Patents

Literature

458 results about "Hydrogen production rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrogen production method

ActiveUS7931888B2Maximize productionSteam flow rate essentially constantHydrogenCombustible gas catalytic treatmentMethane reformerMethane

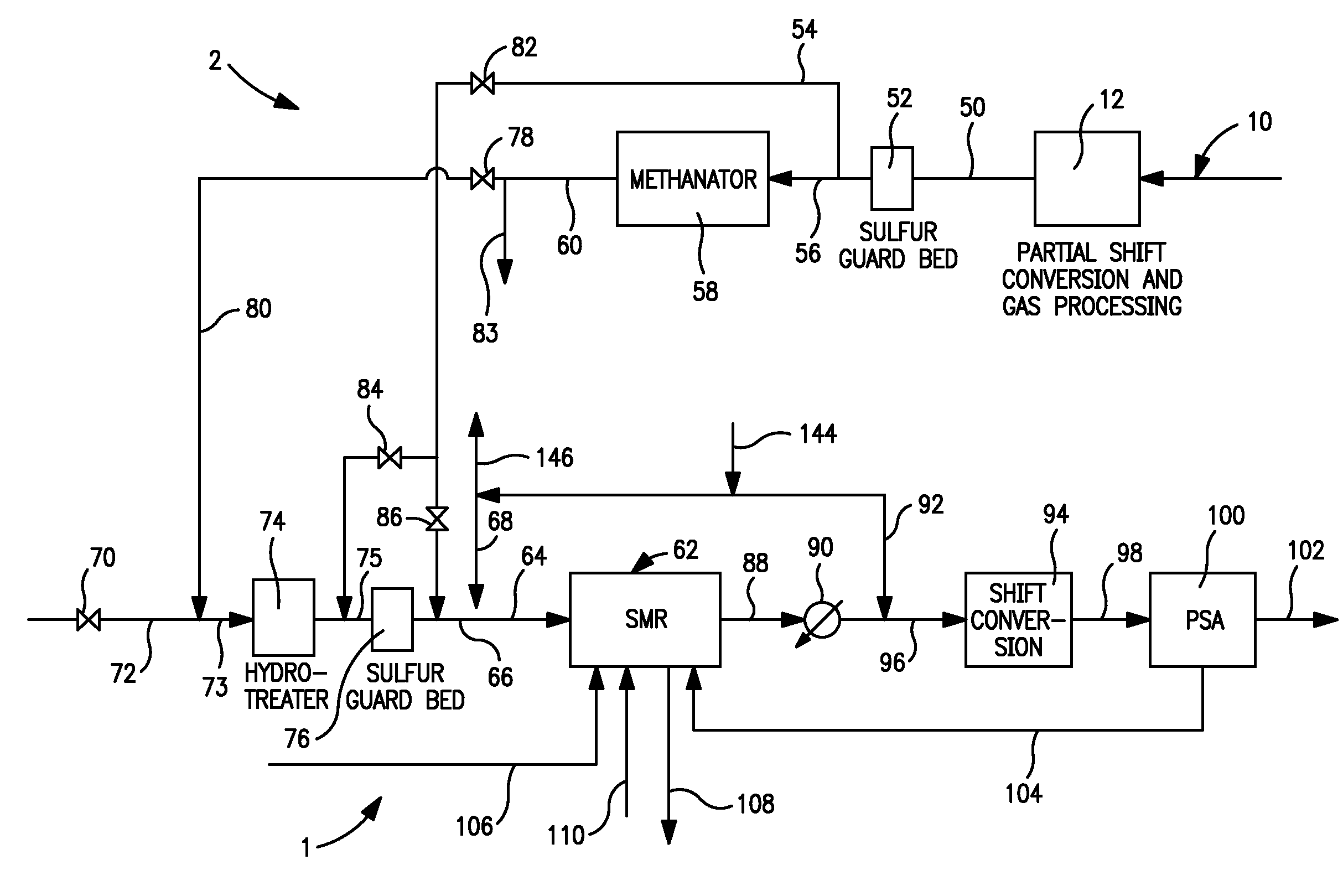

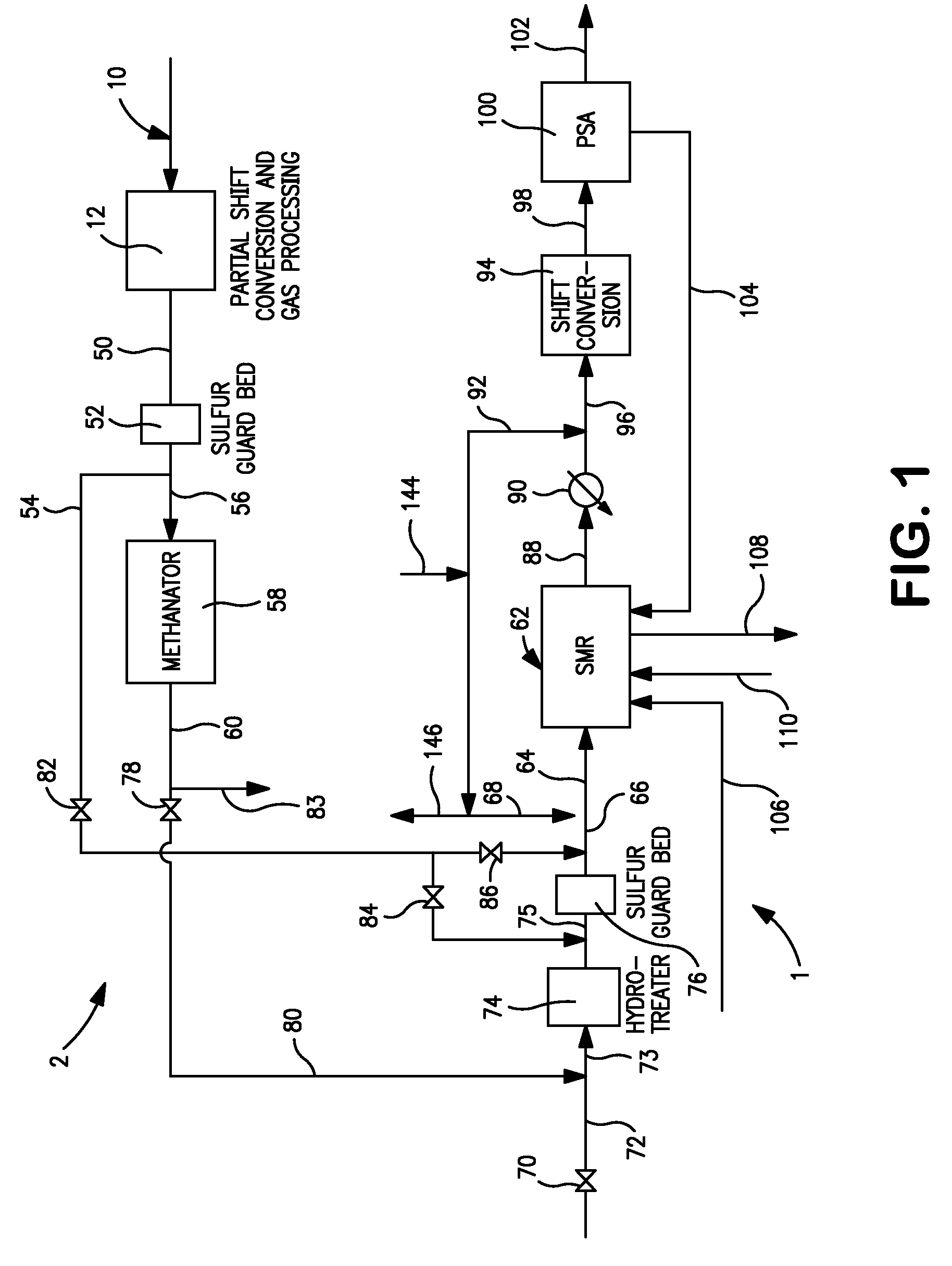

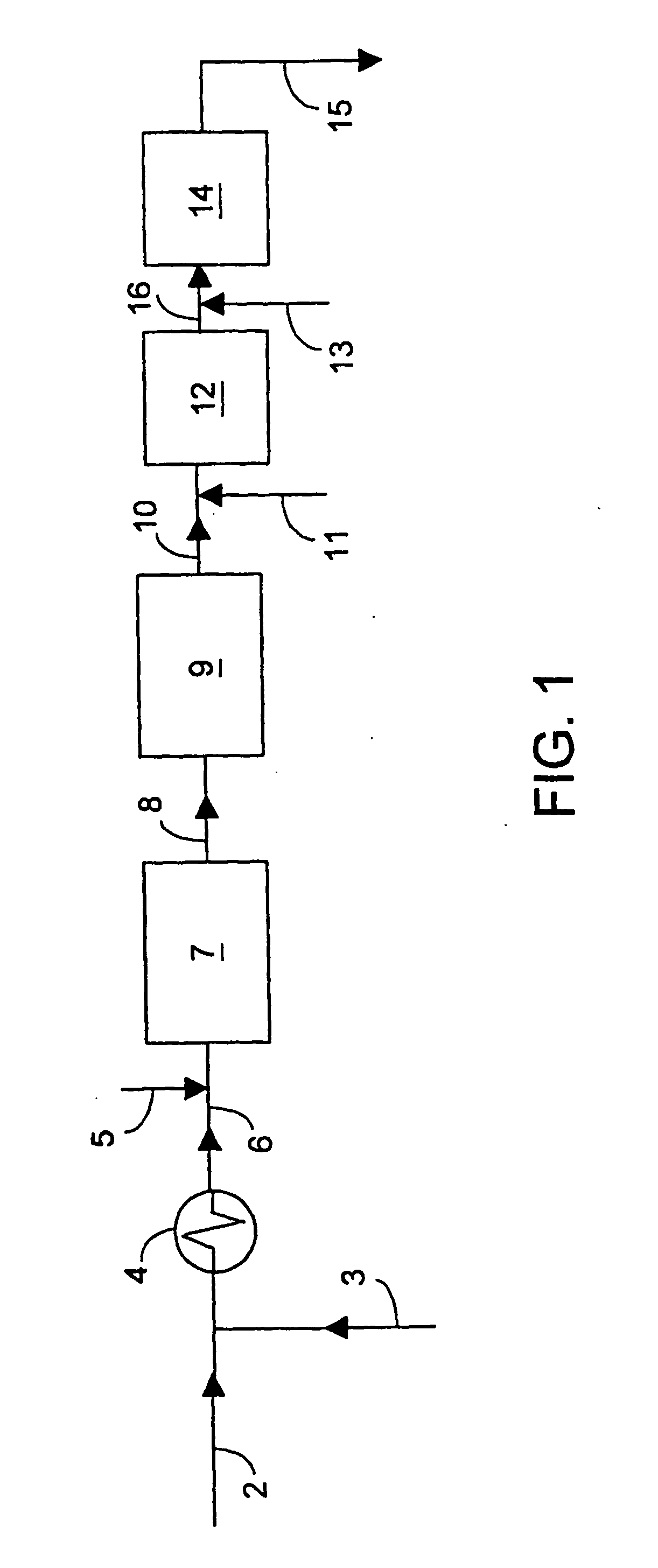

A method of producing a hydrogen product stream in which a steam stream is reacted with a hydrocarbon containing stream within a steam methane reformer. The resulting product stream is subjected to a water gas shift reaction and then to pressure swing adsorption to produce the hydrogen product stream. The hydrocarbon stream is alternatively formed from a first type of feed stream made up of natural gas, refinery off-gas, naphtha or synthetic natural gas or combinations thereof and a second type that is additionally made up of a hydrogen and carbon monoxide containing gas. During use of both of the types of feed streams, the flow rate of the steam stream is not substantially changed and reformer exit temperatures of both the reactant and the flue gas side are held essentially constant.

Owner:PRAXAIR TECH INC

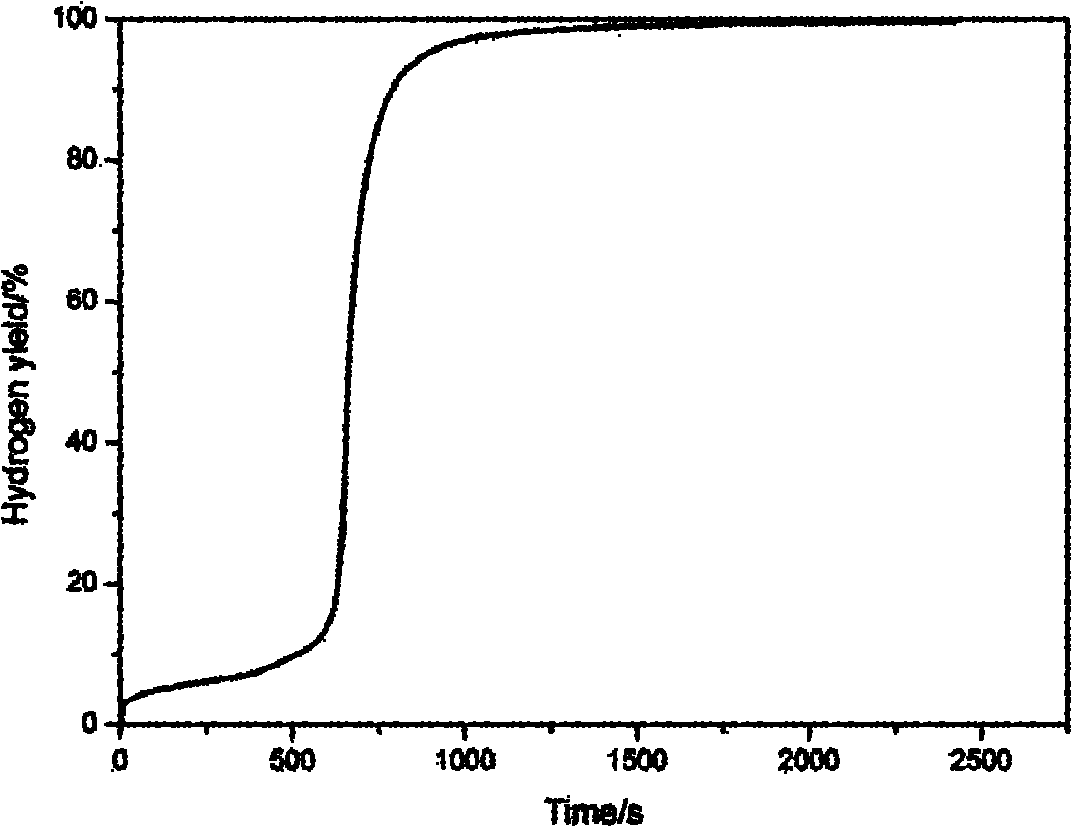

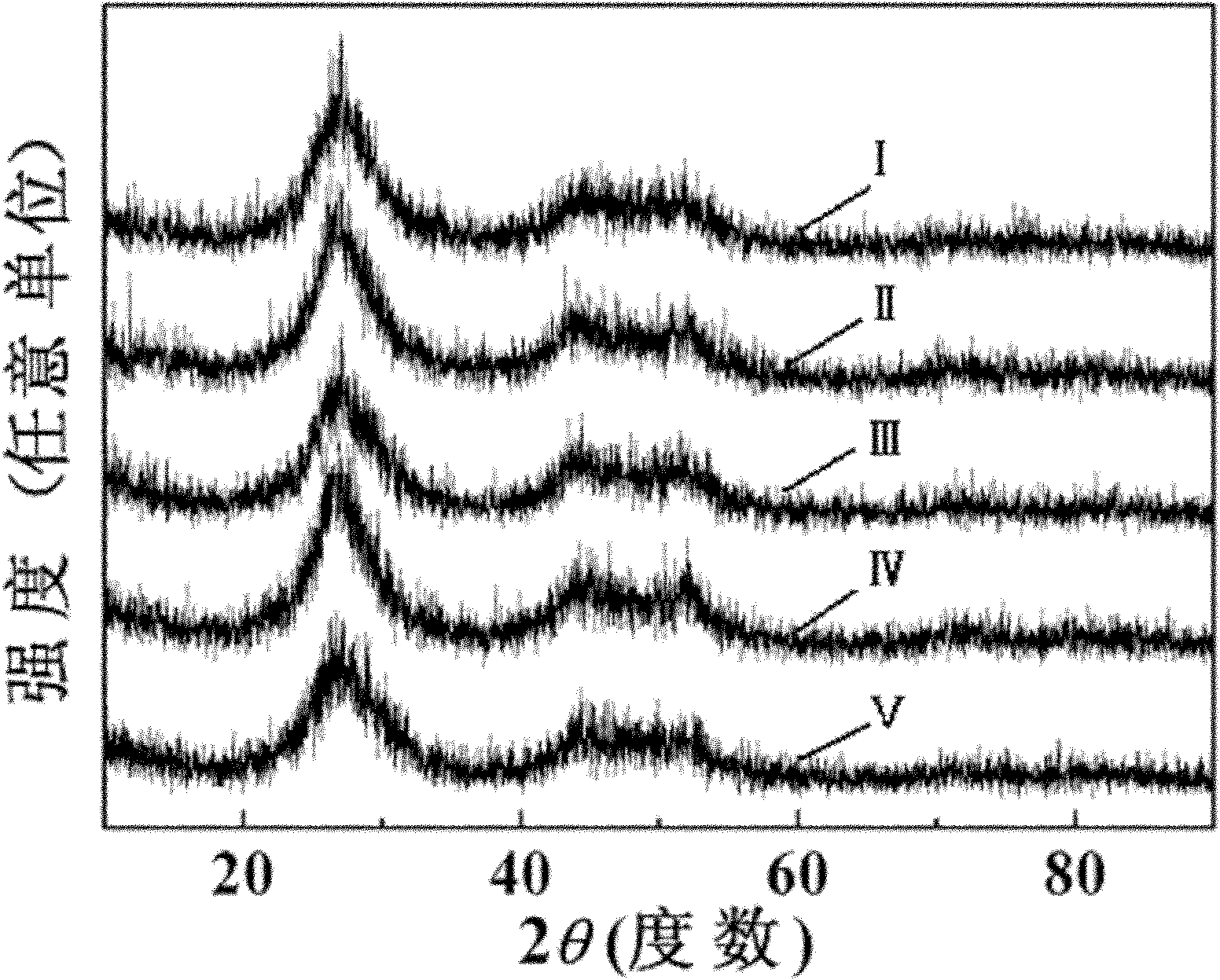

Preparation method for multi-hole carbon nitride photocatalytic material doped with sulphur

InactiveCN103861632AReduce pollutionGood repeatabilityPhysical/chemical process catalystsHydrogen productionSurface-active agentsSolvent

The invention discloses a preparation method for a multi-hole carbon nitride photocatalytic material doped with sulphur, belonging to the technical field of synthesis of photocatalytic materials. The preparation method comprises the following steps of preparing a super-molecule polymer through simple hydro-thermal treatment by taking melamine and trithiocyanuric acid as a raw material and taking water as a solvent, and burning in an inert atmosphere so as to obtain a three-dimensional network sulphur-doped multi-hole carbon nitride photocatalytic material. The preparation method provided by the invention has the advantages that simplicity and easiness in preparation are achieved, a method for burning a super-molecule polymer is adopted, any template agent and a surface active agent do not need to be added, a reaction system is simplified, the cost is low, the pollution of a reagent is slight, the reaction repeatability is good, a preparation condition is mild, the time consumption of a synthetic process is short, and the requirement on equipment is high; the multi-hole carbon nitride photocatalytic material doped with sulphur has excellent catalytic activity in a catalyzing hydrogen production reaction, and the hydrogen production rate of the material is 8.3 times and 5.2times that of a product obtained by burning melamine and trithiocyanuric acid under the same condition.

Owner:JILIN UNIV

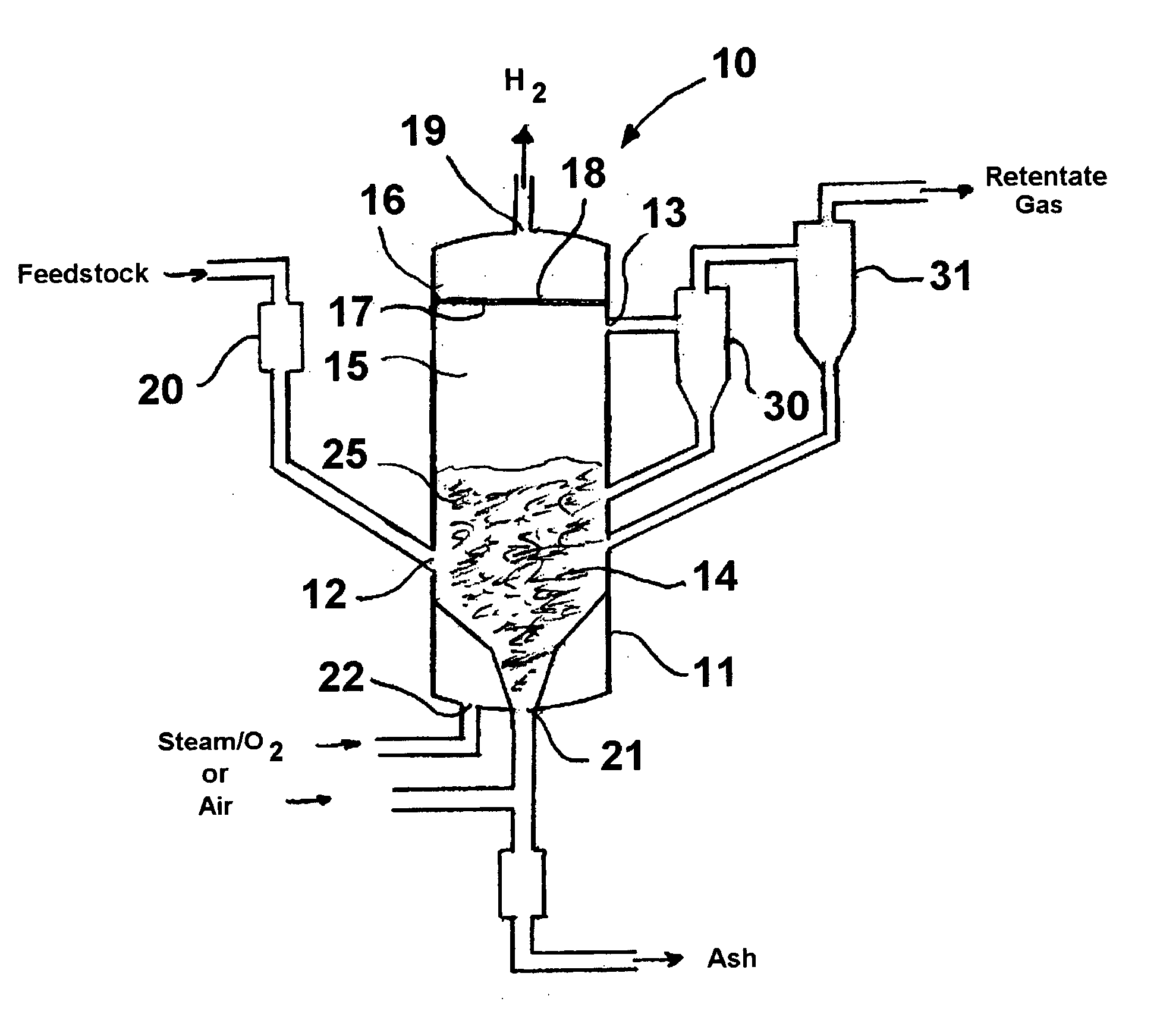

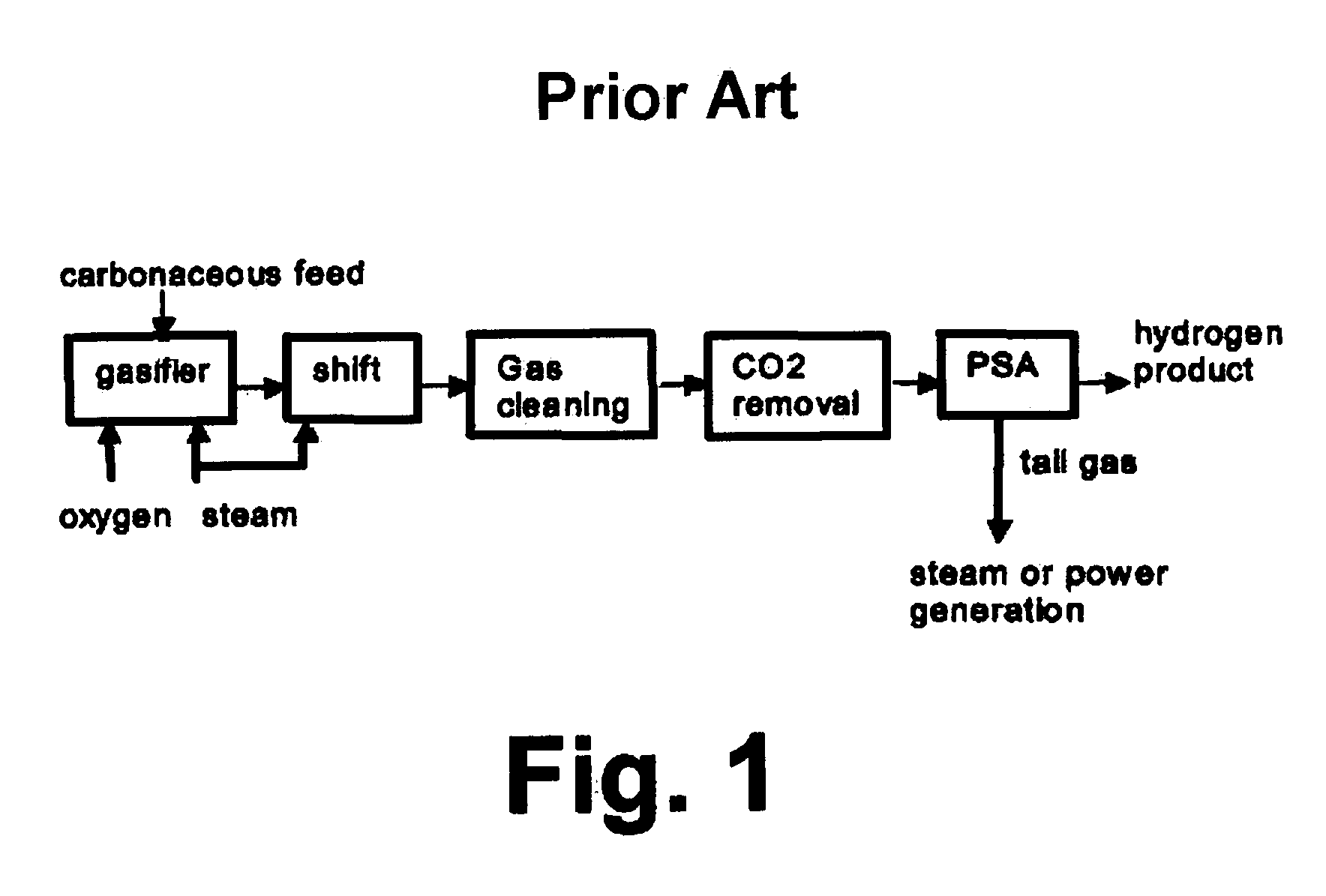

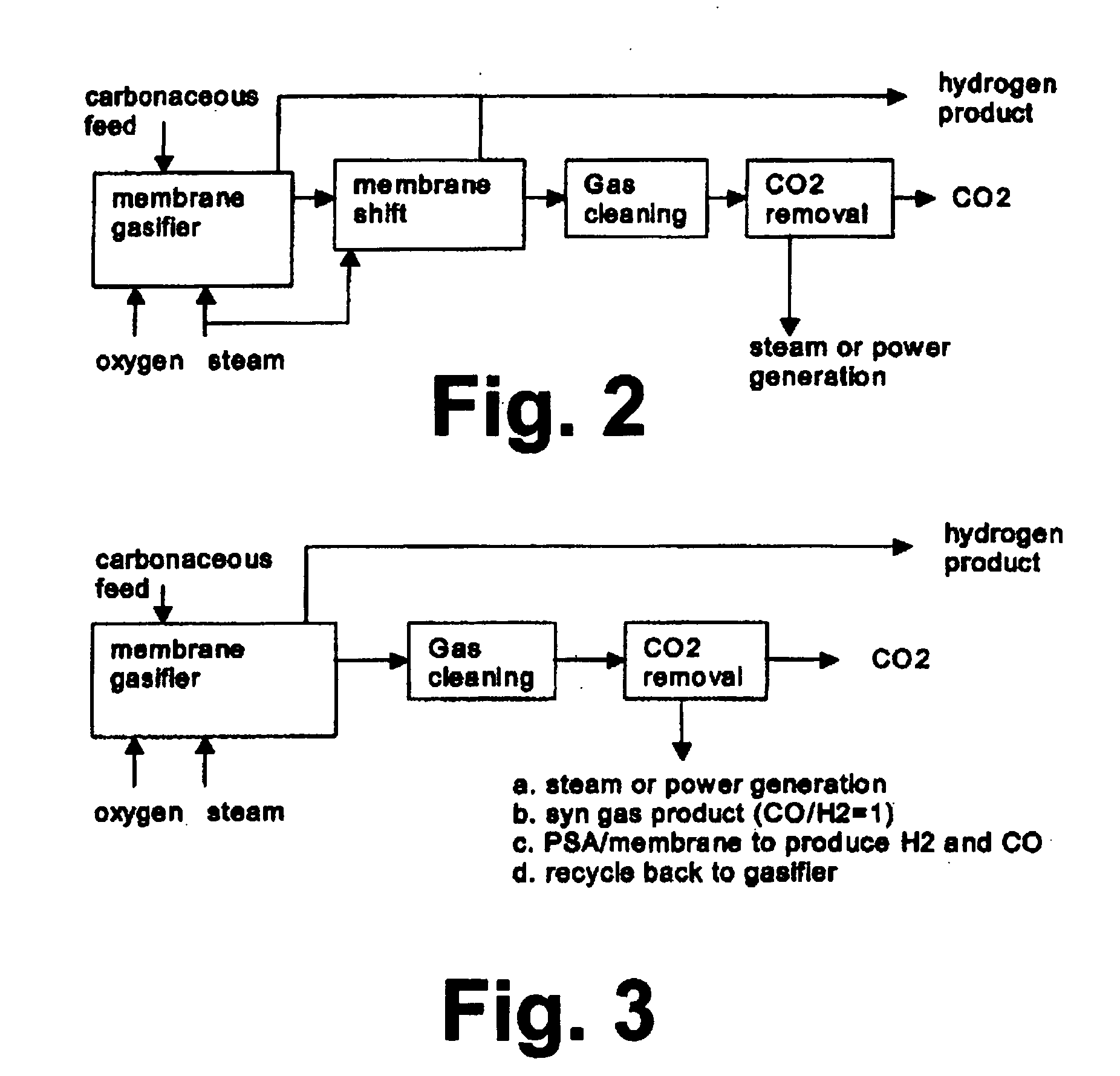

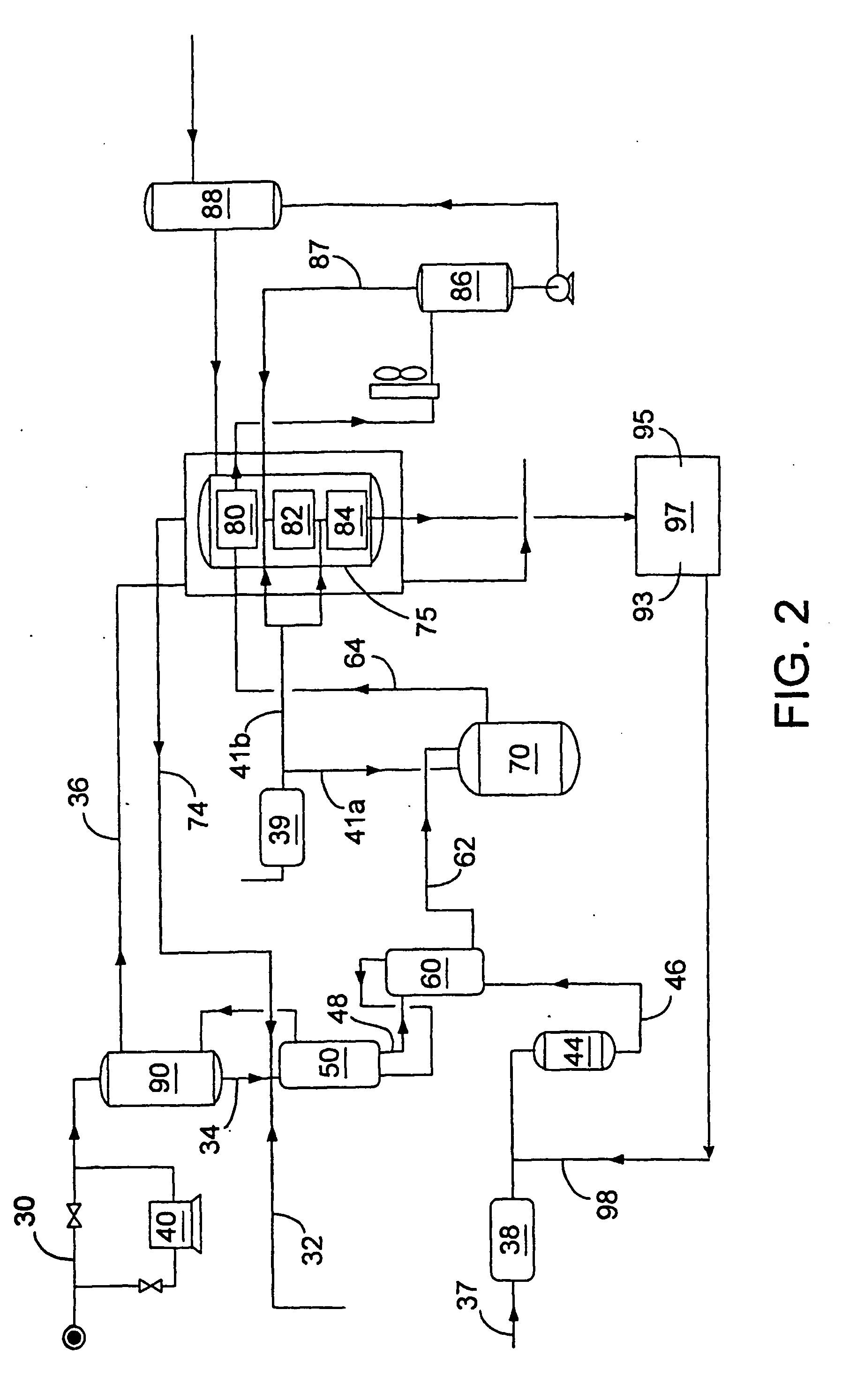

Hydrogen production process from carbonaceous materials using membrane gasifier

InactiveUS20050039400A1Improve thermal efficiencySmall sizeGasifier mechanical detailsHydrogen/synthetic gas productionPermeationThermal efficiency

A method and apparatus for producing hydrogen from carbonaceous materials using a hydrogen-selective permeation membrane incorporated into a carbonaceous material reactor, as a result of which, hydrogen production rate from the reactor is increased, downstream gas cleaning and purification units of conventional systems are eliminated or substantially reduced in size, and the thermal efficiency of producing hydrogen from carbon-containing materials is increased and its production cost is reduced.

Owner:GAS TECH INST

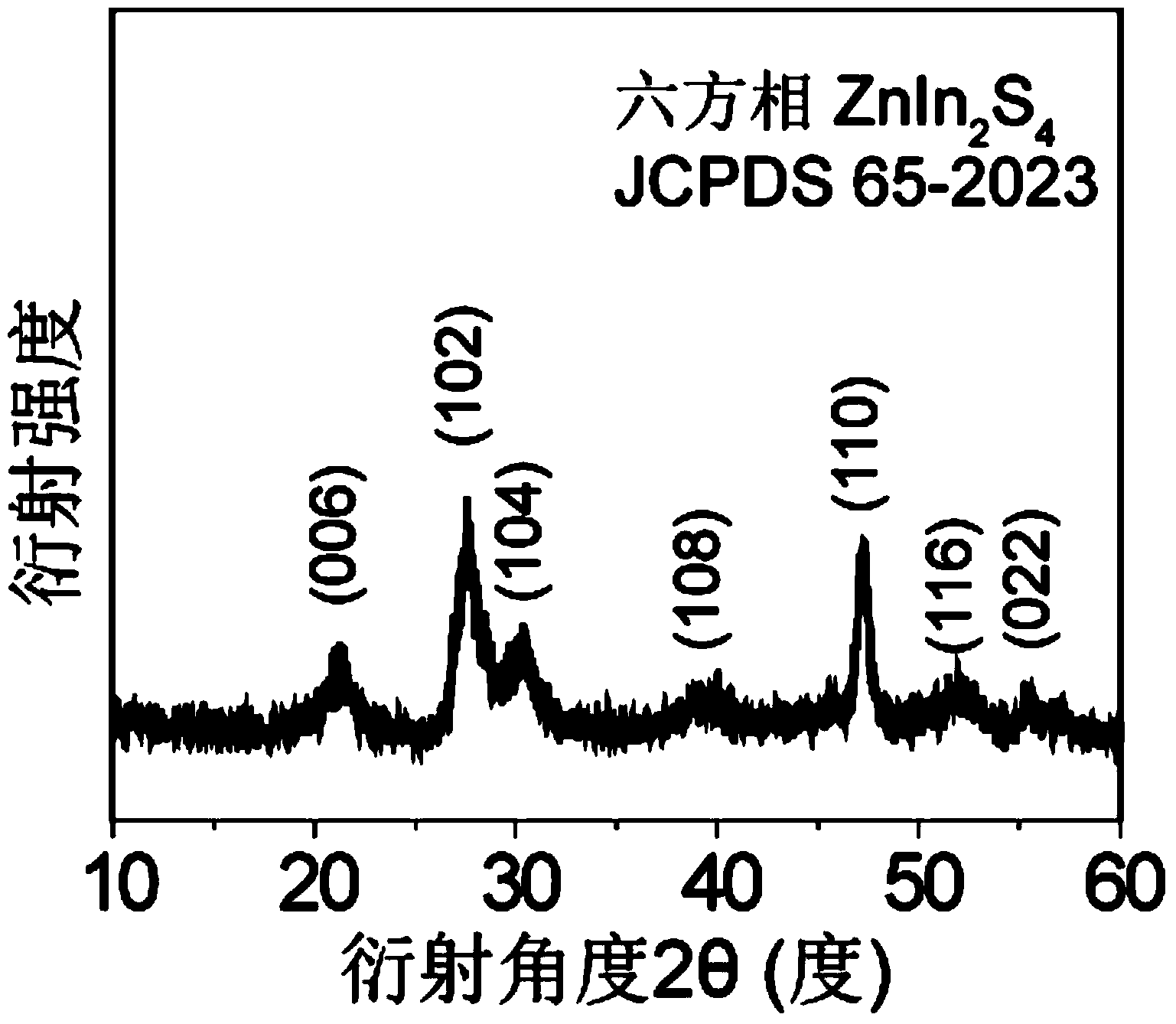

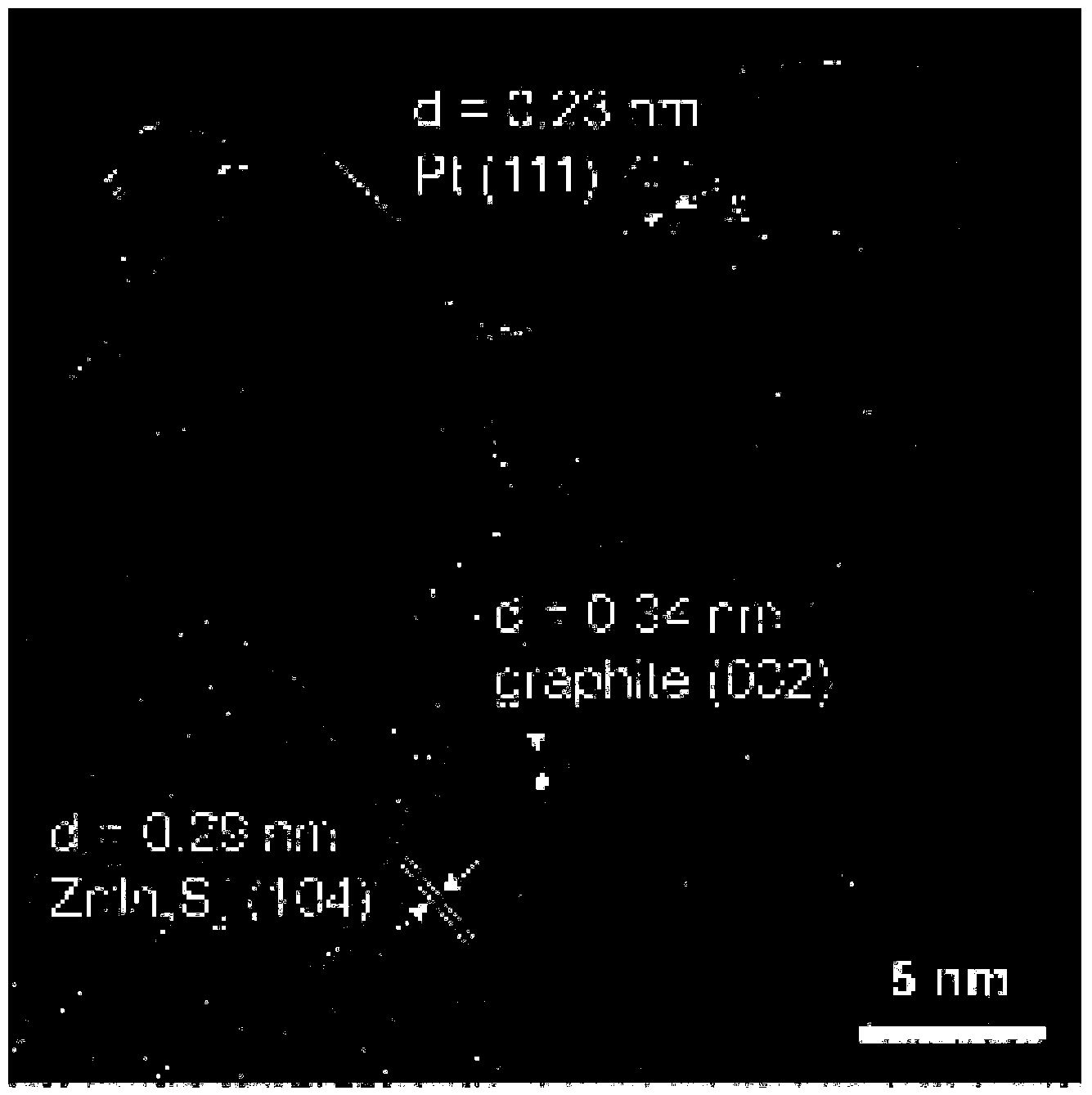

Carbon quantum dot, precious metal and zinc indium sulfide composite photocatalyst and preparation method thereof

InactiveCN103861620AImprove photocatalytic activityExtended service lifePhysical/chemical process catalystsHydrogen productionMaterials sciencePhotochemistry

The invention relates to a carbon quantum dot, precious metal and zinc indium sulfide composite photocatalyst and a preparation method thereof. The composite photocatalyst contains a hexagonal-phase zinc indium sulfide (ZnIn2S4) matrix, and reduced carbon quantum dots and precious metal particles which are carried on the surface of the ZnIn2S4 matrix, wherein the ZnIn2S4 matrix is of a peony-flower-shaped structure, the particle size of the matrix is 0.1-10 micrometers and the BET specific surface area of the matrix is 10-200 m<2> / g; the particle size of the carbon quantum dots and the precious metal particles is 1-10 nm; precious metal refers to one or a mixture of some of gold, platinum, silver or palladium. The composite photocatalyst has high catalytic activity (with a hydrogen production rate up to 1mmol.h<-1>g<-1>) under irradiation of visible light (more than or equal to 400nm), and has long service life (over 50 hours).

Owner:WUHAN UNIV OF TECH

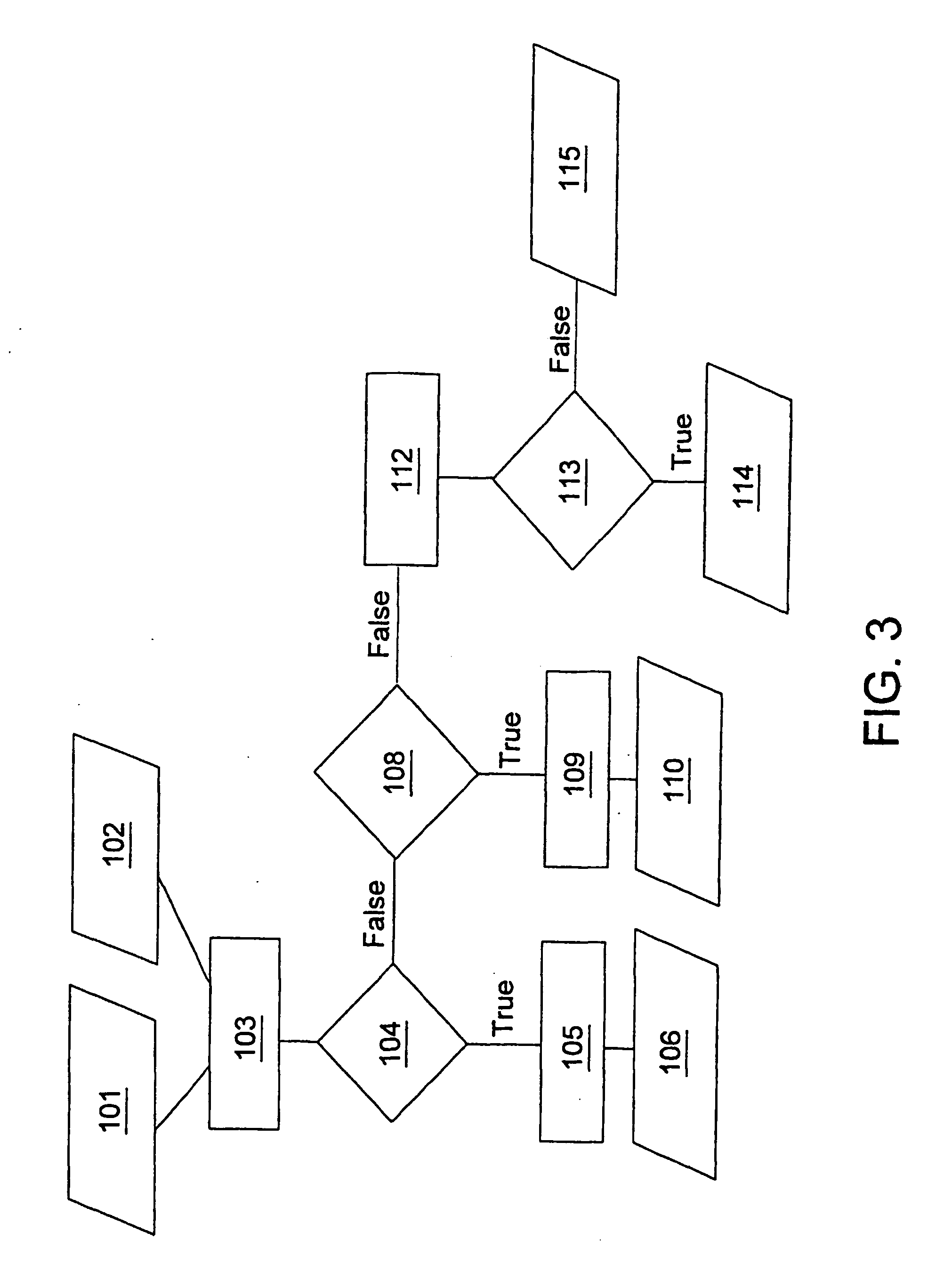

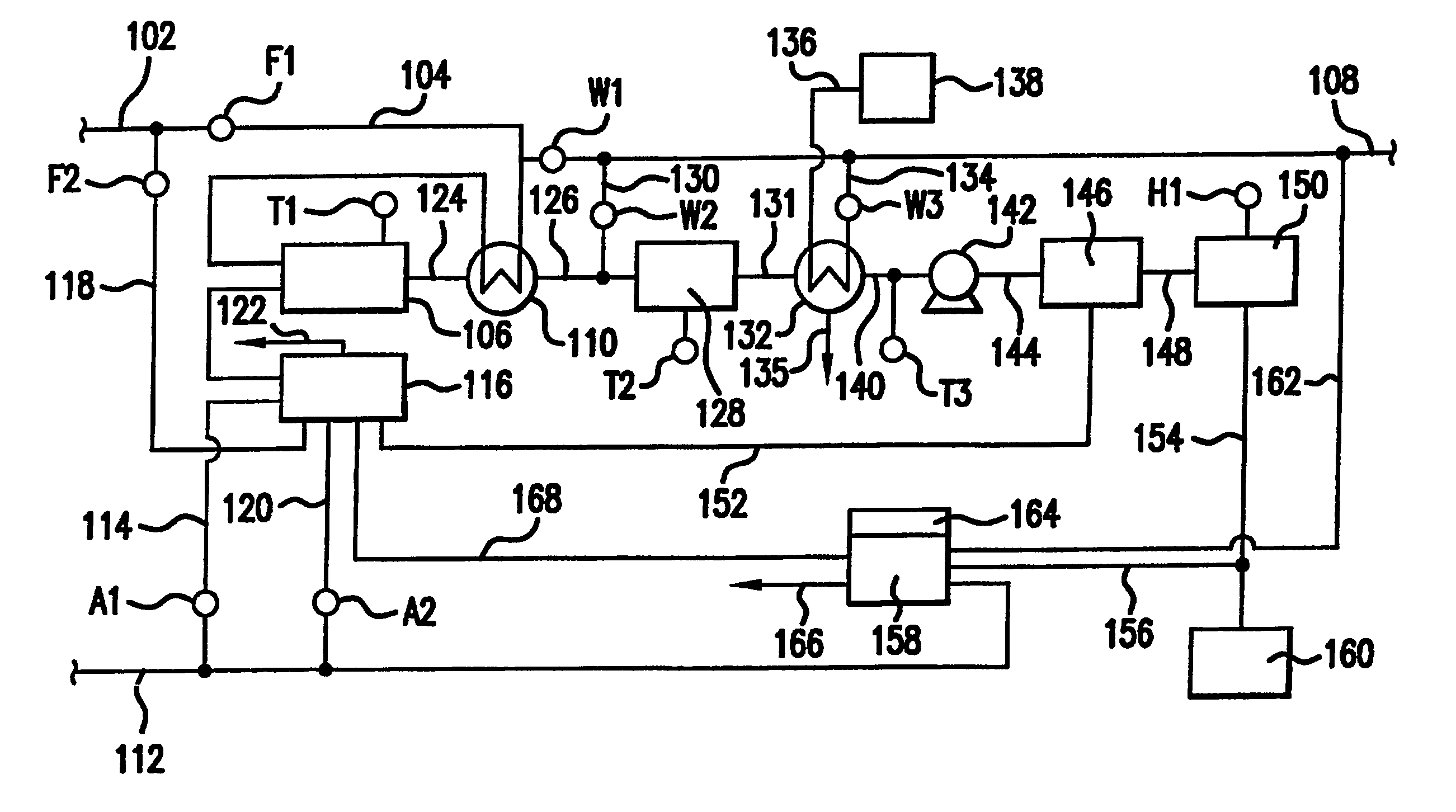

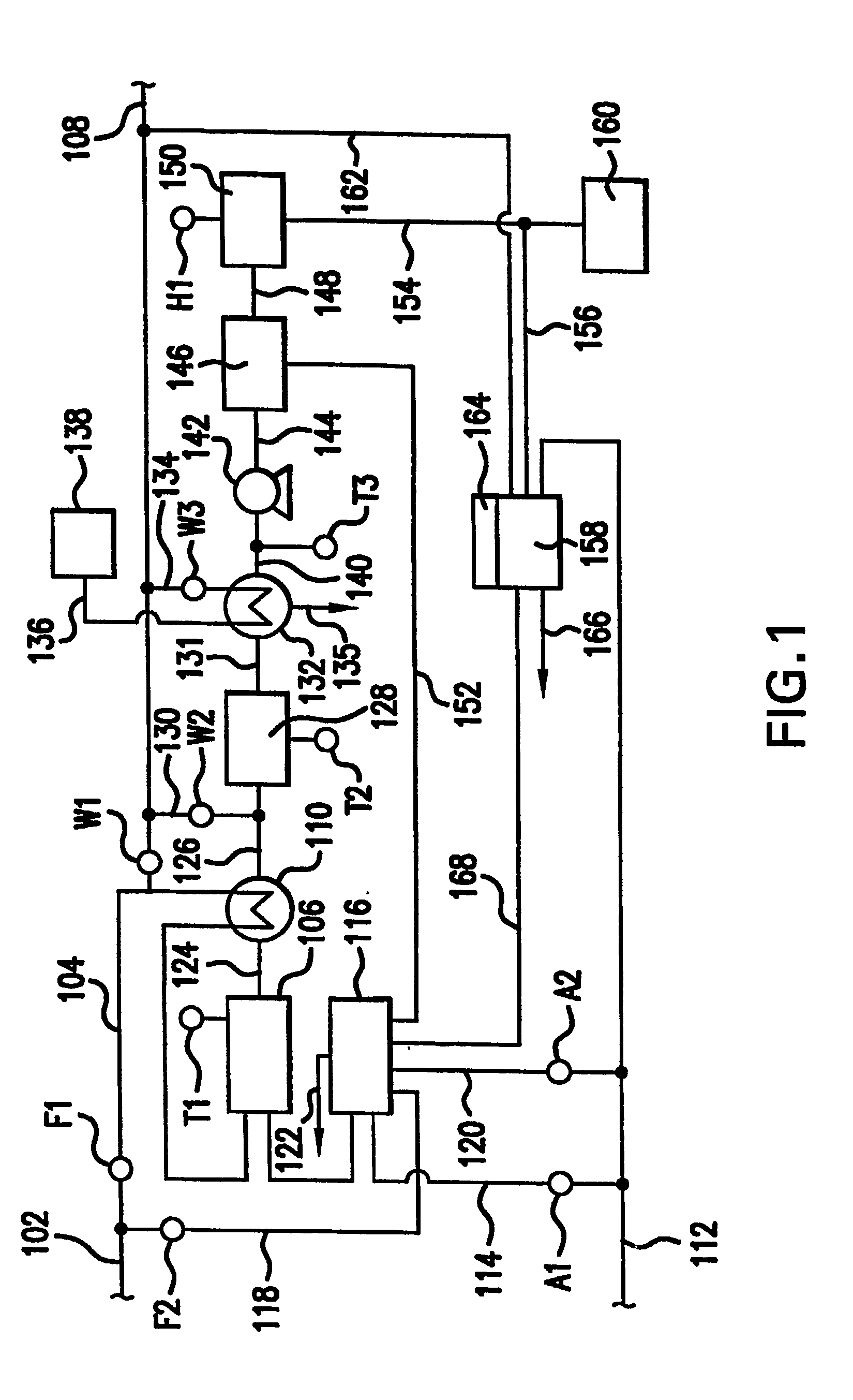

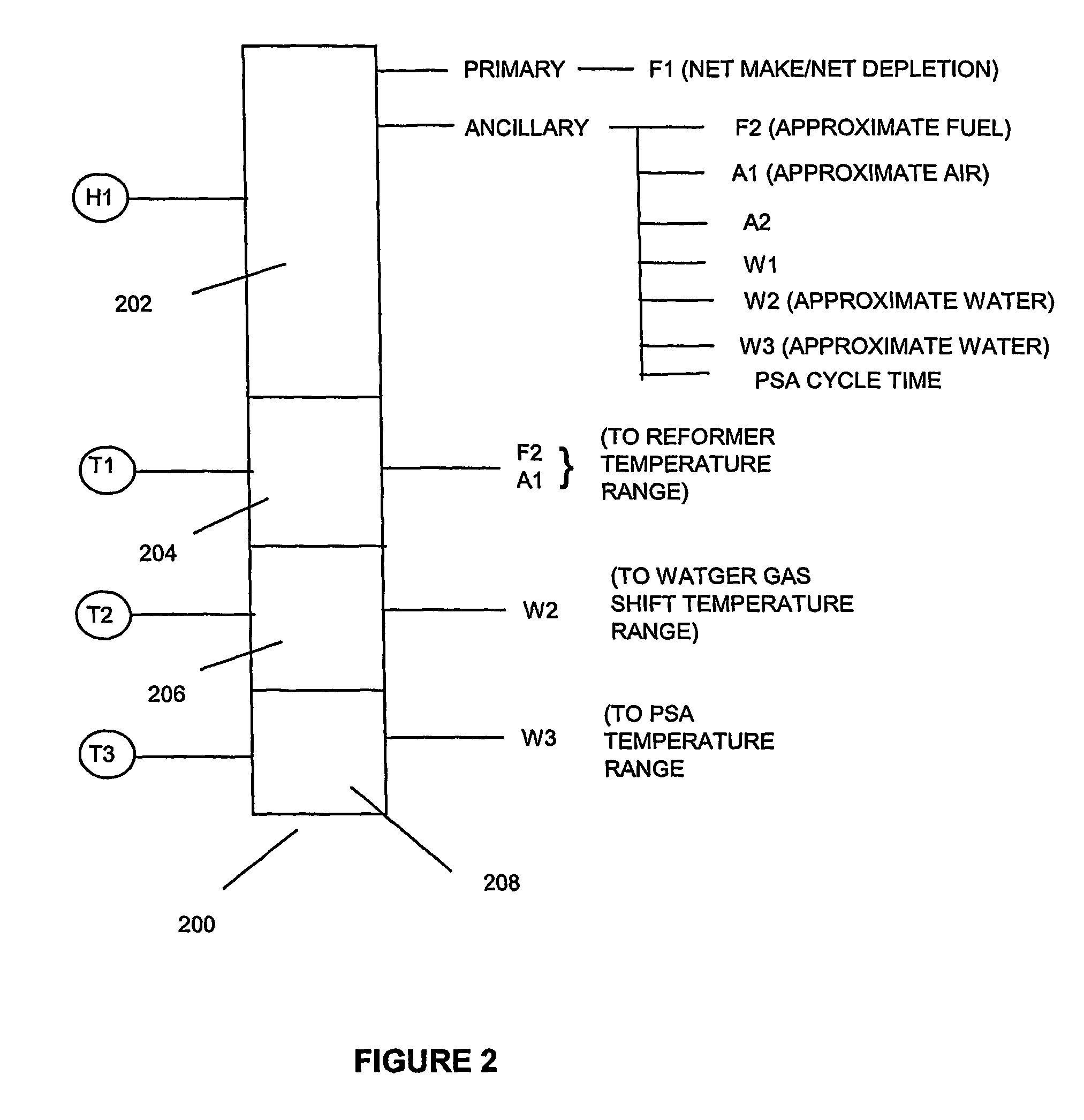

Feedforward control processes for variable output hydrogen generators

InactiveUS20060096175A1Improve efficiencyImprove stabilityProcess control/regulationExhaust apparatusFuel cellsProcess engineering

Hydrogen generators and integrated hydrogen generator / fuel cells systems are operated by determining the condition of the hydrogen generator and the condition of the fuel to the hydrogen generator for selection of predetermined flow rates for each of the externally-provided raw materials. The processes of the invention can provide rapid transitions between hydrogen production rates while enabling enhanced efficiency and stability during transient operations.

Owner:HYRADIX INC

Hydrogen production method by hydrolysis of aluminum-calcium alloy

The invention provides a hydrogen production method by hydrolysis of an aluminum-calcium alloy, wherein, aluminum and calcium in different mass percentages are taken as raw materials, and salt is taken as an activating agent. The obtained aluminum-calcium alloy can react with aqueous solution at different initial temperatures to produce hydrogen rapidly. In addition, hydrogen production rate and yield can be adjusted by changing the percentage of components in the alloy. The aluminum-calcium alloy can inhibit generation of an inertia alumina membrane on a surface, greatly improve the hydrogen production rate of the alloy per unit mass and lower hydrogen production cost.

Owner:CENT SOUTH UNIV

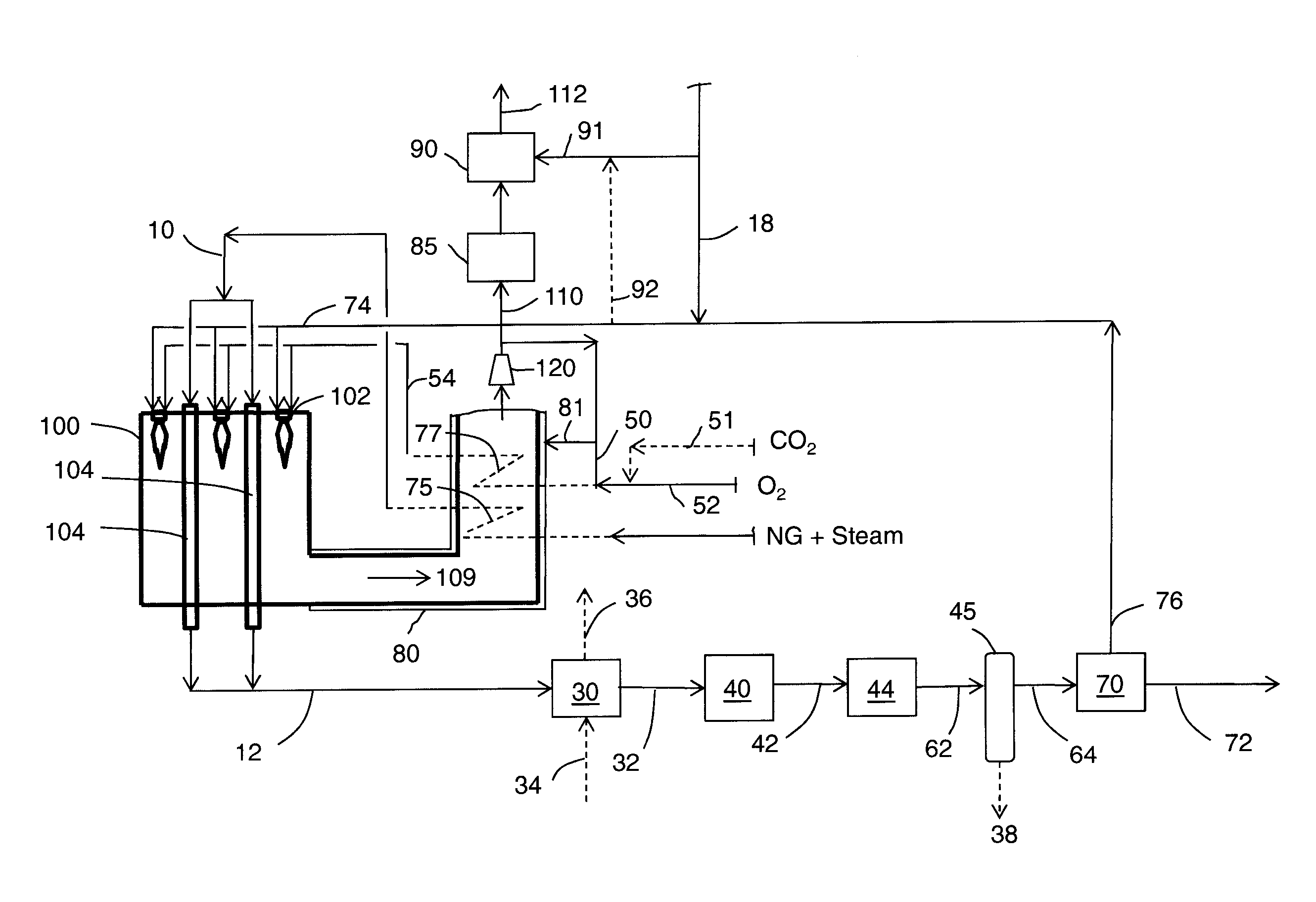

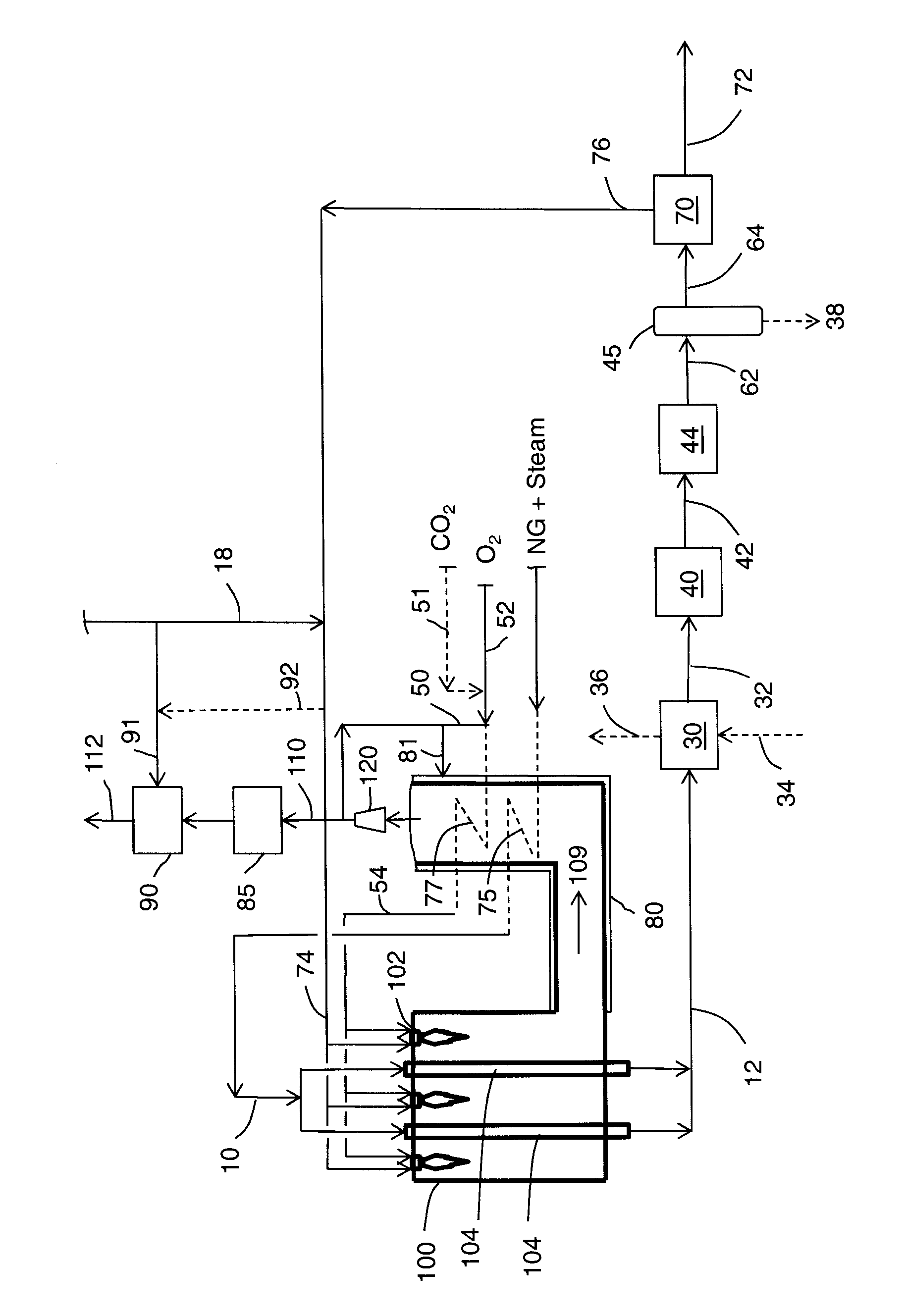

Hydrogen production with CO2 capture

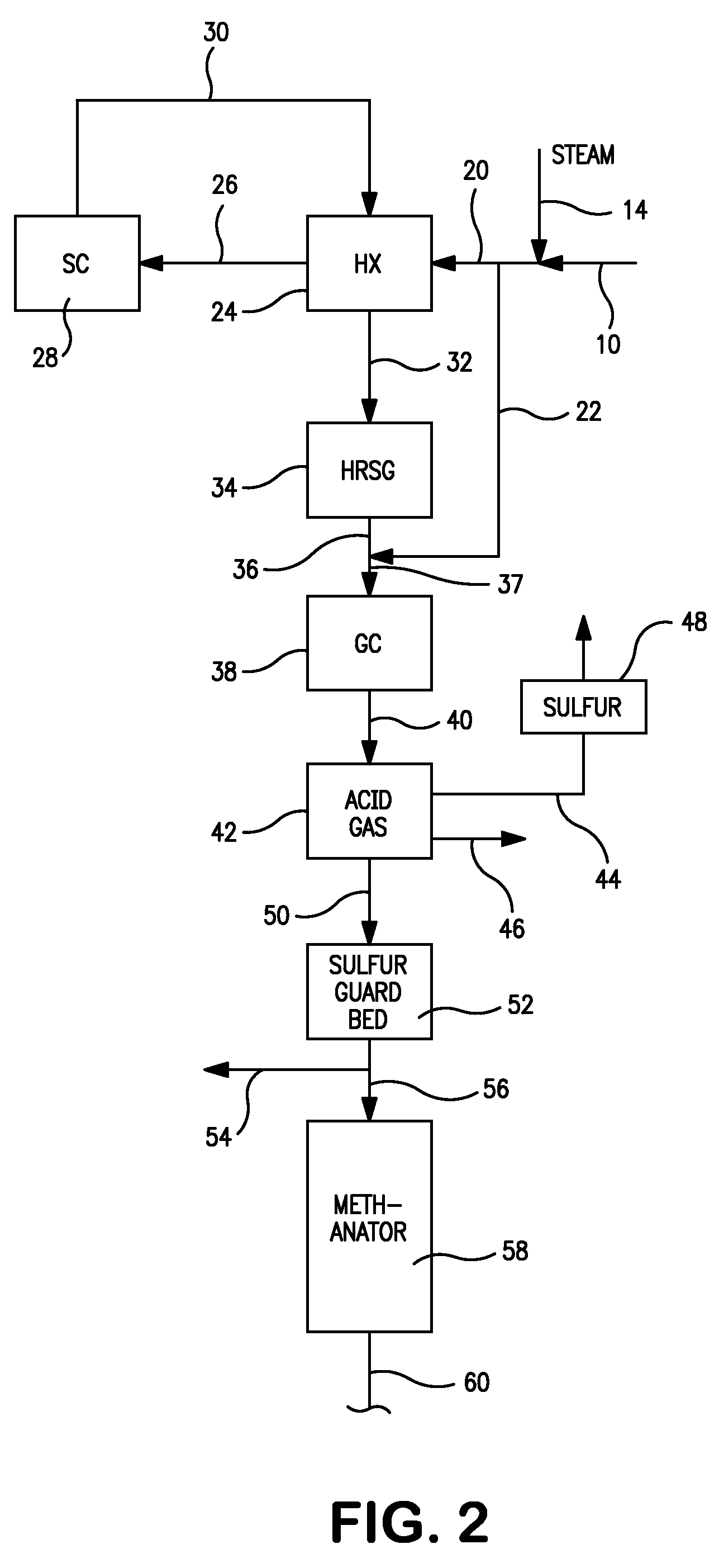

A steam methane reforming process for producing a hydrogen product while capturing CO2 from the process. Steam and a hydrocarbon are reformed in a catalytic reformer. The reformate is separated by pressure swing adsorption to form the hydrogen product and a PSA tail gas. The tail gas is returned to the reformer as a fuel. The fuel is combusted with synthetic air where the synthetic air is formed by combining a portion of the flue gas with industrial grade oxygen. The flue gas consists essentially of CO2 and H2O. The H2O is condensed out of another portion of the flue gas to form an essentially pure CO2 product.

Owner:AIR PROD & CHEM INC

Method for operating a hydrogen generator

InactiveUS20060177372A1Effective controlEffective and control for operationHydrogen separation using solid contactChemical industryLoss rateHydrogen production rate

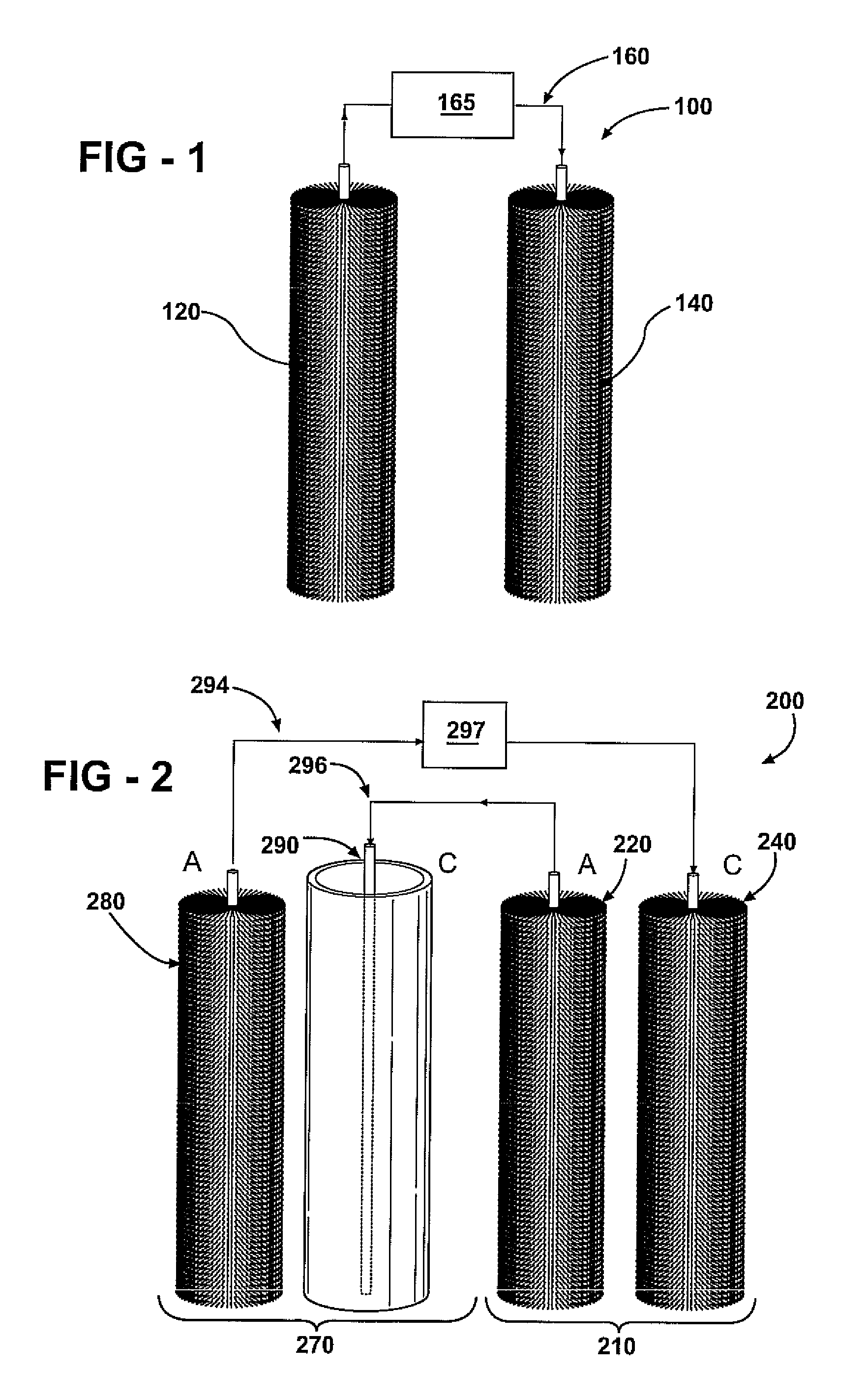

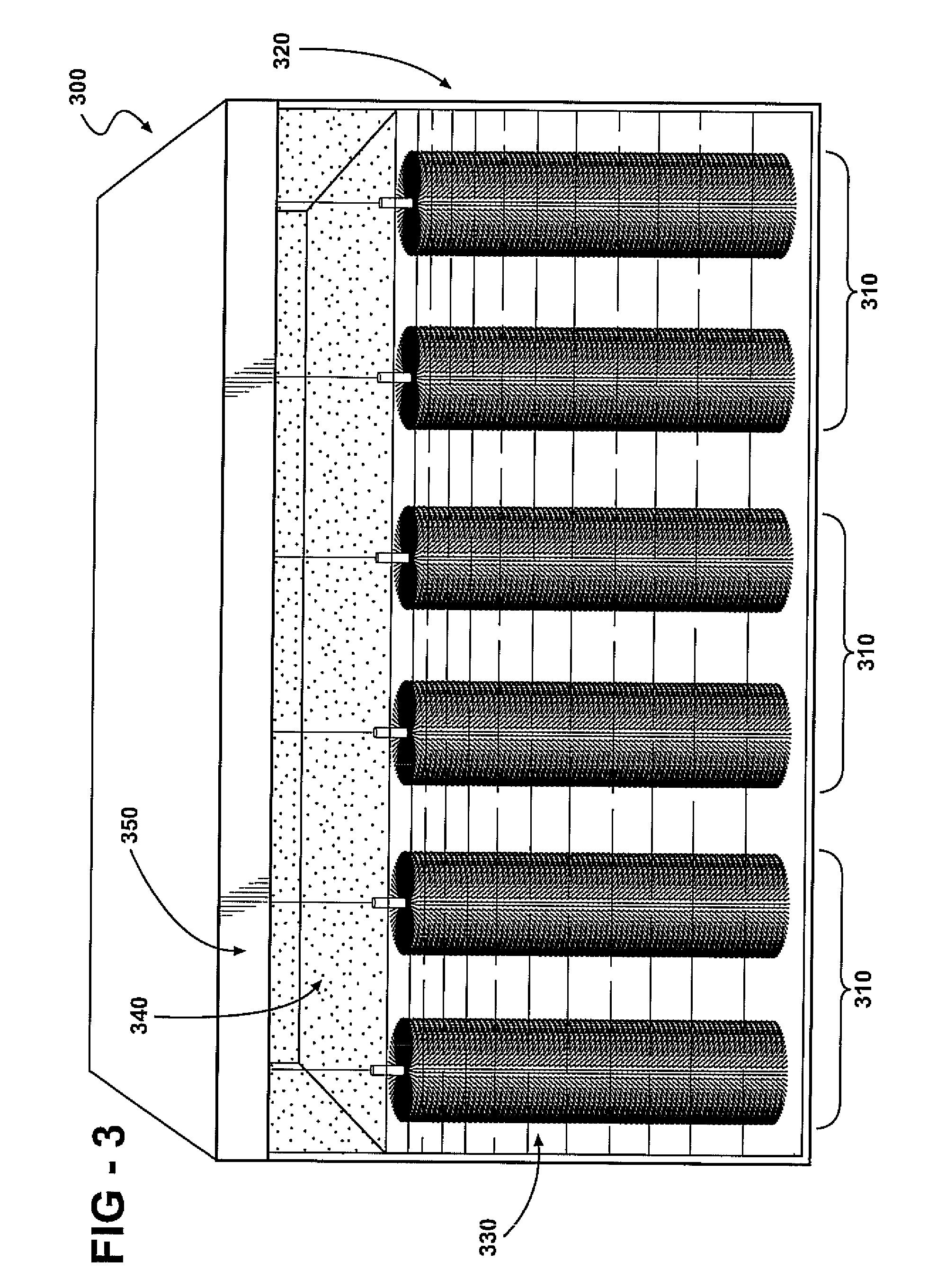

Hydrogen generators operating over a range of hydrogen production rates are controlled by alternating production between a net hydrogen make rate and a net hydrogen loss rate. A hydrogen reservoir (150) is provided and the amount of hydrogen in the reservoir is the determinant as to which hydrogen production rate is employed by the hydrogen generator.

Owner:DOSHI KISHORE J

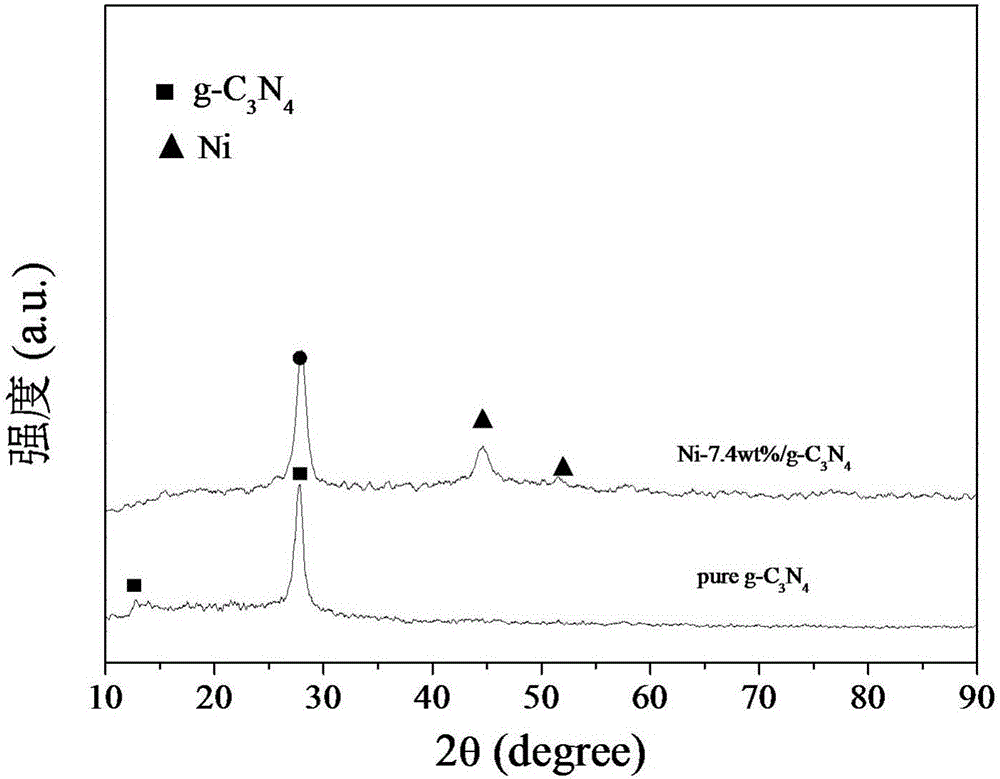

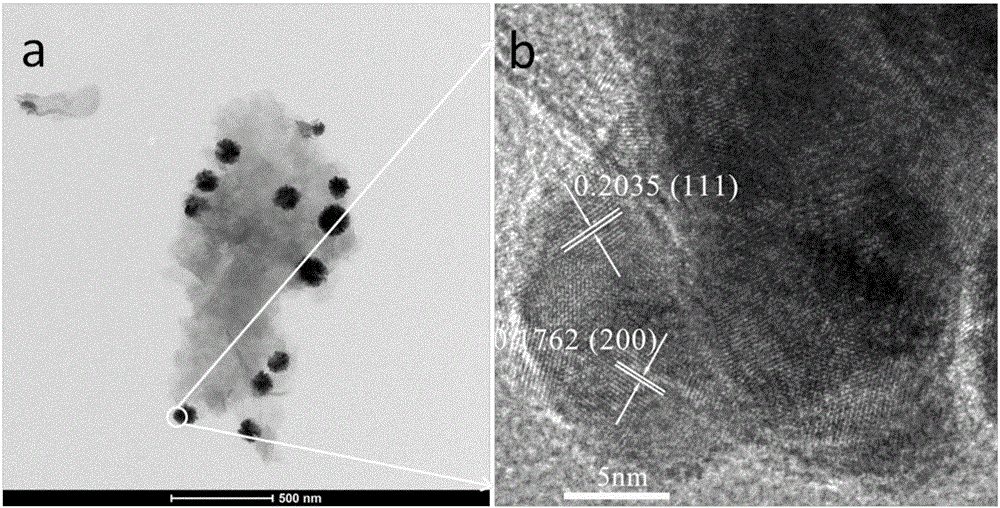

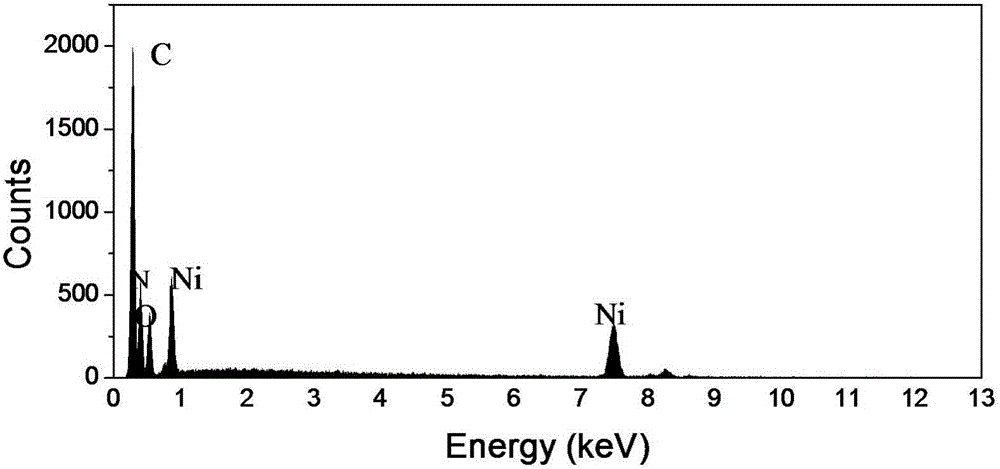

Simple and convenient preparation method for nickle/graphene-like carbon nitride compound composite catalyst

InactiveCN106076383ALow costReduce use costPhysical/chemical process catalystsHydrogen productionSynthesis methodsPollution

The invention aims to create a simple and convenient preparation method for a nickle / graphene-like carbon nitride compound composite catalyst for solving problems of environment pollution, energy crisis and the like at present, lowering the cost of a photocatalyst and increasing the rate of photocatalytic hydrogen production. The preparation method of the composite catalyst is green and environmental-friendly, the principle of the composite catalyst is that a graphene-like carbon nitride compound is taken as a photosensitizer, and the nickle monomer / graphene-like carbon nitride compound composite catalyst is prepared by reducing nickle ions by using a photo-reduction method. The nickle monomer / graphene-like carbon nitride compound composite catalyst provided by the invention is simple and convenient in synthesis method, high in photocatalysis hydrogen production rate, good in stability, low in price, non-toxic and environmental-friendly, and is a novel catalytic material with relatively large industrial photocatalysis hydrogen production prospects, and the cost can be greatly lowered if the catalyst is used in industrial production.

Owner:JIANGNAN UNIV

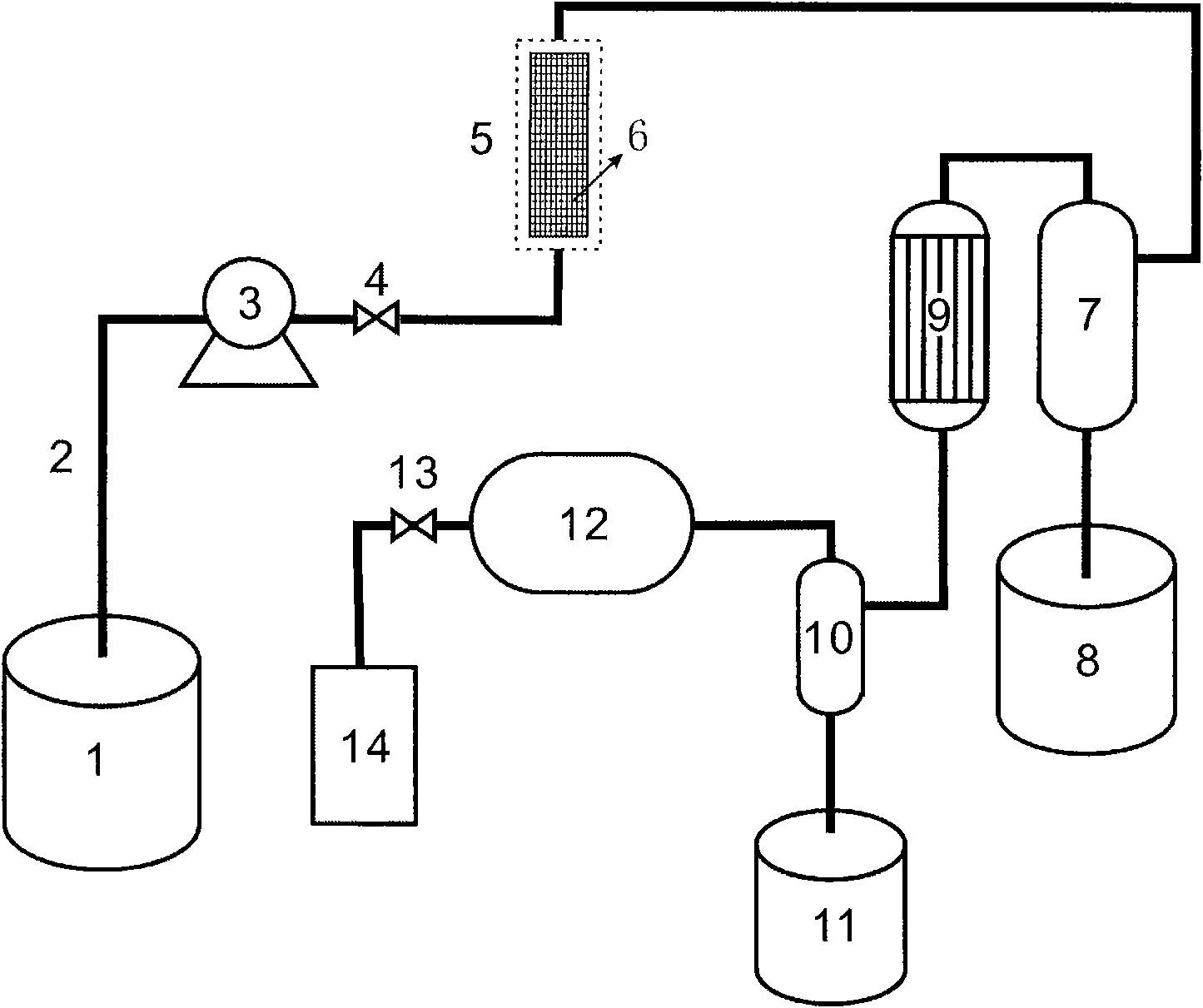

Device and method for chemical hydride catalytic-hydrolysis hydrogen production suitable for onboard hydrogen source

InactiveCN101597023AReal-time adjustment of flow rateIncrease flow rateChemical industryHydrogen productionHydrogen pressureHydrogen fuel cell

The invention relates to a hydrogen storage and production technology, in particular to a device and a method for chemical hydride catalytic-hydrolysis hydrogen production suitable for an onboard hydrogen source. The hydrogen production device mainly comprises a catalytic reaction chamber provided with a heat exchanger, a gas-liquid separator, a fuel pump and a controlling unit, and the hydrogen production method is used for controlling the contact and the separation between liquid fuel and catalyst to achieve the purpose of prompt hydrogen production as required. Since the heat exchanger is additionally arranged at the periphery or inside the catalytic reaction chamber, the heat from hydrolysis reaction is effectively utilized, the initial temperature of the liquid fuel is remarkably improved, the hydrogen-production rate of the device, the fuel conversion ratio and the system energy efficiency are greatly improved; and in addition, due to the design of the controlling unit, the continuous automatic adjustment of the delivery rate of the liquid fuel is realized, the stable hydrogen pressure of the system is ensured, and the hydrogen-storage density of the device is improved when the hydrogen supply demand at the hydrogen use terminal is responded in real time. The provided device for prompting hydrogen production can provide the onboard hydrogen source for hydrogen fuel-cell vehicles and various military and civil portable power supplies.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

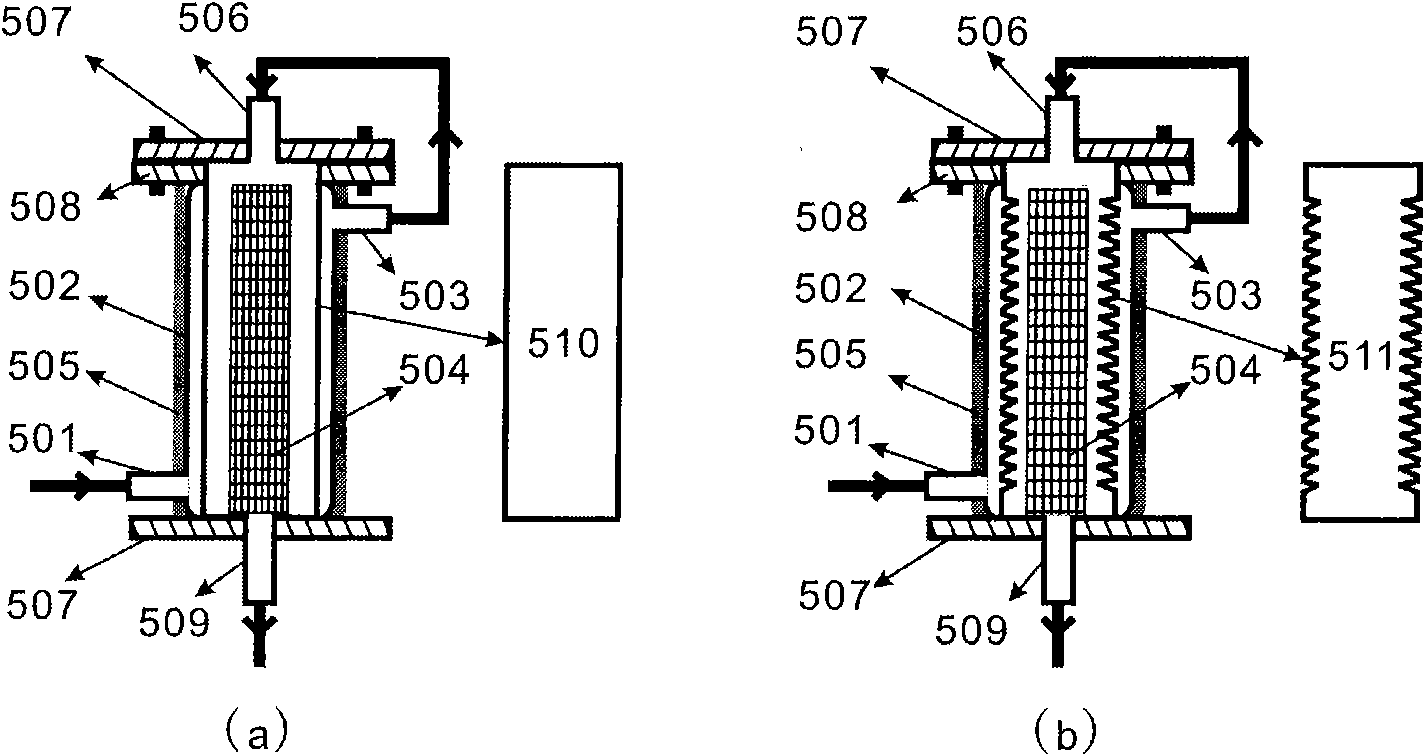

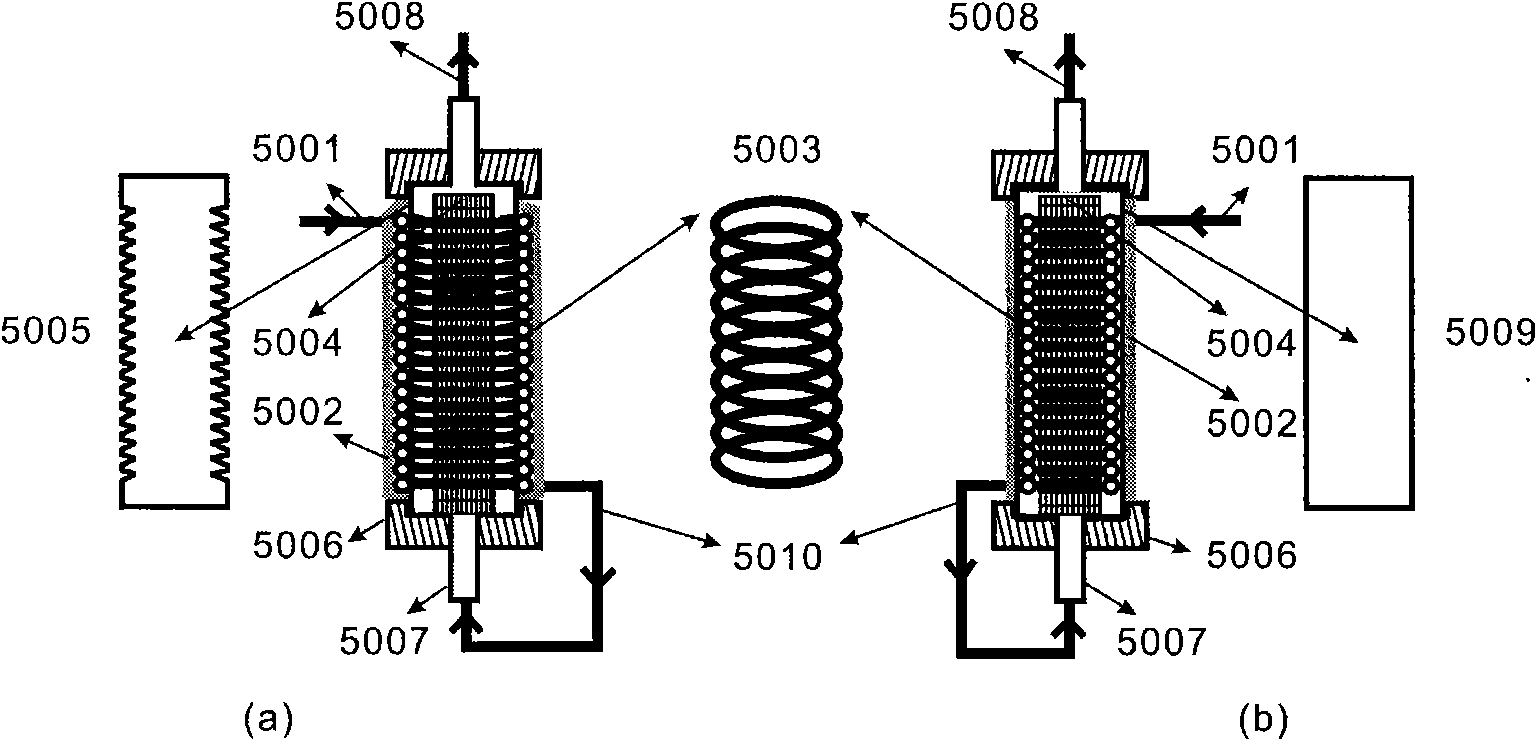

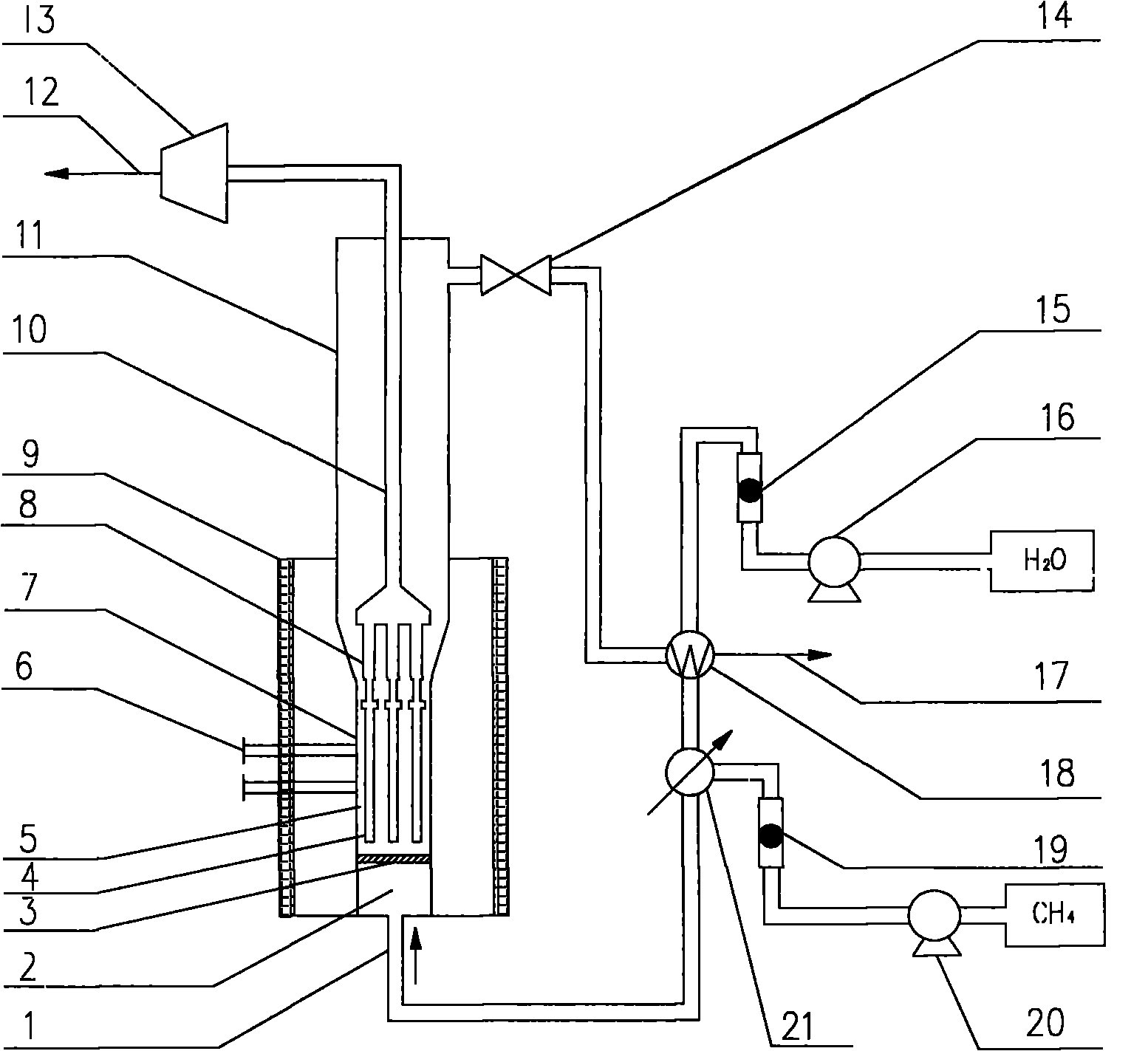

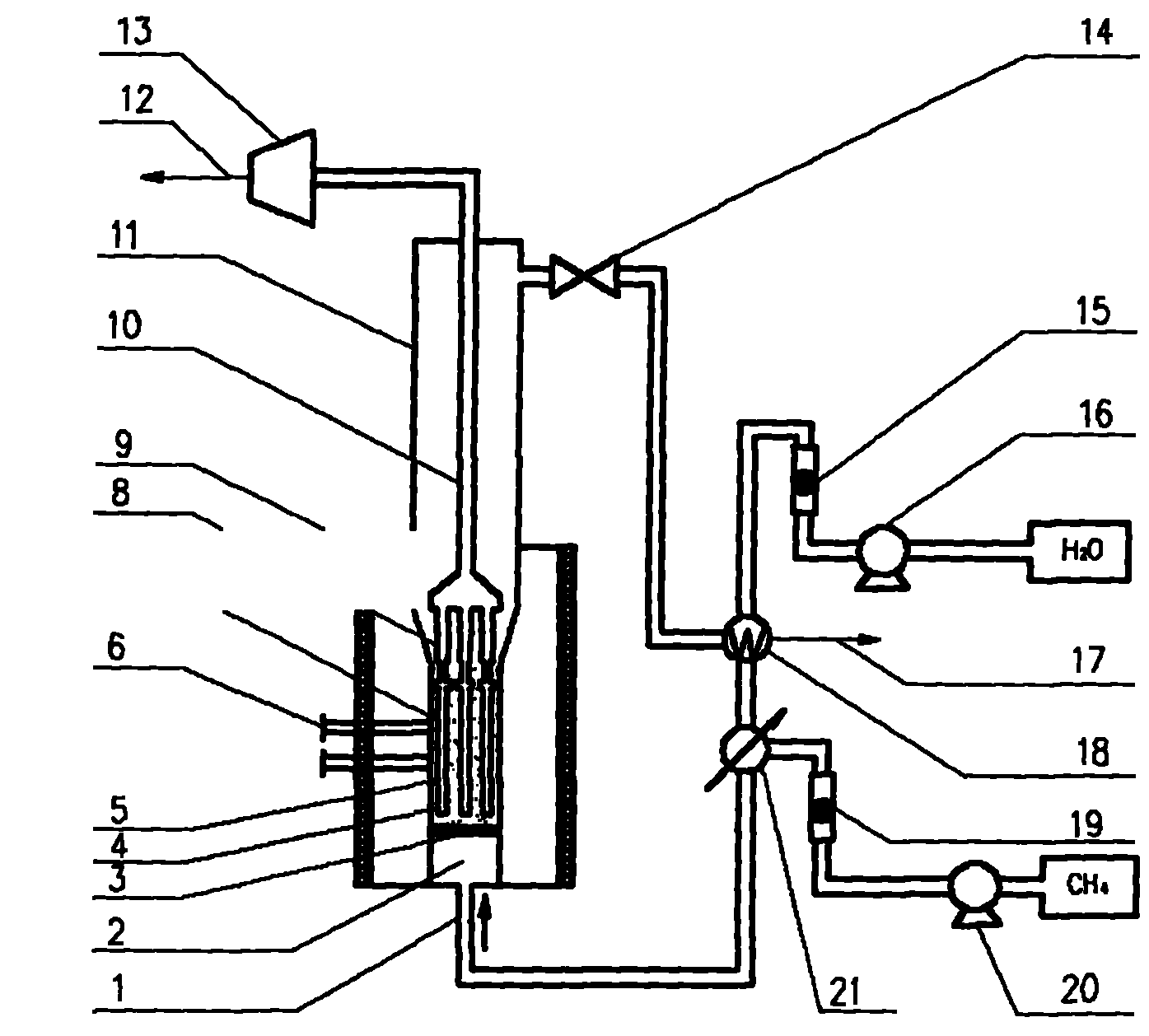

Method for producing hydrogen through coupled catalytic reforming and membrane separation reaction, and device thereof

InactiveCN101837955AAvoid depositionEasy to separateHydrogen separationCatalytic reformingSteam reforming

The invention belongs to the technical field of chemical equipment, and relates to a method for producing hydrogen through coupled catalytic reforming and membrane separation reaction, and a device thereof, in particular to a method for producing hydrogen through fluidized-bed methane steam reforming, and a device thereof, which apply to the fields of petroleum, chemical industry and fuel cells. A main structure comprises a feed gas inlet, a pre-distribution chamber, a gas distribution plate, a palladium membrane component, a catalyst bed layer, a sampling port, a fluidized-bed reaction-zone bed body, a metal connection tube, a heating system, a hydrogen duct, an expansion section, a super pure hydrogen outlet, a vacuum pump, a backpressure valve, a liquid rotor flow meter, a water pump, an exhaust gas outlet, a heat exchanger, a gas rotor flow meter, a gas pump and a preheater, wherein the components are in gas-liquid communication and organic coordination to form a methane steam reforming hydrogen production device or reactor with a hydrogen selective membrane fluidized bed, and the top of the fluidized-bed reaction-zone bed body is sealed by adopting a cover-type structure. The invention has the advantages of simple process, low investment in equipment, good membrane separation performance and high hydrogen production rate.

Owner:QINGDAO UNIV OF SCI & TECH

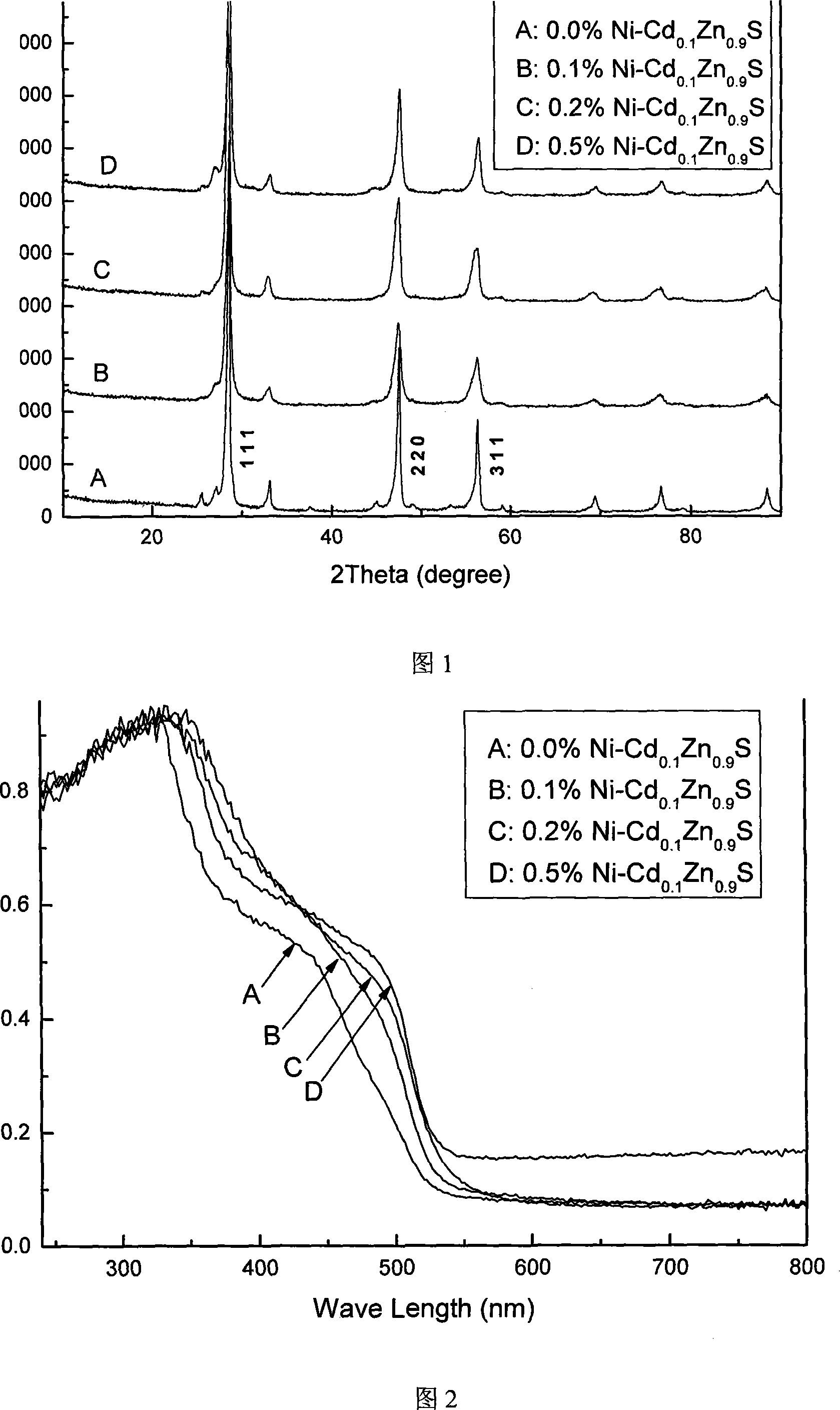

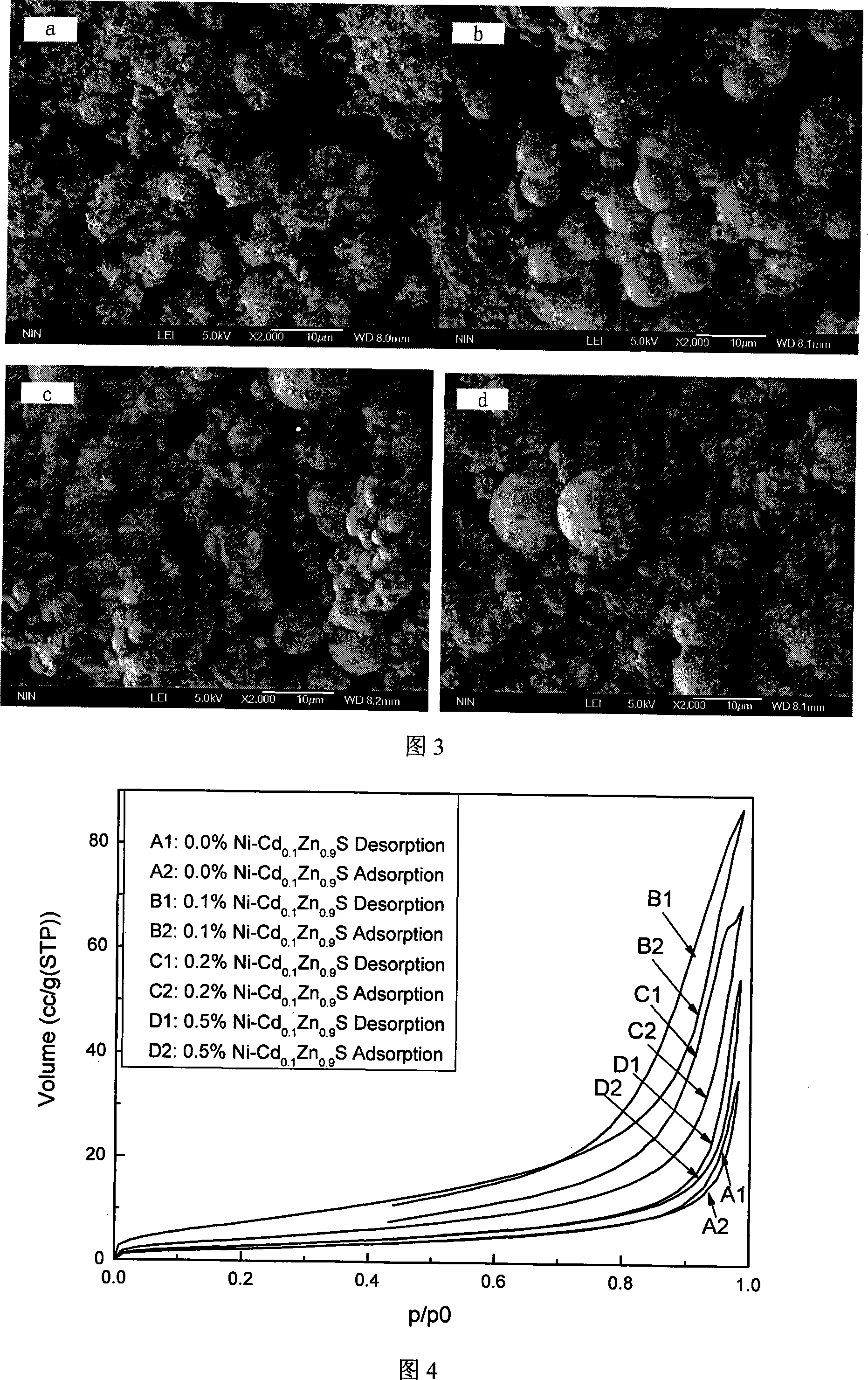

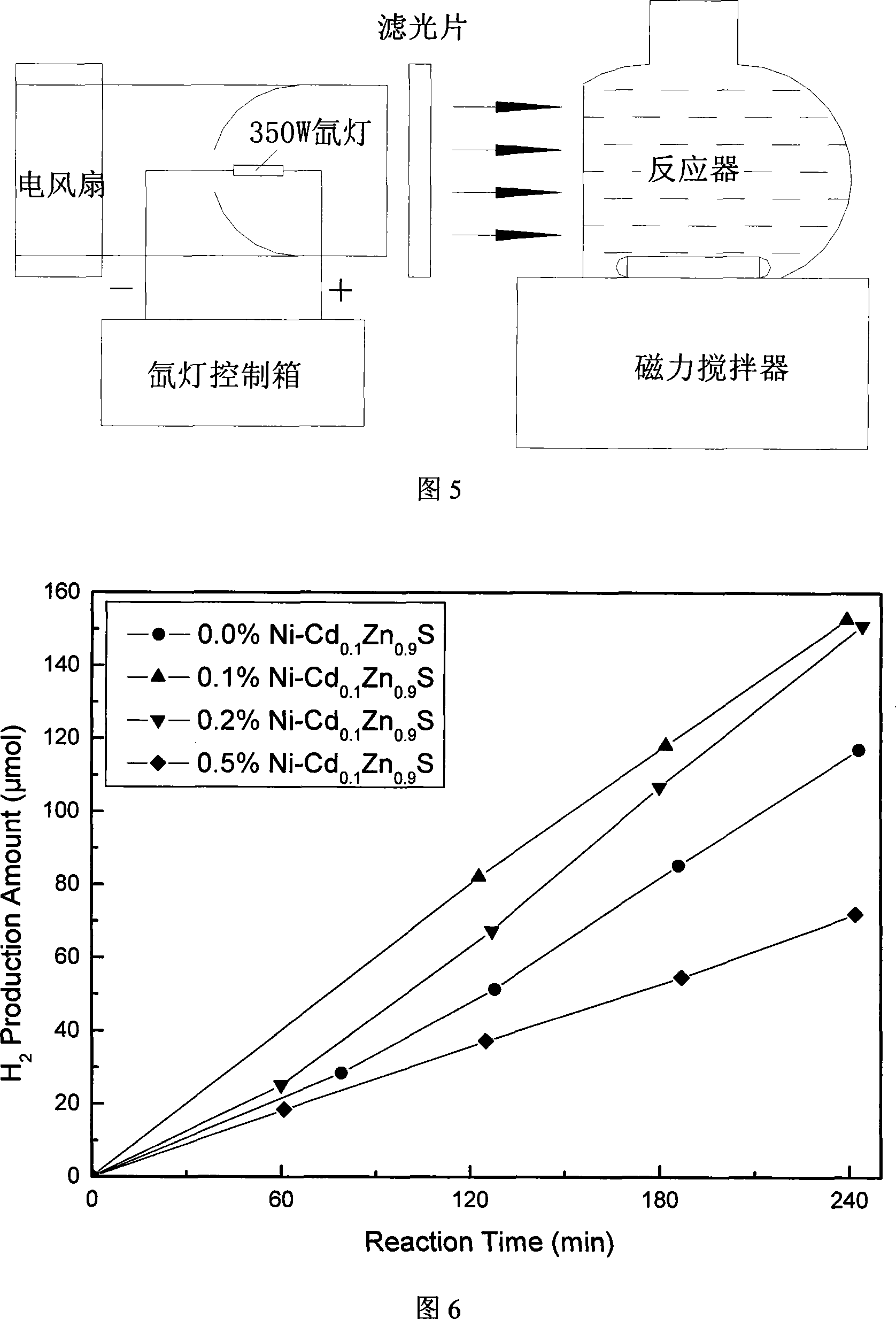

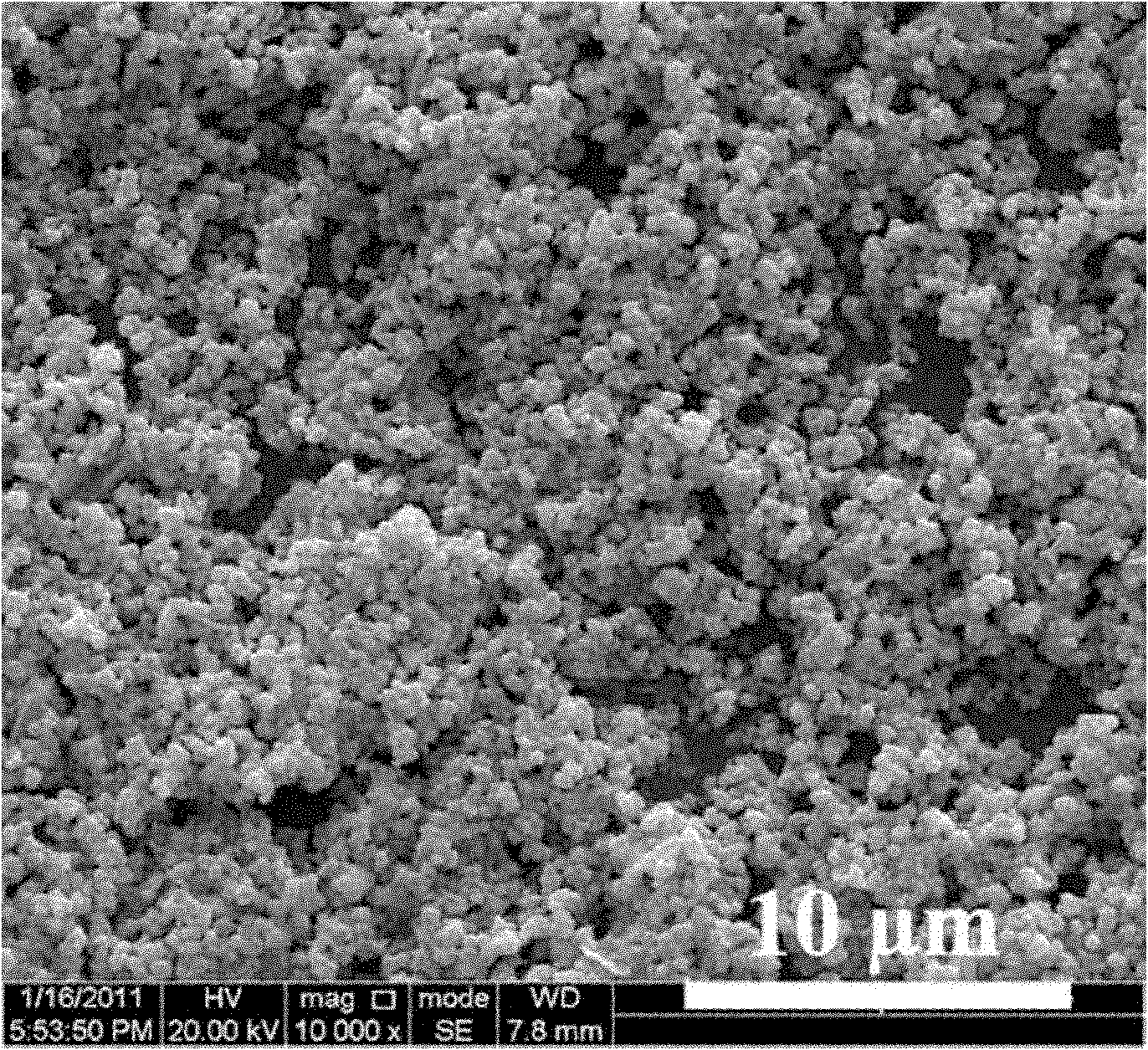

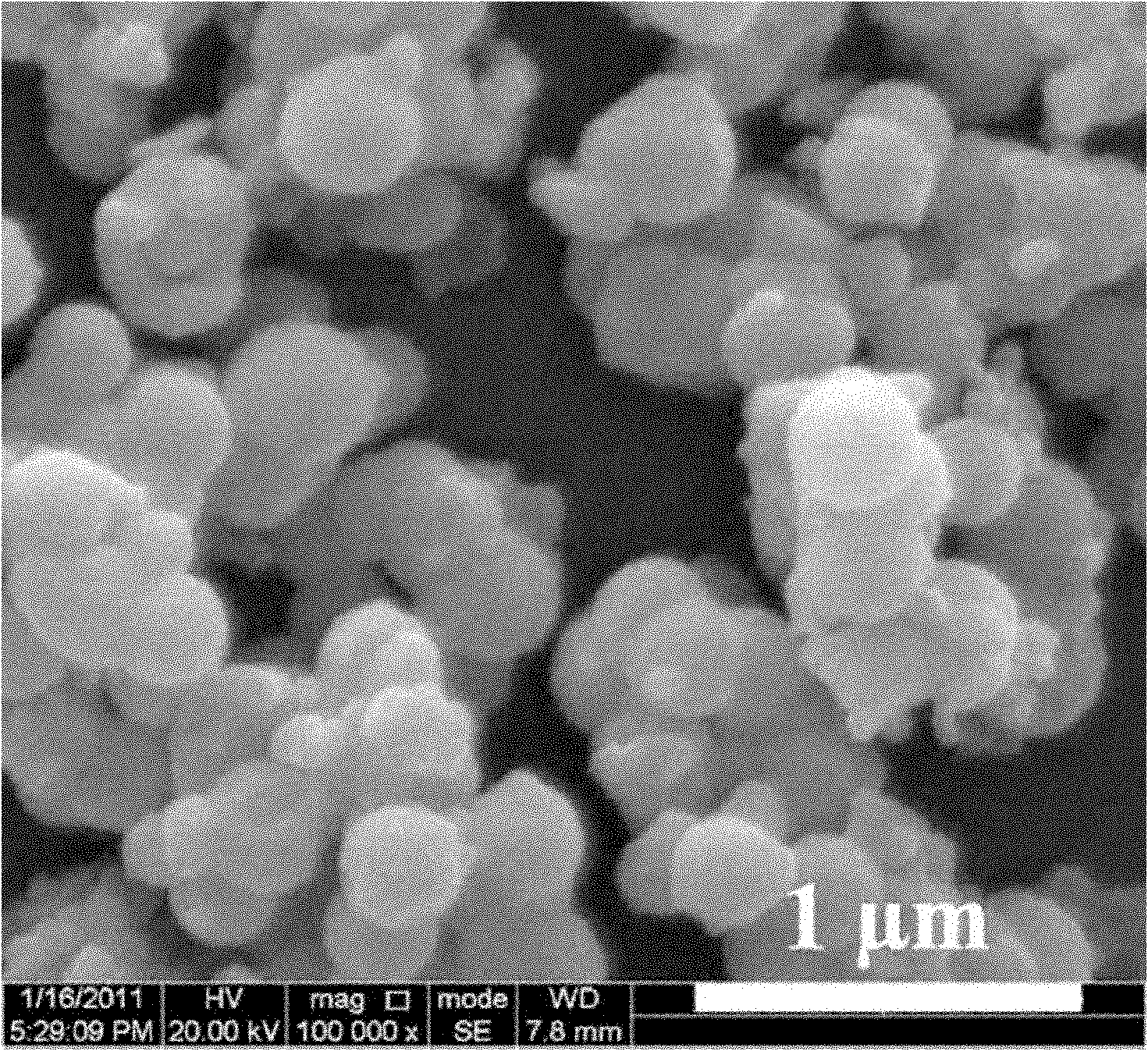

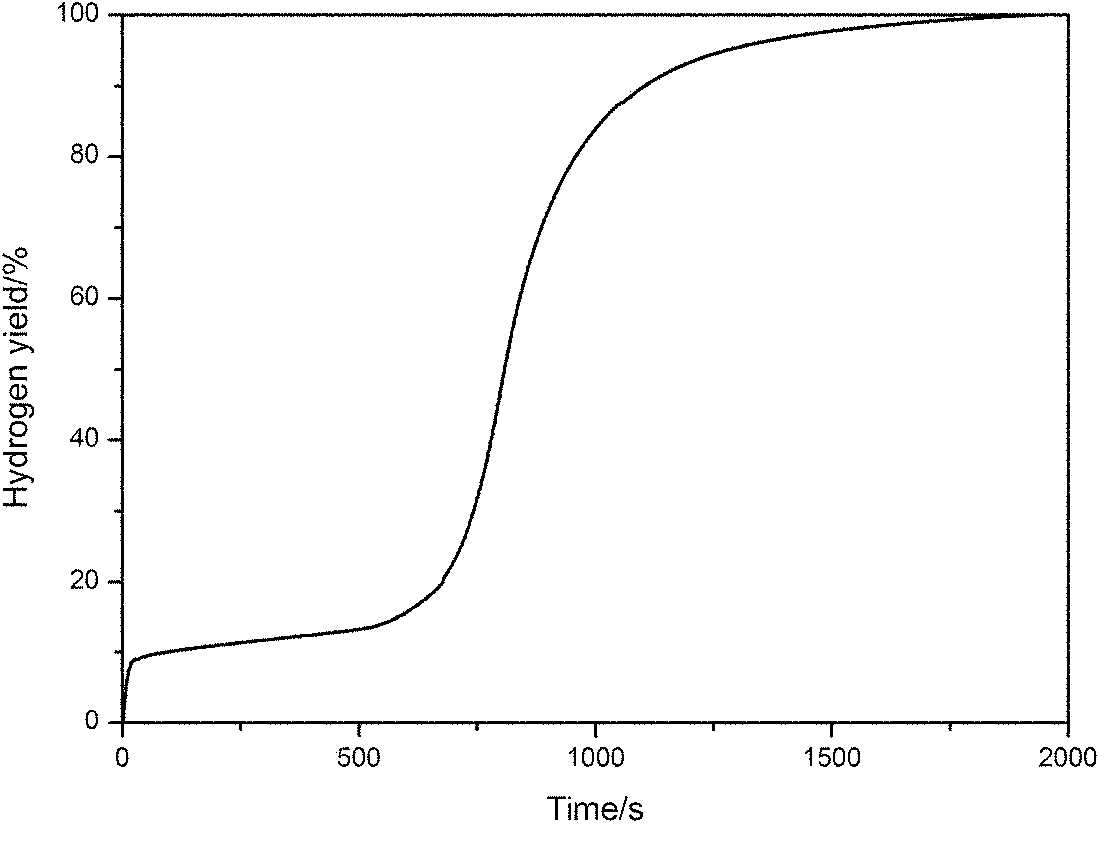

Ni doping Cd*.Zn*.*S micrometre ball photocatalyst and preparation method

ActiveCN101157044AImprove hydrogen production activityHigh activityPhysical/chemical process catalystsHydrogen productionPhotocatalytic water splittingPhotocatalytic reaction

The invention discloses Ni-doped Cd0.1Zn0.9 S microsphere photocatalyst and the preparation method thereof, the particle shape of the produced photocatalyst is a microsphere formed by nanometer crystals, and the doping amount of Ni is 0.1 percent to 0.5 percent of the weight of the catalyst. The invention has the preparation method that zinc sulfate, cadmium sulfate, nickel nitrate, and thioacetamide are taken as raw materials to form mixed solution which is sealed in a hydrothermal caldron and then laid in a baking oven to be insulated, naturally cooled to the room temperature, a resultant is obtained through cleaning, drying, and grinding. The Ni-doped Cd0.1Zn0.9S microsphere photocatalyst is prepared by the invention, and the anti-surface oxidation capability in air and the photo-corrosion resistant capability in the photocatalytic reaction are evenly enhanced greatly. Because the particle of the photocatalyst is microsphere-shaped, the photocatalytic activity for photocatalytic water splitting into hydrogen of visible light of the catalyst is greatly enhanced, and the highest hydrogen production rate reaches 191.01 micromole / (g*h). The quantum efficiency reaches 6.77 percent at the 420 nm position. After Pt of 0.6 wt percent is loaded, the highest hydrogen production rate reaches 585.45 micromole / (g*h), which is three times than the hydrogen production rate when the Pt is not loaded. The quantum efficiency reaches 15.9 percent at the 420 nm position, the activity is high, and the stability is good.

Owner:XI AN JIAOTONG UNIV

Composite visible light photocatalyst loaded with two promoters at the same time and application thereof

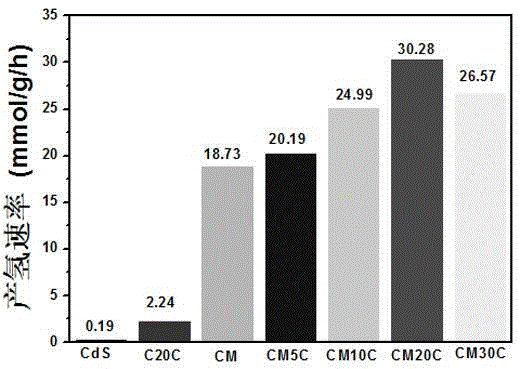

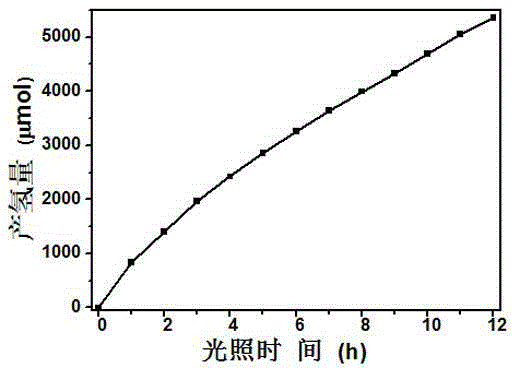

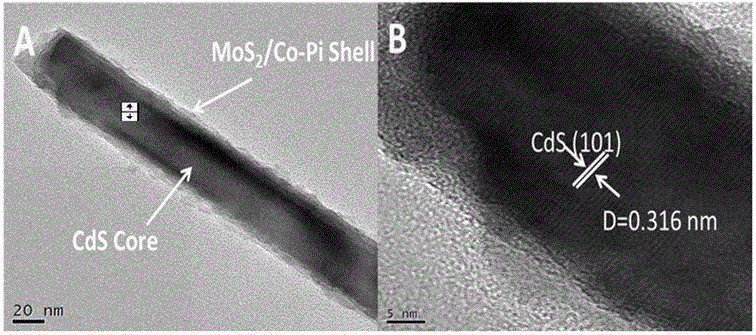

InactiveCN105251522AReduce manufacturing costSimple production processPhysical/chemical process catalystsHydrogen productionNanowireVisible light photocatalytic

The invention discloses a composite visible light photocatalyst loaded with two promoters at the same time and the application thereof. The two-step photodeposition method is adopted, the base metal-based reduced form promoter MoS2 and the base metal-based oxidized form promoter Co-Pi are evenly loaded on the surface layer of a CdS nanowire at the same time, and then the CdS / MoS2 / Co-Pi composite visible light photocatalyst with a one-dimensional core-shell structure is obtained. The CdS / MoS2 / Co-Pi composite visible light photocatalyst has the advantages that the preparing method is simple, catalytic efficiency is high, catalytic performance is stable, and no precious metal is contained. When the CdS / MoS2 / Co-Pi composite visible light photocatalyst is used for catalysis and photolysis of water for hydrogen production under visible light, hydrogen production rate is 30.28 mmol / g.h, apparent quantum yield is 36.4% under the 420 nm wavelength, and sustainable development of the environment and energy is facilitated.

Owner:FUZHOU UNIV

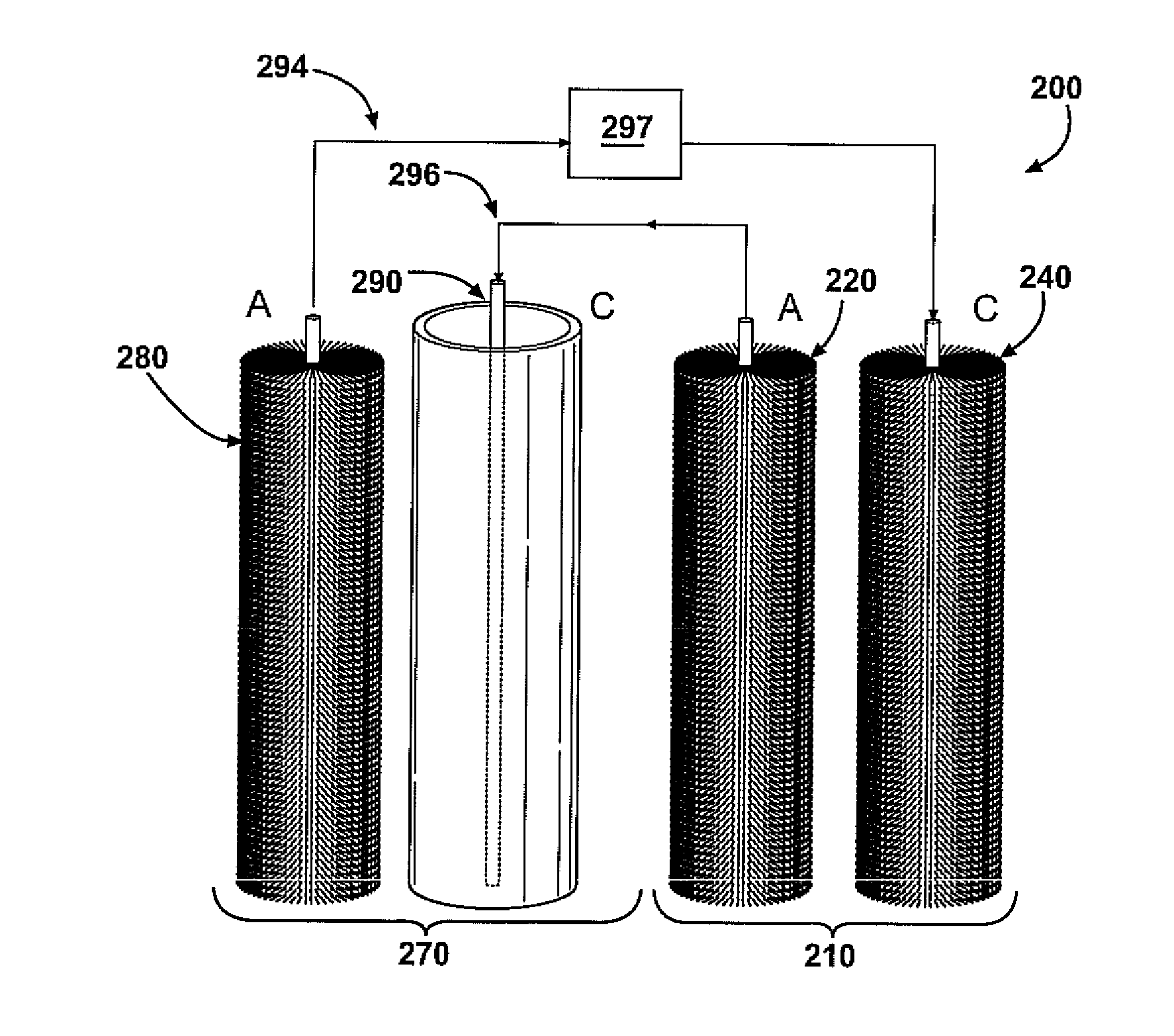

Electrohydrogenic reactor for hydrogen gas production

ActiveUS7922878B2CellsTreatment by combined electrochemical biological processesElectricityInterior space

A system for hydrogen gas generation is provided according to the present invention which includes a hydrogen gas electrode assembly including a first anode in electrical communication with a first cathode; a microbial fuel cell electrode assembly including a second anode in electrical communication with a second cathode, the microbial fuel cell electrode assembly in electrical communication with the hydrogen gas electrode assembly for enhancing an electrical potential between the first anode and the first cathode. A single chamber housing contains the hydrogen gas electrode assembly at least partially in the interior space of the housing.

Owner:PENN STATE RES FOUND

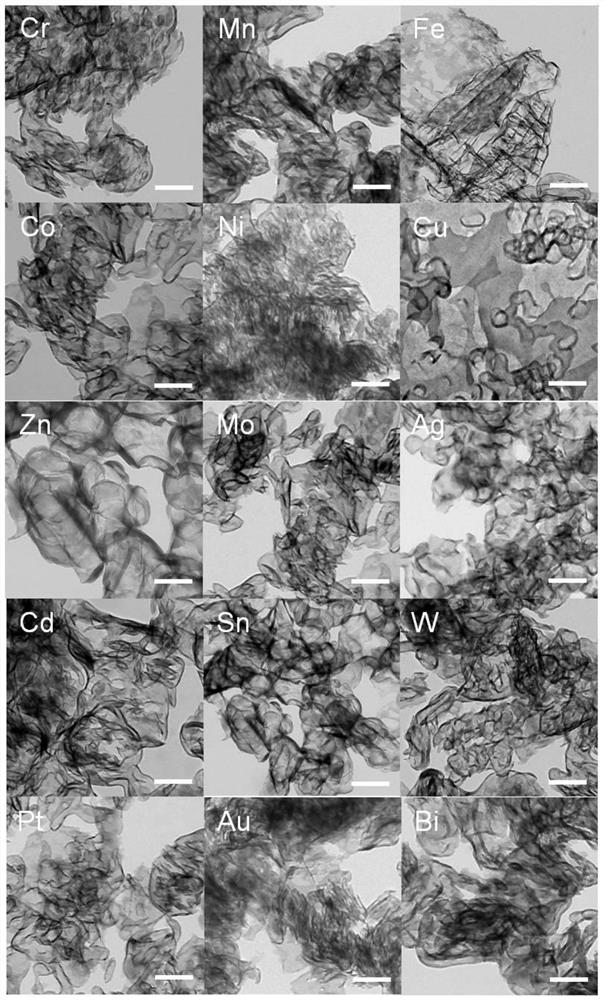

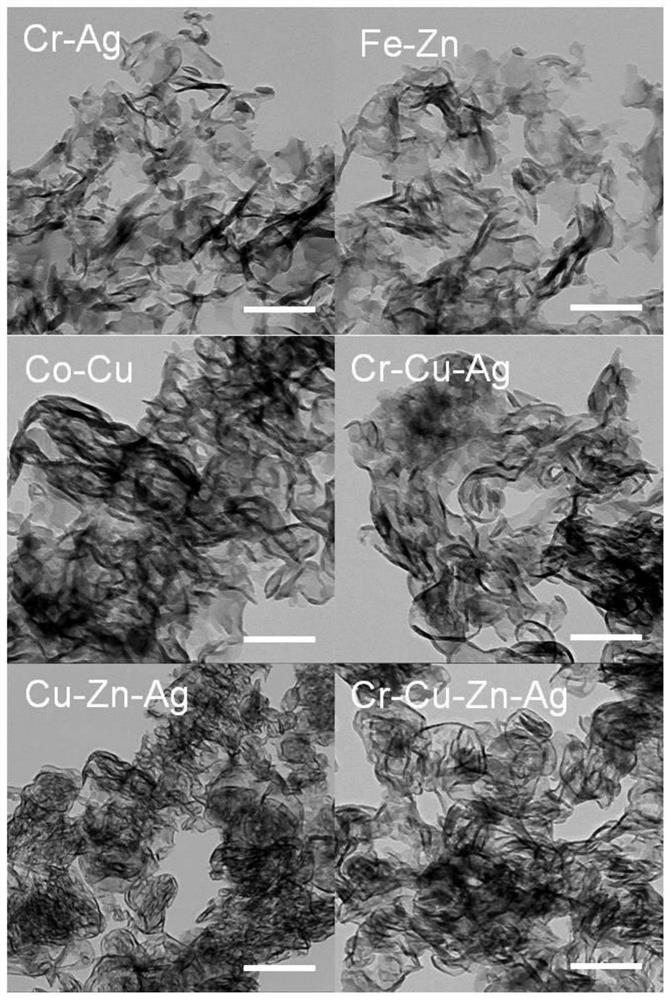

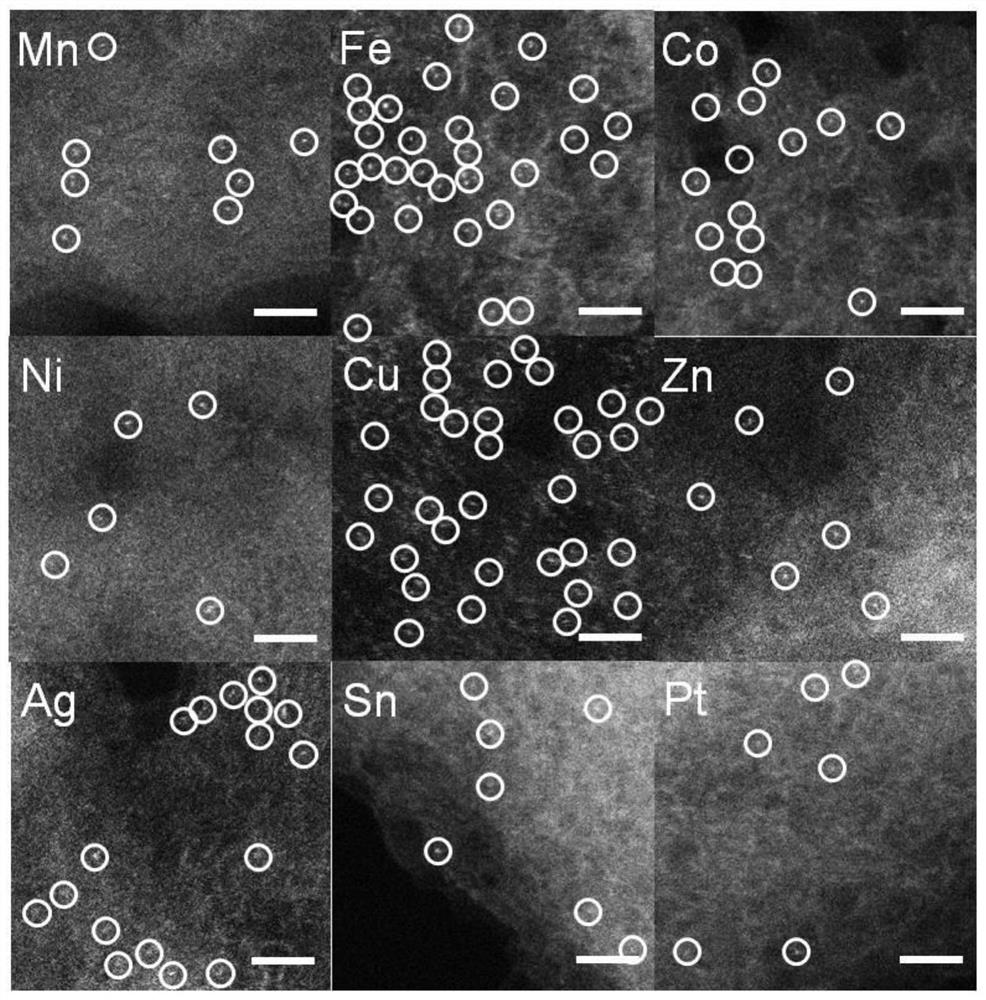

Controllable synthesis method of monoatomic catalyst with low cost and high loading capacity

ActiveCN111939961AIncrease loadThe content is easy to controlPhysical/chemical process catalystsHydrogen productionPhoto catalyticPtru catalyst

The invention discloses a controllable synthesis method of a monoatomic catalyst with low cost and high loading capacity, the monoatomic catalyst prepared by a method takes graphite-phase carbon nitride as a substrate, has the characteristics of low cost, high metal element loading capacity, controllable content and adjustable variety, and meanwhile, the method can be used for preparing the single-metal single-atom catalyst and a multi-metal single-atom catalyst, the single-atom catalyst has excellent catalytic activity and stability, and by taking the silver single-atom catalyst as an example, the visible light hydrogen production rate of the silver single-atom catalyst is 6.2 times that of silver nanoparticle-loaded graphite-phase carbon nitride, and after 60-hour continuous photocatalytic hydrogen production test, the hydrogen production rate is almost unchanged.

Owner:NANCHANG HANGKONG UNIVERSITY

Novel ammonia borane composite material for hydrolysis hydrogen production

InactiveCN101837953AImprove the kinetic performance of hydrolysis hydrogen releaseSmall particle sizeHydrogen productionMetal chlorideAlkaline earth metal

The invention relates to a novel ammonia borane composite material, in particular to the novel ammonia borane (NH3BH3) composite material used for inducing the hydrolysis of an ammonia borane compound to produce hydrogen under a mild condition. The novel ammonia borane composite material comprises hydrogen storage materials which have micron, submicron and nanometer particle sizes and are obtained by using an inducer (metal hydride MHx or a salt) and an ammonia borane mixture as initial raw materials. The metal hydride MHx comprises one of or a combination of a plurality of types of alkali metal hydride, alkaline earth metal hydride, transition metal hydride and rear earth metal hydride; and the salt comprises one of or a combination of a plurality of types of metal chloride and sulfate. The initiative phase component molar ratio of the inducer to the ammonia borane (NH3BH3) is (2-0.02):1. The novel ammonia borane composite material greatly improves the dynamics performance of hydrolysis hydrogen discharge of the ammonia borane, and has a high hydrogen discharge amount and a high hydrogen production rate when hydrolyzed under the mild condition.

Owner:SICHUAN UNIV

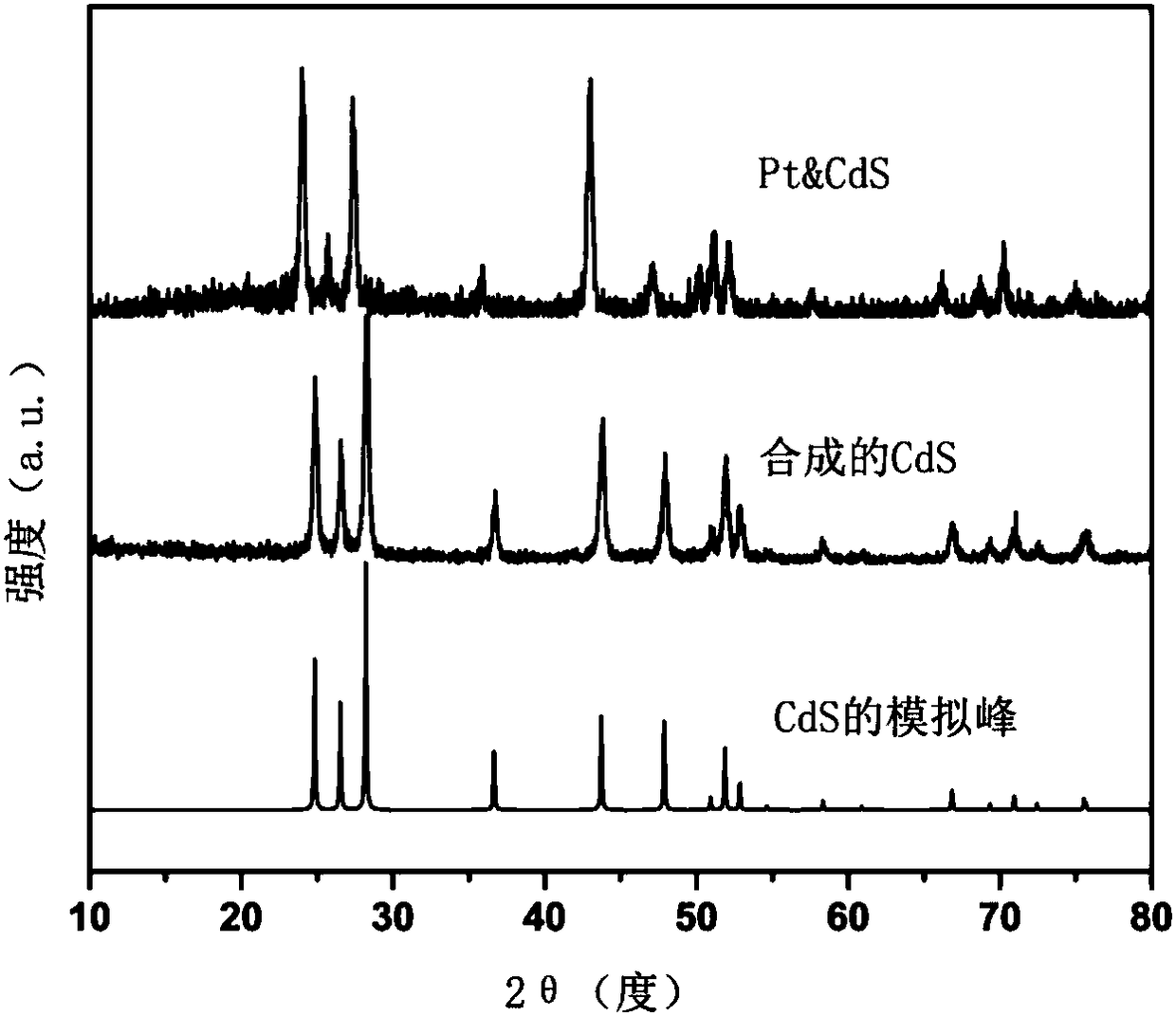

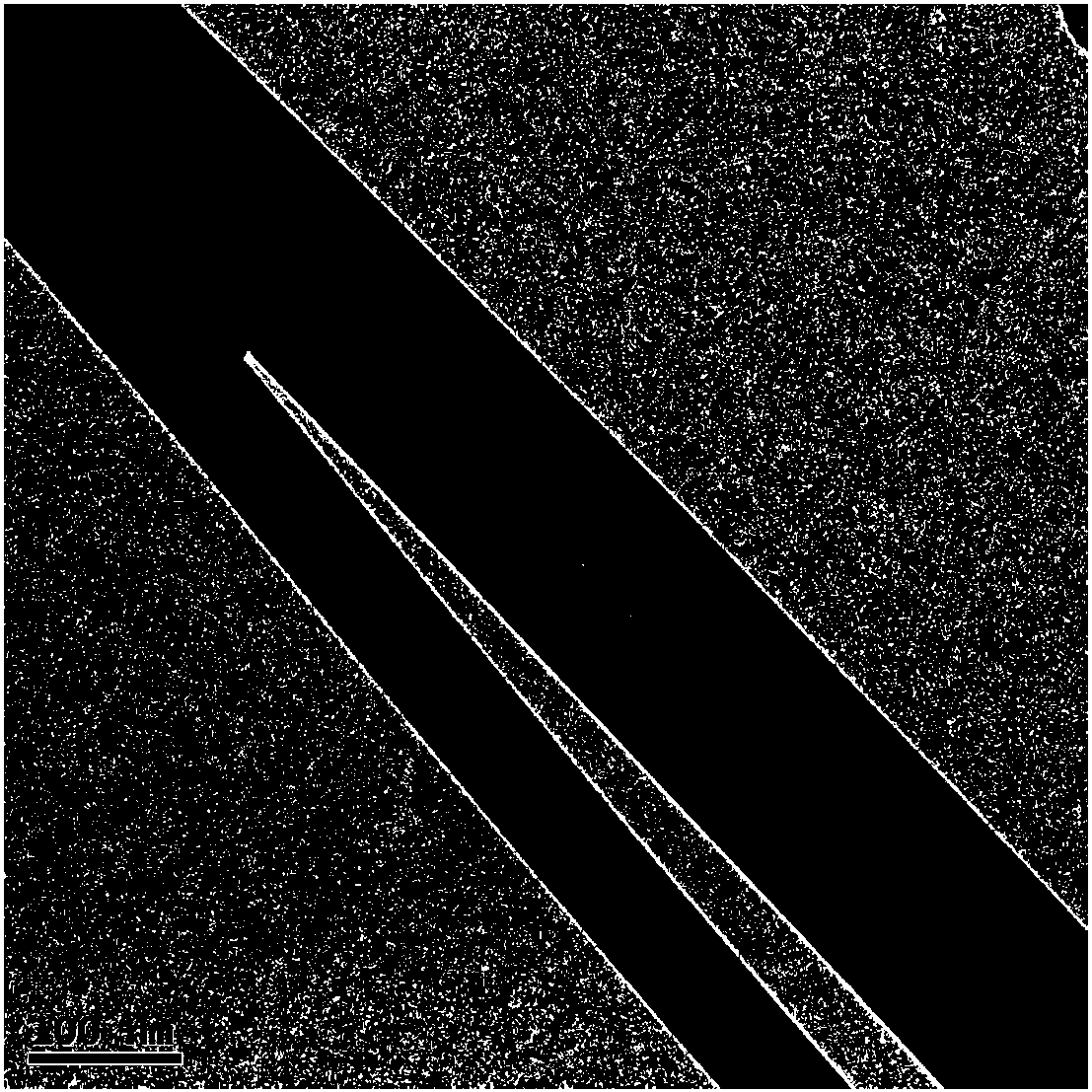

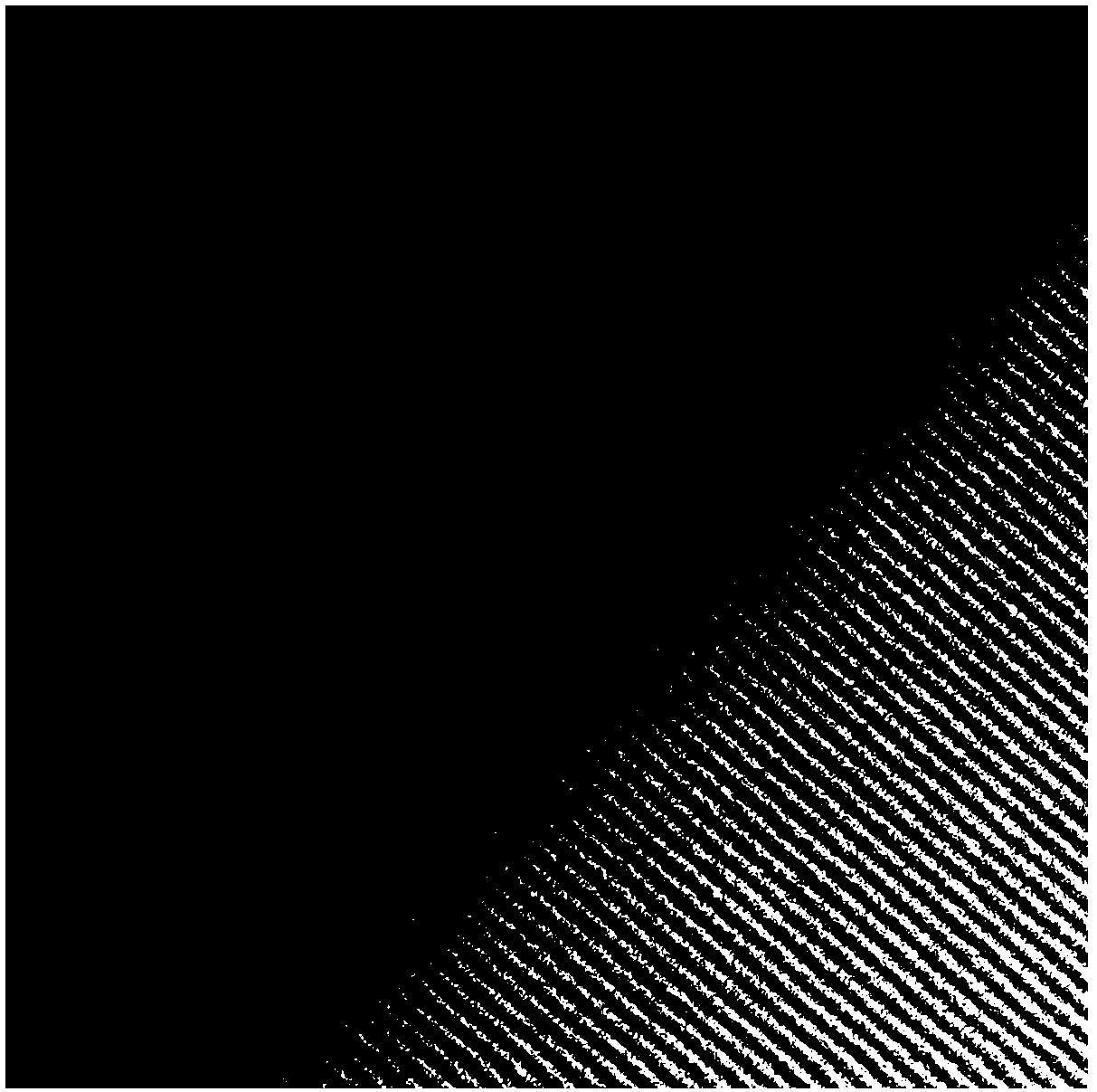

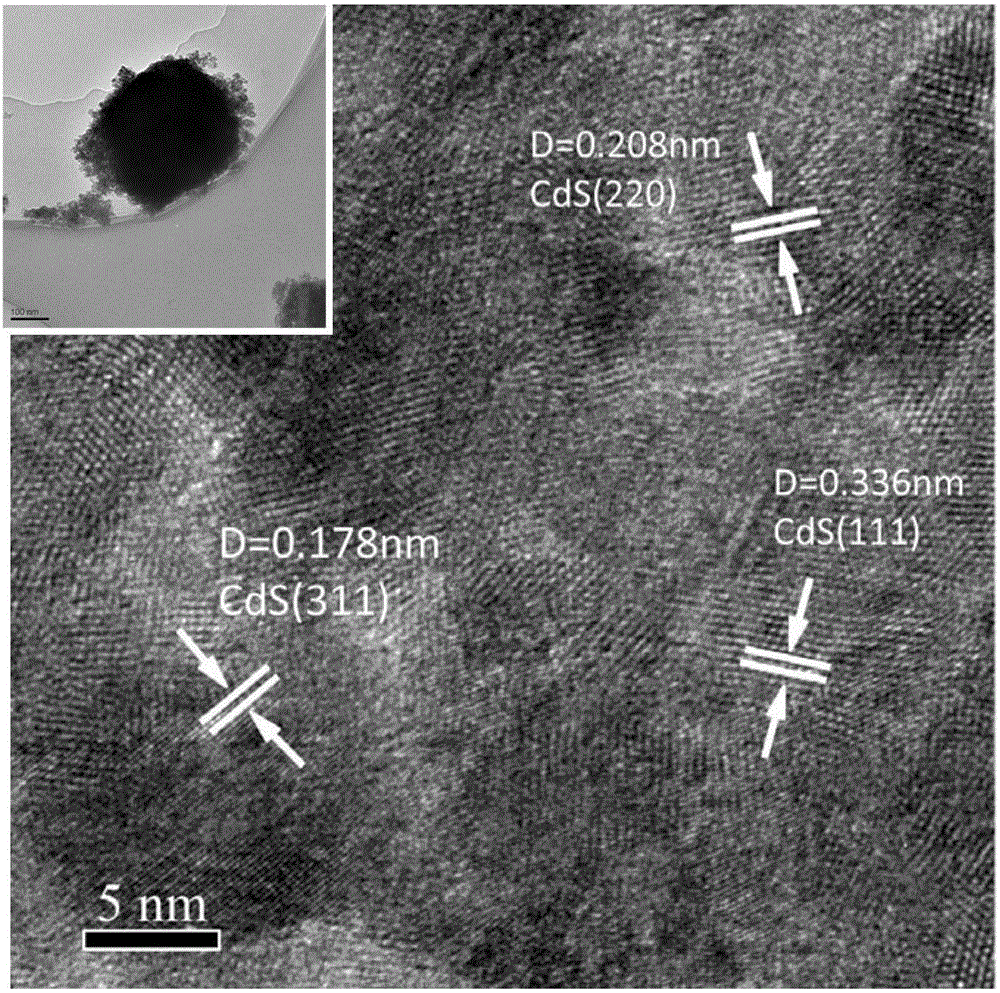

Monoatomic catalyst and preparation method thereof, and application of monoatomic catalyst in photolysis of water to produce hydrogen

InactiveCN108686680AImprove catalytic performanceHigh photocatalytic hydrogen production rateMaterial nanotechnologyPhysical/chemical process catalystsMaterials preparationCadmium sulfide

The invention specifically relates to a monoatomic catalyst and a preparation method thereof, and application of the monoatomic catalyst in photolysis of water to produce hydrogen, belonging to the technical field of nano-material preparation and hydrogen production catalysts. The catalyst is a composite material formed by loading the single atom of precious metal onto a cadmium sulfide nano-material. The preparation method comprises the following steps: (1) preparing a cadmium sulfide nano-material; (2) introducing the cadmium sulfide nano-material prepared in the step (1) into a solution ofa precious metal source to obtain a reaction solution containing a precursor; and (3) separating the precursor from the reaction solution obtained in the step (2), and calcining the precursor so as toobtain the composite material. The monoatomic catalyst of the invention can be used for photolysis of water to produce hydrogen, and the photocatalytic hydrogen production rate of the catalyst can beas high as 47.41 mmol / h / g, which is nearly 50 times the catalytic efficiency of catalysts only using cadmium sulfide; so the photocatalytic hydrogen production effect of cadmium sulfide-based catalysts are remarkably improved.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

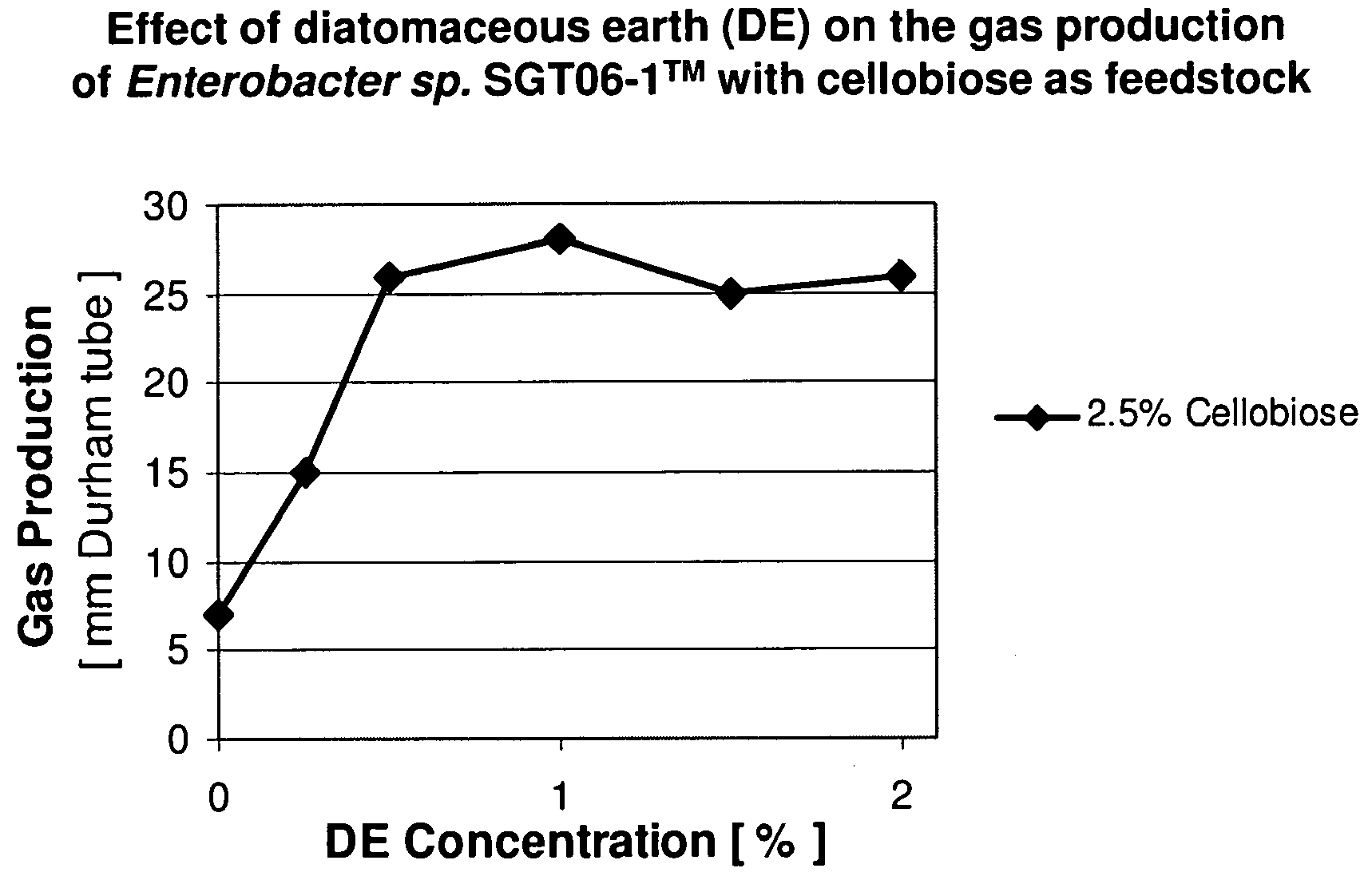

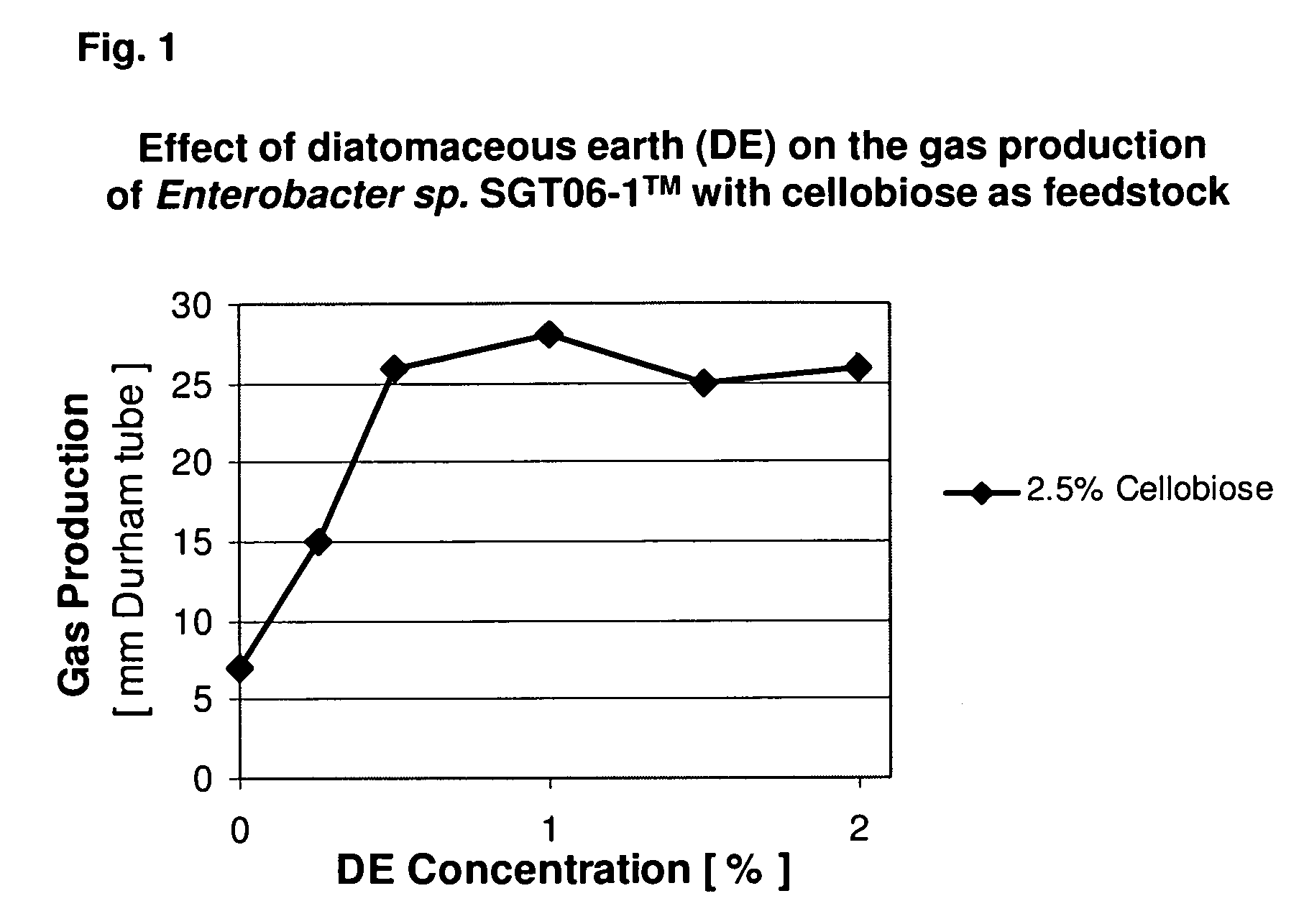

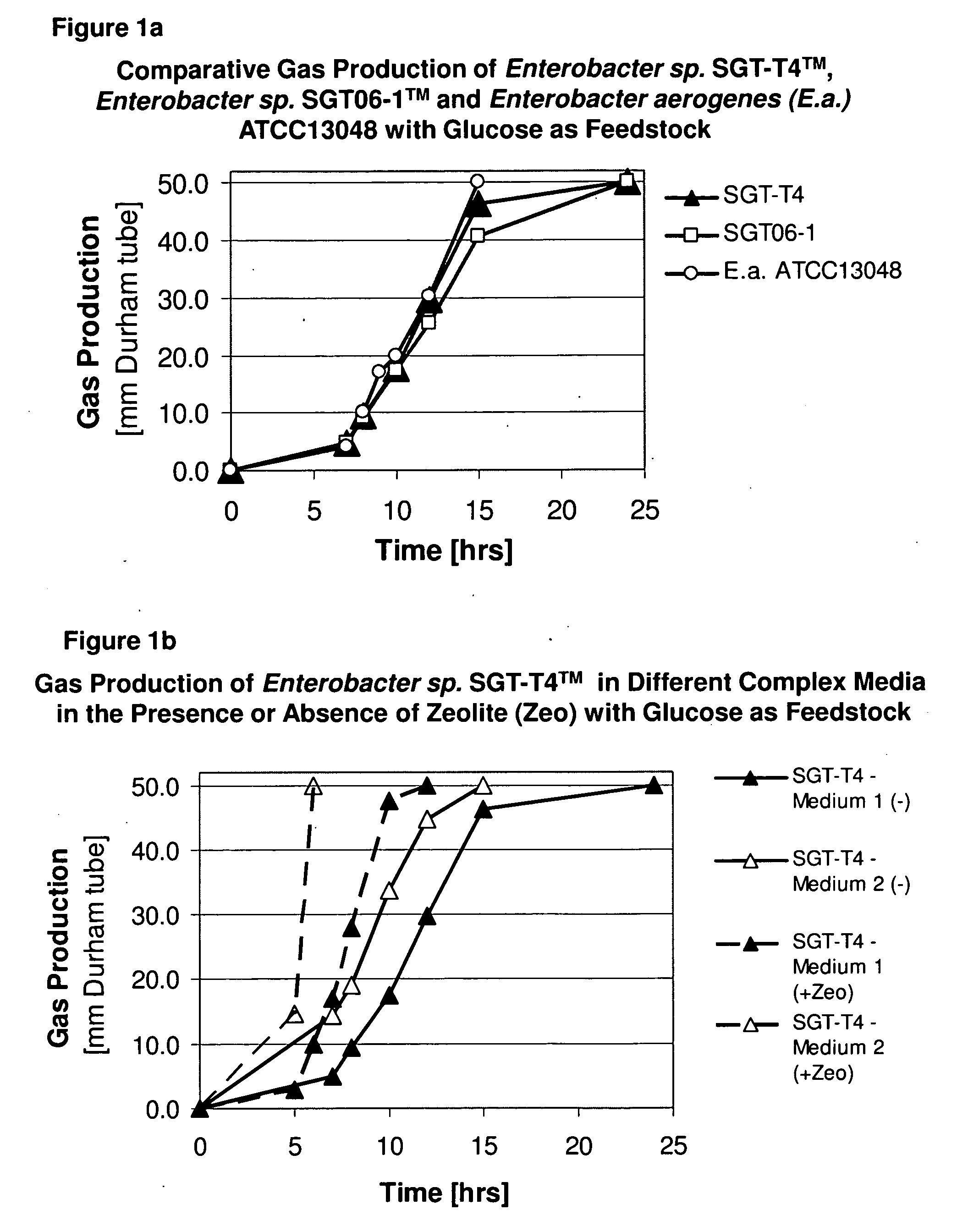

Microorganisms and methods for increased hydrogen production using diverse carbonaceous feedstock and highly absorptive materials

The disclosed invention relates to an isolated hydrogen gas producing microorganism, termed Enterobacter sp. SGT-T4™ and derivatives thereof. Compositions and methods comprising the disclosed microorganisms are also provided. The disclosed invention also relates to a method to increase the hydrogen production rate and yield of hydrogen gas producing microorganism in the presence of diatomaceous earth and other absorptive materials. Further, the disclosure relates to the production of high microalgal biomass and microalgal oils suitable for economical industrial scale bio-diesel production from processed bacterial fermentation wastes as feedstock using the green microalga Chlorella protothecoides.

Owner:SUSTAINABLE GREEN TECH

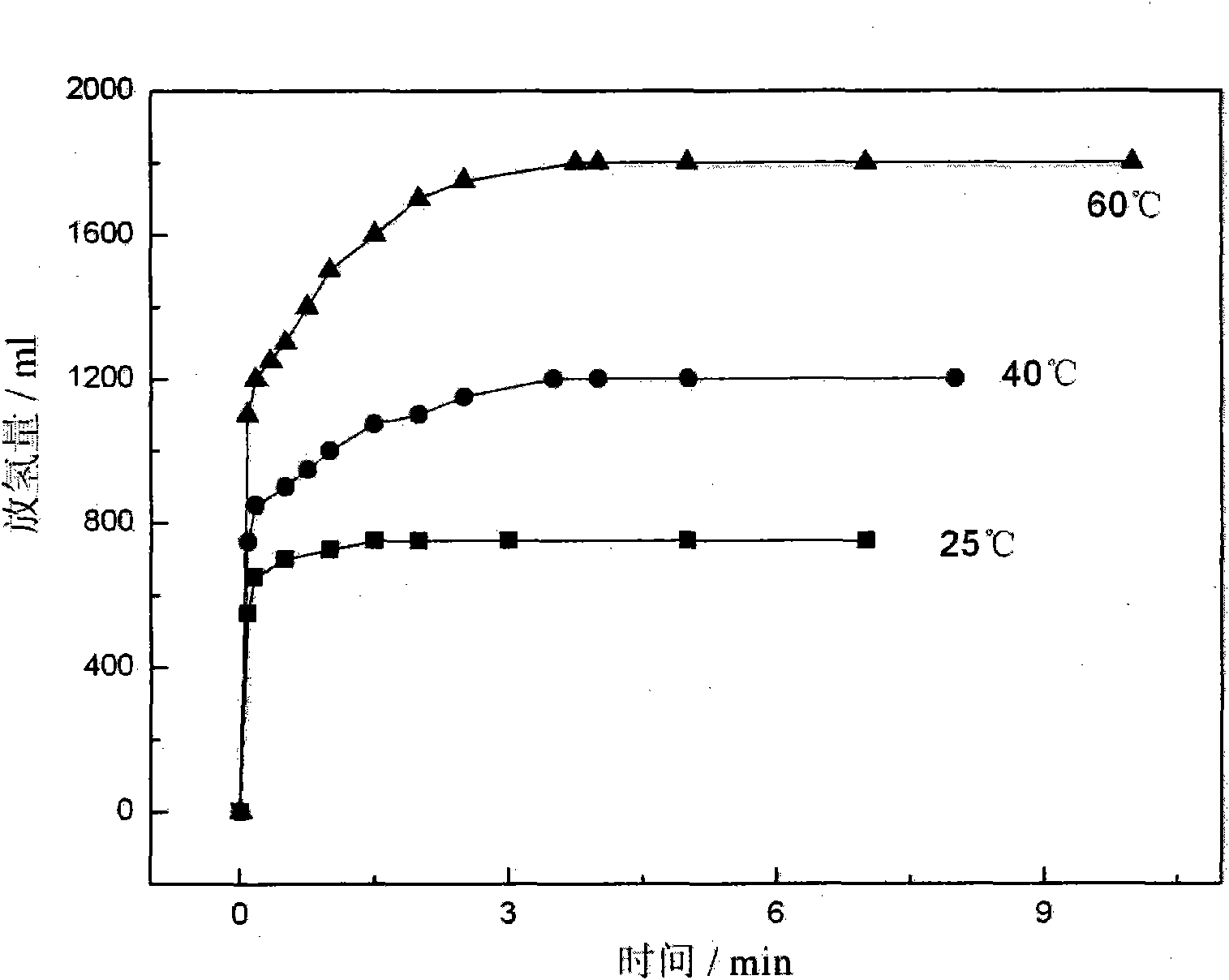

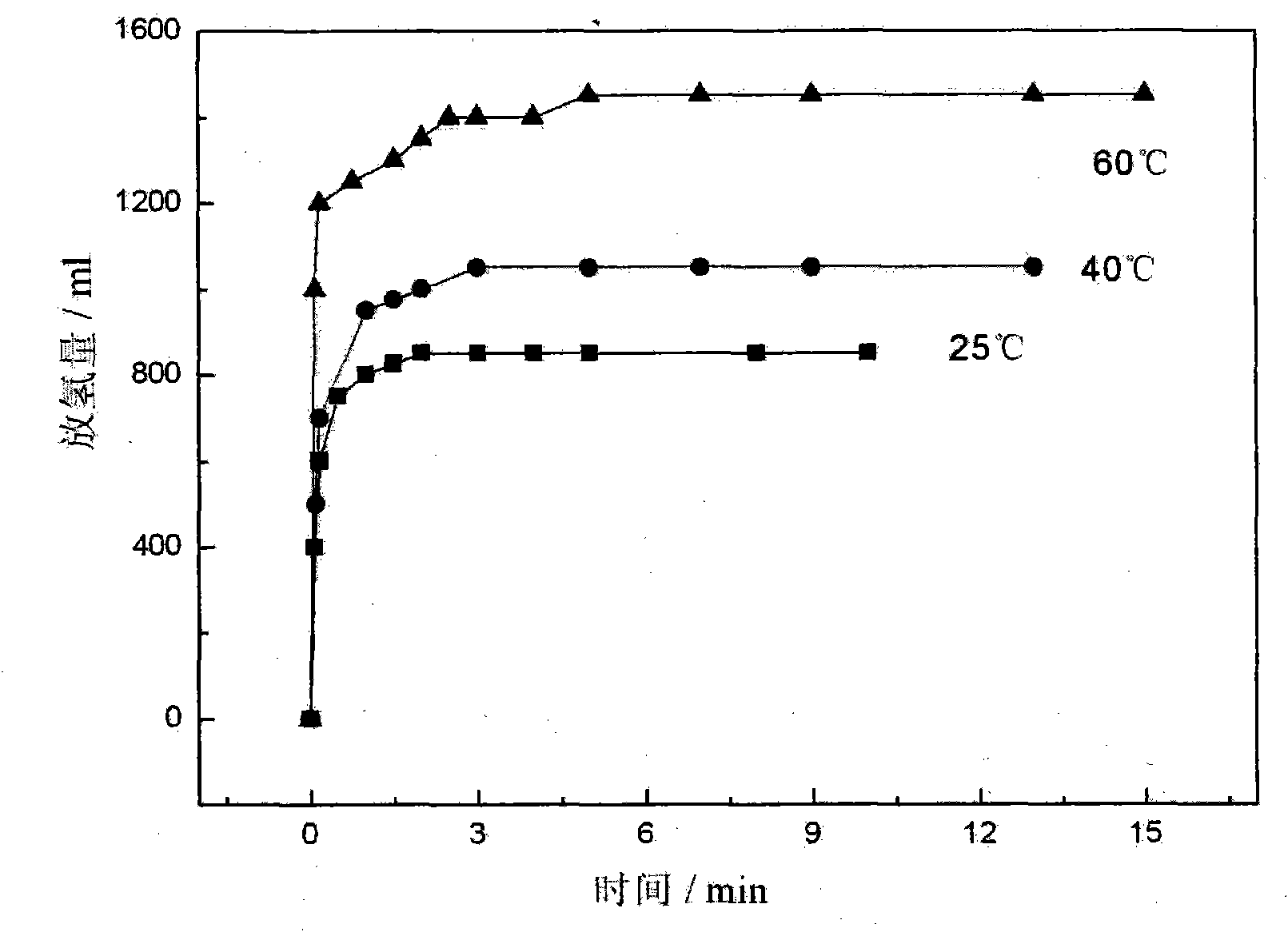

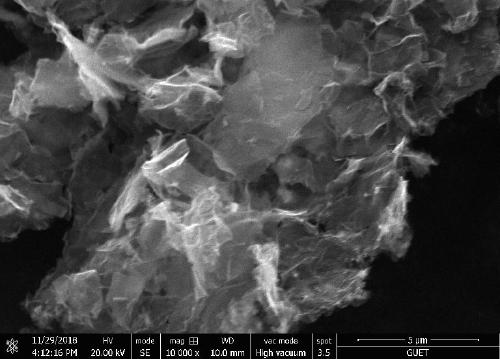

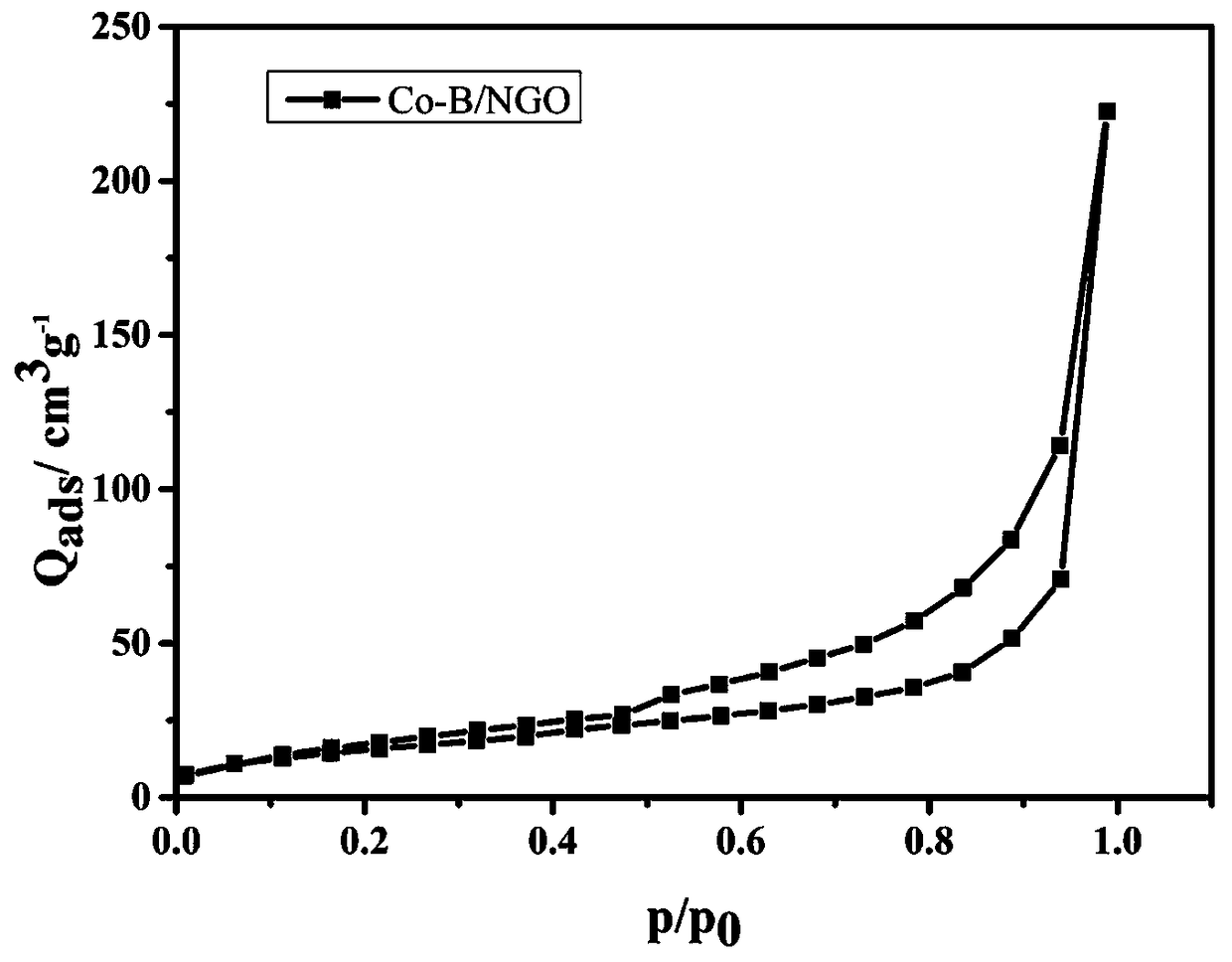

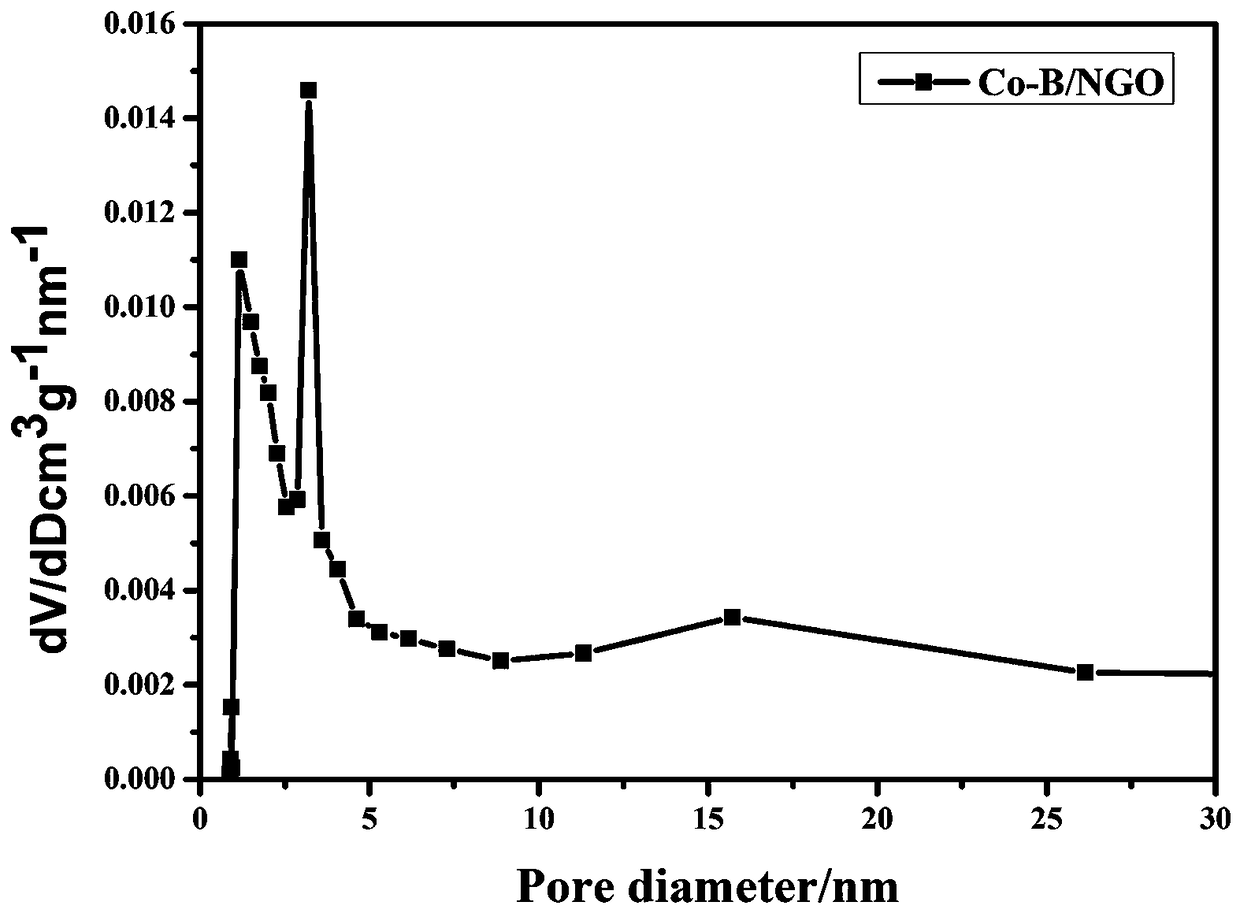

Co-B/NGO composite nanometer material as well as preparation method and application thereof

InactiveCN109499576AChange catalytic performanceLower activation energyMaterial nanotechnologyCatalyst activation/preparationFreeze-dryingHydrogen desorption

The invention discloses a Co-B / NGO composite nanometer material. The Co-B / NGO composite nanometer material is prepared by firstly performing in-site reduction on nitrogen-doped graphene and inorganiccobalt salt through sodium borohydride and then performing freezing-drying, the specific area is 40-100 m<2>g<-1>; the material is magnetic, and can be attracted by a magnet. When the composite nanometer material is used as a catalyst for hydroboron hydrogen generation by hydrolysis, the hydrogen desorption rate is 500-1700mL / min<-1>g<-1>, and the hydrogen production rate is 100%; the material canbe adsorbed and recycled by the magnet, the recycling rate reaches 99.5%, and the hydrogen production rate after being circulated is maintained at 100-1530mL min<-1>g<-1>, namely, maintaining 50-85%of the initial hydrogen production rate. The preparation method comprises the following steps: 1) precursor preparation: adding nitrogen-doped graphene and inorganic cobalt salt in an aqueous solutionfor ultrasonic dispersion mixing, reducing by using sodium borohydride, and finally centrifuging and washing to obtain a precursor; 2) preparation of the Co-B / NGO composite nanometer material: freeze-drying the precursor to obtain the Co-B / NGO composite nanometer material. The Co-B / NGO composite nanometer material disclosed by the invention is simple in preparation, has more excellent catalysis performance, and has an extensive application prospect in the application field of the hydroboron hydrogen generation by hydrolysis.

Owner:GUILIN UNIV OF ELECTRONIC TECH

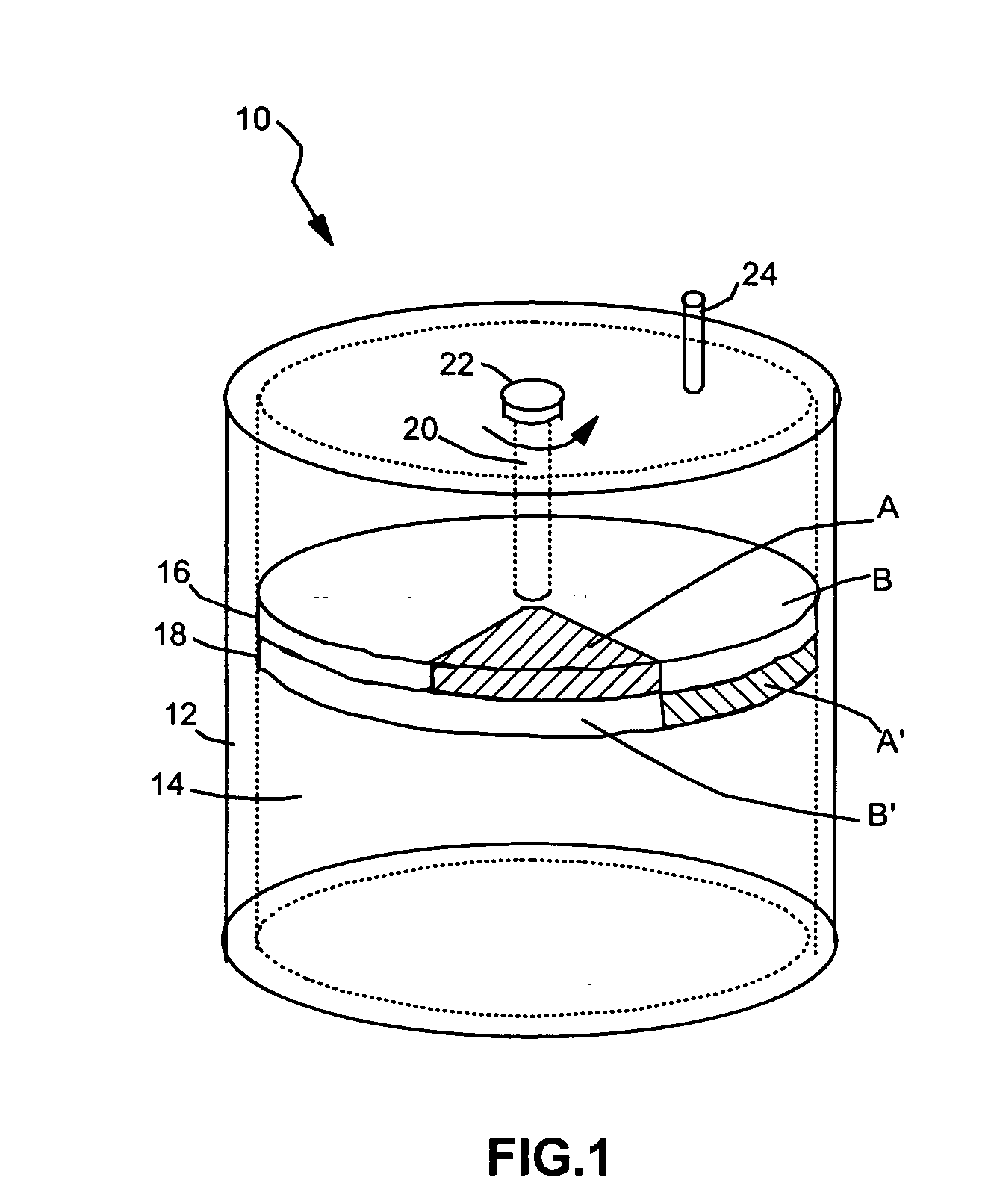

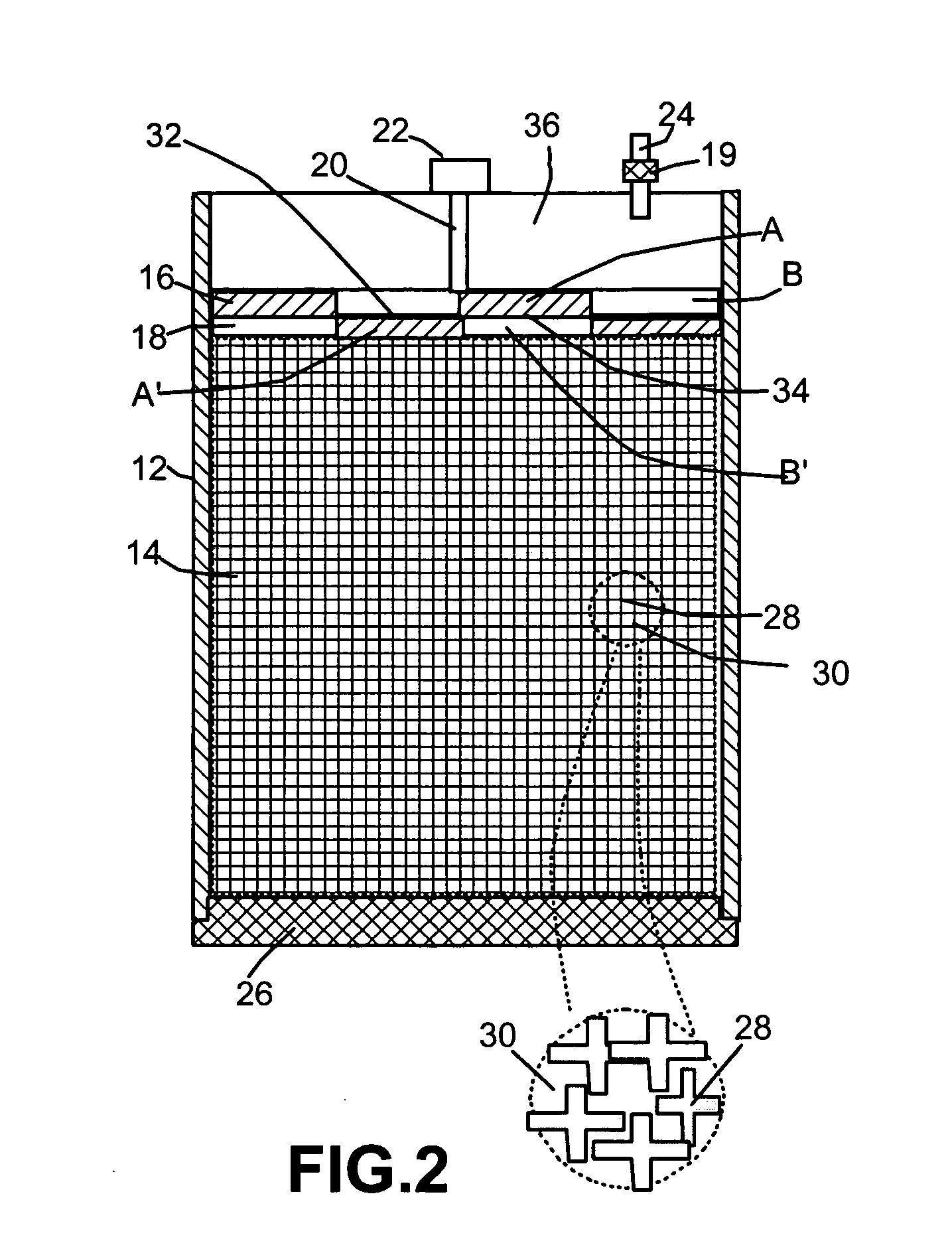

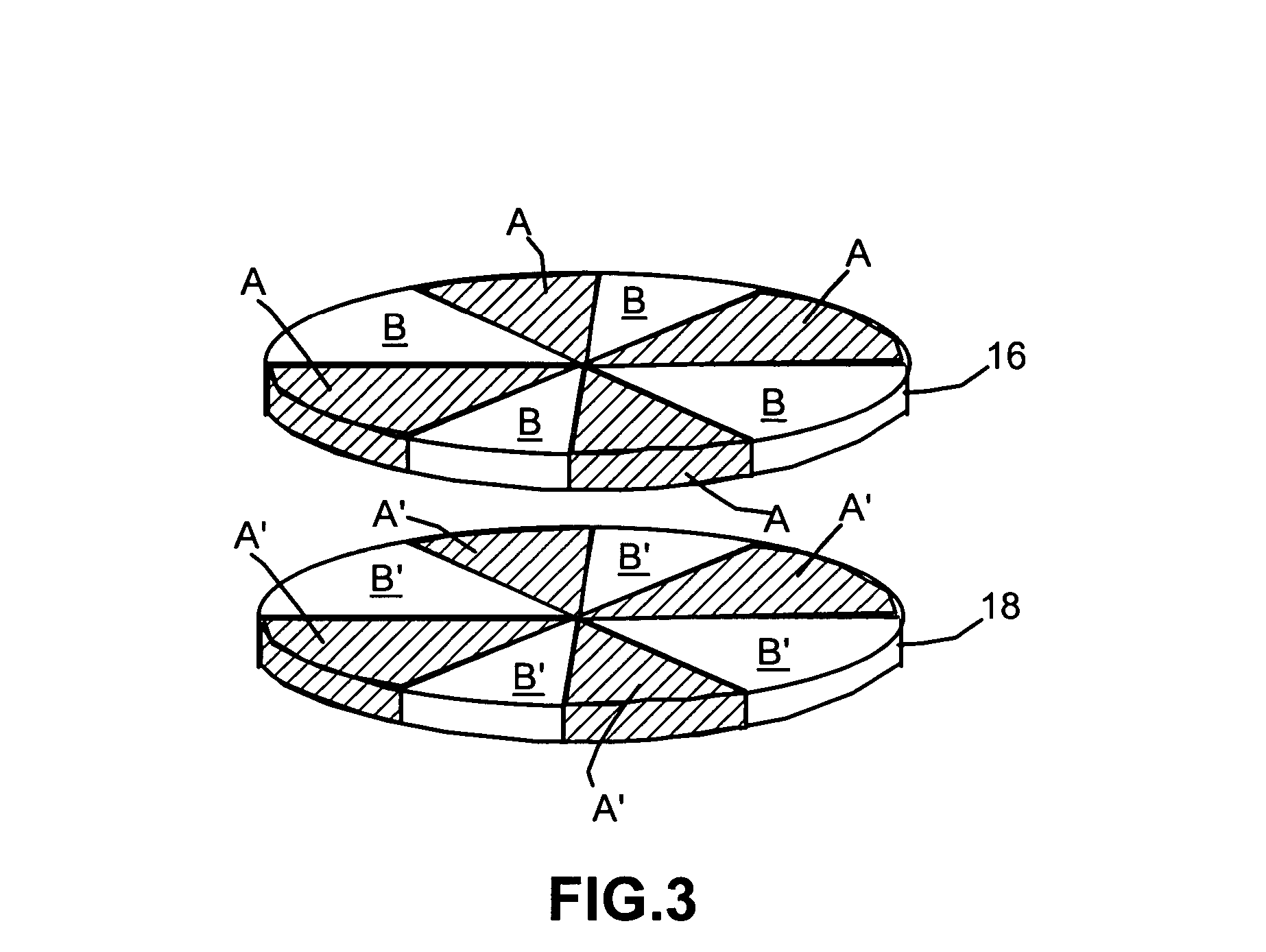

Portable hydrogen generator and fuel cell system

InactiveUS20060112635A1New designEasy to adjustHydrogenReactant parameters controlCircular discFuel tank

A hydrogen generator apparatus that delivers a hydrogen stream at a controlled rate to a fuel cell. The apparatus comprises a fuel tank, a wicking material in the fuel tank, a fluid retained in the wicking material, a first disc bounding the wicking material and comprising a hydrophilic membrane for receiving the fluid from the wicking material by a wicking pressure to form a fluid-wetted surface, a second disc having a porous surface area with the second disc being in contact with the first disc with the two discs moveable relative to each other, a catalyst on the porous surface to form a catalyst-coated surface, and hydrogen generated by hydrolyzation of the fluid contacting the catalyst due to a relative motion between the first disc and the second disc. Major features of this apparatus include simplicity, compactness and portability, hydrogen production rate adjustability, reliability, the ability to operate in any orientation and, in one preferred embodiment, a feedback mechanism to automatically maintain a constant pressure supply of hydrogen or constant hydrogen flow rate. The invention also provides an actively or passively controlled power source featuring such a hydrogen generator.

Owner:NANOTEK INSTR

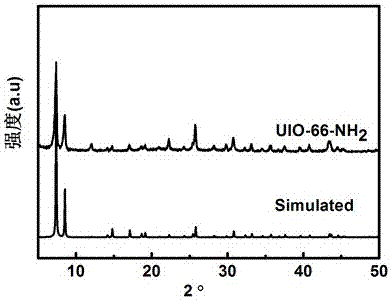

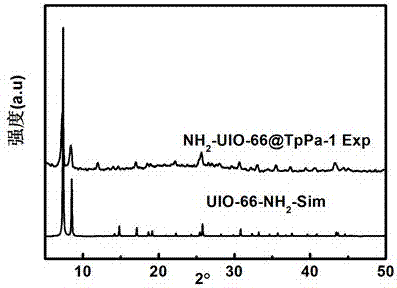

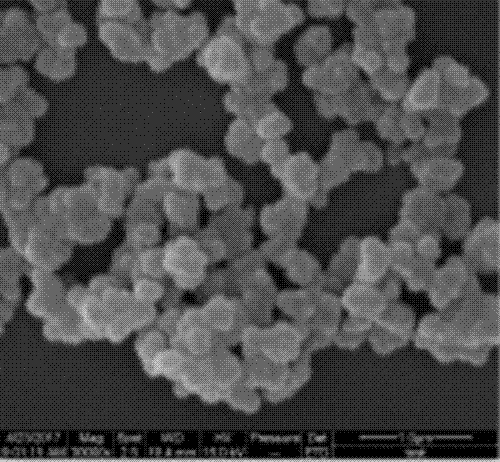

Preparation of composite material NH2-UIO-66@TpPa-1 and water-photodecomposed hydrogen production

InactiveCN107349961AImproving the performance of hydrogen production by photolysis of waterNo photolysis of water to produce hydrogenOrganic-compounds/hydrides/coordination-complexes catalystsHydrogen productionHydrolysisHydrogen production rate

The invention relates to preparation of a composite material NH2-UIO-66@TpPa-1 and water-photodecomposed hydrogen production. The novel composite material NH2-UIO-66@TpPa-1 provided by the invention is used for solving the problem of the existing materials for water-photodecomposed hydrogen production that the efficiency of hydrogen production is not high. The preparation method comprises the steps: 1. preparing NH2-UIO-66; and 2. preparing the composite material NH2-UIO-66@TpPa-1. According to the preparation method, the preparation process is simple and effective, the reagent consumption is low, and the yield is high; and the photocatalyst provided by the invention can be used for effectively solving the problem that the water-photodecomposed hydrogen production of the NH2-UIO-66 is low in efficiency. The composite material NH2-UIO-66@TpPa-1 is applied to the field of photocatalytic-hydrolysis hydrogen production; and shown by experiments, the composite material has excellent water-photodecomposed hydrogen production performance, and the hydrogen production rate can reach 164 micromoles / g / h.

Owner:HARBIN UNIV OF SCI & TECH

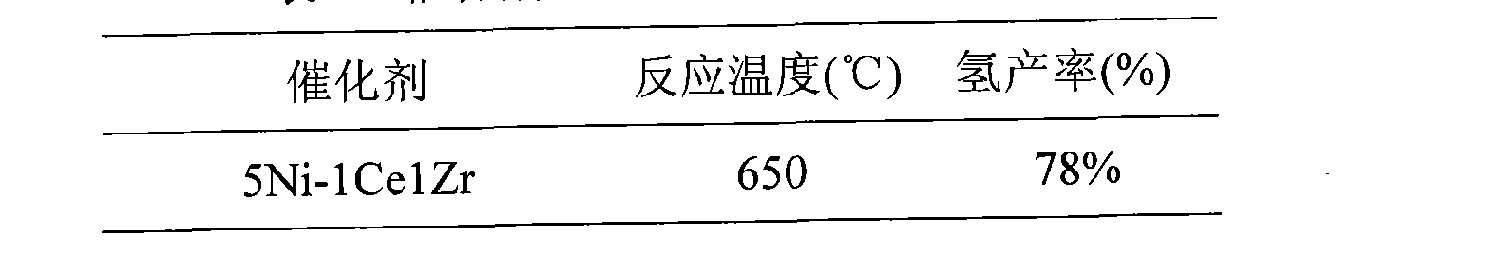

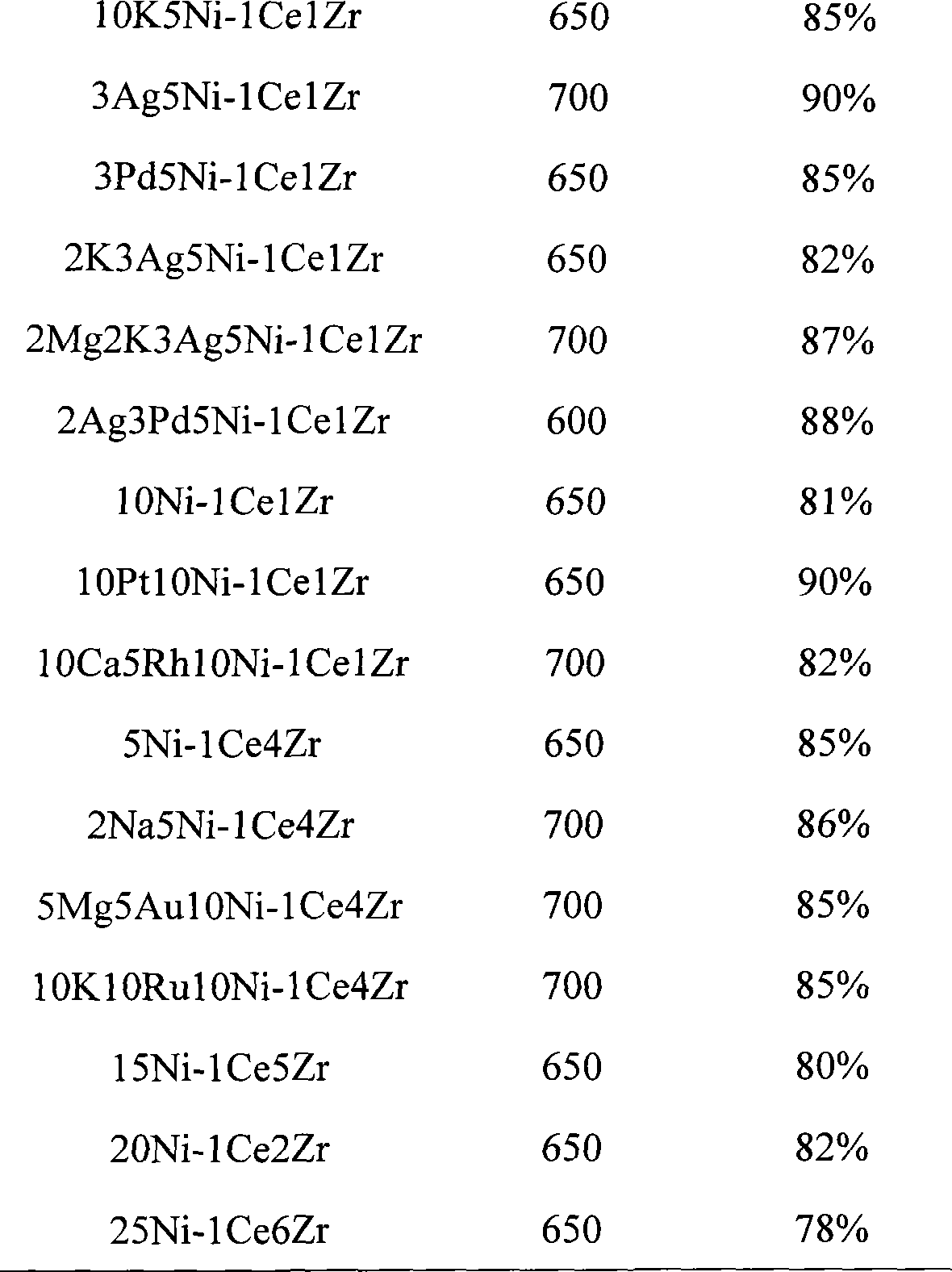

Catalyst for hydrogen production by bio-oil steam reforming and preparation method thereof

InactiveCN101444740ASimple processLow costHydrogenMetal/metal-oxides/metal-hydroxide catalystsSteam reformingNickel salt

The invention discloses a catalyst for hydrogen production by bio-oil steam reforming and a preparation method thereof. The catalyst consists of 5-25wt% of active component nickel, 0-10wt% of an alkali metal promoter, 0-10wt% of a noble metal promoter, and 55-95wt% of a cerium-zirconium compound oxide carrier. The preparation method comprises the following steps: 1) preparing the cerium-zirconium compound oxide carrier; and 2) mixing aqueous solution of soluble nickel salt with aqueous solutions of the catalytic promoters according to the proportion of the catalyst components, stirring evenly, dipping the cerium-zirconium compound oxide carrier in the mixed solution, stirring, ultrasonically dispersing, dipping, drying, roasting, and reducing at the temperature of 400-600 DEG C in hydrogen atmosphere to obtain catalyst powder. The catalyst is applicable to normal pressure, and has the advantages of simple preparation method, high reaction activity, strong anti-carbon deposition ability, good stability, low cost and the like, thus greatly enhancing the transformation ratio of the bio-oil, the hydrogen production rate and prolonging the service life of the catalyst.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

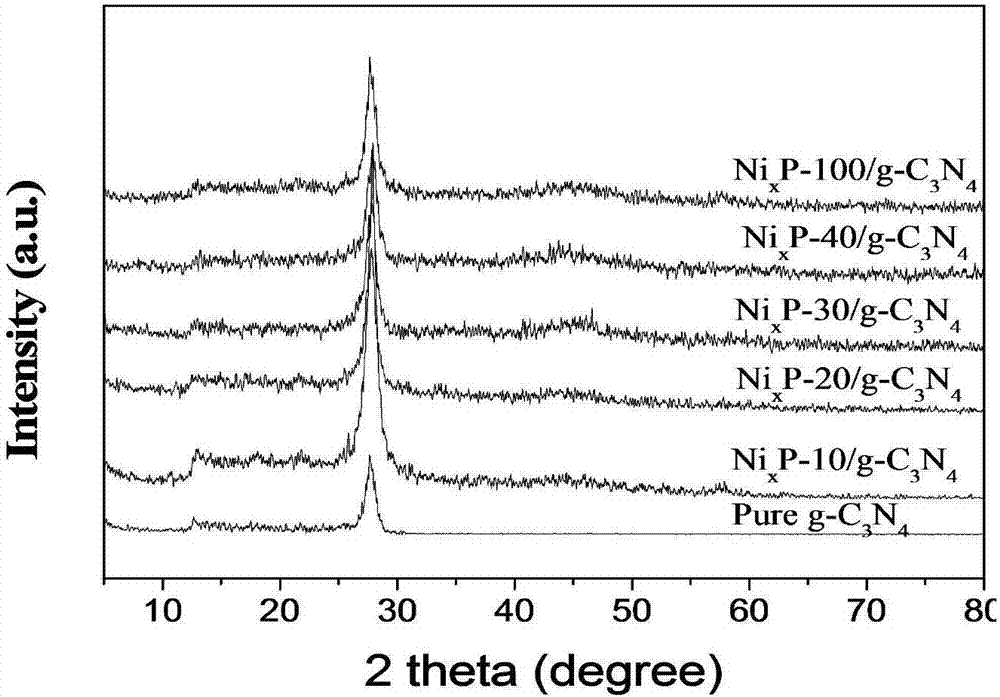

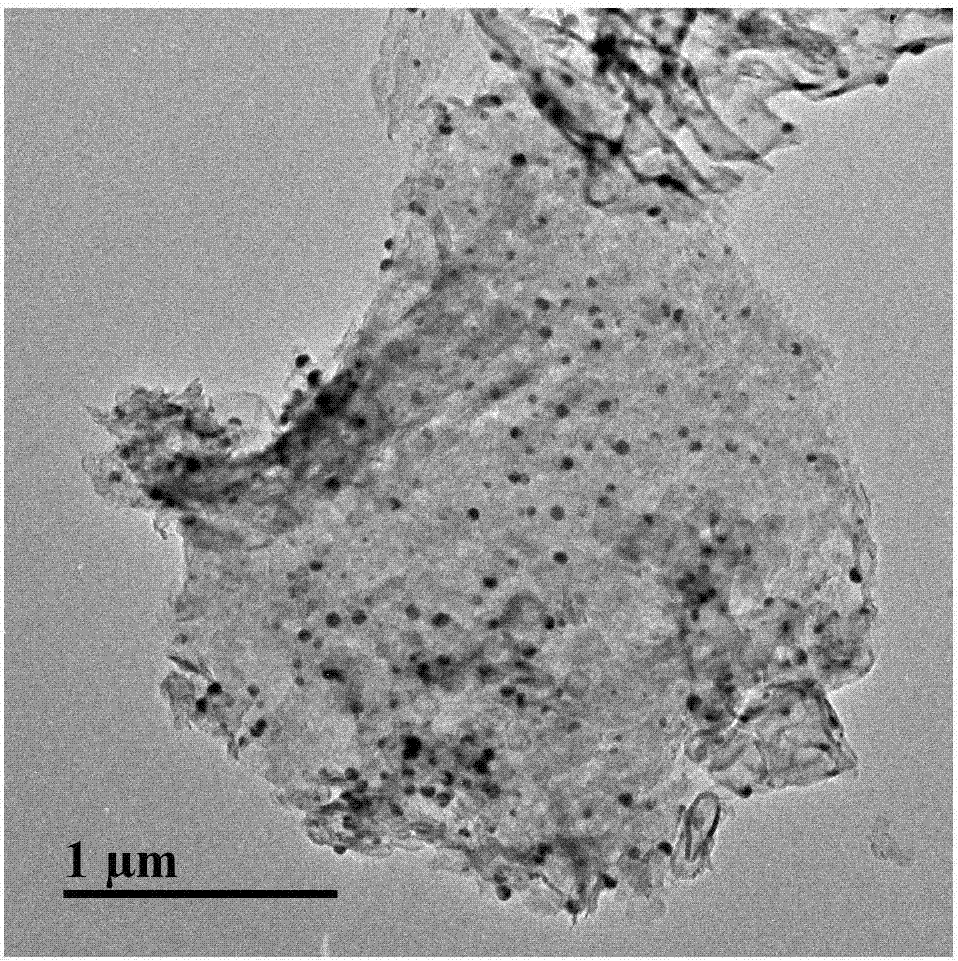

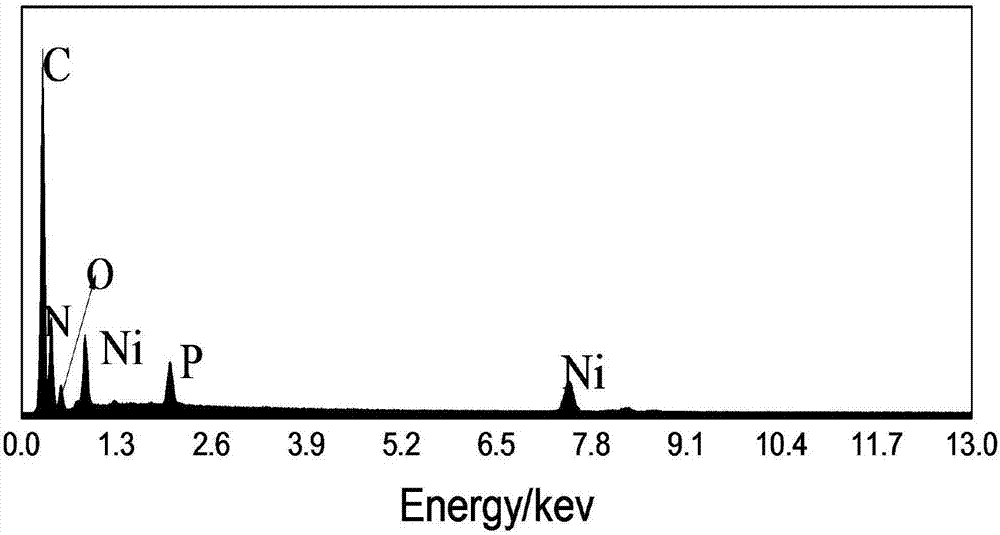

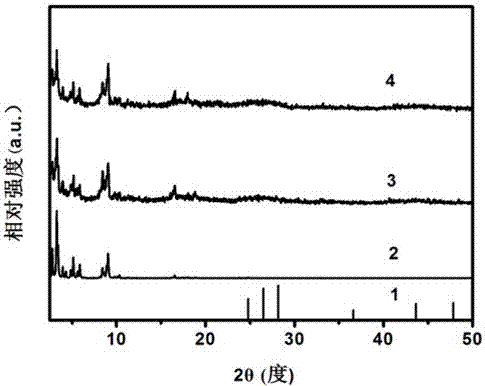

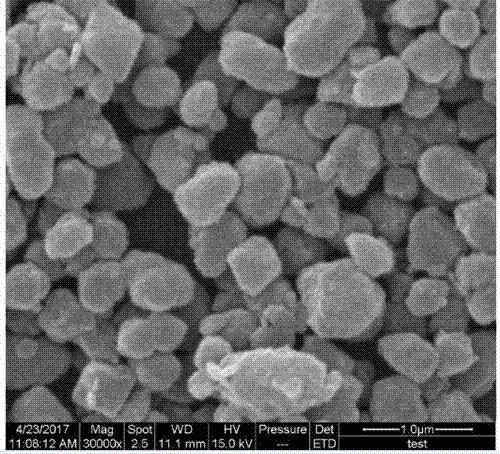

Simple preparation method of amorphous nickel phosphide/graphene-like carbon-nitrogen compound composite catalyst

InactiveCN107138173ALow costSimple methodPhysical/chemical process catalystsHydrogen productionPhotosensitizerGraphene

The invention aims at solving the problems of environment pollution and energy crisis at present and discloses a simple preparation method of a nickel / graphene-like carbon-nitrogen compound composite catalyst, so that cost of a photocatalyst is reduced and hydrogen production rate during photocatalytic decomposition of water is increased. The preparation method of the composite catalyst is environment-friendly, and the principle is that that a graphene-like carbon-nitrogen compound is taken as a photosensitizer and a photoreduction method is used for preparing an amorphous nickel phosphide / graphene-like carbon-nitrogen compound composite catalyst. The prepared amorphous nickel phosphide / graphene-like carbon-nitrogen compound composite catalyst is simple in synthetic method, high in photocatalytic hydrogen production rate, good in stability and low in cost, can greatly save cost when being applied to industrial production and is nontoxic and environment-friendly, and therefore, the prepared amorphous nickel phosphide / graphene-like carbon-nitrogen compound composite catalyst is a novel catalysis material with larger industrial photocatalysis hydrogen production prospect.

Owner:JIANGNAN UNIV

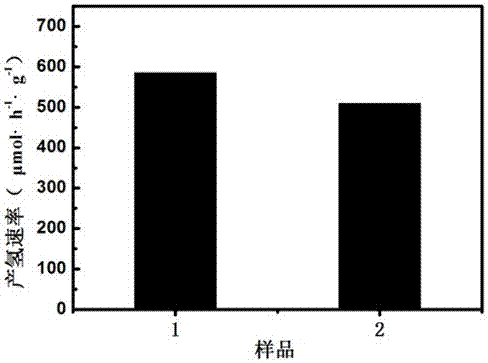

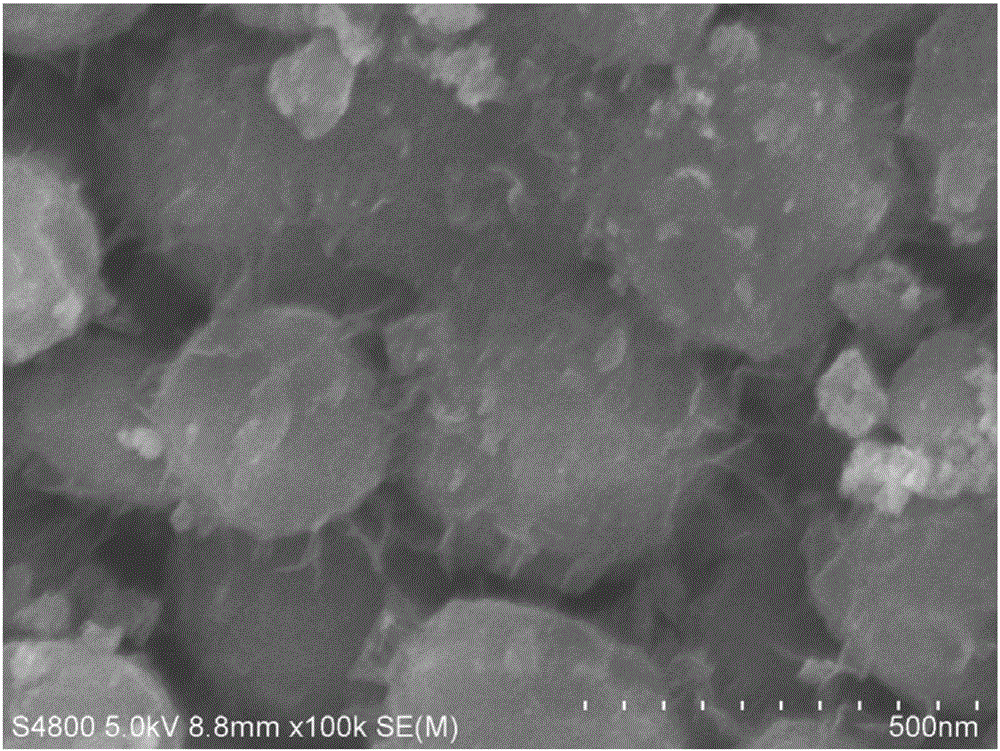

Preparation method of CdS-loaded MIL-101(Cr) hydrogen-production photocatalyst

InactiveCN107362830AReduce photocorrosionImprove photocatalytic activityOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationIrradiationElectron

The invention relates to a preparation method of a CdS-loaded MIL-101(Cr) hydrogen-production photocatalyst, and particularly to a hydrogen-production catalyst preparation method. In the prior art, the existing CdS semiconductor photocatalyst is easily subjected to light corrosion, such that the compounding probability of the photo-generated electrons and the holes is high, and the utilization rate of the sunlight is low so as to provide the low photocatalytic hydrogen production rate. A purpose of the present invention is to solve the problem in the prior art. The preparation method comprises: 1, preparing a CdS-loaded MIL-101(Cr) hydrogen-production photocatalyst crude product; and 2, adding the CdS-loaded MIL-101(Cr) hydrogen-production photocatalyst crude product to a reaction kettle, and carrying out a hydrothermal reaction to obtain the CdS-loaded MIL-101(Cr) hydrogen-production photocatalyst. According to the present invention, the hydrogen peroxide decomposing hydrogen production rate of the CdS-loaded MIL-101(Cr) hydrogen-production photocatalyst can achieve 510.5 [mu]mol.h<-1>.g<-1>-586.1 [mu]mol.h<-1>.g<-1> under the irradiation of a 300 W xenon lamp; and the preparation method of the CdS-loaded MIL-101(Cr) hydrogen-production photocatalyst can be obtained.

Owner:HARBIN UNIV OF SCI & TECH

Perovskite material/organic polymer compound photocatalyst, preparation and application

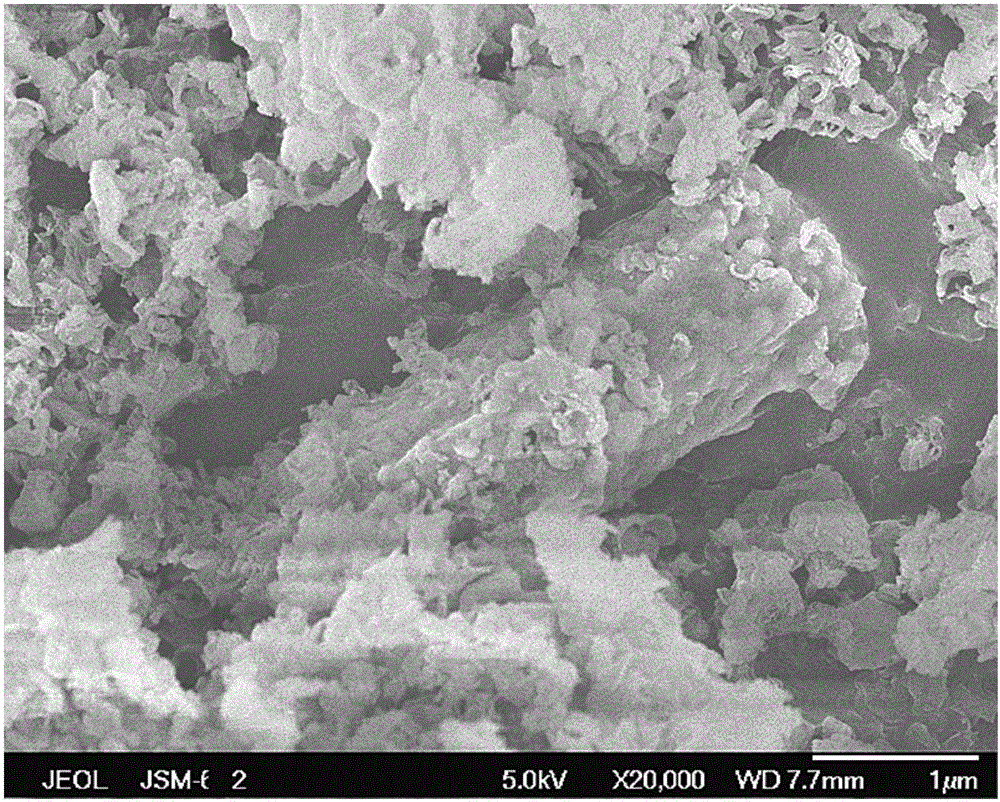

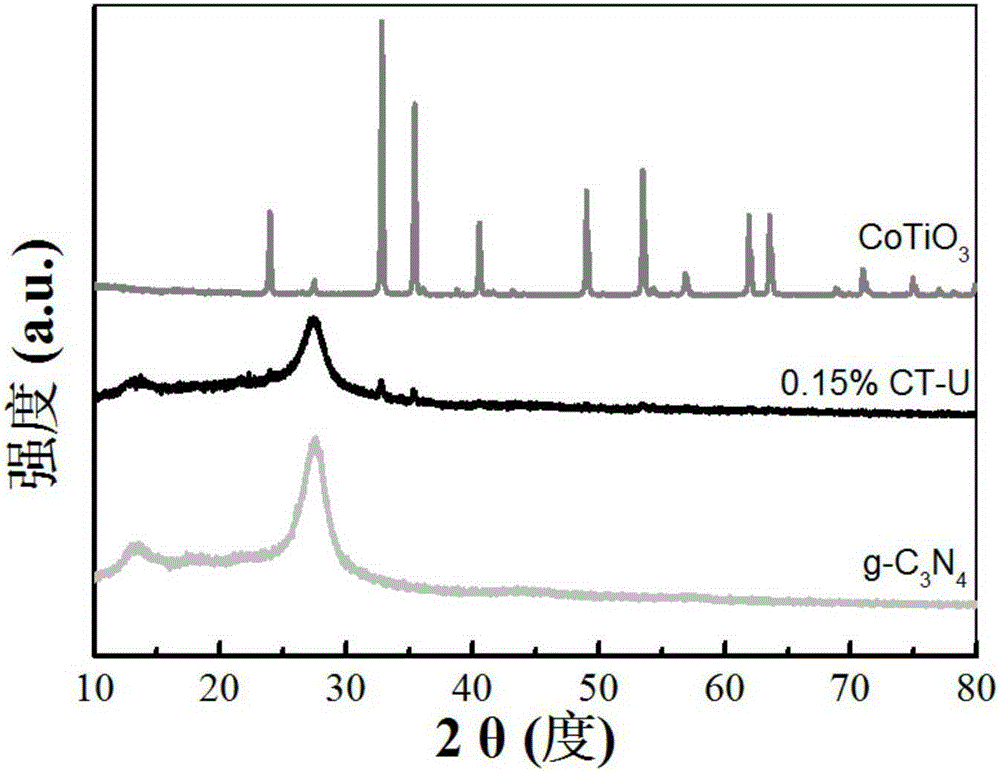

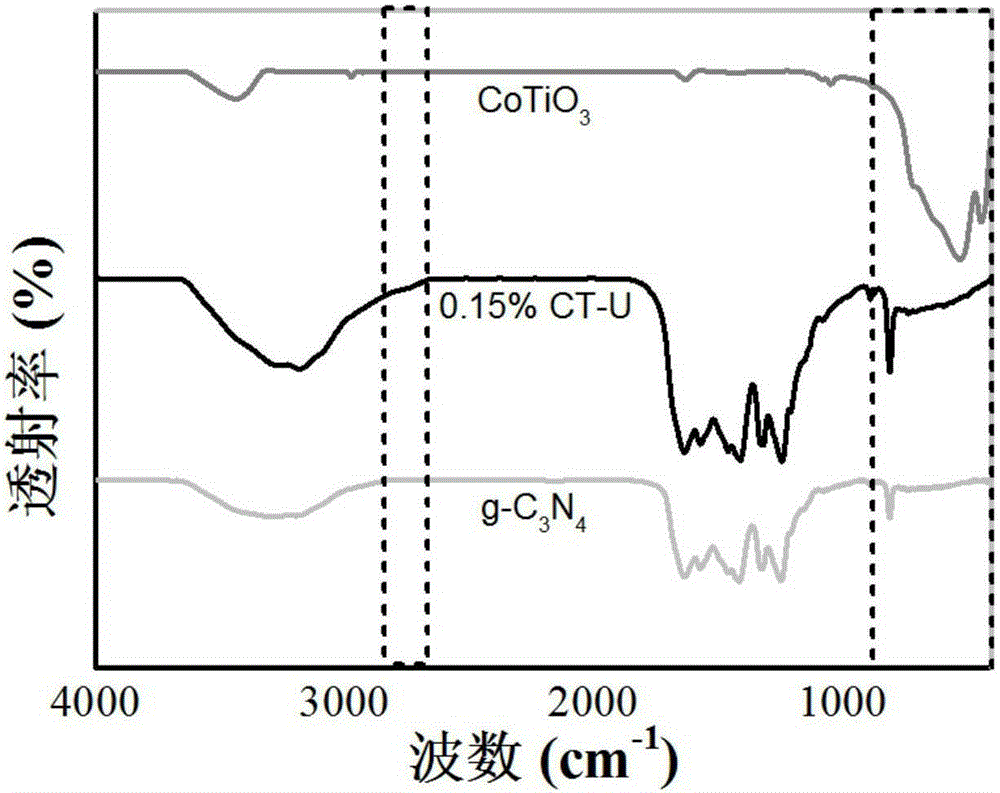

ActiveCN105170173AEasy to prepareEasy to operateOrganic-compounds/hydrides/coordination-complexes catalystsHydrogen productionValence bandCarbon nitride

The invention discloses a perovskite material / organic polymer compound photocatalyst, preparation and application, and belongs to the field of perovskite material / organic polymer compound photocatalyst. Rolled-piece-shaped carbon nitride is successfully dispersed on the surface of cobalt titanate, through compounding of electrons on a cobalt titanate conduction band and holes in a carbon nitride valence band, holes in a cobalt titanate valence band and electrons on a carbon nitride conduction band are separated, and therefore the photocatalytic performance is greatly improved. The material is applied to the field of water photolysis hydrogen production, and the hydrogen production rate is substantially increased compared with pure carbon nitride.

Owner:BEIJING UNIV OF CHEM TECH

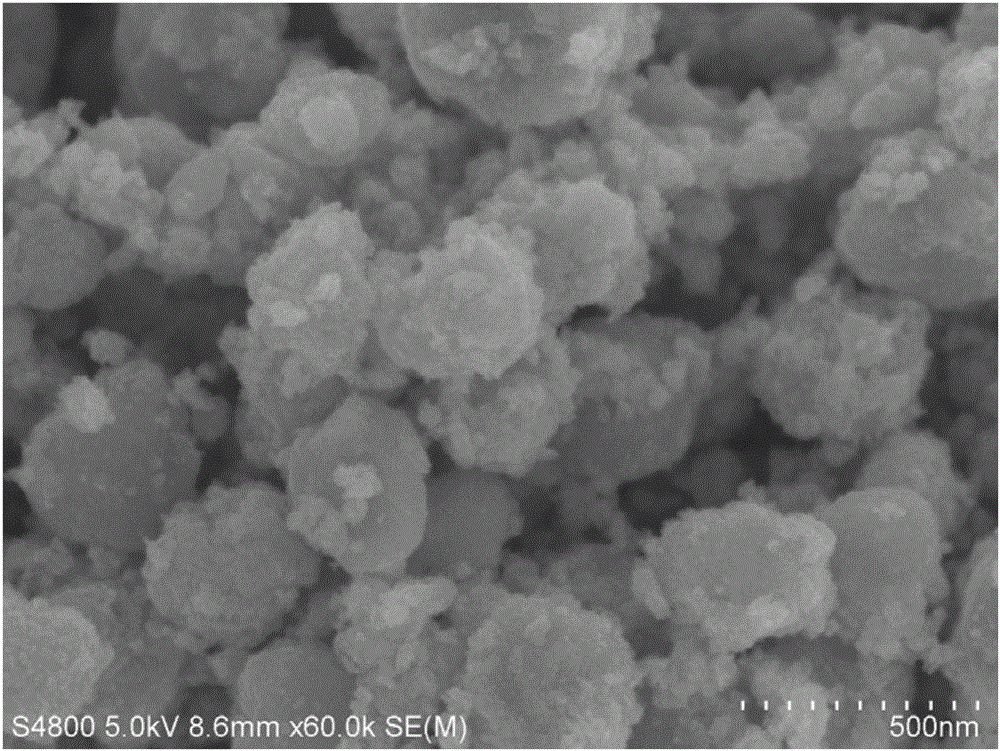

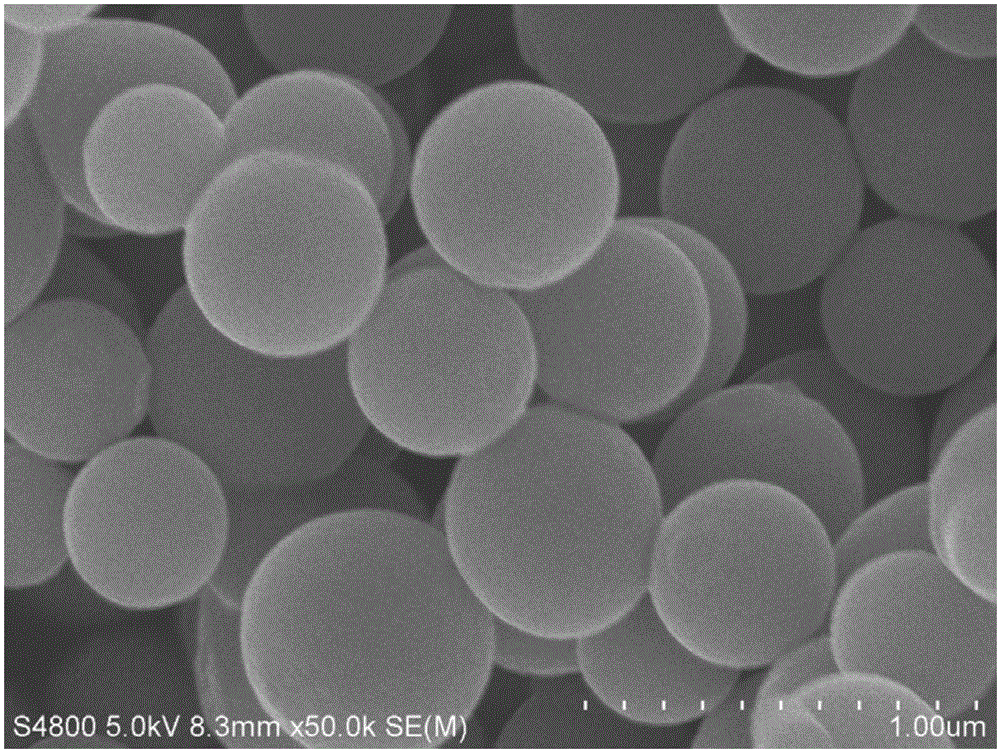

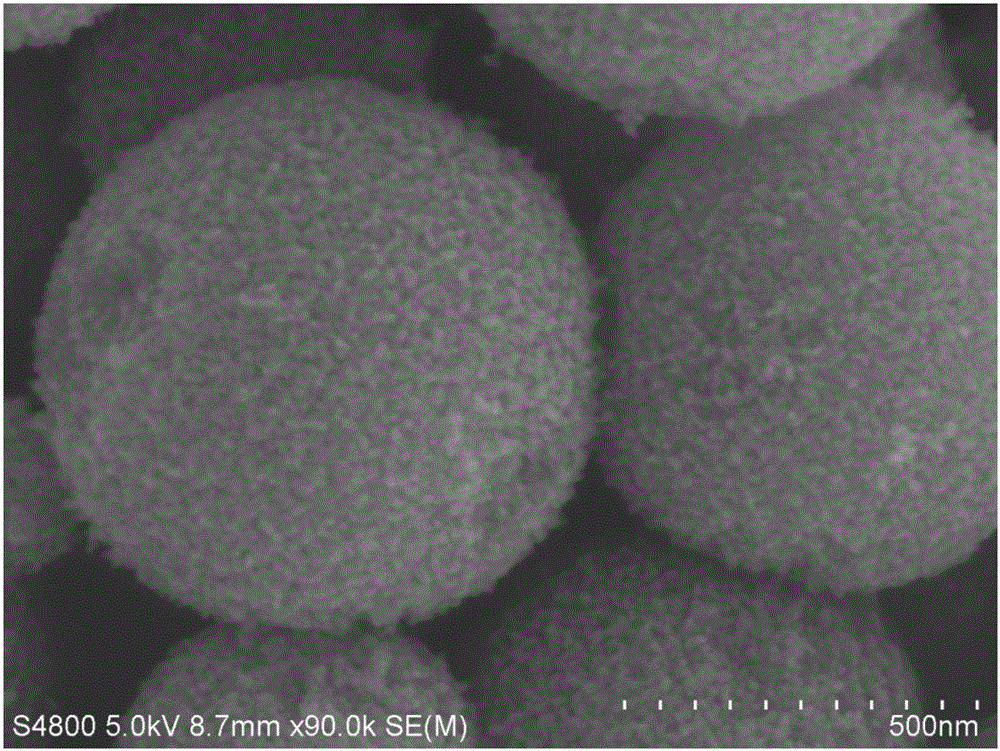

CdS/MoO3 composite photocatalyst and preparation method thereof

InactiveCN102068996AHigh catalytic activityUniform particlesPhysical/chemical process catalystsRoom temperatureNanocrystal

The invention discloses a CdS / MoO3 composite photocatalyst and a preparation method thereof, which relate to a catalyst material and a preparation method thereof. The catalyst solves the problems that the conventional hydrogen production by utilizing the light to decompose H2O is low in catalyst activity and hydrogen yield under visible light and cannot degrade organic pollutants. The CdS / MoO3 composite photocatalyst is prepared from Cd(Ac)2.2H2O, (NH4)6Mo7O24.4H2O and thioacetamide. The preparation method comprises the steps of: adding the Cd(Ac)2.2H2O, the (NH4)6Mo7O24.4H2O and the thioacetamide into solution of acetone or ethanol, sealing the obtained solution, then placing the obtained solution into an ultrasonic reactor to react, then cooling a product to room temperature, and then washing and drying to obtain the CdS / MoO3 composite photocatalyst. The composite photocatalyst is of nanosphere shapes, the particle size of the nanospheres is between 300 and 350nm, the composite photocatalyst is obtained by the self-assembling of each small particle with the particle size of between 5 and 20nm, and additionally, CdS nanocrystals are uniformly embedded in the nanospheres; and the catalyst is high in catalytic activity, and the hydrogen production rate can reach 2 to 5.25mmol / h.

Owner:HARBIN INST OF TECH

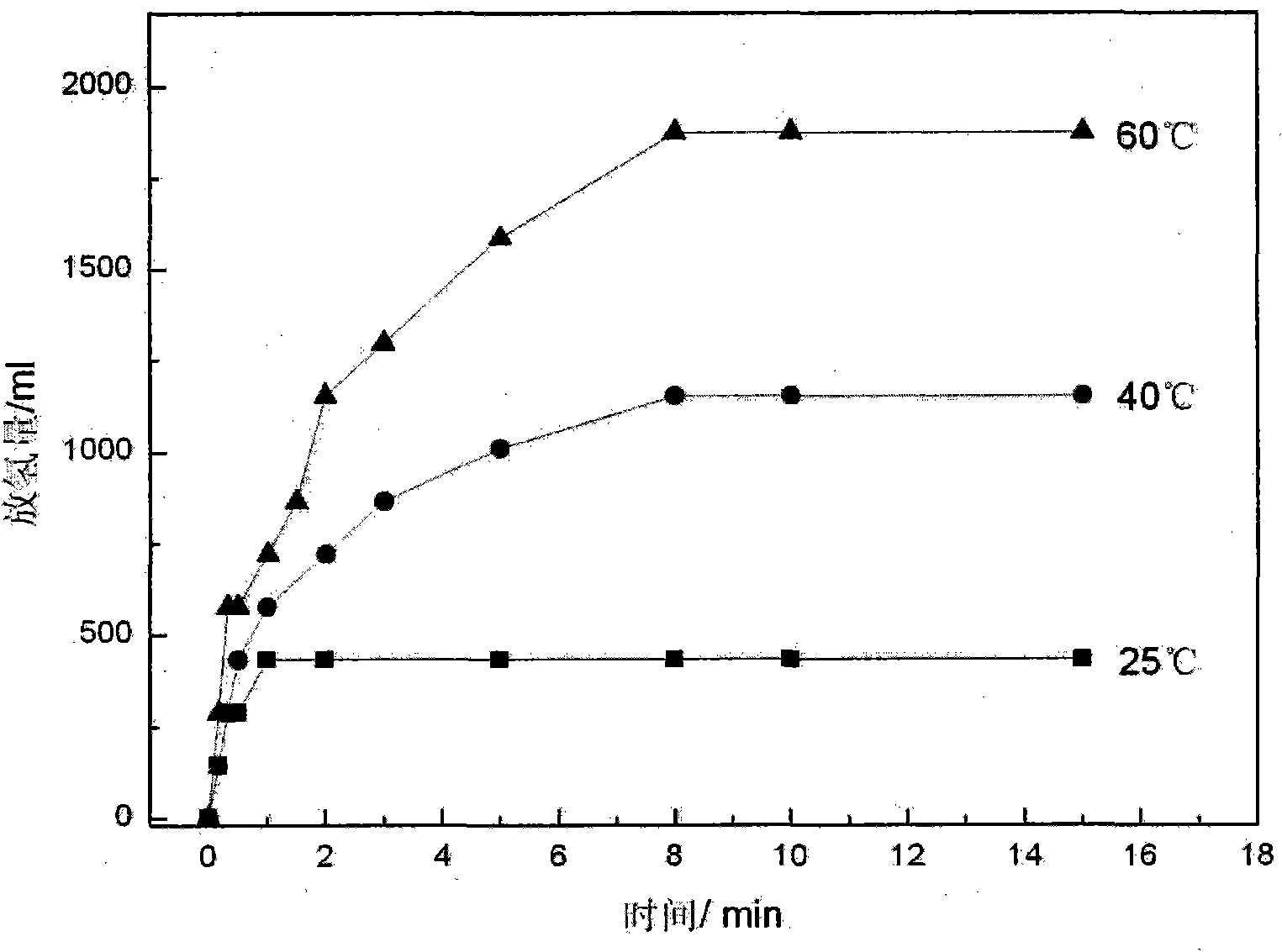

Method for preparing hydrogen by cracking water by using aluminum-based material

InactiveCN101948093AHigh hydrogen production rateWide variety of sourcesHydrogen productionHydrogenPhysical chemistry

The invention provides a method for preparing hydrogen by cracking water by using an aluminum-based material. The aluminum-based material is prepared from aluminum and oxide or carbonate with different mass percents serving as raw materials and an added salt serving as activating agent; and hydrogen is quickly produced by reacting the aluminum-based material with reaction medium. The hydrogen preparation rate and yield can be adjusted by varying the percent of each component in the aluminum-based material. The aluminum-based material can suppress production of an inertial aluminum oxide film on the surface, greatly improve the hydrogen production rate of alloy and reduce the hydrogen preparation cost.

Owner:CENT SOUTH UNIV

Ternary compound optical catalyst and preparation method therefor and application thereof

InactiveCN105107528AImprove photocatalytic performanceEasy to synthesizePhysical/chemical process catalystsHydrogen productionPtru catalystTitanium oxide

The invention provides a preparation method for a titanium dioxide@graphene-cadmium sulfide ternary compound optical catalyst. The preparation method comprises: synthesizing titanium dioxide@graphene-cadmium sulfide in situ by virtue of a hydrothermal method including firstly inducing graphene to wrap titanium dioxide microspheres; and meanwhile, loading cadmium sulfide quantum dots on graphene nanosheets to form a ternary compound structure. Titanium dioxide and graphene are together used as an electron acceptor and a transfer of cadmium sulfide, so that the electron-hole separation time of cadmium sulfide is prolonged, and the purpose of enhancing the optical catalytic performance of the material is achieved. The method provided by the invention is simple to operate, short in synthetic period and easy to control. No additional noble metals are added as a co-catalyst, and the hydrogen production rate of the material can reach 715 [mu]mol / g / h. The optical catalyst prepared by the method provided by the invention can be repeatedly used.

Owner:WUHAN UNIV OF TECH

Nitrogen doped graphene quantum dot/mesoporous titanium dioxide photocatalyst and preparation method thereof

InactiveCN106475127AImprove photocatalytic performanceSolve acid and alkali pollutionPhysical/chemical process catalystsMicrosphereTitanium nitride

The invention provides a nitrogen doped graphene quantum dot / mesoporous titanium dioxide photocatalyst and a preparation method thereof. According to the invention, nitrogen doped graphene quantum dots are distributed to the volume surface and the interior of titanium dioxide solid microspheres; the nitrogen doped graphene quantum dot / mesoporous titanium dioxide is of a spherical shape and has a diameter of 400 to 600 nm and a mesoporous structure; and the titanium dioxide is pure anatase type titanium dioxide. The preparation method provided by the invention comprises the following steps: synthesis of the nitrogen doped graphene quantum dots, and in-situ synthesis of the graphene quantum dot / mesoporous titanium dioxide by adopting a sol-gel method. According to the invention, the graphene quantum dots interact with a structure directing agent due to static electricity, and are gradually distributed to the volume surface and the interior of titanium dioxide microspheres with the structure directing agent in the hydrolysis process of a titanium source; and the graphene quantum dots are used as electron acceptors and transfersomes of the titanium dioxide, thereby enlarging the separation time of electrons and holes, and achieving the purpose of strengthening the photocatalytic performance of a material. The method provided by the invention has the advantages of simple operation, short synthesis period and easy control; and the hydrogen production rate of the material can reach 0.5 mmol<h-1>.

Owner:WUHAN UNIV OF TECH

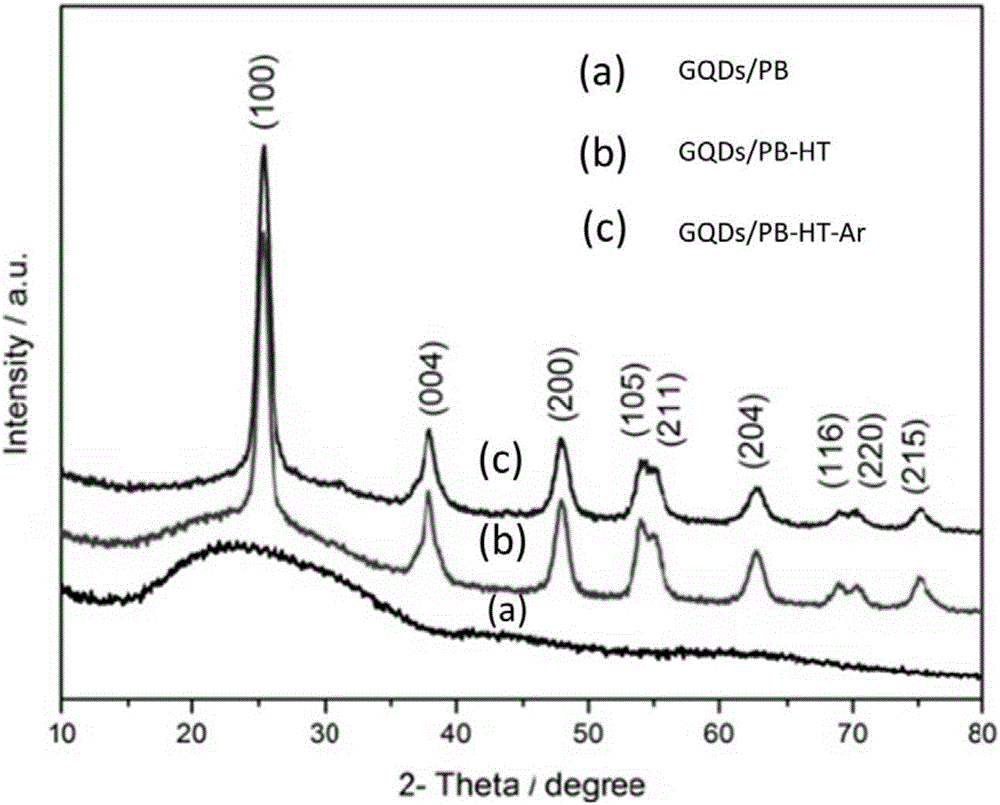

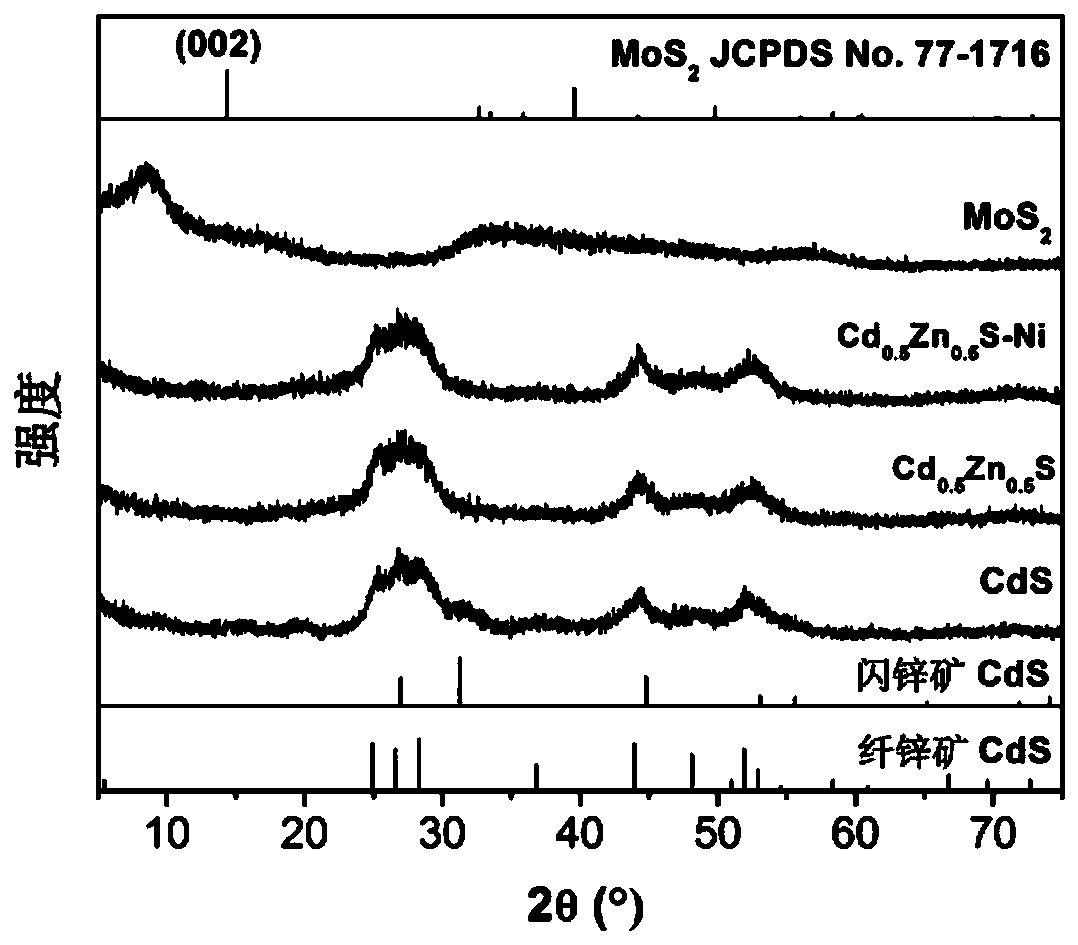

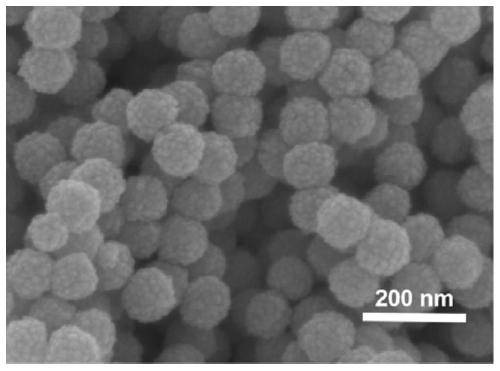

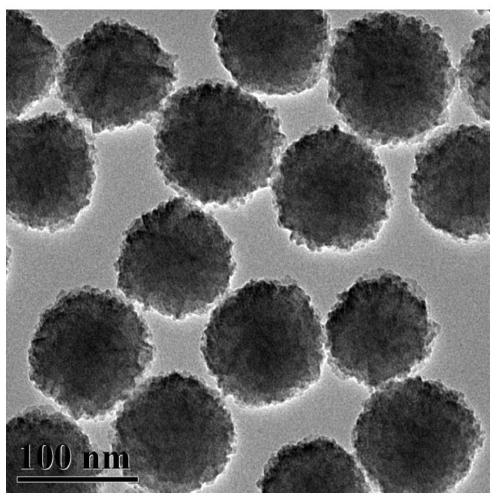

Cd<1-x>Zn<x>S-Ni/MoS<2> composite photocatalyst, and preparation method and application thereof

InactiveCN110227500AIncrease the number ofImprove photocatalytic activityMaterial nanotechnologyCatalyst activation/preparationWater bathsCrystallinity

The invention relates to a Cd<1-x>Zn<x>S-Ni / MoS<2> composite photocatalyst, and a preparation method and application thereof, belonging to the field of inorganic nanomaterials. MoS<2> nanosheets in the composite have low crystallinity and are capable of exposing a large number of hydrogen-producing active sites. The doping of Zn and Ni significantly increases the redox ability of the photogenerated charges of CdS and promotes the separation of the photogenerated charges. Assembled nanospheres with uniform size have good resistance to light corrosion and aggregation. The combination of an ultrasonic water bath method and electrostatic adsorption assembling used for synthesis of the material is simple and controllable; and the composite prepared by using the method can realize high-efficiency photocatalytic decomposition of water for hydrogen production under visible light without loading of precious metals, so energy consumption and cost are greatly reduced. The prepared composite has acatalytic hydrogen production rate of up to 112 mmol / h / g.

Owner:QINGDAO UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com