Hydrogen production reaction with controllable hydrogen production speed

A reaction and speed technology, applied in the chemical industry, can solve problems such as affecting the hydrogen production rate, and achieve the effect of prolonging the service life and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

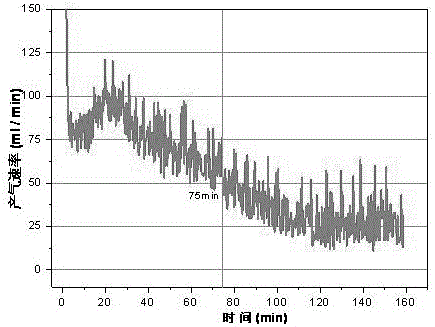

[0025] A solid catalyst in a hydrogen production reaction that can control the hydrogen production rate is mainly a mixture of sodium hydroxide and sodium bicarbonate, wherein the mass fraction of sodium hydroxide is 50% and the mass fraction of sodium bicarbonate is 50%. The mass fraction of aluminum powder in the hydrogen production agent is 79%, the rest of the sustained-release agent and other components account for 21%, and the buffer is mixed with 5% magnesium stearate and 95% sodium carboxymethyl cellulose Composition, the ratio of hydrogen generator to solid catalyst is 1:0.5.

[0026] The above mixture is processed into flakes by stirring, tableting and other processes, and packed in non-woven fabrics. When in use, mix the non-woven bag wrapped with hydrogen-generating agent and catalyst with room temperature water at a ratio of 1:10, and the hydrolysis reaction lasts for about 160 minutes.

Embodiment 2

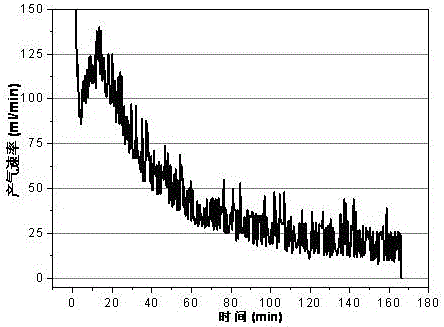

[0028] A solid catalyst in a hydrogen production reaction capable of controlling the hydrogen production rate is mainly a mixture of sodium hydroxide, sodium bicarbonate and calcium oxide. Among them, the mass percentage of sodium hydroxide is 40%, the mass percentage of sodium bicarbonate is 30%, and the mass percentage of calcium oxide is 30%; the mass fraction of aluminum powder in the hydrogen production agent is 80%, and the rest of the slow-release agent and other components account for 20% , the buffering agent is composed of magnesium stearate with a mass fraction of 1% and sodium carboxymethyl cellulose with a mass percentage of 99%, and the ratio of hydrogen-generating agent and solid catalyst is 1:0.3.

[0029] The above mixture is processed into flakes by stirring, tableting and other processes, and packed in non-woven fabrics.

[0030] When in use, mix the non-woven bag wrapped with hydrogen-producing agent and catalyst with room temperature water at a ratio of 1:...

Embodiment 3

[0032] A solid catalyst in a hydrogen production reaction that can control the hydrogen production rate is mainly a mixture of sodium hydroxide and calcium oxide, wherein the mass fraction of sodium hydroxide is 70% and the mass fraction of sodium bicarbonate is 30%. The mass fraction of aluminum powder in the hydrogen production agent is 90%, the rest of the sustained-release agent and other components account for 10%, and the buffering agent is mixed with 10% by mass of magnesium stearate and 90% by mass of sodium carboxymethyl cellulose Composition, the ratio of hydrogen generator to solid catalyst is 1:0.2.

[0033] The above mixture is processed into flakes by stirring, tableting and other processes, and packed in non-woven fabrics. When in use, mix the non-woven bag wrapped with hydrogen-generating agent and solid catalyst with room temperature water at a ratio of 1:5, and the hydrolysis reaction lasts for about 160 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com