Patents

Literature

781results about How to "Increase collection rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

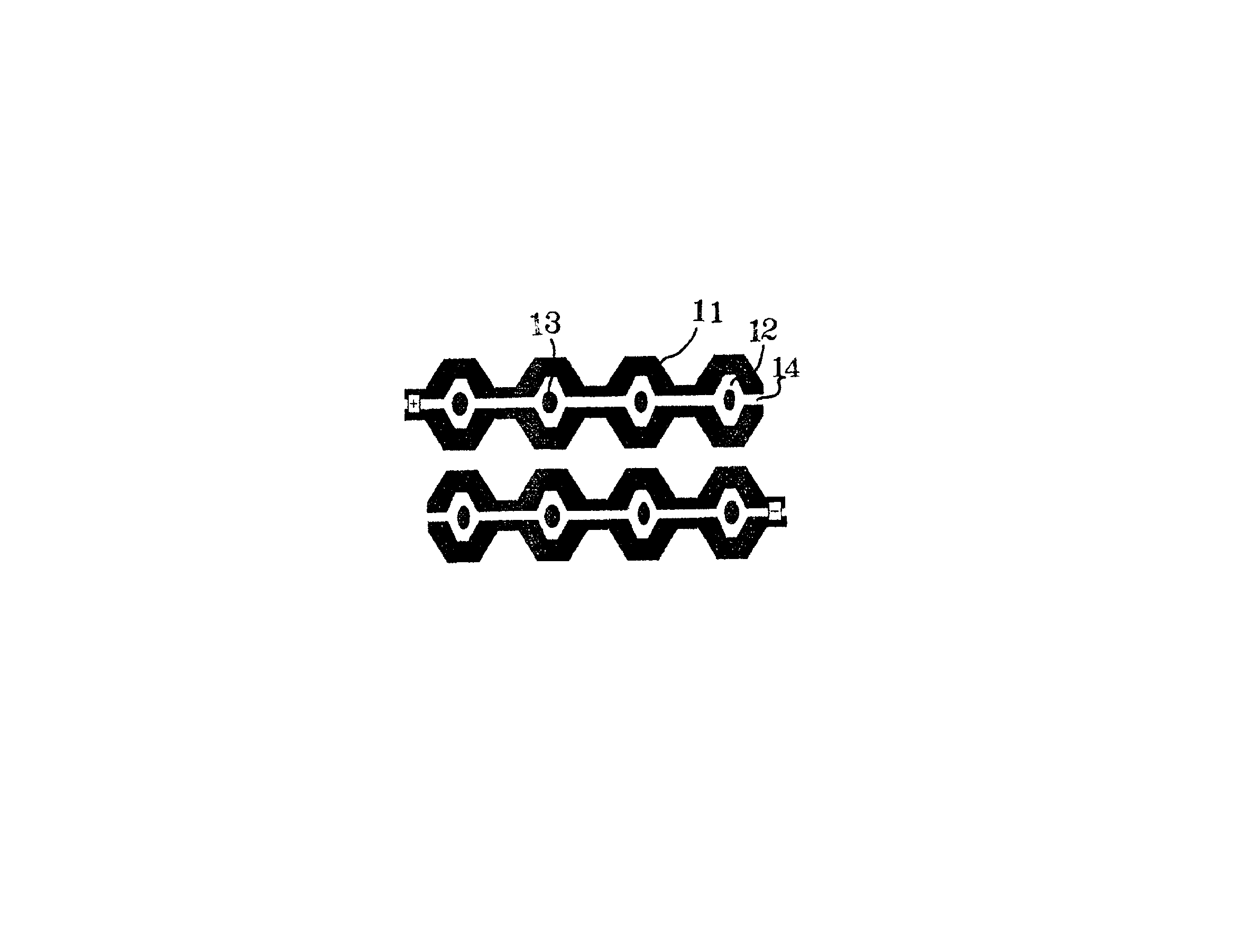

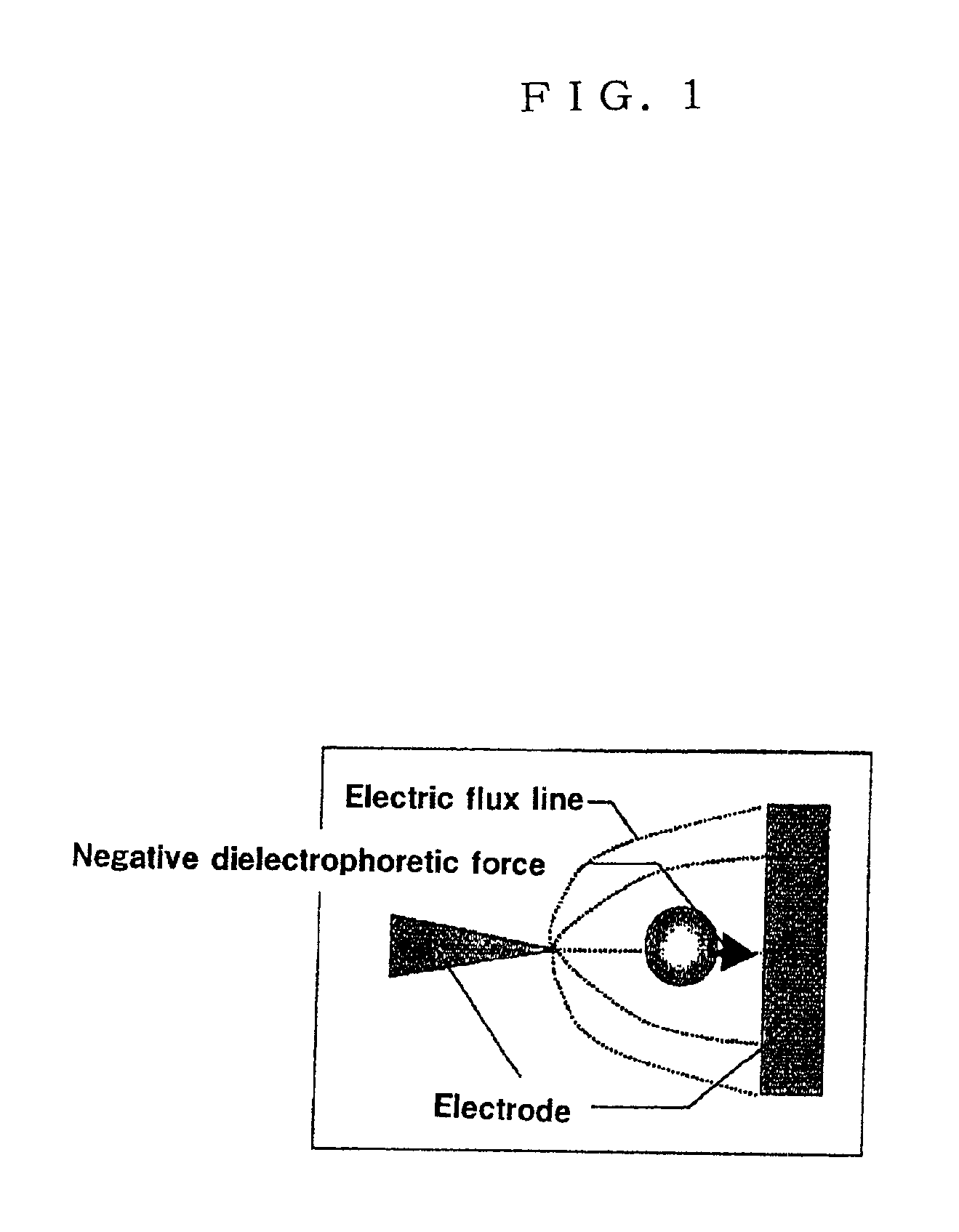

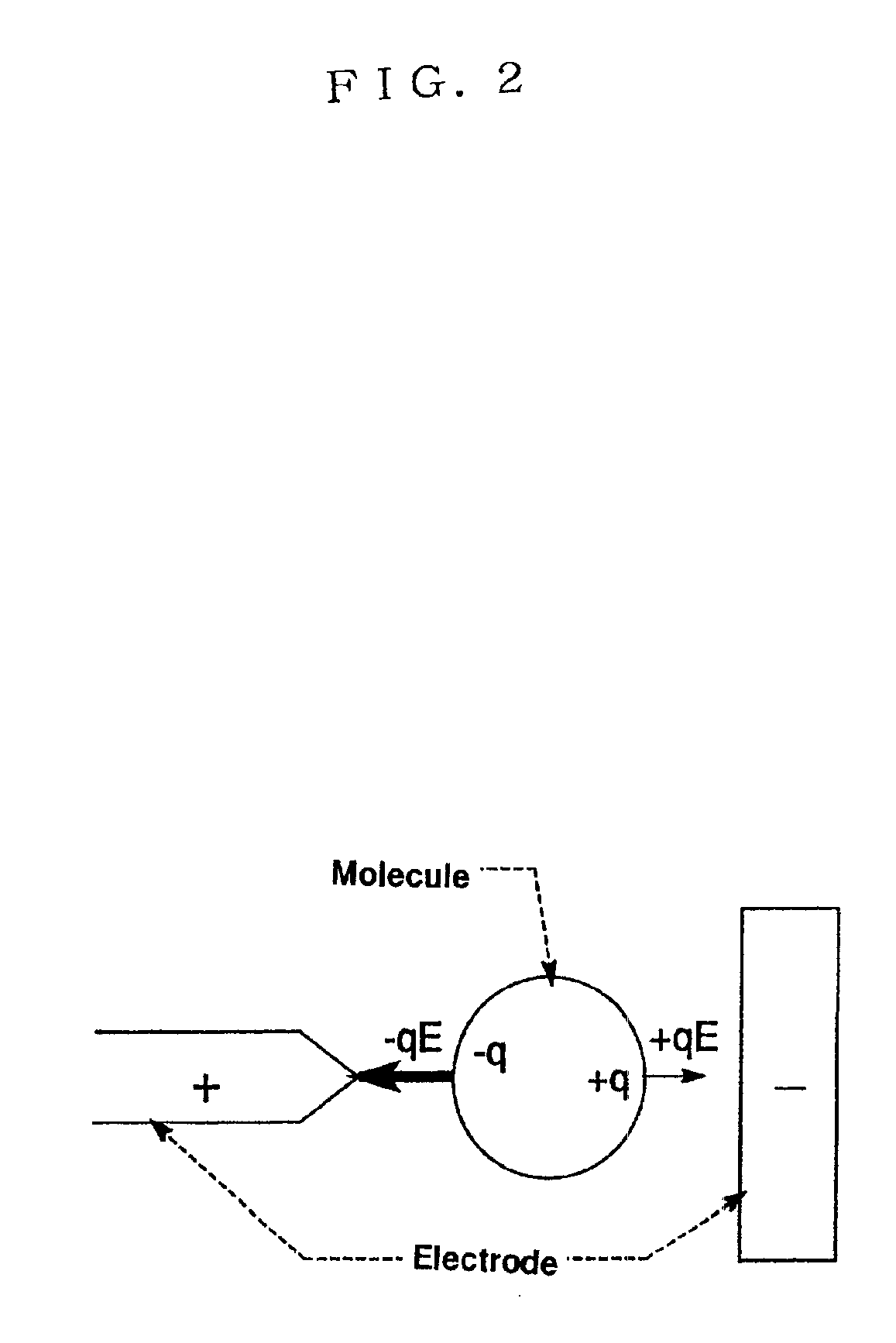

Method for separating substances using a dielectrophoretic apparatus

InactiveUS6875329B2Improve signal-to-noise ratioLow backgroundElectrostatic separatorsSludge treatmentSubstance useDielectrophoretic force

To provide An electrode for a dielectrophoretic apparatus in which a background detected by reflecting an excited light on an electrode present under the substance (molecule) is reduced and an S / N ratio is enhanced. Also, there is provided an dielectrophoretic apparatus, in an apparatus in which a liquid containing substances to be separated is present in a non-uniform electric field formed by a dielectrophoretic electrode, and separation is carried out by a dielectrophoretic force exerting on the substances, wherein the collecting ability of substances is enhanced. The present invention is characterized in that a vacant space is provided in an electrode whereby substances subjected to influence by a negative dielectrophoretic force can be concentrated in said vacant space of an electrode, or above or below portion of the space.

Owner:WAKO PURE CHEMICAL INDUSTRIES

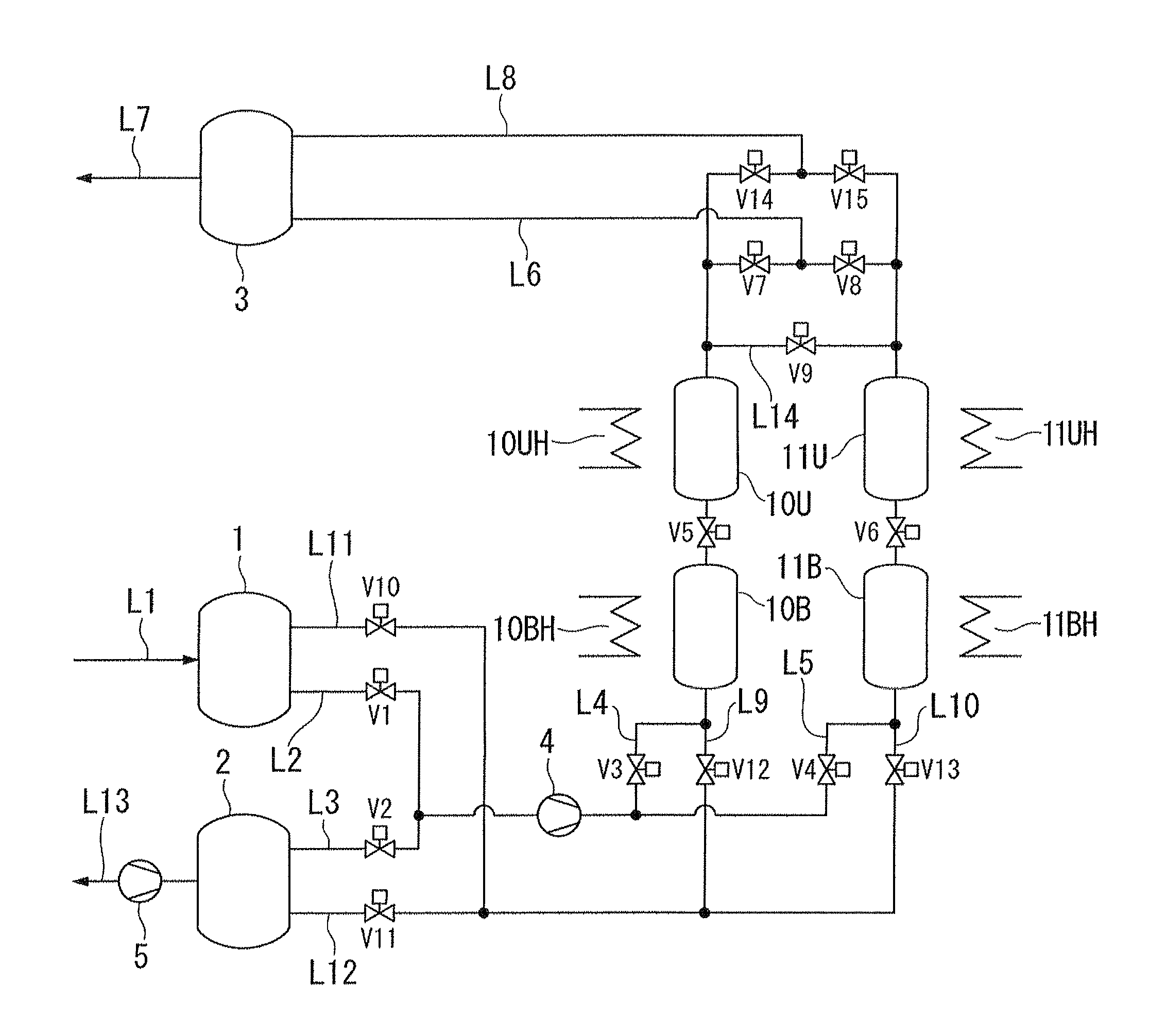

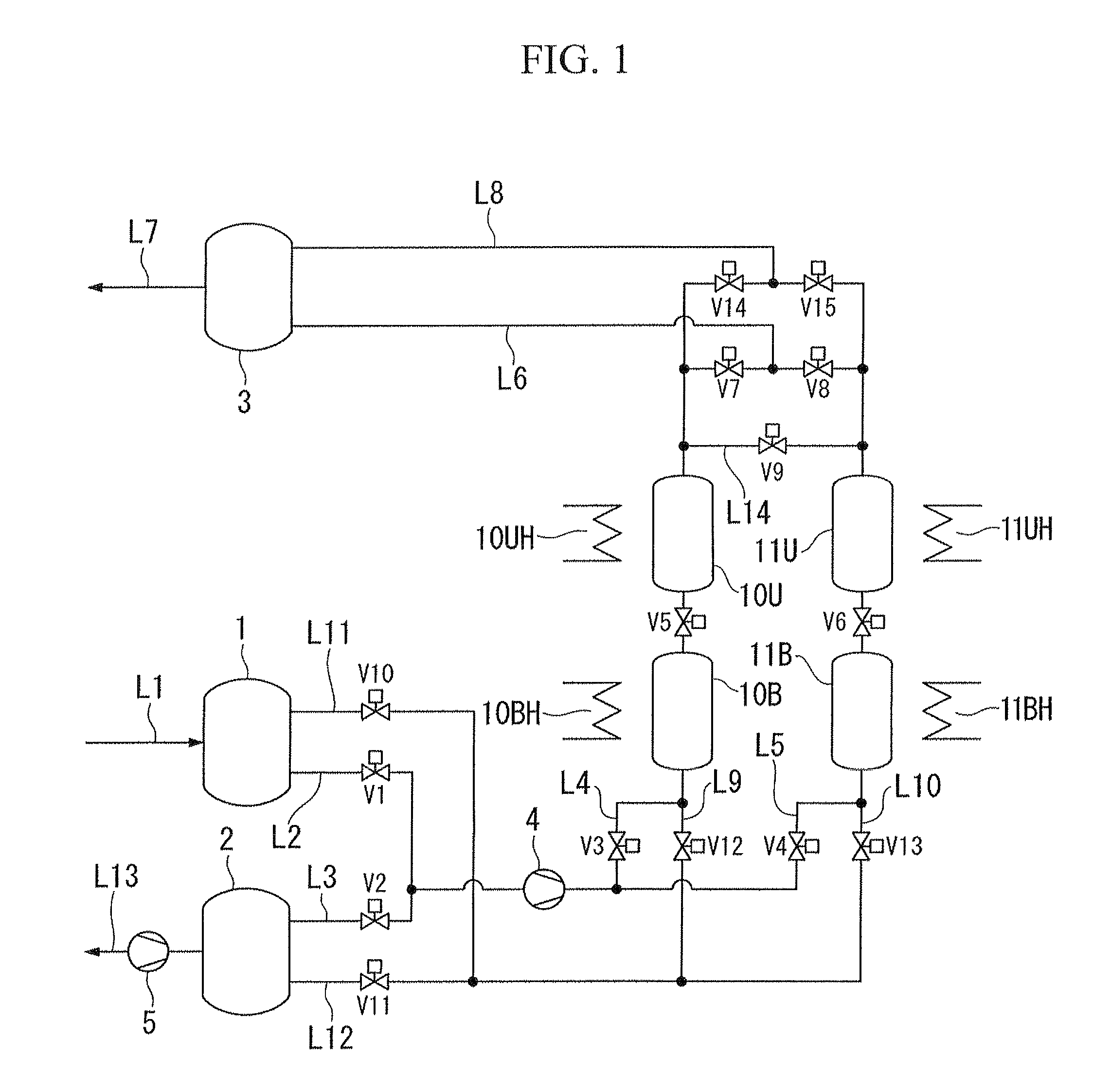

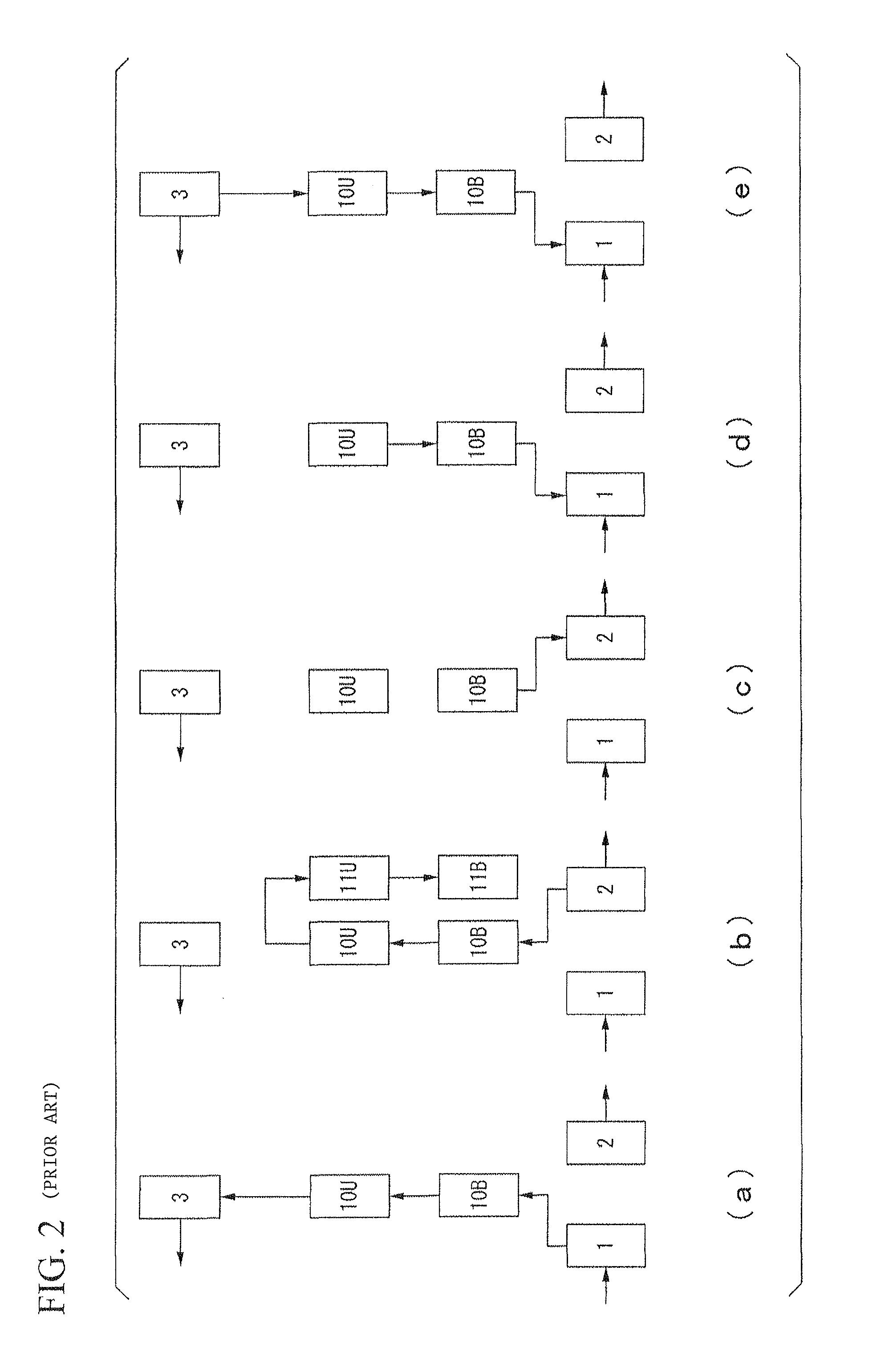

Pressure swing adsorption-type gas separation method and separation apparatus

InactiveUS8657922B2Stably separate and collectIncrease valueGas treatmentIsotope separationChemistryPressure swing adsorption

Owner:NIPPON SANSO CORP

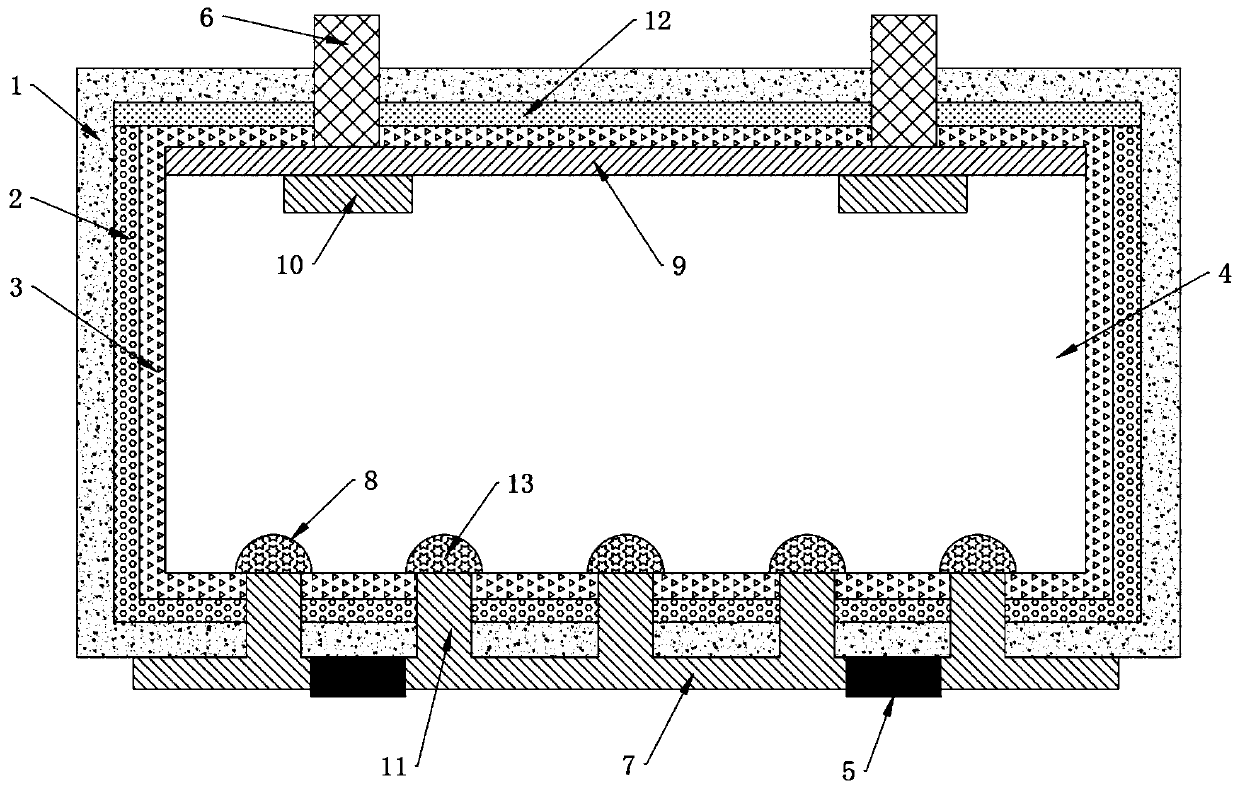

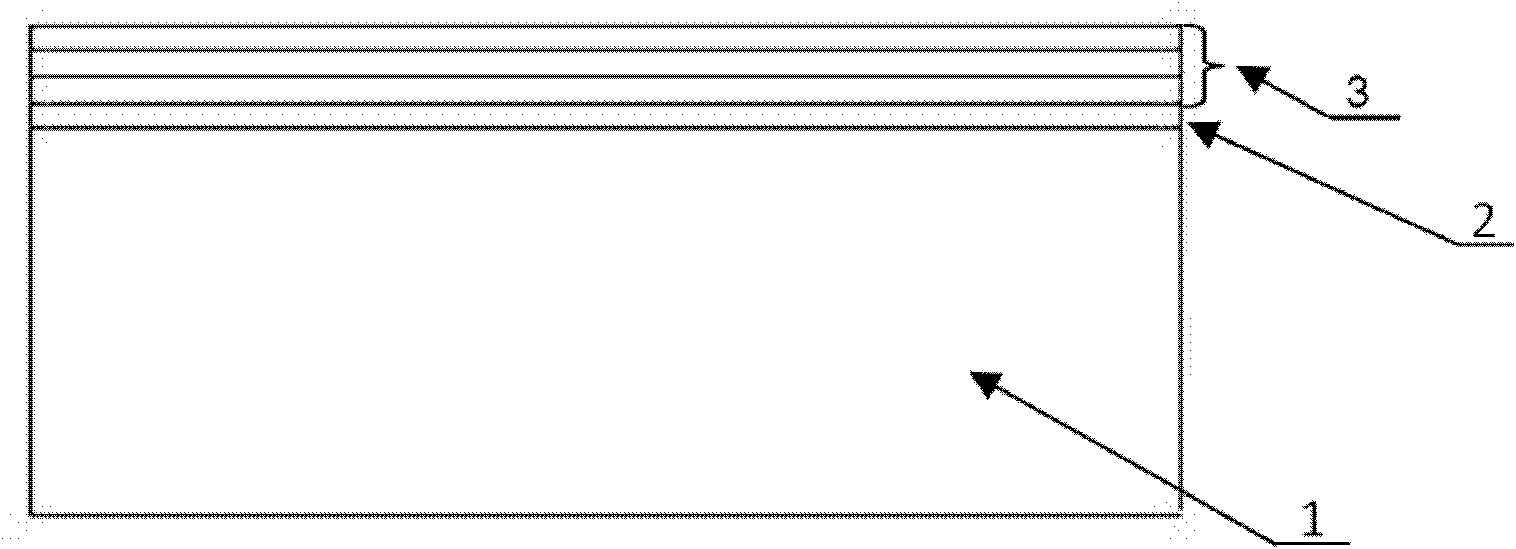

Solar cell with composite dielectric passivation layer structure and preparation process thereof

PendingCN110459615AIncrease short circuit currentIncrease the open circuit voltageFinal product manufacturePhotovoltaic energy generationDielectricRefractive index

The invention discloses a solar cell with a composite dielectric passivation layer structure and a preparation process thereof. A silicon oxide film, an alumina film and a silicon nitride or silicon oxynitride film are deposited in turn on the front, back and sides of a p-type silicon substrate to form a composite dielectric film on the whole surface, and windows are opened locally to lead electrodes out. Through aluminum oxide, silicon dioxide, silicon oxynitride, silicon nitride with different refractive indexes and a back surface passivation layer with a laminated structure of the materials, the back surface recombination rate is greatly reduced, the back reflectivity is improved, the CTM of a module is reduced, and the light attenuation and heat-assisted light attenuation and the anti-PID performance of the cell are improved. The structure can be made on a boron / gallium-doped p-type monocrystalline silicon, p-type polycrystalline silicon or p-type monocrystalline-silicon-like substrate, and a passivation method based on the composite dielectric film passivation structure can be used to manufacture PERC cells, double-sided PERC+ cells and imbricate PERC cells. Based on the preparation process steps and sequence, the corresponding preparation mode and the process parameter range of the laminated structure, the making of the cell can be well completed.

Owner:TONGWEI SOLAR ENERGY CHENGDU CO LID +2

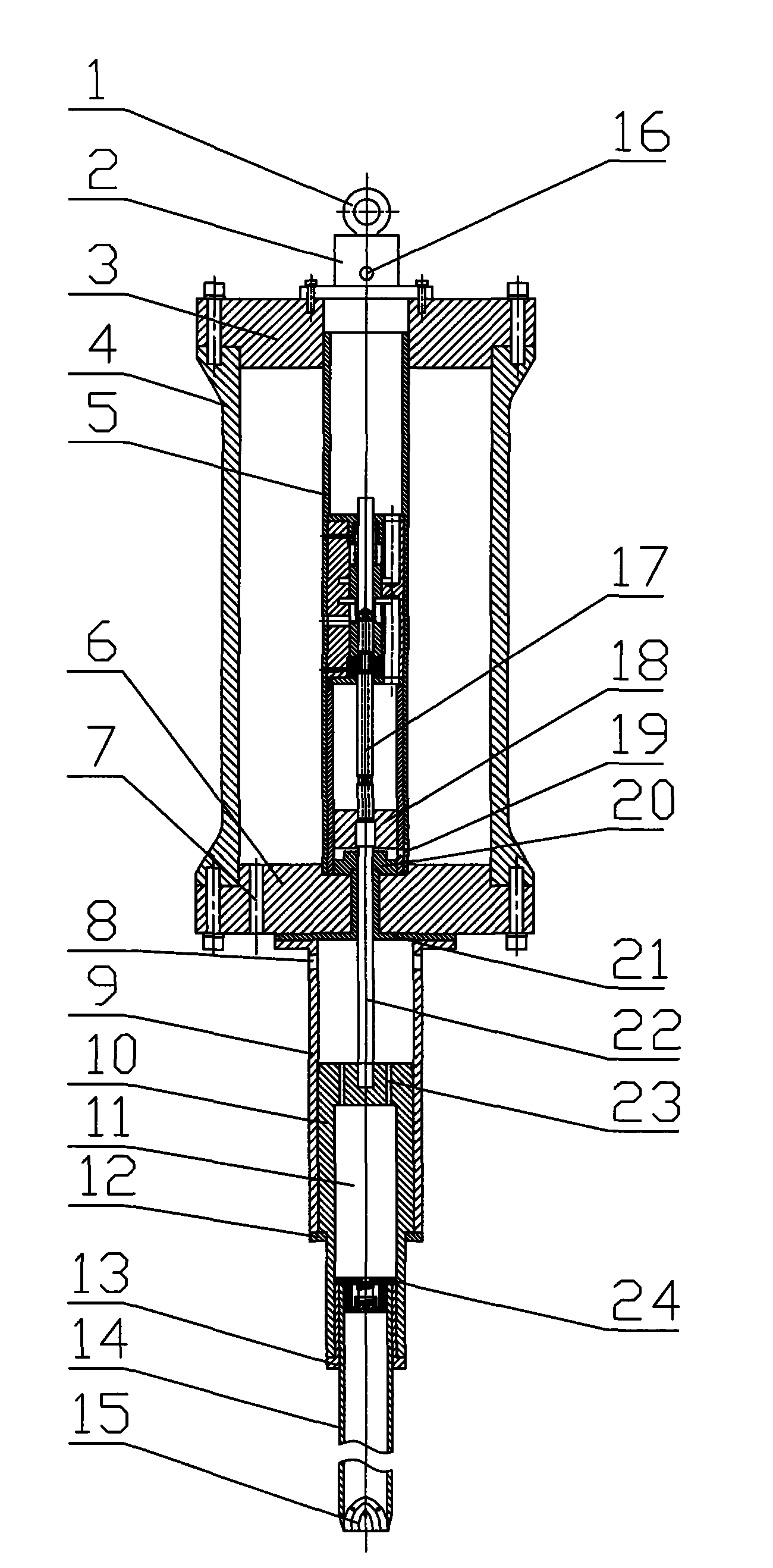

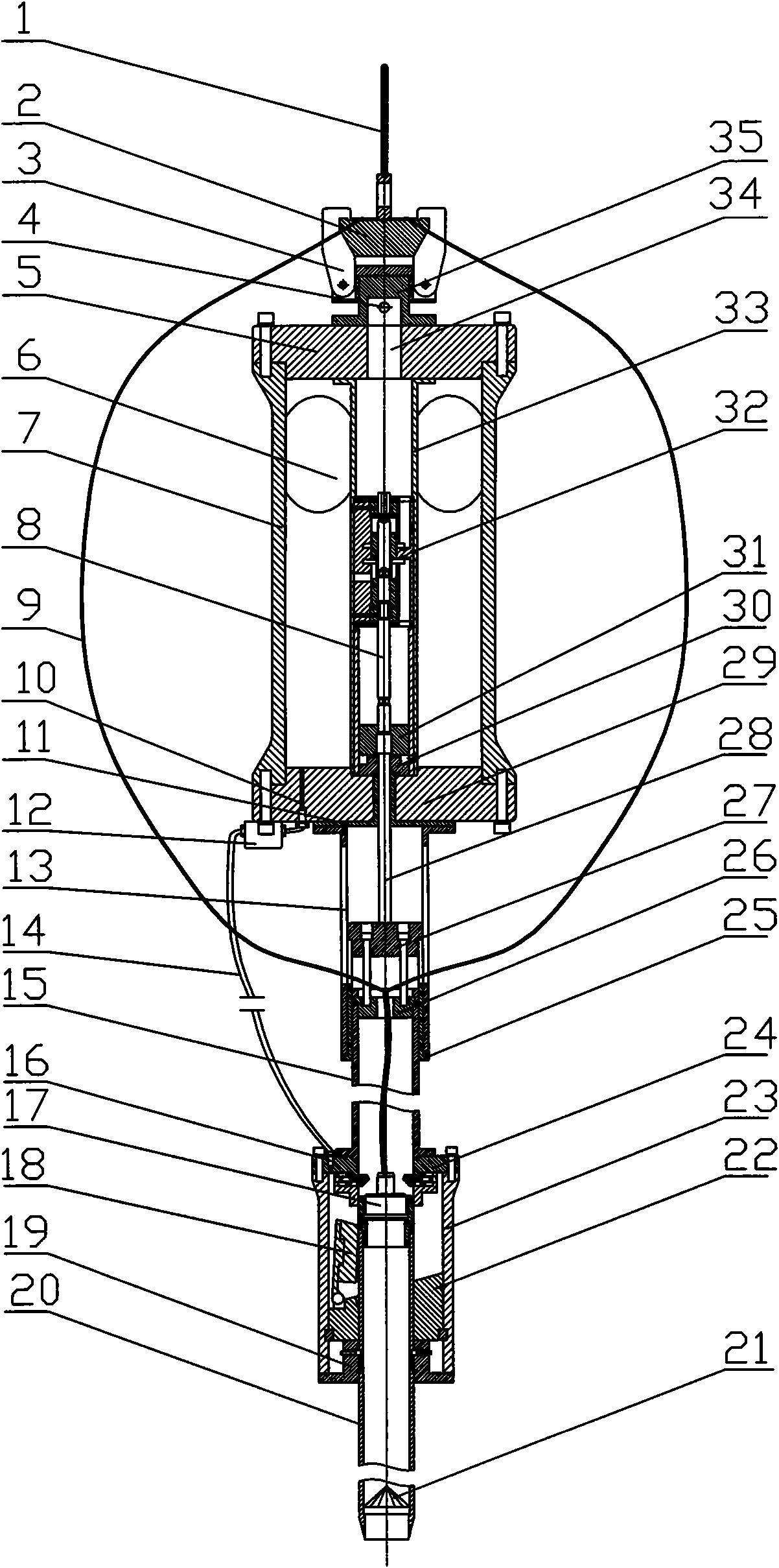

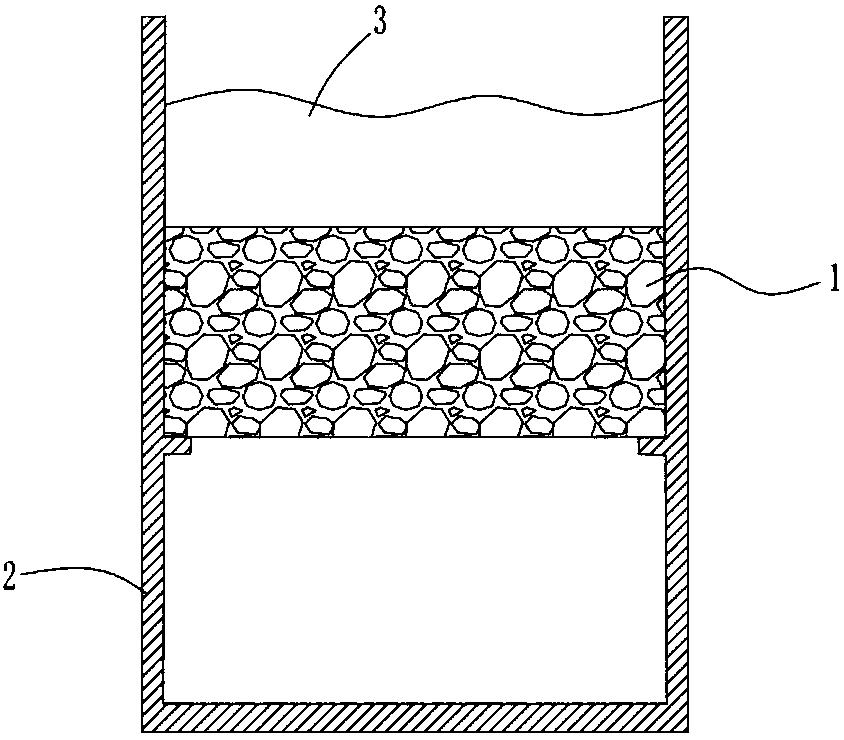

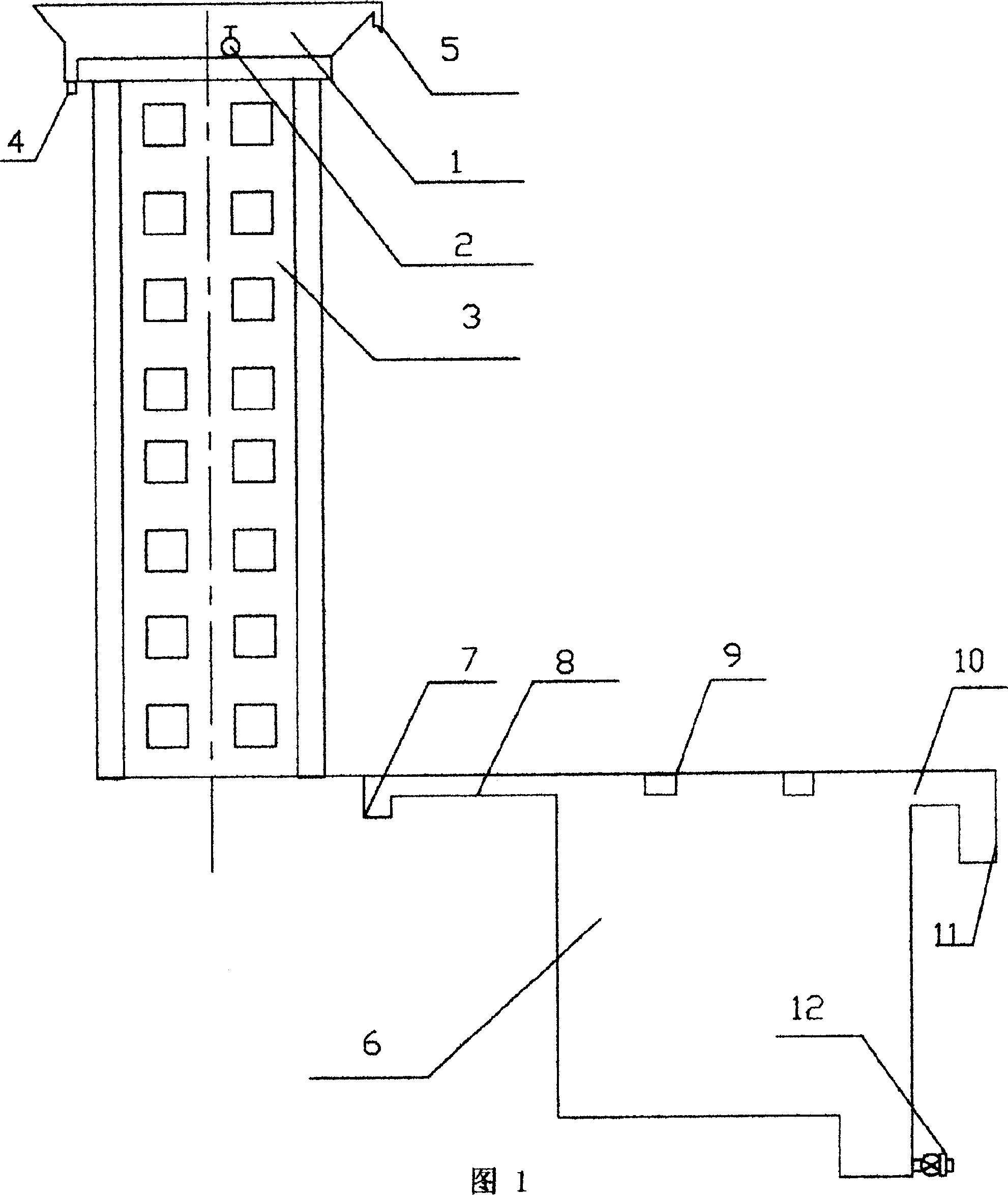

A sediment sampler driven by hydrostatic pressure

InactiveCN101551303AIncrease collection rateDeep sampling depthWithdrawing sample devicesPipe fittingHydrostatic pressure

The invention relates to a sediment sampler driven by hydrostatic pressure. The prior device has finite depth, large and bulky support frame. The invention includes assignment components, drive components, impact components, and sampling pipe fittings. The impact components, include a cylinder, an impact piston cylinder and a slide piston; the assignment components includes a support tube, a flat valve and acompression spring; drive components includes a drive piston cylinder and a drive piston; the sampling tube device includes a sampling tube, an one-way valve and a retaining ring. The invention combines two kinds of drive forms, 'gravity-driven' and 'vibration-driven', can use the gravity force potential energy of the sampler itself and fairly considerable hydrostatic pressure to deeper sampling depth increase the sample collection rate.

Owner:HANGZHOU DIANZI UNIV

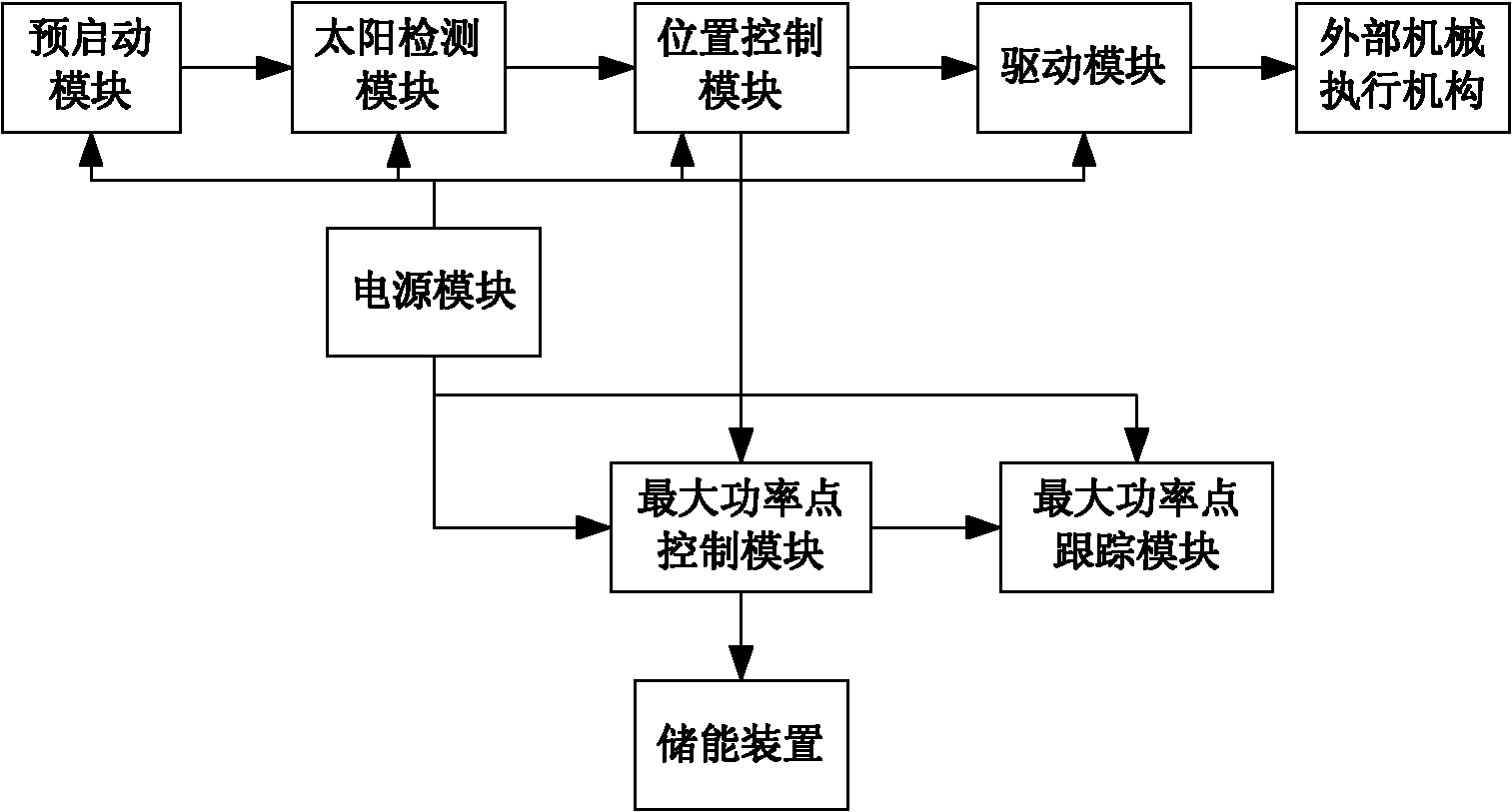

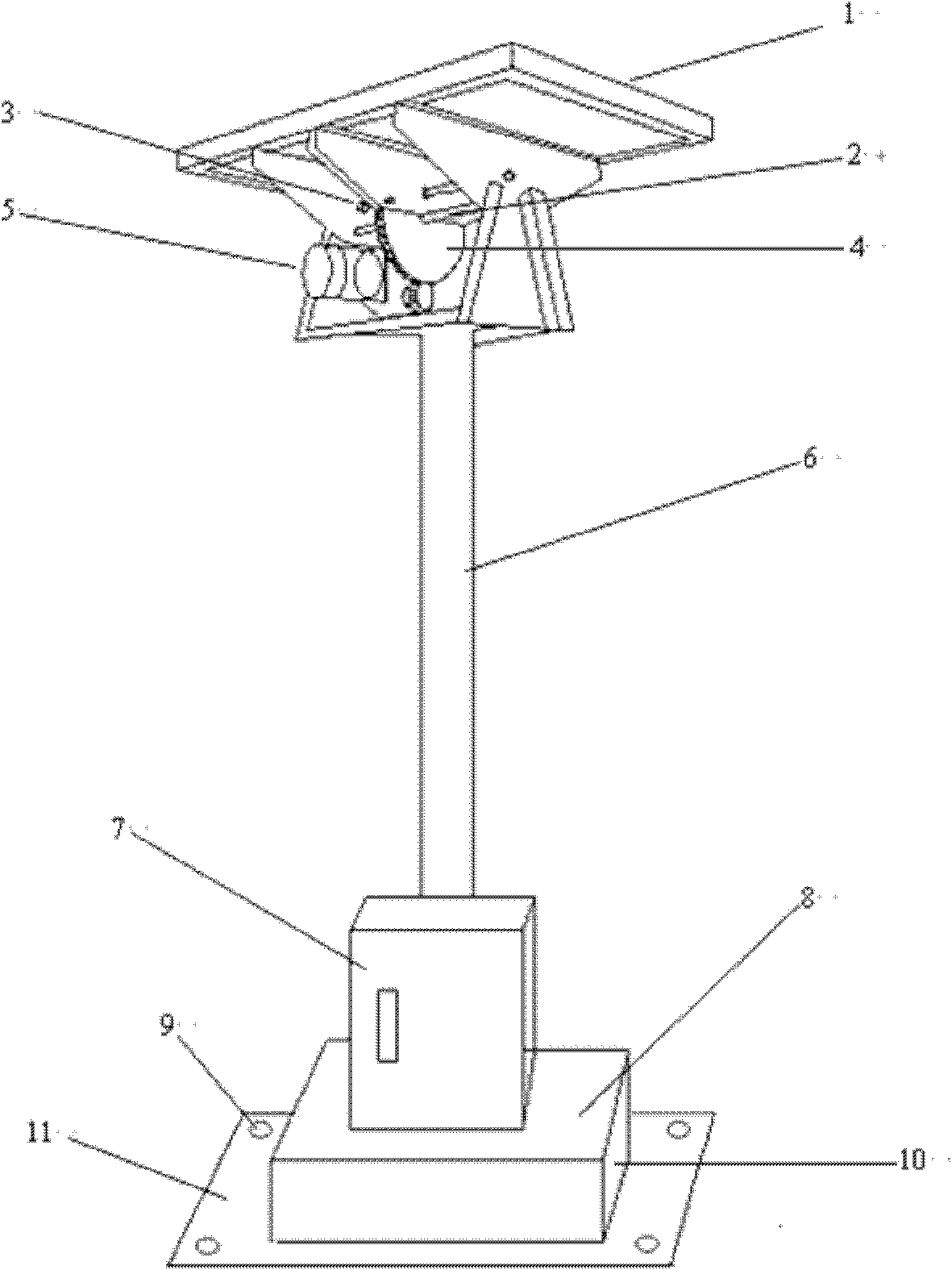

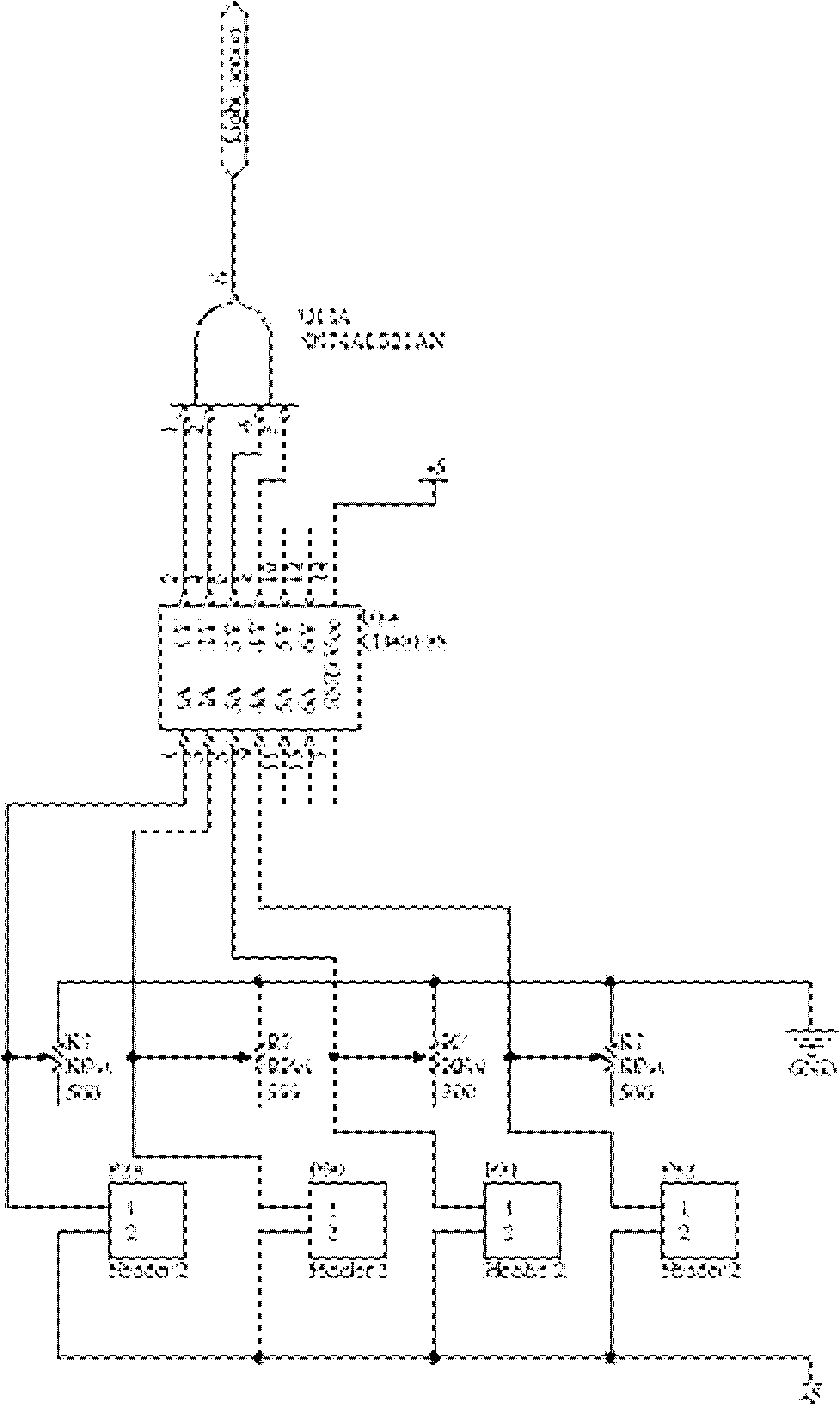

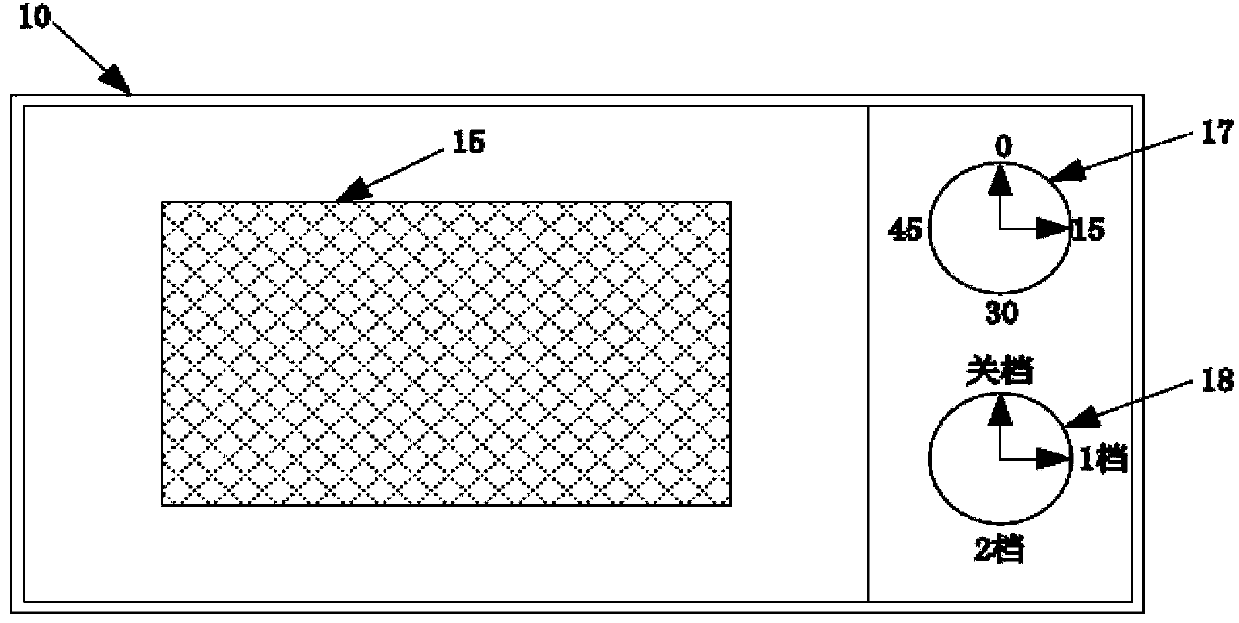

Biaxial automatic tracking device and method for maximum power point of solar panel

InactiveCN102073325AIncrease collection rateEasy to chooseControl using feedbackLight radiation electric generatorMicrocontrollerEngineering

The invention discloses a biaxial automatic tracking device and a biaxial automatic tracking method for a maximum power point of a solar panel. The device comprises a pre-starting module, a sun detection module, a position control module, a driving module, a maximum power point control module, a maximum power point tracking module and a power module, wherein both the pre-starting module and the sun detection module consist of optic probe circuits; both the position control module and the maximum power point control module consist of singlechip circuits and 16-bit interruption circuits; the driving module consists of a direct current motor driving circuit; and the maximum power point tracking module consists of a solar cell panel circuit and a circuit with a maximum power point tracking (MPPT) function. In the method, the position of the sun is tracked along the vertical direction and the horizontal direction; a solar cell panel is driven to be perpendicular to light; and the maximum output power point of the solar cell panel is tracked by a perturbation and observation method to utilize converted solar energy to the greatest extent. By the device and the method, the utilization efficiency of the solar energy can be effectively improved; and the device has a simple structure, is low in cost and has great application and popularization values.

Owner:SOUTH CHINA AGRI UNIV

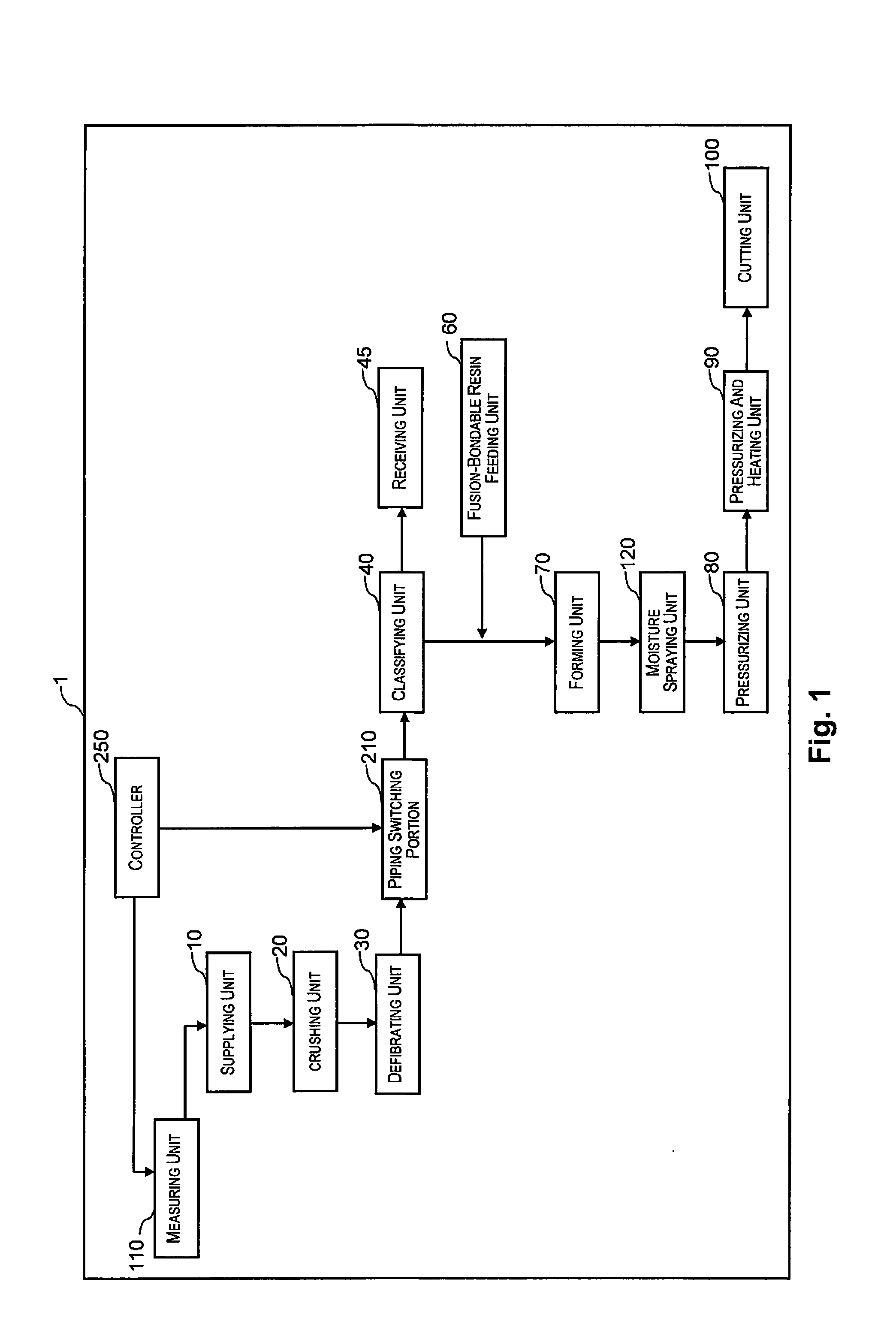

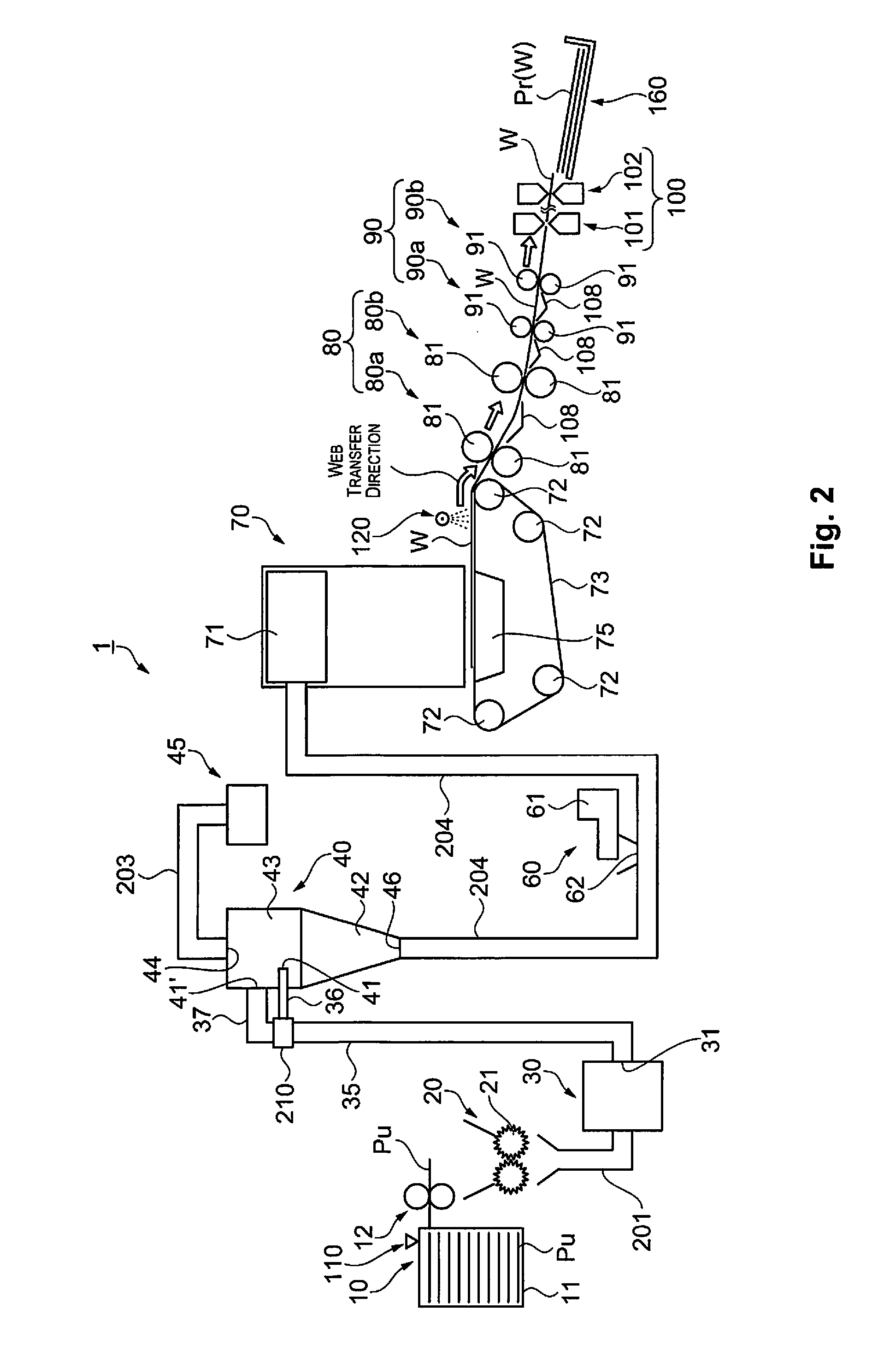

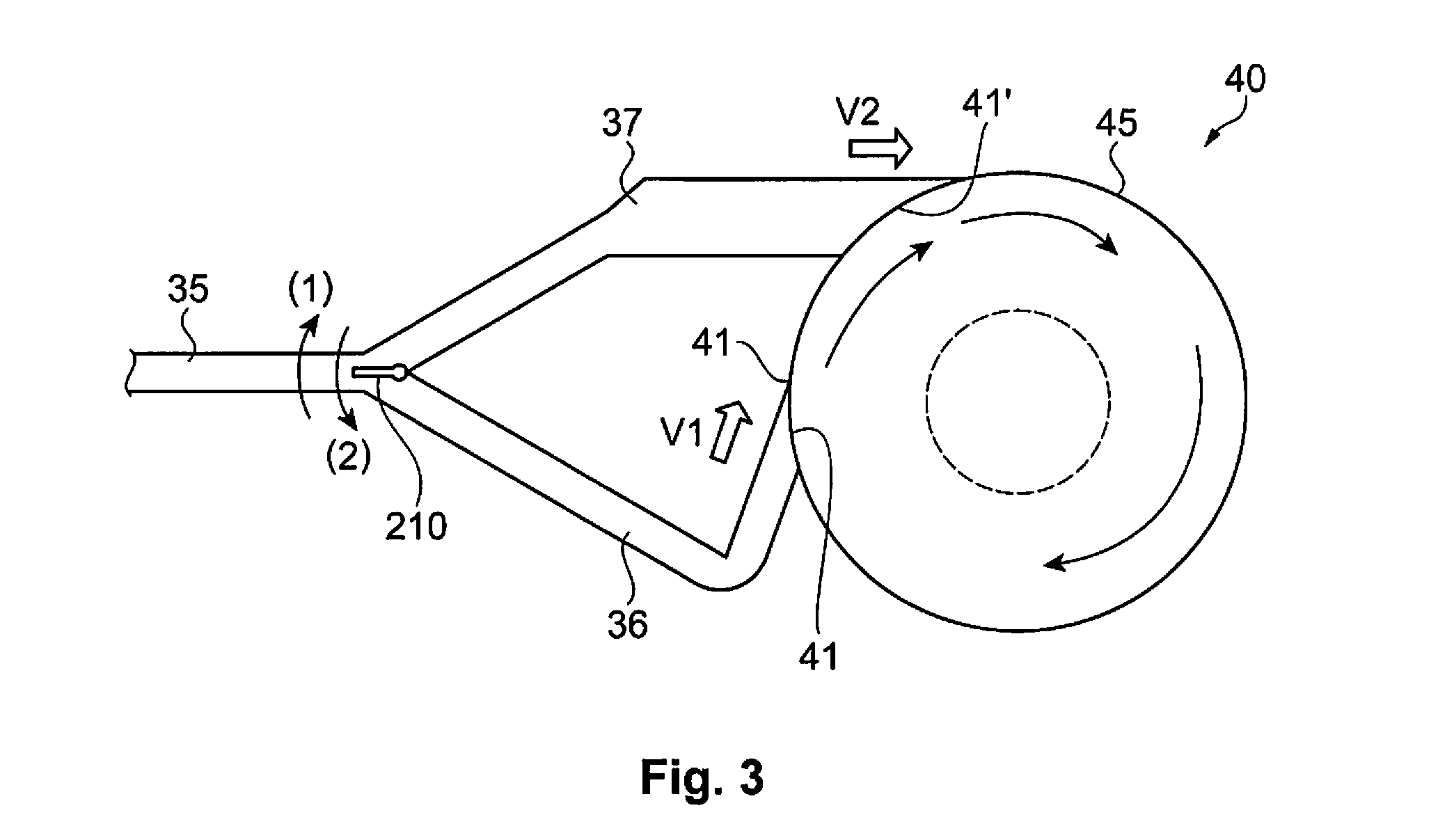

Sheet manufacturing apparatus

ActiveUS20140290888A1Low content rateReduced removal rateMachine wet endDirt cleaningFiberForeign matter

A sheet manufacturing apparatus includes a measuring unit configured to measure thickness and air permeability of a defibration object containing fibers, a defibrating unit configured to dry-defibrate the defibration object, and a classifying unit configured to separate and remove, by airflow classification, foreign substances other than the fibers from the defibrated material defibrated at the defibrating unit.

Owner:SEIKO EPSON CORP

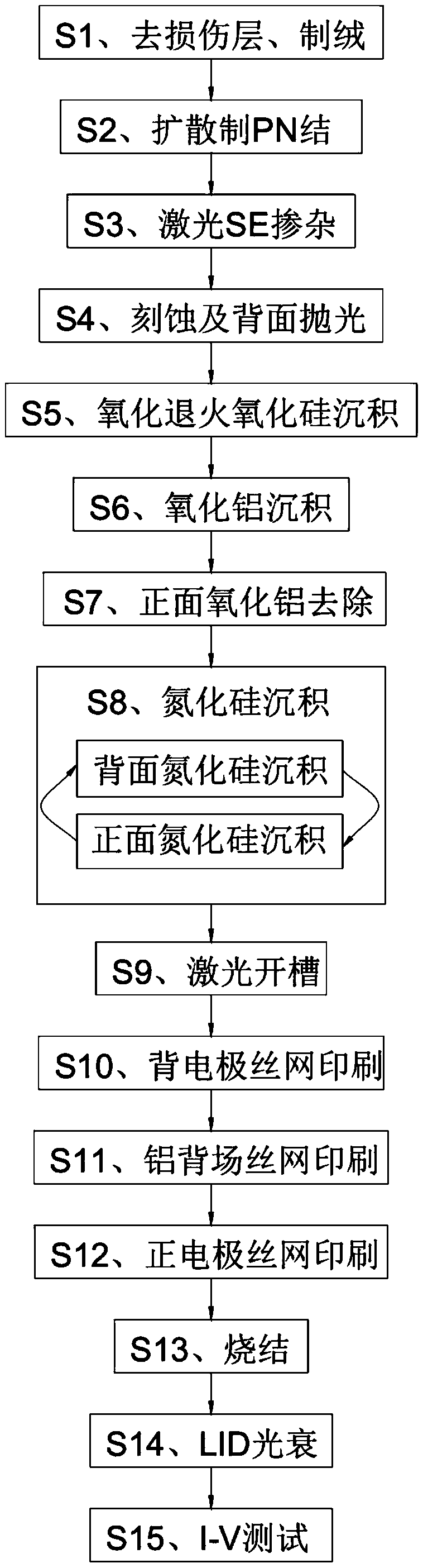

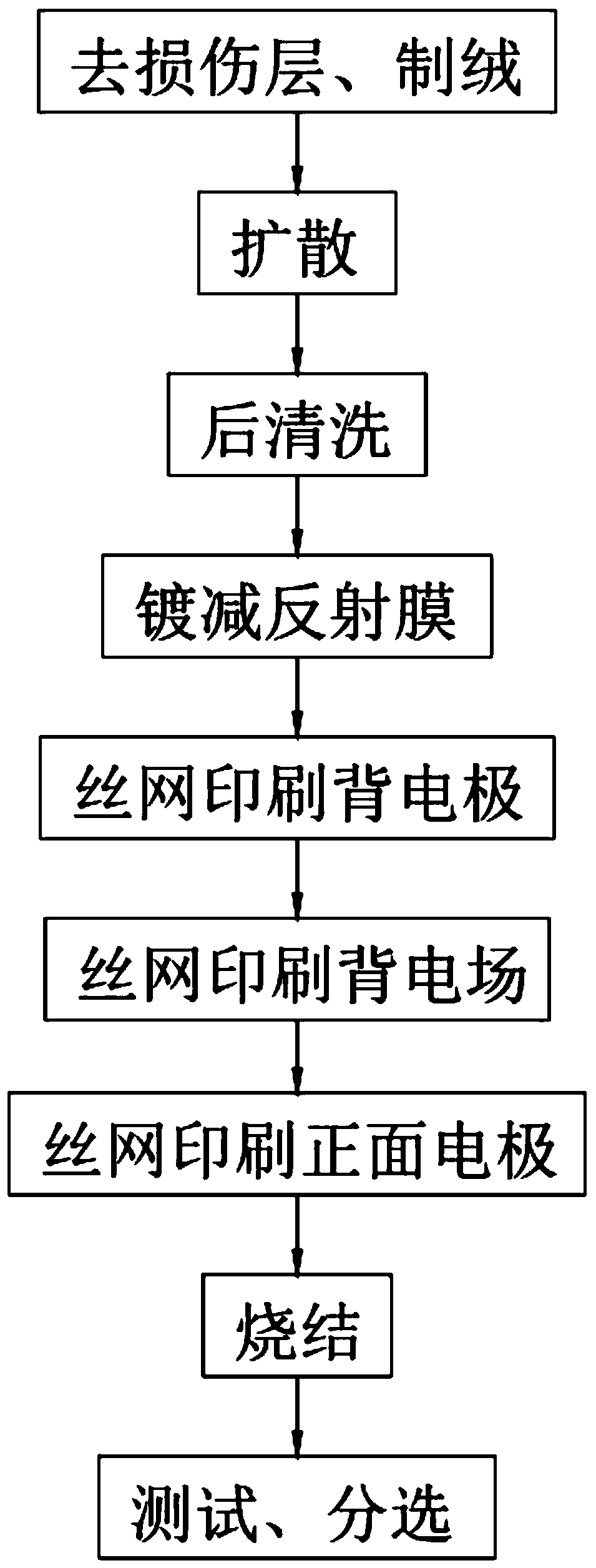

Technology for manufacturing selective emitter junction solar cell by printed phosphorous source one-step diffusion method

ActiveCN101937940ARealize the structureGood diffusion uniformity controlFinal product manufactureSemiconductor devicesDiffusion methodsScreen printing

The invention relates to technology for manufacturing a selective emitter junction solar cell by a printed phosphorous source one-step diffusion method. The method comprises the following steps of: cleaning and texturing a silicon wafer, performing screen printing of phosphorous-containing nano Si slurry, drying at the temperature of between 200 and 350 DEG C for about 20 minutes, and removing the solvent to obtain a phosphorous-containing oxidation layer with the thickness of 30 to 100nm; implementing BOE and RCA cleaning to remove 70 percent of surface phosphorous slurry before diffusion; putting the silicon wafer into a diffusion furnace, adding a POCL3 air source, heating to between 800 and 1,000 DEG C, forming re-diffusion at a grid line of the phosphorous-containing nano slurry on the silicon wafer to form a higher surface concentration-heavily doped region, and forming a shallow diffusion region in other areas. By adopting the screen printing of the phosphorous-containing nano slurry, the phosphorous-containing nano slurry is heated at high temperature for diffusion, forms the heavily doped region at a contact position with the grid line and forms a lightly doped region in other areas. The technology has the efficiency of over 18.5 percent on the premise of better controlling the diffusion uniformity.

Owner:TRINA SOLAR CO LTD

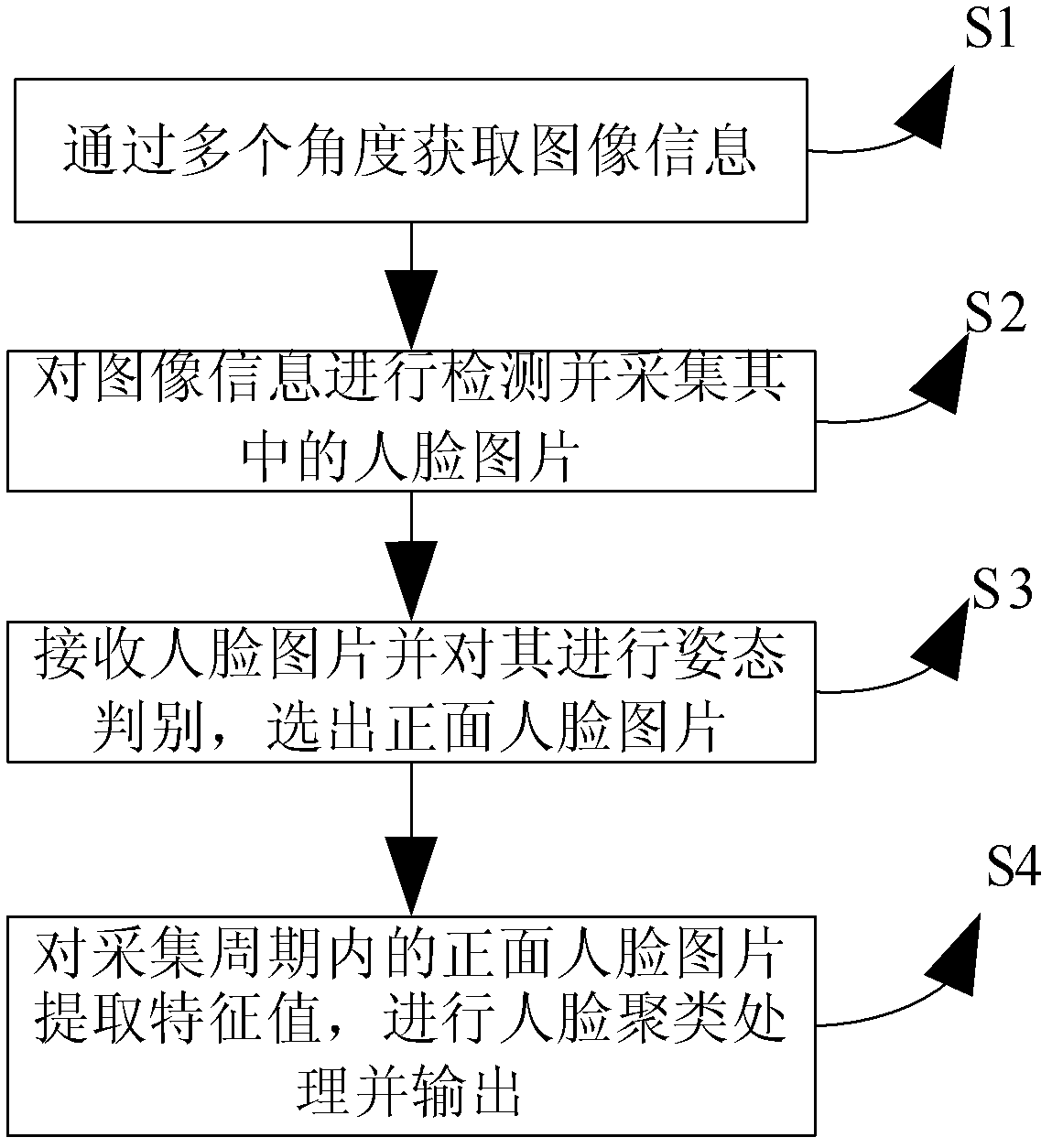

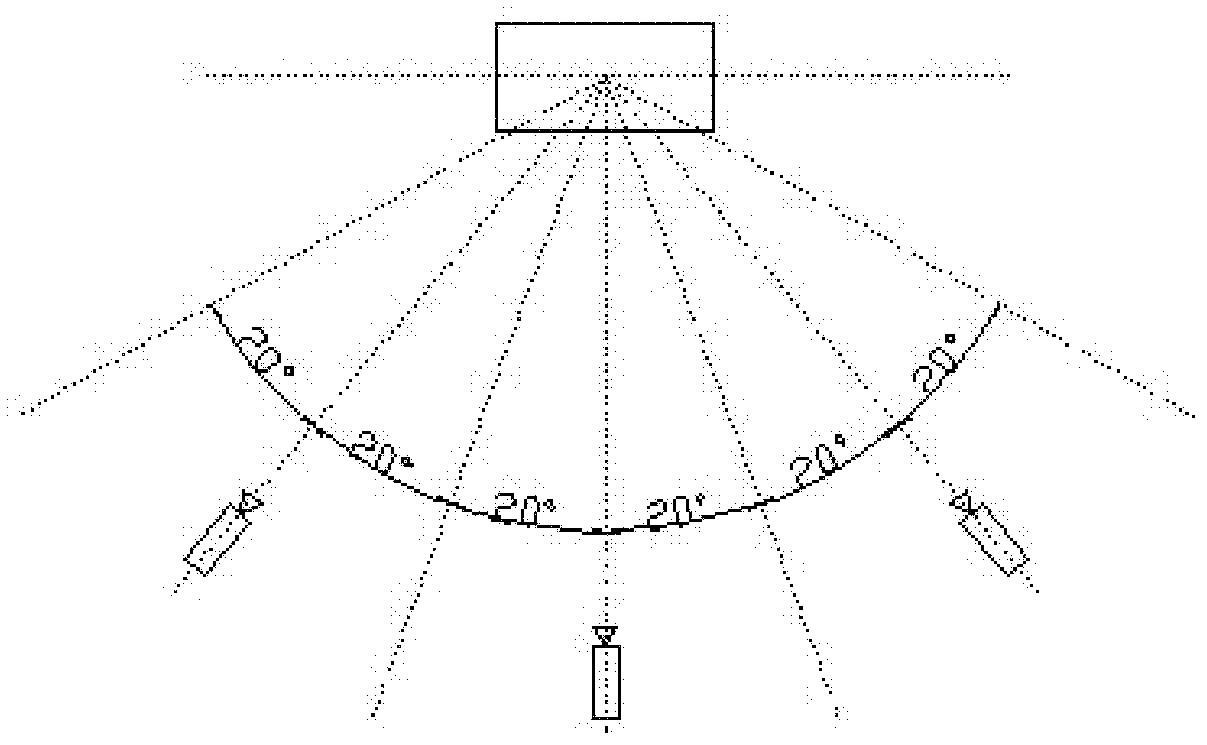

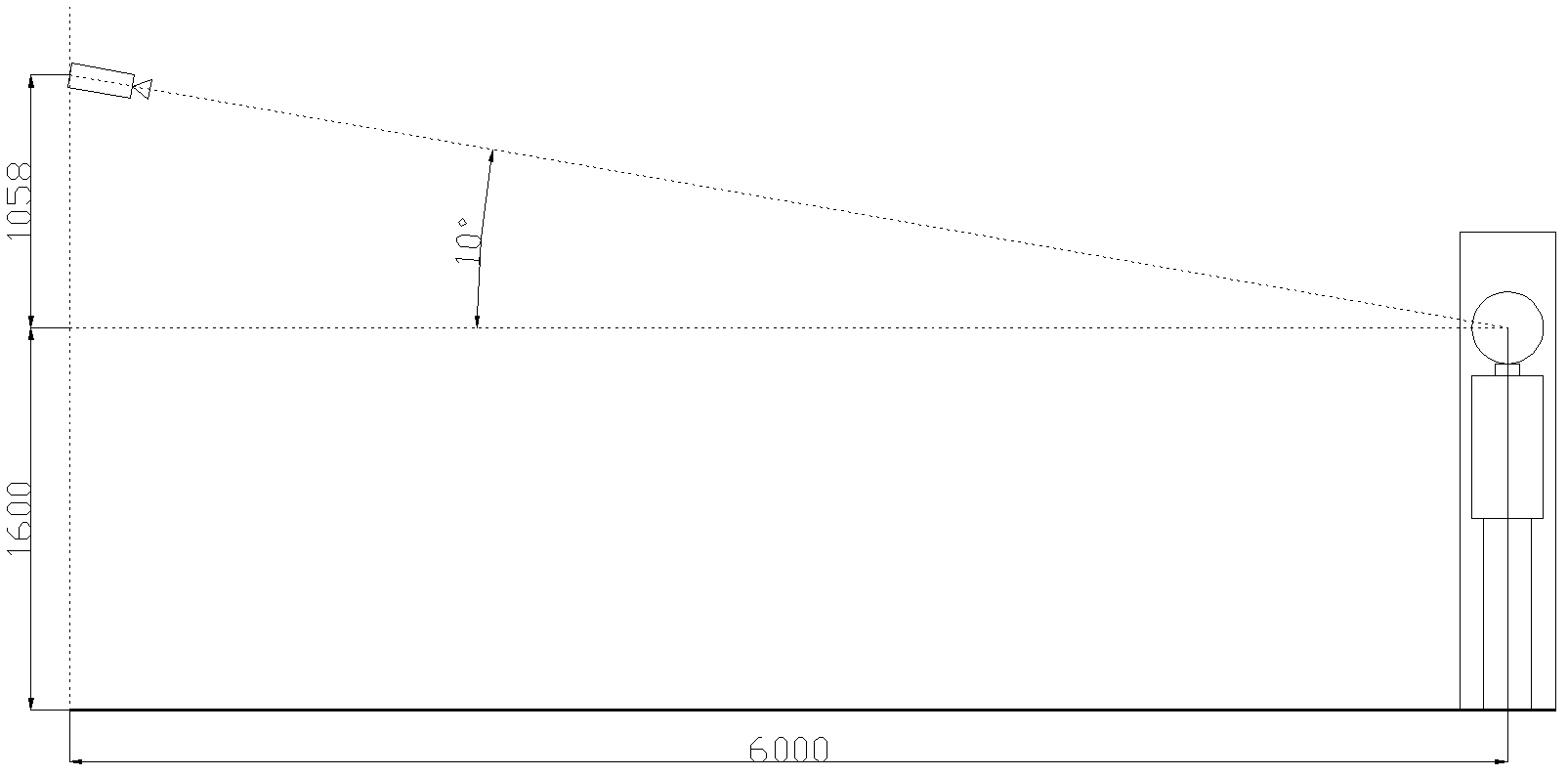

Method and system for recognizing human face from multiple angles

InactiveCN102609695AIncrease collection rateCharacter and pattern recognitionPattern recognitionCollection period

The invention provides a method and system of recognizing the human face from multiple angles. The method comprises the following steps: acquiring image information from multiple angles, detecting the image information, collecting human face images from the image information, receiving the human face images, distinguishing the attitudes of the human faces, selecting front human face images, extracting the feature values of the front human face images in the collection period, classifying the human faces, and outputting. The human face images of the collected object can be collected under the condition that the collected object does not know and does not need to cooperate, and the front human face image collection rate can be improved by collecting from multiple angels under the condition that the attitudes of the human faces change randomly.

Owner:SHANGHAI MUSEUM +1

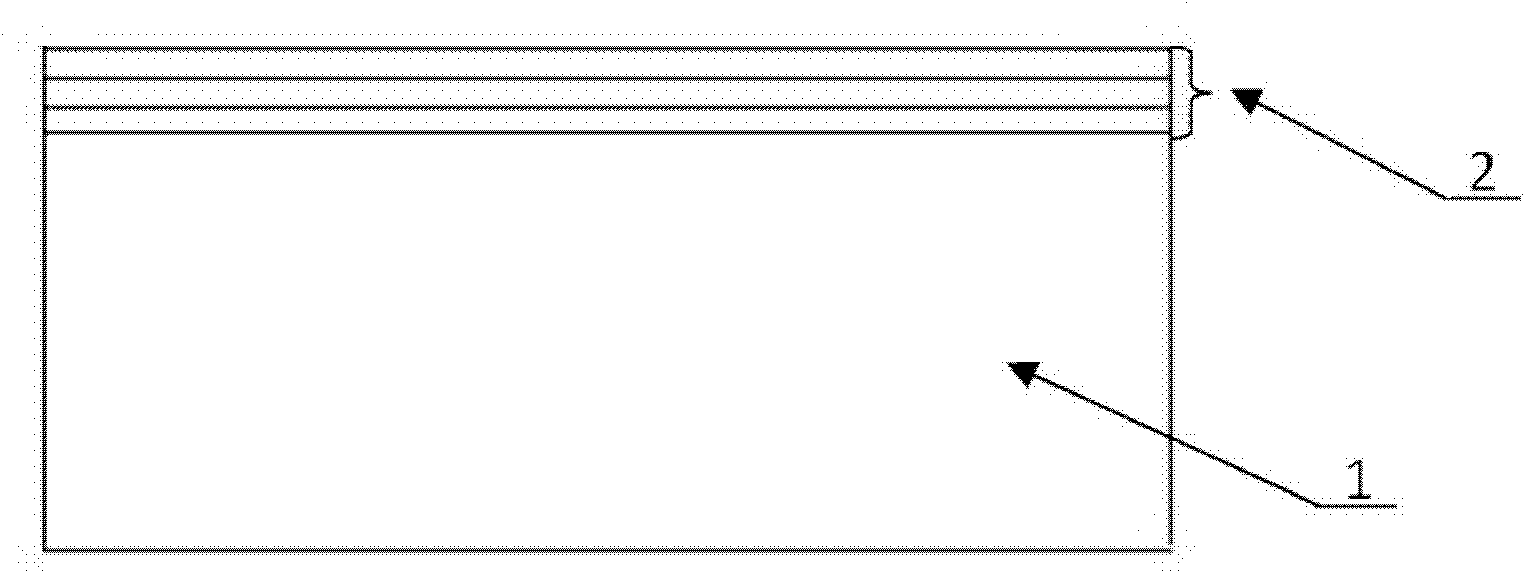

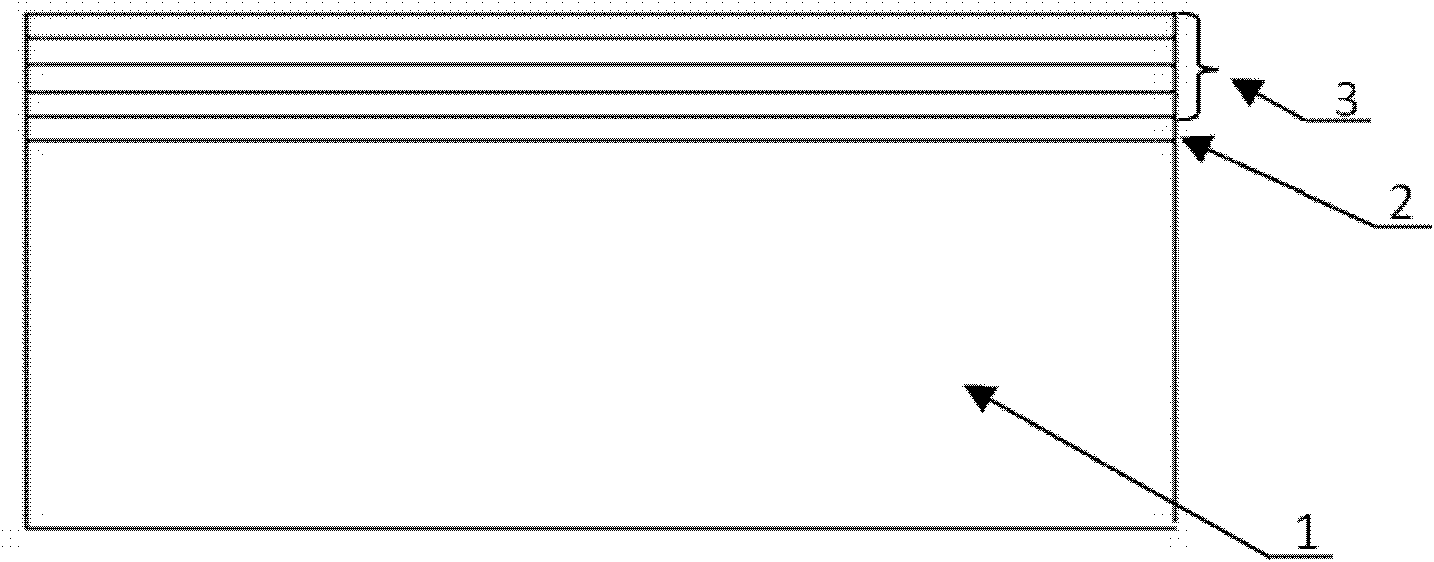

A gradient doped silicon-based heterojunction solar cell and its preparation method

InactiveCN102280502AIncrease collection rateIncrease short circuit currentFinal product manufacturePhotovoltaic energy generationHeterojunctionSilicon heterojunction

The invention discloses a gradient doped silicon-based heterojunction solar cell and a preparation method thereof. A plurality of layers of amorphous silicon membranes of which the doped concentration is increased sequentially are deposited on the surface of crystalline silicon serving as a substrate, and a transparent conductive film with a certain thickness is deposited and an electrode is prepared to prepare the gradient doped silicon-based heterojunction solar cell, wherein the amorphous silicon membranes contact the crystalline silicon to achieve a good passivating effect and obtain highopen-circuit voltage; a plurality of gradient doped amorphous silicon layers can form a strong inner electric field to reduce the composite loss of photo-induced carriers, improve the collection rateof minority carriers and increase short-circuit current; and the doped concentration of the doped amorphous silicon layers contacting the electrode is high, the resistivity is low, and contact resistance between the doped amorphous silicon layers and the electrode can be reduced to improve filling factors of the solar cell. Therefore compared with the conventional silicon-based heterojunction solar cell, the gradient doped silicon-based heterojunction solar cell has high photoelectric conversion efficiency.

Owner:SHANGHAI NORMAL UNIVERSITY

Omnidirectional filtering device for washing machine

ActiveCN101985799AImprove filtering effectSimple structureOther washing machinesTextiles and paperScrapFront cover

The invention discloses an omnidirectional filtering device for a washing machine. The device comprises a filtering cover and a line scrap filter which is embedded into the filtering cover, wherein the line scrap filter comprises a box-type front cover and a rear cover; a transverse bar is arranged in the middle of the front cover and divides a filtering cavity of the line scrap filter into an upper filtering cavity and a lower filtering cavity; and water inlets of the filtering device are formed on left and right side walls of the upper filtering cavity and at the bottom of the lower filtering cavity. Omnidirectional water inlet and omnidirectional filtration are realized through the water inlets on two left and right sides of the upper filtering cavity and at the bottom of the lower filtering cavity. Results show that the line scrap collection rate of the omnidirectional filtering device for the washing machine reaches 80 to 90 percent. The omnidirectional filtering device is simple in structure, low in cost and good in filtering effect, and is a line scrap collecting device worthy of popularization and application.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

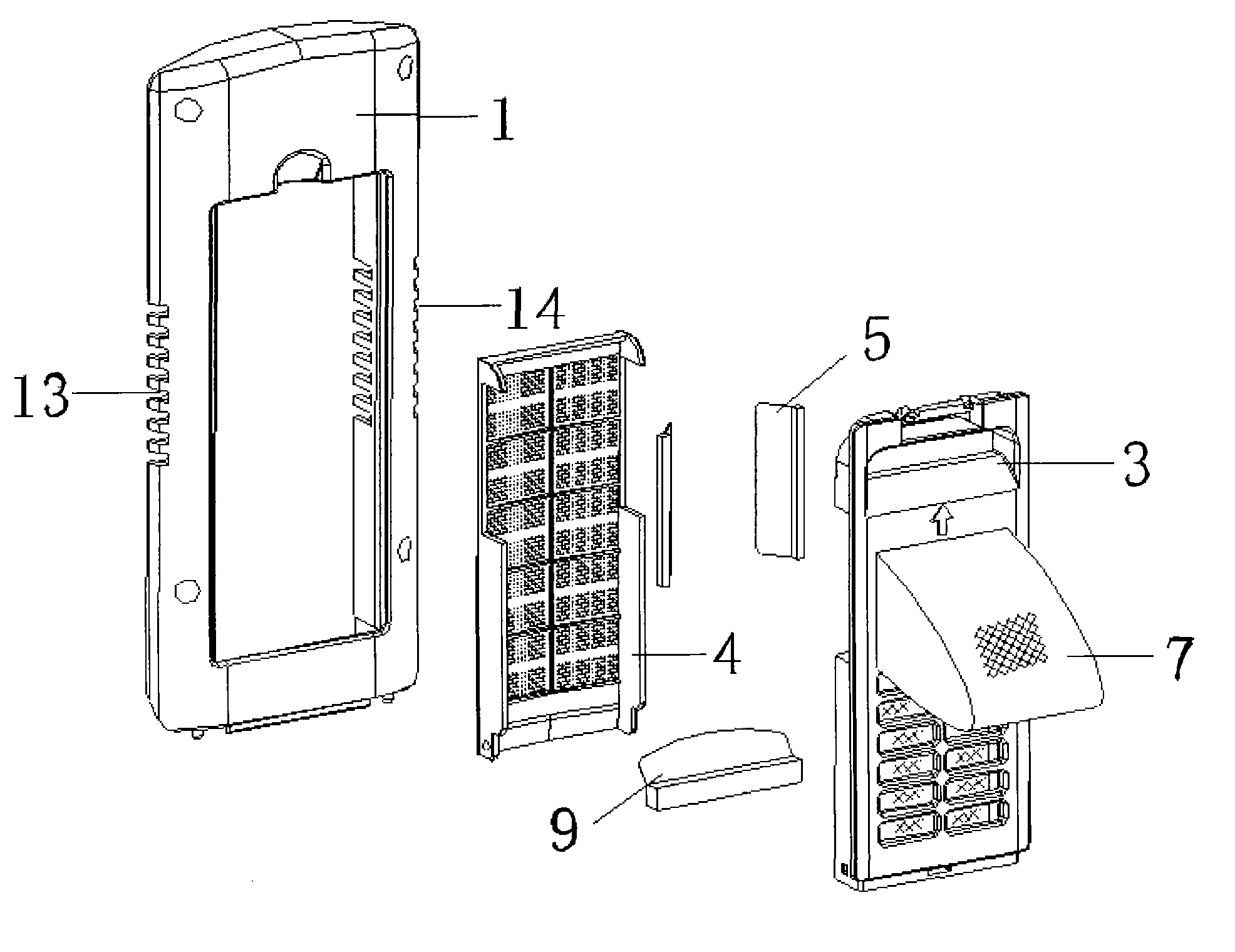

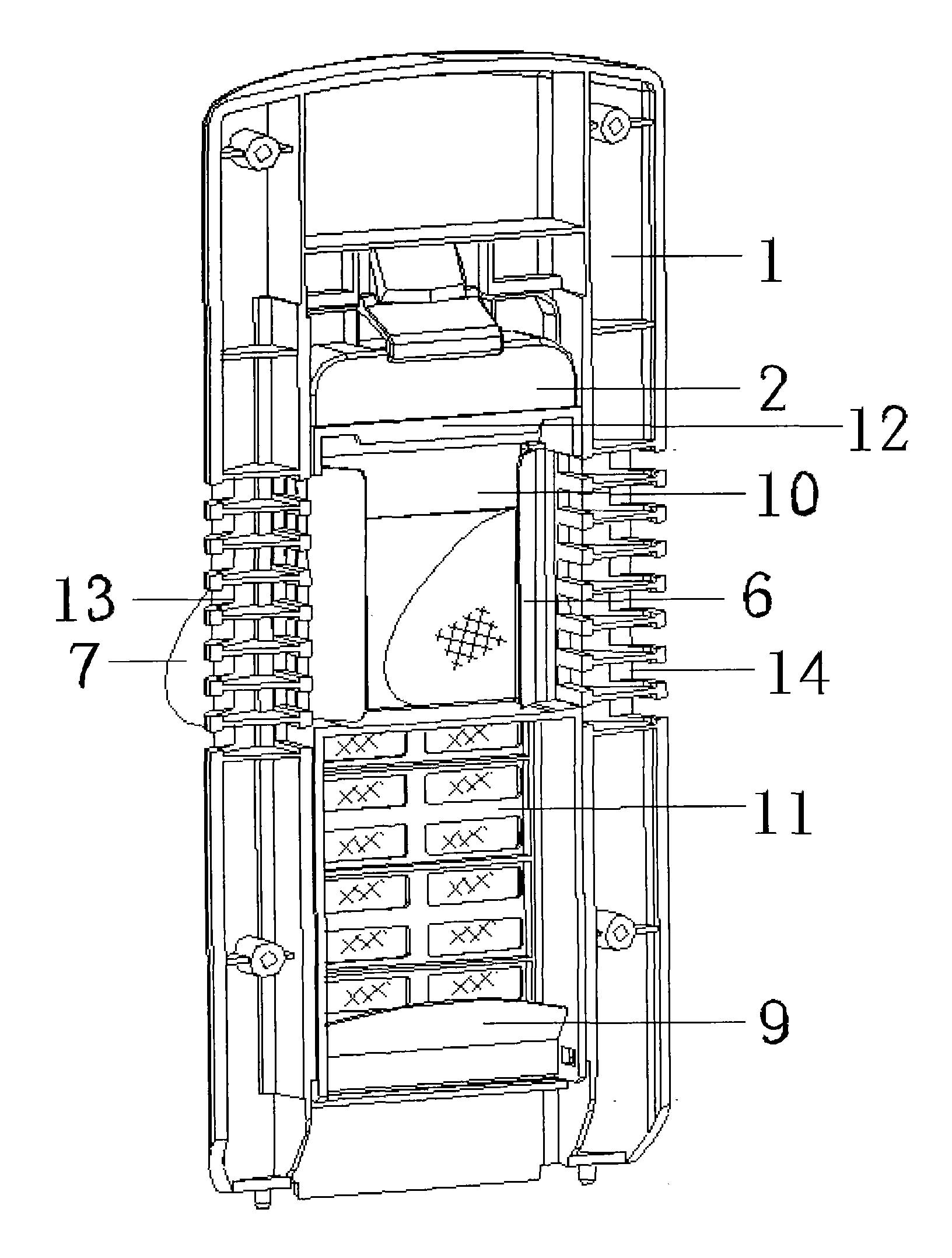

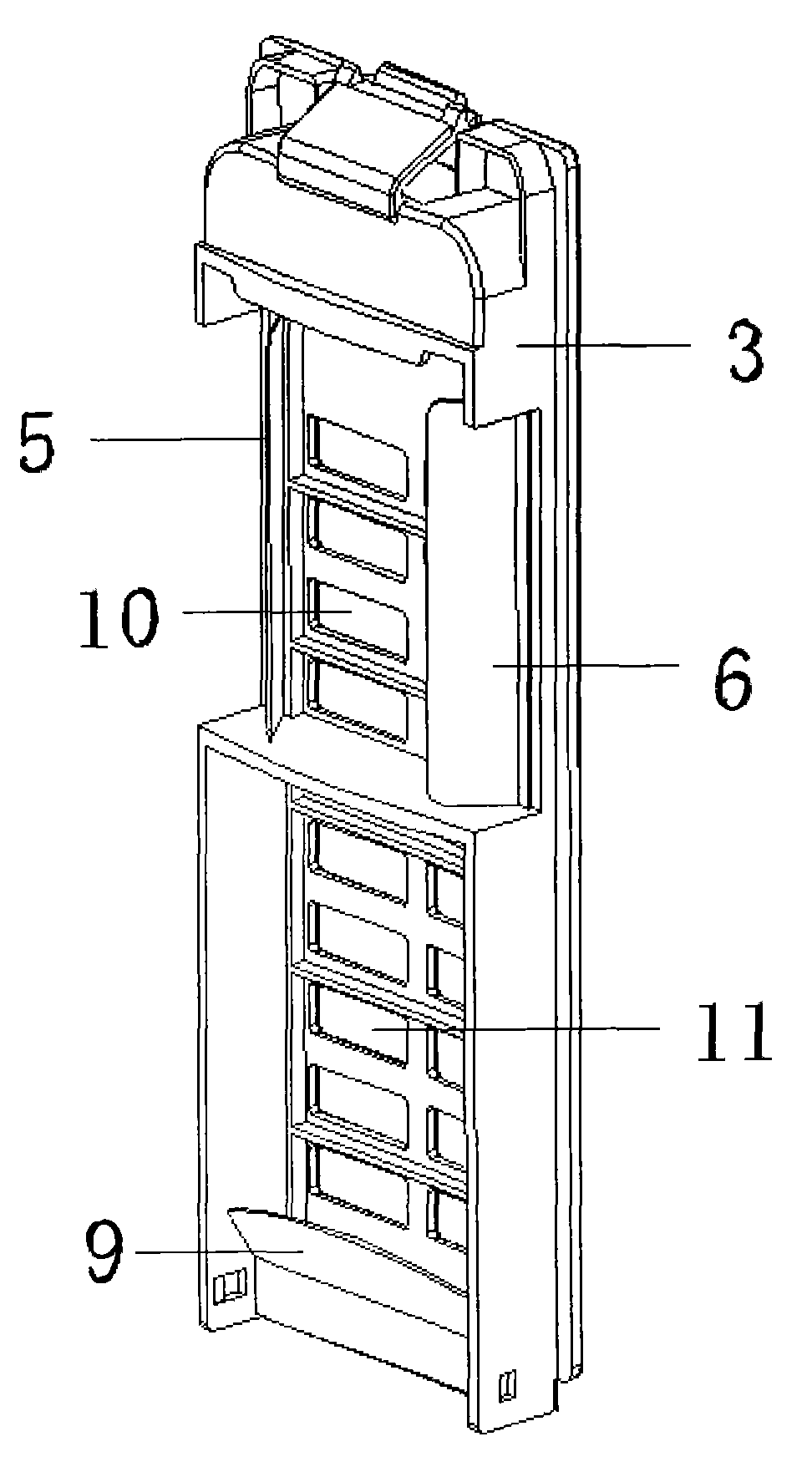

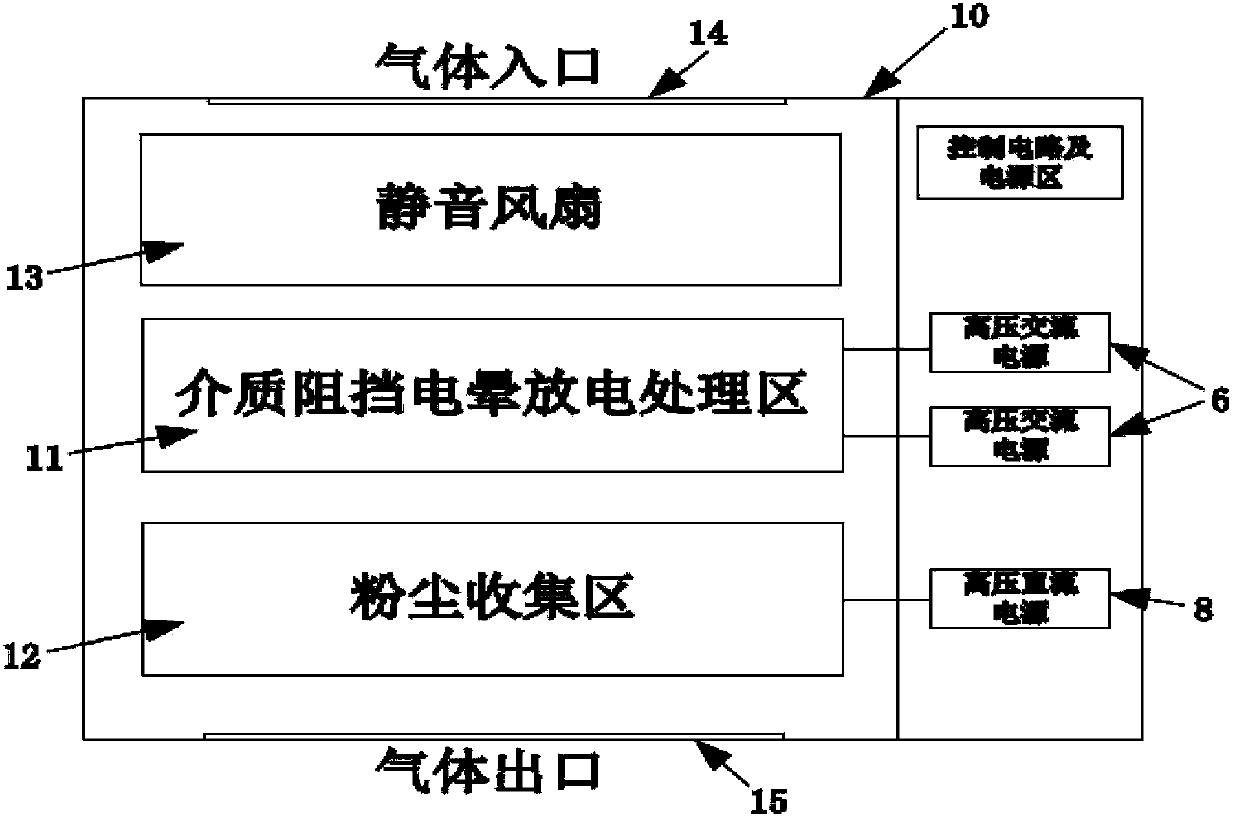

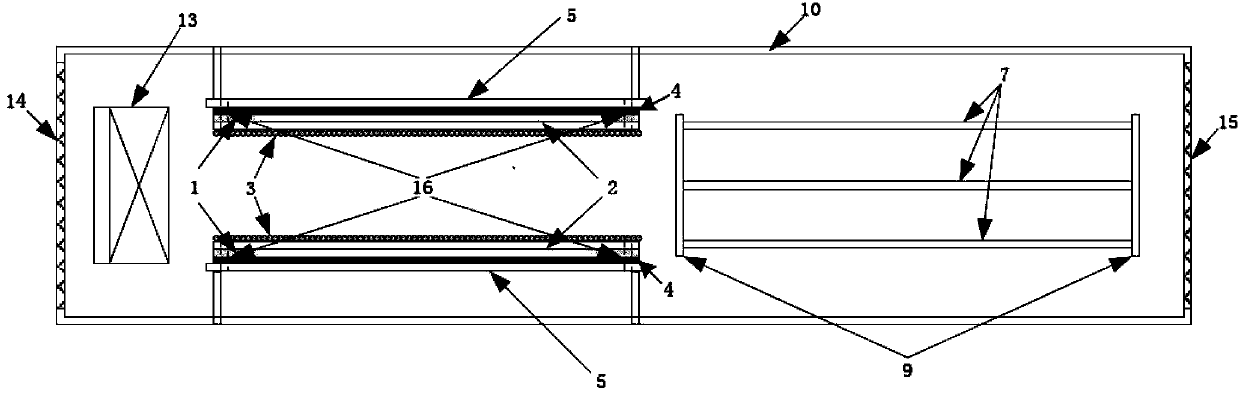

Indoor gas purification device based on discharge plasma

ActiveCN103388858AAchieving heteropolar chargingImprove adsorption capacityLighting and heating apparatusDeodrantsDielectricInhalable particles

The invention discloses an indoor gas purification device based on discharge plasma, comprising a shell provided with a gas inlet and a gas outlet, wherein a fan, a dielectric barrier corona discharge processing region and a dust collecting region are arranged in the shell between the gas inlet and the gas outlet. According to the indoor gas purification device, more uniform low-temperature plasma is generated by two discharge units which are arranged oppositely, oxidation processing is carried out on harmful gas in the dielectric barrier corona discharge processing region, heteropolarity charge electrocoagulation and processing are carried out on inhalable particles, the inhalable particles are collected in the dust collecting region, and the device has the advantages that no chemical agent and no physical additive are used, no special gas atmosphere exists, the energy consumption is low, indoor gas purification is realized under barometric pressure, and the effect is good.

Owner:XI AN JIAOTONG UNIV

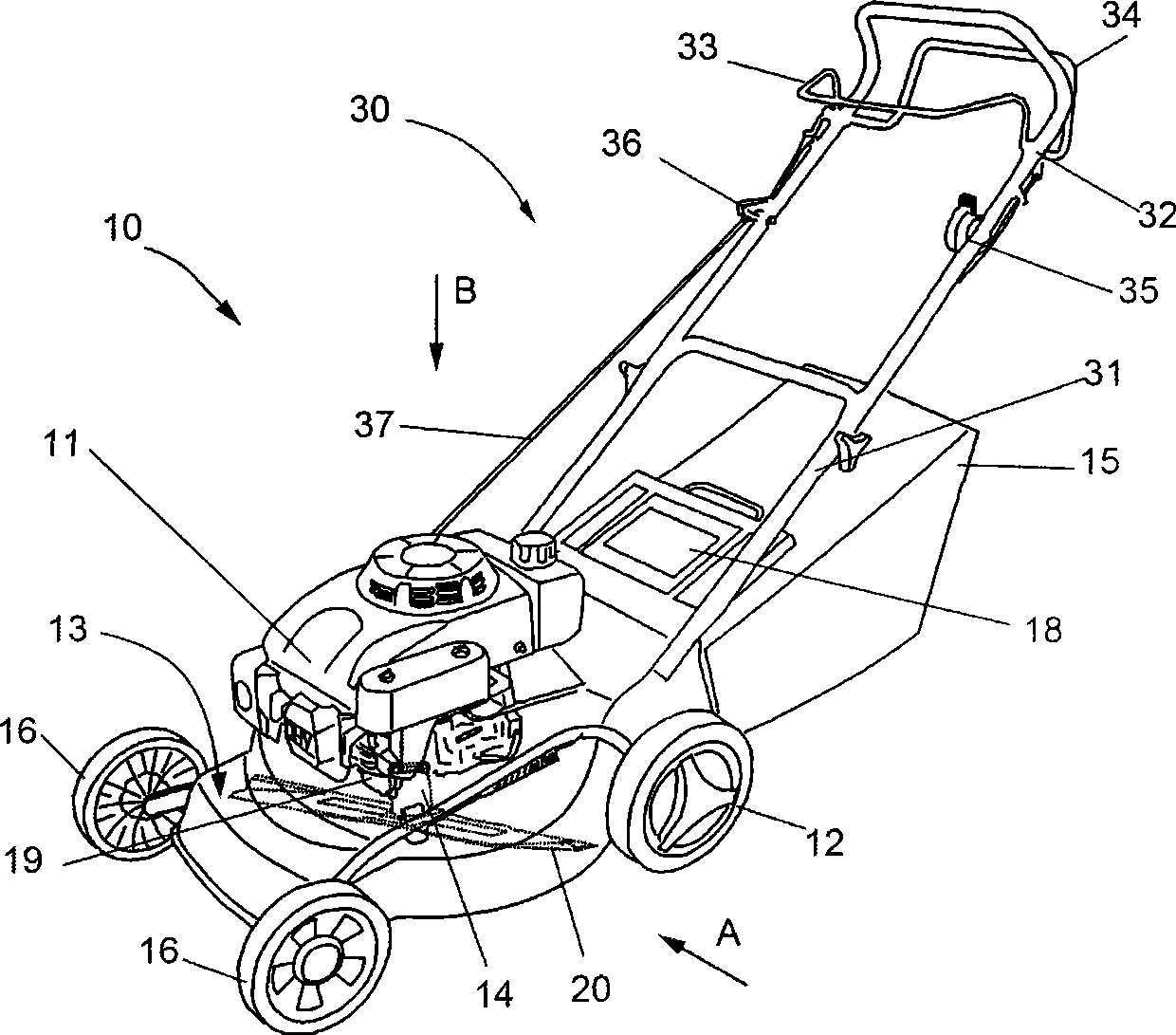

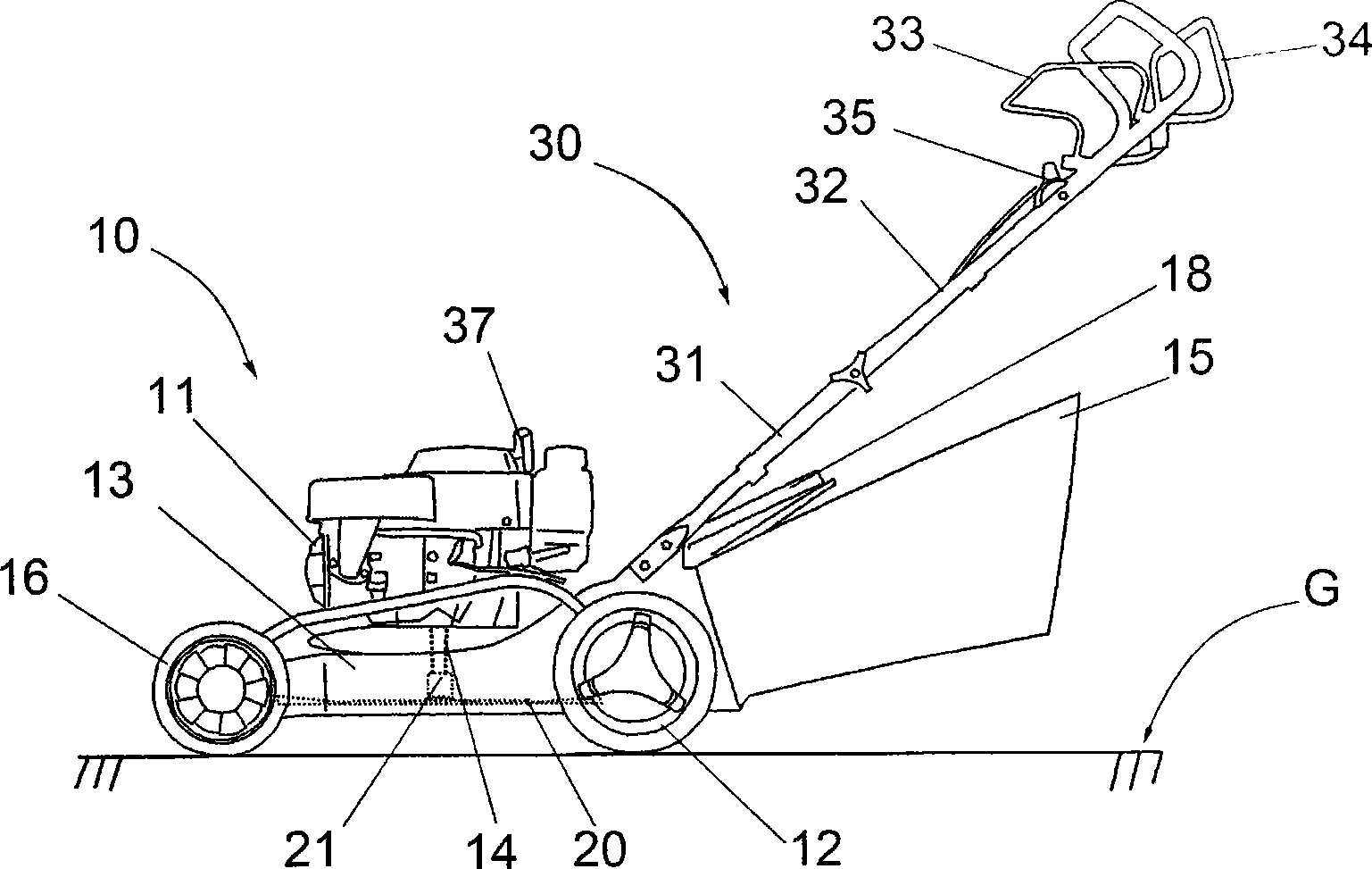

Knife blade rotary grass cutter of rotary grass cutter

A blade of a rotary mower comprises a mounting part, a cutting edge and an airlift part. The mounting part is positioned on the center part of the blade and radially extends outwards in an opposite direction to form two end parts; one edge of each end part is provided with the cutting edge, and the other opposite edge and an outer end side of the end part bend upwards along a first fold line to form the airlift part; the cutting edges and the airlift parts on the two end parts are distributed in the same rotation direction; the head end of the airlift part is positioned on the first fold line, and the tail end of the airlift part bends outwards along a second fold line; the bending part forms a gas flow source; and the inner end of the first fold line is superposed with the inner end of the second fold line. The flat gas flow source on the rear edge is turned to reduce load on the rear part of the airlift part, reduce vortex so as to reduce noise generated by the rotating blade, and the blade has the advantages of simple structure and low cost.

Owner:力帆科技(集团)股份有限公司

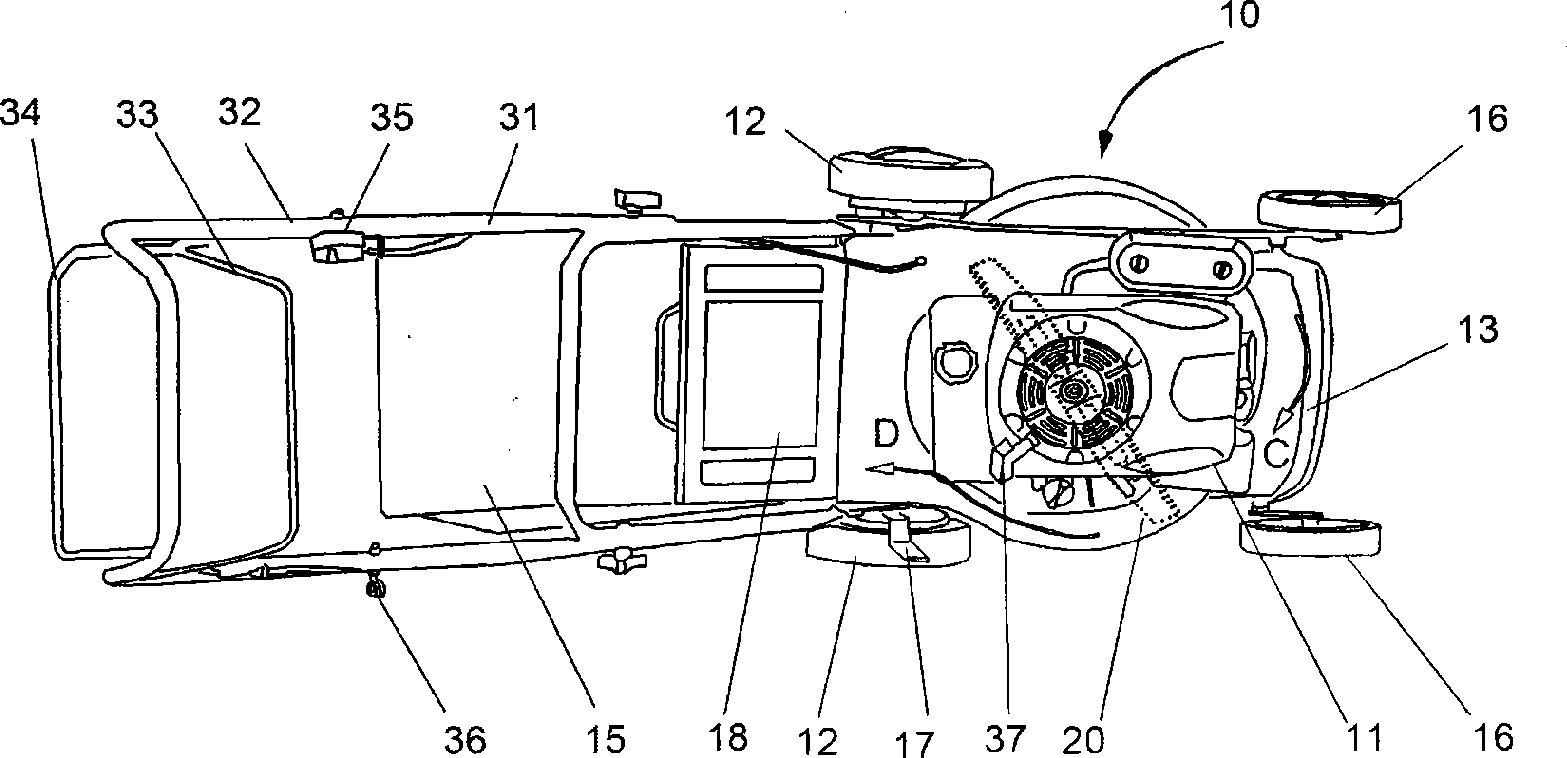

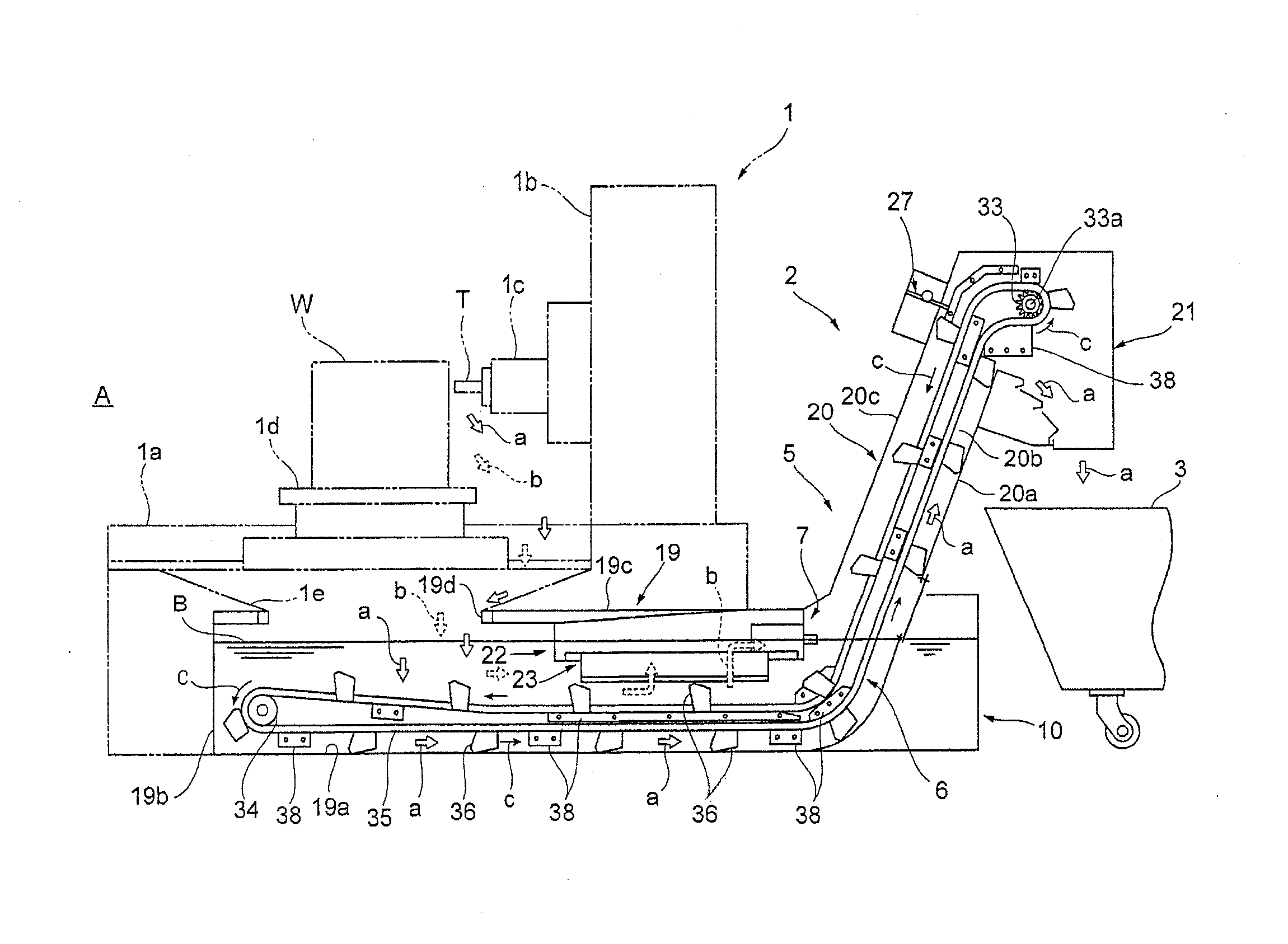

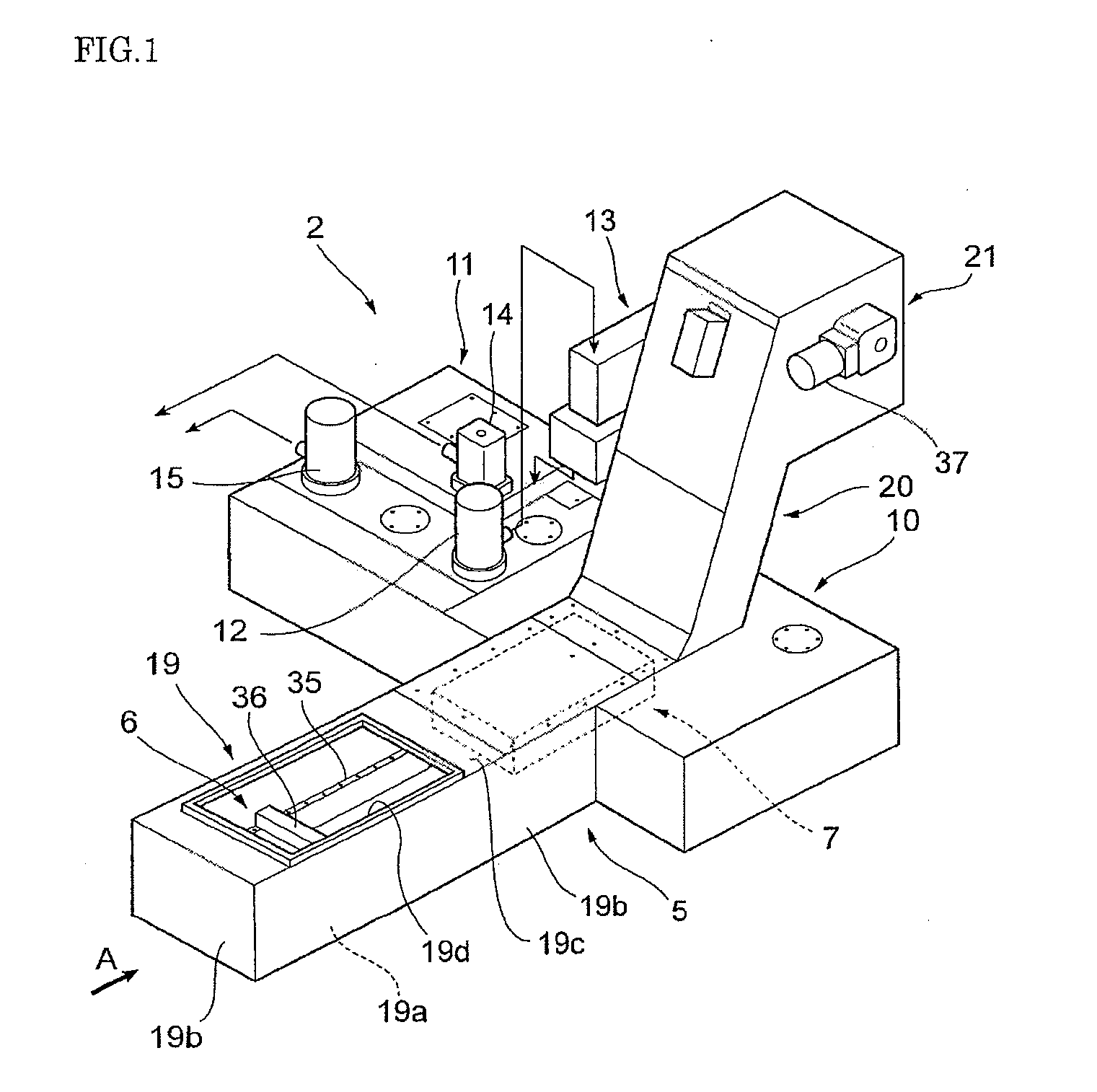

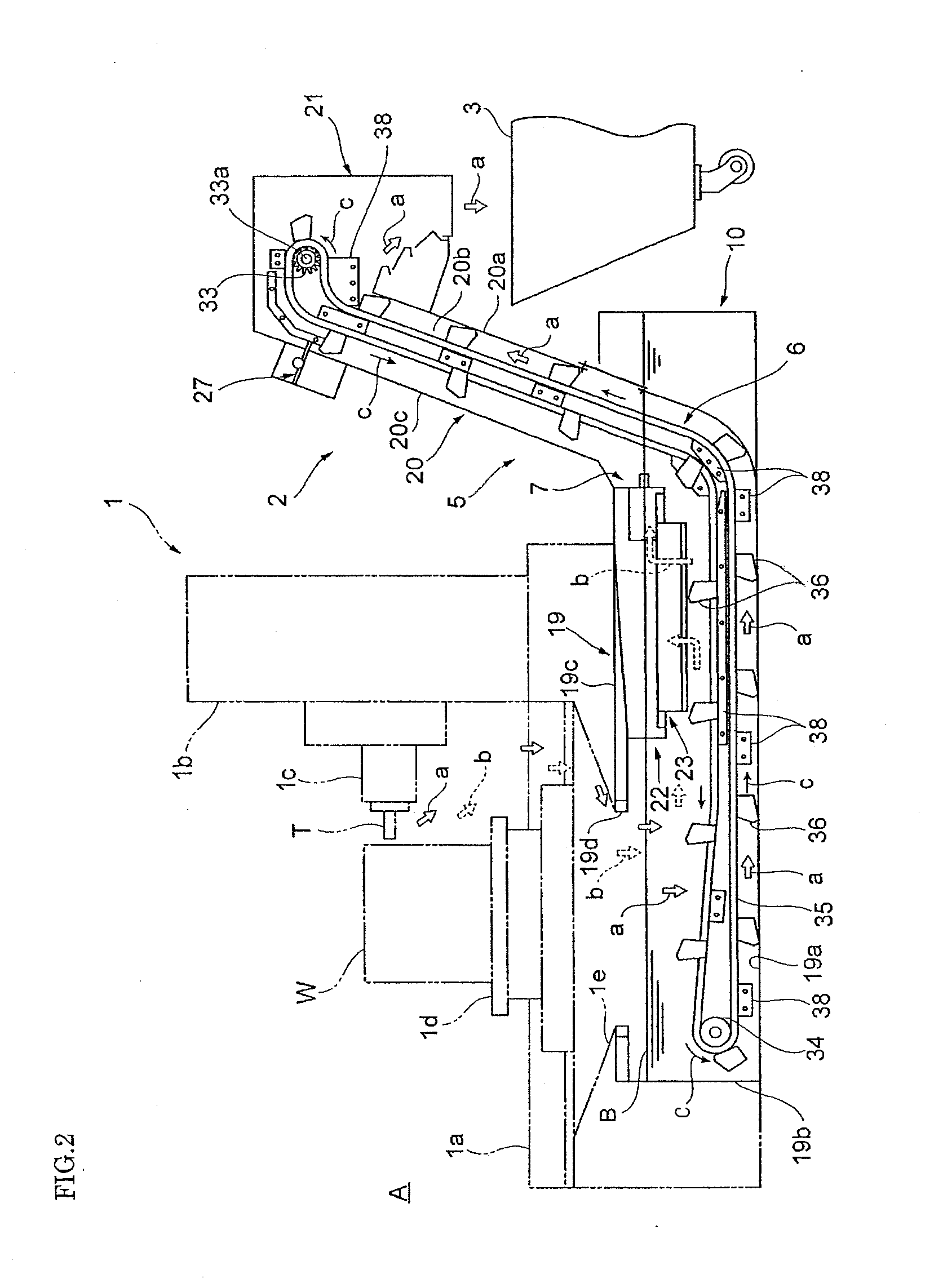

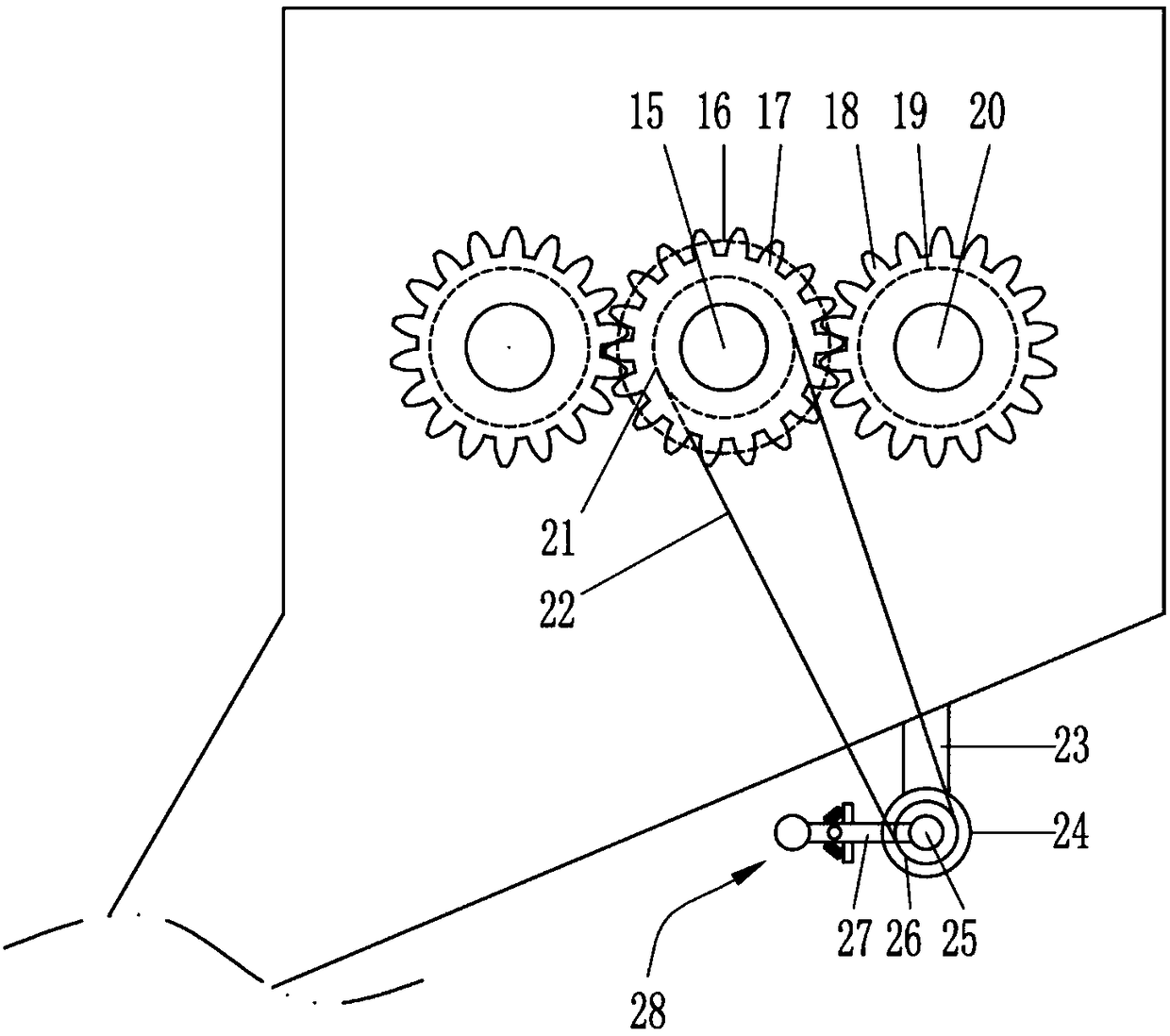

Chip disposal device of machine tool

InactiveUS20150023752A1Increase collection rateA large amountMaintainance and safety accessoriesMoving filtering element filtersMachine toolCutting fluid

To provide a chip disposal device of a machine tool which surely separates and collects a cutting fluid adhering to a chip lump, thereby capable of reducing an amount of the cutting fluid discharged to the outside of the machine. The chip disposal device includes a liquid separating part 65 which separates and collects a cutting fluid adhering to chips, the liquid separating part 65 has a mounting part 66 which is provided continuously from an inclined discharge surface 20a and is inclined so as to get lower as it goes more apart outward from the inclined discharge surface 20a, and to which a first chip lump a1 conveyed by a first scraping plate 36a is transferred. Then, the first chip lump a1 on the mounting part 66 stays on the mounting part 66 until dropping by being pushed by a second chip lump a2 conveyed by a second scraping plate 36b following the first scraping plate 36a.

Owner:DMG MORI CO LTD

Movable distributive continuous exploitation method for deep sea mineral resources

InactiveCN1458391AIncrease collection rateBroken particle sizeMineral miningProduction rateMineral Sources

The movable deep sea mineral resource exploiting system consists of under water positioning base point in the marine mining area, movable distributing mining vehicle, movable ore bin matching the exploitation amount, initial separating and crushing unit capable of inhibiting depletion rate and matching mineral granularity, conveyer to the ore raising unit, movable ore raising unit with driving plant and pipeline, movable underwater power distributing station, movable main control station, surface exploitation ship, transportation ship, etc. The present invention is adaptable to the exploitation of deep sea mineral resources, especially base rock mineral resources and deposit mineral resources, and has high production rate, high collecting rate, low exploitation cost, high reliability, and less marine environmental pollution.

Owner:SUNWARD INTELLIGENT EQUIP CO LTD +1

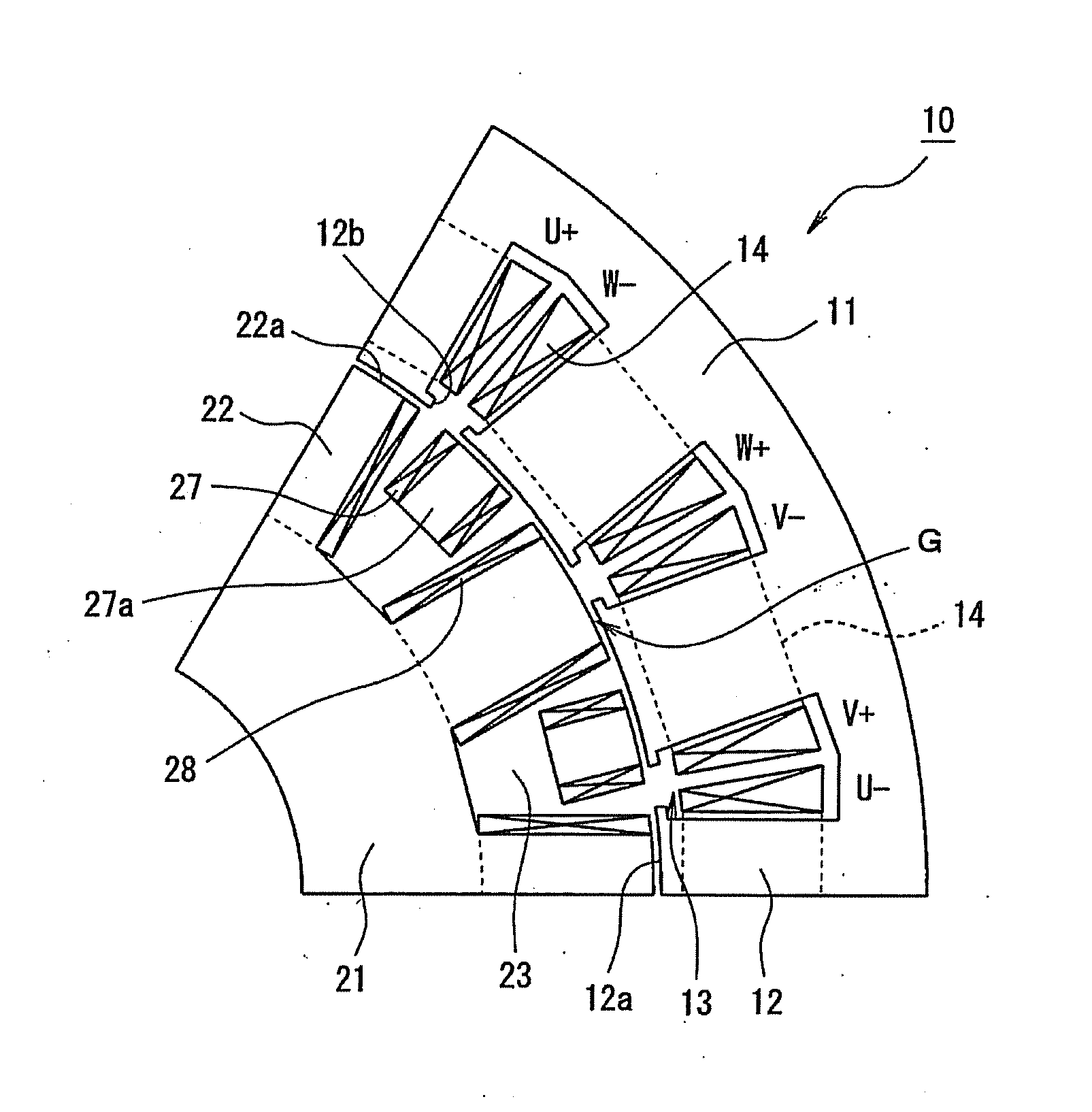

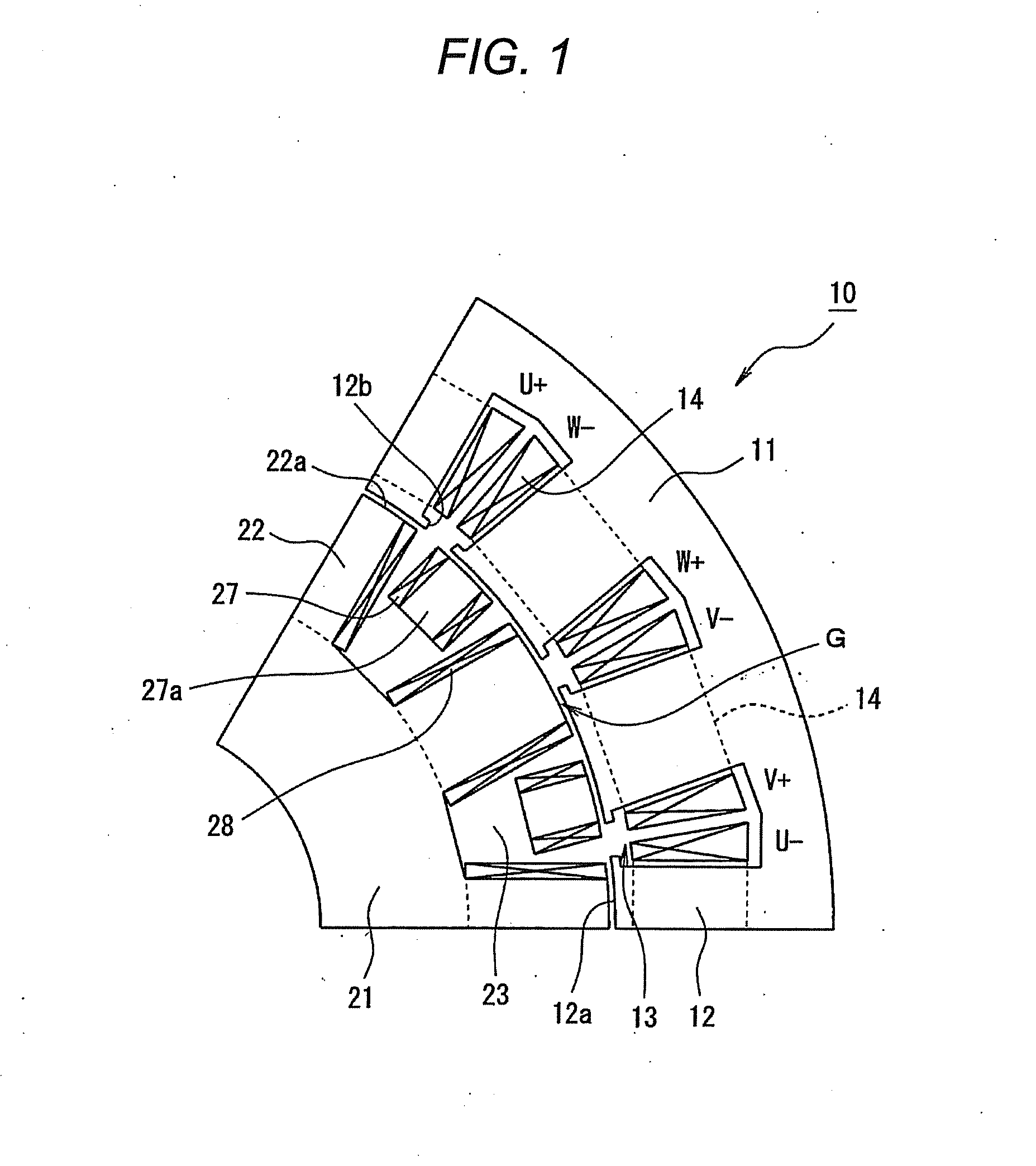

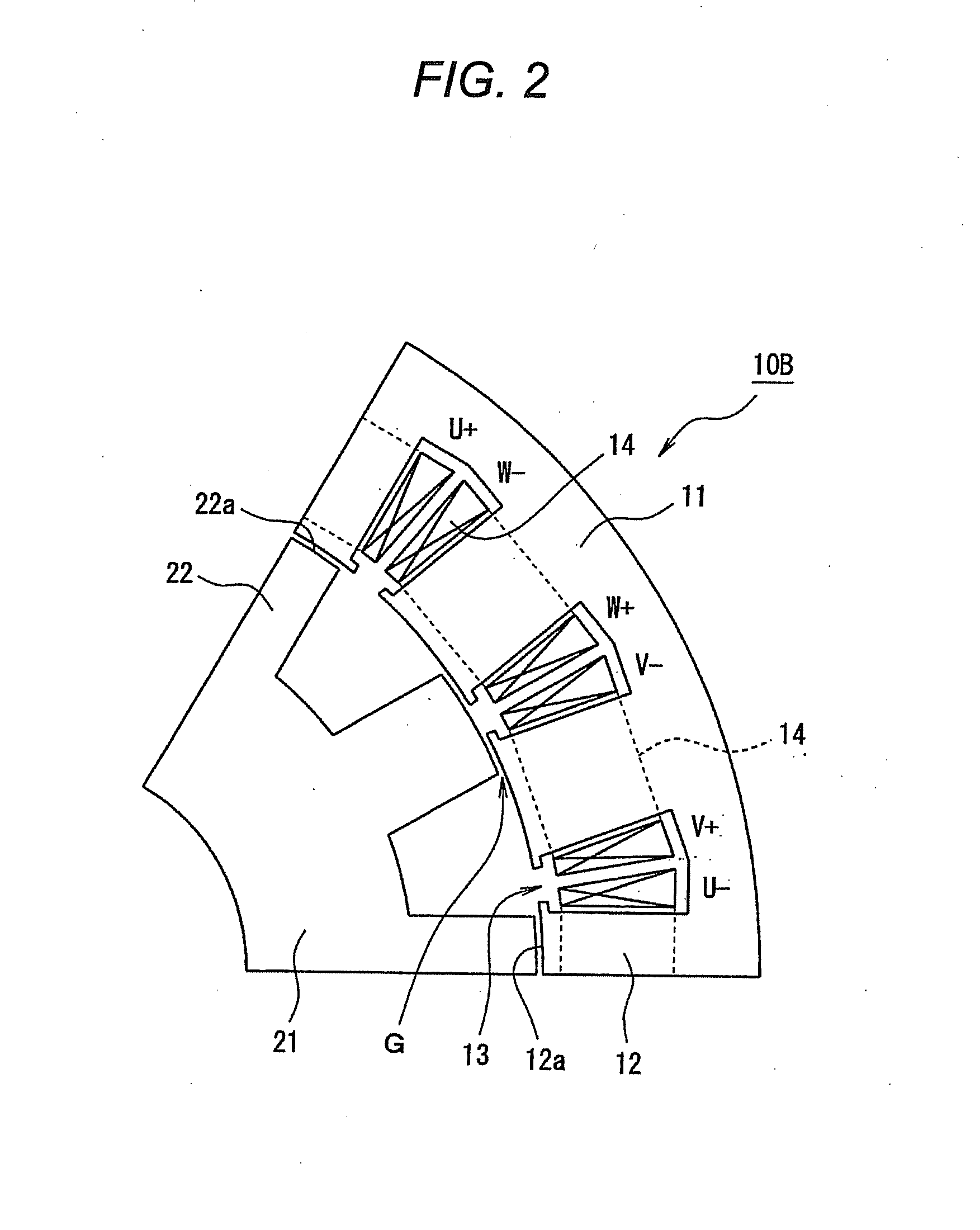

Reluctance motor

ActiveUS20140285057A1Increase torqueImprove efficiencySynchronous generatorsMagnetic circuit rotating partsDriving currentPower flow

A reluctance motor has: a stator provided with drive coils to which multiphase drive currents are inputted; and a rotor provided with a plurality of salient poles which receive primary rotating force when magnetic fluxes generated in the drive coils are interlinked with the rotor, and the rotor has: inductor pole coils which are placed on magnetic paths on which spatial harmonic components superimposed on the magnetic fluxes generated in the drive coils are interlinked with the rotor side so that induced currents can be generated in the inductor pole coils due to the spatial harmonic components of the magnetic fluxes; rectifier elements which rectify the induced currents generated in the inductor pole coils; and electromagnet coils as defined herein, and the inductor pole coils and the electromagnet coils do not serve for each other's purposes but are placed on the rotor individually.

Owner:SUZUKI MOTOR CORP

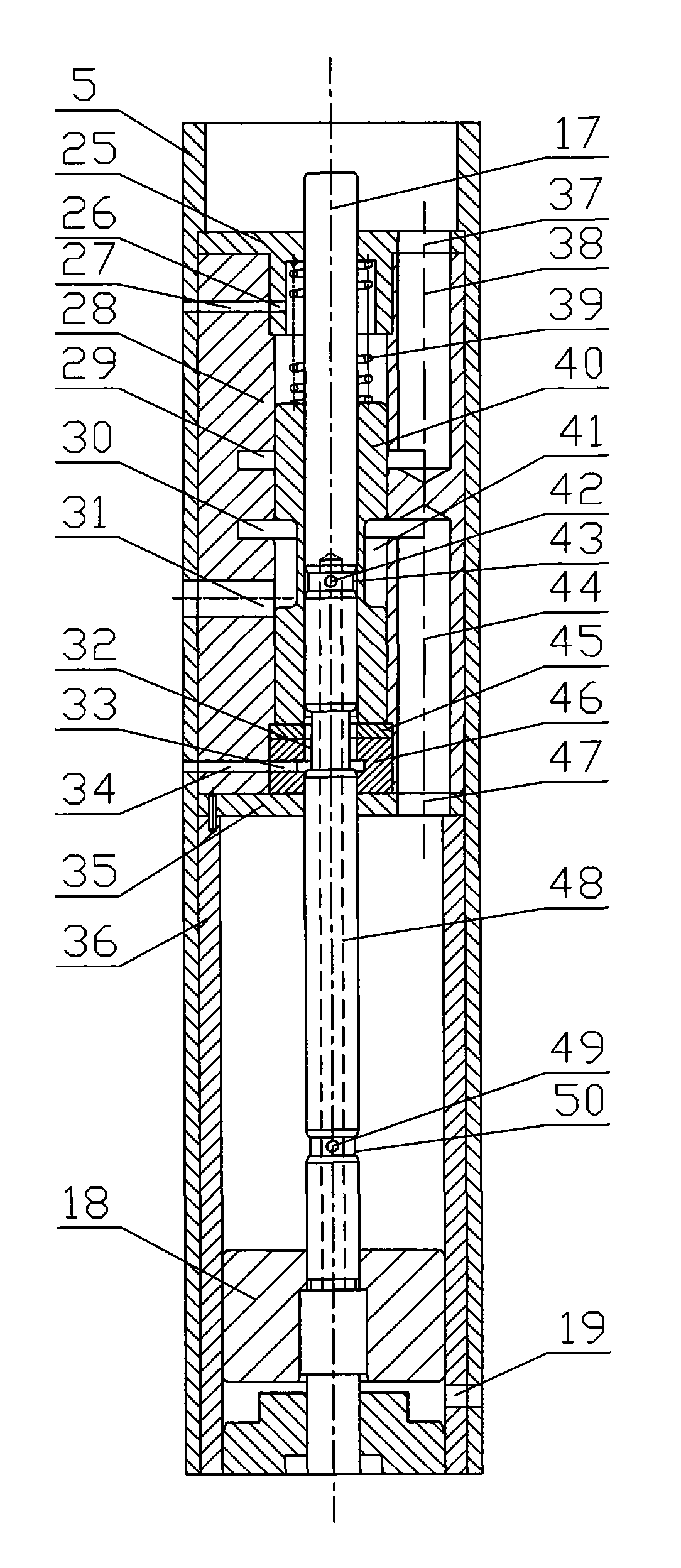

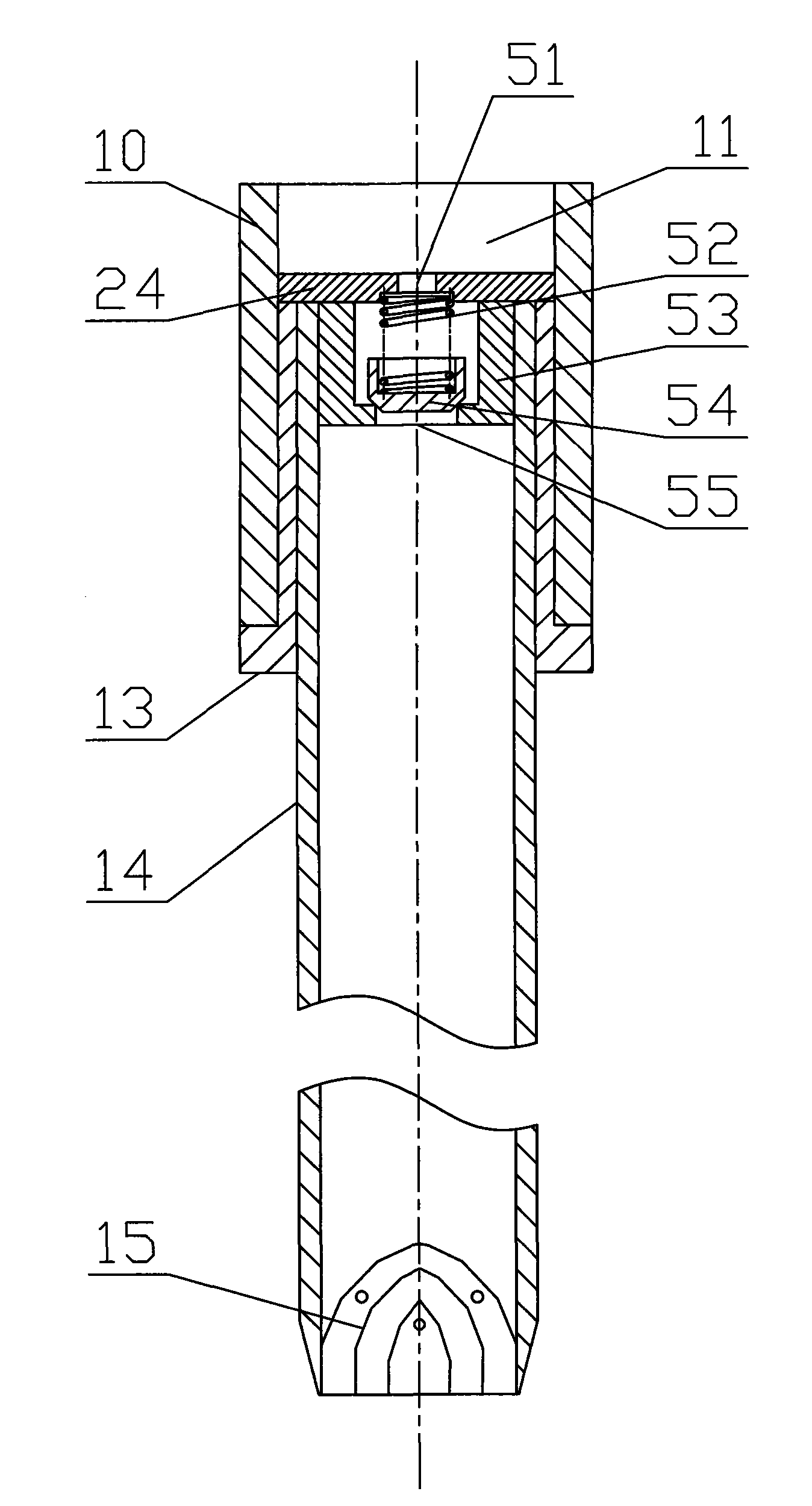

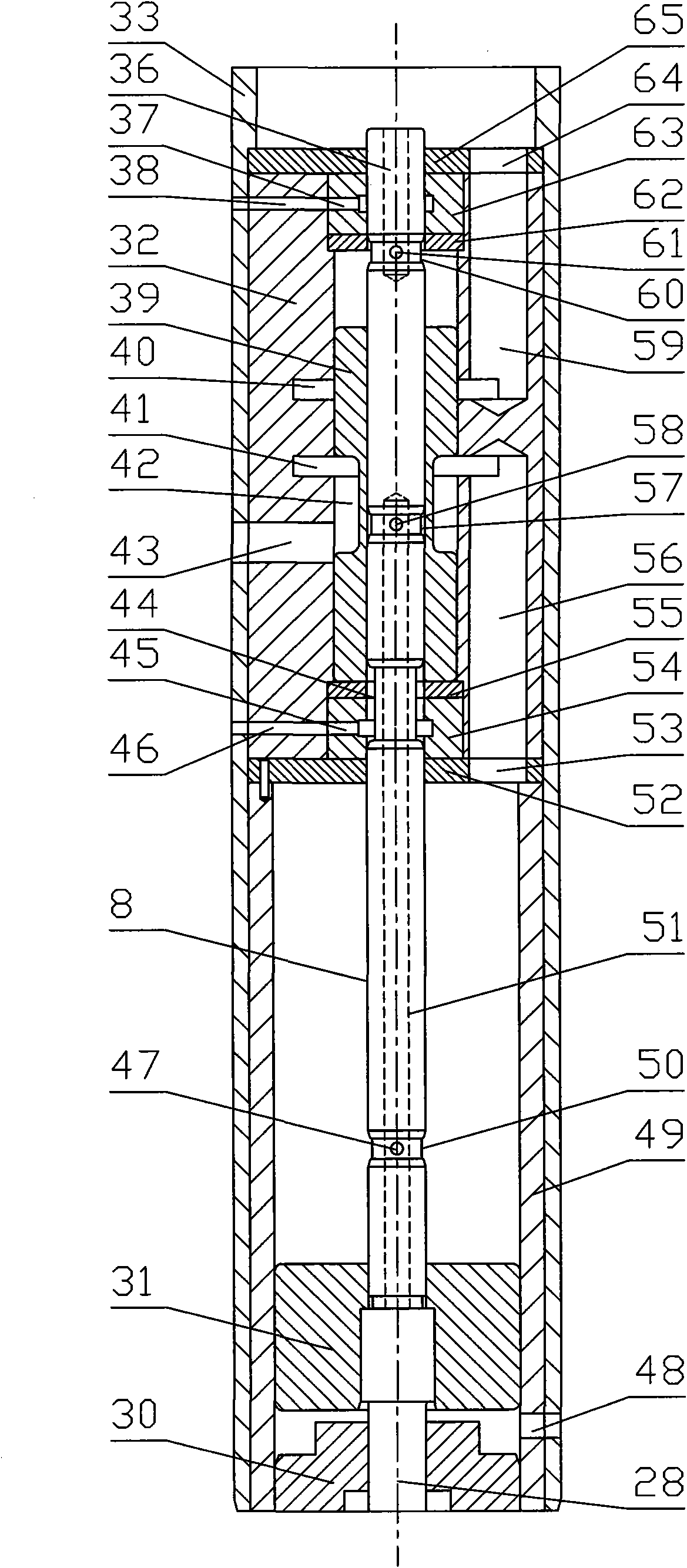

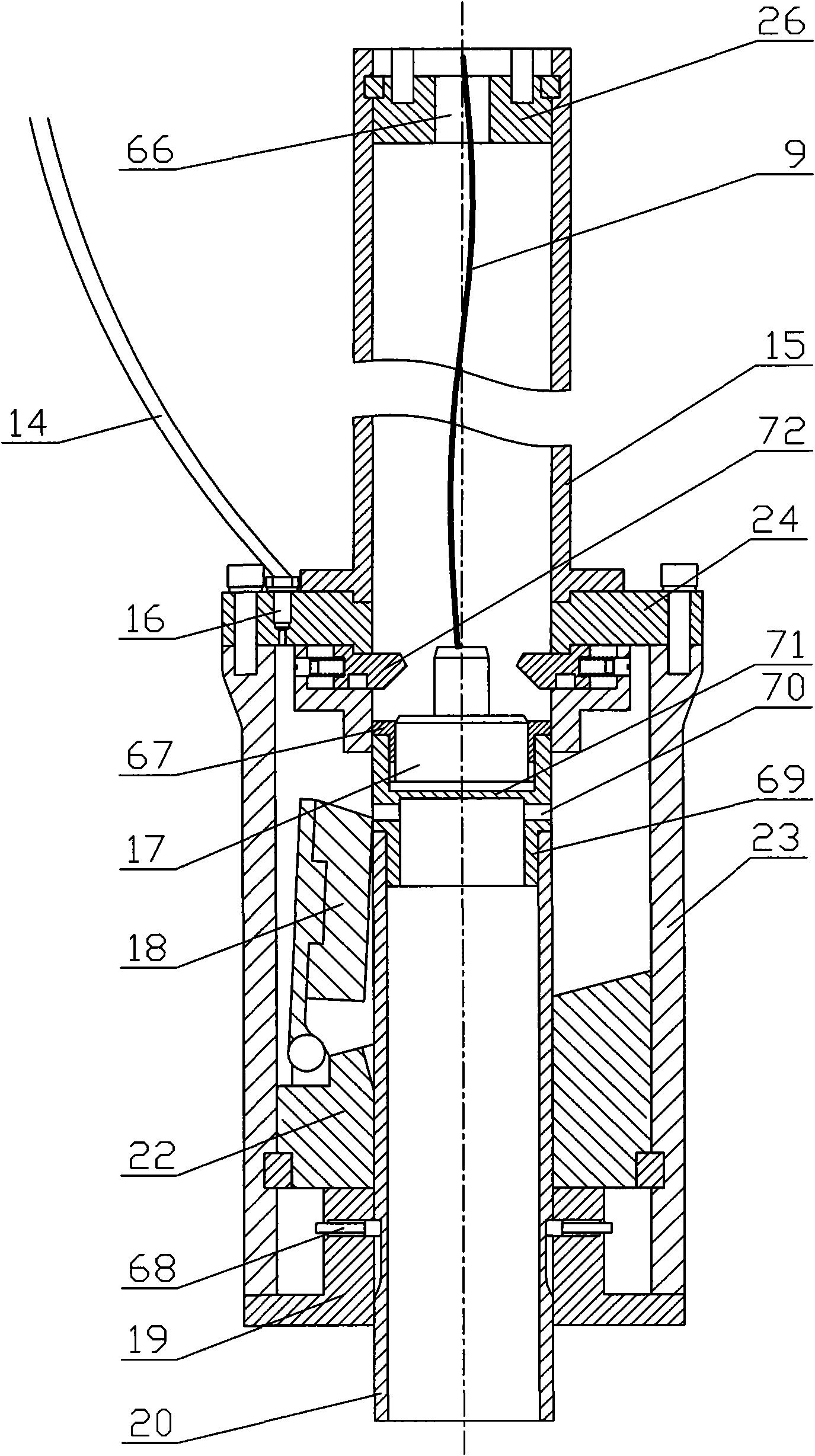

Sediment pressure-holding sampler driven by hydrostatic pressure

InactiveCN101561366AGuaranteed pressureIncrease collection rateWithdrawing sample devicesInsertion depthHydrostatic pressure

The invention relates to a sediment pressure-holding sampler driven by hydrostatic pressure. The prior device is limited in insertion depth, large and heavy in supporting frame. The sampler comprises an impact component, a flow distribution component, a driving component and a sampling tube component, wherein the impact component comprises an impact tube, a guide sleeve and an impact piston cylinder, the flow distribution component comprises a supporting tube and a flow distribution valve; the driving component comprises a driving piston cylinder and a driving piston; the sampling tube component comprises a guide tube, a pressure-holding tube, a sampling pipe and a pressure-replenishing hose; and the impact tube, the supporting tube, the impact piston cylinder, the guide tube, the pressure-holding tube and the sampling pipe are coaxially arranged. The sampler fully utilizes the huge energy of seawater hydrostatic pressure, injects sediment for sampling in a form similar to vibropiling, and can use the energy in subsequent sample pressure holding. Relative to the prior sampler, the sampler has the advantages of larger sampling depth under the same weight condition, obviously promoted sample collection rate and capability of performing truth-preserving sampling on hard sediment which cannot be sampled by gravity-type sediment truth-preserving samplers.

Owner:HANGZHOU DIANZI UNIV

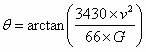

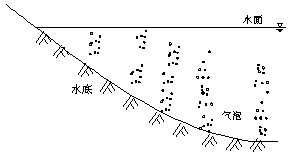

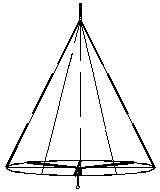

Method for collecting underwater bubbles and method for monitoring underwater bubble flux under hydrodynamic conditions

InactiveCN102608273ASolve the crushing problemImprove air tightnessMaterial analysisGas cylinderEngineering

The invention discloses a method for collecting underwater bubbles and a method for monitoring underwater bubble flux under hydrodynamic conditions. A counterweight pendant is connected with the open part of an inverted funnel of a collection device through a rope; a tubular connector is arranged at the top of the inverted funnel, and is connected with a gas inlet pipe of a gas collecting bottle through a gas hose; and a buoy is connected with the outer surface of the inverted funnel through a rope, ant the gas collecting bottle is fixed together with the buoy. The monitoring method comprises the steps of placing a bubble collecting device in a water body, floating the buoy on the water surface and tying on a water surface anchor rope, and fixing one end of the water surface anchor rope on the bank side and the other end of the water surface anchor rope on a channel buoy or a far bank; and collecting gas, and considering an inclination angle theta of the inverted funnel when the bubble release flux is calculated. The methods disclosed by the invention are convenient for operation, have low sampling errors, and are suitable for collecting underwater bubbles and monitoring underwater bubble flux under complex hydrodynamic conditions of natural water bodies (high water level fluctuation or distinct flow rate in water).

Owner:CHONGQING UNIV

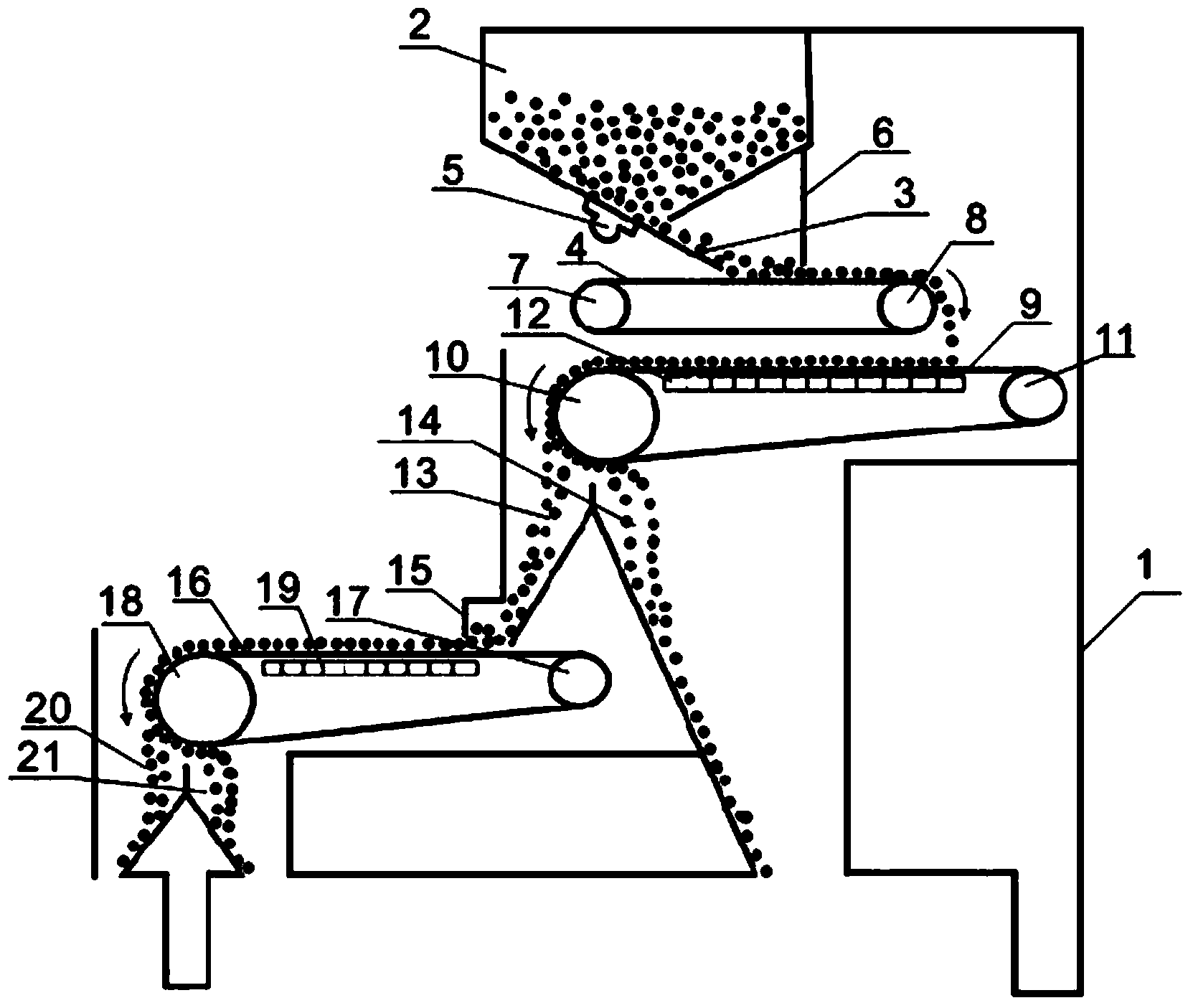

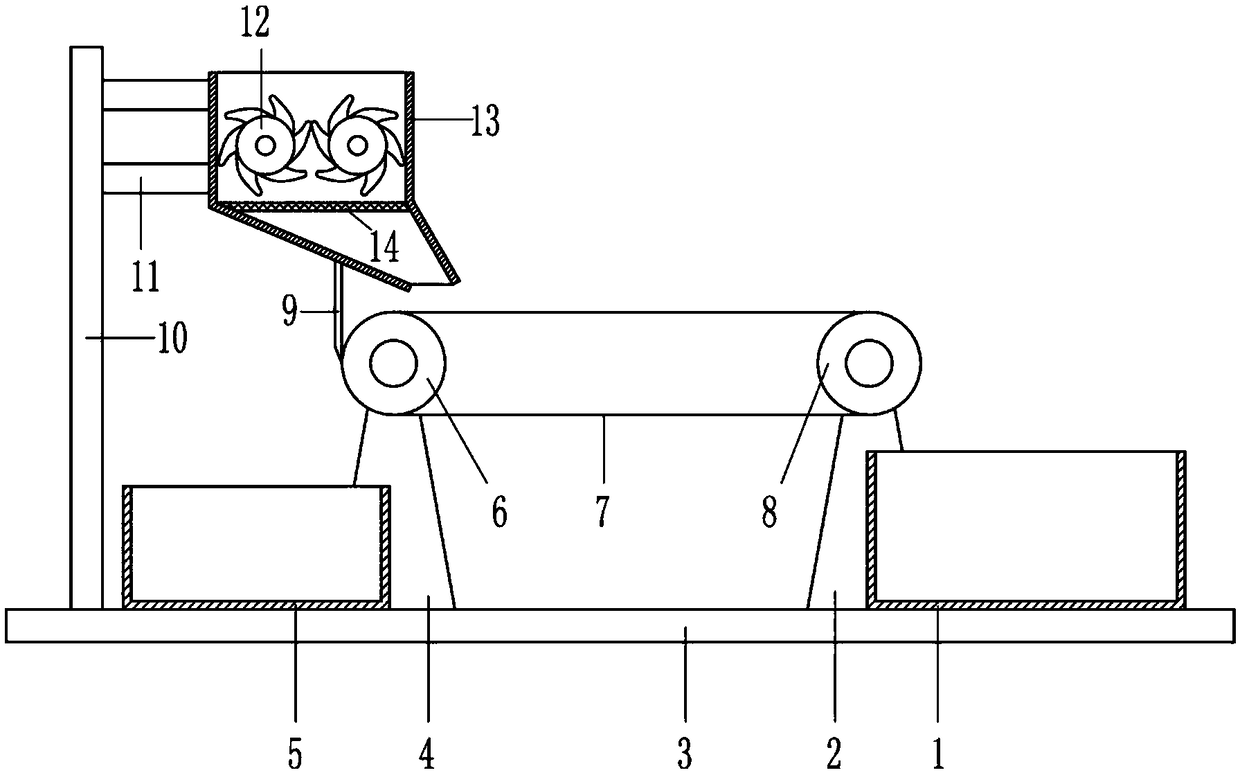

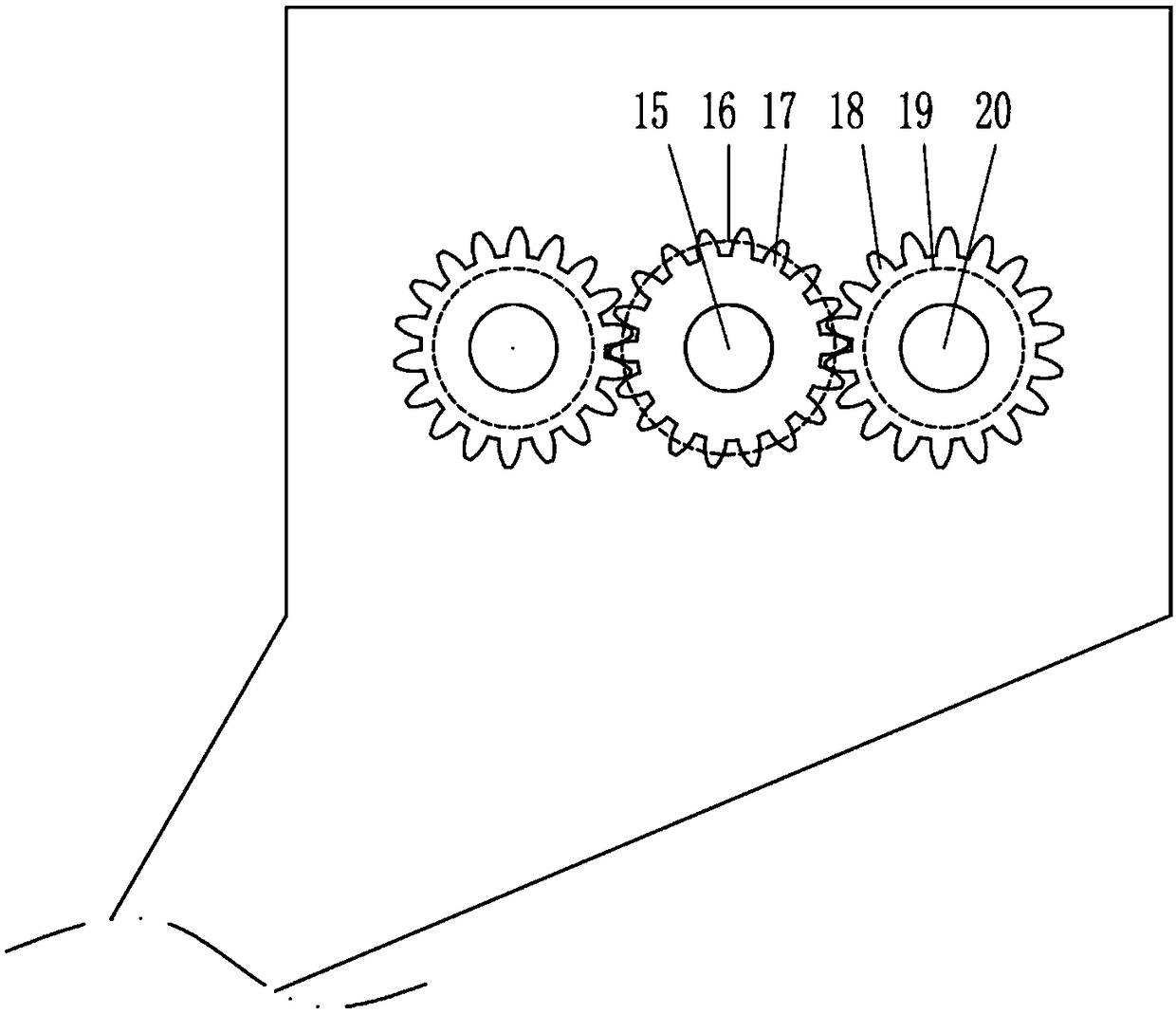

Dry magnetic separator

InactiveCN104069943AIncrease delivery speedImprove screening efficiencyMagnetic separationMagnetic separatorEngineering

The invention relates to a dry magnetic separator. The dry magnetic separator comprises a rack and a charging bin at the top of the rack, wherein a discharging slope is arranged at a discharging opening in the bottom of the charging bin; a first conveying belt is arranged below the discharging slope; a first carrier roller is arranged at one end of the first conveying belt, and a roller shaft is arranged at the other end of the first conveying belt; a second conveying belt is arranged below the roller shaft; a second carrier roller is arranged at one end of the second conveying belt, and a first magnetic roller is arranged at the other end of the second conveying belt; a second separation material inlet and a first separation ore outlet are formed right below the first magnetic roller; a third conveying belt is arranged below the second separation material inlet; a third carrier roller is arranged at one end of the third conveying belt, and a second magnetic roller is arranged at the other end of the third conveying belt; a tailing outlet and a second separation ore outlet are formed right below the second magnetic roller. According to the dry magnetic separator, magnetic separation can be carried out for two times, and materials can be poured uniformly.

Owner:周开雄

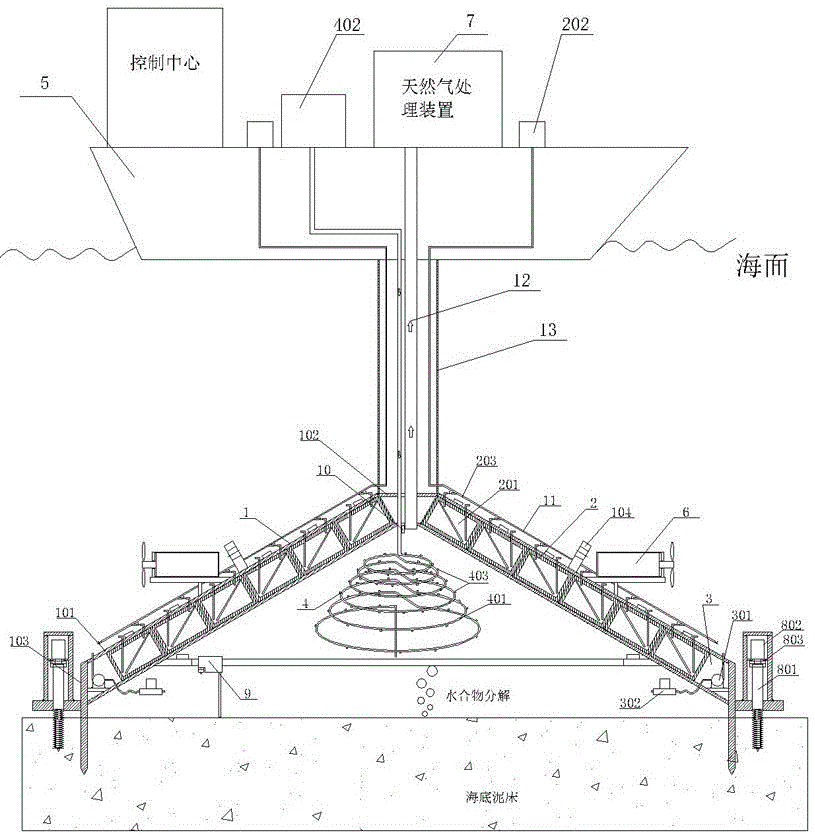

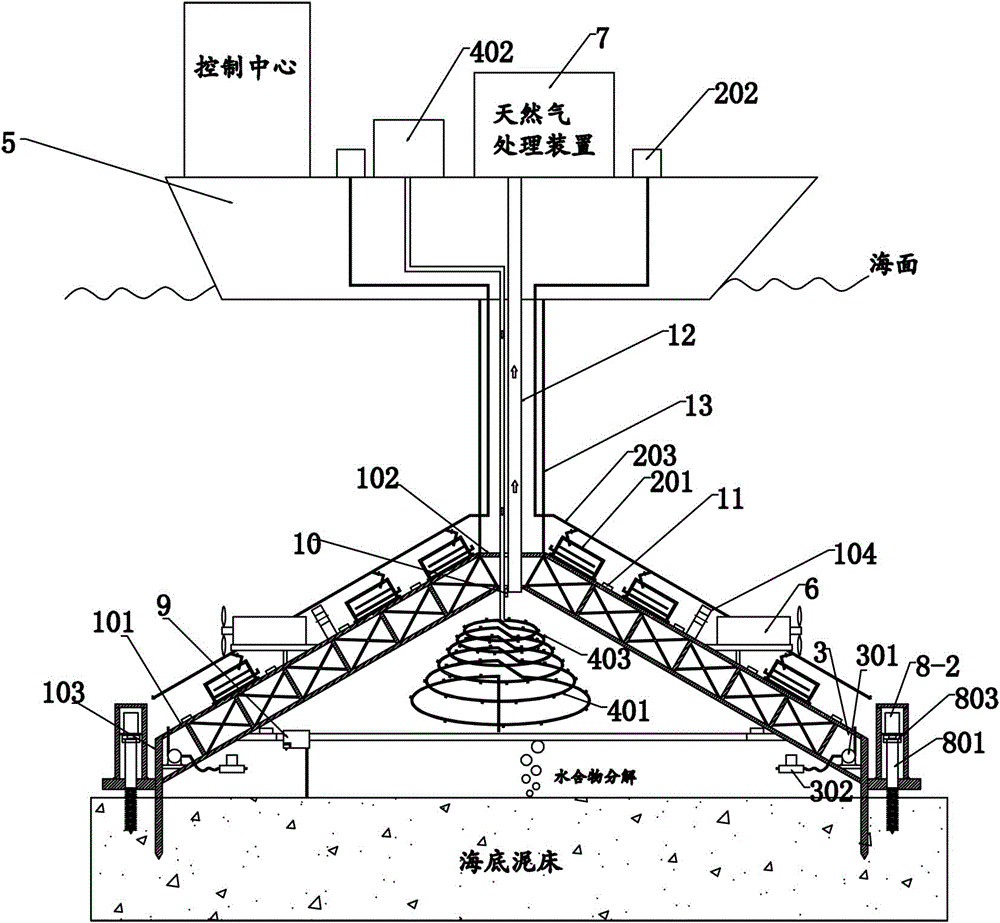

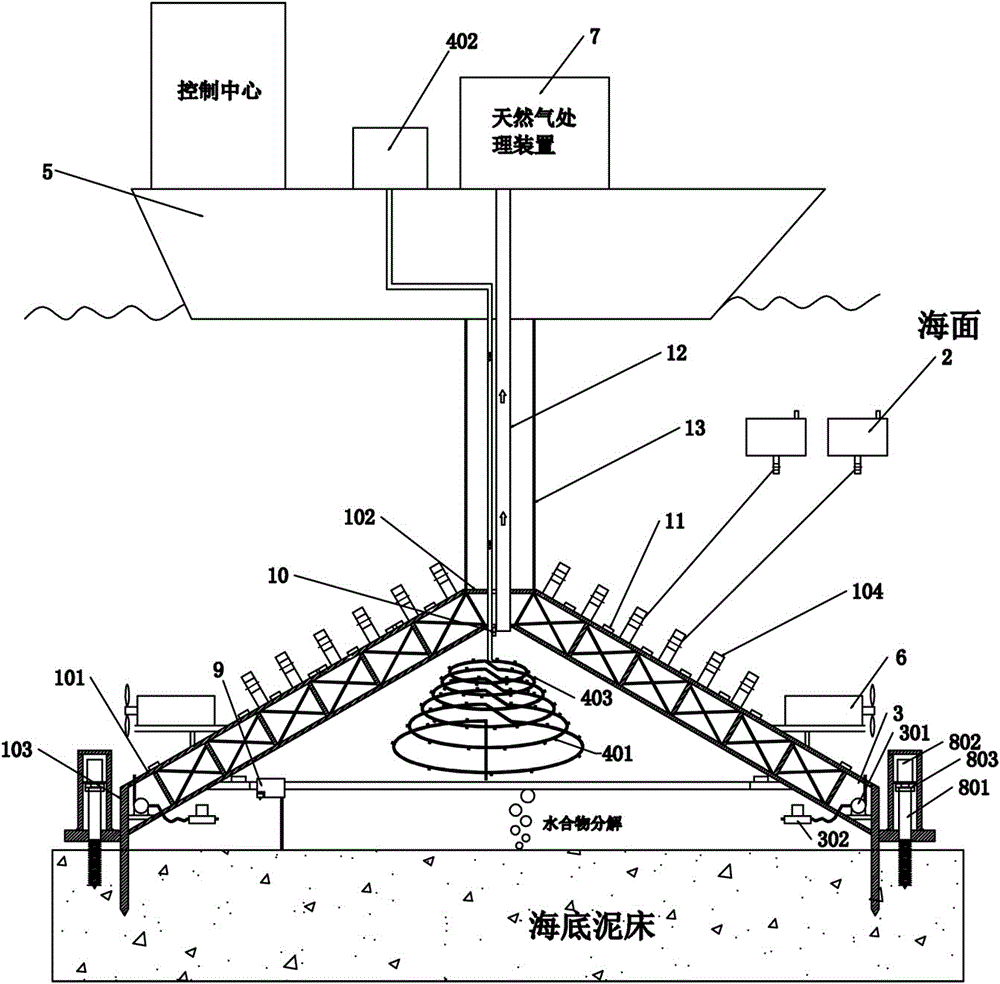

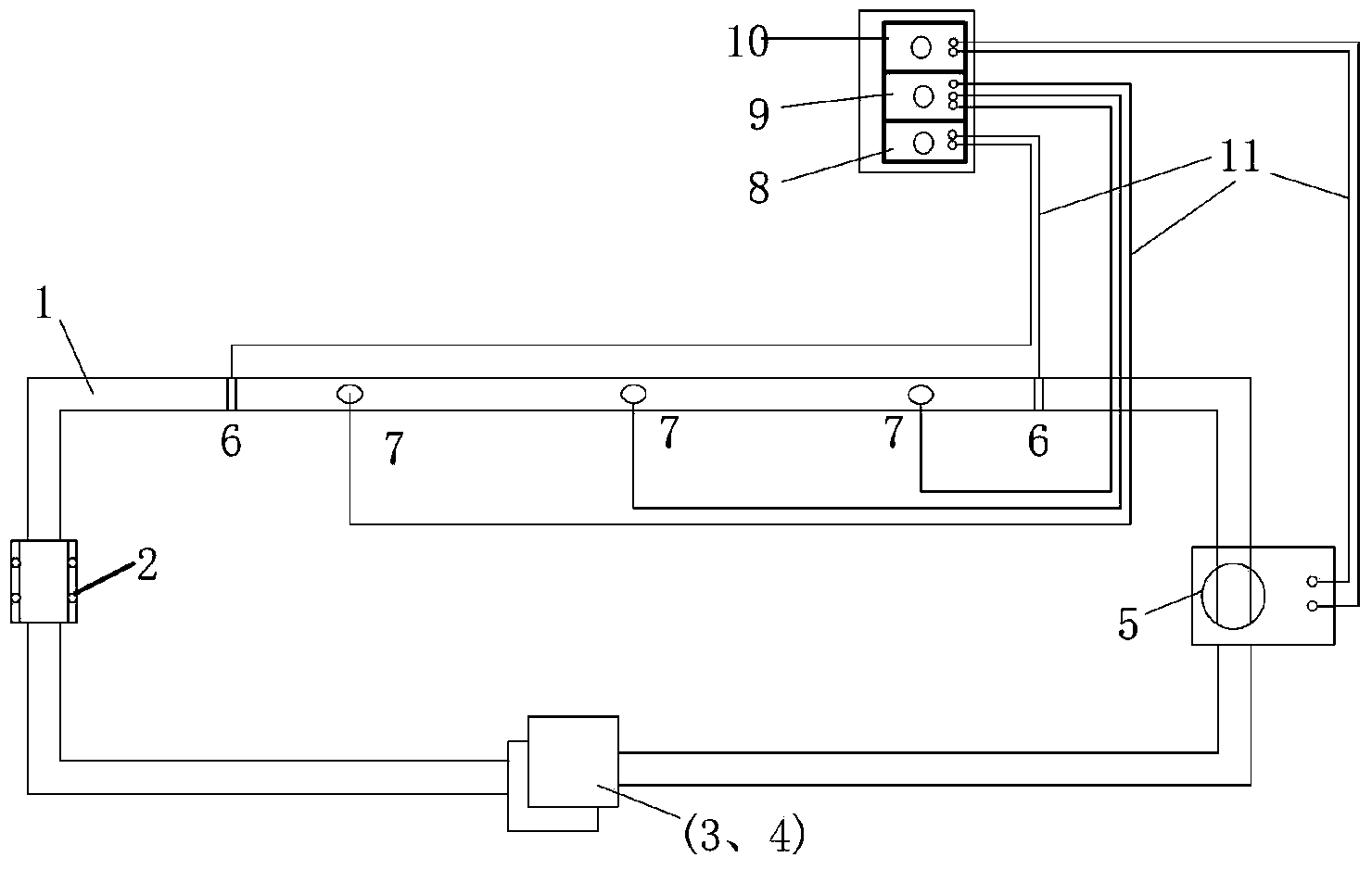

Seabed natural gas hydrate collecting device

ActiveCN105781497AConnect warmUniform temperatureConstructionsFluid removalDecompositionElectric heating

The invention discloses a seabed natural gas collecting device for suspension buoyancy tank electric heating, and belongs to the technical field of natural gas collection. The device comprises a mother ship and a hollowed natural gas collecting cover; a natural gas storage device is arranged on the mother ship, and is connected to the top of the natural gas collecting cover through a gas extracting pipeline; the natural gas collecting cover is connected to the bottom of the mother ship through a water separation pipe; the gas extracting pipeline is arranged in the water separation pipe; anchoring systems are arranged around the bottom of the natural gas collecting cover; a pressure adjusting system is arranged at the bottom of the natural gas collecting cover; a propelling system is arranged on the outer wall of the natural gas collecting cover; a density adjusting system is arranged on the natural gas collecting cover; and a temperature adjusting system and a stirring system are arranged in the natural gas collecting cover. The device mainly solves the problem of incapability of forming emission and leakage of natural gas in the decomposition, collection and extraction process of natural gas hydrates on a seabed mud bed.

Owner:SOUTHWEST PETROLEUM UNIV

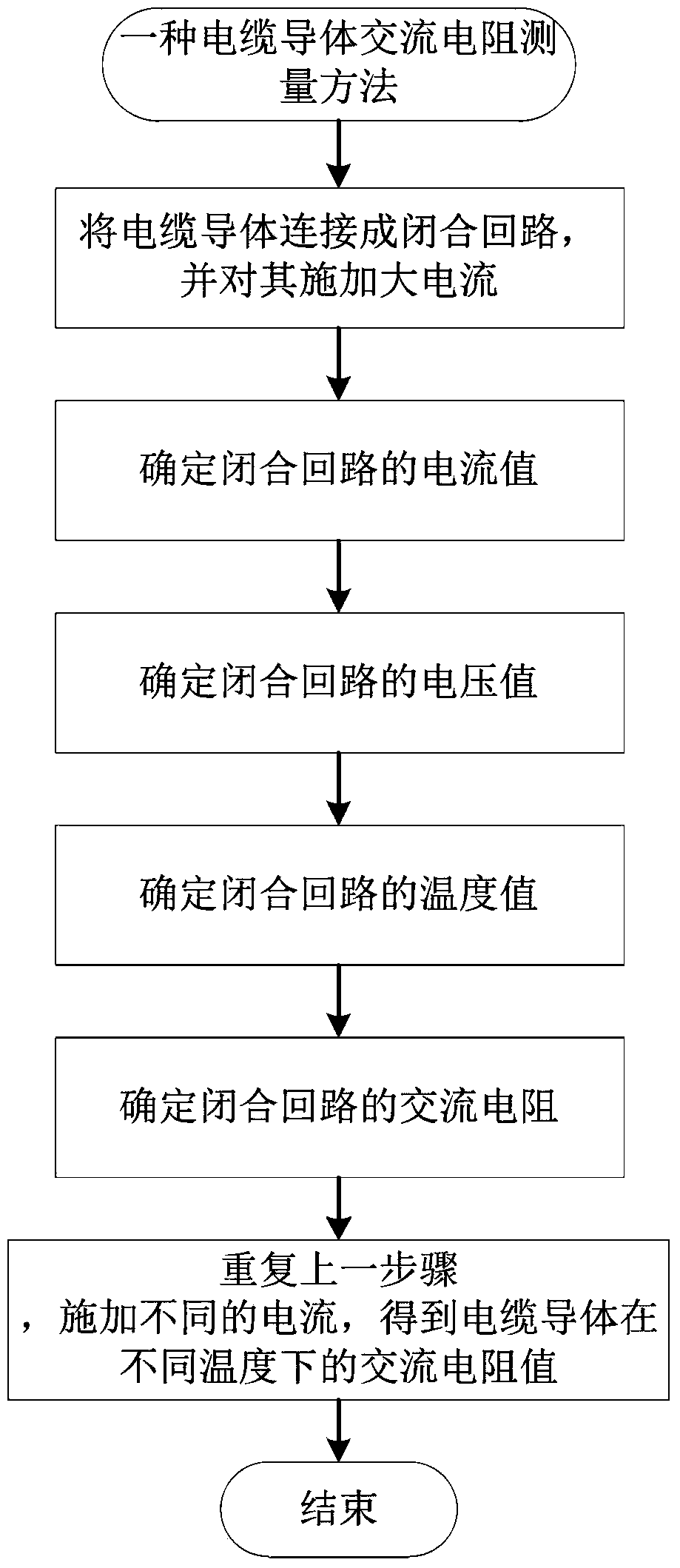

Measurement method for alternating-current resistance of cable conductor

InactiveCN104251936AGood effectHigh precisionResistance/reactance/impedenceElectrical resistance and conductanceElectrical conductor

The invention relates to a measurement method for alternating-current resistance of a cable conductor. The method comprises the following steps: applying large current to a conductor loop by adopting a voltage regulator and a straight-thought transformer; after the temperature of the conductor is stable by long-time current heating and temperature raising, synchronously measuring voltage and loop current in one section of the conductor and the surface temperature of the conductor; extracting amplitudes and phases of voltage and current signals by Fourier transformation, and calculating a phase difference between the voltage and the current; finally, calculating the alternating-current resistance of the conductor by adopting a formula. The method is high in measurement precision, good in stability, good in consistency of repeated measurement, simple in structure and convenient to measure, and is particularly suitable for measuring the alternating-current resistance of the cable conductor with a large section.

Owner:CHINA ELECTRIC POWER RES INST +2

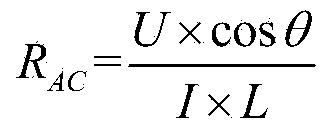

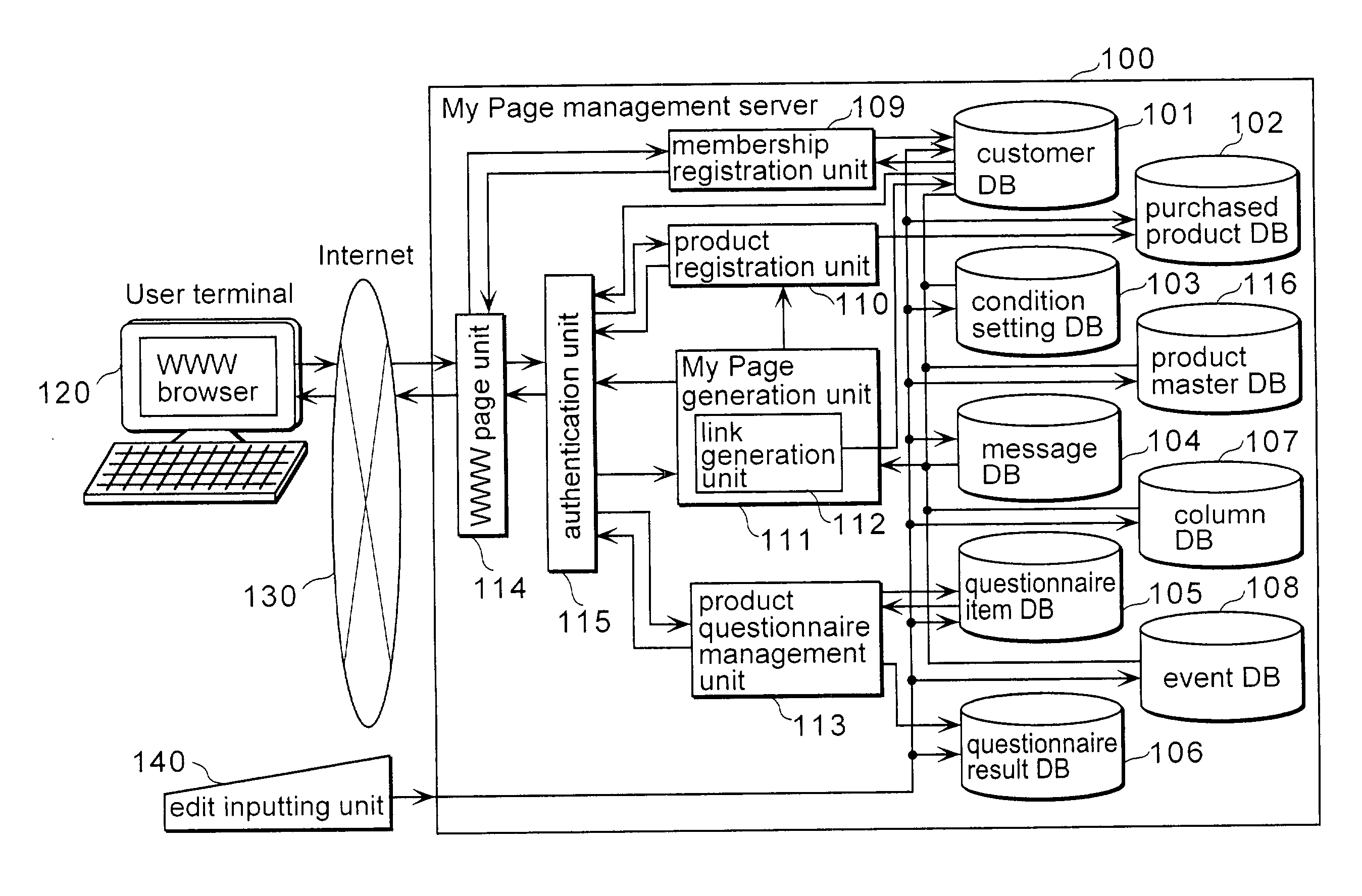

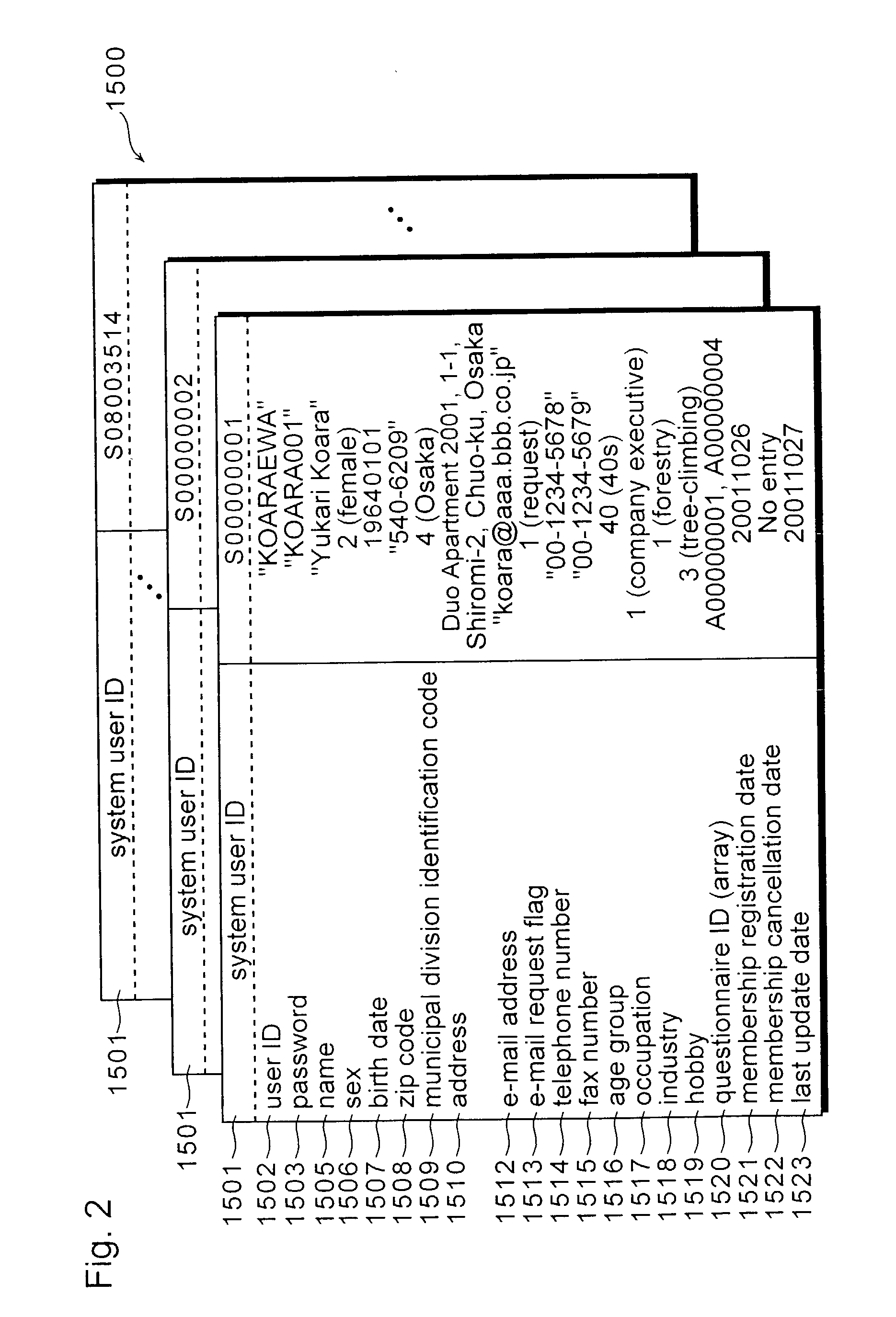

Product information management device

InactiveUS20030083962A1Increasing questionnaire collect rateUsabilityFinanceMultiple digital computer combinationsManagement unitWorld Wide Web

A My Page management server is a server that provides a personal world wide web (WWW) page named My Page for a user who has been registered as a member. The My Page management server includes a product registration unit that acquires information of a product which the user purchased, a link generation unit that generates, on the My Page, a link indicator which is linked to a product questionnaire about the product which the user purchased, based on the acquired information of the product, and a product questionnaire management unit that presents the linked product questionnaire to the user upon receiving a request for the product questionnaire from the user.

Owner:PANASONIC CORP

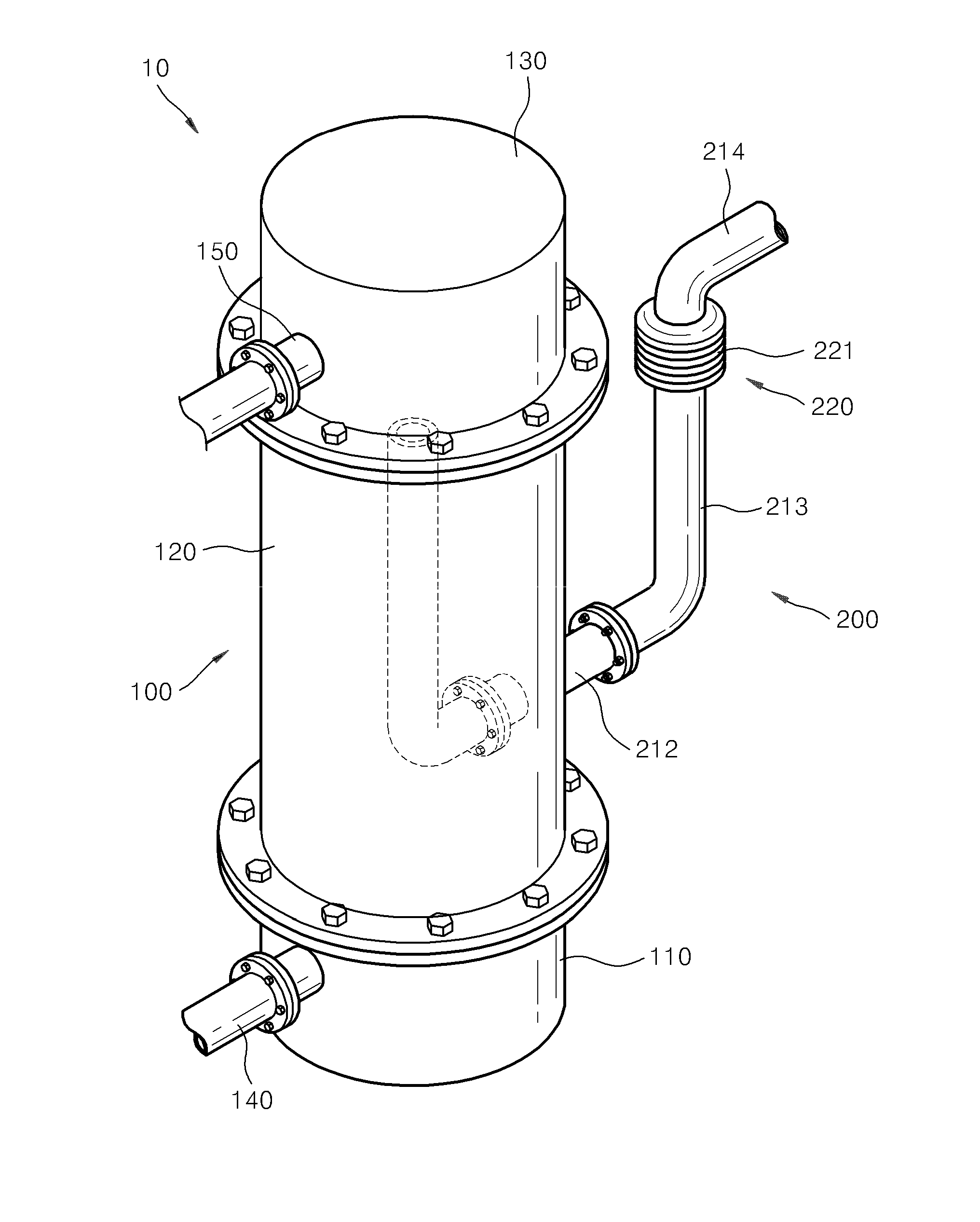

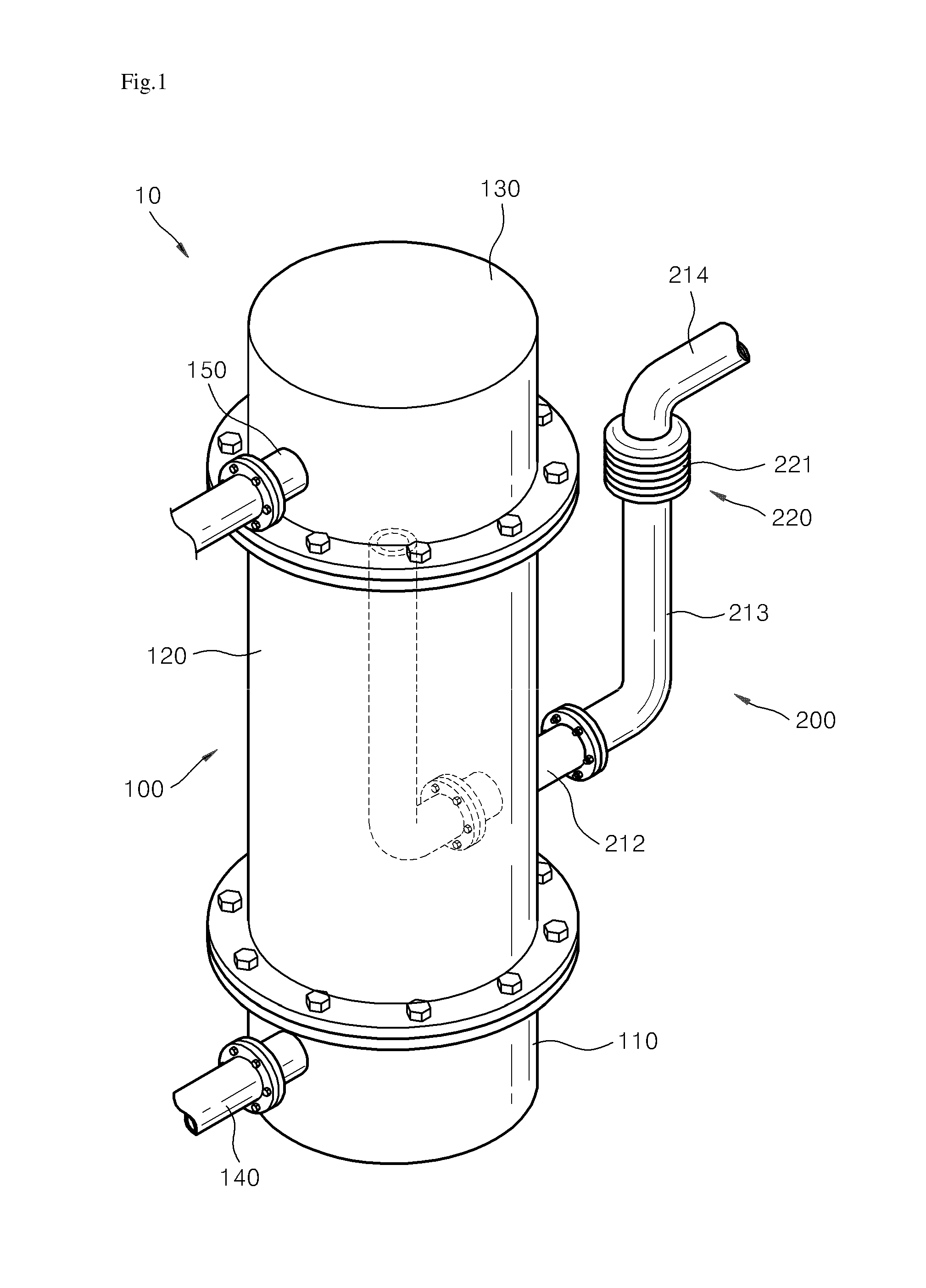

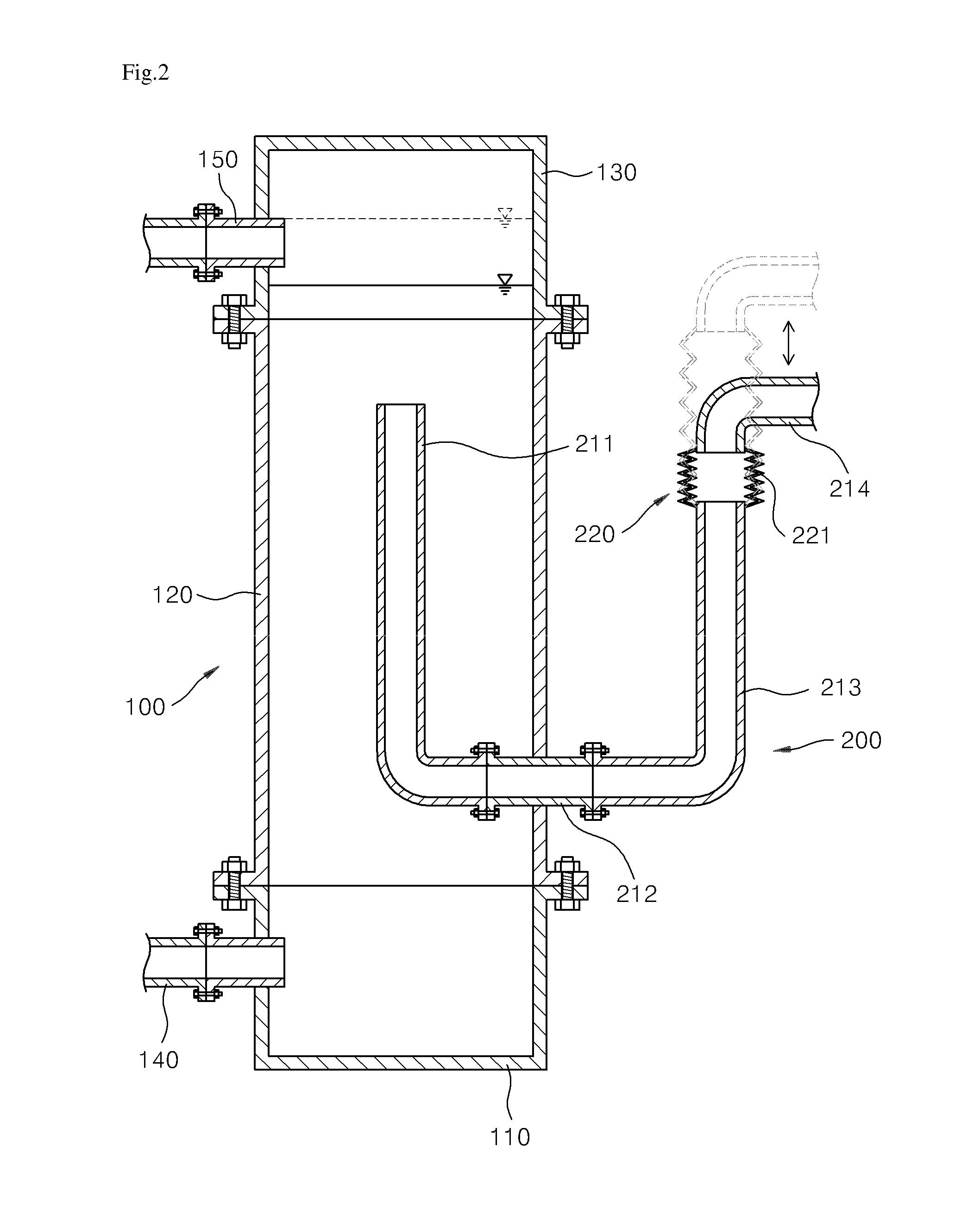

Apparatus for separating and collecting oil spilled in ocean

InactiveUS20160318776A1Simple structureReduce manufacturing costWater treatment parameter controlWater cleaningEngineeringOil spill

Provided is an apparatus for separating and collecting oil spilled in an ocean, which is capable of easily removing the oil spilled in rivers, reservoirs, or oceans using a density difference between water and oil. The apparatus for separating and collecting oil spilled in the ocean according to the present invention includes a separator body having a separation space therein formed to receive mixed water in which water and oil are mixed, and a mixed water introducing part formed at one side thereof to introduce the mixed water, a drainage member which is installed in the separation space, and in which an end thereof is connected and in communication with the separator body to be located lower than a level of the water, such that the water separated from the oil due to a density difference is discharged to an outer side of the separator body, and a length adjusting part configured to move a height of an upper end of the drainage member exposed to the outer side of the separator body vertically to control the level of the water in the separator body.

Owner:GAUDO

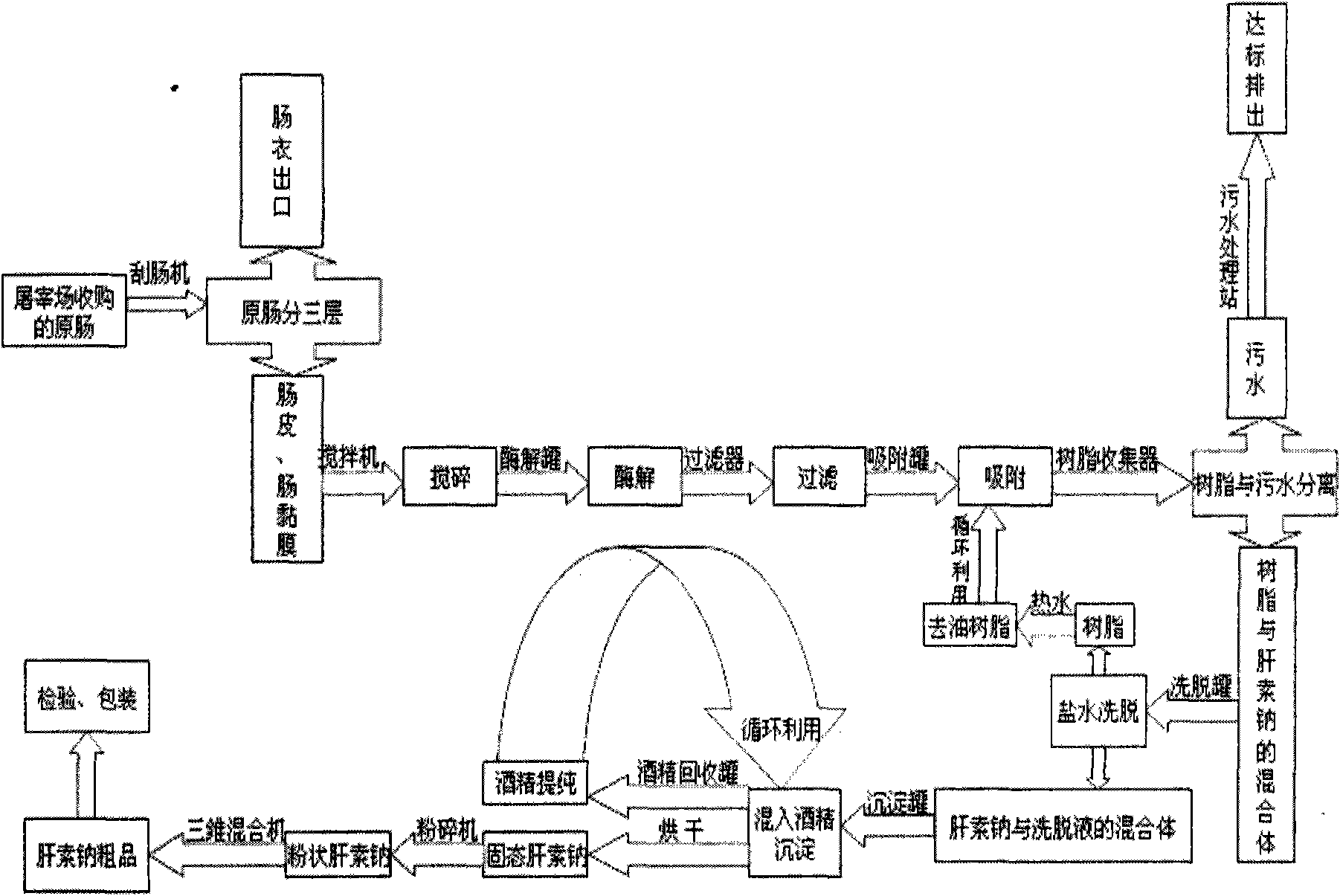

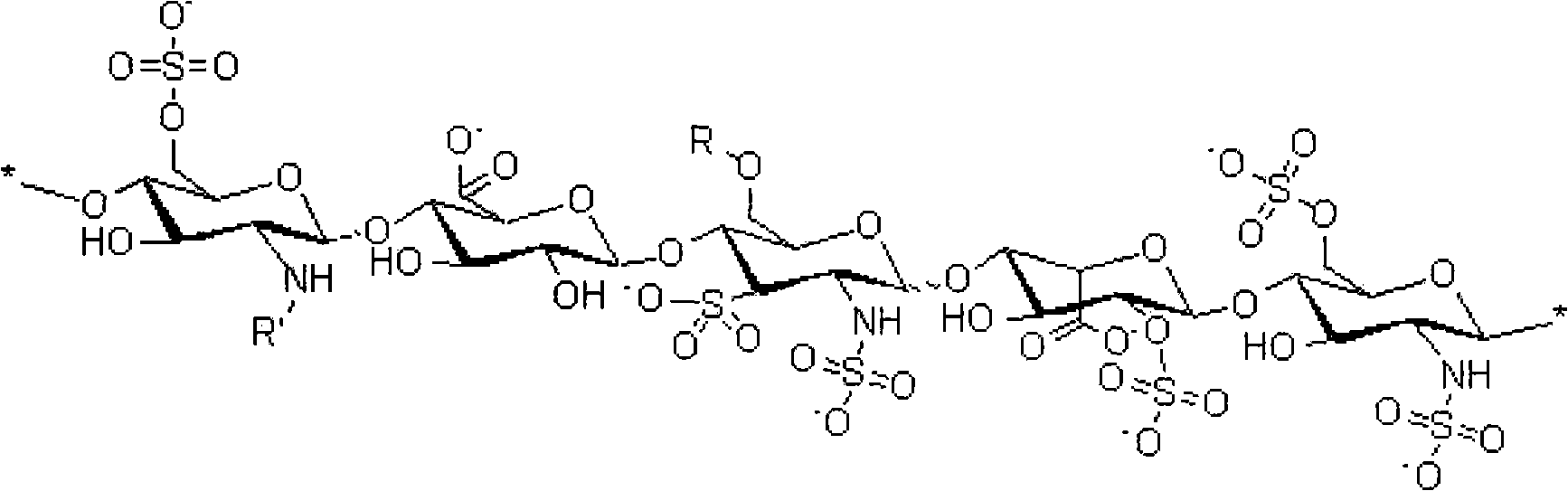

Method for extracting crude product of heparin sodium

The invention relates to a method for extracting a crude product of heparin sodium, which comprises the following steps of: firstly, taking the gut skin and the intestinal mucosa of a primitive gut as raw materials for extracting the heparin sodium, putting sodium chloride, sodium hydroxide and proteinase into an enzymolysis tank simultaneously according to a certain proportion and heating to carry out enzymolysis on the raw materials to form a liquid state; filtering, putting filtrate into an adsorption tank, eluting resin by brine after adsorbing the filtrate by adopting the higher resin, enabling the heparin sodium to enter eluent, putting the eluent into a depositing tank and depositing by alcohol; and drying and pulverizing. The invention has high efficiency, high stability, resource saving and high product yield and purity, is easy for large-scale production, can meet the requirements of markets at home and abroad to a crude product of heparin and has extensive application prospect.

Owner:喻延安

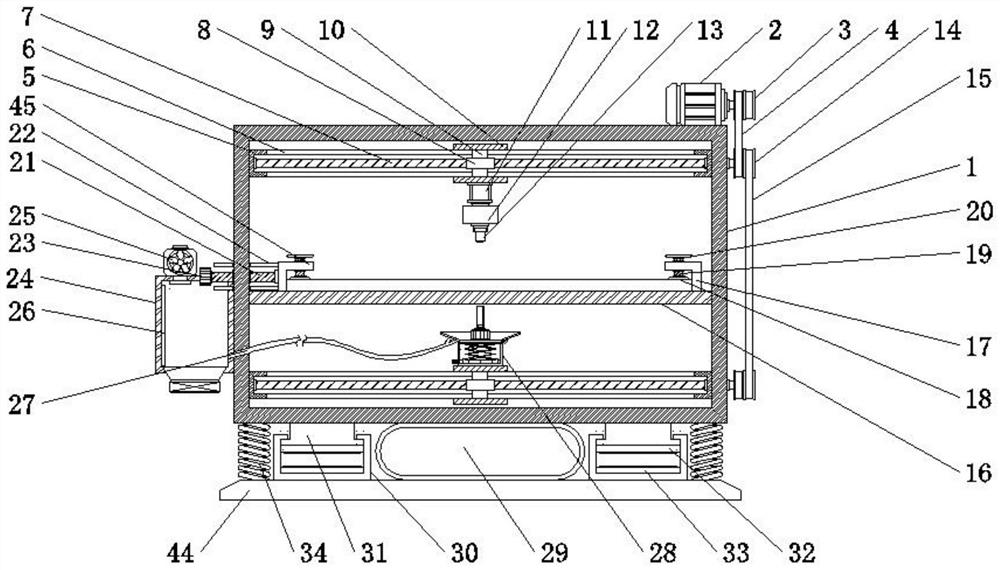

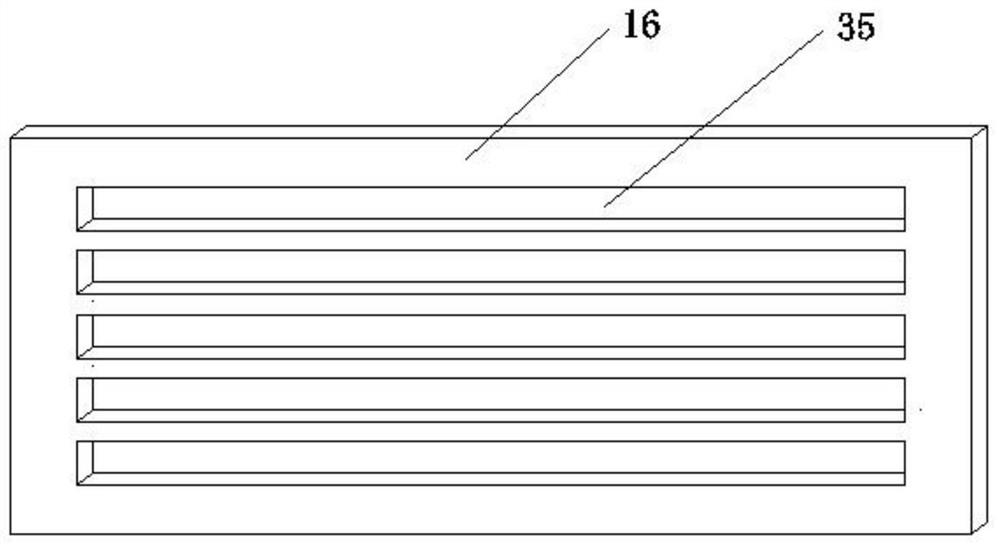

Punching and grinding integrated equipment for intelligent manufacturing and machining of machine screen

PendingCN112355128AImprove work efficiencyPrecise positioningEdge grinding machinesGrinding carriagesPunchingAir pump

The invention discloses punching and grinding integrated equipment for intelligent manufacturing and machining of a machine screen, and relates to the field of machine screen machining. The punching and grinding integrated equipment comprises a device main body, wherein a first servo motor is installed at one side of the top of the device main body, the output end of the first servo motor is connected with a driving rotating wheel, and two sets of fixing cylinders are installed in the device main body. During punching, a dust collecting cover is located under a punching head, scraps generatedby punching can just fall into the dust collecting cover, and when a driving motor drives a grinding head to grind a hole, an air pump exhausts air in a collecting box, and under the action of negative pressure, the scraps generated during grinding and the scraps generated after punching enter the collecting box through the dust collecting cover and a dust collecting pipe, the generated scraps areadsorbed after an electromagnet plate is powered on, then the scraps can be prevented from blocking the air intake end of the air pump, and when the scraps need to be discharged after work is finished, a worker firstly powers off the electromagnet plate, and the scraps are discharged from a scrap discharging opening, so that the scrap collecting rate is improved.

Owner:岳阳市卓立机筛有限公司

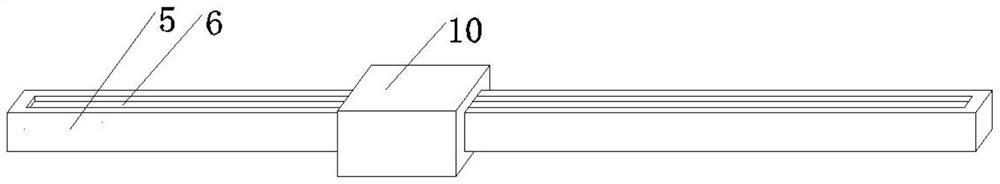

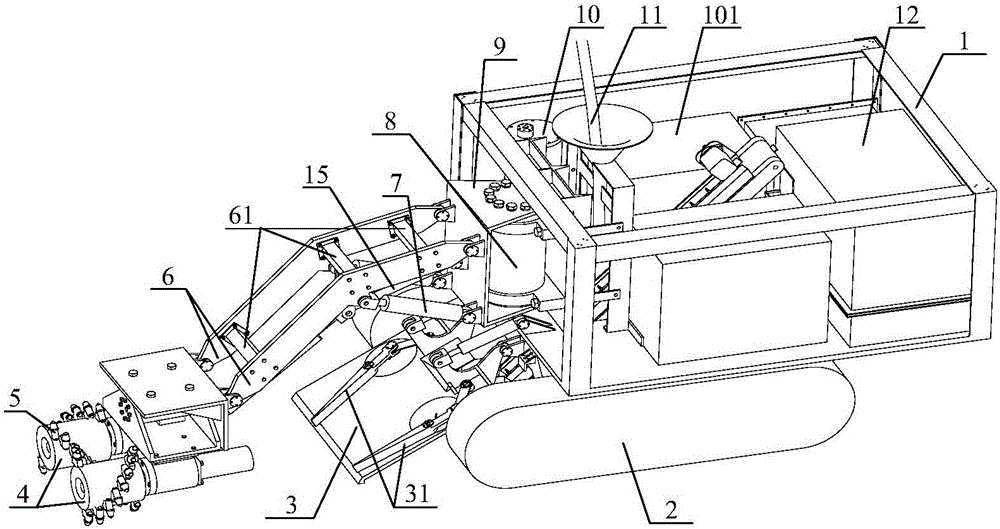

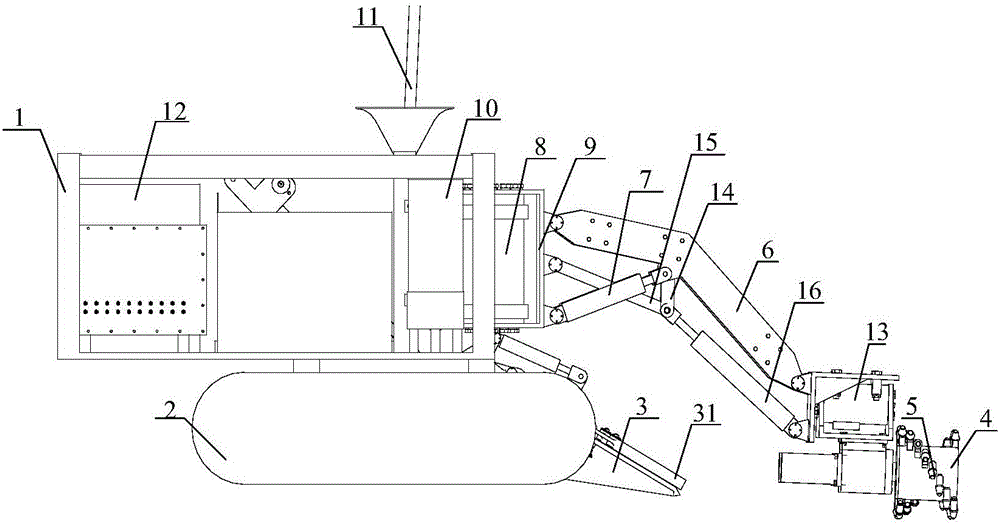

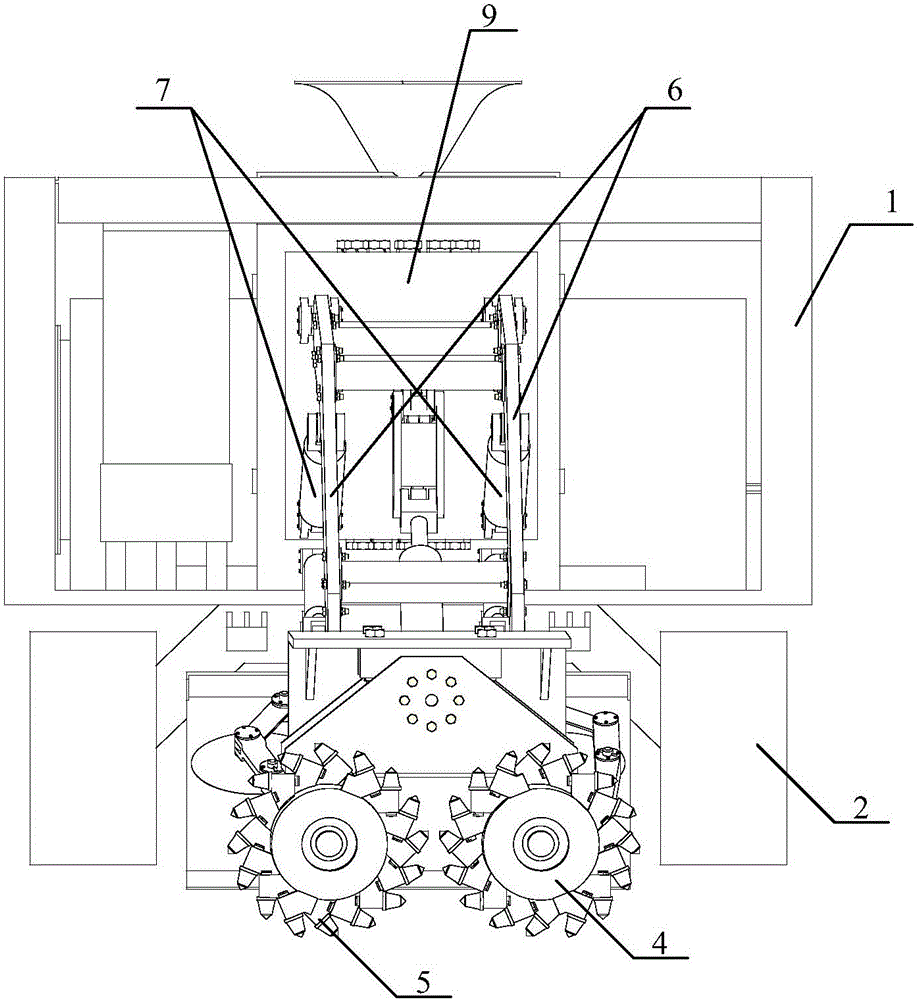

Mining machine

The invention discloses a mining machine. The mining machine comprises a rack, a travelling mechanism, a shovel plate, a conveying device, a crushing device, a movable arm, a first controller and a hydraulic source. The first controller of a ship on water sends a control instruction to a second controller through a watertight cable. The second controller controls the hydraulic source to provide power for the travelling mechanism, the conveying device, a first drive motor, a lifting cylinder and a first swing cylinder of the mining machine, the process that the mining machine travels and performs mining under the sea is achieved, the movable arm moves in four directions through cooperation of the lifting cylinder and the first swing cylinder, and therefore the positions of the crushing device in four directions can be adjusted, the collecting orientation of the crushing device can be changed according to changes of terrain, and therefore the collecting orientation of the crushing device can be flexibly adjusted, and the collecting rate is increased to a certain extent.

Owner:SANYA INST OF DEEP SEA SCI & ENG

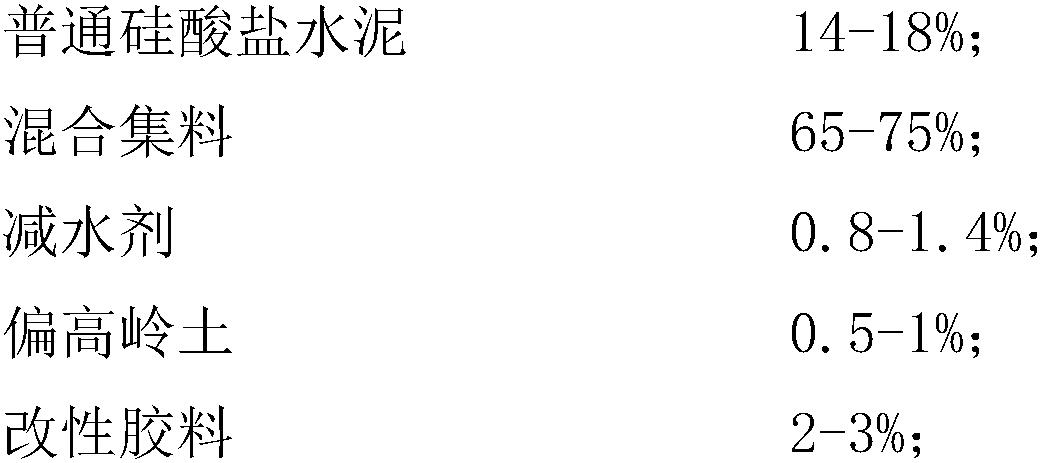

Steel slag pervious concrete

The invention relates to steel slag pervious concrete which contains the following materials in percentage by weight: 14-18% of ordinary Portland cement, 65-75% of blended aggregate, 0.8-1.4% of waterreducing agent, 0.5-1% of metakaolin, 2-3% of modified sizing material, 0.2-0.4% of calcium carbonate powder and the balance of water, wherein the mixed aggregate is a combination of steel slag and macadam; and the modified sizing material is a combination of modified polyacrylate and butadiene styrene rubber. According to the scheme, the concrete material is modified, and therefore, the blockage-proof performance of the concrete after being used for a long time is improved, the rate for rainwater to permeate concrete is increased, the rainwater residual amount in the concrete is effectivelyreduced, the rainwater collection rate is increased, and the practicability of an impounding pavement structure is improved.

Owner:苏州易斯特建材科技有限公司

Furnace slag residual scrap iron separation and recovery device

The invention belongs to the field of metallurgy, and particularly relates to a furnace slag residual scrap iron separation and recovery device. The furnace slag residual scrap iron separation and recovery device aims to achieve the technical effects that scrap iron can be rapidly separated and recovered from furnace slag, and the scrap iron recovery efficiency is improved. The furnace slag residual scrap iron separation and recovery device comprises a first collection frame, a first installation supporting seat, a first installation plate, a second installation supporting seat, a second collection frame, a driving roller, a magnetic conveying belt, a driven roller, a scraping plate, a second installation plate, connecting plates, crushing wheels, a crushing frame, a net plate, a first rotating shaft, a motor, a first gear, second gears, first bearing blocks and second rotating shafts, wherein the first installation supporting seat and the second installation supporting seat are fixedly connected to the top of the first installation plate. According to the furnace slag residual scrap iron separation and recovery device, the effects that the furnace slag and the residual scrap ironin the furnace slag are rapidly separated, and the iron scrap is recovered and reused are achieved.

Owner:内蒙古普源铁合金有限责任公司

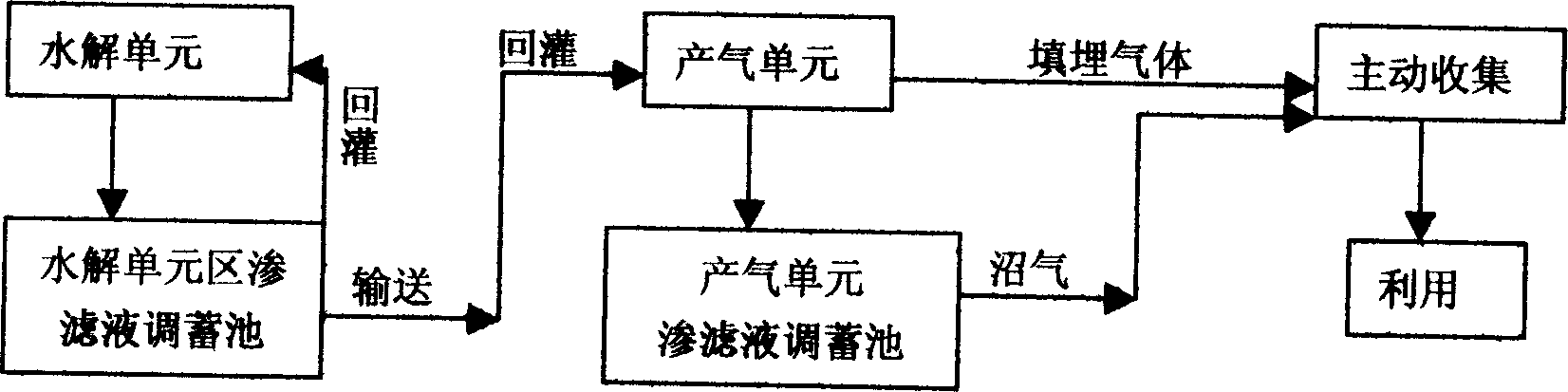

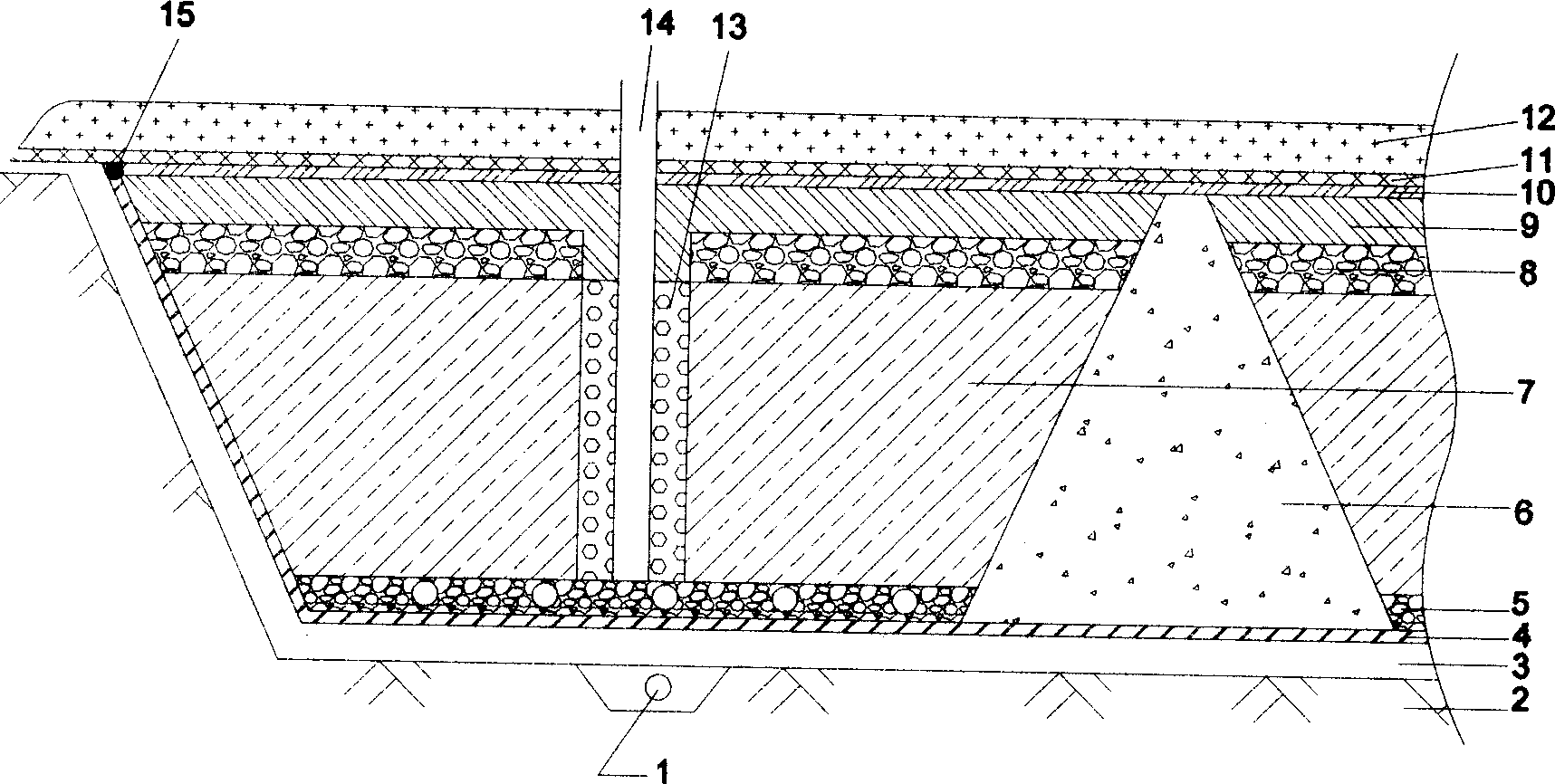

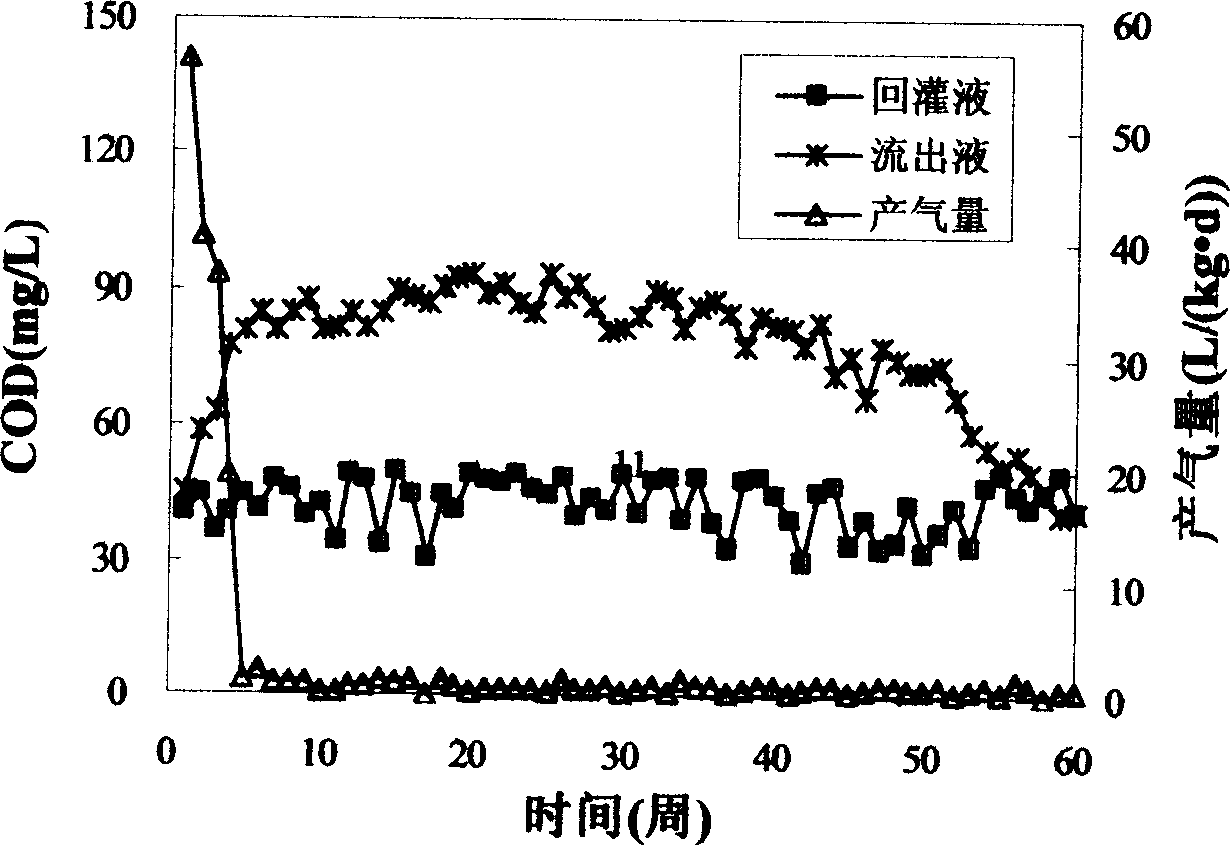

Dumping method for producing garbage dumping gas by using special garbage filling units

InactiveCN1903458AHigh recovery rateActive collection rate increasedSolid waste disposalProduct gasProcess engineering

A life garbage burying method by using special burying unit to generate gas includes such steps as dividing a burying field into hydrolyzing and gas generating units, setting up the burying volume of a single gas generating unit and the number of gas generating units, building up gas generating units, burying job, methanating for speeding up gas generation, building up running hydrolyzing units, refilling the percolated liquid for hydrolyzing and acidifying the organic substance in garbage, delivering the percolated liquid back to gas generating unit, and sealing. Its advantages are low cost and high gas collecting rate (100%).

Owner:TONGJI UNIV

Technology for industrially culturing trichogramma with gelechiid ova

InactiveCN1397159AReduce the impact of changes in ambient temperature and humidityIncrease collection rateAnimal husbandryEngineeringTrichogramma

A technology for reproducing trichogramma with gelechiid ova in industrial mode incldues light-shielding vertical raising, automatical collection of mothes, removing dust and impurities and continuous reproduction.

Owner:DRY LAND FARMING INST OF HEBEI ACAD OF AGRI & FORESTRY SCI +1

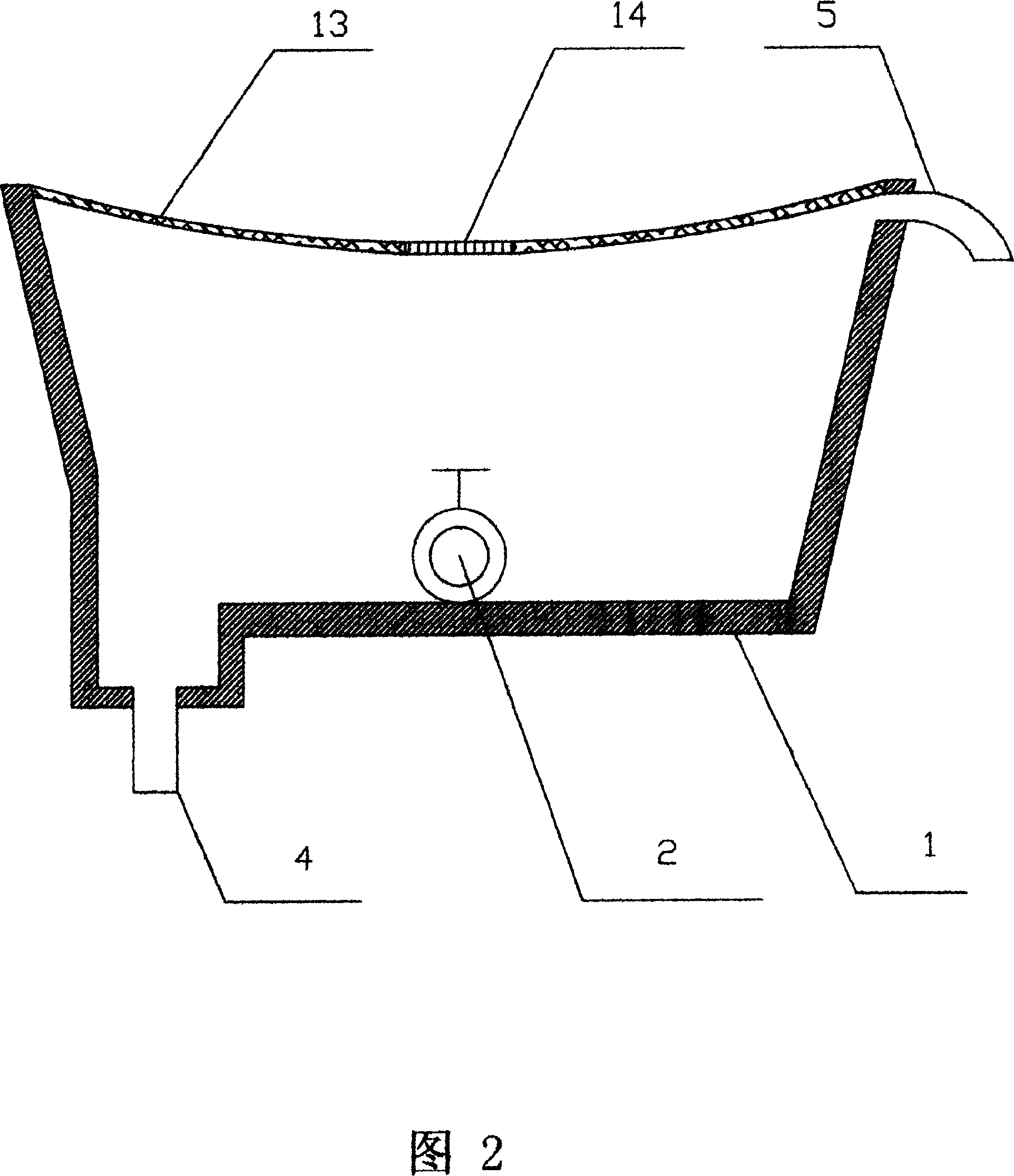

Method for collecting and utilizing rain water

InactiveCN1920192AConvenient facilitiesIncrease collection rateSewerage structuresGeneral water supply conservationSewageEngineering

The invention relates to a method for collecting and using rain, wherein it uses roof water groove (1) to collect the rain; arranges water pool (6) underground; separates the rain tube and sewage tube; uses rain well (7) and rain tube (8) to collect the ground rain to be utilized. Said water collected at the roof can be utilized directly, to save energy, while the invention has simple structure and high efficiency.

Owner:杨继新

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com