Patents

Literature

830results about How to "Increase short circuit current" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

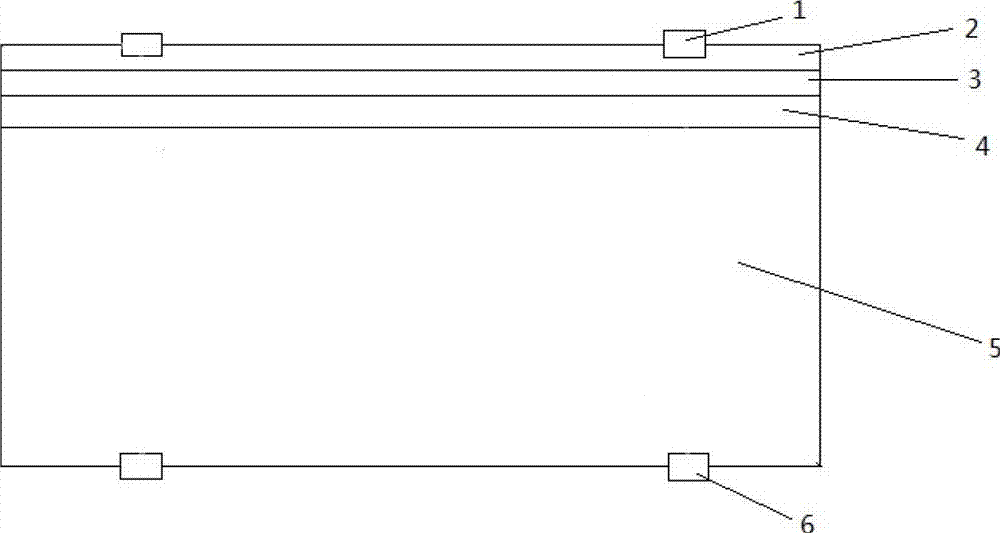

Laminated organic thin-film solar cell and preparation method thereof

InactiveCN102088060AIncrease short circuit currentGood electron transport propertiesSolid-state devicesSemiconductor/solid-state device manufacturingElectronic transmissionHigh energy

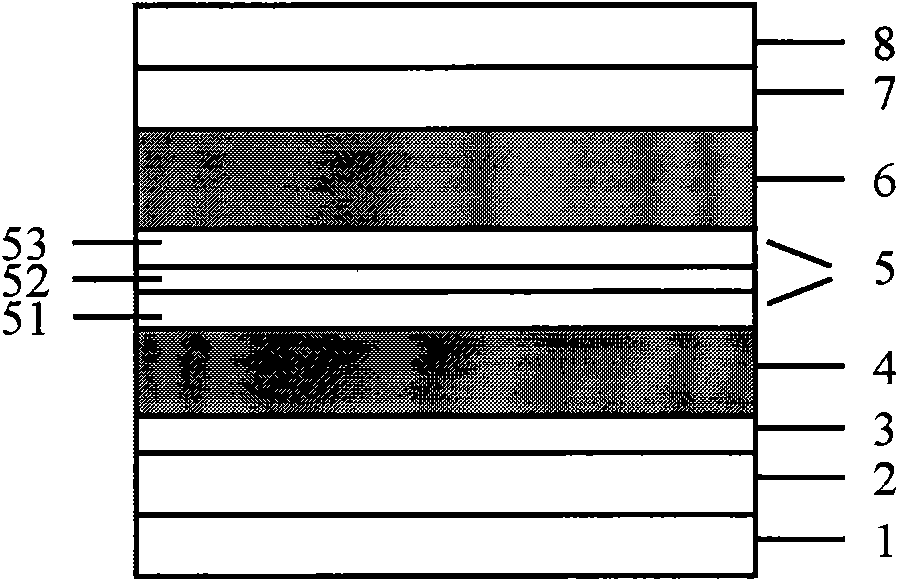

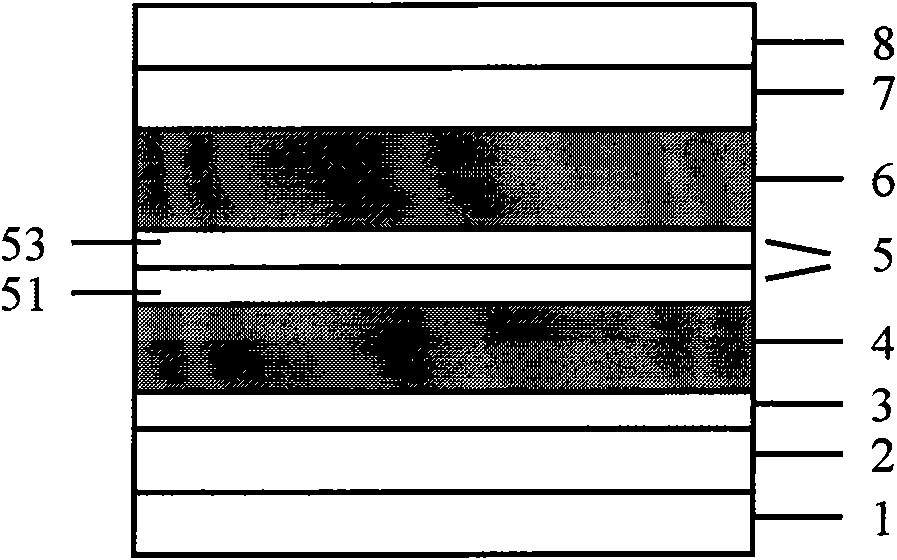

The invention discloses a laminated organic thin-film solar cell comprising a substrate, a transparent anode layer, an anode buffering layer, an organic photoelectric conversion layer 1, a connecting layer, an organic photoelectric conversion layer 2, a cathode buffering layer and a cathode layer, wherein the connecting layer can be formed by the following two methods: (1) an enhancement reflection film and a hole transporting layer are combined into the connecting layer; and (2) an enhancement reflection film, a metal thin layer and a hole transporting layer are combined into the connecting layer. The enhancement reflection film can improve the reflectivity of the connecting layer according to the specified range of wavelength. Simultaneously, the enhancement reflection film has better electronic transmission performance, guarantees electrons and holes to be effectively compounded on the connecting layer. The laminated organic thin-film solar cell prepared by the method is characterized by high energy conversion efficiency and good stability.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

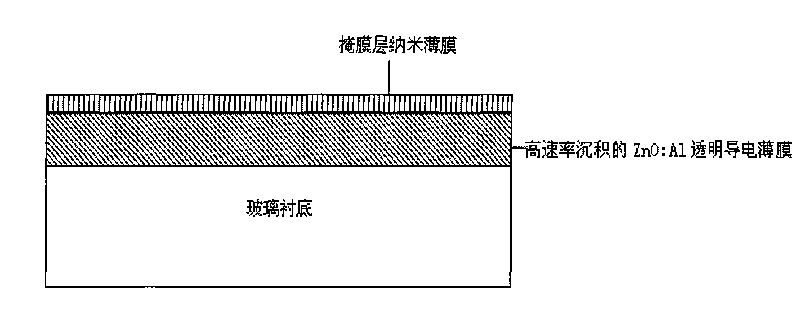

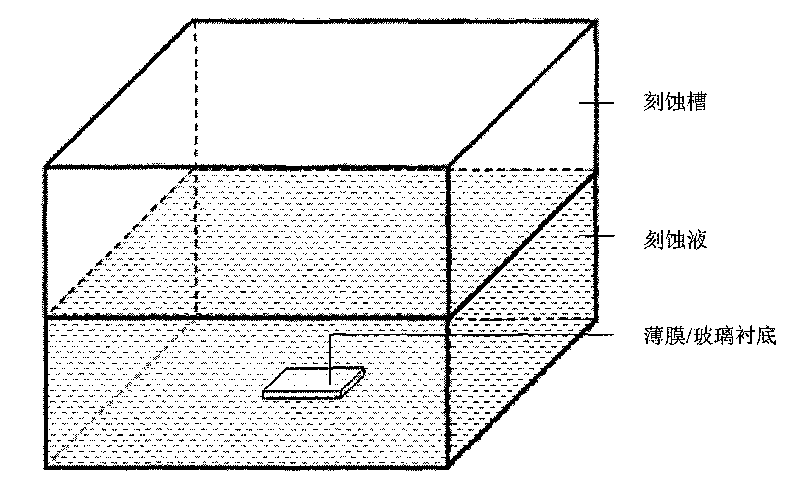

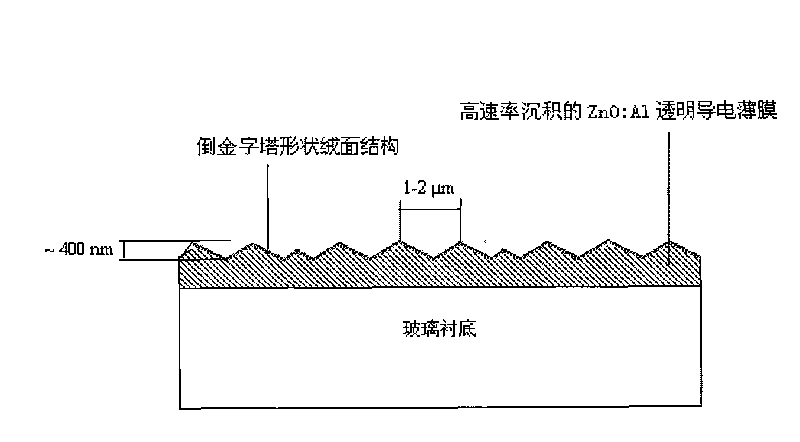

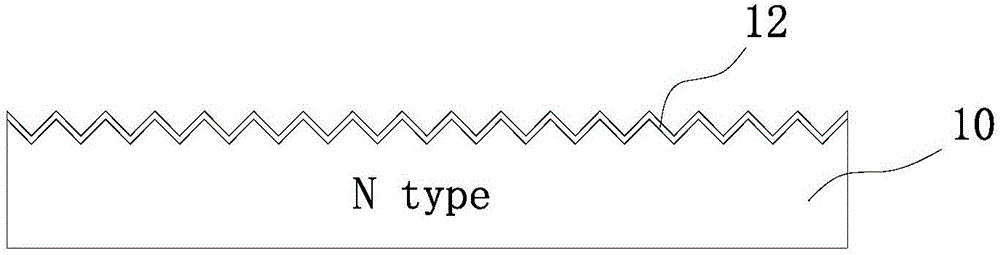

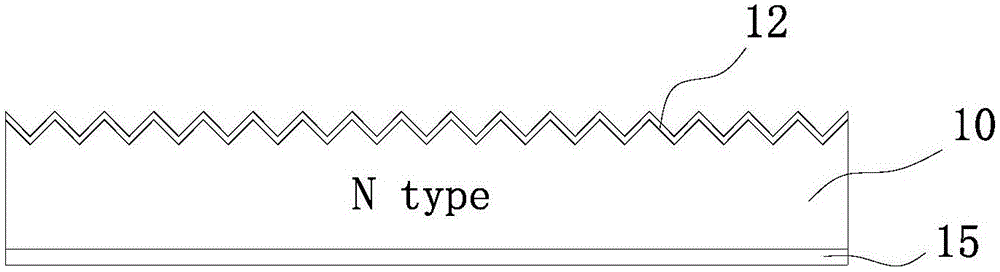

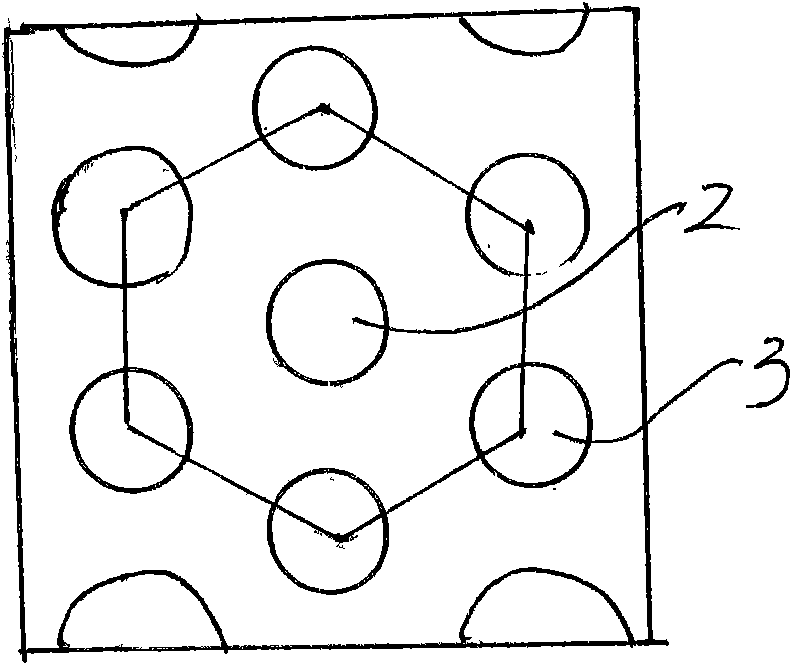

Method for preparing pile face doped zinc oxide transparent conductive film

InactiveCN101692357AImprove trapping effectImprove photoelectric conversion efficiencyConductive layers on insulating-supportsFinal product manufactureAluminum doped zinc oxideTrapping

The invention discloses a method for preparing a pile face doped zinc oxide transparent conductive film. The method comprises magnetic control sputtering growth of an aluminum doped zinc oxide(ZnO:Al) transparent conductive film, preparation of a masking layer nanometer film and formation of a pile face structure by the wet method chemical etching treatment of the deposited transparent conductive film at a later stage. The ZnO:Al transparent conductive film is prepared by the non-reaction magnetic control sputtering deposition, and the target materials used in the magnetic control sputtering are ZnO:Al203 ceramic target materials at doping concentrations; and the pyramid-inversed pile face ZnO:Al transparent conductive film is prepared by designing a masking layer for the ZnO:Al transparent conductive film and adopting the wet method chemical etching. The method has the advantages that: the process is simplified; the cost is reduced; and the conductive film prepared by the method has good light trapping effect and can be widely used in various highly efficient photoelectric devices, flat panel displayers and film solar cells to improve efficiency of the devices, in particular in the preparation of the silicon film solar cells to improve the photoelectric conversion efficiency of the solar cells.

Owner:EAST CHINA NORMAL UNIV

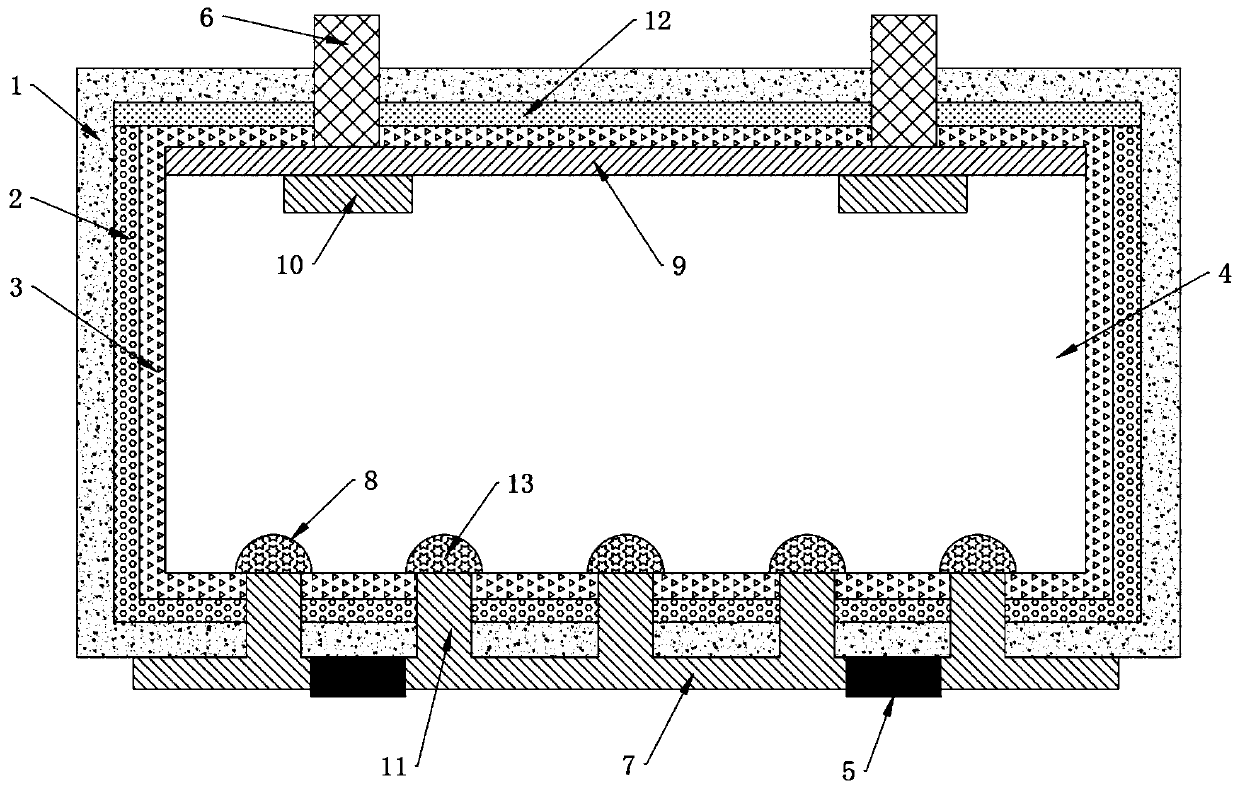

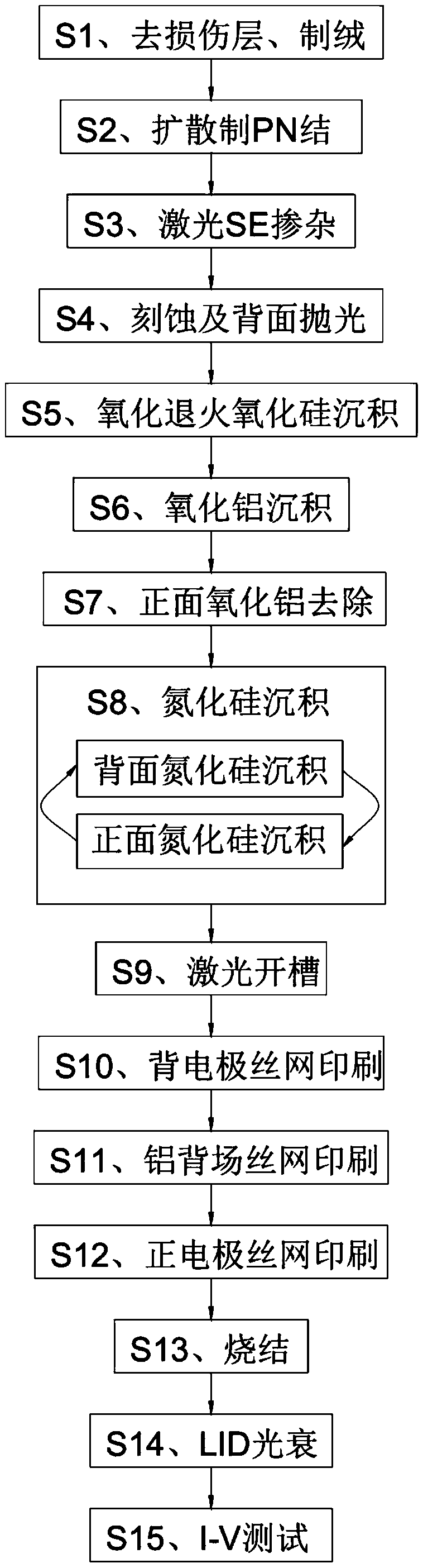

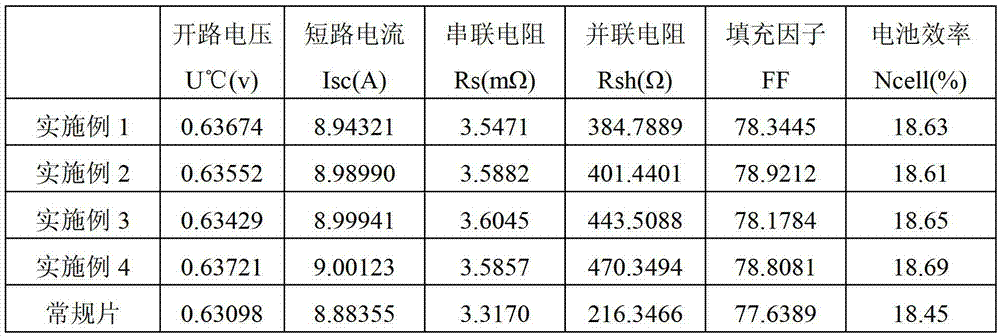

Solar cell with composite dielectric passivation layer structure and preparation process thereof

PendingCN110459615AIncrease short circuit currentIncrease the open circuit voltageFinal product manufacturePhotovoltaic energy generationDielectricRefractive index

The invention discloses a solar cell with a composite dielectric passivation layer structure and a preparation process thereof. A silicon oxide film, an alumina film and a silicon nitride or silicon oxynitride film are deposited in turn on the front, back and sides of a p-type silicon substrate to form a composite dielectric film on the whole surface, and windows are opened locally to lead electrodes out. Through aluminum oxide, silicon dioxide, silicon oxynitride, silicon nitride with different refractive indexes and a back surface passivation layer with a laminated structure of the materials, the back surface recombination rate is greatly reduced, the back reflectivity is improved, the CTM of a module is reduced, and the light attenuation and heat-assisted light attenuation and the anti-PID performance of the cell are improved. The structure can be made on a boron / gallium-doped p-type monocrystalline silicon, p-type polycrystalline silicon or p-type monocrystalline-silicon-like substrate, and a passivation method based on the composite dielectric film passivation structure can be used to manufacture PERC cells, double-sided PERC+ cells and imbricate PERC cells. Based on the preparation process steps and sequence, the corresponding preparation mode and the process parameter range of the laminated structure, the making of the cell can be well completed.

Owner:TONGWEI SOLAR ENERGY CHENGDU CO LID +2

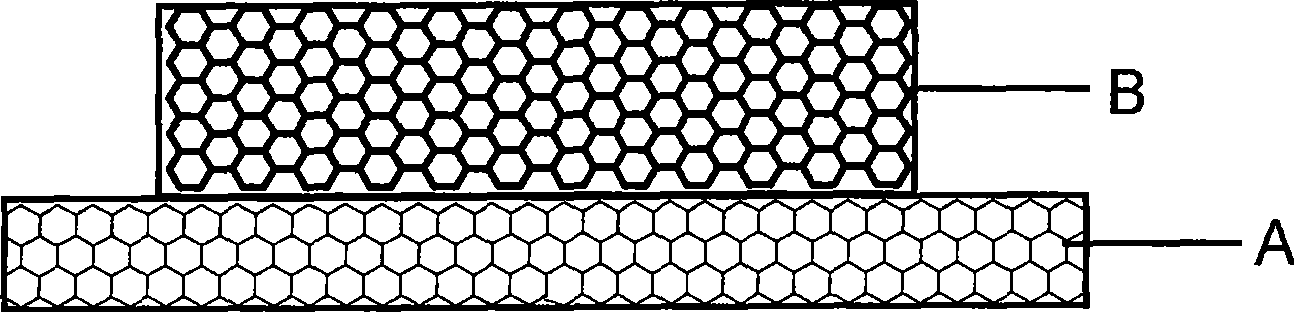

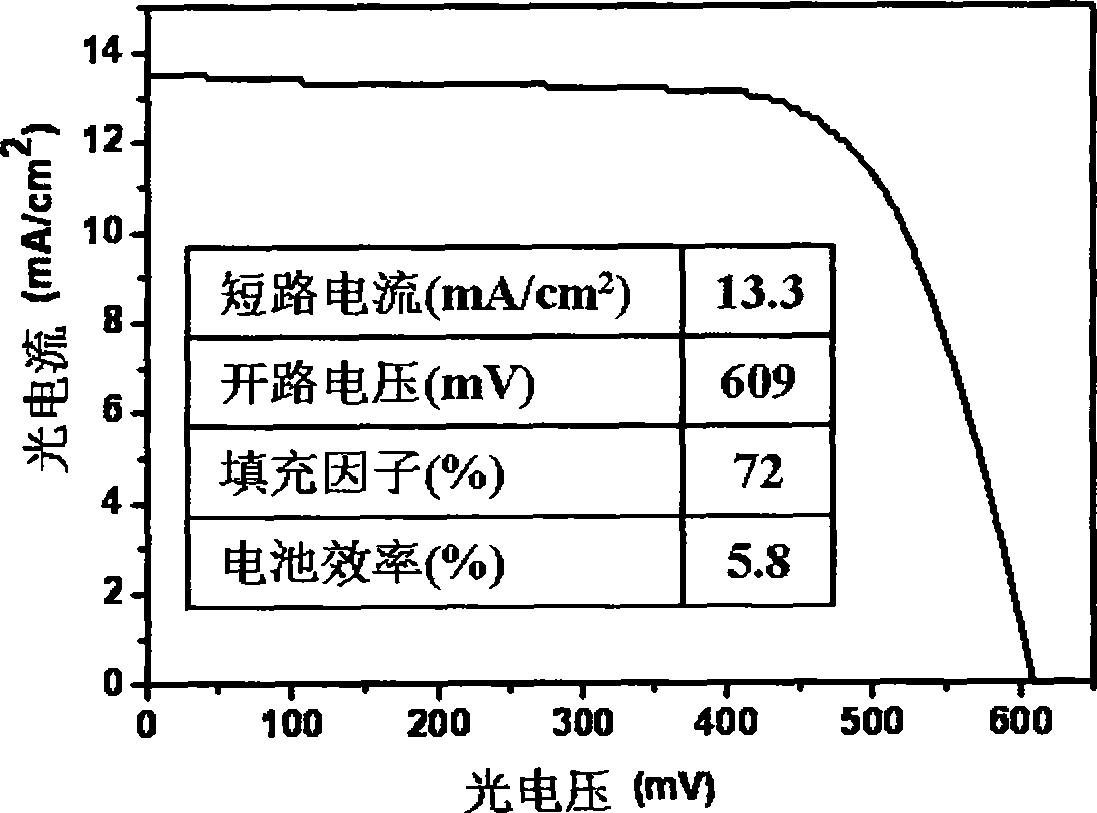

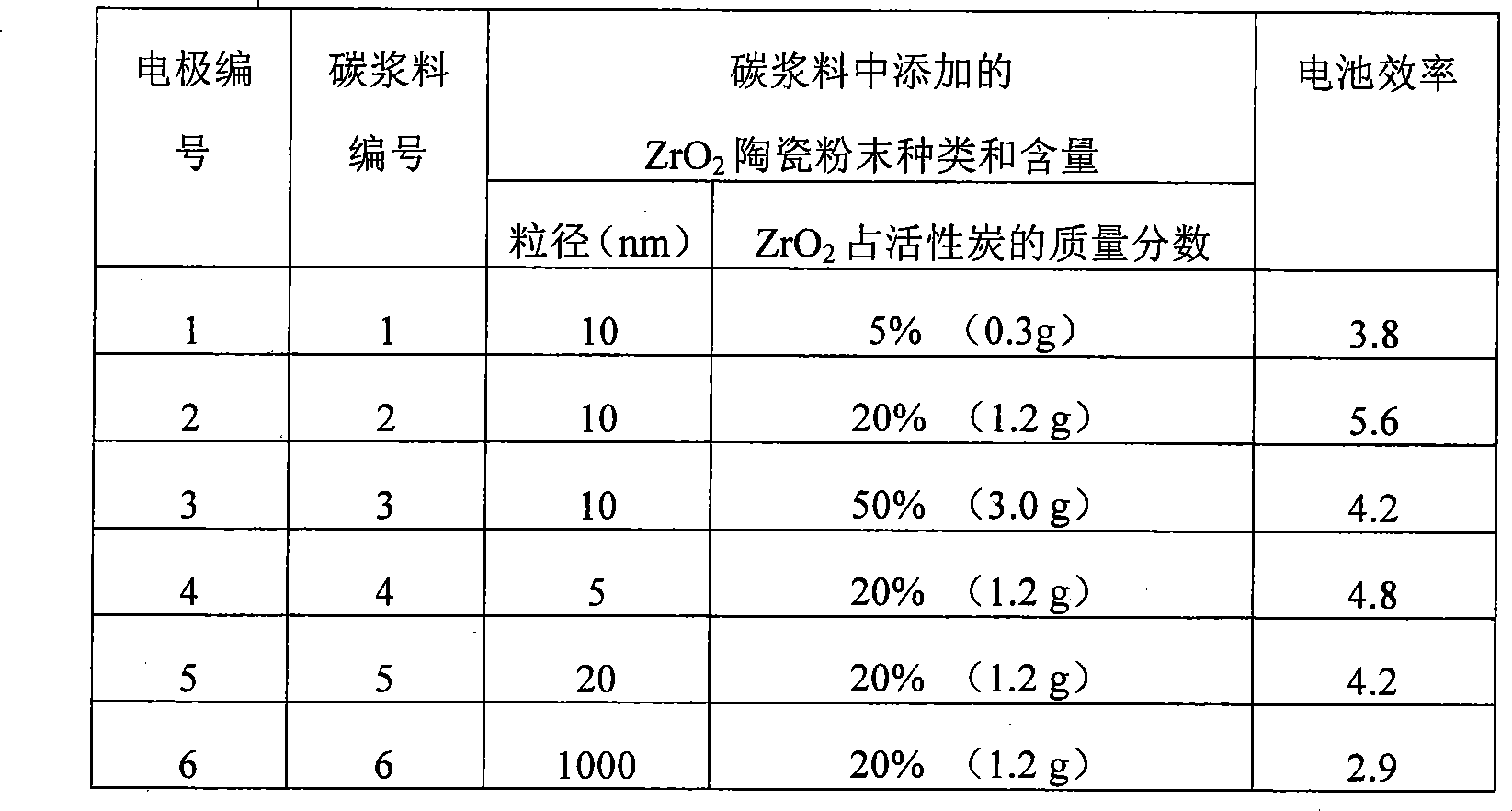

Full carbon counter electrode dye-sensitized solar cell and preparing method

ActiveCN101388294AGood mechanical properties such as friction resistanceImprove mechanical propertiesLight-sensitive devicesElectrode manufacturing processesElectrical batteryFilm coating

The invention relates to an all carbon counter electrode for a dye-sensitized solar cell and a process for preparation, wherein the all carbon counter electrode is formed by a carbon substrate A and a carbon catalytic active layer B which is coated on the carbon substrate. The process for preparing the all carbon counter electrode comprises firstly dispersing carbon catalytic active material and making into carbon paste according to the process of preparing carbon paste disclosed by the patient closure number CN101188257A, then transferring to the clean carbon substrate A through the methods of screen painting, spread coating, rotary film coating, film dropping or Czochralski method, and finally preparing the all carbon counter electrode through drying or kilning. The all carbon electrode of the invention can reduce series resistance and interface resistance, thereby increasing the short-circuit current (Jsc), filling factor (FF) and photoelectric transformation efficiency of the dye-sensitized solar cell. The substrate material adopted by the all carbon counter electrode of the invention has smaller resistance, can reduce using or avoid using metal flow concentration leads, and simplifies preparation technology.

Owner:深圳市华物光能技术有限公司

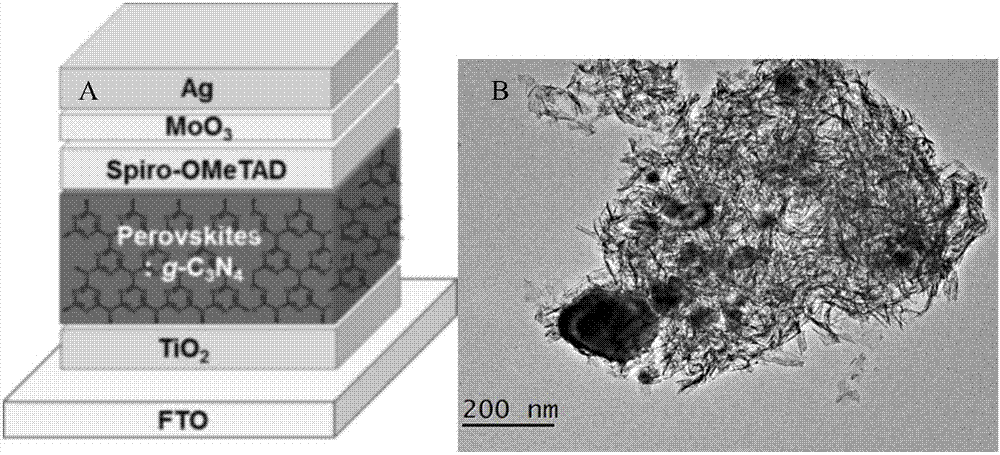

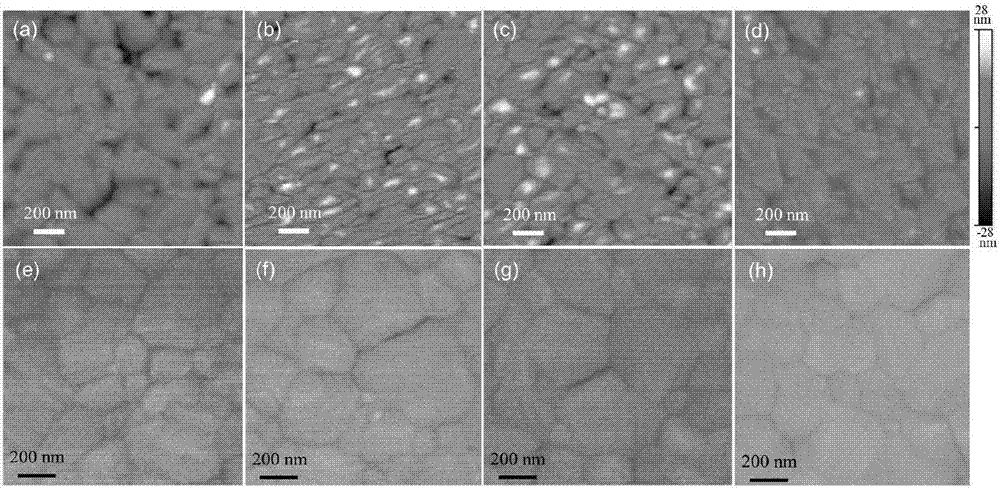

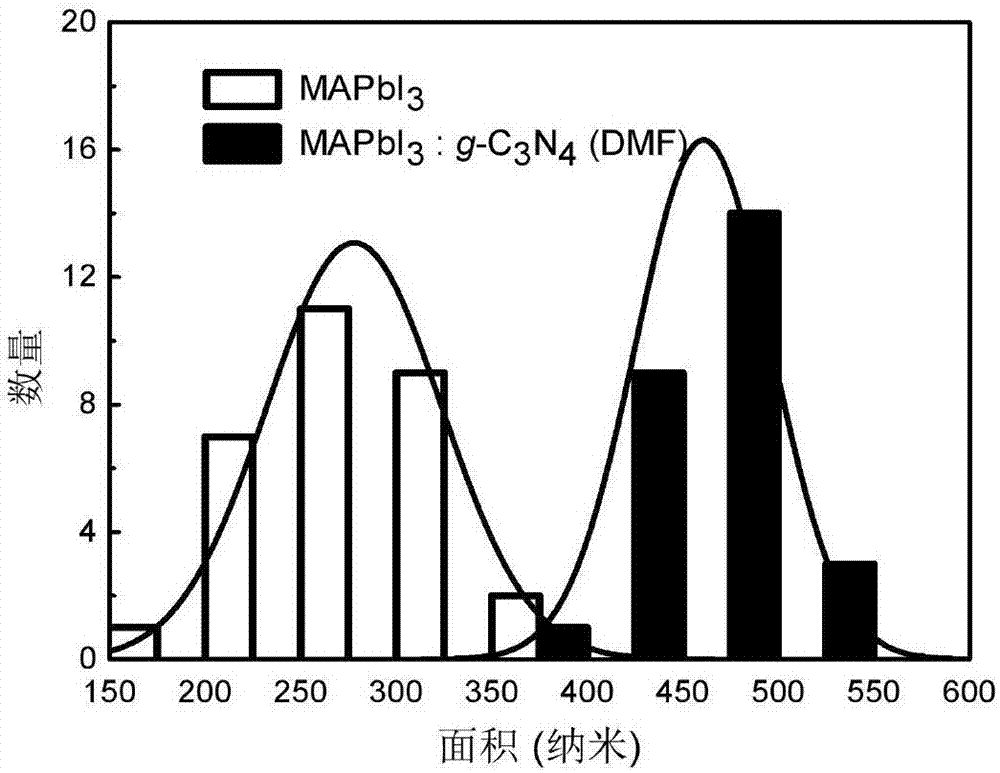

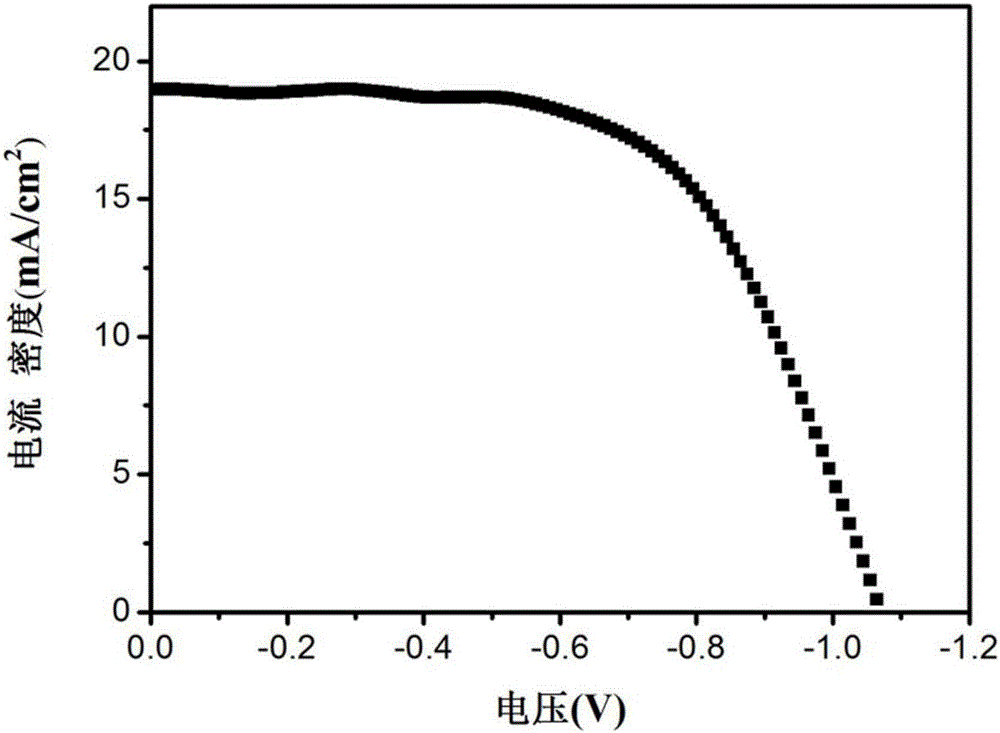

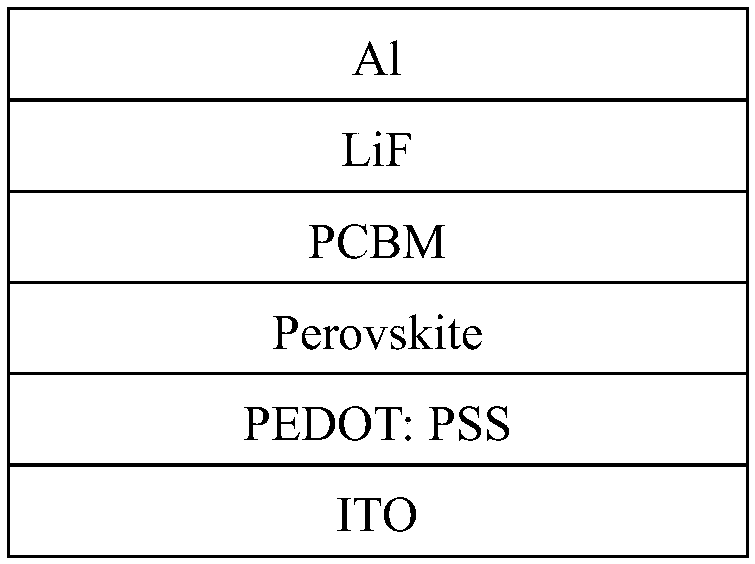

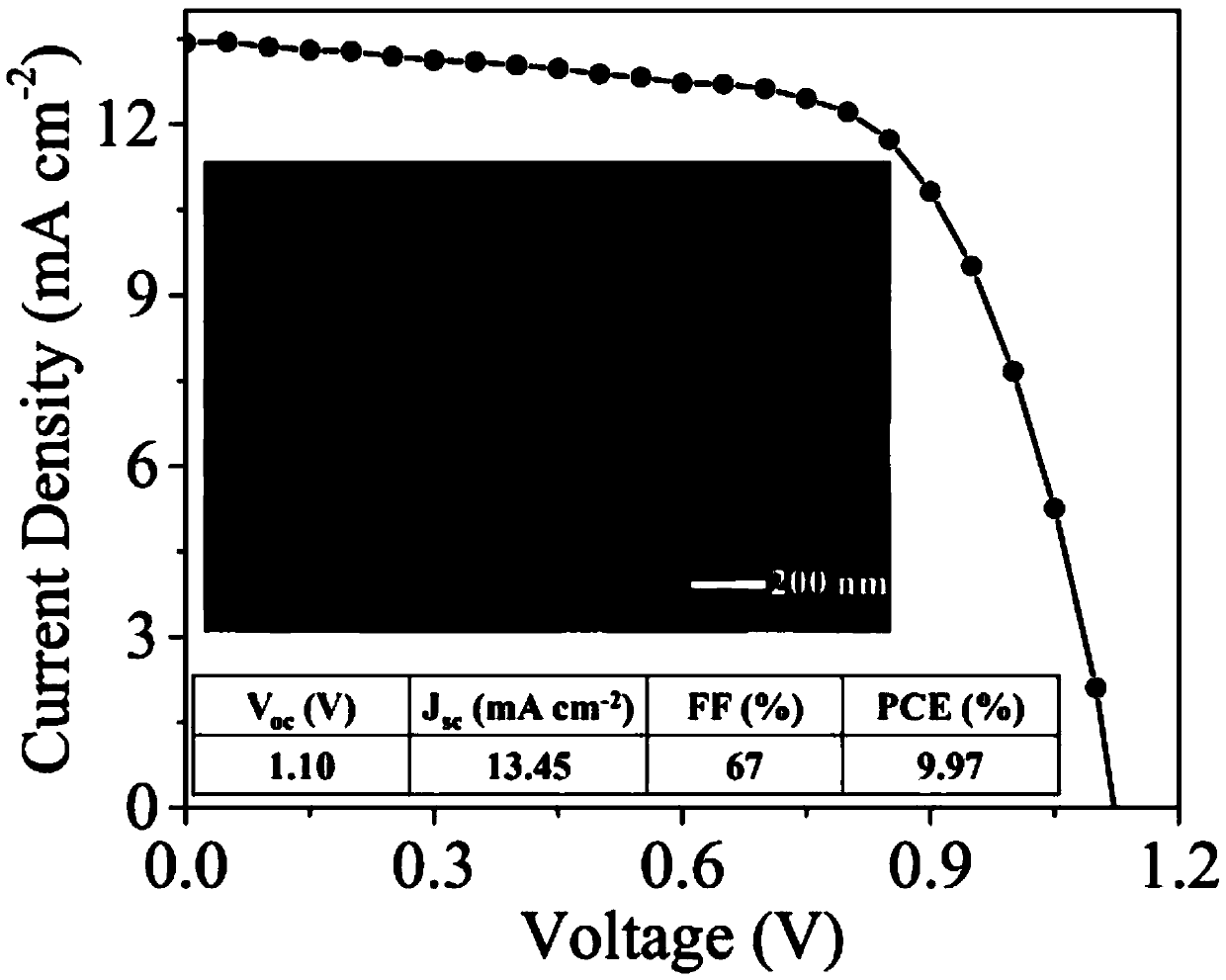

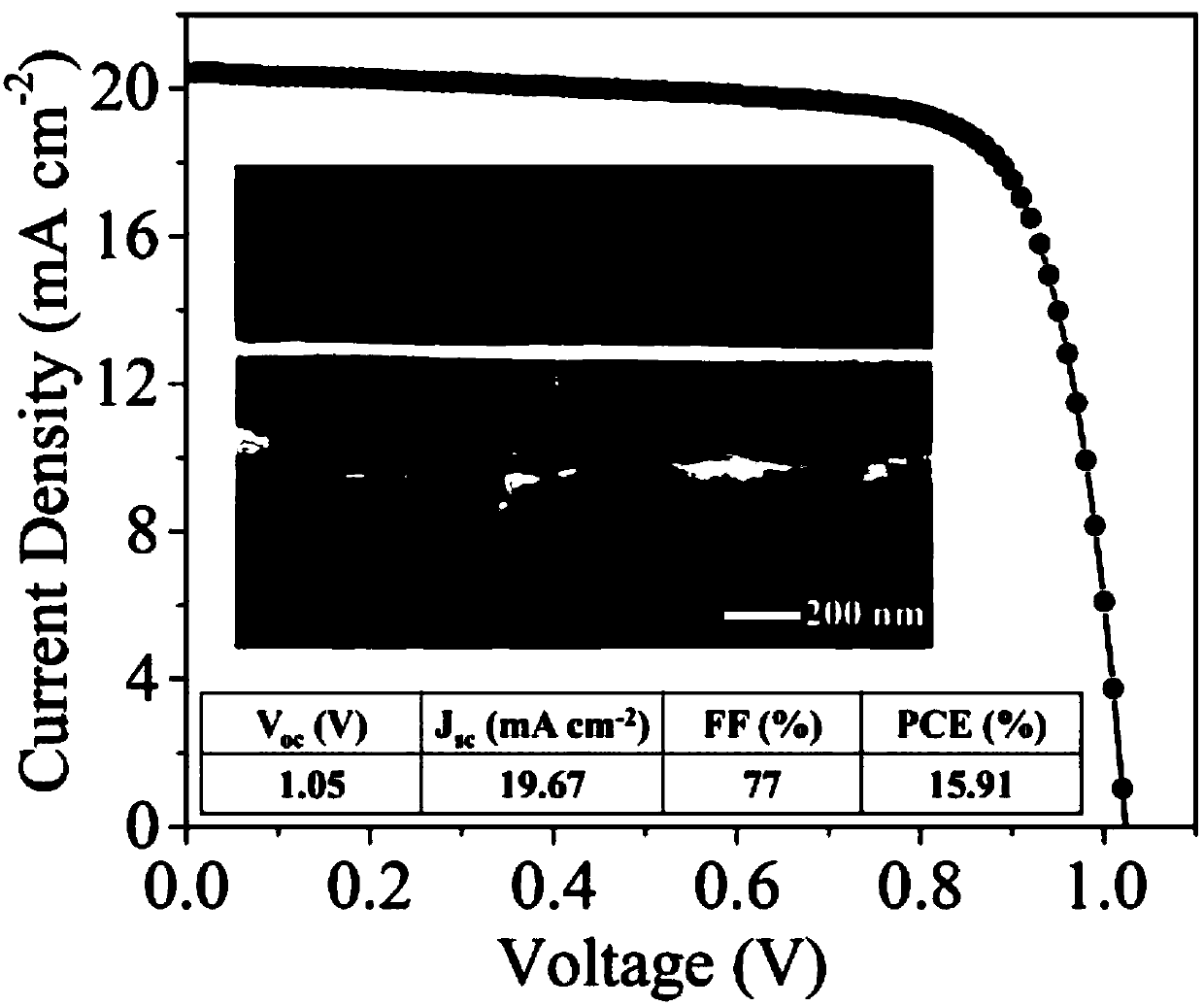

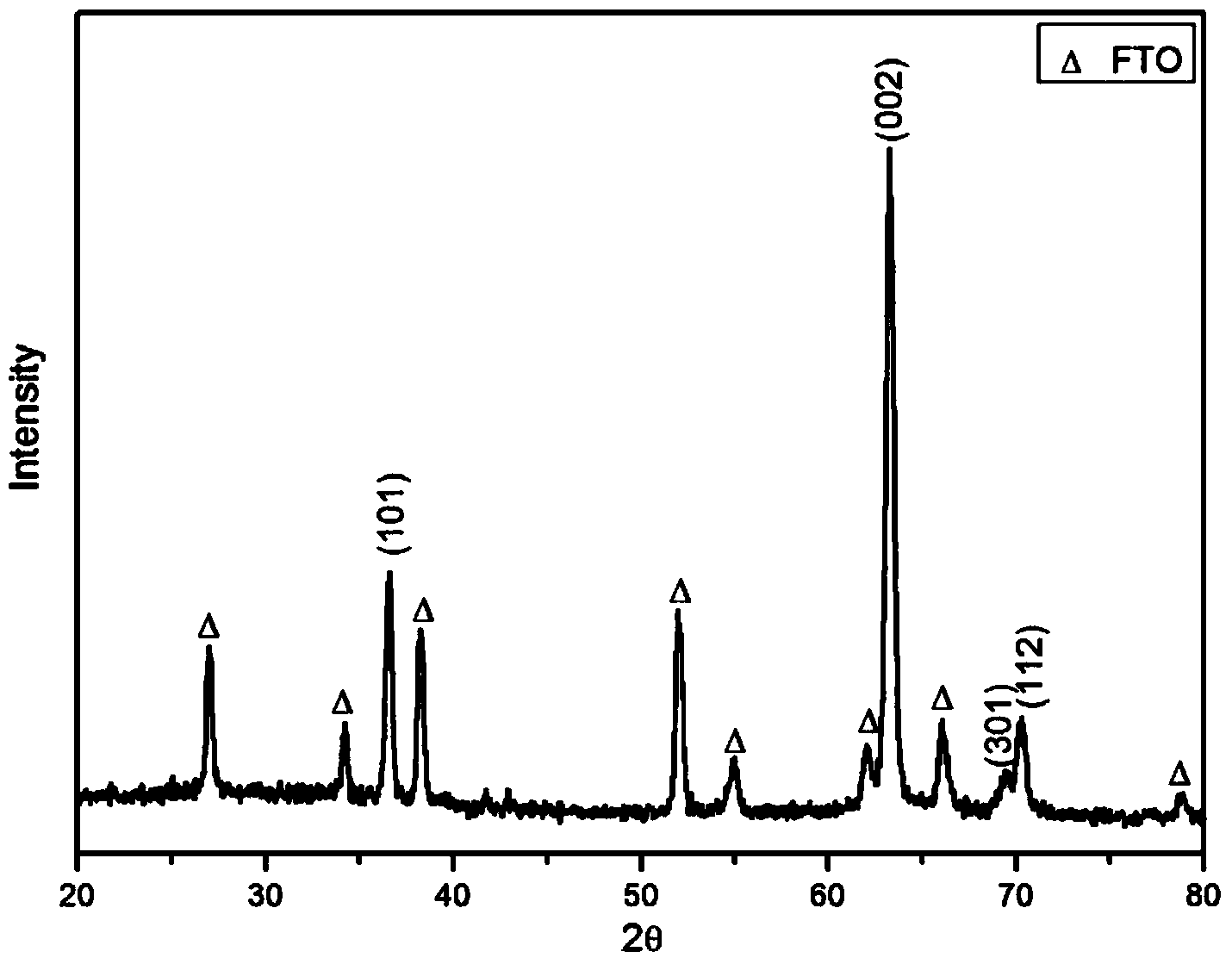

Method for preparing perovskite solar cell on basis of two-dimensional material graphene-phase carbon nitride

ActiveCN107887511AImprove crystallizationStable manufacturingSolid-state devicesSemiconductor/solid-state device manufacturingOptoelectronicsSolvent

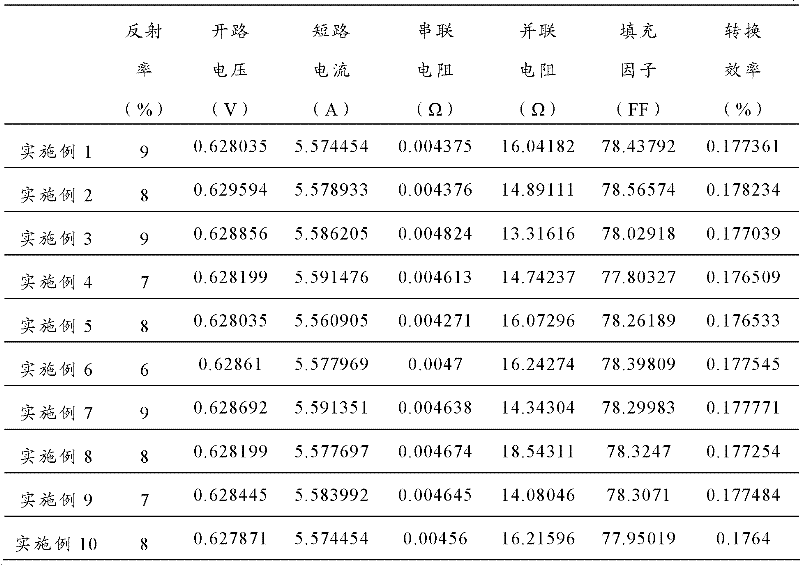

The invention provides a method for preparing a perovskite solar cell on the basis of a two-dimensional material graphene-phase carbon nitride. The graphene-phase carbon nitride is doped into a perovskite precursor solution to prepare the perovskite solar cell. The method has the following advantages that (1) the raw material required for synthesis of the material is low in cost, and the product is small in toxicity; (2) solvent volatilization during the annealing process is effectively slowed down, so that a perovskite thin film crystal is more uniform and compact; (3) the grain crystal sizeof a perovskite layer is increased, a crystal boundary easy to combine with charge is effectively reduced, and the filling factor of a device is improved; (4) a surface of the perovskite thin film ispassivated, and the hysteresis phenomenon of the device is effectively improved; and (5) the conductivity of the surface of the perovskite thin film is improved, the contact resistance of the interface is reduced, and the short-circuit current of the device is increased. The preparation process is simple and convenient and is low in preparation difficulty; by doping of the graphene-phase carbon nitride, the smoothness and the uniformity of the perovskite thin film can be effectively improved; and by a series of gradient doping, the device performance is remarkably changed.

Owner:SUZHOU UNIV

Spiro-OMeTAD/PbS composite hole transport layer based perovskite solar cell and preparation method therefor

ActiveCN106129252AImprove photoelectric conversion efficiencyImprove stabilitySolid-state devicesSemiconductor/solid-state device manufacturingSolar lightEvaporation

The invention discloses a Spiro-OMeTAD / PbS composite hole transport layer based perovskite solar cell and a preparation method therefor. The perovskite solar cell comprises a transparent conductive substrate, an oxide electron transport layer, a perovskite solar light absorption layer, the Spiro-OMeTAD / PbS composite hole transport layer and a metal electrode. The perovskite thin film solar cell adopts a simple process; a lead sulfide thin film can be prepared by a large-area evaporation method; and the lead sulfide thin film can be inserted between the Spiro-OMeTAD and the metal electrode layer to be used as a buffer layer. The Spiro-OMeTAD / PbS composite hole transport layer based perovskite solar cell achieves a high photoelectric conversion efficiency which is as high as 15.11%; the lead sulfide, which is used as the buffer layer between the hole transport layer and the metal electrode, has higher hole mobility, and higher humidity stability and light and heat stability, so that the recombination of electron-hole pairs can be reduced; meanwhile, the stability of the cell can be improved; compared with other buffer layer materials, the lead sulfide can protect a device and improve the performance of the device as well; and therefore, a positive promotion effect is realized on the industrial development of the solar cell.

Owner:WUHAN UNIV

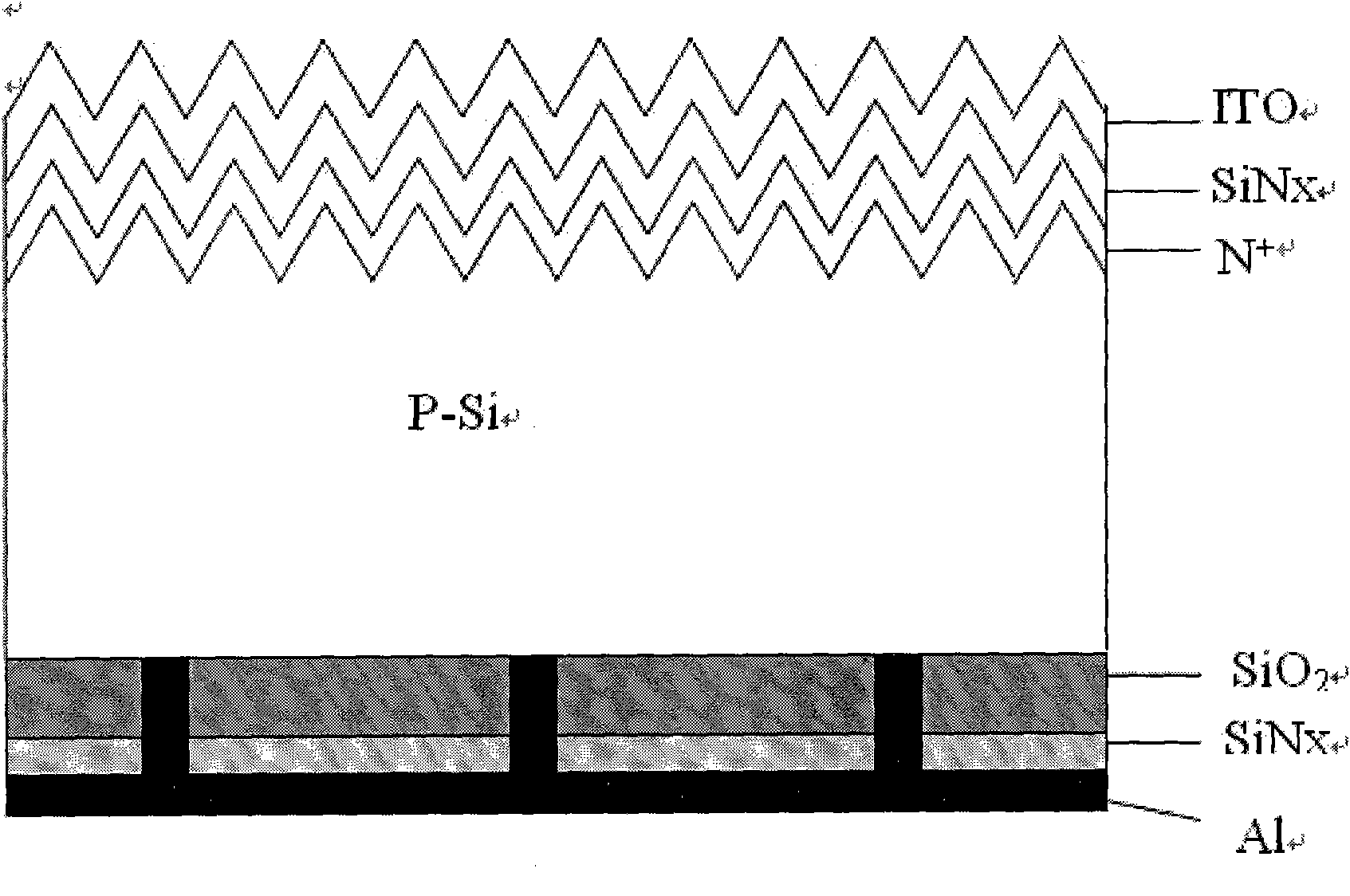

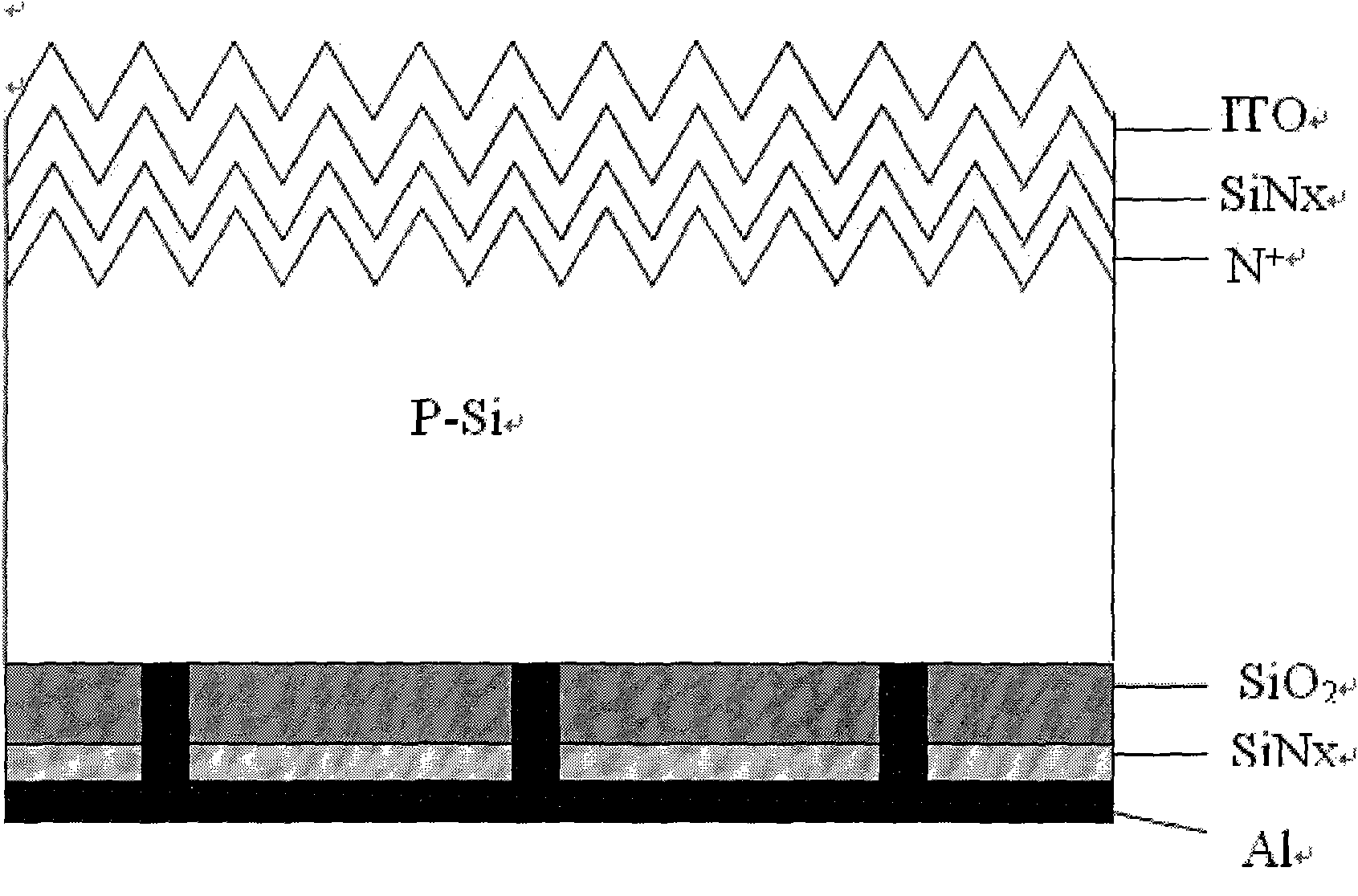

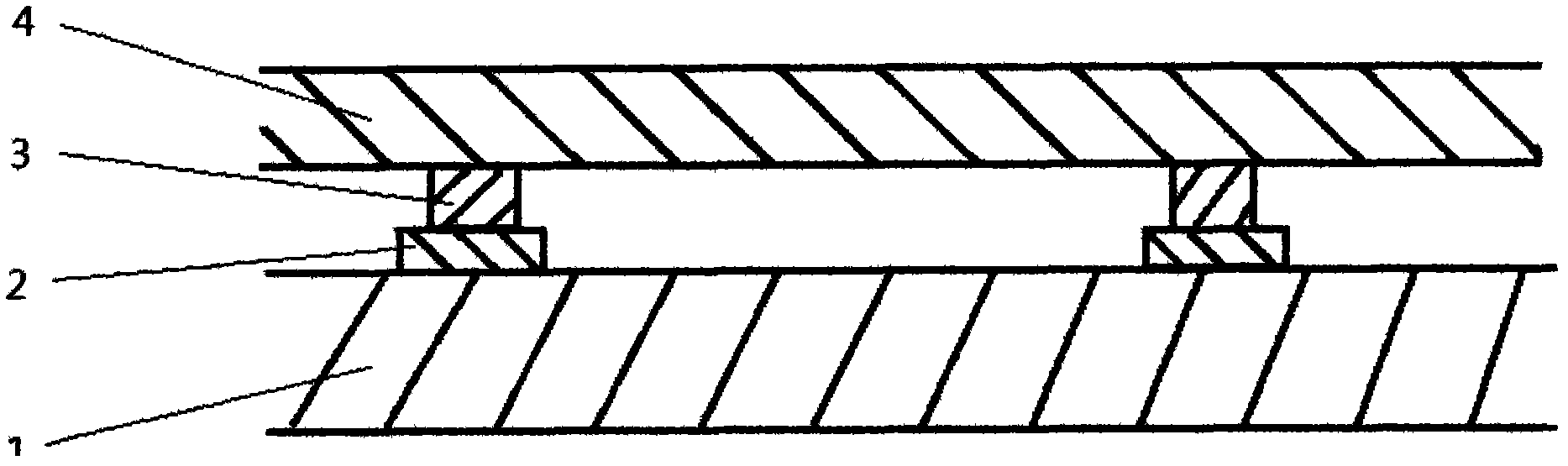

Preparation method of solar cell with buried charge layer

ActiveCN101882650AIncrease short circuit currentAvoid churnFinal product manufactureSemiconductor devicesCharge layerElectrode Contact

The invention relates to a monocrystalline silicon solar cell and a preparation method thereof, in particular to a monocrystalline silicon solar cell with a buried charge layer introduced into a passivating dielectric layer, and belongs to the technical field of the preparation of solar cell devices. The monocrystalline silicon solar cell is developed based on the preparation scheme of the general monocrystalline silicon solar cell and adopts a structure of partial back contact, and the preparation method is characterized by comprising the steps of: growing an SiO2 layer on the back of a solar cell by utilizing a thermal oxidation or atomic layer deposition technology, growing a layer of SiNx thin film by using PECVD (Plasma Enhanced Chemical Vapor Deposition), etching a back electrode contact area by using a laser grooving technology, then injecting electrons with a corona mode, and finally depositing an Al electrode with a vacuum evaporation mode. The invention can effectively improve the solar cell efficiency.

Owner:南通东湖国际商务服务有限公司

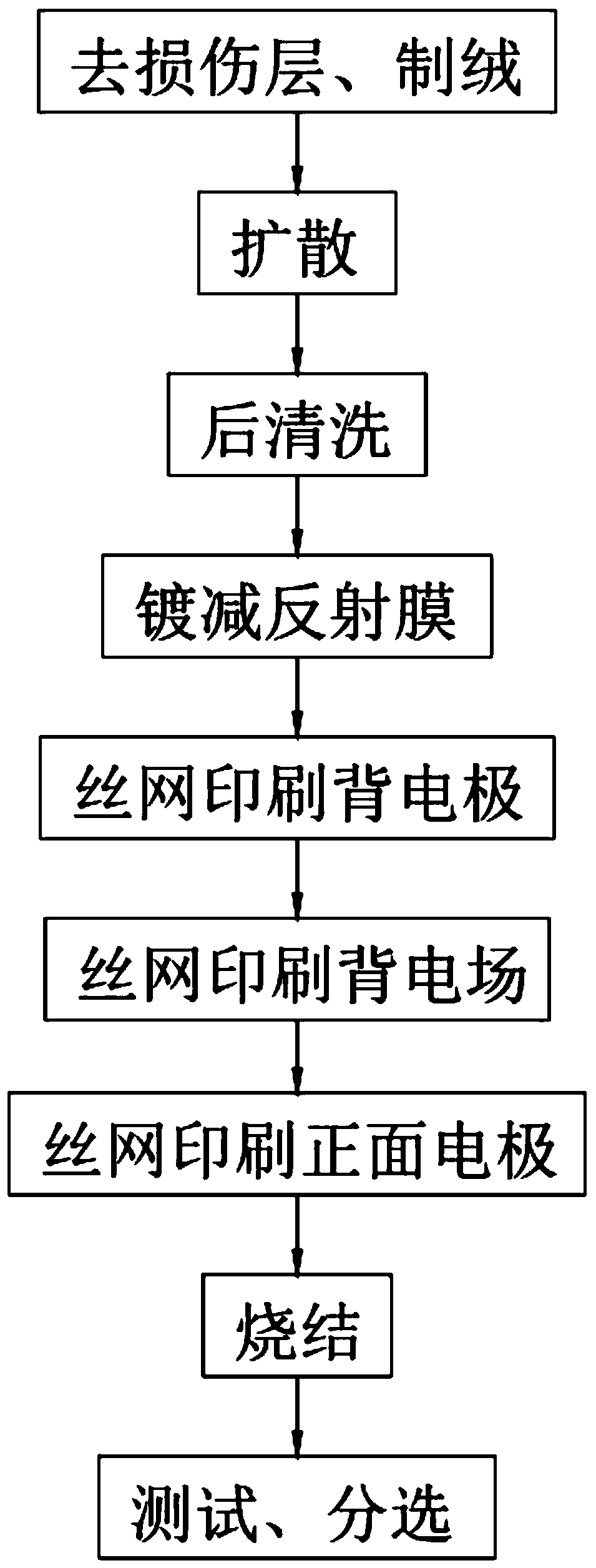

Technology for manufacturing selective emitter junction solar cell by printed phosphorous source one-step diffusion method

ActiveCN101937940ARealize the structureGood diffusion uniformity controlFinal product manufactureSemiconductor devicesDiffusion methodsScreen printing

The invention relates to technology for manufacturing a selective emitter junction solar cell by a printed phosphorous source one-step diffusion method. The method comprises the following steps of: cleaning and texturing a silicon wafer, performing screen printing of phosphorous-containing nano Si slurry, drying at the temperature of between 200 and 350 DEG C for about 20 minutes, and removing the solvent to obtain a phosphorous-containing oxidation layer with the thickness of 30 to 100nm; implementing BOE and RCA cleaning to remove 70 percent of surface phosphorous slurry before diffusion; putting the silicon wafer into a diffusion furnace, adding a POCL3 air source, heating to between 800 and 1,000 DEG C, forming re-diffusion at a grid line of the phosphorous-containing nano slurry on the silicon wafer to form a higher surface concentration-heavily doped region, and forming a shallow diffusion region in other areas. By adopting the screen printing of the phosphorous-containing nano slurry, the phosphorous-containing nano slurry is heated at high temperature for diffusion, forms the heavily doped region at a contact position with the grid line and forms a lightly doped region in other areas. The technology has the efficiency of over 18.5 percent on the premise of better controlling the diffusion uniformity.

Owner:TRINA SOLAR CO LTD

Method for manufacturing silicon solar cell

InactiveCN101783374ALow sheet resistanceLower ohmic contactFinal product manufactureSemiconductor devicesMetallic electrodeOhmic contact

The invention discloses a method for manufacturing a silicon solar cell. In the process of manufacturing a PN junction on a silicon wafer, a selective diffusion technology method is adopted, i,e. laser is utilized to heat a position, on which a positive electrode intends to be manufactured, on the surface of the silicon wafer; and under the action of heating, phosphorus in a phosphorus source uniformly adhered on the surface diffuses towards the inner of the silicon wafer, thus a heavy doping zone with smaller sheet resistance is formed at the position on which the positive electrode intends to be manufactured to effectively reduce the sheet resistance of the silicon solar cell, thereby not only being beneficial for increasing the open-circuit voltage of the silicon solar cell; the increase of the open-circuit voltage effectively improves the conversion efficiency of the silicon solar cell, reduces ohmic contact of a metal electrode and the silicon solar cell, thereby reducing the series resistance of the silicon solar cell, and being capable of meeting the purpose of industrialized production better.

Owner:SUN EARTH SOLAR POWER

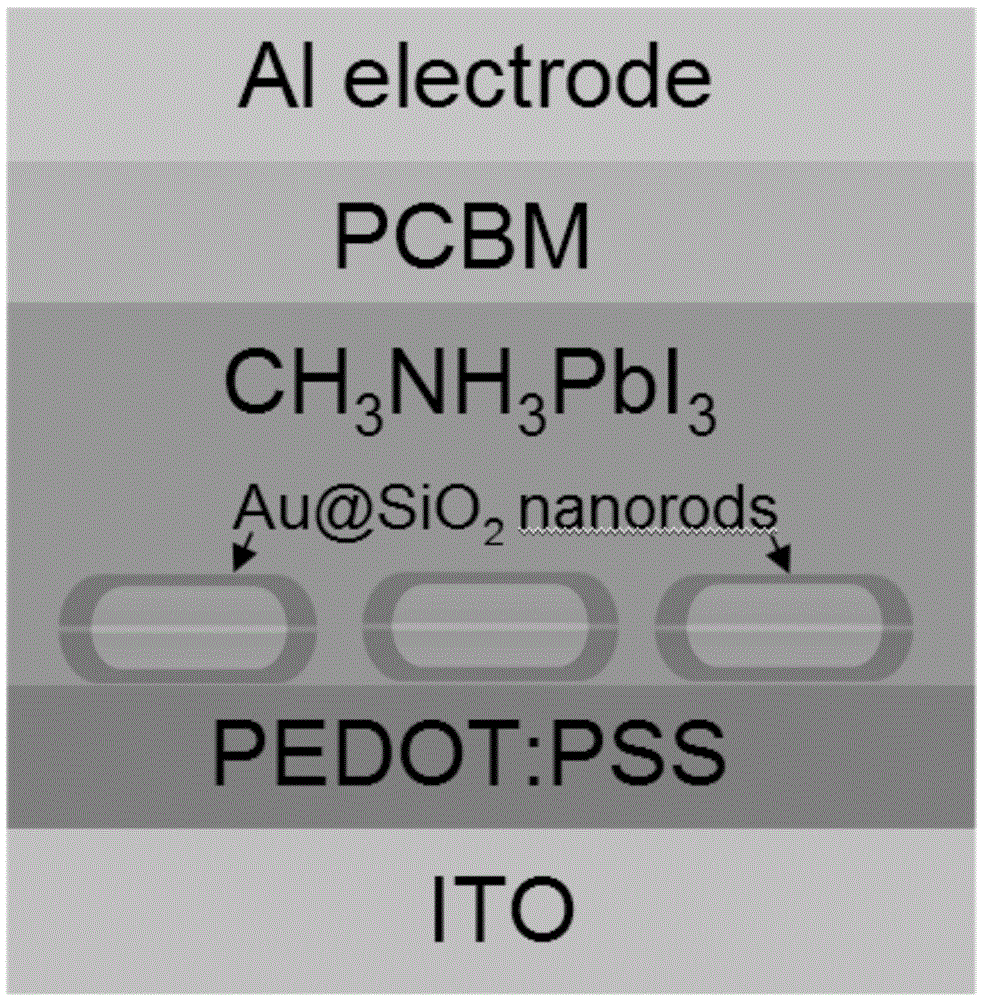

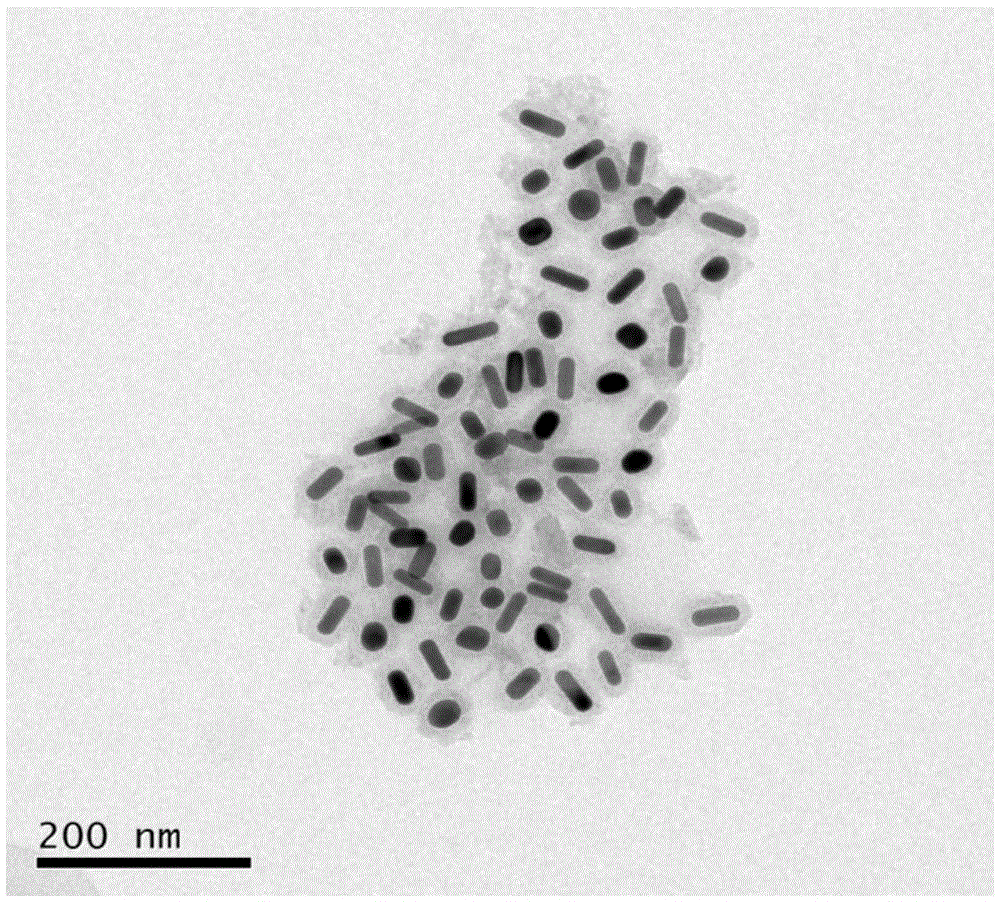

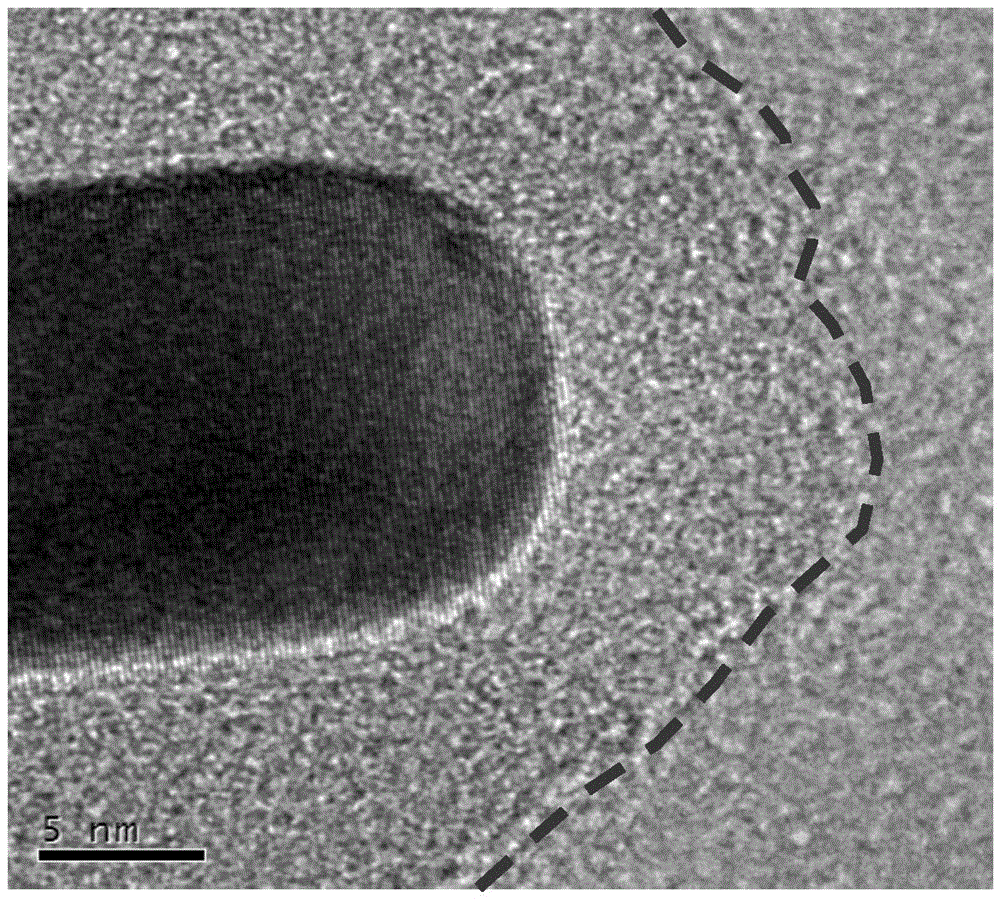

Perovskite solar cell based on metal nanoparticle interface modification and preparation method of perovskite solar cell

ActiveCN105469996APromote absorptionIncrease incidenceLight-sensitive devicesFinal product manufactureHeterojunctionSio2 nanoparticle

The invention discloses a perovskite solar cell based on metal nanoparticle interface modification and a preparation method of the perovskite solar cell. In the perovskite solar cell, a thin layer of silicon dioxide coated gold (Au@SiO2) nanoparticles is additionally arranged between a hole transmission layer and a perovskite active layer of a planar heterojunction perovskite solar cell, the length of the Au@SiO2 nanoparticles is ranging from 20 nanometers to 60 nanometers, and the width of the Au@SiO2 nanoparticles is ranging from 5 nanometers to 25 nanometers; surface plasma resonance can be generated by the Au@SiO2 nanoparticles, so that the optical path of light in the perovskite active layer is increased, the absorption of the perovskite active layer to the light is improved, and the photoelectric conversion efficiency of the perovskite solar cell can be obviously improved; and compared with the perovskite solar cell without the Au@SiO2 nanoparticles, the photoelectric conversion efficiency of the perovskite soalr cell with the Au@SiO2 nanoparticles can be improved by over 35%. The preparation method of the perovskite solar cell based on metal nanoparticle interface modification, disclosed by the invention, is implemented by a solution technique at a low temperature, is high in repeatability and low in cost, and has a wide application prospect.

Owner:CENT SOUTH UNIV

Silicon solar cell front face electrode lead-free silver paste and preparing method thereof

InactiveCN104157332AImprove compactnessImprove smoothnessNon-conductive material with dispersed conductive materialCable/conductor manufactureTetramethylammonium hydroxidePotassium

The invention discloses silicon solar cell front face electrode lead-free silver paste and a preparing method thereof. The silicon solar cell front face electrode lead-free silver paste is characterized in that inorganic glass powder is not contained in the silver paste, and the silver paste comprises, by mass, 75-85 percent of conductive silver powder, 1-5 percent of antireflective film corrosive, 10-20 percent of organic vehicle and 1-5 percent of additive; the conductive silver powder is formed by mixing micro silver powder and nano silver powder with the mass ratio of 10:1-2; the antireflective film corrosive comprises one or more of potassium fluotitanate, potassium fluoroaluminate, potassium fluosilicate and potassium fluoborate; the additive comprises one or more of ethanol amine, diethanol amine, triethanol amine, tetramethylammonium hydroxide, tetraethylammonium hydroxide and tetramethylammonium hydroxide. According to the silicon solar cell front face electrode lead-free silver paste and the preparing method thereof, lead-free silver paste printing and antireflective film removing are conducted in one step, sintering can be conducted at a low temperature, the compactness and the smoothness of a silver electrode film are improved, and the photoelectric conversion efficiency of a silicon cell piece is improved.

Owner:TIANJIN VOCATIONAL INST

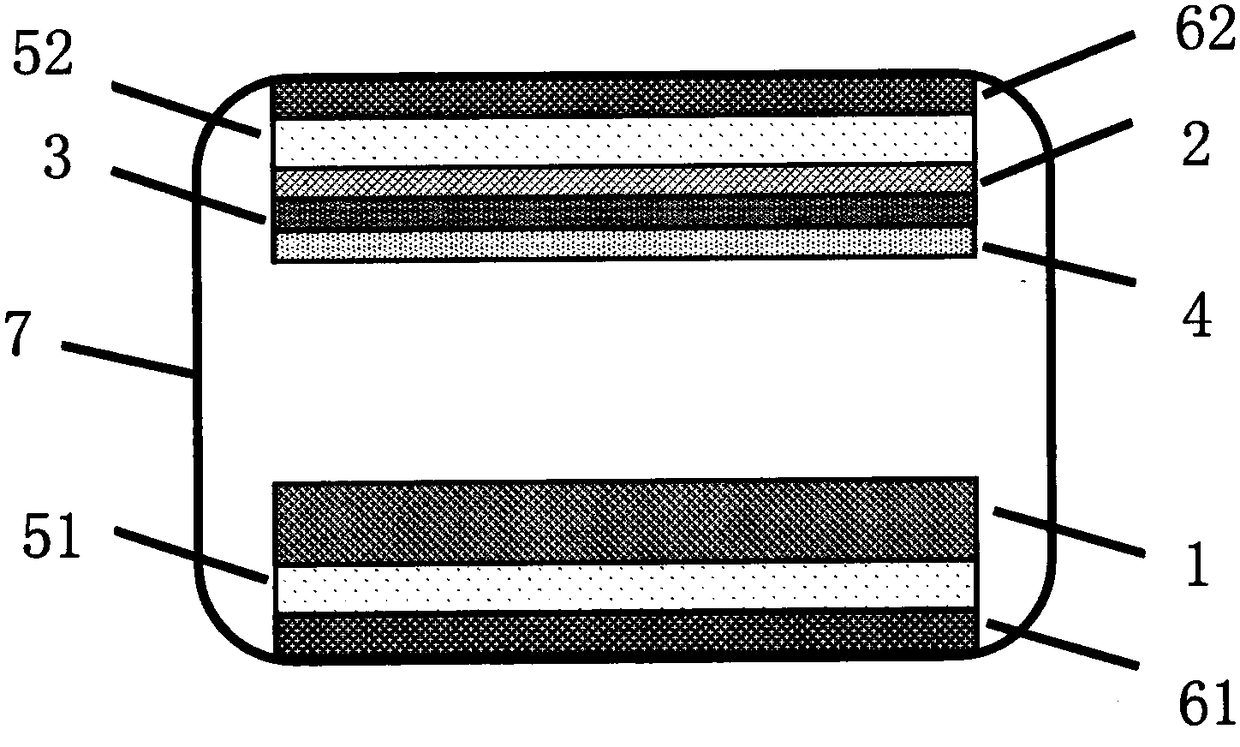

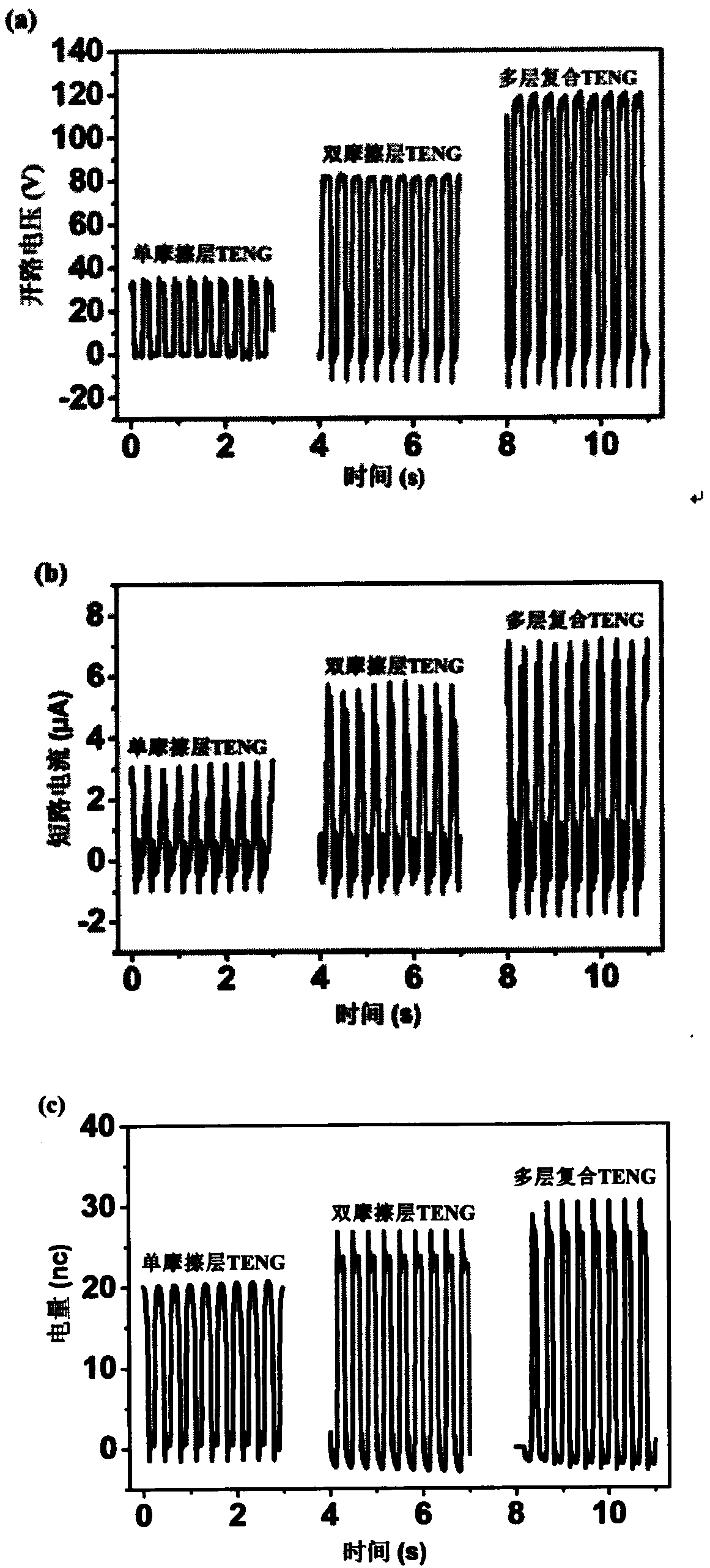

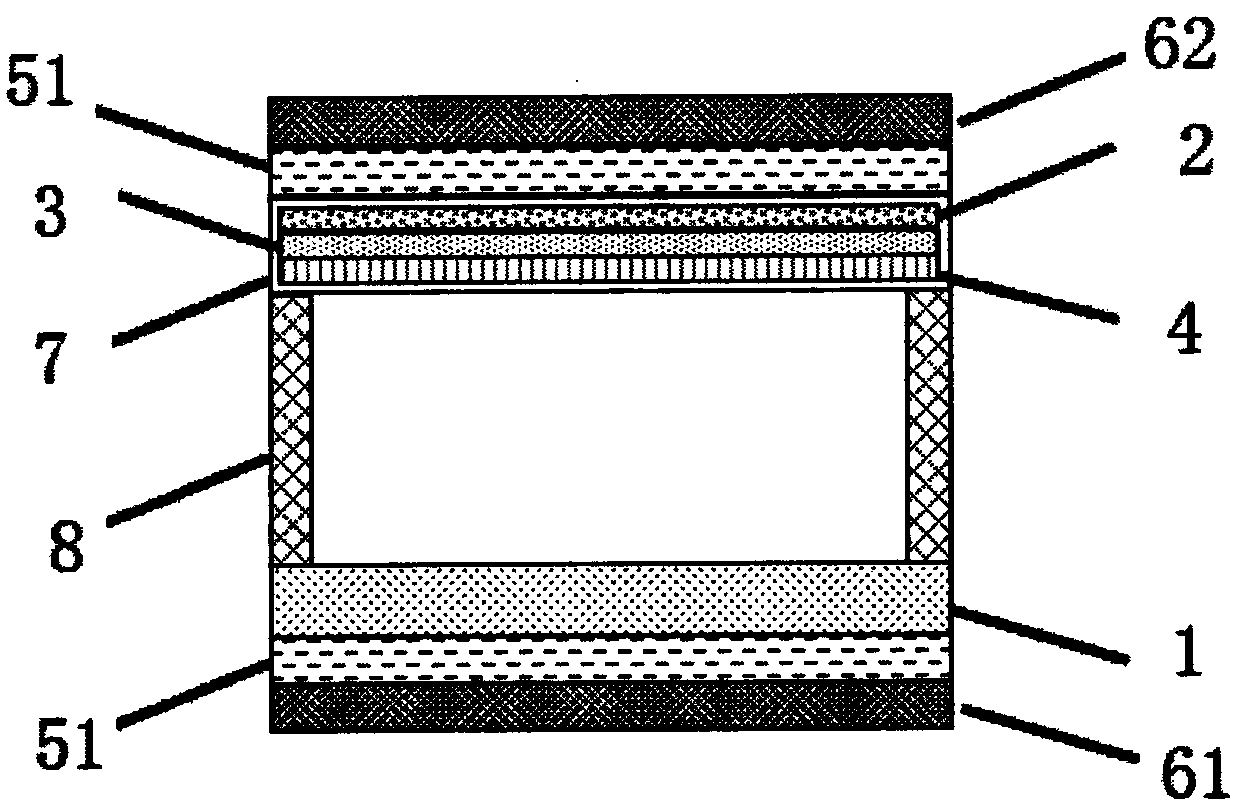

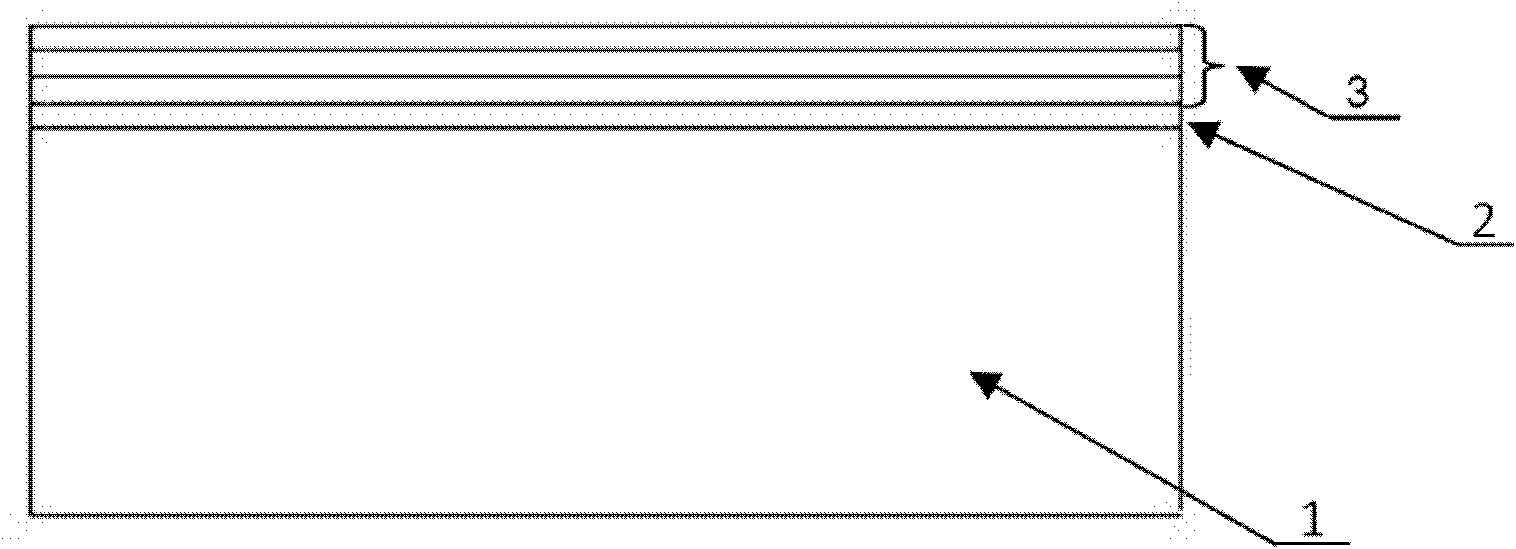

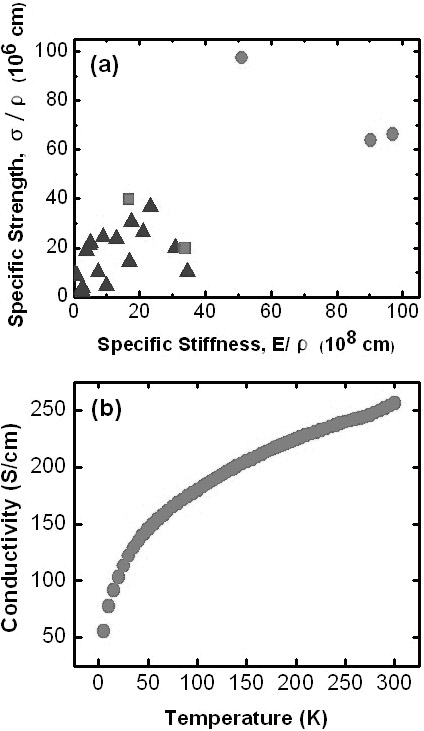

Fiber base multilayer structure friction nanometer power generator and preparation method thereof

InactiveCN108616225ALarge specific surface areaHigh porosityFriction generatorsFiberMechanical energy

The invention provides a fiber base multilayer structure friction nanometer power generator and a preparation method thereof. The fiber base multilayer structure friction nanometer power generator ischaracterized in that the power generator comprises an electropositive friction layer and a multilayer structure electronegative friction layer; the electropositive friction layer and the multilayer structure electronegative friction layer are static spinned nanofiber films; the multilayer structure electronegative friction layer comprises an electric storage layer, a conductive layer and a friction contact layer, wherein the electric storage layer, the conductive layer and the friction contact layer are successively arranged from bottom to top; and the electropositive friction layer and the electronegative friction layer can contact with each other or be separated from each other for generating electric charges. The prepared multilayer structure friction nanometer power generator has advantages of increasing shortcircuit current by 40-150%, boosting open-circuit voltage by 100-250%, and increasing electric quantity by 40-100%. The friction nanometer power generator according to the invention has advantages of high surface charge density, low volume mass, simple structure and short process flow. The fiber base multilayer structure friction nanometer power generator can efficientlycollect mechanical energy generation in human body movement and has wide application range in the field of microelectronics.

Owner:DONGHUA UNIV

A gradient doped silicon-based heterojunction solar cell and its preparation method

InactiveCN102280502AIncrease collection rateIncrease short circuit currentFinal product manufacturePhotovoltaic energy generationHeterojunctionSilicon heterojunction

The invention discloses a gradient doped silicon-based heterojunction solar cell and a preparation method thereof. A plurality of layers of amorphous silicon membranes of which the doped concentration is increased sequentially are deposited on the surface of crystalline silicon serving as a substrate, and a transparent conductive film with a certain thickness is deposited and an electrode is prepared to prepare the gradient doped silicon-based heterojunction solar cell, wherein the amorphous silicon membranes contact the crystalline silicon to achieve a good passivating effect and obtain highopen-circuit voltage; a plurality of gradient doped amorphous silicon layers can form a strong inner electric field to reduce the composite loss of photo-induced carriers, improve the collection rateof minority carriers and increase short-circuit current; and the doped concentration of the doped amorphous silicon layers contacting the electrode is high, the resistivity is low, and contact resistance between the doped amorphous silicon layers and the electrode can be reduced to improve filling factors of the solar cell. Therefore compared with the conventional silicon-based heterojunction solar cell, the gradient doped silicon-based heterojunction solar cell has high photoelectric conversion efficiency.

Owner:SHANGHAI NORMAL UNIVERSITY

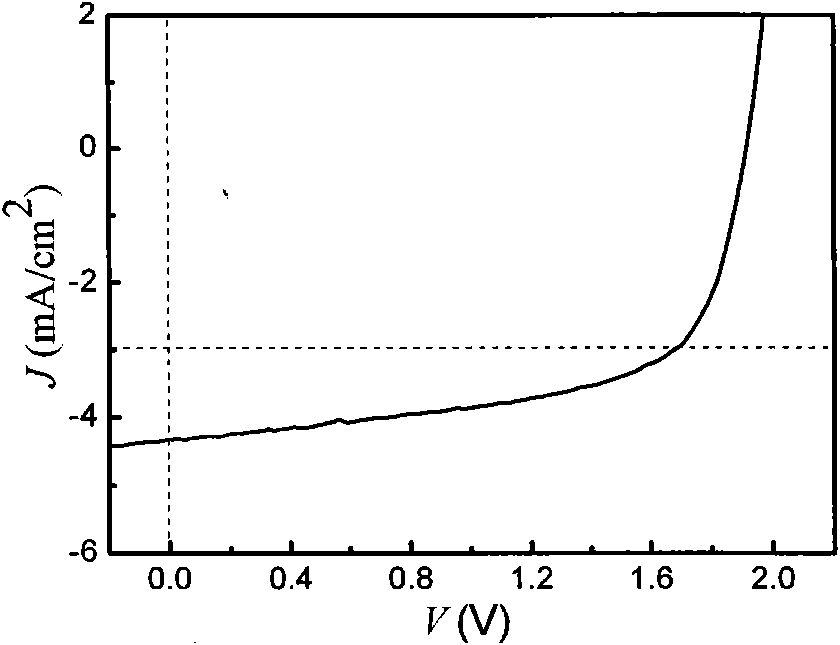

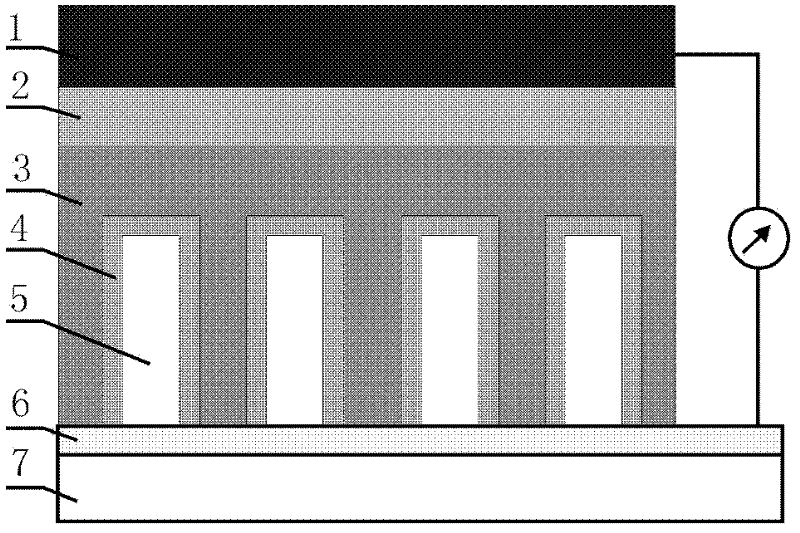

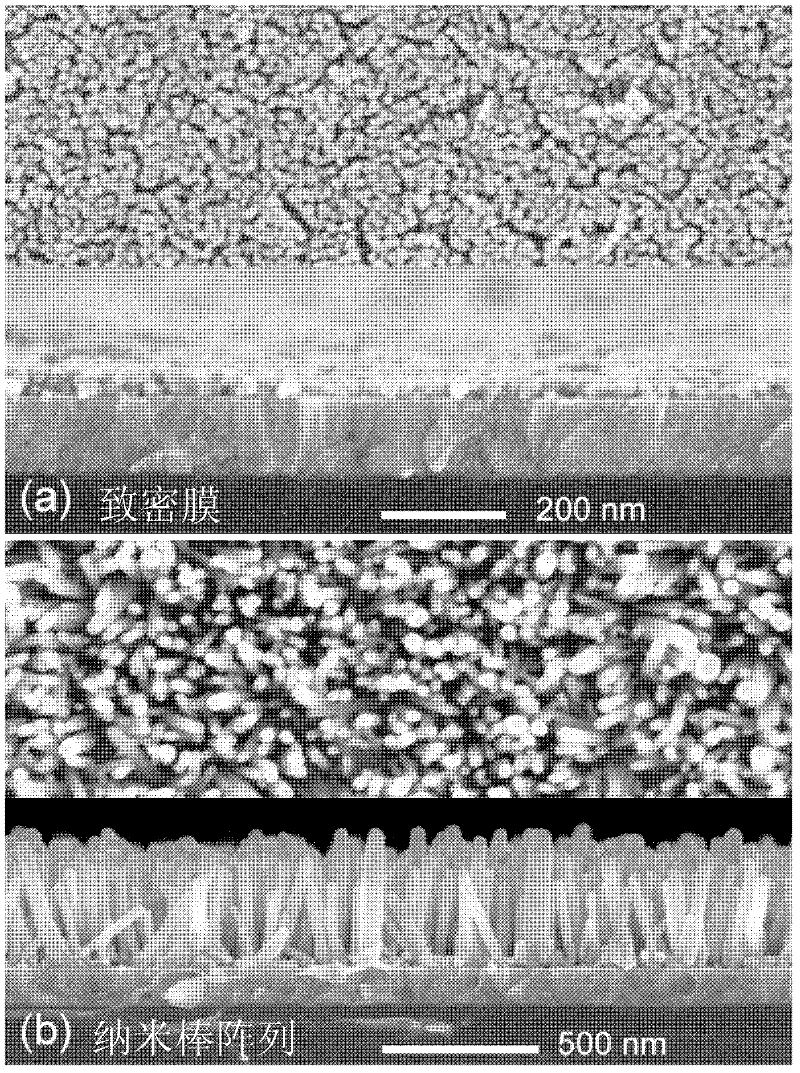

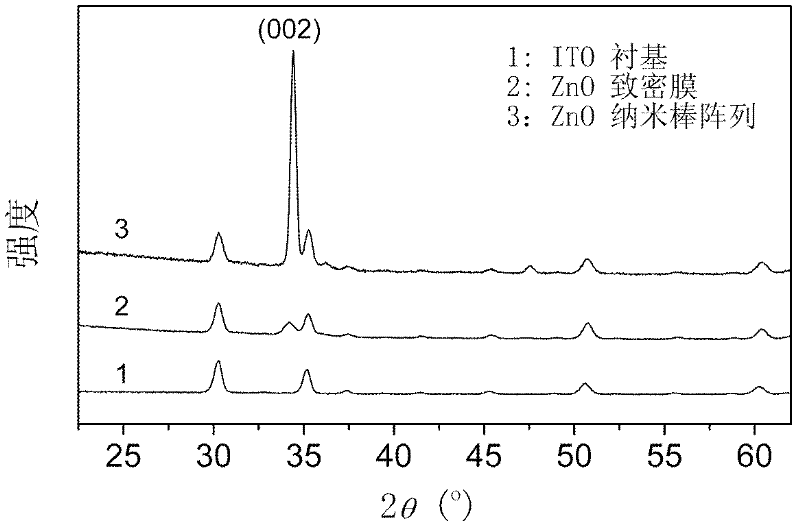

Organic/inorganic hybrid solar cell and preparation method thereof

InactiveCN102412369AEasy to prepareImprove performanceSolid-state devicesSemiconductor/solid-state device manufacturingCompound aEngineering

The invention discloses an organic / inorganic hybrid solar cell and a preparation method thereof. A ZnO nanorod array which is vertically grown on an ITO substrate is taken as a template, and a ZnO-CdS heterogeneous core shell structure nanorod array with a core of ZnO and a shell of CdS is prepared. Through compounding a polymer and the ZnO-CdS heterogeneous core shell structure nanorod array, a solar cell with an anode of ITO and a cathode of an Au film is prepared. When thickness of the CdS shell is about 6 nm, cell performance is best, open-circuit voltage reaches 0.89 V, short circuit current is 2.83 mA / cm<2>, and conversion efficiency reaches 0.74%. Compared with a pure ZnO nanorod array cell, open-circuit voltage of a ZnO-CdS array cell is raised by 170%, short circuit current of the ZnO-CdS array cell is increased by 146%, and conversion efficiency of the ZnO-CdS array cell is raised by 517%.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

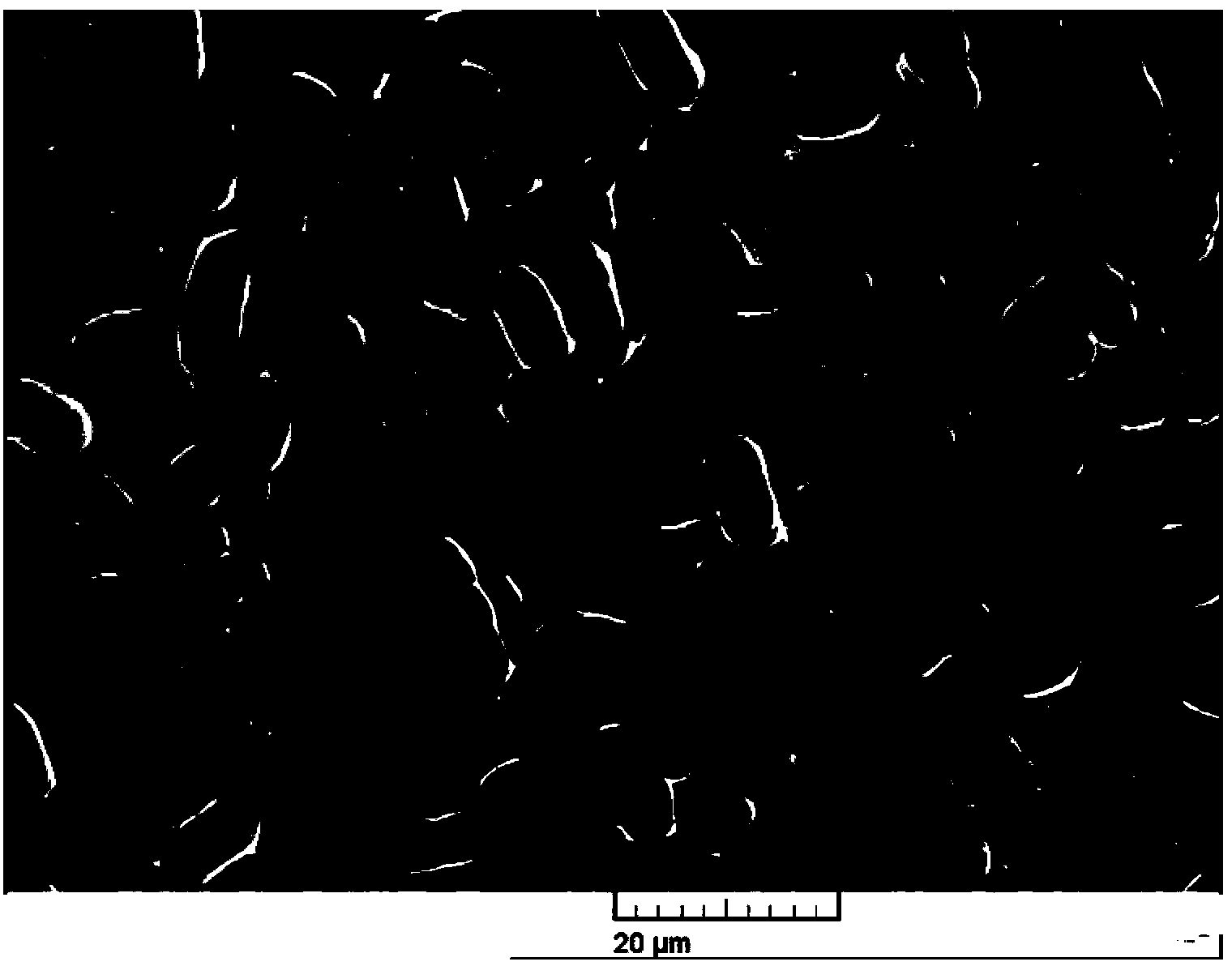

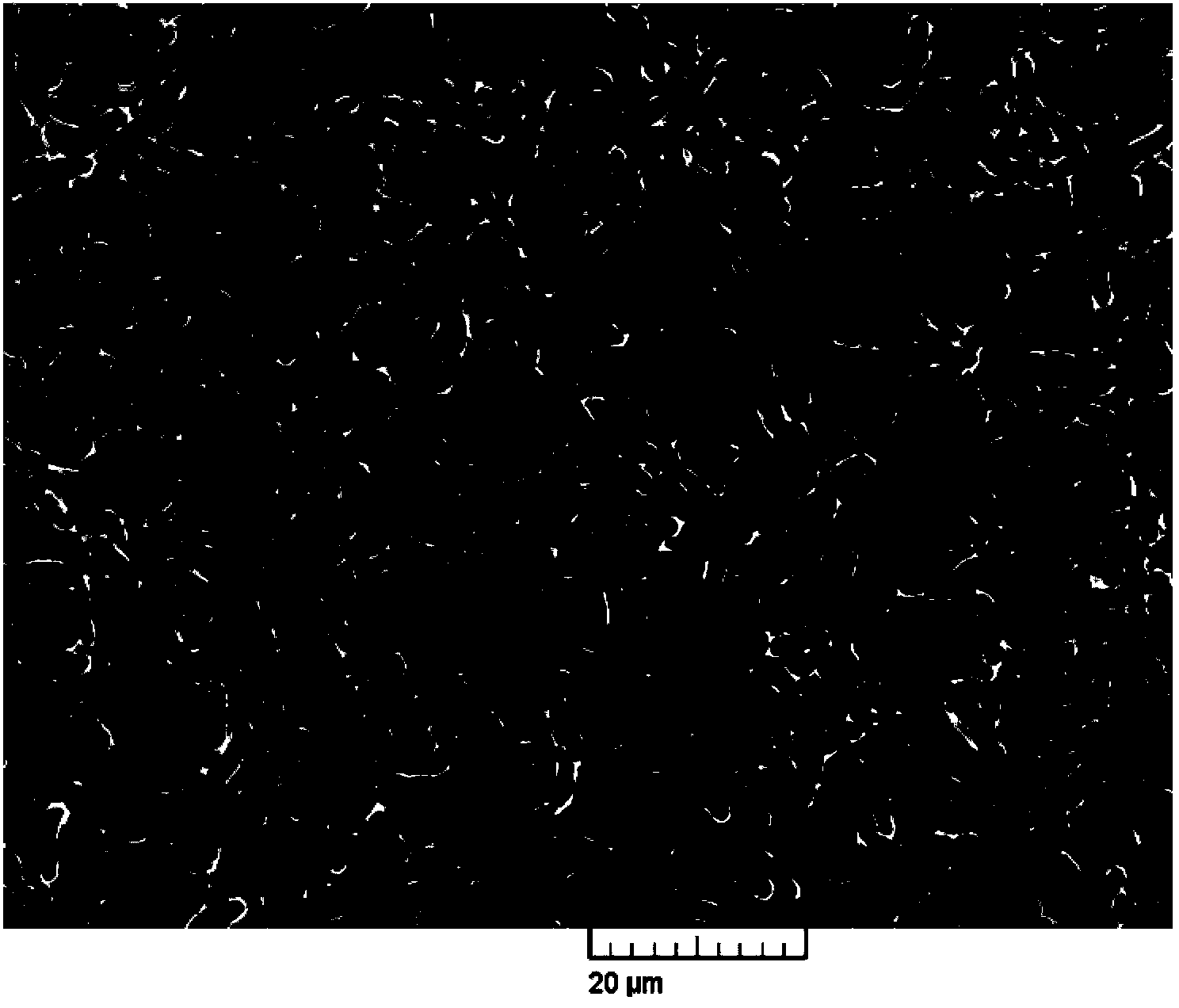

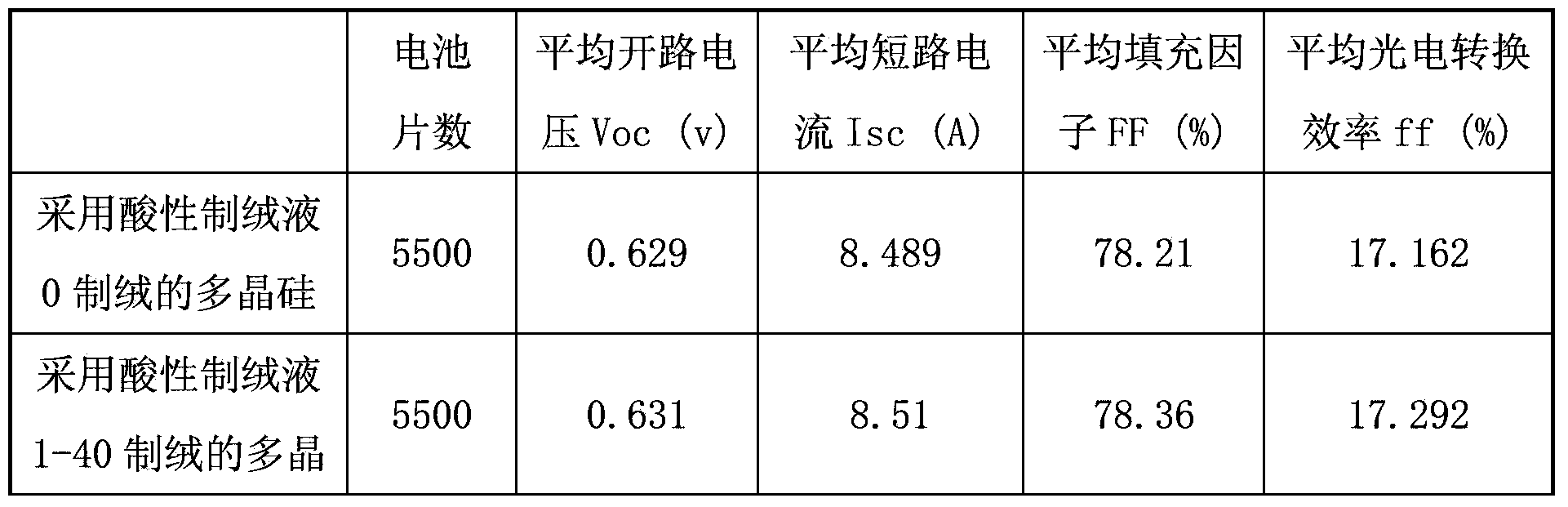

Auxiliary chemical composition for monocrystalline silicon or polycrystalline silicon acidic wool making

InactiveCN104342702AEasy to prepareEasy to useAfter-treatment detailsChemical compositionMaterials science

The invention provides an auxiliary chemical composition for monocrystalline silicon or polycrystalline silicon acidic wool making. The auxiliary chemical composition comprises 0.0001-75 weight% of surface catalysts and the balance of water. The auxiliary chemical composition has the advantages of simple preparation and application methods, easy implementation and good repeatability; when the auxiliary chemical composition is used for the monocrystalline silicon or polycrystalline silicon wool making, the wool making temperature can be increased, and the wool making effect is obviously improved; prepared silicon discs have the characteristics of low reflectivity, clean surfaces and low fragment rate; and the photoelectric conversion efficiency of silicon batteries can be largely improved.

Owner:NANJING KENAI DIKE ENVIRONMENTAL PROTECTION TECH CO LTD

Passivated contact N-type solar cell, preparation method, assembly and system

InactiveCN105895738AGood surface passivation effectExcellent field passivation effectFinal product manufacturePhotovoltaic energy generationCharge carrierAmorphous silicon

The invention relates to a passivated contact N-type solar cell, a preparation method, an assembly and a system. The preparation method for a passivated contact N-type solar cell includes the steps of conducting doping treatment for the front surface of an N-type crystalline silicon substrate to form a p+ doped region; preparing a tunneling oxide layer on the back surface of the N-type crystalline silicon substrate, then preparing a phosphorus-containing amorphous silicon layer or phosphorus-containing polysilicon layer on the tunneling oxide layer, and then conducting annealing; and after preparation of passivated anti-reflection film and a passivated film, printing and sintering metal slurry to obtain a front electrode and a back electrode. The beneficial effects of the invention lie in that the tunneling oxide layer can provide the silicon substrate with an excellent surface passivated effect and achieve selective tunneling of carriers, the n+ doped polysilicon layer can effectively transmit the carriers for the metal electrode on the back surface to collect, the back metal electrode does not destroy the passivated layer on the surface of the crystalline silicon substrate, and thus thereby open-circuit voltage of the cell can be greatly increased.

Owner:TAIZHOU ZHONGLAI PHOTOELECTRIC TECH CO LTD

Solar cell passivation antireflection film and preparation technology and method thereof

InactiveCN103094366AReduce reflectivityImprove photoelectric conversion efficiencyFinal product manufactureChemical vapor deposition coatingPower flowRefractive index

The invention discloses a solar cell passivation antireflection film and a preparation technology and a method of the solar cell passivation antireflection film. The preparation technology and the method utilize a plasma enhanced chemical vapor deposition (PECVD), a layer of silicon dioxide film is deposited on the surface of a silicon slice, then a silicon nitride layer with high refractive index is deposited on the prepared silicon dioxide film, and finally a silicon nitride layer with low refractive index is deposited on the silicon nitride layer with high refractive index. The technology and the method have the advantages of being convenient to operate, low in operation cost, good in passivation and good in antireflection performance for the cell surface. The passivation antireflection film prepared by the technology can obviously improve the open circuit voltage, short circuit current and the cell efficiency of the solar cell, compared with a traditional single-layer or double-layer silicon nitride film.

Owner:SUN YAT SEN UNIV

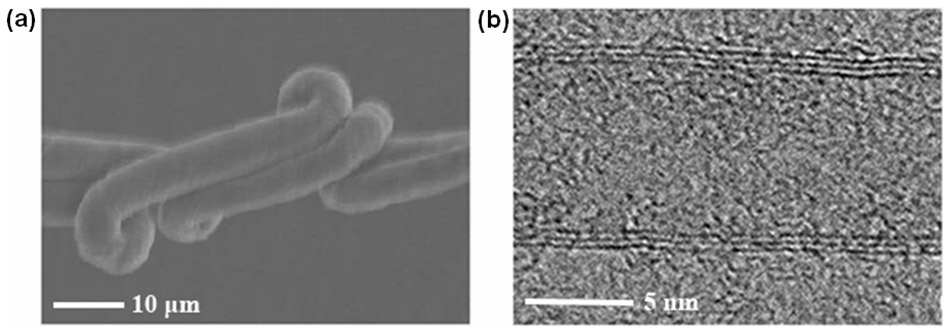

Organic solar cell based on carbon nanotube fiber and preparation method thereof

InactiveCN101982895ALowering the Fermi levelEfficient separationSolid-state devicesSemiconductor/solid-state device manufacturingOrganic solar cellElectrolytic agent

The invention belongs to the technical field of solar cells and in particular relates to an organic solar cell based on a carbon nanotube fiber and a preparation method thereof. In the invention, a carbon nanotube fiber sensitized by N719 serves as a working electrode material, FTO conducting glass or a FTO-PEN conductive plastic serves as the substrate of the working electrode and a counter electrode and anhydrous acetonitrile solution of LiI, I2, dimethyl-3-N-propyl group imidazole iodine and butyl group pyridine serves as electrolyte. Short-circuit photocurrent of the solar cell reaches 10.3mA / cm<2>, the maximum monochromatic light photoelectric conversion efficiency is over 90% and energy conversion efficiency reaches 2.2%.In particular, a Pt / FTO conductive plastic is used for preparing a flexible bendable organic solar cell, the scope of available materials of the efficient solar cell is expanded and a novel approach is provided for manufacturing novel, efficient and practical photovoltaic devices.

Owner:FUDAN UNIV

Stable and high-efficiency two-dimensional layered perovskite solar cell and preparation method therefor

ActiveCN108365102AIn line with the concept of green chemistryLarge grainSolid-state devicesSemiconductor/solid-state device manufacturingPerovskite solar cellSolvent

The invention discloses a method for preparing a stable and high-efficiency two-dimensional layered perovskite solar cell, and the method is characterized in that the method achieves the growth of micron-order perovskite crystalline grains in the air through the continuous heating in the whole spin coating process, and achieves the preparation of a flat high-quality perovskite film and a stable and high-efficiency perovskite photovoltaic device. A continuous heating method in the whole spin coating process, which is disclosed by the invention, enables a solvent to quickly volatilize to speed up the growth and conversion of the crystalline grains, also facilitates the growth of two-dimensional layered perovskite in a direction perpendicular to a substrate, and finally forms a flat and denseuniform perovskite film. The method disclosed by the invention does not need inert atmosphere for protection, facilitates the preparation of the large-area perovskite, and reduces the cost.

Owner:NANJING TECH UNIV

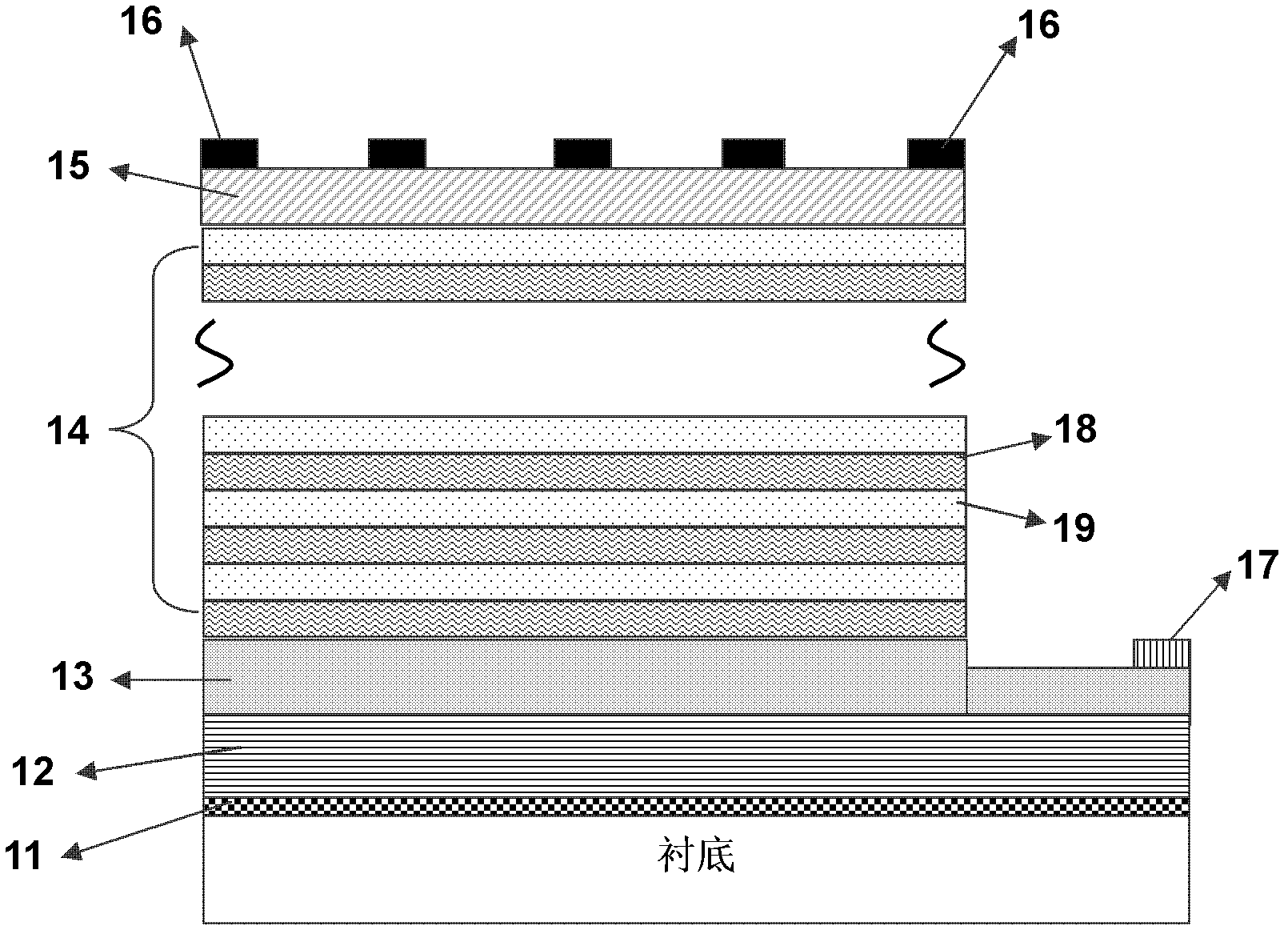

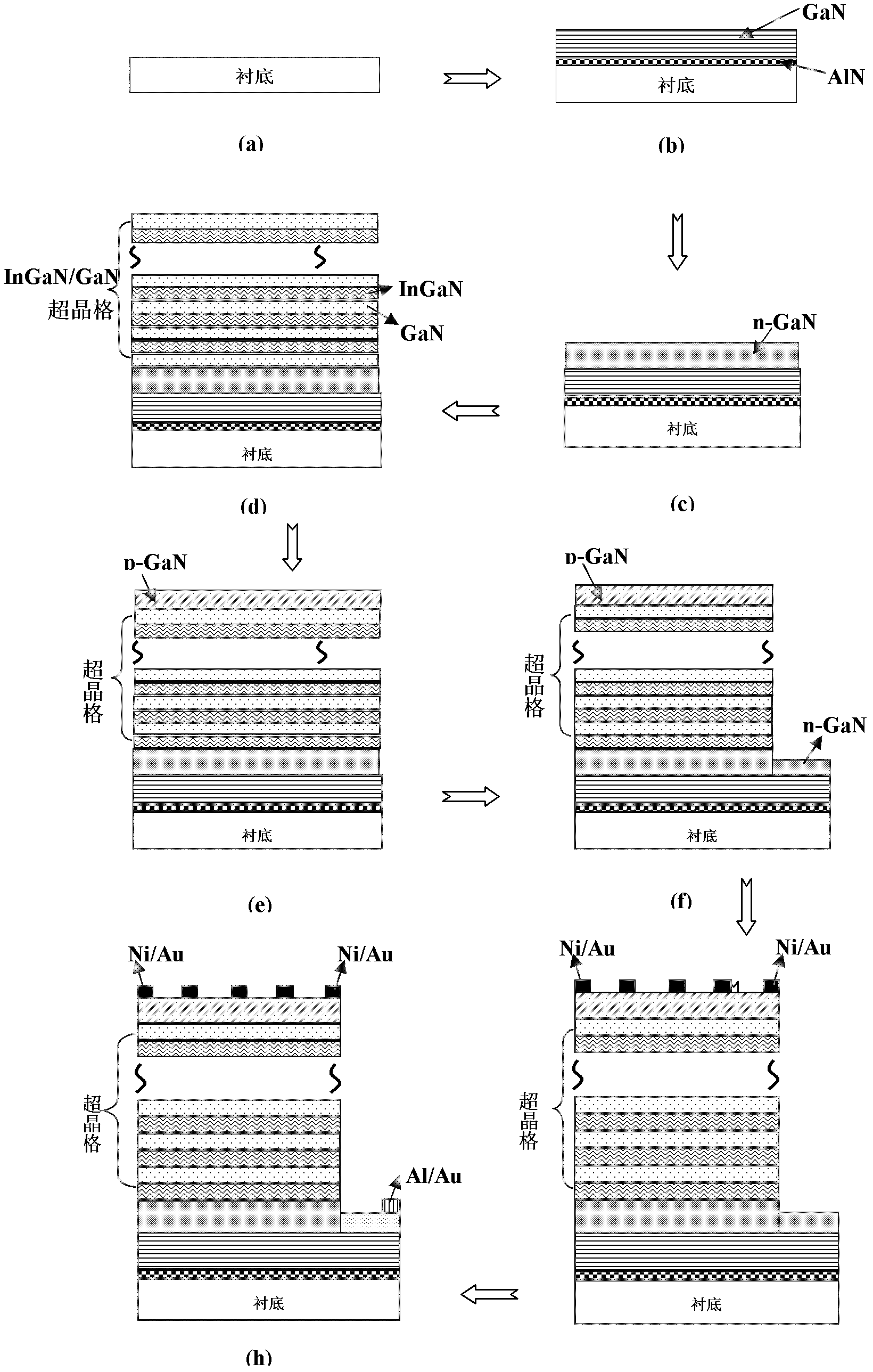

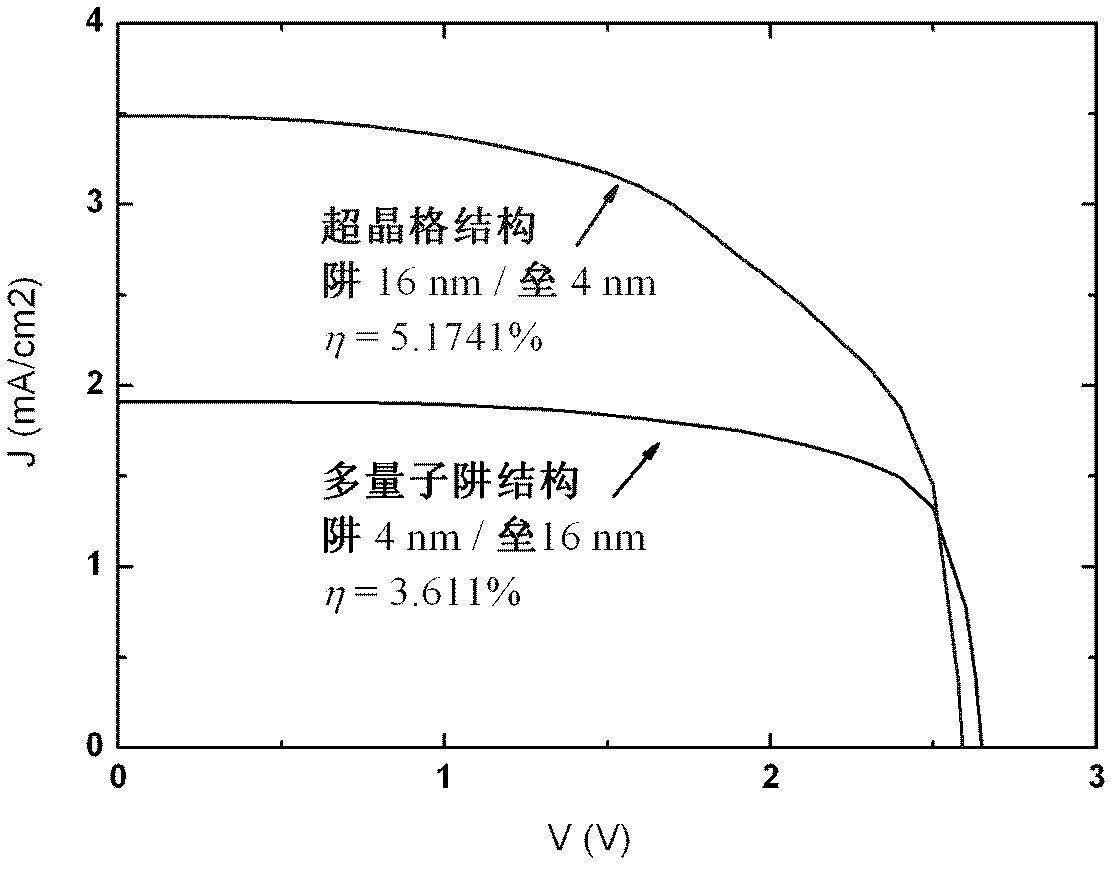

P-i-n type InGaN solar cell possessing superlattice structure

InactiveCN102315291AIncrease short circuit currentImprove conversion efficiencyFinal product manufacturePhotovoltaic energy generationPower flowSolar cell

The invention discloses a p-i-n type InGaN solar cell possessing a superlattice structure. The current p-i-n type InGaN solar cell possesses a problem of low conversion efficiency. The p-i-n type InGaN solar cell provided in the invention can solve the above problem. The solar cell comprises, from bottom to top: a substrate; an AlN nucleating layer (11), which is growth at a high temperature; an unintended doped GaN buffer layer (12); an n-GaN layer (13) possessing a thickness of 50-100nm and an electron concentration of 1x1018-6x1019 / cm<3>; a InGaN / GaN superlattice structure (14) possessing a period of 8-30; a p-GaN layer (15) possessing the thickness of 50-100nm and a hole concentration of 1x1017-6x1018 / cm<3>. The thickness of a trap layer InGaN (18) of the InGaN / GaN superlattice is 8-16nm. In ingredients are 15%-90%. The thickness of a barrier layer GaN (19) is 3-8nm. The concentration of carriers is 1x1016-2x1017 / cm<3>. Grid-shaped Ni / Au ohmic electrodes (16) are distributed on the surface of a P-GaN layer (15). An Al / Au ohmic electrode (17) is led out from a right side of the surface of the n-GaN layer (13). By using the solar cell of the invention, a short circuit current of the cell can be raised. The solar cell possesses high conversion efficiency and can be used for solar photovoltaic power generation.

Owner:XIDIAN UNIV

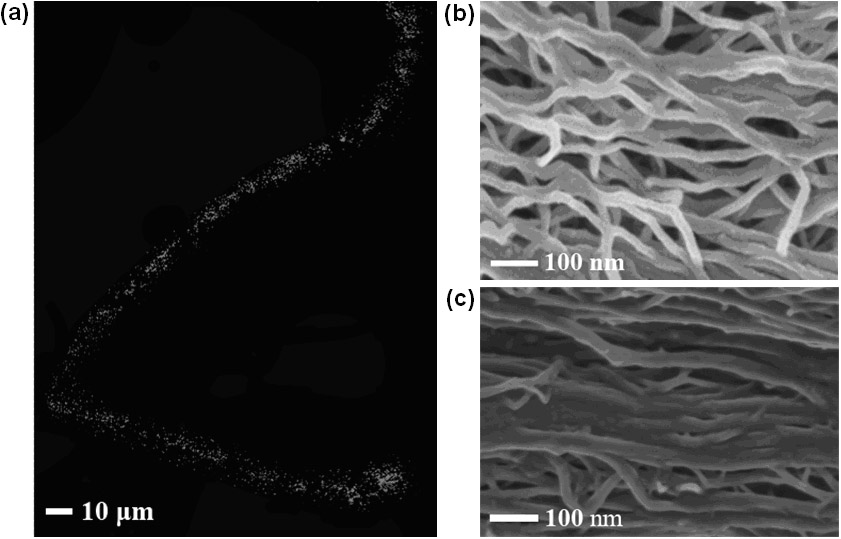

Preparation method of three-dimensional dendritic TiO2 (titanium dioxide) array with rapid electronic transmission performance

ActiveCN103523827AFew grain boundariesFew defectsMaterial nanotechnologyLight-sensitive devicesElectronic transmissionOxygen plasma

The invention discloses a preparation method of a three-dimensional dendritic TiO2 array with rapid electronic transmission performance. The preparation method comprises the steps as follows: 1), a one-dimensional nanometer TiO2 rod array with rapid electronic transmission performance is grown on the surface of a conductive substrate deposited with a TiO2 crystal seed layer with a hydrothermal method; 2), the one-dimensional nanometer TiO2 rod array obtained in the step 1) is subjected to surface treatment, and a three-dimensional dendritic structure is grown on a no-seed layer in an epitaxial manner with a water-bath method; and 3), an obtained sample with the three-dimensional dendritic structure is subjected to oxygen plasma cleaning and oxygen atmosphere sintering treatment, so that a three-dimensional dendritic TiO2 array nano-structure is obtained. According to the preparation method, the technological operation is simple, the cost is low, the controllability is high, grain boundaries and defects of the obtained TiO2 array are few, high electrical transmission rate and large specific surface area are provided, the TiO2 array can be used for a photo-anode of an photoelectric device, the device performance is improved greatly, and a good application prospect is provided.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

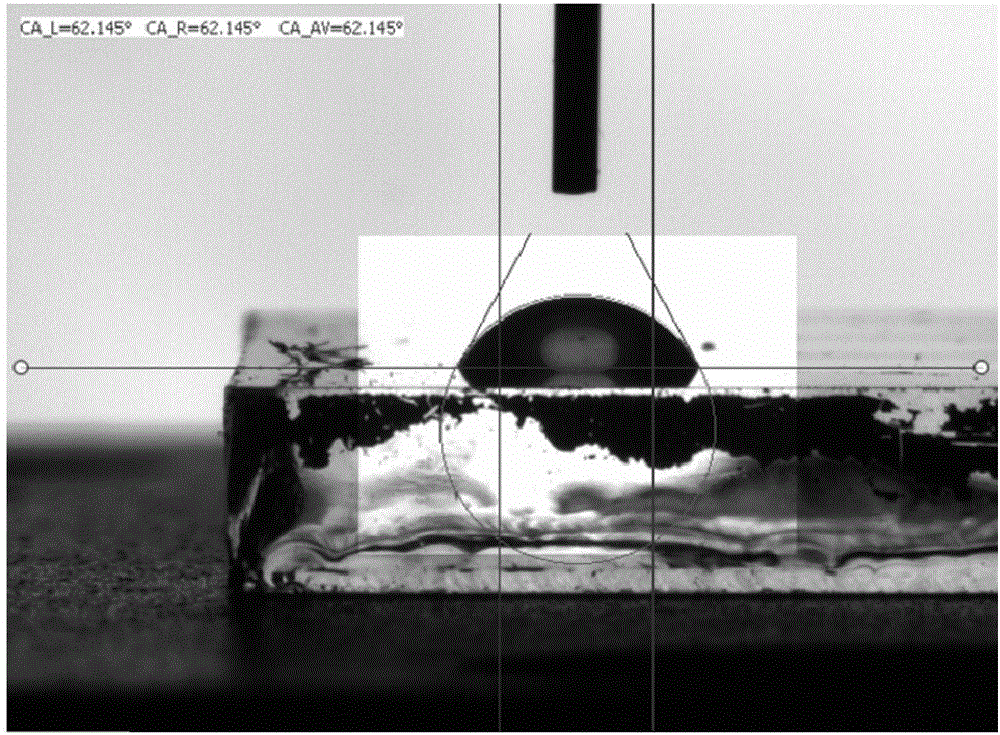

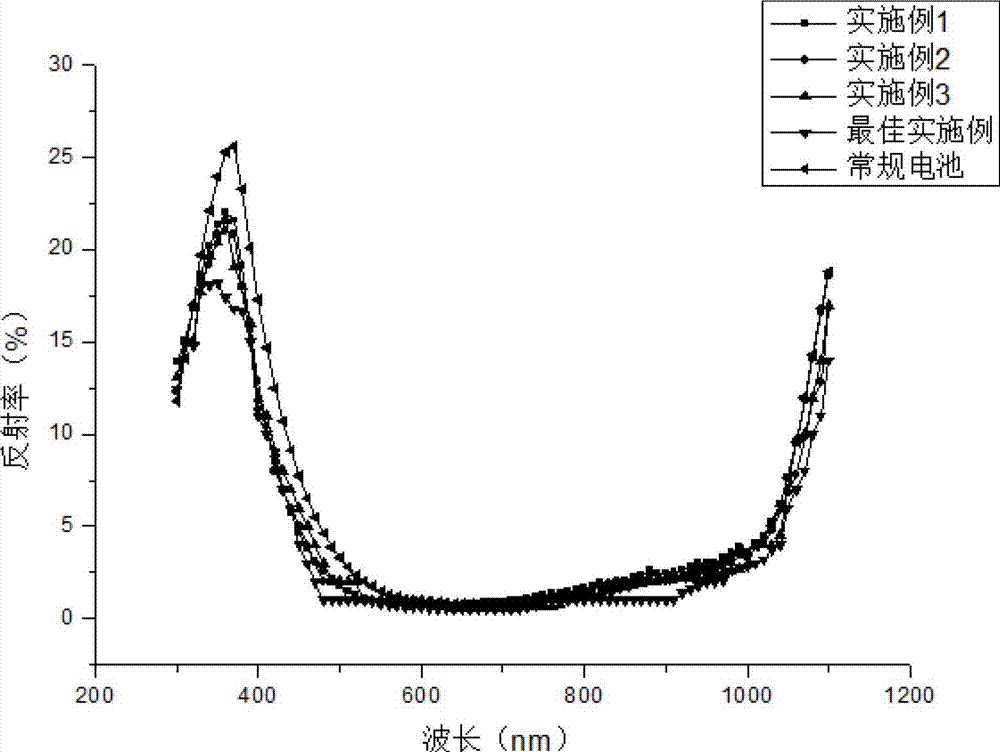

Method and corrosive liquid for making texture surface of monocrystalline silicon

ActiveCN102181935AIncrease short circuit currentImprove photoelectric conversion efficiencyAfter-treatment detailsFinal product manufactureChemistryIsopropyl alcohol

The invention provides a corrosive liquid for making the texture surface of monocrystalline silicon. The corrosive liquid comprises the following components based on mass concentration: 0.1 to 0.5 percent of NaOH and / or KOH, 5 to 8 percent of isopropyl alcohol and / or ethanol, 0.3 to 0.5 percent of sodium lactate, 1 to 2 percent of urea and the balance of water; and the sodium lactate and the urea are selected as additives and are matched with an alkali solution and an alcoholic solution to prepare the corrosive liquid. Compared with the prior art, the invention has the advantages that: experimental results show that the reflectivity of solar light can be reduced to between 6 and 8 percent by adopting the texture surface of the monocrystalline silicon prepared by the corrosive liquid. Moreover, the texture surface of the monocrystalline silicon has higher short-circuit current and higher photoelectric conversion efficiency.

Owner:JETION SOLAR HLDG

Process applied to single-surface corroded p-n junction or suede structure of crystalline silicon solar cell

InactiveCN102064232AIncrease the open circuit voltageIncrease short circuit currentFinal product manufactureSemiconductor devicesFilm materialCompound (substance)

The invention discloses a process applied to a single-surface corroded p-n junction or suede structure of a crystalline silicon solar cell, which comprises the steps of: firstly, chemically preprocessing a silicon sheet to form a suede structure; secondly, carrying out high-temperature phosphorus diffusion or boron diffusion on the silicon sheet to form a p-n junction; thirdly, removing phosphorosilicate glass or borosilicate glass with an acid chemical liquid; fourthly, carrying out dielectric film protection on the p-n junction of a non-corroding surface of the silicon sheet; fifthly, removing a naturally oxidizing layer of a non-protecting surface, i.e. a corroding surface, or a dielectric film material of the corroding surface with the acid chemical liquid; sixthly, carrying out chemical reaction corrosion on the p-n junction or suede structure of the corroding structure by adopting an alkali chemical liquid; and finally, effectively cleaning the dielectric film on the silicon sheet and the corroding surface of the silicon sheet, and remaining the dielectric film as a functional film of the crystalline silicon solar cell. According to the invention, the process of re-preparing the functional film is avoided, the production cost of the crystalline silicon solar cell is effectively lowered, the low-cost single-surface corroded p-n junction or suede structure is realized, the open-circuit voltage and the short-circuit current of the crystalline silicon solar cell are effectively improved, and the photoelectric conversion efficiency of the cell is finally improved.

Owner:SUN YAT SEN UNIV

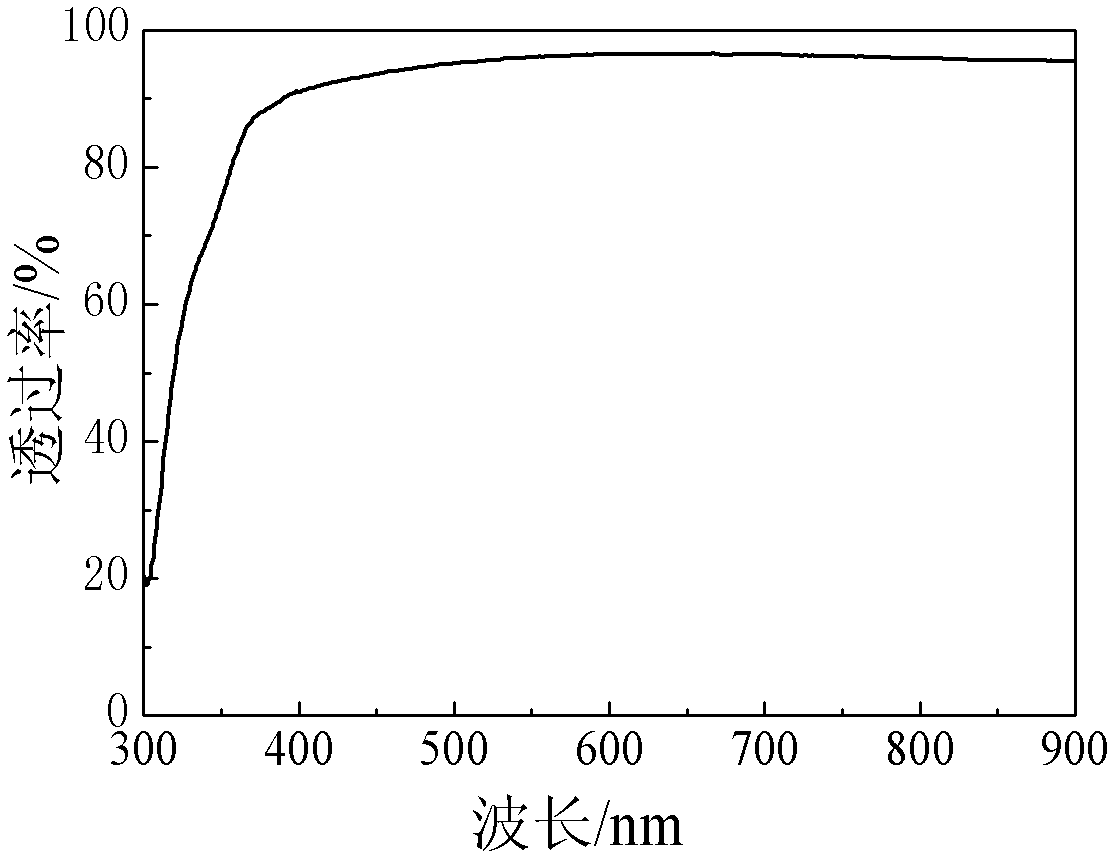

Preparation method for buffering layer material of copper indium gallium selenide film solar battery

InactiveCN102544237AQuality improvementControl reaction speedFinal product manufactureSemiconductor devicesIndiumElectrical battery

The invention discloses a preparation method for a buffering layer material of a copper indium gallium selenide film solar battery. By the method, a precursor of chemical bath reaction is prepared by using a zinc sulfate solution as a Zn<2+> source, a thiourea solution as a S<2-> source, ammonia water as a buffering agent and sodium citrate as a complexing agent; and a Zn(O,S) semiconductor film with uniform and compact grain size distribution and good adhesive force is prepared on a copper indium gallium selenide film and the common glass substrate and serves as the buffering layer of the copper indium gallium selenide film solar battery. The Zn(O,S) instead of CdS serves as the buffering layer of the copper indium gallium selenide film solar battery, so production of the copper indium gallium selenide film solar battery is environment-friendly and economic. The band gap width of the Zn(O,S) is more than that of the CdS, so more incident photons can reach an absorption layer through the buffering layer, short-circuit current of the battery is increased and photoelectric conversion efficiency of the battery is improved.

Owner:GUANGDONG UNIV OF TECH

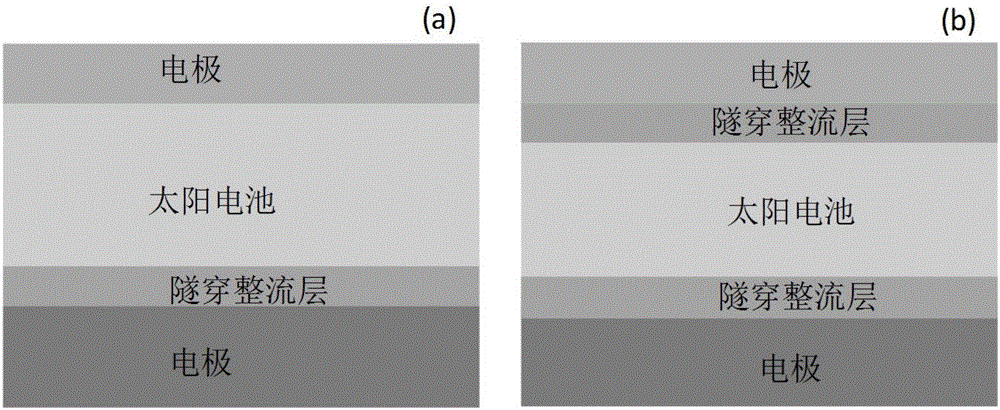

Film solar cell and preparation method thereof

ActiveCN105140319AIncrease short circuit currentIncrease the open circuit voltageFinal product manufactureSolid-state devicesMetallic sulfideElectron

The invention discloses a film solar cell and a preparation method thereof. The film solar cell comprises a front electrode layer, a semiconductor layer, a back electrode layer and a tunneling rectification layer. The tunneling rectification layer of a single-layer or multi-layer structure is arranged between the front electrode layer and the semiconductor layer and / or between the semiconductor layer and the back electrode layer, and is made of at least one selected from metal oxide, metal nitride, metal sulfide and metal fluoride. The surface(s) of the front and / or back electrode layer are / is provided with the tunneling rectification layer, the tunneling rectification layer is used to carry out electron rectification, and thus, carrier combination is effectively avoided, the short-circuit current and open-circuit voltage of the solar cell are improved, and the photoelectric conversion efficiency is further improved.

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL

Texture etching method for single crystalline silicon solar cell

InactiveCN101431124AImprove conversion efficiencyIncrease short circuit currentFinal product manufactureSemiconductor devicesHydrofluoric acidEtching

The invention discloses a preparation method of a monocrystalline silicon solar cell texture, the process is as follows: a monocrystalline silicon wafer which is rinsed cleanly by pure water after the chemical pre-cleaning in the former step is put in an ultrasonic tank of an ultrasonic cleaning machine with the power of 1,800-2,400w and the frequency of 25-40kHz, mixed water solution with 1 percent-2 percent NaOH and 3 percent-6 percent isopropyl alcohol according to the weight percentage is prepared in the ultrasonic tank, the temperature of the mixed water solution is set to be 75-85 DEG C, the ultrasound time is 30-35min, then the monocrystalline silicon wafer is taken out and put in hydrochloric acid water solution with the volume percentage of 10 percent for soaking for 4-6min, hydrofluoric acid water solution with the volume percentage of 10 percent is further used for soaking for 4-6min after the rinsing, then deionized water is used for cleaning, and drying is finally carried out. The silicon wafer texture prepared by the preparation method is even and low in reflection rate; furthermore, the preparation method reduces the fragmentation rate and improves the production efficiency and the production capacity.

Owner:NINGBO ULICA SOLAR SCIENCE & TECHNOLOGY CO LTD

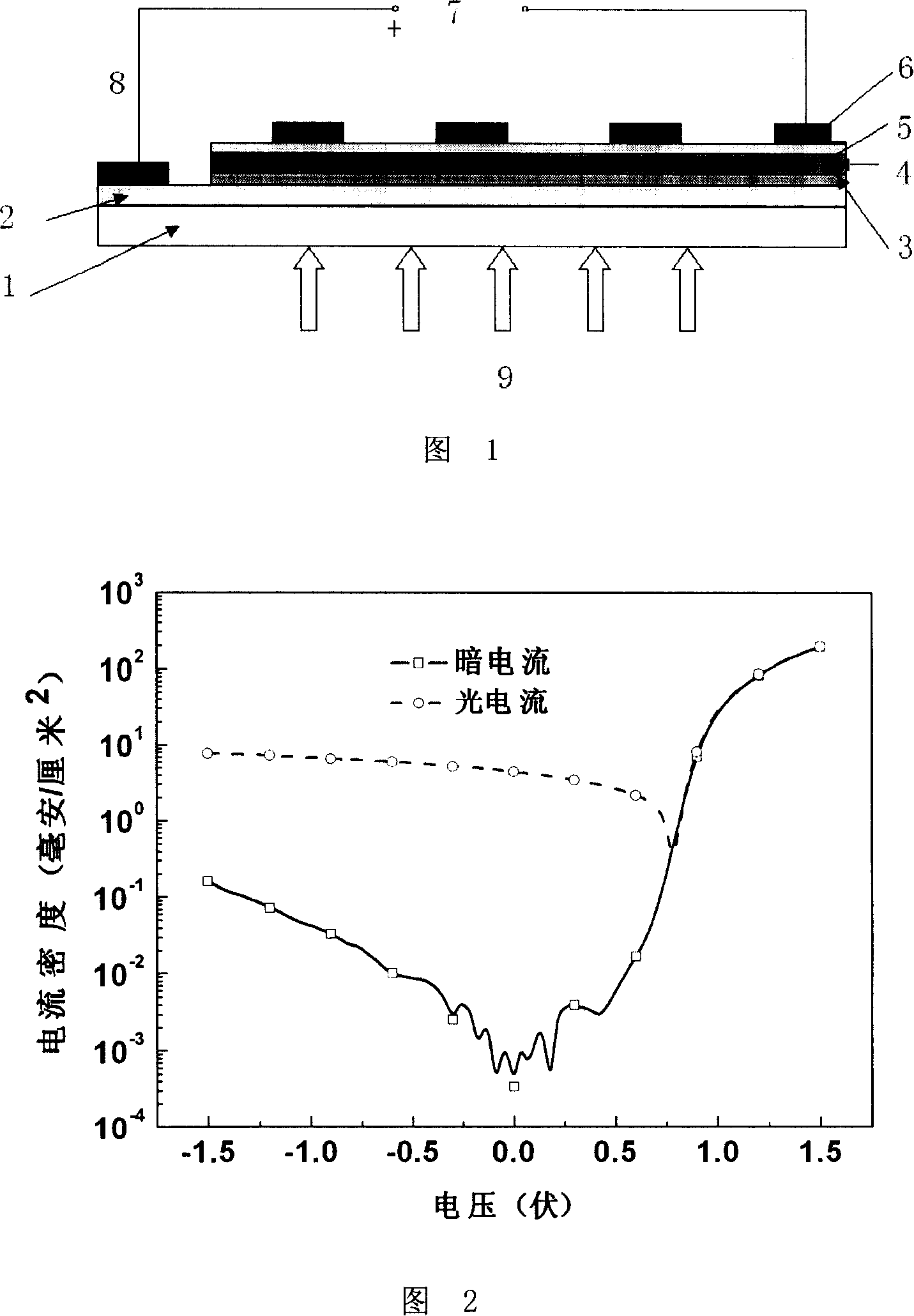

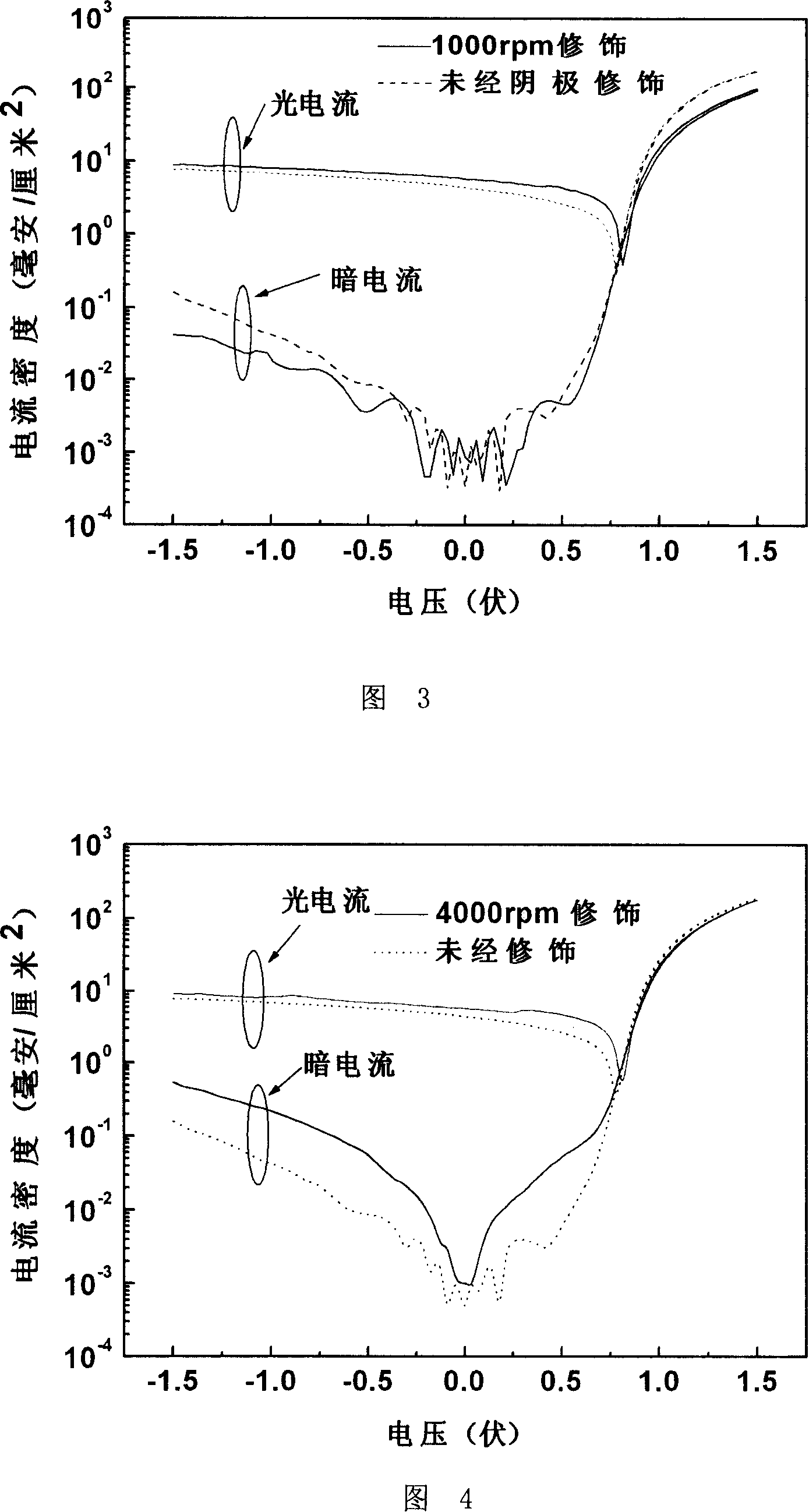

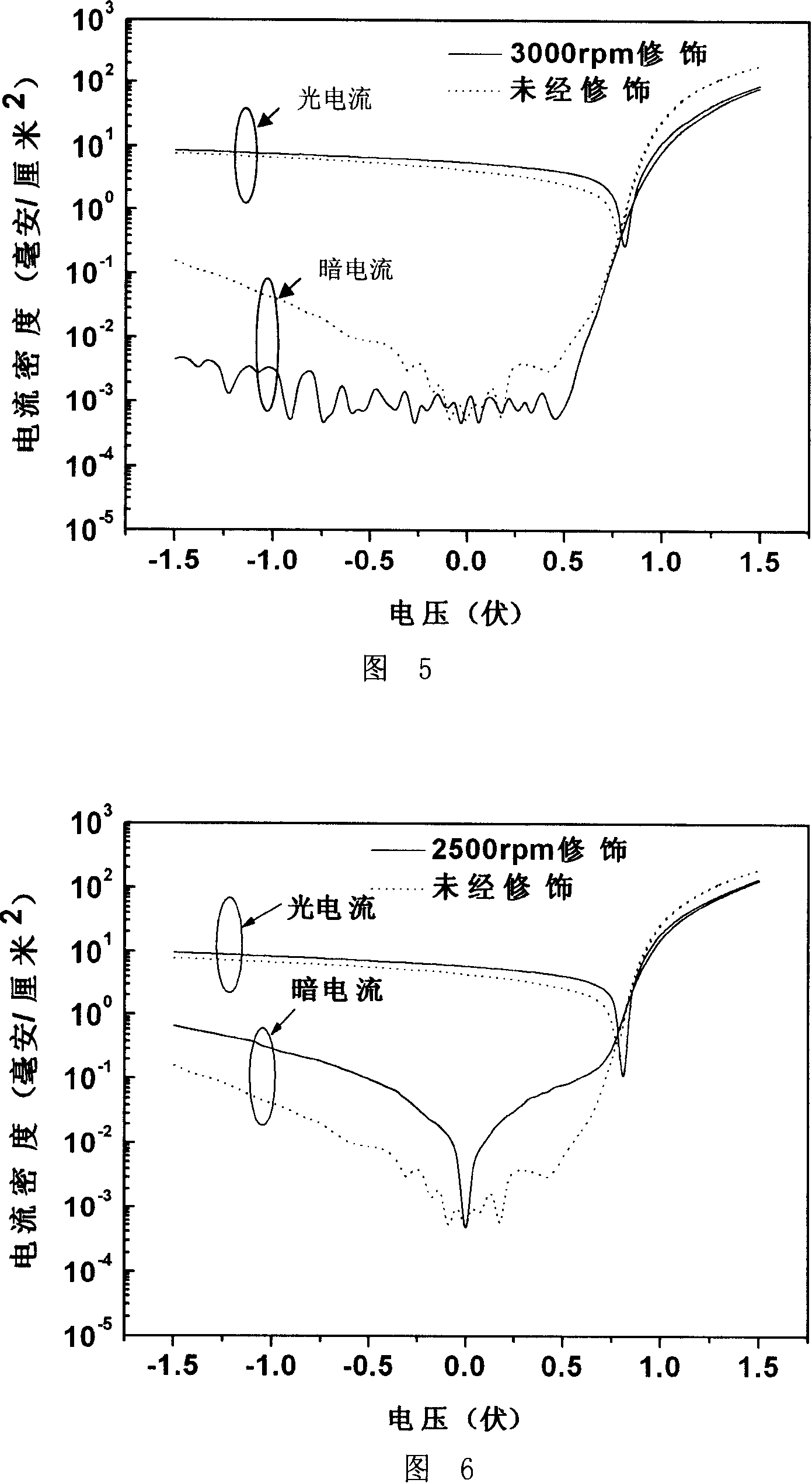

A polymer solar battery and its making method

InactiveCN101123296AIncrease the open circuit voltageIncrease short circuit currentFinal product manufactureSolid-state devicesTitaniumLithium fluoride

The invention discloses a polymer solar cell and a preparation method. The polymer solar cell comprises a substrate, an anode layer, a modification layer of anode, a photovoltaic active layer, a modification layer of cathode and a cathode layer which are connected mutually and successively in two pieces, wherein, the modification layer of cathode is titanium dialkoxy acetylacetonate film. The invention uses titanium diisopropoxide acetylacetonate as the material of the modification layer of cathode and introduces the material into the polymer solar cell, so increases the photovoltaic conversion efficiency of the solar cell. Meanwhile, the invention has the advantages of simple process, low cost and good experiment repeatability by comparing to the existing cell of the modification layer of cathode with lithium fluoride. Moreover, a very simple spin-coating method coats titanium diisopropoxide acetylacetonate on the photovoltaic active layer, so the invention also has the advantages of simple preparation process, easy control of thickness, no damage on the lower photovoltaic active layer, and being suitable for large-scale industrial production.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Front and back surface electrodes of screen printing crystalline silicon solar cell and manufacturing method thereof

ActiveCN101609848AStress reliefLess bendingFinal product manufactureSemiconductor devicesScreen printingConductive paste

The invention discloses front and back surface electrodes of a screen printing crystalline silicon solar cell and a manufacturing method thereof; array points which are not printed into conductive paste are manufactured in an electrode main gate line; and the graphics of each array point is in a closed type. The manufacturing method comprises the step of arranging latex film array points on the screen printing plate electrode main gate line for blocking the conductive paste. The positive and back surface electrodes of the screen printing crystalline silicon solar cell and the manufacturing method thereof can effectively save the conductive paste on the positive and back surfaces of the crystalline silicon solar cell, and effectively eliminate the stress caused by different expansion coefficients of silver silicon alloy and silicon, thereby reducing the bending rate of a cell film and the welding debris rate of a component; the invention can enhance the adhesion firmness of the main gate line conductive paste on the silicon surface after being sintered and effectively solve the falling-off problem of a silver main gate line; and the invention reduces the surface contact area of the conductive paste and the silicon, and increases the open-circuit voltage and the short-circuit current.

Owner:HANWHA SOLARONE QIDONG

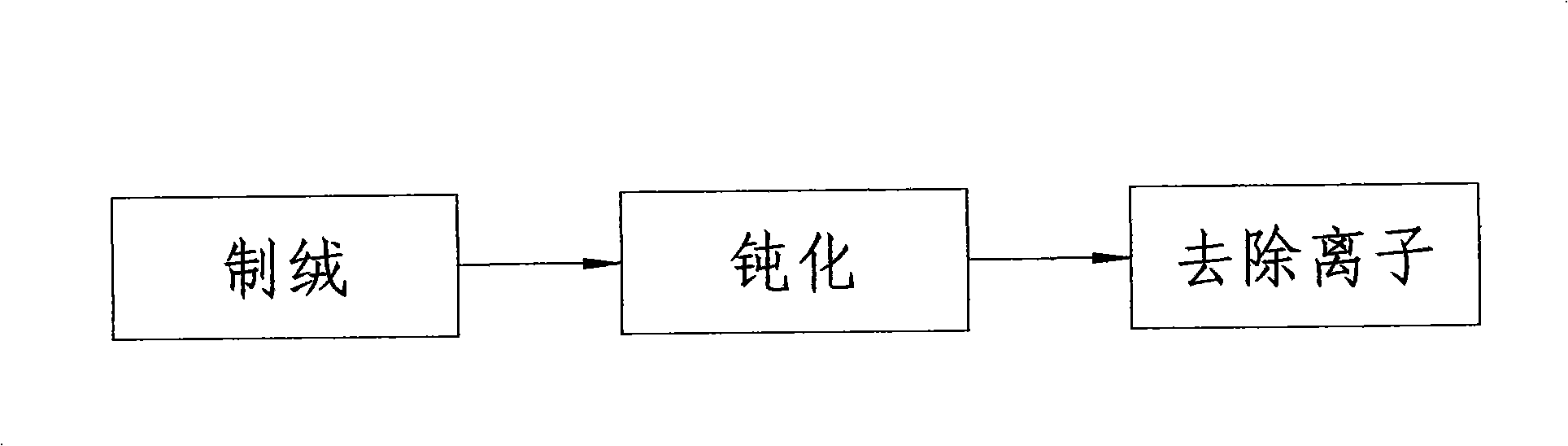

Method for fine-hair maring using monocrystalline silicon slice

InactiveCN101409312AUnbreakableUniform and fine suedeFinal product manufactureSemiconductor devicesHigh reflectivitySteady state

The invention discloses a method for texturing a monocrystalline silicon wafer. The method comprises the steps of texturing by corrosion, passivation and deionization. By the technical scheme of cancelling rough polishing, and changing a formula, reaction conditions and treatment flow, the method overcomes the problems and the disadvantages of the prior art that the texturing technological process is difficult to be controlled, the thickness reduction of the monocrystalline silicon wafer is greater, the silicon wafer is easily cracked during the treatment process, the textures formed on the silicon wafer is uneven, and bulky dimension of a cone structure leads to high reflectivity of the silicon wafer, lower short circuit current (Isc) and lower photoelectric conversion rate. The method provided for texturing the monocrystalline silicon wafer realizes that corrosive liquid is in a steady state which is easy to be controlled, the thickness reduction of the silicon wafer is reduced, the formed textures are even and the dimension of the cone structure is compact; the method reaches the purposes of reducing the reflectivity of the silicon wafer, increasing the short circuit current (Isc), and improving the photoelectric conversion rate, meanwhile, the method improves the quality and the qualification rate of the product on the whole, reduces the consumption of chemical reagents and lowers the cost.

Owner:SHANGHAI CHAORI (LUOYANG) SOLAR ENERGY CO LTD

Front electrode of solar cell

The invention relates to a point-contact front electrode structure of a solar cell. The front electrode structure is a bridge structure. The bridge structure comprises a bridge foundation, bridge piers and a bridge girder; the bridge foundation is weldable, silver paste or nickel paste is sintered to form the bridge foundation, and the bridge foundation is in excellent ohmic contact with a semiconductor of a substrate; solder paste is melted by heat to form the bridge piers, and the bridge girder can be conductively and mechanically connected with the bridge foundation by the bridge piers; the bridge girder comprises conducting metal wires, and currents of the various bridge piers can be gathered and led out by the aid of the bridge girder. The front electrode structure has the advantages that points of a point-contact electrode can be connected with one another by the metal wires, so that the total area of an electrode region is reduced, photon-generated carriers which are composited with one another on the surface of the cell are effectively reduced, the illumination shielding area of the electrode can be effectively reduced owing to the suspended metal wires, light injection is effectively increased, an open-circuit voltage and a short-circuit current are increased, and the conversion efficiency of the solar cell is improved; consumption of expensive silver is reduced owing to the structure, and accordingly the production cost of the solar cell is lowered.

Owner:陕西众森电能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com