Sediment pressure-holding sampler driven by hydrostatic pressure

A hydrostatic pressure and sediment technology, applied in the direction of sampling devices, etc., can solve the problems of large support frame, limited insertion depth, and bulky, etc., and achieve the effect of increasing sample collection rate, deep sampling depth, and reducing "pile effect"

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

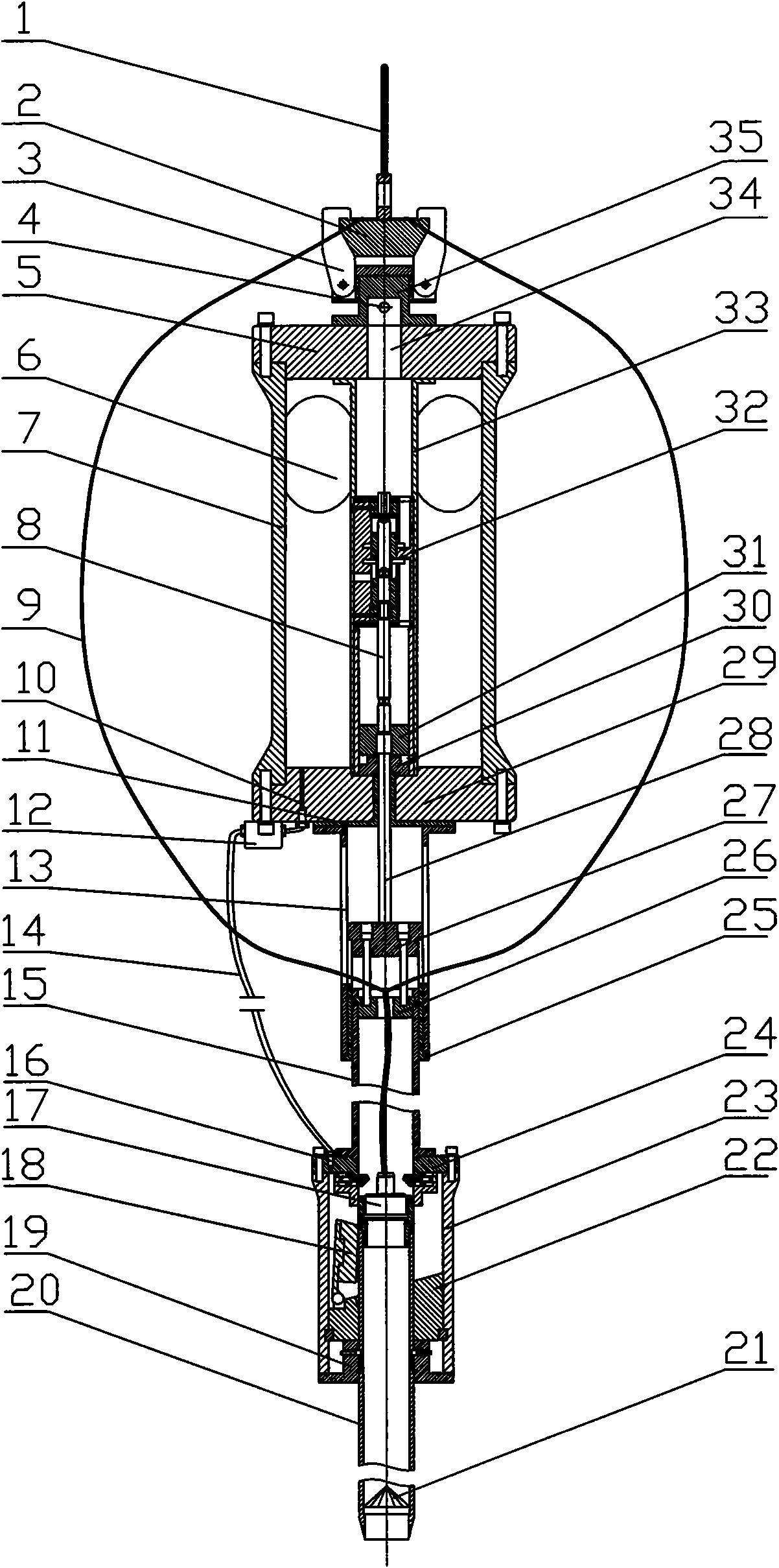

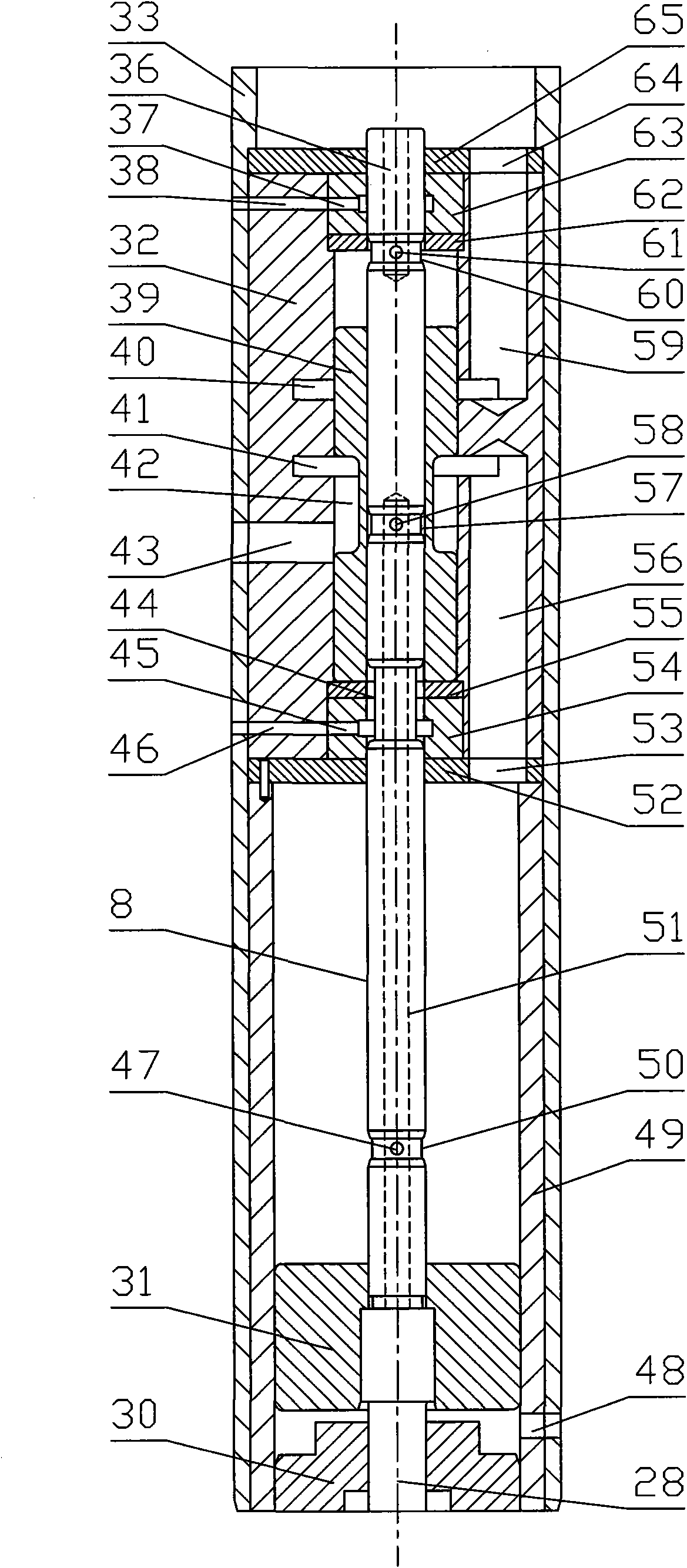

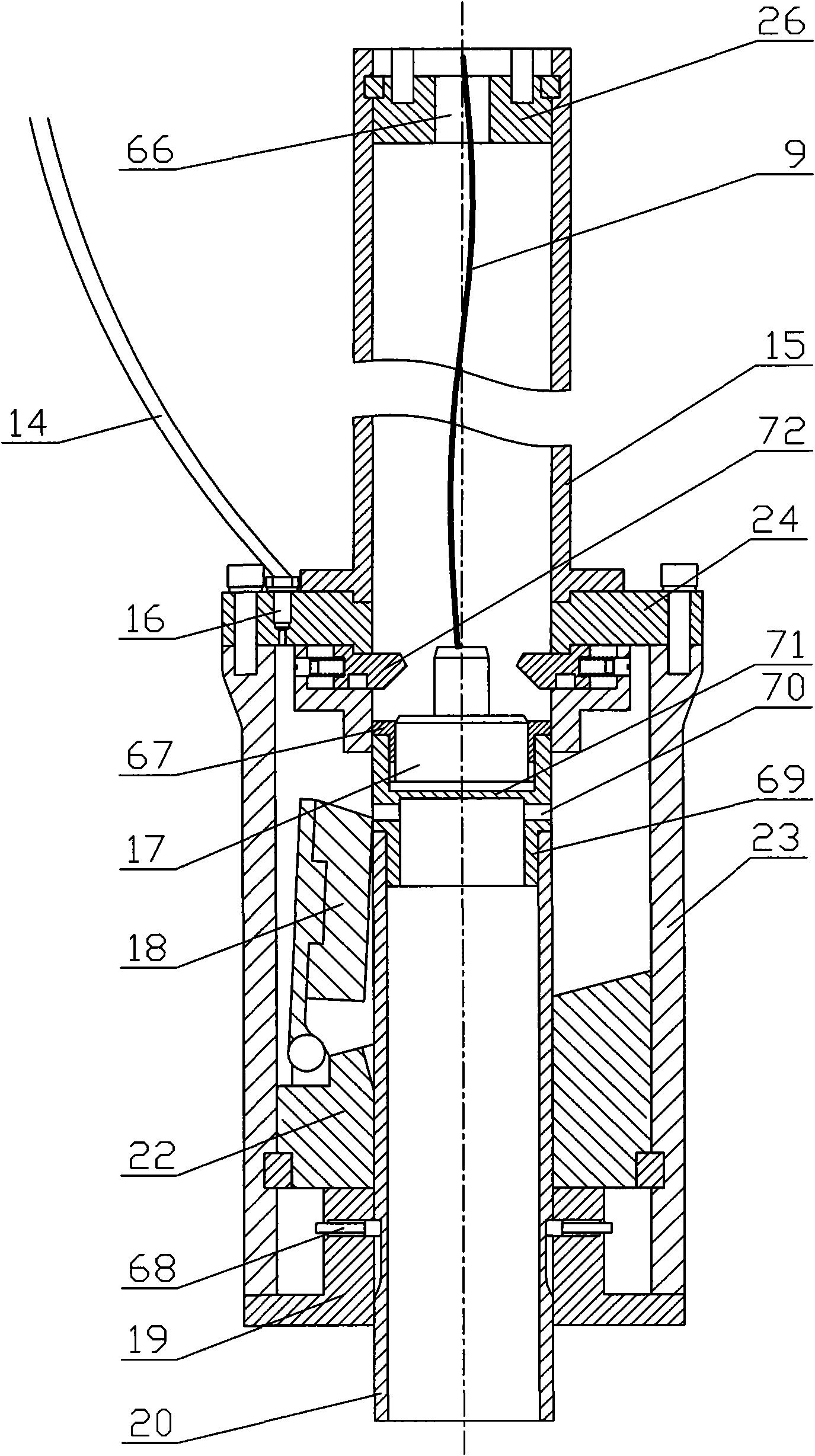

[0017] like figure 1 Shown is a schematic diagram of the overall structure of the present invention, and the hydrostatic pressure-driven sediment pressure retaining sampler includes an impact component, a flow distribution component, a driving component, and a sampling cylinder component.

[0018] The impact components include an upper end cover 5 , an impact cylinder 7 , a lower end cover 29 , a guide sleeve 11 , an impact piston cylinder 13 , a sliding piston 27 , and a piston retaining ring 25 . The upper end cover 5 and the lower end cover 29 are respectively fixed on the two end faces of the impact cylinder 7, the center of the upper end cover 5 has an impact cylinder water inlet 34, and the top surface of the upper end cover 5 corresponds to the impact cylinder water inlet 34. Claw seat 35. The claw seat 35 is provided with a water inlet 4 connected to the water inlet hole 34 of the impact cylinder, and a lifting block 2 is arranged at the position corresponding to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com