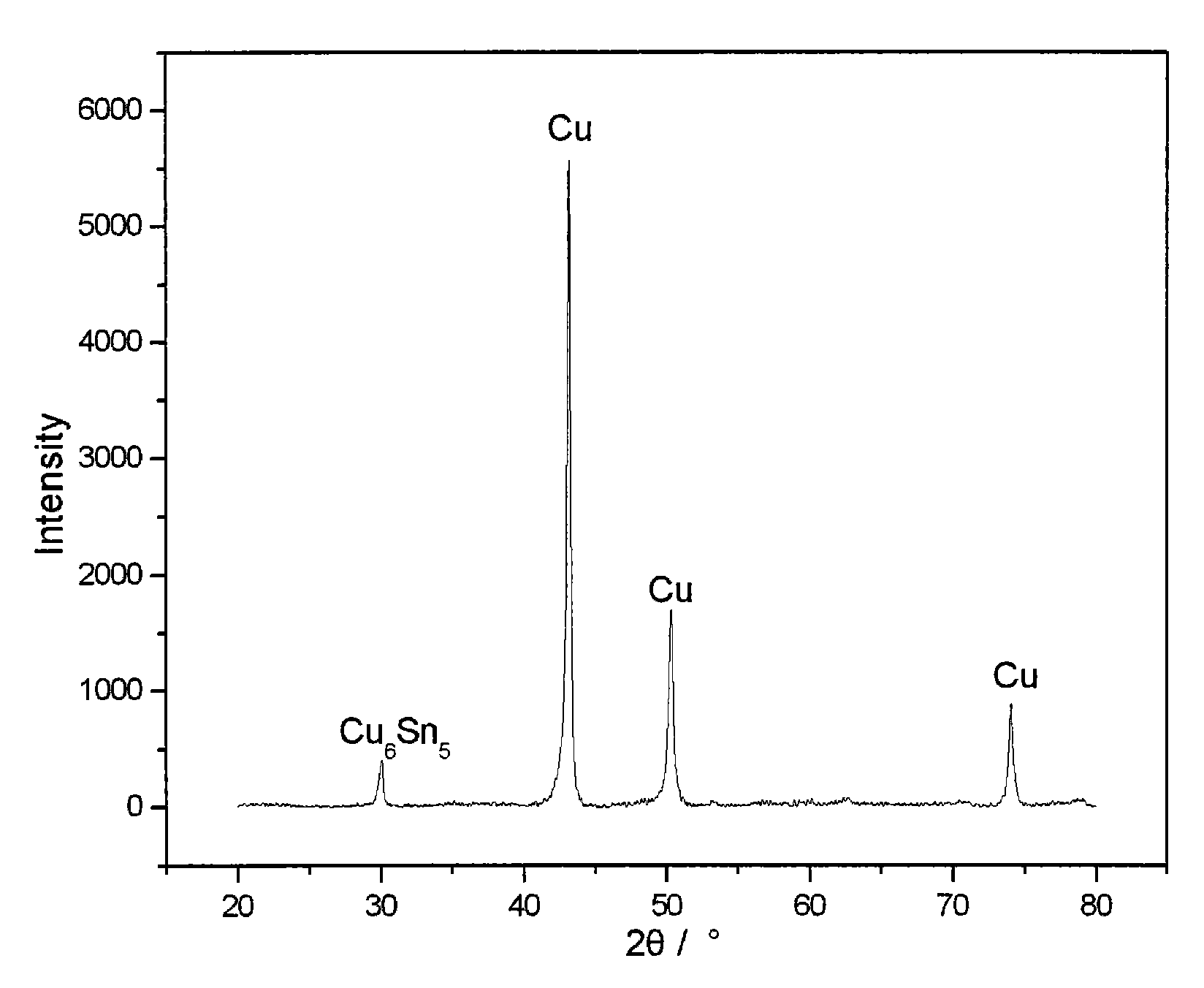

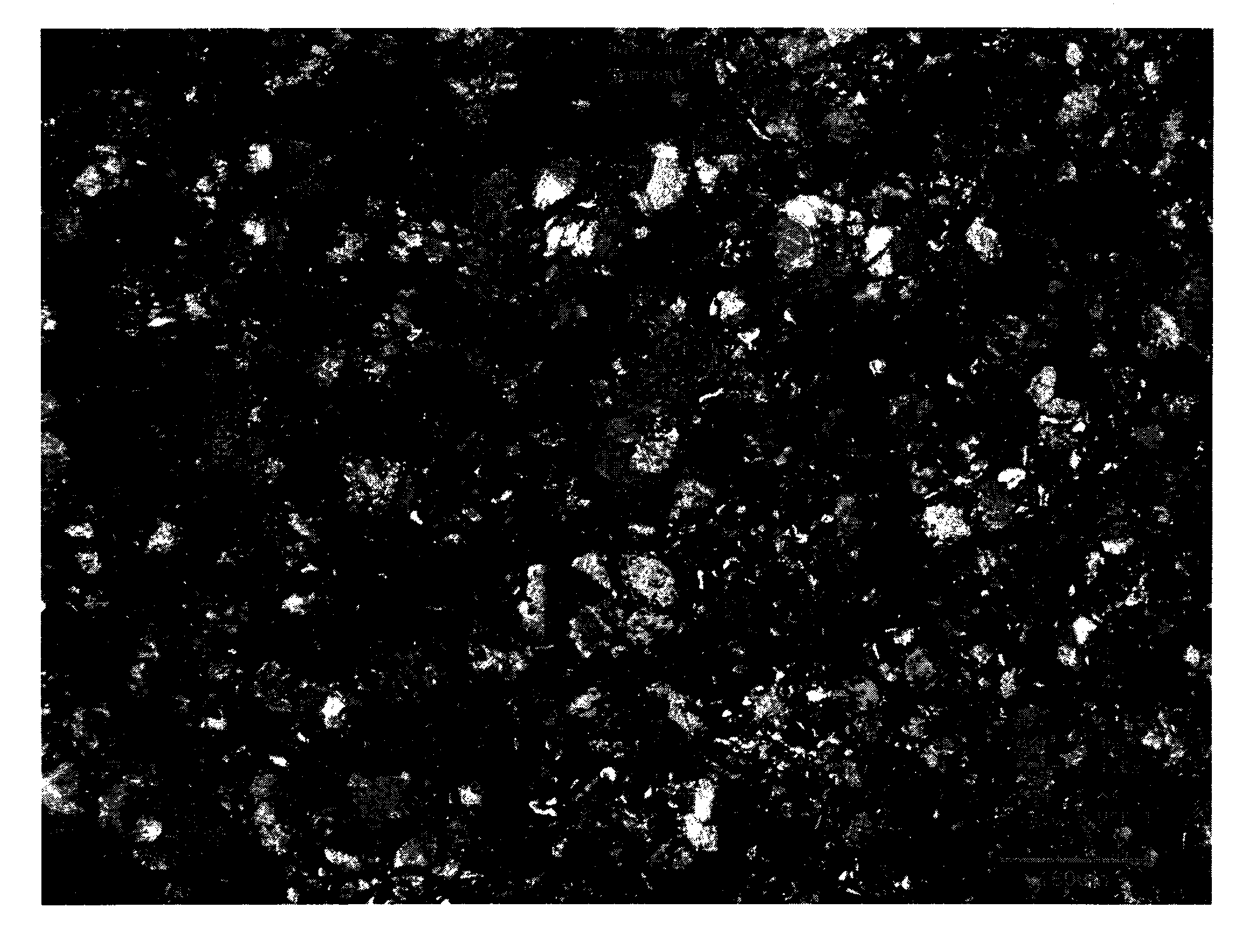

Metal-based powder metallurgy brake lining material and preparation methods thereof

InactiveCN101602105AExcellent material performanceSimple material compositionFriction liningPowder metallurgyCeramic particle

The invention discloses a metal-based powder metallurgy brake lining material and preparation methods thereof. The invention aims to solve the problems that the strength of a material is reduced along with the adding of ceramic particles when the powder metallurgy brake lining material is produced by the prior art and the like. The material comprises the following components in percentage by weight: 10 to 80 percent of Cu-Sn mechanical alloy powder, 1.25 to 15 percent of Ti-C mechanical activated powder, 2 to 65 percent of Fe powder, 0 to 10 percent of Ni powder, 0 to 12 percent of Cr powder, 2 to 8 percent of Al2O3 powder, and 7.75 to 23 percent of graphite, wherein the Cu-Sn mechanical alloy powder is prepared from Sn powder and Cu powder which contains 6 to 10 percent of Sn powder by mechanical alloying beforehand; and the Ti-C mechanical activated powder is prepared from Ti powder and C powder according to the ratio of 2:1-8:1 through mechanical activation beforehand, and forms TiC during the sintering. The invention also provides two preparation methods which combine the mechanical activation and the mechanical alloying with the prior powder metallurgy or discharge plasma sintering method.

Owner:JILIN UNIV

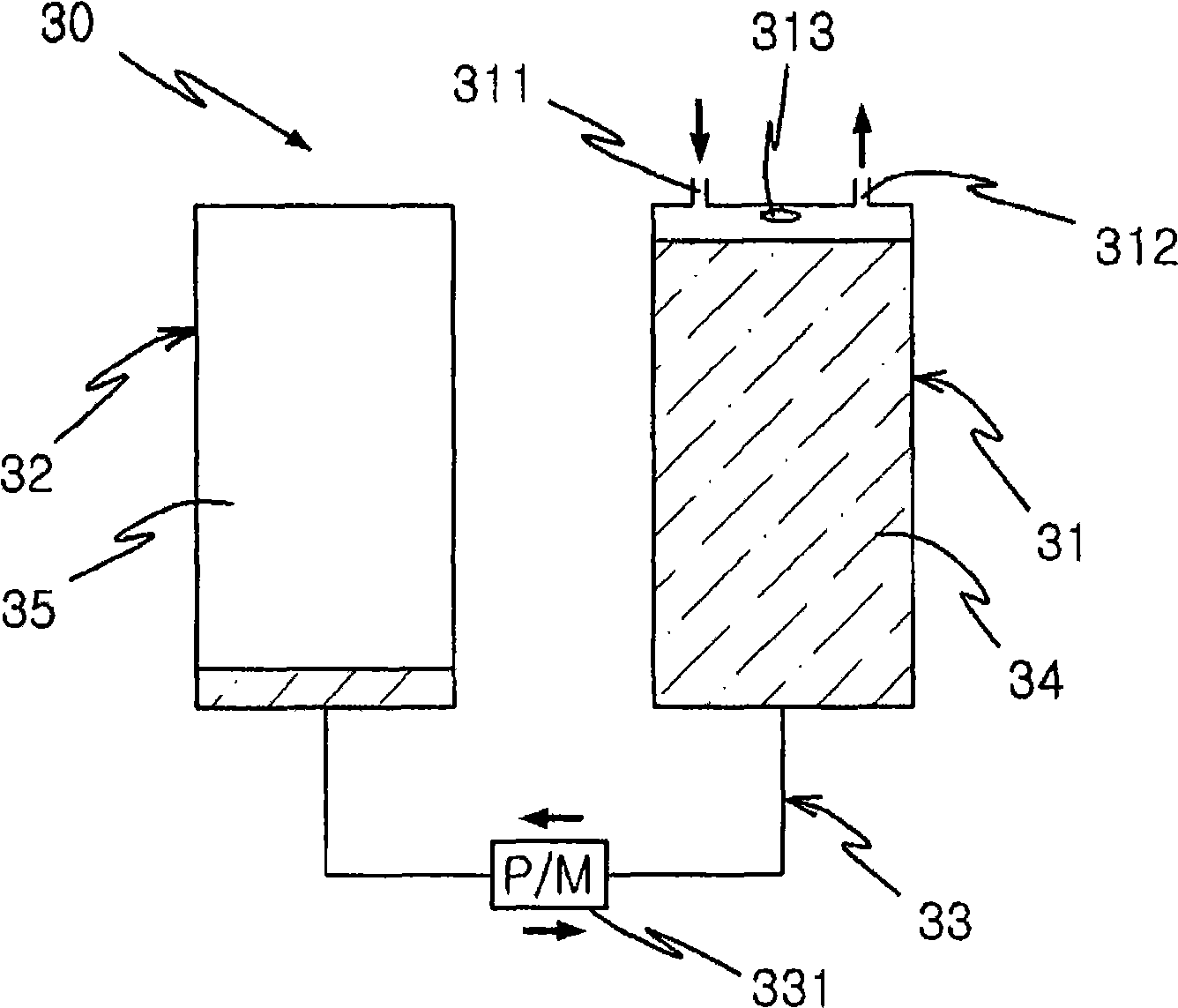

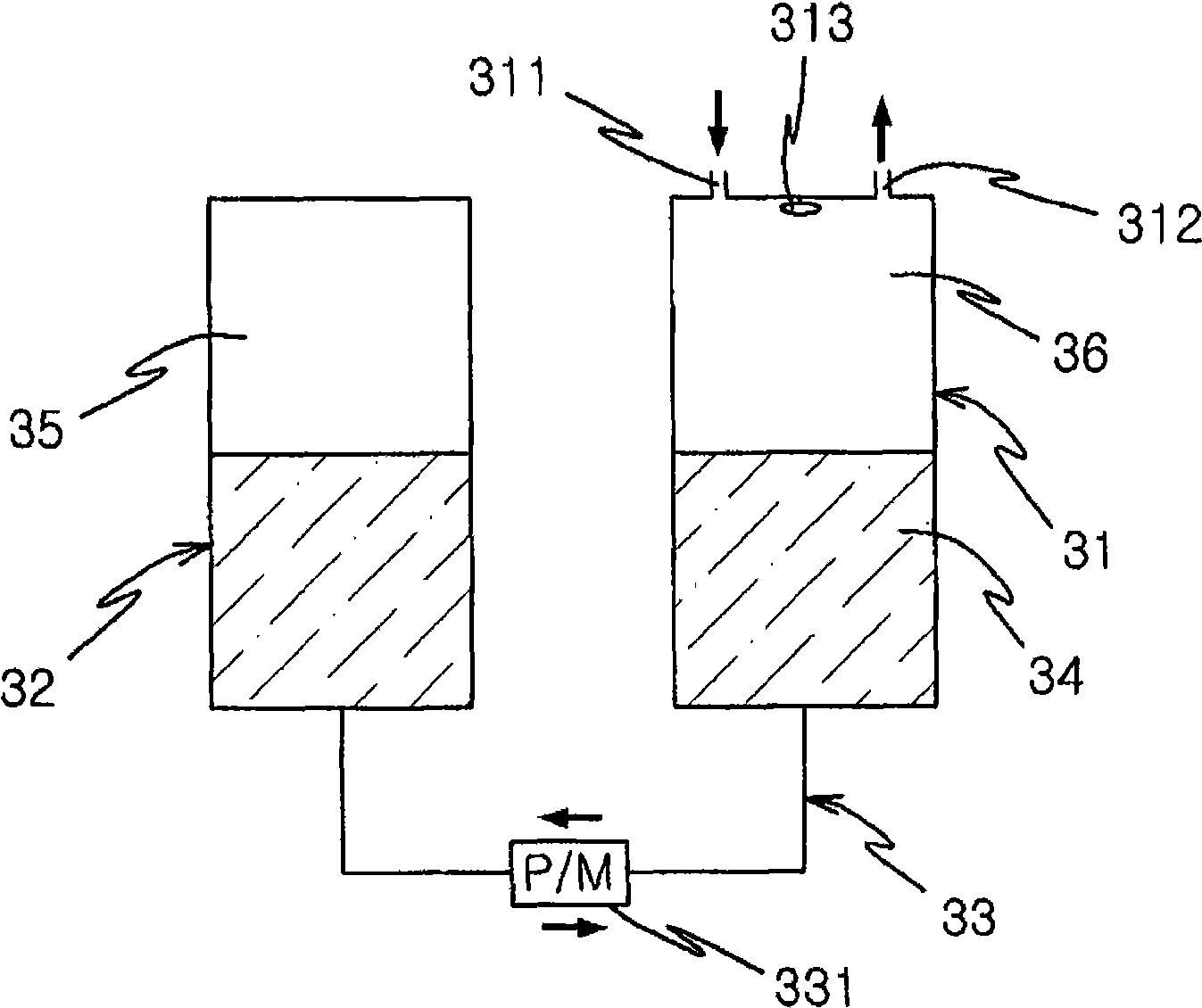

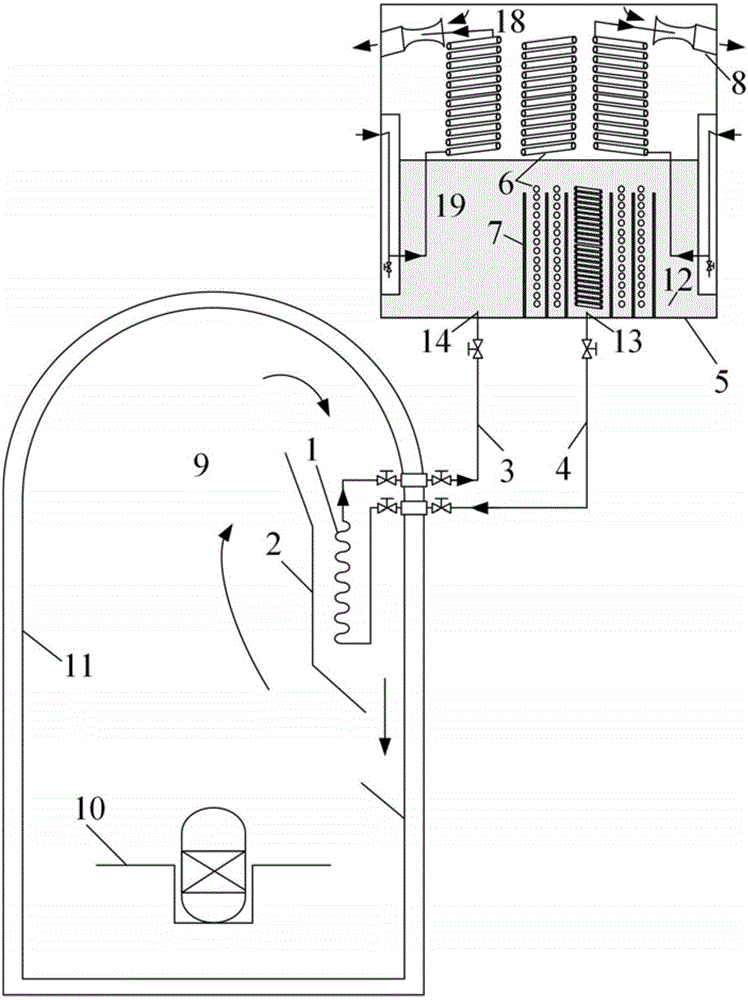

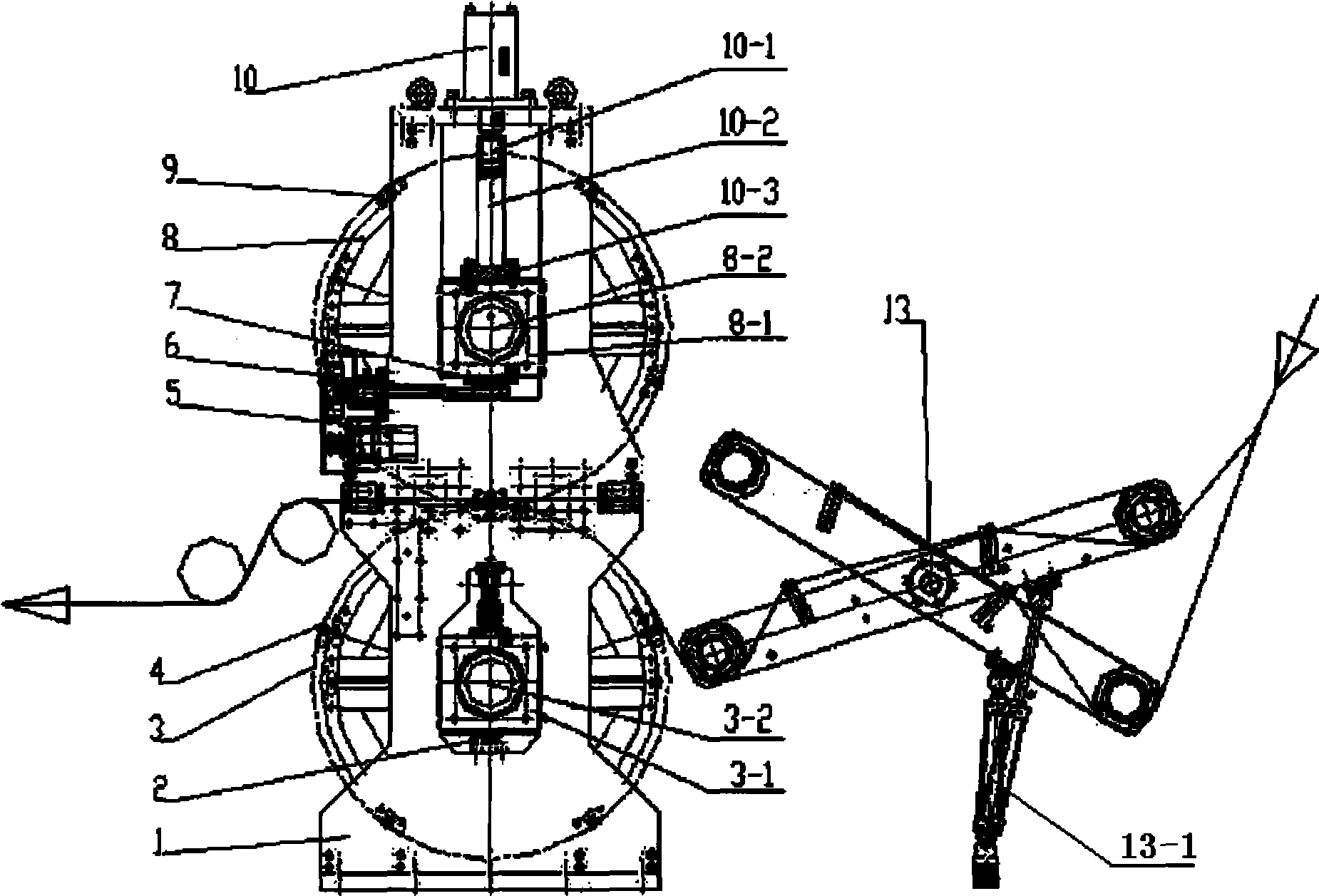

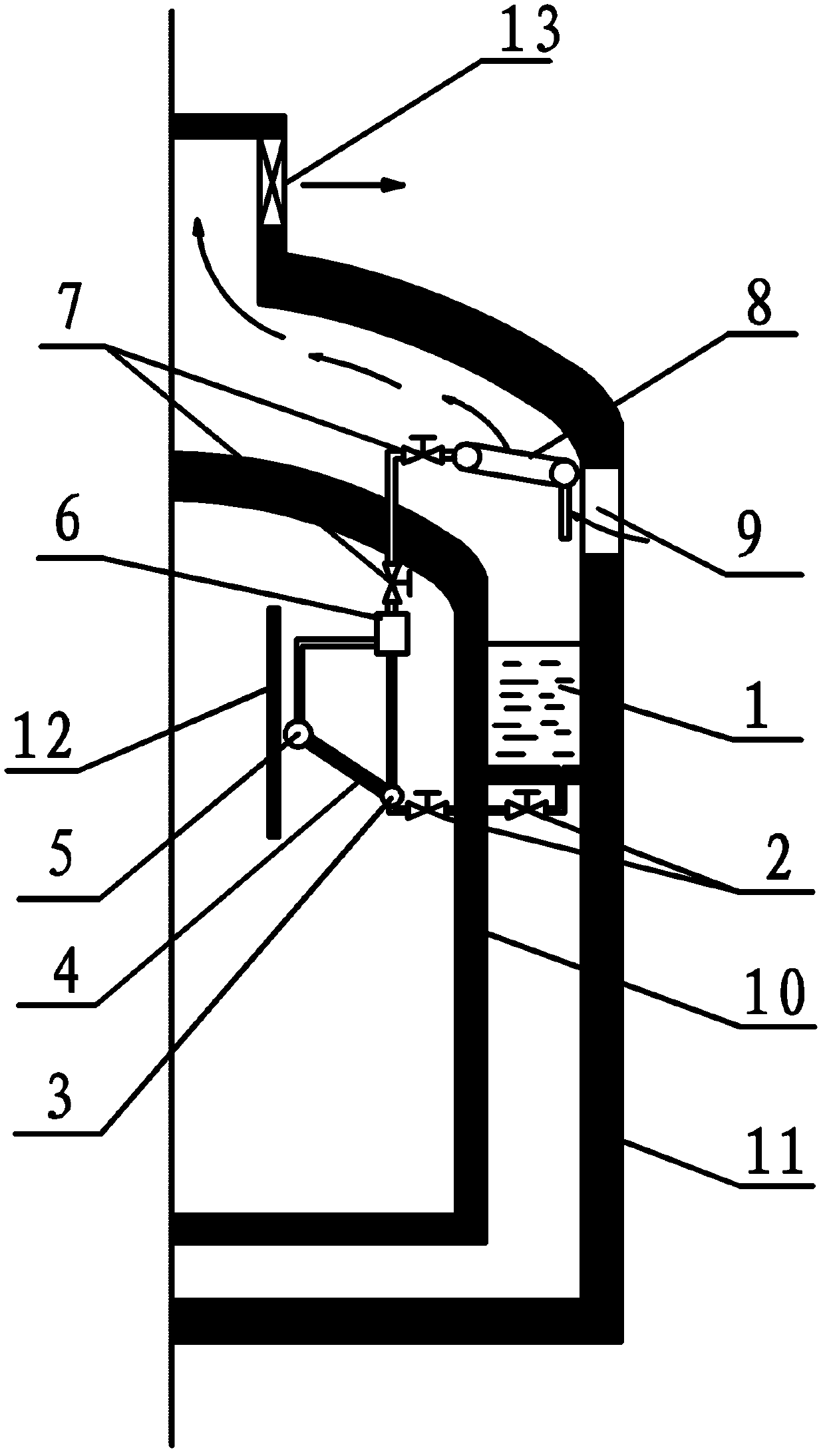

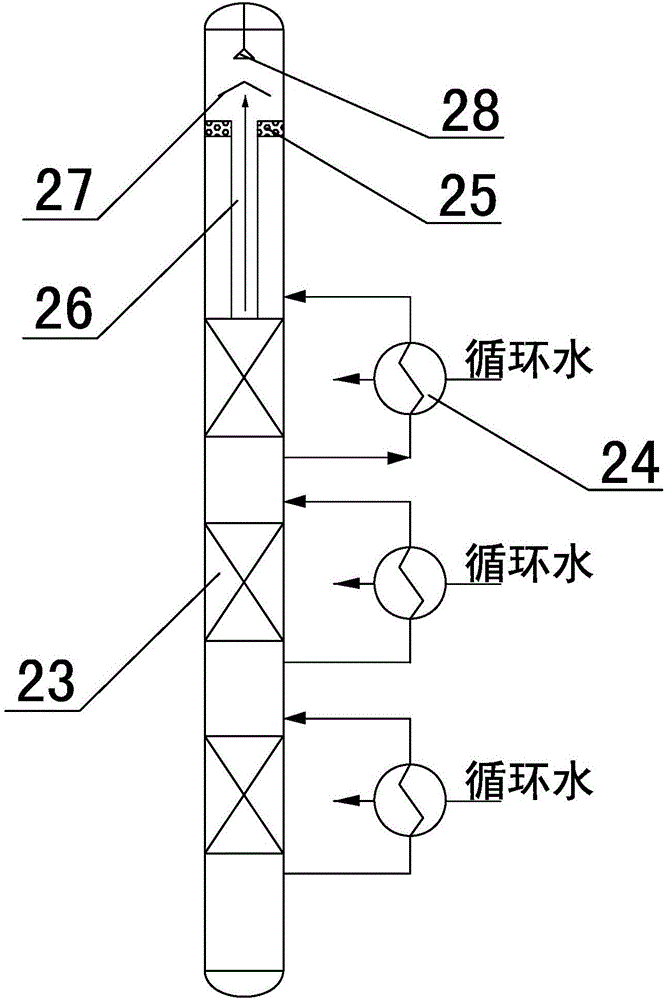

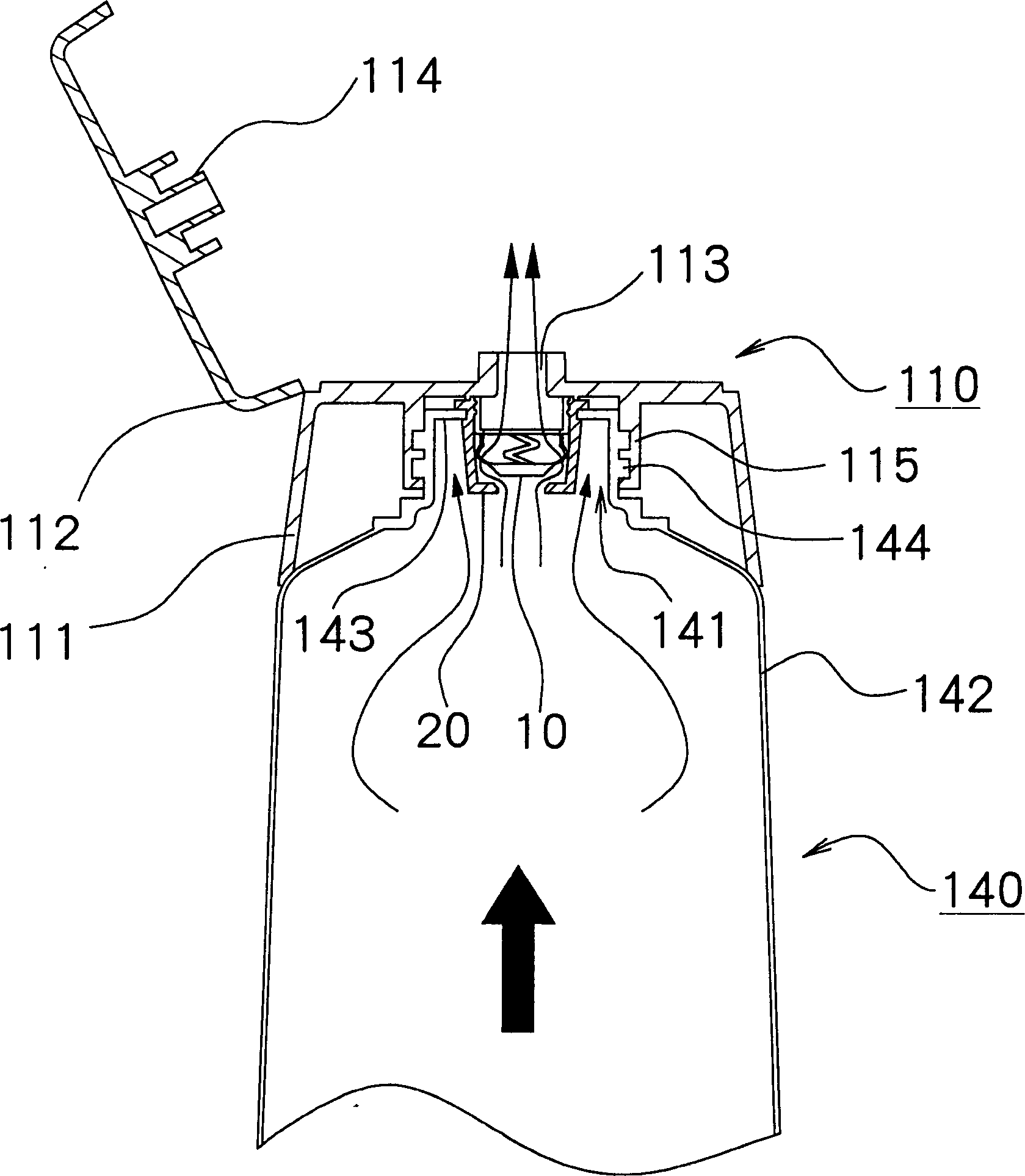

Long-term efficient passive containment cooling system utilizing jetting technique

ActiveCN106782698AImprove cooling efficiencyReduce evaporationNuclear energy generationCooling arrangementDischarge efficiencyWater vapor

The invention aims to provide a long-term efficient passive containment cooling system utilizing a jetting technique. A built-in heat exchanger of a containment and upper and lower pipe sections form a first-stage heat discharging system; an air cooler, a water tank baffle plate and a steam-air jet device in an external water tank form a second-stage heat discharging system of a cooling system; the steam-air jet device is located on the side wall surface of a gas space in the water tank and is used for introducing water steam produced by virtue of the first-stage heat discharging system into an ejector to jet air of the second-stage heat discharging system, so as to decrease the inlet temperature of the first-stage heat discharging system, so that the heat discharging efficiency of the system is improved; and a passive containment heat exchanger adopts an intensified heat exchange pipe and is located in the containment, the heat exchange pipe adopts a small-coil-pipe light pipe, and drainage plates are mounted on the periphery of the heat exchanger. According to the long-term efficient passive containment cooling system, when a crevasse accident occurs at a main cooling agent loop or a main steam pipeline, the internal heat in the containment can be efficiently taken away in a long term, so that the internal temperature and pressure of the containment can be below safety limit values for a long time under accident conditions.

Owner:HARBIN ENG UNIV

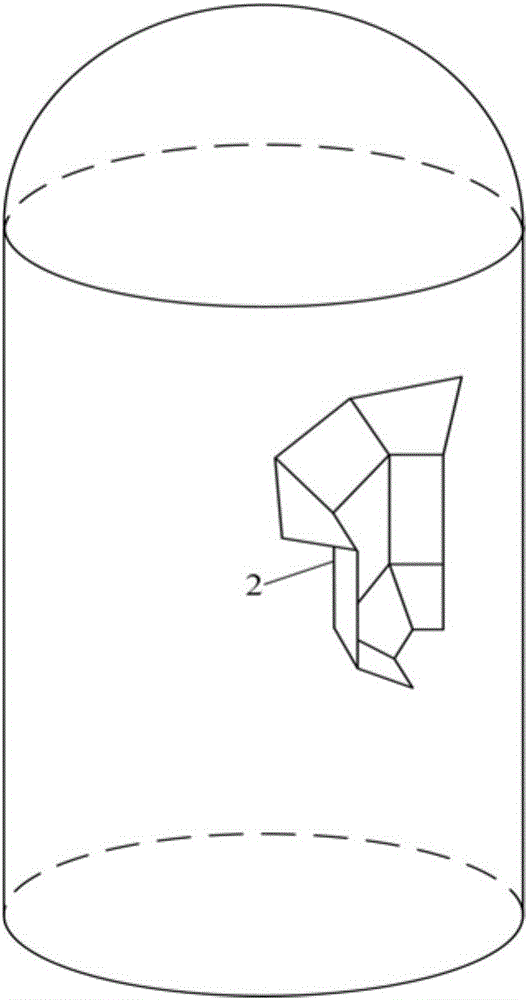

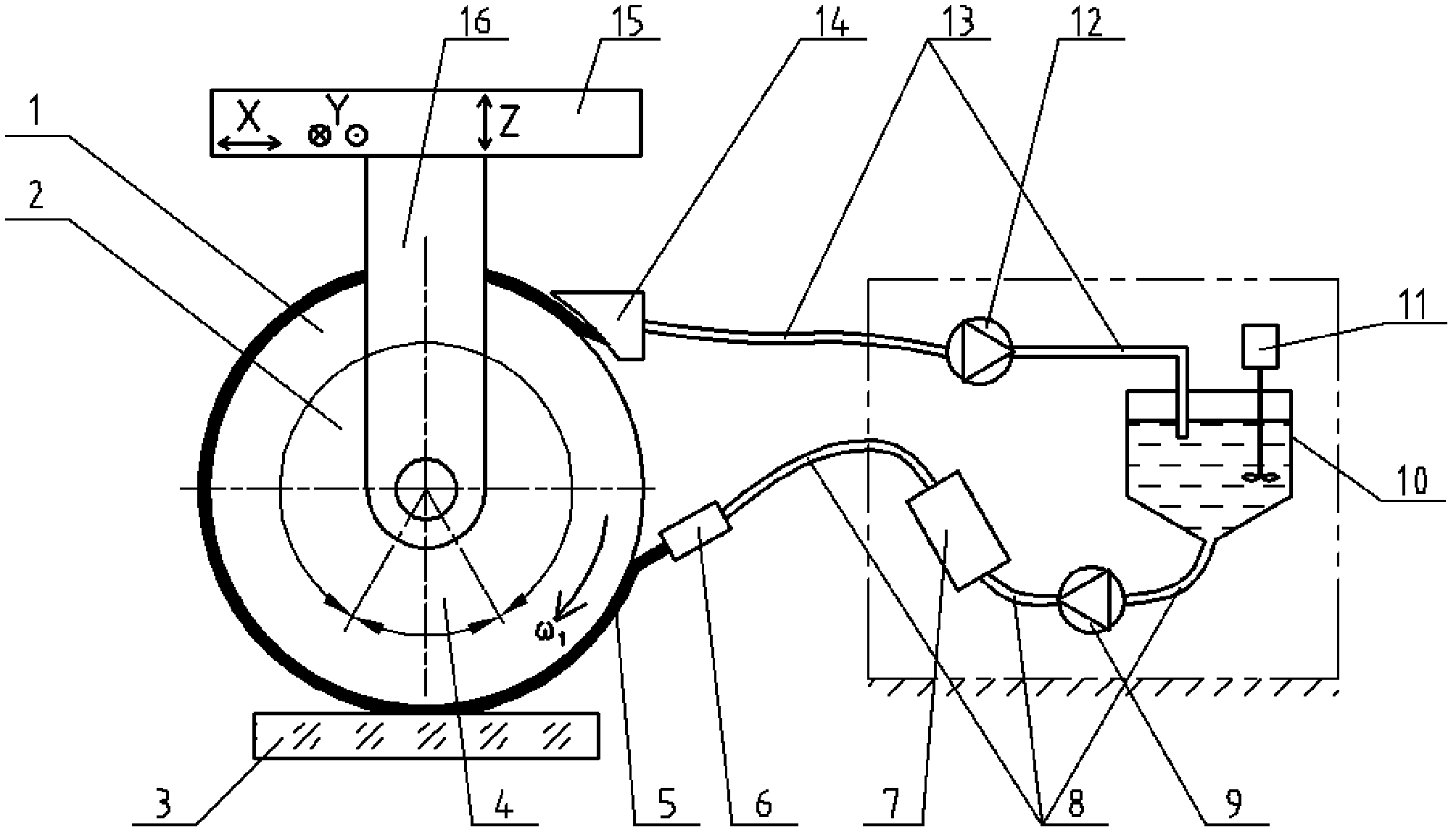

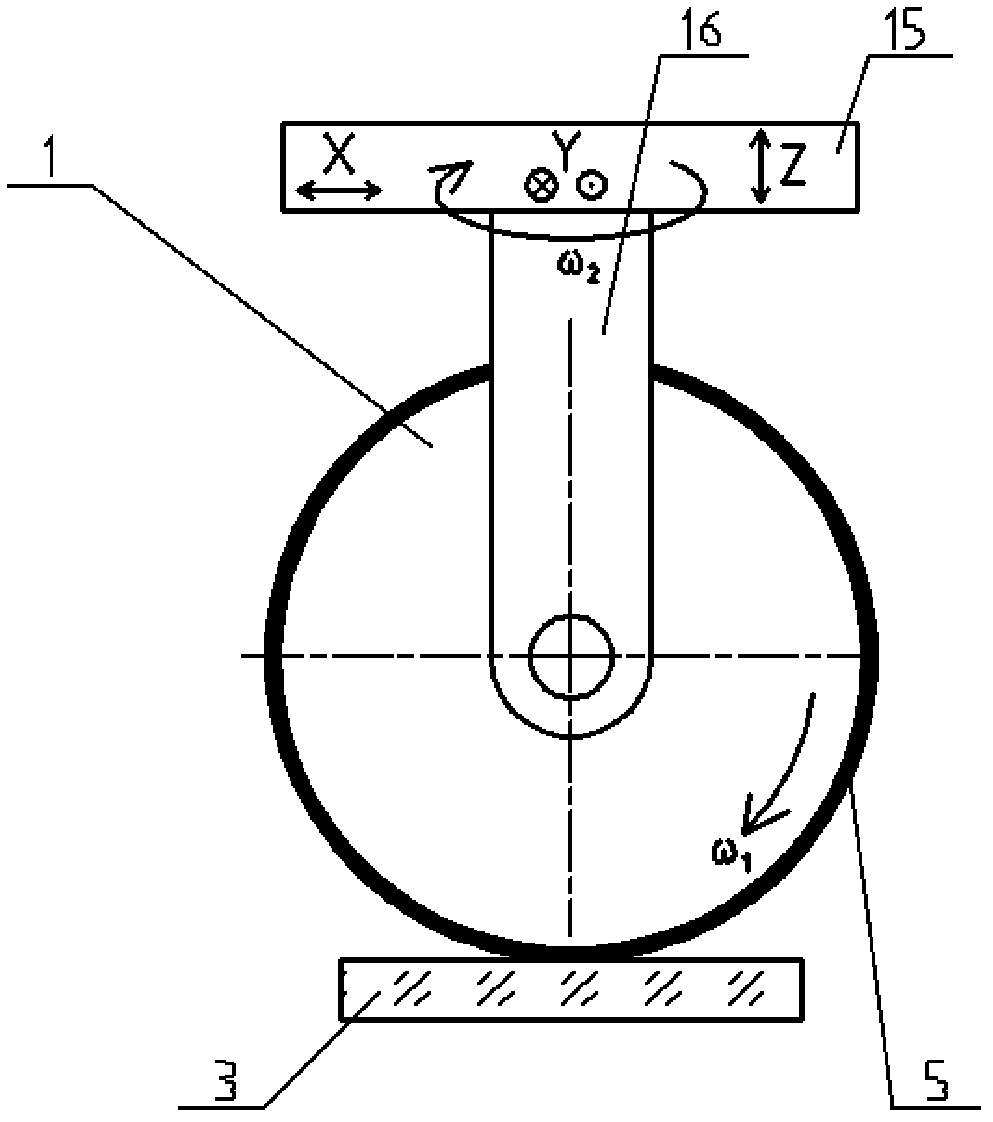

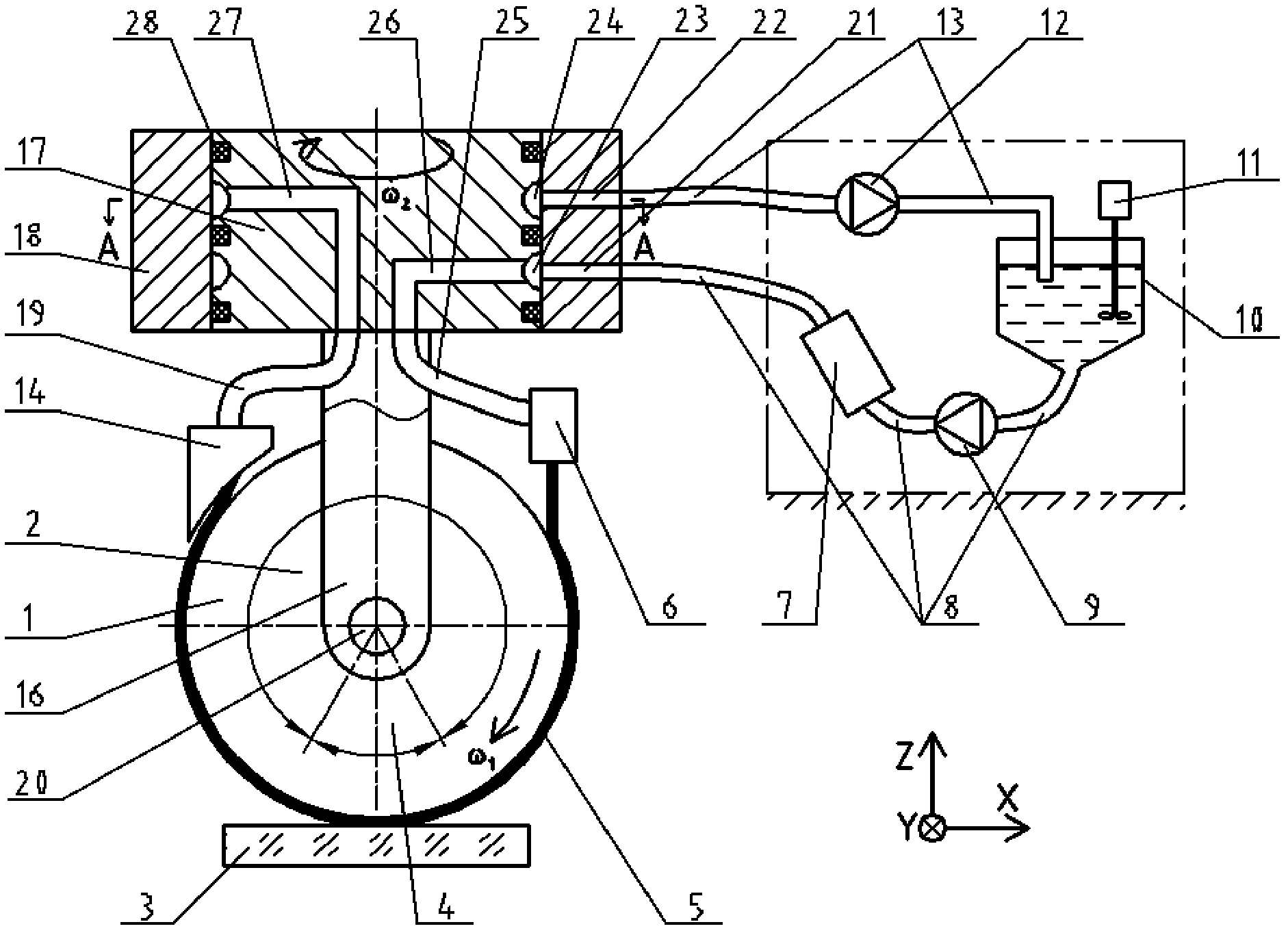

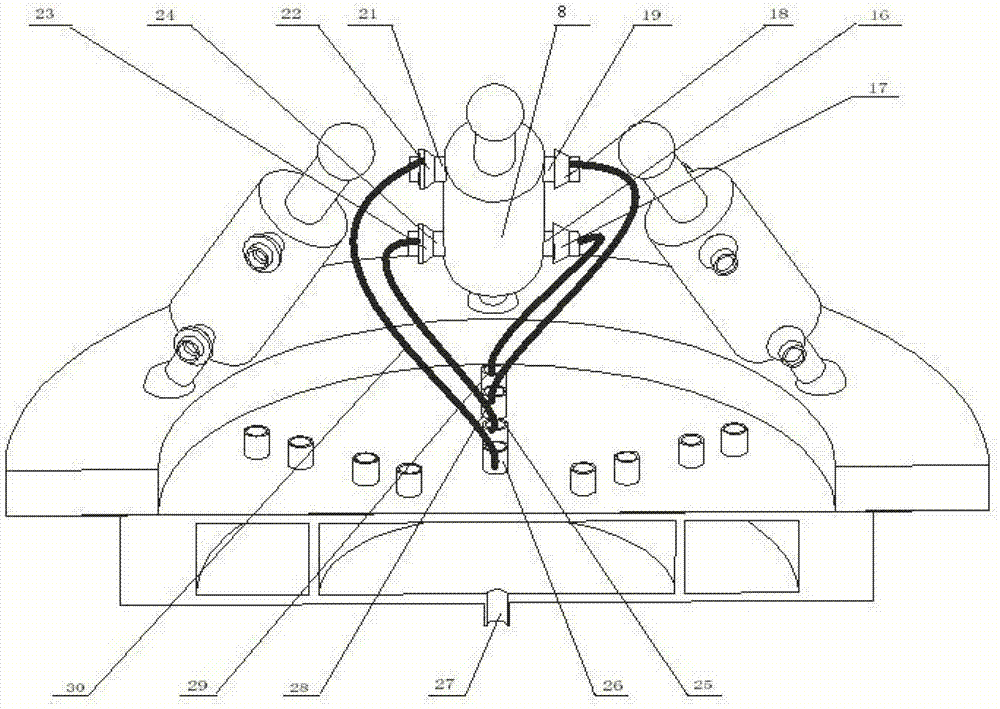

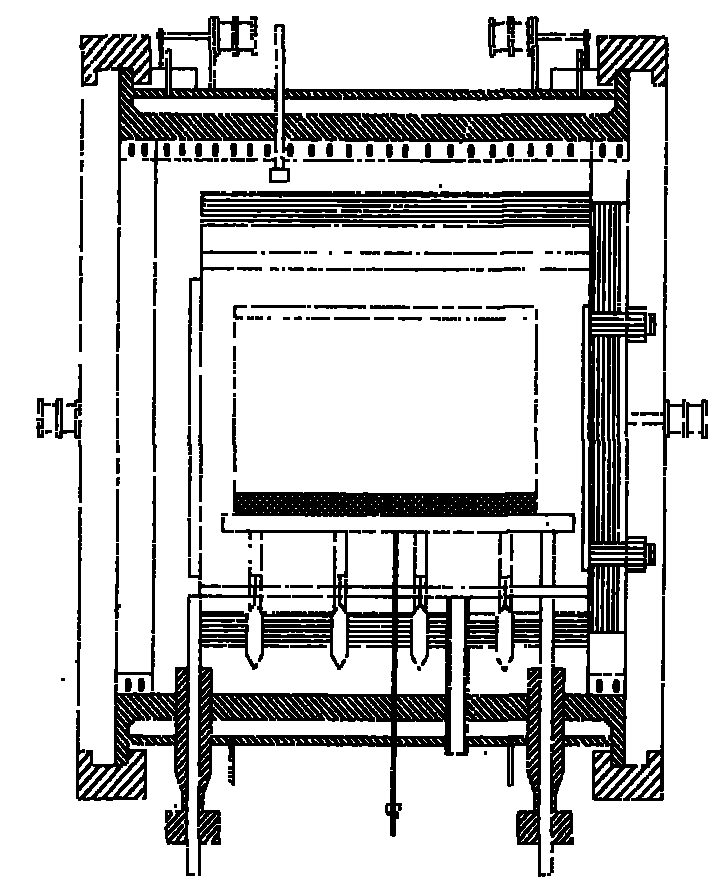

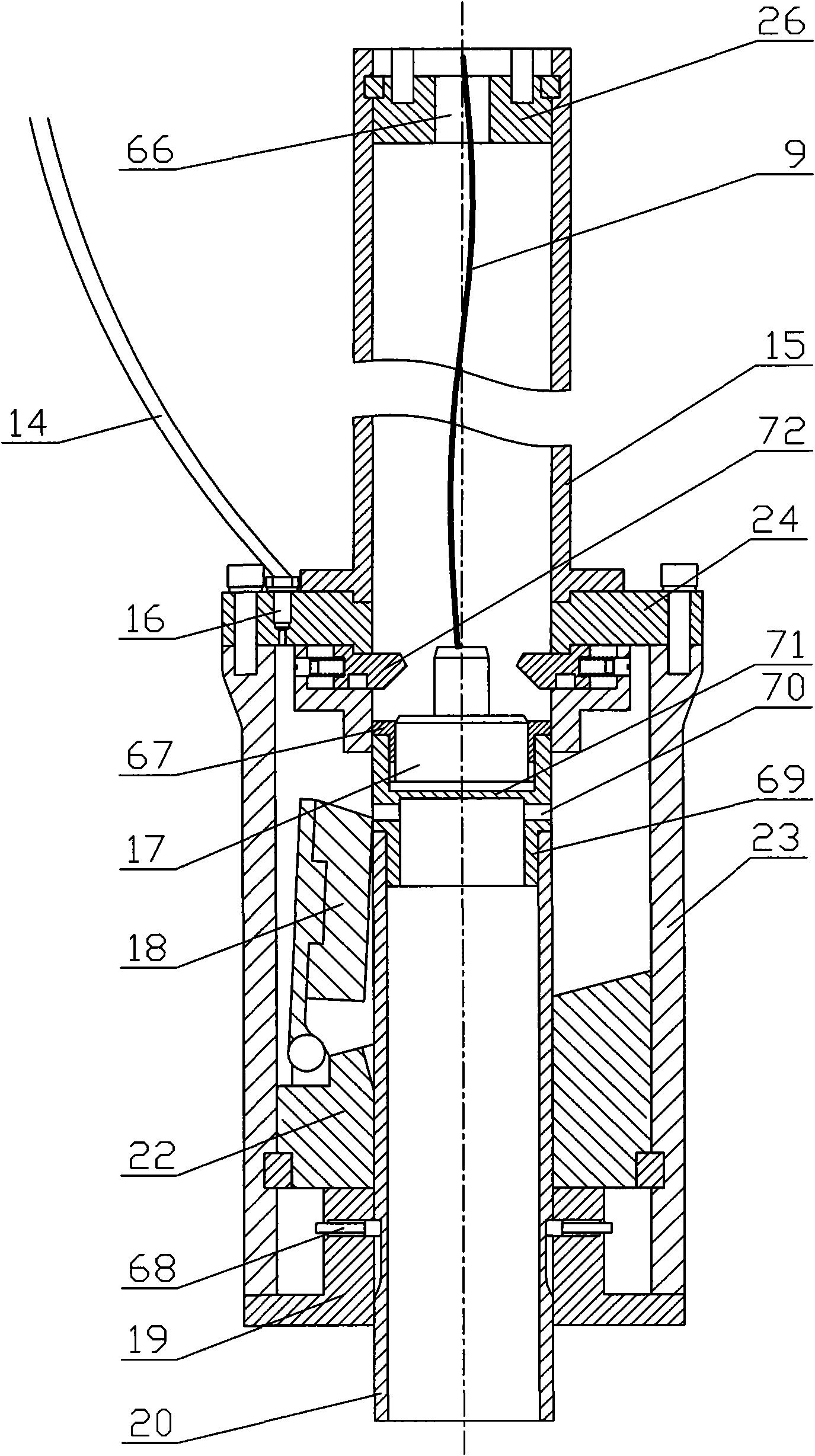

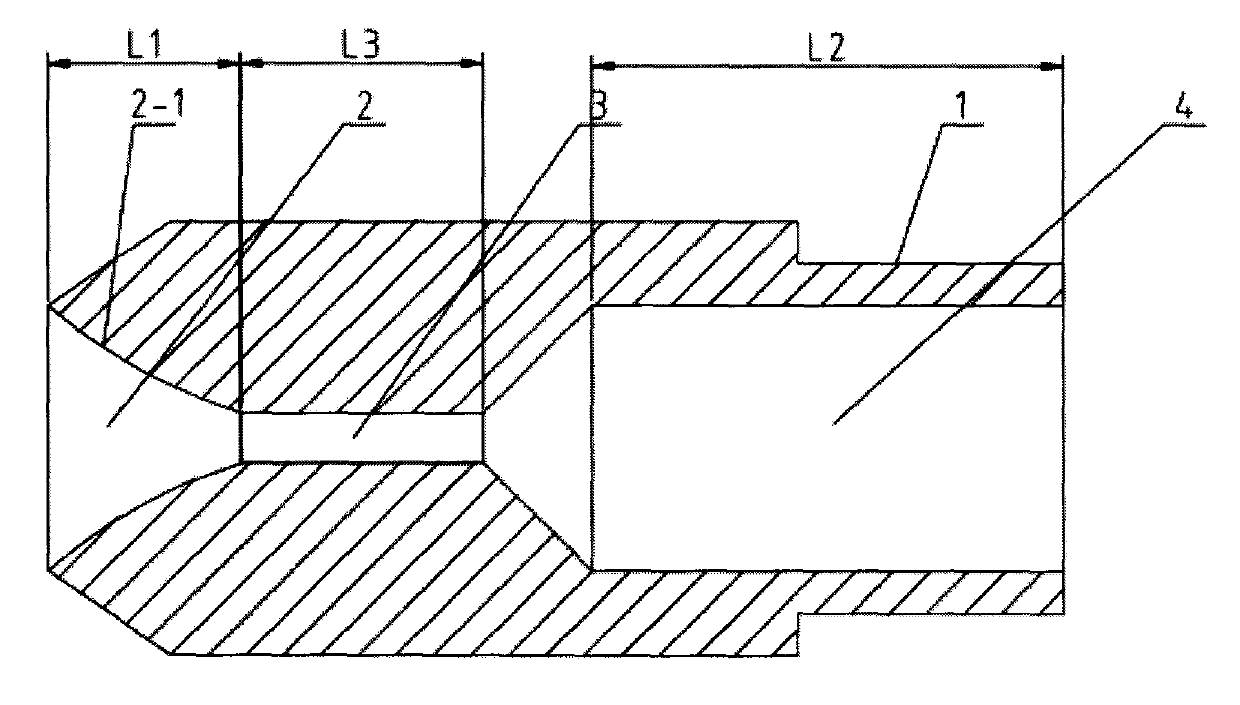

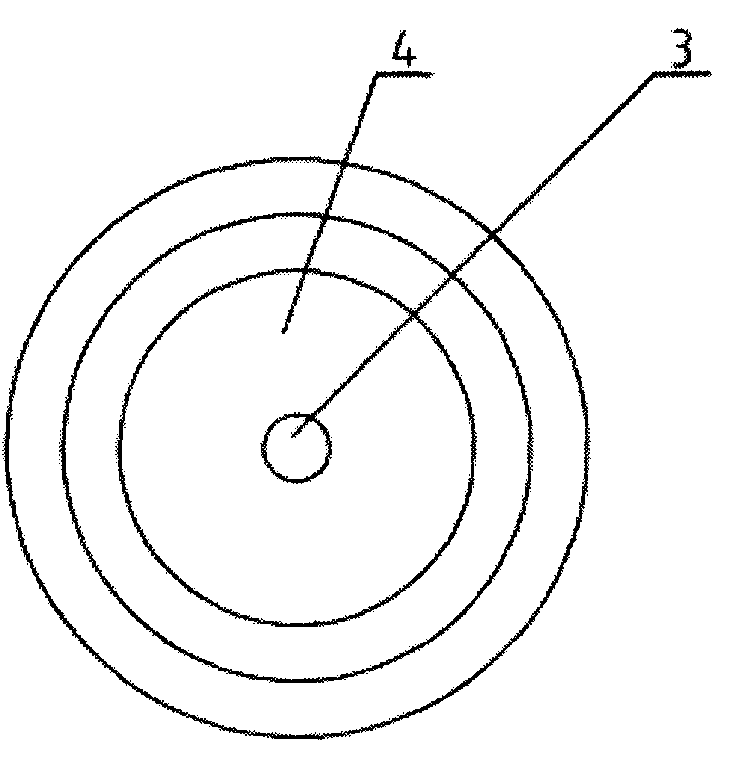

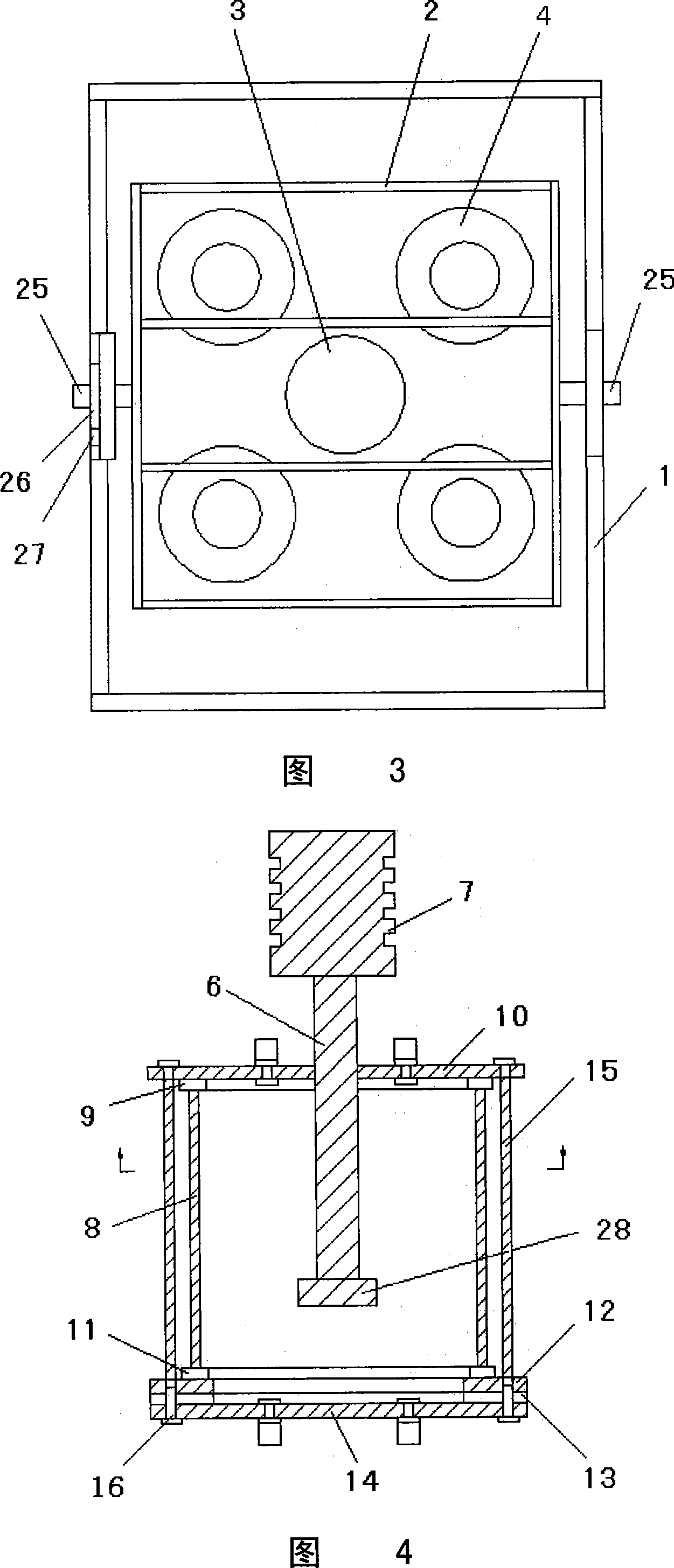

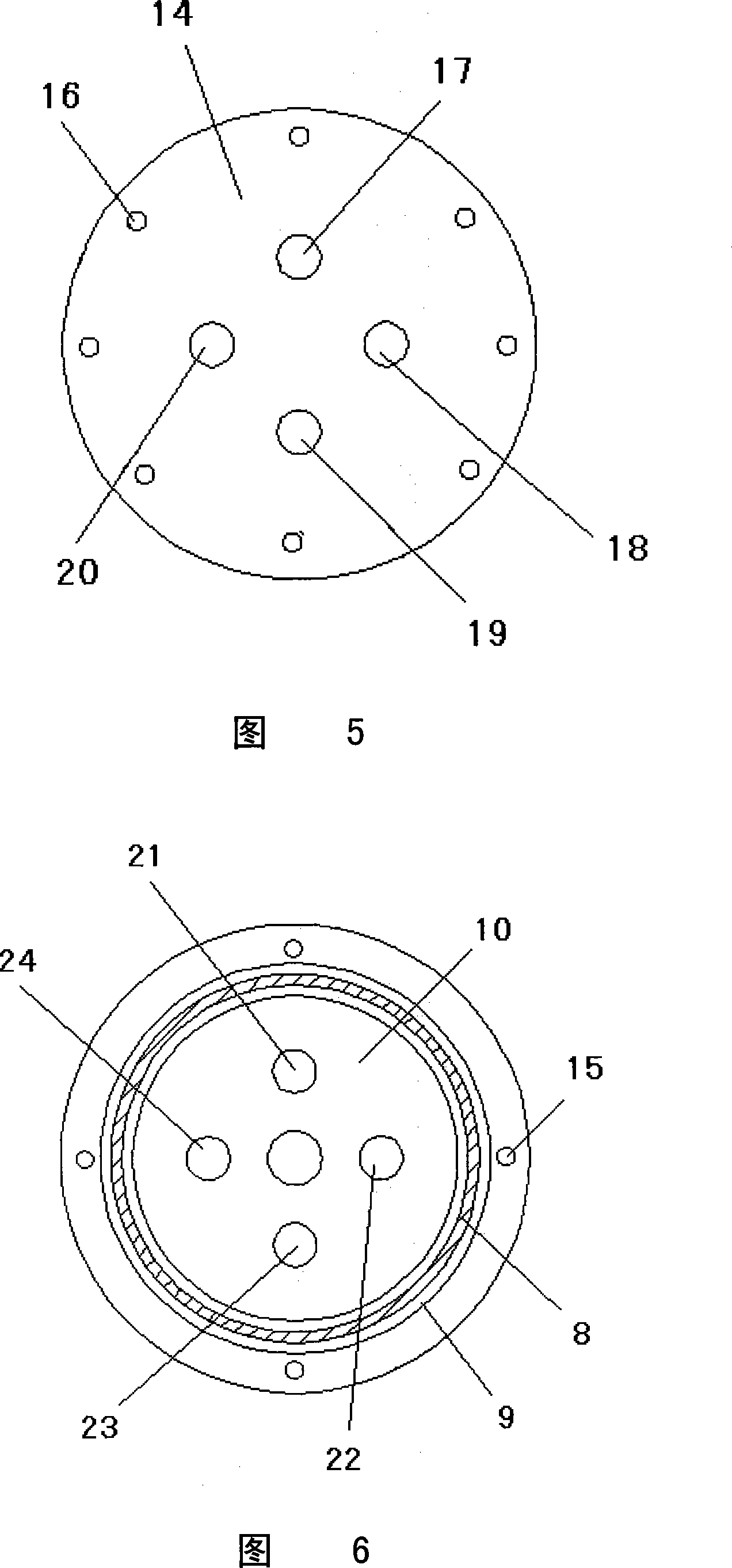

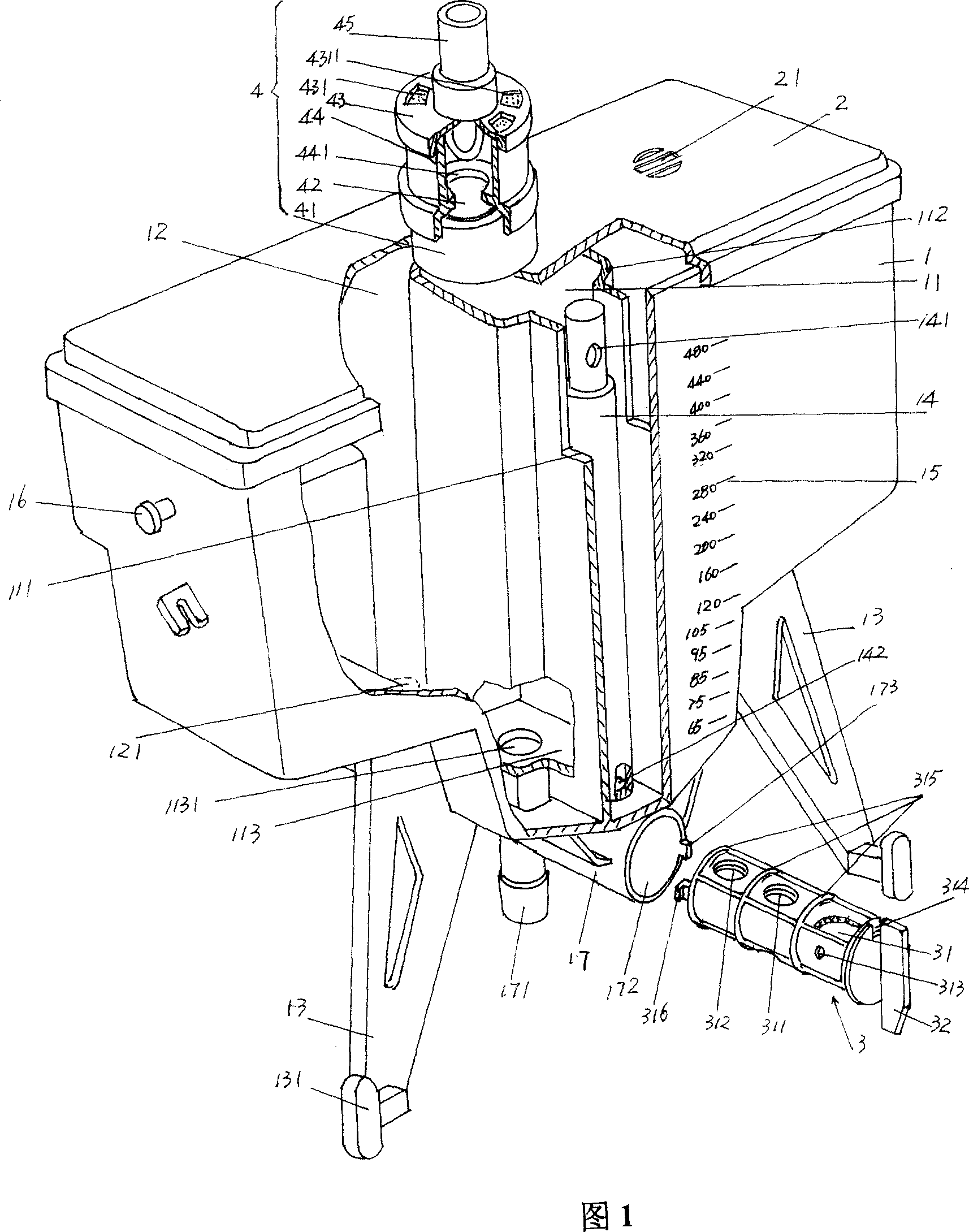

Device for realizing rotary fluid supply and recycle during revolving/rotating type magnetorheological polishing

InactiveCN102501146AGuaranteed pressureAvoid depositionGrinding/polishing apparatusEngineeringLiquid tank

The invention relates to a device for realizing rotary fluid supply and recycle during revolving / rotating type magnetorheological polishing, which comprises a shell, a revolving base, a bearing block, a rotating shaft, a polishing wheel, a circulating system and other necessary auxiliary devices, and is characterized in that the circulating system comprises a first fluid injection channel, a second fluid injection channel, a first fluid extraction channel, a second fluid extraction channel, a fluid injection annular groove, a fluid extraction annular groove and a sealing ring. Magnetorheological polishing fluid in a fluid storage tank flows into the fluid injection annular groove and the second fluid injection channel through the first fluid injection channel on the shell and is added onto the polishing wheel through a fluid injection nozzle. The magnetorheological polishing fluid recycled by a collector flows into the second fluid extraction channel on the shell through the first fluid extraction channel and the fluid extraction annular groove and finally returns to the fluid storage tank. The problem of settlement and unsmooth operation of the magnetorheological polishing fluid during circulation in the existing revolving / rotating type magnetorheological polishing technology can be solved, and the problem that the pipeline cannot be cleaned automatically via the operation of a pump also can be solved.

Owner:TSINGHUA UNIV

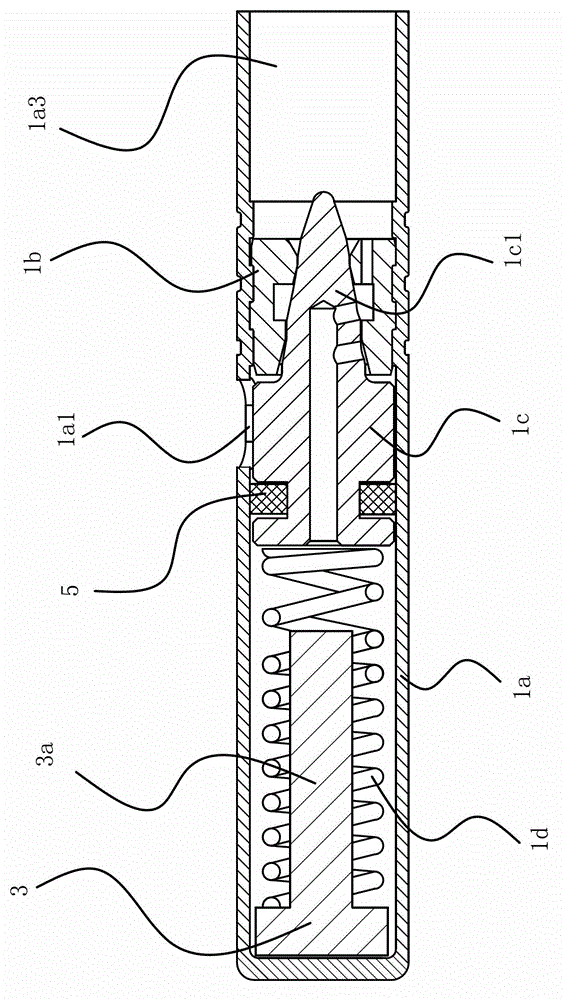

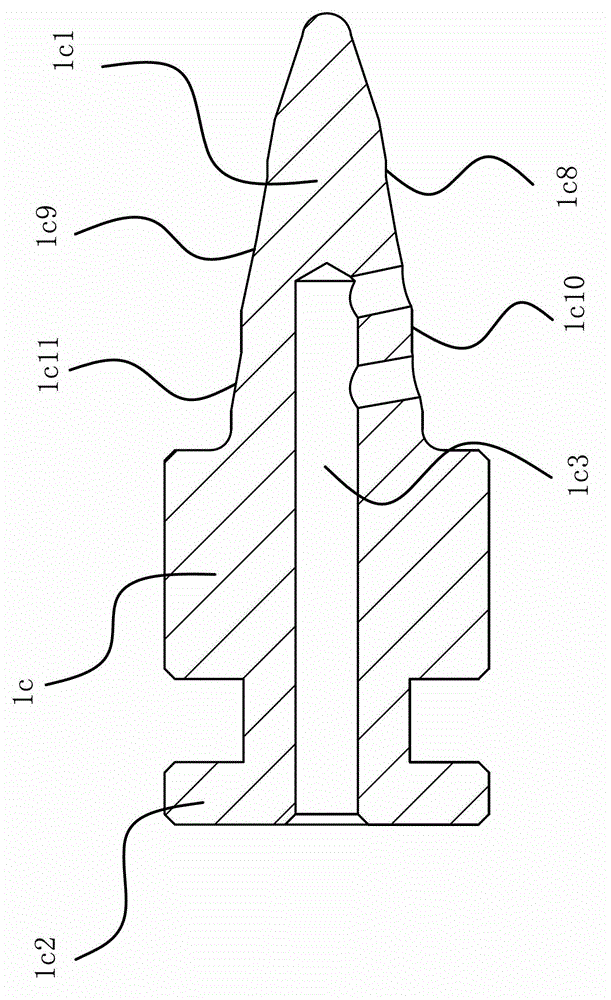

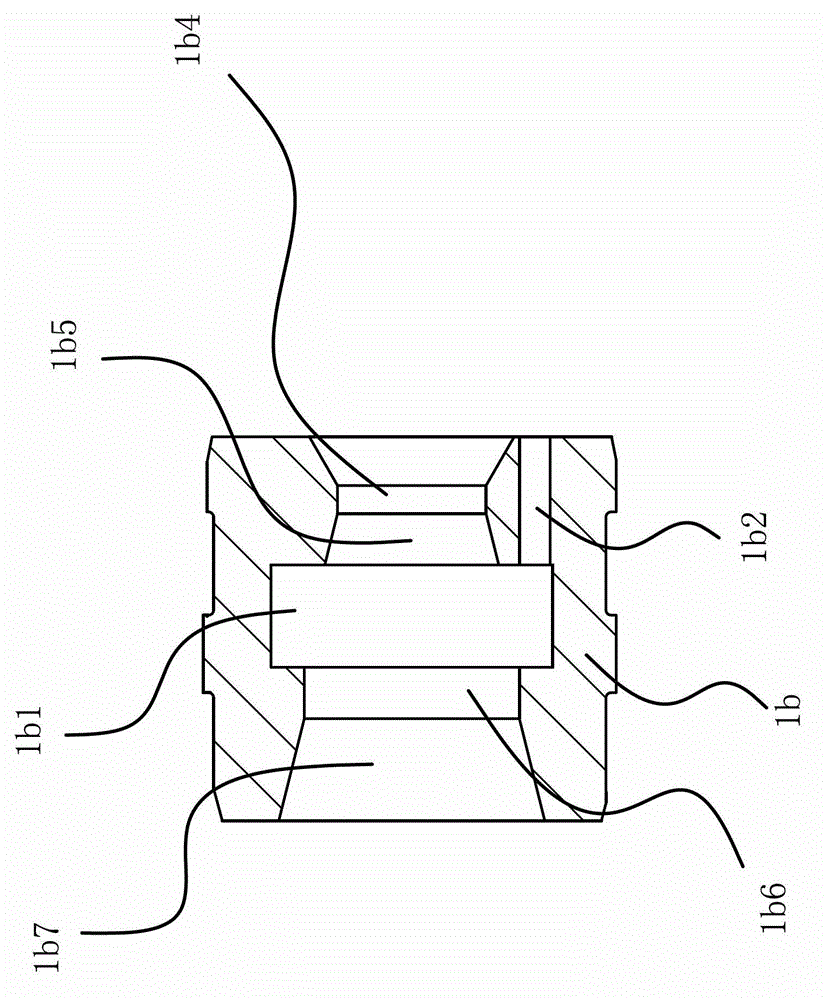

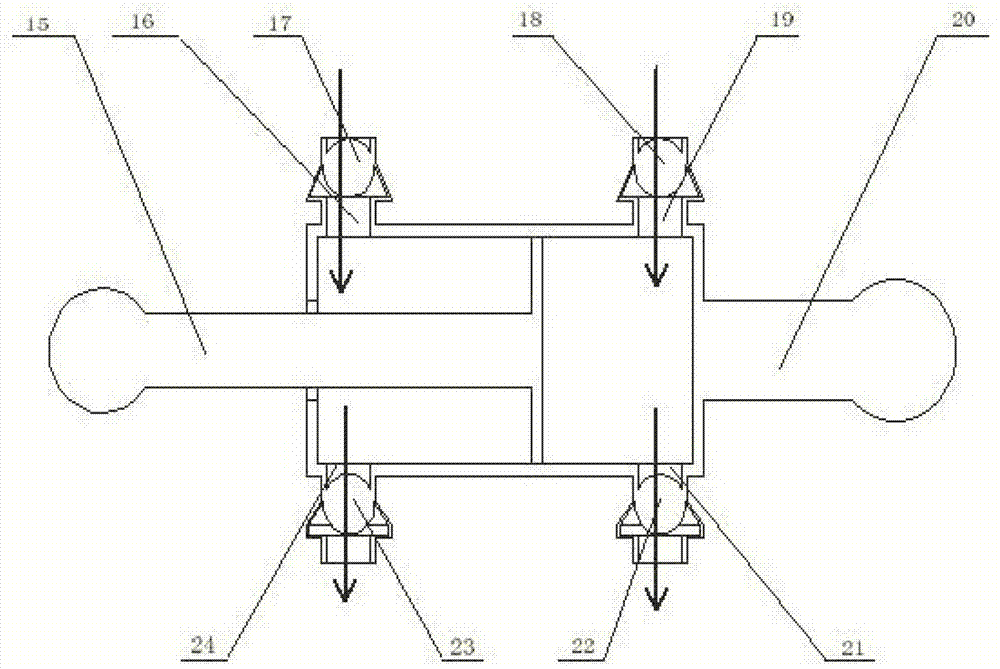

Expansion valve components, one-way expansion valve and two-way circulation expansion valve

ActiveCN102878733AReduce shockReduce wearCheck valvesValve members for absorbing fluid energyParallel channelEngineering

The invention provides expansion valve components, a one-way expansion valve and a two-way circulation expansion valve, belonging to the technical field of refrigeration of variable frequency air conditioners. The invention solves the problem that the service life of a valve is shortened due to frequent abrasion of the conventional valve cores and the conventional vale bases. The two-way circulation expansion valve comprises a valve block which is provided with two parallel channels, wherein each channel is provided with an inlet end and an outlet end; an expansion valve component which is provided with a damping structure is connected to each outlet end; a bypass hole for communicating an outlet of the expansion valve component on one channel with the inlet end of the other channel is formed in the valve block; and a protection cover for preventing a medium from being leaked when flowing through the bypass hole and the outlet is welded at each outlet end. The two expansion valve components are arranged in parallel to ensure that a function of two-way circulation is realized; and the movement of a valve core is reduced by the damping structures, so that the service life of the expansion valve components is prolonged and the energy efficiency ratio of the expansion valve components is improved, thereby being of great significance for energy conservation and emission reduction.

Owner:浙江泽顺制冷科技有限公司

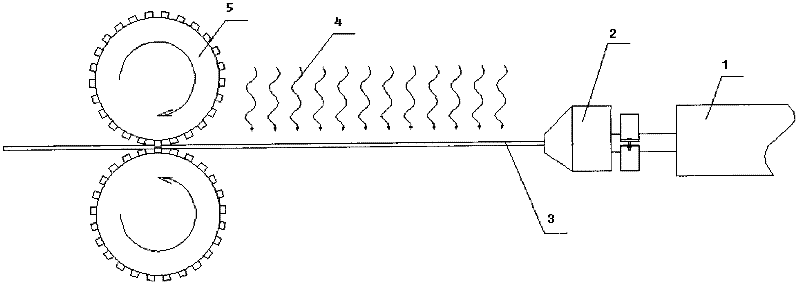

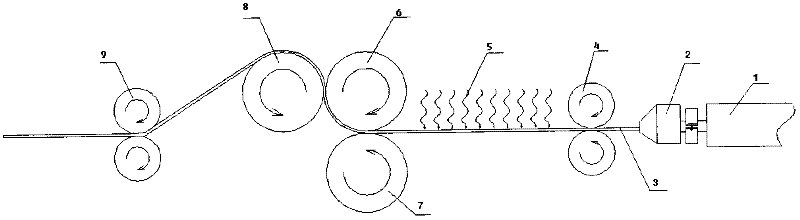

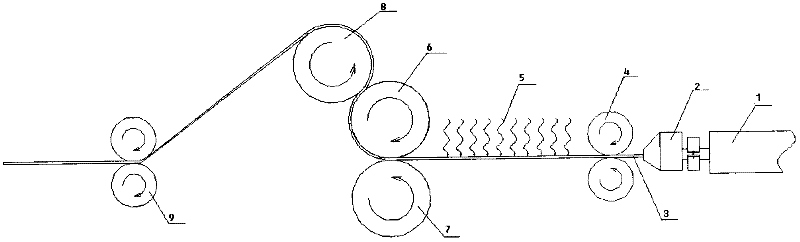

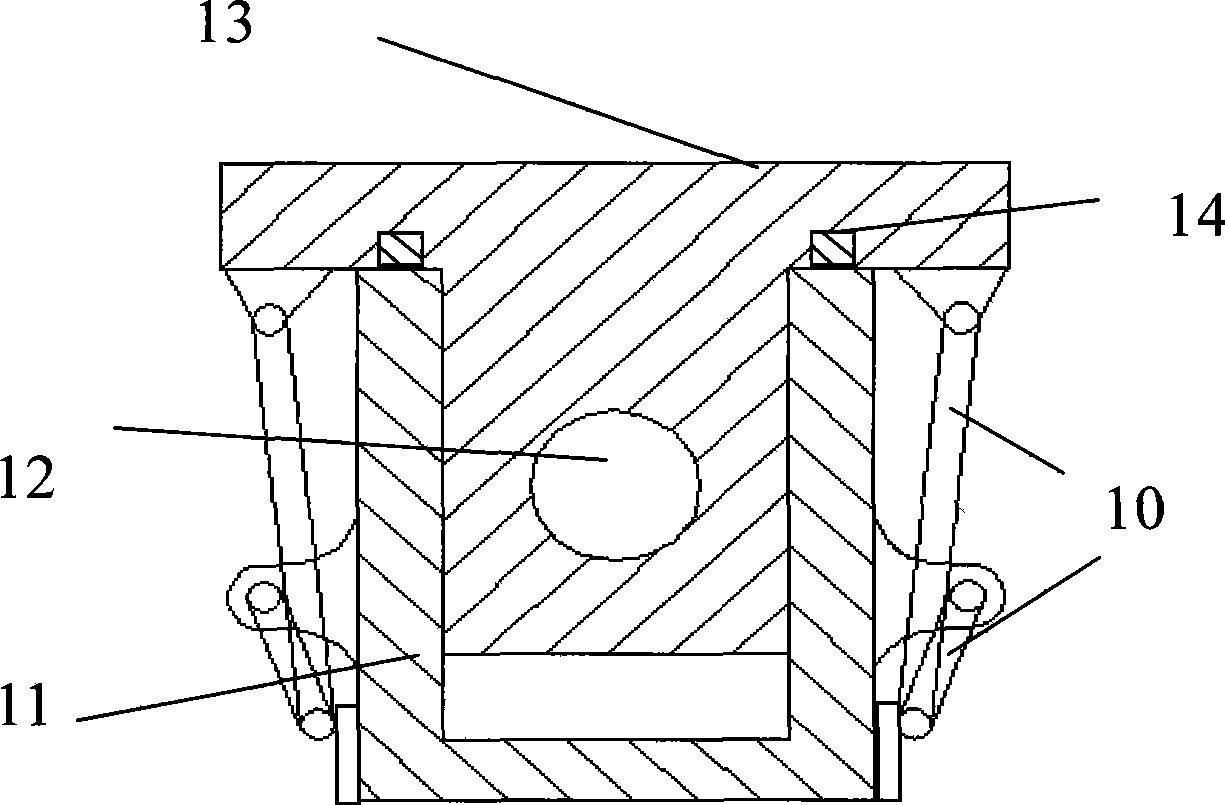

Method for polymer extruding and micro embossing shaping

Polymer micro embossing is a shaping method for forming micro-nano-structured patterns on polymer substrate materials by hot embossing. Polymer micro embossing method is widely applied in the manufacturing of various polymer micro-nano structures. The experiment apparatus mainly comprises: a polymer substrate extruder, a substrate pressing and thickness adjusting apparatus, a temperature controlling apparatus, an embossing apparatus, a pressure controlling apparatus, a pressure maintaining cooling apparatus, and a pulling apparatus. The pressing and thickness adjusting apparatus is used for flattening the extruded polymer; the temperature controlling apparatus is used for ensuring the surface temperature of the polymer substrate requiring flattening; the embossing apparatus is provided with embossing molds with micro embossing structures, wherein the micro embossing structures are transferred with applied pressures; the pressure controlling apparatus is used for adjusting the pressures applied to the polymer substrate; and the pressure maintaining cooling apparatus is used for cooling and shaping the micro structures. With the shaping method, a large amount of time and energy required by heating and cooling can be saved, the embossing equipment can be greatly simplified, the production efficiency is high, the operation is simple, and the cost is low.

Owner:BEIJING UNIV OF CHEM TECH

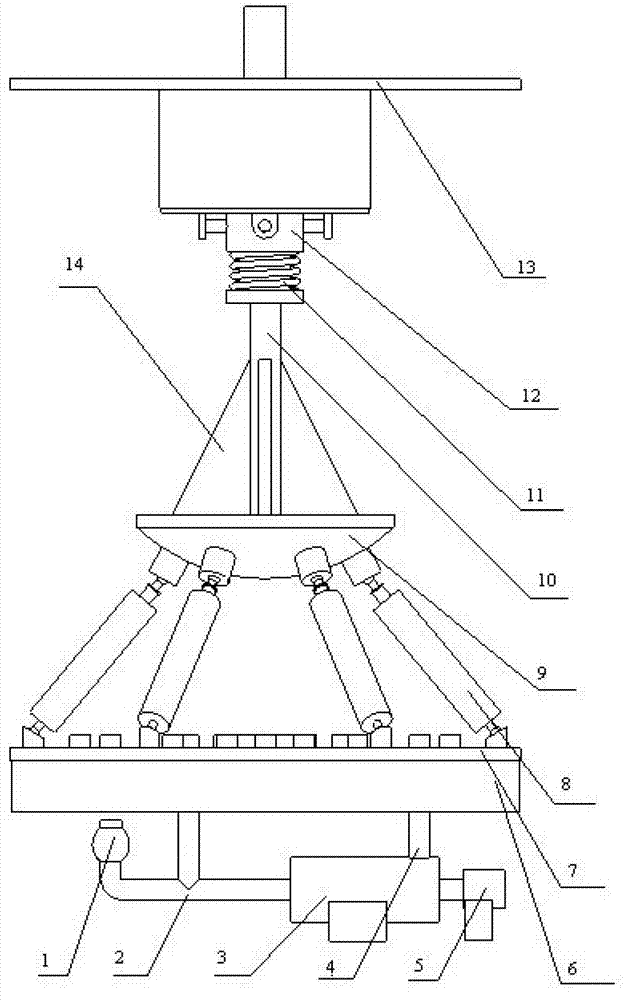

Multi-dimensional and parallel-swing sea wave power generation device

InactiveCN103306881AWon't be corrodedImprove sealingMachines/enginesEngine componentsHydraulic cylinderHydraulic motor

The invention discloses a multi-dimensional and parallel-swing sea wave power generation device. A top cover is fixedly connected with the top wall of a buoyancy box, one end of a three-degree-of-freedom movement pair is fixedly connected with the top cover, the other end of the three-degree-of-freedom movement pair is engaged with a swing rod, one end of the swing rod penetrates through the top wall of the buoyancy box and is fixedly connected with an outside device, the other end of the swing rod is fixedly arranged on an upper platform through the support of rib plates, a spring is fixedly connected with a shaft shoulder of the swing rod, six parallel hydraulic cylinders are arranged between the upper platform and a lower platform, piston rods of the six parallel hydraulic cylinders are hinged to the upper platform, cylinder bodies of the six parallel hydraulic cylinders are hinged to the lower platform, the lower platform is fixedly arranged on an oil mixture tank, the oil mixture tank is fixedly connected with the side wall of the buoyancy box, the oil mixture tank is connected with a hydraulic motor through a separating pipe and a return pipe, a generator is connected with the hydraulic motor, the generator and the hydraulic motor are arranged at the bottom of the buoyancy box, and an energy accumulator is connected with the hydraulic motor. The device has the characteristics that the service life is long, and the pollution is little; and while the energy of the sea wave in the transverse swinging is absorbed, the energy of the sea wave in the vertical direction can also be absorbed.

Owner:SHANGHAI JIAO TONG UNIV

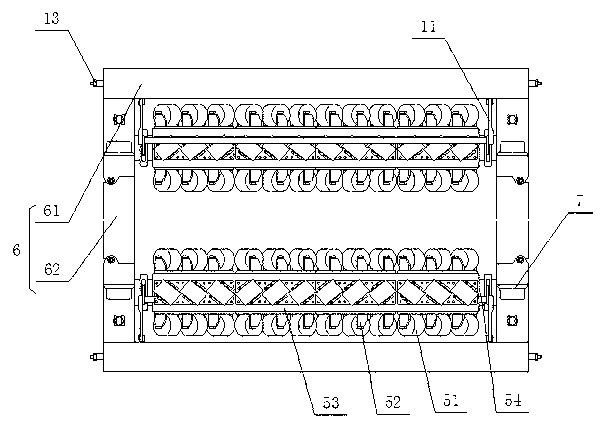

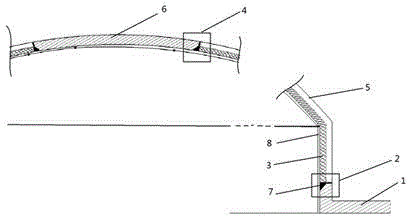

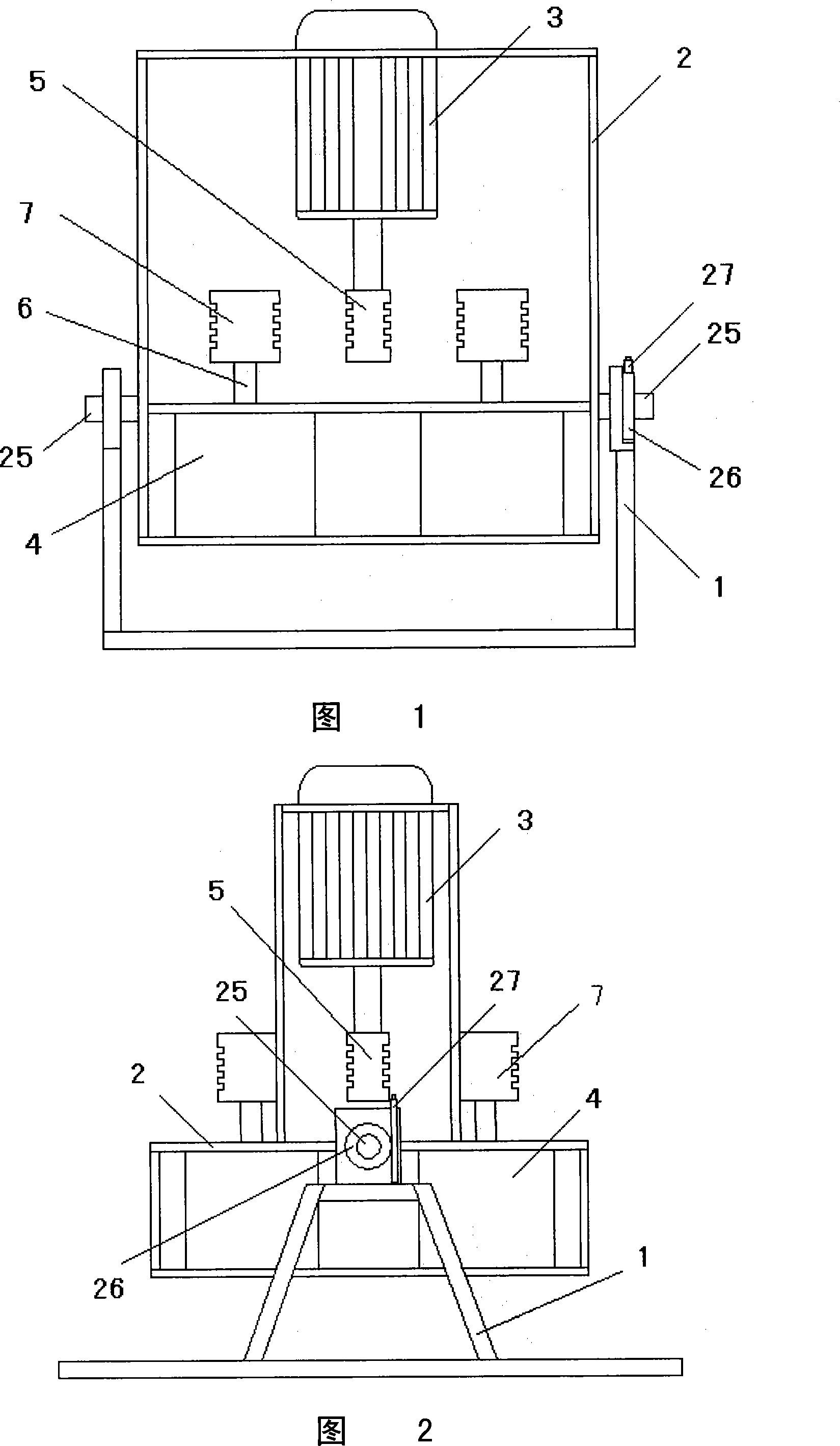

Full self-control non-woven fabrics thermal compression welding device and method

ActiveCN101508186AReliable weldingGuaranteed pressureMechanical working/deformationSeaming textilesEngineeringNonwoven fabric

The invention relates to rapid, convenient, intellectually-controlled full autocontrol nonwoven fabric hot-press welding equipment and a welding method. The full autocontrol nonwoven fabric hot-press welding equipment comprises a PLC controller, a stand, a lower electric heating welding wheel axle, an upper electric heating welding wheel axle, a step motor, an oil cylinder, wherein the upper part of the stand has a groove structure; the lower part of the stand is provided with a hole; the lower electric heating welding wheel axle is positioned in the hole of the lower part of the stand by a lower slide block; the lower end face of the lower slide block is pressed on a pressure sensor; the upper electric heating welding wheel axle is positioned in a groove of the upper part of the stand; the lower end face of an upper slide block is positioned on an adjustable oblique wedge block of a screw rod; the adjustable oblique wedge block of the screw rod passes through a transmission mechanism and is driven by the step motor; the power end of the step motor is controlled by the PLC controller; the oil hydraulic cylinder is positioned on the upper end of the stand; a piston of the oil hydraulic cylinder is connected with the upper slide block by a connecting rod and a connecting plate; and the operation of the oil hydraulic cylinder is controlled by the PLC controller. The equipment has the advantages of: 1, realizing the reliable welding of more than four layers of nonwoven fabric on a production line at an online speed of more than 120 meters per minutes; and 2, according to predetermined welding pressure and welding temperature, freely and automatically carrying out free micro-adjustment by online construction and the change of welding temperature and ambient temperature and ensuring pressure and temperature needed for high-efficient welding.

Owner:杭州珂瑞特新机械制造有限公司

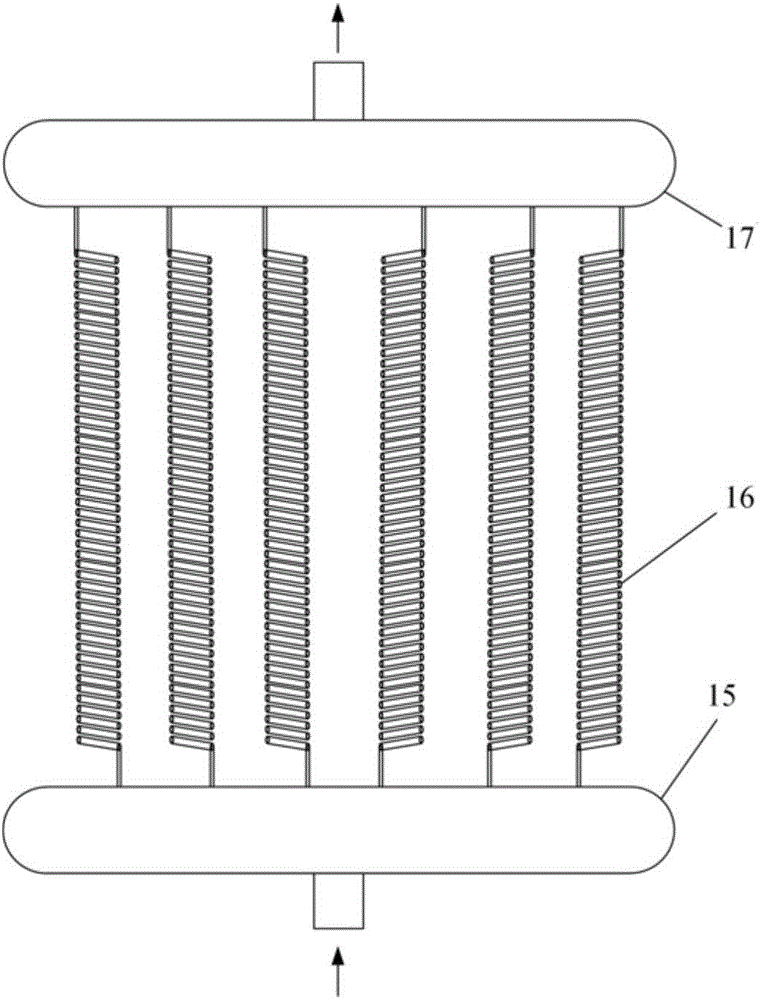

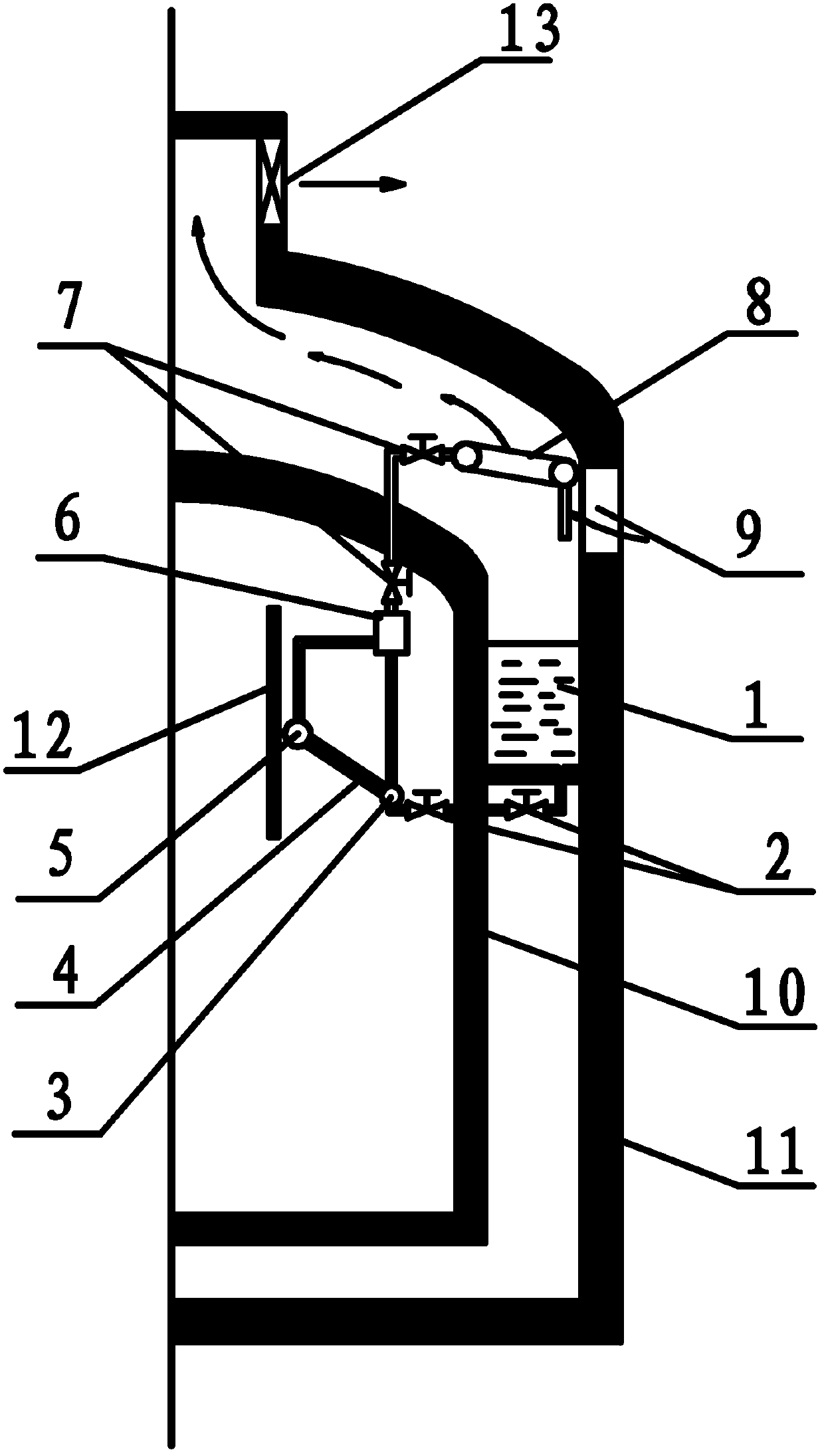

Passive safety shell cooling system

ActiveCN102637465AMaintain integrityAchieve recyclingNuclear energy generationCooling arrangementChillerEvaporator

The invention aims at providing a passive safety shell cooling system comprising a water tank, an inner evaporator pipe bundle, a steam-water separator and an outer air cooler, wherein the water tank is positioned in an annular cavity formed by an inner-layer concrete safety shell and an outer-layer concrete safety shell; the outer air cooler is positioned between the dome of the inner-layer concrete safety shell and the dome of the outer-layer concrete safety shell; both an inner evaporator and the steam-water separator are positioned inside the inner-layer concrete safety shell; two ends of the inner evaporator are respectively connected with the steam-water separator through two pipes; the steam-water separator is connected with the outer air cooler through a first pipe extending out of the inner-layer concrete safety shell; and the inner evaporator pipe bundle is communicated with the water tank through a second pipe extending out of the inner-layer concrete safety shell. When accidents such as LOCA (Loss Of Coolant Accident) and MSLB (Main Steam Line Break) occur, the passive safety shell cooling system can be used for safely and reliably conducting heat out of the safety shell for a long term, ensuring the temperature inside the safety shell, and guaranteeing that pressure is no more than a limiting design value, thereby maintaining the integrity of the safety shell.

Owner:HARBIN ENG UNIV

Gas gun system for shooting hail

ActiveCN101451798AIntegrity guaranteedImprove continuous launch capabilityCompressed gas gunsStress concentrationInlet valve

The invention discloses a gas launcher system for launching hails, belonging to the launching field of bullets; the gas launcher system is a special hail accelerating system for simulating hail impaction and is specially designed with the consideration of the unique physical characteristics and high running speed of hails, comprising a high-pressure gas chamber, a fast control valve, a fast loading mechanism, a transmitting tube, a high-pressure gas pipe, a gas inlet valve, a gas discharge valve and a high-pressure pump; wherein the gas launcher system ensures the integrity of the hails by using gas to push hail bullets directly to reduce local stress concentration; the fast control valve effectively saves high-pressure gas and keeps the pressure of the high-pressure gas chamber; and the fast loading mechanism greatly improves the loading speed to realize the fast emission of the bullets.

Owner:HAIAN CHANGDA TECH TRANSFER CENT +1

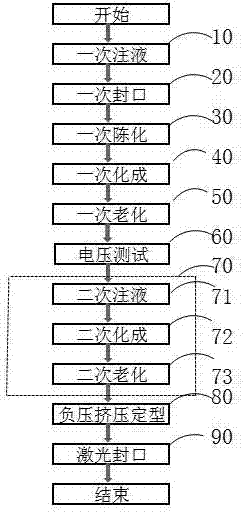

Novel making process method of lithium ion battery

InactiveCN107464956AEfficient dischargeAvoid enteringFinal product manufactureElectrolyte accumulators manufactureElectrical batteryPre-charge

The invention provides a novel making process method of a lithium ion battery and relates to making of a square lithium ion power battery and an energy storage battery, in particular to a static activation after lithium ion liquid injection-formation-high-temperature aging-secondary liquid injection-formation-sealing process. The novel making process method comprises the following steps: the static step after liquid injection: after battery liquid injection, plugging a liquid injection hole by using a special plug and then storing; the formation step: piercing the plug with a needle, connecting the other end of the needle and a pipeline on formation equipment and pre-charging or charging and discharging the battery in vacuum; the aging step: discharging gas generated inside the battery in manners of piercing the plug with the needle and vacuum pumping; the secondary liquid injection step: supplementing liquid in a manner of piercing the plug with the needle; the secondary formation step: piercing the plug with the needle, connecting the other end of the needle and the pipeline on the formation equipment and charging the battery in the vacuum-pumping process; the sealing step: piercing the sealed plug, pressing the plug under the situation of negative pressure extrusion and then performing laser sealing.

Owner:YUNNAN TIN GROUP HLDG

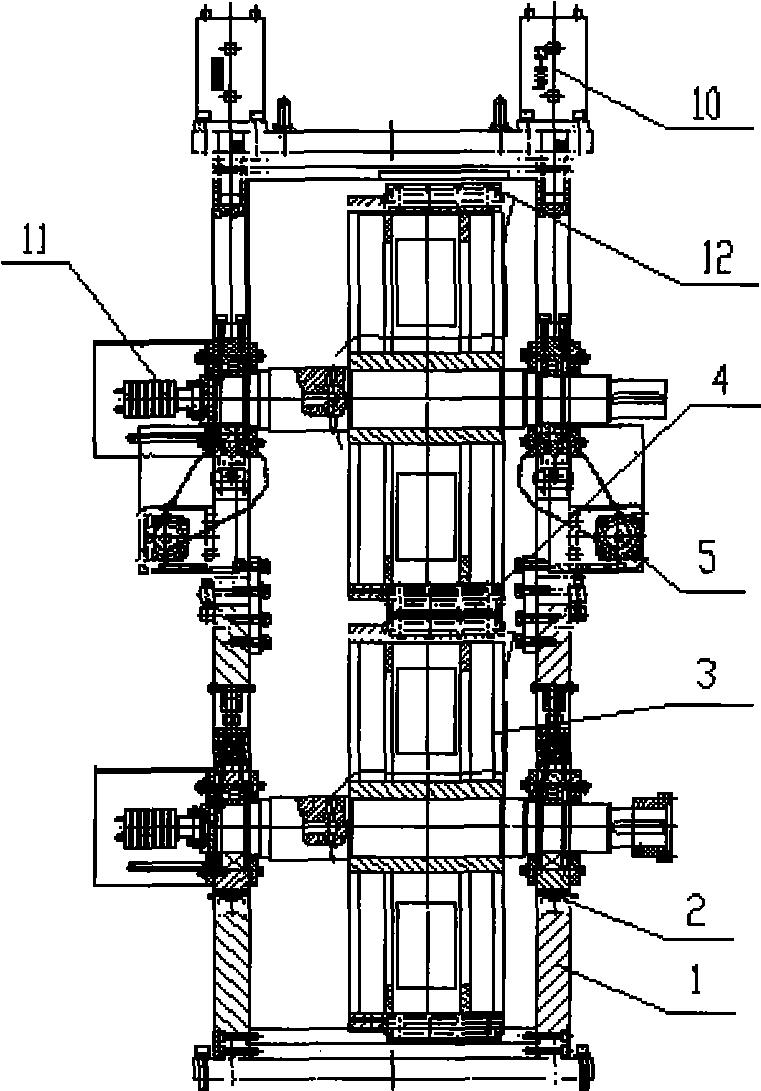

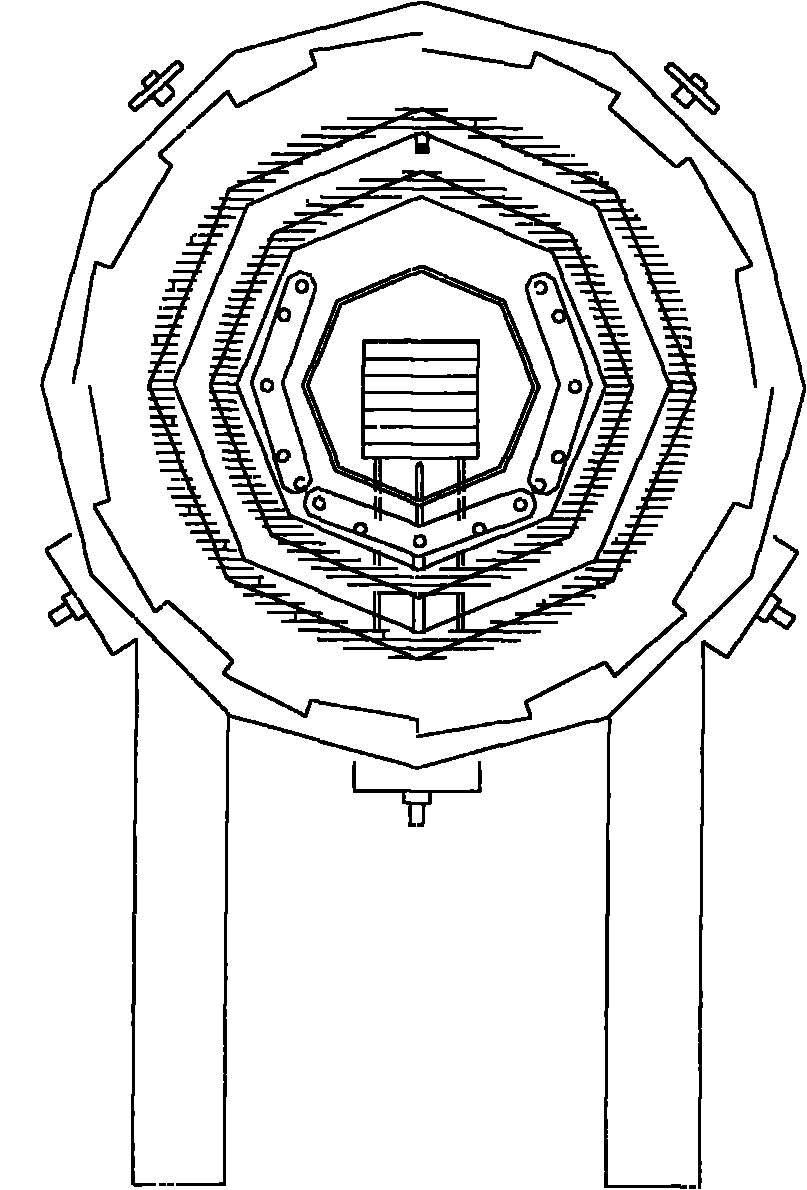

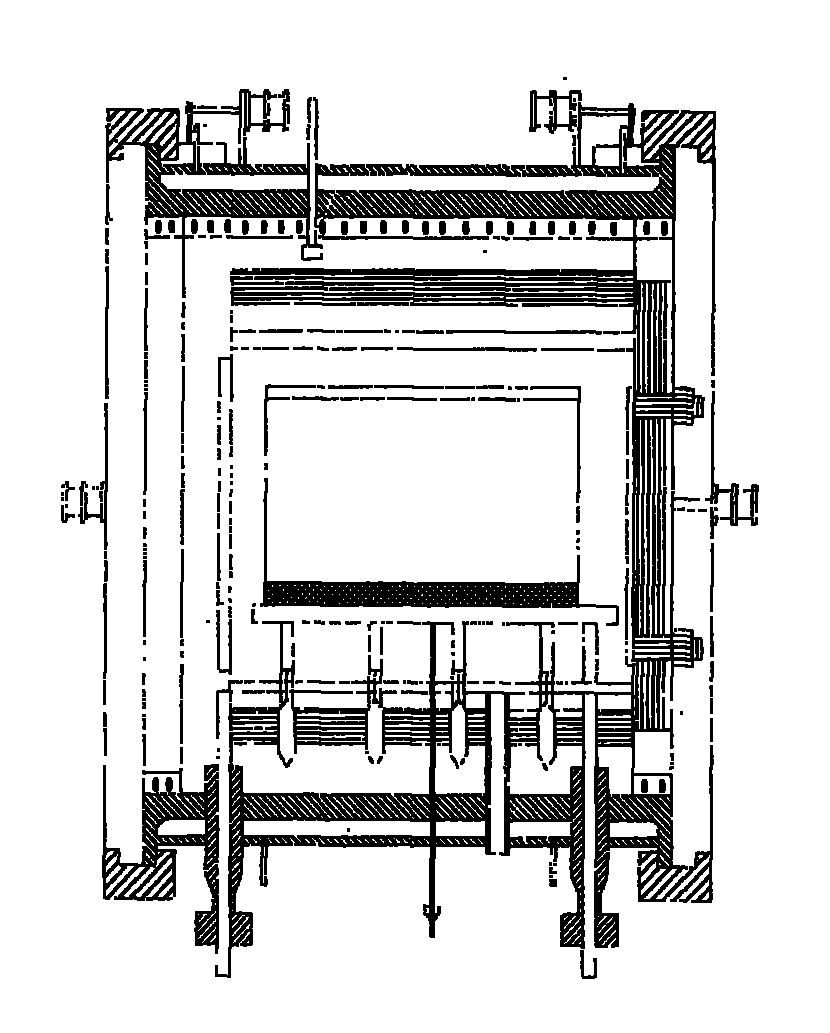

Pressure sintering furnace

InactiveCN101788226AAchieve elastic compressionSolve elastic compression problemsFurnace componentsMuffle furnacesCouplingDistribution system

The invention relates to a pressure sintering furnace used for producing hard alloys. The pressure sintering furnace comprises a furnace shell, a vacuum system, an air distribution system, a heating and thermal-insulating device, a compression system, a cooling system and a decompression device. The pressure sintering furnace is characterized in that the furnace shell is a horizontal cylinder provided with a double-wall water jacket, the furnace door on the furnace shell has a quick-opening hydraulic side-rotating structure, the furnace door of the furnace shell comprises a thermal-insulating door on the external layer of the furnace and a graphite door on the internal side of the furnace, the opening of the furnace door is controlled by a hydraulic locking device with a door-closing air cylinder, the door-closing air cylinder is provided with an elastic coupling device, and the thermal-insulating door of the furnace door is a boss thermal-insulating door. The pressure sintering furnace has stable performance and low cost and safety production can be realized by using the pressure sintering furnace, thus the uniformity of temperature field distribution in the furnace can be effectively improved and the qualification rate of products can be more than 90%.

Owner:ZHUZHOU CEMENTED CARBIDE EQUIP

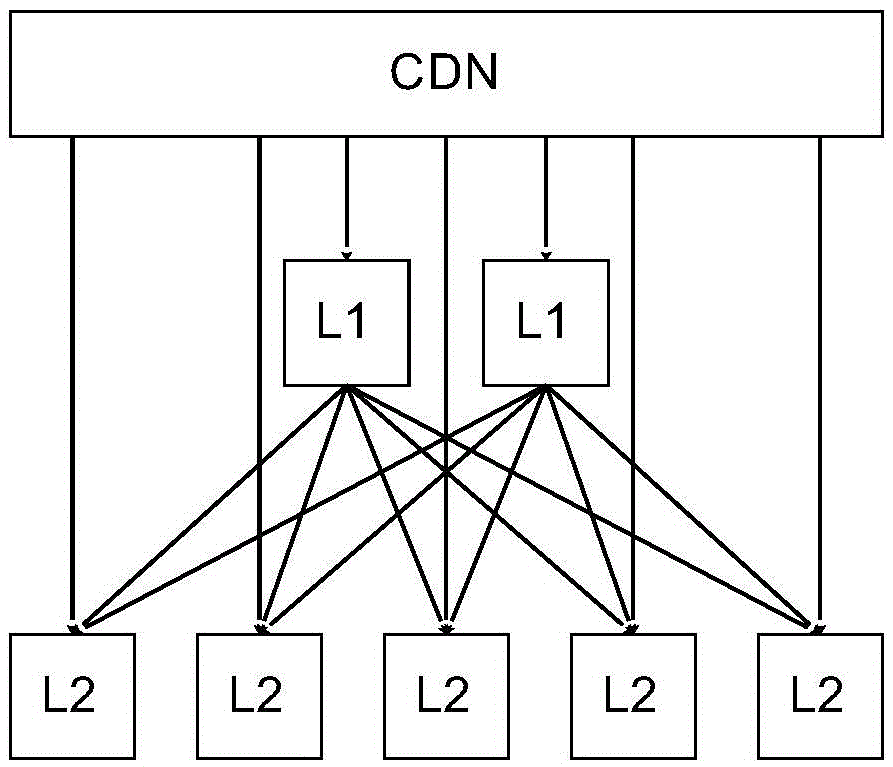

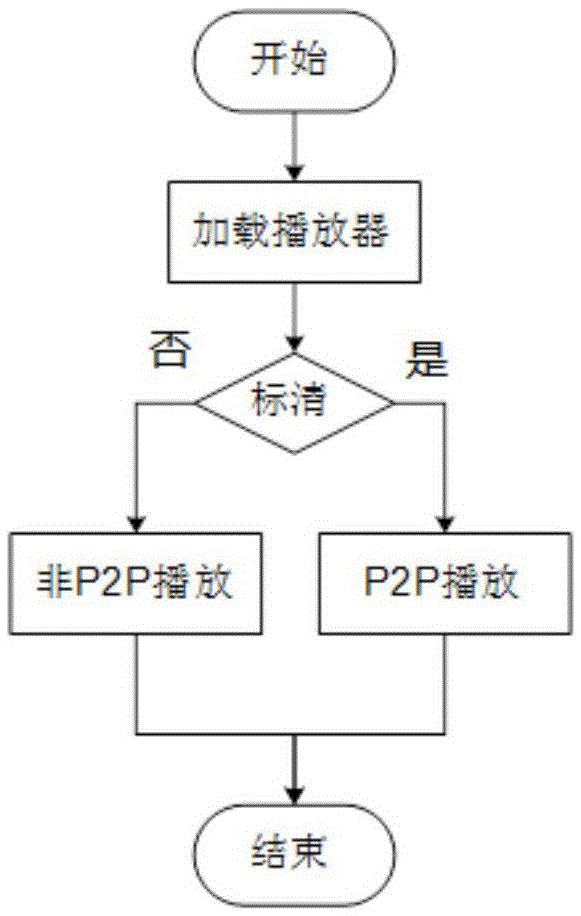

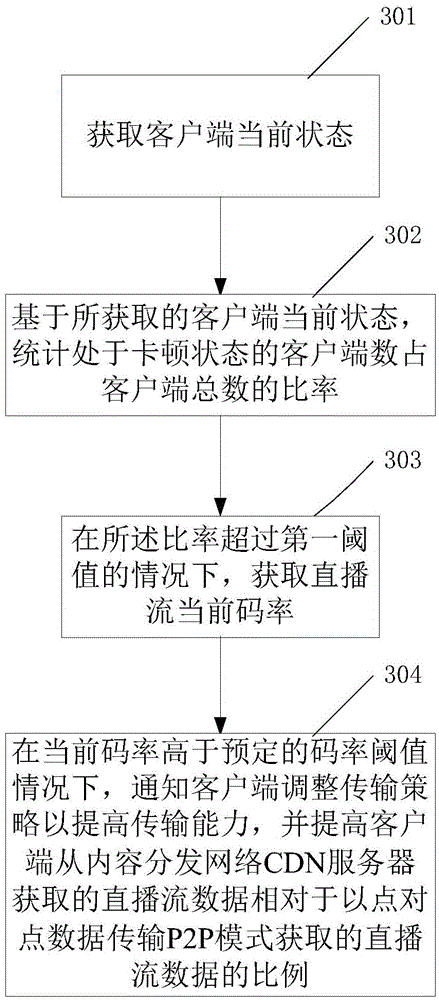

Direct-broadcast flow transmission method and apparatus

ActiveCN105635755ARelieve pressureGuaranteed pressureTransmissionSelective content distributionContent distributionBroadcasting

The invention relates to a direct-broadcast flow transmission method and apparatus. The method comprises: a current state of a client is obtained; on the basis of the obtained current state of the client, statistics of a ratio of the number of clients in a freezing state to the total number of clients is carried out; when the ratio exceeds a first threshold value, a current code rate of a direct-broadcast flow is obtained; and when the current code rate is higher than a predetermined code rate threshold value, the client is notified to adjust a transmission strategy to improving the transmission capability and enhance a proportion of direct-broadcast flow data obtained by the client from a content distribution network (CDN) server to direct-broadcast flow data obtained by a point-to-point (P2P) data transmission mode. According to embodiments of the invention, the transmission strategy of the client is adjusted based on the direct-broadcast flow code rate and the client state, so that the service and bandwidth resources are saved and the direct broadcasting smoothness is guaranteed.

Owner:ALIBABA (CHINA) CO LTD

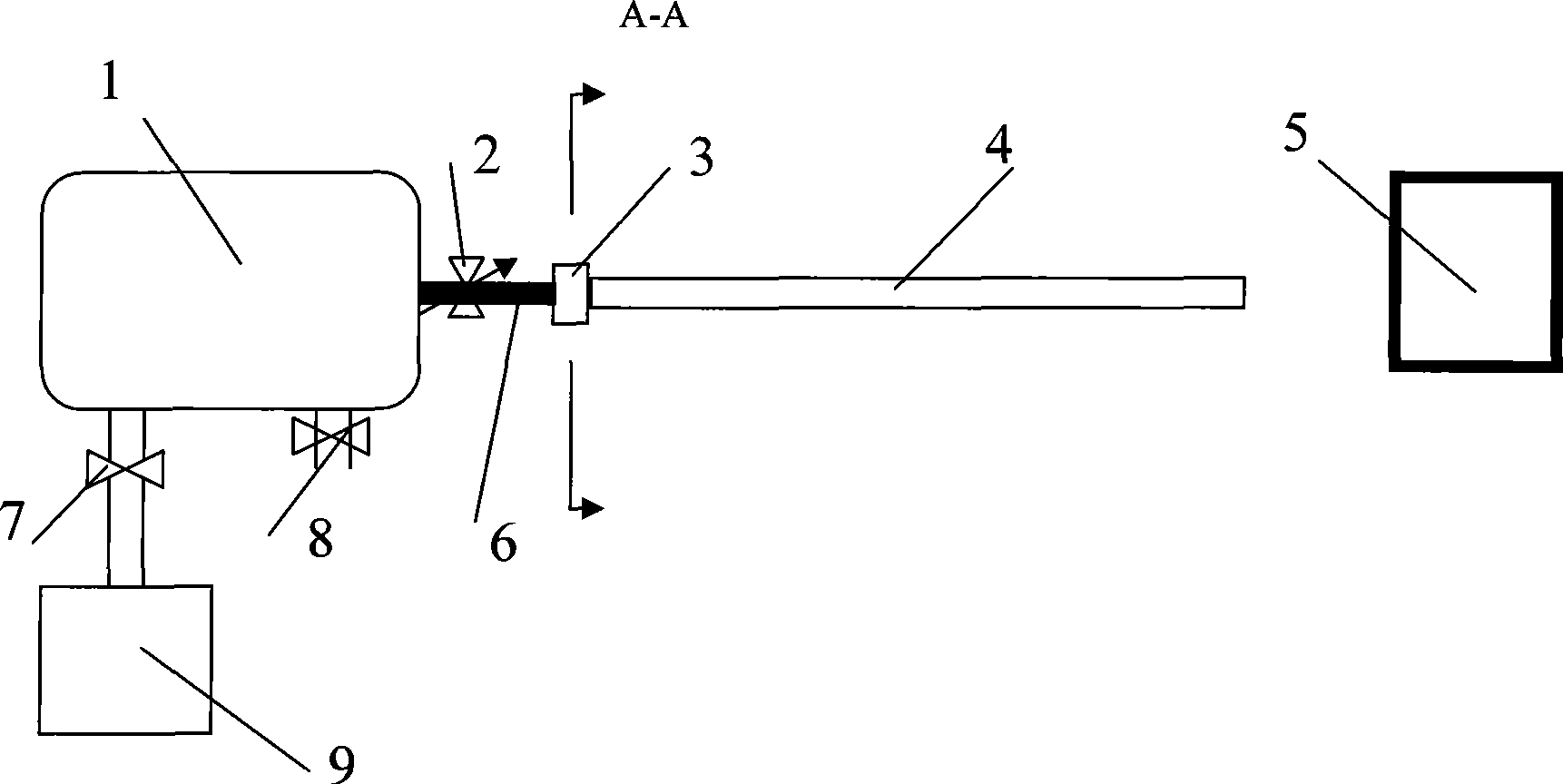

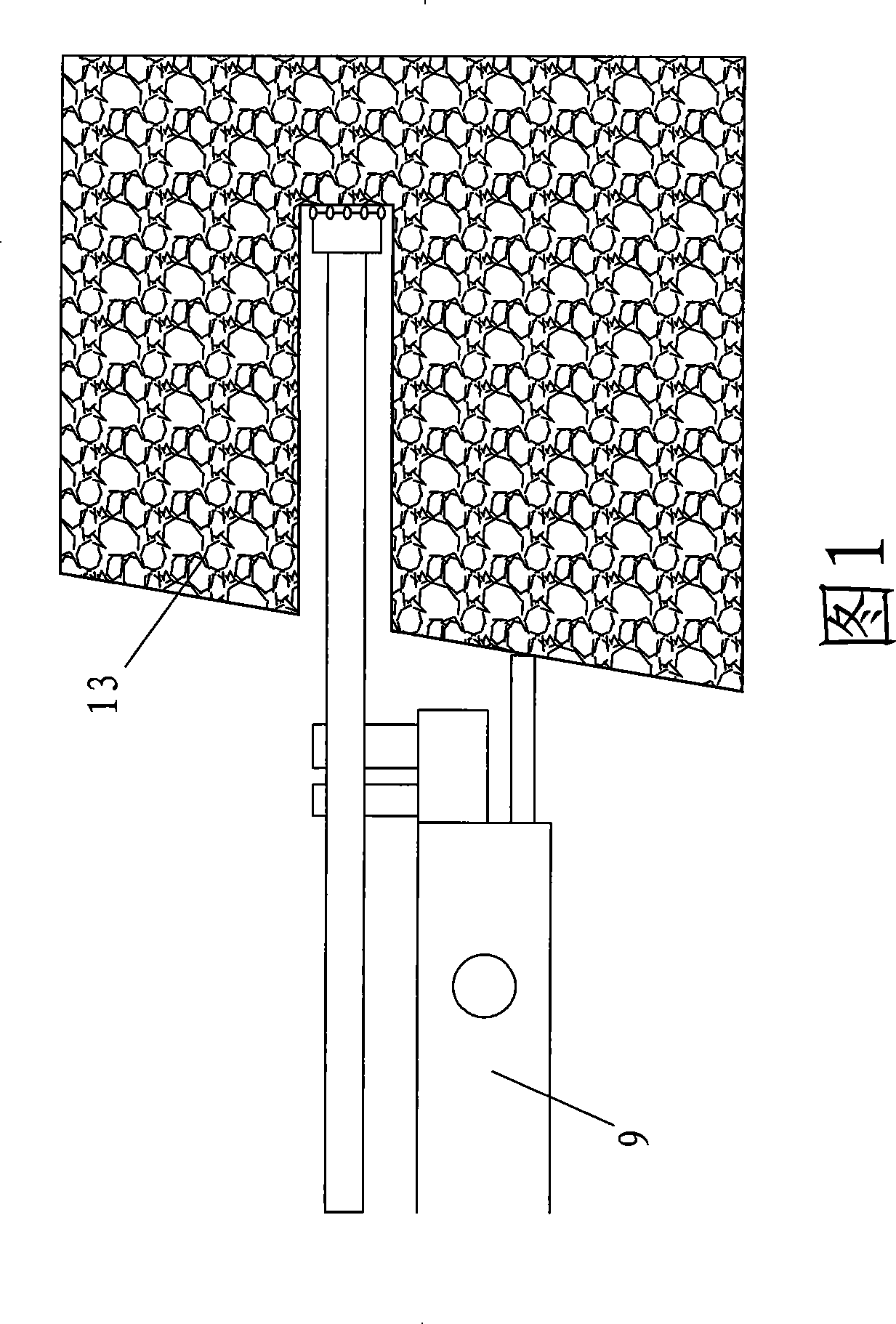

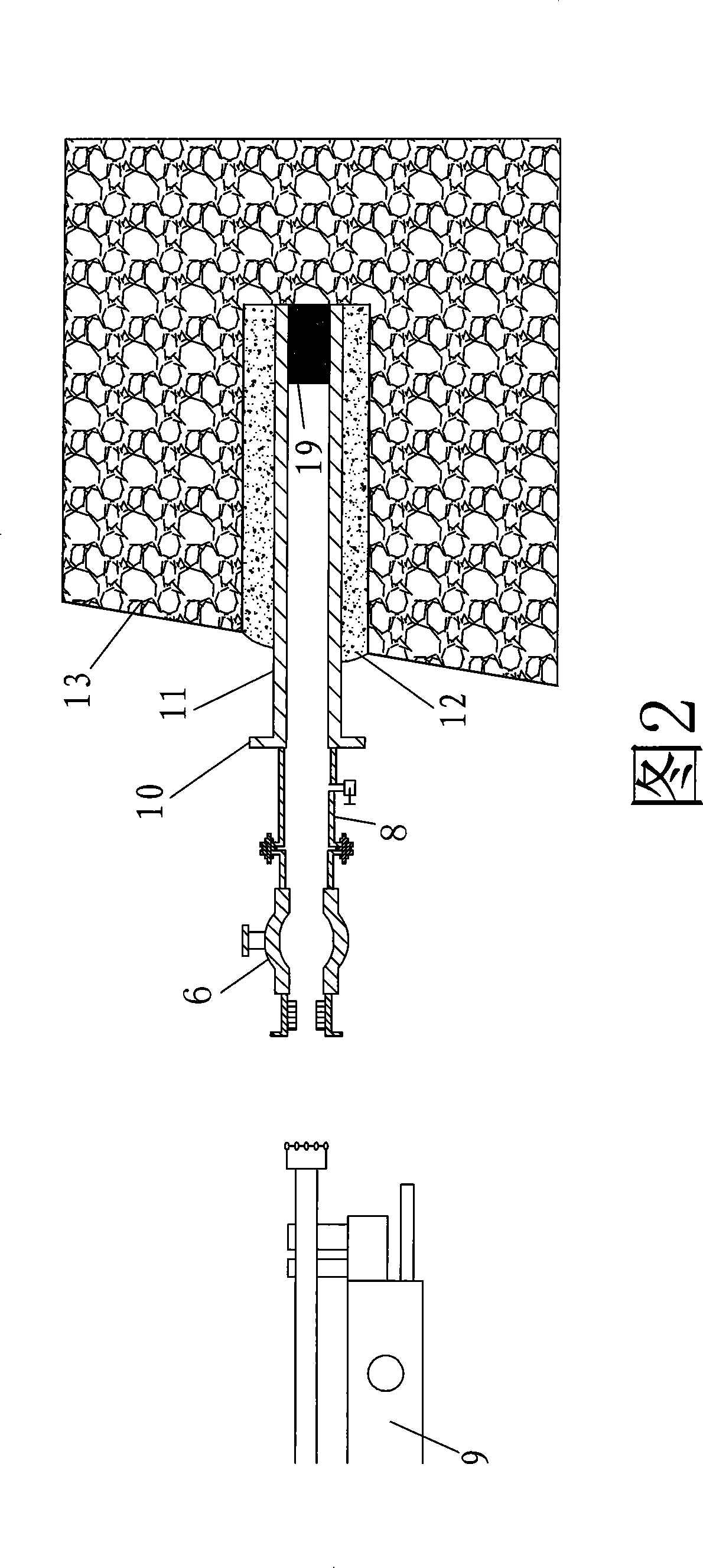

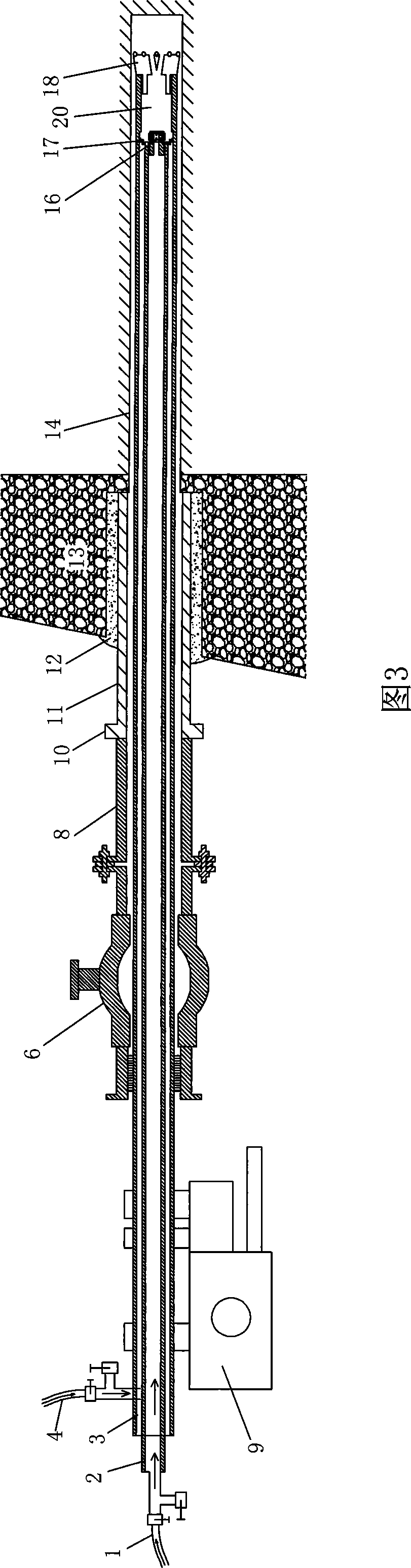

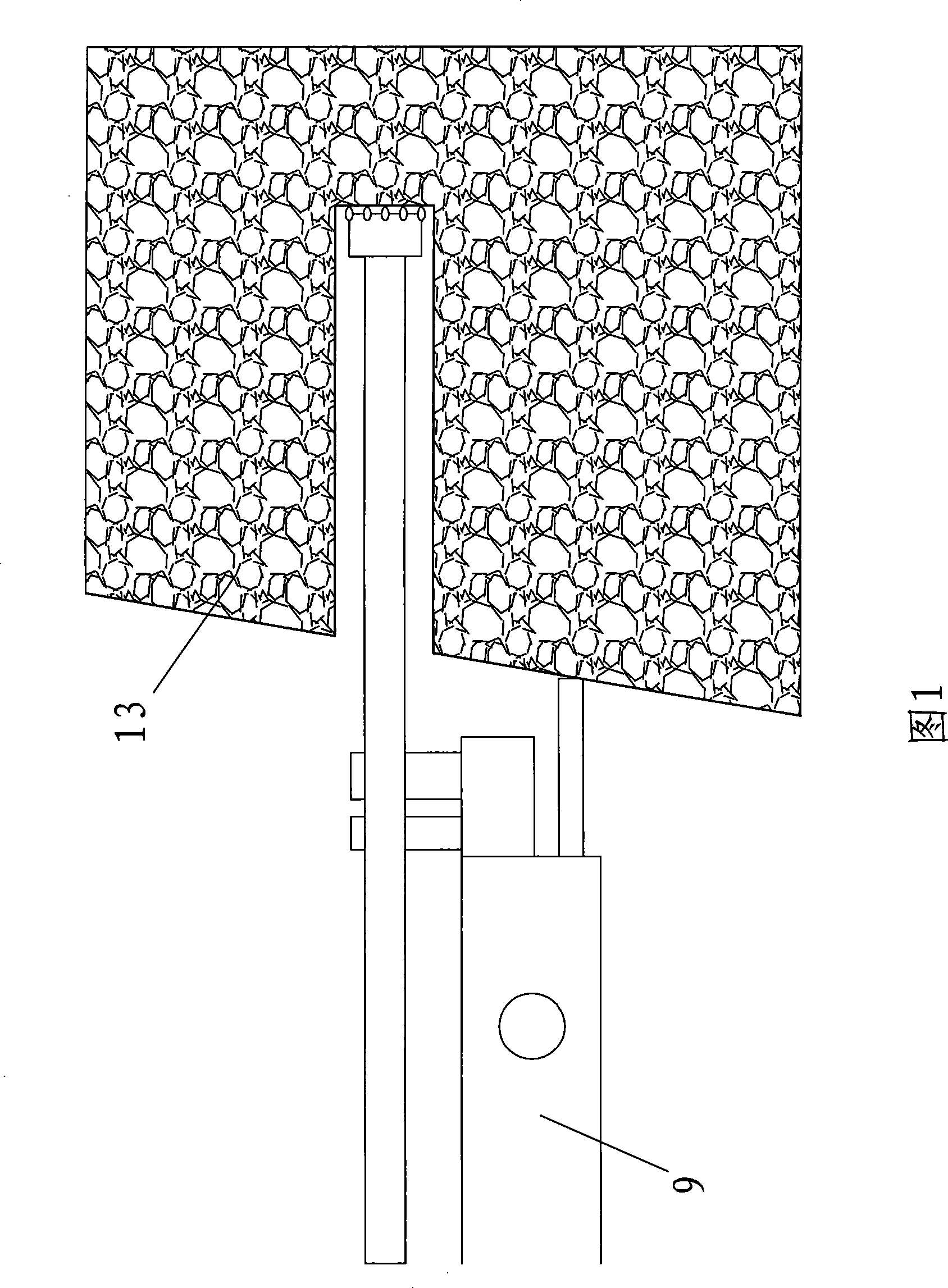

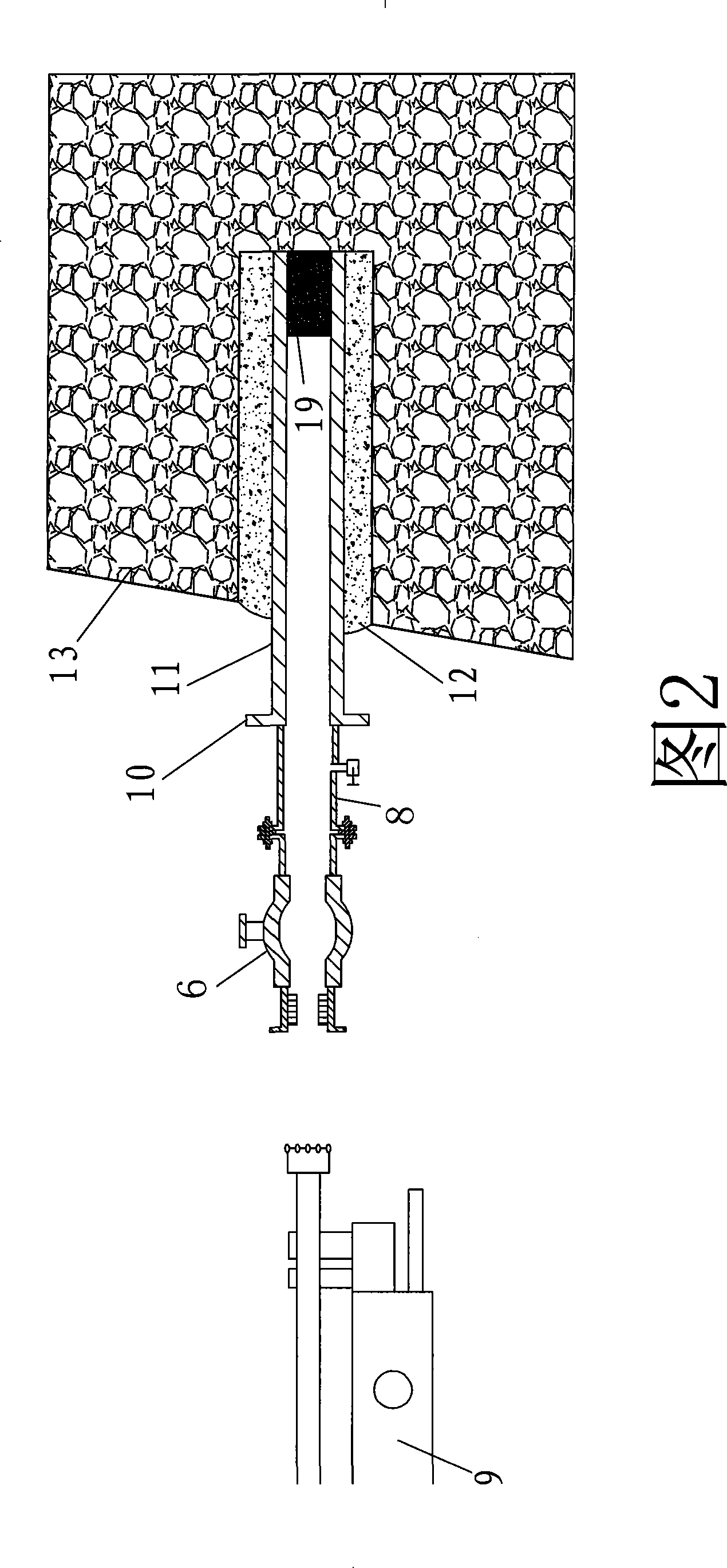

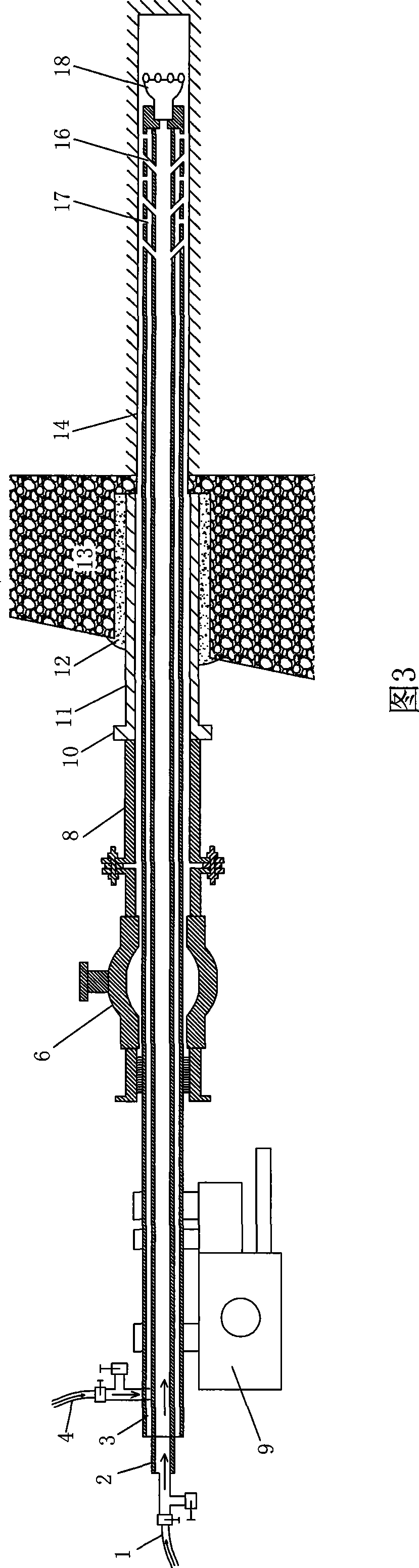

Subsection retrusive slip-casting method for porthole slurry-stop mixed double-pipe within tube

ActiveCN101251019AGuaranteed mixing effectGuaranteed pressureUnderground chambersTunnel liningDouble tubeEngineering

The invention provides a sectional retreating grouting method for a mixed duplex pipe inside an orifice stop-grouting pipe, comprising the following technological steps that: a shallow hole is drilled on a grouting wall (13) by utilization of a drilling machine at first; a drill rod is retreated; an orifice pipe (11) is arranged and then fixed on the orifice wall by utilization of anchor agents (12); the drill rod with a single drill bit and the structure of an inner sleeve and an outer sleeve is adopted for drilling; one end of the orifice pipe positioned on the outside of the drill hole is connected with a drainage (8) and a water inrush resistant device (6) during the drilling process; tail ends of both an inner pipe (2) and an outer pipe (3) of the drill rod are connected with water supply pipes; drilling is performed through the water inrush resistant device, the drainage and the orifice pipe until the designed drilling depth is reached; the water inrush resistant device is disassembled; a hollow pressure plate (5) and a stop-grouting plug (7) are sleeved on the drill rod; the water supply pipes on tail ends of the inner pipe and the outer pipe are respectively connected with a cement slurry supply pipe and a water glass slurry supply pipe; grouting is performed and cement slurry and water glass slurry are mixed in a hybrid chamber (20) and then ejected from the front of the drill bit; when the designed grouting quantity is reached, the drill rod is released by the stop-grouting plug; after the drill rod is retreated for a section of distance, the stop-grouting plug is sealed again, and a gap between the drainage and the outer pipe is grouted continuously; in such manner, a section is grouted and retreated and then another section is grouted until grouting of the hole is finished.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD

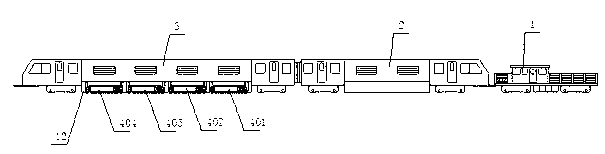

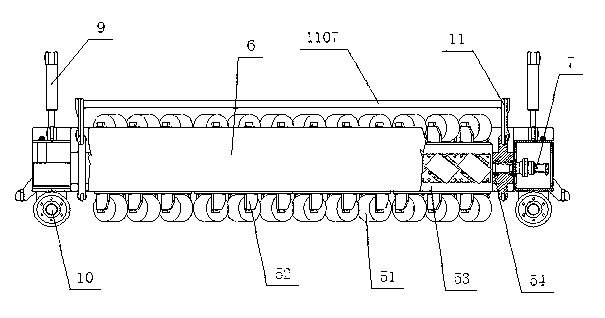

High-speed grinding train for rails

ActiveCN103015279ASave human effortImprove efficiencyRailway track constructionHinge angleEngineering

The invention discloses a high-speed grinding train for rails. The high-speed grinding train comprises a grinding operating train and grinding devices with grinding assemblies. Each grinding device further comprises a grinding frame, the grinding frame is a square frame, two U-shaped beams are opposite to each other and are integrally connected with each other by short crossbeams to form the square frame, two ends of each short crossbeam are connected with the U-shaped beams by hinge pins, the short crossbeams can slide up and down along the hinge pins, the two grinding assemblies of the grinding device are parallelly mounted in the grinding frame, two ends of each rotary frame are rotatably connected with the grinding frame, at least one end of each rotary frame is provided with a rotation driving device, the upper portion of the grinding frame is hinged with the bottom of a carriage of the grinding operating train by a lift cylinder, and support wheels are mounted on the lower portion of the grinding frame. The high-speed grinding train is high in stability, and can meet grinding requirements of various roads, skylight operation is omitted, a grinding procedure is controllable and adjustable, full surfaces of the rails can be ground, and the high-speed grinding train is safe and environment-friendly.

Owner:CHENGDU XINZHU ROAD & BRIDGE MASCH CO LTD

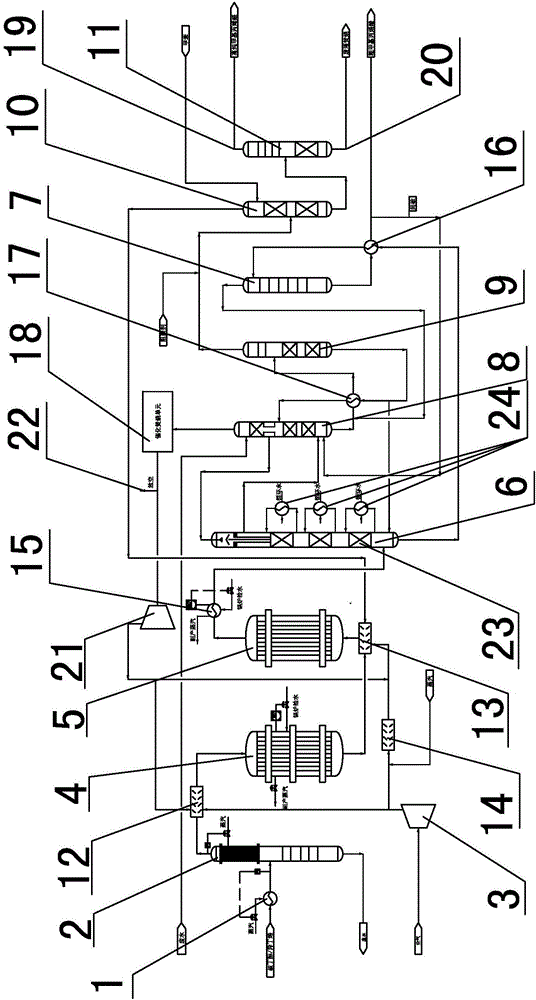

System and method for simultaneously producing methacrylic acid and methacrolein

ActiveCN106631759AGuaranteed conversion rateGuaranteed pressureOrganic compound preparationChemical industryFixed bedAcid washing

The invention discloses a method and system for simultaneously producing methacrylic acid and methacrolein. The system comprises a raw material feed preheater, a raw material vaporizing tower, a first oxidation reactor, a second oxidation reactor, a rapid cooling / acid washing coupled tower, a methacrolein stripping tower, a methacrolein absorption tower, a methacrolein recovery tower, a methacrolein light component removal tower and a methacrolein heavy component removal tower. The method comprises the following steps: preheating and vaporizing a raw material tert-butyl alcohol or isobutylene; then mixing with air and water; feeding to a catalyst-filled fixed-bed reactor; performing oxidation reaction to generate methacrylic acid and methacrolein; and performing effective rapid cooling, absorption and rectification to finally obtain 99%wt methacrolein and 30%wt crude methacrylic acid. The method and system have the advantages that the reaction conversion rate is high, the unreacted raw material can be effectively recovered, impurities and solid particles are removed, and high-purity methacrylic acid and methacrolein are produced.

Owner:齐翔华利新材料有限公司

Subsection retrusive slip-casting method for porthole slurry-stop mixed double-pipe

ActiveCN101251018AWell mixedGuarantee the quality of groutingUnderground chambersTunnel liningDouble tubeEngineering

The invention provides a sectional retreating grouting method for a mixed duplex pipe on the outside of an orifice stop-grouting pipe, comprising the following technological steps that: a shallow hole is drilled on a grouting wall (13) by utilization of a drilling machine at first; a drill rod is retreated; an orifice pipe (11) is arranged and then fixed on the orifice wall by utilization of anchor agents (12); the drill rod with a single drill bit and the structure of an inner sleeve and an outer sleeve is adopted for drilling; one end of the orifice pipe positioned on the outside of the drill hole is connected with a drainage (8) and a water inrush resistant device (6) during the drilling process; tail ends of both an inner pipe (2) and an outer pipe (3) of the drill rod are connected with water supply pipes; drilling is performed through the water inrush resistant device, the drainage and the orifice pipe until the designed drilling depth is reached; the water inrush resistant device is disassembled; a hollow pressure plate (5) and a stop-grouting plug (7) are sleeved on the drill rod; the water supply pipes on tail ends of the inner pipe and the outer pipe are respectively connected with a cement slurry supply pipe and a water glass slurry supply pipe; grouting is performed and cement slurry is driven to be ejected from the front of the drill bit along the inner pipe, and simultaneously the cement slurry and water glass slurry are ejected respectively from a water and slurry outlet hole (16) and a water and slurry outlet hole (17) on the front section of the inner pipe and the outer pipe, mixed on the outside of the pipes and then enter into the stratum; when the designed grouting quantity is reached, the drill rod is released by the stop-grouting plug; after the drill rod is retreated for a section of distance, the stop-grouting plug is sealed again, and a gap between the drainage and the outer pipe is grouted continuously; in such manner.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD

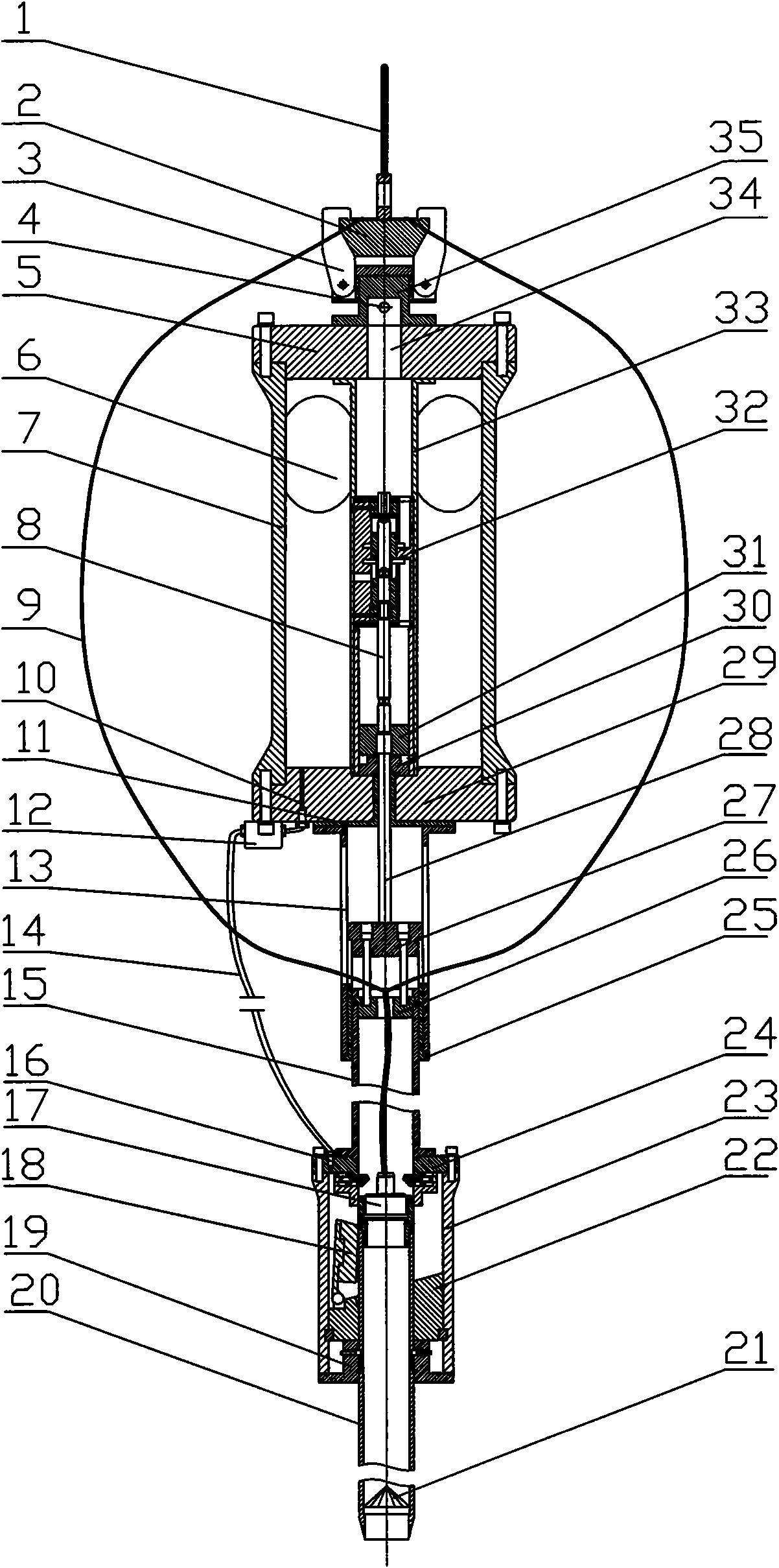

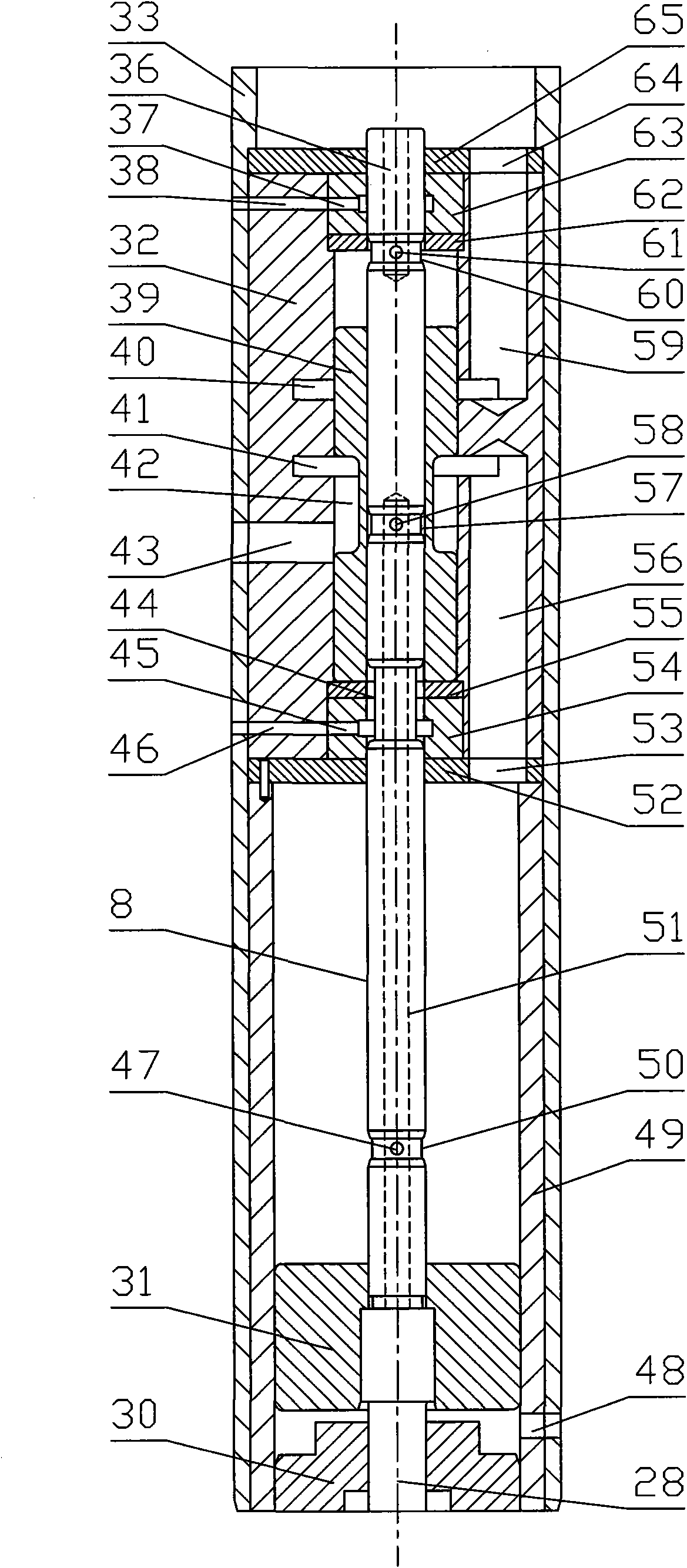

Sediment pressure-holding sampler driven by hydrostatic pressure

InactiveCN101561366AGuaranteed pressureIncrease collection rateWithdrawing sample devicesInsertion depthHydrostatic pressure

The invention relates to a sediment pressure-holding sampler driven by hydrostatic pressure. The prior device is limited in insertion depth, large and heavy in supporting frame. The sampler comprises an impact component, a flow distribution component, a driving component and a sampling tube component, wherein the impact component comprises an impact tube, a guide sleeve and an impact piston cylinder, the flow distribution component comprises a supporting tube and a flow distribution valve; the driving component comprises a driving piston cylinder and a driving piston; the sampling tube component comprises a guide tube, a pressure-holding tube, a sampling pipe and a pressure-replenishing hose; and the impact tube, the supporting tube, the impact piston cylinder, the guide tube, the pressure-holding tube and the sampling pipe are coaxially arranged. The sampler fully utilizes the huge energy of seawater hydrostatic pressure, injects sediment for sampling in a form similar to vibropiling, and can use the energy in subsequent sample pressure holding. Relative to the prior sampler, the sampler has the advantages of larger sampling depth under the same weight condition, obviously promoted sample collection rate and capability of performing truth-preserving sampling on hard sediment which cannot be sampled by gravity-type sediment truth-preserving samplers.

Owner:HANGZHOU DIANZI UNIV

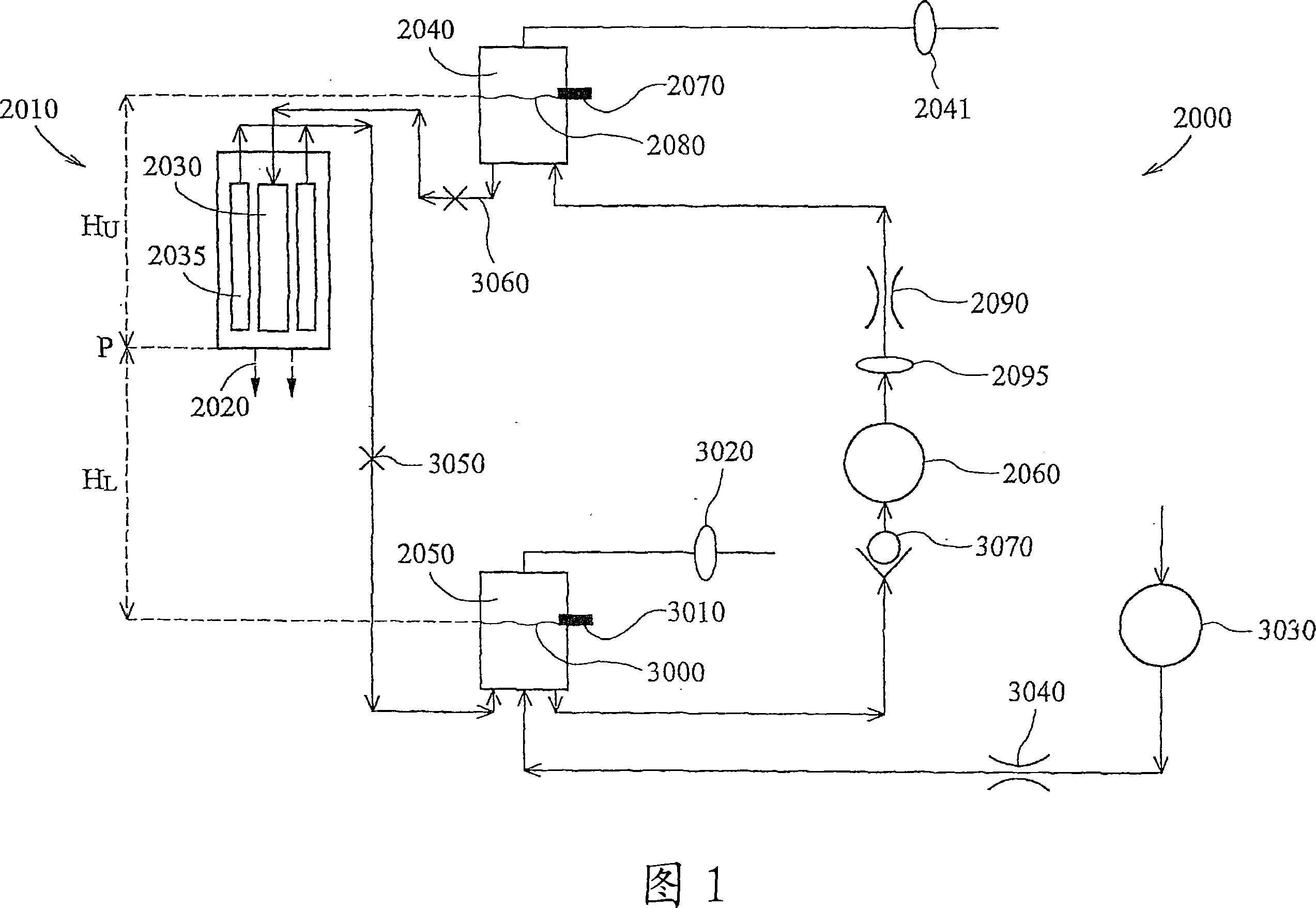

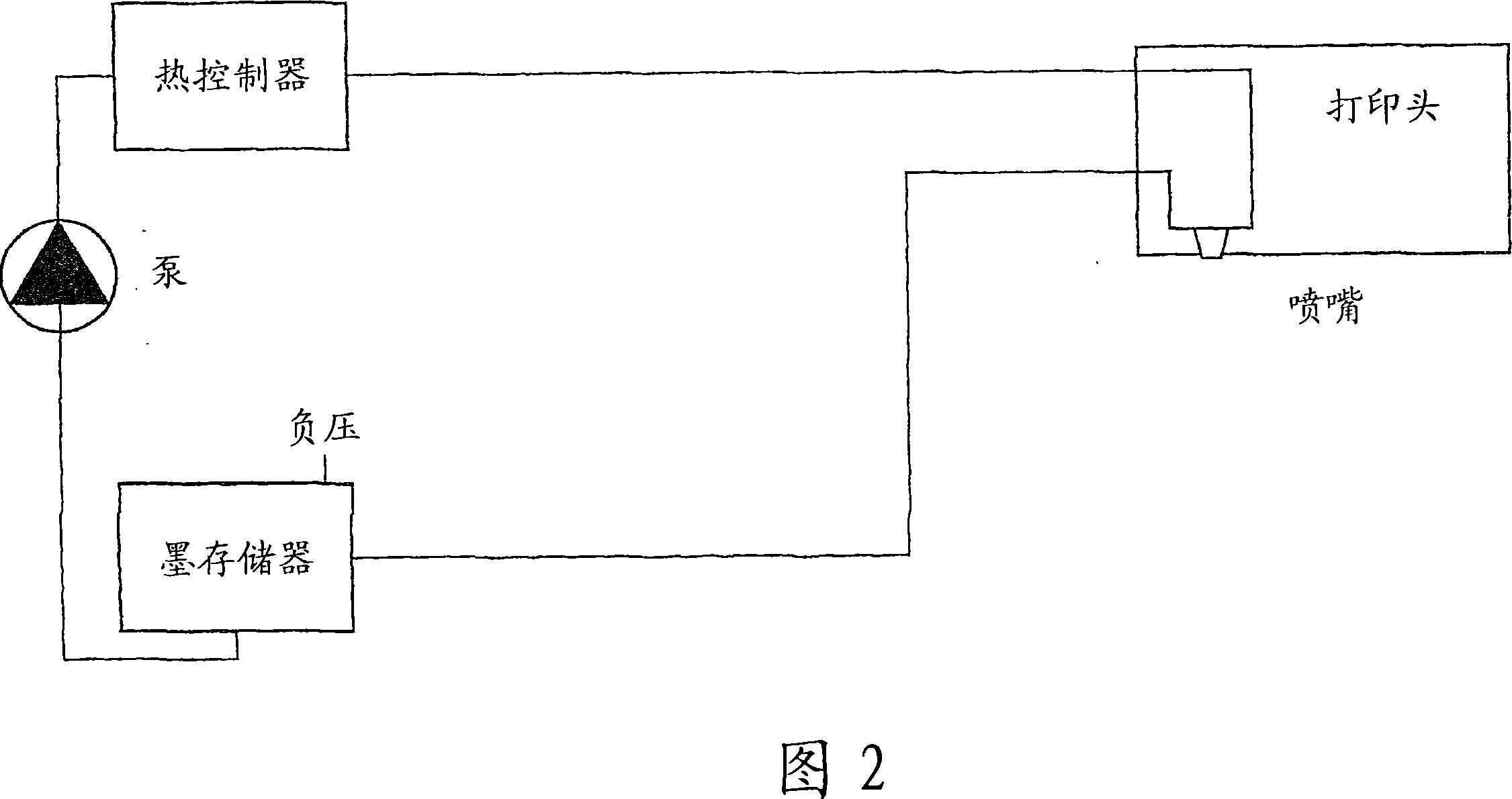

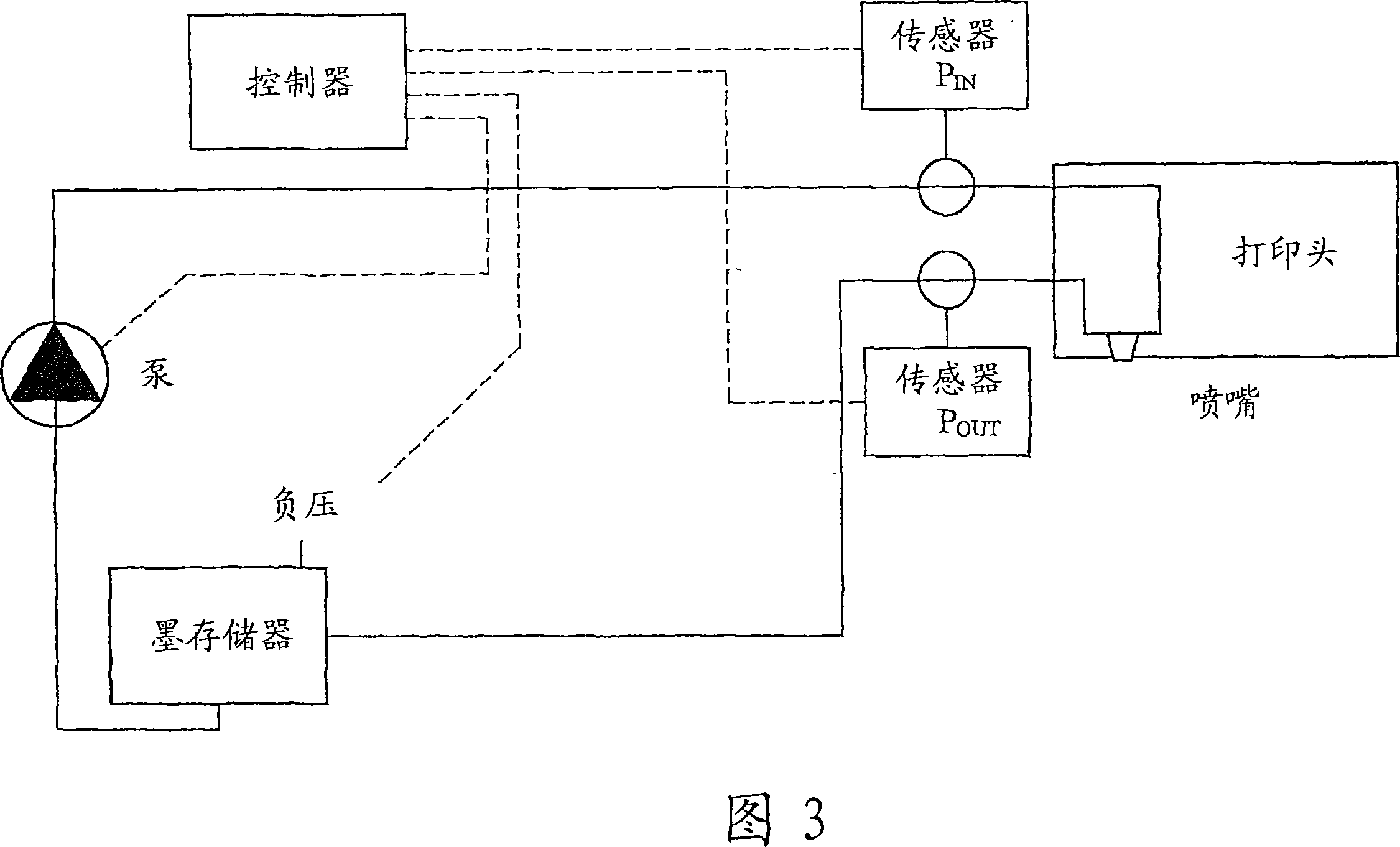

Fluid supply method and apparatus

A method and apparatus for supplying fluid to a deposition device or printhead using the through flow principle. The pressure of fluid entering and exiting the printhead is controlled directly at the printhead by respective pressure controllers, preferably a transducer and control system or a weir. The pressure controllers can be integrated together and mounted on or further integrated with the printhead. The supply system preferably forms a closed loop including a remote reservoir, and the entire system can be arranged such that the overall free surface of fluid is exposed on average to a negative gauge pressure.

Owner:XAAR TECH LTD

Hydrogen peroxide working solution and its application in preparation of hydrogen peroxide

ActiveCN103588177AReduce solubilityImprove solubilityPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesOrganic solventPhosphate

The invention belongs to the technical field of hydrogen peroxide, and especially relates to a hydrogen peroxide working solution and its application in the preparation of hydrogen peroxide. The hydrogen peroxide working solution comprises 2-ethylanthraquinone having a mass concentration of 120-200g / L and an organic solvent, and the organic solvent comprises, by volume, 70-80% of a C9-C10 aromatic hydrocarbon, 14-20% of trioctyl phosphate, 4-10% of 2-methylcyclohexyl acetate and 0.4-0.9% of tertiary amine When the hydrogen peroxide working solution is used in the preparation of hydrogen peroxide, the hydrogen peroxide working solution can greatly improve the hydrogenation efficiency and the oxidation efficiency of 2-ethylanthraquinone, and has the advantages of low production cost, no peculiar smell and product yield improvement.

Owner:WEIFANG MENJIE CHEM

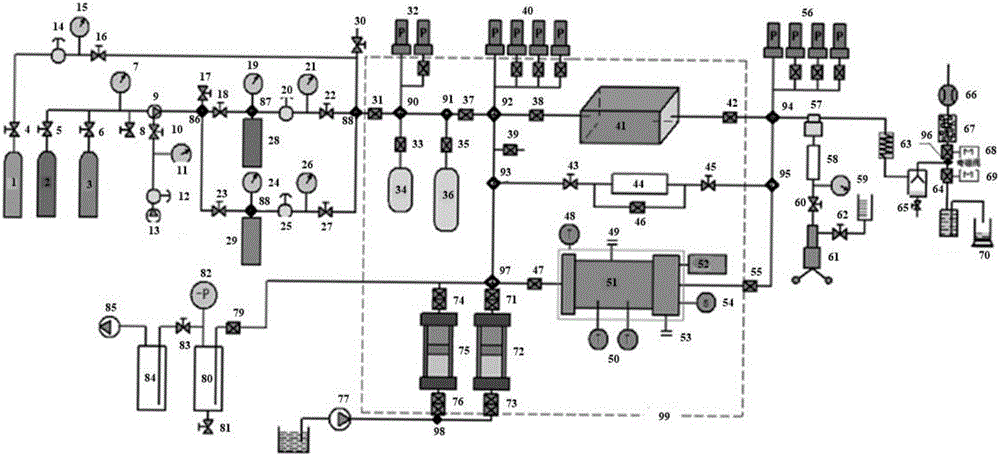

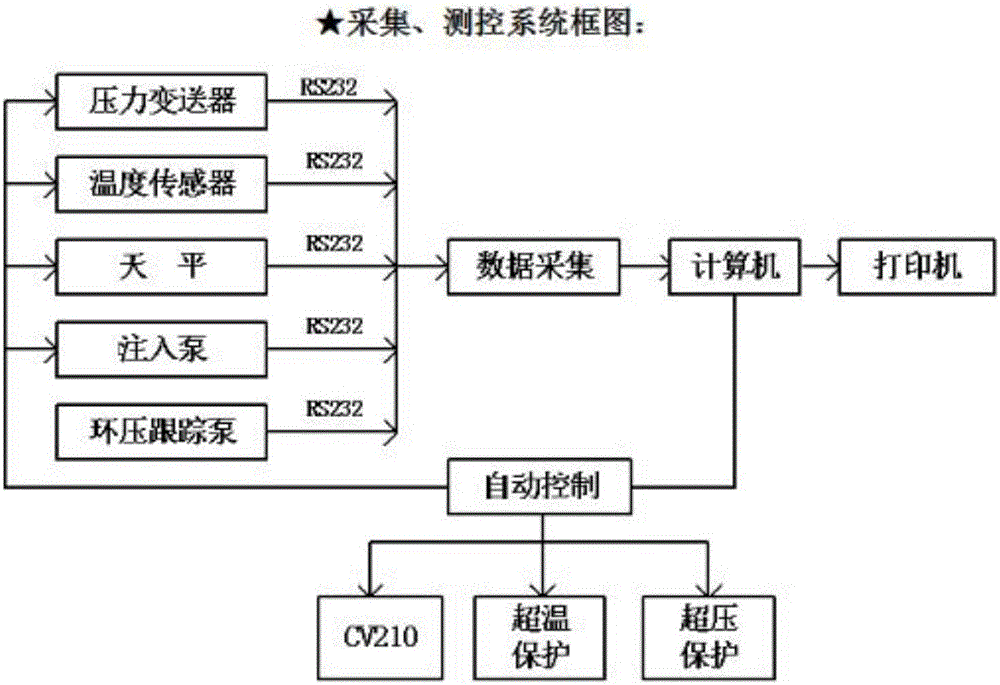

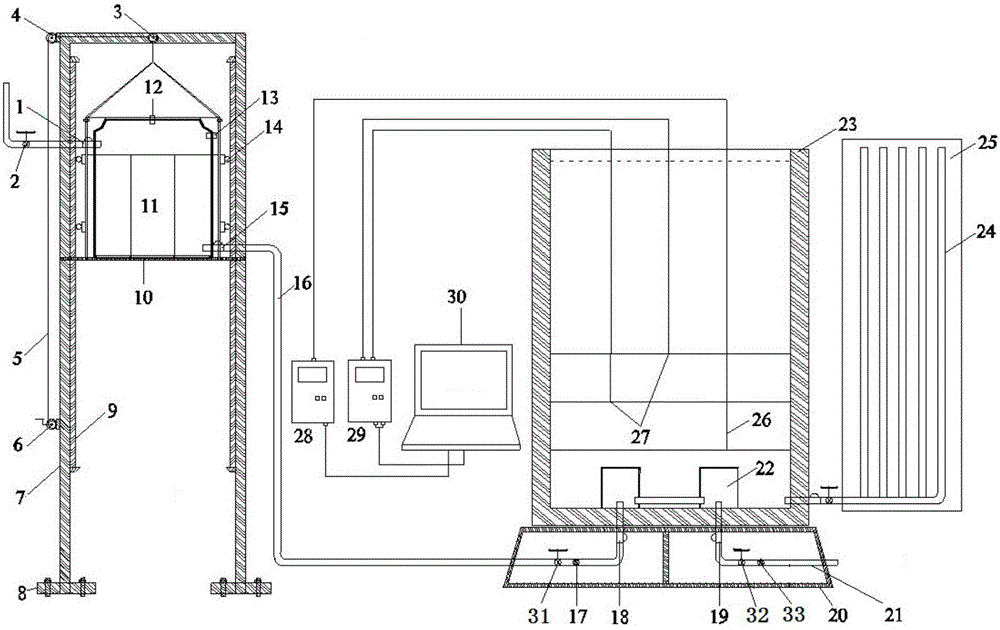

Nonconventional natural gas rock-gas-heat multi-process coupling test system

ActiveCN106840991AGuaranteed pressureGuaranteed experimental accuracyEarth material testingPermeability/surface area analysisFluid controlNatural gas

The invention discloses a nonconventional natural gas rock-gas-heat multi-process coupling test system. The nonconventional natural gas rock-gas-heat multi-process coupling test system consists of a fluid control system, a rock core adsorbing / desorbing and gas analyzing system, a vacuum suction system and a hydraulic cracking system, wherein the fluid control system is respectively communicated with the rock core adsorbing / desorbing and gas analyzing system, the vacuum suction system and the hydraulic cracking system. The nonconventional natural gas rock-gas-heat multi-process coupling test system has the advantages that the multiple coupling process tests of coal rock permeation evolution under the real three-axis or false three-axis stress loading, temperature loading, and multi-component gas diffusion conditions are realized, the whole-process data, such as experiment temperature, component gas flow rate and adsorbing characteristic, are dynamically stored and processed through software, and the nonconventional gas-enriching reservoir forming, adsorbing and desorbing rule of rock at stratum temperature, pressure and fluid medium can be scientifically simulated; the scientific experiment support is provided for the extreme complicated deep resource exploitation.

Owner:CHINA UNIV OF MINING & TECH

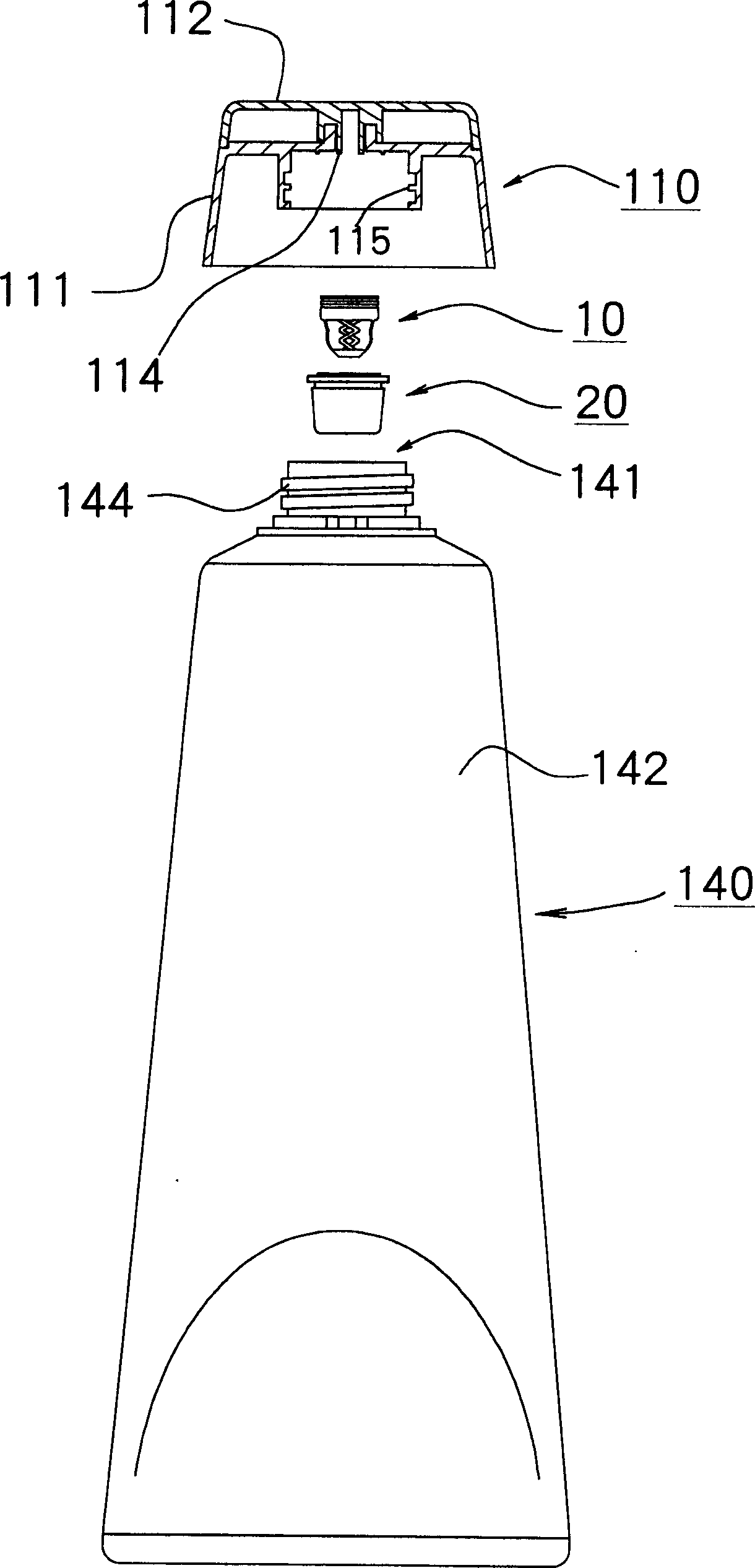

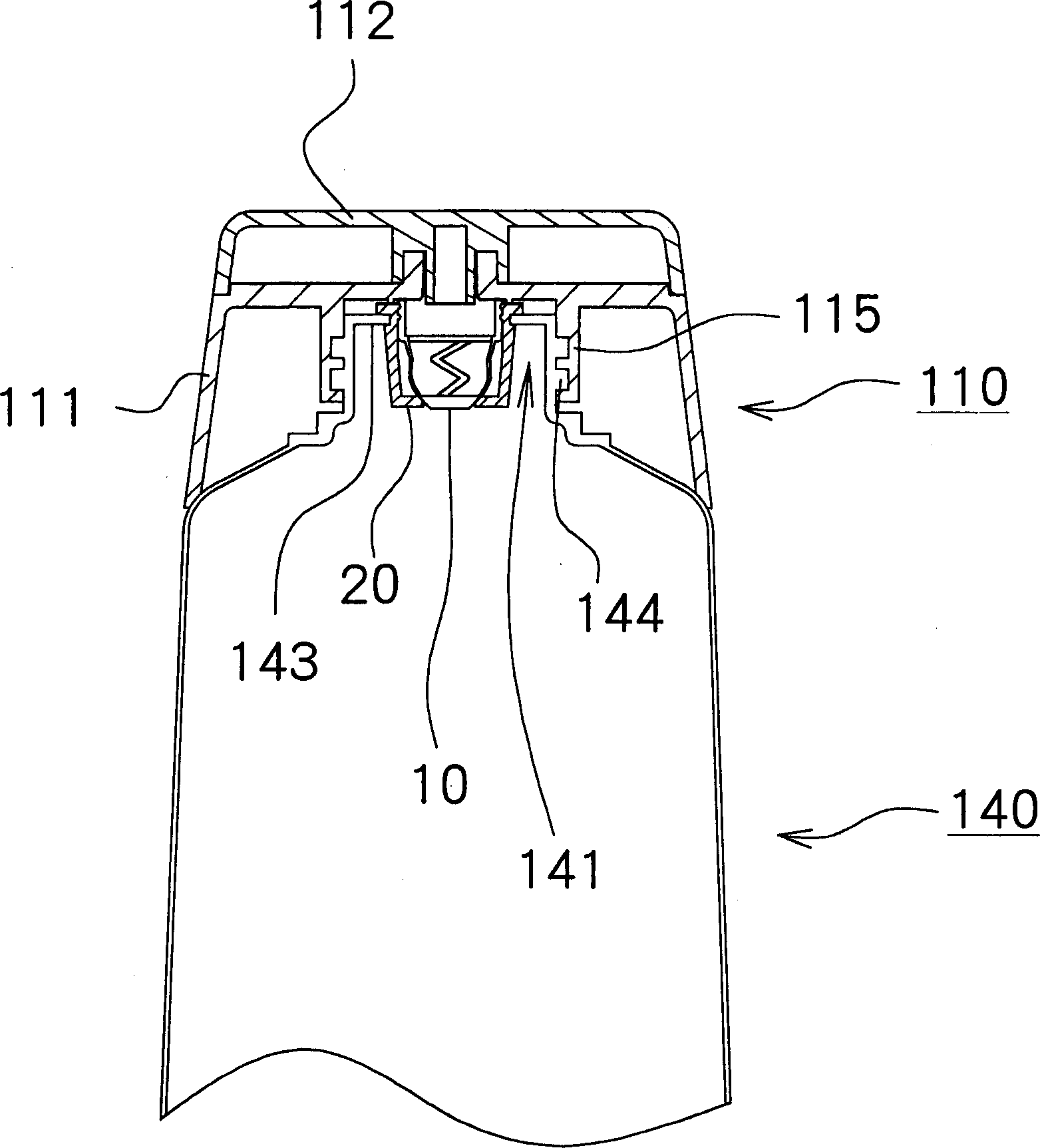

Valve mechanism for tubular fluid container

InactiveCN1470438APrevent improper tiltingImprove sealingClosuresDispensing apparatusCouplingEngineering

Owner:增田胜利

Spray tube electrospinning head

InactiveCN103422180AIncrease speedIncreased polarizationSpinnerette packsFilament/thread formingTaylor coneElectric field

The invention discloses a spray tube electrospinning head, and belongs to the field of electrospinning. The spray tube electrospinning head comprises an electrospinning head body, wherein a solution connecting portion is arranged on the tail portion of the electrospinning head body, a horn-shaped spinning nozzle, a polarization throat port and a solution chamber hole are formed in the electrospinning head body in sequence from top to bottom, and are communicated with one another, the inner wall face of the spinning nozzle is a circular-arc curved surface which gradually expands outwards, the port diameter of the polarization throat port is smaller than the hole diameter of the solution chamber hole, the outer wall of the head portion of the electrospinning head body is of a cone shape, and the diameter of the cone gradually decreases outwards. The spray tube electrospinning head can increase the forming speed of a Taylor cone, improve the velocity of a solution when the solution passes through the spray tube electrospinning head, and is better in electric field directivity.

Owner:常州市亚国新能源科技有限公司

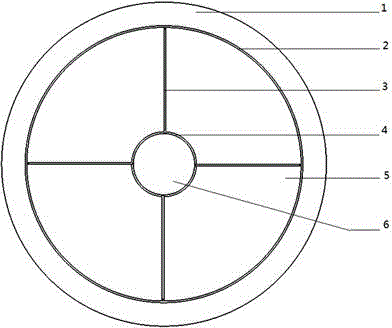

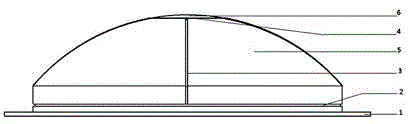

Multi-petal composite material launching box cover and preparation method thereof

The invention relates to a multi-petal composite material launching box cover and a preparation method thereof and belongs to the technical field of missile launching. The multi-petal composite material launching box cover sequentially comprises a frame (1), a side sub-cover (5) and a top sub-cover (6). The side sub-cover (5) is connected with the frame (1) through a thrown body separating area (2), the top sub-cover (6) is connected with the side sub-cover (5) through a top sub-cover separating area (4), the side sub-cover (5) is evenly divided into 4-8 side sub-cover units in the circumference, and the side sub-cover units are connected through side sub-cover unit separating areas (3). Under the effect of missile launching tail flow, the launching box cover is broken into a plurality of sub-covers to fly away from a launching box, and accordingly missile launching is not influenced. The problem that a thrown object of the fragile cover is high in mass is solved, and the threat to surrounding devices and workers caused by the thrown object is effectively reduced.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Erosion simulation experiment method and apparatus

ActiveCN101226135AEasy to adjustSimple structureWeather/light/corrosion resistanceSample rotationExperimental methods

The invention relates to a corrosion simulation test method and a relative device, which is characterized in that the invention uses one motor to rotate the sample rotation shafts in a plurality of autoclaves, respectively fixes and connects the motor and autoclaves with one rotary mount capable of being positioned, and adjusts the inclination angle of the mount to realize the sample corrosion simulation test under variable flow forms in the autoclaves. The device comprises a base which can be rotationally connected with a mount, a motor on the top of the mount, a plurality of autoclaves in the bottom of the mount, a multi-concave-channel belt wheel fixed on the extrusion shaft of the motor while the extrusion end of the sample rotation shaft in each autoclave is fixed with a multi-concave-channel belt wheel and each concave channel on the multi-concave-channel belt wheel is connected with one belt relative with the multi-concave-channel belt wheel on one sample rotation shaft. The invention is suitable for simulating the corrosion tests of collecting and feeding pipe of oil and natural gas.

Owner:CHINA NAT OFFSHORE OIL CORP +2

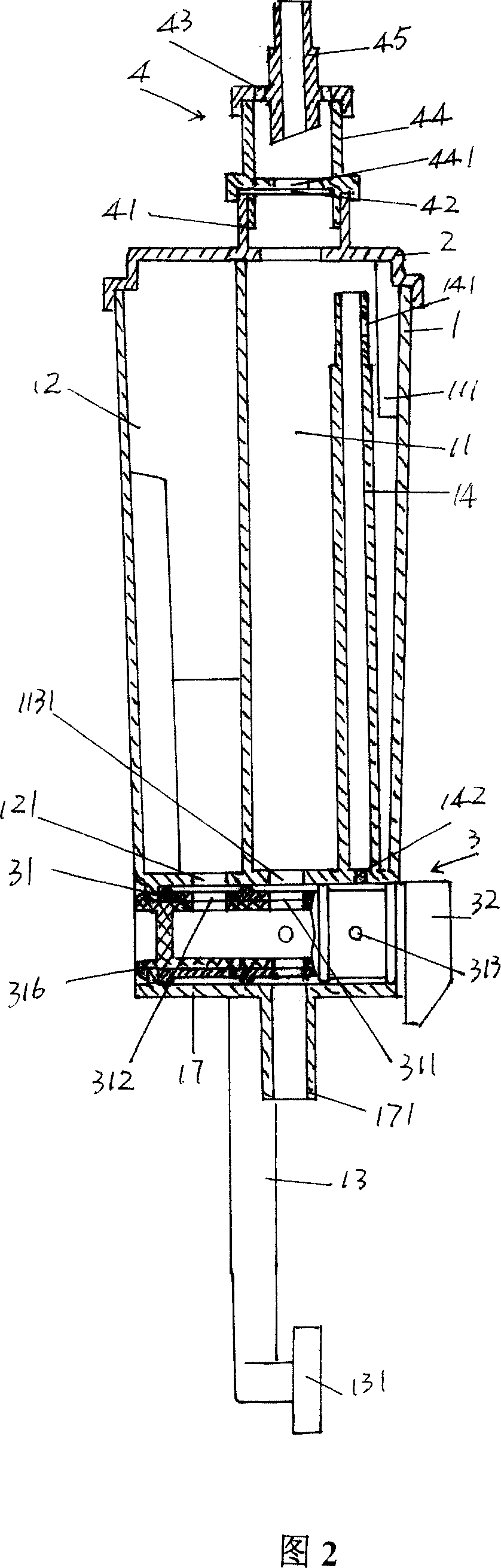

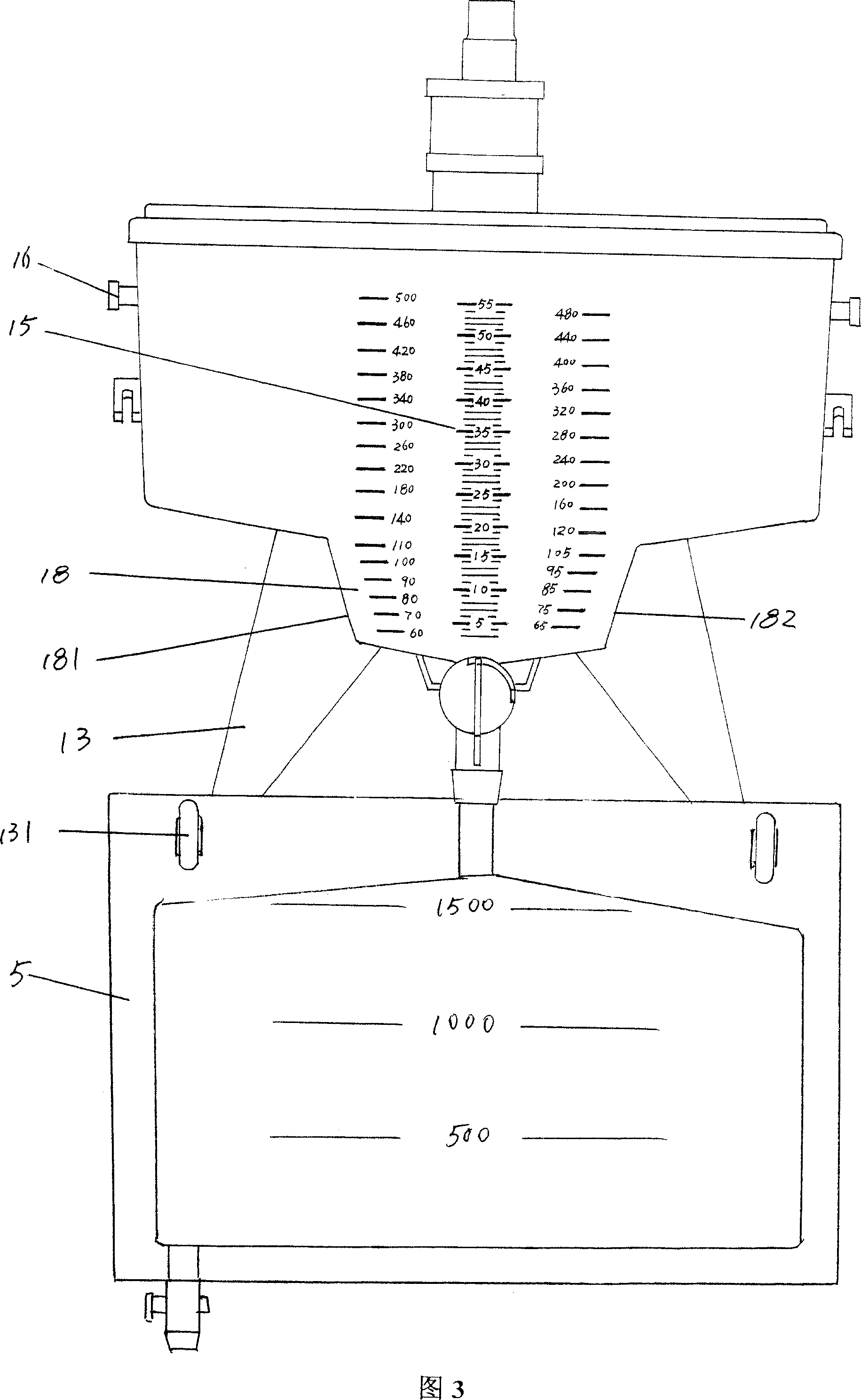

Medical semi-automatic drain liquid metering and storing apparatus

InactiveCN100998540AConducive to exhaustionAccurate measurementVolume measurement and fluid deliveryPharmaceutical containersSemi automaticEngineering

A semi-automatic metering accumulator of drainage fluid for medical purpose is composed of a box body, a box cover with the guide and anti-reflux mechanism of drainage fluid, a panel with a longitudinal metering scale, and a drainage fluid discharging valve. Said box body has a big fluid storage cavity, a cylindrical small fluid storage cavity, and a tubular over-flow cavity arranged vertically in said small fluid storage cavity.

Owner:常熟市神灵医用器材有限公司

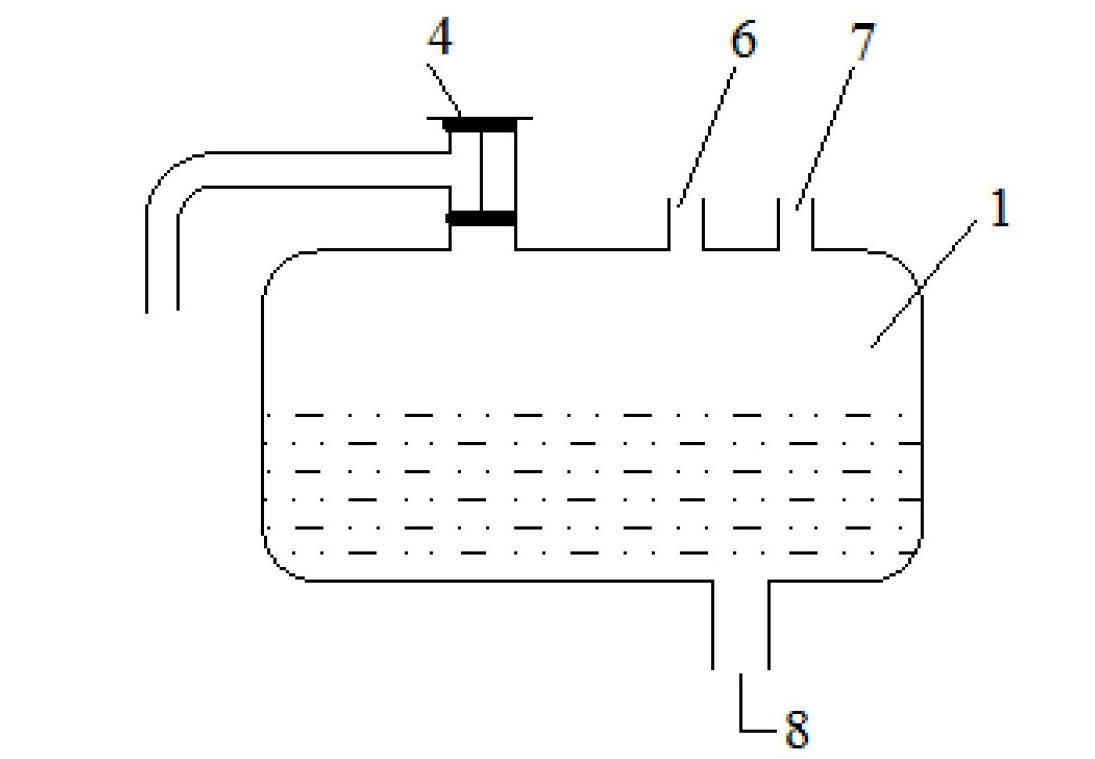

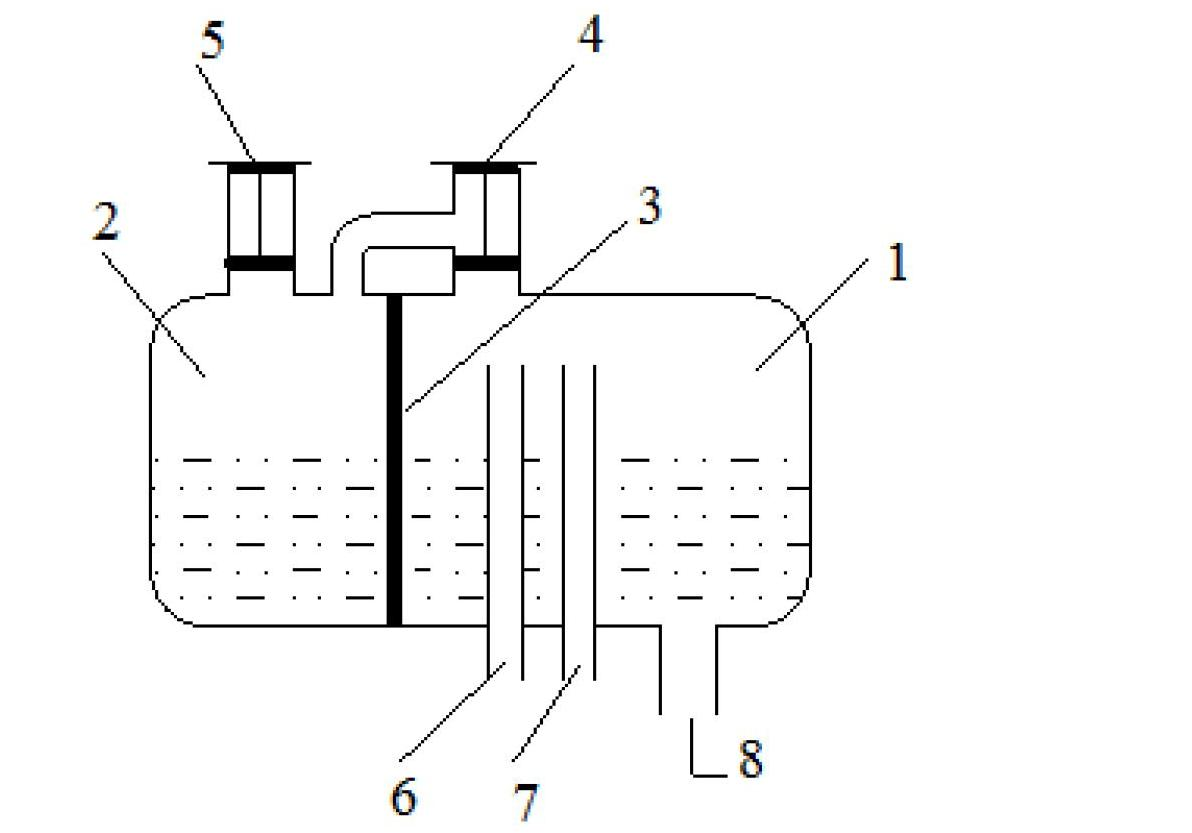

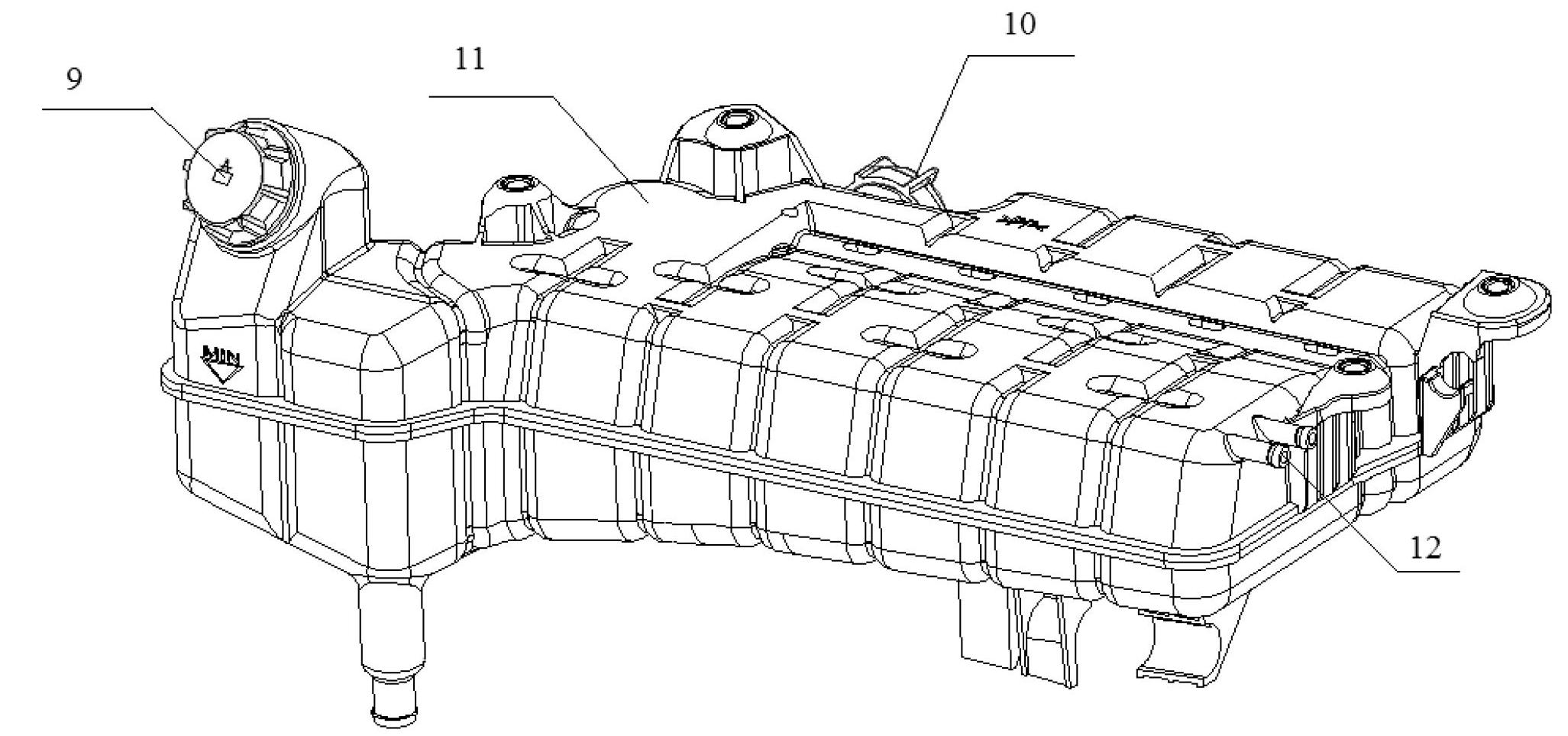

Energy-saving environment-friendly automobile expansion water tank

InactiveCN102635432ASimple structureEasy to useMachines/enginesEngine cooling apparatusExpansion tankEngineering

The invention discloses an energy-saving environment-friendly automobile expansion water tank, comprising a primary chamber and an auxiliary chamber separated by a separator. The primary chamber is provided with a first air removing port and a second air removing port respectively connected with an engine and a radiator; a pipeline connected with a water pump is arranged at the lower part of the primary chamber; a primary pressure valve is arranged at the upper part of the primary chamber and connected with the auxiliary chamber through a pressure releasing pipe; and the auxiliary chamber is provided with an auxiliary pressure valve. The water tank is simple in structure and convenient to use, and ensures that the engine can operate at any temperature, the normal pressure in the water tank is maintained and overflowing of hot water is avoided.

Owner:山东统亚塑料制品有限公司

Water level cycle rising and falling induced ground settlement test apparatus and test method thereof

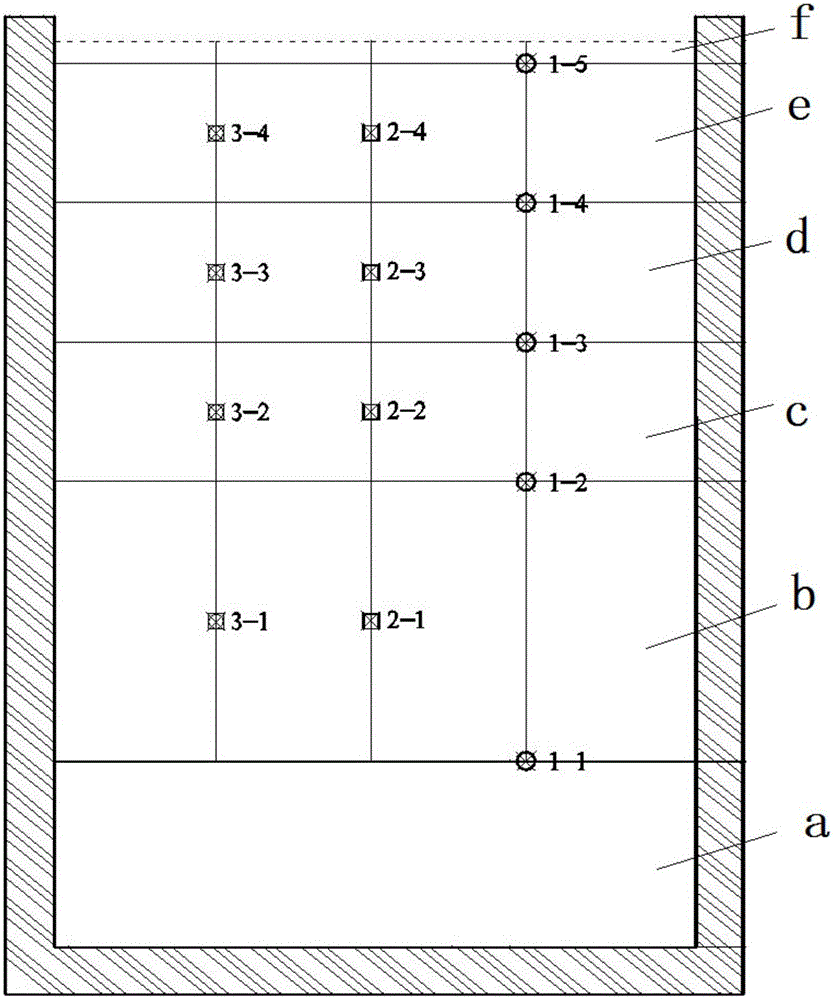

ActiveCN105974088AReduce penetrationRelieve pressureEarth material testingData informationPore water pressure

The invention relates to a water level cycle rising and falling induced ground settlement test apparatus and a test method thereof. The apparatus comprises a model column (23) used for containing soil for test, a water supply unit, a water drainage unit, a data measurement unit and a data acquisition unit, the bottom of the model column is provided with a model column water inlet (18) and a model column water outlet (19), the water supply unit is connected with the model column water inlet (18), the water drainage unit is connected with the model column water outlet (19), the data measurement unit is arranged in the soil for test in the model column (23), and the data acquisition unit is connected with the data measurement unit; and the on or off state of the water supply unit and the water drainage unit is adjusted to carry out water level cycle rising and falling adjustment, the data measurement unit measures data information of the soil for test in the model column (23), and the data acquisition unit acquires data information, and analyzes the data information. Compared with the prior art, the apparatus and the method realize effective research of the change rules of the settlement volume, the soil pressure and the aperture water pressure of different soil layers, induced by water level cycle rising and falling.

Owner:TONGJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com