Patents

Literature

270results about How to "Control reaction speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

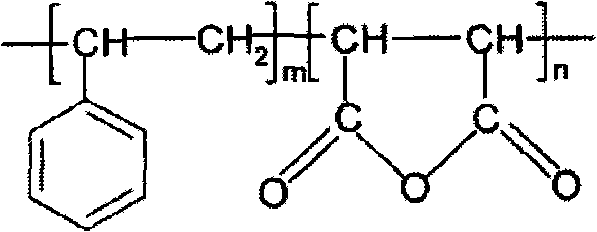

Halogen-less high frequency resin composition, and prepreg and laminate manufacturing by using same

ActiveCN101684191ALow heat resistanceImprove heat resistanceSynthetic resin layered productsWoven fabricsStyrene maleic anhydrideAbsorbance

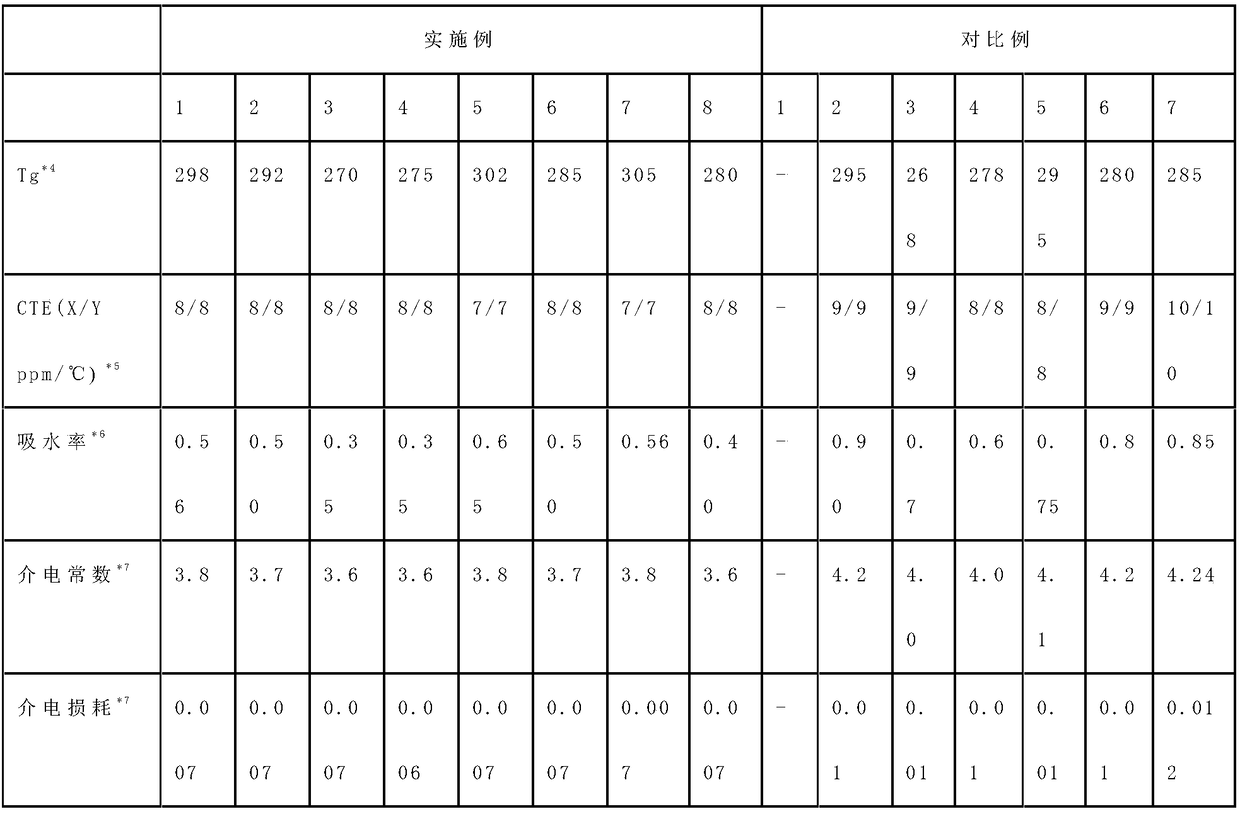

The invention relates to a halogen-less high frequency resin composition, and a prepreg and a laminate manufactured by using the same. The halogen-less high frequency resin composition comprises the following components based on weight part of the organic solids: (A) 10 to 50 parts of styrene-maleic anhydride oligomer; (B) 10 to 50 parts of at least one compound containing dihydro-benzoxazine ring; (C) 10 to 50 parts of at least one polyepoxide; and (D) 5 to 30 parts of at least one phosphorus-containing flame retardant. The prepreg and the laminate manufactured by using the halogen-less highfrequency resin composition has low dielectric constant, low dielectric loss factor, high glass transition temperature, good heat resistance, low water absorbance, and simple and convenient technological operation.

Owner:GUANGDONG SHENGYI SCI TECH

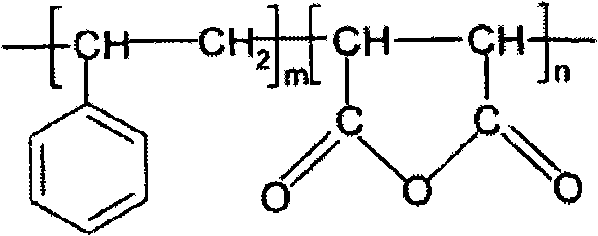

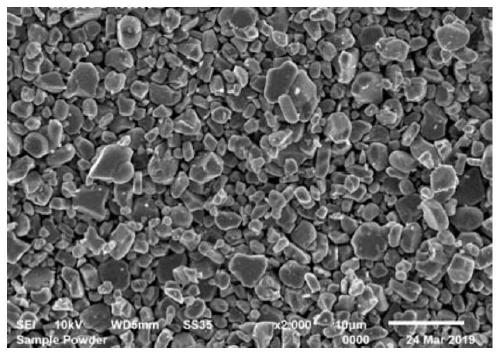

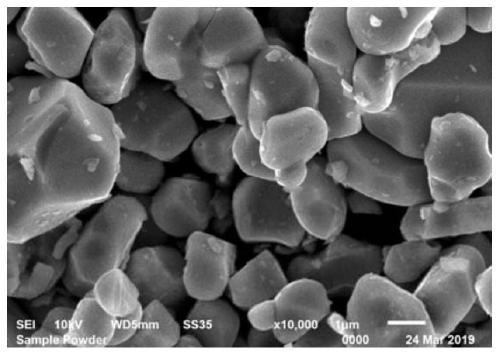

High-nickel single-crystal ternary cathode material with low surface residual alkali content and preparation method thereof

InactiveCN110436531AIn-situ encapsulationUniform coating in situCell electrodesSecondary cellsLithium hydroxideSingle crystal

The invention discloses a high-nickel single-crystal ternary cathode material with low surface residual alkali content and a preparation method thereof. The preparation method comprises the followingsteps: weighing lithium hydroxide, an oxide additive and a nickel-cobalt-manganese ternary precursor, and carrying out uniform mixing through a dry high-speed mixing process so as to prepare a mixed material; subjecting the mixed material to first sintering so as to obtain a first sintered material; crushing the first sintered material, and carrying out sieving so as to obtain a first crushed material; weighing the first crushed material, a coating agent and deionized water, and carrying out water washing under stirring so as to prepare a slurry, wherein the coating agent comprises an elementX which is one or more selected from the group consisting of B, Al, Ba, Zr, Mg, Ca, Ti, Si, V, Sc, Nb, Ta and Z; drying the slurry under a vacuum condition through a dynamic rotary drying process so as to obtain a dry material; subjecting the dry material to secondary sintering so as to obtain a secondary sintered material; and crushing the secondary sintered material, and carrying out sieving soas to obtain a product. The high-nickel single-crystal ternary cathode material and the preparation method thereof provided by the invention has the following advantages: alkali reduction by water washing and in-situ coating by a wet process can be synchronously completed; the process is simple; high compaction density is realized; and the content of residual alkali is low.

Owner:ZHEJIANG MEIDU HITRANS LITHIUM BATTERY TECHNOLOGY CO LTD

Additive used for monocrystalline silicon wafer alkaline flocking and application method thereof

InactiveCN102312294AExtended failure cycleIncrease contact rateAfter-treatment detailsTO-18Temperature control

The invention relates to an additive used for monocrystalline silicon wafer alkaline flocking and an application method thereof, belonging to the technical field of solar batteries. The additive is prepared by the following components: ethanolamine, polyphosphate, sodium dodecylbenzene sulfonate, sodium hydroxide and water. A flocking agent is prepared through the following steps: (1) dissolving sodium hydroxide in deionized water so as to obtain alkaline flocking liquid; (2) adding the additive motioned above into the alkaline flocking liquid to obtain the flocking agent. During flocking, monocrystalline silicon wafers used for solar batteries are immersed in the flocking agent with temperature controlled to be 75 to 85 DEG C and flocking time controlled to be 15 to 18 minutes. The additive used for monocrystalline silicon wafer alkaline flocking in the invention enables flocking reaction time to be shortened and productivity to be enhanced; prepared texture surface pyramids have a uniform size and low reflectivity; the additive is applicable to solar battery silicon wafer alkaline flocking of different specifications and meets the purpose of industrial production.

Owner:浙江向日葵聚辉新能源科技有限公司

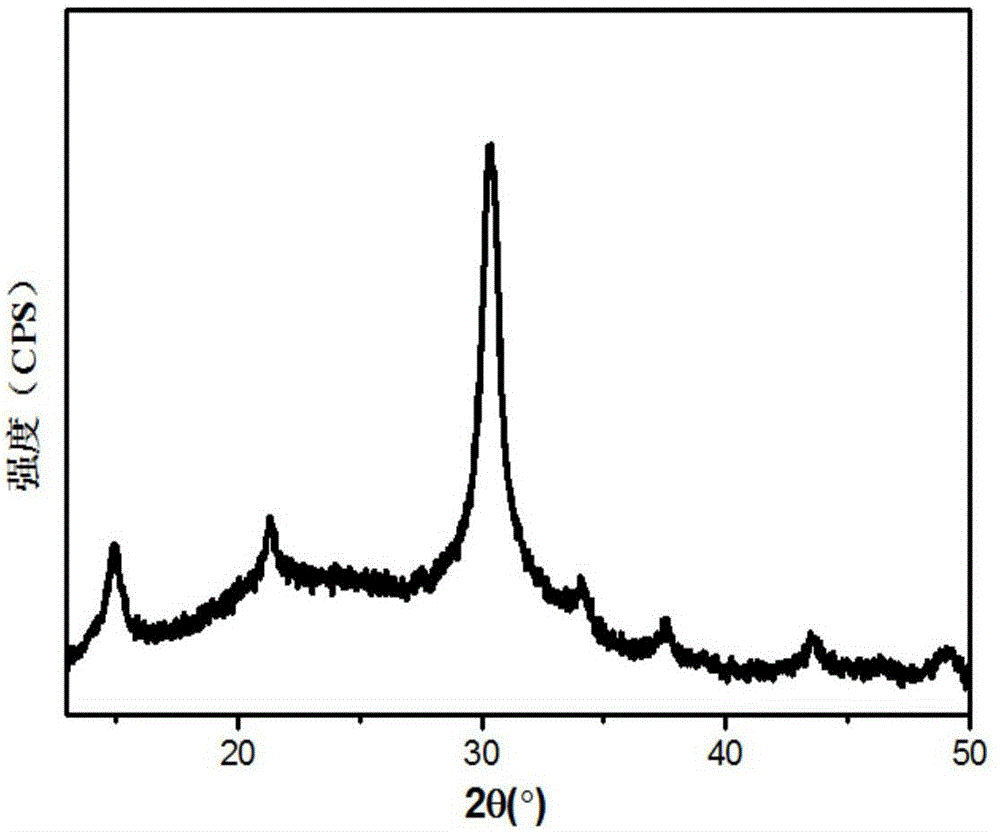

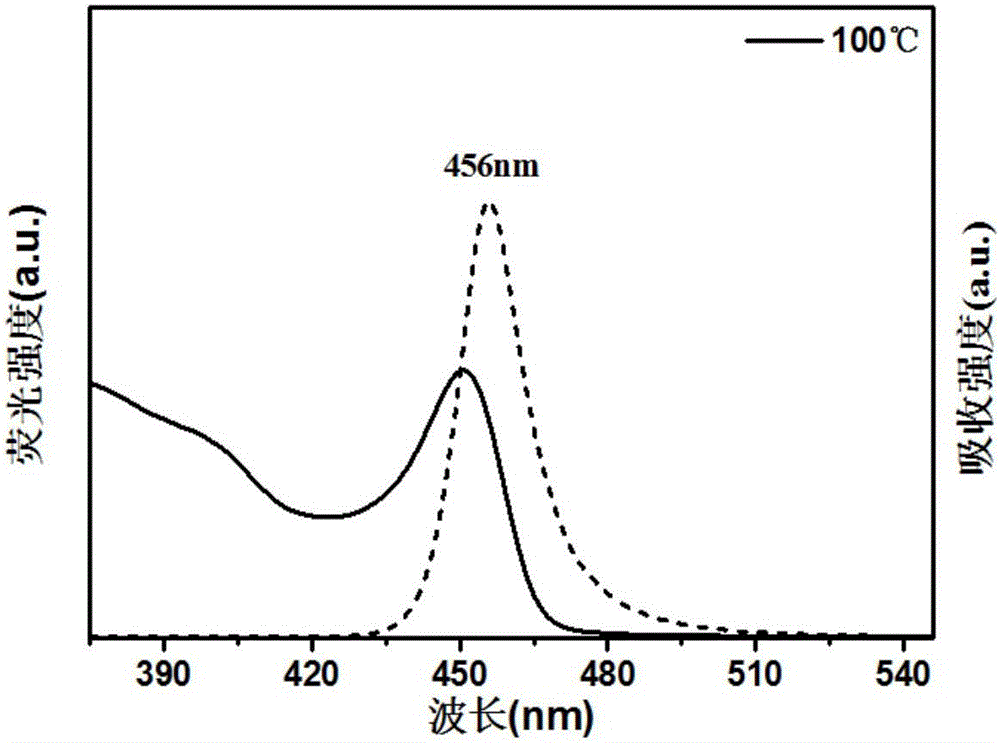

Synthesizing method of inorganic perovskite nanosheets

ActiveCN107522225AUniform sizeImprove controllabilityNanotechnologyLead compoundsQuantum efficiencyQuantum

The invention relates to a synthesizing method of inorganic perovskite nanosheets. The method includes: adding the precursor solution of cesium into the precursor solution of lead halide, performing ultrasonic treatment for 10-30 minutes to obtain a mixed solution, transferring the mixed solution into a reaction kettle, performing reaction under 60-150 DEG C for 30-420 minutes, and naturally cooling to obtain reactants; performing centrifugal processing and washing to obtain the inorganic perovskite CsPbX3 nanosheets. The method has the advantages that the method is simple to operate and does not need harsh experiment conditions, and the prepared nanosheets are uniform in size, high in controllability and high in yield, and the quantum efficiency of the nanosheets reaches up to 48%.

Owner:HEBEI UNIV OF TECH

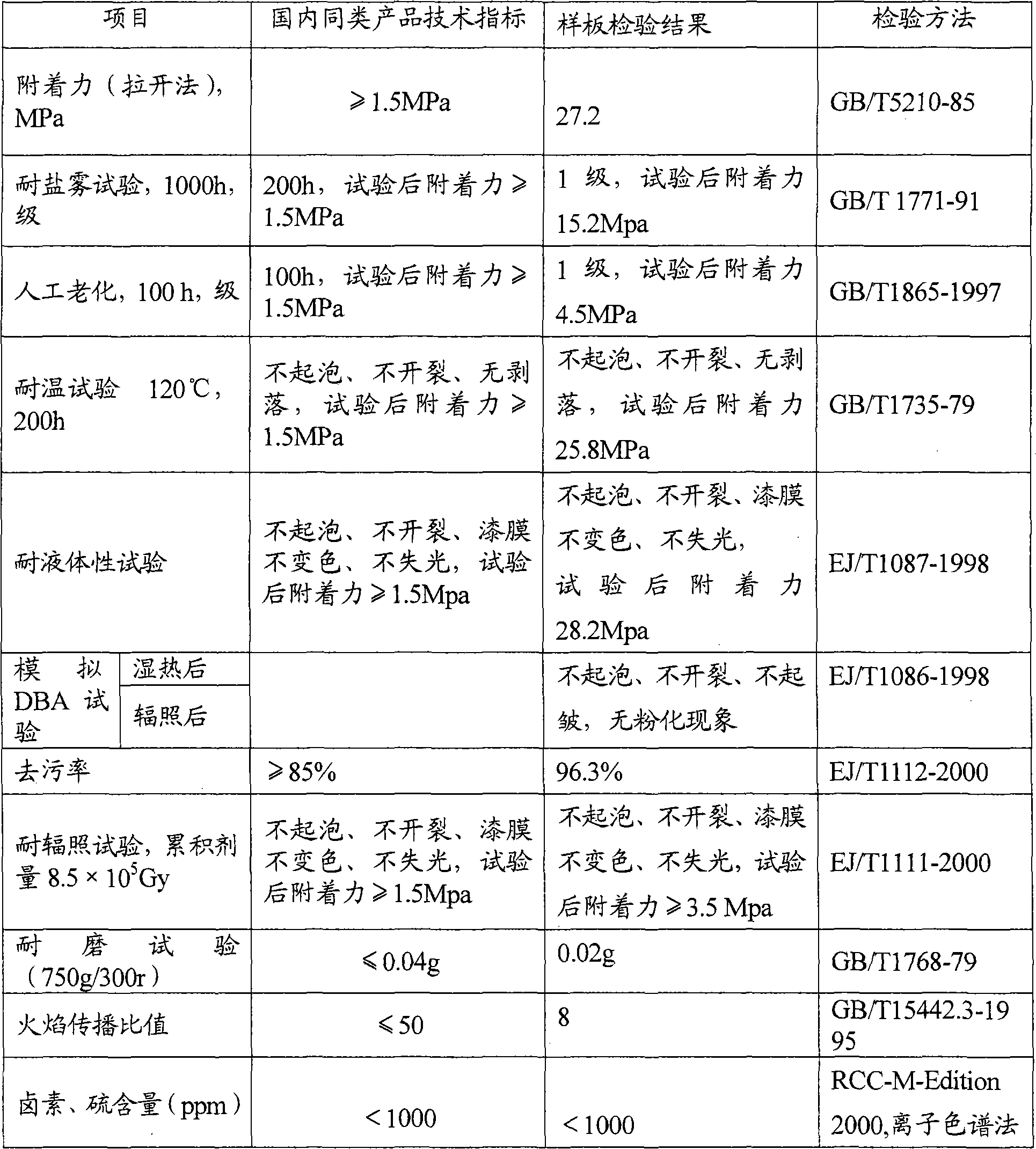

Epoxy protective coating system for high-power nuclear power station

ActiveCN101781508AImprove corrosion resistanceGood radiation protectionAnti-corrosive paintsShieldingNuclear gradeNuclear power

The invention relates to an epoxy protective coating system for a high-power nuclear power station. Priming coat comprises a component A1 and a component B with the weight ratio of 4-6, and finishing coat comprises a component A2 and the component B with the weight ratio of 3-5:1.. The component A1 comprises 20 to 50% of epoxy resin, 10 to 40% of anti-corrosion paint, 10 to 25% of radiation-resistant stuffing, 0.1 to 3% of addition agent and the balance of menstruum by weight percent. The component A2 comprises 20 to 50% of the epoxy resin, 10 to 40% of the anti-corrosion paint, 5 to 20% of the radiation-resistant stuffing, 0.1 to 3% of the addition agent and the balance of the menstruum by weight percent. The component B is a radiation-resistant epoxy-amine adduct curing agent, and is synthesized by 10 to 30% of liquid epoxy resin, 30 to 70% of polyamine with primary amine groups and 20 to 60% of the menstruum. The corrosion resistance and radiation resistance can meet the requirements of nuclear grade paint and can pass simulation DBA tests when the coating system is used for a high-power nuclear power station.

Owner:CHINA NAT OFFSHORE OIL CORP +2

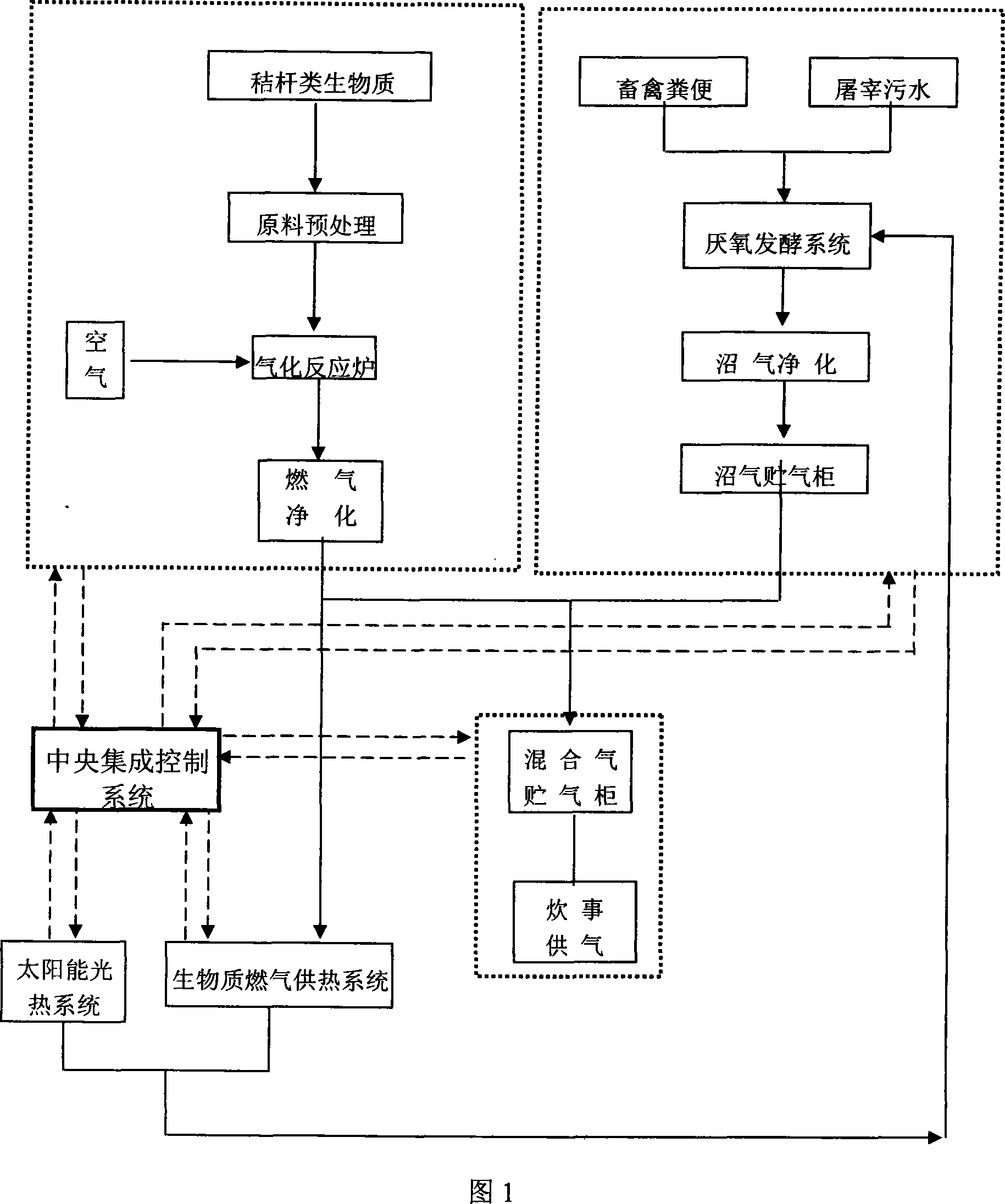

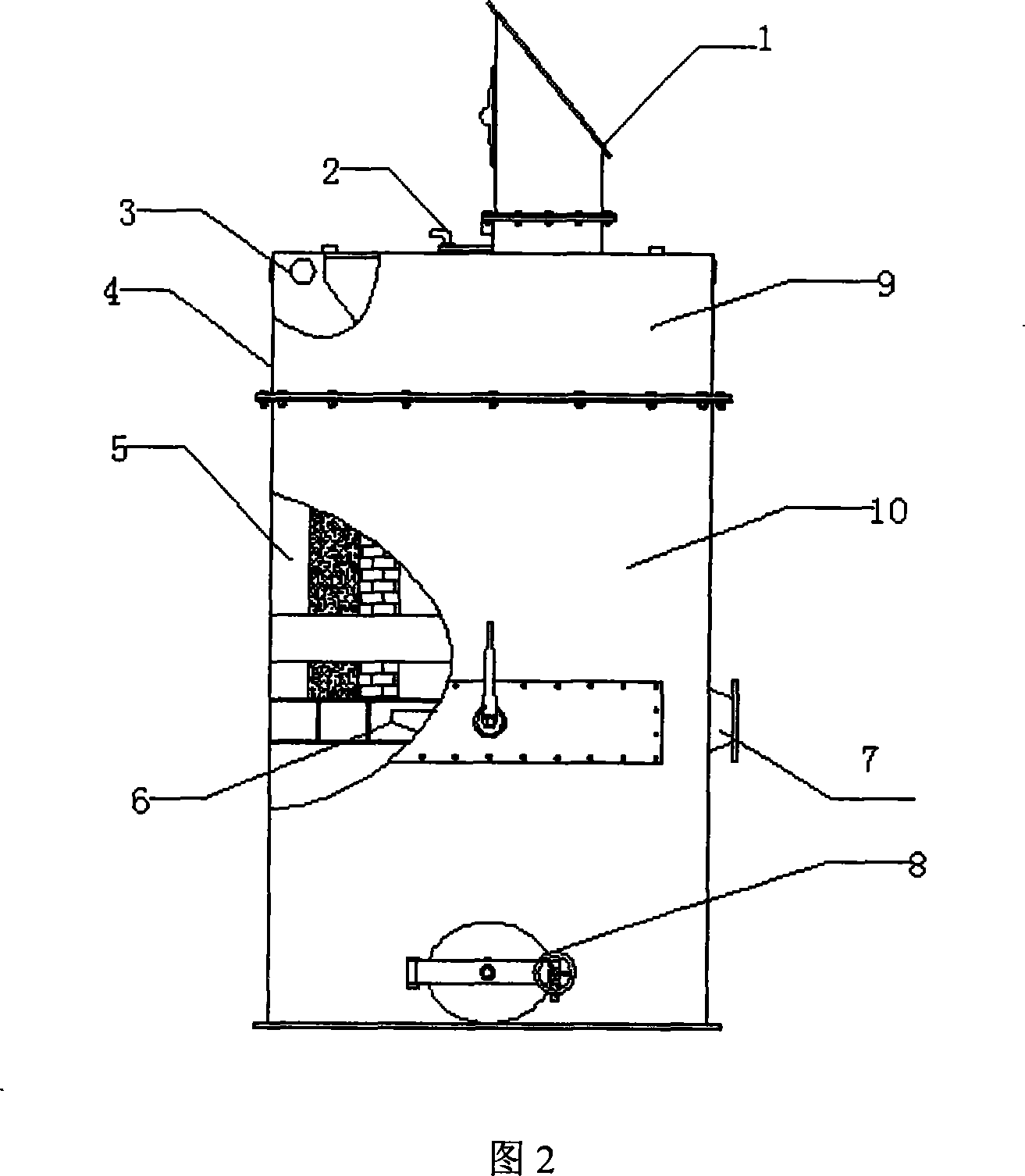

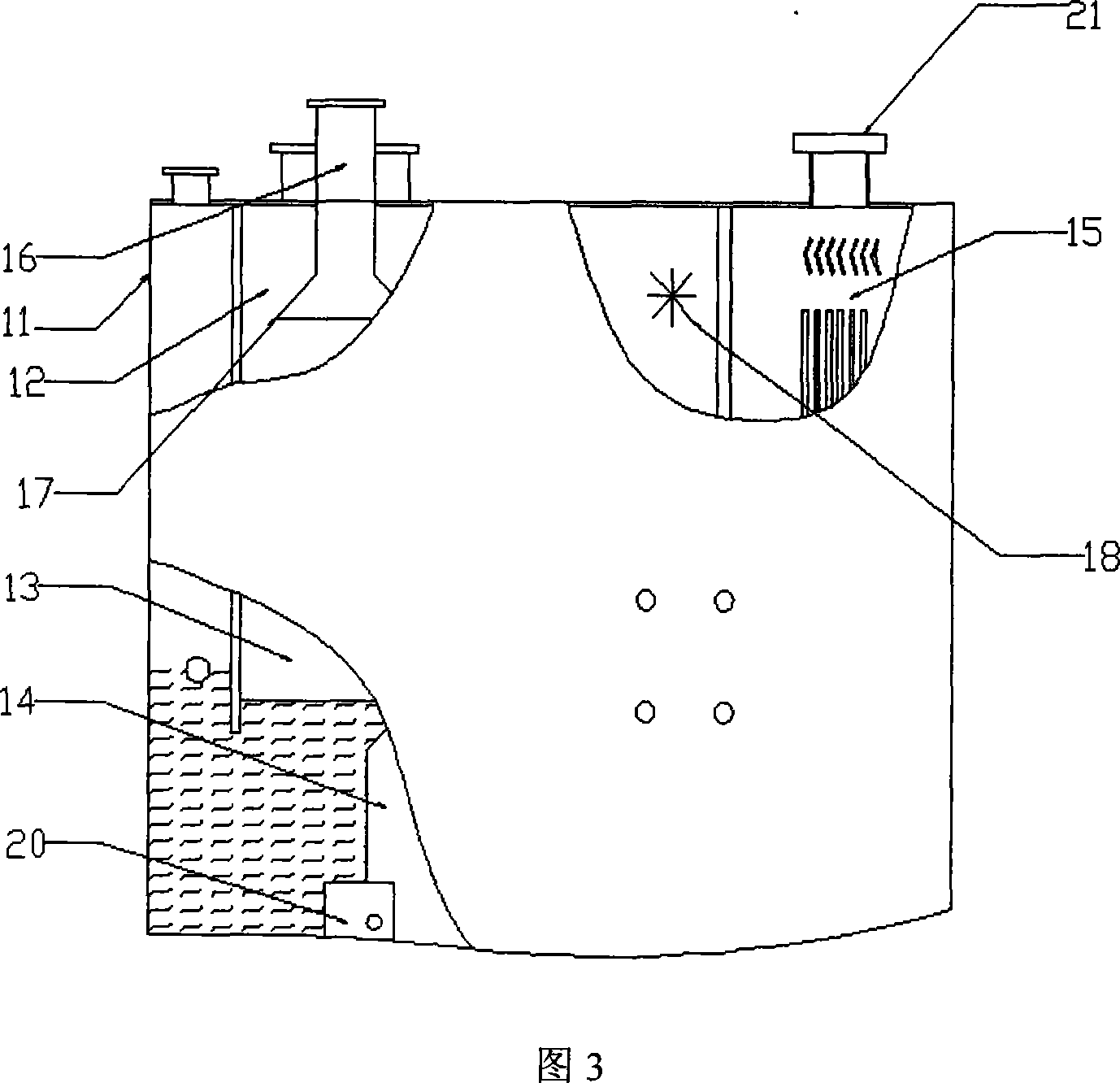

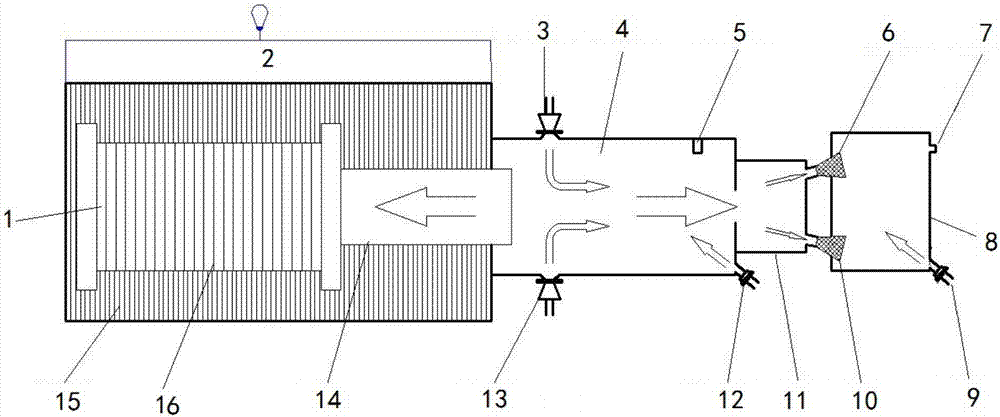

Biological energy-marsh gas fermentation-solar energy integrated utilization system

InactiveCN101063080AEfficient use ofAvoid corrosionSolar heat devicesGas production bioreactorsMarshFermentation

The invention discloses a biological mass energy-marsh gas fermentation-solar energy integrated usage system, which is characterized by the following: comprising biomass evaporated unit, marsh gas anaerobic fermentation unit, central integrated control unit, solar energy light hot unit, biomass gas heat supply unit, biomass fuel and marsh gas automatic mixed unit, fuel transmitting and distributing and user unit; connecting the central control unit and the other units separately; connecting the biomass gasifying unit with the biomass fuel heat supply unit, biomass fuel and marsh gas automatic mixed unit separately; connecting the marsh gas anaerobic fermentation unit with the biomass fuel and marsh automatic mixed unit; connecting the biomass fuel and marsh automatic mixed unit with fuel transmitting and distributing and user unit; connecting the solar energy light hot unit and biomass gas heat supply unit with the marsh gas anaerobic fermentation unit separately. This invention can transform the pollution as marsh gas source.

Owner:浙江网新百川环境科技有限公司

Texturization additive for polycrystalline silicon slices and use method of texturization additive

ActiveCN103409808AImprove uniformityReduce the number of generatedAfter-treatment detailsSemiconductor/solid-state device manufacturingCrystallographyElectrical battery

The invention provides a texturization additive for polycrystalline silicon slices. The invention further provides a texturization liquid used for texturization for the polycrystalline silicon slices, which contains an acid solution and the texturization additive for the polycrystalline silicon slices. The invention further provides a texturization method for the polycrystalline silicon slices, which is used for performing surface texturization on the polycrystalline silicon slices by virtue of the texturization liquid. The texturization additive for the polycrystalline silicon slices is applied to texture surface production for the polycrystalline silicon slices, and capable of obtaining a micro-structure texture surface which is good in uniformity and free of obvious chromatic aberration among crystalline particles, so that reflectivity is decreased, and the generation quantity of black lines is effectively reduced; the texturization additive for the polycrystalline silicon slices is used for changing a reaction mechanism and controlling a reaction speed, so that texturization can be performed in an approximate room-temperature condition, and temperature control cost is greatly decreased; roller trace can also be effectively removed, so that the silicon slices are cleaner and higher in matching with the next process, and battery performance is more stable.

Owner:JIANGSU JIEYANG ENERGY EQUIP CO LTD

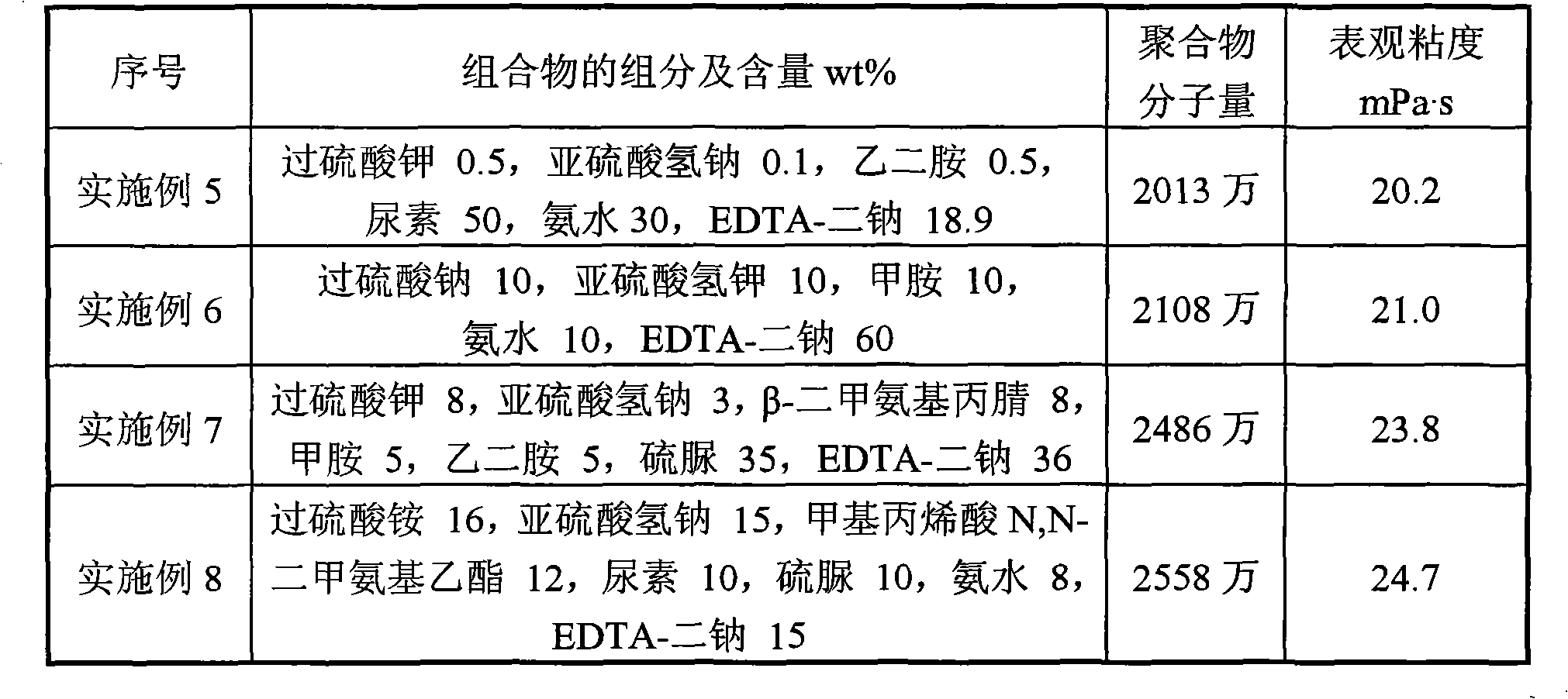

Initiator composition used for synthesizing polyacrylamide capable of displacing oil

ActiveCN102372806AImprove solubilityEven growthDrilling compositionEthylenediamineAmmonium compounds

The invention relates to an initiator composition used for synthesizing polyacrylamide capable of displacing oil, which mainly solves the problems of low polyacrylamide molecular weight, poor heat resistance and salt resistance performances and difficult satisfaction for technical requirement of tertiary oil extraction. The initiator composition used for synthesizing polyacrylamide capable of displacing oil comprises the following ingredients by weight percentage: (a) 0.5-20% of persulfate; (b) 0.1-40% of sulfite or acid sulfite; (c) 0.5-20% of NR1R2R3-represented trialkylamine compounds or N<+>R4R5R6R7-represented quaternary ammonium compounds or NH2R8-represented aliphatic amine compounds, wherein R1-R7 in the formula are selected from C1-C14 straight chain or branched chain alkyl or alkyl derivatives, R8 is selected from straight chain or branched chain alkyl or alkyl derivatives; (d) 10-80% of urea, thiourea or ammonia liquor; (e) 5-60% of ethylenediaminetetraacetic acid. The technical scheme of the invention better solves the problems and can be used in industrial production of oil displacement.

Owner:CHINA PETROLEUM & CHEM CORP +1

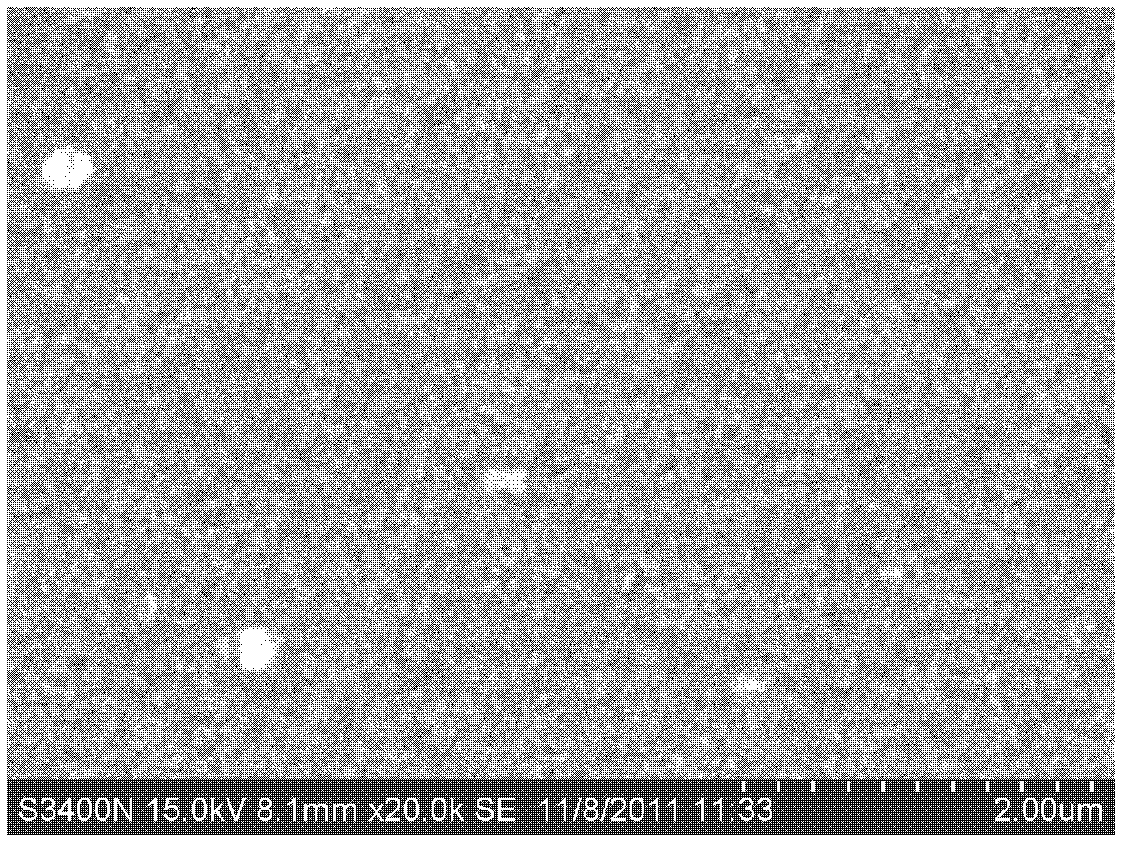

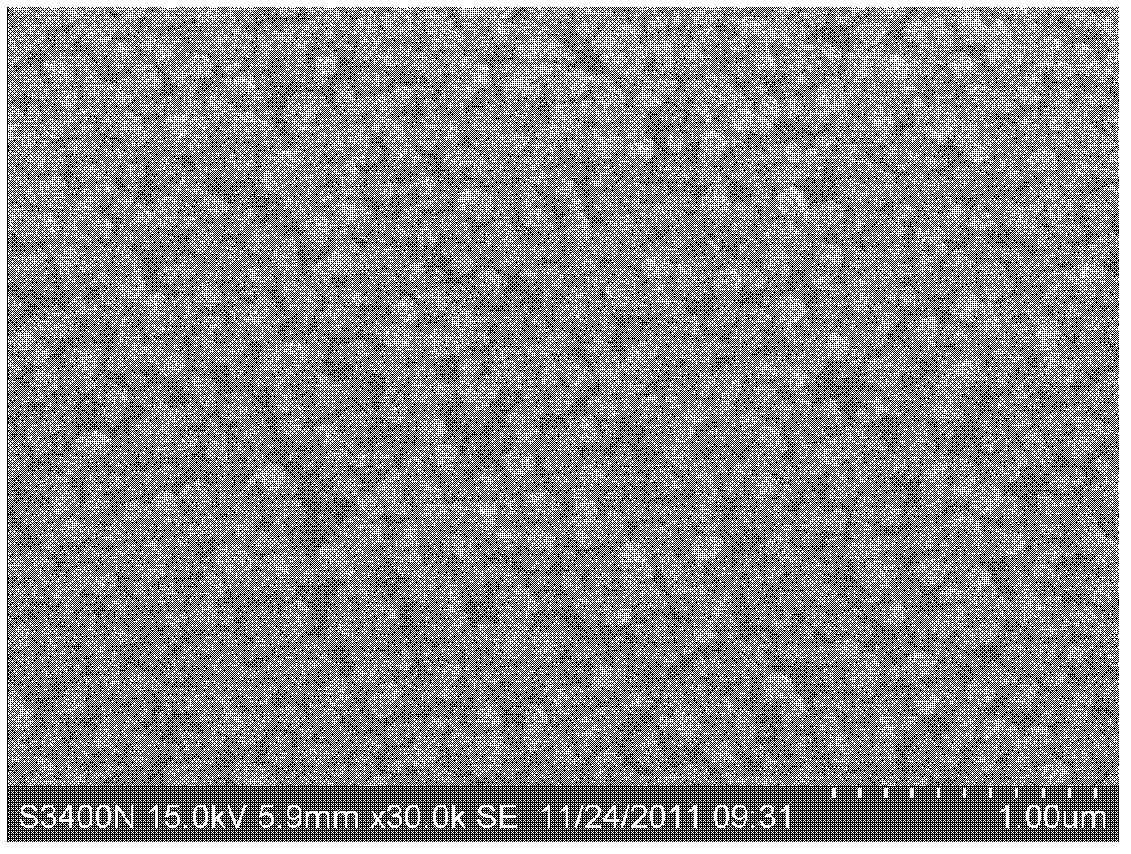

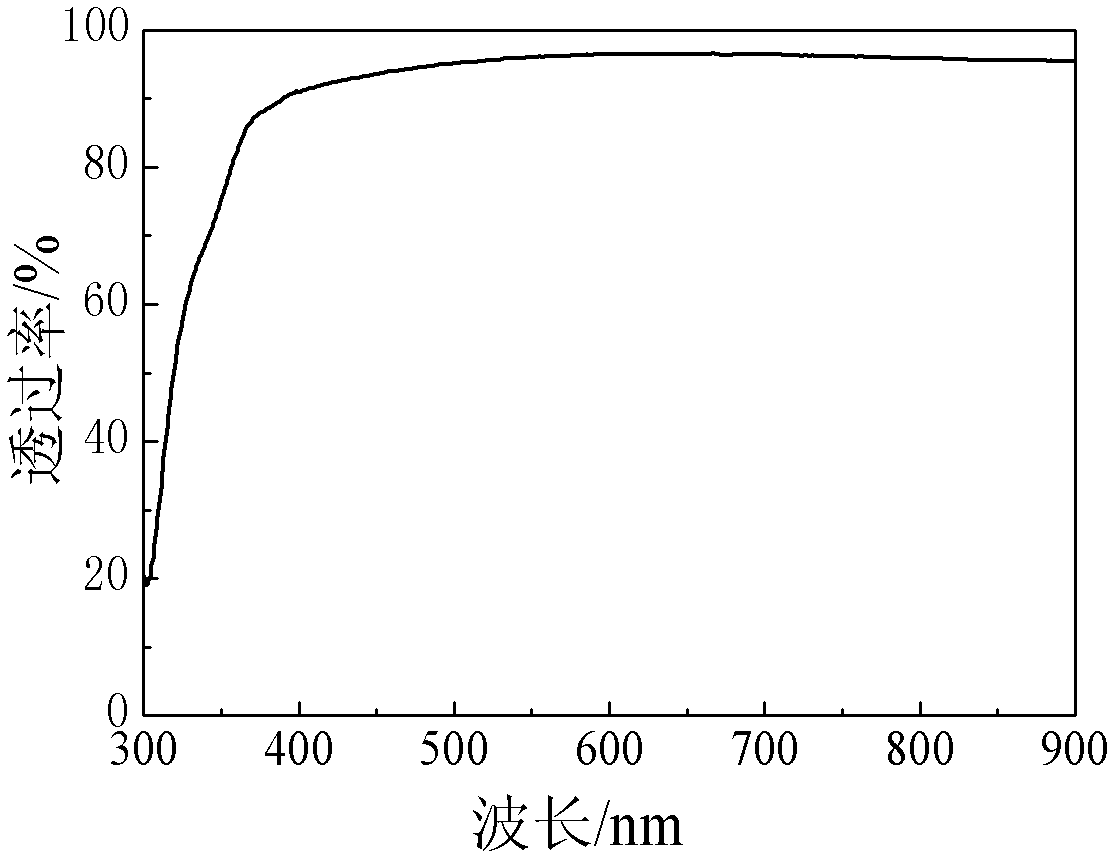

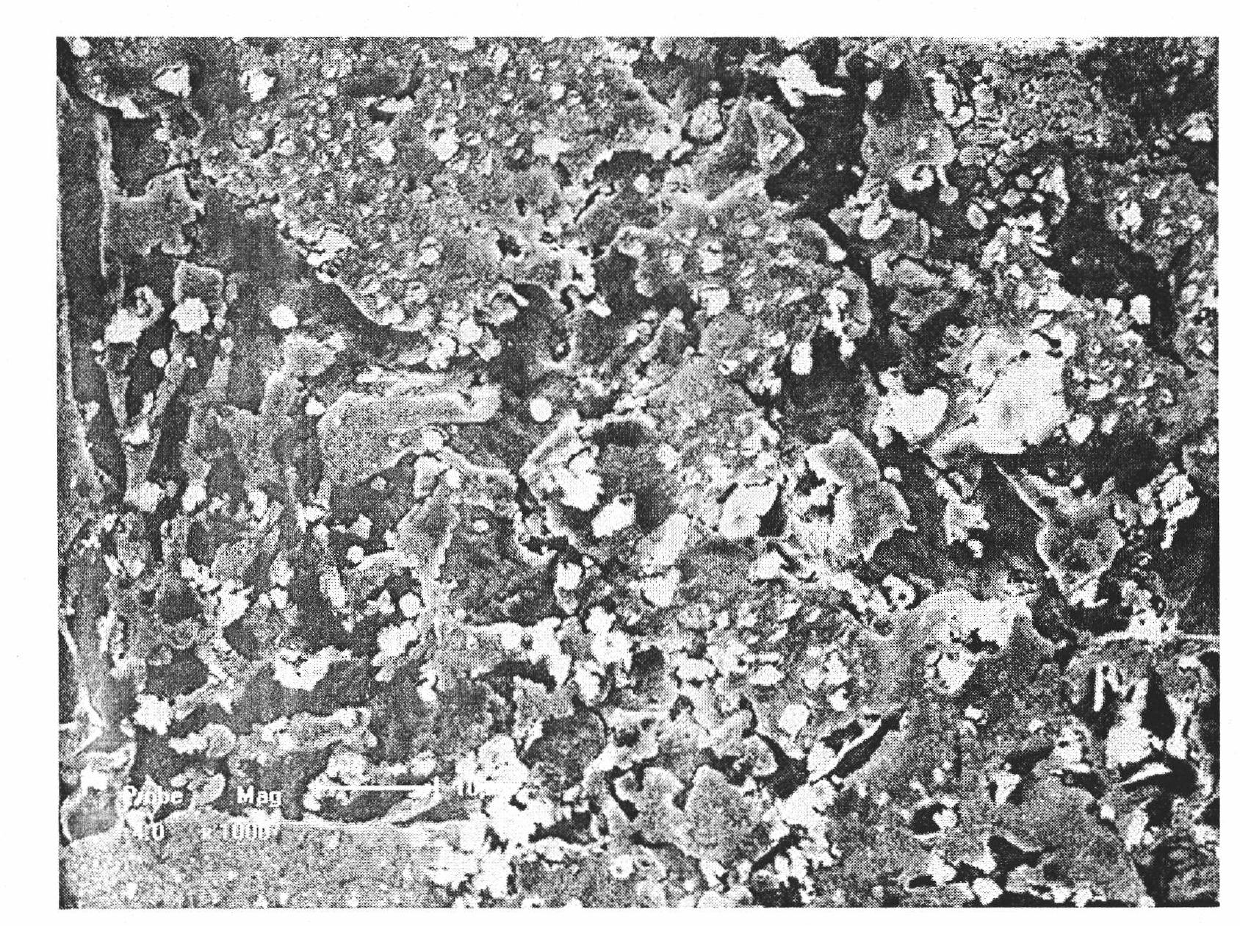

Preparation method for buffering layer material of copper indium gallium selenide film solar battery

InactiveCN102544237AQuality improvementControl reaction speedFinal product manufactureSemiconductor devicesIndiumElectrical battery

The invention discloses a preparation method for a buffering layer material of a copper indium gallium selenide film solar battery. By the method, a precursor of chemical bath reaction is prepared by using a zinc sulfate solution as a Zn<2+> source, a thiourea solution as a S<2-> source, ammonia water as a buffering agent and sodium citrate as a complexing agent; and a Zn(O,S) semiconductor film with uniform and compact grain size distribution and good adhesive force is prepared on a copper indium gallium selenide film and the common glass substrate and serves as the buffering layer of the copper indium gallium selenide film solar battery. The Zn(O,S) instead of CdS serves as the buffering layer of the copper indium gallium selenide film solar battery, so production of the copper indium gallium selenide film solar battery is environment-friendly and economic. The band gap width of the Zn(O,S) is more than that of the CdS, so more incident photons can reach an absorption layer through the buffering layer, short-circuit current of the battery is increased and photoelectric conversion efficiency of the battery is improved.

Owner:GUANGDONG UNIV OF TECH

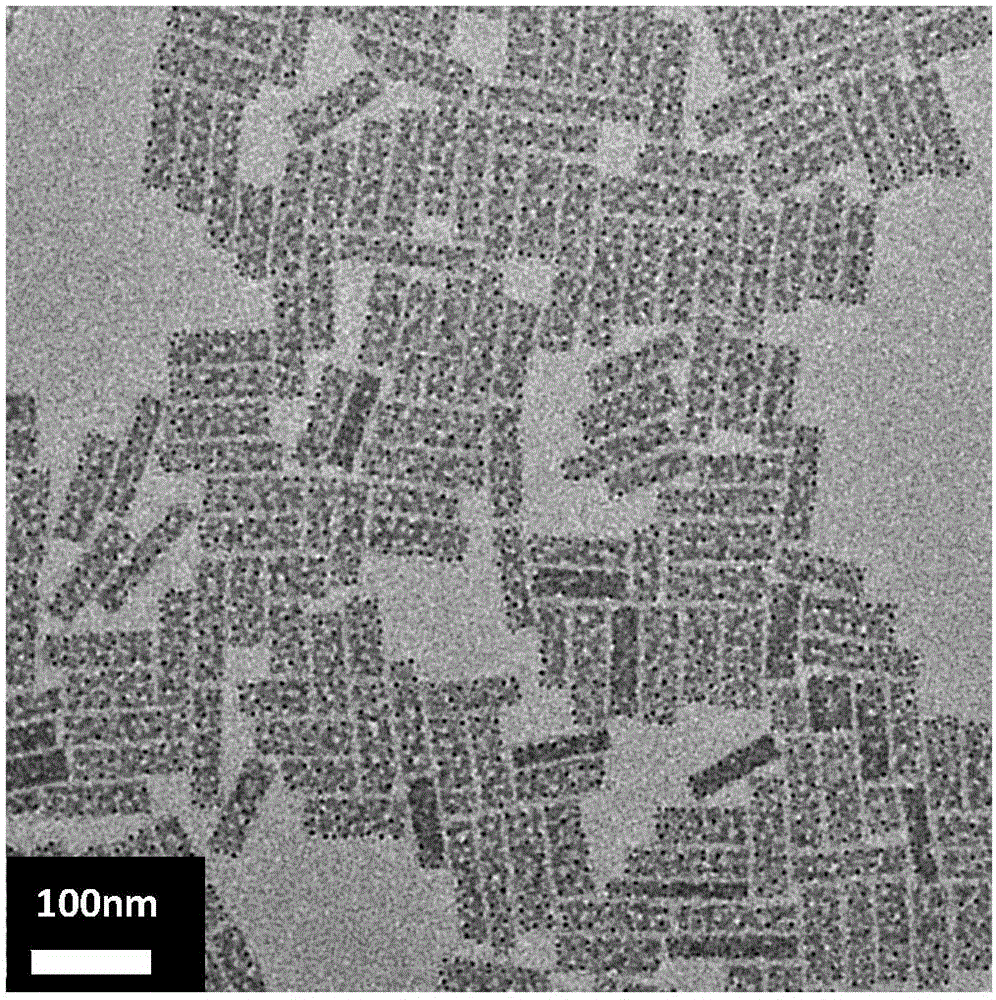

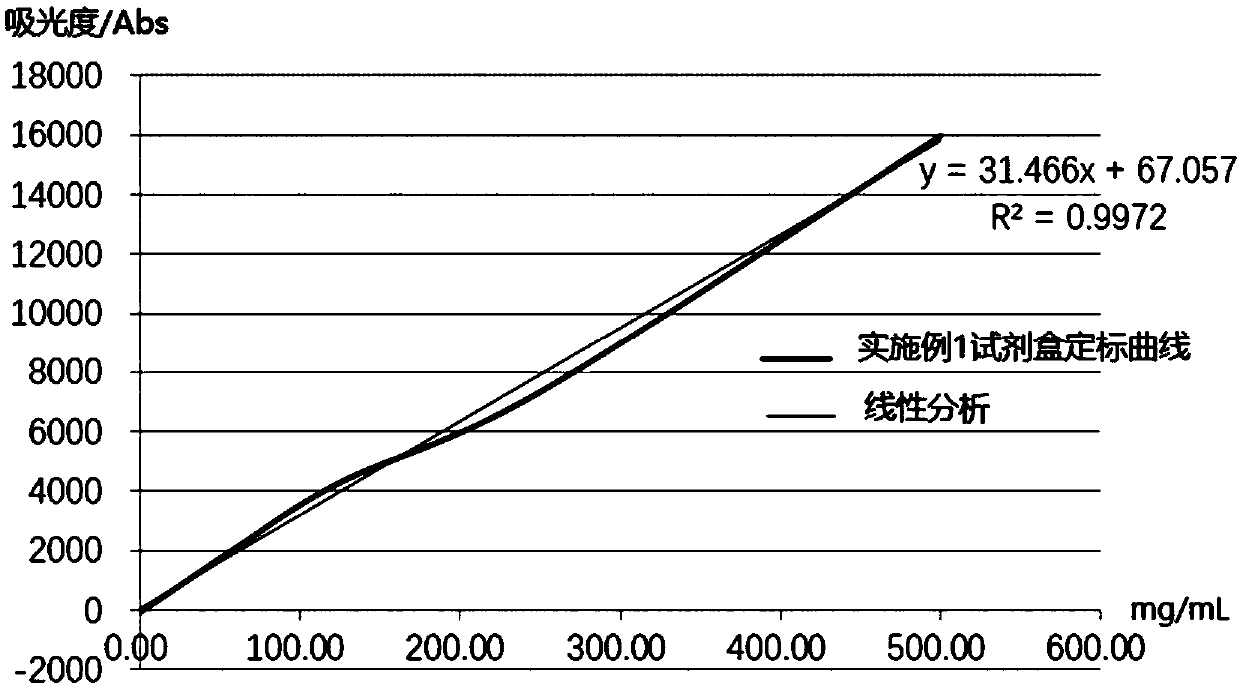

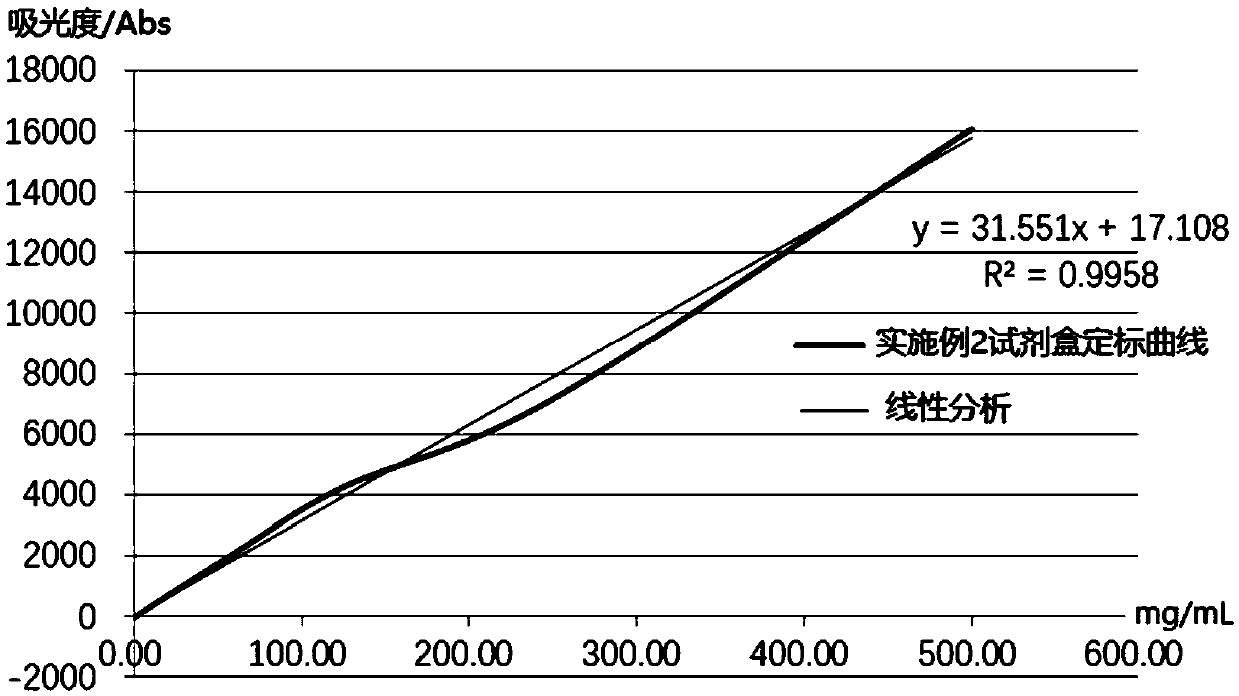

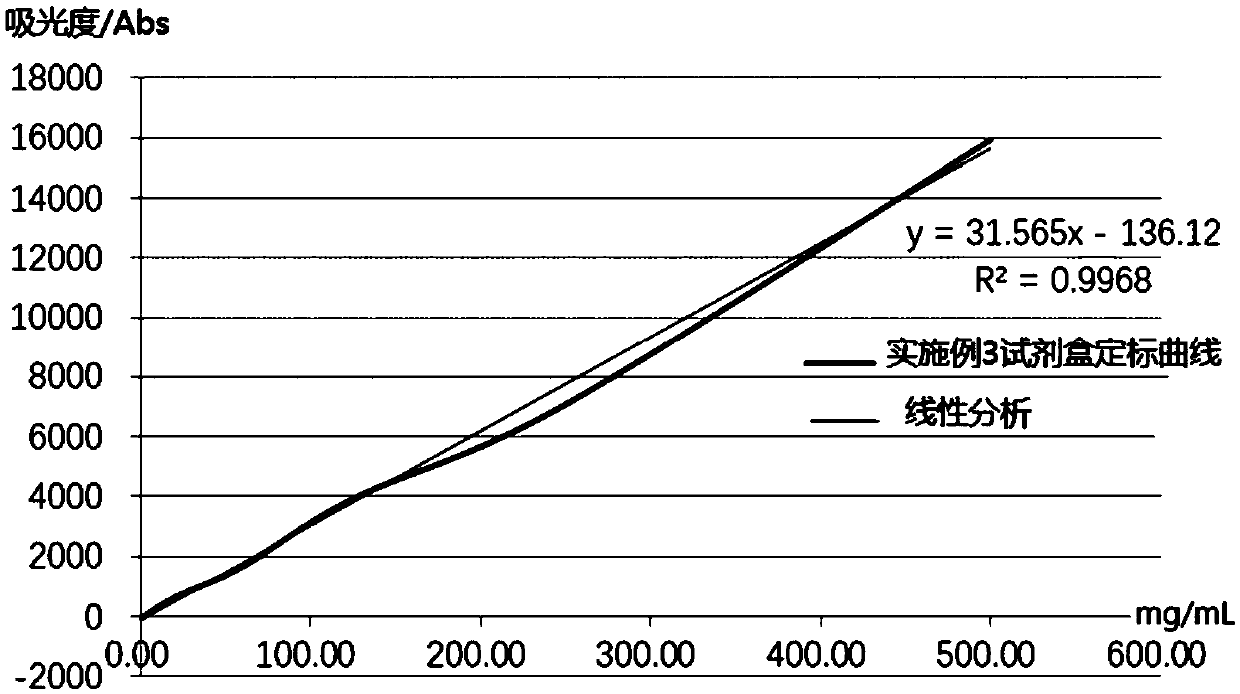

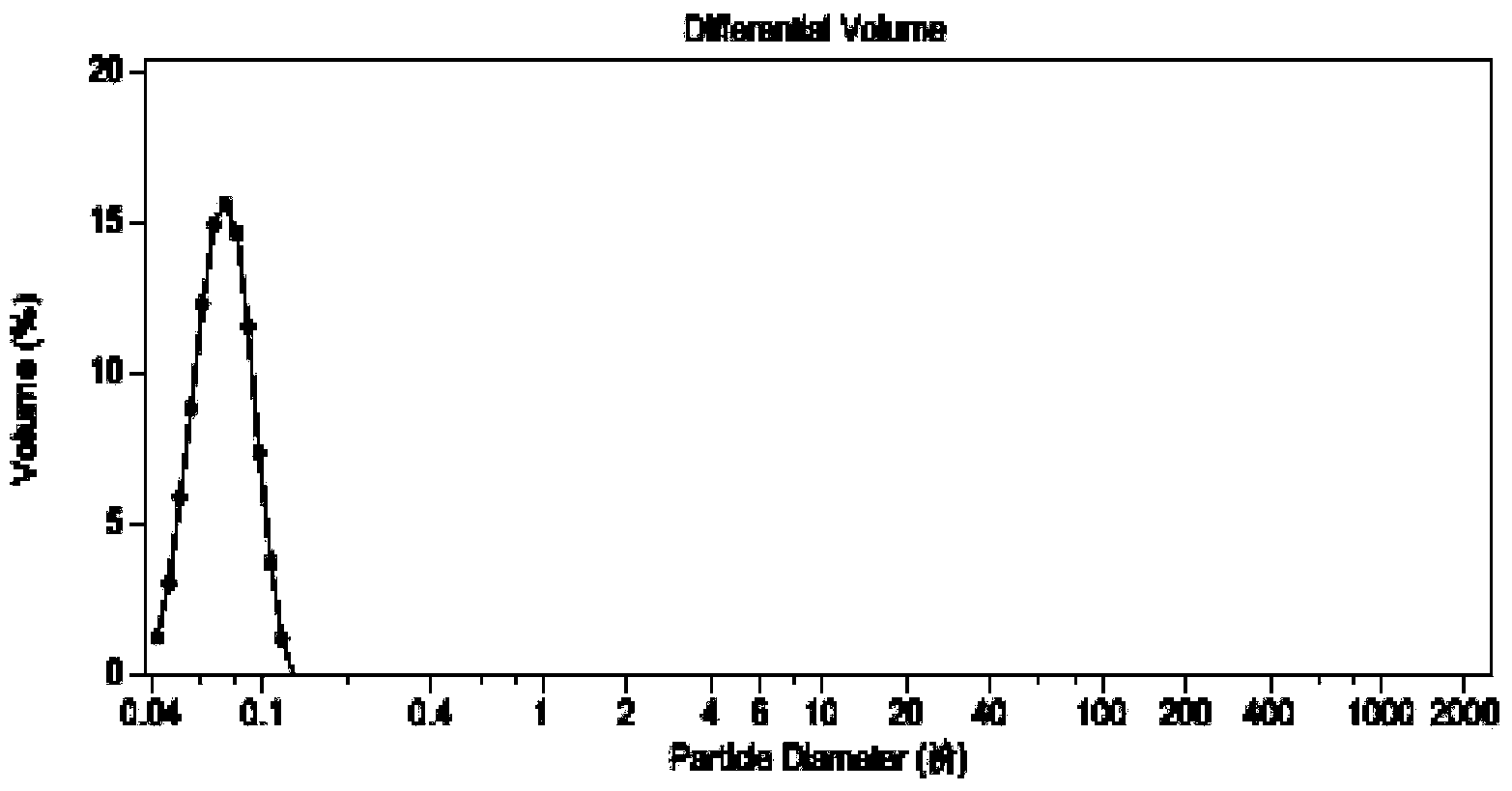

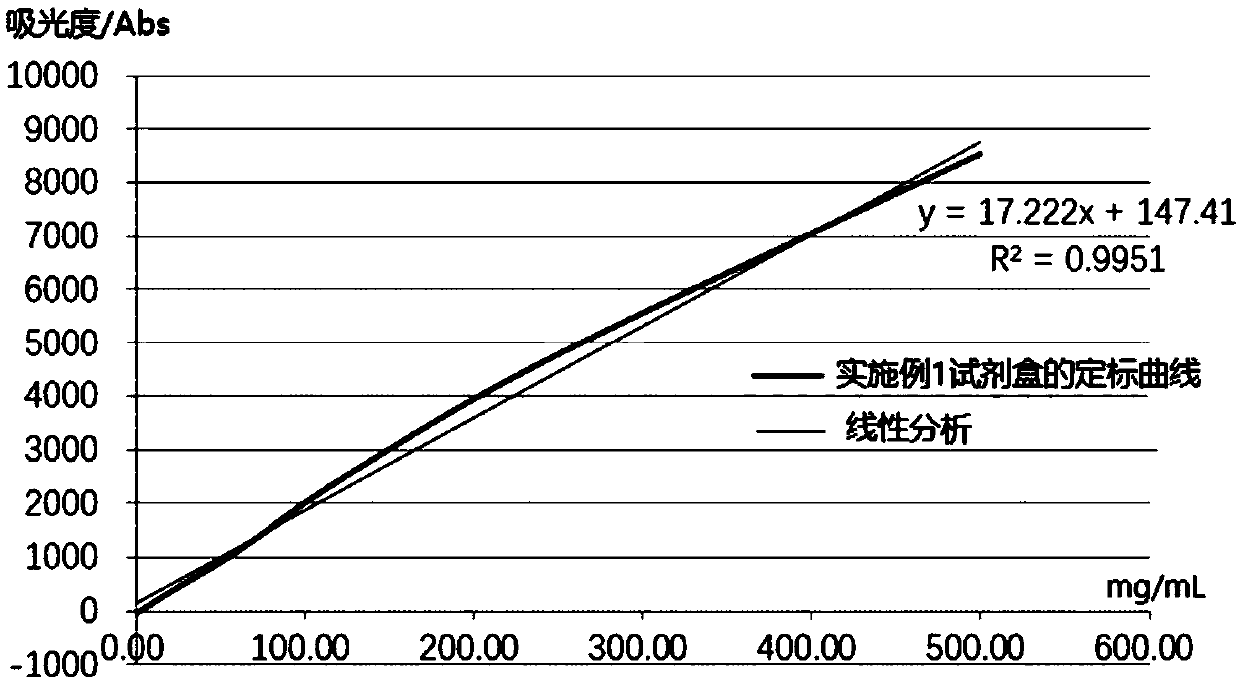

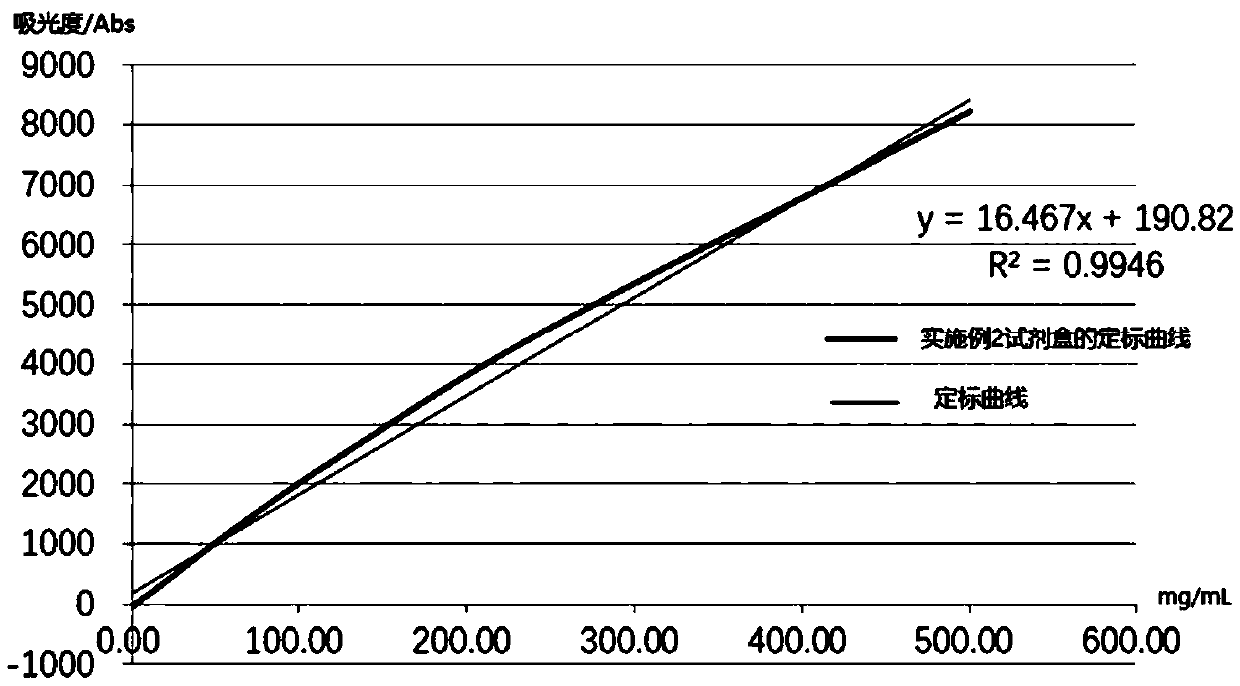

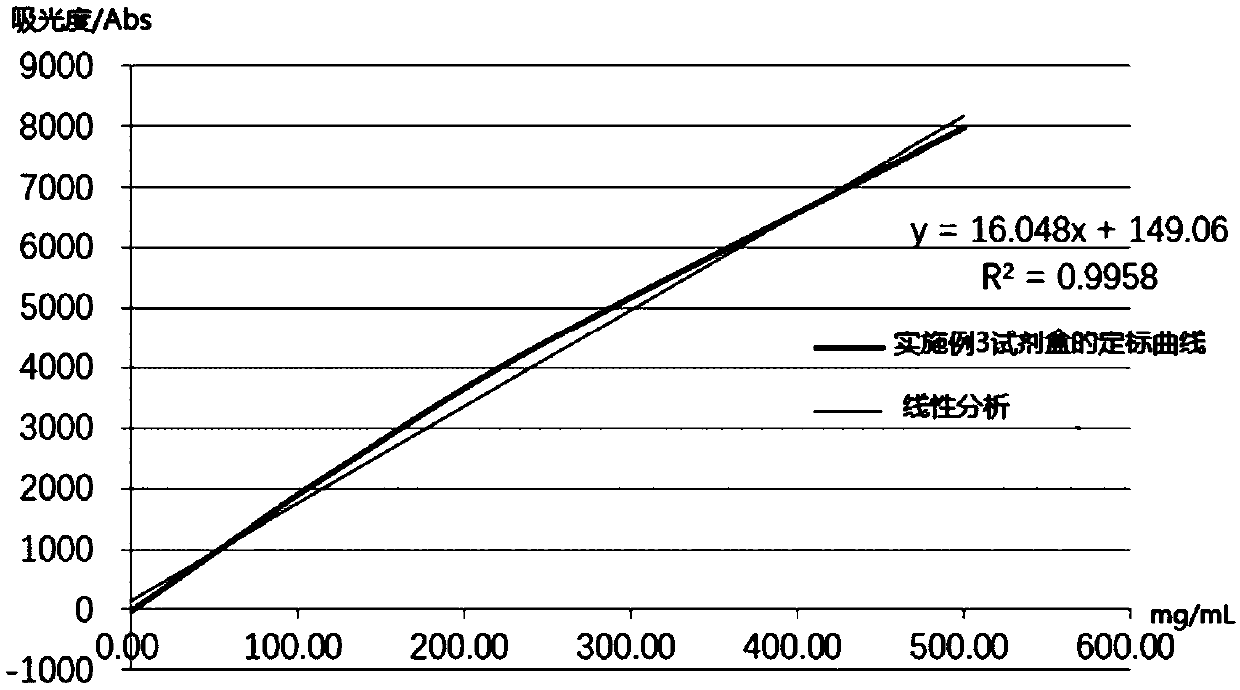

Human serum amyloid protein A determination kit with high sensitivity and wide detection range

InactiveCN109633167AWide detection rangeGuaranteed SensitivityDisease diagnosisBiological testingMicrosphereConcentration gradient

The embodiment of the invention relates to the field of immunodetection, in particular to a human serum amyloid protein A determination kit with high sensitivity and a wide detection range. The humanserum amyloid protein A determination kit comprises a reagent 1, a reagent 2 and SAA calibrators with different concentration gradients, wherein the reagent 2 comprises carboxylated latex microspheresonly labeled with human SAA monoclonal antibodies and carboxylated latex microspheres only labeled with human SAA polyclonal antibodies; the average particle size of the carboxylated latex microspheres only labeled with the human SAA monoclonal antibodies is larger than the average particle size of the carboxylated latex microspheres only labeled with the human SAA polyclonal antibodies. The kitcan be used for detecting a single sample within 10 minutes; the kit has the advantages that the kit is simple in structure and excellent in precision, accuracy, linearity, interference resistance andother indexes, can well diagnose early inflammation of infectious diseases, can detect the content of SAA in serum and the content of SAA in blood plasma, is very suitable for clinical biochemical analyzers, and greatly facilitates clinical examination.

Owner:BEIJING BEIER BIOENG

Special slow/controlled release compound fertilizer for capsicum, and preparation method thereof

ActiveCN103483095AIncrease productionReduce releaseFertilizer mixturesControl releaseCapsicum annuum

The invention provides a special slow / controlled release fertilizer for capsicum. The special slow / controlled release fertilizer for capsicum is characterized in that the special slow / controlled release fertilizer for capsicum comprises, by mass, 0.10-0.15% of N-(n-Butyl)thiophosphoric triamide or quinhydrone and 0.25-0.30% of dicyandiamide. A preparation method of the special slow / controlled release fertilizer for capsicum comprises the following steps: combining fertilizers of macro, medium and trace elements of N, P, K, Mg, B, Zn and the like with organic fertilizers comprising high-quality decomposed rapeseed meal, chicken manure and the like, adding a urease inhibitor and a nitration inhibitor, and mixing. The special slow / controlled release fertilizer for capsicum has a slow release effect in soil, is rich in all nutritional elements specially required by the growth of capsicum, can effectively satisfy the nutrient needs of the capsicum of different growth stages, and can effectively improve the capsicum output.

Owner:SOUTHWEST UNIV

Anti-scaling multi-hydrogen retarded acid for highly argillaceous sandstone reservoir

The invention provides an anti-scaling multi-hydrogen retarded acid for a highly argillaceous sandstone reservoir. The retarded acid is prepared from the following raw materials by weight: 3 to 5 parts of hydrochloric acid, 3 to 5 parts of amino trimethylene phosphonic acid, 3.5 to 6 parts of ammonium bifluoride, 1 to 2.2 parts of a corrosion inhibitor, 0.5 to 1 part of a ferric ion stabilizing agent, 0.2 to 1 part of a clay stabilizing agent, 0.3 to 1 part of a de-emulsifier, 0.2 to 1 part of a mutual solvent and 78 to 87 parts of water. The anti-scaling multi-hydrogen retarded acid is used in the petroleum industry to control a reaction speed of hydrofluoric acid and clay so as to realize deep acidization of the highly argillaceous reservoir.

Owner:CHINA PETROLEUM & CHEM CORP +1

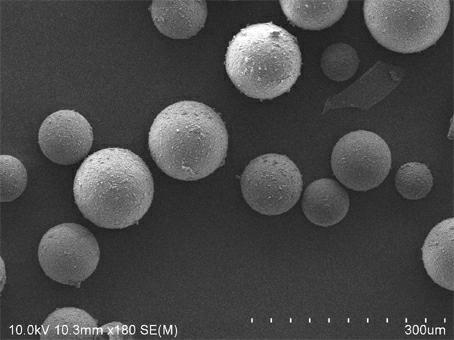

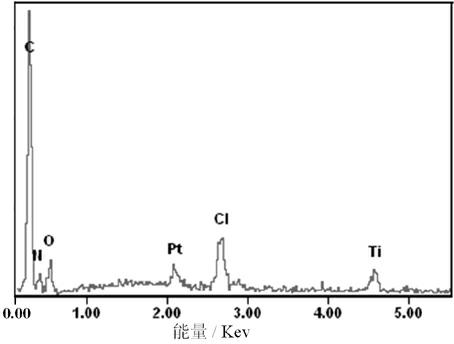

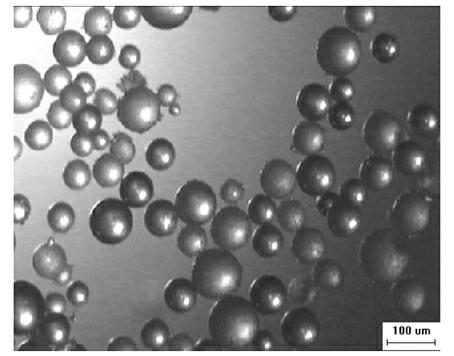

High-intensity urea-formaldehyde resin microcapsule and preparation method thereof

InactiveCN102167885ARegular shapeFlat surfaceMicroballoon preparationMicrocapsule preparationInorganic particleDistilled water

The invention relates to a high-intensity urea-formaldehyde resin microcapsule. Titanium dioxide or silicon dioxide inorganic nanoparticles with particle diameter of 10 to 50 nm are doped in the wall material of the microcapsule. A preparation method of the high-intensity urea-formaldehyde resin microcapsule comprises the following steps of: mixing urea and formaldehyde according to a molar ratio of the urea to the formaldehyde of 1:1.75; adjusting the pH value to 8.5 to 9.0; stirring at the constant temperature of between 70 and 75 DEG C for 1 hour; diluting by adding distilled water to obtain urea-formaldehyde prepolymer solution with mass concentration of 35 to 60 percent; taking 10 to 20 milliliters of the urea-formaldehyde prepolymer solution and adjusting the pH value to 4.0 to 4.2; reacting at the temperature of between 23 and 26 DEG C for 1 hour to obtain water-soluble urea-formaldehyde resin; dispersing the inorganic nanoparticles into an oil phase to prepare 0.04 to 0.2 mass percent of inorganic particle dispersion liquid; adding 40 milliliters of 7.3 mass percent of deionized water solution of a system modifier into the water-soluble urea-formaldehyde resin; adding 4.5 milliliters of inorganic particle dispersion liquid dropwise under stirring to form emulsion and then adjusting the pH value to 3.0 to 3.5; reacting at the temperature of between 23 and 26 DEG C for 1 hour; adding 0.3 to 3 grams of curing agent; heating the product to 45 to 50 DEG C; performing heat-preserving reaction for 2 hours; and performing suction-filtration and drying to obtain the urea-formaldehyde resin microcapsule, of which the wall material is doped with the inorganic nanoparticles.

Owner:SOUTHEAST UNIV

Microcapsule embedded leavening agent and preparation method thereof

The present invention relates to the technical field of food additives and particularly relates to a microcapsule embedded leavening agent and a preparation method thereof. The microcapsule embedded leavening agent comprises wall materials at a weight percentage of 30%-80% and preservative core materials at a weight percentage of 20%-70%. The core materials of the leavening agent are embedded with the wall materials; the wall materials are at least one of distilled glyceryl monostearate, hydrogenated vegetable oil, diacetyl tartaric acid monoglyceride or diglyceride, polyglycerol fatty acid esters, sodium stearoyl lactate, phospholipids and beeswax; and the core materials of the leavening agent are at least one of sodium bicarbonate, dihydrogen disodium pyrophosphate, calcium hydrophosphate and calcium carbonate. The microcapsule embedded leavening agent is good in use effects, can control the speed of the reaction of the leavening agent, is conductive to releasing in the subsequent baking process, and thereby grants baked food fluffy volume and soft quality.

Owner:GUANGDONG GUANGYI TECH IND

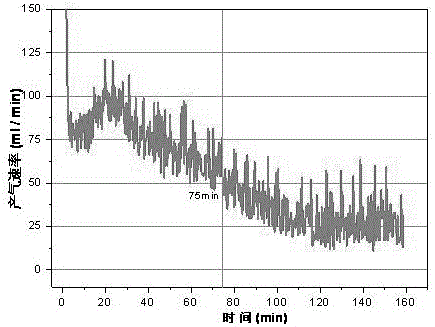

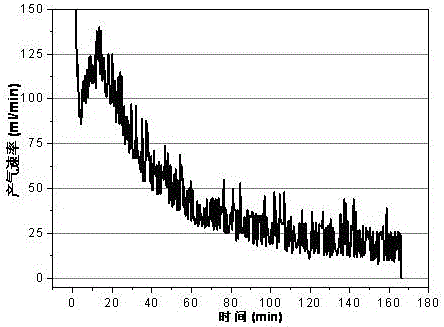

Hydrogen production reaction with controllable hydrogen production speed

InactiveCN105819399AHigh purityExtended service lifeHydrogen productionHydrogen/synthetic gas productionChemistryAluminium

The invention belongs to the technical field of chemical engineering and provides a hydrogen production reaction with the controllable hydrogen production speed to solve the problem that the hydrogen production rate is affected due to different degrees of alkalinity in a traditional aluminum water hydrogen production method and the problem that manual control cannot be achieved due to the high hydrogen production speed generated when PH is too high.The hydrogen production reaction includes the process that a hydrogen production agent generates a hydrolysis reaction under the effect of a solid catalyst.The alkaline solid catalyst is added in the process of mixed hydrogen production of a hydrogen-from-aluminum agent and a sustained-release agent, the hydrogen production rate and time period can be effectively controlled, and hydrogen is generated at a uniform speed for use.

Owner:ZHEJIANG GEELY HLDG GRP CO LTD +1

Method for synthesizing in-situ formed ceramic particle reinforced iron-aluminum-based composites by laser combustion

InactiveCN101906572AIncrease profitImprove performanceSelf-propagating high-temperature synthesisIron powder

The invention discloses a method for synthesizing in-situ formed ceramic particle reinforced iron-aluminum-based composites by laser combustion, belonging to the technical field of materials. The in-situ formed ceramic particle reinforced iron-aluminum-based composites are prepared by the following steps of: putting tungsten ore powder, iron powder, aluminum powder and carbon powder in a ball mill for milling to obtain a mixed powder material; and compressing the mixed powder material into a pressed compact, transmitting a high-energy laser beam by employing a CO2 laser processing machine to ignite the surface of the pressed compact and trigger self-propagating high temperature synthesis of the pressed compact. By the invention, two ceramic particle reinforced phases are simultaneously formed on one substrate, which shortens the preparation process of the composites, lowers material manufacture cost and facilitates large-scale production and application.

Owner:LIAONING TECHNICAL UNIVERSITY

Molybdenum-aluminum intermediate alloy and production method thereof

The invention relates to an intermediate alloy for a titanium alloy and a production method thereof and specifically relates to a molybdenum-aluminum intermediate alloy and a production method thereof, belonging to the field of metallurgy. The alloy comprises the following components: 60-90% of Mo, not more than 0.1% of Fe, not more than 0.1% of O, not more than 0.1% of Si, not more than 0.05% of C, not more than 0.03% of N, not more than 0.01% of H and the balance of Al, wherein the percentage is the percentage by weight. The invention provides a process for granulating molybdenum oxide and an ATR (aluminothermic reduction) reaction process of the molybdenum-aluminum alloy, and the particle size of the molybdenum oxide after granulation is 0-15mm, so that the phenomenon of violent reaction during the ATR process because the molybdenum oxide particles are too fine can be solved, the safety in production is ensured, and the yield of the alloy can be improved.

Owner:BHN SPECIAL MATERIALS

Preparation method of eggshell hydrolysate, as well as product and application of eggshell hydrolysate

InactiveCN102524521AQuality improvementIncrease egg productionAnimal feeding stuffBiotechnologyElectrolytic agent

The invention discloses a preparation method of eggshell hydrolysate. The preparation method comprises the following specific steps of: collecting eggshells, and washing the collected eggshells to obtain the clean eggshells; placing the washed eggshells into an electrolyte solution prepared by a mixed solution of sodium chloride and hydrochloric acid for sterilization; collecting the sterilized eggshells, then drying and smashing the sterilized eggshells; and adding hydrochloric acid or acetic acid for carrying out acidolysis till the eggshells react with the hydrochloric acid or the acetic acid completely, filtering, collecting a filtrate, and obtaining the eggshell hydrolysate. The preparation method is simple, is low in cost, does not need any special equipment or reagent; and the prepared eggshell hydrolysate contains elements such as calcium, phosphorus, magnesium, and zinc, and can be used for improving the laying rate of poultry in later egg-laying period.

Owner:CHONGQING ACAD OF ANIMAL SCI

Nano-iron powder fuel power generation method and device

InactiveCN107355300AHigh activityHigh heat of reactionInternal combustion piston enginesExhaust apparatusThermal energyEnvironmental resistance

The invention discloses a nano-iron powder fuel power generation method and device. According to the scheme, nano-iron powder serves as fuel; the nano-iron powder and oxygen are mixed and ignited, and generated thermal energy is converted onto electric energy to realized power generation; hydrogen is introduced into a combustion product Fe3O4 for hydrogen reduction of Fe3O4, and recovery of the combustion product is realized. The nano-iron powder power generation method and device are high in thermal efficiency, friendly to environment, free of pollution, reusable, energy-saving, safe, reliable, low in cost and capable of replacing existing no-renewable energy resources and has great development prospects.

Owner:HEBEI HANGUANG HEAVY IND

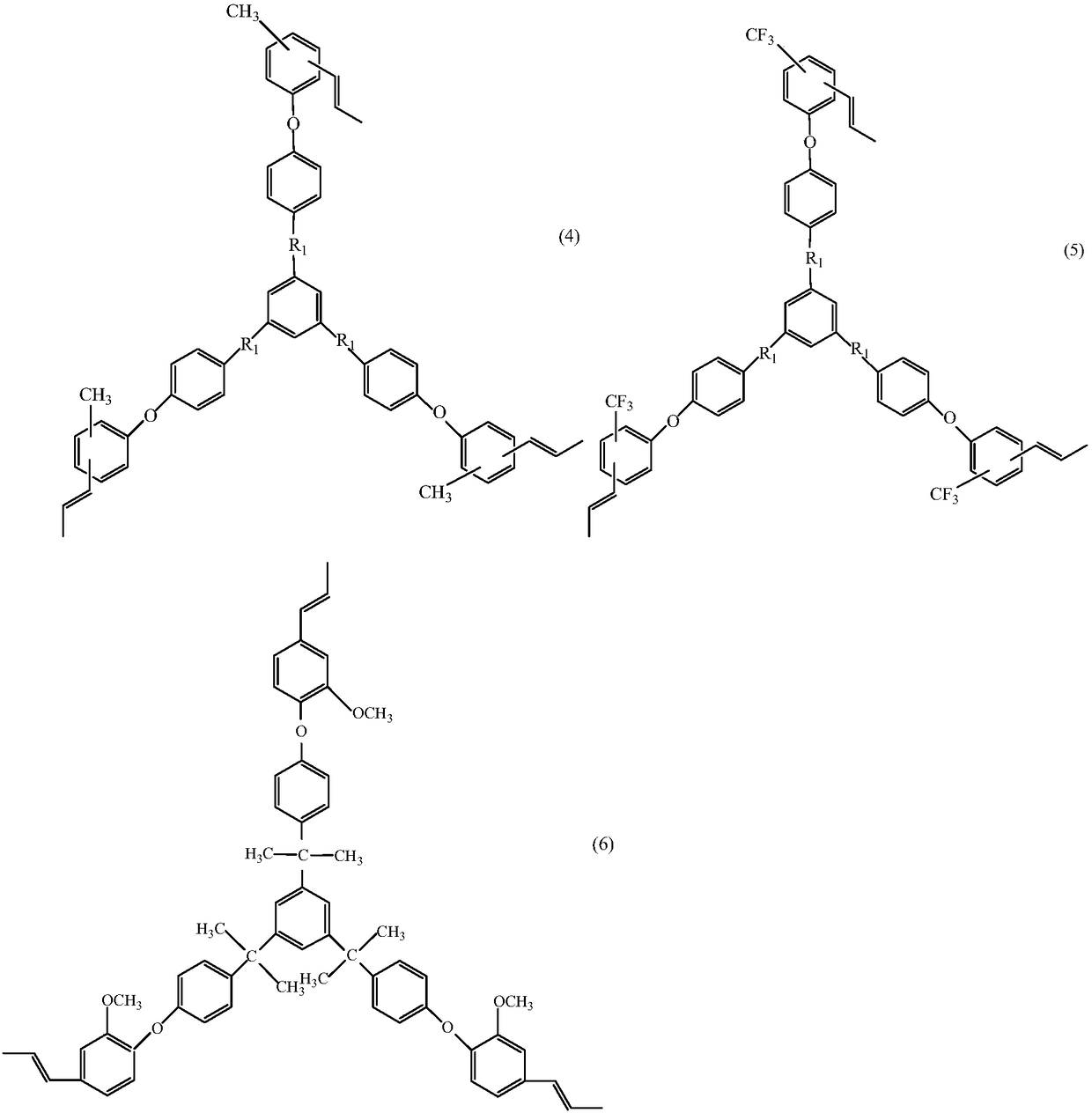

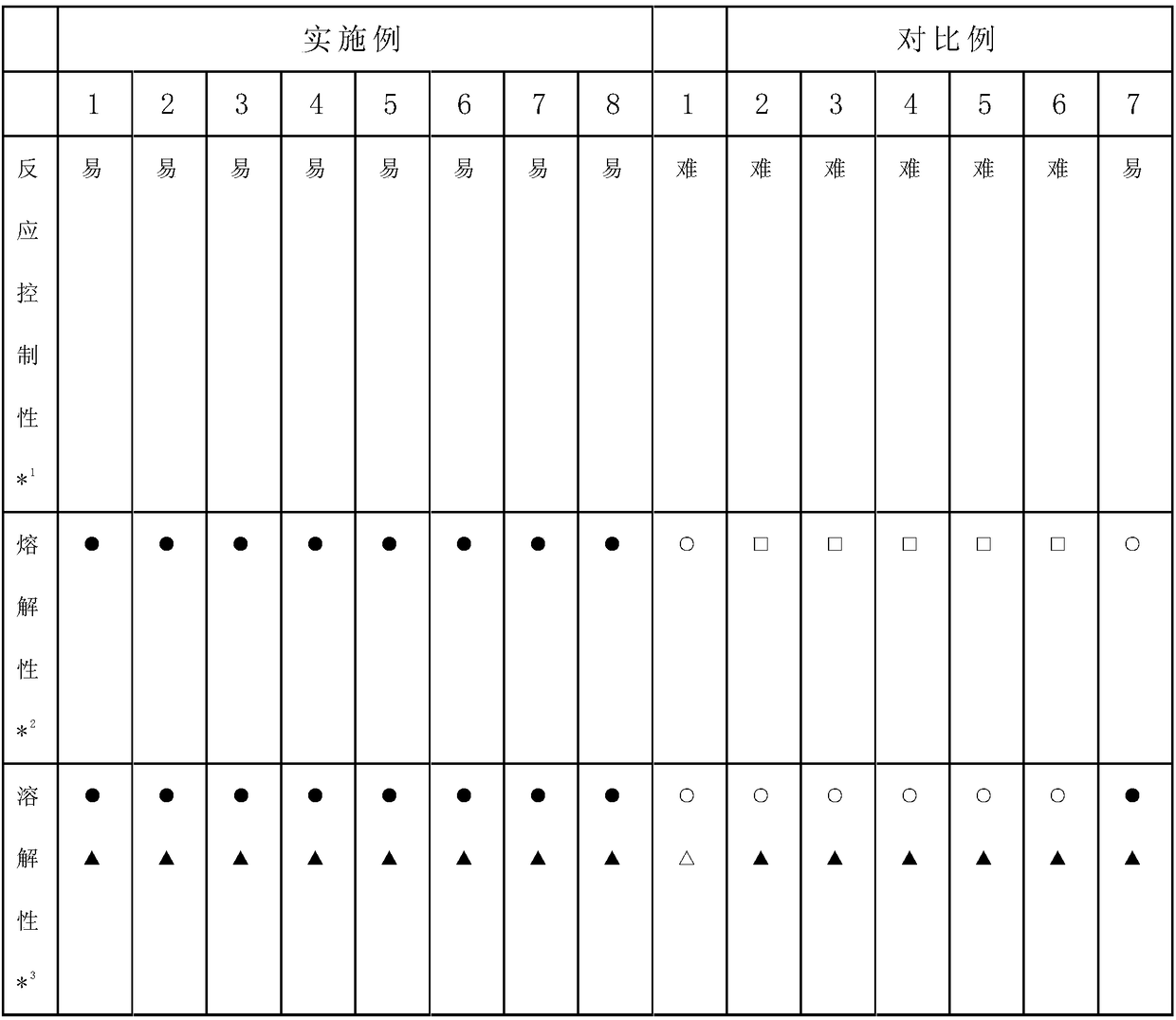

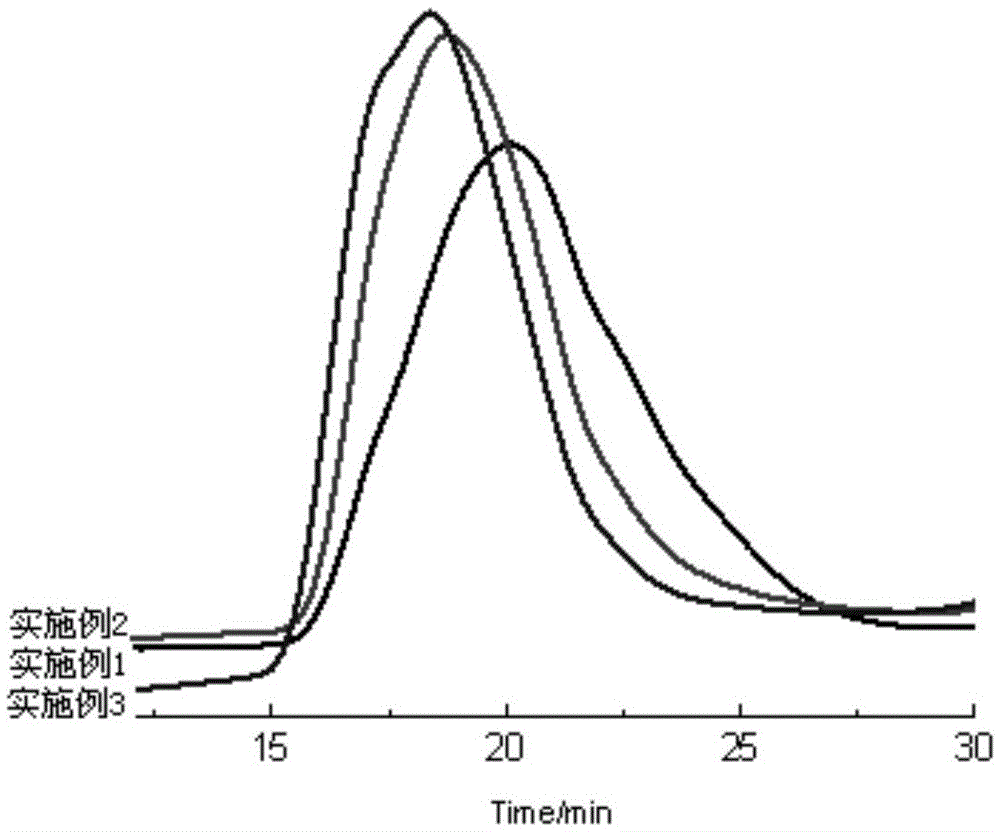

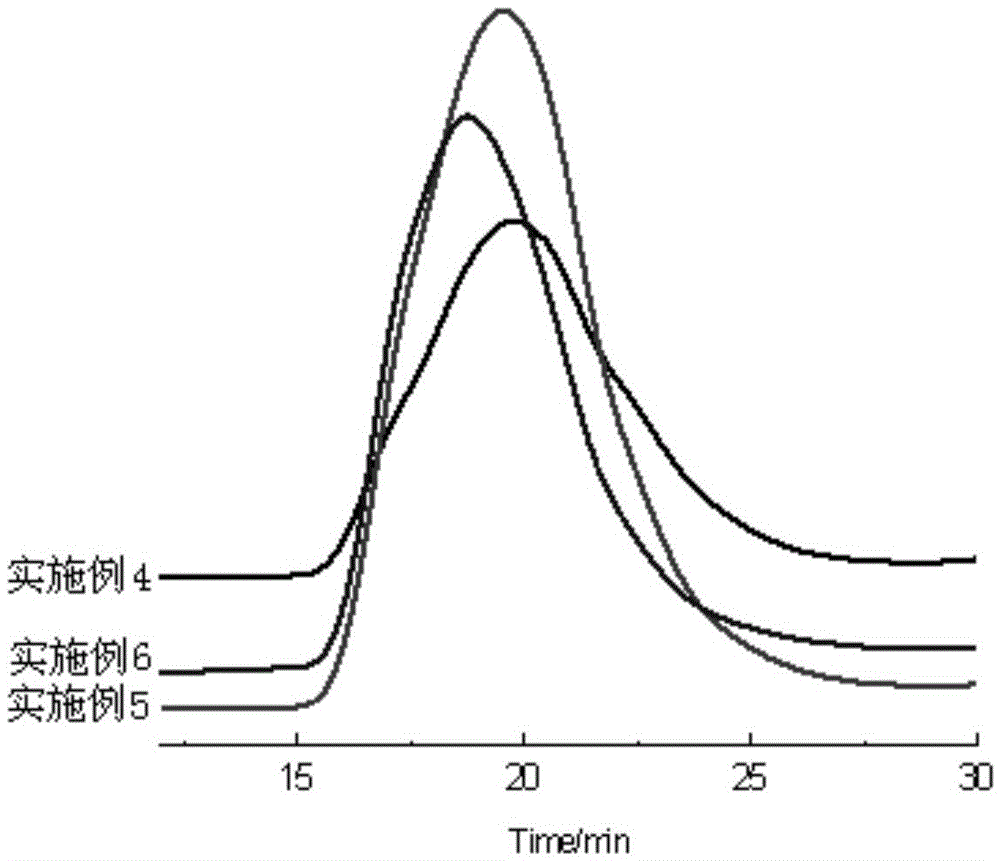

Modified composite bismaleimide resin prepolymer, resin composition, and semi-cured sheet and laminated board produced therewith

ActiveCN108219134AControllable reaction speedAddress reactivitySynthetic resin layered productsElectrical equipmentHot meltReaction speed

The invention discloses a modified composite bismaleimide resin prepolymer, which is a prepolymer prepared from composite bismaleimide resin and a propenyl phenoxyl compound. The weight ratio of the composite bismaleimide resin to the propenyl phenoxyl compound is 100:50-120. In the invention, some special bismaleimide structures are employed for composition, wherein the structures can control reaction speed due to a steric effect, so that the bismaleimide can be completely hot-melted and reacted with the propenyl phenoxyl compound. The technology solves a problem that a reaction on the bismaleimide in the prior art cannot be controlled and other processing problems are also solved.

Owner:SHENGYI TECH SUZHOU

Phosphate laser glass surface enhancement processing method

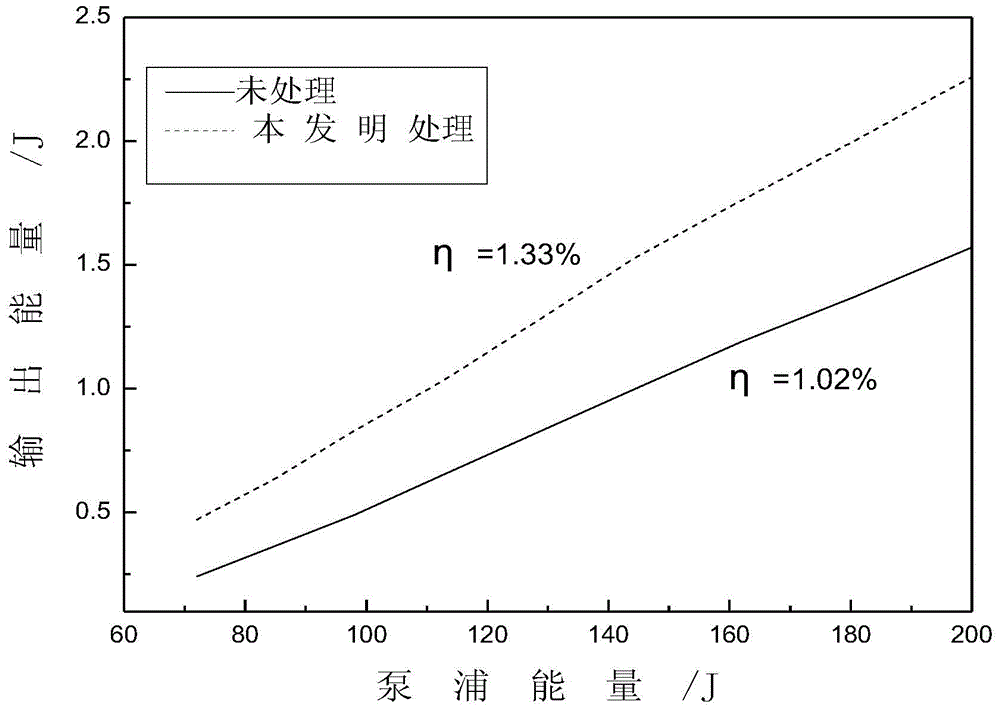

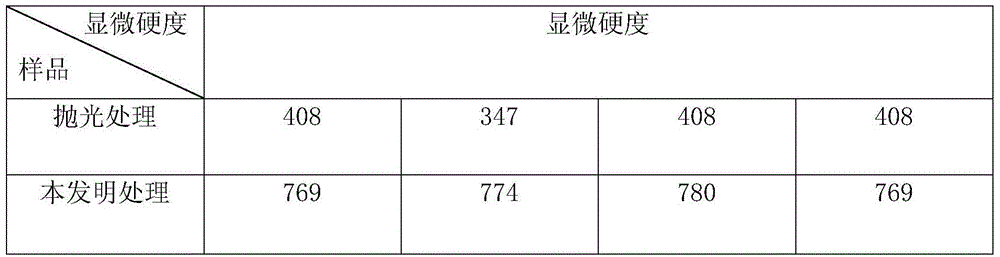

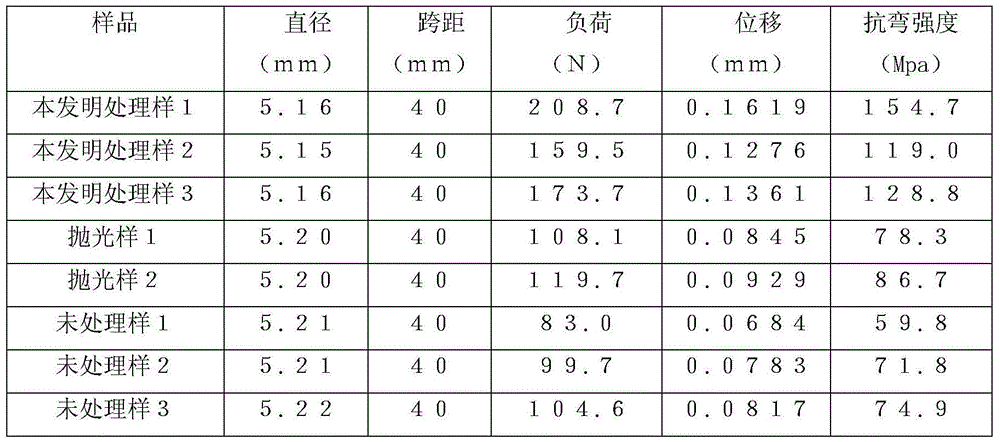

The invention discloses a phosphate laser glass surface enhancement processing method. The phosphate laser glass surface enhancement processing method comprises following steps: mixed acid is used for immersion erosion of phosphate laser glass; and then mixed alkali is used for surface removing of phosphate laser glass. The phosphate laser glass surface enhancement processing method is not limited by the shape of samples to be processed. The phosphate laser glass surface enhancement processing method is capable of removing micro-cracks and impurity particles on the surface of phosphate laser glass to a maximum degree, reducing surface roughness of phosphate laser glass after fine grinding, providing phosphate laser glass with higher microhardness and rupture strength, increasing repetition frequency and thermal damage threshold of phosphate laser glass under flashlamp pumped greatly, and increasing laser gain of phosphate laser glass via reducing scattering on incident light.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

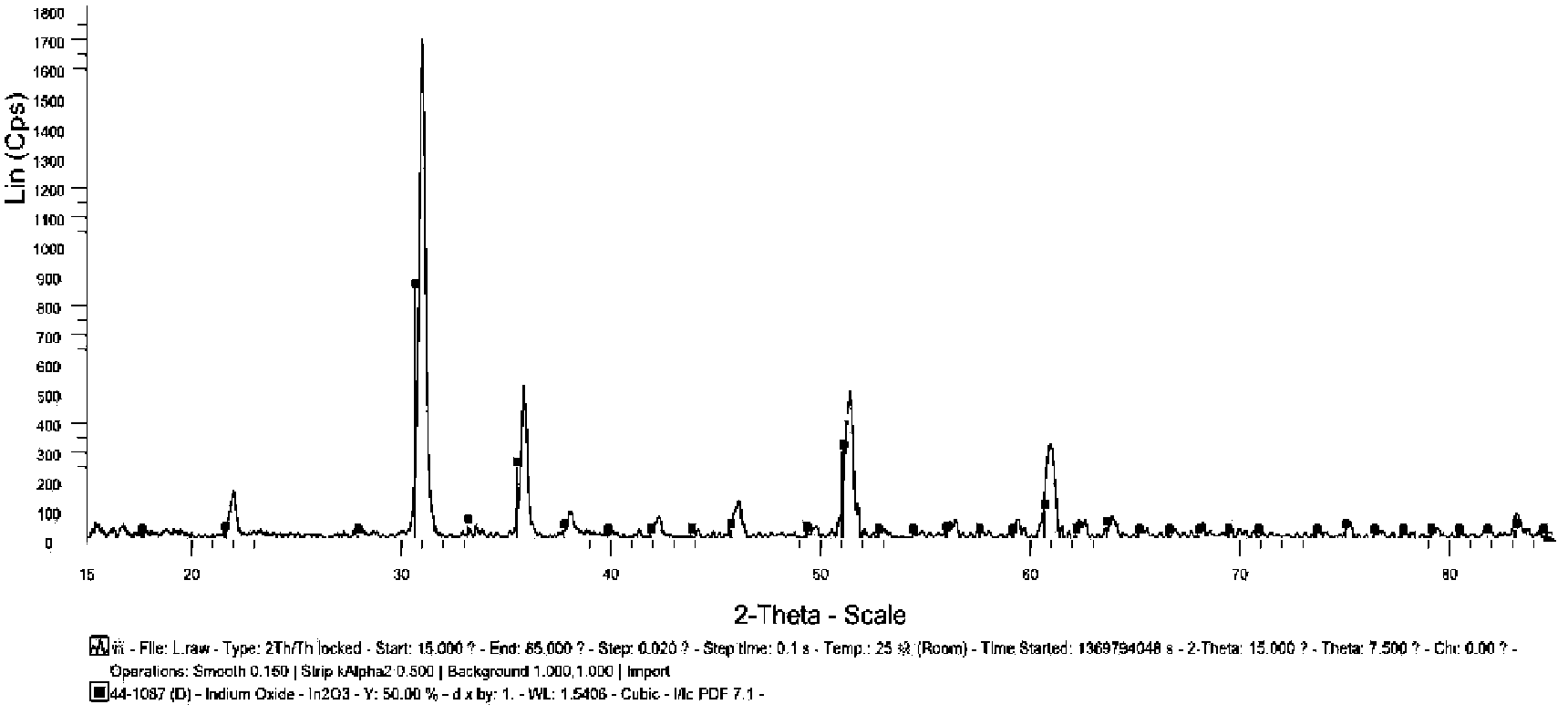

Preparation method of blue nanometer tin indium oxide powder

ActiveCN103771499APrevent sinteringNo dilution requiredGallium/indium/thallium compoundsNanotechnologyIndiumShielding gas

The invention relates to a preparation method of blue nanometer tin indium oxide powder. The preparation method comprises the following steps: (1) adopting a weakly alkaline precipitant for titrating an indium and tin compound aqueous solution and enabling the indium and tin compound aqueous solution to uniformly precipitate; (2) washing an ITO precursor with water for three times, washing with alcohol for two times, drying, then grinding, putting in a crucible, feeding in a muffle furnace, and carrying out calcination treatment to obtain yellow ITO; and (3) adding the yellow powder obtained by calcination to ethylene alcohol, carrying out emulsification dispersion, feeding into a high-pressure autoclave, carrying out thermal treatment, centrifuging so as to obtain ITO precipitates, washing with alcohol, and drying so as to obtain the blue ITO powder. The preparation method has the advantages that the weakly alkaline precipitant is used for reaction, and the reaction speed is controlled, so that the obtained precursor is relatively fine; and the protective gas sintering is avoided, required equipment is simple, and the powder does not need to be made thinner.

Owner:烟台佳隆纳米产业有限公司

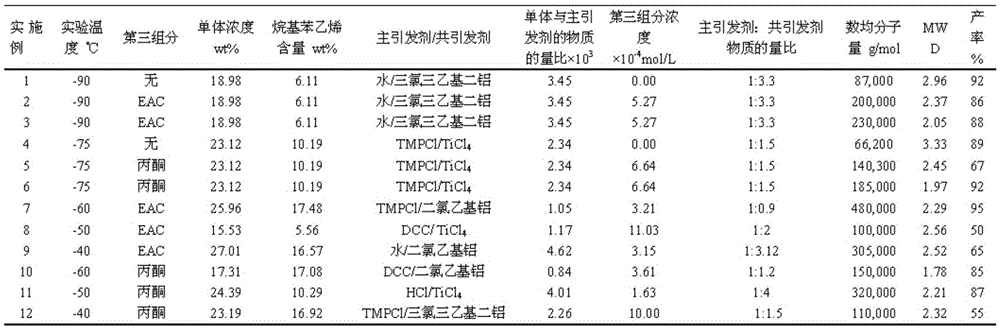

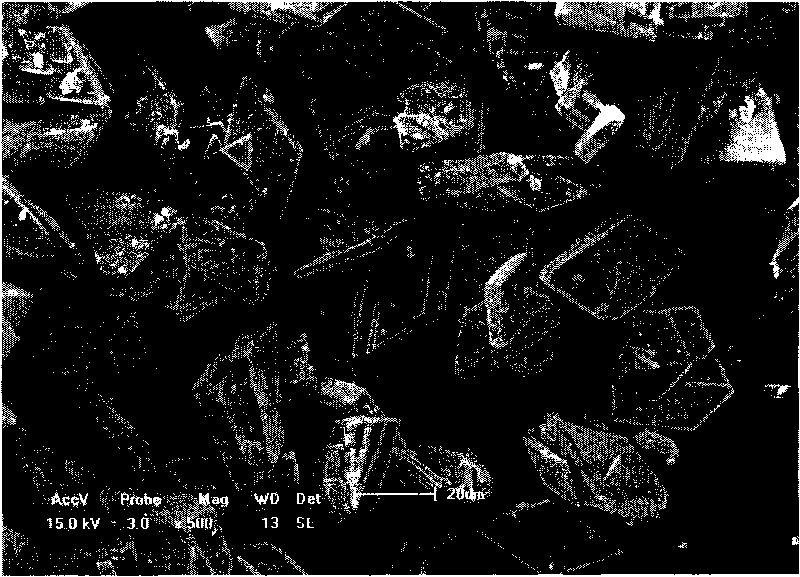

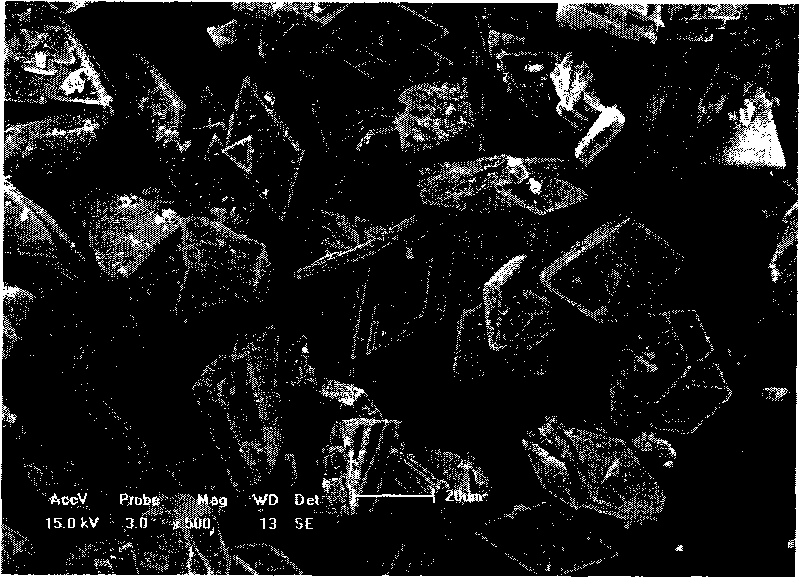

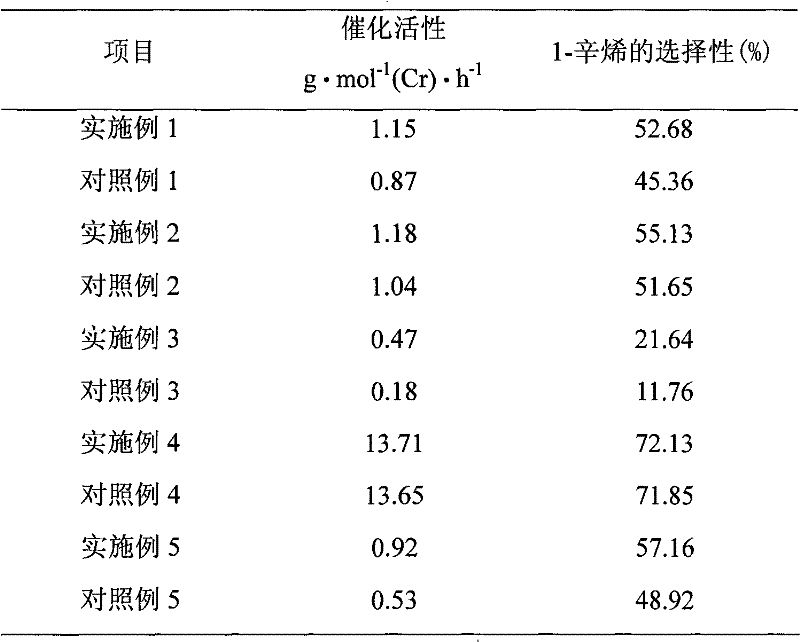

Preparation method of isobutene-alkyl styrene random copolymer

The invention discloses a preparation method of an isobutene-alkyl styrene random copolymer, and belongs to the technical field of macromolecular copolymer synthesizing methods. The preparation method comprises the steps of reactor feeding, initiator system preparing and polymer synthesizing and particularly comprises the two forms that a third component is added into a reactor along with a monomer raw material or the third component is added into the reactor after being aged together with a coinitiator and a main initiator. According to the preparation method, an ester compound or a ketone compound is taken as the cationic copolymerization third component, therefore, the cationic activity center can be stabilized, the reaction speed can be controlled, the molecular weight of the polymer can be increased, the molecular weight distribution can be reduced, and the reaction temperature can be increased, so that a reaction is performed at the higher temperature to achieve the effects of energy conservation and emission reduction. The property of the synthesized isobutene-alkyl styrene random copolymer is the same as that of a copolymer synthesized at the lower temperature, and the isobutene-alkyl styrene random copolymer can serve as a tire inner liner and a vibration-absorptive material or damping material.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

Method for preparing battery cathode active substance calcium zincate

InactiveCN101746810AControl granularityControl reaction speedCell electrodesZinc compoundsZincateElectrical battery

The invention relates to a method for preparing a battery cathode active substance calcium zincate. The calcium zincate is prepared by adopting a microemulsion method; the calcium zincate is generated through the reaction of zinc chloride or other soluble zinc salts, calcium chloride or other soluble calcium salts and hydroxide; n-hexyl alcohol, OP-10 emulsifying agent, cyclohexane or other dispersant and emulsifying agent are used as emulsifying materials; the speed of the reaction and the granularity and apparent density of the generated calcium zincate are effectively controlled by adopting fixed flow injection technology; and the granularity and the apparent density of the generated calcium zincate serving as a reaction product can be adjusted by adjusting the adding amount of the emulsifying agent, concentration and reaction speed and can reach nano scale at least. The method can be used for producing zinc electrodes of zinc series batteries such as square and cylindrical zinc-silver batteries, zinc-nickel batteries and the like.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST +1

Method for preparing modification aluminoxane

InactiveCN102190678AHigh reaction yieldIncrease productivityOrganic-compounds/hydrides/coordination-complexes catalystsGroup 3/13 element organic compoundsAluminoxaneAluminium alkyl

The invention discloses a preparation method for modification aluminoxane, comprising the following steps: a) preparing an inertia solvent solution of aluminium alkyl under the protection of an inert gas; b) mixing water, a modifier and an inertia solvent to prepare a hydrolysis agent under the protection of an inert gas; c) mixing the inertia solvent solution of aluminium alkyl and the hydrolysis agent in a T-type pipe reactor at a temperature of between -10 DEG C and -50 DEG C, flowing the mixture into a kettle reactor, heating the mixture to a temperature of between 10 to 100 DEG C and reacting for 1 to 10 hours; d) obtaining a reaction solution by filtering, reducing pressure to remove the solvent to obtain alkylauminoxane. According to the method of the invention, the interacting effect of the modifier and water is utilized to control the local concentration of water and the composition and concentration of the modifier are used to influence the composition of the generated aluminoxane so as to improve the storage stability and usage effect of the alkylauminoxane.

Owner:NORTHEAST GASOLINEEUM UNIV

Method for preparing ramie fibers through oxidation, degumming and repeated multiple-step feeding

ActiveCN103233279AAvoid damageBreak down evenlyFibre treatment to obtain bast fibreDecompositionColloid

The invention provides a method for preparing ramie fibers through oxidation, degumming and repeated multiple-step feeding, which comprises three feeding processes and comprises the following specific steps: in the first feeding process, preparing a degumming solution from surfactant, a fiber expanding agent, peroxide stabilizer, a defoaming agent, sodium hydroxide, peroxide and water, mixing raw hemp of ramie and the degumming solution to form a degumming solution system, and heating to remove part of colloid; in the second feeding process 20-50 minutes later, adding peroxide and sodium hydroxide, and keeping the temperature to further remove the colloid; in the third feeding process 20-50 minutes later, adding peroxide, and further keeping the temperature until the reaction is finished and the colloid is completely removed; and finally, washing refined dried hemp fibers with clear water, oiling, drying, opening, and combing to obtain the prepared ramie fibers. The method provided by the invention overcomes the defects in the existing oxidation and degumming technology; a repeated multiple-step method is used, so that the reaction is uniform and moderate, the damage to the fibers caused by over too high initial concentration of initial concentration is reduced, and the quality of the refined dried hemp product is improved; and meanwhile, the ineffective decomposition of the peroxide and the consumption of the defoaming agent are reduced, thereby saving the cost.

Owner:DONGHUA UNIV

Human heparin binding protein assay kit with high sensitivity and wide detection range

InactiveCN109613259AWide detection rangeGuaranteed SensitivityBiological testingMicrosphereConcentration gradient

The embodiments of the invention relate to the field of immunoassay, and in particular to a human heparin binding protein assay kit with high sensitivity and wide detection range. The human heparin binding protein assay kit comprises: a reagent 1, a reagent 2 and human HBP calibrators with different concentration gradients. The reagent 2 comprises a carboxyl latex microsphere labeled only with human HBP monoclonal antibody and a carboxyl latex microsphere labeled only with human HBP polyclonal antibody. The average particle diameter of the carboxyl latex microsphere labeled only with the humanHBP monoclonal antibody > the average particle diameter of the carboxyl latex microsphere labeled only with the human HBP polyclonal antibody. The human heparin binding protein assay kit provided bythe invention can complete a single sample test within 10 minutes, and indexes of precision, accuracy and anti-interference are excellent. The invention can be used clinically to predict an organ dysfunction caused by sepsis, and can be used as an early diagnostic marker for sepsis, especially serious bacterial infection.

Owner:BEIJING BEIER BIOENG

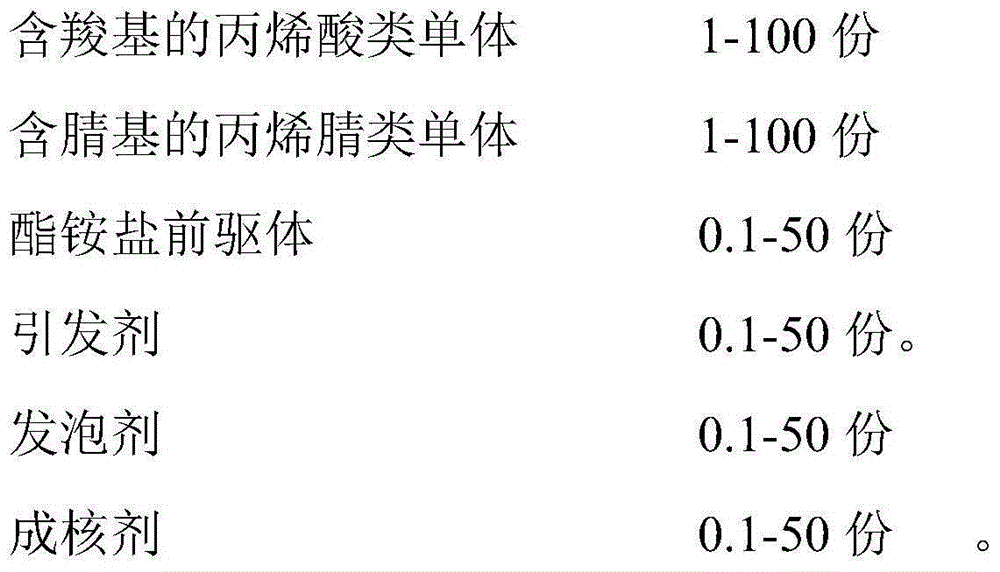

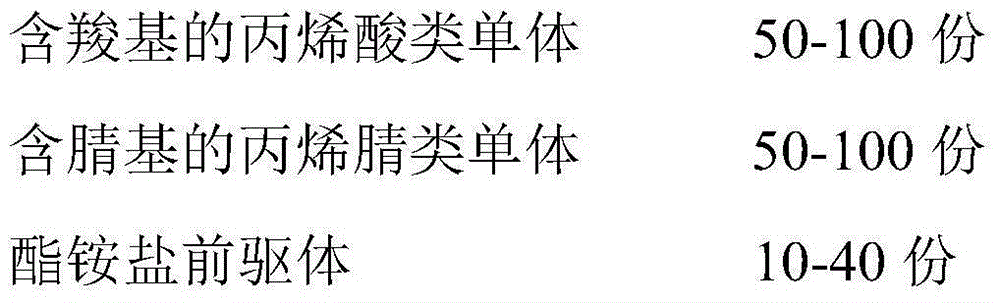

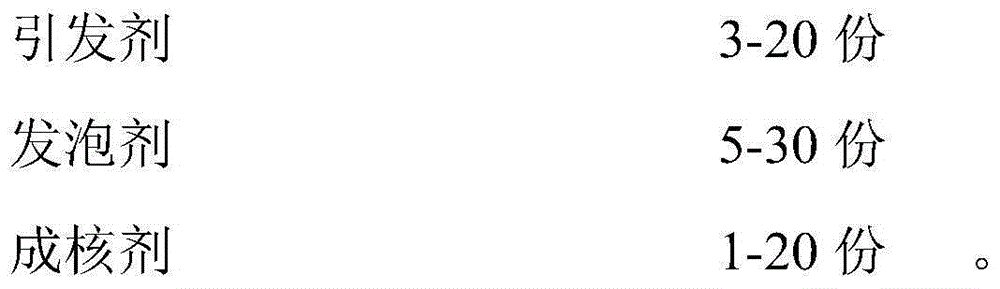

Polyacrylic imide foam material, and preparation method and application thereof

The invention relates to a polyacrylic imide foam material prepared by an esterquat precursor, and a preparation method and application of the polyacrylic imide foam material. In a preparation process of polyacrylic imide foam prepolymer, the esterquat precursor of PMR type polyimide is added, endothermic reaction of amidation of the esterquat precursor is matched with exothermic reaction of free radical polymerization in the preparation process of the polyacrylic imide foam prepolymer, and the purpose of effectively controlling reaction speed of polyacrylic imide is achieved. The prepared polyacrylic imide foam material has the advantages of high closed porosity, good high-temperature resistance and high compression resistance. The density of prepared foam is 30-250kg / m (3), closed porosity is greater than 90%, and a glass transition temperature is greater than 220 DEG C. At a room temperature, the density of the prepared foam is greater than 110kg / m (3), and compression strength of the foam is greater than 3.0MPa; and at a high temperature of 180 DEG C and under pressure of 0.3MPa, the compression deformation rate of the foam of which the density is 110kg / m (3) is lower than 1% after the foam is technologically treated for 2 hours.

Owner:CASHEM ADVANCED MATERIALS HI TECH CO LTD ZHEJIANG

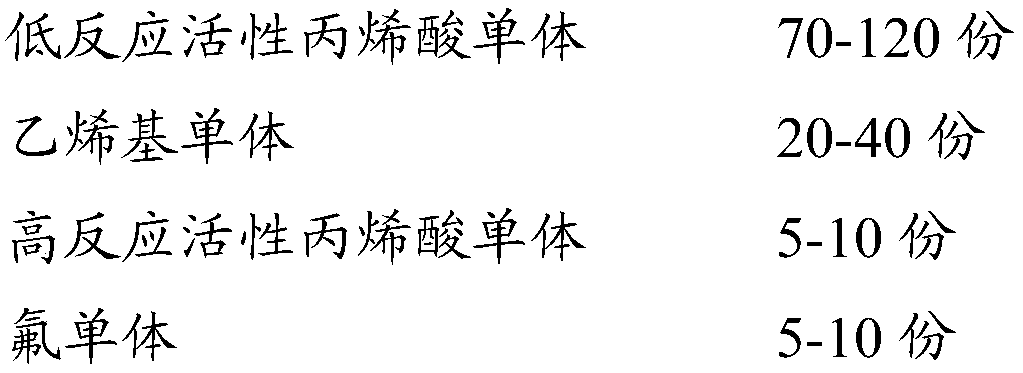

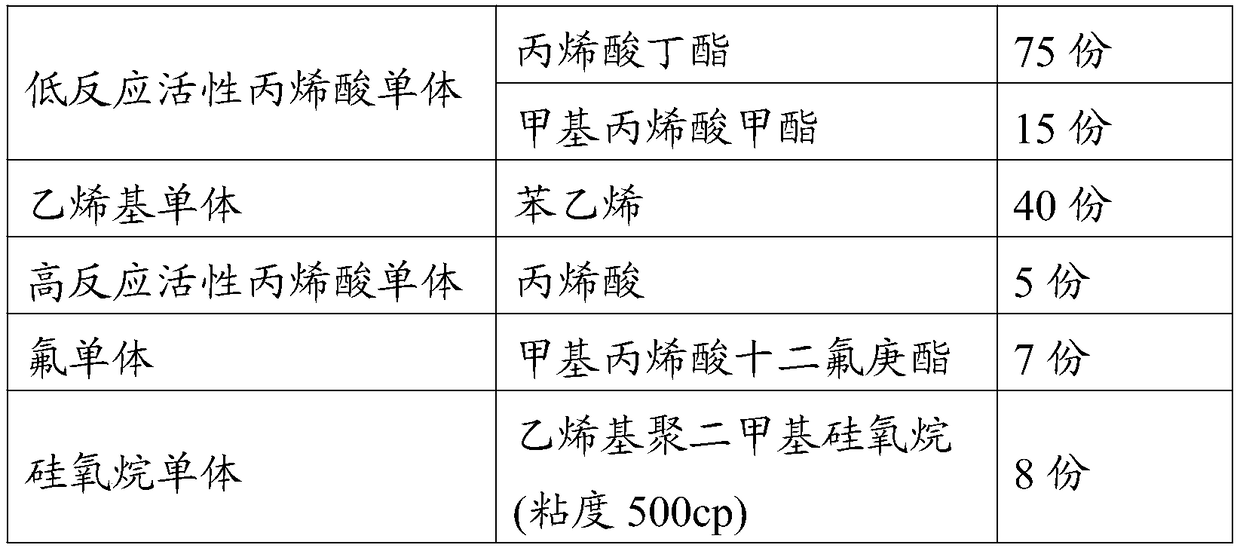

Hydrophobically modified acrylate emulsion and preparation method thereof

The invention provides a hydrophobically modified acrylate emulsion and a preparation method thereof. The preparation method includes: preparing raw materials including, by weight, 70-120 parts of a low-reaction-activity acrylic monomer, 20-40 parts of a vinyl monomer, 5-10 parts of a high-reaction-activity acrylic monomer, 5-10 parts of a fluoro-monomer, 5-10 parts of a siloxane monomer, 5-15 parts of an emulsifier, 0.5-1.2 parts of an initiator and 130-230 parts of distilled water. The method includes: respectively preparing a first pre-emulsified liquid, a second pre-emulsified liquid and an initiator solution; preparing a core layer emulsion from the first pre-emulsified liquid; dropwise adding the second pre-emulsified liquid and the initiator solution to the first pre-emulsified liquid to prepare a core-shell emulsion; and regulating pH value to obtain the hydrophobically modified acrylate emulsion. The preparation method is suitable for industrial large-scale production; the hydrophobically modified acrylate emulsion is excellent in hydrophobicity and is more than 130 degrees in static water contact angle, so that the emulsion has excellent film-coating performance.

Owner:中安瑞材(北京)科技有限公司

Vacuum paste mixing process of lead-acid power battery

ActiveCN104241609ATemperature controlControl reaction speedLead-acid accumulator electrodesPower batteryDry mixing

The invention discloses a vacuum paste mixing process of a lead-acid power battery, which is used for solving the problems of the paste mixing process of the prior art that the paste mixing temperature of the lead paste cannot be precisely controlled, the ratio of components in the prepared lead paste is unbalanced, the structure constitution is inconsistent, and thus the initial capacity and cycling performance of the lead paste are not ideal. The paste mixing process comprises the steps of feeding material, dry mixing, adding water, wet mixing, acidifying and stirring, wherein both the acidification and the stirring are performed in five steps, the acidification amount and lead paste temperature are controlled in each step of the acidification, the lead paste is maintained at the temperature of 72 to 82 2DEG C for 4 to 6 minutes in the acidifying process to form a generation stage of tetrabasic lead sulfate, the stirring time and cooling speed of the lead paste are controlled in each step of the stirring process, and the lead paste is maintained at the temperature of 45 to 50 DEG C for 0.5 to 1.5 minutes in the stirring process to form a performance stable stage. The process is simple in procedures, strong in operability and stable and controllable in process, and the prepared lead paste is good in consistent, high in initial capacity and good in cycling performance.

Owner:ANHUI YONGHENG STORAGE BATTERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com