Patents

Literature

111results about How to "Strong ability to resist carbon deposition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anti-carbon-deposition Ni-based catalyst for hydrogen production by methane steam reforming and preparation method thereof

ActiveCN103752319AMeet activityMeet service life requirementsHydrogenMetal/metal-oxides/metal-hydroxide catalystsSteam reformingWater vapor

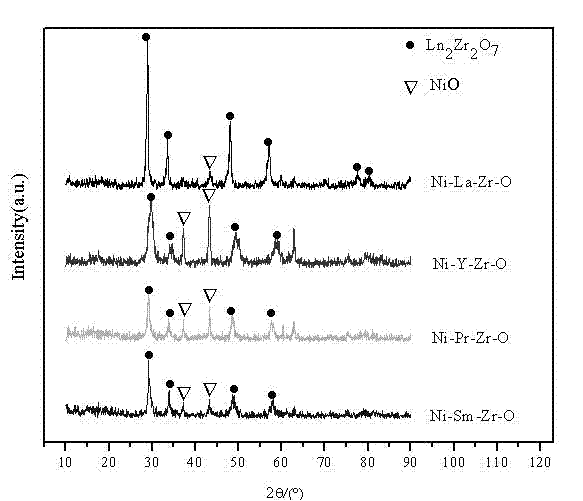

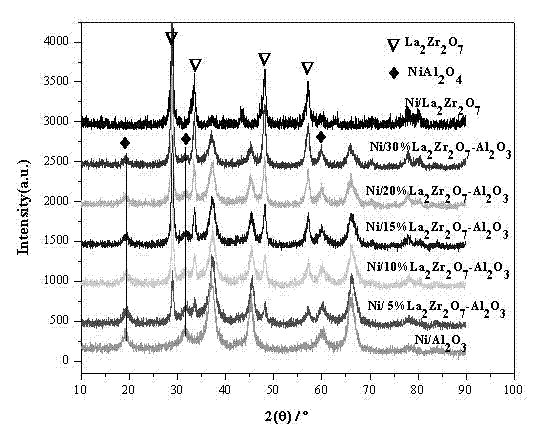

The invention relates to an anti-carbon-deposition Ni-based catalyst for hydrogen production by methane steam reforming and a preparation method thereof. By taking lanthanum nitrate, praseodymium nitrate, samarium nitrate, yttrium nitrate, zirconium nitrate, zirconium carbonate, zirconium oxychloride, and the like as precursors and taking ammonia as a precipitant, a pyrochlore composite oxide is prepared through using a coprecipitation method; and then the pyrochlore composite oxide is mixed with alumina by using a mechanical mixing method so as to obtain a pyrochlore alumina composite carrier. Nickel nitrate, nickel chloride, nickel sulfate, nickel oxalate and the like serving as nickel sources are loaded on the pyrochlore alumina composite carrier through direct immersion. The loading capacity of nickel in the catalyst accounts for 5-30% of the weight of the catalyst, the pyrochlore content of the catalyst is 5-50%, and the alumina content of the catalyst is 20-90%. By taking the pyrochlore alumina composite oxide as a carrier, the reaction activity and anti-carbon-deposition performance of the catalyst can be greatly increased; the preparation method of the catalyst is simple; and the catalyst has excellent catalytic activity and stability to methane steam reforming in a stationary bed.

Owner:NANCHANG UNIV +1

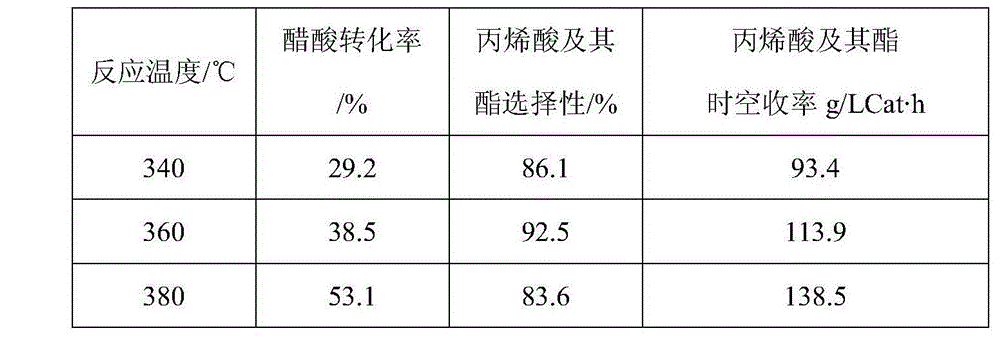

Vanadium-phosphorus-zirconium-titanium composite oxide catalyst for synthesising acrylic acid (ester) as well as preparation method and application of vanadium-phosphorus-zirconium-titanium composite oxide catalyst

ActiveCN104475138AExtended service lifeImprove thermal stabilityMolecular sieve catalystsOrganic compound preparationMolecular sieveChemistry

The invention relates to a catalyst for synthesising acrylic acid (ester), especially relates to a vanadium-phosphorus-zirconium-titanium composite oxide catalyst for synthesising acrylic acid and ester as well as a preparation method and application of the vanadium-phosphorus-zirconium-titanium composite oxide catalyst, and belongs to the field of catalytic material preparation technologies and application. The catalyst disclosed by the invention takes one or the mixture of more of TiO2, SiO2 and a molecular sieve as a support for supporting active components and active auxiliaries; the active components are composite oxides of V, P, Zr and Ti, and the active auxiliaries are one or more oxides of B, Al, Ce and La and can be used for modifying the support. The catalyst disclosed by the invention is used in the reaction of synthesising acrylic acid (ester) from formaldehyde and acetic acid, and has high activity and selectivity; the per-pass conversion rate of the acetic acid achieves 50%, and the selectivity of the acrylic acid and ester of products is up to 90%; moreover, the catalyst is good in thermostability, and good in water resistance and carbon deposition resistance.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

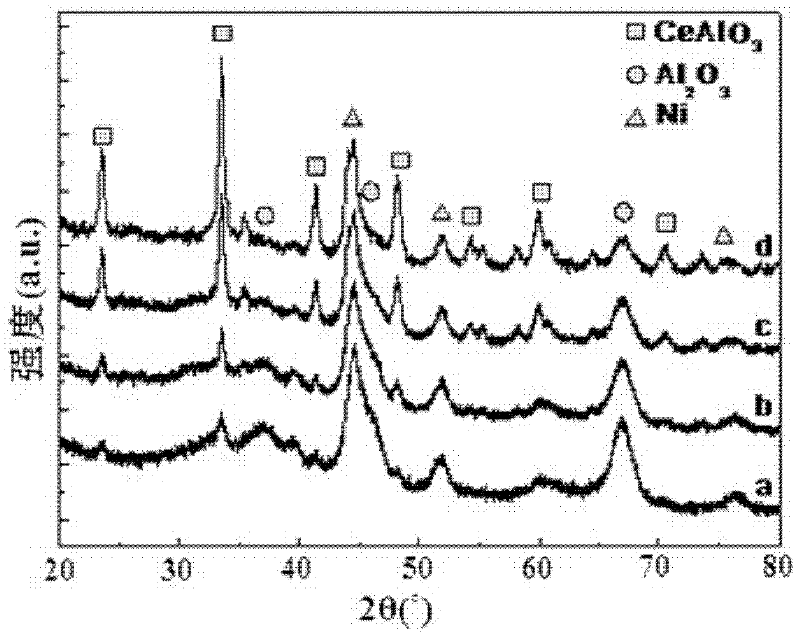

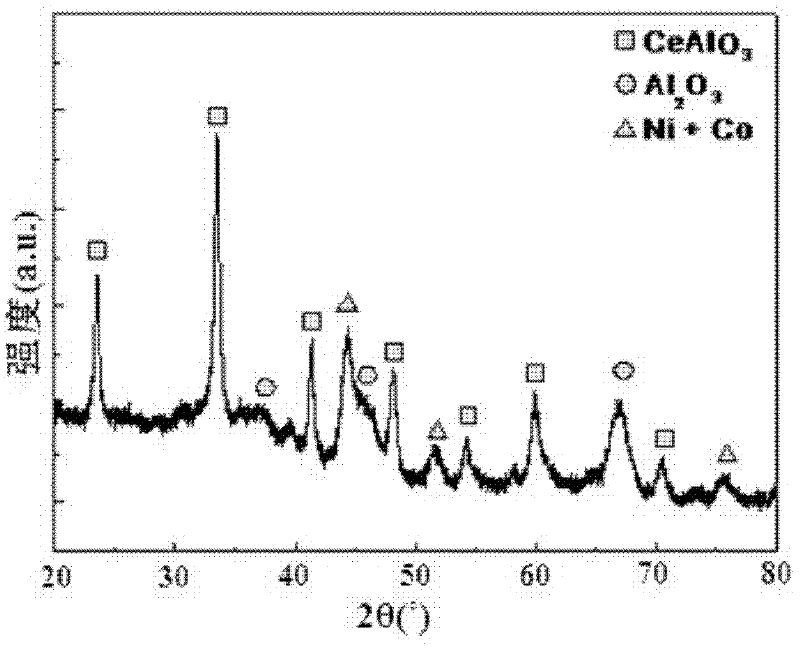

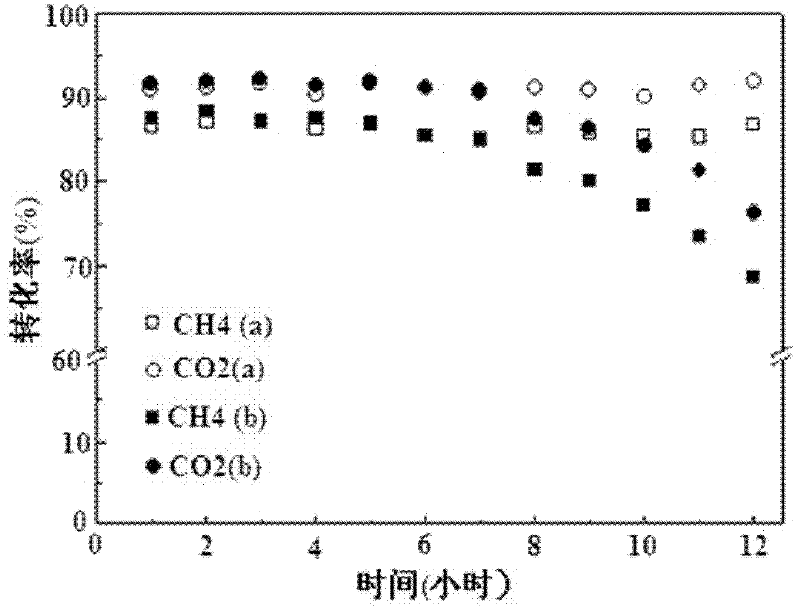

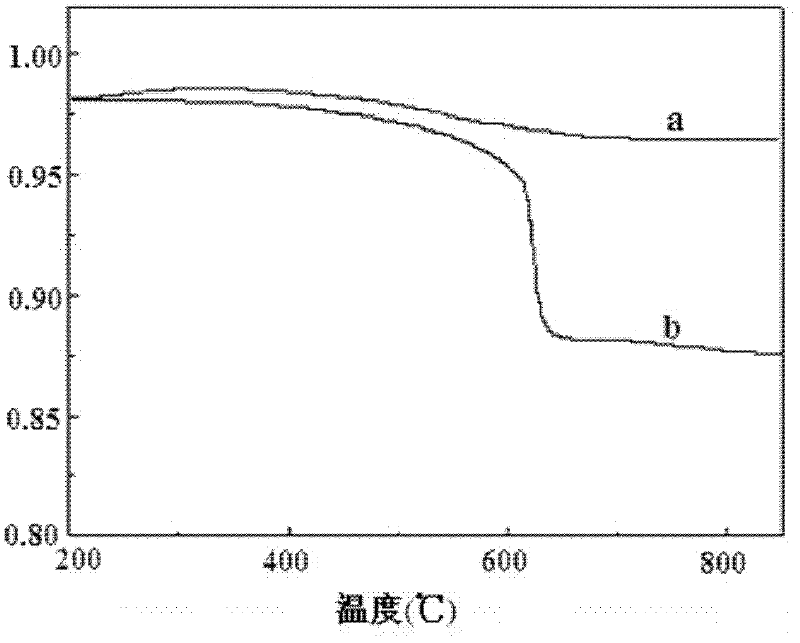

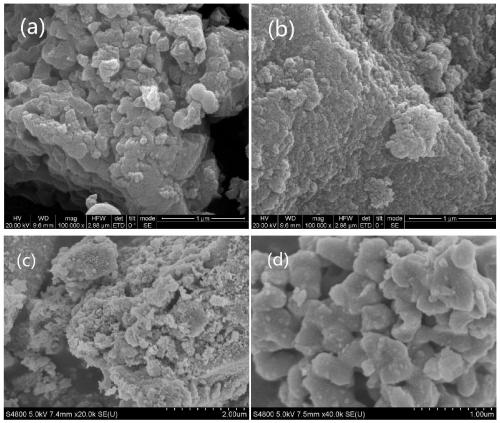

Nickel-based catalyst as well as preparation method and application thereof

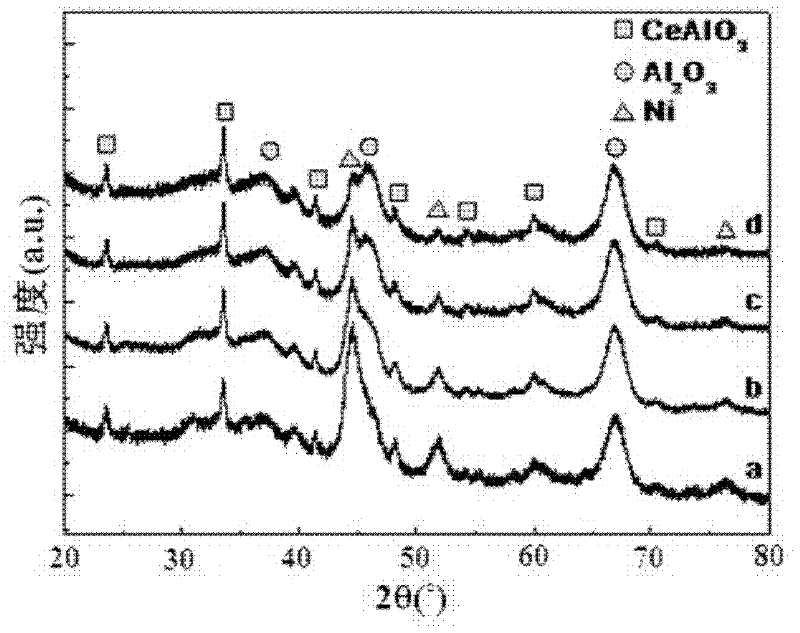

InactiveCN102335609AStrong ability to resist carbon depositionHigh reactivityHydrogenMetal/metal-oxides/metal-hydroxide catalystsAir atmosphereSyngas

The invention discloses a nickel-based catalyst as well as a preparation method and application thereof. The nickel-based catalyst has the following structural general formula: xNi.yCeAlO3.(100-x-y) Al2O3, wherein 1<=x<=20, 1<=y<=30. The catalyst is prepared by the following steps of: firstly, impregnating dried gamma-Al2O3 in a ceric salt solution at room temperature by using an incipient-wetness impregnation method, drying and roasting at the air atmosphere to obtain a modified carrier; then impregnating the modified carrier obtained at room temperature in a nickel salt solution by using the incipient-wetness impregnation method, drying and roasting at the air atmosphere to obtain a catalyst precursor; and finally, reducing the obtained catalyst precursor in hydrogen gas at 850-1050 DEGC. The catalyst provided by the invention has the advantages of strong coke resistance, good reaction stability and heat stability, high chemical and structural stability and the like and can be usedas the catalyst for preparing synthesis gas from methane.

Owner:EAST CHINA NORMAL UNIV

Method for preparing propylene from methyl alcohol

InactiveCN101407441AHigh selectivityImprove stabilityMolecular sieve catalystsHydrocarbon from oxygen organic compoundsHeteropoly acidSolid acid

The invention discloses a method for preparing propylene by methanol, which consists of the following procedures: a. methanol is used as raw material to generate reacting effluent I after passing through a first reactor at the temperature of 150-350 DEG C; in the first reactor, at least one solid acid catalyst chosen from activated aluminum oxide, heteropoly acid and molecular sieve is provided; b. the reacting effluent I is mixed with thinner water, with a mass ratio of 0.2-5:1 between methanol and water; at the temperature of 400-550 DEG C, the mixture passes through a second reactor provided with HZSM-5 molecular sieve catalyst; the mass of airspeed of methanol relative to the HZSM-5 molecular sieve catalyst is 0.2-10h<-1>; and effluent II containing propylene is generated. The method for preparing propylene by methanol has the advantages of high selectivity of propylene and good stability of catalyst by means of the advantages of high activity, little carbon deposit, and strong anti-carbon capacity of nanometer ZSM-5 molecular sieve.

Owner:SHANGHAI INST OF TECH

Catalyst for hydrogen production by bio-oil steam reforming and preparation method thereof

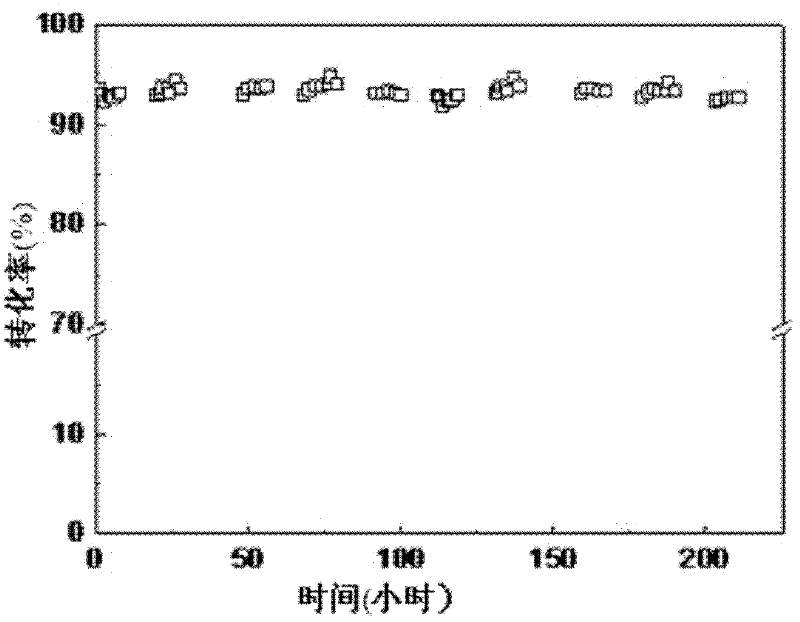

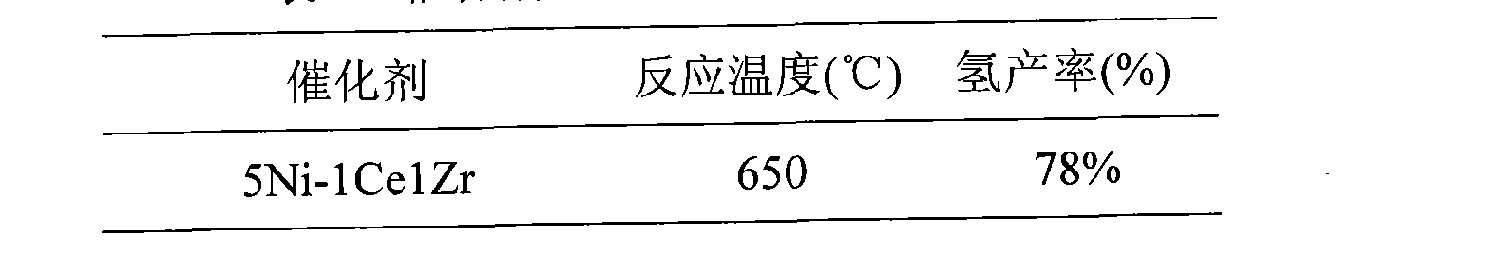

InactiveCN101444740ASimple processLow costHydrogenMetal/metal-oxides/metal-hydroxide catalystsSteam reformingNickel salt

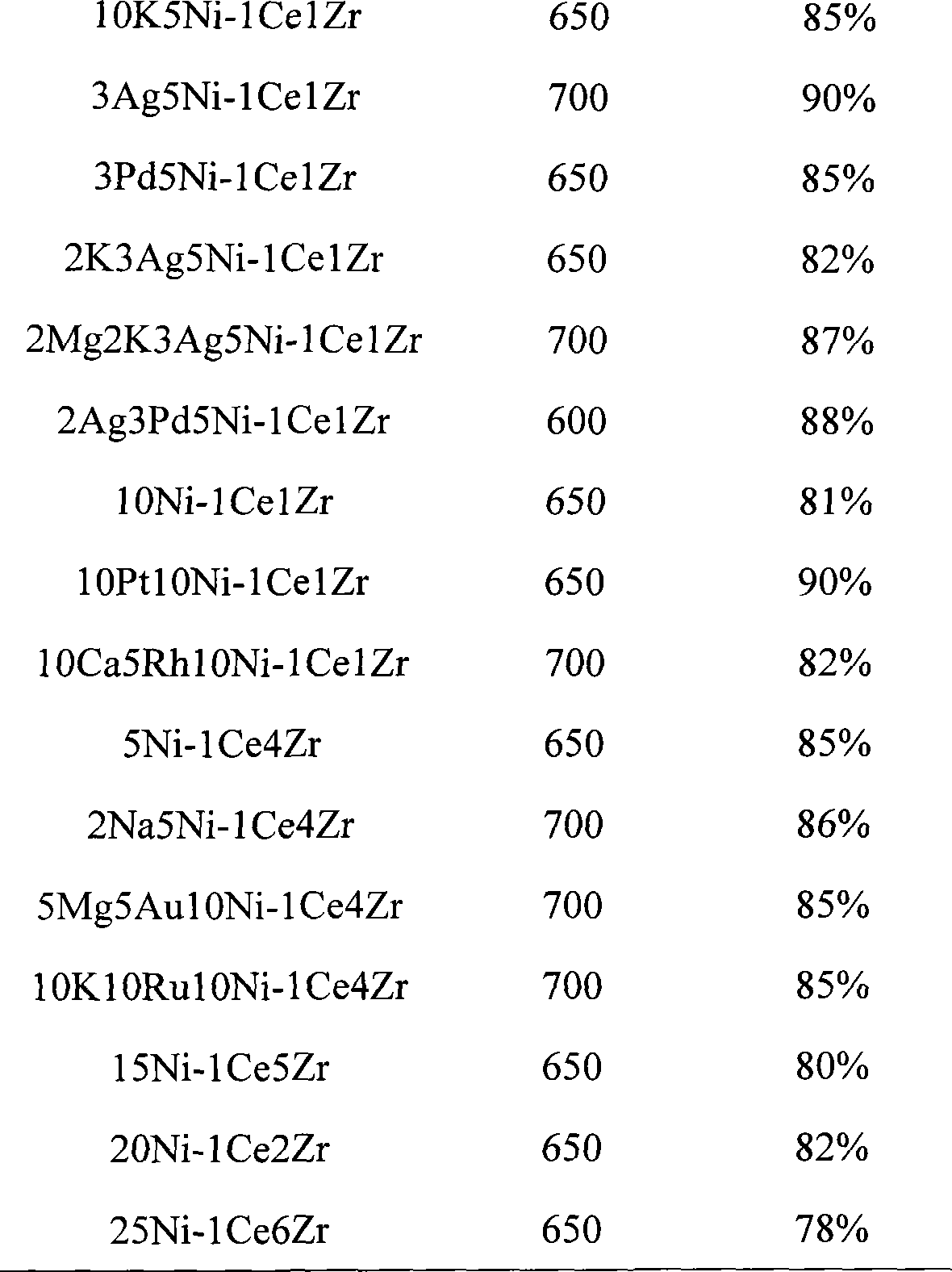

The invention discloses a catalyst for hydrogen production by bio-oil steam reforming and a preparation method thereof. The catalyst consists of 5-25wt% of active component nickel, 0-10wt% of an alkali metal promoter, 0-10wt% of a noble metal promoter, and 55-95wt% of a cerium-zirconium compound oxide carrier. The preparation method comprises the following steps: 1) preparing the cerium-zirconium compound oxide carrier; and 2) mixing aqueous solution of soluble nickel salt with aqueous solutions of the catalytic promoters according to the proportion of the catalyst components, stirring evenly, dipping the cerium-zirconium compound oxide carrier in the mixed solution, stirring, ultrasonically dispersing, dipping, drying, roasting, and reducing at the temperature of 400-600 DEG C in hydrogen atmosphere to obtain catalyst powder. The catalyst is applicable to normal pressure, and has the advantages of simple preparation method, high reaction activity, strong anti-carbon deposition ability, good stability, low cost and the like, thus greatly enhancing the transformation ratio of the bio-oil, the hydrogen production rate and prolonging the service life of the catalyst.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Mesoporous Co/CeO2 catalyst for hydrogen preparation reaction by reforming ethanol vapor and preparation method thereof

InactiveCN103752318AStrong ability to resist carbon depositionLarge specific surface areaMaterial nanotechnologyHydrogenHydrogenHigh energy

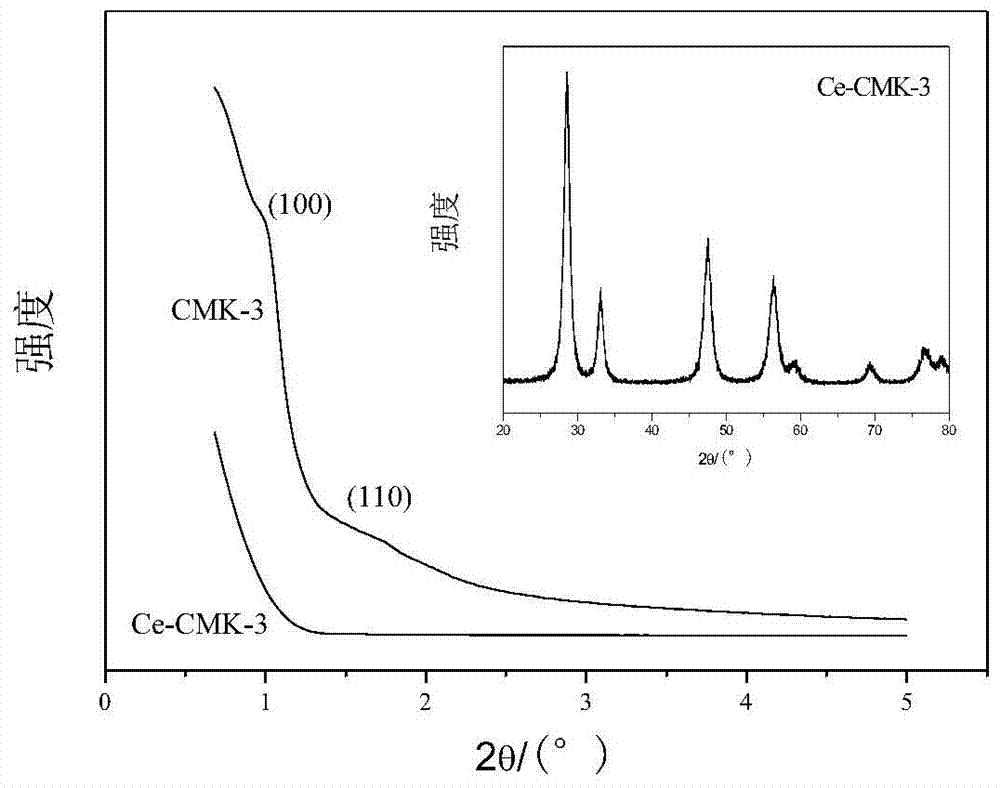

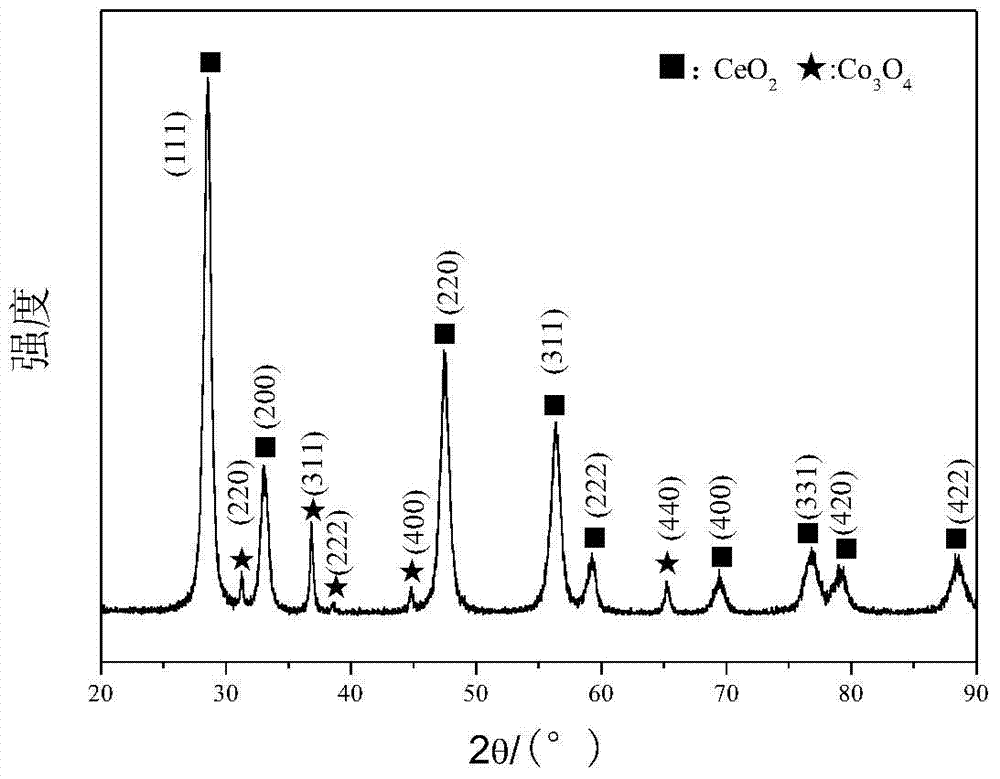

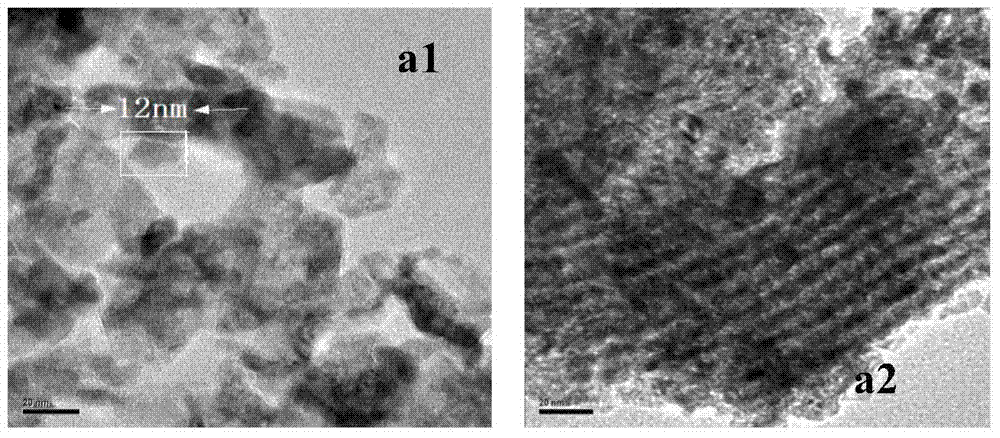

The invention relates to a mesoporous Co / CeO2 catalyst for a hydrogen preparation reaction by reforming an ethanol vapor and a preparation method thereof. The size of the particle diameter of a mesoporous CeO2 carrier is 12nm or so; the specific surface area of the mesoporous CeO2 carrier can reach up 177m<2> / g; the pore structures of the mesoporous CeO2 carrier are sequentially arranged in a short range; the bore diameters of the mesoporous CeO2 carrier are mainly distributed within 3nm or so; cobalt (Co) taken as an active component is carried on the mesoporous CeO2 carrier; the carrying quantity of CoO2 is 5% to 20% of the mass of the catalyst. The mesoporous CeO2 prepared by using a hard template method has the large specific surface area, the short-range and sequential pore structures and the uniformly distributed bore diameters. The mesoporous CeO2 prepared from mesoporous carbon CMK-3 is mainly used for exposing a high-energy crystal face (110) and has a better oxygen storing / releasing capacity.

Owner:INNER MONGOLIA UNIV OF TECH

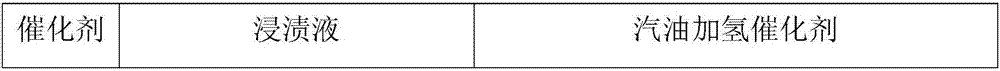

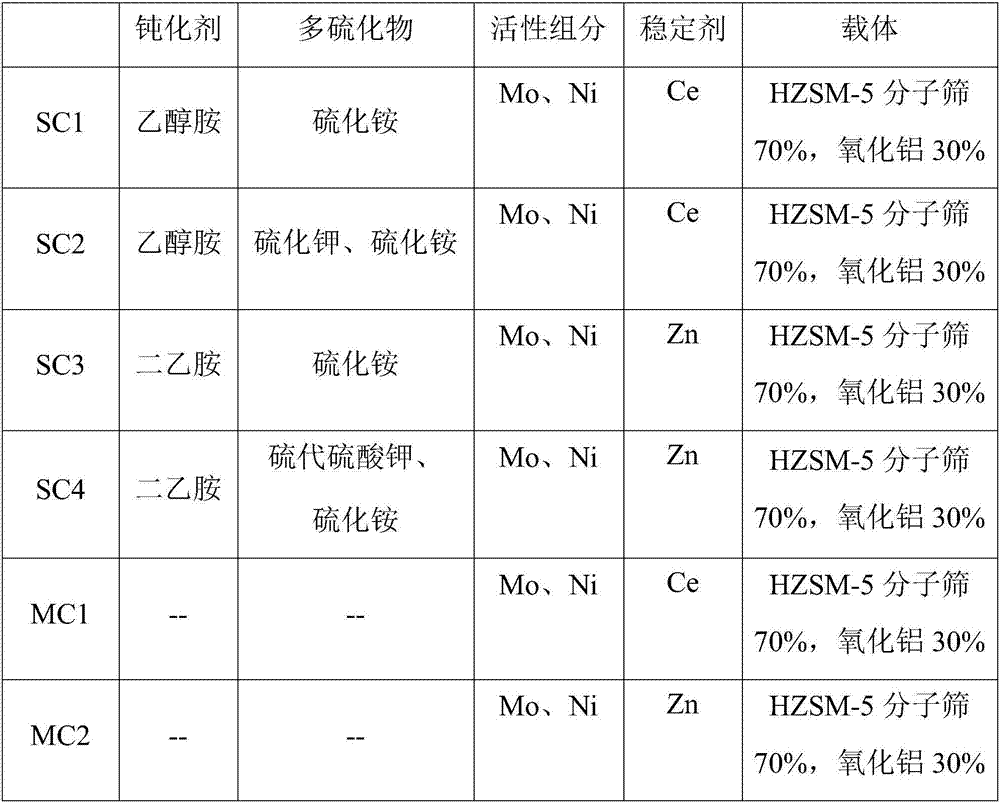

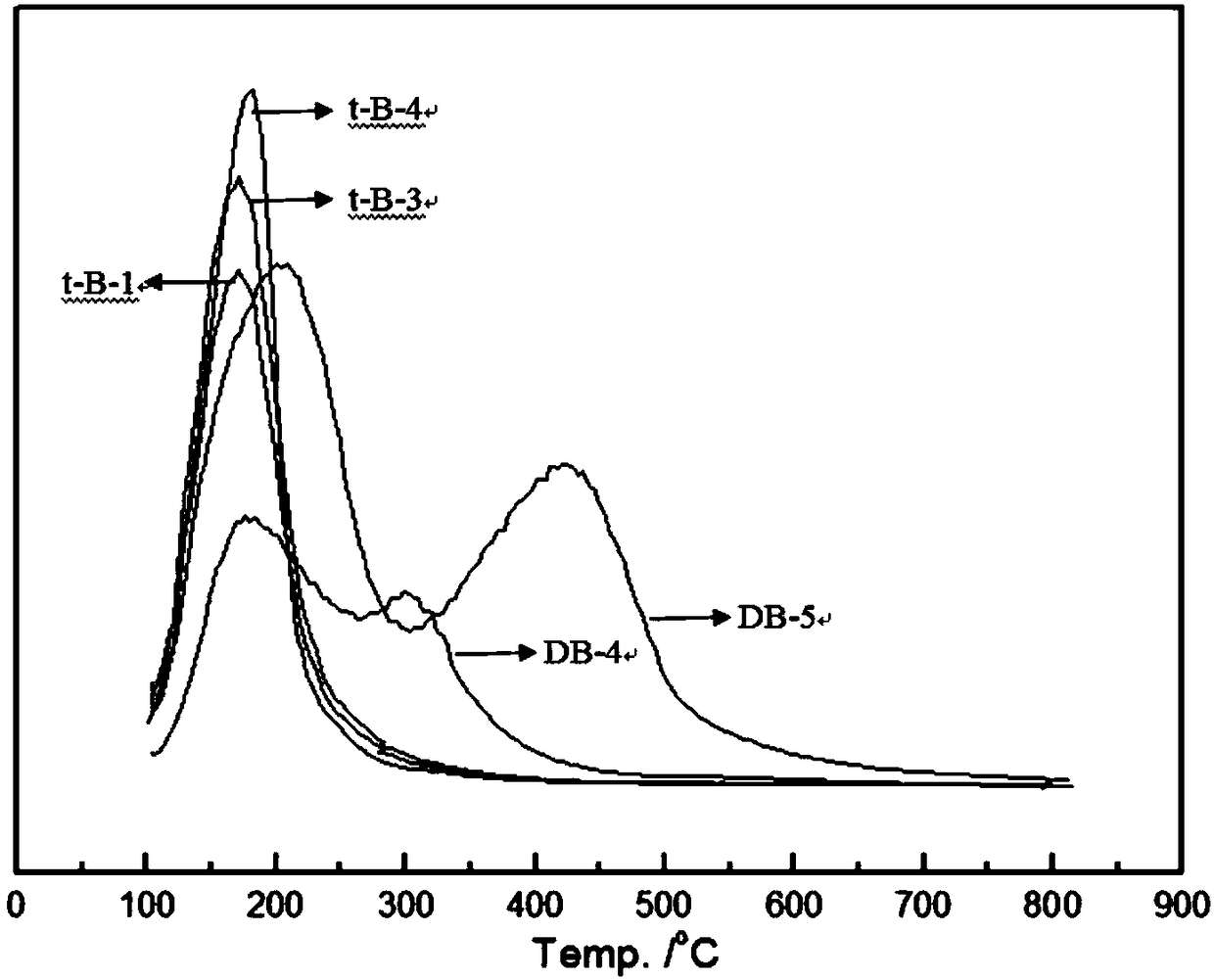

Vulcanization type gasoline hydrogenation upgrading catalyst and method for preparing same

ActiveCN107185597AEasy to introduceEasy to implementMolecular sieve catalystsCatalyst activation/preparationVulcanizationRare earth

The invention relates to a method for preparing a vulcanization type gasoline hydrogenation upgrading catalyst. Gasoline hydrogenation catalysts are treated by vulcanizing agents with multiple sulfur ions and organic nitride which is used as a passivator at the low temperatures, active components in the gasoline hydrogenation catalysts comprise a type or a plurality of types of Mo and W of VI B groups and Co and Ni of VIII B groups, and stabilizers comprise a type or a plurality of types of Zn and Cd of II B groups, Na and K of I A groups and rare earth metal La and Ce. The method has the advantages that cascade full vulcanization can be carried out on metal oxide or precursors of the metal oxide, and strong acidic sites in ZSM-5 molecular sieve composite carriers can be selectively passivated; the vulcanization type gasoline hydrogenation upgrading catalyst prepared by the aid of the method is short in on-stream time, high in hydrogenation and olefin reduction upgrading activity, selectivity, carbon deposition resistance and liquid yield and low in octane number loss, and accordingly the method and the vulcanization type gasoline hydrogenation upgrading catalyst are particularly applicable to producing clean gasoline components from inferiorly catalytically cracked gasoline by means of hydrogenation and olefin reduction upgrading at a low cost.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

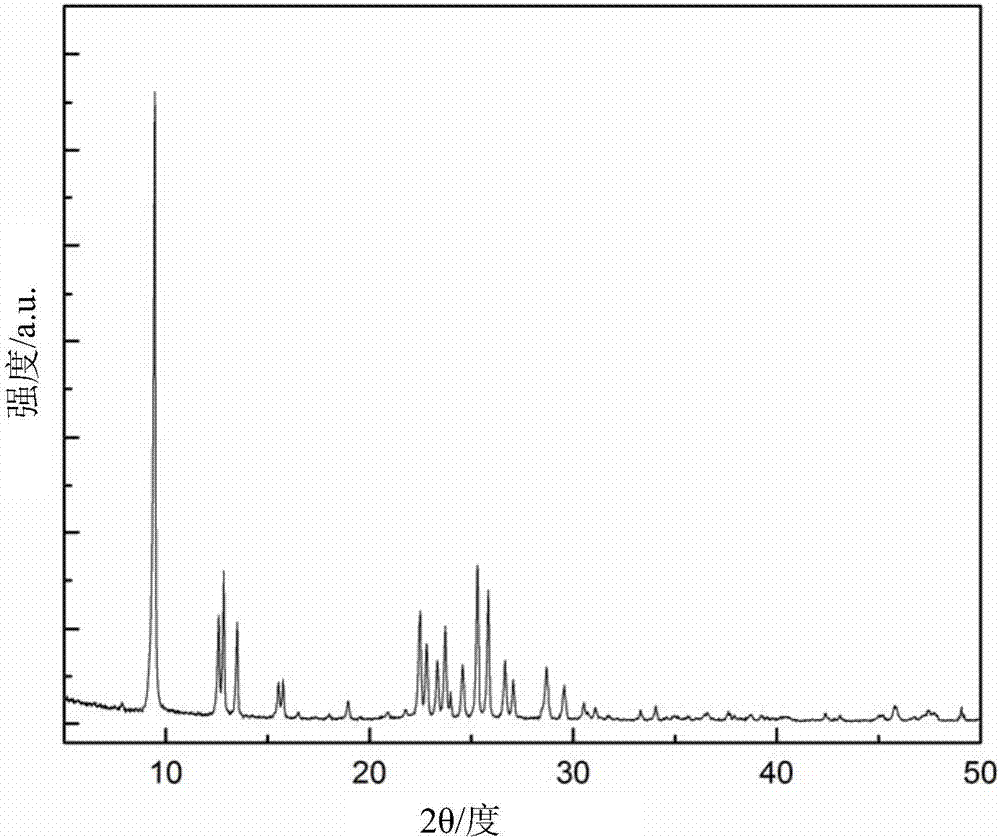

Solid acid catalyst and preparation method and applications thereof

ActiveCN108654594AReduce manufacturing costLow costMetal/metal-oxides/metal-hydroxide catalystsAmino compound preparation by condensation/addition reactionsLanthanideSolid acid

The invention relates to a solid acid catalyst and a preparation method and applications thereof. The catalyst includes lanthanide rare earth metal ions, halogen and a carrier. The carrier includes aboron-silicon composite oxide and silicon oxide; and the boron-silicon composite oxide is an amorphous compound, and can be obtained by mixing boron source and silicon source compounds, adjusting pH to form gel, adding a surfactant as a pore forming agent during a gel synthesizing process, and performing hydrothermal reaction, hole expansion with ammonia, drying and roasting, etc. According to thecatalyst, the amorphous boron-silicon composite having a high specific surface area and specific pore size distribution is molded to form the carrier and a lanthanide rare earth metal oxide which canform a specific acid site and the halogen are added for modification. The catalyst can be used for direct amination of isobutene to prepare tert-butylamine; and high isobutene one-way conversion rateand tert-butylamine selectivity can be achieved, and the catalyst has good stability.

Owner:WANHUA CHEM GRP CO LTD

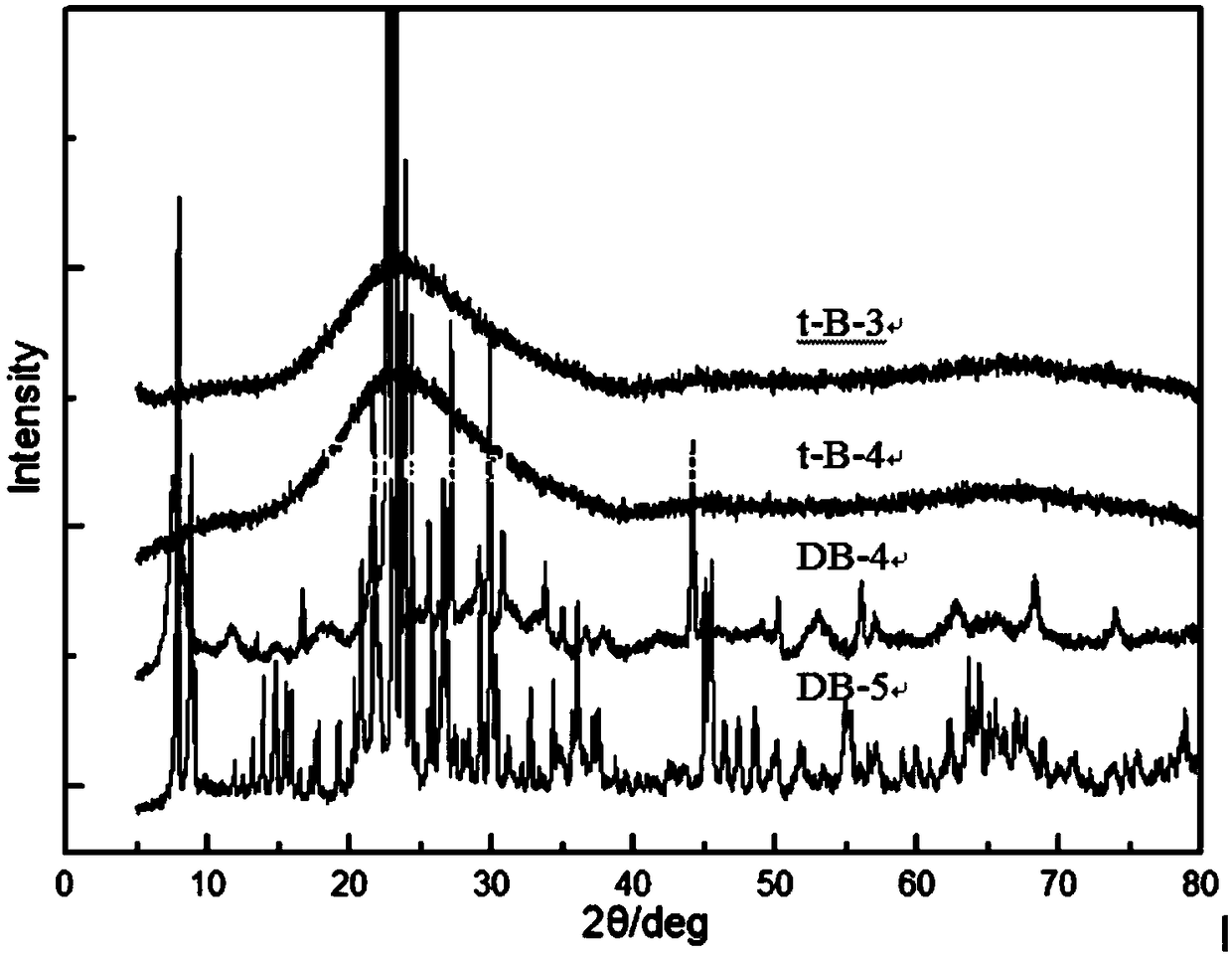

Boron-modified ferrierite molecular sieve catalyst as well as preparation method and application thereof

ActiveCN107265478AHigh activityLong life one wayFerrierite aluminosilicate zeoliteHydrocarbon by isomerisationPtru catalystIon exchange

The invention provides a boron-modified ferrierite molecular sieve catalyst as well as a preparation method and application thereof. The preparation method comprises the following steps: adding an alkali source, an aluminum source and a boron source into water, and stirring to form a uniform solution; adding a ferrierite molecular sieve seed crystal, a silicon source and a template agent into the uniform solution, and stirring until a sol solution is formed; crystallizing the sol solution under a hydrothermal condition, and carrying out filtration, drying and roasting, so as to obtain boron-modified sodium-type ferrierite molecular sieve raw powder; carrying out ion exchange on the boron-modified sodium-type ferrierite molecular sieve raw powder and an ammonium salt water solution or diluted hydrochloric acid, filtering, and drying, so as to obtain hydrogen-type molecular sieve raw powder; and mixing the hydrogen-type molecular sieve raw powder with a binder and water, carrying out extrusion formation, drying, and roasting, so as to obtain the boron-modified ferrierite molecular sieve catalyst. The boron-modified ferrierite molecular sieve catalyst prepared by virtue of the preparation method has the advantages of high activity, long single pass life, strong anti-carbon property and low liquid phase yield.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Catalyst used for producing dimethyl ether through methanol dehydration, and preparation method thereof

ActiveCN104588106AHigh low temperature activityGood choiceOrganic-compounds/hydrides/coordination-complexes catalystsEther preparation by compound dehydrationAlkaneHeteropoly acid

The invention discloses a catalyst used for producing dimethyl ether through methanol dehydration, and a preparation method thereof. The catalyst comprises an active component, an auxiliary agent and a carrier. The active component is heteropoly acid ammonium salt. The auxiliary agent is lanthanum oxide and / or cerium oxide. The carrier is silicon oxide. The preparation method comprises the following steps: alkane, an organic acid, and an ammonium-containing alkaline solution or ammonia gas are sequentially loaded on the silicon oxide carrier; heteropoly acid and the auxiliary agent are loaded on the carrier; and drying and roasting are carried out, such that the catalyst is obtained. The catalyst provided by the invention has relatively high low-temperature activity, selectivity and coking resistance. Also, the stability of the catalyst is improved. The catalyst provided by the invention is especially suitable for a reaction for producing dimethyl ether with a methanol raw material with relatively high water content.

Owner:CHINA PETROLEUM & CHEM CORP +1

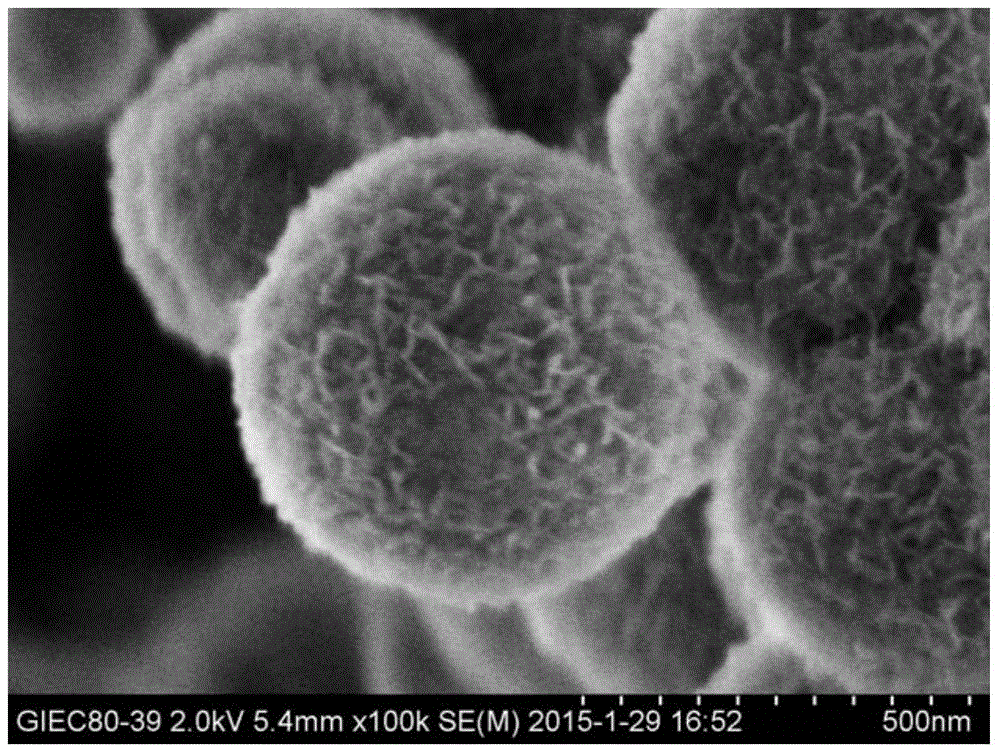

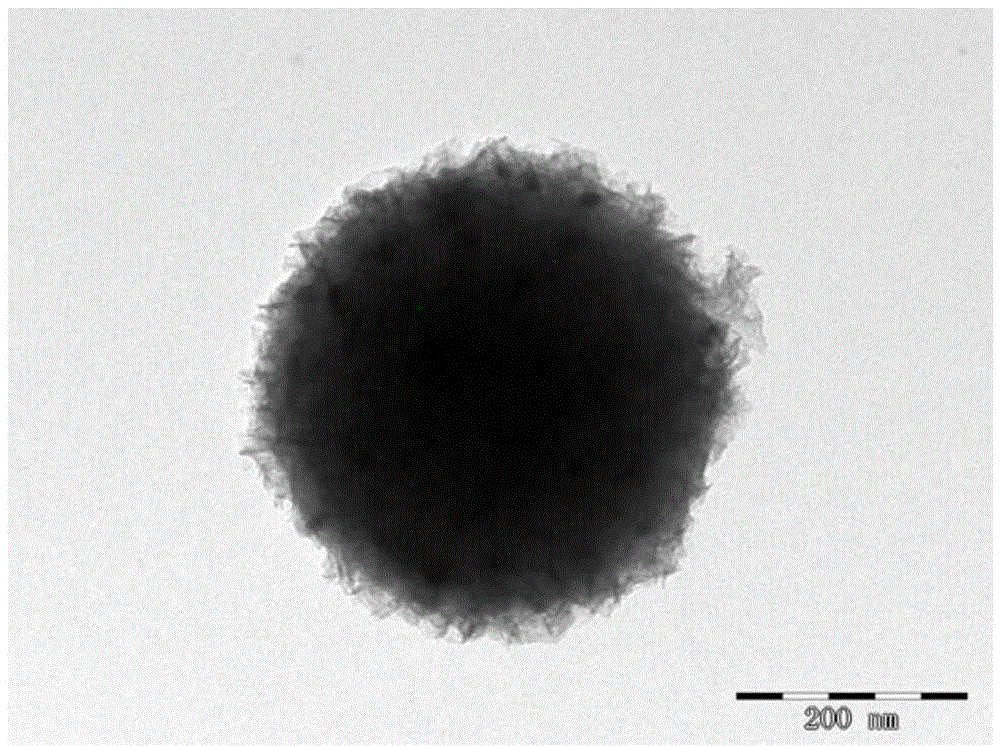

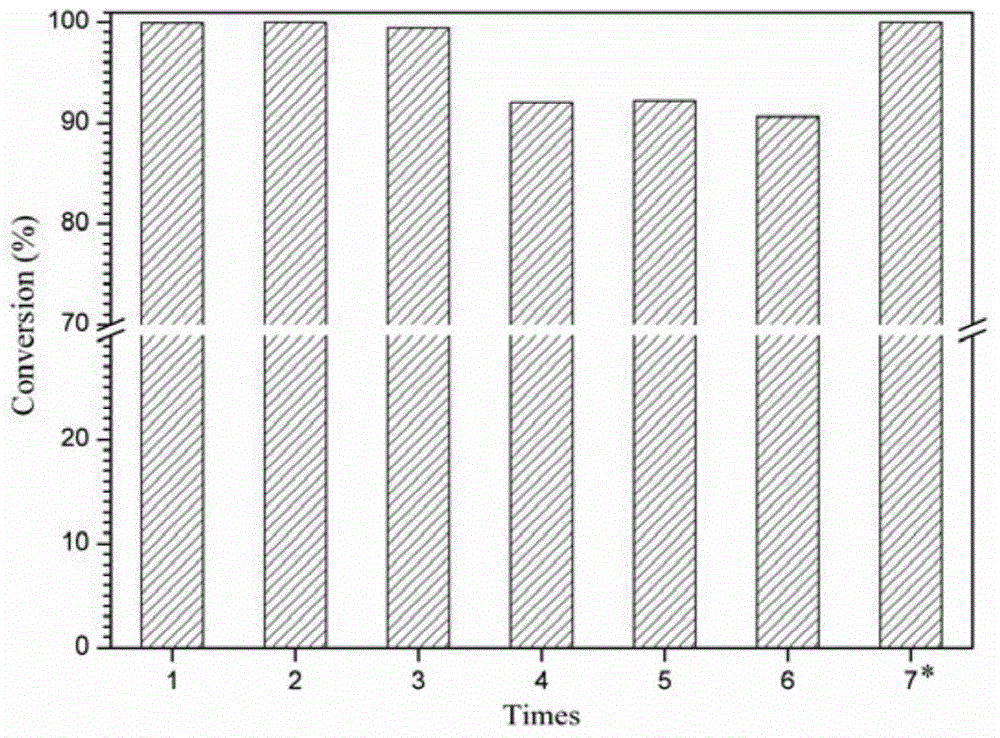

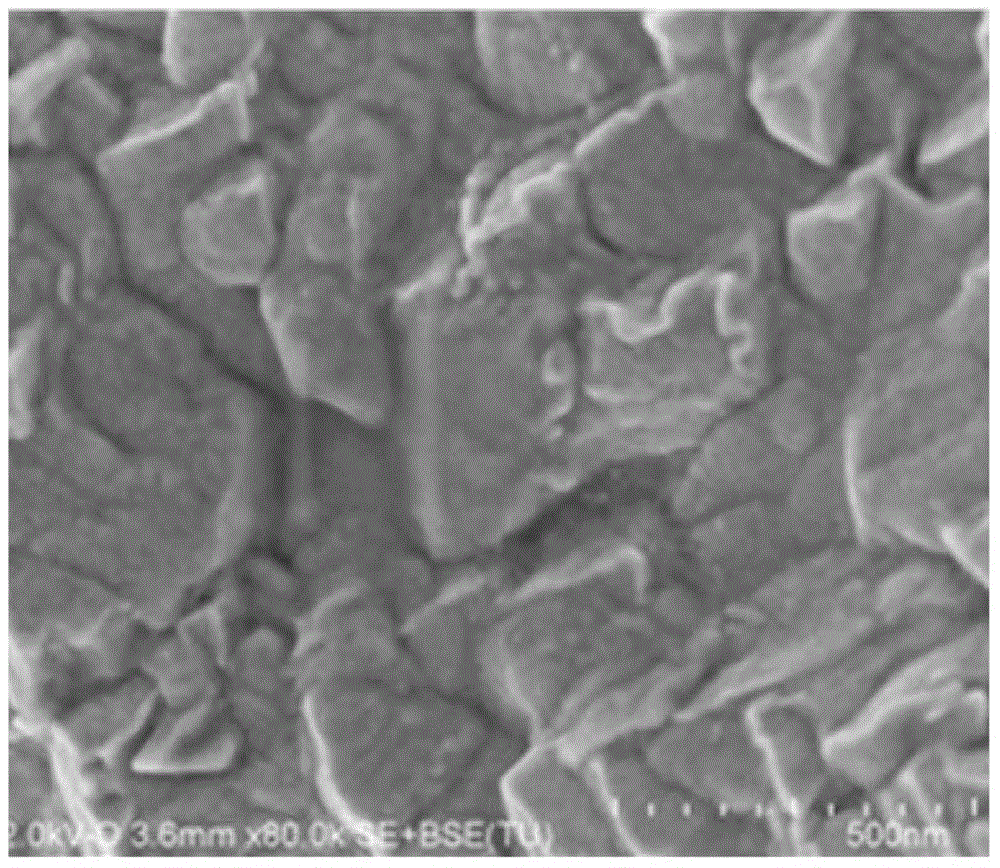

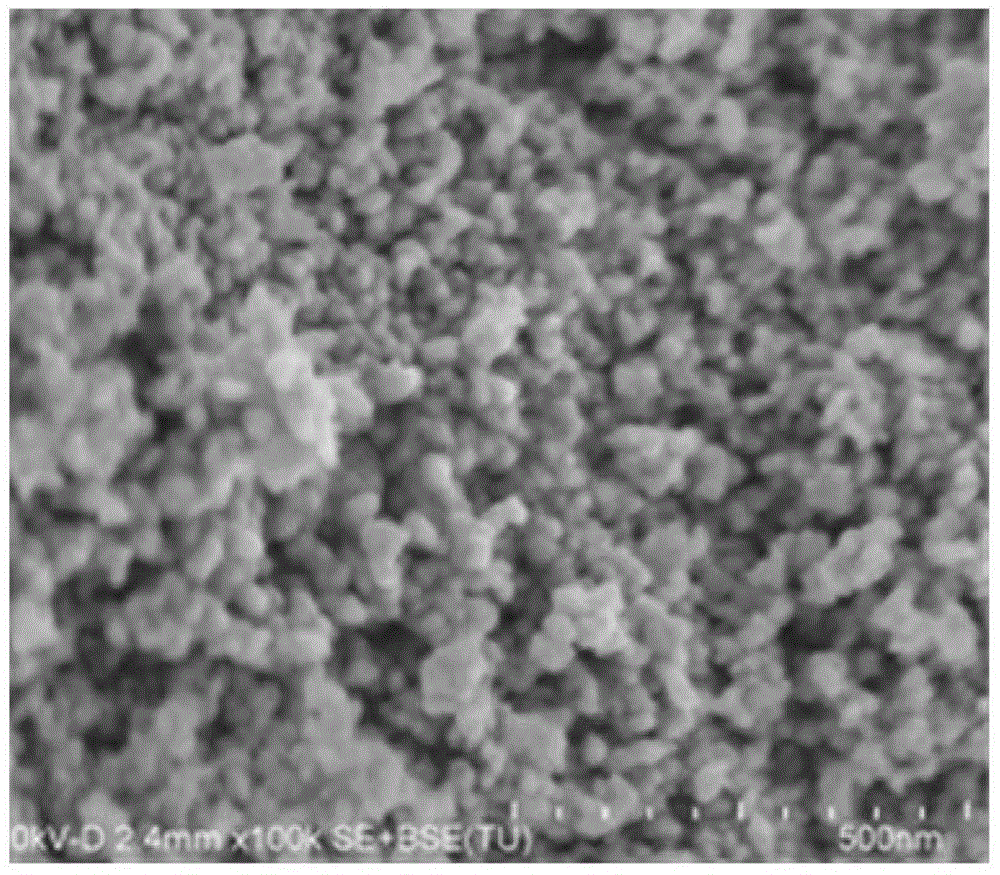

Multistage duct type cobalt-based Fischer-Tropsch synthesis catalyst with core-shell structure and preparation method of multistage duct type cobalt-based Fischer-Tropsch synthesis catalyst

ActiveCN105879899AExtended service lifeAvoid reunionMolecular sieve catalystsLiquid hydrocarbon mixture productionActive componentCobalt

The invention discloses a multistage duct type cobalt-based Fischer-Tropsch synthesis catalyst with a core-shell structure and a preparation method of the multistage duct type cobalt-based Fischer-Tropsch synthesis catalyst. The catalyst comprises a catalyst carrier S, a metal active component Co loaded on the catalyst carrier S and a shell layer zeolite membrane M which wraps the surface of the catalyst carrier S, wherein the catalyst carrier S is a mixture of one or two of SiO2 and Al2O3 according to an optional ratio, the microstructure form of SiO2 and Al2O3 is spherical, the specific surface area of the microstructure form is 160-290 m(2) / g, and the average particle size ranges from 10 meshes to 50 meshes; the shell layer zeolite membrane M is a cluster aggregation of H-ZSM-5 nano particles which are dispersed uniformly, the particle size range of the H-ZSM-5 nano particles is between 10 nm and 30 nm, the micropore aperture of the H-ZSM-5 is smaller than or equal to 2.0 nm, and gaps among the adjacent H-ZSM-5 nano particles are smaller than or equal to 100 nm; and the loading capacity of the metal active component Co accounts for 10-30% of the sum of the weight of the catalyst carrier S and the weight of the metal active component Co. The shell layer of the Fischer-Tropsch synthesis catalyst has a multistage duct and high catalyzing efficiency. Meanwhile, the preparation method is simple in technology and low in energy consumption.

Owner:WUHAN KAIDI ENG TECH RES INST CO LTD

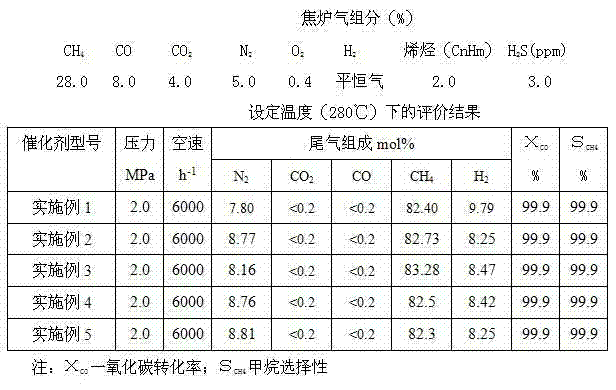

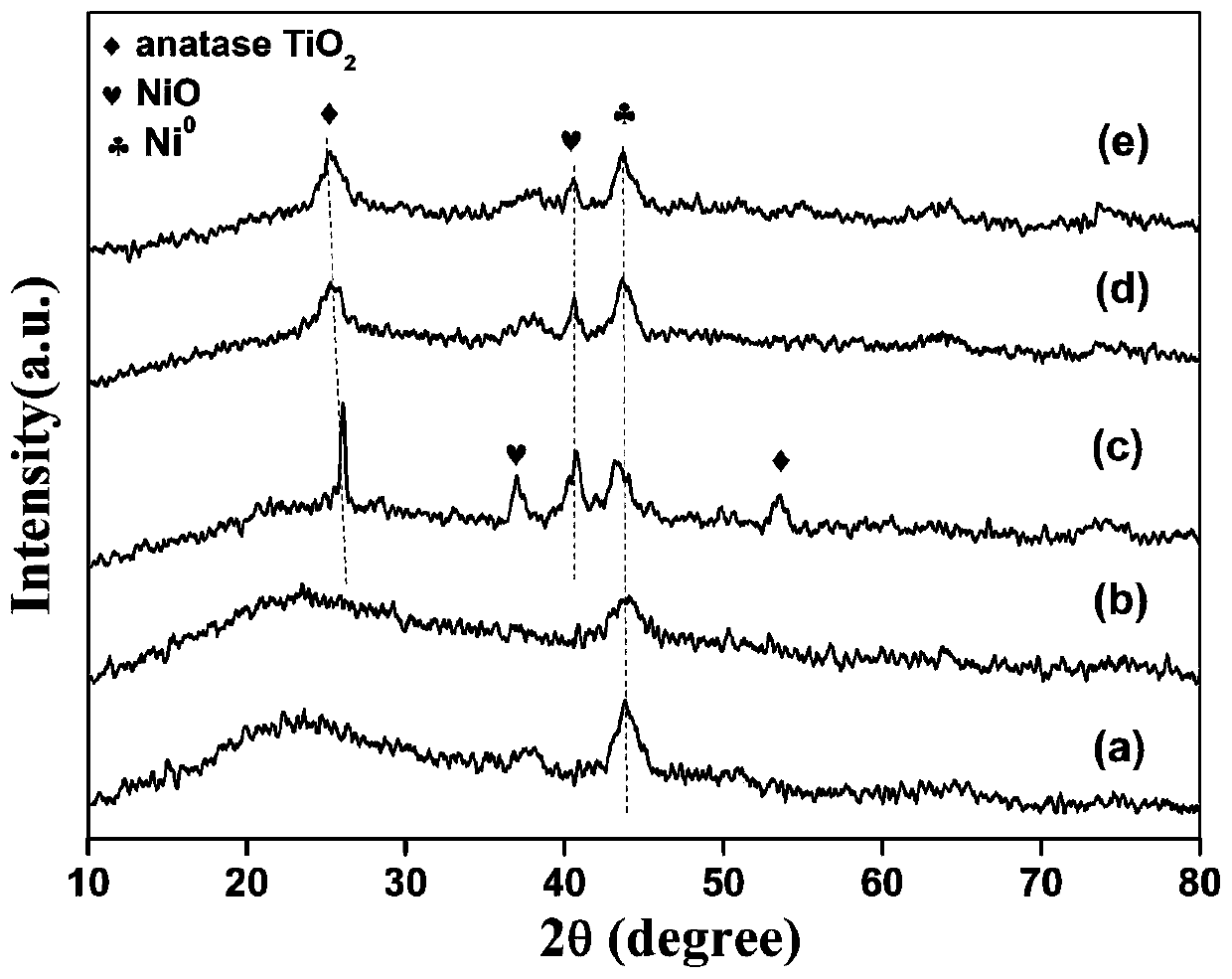

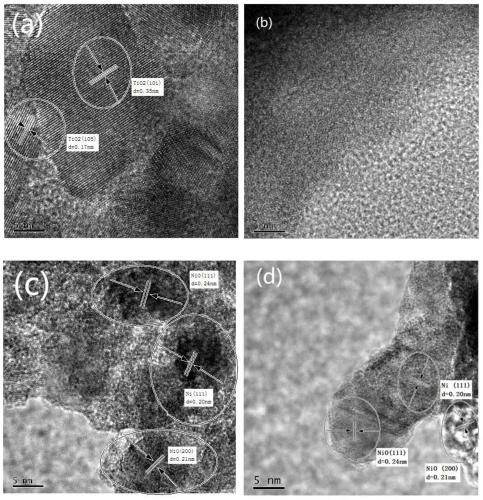

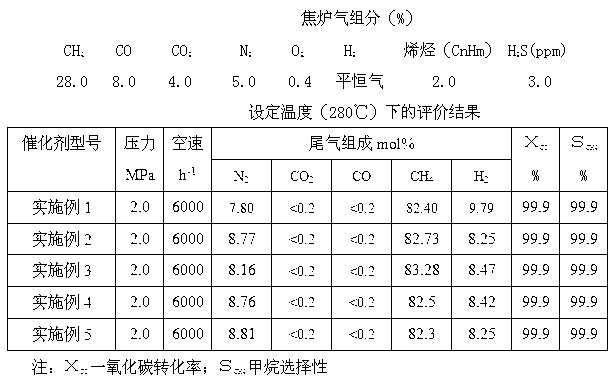

Coke oven gas hydrodesulfurization catalyst and preparation method thereof

InactiveCN106268848AHigh activityStrong ability to resist carbon depositionHeterogenous catalyst chemical elementsCatalyst activation/preparationDispersityHydrodesulfurization

Owner:XIAN SUNWARD AEROSPACE MATERIAL CO LTD

Core-shell structured catalyst for preparation of cyclohexanol by selective hydrodeoxygenation of catalytic guaiacol

ActiveCN104923233ARaw materials are cheap and easy to getEasy and quick to makePreparation by hydrogenationMetal/metal-oxides/metal-hydroxide catalystsNickel saltAlcohol

The invention discloses core-shell structured catalyst for preparation of cyclohexanol by selective hydrodeoxygenation of catalytic guaiacol. A preparing method of SiO2-clad Ni@SiO2 core-shell structured catalyst includes the steps of adding soluble nickel salt and polyvinylpyrrolidone to alcohol-water mixed solvent, performing mixing, dropwise adding ammonia water under stirring, adding cetyltrimethylammonium bromide as surfactant, dropwise adding soluble silicon source, and performing violent mixing; and performing filtering, collecting, washing, drying, calcining and reducing to obtain the Ni@SiO2 core-shell structured catalyst. In hydrodeoxygenation reaction of the guaiacol, the Ni@SiO2 core-shell structured catalyst prepared by the preparing method has high target product selectivity, good sintering resistance, carbon accumulation resistance and the like.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Waste hydrogenation catalyst utilization method

ActiveCN106944137AIncrease profitImprove pore structureOrganic-compounds/hydrides/coordination-complexes catalystsCatalystsHeteropoly acidFurfural

The present invention discloses a waste hydrogenation catalyst utilization method, which comprises: grinding a waste hydrogenation catalyst, soaking with ammonia water, adding alumina, a binder and an acid solution to the remaining solid, and carrying out mixing kneading molding; carrying out reducing treatment with hydrogen gas in a high pressure reaction kettle; adding a polyol and / or furfural solution to the high pressure reaction kettle, and carrying out a hydrogenation reaction; and drying the material obtained after the reaction until the surface is liquid-free, sequentially contacting an organic acid, ammonium or ammonia, and loading a heteropoly acid to produce the catalyst for ethylene preparation through ethanol dehydration. According to the present invention, with the method, the hydrogenation activity metal component and the carrier component in the waste hydrogenation catalyst are utilized, and the hydrogenation activity of the waste hydrogenation catalyst is completely utilized, such that the utilization rate of the waste catalyst is improved, the pollution problem of the waste catalyst is solved, and the obtained catalyst for ethylene preparation through ethanol dehydration has the excellent performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

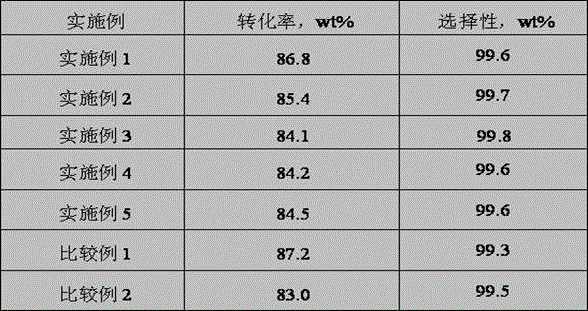

Sulfur-resistant methanation catalyst and preparation method thereof

ActiveCN102389808AStrong ability to resist carbon depositionGood CO conversionGaseous fuelsMetal/metal-oxides/metal-hydroxide catalystsCoke oven gasAccelerant

The invention discloses a sulfur-resistant methanation catalyst, which is used for preparing methane from coke oven gas. The catalyst is a precipitation type catalyst which mainly adopts oxides of Mo, Co and Ni as active ingredients, Al2O3 as a carrier and La2O3 as an accelerant. The catalyst can be used for realizing good methanation of coke oven gas containing 1-3 ppm of H2S at1.0-3.0 MPa and 280-450 DEG C on the premise of not deeply purifying coke oven gas, and also has good selectivity. The invention also discloses a preparation method of the sulfur-resistant methanation catalyst.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

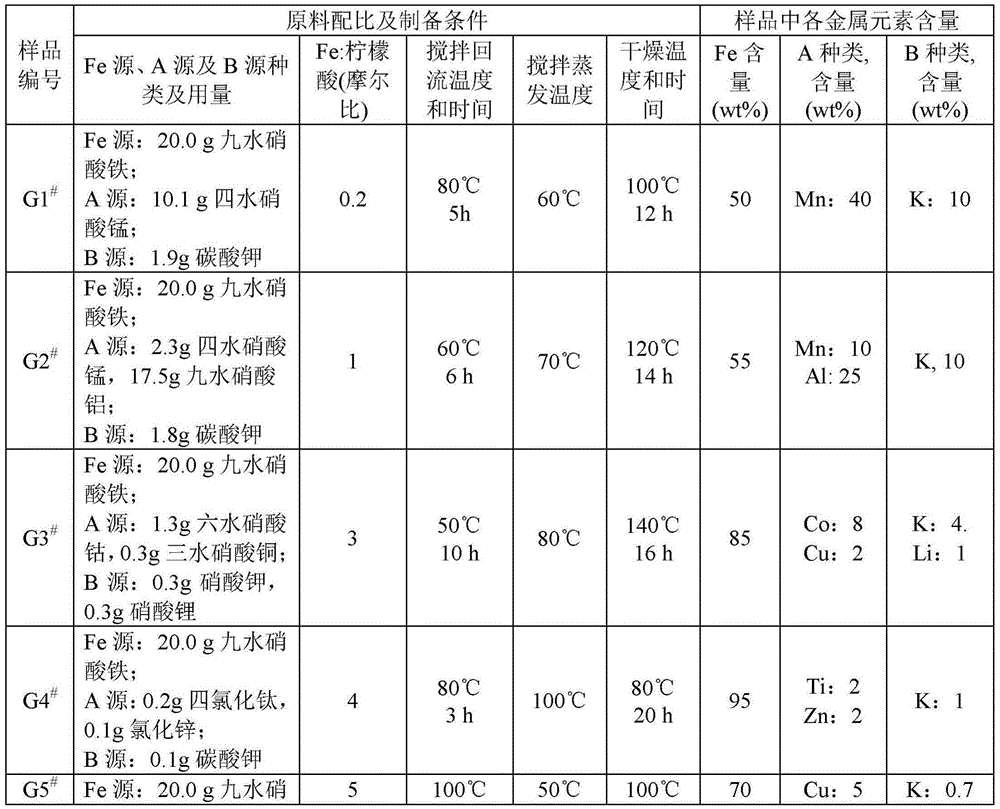

Iron-based catalyst prepared by sol-gel combustion method, and preparation method and applications of iron-based catalyst

ActiveCN106311269AStrong ability to resist carbon depositionHigh selectivityHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsCombustionMetal

The invention discloses an iron-based catalyst prepared by a sol-gel combustion method, which is characterized by containing a metal element Fe, a metal element A and a metal element B, wherein A is at least one selected from the group consisting of Mn, Co, Cu, Zn, Ti, Al, Cr, Ni, Ce, and Zr; B is at least one selected from the group consisting of Li, Na, K, Mg, and Ca; each metal element exists in the form of a metal simple substance and / or a metal oxide; and the content of the metal element A in the catalyst is 0.1-50 wt%, the content of the metal element B in the catalyst is 0.01-40 wt%, and the content of the metal element Fe in the catalyst is 50-99 wt%, based on the total amount of the metal elements contained in the catalyst. The catalyst has good resistance to carbon deposition, is used for reaction of preparation of low-carbon olefins by use of synthetic gas, and shows higher catalytic activity and low-carbon olefin selectivity.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

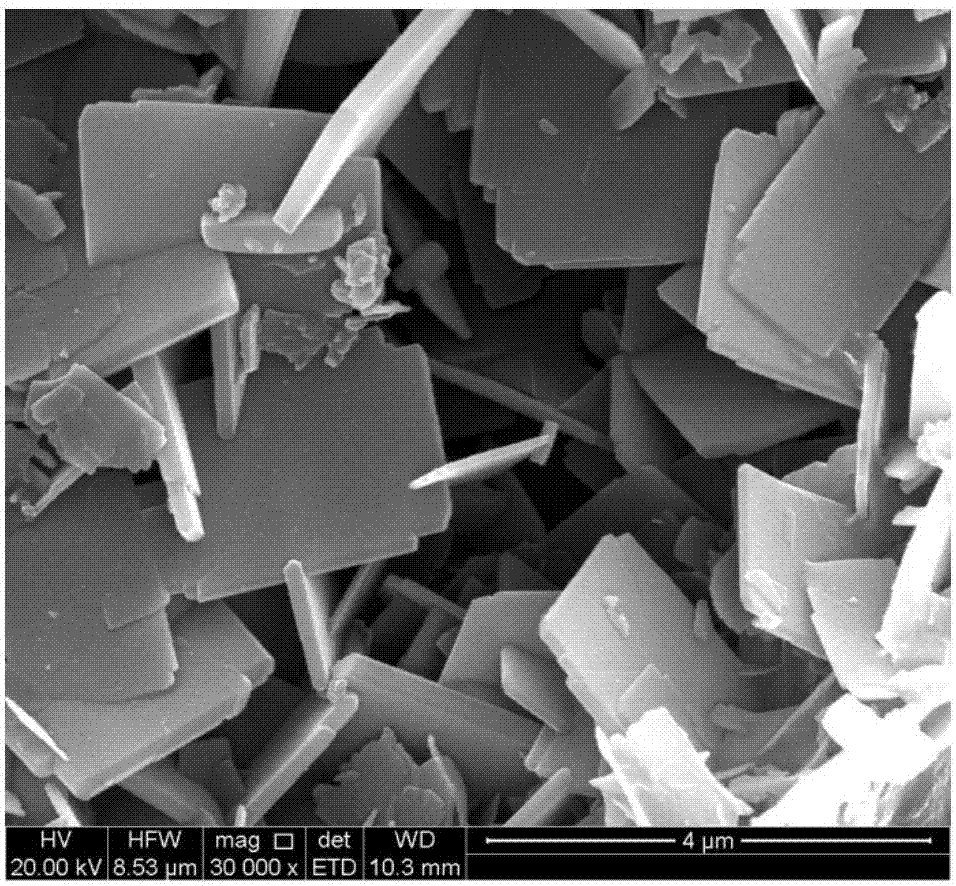

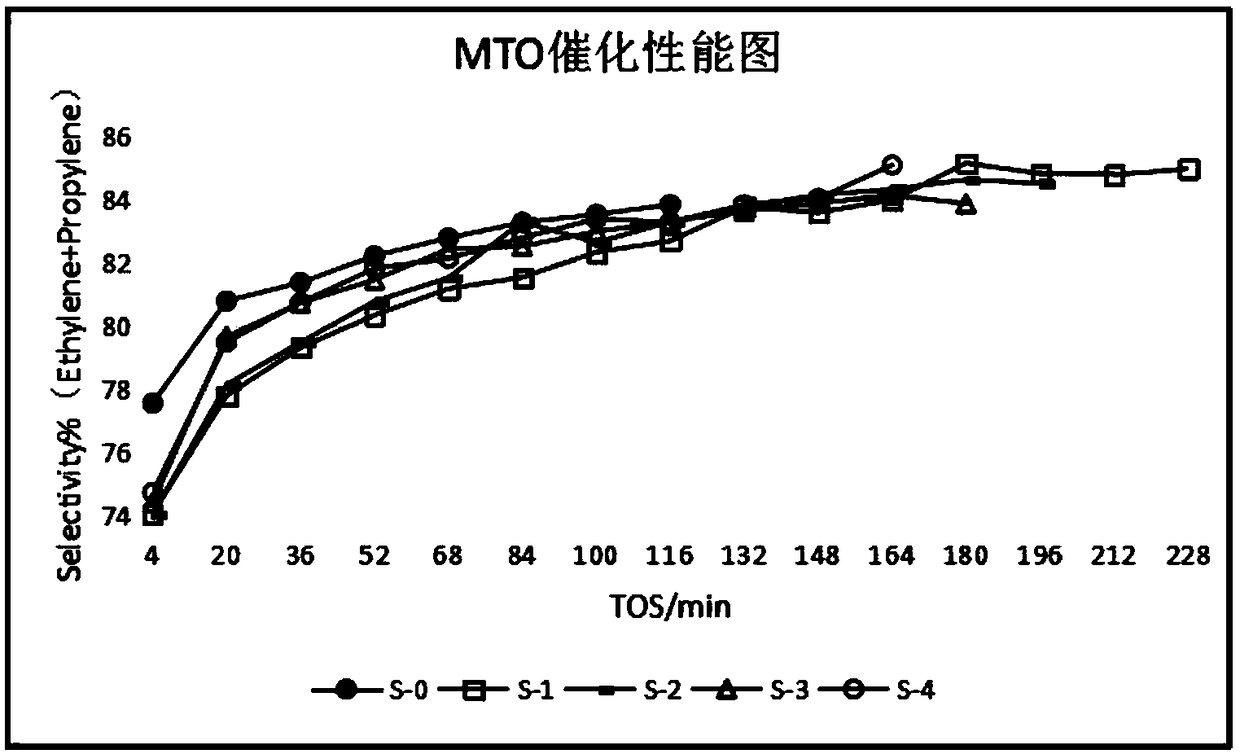

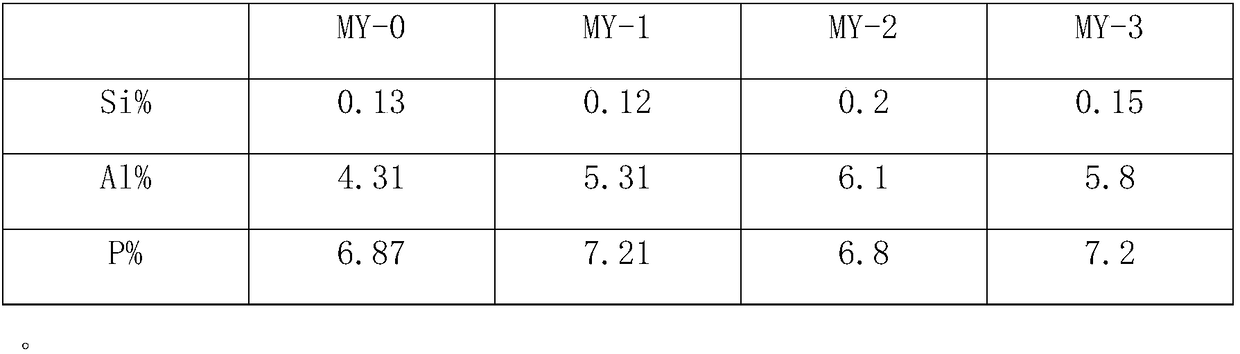

Method for synthesizing flaky SAPO-34

ActiveCN108314055AImprove catalytic performanceStrong ability to resist carbon depositionMolecular sieve catalystsHydrocarbon from oxygen organic compoundsMolecular sieveDistillation

A method for synthesizing flaky SAPO-34 comprises the following steps: carrying out reduced pressure distillation on an SAPO-34 crystallization mother liquor, evaporating away a part of water, addingan aluminum source, a phosphorus source, a silicon source and fluoride, uniformly dispersing the added substances, adding the obtained solution into a kettle, and crystallizing the solution to obtaina crystal nucleus solution; sequentially adding the aluminum source, the silicon source, an organic amine template and the phosphorus source to deionized water, and fully dispersing the added substances to form an initial gel; and adding a crystal nucleus solution to the initial gel, uniformly dispersing the initial gel, adding the obtained solution to a high pressure reactor, crystallizing the solution, and centrifuging, washing, drying and calcining obtained crystals to obtain flaky SAPO-34 raw powder. The method effectively prolongs the MTO catalysis life of the SAPO-34 molecular sieve, andreuses a large amount of the crystallization mother liquor produced in the production process of the SAPO-34 molecular sieve.

Owner:深圳科冠华太新材料技术有限公司

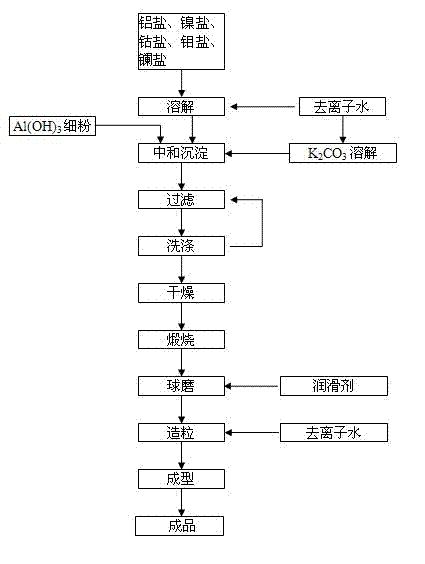

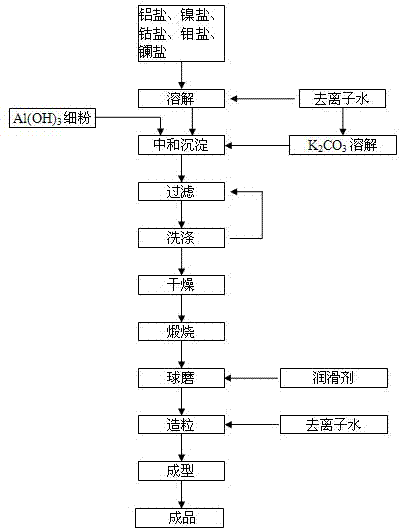

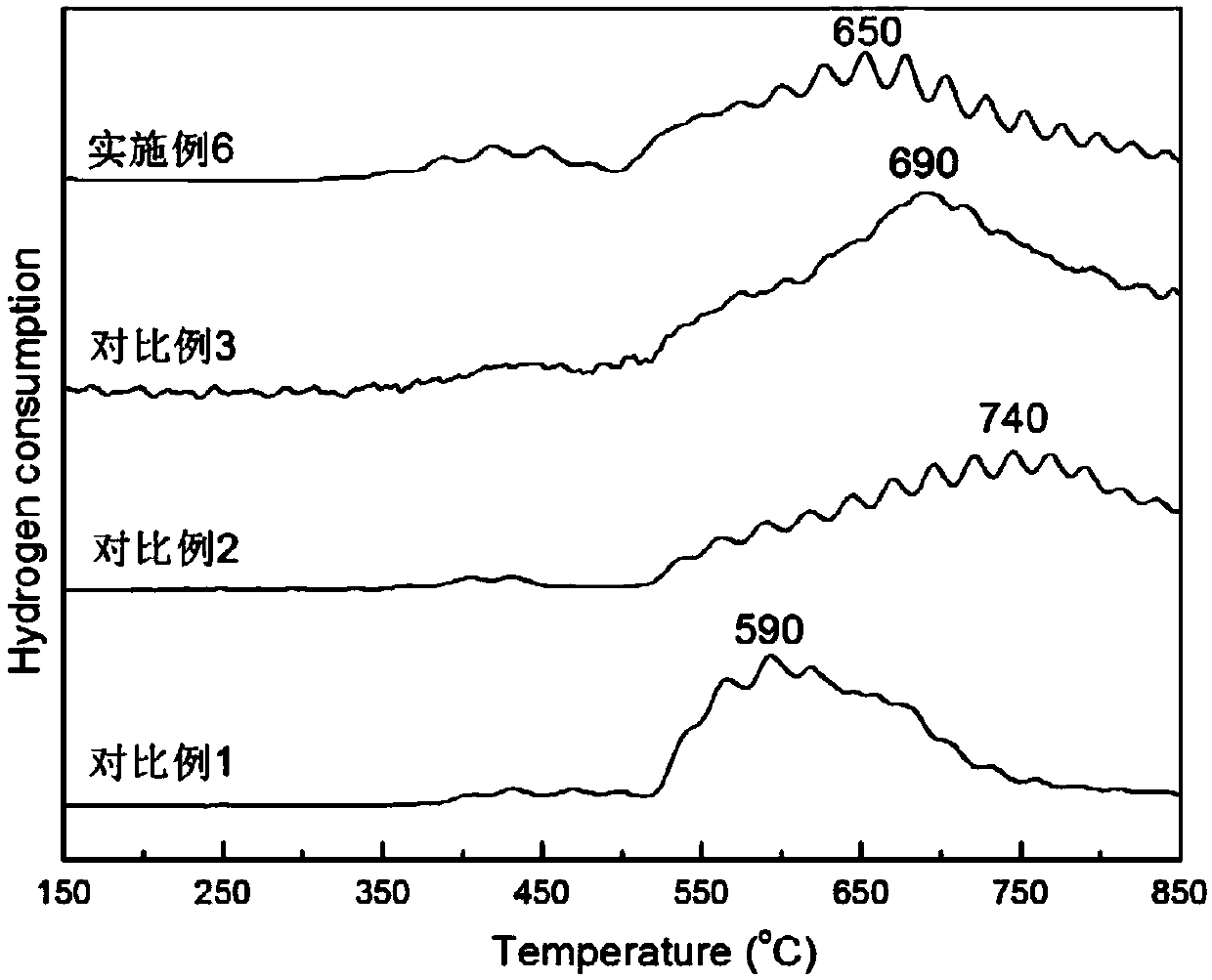

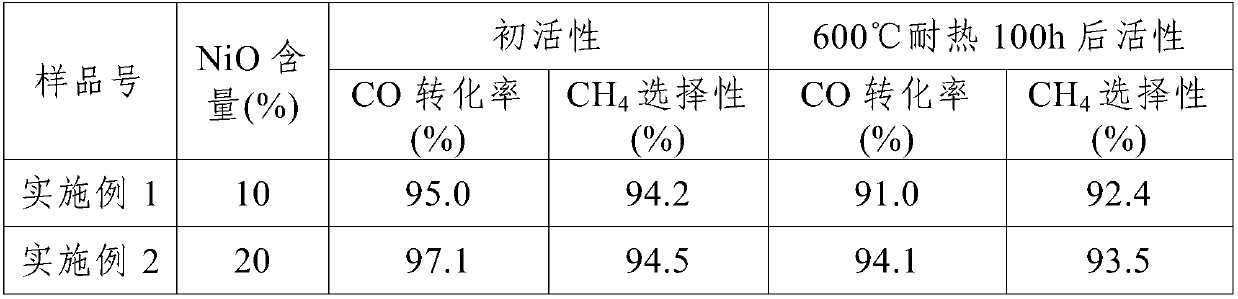

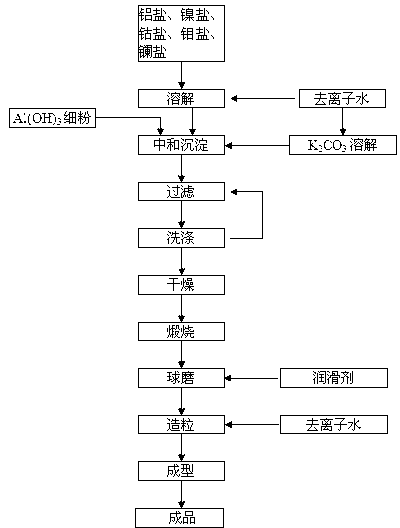

Preparation method of high-temperature-resistant methanation catalyst

ActiveCN107790136AHigh activityStrong anti-sintering abilityHydrocarbon from carbon oxidesHeterogenous catalyst chemical elementsNickel saltFiltration

The invention discloses a preparation method of a high-temperature-resistant methanation catalyst. The method comprises the following steps of firstly dissolving a soluble nickel salt and a soluble aluminum salt in deionized water, confecting to form a mixed solution, afterwards, adding a precipitator into the solution, carrying out a precipitation reaction in a condition that a temperature is 25to 90 DEG C, after the precipitation reaction is finished, adding a silicon reagent and hydrated alumina in sequence, uniformly agitating and mixing, then carrying out filtration, washing, drying andcalcination in sequence, finally, mixing graphite, and carrying out press forming to obtain a finished product of the methanation catalyst. The method provided by the invention is simple and novel; the methanation catalyst which is high in activity and high in strength is prepared; the nickel content in the catalyst is low; the preparation cost is low; however, the catalyst is high in activity andhigh in carbon deposition resisting ability, is stable in activity in a long-time use process and is not crushed and problems that an existing high-temperature-resistant methanation catalyst is easyto sinter in active component, is easy in carbon deposition to be inactivated and is easy to crush when being used for a long time are solved.

Owner:XIAN SUNWARD AEROSPACE MATERIAL CO LTD

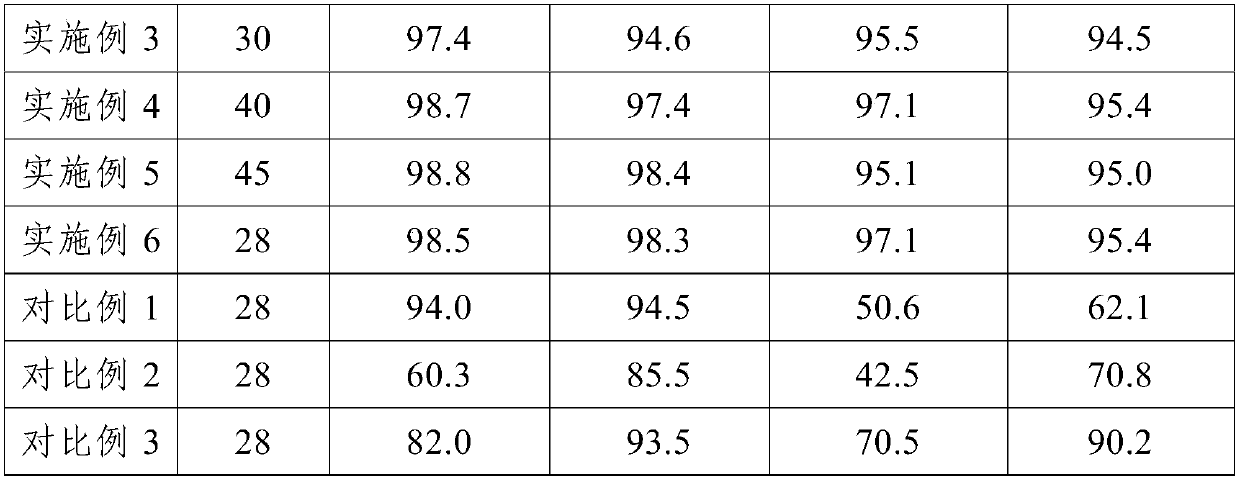

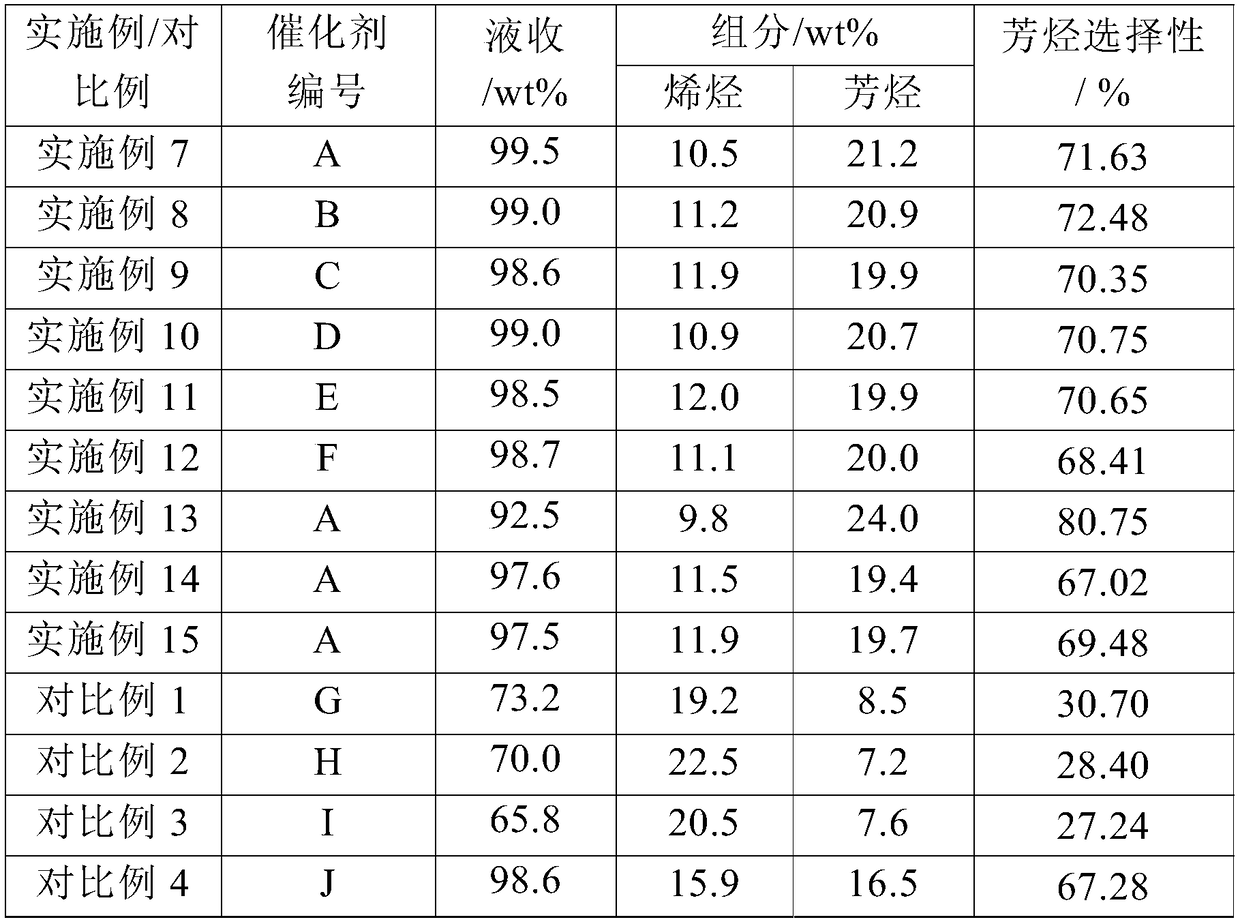

Aromatization catalyst, preparation method thereof, regeneration method and aromatization method

ActiveCN108404972AReduce olefin contentReduce generationMolecular sieve catalystsCatalyst regeneration/reactivationIon exchangeCalcination

The invention provides an aromatization catalyst, a preparation method thereof, a regeneration method and an aromatization method. The preparation method comprises the steps: mixing a silicon source,an aluminum source, a templating agent, an alkali source, water and a silane coupling agent according to a molar ratio of (80.0 to 98.5): (0.1 to 20.0): (0.1 to 2.0): (0.01 to 0.2): (1.0 to 14.0): (0.02 to 1.0) for crystallization, calcination and acid exchange to obtain a catalyst carrier; allowing the catalyst carrier to sequentially go through ion exchange modification, first modification treatment, hydrothermal treatment, active metal loading and second modification treatment to obtain the aromatization catalyst. The present invention also provides the aromatization method using the aromatization catalyst and the regeneration method of the aromatization catalyst. The aromatization catalyst has good carbon deposition resistance and high aromatization activity, enables the aromatizationreaction to be carried out under mild conditions, and meanwhile has a high olefin conversion rate and a very high liquid yield.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Nickel-cobalt based catalyst as well as preparation method and application thereof

InactiveCN102335610AStrong ability to resist carbon depositionHigh reactivity and selectivityHydrogenMetal/metal-oxides/metal-hydroxide catalystsSyngasIncipient wetness impregnation

The invention discloses a nickel-cobalt based catalyst as well as a preparation method and application thereof. The catalyst has the following structural general formula: xNi.yCo.zCeAlO3.(100-x-y-z) Al2O3, wherein 0.5<=x<=15, 0.5<=y<=5 and 1<=z<=30. The catalyst is prepared by the following steps of: firstly, impregnating dried gamma-Al2O3 in a ceric salt solution at room temperature by using an incipient-wetness impregnation method, drying and roasting to obtain a modified carrier; then impregnating the modified carrier obtained at room temperature in a mixed water solution of nickel salt and cobalt salt by using the incipient-wetness impregnation method, drying and roasting to obtain a catalyst precursor; and finally, reducing the obtained catalyst precursor in hydrogen gas at 850-1050 DEG C. The catalyst provided by the invention has the advantages of strong coke resistance, high reactivity and selectivity, good reaction stability and heat stability, high chemical and structural stability and the like and can be used as the catalyst for preparing synthesis gas from methane.

Owner:EAST CHINA NORMAL UNIVERSITY

Catalyst for preparing tetrafluoroethylene and hexafluoropropylene through catalytic cracking of trifluoromethane and preparation method thereof

ActiveCN109261142ASolve cokingExtended service lifeChemical recyclingHalogenated hydrocarbon preparationNitrateHexafluoropropylene

The invention provides a catalyst for preparing tetrafluoroethylene and hexafluoropropylene through catalytic cracking of trifluoromethane and a preparation method thereof. The catalyst is prepared through the steps of preparing a precursor from a carrier and an active component through an impregnation method and then carrying out roasting and trifluoromethane fluorination; the carrier is Al2O3 orAlF3; the active component is one or a combination of two of nitride and nitrate of Cs, La, Sm, Pd, Pt, K or Na. The preparation method provided by the invention is simple, is capable of catalytically cracking the trifluoromethane under lower temperature and mild conditions, and is low in equipment requirements, low in energy consumption and low in cost; the prepared catalyst is capable of effectively reducing the reaction temperature of the catalytic cracking of the trifluoromethane, the conversion rate of raw materials and selective increment of a target product can be realized under milderconditions, the problem of coking of the catalyst can be effectively solved, and the service life of the catalyst can be prolonged.

Owner:SHANDONG DONGYUE CHEM

Sulfur-free nickel-molybdenum bimetallic hydrodeoxygenation catalyst

ActiveCN111111679AEasy to manufactureHigh catalytic activityCatalystsHydrocarbon preparation catalystsLiquid productPtru catalyst

The invention discloses a sulfur-free nickel-molybdenum bimetallic catalyst Ni-Mo / TiO2-SiO2 and a method for catalyzing hydrodeoxygenation of fatty acid methyl ester by the sulfur-free nickel-molybdenum bimetallic catalyst Ni-Mo / TiO2-SiO2. The catalyst has the advantages of high catalytic activity, strong carbon deposition resistance, easiness in separation from a liquid product and the like. Whenthe mass ratio of the catalyst to the reaction raw material methyl laurate to the reaction solvent is 0.1: 1: 20, the reaction temperature is 300 DEG C, and the reaction time is 4 hours, the mass yield of the obtained hydrodeoxygenation product n-dodecane product is up to 92%, and the purity mass percent of the product is up to 95%.

Owner:XIANGTAN UNIV

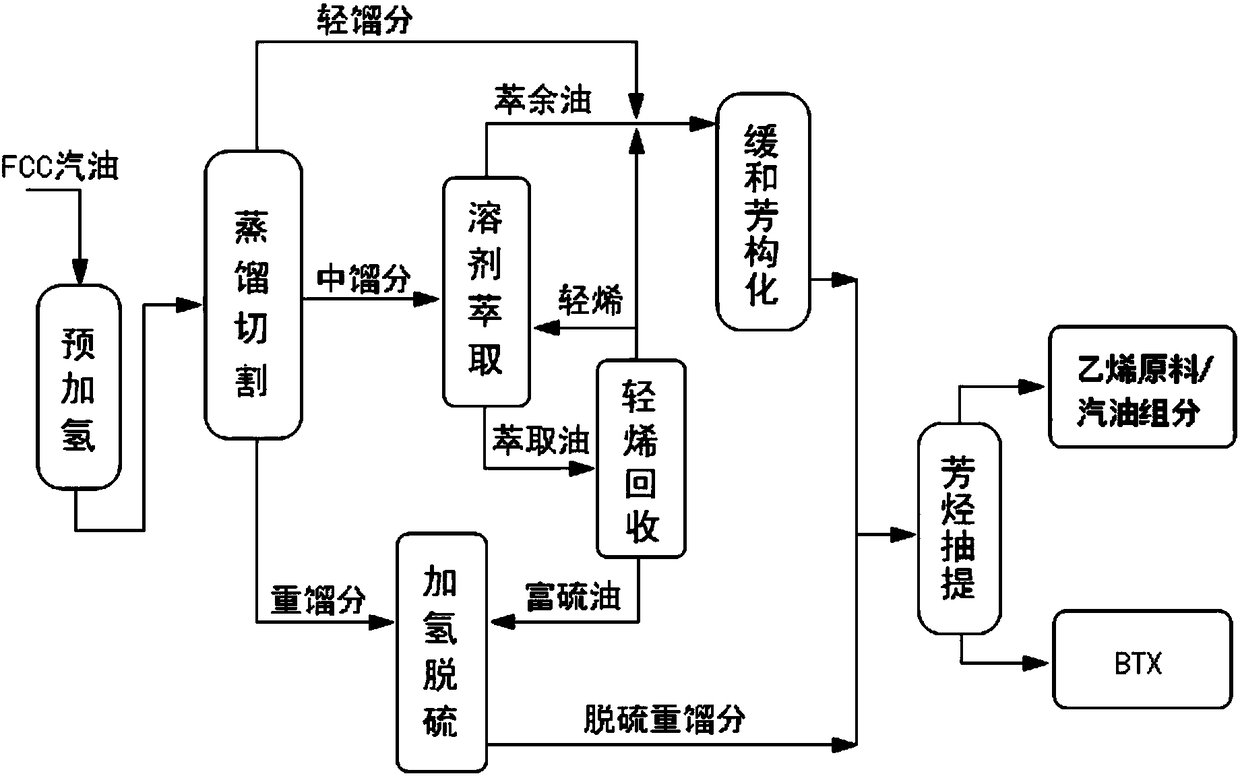

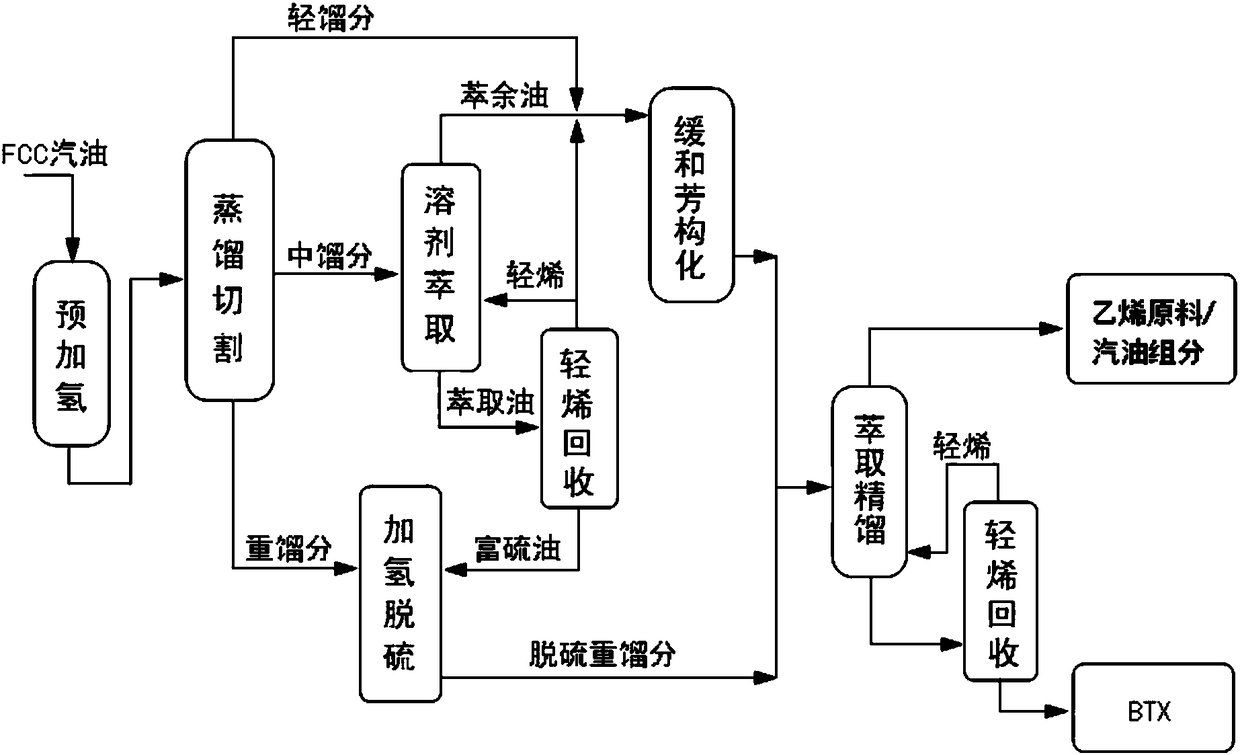

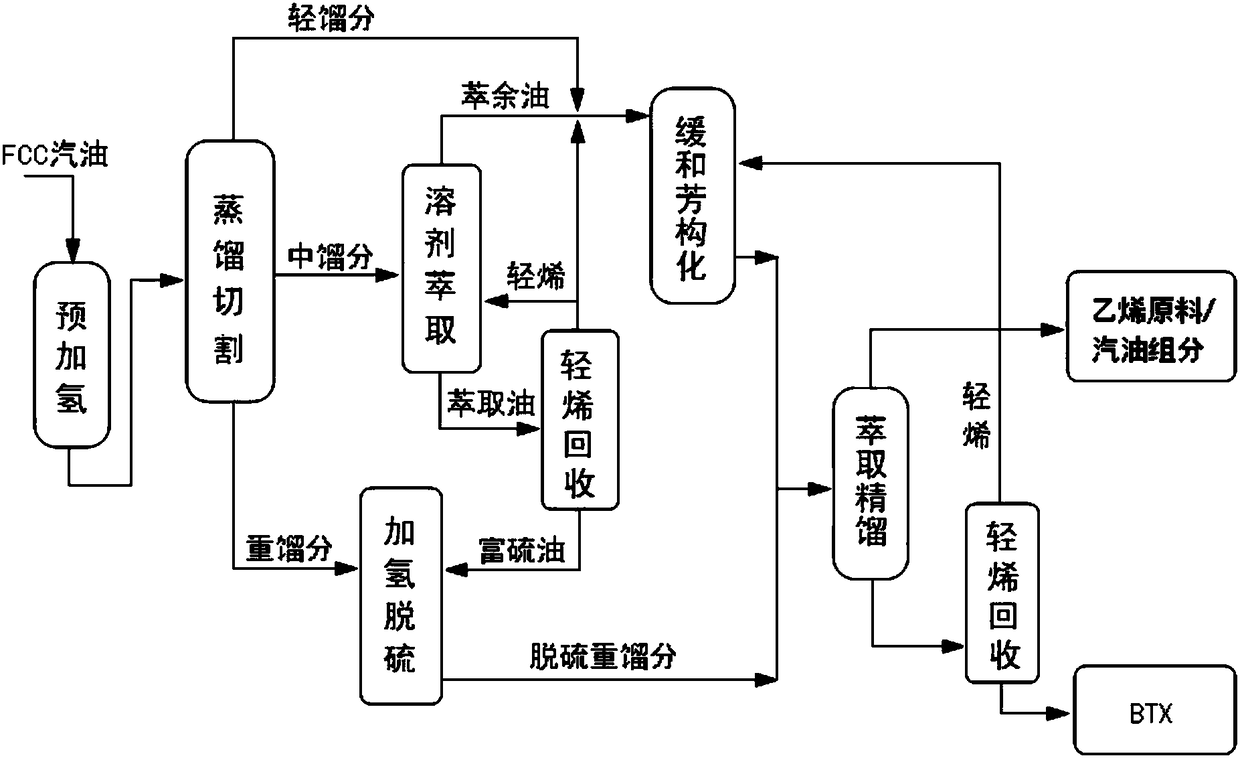

Method for maximally producing aromatic hydrocarbons from catalytic cracking gasoline

ActiveCN108485702AAchieve productionOvercome inability to prepareMolecular sieve catalystsTreatment with hydrotreatment processesHydrodesulfurizationSulfur

The invention provides a method for maximally producing aromatic hydrocarbons from catalytic cracking gasoline. The method comprises pre-hydrogenating catalytic cracking gasoline to obtain pre-hydrogenated catalytic cracking gasoline, dividing the pre-hydrogenated catalytic cracking gasoline into a light fraction, a middle fraction and a heavy fraction, extracting the middle fraction through a solvent to obtain olefin-rich raffinate and aromatic-rich extract, carrying out mild aromatization on the light fraction and the raffinate to obtain an aromatization product, recovering the light olefinfrom the extract to obtain a light olefin and sulfur-rich oil, carrying out selective hydrodesulfurization on the heavy fraction and the sulfur-rich oil to obtain a desulfurized heavy fraction, and carrying out aromatic extraction or extraction rectification on the aromatization product and the desulfurized heavy fraction. The method realizes olefin reduction, desulfurization and octane value increasing treatment on catalytically cracked gasoline and maximizes aromatic hydrocarbon production.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Heteropolyacid ammonium salt catalyst and preparation method thereof

ActiveCN106944152AIncrease acidityLarge specific surface areaMolecular sieve catalystsMolecular sieve catalystHigh selectivityEthanol

The present invention discloses a heteropolyacid ammonium salt catalyst and a preparation method thereof. The catalyst comprises an active component, auxiliary agents and a carrier, wherein the active component is a heteropolyacid ammonium salt, the auxiliary agents are nickel, phosphorus and vanadium, the carrier is an amorphous silicon-aluminum coated molecular sieve, the auxiliary agents comprise (calculated as the oxide) 3.0-10.0% of P2O5, 0.2-4.0% of V2O5 and 8-20% of NiO by adopting the weight of the carrier as the reference, the heteropolyacid ammonium salt content is 8-30% by adopting the weight of the catalyst as the reference, and the total content of the auxiliary agents and the carrier is 70-92% (calculated as the oxide). According to the present invention, the catalyst has advantages of high low-temperature activity, high selectivity, high carbon deposition resistance and improved stability, and is particularly suitable for the ethylene preparation reaction through dehydration by using the low-concentration ethanol aqueous solution as the raw material.

Owner:CHINA PETROLEUM & CHEM CORP +1

Heteropolyacid ammonium salt catalyst and preparation method thereof

ActiveCN106944139AIncrease acidityDoes not change the pore structureOrganic-compounds/hydrides/coordination-complexes catalystsCatalystsHigh carbonHigh selectivity

The present invention discloses a heteropolyacid ammonium salt catalyst and a preparation method thereof. The catalyst comprises an active component, auxiliary agents and a carrier, wherein the active component is a heteropolyacid ammonium salt, the auxiliary agents are nickel oxide and ferric oxide, and the carrier is amorphous silicon-aluminum coated silica. The catalyst of the present invention has advantages of high low-temperature activity, high selectivity, high carbon deposition resistance and improved stability, and is particularly suitable for the ethylene preparation reaction through dehydration by using the low-concentration ethanol aqueous solution as the raw material.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing dimethyl ether through methanol dehydration

ActiveCN104591978AHigh low temperature activityGood choiceOrganic-compounds/hydrides/coordination-complexes catalystsEther preparation by compound dehydrationHeteropoly acidActive component

The invention discloses a method for preparing dimethyl ether (DME) through methanol dehydration. According to the method, a catalyst A and a catalyst B are subjected to graded loading. The catalyst A is composed of an active component heteropoly acid ammonium salt, an auxiliary agent lanthanum oxide and / or cerium oxide, and a carrier silicon oxide. The catalyst B is composed of an active component heteropoly acid, an auxiliary agent lanthanum oxide and / or cerium oxide, and a carrier silicon oxide. According to the invention, the two catalysts cooperate with each other, and fully perform their advantages. Under a situation with a relatively low reaction temperature, the catalysts comprehensively have relatively high activity and selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Sulfur-resistant methanation catalyst and preparation method thereof

ActiveCN102389808BStrong ability to resist carbon depositionSingle and reliable technologyMetal/metal-oxides/metal-hydroxide catalystsPtru catalystMethanation

The invention discloses a sulfur-resistant methanation catalyst, which is used for preparing methane from coke oven gas. The catalyst is a precipitation type catalyst which mainly adopts oxides of Mo, Co and Ni as active ingredients, Al2O3 as a carrier and La2O3 as an accelerant. The catalyst can be used for realizing good methanation of coke oven gas containing 1-3 ppm of H2S at1.0-3.0 MPa and 280-450 DEG C on the premise of not deeply purifying coke oven gas, and also has good selectivity. The invention also discloses a preparation method of the sulfur-resistant methanation catalyst.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

Heteropolyacid ammonium type catalyst and preparation method thereof

ActiveCN106944147AHigh low temperature activityGood choiceOrganic-compounds/hydrides/coordination-complexes catalystsCatalystsReduction treatmentHeteropoly acid

The present invention discloses a heteropolyacid ammonium type catalyst and a preparation method thereof. According to the catalyst, active components are heteropolyacid and a heteropolyacid ammonium salt, the auxiliary agent is nickel oxide, and the carrier is silicon oxide. The preparation method comprises: sequentially loading an organic acid, an ammonium-containing alkaline solution or ammonia gas, heteropolyacid and an auxiliary agent on a silicon oxide carrier to obtain a catalyst precursor, carrying out reduction treatment and furfural reaction treatment, impregnating in a heteropolyacid solution, drying, and calcining to obtain the catalyst. According to the present invention, the active component on the surface adopts the strong acidity heteropolyacid and the ammonium salt thereof as the main component, and the active component in the pore channel uses the weak acidity heteropolyacid ammonium salt as the main component, such that the catalyst has advantages of high low-temperature activity, high selectivity, high carbon deposition resistance and improved stability, and is particularly suitable for the ethylene preparation reaction through dehydration by using the low-concentration ethanol aqueous solution as the raw material.

Owner:CHINA PETROLEUM & CHEM CORP +1

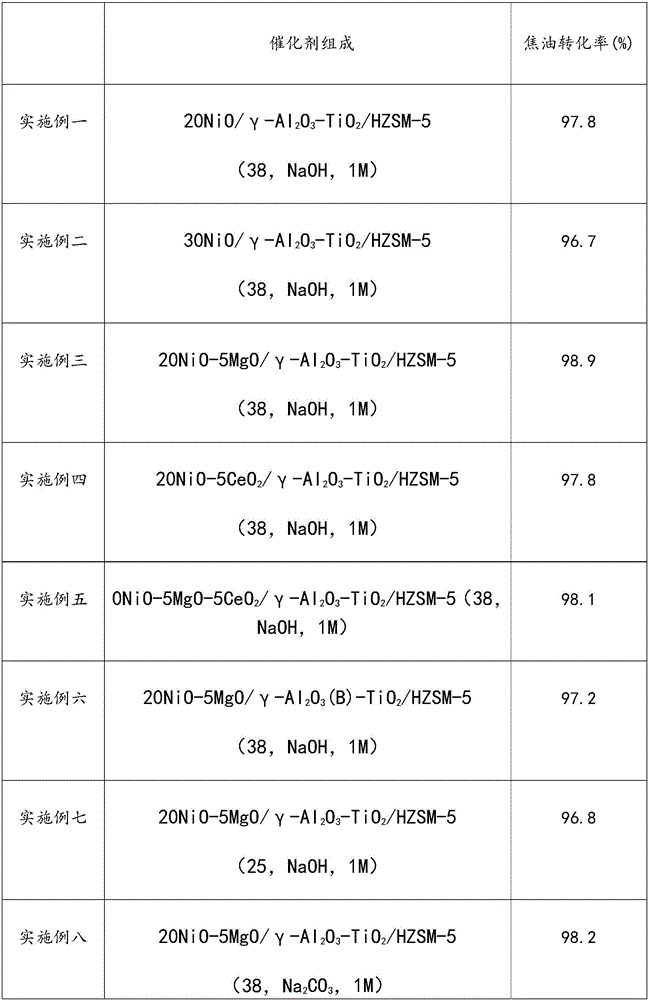

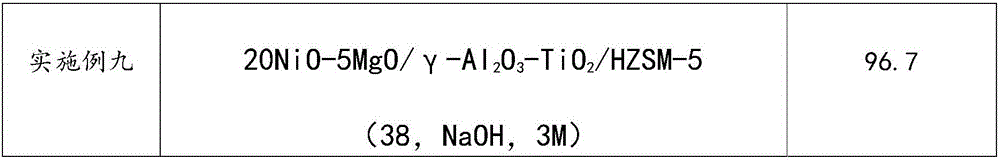

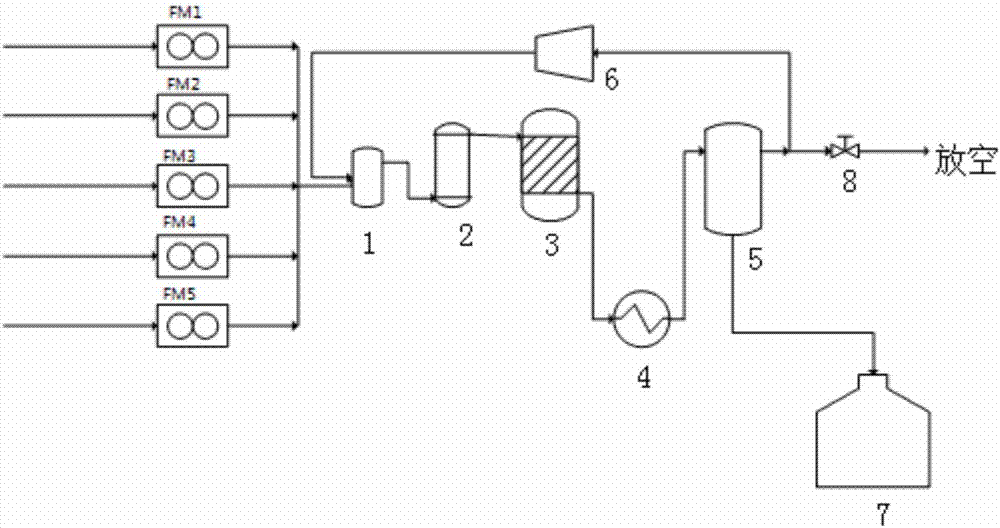

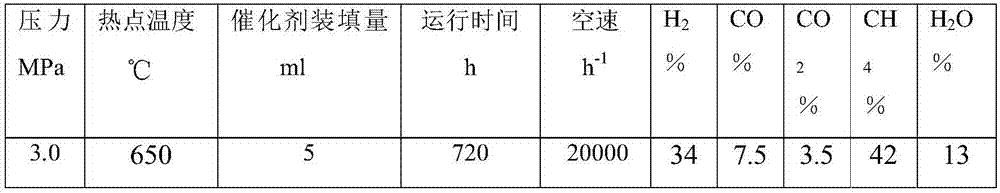

Preparation method for tar-removing catalyst of nickel-based nanometer compound carrier

ActiveCN106622351AStrong ability to resist carbon depositionImprove anti-carbon performanceMolecular sieve catalystsGas purification by catalytic conversionMolecular sieveAlcohol

The invention discloses a preparation method for a tar-removing catalyst of a nickel-based nanometer compound carrier. The preparation method for a catalyst containing no auxiliary comprises the following steps: 1) acquiring a tetrabutyl titanate and ethyl alcohol mixed solution and preparing an ethyl alcohol and nitric acid mixed aqueous solution; 2) preparing nanometer TiO2 powder; 3) preparing a modified molecular sieve; 4) preparing a gamma-Al2O3-TiO2 / HZSM-5 catalyst carrier; and 5) adopting a saturated impregnation method for steeping gamma-Al2O3-TiO2 / HZSM-5 carrier with a nickel nitrate solution, drying and staying overnight, drying 6h at 105 DEG C, putting into a calcining furnace and calcining for 3-8h at 400-600 DEG C, thereby acquiring a NiO / gamma-Al2O3-TiO2 / HZSM-5 catalyst. The preparation method has the effects of promoting the reactivity and anti-carbon capacity of the catalyst and prolonging the service life of the catalyst.

Owner:广东国能中林实业有限公司

Method for quickly detecting carbon deposition resistance performance of methane synthesis catalyst

ActiveCN107449692AStrong ability to resist carbon depositionReliable conclusionChemical analysis using catalysisGas compositionMethanation

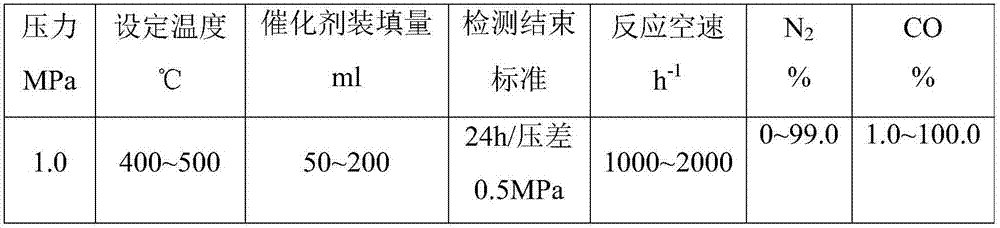

The invention relates to a method for quickly detecting the carbon deposition resistance performance of methane synthesis catalyst. The method comprises the following steps: flatly filling the catalyst into the constant-temperature section of a methanation reactor; two sides of the catalyst are isolated, pressure is built for testing leakage, air is introduced into a nitrogen replacement system, then, pressure is built, nitrogen stops being introduced, hydrogen reduction catalyst is introduced, nitrogen stops being introduced after reaction is finished, pressure is released, hydrogen in the system is replaced by nitrogen, temperature is raised, and pressure is built after a situation that no hydrogen is detected in the system is confirmed; then, raw material gas used for methanation reaction is introduced to carry out methanation reaction, the inlet and outlet gas composition of the methanation reactor is measured by a gas chromatograph, a molar ratio of the carbonic oxide to the carbon dioxide of the outlet of the reactor is measured, and reaction time and a pressure difference value generated until reaction is finished are recorded; a carbon deposition amount and a catalyst particle integrity rate are measured, and a detected parameter is used for judging the index of the carbon deposition resistance performance of the catalyst.

Owner:XINDI ENERGY ENG TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com