Catalyst for hydrogen production by bio-oil steam reforming and preparation method thereof

A steam reforming and catalyst technology, which is applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc. Due to the low carbon deposition rate of precious metal catalysts and the limitation of industrial application, the effects of improving the conversion rate of bio-oil, strong anti-coking ability and simple preparation method are achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

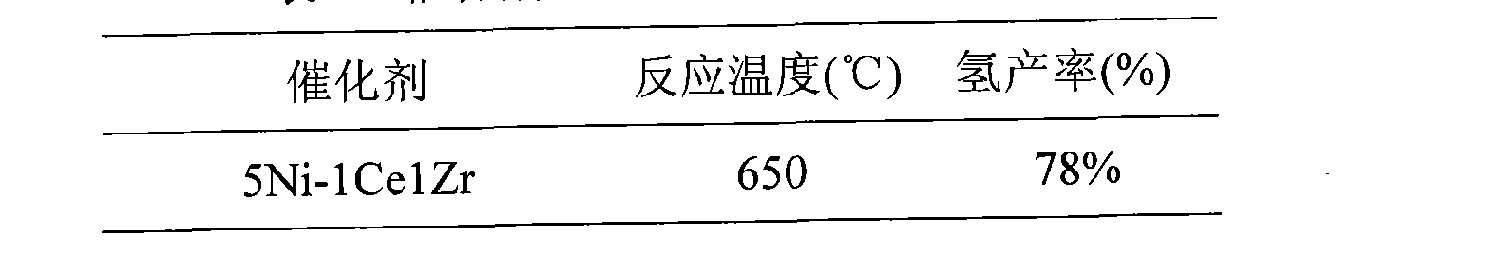

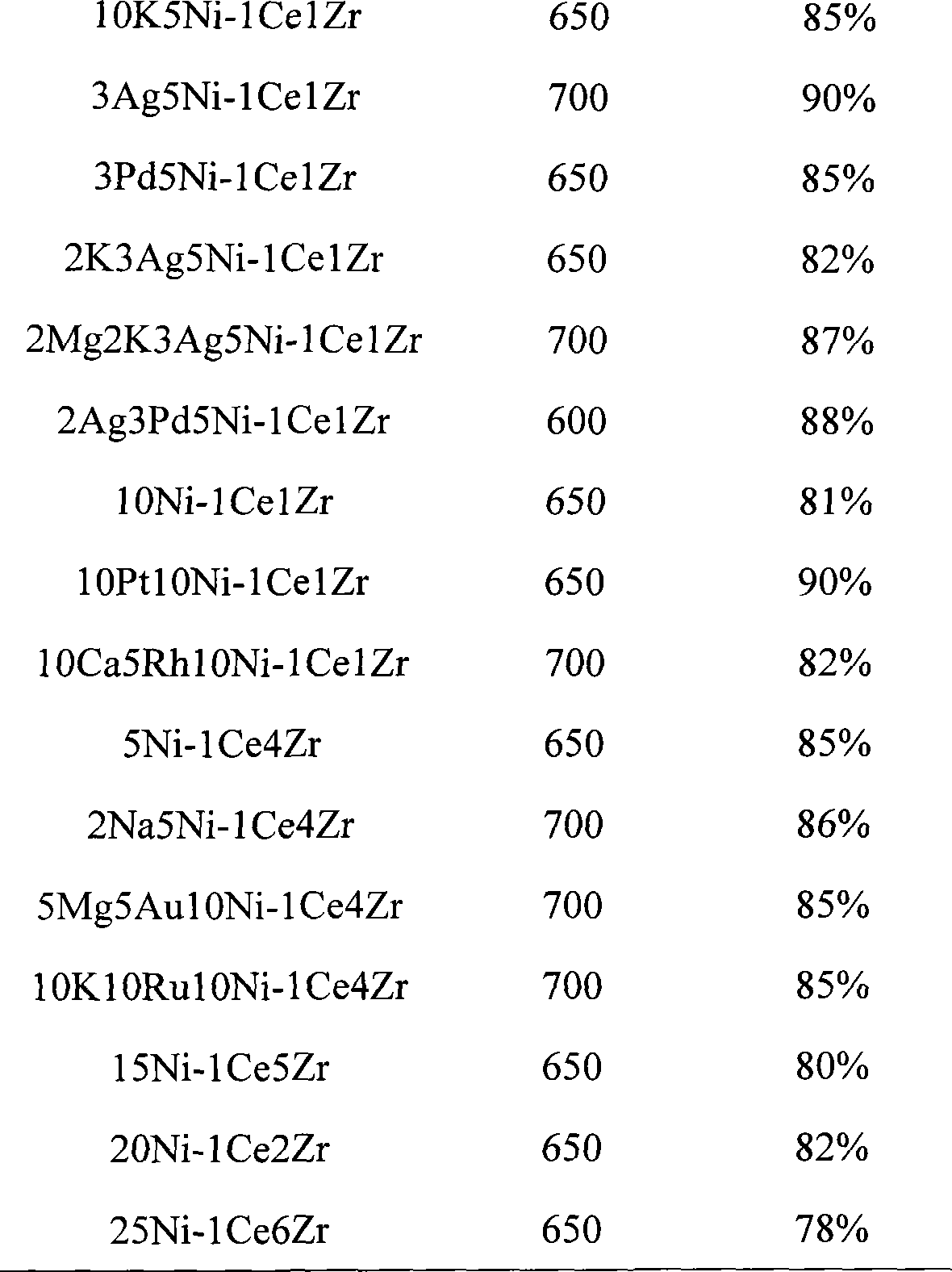

Embodiment 1

[0025] The preparation of embodiment 1 5Ni-1CelZr catalyst

[0026] The preparation method is as follows:

[0027] 1) Dissolve cerium nitrate and zirconium nitrate with a Ce:Zr (molar ratio) of 1:1 in deionized water to form a solution 1 with a concentration of 0.5mol / L;

[0028] 2) With 1mol / L ammonia water as the precipitating agent, under continuous stirring, solution 1 was added dropwise at the speed of 10ml / min

[0029] In the precipitating agent, the pH value was controlled to be 9. After the precipitation was complete, it was aged at room temperature for 12 hours, washed with deionized water, dried at 110°C, and calcined at 600°C for 6 hours to obtain a zirconium-cerium composite oxide carrier;

[0030] 3) Dissolve nickel nitrate with a nickel content of 5% by mass of the catalyst in metered deionized water, impregnate the prepared zirconium cerium oxide carrier with equal volume, let stand at room temperature for 12 hours, disperse ultrasonically for 30 minutes, dry a...

Embodiment 2

[0031] Embodiment 2: Preparation of 10K5Ni-1Cel Zr catalyst

[0032] The preparation method is as follows:

[0033] 1) Dissolve cerium nitrate and zirconium nitrate with a Ce:Zr (molar ratio) of 1:1 in deionized water, and prepare a solution 1 with a concentration of 0.5 mol / l;

[0034] 2) With 1mol / l ammonia water as the precipitant, under continuous stirring, add solution 1 dropwise to the above precipitant at a rate of 10ml / min, control the pH value to 9, after the precipitation is complete, age at room temperature for 12h, use Washing with deionized water, drying at 110°C, and calcining at 600°C for 6 hours to obtain a zirconium-cerium composite oxide carrier;

[0035] 3) Dissolve nickel nitrate with a nickel content of 5% of the catalyst mass and 10% potassium nitrate in metered deionized water, impregnate the prepared zirconium cerium oxide carrier with equal volume, let stand at room temperature for 12 hours, ultrasonically disperse for 30 minutes, and heat at 110°C D...

Embodiment 3

[0036] Embodiment 3: Preparation of 3Ag5Ni-1CelZr catalyst

[0037] The preparation method is as follows:

[0038] 1) Dissolve cerium nitrate and zirconium nitrate with a Ce:Zr (molar ratio) of 1:1 in deionized water, and prepare a solution 1 with a concentration of 0.5 mol / l;

[0039] 2) With 1mol / l ammonia water as the precipitant, under continuous stirring, add solution 1 dropwise to the above precipitant at a rate of 10ml / min, control the pH value to 9, after the precipitation is complete, age at room temperature for 12h, use Washing with deionized water, drying at 110°C, and calcining at 600°C for 6 hours to obtain a zirconium-cerium composite oxide carrier;

[0040] 3) Dissolve nickel nitrate with a nickel content of 5% by mass of the catalyst and 3% silver nitrate in metered deionized water, impregnate the obtained zirconium cerium oxide carrier with equal volume, let stand at room temperature for 12 hours, ultrasonically disperse for 30 minutes, and heat at 110°C Dry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com