Erosion simulation experiment method and apparatus

A simulation experiment device and simulation experiment technology, applied in the field of dynamic high temperature and atmospheric pressure multi-flow state corrosion simulation experiment methods and devices, can solve the problems of long experiment period, high investment and maintenance costs, and restrictions on the development of simulation experiments, and achieve simple structure , Shorten the experimental cycle, facilitate temperature control and measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

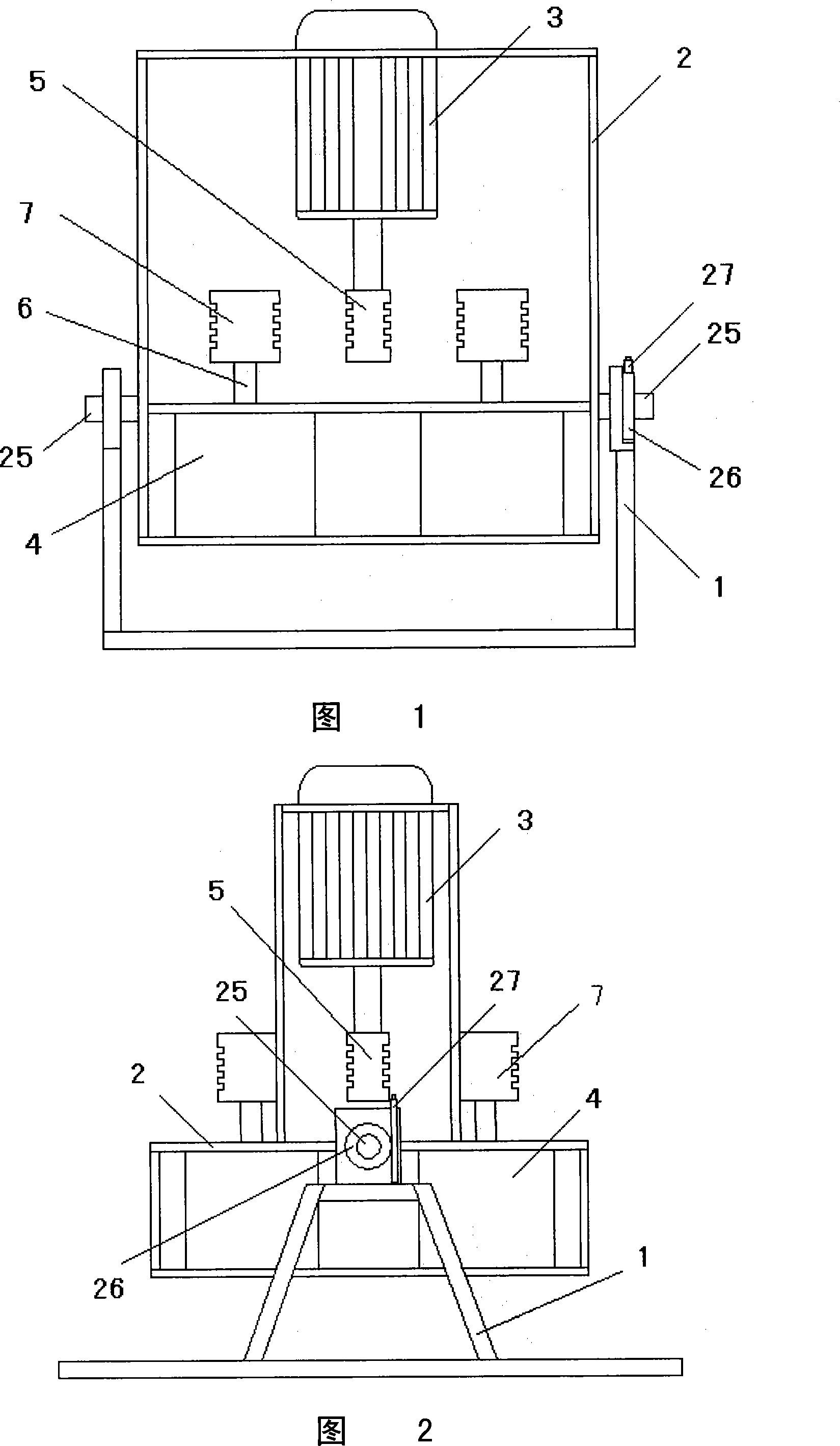

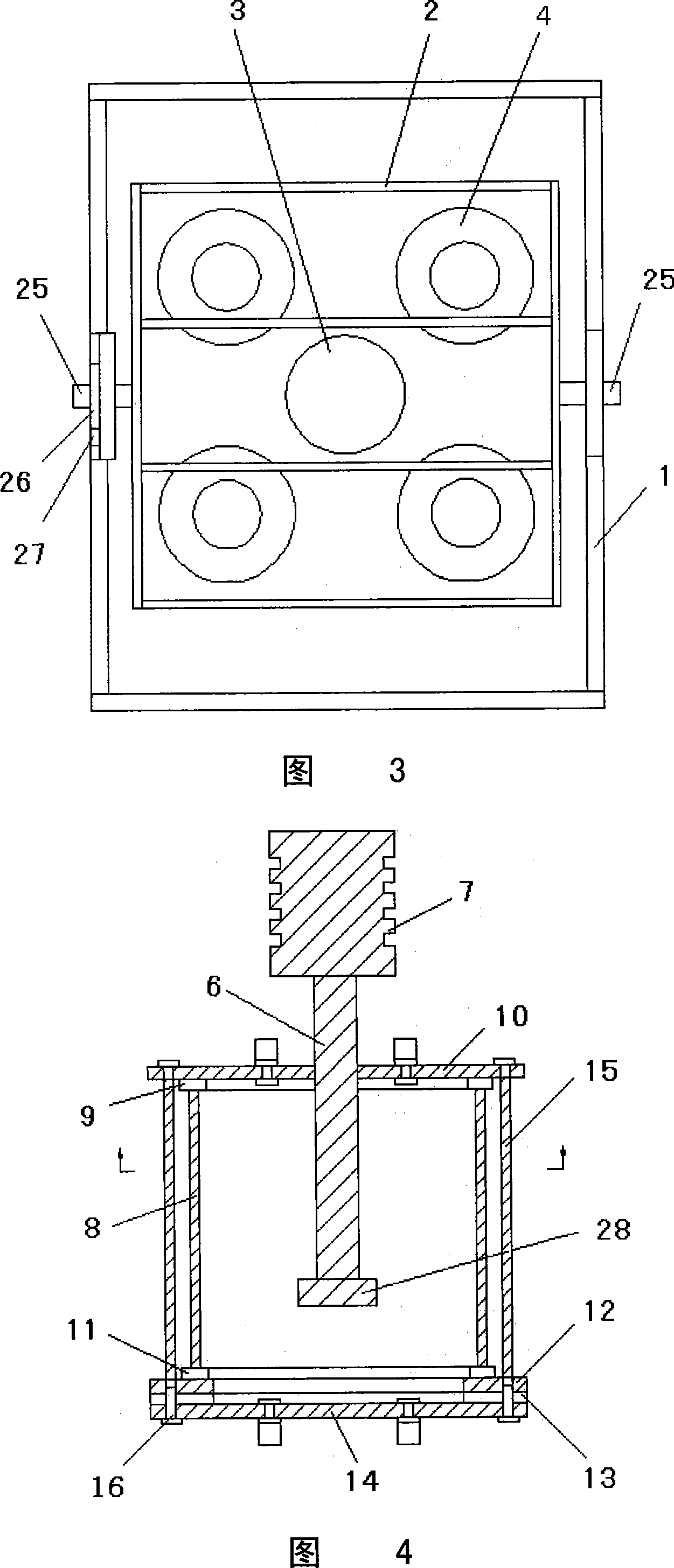

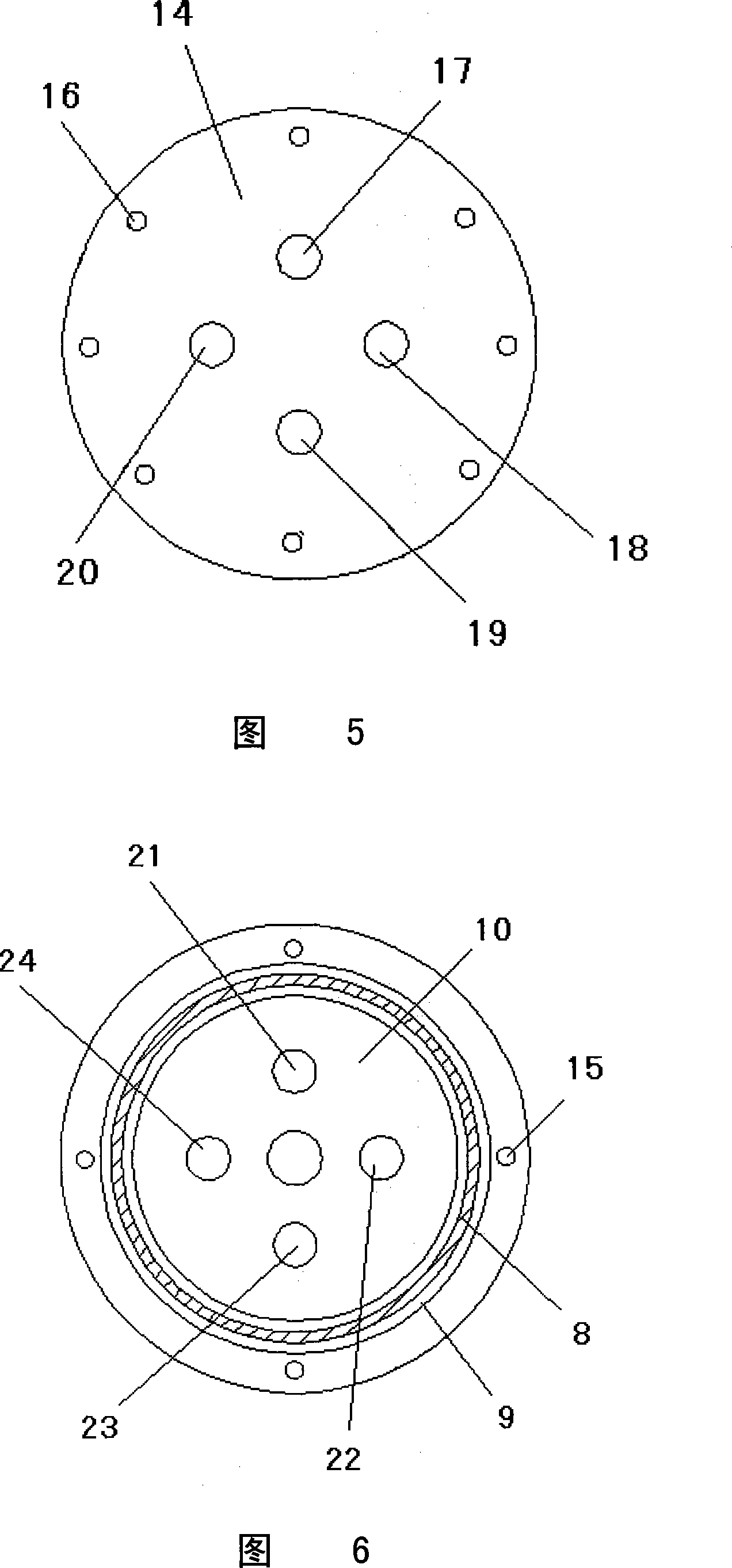

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0021] As shown in Figures 1 to 4, the present invention includes a base 1, which is rotatably connected to both sides of a support 2 on both sides of the base 1, a motor 3 is arranged on the top of the support 2, and several reaction kettles 4 are arranged in the bottom of the support 2 , on the extension shaft of motor 3 is fixedly connected with a multi-recess belt pulley 5, and the extension end of the sample rotating shaft 6 provided in each reaction kettle 4 is also fixedly connected with a multi-recess pulley 7, the motor 3 Each groove on the multi-groove pulley 5 is respectively connected to a belt (not shown in the figure) corresponding to the multi-groove pulley 7 on a sample rotating shaft 6, so that each reaction can be simultaneously driven by a motor 3 The sample rotating shaft 6 in the kettle 4 rotates simultaneously.

[0022] As shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com